Patents

Literature

1560results about "Primary cell manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

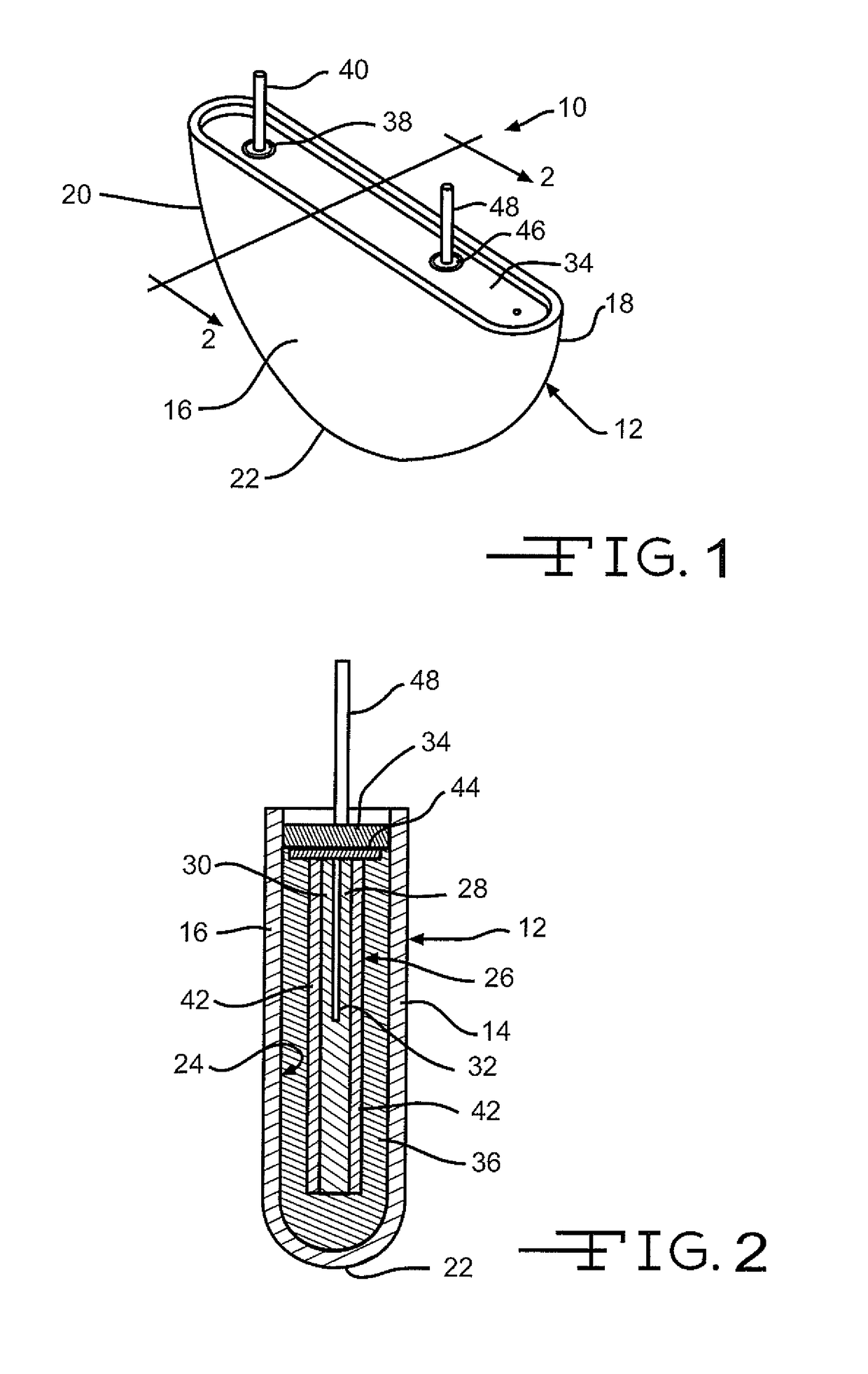

Ingestible event marker systems

ActiveUS20100185055A1Rapid and simple notationPrimary cell manufactureSurgeryComputer scienceDigestive tract

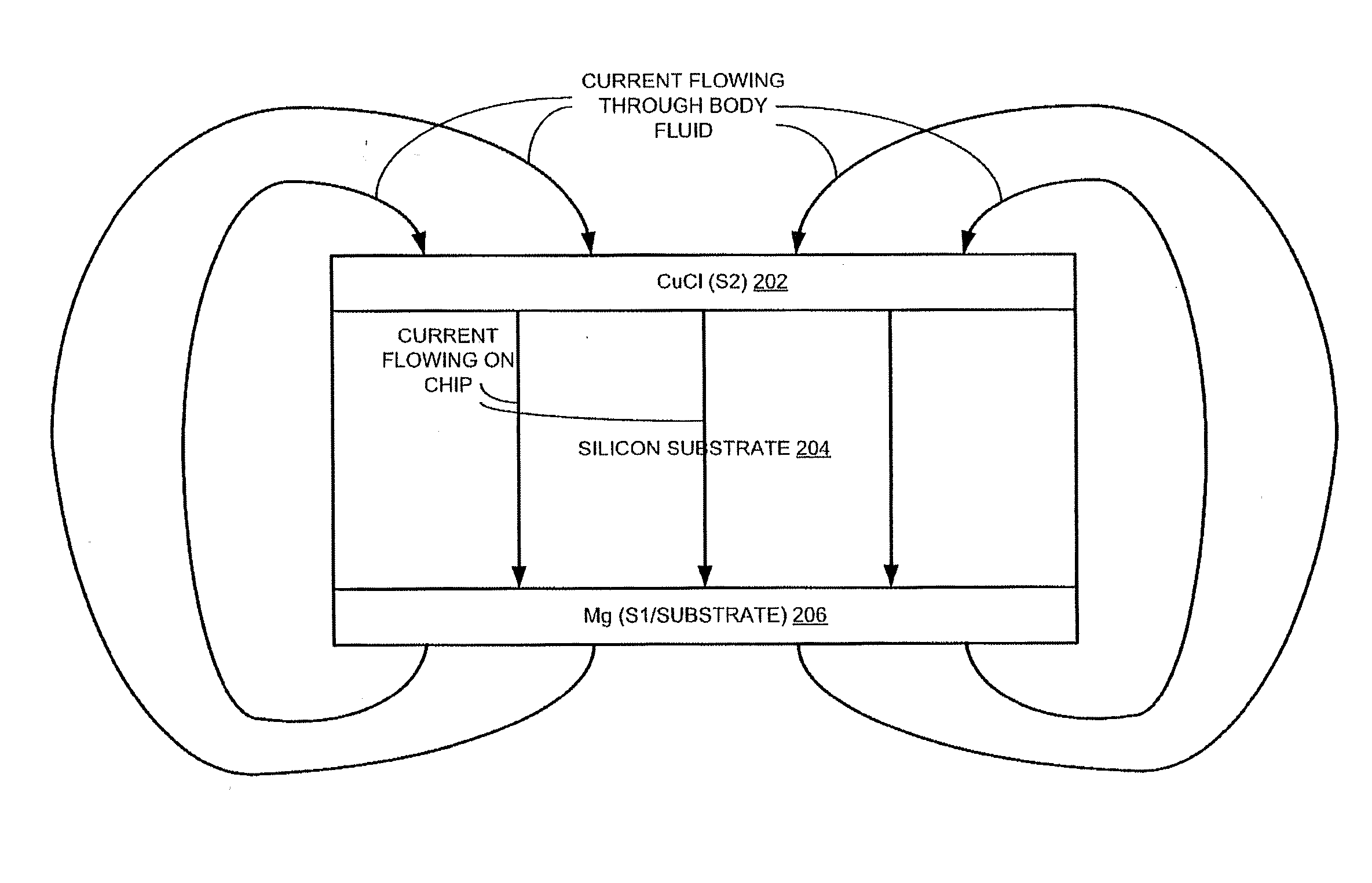

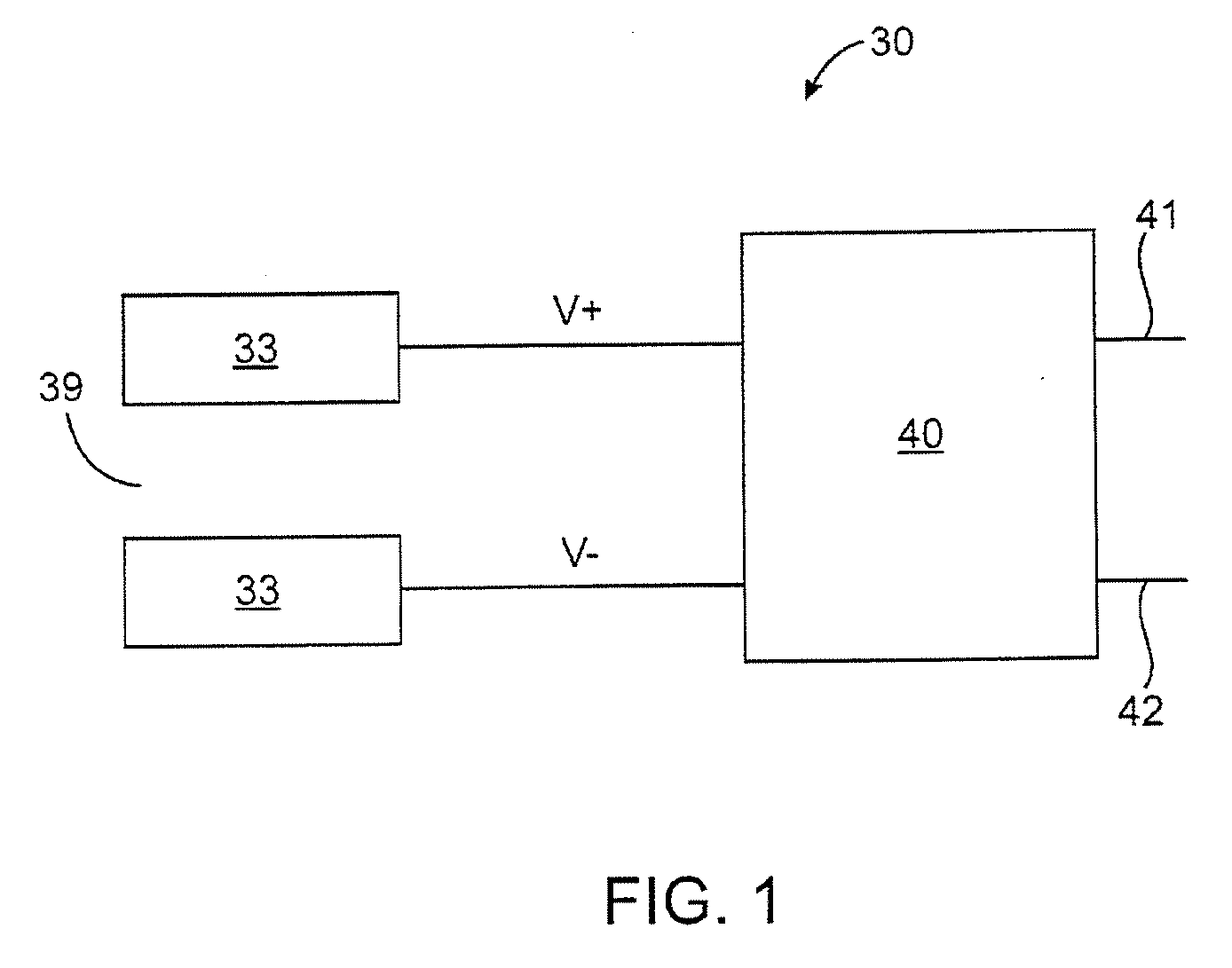

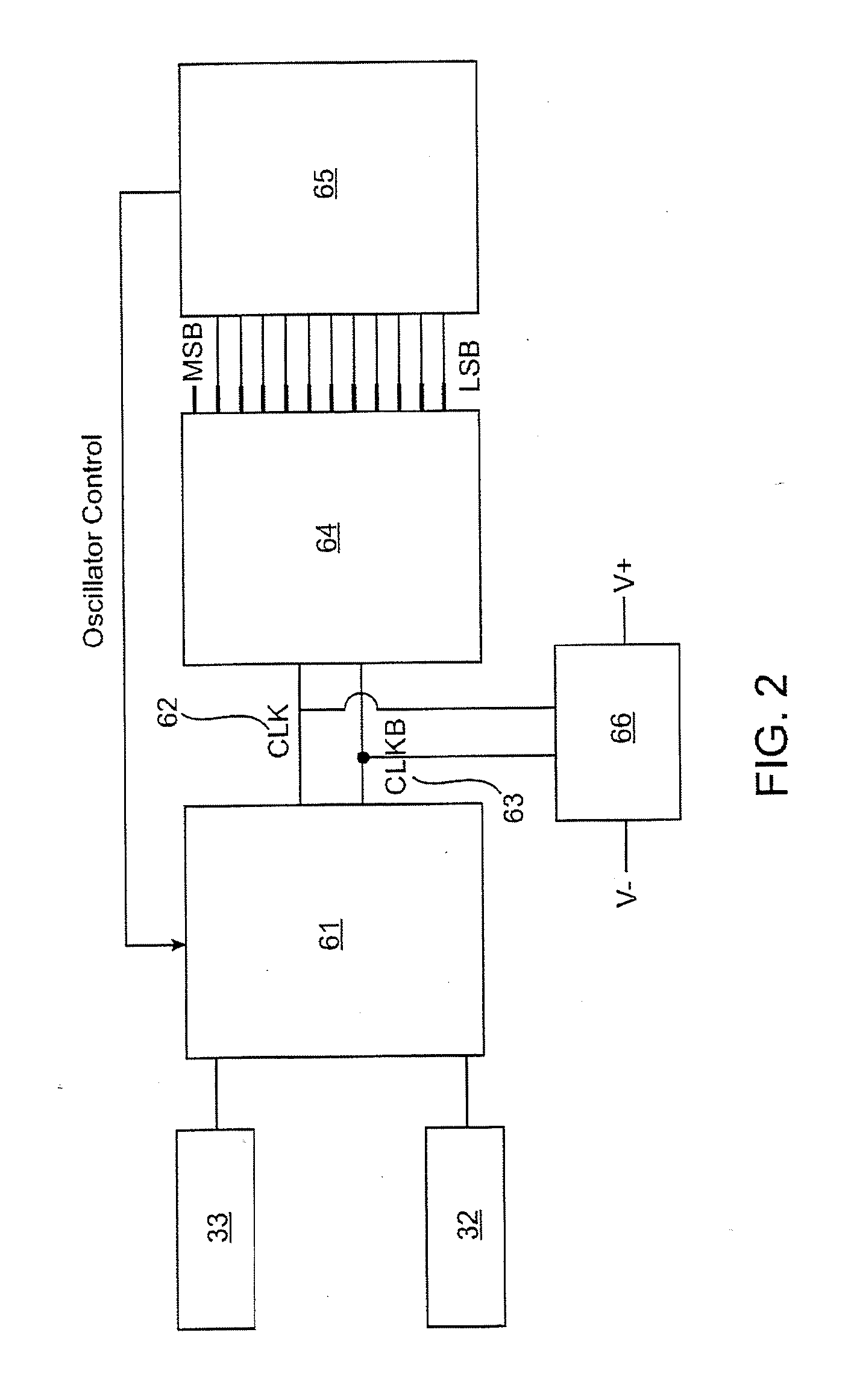

Ingestible event marker systems that include an ingestible event marker (i.e., an IEM) and a personal signal receiver are provided. Embodiments of the IEM include an identifier, which may or may not be present in a physiologically acceptable carrier. The identifier is characterized by being activated upon contact with a target internal physiological site of a body, such as digestive tract internal target site. The personal signal receiver is configured to be associated with a physiological location, e.g., inside of or on the body, and to receive a signal the IEM. During use, the IEM broadcasts a signal which is received by the personal signal receiver.

Owner:PROTEUS DIGITAL HEALTH INC

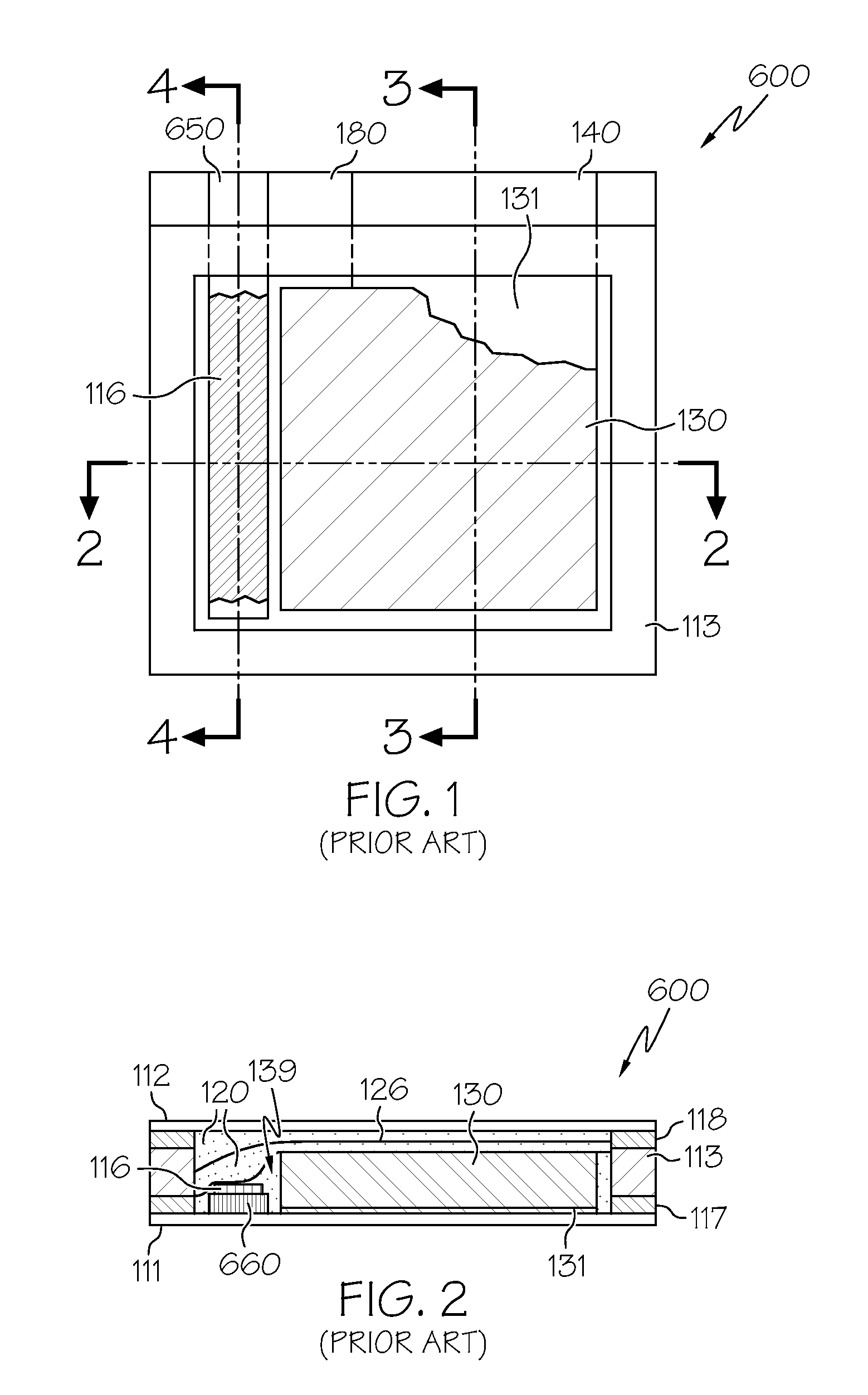

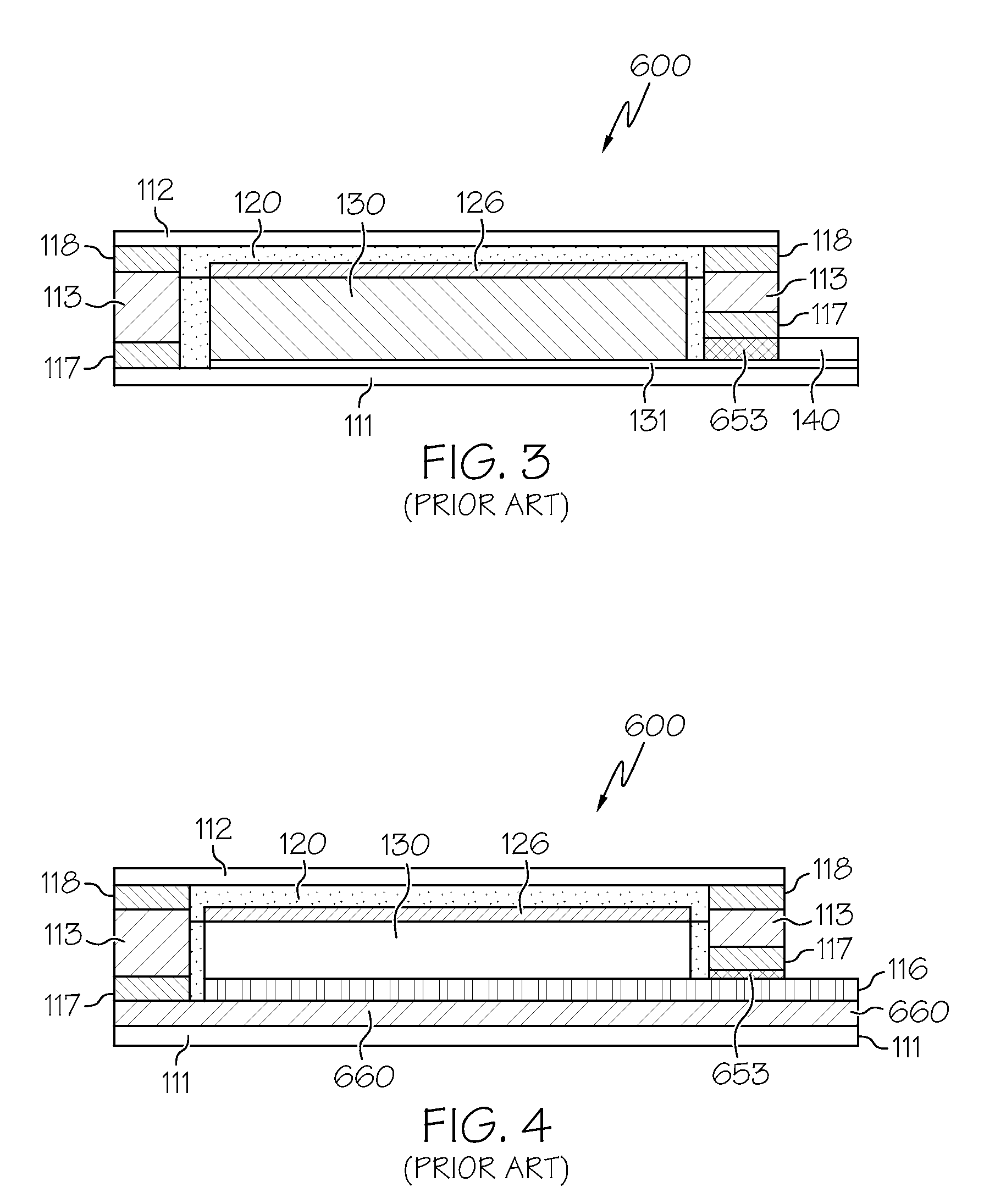

High current thin electrochemical cell and methods of making the same

ActiveUS20100266895A1Well formedPrimary cell manufactureElectrode carriers/collectorsEngineeringPrinting press

A battery including at least one electrochemical cell for generating an electrical current is provided, along with its method of manufacture. In one example, the electrochemical cell is provided on a first substrate and includes an anode and a plurality of cathodes. At least a portion of said anode is located between an adjacent two of said plurality of cathodes. In one example method of manufacture, the electrochemical cell is made via a printing press process.

Owner:BLUE SPARK INNOVATIONS LLC

Method of making printed battery structures

A battery is made by drop on demand printing a first electrode pattern and a second electrode pattern, and applying an electrolyte region over a portion of the first electrode pattern and a portion of the second electrode pattern.

