Patents

Literature

294results about How to "Improve stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

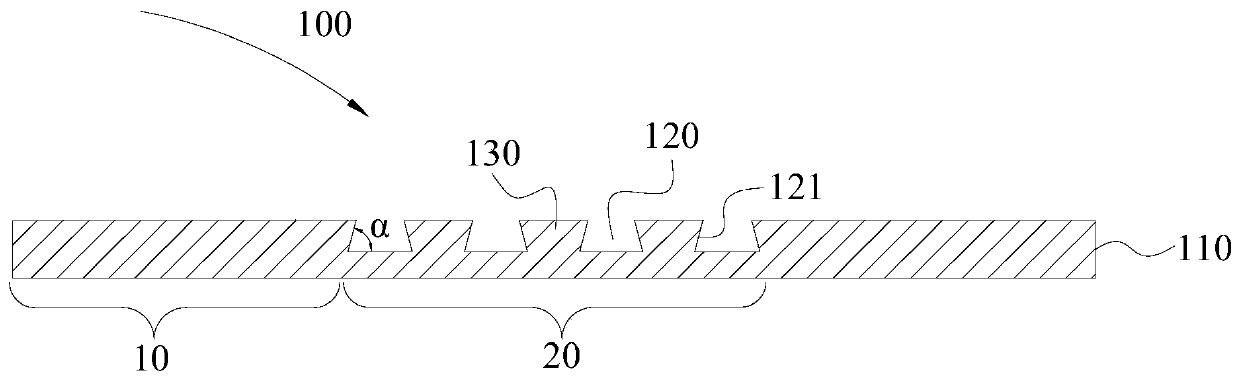

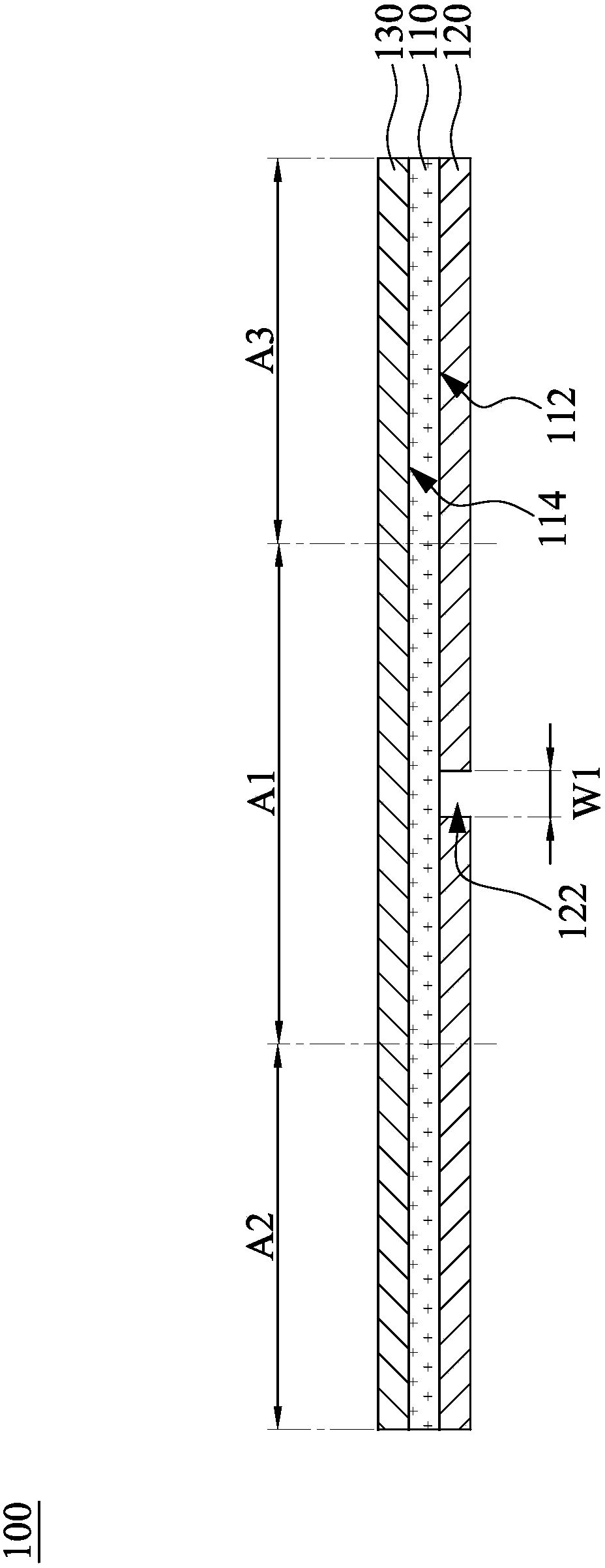

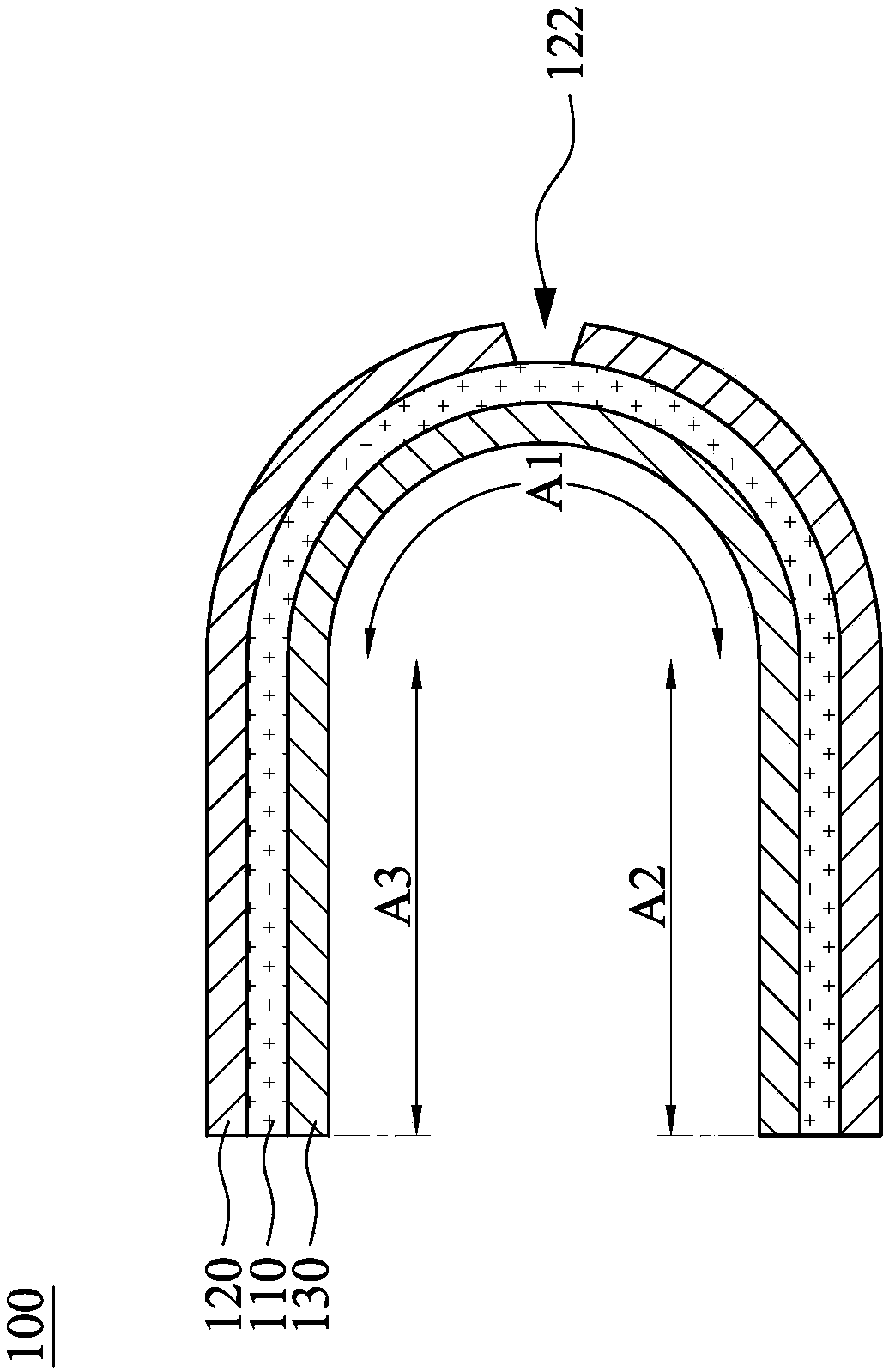

Foldable supporting piece and preparation method and display device

PendingCN110767098AImprove stress concentrationImprove bending performanceDetails for portable computersIdentification meansEngineeringMechanical engineering

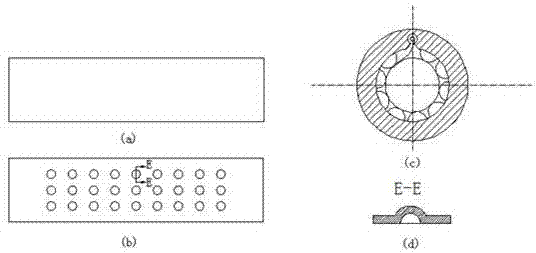

The invention discloses a foldable supporting piece and a preparation method and a display device. The foldable supporting piece comprises a metal layer, wherein the metal layer comprises a non-bending region and at least one bending region; the part, located in the bending region, of the metal layer has a plurality of concave parts; and at least one sidewall of the concave parts are not perpendicular to the plane where the metal layer is located. Therefore, the foldable supporting piece can provide a high plane support function for a flexible display panel, in particular to provide high support for the bending region of the flexible display panel, and the overall anti-extrusion capability of the flexible display panel is improved; and meanwhile, the bending performance of the foldable supporting part and the performance of flatness recovery after bending are effectively improved, the problem of peeling of the flexible display panel and the foldable supporting piece can be effectivelyimproved, and the problem of creasing of the foldable supporting piece can be solved.

Owner:BOE TECH GRP CO LTD

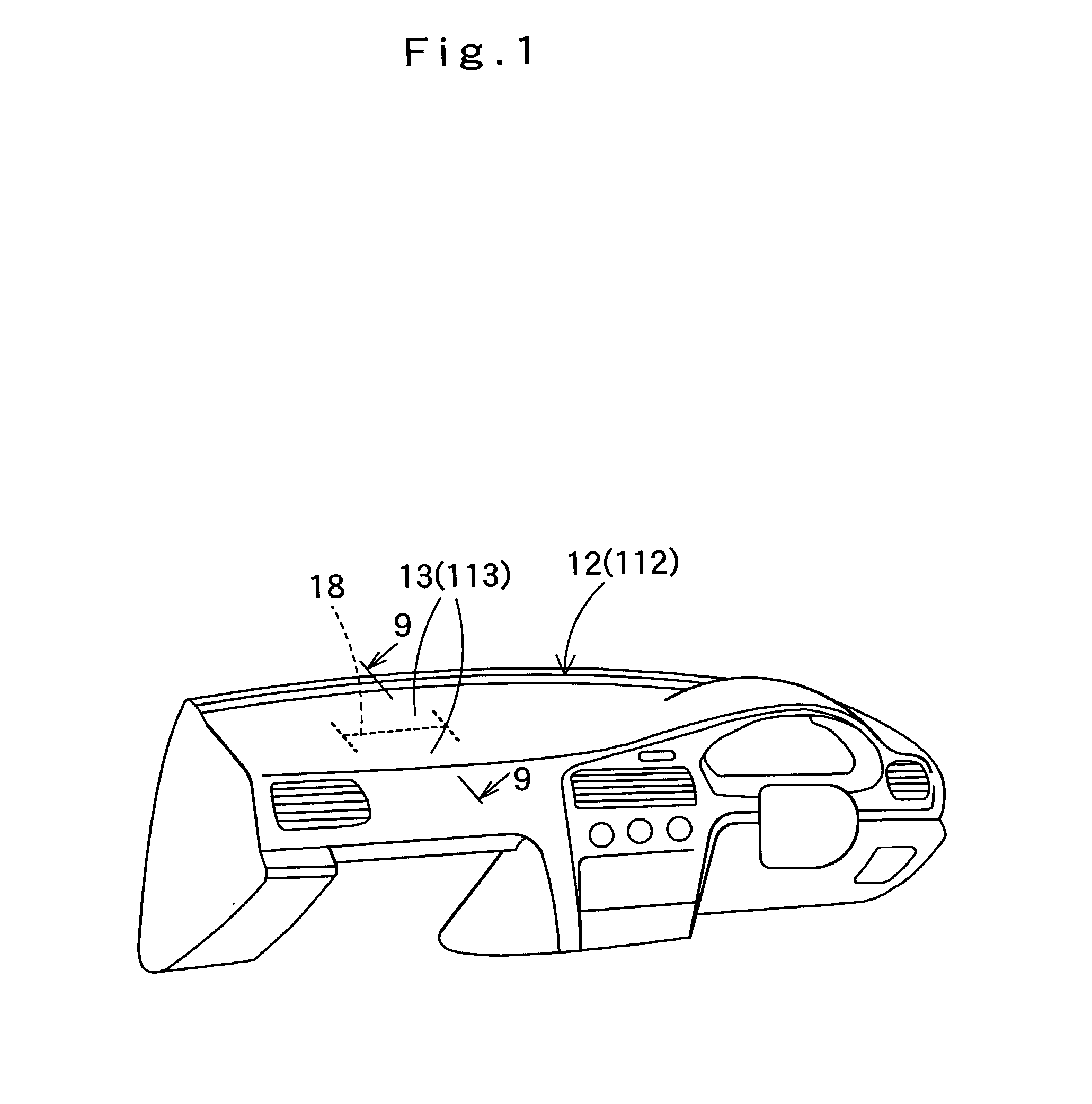

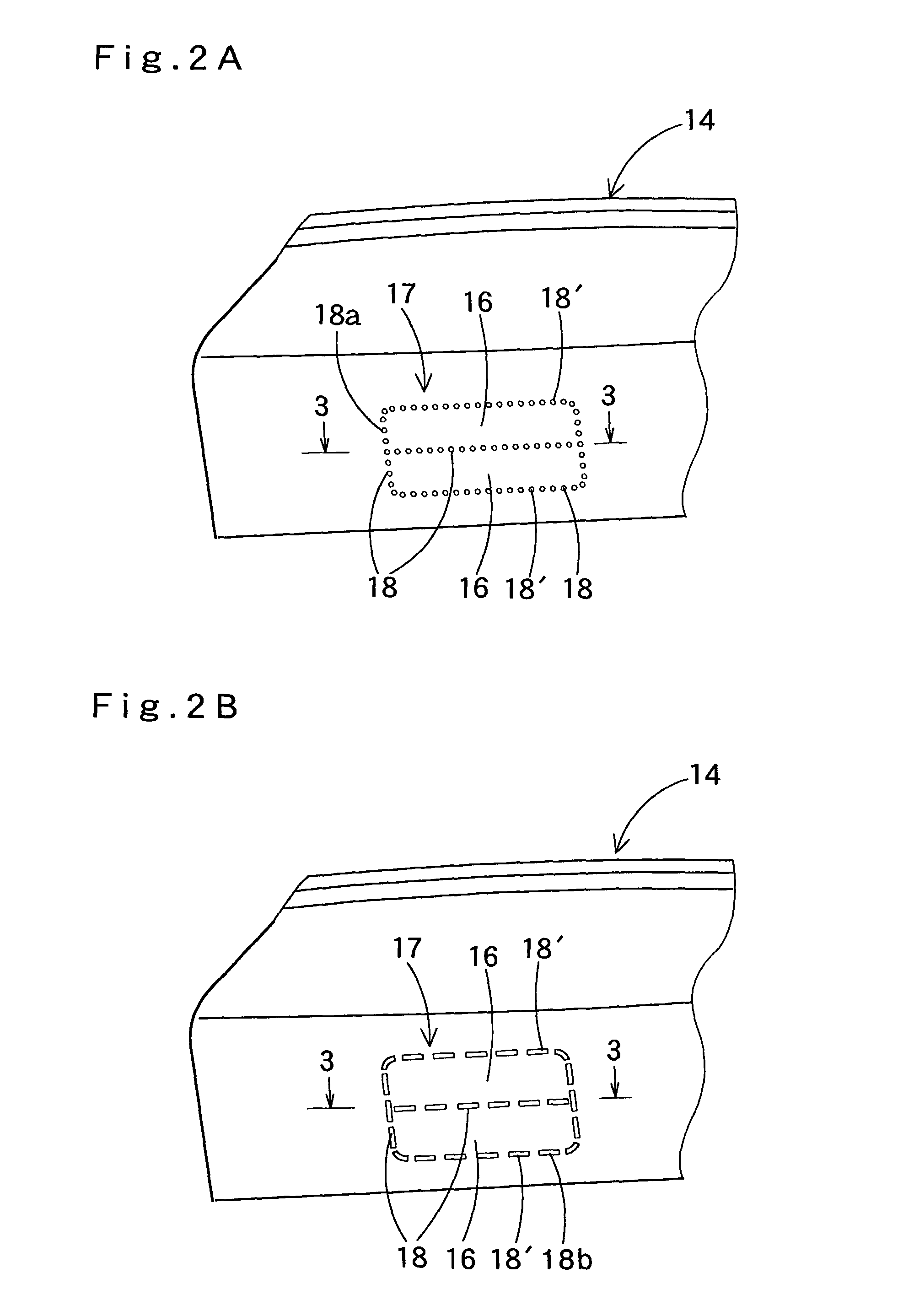

Method for manufacturing automobile interior article

InactiveUS20030020202A1Poor reproductionImprove productivityButtonsMouldsEngineeringAirbag deployment

A method for forming tear lines in the rear side of an automobile interior article having a cover portion being developed from which an airbag inflates. When either an automobile interior article body having an integrally molded surface portion or an automobile interior article surface portion is to be molded, the mold is opened after tear line forming projections are moved forward and backward with the mold closed. Thus, the tear lines can be formed at the molding time without any visible extrusion marks of the tear line forming projections on the front surface side (the design face).

Owner:TOYODA GOSEI CO LTD

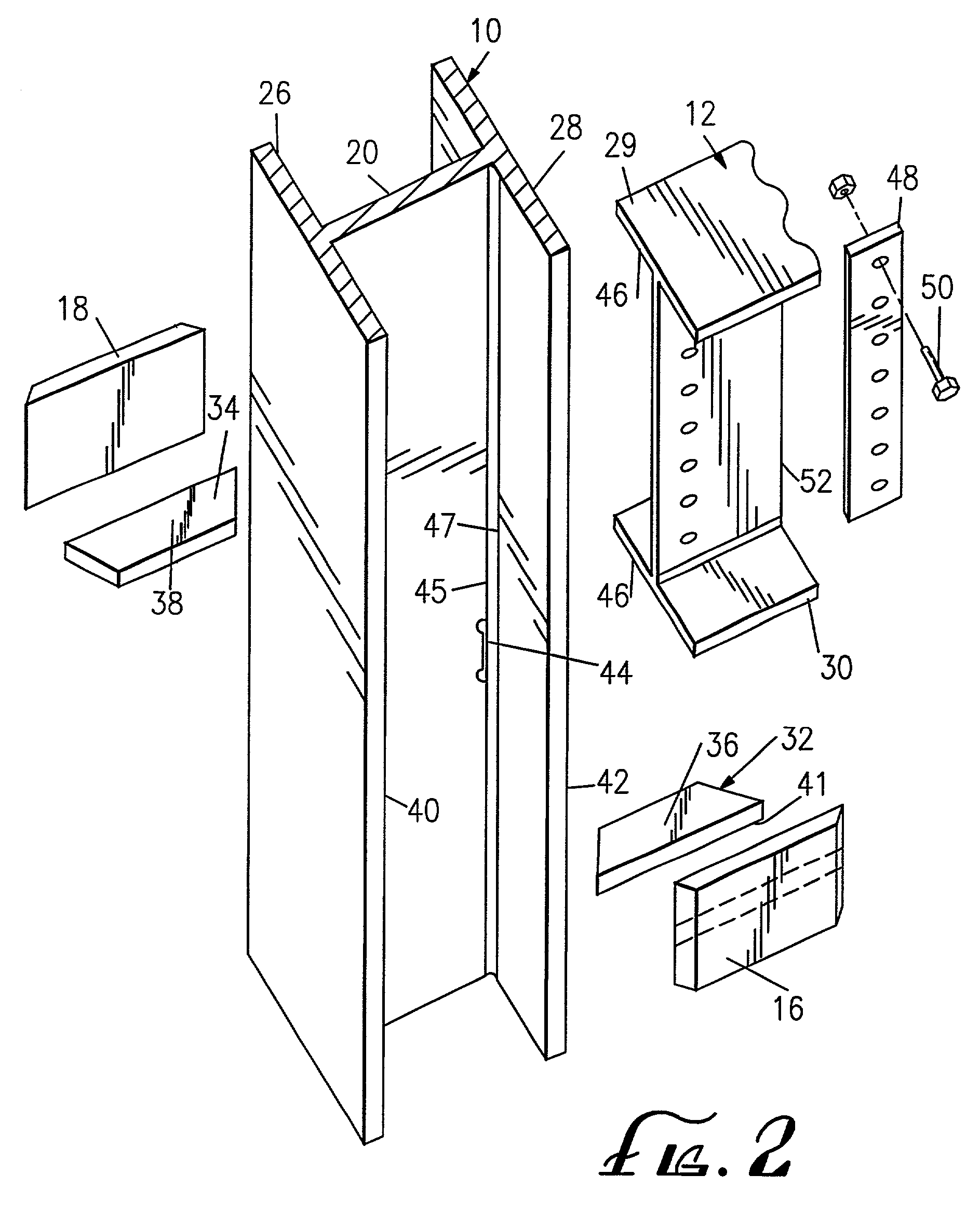

Steel frame stress reduction connection

The present invention provides for improvement of ductility and strength performance of connections in structural steel buildings made typically with rolled structural shapes, specifically in bolted and / or welded beam-to-column connections with welded flanges, by greatly reducing the very significant uneven stress distribution found in the conventionally designed connection at the column / beam weld, through use of slots in column and / or beam webs with or without continuity plates in the area of the column between the column flanges, as well as, optionally, extended shear plate connections with additional columns of bolts for the purpose of reducing the stress concentration factor in the center of the flange welds. Moreover, the slots in beam web adjacent to the beam flanges allow the beam web and flange to buckle independently thereby eliminating the degrading of the beam strength caused by lateral-torsional bucking.

