Patents

Literature

119results about How to "Uniform contact pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

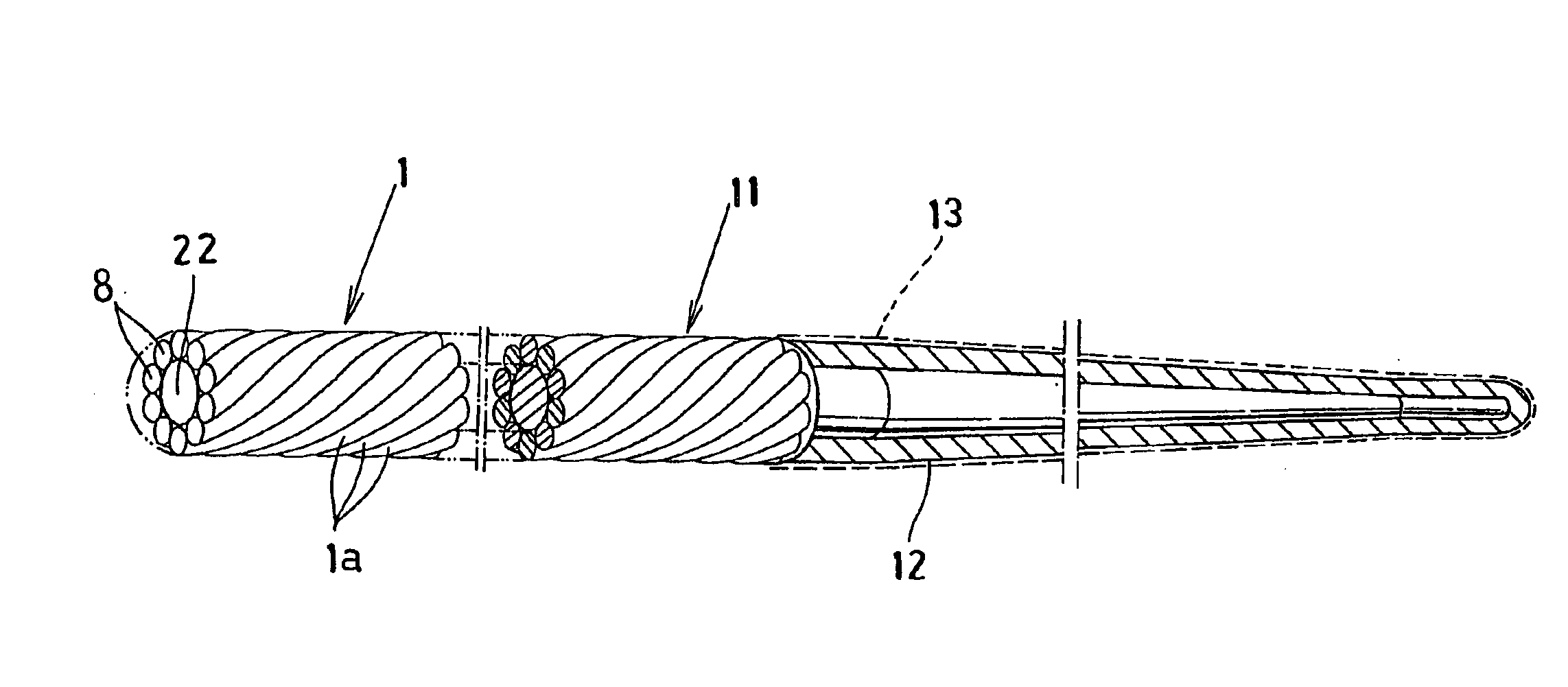

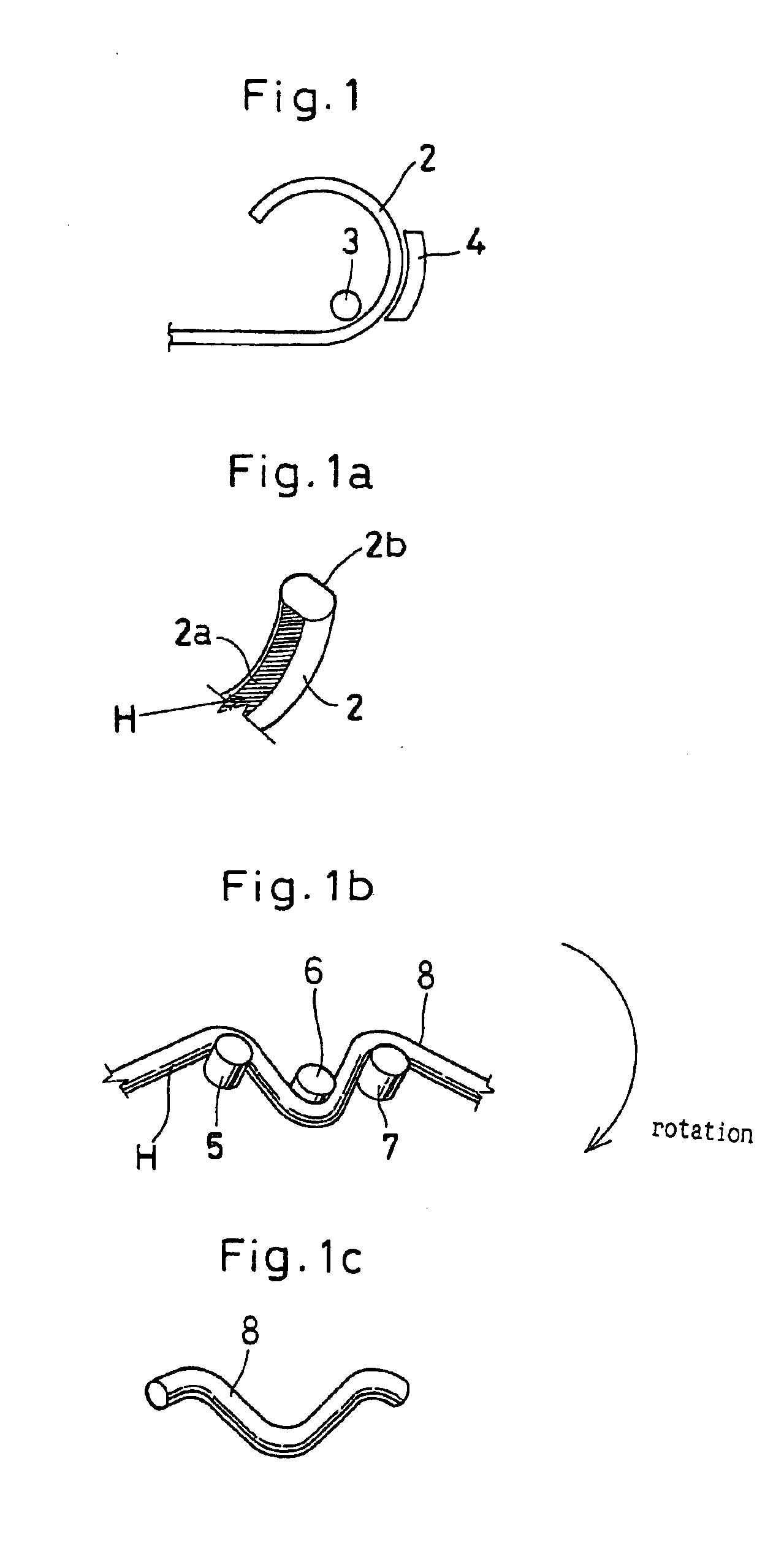

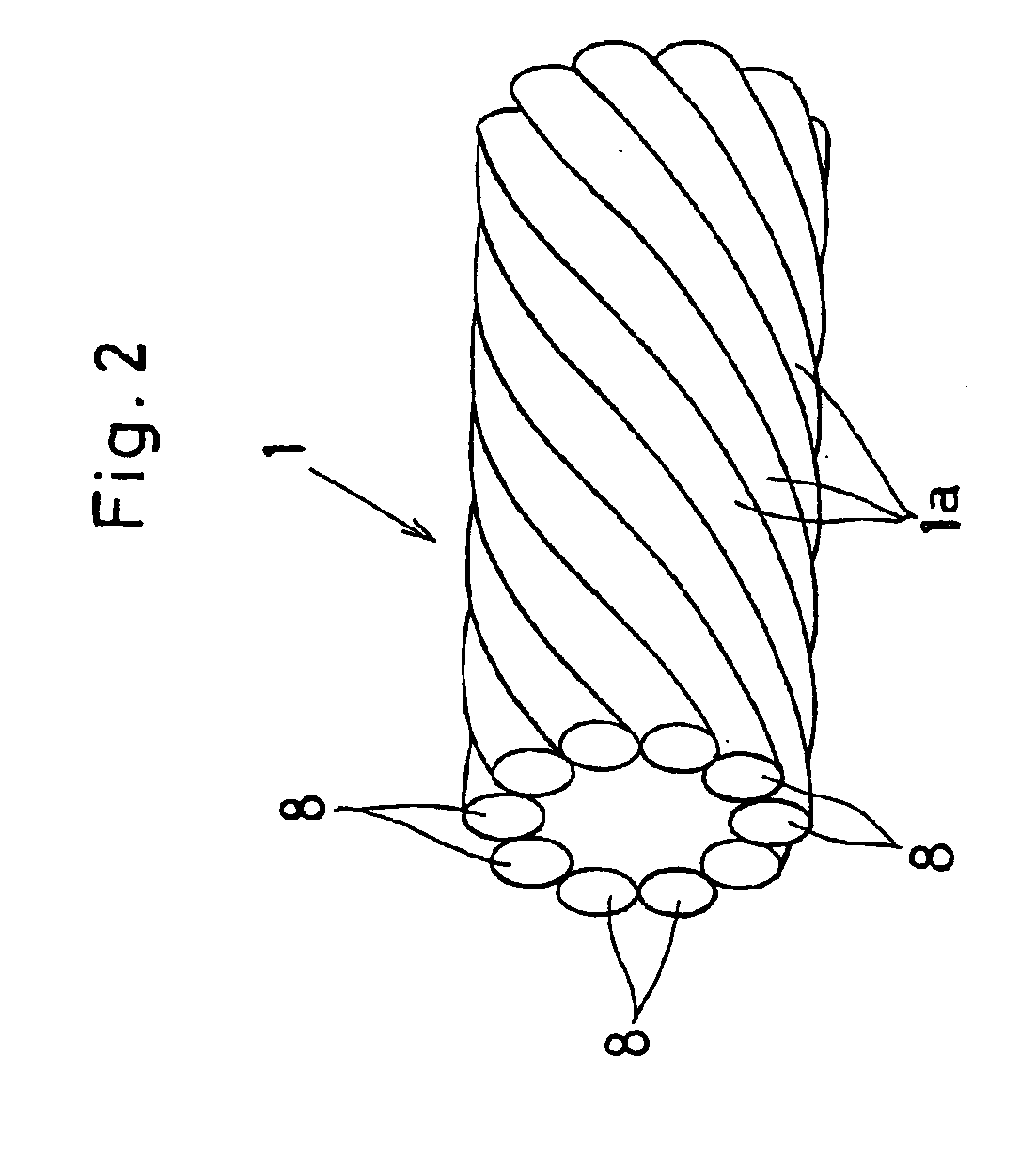

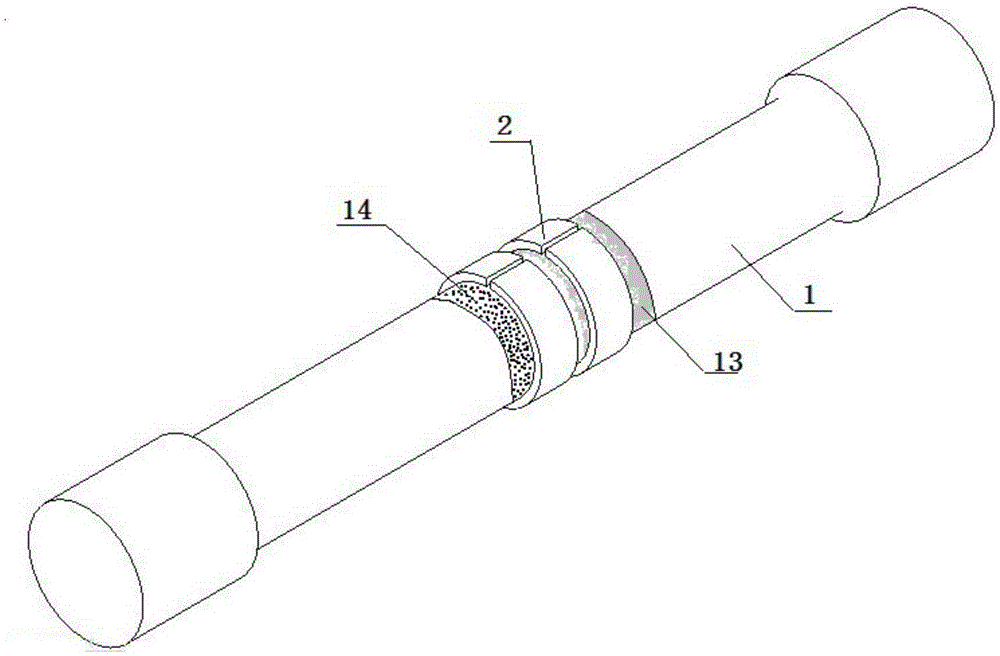

Wire-stranded medical hollow tube, and a medical guide wire

InactiveUS6881194B2Good flexibilitySmoothly introducedGuide wiresMedical devicesContact pressureEngineering

In a wire-stranded hollow tube (1), a plurality of metallic wires (8) preformed with a predetermined forming rate are twisted along a circular line into a careless hollow configuration. When twisting the metallic wires (8), the neighboring metallic elements (1a, 1a) are subjected to compression with no gap between the neighboring metallic elements (1a, 1a). This increases a contact pressure between the neighboring metallic elements (1a, 1a) to attain a good tightness with a good circularity and diametrical uniformity secured therebetween, thus preventing the wire-stranded hollow tube (1) from inadvertently collapsing. A tightness is strengthened between the neighboring metallic elements (1a, 1a) when the metallic elements (1a, 1a) of different helical pitch are used. By applying the wire-stranded hollow tube (1) to a medical guide wire, a quick torque response and a good torque transmissibility are ensured which lead to a good manipulatability with a favorable follow-on capability.

Owner:ASAHI INTECC CO LTD

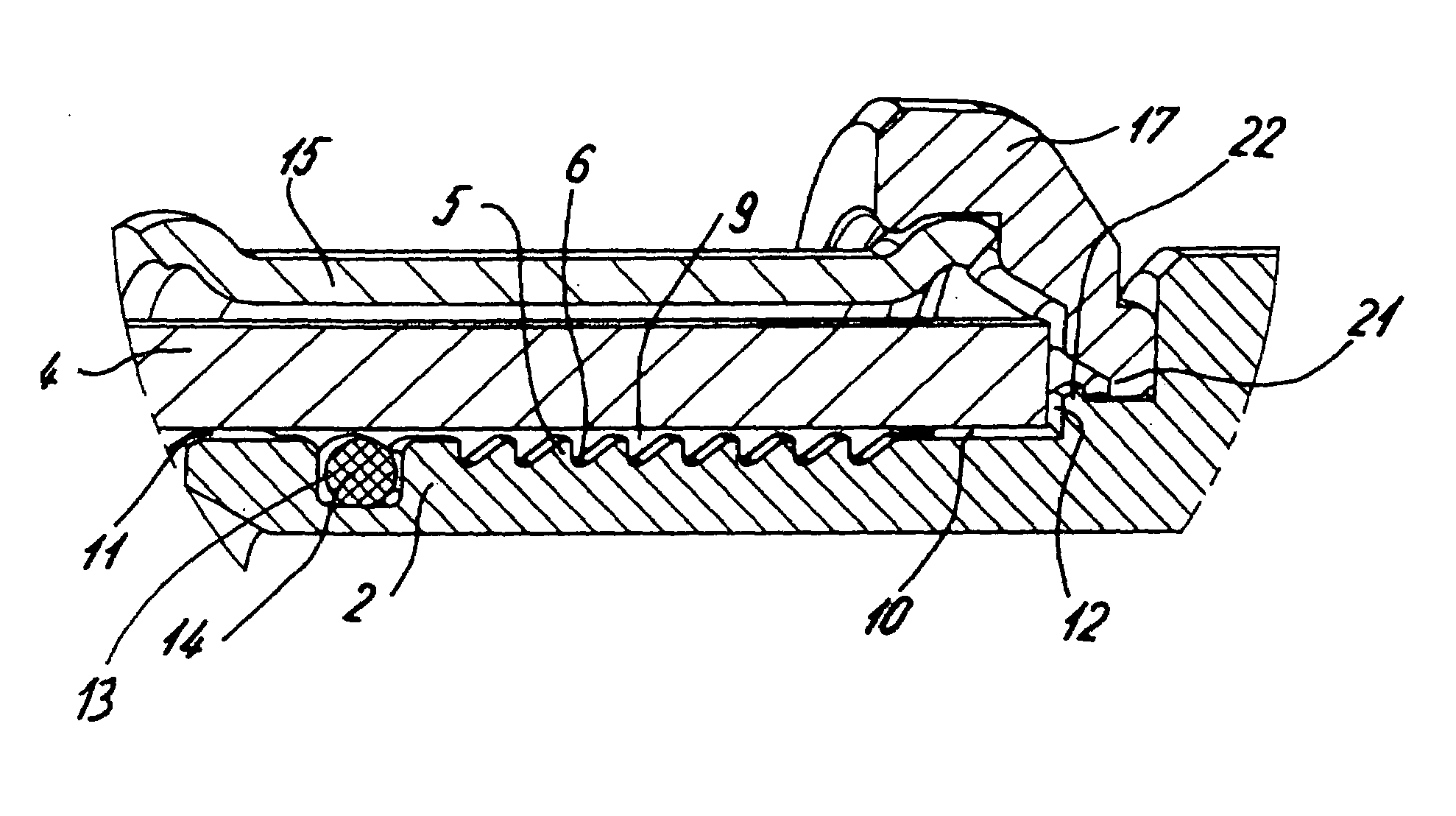

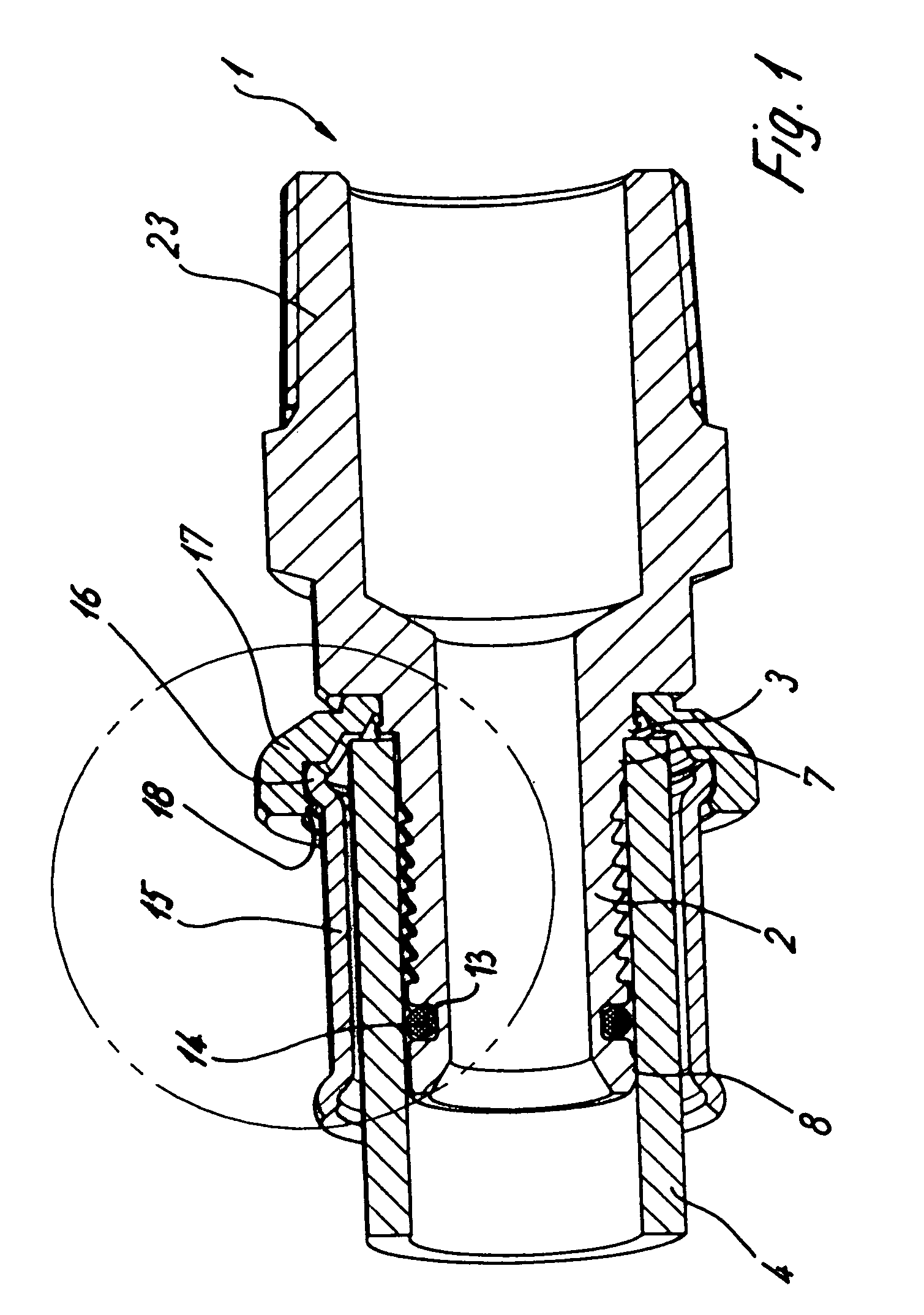

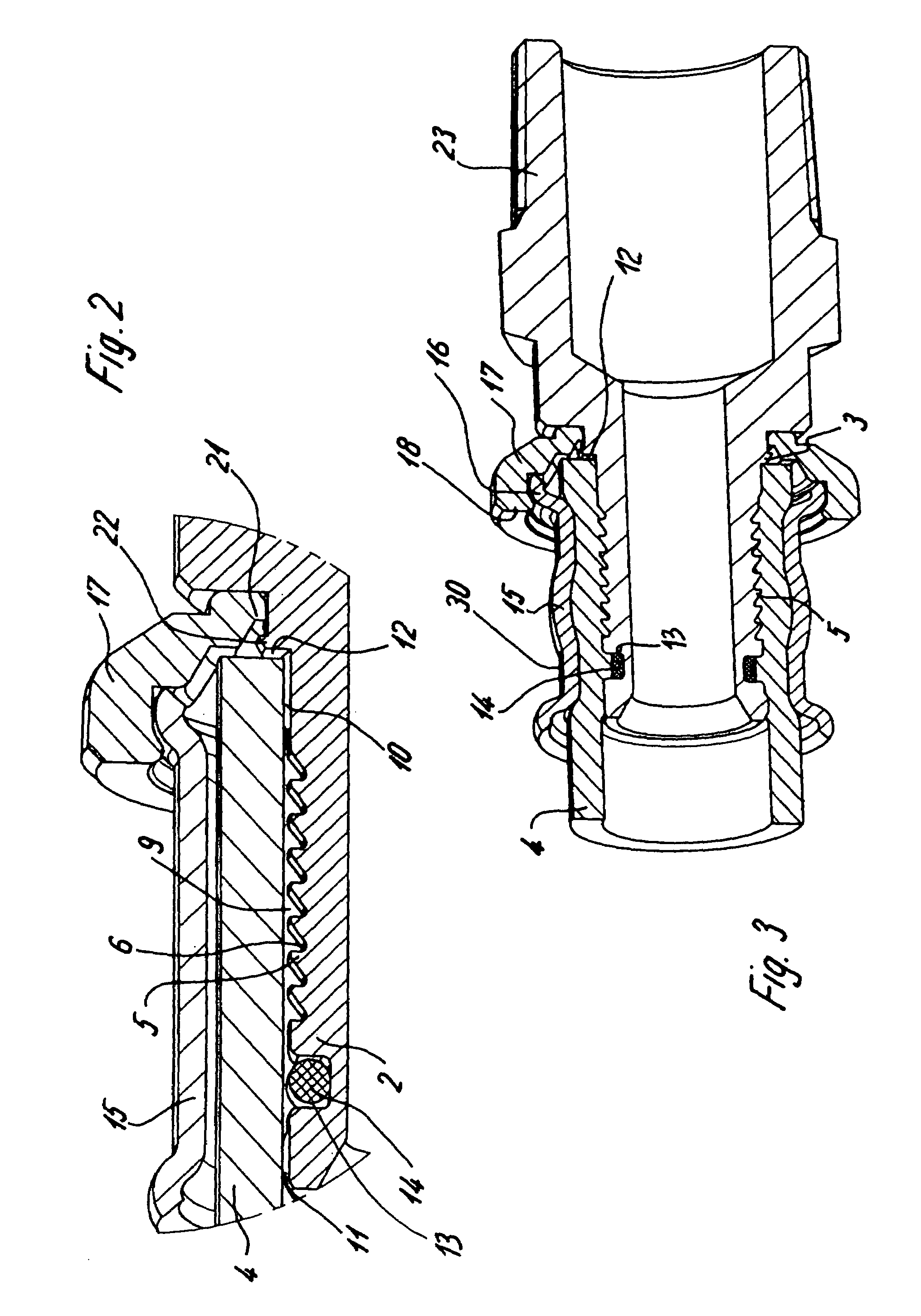

Connecting piece and connecting arrangement

InactiveUS6874823B2Durable pressed connectionPrevent movementJoints with sealing surfacesPipe couplingsEngineeringMechanical engineering

A connecting piece for establishing a connecting arrangement for a pipe which can be pressed together comprises a stub which can be inserted into a pipe. Profilings for the pressing-together with the pipe and a stop are on the stub. At least one radially projecting spacer is provided on the stub. The spacer defining a gap for forming a flow duct between the stub and the pipe. The spacer may have an interruption for forming part of the flow duct.

Owner:FRANZ VIEGENER II GMBH & CO KG

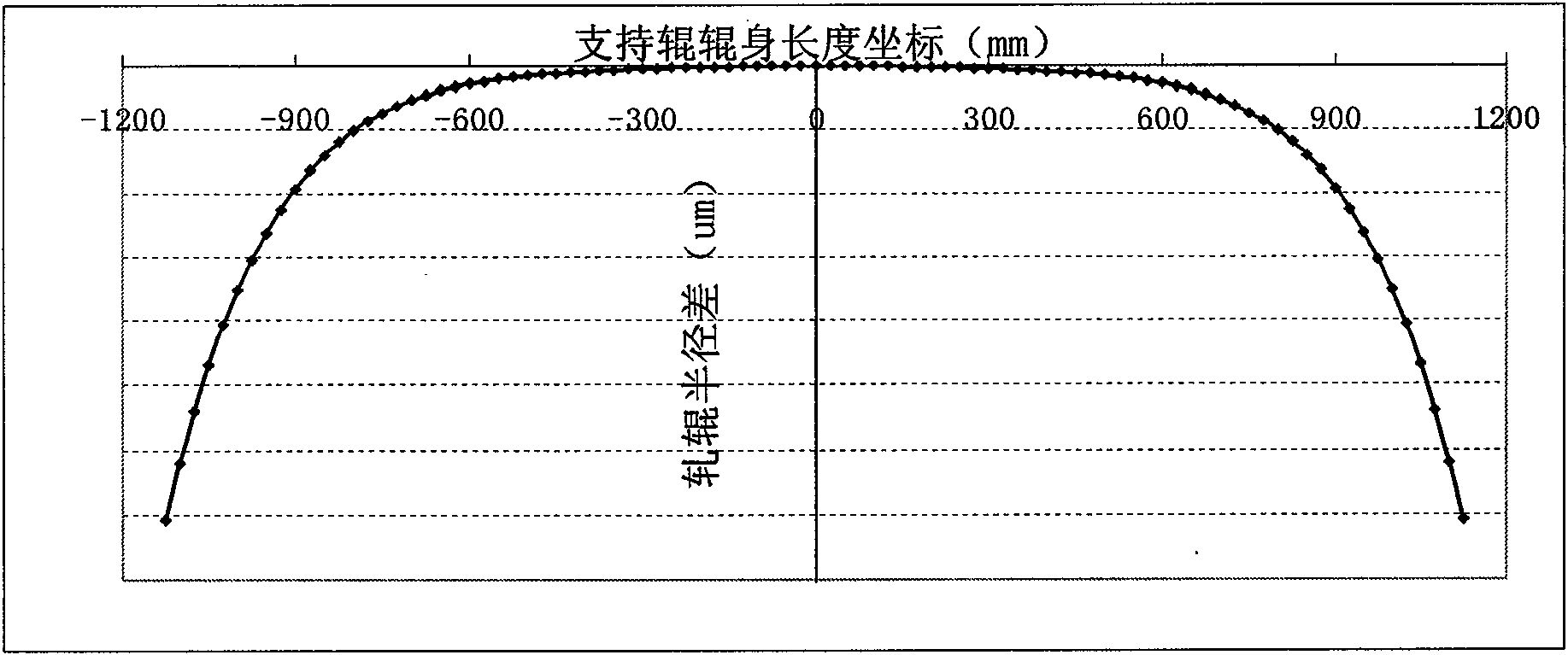

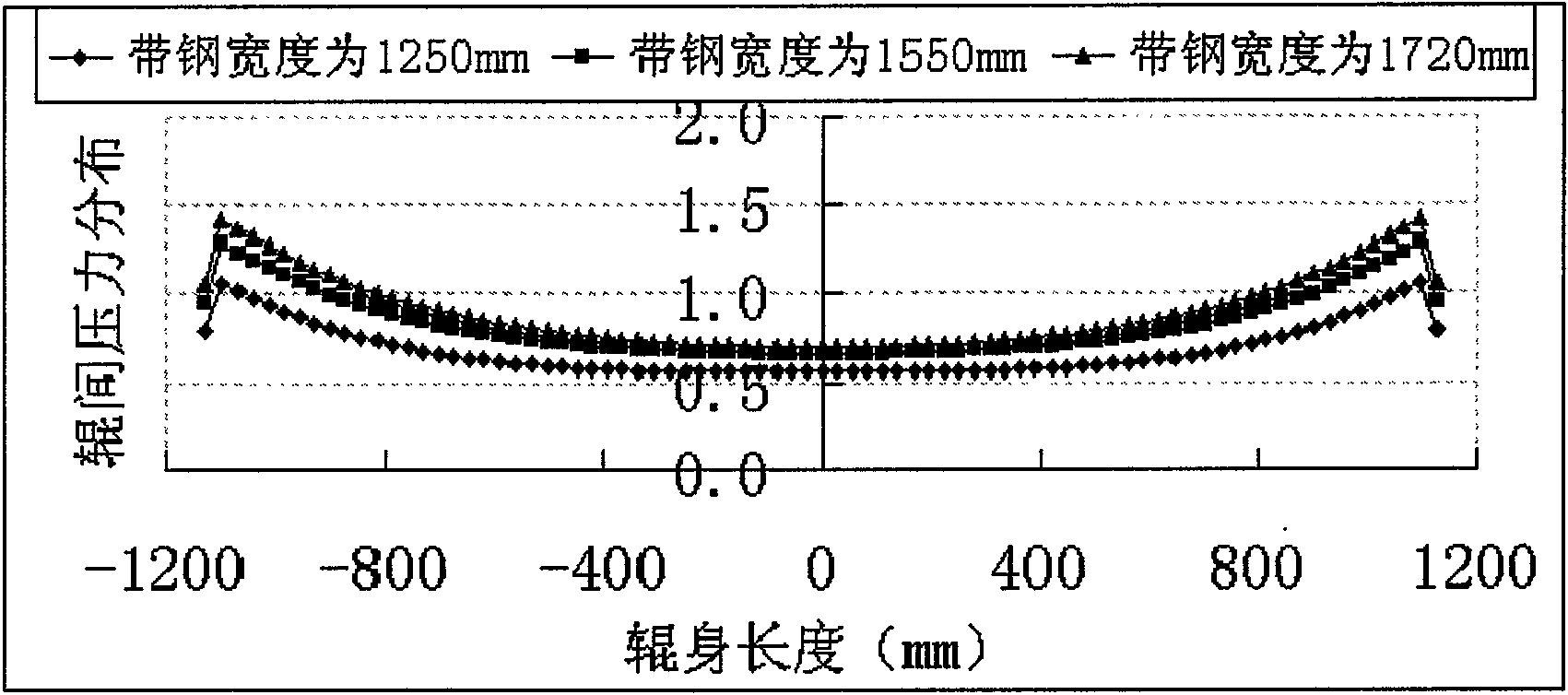

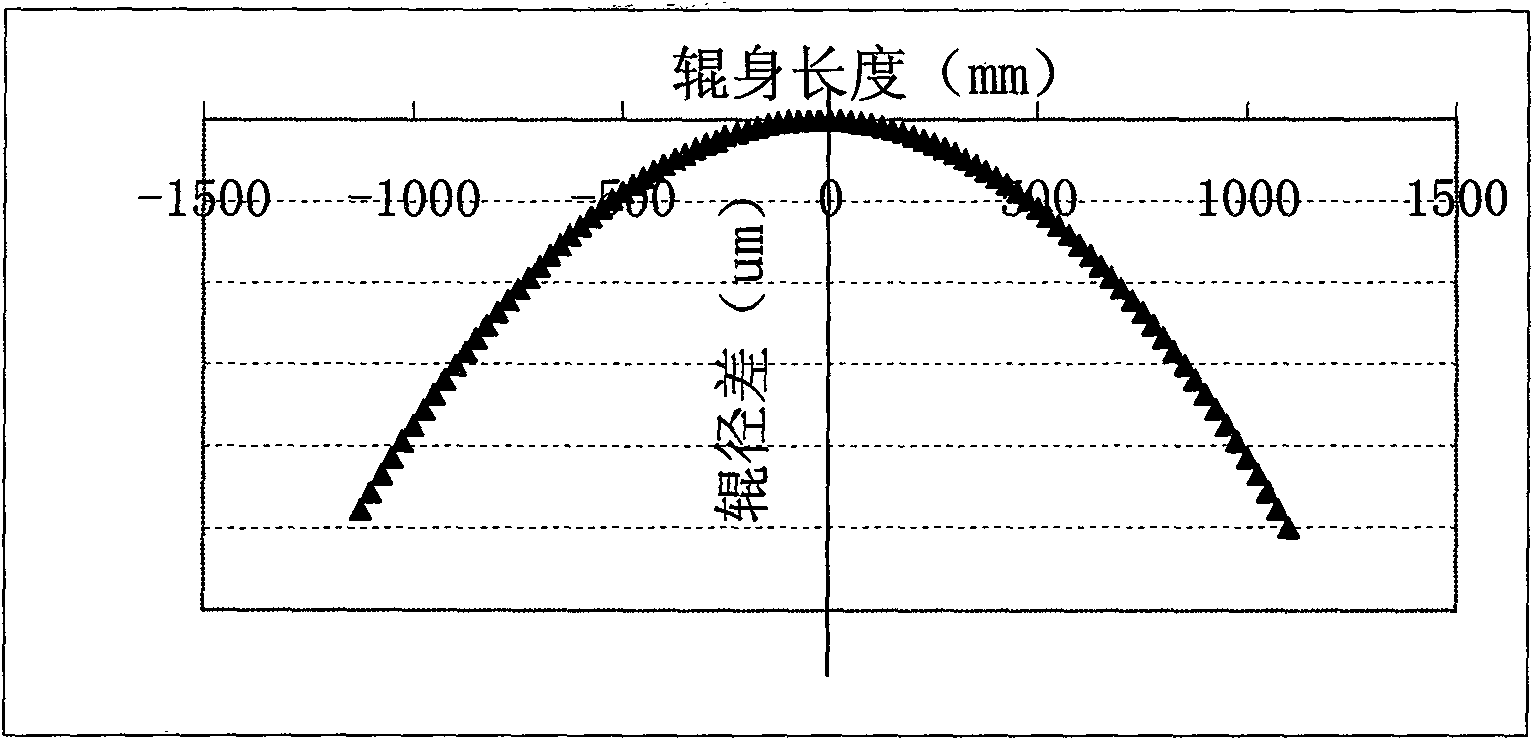

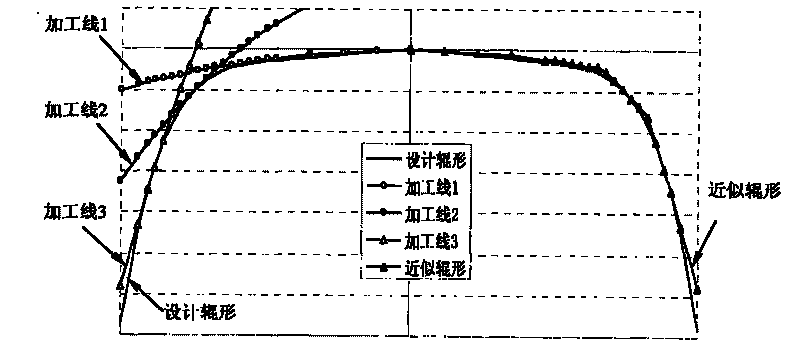

Method for configuring shape of supporting roll of four-high mill and shape of working roll thereof

ActiveCN101554635ASolve peelingSolve the large amount of wear and tearCounter-pressure devicesRollsProduction lineStress concentration

The invention relates to a method for configuring the shape of a supporting roll of a four-high mill and the shape of a working roll thereof, belonging to the technical field of steel rolling. According to three types of width specifications of band steel which are most rolled by hot-rolling band steel production line, sixth-power polynomial supporting roll shape technology and second-power working roll shape curve are used for configuration so as to lead the contact length of the supporting roll and the working roll and the width of the rolled band steel to be fit. The method has the advantages of eliminating hazardous contact areas in which the parts of the two ends of the supporting roll with the flat roll shape and the working roll expand out of the edge of the band steel to generate large deflection and deformation, solving the problems that the stress concentration of the edges of the supporting roll and the working roll in a hot continuous mill for wide band steel causes stripping and the mill roll with the flat roll shape has large wearing capacity and is not even, reducing the consumption of the mill rill, saving energy, reducing consumption and reducing cost for rolling steel; and by the technical configuration of R2 working roll shape and the supporting roll shape, the invention solves the plate-shape problems that the middle blank generates negative convexity and the wedge shape is large, and improves the control precision of the shape of hot-rolled band steel.

