Patents

Literature

54results about How to "Guarantee the quality of lamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

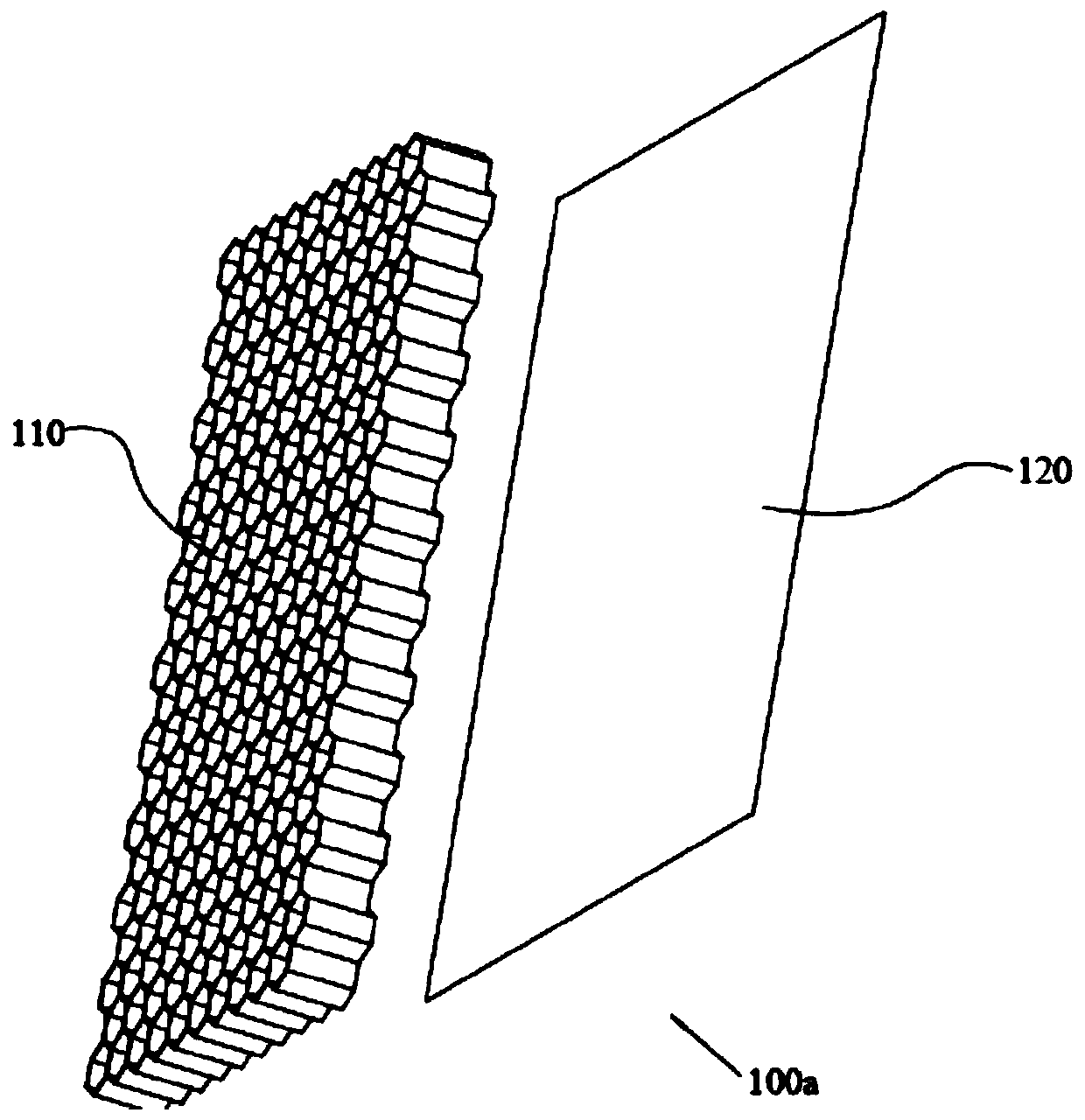

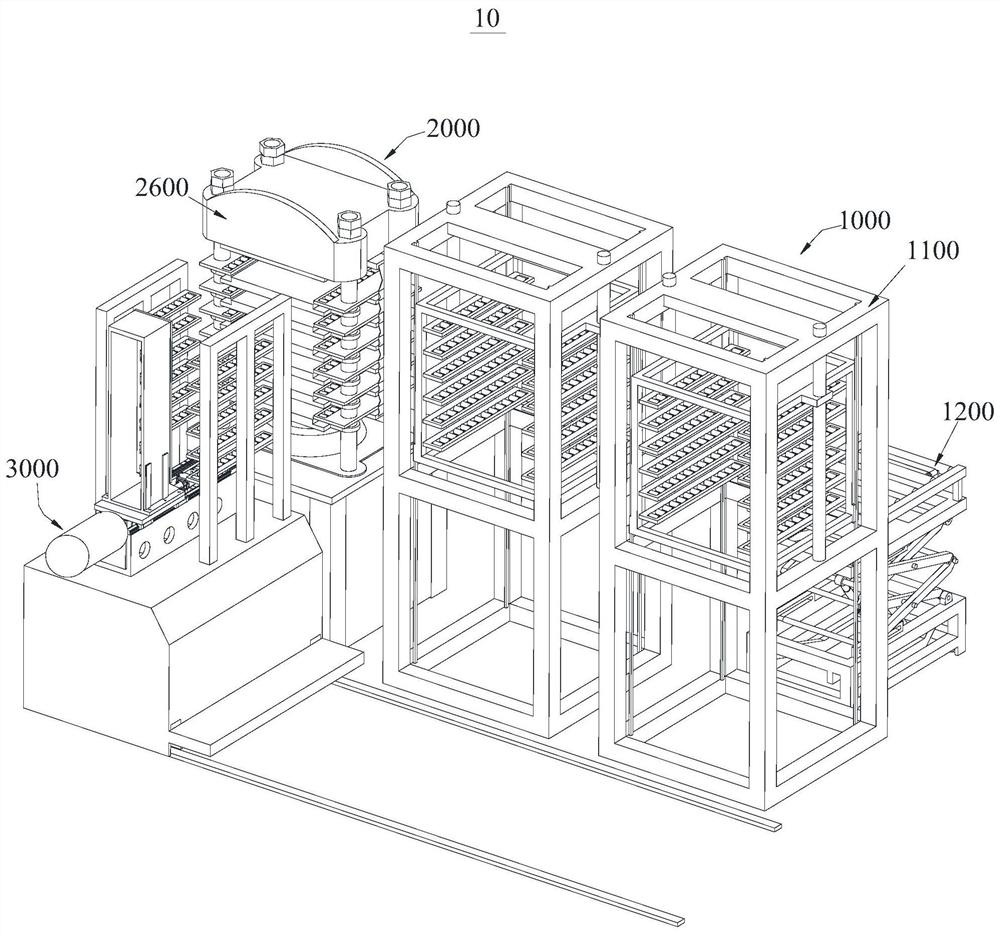

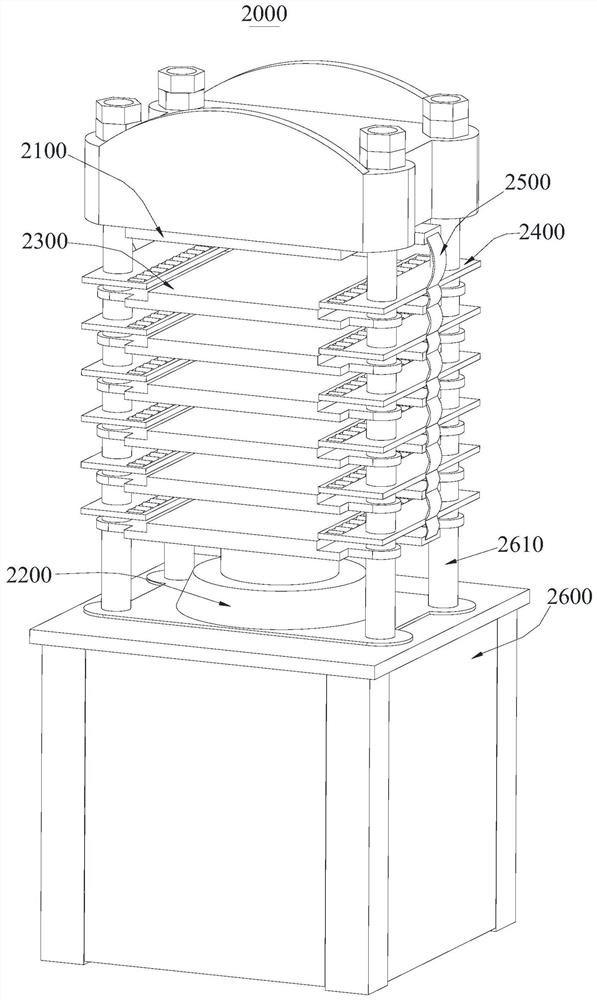

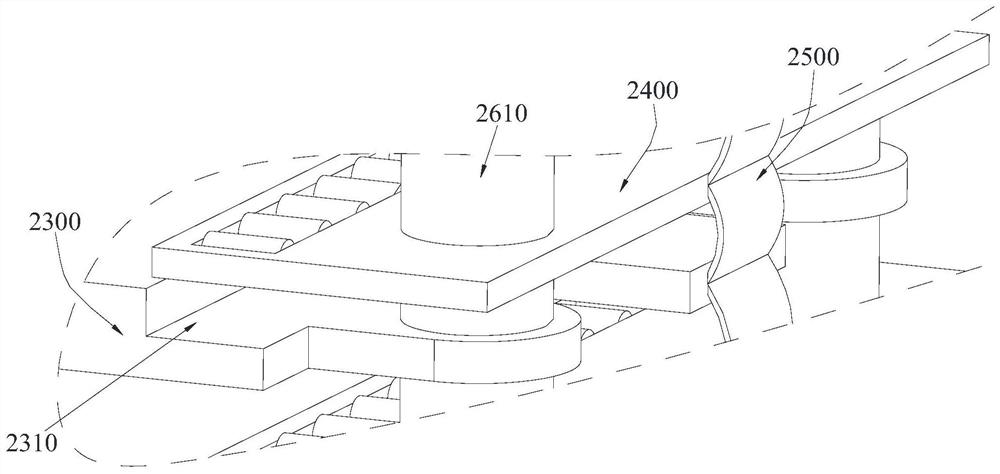

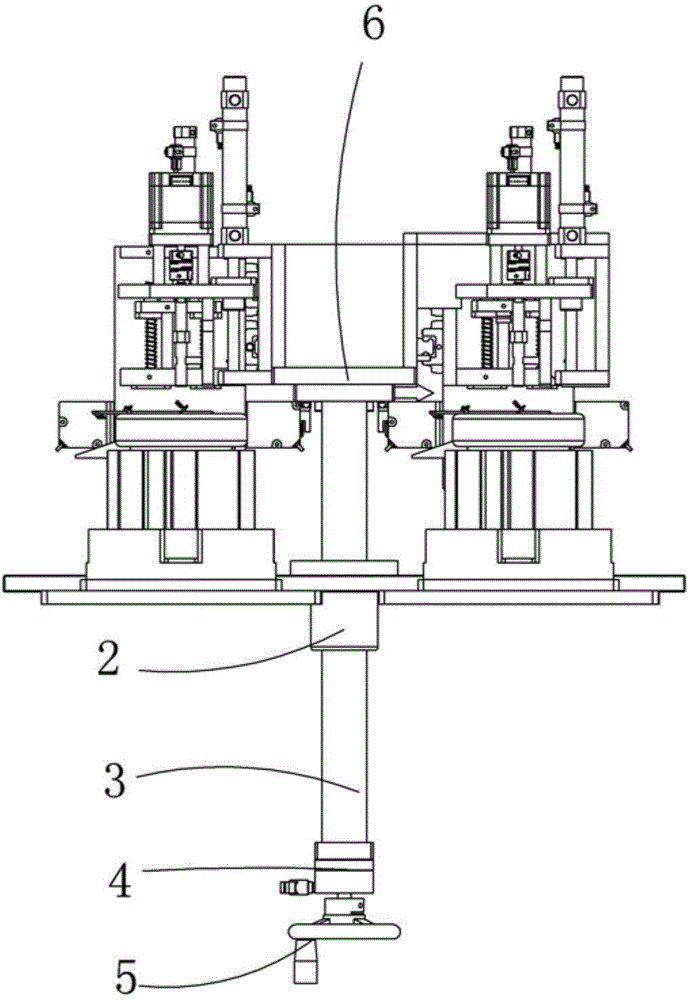

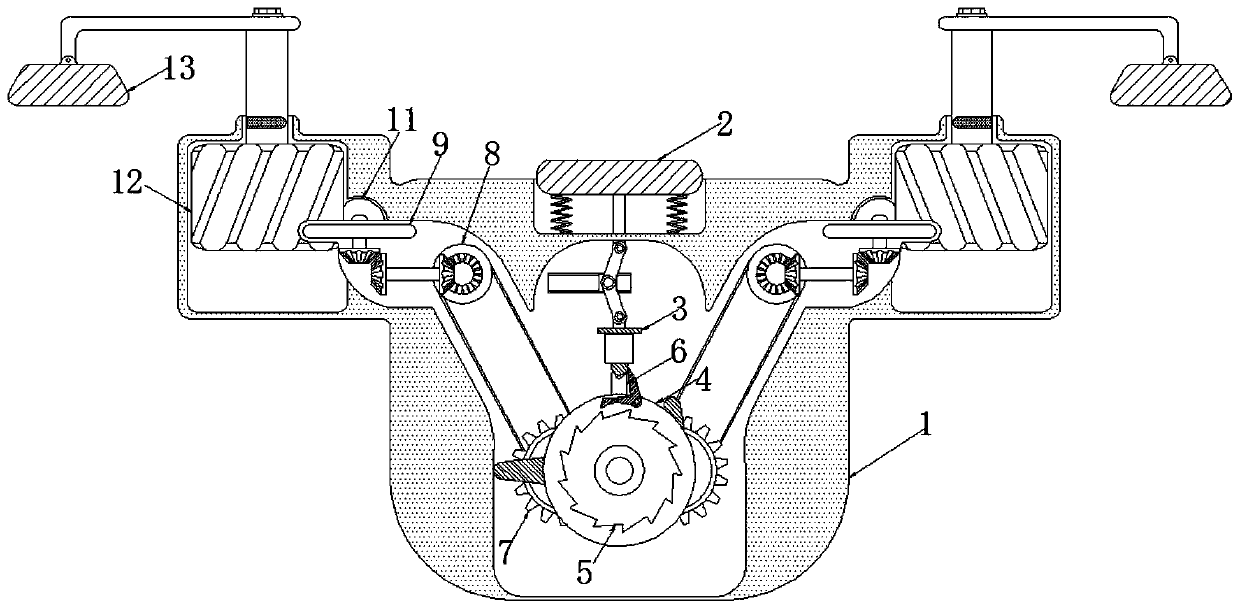

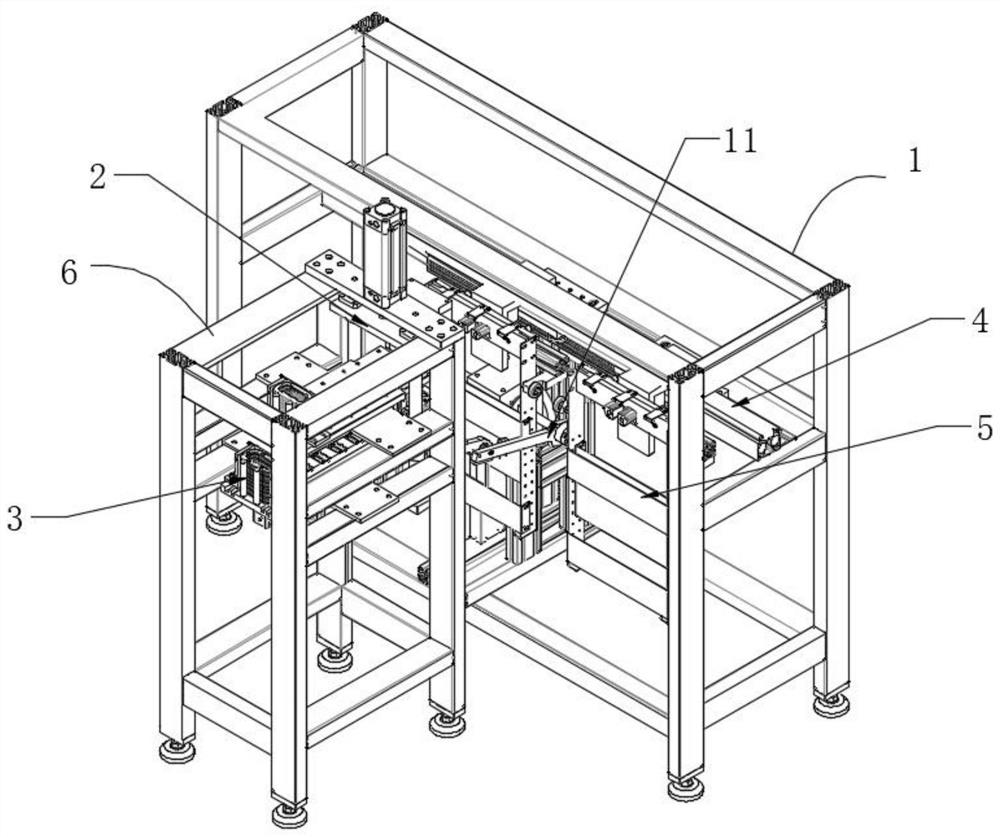

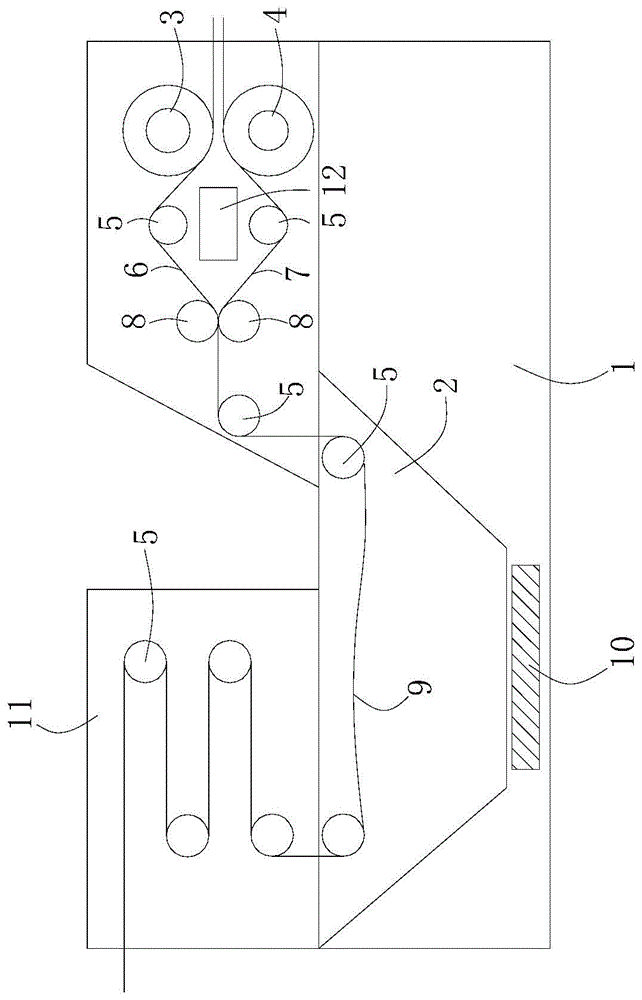

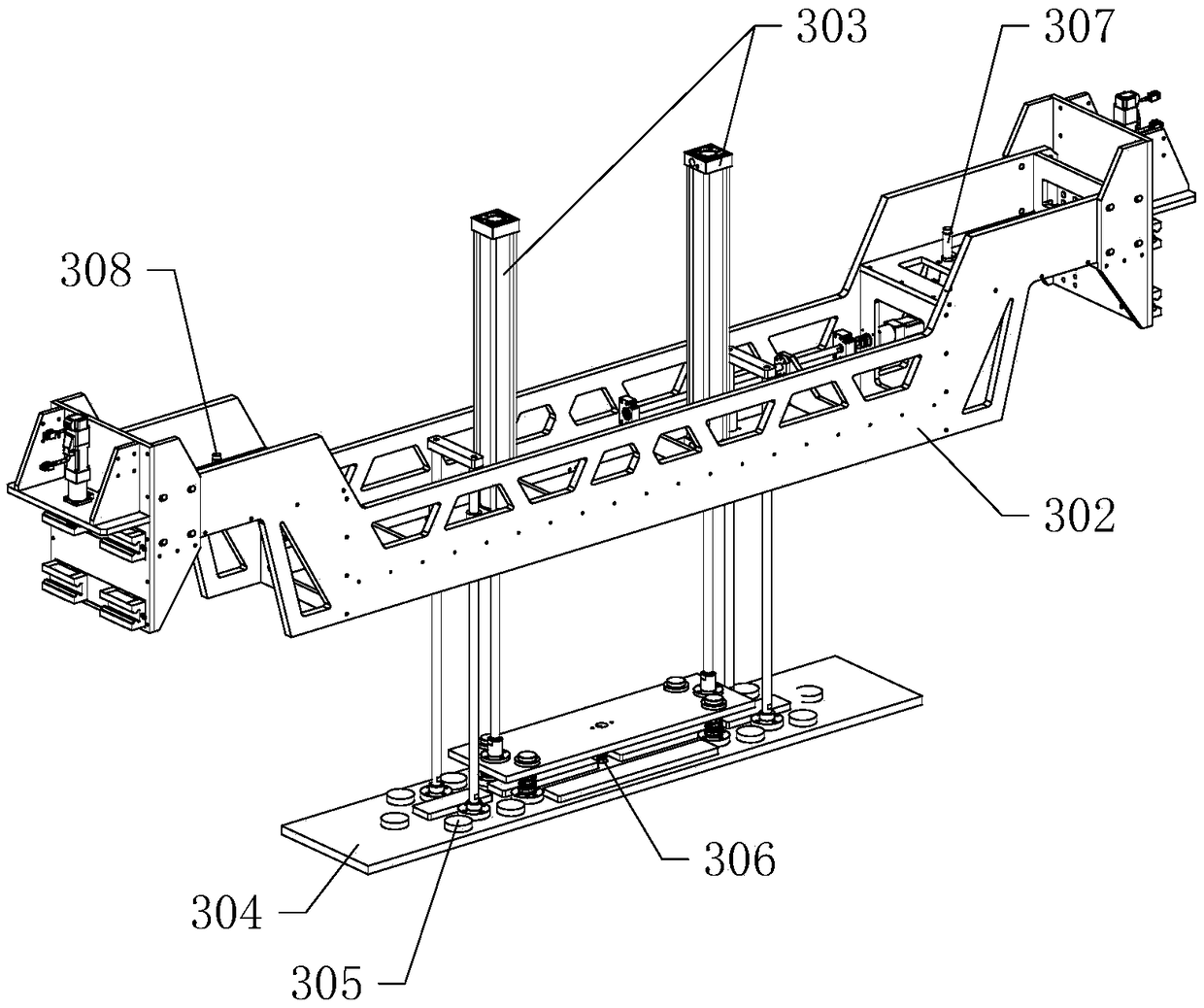

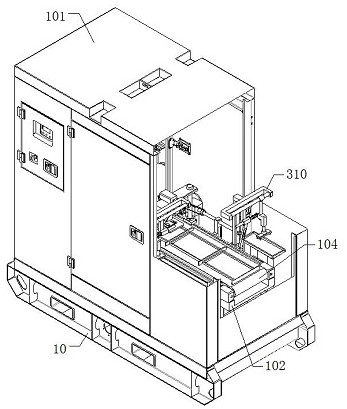

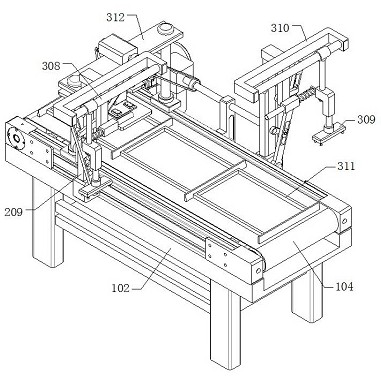

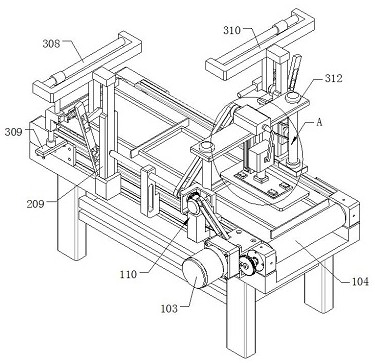

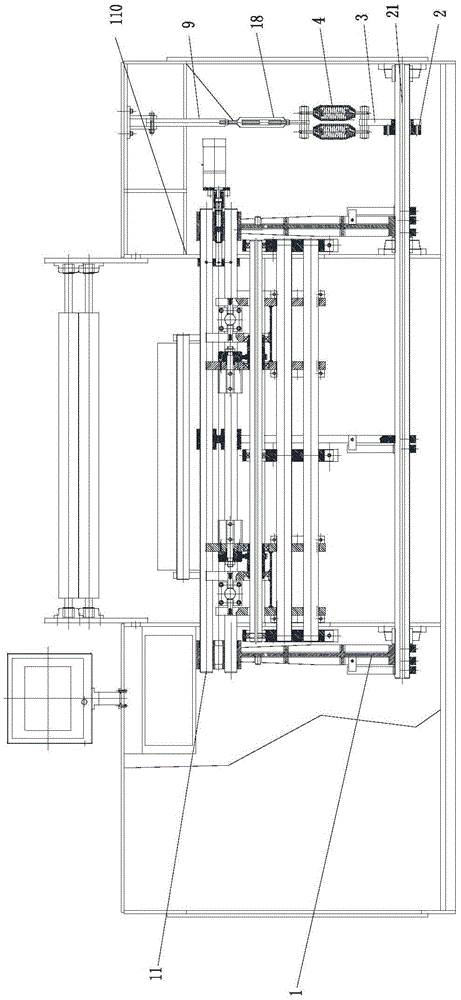

A continuous composite molding lightweight photovoltaic module and its continuous composite molding equipment

