Patents

Literature

74results about How to "Reduce transfer process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

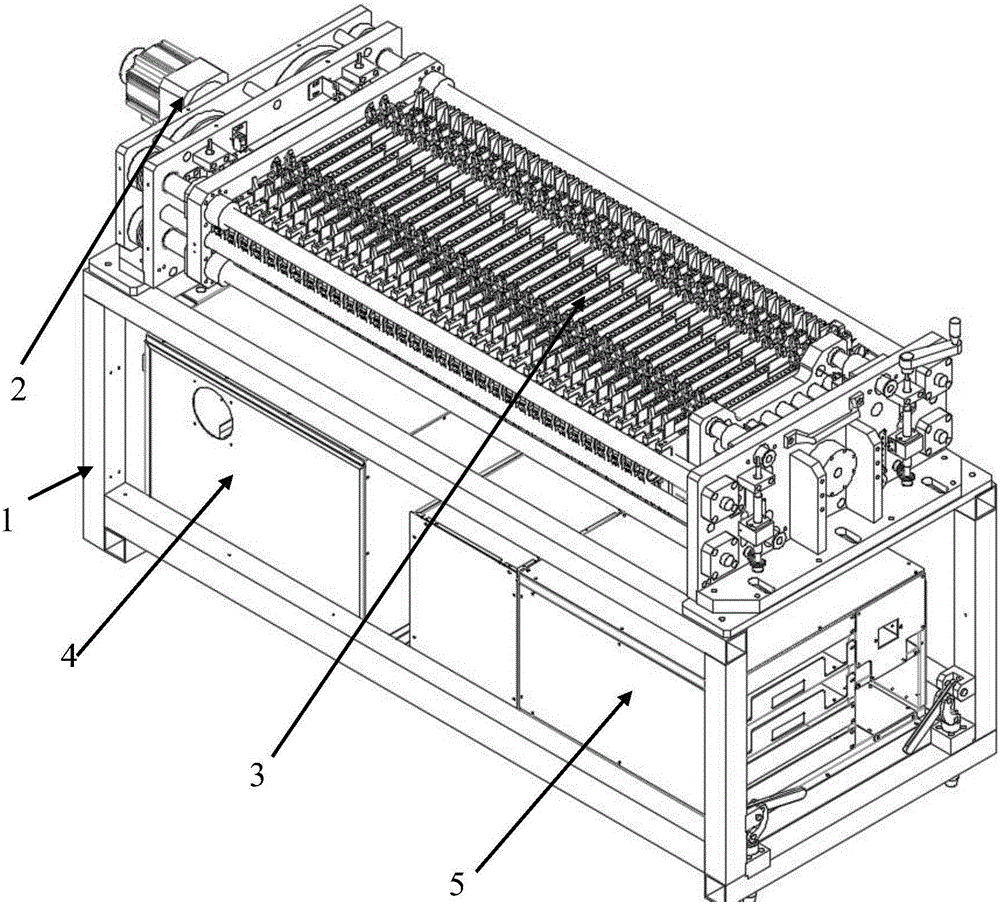

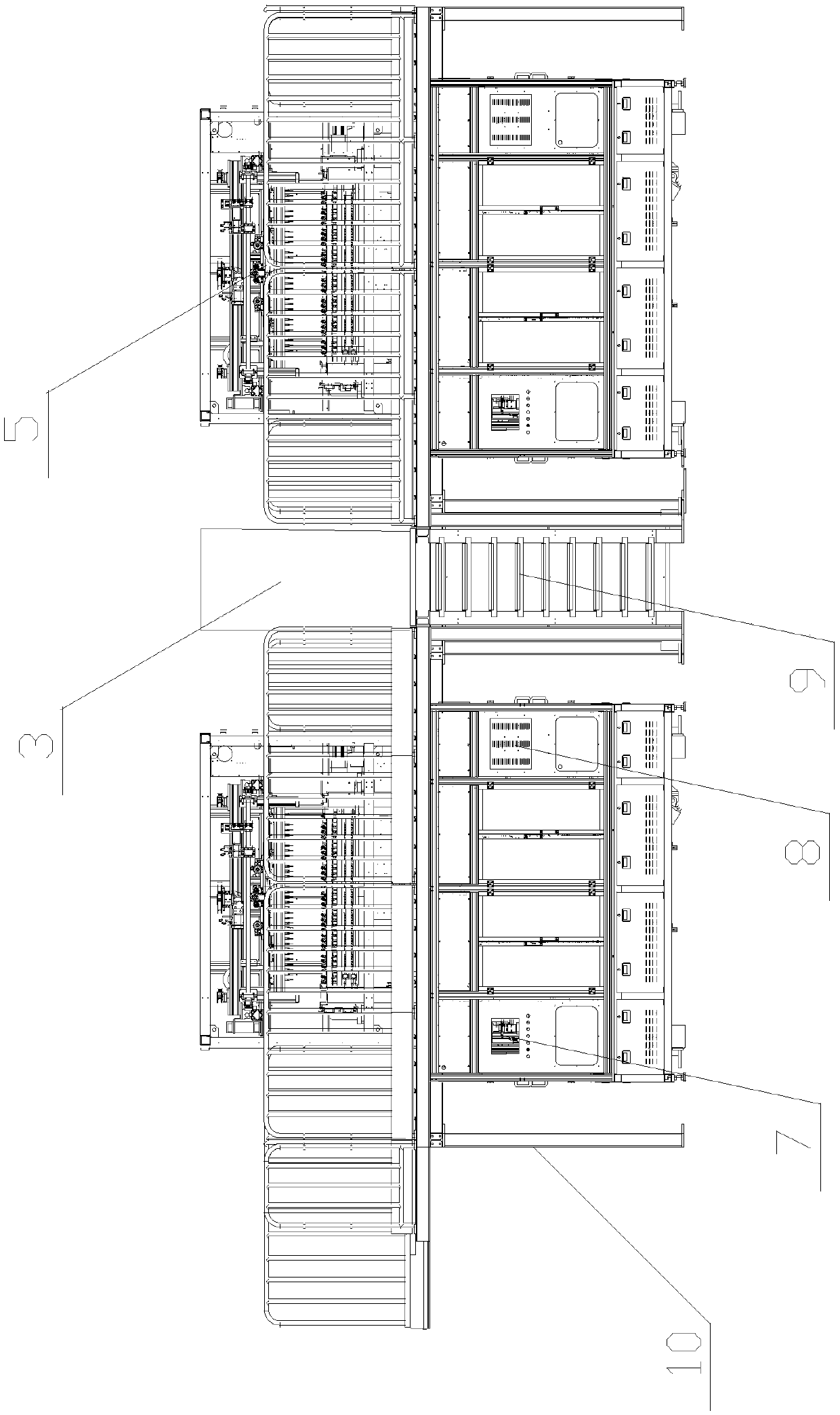

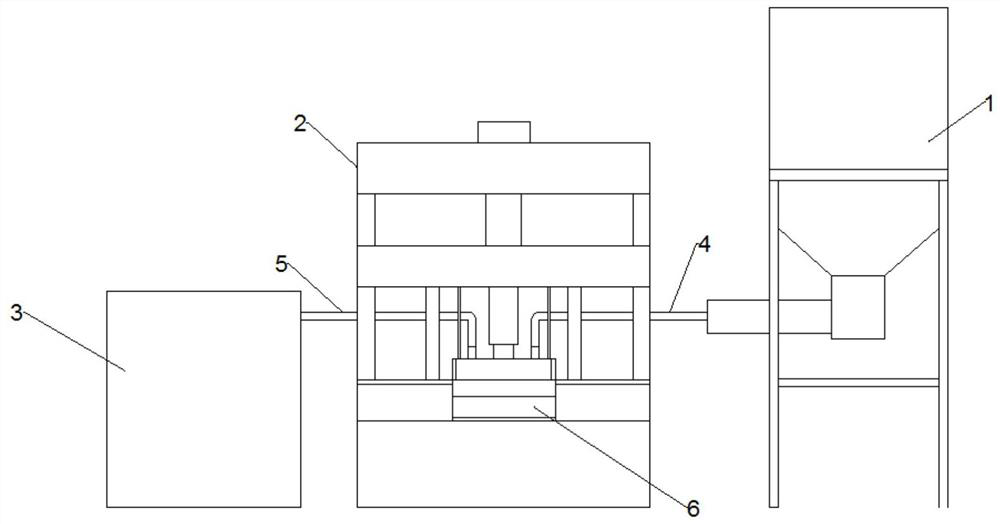

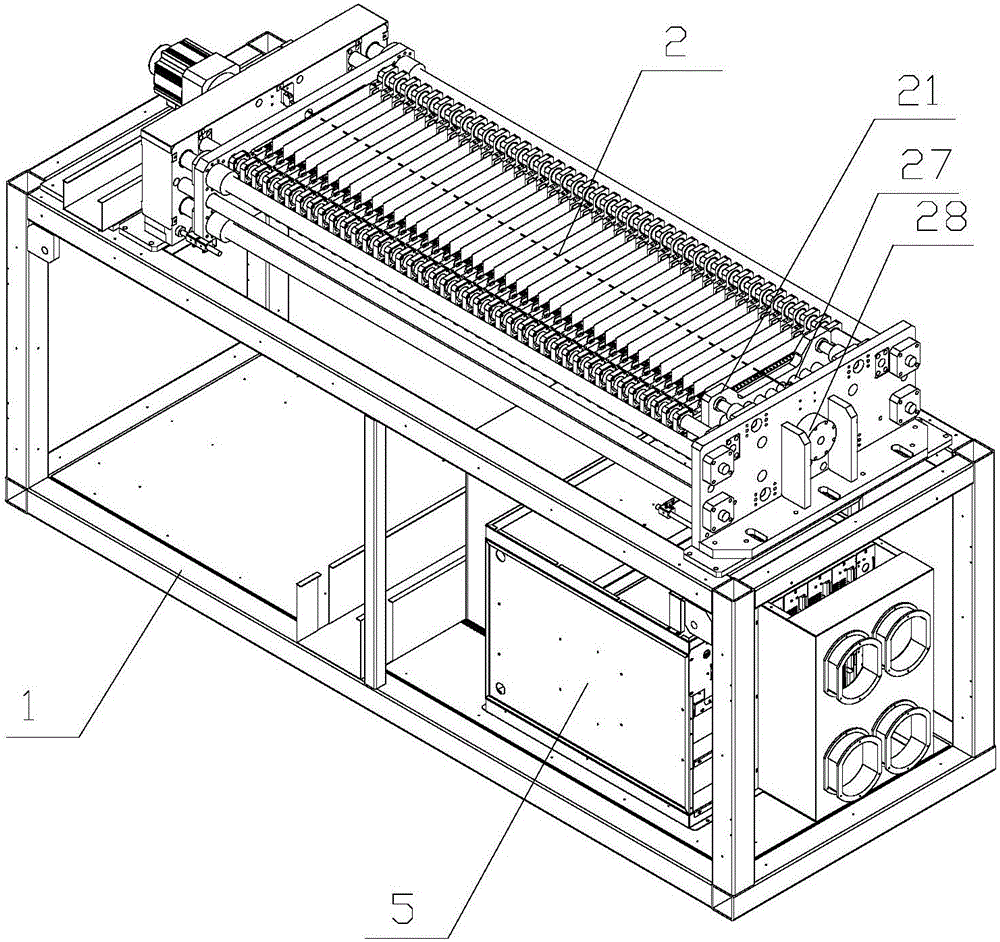

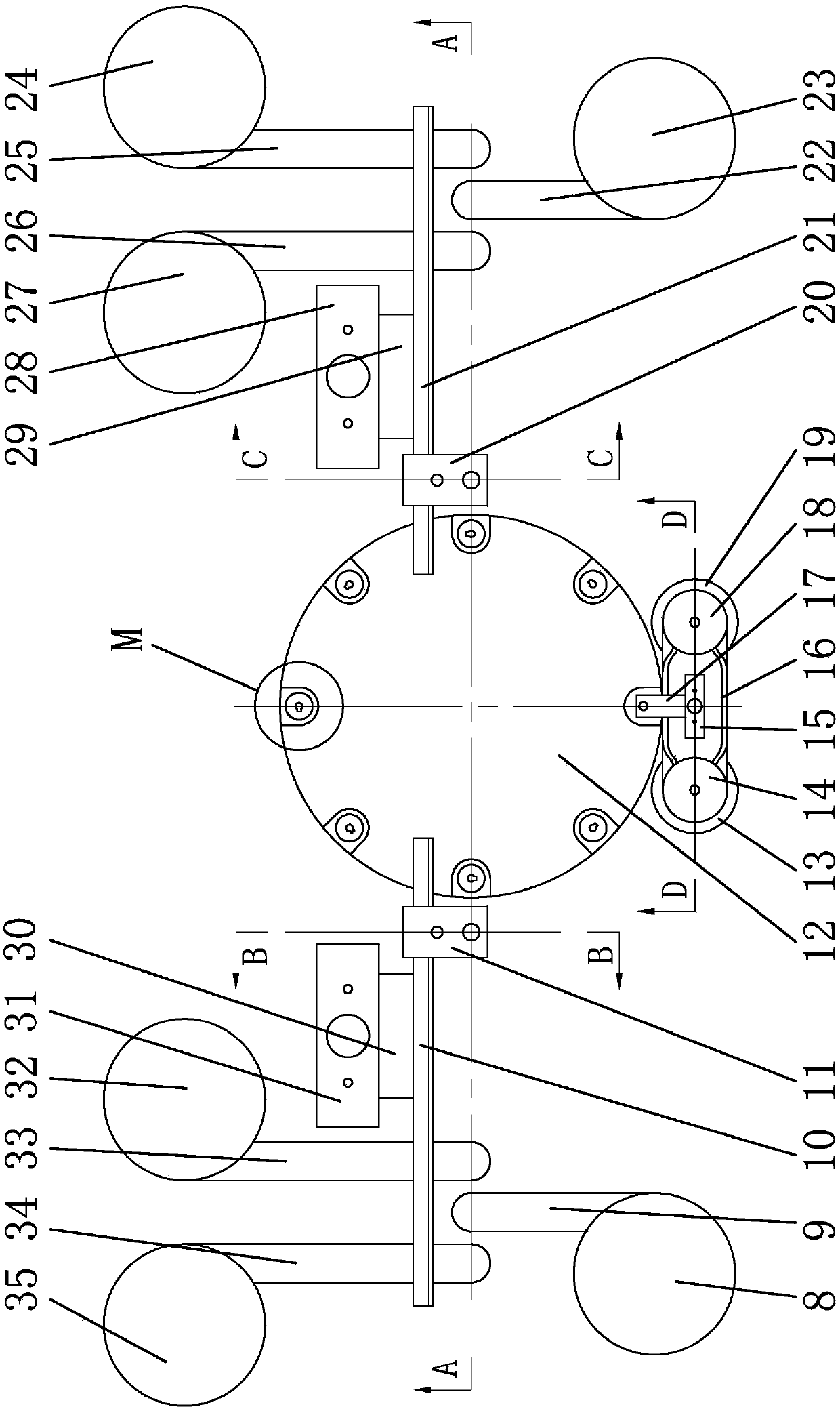

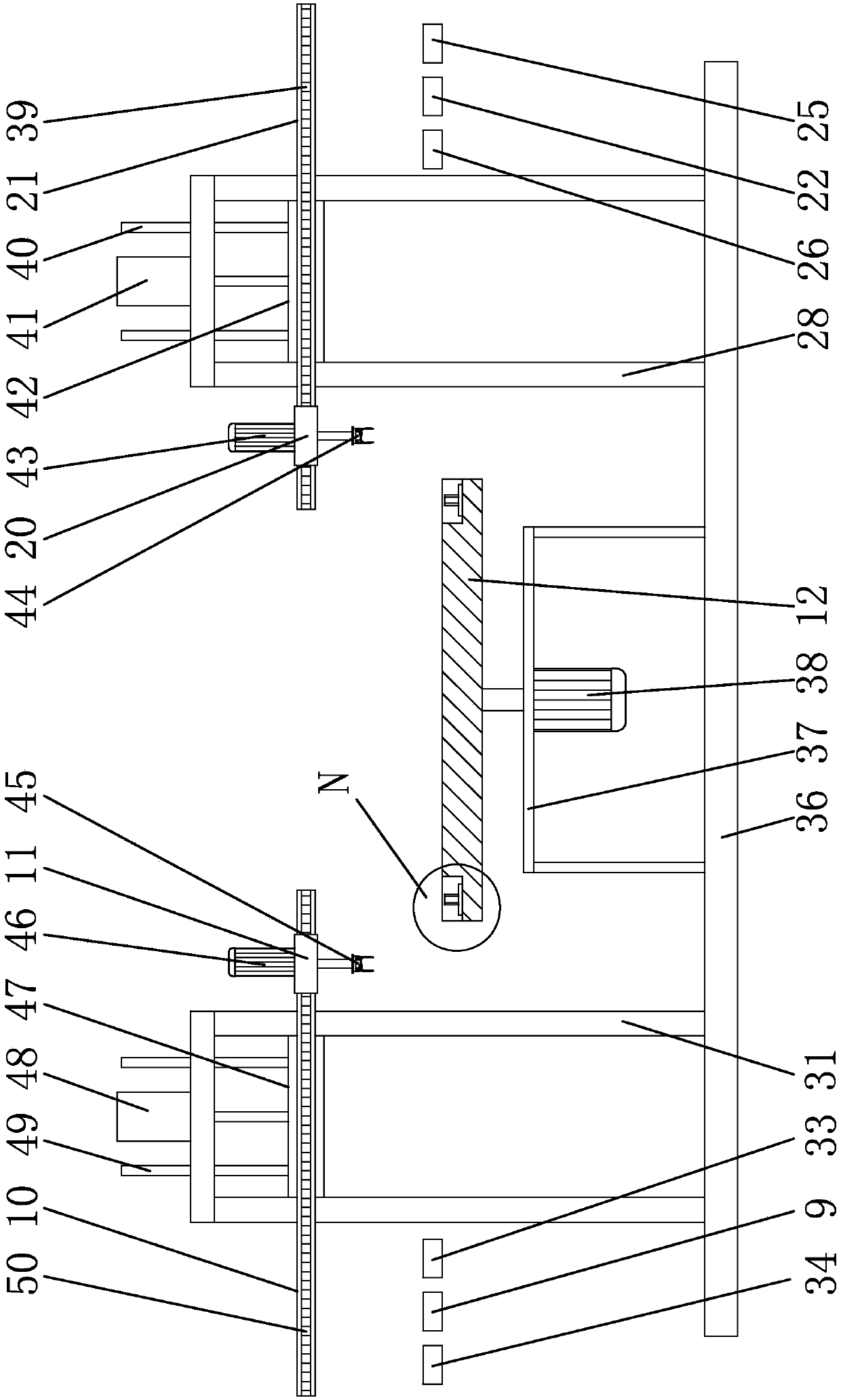

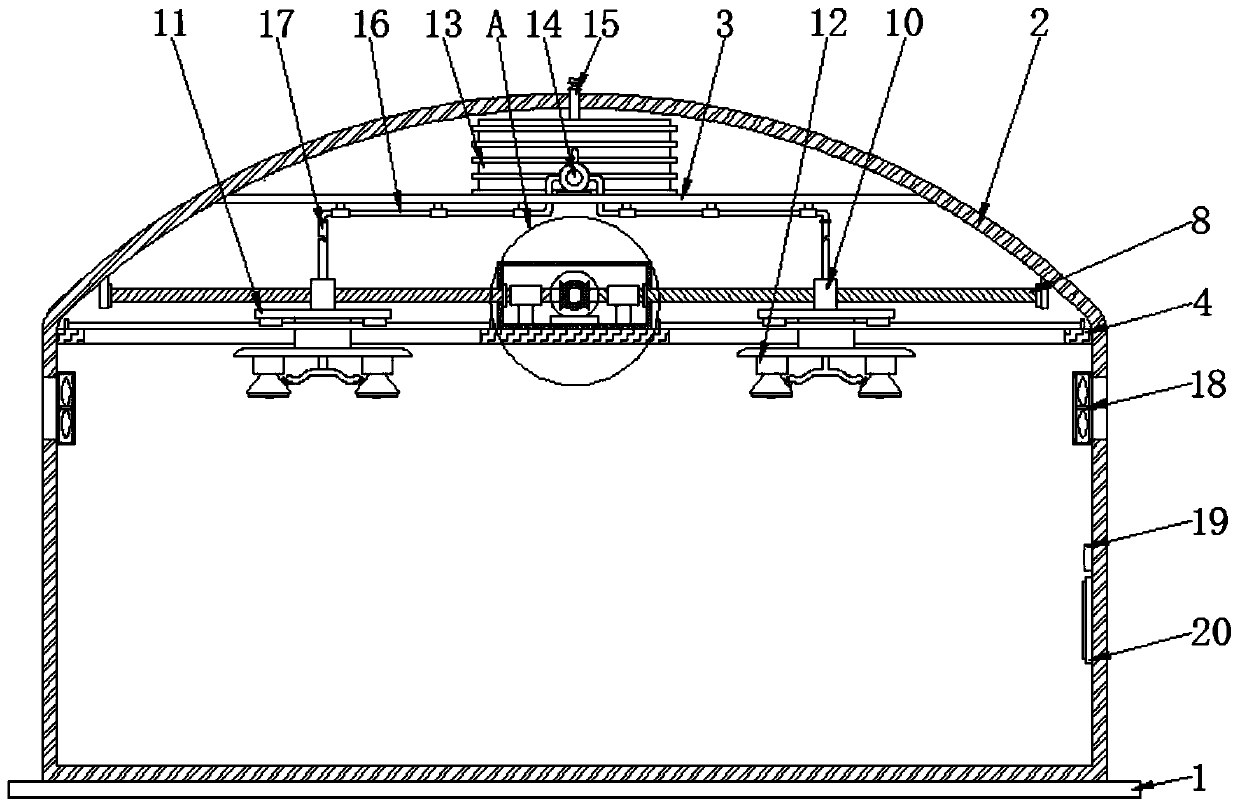

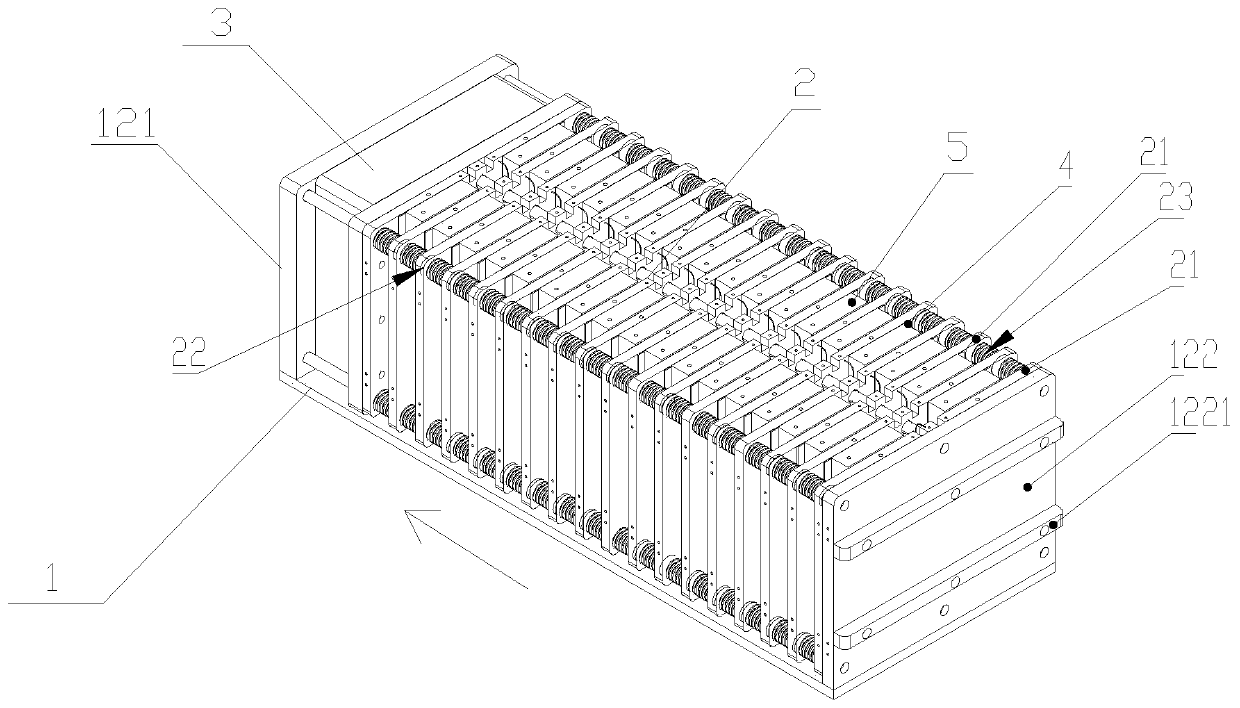

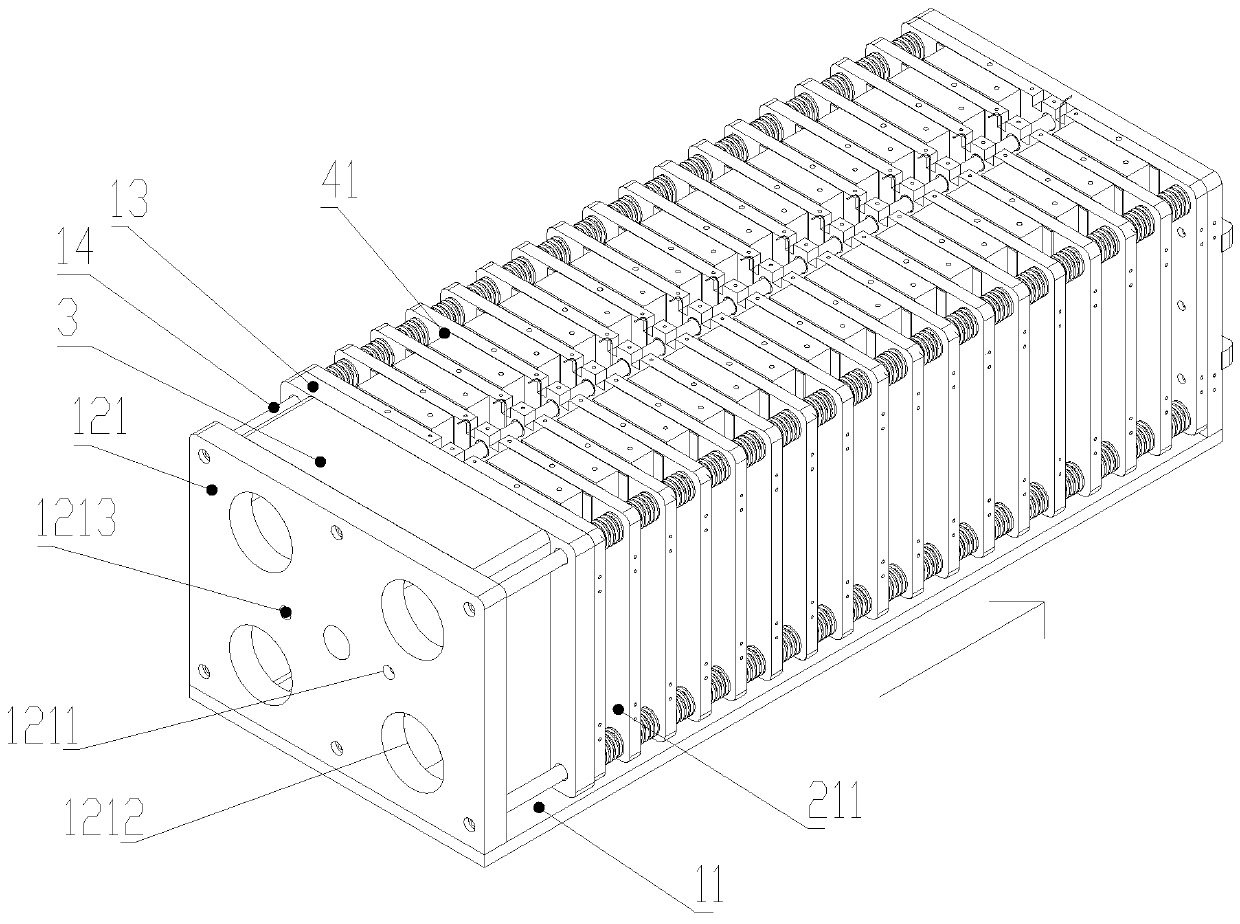

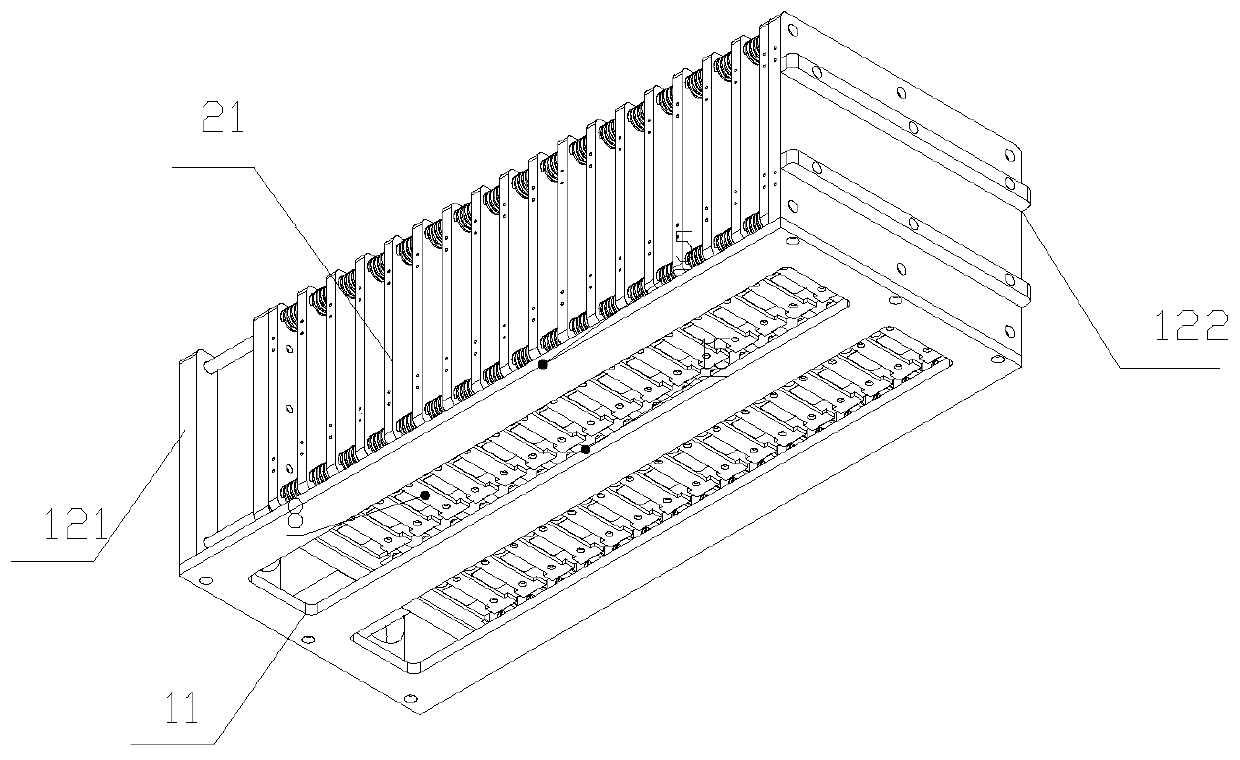

Motor-drive type hot pressing and cold pressing formation clamp equipment of flexibly-packaged power lithium flexibly-packaged battery

ActiveCN107565169AEnsure consistencyReduce transfer processFinal product manufactureSecondary cells manufactureElectricityMotor drive

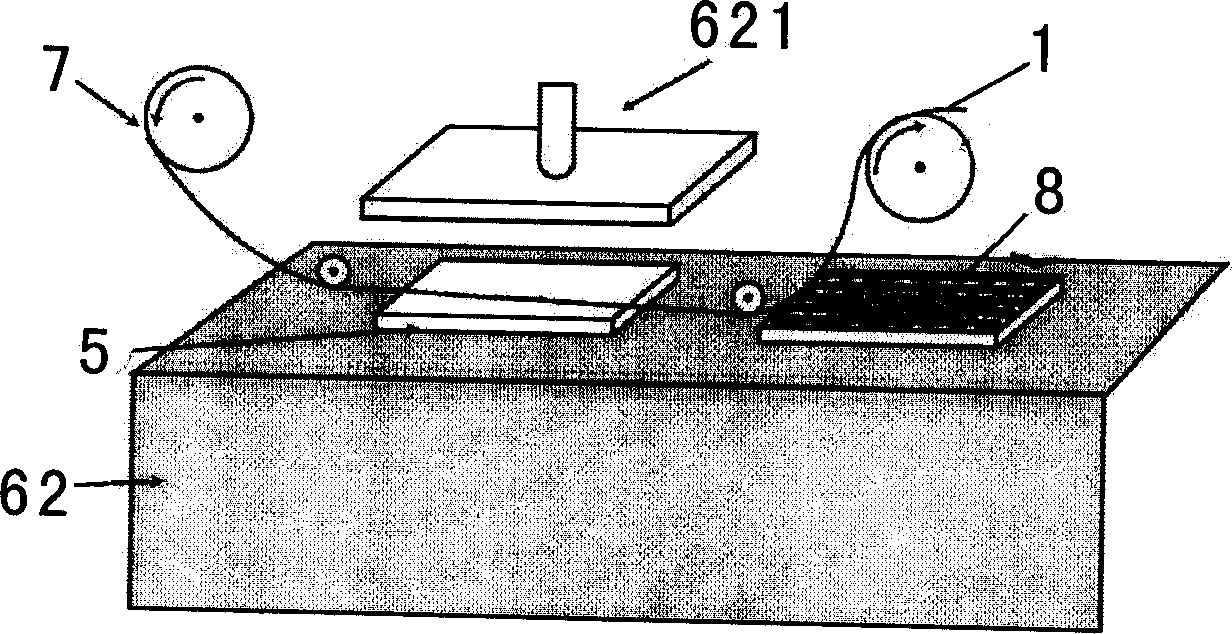

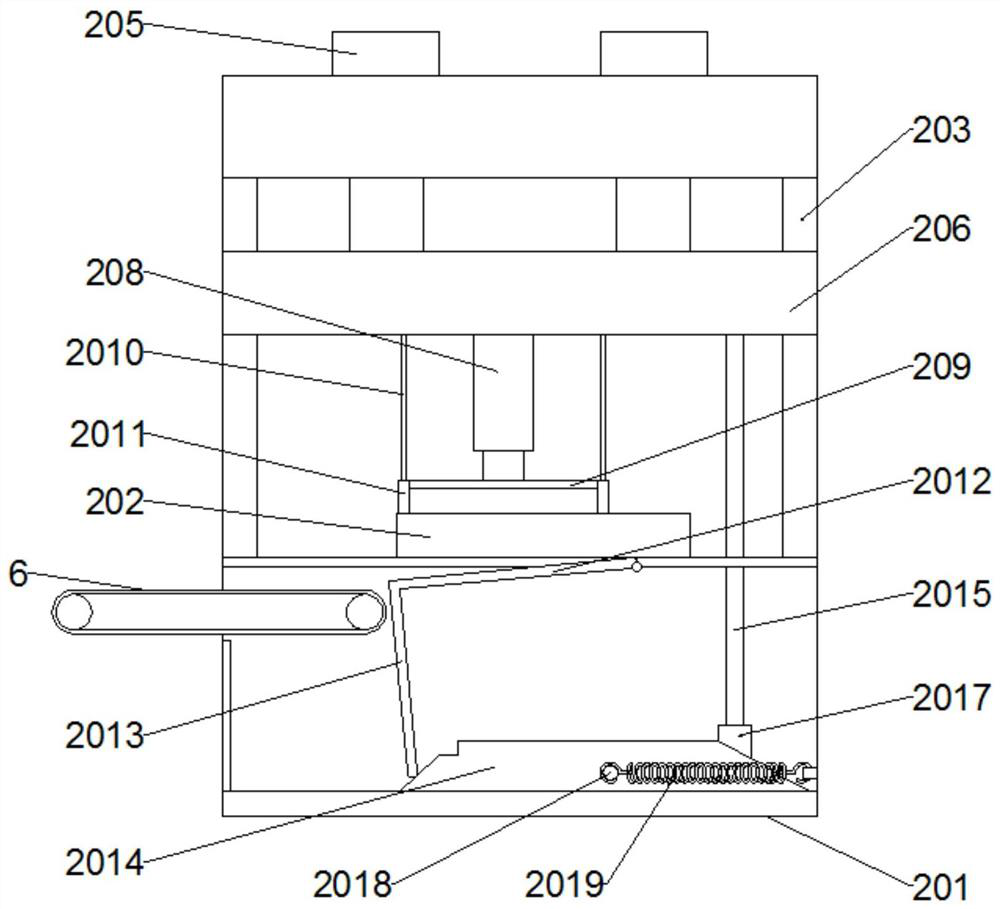

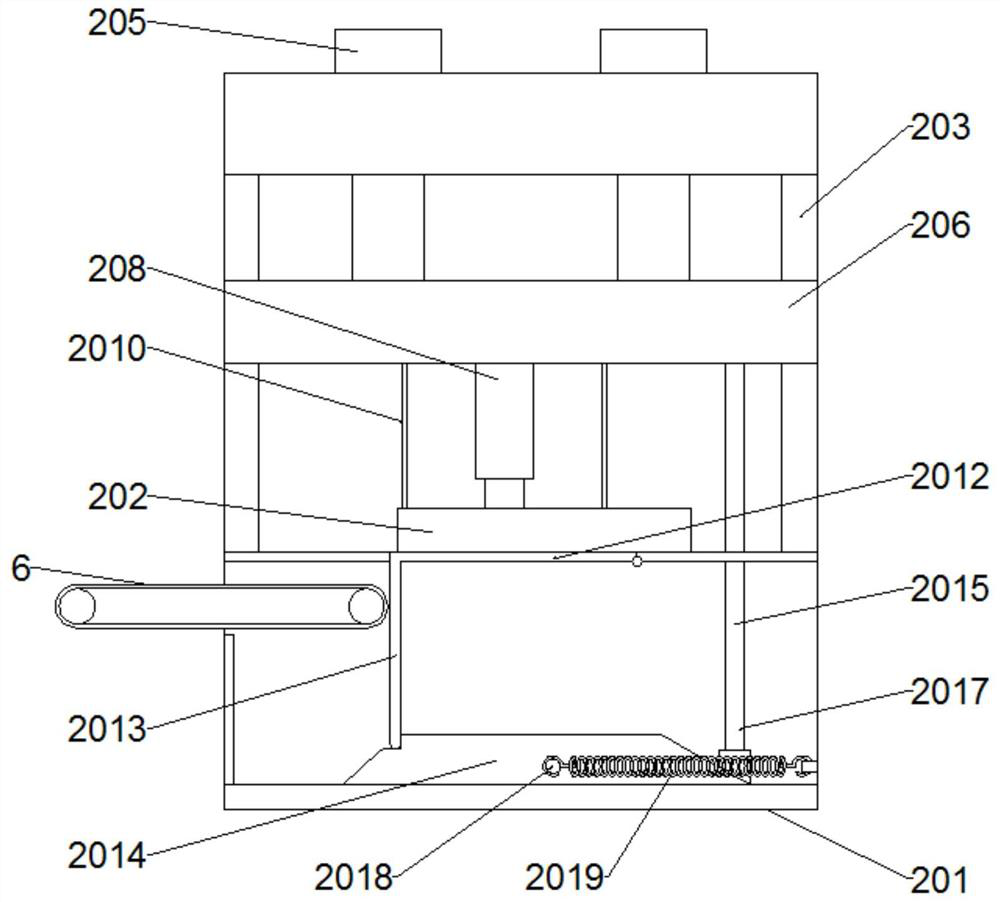

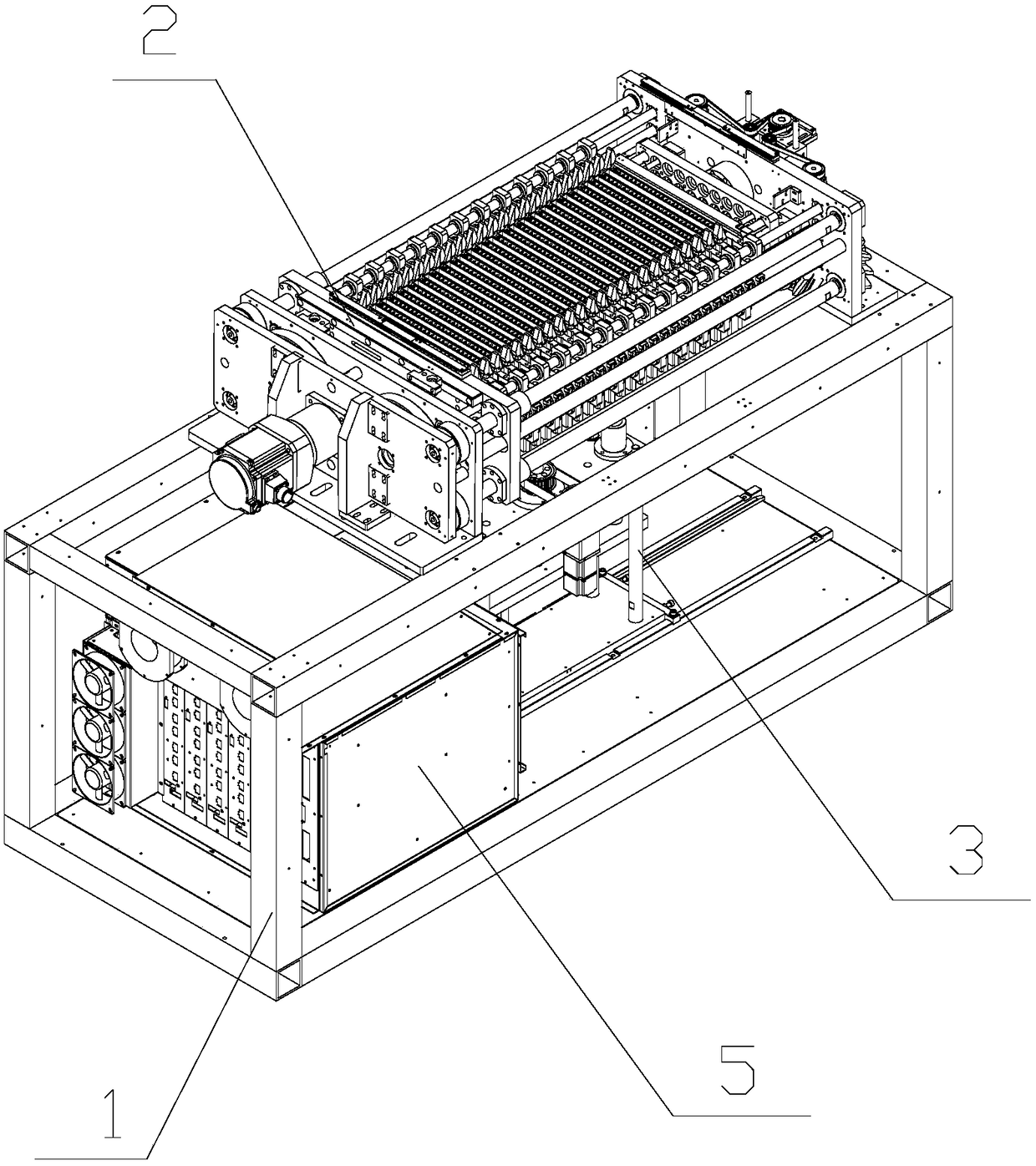

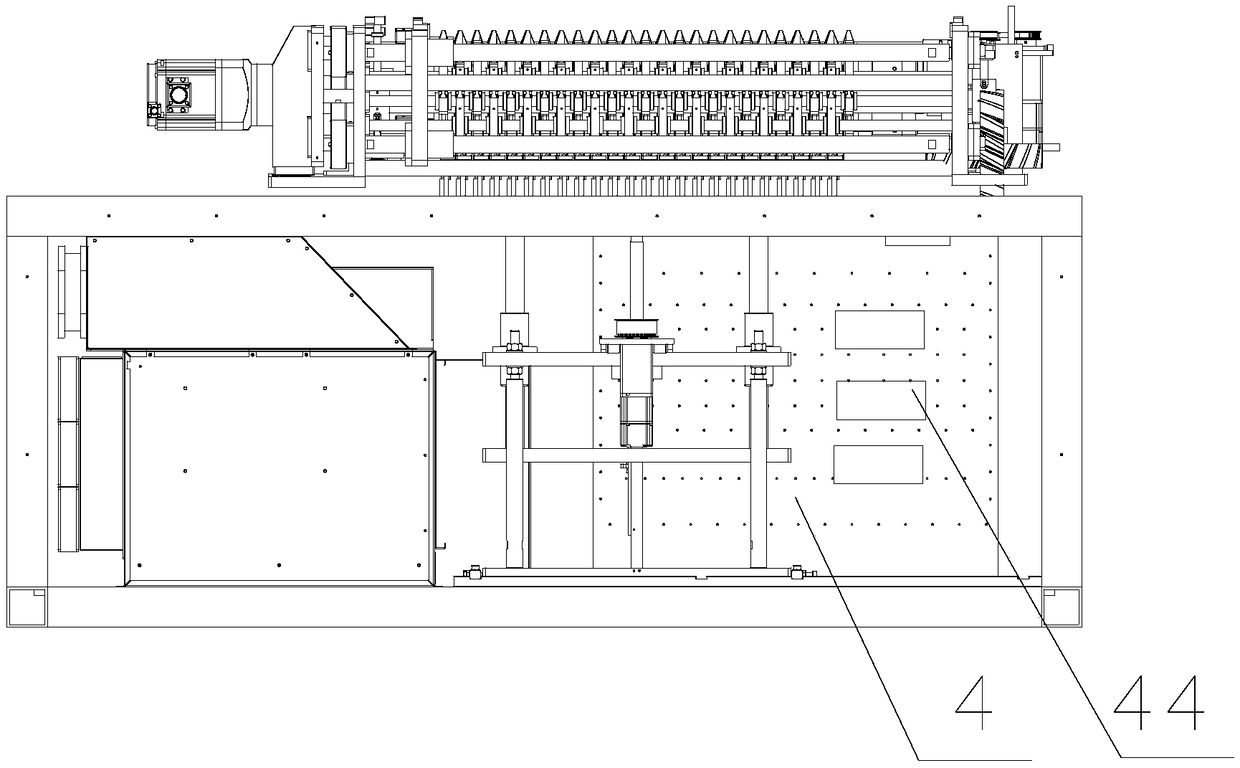

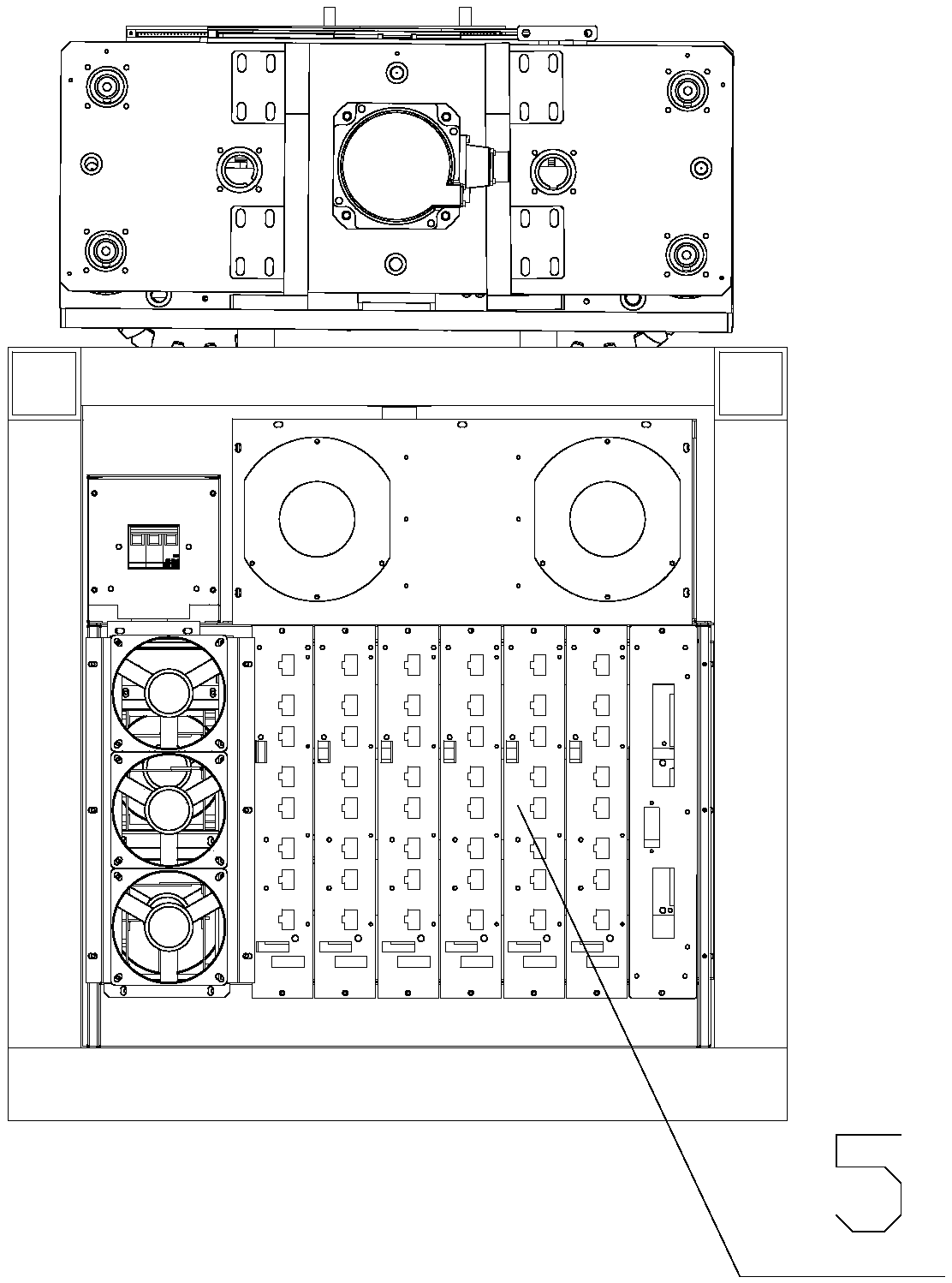

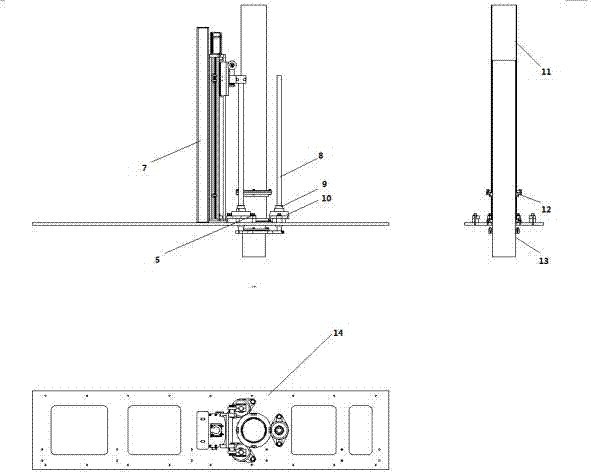

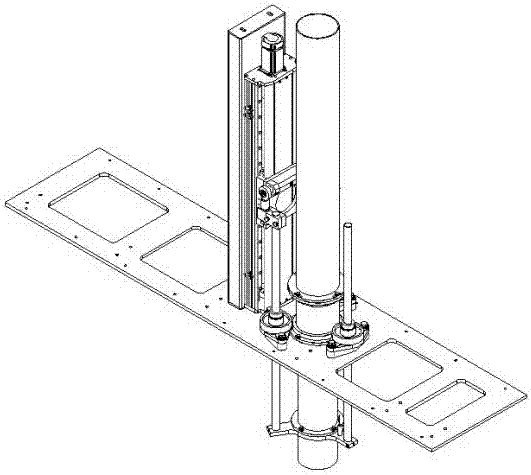

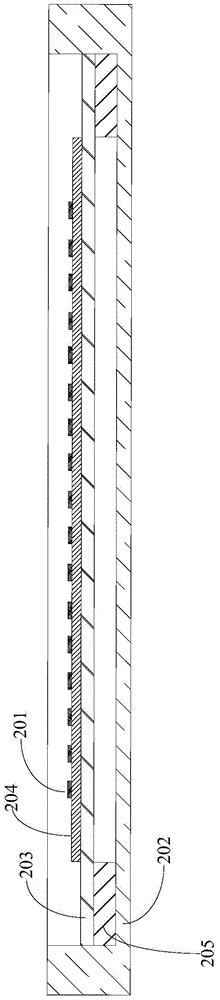

Disclosed is motor-drive type hot pressing and cold pressing formation clamp equipment of a flexibly-packaged power lithium flexibly-packaged battery. The equipment comprises a rack, a feeding platform, a feeding and discharging mechanical arm, a cold-pressing forming clamp, multiple sets of hot-pressing forming clamps, a plurality of charging-discharging power supplies, a safety alarming module and a central control unit; the feeding platform, the cold-pressing forming clamp and the hot-pressing forming clamps are arranged in the middle layer of the rack in the length direction of the rack insequence; the charging-discharging power supplies are mounted at the bottom layer of the rack; each set of the hot-pressing forming clamp is corresponding to one set of charging-discharging power supply; the feeding and discharging mechanical arm is arranged on the upper layer of the rack; the movement travel of the feeding and discharging mechanical arm covers the whole hot-pressing forming clamps; and the feeding platform, the feeding and discharging mechanical arm, the cold-pressing forming clamp, the multiple sets of hot-pressing forming clamps, the charging-discharging power supplies andthe safety alarming module are all electrically connected with the central control unit. The equipment has the beneficial effects of integrating the three working procedures of lithium battery formation, hot pressing and cold pressing on one equipment, so that time can be shortened, equipment investment can be lowered, production efficiency can be improved, and the quality of the flexibly-packaged battery can be improved.