Owner:SEISMIC STRUCTURAL DESIGN ASSOCS

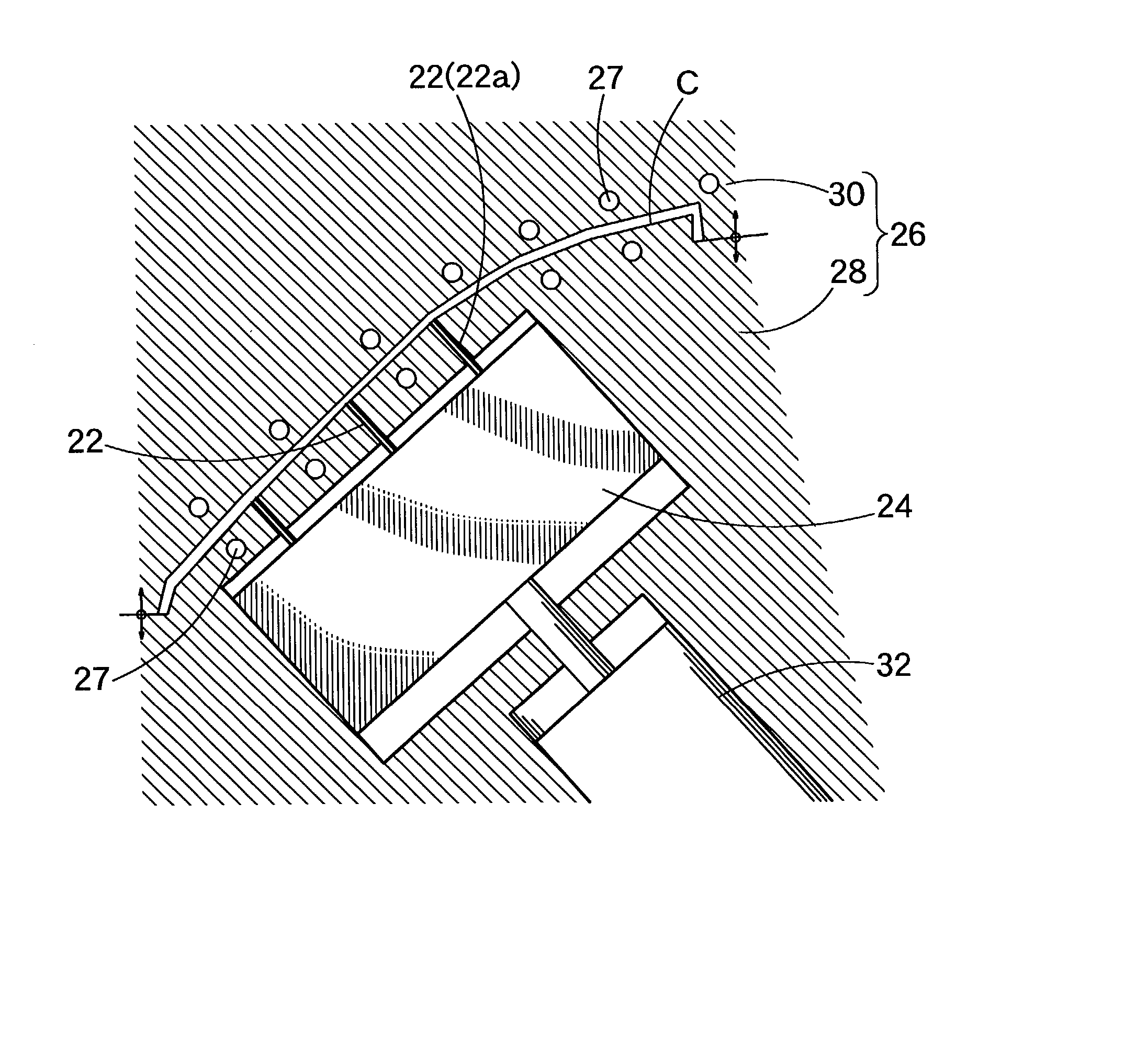

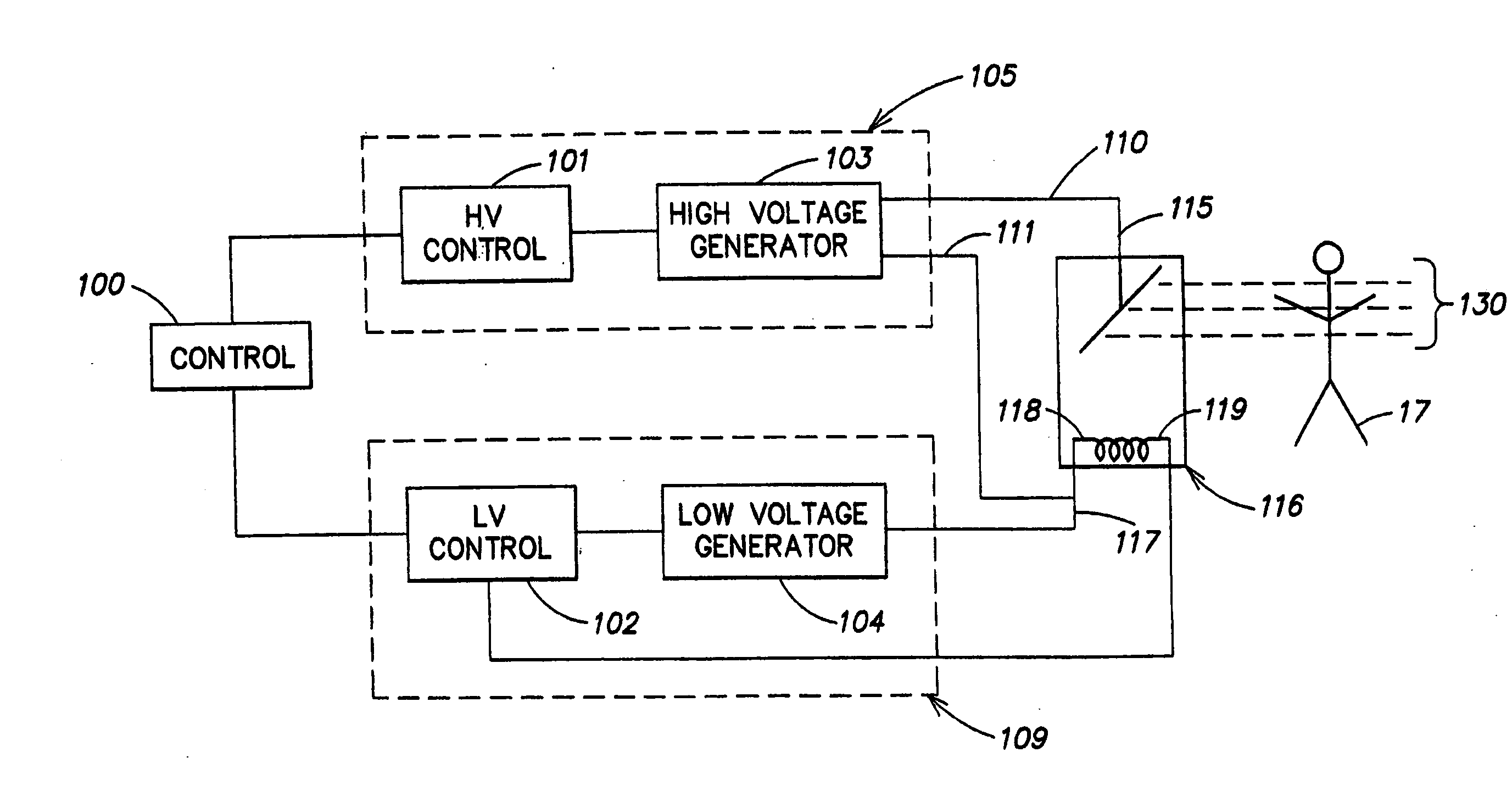

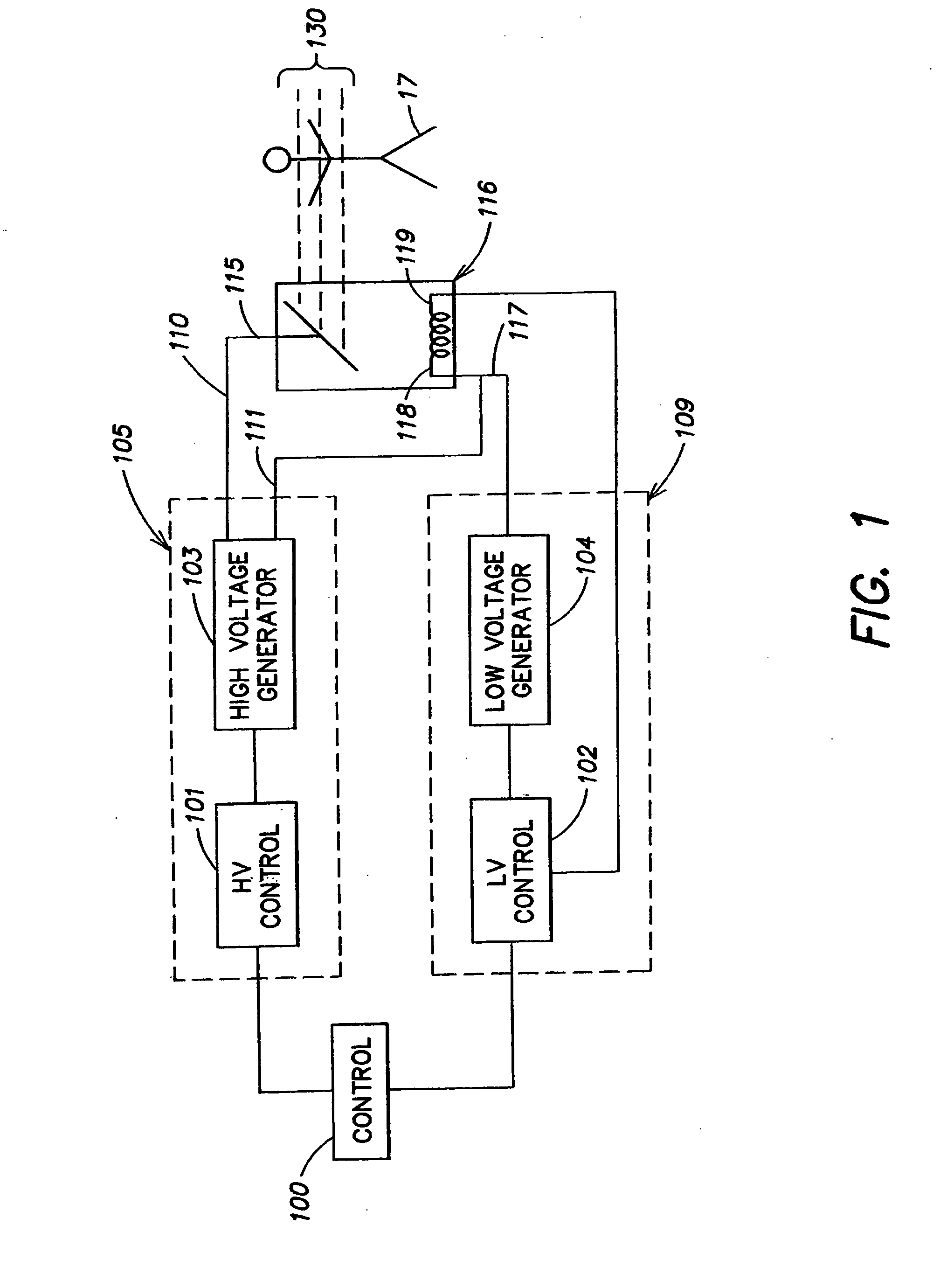

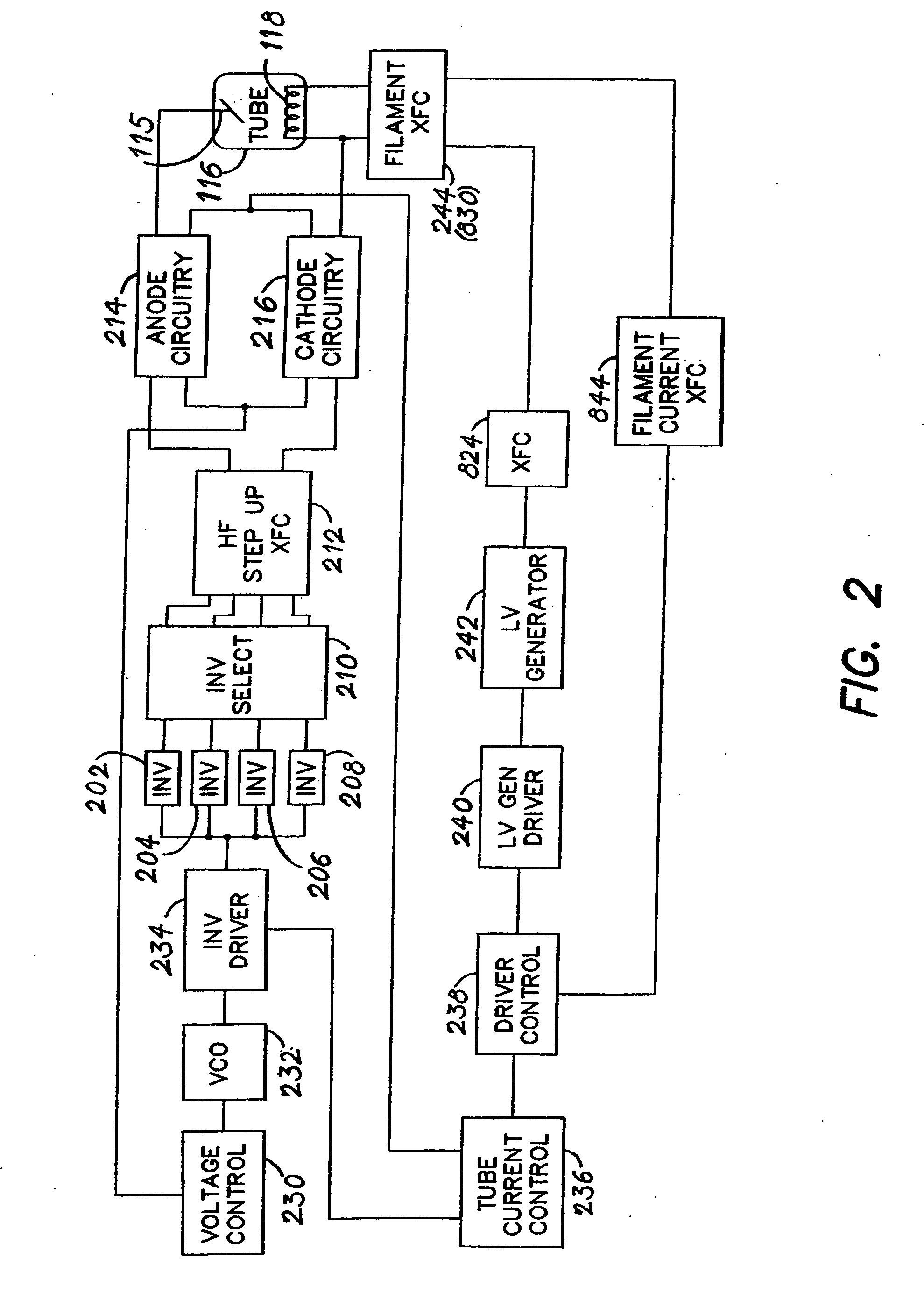

Computed tomography systems

InactiveUS20110002446A1Reduce maintenance costsReduce manufacturing costMaterial analysis using wave/particle radiationRadiation/particle handlingPower inverterComputed tomography

A power delivery system for computed tomography includes at least one transformer (e.g., an isolation transformer, a coupling transformer, an adaptation transformer), a rotary transformer, and at least two power inverters. The rotary transformer includes a stationary winding disposed on a stationary side and a rotational winding disposed on a rotating side. The isolation or adaptation transformer is coupled to the stationary winding or the rotating winding of the rotary transformer. At least two power inverters are constructed and arranged to provide power to the primary winding of the rotary transformer. The high-voltage unit is disposed on the rotating side and connected to receive power from the rotational winding and constructed to provide power to an X-ray source.

Owner:BELAND ROBERT

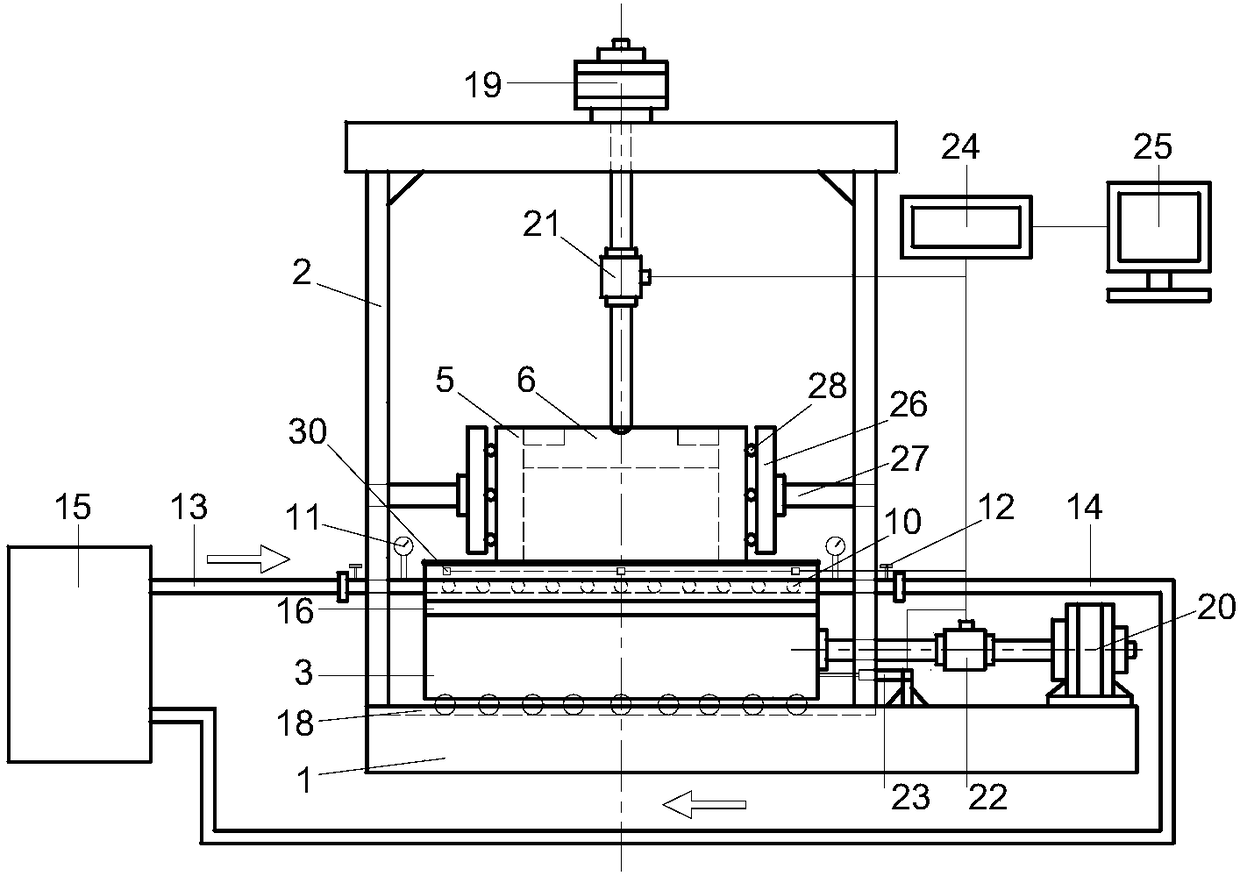

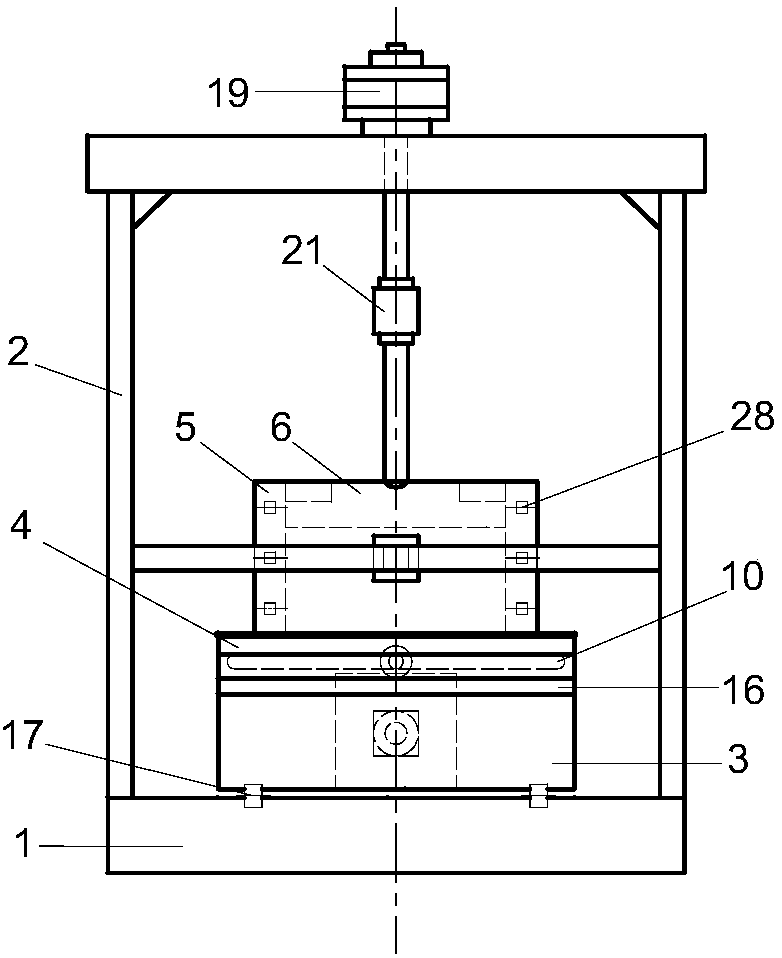

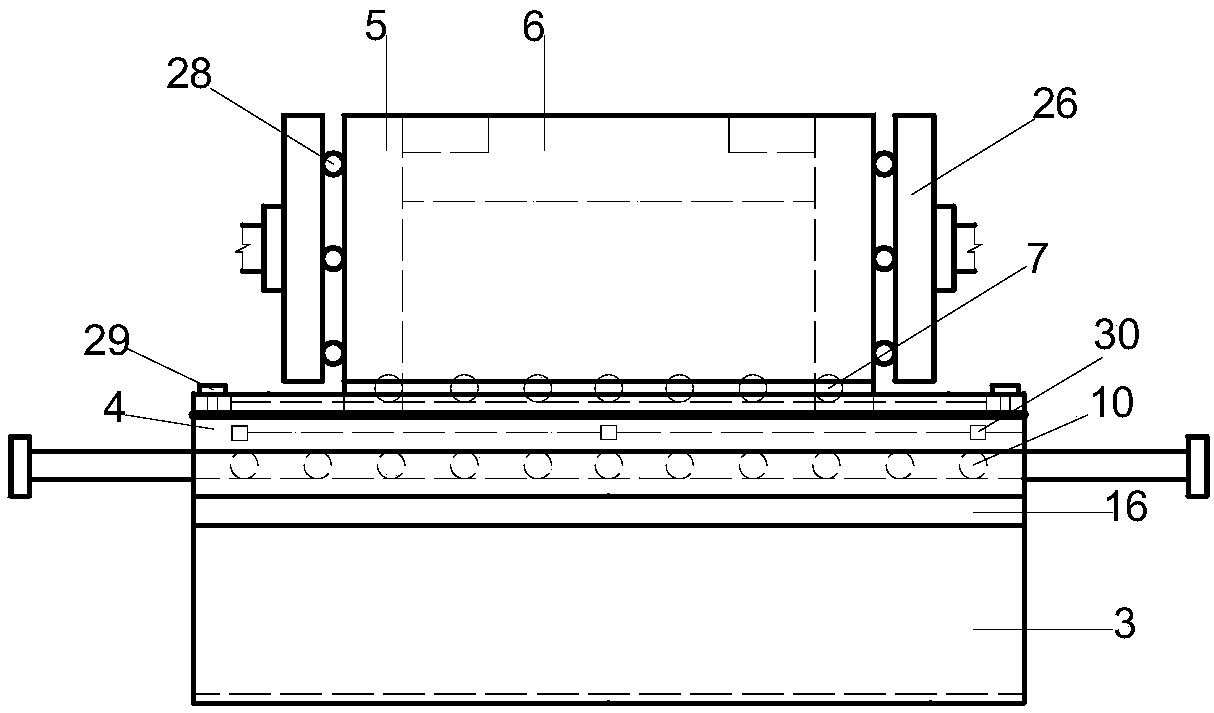

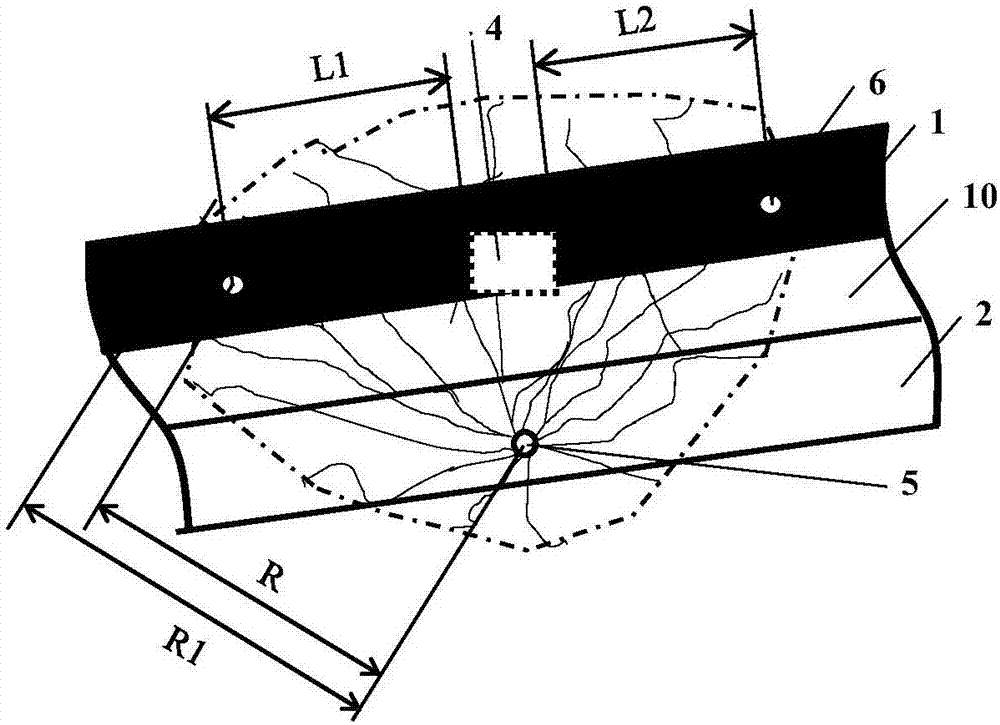

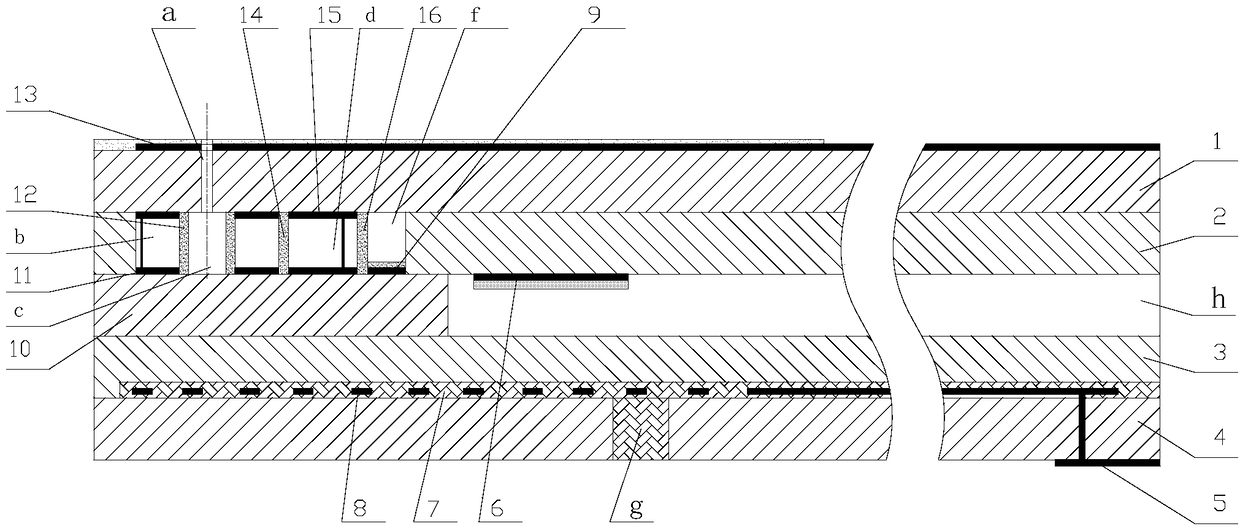

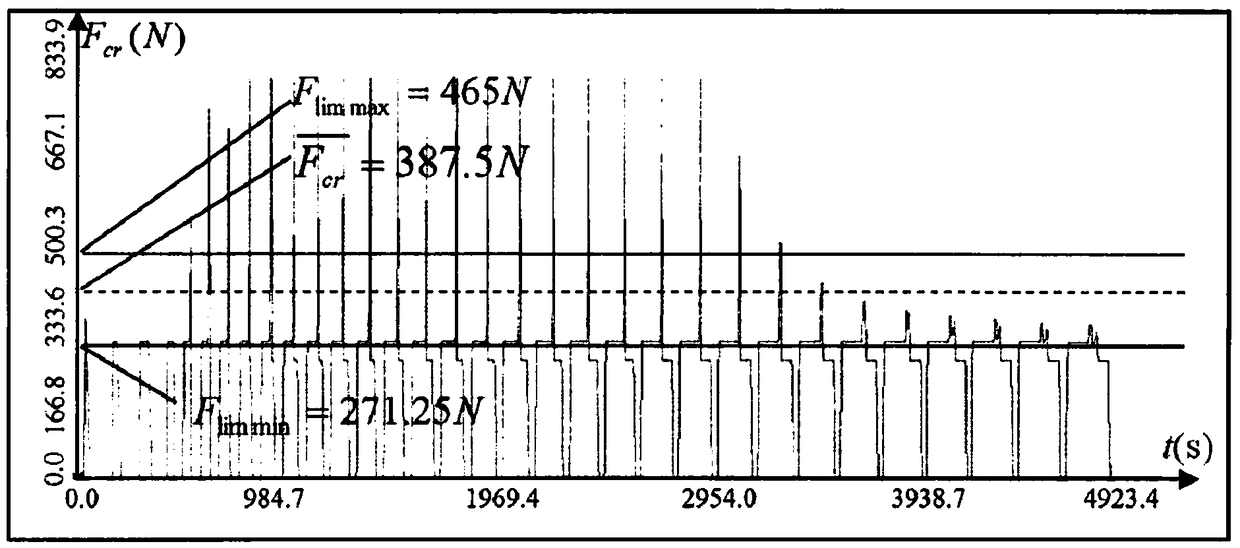

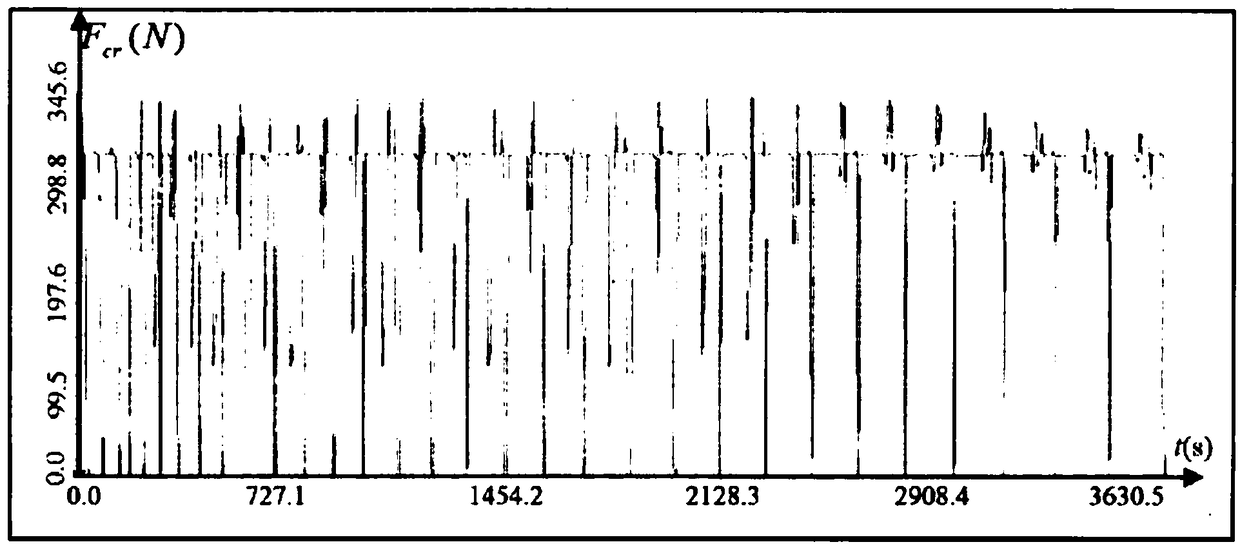

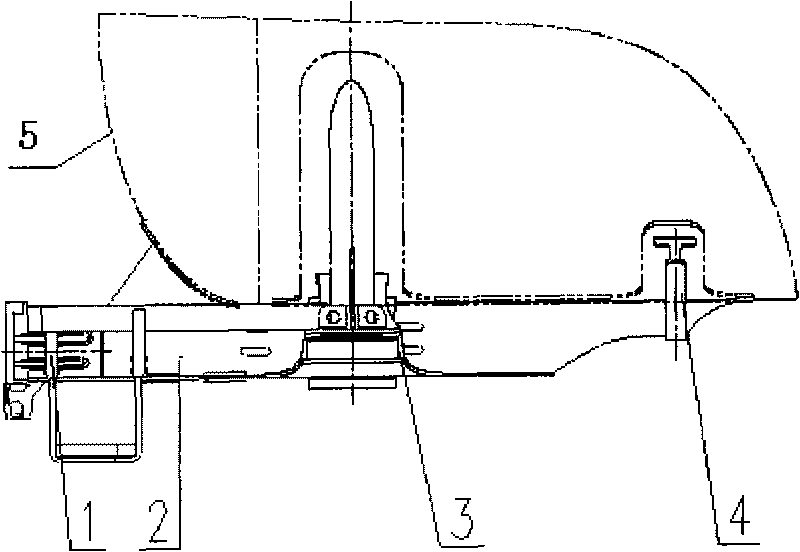

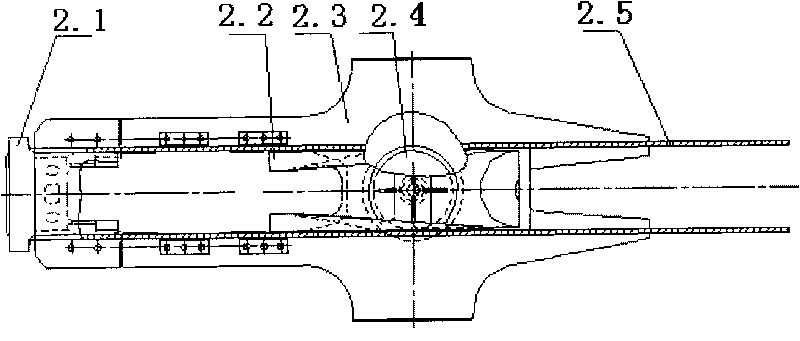

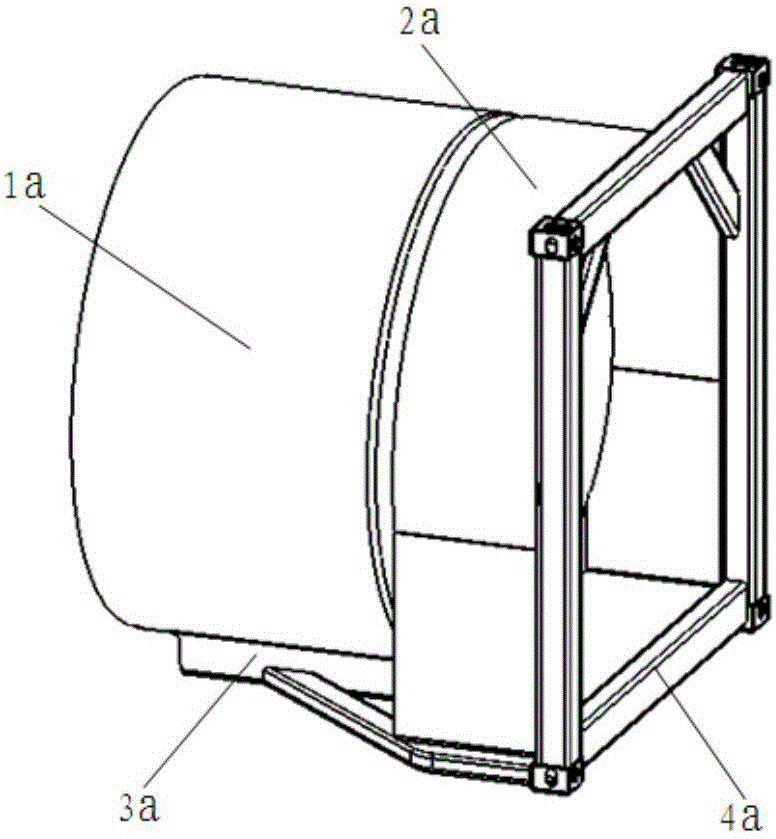

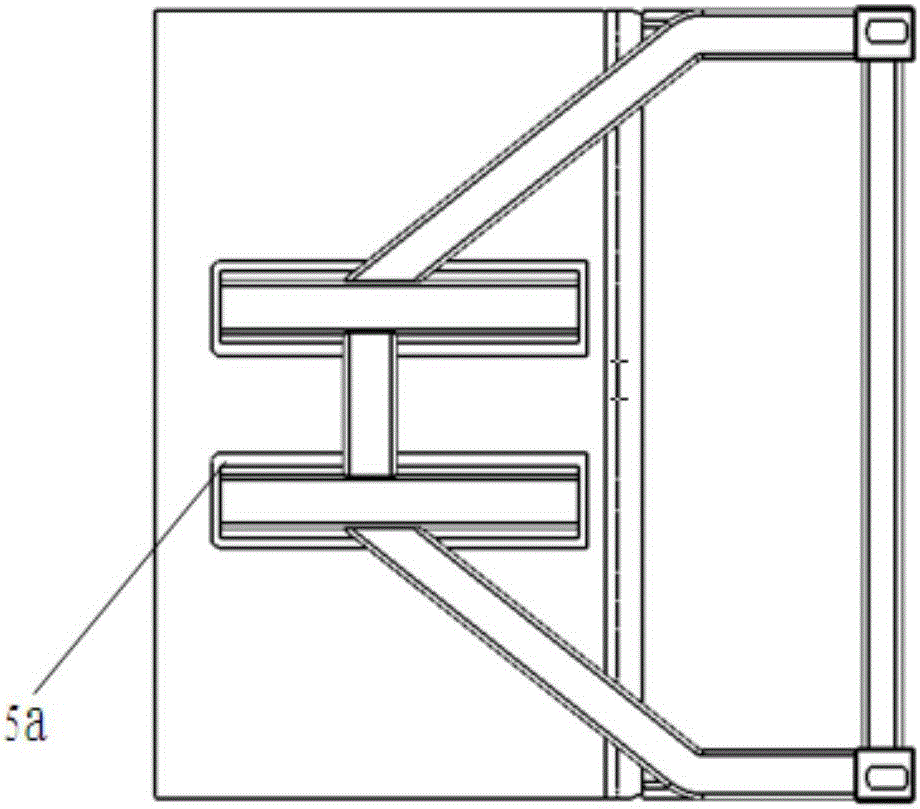

Method for shearing testing apparatus of contact surface of geomembrane and soil with controlled temperature and testing method thereof

ActiveCN108398338AEasy to operateAchieving Shear Strength TestsMaterial strength using steady shearing forcesEngineeringGeomembrane

The invention discloses a method for a shearing testing apparatus of a contact surface of a geomembrane and soil with controlled temperature and a testing method thereof According to the invention, awater-bath pipeline is arranged in a lower shearing box, water temperature can be adjusted on the water-bath pipeline by a water temperature regulating tank, the geomembrane is positioned under different test temperatures, temperature change of the usage environment of the geomembrane can be simulated, and the testing for the shearing intensity of the contact surface of the geomembrane and the soil under different temperatures is realized; according to the testing method, a change curve of the shearing intensity of the contact surface of the geomembrane and the soil with shear displacement under same normal stress and different ambient temperatures can be measured, a change curve of the shearing intensity of the contact surface of the geomembrane and the soil with shear displacement underdifferent normal stress and different ambient temperatures can be measured, and the difference of the shearing intensity of the contact surface of the geomembrane and the soil is obtained. During testing, the temperature setting, loading applying, shearing displacement and shearing rate setting, and data acquisition are completed by arrangement of a computer, and the operation is convenient and easy to carry out.