ActiveCN110491961BGuarantee the quality of laminationImprove yield rateFinal product manufacturePhotovoltaic energy generationBattery cellMaterials science

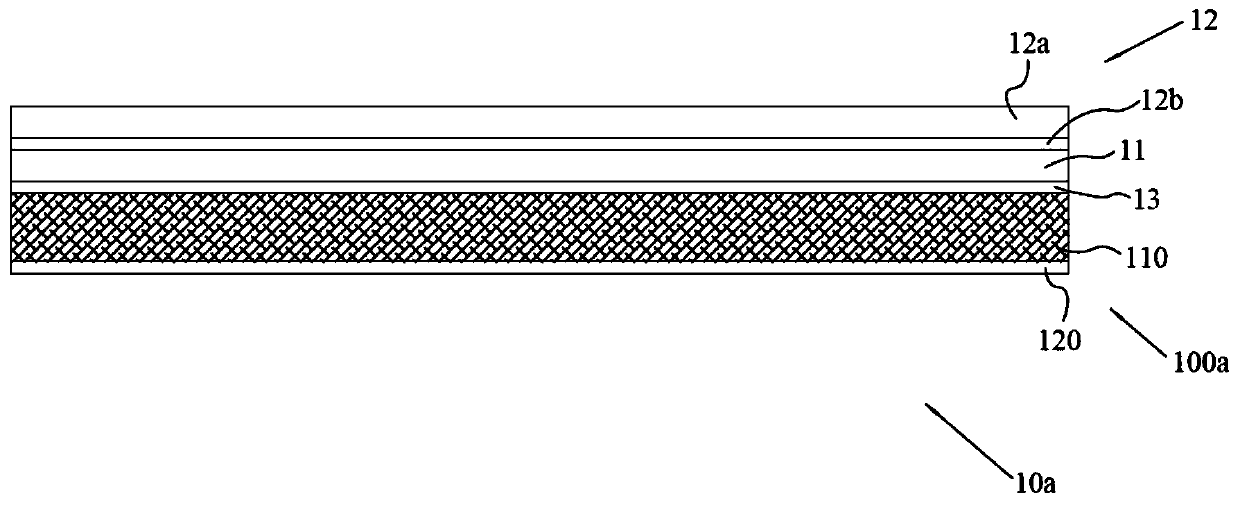

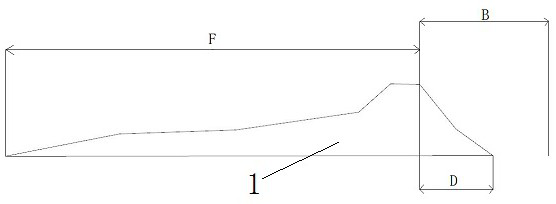

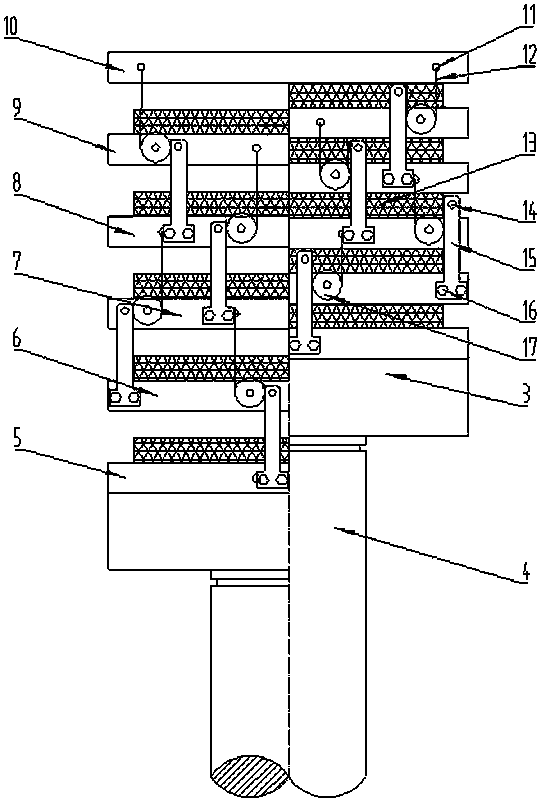

The invention discloses a continuous composite molding lightweight photovoltaic module, which includes a photovoltaic laminate and a lightweight photovoltaic backplane. The photovoltaic laminate includes a front flexible packaging layer, a battery sheet layer, and a back flexible packaging that are laminated and packaged as one. layer, the lightweight photovoltaic backplane includes at least a thermoplastic core layer in the shape of a honeycomb or porous foam and a first thermoplastic substrate layer, and the photovoltaic laminate and the lightweight photovoltaic backplane are composited into one body through a continuous composite molding process; The invention also discloses continuous composite molding equipment; the invention also has the advantages of light weight, safety and reliability, frameless design is not easy to accumulate dust and does not need to be grounded, and its layout can be flexible and changeable, avoiding the high burst problem of traditional double glass components, Moreover, the present invention will not cause problems such as bubbling, degumming, deformation and creep under the lightweight photovoltaic backplane scheme using the adhesive film layer structure, and will not be limited by the thickness of the light photovoltaic backplane, which fully meets the requirements of photovoltaic standards. , can realize real-scale promotion and application.

Owner:SUNMAN (ZHENJIANG) CO LTD

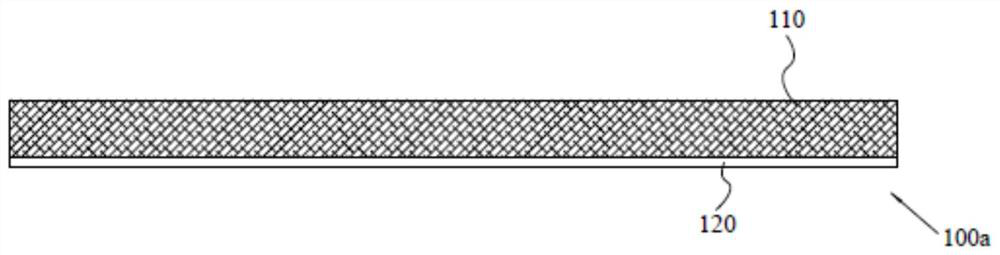

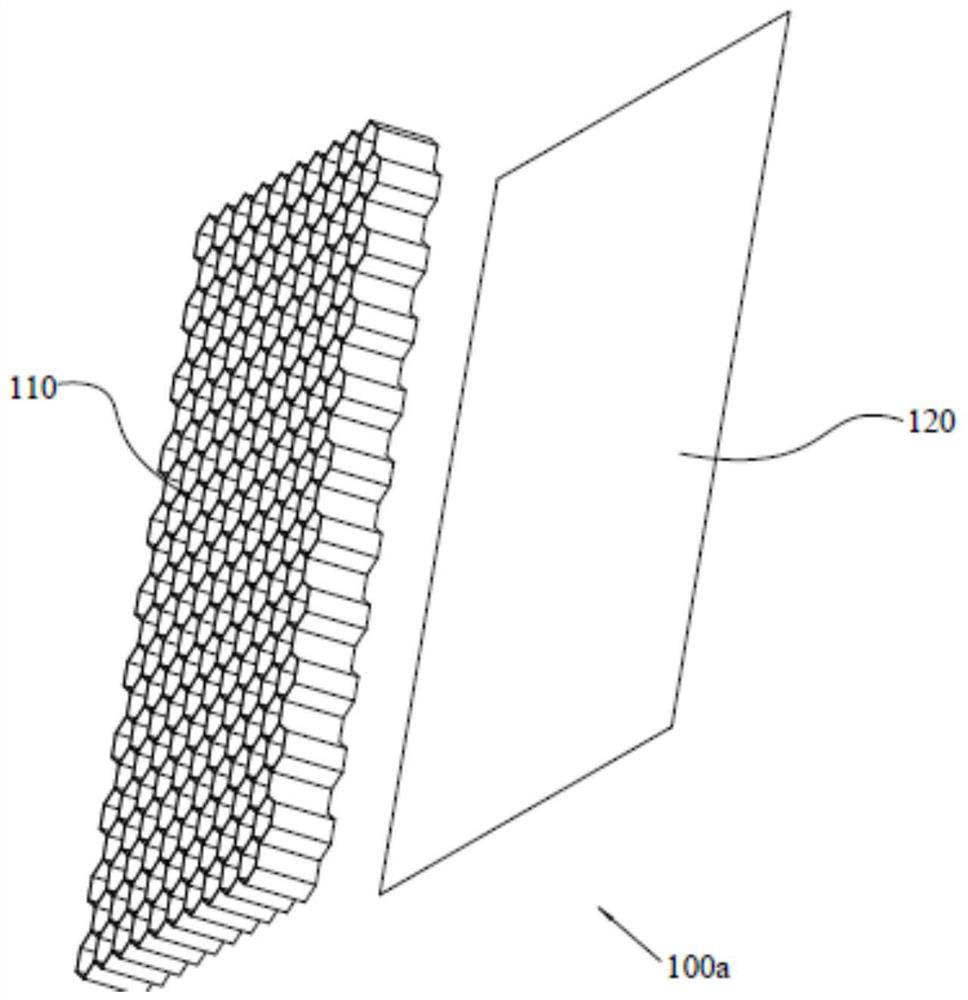

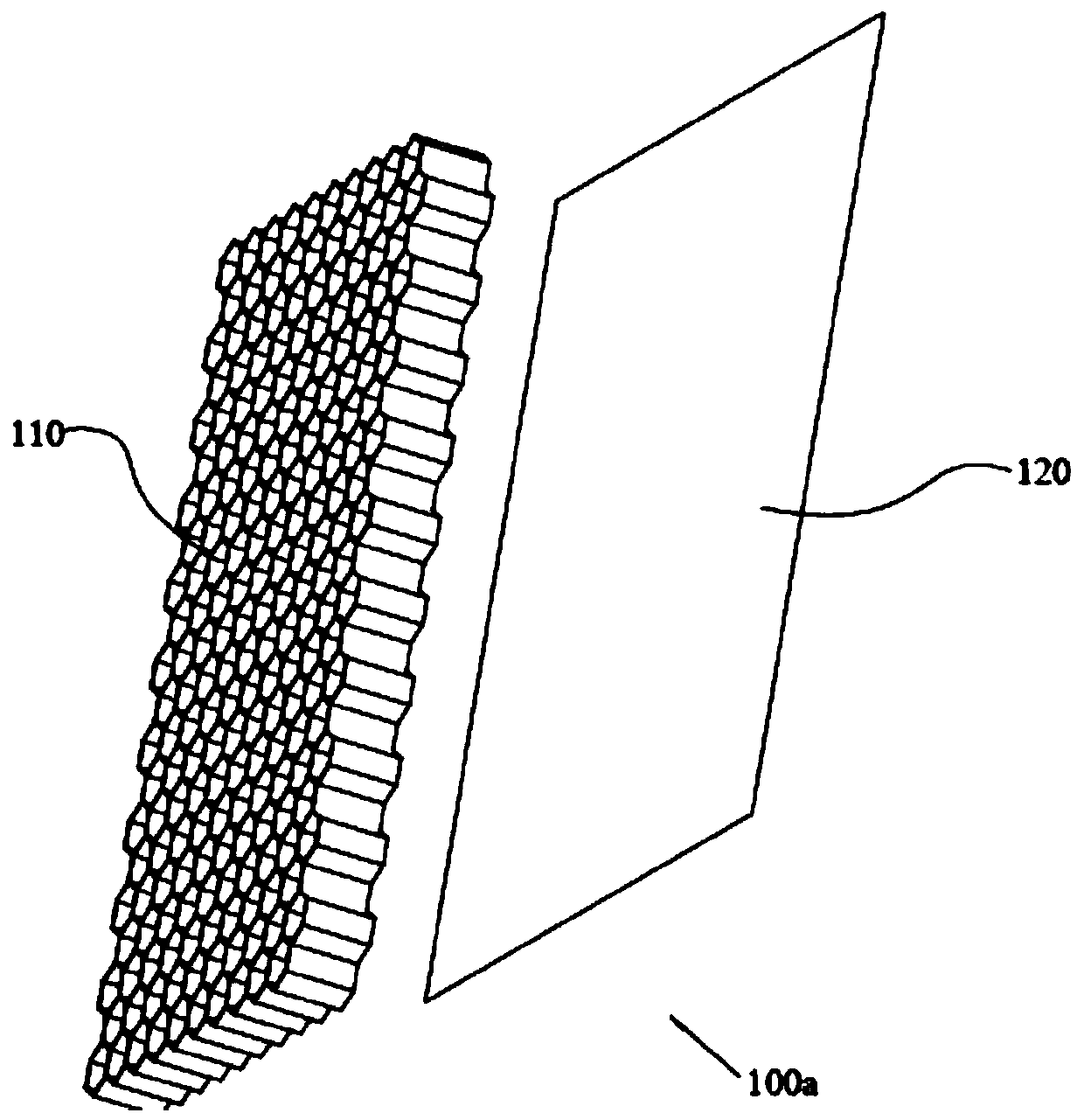

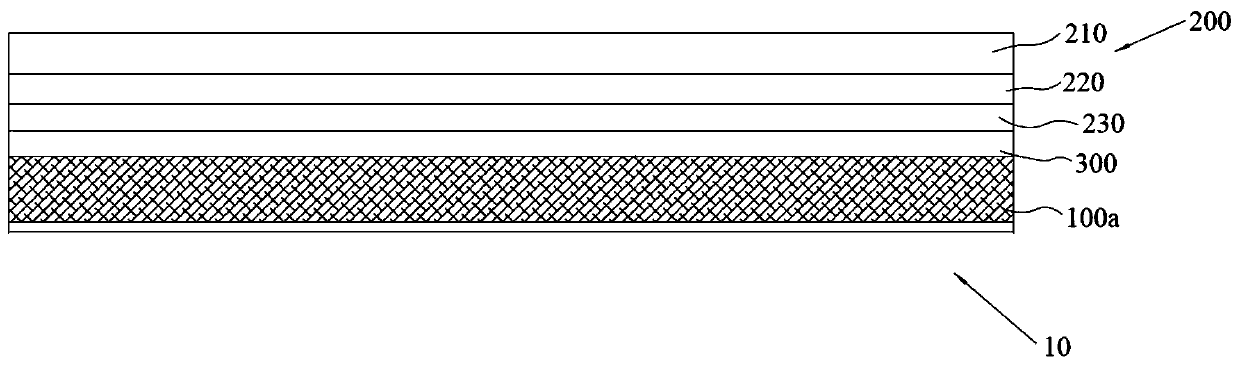

Lightweight backsheet for photovoltaic module, and photovoltaic module therefor and preparation method thereof

PendingCN110400853AGuarantee the quality of laminationAvoid high burst problemsSynthetic resin layered productsPhotovoltaic energy generationThermoplastic elastomerHoneycomb

The invention discloses a lightweight backsheet for a photovoltaic module, and a photovoltaic module therefor and a preparation method thereof. The lightweight backsheet at least comprises a thermoplastic core layer and a first thermoplastic substrate layer which are integrated by hot melt pressing, wherein the base material of the thermoplastic core layer is a core layer thermoplastic polymer, the base material of the first thermoplastic substrate layer is a substrate layer thermoplastic polymer, and the core layer thermoplastic polymer is the same as the material of the substrate layer thermoplastic polymer; the thermoplastic core layer has a honeycomb shape or a porous foam shape; the lightweight backsheet can simultaneously replace a metal frame as the lining structure of the photovoltaic module; the lightweight backsheet for the photovoltaic module, and the photovoltaic module therefor and the preparation method thereof have the advantages of the light weight, safety and reliability, no border design, no easy accumulation of dust and no grounding, The version can be flexible and changeable, avoiding the high bursting problem of the traditional double glass component, and the lightweight backsheet for the photovoltaic module, and the photovoltaic module therefor and the preparation method thereof fully meet the requirements of the photovoltaic standard, and can achieve thereal scale promotion application.