Owner:ZHEJIANG HANGKE TECH

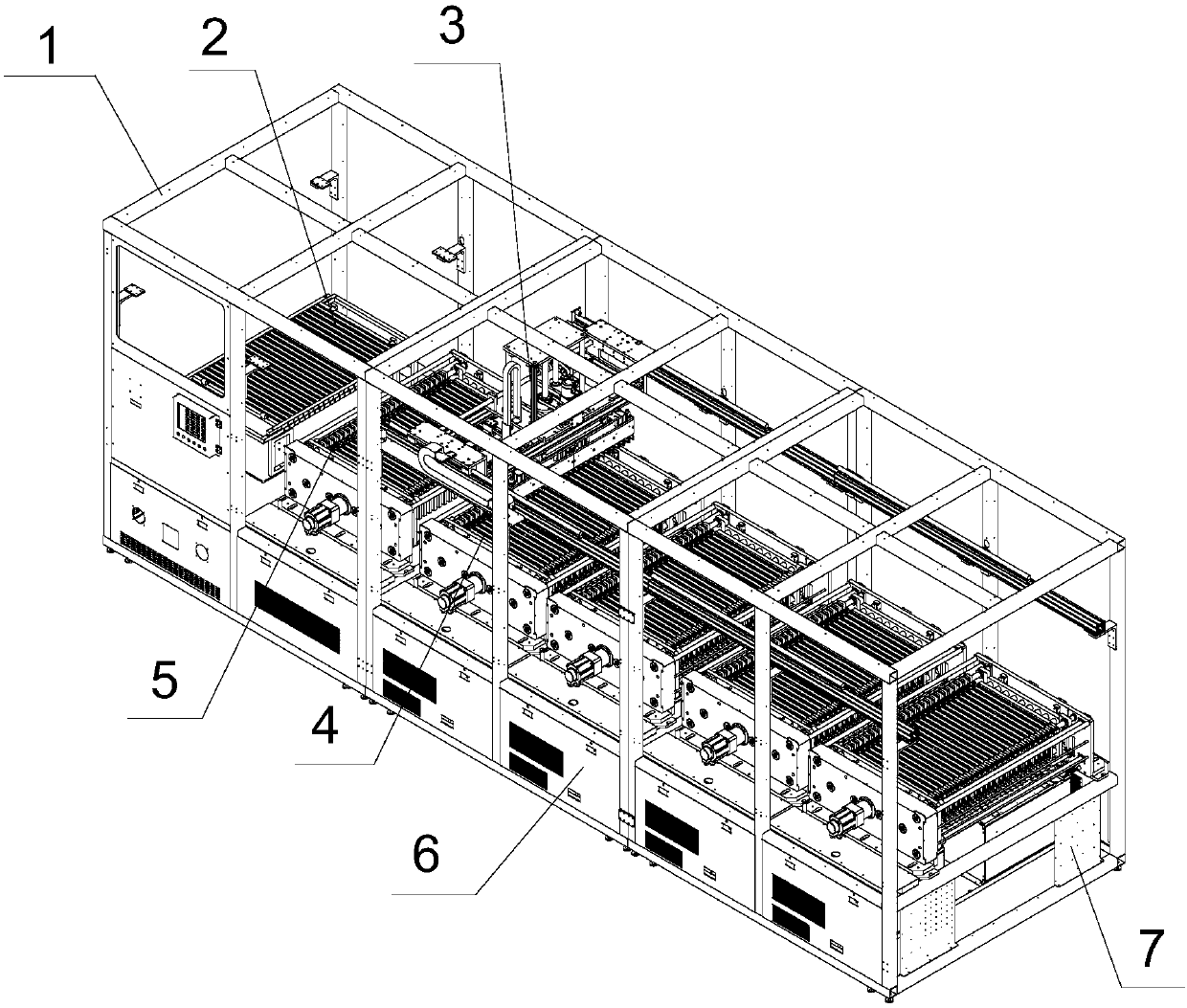

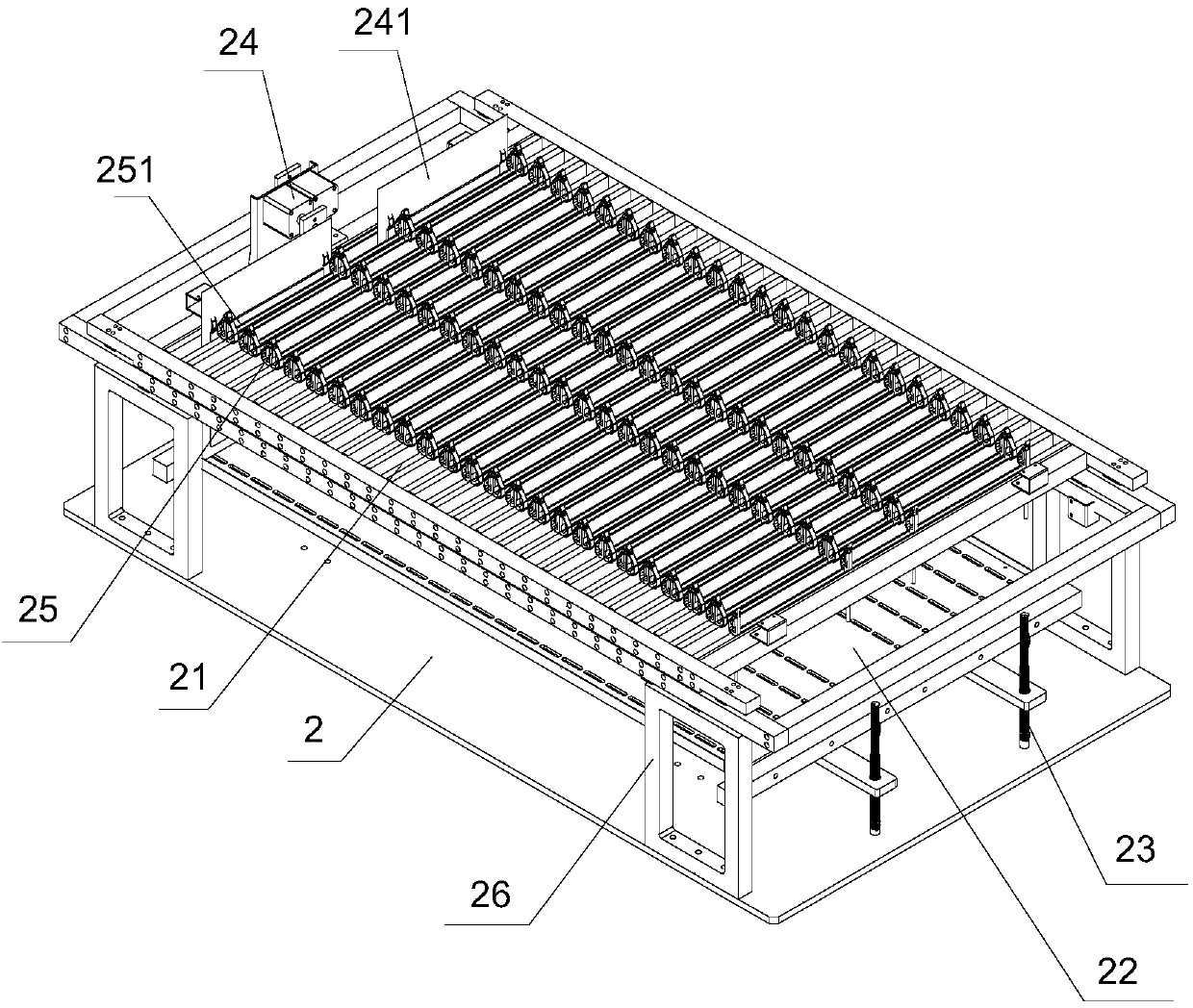

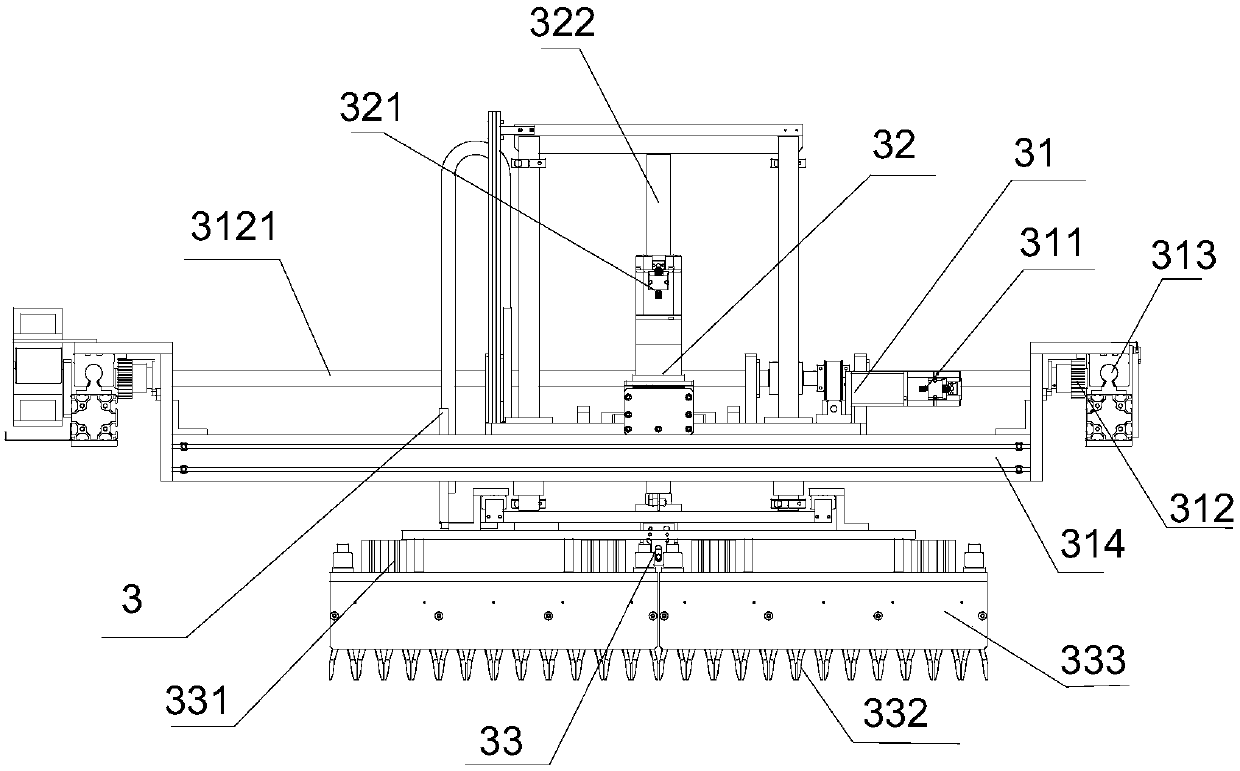

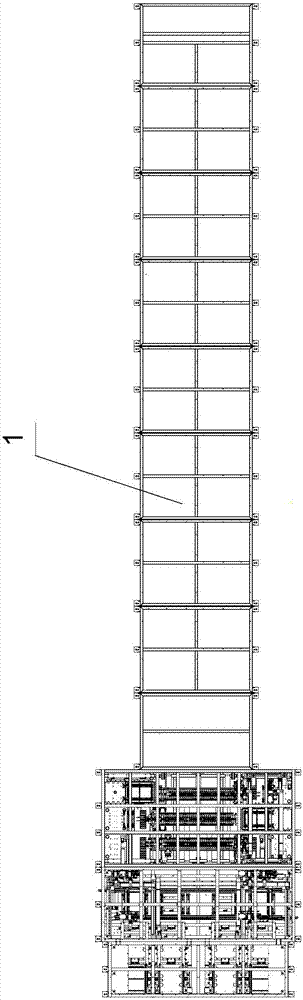

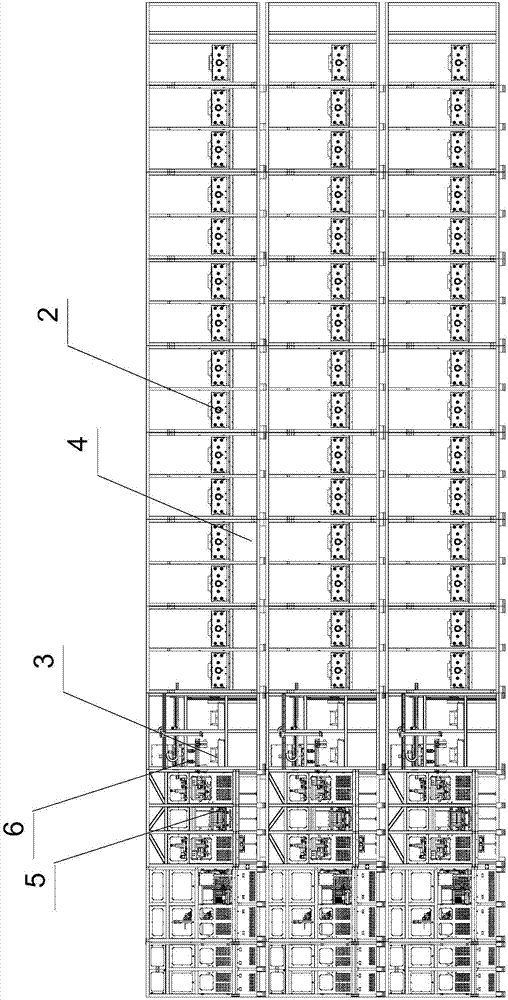

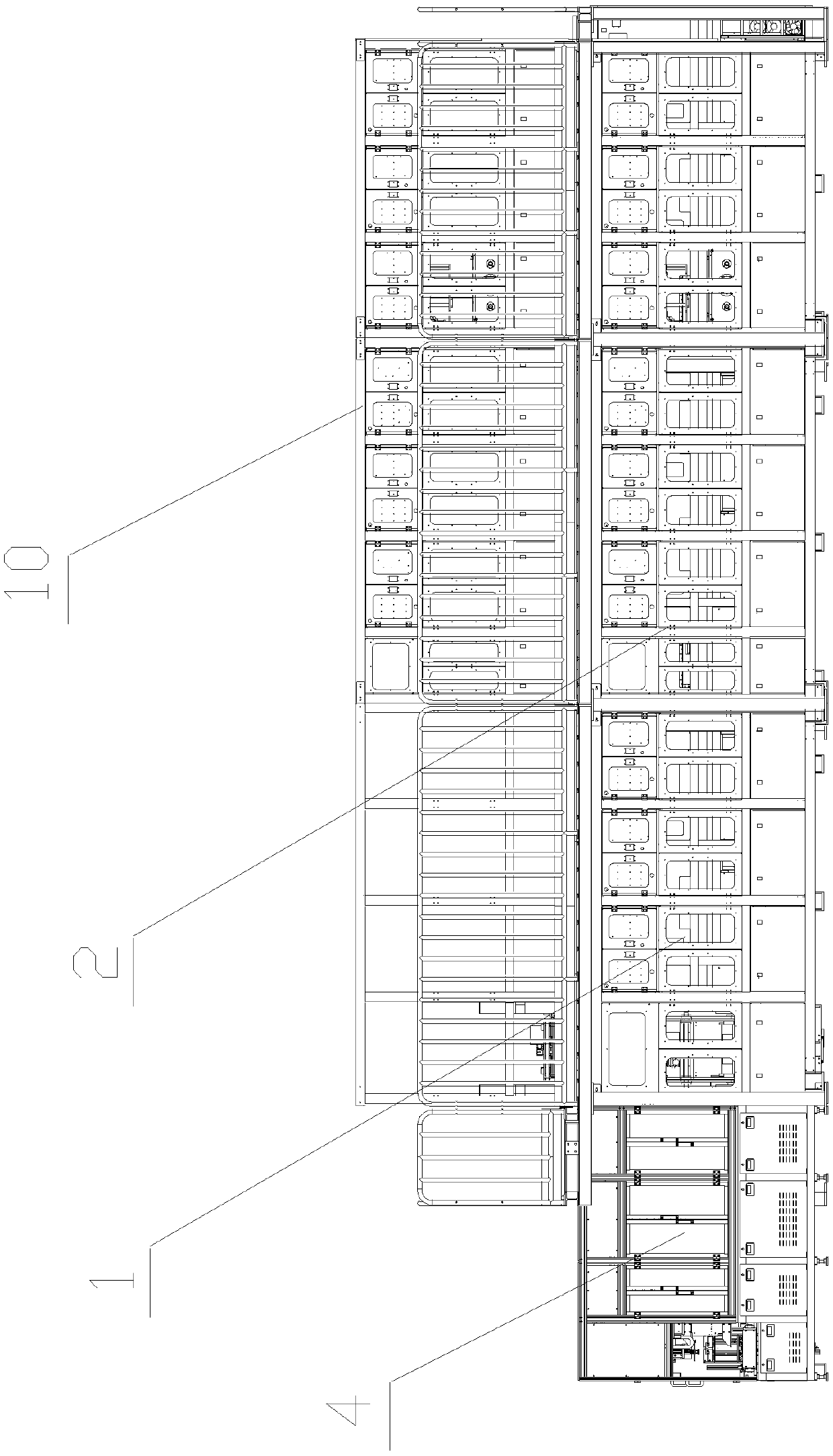

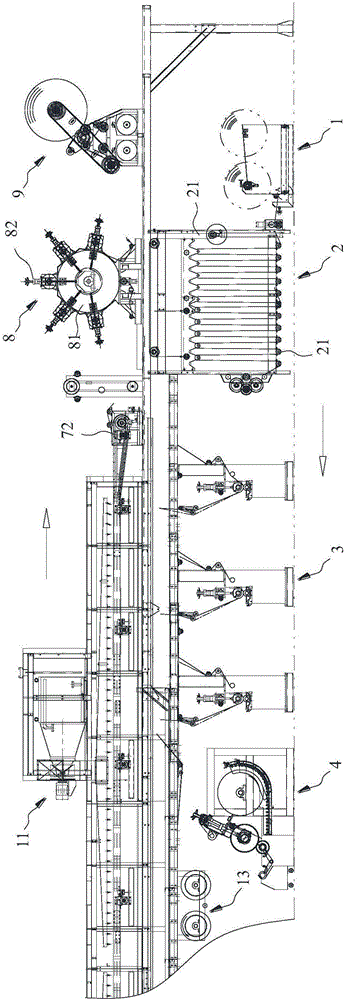

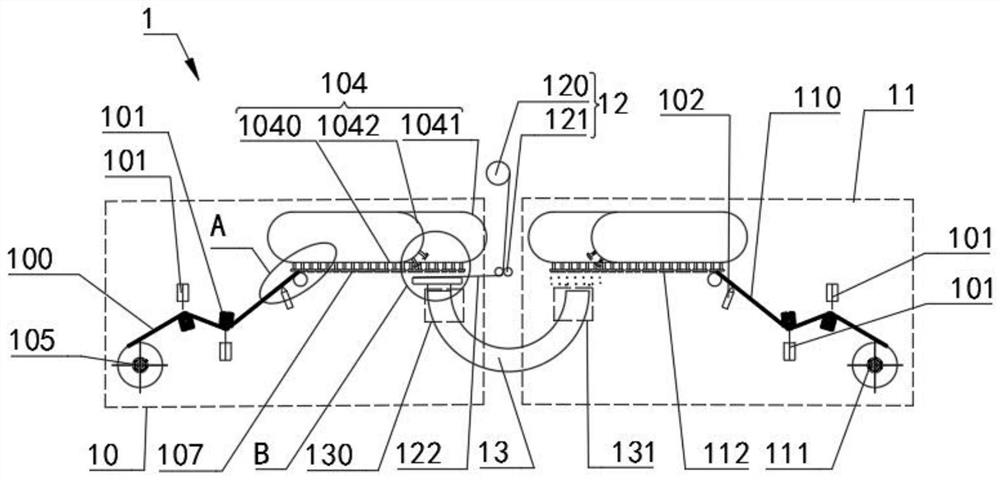

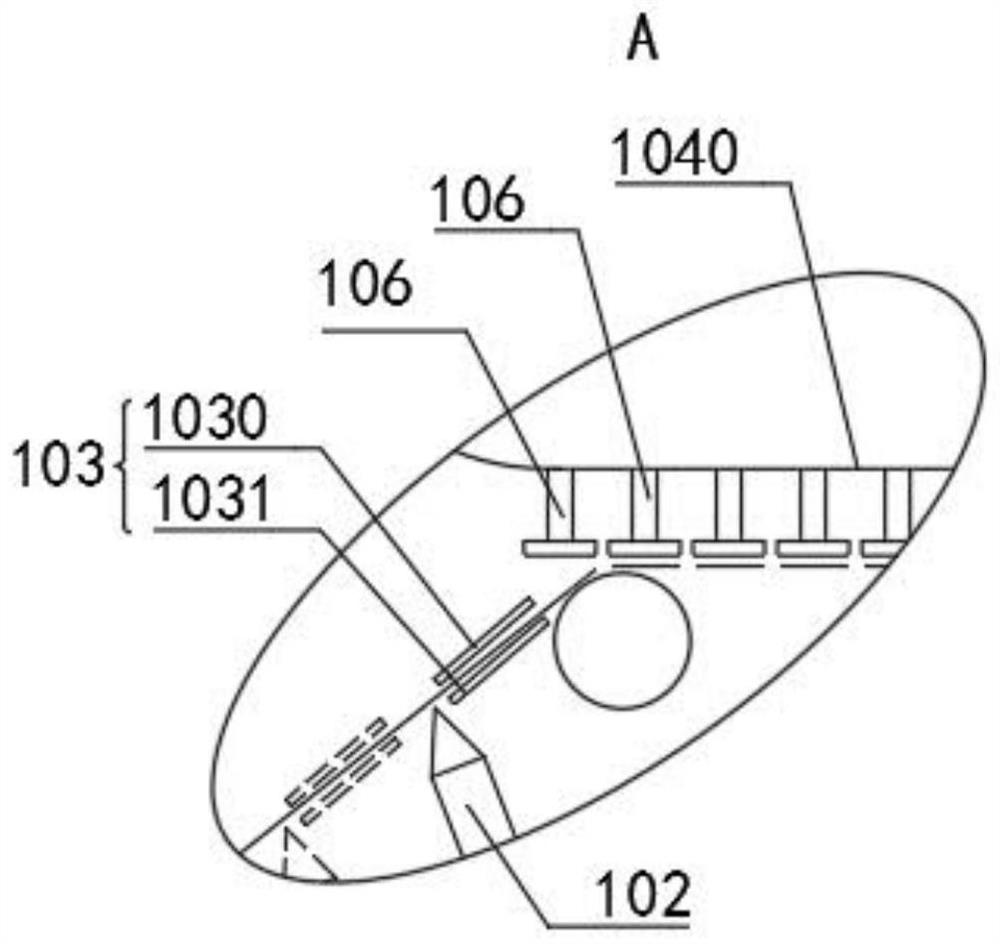

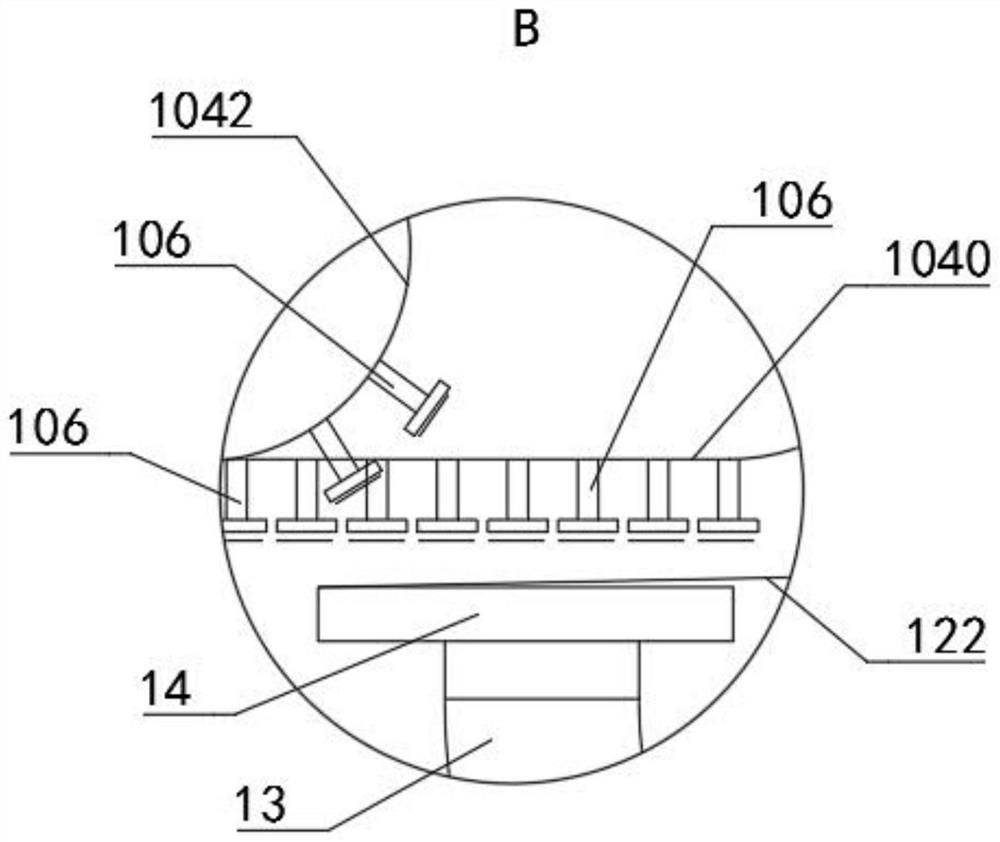

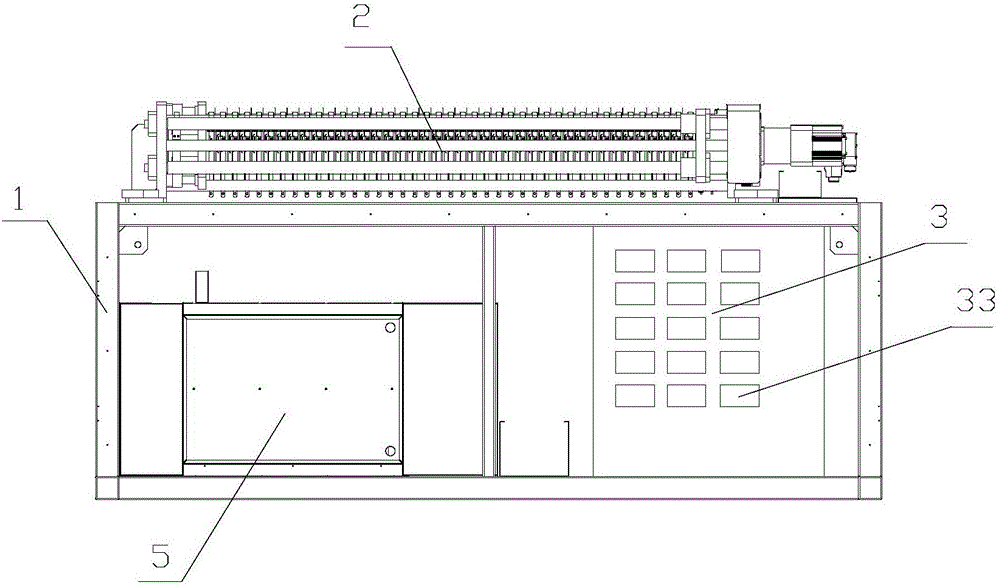

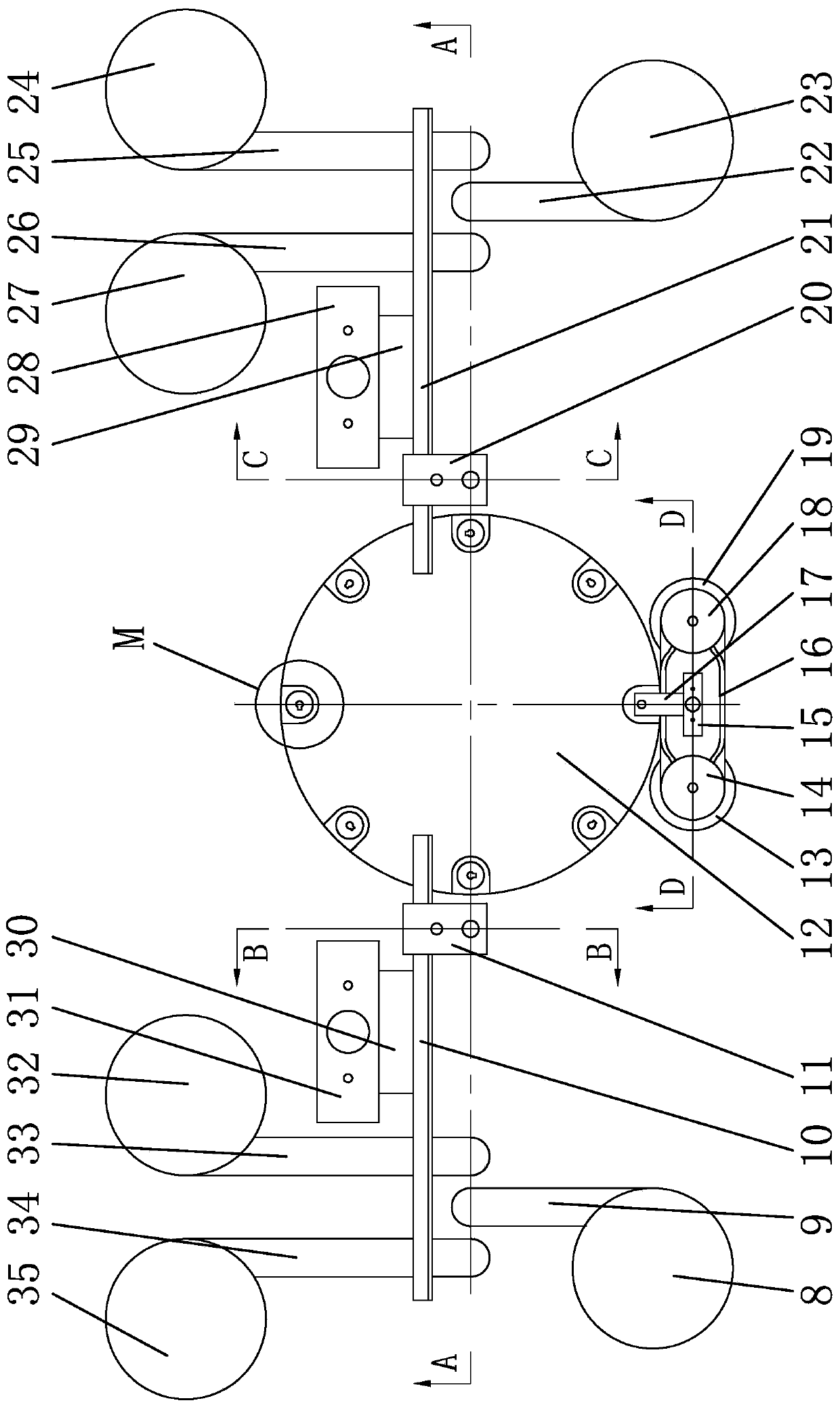

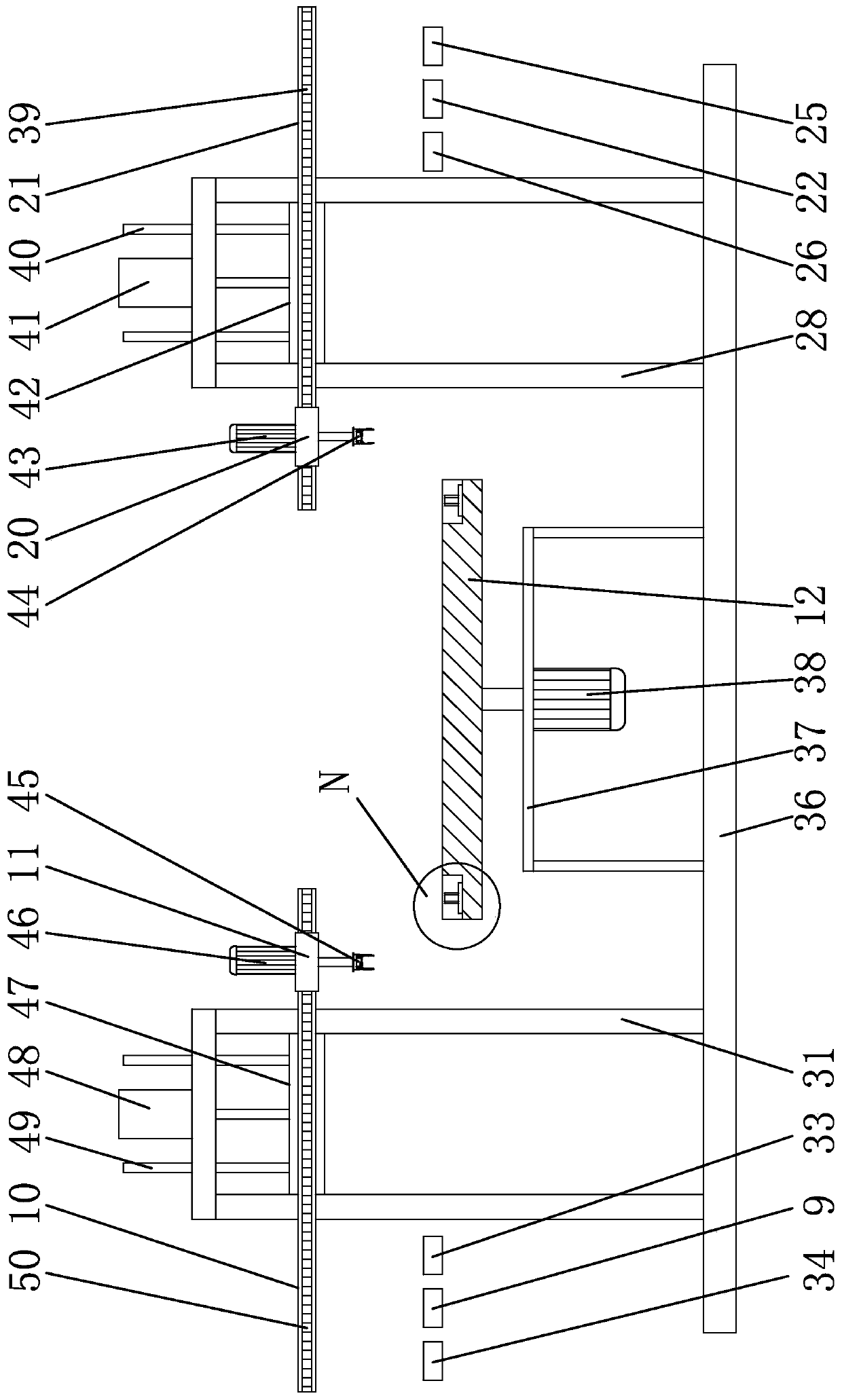

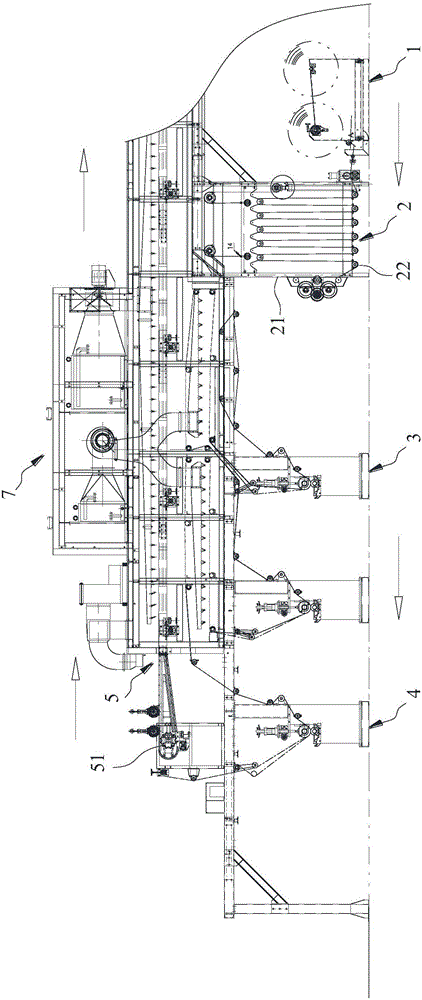

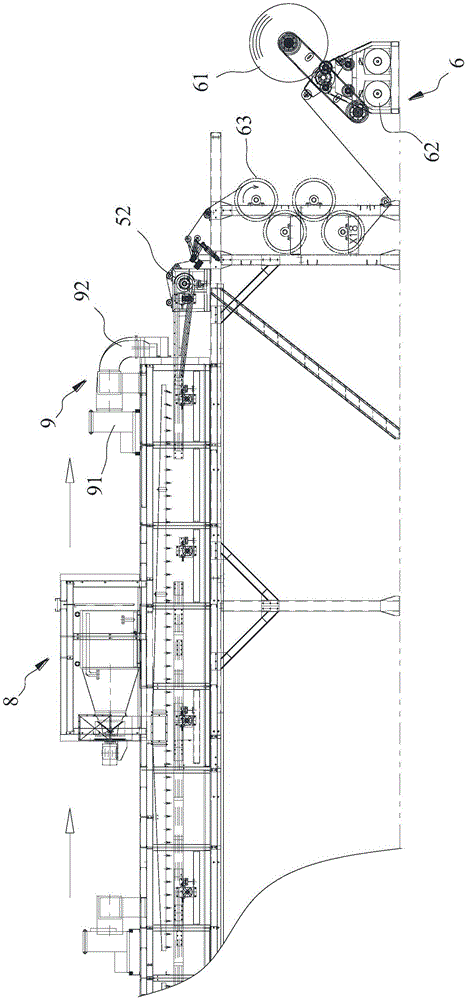

Soft package lithium battery hot and cold pressed fixture formation automatic production line

ActiveCN106935877AEnsure consistencyReduce transfer processPrimary cell manufactureAssembling battery machinesProduction lineThermal compression

The invention relates to a soft package lithium battery hot and cold pressed fixture formation automatic production line, which consists of a rack, hot press fixture formation units, a cold press shaping fixture unit, charge-discharge formation control units, a battery loading and unloading unit, a transplanting manipulator unit, a production process control and detection unit, a safety alarming unit and a controller. The hot