Process cover plate with groove structure and manufacturing method for process cover plate

A technology of cover plate and process, which is applied in the field of manufacturing aircraft metal adhesive components, and can solve problems such as large local stress, stress concentration, and too thin adhesive film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

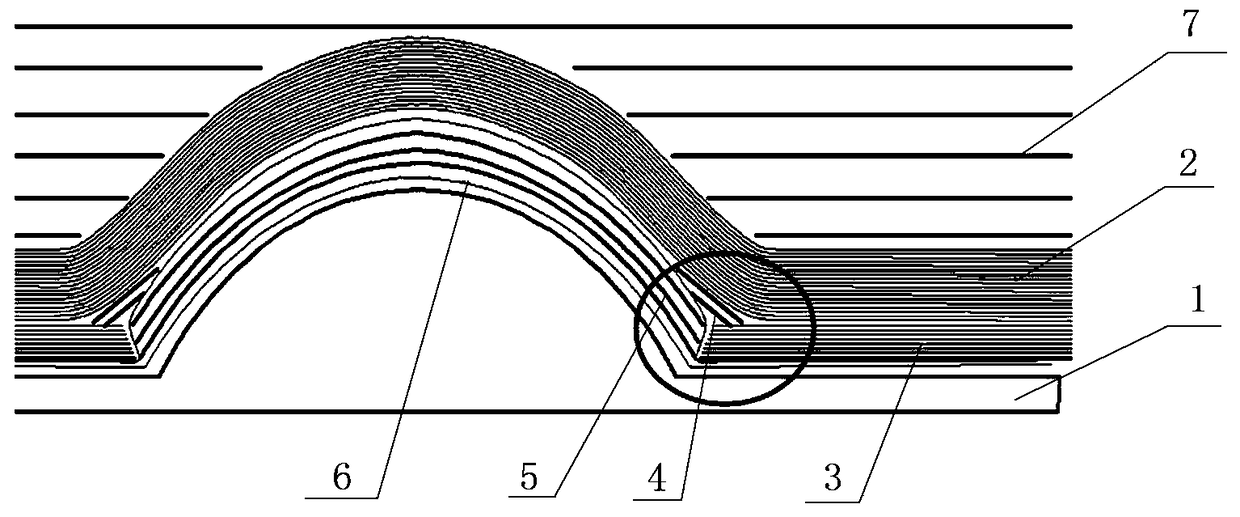

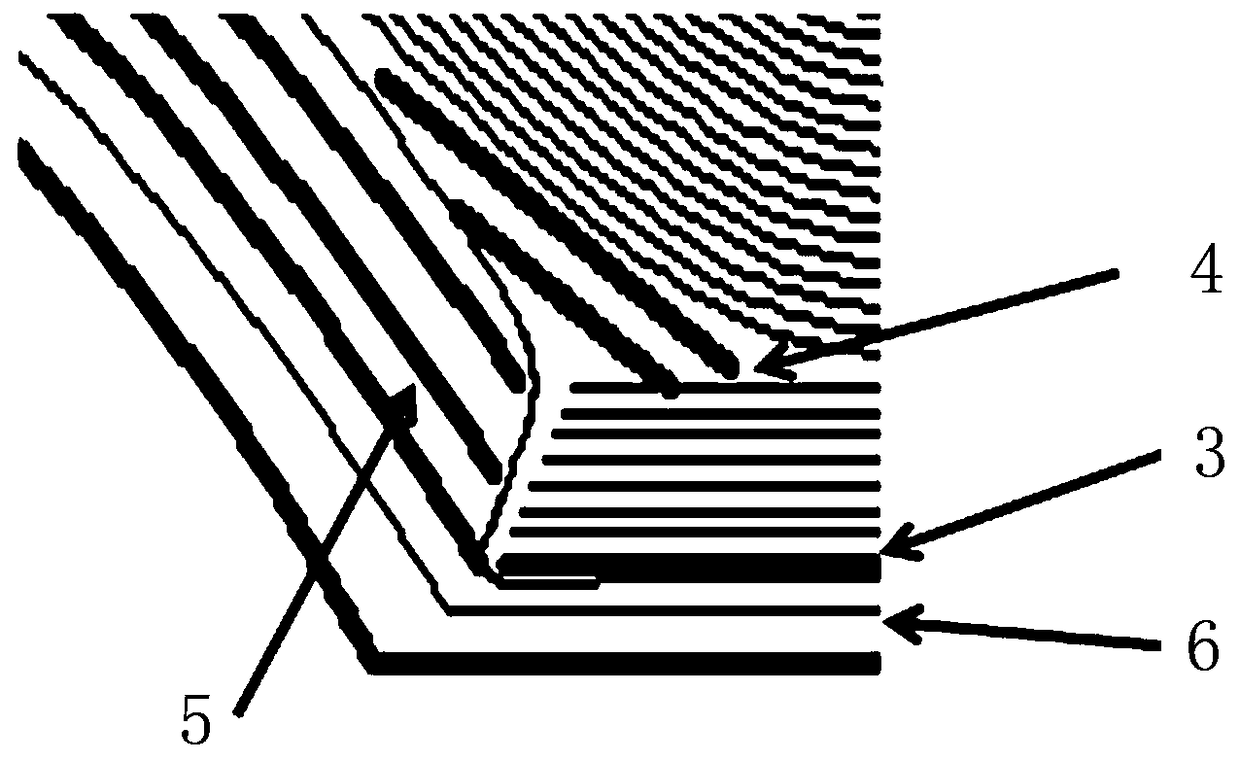

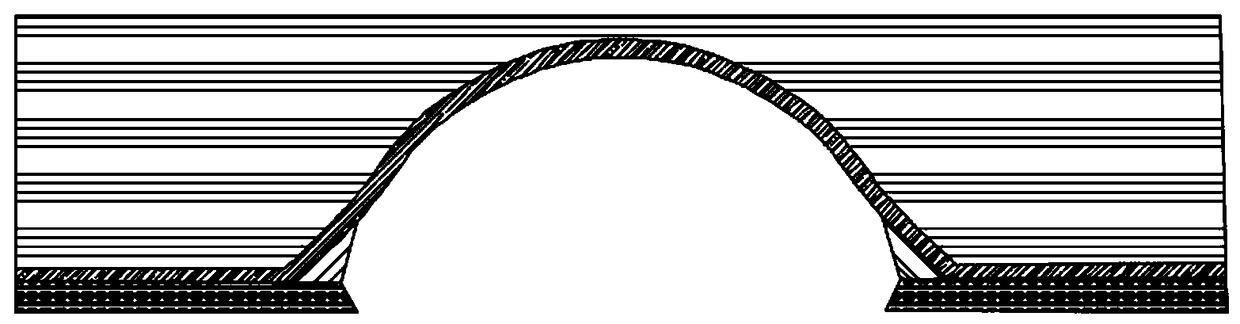

[0026] like figure 1 and figure 2 As shown in the figure, a groove structure process cover plate is composed of four parts: a filling layer, a shell layer, a flat plate layer and an R-angle filling body; A shell layer is arranged on the surface, and the shell layer is composed of several layers of glass fiber woven prepreg; a flat plate layer is arranged on the lower surface of the shell layer, and the flat layer is composed of a bottom layer of unvulcanized rubber and several upper layers of glass fiber woven prepreg The bottom surface of the process cover is provided with several grooves, and the position of the grooves corresponds to the position of the hollow protrusion of the glued member. The flat layer is broken at the groove, and the shell layer is arched upward at the groove. A convex structure is formed; the R-angle filler is formed by a combination of unvulcanized rubber steps, and is supported at the transition fillet between the shell layer and the flat plate la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com