Owner:HOHAI UNIV

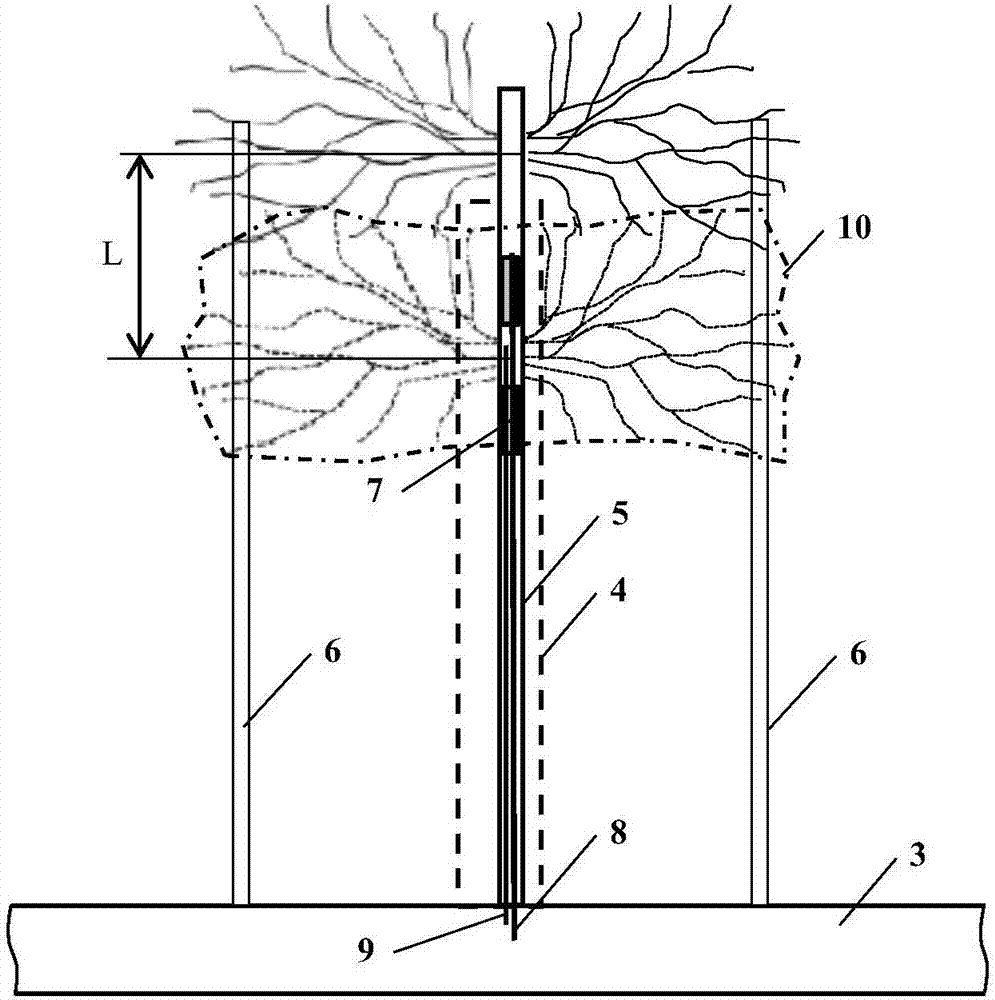

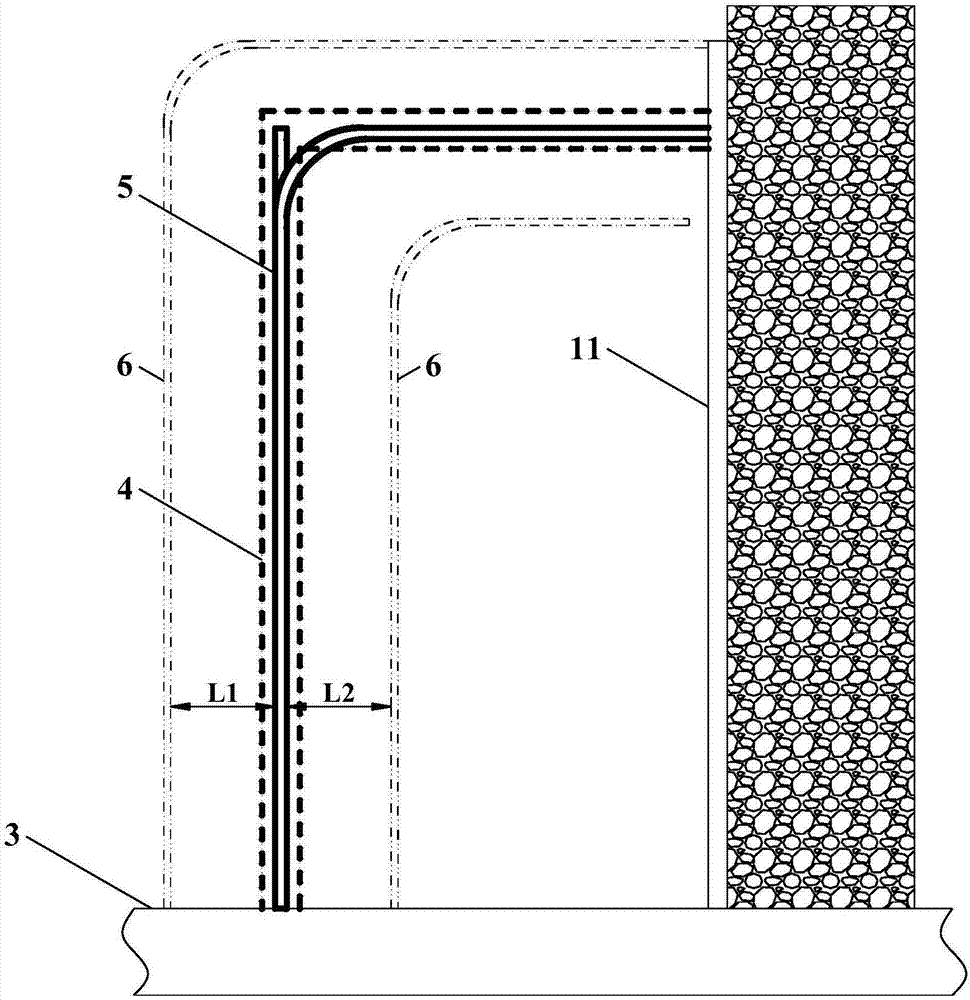

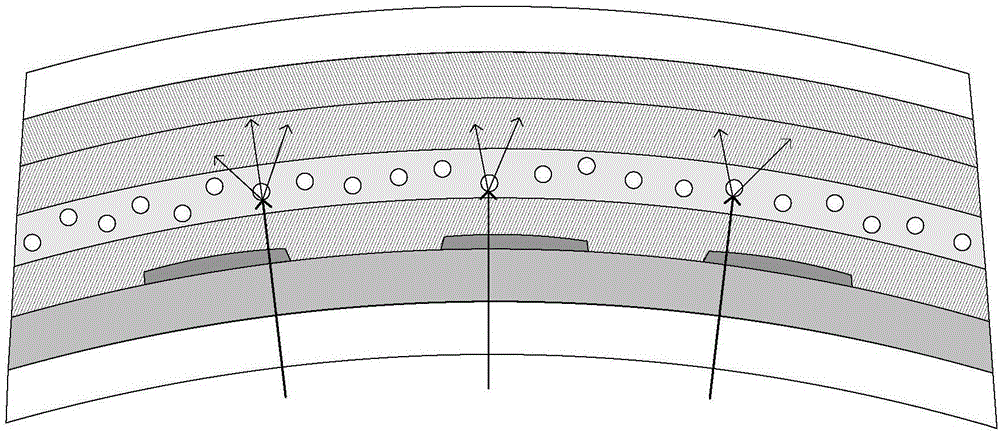

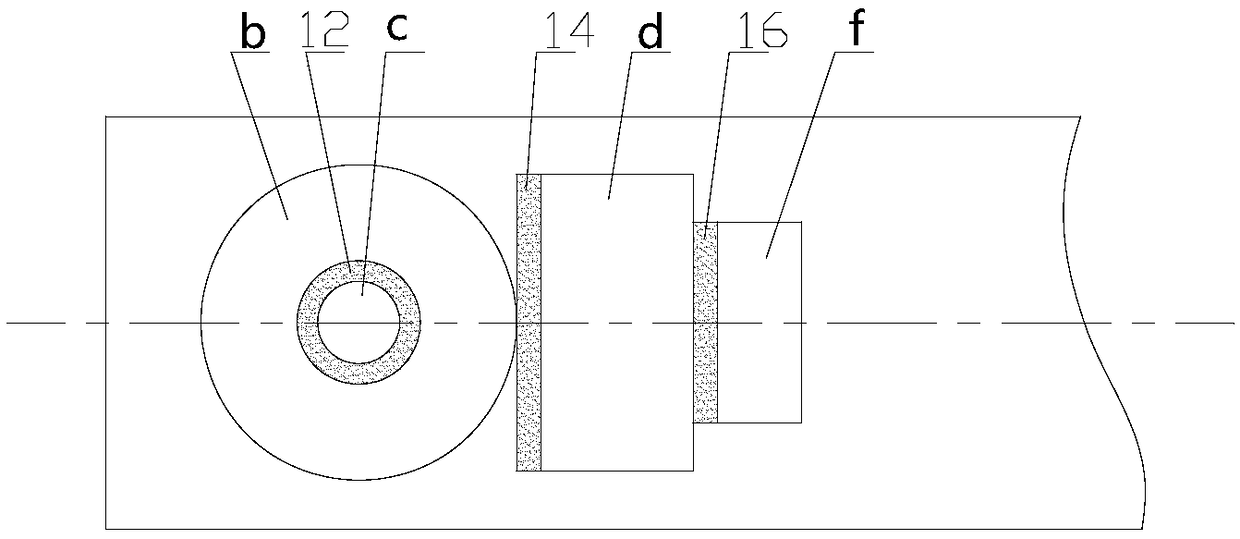

Method for gas drainage and regional outburst elimination of coal roadway strips by staged fracturing and along seam long borehole drilling in floor strata

ActiveCN106907175ANo increase in roadway engineering volumeReduce the amount of drilling workFluid removalGas removalCoalStandard time

The invention provides a method for gas drainage and regional outburst elimination of coal roadway strips by staged step-by-step fracturing and along seam long borehole drilling in a floor strata. The method is suitable for being applied to coal roadway excavating region outburst elimination, backstoping region outburst elimination and other projects. Along seam long boreholes are drilled in the hard floor strata with outburst-hazard coal seams in an existing roadway along the to-be-excavated coal roadway direction, staged step-by-step fracturing is conducted, fracturing holes are used for segmental drainage or the whole drainage, and outburst elimination is conducted on the coal roadway strips; according to the drainage amount, exhausting and mining standard evaluation is conducted, after exhausting and mining reach the standard, boreholes are drilled in the coal seams at the boundaries, in the range of regions adopting effective outburst prevention measures, on the two sides of the coal roadway, regional outburst prevention measure effect checking is conducted, drainage is then conducted, and coal roadway excavating is conducted when regional checking measures and local four-in-one measures are implemented. The method has the advantages that boreholes replace the roadway, drilling project amount is less, the fracturing range is large, the fracturing region surrounding coal stress concentration degree is low, stress relieving and permeability improving effects are good, exhausting and mining up-to-standard time is short, the coal parameter adaptability is high and the application range is wide.

Owner:CHINA UNIV OF MINING & TECH

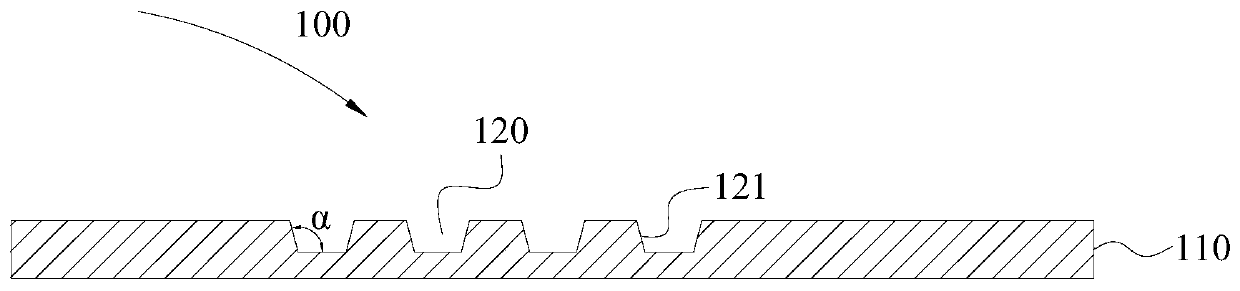

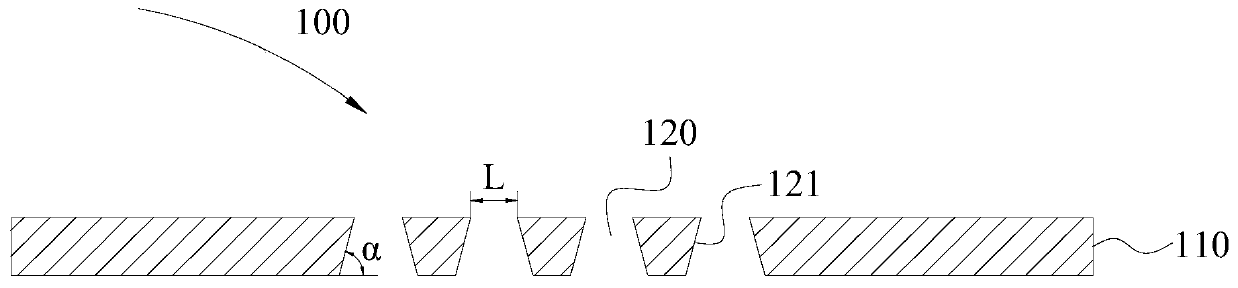

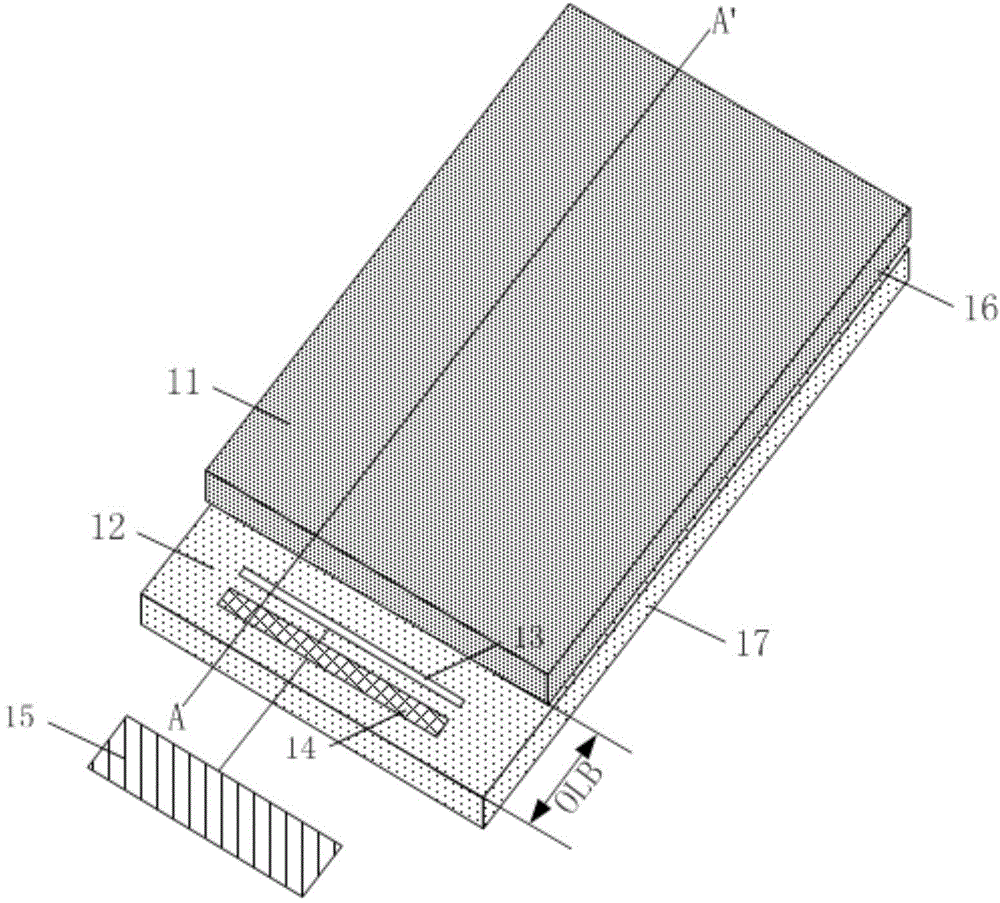

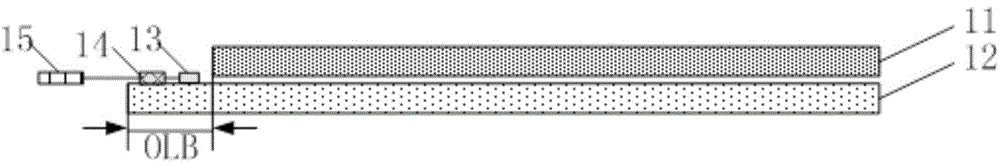

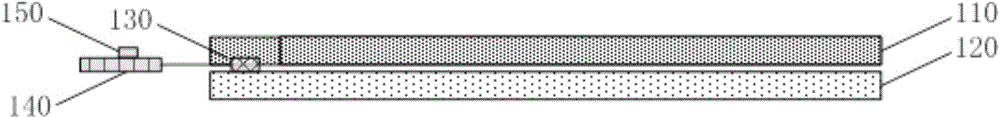

Foldable electronic paper display device and manufacturing method thereof

The invention discloses a foldable electronic paper display device and a manufacturing method of the foldable electronic paper display device. The foldable electronic paper display device comprises anelectronic paper display panel and a rear protection plate, wherein the electronic paper display panel is provided with a bent area and two plane areas respectively being adjacent to two edges of thebent area. When the electronic paper display panel is folded, the two plane areas are approximately parallel to each other. The rear protection plate is positioned on the back of the electronic paperdisplay panel, and is positioned in the plane areas and the bent area. The rear protection plate is provided with at least one groove, the at least one groove is at least partially positioned in thebent area, and the width of the at least one groove is smaller than that of the bent area. The rear protection plate is provided with the at least one groove positioned in the bent area, therefore, the internal stress between the layers can be reduced in the bent area with large strain differences, and thus the rear protection plate is prevented from being separated from the back of the electronicpaper display panel.

Owner:E INK HLDG INC

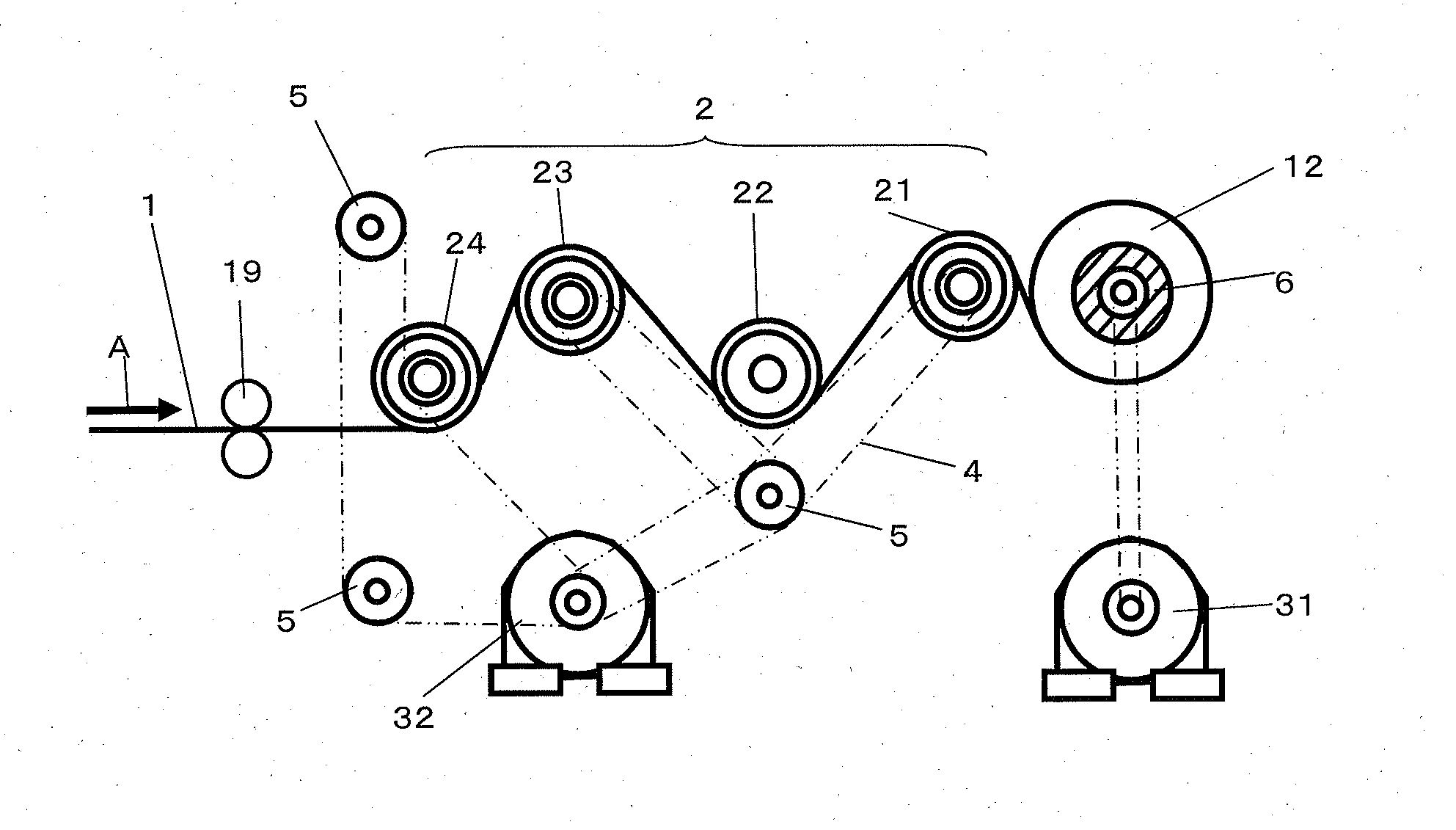

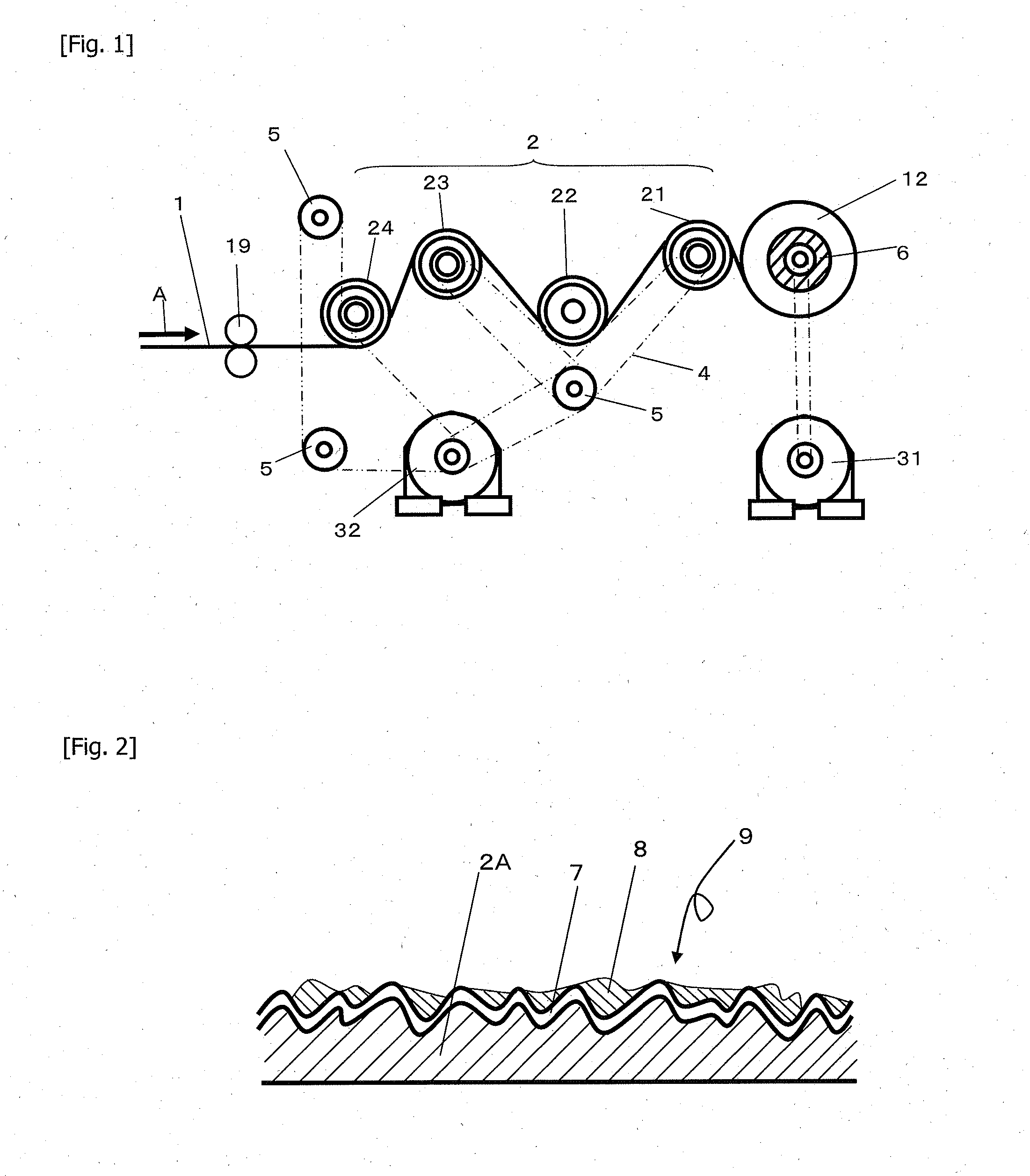

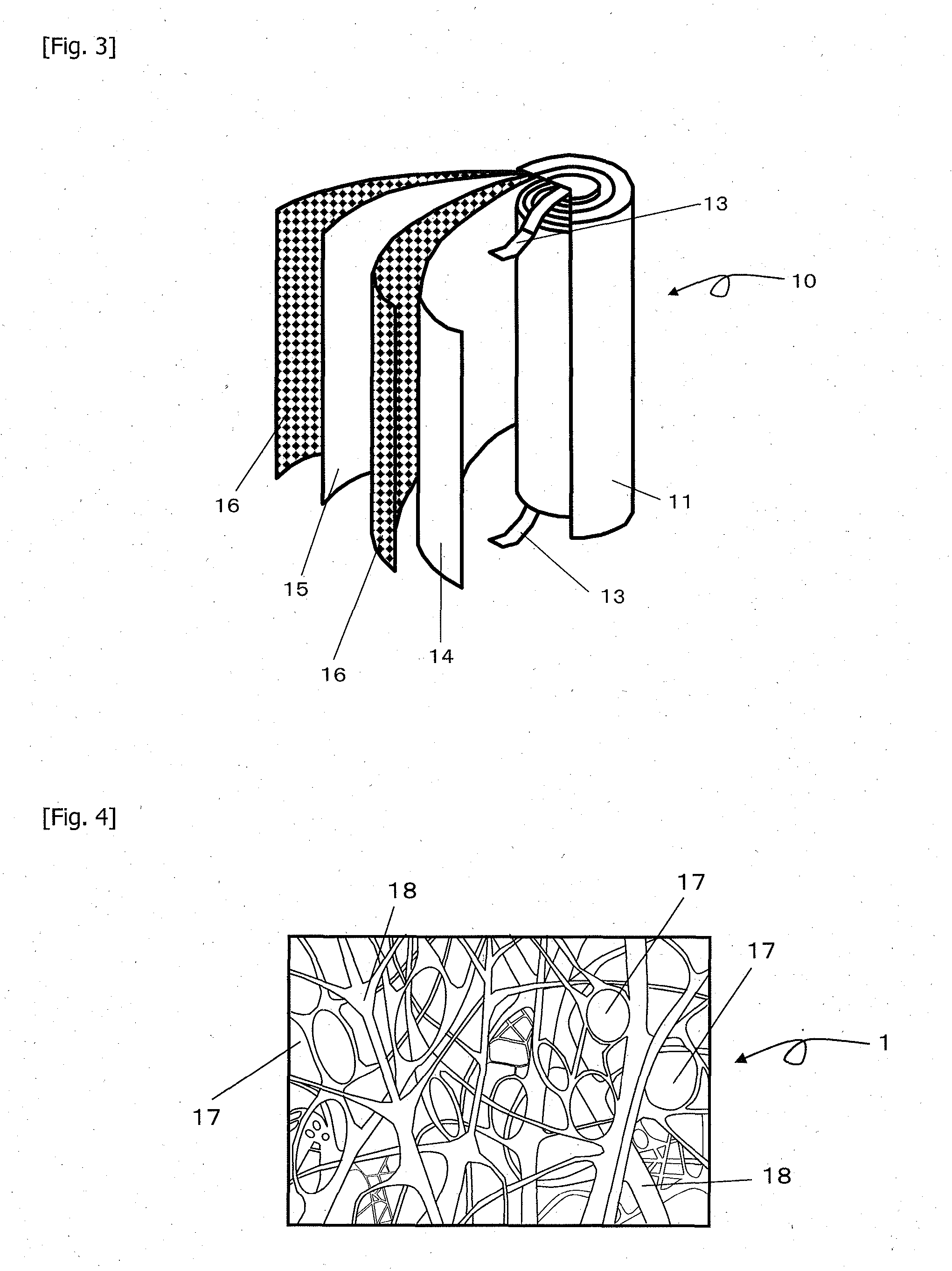

Process for producing roll of microporous plastic film

InactiveUS20140014762A1Lower average tensionPrevent from being easily brokenHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersMicrocellular plasticSurface roughness

A microporous plastic film roll production method, comprising the steps of: conveying microporous plastic film having through-holes in its interior by using a plurality of conveyance rollers at least one conveyance roller of which has a surface roughness RzJIS (μm) of 0.3≦RzJIS≦30 and has a surface made of fluorine resin, silicone rubber, or a composite material containing one of them; and winding it up in a roll.