press fixture formation units and the charge-discharge formation control units are both disposed on the surface of the rack along an axial direction, each set of hot press fixture formation unit corresponds to a set of charge-discharge formation control unit, and the moving range of the transplanting manipulator unit covers the whole processing station. The production process control and detection unit, the safety alarming unit and the central controller are all mounted on the rack. According to the invention, battery turnover, pressurization, heating, formation, cooling forming and data acquisition are integrated in one set of system to proceed, the transit process between procedures is reduced, the orginal two procedures are combined into one, the production efficiency is improved, the battery consistency is ensured, and an automatic assembly line is realized.

Owner:ZHEJIANG HANGKE TECH

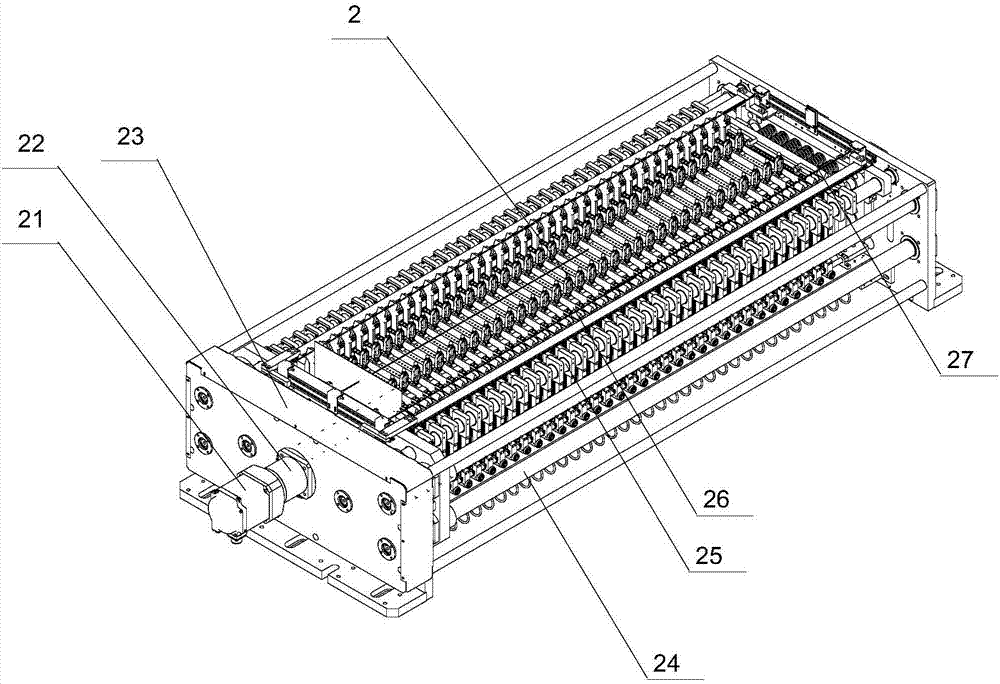

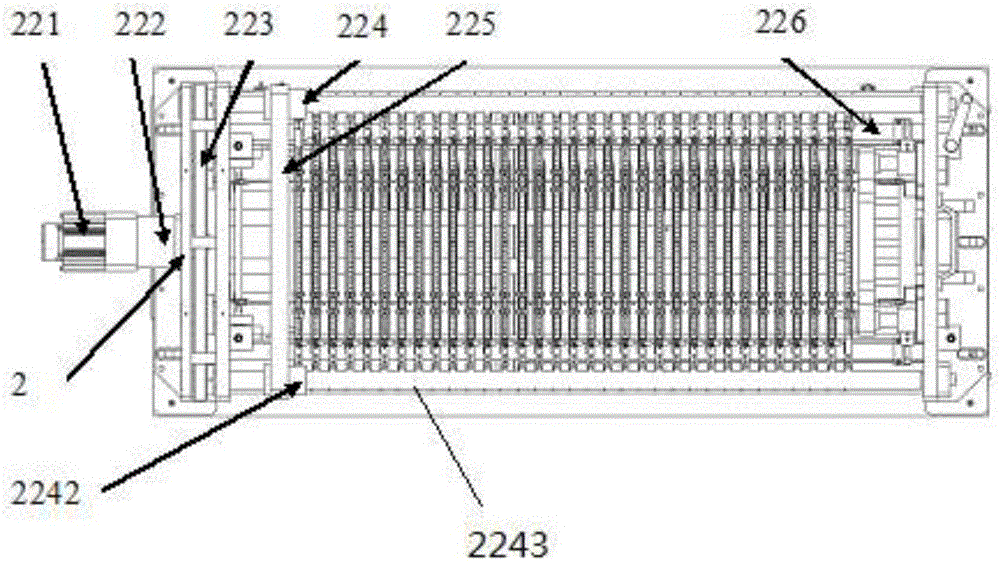

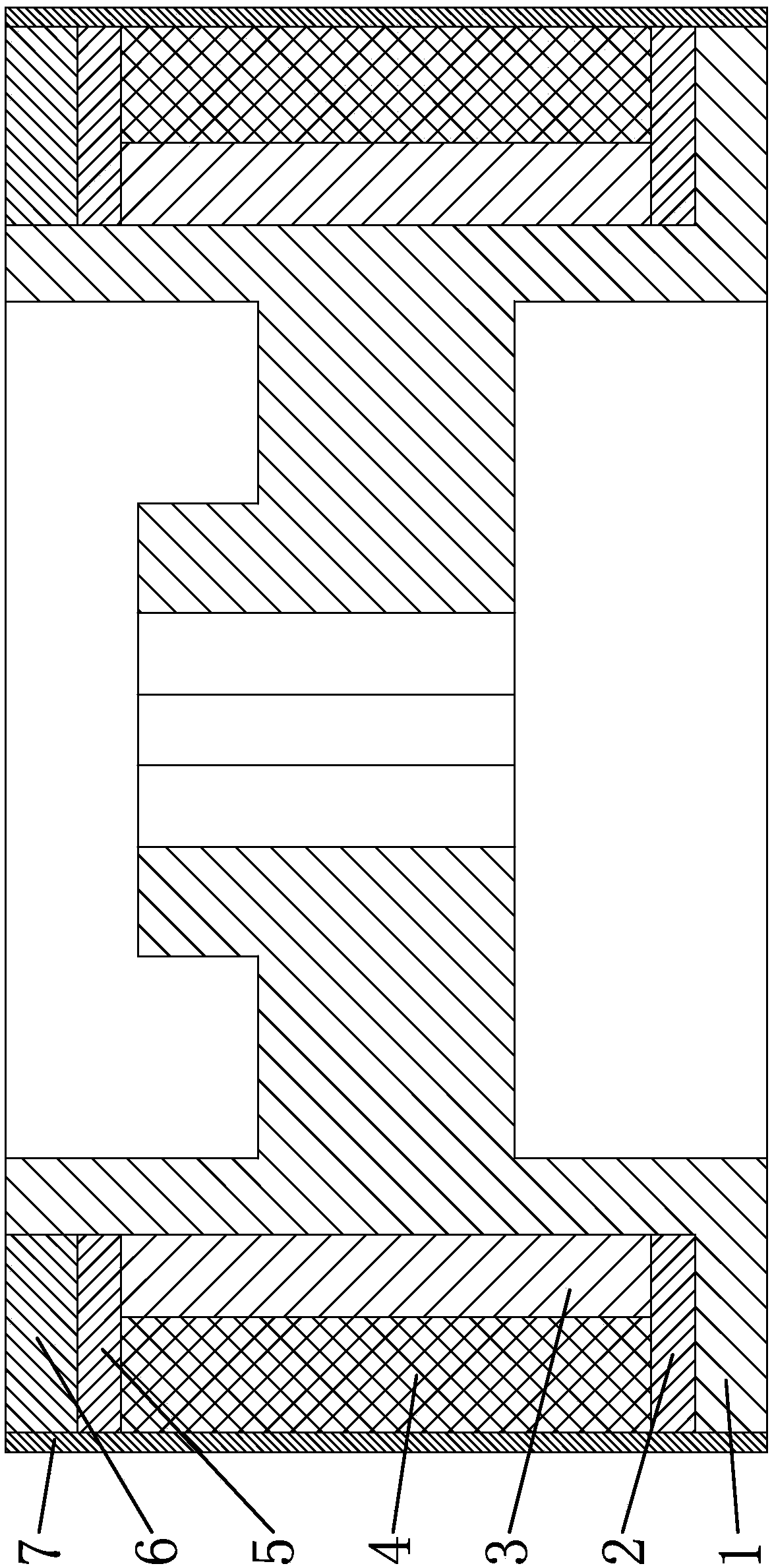

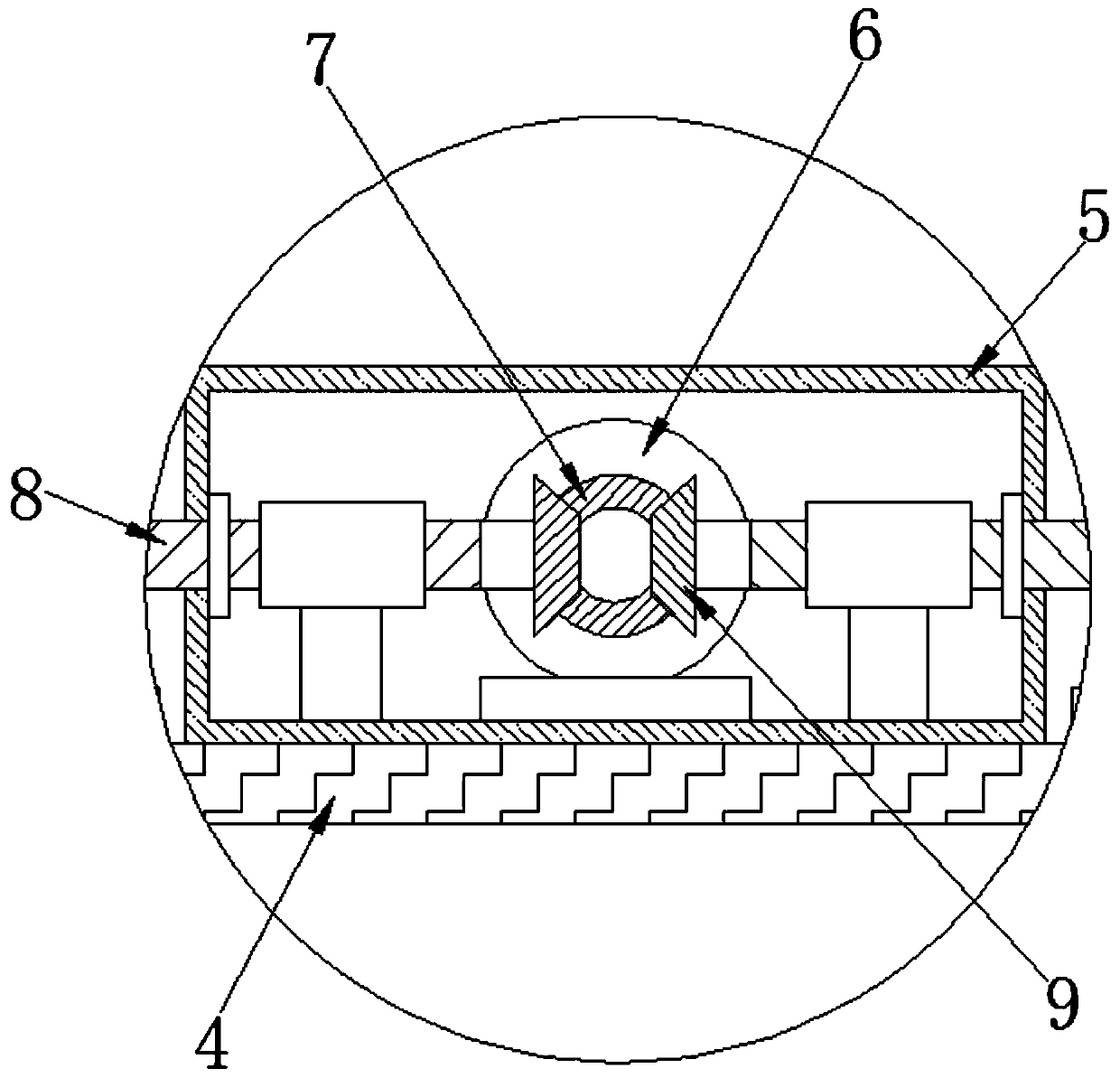

64-channel polymer lithium-ion battery formation clamp machine

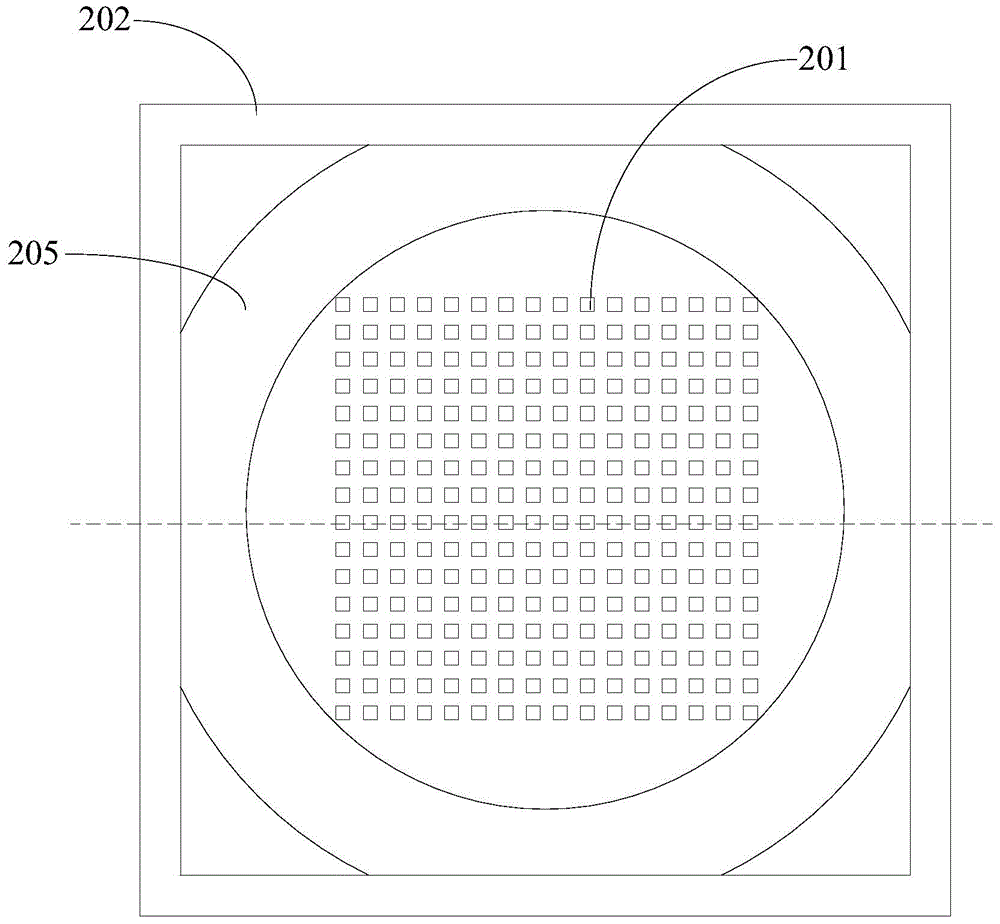

PendingCN105958123AReduce transfer processIncrease productivityFinal product manufactureElectrolyte accumulators manufactureLithium electrodeEngineering

