Layered rock thin plate-shaped sample production and loading method

A technology of rock sample and production method, which is applied in the preparation and sampling of test samples, and the use of stable tension/pressure to test the strength of materials, etc. and other problems to achieve the effect of reducing buckling and stabilizing the failure process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0056] Take the production of a layered rock thin plate sample with a size of 40mm×20mm×5mm as an example.

[0057] A method for preparing a layered rock sheet sample, comprising the steps of:

[0058] Step 1: Drill and cut the column sample

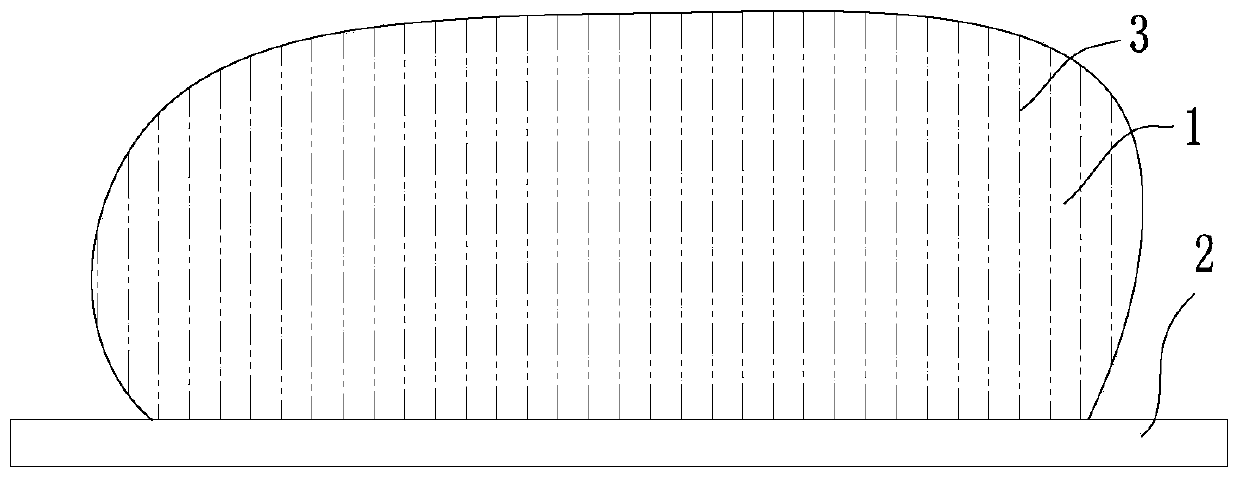

[0059] ①, such as figure 1 As shown, the layered rock specimen 1 is fixed on the drilling rig workbench 2, so that the layer 3 of the layered rock specimen 1 is kept vertical to the drilling rig workbench 2;

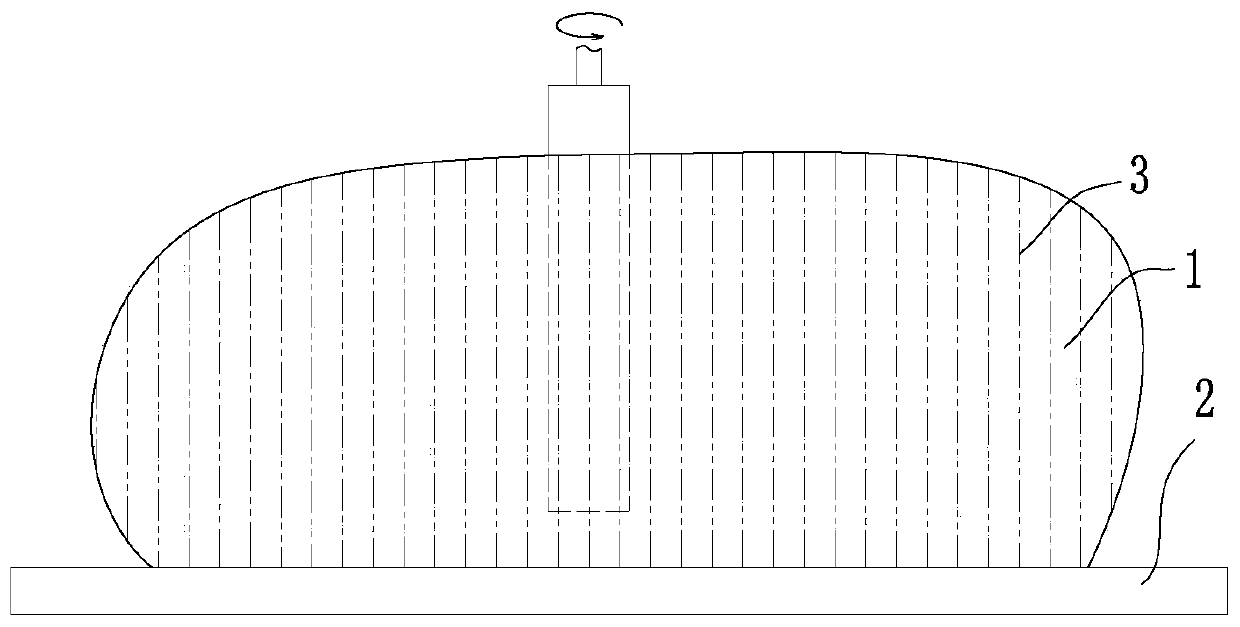

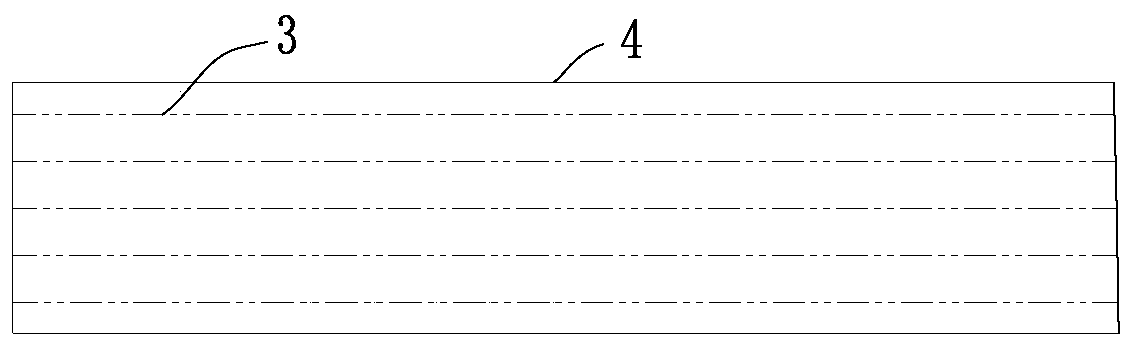

[0060] ②. Start the drilling machine, and the drilling direction is perpendicular to the horizontal plane, such as figure 2 shown, and a cylindrical rock sample 4 is drilled on the layered rock sample 1, such as image 3 shown;

[0061] ③. Place the drilled cylindrical rock sample 4 on the cutting machine platform so that the central axis of the cylindrical rock sample 4 is parallel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com