Patents

Literature

10123 results about "Printing press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A printing press is a mechanical device for applying pressure to an inked surface resting upon a print medium (such as paper or cloth), thereby transferring the ink. It marked a dramatic improvement on earlier printing methods in which the cloth, paper or other medium was brushed or rubbed repeatedly to achieve the transfer of ink, and accelerated the process. Typically used for texts, the invention and global spread of the printing press was one of the most influential events in the second millennium.

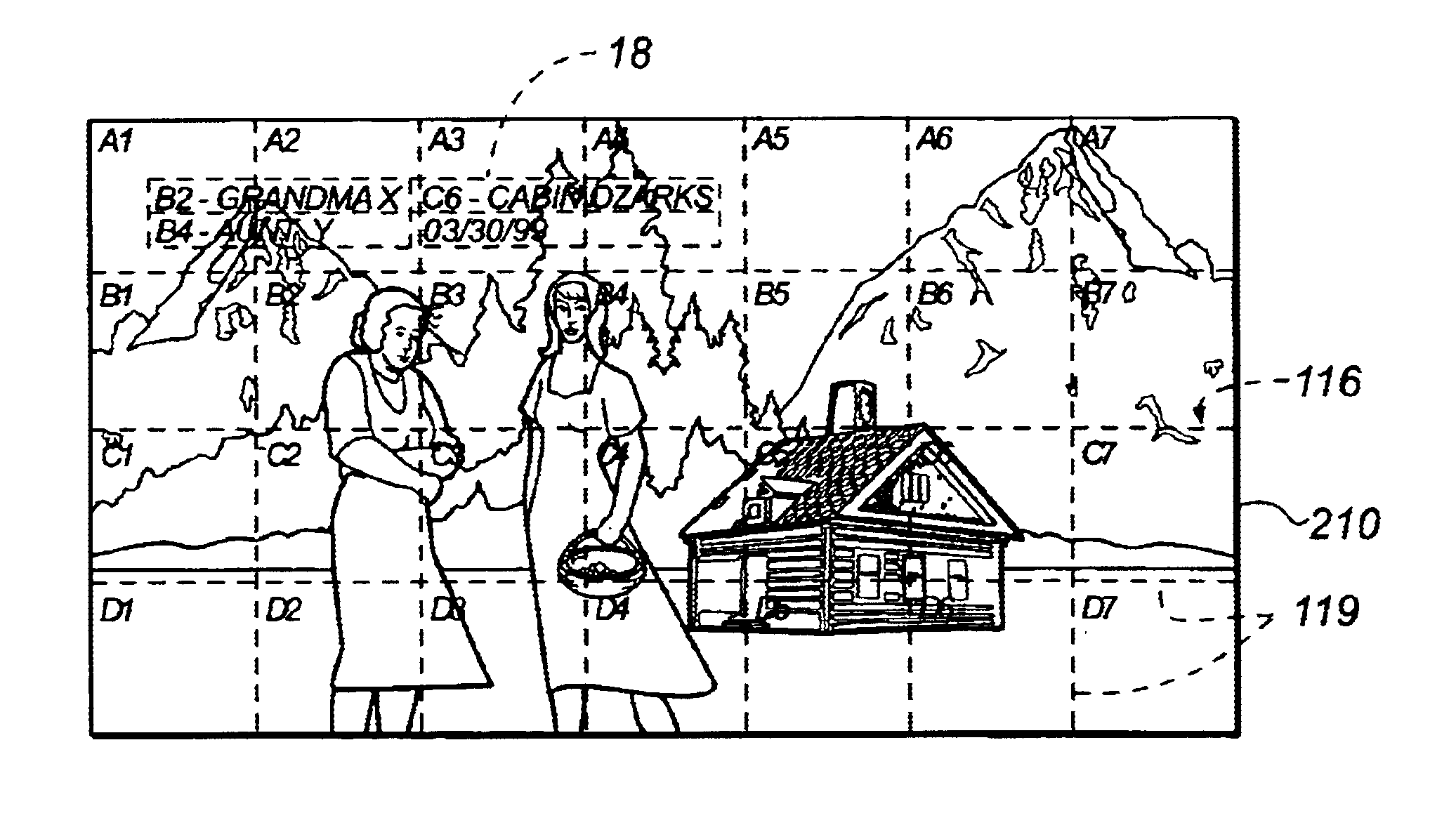

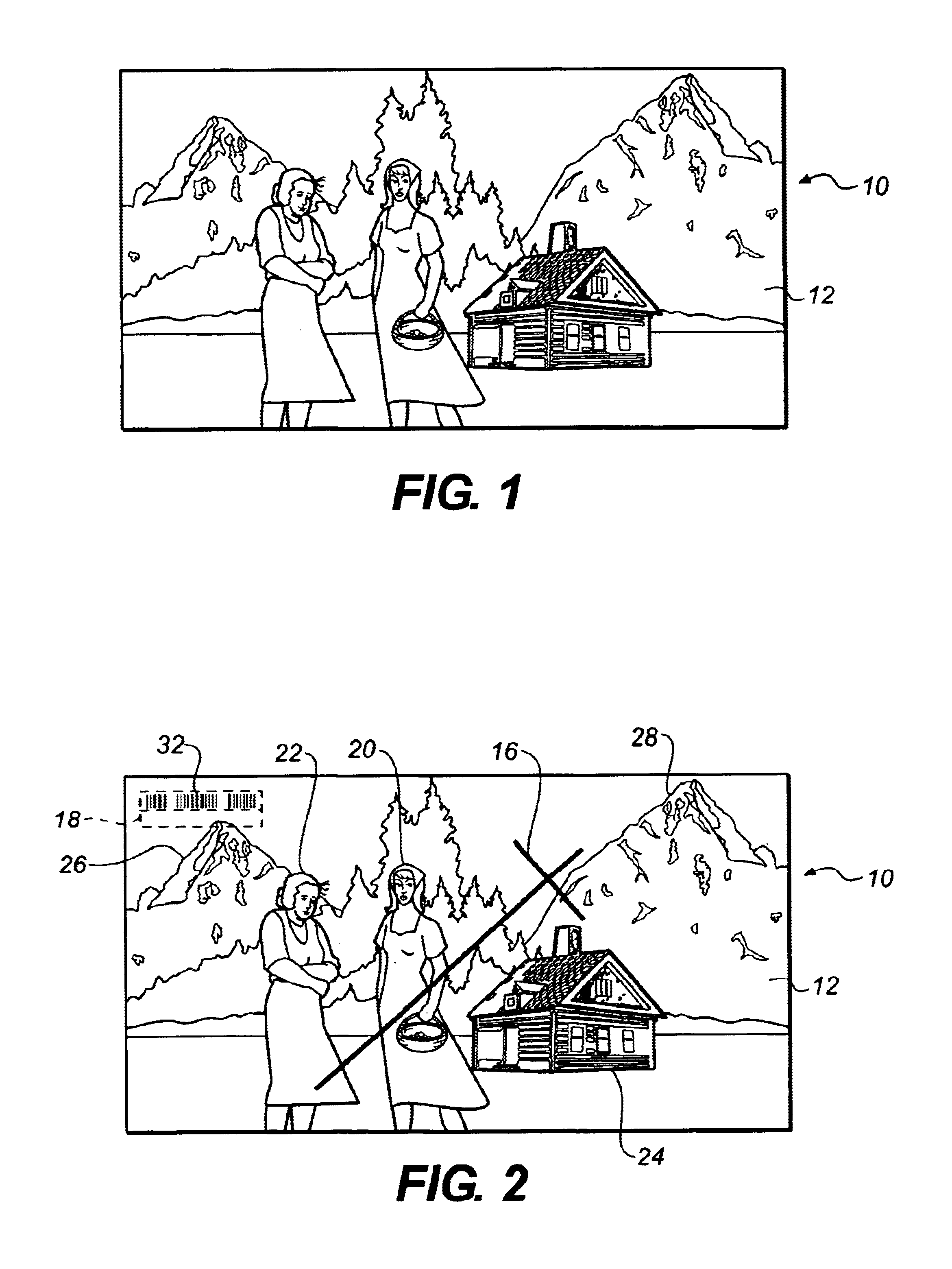

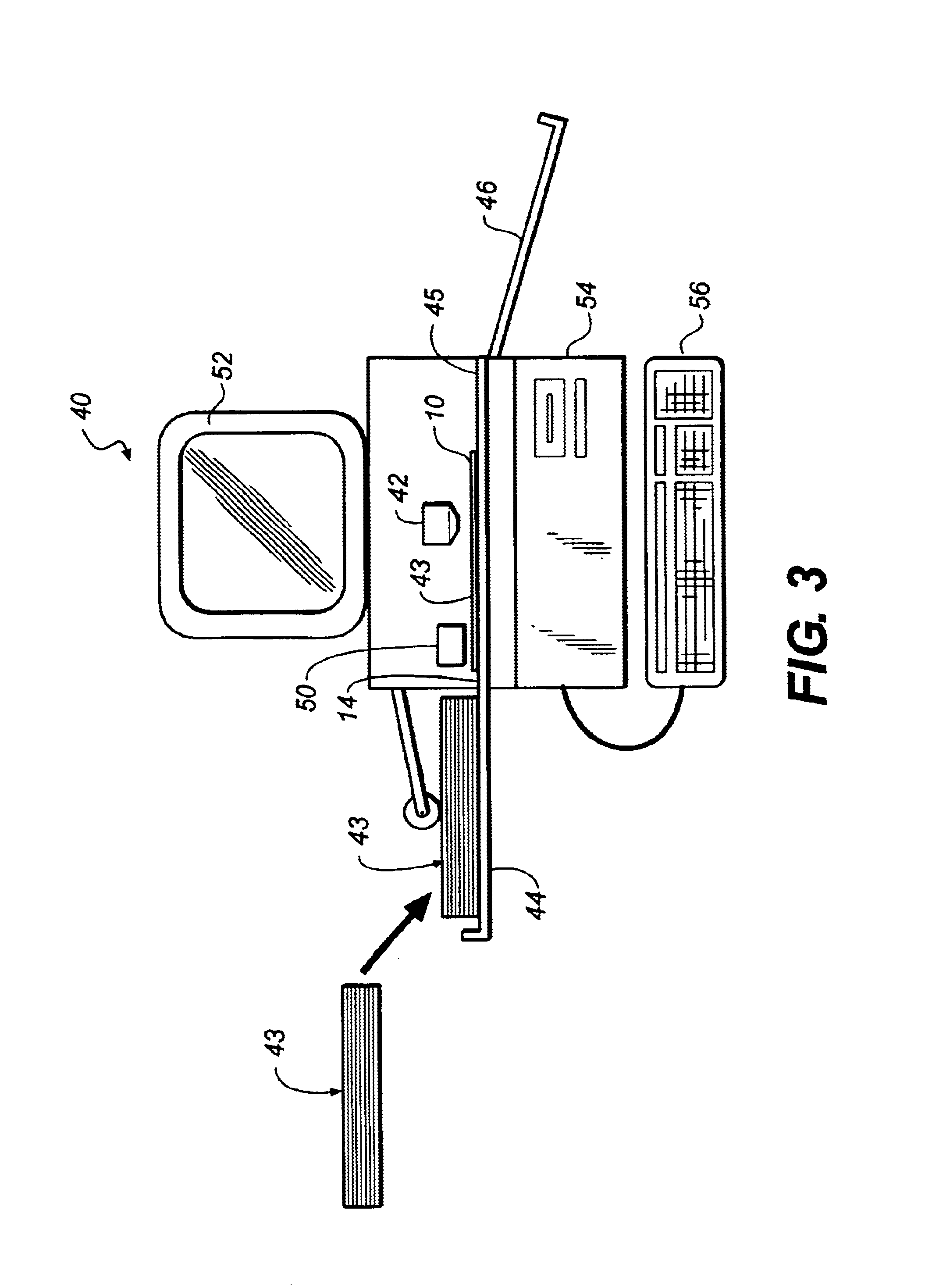

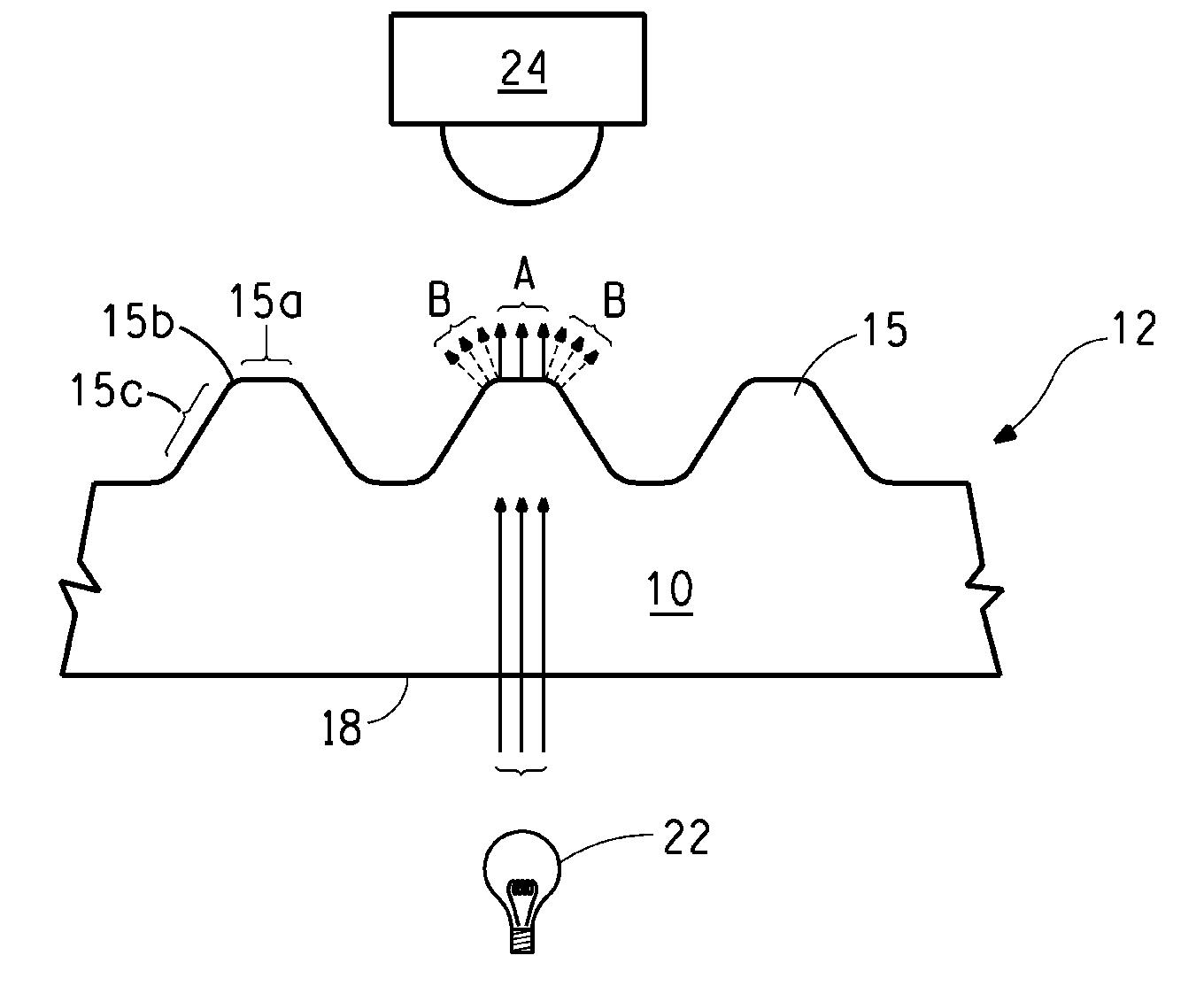

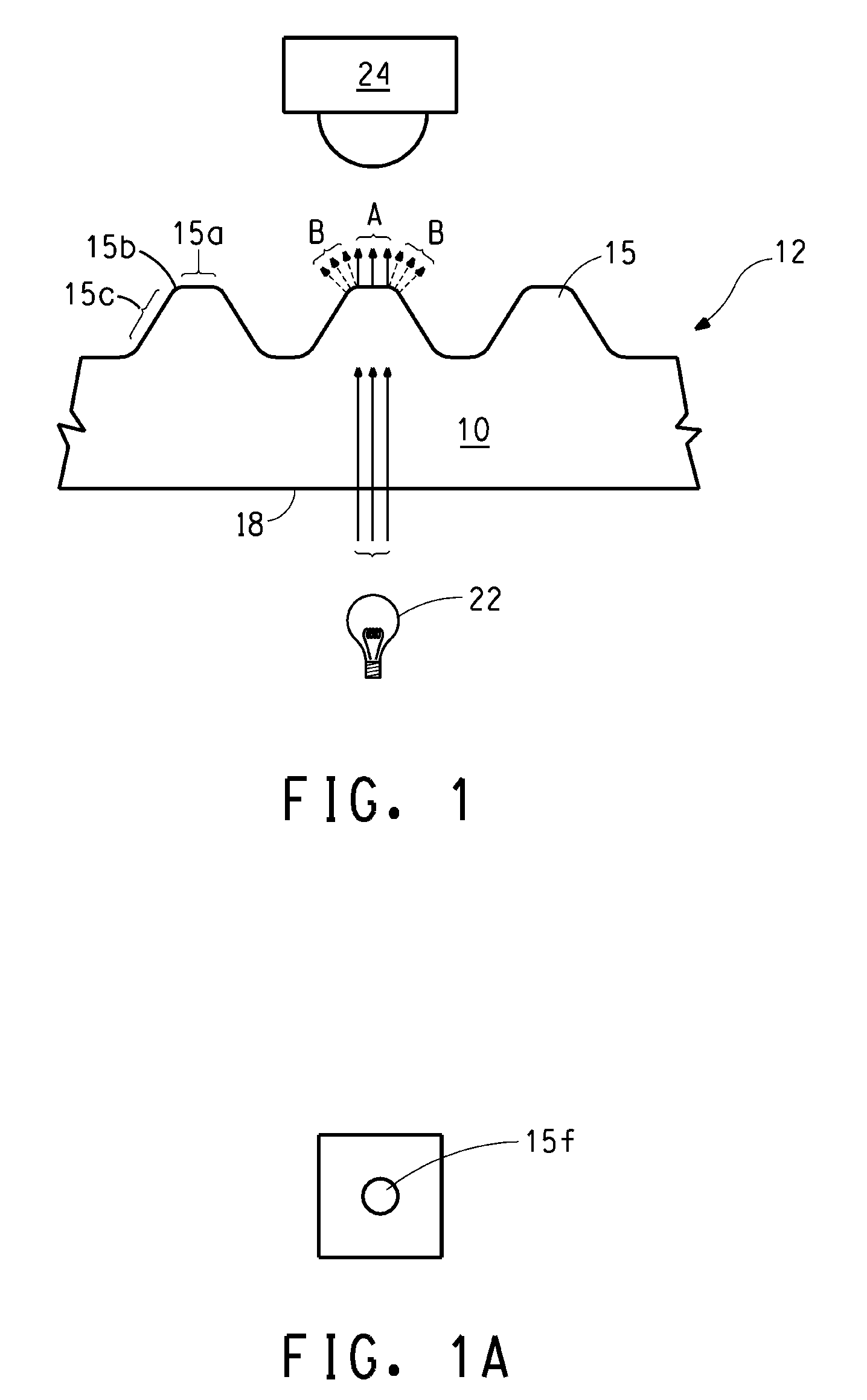

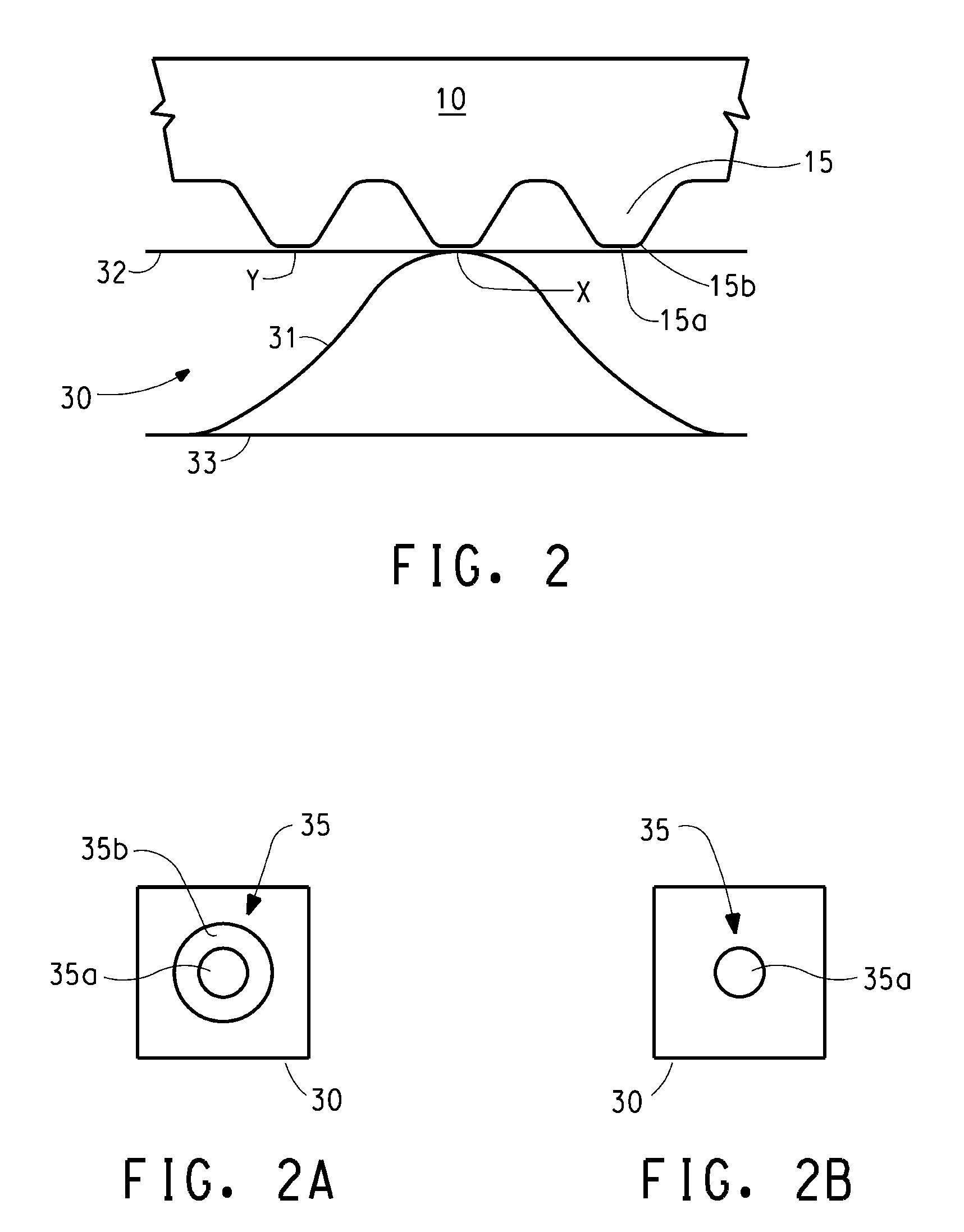

Method and apparatus for making a print having an invisible coordinate system

InactiveUS6894794B1Digitally marking record carriersDigital computer detailsPrinting pressComputer science

A print and method of making a print having a invisible coordinate system on the same side as the image using a digital printer. The print may include additional invisible information which relates to specific parts of the image.

Owner:EASTMAN KODAK CO

Method for making a lithographic printing plate involving on press development

InactiveUS6030750AImprove printing effectSemiconductor/solid-state device manufacturingPlate printingEngineeringPrinting press

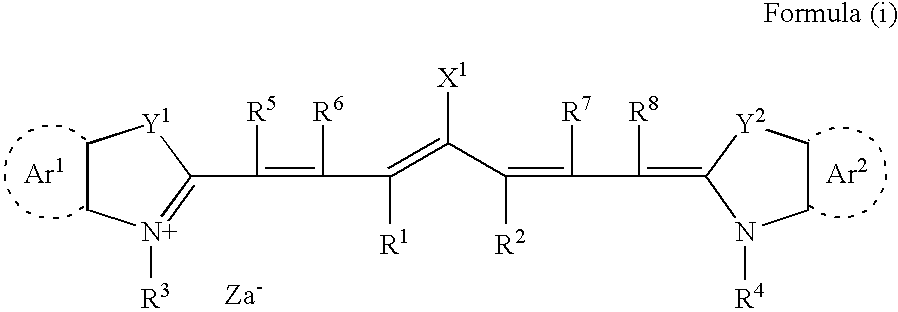

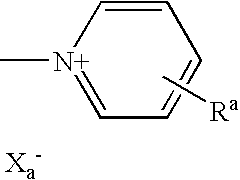

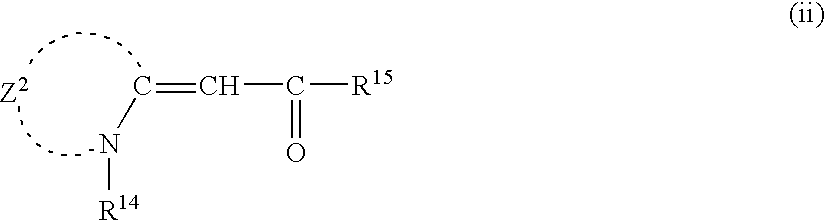

The present invention provides a method for making a lithographic printing plate comprising the steps of: (1) image-wise exposing to light an imaging element comprising (i) on a hydrophilic surface of a lithographic base an image forming layer comprising hydrophobic thermoplastic polymer particles capable of coalescing under the influence of heat and dispersed in a hydrophilic binder and (ii) a compound capable of converting light to heat, said compound being comprised in said image forming layer or a layer adjacent thereto; (2) and developing a thus obtained image-wise exposed imaging element by mounting it on a print cylinder of a printing press and supplying an aqueous dampening liquid and / or ink to said image forming layer while rotating said print cylinder.