Owner:TORAY IND INC

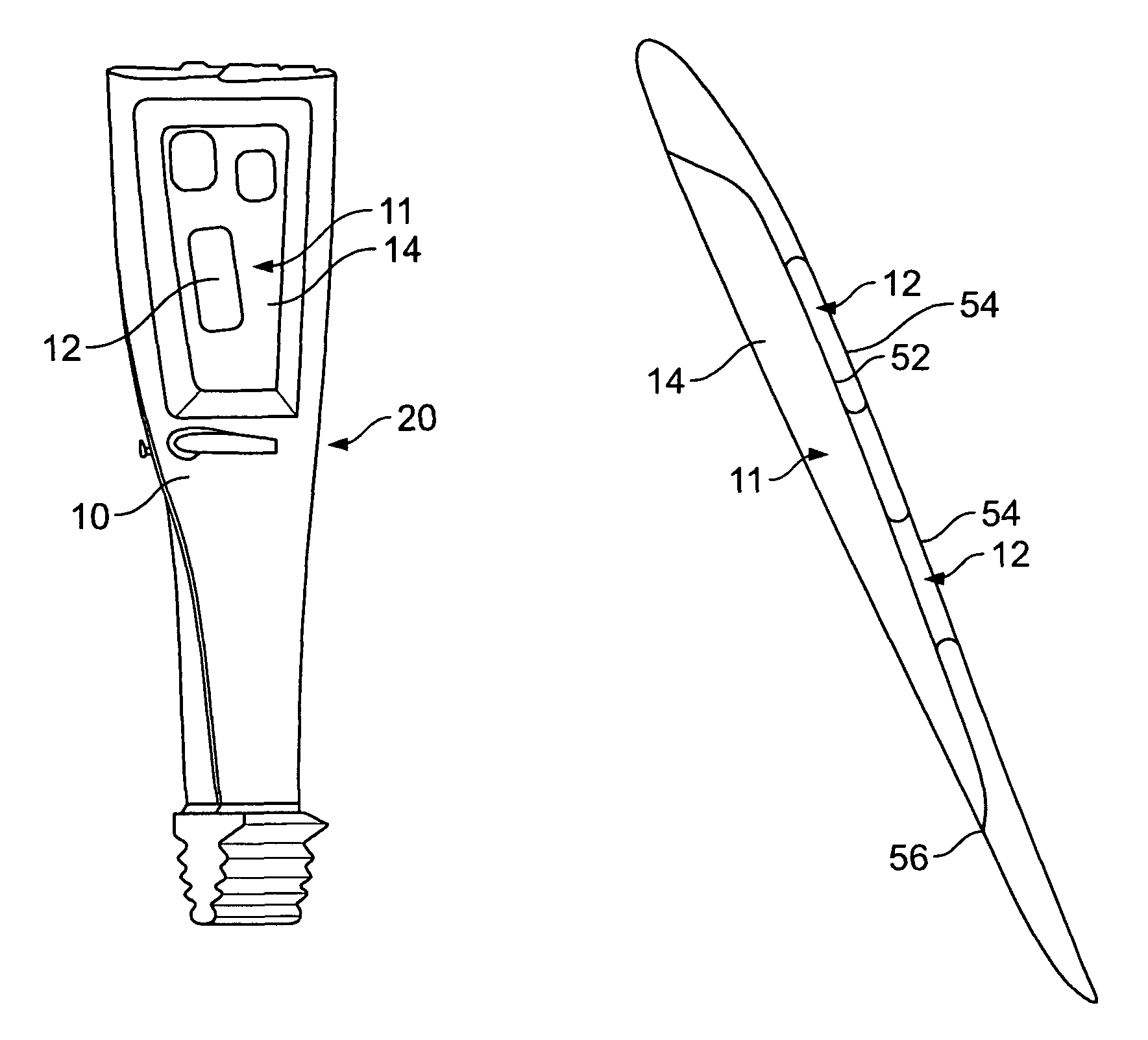

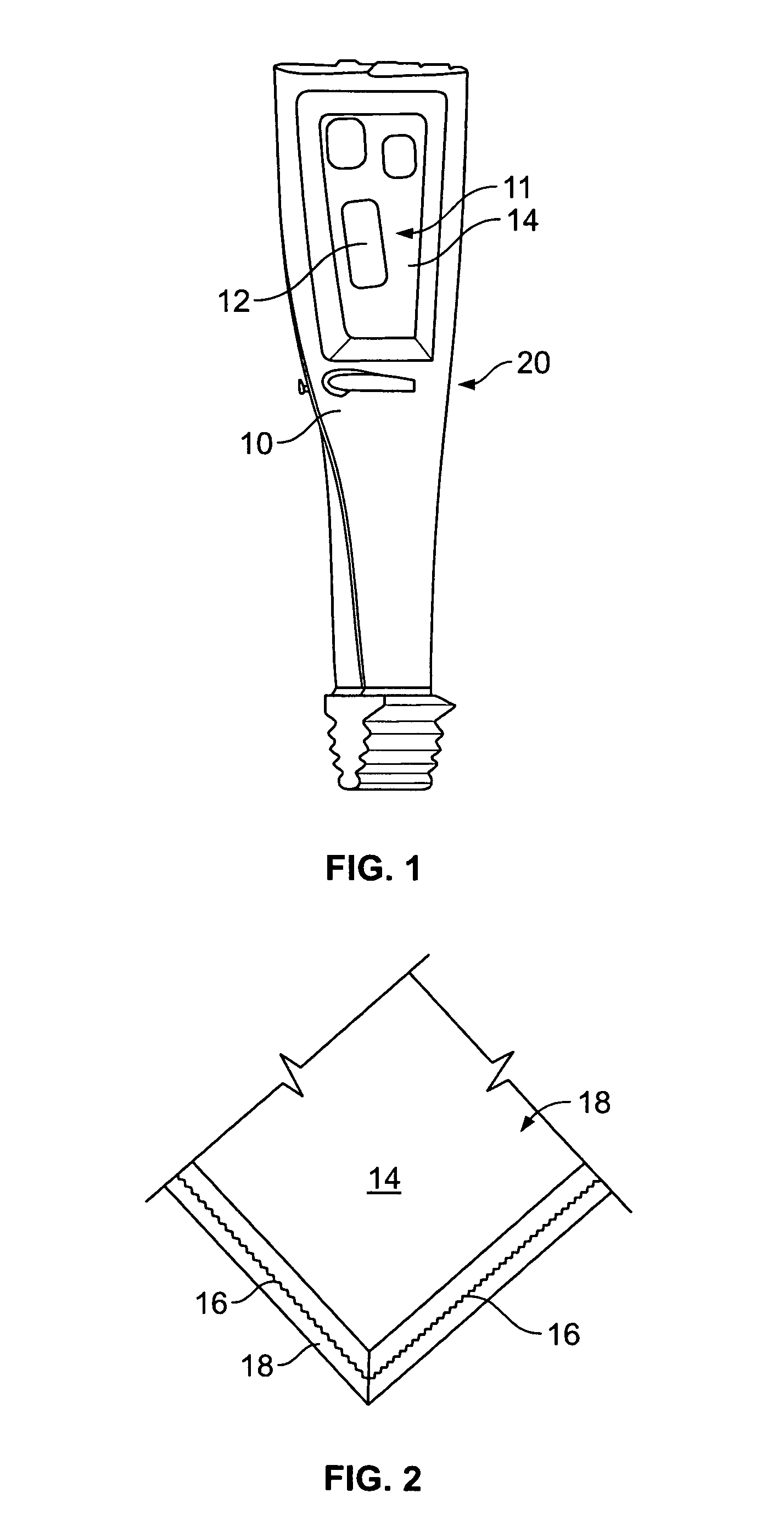

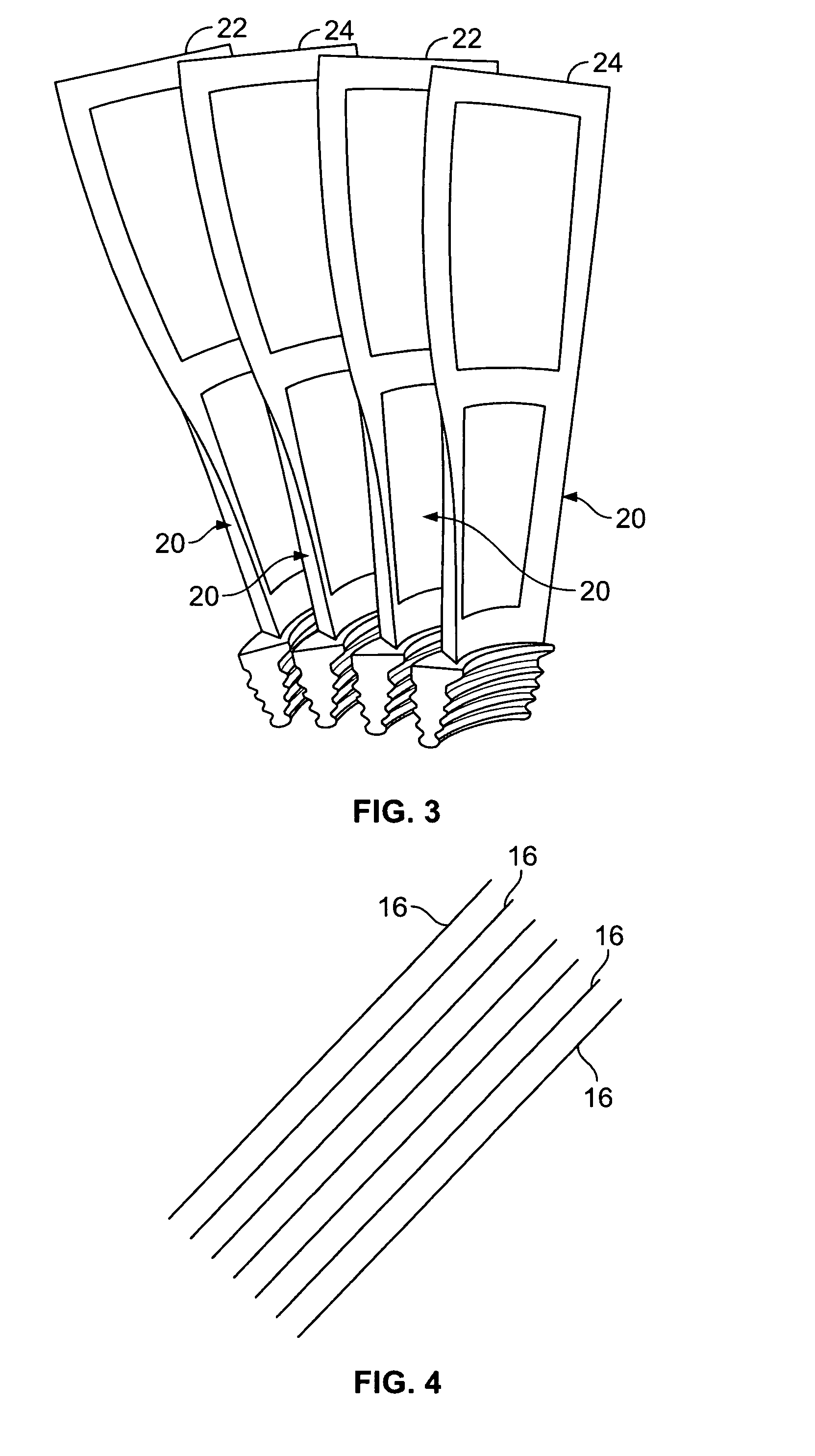

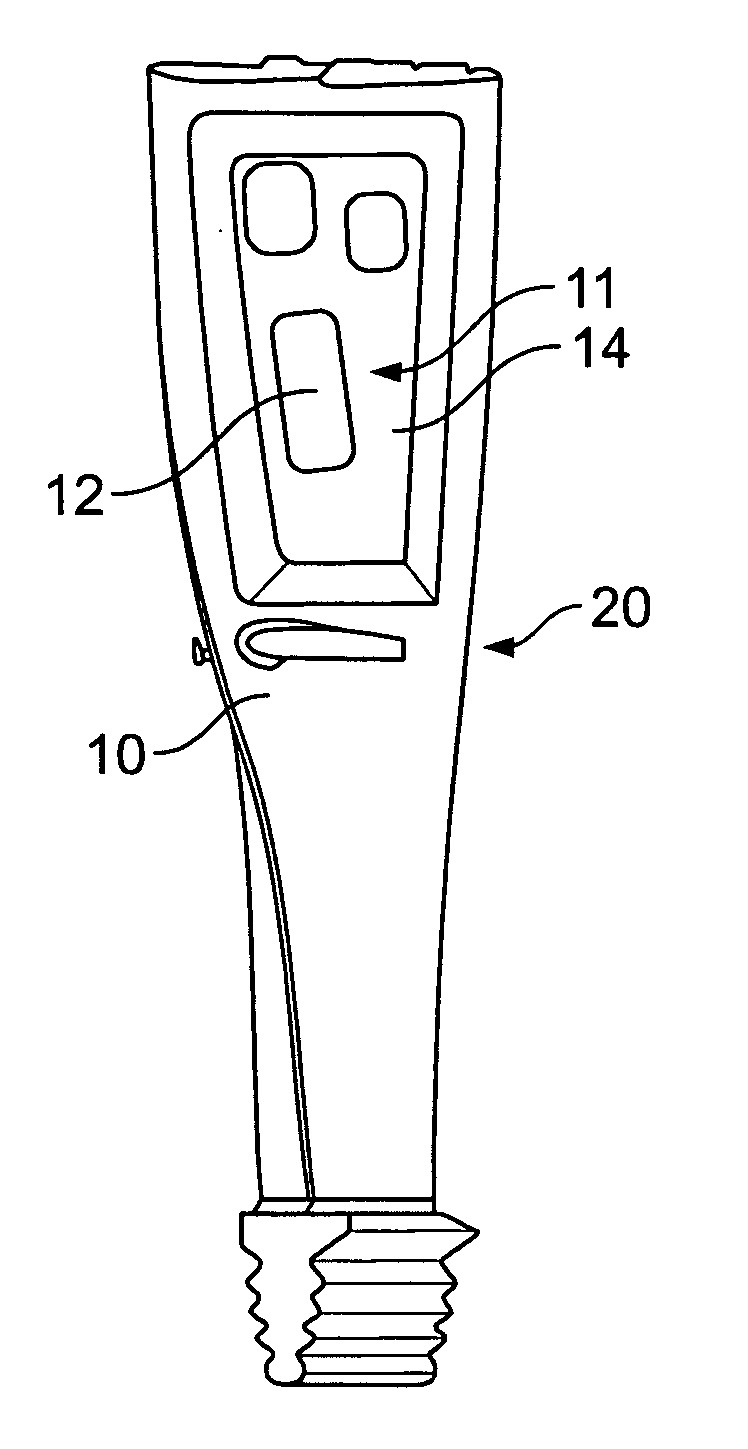

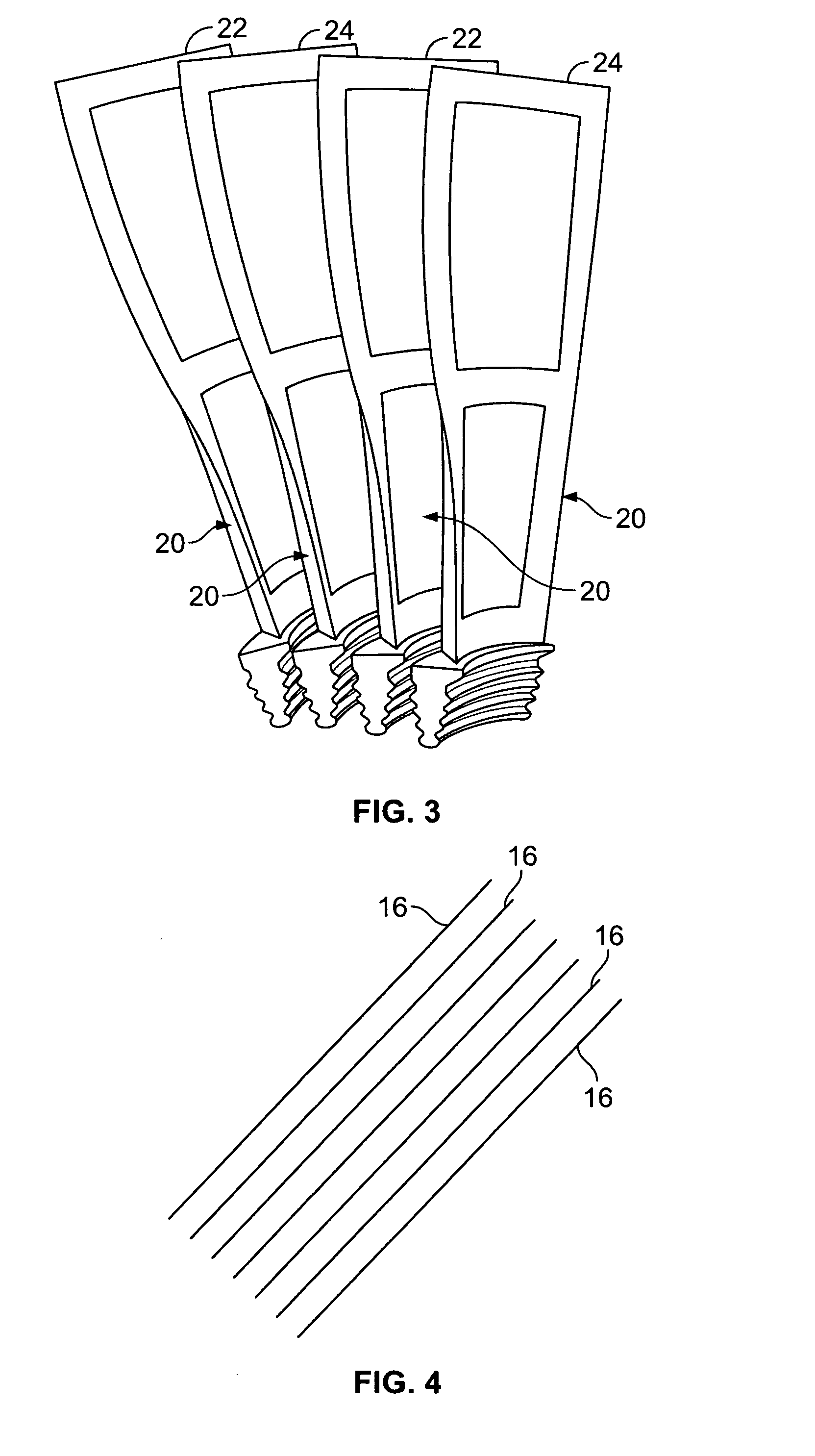

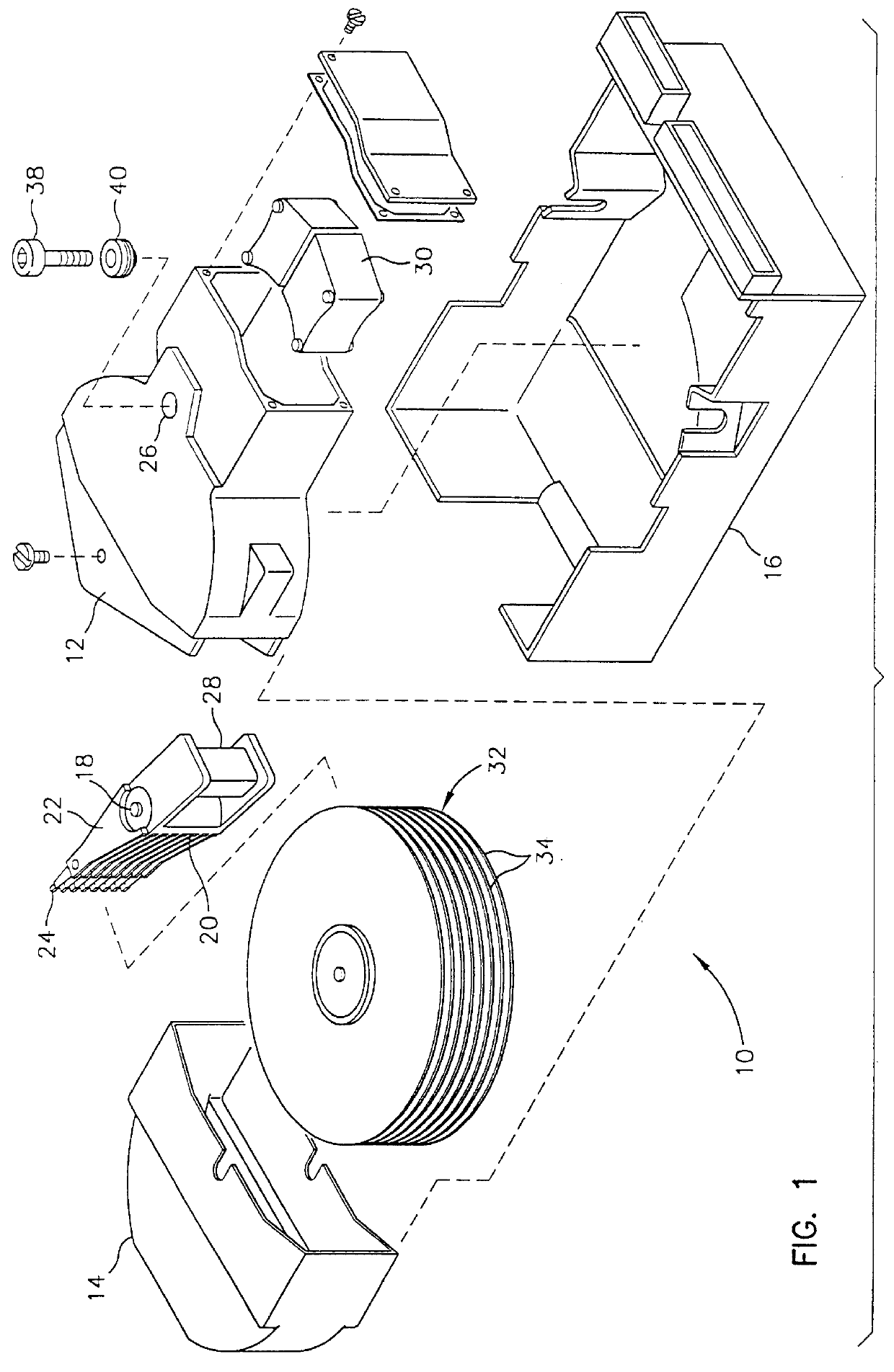

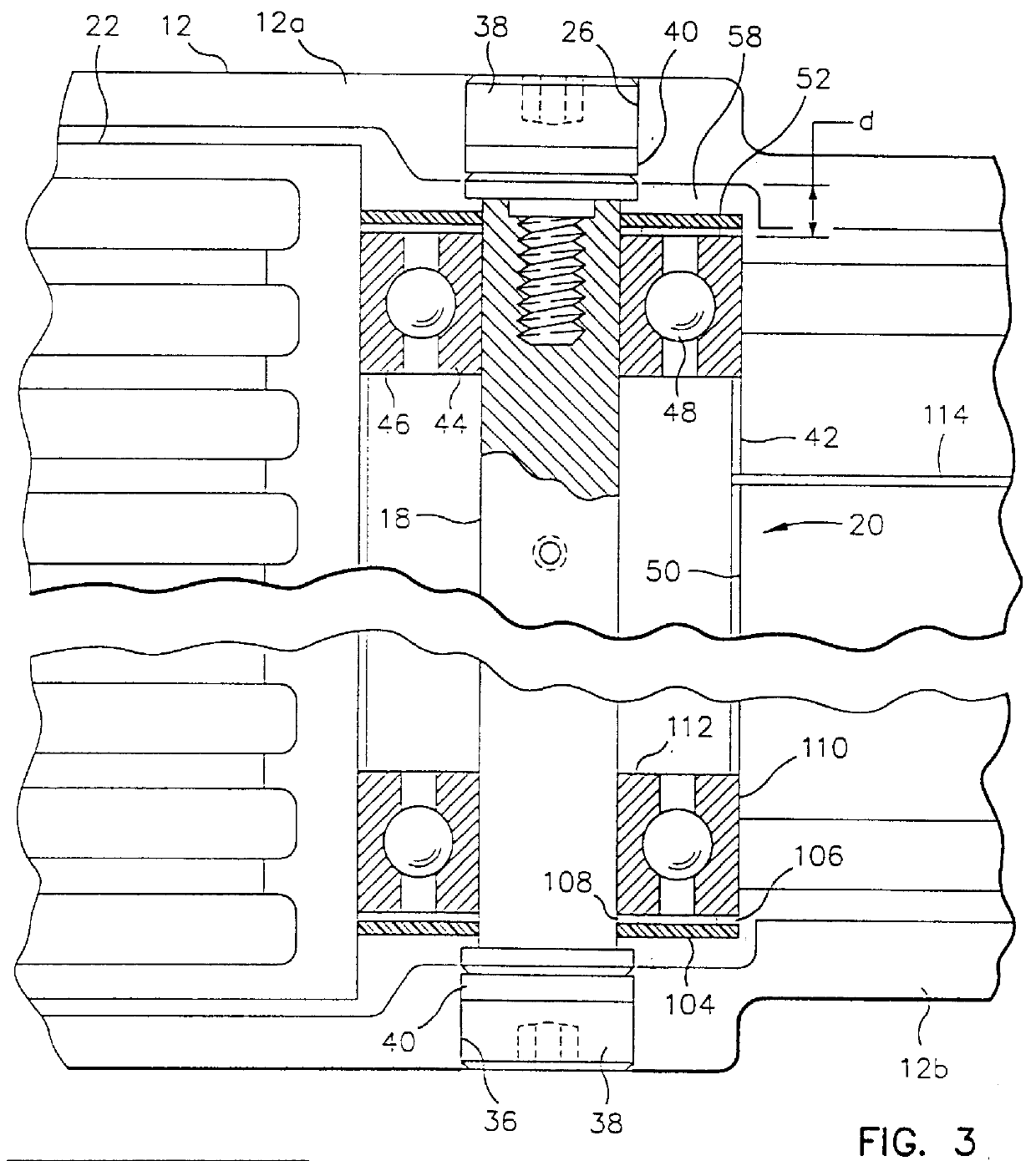

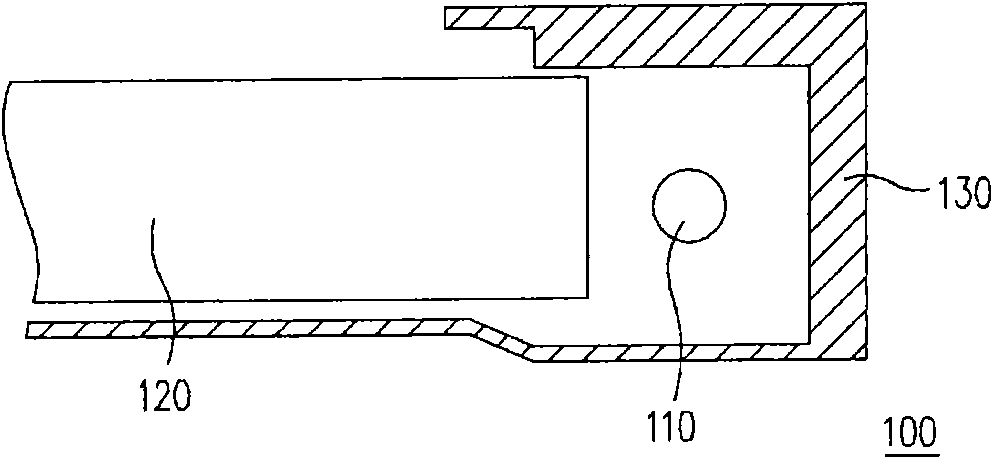

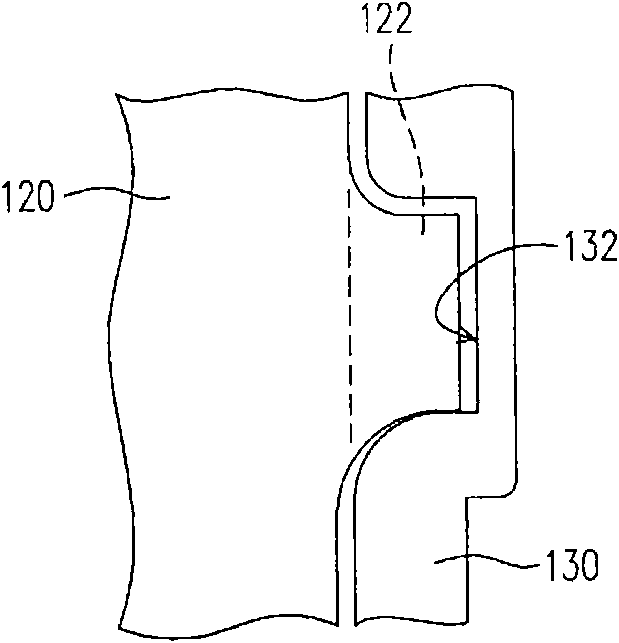

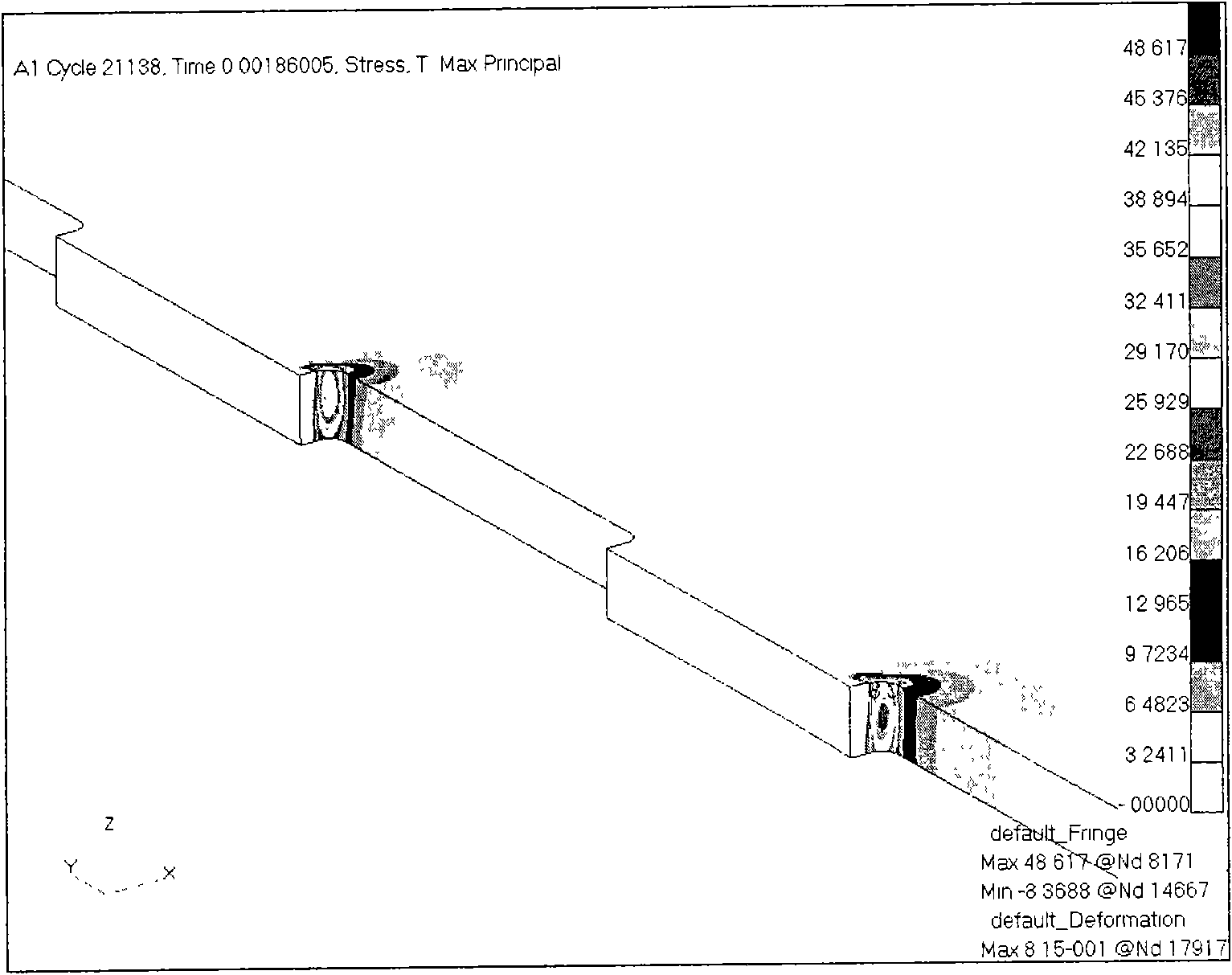

Methods and apparatus for reducing stress in turbine buckets

InactiveUS7766625B2Relieve pressureImprove stress concentrationPropellersPump componentsFiberResin matrix

A method facilitates reducing stress in a turbine bucket including a metallic base metal. The method comprises providing a turbine bucket including at least one pocket formed therein, and filling at least one pocket defined in the bucket with a polymer composite having continuous fibers oriented in a resin matrix, such that the fibers have an orientation determined in accordance with a pre-selected frequency tuning of the bucket.

Owner:GENERAL ELECTRIC CO

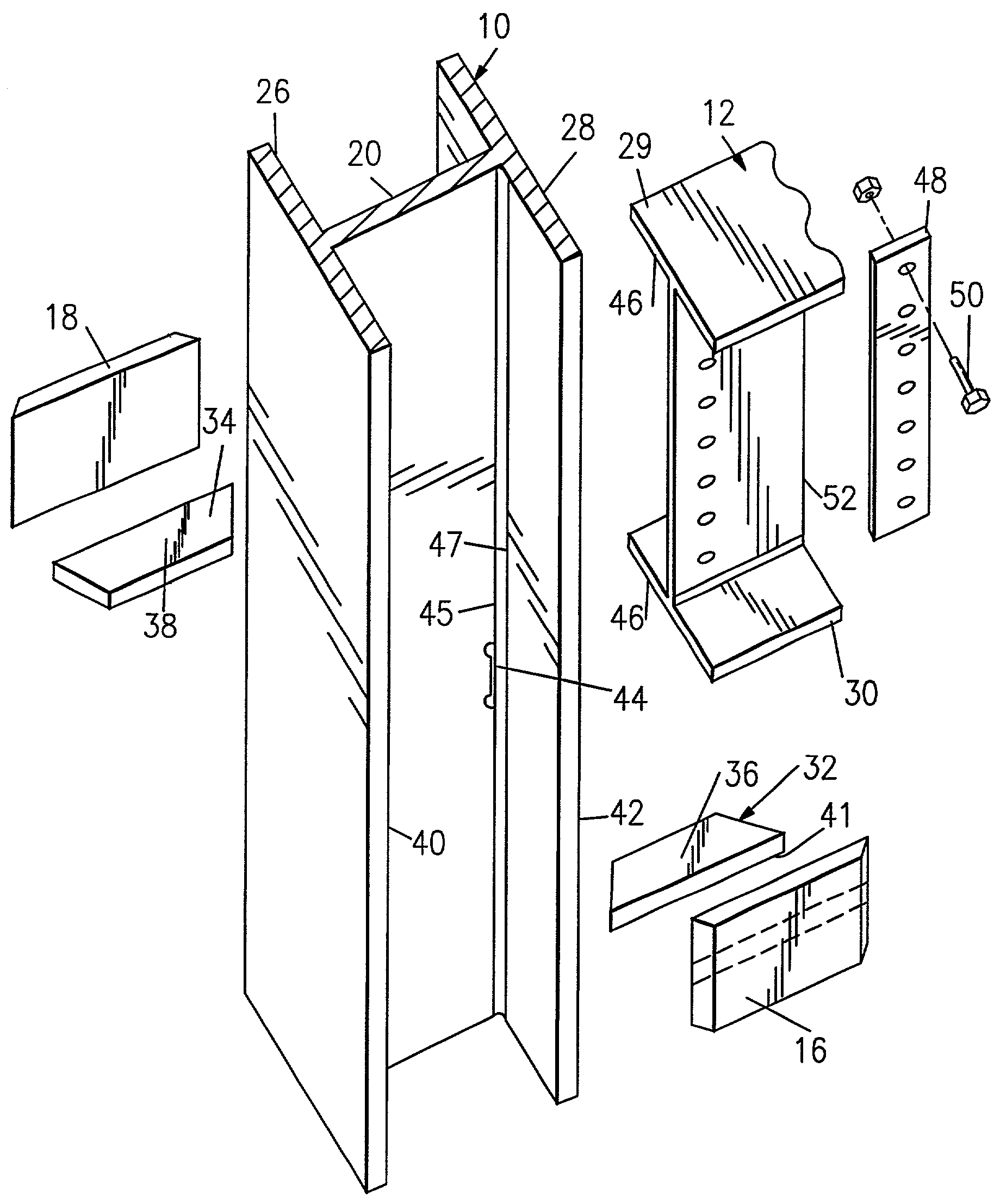

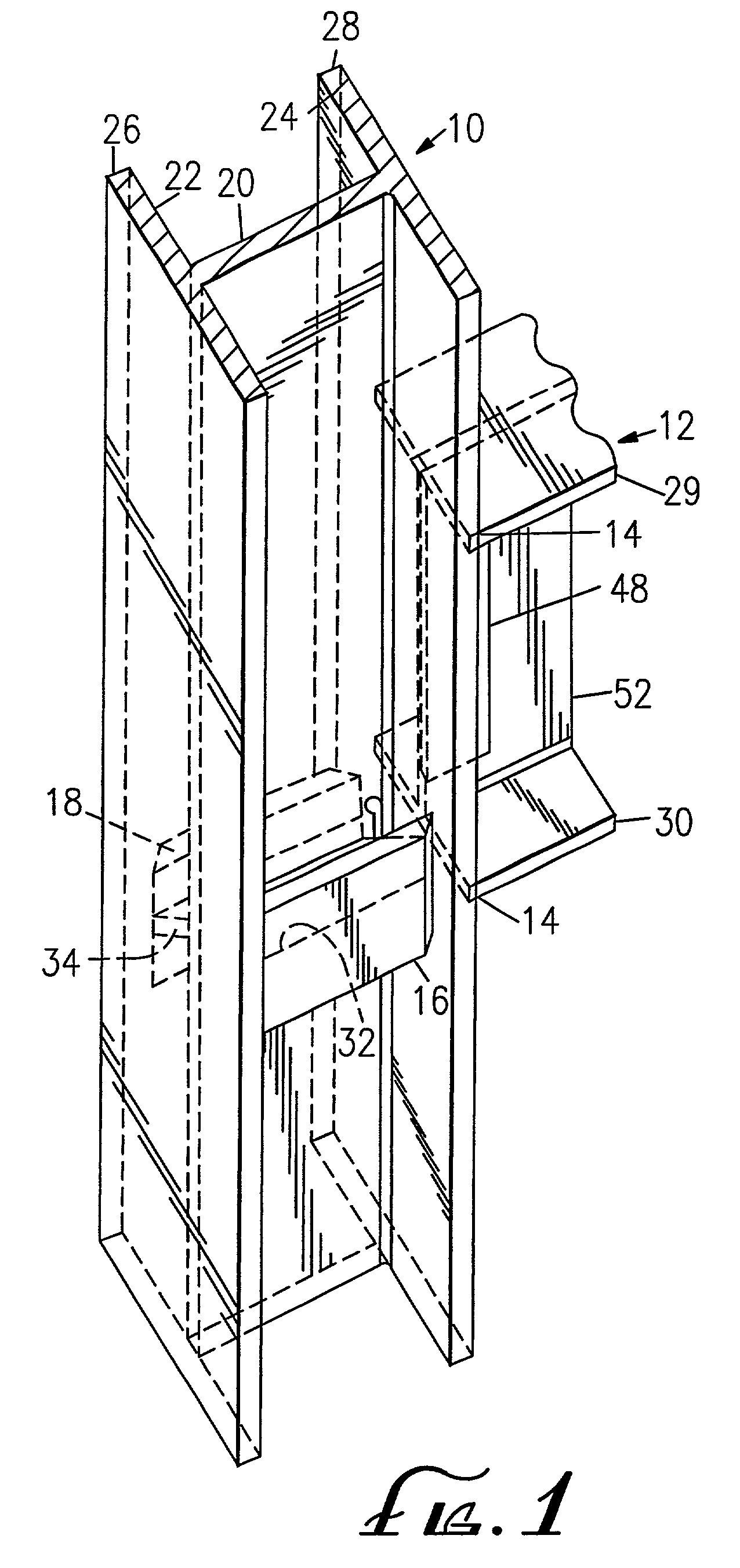

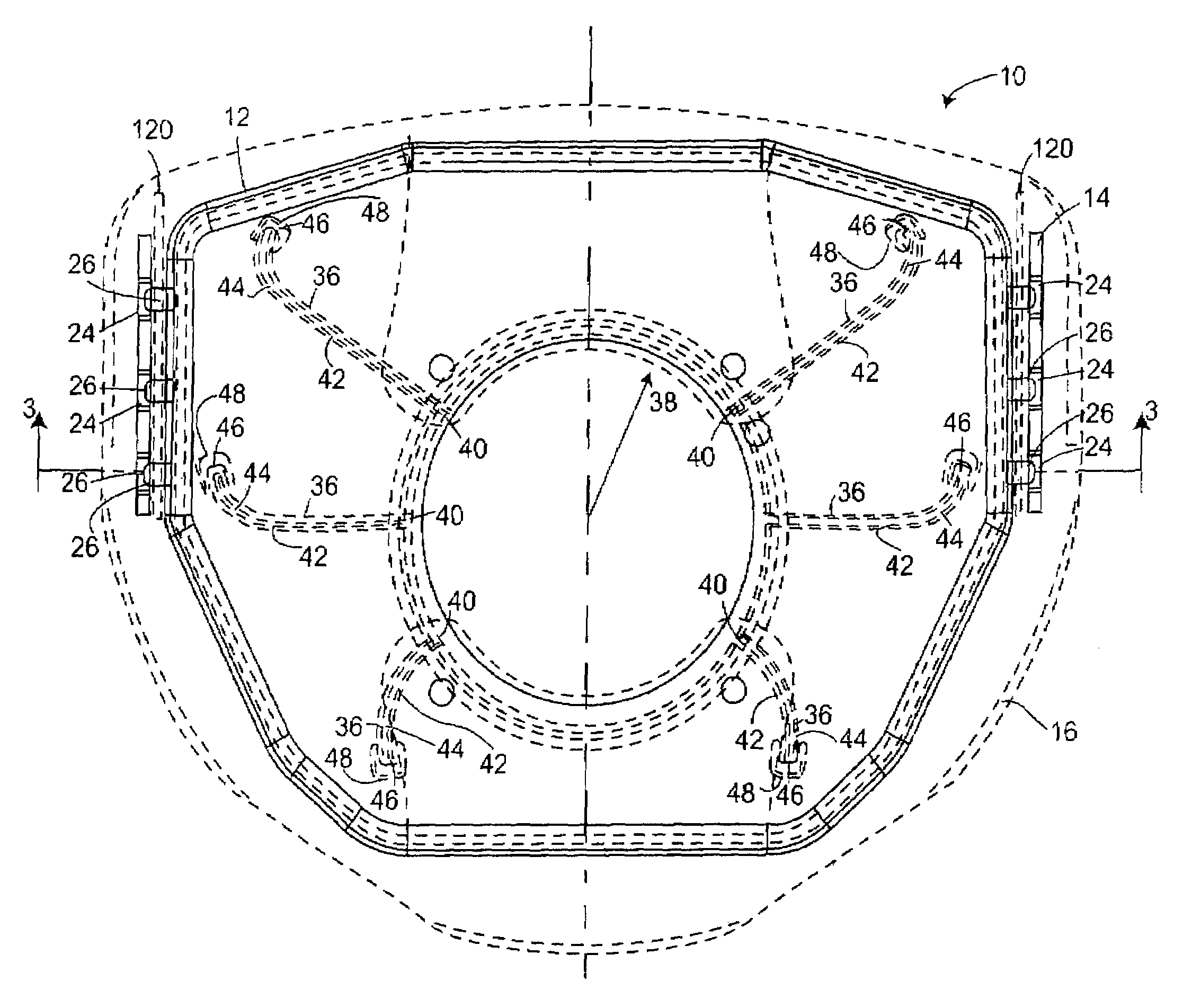

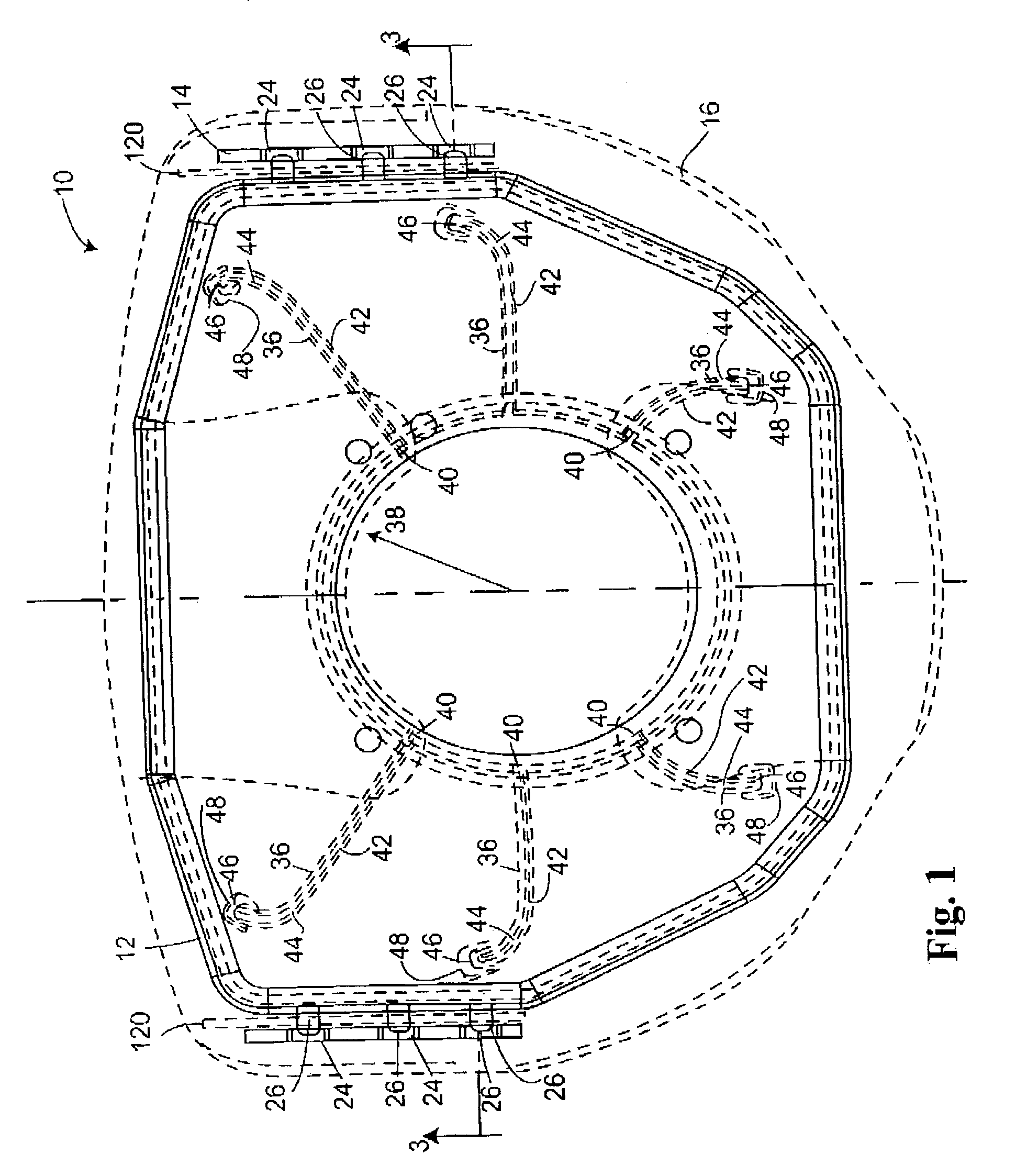

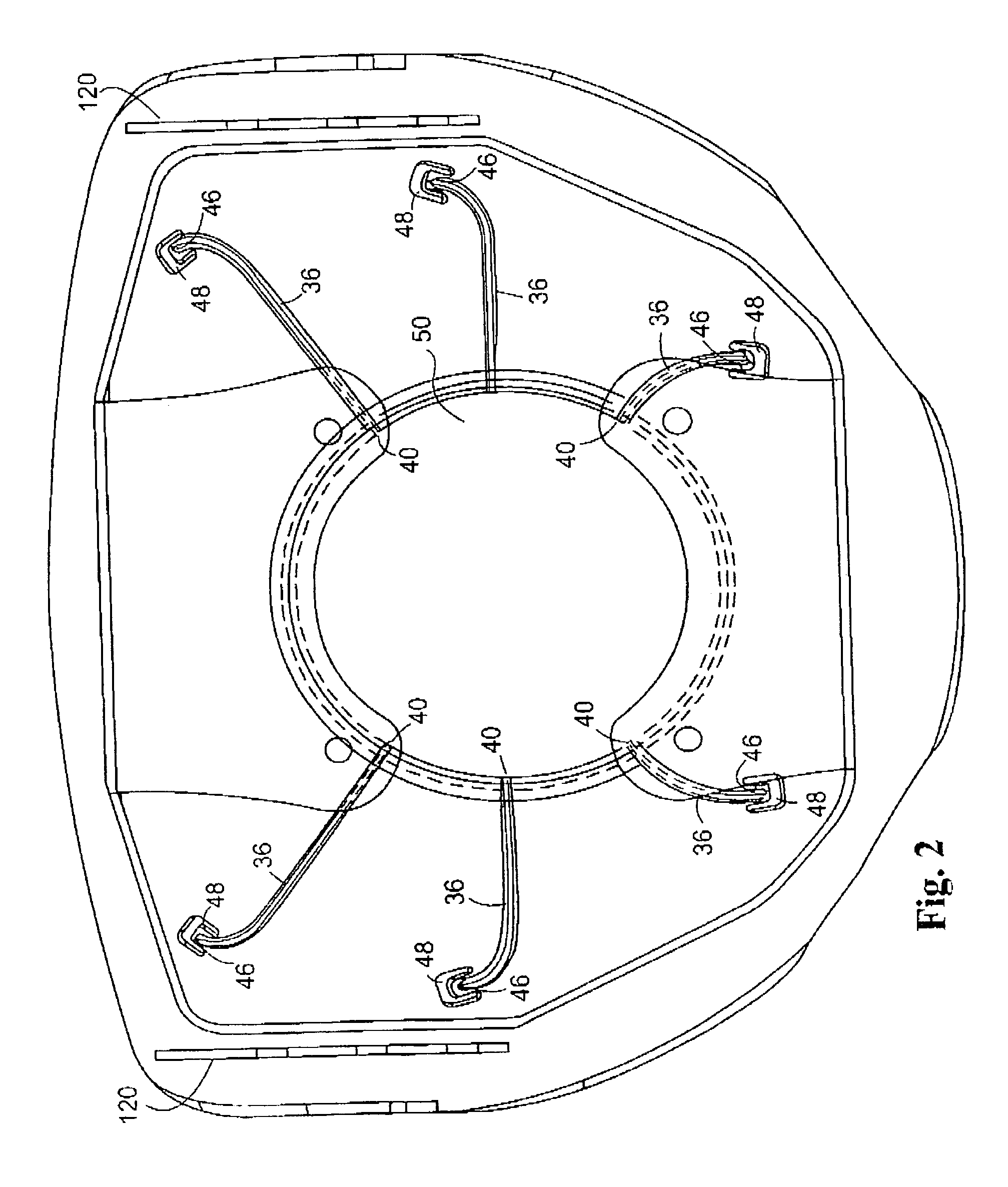

Air bag cover with articulated tear seam

InactiveUS6994372B2Reduced integrityLess forcePedestrian/occupant safety arrangementSteering wheelEngineering

A steering wheel assembly having a fastenerless air bag module assembly is disclosed. This assembly employs a housing with a projection and a steering wheel armature configured to receive the projection. The cover is retained between the housing and the steering wheel armature. Furthermore, the present invention provides a steering wheel cover with a tear seam that permits the air bag to deploy more efficiently with less damage to the occupants.

