Modification configuration finishing roll group and modification configuration method thereof

A configuration method and technology of finishing rolls, applied in rolls, keeping roll equipment in an effective state, metal rolling, etc., can solve the complex control of curve equation parameters, failure to take into account the wear of backup rolls and work rolls, and unsuitable patterned steel plates, etc. question

Inactive Publication Date: 2011-09-21

SHANGHAI MEISHAN IRON & STEEL CO LTD

View PDF8 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this patent also fails to take into account the wear of backup rolls and work rolls, and its curve equation parameters are complicated to control. Since the patterned rolls cannot grind the CVC roll profile when rolling checkered plates, it is not suitable for rolling checkered steel plates.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

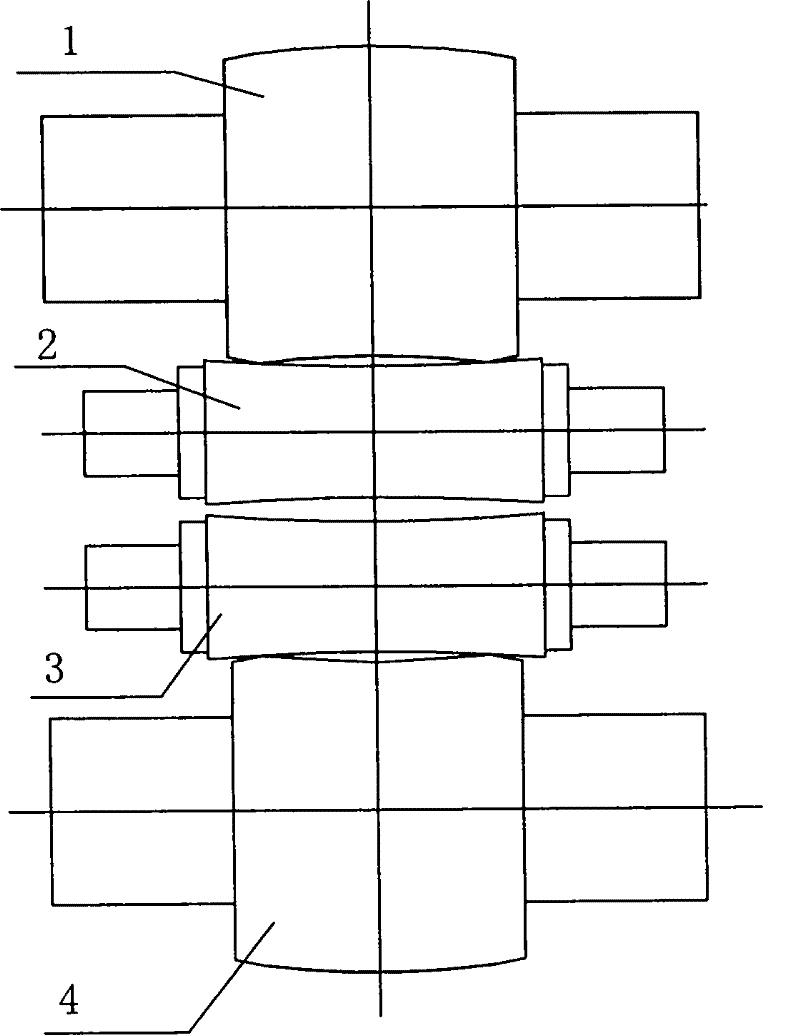

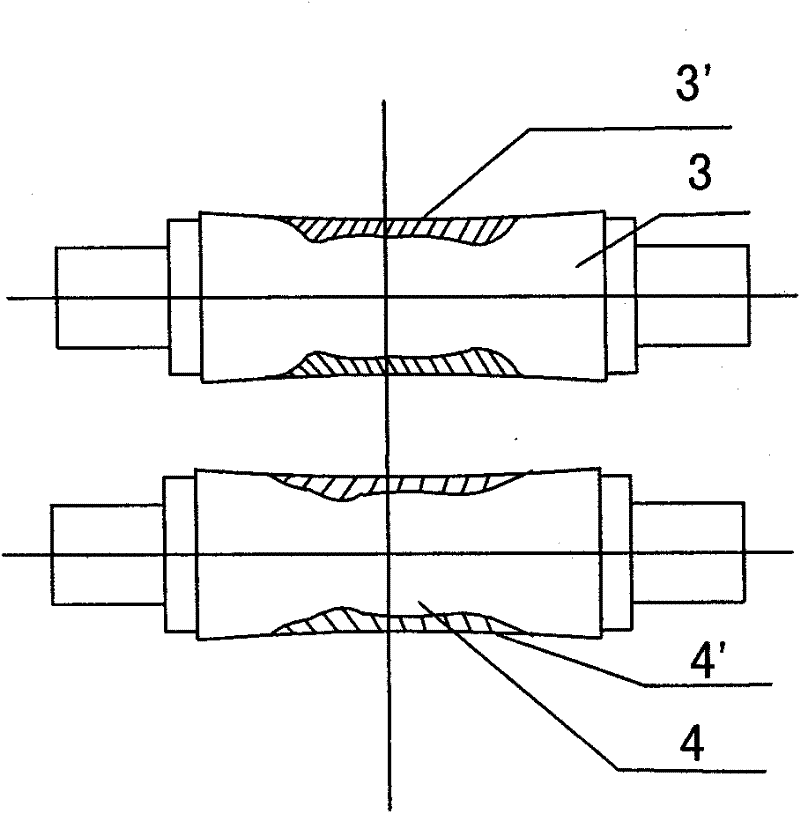

The invention relates to a modification configuration finishing roll group and a modification configuration method thereof, belonging to the technical field of metallurgical production equipment. The finishing roll group comprises an upper support roll, a lower support roll, an upper working roll and a lower working roll, wherein the upper and lower support rolls are supported on the rear sectionof a rack; the upper and lower working rolls are located between the upper and lower support rolls; and the generatrices of the upper and lower working rolls are formed according to an equation respectively, wherein the upper working roll is '+', and the lower working roll is '-'. Through the invention, the practical shapes of the upper and lower