Owner:HEWLETT PACKARD DEV CO LP

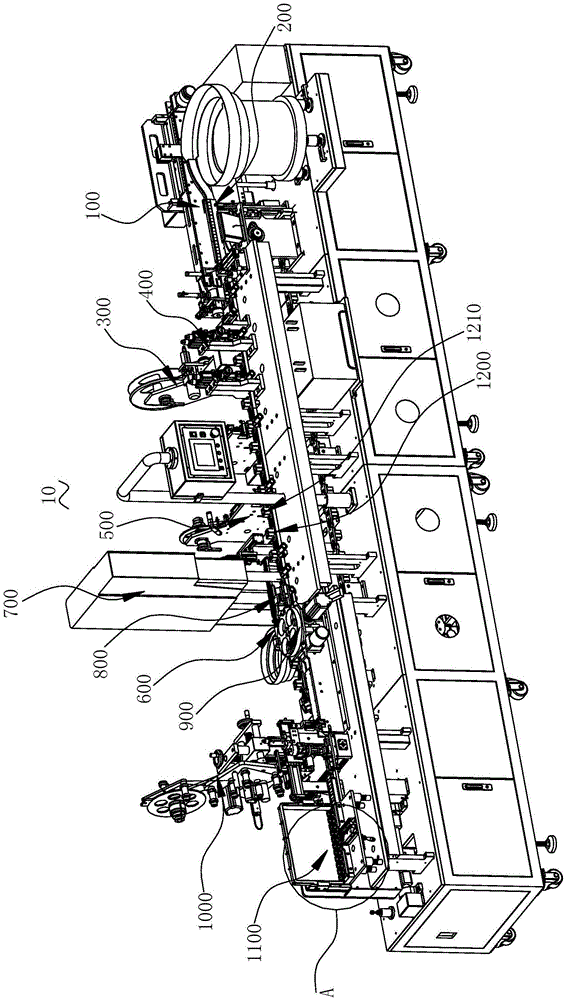

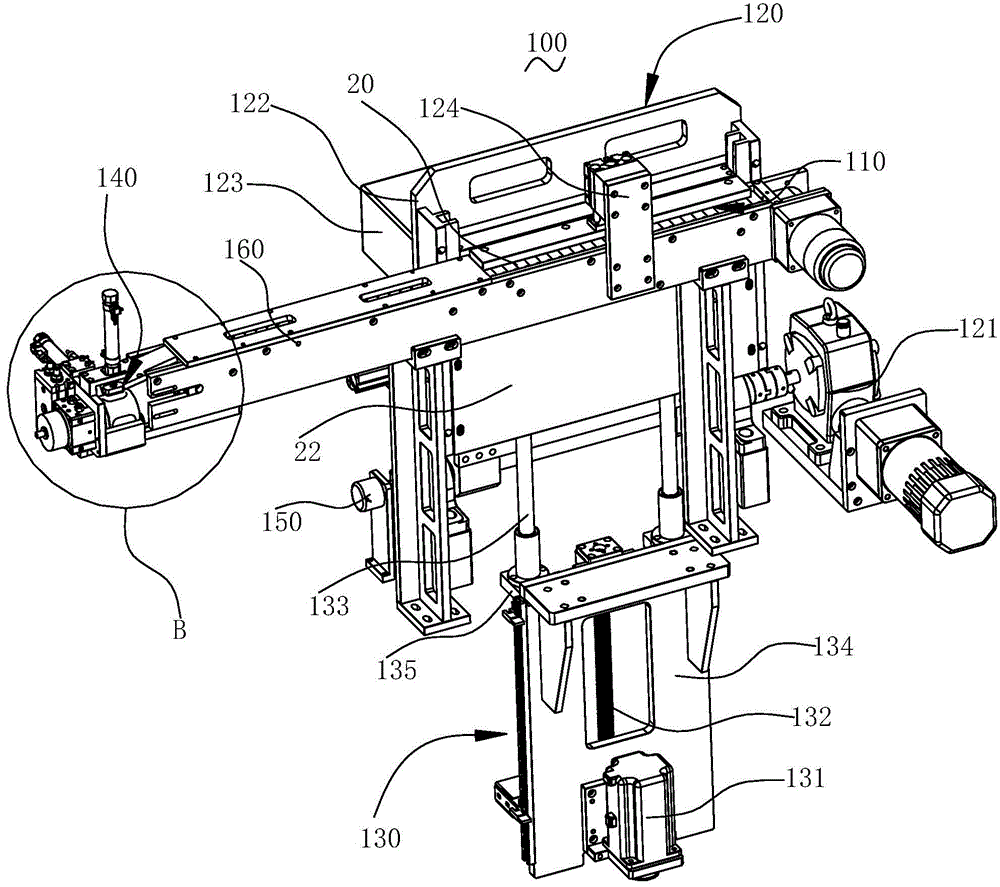

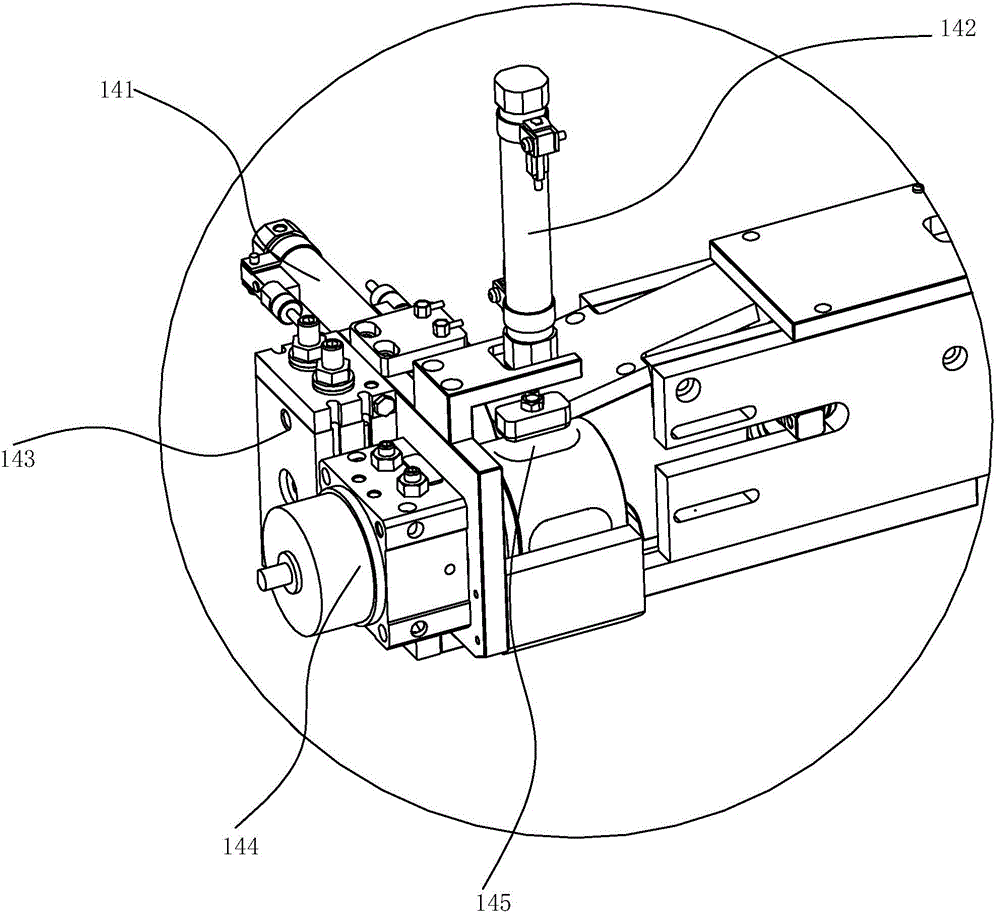

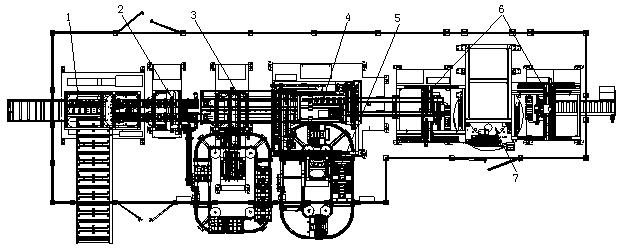

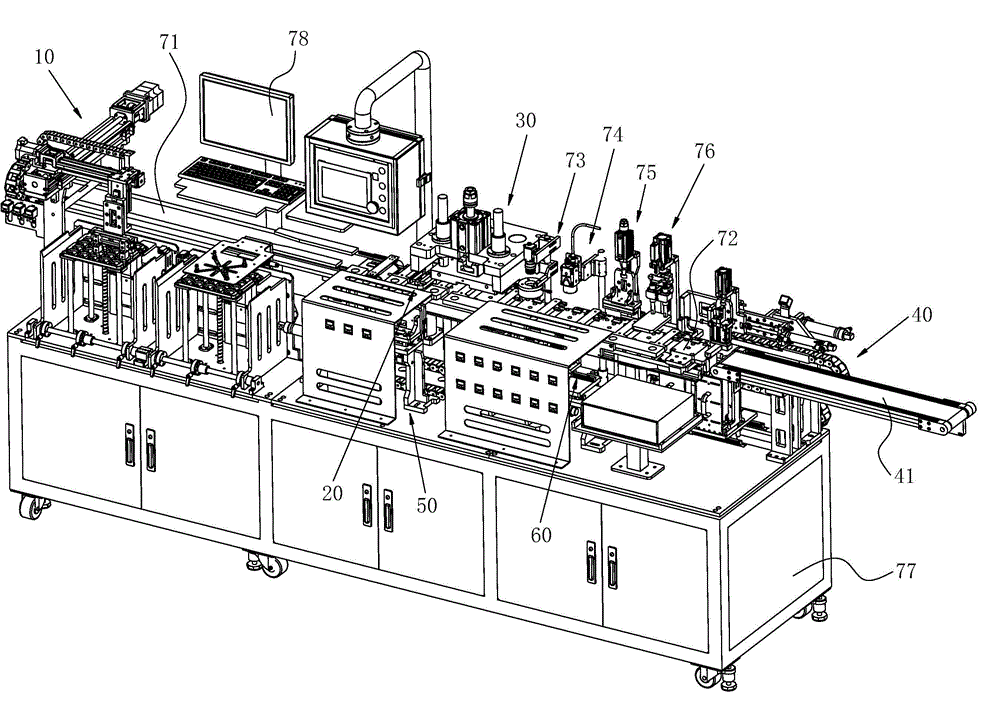

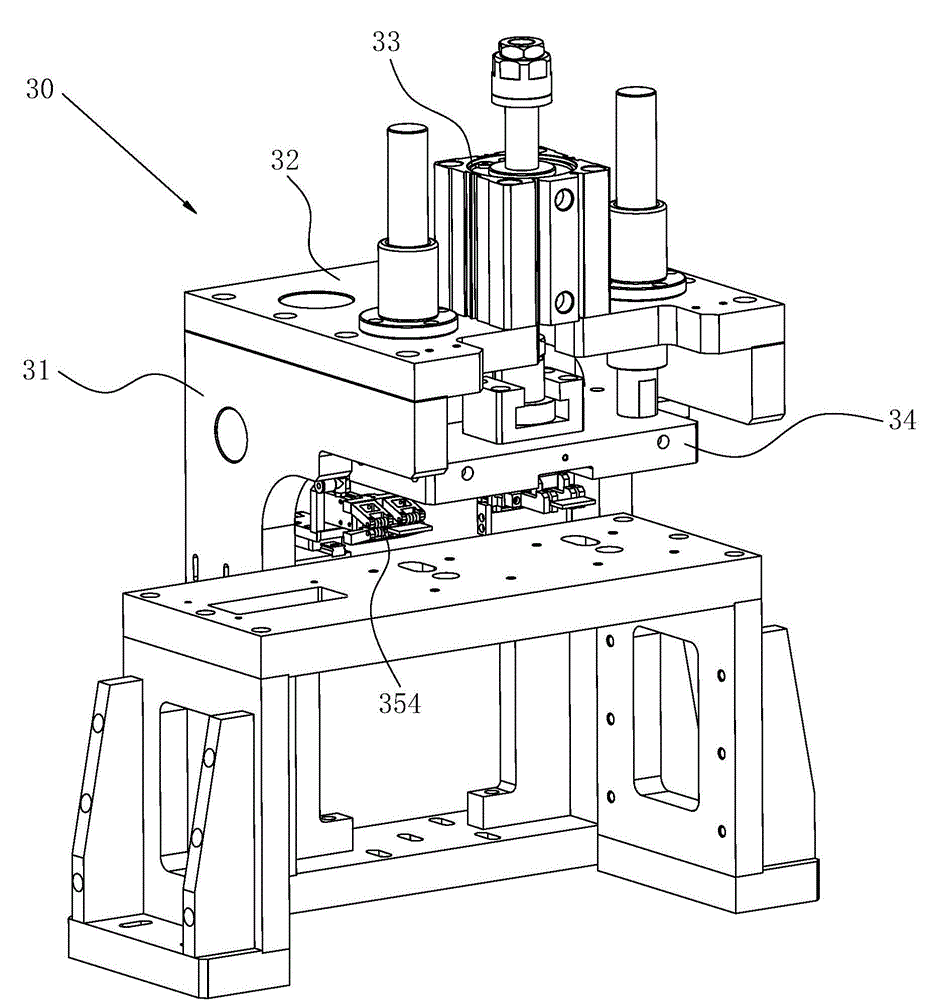

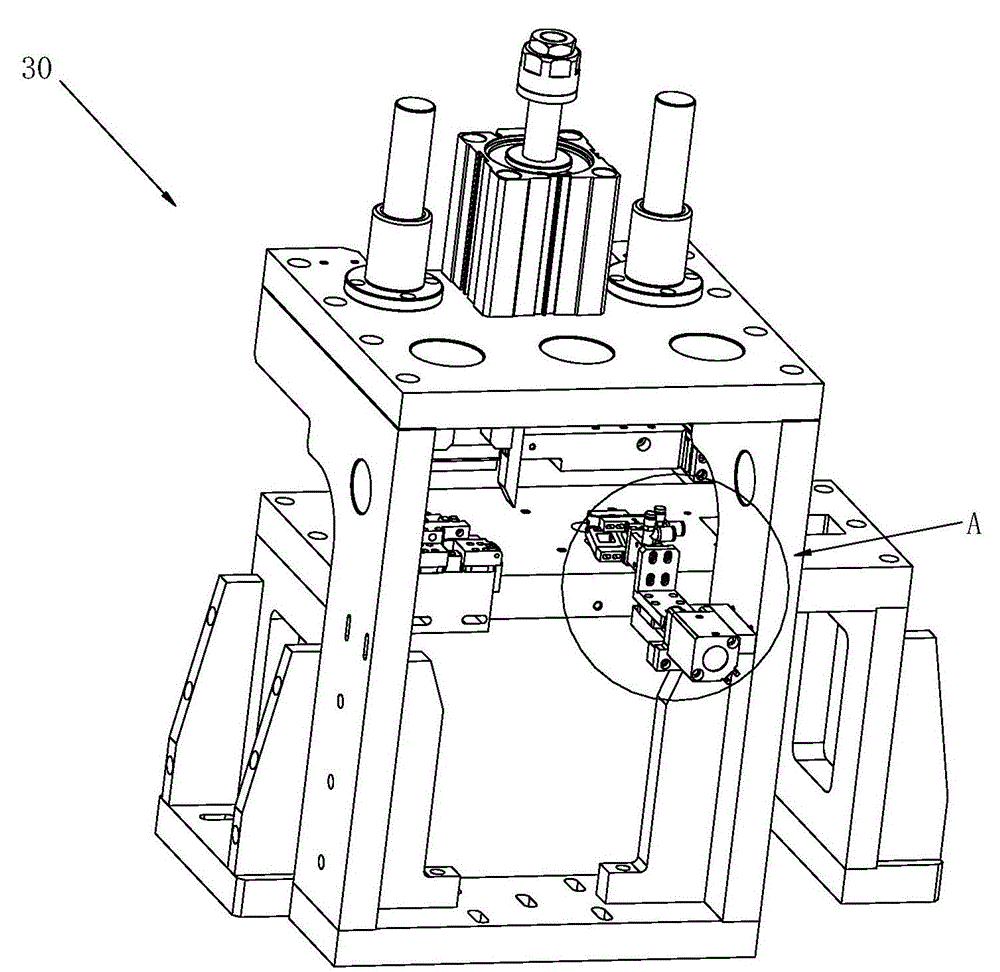

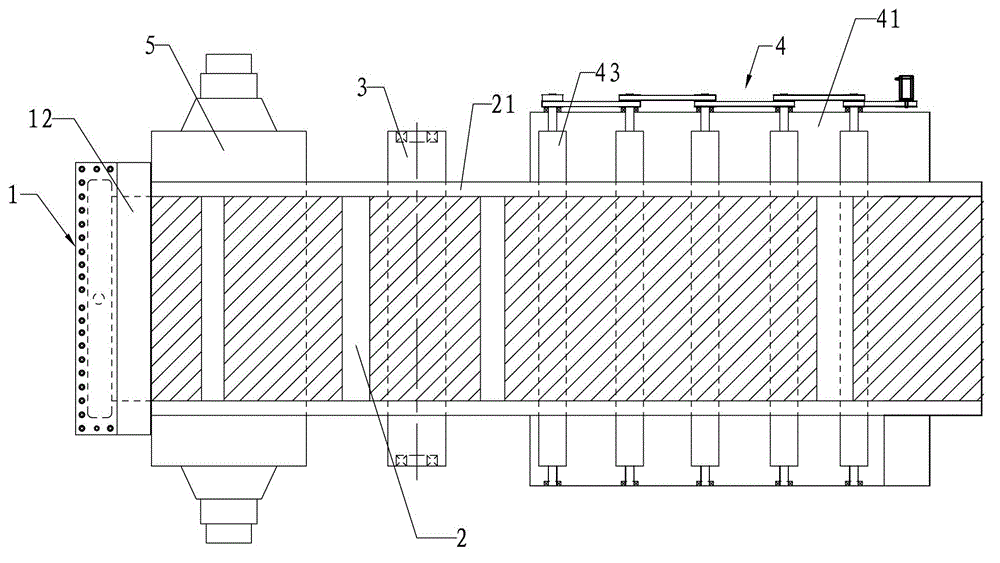

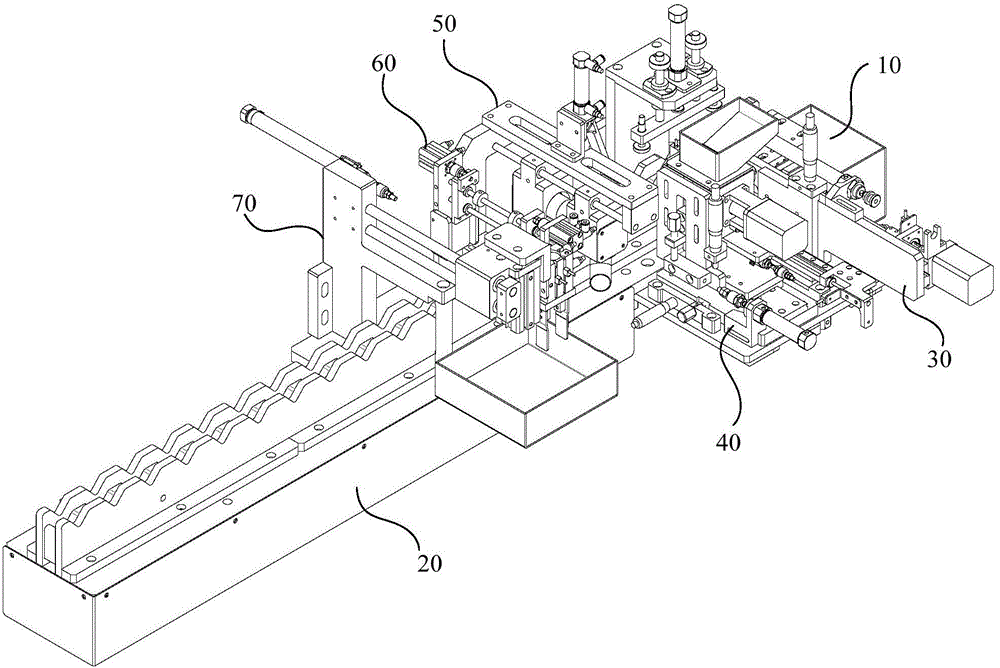

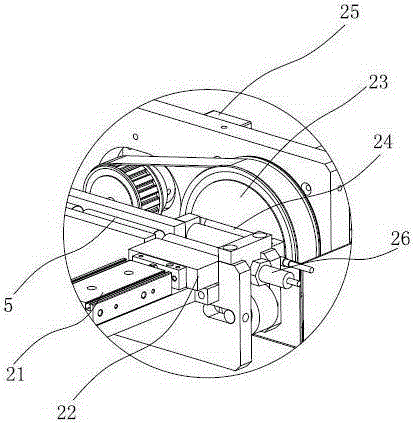

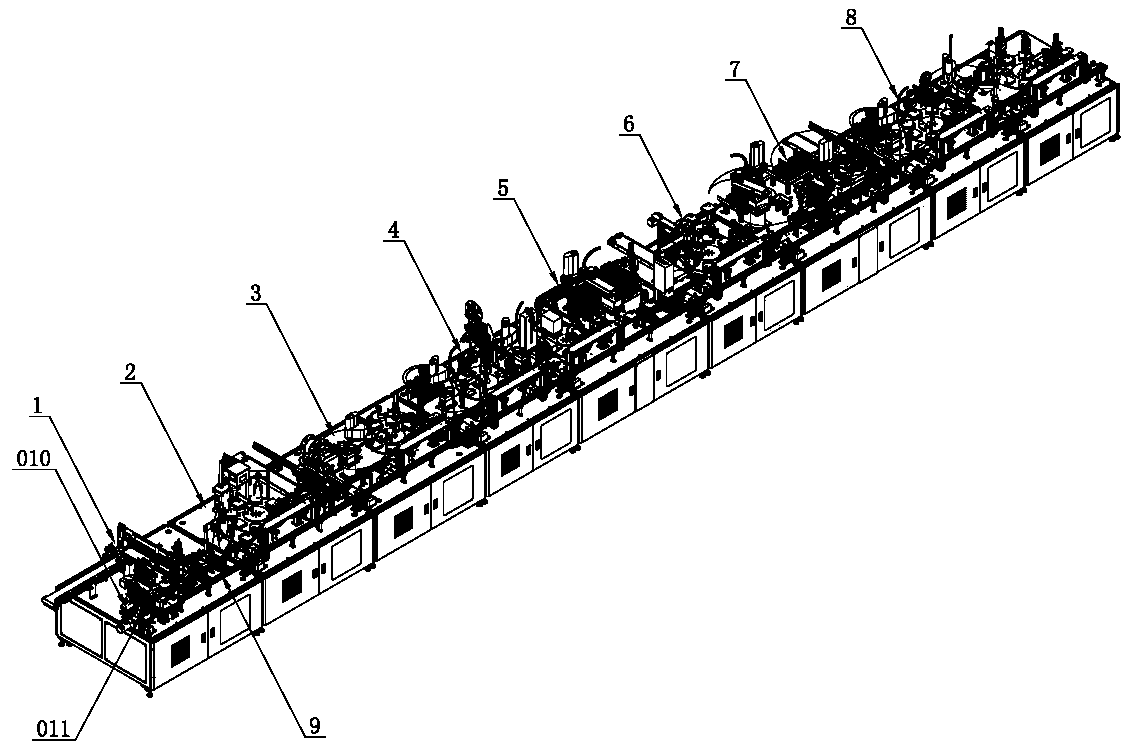

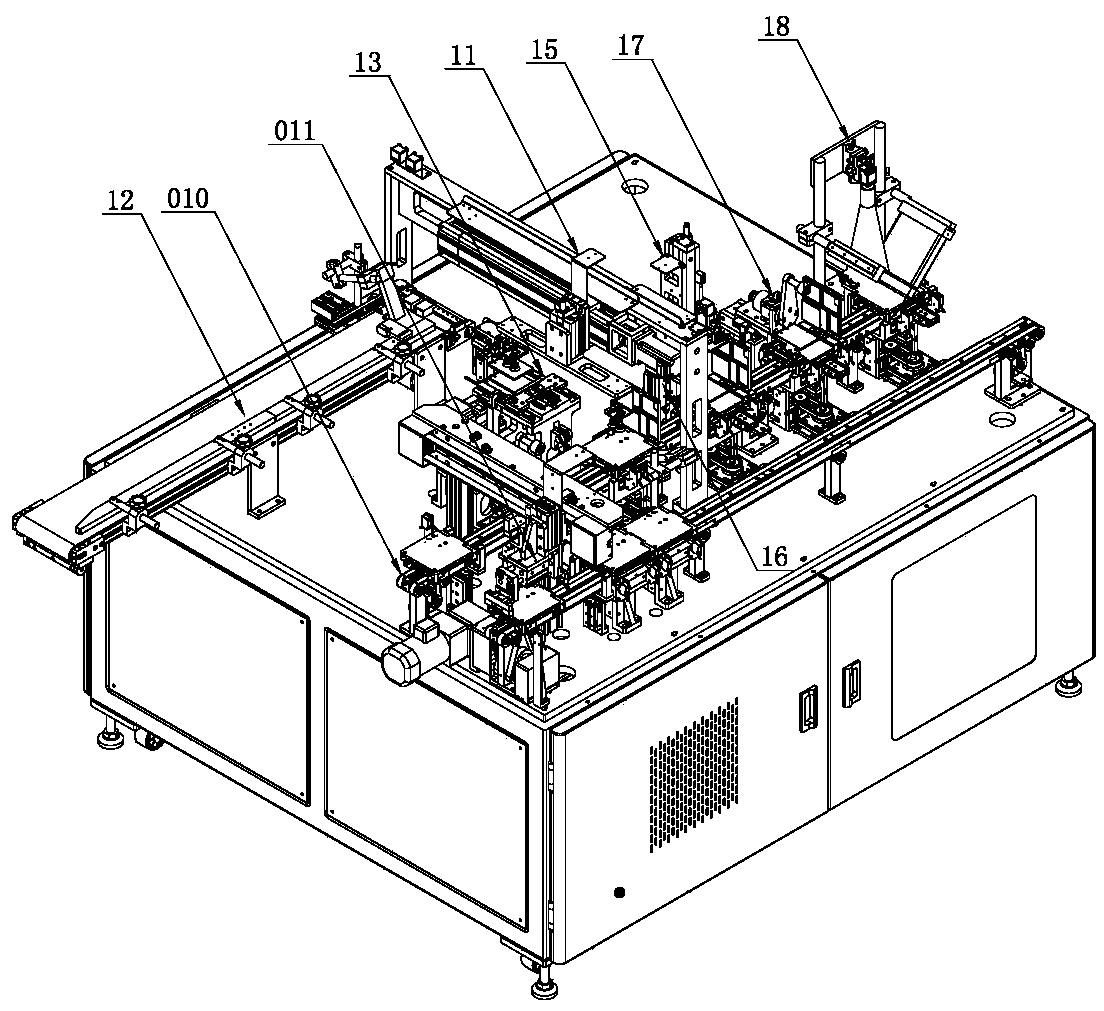

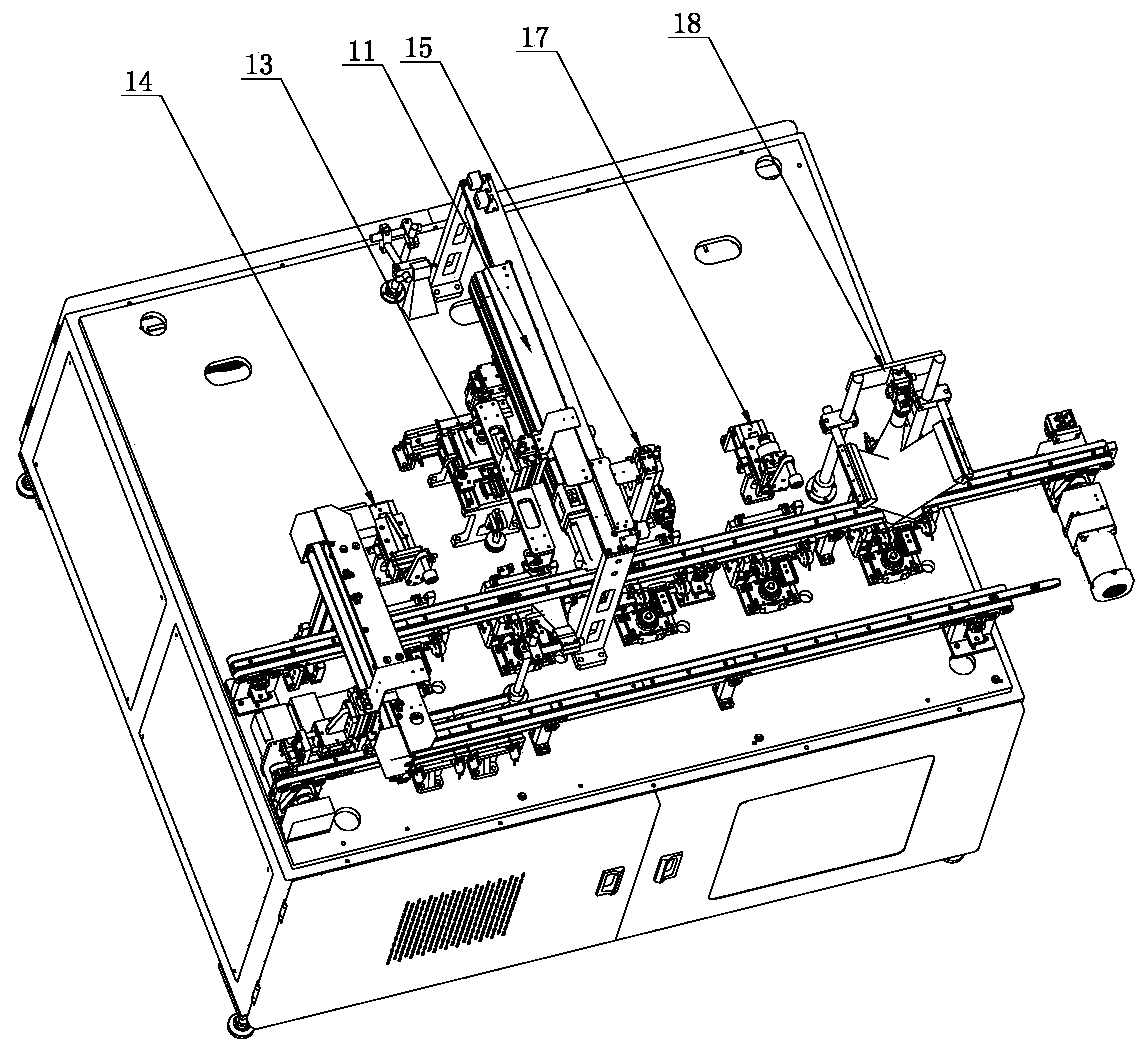

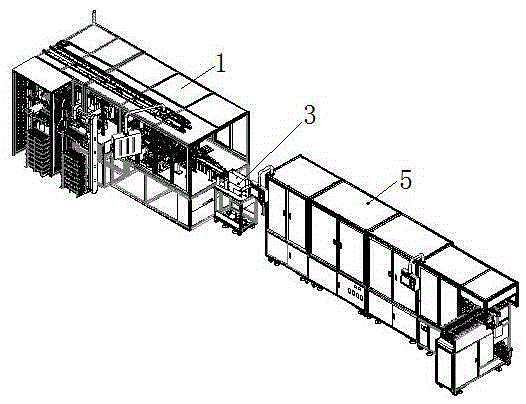

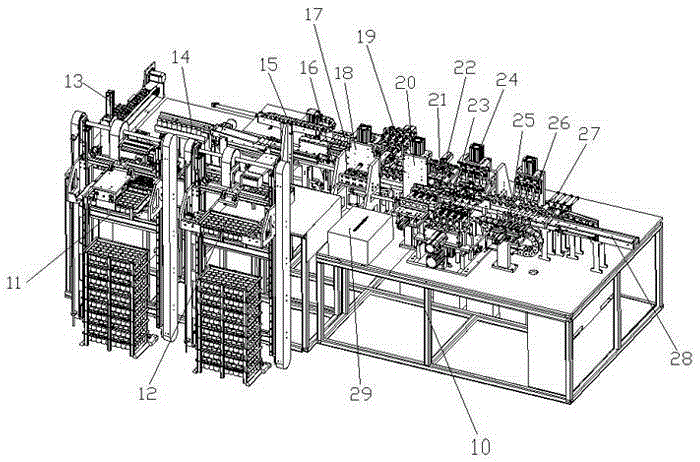

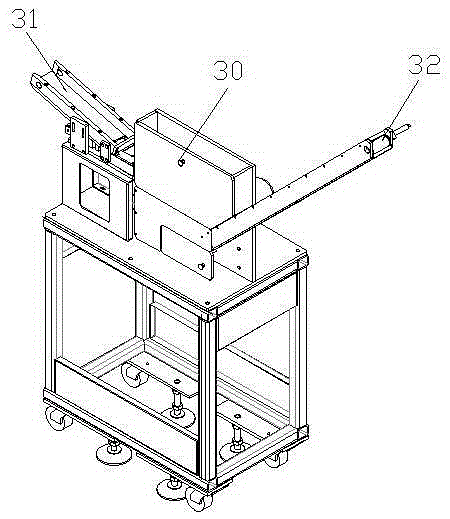

Battery production equipment

ActiveCN104485472APrimary cell manufactureAssembling battery machinesUltrasonic weldingAssembly line

The invention discloses battery production equipment. The battery production equipment is used for assembling a cell on a tray into a glue shell, welding a resistor on a resistance material strap to the cell, pasting a buffer glue on the cell, covering the glue shell with a cover plate, welding the cover plate and the glue shell, screening good and bad products, pasting a brand on the surface of the glue shell, and panning finished products. The battery production equipment comprises a cell loading mechanism, a glue shell loading mechanism, a resistor conveying mechanism, a resistor welding mechanism, a buffer glue pasting mechanism, a cover plate assembling mechanism, an ultrasonic welding mechanism, a detection mechanism, a detaching mechanism, a brand pasting mechanism, a panning mechanism and an assembly line, the battery production equipment finishes the operations of loading the cell into the glue shell, welding the resistor, pasting the buffer glue, loading the cover plate and performing sealing weld, screening the good and bad products, pasting the brand and panning by virtue of the cell loading mechanism, the glue shell loading mechanism, the resistor conveying mechanism, the resistor welding mechanism, the buffer glue pasting mechanism, the cover plate assembling mechanism, the ultrasonic welding mechanism, the detection mechanism, the detaching mechanism, the brand pasting mechanism and the panning mechanism, so that the standardized, mechanized, and automated production is finished.