Owner:SHOUGANG CORPORATION

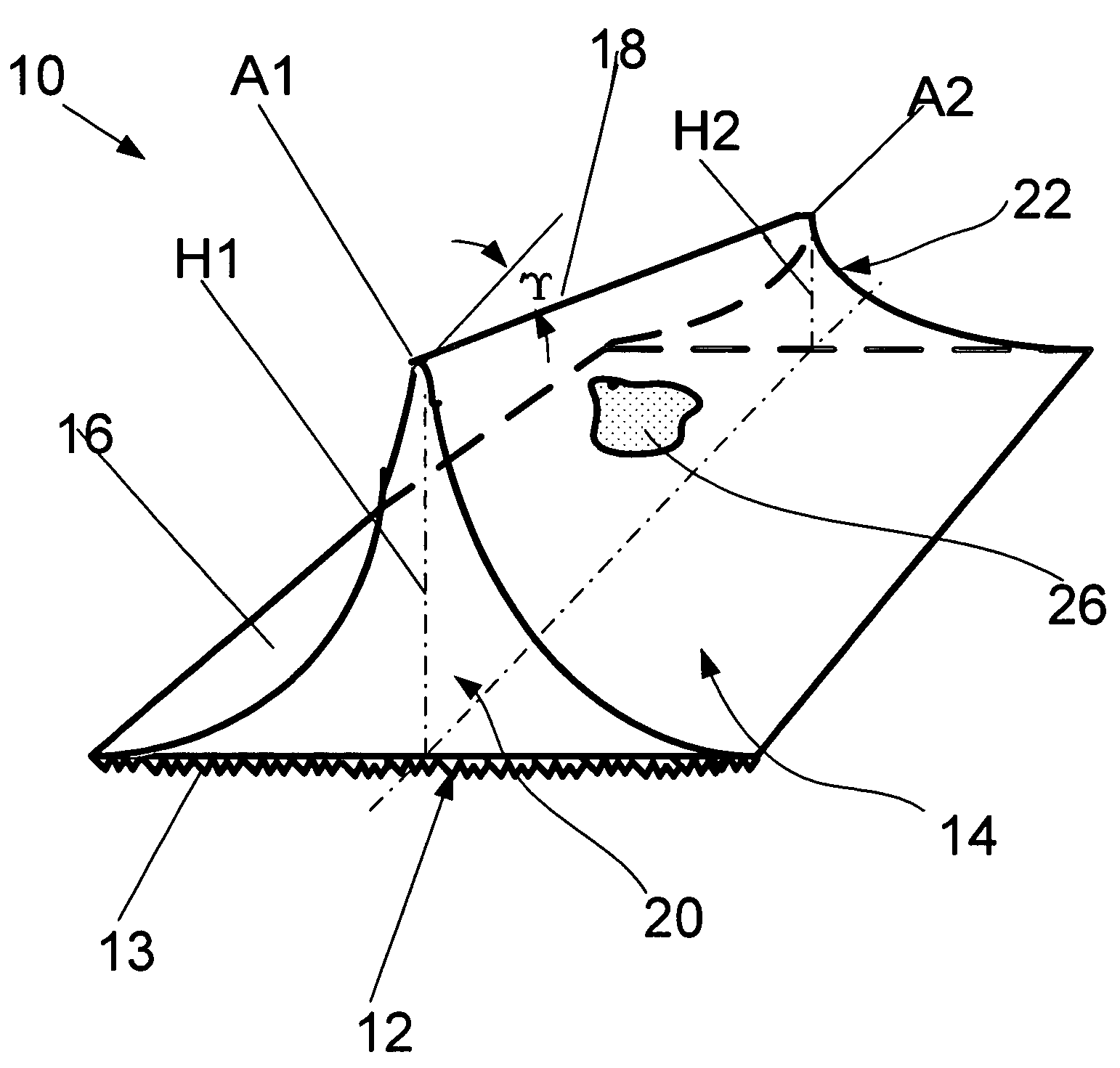

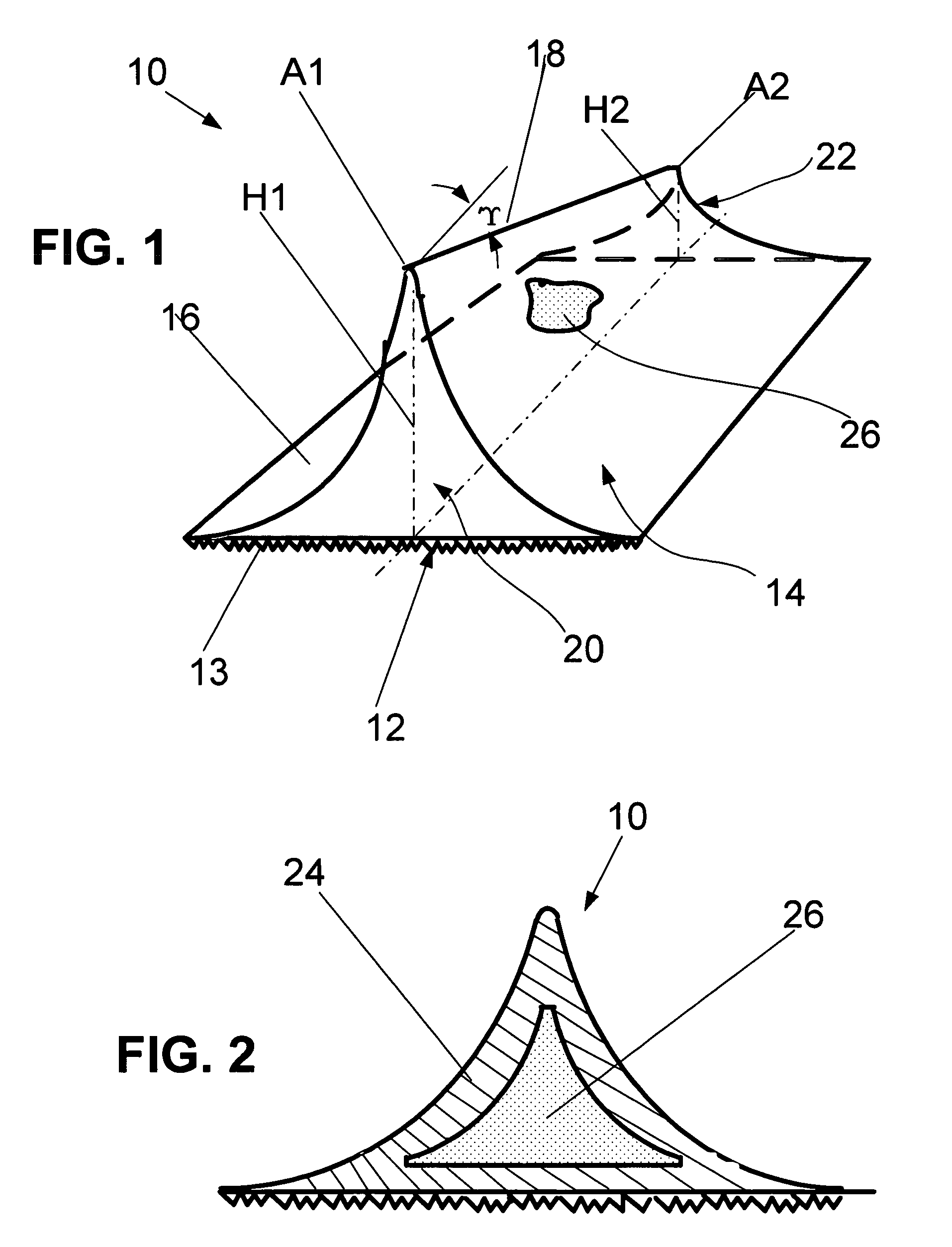

Ergonomic thigh support and method of uniformly distributing pressure on the thigh surface of a seated person

InactiveUS7255396B1Reduce contact pressureEasy to transportSafety beltsPedestrian/occupant safety arrangementThighMedicine

A pad for supporting a thigh of a person sitting on a seat in a position that alleviates pressure applied to the lower surface of the thigh and thus for improving blood circulation through the leg without numbness or similar phenomena associated with long-time sitting. The pad is made in the form of a soft deformable body filled, e.g., with a silicone gel. The pad has a flat rectangular bottom surface and curvilinear lateral sides. In the plane perpendicular to the bottom, the pad has a triangular cross-section with heights of the triangles gradually reduced from one end face of the pad to the opposite end face of the pad so that the ridge that connects the apexes of the triangular cross-sections from one end face to the other is inclined with respect to the flat bottom.

Owner:ANIKIN SERGEY

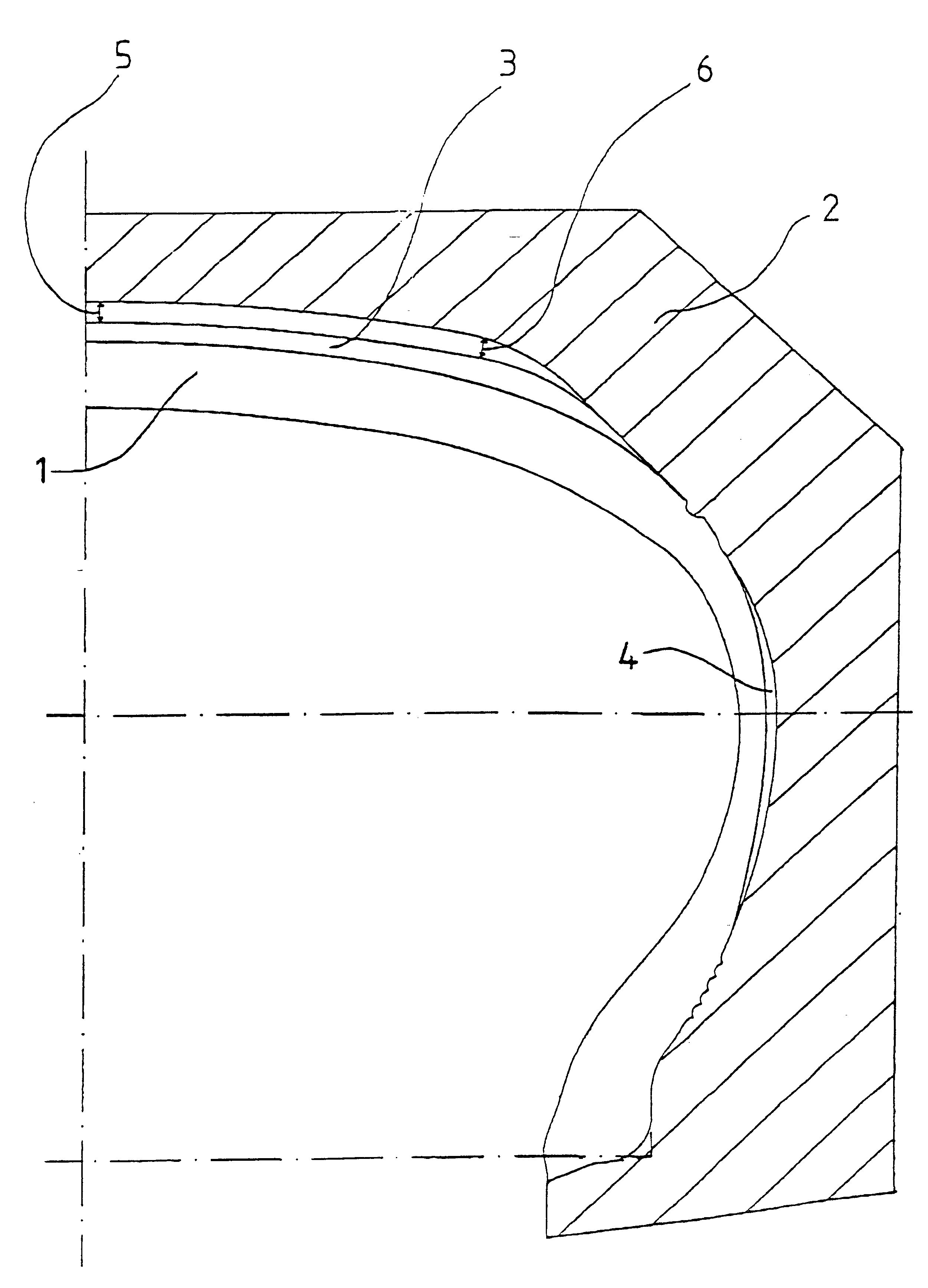

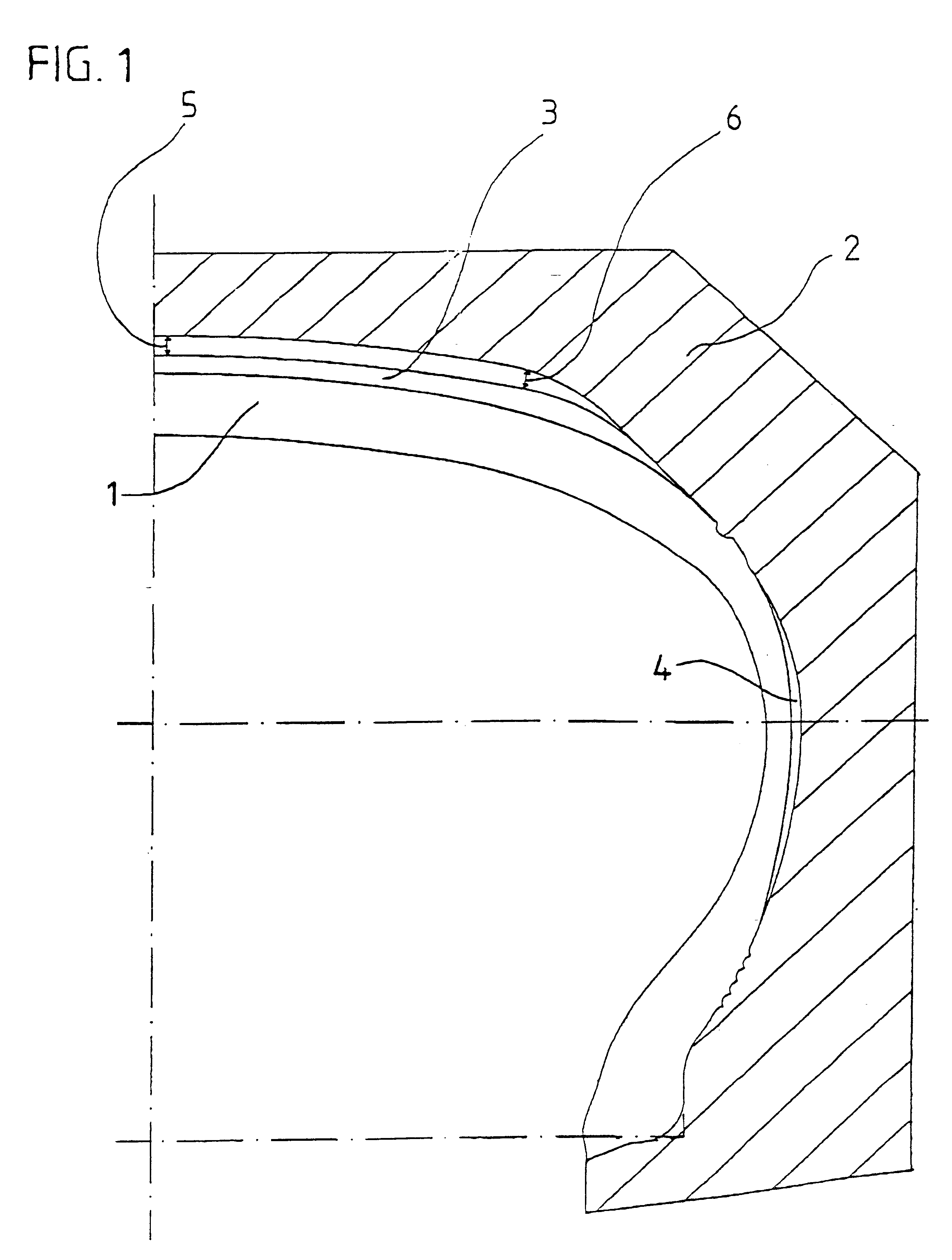

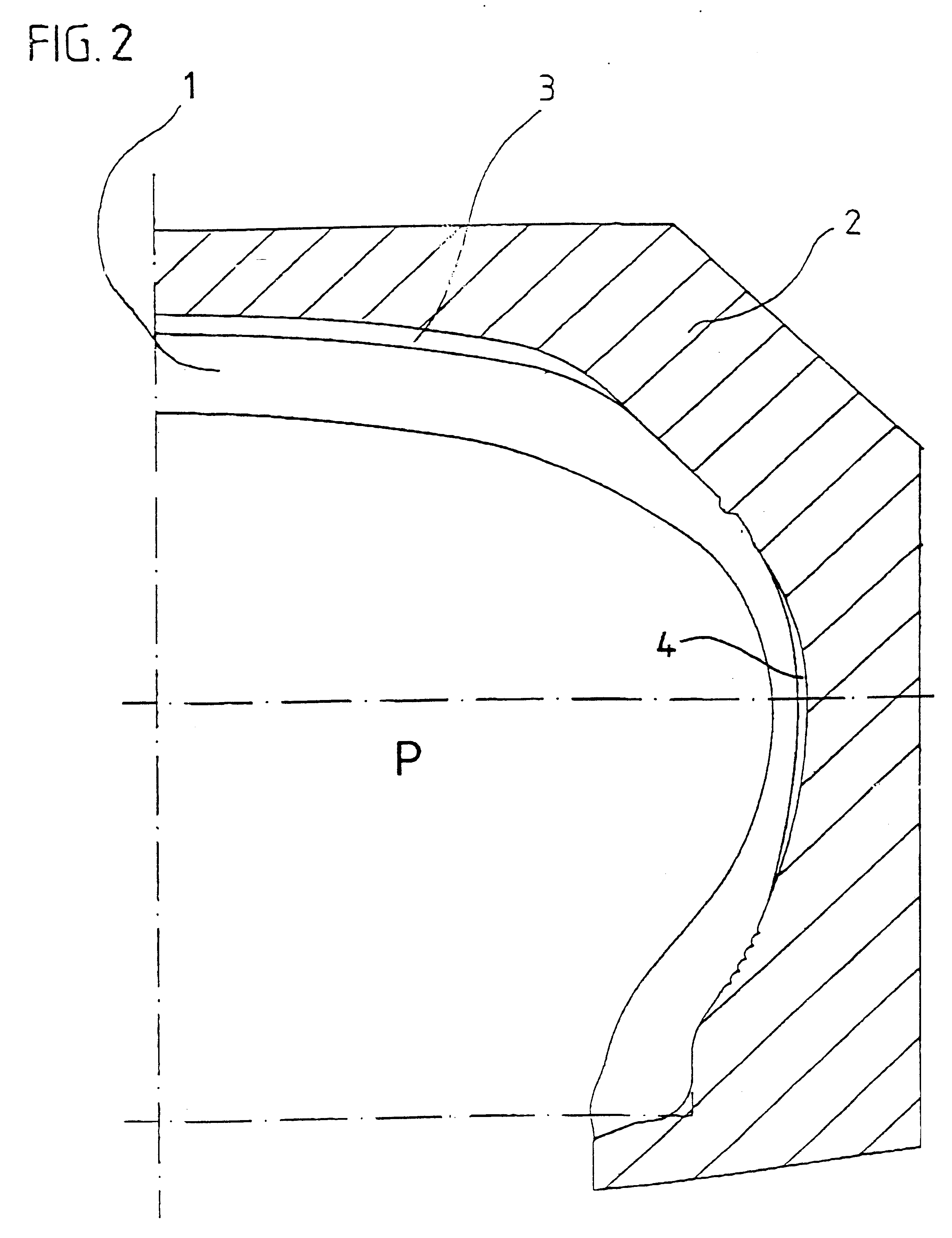

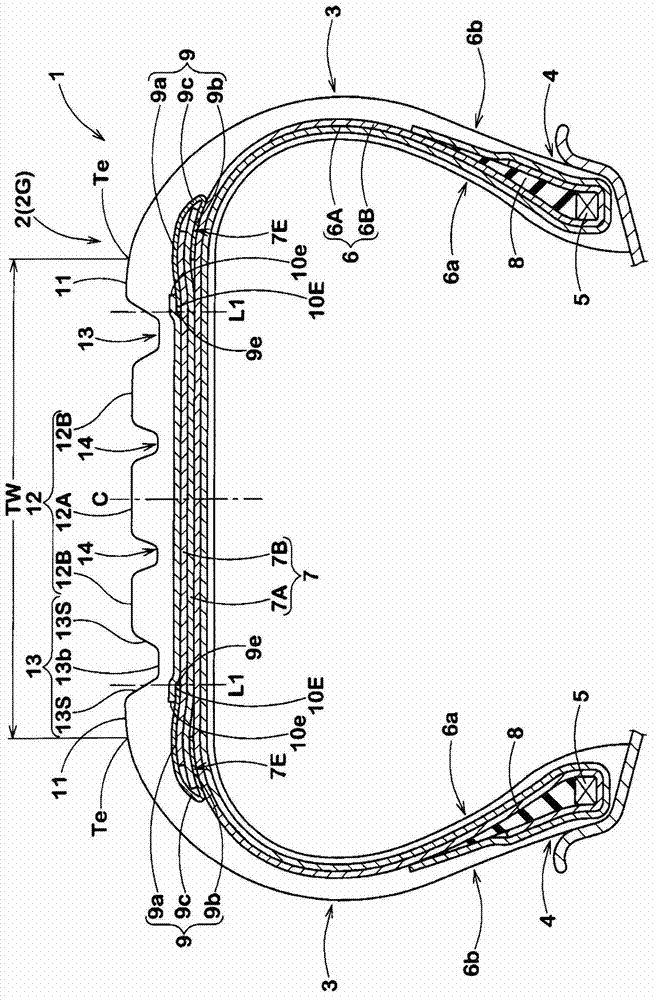

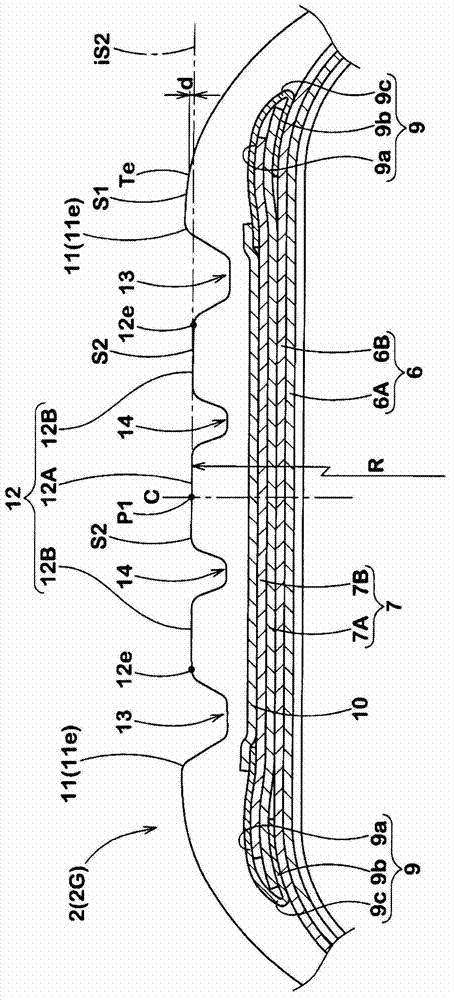

Process for producing a pneumatic tire

InactiveUS6406575B1Reducing cord forceGood effectTyresTyre tread bands/patternsInternal pressureVulcanization

Process for producing a pneumatic tire that includes an inner liner of a layer that is as air-impermeable as possible, at least one carcass ply provided with strength supports, horn profiles, bead cores, sidewalls, a belt assembly, and a tread. The process includes building-up a partial tire in a production part A, where the partial tire includes at least a carcass body that includes the at least one carcass ply provided with the strength supports, bead reinforcements and cores, core fillers and horn profiles, and an undertread, and shaping and at least partially vulcanizing the partial tire under an internal pressure in a vulcanization mold in a first vulcanization procedure. The process also includes determining a cross-sectional contour for a completed tire and an amount of surface and strength supports to be added to the partial tire prior to a production part B, and building-up the partial tire in the production part B by adding remaining tire components to produce a complete tire. Further, the process includes vulcanizing the complete tire in the vulcanization mold, thereby bonding the partial tire to the remaining tire components. While vulcanizing the complete tire, a residual elevation produced by internal pressure is applied, whereby the complete tire is molded to its final contour. The residual elevation in shoulder areas of the completed tire is greater than or equal to the residual elevation in a zenith area.

Owner:CONTINENTAL AG

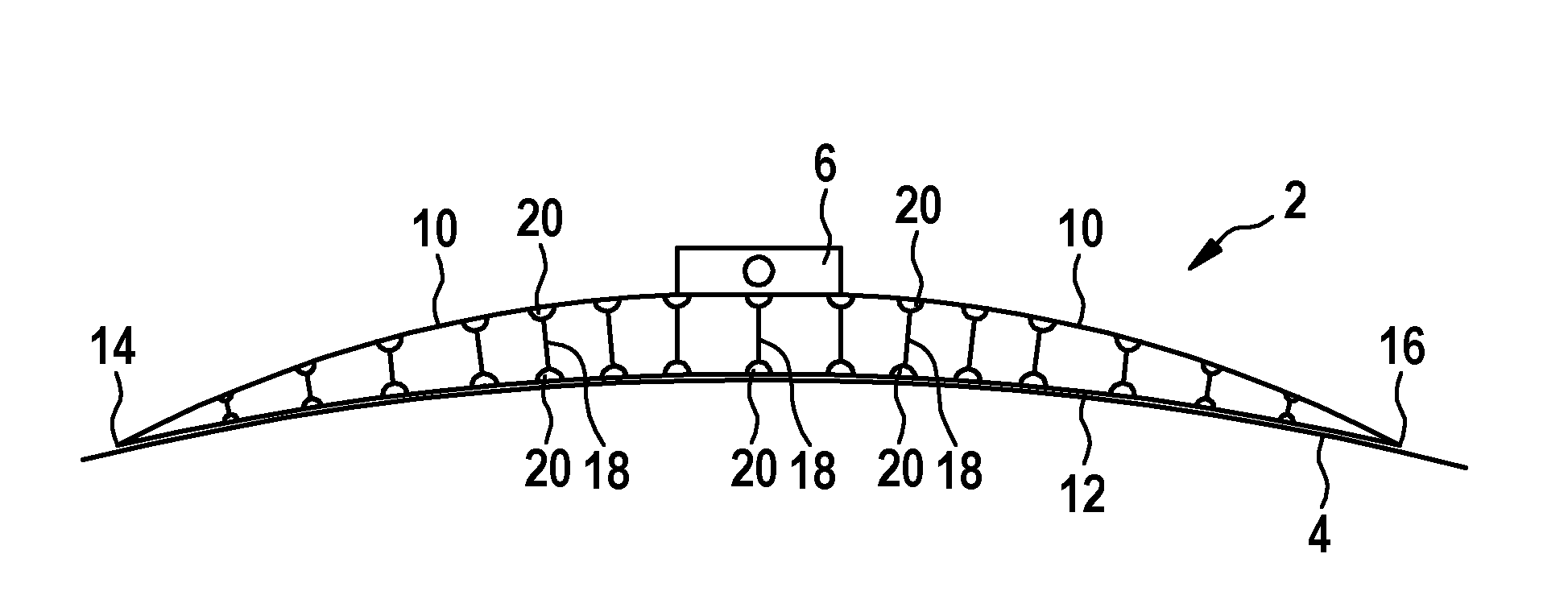

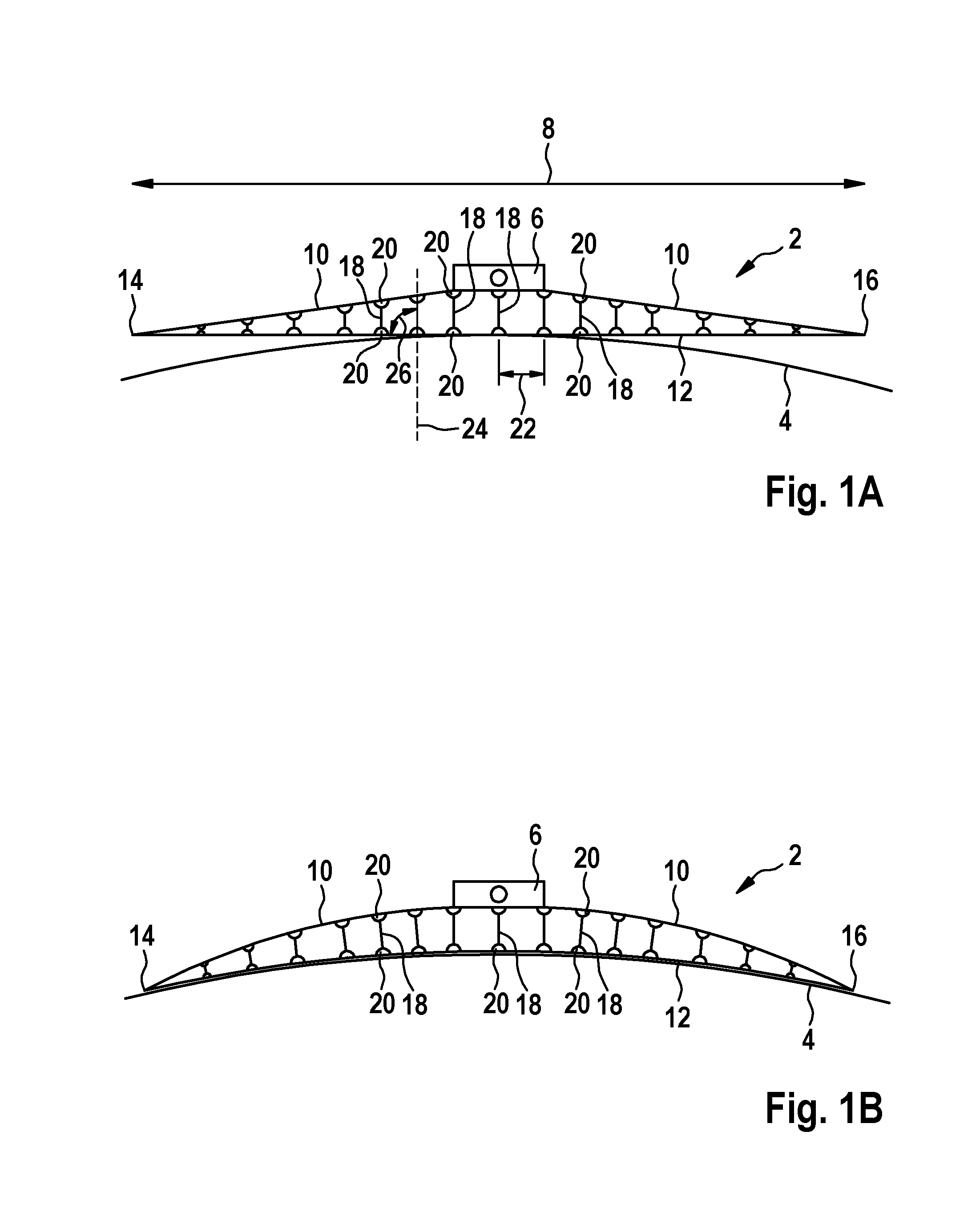

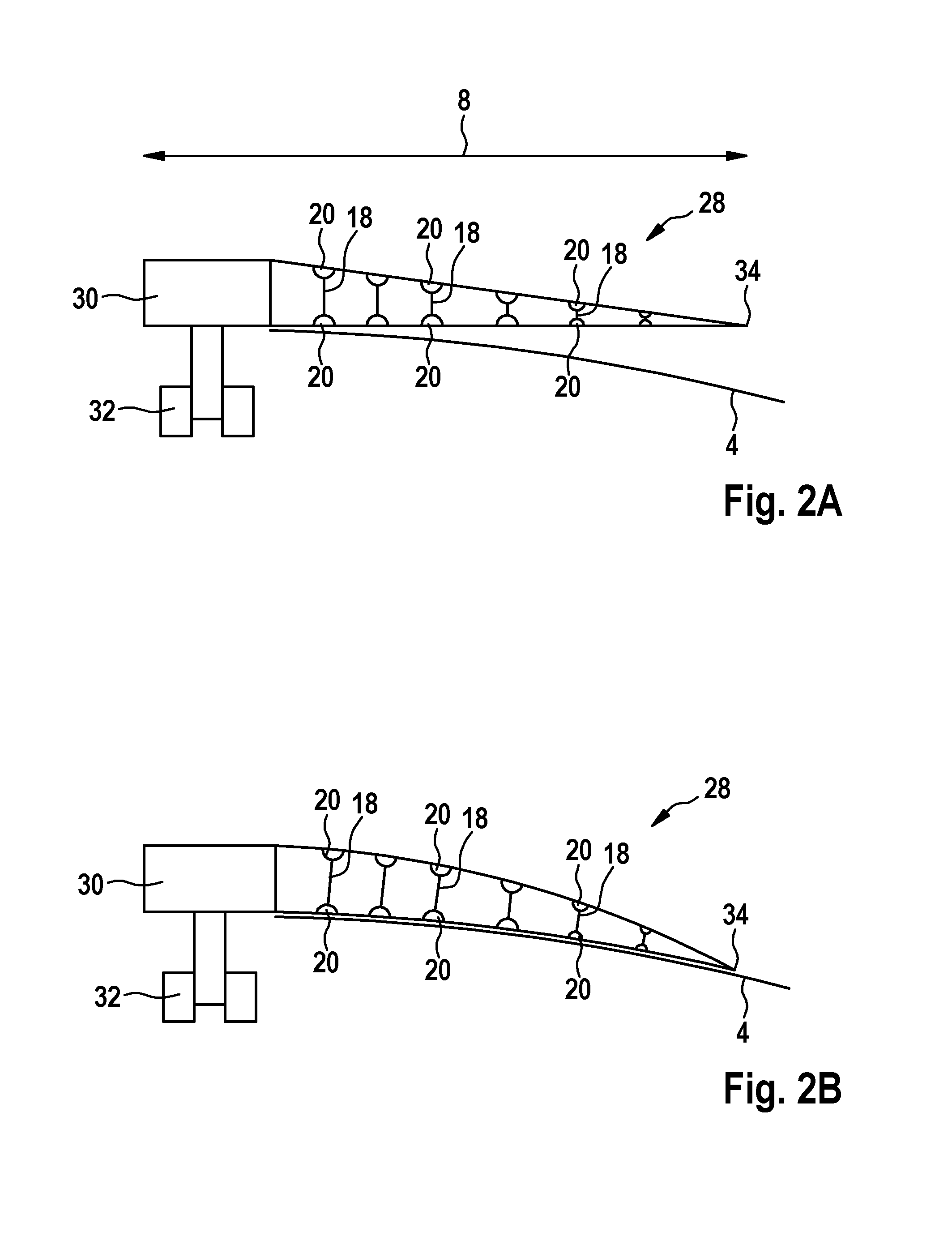

Windscreen wiper device for a vehicle

InactiveUS20160159322A1Easy to adaptGood and precise wipingWindow cleanersVehicle cleaningEngineeringMotorized vehicle

The invention concerns a windscreen wiper device (2; 28, 30; 74; 78) for a vehicle, in particular a motor vehicle. The windscreen wiper device (2; 28, 30; 74; 78) comprises an elongate upper part (10) which is designed to be at least partially flexible. It further comprises an elongate lower part (12) which is designed to be at least partially flexible. Further present are a plurality of connection elements (18) for connecting the upper part (10) and the lower part (12), the connection elements (18) being disposed at spacings from each other along a longitudinal extension (8) of the windscreen wiper device (2; 28, 30; 74; 78) and secured to the lower part (12) by means of swivel joints (20; 122, 130).

