Square battery heating and pressurizing tray

A technology of heating and pressurizing square batteries, which is applied in the direction of secondary batteries, battery pack components, secondary battery charging/discharging, etc., can solve problems such as bulging, achieve reduced loss, good high temperature consistency, and reduce transfer processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

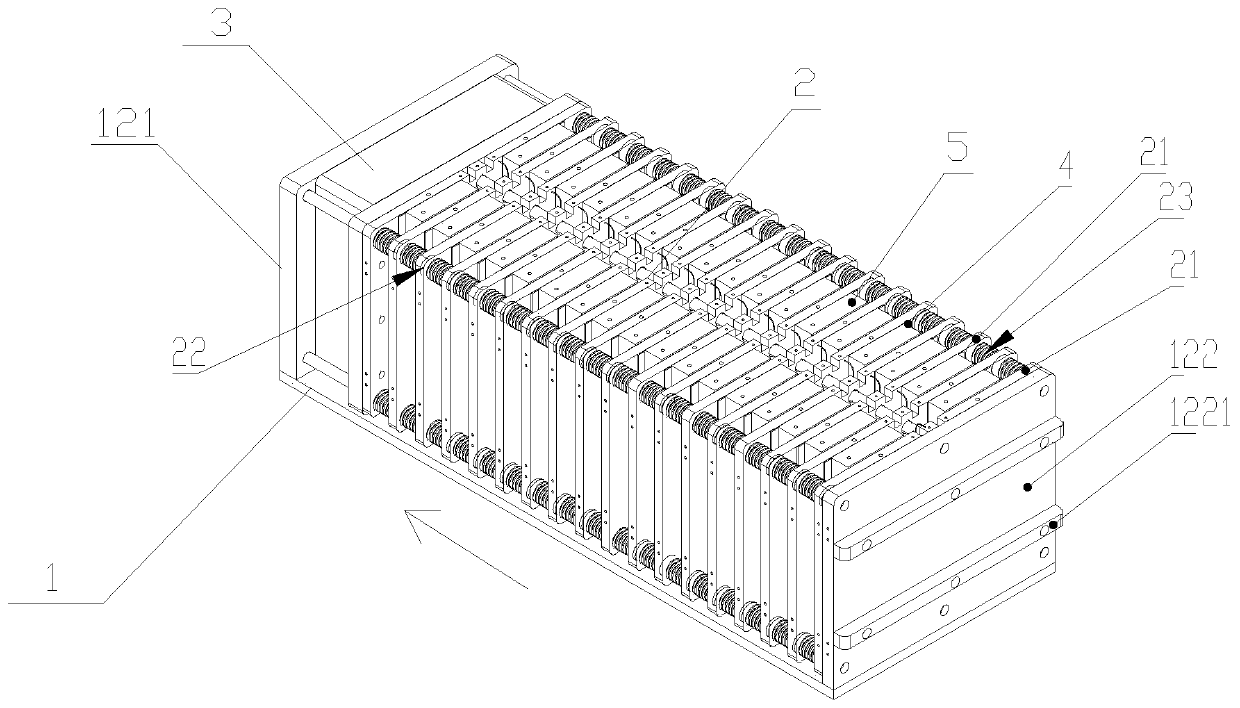

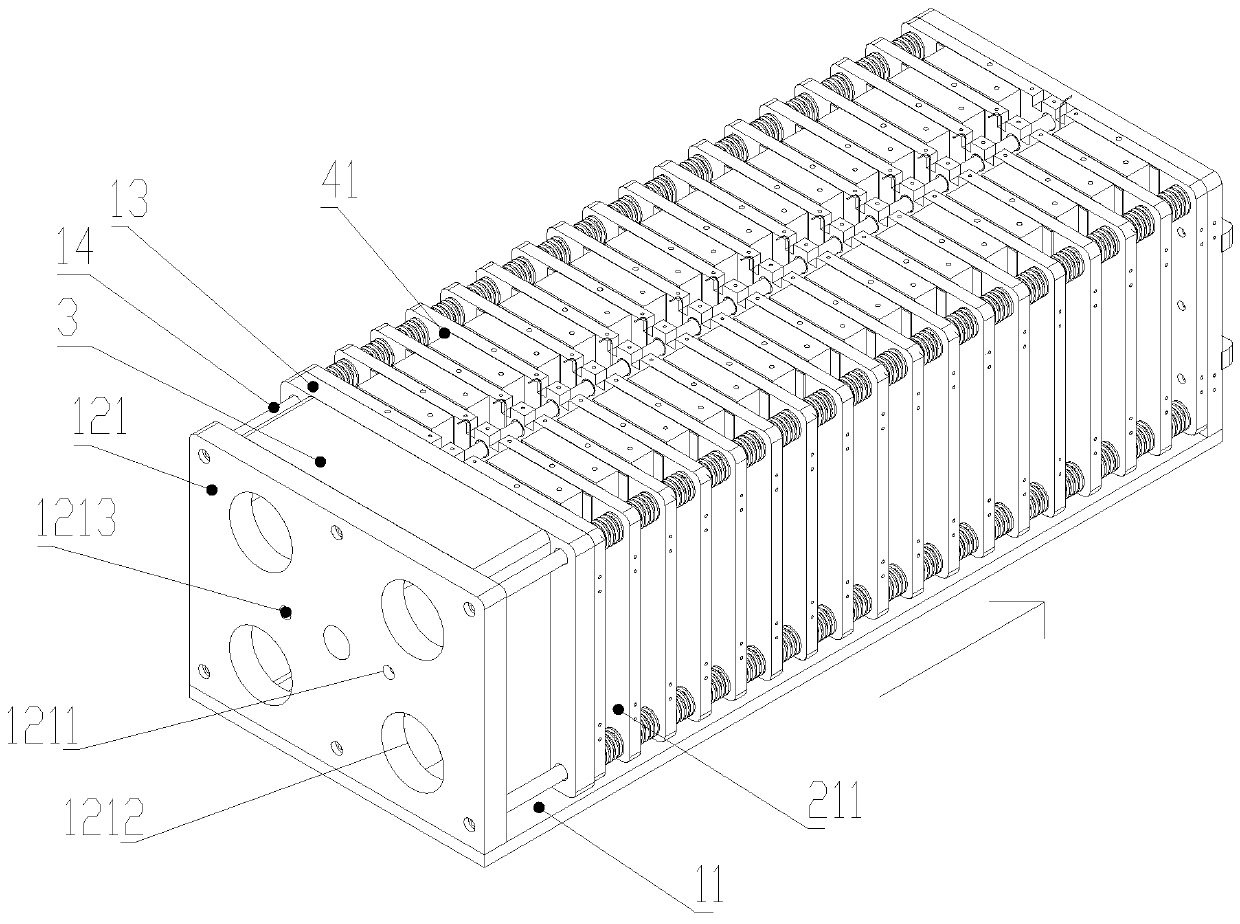

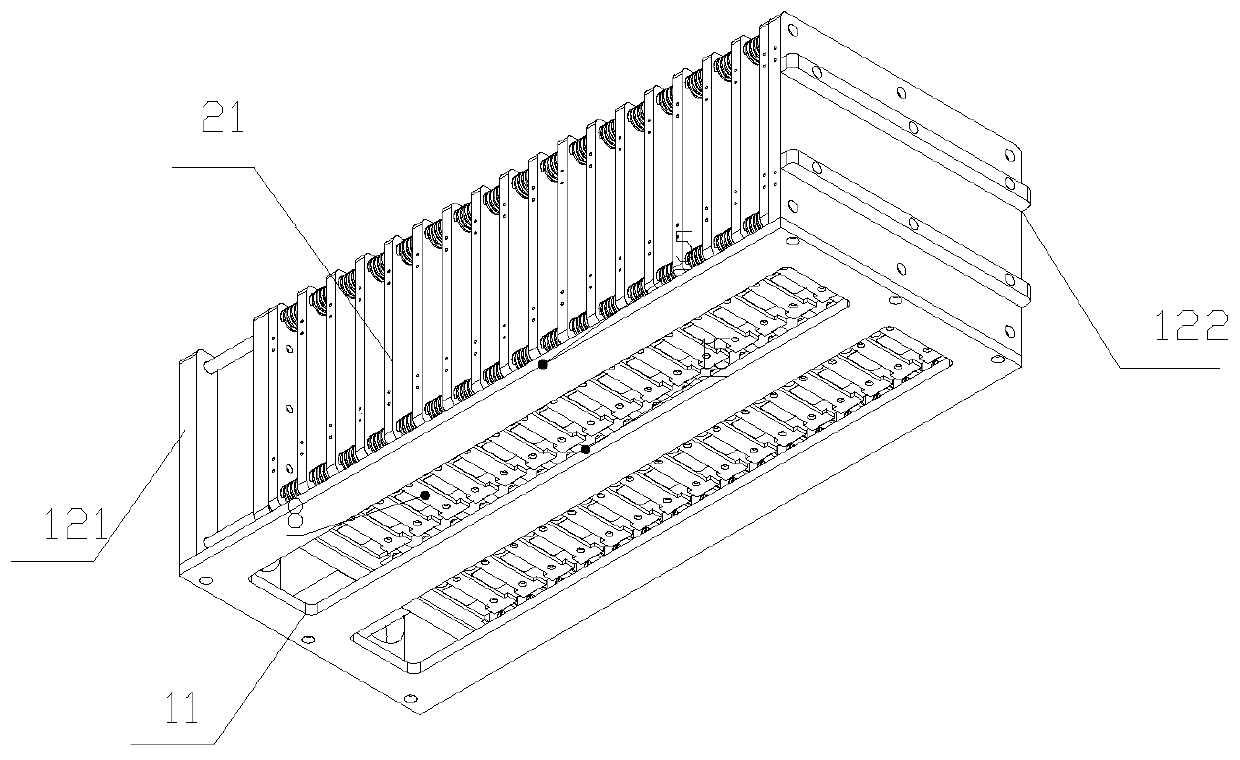

[0027] Embodiment 1 The square battery heating and pressurizing tray of the present invention includes:

[0028] The frame 1 includes a base plate 11, an end plate, a baffle plate 13 and a support rod 14, wherein the two end plates are respectively installed at both ends of the base plate, and the support rods are connected