A method for manufacturing an HDI rigid-flex board ink printing carrier

A technology of rigid-flex board and ink printing, which is applied in the fields of printed circuit manufacturing, printed circuit, and removal of conductive materials by chemical/electrolytic methods, which can solve the problems of affecting market competitiveness, affecting production progress, time-consuming and laborious, etc. , to achieve the effect of avoiding manual bonding of bumps, low production cost, efficient and accurate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

[0028] refer to Figure 1-5 , a method for manufacturing an HDI rigid-flex board ink printing carrier, comprising the following steps,

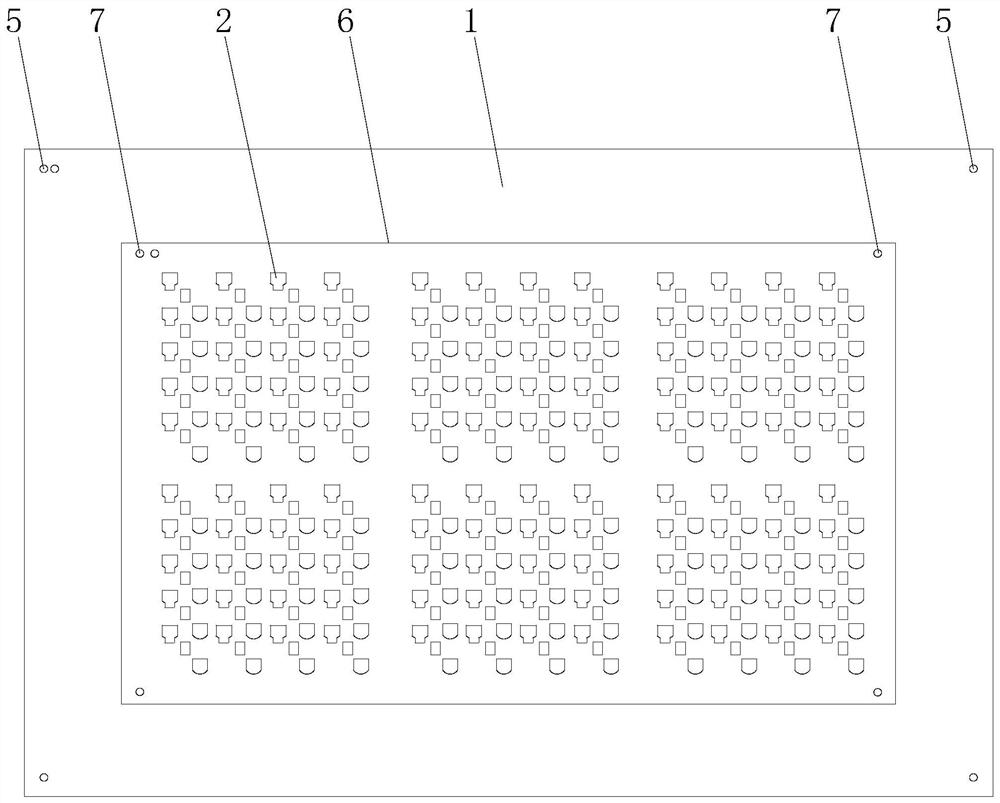

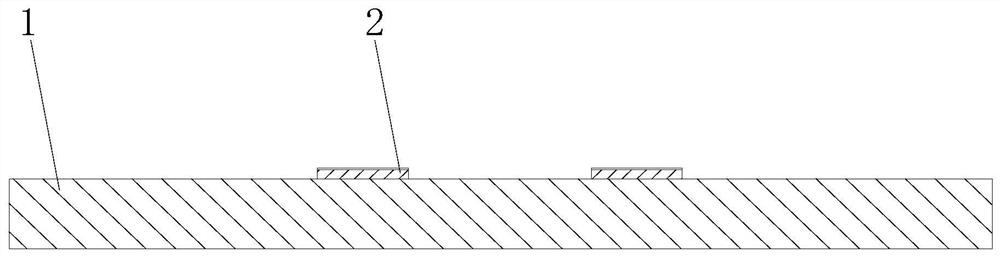

[0029] S1. Etch on the copper substrate 1 to obtain copper bumps 2 corresponding to the printing ink area, and the copper substrate 1 is an FR-4 copper substrate;

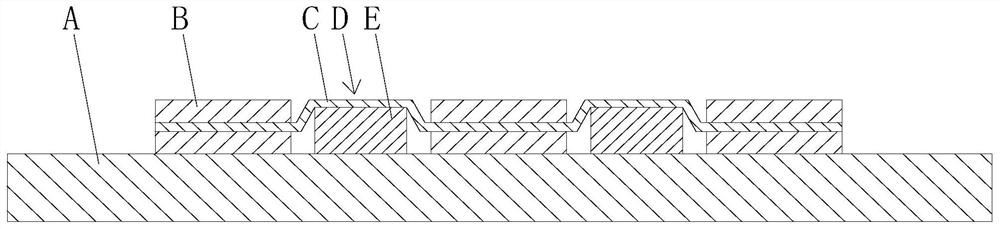

[0030] S2. Print and bond water glue on the top of the copper bump 2, cover the copper-free substrate 3 on the copper-coated substrate 1 and make the copper-free substrate 3 and the copper bump 2 completely fit tightly, and the copper-free substrate 3 is FR- 4 No copper substrate;

[0031] S3, cutting out the substrate bump 4 corresponding to the printed ink area on the copper-free substrate 3 to obtain a carrier.

[0032] In step S1, the following steps are included,

[0033] S11. Process alignment holes 5 on the four corners of the copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com