Patents

Literature

97 results about "Solid rock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

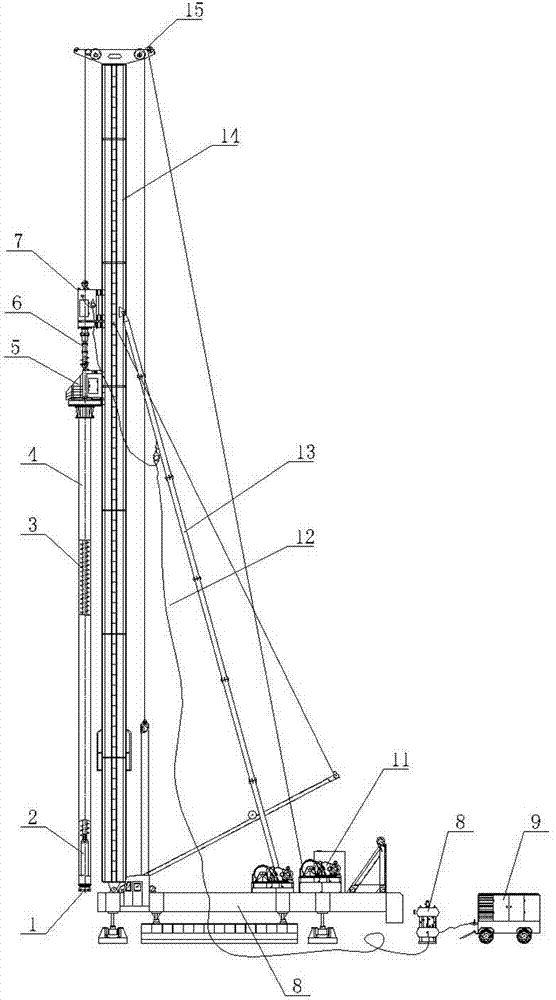

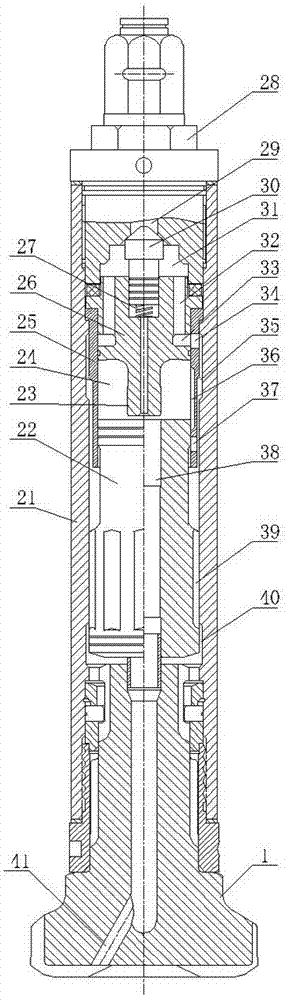

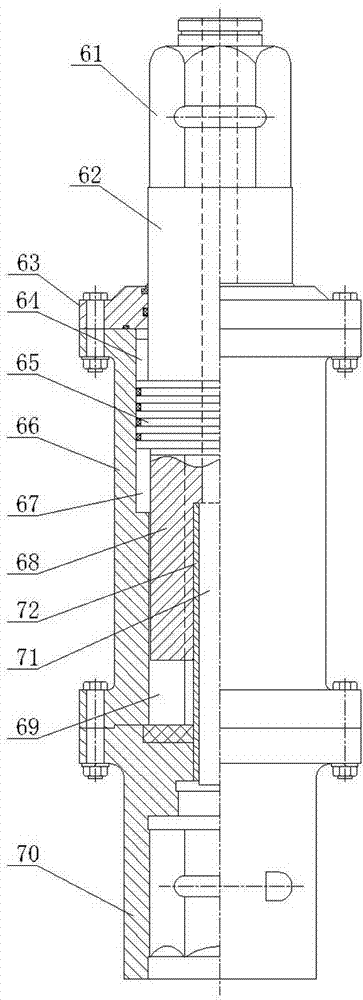

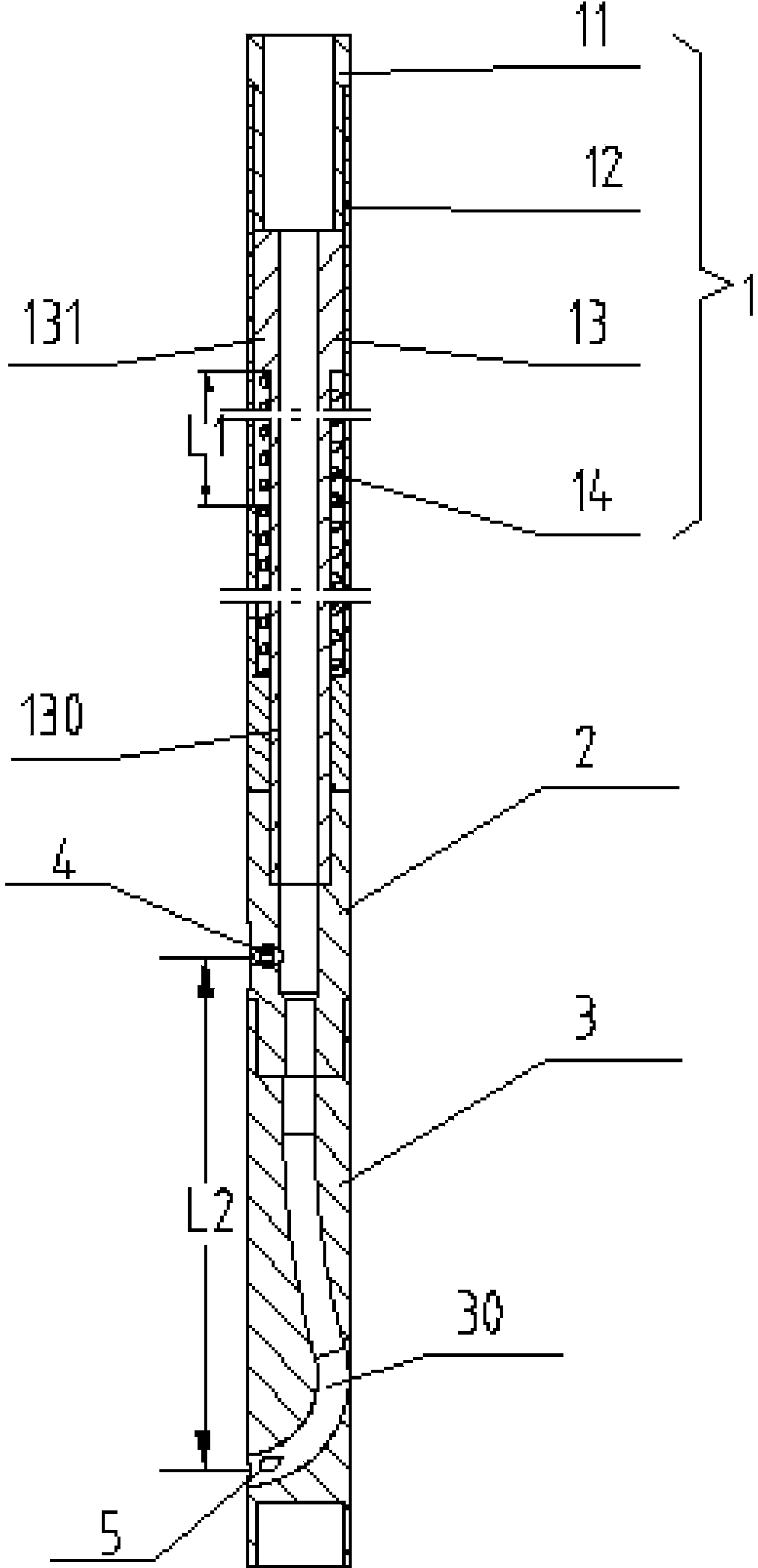

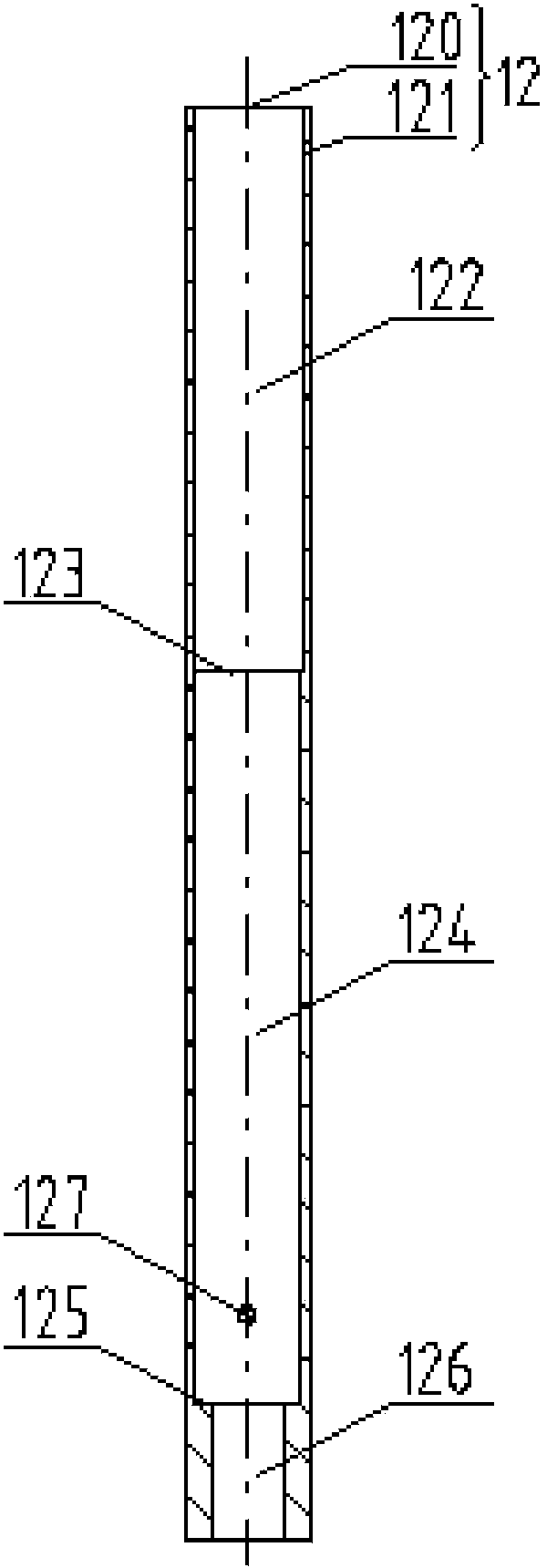

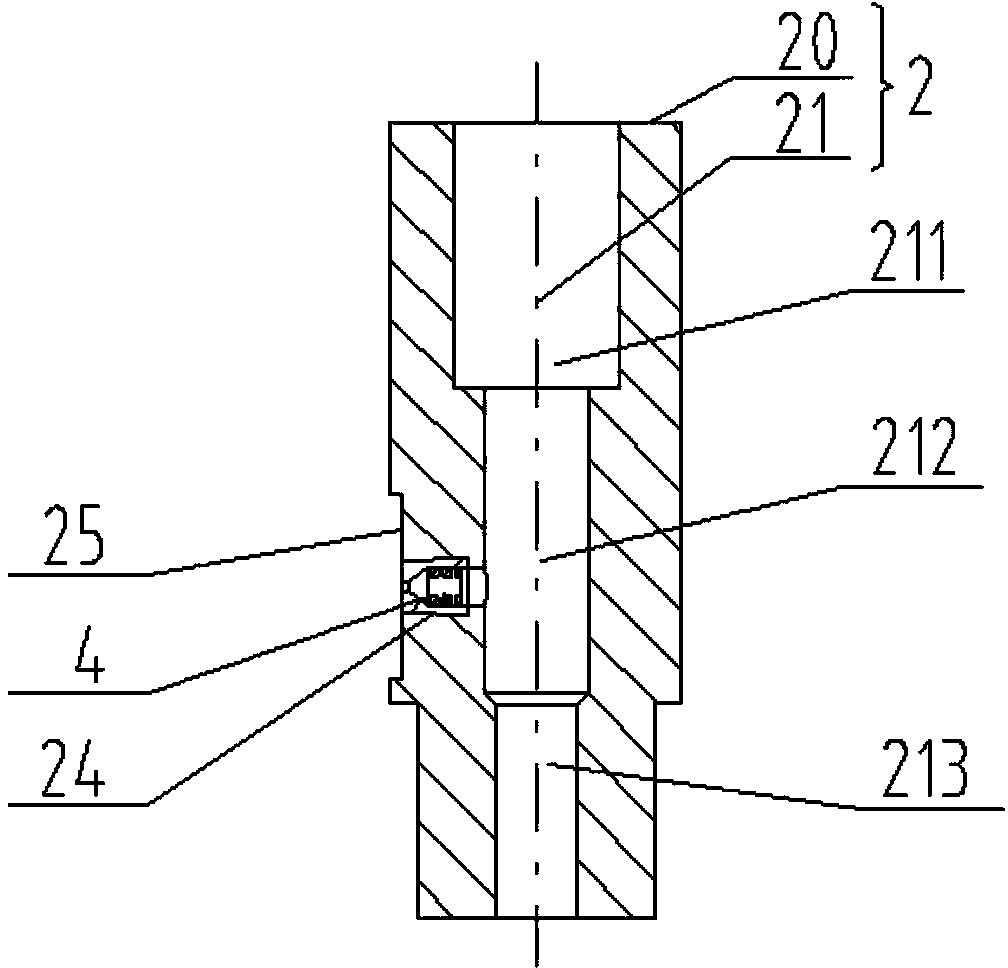

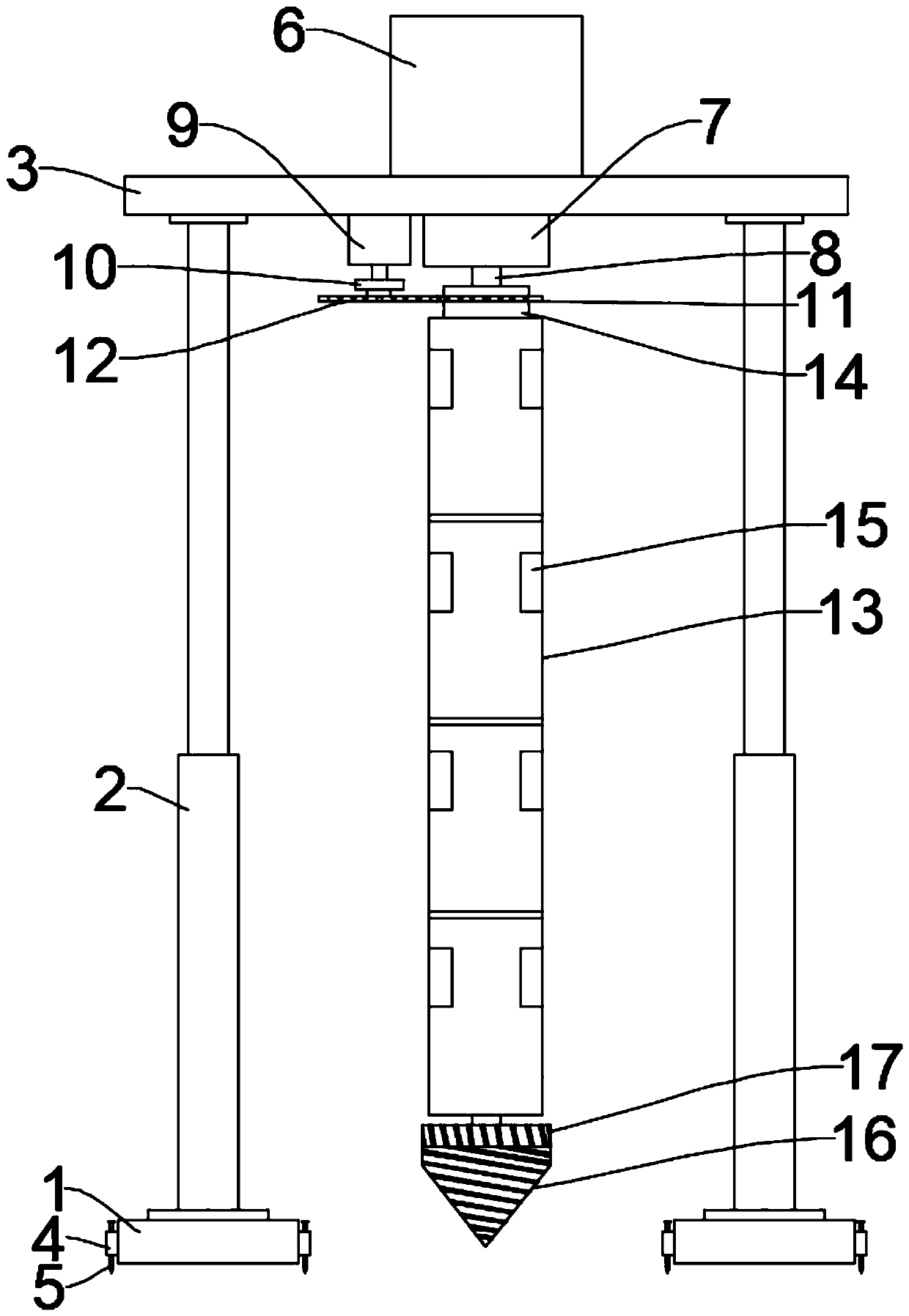

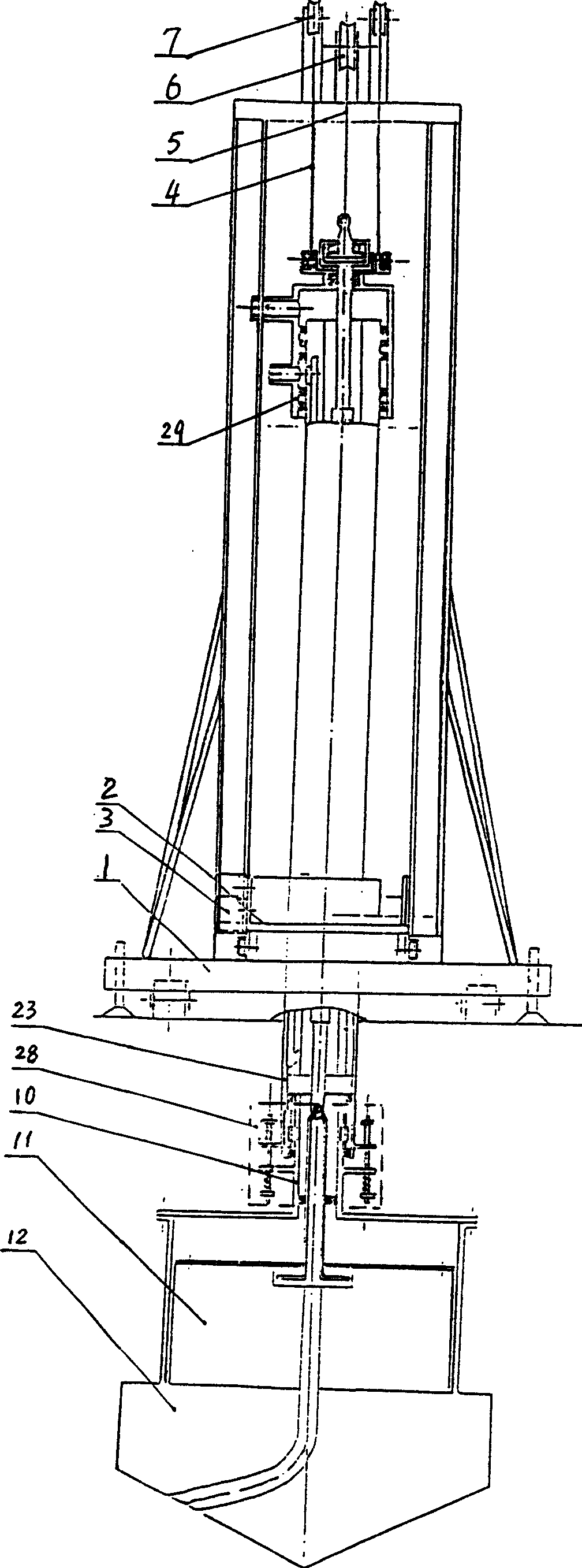

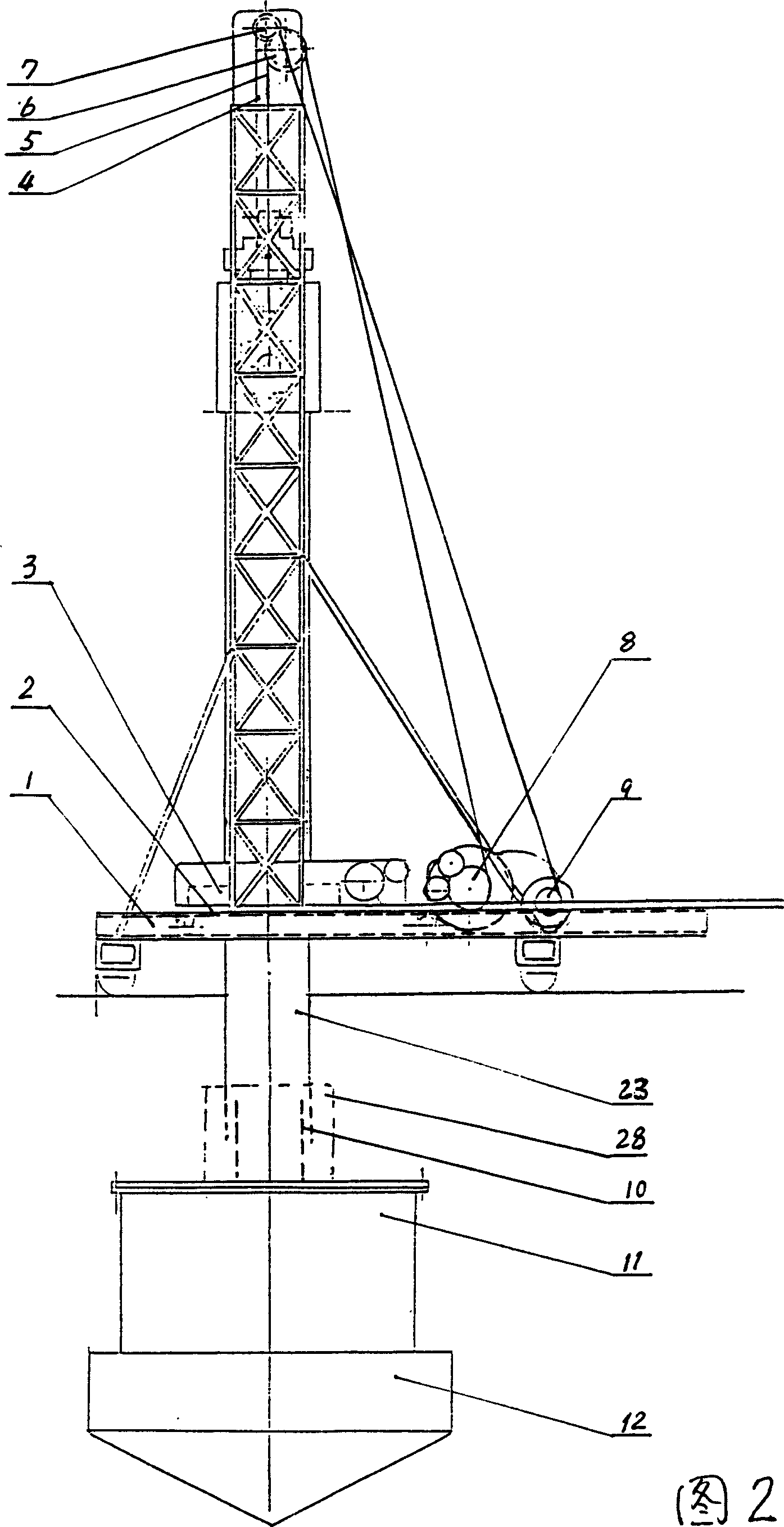

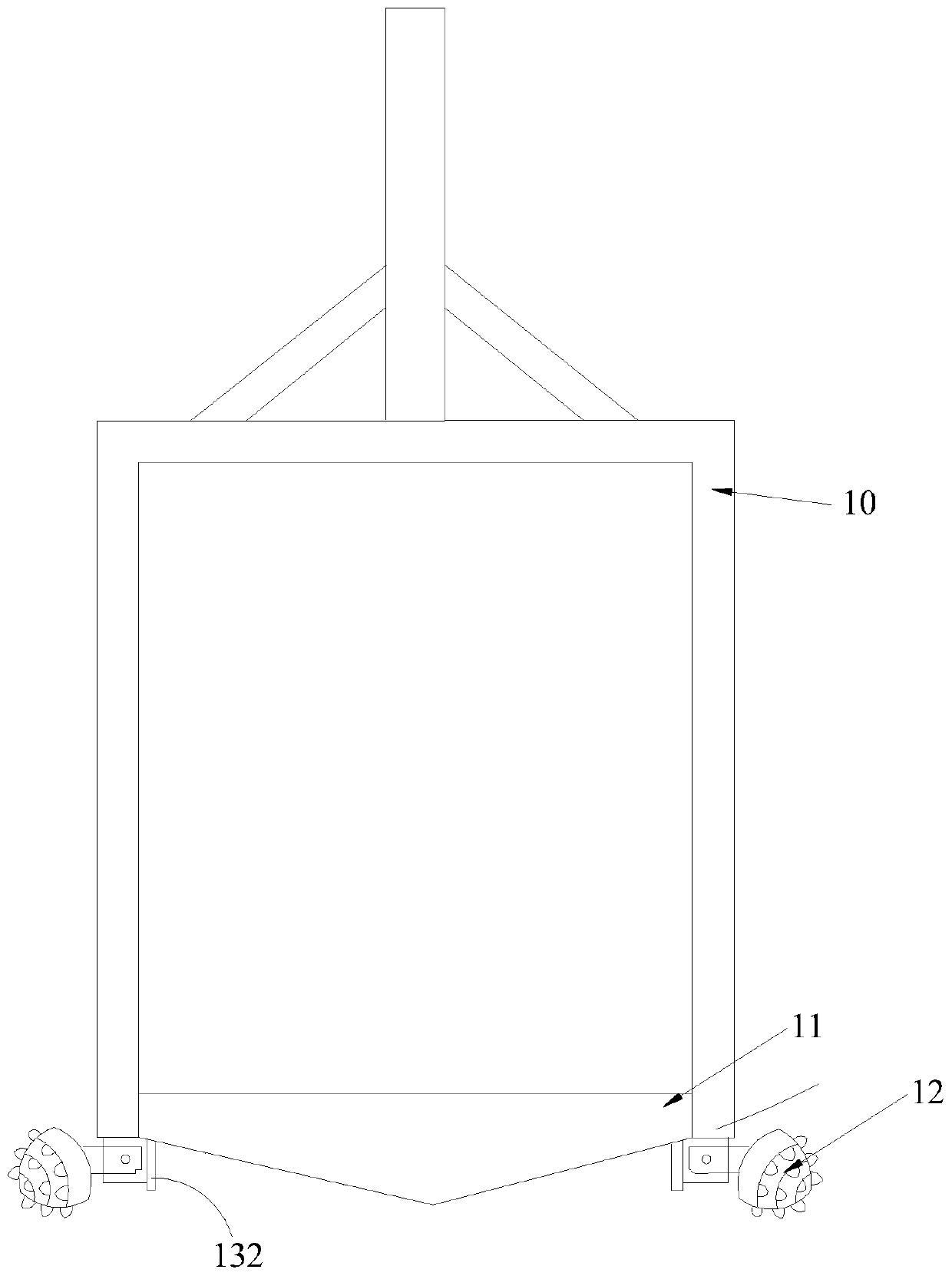

Walking dual-swing downhole drill

ActiveCN102828690AFully lubricatedOil Mist StabilizationConstructionsReciprocating drilling machinesEngineeringHigh pressure