Owner:ROBERT BOSCH GMBH

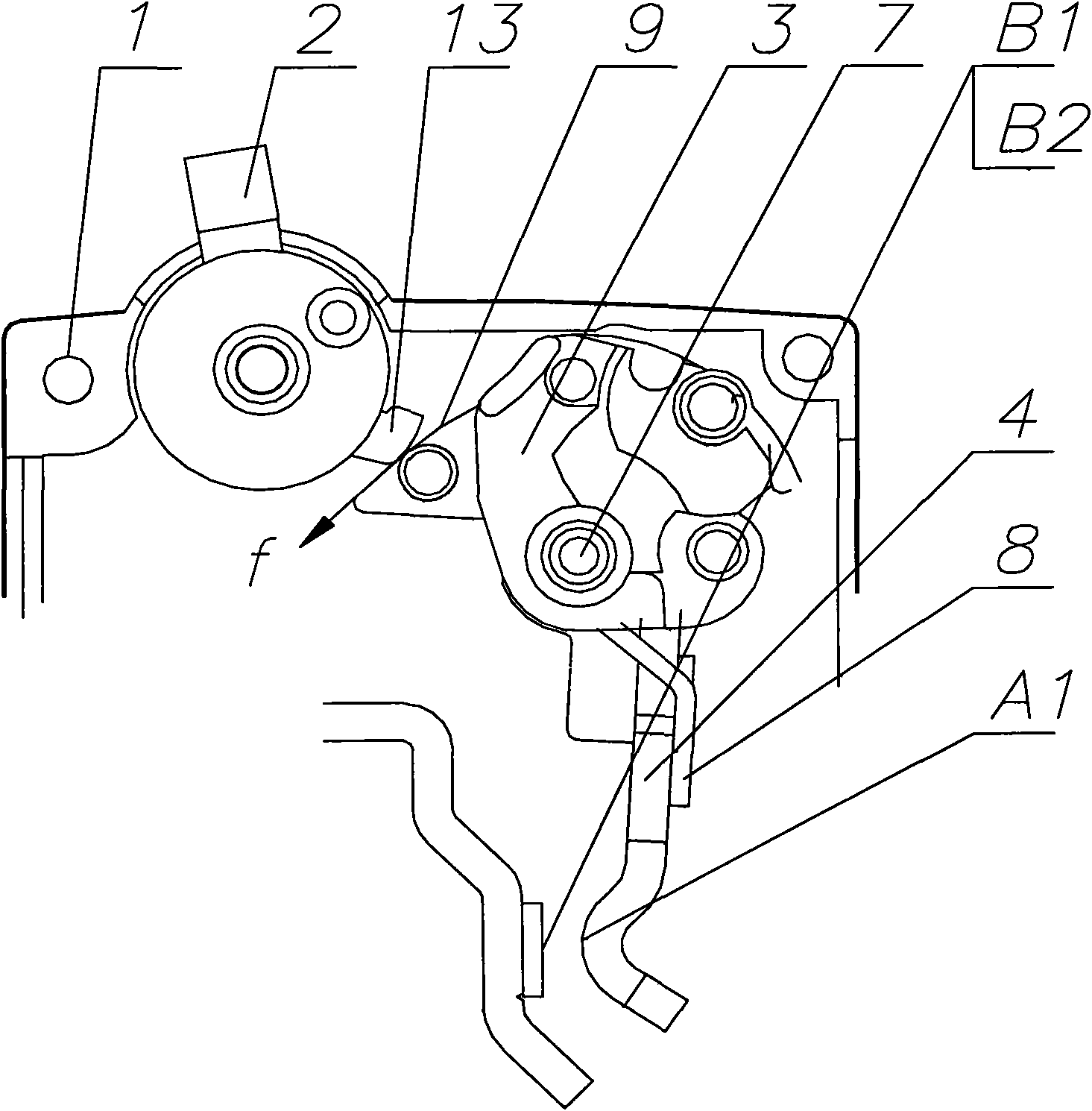

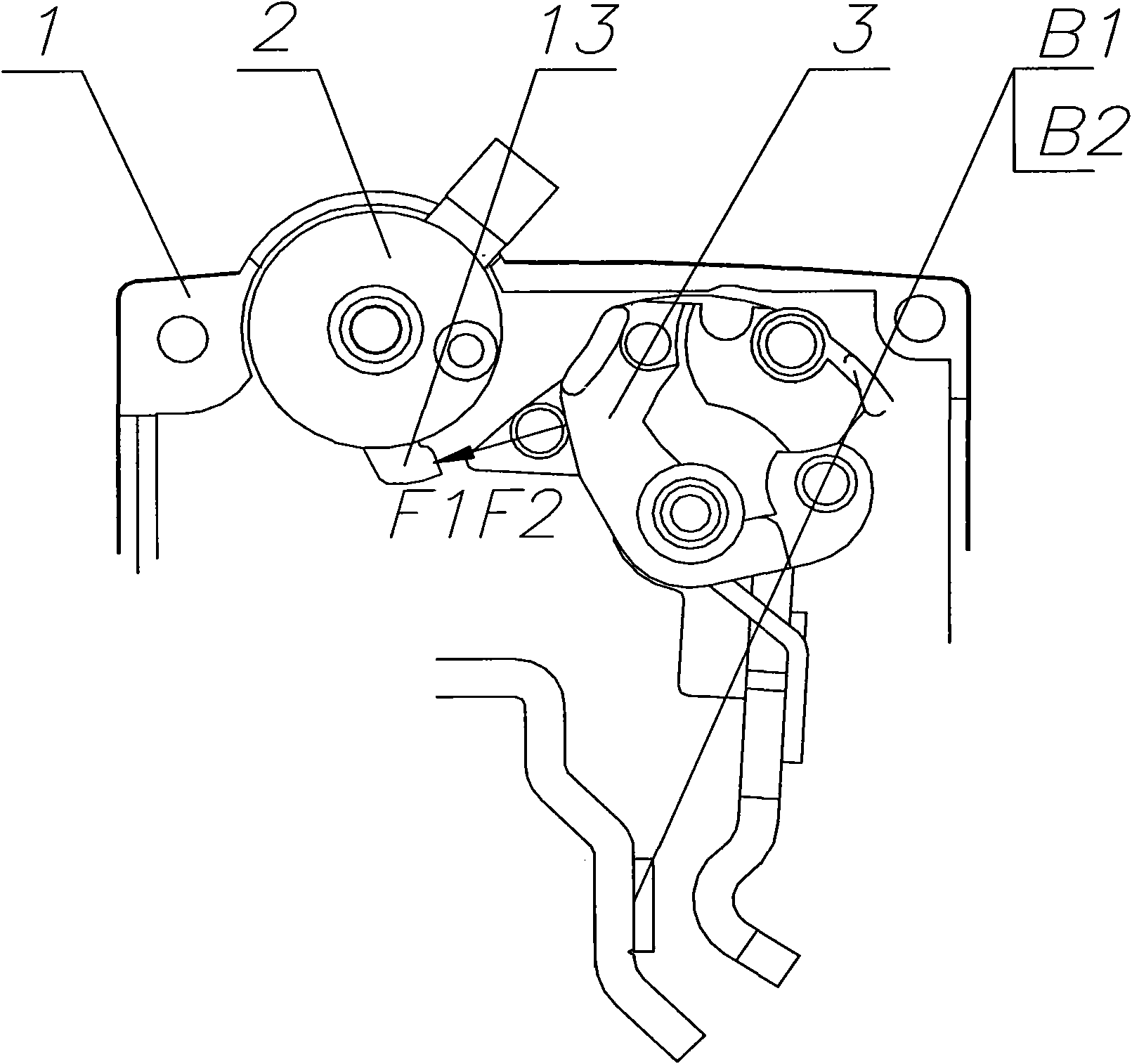

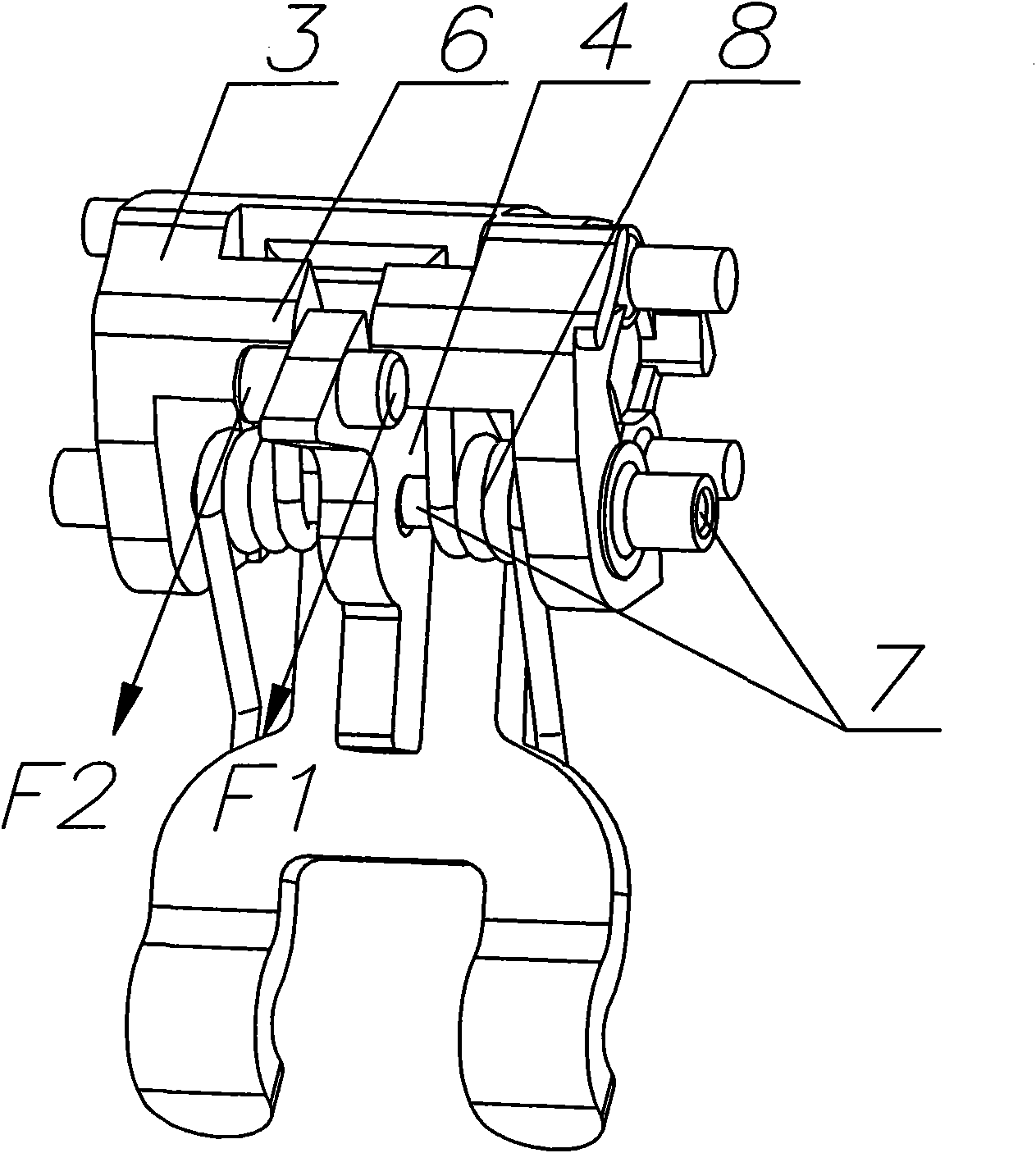

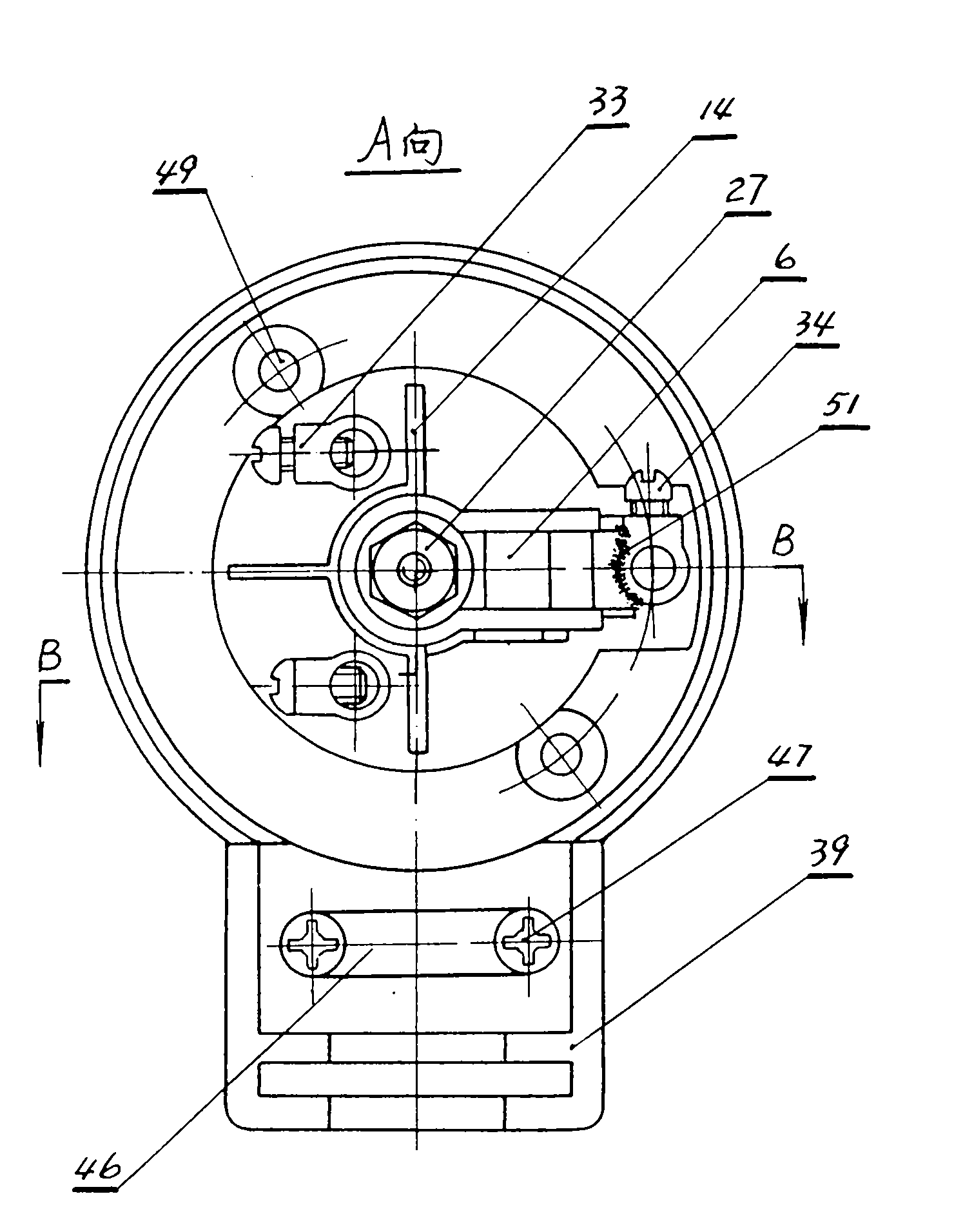

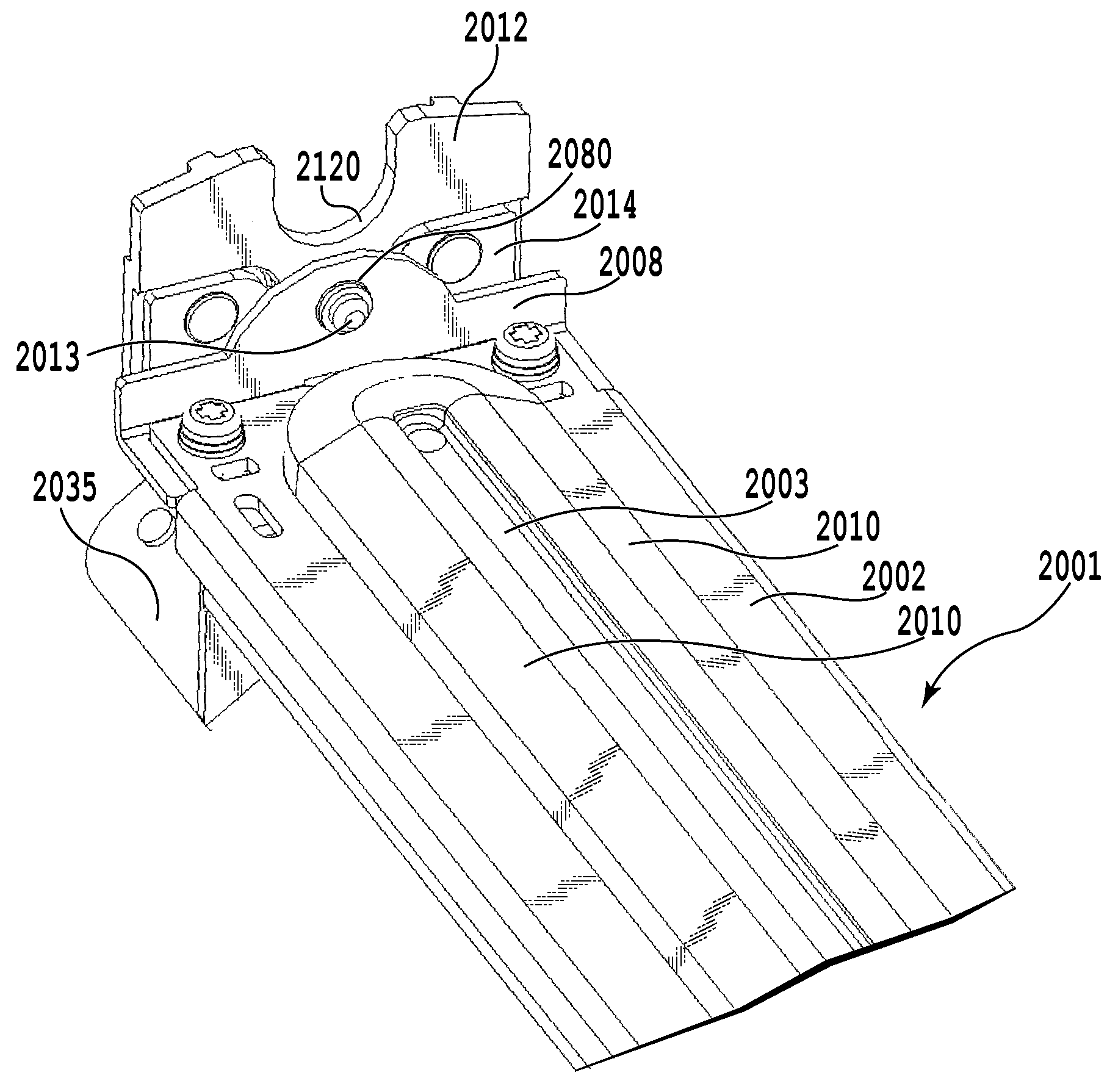

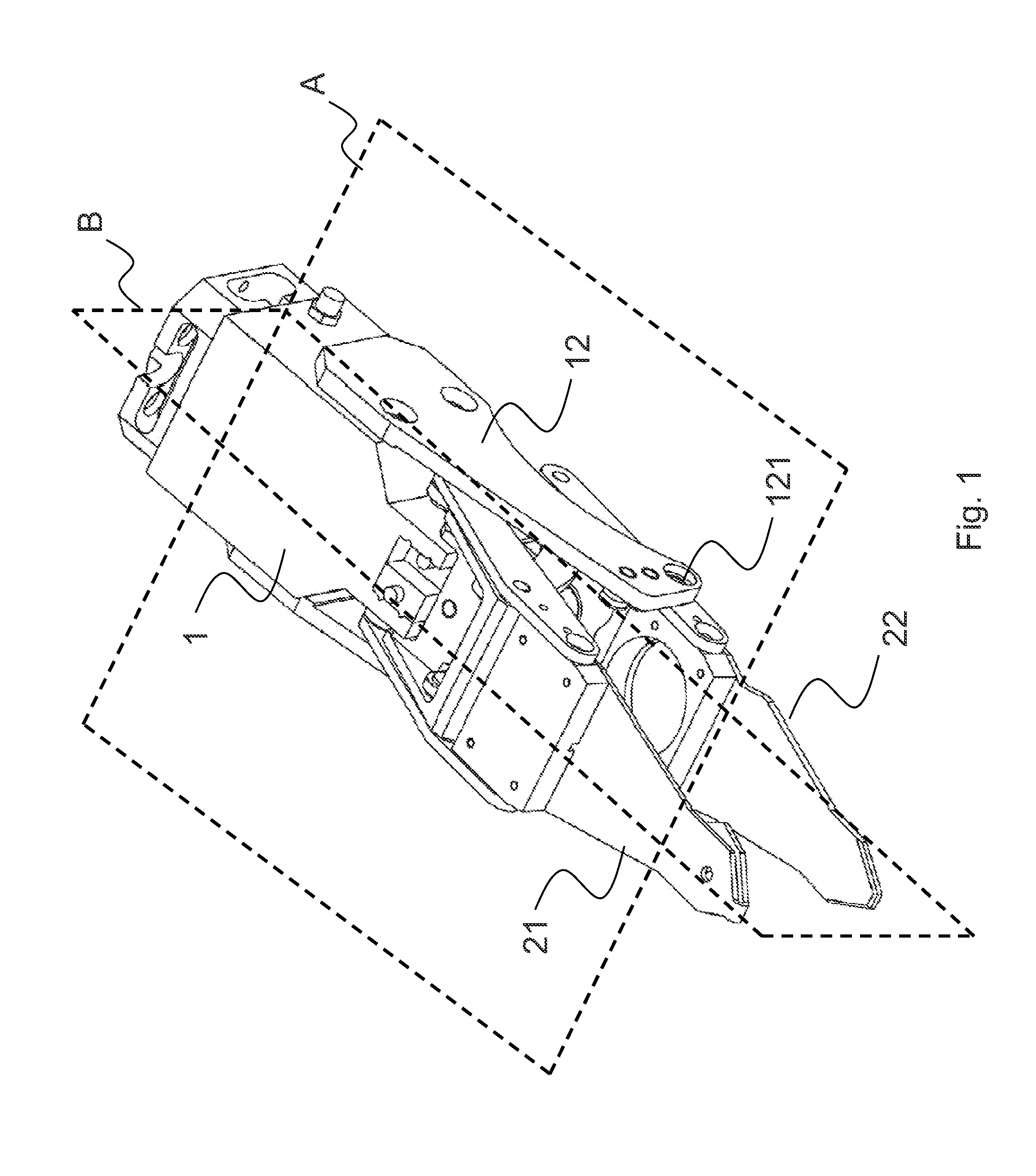

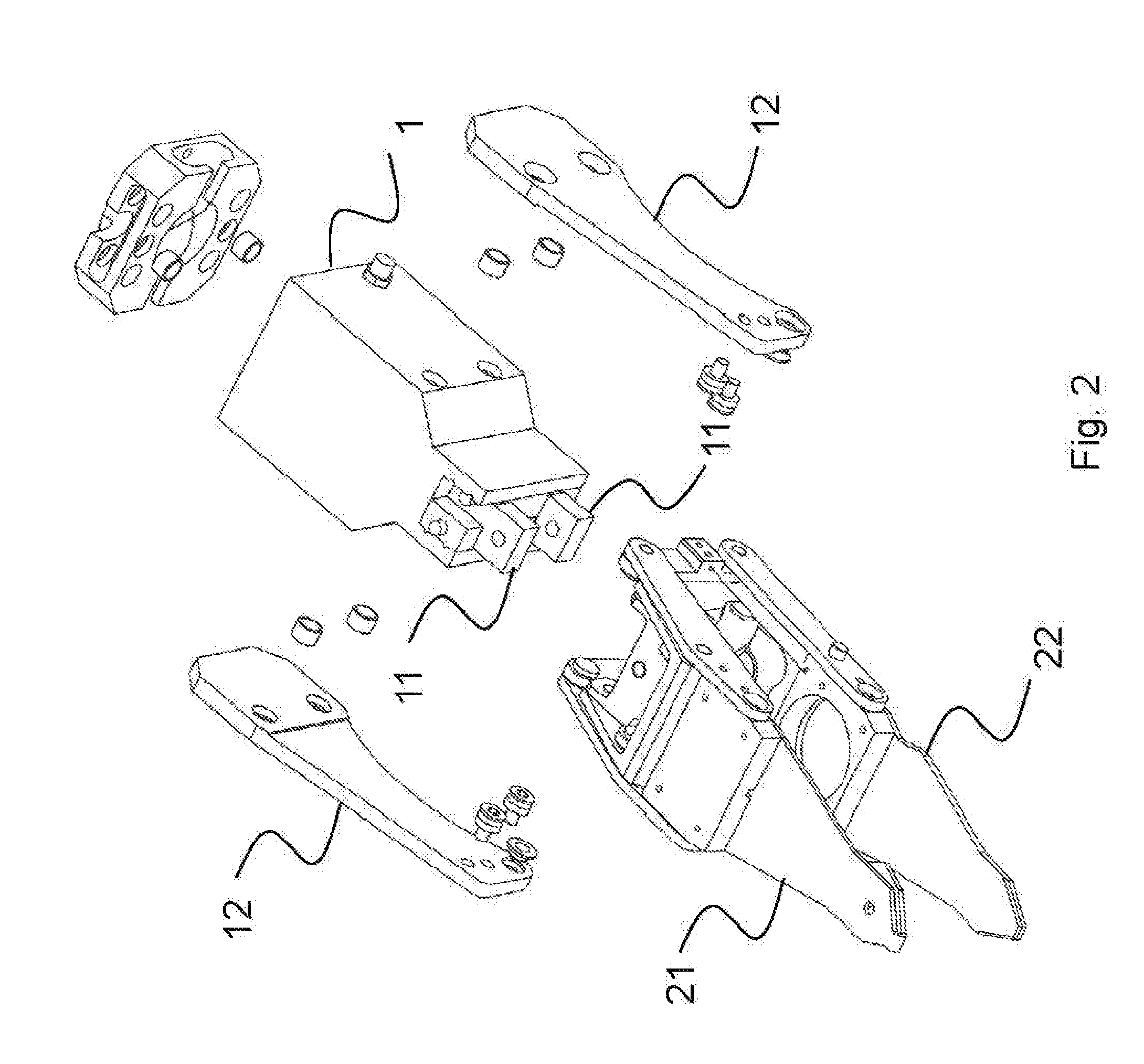

Co-directional serial double-break small circuit breaker

ActiveCN101656179AUniform contact pressureAdaptableCircuit-breaking switch contactsContact pressureCage device

The invention discloses a small molded case circuit breaker adopting co-directional serial double breakpoints, which comprises an operating mechanism, a contact device, an energy storage device, and acaging device. The energy storage device comprises a contact surface formed on a supporting part, a driving finger which is matched with the contact surface and co-directionally moves along with a handle of the operating mechanism, and an energy storage spring connected between a lever of the operating mechanism and a moving contact. The caging device comprises two bosses corresponding to two moving contact points of the moving contact respectively, and two surfaces which are formed on the lever of the operating mechanism and are matched with the two bosses respectively, and has the functionsof strengthening the uniformity of contact pressure of two breakpoints and the synchronous closing / breaking adaptability, so that the caging device can still keep reliable work under the condition ofinconsistent wear of contacts of the two breakpoints. The energy storage device and the caging device are non-independent devices, so a mechanism is greatly simplified, the space of the mechanism isreduced, the external dimension of a circuit breaker product fully meets the modular standard requirement and the volume is smarter.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

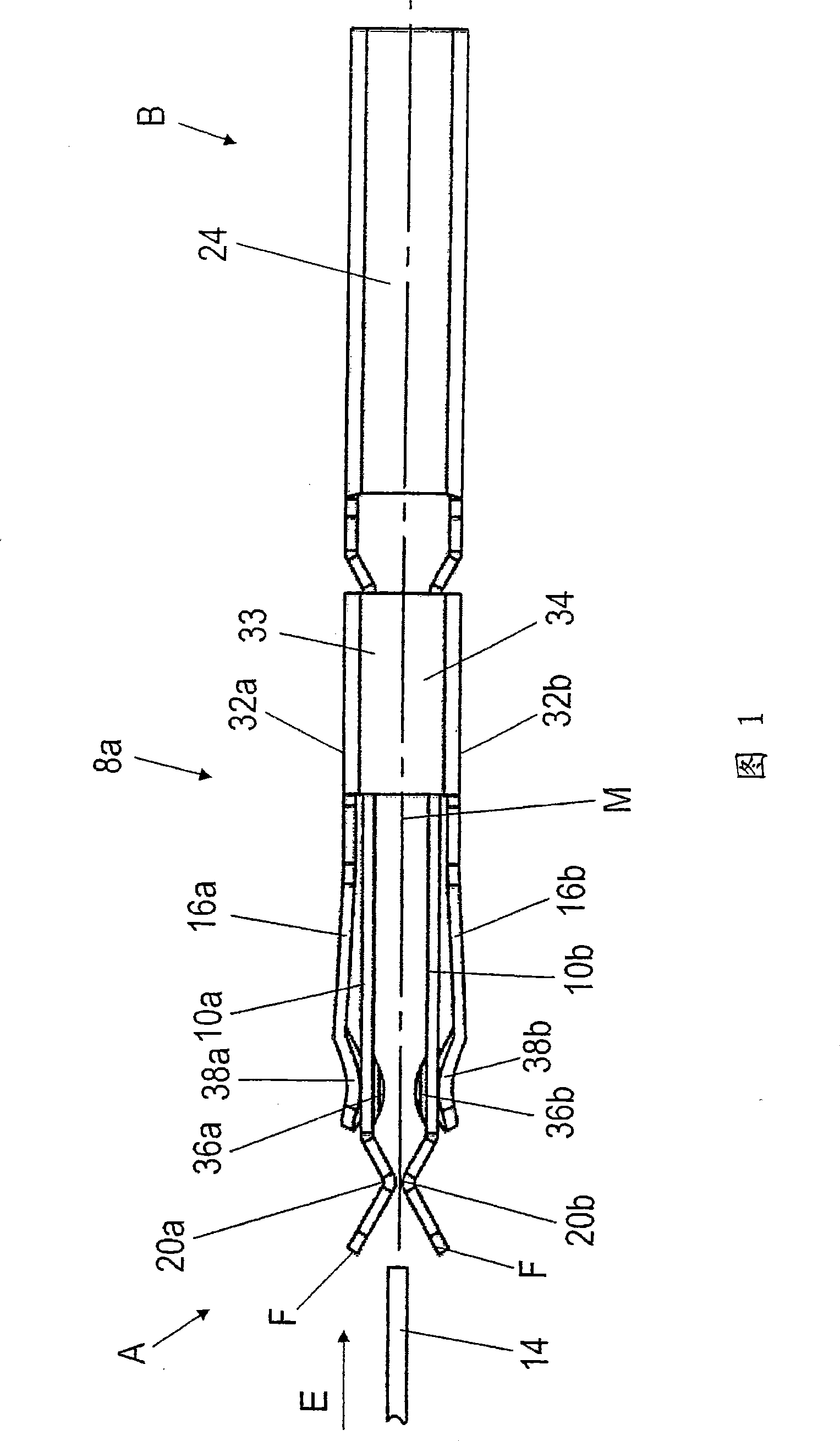

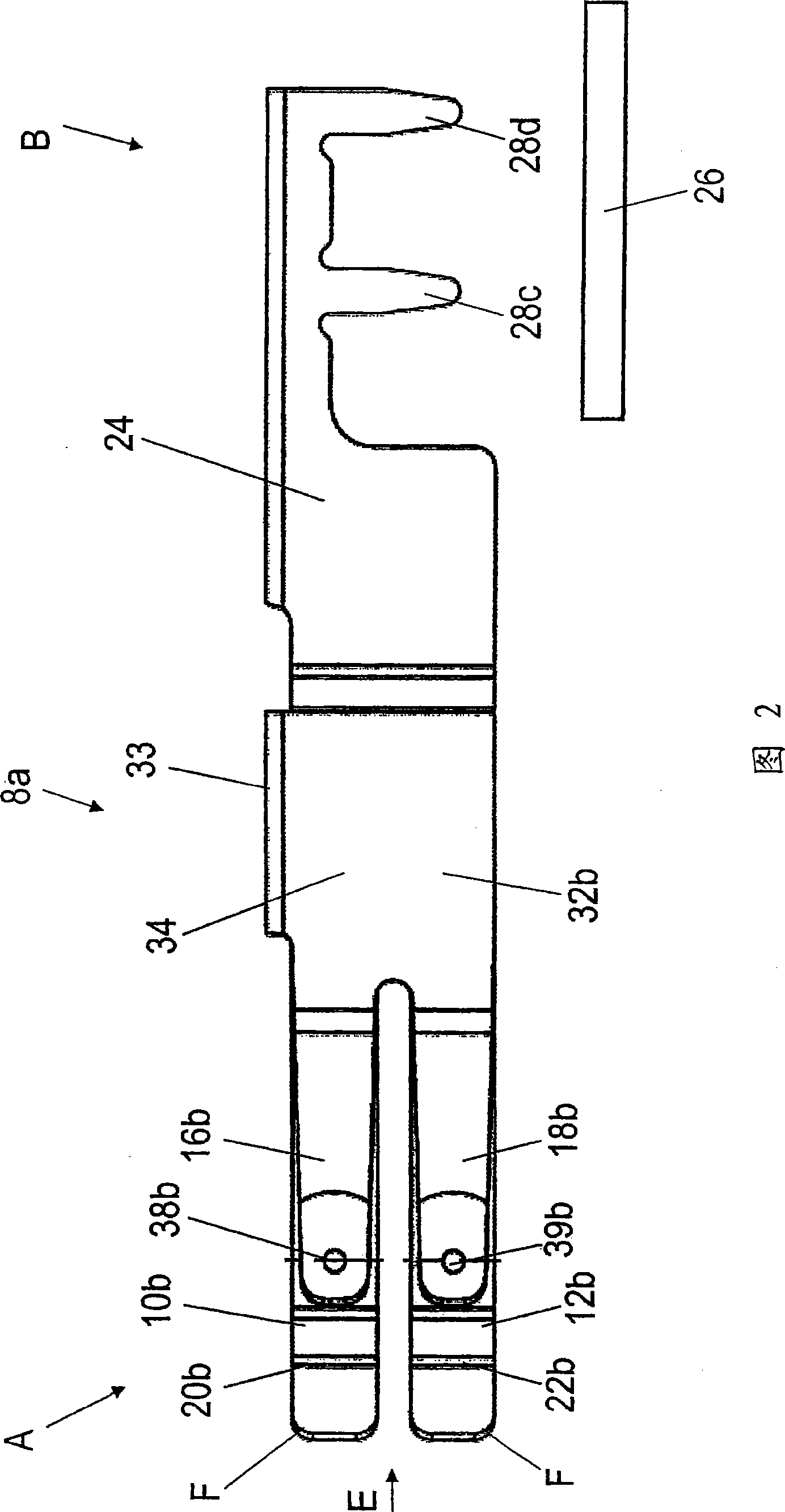

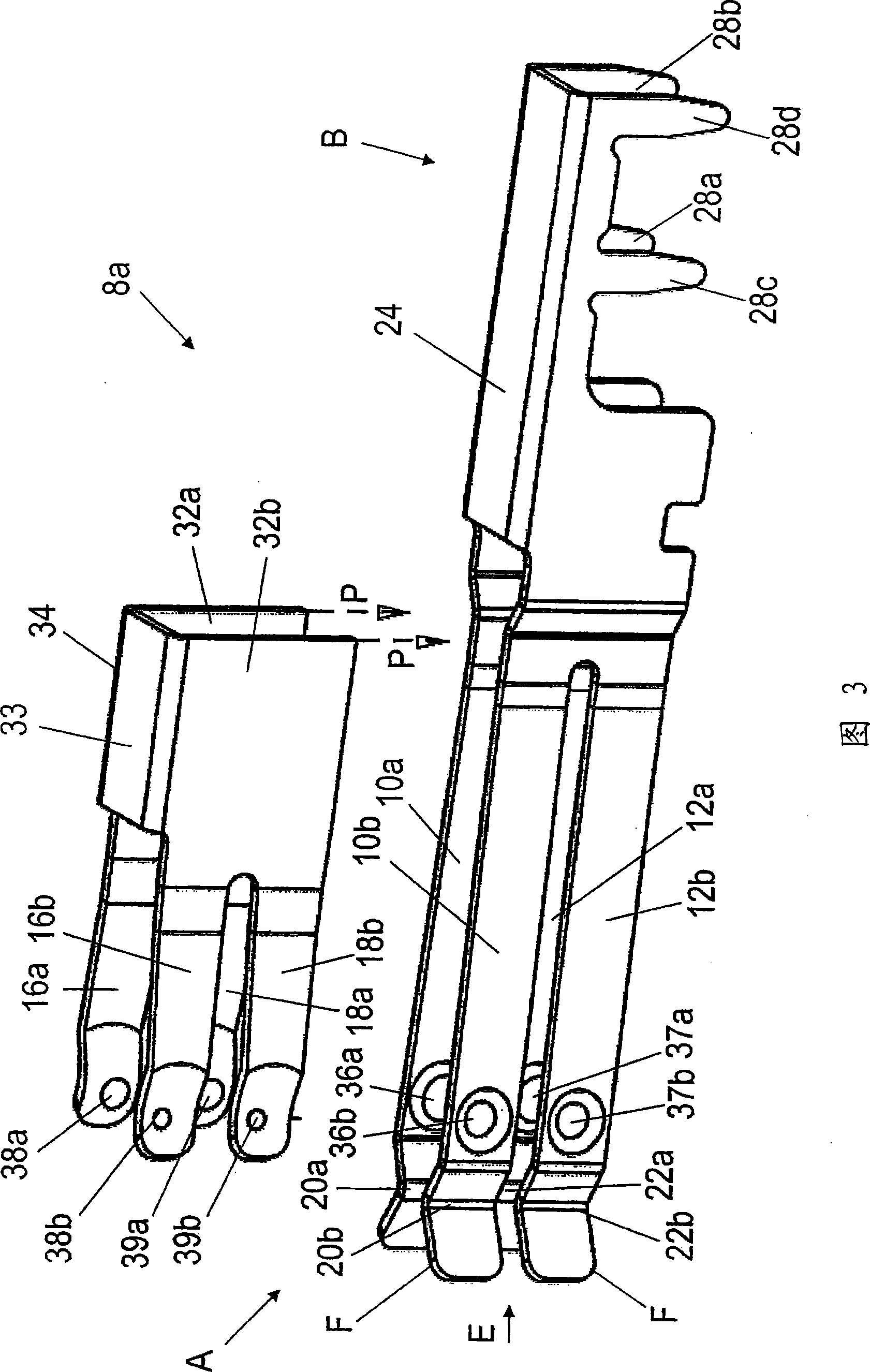

Spring contact for an electric connector and connection

InactiveCN101394037AAdaptableUniform contact pressureElectrically conductive connectionsCoupling contact membersMechanical engineeringPhysics

A spring contact for an electrical plug connection, which at one end has at least two opposing spring-elastic contact legs for receiving a counterpart contact that can be inserted between the two contact legs in an insertion direction along a central longitudinal axis of the spring contact. The outsides of the contact legs oriented away from the central longitudinal axis are each engaged by respective spring legs which press the respective opposing contact legs toward each other perpendicular to the central longitudinal axis and, when a counterpart contact is inserted, exert a respective contact pressure on the latter. A plug connection equipped with at least one spring contact is also disclosed.

