Silk fabric dyeing device with drying function

A drying device and technology for silk fabrics, applied in the field of textile printing and dyeing, can solve the problems of long production line, occupy large space, single function, etc., and achieve the effect of utilizing production line space, occupying small space, and ensuring the quality of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0016] It should be noted that in this embodiment, "left side" and "right side" refer to the left and right orientations that people consider when viewing from conventional angles, which can be understood correspondingly according to the text description and the accompanying drawings.

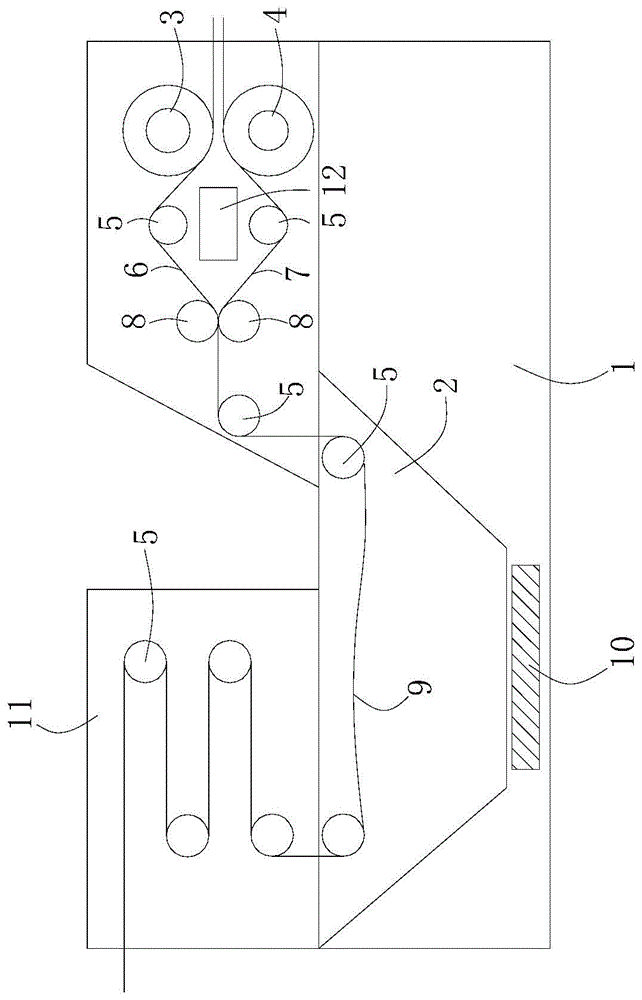

[0017] Such as figure 1 As shown, a silk fabric printing and dyeing device with a drying function includes a box body 1, a printing and dyeing water tank 2 is arranged on the left side of the box body 1, and a silk fabric pressing device is arranged on the upper right side of the box body 1, and the silk fabric pressing device It includes the first conveying roller 3 that conveys the pattern printing film 6 and the second conveying roller 4 that conveys the silk fabric 7 aligned up and down, and a pair of pressure ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com