Owner:KEY SAFETY SYST

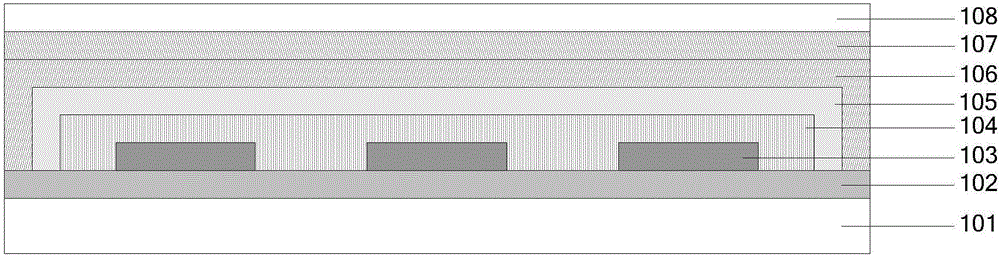

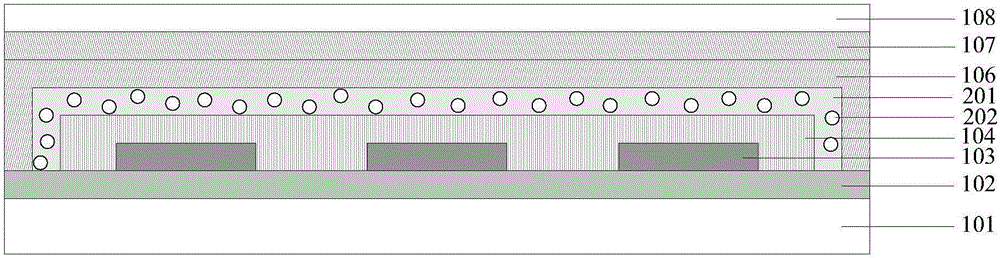

Display panel and preparation method

ActiveCN106206994AImprove stress concentrationExtended permeation pathFinal product manufactureSolid-state devicesMicrostructureCorrosion

The invention provides a display panel and a preparation method. The stress of stress faces of water resisting layers in the buckling process is dispersed through a microdroplet microstructure in an organic buffer layer, and the problems that the stress of the stress faces of the water resisting layers is centralized and the problem that due to water resisting layer fracture caused by the toughness difference of the water resisting layers, new water molecule corrosion channels are formed at fracture positions are changed. The microdroplet microstructure in the organic buffer layer lengthen the path of water molecule permeation, the time for water molecules to reach a light emitting layer in the display panel is prolonged, and the service life of devices of the light emitting layer is prolonged. The display panel comprises the first inorganic water resisting layer, the second inorganic water resisting layer and the organic buffer layer located between the first inorganic water resisting layer and the second water resisting layer. The organic buffer layer comprises the microdroplet microstructure used for dispersing stress of the organic buffer layers.