Owner:EVE ENERGY CO LTD

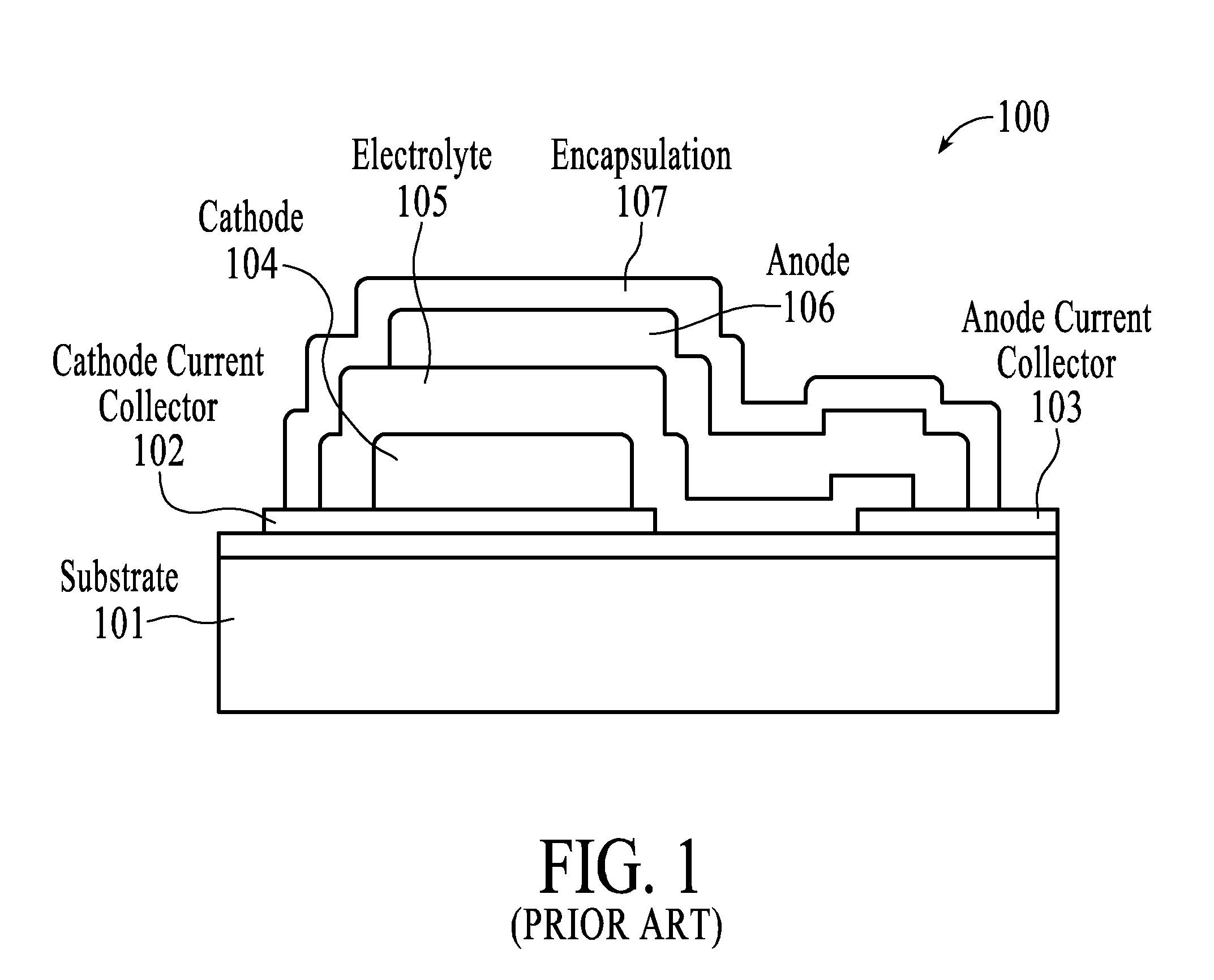

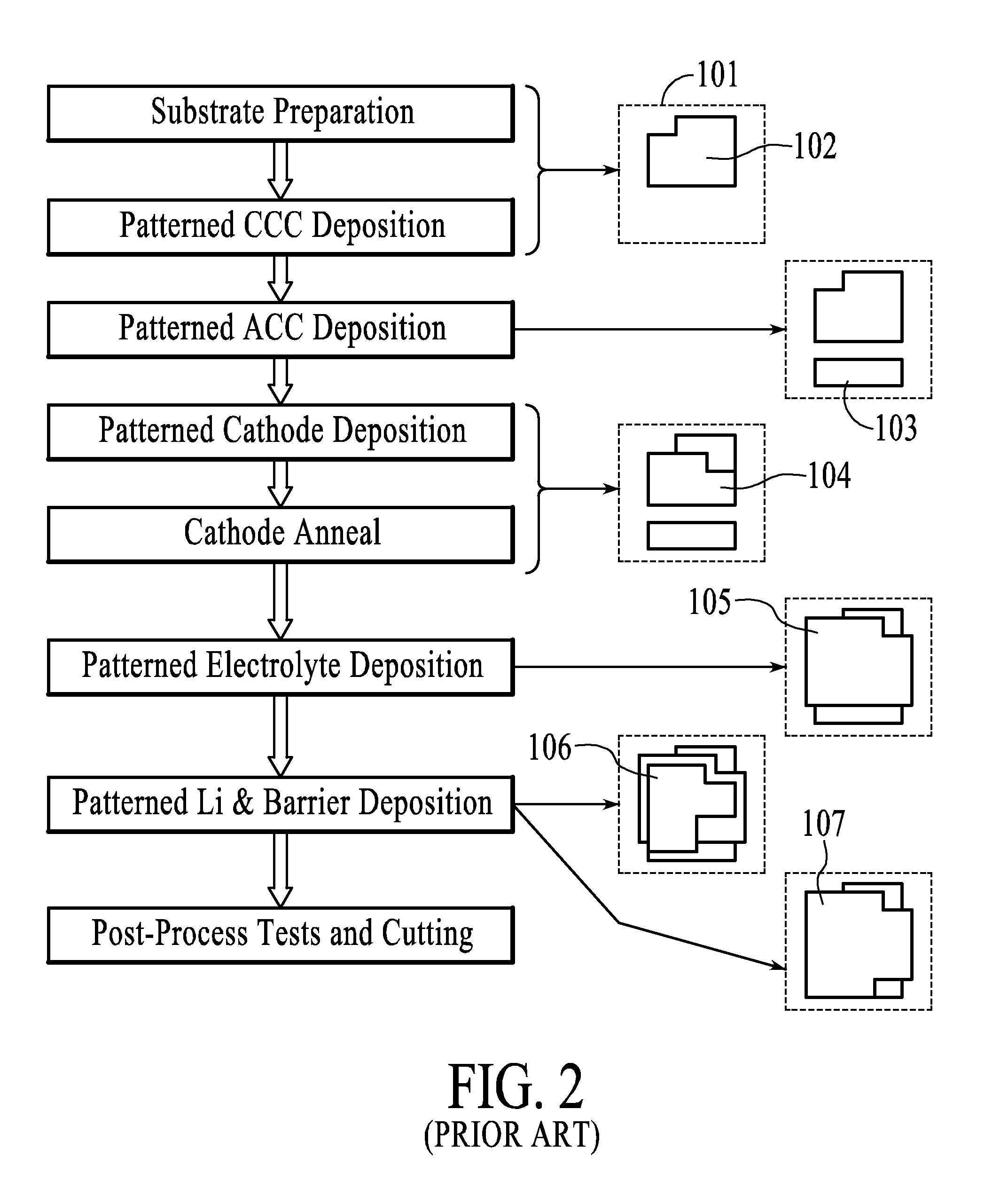

Mask-Less Fabrication of Thin Film Batteries

InactiveUS20140007418A1Reduce complexityLow costNitrogen compoundsFinal product manufactureLaser patterningOptoelectronics

Thin film batteries (TFB) are fabricated by a process which eliminates and / or minimizes the use of shadow masks. A selective laser ablation process, where the laser patterning process removes a layer or stack of layers while leaving layer(s) below intact, is used to meet certain or all of the patterning requirements. For die patterning from the substrate side, where the laser beam passes through the substrate before reaching the deposited layers, a die patterning assistance layer, such as an amorphous silicon layer or a microcrystalline silicon layer, may be used to achieve thermal stress mismatch induced laser ablation, which greatly reduces the laser energy required to remove material.

Owner:APPLIED MATERIALS INC

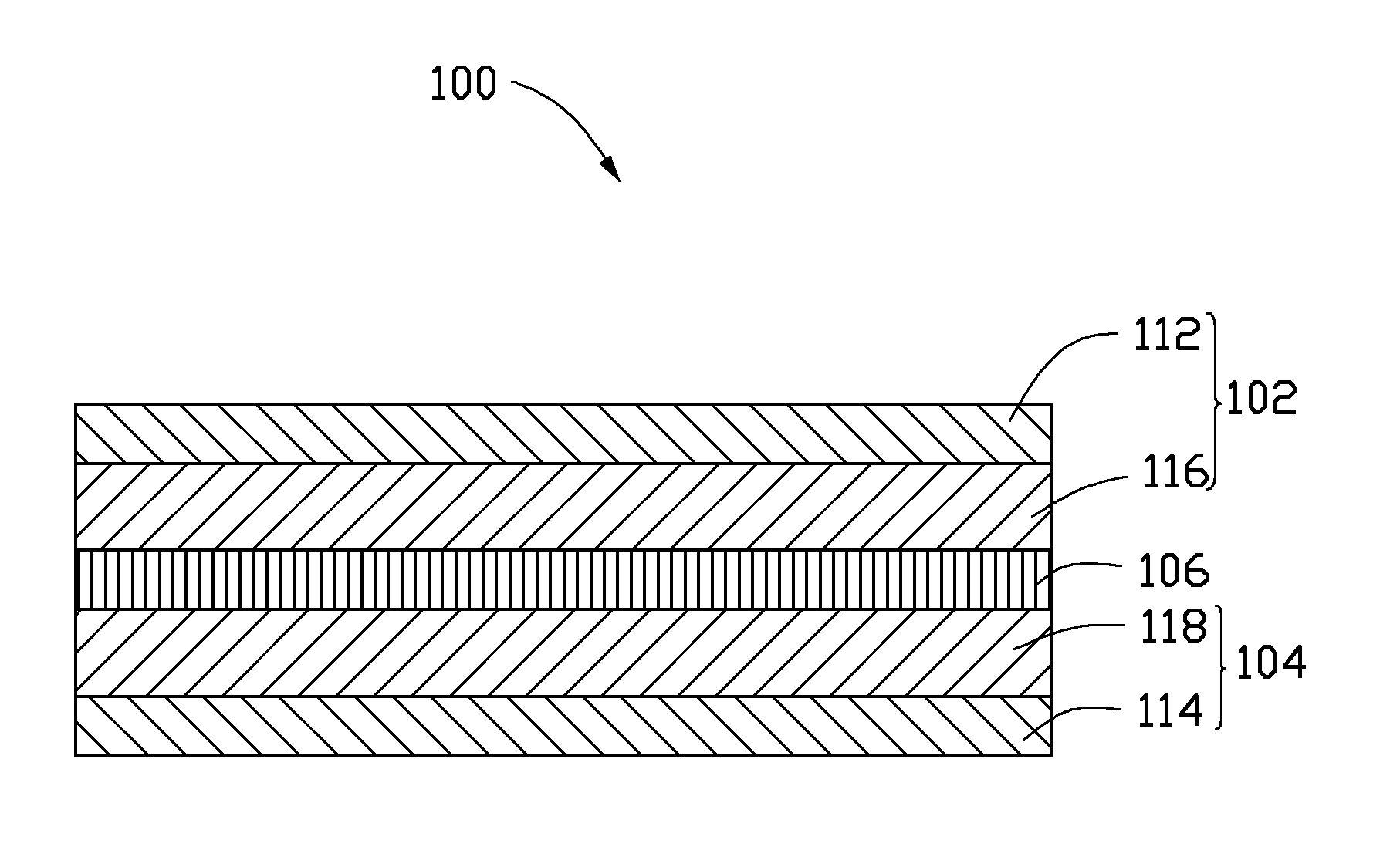

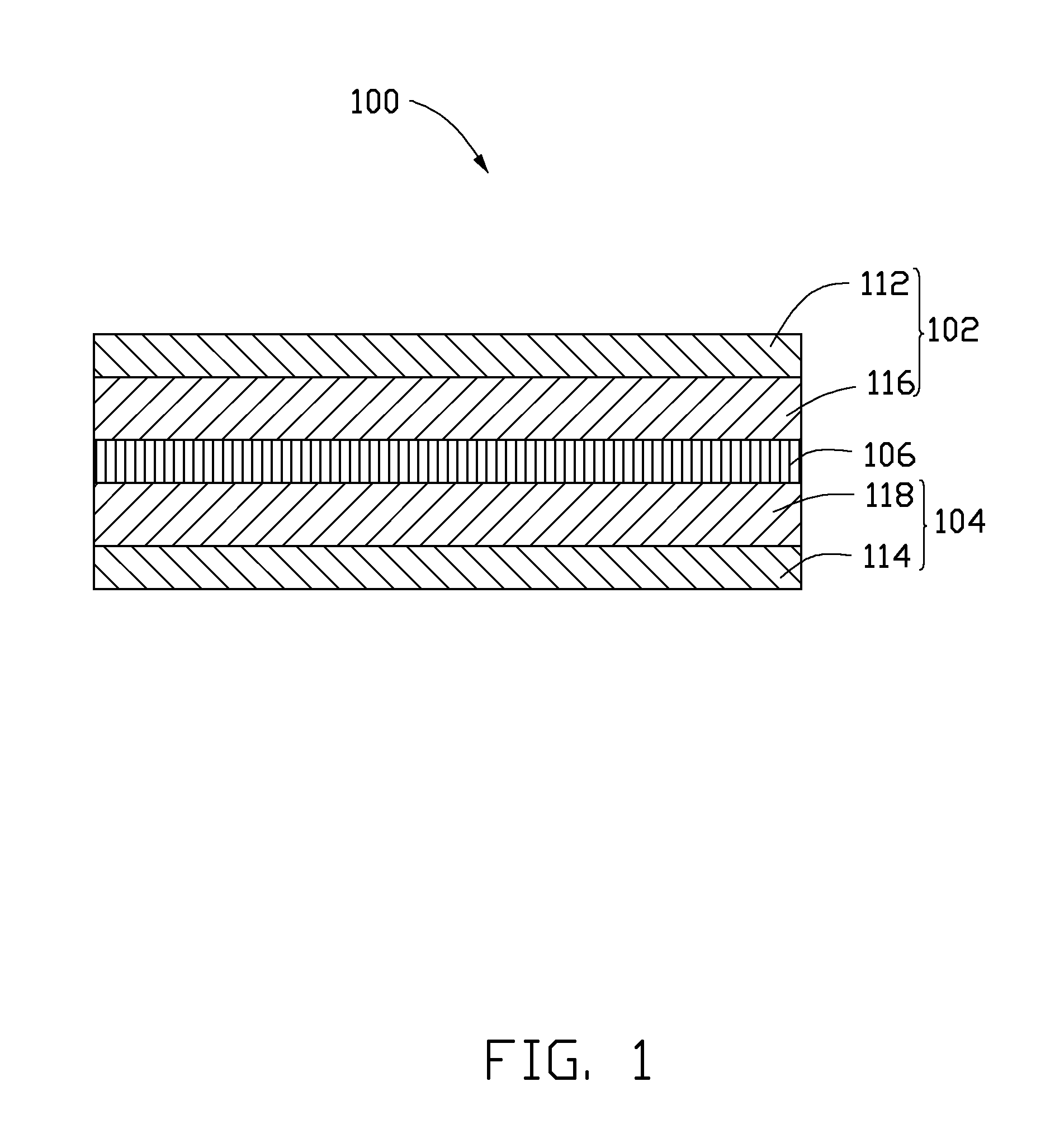

Method for making thin film lithium ion battery

InactiveUS20140013588A1Reduce power densityShortened life-spanPrimary cell manufactureFinal product manufactureOptoelectronicsThin film rechargeable lithium battery

A method for making a thin film lithium ion battery is provided. A cathode material layer and an anode material layer are provided. A cathode current collector is formed on a surface of the cathode material layer to obtain a cathode electrode. The cathode current collector includes a graphene layer. An anode current collector is applied on a surface of the anode material layer to obtain an anode electrode. A solid electrolyte layer is applied between the cathode electrode and the anode electrode, thereby forming a battery cell. Then at least one battery cell is encapsulated in an external encapsulating shell.

