Press-fitting device used after dispensing of mobile phone rear cover

A technology for pressing equipment and mobile phone back cover, applied in mechanical equipment, material gluing, connecting components and other directions, can solve the problems of low efficiency, large workload, affecting the appearance of mobile phones, etc. The effect of preventing excessive adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A pressing device for dispensing glue on the back cover of a mobile phone, such as figure 1 As shown, it includes a base 1, a mounting seat 2, a pressing mechanism 3, a feeding mechanism 4, and a discharge guide plate 5. The right side of the top of the base 1 is connected with a mounting seat 2, and the mounting seat 2 is connected with a pressing mechanism 3. A feeding mechanism 4 is connected to the left side of the top of the base 1, and a discharge guide plate 5 is connected to the right side of the top of the base 1.

[0058] The staff can place the mobile phone that needs to be pressed on the feeding mechanism 4, start the pressing mechanism 3 to drive the feeding mechanism 4 to work, the feeding mechanism 4 works to drive the mobile phone to move to the right and enter the pressing mechanism 3, and the pressing mechanism 3 Work to press the mobile phone that has moved to the bottom, and the pressed mobile phone is squeezed out of the pressing mechanism 3, and au...

Embodiment 2

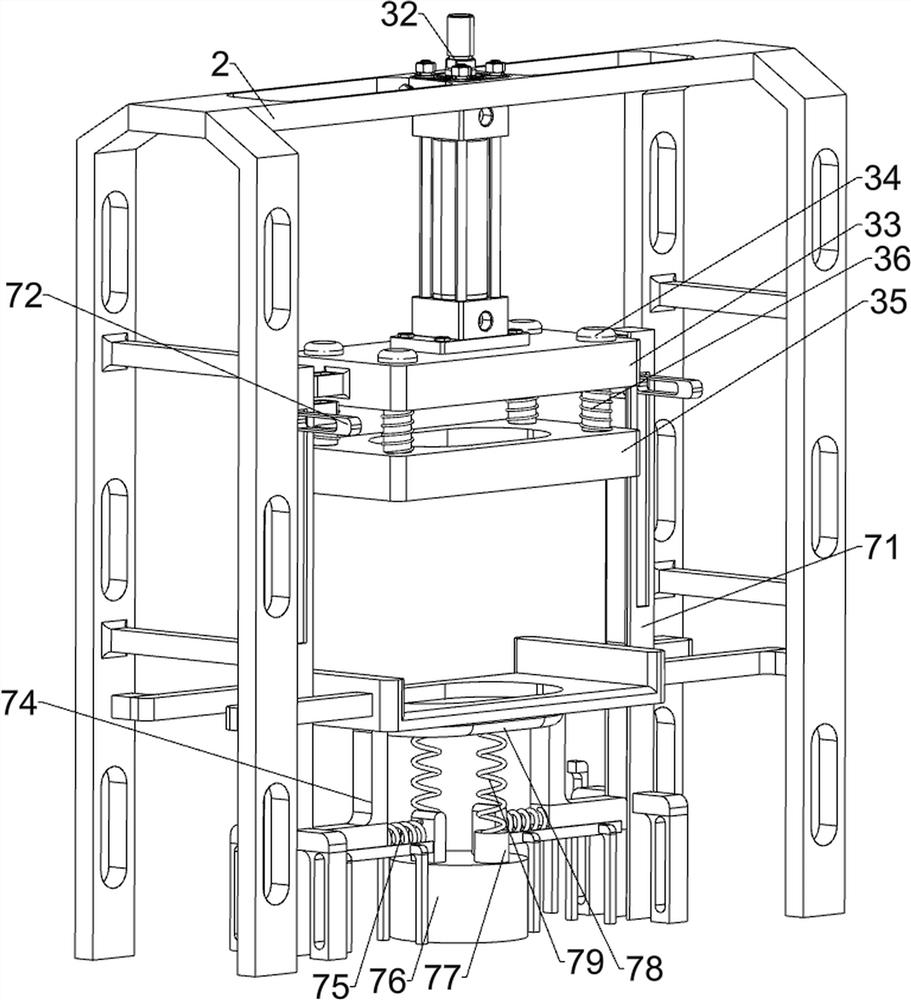

[0060] On the basis of Example 1, such as figure 2As shown, the pressing mechanism 3 includes a fixed nut 31, a lifting cylinder 32, a push plate 33, a connecting column 34, a pressing plate 35, a damping spring 36 and a material receiving plate 37, and the upper part of the mounting seat 2 is connected with a