Owner:ELRAD INT D O O

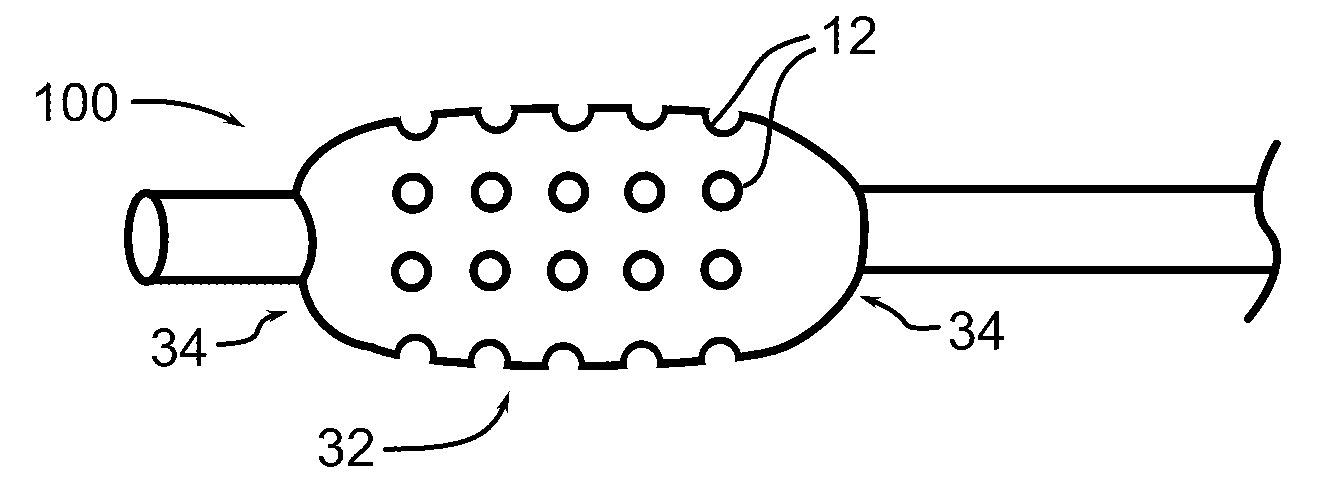

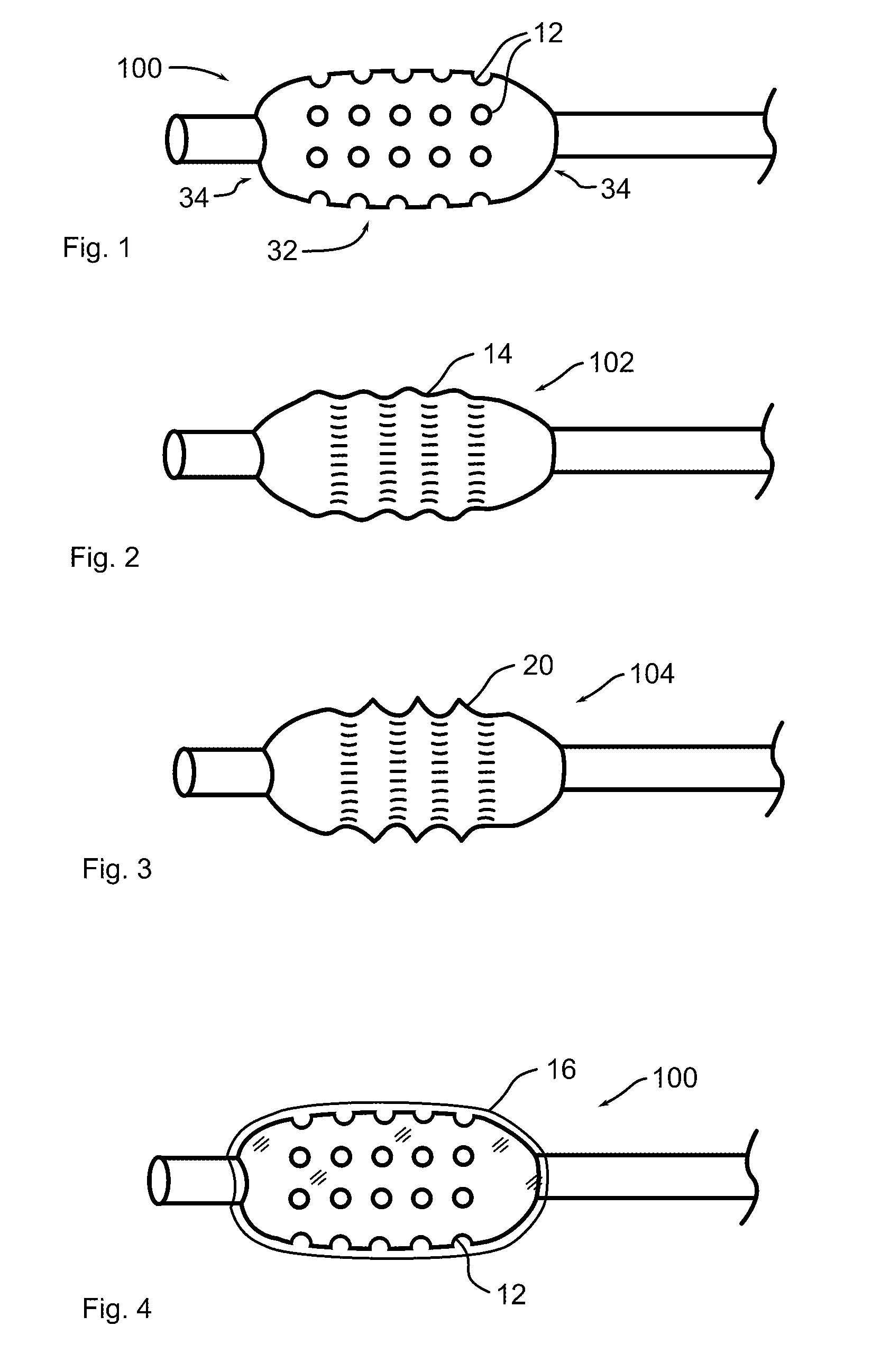

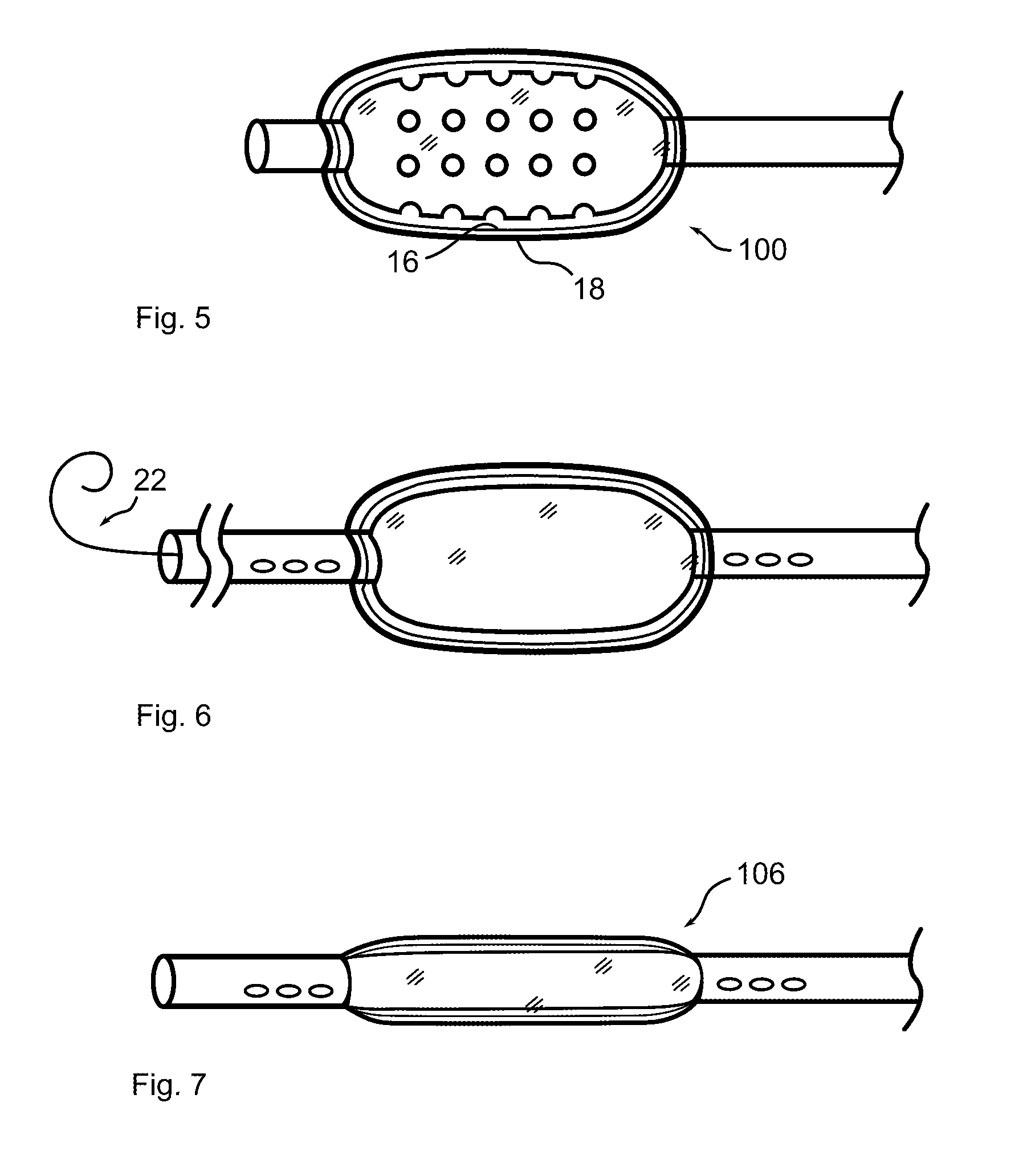

Delivery of therapeutic and marking substance through intra lumen expansion of a delivery device

ActiveUS8162880B2Uniform contact pressureRaise the possibilityStentsBalloon catheterCell layerBalloon catheter

A balloon catheter is formed with a plurality of depressions. The balloon is coated with a matrix incorporating a therapeutic substance, which additionally fills the depressions. When the balloon is expanded within a body lumen, the therapeutic substance may diffuse into the lumen wall, or all or a portion of the coating transfers to the lumen wall. A lattice frame may surround the balloon, applied prior to coating if the coating is to transfer, operative to maintain a more linear balloon profile during inflation, promoting more even transfer pressure. A contrast dye is incorporated into the transferred coating, enabling ready location and inspection of the treated lumen area. Projections may alternately be formed in the balloon surface, operative to urge the coating and therapeutic substance between cells, or past cell layers of the lumen, to the interior of the lumen wall. Prior to transfer, an extended inflation period, possibly including the use of perfusion ports to maintain blood supply, enables a larger initial quantity of therapeutic substance to diffuse into the body lumen, prior to transfer of the coating and withdrawal of the catheter, balloon, and frame.

Owner:JAYARAMAN SWAMINATHAN

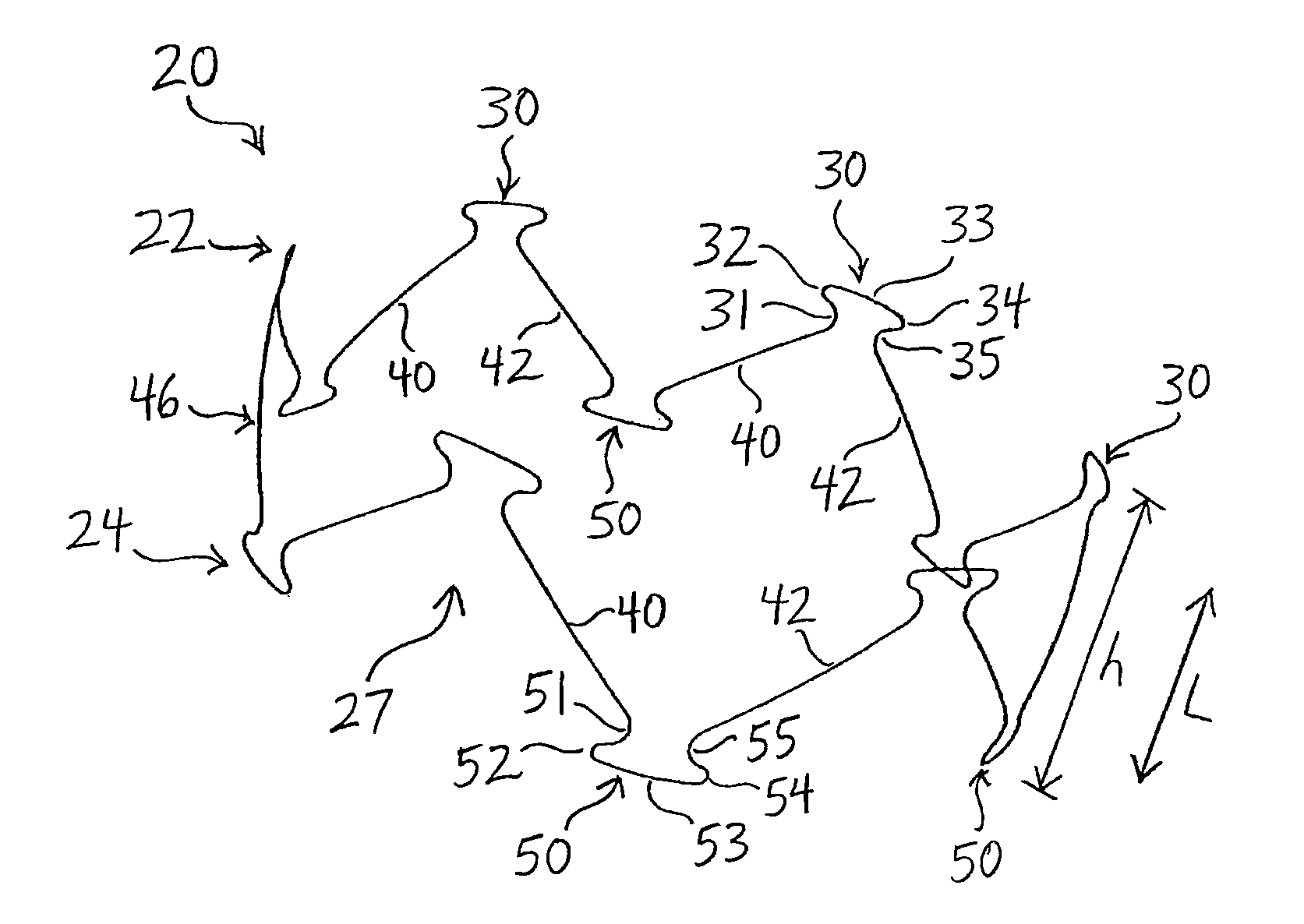

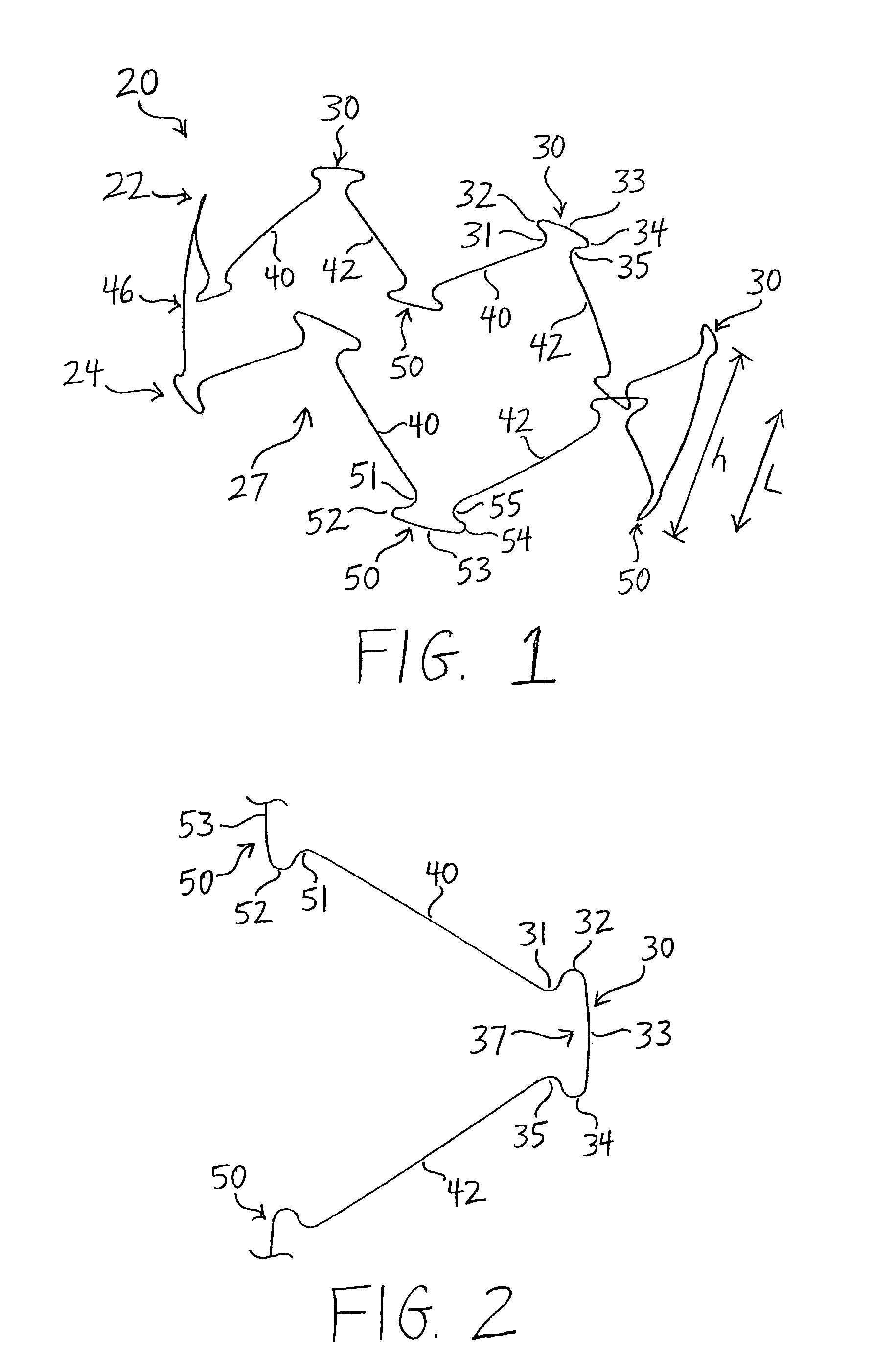

Stent having less invasive ends and improved radial force

The present invention provides a stent having less invasive ends and improved radial force. In one embodiment, the stent comprises a series of proximal apices disposed at a proximal end of the stent, a series of distal apices disposed at a distal end of the stent, and at least one angled strut segment disposed between the proximal and distal apices of the stent. At least one apex of the stent may comprise multiple curved portions. In one example, the radius of curvature of one of the curved portions is significantly greater, for example, at least 10 times greater, than each of the other radii of curvature of the apex. The curved portion having the significantly greater radius of curvature may be configured to engage a vessel wall in a less invasive manner.

Owner:COOK MEDICAL TECH LLC

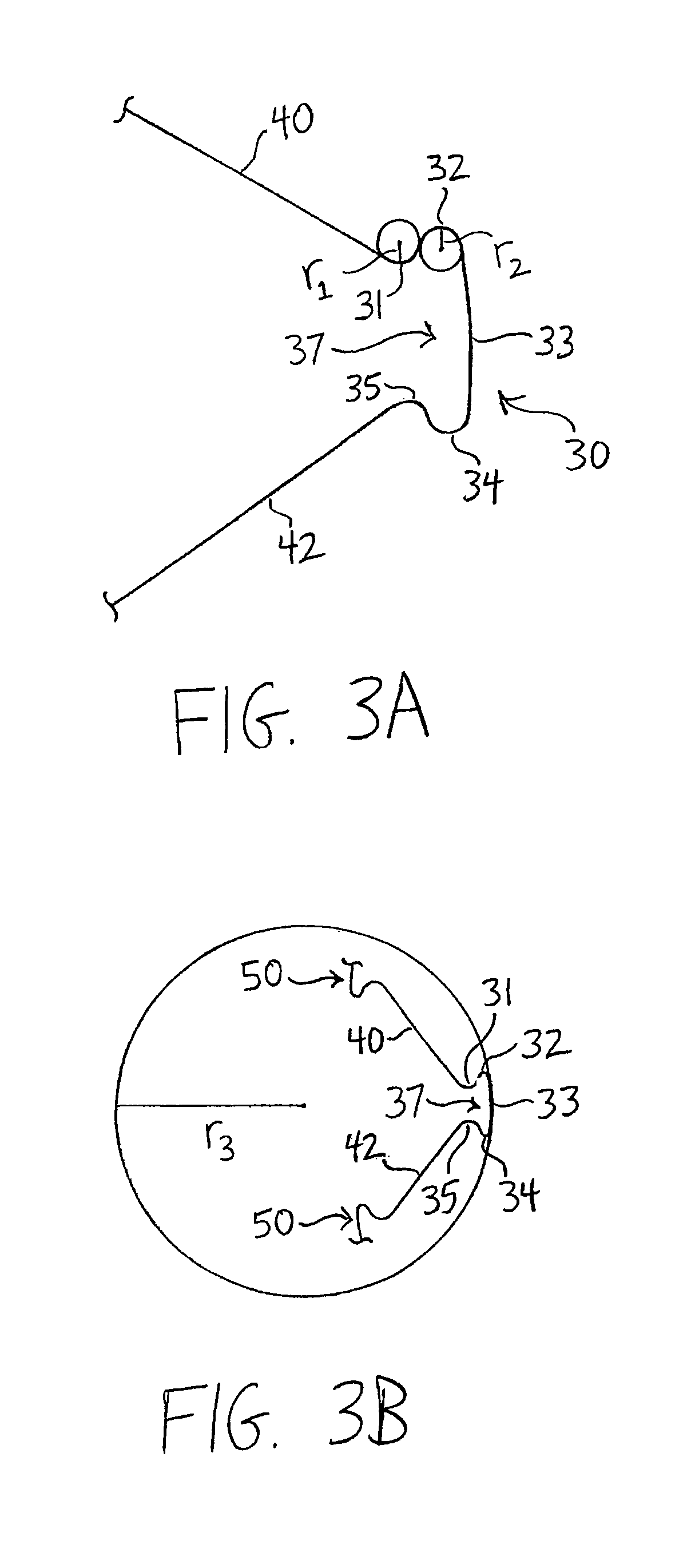

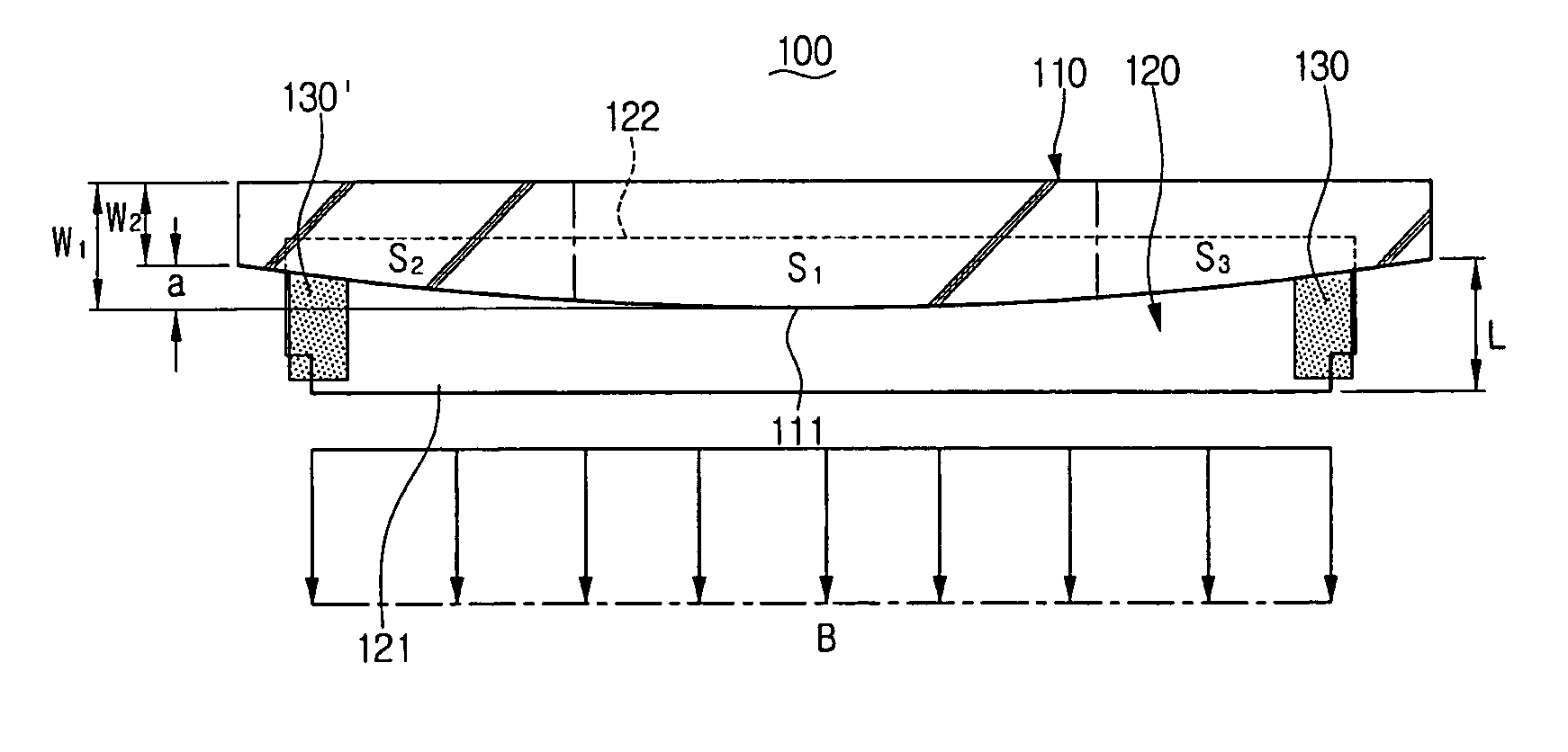

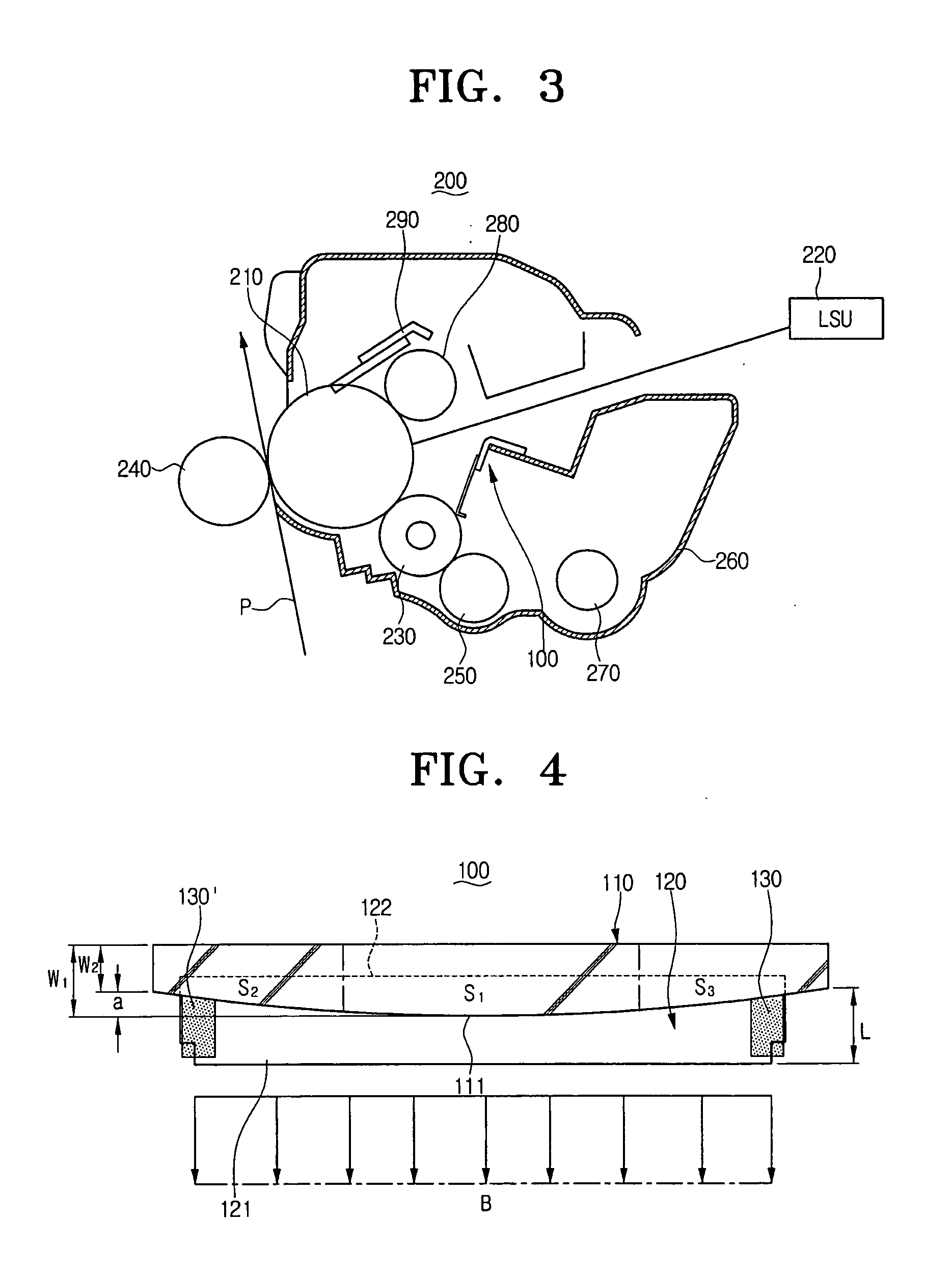

Doctor blade and development unit having the same

InactiveUS20060263117A1Uniform contact pressureUniform maintenanceElectrographic process apparatusEngineeringContact pressure

A doctor blade and a development unit having the same are disclosed. The doctor blade includes: an elastic blade having one edge contacting a developer roller with a predetermined pressure to control a toner layer formed on the developer roller; and a supporting member supporting the other edge portion of the elastic blade, wherein a middle portion of the supporting member is larger than each end portion of the supporting member. Accordingly, contact pressure between the elastic blade and the developer roller is uniformly distributed along a length direction of the elastic blade.

Owner:SAMSUNG ELECTRONICS CO LTD

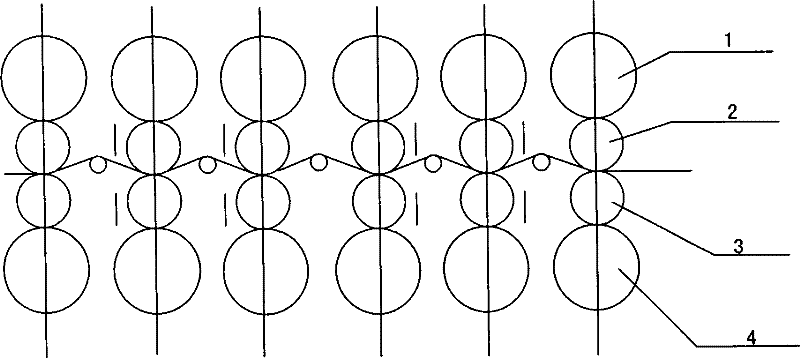

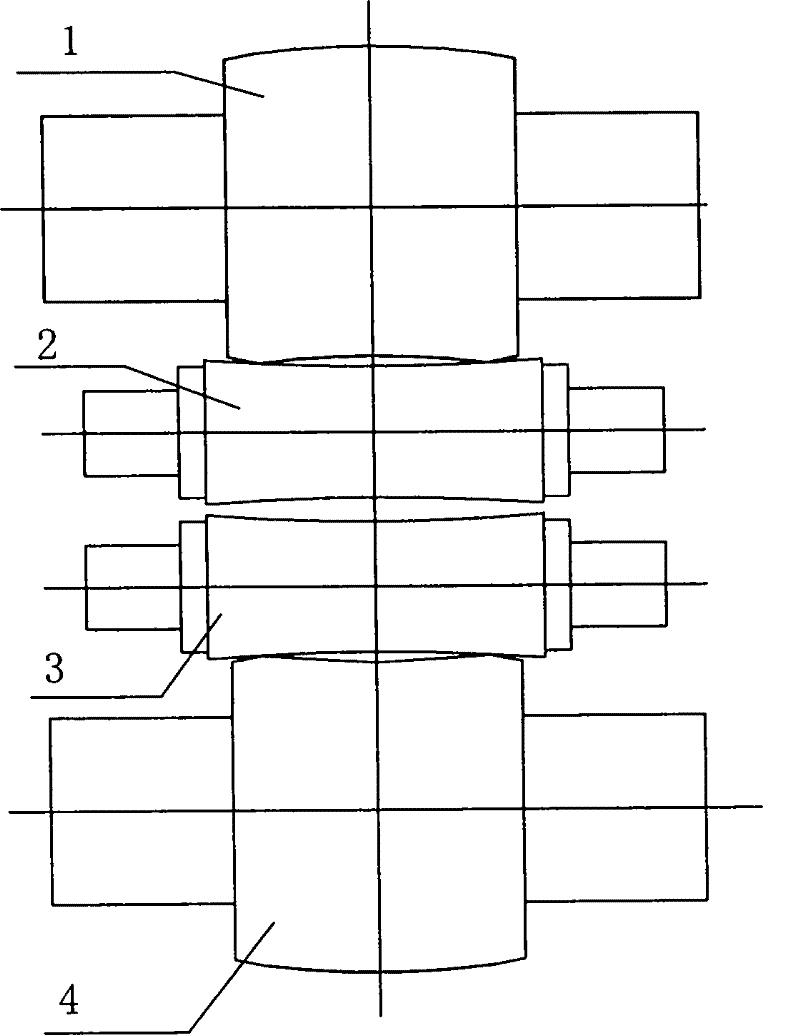

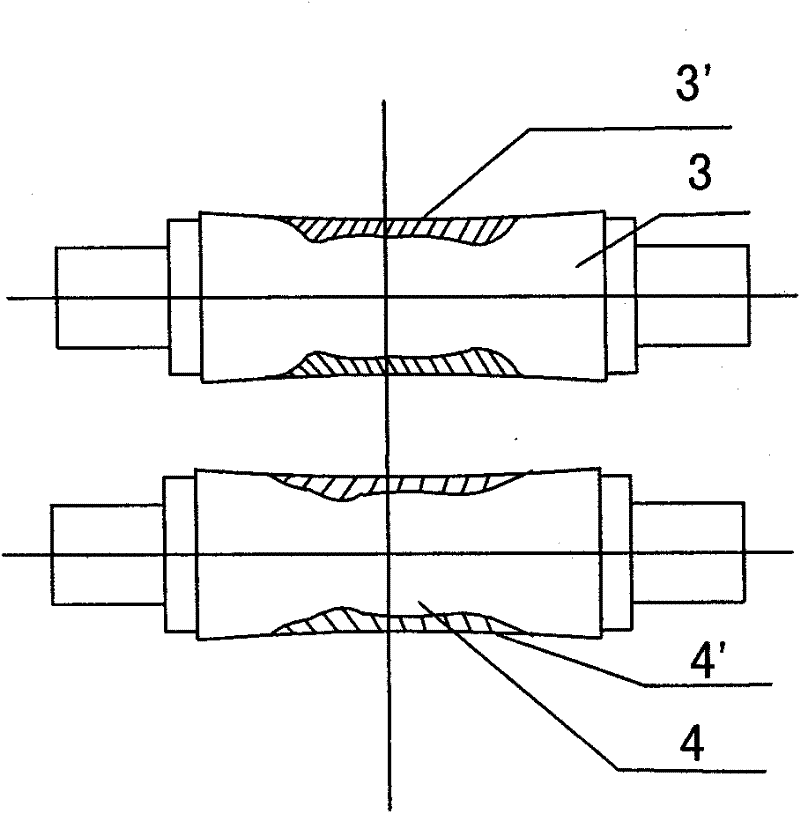

Modification configuration finishing roll group and modification configuration method thereof

InactiveCN102189109AExtended service lifeUniform contact pressureRolling equipment maintainenceRollsStress conditionsContact pressure

The invention relates to a modification configuration finishing roll group and a modification configuration method thereof, belonging to the technical field of metallurgical production equipment. The finishing roll group comprises an upper support roll, a lower support roll, an upper working roll and a lower working roll, wherein the upper and lower support rolls are supported on the rear sectionof a rack; the upper and lower working rolls are located between the upper and lower support rolls; and the generatrices of the upper and lower working rolls are formed according to an equation respectively, wherein the upper working roll is '+', and the lower working roll is '-'. Through the invention, the practical shapes of the upper and lower working rolls on the rear section of the rack forma corresponding convex roll and a concave roll respectively, and the rolling clearance conforms to the requirement; due to the abrasion of the support rolls, the contact pressure between the working roll and corresponding support roll is more uniform, and the local centralized stress condition between rolls is obviously improved; and meanwhile, as the protuberance of the upper working roll effectively compensates for the abrasion, the service life of the working roll is greatly prolonged.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