Owner:EASTMAN KODAK CO

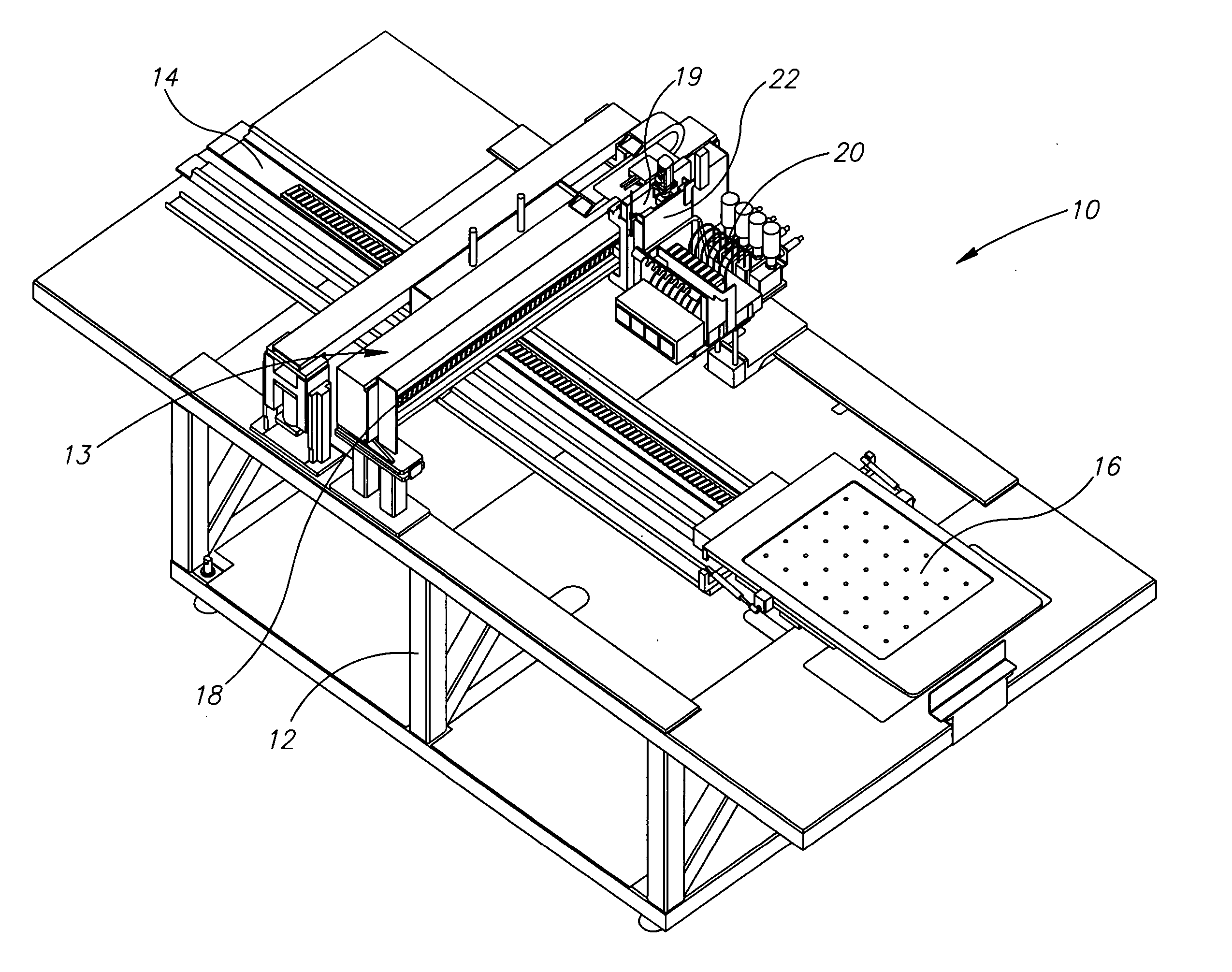

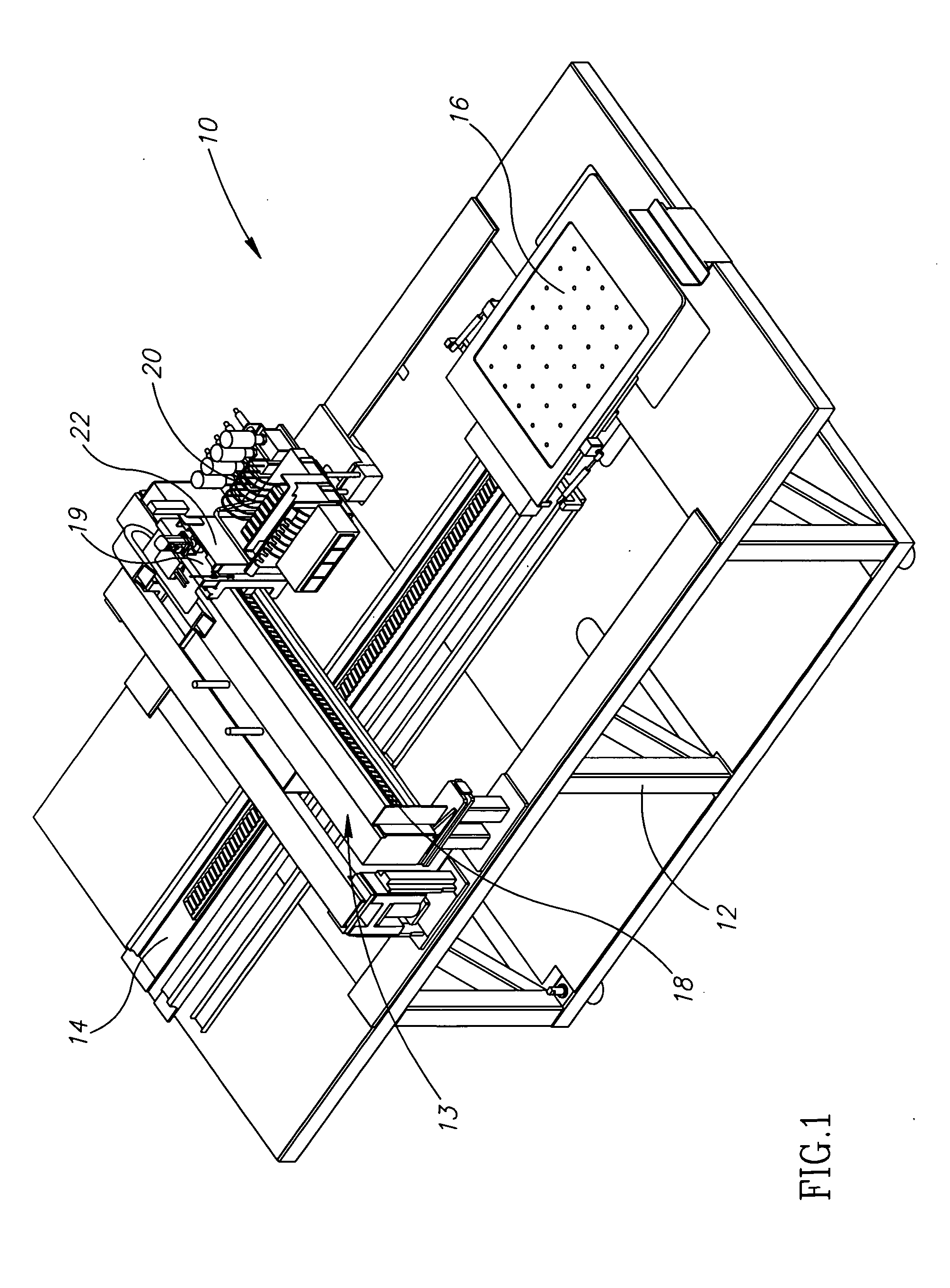

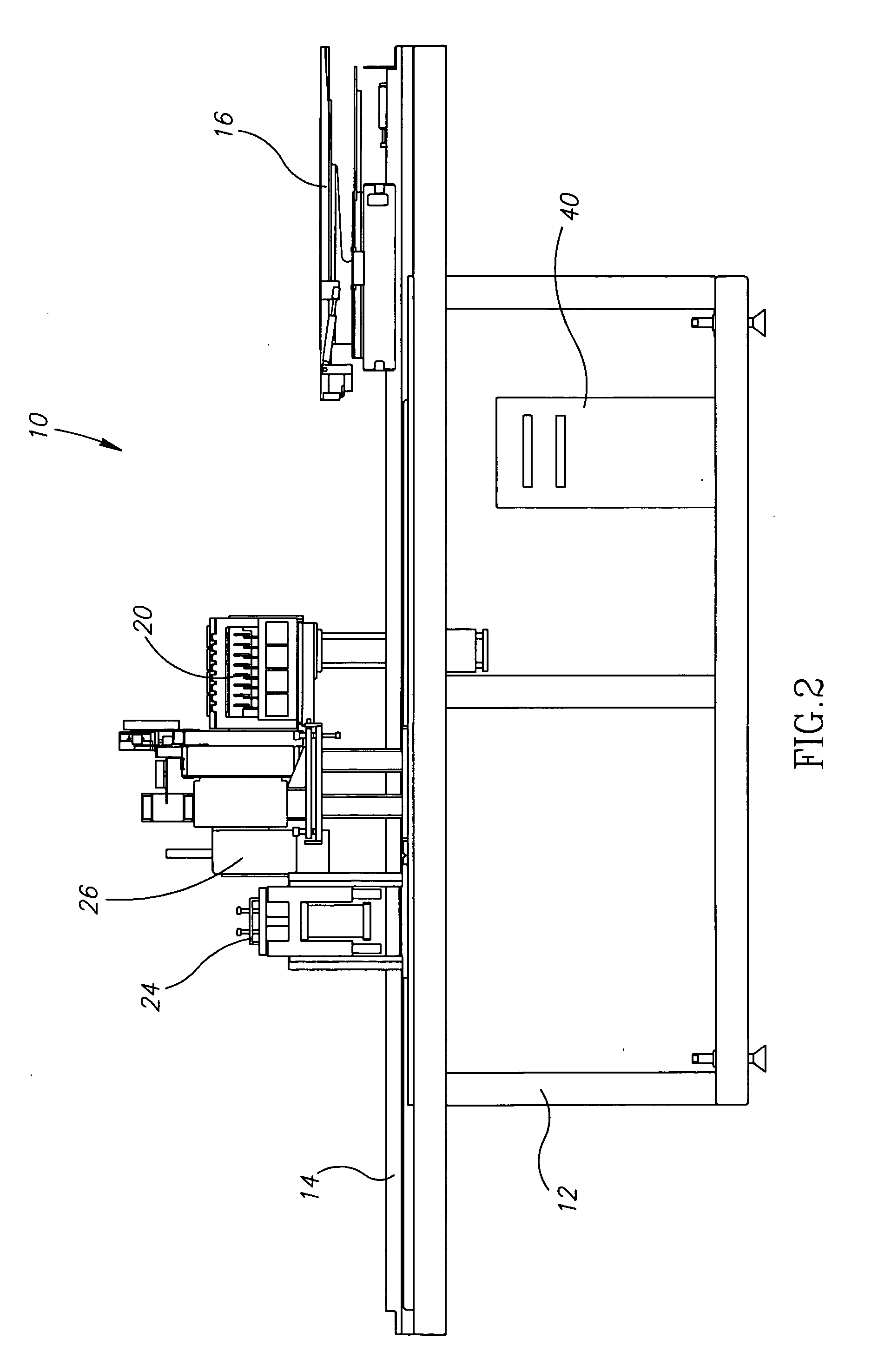

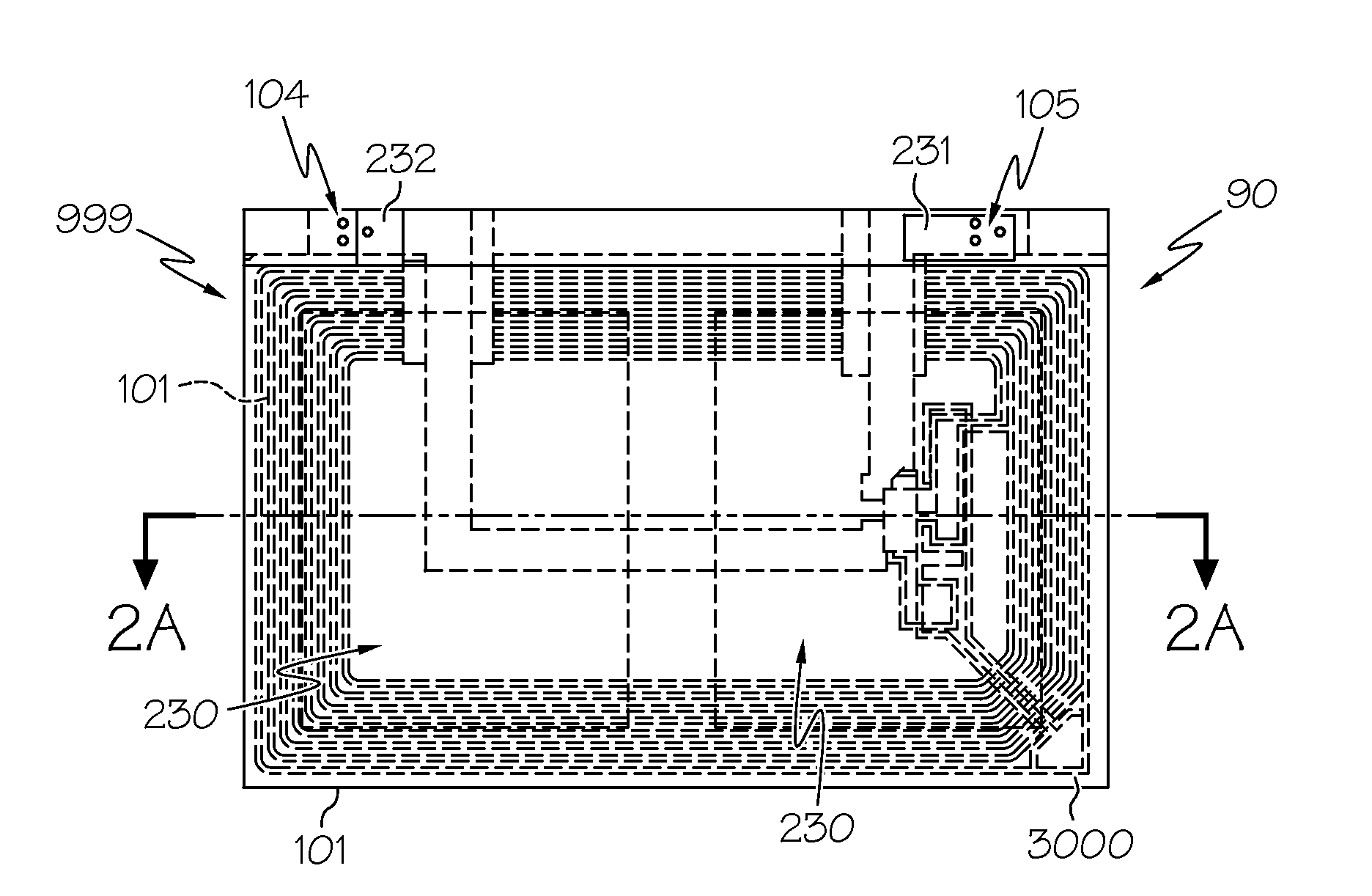

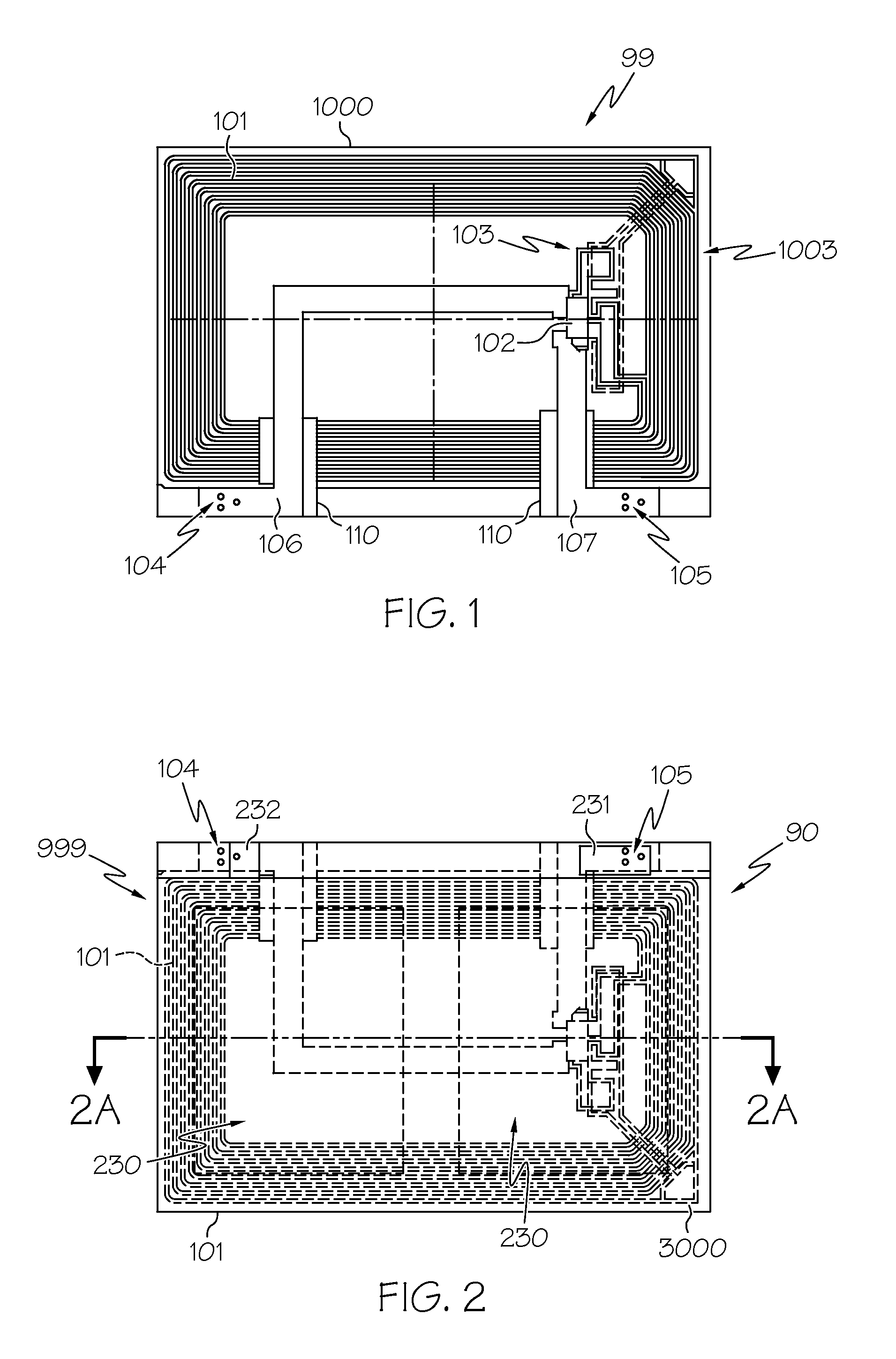

Digital printing machine

ActiveUS20050179708A1Accurate and high resolution printingImprove efficiencyTypewritersOther printing apparatusLinear motionEngineering

A digital printing machine including a rigid frame, a first linear motion X axis stage mounted on the frame, a printing table assembly movable on each linear X axis stage, a linear motion Y axis stage mounted on the frame perpendicular to the linear X axis stages, above the printing table assemblies, and an array of inkjet nozzles mounted on the linear Y axis stage for linear motion perpendicular to the X axis stage. The printing machine may include a second linear motion X axis stage mounted on the frame parallel to the first axis stage and arranged for operation independently of the first axis stage, and / or a curing unit located above the printing table assembly and arranged to cure ink on media on the printing table assembly and / or an ironing unit located above the printing table assembly and arranged to iron media on the printing assembly before printing thereon, or a first printing table assembly movable on the base of the linear X axis stage and a second printing table assembly movable on the linear X axis stage base independently of the first printing table assembly.

Owner:KORNIT DIGITAL LTD

Lithographic printing plate precursor and lithographic printing method

InactiveUS20050170282A1Photomechanical apparatusPhotosensitive material auxillary/base layersLaser exposureEngineering

An on-press development or non-processing (non-development) type lithographic printing plate precursor capable of giving a printout image having a large lightness difference, and a lithographic printing method using this lithographic printing plate precursor are provided, a lithographic printing plate precursor comprising a support and a photosensitive-thermosensitive layer capable of recording an image by infrared laser exposure, the lithographic printing plate precursor being capable of performing a printing by loading on a printing press without passing through a development processing step after recording an image, or by recording an image after loading on a printing press, wherein said photosensitive-thermosensitive layer comprises (1) an infrared absorbent and (2) a discoloring agent or discoloration system capable of generating a color change upon exposure; and the lithographic printing method performing a printing using the above-described lithographic printing plate precursor.

Owner:FUJIFILM CORP

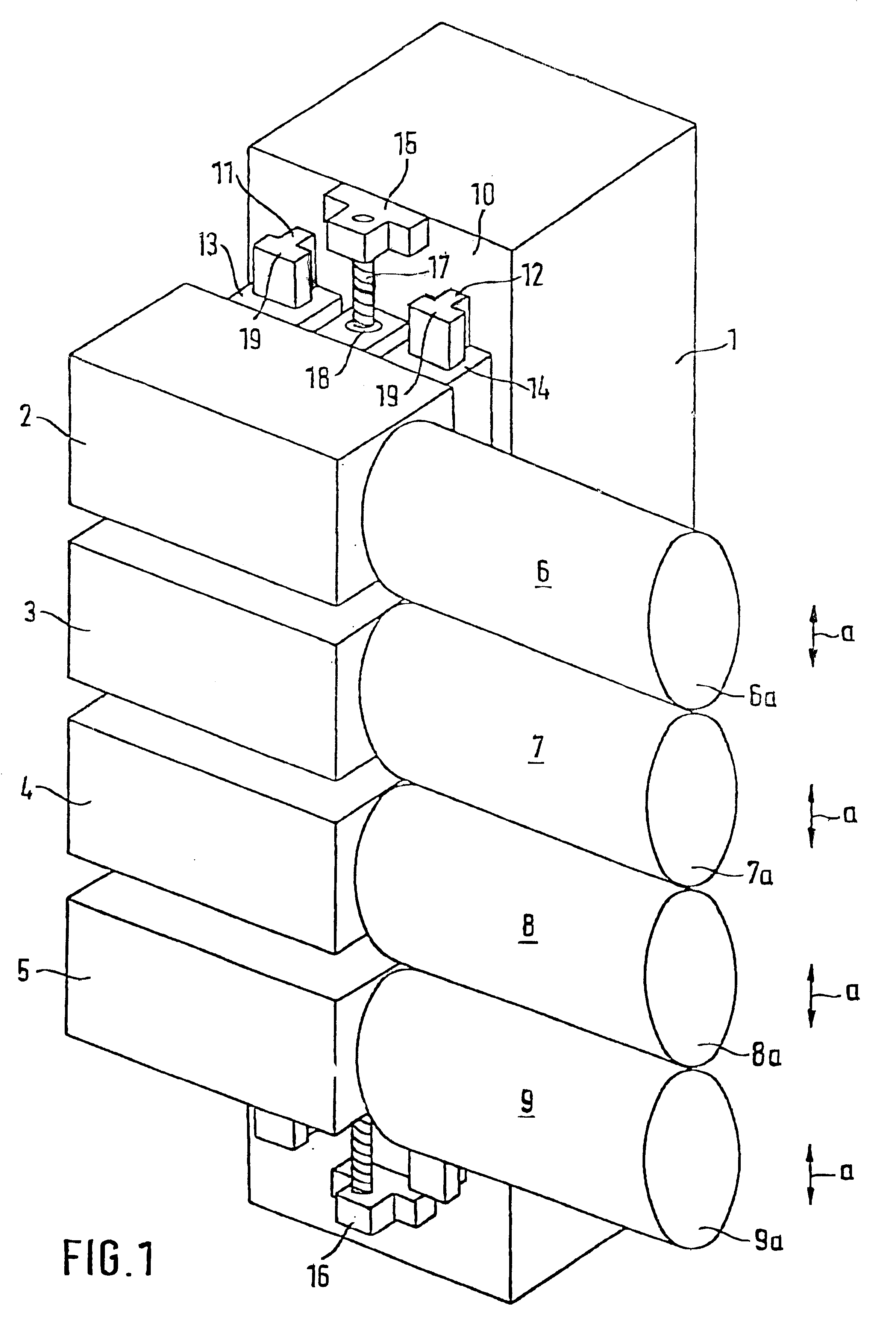

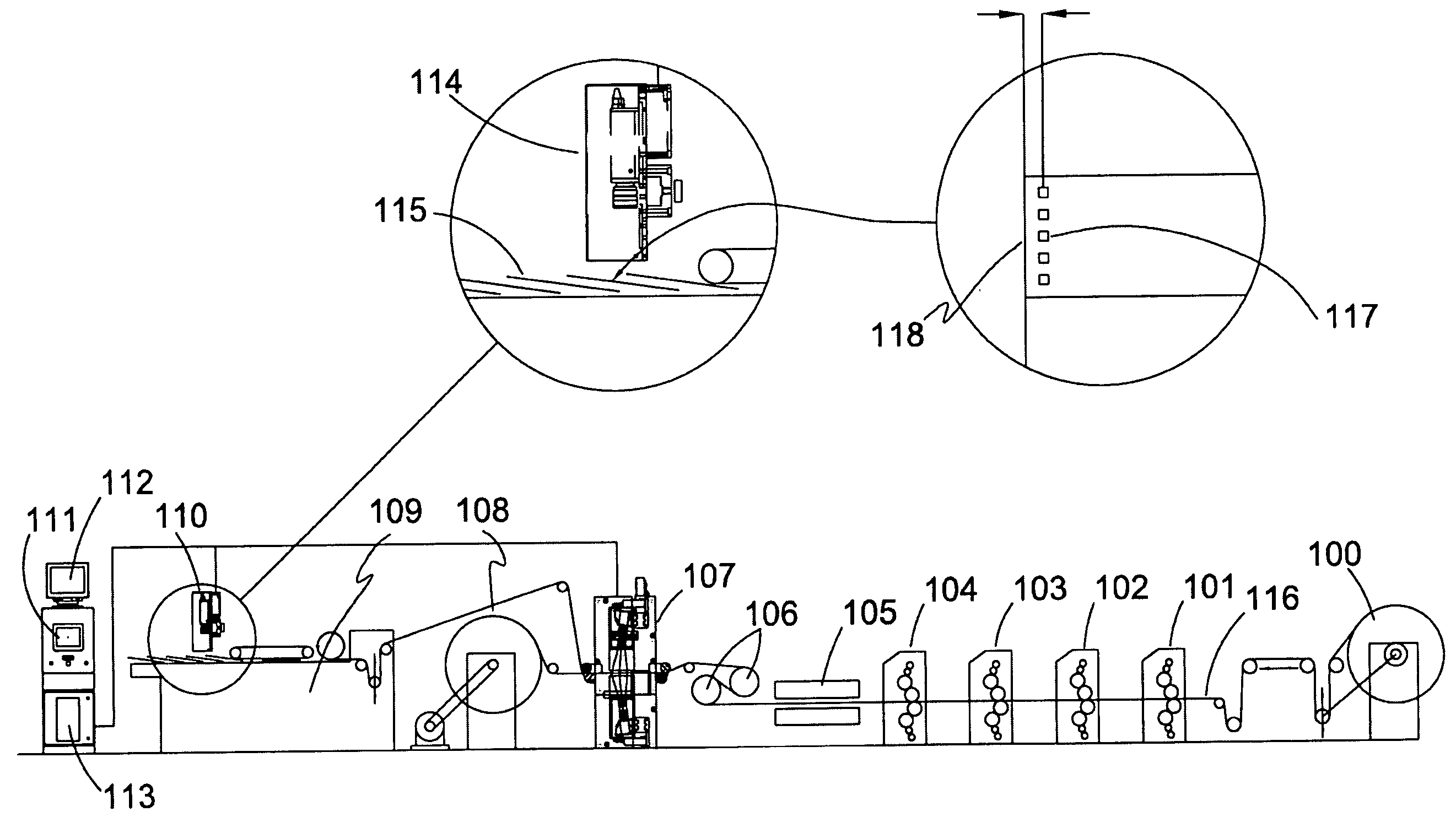

Web-fed rotary printing press for rapid change in production

InactiveUS6019039APrinting platesOther printing apparatusPrinting pressElectrical and Electronics engineering

The invention relates to a web-fed rotary printing press having a plurality of double printing units in which each of the printing units of the double printing units work together in the blanket-blanket method and each has its own drive. Transfer cylinders of each printing unit are driven independently. To permit a rapid change in production, both upon recto and verso printing, the transfer cylinders of the disconnectable double printing units are separable by eccentric bushings or swingable levers such that a web which passes through the printing press is conducted between them without being printed.

Owner:MANROLAND WEB SYST

Apparatus for longitudinally perforating a web of paper in a rotary printing press

A rotary printing press has a folding station where the printed web is perforated both transversely and longitudinally in order to expedite subsequent folding thereof into signatures. In order to incorporate a longitudinal perforator into the folding station without adding to its size, a longitudinally perforating blade similar to a circular saw is mounted to a blade carrier shaft which is rotatably supported opposite a feed roller by which the web is frictionally fed into and through the folding station. An annular, longitudinally grooved anvil is formed circumferentially on the feed roller for engaging the longitudinally perforating blade via the web being thereby perforated. The longitudinally perforating blade is movable with the blade carrier shaft into and out of perforating engagement with the anvil on the feed roller.

Owner:TOKYO KIKAI SEISAKUCHI LTD

Use and production of coated filaments for extrusion-based 3D printing processes

ActiveUS20140134335A1Additive manufacturing apparatusFilament manufacturePolymer sciencePrinting press

Owner:EVONIK OPERATIONS GMBH

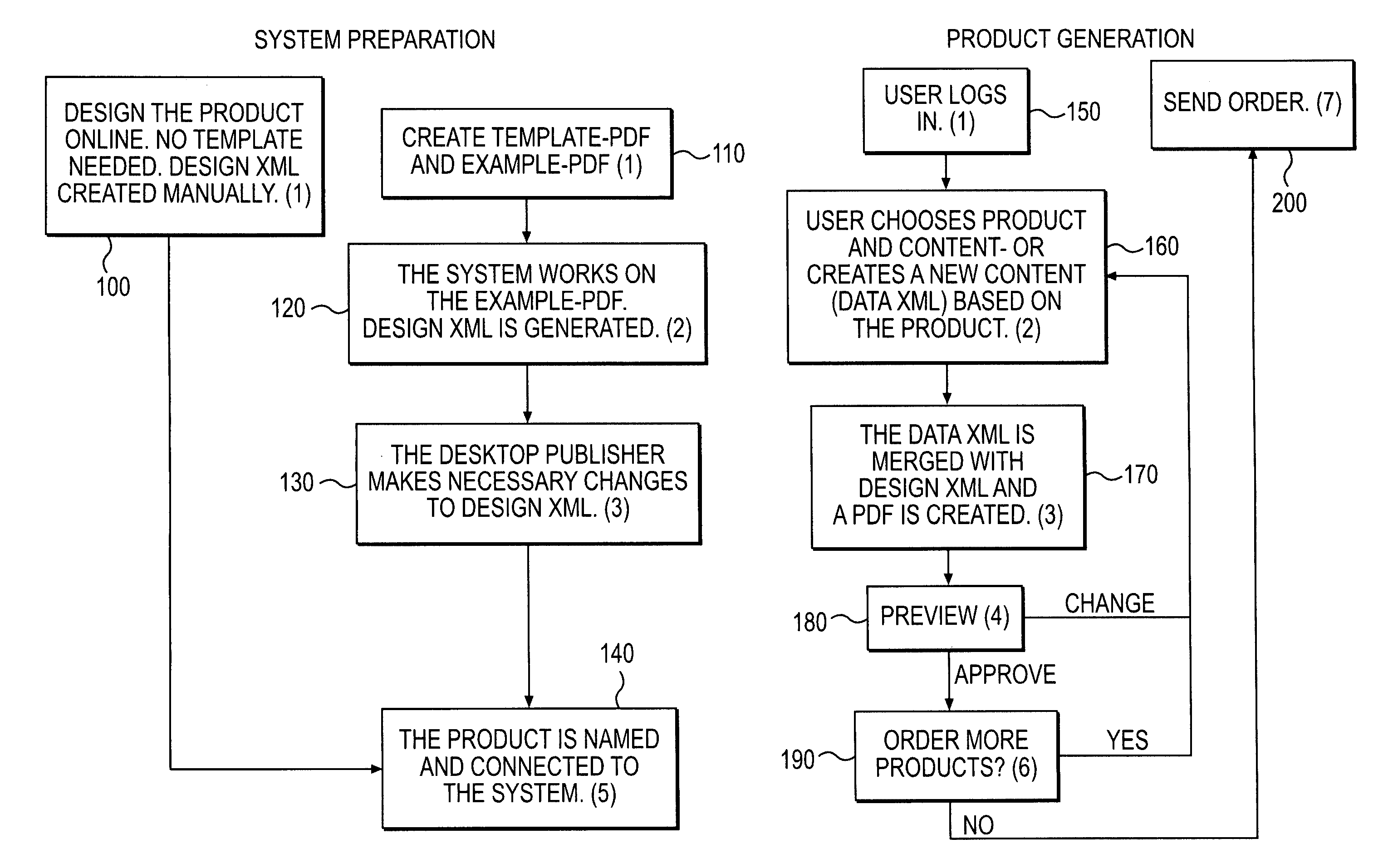

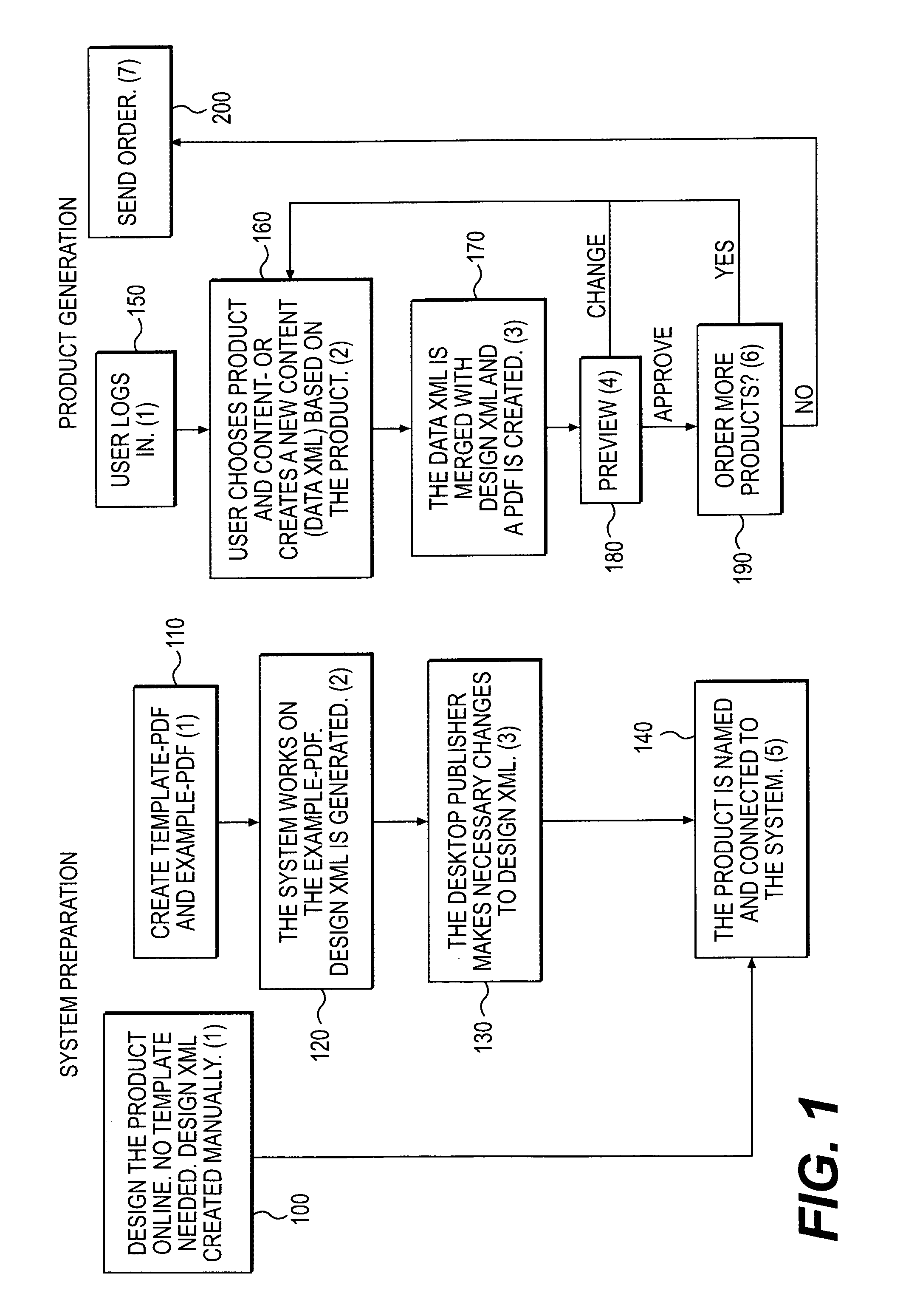

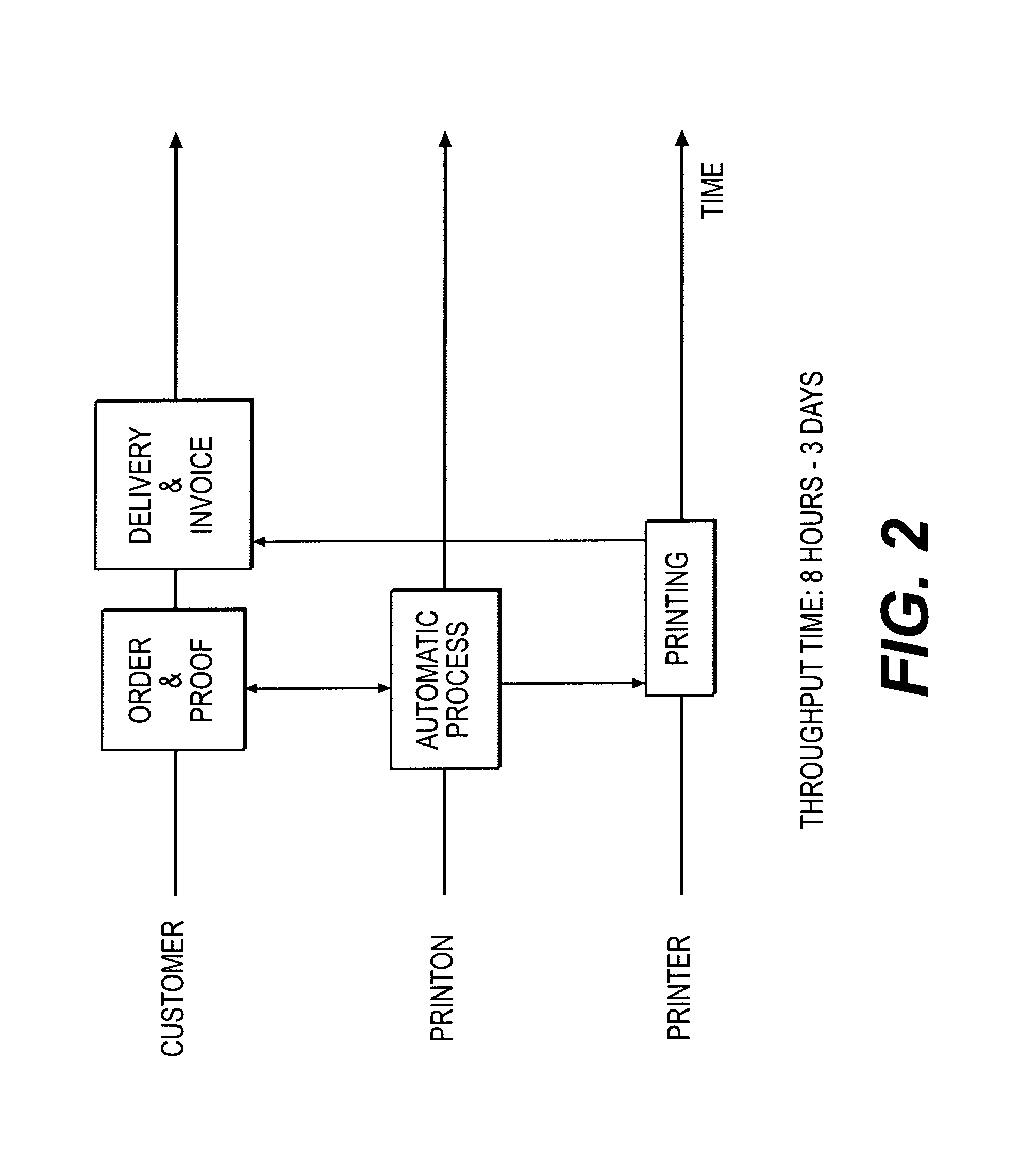

Method and system for online creation and ordering of customized material for printing

InactiveUS6992786B1Digital computer detailsNatural language data processingService provisionThe Internet

The present invention relates to a method and a system for online creation and ordering of customized material for printing, where each customer at front end, through a computerized interface, participates in the process of creating, editing, proof printing and finally ordering print-ready files through Internet, via a printing service provider which automates the production of the print-ready files, and where print shops carefully chosen by the printing service provider automatically receives the print-ready files directly into their printing press. A PDF engine uses two XML files to create a customer PDF document for printing on demand. One XML file, the data XML file, comprises the data and it's typing for printing, and is created by the customer through the computerized interface. The second XML file, design XML file, comprises a description of how said data can be positioned and formatted, in a created document by the customer through said interface. The PDF engine generates the print-ready document through providing a new structure by analyzing the two XML files, while analyzing merging data and formatting information, thus making it possible to create a PDF document with a distinct difference between data to be printed and the design of the PDF document.