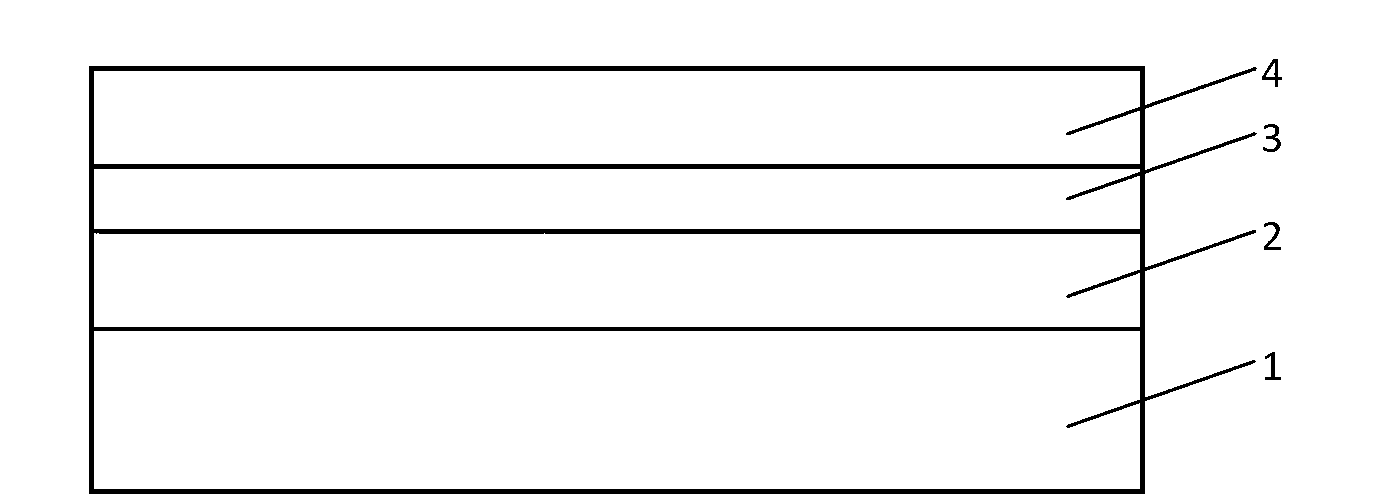

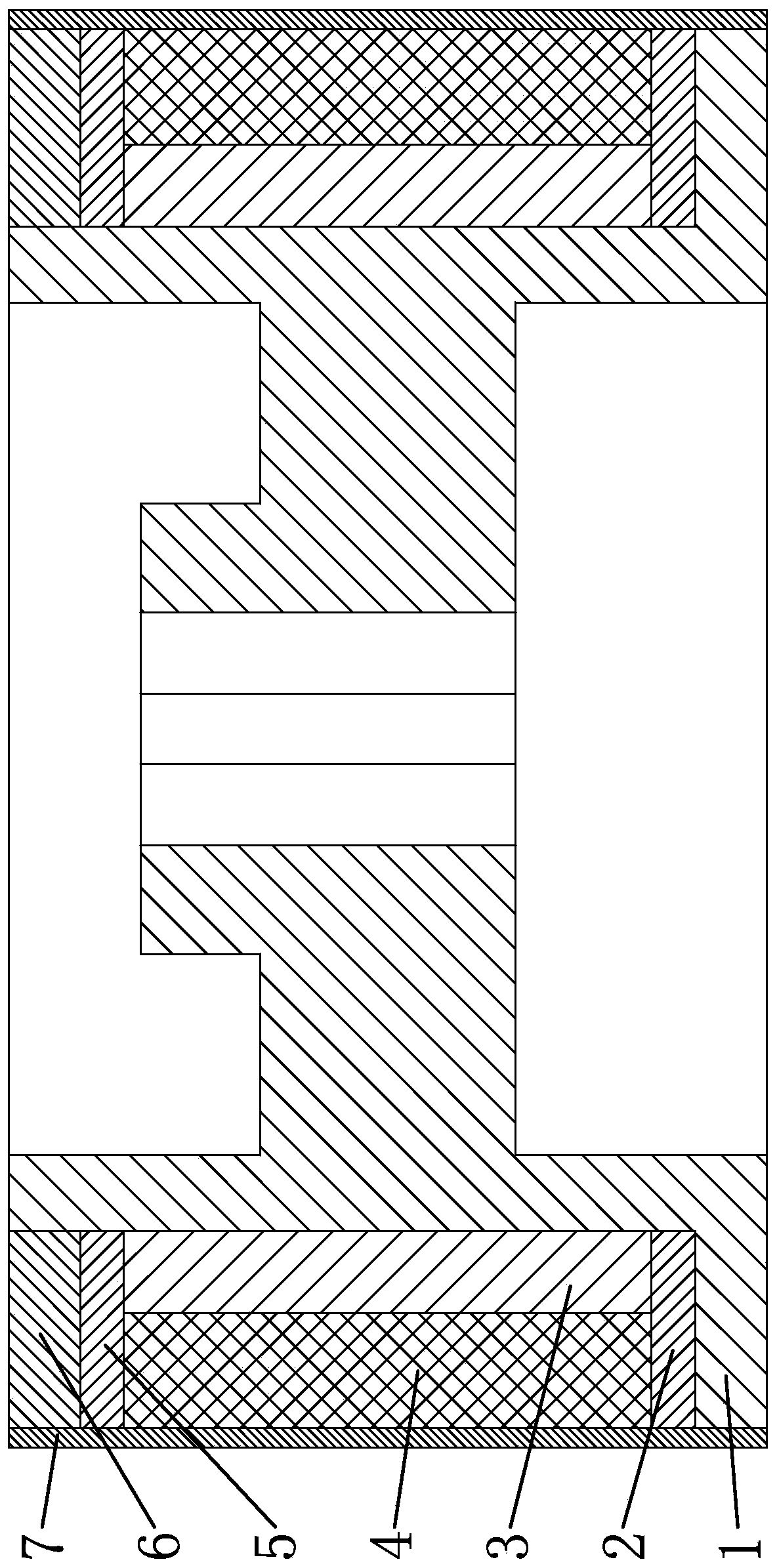

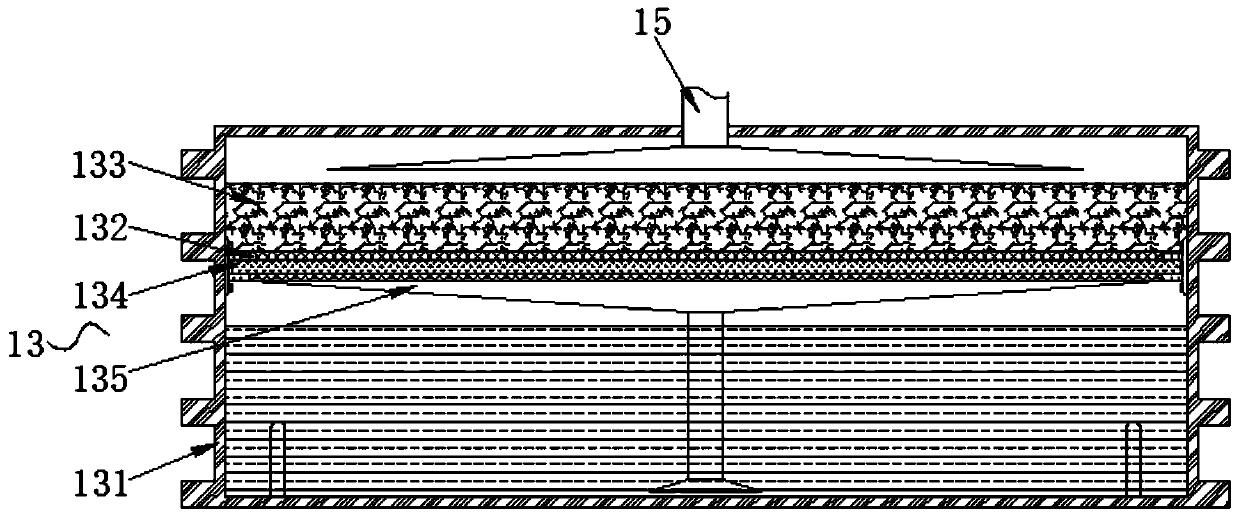

The invention discloses a 64-channel polymer lithium-ion battery formation clamp machine, which comprises a rack, a pressure control device, a 64-channel laminated board, a temperature control cabinet and a battery formation cabinet, wherein the pressure control device is arranged on the rack; the 64-channel laminated board is arranged on the pressure control device and comprises a heating plate, clamp pressure plates, temperature sensors, connection chains, silica gel plates and battery tab contact pins for clamping tabs of polymer lithium-ion batteries; a plurality of clamp pressure plates are arranged in parallel; one polymer lithium-ion battery is clamped between every two clamp pressure plates; each heating plate is attached to the surface, for clamping the corresponding polymer lithium-ion battery, of the corresponding clamp pressure plate; each silica gel plate is attached to the surface opposite to the surface on which the corresponding heating plate is arranged; each temperature sensor is arranged in the corresponding clamp pressure plate; and the end parts of the clamp pressure plates are mutually connected through the connection chains. Pressurization, heating and formation are integrated into one clamp, so that the transfer process among the procedures is reduced.

Owner:ZHEJIANG HANGKE TECH

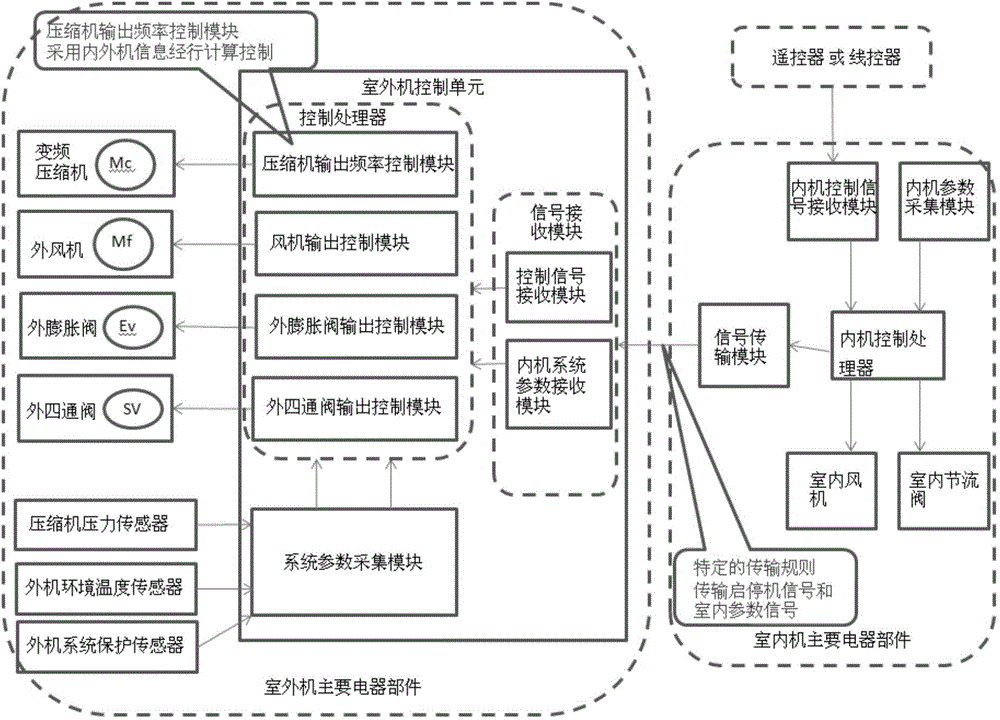

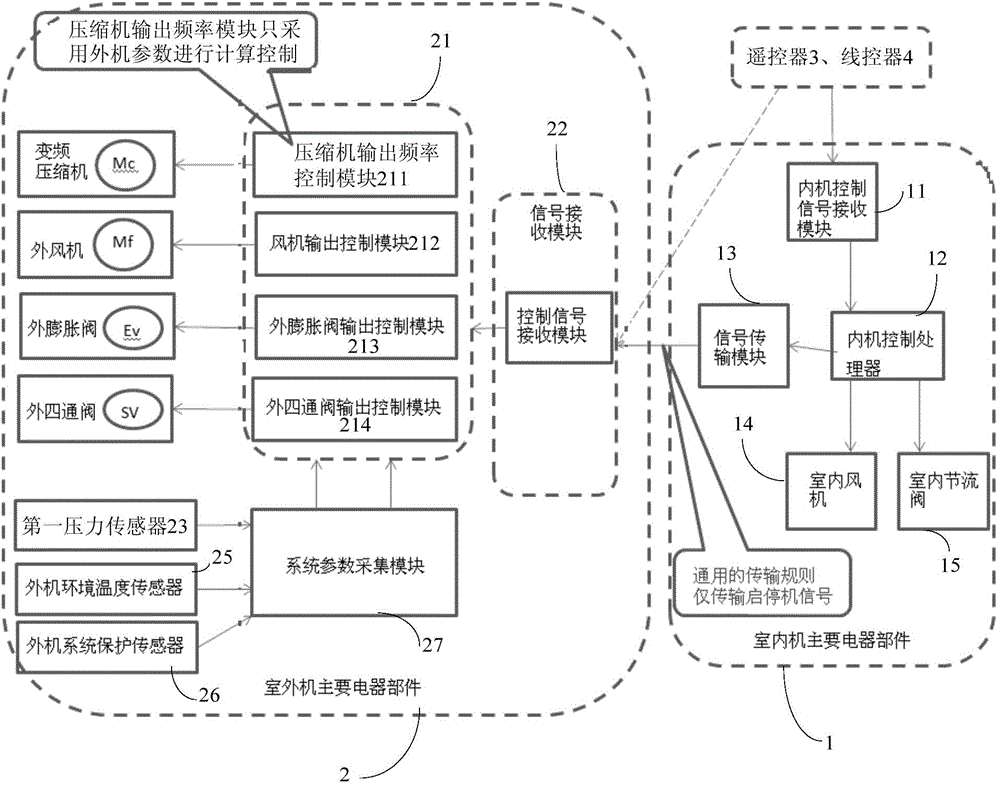

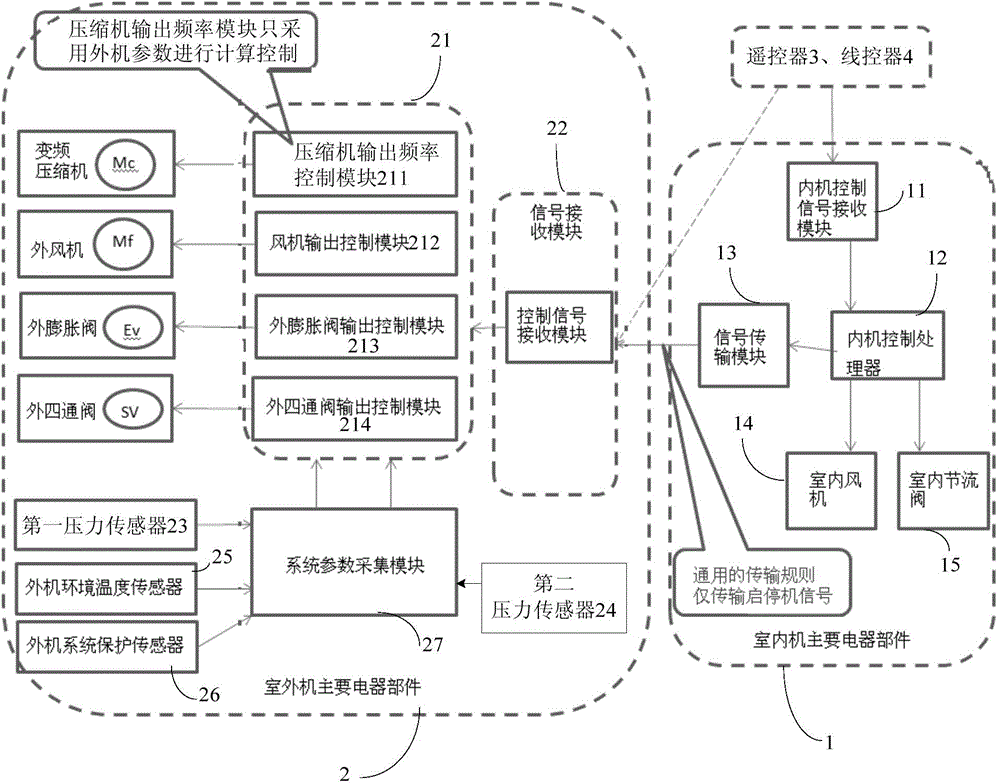

Air conditioner system, control method of air conditioner system and outdoor unit of air conditioner system

ActiveCN104791943AReduce transfer processReduce complexityMechanical apparatusSpace heating and ventilation safety systemsControl parametersFrequency conversion

The invention provides an air conditioner system, a control method of the air conditioner system and an outdoor unit of the air conditioner system. The control method comprises the following steps that the working mode of the air conditioner system is acquired, and an inverter compressor is started according to the working mode; the target refrigerant saturation temperature is acquired; frequency conversion control is conducted on the inverter compressor according to the target refrigerant saturation temperature; in the frequency conversion control process, the running time of the inverter compressor and the start-up and shutdown frequency of the inverter compressor in a third preset time period are acquired; and the target refrigerant saturation temperature is adjusted according to a preset step length when the value of the running time is larger than or equal to a third time threshold value, the start-up and shutdown frequency of the inverter compressor in the third preset time period is larger than or equal to a second preset frequency threshold value, and the value of the target refrigerant saturation temperature is larger than or equal to a preset saturation temperature threshold value. The control method can conduct frequency conversion control over the inverter compressor of the outdoor unit in a mode of being independent of an indoor unit, the control parameter transmission process is shortened, the complexity of the air conditioner system is reduced, and the running reliability of the air conditioner system is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

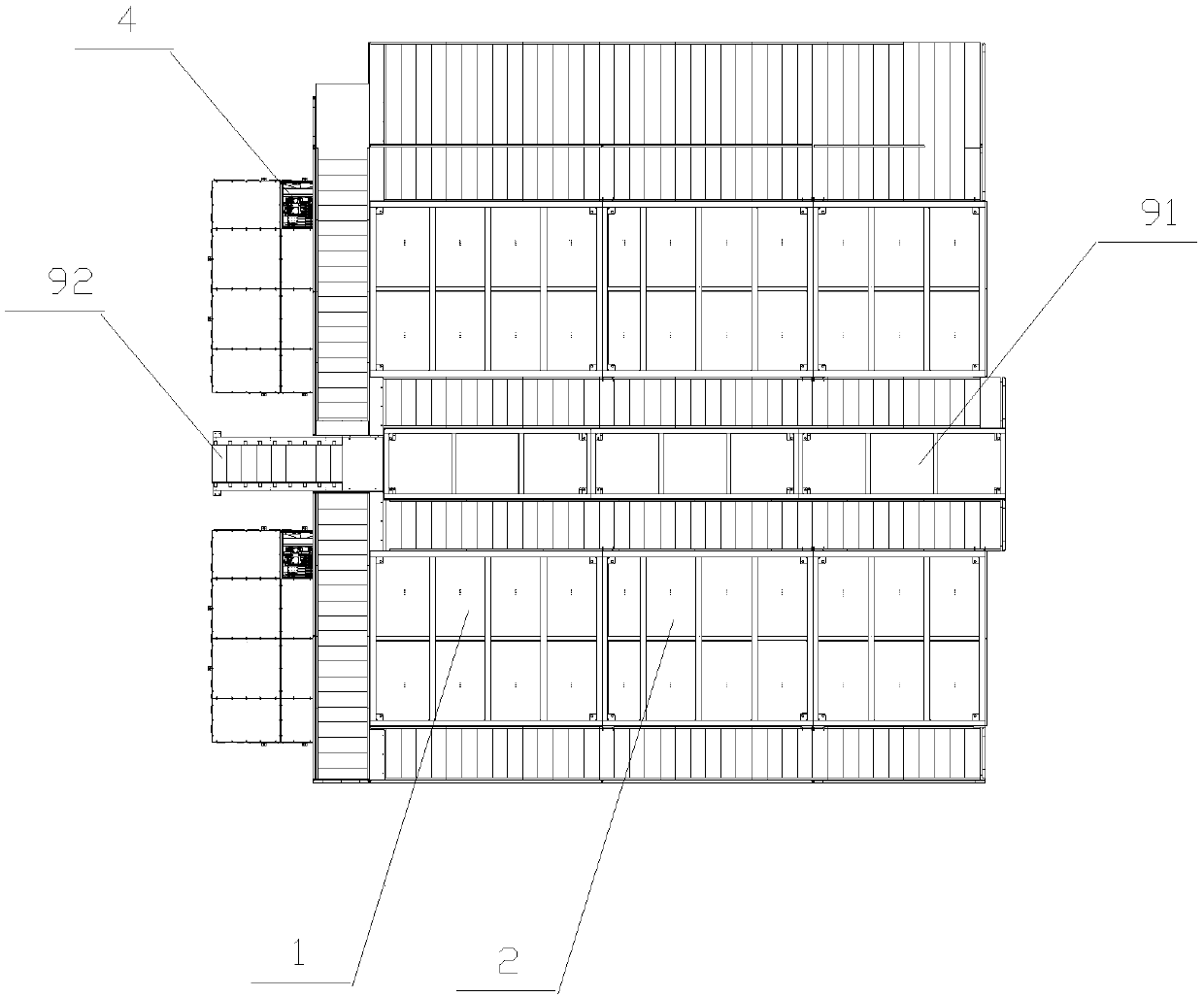

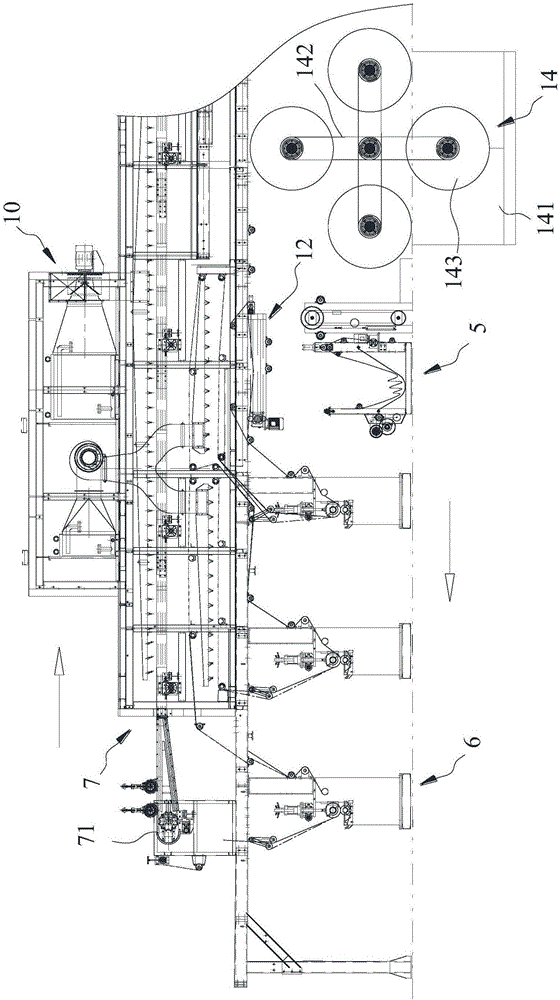

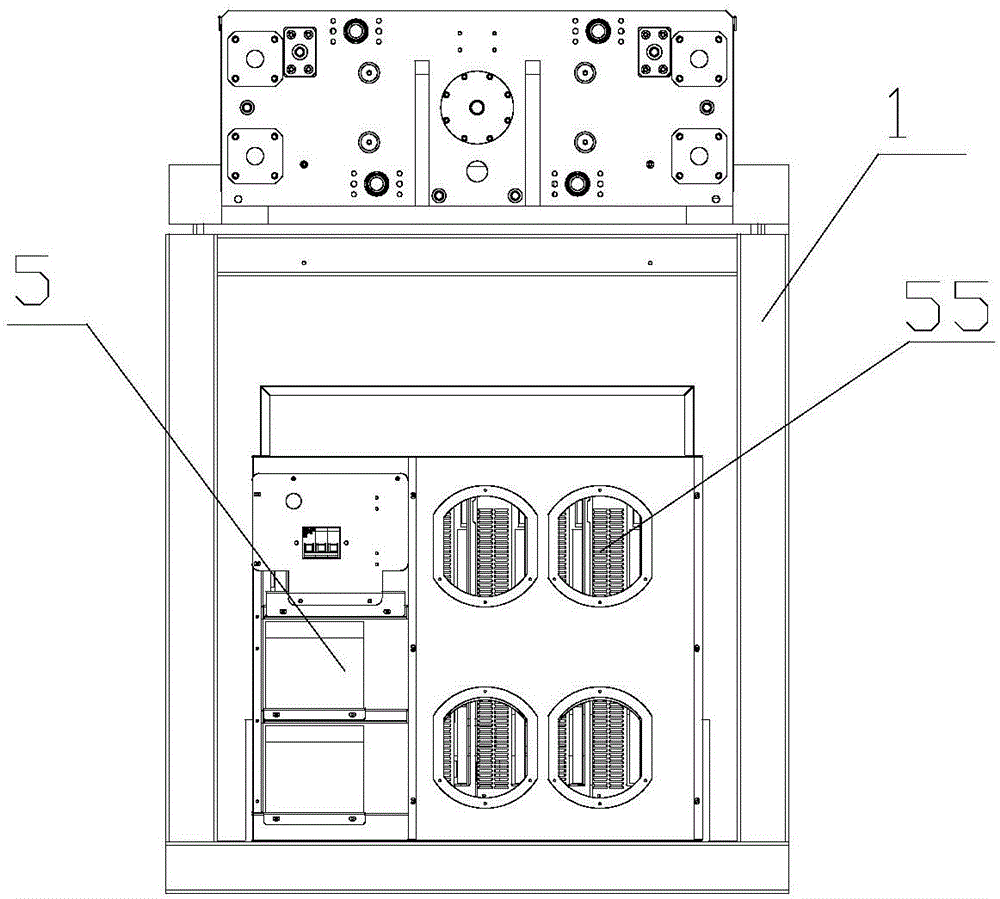

Cold- and hot-press fixture formation capacity division machine of soft pack lithium battery

PendingCN109560338AEnsure consistencyLow costAssembling battery machinesCell electrodesThermal compressionModular design

A cold- and hot-press fixture formation capacity division machine of a soft pack lithium battery comprises a plurality of sets of capacity division devices and maintenance units, wherein the maintenance units are used for connecting the capacity division devices, the capacity division devices are laminated to form a layered structure and are maintained in axial parallel, the maintenance units arearranged on side surfaces of the capacity division devices, and each capacity division device comprises an outer frame, a hot-press formation capacity division hot-press fixture unit, a cold-press formation fixture unit, a charge-discharge formation control unit, a battery loading and unloading unit, a transplant manipulator unit, a production flow control detection and safety warning unit, a central controller and a database unit. The cold- and hot-press fixture formation capacity division machine has the beneficial effects that battery carrying, turnover, pressurization, warning, formation,capacity division, cooling and formation are integratedly performed by a set of system, the production efficiency is improved, the battery consistency is ensured, and the battery production cost is reduced; and with the adoption of a standard and modular design mode, random assembly and lamination can be performed, and customized automatic assembly line is achieved.