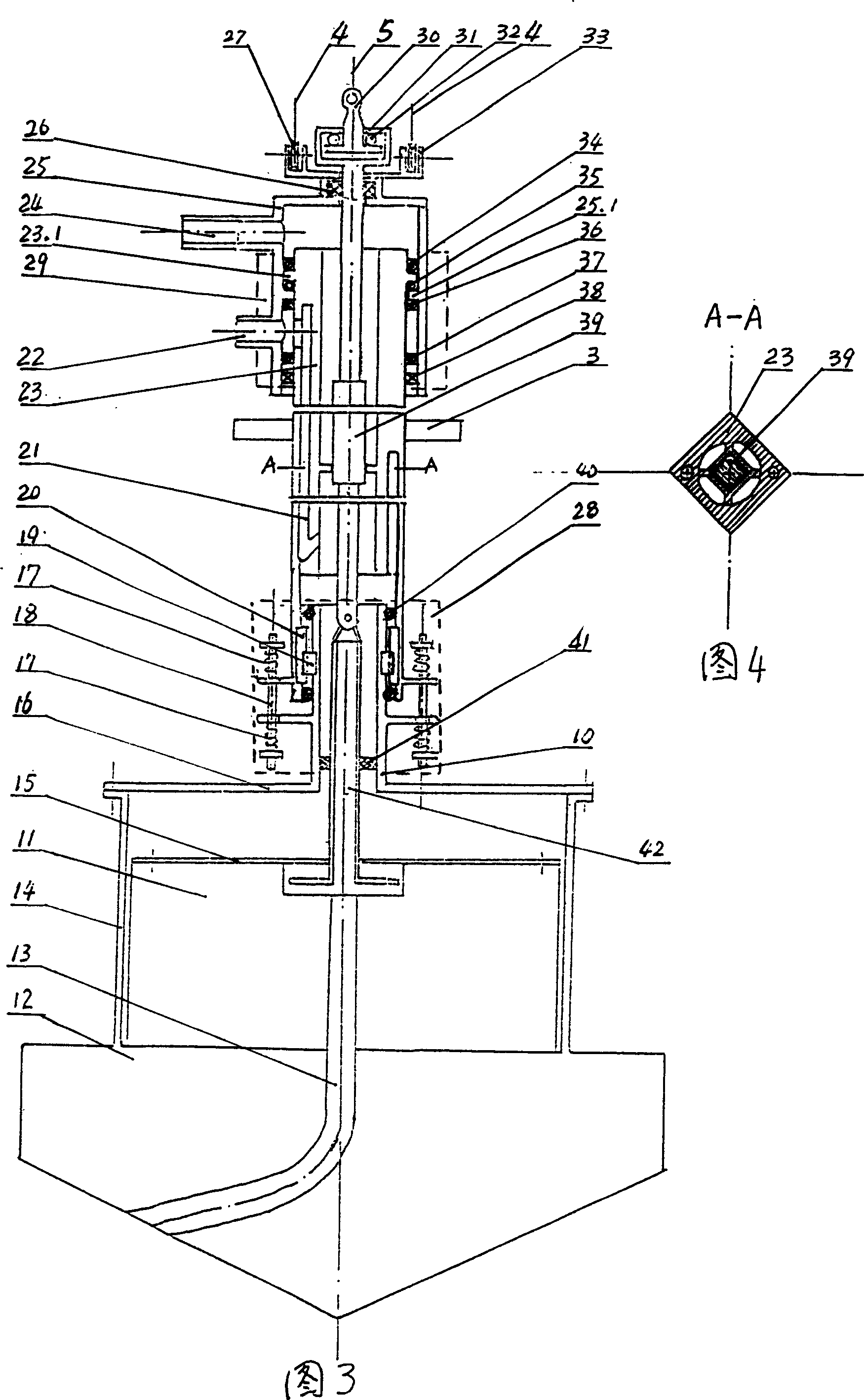

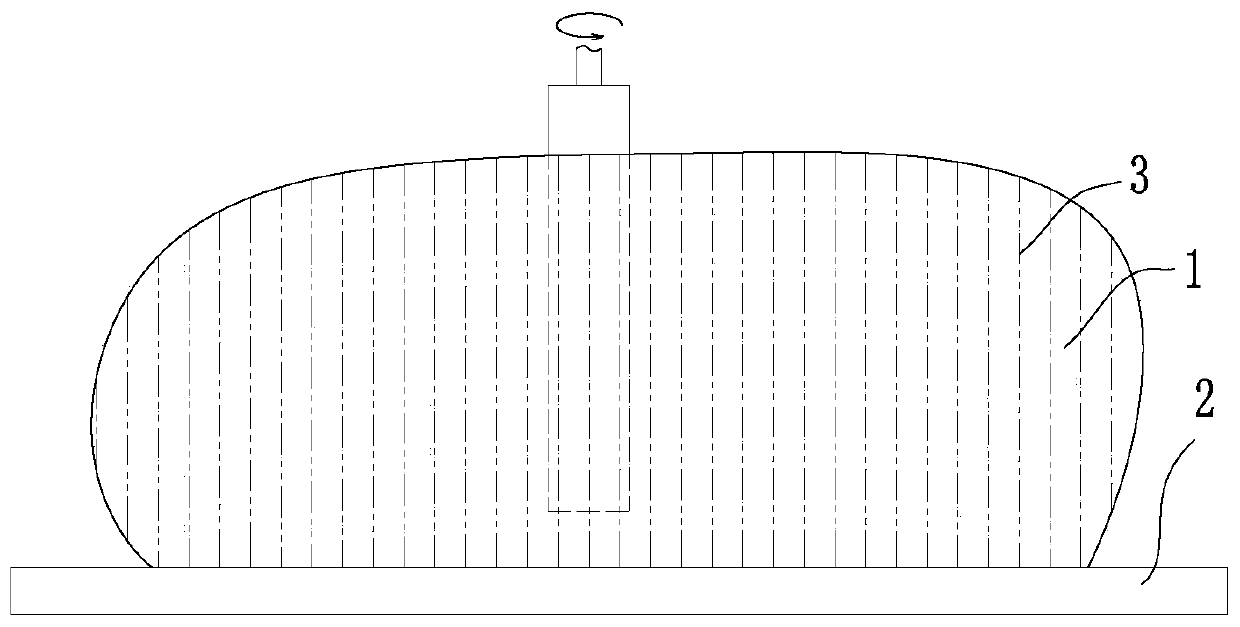

The invention discloses a walking dual-swing downhole drill, which comprises a pile frame main body and a drilling main body, wherein the drilling main body comprises an upper power head, a lower power head, an outer sleeve, a spiral drill stem and a downhole hammer; the upper power head is connected with the top end of the spiral drill stem; the bottom end of the spiral drill stem is connected with the downhole hammer; the upper power head drives the spiral drill stem and the downhole hammer to rotate clockwise when working; the lower power head is connected with the outer sleeve and drives the outer sleeve to rotate anticlockwise when working; the downhole hammer comprises an impacter and an impact hammer; the hammer head of the impact hammer is exposed out of the lower opening of the outer sleeve; a high-pressure gas channel is arranged inside the drilling main body, and the high-pressure gas passes through the upper power head, a buffer, the spiral drill stem and the impacter and is finally blown outwards from the bottom part of the impact hammer. The walking dual-swing downhole drill has main characteristics of taking soil to form a hole by a dry method without pollution, and being adapted to various geologies and stratums, such as hard lithosphere, tundra, sand bed with abundant underground water, a rubble layer and boulder, which are difficult to drill by other pile drivers.

Owner:瑞安市八达工程机械有限公司

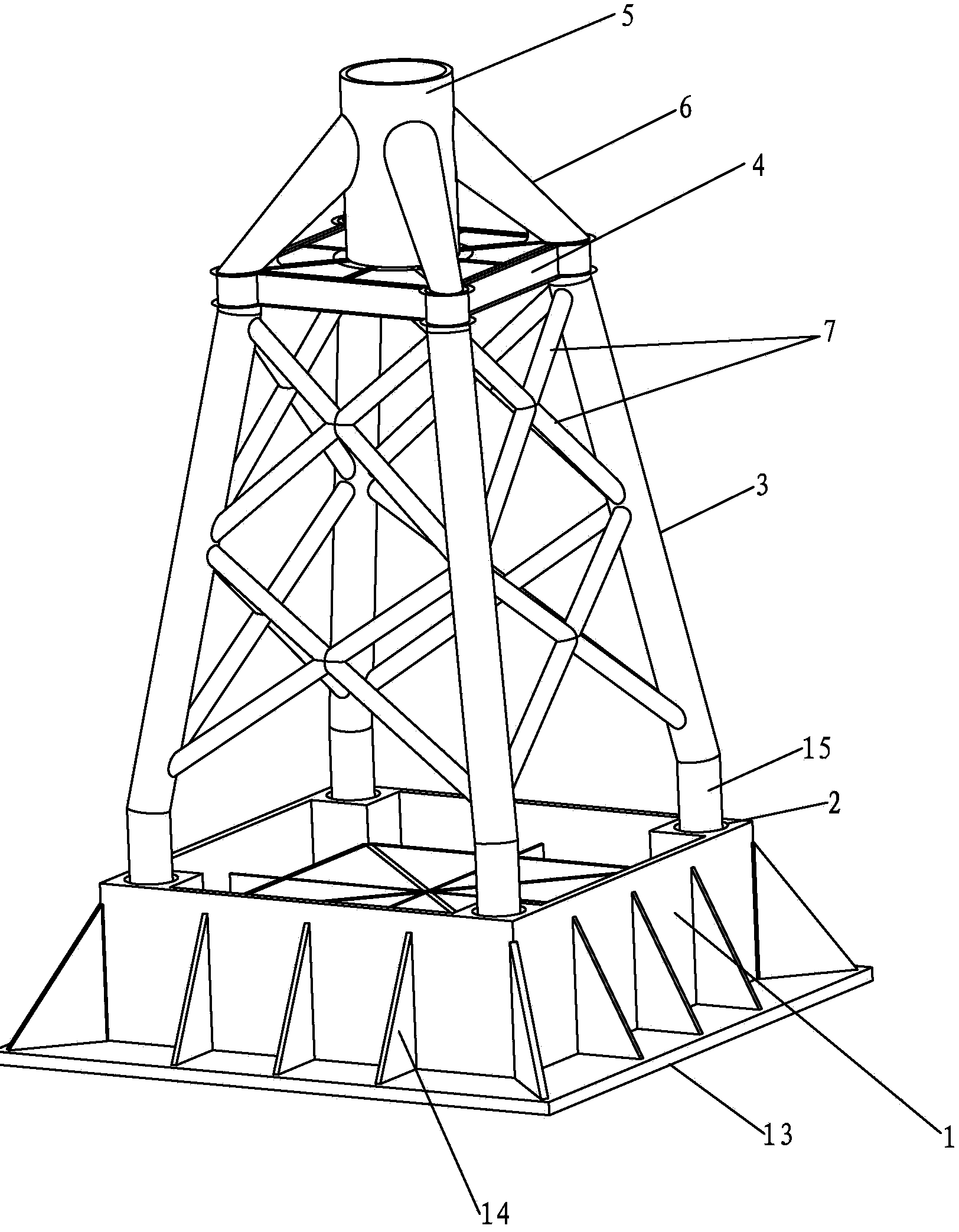

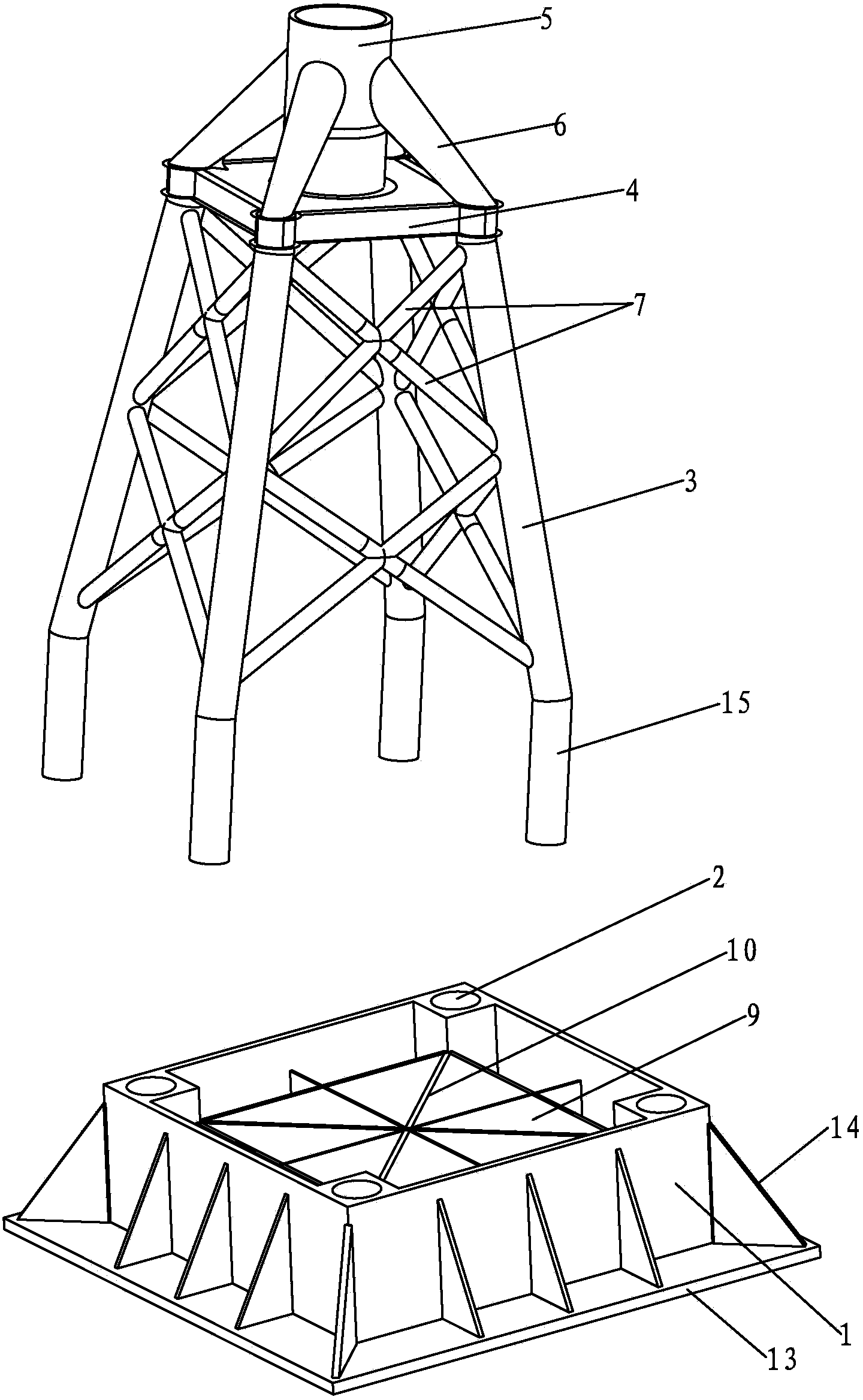

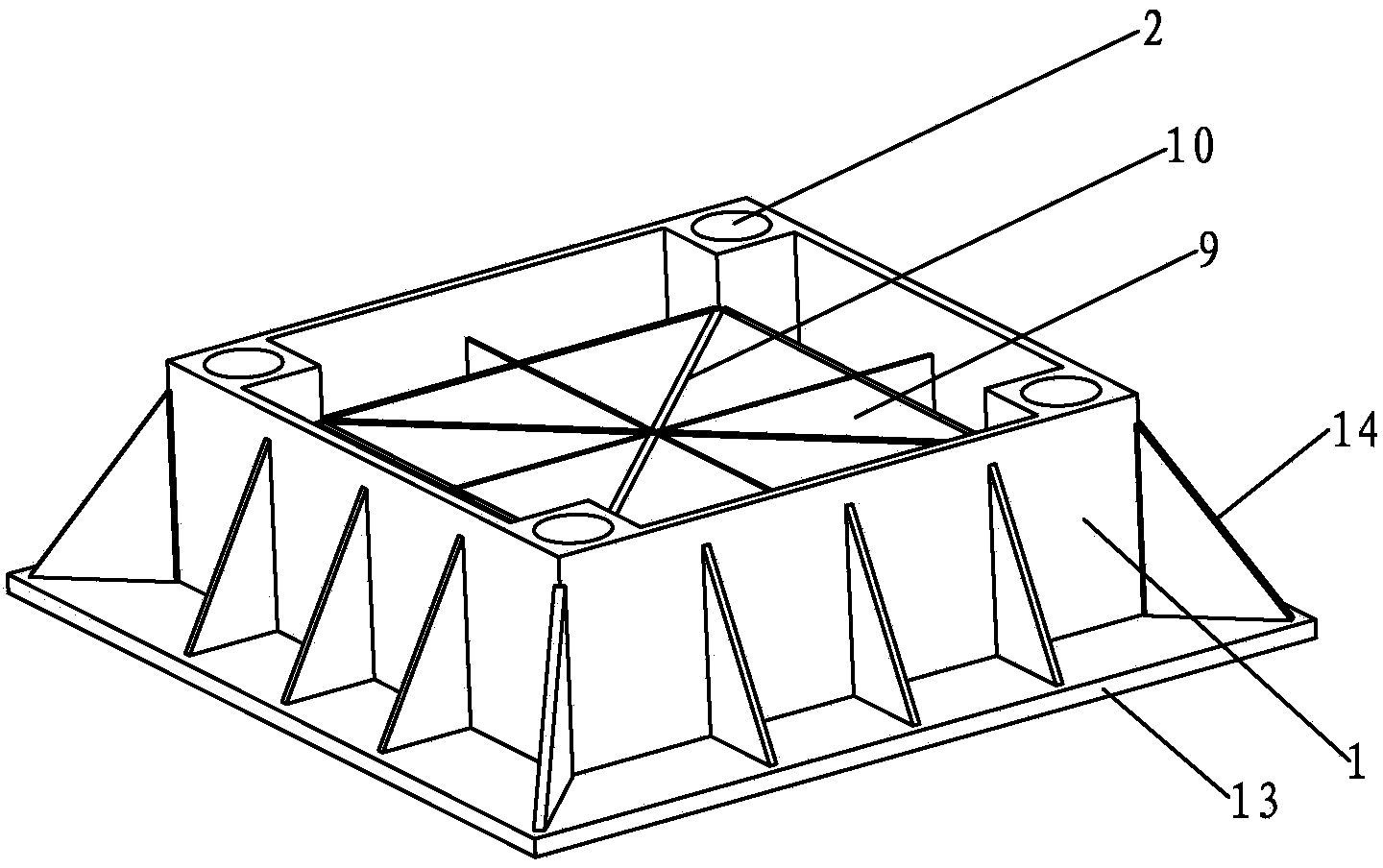

Offshore wind turbine foundation integrating concrete caisson and jacket

ActiveCN103469808AEasy to transportEasy to liftArtificial islandsFoundation engineeringStructural engineeringTurbine

The invention discloses an offshore wind turbine foundation integrating a concrete caisson and a jacket, which is mainly applied to hard rock stratum seabed foundations with higher carrying capabilities. A concrete caisson main body in which a filling cavity with an upward opening is formed is adopted; the concrete caisson main body is provided with installation connecting holes fixedly connected with pile legs; after the concrete caisson main body is placed onto a pretreated seabed, sand and stones are filled into the filling cavity to increase the weight of the concrete caisson main body, so that an offshore wind turbine is effectively prevented from being overturned, and meanwhile, convenience is brought to transportation and hoisting of the concrete caisson main body; the offshore wind turbine foundation has the characteristics of convenience in constructing and low cost.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Biomimetic golden-embedded diamond drilling bit and its production

InactiveCN1896451ASolution to short lifeIncrease drilling speedDrill bitsBiological bodyTransition layer

This invention discloses a kind of bionic diamond-impregnated bit and its producing method. It uses the shape characteristic that the surface of organism is not smooth. This invention is fit for various saw blades of diamond, diamond abrasive tips and solid rock geologic drillings. This invention includes the steel body; the transition-layer; the shape material with unsmooth surface; the diamond; the carcass. The shape materials with unsmooth surfaces are distributed at working layer according to the request. Thus, it decreases the cutting adherence and cutting frictional resistance. It also increases the service life and cutting efficiency of the cutting tool. Compared with normal diamond products, this invention has long lifetime and quick drilling rate. The energy consumption is low.

Owner:JILIN UNIV

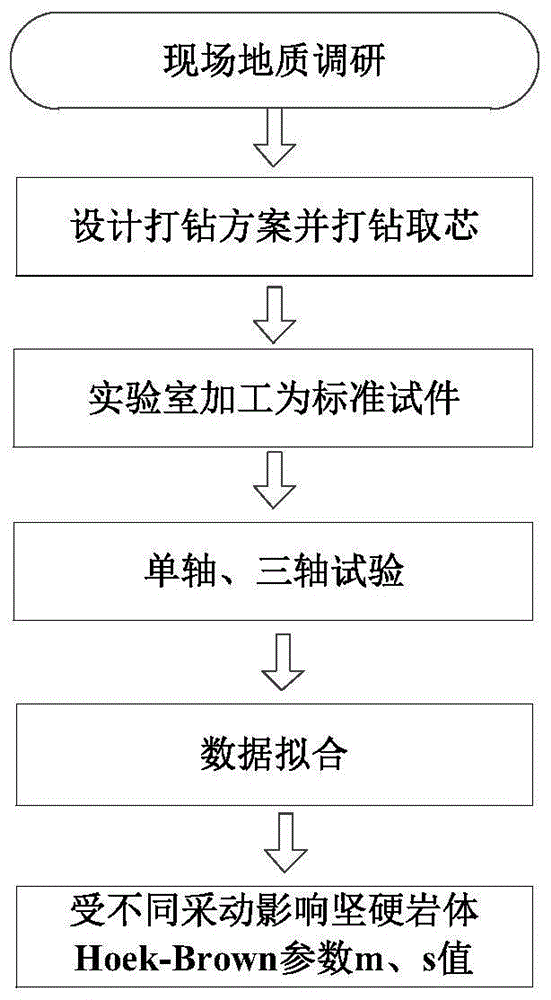

Calculation method of Hoek-Brown parameter m and s of solid rock influenced by different mining

ActiveCN104977210AMaterial strength using tensile/compressive forcesAxial pressureTechnical standard

The invention belongs to the field of rock mass mechanics and engineering geology, and specifically discloses a calculation method of Hoek-Brown parameter m and s of solid rock influenced by different mining. The calculation method comprises following steps: drilling and coring of solid rock influenced by different mining are carried out, and standard samples are obtained via laboratory processing; uniaxial compressive strength of complete solid rock is obtained via uniaxial compression test; the samples influenced by different mining are provided with different confining pressure ranging from 5 to 40MPa via triaxial test, and are provided with axial pressure until the samples are destroyed, and load-displacement curve of the whole loading process is recorded; and at last, m values and s values under each set of conditions are calculated based on Hoek-Brown standard. According to the calculation method, the values of the Hoek-Brown parameter m and s of solid rock influenced by different mining are obtained via on-site coring and laboratory test.

Owner:SHANDONG UNIV OF SCI & TECH

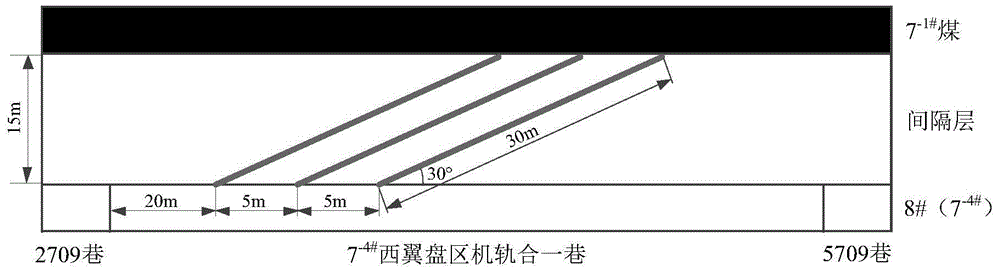

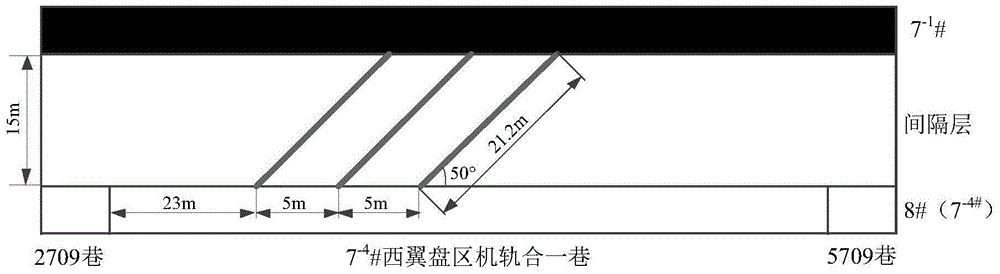

Medium-length hole mixed wedge cut blasting method capable of realizing directed fracture using cutting cartridge bag for solid rock roadway

InactiveCN103983146AReduce unit consumptionControl disturbance damageBlastingEngineeringUltimate tensile strength

The invention discloses a medium-length hole mixed wedge cut blasting method capable of realizing directed fracture using a cutting cartridge bag for a solid rock roadway. According to the method disclosed by the invention, 3-4 pairs of vertical wedge cutting holes are arranged at lower half places of an excavating working face; the vertical wedge cutting holes comprise mirror-arranged primary cutting holes and secondary cutting holes that are arranged at the two sides of the primary cutting holes; the primary cutting holes comprise three blast holes that are arranged side by side; the secondary cutting holes comprise four blast holes that are arranged side by side; 1-2 straight holes are formed in the middle portion of each primary cutting hole; a distance between every two adjacent blast holes in the primary cutting holes is 800-1000mm. According to the method disclosed by the invention, the advantage of directed fracture blasting of the cutting cartridge bag is fully utilized, so that an orifice distance and a row distance of the primary cutting holes are increased, the number of blasting holes is reduced, explosive unit consumption is decreased, disturbance damage to the roadway surrounding rocks by cut blasting is effectively controlled, the original strength and stability of the roadway surrounding rocks are guaranteed, and favourable conditions are provided for repairing and maintenance works during later roadway support and operation progresses.

Owner:HENAN POLYTECHNIC UNIV

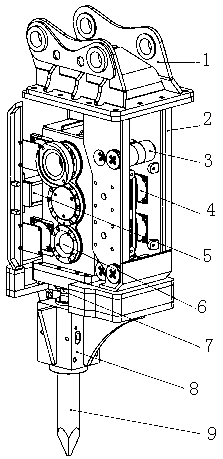

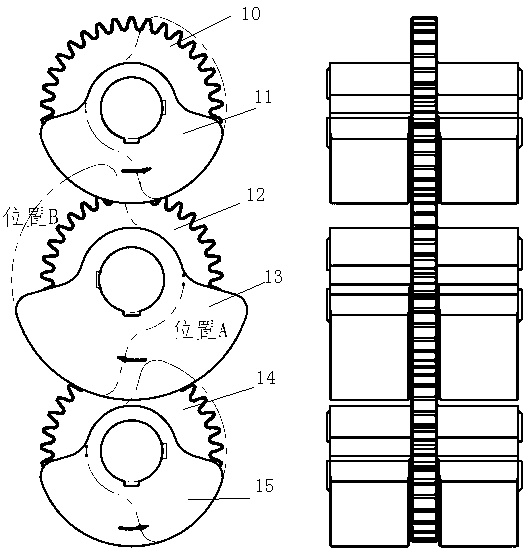

High-frequency vibrating hammering stone crusher

InactiveCN103233490AOvercoming the disadvantages of not being able to break hard rocksImprove work rateSoil-shifting machines/dredgersHydraulic motorReciprocating motion

The invention discloses a high-frequency vibrating hammering stone crusher. The stone crusher comprises a casing, excavator connectors, a vibrating element, an impacting hammer, a steel chisel retainer, a steel chisel, a connecting column, a limit box and a hydraulic motor. The stone crusher is characterized in that the steel chisel retainer and the steel chisel are arranged on the lower portion of the casing, and the vibrating element is arranged in the casing and connected with the casing in a four-rod mode through anti-vibration pads to maintain a relative position. A single row of three eccentric wheels or two rows of six eccentric wheels are arranged on the vibrating element, small eccentric wheels are arranged on the upper and lower portions of each row, the large eccentric wheel is arranged in the middle of each row, and gears are mounted coaxially and meshed with the eccentric wheels. The gears are driven by the hydraulic motor, the vibrating element reciprocates in the casing through vibrating force generated by rotation of the eccentric wheels which are driven by rotation of the gears, and the impacting hammer impacts on the steel chisel directly to produce huge impact force. According to the high-frequency vibrating hammering stone crusher, the eccentric wheels producing high-frequency vibration are used as vibrating sources, so that the impacting hammer with huge inertia force is driven to hammer the steel chisel directly to crush brittle materials of hard stone and the like, and high operation efficiency is obtained.