Owner:PRINTON

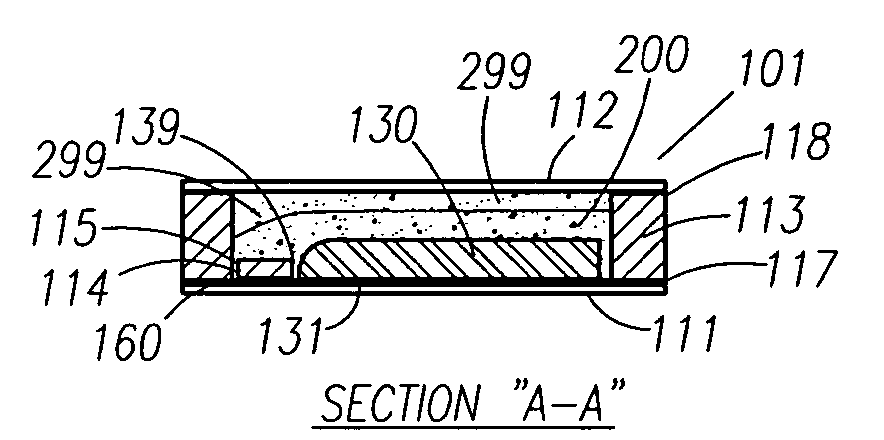

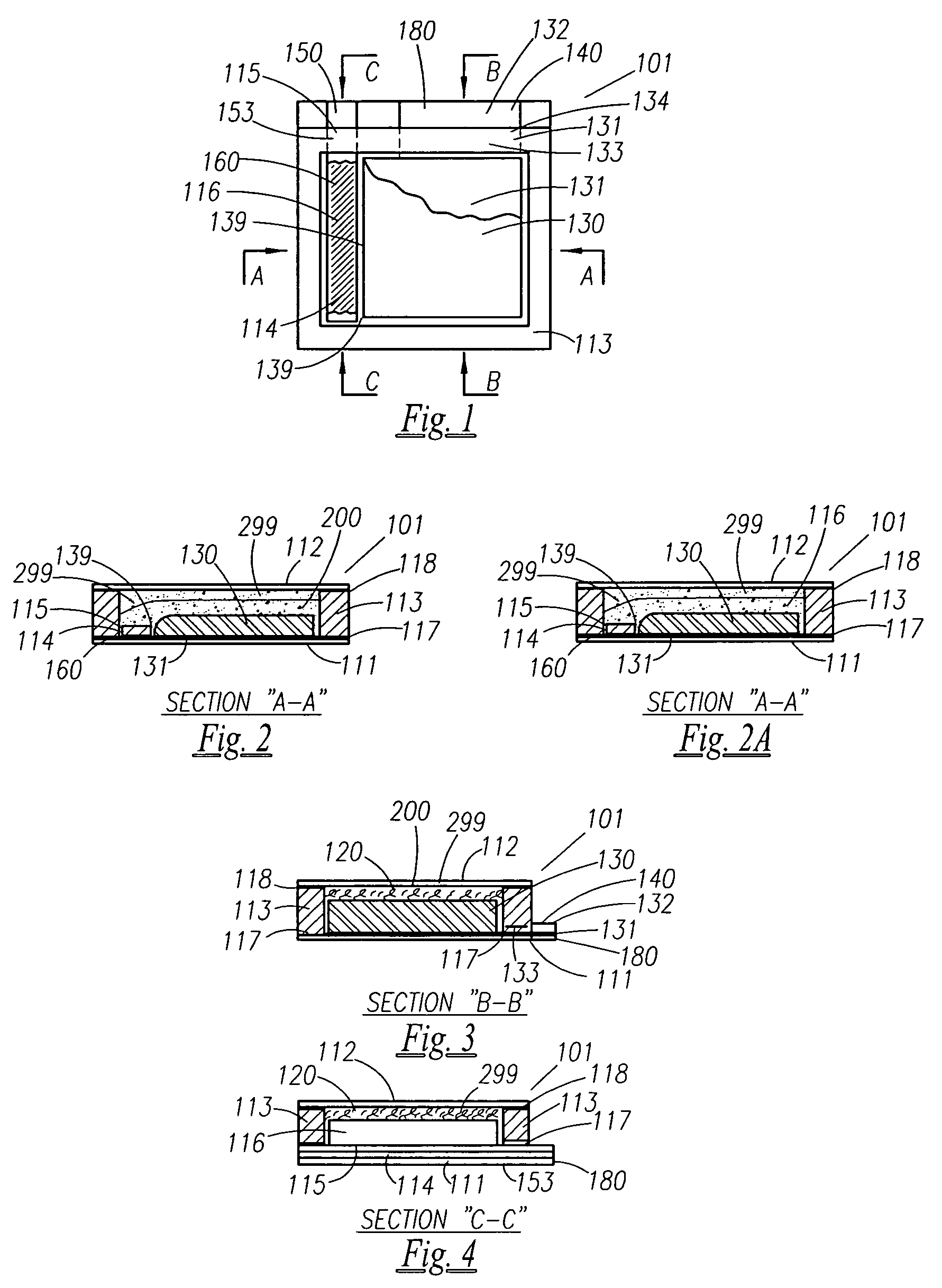

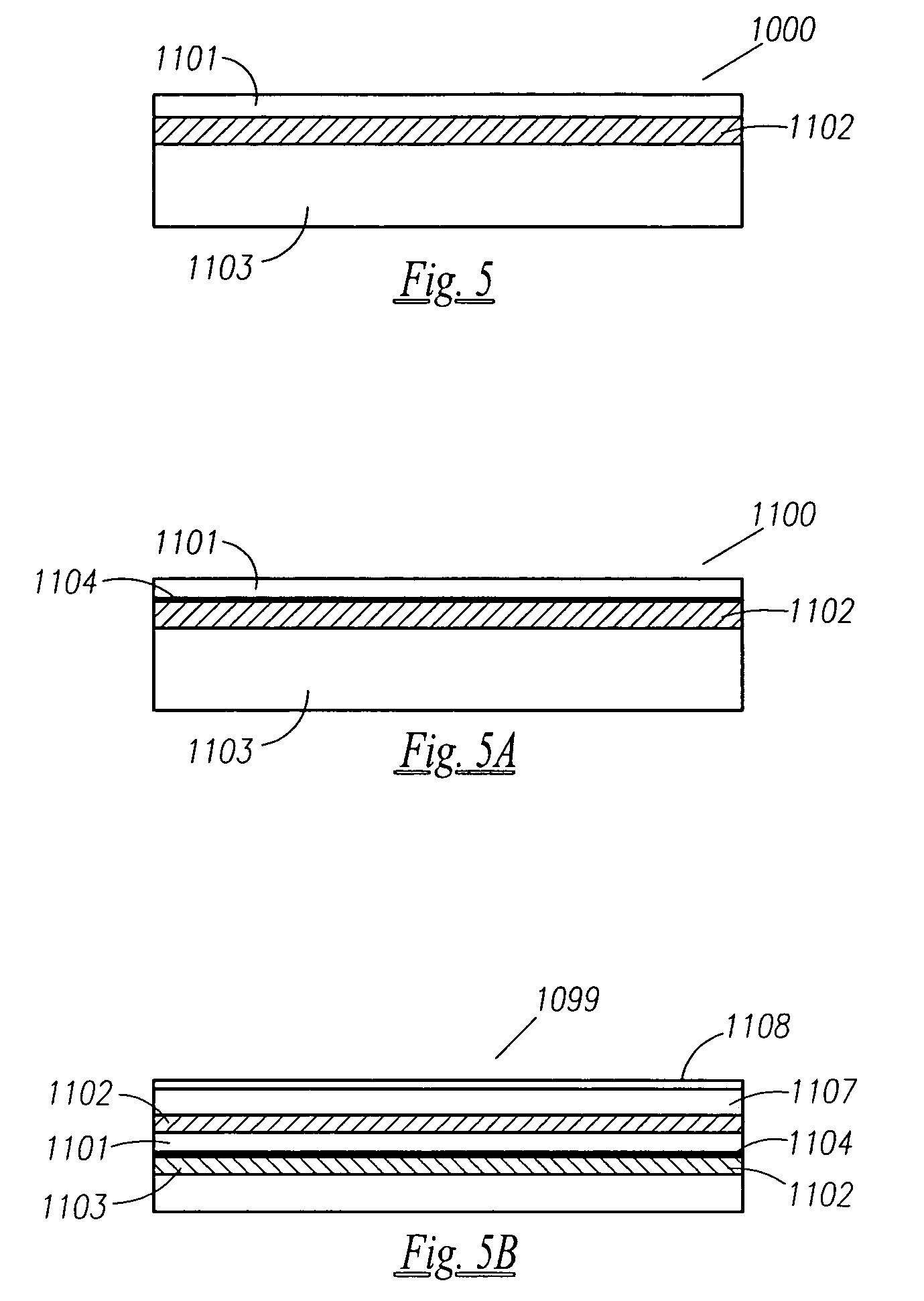

Thin printable electrochemical cell utilizing a "picture frame" and methods of making the same

A thin printed flexible electrochemical cell, and its method of manufacture, using a “picture frame” structure sealed, for example, with a high moisture and oxygen barrier polymer film and featuring, for example, a printed cathode deposited on an optional, highly conductive carbon printed cathode collector with a printed or a foil strip anode placed adjacent to the cathode. A viscous or gelled electrolyte is dispensed and / or printed in the cell, and a top laminate can then be sealed onto the picture frame. Such a construction could allow the entire cell to be made on a printing press, for example, as well as gives the opportunity to integrate the battery directly with an electronic application, for example.

Owner:BLUE SPARK INNOVATIONS LLC

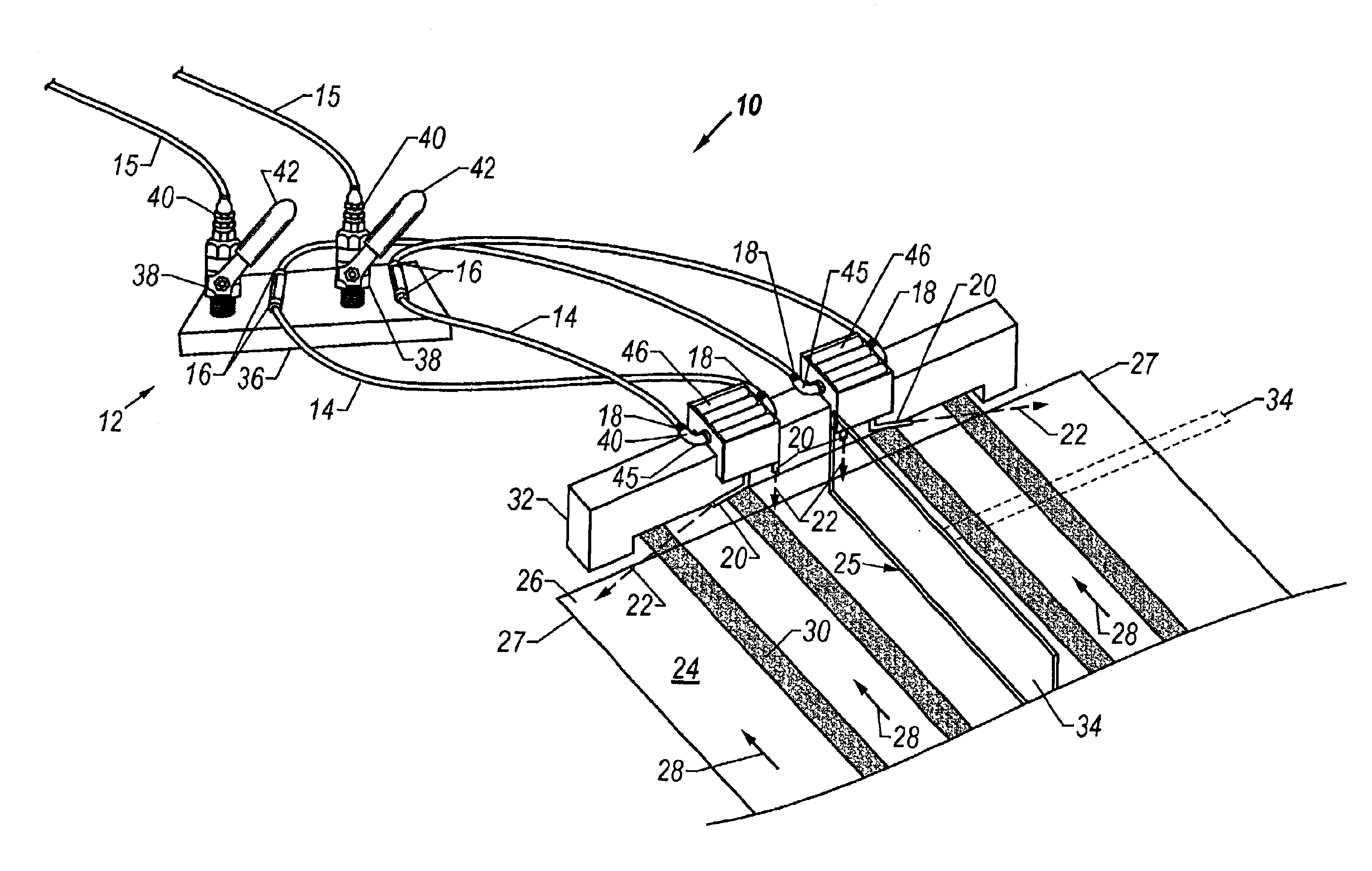

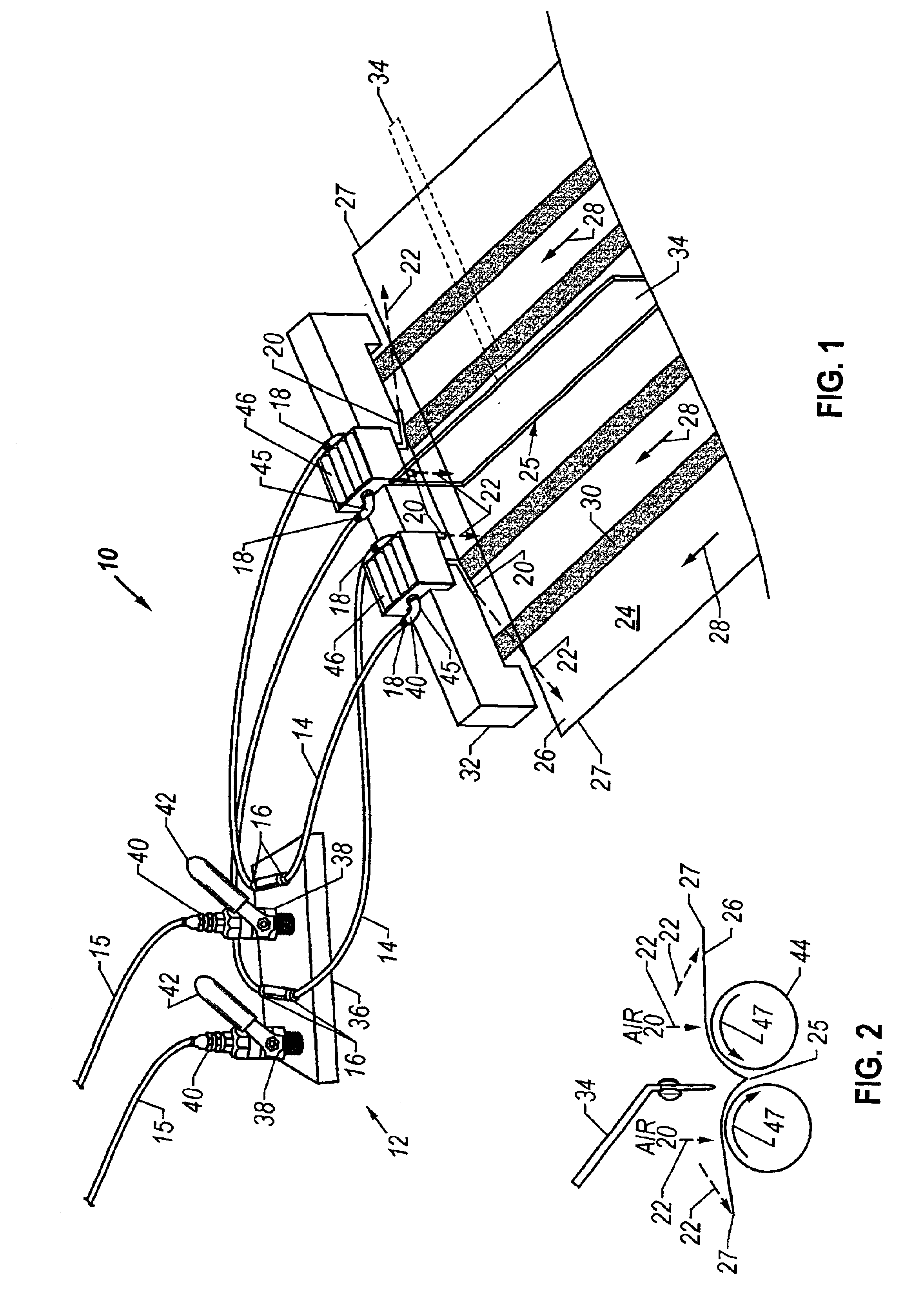

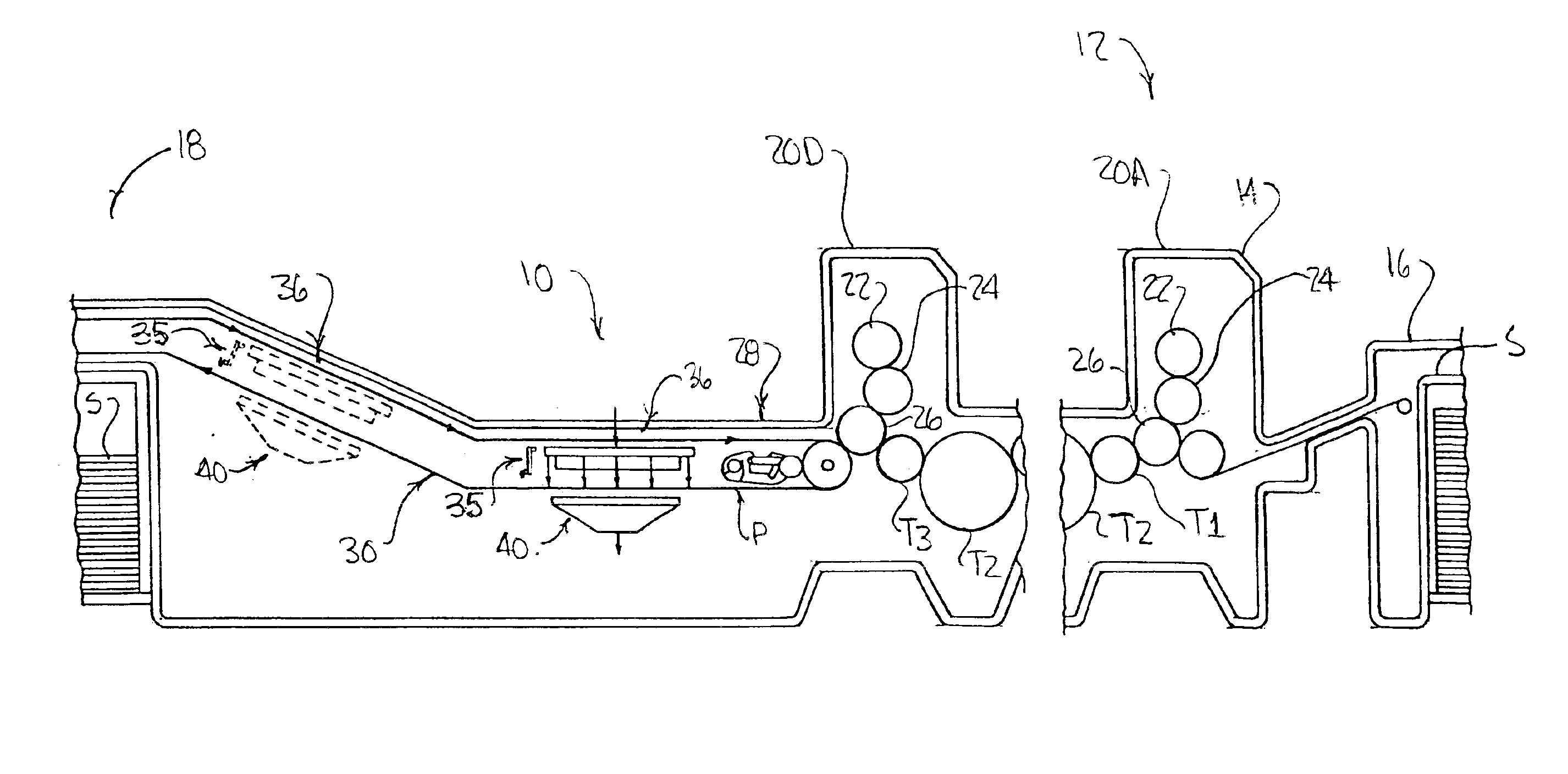

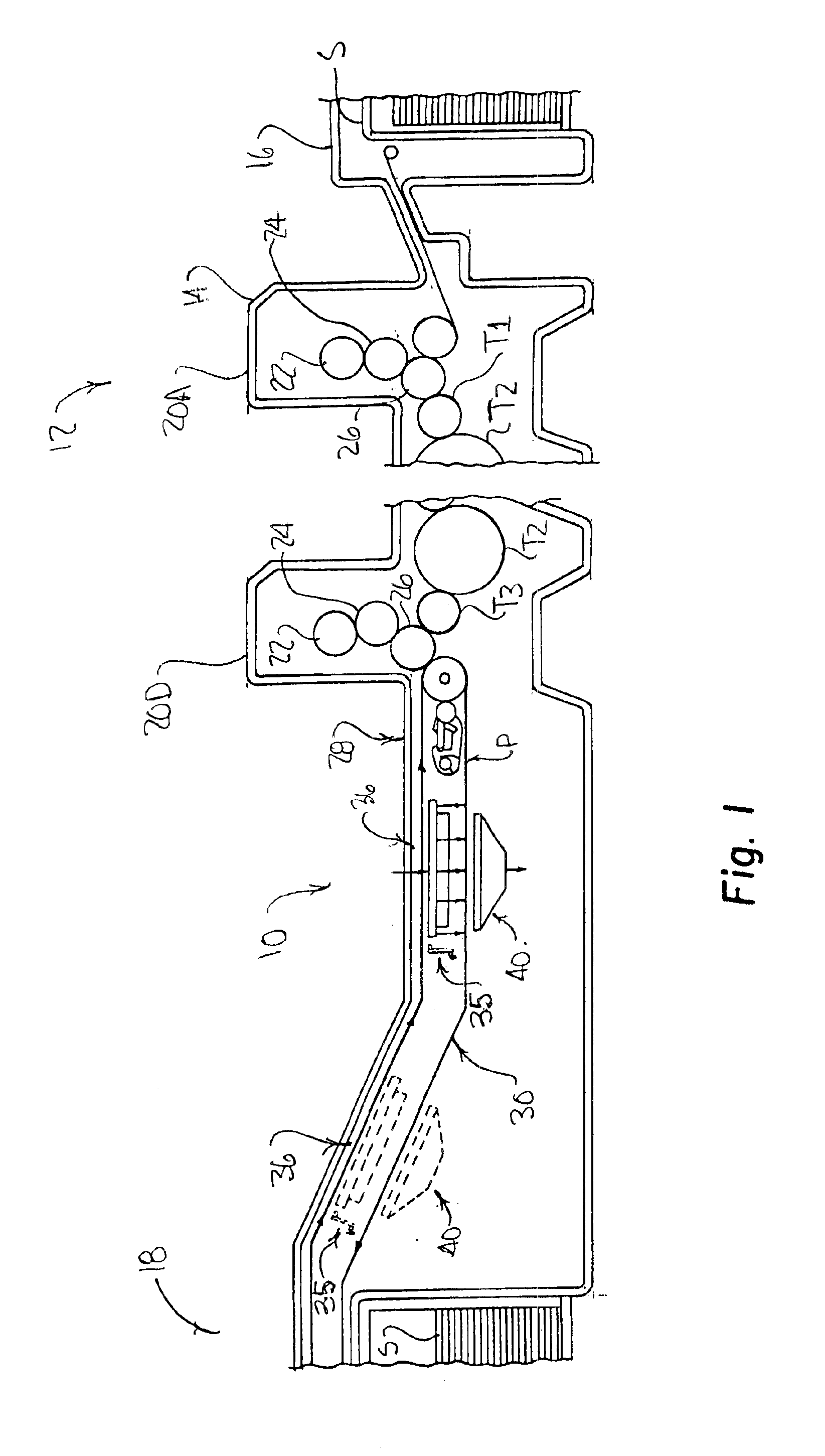

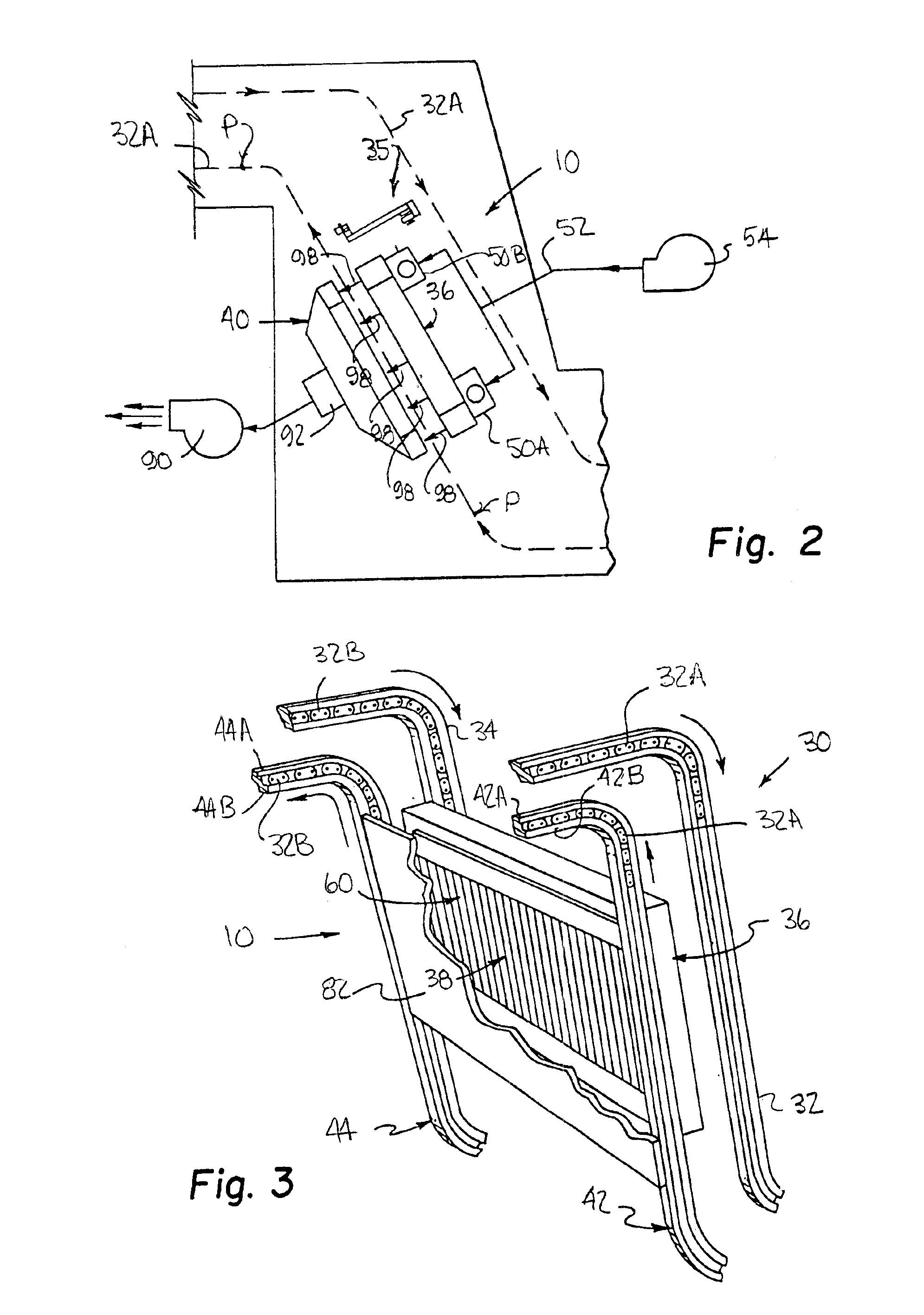

Air folder adjuster apparatus and method

InactiveUS6840616B2Mechanical working/deformationFolding thin materialsPaper documentDocument preparation

An air folder adjuster (10) includes an air supply (12) and air supply tubing (14) connected to air supply (12) at end (16). The opposite end (18) of air supply tubing (14) is connected to one or more air nozzles (20). In a printing press utilized for folding documents such as books, air folder adjuster (10) is positioned so that air nozzles (20) direct compressed air from air supply (12) downward onto the head (26) of document (24) on either side of chopper arm (34) during the folding process thus ensuring that the document (24) lies flat, square, and untouched during the folding process and thereby allowing the elimination of chopper brushes altogether.