Owner:SUNMAN (ZHENJIANG) CO LTD

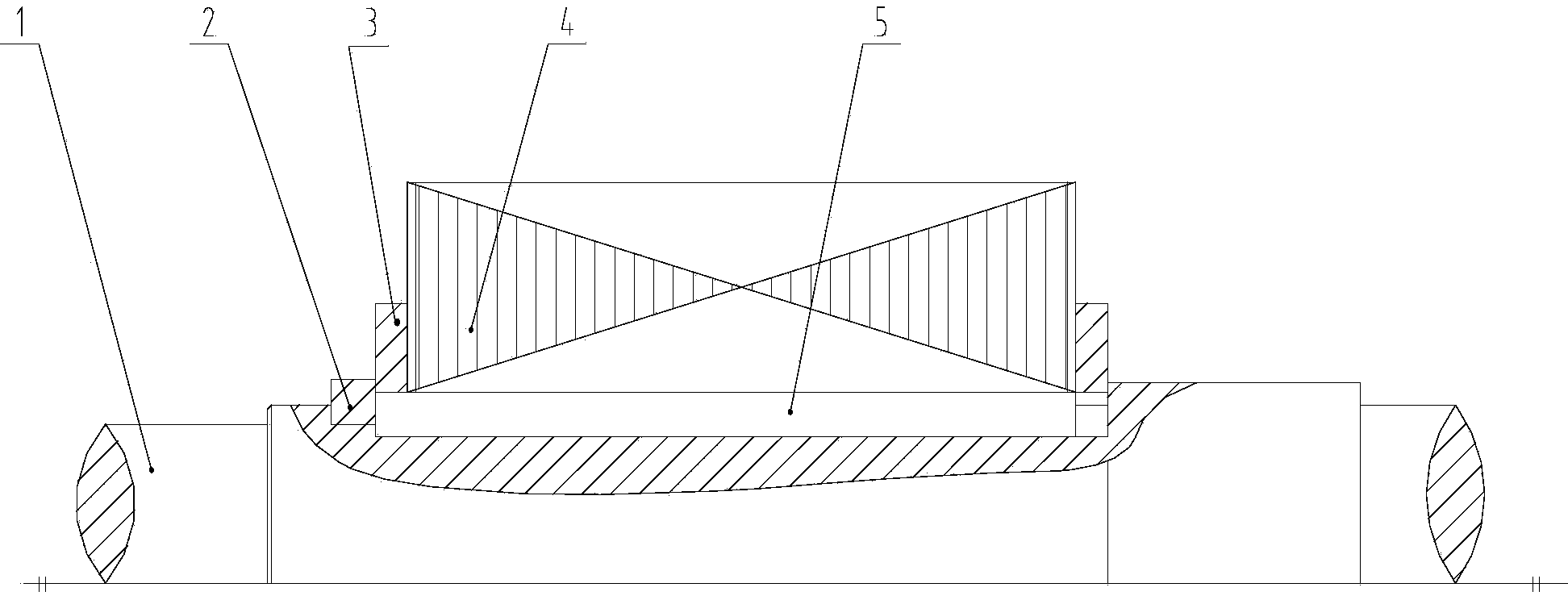

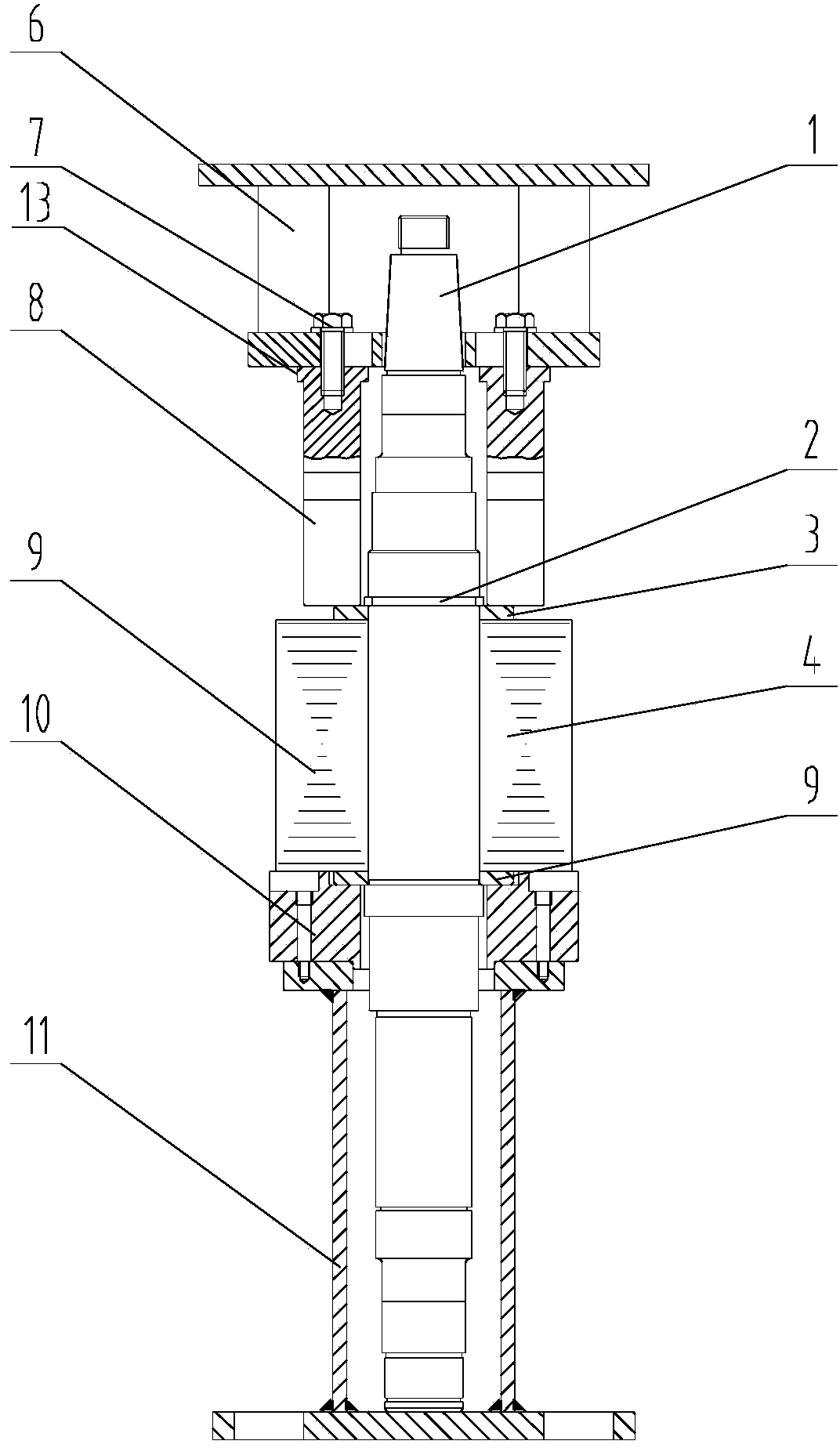

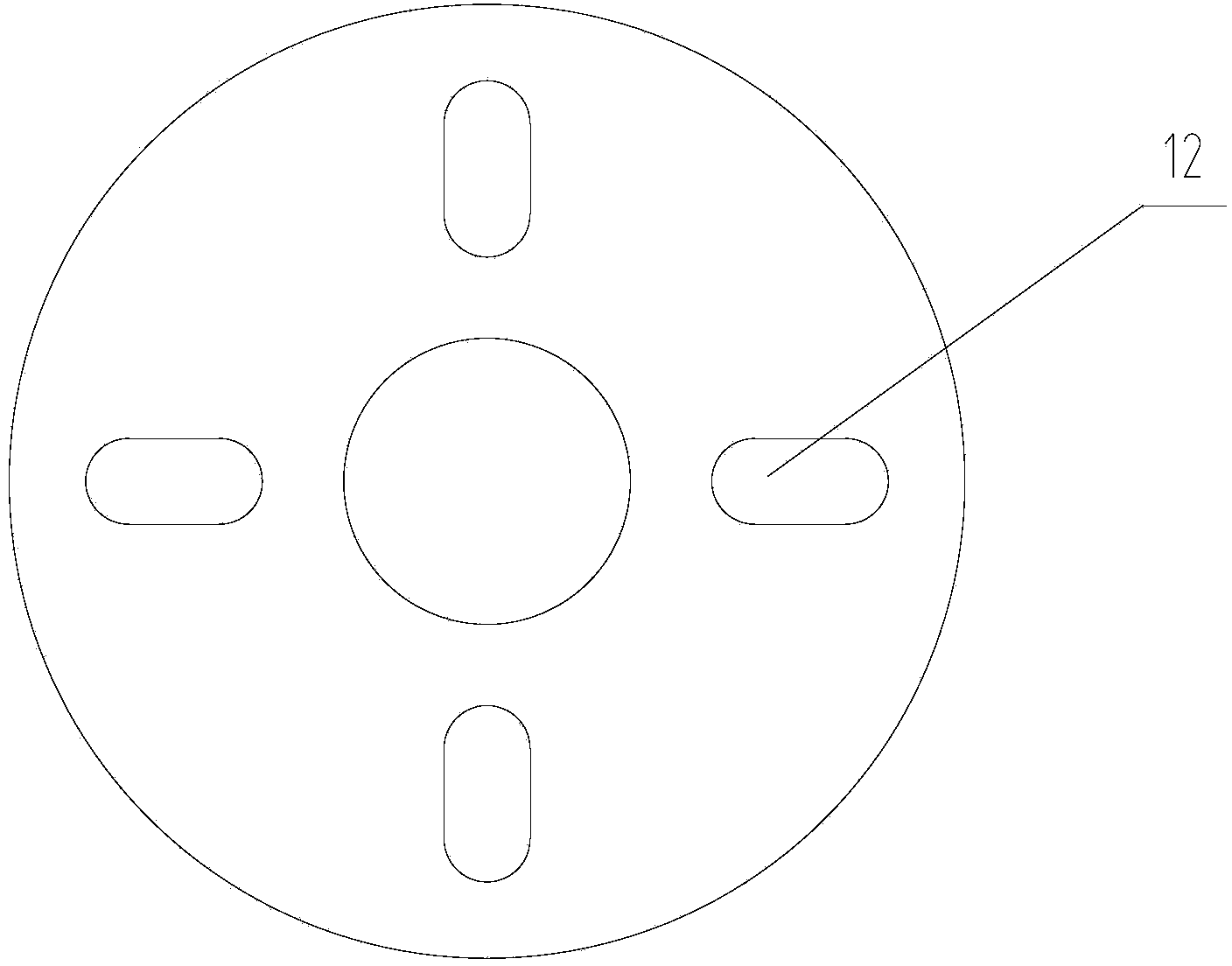

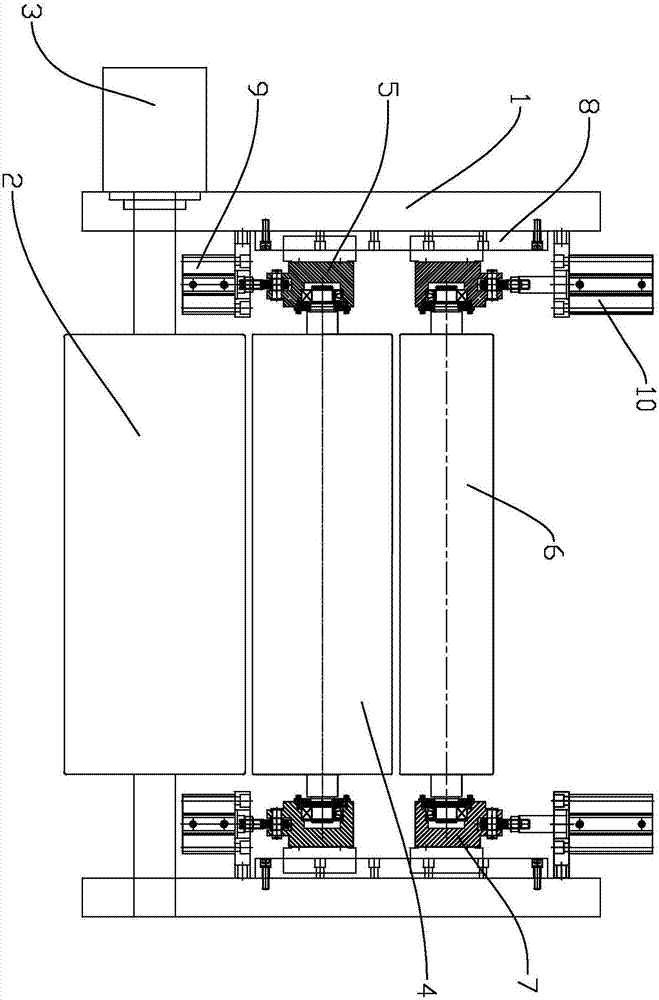

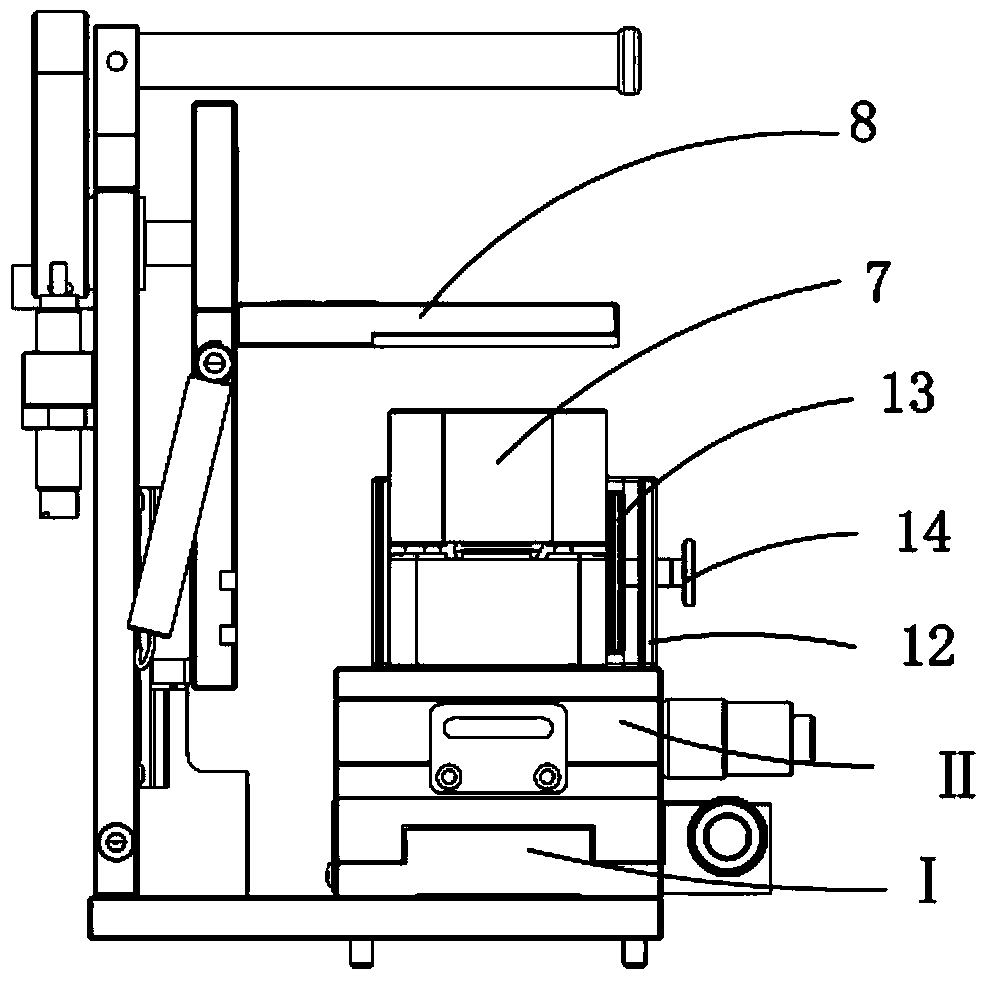

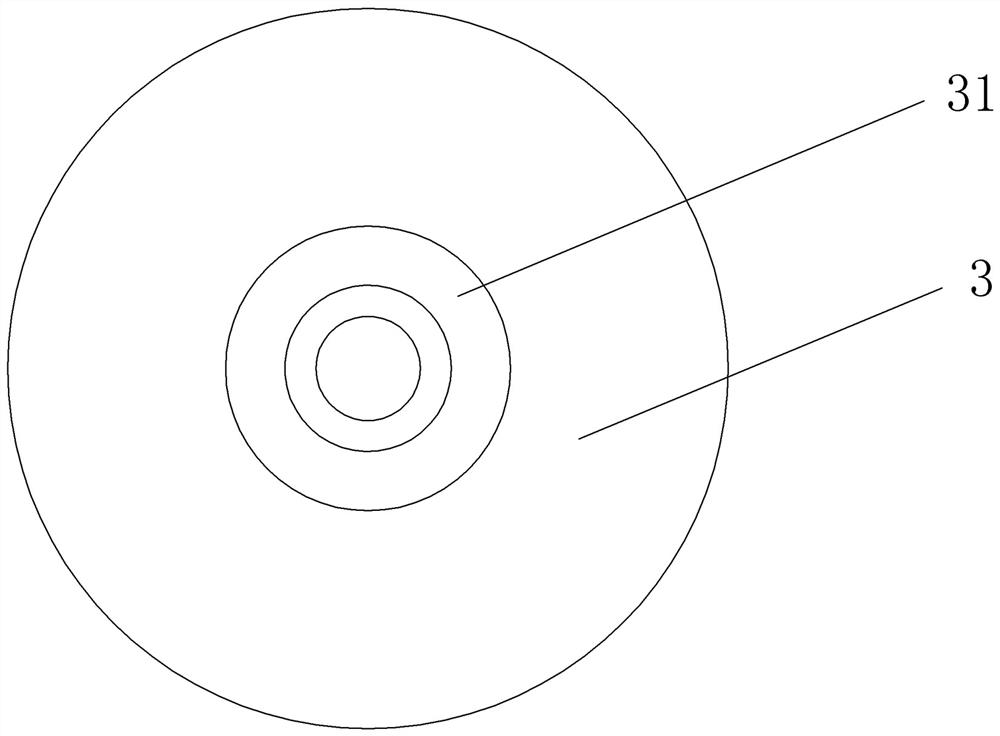

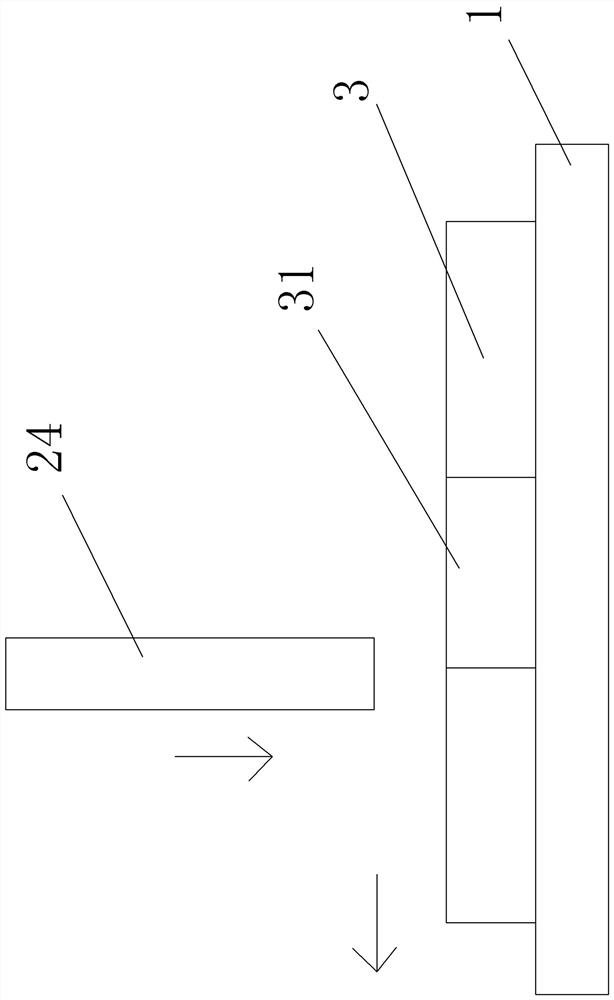

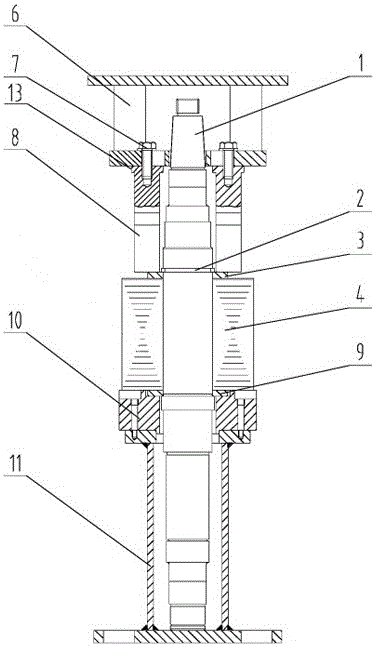

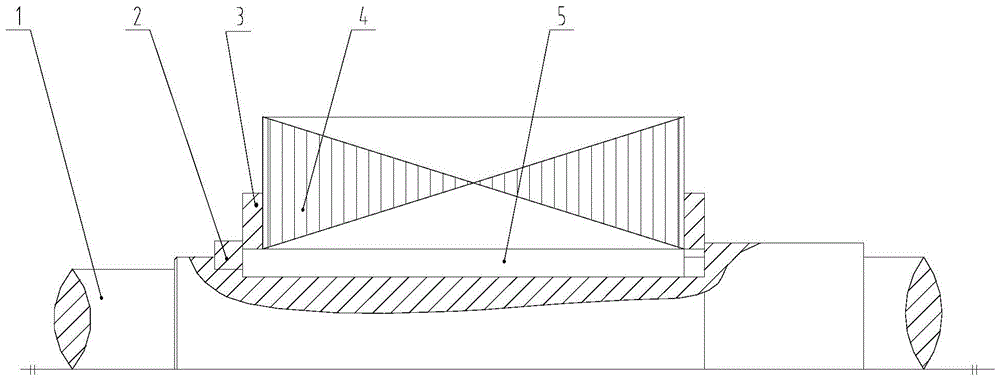

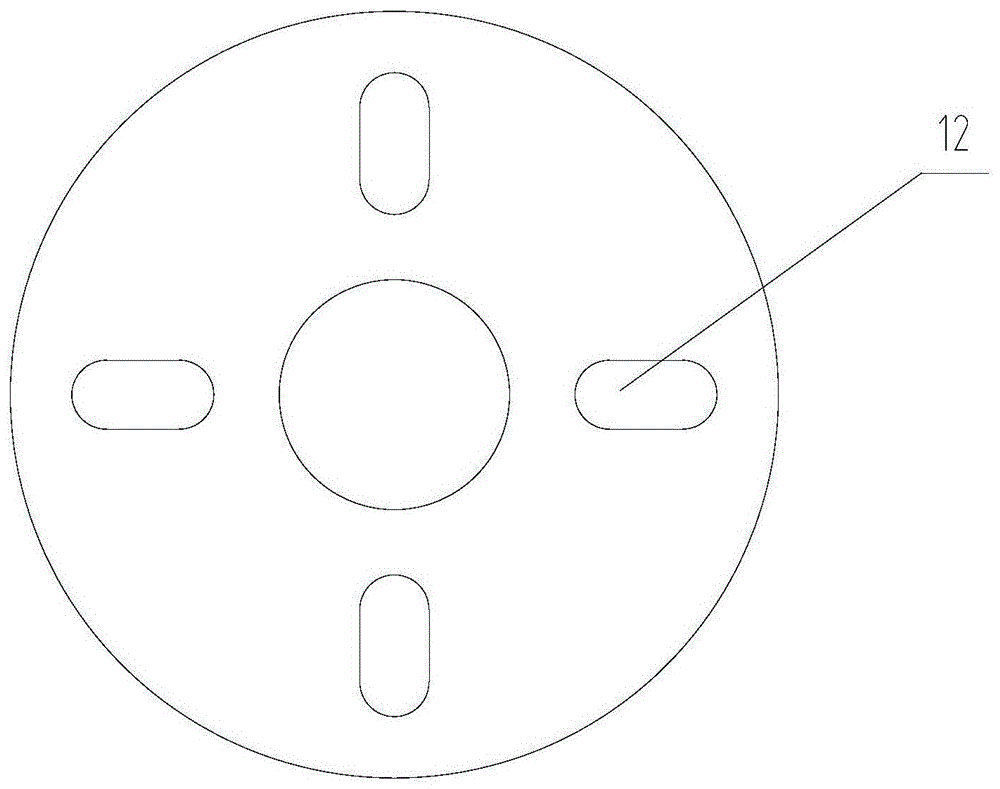

Universal type rotor core overlaying tool and method

ActiveCN104242568AImprove securityReduce the impactManufacturing stator/rotor bodiesEngineeringRadial clearance

The invention discloses a universal type rotor core overlaying tool which comprises a platen, a base and a mandrel. The mandrel is sleeved with rotor cores in an overlaid mode. The rotor cores are located between the platen and the base, and core laminations are overlaid through the platen and the base jointly. The universal type rotor core overlaying tool is characterized in that a plurality of pressing columns are connected with the lower portion of the platen and are evenly and annularly distributed at intervals, and the platen drives the pressing columns to enable the iron laminations to be overlaid. According to the universal type rotor core overlaying tool, the pressing column structure is adopted, and radial clearances exist between the pressing columns; compared with a traditional closed overlaying tool, rotor core end fixing keys can be installed when the rotor cores are compressed, the influences of the oil press stroke on rotor core overlaying specifications can be lowered, the security coefficients in the rotor core overlaying process are increased, working procedure tome is shortened, and production efficiency is improved by about 30%.