Owner:ZHEJIANG HANGKE TECH

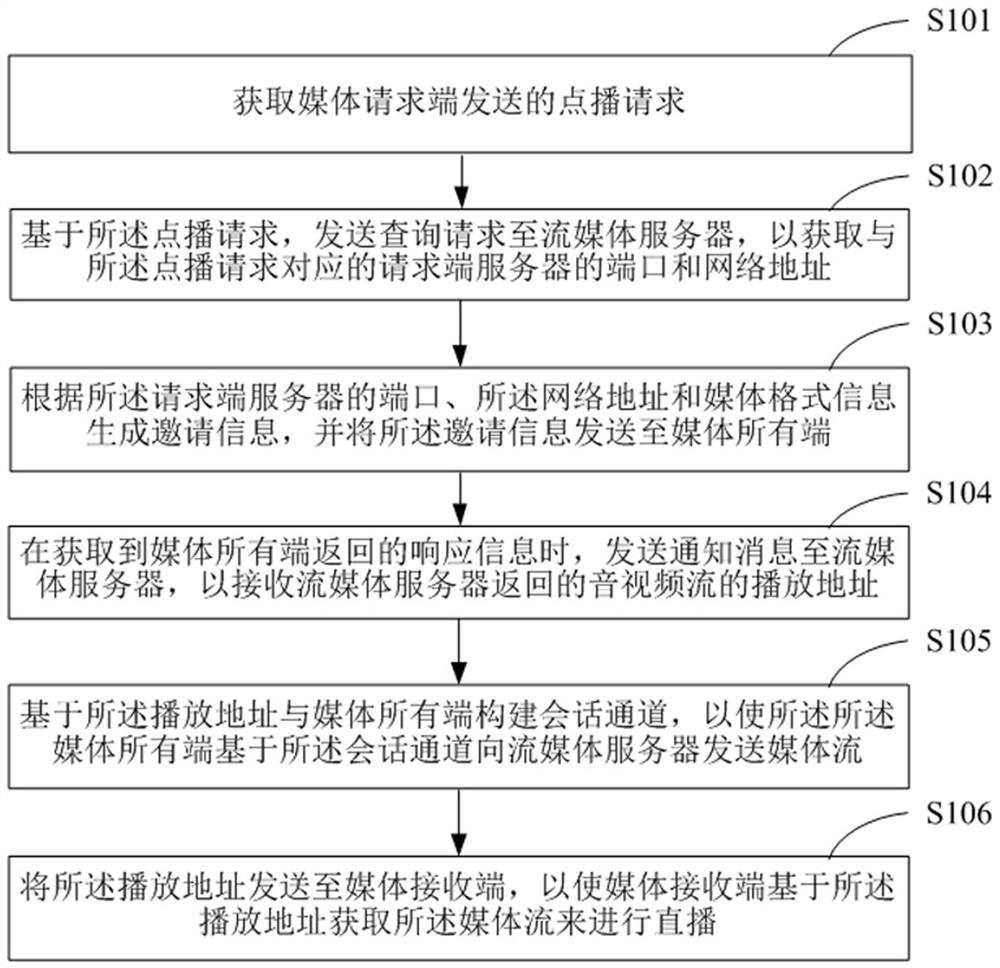

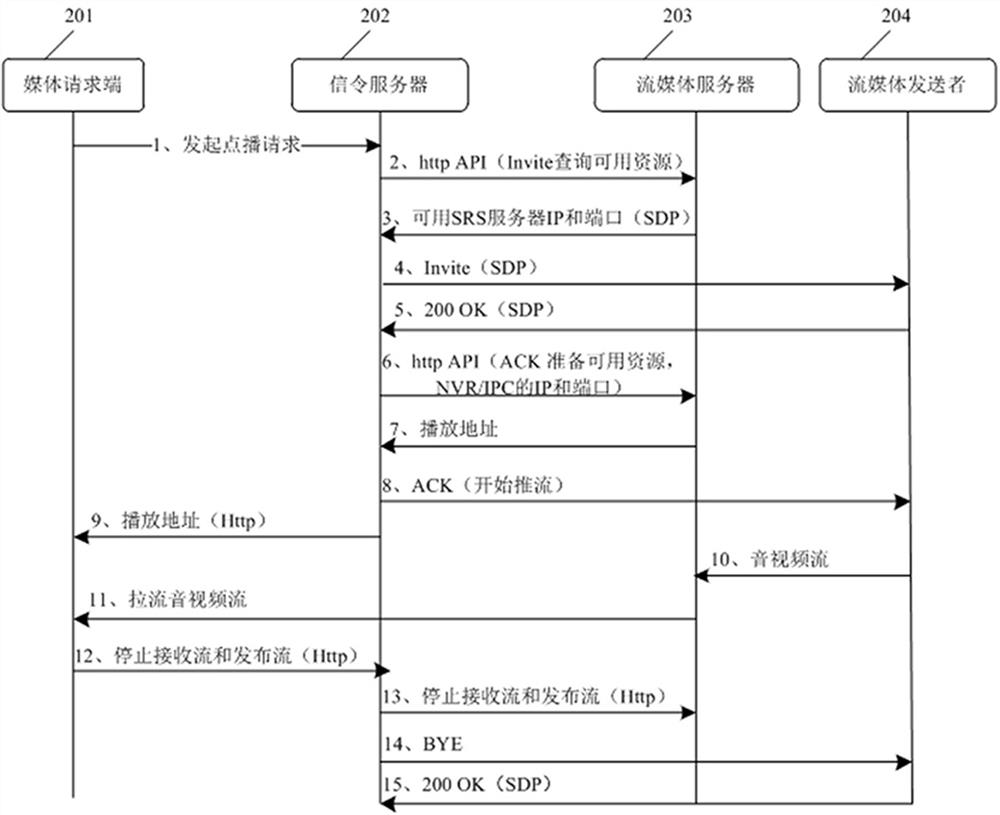

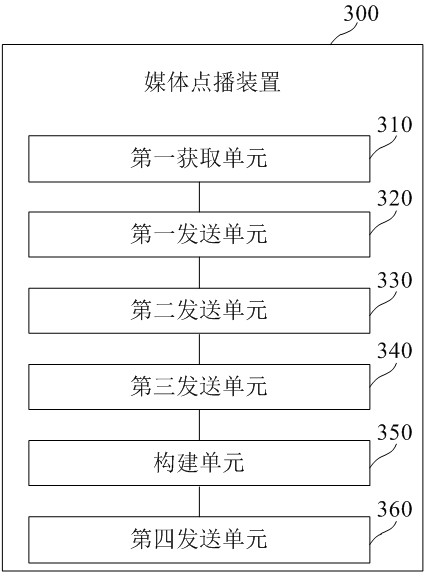

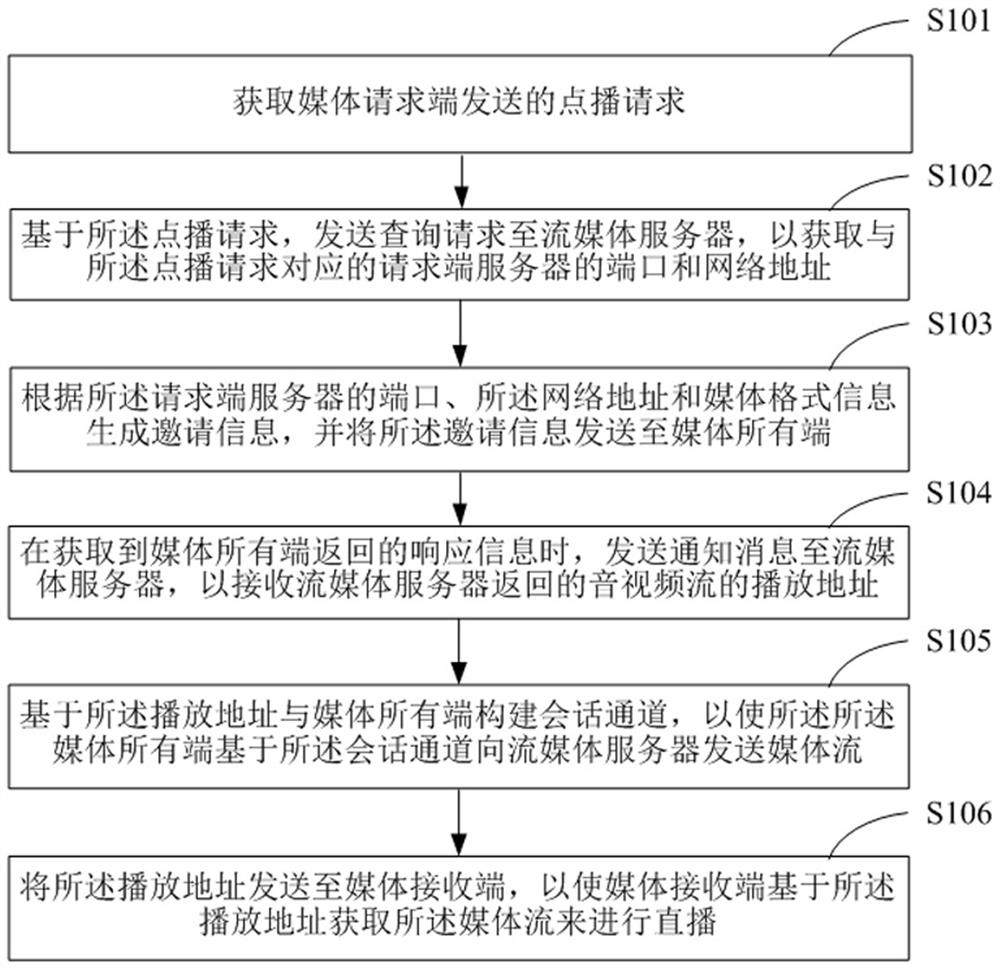

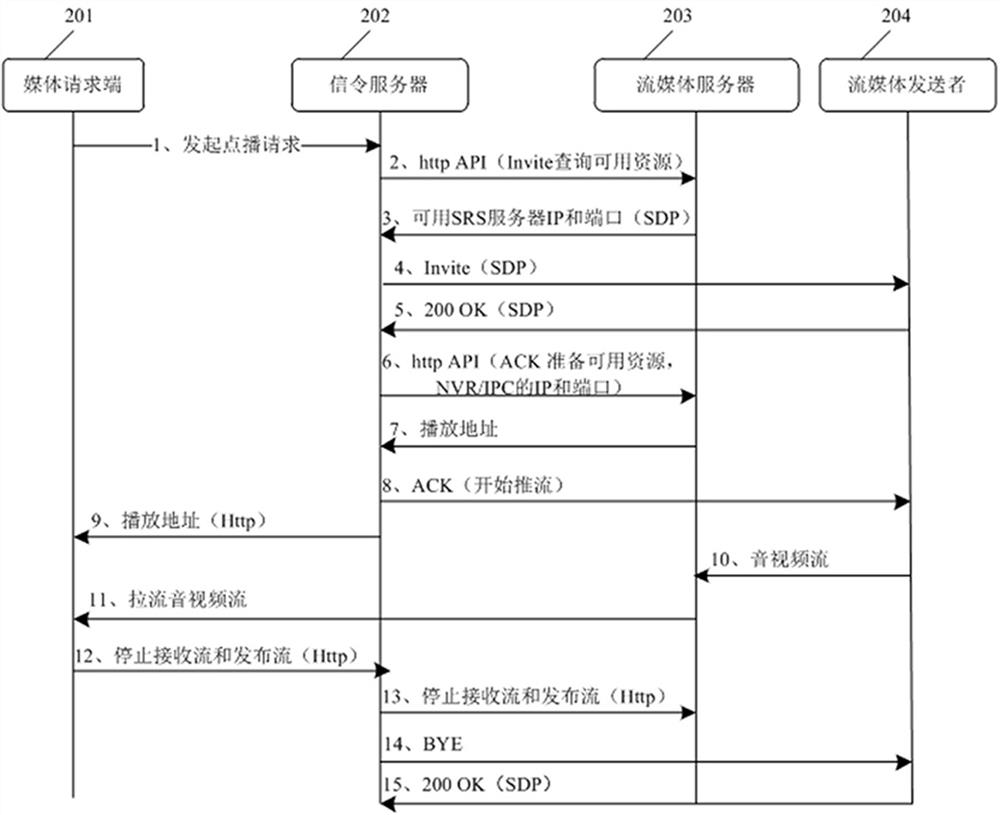

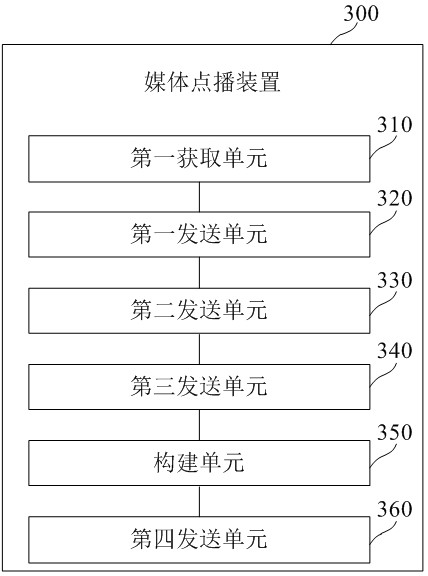

Media on-demand method, system and device

ActiveCN111818360AGuaranteed transmission efficiencyReduce transfer processSelective content distributionTelecommunicationsMediaFLO

The invention is suitable for the technical field of computer application, and provides a media on-demand method, system and device, and the method comprises the steps: obtaining an on-demand requesttransmitted by a media request end; establishing a session channel between a signaling server and a streaming media server; obtaining the audio and video streams sent by all media ends based on the streaming media server, and pulling the audio and video time-frequency streams in the media request to realize live broadcast of the audio and video streams, so that the transmission process between a media receiving end and all the media ends can be reduced, the development efficiency can be improved, and the transmission efficiency of the audio and video streams can be ensured.

Owner:PINGAN INT SMART CITY TECH CO LTD

Method for preparing square copper nanoparticles-graphene-foamed nickel material

ActiveCN106994347AImprove mechanical propertiesReduce transfer processMetal/metal-oxides/metal-hydroxide catalystsElectricityBiocompatibility Testing

The invention provides a method for preparing a square copper nanoparticles-graphene-foamed nickel material. The method comprises the following technological steps: 1, growing a layer of graphene on a foamed nickel basal body by using a chemical vapor deposition (CVD) method to prepare a graphene-foamed nickel basal body; 2, directly immersing the graphene-foamed nickel basal body material into a CuSO4 solution to obtain a mixture, and carrying out displacement reaction on the mixture for 1-1.5 hours to obtain a square copper nanoparticles-graphene-foamed nickel composite material. The prepared square copper nanoparticles are uniformly distributed on the surface of three-dimensional framework graphene, are difficultly aggregated and are uniform in sizes; moreover, by fully utilizing synergistic effects of excellent performances such as electricity, catalysis and sensing of both of the graphene and copper particles, the prepared composite material has more reactive activity sites, is large in specific surface area, is good in biocompatibility, is good in electrical conductivity, and has wide application prospects in the fields of catalysis, biosensing, environment protection, surface-enhanced Raman scattering, energy and the like.

Owner:SOUTHEAST UNIV

Tissue culture and rapid propagation method for Gerbera jamesonii Bolus

InactiveCN101496496ASimplify tissue culture proceduresReduce transfer processPlant tissue cultureHorticulture methodsCell buddingBud

The invention discloses a tissue culture and quick propagation method for flameray gerbera, and in particular relates to a flameray gerbera two-step seedling raising method. A leaf of a test-tube seedling is taken as an explant to directly induce an indefinite bud and carry out the rootage culture; and the whole process of the flameray gerbera tissue culture seedling is completed in two steps. The method which is used to produce the flameray gerbera germchit not only solves the problem that the flameray gerbera black pistil variety has difficulty in the indefinite bud induction and a low induction rate, but also breaks down the boundary between the flameray gerbera green pistil variety and the flameray gerbera black pistil variety, and realizes above 98 percent indefinite bud high-efficiency induction for the green pistil variety and above 90 percent indefinite high-efficiency induction for the black pistil variety through one culture medium. In addition, the method simplifies the tissue culture process. The method not only reduces the tissue culture period from originally 7 months to 4 months, but also reduces a shifting procedure. Therefore, the tissue culture cost is reduced by 1 / 3.

Owner:SHANDONG INST OF POMOLOGY

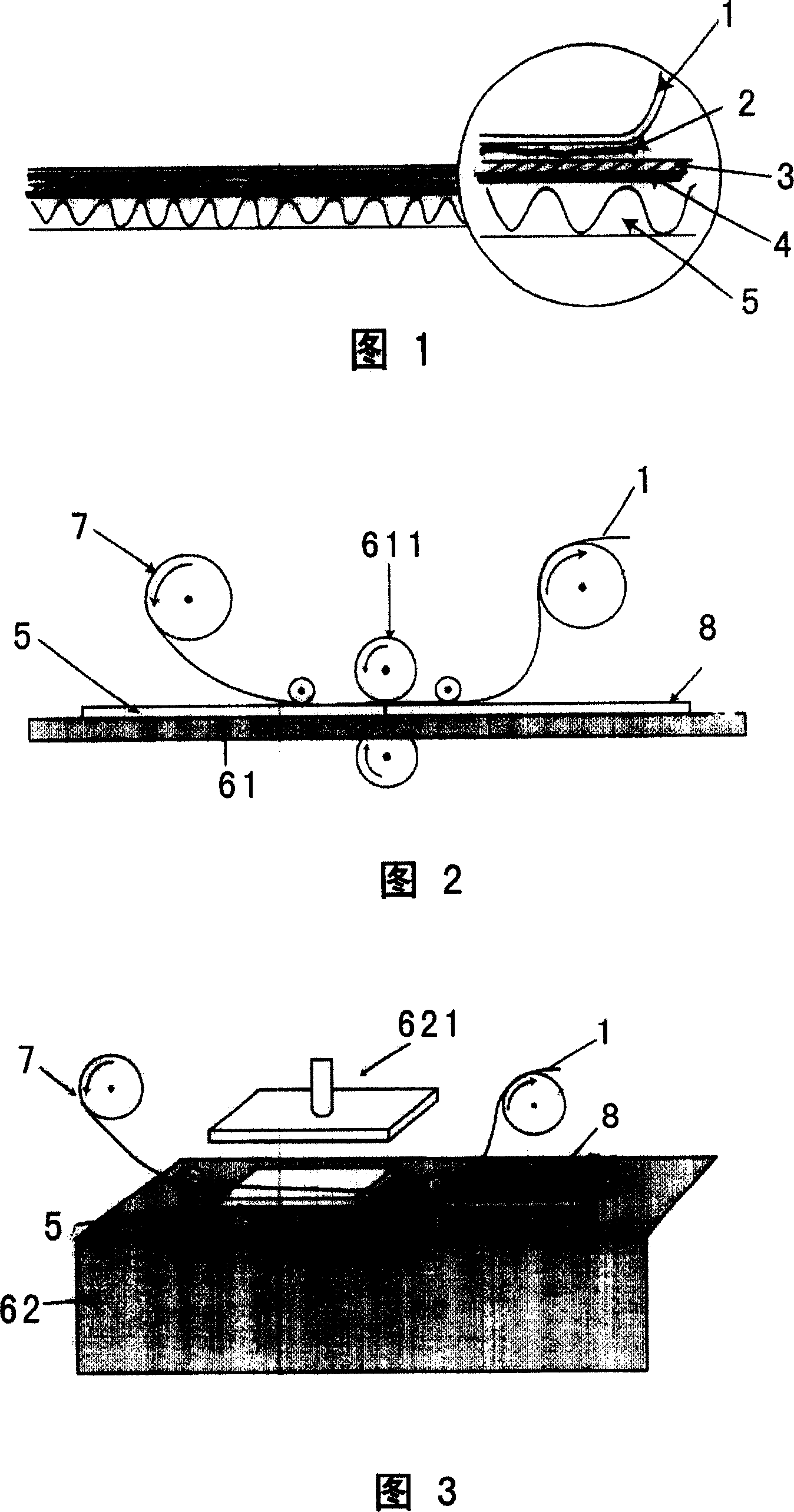

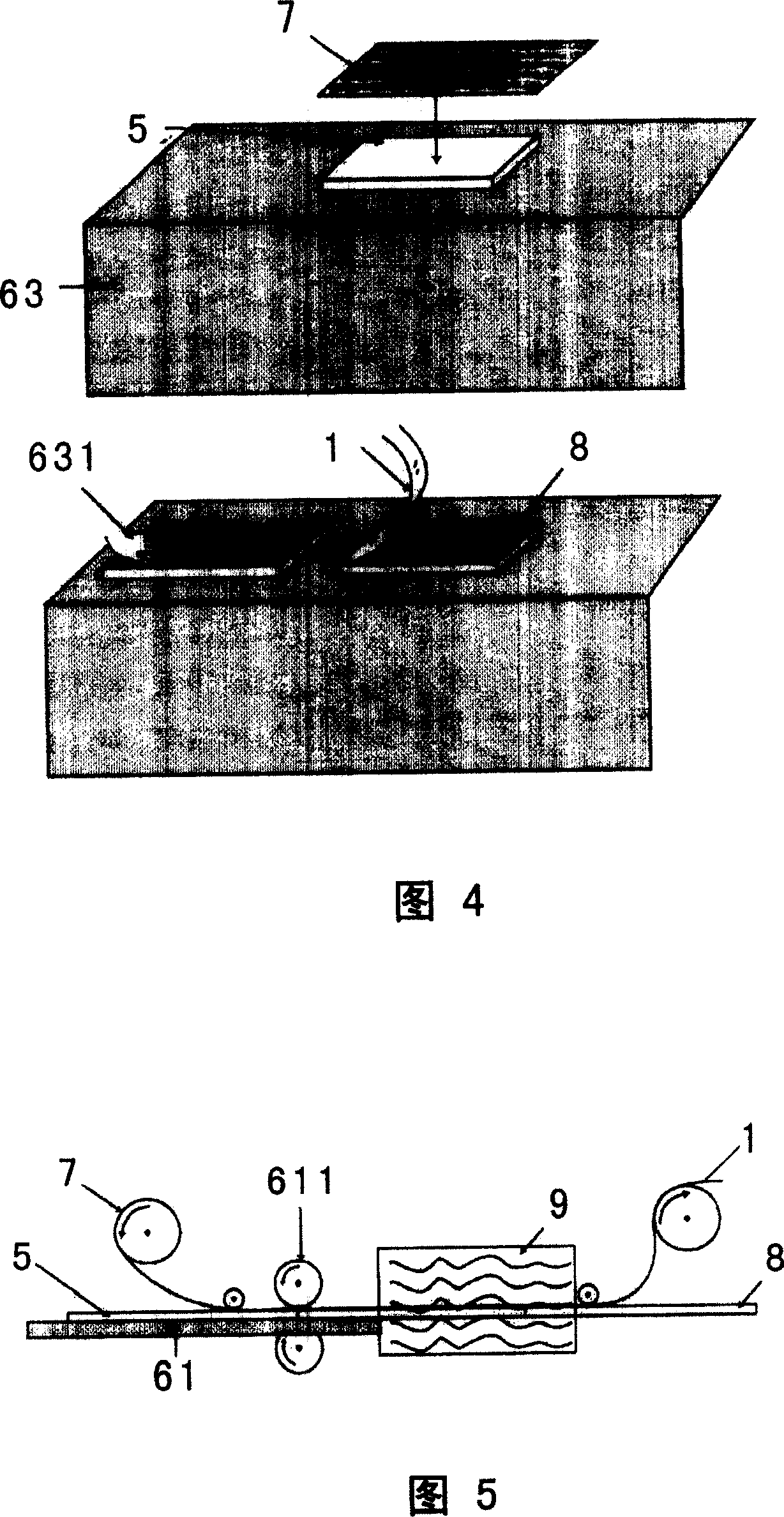

Transfer printing method

InactiveCN1695958AAvoid distortion errorsImprove transfer qualityInk transfer from master sheetAdhesiveEngineering

A transfer printing method includes coating the solvent-type adhesive on the surface of product, semi-drying, attaching a transfer film to it, pressing, and tearing off the plastic film. Another method is also disclosed.

Owner:惠州全品科技工业有限公司

Method for monitoring periphery displacement of construction field through total station instrument carried by unmanned aerial vehicle

ActiveCN108318011ASave human resourcesReduce transfer processSurveying instrumentsUncrewed vehicleTotal station

The invention discloses a method for monitoring periphery displacement of a construction field through a total station instrument carried by an unmanned aerial vehicle. According to the method, displacement variations of the periphery of a subway construction site are monitored through an unmanned aerial vehicle, a damping cloud deck, a total station instrument and a database, testing points and reference points have the characteristics of being scientific and reasonable to set up, convenient in monitoring, accurate in data and high in efficiency, the monitoring process can be automatically carried out, a great amount of human sources can be saved, the instrument transferring process in complex regions of cities is reduced, the monitoring efficiency and precision can be improved, and scientific bases can be made for construction of subways and other underground buildings.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Method for directly plating plastic with drawn wire appearance

A method for directly plating plastic with drawn wire appearance relates to a plastic plating process. The provided method for directly plating plastic with drawn wire appearance can realize drawn wire appearance for various plastic substrates. The method includes the following steps: (1) manual drawing is carried out on a plastic substrate; (2) the oil of the plastic substrate treated in step (1) is manually wiped off; (3) a metal film is coated on the workpiece treated in step (2) by physical vapor deposition; (4) a nickel layer is plated on the workpiece treated in step (3); and (5) after the workpiece treated in step (4) is washed with water and dried, a pigment film is coated on the workpiece by physical vapor deposition, and therefore a plastic workpiece with drawn wire appearance is obtained. Nickel can be directly plated on various drawn wire plastic substrates after films are coated, processes, such as roughening, sensitization and activation, are not needed, drawn wire appearance can be obtained, and has high metal texture.

Owner:XIAMEN RUNNER IND CORP

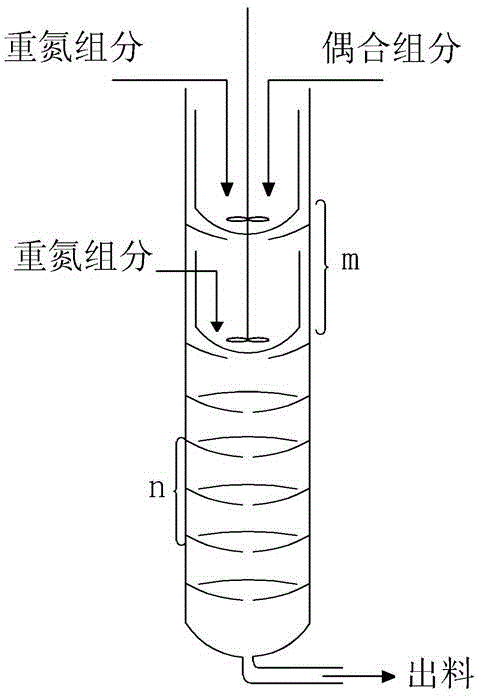

Dye continuous coupling method with reduced energy consumption

ActiveCN104830089ARealize segmented couplingIncrease productivityMonoazo dyesCarboxylic acid nitrile preparationThermodynamicsProcess engineering

The invention relates to a dye continuous coupling method with reduced energy consumption. The method comprises the following steps: mixing a coupling component, water and aids together, pulping to obtain a coupling liquid, continuously pumping the obtained coupling liquid into a coupling reactor through a metering device; at the same time, continuously pumping a diazo salt solution into a multi-stage coupling reactor in batches through a metering device, controlling the mole ratio of diazo salt to the coupling component in a range of 1:0.95-1.05; adjusting the cooling medium flow by the affiliated heat-exchange device of the coupling reactor to control the coupling temperature in a range of -10 to 30 DEG C, carrying out coupling reactions under stirring, after the reaction, pouring out the reaction products, and carrying out a post treatment. The provided method achieves continuous coupling production, the coupling is performed in multiple stages, the production efficiency, product yield and production quality are all improved, furthermore, a tower type reactor is adopted, the reaction fluid is guided by the gravity, and thus the energy consumption during the stirring process is reduced.