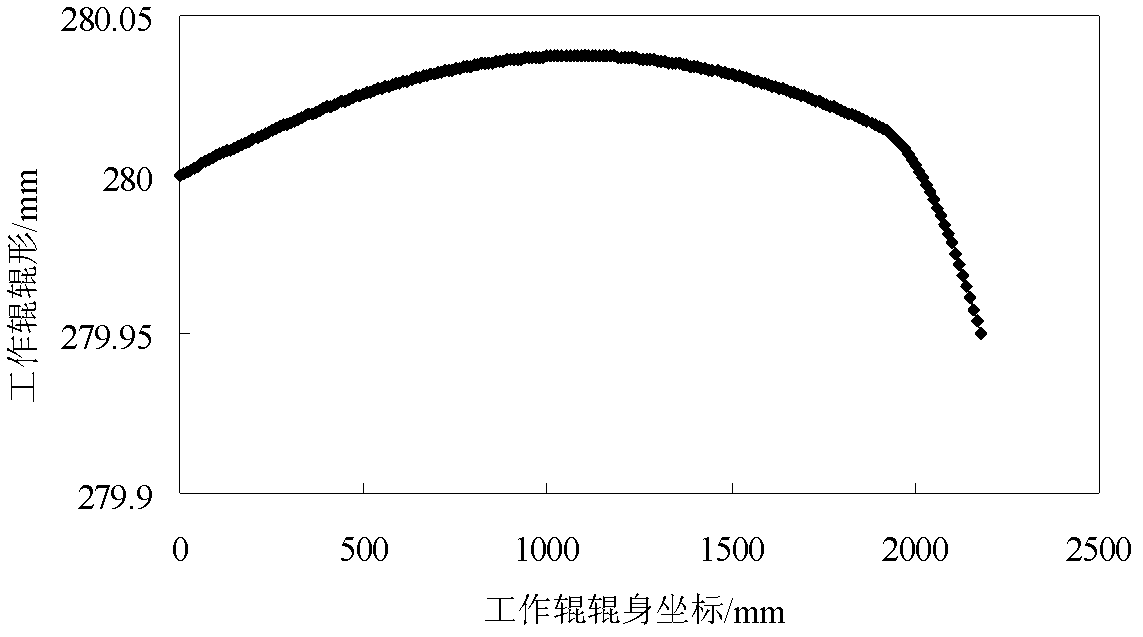

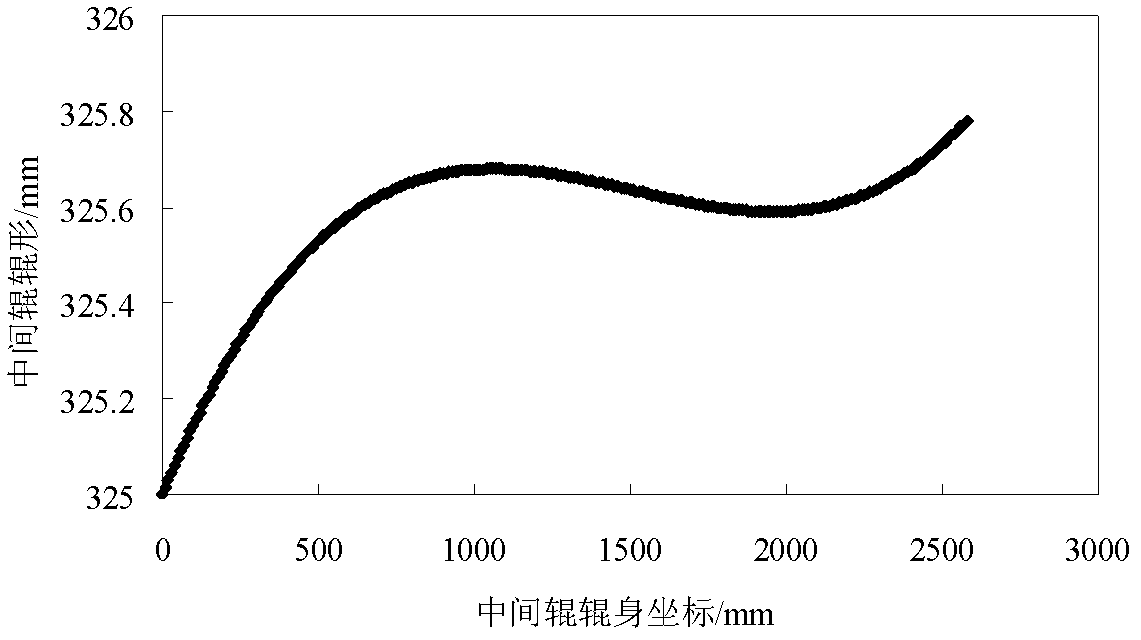

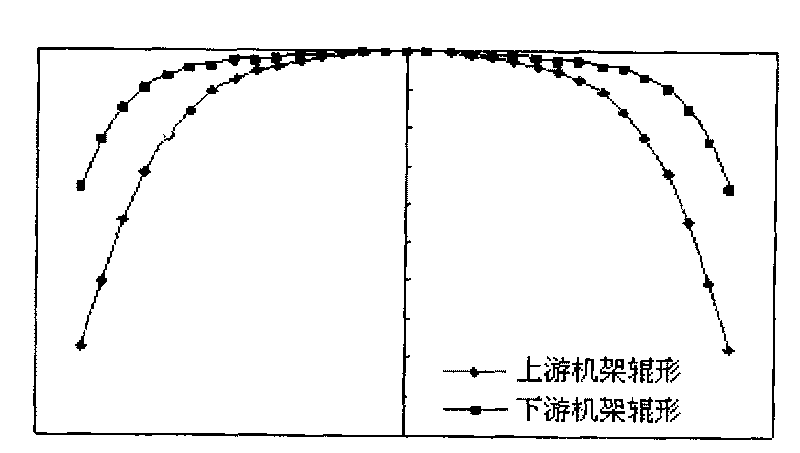

Roll-shape configuration method of ultra-wide six-roll variable-crown cold continuous rolling mill

InactiveCN102527738AImprove self-retentionUniform contact pressureProfile control deviceContact pressureWork roll

The invention provides a roll-shape configuration method of an ultra-wide six-roll variable-crown cold continuous rolling mill. The method adopts a configuration scheme of a small-side-wave control working roll shape, a continuously-variable-crown middle roll shape and a variable-crown supporting roll shape, wherein the design of the small-side-wave control working roll shape eliminates local wave shapes by reducing the screw-down rate of the edge part of band steel; the continuously-variable-crown middle roll shape mainly controls symmetric secondary wave shapes; and the variable-crown supporting roll shape can lead the contact pressure among rolls to be uniform so as to improve the self retainability of the roll shape. By utilization of the roll-shape configuration method provided by the invention, the wave-shaped problem in the process of producing the ultra-wide six-roll variable-crown cold continuous rolling mill can be obviously solved and the quality of a plate shape can be improved.

Owner:武汉钢铁有限公司

Strip-rolling variable contact support roller and processing method thereof

InactiveCN101758080AImprove regulatory efficacyIncrease lateral stiffnessCounter-pressure devicesMetal rolling arrangementsControl functionEngineering

The invention discloses a strip-rolling variable contact support roller and a processing method thereof. Roll forming curves are superposed by using a five-section sine function, so the contact line length between the support roller and a working roller is close to the width of the rolled strip steel, the harmful contact area during the rolling process is decreased, the regulating and controlling function of the roller force is promoted, the roll-gap crosswise rigidity is increased, the contact pressure between rollers is uniformed, and the accident that the edge of the roller falls off is decreased or completely eradicated. During the grinding process, a superposed roller forming of a variable contact section and a chamfer section at two sides of the roller is firstly grinded and then the whole roller is grinded so as to promote the processing efficiency and decrease the grinding wheel consumption. The support roller of the invention is convenient to design and process and is easy to realize the industrial application.

Owner:UNIV OF SCI & TECH BEIJING

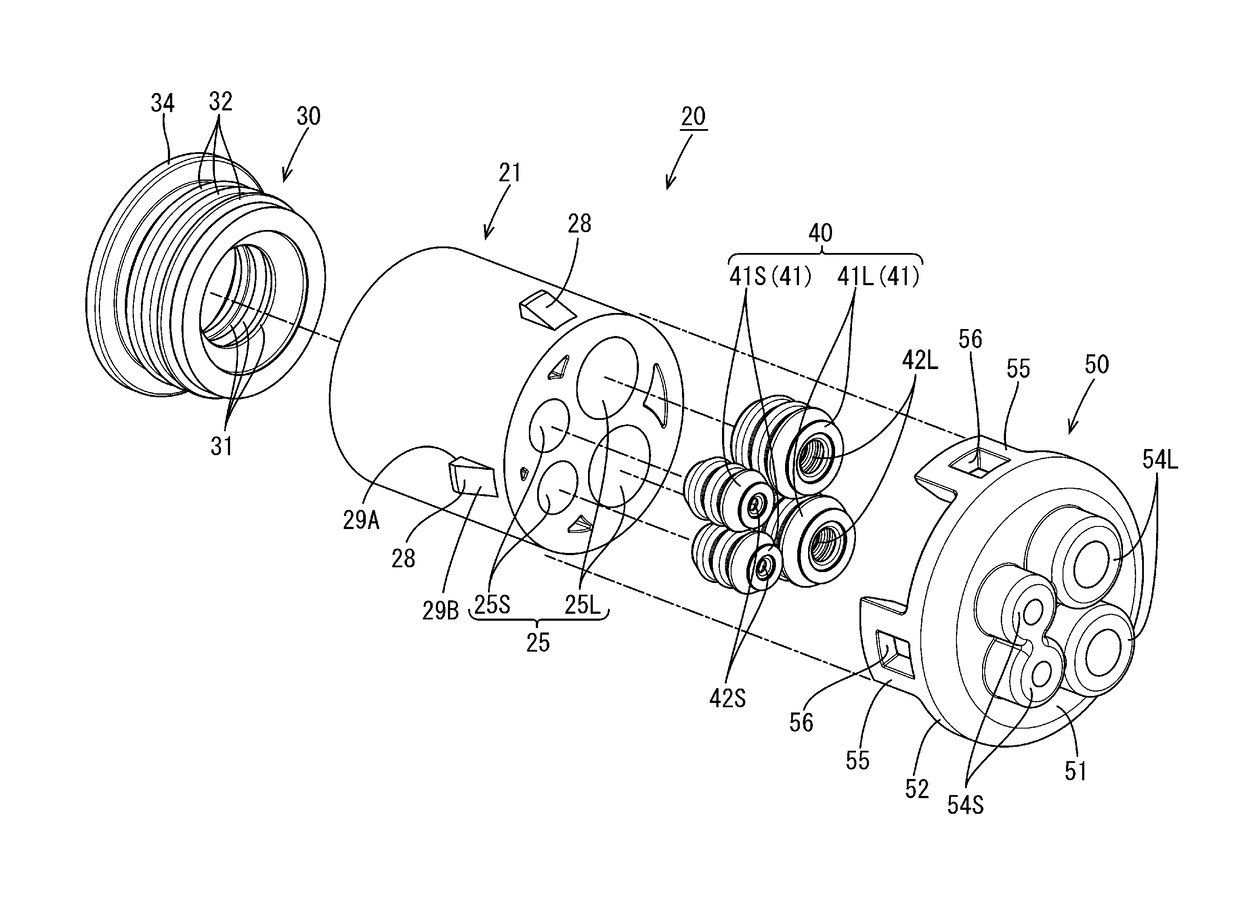

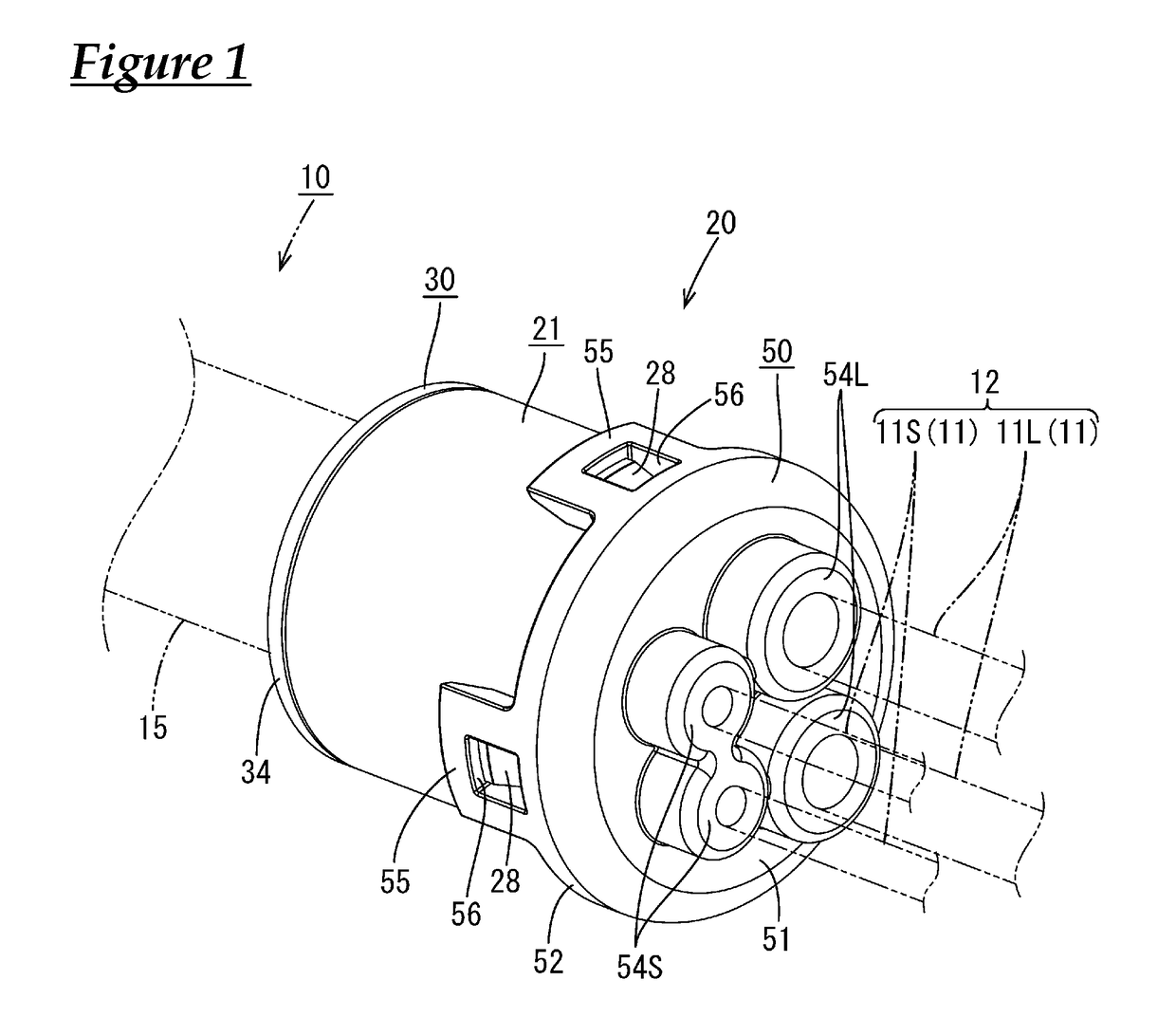

Seal structure for multi-core cable

ActiveUS20180048081A1Increase contact pressureReduce manufacturing costCoupling device detailsConnection insulationEngineeringElectric wire

Owner:AUTONETWORKS TECH LTD +2

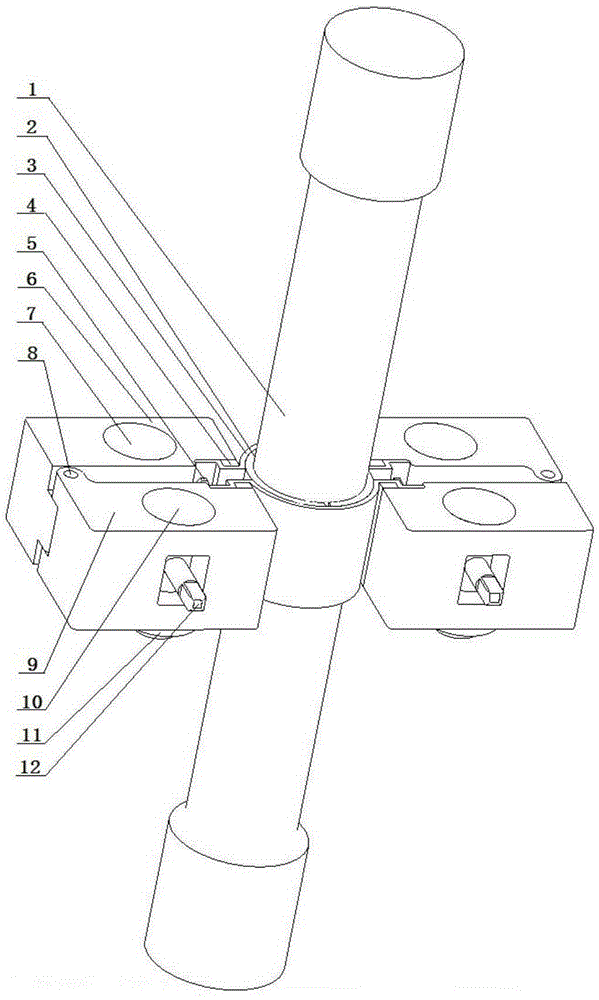

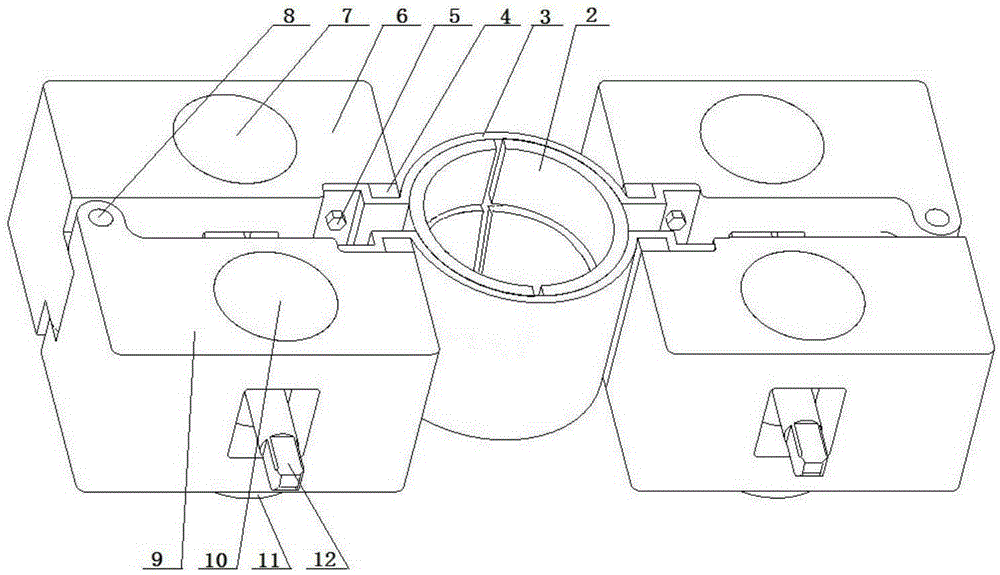

Contrast test method for improving fretting fatigue resistance performance of material by laser shot blasting strengthening and test sample clamping device

ActiveCN105259059AUniform contact pressureRealize fretting fatigue testPreparing sample for investigationMaterial strength using repeated/pulsating forcesRound barSurface modification

The invention discloses a contrast test method for improving the fretting fatigue resistance performance of a material by laser shot blasting strengthening and a test sample clamping device. The device comprises a clamping device, a compacting metal sheet, a force measurement element, circular ring surface micro mats, a test sample subjected to surface modification and the like. The method comprises the following steps: firstly, laser shot blasting strengthening is performed on the side surface region of the whole circumference of a round bar test sample to be tested, a test region which is not subjected to any treatment is retained at an axial adjacent position for contrast, the four circular ring surface micro mats surround the two test regions in a fitting manner, and the compacting metal sheet applies a controllable uniform contact load to the micro pads through the clamping device. Under the surface-surface contact tension-torsion composite fatigue test condition with the same test parameter, the device can realize a contrast between the non-treated region and the region subjected to laser shot blasting strengthening on the fretting fatigue resistance performance according to crack generation and expansion situations of the round bar test sample in different test stages.

Owner:JIANGSU UNIV

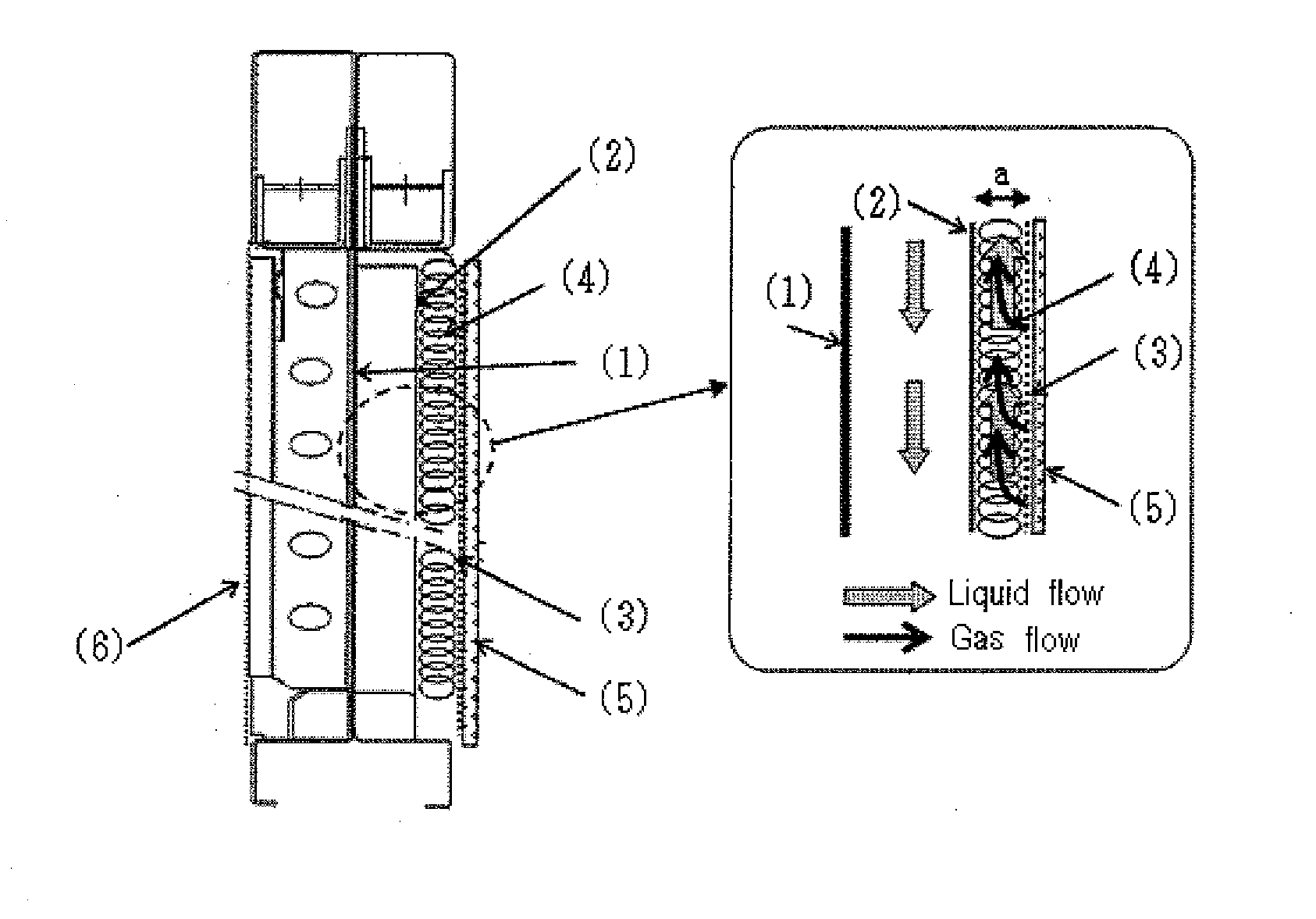

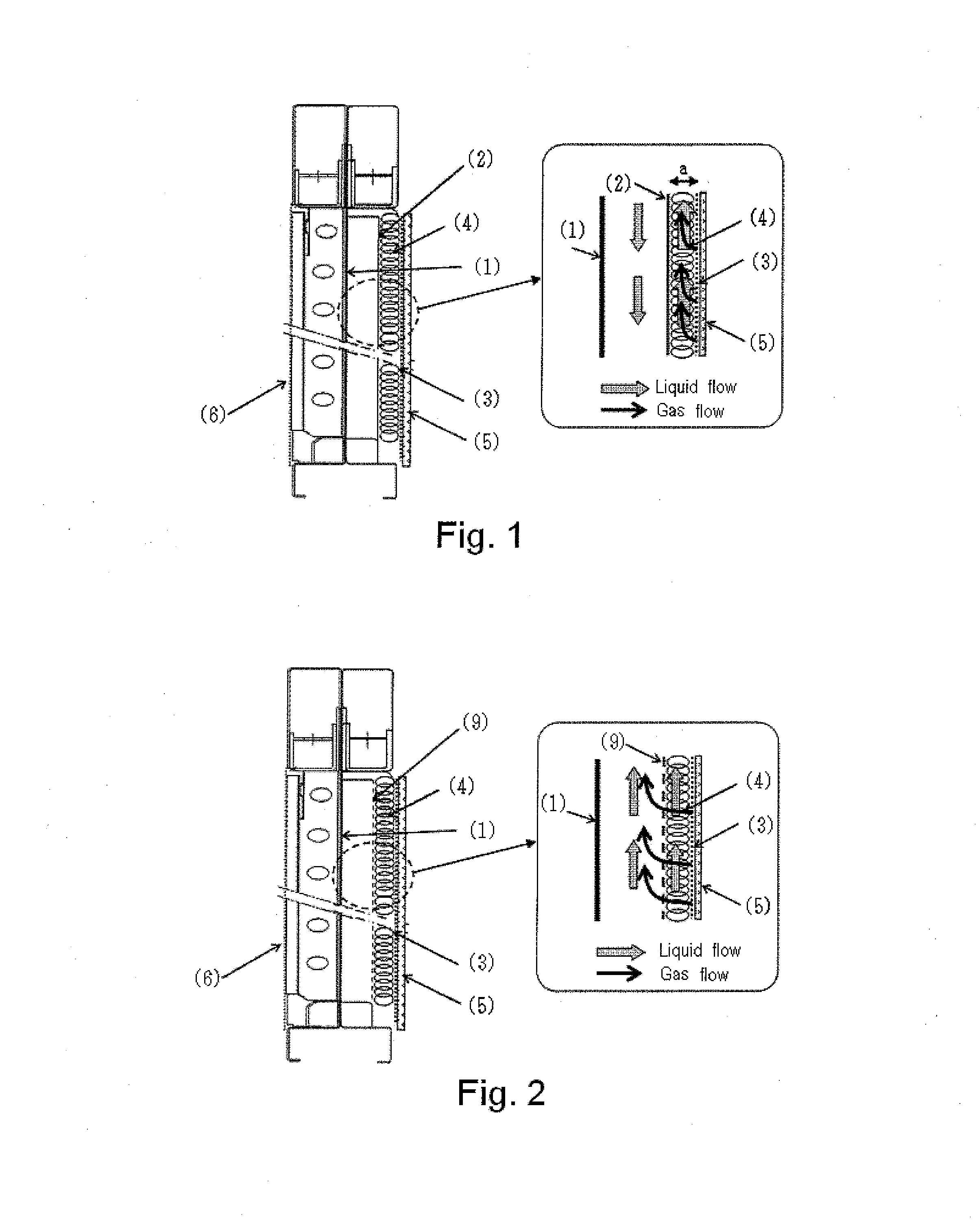

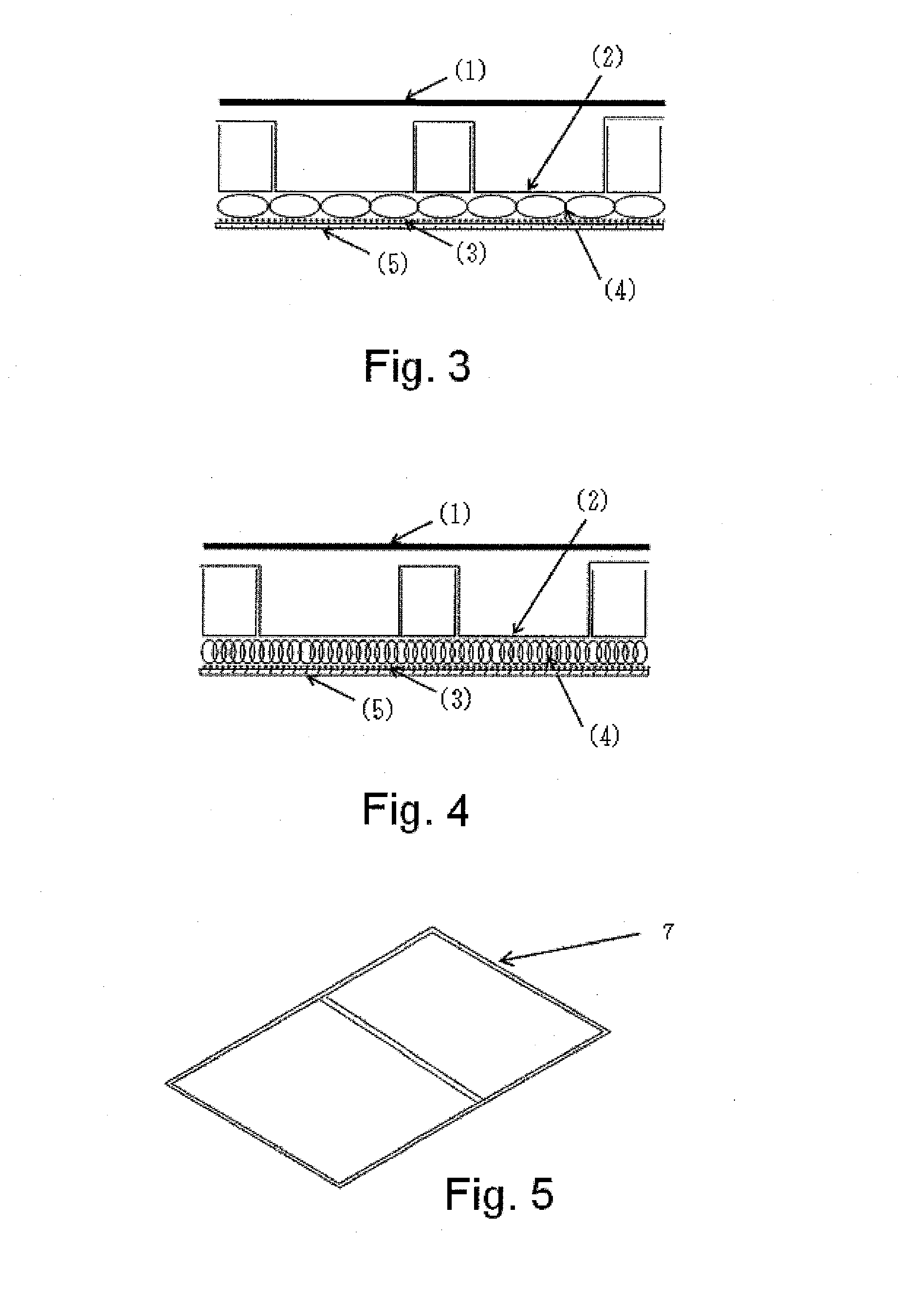

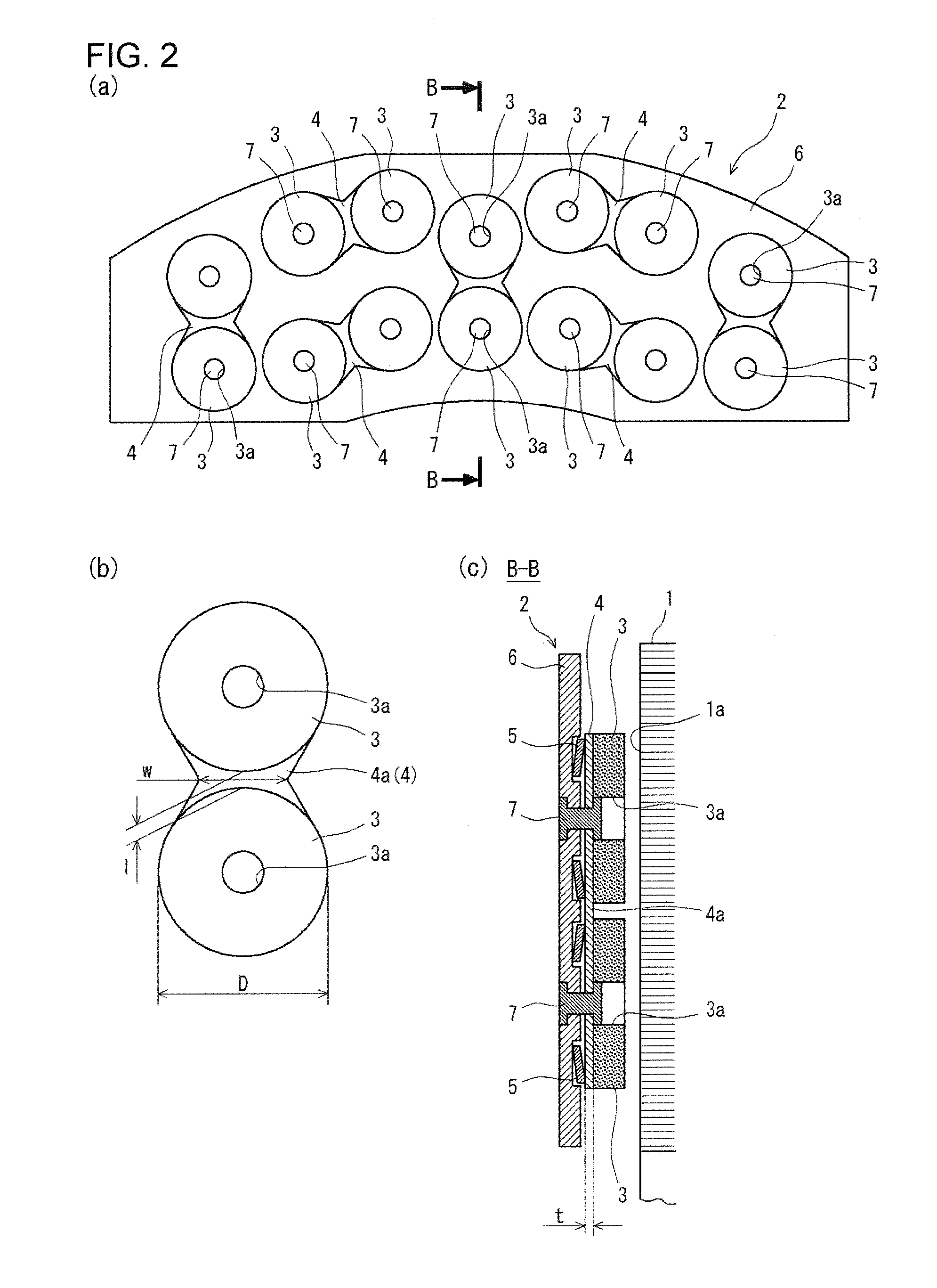

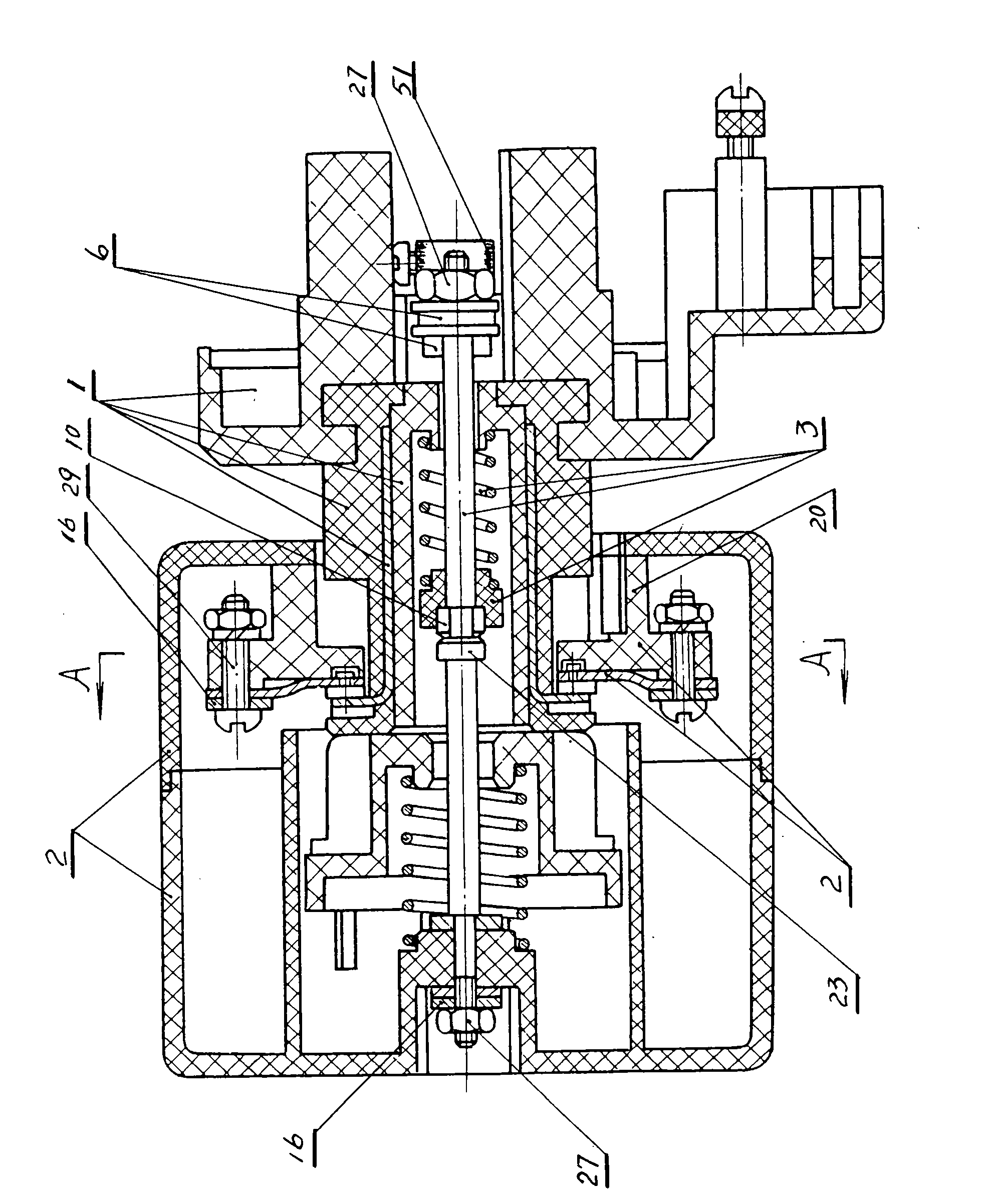

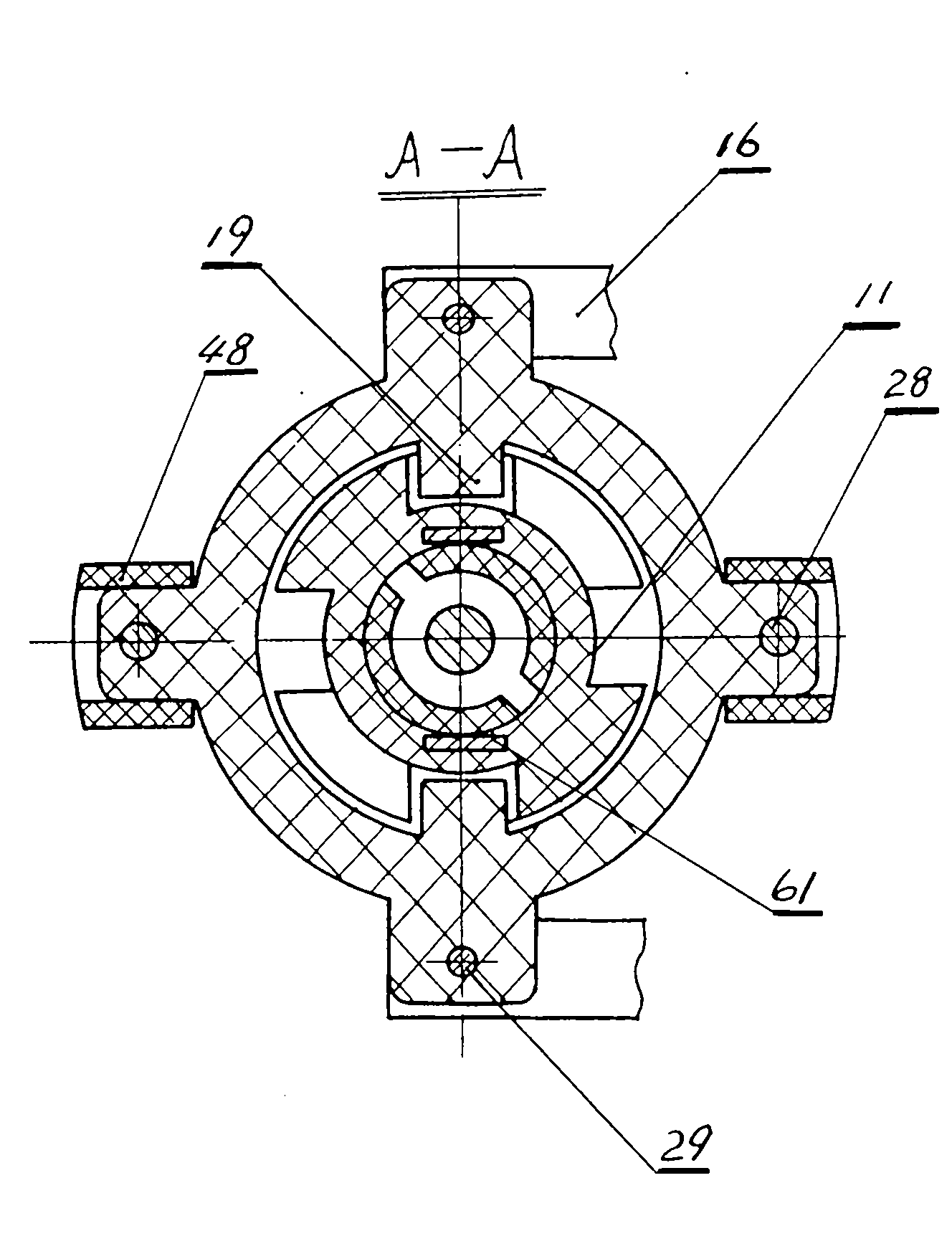

Ion exchange membrane method electrolytic cell

ActiveUS20130299342A1Easy to adjustReduce energy consumptionCellsElectrode shape/formsEngineeringIon-exchange membranes

An ion-exchange membrane method electrolytic cell comprising a coil cushion arranged between a conductive plate and a cathode in a cathode chamber, and further an ion-exchange membrane arranged in contact with the cathode. The conductive plate is not perforated, and the coil cushion is arranged so that its axial direction is in agreement with the vertical direction of electrolytic cell. Preferably the coil cushion is made of a metal coil and has an impact resilience of 7-17 kPa. The cathode preferably has supported electrode catalyst and is made of an expanded metal with strands of 0.1-1.0 mm width and 0.1-1.0 mm thickness, and having SW of 0.5-5.0 mm and LW of 1.0-10 mm, and 48-60% open area. The electrolytic cell is energy-saving, and damage thereof can be avoided over a long period, and elevation of voltage and reduction of current efficiency with time can be minimized.