Owner:SHANGHAI HAOHONG MACHINERY MFG

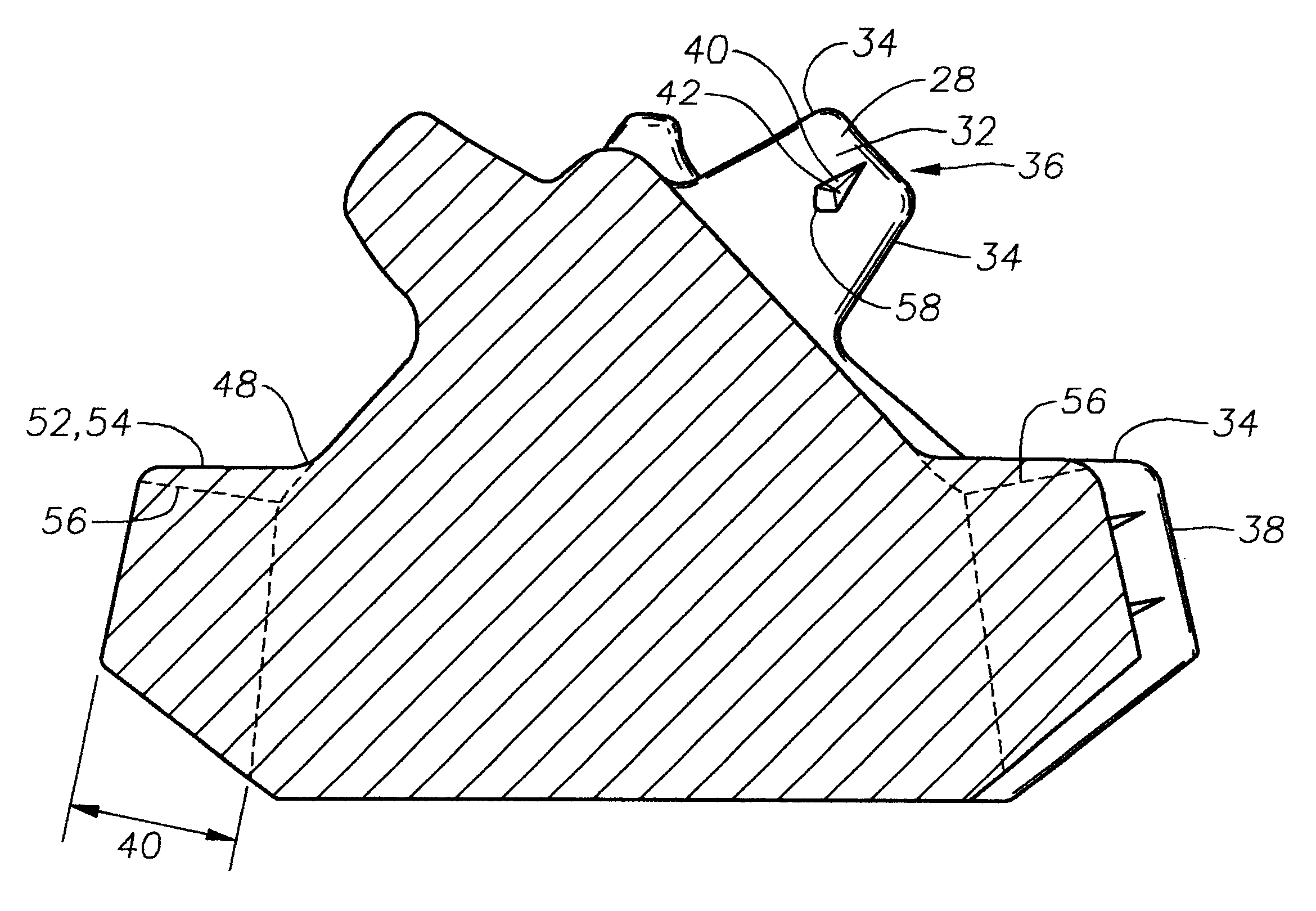

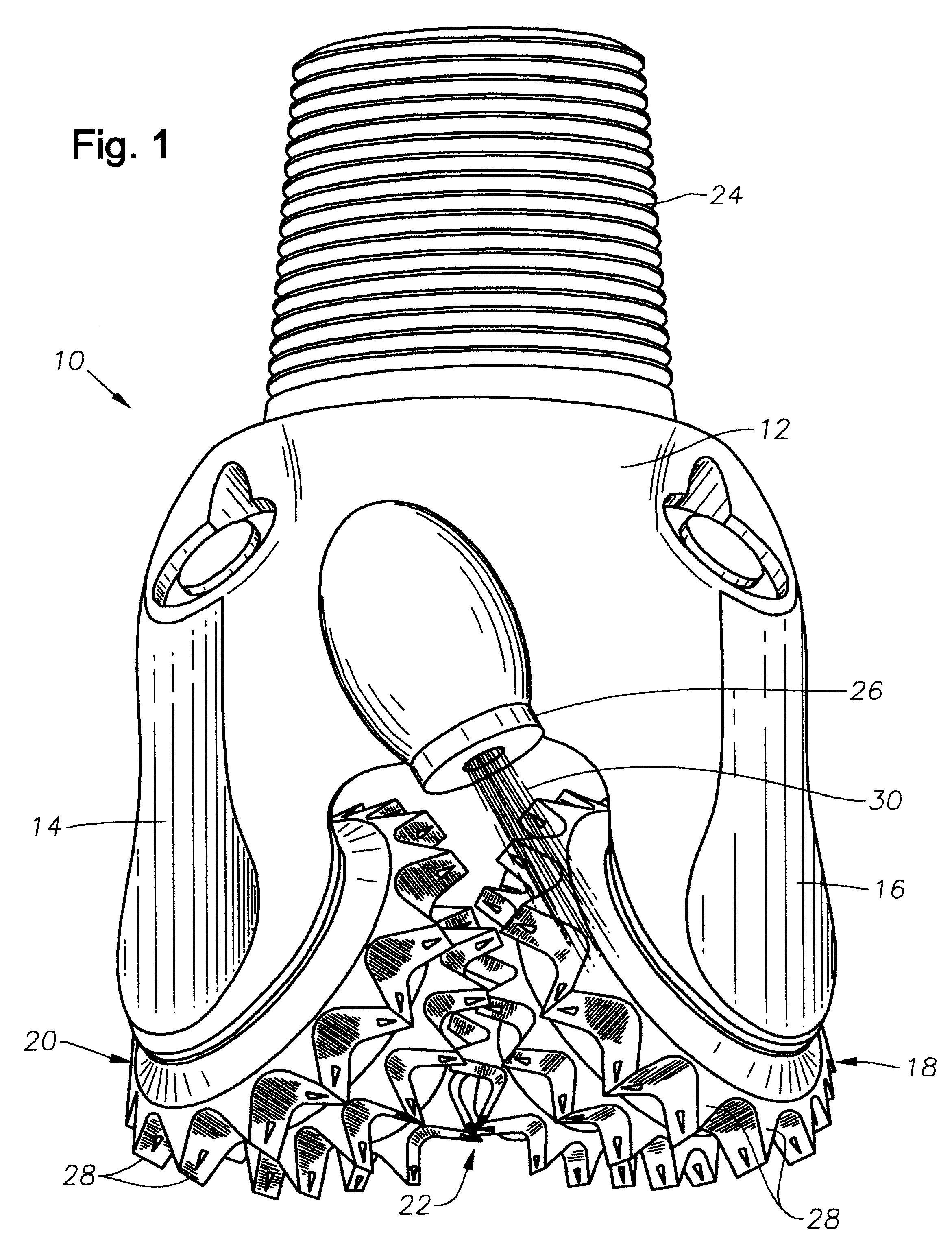

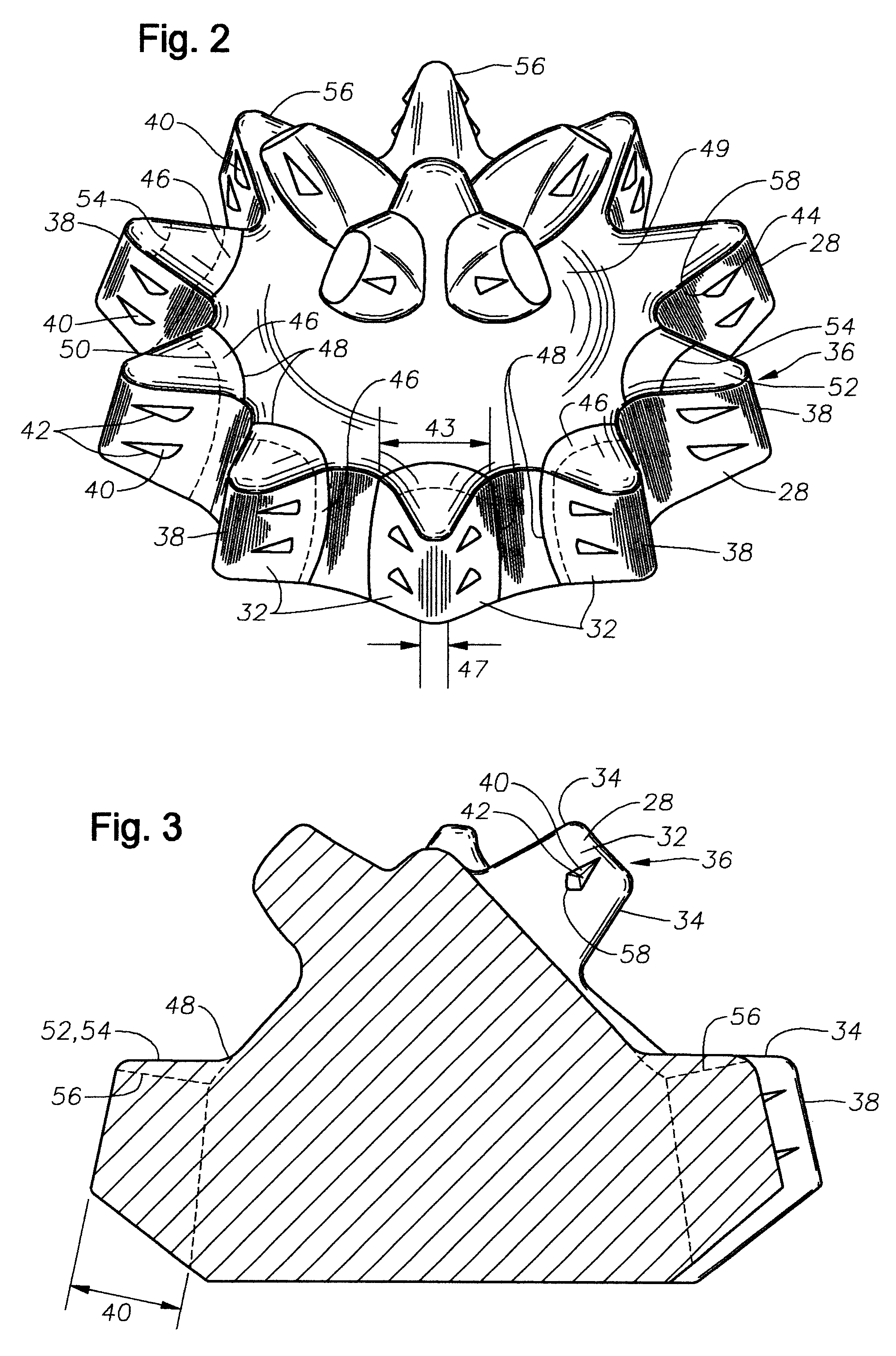

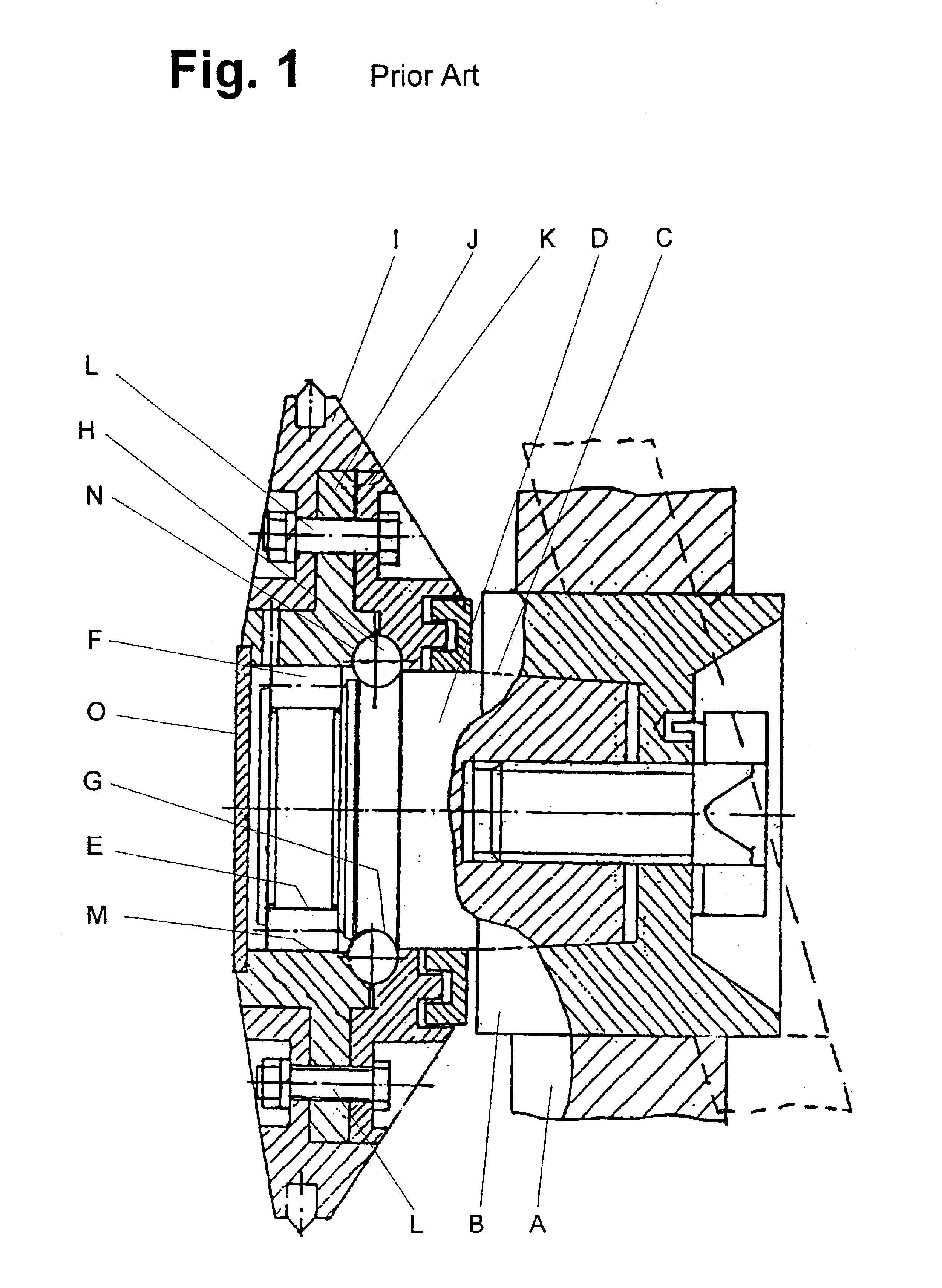

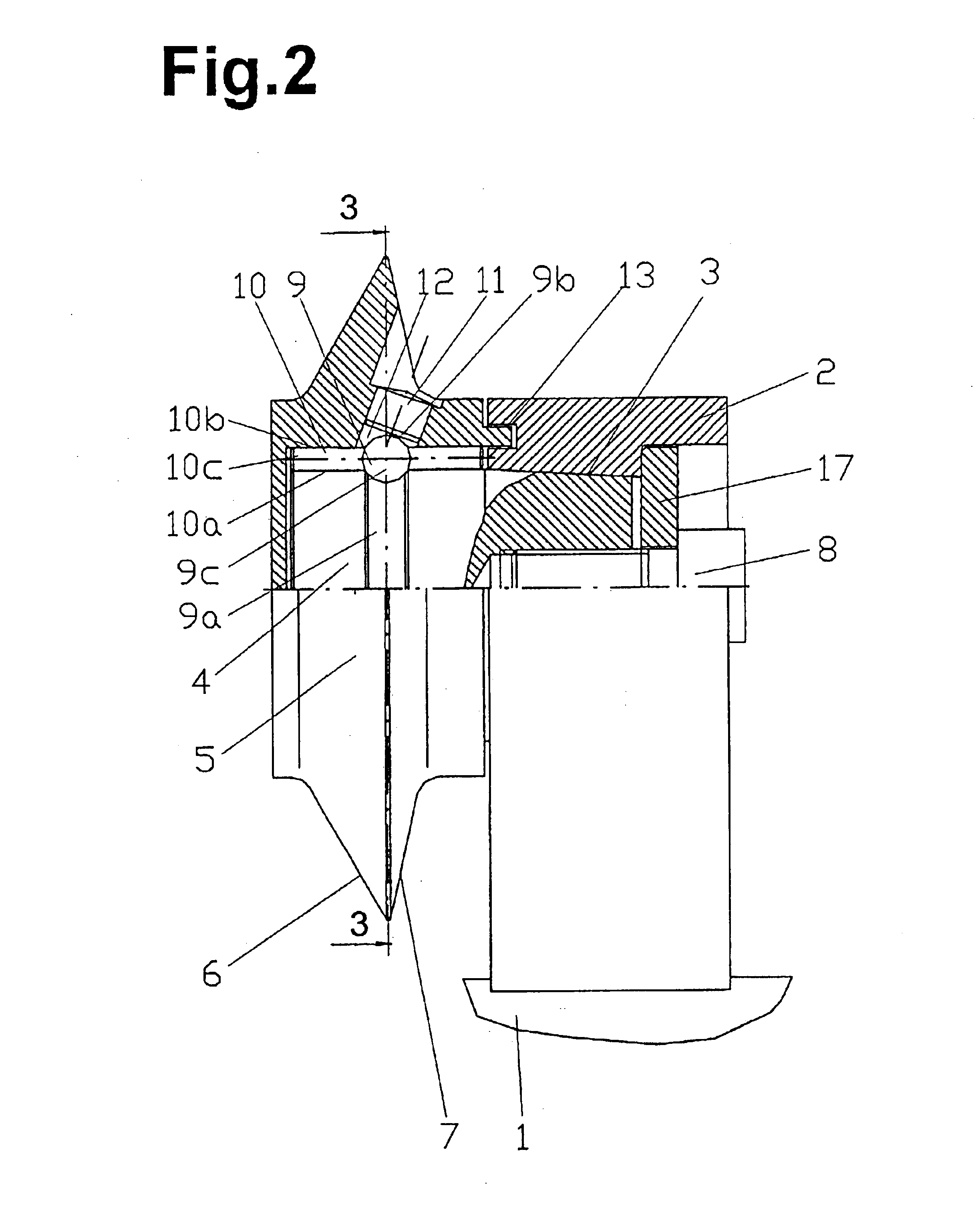

Tooth type drill bit with secondary cutting elements and stress reducing tooth geometry

Disclosed is a tooth type rolling cutter earth boring drill bit with secondary cutting elements on the tooth surfaces. The secondary cutting elements provide additional, relatively sharp edges that help cut hard rock. The teeth also have convex radiused buttresses at their bases to reduce the stresses the teeth experience when drilling through extremely hard rock. This allows the tooth bit to survive the high loads encountered when drilling hard, tough rock formations, without breaking the teeth. The combination of teeth with secondary cutting elements and convex radiused buttresses at their base provide a tooth type rotary drill bit that has superior resistance to wear and breakage when drilling through hard, tough rock without significantly reducing the drilling rate of penetration when drilling through soft rock.

Owner:REEDHYCALOG LP

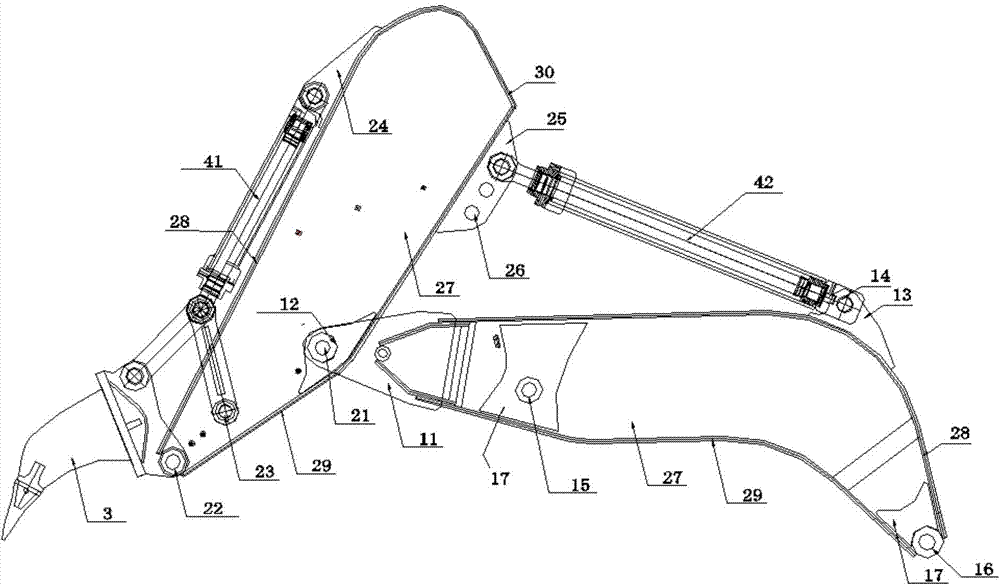

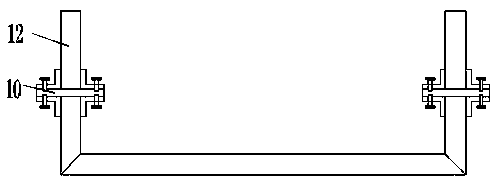

Excavator big arm and small arm structure

InactiveCN103669452AEnsure safetyMaximum digging forceMechanical machines/dredgersWorking environmentEngineering

The invention provides an excavator big arm and small arm structure. One end of a big arm body is provided with a big arm fork. A small arm is connected to the big arm fork of a big arm. The big arm and the small arm are of hollow body structures. The hollow body structure of the big arm and the hollow body structure of the small arm are filled with padding. The excavator big arm and small arm structure is characterized in that the hollow body structure of the big arm and the hollow body structure of the small arm are not provided with feed and discharge openings for the padding. According to the lever principle, the excavator big arm and small arm structure achieves maximization of the excavating force output by equipment. As the sizes and the structures of the big arm and the small arm of an excavator are changed, the excavating force point of the big arm and the excavating force point of the small arm are closer to the center of a complete machine, the output force of the complete machine is maximum, and the complete machine is balanced and stable. As the big arm is not provided with the feed and discharge hole, the work safety of the big arm can be ensured. The weight of the padding of the big arm is designed according to the weight of the big arm required by the hardest rocks of rock soil conventionally excavated, and therefore the big arm can be comprehensively applied to various work environments.

Owner:CHENGDU KAILONG MACHINERY MAINTENANCE

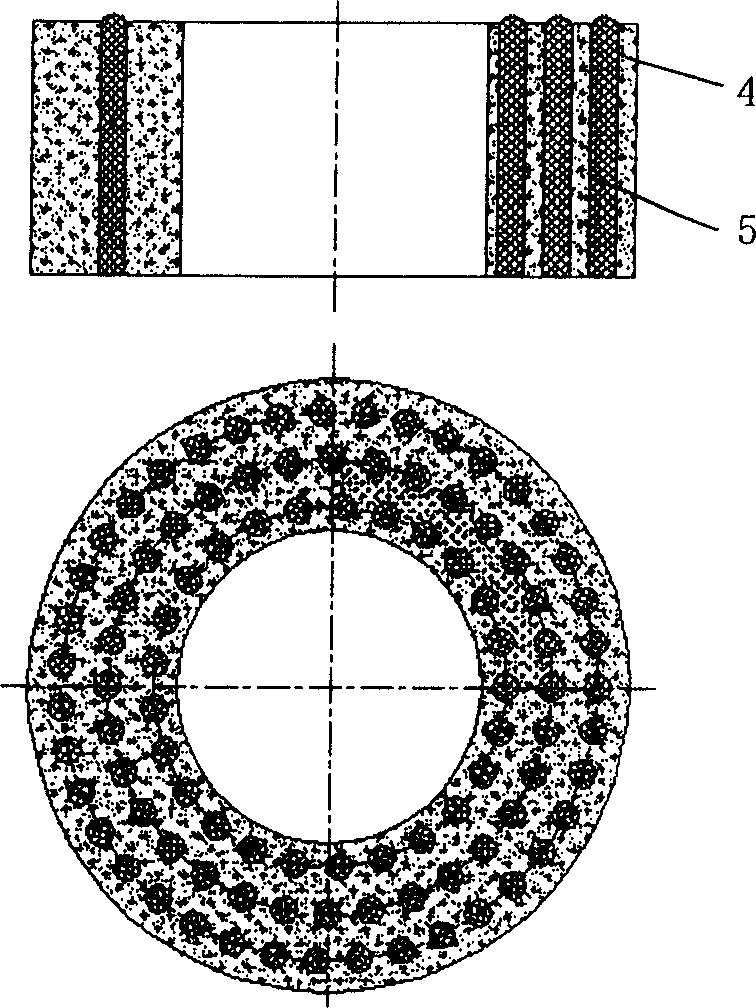

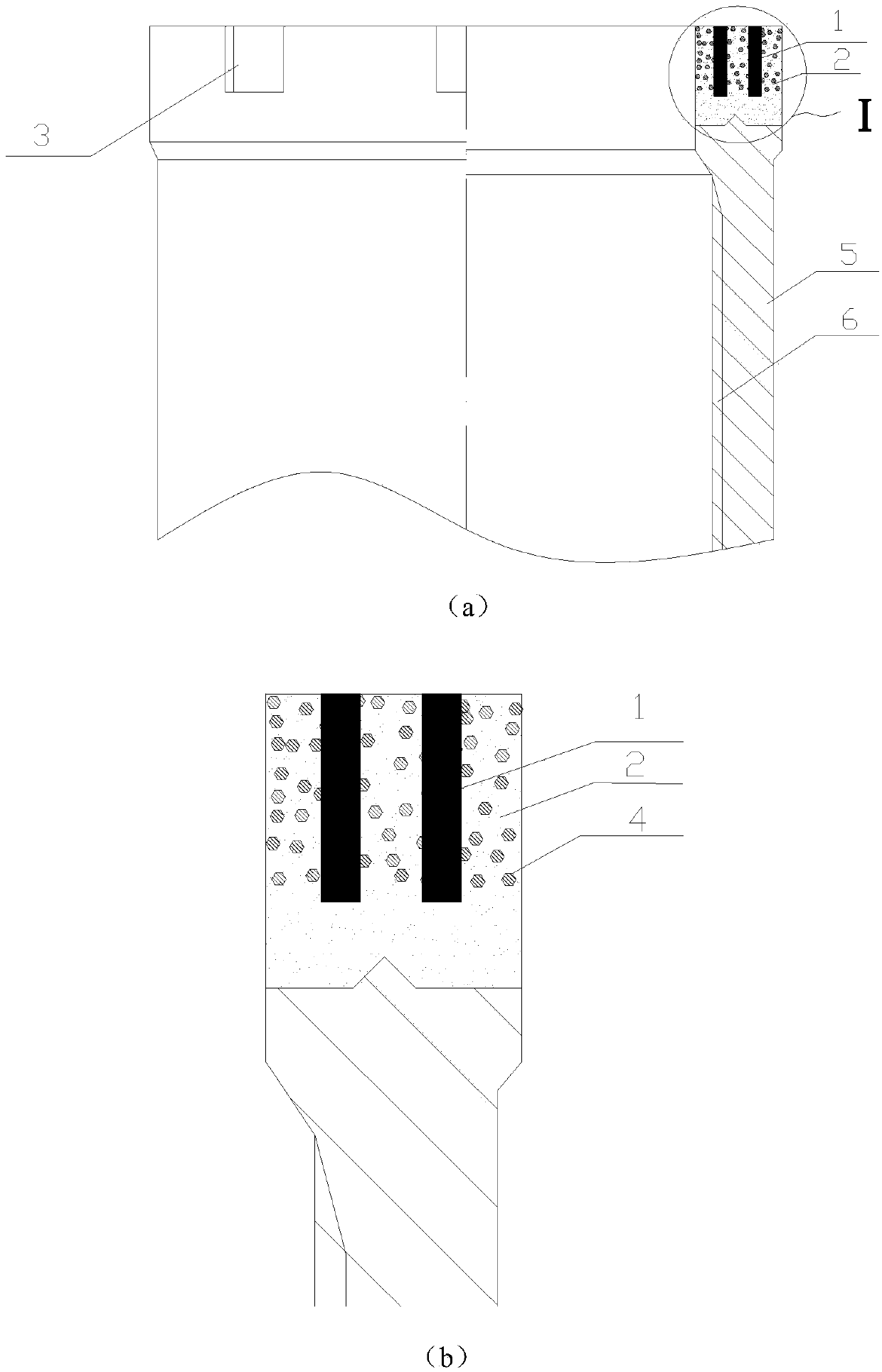

Braze welding nickel base impregnated diamond bit for deep part solid rock drilling, and manufacturing method of braze welding nickel base impregnated diamond bit

