A method for making transversely isotropic true triaxial rock samples

A technology of transverse isotropy and production method, which is applied in the field of rock mass engineering, can solve the problems of core damage, influence on the accuracy of experimental results, sample preparation efficiency, fracture, etc., reduce damage and damage, and improve sample preparation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Take the production of a transversely isotropic true triaxial rock sample with a dimension of 100mm×50mm×50mm as an example.

[0051] A method for making a transversely isotropic true triaxial rock sample, comprising the steps of:

[0052] Step 1: Cut the flat surface

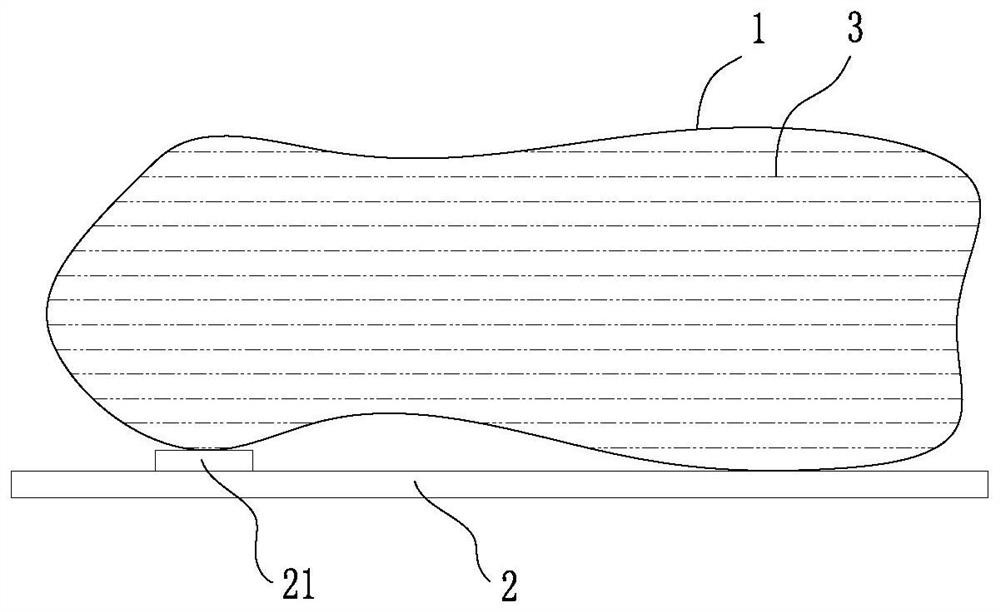

[0053] ①. Place the irregularly shaped rock specimen 1 on the cutting machine platform 2, and at the same time adjust the layer 3 of the rock specimen 1 to be parallel to the cutting machine platform 2 by means of a backing plate 21 and a level, as shown in FIG. figure 2 shown;

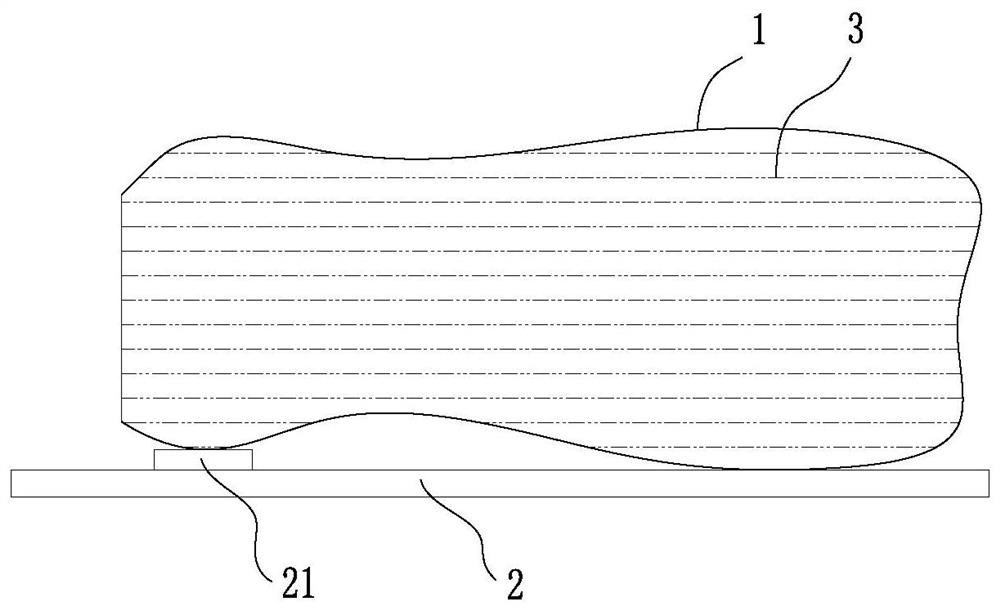

[0054] ②, start the cutting machine, the cutting direction is perpendicular to the layer 3 of the rock sample 1, and cut out the first flat layer on the rock sample 1, such as image 3 shown;

[0055] ③. Rotate the rock specimen 1 by 90° so that the first plane of the rock specimen 1 faces down and is placed on the cutting machine platform 2. At this time, the layer 3 of the rock specimen 1 is perpendicular to ...

Embodiment 2

[0076] Embodiment 2: Take the production of a transversely isotropic true triaxial rock sample with a dimension of 50mm×25mm×25mm as an example.

[0077] A method for making a transversely isotropic true triaxial rock sample, comprising the steps of:

[0078] Step 1: Cut the flat surface

[0079] ①. Place the irregularly shaped rock specimen 1 on the cutting machine platform 2, and at the same time adjust the layer 3 of the rock specimen 1 to be parallel to the cutting machine platform 2 by means of a backing plate 21 and a level, as shown in FIG. figure 2 shown;

[0080] ②, start the cutting machine, the cutting direction is perpendicular to the layer 3 of the rock sample 1, and cut out the first flat layer on the rock sample 1, such as image 3 shown;

[0081] ③. Rotate the rock specimen 1 by 90° so that the first plane of the rock specimen 1 faces down and is placed on the cutting machine platform 2. At this time, the layer 3 of the rock specimen 1 is perpendicular to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com