Owner:安徽金箔机电产业集团股份有限公司

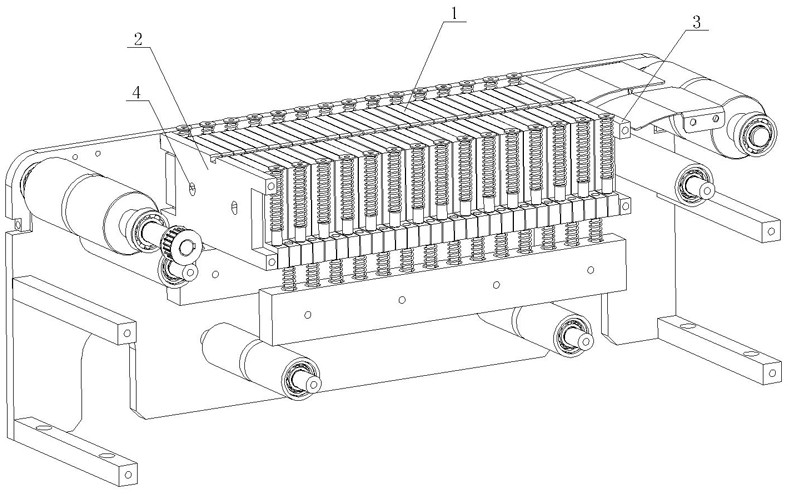

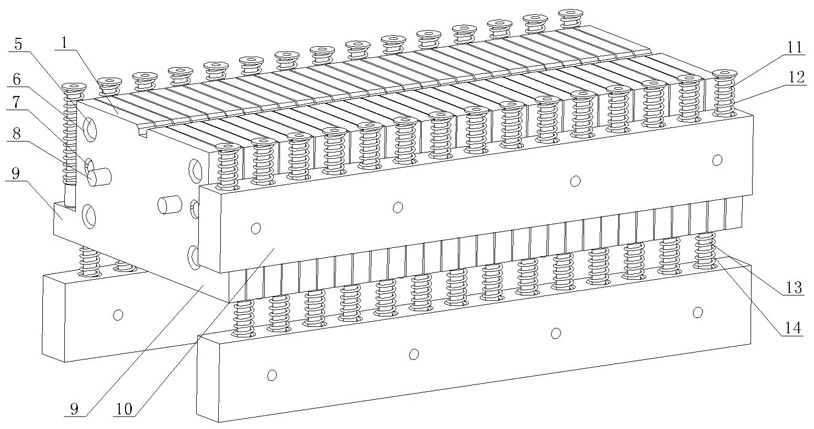

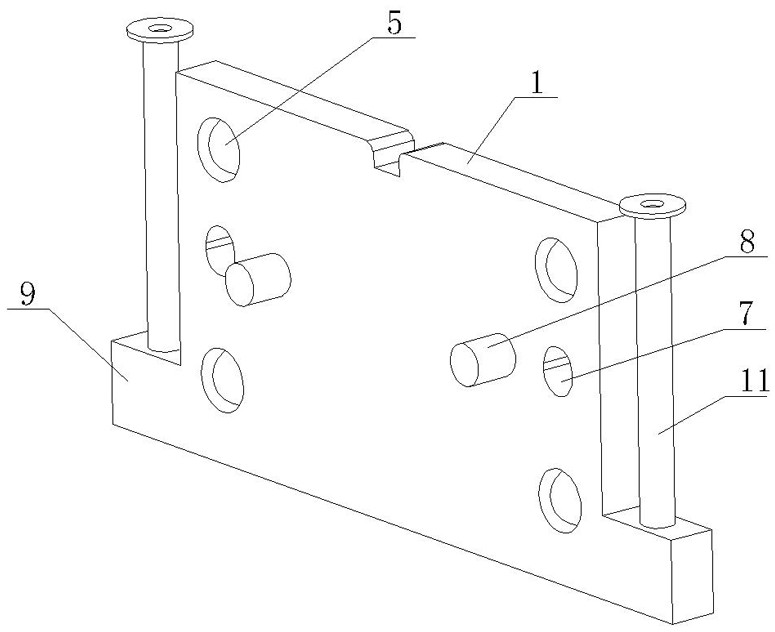

Multilayer circuit board laminating equipment

ActiveCN112312685AGuarantee the quality of laminationAvoid wear and tearFinal product manufactureMultilayer circuit manufactureStructural engineeringMechanical engineering

Owner:HUIZHOU YUXINDA TECH CO LTD

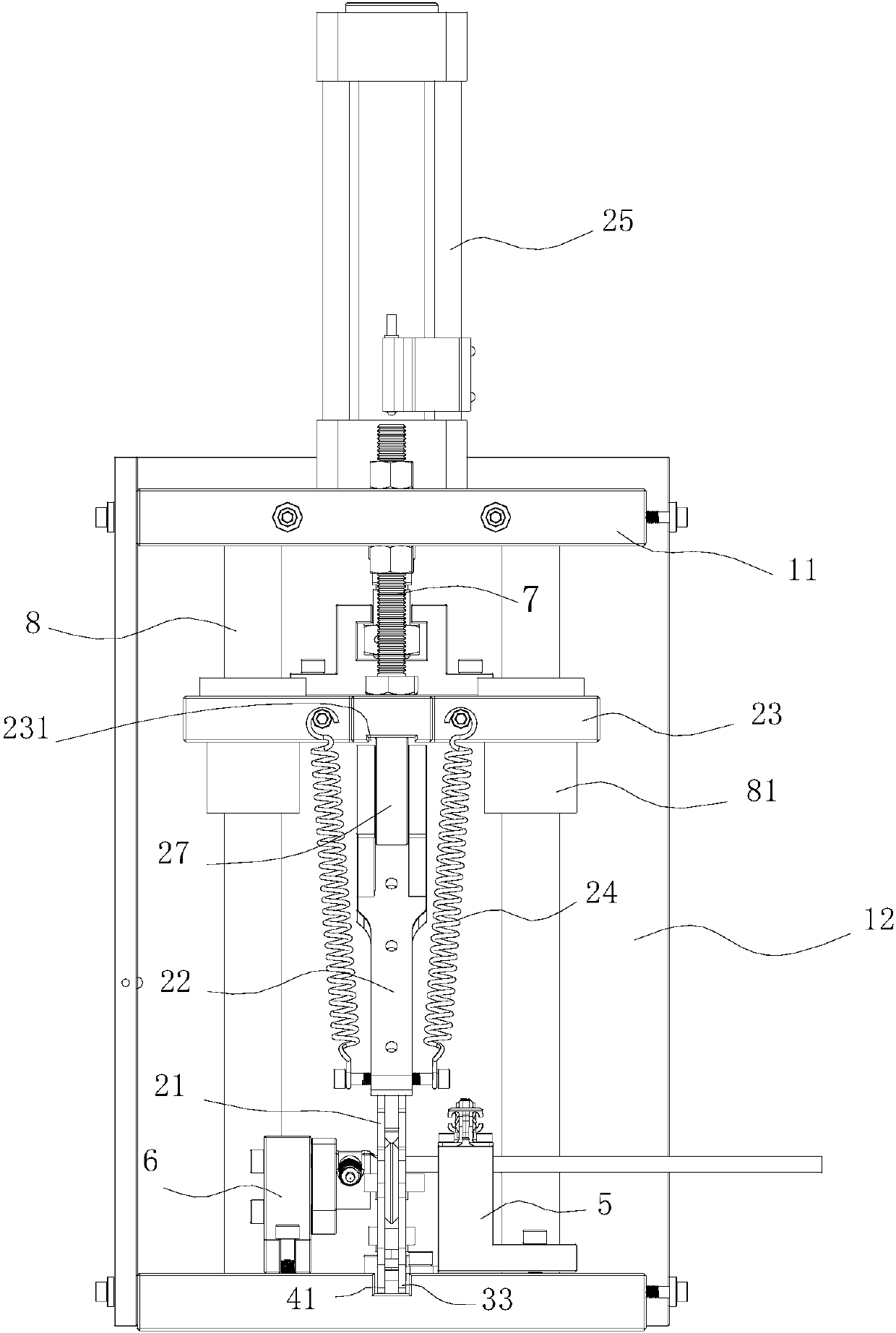

Wire and crimping terminal laminating machine

PendingCN107706692AEven by forceRealize automated productionLine/current collector detailsElectricityEngineering

The invention relates to the technical field of electric connectors, in particular to a wire and crimping terminal laminating machine. The wire and crimping terminal laminating machine comprises a rack, wherein a lifting mechanism is arranged in the rack and connected with a laminating mechanism; a workbench is arranged at the bottom of the rack; and the workbench is also provided with a pressingmechanism for fixing wires and a fixing mechanism for fixing crimping terminals. According to the wire and crimping terminal laminating machine, the lifting mechanism is connected with the laminatingmechanism, the lifting mechanism can control lamination of the laminating mechanism, and meanwhile, the pressing mechanism and the fixing mechanism are arranged at two sides of the laminating mechanism separately to fix the wires and the crimping terminals separately, so that double hands of an operator can be liberated in the laminating process; and meanwhile, the stress between each wire and thecorresponding crimping terminals is uniform through the laminating mechanism and the problem of defective goods caused by excessive or insufficient laminating force is solved. According to the wire and crimping terminal laminating machine, automatic production can be achieved, the work efficiency is improved, and meanwhile, the laminating quality can also be ensured.

Owner:KUNSHAN KERSEN SCI & TECH

Lead access mechanism for stator winding

ActiveCN104795712AEasy to placeEasy to guide in placeLine/current collector detailsElectrical testingElectric machineEngineering

The invention relates to a lead access mechanism for a stator winding. A screw rod is arranged on a bottom plate through a feed screw nut; a hand wheel is connected with the lower end of the screw rod; the upper end of the screw rod is connected with a transport motor fixing plate; transport modules are arranged on the left side and the right side of the transport motor fixing plate through side fixing plates; a pressing module and a wire-drawing module are arranged on the outer sides of each group of transport modules; conduction modules are arranged on the outer sides of each group of pressing modules; a group of stator tools are arranged below each group of wire-drawing modules; a stator with a stator winding is arranged on each stator tool; a lead terminal is connected with a stator winding lead; the wire-drawing modules are used for drawing the stator winding lead to horizontally bend around the root part of the lead in an XY-axis plane; telescopic cylinders of the conduction modules extend outside and drive a contact to contact the stator surface. According to the lead terminal, through mechanism guide, position confirmation, rectification and pressing, the stator lead terminal and a conductive platform of a stator pulse testing machine are in reliable contact conduction; and the electric properties of the stator winding are automatically tested.

Owner:BOZHON PRECISION IND TECH CO LTD

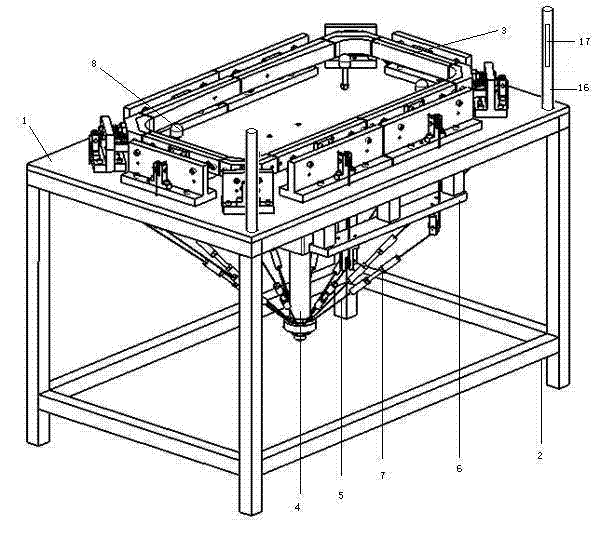

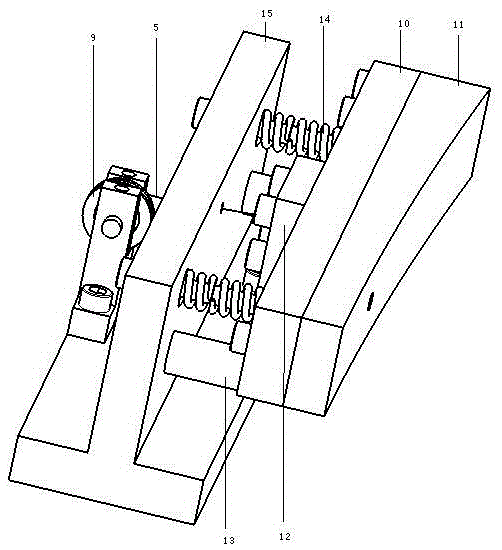

Novel equipment special for automatically pressing skylight glass sealing strip

ActiveCN103921249APress tightlyEven by forceMetal-working hand toolsEngineeringMechanical engineering

The invention provides novel equipment special for automatically pressing a skylight glass sealing strip. The novel equipment comprises a workbench, a support, glass supporting feet, an air cylinder, steel wires, a steel wire support and 10 sets of pressing die blocks, each long side is provided with two sets of the pressing die blocks, each short side is provided with a set of the pressing die block, each corner is provided with a set of the pressing die block, each set of the pressing die block comprises a supporting block, a pressing block and a shape-preserving block, rod-shaped action sensors are arranged on two sides of a near side of the workbench respectively, opposite sides of the action sensors are provided with transparent windows, and the air cylinder is controlled by the action sensors arranged on the workbench. By the novel equipment, when the skylight sealing strip is pressed, the sealing strip is enabled to be stressed more uniformly, and each position is pressed more closely, so that pressing quality is guaranteed, and more convenience is brought to operation.

Owner:WUHU MOTIONTEC AUTOMOTIVE

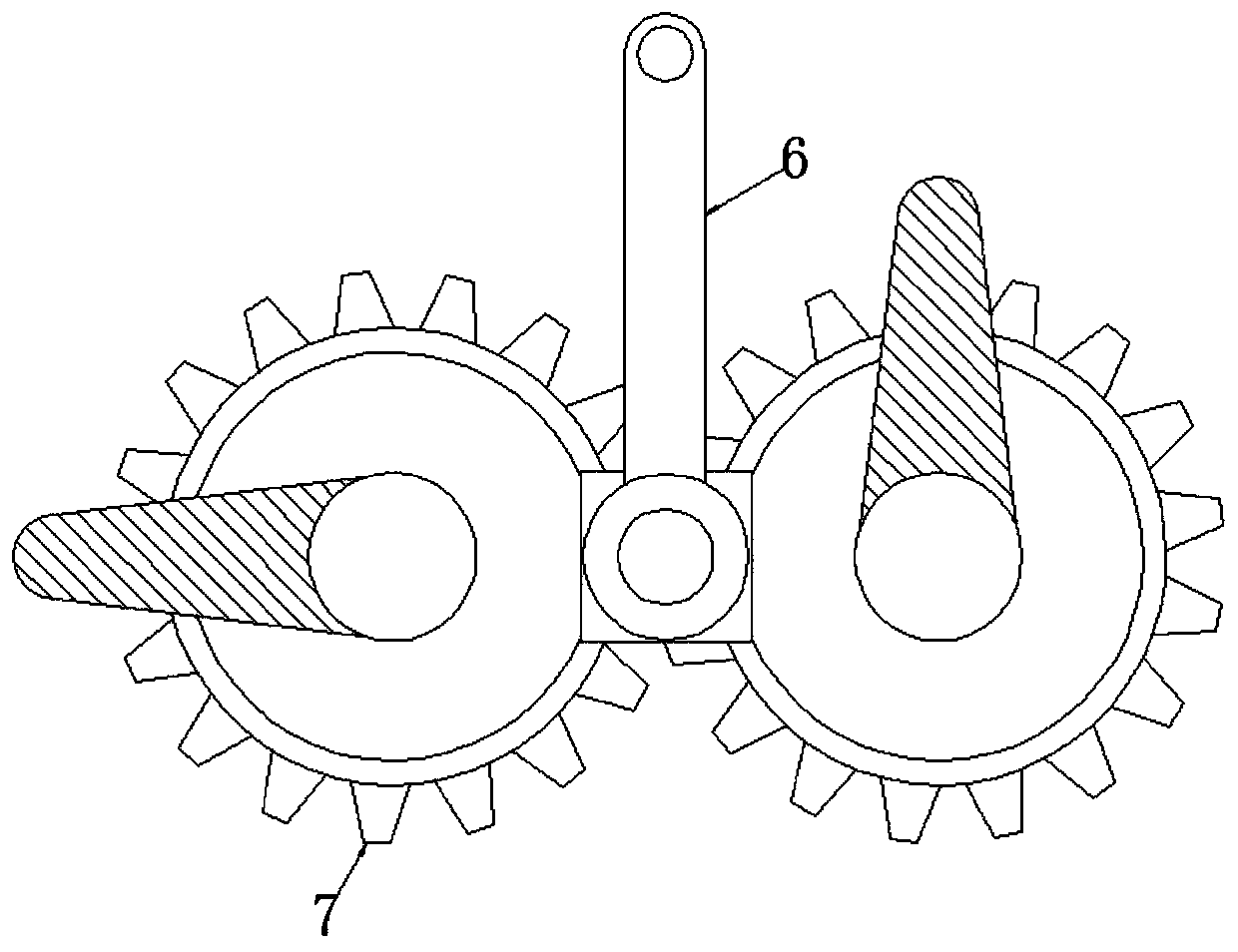

Blockboard pressing auxiliary device capable of automatically pressing edges based on gravity principle

InactiveCN111409155AHigh degree of automationIncrease linkagePlywood pressesVeneer pressesRatchetGear wheel

The invention relates to the technical field of blockboards, and discloses a blockboard pressing auxiliary device capable of automatically pressing edges based on the gravity principle. The blockboardpressing auxiliary device comprises a shell, and a movable plate is movably connected to the outer side of the shell; the movable plate moves downwards and extrudes a spring at the bottom to enable aclamping column to cause rotation of a first rotary disc along with a ratchet wheel, edge pressing operation is automatically triggered through the gravity effect of materials, the two hands are liberated, the high automation degree is achieved, a first rotary rod rotates to enable a gear to intermittently rotate in a reciprocating mode, a power source is provided for follow-up edge pressing operation, the linkage of structures is increased, and operation is more convenient and quick; and a rotary disc rotates to enable a pressing block to move to the position above the materials and move downwards and then upwards to be away from the materials, edge pressing is automatically conducted on the materials, the situation that in the pressing process, edge warping happens to the corners of theboards is avoided, the pressing quality of the boards is guaranteed, after operation is completed, edge pressing operation is automatically relieved, the boards are convenient to take, and operationis more convenient and quicker.