The invention discloses a braze welding nickel base impregnated diamond bit for deep part solid rock drilling, and a manufacturing method of the braze welding nickel base impregnated diamond bit. A braze welding nickel base body mixture of the braze welding nickel base impregnated diamond bit is formed by sintering a nickel base casing, a thin metal wire and diamond, the diamond is impregnated into the sintering nickel base casing, the content of diamond accounts for 30 to 80 percent by volume, and the granularity is 35 / 60 mesh; the sintering nickel base casing comprises the following components in mass percent: 35 to 75 percent of nicochrome powder and 25 to 35 percent of iron powder; the diameter of the thin metal wire is 1.0 to 1.6 mm; a nickel base prealloyed brazing filler metal is used, the performance of a drill bit is improved greatly, the sintering temperature is lowered, and the diamond damage degree is lowered; the content of the iron powder is higher, and the cost of the drill bit is lowered; the thin metal wire is embedded, so that the abrasive resistance of the casing is lowered and diamond exposure and drilling hole deviation preventing are facilitated. The braze welding nickel base impregnated diamond bit provided by the invention is particularly suitable for deep part solid rock drilling, and is also suitable for shallow slippery formation drilling.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

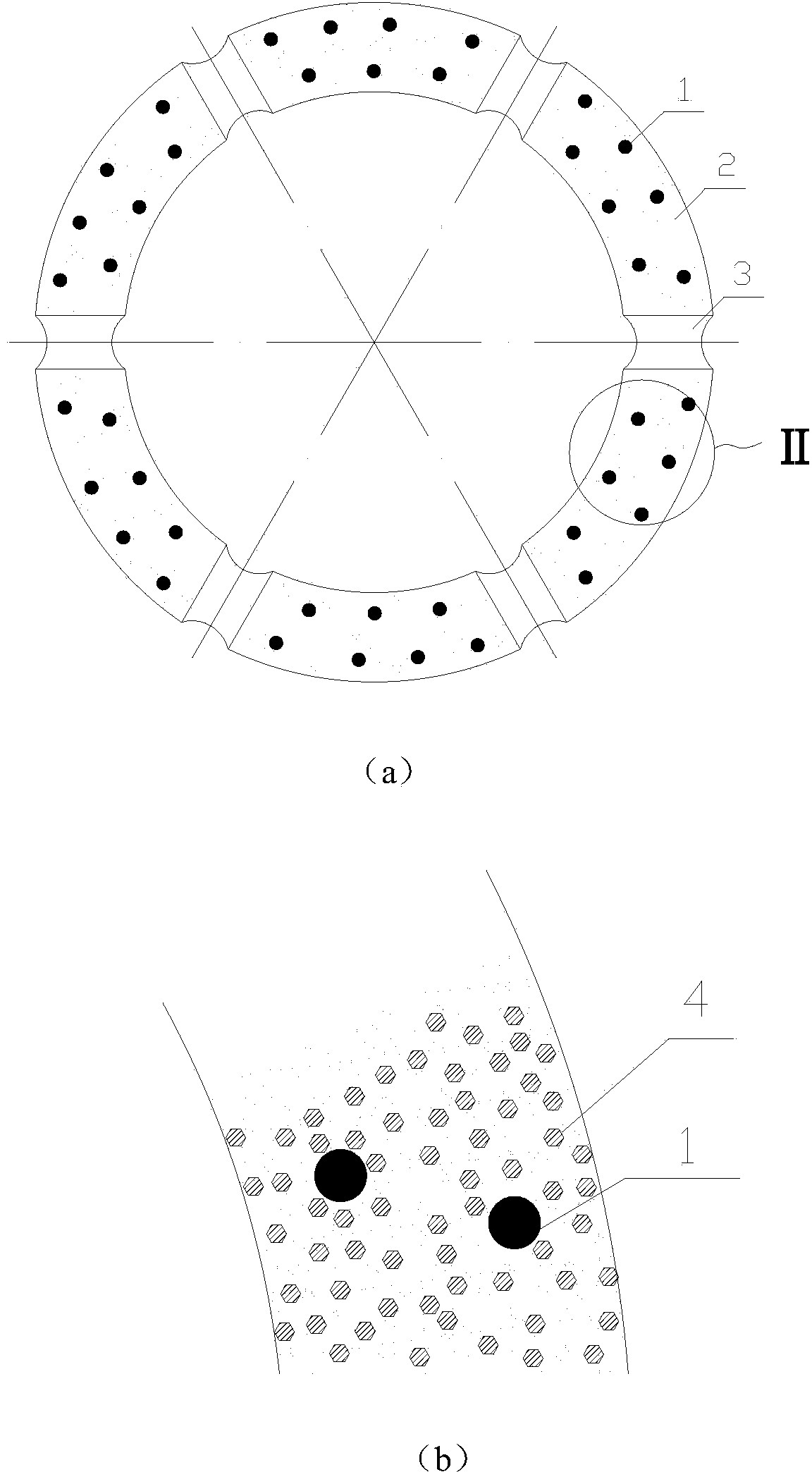

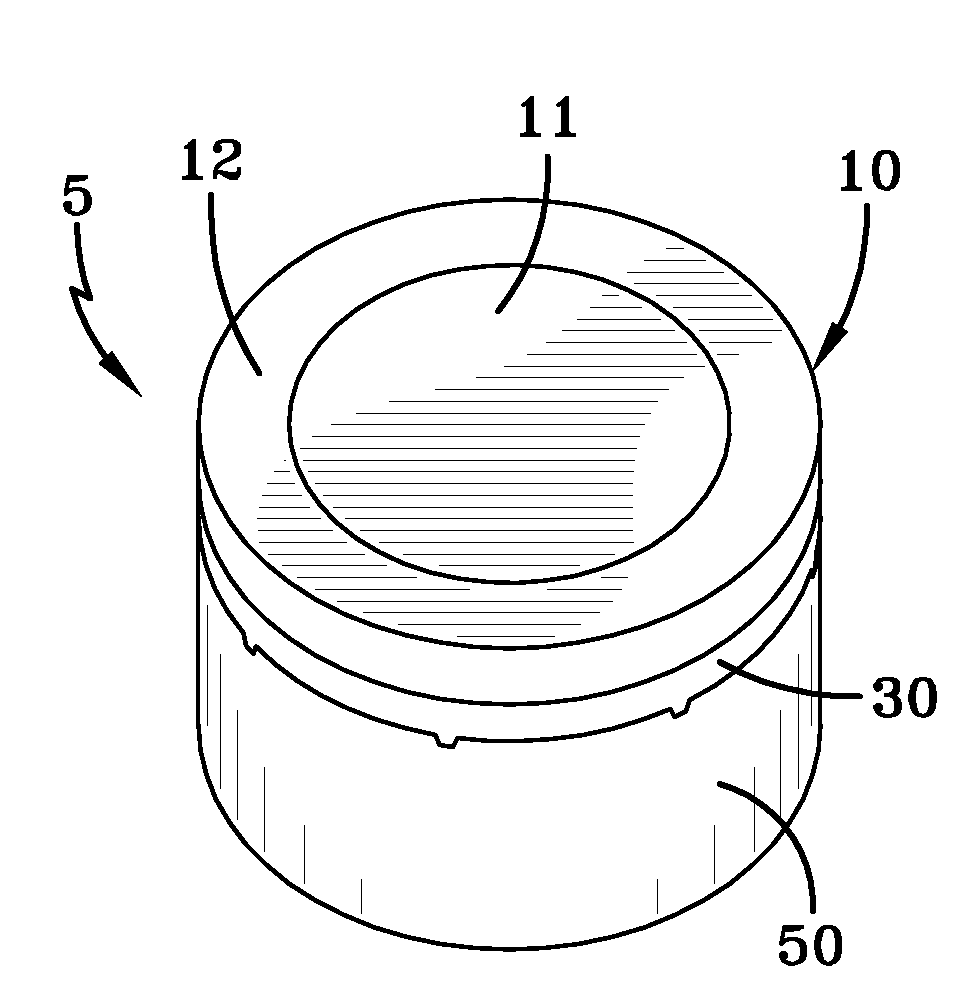

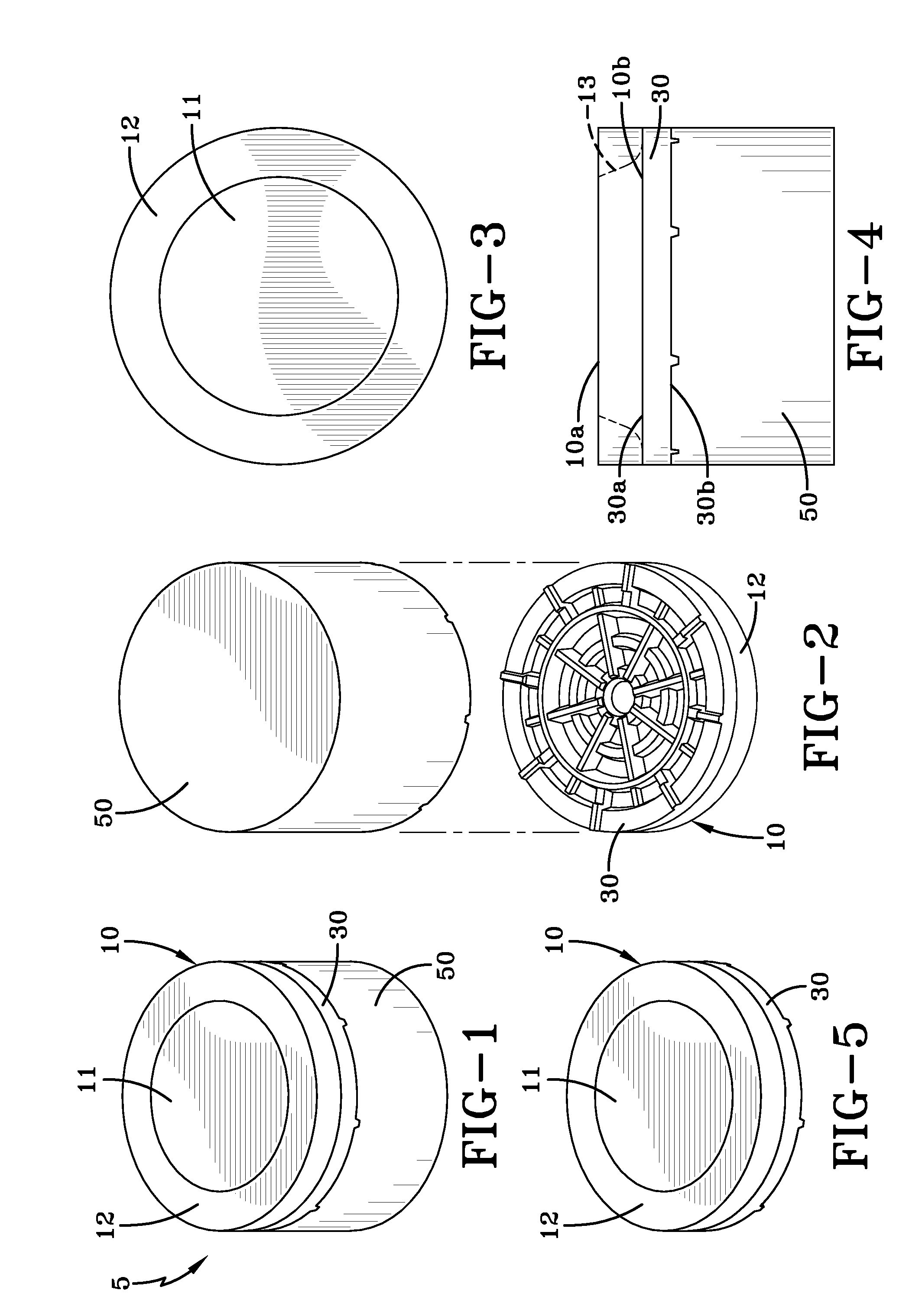

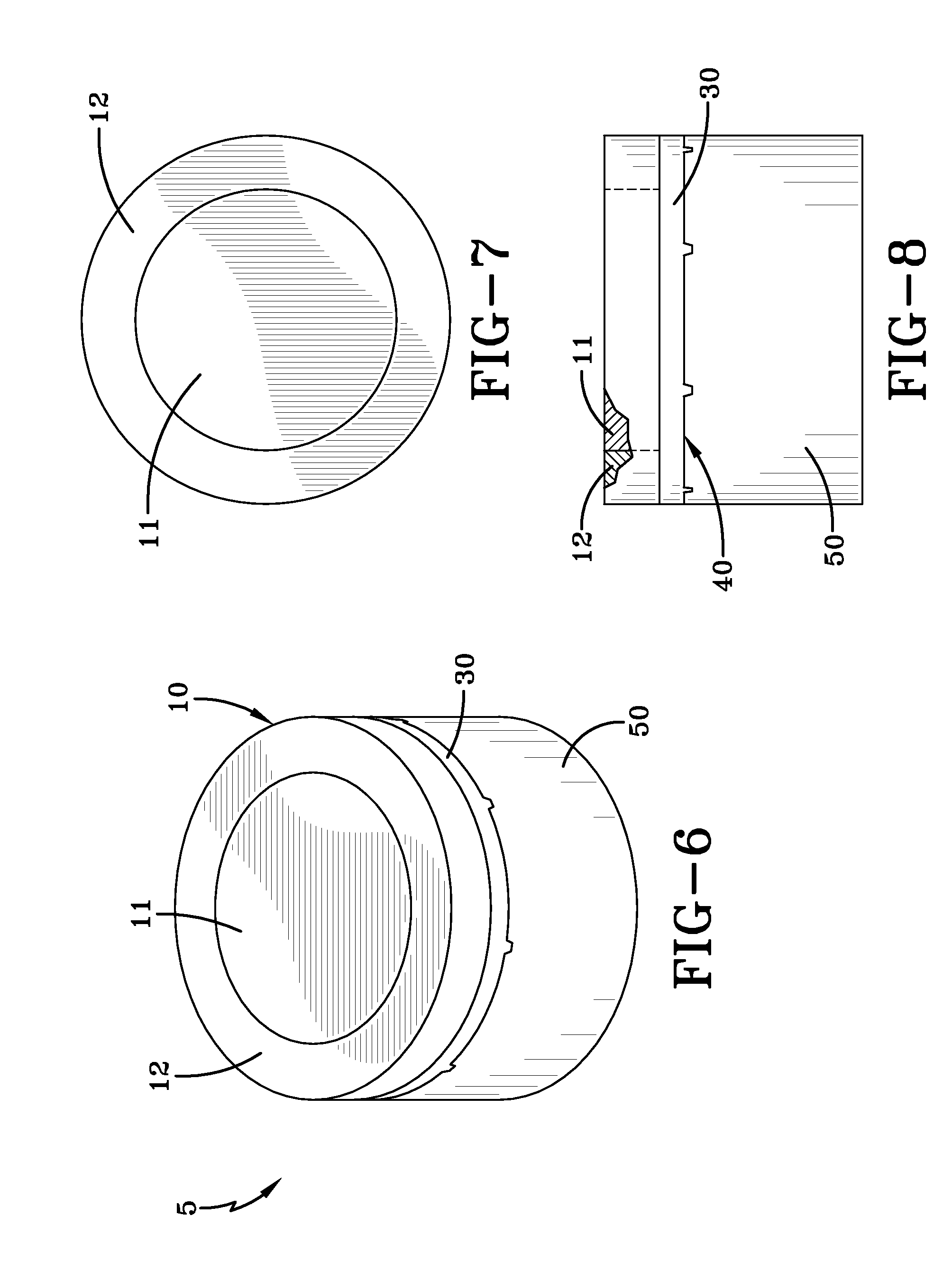

Composite polycrystalline diamond body

In this novel PDC cutter, diamond powders of different composition and / or different grain size, are distributed, shaped, and compacted with a novel pressing tool, in multiple stages, spatially arranged into different regions of the PDC diamond body, then HPHT sintered to form one PDC body with spatially varying hardness, toughness and thermal resistance more optimal for machining, drilling and / or cutting of hard rock and stone.

Owner:INT DIAMOND SERVICES

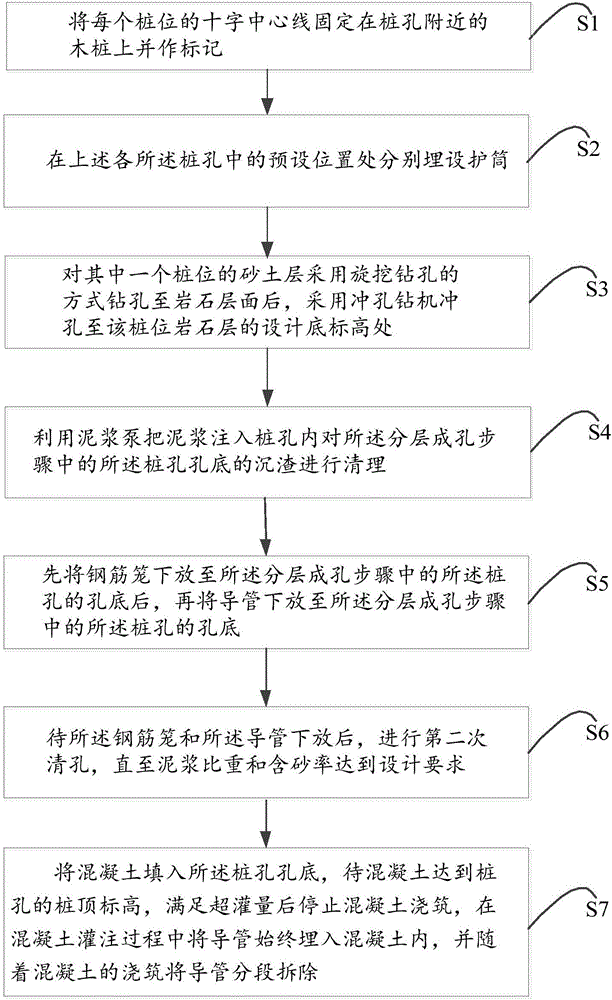

Mud protection wall bored pile construction method

InactiveCN107524142AAvoid easily falling bitsAvoid the disadvantages of being unable to drill in hard rockBulkheads/pilesHigh densityPunching

The invention provides a mud protection wall bored pile construction method. The method comprises the steps of: a pile hole positioning step; a protection cylinder embedding step; a layered hole forming step: after a sand soil layer in one pile position is drilled to a rock layer by adopting a rotary excavation drilling mode, a punching drill is adopted to drill to a designed bottom elevation of a rock layer in the pile position; a primary hole cleaning step; a reinforcement cage and guide pipe placing step; a secondary hole cleaning step; and a concrete casting and guide pipe disassembly step. In the method, a rotary excavator is adopted to drill the sand soil layer of a pile hole to a rock layer interface; a punching pile drier is adopted to drill a pile end bearing course to the designed bottom elevation of the rock layer in the pile position; and through use of the advantage of high construction efficiency of the rotary excavator on the sand soil layer and use the advantage of capability of effectively preventing easy fall of a drill bit of the rotary excavator in high-density clay or incapability of drilling hard rock in the punching pile driver, the construction speed is greatly accelerated, the construction period is shortened, and the hole forming quality is improved.

Owner:CHINA MCC20 GRP CORP

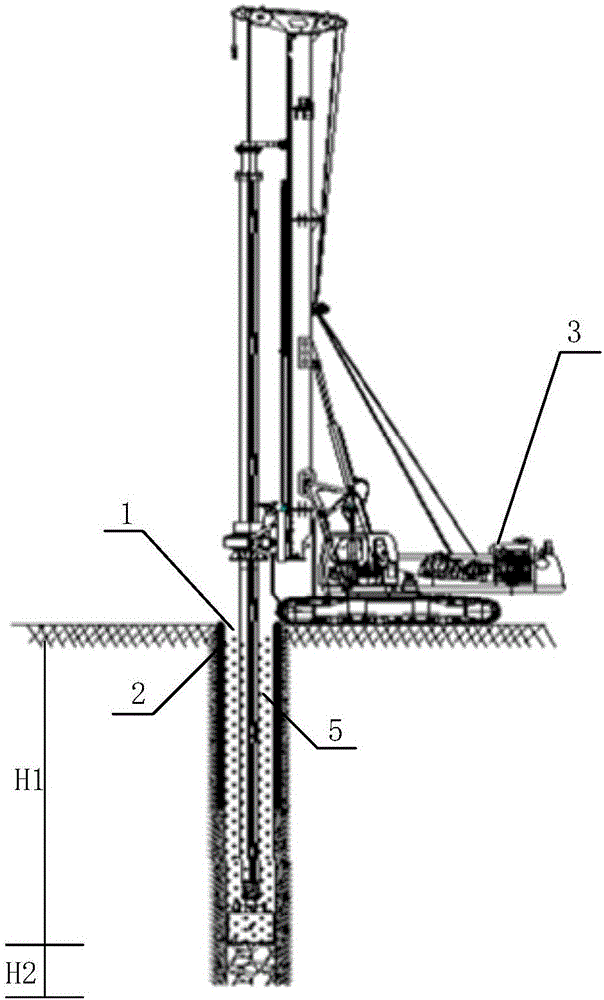

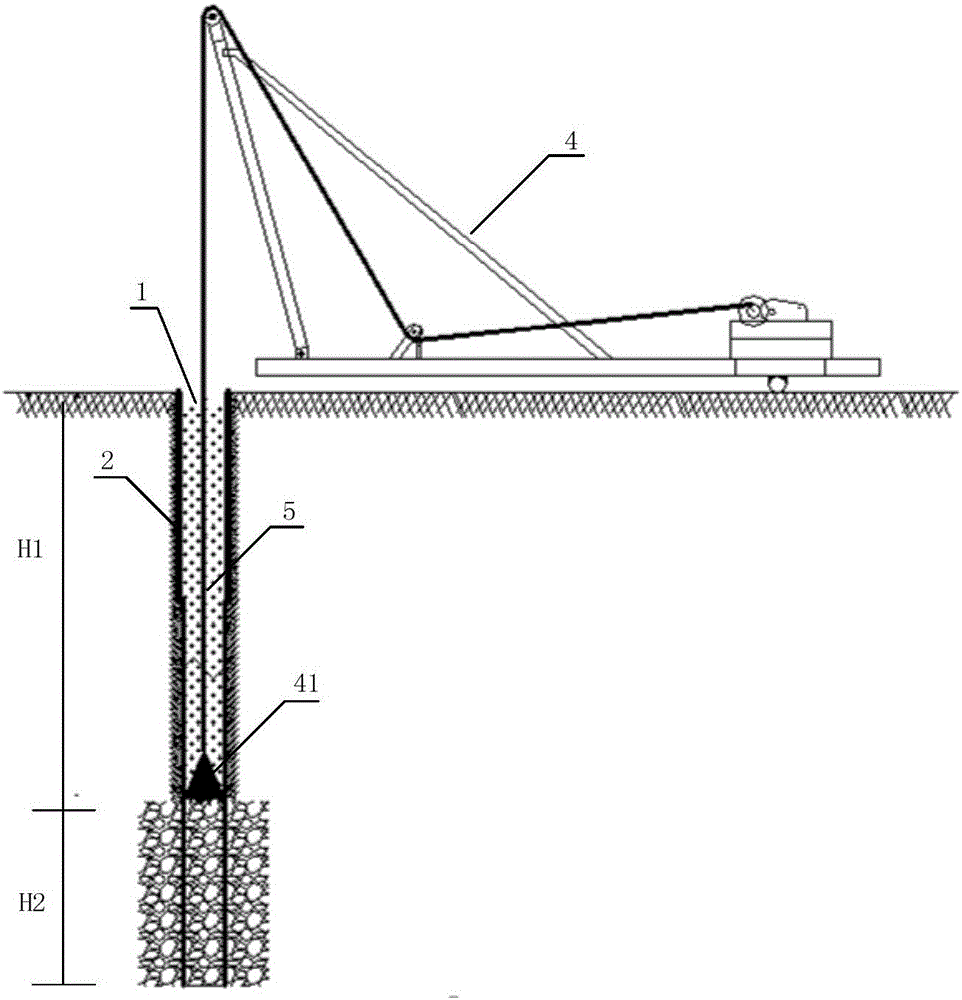

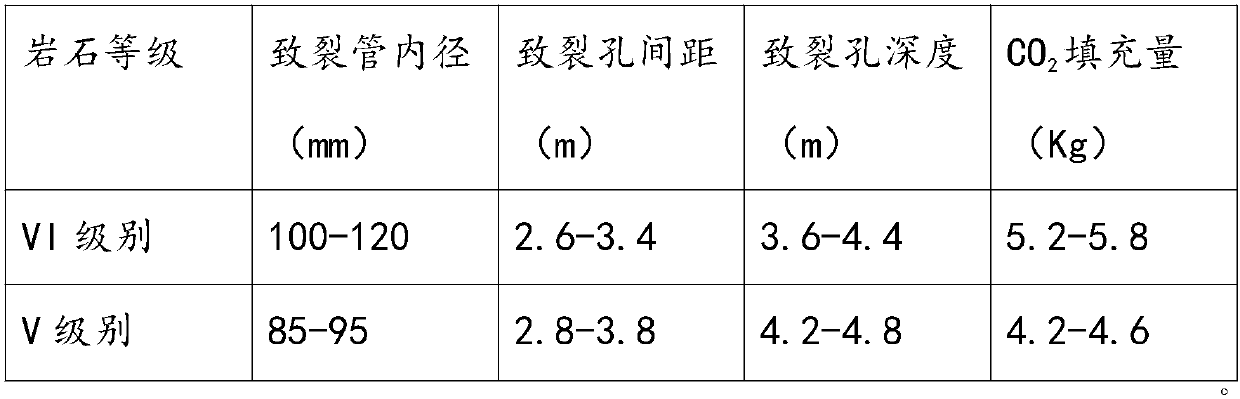

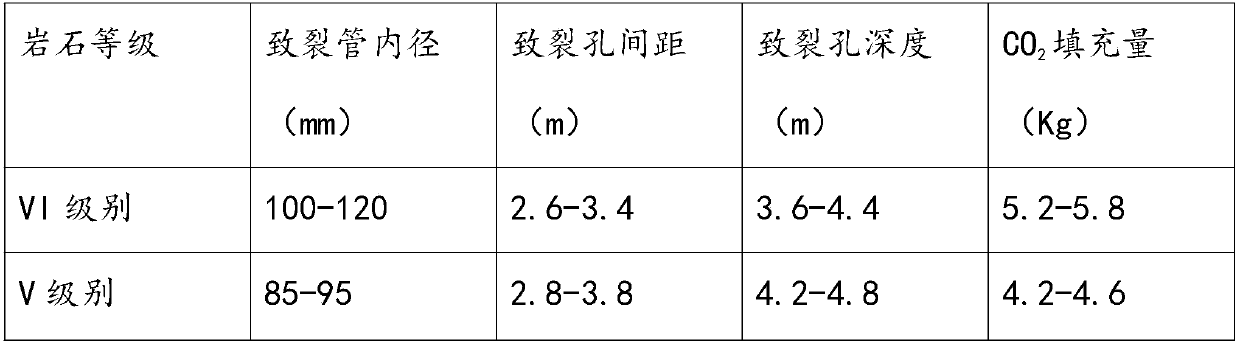

Process for liquid-state carbon dioxide cracking rocks

InactiveCN107941097APromote expansionPromote fragmentationBlasting cartridgesBlastingLow noiseLiquid state

The invention discloses a process for liquid-state carbon dioxide cracking rocks. The process comprises the following steps: (S1) rock grades are detected for blasting objects; (S2) inner diameters ofcracking pipes, a filling quantity of liquid-state carbon dioxide, arrangement gaps of cracking holes and drilling depths of the cracking holes are selected; (S3) free faces and the cracking holes needed by blasting are provided; (S4) the drilled cracking holes are checked and cleared if water is in the holes to prevent the pipe flying phenomenon; (S5) cracking pipes are assembled and inflated; (S6) the cracking holes are blocked; the cracking pipes are put in the cracking holes; and the backfill is performed after placement in place; and (S7) the blasting process is performed; the detonationvoltage is 18800 V; and the technical effects of low blasting vibration, low noise, quick blasting of more solid rocks, low influence on surrounding buildings and crowds and shortening of the total construction period are achieved.