Owner:SUMMERS SCOTT

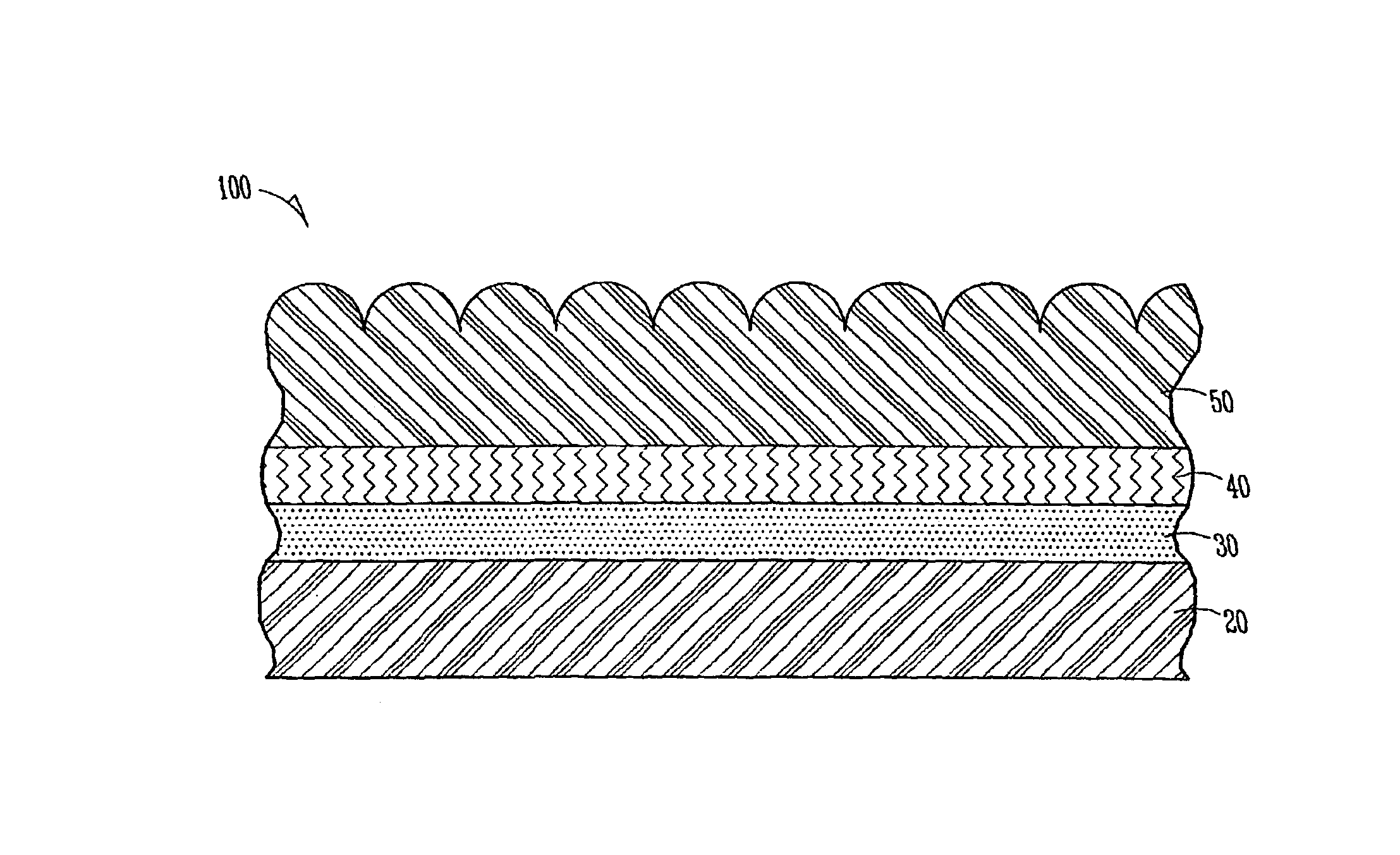

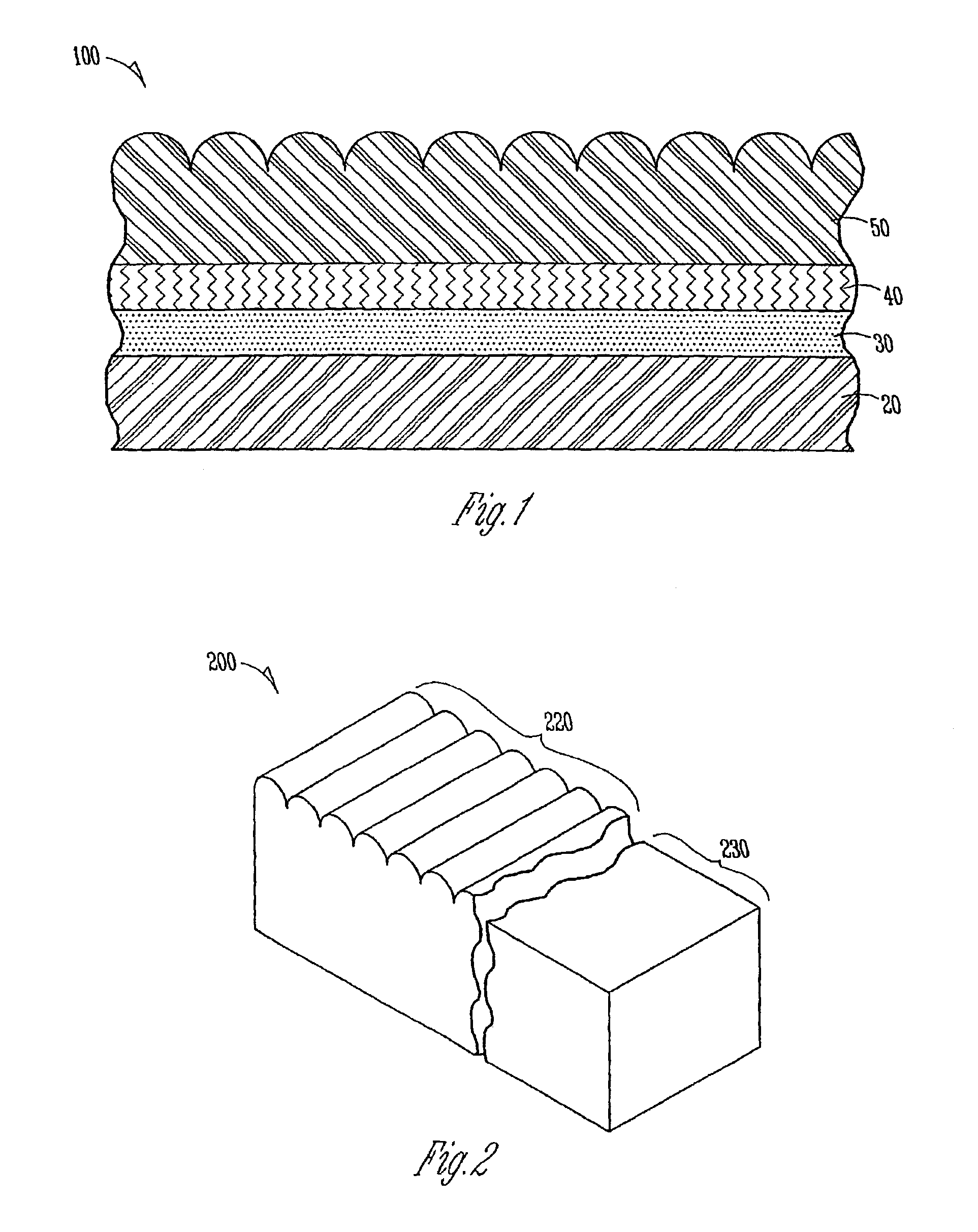

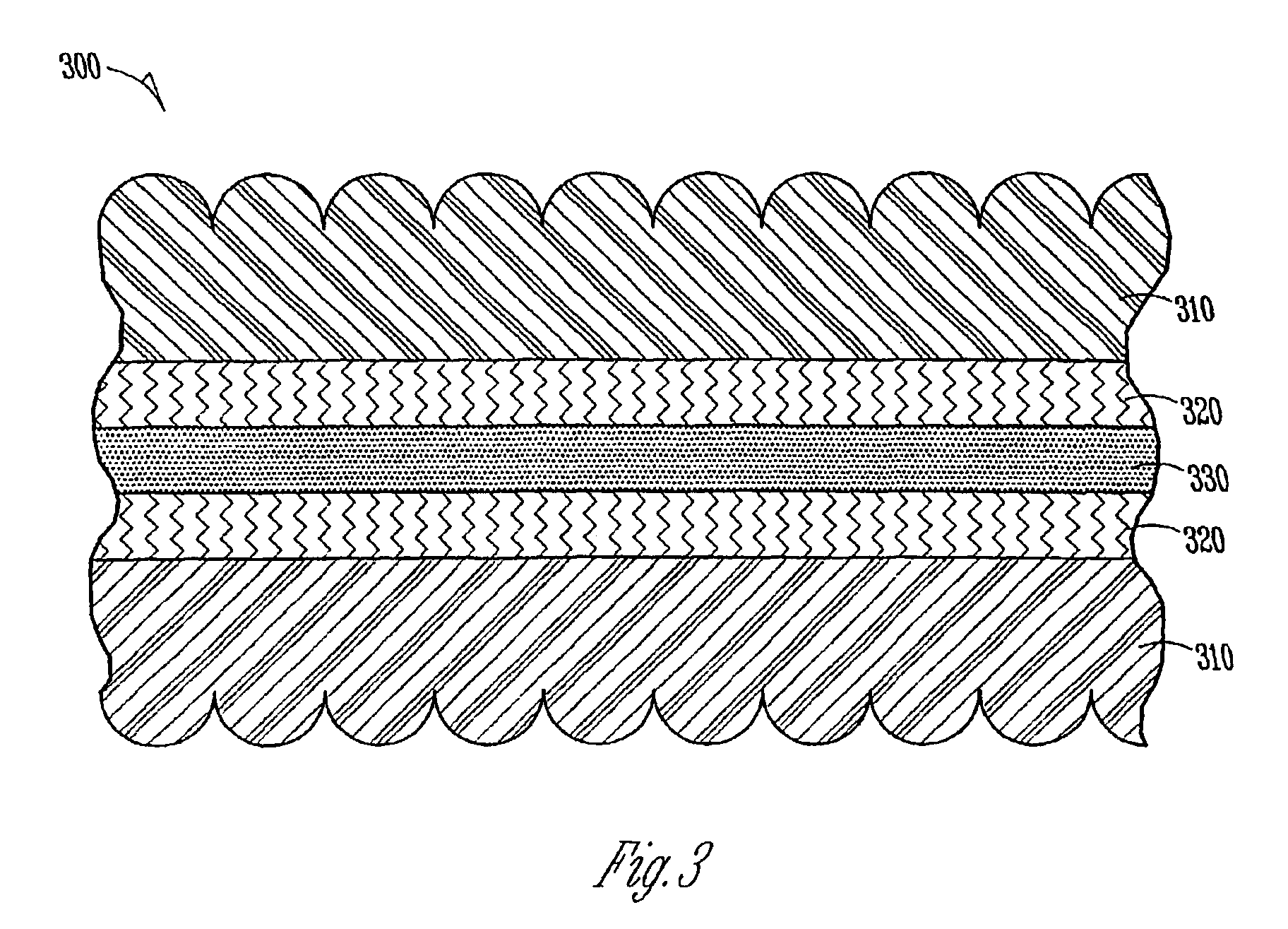

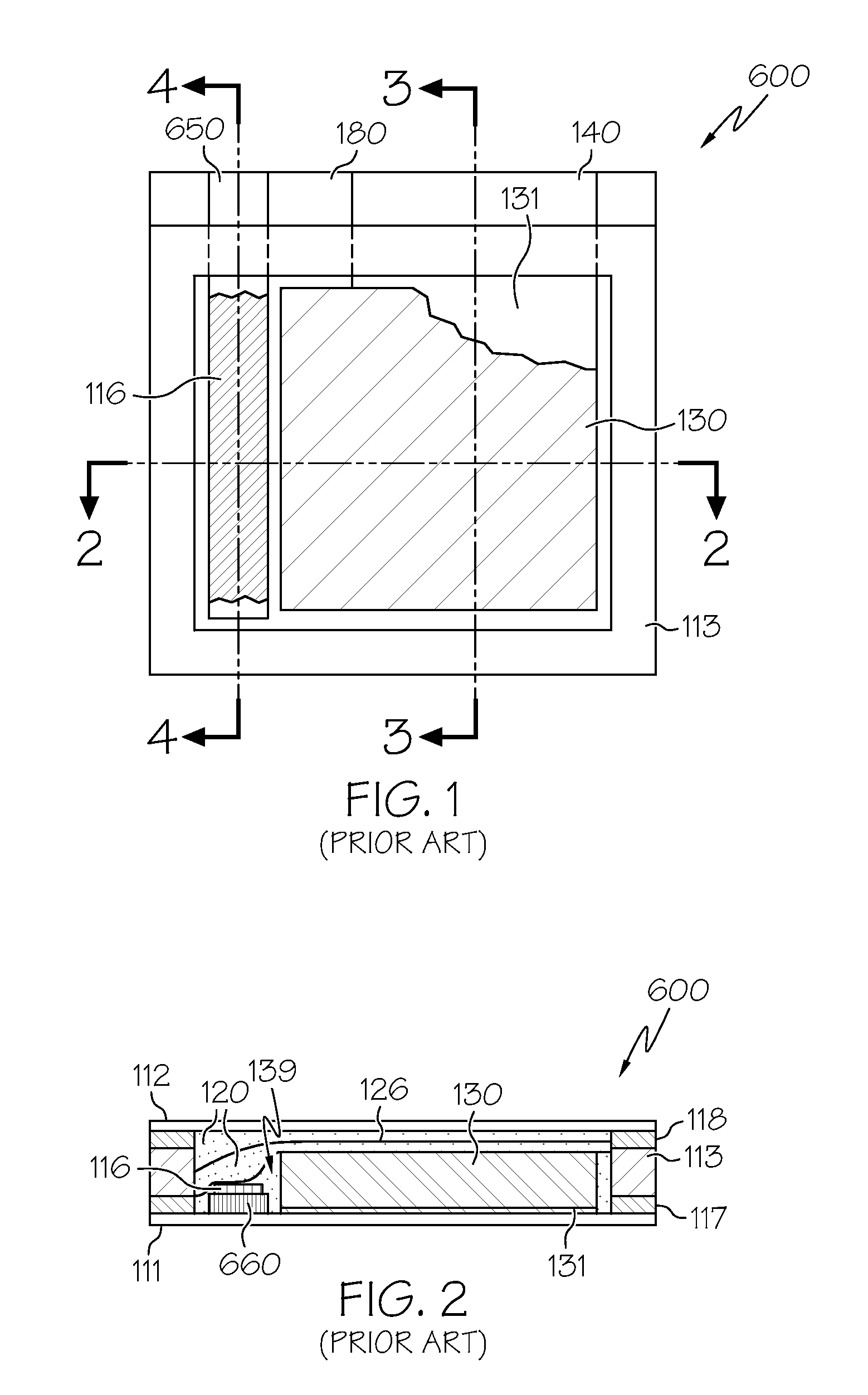

Lenticular card and processes for making

InactiveUS6900944B2Improve propertiesImproved indestructibilityDecorative surface effectsLayered productsAdhesiveEngineering

A process for making a lenticular card including: providing an imaged transparent sheet having a first smooth side and a second side with a lenticulated region, the transparent sheet optionally having at least one printed image area on the first smooth side and a moisture cure adhesive layer over the printed image areas and non-image areas of the first smooth side, and the moisture cure adhesive layer being applied with a screen press through a screen; and combining the imaged transparent sheet on the adhesive layer side of the transparent sheet with a backing sheet by nipping the paired sheets with a nip roller. The invention also provides processes useful for preparing a lenticular card including an optional core sheet, or optional primer layers.

Owner:TRAVEL TAGS

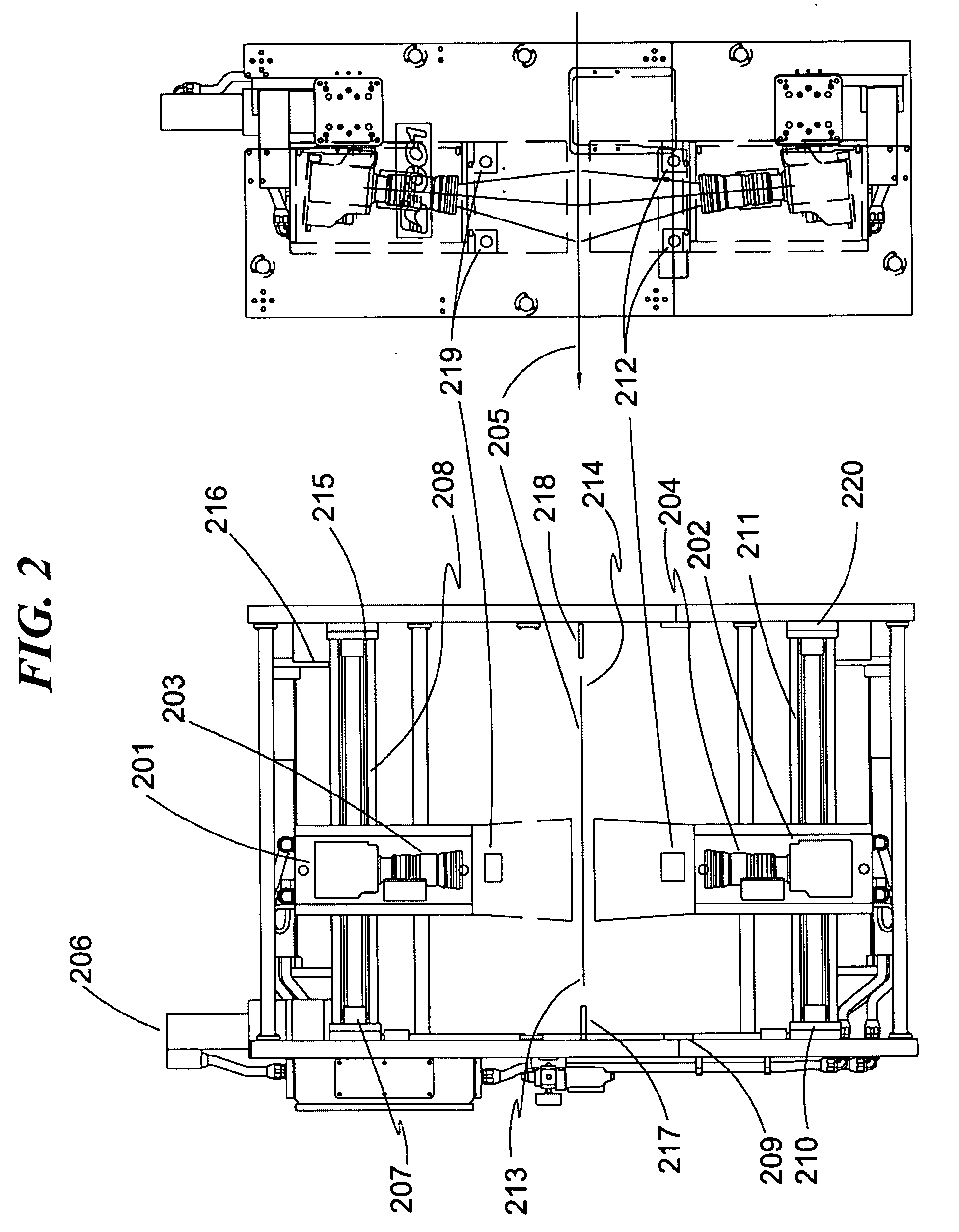

Printing unit

A printing unit is provided for a web fed printing machine having at least two cylinders where at least one of the cylinders is adjustable with respect to another of the cylinders; a machine frame having at least one load bearing wall arranged laterally beside an end of the cylinders; a drive motor corresponding to each cylinder; at least one guide element operably attached to the load bearing wall at a surface of the load bearing wall that runs perpendicular to a plane through the end faces of the cylinders; and a plurality of carriages attached to the guide element. At least one of the cylinders is connected to the carriages so that a distance from another of the cylinders can be adjusted.

Owner:MANROLAND WEB SYST

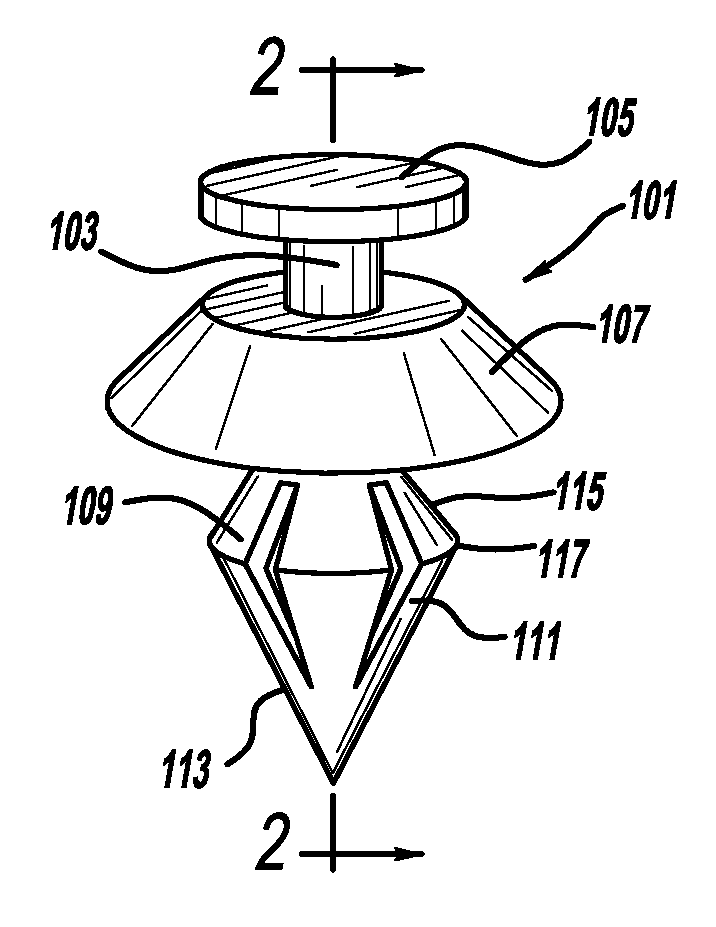

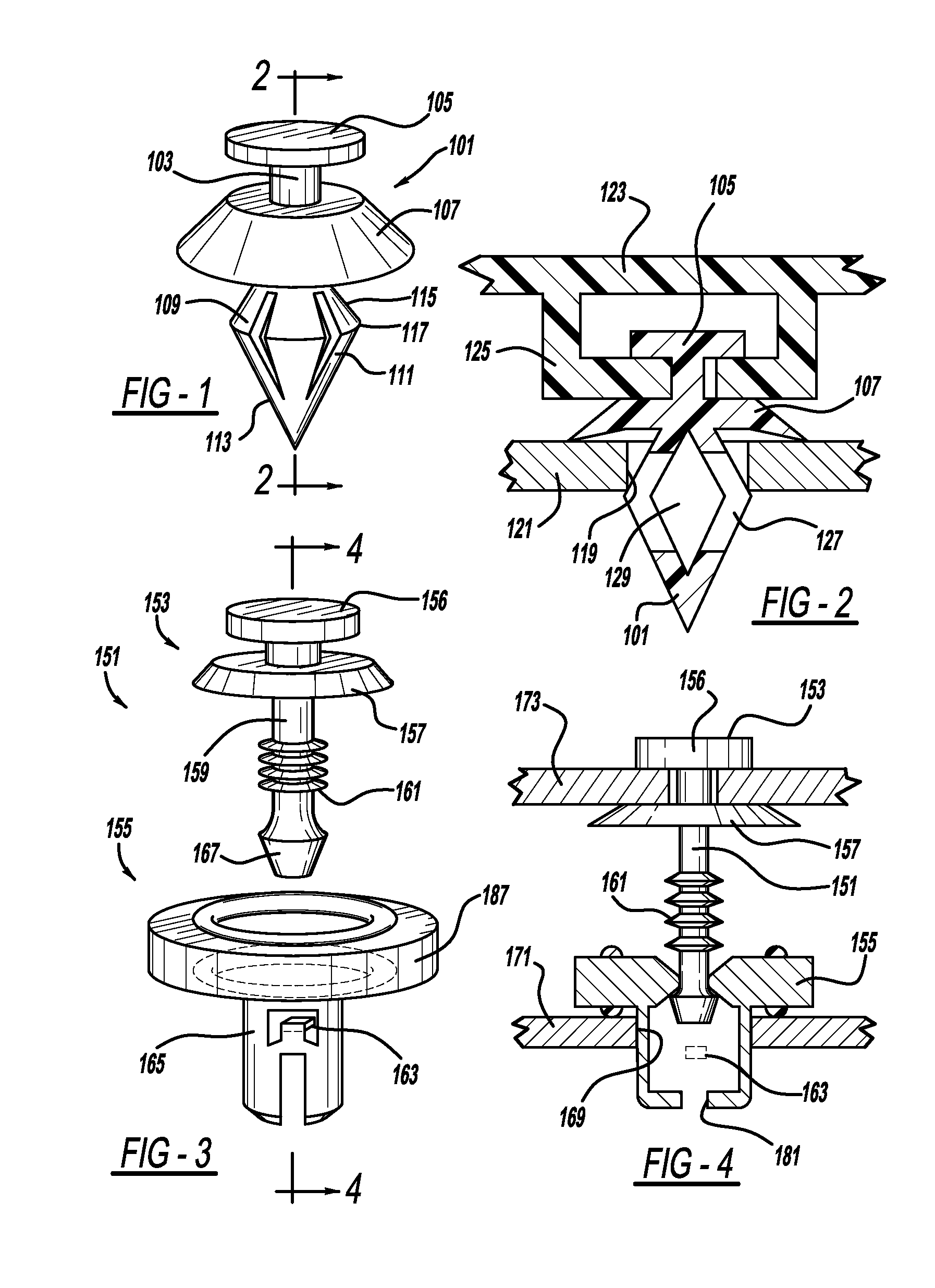

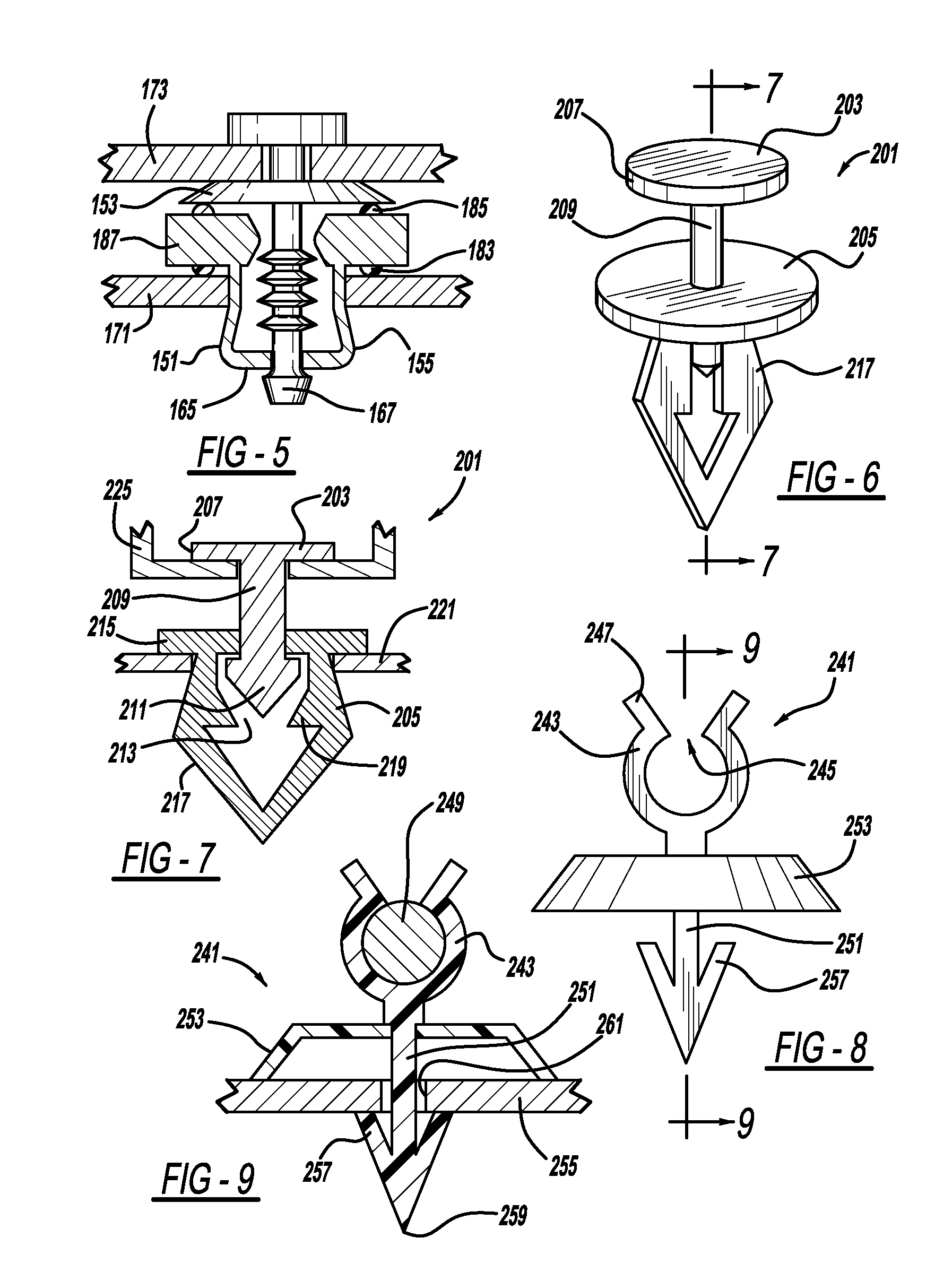

Fasteners manufactured by three-dimensional printing

InactiveUS20140086704A1Many timesQuick and inexpensive designDeformable pinsPinsEngineeringPrinting press

Owner:A RAYMOND & CO

Water-based intaglio ink equal to plate engraving ink and uses thereof

ActiveCN101284965AOptimizing physical fastnessNo pollutionInksOther printing apparatusScreen printingSolubility

The invention is equivalent to water soluble intaglio ink of plate engraving ink and / or equivalent to water-soluble screen printing ink of the ink, suitable for a gravure printing machine. The ink has the advantages of nontoxicity, tastelessness, nonflammable property, water solubility, non-environmental pollution and rapid drying; the printing effect of the obtained presswork is the same as or equivalent to the printing effect of the plate engraving presswork; the materialized firmness of the presswork is superior to the materialized firmness of the plate engraving presswork; the ink is low in printing cost and suitable for printing secure and confidential documents with deep printing lines, such as bank notes, securities, stamps, food packing, etc.