Owner:湖州林立木业有限公司

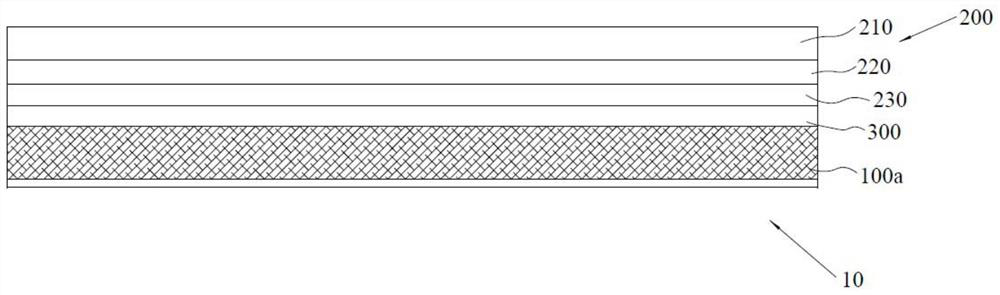

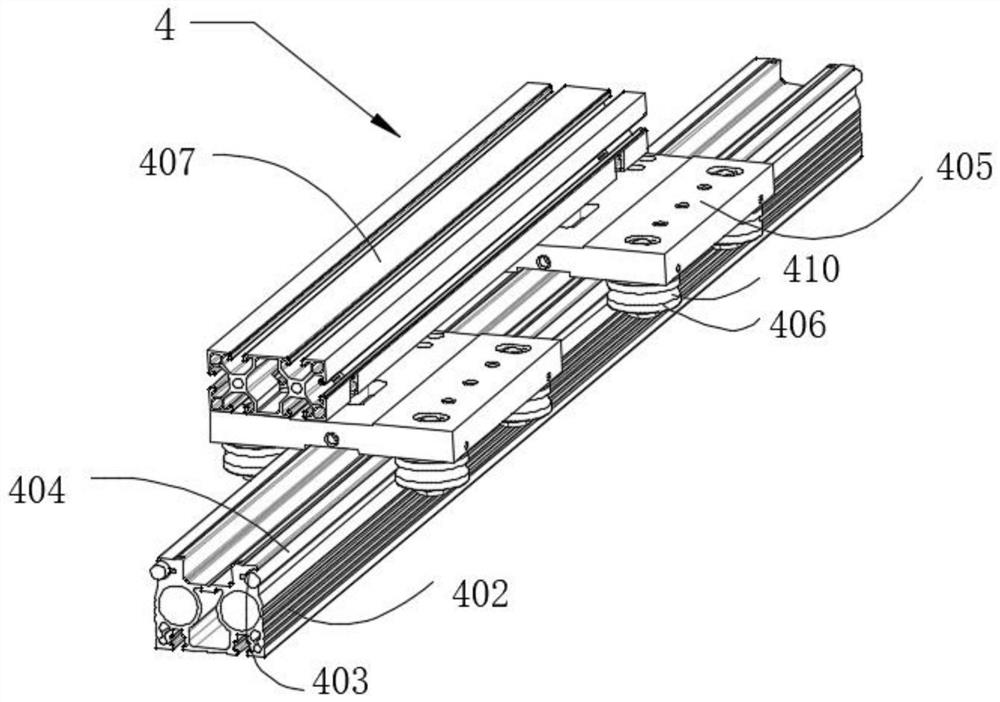

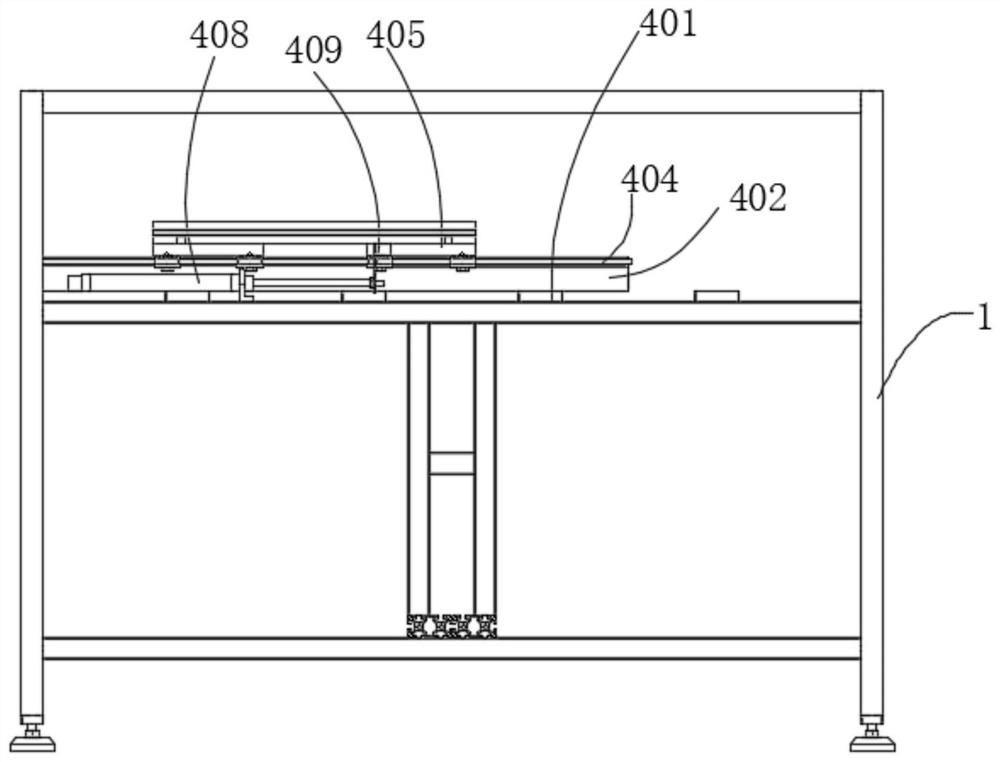

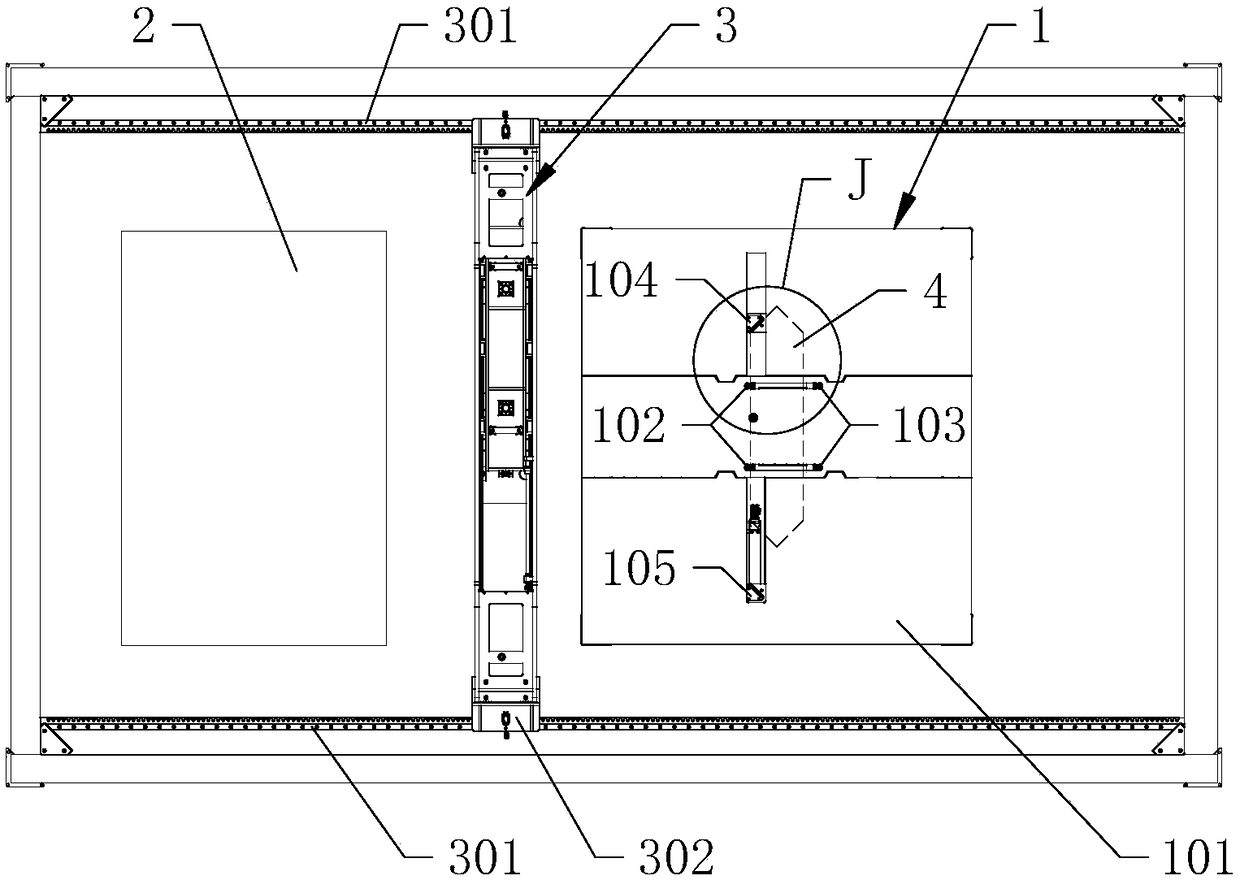

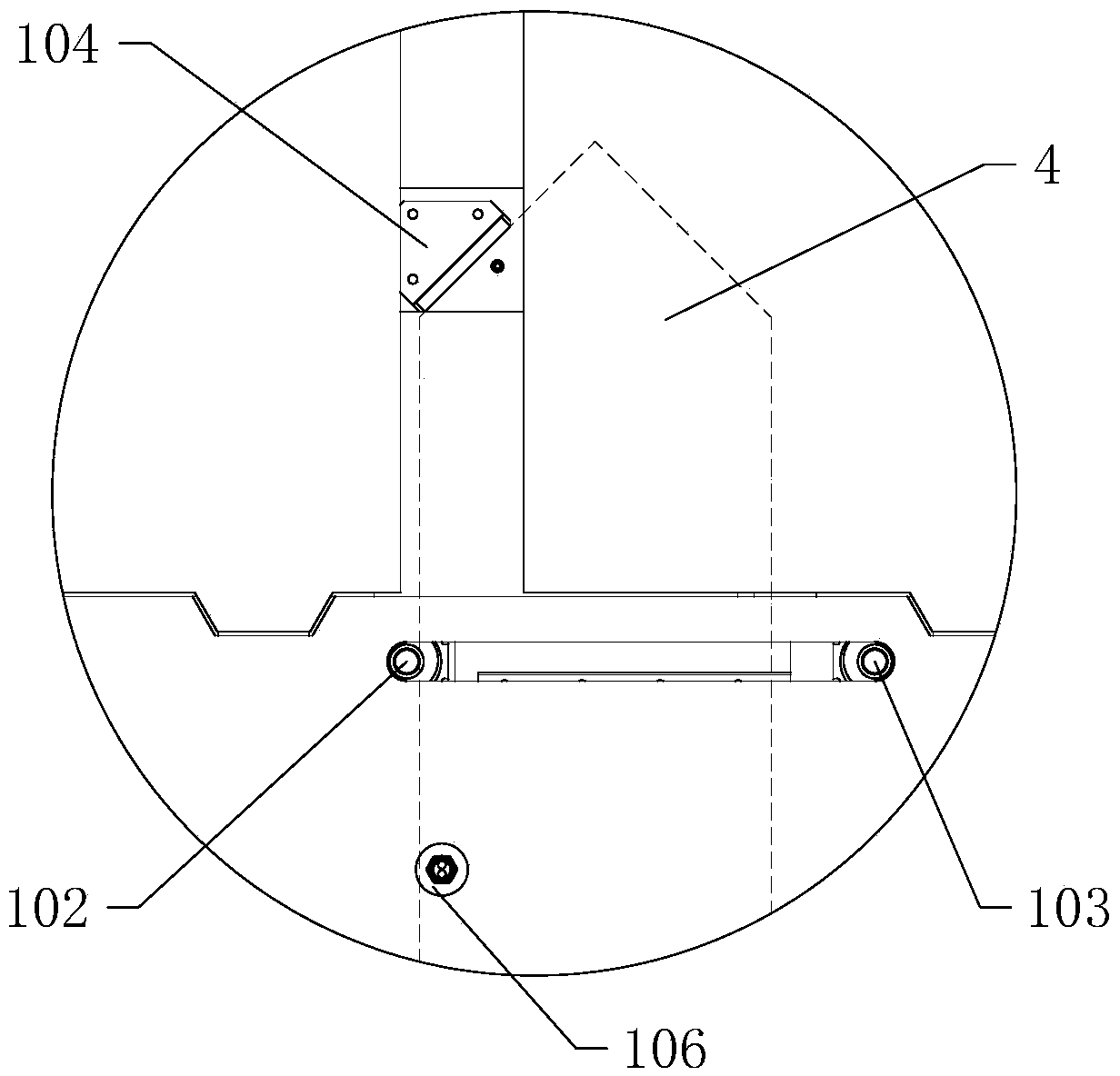

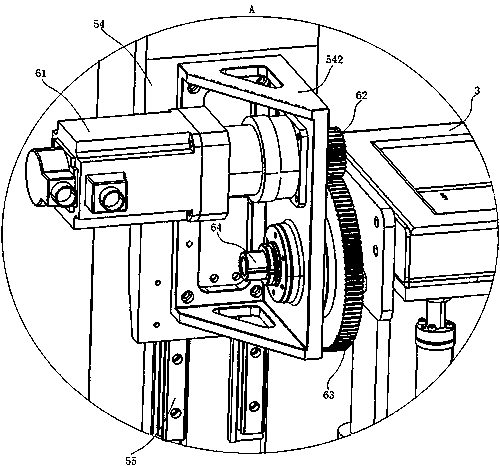

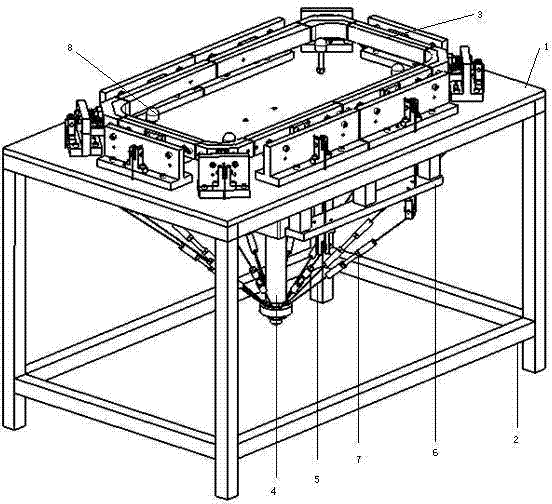

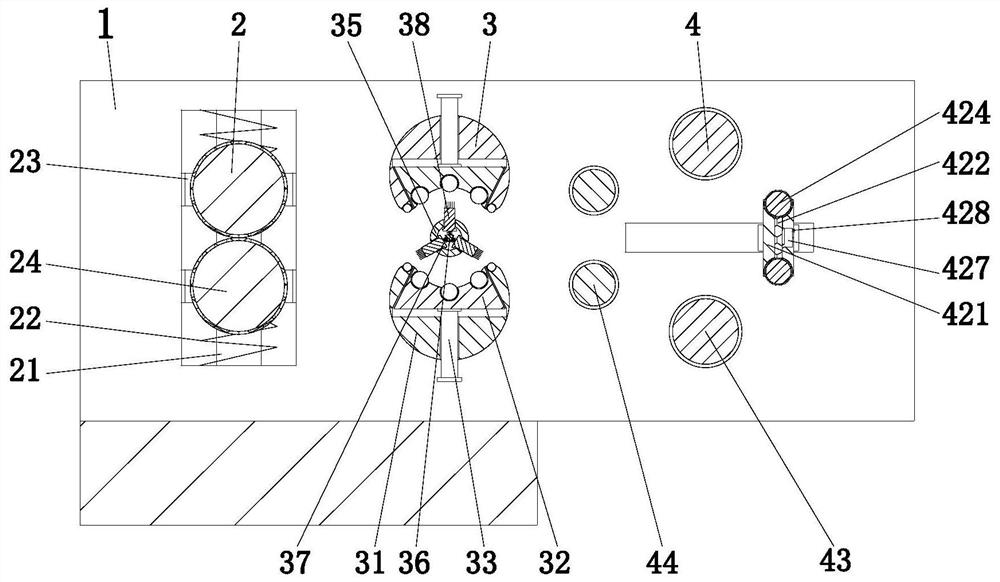

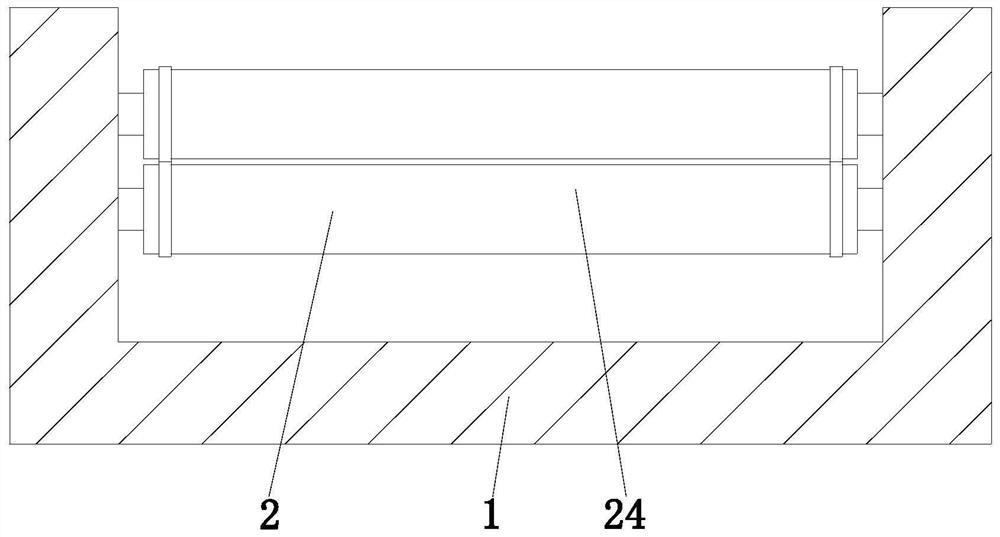

Continuous composite molding light photovoltaic module and continuous composite molding equipment thereof

ActiveCN110491961AGuaranteed lamination qualityImprove yield rateFinal product manufacturePhotovoltaic energy generationHoneycombBackplane

The invention discloses a continuous composite molding light photovoltaic module that comprises a photovoltaic laminated piece and a light photovoltaic back plate, wherein the photovoltaic laminated piece comprises a front flexible packaging layer, a battery piece layer and a back flexible packaging layer which are laminated and packaged into a whole; the light photovoltaic back plate at least comprises a thermoplastic core layer and a first thermoplastic substrate layer which are honeycomb-shaped or porous foaming-shaped, and the photovoltaic laminated piece and the light photovoltaic back plate are compounded into a whole through a continuous composite molding process; the invention further discloses continuous composite molding equipment. The module and equipment have the advantages oflight weight, safety, reliability, no frame design, low possibility of dust accumulation, no need of grounding, and flexible and changeable model; the problem of high burst of a traditional double-glass assembly is avoided, the problems of bubbling, degumming, deformation, wriggling and the like cannot occur under the scheme of using the light photovoltaic back plate of an adhesive film layer structure, meanwhile, the limitation of the thickness of the light photovoltaic back plate is avoided, the photovoltaic standard requirement is completely met, and real-scale application and popularization can be achieved.