Owner:中铁十局集团第八工程有限公司

A high-pressure waterway anti-seepage method and a high-pressure waterway annular anti-seepage curtain

InactiveCN102277858AExcellent mechanical propertiesImprove anti-seepage performanceMarine site engineeringChemical groutingReinforced concrete

The invention discloses a high-pressure waterway anti-seepage method and a high-pressure waterway annular anti-seepage curtain, which belong to the field of rock mass anti-seepage, in particular to the field of rock mass anti-seepage treatment in a relatively high water head environment. The present invention aims at the disadvantages of the existing high-pressure waterway that needs to set up hanging curtains upstream of the underground powerhouse. Consolidate grouting holes and anti-seepage grouting holes; then use 0.3Mpa~0.5Mpa pressure for anti-seepage grouting and surrounding rock consolidation grouting; finally use ultra-fine cement chemical grouting and anti-seepage grouting holes with a grouting pressure greater than 2.0MPa to improve the surrounding area. The anti-seepage performance of the rock can reduce the leakage of high-pressure waterways, and then achieve the purpose of canceling the hanging curtain. The method has reasonable process layout design, simple structure and convenient operation, and can greatly save engineering cost.

Owner:POWERCHINA ZHONGNAN ENG

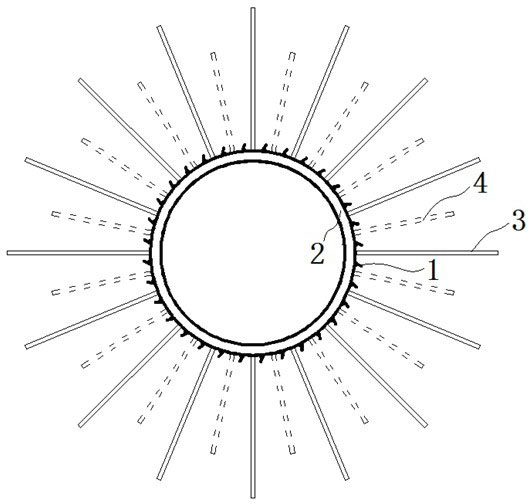

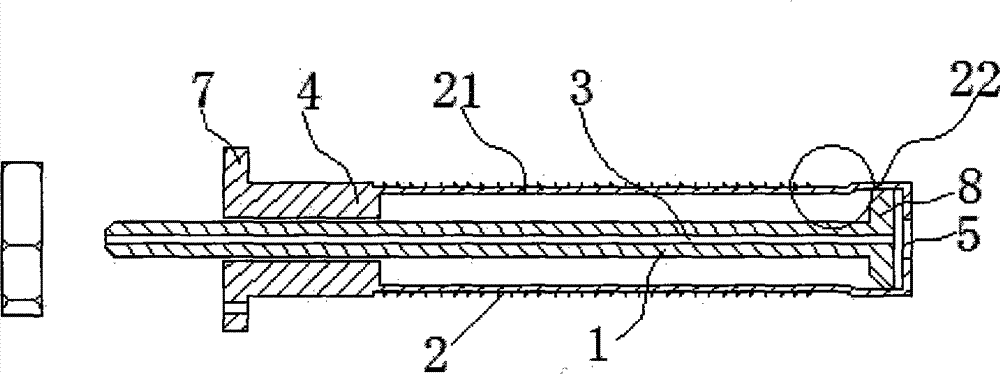

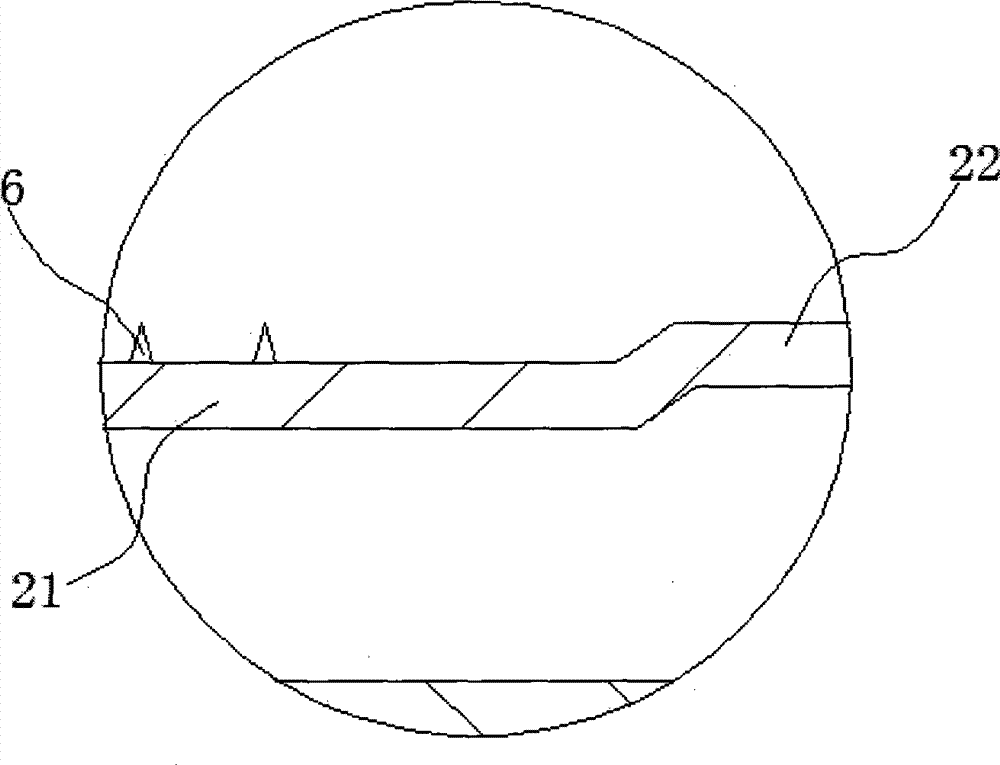

Rock thermophysical parameter testing method and testing system under conditions of high temperature and high pressure

InactiveCN106442614AAccurately Simulate High Pressure ConditionsPrecise control of pressurizationMaterial thermal conductivityMaterial heat developmentTemperature controlRock sample

The invention provides a rock thermophysical parameter testing method under the conditions of high temperature and high pressure. The method comprises the following steps: processing a deep-layer rock into a rectangular-solid rock sample, putting the rock sample into an MTS true triaxial testing cylinder, carrying out heating and pressurization on the rock sample under the control of an MTS controller, and measuring the thermophysical parameters of the rock sample. The invention also provides a testing system which comprises the MTS controller, the MTS true triaxial testing cylinder, an MTS servo supercharger and an MTS hydraulic machine. The method and system can be utilized to accurately simulate the underground deep layer rock high-pressure state; and the temperature control and acquisition module can keep the rock sample temperature constant, accurately measure the rock sample temperature and accurately simulate the high-temperature state of the underground deep layer rock. A stable flat band process is utilized to measure the heat conductivity coefficient of the rock sample. The system is simple to operate, and has the advantages of high measuring accuracy, short testing period and accurate thermophysical parameter measurement result.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

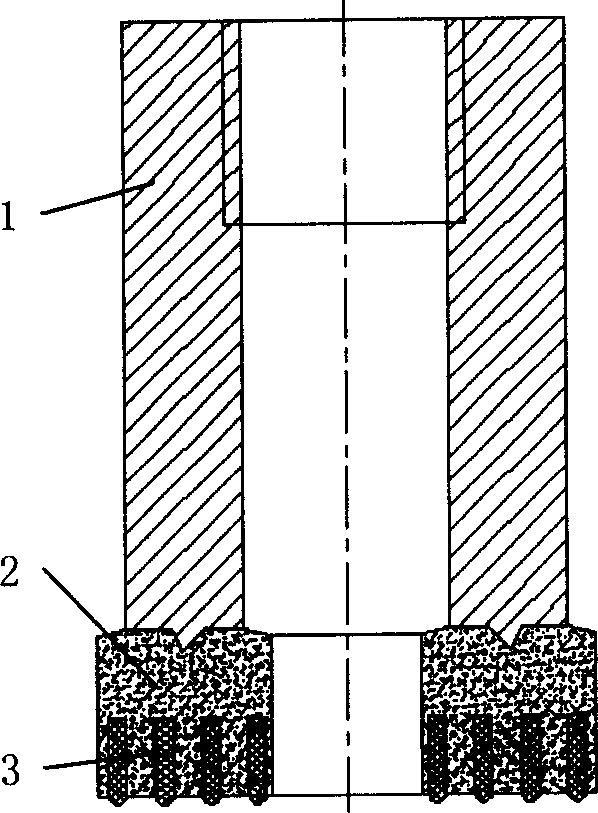

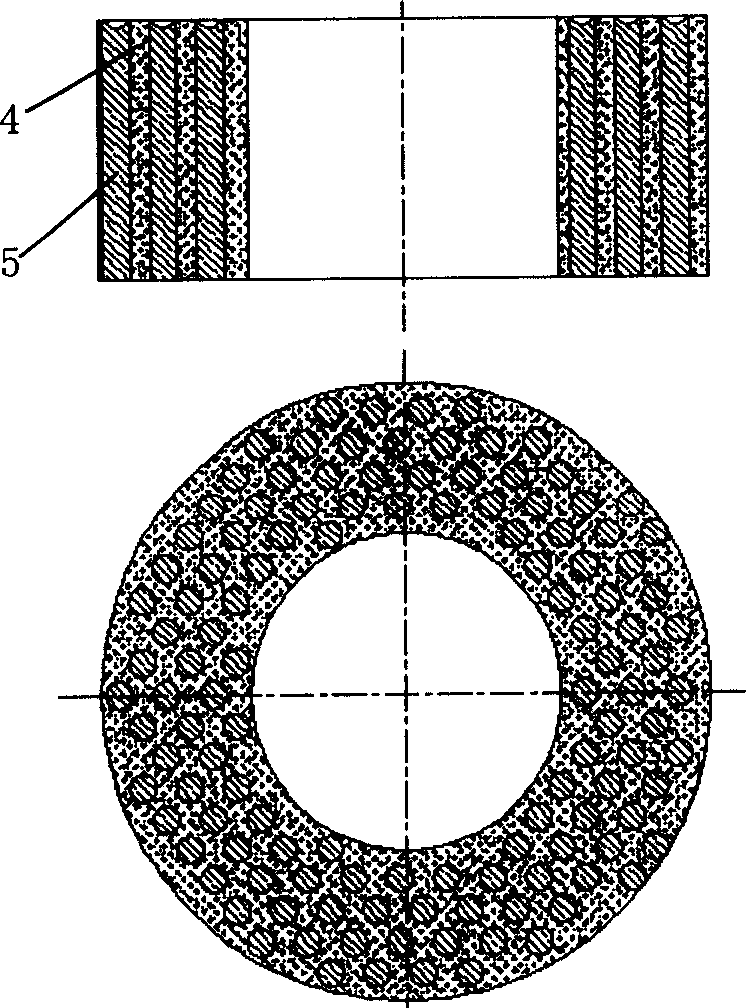

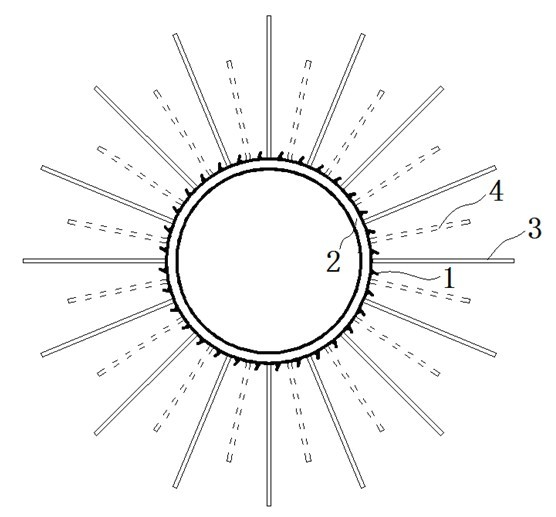

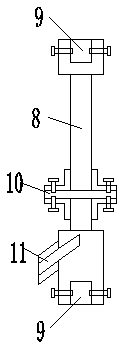

Expansion grouting anchor rod

The invention discloses an expansion grouting anchor rod which comprises an anchor rod assembly and a sleeve. The sleeve is connected with the anchor rod assembly in a sleeved and matched mode. A grouting tube is axially arranged in a threaded rod of the anchor rod assembly. The sleeve is of a hollow tubular structure integrally. The inlet end of the sleeve is provided with a locating sleeve matched with the anchor rod assembly. The other end of the sleeve is provided with a grouting hole. The outer circumferential surface of the sleeve is provided with a circle of concave expansion tube. The outer surface of the expansion tube is provided with circular teeth. The cross section of each circular tooth is of an isosceles triangle structure, and the top angles of the circular teeth are flush with the locating sleeve. The expansion grouting anchor rod is simple in structure and convenient to use. When the expansion grouting anchor rod is used for carrying out punching and anchoring on hard rocks, the expansion tube can be expanded by an expansion head and simultaneously the top angles of the circular teeth can be further embedded into a hole wall. When the expansion grouting anchor rod is used for carrying out punching and anchoring on soft coal beds, grouting operation can be carried out on the grouting tube through a grouter, so the bonding degree and stability between the soft coal beds near the hole wall can be enhanced.

Owner:LIAONING TECHNICAL UNIVERSITY

Radial drilling device for abrasive water jet flow

ActiveCN104295238AShorten the timeImprove efficiencyLiquid/gas jet drillingDirectional drillingEngineeringAbrasive water jet

The invention discloses a radial drilling device for abrasive water jet flow, and the device comprises an outer barrel, a central tube, a windowing mechanism, a steering mechanism, and a resetting mechanism, wherein the central tube can slidingly pass through the outer barrel along the axial direction of the outer barrel and is provided with a stressed part to drive the central tube to be moved along a first direction under hydraulic pressure; the windowing mechanism oppositely sliding along the central tube is provided with a jet element to window a sleeve; a steering passageway with an inlet end and an outlet end is arranged in the steering mechanism fixedly connected with the windowing mechanism, the steering mechanism can be provided with a drilling element for drilling rocks at the windowed position; the resetting mechanism is used to drive the central tube to be moved along a second direction after the steering mechanism is decompressed, and the first direction is opposite to the second direction; the resetting distance of the resetting mechanism is the same as that between the jet element and the outlet end of the steering passageway. Through the radial drilling device for abrasive water jet flow, the compact and hard rock can be effectively opened.

Owner:PETROCHINA CO LTD

Rock-soil sampling mechanical device for civil engineering

InactiveCN110793808AEasy to collectAccurate analysisWithdrawing sample devicesStructural engineeringDrill bit

The invention relates to a rock-soil sampling mechanical device for civil engineering and belongs to the technical field of rock-soil analysis of civil engineering. The rock-soil sampling mechanical device comprises a top frame, a vertically arranged hydraulic telescopic rod whose upper end is fixedly connected with a bottom end of the top frame, a sampling pipe which is vertically arranged underthe top frame and is provided with sampling windows which are uniformly distributed at intervals from the top to bottom, a first rotating shaft which is vertically arranged and is rotationally arranged in the sampling pipe, a drill bit which is fixedly connected with a lower end of the first rotating shaft, and a first driving device which is fixedly connected to the top frame and is in transmission connection with an upper end of the first rotating shaft, wherein two ends of the first rotating shaft rotationally extend out of the sampling pipe. The rock-soil sampling mechanical device has theadvantages that hard rock in the soil can be drilled, the soil collection in deep soil can be facilitated, meanwhile, soil samples of different soil layers can be collected separately, and the soil sample analysis is facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

Rotative drill rig in punching and smashing type

The present invention relates to a rotary percussion ramming driller, including machine frame, machine seat, rotary powder head, vibration-damping device, hoister, drill rod, drill bit, airlift channel, air compressor connecting nozzle, slurry connecting nozzle, water pump circulation equipment and ramming or percussion hammerhead placed on the upper portion of the drill bit. Said driller is not only applicable to general soil layer and soil layer with block stone and pebble, but also is applicable to solid rock layer.

Owner:万泽仁 +2

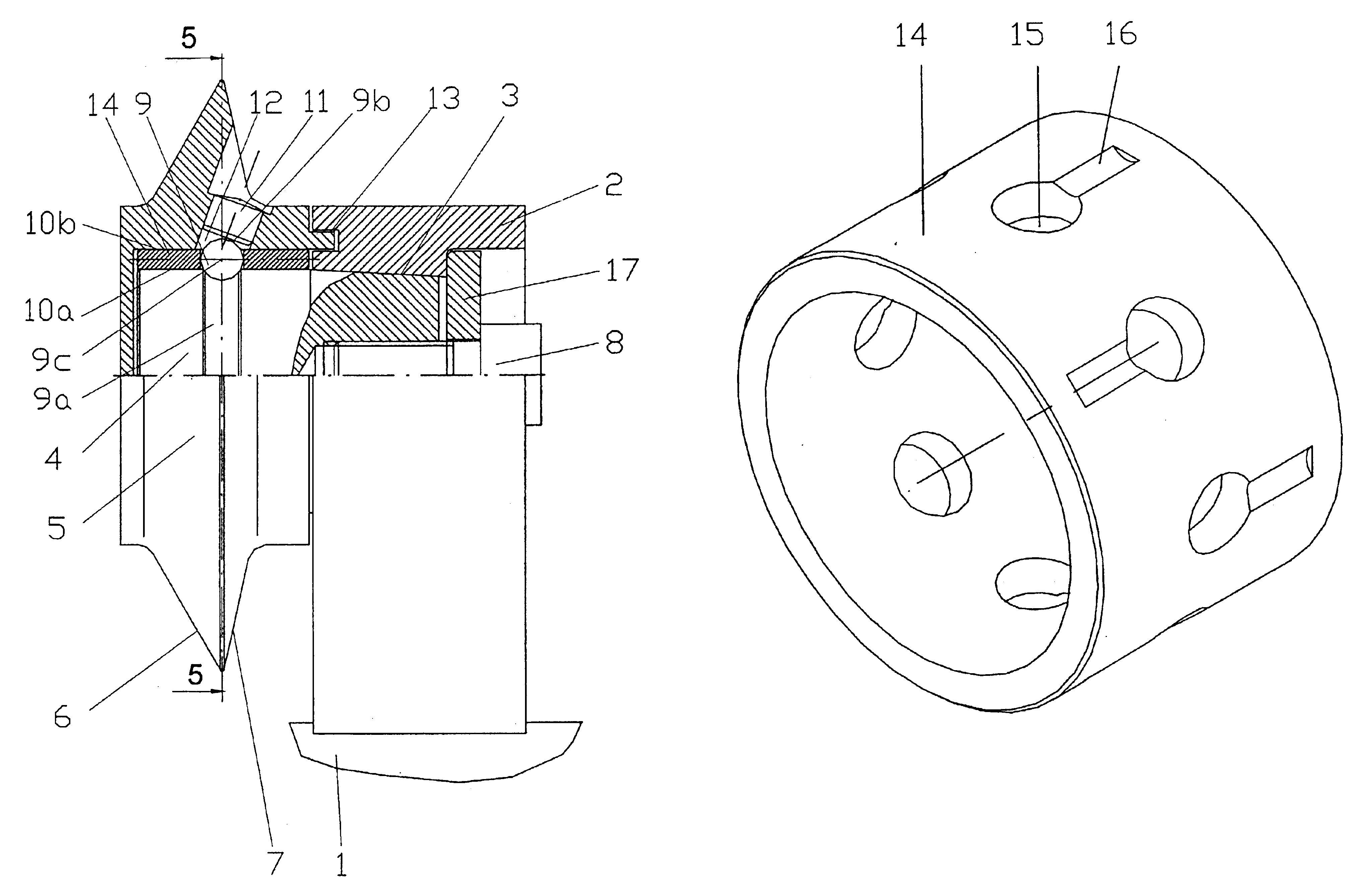

Mini disk bit

InactiveUS6935443B2Extended service lifeImprove stabilityDrill bitsRotary combination bearingsCircular discNeedle roller bearing

A small sized disk bit includes a bit holder accommodated in a bearing journal on its side (overhangingly), and a disk body with asymmetrically designed wedge flanks mounted rotatably thereon. To enable the disk body to absorb high radial and axial strong forces encountered during the engagement of the disk on a solid rock, the disk body is designed as a one-part disk body with a blind hole with its surface and the bearing journal surface being designed as components of the bearing. The bearing involves the combination of a radial and thrust bearing each, where the thrust bearing is milled into the track of the radial bearing. A ball bearing is used as the axial bearing and a needle roller bearing, a cylindrical roller bearing or a slide bearing is used as the radial bearing. The diameter of the ball bearing is larger than the diameter of the needle rollers, or the cylindrical rollers or the thickness of the sliding bush of the slide bearing.