between the two end plates; the baffle plate is sleeved on the support rod , and separate the concave cavity surrounded by the end plate and the bottom plate into a battery clamping area and a clamping degree adjustment area that can be converted into each other;

[0029] The adjustable battery clamp mechanism 2 has several battery clamping blocks, which are arranged in the battery clamping area of the frame, and are slidably connected with the support rods, and are used to clamp the battery 5 placed in the block;

[0030] The clamping degree adjustment mechanism 3 is detachably installed in the clamping degree adjustment area, and is used to adjust the p...

Embodiment 2

[0038] Embodiment 2 In the square battery heating and pressurizing tray according to the present invention: support rods: 6 pairs in a group, installed between the front end plate and the rear end plate respectively, so that the splints socketed on them are parallel to each other; There are two types of clips: one is the outermost clip, a total of two pieces, the other is the middle clip, a total of 16 pieces; heating sheet: 17 pieces; positioning pin: 2 pieces; baffle plate: 1 piece; There are two battery trays at the bottom of each intermediate clip: a total of 32 pieces; reinforcing ribs: 2 pieces; bushings: 102 pieces; rectangular springs: 68 pieces; adjustment block: 1 piece.

[0039] refer to Figure 1 to Figure 7 , square battery heating and pressurizing tray, 5, heating sheet 6, heating sheet 1 and 8, the bottom edge of the battery is installed on the above-mentioned 15, clip 2, the battery is placed between the heating sheets, and there is a battery supporting plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com