Owner:TOSOH CORP +1

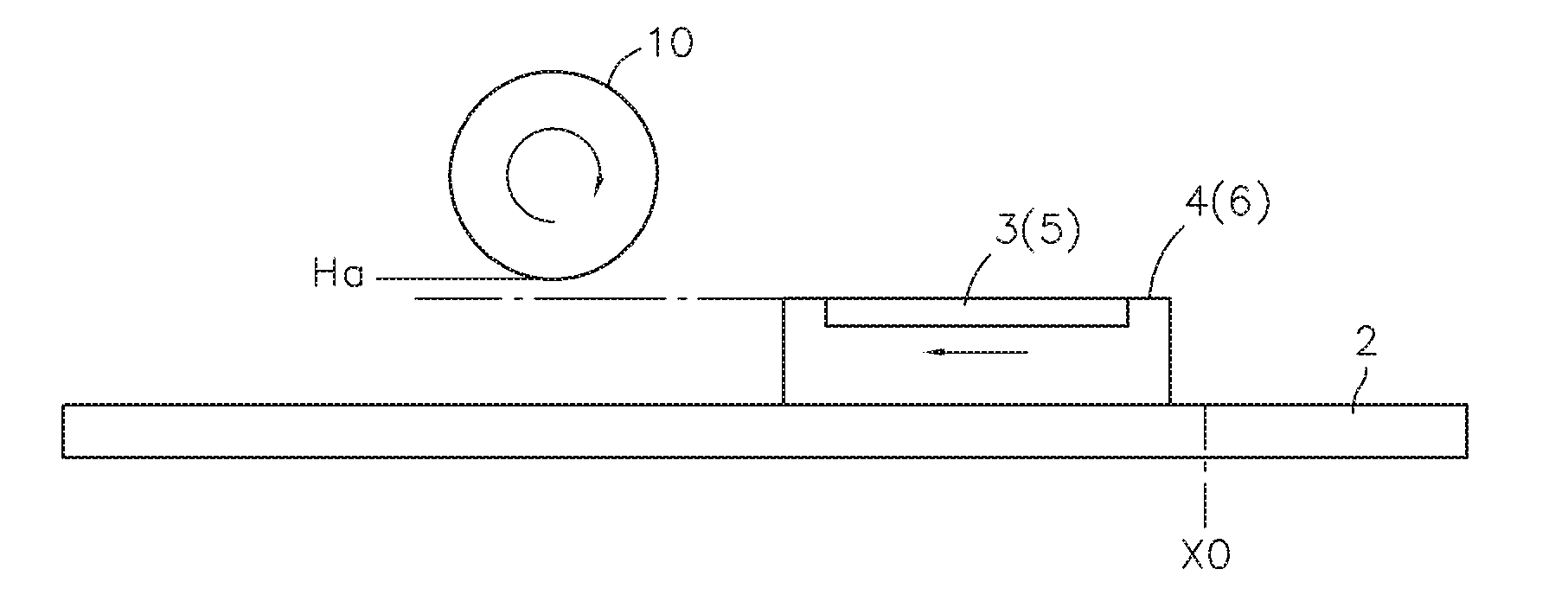

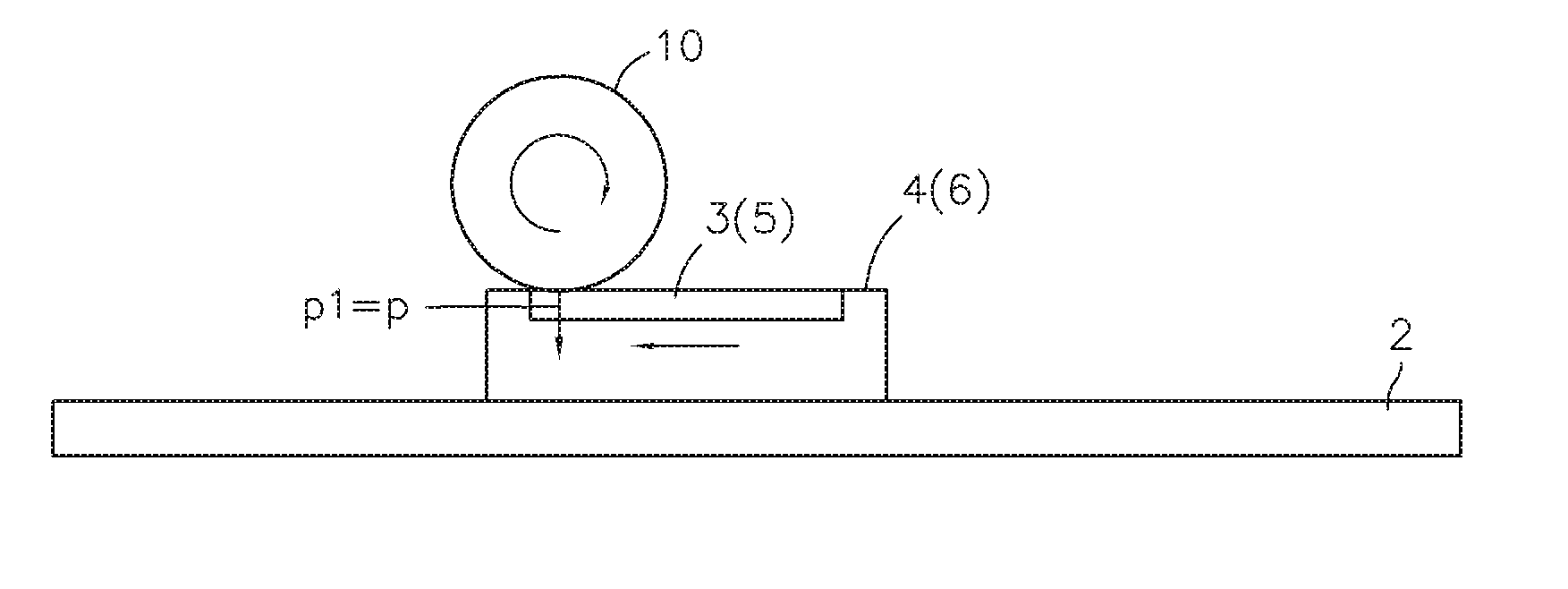

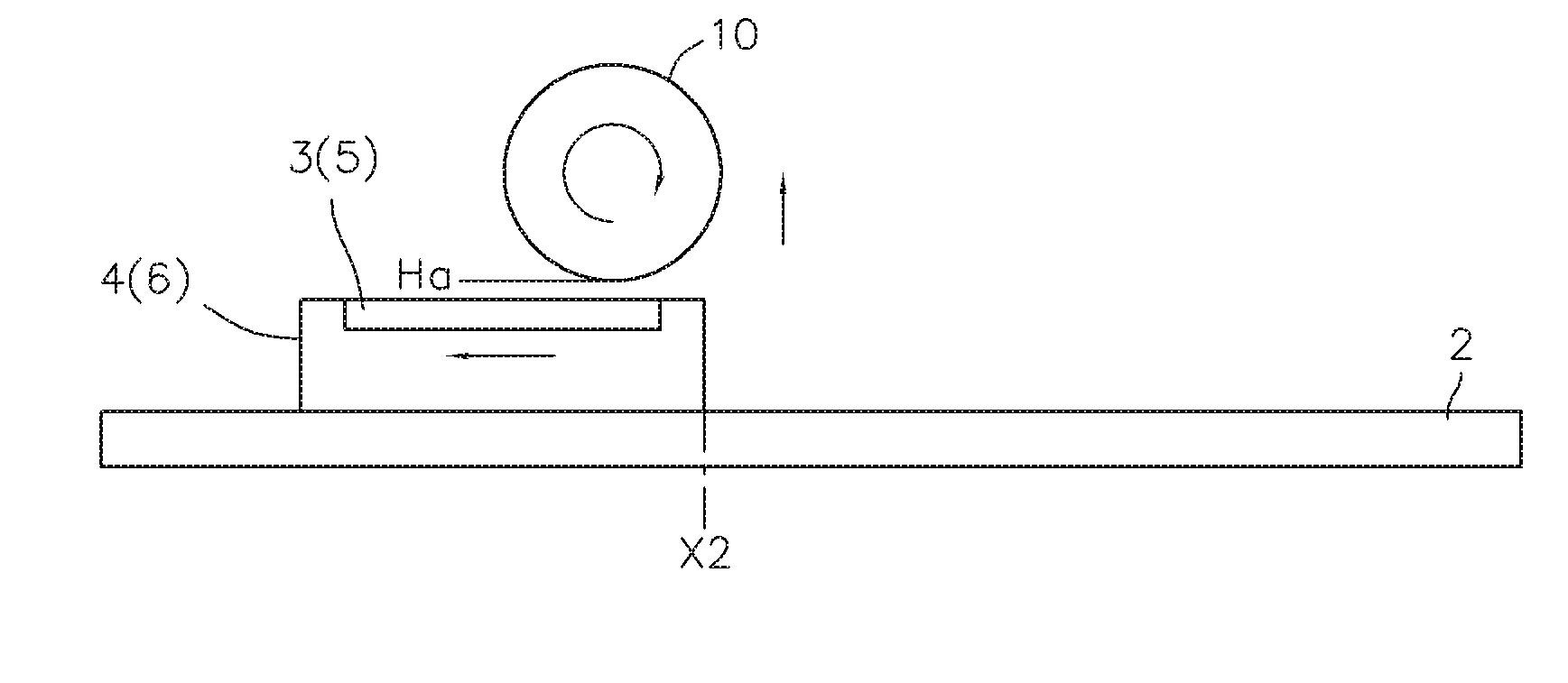

Offset printing method and device

InactiveCN102548763AUniform deformationUniform contact pressureCylinder pressesRotary pressesContact pressureEngineering

Disclosed is an offset printing device in which a printing-plate table (4) and a base-plate table (6) are movably provided on a guide rail (2) which is provided on a stand (1). A transfer mechanism (9) is provided at a location on the guide rail (2) corresponding to an intermediate section thereof in the longitudinal direction, the transfer mechanism (9) comprising: a blanket roll (10); a blanket roll raising / lowering actuator (13); a blanket roll height sensor (14); and a pressure sensor (15) for detecting the contact pressure of the blanket roll with respect to a printing plate (3) or a base plate (5). Furthermore, a controller controls the raising / lowering actuator (13) in such a way that the contact pressure detected by the pressure sensor (15) when the blanket roll (10) contacts the printing plate (3) or the base plate (5) reaches a prescribed value. The contact pressure when transfer is performed from the printing plate (3) to the blanket roll (10) and the contact pressure when re-transfer is performed from the blanket roll (10) to the base plate (5) are both made uniform, whereby the amount of deformation of the portion which contacts the printing plate (3) or the base plate (5) is made uniform and the peripheral speeds are made equal. As a result, the printing precision can be improved.

Owner:IHI CORP

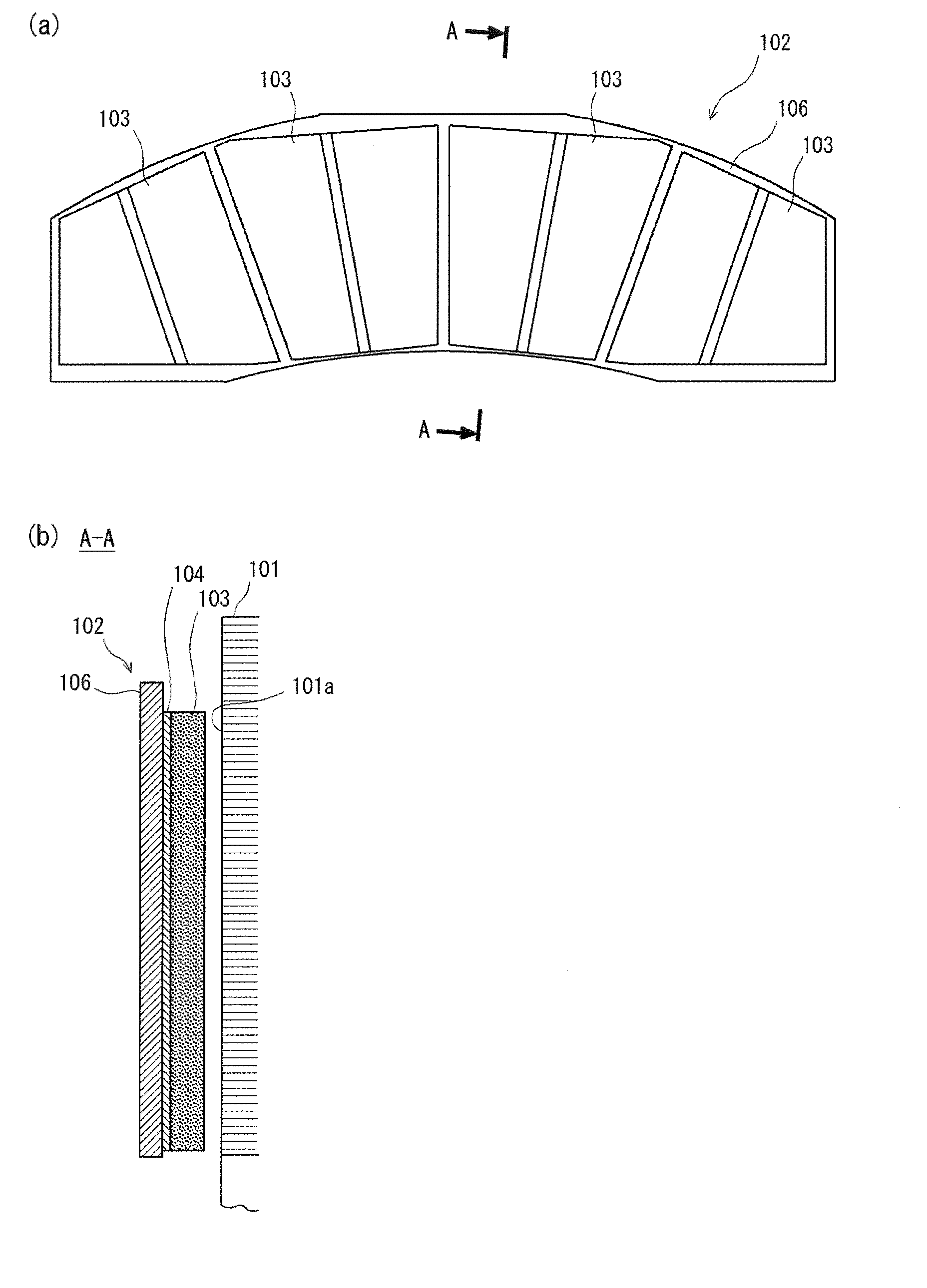

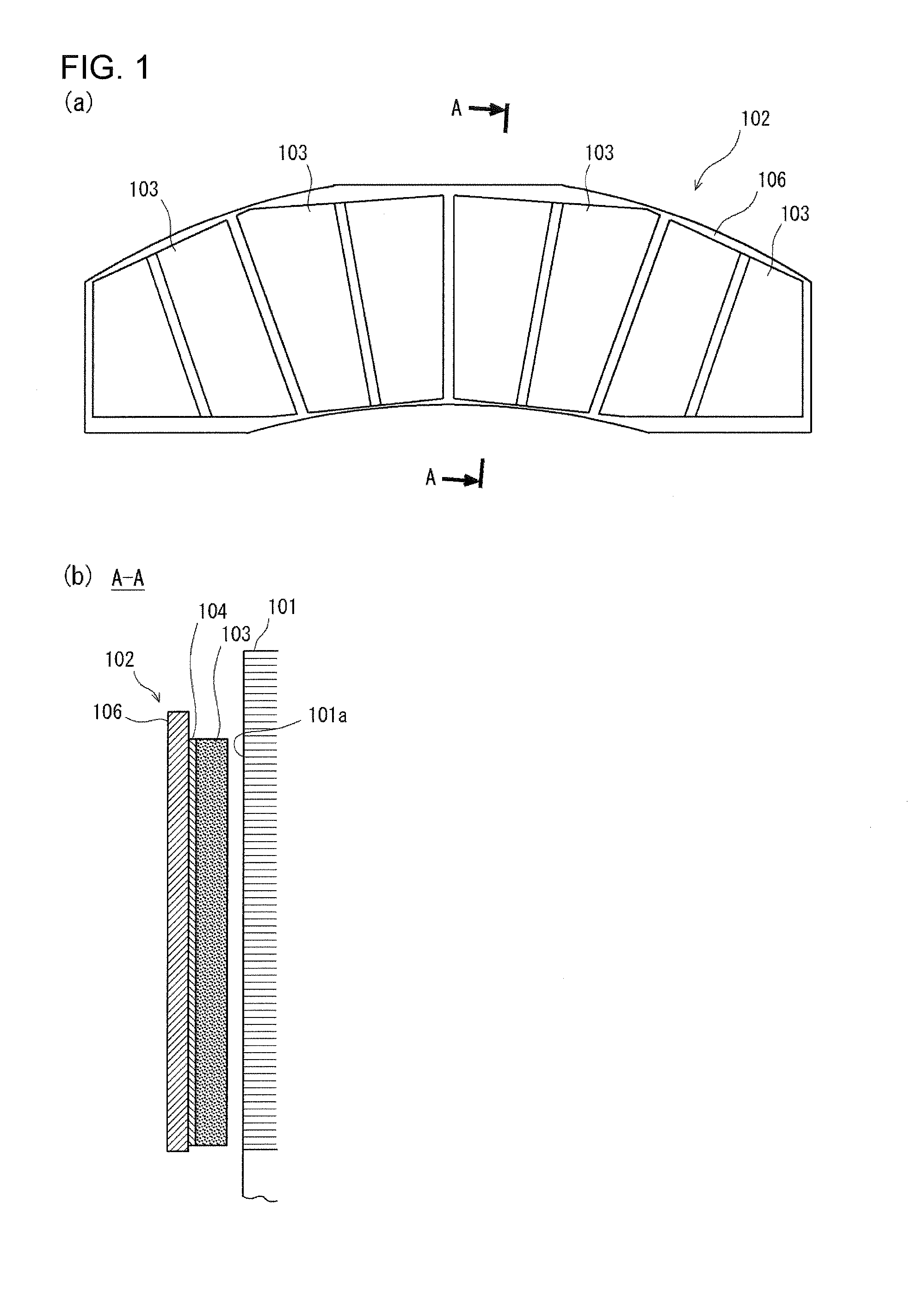

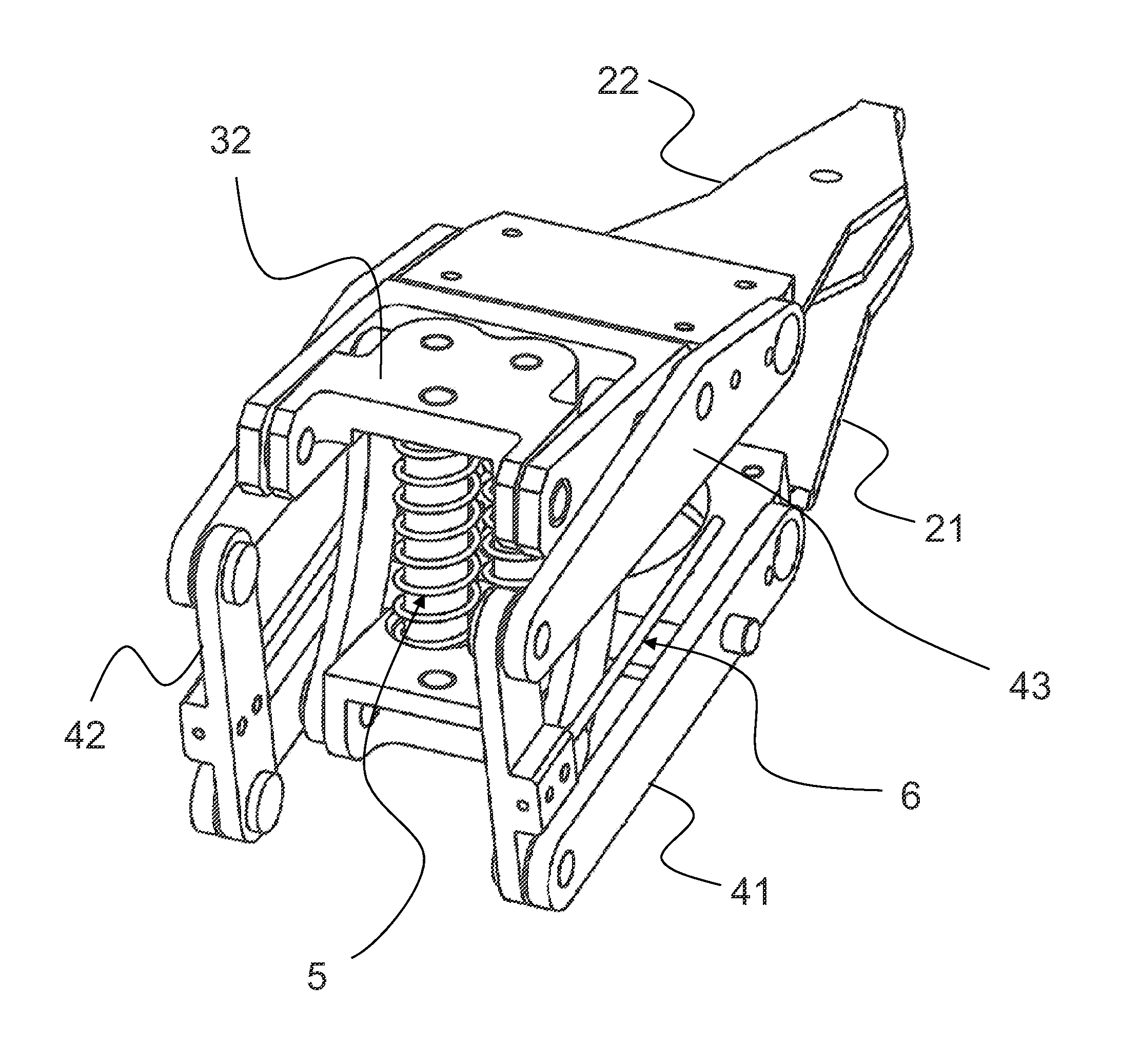

Brake lining for railway vehicles and disc brake equipped with the same

ActiveUS20140097049A1Stable coefficient of frictionIncreased durabilityAxially engaging brakesBraking elementsEngineeringCalipers

A disc brake for railway vehicles includes a brake disc fixed to a wheel or an axle of a railway vehicle and a brake lining configured to be pressed against a frictional surface of the brake disc by a brake caliper. The brake lining includes a plurality of friction members arranged to be spaced from each other, each of the friction members having a surface that faces the frictional surface of the brake disc, a metallic backing secured to back surfaces of the friction members, and a base plate supporting the friction members on the back surface side via spring members. The base plate is mounted to a brake caliper; wherein the friction members are provided in pairs with each pair being formed by two adjacent ones of the friction members, and the metallic backing is a one-piece member provided for each pair of the friction members.

Owner:RAILWAY TECH RES INST +2

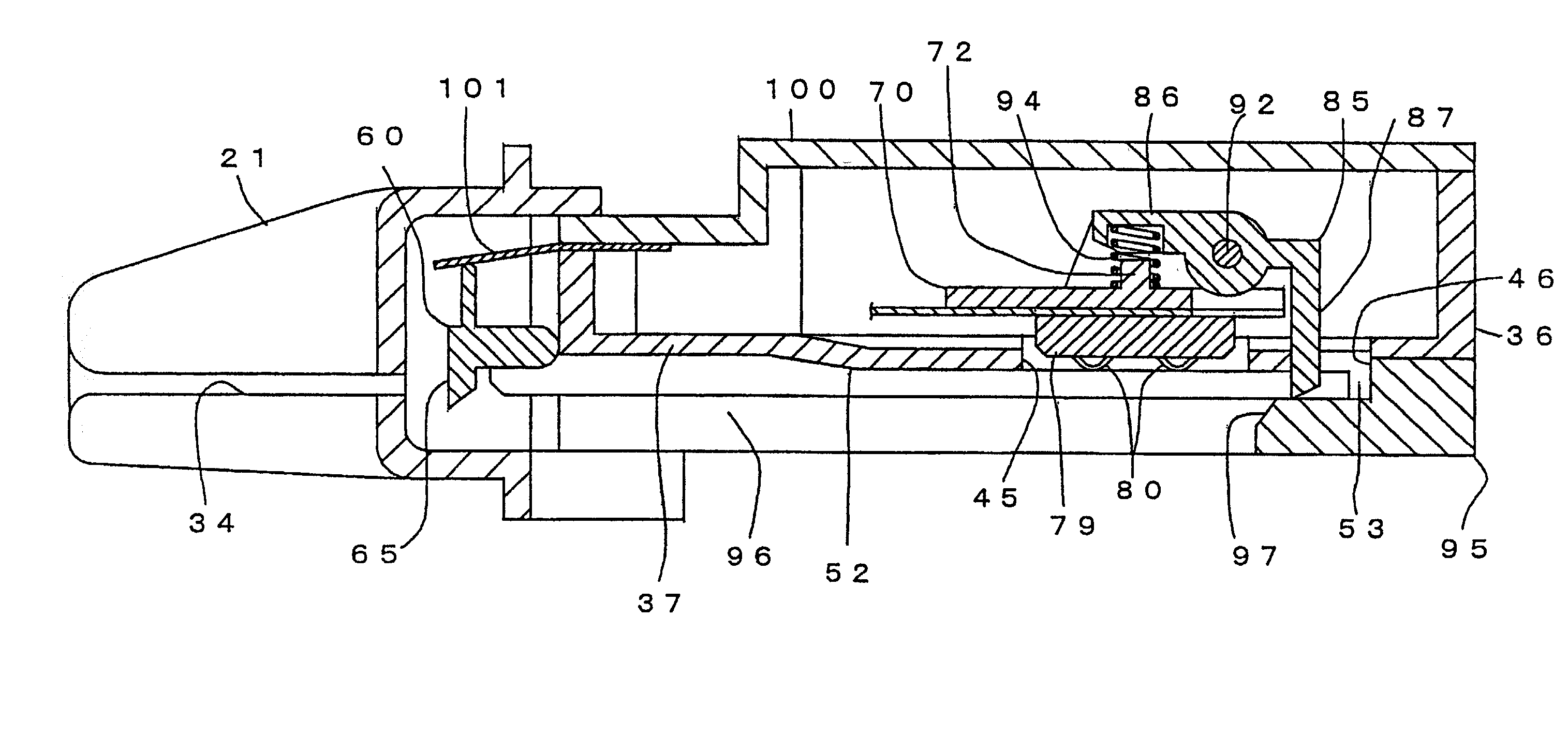

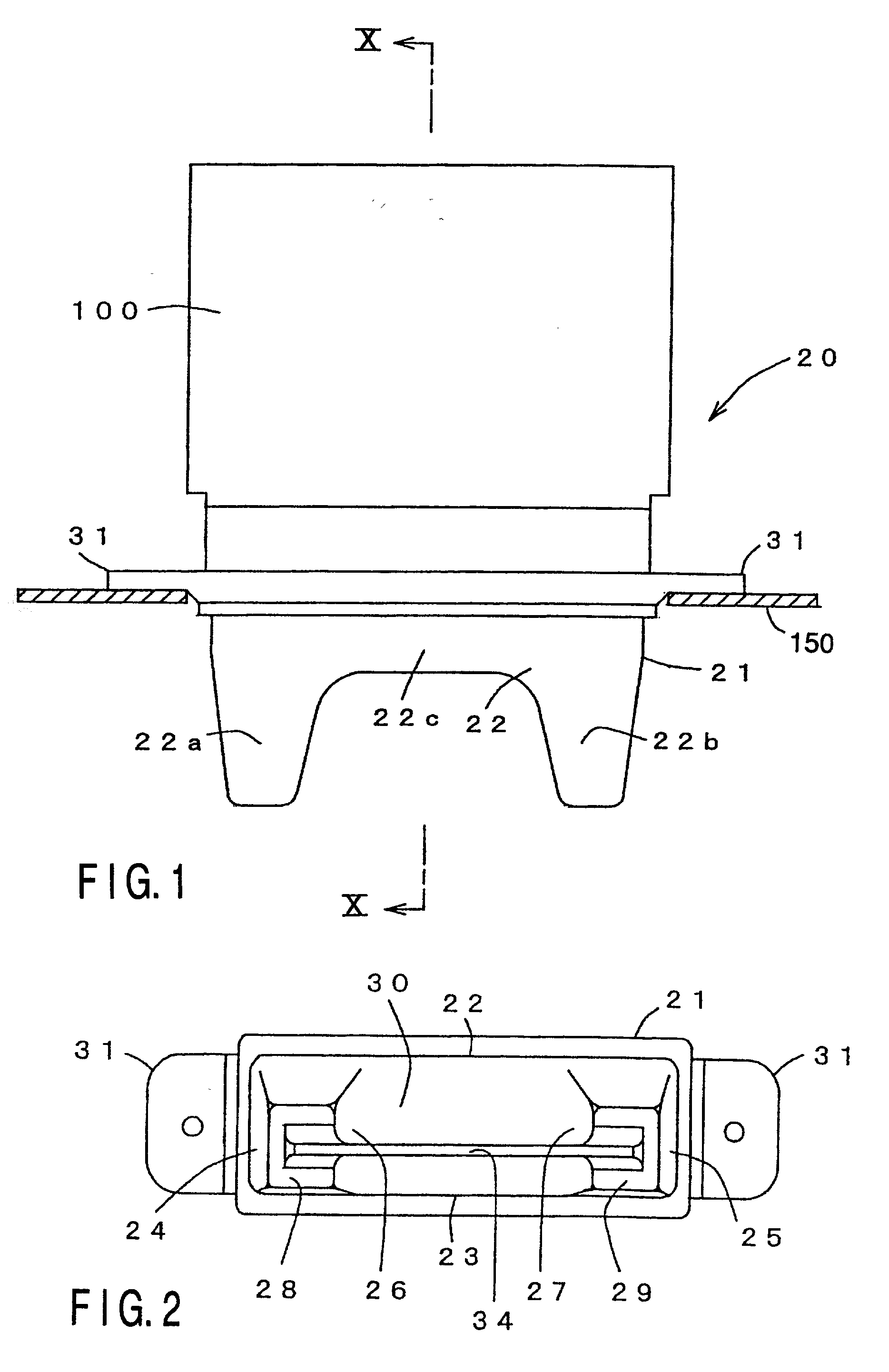

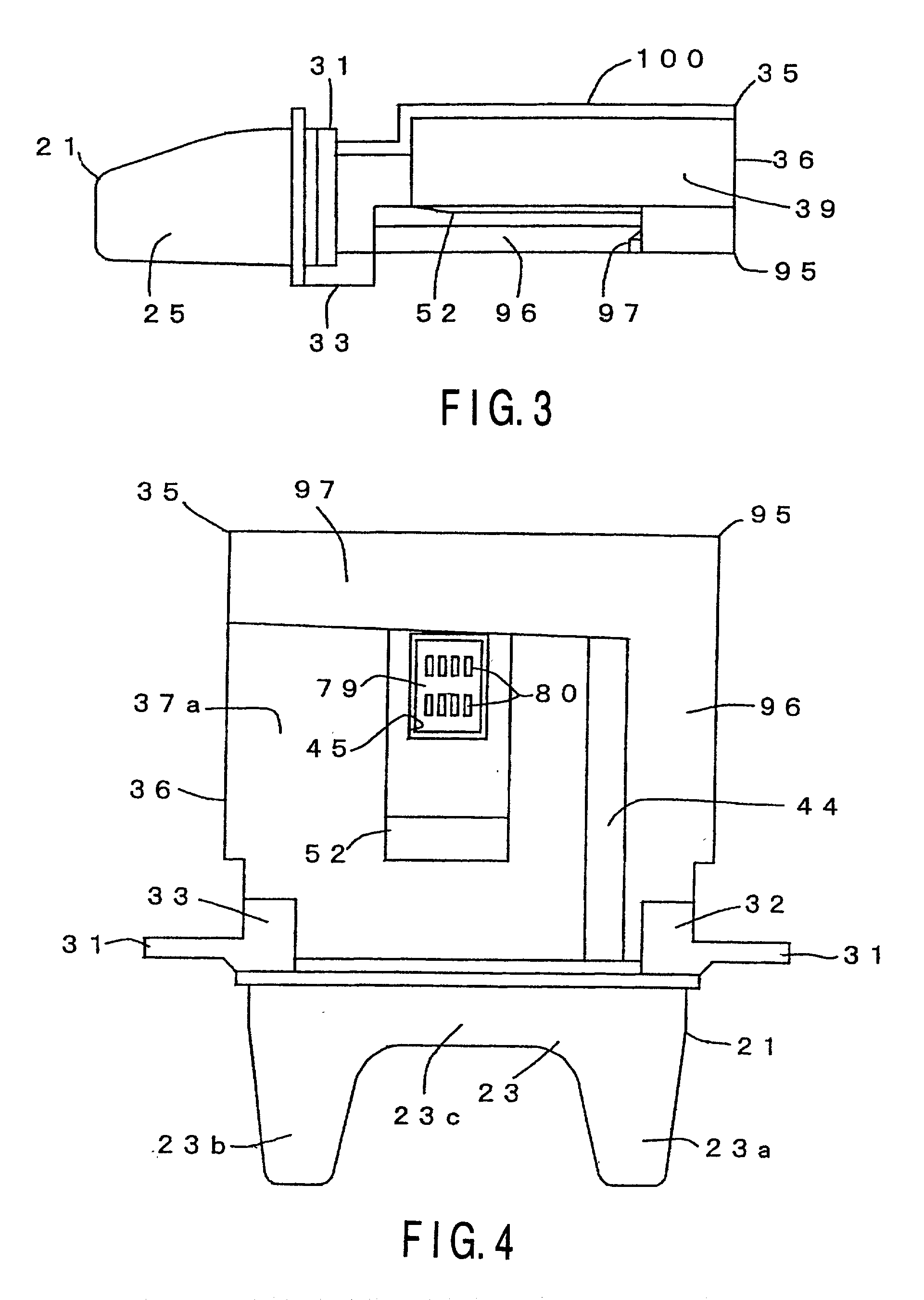

Ic card handling device

InactiveUS20020153420A1No damageUniform contact pressureConveying record carriersCoupling contact membersMechanical engineeringCross point

A card slot defines a space for receiving an IC card. A contact block has a plurality of contacts on one surface for contacting a plurality of contact points, respectively which are provided on one surface side of the IC cared received inside the card slot. A supporting mechanism movably supports the contact block in the vertical direction to the one surface of the IC card received inside the card slot, swingingly around a first axis line which passes through the center of the plurality of contacts of the contact block in the inserting direction of the IC card, and swingingly around a second axis line which passes through the center of the plurality of contacts of the contact block in the inserting direction of the IC card. An elastic member abuts against the contact block at one point only and applies a force to press the plurality of contacts of the contact block against one surface side of the IC card. A point of the place to which the pressing force is applied by the elastic member exists on an axis line which passes a cross point between the first axis line and the second axis line and extends vertically.