Owner:北京万垟防伪技术有限责任公司 +2

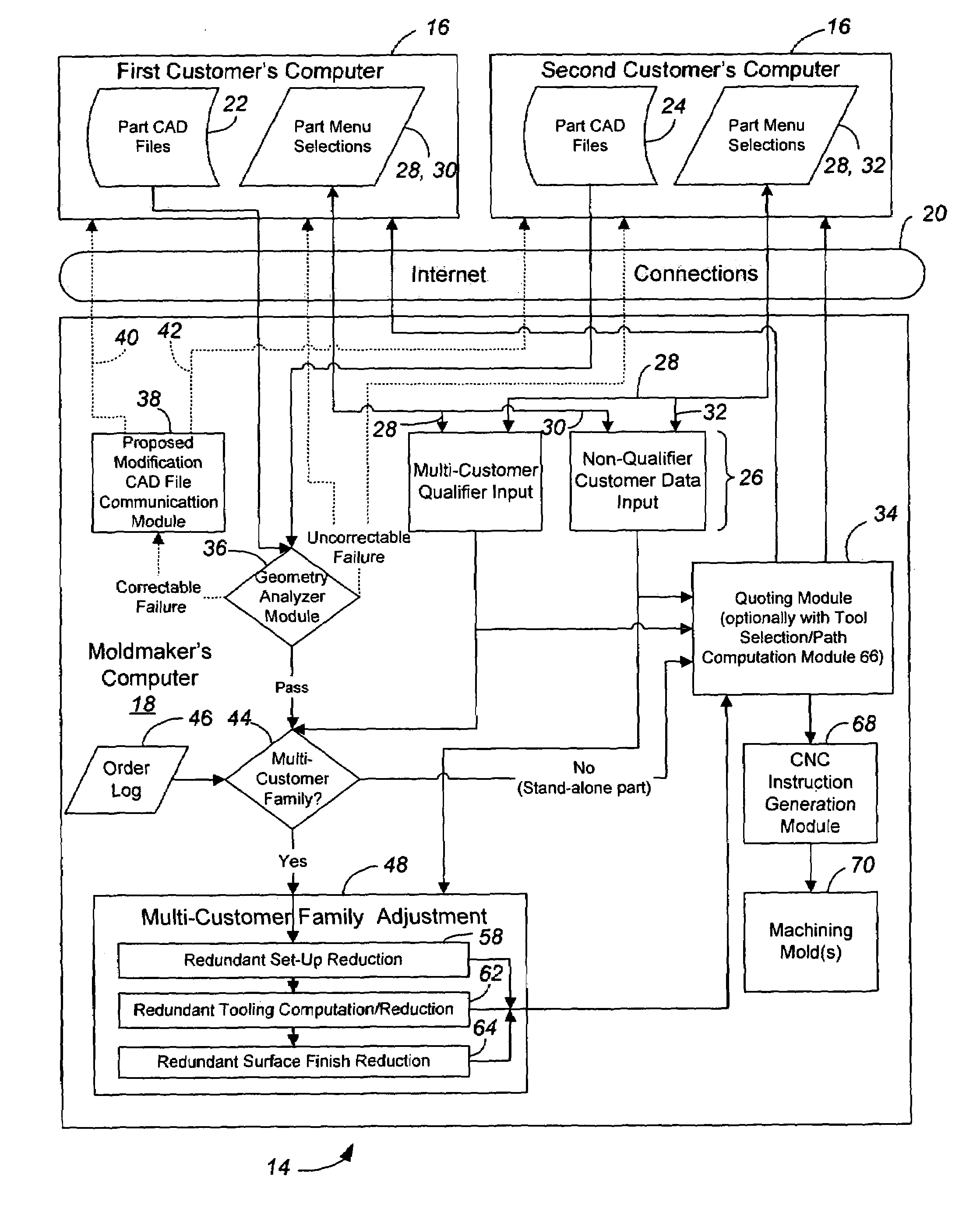

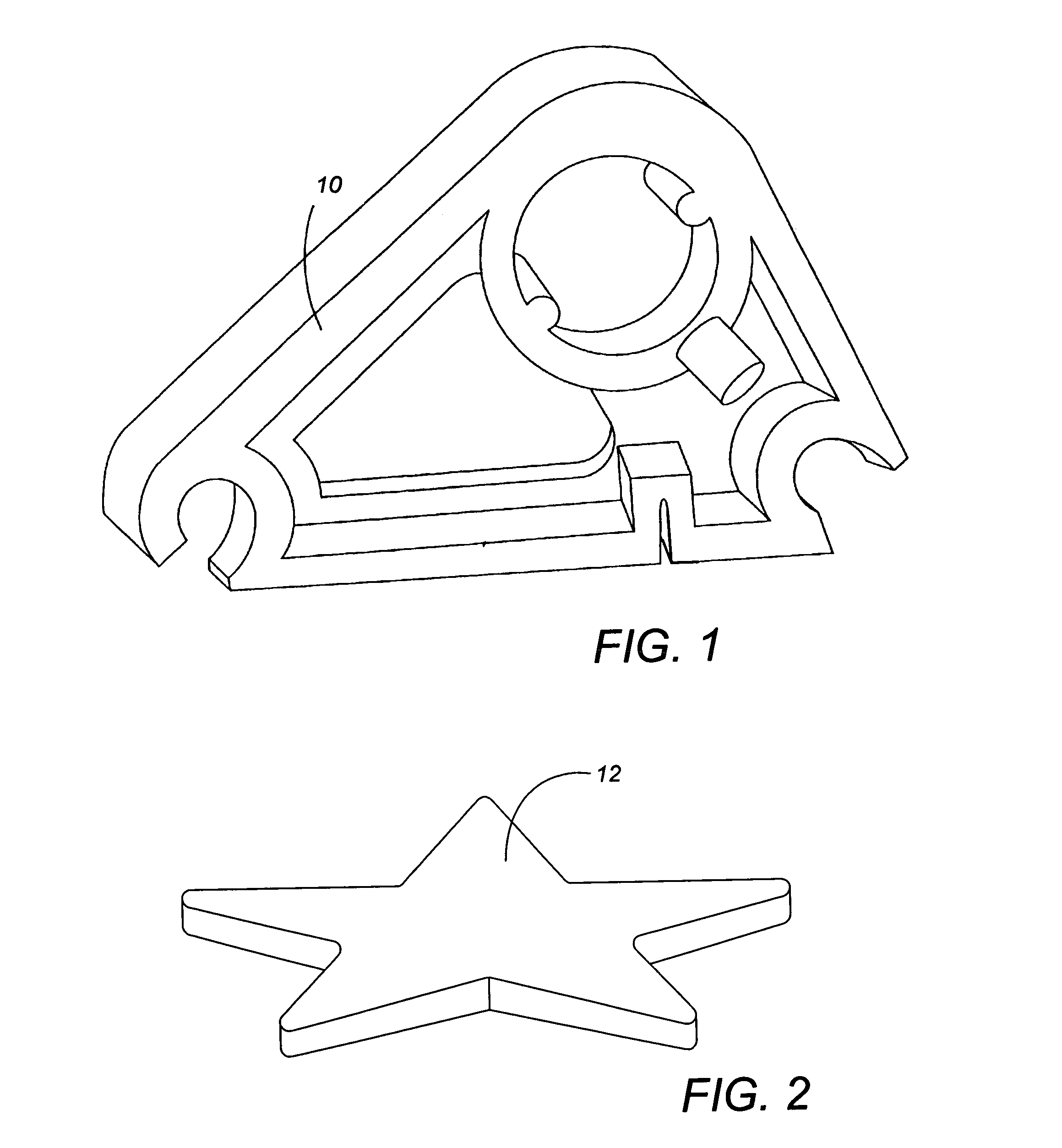

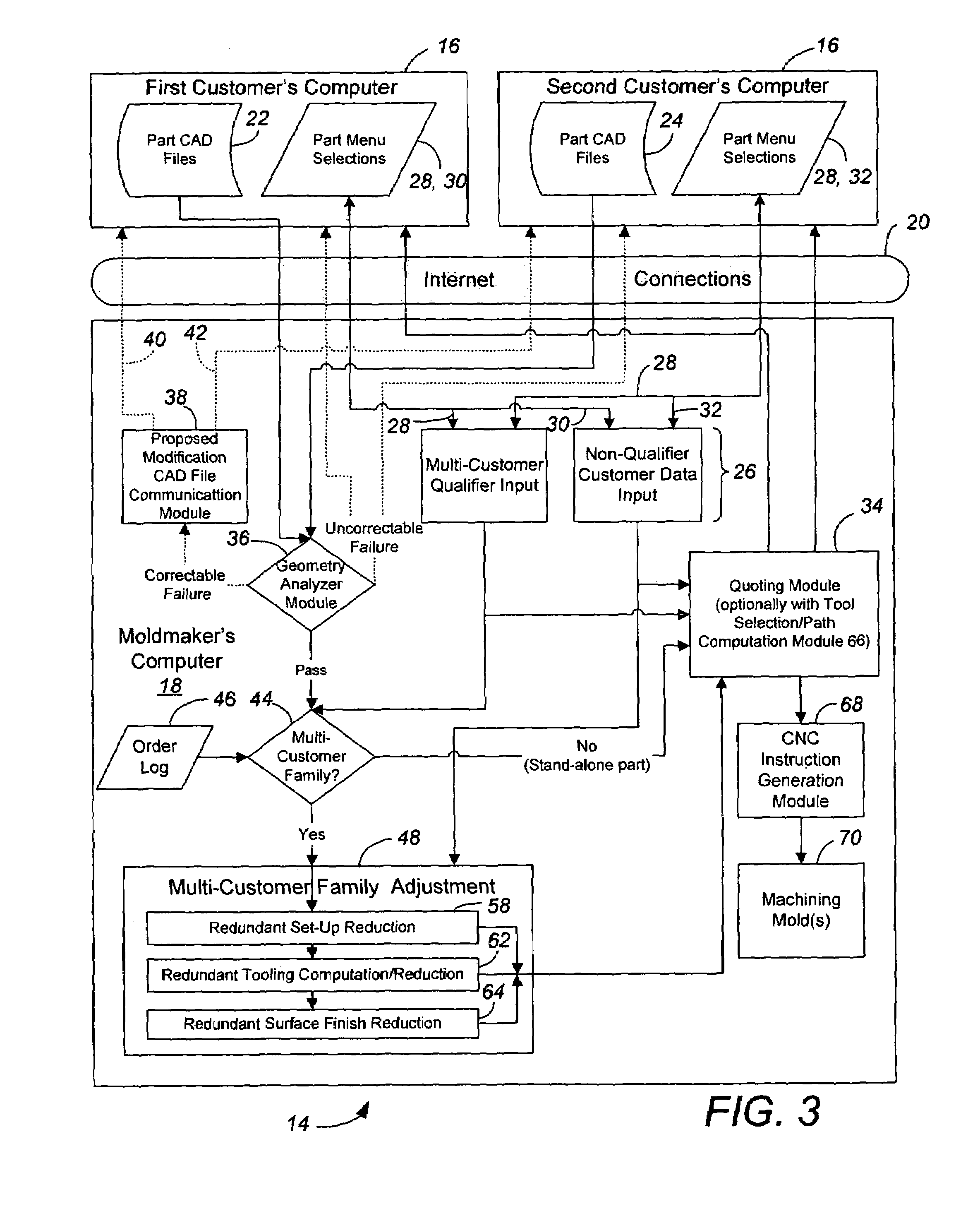

Automated multi-customer molding

A first customer provides a CAD file defining the surface profile for a part to be molded to the system, and a second customer does the same for a second part. The system determines whether the materials match and the run dates overlap, thereby qualifying the parts for use in a multi-customer mold block. The system assesses the part surface profile (which could have any of a virtually infinite number of shapes) of the parts submitted and lays out the parts from multiple customers on one or more multi-customer mold blocks. Savings are generated, such as by reducing redundancies in press clean-up, in set-up, in tooling, and in surface finishing. Due to these savings, the system provides a quotation of the part to at least one of the customers which differs from the quotation that would be provided if each part was run independent of parts of other customers.

Owner:PROTOLABS INC

Lithographic printing plate precursor and lithographic printing method

ActiveUS20050069811A1Excellent developabilityProlong lifeRadiation applicationsSemiconductor/solid-state device manufacturingActinic RaysImage recording

A lithographic printing plate precursor comprising: a support; an image recording layer comprising (A) an actinic ray absorber, (B) a polymerization initiator, and (C) a polymerizable compound, wherein the image recording layer is capable of being removed with at least one of a printing ink and a fountain solution; and an overcoat layer comprising an inorganic laminar compound. And a lithographic printing method comprising: mounting a lithographic printing plate precursor on a printing press; imagewise exposing the lithographic printing plate precursor with laser beams; and feeding at least one of a printing ink and a fountain solution to the lithographic printing plate precursor to remove a laser beams non-exposed area in an image recording layer; and performing printing.

Owner:FUJIFILM CORP

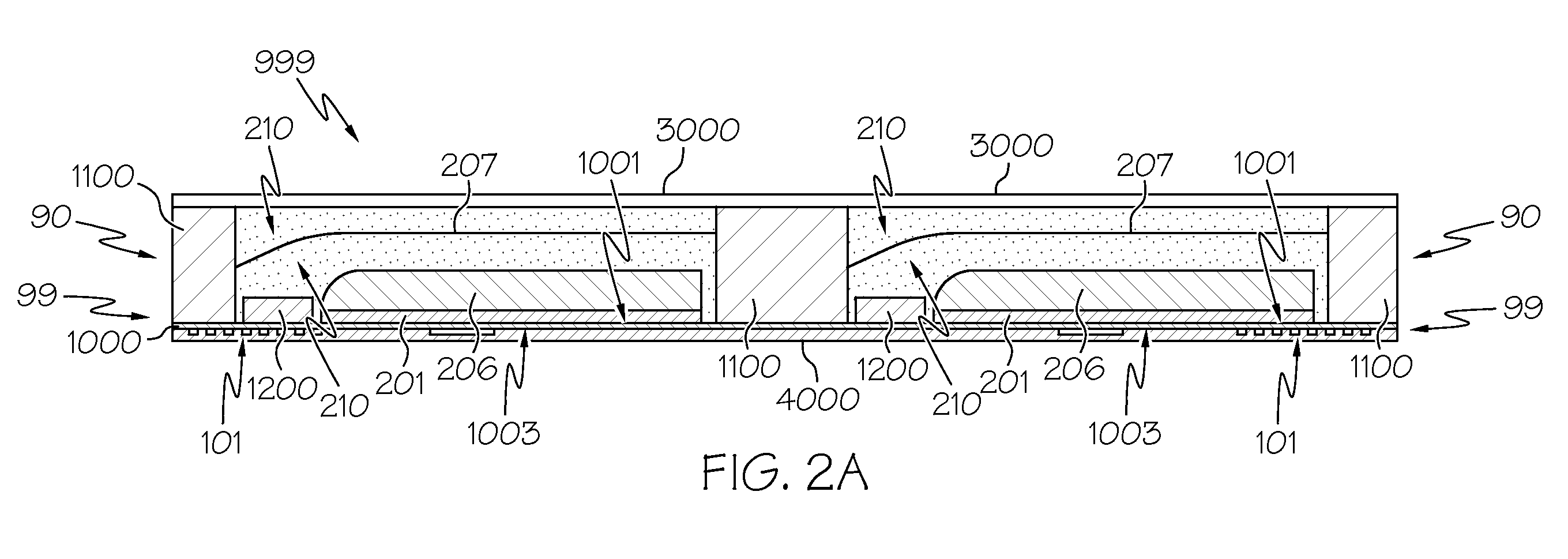

Integrated Electronic Device and Methods of Making the Same

ActiveUS20100196744A1Final product manufactureSmall-sized flat cells/batteriesElectricityEntire cell

An integrated electronic device, and its method of manufacture, are provided. The integrated electronic device can include an electronic assembly, such as an active RFID assembly, that is electrically coupled to a thin printed flexible electrochemical cell. In one example, the electronic assembly and the electrochemical battery are provided on a single substrate. In one example method of manufacture, the entire cell to be made on a printing press to integrate the battery directly with the electronic assembly.

Owner:BLUE SPARK INNOVATIONS LLC

High current thin electrochemical cell and methods of making the same

ActiveUS20100266895A1Well formedPrimary cell manufactureElectrode carriers/collectorsEngineeringPrinting press

A battery including at least one electrochemical cell for generating an electrical current is provided, along with its method of manufacture. In one example, the electrochemical cell is provided on a first substrate and includes an anode and a plurality of cathodes. At least a portion of said anode is located between an adjacent two of said plurality of cathodes. In one example method of manufacture, the electrochemical cell is made via a printing press process.

Owner:BLUE SPARK INNOVATIONS LLC

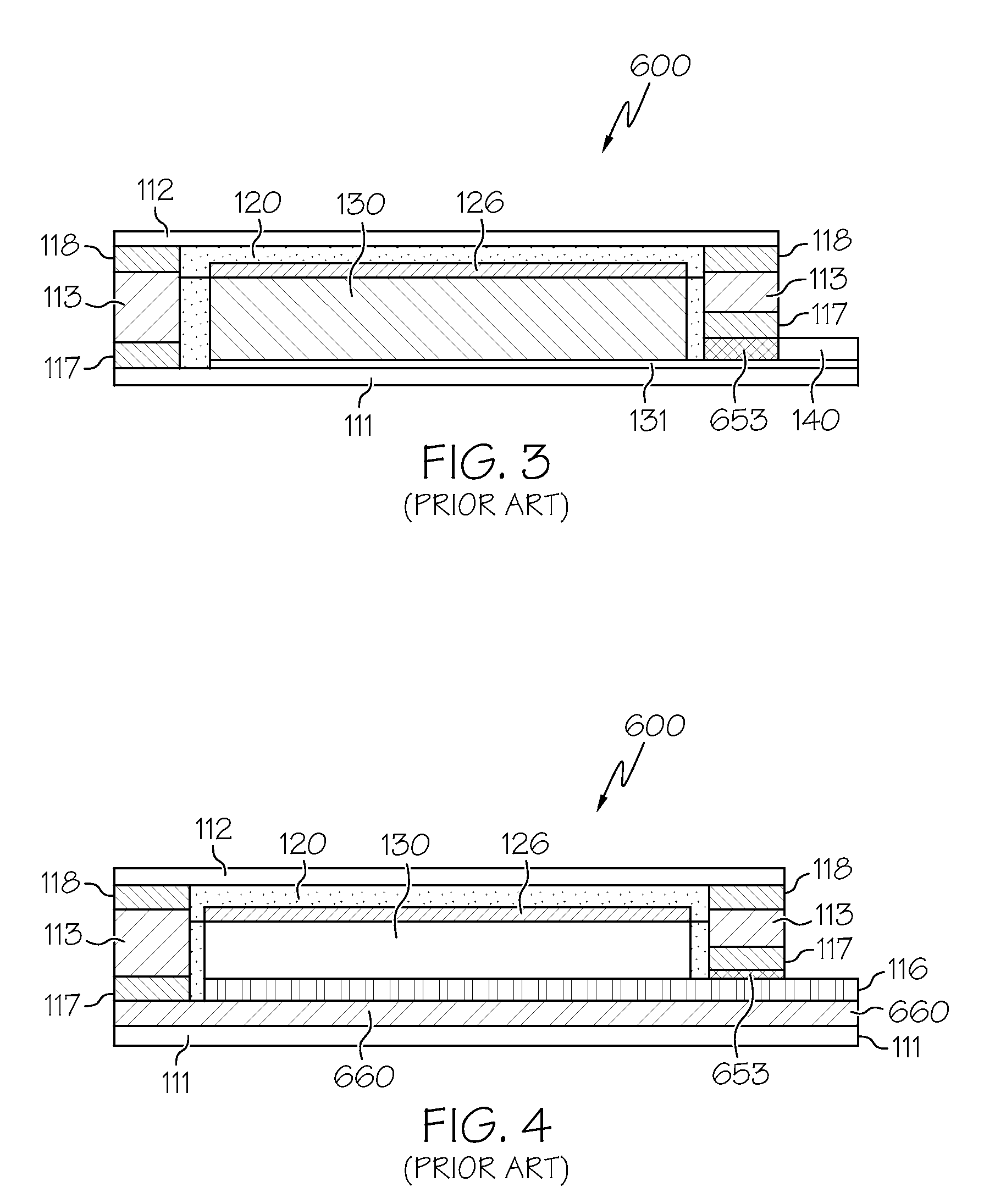

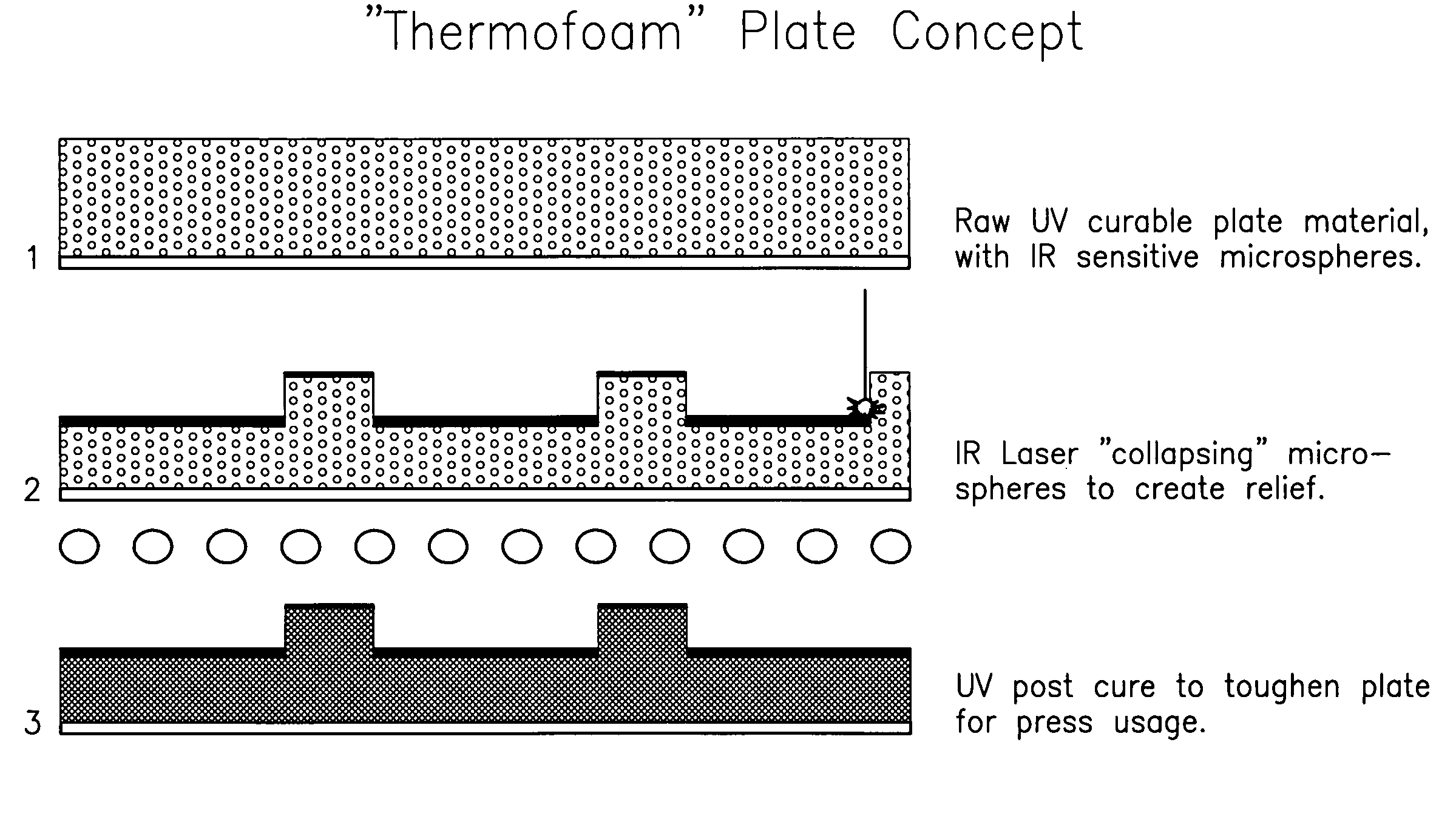

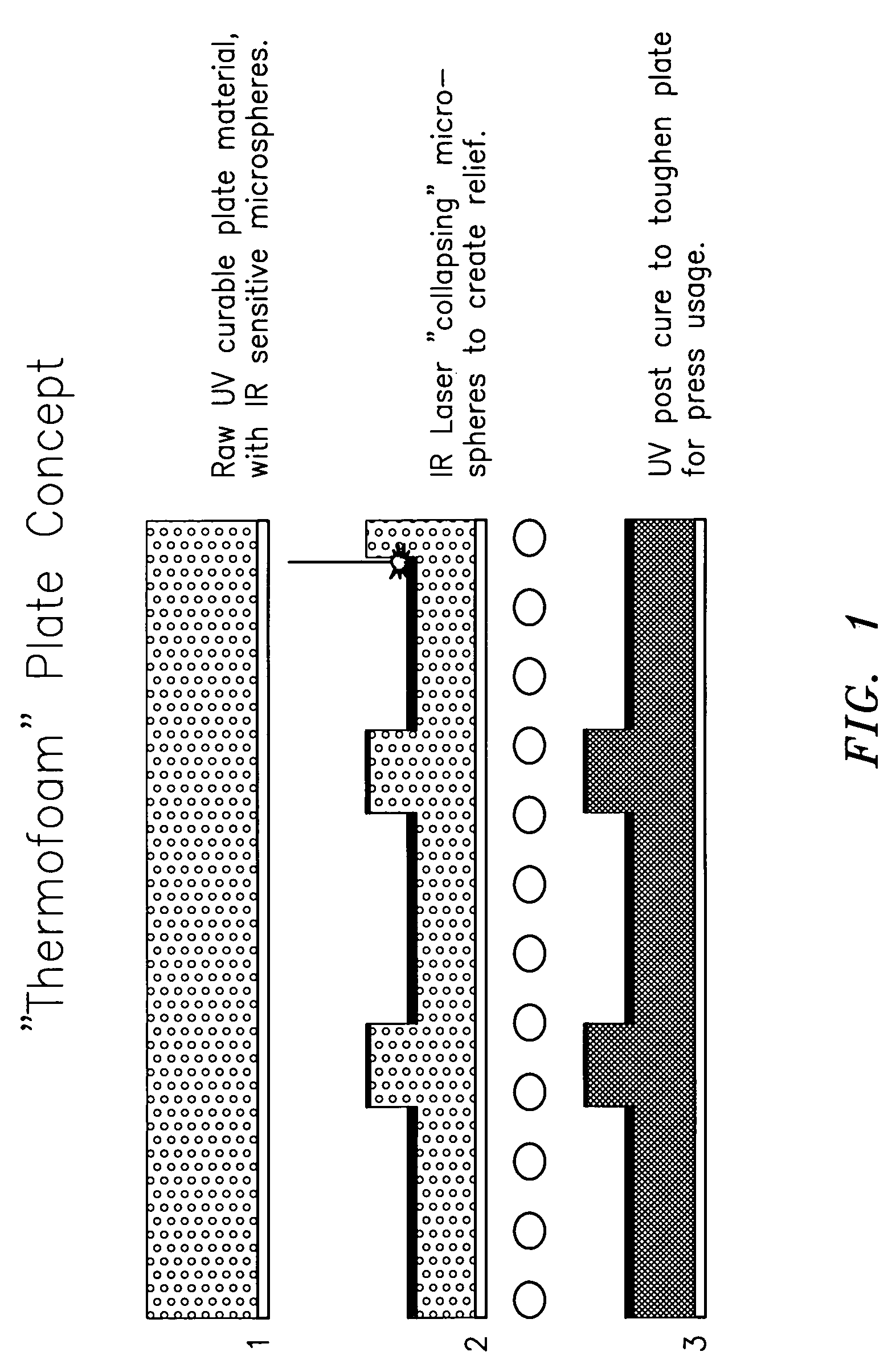

Processless digitally imaged photopolymer elements using microspheres

InactiveUS6989220B2Decrease final densityLow densityPhotosensitive materialsRadiation applicationsChemical treatmentMicrosphere

Laser imageable flexographic printing elements, including printing plates and printing sleeves and methods of making the laser imageable flexographic printing elements using a collapsible cross-linkable material comprising a curable elastomer, a material that absorbs laser radiation at a selected wavelength, and microspheres are disclosed. A laser is used to collapse and melt the collapsible cross-linkable material to form a relief image on the printing element. The printing element is thereafter cured by face exposure to crosslink and cure the formed relief image. The invention addresses a market need for eliminating chemical processing of printing elements, thus going from printing element to press much more quickly and using an environmentally friendly process.

Owner:MACDERMID PRINTING SOLUTIONS

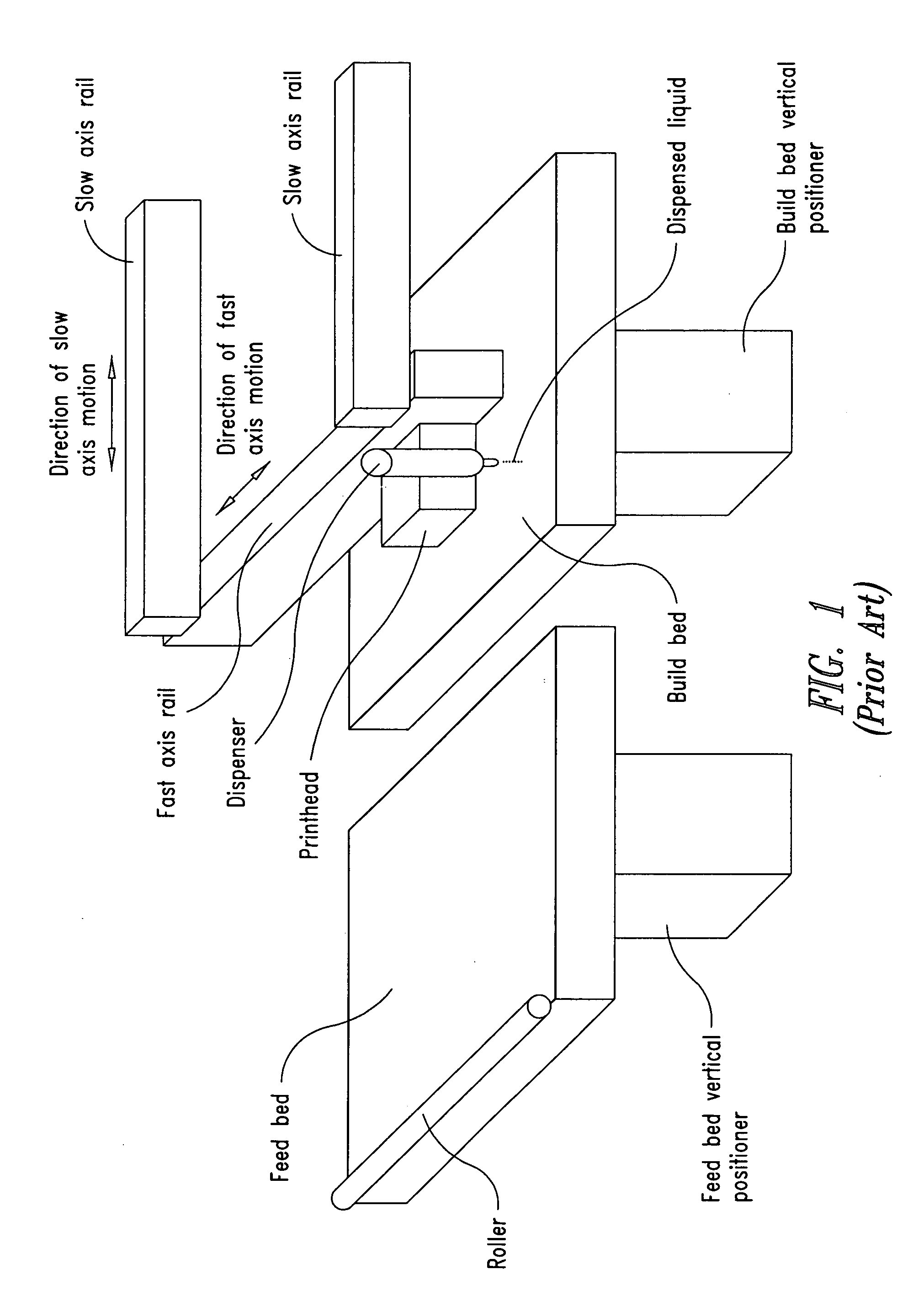

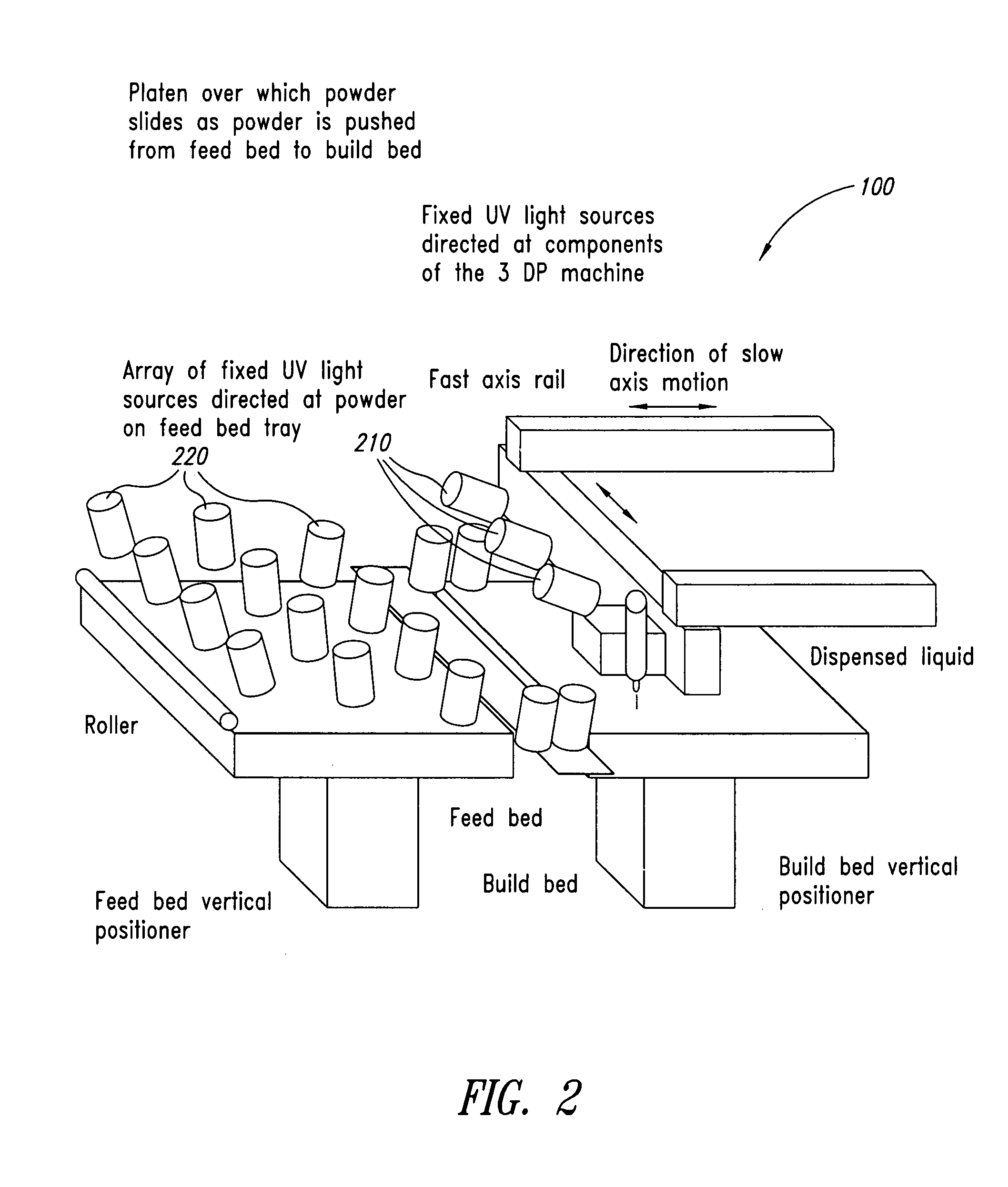

Three-dimensional printing apparatus and methods of manufacture including sterilization or disinfection, for example, using ultraviolet light

The invention includes a three-dimensional printing (3DP) machine that has at least one ultraviolet (UV) light source directed at powder or slurry being processed by the 3DP machine and / or directed at any of various surfaces or machine components, in a manner suitable to kill or damage microorganisms to a desired extent. The UV light sources may be either stationary or movable, and may be either pulsed or substantially continuous, and may operate in any desired sequence and timing with respect to other operations performed by the machine. The invention may include ultraviolet illumination in such a way as to interact with powder to sterilize or disinfect powder either while the powder is stationary or, alternatively, as powder is being moved from one place to another within the 3DP machine, or both. The invention also includes methods of performing three-dimensional printing using such illumination. The invention also includes the combination of other methods of sterilization or disinfection with the use of ultraviolet light. The invention also includes the use of ultraviolet light sources for a combination of polymerization / cross-linking in addition to sterilization / disinfection.

