Novel feeder

A feeding machine, a new type of technology, applied in the fields of application, tobacco, and cigarette manufacturing, etc., can solve the problems of large statistical errors in tobacco consumption and large feeding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

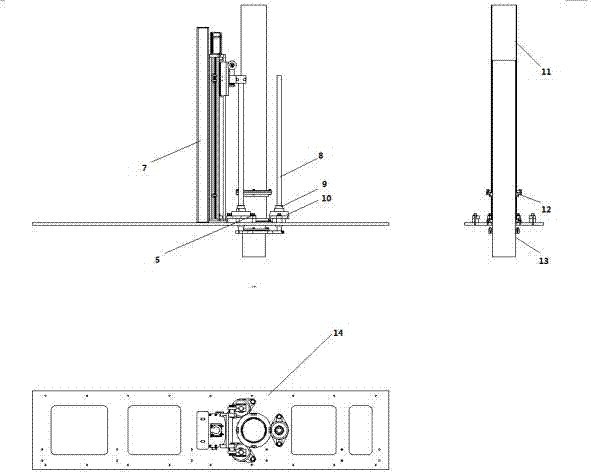

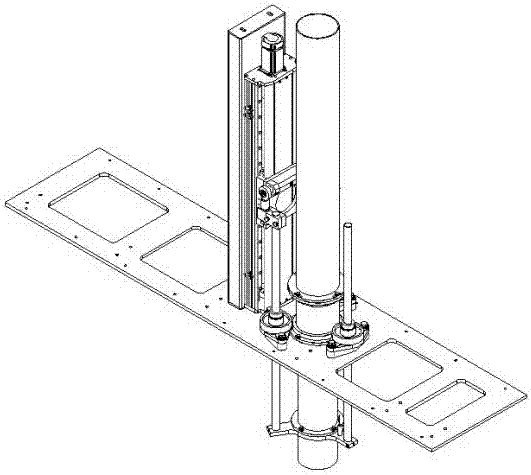

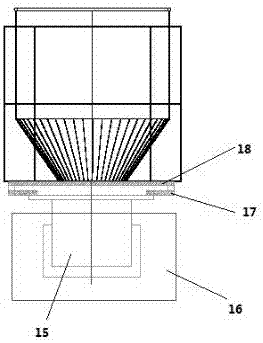

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] A new type of feeding machine, comprising a body 1, a smoke box transfer manipulator device 22, a smoke box transfer manipulator 7, a lifting and weighing device 15 and a silk suction device 5, characterized in that the first layer 24 of the body is in the middle There is at least one smoking wire station 2, and the smoking wire station 2 is equipped with a lifting weighing device 15, which is used for weighing the cigarette box. Separator; there is also a shredded tobacco loading station 3 next to the shredded smoking station 2, the shredded smoking station 2 and the shredded tobacco loading station 3 are arranged in a straight line on the first layer 24 of the body, on both sides of the first layer 24 of the body A conveyor 4 is provided, and a guardrail 23 is provided on the conveyor 4; a smoke box transfer manipulator device 22 is provided on one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com