Owner:ANRITSU CORP

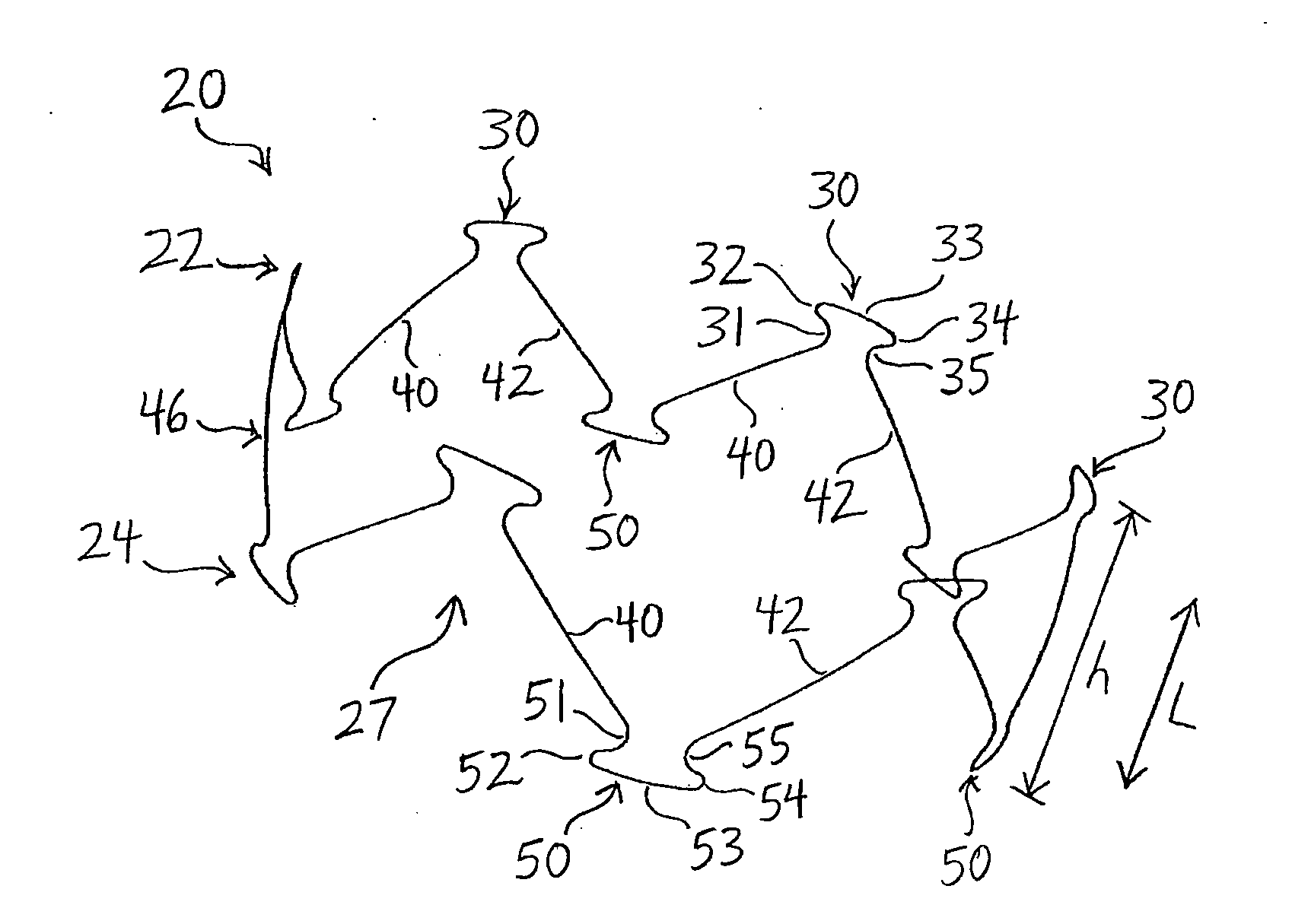

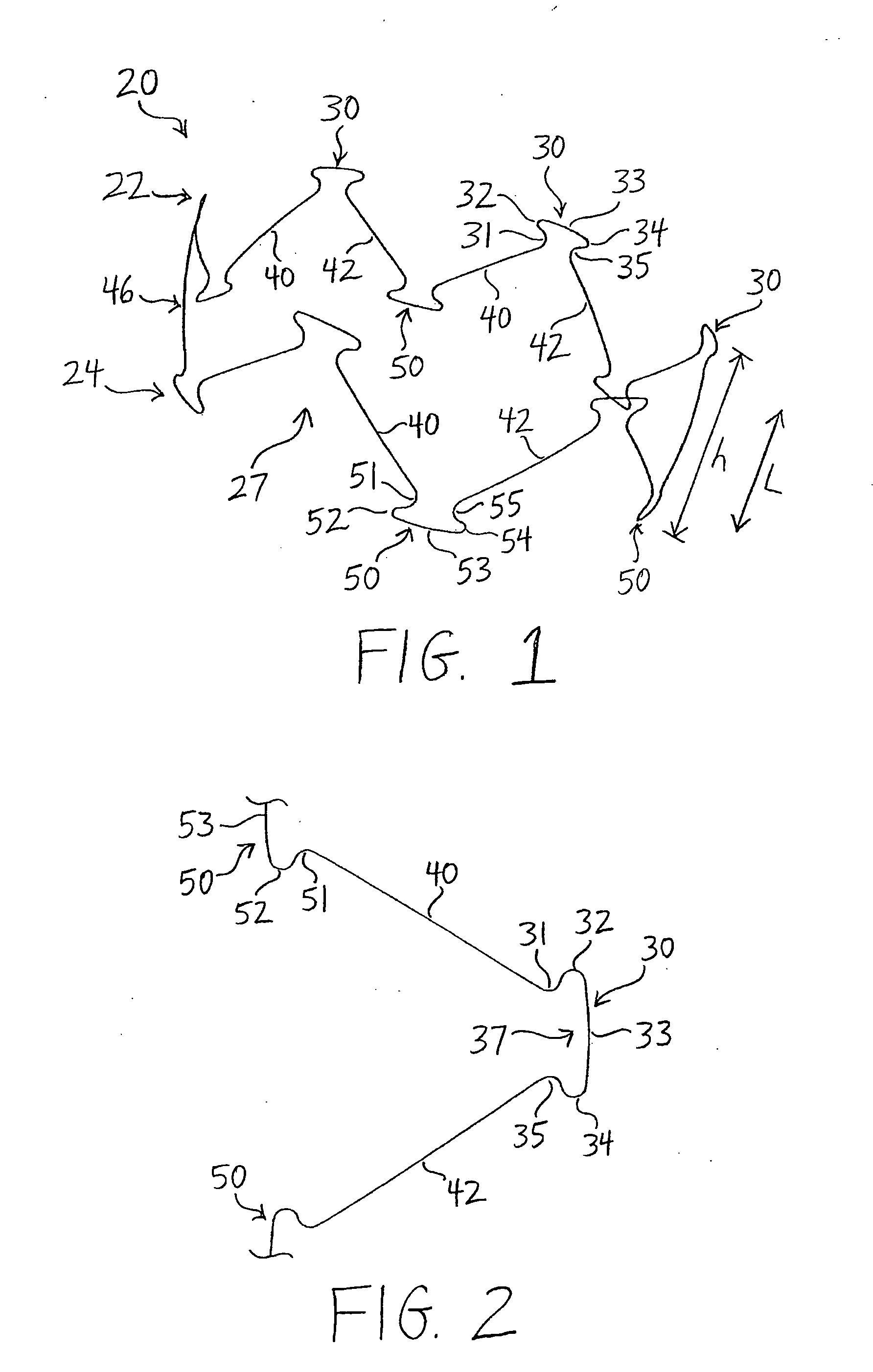

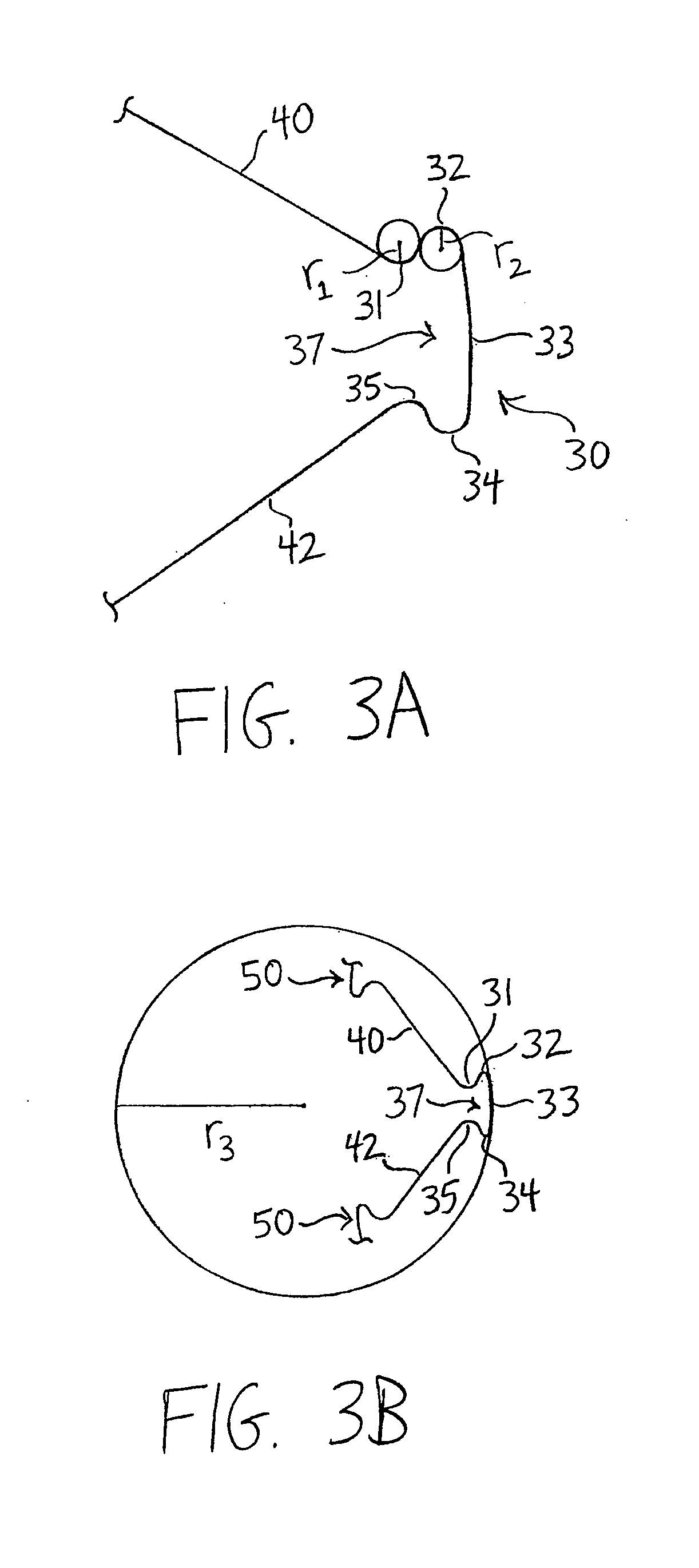

Stent having less invasive ends and improved radial force

The present invention provides a stent having less invasive ends and improved radial force. In one embodiment, the stent comprises a series of proximal apices disposed at a proximal end of the stent, a series of distal apices disposed at a distal end of the stent, and at least one angled strut segment disposed between the proximal and distal apices of the stent. At least one apex of the stent may comprise multiple curved portions. In one example, the radius of curvature of one of the curved portions is significantly greater, for example, at least 10 times greater, than each of the other radii of curvature of the apex. The curved portion having the significantly greater radius of curvature may be configured to engage a vessel wall in a less invasive manner.

Owner:COOK MEDICAL TECH LLC

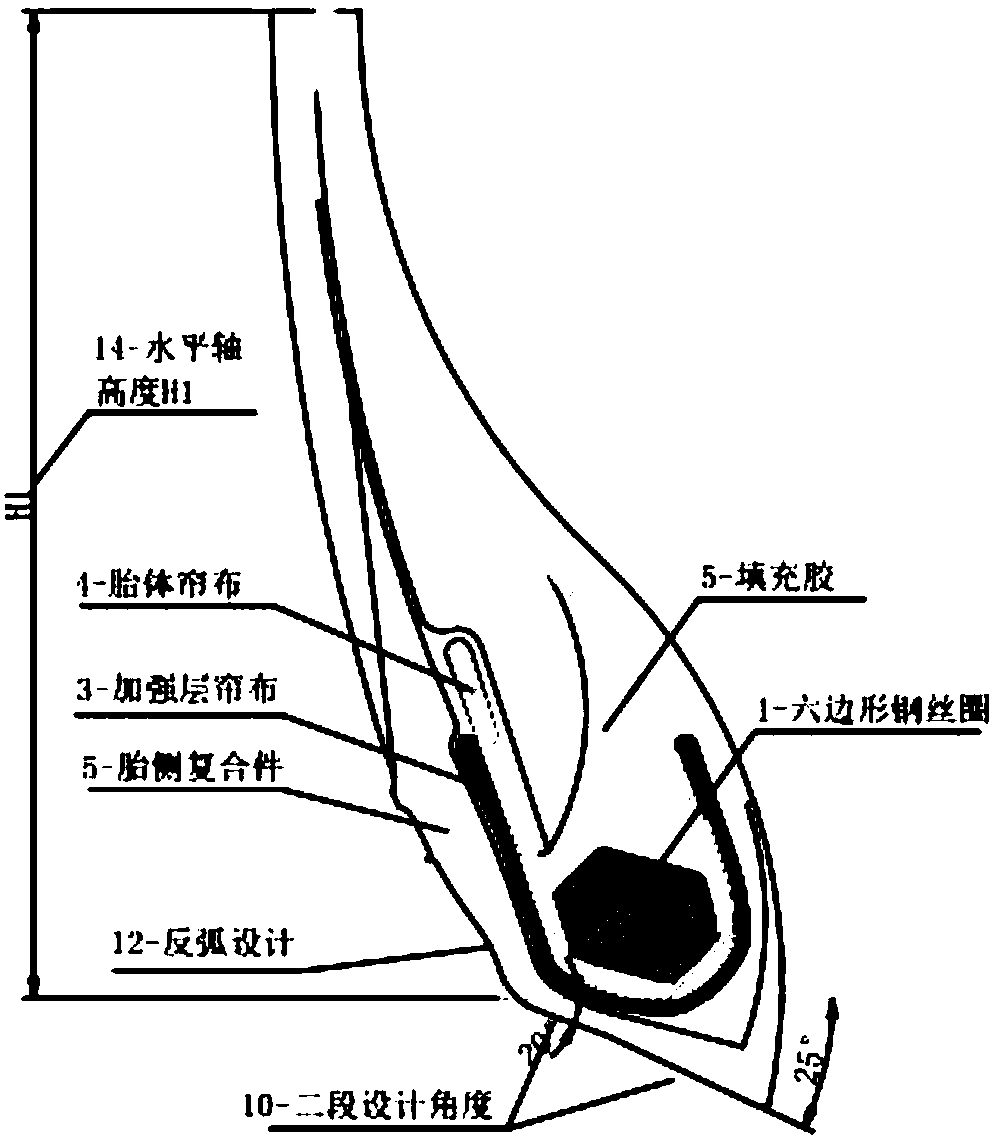

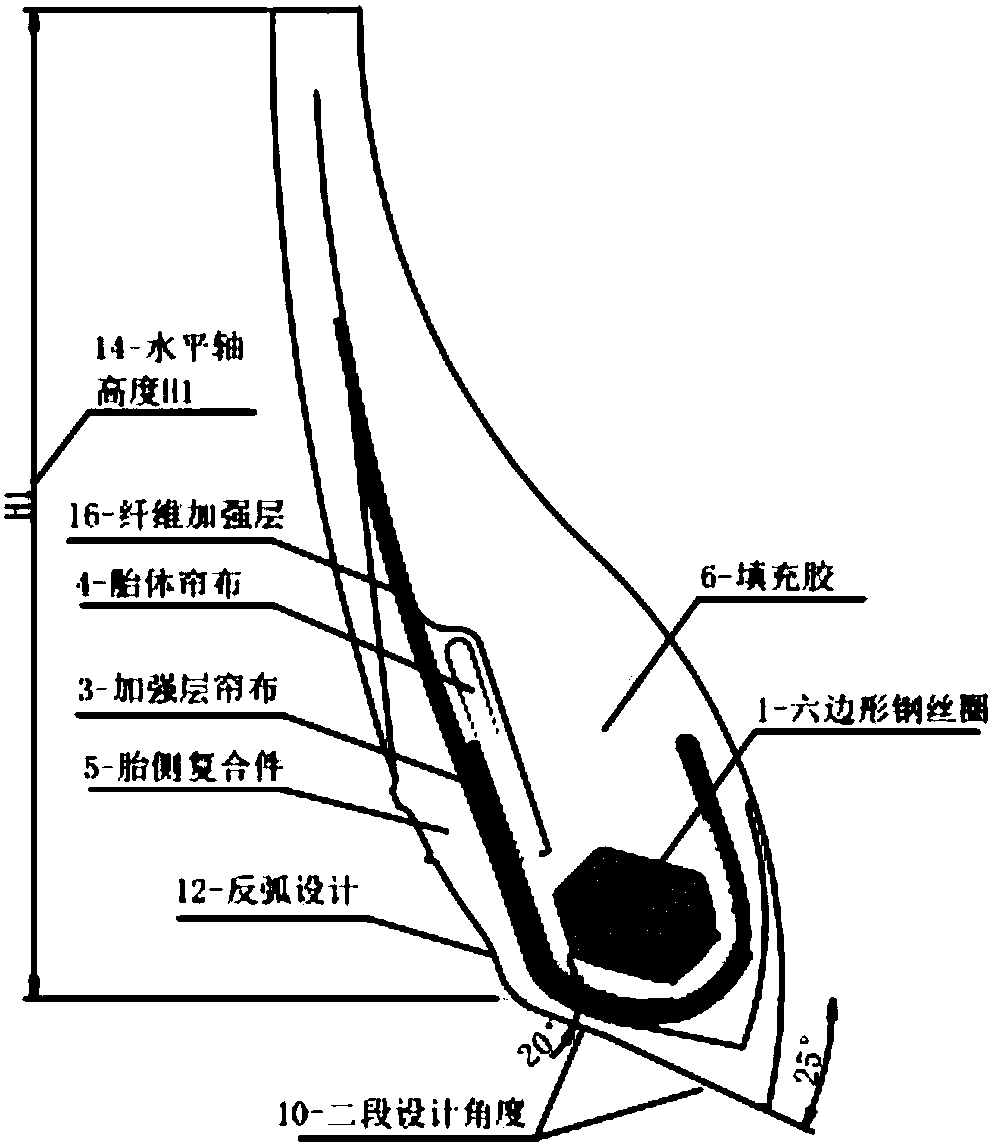

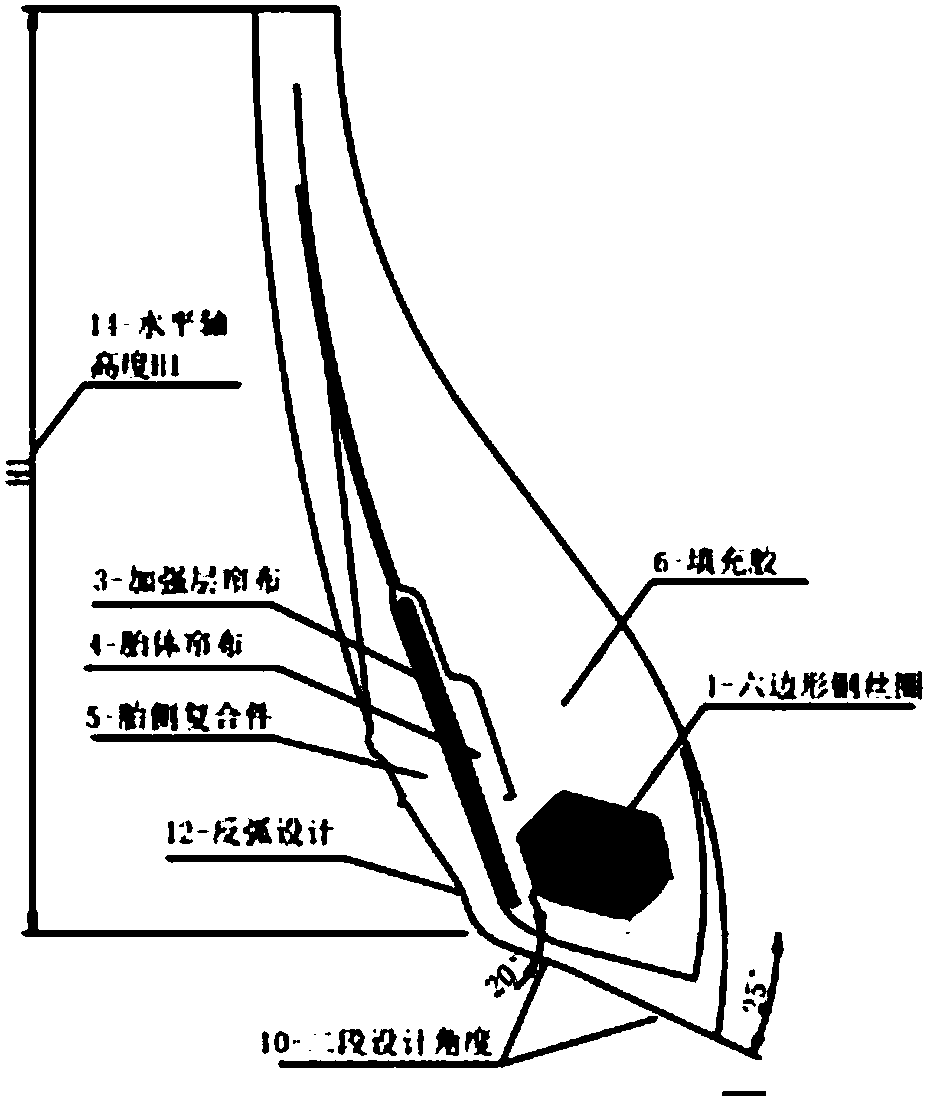

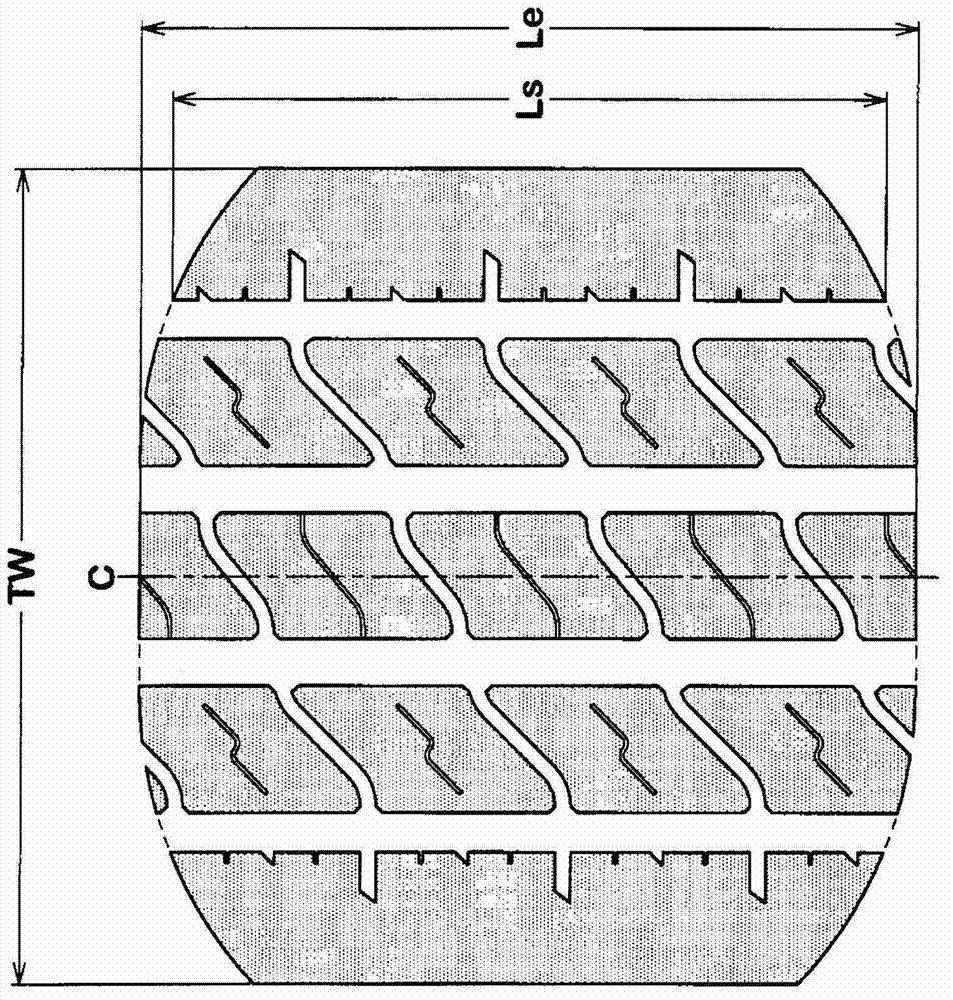

All-steel tubeless radial tire with high load performance and manufacturing method thereof

PendingCN107719029AConformationally stableImprove strength utilizationTyresTyre beadsTire beadEngineering

The invention discloses an all-steel tubeless radial tire with a high load performance and a manufacturing method thereof. A rectangular bead ring is arranged in a compound bead ring; a section designangle is adopted by a profile curve at the bottom of a bead base; a tangent design angle is adopted by the profile curve of a tire bead heel; a sizing material is thickened on a contact position of the bead heel and the rim; binding rubber slices are arranged at two endpoints of a tire cord fabric and a reinforced cord fabric; the height of reverse binding sections of the binding rubber slices isarranged close to the height H1 of a horizontal shaft; an upper filling glue and a lower filling glue for isolation are successively arranged between the reverse binding sections of the binding rubber slices and the tire body from top to bottom; a U-shaped reinforced cord fabric layer is paved on the outer layer of the tire cord fabric; an inside liner and a sidewall compound piece are respectively arranged on the inner and outer sides of the reinforced cord fabric. The bead ring is stable in construction, is free from deformation under a stressed state and is high in strength use ratio; thebottom of the bead ring is in surface contact with the rim; the stress is uniform and the load resistance is promoted; the stress between the tire body and the tire cord fabric is buffered by the isolating rubber slices; the loading capacity is promoted by the reinforced cord fabric.

Owner:SAILUN GRP CO LTD

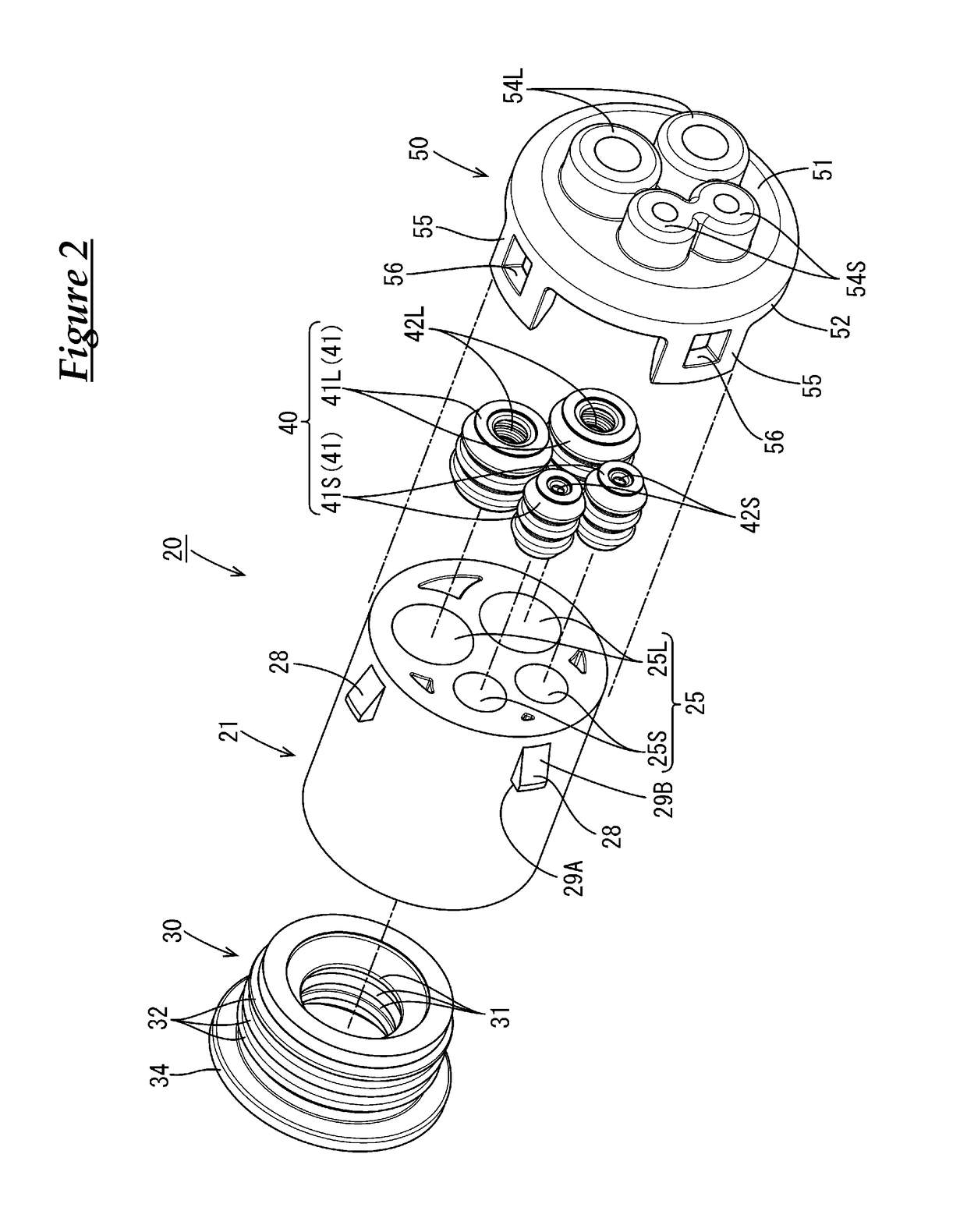

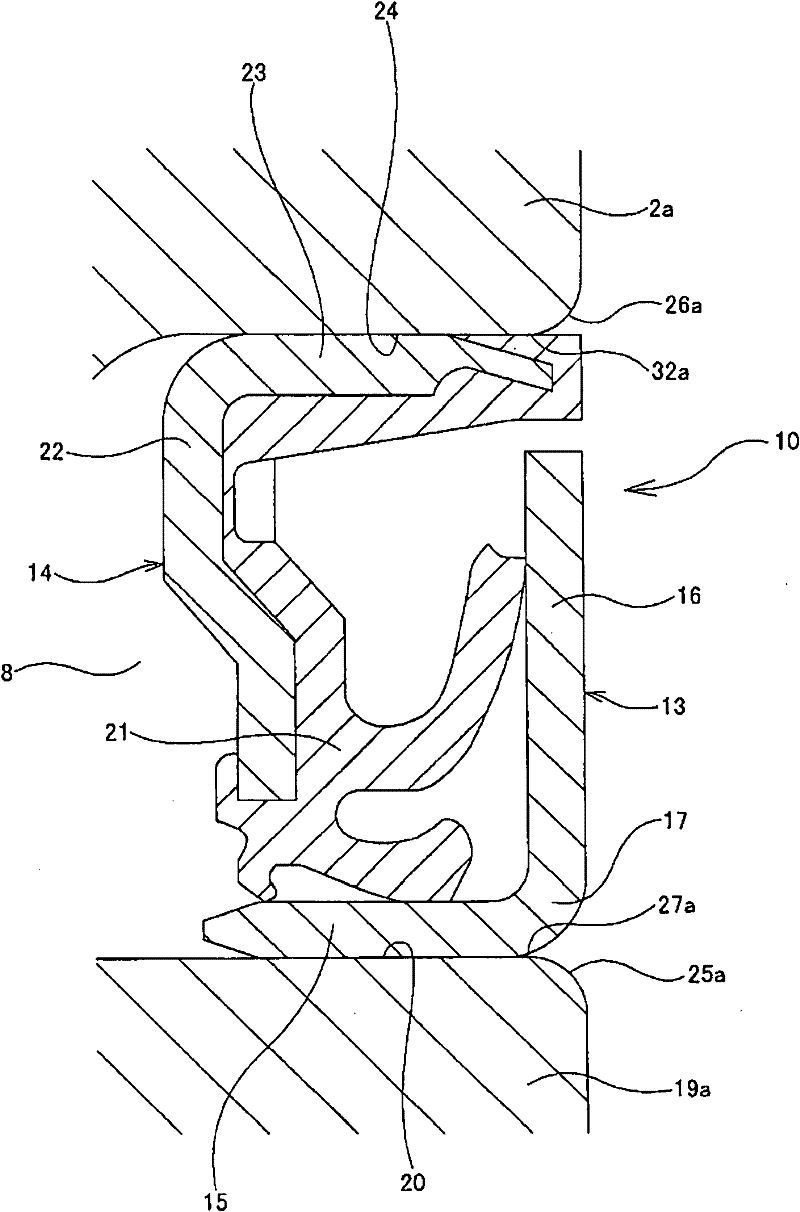

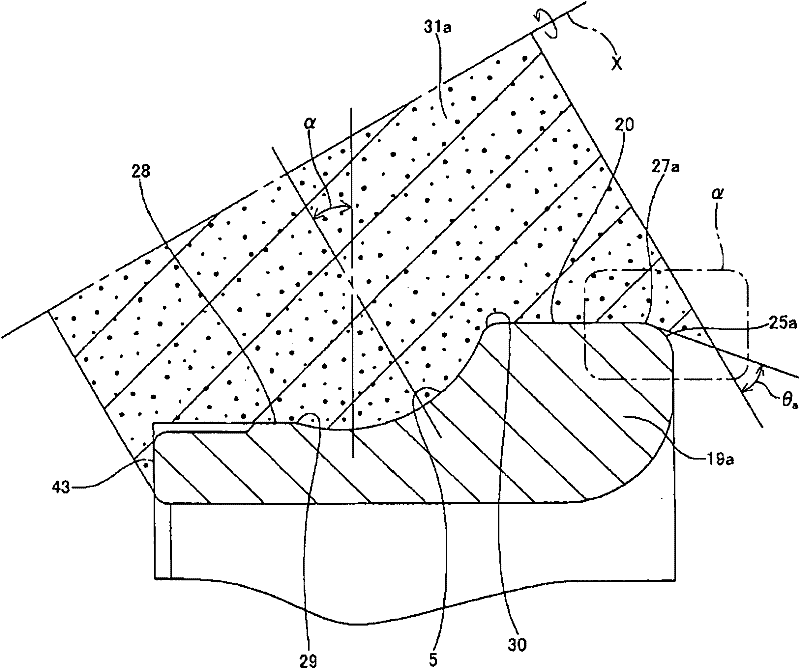

Rolling bearing unit with combination seal ring, and method for manufacturing same

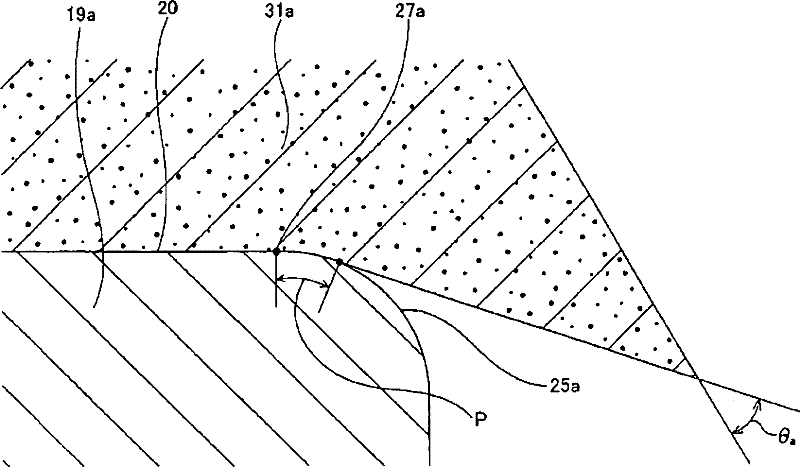

ActiveCN102239341AAvoid leaningNormal performanceRolling contact bearingsBearing assemblyRolling-element bearingEngineering

A structure which enables a cylindrical section (15) of a slinger (13) to be press-fitted into a slinger fitting surface (20) of an inner ring (19a) without impairing the sealing ability between the cylindrical section (15) and the slinger fitting surface (20). A continuous portion of the surface of an inner ring (19a) are ground at a time by a vertical rotary grinding stone after the inner ring (19a) is subjected to heat treatment, the continuous portion being composed of the portion of the slinger fitting surface (20), the portion of a chamfered section (25a), and the portion of the joint (27a) between the portion of the slinger fitting surface (20) and the portion of the chamfered section (25a). As a result, the entire continuous portion is formed as a flat smooth surface in which a corner which cannot be differentiated with respect to a cross-sectional shape thereof, that is, a corner which has a pointed edge, is not present.