Owner:TSINGHUA UNIV +1

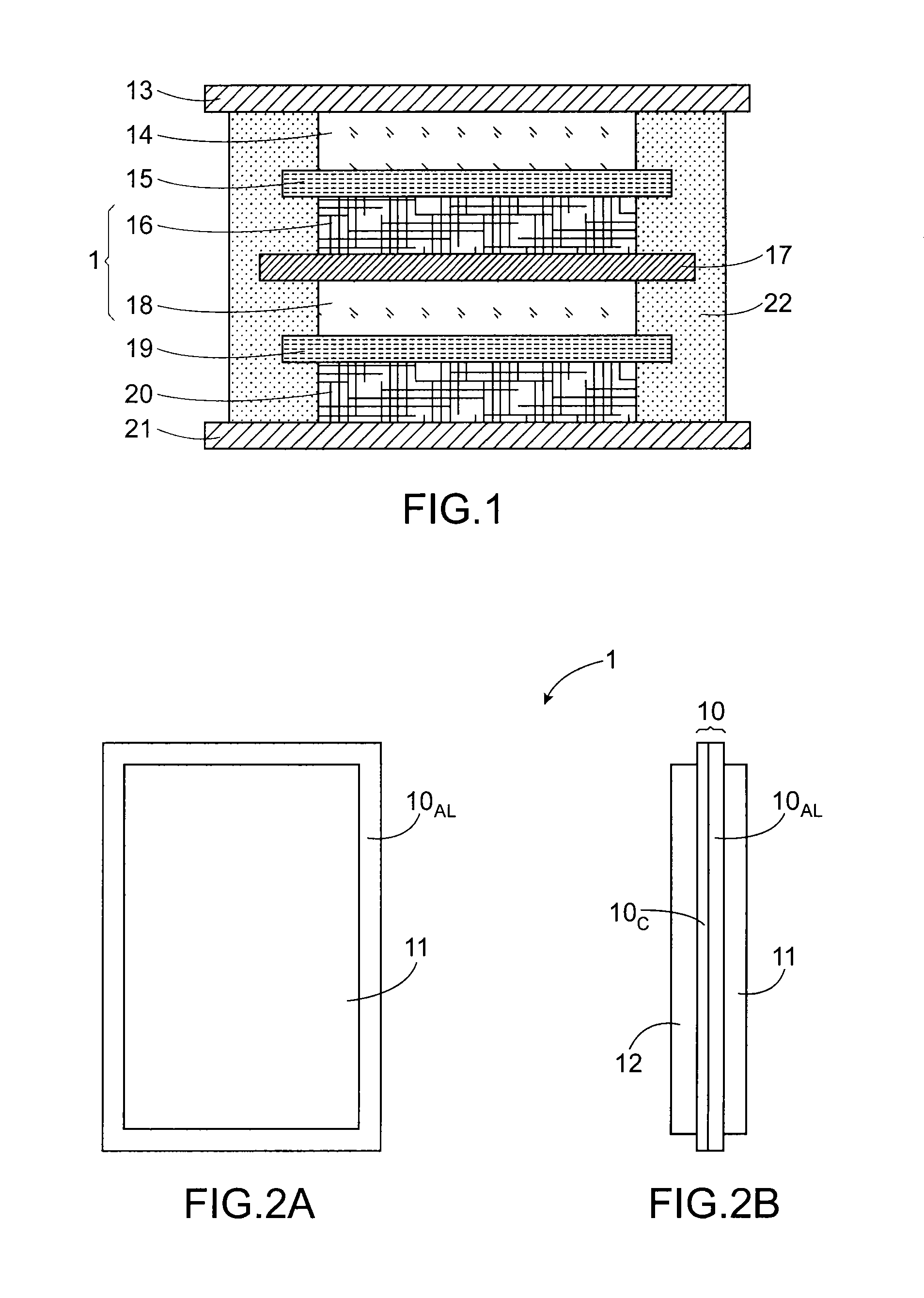

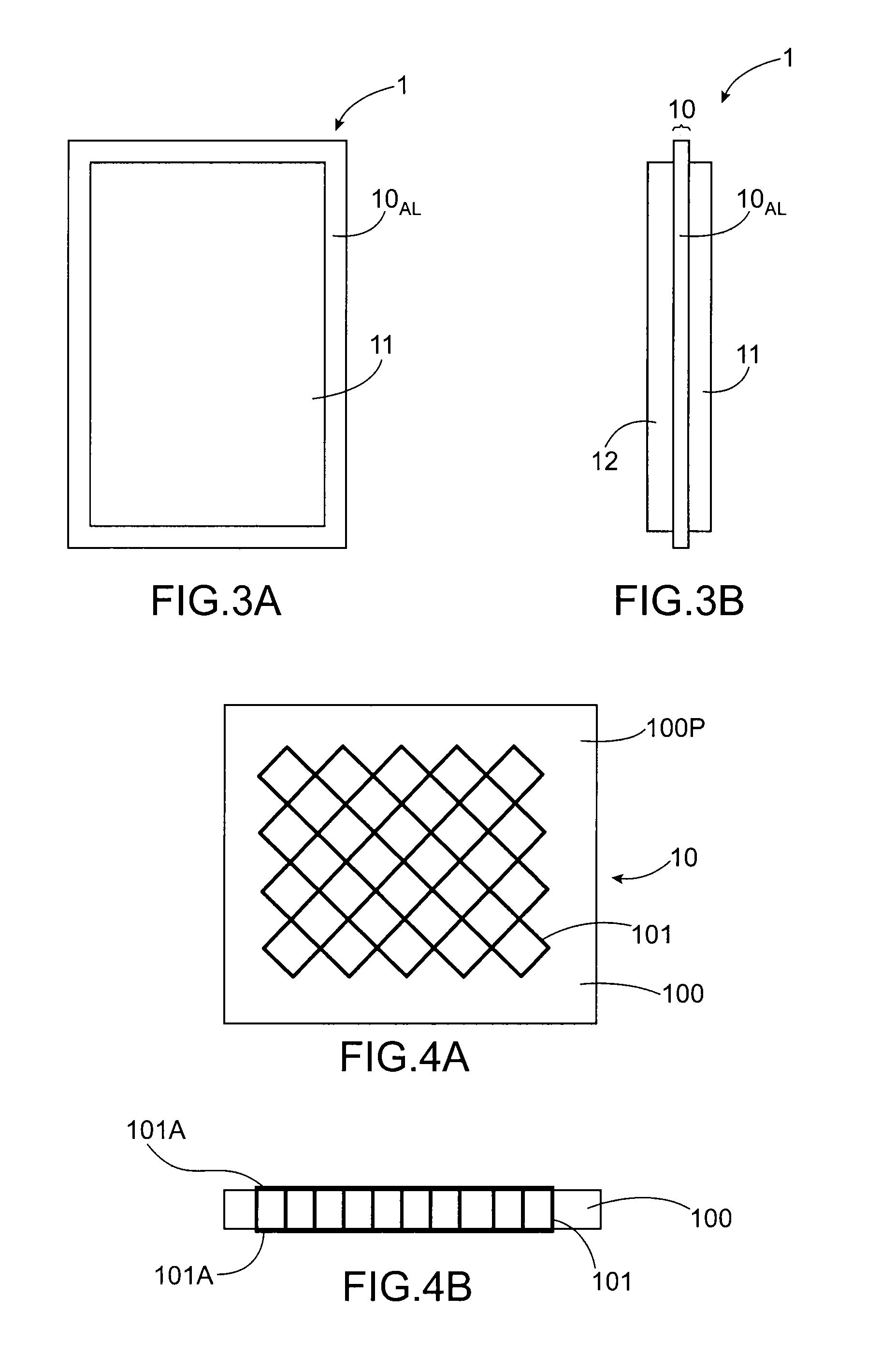

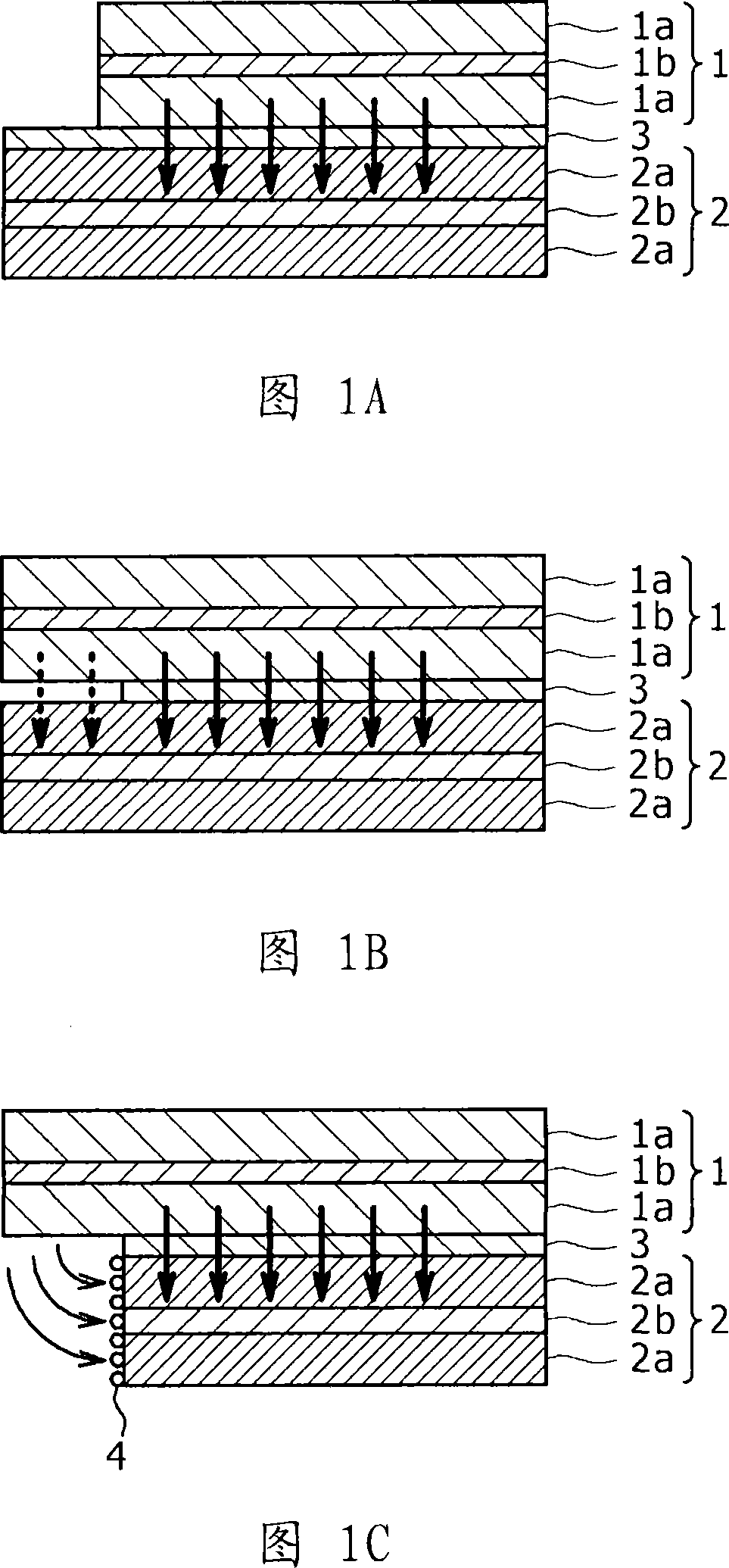

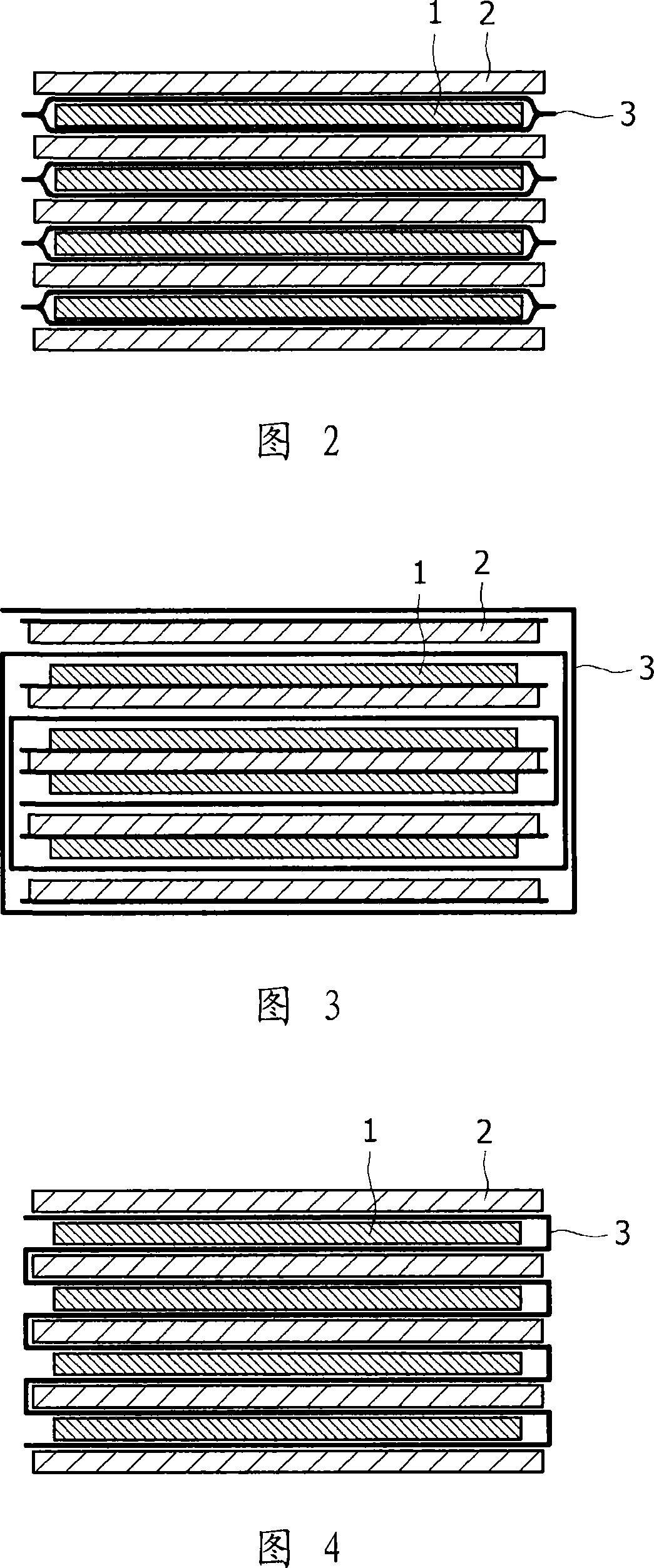

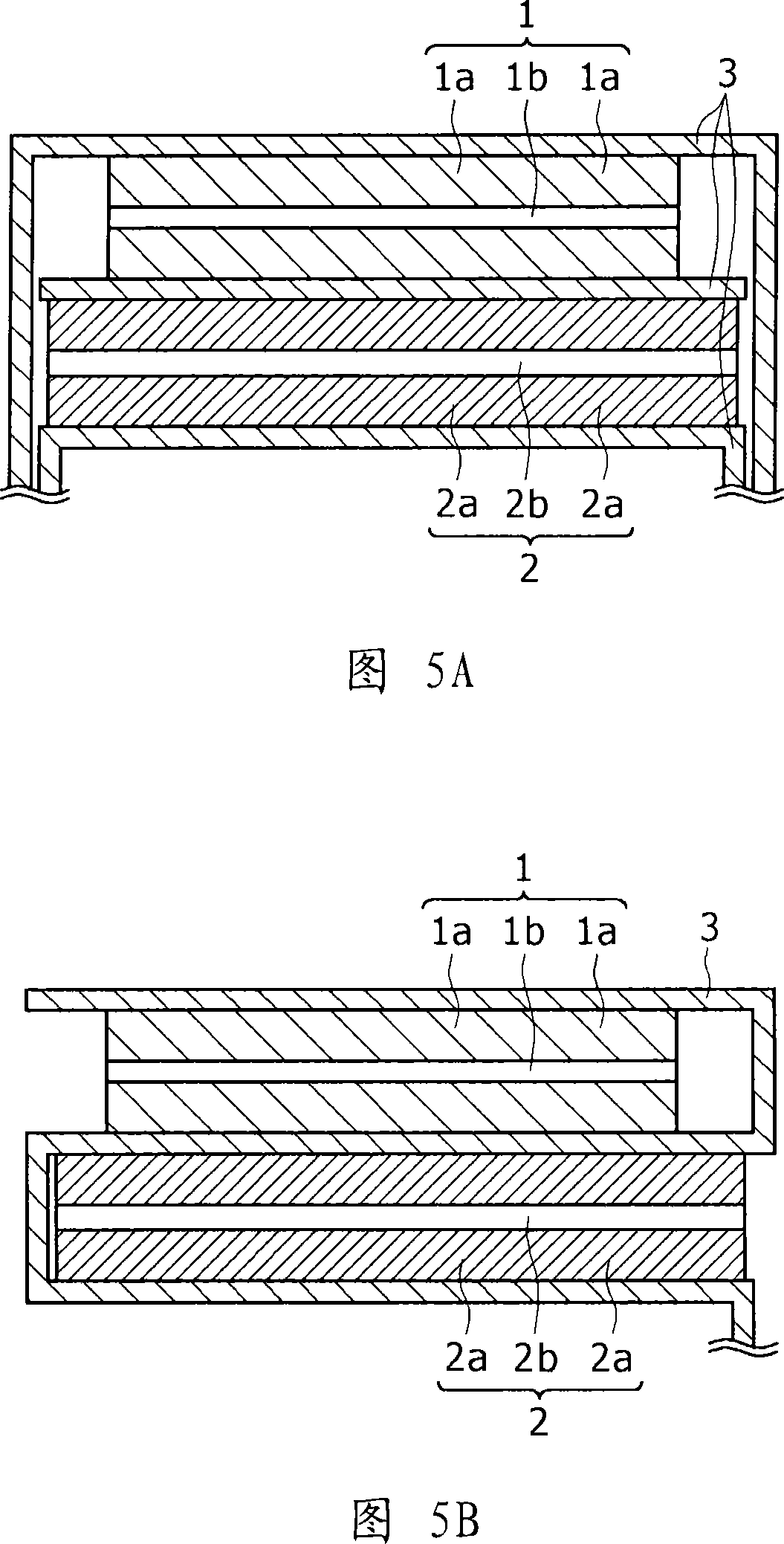

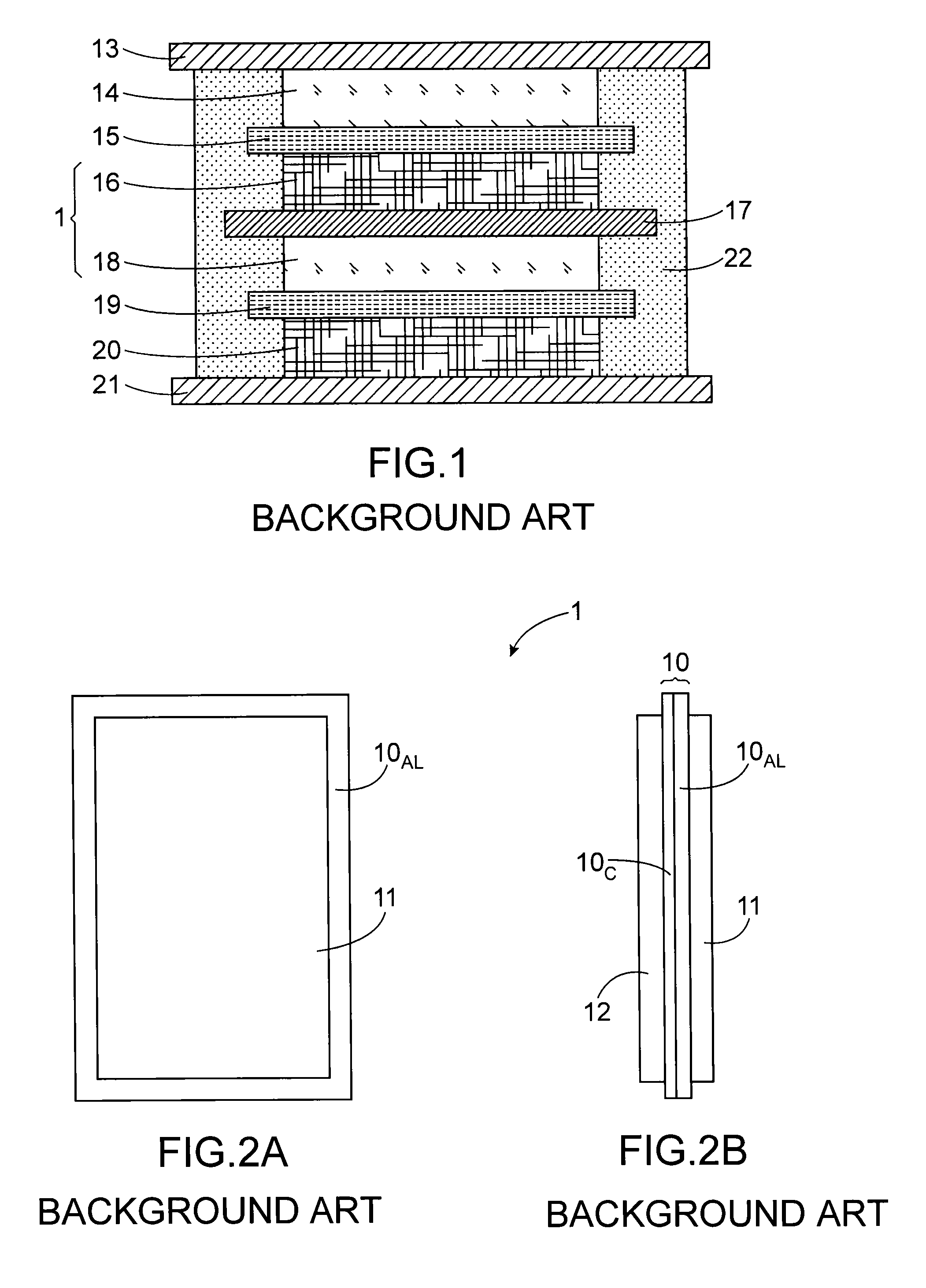

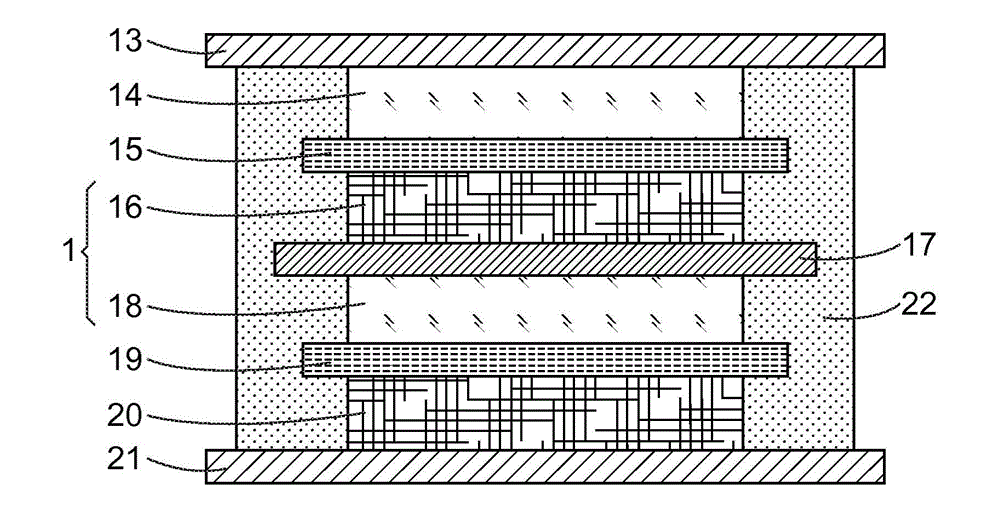

Current collector having built-in sealing means, and bipolar battery including such a collector

ActiveUS20130089774A1Improve performanceLeak-proofing itself to be simplifiedPrimary cell to battery groupingElectrode rolling/calenderingLithiumEngineering

In lithium bipolar batteries, to improve sealing against electrolytes between adjacent electrochemical cells, mixed current collector-electrode supports are produced, in a form of a metal grate or raised metal sheet housed in a strip made of electrical insulator material, the function of the periphery of which is to constitute a sealing area.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

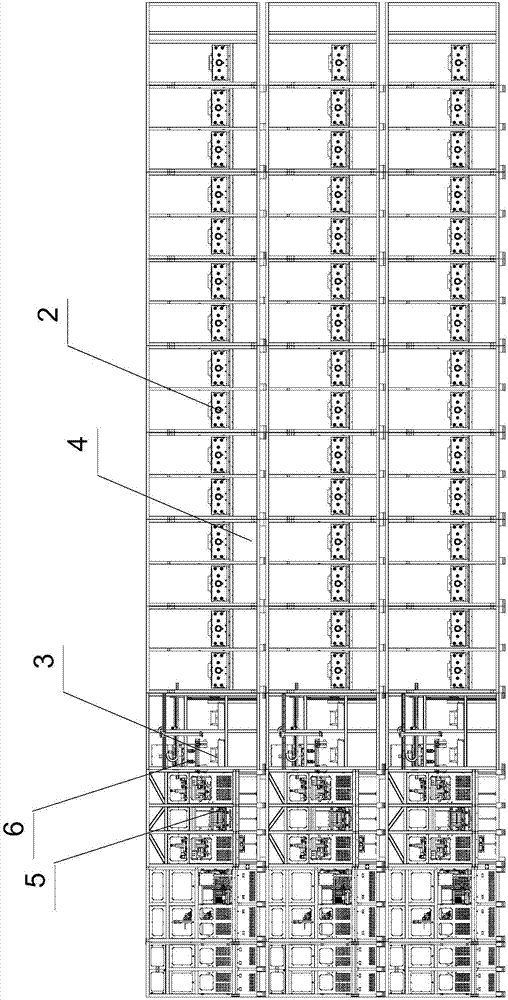

New energy power module assembling line

ActiveCN107819134ARealize the assemblyRealize automatic assemblyPrimary cell manufactureAssembling battery machinesNew energyBattery cell

The invention discloses a new energy power module assembling line relating to the technical field of tools for battery modules. A battery cell detection station is arranged on one side of a battery cell loading assembly, a automatic battery cell frame mounting station is arranged on one side of the battery cell detection station, a battery cell splicing station is arranged on one side of the automatic battery cell frame mounting station, a side loading line of the battery cell splicing station is arranged on one side of the battery cell splicing station, a battery cell module transplanter is arranged on one side of the side loading line of the battery cell splicing station, and a riveting machine is mounted on the battery cell module transplanter. The new energy power module assembling line can achieve assembly of a new energy battery module and can achieve automatic assembling, so that the labor and the time are saved and the efficiency is high.

Owner:丁琛琦

Square battery shaping and testing machine

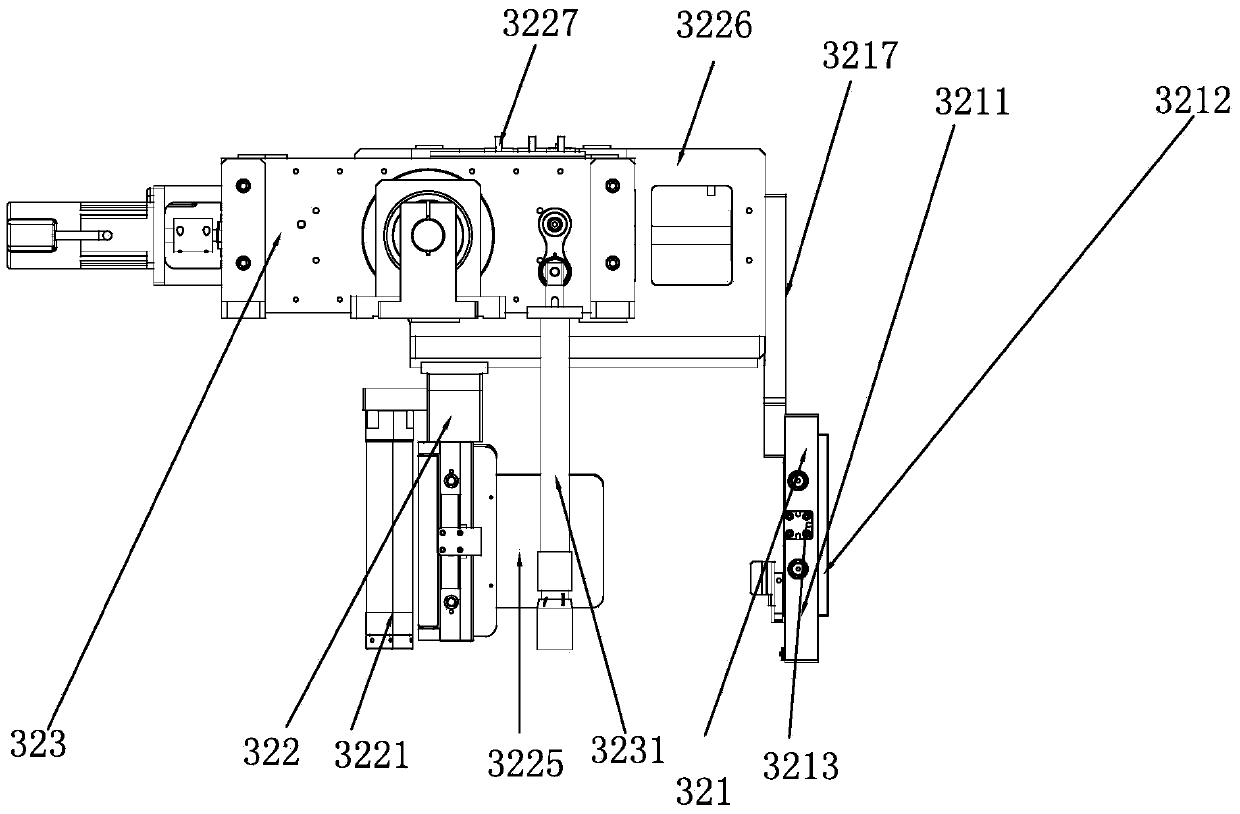

ActiveCN104934625AImprove processing efficiencyHigh positioning accuracyPrimary cell manufactureAssembling battery machinesManipulatorTraining set

The invention discloses a square battery shaping and testing machine. The machine comprises an operation conveying line, a battery universal feeding system and a battery classification blanking system which are arranged at two ends of the operation conveying line. A feeding connecting line for conveying batteries is arranged between the battery universal feeding system and the operation conveying line. One end of the operation conveying line, close to the feeding connecting line, is provided with a first conveying mechanical arm for transferring the batteries from the feeding connecting line to the operation conveying line. One side of the operation conveying line is provided with a second conveying mechanical arm for transferring the batteries from the start end of the operation conveying line to the tail end of the operation conveying line. The other side of the operation conveying line is sequentially provided with a battery shaping device, an appearance testing device, a code scanning device, a performance testing device and a thickness testing device. Due to arrangement of the battery universal feeding system and the battery classification blanking system, full automated processing of battery feeding, shaping, testing and classified recovery is realized, and the battery processing efficiency is improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

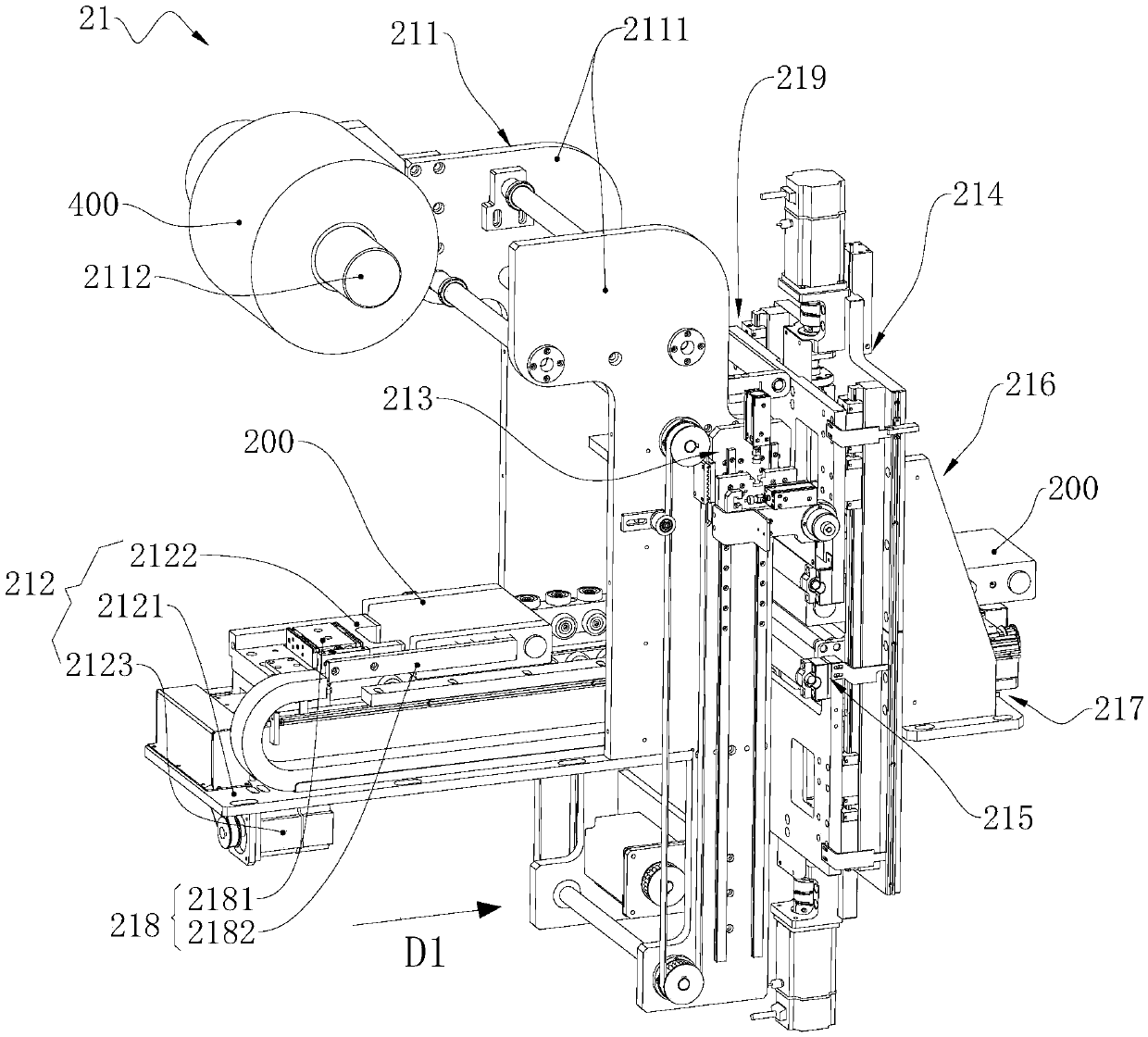

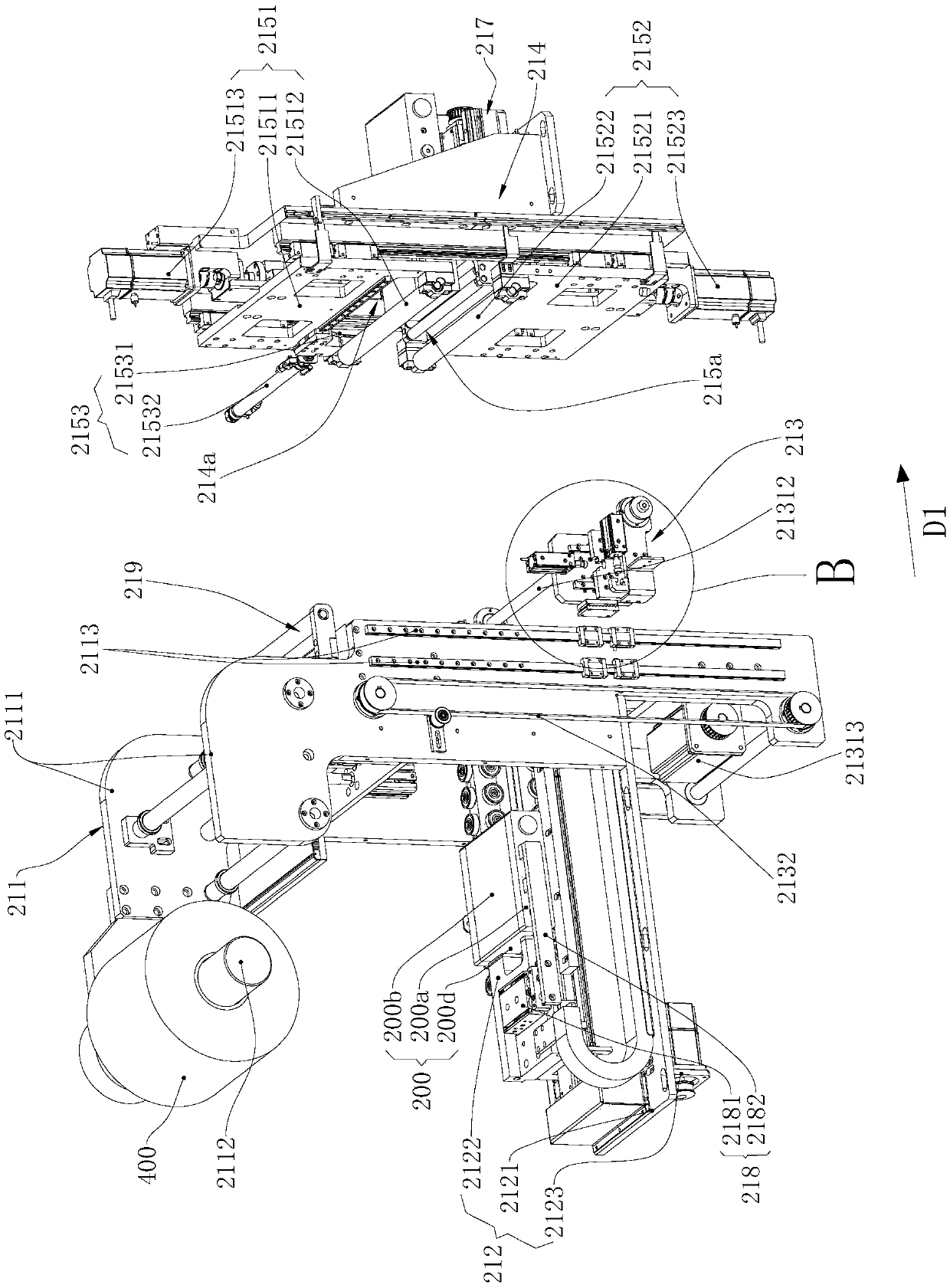

Battery enveloping device and enveloping equipment

ActiveCN105514477ARealize automatic coatingAvoid contactPrimary cell manufactureAssembling battery machinesSize measurementElectrical battery

The invention relates to the technical field of battery enveloping and provides a battery enveloping device and enveloping equipment. The battery enveloping device comprises a side enveloping device for coating the side surface of a battery with a film, wherein the side enveloping device comprises a first mounting rack, a second mounting rack, a film drawing mechanism, a battery pushing mechanism, a first enveloping mechanism, a battery discharging mechanism and a second enveloping mechanism. Compared with the prior art, the battery enveloping device provided by the invention can be used for enveloping batteries automatically so as to lower labor intensity, is high in productivity and production efficiency, and can avoid contact between workers and batteries and eliminate hidden danger to quality. The enveloping equipment can be used for attaching insulation films to batteries and for performing insulation test and size measurement on the batteries, and is capable of effectively improving the yield of batteries and guaranteeing production quality.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

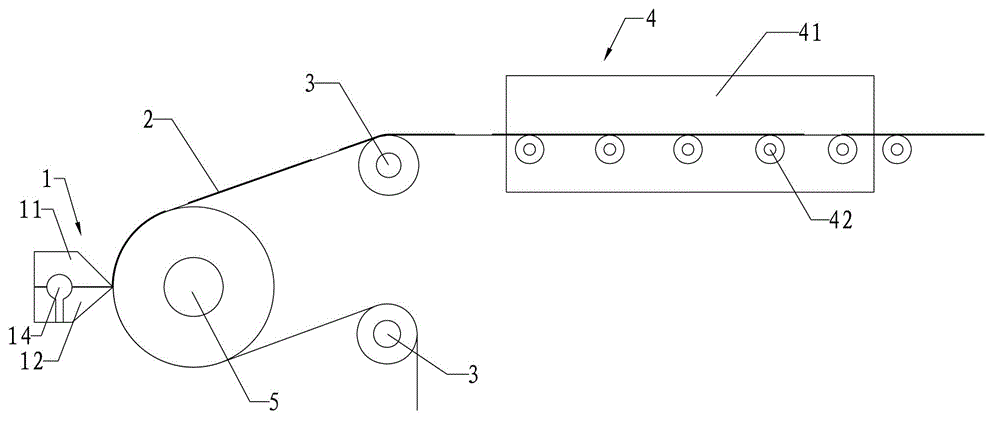

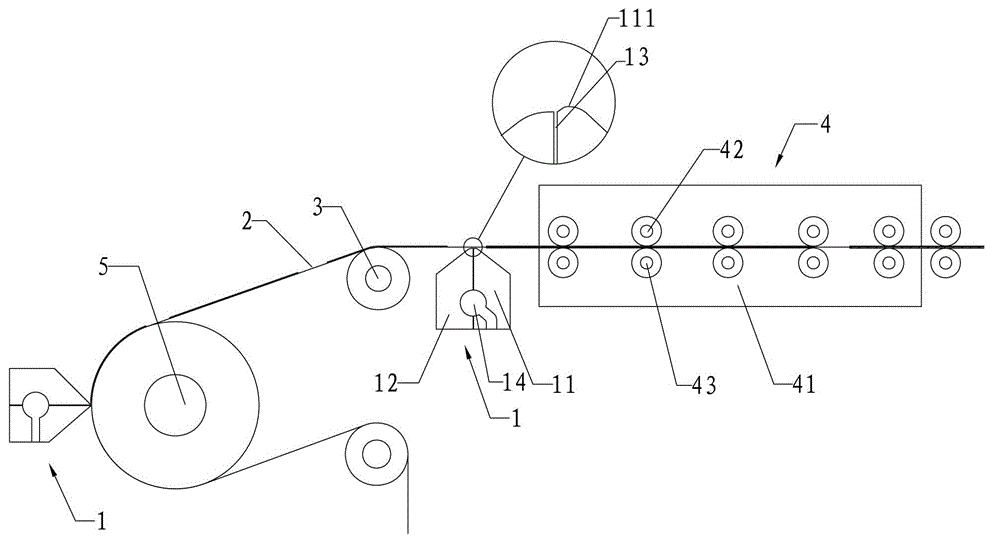

Reeling machine

ActiveCN104009249ATension balanceStable tensionPrimary cell manufactureAssembling battery machinesControl engineeringMachine

The invention discloses a reeling machine which comprises a rack assembly, an unreeling mechanism, a reeling mechanism, a feeding mechanism, a rubberizing device and a tension control mechanism, wherein the tension control mechanism comprises a pole piece deviation correcting device and a driving device which are arranged between the unreeling mechanism and the reeling mechanism; a reeling needle of the reeling mechanism performs a cam motion; the driving device is used for driving a pole piece to be synchronous with the traction of the reeling needle performing the cam motion to the pole piece and simultaneously preventing the unreeling of the pole piece and an deviation correcting operation from influencing the tension of the pole piece. According to the reeling machine, the stable tension control is effectively realized.

Owner:SHENZHEN YINGHE TECH

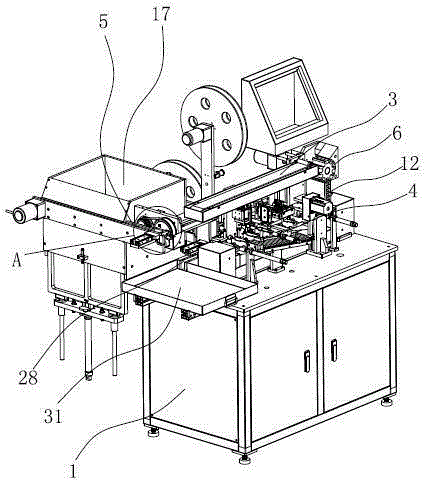

Automatic cylindrical battery assembling machine

ActiveCN104505531ARealize fully automatic assemblyShorten the timePrimary cell manufactureAssembling battery machinesEngineeringAutomatic testing

The invention provides an automatic cylindrical battery assembling machine. The automatic cylindrical battery assembling machine comprises a rack and an indexing plate arranged on the rack and driven to rotate by a divider controlled by a stepping motor, wherein a clamping groove for adsorbing a cylindrical battery to be assembled is arranged on the circumference of the indexing plate according to the dividing angle of the divider; and the automatic cylindrical battery assembling machine also comprises a feeding chute, a tab locating device, a tab shaping device, a groove rolling device, a gluing device, a cap welding device, a liquid injection device, an unqualified product discharging device, a cap pressing device, an automatic sealing machine and a finished product discharging device which are arranged around the indexing plate and sequentially work cooperatively. According to the automatic cylindrical battery assembling machine, the working procedures such as feeding, tab locating, tab shaping, groove rolling, gluing, cap welding, liquid injection, discharging of unqualified products, cap pressing, and automatic sealing and discharging of finished products in the assembling procedures of the cylindrical battery are integrated, the cylindrical battery can be assembled in a full-automatic manner, the whole machine only is required to be monitored by one person, the cost and the time are saved, and the production efficiency is greatly improved.