Owner:THEKEN SPINE

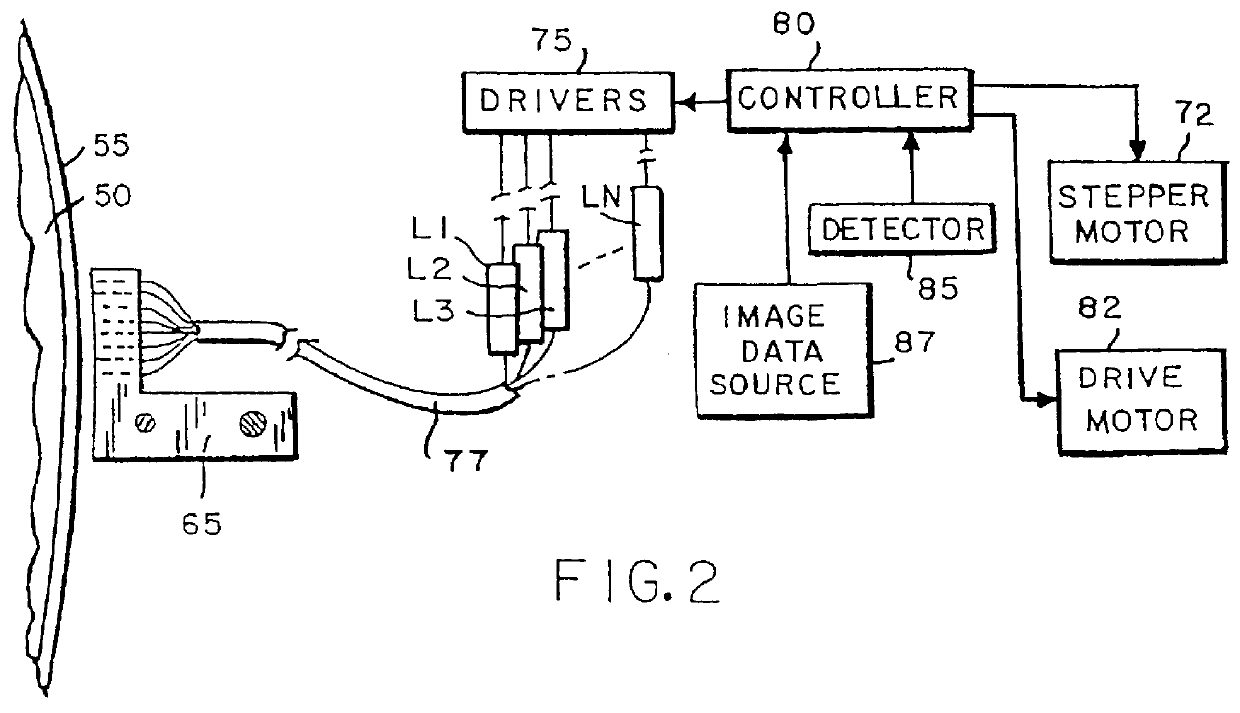

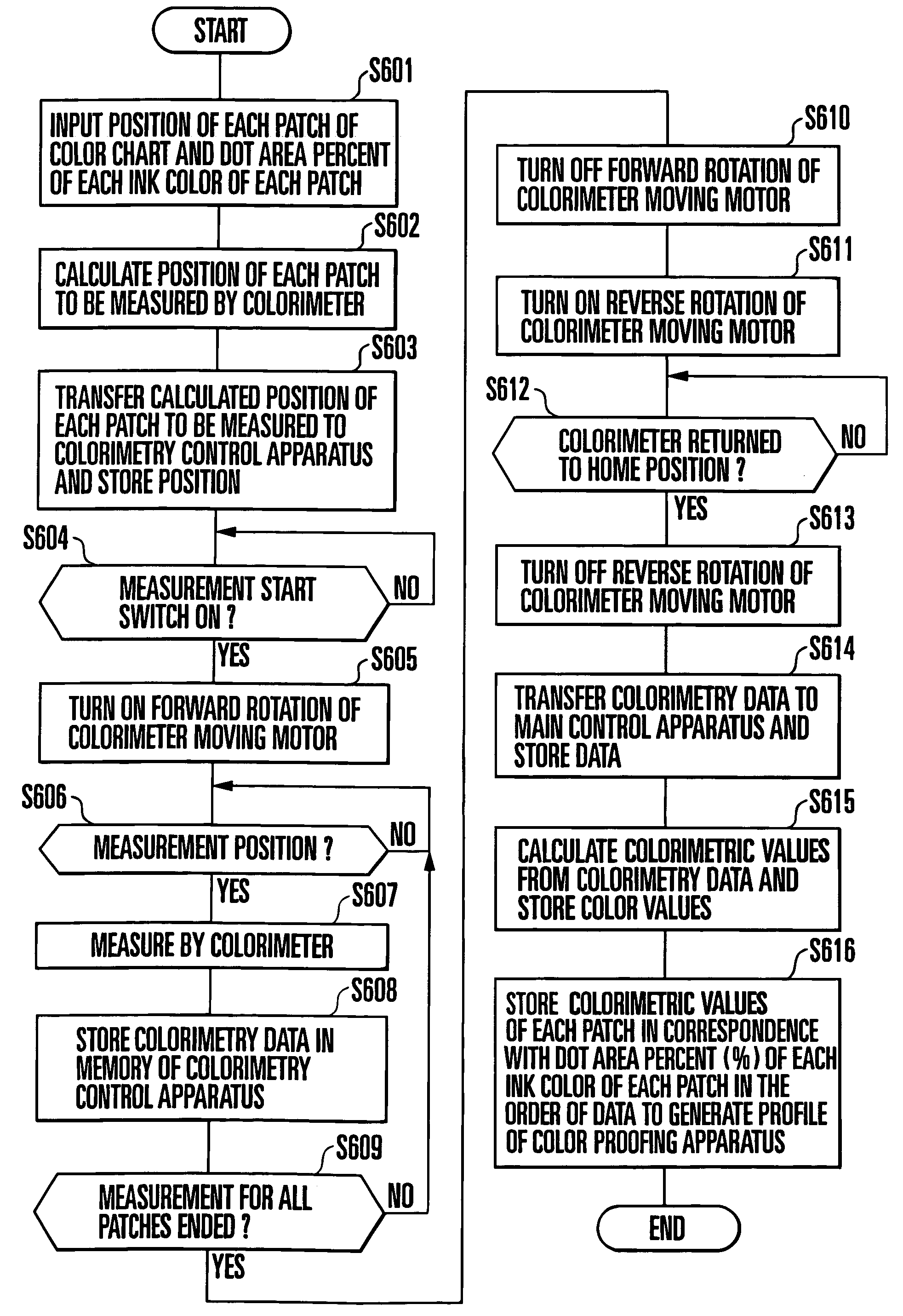

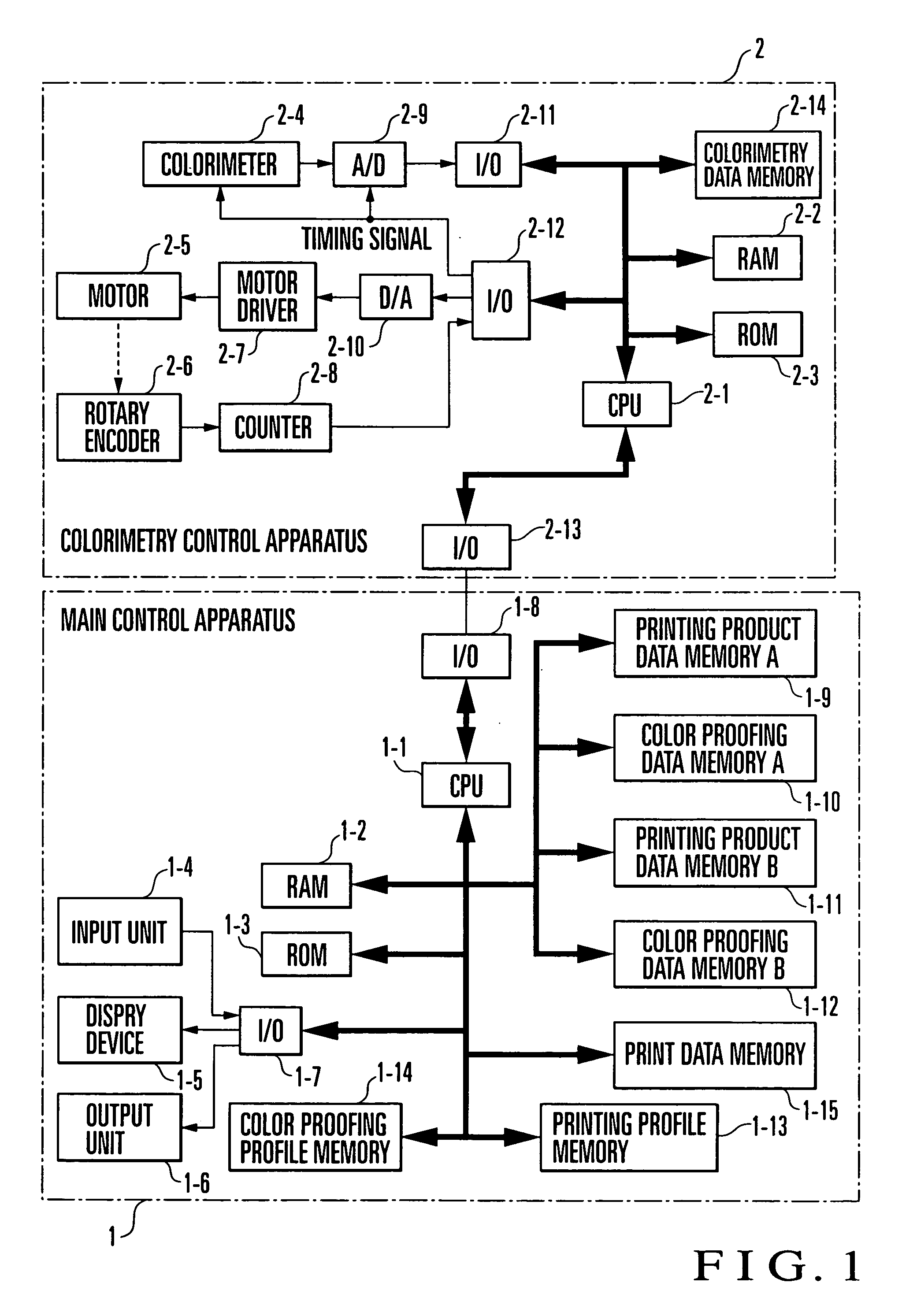

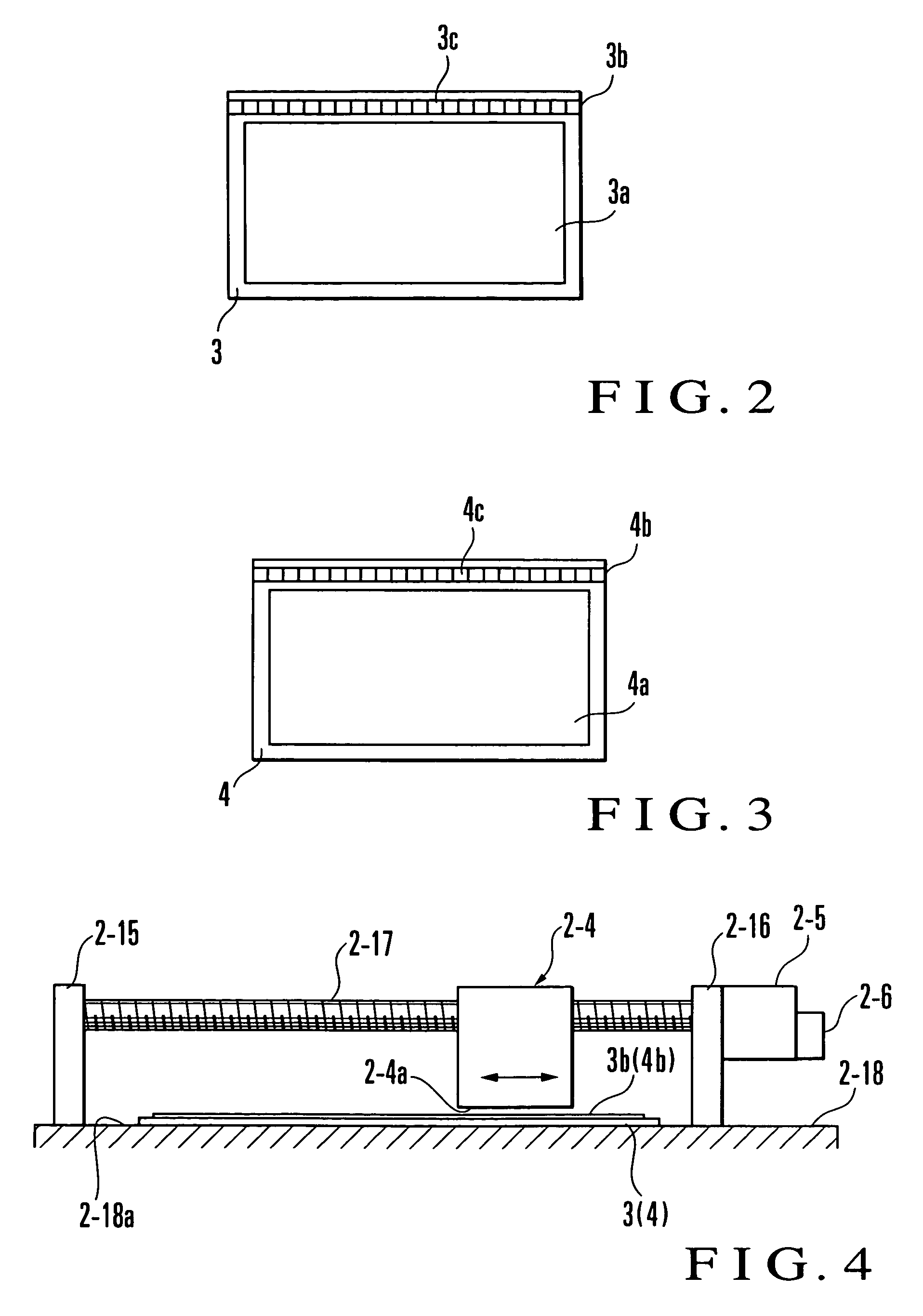

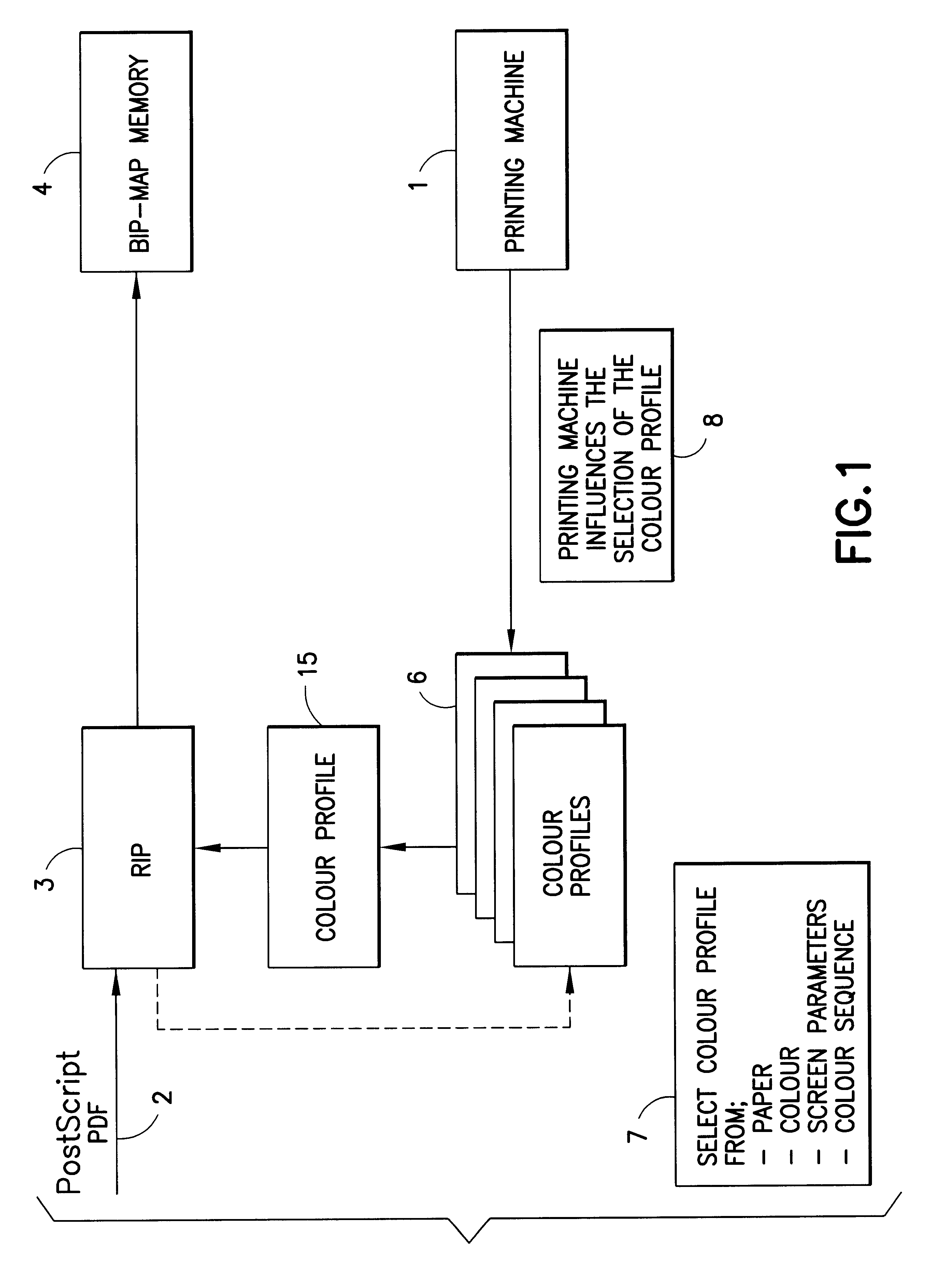

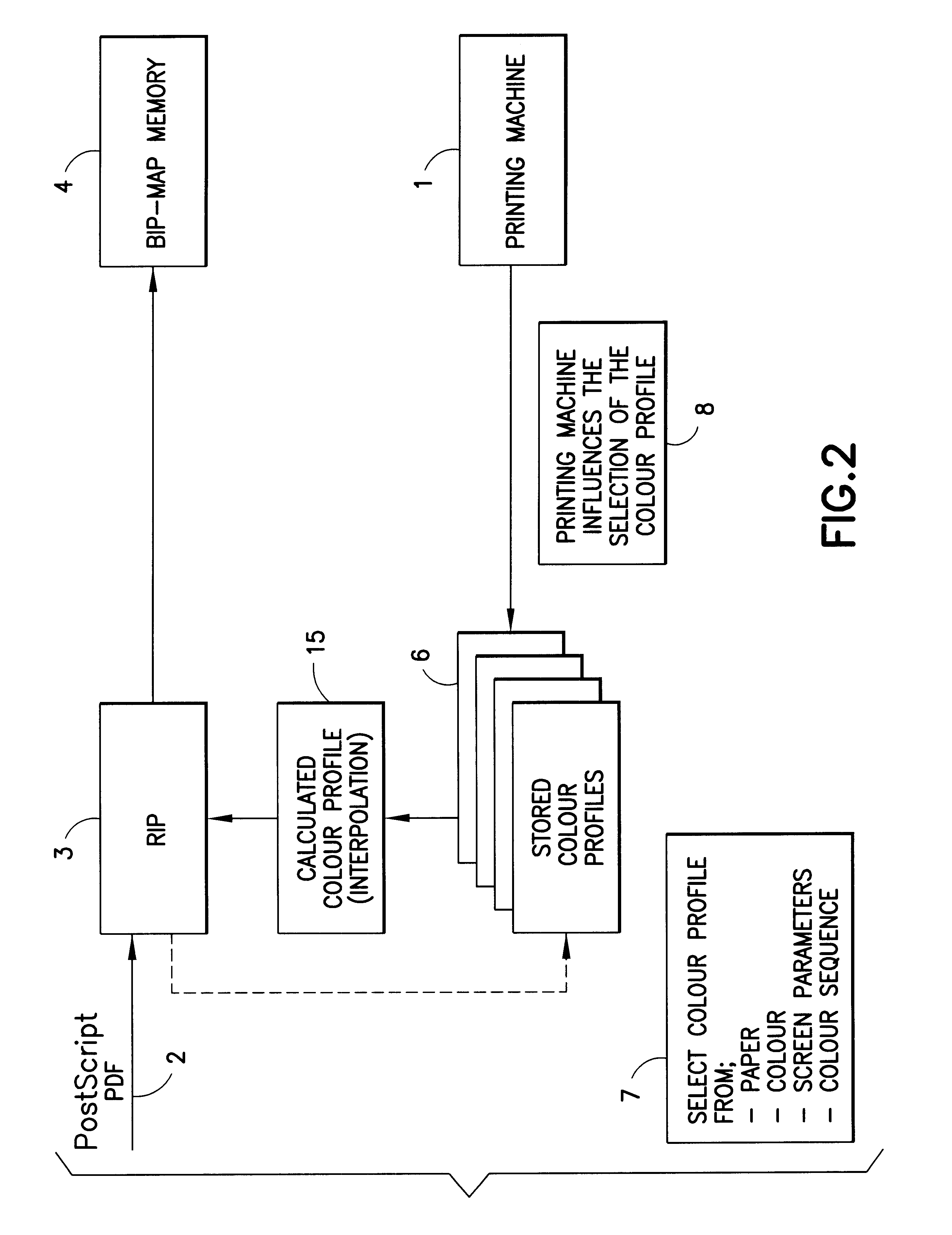

Color management method and apparatus for printing press

InactiveUS7031022B1Exact matchShort profileDigitally marking record carriersDigital computer detailsColor printingEngineering

In a color management method for a printing press, a color chart formed from a plurality of patches is printed by multi-color printing using the printing press and a plurality of ink colors. Each of the patches has a predetermined combination of dot area percent of the ink colors. The printed color chart is automatically scanned using a calorimeter to sequentially obtain color data of all the patches. A first profile representing a color reproduction characteristic of the printing press is generated on the basis of the obtained color data of the patches and the dot area percent of the ink colors set in the patches. A color management apparatus is also disclosed.

Owner:KOMORI CORP

Power saving automatic zoned dryer apparatus and method

InactiveUS6877247B1Eliminates and greatly reduces needImprove paper qualityDrying solid materials with heatDrying gas arrangementsAuto regulationEngineering

A computer controlled power saving automatic zoned dryer for a printing press has a dryer head facing the substrate travel path, having a multiplicity of IR lamps connected individually or in groups to form a plurality of heating zones running longitudinally and each extending laterally side by side across the substrate travel path. The radiant heat output of each heating zone is controlled separately by means of a control unit connected to a power supply. The control unit individually regulates output of the heating zones. Unneeded zones are turned off to reduce cost of power and conserve energy. A plurality of heat sensors spaced laterally across the substrate path measure the surface temperature of substrate heated areas corresponding to the heating zones being operated and maintain an automatic set point temperature. The temperature of each individual heated area can be regulated automatically by adjusting the output of its heating zone whereby printed substrates having a more even temperature profile are delivered. In an alternate manual mode any zone can be set independently to operate at any percentage of full available power from zero to 100%. Separate high velocity air scrubbers and additional air extraction are used to enhance the total drying effect of the zoned dryer assembly.