Owner:BOE TECH GRP CO LTD

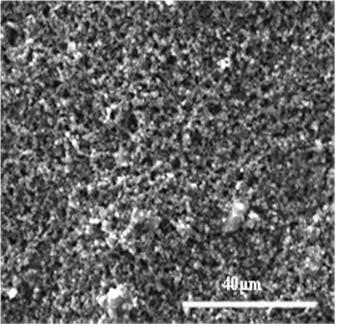

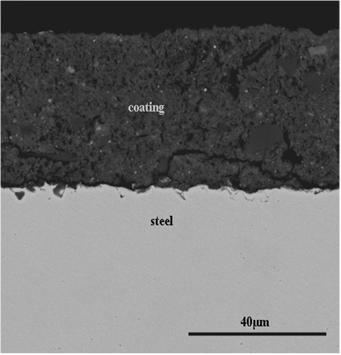

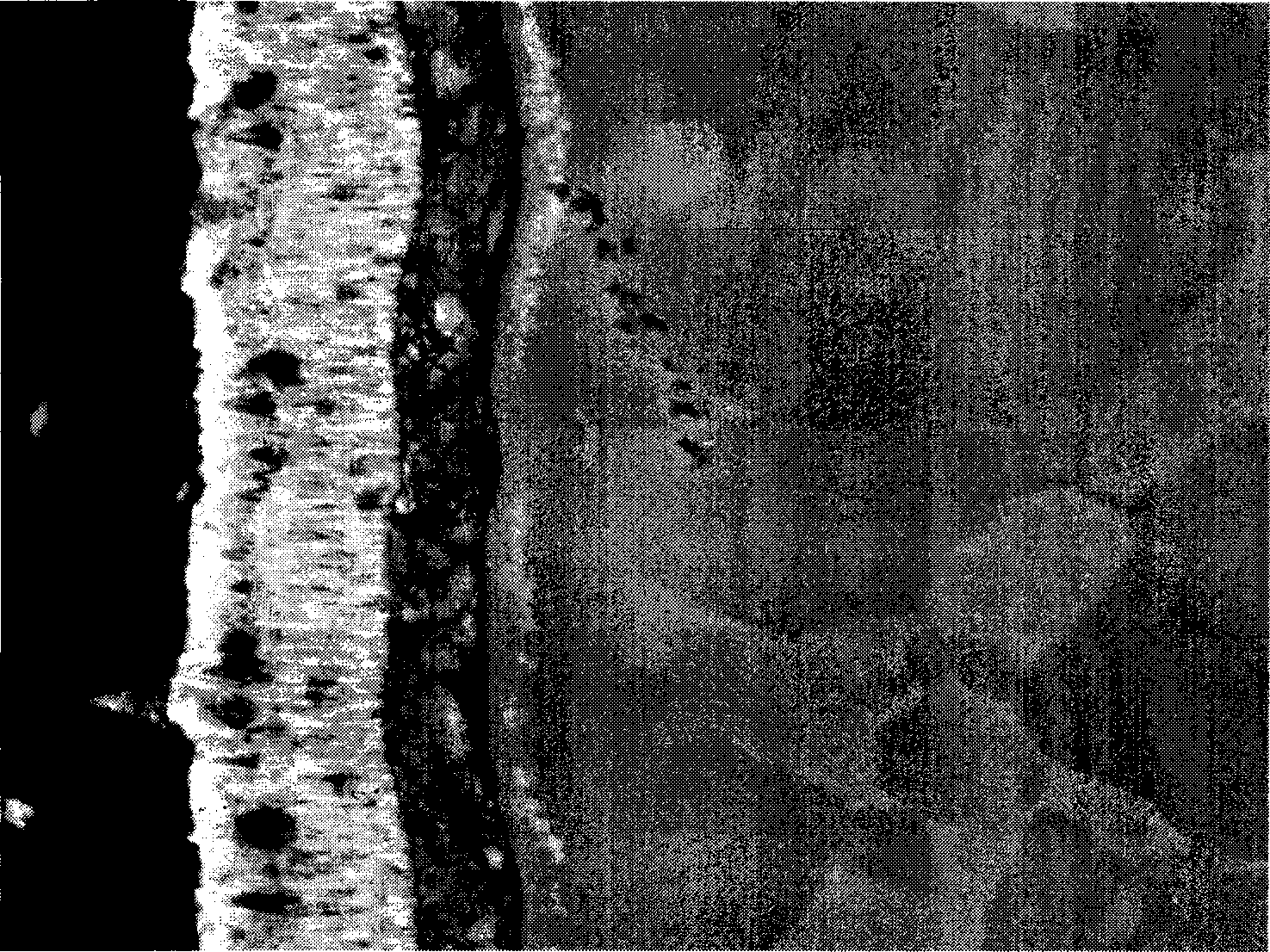

High temperature resistant environment-friendly nano modified inorganic coating, its preparation method and application

The invention, relating to an alloy high temperature protection technology, discloses a high temperature resistant environment-friendly nano modified inorganic coating, its preparation method and application. The coating comprises liquid potassium metasilicate, aluminium trippolyhosphate, aluminium oxide, nano metal powder and Zn powder. The preparation method comprises the following steps: uniformly mixing aluminium trippolyhosphate, aluminium oxide, nano metal powder and Zn powder to obtain a mixture; then, adding the mixture in potassium metasilicate with stirring and fully mixing; adding distilled water in the mixture obtained by the last step, stirring in a mixer with the rotating speed of 2000-2600 rpm for 5-30 min, and then filtering with 200-mesh sieve to obtain the coating, wherein, the weight ratio of distilled water to the mixture obtained by the last step is 1: (3-10). According to the invention, the problems that inorganic coating is easy to peel of base material and the like existing in the prior art are solved. The coating has the advantages of high temperature resistance, corrosion resistance, water resistance, good thermal shock resistance, no toxicity, no pollution, and favorable environmental protection, and is suitable for alloy products operating in high temperature environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

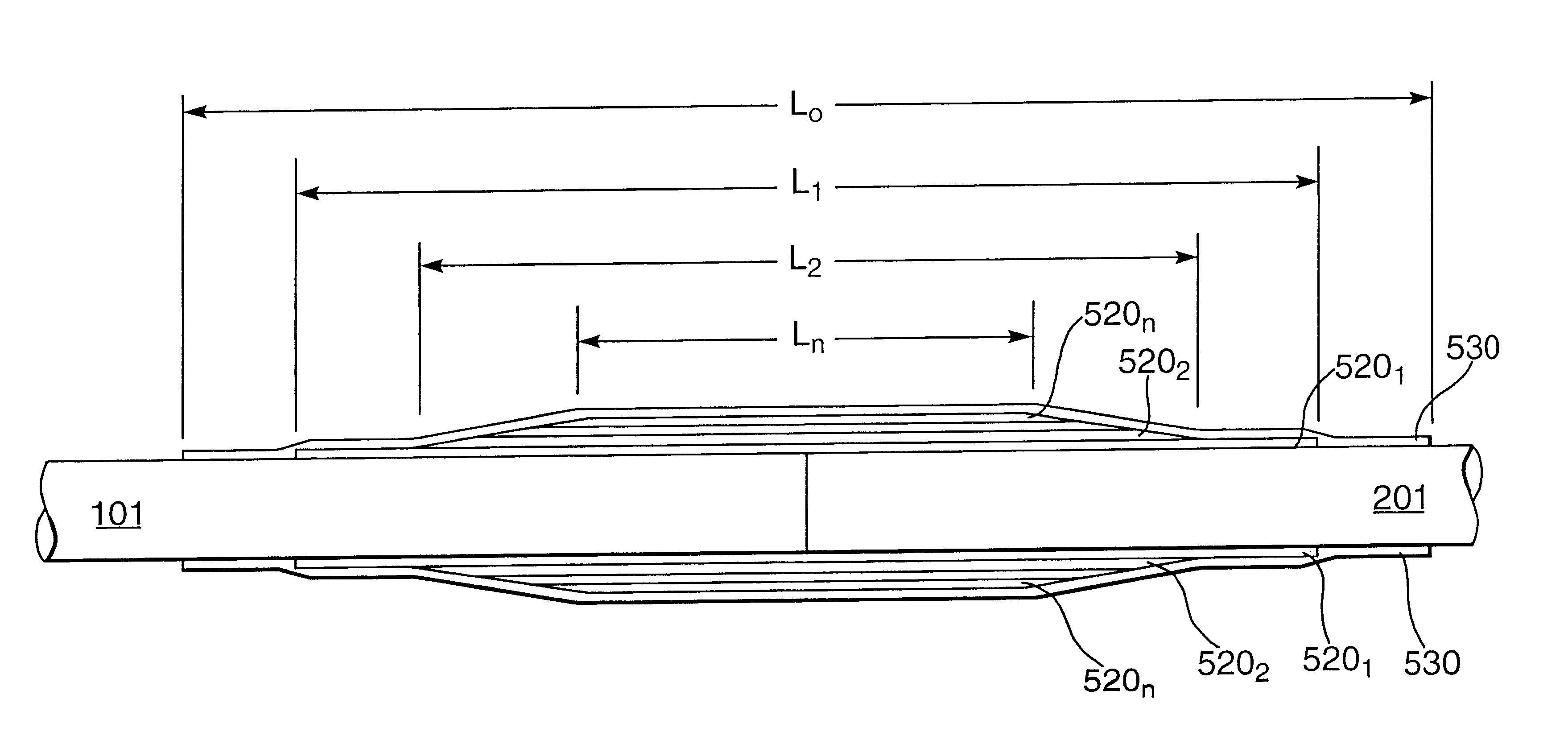

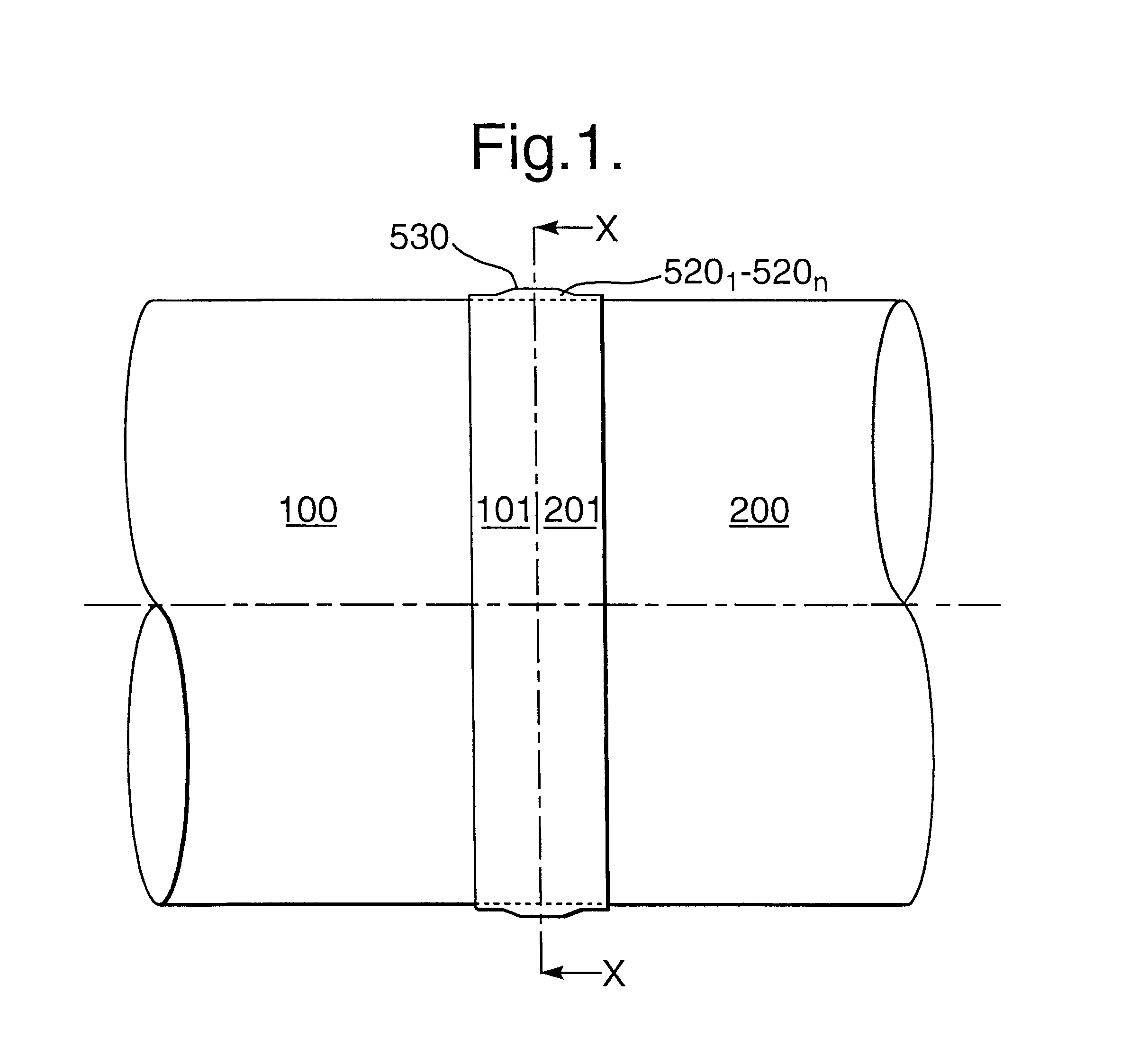

High-strength butt-wrap joint for reinforced plastic pipes

InactiveUS6585298B2Increased longitudinal stiffnessControl stressSleeve/socket jointsFluid pressure sealed jointsButt jointEngineering

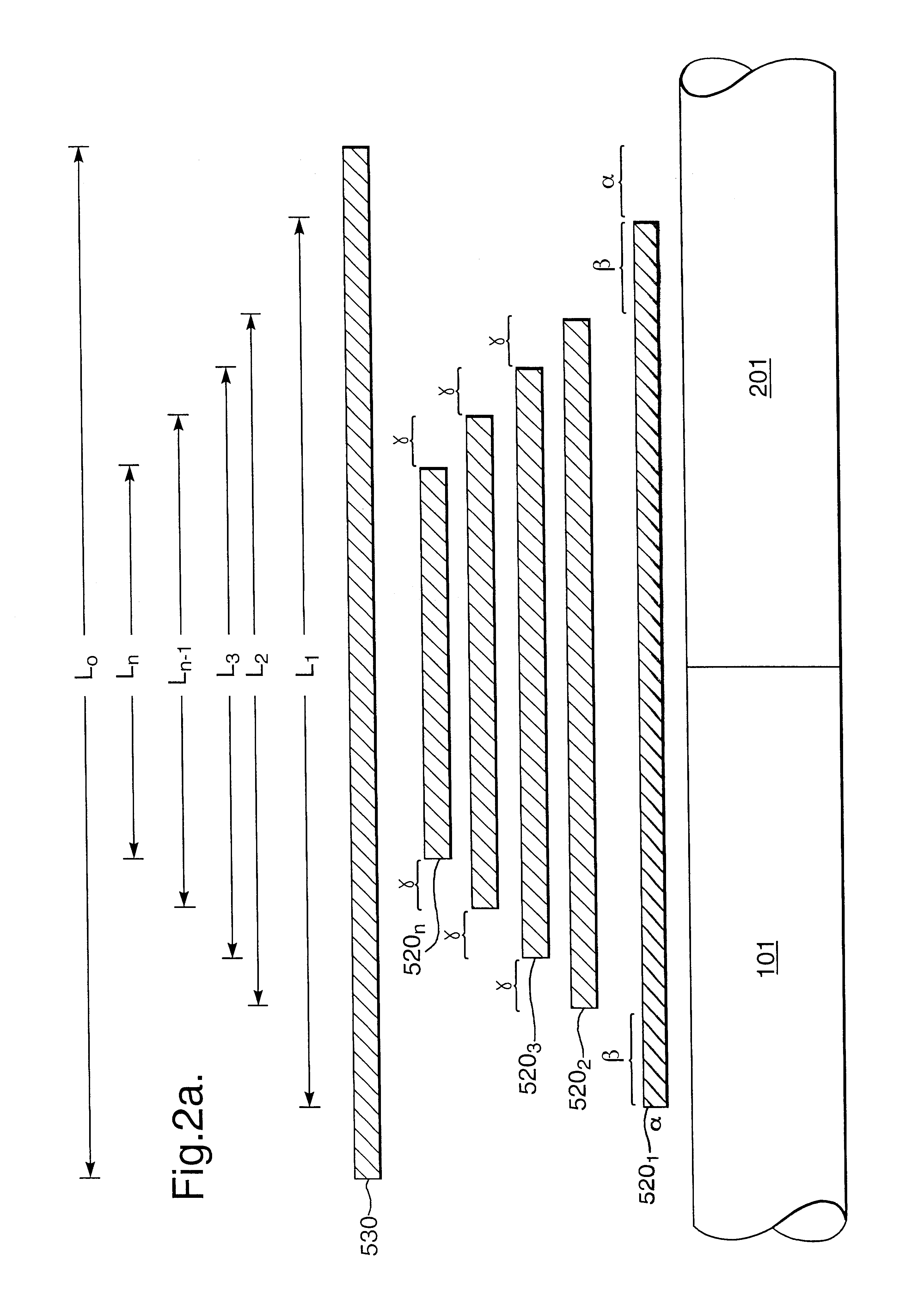

A butt-wrap joint includes a plurality of wraps 5201-520n of material wetted with a thermosetting resin and wrapped circumferentially about two abutting pipe ends 101, 201. The first wrap is disposed relative to the respective pipes and the second through n-th wrap is deposed successively outwardly, relative of the respective preceding wrap. The wraps are covered by a chopped strand mat 530 wetted with the thermosetting resin.

Owner:FLOWTITE TECH

Preparation methods of high temperature resistant anticorrosion potassium silicate coating and corresponding coat

ActiveCN102558924AImprove antioxidant capacityAccelerated corrosionAlkali metal silicate coatingsAnti-corrosive paintsPotassium silicateSilicic acid

The invention relates to preparation methods of a high temperature resistant anticorrosion potassium silicate coating and a corresponding coat. The high temperature resistant anticorrosion potassium silicate coating is formed by a solute and a solvent, wherein the solute comprises a component A liquid potassium silicate having a module of 3.0-4.0 and a weight accounting for 30-80% of the total weight of the coating, and a component B which comprises nanometer Cr powder having a weight accounting for 1-15% of the total weight of the coating, aluminum triphosphate having a weight accounting for 3-20% of the total weight of the coating, Zn powder having a weight accounting for 5-20% of the total weight of the coating and Al2O3 having a weight accounting for 10-50% of the total weight of the coating; and the solvent is water, and the weight ratio of the solvent to the solute is 1:3-10. The method for preparing the coat through utilizing the coating comprises the following steps: spraying or brushing the coating on the surface of a sandblasted steel iron part, drying the surface for 5-10min, carrying out temperature maintenance for 0.5-4h according to a furnace temperature of 200-260DEG C, taking out the part, and air-cooling the part to obtain the coat. The coat of the invention has the characteristics of high temperature resistance, anticorrosion and water resistance, and has the advantages of good thermal shock resistance, nontoxicity, no pollution, and environmental protection benefiting.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

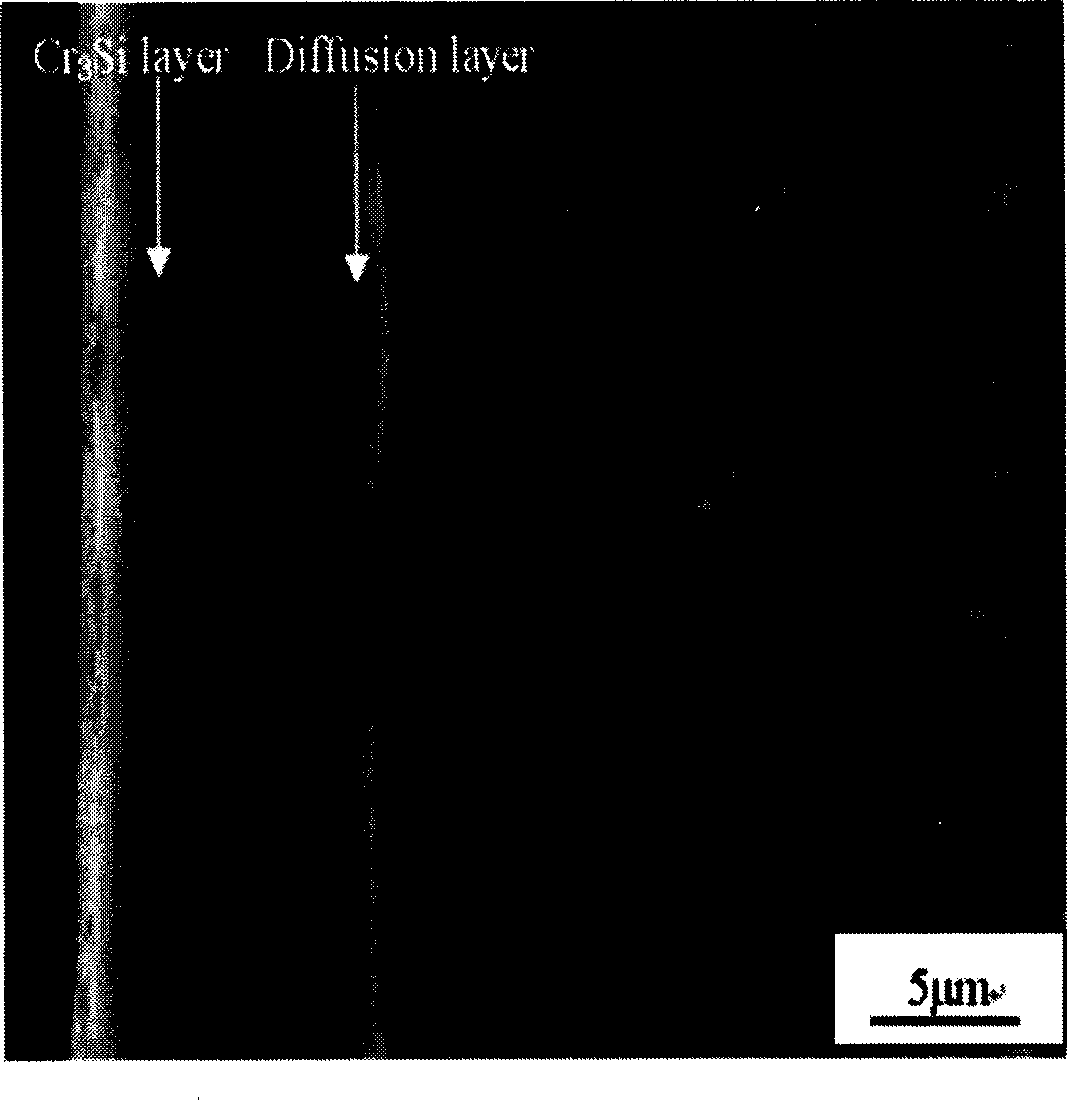

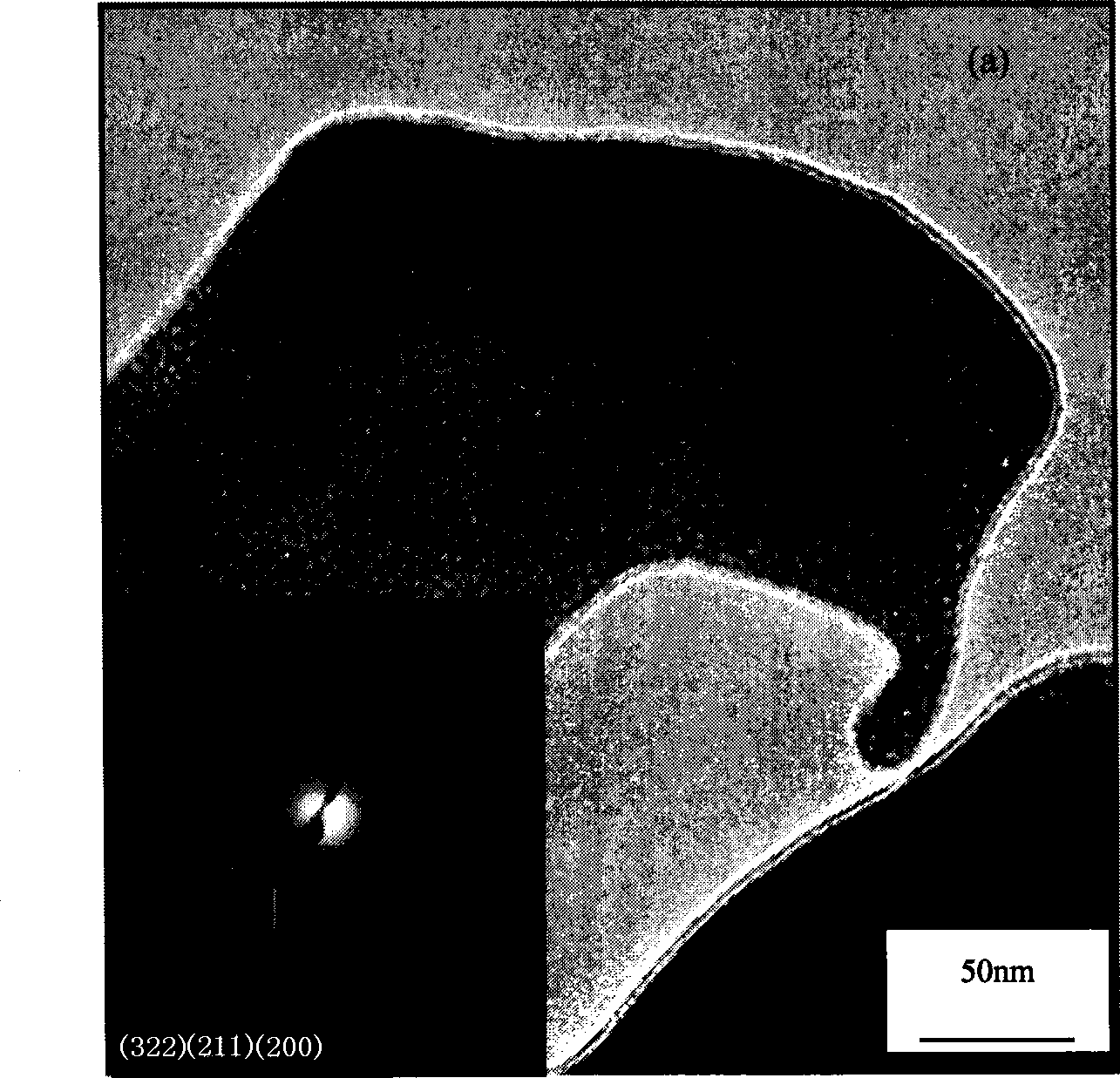

Preparation of high tenacity nanocrystalline silicide coating

InactiveCN101481791AReduce intensityReduce hardnessVacuum evaporation coatingSputtering coatingVoltageTitanium alloy

The invention discloses a preparation method of high-tenacity nanocrystalline silicide coating, which uses the technology of twin cathode plasma sputtering sedimentation to control the sputtering amount of a target material and the temperature of a work surface by adjusting the target material and workpiece voltage as well as argon pressure led into a vacuum chamber; the dense nanocrystalline silicide coating is formed at the surface of titanium alloy; the technological parameters of twin cathode sputtering are as follows: the voltage of the target material is 500 to 1000 V; the workpiece voltage is 300 to 450 V; the distance between the target material and the workpiece is 10 to 30 mm; the argon pressure is 20 to 45 Pa; the type of the sputtered target material is Cr-Si alloy, and the like; and the type of the workpiece material is titanium alloy. Compared with an ordinary macrocrystal silicide material, the nanocrystalline silicide coating prepared by the invention has higher tenacity, oxidation resistance, high temperature resistance and high wearing resistance. The preparation method is applied to the field of propulsion of aviation and aerospace, and the coating is an indispensable special coating material with high temperature resistance and high wearing resistance.