Owner:SUNMAN (ZHENJIANG) CO LTD

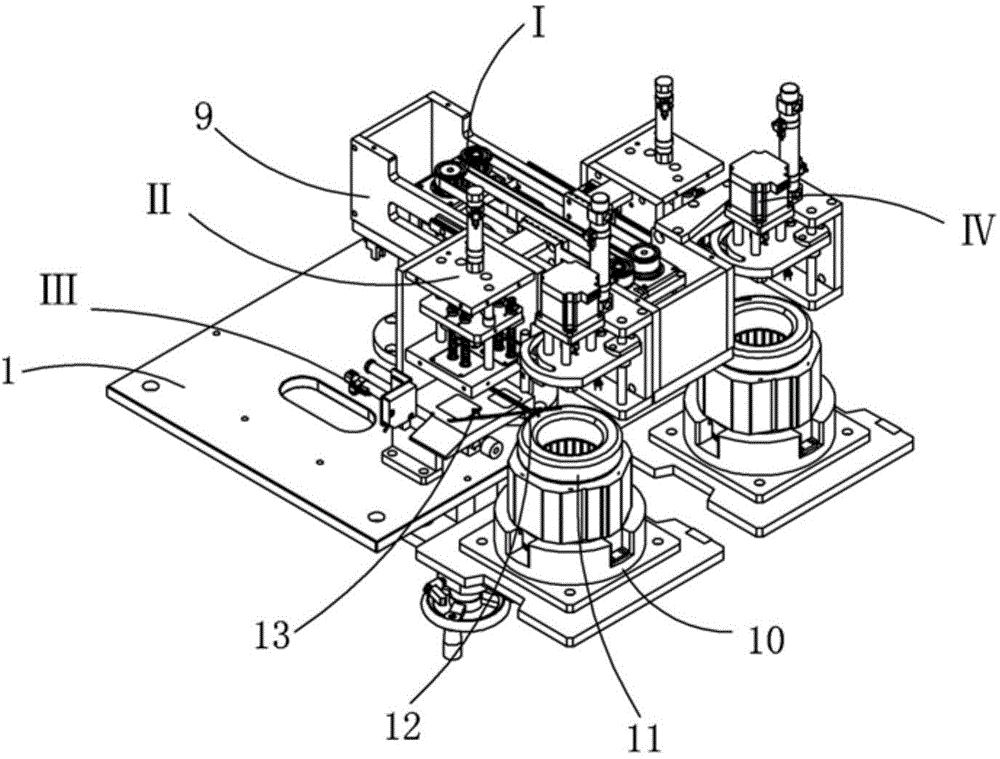

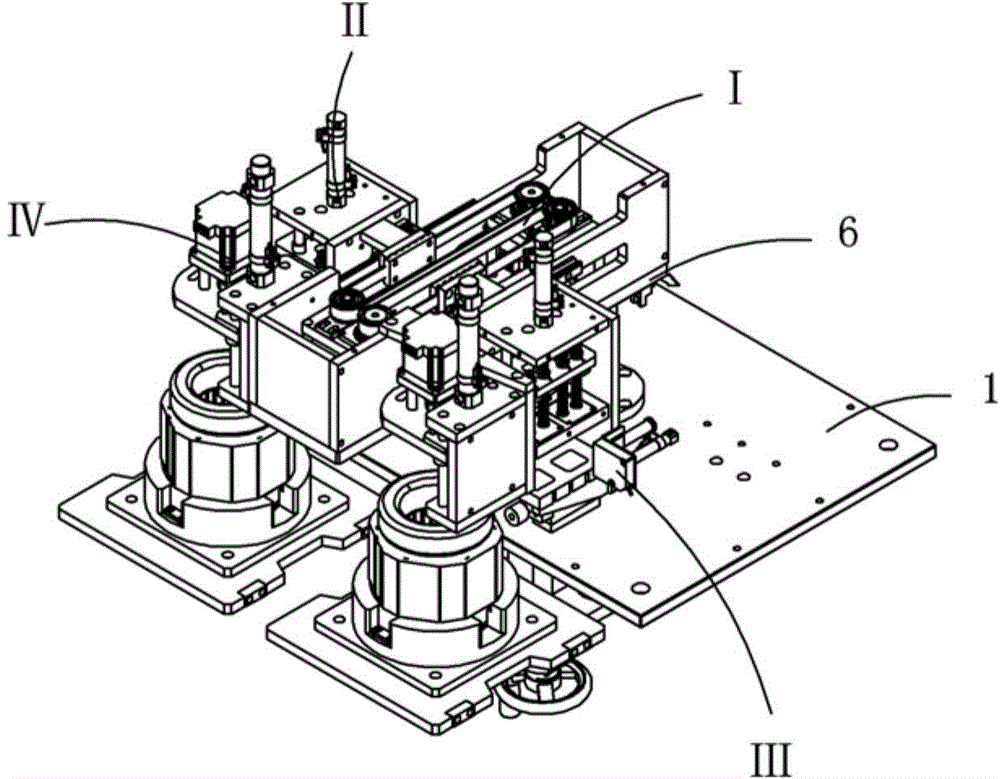

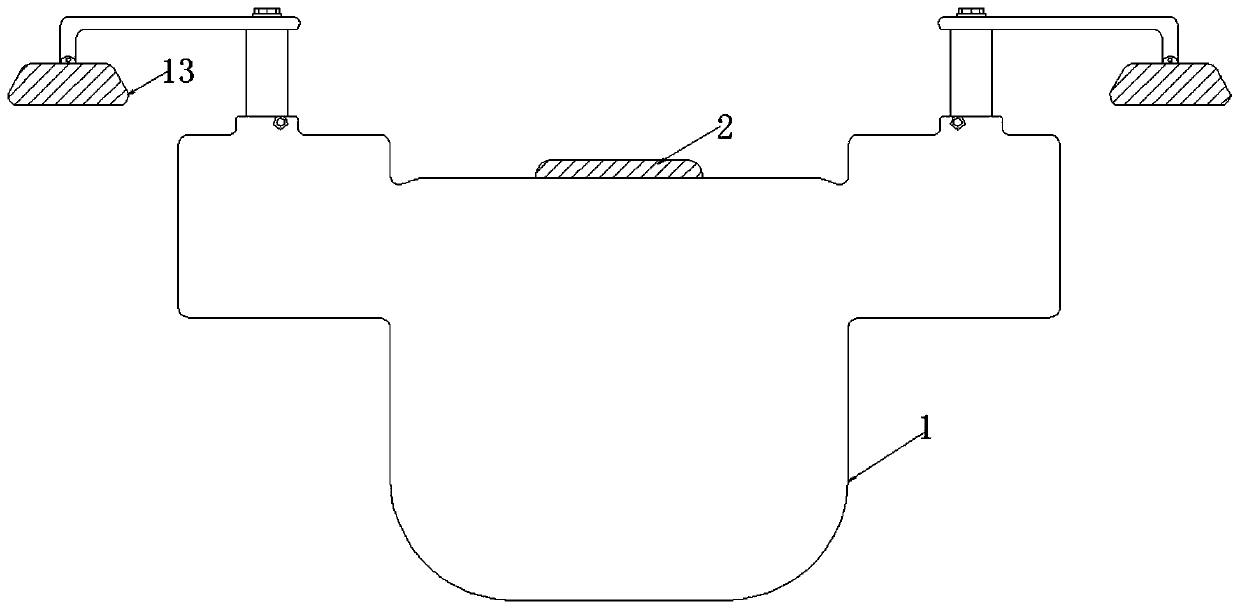

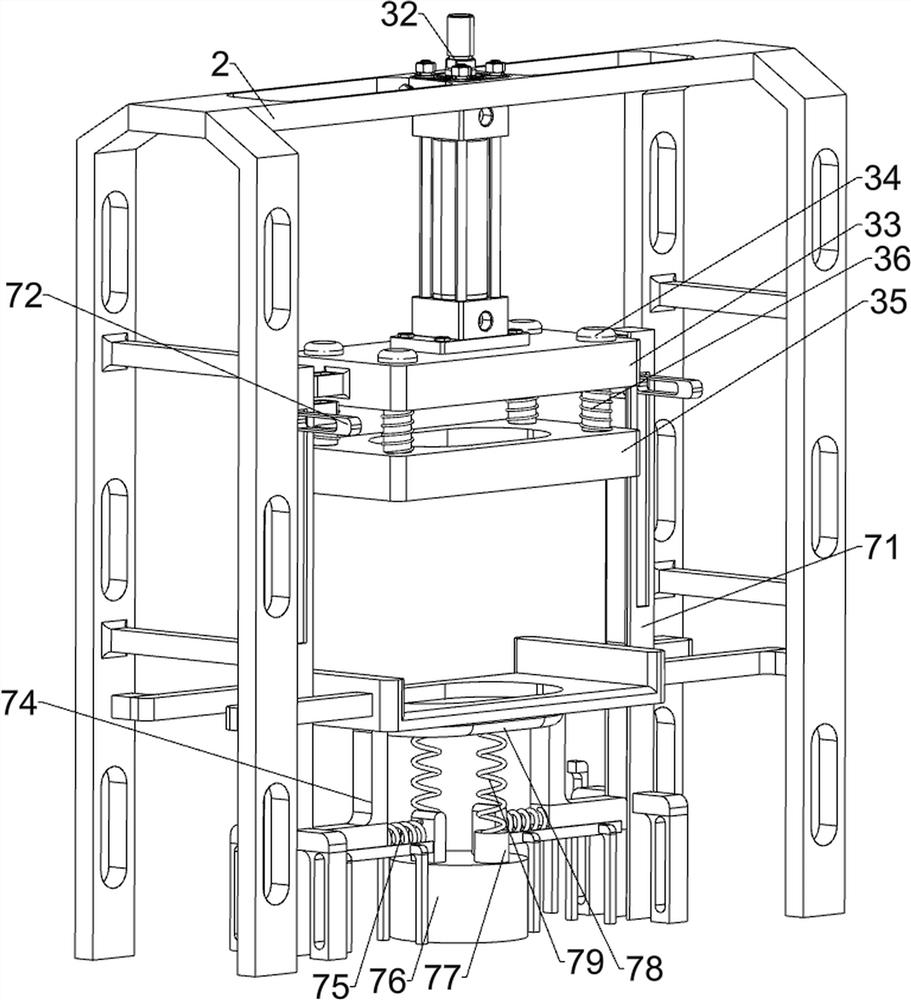

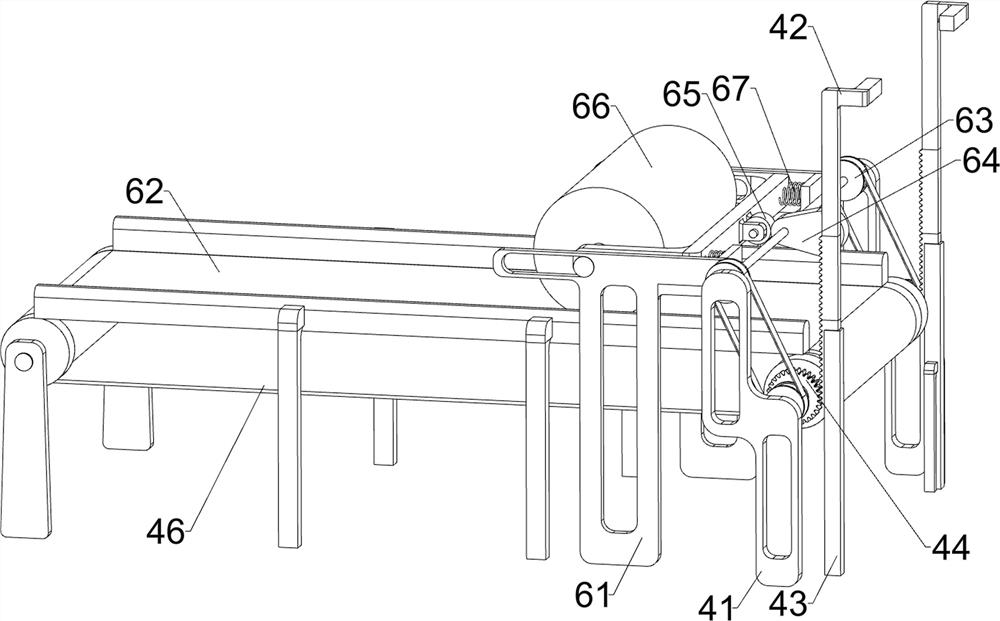

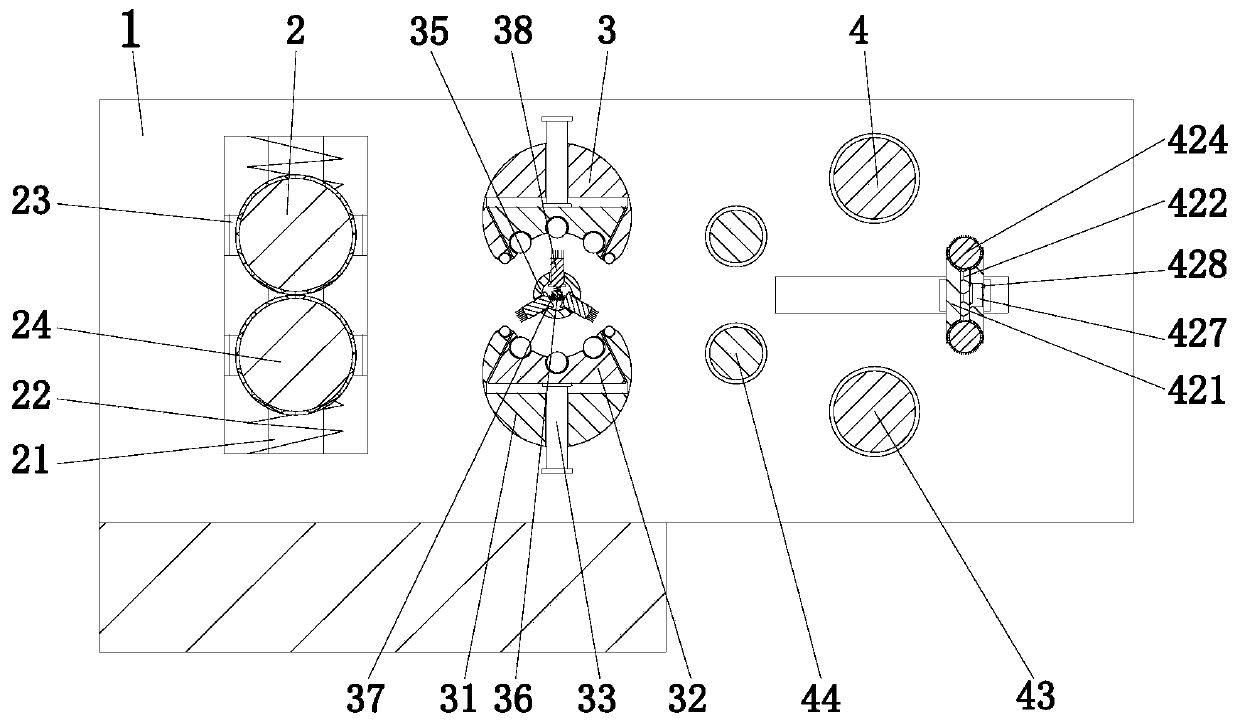

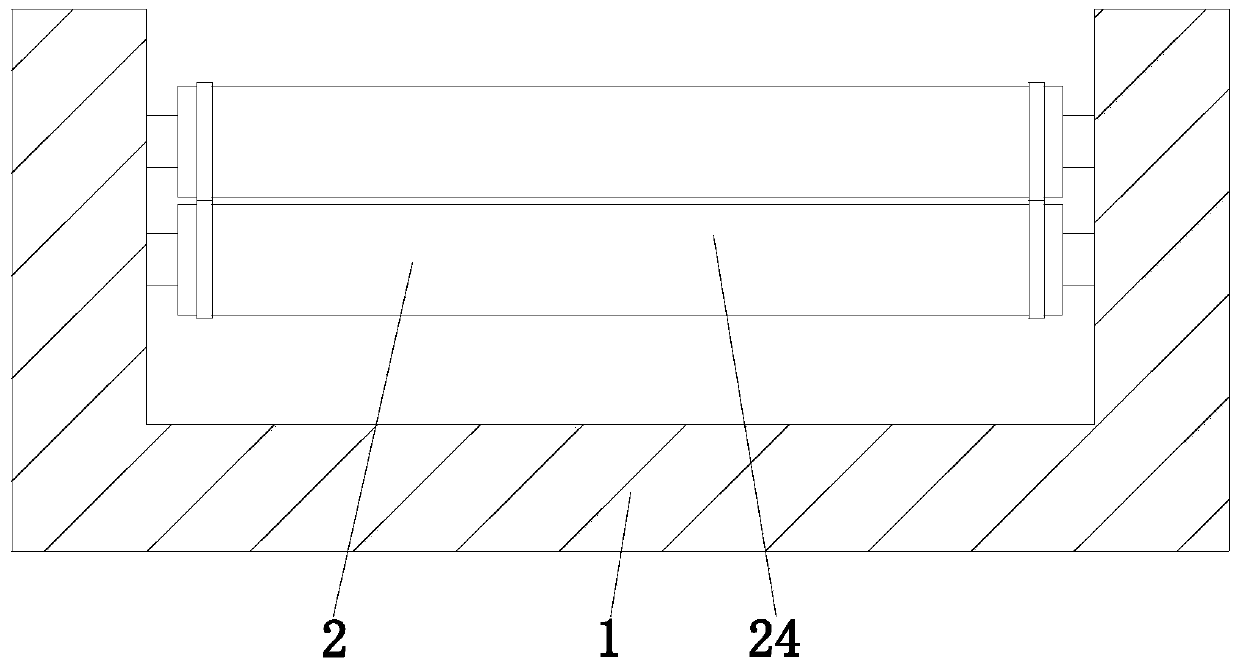

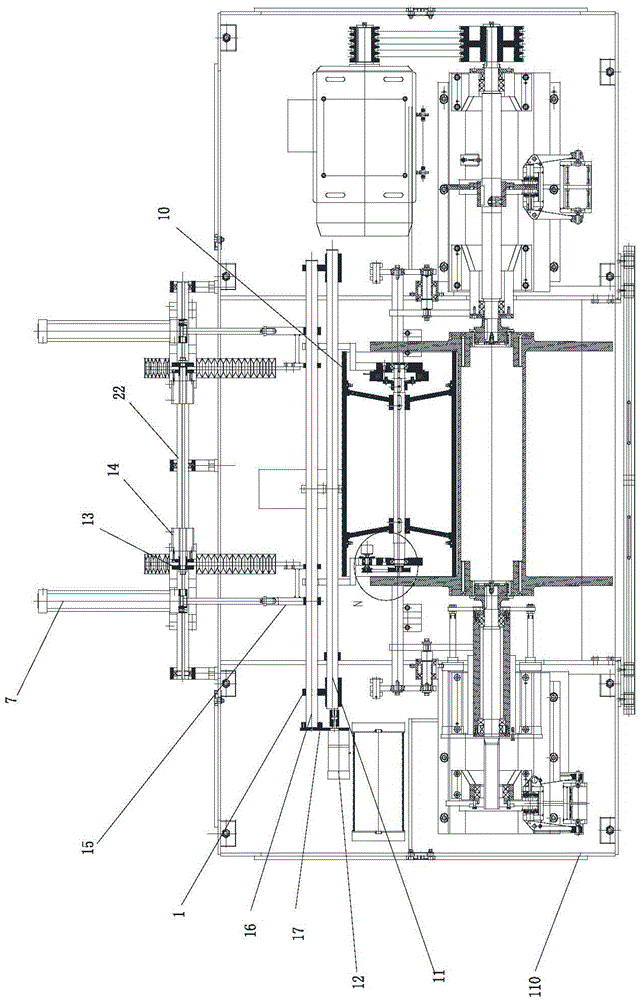

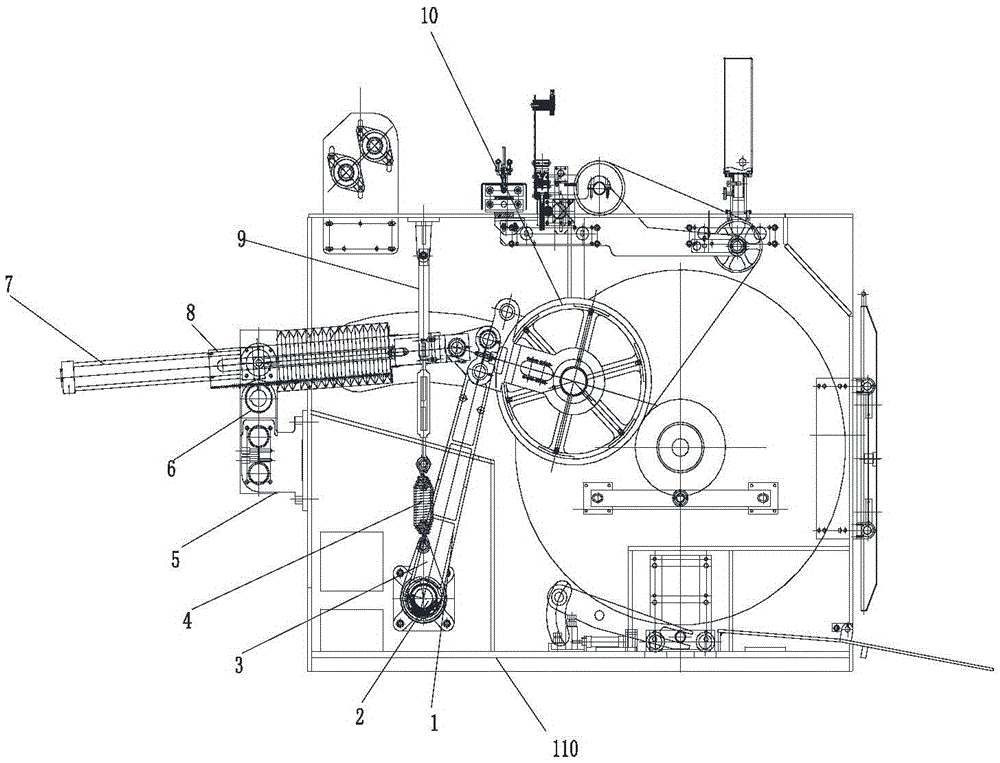

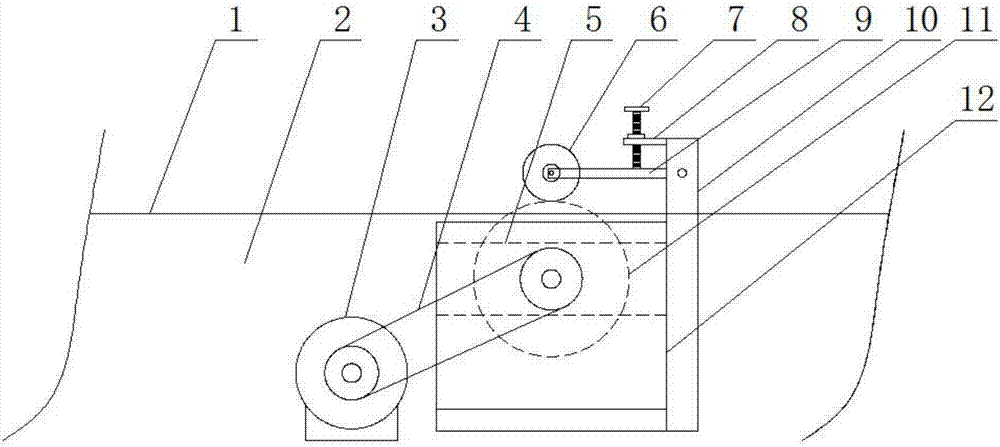

Rice bag lifting handle pressing machine

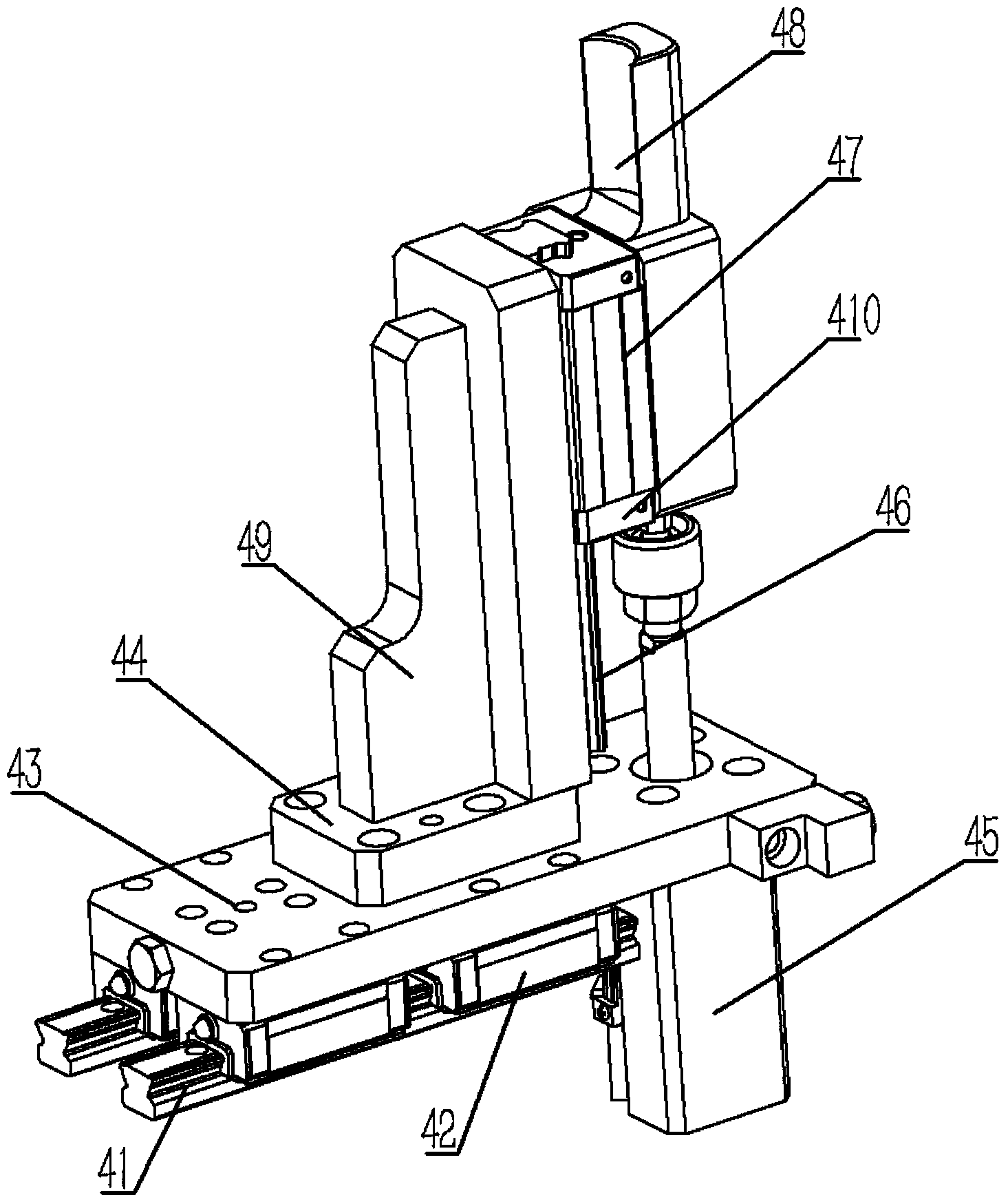

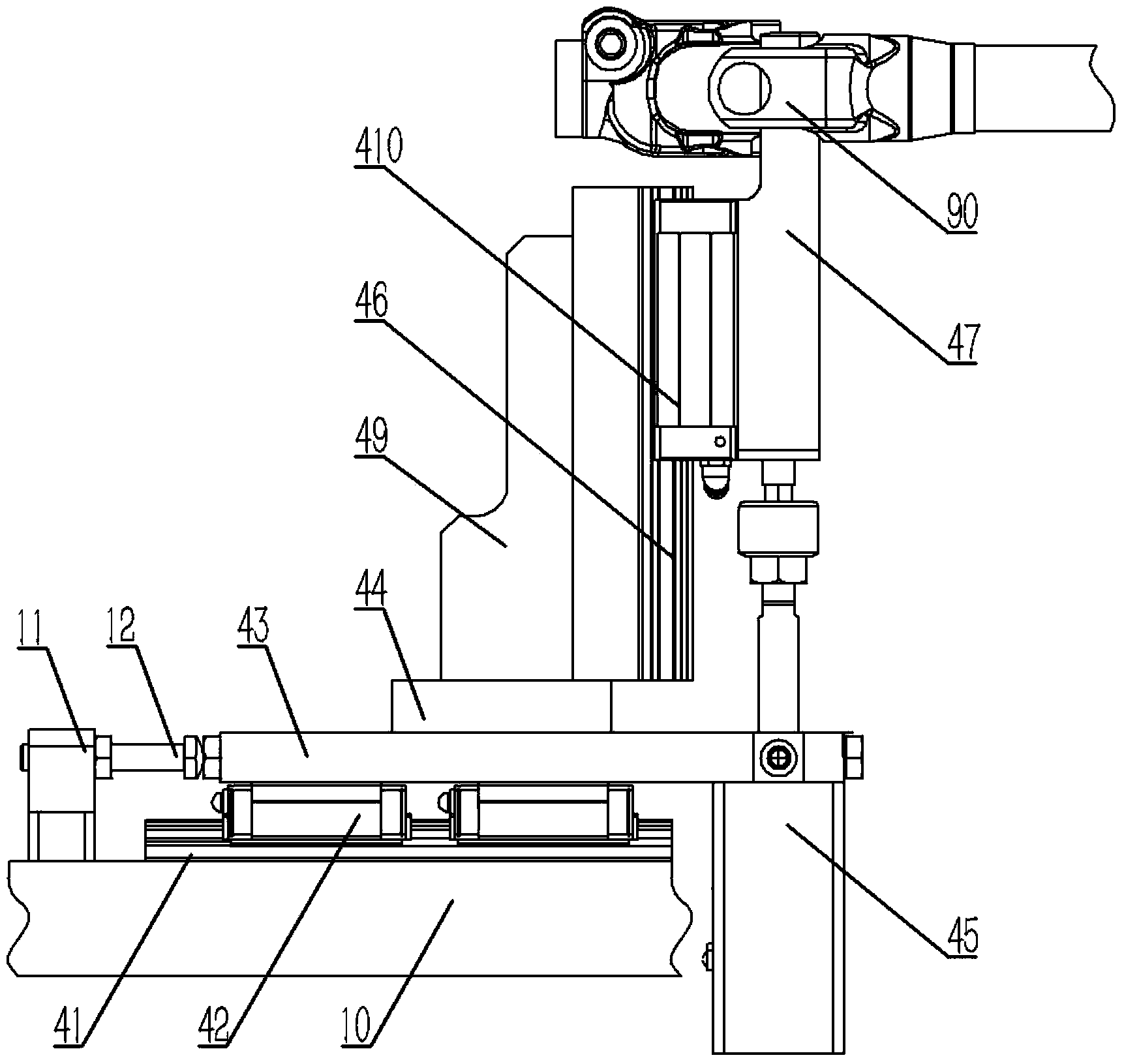

ActiveCN111716823AGuarantee the quality of laminationImprove pressing efficiencyBag making operationsPaper-makingAgricultural engineeringStructural engineering

The invention discloses a rice bag lifting handle pressing machine. The rice bag lifting handle pressing machine comprises a first rack (1), wherein a multi-station mechanism (4) is arranged on the first rack (1); a packaging bag supporting device (5) is fixedly arranged on the multi-station mechanism (4); a rotary bag placing mechanism (11) is arranged under the multi-station mechanism (4); one side of the first rack (1) is provided with a second rack (6); a lifting handle conveying mechanism (3) is arranged on the second rack (6); and one end of the lifting handle conveying mechanism (3) isprovided with a lifting handle pressing mechanism (2). The rice bag lifting handle pressing machine has characteristics of a small size, high pressing efficiency and high pressing quality.