Owner:PRINTING RES

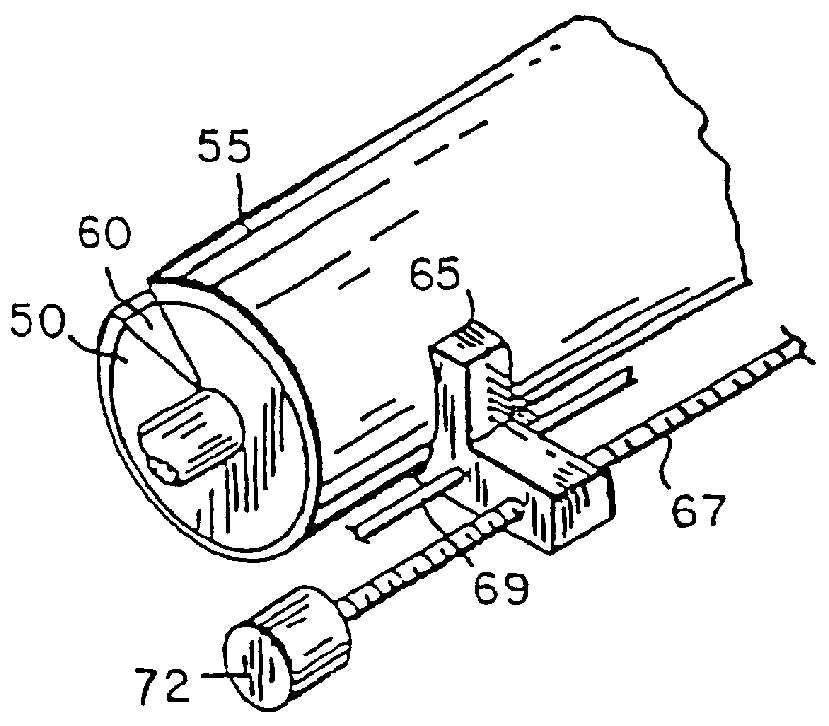

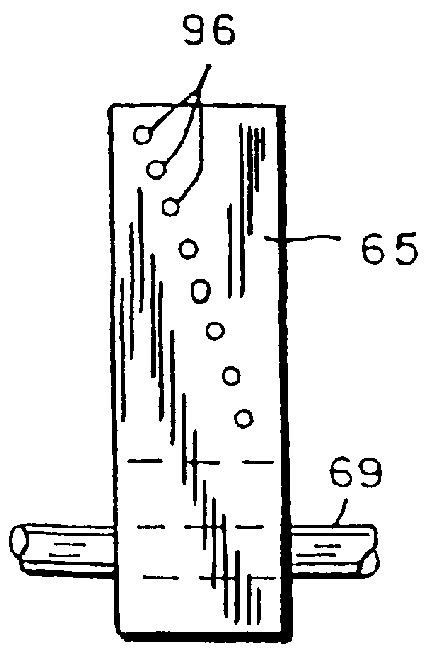

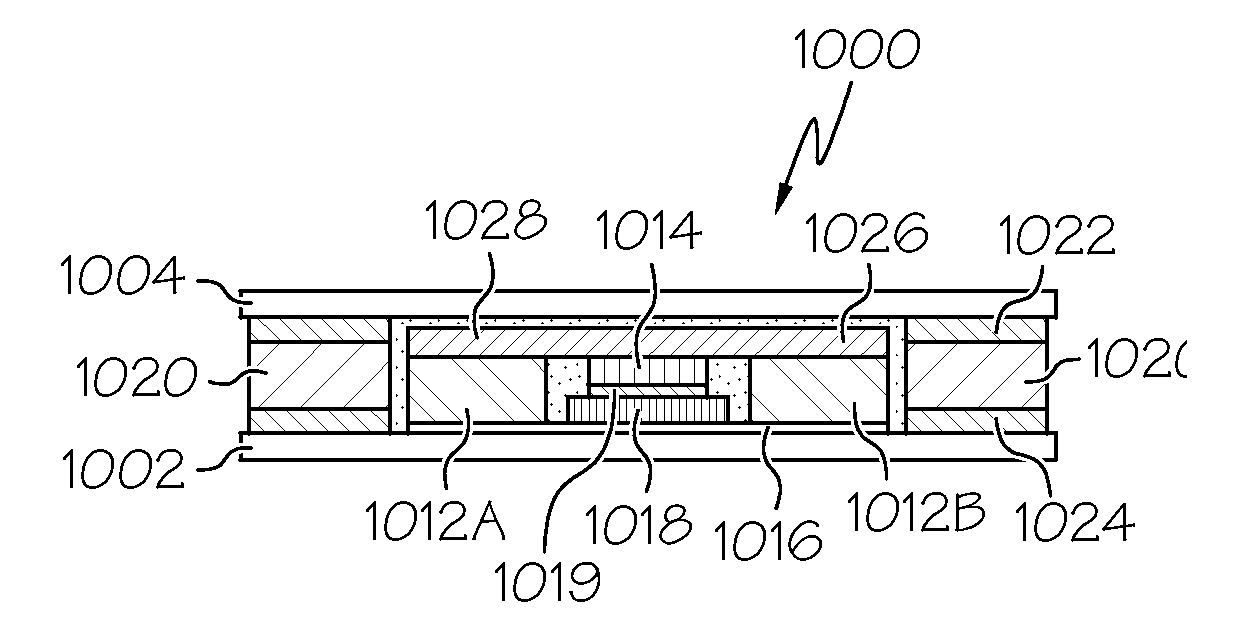

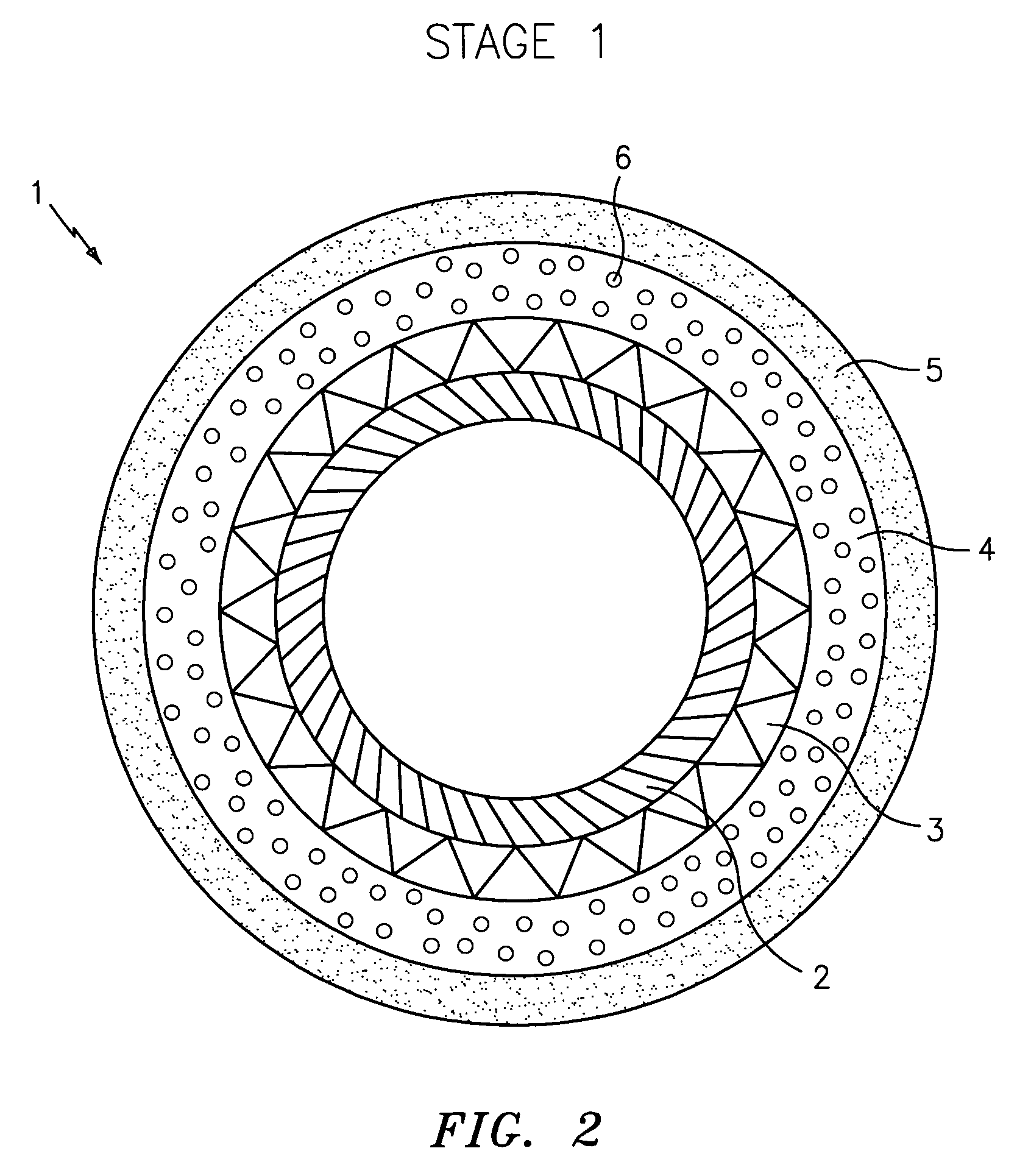

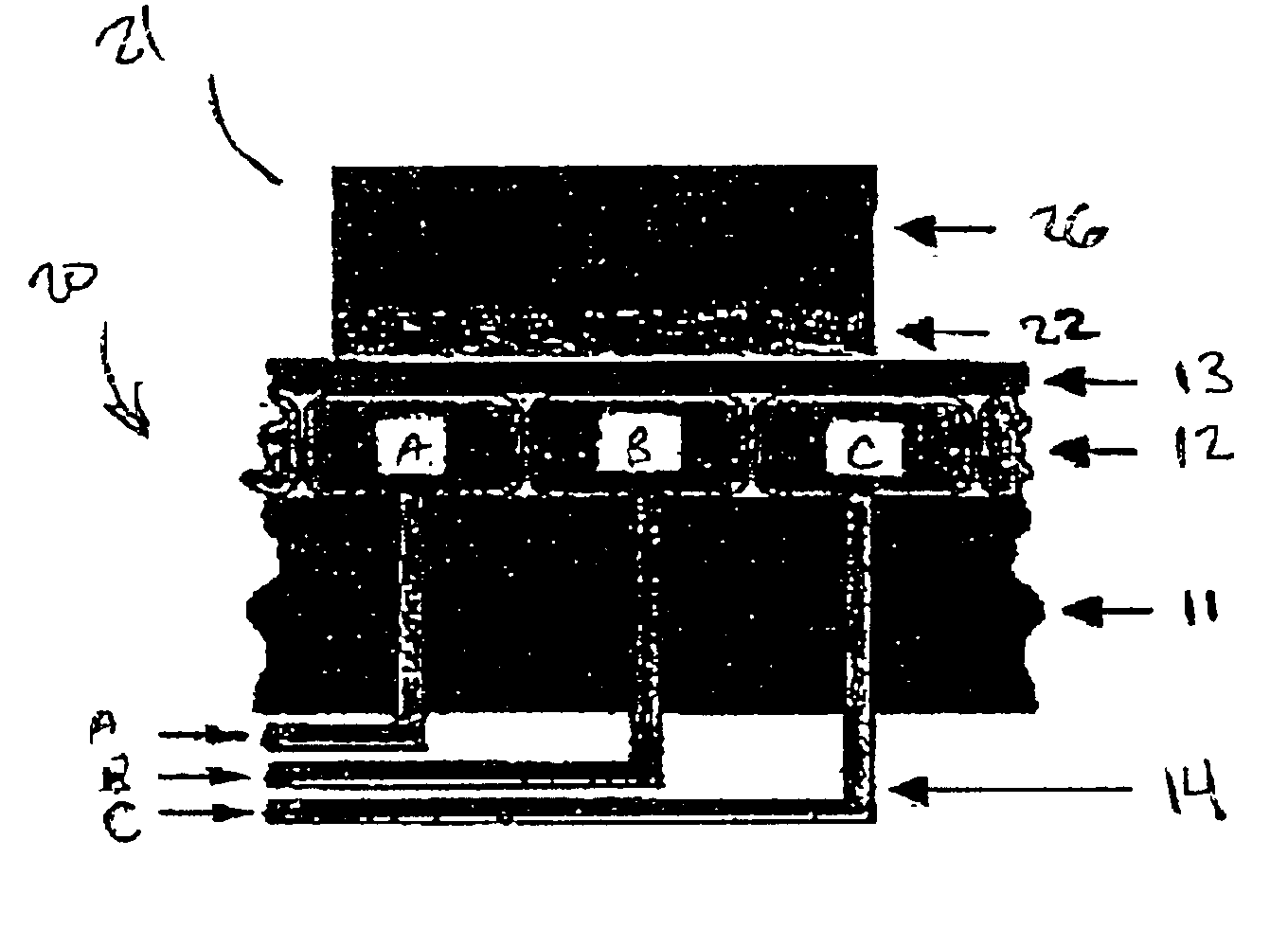

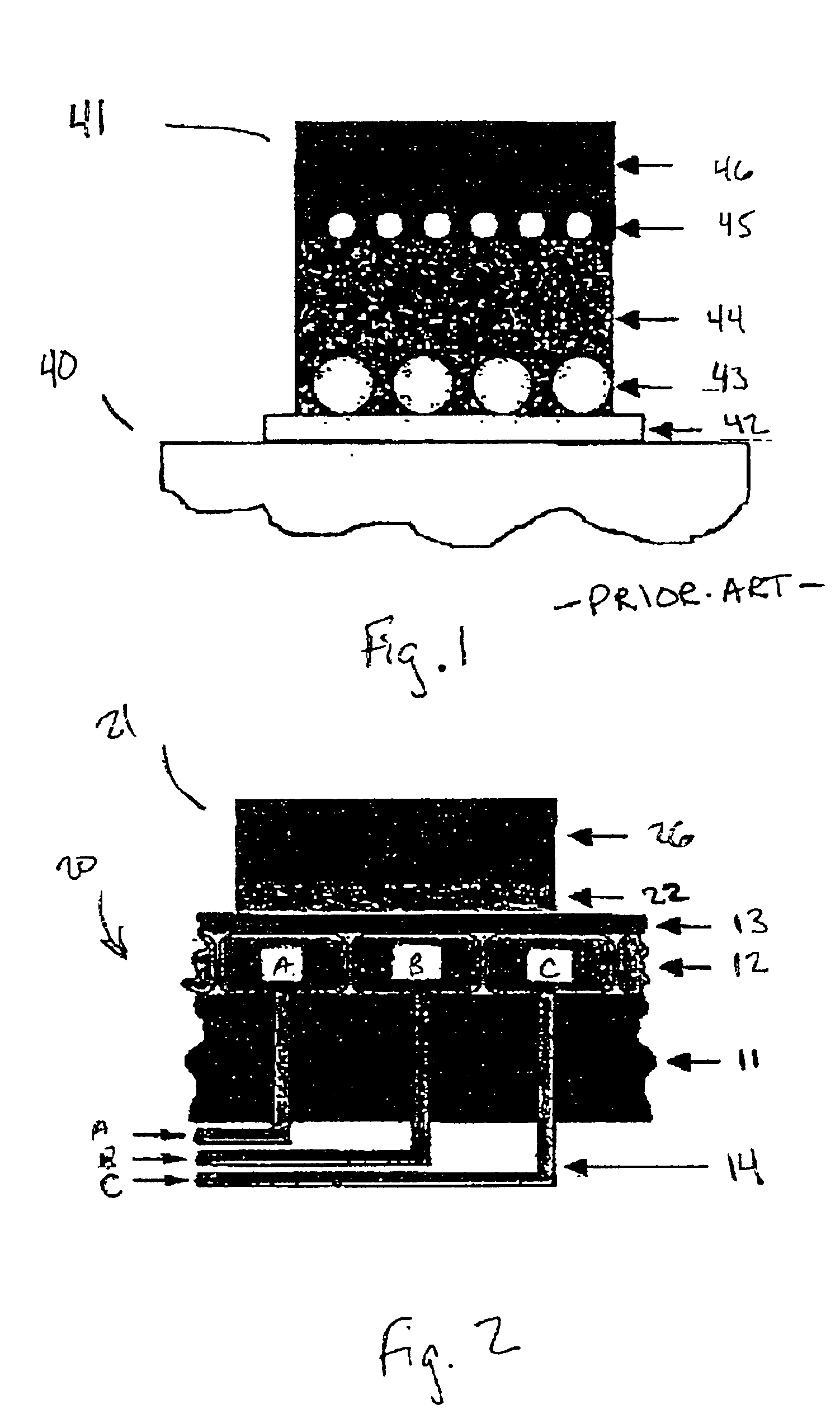

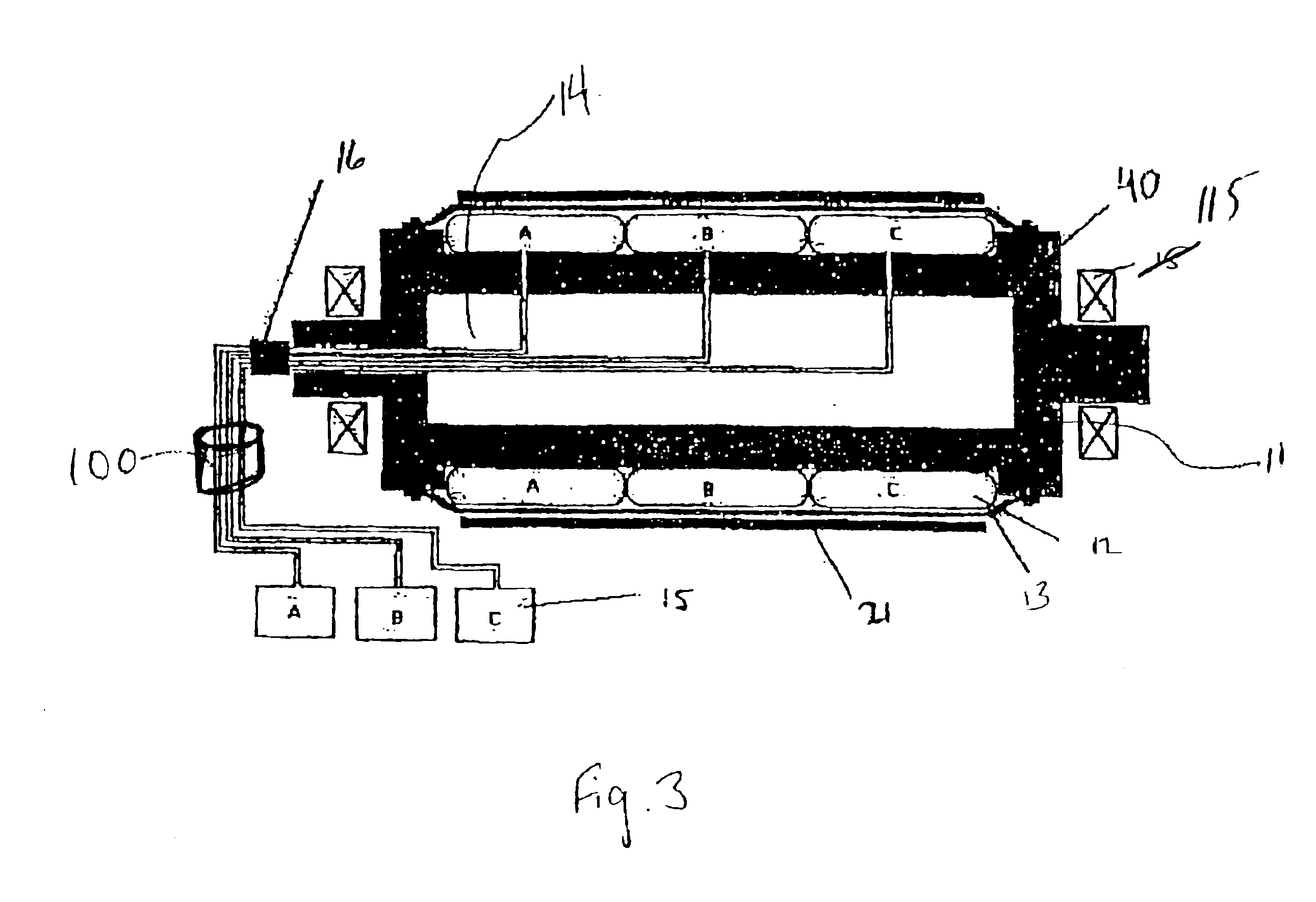

Blanket cylinder with integrated compressible layer

A printing unit including a rigid cylinder rotatable about an axis of rotation, a plurality of inflatable bladders disposed on a circumferential surface of the cylinder, and a first fluid supply regulation unit configured to supply a first fluid to a first set of inflatable bladders of the plurality of inflatable bladders and to regulate a first fluid pressure inside the first set inflatable bladders. In addition, a method for mounting a sleeve-shaped printing sock onto a blanket cylinder of an offset printing press, in which a set of inflatable bladders disposed at an outer region of the blanket cylinder are at least partially deflated. The sleeve-shaped printing sock is slid over one end of the blanket cylinder so that the printing sock at least partially surrounds a circumference of the blanket cylinder. The set of inflatable bladders are then inflated so that the printing sock fits tightly around the circumference of the blanket cylinder.

Owner:SHANGHAI ELECTRICGROUP CORP

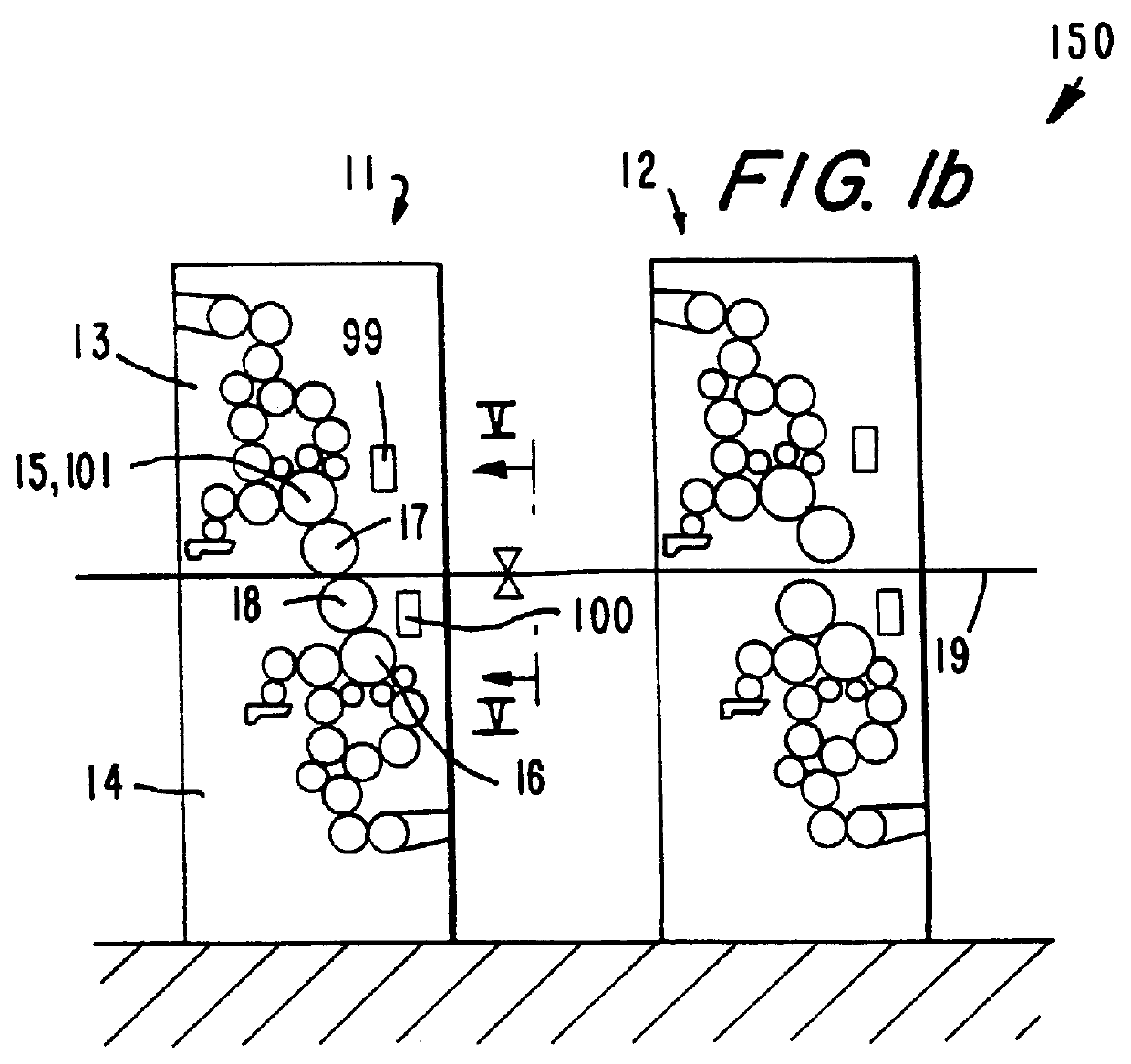

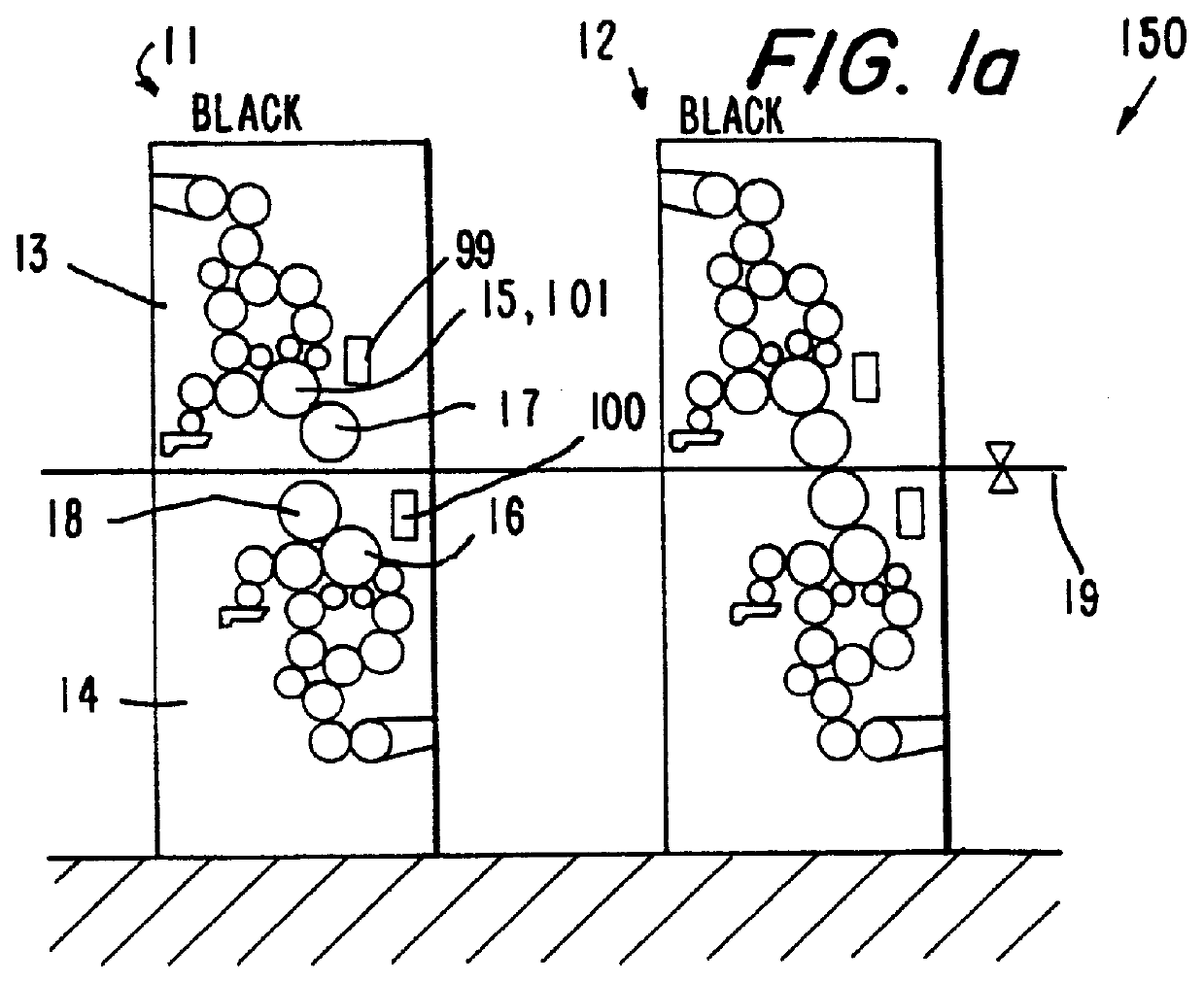

System and method for register mark recognition

InactiveUS20040163562A1Minimize timeReduce material wastePlaten pressesInvestigating moving sheetsOperator interfacePunching

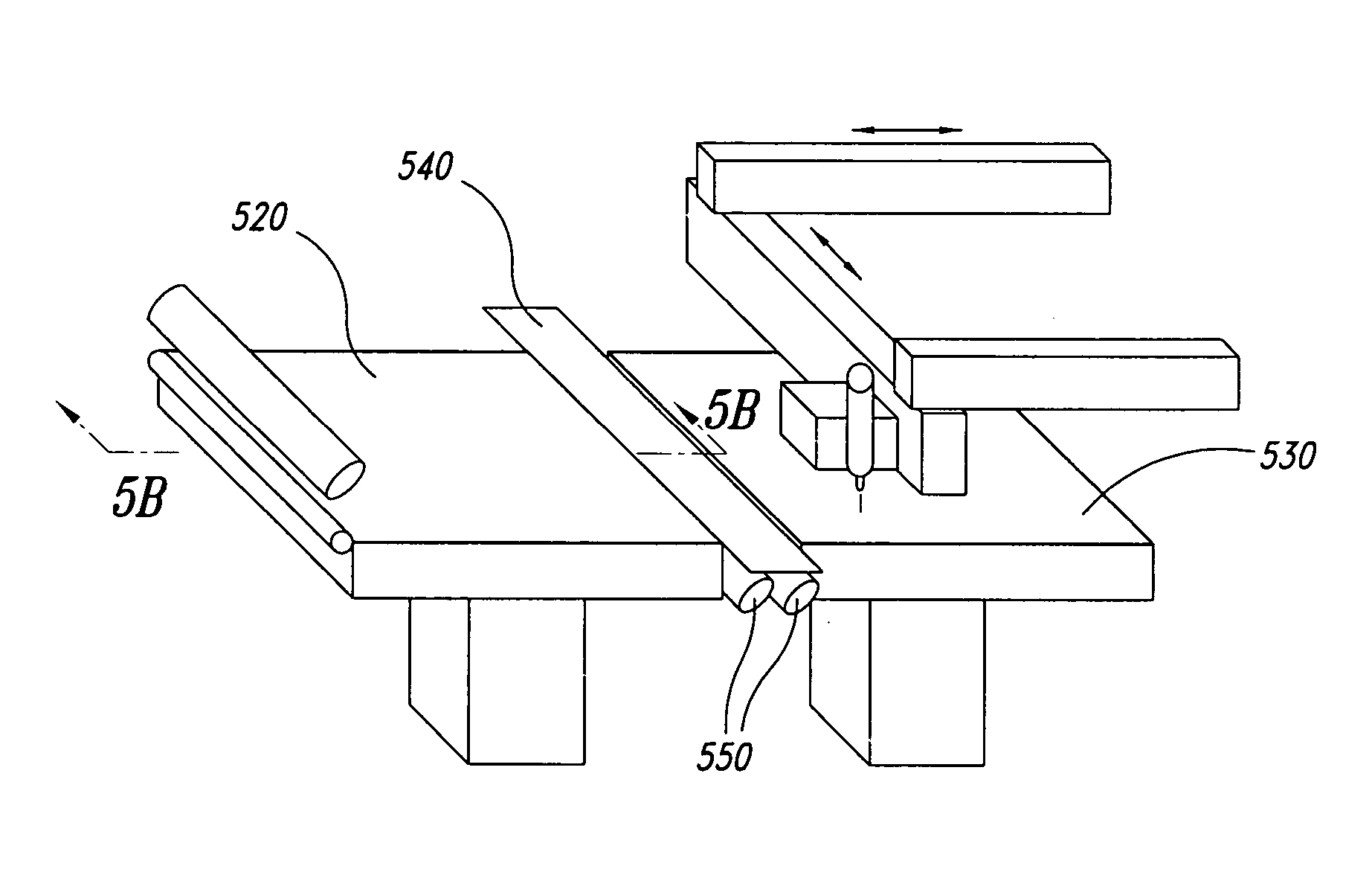

A system, method, and process that determine and automatically correct registration errors between printed objects and mechanically produced objects using advanced image processing techniques is disclosed. Means are also presented for maintaining all registered functions to within very close tolerances during normal running, with other means for rapidly obtaining initial registration with substantial savings in material waste. The disclosed system and method / process are compatible with the printing and converting industry in which rolls of material are processed by printing a number of colors that require close registration especially in pictorial representation. These roll-fed printing machines are quite versatile and in addition to the printing of any number of colors on both front and back can perform any number of additional operations on the printed web at the same time. Some of these additional operations can be the punching of line holes, scoring, perforation and die cutting all of which impart a specific shape mechanically on the printed web. All of these functions must be initially registered to each other and maintained within close tolerances during normal running conditions. The presently disclosed registration system permits these initial registration procedures to be performed with high accuracy, speed, and across a wide variety of web materials and colors. The system generally applies to any web material (5701) on which register marks (5702) are applied, wherein images of the web are obtained (5703) and image processed (5704) under optional control of an operator interface display (5705), resulting in web press motor control (5706) to affect improved print registration on the web material (5701).

Owner:CC1

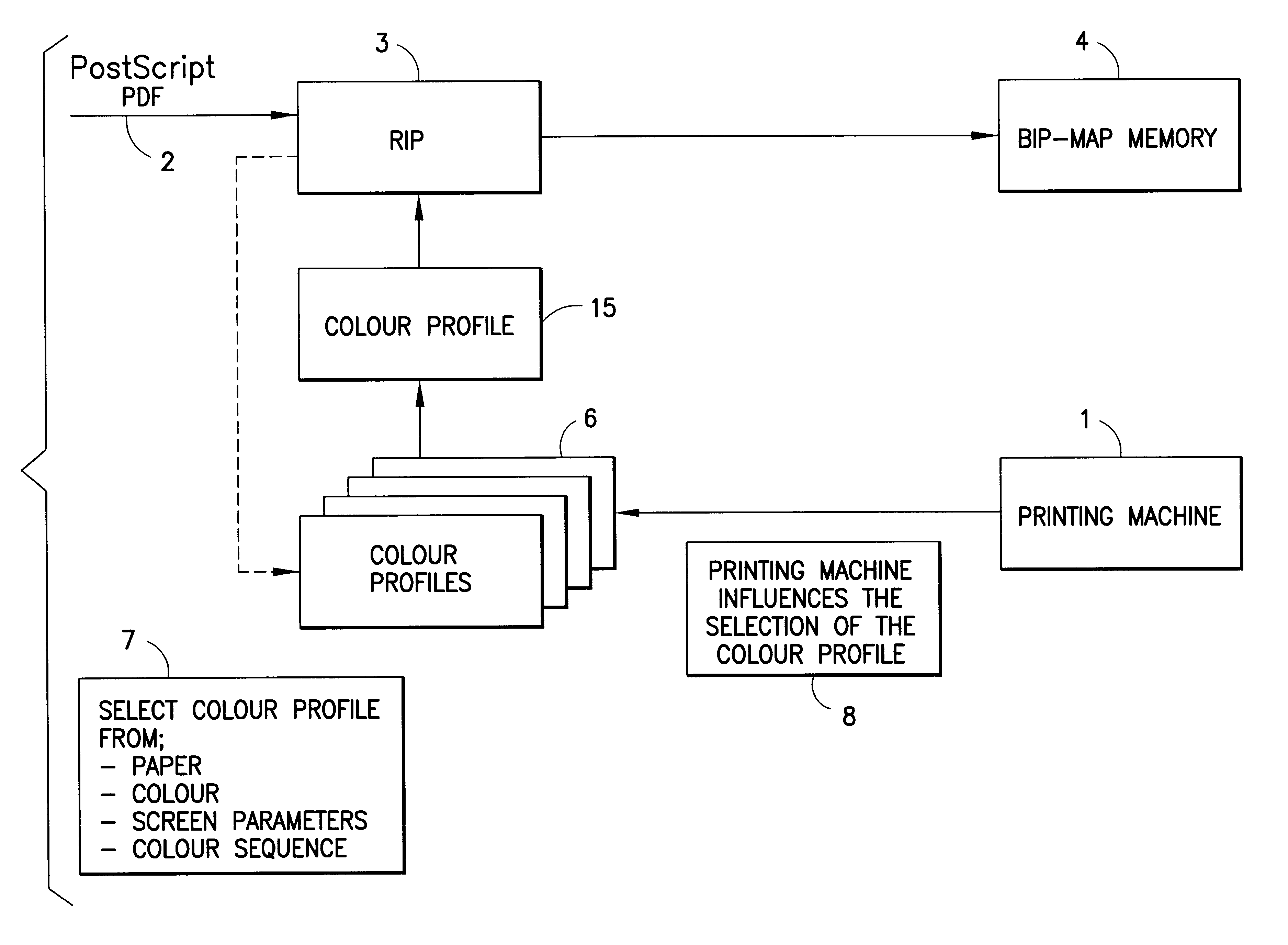

Method for profiling and calibrating a digitally controllable printing machine having a permanent printing plate

A method for calibrating a digitally controllable printing machine having a permanent printing plate, for which image data has been created in machine-independent format in a pre-press stage. The image data is prepared for the printing process by a data processing device and is fed in adapted form to the printing machine 1. The data processing device uses a profile which corresponds precisely with the current machine condition, for the final data preparation for printing. The profile can be addressed using the correct color-space conversion for the printing machine (i.e., calibrated). For this purpose, at the time at which the data is prepared for image setting, a machine condition forecast for the time of printing is called up and, from this, together with the knowledge of the operating materials, the machine profile which most closely approaches that for the print job is determined. This profile is then used for the data preparation.

Owner:MANROLANAD AG

Rapid prototyping and filling commercial pipeline

InactiveUS20050247216A1Cheap and quickFast formingAdditive manufacturing apparatusMechanical working/deformationEngineeringDigital printing

Methods and apparatus provide a means to rapidly develop and modify prototype surface coverings for customer review and approval, and fill the commercial pipeline while more conventional production equipment is obtained, installed and tested. The present apparatus to rapid prototype and fill the commercial pipeline includes a digital printing system to print a film and a press for laminating and embossing the printed film to a substrate. The press uses an embossing plate or roll, which is made from ebonite or by three-dimensional printing equipment. These plates and rolls can be produced within two or three days or less.

