Fabrication and loading method of a layered rock thin plate sample

A thin plate and rock technology, applied in the field of layered rock thin plate sample production and loading, can solve the problems of damage and failure, low strength, difficult processing of small-sized thin plate samples, etc., and achieve the effect of stabilizing the failure process and reducing buckling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0056] Take the production of a layered rock thin plate sample with a size of 40mm×20mm×5mm as an example.

[0057] A method for preparing a layered rock sheet sample, comprising the steps of:

[0058] Step 1: Drill and cut the column sample

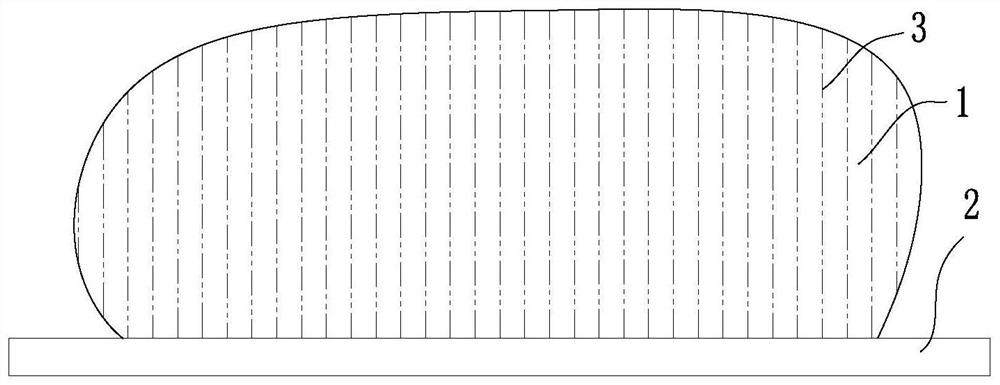

[0059] ①, such as figure 1 As shown, the layered rock specimen 1 is fixed on the drilling rig workbench 2, so that the layer 3 of the layered rock specimen 1 is kept vertical to the drilling rig workbench 2;

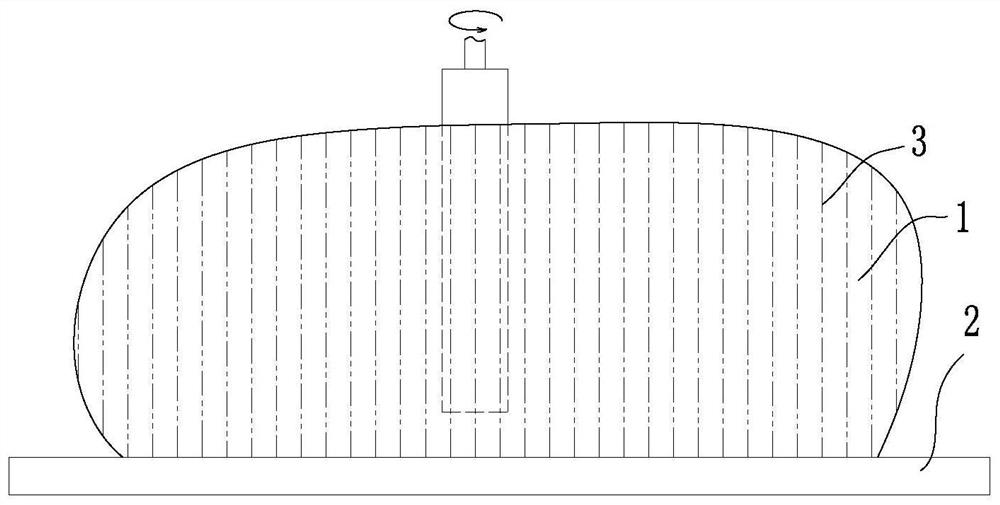

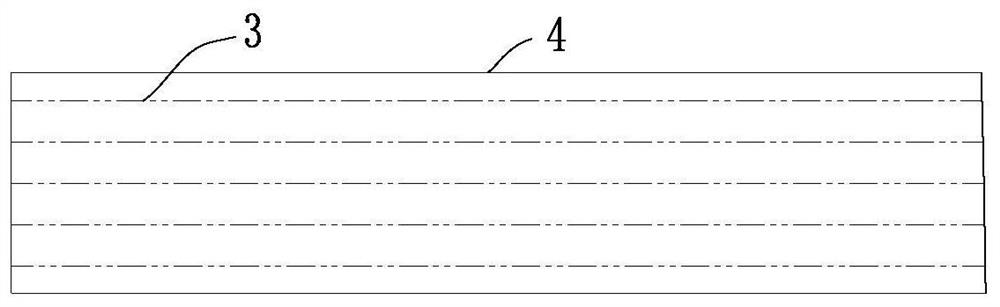

[0060] ②. Start the drilling machine, and the drilling direction is perpendicular to the horizontal plane, such as figure 2 shown, and a cylindrical rock sample 4 is drilled on the layered rock sample 1, such as image 3 shown;

[0061] ③. Place the drilled cylindrical rock sample 4 on the cutting machine platform so that the central axis of the cylindrical rock sample 4 is parallel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com