Owner:温州大学平阳智能制造研究院

Press-fitting device used after dispensing of mobile phone rear cover

PendingCN112793174AAffect the appearanceGood adhesionMaterial gluingDomestic articlesMechanical engineeringMobile phone

The invention relates to a press-fitting device, in particular to press-fitting device used after dispensing of a mobile phone rear cover. The press-fitting device used after dispensing of the mobile phone rear cover mainly achieve the effects that press-fitting is carried out by virtue of a machine without touching the press-fitting process by hand, and generated excessive glue can be timely wiped. The press-fitting device used after dispensing of the mobile phone rear cover comprises a base, a press-fitting mechanism, a feeding mechanism and a discharging guide plate, wherein one side of the top of the base is connected with a mounting base, the mounting base is connected with the press-fitting mechanism, the other side of the top of the base is connected with the feeding mechanism, and one side of the top of the base is connected with the discharging guide plate. By arranging the feeding mechanism, a mobile phone needing to be subjected to press fitting is conveyed, manual pushing is not needed, and safety is guaranteed; and by arranging the press-fitting mechanism and a pre-pressing mechanism, the mobile phone needing to be subjected to press fitting is subjected to secondary press fitting, and the press-fitting quality is guaranteed.

Owner:谢昌杰

Silk fabric dyeing device with drying function

InactiveCN105584202AGuaranteed bonding qualityIncrease profitTransfer printingProduction lineEngineering

The invention discloses a silk fabric dyeing device with a drying function. The silk fabric dyeing device comprises a box body. A dyeing water tank is formed in the left side of the box body. A silk fabric pressing device is arranged at the position, close to the right side, above the box body. The silk fabric pressing device comprises a first conveying roller used for conveying a pattern printing film and a second conveying roller used for conveying silk fabric, wherein the first conveying roller and the second conveying roller are arranged vertically and aligned with each other. A pair of vertically-arranged compression rollers are arranged on the left side of the first conveying roller and the left side of the second conveying roller. Middle conveying rollers are arranged between the first conveying roller and the corresponding compression roller, between the second conveying roller and the corresponding compression roller, on the left sides of the compression rollers and in the dyeing water tank. An activating agent spraying device is arranged at the position, corresponding to the pressing joint of the compression rollers, of the right side of the compression rollers. A drying device is arranged above the dyeing water tank. The drying device with the drying function is arranged on the dyeing device so that the silk fabric can rapidly and efficiently enter the drying device to be dried after being dyed, the production line space is effectively utilized, and cost is saved.

Owner:WUXI QIAOYANG MACHINERY MFG

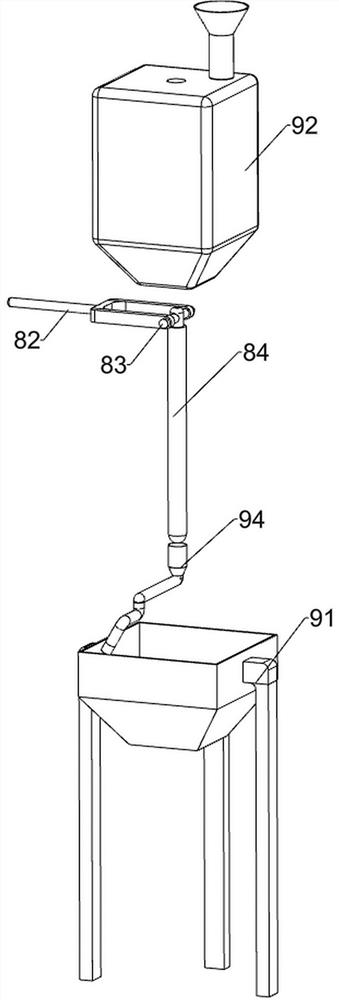

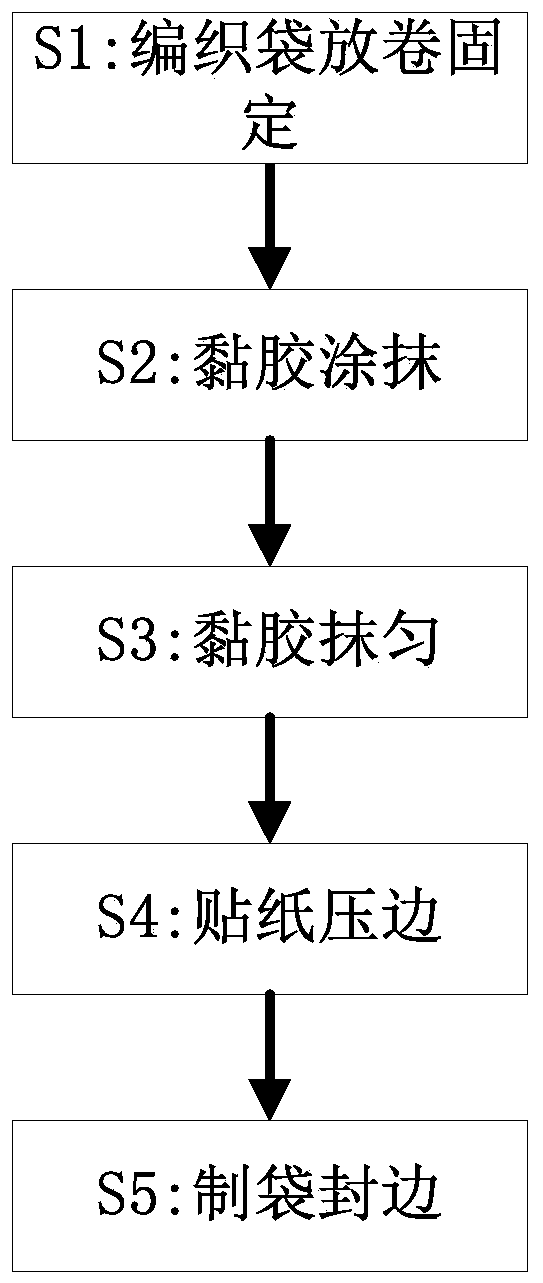

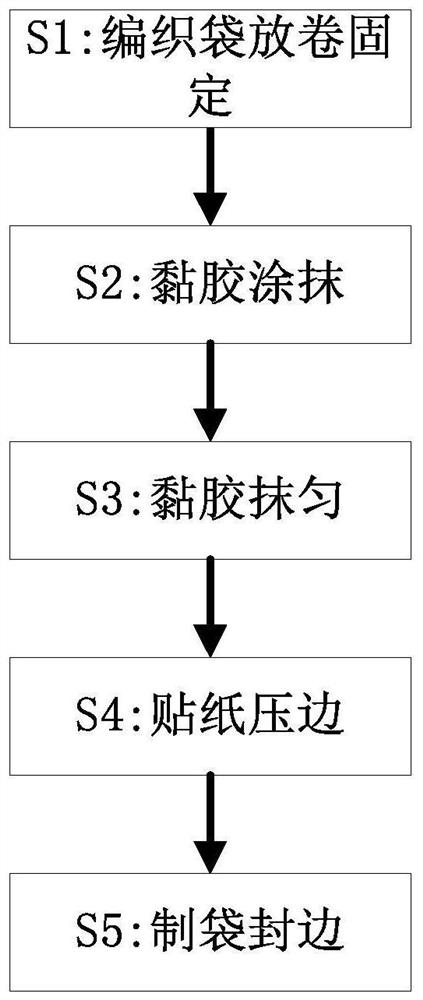

Preparation process of composite plastic bag

ActiveCN111559119AUniform thicknessGuarantee the quality of laminationLiquid surface applicatorsBag making operationsAir bubblePlastic bag

The invention provides a preparation process of a composite plastic bag. The composite plastic bag is prepared through cooperation among a clamping frame, a pressing device, a gluing device and a gluecoating device. The process can solve the problems for an existing woven bag during a production and processing that 1 the glue coating effect is poor when the woven bag is subjected glue coating, coating is uneven, the thickness of a glue solution is inconsistent, and the coating leakage phenomenon is prone to occur; and 2, a large quantity of air bubbles exist between woven fabric and a stickerin a process of woven fabric and sticker pressing due to incomplete pressing, and the use of the later woven bag is affected.

Owner:上海翰册塑料科技有限公司

Photoelectric measuring device for the stepping and shaft center of a middle column sheet during automatic lamination of a transformer iron core

PendingCN109273239AImprove the efficiency of dislocation stackingGuaranteed lamination qualityInductances/transformers/magnets manufactureUsing optical meansTransformerMechanical engineering

The invention relates to the technical field of transformers, in particular to a photoelectric measuring device for the stepping and shaft center of a middle column sheet during automatic lamination of a transformer iron core, comprising a positioning platform for placing silicon steel sheets which are not stacked in a staggered position; A storage platform for placing stacked silicon steel sheetsthat have been stacked in a staggered position; Control means for storing target calibration data and target stepping distances related to sizes of various types of silicon steel sheets; A suction detection device is electrically connecte with that control device, and is used for suck silicon steel sheet from the positioning platform and carrying out measurement. If the measurement result matcheswith the target calibration data, the silicon steel sheet is released into the storage platform accord to the target stepping distance. The photoelectric measuring device of the center column sheet step and the shaft center when the transformer iron core is automatically laminated can improve the staggered stacking efficiency of the center column sheet and ensure the stacking quality of the center column sheet by measuring and checking the related dimensions of the silicon steel sheet before the staggered stacking.

Owner:GUANGDONG UNIV OF TECH

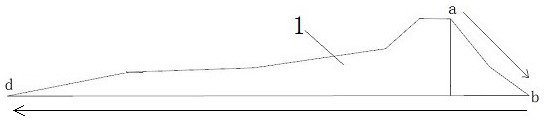

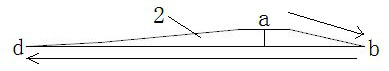

Compound pressing roller mechanism of novel coating machine

PendingCN107225069ACorrect the amount of bending deformationMeet the development requirements of qualityLiquid surface applicatorsCoatingsStructural engineeringMachine

The invention discloses a compound pressing roller mechanism of a novel coating machine. The mechanism comprises a frame, a compound roller, a pressing roller and a back pressure roller, wherein the compound roller is rotationally mounted on the frame; two ends of the pressing roller are rotationally mounted on a first slide base; the first slide base is slidingly mounted on the frame; two ends of the back pressure roller are rotationally mounted on a second slide base; the second slide base is slidingly mounted on the frame; the compound roller, the pressing roller and the back pressure roller are arranged side by side; and the pressing roller is positioned between the compound roller and the back pressure roller. The pressing roller and the compound roller can be singly used; if the force applied to the pressing roller is insufficient or the pressing roller is deformed, the back pressure roller can be stacked based on the pressing roller; the back pressure roller extrudes the pressing roller to correct the bending deformation of the pressing roller, so that the whole roller surface of the pressing roller is more uniform; and meanwhile, more extrusion force can be provided, so that the pressing quality can be guaranteed, and the development requirements of high-precision coating machine compound product quality are met.

Owner:ZHONGSHAN SONGDE NEW MATERIAL EQUIP CO LTD

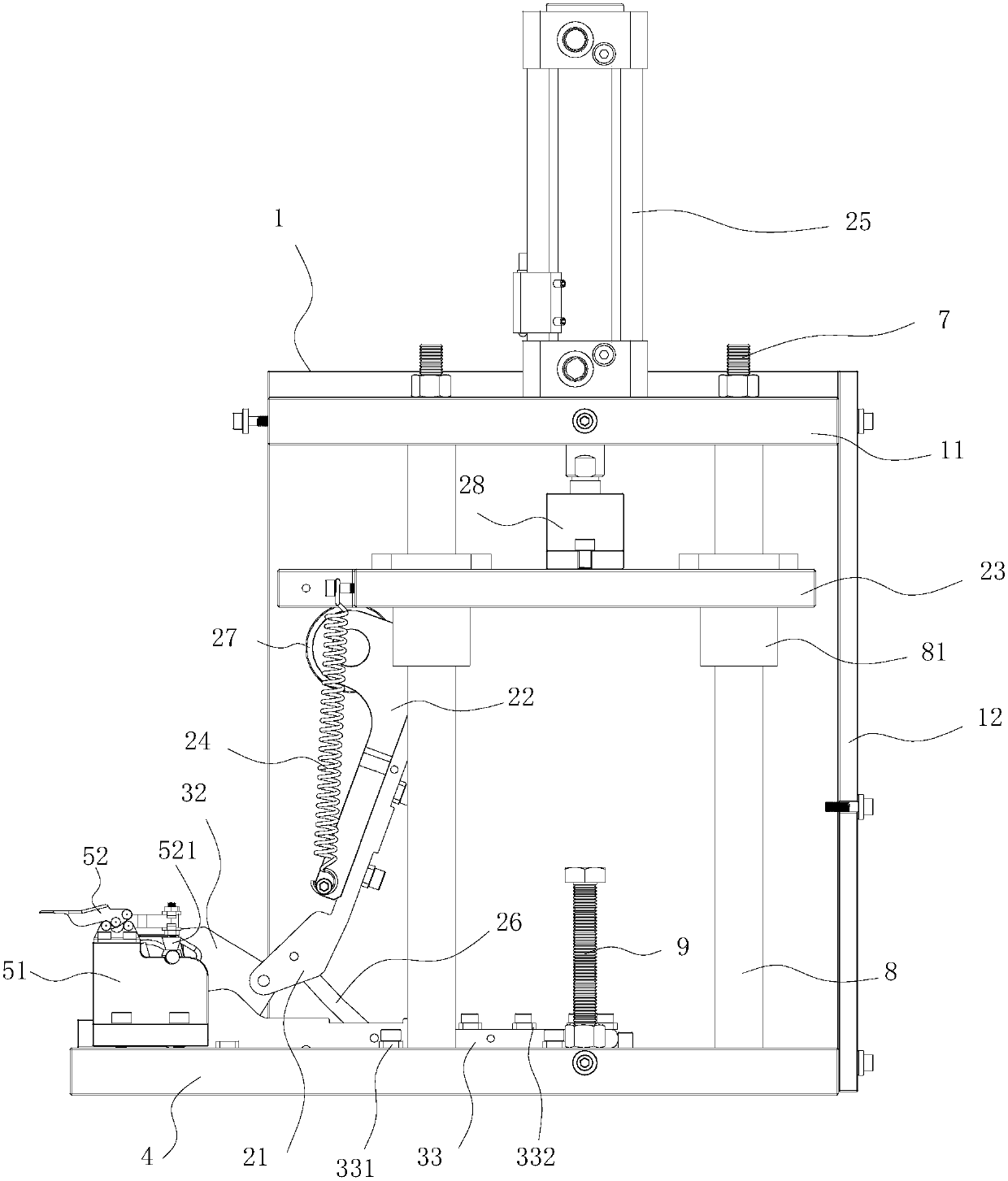

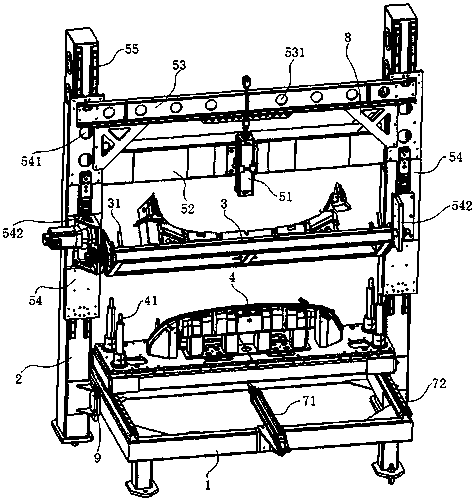

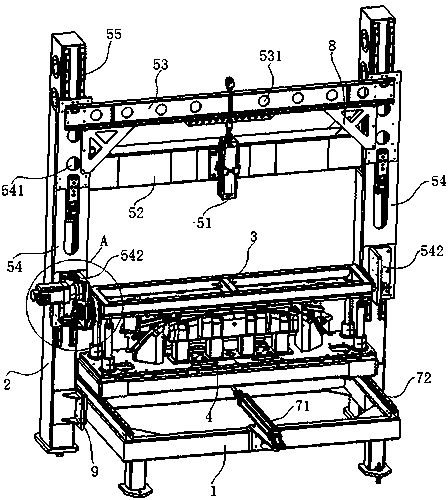

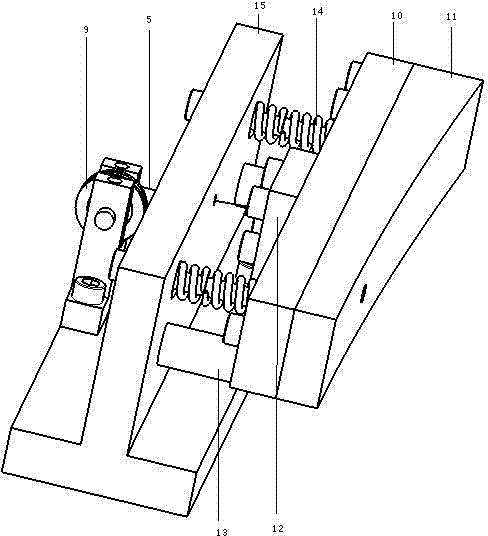

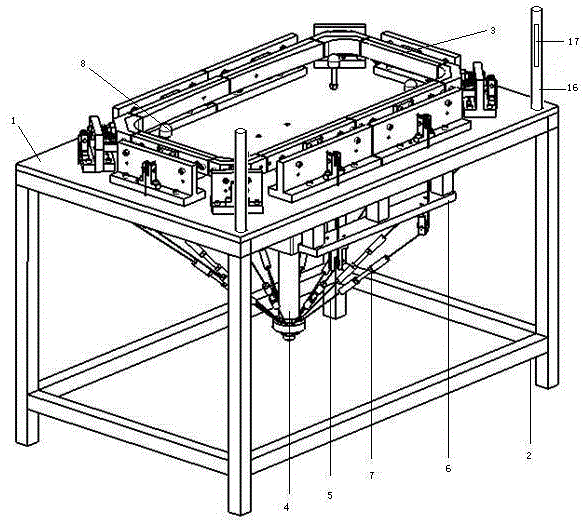

Rotary press fit tool and press fit method for plastic exterior trimming part

The invention discloses a rotary press fit tool and a press fit method for a plastic exterior trimming part, and relates to the field of plastic exterior trimming part manufacturing. The tool comprises two stand columns located on the left side and the right side of a base respectively, an inner plate workbench and an outer plate workbench, wherein the inner plate workbench is arranged on the base, the outer plate workbench is located over the inner plate workbench, the outer plate workbench is arranged between the two stand columns in a lifting mode through a lifting mechanism, the lifting mechanism is slidably arranged on the two stand columns, the two ends of the outer plate workbench are correspondingly mounted on two mounting plates of the lifting mechanism, and a rotating mechanism for driving the outer plate workbench to rotate is arranged on one mounting plate. The tool integrates the inner plate workbench and the outer plate workbench, so that the working efficiency and the space utilization rate are improved, and the labor equipment cost is saved. Meanwhile, a whole frame body for installing the inner and outer plate workbenches is universal, and the press fit requirementof different products can be met by replacing the inner and outer plate workbenches.

Owner:WUHU HENGXIN AUTO INTERIOR TRIM COMPANY

New special skylight glass sealing strip pressing equipment

The invention provides new special skylight glass sealing strip pressing equipment using a new pressing module and cylinder structure, and when a skylight sealing strip is pressed, the skylight sealing strip is in more uniform stress, and the skylight sealing strip is pressed more closely in everywhere, so that the pressing quality is ensured, and the operation is more convenient.