working rolls on the rear section of the rack forma corresponding convex roll and a concave roll respectively, and the rolling clearance conforms to the requirement; due to the abrasion of the support rolls, the contact pressure between the working roll and corresponding support roll is more uniform, and the local centralized stress condition between rolls is obviously improved; and meanwhile, as the protuberance of the upper working roll effectively compensates for the abrasion, the service life of the working roll is greatly prolonged.

Description

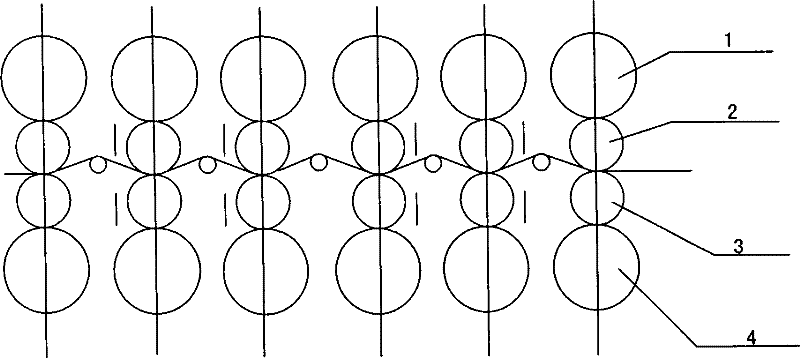

Finishing roll set for configuration modification and method for configuration modification technical field The invention relates to a configuration of finishing rolls, in particular to a configuration of finishing rolls configured for modification and a configuration method thereof, belonging to the technical field of metallurgical production equipment. Background technique In the hot rolling production process, the upper and lower work rolls 2, 3 and / or backup rolls 1, 4 (see Figure 1) of the four-high mill are affected by the rolling force, temperature and cooling conditions, and there are obvious wear and tear inconsistencies Phenomenon. For example, the wear 2' of the upper work roll 2 of the post-finishing stand is more serious than the wear of the lower work roll 2 3' (see Figure 3), and the wear of the lower support roll 4 of the last stand is generally greater than that of the upper support Wear 1' of roll 1 (see Figure 4). Due to the inconsistent wear of the ro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21B27/02B21B28/02

Inventor 李欣波王宁宁

Owner SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com