Owner:MAN TAKRAF FORDERTECHN

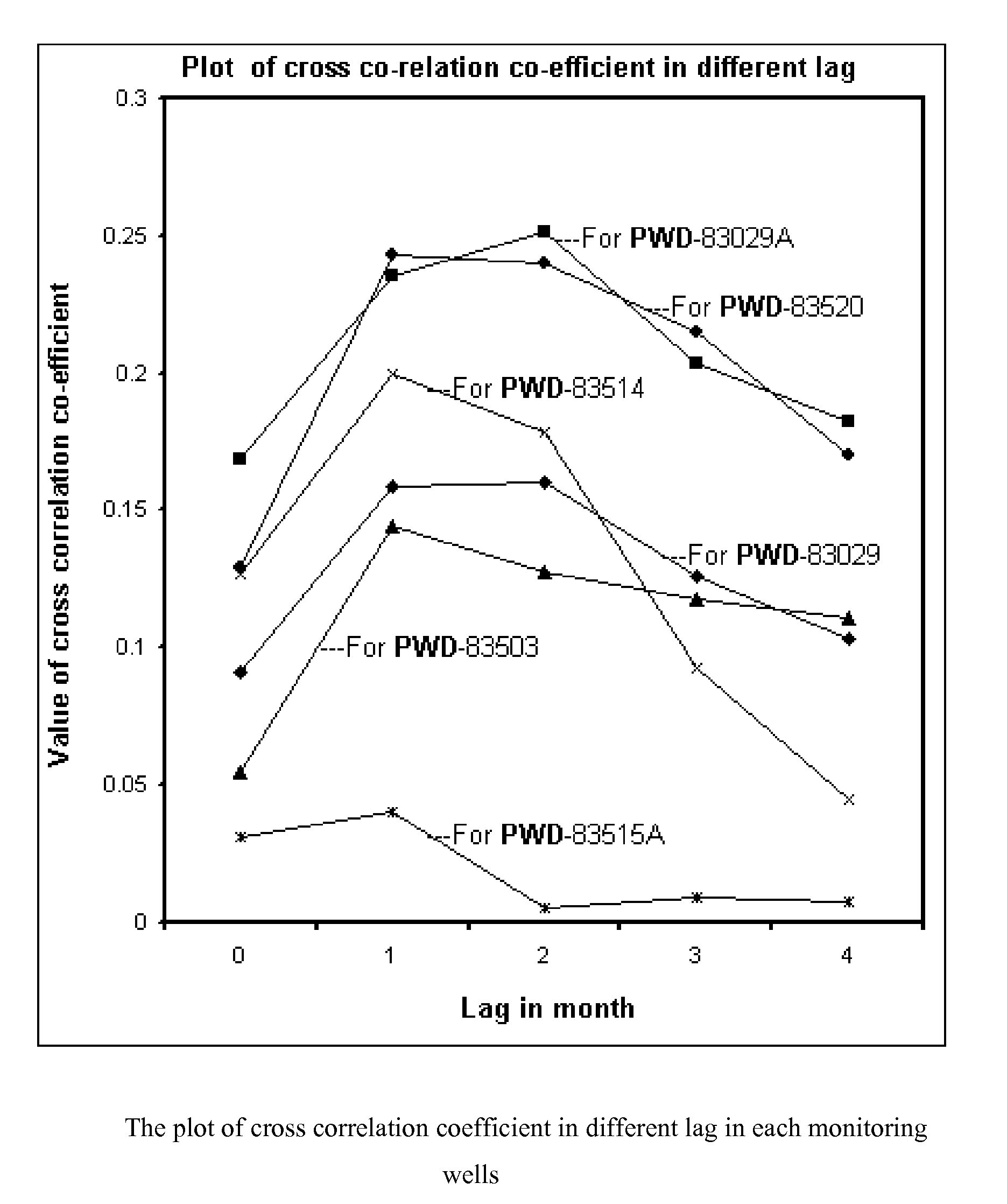

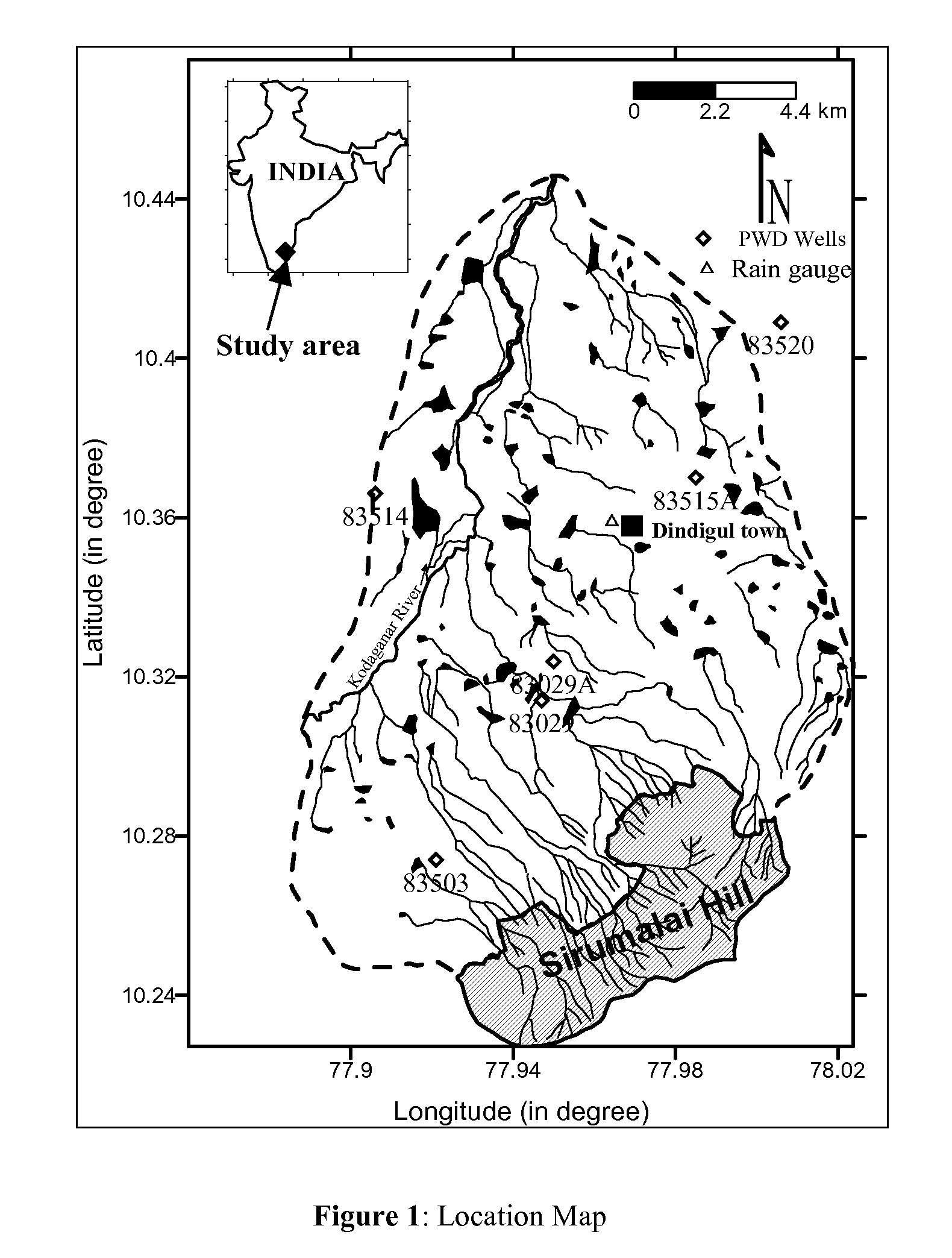

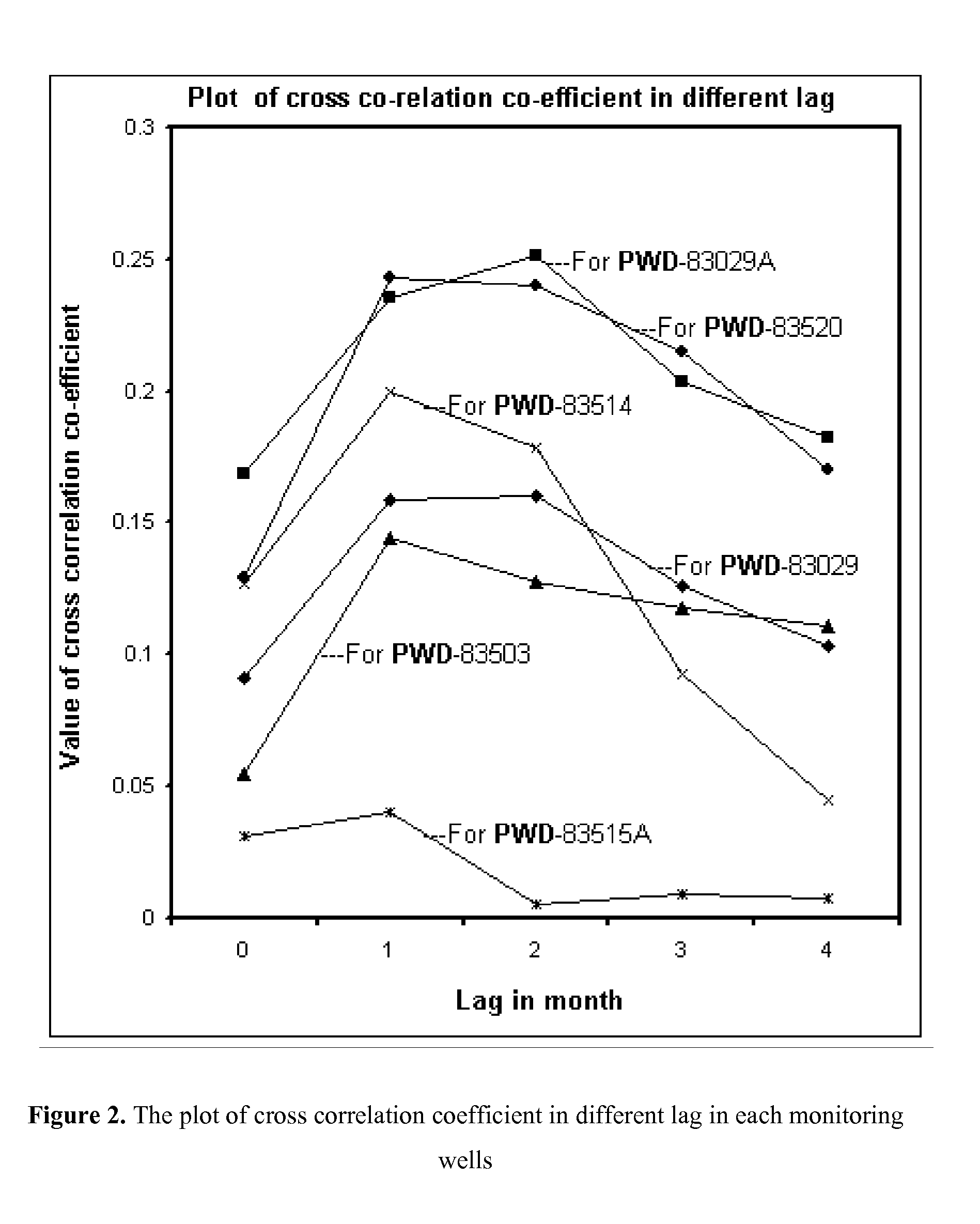

Cross correlation technique to delineate groundwater recharge potential zone in hard rock terrain

InactiveUS20080162047A1Improve understandingProspecting/detection of underground waterElectric/magnetic detectionTerrainArid

In the semi-arid region, particularly in hard rock terrain, shallow aquifers are major source of potable groundwater. These aquifers are indiscriminately exploited to meet the growing demand of water for domestic, irrigation as well as industrial use. In order to achieve a sustainable development, it is essential not only to delineate the groundwater potential zone and but also suitable augmentation scheme which in turn requires delineation of feasible recharge zone. Such zones are conventionally delineated through the application of various indirect methods such as hydro-geomorphological, geological and geophysical, which many times are time consuming and uneconomical. A simple, efficient and cost-effective cross correlation based process which takes into consideration the study of aquifer response to rainfall is provided in the present invention to delineate groundwater recharge zone.

Owner:COUNCIL OF SCI & IND RES

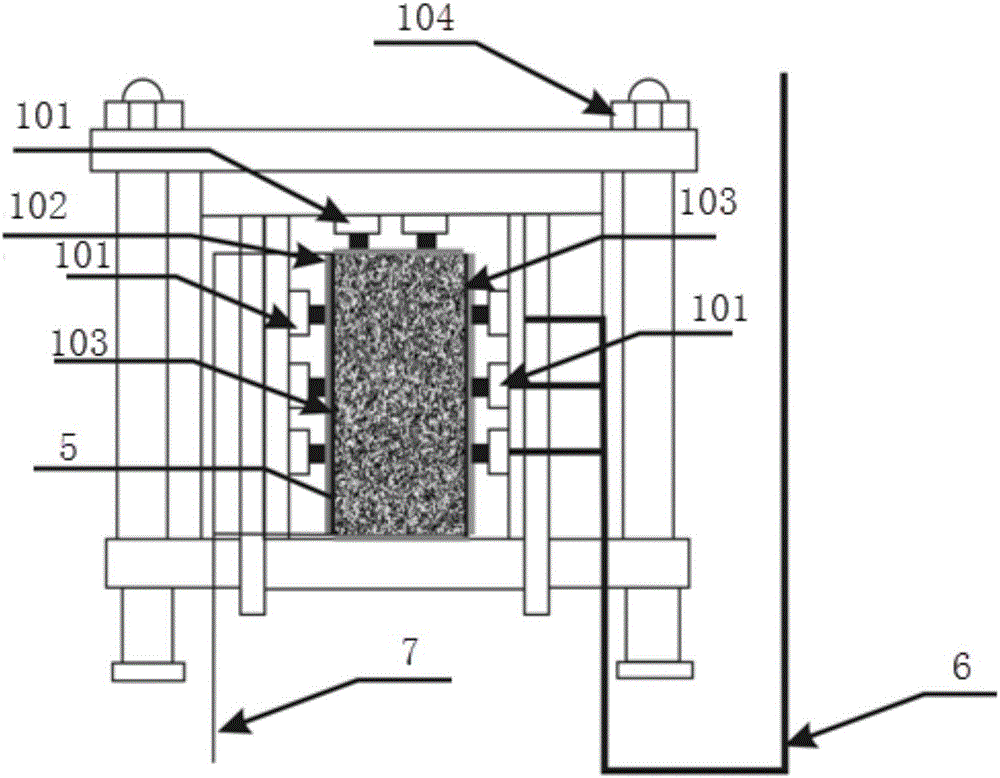

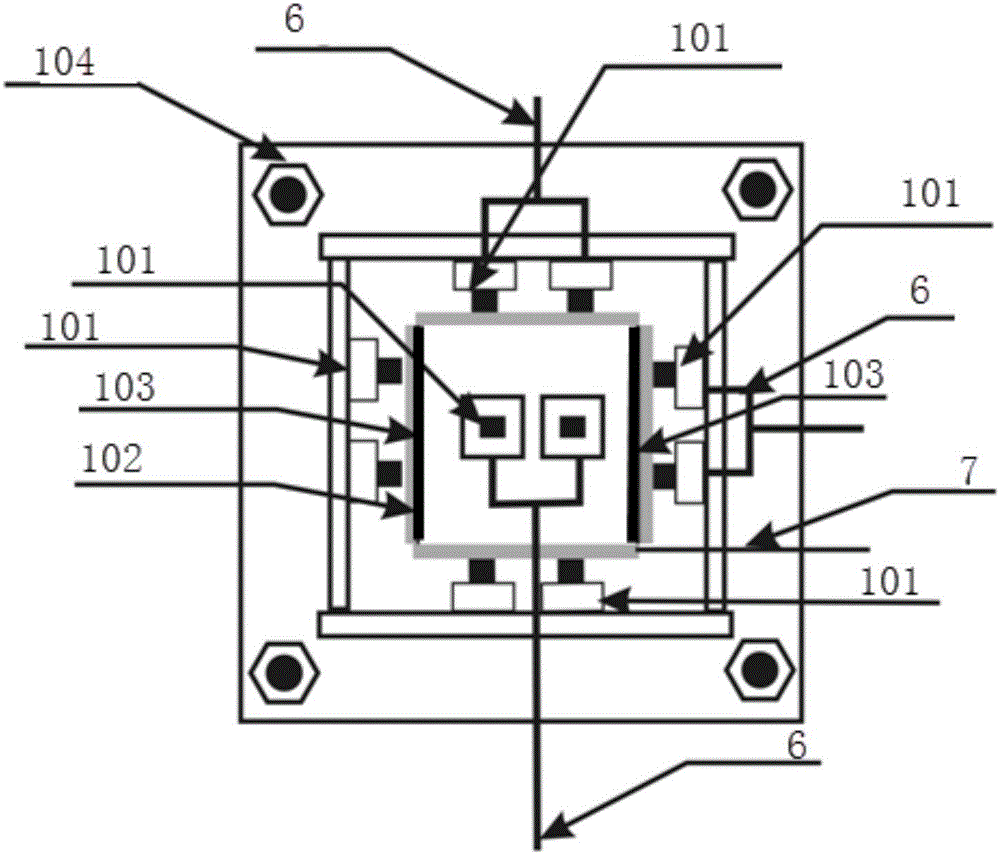

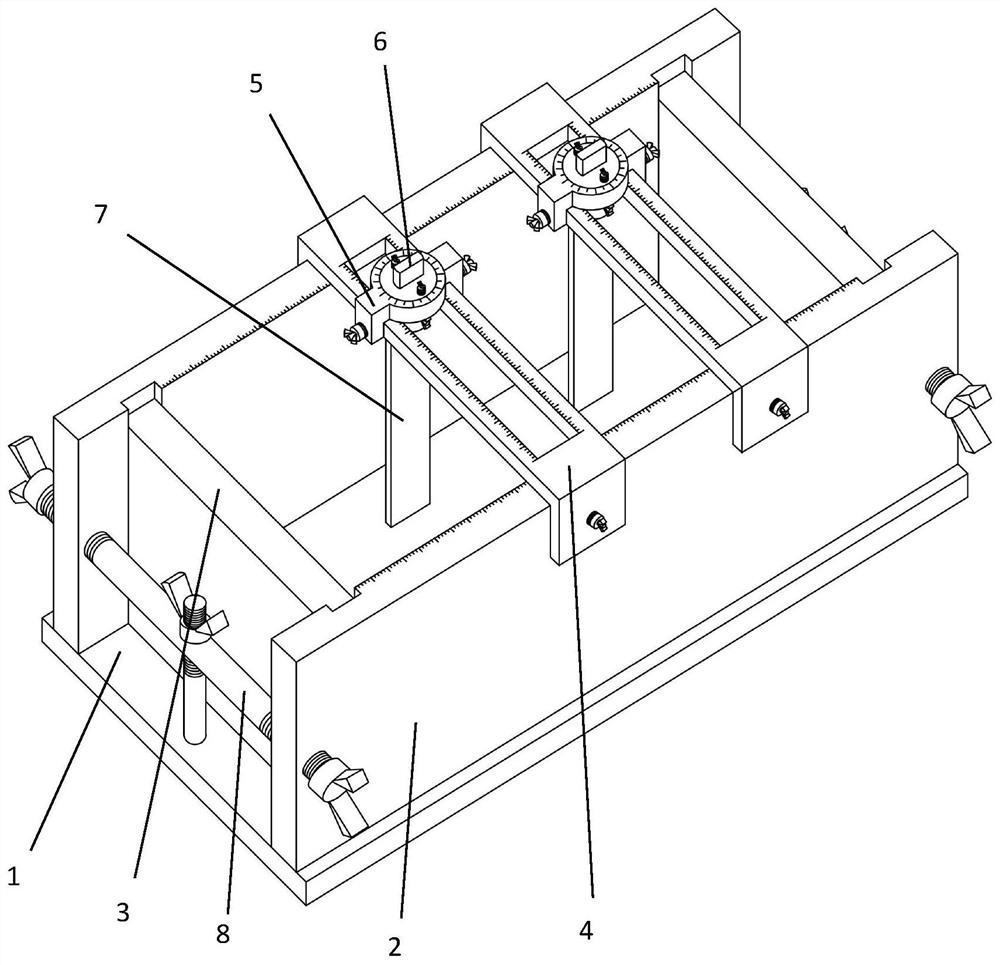

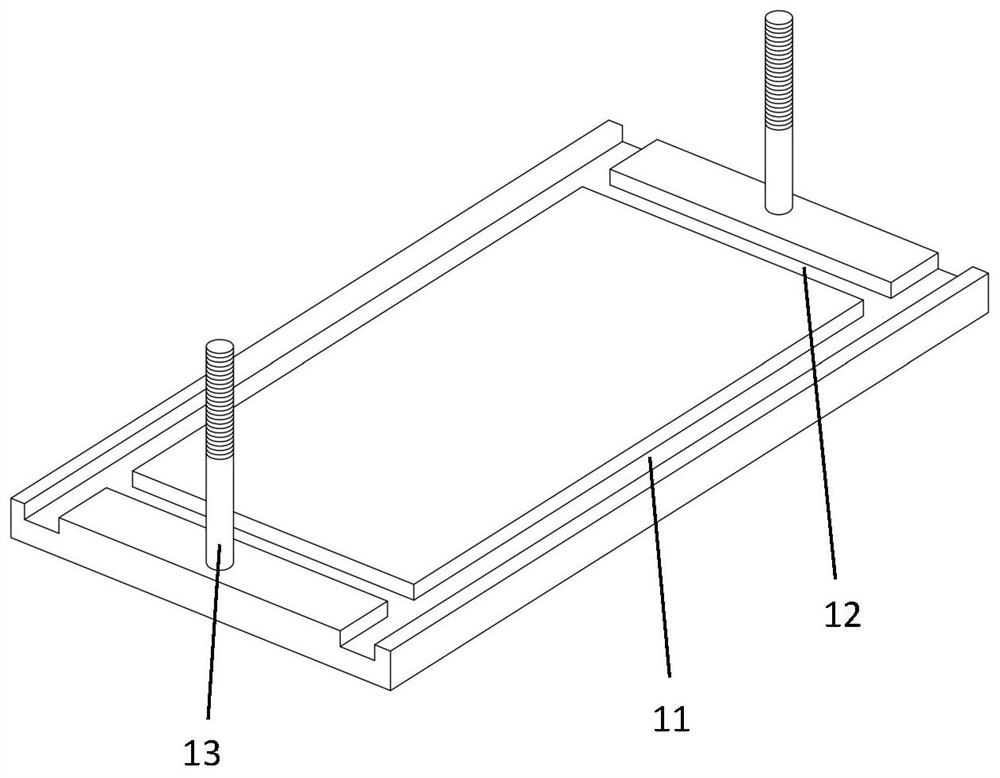

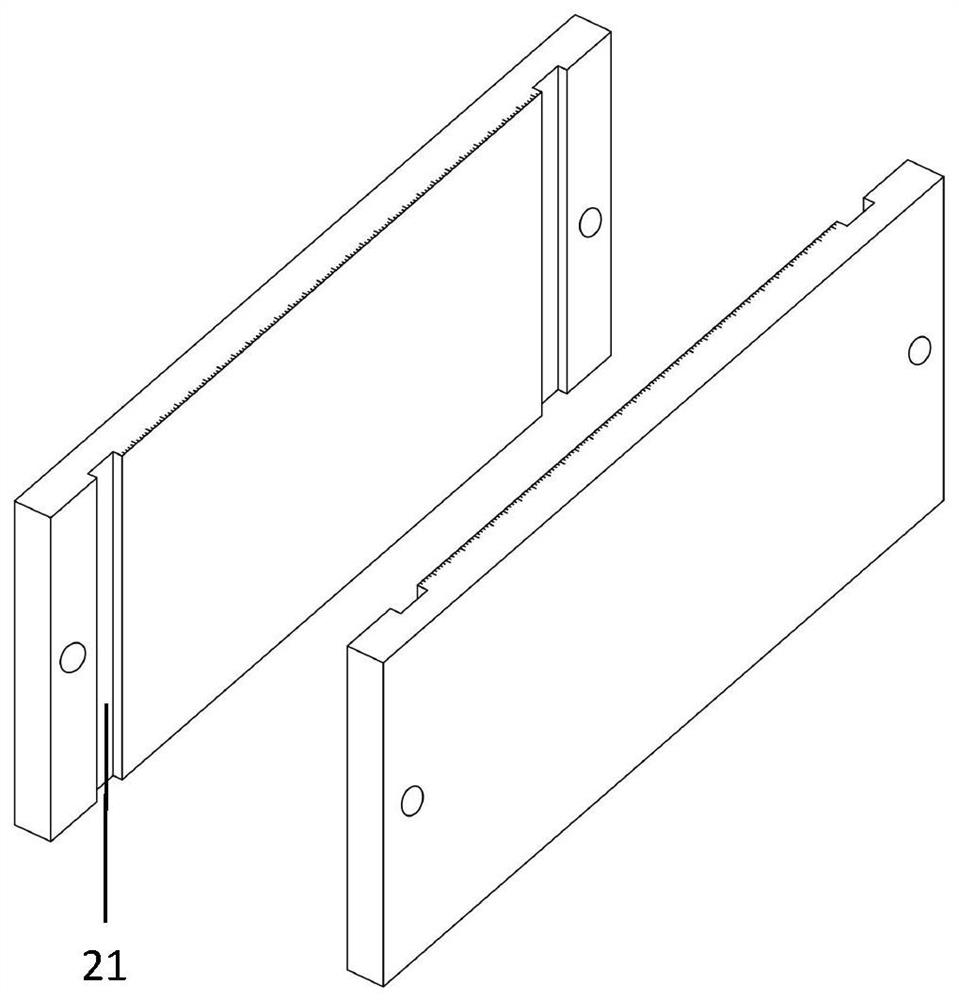

Rock-like sample manufacturing mold and using method thereof

PendingCN112362442AAvoid restrictionsEasy to adjustPreparing sample for investigationClassical mechanicsStructural engineering

The invention discloses a rock-like sample manufacturing mold which comprises a bottom plate, side plates, clamping plates, transverse positioning pieces, longitudinal positioning pieces, steel sheetfixing pieces and prefabricated crack steel sheets, the side plates, the clamping plates and the bottom plate form a rock-like sample pouring space, and the transverse positioning pieces, the longitudinal positioning pieces and the steel sheet fixing pieces jointly form a crack positioning assembly for positioning of fracture locations. The mold has the characteristics of being simple in structure, convenient to operate, good in sealing performance and capable of controlling different sizes and orientations of the double fractures, can effectively solve the problem that an original rock sampleis difficult to prefabricate multiple fractures due to the limitation of a cutting technology, and is used for analogy research on a fracture mechanism, the crack size effect and the crack orientation effect of a fracture-containing solid rock material.

Owner:WUHAN UNIV OF SCI & TECH

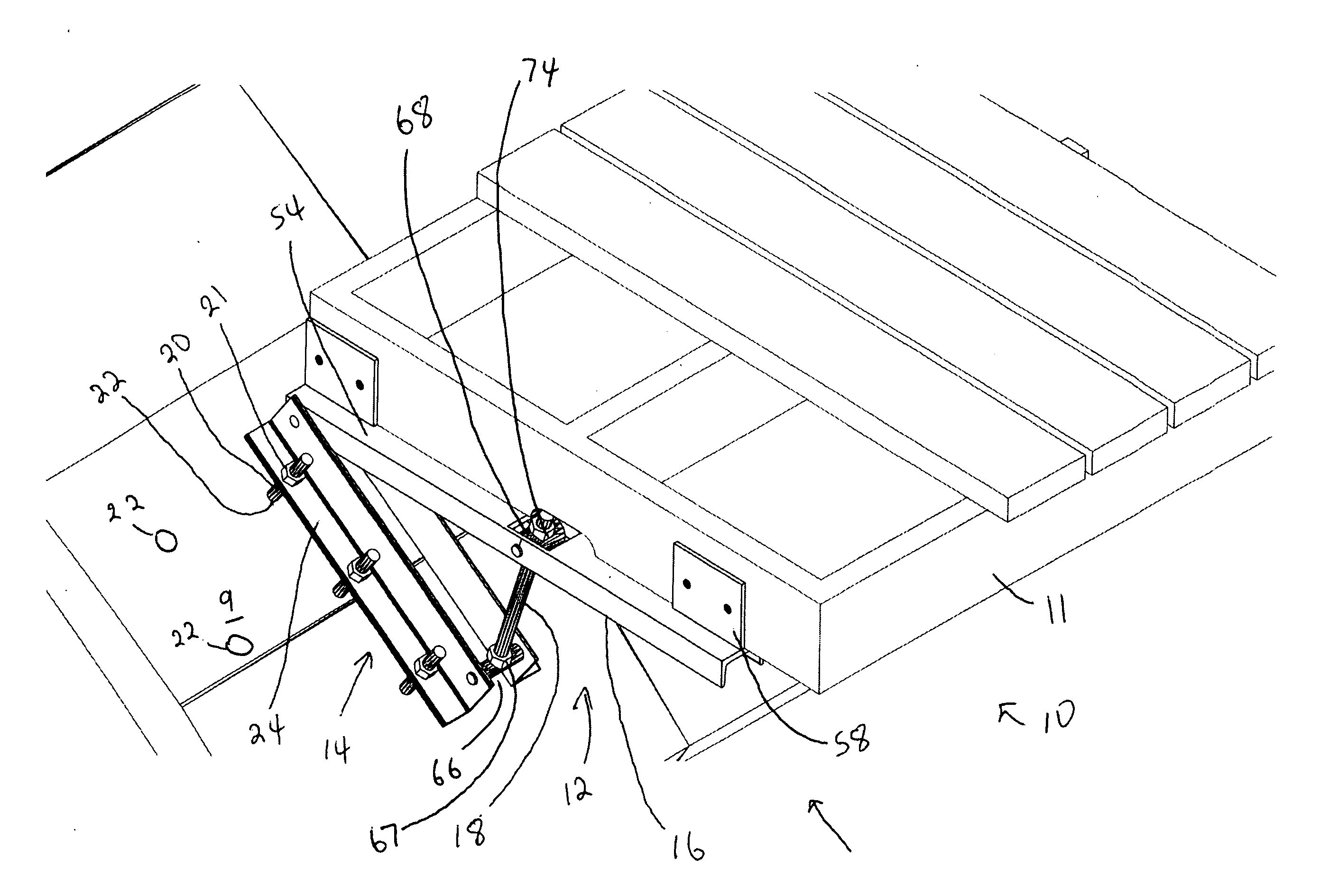

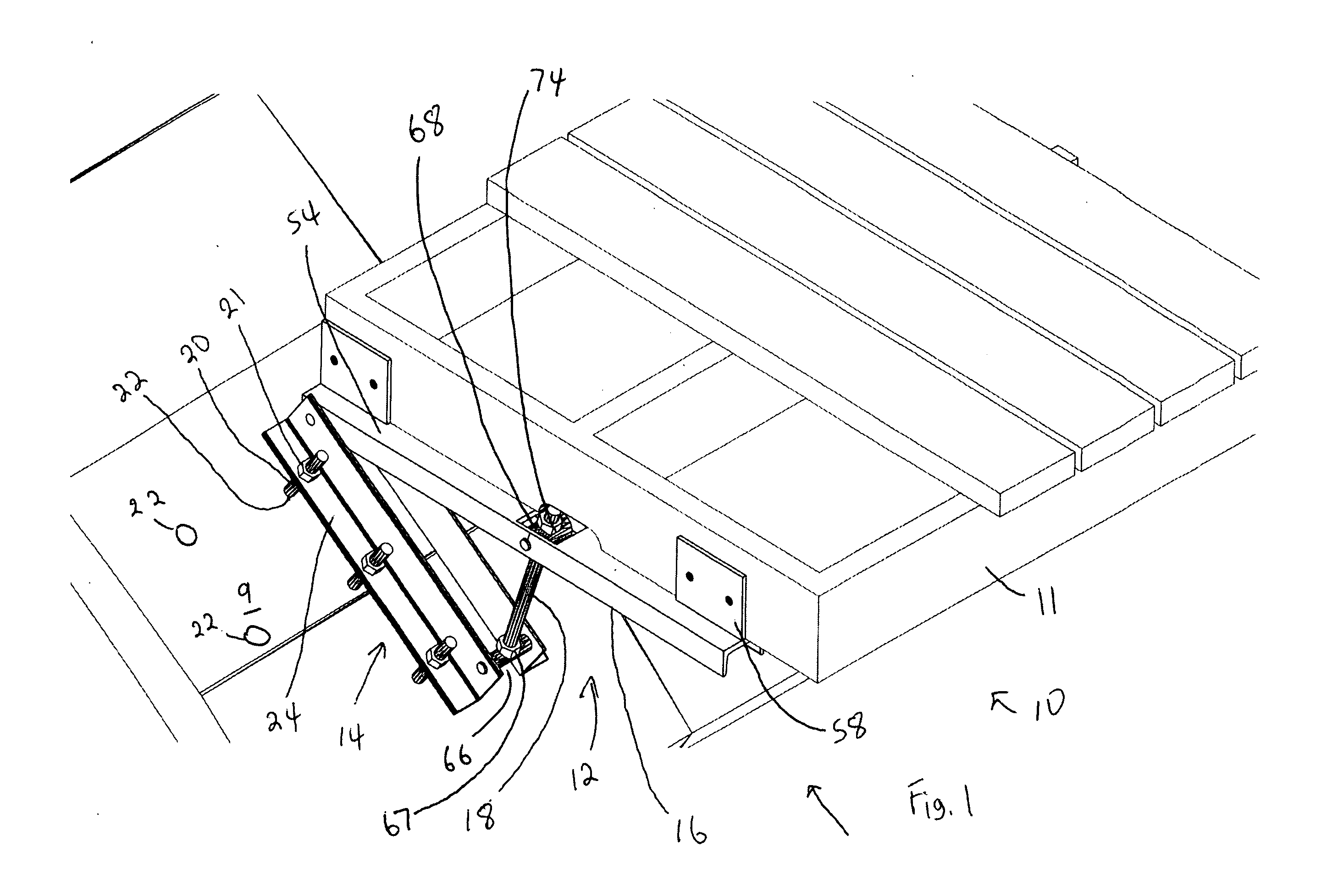

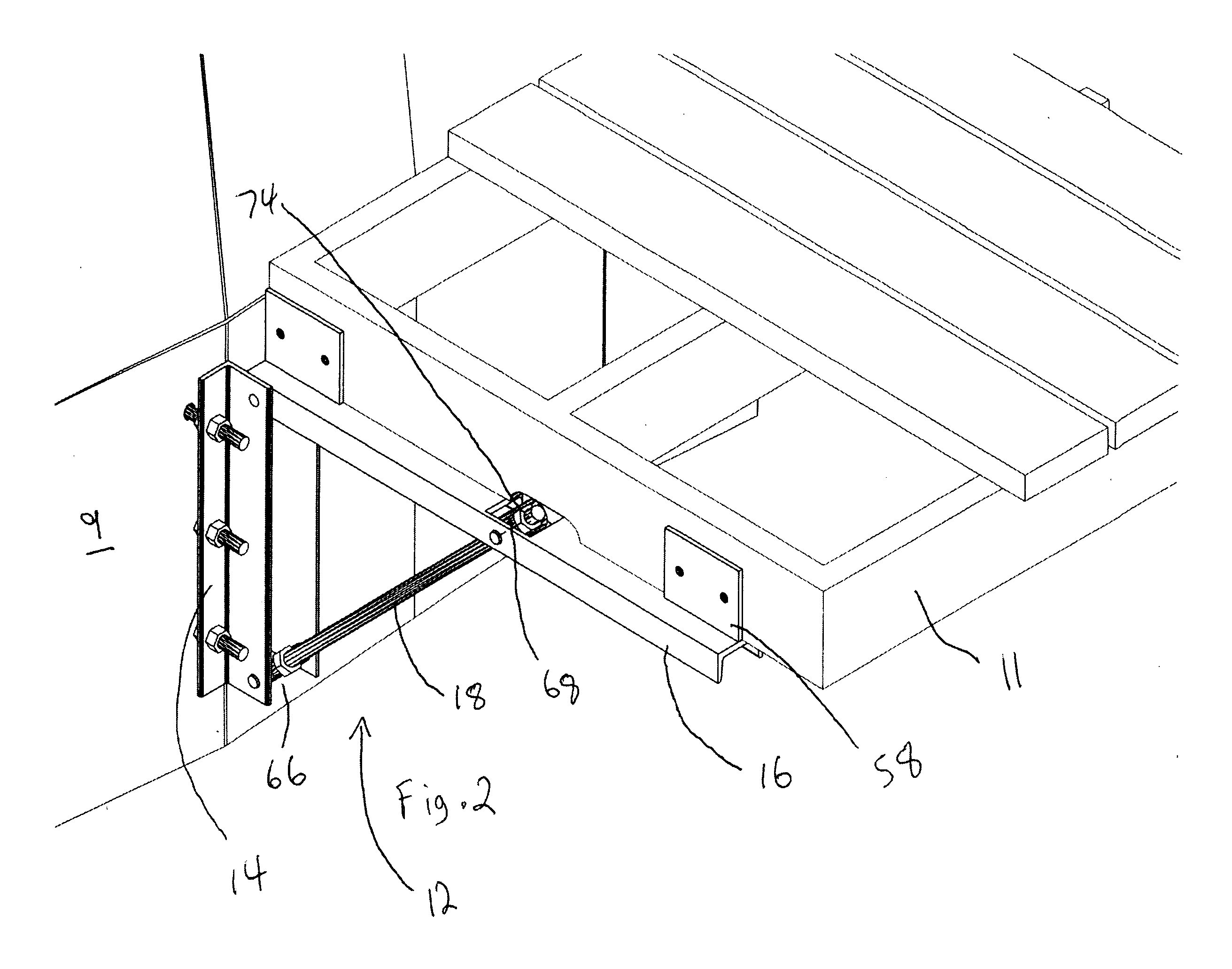

Bracket System for Building a Deck or Dock on a Rock Face

There is disclosed an improved bracket and method for constructing a dock or deck over water on a rocky shore line or on a hard rock face. The present invention includes a base bracket structure having opposite first and second ends, the base bracket being mountable to the rock by a plurality of anchor bolts. A boom having opposite first and second ends is pivotally connected to the base bracket structure adjacent the first end of the angle brackets such that the boom can be set at an angle relative to the base bracket structure, the boom being configured to mount the deck or dock thereon. The improved structure further includes a support rod having opposite first and second ends, the first end of the support rod being pivotally connected to the base bracket structure. The support rod is coupled to the boom by a connector joint located on the boom at a point on the boom between the booms opposite first and second ends. The connector joint is configured to selectively adjust the angle of the boom relative to the base bracket portion such that the boom is substantially horizontal. The connector joint is further configured to fix the boom in place relative to the base bracket portion.