Owner:JIANGSU HUAYANG PIPE & FITTINGS +1

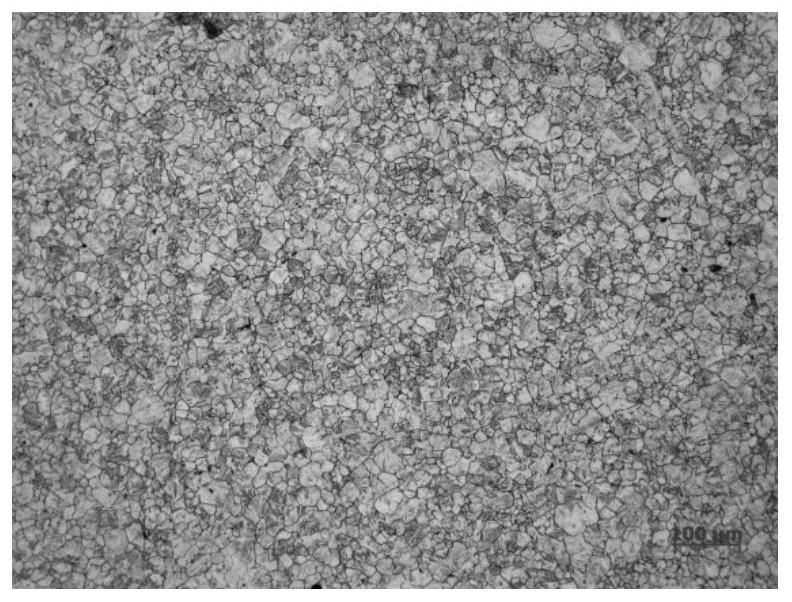

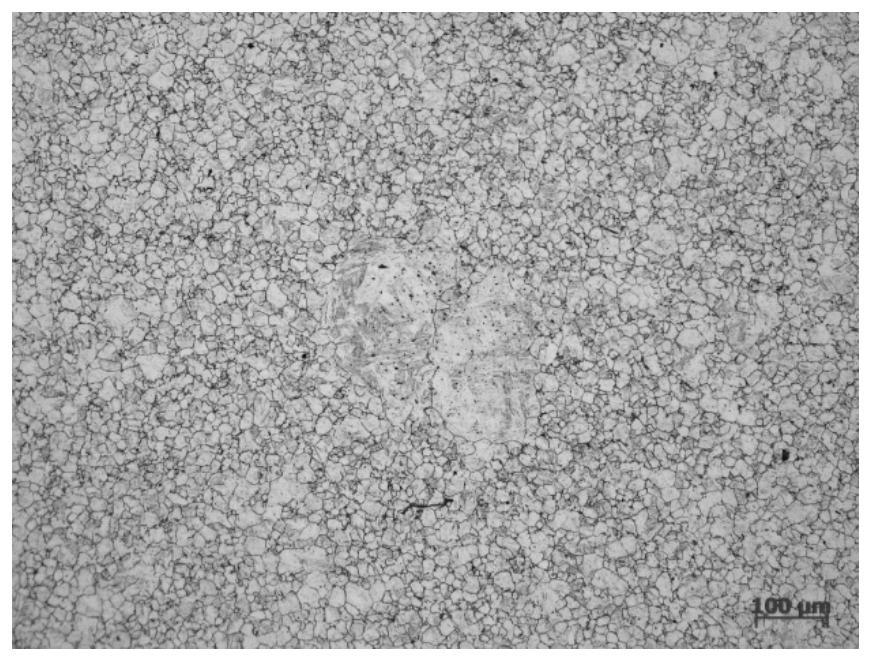

Manufacturing method of steel for speed reducer gear of electric automobile

PendingCN112981271AHigh strengthUniform plastic deformationProcess efficiency improvementScrapElectric furnaces

The invention relates to a manufacturing method of steel for a speed reducer gear of an electric automobile, belongs to the technical field of iron-based alloys, and particularly relates to steel for gears. According to the element composition design related, the steel comprises, by mass, 0.20%-0.35% of C, 0.05%-0.35% of Si, 1.20%-1.60% of Mn, 1.10%-1.50% of Cr, 0.20%-0.50% of Mo, smaller than or equal to 0.035% of S, smaller than or equal to 0.015% of P, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.20% of Ni, 0.010%-0.080% of Al, 0.0060%-0.0260% of N and the balance Fe and inevitable impurities, wherein Al / N is equal to 1.5 to 3.9. The smelting technological process comprises the following steps of pre-treated molten iron and optimized scrap steel, primary smelting in an electric furnace, refining in an LF furnace, vacuum degassing in a VD furnace, continuous casting of square billets, shot blasting of the continuously-cast square billets, heating in a walking beam furnace, descaling with high-pressure water, rolling of the continuous casting billets, surface flaw detection and internal ultrasonic flaw detection of hot-rolled round steel, quality inspection and warehousing. The element components are matched with the smelting process, and the steel meets the requirements of high strength and long fatigue life of the steel for an electric automobile speed reducer. And remarkable advantages are obtained on the aspects of hardenability and grain uniformity.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

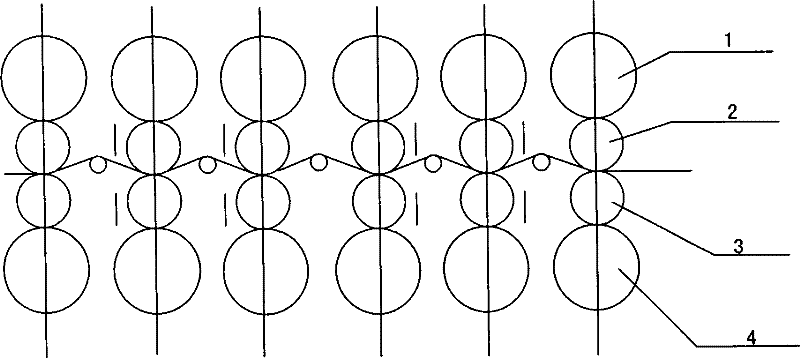

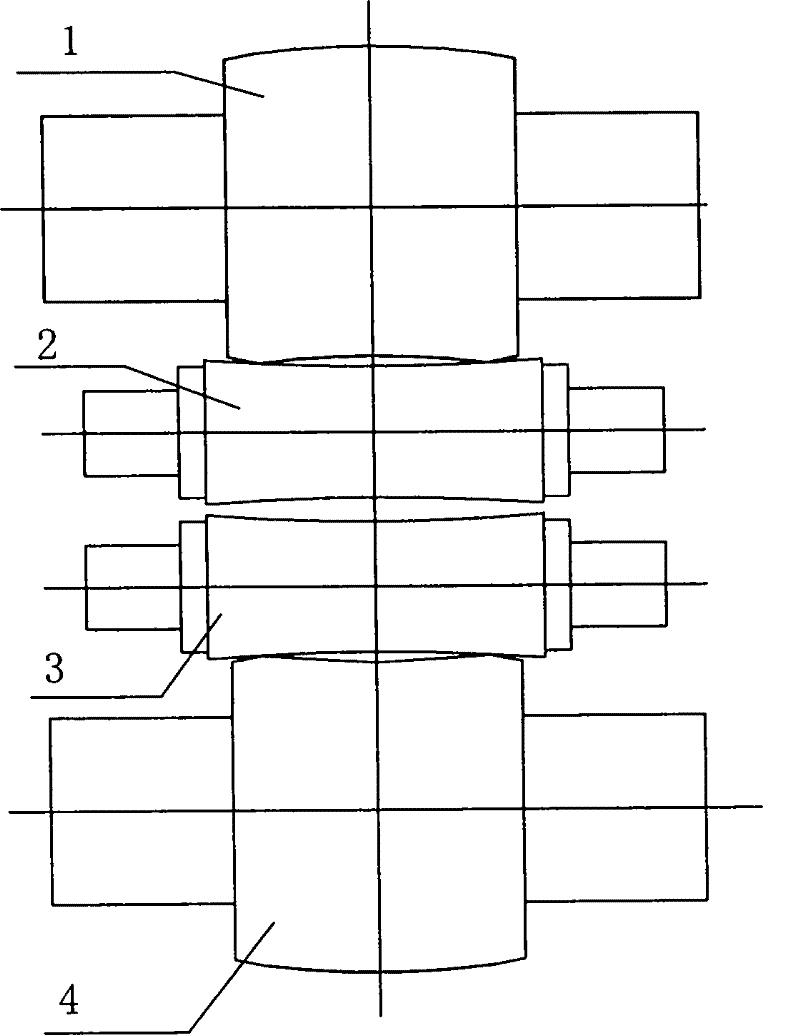

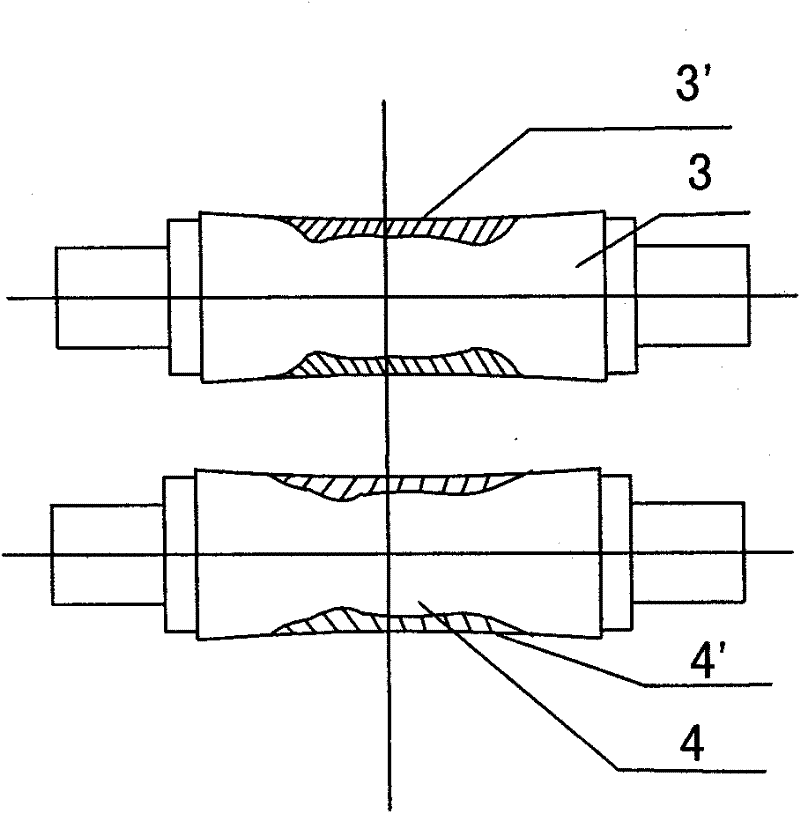

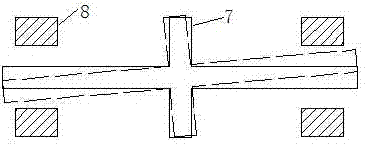

Modification configuration finishing roll group and modification configuration method thereof

InactiveCN102189109AExtended service lifeUniform contact pressureRolling equipment maintainenceRollsStress conditionsContact pressure

The invention relates to a modification configuration finishing roll group and a modification configuration method thereof, belonging to the technical field of metallurgical production equipment. The finishing roll group comprises an upper support roll, a lower support roll, an upper working roll and a lower working roll, wherein the upper and lower support rolls are supported on the rear sectionof a rack; the upper and lower working rolls are located between the upper and lower support rolls; and the generatrices of the upper and lower working rolls are formed according to an equation respectively, wherein the upper working roll is '+', and the lower working roll is '-'. Through the invention, the practical shapes of the upper and lower working rolls on the rear section of the rack forma corresponding convex roll and a concave roll respectively, and the rolling clearance conforms to the requirement; due to the abrasion of the support rolls, the contact pressure between the working roll and corresponding support roll is more uniform, and the local centralized stress condition between rolls is obviously improved; and meanwhile, as the protuberance of the upper working roll effectively compensates for the abrasion, the service life of the working roll is greatly prolonged.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Ceramic chip of NOx sensor

ActiveCN109001284AImprove stress concentrationHigh strengthMaterial electrochemical variablesNitrogen oxide sensorSlurry

The invention discloses a ceramic chip of a NOx sensor. An oxygen pump anode covered with a protective layer on the surface is arranged on a first-layer membrane, an acquisition cavity is formed on the oxygen pump anode and the first-layer membrane, second to fourth through holes are formed in a second-layer membrane, a first diffusion barrier is formed in the second through hole and divides the second through hole into a first measurement chamber and a buffer cavity, a main oxygen pump cathode is arranged in the first measurement chamber, a second diffusion barrier is arranged between the second through hole and a third through hole, the third through hole is a second measurement chamber, an auxiliary pump cathode is arranged in the second measurement chamber, a third diffusion barrier isarranged between the third through hole and the fourth through hole, the fourth through hole is a third measurement chamber, a measurement electrode covered with a protective layer on the surface isarranged in the third measurement chamber, a reference channel is formed in a third-layer membrane, a reference electrode covered with a protective layer on the surface is arranged in the reference channel, a heating electrode wrapped in a heating electrode insulating layer is arranged between the fourth-layer membrane and a fifth-layer membrane, an outer lead of the heating electrode penetrates through the fifth-layer membrane to be located on the lower surface of the fifth-layer membrane, and a stress release hole filled with heating electrode insulating layer slurry is formed in the fifth-layer membrane.

Owner:西安创研电子科技有限公司

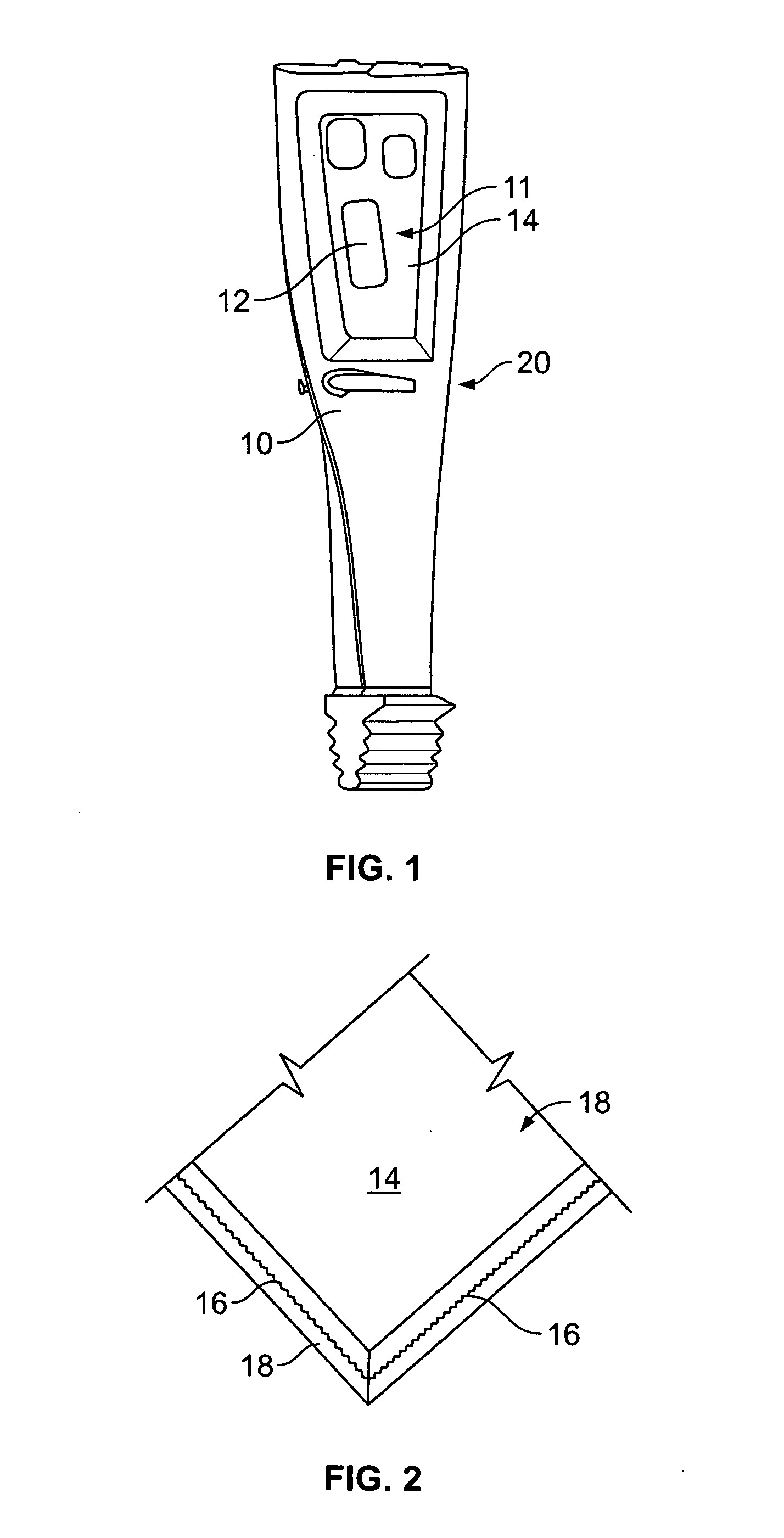

Methods and apparatus for reducing stress in turbine buckets

InactiveUS20070231154A1Relieve pressureImprove stress concentrationPropellersRotary propellersFiberTurbine blade

A method facilitates reducing stress in a turbine bucket including a metallic base metal. The method comprises providing a turbine bucket including at least one pocket formed therein, and filling at least one pocket defined in the bucket with a polymer composite having continuous fibers oriented in a resin matrix, such that the fibers have an orientation determined in accordance with a pre-selected frequency tuning of the bucket.

Owner:GENERAL ELECTRIC CO

Method for controlling surface stress-strain field of casing part based on constant cutting force

ActiveCN109343472AImprove surface stress distributionImprove processing qualityComputer controlSimulator controlNumerical controlSurface stress

The invention relates to a method for controlling the surface stress-strain field of a casing part based on a constant cutting force, and belongs to the technical field of aerospace numerical controlmachining. The control method includes the following steps: (1) importing a part model into a computer; (2) importing an original numerical control program into the computer; (3) importing machine tool information into the computer; (4) setting cutter parameters; (5) simulating a cutting force; (6) analyzing simulation data; (7) judging the stability of the cutting process; (8) judging whether thecutting process belongs to local run-out; (9) adjusting the original numerical control program: (10) interrupting the original numerical control program adaptively; (11) optimizing the cutting parameters of the numerical control program by segments; (12) outputting an optimal numerical control program; and (13) applying the optimal numerical control program for processing verification. The methodof the invention can be applied to the surface stress-strain field control of various integral casing parts, and has huge economic and social benefits.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

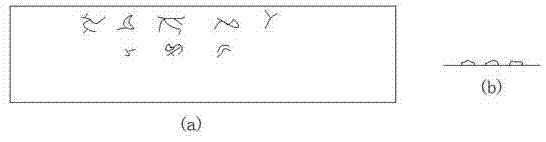

Dynamic pressure gas radial bearing with axial variable stiffness and viscoelastic structure

ActiveCN103867571ASimple structureGuaranteed uptimeElastic bearingsBearing unit rigid supportVibration amplitudeVariable stiffness

The invention discloses a foil dynamic pressure gas bearing structure with the axial variable stiffness and a viscoelastic structure. The foil dynamic pressure gas bearing structure with the axial variable stiffness and the viscoelastic structure comprises a bearing seat and a foil component which is fixed on the bearing seat. The foil dynamic pressure gas bearing structure is characterized in that a smooth metal flat foil is arranged on a top layer of the foil component; a high-temperature-resistant viscoelastic foil is arranged on a middle layer of the foil component; a metal foil with a bubble-shaped protrusion is arranged on a bottom layer of the foil element; the height of the bubble-shaped protrusion gradually changes in the axial direction; the winding direction of the foil component is opposite to the rotation direction of a rotor. Compared with the prior art, the bearing is simple in structure and easy to process and assemble; the viscoelastic foil can improve the stress concentration condition of the bubble-shaped protrusion, absorb the vibration and the shock of a rotor-bearing system when operating and inhibiting the increase of vibration amplitude of the rotor; the foil at the bottom layer can reduce the negative influence of axle journal inclination on a gas member gap, and reduce the possibility of damaging the surface of the bearing, so that the operation reliability is obviously improved and the bearing capacity is improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

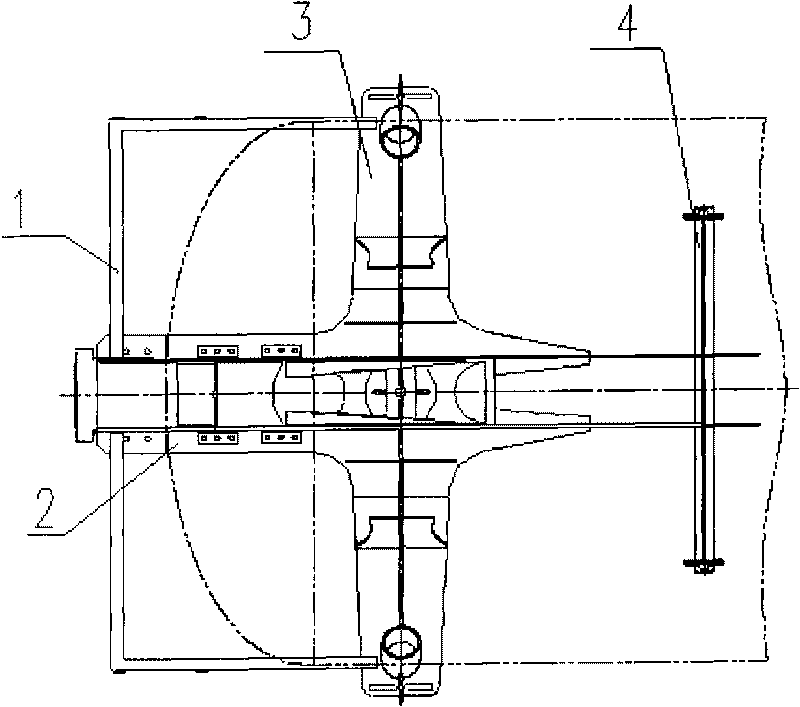

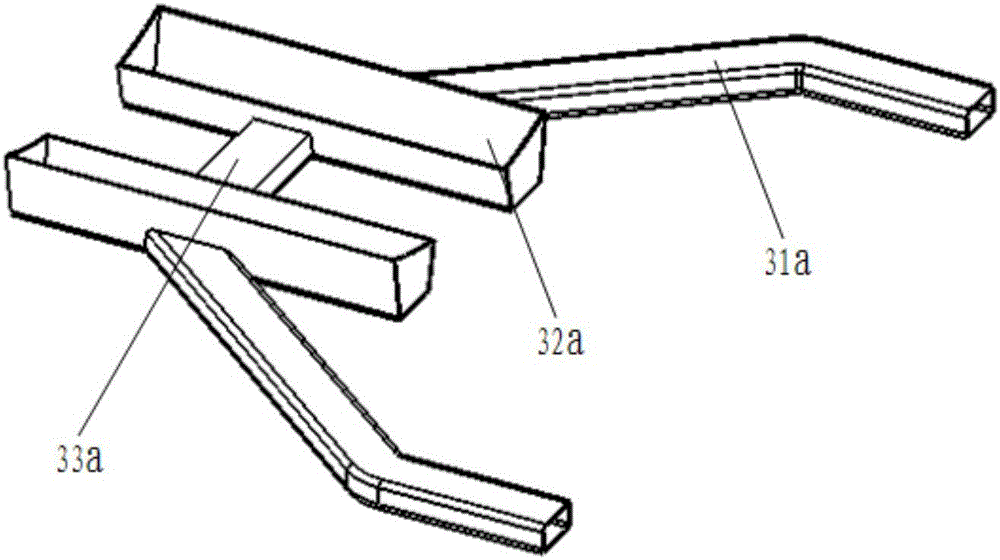

Rail road tank car traction and bolster device with beam structure

InactiveCN101746381AControl deformationImprove stress concentrationTank wagonsEngineeringAssembly structure

The invention discloses a rail road tank car traction and bolster device with a beam structure, comprising an end beam, towering beam assembly and sleeper beam assembly, a beam assembly structure at the tail part of a towering beam is connected with the tail part of the towering beam; the beam assembly structure comprises a bent beam web plate of which the upper surface is consistent to the shape of the lower part of the tank car horizontally, a beam lower cover board is connected at the lower part of the beam web plate, and two ends of the beam web plate are provided with beam side cover boards; the device can effectively reduce the stress value of a tank plate of the tail part of the towering beam and effectively solve the problem that the stress value of the tank plate of the tail part of the towering beam is high and even exceeds the evaluation requirements of the TB / T1335 intensity; in addition, the bolster device structure is adopted, the intensity of the tank plate of the tail part of the towering beam can meet the intensity evaluation requirements of the association of American railroads AAR; the invention has simple and rational structure, equal distribution of the adopted structure, convenient manufacturing process, prolonging the service life of the vehicle, reducing the maintenance and saving the repairing cost.

Owner:CRRC YANGTZE CO LTD

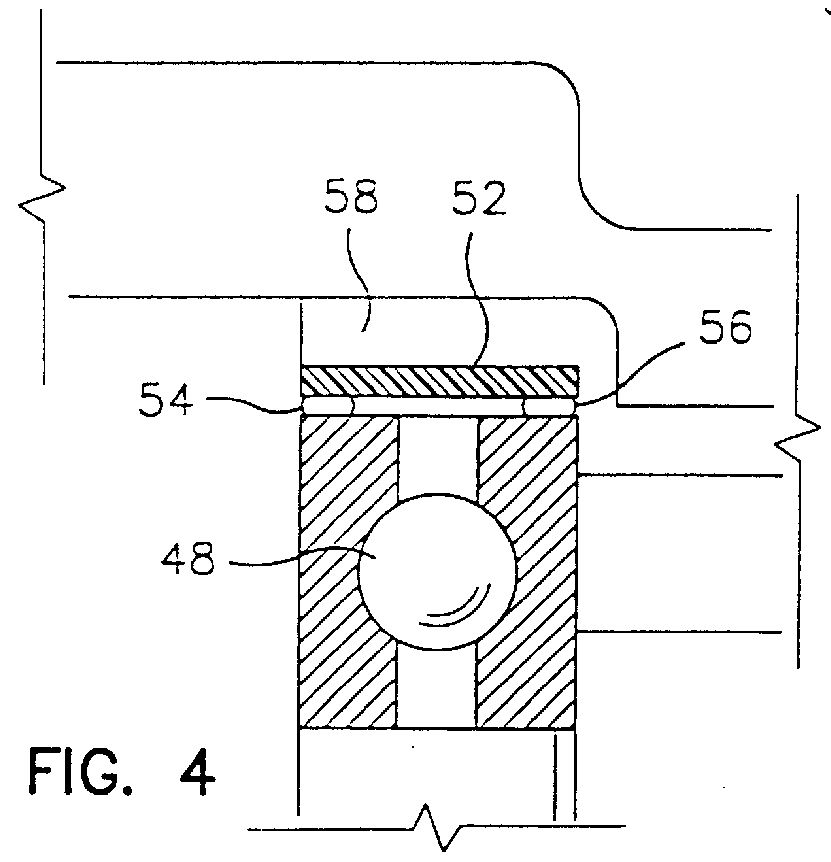

Membrane seal secured to inner and outer oscillating bearing members for small angle oscillations within confined axial space

InactiveUS6125007AReduced torque requirementsMinimal stressApparatus for flat record carriersBall bearingsEngineeringActuator

A bearing seal assembly for an oscillating actuator, comprises an outer bearing raceway, an inner bearing raceway mounted concentric with the outer raceway, and an annular deformable liquid impermeable membrane having an axial length of not more than one tenth the radius thereof, an inner peripheral edge sealingly secured to the inner bearing raceway, and an outer peripheral edge sealingly secured to the outer raceway for enabling limited relative rotation between the inner raceway and the outer raceway with minimum axial distortion of said membrane. In one embodiment, the membrane is stretched to eliminate surface distortion under torsional stress. Another embodiment illustrates waves molded into the membrane for reducing torsional forces.

Owner:WESTERN DIGITAL TECH INC

Backlight module and liquid crystal display

InactiveCN101598869AImprove stress concentrationImprove yieldNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a backlight module and a liquid crystal display. The backlight module comprises an outer frame, a light source, a light guide plate, a glue frame and a plurality of buffer structures. The light source is arranged at one side in the outer frame; the light guide plate is arranged in the outer frame, positioned aside the light source and provided with a plurality of lugs, wherein the lugs are positioned at the two opposite sides of the light guide plate. The glue frame is arranged in the outer frame and positioned between the light guide plate and the light source, wherein the glue frame is provided with a plurality of recessed openings at a place corresponding to the lugs, and the recessed openings are suitable for bearing the lugs. In addition, the buffer structures are arranged on a bearing surface of the recessed openings of the glue frame. By the arrangement of the buffer structures, the backlight module has the preferential shock resistance effect.