Owner:惠州亿恒特自动化科技有限公司

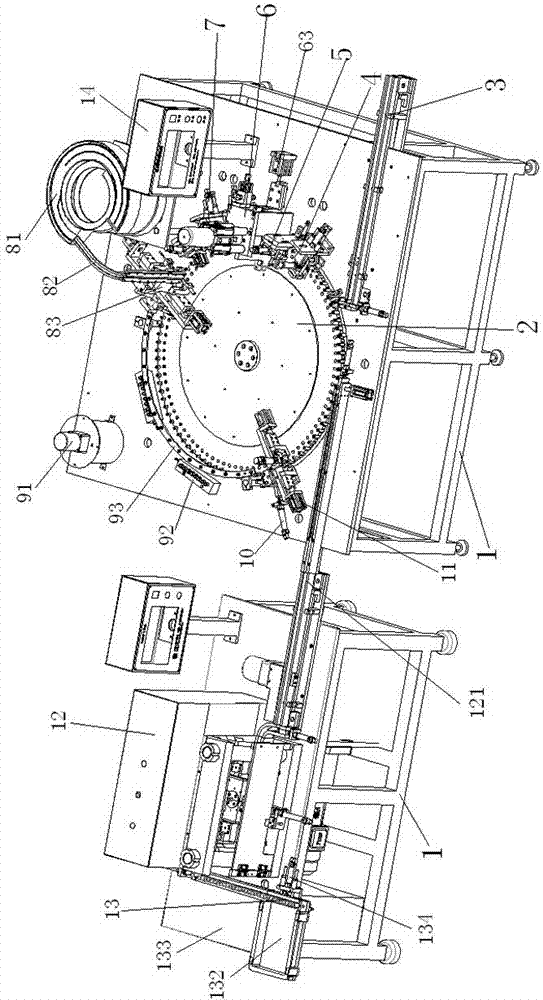

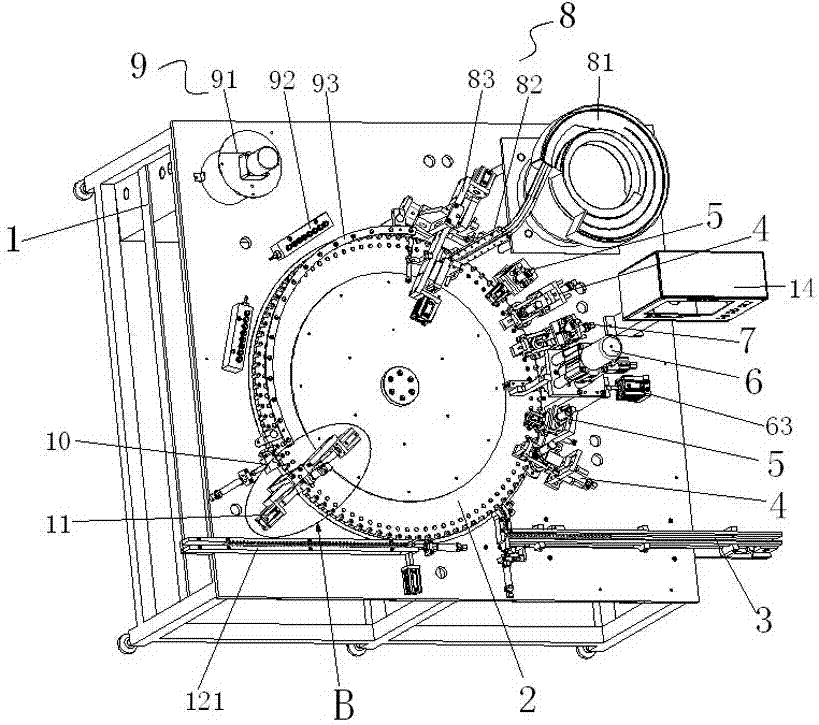

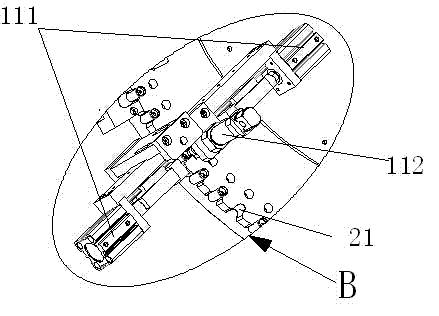

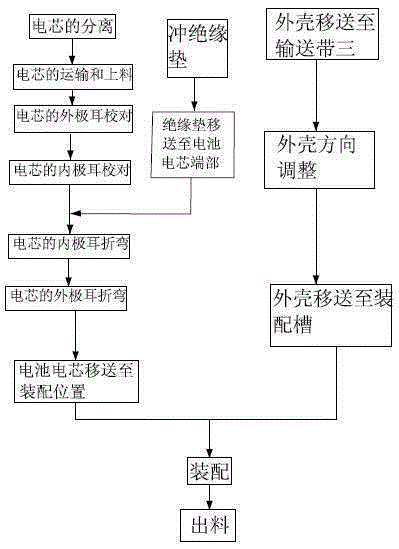

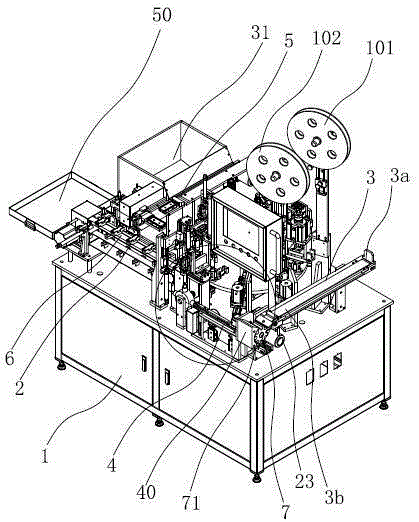

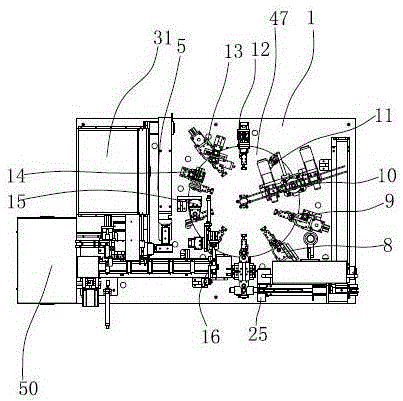

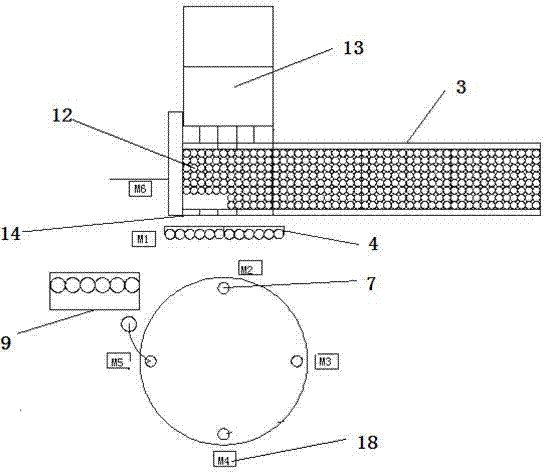

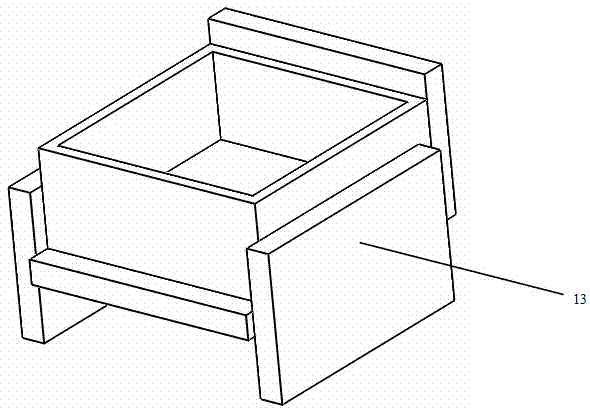

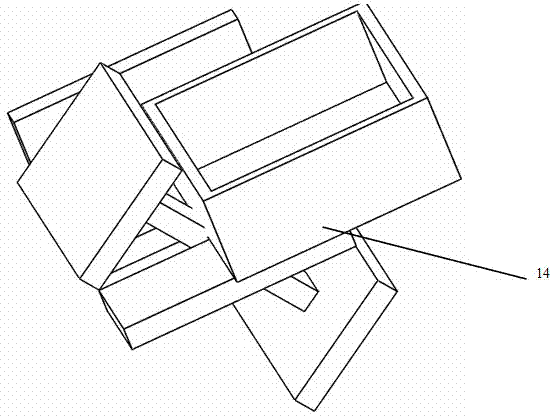

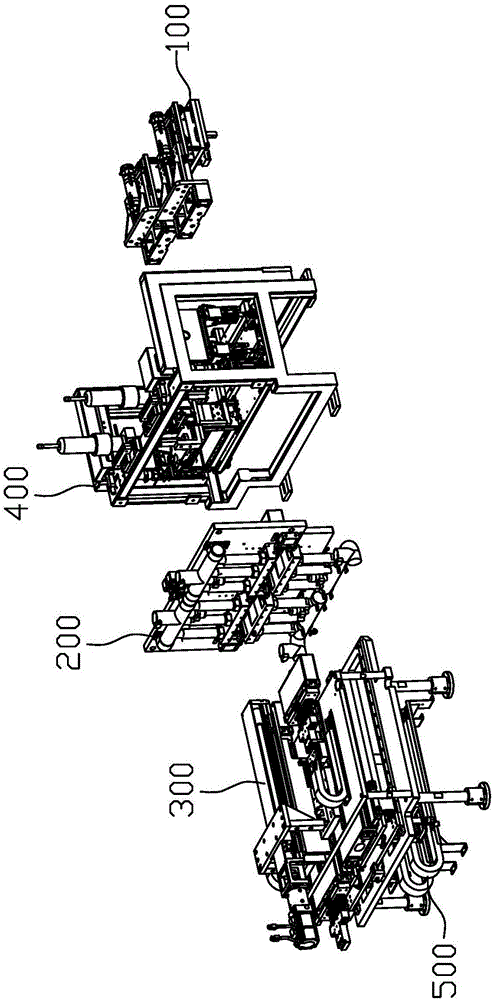

Automatic casing machine of power type cylindrical battery

ActiveCN105304928ASimple structureSmall footprintPrimary cell manufactureAssembling battery machinesCircular discManufacturing technology

The invention provides an automatic casing machine of a power type cylindrical battery, and belongs to the field of a battery manufacture technology. The invention solves the technology problem of low automation degree of present cylindrical battery electrical core casing assembling and the like. The casing machine comprises a rack; the rack is provided with a conveyer belt 1 and a conveyer belt 2 for conveying electrical cores as well as a conveyer belt 3 for conveying casings and a conveyer belt 4 for conveying electrical core carry tools; a rotary disc is horizontally installed on the rack, and several clamping mechanisms for clamping electrical cores are arranged at a circumferential direction of the upper side surface of the rotary disc; an external tab checking apparatus, an internal tab checking apparatus, an upper insulating pad apparatus, an internal tab folding apparatus, an external tab folding apparatus, a defective product detection apparatus and a blanking apparatus are fixedly installed at the circumferential direction of the rotary disc in sequence on the rack, and the external tab checking apparatus, the internal tab checking apparatus, the upper insulating pad apparatus, the internal tab folding apparatus, an external tab measuring apparatus and the external tab folding apparatus are provided. The invention has the advantage of high automation degree.

Owner:深圳市圣瀚宇自动化设备有限公司

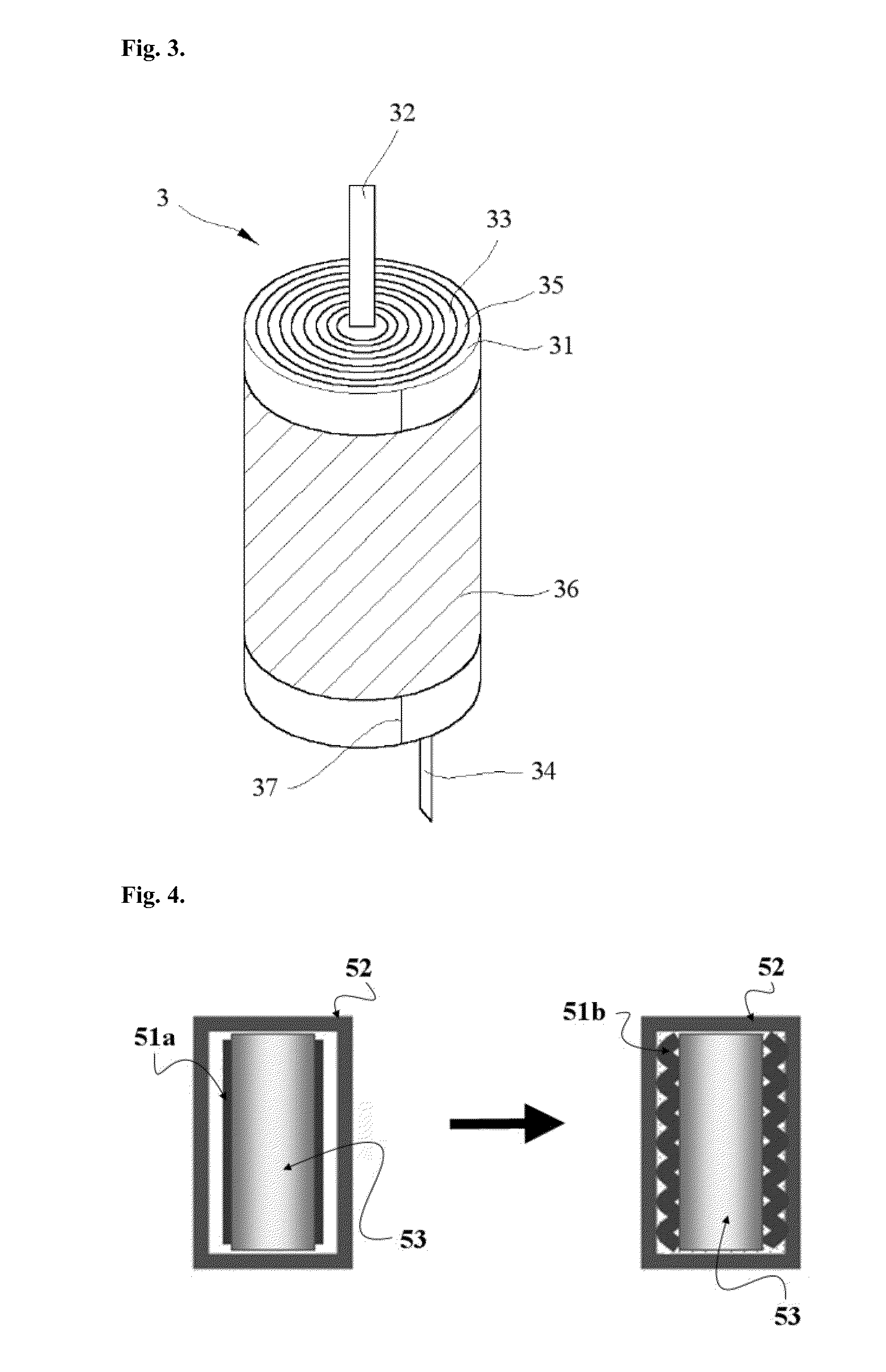

Method for preparing thin single cell thermal battery in laminated mode based on molten salt thermal spraying technology and thin single cell thermal battery

ActiveCN107394224AImprove discharge performanceSolve the inability to achieve thinningPrimary cell manufactureDeferred-action cellsLithiumThermal spraying

The invention discloses a method for preparing a thin single cell thermal battery in a laminated mode based on a molten salt thermal spraying technology and the thin single cell thermal battery, belonging to the field of battery preparation technology. The method comprises the following steps: (1) preparing positive molten salt, and spraying the positive molten salt on a collector plate to form a positive electrode layer; (2) preparing electrolyte molten salt, and spraying the electrolyte molten salt on the positive electrode layer to form an electrolyte layer; (3) preparing negative molten salt, and spraying the negative molten salt on the electrolyte layer to form a negative electrode layer; or, setting a lithium-boron alloy negative plate on the electrolyte layer; and (4) setting the collector plate on the negative electrode layer or the lithium-boron alloy negative plate, and performing compression moulding to obtain the thin single cell thermal battery. The preparation method disclosed by the invention is simple, and can be used for improving the discharge capacity and stability of the battery.

Owner:西科微纳(重庆)新能源技术研究院有限公司

Automatic assembly device for battery pack

ActiveCN104300162AIncrease automation rateAutomatic assembly equipment can be automatedPrimary cell manufactureAssembling battery machinesElectrical batteryElectrical polarity

The invention discloses an automatic assembly device for a battery pack. Standard boxed batteries are fed into a feeding mechanism, a mechanical arm is intelligently controlled by a control mechanism, the state of an electromagnetic chuck is changed, the batteries are sucked onto a rotary working table by the action of magnetic force of an electromagnet, sticking of insulating paper, polarity reversal and other operations are realized on the rotary working table through the mechanical arm respectively, and the batteries are finally arranged inside a battery box through the mechanical arm sequentially to complete automated assembly of the battery pack. According to the automatic assembly device disclosed by the invention, the sticking of the insulating paper of each battery and automatic polarity reversal can be realized, the batteries can be automatically loaded onto a bottom bracket to form the battery pack, automated assembly work of the battery pack can be realized, the working efficiency is improved, and the labor force is greatly saved.

Owner:江苏金猫机器人科技有限公司

Extrusion head, coating device and coating system

InactiveCN102744183ASolve the technical bottleneck that can not realize the simultaneous coating of the front and back of the compact structureSolve the long-awaited technical problemsPrimary cell manufacturePretreated surfacesCoating systemSlurry

A coating system comprises an extrusion head, a transition roll, a base material and a drying box, wherein the base material strides on the transition roll and passes through the extrusion head and the drying box in the base material transmission direction through the transition roll. The head portion of the extrusion head faces to the base material, the extrusion head comprises an extrusion head lower lip and an extrusion head upper lip, the extrusion head upper lip is arranged at the front end in the base material transmission direction, and a channel for slurry to pass is arranged between the extrusion head lower lip and the extrusion head upper lip. The extrusion head is further provided with a cavity which is filled with the slurry from the outside and communicated with the channel. The head portion of the extrusion head lower lip is higher than that of the extrusion head upper lip, and the head portion of the extrusion head lower lip is a fillet. Particularly provided are a coating device and the extrusion head. The slurry can be directly coated on suspended base material through the extrusion head, so that possibility of double-side coating can be achieved. An upper roll and a lower roll are adopted to respectively clamp blank positions on two sides of the base material, and a double-layer stove can achieve simultaneous double-side drying, so that energy consumption can be saved by above 50%. In addition, time for material replacing is saved, the structure is compact and device efficiency is improved.

Owner:SHENZHEN HAONENG TECH

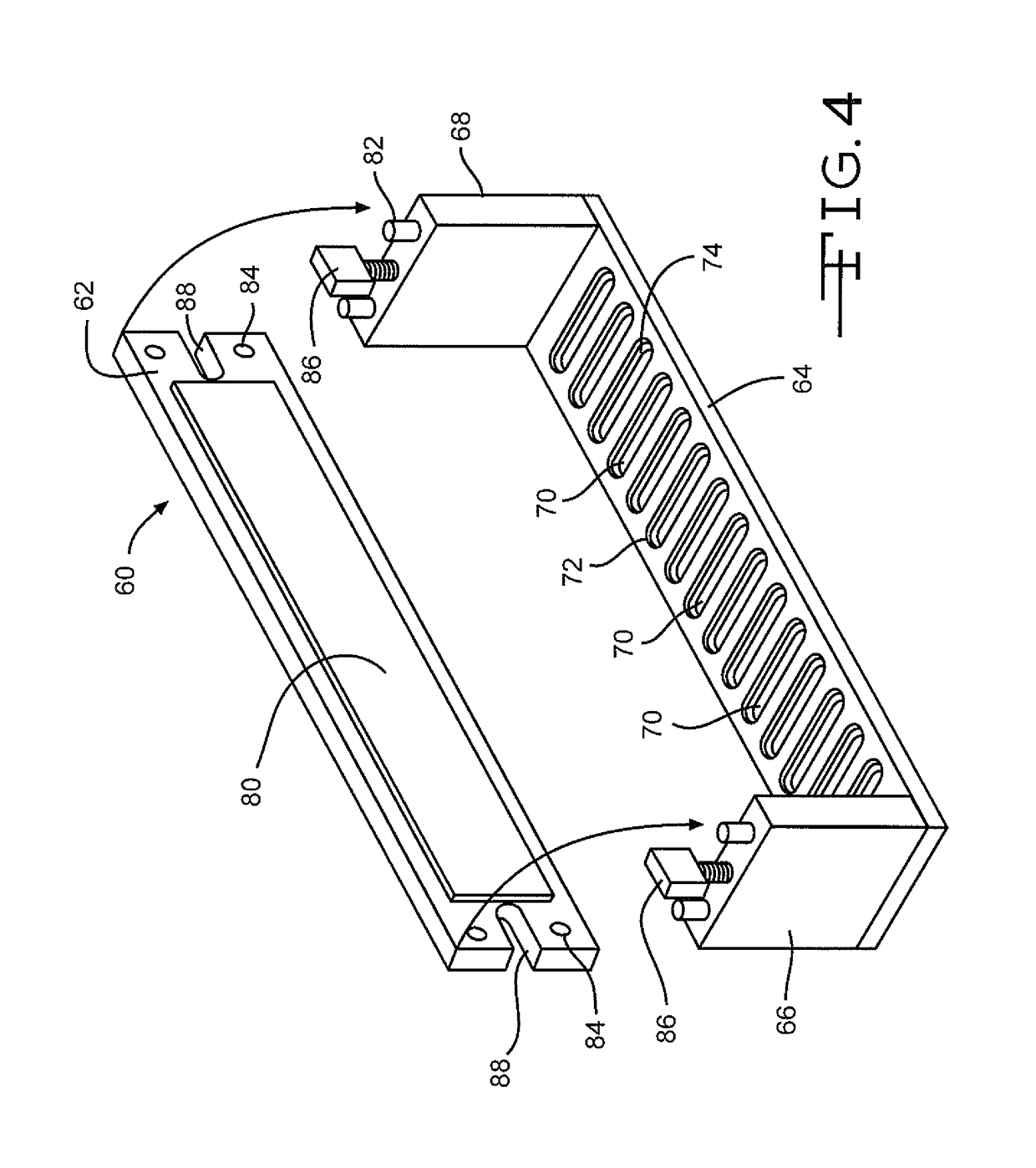

Mechanical conditioning by bead blasting lithium iodine cell case

ActiveUS10141545B2Undesirable surface contaminationEliminate surface contaminationPrimary cell manufactureSmall-sized cells cases/jacketsLithiumEngineering

Bead blasting the inner, contact surface of an electrochemical cell casing to render the inner surface thereof essentially contamination free and suitable as a current collector is described. The casing is preferably of stainless steel and houses the alkali metal-halogen couple in a case-positive configuration.

Owner:WILSON GREATBATCH LTD

Electrical core processing device and method

ActiveCN104795589AImprove processing efficiencyHigh degree of automationPrimary cell manufactureAssembling battery machinesEngineeringAutomation

The invention relates to an electric core processing device and method, the device includes a screening mechanism, used for screening winded electric cores which are provided by upstream; a transmitting mechanism, used for receiving a screening-qualified electric core which is provided by the screening mechanism, and transmitting the electric core to a downstream hole reaming mechanism, a tube penetration mechanism, a dust removal mechanism, a short circuit testing mechanism and an inferior elimination mechanism; the hole reaming mechanism, used for reaming of shaft hole of the electric core so as to press a diaphragm close to shaft hole wall; the tube penetration mechanism, used for inserting a core tube into the shaft hole of the electric core; the dust removal mechanism, used for dust removal of the electric core; the short circuit testing mechanism, used for short circuit testing of the electric core; and the inferior elimination mechanism, used for eliminating the unqualified electric cores which are on the transmitting mechanism from the transmitting mechanism. By integration of the hole reaming, tube penetration, dust removal, short circuit testing and inferior elimination and other processes into one same transmitting mechanism, the degree of automation can be greatly improved, and the processing efficiency of the electric core can be improved.