Owner:MCKAY MICHAEL

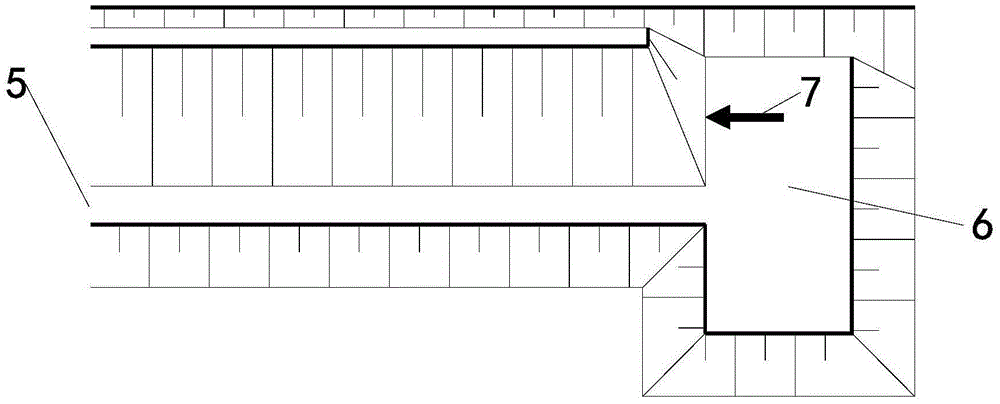

High-efficiency mining method of dragline saw-tooth type working bench

InactiveCN105626076ASimplify the shoveling processImprove work efficiencyUnderground miningSurface miningEngineeringTruck

The embodiment of the invention discloses a high-efficiency mining method of a dragline saw-tooth type working bench, which relates to the technical field of open coal mining and can improve the operating efficiency of draglines. The high-efficiency mining method of a dragline saw-tooth type working bench comprises the steps of: carrying out pin-point blasting on solid rock steps above a coal seam to form a blasting muck pile; leveling and stripping the blasting muck pile by joint operation of push dozers, single-bucket excavators and trucks to form a dragline working bench of a predetermined height, forming a saw-tooth type wharf by extension on the edge of one side of the dragline working bench near the dumping site; when not less than one saw-tooth type wharf is formed by extension on the edge of one side of the dragline working bench near the dumping site, driving the dragline into the ditch to the working area; and driving the dragline in a predetermined traveling line sequentially through the saw-tooth wharf inside bench and the saw-tooth wharf to carry out casting operation. The high-efficiency mining method of a dragline saw-tooth type working bench is suitable for open coal mining by a dragline casting process without transportation.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

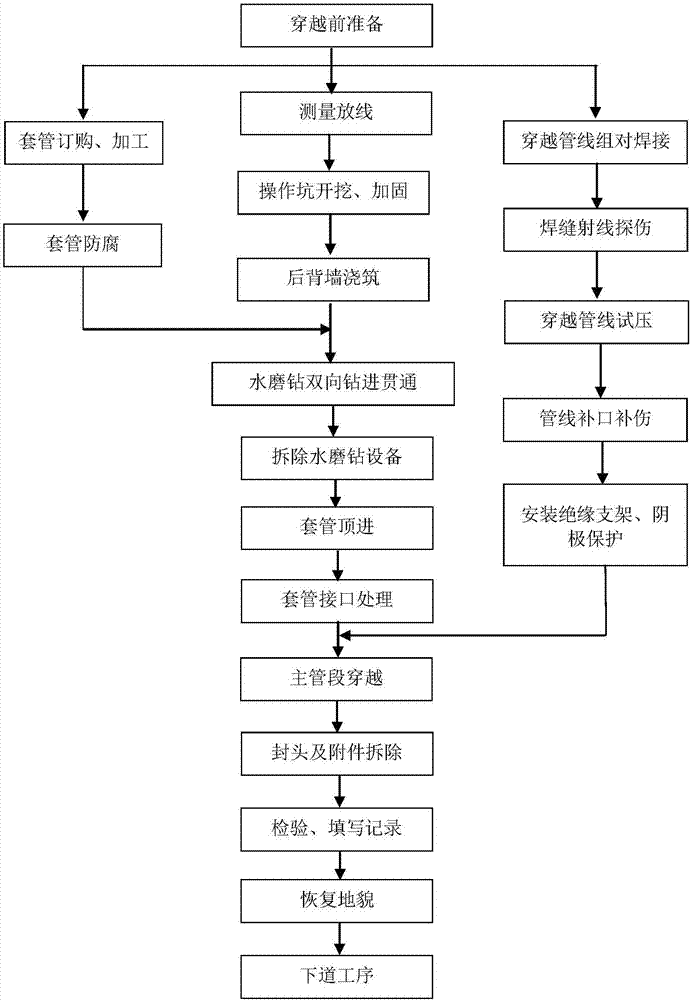

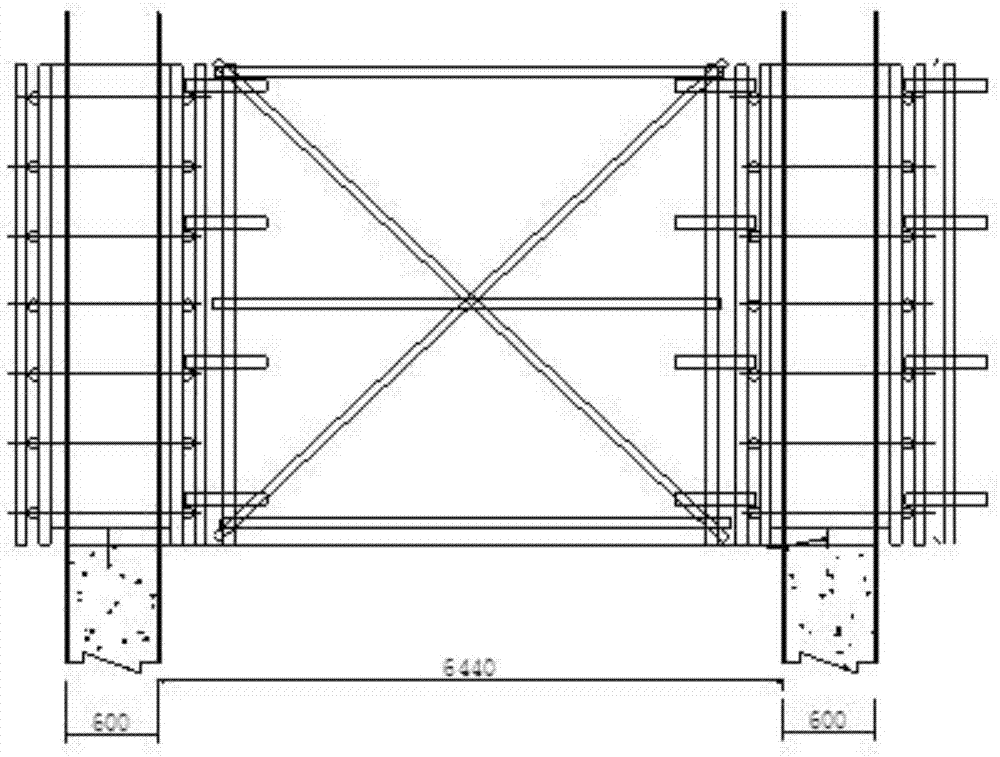

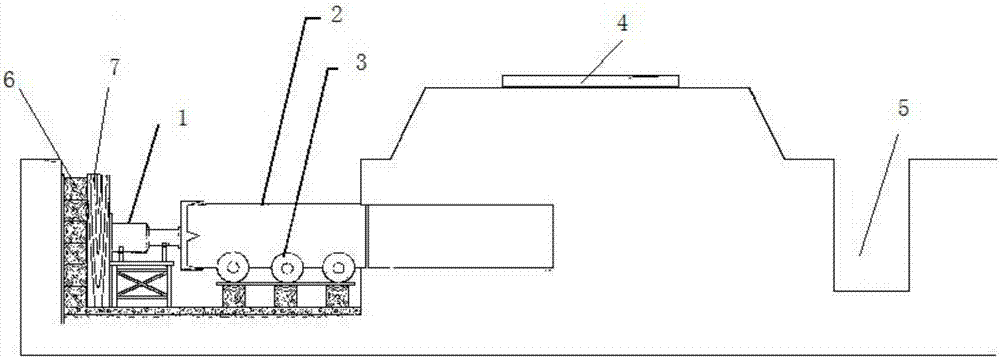

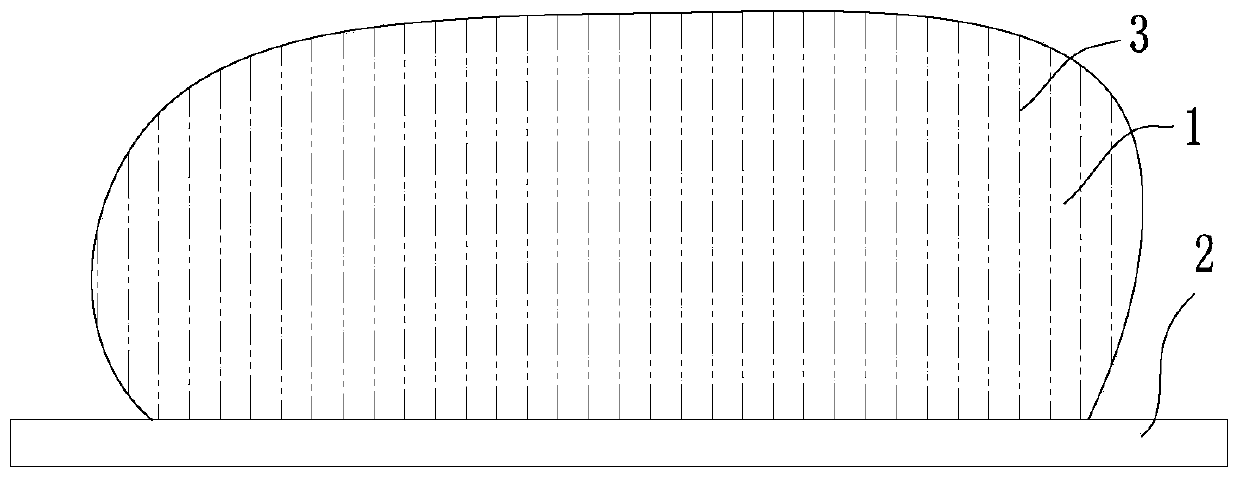

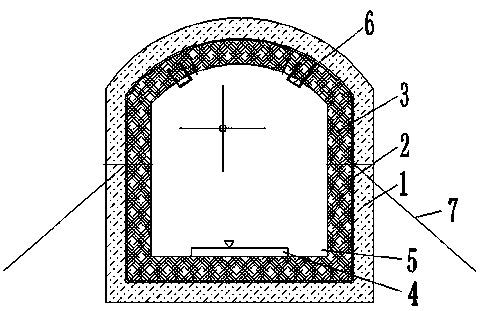

Bidirectional drilling construction method of non-demolition water drill for pipe-jacking in solid rock sections

InactiveCN107269288APromote recoverySmall footprintUnderground chambersTunnel liningUltimate tensile strengthDrill

The invention relates to a bidirectional drilling construction method of a non-demolition water drill for pipe-jacking in solid rock sections. The method includes the steps of firstly conducting surveying and setting-out to draw a center line and boundary lines; digging operation holes which can satisfy strength demands of pipe-jacking of casing pipes and conducting reinforcement construction on the operation holes in the both ends of a crossing section; utilizing the water drill to drill and form an annular crossing surface separated from the rock bodies; cleaving rock and delivering the cleaved rock out of the hole body. By adopting the bidirectional drilling process of the water drill, hole penetration can be completed safely and efficiently in the solid rock sections, and the process has the advantages of being advanced, simple in construction process, high in construction speed and reasonable in price, providing no potential safety hazards for overground roads, requiring less investment of equipment and workers and the like.

Owner:曹丽召 +2

Layered rock thin plate-shaped sample production and loading method

ActiveCN110208053AEfficient and accurate productionReduce unreasonable damagePreparing sample for investigationMaterial strength using tensile/compressive forcesWire cuttingDisplacement control

The invention relates to a layered rock thin plate-shaped sample production and loading method. A sample production stage comprises the following steps: preparing a cylindrical rock sample by utilizing a drilling machine, preparing a rock cylindrical sample with scale height by utilizing a cutting machine, sequentially preparing a rectangular solid rock sample and a thin plate-shaped sample by utilizing a wire cutting machine, fixing the thin plate-shaped sample into a matched polishing fixture, and polishing the thin plate-shaped sample by utilizing a grinding and polishing machine until design dimensions are met. A sample loading stage comprises the following steps: cleaning and drying the thin plate-shaped sample, and performing an anti-friction agent operation on a loading surface of the thin plate-shaped sample; fixing a ball head loading mechanism on a lower pressing head of a press, sequentially fixing a rigid base plate and a sample locating cover at the top of the ball head loading mechanism, inserting the loading surface of the thin plate-shaped sample into a location slot of the locating cover, and adjusting a position of the thin plate-shaped sample to be centered withthe ball head loading mechanism; applying a pre-tightening force to the thin plate-shaped sample to a set value in a displacement / load control mode; and after the pre-tightening force is reset, applying load to the thin plate-shaped sample in a displacement control mode until the thin plate-shaped sample is destroyed.

Owner:NORTHEASTERN UNIV

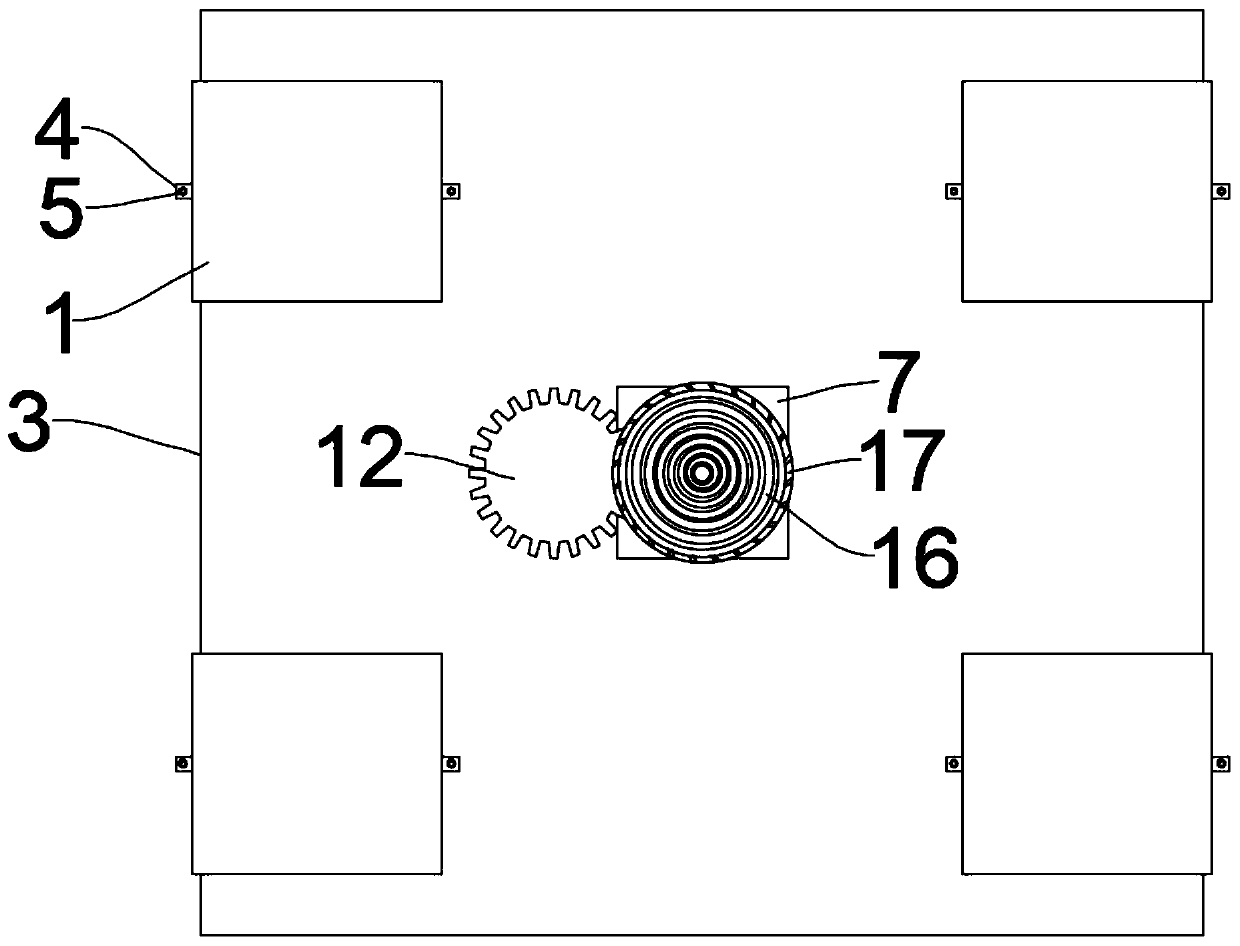

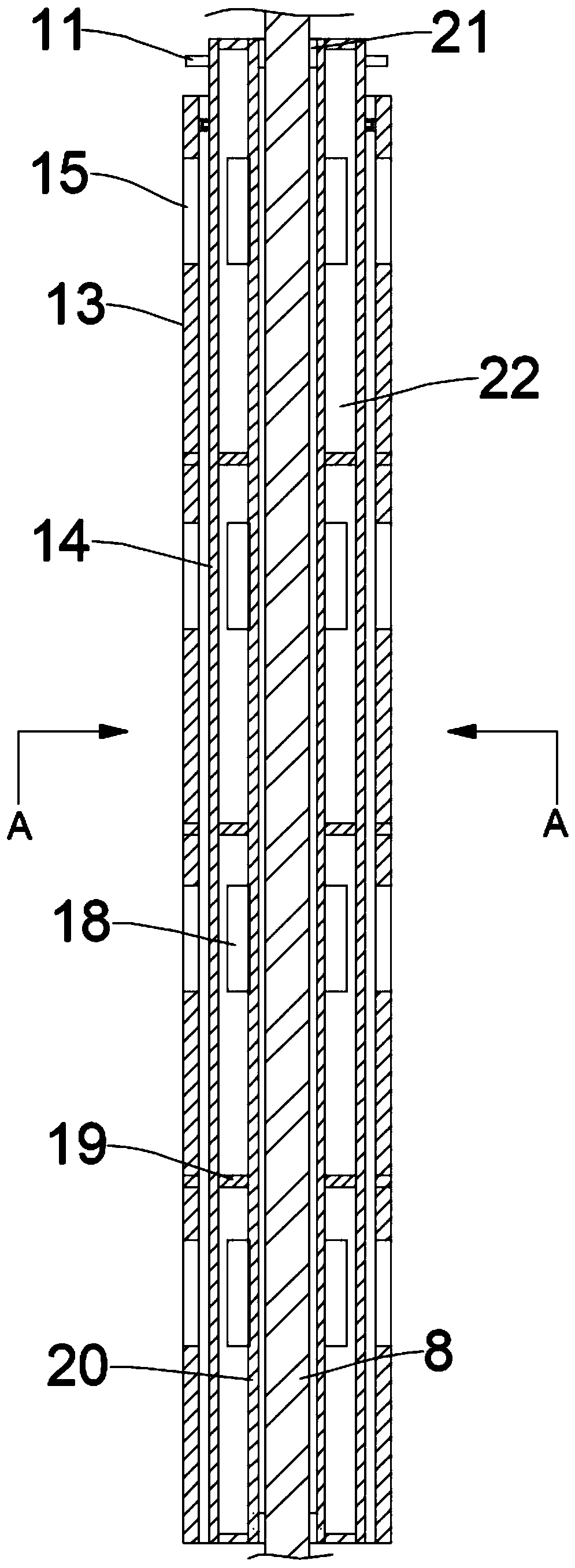

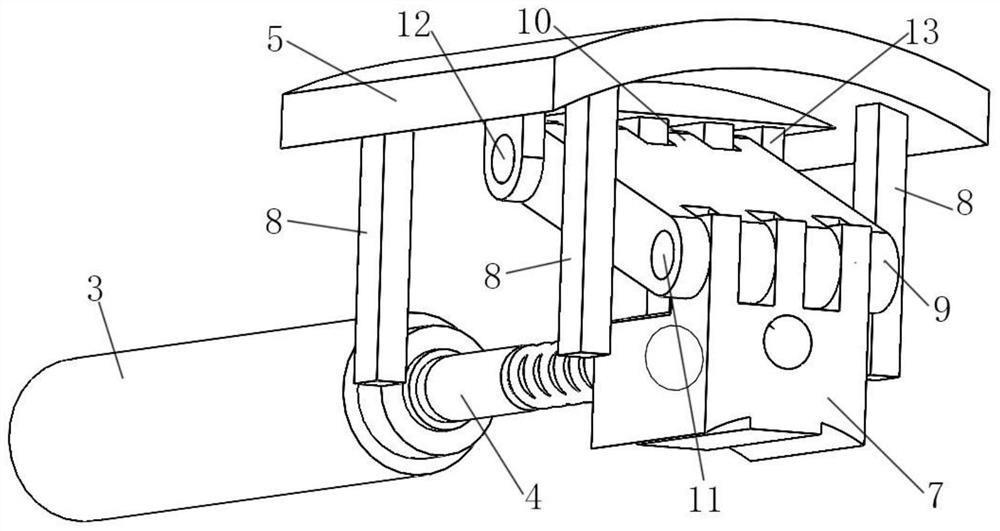

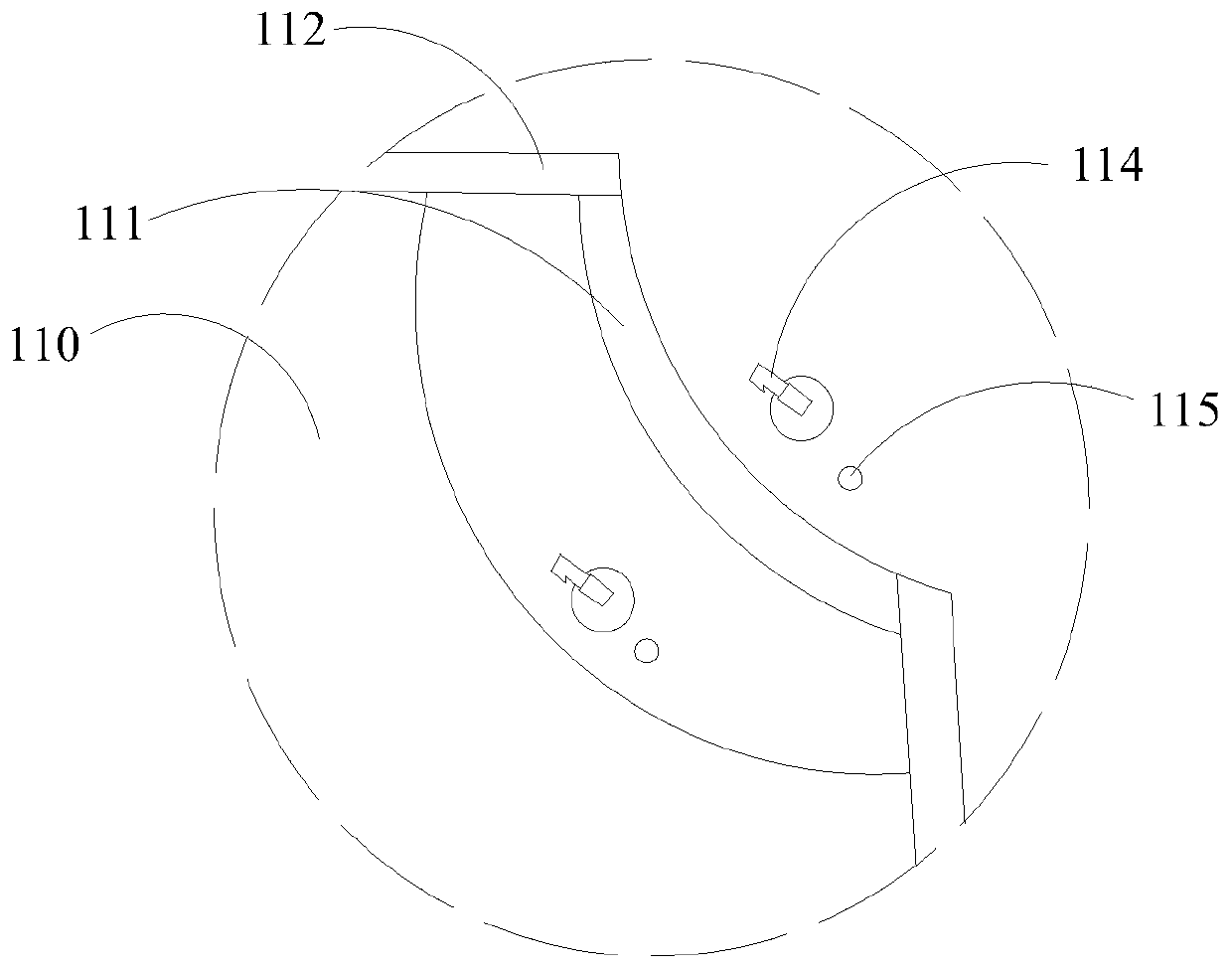

Deep lunar soil rotary guide drilling mechanism

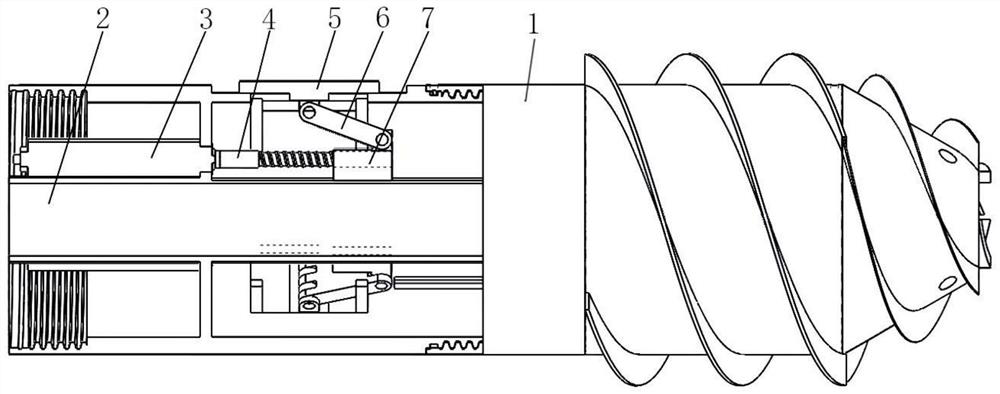

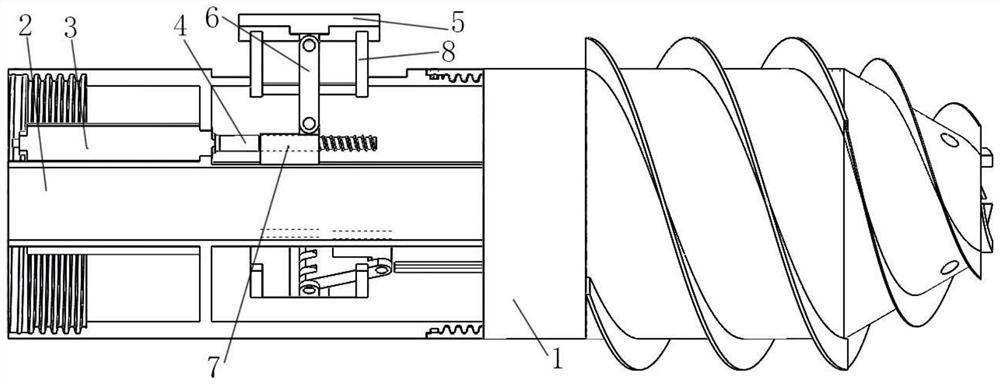

ActiveCN111911076AChange drilling directionGuaranteed accuracyDrill bitsDirectional drillingLunar soilStructural engineering