Owner:INNOLUX CORP

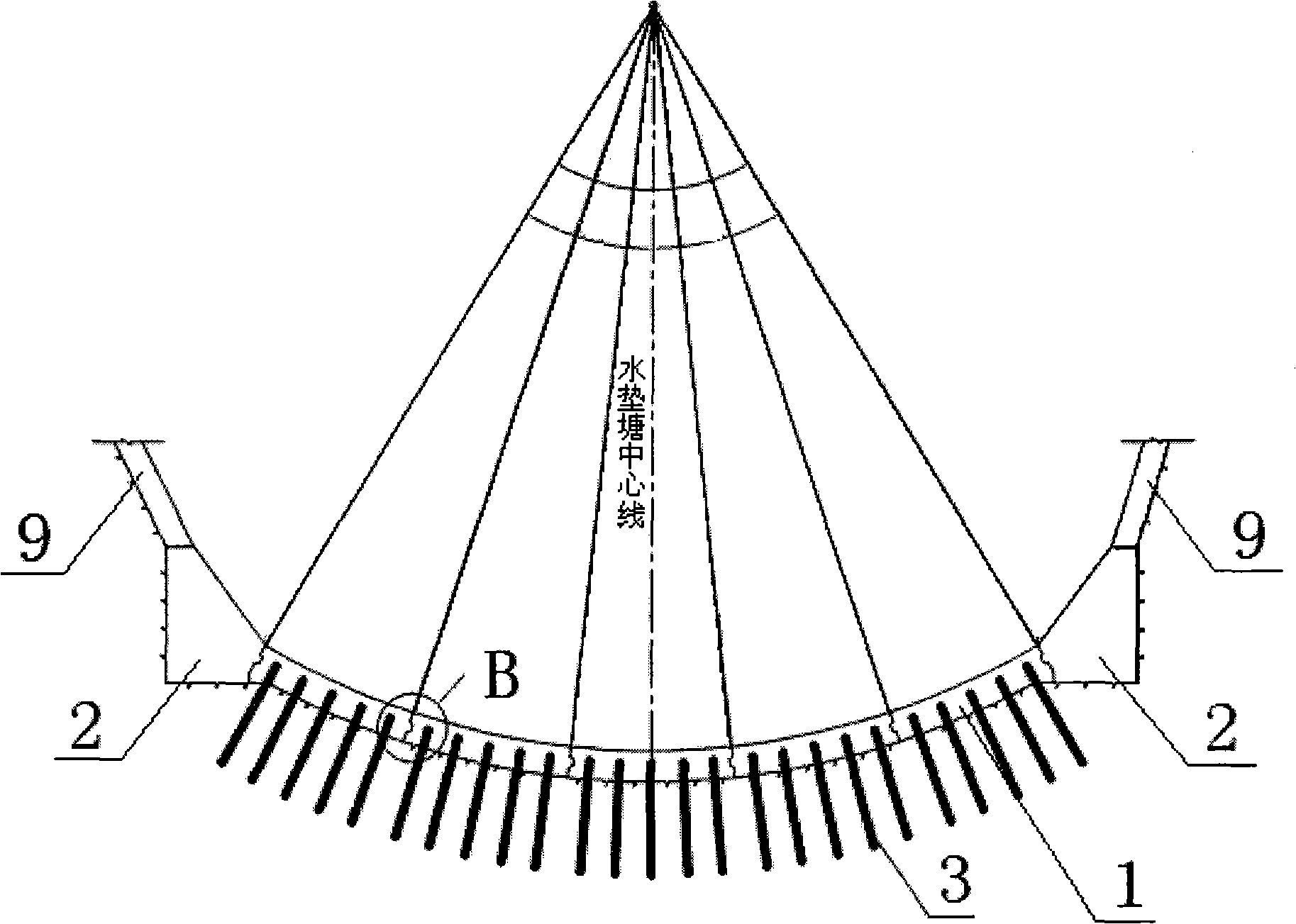

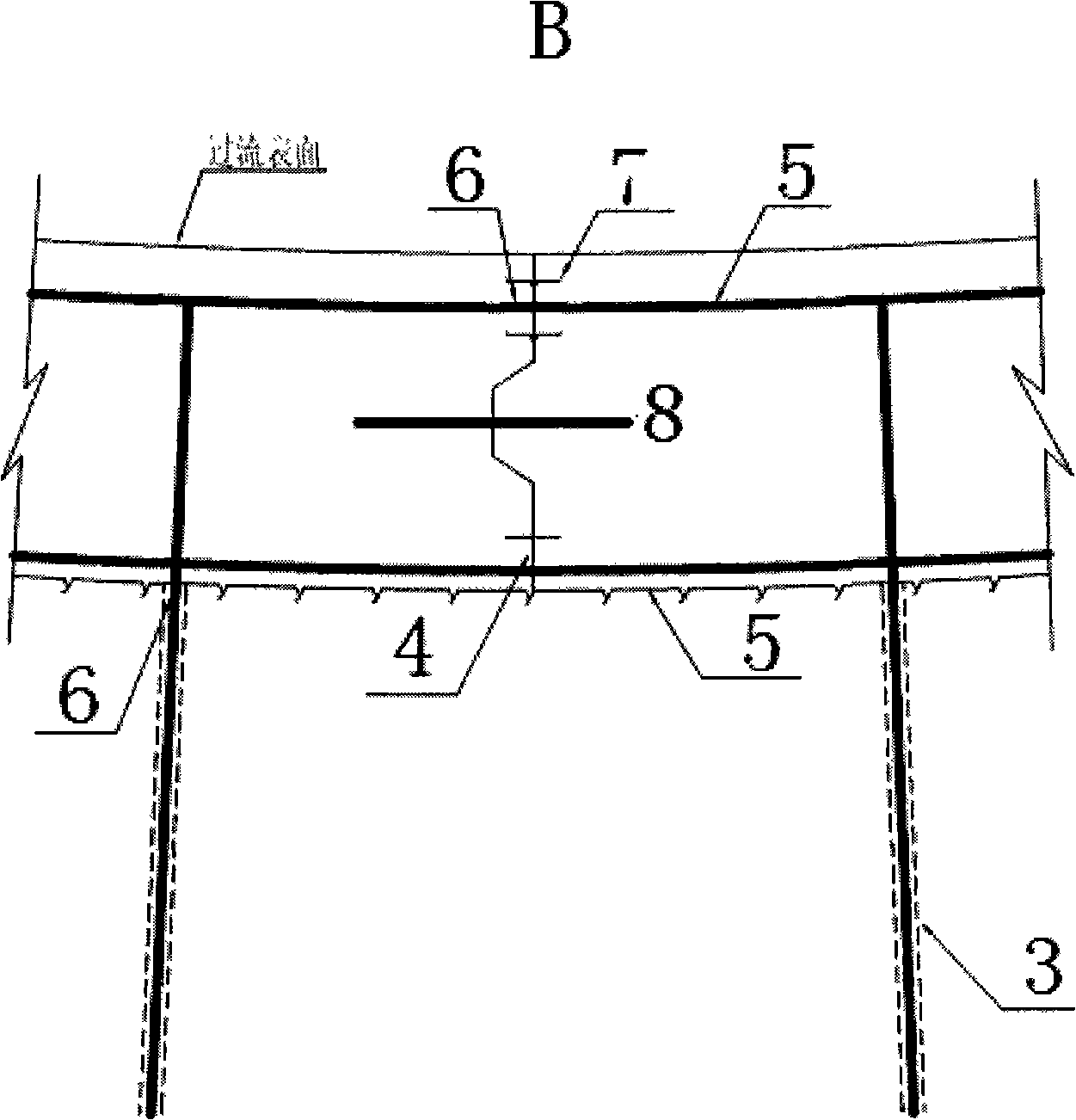

High-geostress narrow-valley inverted arch plunge pool and design method thereof

ActiveCN101555687AAvoid touchingImprove stress concentrationBarrages/weirsStress concentrationRiver bed

The invention belongs to a concentrated flood discharge and energy dissipation structure behind a hydroelectric dam, and more particularly relates to a high-geostress narrow-valley inverted arch plunge pool and a design method thereof. The plunge pool is structurally characterized by comprising a bottom plate (1), arch supports (2) and anchor bar piles (3), wherein the bottom plate (1) is an arched concrete structure on the whole, and two ends of the arched concrete bottom plate (1) is connected with the arch supports (2) into a whole; the anchor bar piles (3) are arranged at the lower end of the arched concrete bottom plate (1) at intervals, and each anchor bar pile (3) keeps perpendicular to the lower end of the bottom plate (1); and the arch supports (2) at the two ends are positioned at the lower ends of protection slopes (9) at the two ends. The design method is completed by five steps, makes full use of the natural 'pan bottom'-shaped river beds, avoids touching geostress concentration areas at the bottom of the valley due to trapezoid excavation, and adopts the inverted arch structure to finally transfer most of load to rock mass through the arch supports instead of bearing all the load by the river beds, thus improving the stress concentration phenomenon at the bottom of the valley.

Owner:POWERCHINA XIBEI ENG

Skirt and frame of tank container

InactiveCN106185069AMeet the transportation conditionsSimple pathLarge containersStress concentrationButt joint

The invention relates to a skirt and frame of a tank container. The skirt comprises a box body and two rear sealing plates. The box body comprises a top straight-barrel arc section, a bottom straight-barrel arc section, a first connection section and a second connection section. One end of the top straight-barrel arc section is connected with one end of the bottom straight-barrel arc section through the first connection section. The other end of the top straight-barrel arc section is connected with the other end of the bottom straight-barrel arc section through the second connection section. The outer diameter of the top straight-barrel arc section and the outer diameter of the bottom straight-barrel arc section are both the same as the outer diameter of a tank body. The upper arc section and the lower arc section are both connected with the tank body through butt joint welding seams. By means of the design of the structure of the skirt, the longitudinal impact force borne by the tank container can be uniformly dispersed and transmitted through multiple routes, each transmission route is simple and direct, the whole frame is reasonable in force bearing, no large stress concentration can be generated, and the railway transportation working conditions can be completely met.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

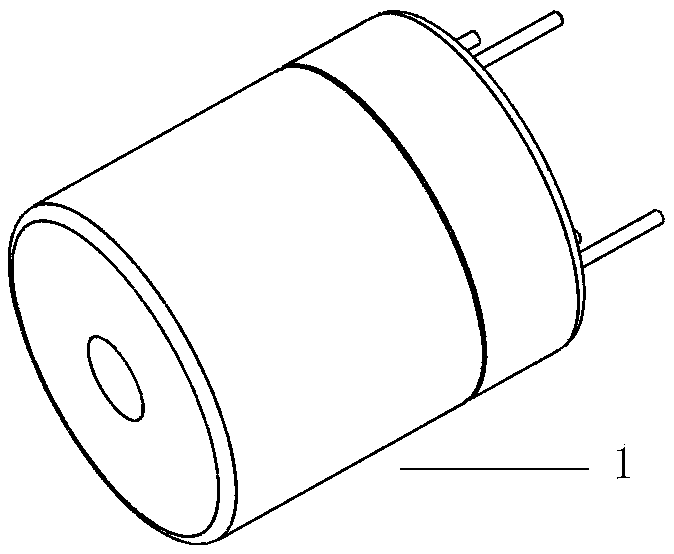

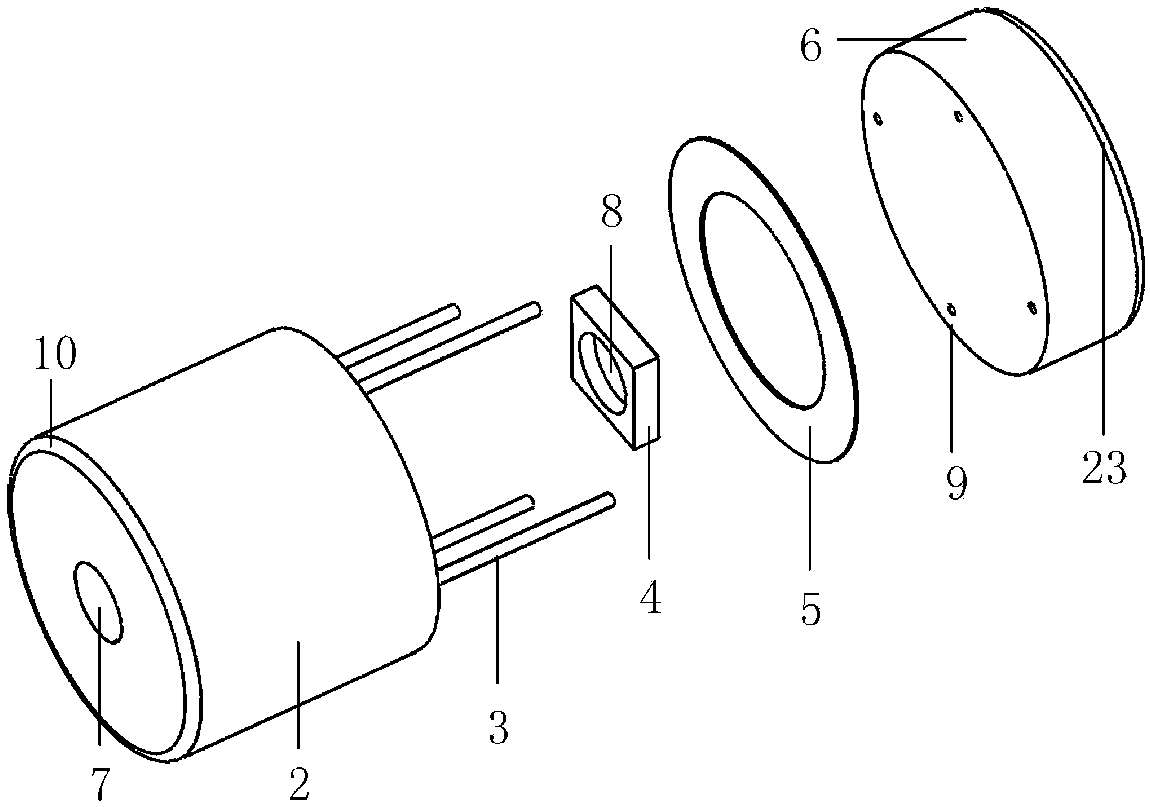

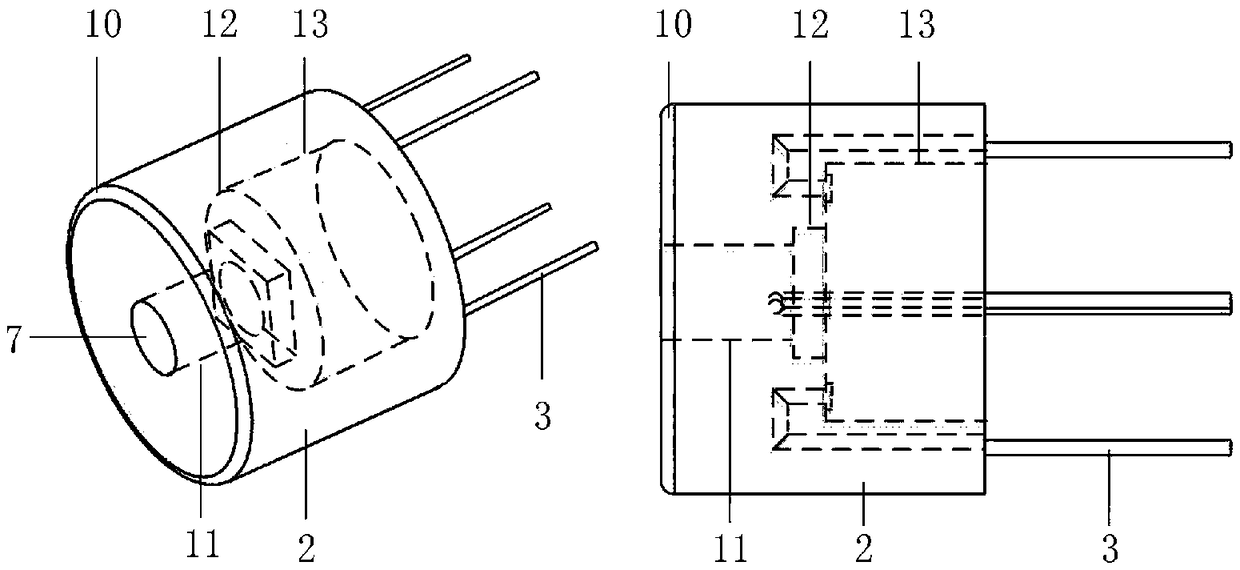

Miniaturized heat-resistant and high-dynamic pressure sensor

ActiveCN108871652ASolve the problem of high temperature failureImprove high temperature stabilityFluid pressure measurement by electric/magnetic elementsAdhesiveEngineering

A miniaturized heat-resistant and high-dynamic pressure sensor comprises a sensor probe which is internally provided with a sensor chip, the sensor chip is fixed through a heat-resistant ceramic adhesive, the sensor probe is connected with a metal tungsten filament which passes through a seal plate, and the seal plate is connected with the sensor probe; the front end face of the sensor probe is provided with a pressure guidance hole which communicates with a pressure channel and a square sensor chip in the sensor probe, the rear end of the sensor chip installation groove is provided with a sensor vacuum chamber, and the side wall of the sensor probe is internally provided with a the metal tungsten filament taken as a lead terminal of the pressure sensor; the sensor chip is square-shaped, four sensitive resistors are arranged at the front surface of the sensor chip in the same direction, the back surface of the sensor chip is a square cavity corresponding to a square sensitive film, andthe pressure is applied to the square sensitive film through the pressure guidance hole. The miniaturized heat-resistant and high-dynamic pressure sensor is small in volume, resistant to heat and fast in response, and can be used for measurement of the total pressure and the static pressure.

Owner:XI AN JIAOTONG UNIV

Display panel, display device and manufacturing method of display panel

InactiveCN104460092AReduce the chance of fragmentationImprove stress concentrationSolid-state devicesNon-linear opticsStress concentrationDisplay device

The invention discloses a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a first substrate and a second substrate, the first substrate and the second substrate are opposite, the first substrate comprises multiple first side edges and at least one second side edge, and the second substrate comprises multiple third side edges and at least one fourth side edge. The first side edges correspond to the third side edges and are flush with the third side edges. The second side edges correspond to the fourth side edges. At least one notch is formed in the second side edges, and the length of each notch is smaller than that of the corresponding second side edge. According to the display panel, the positions of the side edge of the first substrate and the side edge of the second substrate correspond to each other, the notches are formed in the second side edges of the first substrate, the probability of breaking of the display panel when the display panel falls down or is impacted is lowered, the stress concentration problem of the display panel is solved, and the strength of the display panel is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

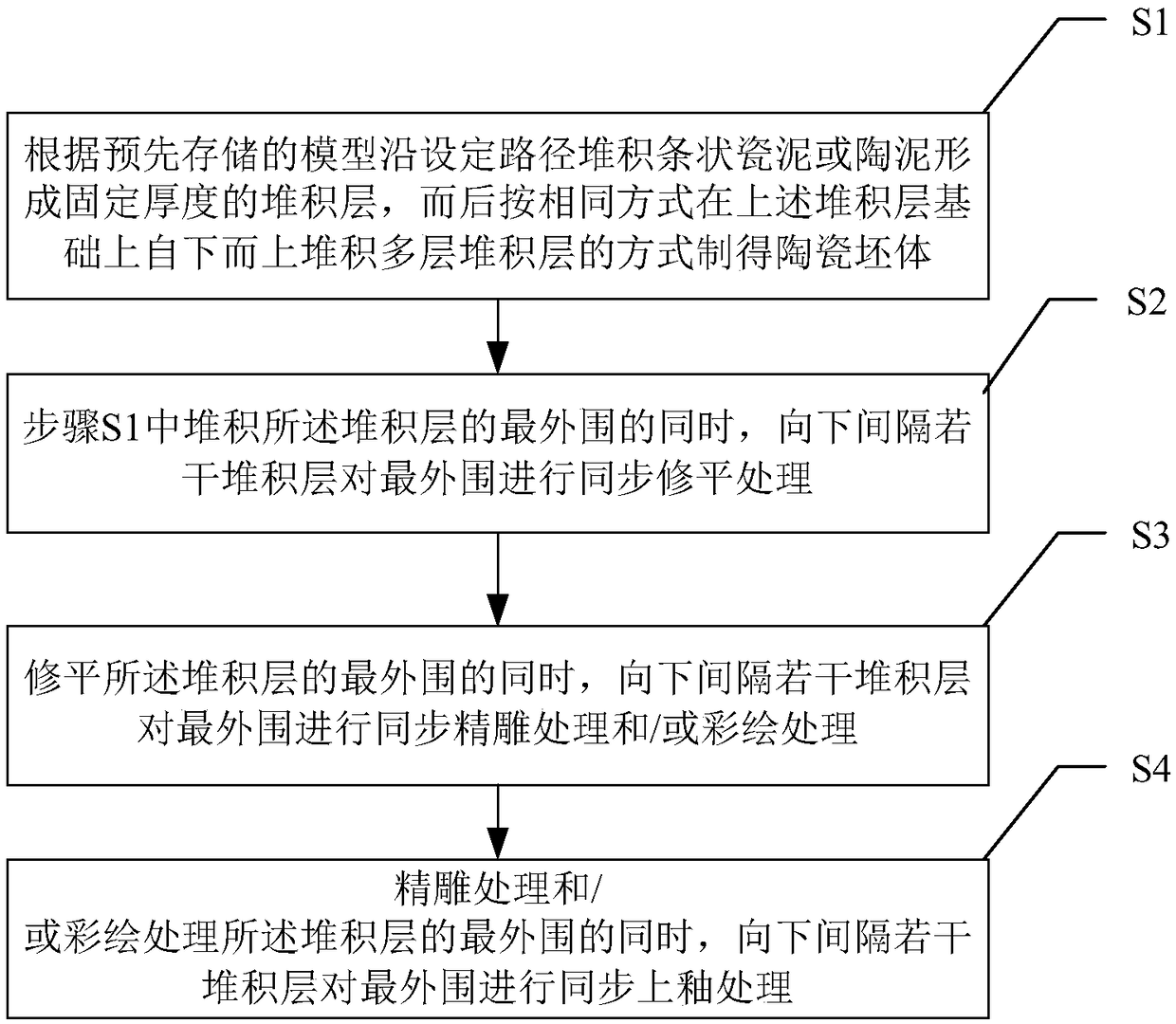

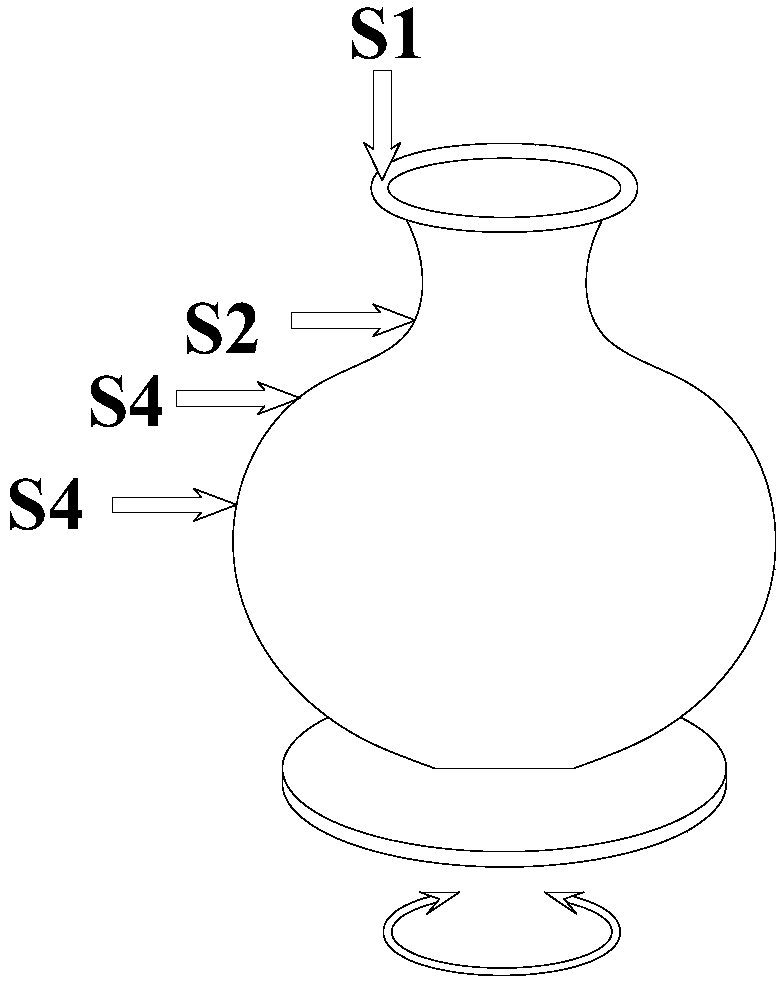

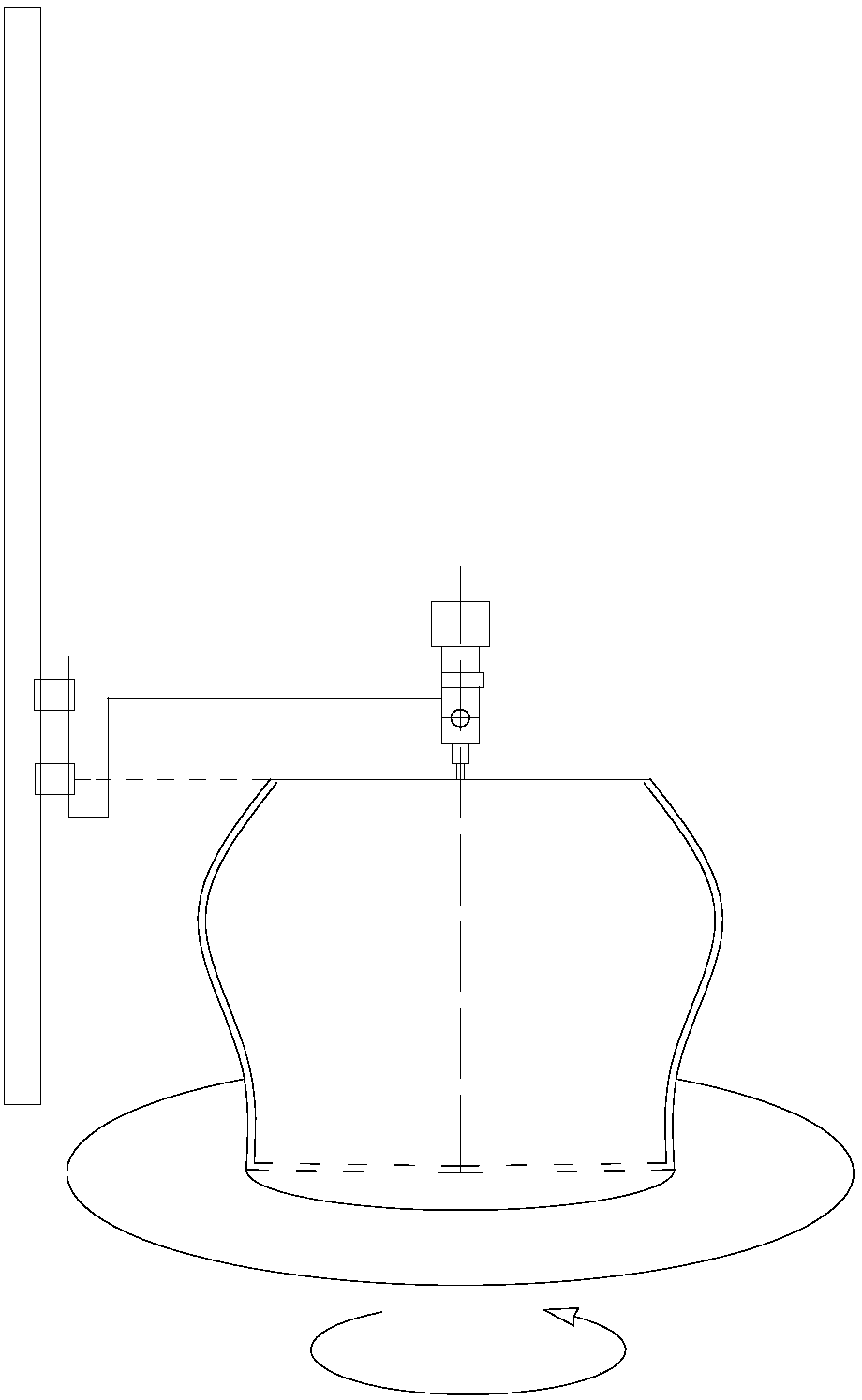

Large and medium chinaware manufacturing method

ActiveCN108582416ARich Applicable TypesReduce manufacturing costCeramic shaping apparatusClaywaresTime spaceCeramic

The invention discloses a large and medium chinaware manufacturing method. Compared with a traditional method, such subsequent treatment processes as outer surface finishing, finish carving treatmentand / or colored drawing treatment and glazing of large and medium chinaware ceramic blanks and production of chinaware outer profile surfaces belong to simultaneous asynchronous treatment spaced by specific space-time intervals, so that the problem of performing subsequent processes one by one after completion of previous treatment procedures in the traditional method is overcome, and saving of a lot of time and delication of the artistic effect can be both considered. In addition, the method can finish complex shapes, is more suitable for manufacturing of large and medium artistic shape chinaware, meanwhile, greatly enriches the shaping range of large and medium chinaware, and greatly reduces the manufacturing cost of large artistic porcelains.

Owner:湖南筑巢智能科技有限公司

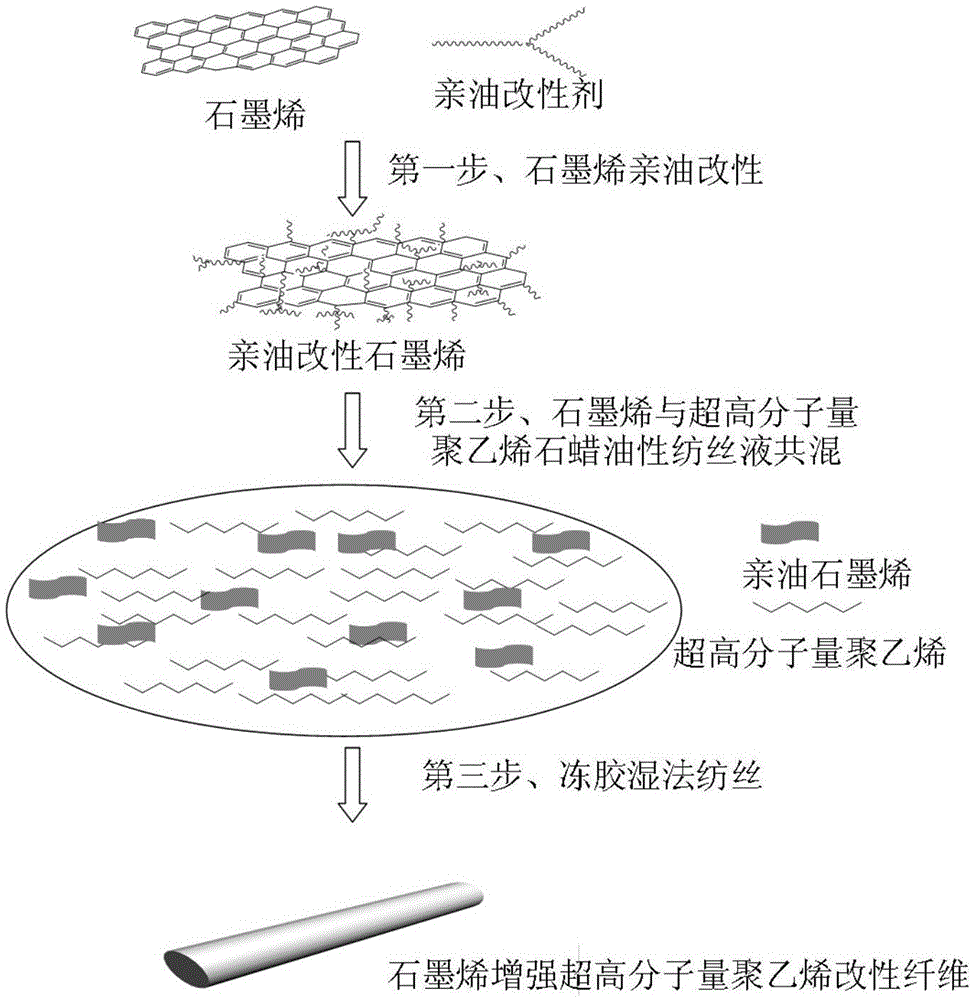

Preparation method of graphene ultra-high molecular weight polyethylene hybrid fiber

InactiveCN105483848AHigh strengthImprove lipophilicityMonocomponent polyolefin artificial filamentArtifical filament manufactureStress concentrationPolymer science

The invention belongs to the technical field of high-performance fiber preparation and relates to a preparation method of a graphene ultra-high molecular weight polyethylene hybrid fiber. The preparation method comprises three technological steps of graphene (or oxidized graphene) lipophilic modification, oleophilic modified graphene dispersion liquid and ultra-high molecular weight polyethylene paraffin oil spinning solution co-mixing and gel wet spinning, and particularly comprises the following steps: dispersing graphene or oxidized graphene in an ethanol solution; adding an oleophilic modifier for co-mixing; performing oleophilic graft modification; adding an antioxidant and ultra-high molecular weight polyethylene into paraffin to prepare an ultra-high molecular weight polyethylene paraffin oil spinning solution; co-mixing an oleophilic modified graphene dispersion liquid and the ultra-high molecular weight polyethylene paraffin oil spinning solution. The prepared fiber is high in matrix strength, has the mechanical properties of creep resistance, good heat resistance, improved stress concentration and the like; the preparation method is simple, convenient to operate and wide in application.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com