Owner:SHENZHEN YINGHE TECH

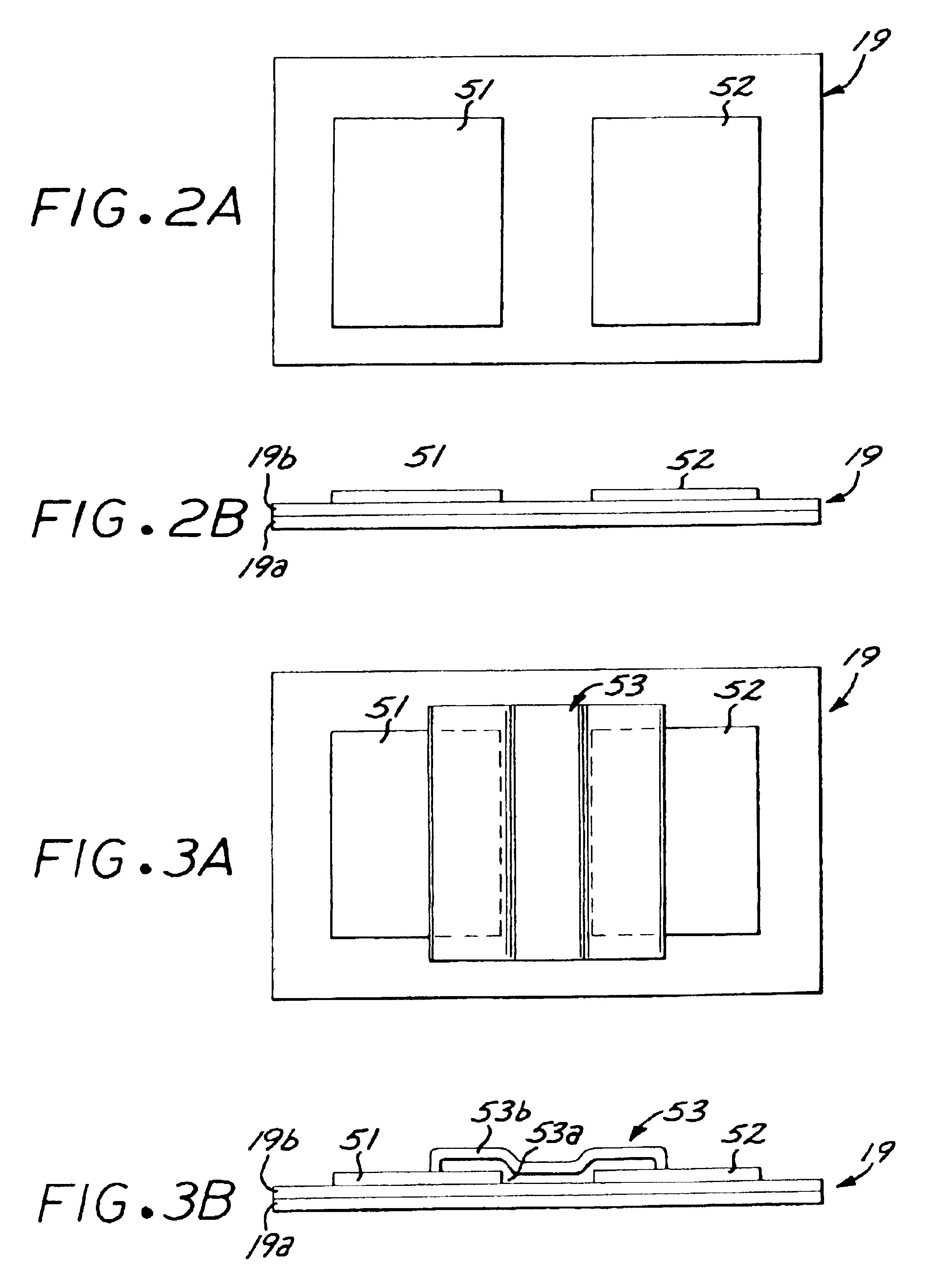

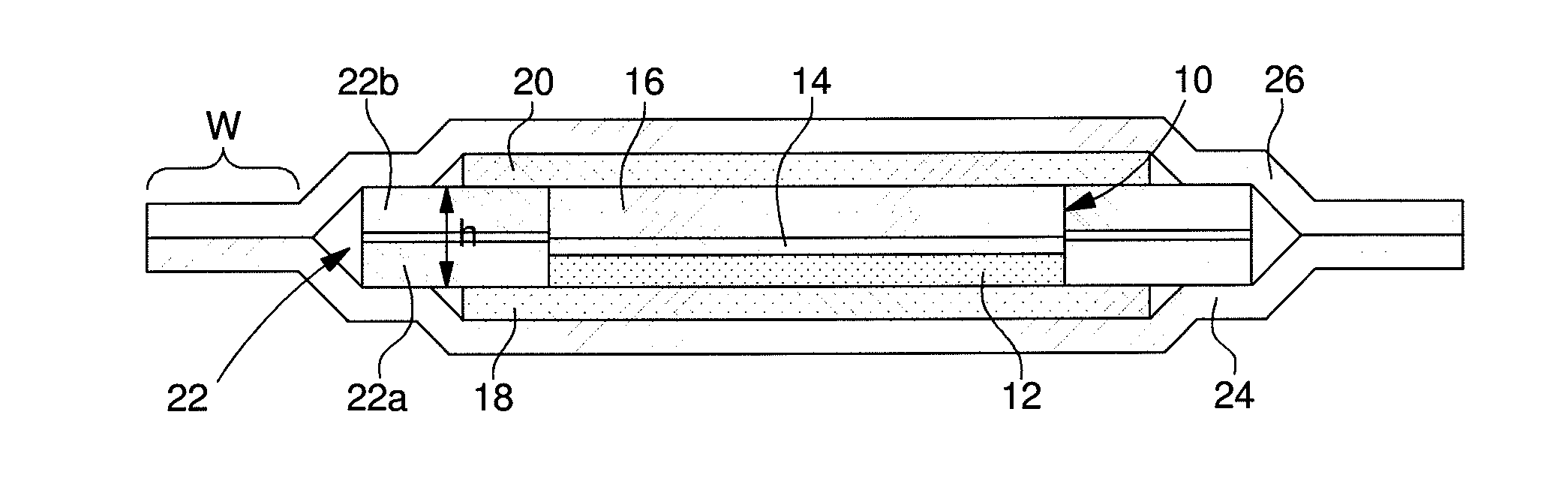

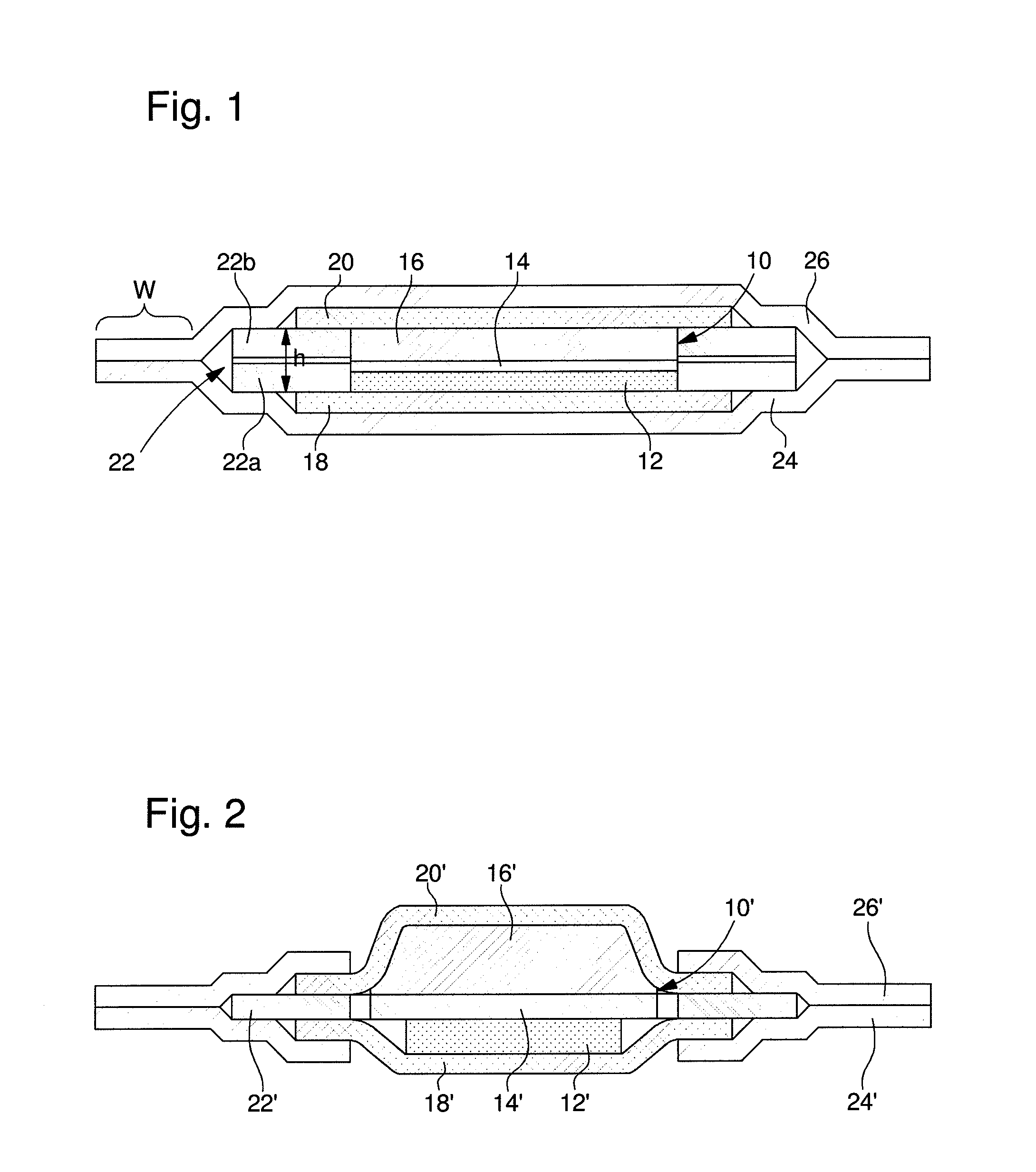

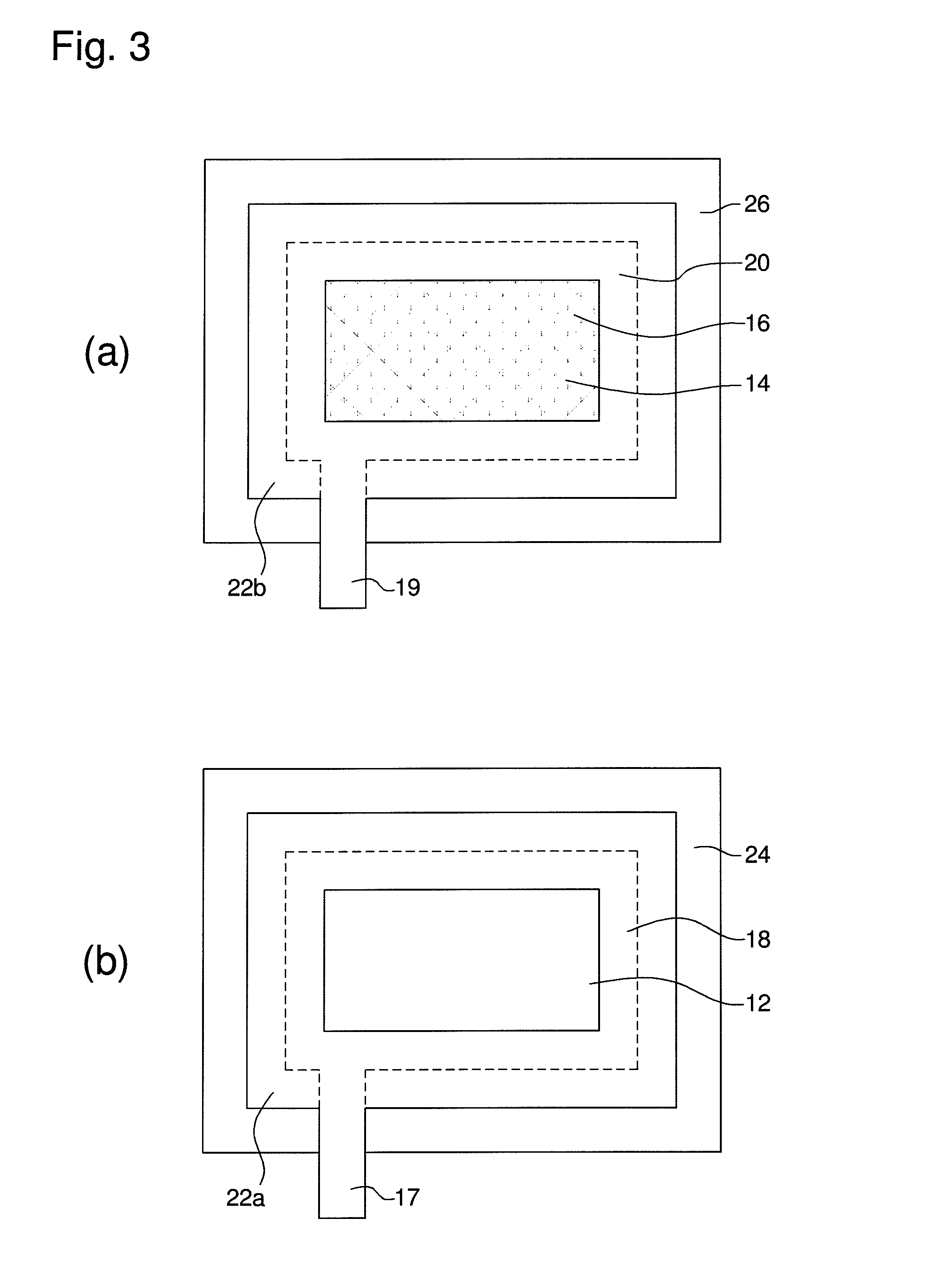

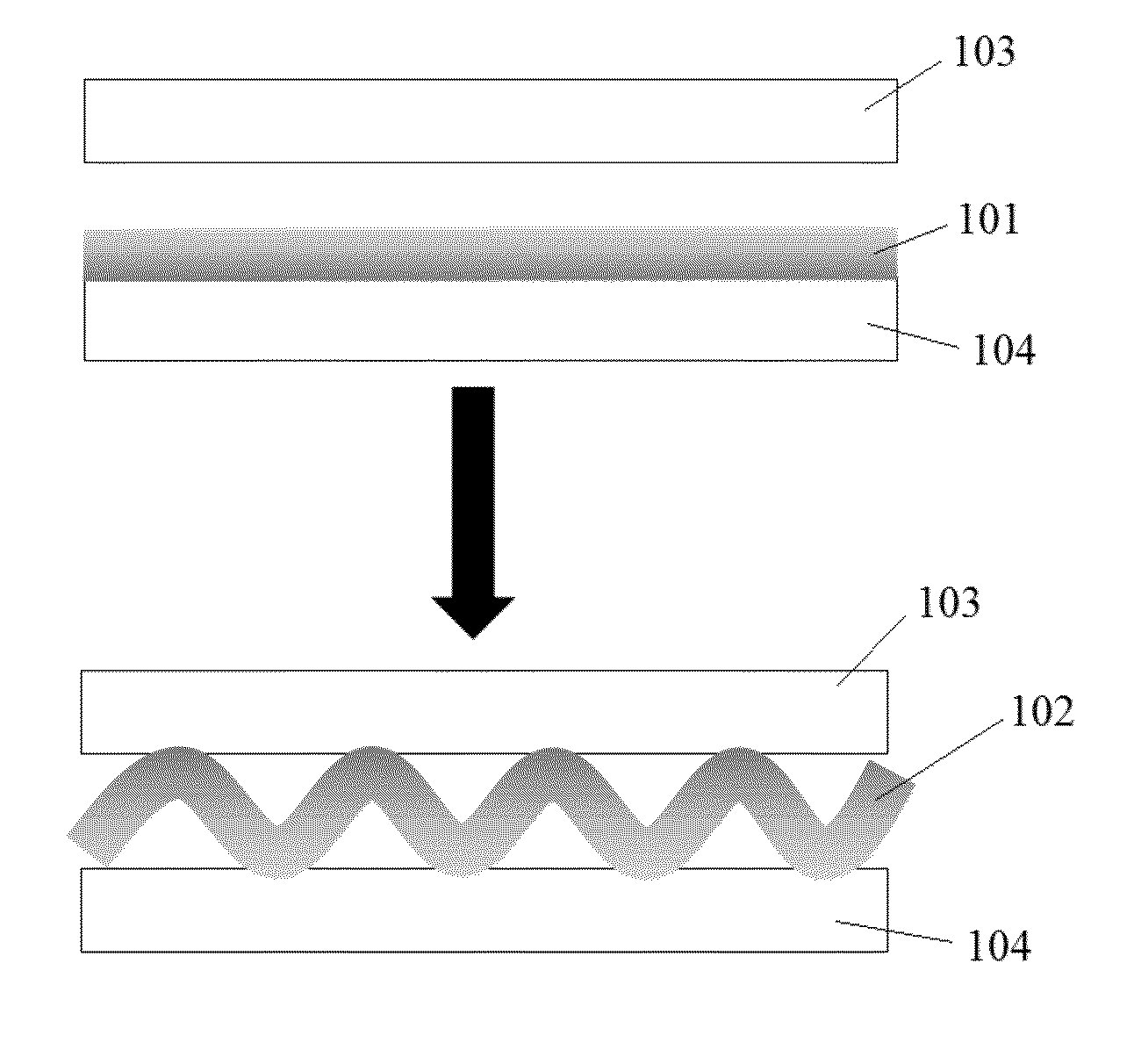

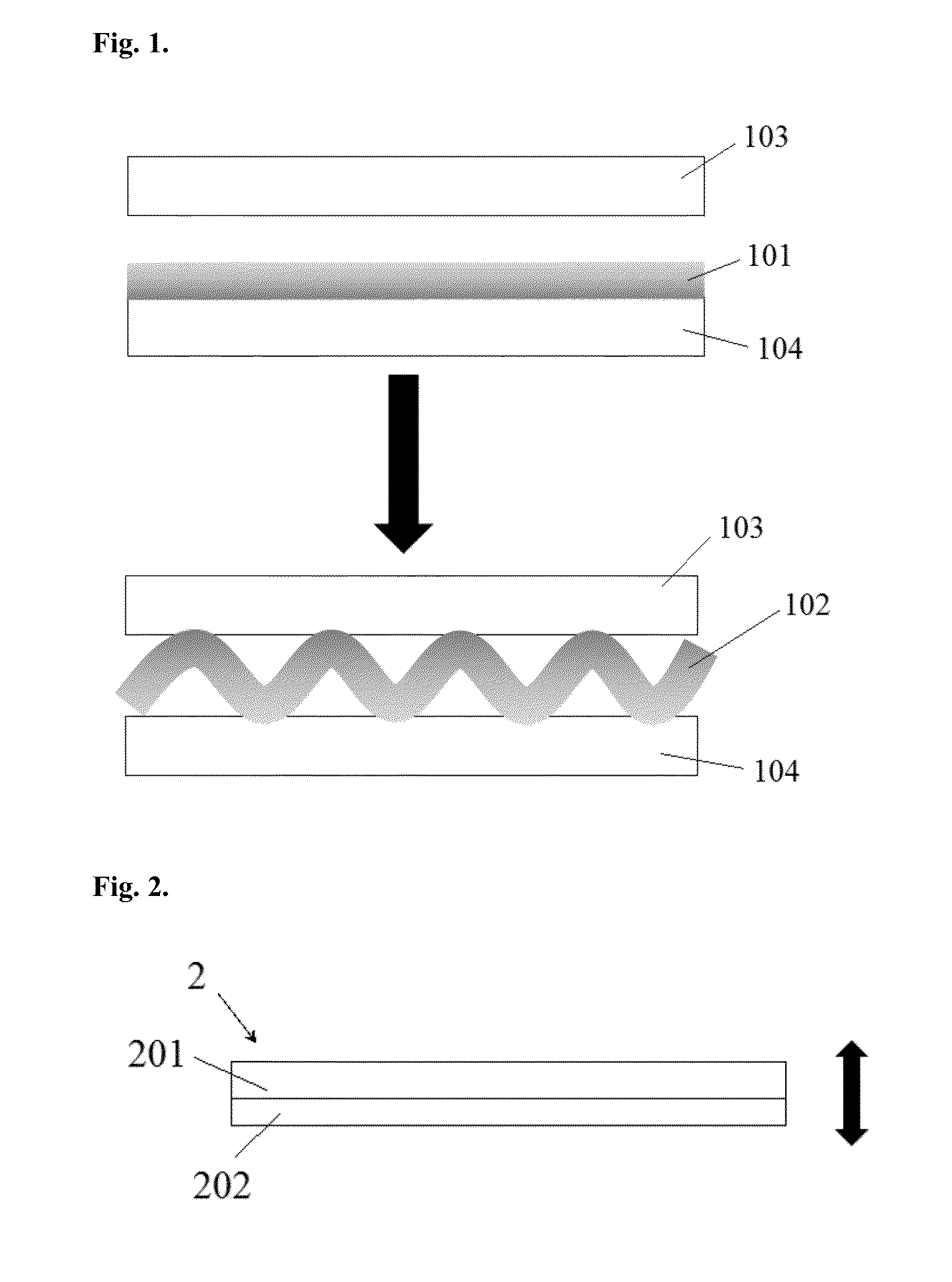

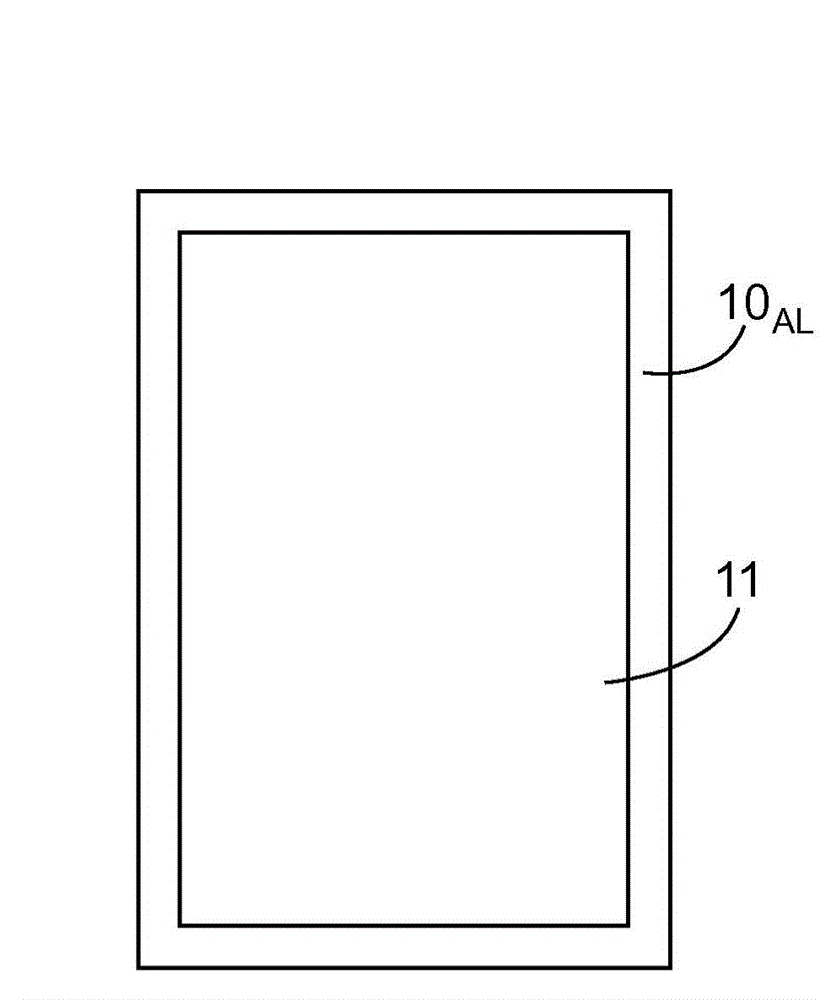

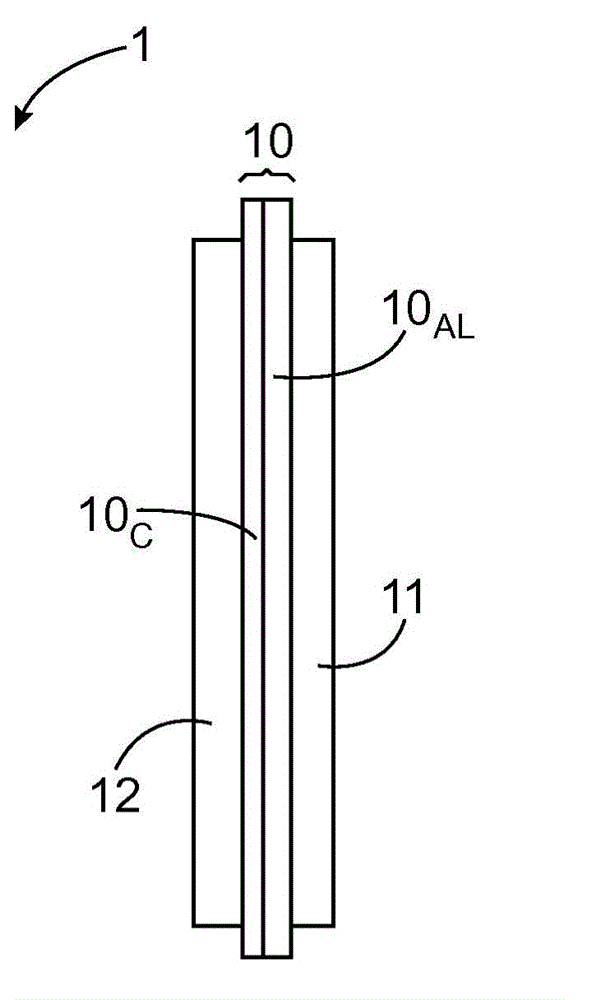

Thin film battery

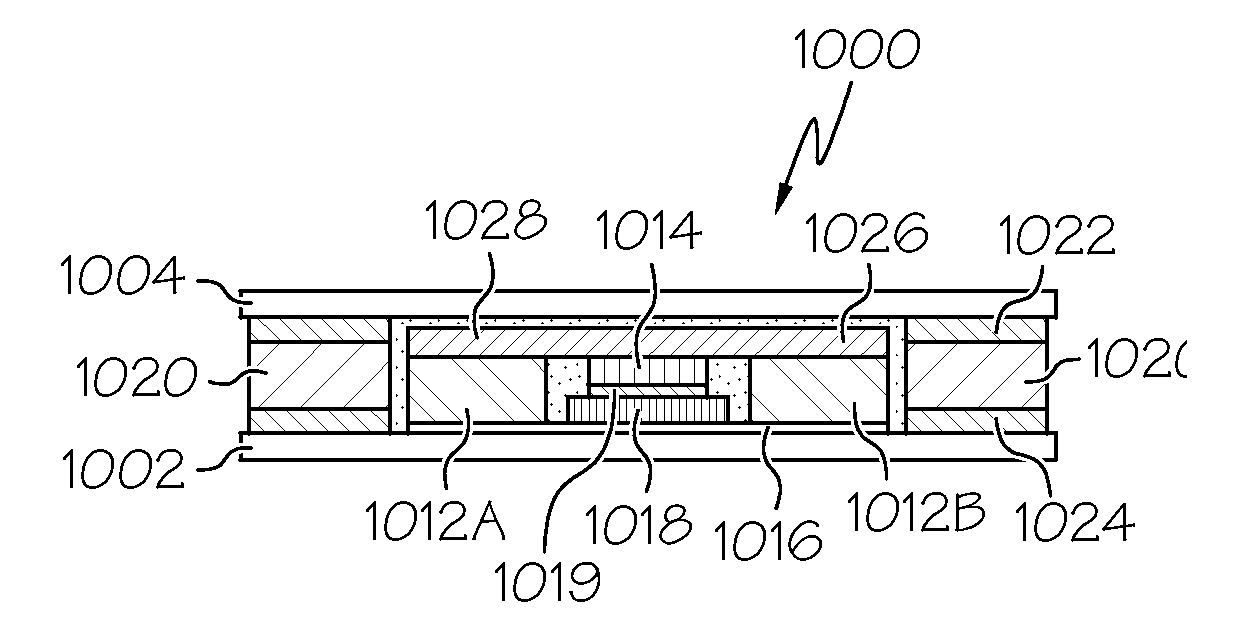

ActiveUS20110189528A1Quality improvementHigh ratePrimary cell manufactureNon-aqueous electrolyte cellsEngineeringPolymer

The present invention concerns a flat battery comprising a package formed by a cathode, an anode, and a separator layer sandwiched between the cathode and the anode, a sealing frame extending circumferentially around said package, a first current collector contacting the anode, and a second current collector contacting the cathode. The first and second current collectors each partly cover the sealing frame in a zone being adjacent to the package. According to the invention, the battery further comprises a first polymeric jacket layer being arranged on the first current collector and a second polymeric jacket layer being arranged on the second current collector, said first and second polymeric jacket layers extending circumferentially beyond the current collectors and beyond the sealing frame and being sealed together to form an outer jacket for the battery. Furthermore, the present invention also concerns a method to produce such a battery.

Owner:RENATA

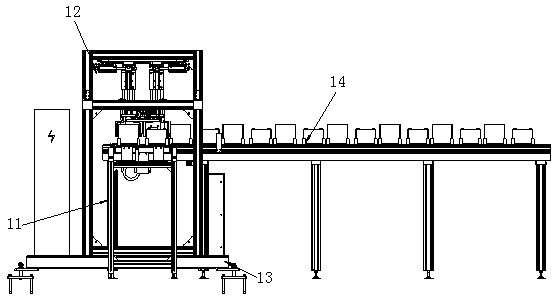

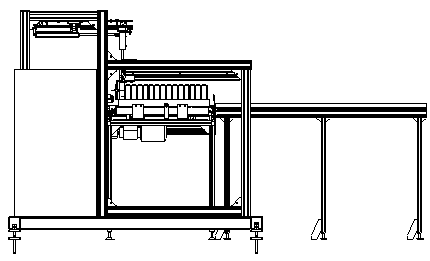

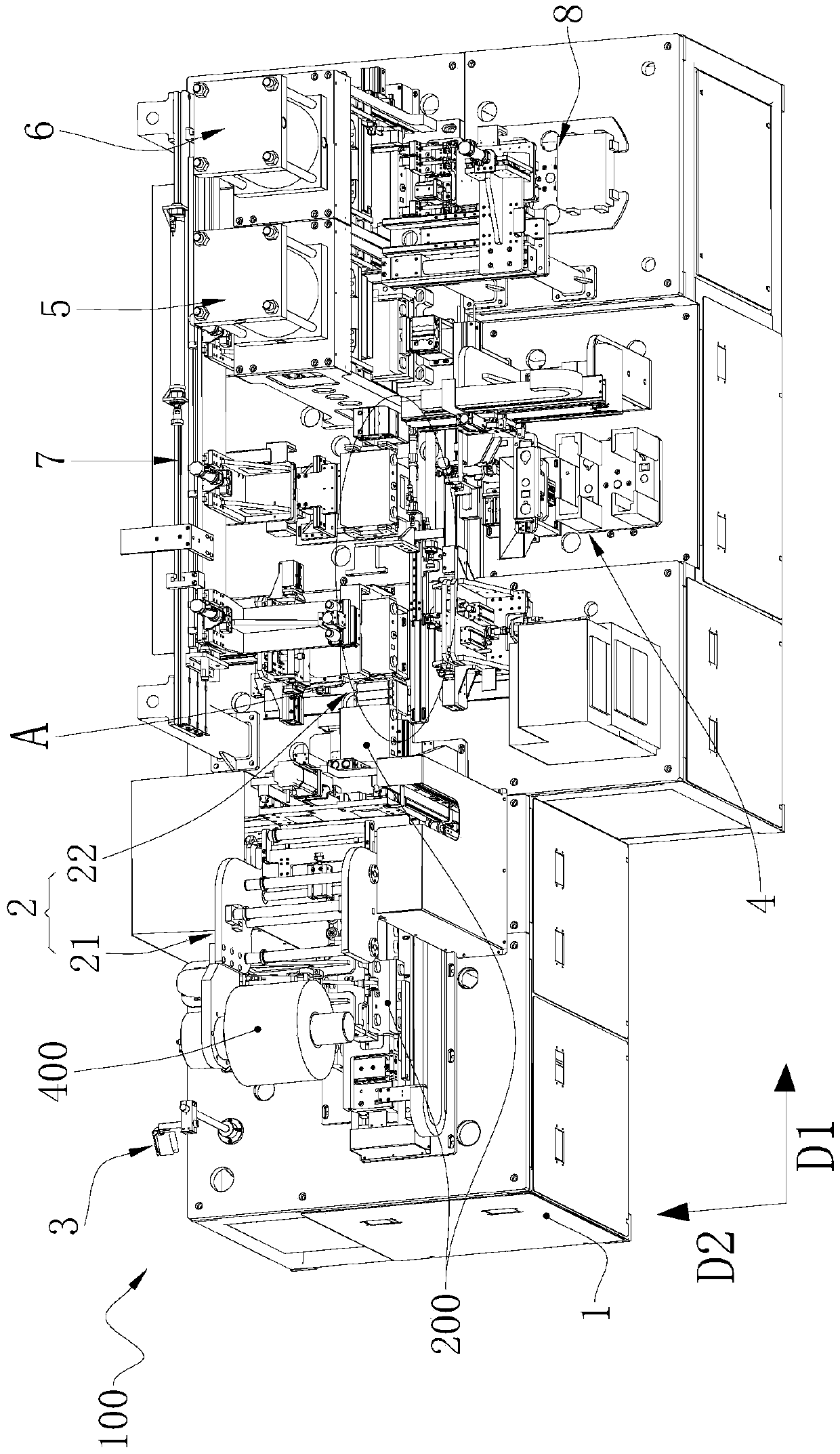

Soft package lithium battery hot and cold pressed fixture formation automatic production line

ActiveCN106935877AEnsure consistencyReduce transfer processPrimary cell manufactureAssembling battery machinesProduction lineThermal compression

The invention relates to a soft package lithium battery hot and cold pressed fixture formation automatic production line, which consists of a rack, hot press fixture formation units, a cold press shaping fixture unit, charge-discharge formation control units, a battery loading and unloading unit, a transplanting manipulator unit, a production process control and detection unit, a safety alarming unit and a controller. The hot press fixture formation units and the charge-discharge formation control units are both disposed on the surface of the rack along an axial direction, each set of hot press fixture formation unit corresponds to a set of charge-discharge formation control unit, and the moving range of the transplanting manipulator unit covers the whole processing station. The production process control and detection unit, the safety alarming unit and the central controller are all mounted on the rack. According to the invention, battery turnover, pressurization, heating, formation, cooling forming and data acquisition are integrated in one set of system to proceed, the transit process between procedures is reduced, the orginal two procedures are combined into one, the production efficiency is improved, the battery consistency is ensured, and an automatic assembly line is realized.