Owner:AFI LICENSING

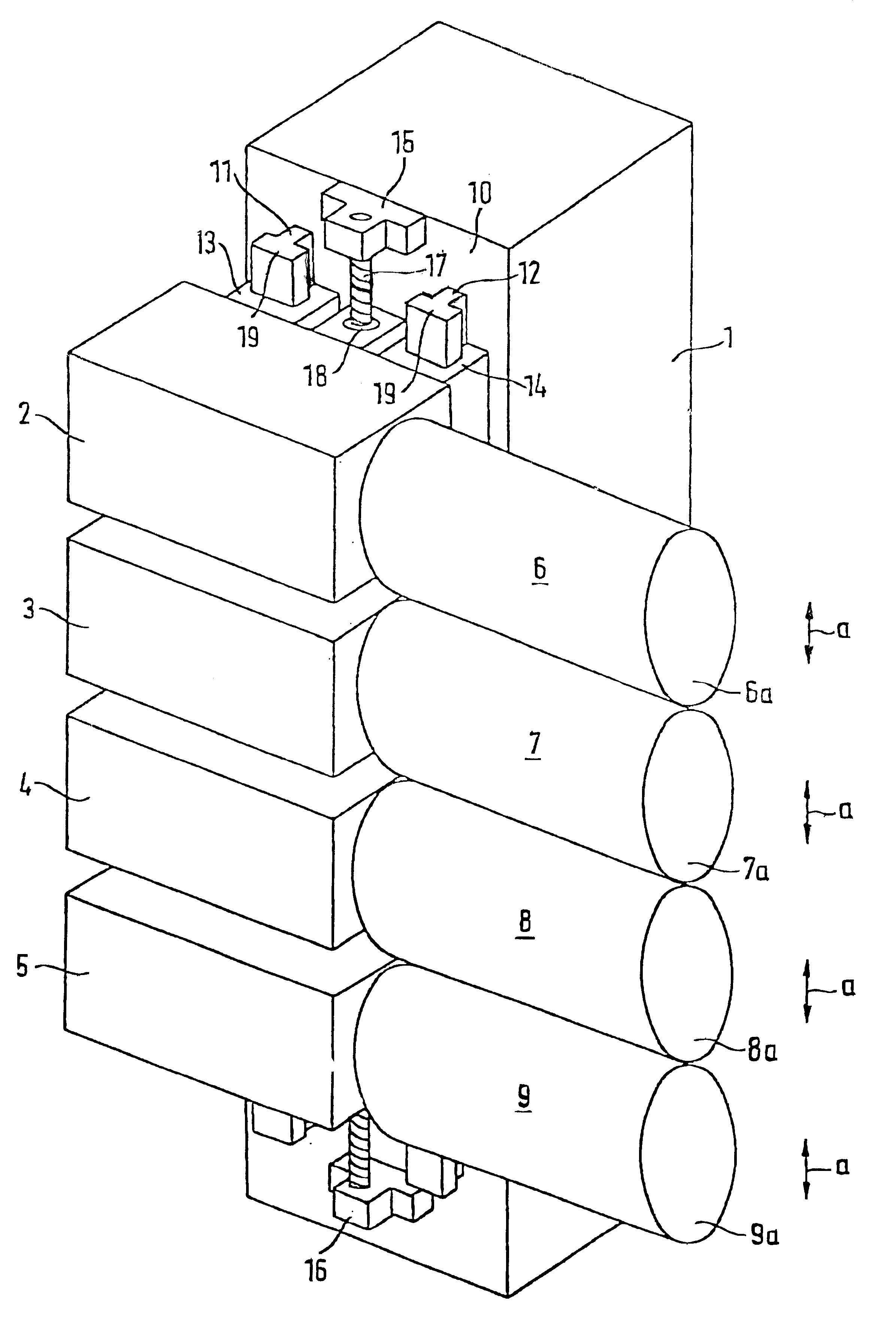

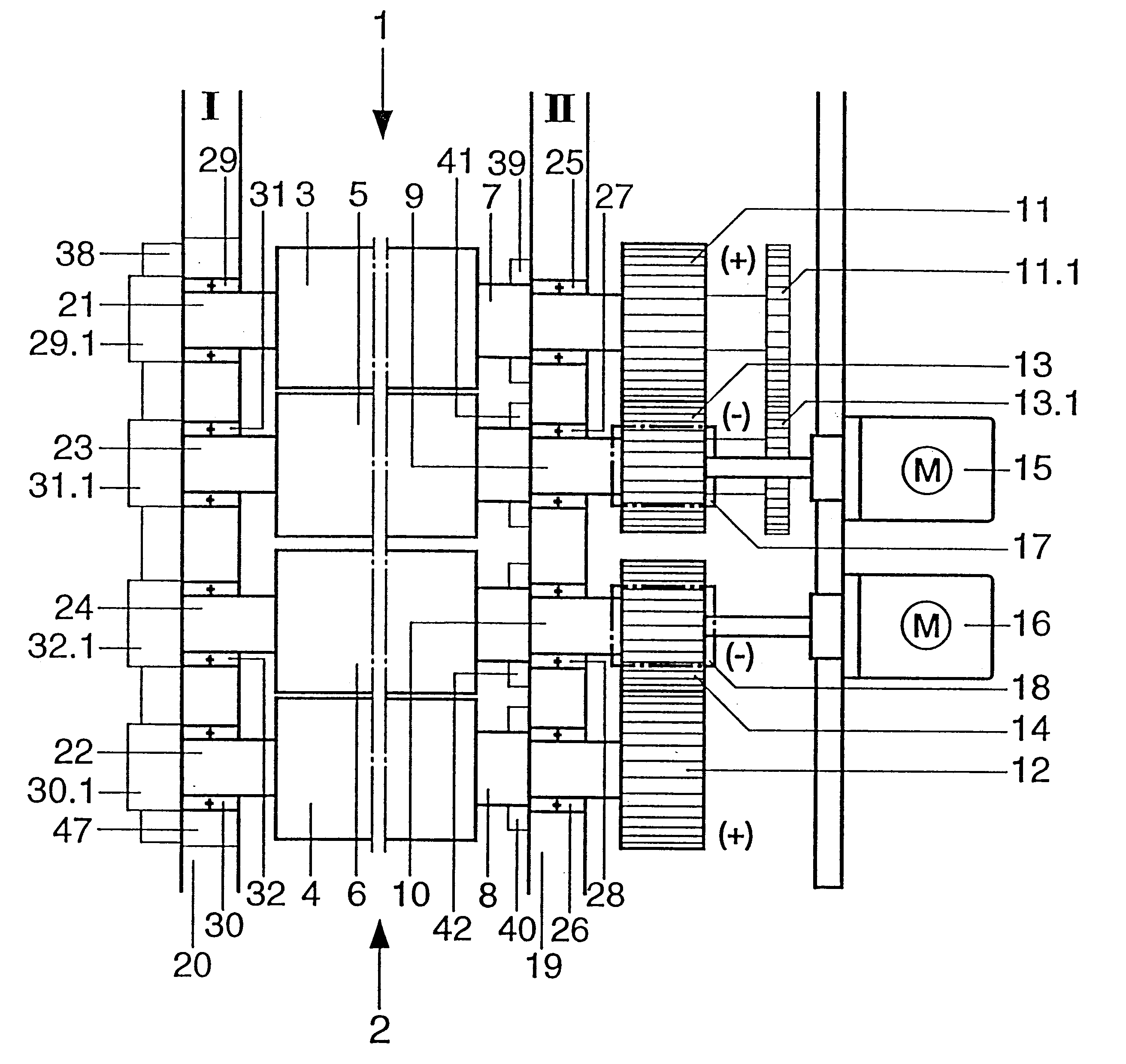

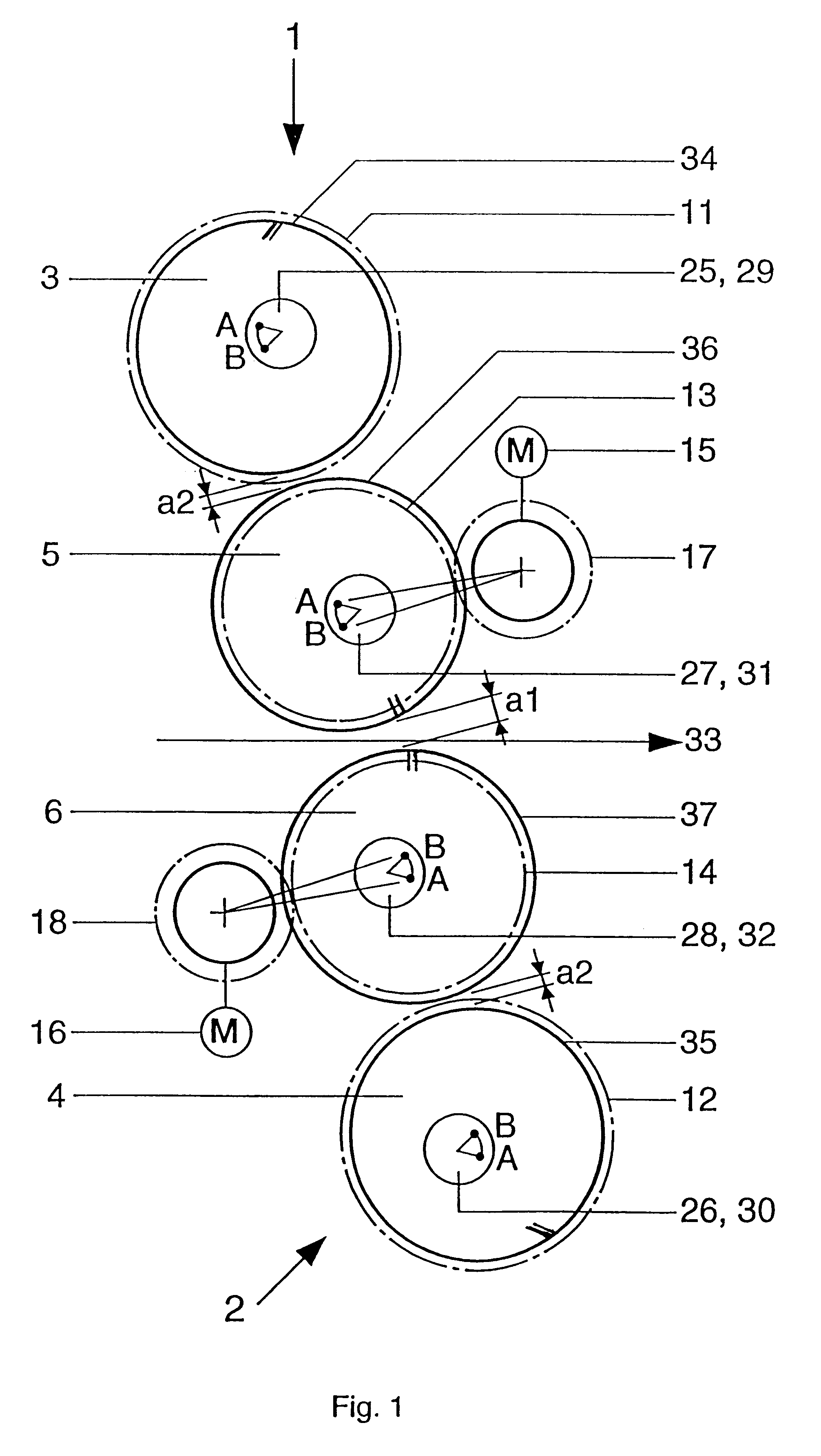

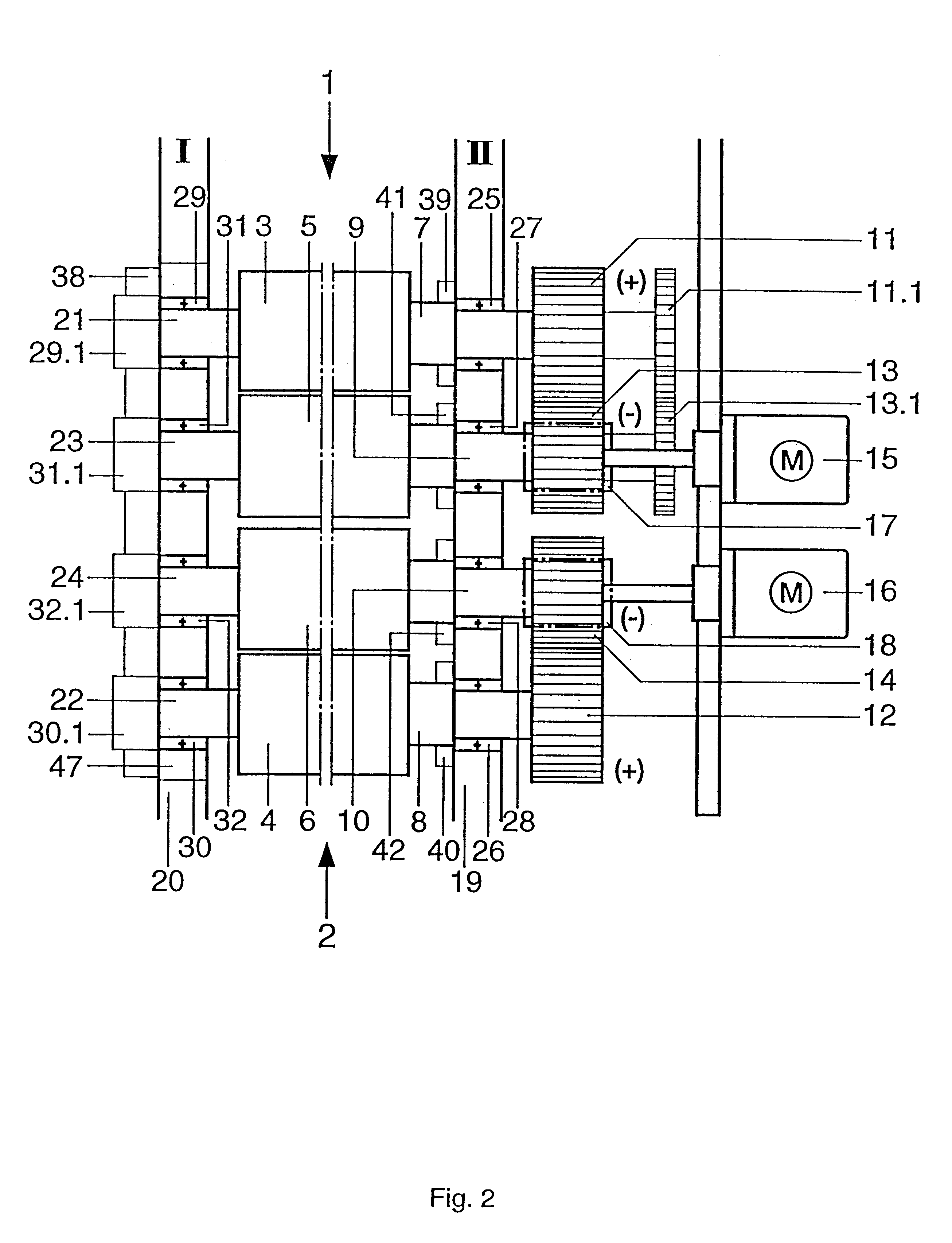

Double printing unit of a rotary printing machine

Large throw-off distances of the transfer cylinders in a double printing unit of a rotary printing machine operating on the rubber / rubber principle are achieved by enabling the two transfer cylinders to be set away from each other, and enabling the two form cylinders to be set away from the respective transfer cylinder. The form cylinder and the transfer cylinder of each printing unit have a drive connection via spur gears, the transfer cylinders are not in tooth engagement via their spur gears, and each printing unit has its own electric motor.

Owner:MANROLAND WEB SYST

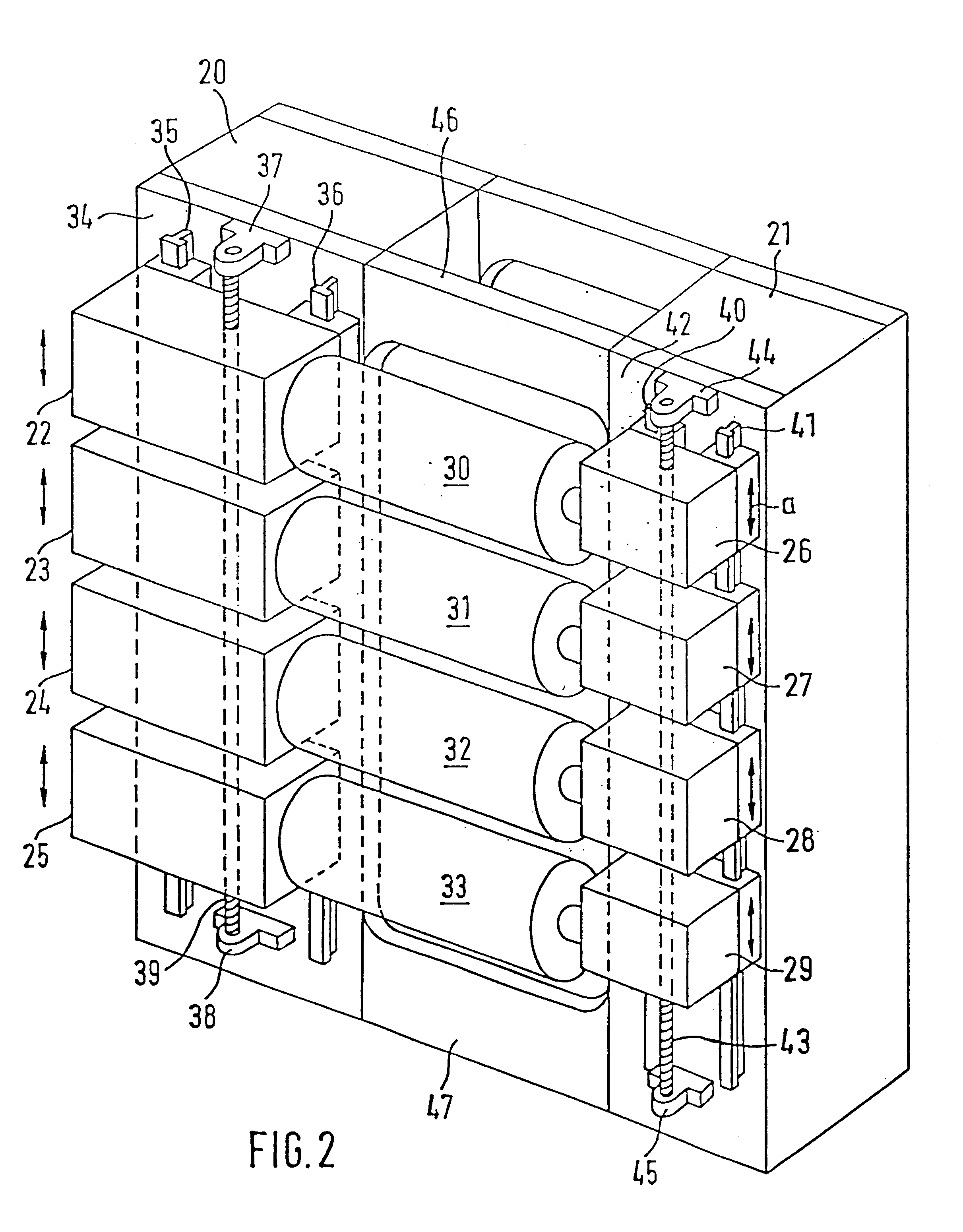

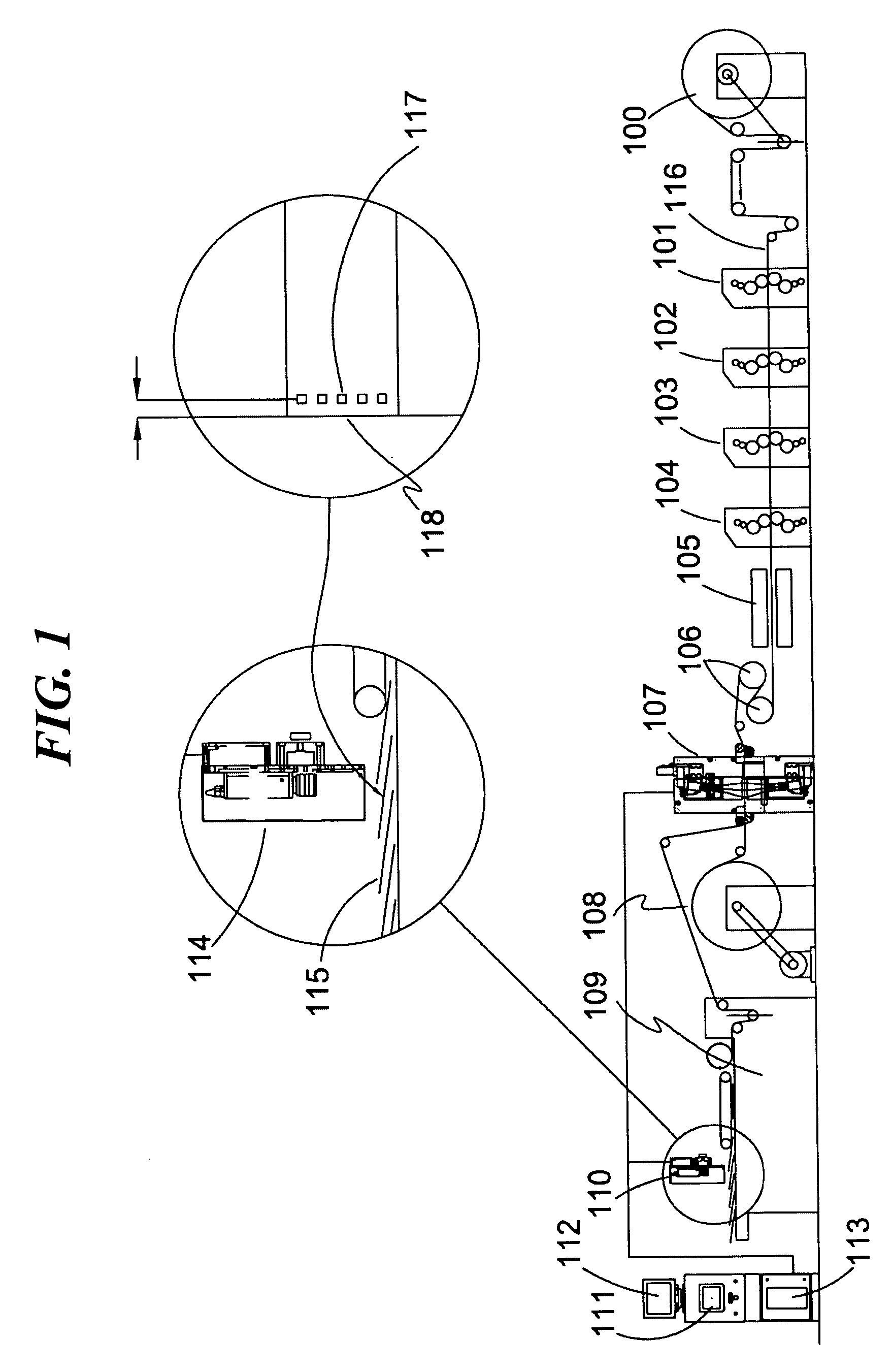

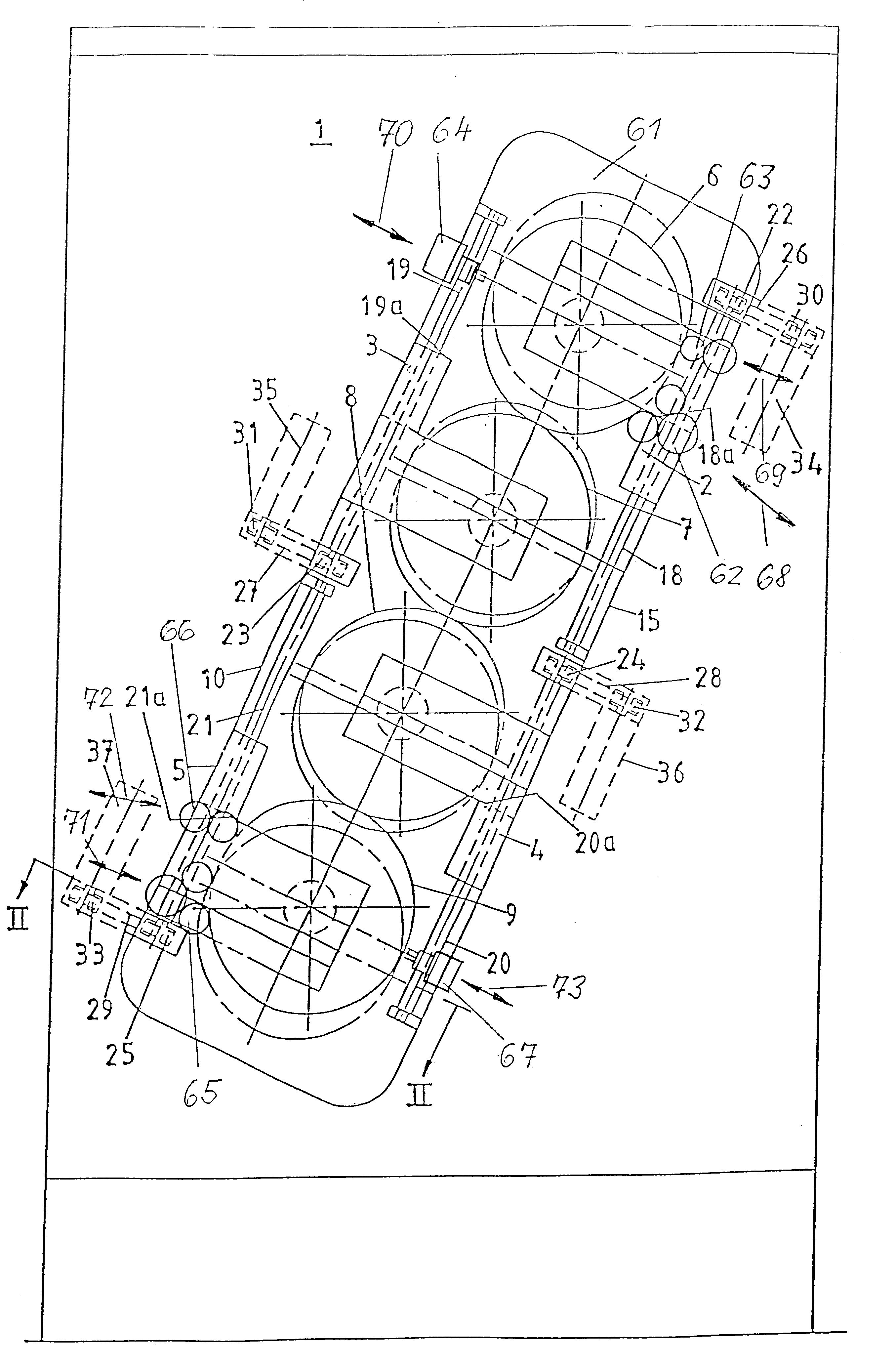

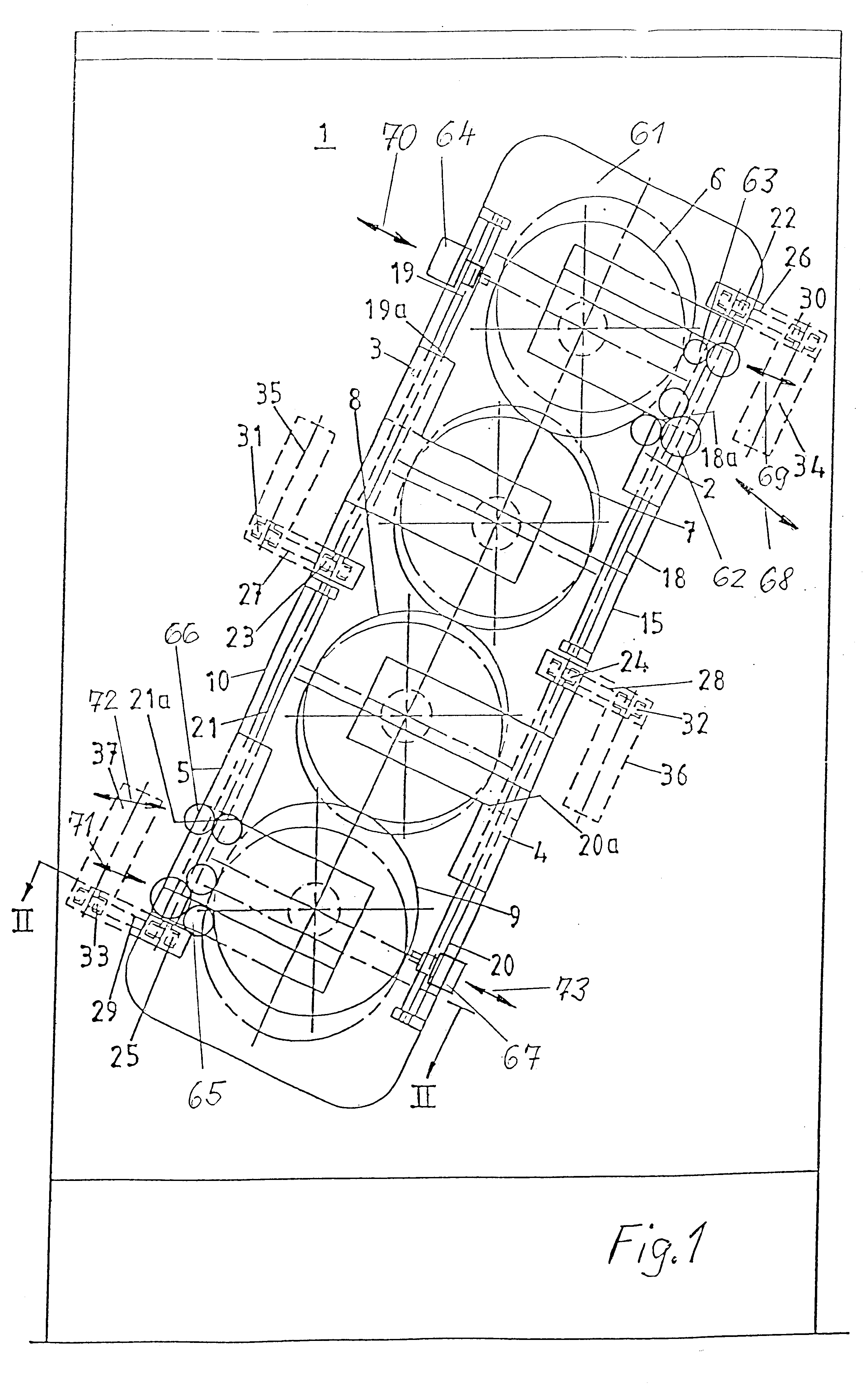

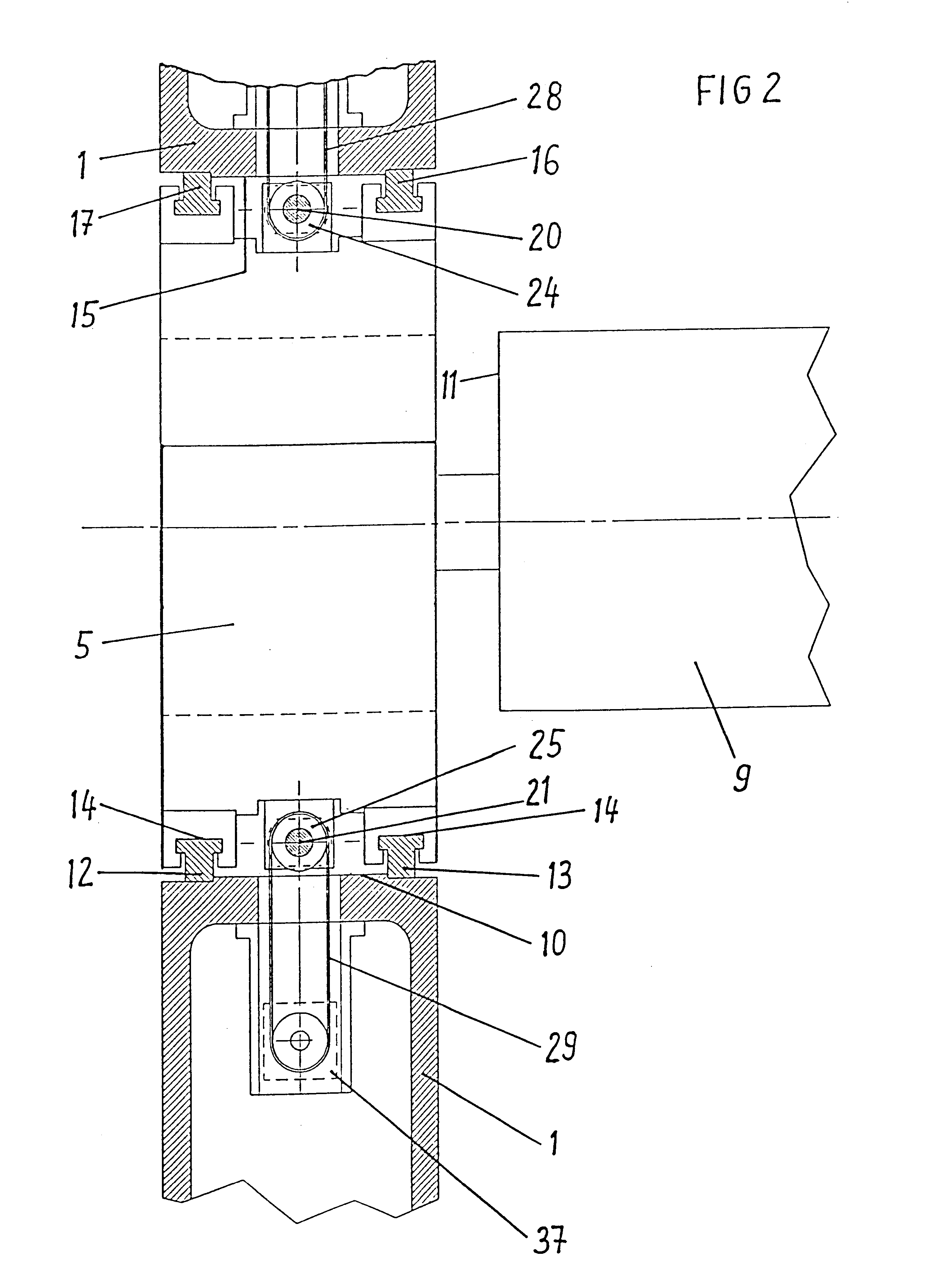

Printing unit

A printing unit for a web-fed rotary printing machine is provided having at least one carrying wall, a plurality of cylinders mounted on the carrying wall, a drive motor corresponding to each cylinder and a slide corresponding to each cylinder. Each slide carries its corresponding cylinder and receives the corresponding drive motor. A drive means is provided for driving the slides and a plurality of guide elements are mounted on the carrying wall and arranged laterally next to the adjacent end faces of the cylinders for guiding the slides along the wall. The guide elements are arranged opposite and parallel to one another on the carrying wall. Optionally, the carrying wall includes panels defining an orifice to allow cylinders, journals and sleeves of the printing machine of varying sizes to be changed readily.

Owner:MANROLANAD AG

Method for printing a pattern on a substrate

ActiveUS20090186308A1Photosensitive materialsSemiconductor/solid-state device manufacturingPaperboardEngineering

The invention provides a method for printing a pattern of ink on a substrate, such as corrugated paperboard, with a relief printing form made from a photosensitive element. The method includes forming an in-situ mask for the photosensitive element, exposing the element to actinic radiation through the in-situ mask in an environment having an inert gas and a concentration of oxygen between 190,000 and 100 ppm, and treating the exposed element to form the relief printing form having a pattern of printing areas. Printing is accomplished by securing the relief printing form to a print press, applying the ink to the printing areas on the printing form, and contacting the ink from the printing areas to the substrate to transfer the pattern of ink onto the substrate.

Owner:DUPONT ELECTRONICS INC

Printing color quality detecting method of integrating visual measurement, density measurement and color measurement

InactiveCN101518980AAdapt to the trend of multi-color printingAccurately reflectPrinting press partsPattern recognitionPrinting press

The invention discloses a printing color quality detecting method of integrating visual measurement, density measurement and color measurement, which comprises the following steps: (1) based on the prior control strips, adding a spot color block, and placing the spot color block into an ink key area corresponding to a spot color part in a printed matter; (2) printing on a machine; (3) extracting the printed matter after a printing machine is stabilized to carry out visual measurement inspection, and taking out the printed matter passing the visual measurement; (4) measuring the colorimetric value of the printed matter by a colorimeter, and using the colorimetric value of the printed matter, the specified value of a sample and the color difference value of a digital sample or the prior sample as standards of qualification judgment; and (5) monitoring the density by adopting a density detecting method during printing. The method integrates respective advantages of the visual measurement, the density measurement and the color measurement, can detect the printing color quality more accurately, is simple and convenient, and is quite suitable for detecting the color quality of the printed matter.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com