Owner:NSK LTD

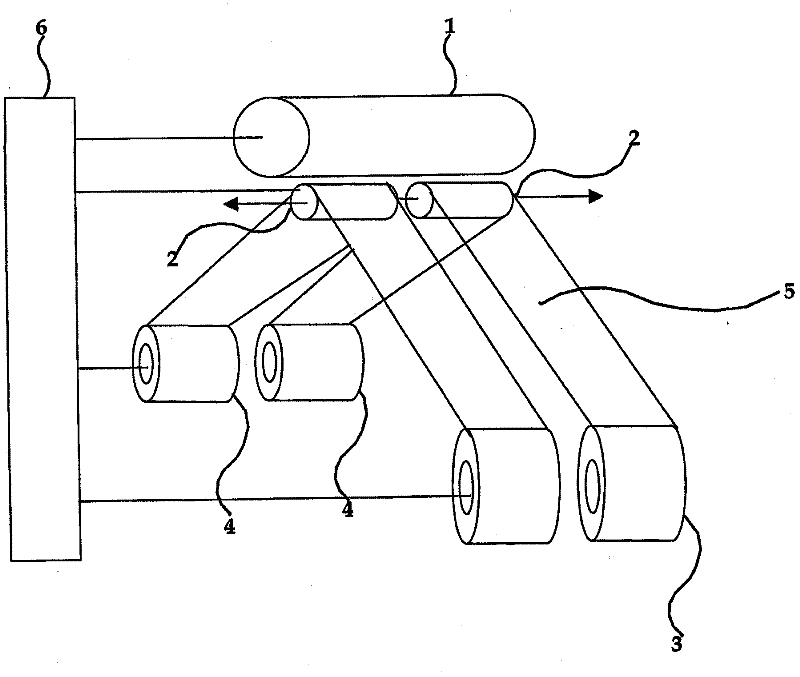

Apparatus and method for cleaning rubber blankets on rubber blanket cylinders

The invention relates to an apparatus for cleaning the rubber blanket stretched over a rubber blanket cylinder (1) of a printing press, using a cleaning apparatus, characterized in that the cleaning apparatus comprises at least one moving and transporting apparatus (6), at least two cleaning modules (2) which are connected to each other, at least one cleaning cloth winding reel (4), and at least one cleaning cloth supply reel (3), wherein the moving and transporting apparatus (6) is designed such that it can move the cleaning modules (2) connected to each other parallel to the axis of the rubber blanket cylinder (1), and the moving and transporting apparatus (6) is furthermore designed such that it transports a cleaning cloth provided on the cleaning cloth supply reel (3) onto the cleaning cloth winding reel (4) by way of the cleaning modules (2).

Owner:迈克尔·卡斯帕

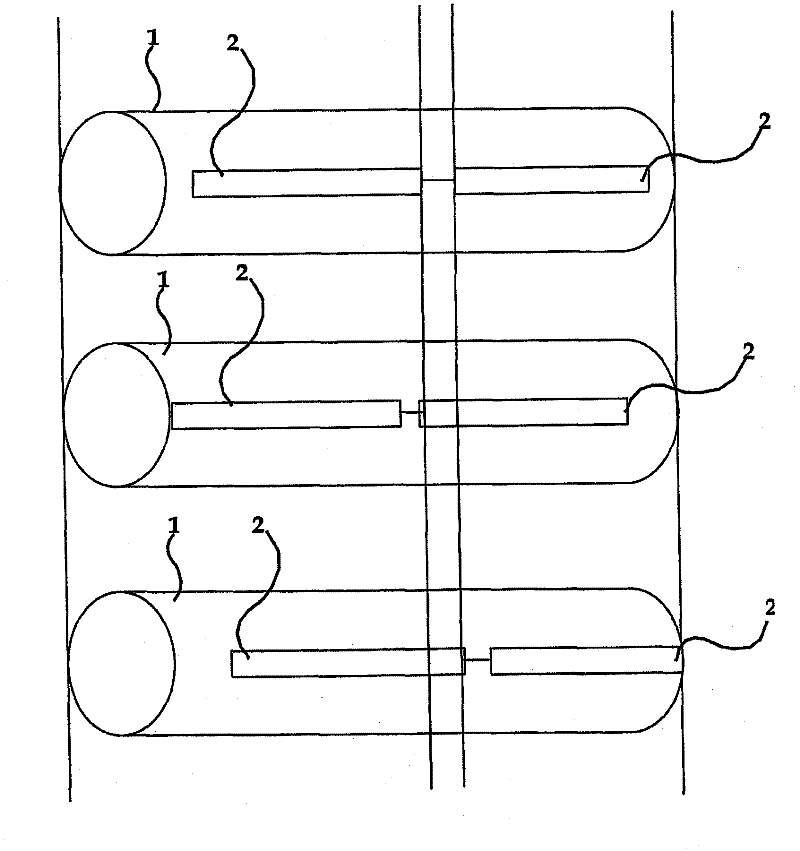

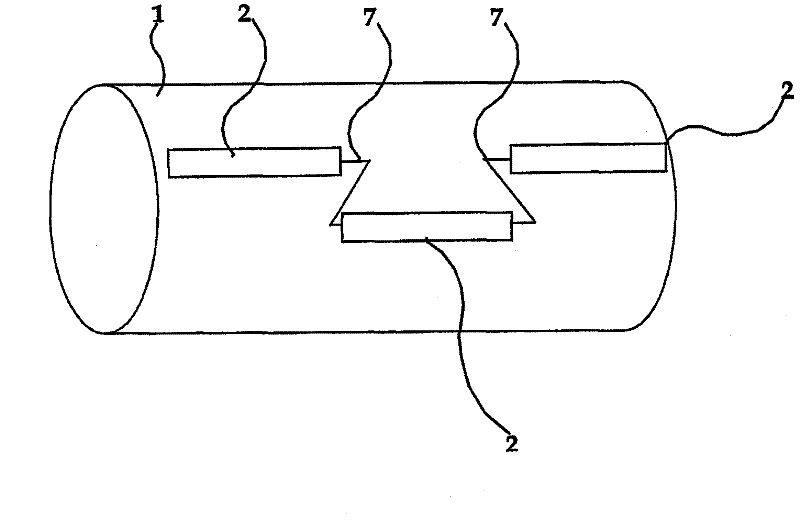

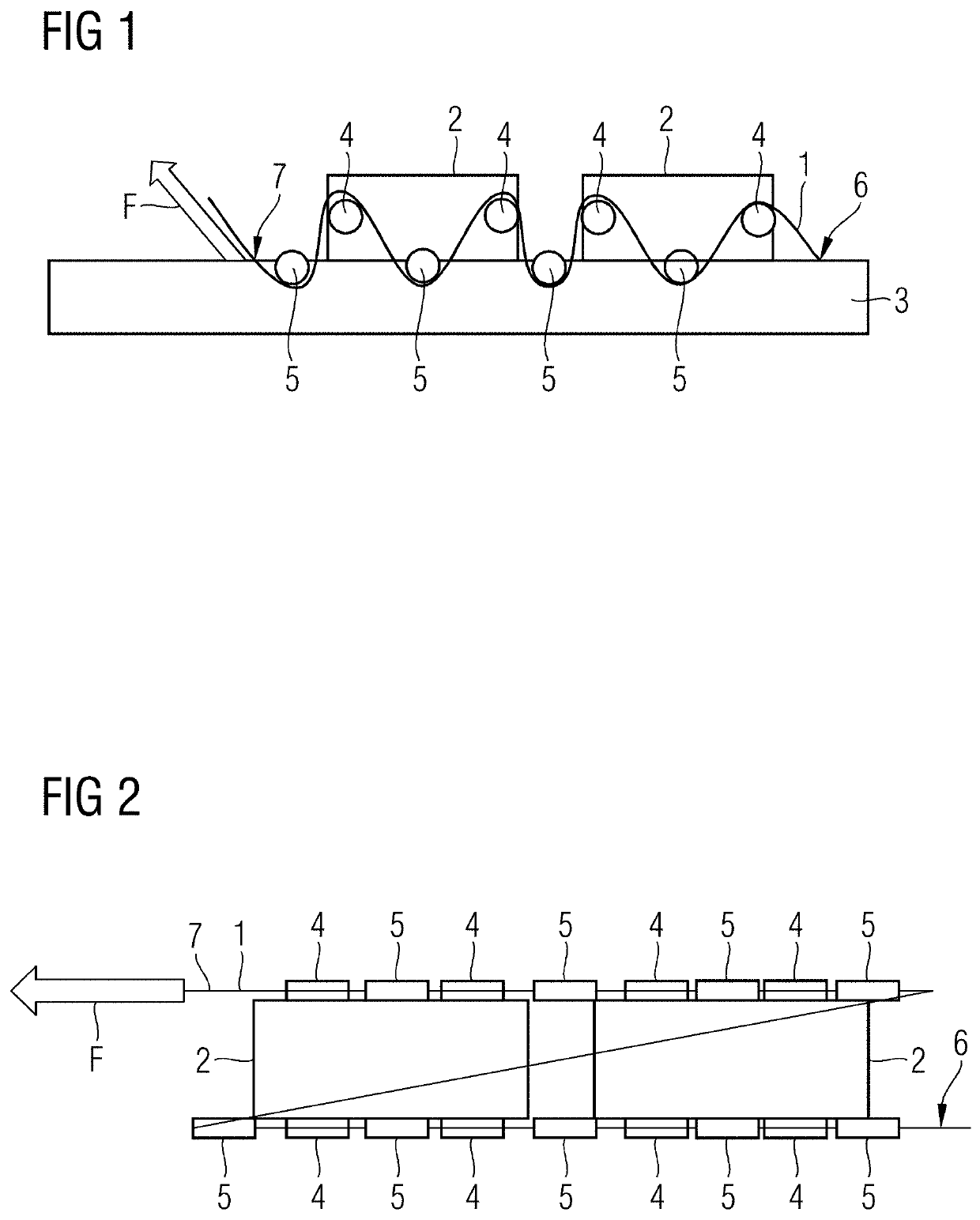

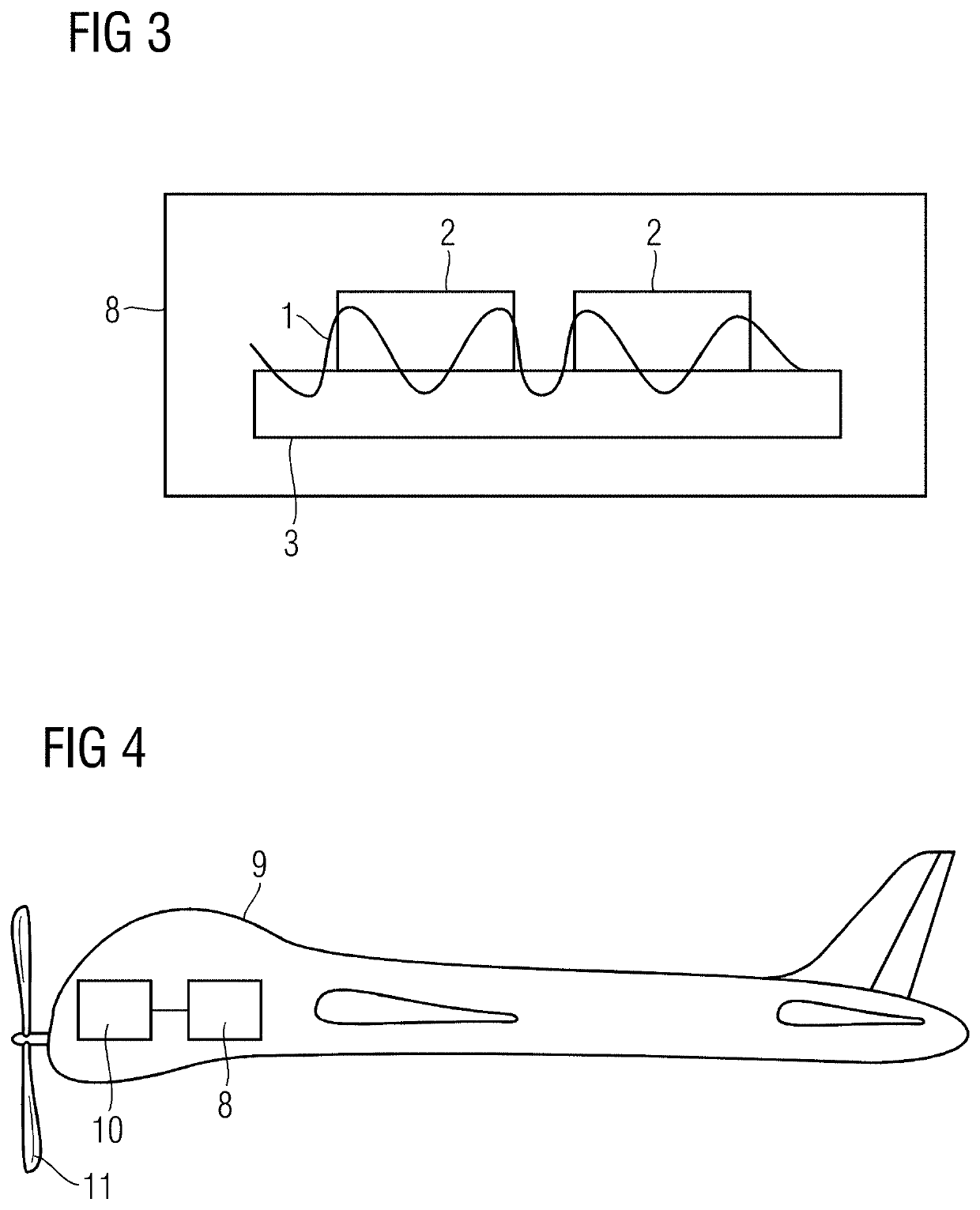

Arrangement of electrical modules, converter and aircraft with such an arrangement, and method for producing the arrangement

ActiveUS20210219456A1Minimize tensile forceUniform contact pressurePower plant cooling arrangmentsSemiconductor/solid-state device detailsConvertersFlight vehicle

The invention specifies an arrangement having at least one electrical module (2) which is arranged on a heat sink (3). The arrangement has:—first deflection elements (4) which are formed in or on the electrical module (2),—second deflection elements which are formed in or on the heat sink (3), and—at least one flexible, cable- or strip-like tensioning element (1),—which is arranged between the first and second deflection elements (4, 5) under tension (F) in such a way that the electrical module (2) is pressed onto the heat sink (3). A converter and an aircraft having an arrangement of this kind and also a method for producing an arrangement of this kind are likewise specified.

Owner:ROLLS ROYCE DEUT LTD & CO KG

Earthed telescopic meshed-type civil electrical connecting device as well as plug and socket thereof

InactiveCN102655281AUniform contact pressureWith self-locking functionCoupling contact membersTwo-part coupling devicesElectricityContact pressure

The invention provides an earthed telescopic meshed-type civil electrical connecting device as well as a plug and a socket thereof. The earthed telescopically-meshed civil electrical connecting device is particularly suitable for wired or wireless plugs, fixed or movable sockets, interconnecting couplers, appliance couplers and the like used for the indoor or outdoor. The earthed telescopically-meshed civil electrical connecting device comprises a rotary springback meshed-type electrical connecting plug and a rotary spirngback meshed-type electrical connecting socket, wherein the rotary springback meshed-type electrical connecting plug is provided with a metal contact A and the like, the rotary spirngback meshed-type electrical connecting socket is provided with a metal contact B and the like, and the metal contact A and the metal contact B are electrically connected through mutually meshing under the action of an earthed telescopic spring mechanism. The earthed telescopic meshed-type civil electrical connecting device has the advantages of wide application range, simple structure, simplicity and convenience in operation, reliable connection performance and capability of ensuring that earthed metal contacts are firstly connected, and then a firing line and a zero line are connected when the connecting device is spliced every time, ensuring that the firing line and the zero line are firstly disconnected, and then the earthed metal contacts are disconnected when the connecting device is pulled out, ensuring that the firing line and the zero line are uniform and reliable in contact pressure, ensuring safety and preventing accidental electric shock.

Owner:张宁

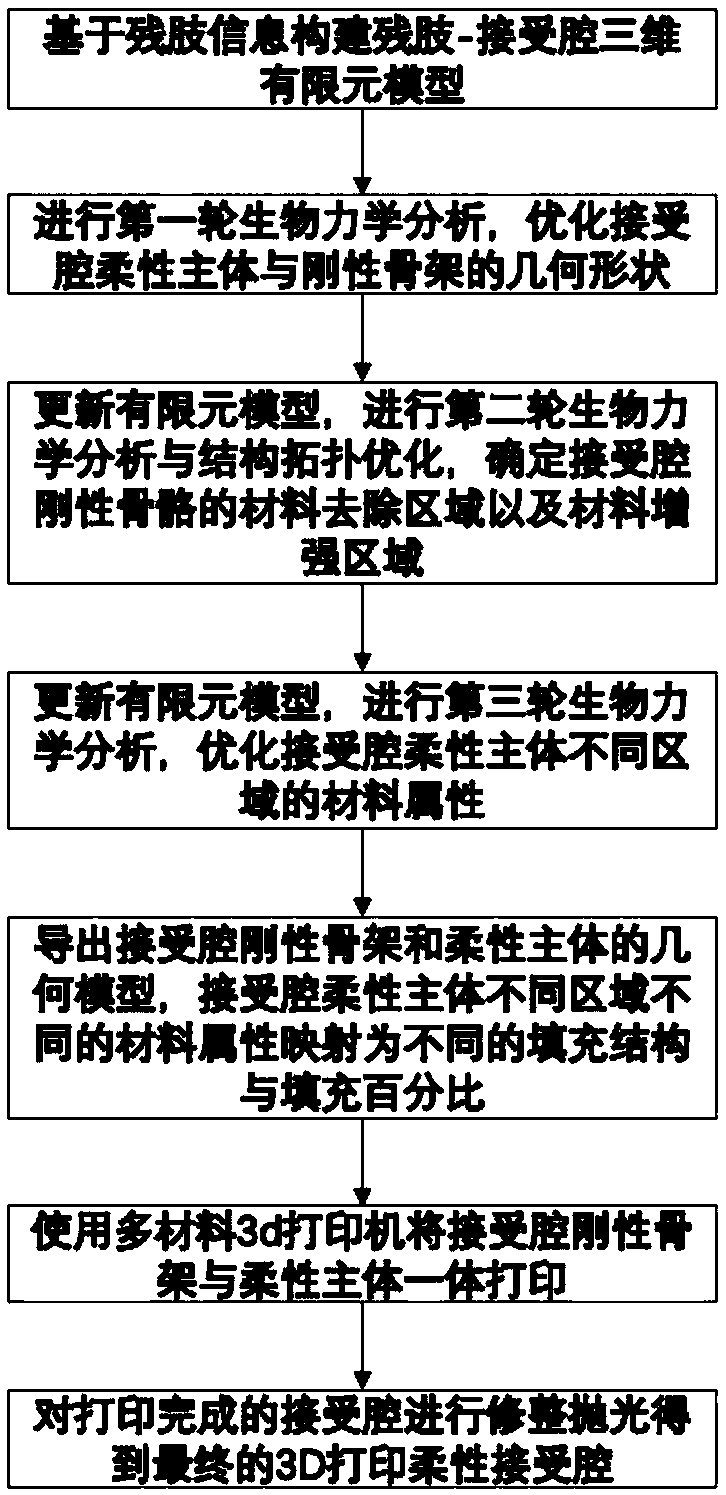

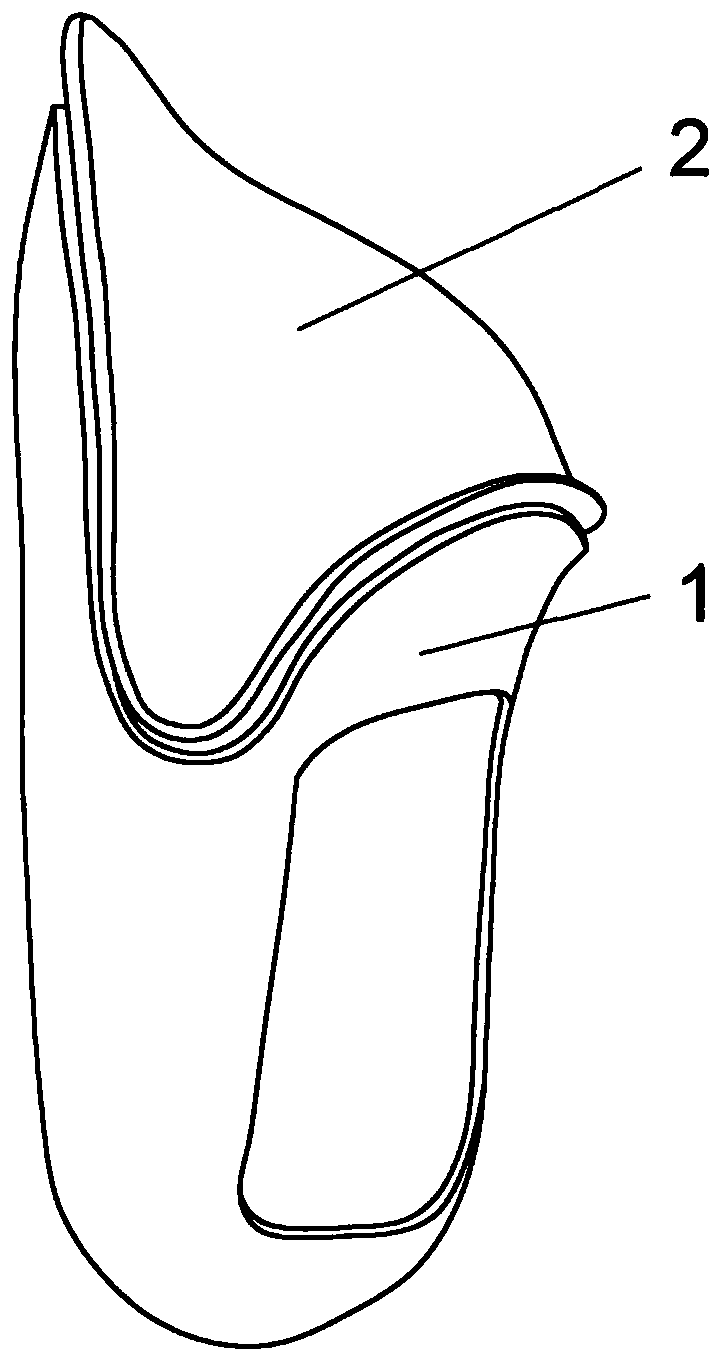

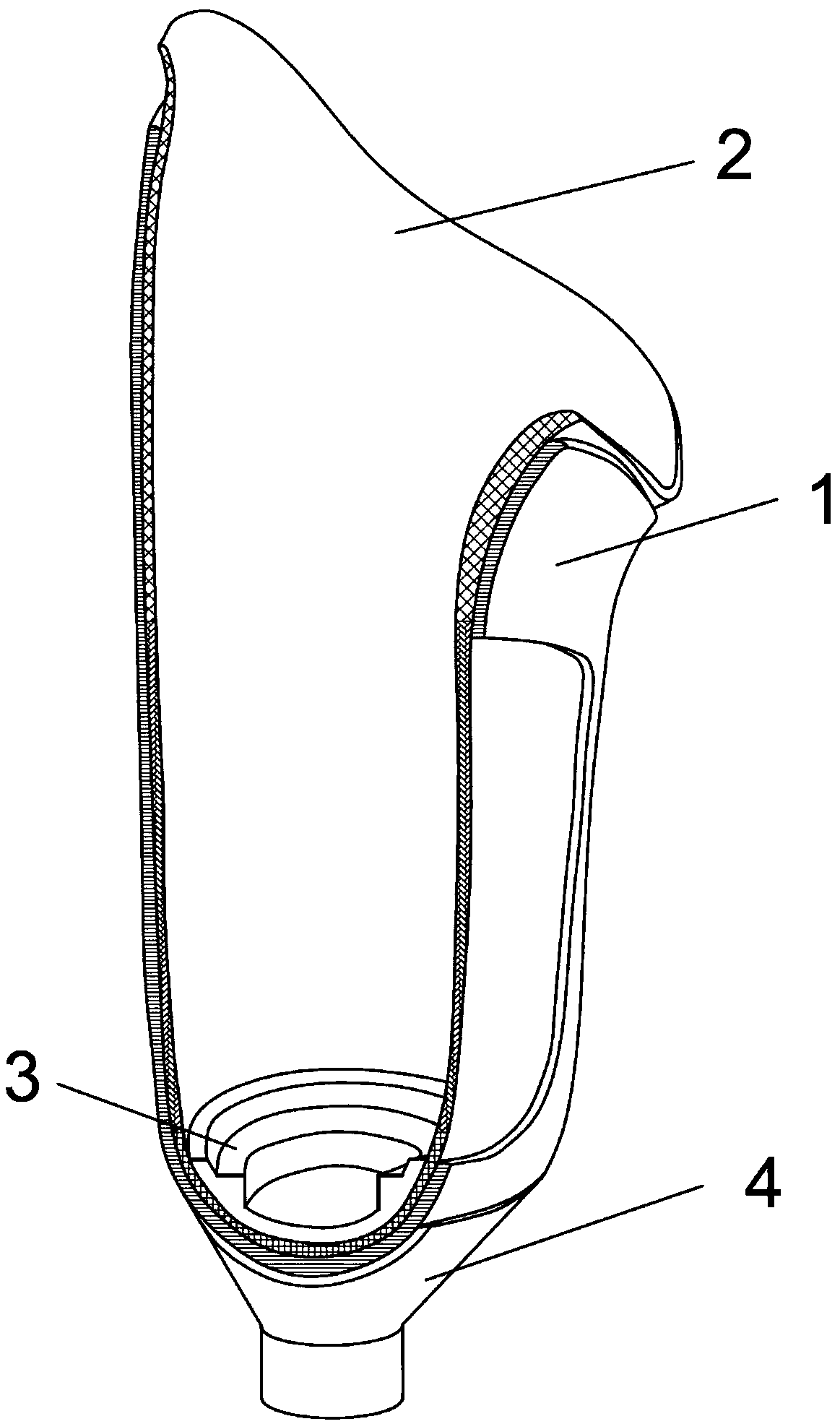

Receiving cavity for lower limb prosthesis and preparation method thereof

ActiveCN109549764AReduced professional level requirementsSimplify the design processArtificial legsSurface fittingKnee Joint

The present invention discloses a receiving cavity for a lower limb prosthesis and a preparation method thereof. An outer surface of a flexible receiving cavity main body closely fits with an inner surface of a rigid receiving cavity skeleton, a lower part of the rigid receiving cavity skeleton is connected with a connecting device, the connecting device is connected with a prosthetic knee joint component through a threaded connection member, the rigid receiving cavity skeleton is provided with a material removing region and a material reinforcing region, shapes, positions and thickness of thematerial removing region and material reinforcing region are determined according to biomechanical interface analysis and structural topology optimization, the flexible receiving cavity main body isprovided with gradient-distributed porous filling regions, and shapes, positions, filling structures and gradient distribution of filling percentage of the filling regions are determined according tothe biomechanical interface analysis of multi-gait residual limbs. A personalization degree of the receiving cavity can be significantly improved and the receiving cavity improves comfort and functiontransfer performance of users during use.

Owner:XI AN JIAOTONG UNIV

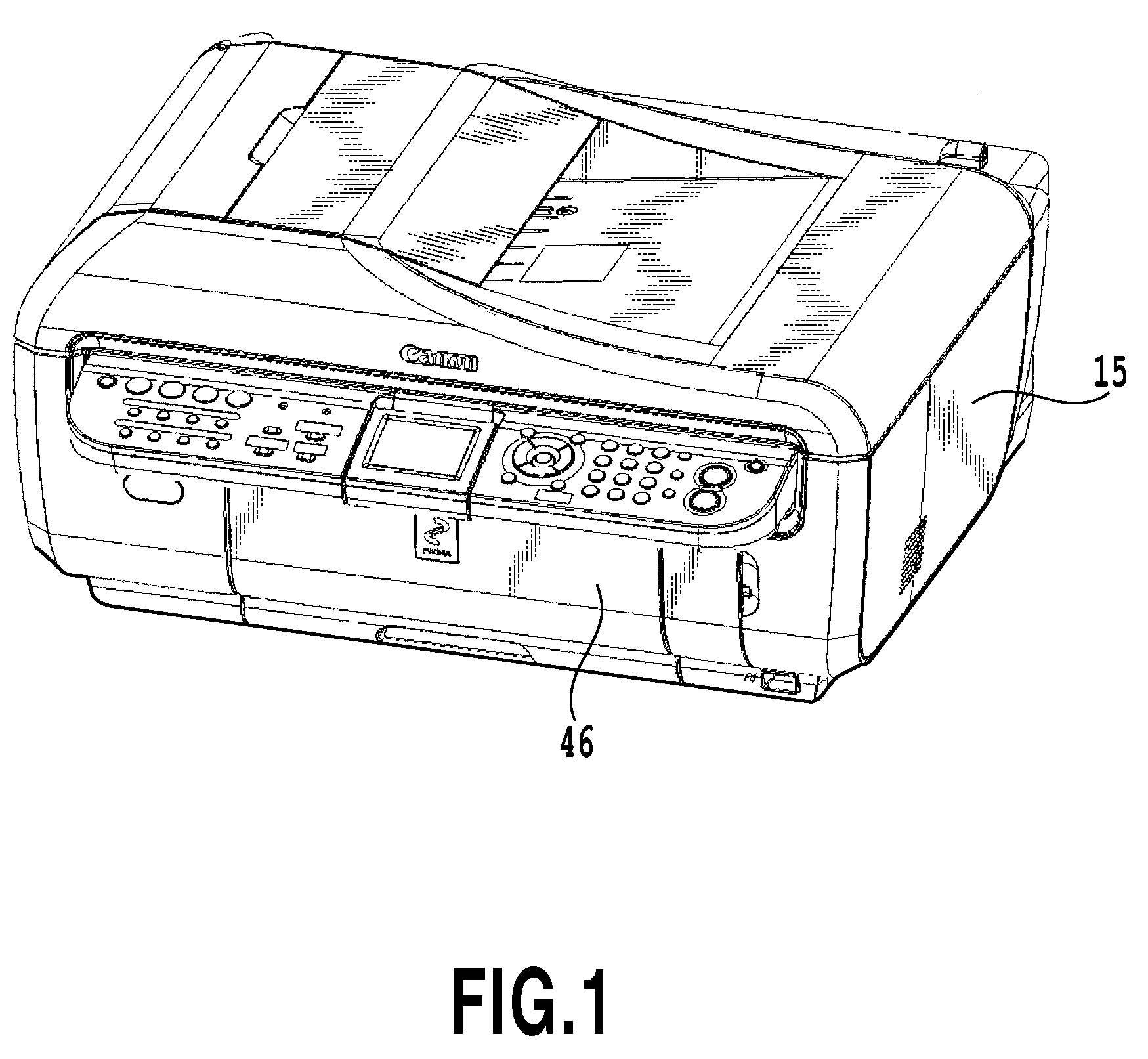

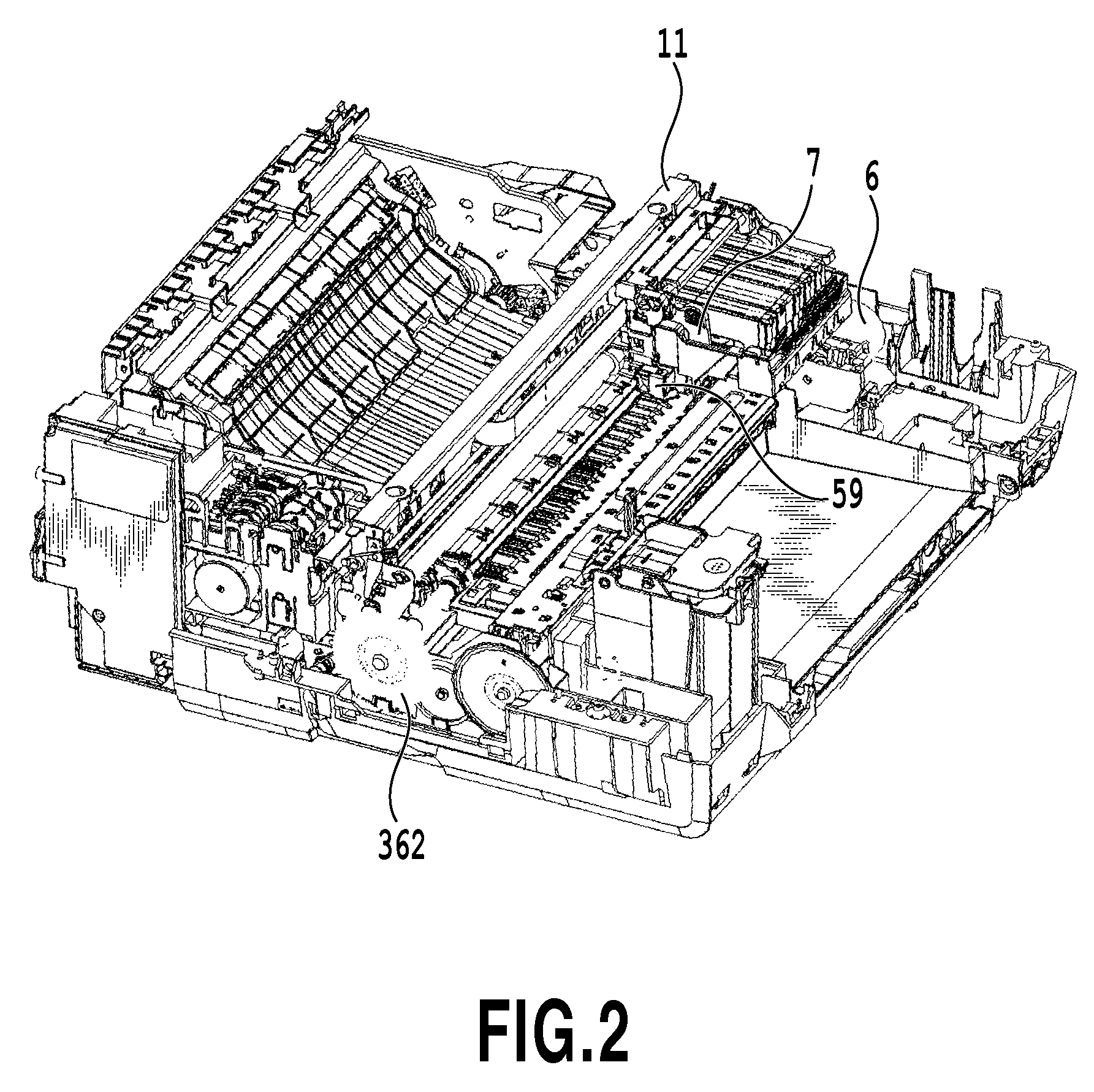

Inkjet printing apparatus for applying uniform pressure on an applying roller

InactiveUS8789491B2Apply evenlyStably and evenly appliedLiquid/solution decomposition chemical coatingElectrographic process apparatusContact pressureEngineering

Owner:CANON KK

Gripper

InactiveUS20140232125A1Uniform contact pressureEasy to industrializeGripping headsTextiles and paperGrippersUnit/actuation

A gripper for grasping and handling textiles and other flexible materials includes an external body housing a driving unit, which actuates a plurality of sliding elements moving away and approaching symmetrically; and a plurality of gripping members, each connected to one of the sliding elements by a first transmission group that includes a kinematic chain with levers that invert motion such that, during the approaching of the sliding elements, the gripping members move away from each other, and during the distancing of the sliding elements, the gripping members approach each other.

Owner:ZOPPI MATTEO +3

Pneumatic tire

InactiveCN103072432AAvoid delaminationImproved high-speed durabilityPneumatic tyre reinforcementsTyre tread bands/patternsAutomotive engineering

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com