Owner:ZHEJIANG HANGKE TECH

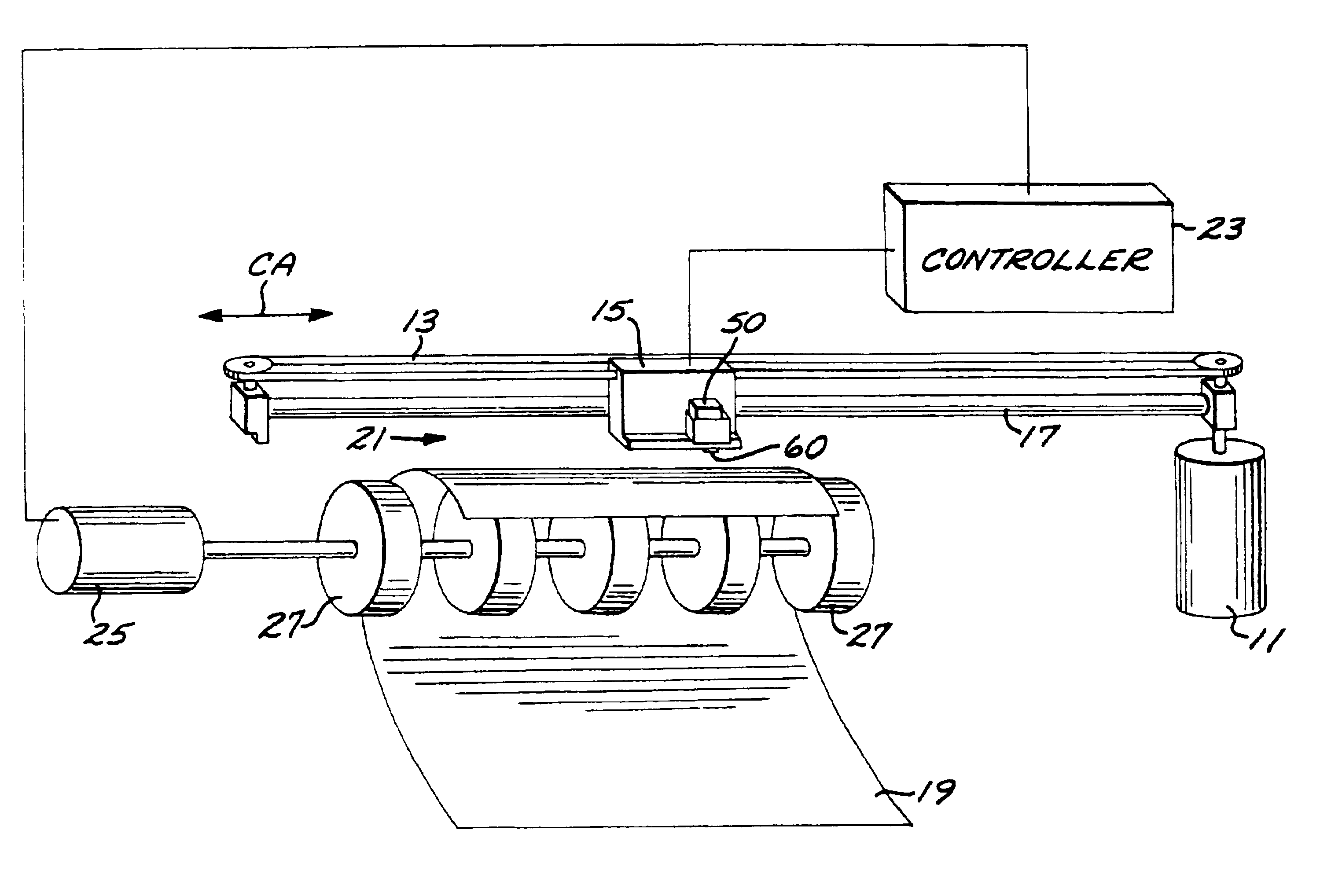

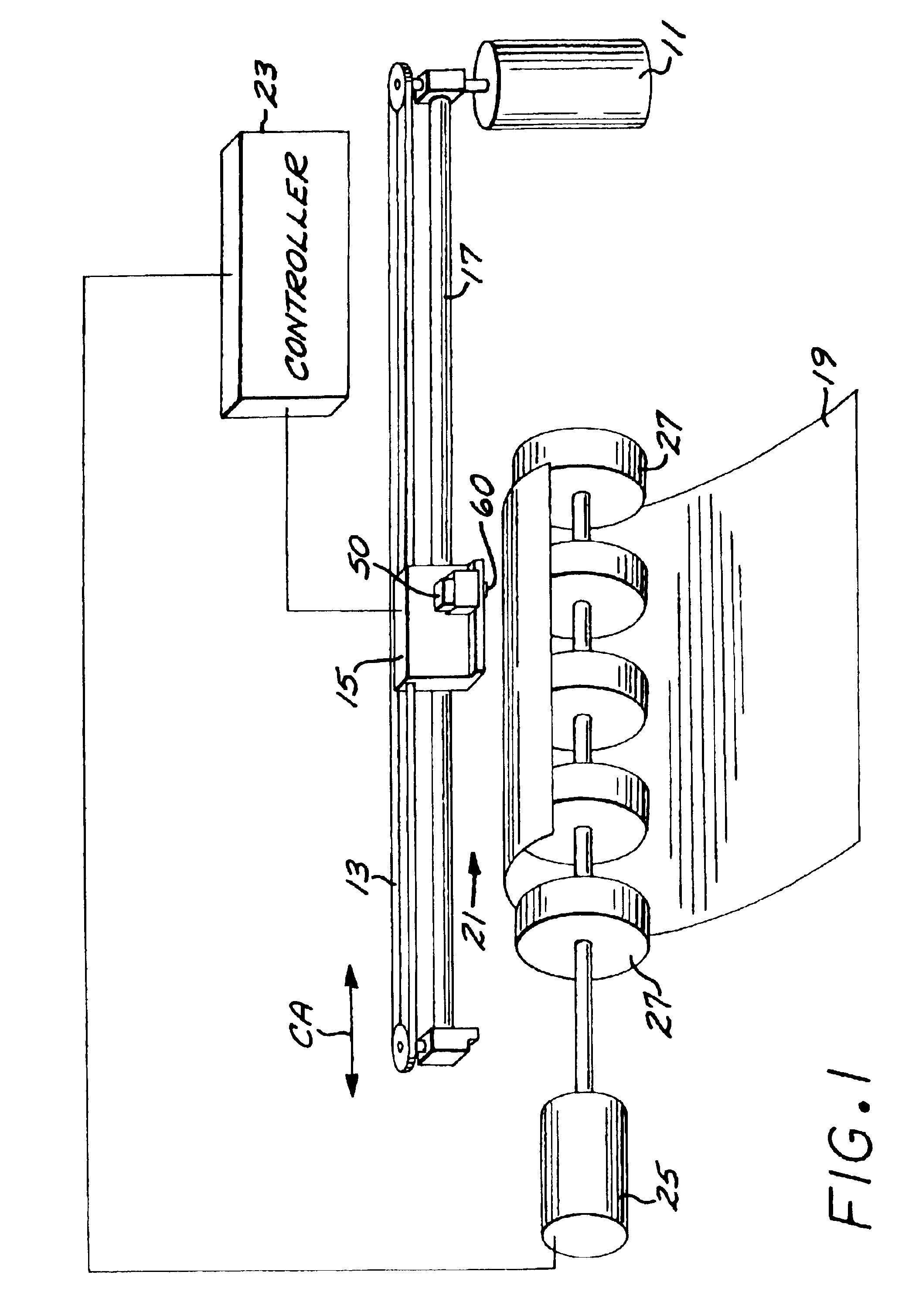

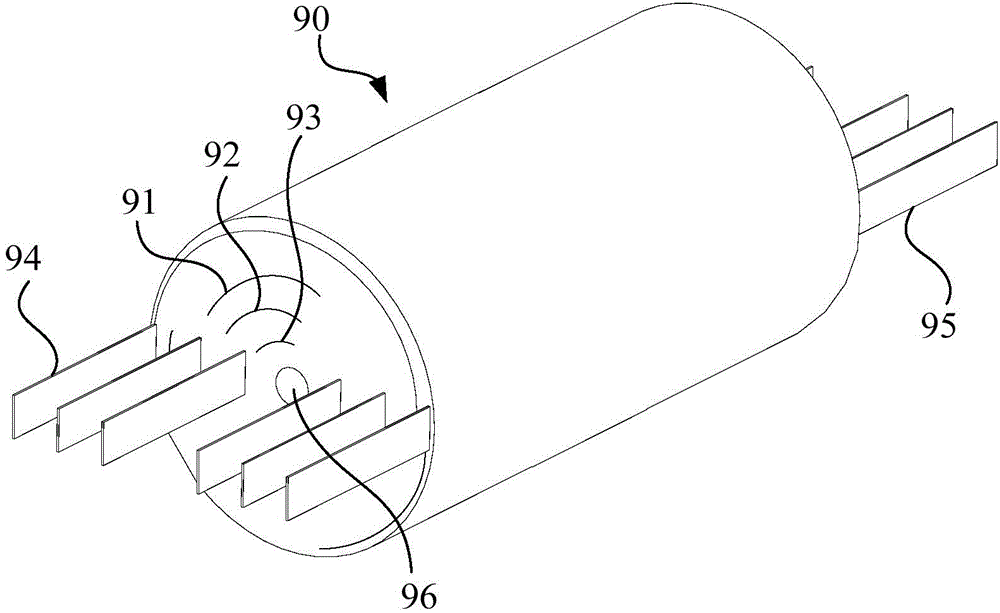

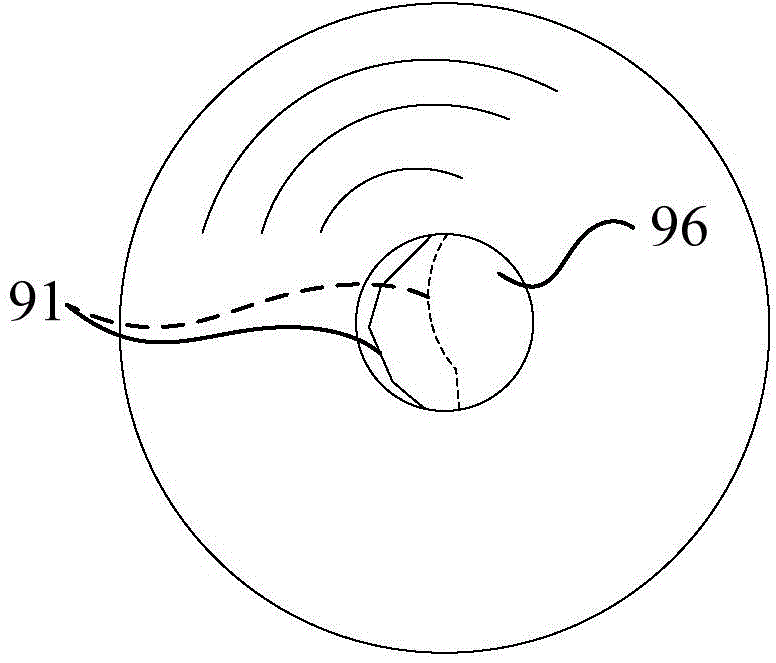

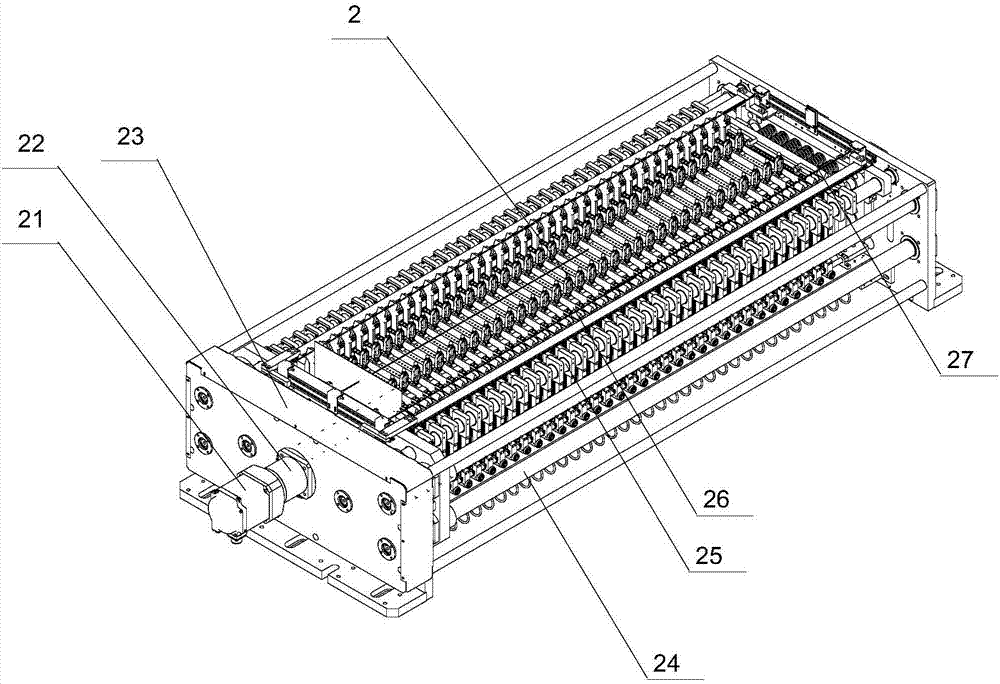

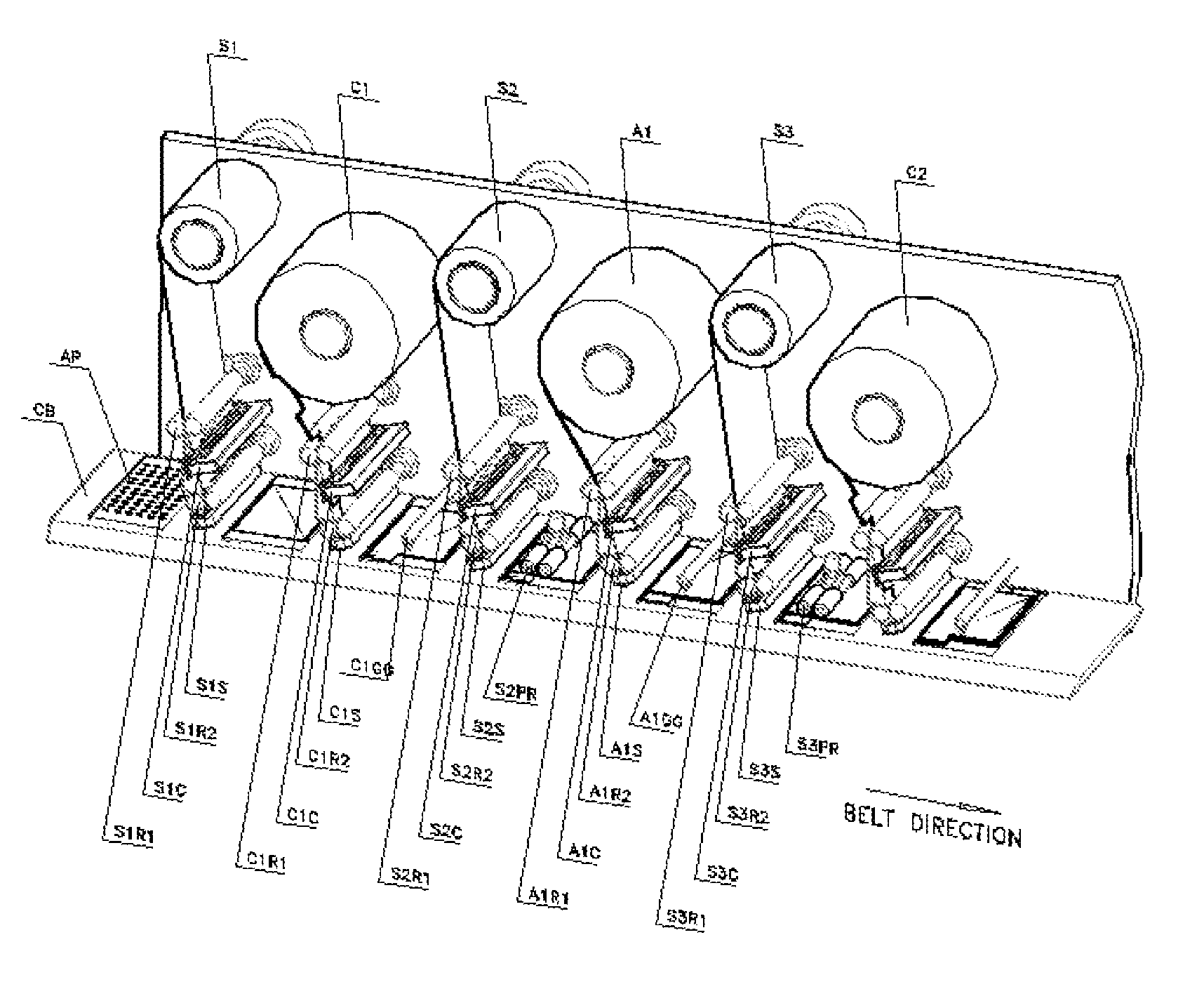

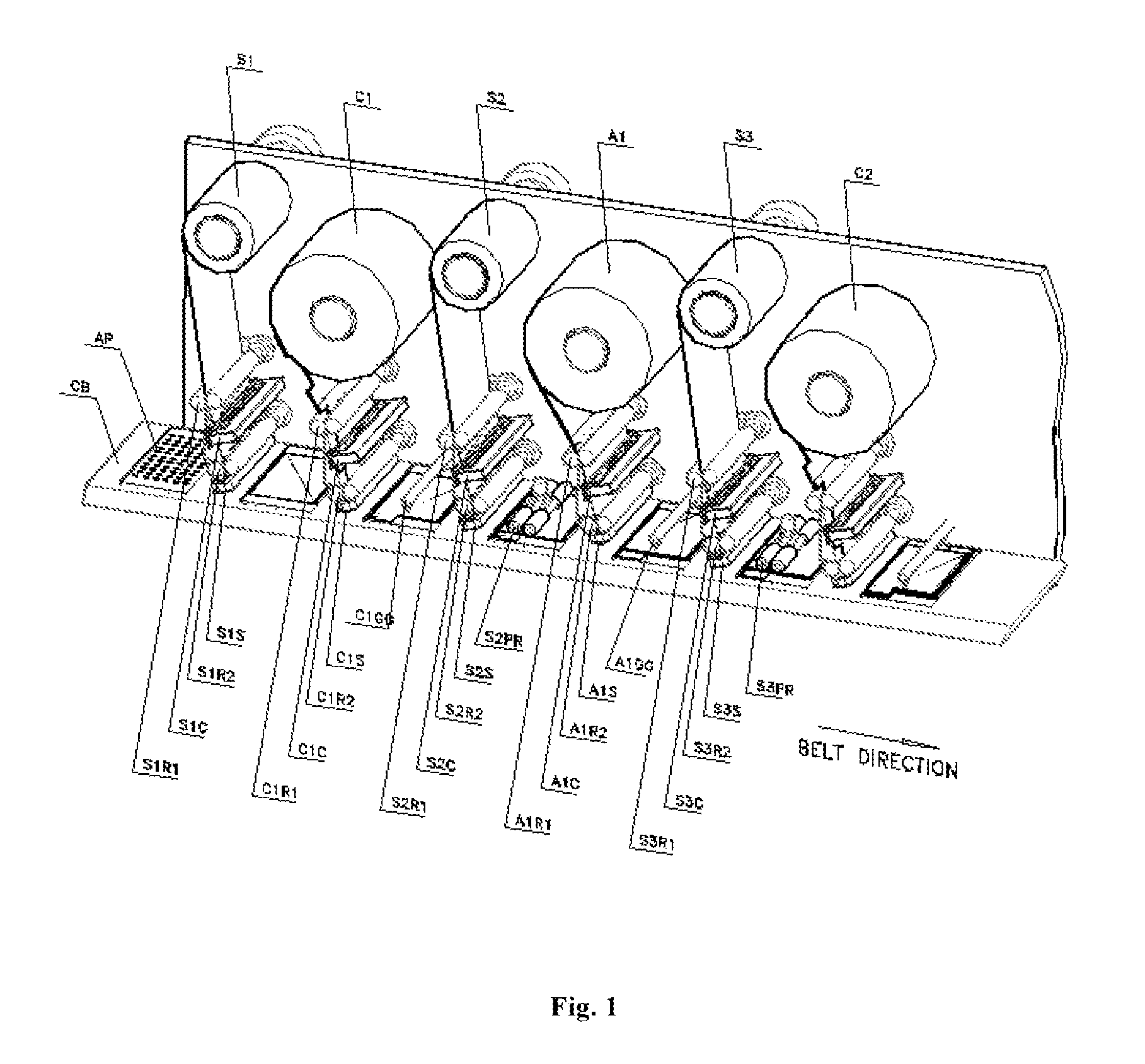

Continuous prismatic cell stacking system and method

ActiveUS20130111739A1Rapid productionTight tolerancePrimary cell manufactureAssembling battery machinesEngineeringAnode

A continuous prismatic cell stacking system and method are disclosed. The continuous prismatic cell stacking system, comprises: a frame; a conveyer belt; a plurality of air suction pans; at least three units for distributing separator including separator spool, positioning sensor of separator layer, upper roller of separator layer, lower roller of separator layer and cutter of separator layer; at least one unit for distributing cathode including cathode spool, positioning sensor of cathode layer, upper roller of cathode layer, lower roller of cathode layer, and cutter of cathode layer; and at least one unit for distributing anode including anode spool, positioning sensor of anode layer, upper roller of anode layer, lower roller of anode layer, and cutter of anode layer.

Owner:MICROVAST

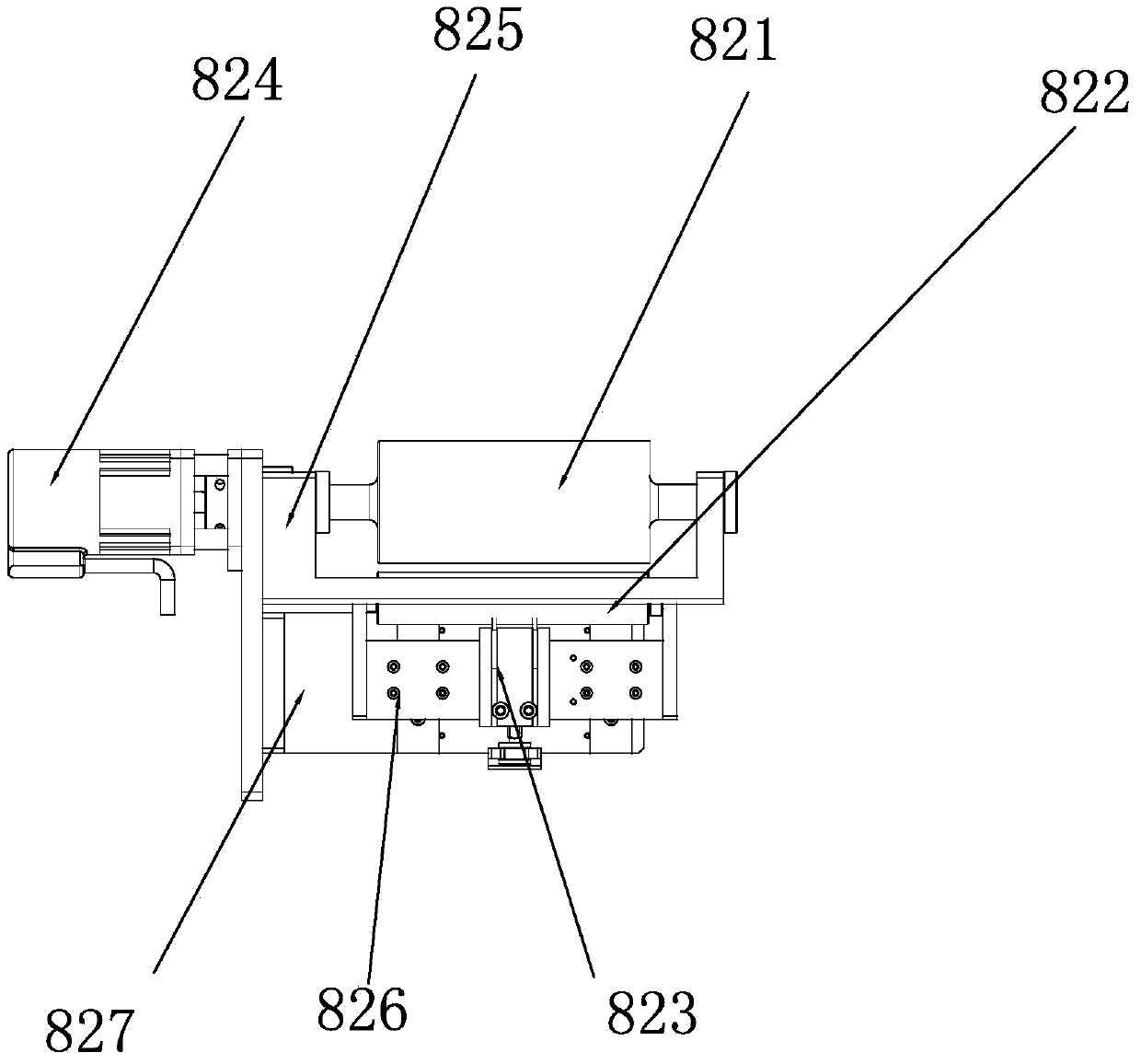

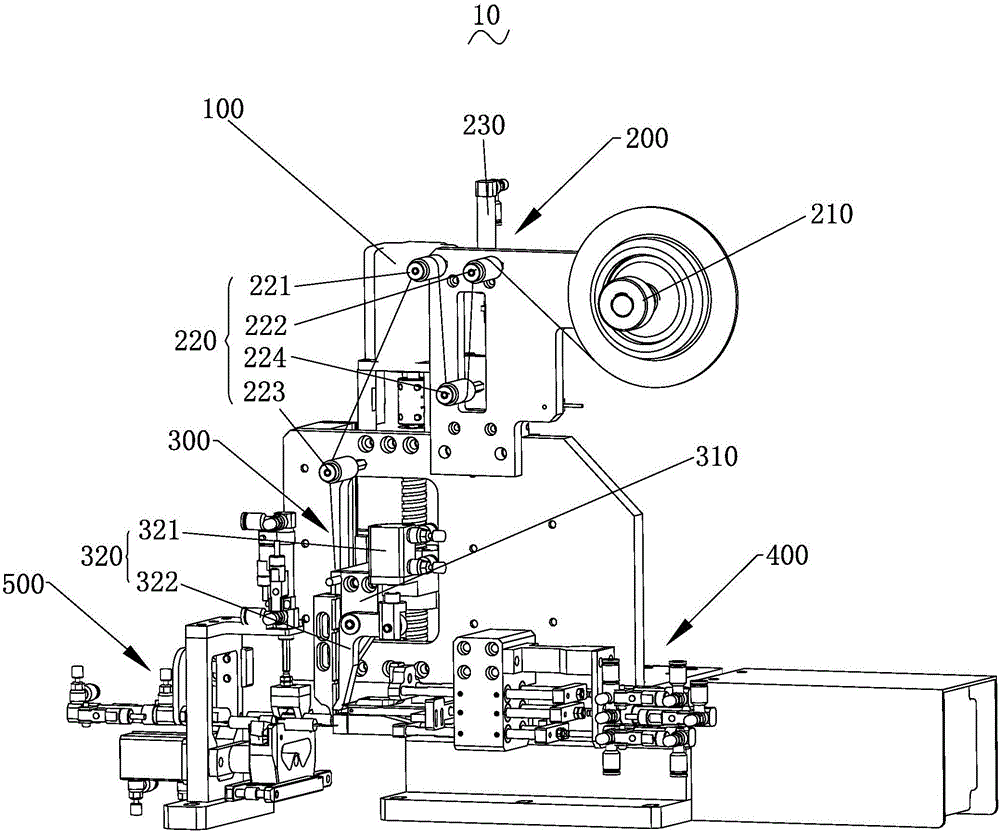

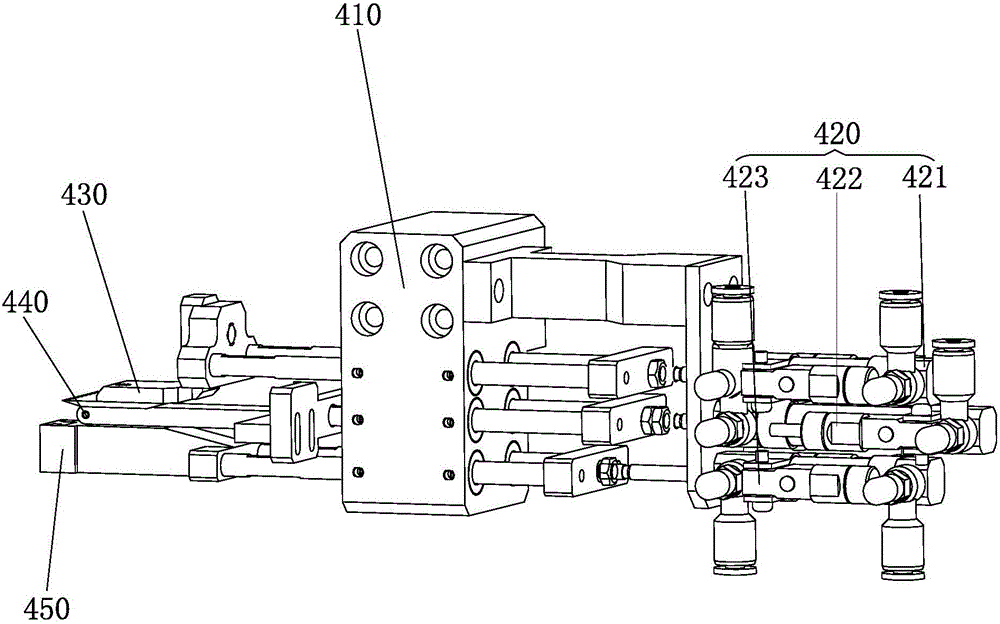

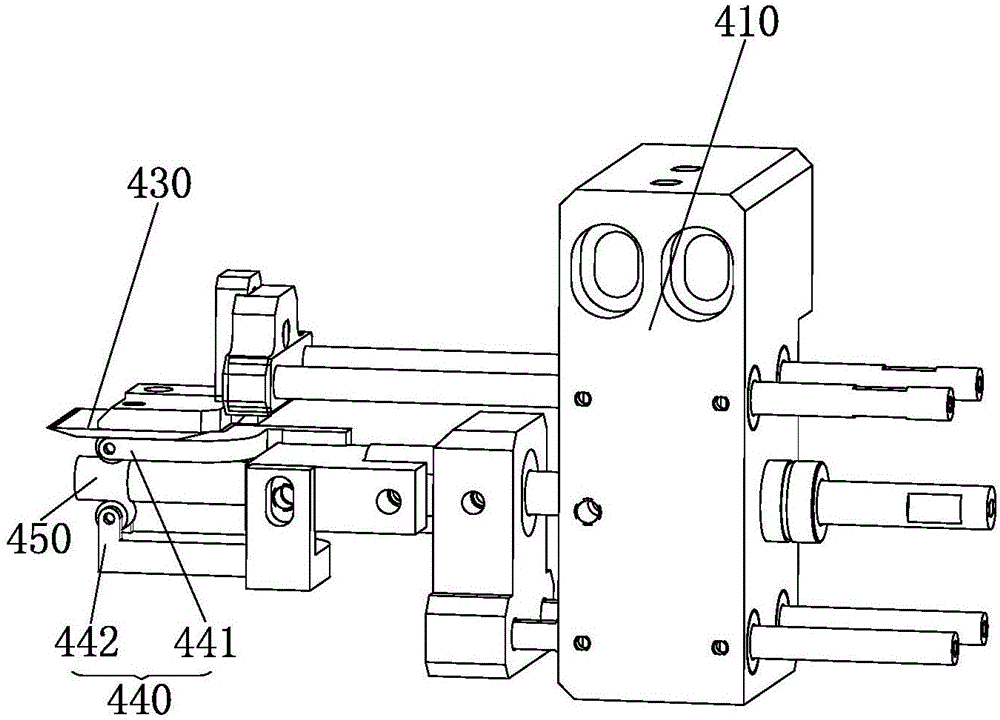

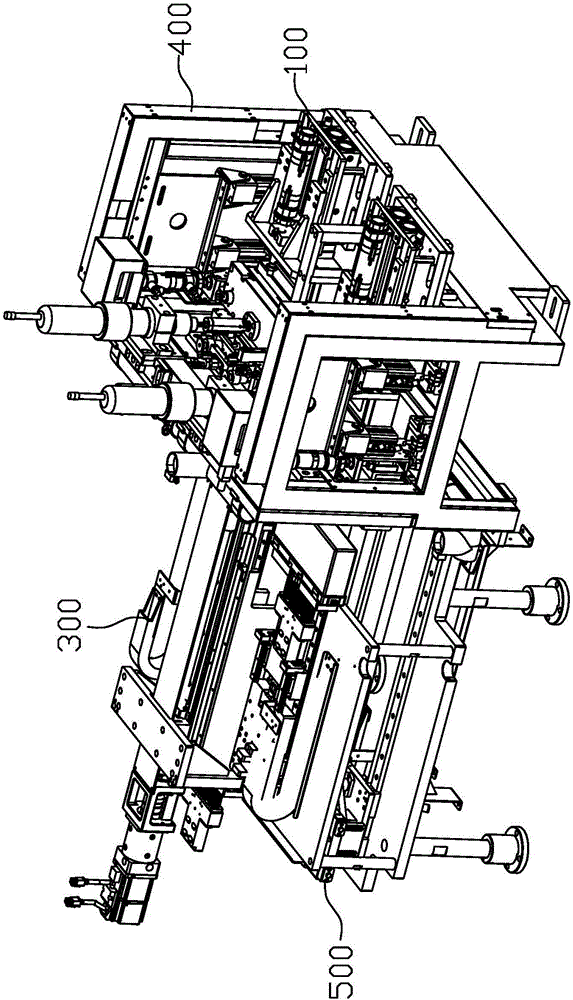

Battery gluing machine

ActiveCN105742684AEasy to operateReduce labor costsPrimary cell manufactureAssembling battery machinesPulp and paper industryPaper cut

The invention discloses a battery gluing machine. The battery gluing machine is characterized by comprising a rack, an adhesive paper feeding device, an adhesive paper transmitting device and an adhesive paper gluing device, wherein the adhesive paper feeding device, the adhesive paper transmitting device and adhesive paper gluing device are sequentially arranged on the rack, a battery placing device is further arranged on the rack and is used for fixing and placing a battery, the adhesive paper gluing device comprises a support block, a power driving part, an adhesive paper cutting part, an adhesive paper press part and an adhesive paper gluing part, the adhesive paper cutting part, the adhesive paper press part and the adhesive paper gluing part are sequentially and movably arranged on the support block, the power driving part is provided with a first driving air cylinder, a second driving air cylinder and a third driving air cylinder, the first driving air cylinder is in driving connection with the adhesive paper cutting part, the second driving air cylinder is in driving connection with the adhesive paper press part, and the third driving air cylinder is in driving connection with the adhesive paper gluing part. In the winding gluing machine disclosed by the invention, through mutual matching of all devices, automatic gluing operation on the battery is achieved, and the production efficiency is improved; and moreover, the whole structure is simple, 7-shaped or n-shaped gluing operation on different types of battery products can be achieved, and thus, the universality of the battery gluing machine is improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Full automatic cell casing apparatus