The invention relates to a deep lunar soil rotary guide drilling mechanism. The mechanism comprises a shell, driving devices, guide blocks, push rods and telescopic blocks which are installed in a drill rod and coaxially arranged with the drill rod, the shell and the drill rod are arranged at an interval, and the driving devices are installed on the shell and located in the interval. The telescopic blocks are driven by the driving devices to be slidably connected to the shell in the direction parallel to the axis of the drill rod. The guide blocks are slidably connected to the drill rod in thedirection perpendicular to the axis of the drill rod, and the two ends of the push rods are hinged to the telescopic blocks and the guide blocks correspondingly. The telescopic blocks slide along theshell to drive the push rods to push out or withdraw the guide blocks from the drill rod. The mechanism can assist a deep lunar soil drilling system to laterally extend out of the guide blocks to complete the guide action when moving forwards in lunar soil, and when the drilling system encounters hard rock or other special conditions and needs to change the drilling direction of a drill bit, a guide module pushes the guide blocks out by a certain distance, so that the front end of the drill bit deviates by a certain angle, and the direction of the drill bit is changed.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

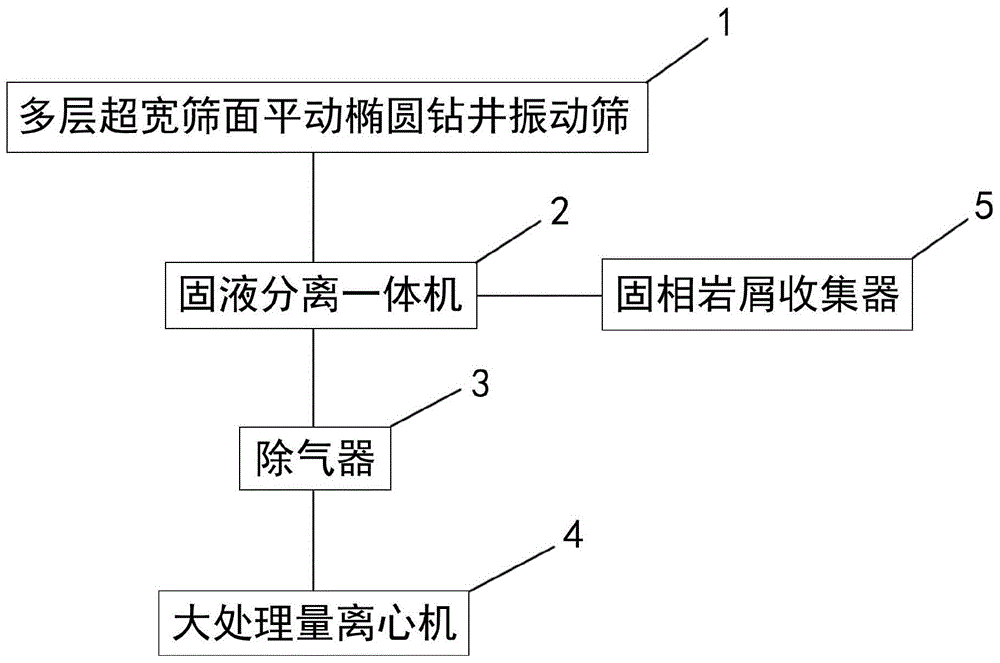

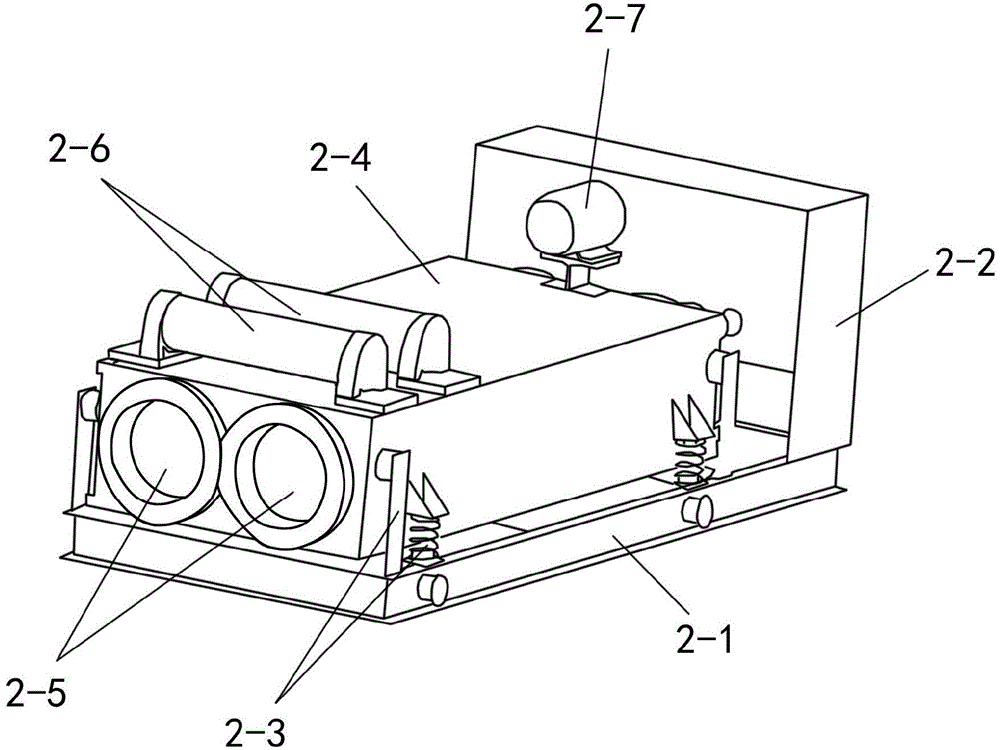

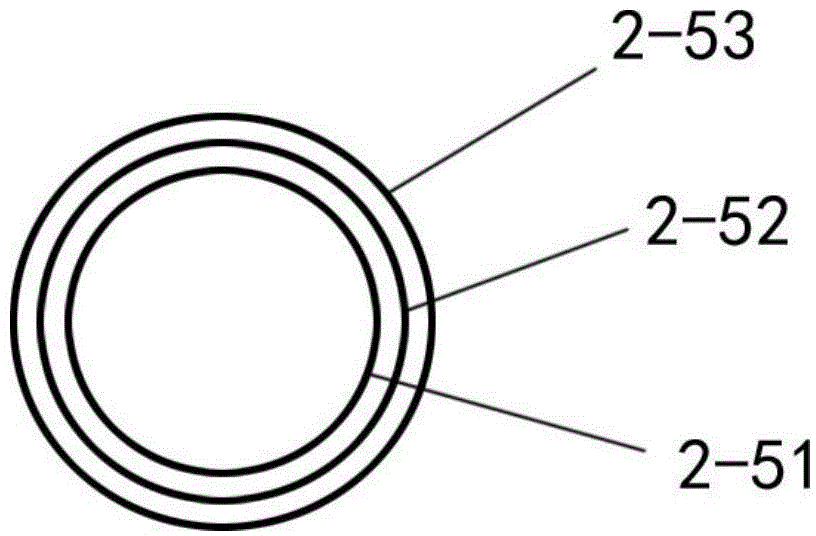

Novel mud solid control system and technology

InactiveCN104612608ASimple maintenance and managementSmall footprintSievingScreeningCentrifugationControl system

The invention discloses a novel mud solid control system. The novel mud solid control system comprises a multilayer ultra-wide screen surface translational elliptical drilling shaker, a deaerator, a solid-liquid separation integrated machine, a large-capacity centrifuge and a solid rock debris collector. The solid-liquid separation integrated machine comprises a base. The base is provided with a feeding box and oscillation supports. The oscillation supports are fixedly provided with an oscillation box. Screen drums, exciting vibration motors and a vibration-proof driving motor are installed on the oscillation box. The vibration-proof driving motor is connected with the screen drumseach of which comprises an inner drum body, a middle drum body and an outer drum body. A technological process comprises the sequential steps of ultra-large solid particle removal, screen net separation, solid-liquid separation, deaeration and centrifugation. Compared with the prior art, the novel mud solid control system has the advantages that the technological process and relevant solid control equipment systems of an existing mud solid control system can be greatly simplified and improved, the usage effect is improved, the cost is lowered, electric power is saved, the occupied area is reduced, and maintenance and management of the equipment are simplified.

Owner:张劲南

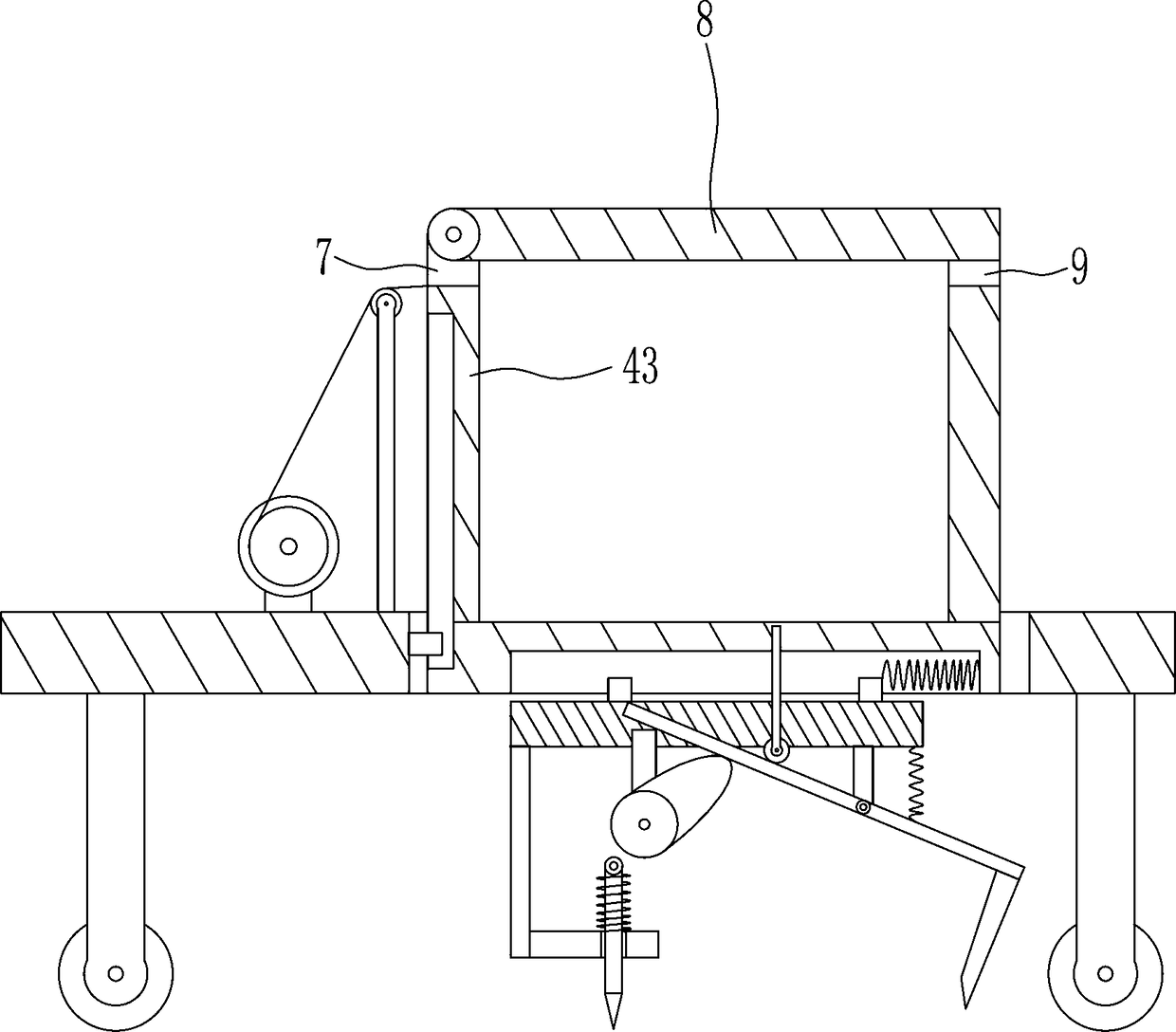

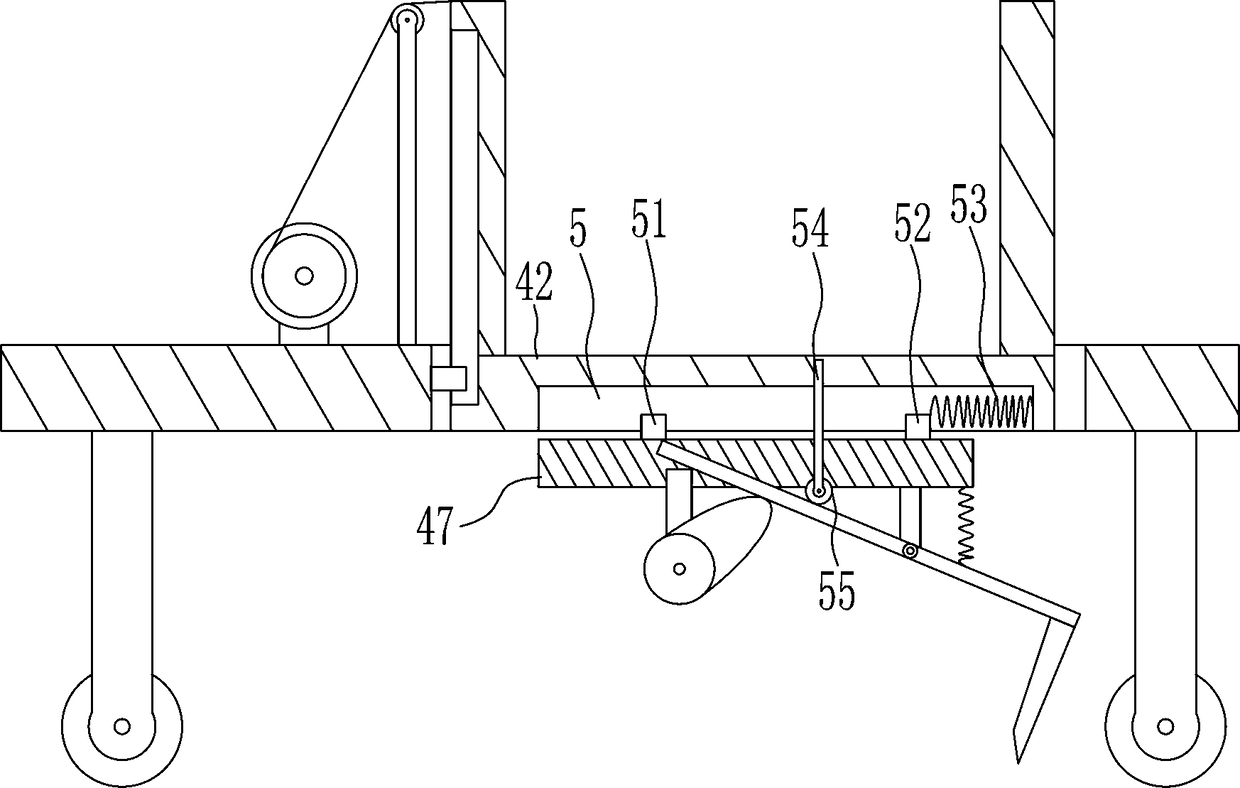

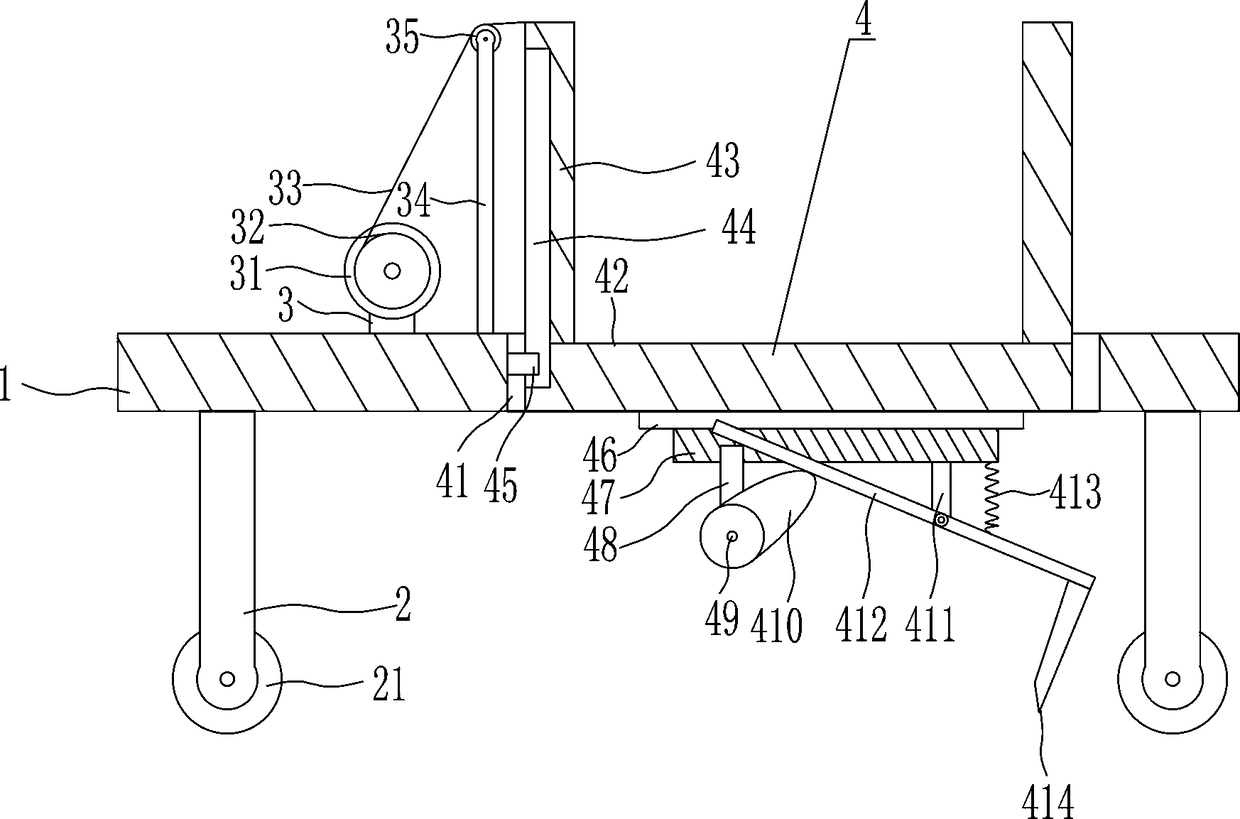

Foundation excavation device for building

The invention relates to a foundation excavation device, in particular to a foundation excavation device for building. The invention aims to solve the technical problem of providing the multifunctional foundation excavation device for building. The foundation excavation device for building comprises a vehicle plate, vehicle legs, vehicle wheels, a first supporting block, a first motor, a reel, a pull rope and the like, wherein the vehicle legs are connected to the front side, the rear side, the left side and the right side of the bottom of the vehicle plate, the vehicle wheels are connected tothe bottoms of the vehicle legs in a rotating mode, the first supporting block is fixedly connected to the left side of the upper part of the vehicle plate, the first motor is arranged at the upper part of the first supporting block, an output shaft of the first motor is in interference connection with the reel, the pull rope is connected to the reel, and a large support rod is fixedly connectedto the upper part of the vehicle plate and is located on the right side of the first supporting block. According to the foundation excavation device, the function of excavating a foundation by utilizing manpower instead of machinery can be achieved, a chisel rod is pushed to chisel solid rock by utilizing a cam, and therefore the effect of quickly excavating the foundation and chiseling the rock can be achieved.

Owner:珠海市三湘建筑基础工程有限公司

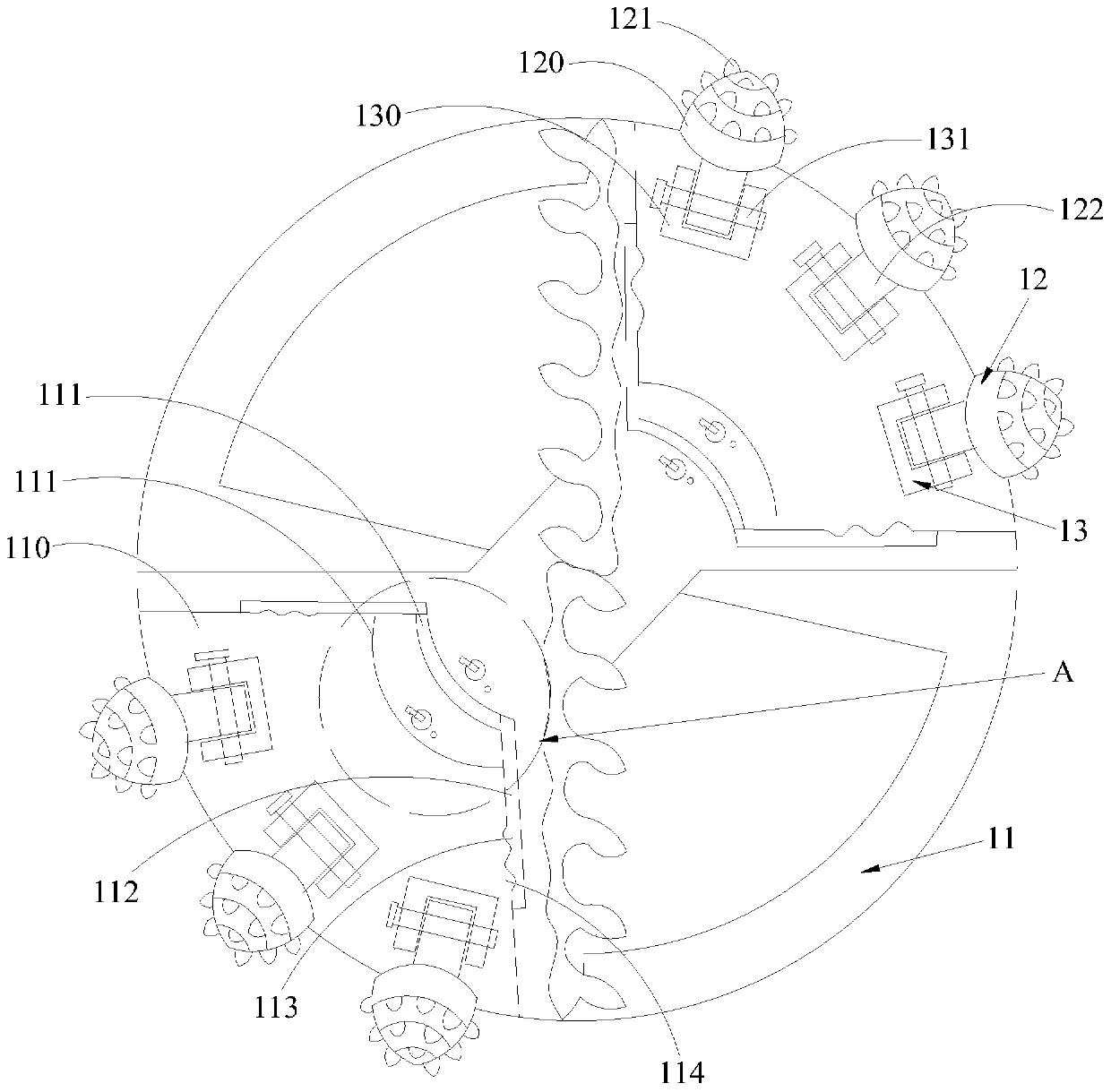

Reamer bit structure of sand-bailing hopper for embedding rocks onto secant pile

The invention relates to the technical field of ground and foundation engineering and discloses a reamer bit structure of a sand-bailing hopper for embedding rocks onto a secant pile. The reamer bit structure comprises a bit body, wherein a base is arranged at the bottom of the bit, a plurality of hob structures are movably connected to the base for grinding the rocks, the bits with the hob structures are replaced to drill holes when hard rocks are available in drilling, the hob structures can grind the rocks and crush the rocks for drilling holes smoothly. Each hob structure comprises a rolling head for grinding the rocks, and a plurality of grinding sheets are arranged in a spaced manner on the surface of the rolling head; and when the bits rotate to drill holes, the hob structures rotate and the grinding sheets grind the rocks.

Owner:SHENZHEN HONGYEJI GEOTECHNICAL TECH CO LTD

Deformation control construction method for shallow-buried underground excavation foundation of power tunnel in cobble stratum

ActiveCN111119931AImprove pore forming efficiencyImprove hole qualityUnderground chambersMaterial fill-upDeformation controlGroundwater

The invention belongs to the technical field of power tunnel construction, discloses a deformation control construction method for a shallow-buried underground excavation foundation of a power tunnelin the cobble stratum, and aims to solve the problem that the existing shallow-buried underground excavation construction cannot meet the requirement of the coble stratum. Through the adoption of thedeformation control construction method for the shallow-buried underground excavation foundation of the power tunnel in the cobble stratum, a stratum area constructed by dense cobble stratums can be effectively avoided. Rocks are complex in composition and different in particle sizes, and even include boulders and solid rock stratums, the underground water volume is large, and even local areas have the phenomena of diameter expansion and hole collapse in the presence of cavities, so that the method effectively improves the pore formation efficiency and the pile base quality.

Owner:CHINA MCC5 GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com