Owner:WUHU MOTIONTEC AUTOMOTIVE

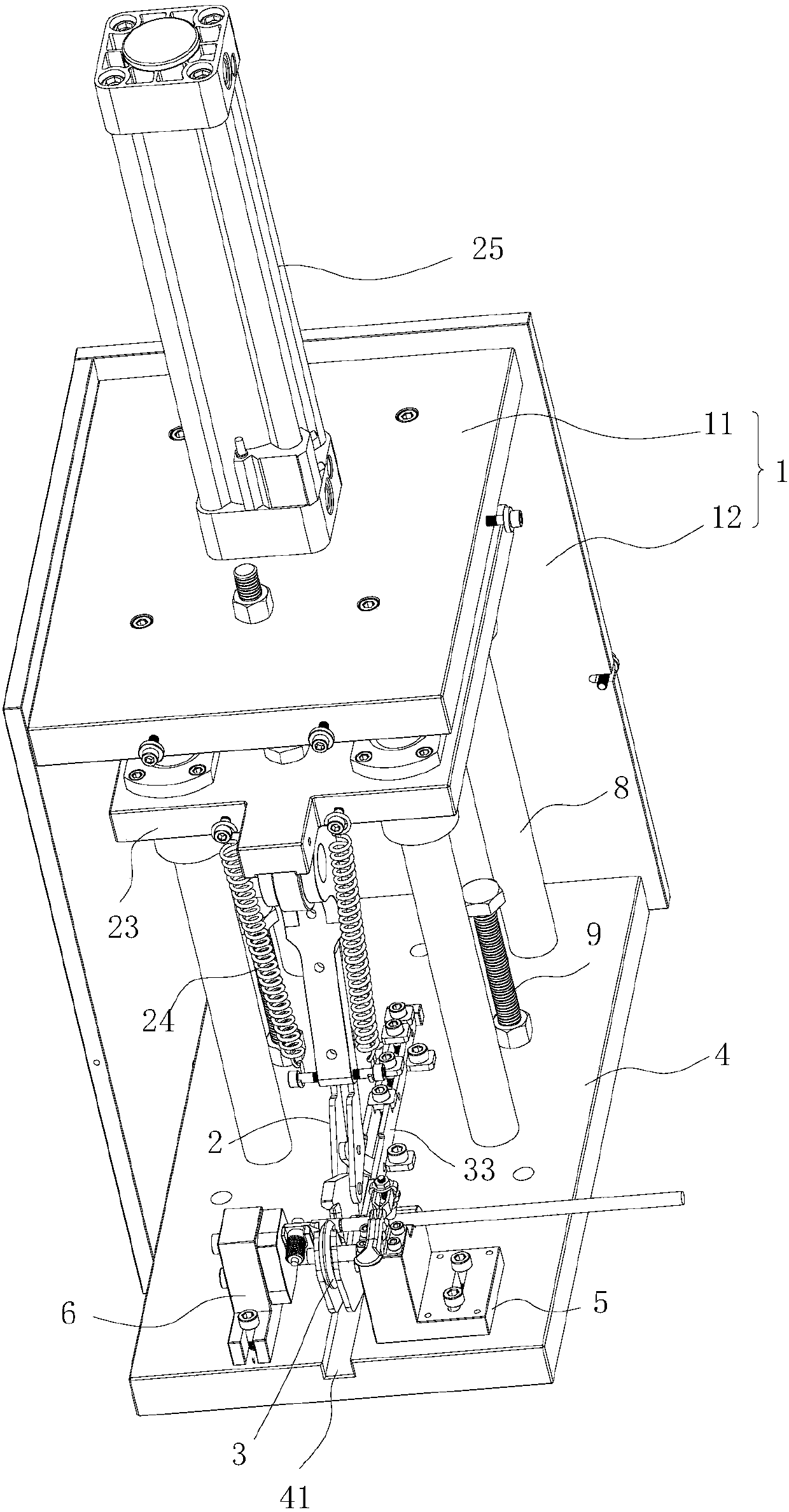

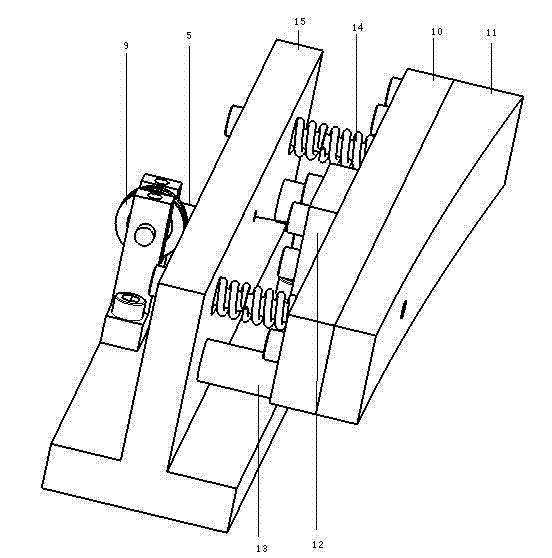

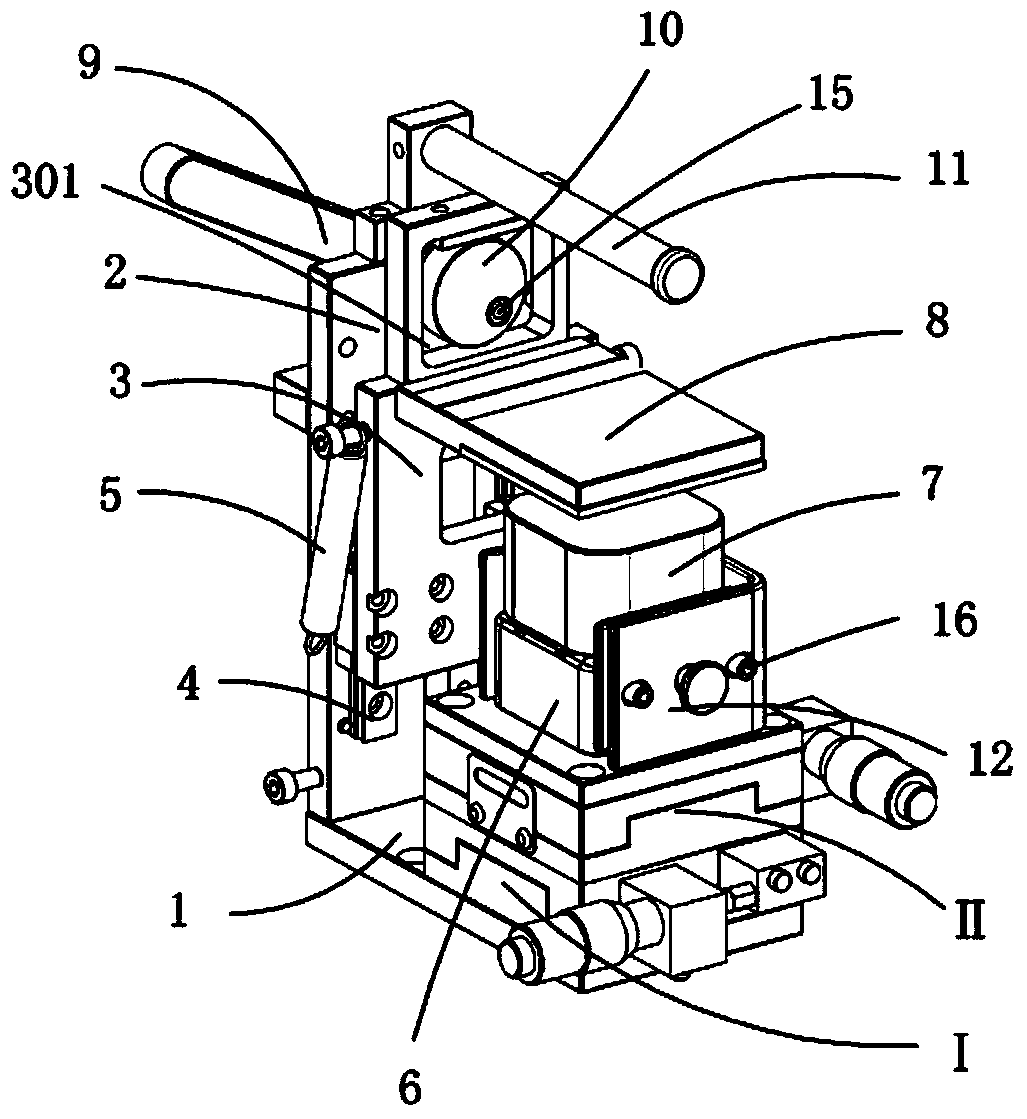

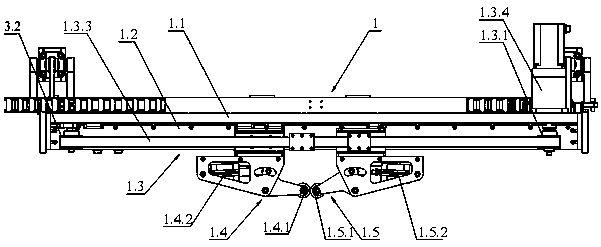

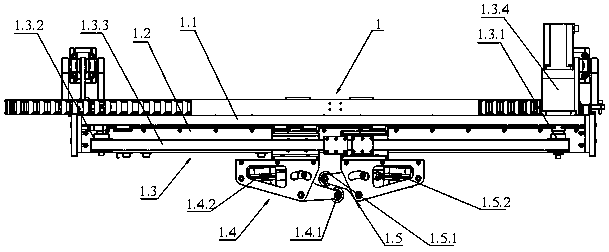

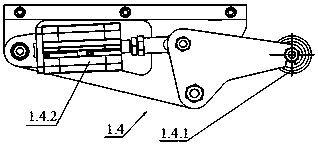

Automatic press-fitting mechanism for earphones

ActiveCN103634732AReduce labor intensityImprove pressing accuracyElectrical transducersEngineeringSlide plate

The invention relates to an automatic press-fitting mechanism for earphones. A rear vertical plate is disposed on a bottom plate and provided with a slide rail; a sliding plate is mounted on the slide rail; the upper portion of the sliding plate is provided with a square slot; a position handle is mounted behind a rear vertical plate through a rotating shaft; an eccentric wheel is mounted on the rotating shaft and disposed in the square slot; a pressure plate is mounted on the sliding plate; a left-right adjustment component is mounted on the bottom plate and provided with a front-back adjustment component; a lower press block is mounted on the front-back adjustment component; an upper press block is arranged above the lower press block, and an earphone is arranged between the upper press block and the lower press block; a knob is adjusted to adjust the front-back position of an elastic press block so as to align the upper press block and the lower press block; after alignment, an alignment regulator is removed; the front-back and left-right positions of the upper and lower press blocks are adjusted, the position handle is then manually operated to rotate the eccentric wheel, the sliding plate drives the pressure plate to move down, a spring on the side acts for buffering, the pressure plate presses down against the upper press plate, and the upper press block and the lower press block co-act to press-fit front and rear covers of the earphone.

Owner:BOZHON PRECISION IND TECH CO LTD

Intelligent manufacturing platform-based automatic assembling mechanism for power equipment

ActiveCN113991495ASimple working processIncrease incomeMetal working apparatusSwitchgearElectric power equipmentElectric machinery

The invention provides an intelligent manufacturing platform-based automatic assembling mechanism for power equipment. The automatic assembling mechanism comprises a base and a box body arranged at the top of the base. The automatic assembling mechanism further comprises a supporting table fixedly connected in the box body through a connecting column; a driving motor is connected to the outer wall of the supporting table; a conveying belt component is rotatably connected in the supporting table; the top of the supporting table is connected with a supporting column; the top of the supporting column is provided with a reciprocating device matched with the end, away from the driving motor, of an auxiliary device and the conveying belt component; and the side wall of the supporting table is provided with a first picking and placing mechanism and a second picking and placing mechanism; and a first placing rack and a second placing rack which are matched with the first picking and placing mechanism and the second picking and placing mechanism are arranged in the box body. The mechanism is simple in structure and convenient to operate; the working process of an operator is simplified;it is guaranteed that the pressing quality is not affected by the shaking condition in the pressing process; the production quality of the device is guaranteed; the production cost of the device is reduced; and the factory income is increased.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Roller mechanism of tire building machine, joint pressing device and tire building machine

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

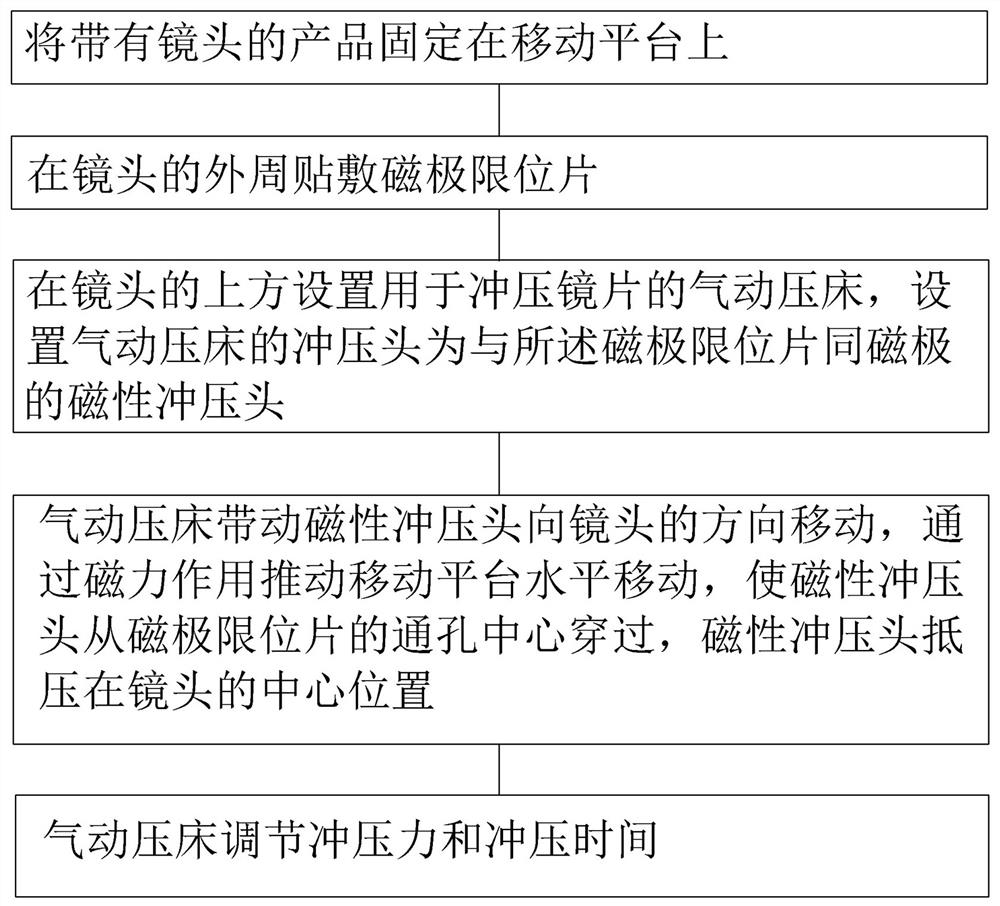

Lens pneumatic pressing method

ActiveCN114347490AGuaranteed accuracyRealize alignment pressingOptical articlesStampingMagnetic poles

The invention relates to a pneumatic lens pressing method. A product with a lens is fixed on a moving platform; a magnetic limit piece is attached to the periphery of the lens, and a through hole concentric with the lens is formed in the magnetic limit piece around the lens; a pneumatic press for stamping the lens is arranged above the lens, and a stamping head of the pneumatic press is a magnetic stamping head with the same magnetic pole as the magnetic limit sheet; the pneumatic press drives the magnetic stamping head to move towards the lens, the movable platform is pushed to move horizontally under the action of magnetic force, so that the magnetic stamping head penetrates through the center of a through hole of the magnetic limit piece, and the magnetic stamping head abuts against the central position of the lens; the pneumatic press determines and adjusts different stamping forces according to the size of the press-fit lens, and the pneumatic press determines and adjusts different stamping times according to the bonding material of the lens and the lens. According to the invention, the press-fit position can be accurately determined, the press-fit force and time can be controlled, and the press-fit quality and the press-fit efficiency of the lens and the lens can be improved.

Owner:SUZHOU KECHUAN ELECTRONICS TECH

The method of guaranteeing the pressing quality of special-shaped parts in the forming process

ActiveCN114523702BAvoid material misalignment issuesGuaranteed complianceTyresTravel modeIndustrial engineering

The invention discloses a method for ensuring the pressing quality of special-shaped parts in the molding process, and belongs to the technical field of construction machinery tire manufacturing. The technical scheme is as follows: when the cushion rubber component and the sidewall component are pressed together, the pressing is performed in the order of the thickest point, the inner end point and the outer end point of the components. The present invention designs the traveling mode of the pressing roller, which can avoid the abnormal material deviation of the pad rubber and the sidewall components during the pressing process, ensure the conformity of the positioning of the components, and reduce the early quality problems in the market.

Owner:广饶县计量测试检定所(广饶县产品质量检验所广饶县橡胶轮胎产品与材料质量检验中心) +1

Universal Rotor Core Lamination Tooling and Lamination Method

ActiveCN104242568BImprove securityReduce processing timeManufacturing stator/rotor bodiesRisk strokeRadial clearance

The invention discloses a universal type rotor core overlaying tool which comprises a platen, a base and a mandrel. The mandrel is sleeved with rotor cores in an overlaid mode. The rotor cores are located between the platen and the base, and core laminations are overlaid through the platen and the base jointly. The universal type rotor core overlaying tool is characterized in that a plurality of pressing columns are connected with the lower portion of the platen and are evenly and annularly distributed at intervals, and the platen drives the pressing columns to enable the iron laminations to be overlaid. According to the universal type rotor core overlaying tool, the pressing column structure is adopted, and radial clearances exist between the pressing columns; compared with a traditional closed overlaying tool, rotor core end fixing keys can be installed when the rotor cores are compressed, the influences of the oil press stroke on rotor core overlaying specifications can be lowered, the security coefficients in the rotor core overlaying process are increased, working procedure tome is shortened, and production efficiency is improved by about 30%.

Owner:安徽金箔机电产业集团股份有限公司

Upper and outsole press-fit workbench

PendingCN112656090ARapid automated productionHigh compression support strengthShoe gluingEngineeringWorkbench

The invention discloses an upper and outsole press-fit workbench which is characterized in that the press-fit workbench comprises a platform support and a floating block set arranged on the platform support, the floating block set is formed by connecting a plurality of longitudinally-arranged floating blocks front and back, the adjacent floating blocks move up and down relatively, and the floating blocks are supported by springs in a floating mode. The workbench is used for fixing and pressing uppers and rubber outsoles in the shoemaking process, the press-fit quality is better guaranteed, degumming is prevented, and automatic production of a press-fit machine at a higher speed is achieved.

Owner:温州市德立智能科技有限公司

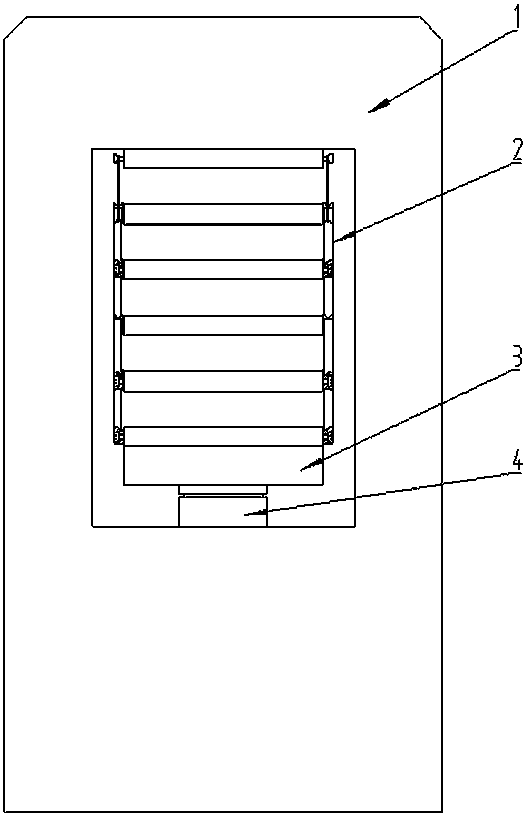

Multilayer synchronous constant pressure pressing machine of high-sensitivity circuit board

PendingCN110876241AOvercome product differences caused by differentGuarantee the quality of laminationMultilayer circuit manufactureManufacturing technologyEngineering

The invention relates to a multilayer synchronous constant pressure pressing machine of a high-sensitivity circuit board which is suitable for high-sensitivity circuit board pressing, and belongs to the electromechanical integration electronic equipment manufacturing technology field. A hot plate group is arranged in the pressing machine. The hot plate group is a simultaneous closed structure. Thesimultaneous closed structure consists of multiple layers of hot plates. A supporting rod is fixedly arranged on a first-layer hot plate at a lower end. A hot plate fixing point is arranged on the uppermost layer of hot plate. Movable pulleys and the supporting rods are arranged on the other hot plates. One end of a stress rope is fixed on the upper-layer hot plate through the movable pulley, theother end is fixed on the supporting rod of the lower-layer hot plate, a lower end of the supporting rod is fixed on the lower-layer hot plate of the hot plate where the movable pulley is located through a fixing bolt, and the hot plates are successively and synchronously connected through the movable pulley, the stress rope and the supporting rod. All layers of hot plates in the pressing machineare closed at the same time, pressed products are good in quality, production efficiency is good, and a rate of finished products is high.

Owner:咸阳威迪机电科技有限公司

Limiting mechanism for oval press-fit machine

The invention discloses a limiting mechanism for an oval embedding machine. The limiting mechanism comprises two sets of horizontal guide rails fixed to a work table of a machine frame. A plurality of horizontal slide blocks are inserted in the horizontal guide rails in a sleeved mode. Horizontal installation plates are fixed to the horizontal slide blocks. L-shaped installation supports are fixed to the horizontal installation plates. Vertical guide rails are fixed to the vertical faces of the installation supports. Vertical slide blocks are inserted in the vertical guide rails in a sleeved mode. Limiting blocks are fixed to the vertical slide blocks. Inserting rods with one sides being arc faces are formed at the upper ends of the limiting blocks. The lower ends of the limiting blocks are fixedly connected to a piston rod of an air cylinder. The air cylinder is fixed to the lower end faces of the horizontal installation plates. The inserting rods on the limiting blocks are inserted into the joint portion of a transmission shaft, and therefore the transmission shaft can be effectively prevented from rotating, the press fit point of the transmission shaft can be located, and the press fit quality of the transmission shaft is effectively ensured.

Owner:湖州奇奇机电科技有限公司

A kind of composite plastic bag preparation technology

ActiveCN111559119BUniform thicknessGuarantee the quality of laminationLiquid surface applicatorsBag making operationsPolymer sciencePolymer chemistry

The invention provides a preparation process of a composite plastic bag. The preparation of the composite plastic bag is completed by the cooperation of a clamping frame, a pressing device, a gluing device and a gluing device; Existing 1. When gluing the woven cloth, the gluing effect is poor and the smearing is uneven, resulting in inconsistent thickness of the glue and easy occurrence of missing coating; 2. In the process of laminating the woven cloth and the sticker, due to insufficient It completely causes a large number of air bubbles between the woven cloth and the sticker; it affects the use of the woven bag in the later stage and other problems.

Owner:上海翰册塑料科技有限公司

Roller Adjustment Mechanism of Flat Yarn Warping Machine

The invention relates to the field of a warping machine accessory, in particular to a compression roller adjusting mechanism of a flat-filament warping machine. The compression roller adjusting mechanism comprises a lateral adjusting mechanism which is arranged between swinging arms, wherein a compression roller installation frame is arranged on the lateral adjusting mechanism, a pressure adjusting mechanism is also arranged on the stander, installation plates are symmetrically arranged on the stander, each installation plate is provided with the pressure adjusting mechanism, each pressure adjusting mechanism comprises an adjusting air cylinder which is arranged on the installation plate, the output end of each adjusting air cylinder is connected with the lateral adjusting mechanism through a connecting frame, a slidable rack connecting plate with racks on the lower surface is also arranged on the installation plate, one end of the rack connecting plate is connected to the connecting frame, a positioning gear which is matched with the rack connecting plate is also arranged on the installation plate, and a synchronous rotating shaft is arranged between the positioning gears on the two installation plates. By adopting the compression roller adjusting mechanism, the compression stability between the compression roller and a disc head can be guaranteed, and the warping quality can be guaranteed.

Owner:NEWTRY COMPOSITE

Special equipment for automatic sunroof glass sealing strip pressing

The invention provides novel equipment special for automatically pressing a skylight glass sealing strip. The novel equipment comprises a workbench, a support, glass supporting feet, an air cylinder, steel wires, a steel wire support and 10 sets of pressing die blocks, each long side is provided with two sets of the pressing die blocks, each short side is provided with a set of the pressing die block, each corner is provided with a set of the pressing die block, each set of the pressing die block comprises a supporting block, a pressing block and a shape-preserving block, rod-shaped action sensors are arranged on two sides of a near side of the workbench respectively, opposite sides of the action sensors are provided with transparent windows, and the air cylinder is controlled by the action sensors arranged on the workbench. By the novel equipment, when the skylight sealing strip is pressed, the sealing strip is enabled to be stressed more uniformly, and each position is pressed more closely, so that pressing quality is guaranteed, and more convenience is brought to operation.

Owner:WUHU MOTIONTEC AUTOMOTIVE

Automatic gumming machine for packaging carton box

InactiveCN107571543AUniform adhesionAttachmentBox making operationsPaper-makingWorking environmentCarton

The invention relates to an automobile gumming machine for a packaging carton box. The automatic gumming machine is characterized by comprising a rack, a conveyor belt, a glue case, a heater, a gumming roller, a pressing-fitting roller, an adjusting support and a motor, wherein the conveyor belt is arranged on the rack; the glue case, the bottom of which is provided with the heater, is mounted onthe side surface of the rack; the gumming roller driven by a motor chain is disposed in the glue case; the height of the gumming roller is slightly larger than the height of the conveyor belt; the pressing-fitting roller is arranged right over the gumming roller and adjustably mounted on the adjusting support; and the adjusting support is mounted on the side surface of the glue case. The automaticgumming machine is scientifically and rationally designed and advantaged by labor and effort use reduction, production cost reduction, even coating, product pasting quality guarantee, glue use decrease and work environment tidiness guarantee; and the automatic gumming machine for the packaging carton box has great innovativeness.

Owner:TIANJIN JINGHAI COUNTY LIHUA PRINTING PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com