lifting cylinder 32. A plurality of fixing nuts 31 are connected between the cylinder 32 and the upper part of the mounting seat 2, and the telescopic end of the lifting cylinder 32 is connected with a push plate 33, and the four corners of the push plate 33 are slidably connected with a connecting column 34, between the bottom of the connecting column 34 A press plate 35 is connected, a damping spring 36 is connected between the top of the press plate 35 and the connecting column 34, and a material receiving plate 37 is connected between the bottom of the mounting seat 2, and the material receiving plate 37 is located on the left side of the discharge guide plate 5.

...

Embodiment 3

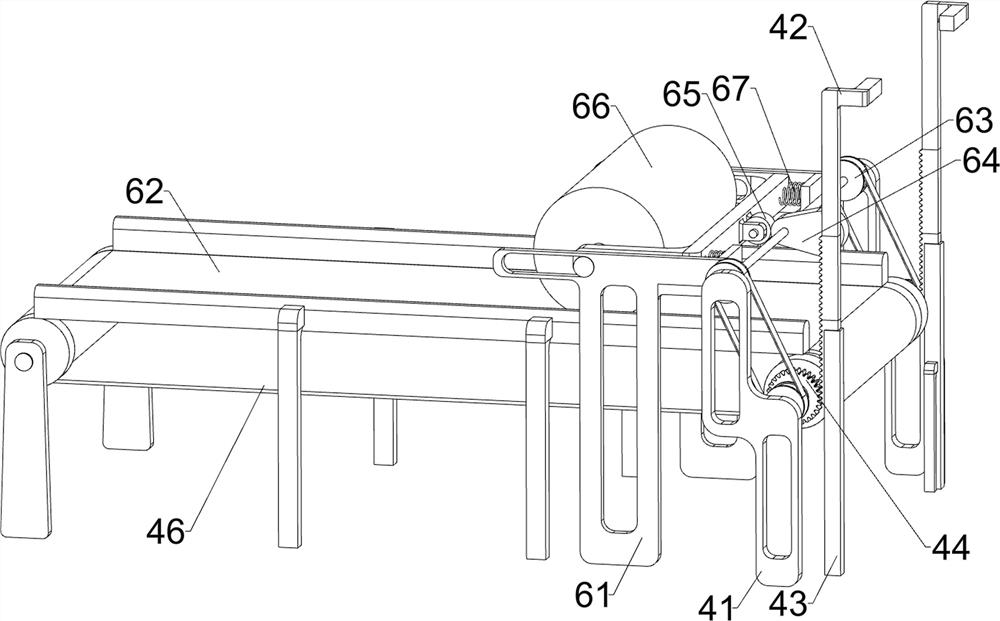

[0064] On the basis of Example 2, such as Figure 3 to Figure 7 As shown, a preloading mechanism 6 is also included. The preloading mechanism 6 includes a bearing seat 61, a limit plate 62, a second pulley assembly 63, a cam 64, a propulsion column 65, a flattening wheel 66 and a return spring 67. The base 1 The top is symmetrically provided with a bearing seat 61, and the upper part of the bearing seat 61 is slidingly connected with a flattening wheel 66, and the right side of the flattening wheel 66 is rotationally connected with a propulsion column 65. A return spring 67 is connected between the left side, and a rotating shaft is connected in rotation between the inner side of the upper part of the support base 41, and a second pulley assembly 63 is connected between the front and rear sides of the rotating shaft and the first pulley assembly 46 right transmission shaft. , the rotating shaft is connected with a cam 64, and the cam 64 cooperates with the propulsion column 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com