Integrated processing device of synthetic leather

A processing device and technology for synthetic leather, applied in textiles and papermaking, etc., can solve problems such as low production efficiency, and achieve the effects of improving production efficiency, controllable processing process, and speeding up processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

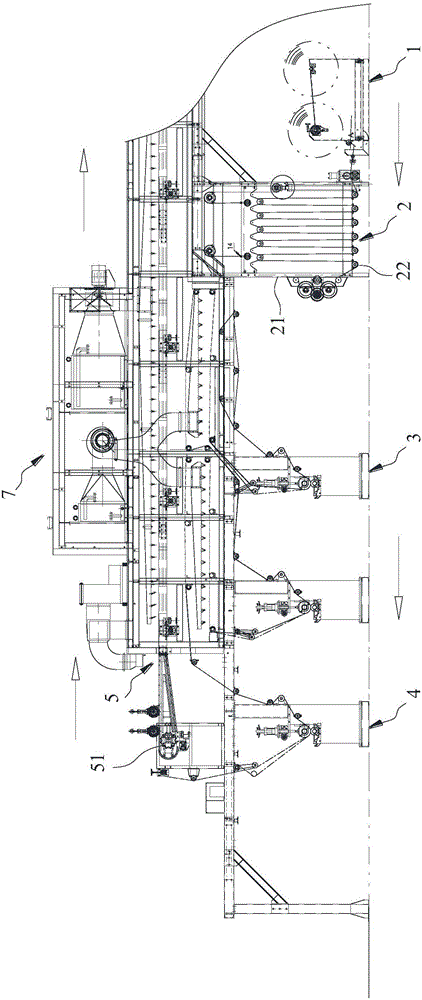

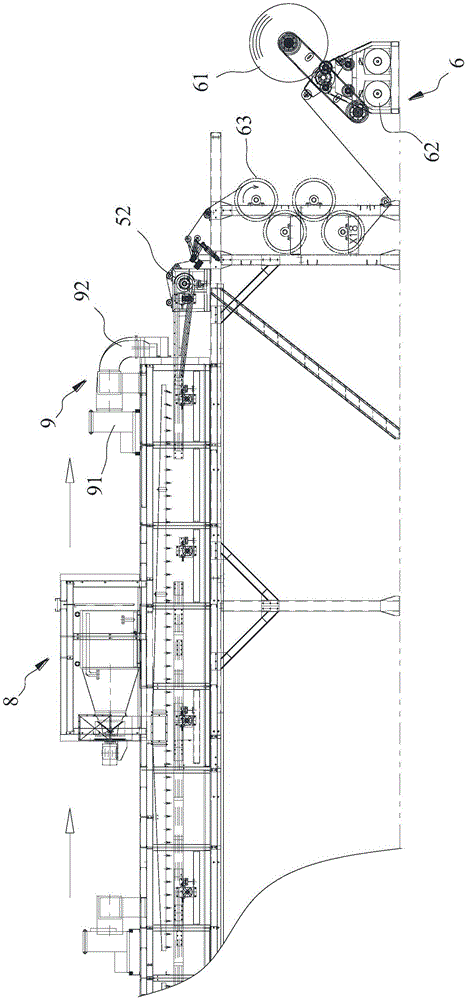

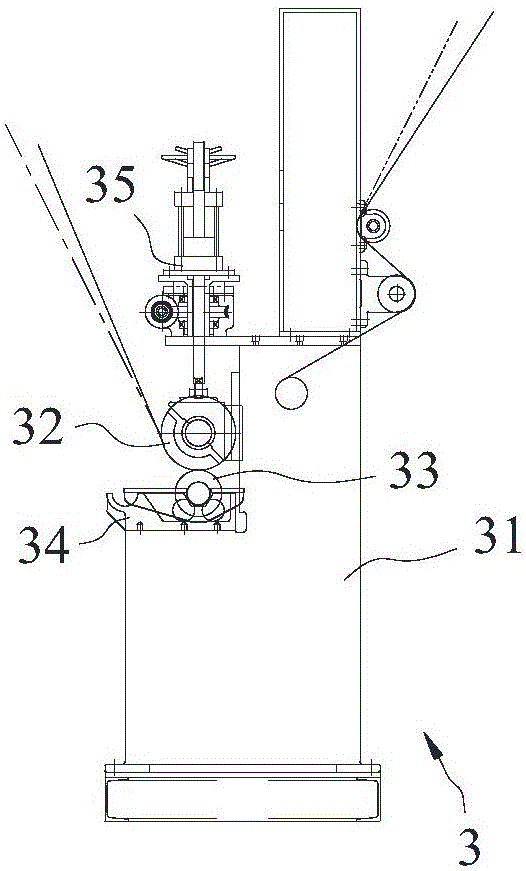

[0020] Such as Figure 1-2 The synthetic leather integrated processing device shown includes an unwinding mechanism 1 for sending out the cloth to be processed, a cloth storage rack 2 for carding and buffering the cloth to be processed, and a storage rack for dyeing and printing, which are sequentially connected along the feeding direction of the cloth. The first printing unit 3, the second printing unit 4 for sizing printing, the stretching mechanism 5 for stretching the cloth, the cooling mechanism 9 for cooling the synthetic leather and the winding mechanism for winding the finished synthetic leather 6. The synthetic leather integrated processing device also includes a plate-to-plate oven 7 and a stretching and shaping oven 8 arranged above the stretching mechanism 5 .

[0021] The continuous integration of unwinding mechanism 1, cloth storage rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com