Owner:SHAOXING UNIVERSITY +1

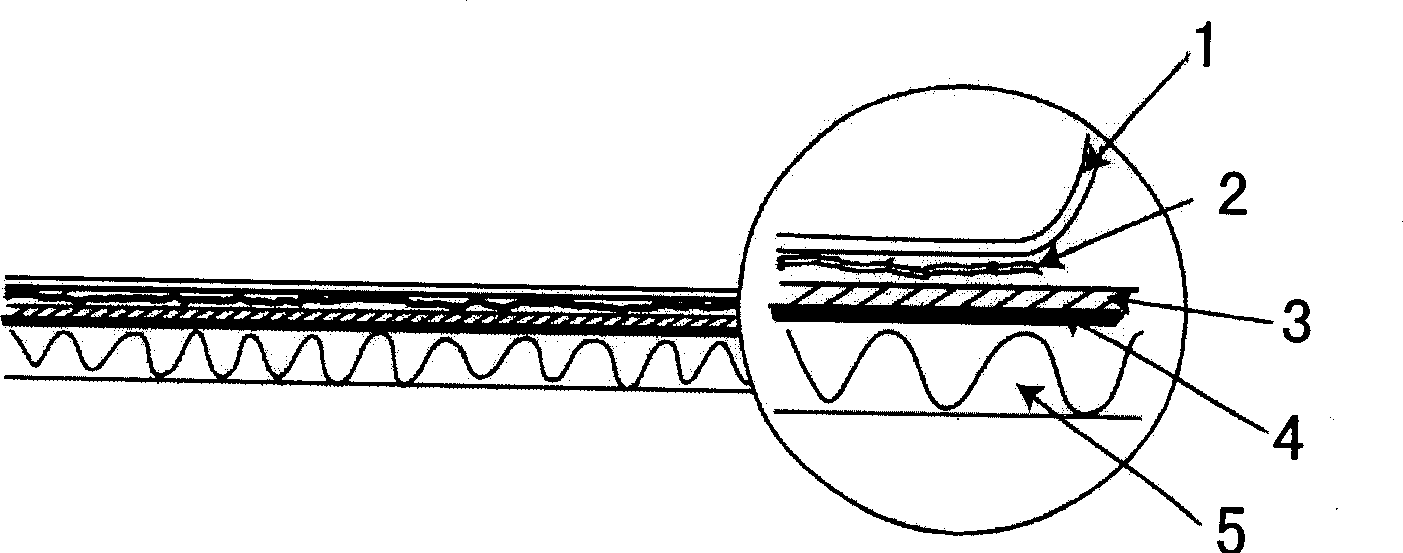

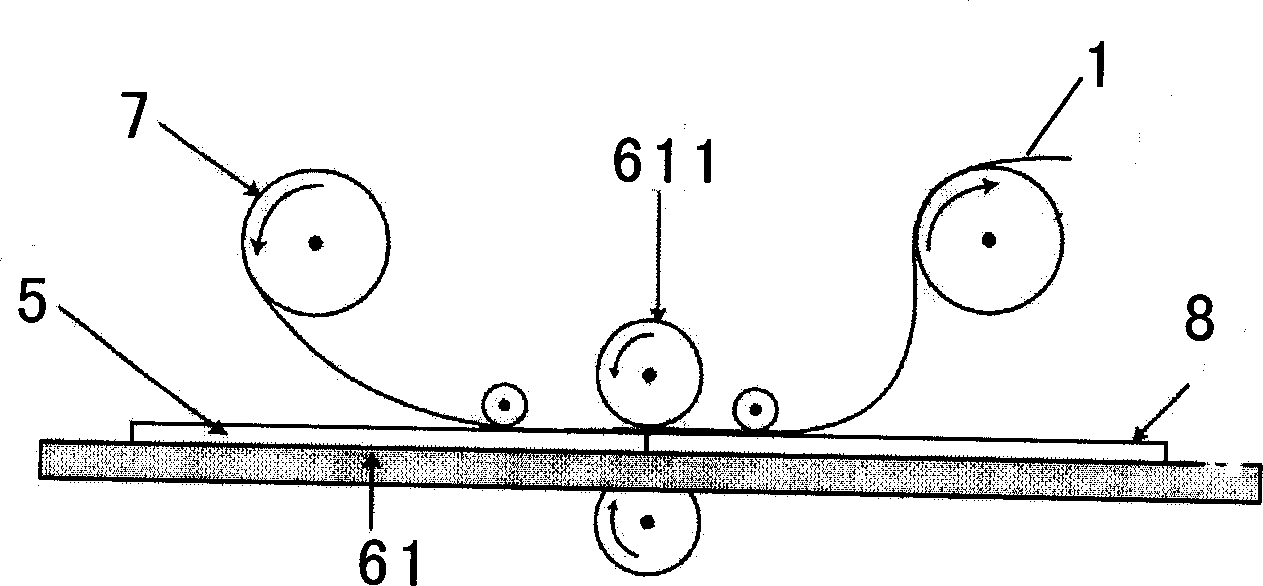

Integrated synthetic leather processing device

ActiveCN106521977AIncrease productivityThe processing process is easy to controlTextiles and paperEngineeringWork in process

The invention discloses an integrated synthetic leather processing device. The integrated synthetic leather processing device comprises an unwinding mechanism, a cloth storage rack, a first printing component, an embossing machine, a storage tank, a second printing component, a widening mechanism, a polishing mechanism and a winding mechanism which are sequentially connected along the conveying direction of cloth, wherein the unwinding mechanism is used for delivering to-be-processed cloth, the cloth storage rack is used for carding and temporarily storing the to-be-processed cloth, the first printing component is used for dyeing printing, the embossing machine is used for printing patterns, the storage tank is used for stretching and extending cloth, the second printing component is used for sizing material printing, the widening mechanism is used for widening the cloth, the polishing mechanism is used for polishing semi-product synthetic leather, and the winding mechanism is used for winding the finished-product synthetic leather. The integrated synthetic leather processing device further comprises a gravure dryer and a widening forming dryer which are located above the widening mechanism. The integrated synthetic leather processing device has the advantages that integrated synthetic leather processing is achieved, and processing and production efficiency are increased.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

Pole piece cutting and conveying device and lamination system

ActiveCN114122528AHigh precisionReduce transfer processFinal product manufactureSecondary cellsPole pieceMechanical engineering

The invention relates to the technical field of lithium battery production equipment, in particular to a pole piece cutting and conveying device and a piece stacking system. The pole piece cutting and conveying device comprises a pole piece unwinding mechanism, a pole piece cutting mechanism and a pole piece conveying mechanism which are arranged in sequence, the pole piece cutting mechanism is used for cutting the pole piece material belt unwound by the pole piece unwinding mechanism to obtain a pole piece; the pole piece conveying mechanism comprises an annular feeding track and a plurality of conveying trolleys; the annular feeding track comprises a feeding section and a backflow section which are connected end to end, the end-to-end connecting positions of the feeding section and the backflow section are a feeding station and a discharging station respectively, and each conveying trolley can pick up the pole pieces at the feeding station and release the pole pieces at the discharging station. The lamination system comprises the pole piece cutting and conveying device. According to the pole piece cutting and conveying device and the piece stacking system, the pole pieces are picked up, conveyed and released through the material conveying trolley, the transfer offset is small, the transfer process is few, and piece cutting, conveying and piece stacking can be efficiently and accurately conducted.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Method for quickly preparing silver nanoparticle block-graphene-nickel foam composite material

ActiveCN107245597AImprove mechanical propertiesReduce usageGrapheneUltrasound attenuationAlcohol reduction

The invention provides a method for quickly preparing a silver nanoparticle block-graphene-nickel foam composite material. The method mainly comprises the following process steps that (1) a chemical vapor deposition method (CVD) is used for growing a layer of graphene on a nickel foam substrate, and a graphene-nickel foam substrate is prepared; (2) a polyhydric alcohol reduction method is adopted for preparing a silver nanoparticle block; (3) the above graphene-nickel foam substrate material is placed into a reactor with magnetons, the silver nanoparticle block obtained after acetone centrifugal attenuation is added, the reactor is placed into an oil bath pan, the rotating speed is adjusted to be 260 r / min to 360 r / min, heat preservation is carried out at a certain temperature for a certain time, taking out, rinsing and drying are carried out, and the silver nanoparticle block-graphene-nickel foam composite material is obtained; and (4) the obtained silver nanoparticle block-graphene-nickel foam composite material is placed into a tube furnace for annealing treatment.

Owner:SOUTHEAST UNIV

Construction waste treatment equipment

ActiveCN113478613AImprove structural strengthReduce transfer processConstruction waste recoveryFeeding arrangmentsStructural engineeringRefuse Disposals

The invention discloses construction waste treatment equipment which comprises a stirring assembly and a forming assembly. The forming assembly comprises a machine station, and a pair of parallel and opposite first side templates are arranged on the top face of the machine station; the four corners of the top face of the machine station are each provided with a vertical guide column, and the top ends of the four guide columns are jointly connected with a top plate right facing the top face of the machine station; a first hydraulic machine is arranged on the top plate, and a piston rod of the first hydraulic machine stretches downwards; the lower end of the piston rod of the first hydraulic machine is connected with a movable plate; a second hydraulic machine is arranged on the movable plate, a piston rod of the second hydraulic machine stretches downwards, and the lower end of the piston rod of the second hydraulic machine is connected with a pressing plate; the movable plate is connected with a pair of parallel and opposite second side templates through first connecting rods; and when the piston rod of the first hydraulic machine is in the maximum stroke, the second side templates are inserted between the first side templates to form a surrounding cavity. According to the construction waste treatment equipment, a plurality of manufacturing procedures for baking-free bricks are integrated and completed through the equipment, and the transferring procedure is omitted.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

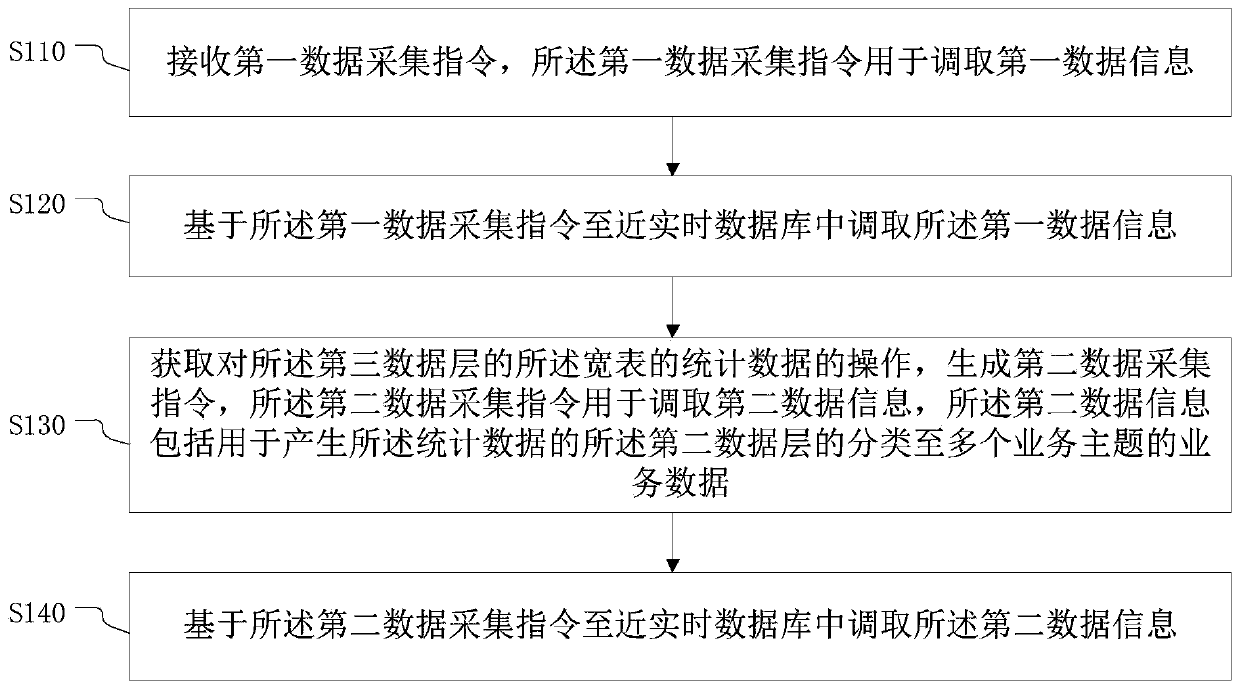

Near-real-time data acquisition method and device, electronic device and storage medium

ActiveCN110502566ARealize acquisitionReduce transfer processDatabase management systemsDatabase modelsReal-time dataData information

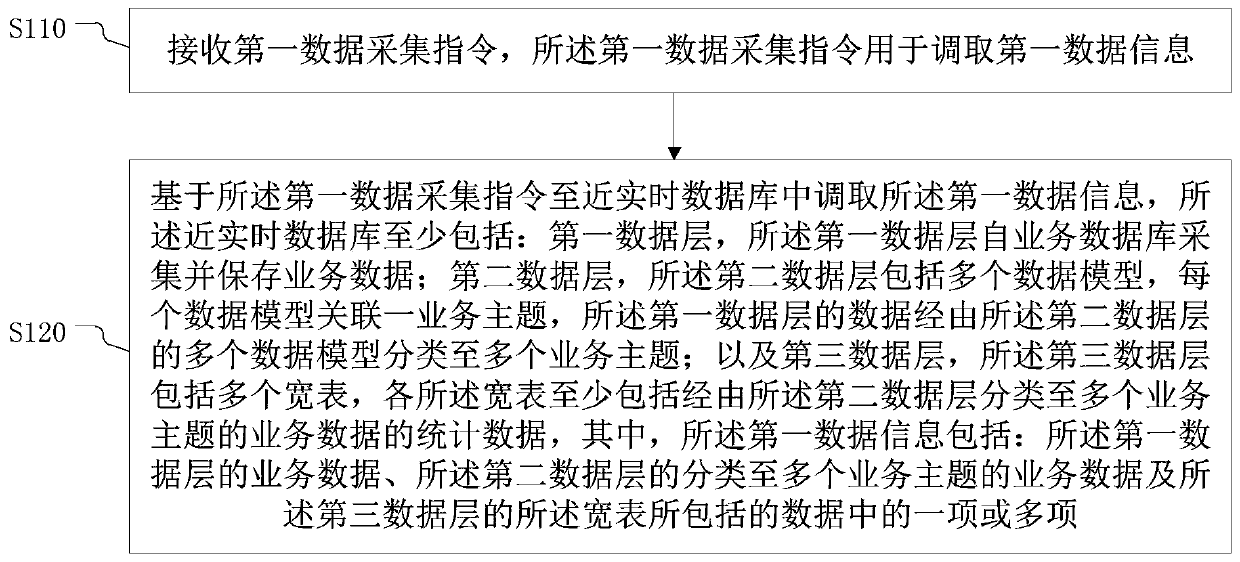

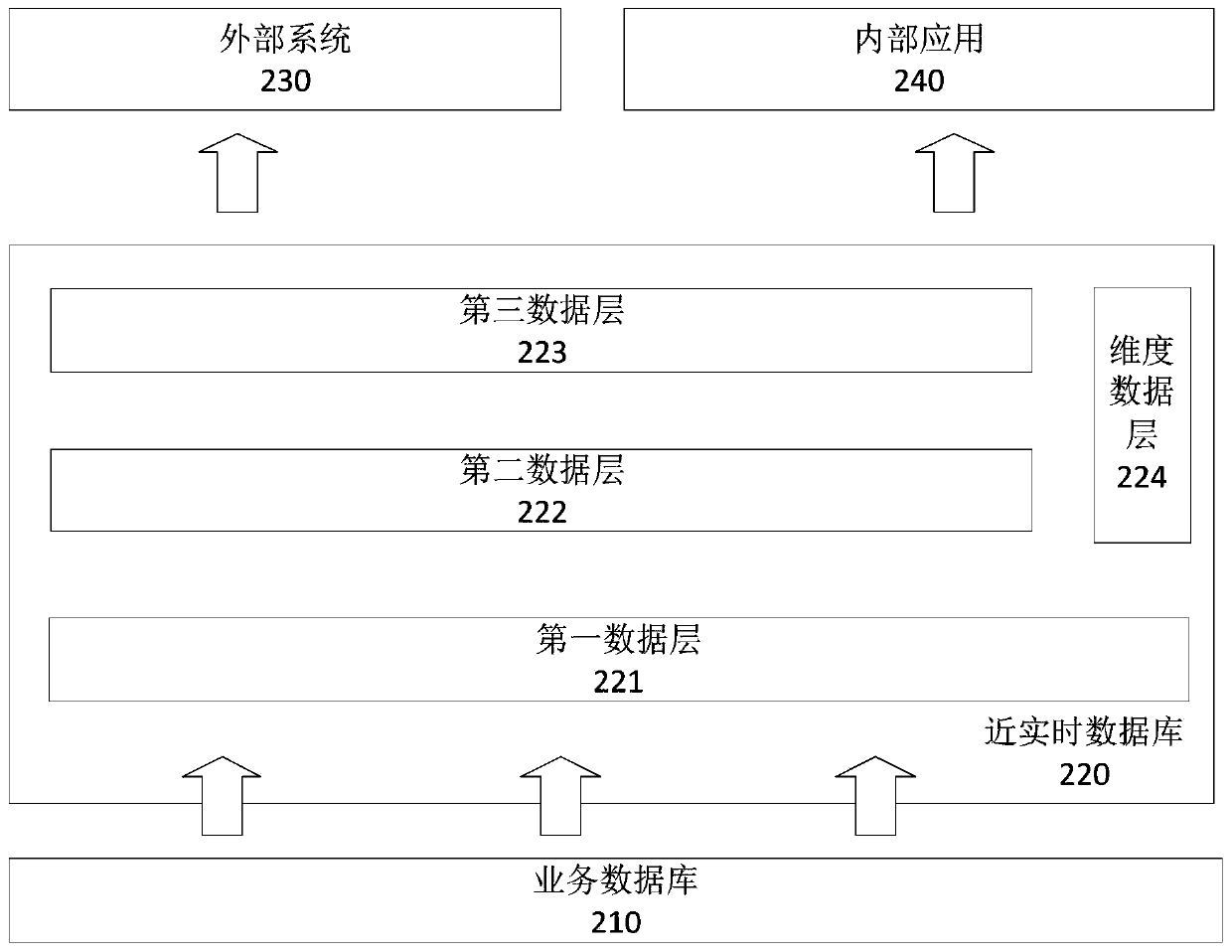

The invention provides a near-real-time data collection method and device, an electronic device and a storage medium, and the method comprises the steps: receiving a first data collection instructionwhich is used for calling first data information; calling the first data information from a near-real-time database based on the first data acquisition instruction, the near-real-time database at least comprising: a first data layer which acquires and stores service data from a service database; a second data layer, comprising a plurality of data models, each data model being associated with a business theme, and the data of the first data layer being classified into a plurality of business themes through the plurality of data models of the second data layer; and a third data layer, comprisinga plurality of wide tables, and each wide table at least comprising statistical data of service data classified to a plurality of service themes through the second data layer. According to the methodand the device provided by the invention, near-real-time data processing is realized.

Owner:JIANGSU MANYUN SOFTWARE TECH CO LTD

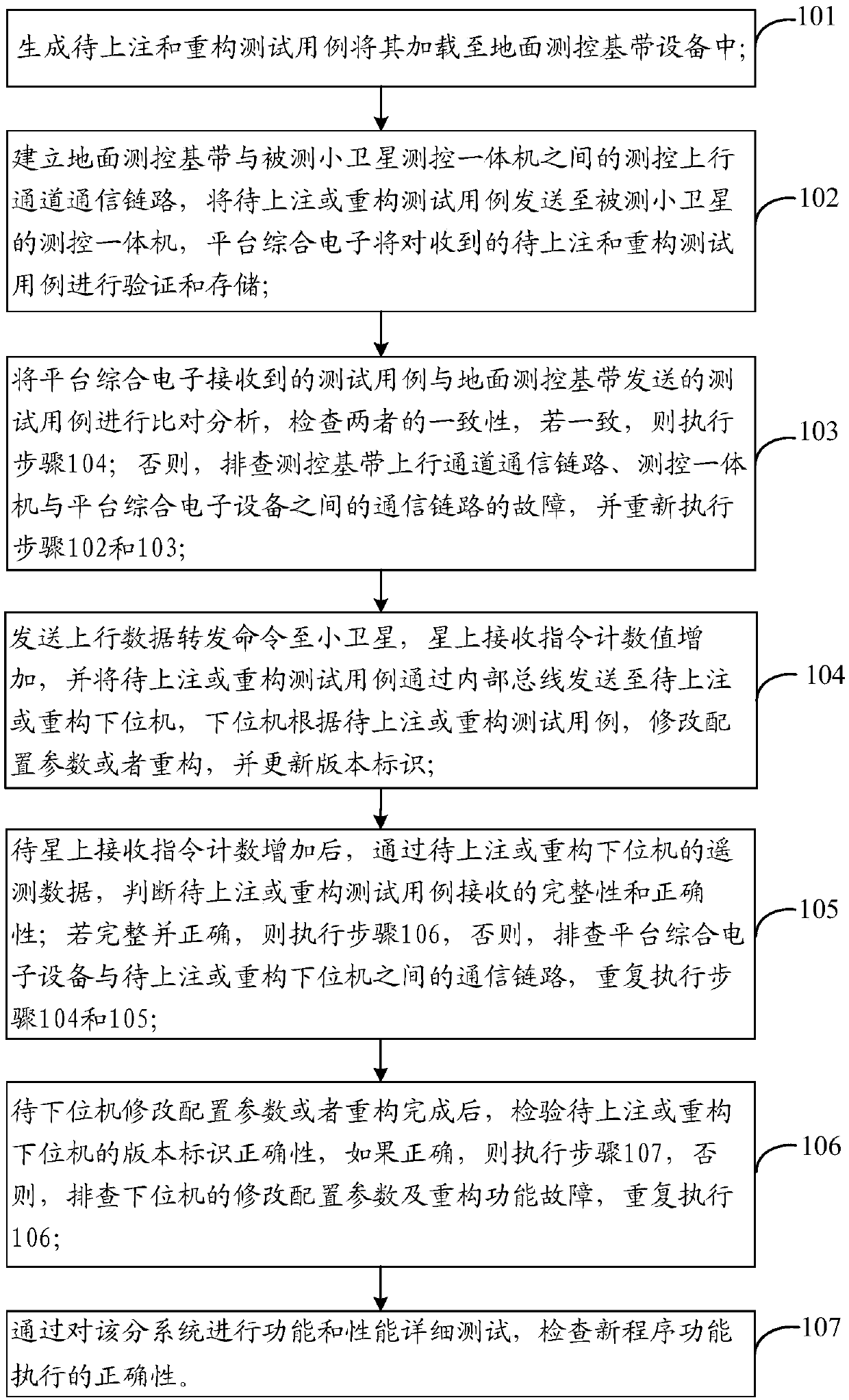

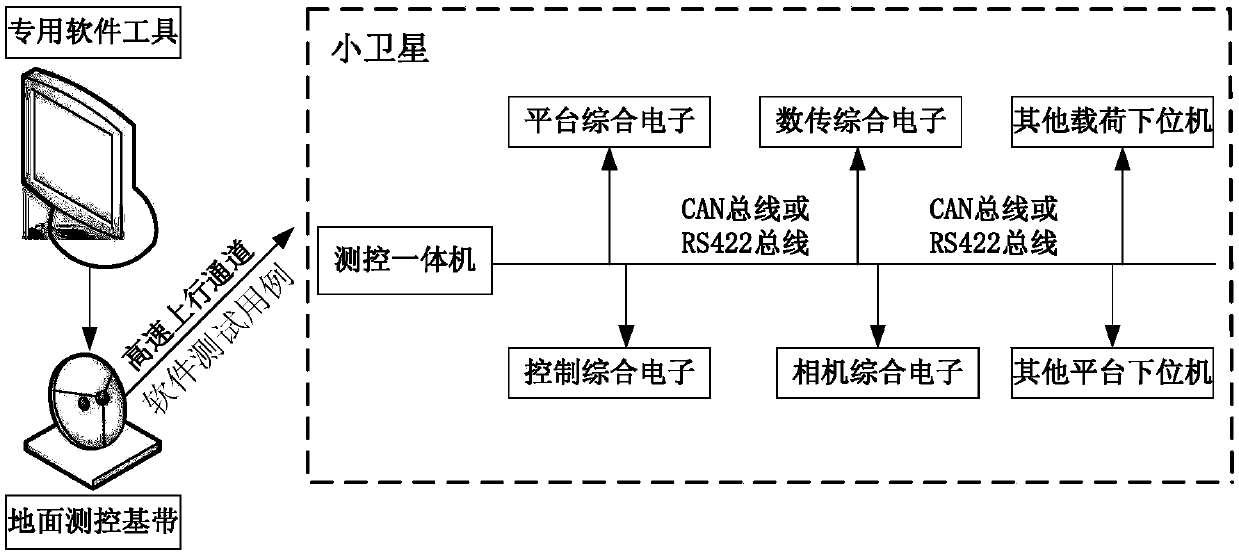

Minisatellite on-satellite software injection and reconstitution ground test validation method and system

ActiveCN109672470AImprove sending and transferring speed and efficiencyReduce transfer processRadio transmissionSatelliteTelemetry Equipment

The invention discloses a minisatellite on-satellite software injection and reconstitution ground test validation method, comprising the following steps: (1) using an automation method to generate a test case to be injected and reconstituted; (2) sending the test case to be injected and reconstituted to a tested minisatellite through a measurement and control baseband uplink channel; (3) performing comparison and analysis on the test case to be injected and reconstituted, received by a platform integrated electronic device, with the test case to be injected and reconstituted, sent by a groundmeasurement and control baseband device, to verify a measurement and control baseband uplink channel communication link and a communication link between a measurement and control all-in-one machine and the platform integrated electronic device; (4) judging the integrity and correctness of acceptance of the test case to be injected or reconstituted through telemetry data of a lower computer to be injected or reconstituted; (5) verifying the correctness of the version identification of the lower computer to be injected or reconstituted so as to verify a modification configuration parameter and areconstitution function of the lower computer; and (6) performing a detailed test of function and performance on the lower computer so as to check the function and performance of a new program of thelower computer.