ActiveCN106129448AAssembly precisionQuick assemblyPrimary cell manufactureAssembling battery machinesEngineering

The present invention relates to the field of automated equipment, and discloses a full automatic cell casing apparatus. The full automatic cell casing apparatus comprises a case pushing apparatus, a casing location apparatus, and a cell pushing apparatus. The case pushing apparatus is used for pushing a case into the casing location apparatus to be located, and resisting the case to keep the pressure after the case is located. The cell pushing apparatus is used for pushing a cell into the casing location apparatus, pushing the cell into the case after the cell is located, and pushing the cased cell and the case out from the casing location apparatus. Through adoption of the full automatic cell casing apparatus, the cell and the case can be assembled accurately, the whole process is performed automatically, casing accuracy is ensured, and rapid assembly is realized. The full automatic cell casing apparatus is applicable to mass production, and can help improve the production capacity of the enterprise.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

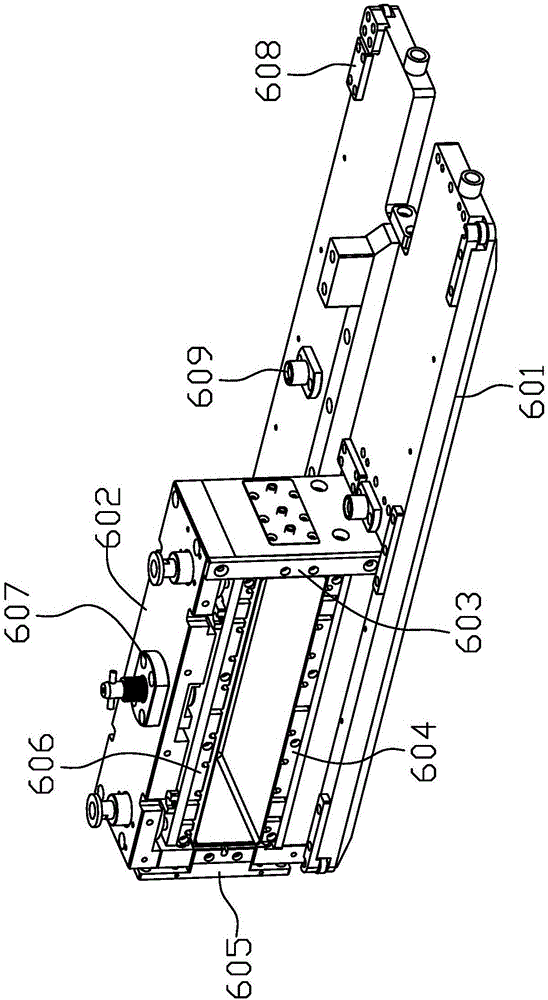

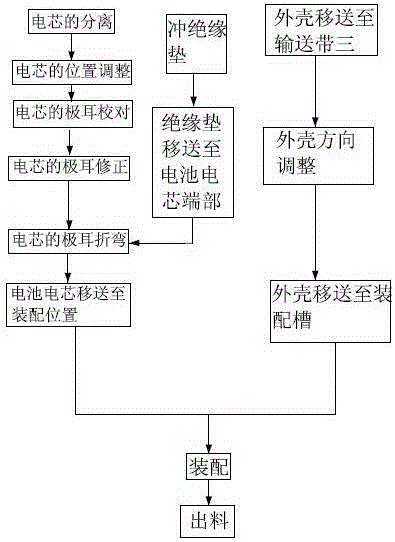

Machine for automatically assembling cylindrical battery into shell

InactiveCN105280932ASimple structureSmall footprintPrimary cell manufactureAssembling battery machinesEngineeringAssembly automation

The invention provides a machine for automatically assembling a cylindrical battery into a shell, and belongs to the technical field of battery manufacturing. The technical problem that the existing operation of assembling a cylindrical battery cell into a shell is low in automation degree and the like is solved. The machine comprises a machine cabinet and a plurality of battery cell carriers capable of carrying battery cells. The machine cabinet is provided with a first conveying belt capable of conveying the battery cells, a second conveying belt capable of conveying the battery cell carriers, and a third conveying belt capable of conveying a shell. A battery cell channel is arranged below the discharge end of the first conveying belt and provided with a separating mechanism capable of separating the battery cells. The second conveying belt is located below the battery cell channel. A battery cell adjustment mechanism, a pole lug proofreading mechanism, a pole lug correcting mechanism and a pole lug bending mechanism are arranged on the two sides of the second conveying belt in sequence. The machine cabinet is provided with an assembly groove. The two ends of the assembly groove are provided with a propulsion air cylinder and a sucking air cylinder. A piston rod of the propulsion air cylinder is provided with a hollow ejector column right opposite to the assembly groove. The machine has the advantages of being simple in structure and high in automation degree.

Owner:罗林波

Stacking nonaqueous electrolytes battery and manufacturing method thereof and stacking equipment

ActiveCN101252208APrimary cell manufactureAssembling battery machinesEngineeringNon aqueous electrolytes

The invention provides a pile non-aqueous electrolyte battery, method for producing the battery and pile equipment of the battery. The pile non-aqueous electrolyte battery comprises multiple alternate pile electrode body, each of which comprises an anode and cathode overlapped through a partition. The partition has an edge part upraising along the edge part of one of the anode and cathode. The upraising edge parts of multiple partitions are overlapped with each other.

Owner:MURATA MFG CO LTD

Current collector having built-in sealing means, and bipolar battery including such a collector

InactiveUS9142811B2Improve performanceLeak-proofing itself to be simplifiedElectrode rolling/calenderingPrimary cell manufactureLithiumElectricity

In lithium bipolar batteries, to improve sealing against electrolytes between adjacent electrochemical cells, mixed current collector-electrode supports are produced, in a form of a metal grate or raised metal sheet housed in a strip made of electrical insulator material, the function of the periphery of which is to constitute a sealing area.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

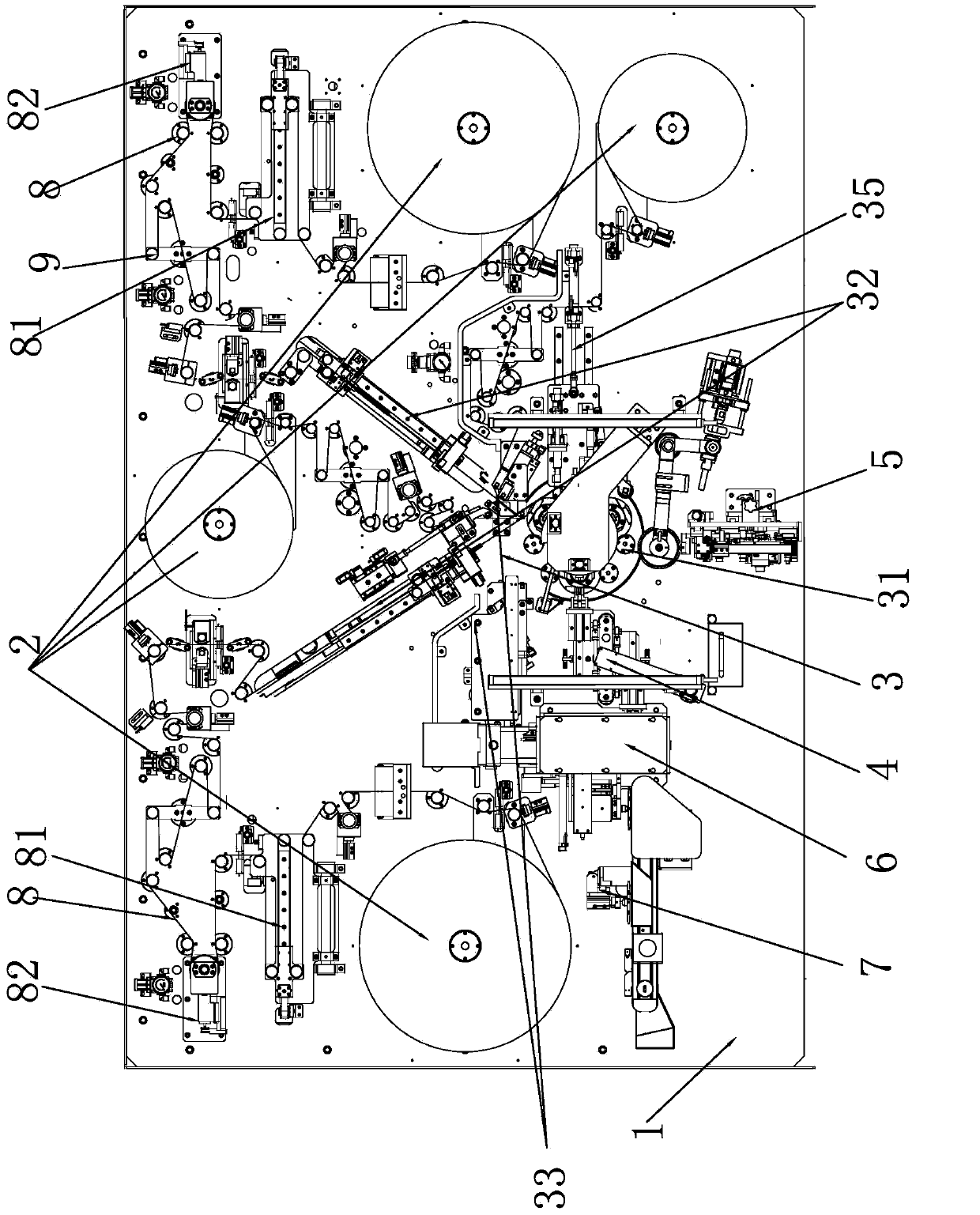

Full-automatic battery adhesive tape pasting production line

PendingCN110048152ARealize fully automated operationNo manual interventionPrimary cell manufactureAssembling battery machinesProduction lineAdhesive

The invention relates to the technical field of battery production equipment, in particular to a full-automatic battery adhesive tape pasting production line. According to the production process, a battery cell feeding machine, a tab cutting machine, a molding adhesive tape pasting machine, a head adhesive tape and gasket adhesive tape pasting machine, a protection plate laser welding machine, a protection plate bending and shaping machine, a protection plate plastic case assembling machine and a PI adhesive tape and double-sided adhesive tape pasting machine are sequentially arranged. A no-load carrier conveying line and a carrier conveying line are connected between the mechanisms respectively, and a feeding mechanical arm is arranged between the no-load carrier conveying line and the carrier conveying line. Full-automatic operation is achieved, manual intervention is not needed, the production cost is reduced, and the production efficiency and the product percent of pass are improved.

Owner:GUANGDONG DONGBO AUTOMATION EQUIP CO LTD

Electrode assembly

ActiveUS20130280570A1Avoid degradationEfficient curingElectrode manufacturing processesFinal product manufacture3d shapesElectrical battery

An electrode assembly and a battery are provided. The electrode assembly may be effectively fixed inside a can as a pressure-sensitive adhesive tape attached to an outer circumferential surface of the electrode assembly is formed into a 3D shape by an electrolyte. Thus, the electrode assembly does not move and rotate inside the can due to external vibration or impact and damage of welded regions of a tab or disconnection of inner circuits can be prevented.

Owner:LG ENERGY SOLUTION LTD

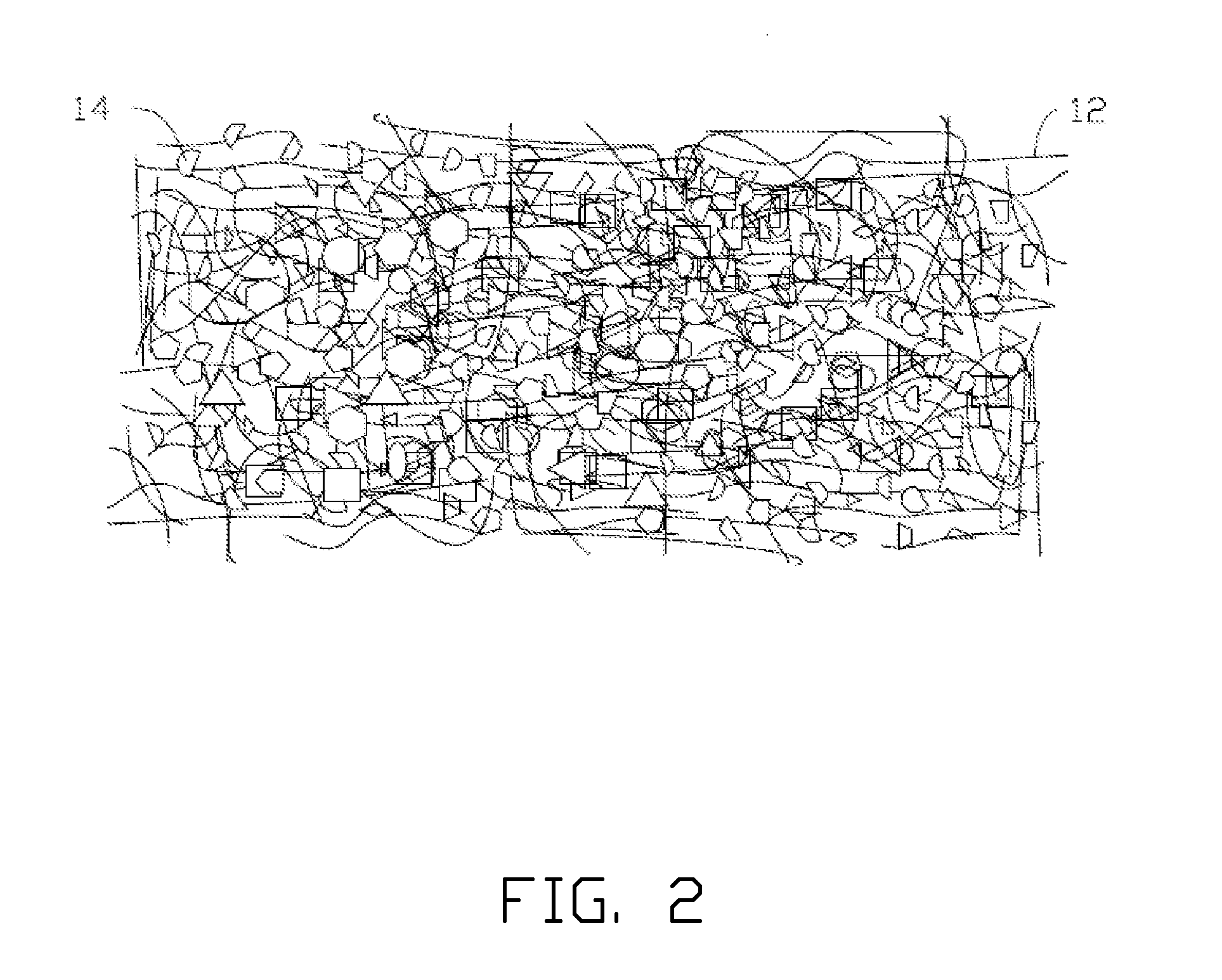

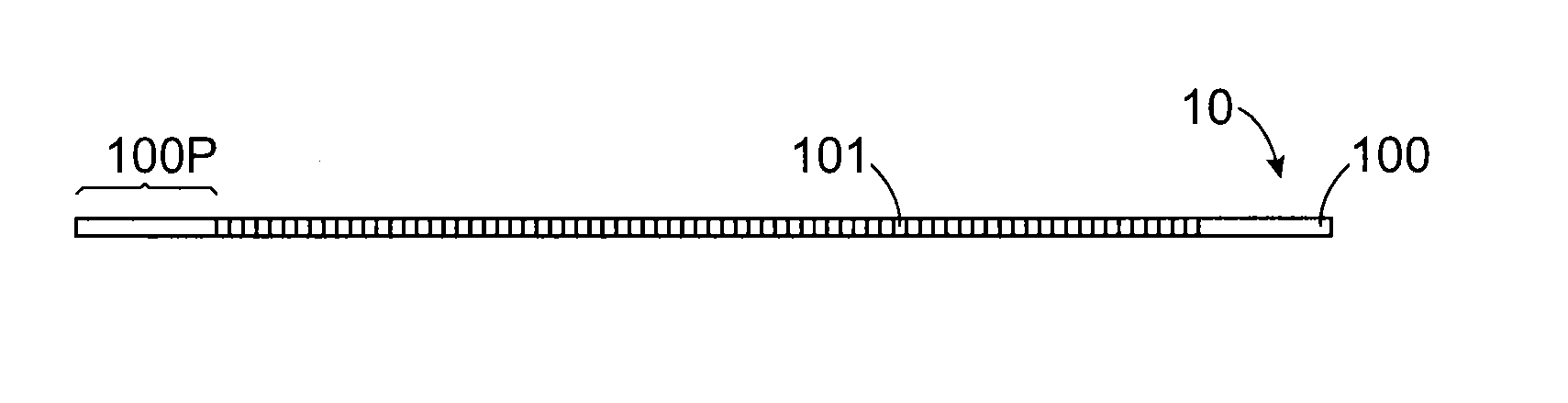

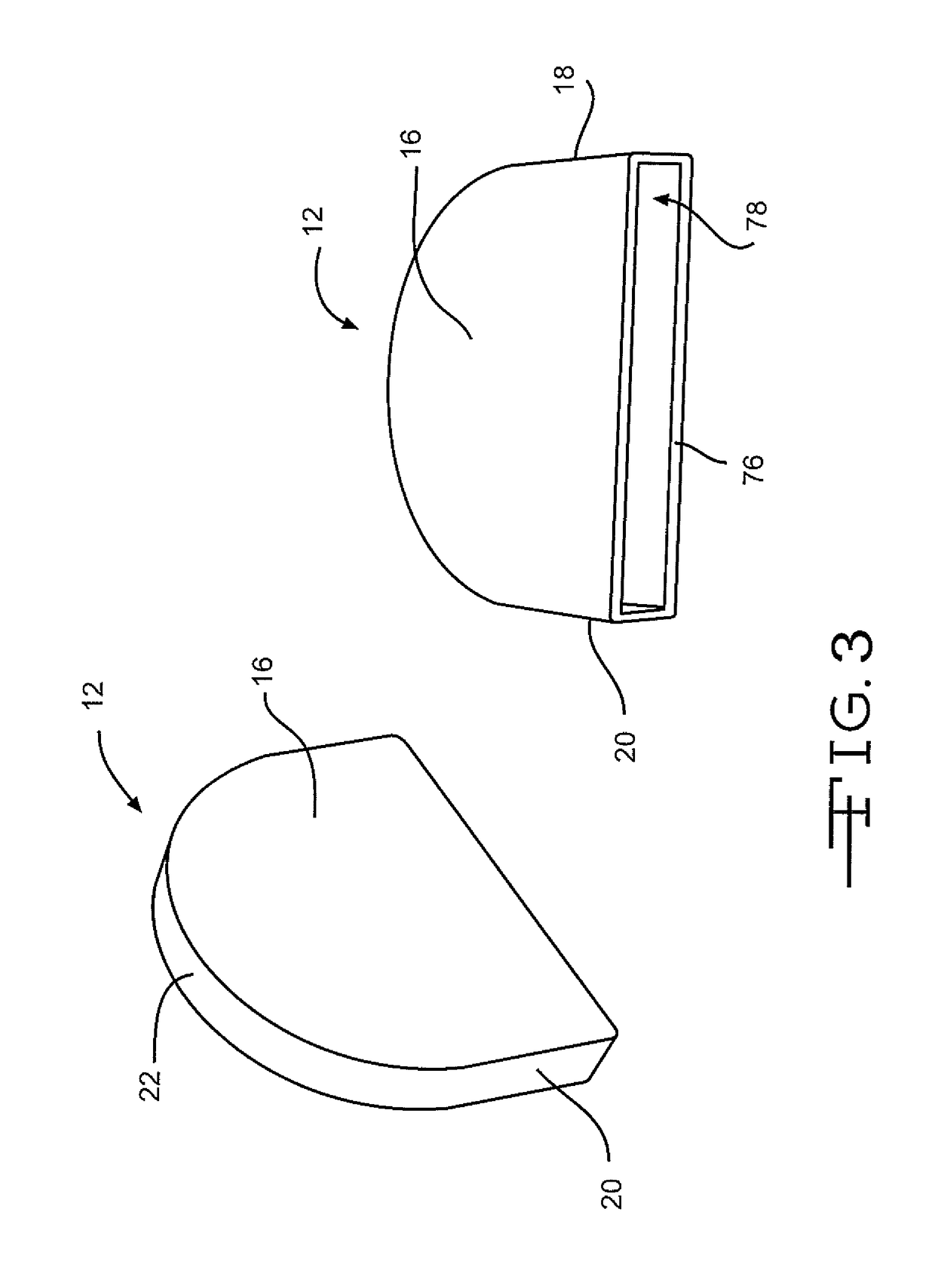

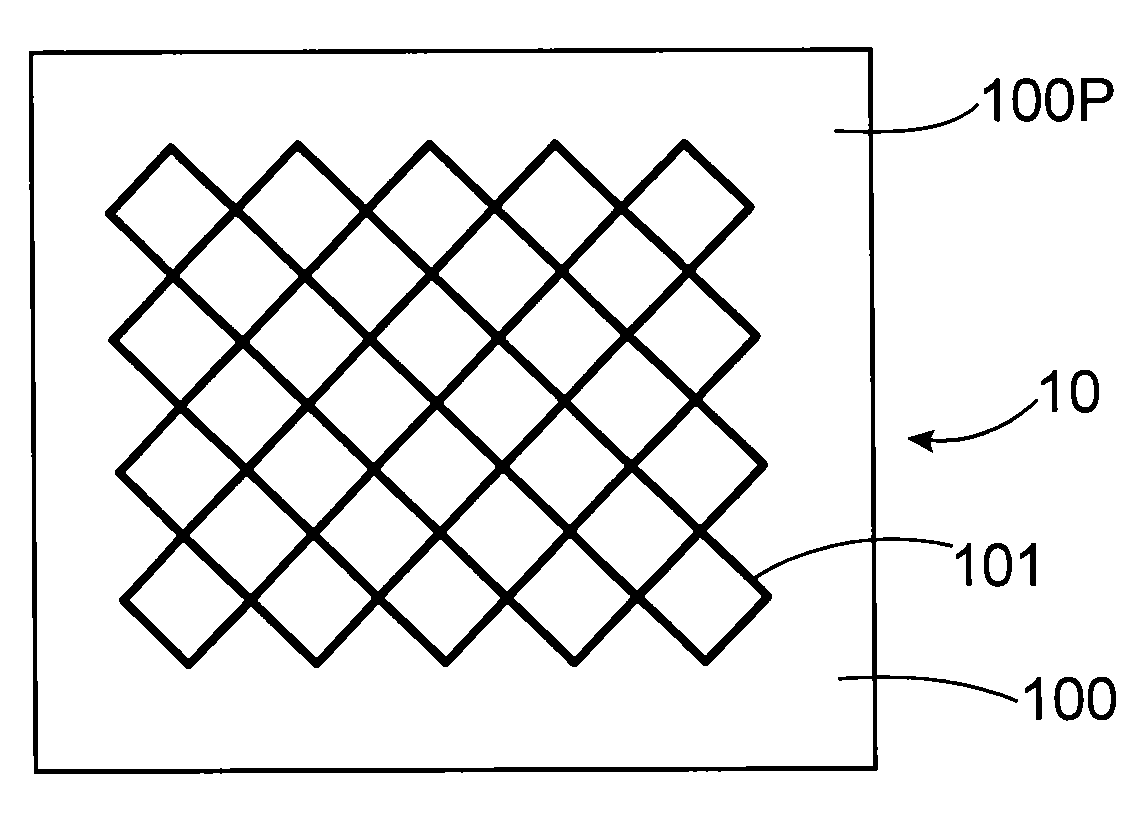

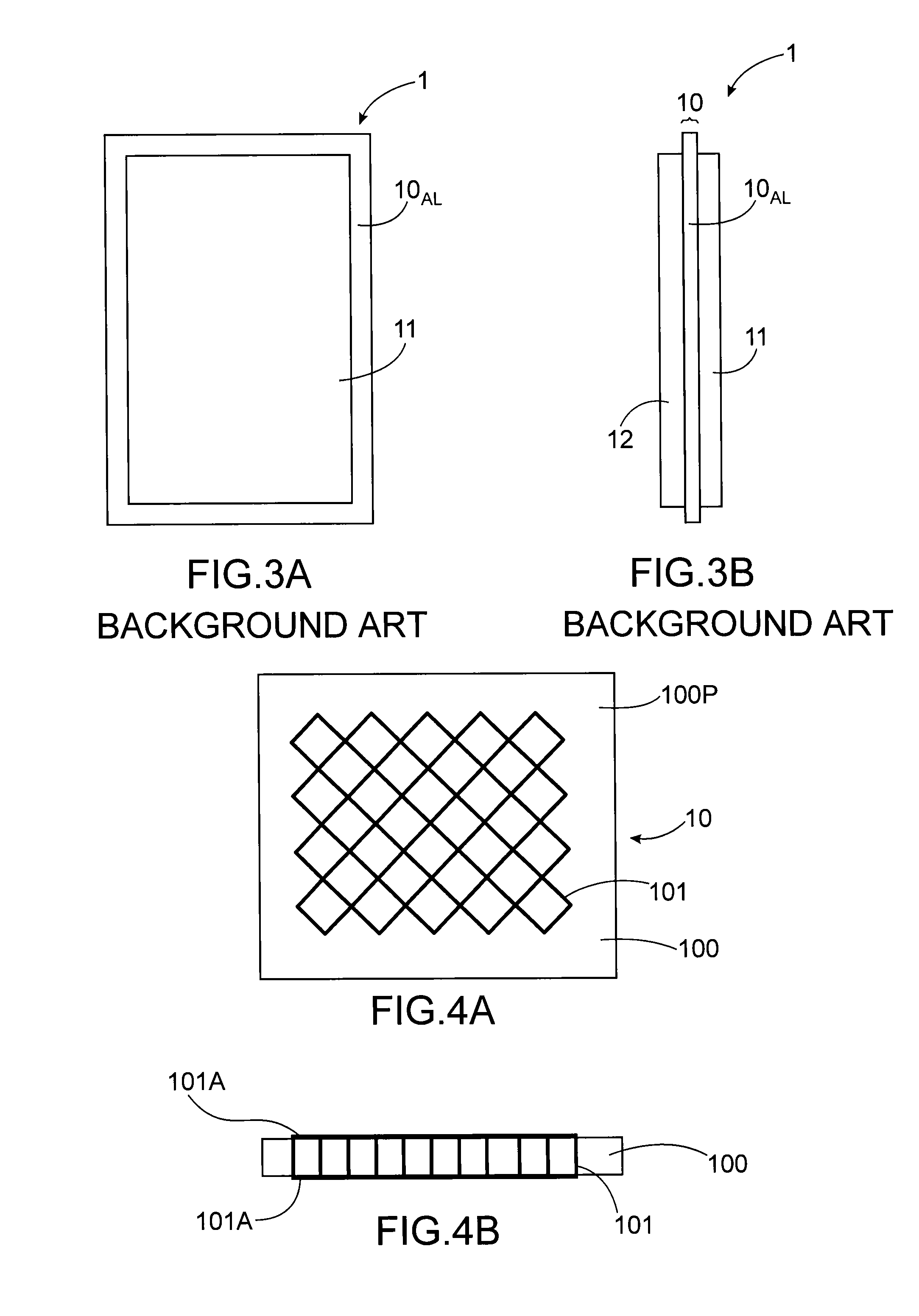

Current collector having built-in sealing means, and bipolar battery including such a collector

InactiveCN103069614AElectrode rolling/calenderingPrimary cell manufactureElectrical batteryEngineering

The invention relates to bipolar lithium batteries. In order to improve the seal with respect to the electrolytes between adjacent electrochemical cells, the invention involves producing novel mixed electrode-supporting current collectors (10), in the form of a metal grate (101) or a raised metal sheet accommodated in a strip (100) made of an electrically insulating material, the periphery (100p) of which has the function of forming the sealing area.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

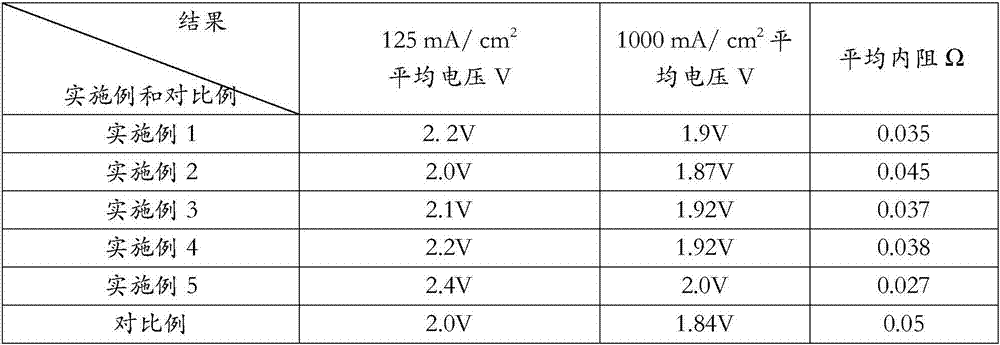

Positive and negative electrode welding and membrane covering assembly line of battery

InactiveCN105428668AImprove intelligenceHigh degree of automationPrimary cell manufactureAssembling battery machinesBattery chargeInternal resistance

The invention provides a positive and negative electrode welding and membrane covering assembly line of a battery. The assembly line comprises a positive and negative electrode welding machine, a membrane covering machine and a cache mechanism, wherein the positive and negative electrode welding machine comprises a battery charging conveyor module and a welding concentricity detector module; the membrane covering machine comprises a battery membrane covering module and a battery boxing module; the cache mechanism comprises a cache box, a battery charging channel and a battery discharging channel. The assembly line can be used for carrying out charging, conveying, positive electrode welding, positive electrode concentricity detection, positive electrode welding, negative electrode concentricity detection, sorting of accepted weld products, battery conveying caching, battery internal resistance testing, battery meson assembly, battery membrane covering, battery membrane baking, sorting of accepted battery products, battery boxing, discharging and recycling in a full automatic way and integrates all these functions into a whole; the assembly line has the advantages of high intelligent level, high automatic operation degree, high detection accuracy, high welding and assembling working efficiency, high yield, good quality effect and low cost; in addition, the assembly line can produce over 55 batteries per minute.

Owner:广东彩扬能源装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com