Owner:AEROSPACE DONGFANGHONG SATELLITE

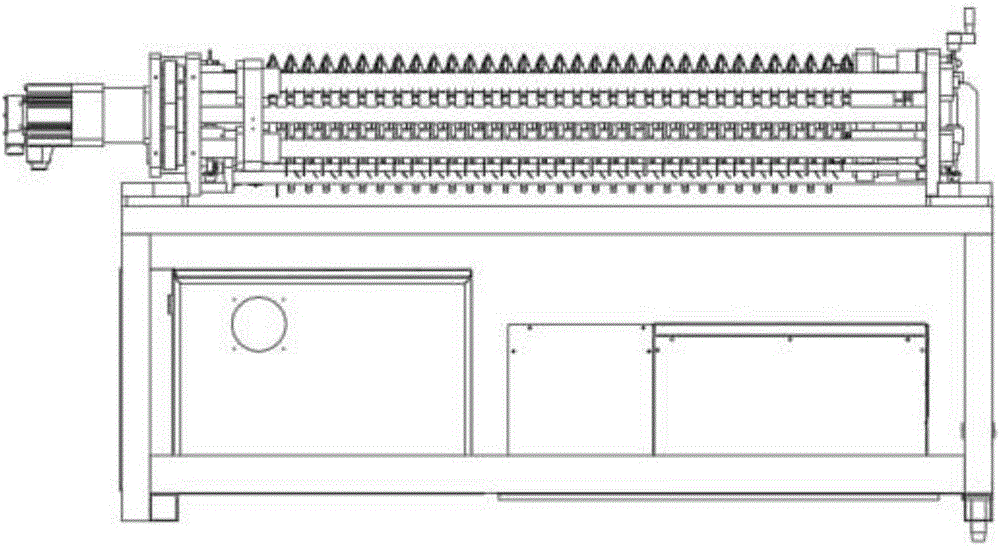

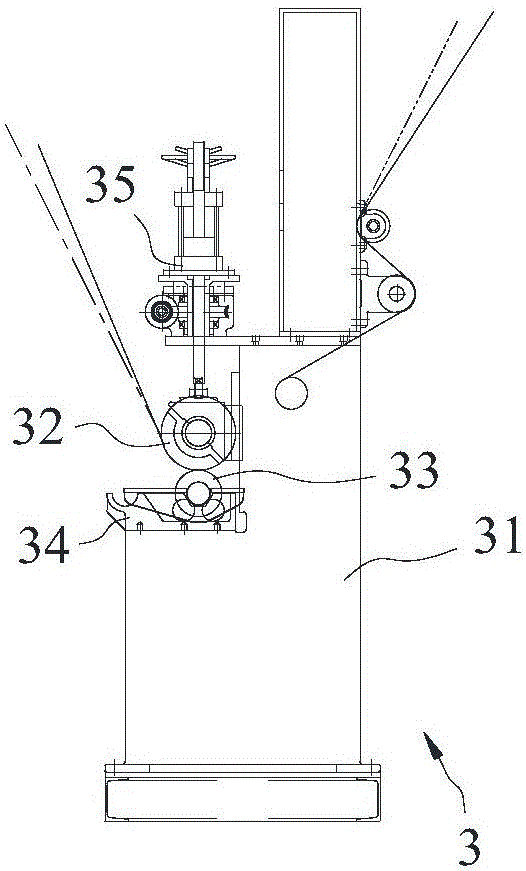

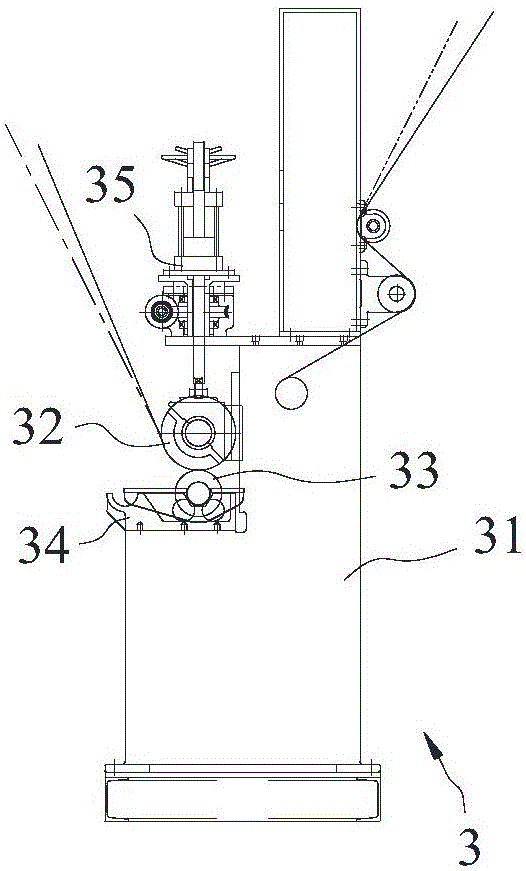

Formation clamp machine for bilateral-tab polymer soft-package power battery

PendingCN106784981ASolve the problem of batch fixture formationReduce transfer processAssembling battery machinesFinal product manufactureElectricityPower battery

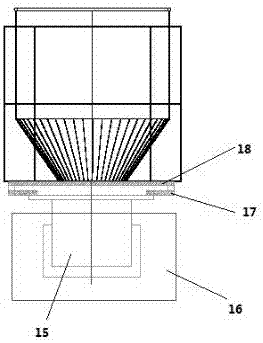

The invention discloses a formation clamp machine for a bilateral-tab polymer soft-package power battery. The formation clamp machine comprises a frame, a pressure control component, a heating control component, a charging-discharging device and a controller, wherein the pressure control component, the heating control component and the charging-discharging device are all arranged on the frame; the pressure control component and the heating control component are both connected with a power supply end of the charging-discharging device; the pressure control component is arranged on a working table-board of the frame; the heating control component is arranged on the pressure control component; a control end of the pressure control component, a control end of the heating control component and a control end of the charging-discharging device are electrically connected with corresponding control pins of the controller respectively. The formation clamp machine has the beneficial effects that the batch clamp formation problem of a battery with bilateral-outgoing tabs is solved; through the scheme of automation, the pressurization, the heating and the formation are gathered in one clamp to be carried out, transfer processes among working procedures are reduced, moreover, two original working procedures are combined into one working procedure, and the production efficiency is promoted.

Owner:ZHEJIANG HANGKE TECH

Manufacturing process of inner magnetic rotor in magnetic pump

ActiveCN109604976AReduce labor costsEasy to assembleAssembly machinesPump installationsMagnetic tension forceMachining

The invention provides a manufacturing process of an inner magnetic rotor in a magnetic pump. The manufacturing process solves the technical problems that an existing manufacturing process is long inmanufacturing time, low in production efficiency and the like. According to the manufacturing process of the inner magnetic rotor in the magnetic pump, the inner magnetic rotor comprises a rotor seat,a first check ring, an annular sizing block, an inner magnetic steel piece, a second check ring, a sheath baffle and a packaging sheath. The manufacturing process comprises the following steps that S1, the rotor seat, the first check ring, the annular sizing block, the inner magnetic steel piece, the second check ring, the sheath baffle and the packaging sheath are placed in an assembling machinesequentially to be manufactured into a magnetic pump inner magnetic rotor workblank; S2, the magnetic pump inner magnetic rotor workblank is placed on a welding tool, the sheath baffle is welded withthe rotor seat, and the two ends of the packaging sheath are welded with the rotor seat and the sheath baffle respectively to manufacture a magnetic pump inner magnetic rotor semi-finished product; and S3, the magnetic pump inner magnetic rotor semi-finished product is machined, and after the semi-finished product is detected qualified, a magnetic pump inner magnetic rotor finished product is obtained. The manufacturing process has the advantage of being high in production efficiency.

Owner:江门旭弘磁材有限公司

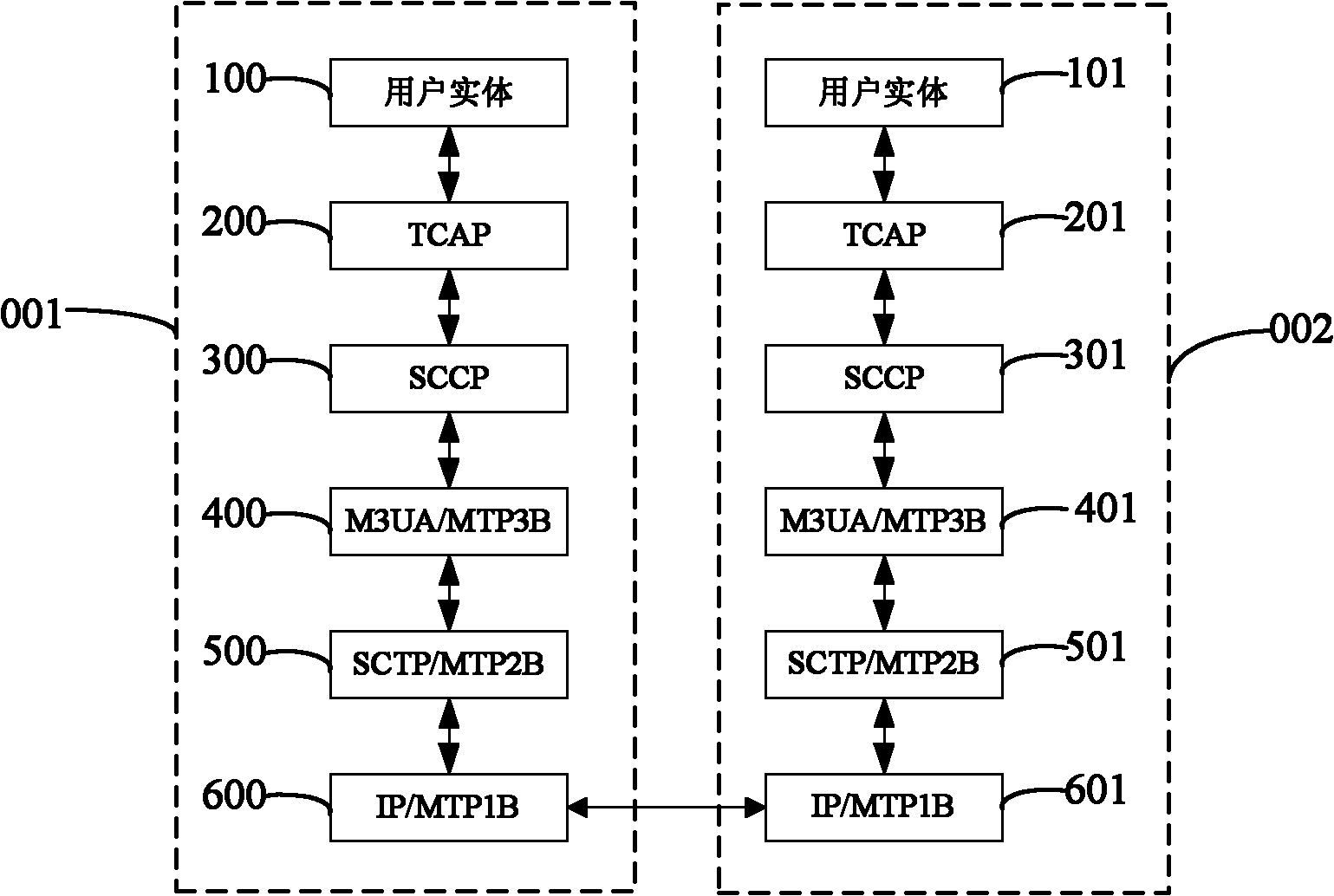

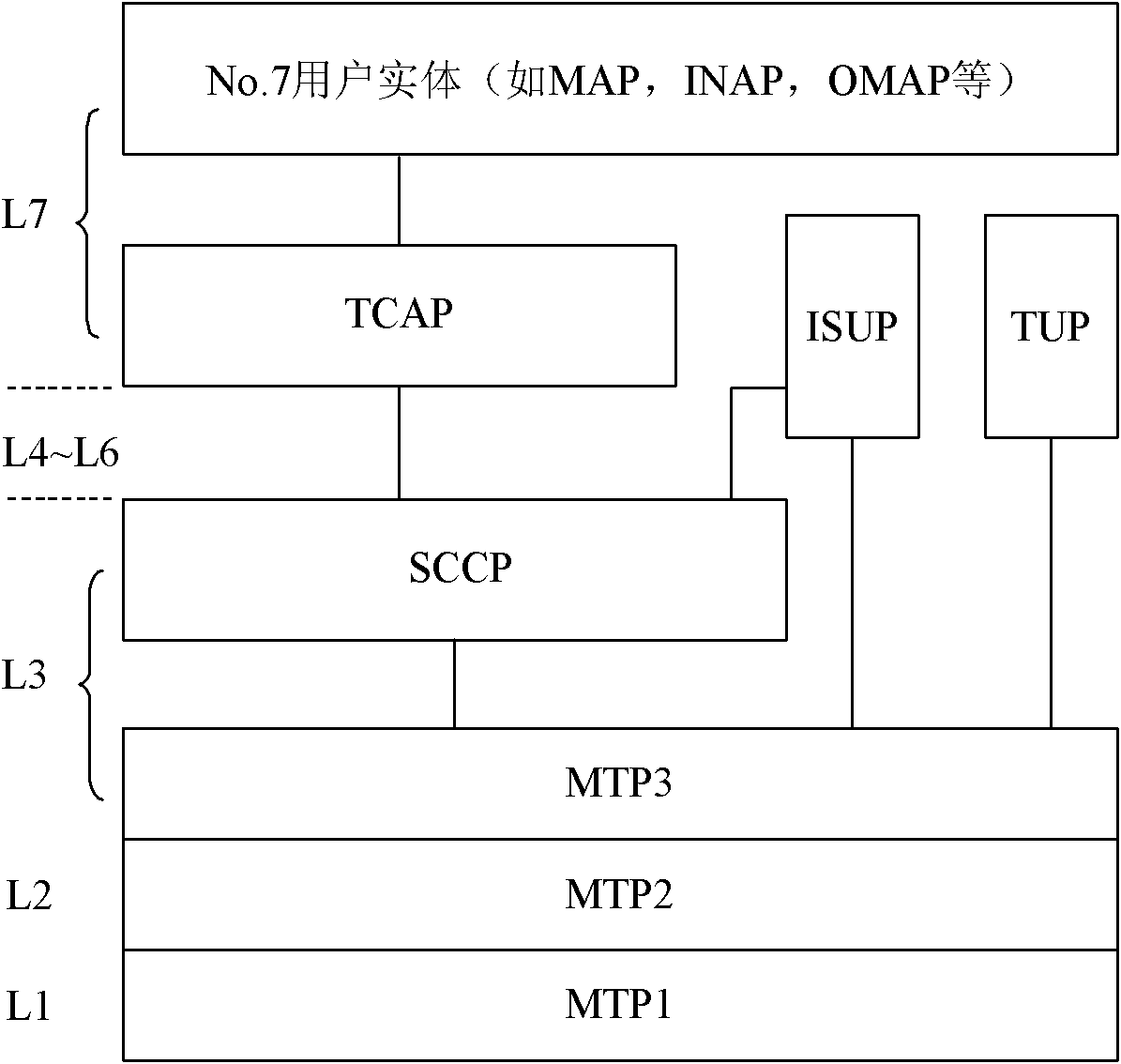

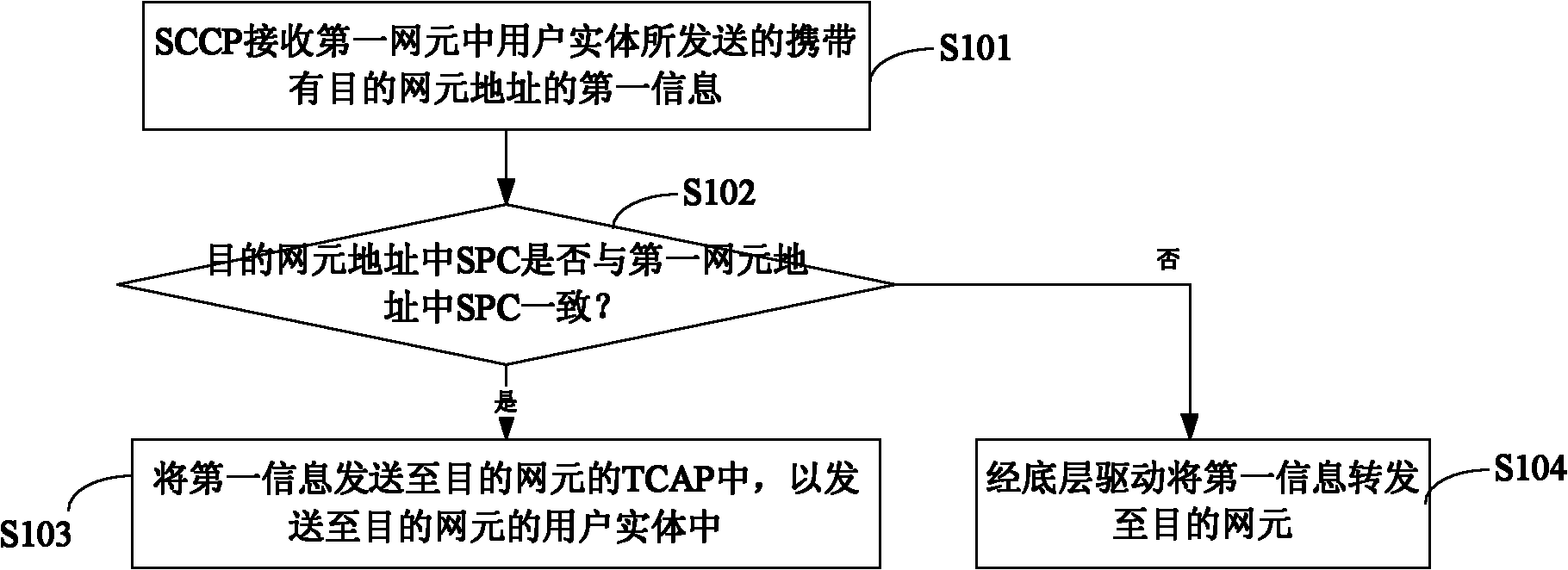

Information transmission method based on number 7 signaling and system using the same

ActiveCN103139665AReduce transfer processReduce transmission delaySelection arrangementsInformation transmissionCommunications system

The invention discloses an information transmission method based on a number 7 signaling and a system using the information transmission method based on the number 7 signaling can send information sent by a network element of a sending terminal to transaction processing capacity application portion (TCAP) of a target network element when the sending terminal network element and the target network element are positioned in the same communication device, namely, whether a signaling point of coding (SPC) of the target network element location is consistent with an SPC of the sending terminal network element location, and therefore the information transmission method based on the number 7 signaling and the system using the information transmission method based on the number 7 signaling need not transmission through a base drive, shorten transmission flow, reduce transmission delay, and are suitable for communication system flattening system structures.

Owner:大唐联诚信息系统技术有限公司

Fully automatic battery forming fixture machine

PendingCN109037783AReduce transfer processIncrease productivityFinal product manufactureSecondary cells charging/dischargingTemperature controlEngineering

The fully automatic battery forming fixture machine comprises a frame, an automatic fixture mechanism mounted on the rack for clamping the battery and pressurizing the battery while contacting with the pole ear of the battery; A battery support adjusting mechanism mounted on the rack and positioned directly below the battery for automatically replacing and supporting the battery according to the type of the battery; A temperature control mechanism mounted on the rack is used for heat the battery clamped on the automatic clamping device; Battery-forming cabinet, mount on the rack and in contactwith the battery electrode ear, is used for char and discharging the battery; And a controller mounted on the rack and electrically connected with an automatic fixture mechanism, the battery supportadjusting mechanism and the temperature control mechanism. The invention has the beneficial effects that the pressurization, the heating and the formation are assembled in a fixture, the transfer flowbetween the processes is reduced, and the original two processes are combined into one process, thereby improving the production efficiency.

Owner:ZHEJIANG HANGKE TECH

Third assembling mechanism in automatic assembling machine of magnetic drive pump inner magnetic rotor

InactiveCN111215892ARealize automated assemblyRealize the periodic operation of the assembly processAssembly machinesMetal working apparatusControl engineeringElectric machinery

The invention provides a third assembling mechanism in an automatic assembling machine of a magnetic drive pump inner magnetic rotor. The technical problems that in the assembling process of an innermagnetic rotor, an assembling machine capable of replacing manual assembling is not adopted in the existing manufacturing process, a large amount of labor is needed during batch production, multiple auxiliary tools need to be matched, occupied resources are large, the production cost is high, the manufacturing time is long, and the assembling efficiency is low are solved. According to the third assembling mechanism in the automatic assembling machine of the magnetic drive pump inner magnetic rotor, the inner magnetic rotor comprises a rotor base, a first baffle ring, an annular sizing block, an inner magnetic steel sheet, a second baffle ring, a sheath baffle and a sheath; the assembling machine comprises a base, a first support is fixed to the base, and a first stepping motor is fixed tothe first support; and an output shaft of the first stepping motor is vertically upward, a stepping rotary disc is fixed to the end of the output shaft of the first stepping motor, a limiting groove is formed in the stepping rotary disc, and a limiting table is arranged in the limiting groove. The method has the advantage of high assembly efficiency.

Owner:时飞龙

Transfer printing method

InactiveCN100372692CAvoid distortion errorsImprove transfer qualityInk transfer from master sheetAdhesivePlastic film

Owner:惠州全品科技工业有限公司

A method, system and device for media on demand

ActiveCN111818360BGuaranteed transmission efficiencyReduce transfer processSelective content distributionTelecommunicationsMediaFLO

Owner:深圳平安智慧医健科技有限公司

Integrated processing device of synthetic leather

InactiveCN106521979AIncrease productivityFast processingTextiles and paperEngineeringIntegrated processing

The invention discloses an integrated processing device of synthetic leather. The device comprises an unwinding mechanism, a cloth storage rack, a first printing component, a second printing component, a widening mechanism, a cooling mechanism and a winding mechanism sequentially connected along the cloth conveying direction, wherein the unwinding mechanism is used for delivering the to-be-processed cloth; the cloth storage rack is used for carding and temporarily storing the to-be-processed cloth; the first printing component is used for dyeing printing; the second printing component is used for sizing material printing; the widening mechanism is used for widening the cloth; the cooling mechanism is used for cooling the synthetic leather; the winding mechanism is used for winding a finished product of synthetic leather; and the integrated processing device of synthetic leather also comprises an inter-plate dryer and a widening setting dryer arranged above the widening mechanism. In the invention, the processing speed of synthetic leather can be increased, and the transfer loss is reduced.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

Multifunctional dry material shed for preparing dry materials based on biological power generation smoke afterheat

InactiveCN110242975AEasy to cleanAvoid pollutionLighting and heating apparatusBiomass combustionEngineering

The invention discloses a multifunctional dry material shed for preparing dry materials based on biological power generation smoke afterheat. The multifunctional dry material shed comprises a ground base and a material shield main body; the top of the ground base is fixedly connected with the bottom of the material shield main body; a first mounting plate and a second mounting plate are fixedly connected between the two sides of the inner wall of the material shield main body in sequence from top to bottom; a chassis is fixedly connected to the top of the second mounting plate; and the multifunctional dry material shed relates to the technical field of biomass power generation facilities. The multifunctional dry material shed for preparing the dry materials based on the biological power generation smoke afterheat can enrich the functions of a material shed, achieves an effect of storing biomass materials, realizes drying and storage of the materials in the material shed, preferably achieves the purpose of reducing the biomass power generation cost through saving of a material transfer procedure, and meanwhile, recovers afterheat in high-temperature smoke generated by biomass combustion for drying of the materials in the material shed to save a lot of heat energy and to achieve both energy conservation and environmental protection.

Owner:山东郓城琦泉生物发电有限公司

Novel feeder

The invention discloses a novel feeder. The novel feeder comprises a machine body, a cigarette box transfer manipulator device, a feeding cigarette box transfer manipulator, a lifting and weighing device and a cut tobacco suction device. The novel feeder is characterized in that the machine body is provided with the cigarette box transfer manipulator device, the cigarette box transfer manipulator device is located at a cut tobacco loading station, the cigarette box transfer manipulator device is provided with a box pushing rod, conveyors are arranged in two sides of the cut tobacco loading station, a cut tobacco suction station is arranged between the two conveyors, a guard bar is arranged in one side of each one of the conveyors, the lifting and weighing device is arranged in the cut tobacco loading station, the cut tobacco suction device is arranged right above the cut tobacco suction station, the cut tobacco suction device is fixed to a plate in the second layer of the machine body and the plate is provided with the feeding cigarette box transfer manipulator. The novel feeder realizes single quantitative statistics of cut tobacco used by each cigarette making machine and reduces cut tobacco transfer processes, fragmentation and cut tobacco layering.

Owner:玉溪市新特科技有限公司

Square battery heating and pressurizing tray

PendingCN109830622AAffect the appearanceGood high temperature consistencySecondary cells charging/dischargingCell component detailsEngineeringElectrical and Electronics engineering

A square battery heating and pressurizing tray comprises a frame including a bottom plate, two end plates, a baffle and a support rod, wherein the two end plates are installed on the two ends of the bottom plate respectively and are connected through the support rod, and the baffle sleeves the support rod and divides a cavity defined by the end plates and the bottom plate into a battery clamping zone and a clamping degree adjustment zone which are mutually convertible; an adjustable battery clamp mechanism having a plurality of battery clamping blocks, arranged in the battery clamping zone ofthe frame and slidably connected with the support rod; a clamping degree adjusting mechanism detachably mounted in the clamping degree adjustment zone; and a heating mechanism including a plurality ofheating sheets each of which is laid on the wall surface of the corresponding battery clamping block. The square battery heating and pressurizing tray can achieve one-time feeding and only one tray is just required to be heated and pressurized. The square battery heating and pressurizing tray is easy to operate, saves energy, reduces loss, can increase a battery output and reduce production cost.

Owner:ZHEJIANG HANGKE TECH

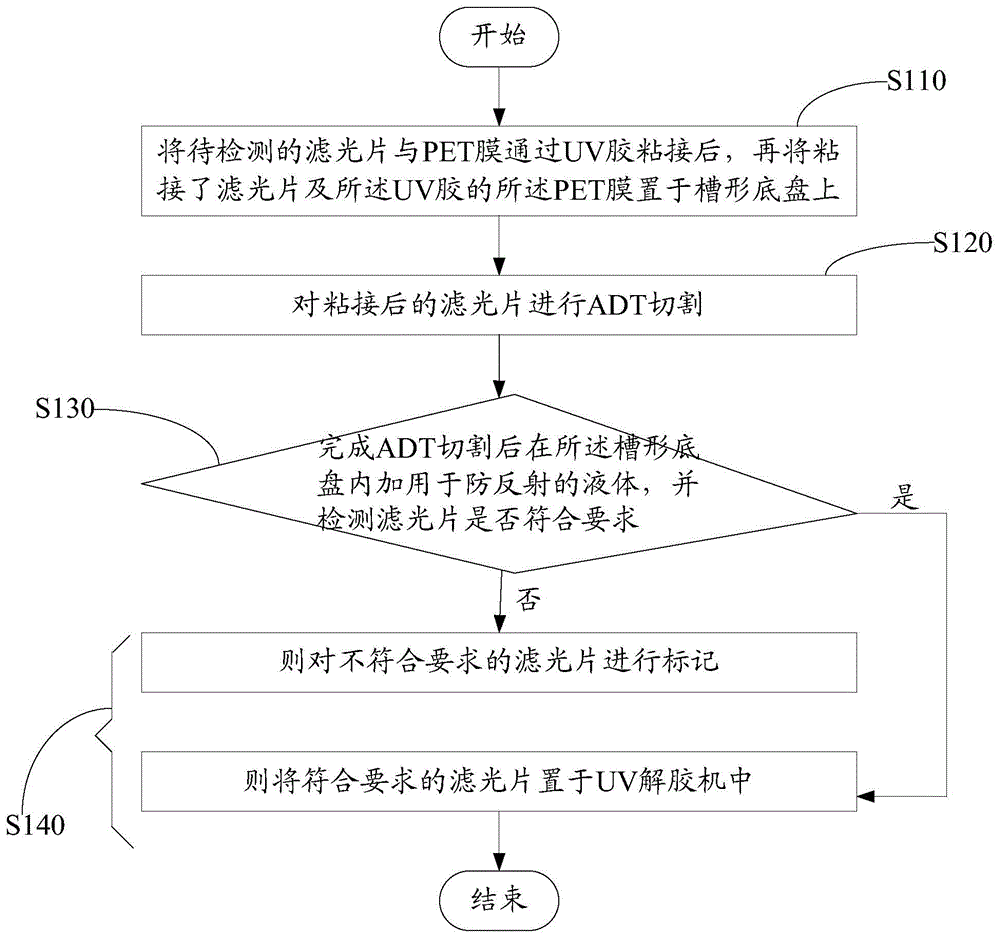

Optical filter testing method and optical filter testing device

InactiveCN105571824AReduce transfer processReduce operating proceduresMaterial analysis by optical meansTesting optical propertiesAdhesiveEngineering

An optical filter testing method comprises the steps of after binding an optical filter and a PET film through an UV adhesive, performing ADT cutting; and placing the PET film on which the optical filter and the UV adhesive are bound on a trough-shaped chassis. Therefore, when ADT cutting is performed, the optical filter is placed on the trough-shaped chassis. After cutting is finished, antireflection liquid is added into the trough-shaped chassis, and then whether the optical filter satisfies a requirement is directly tested on the trough-shaped chassis. Therefore, testing position change of the optical filter is not required in the optical filter testing method, number of operation processes is reduced and an optical filter conveying process is saved. Furthermore the invention provides an optical filter testing device.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com