All-steel tubeless radial tire with high load performance and manufacturing method thereof

A radial tire, high-load technology, applied to tire parts, tires, tire edges, etc., can solve problems such as spinning bursts, ring cracks, and poor load performance, and achieve the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

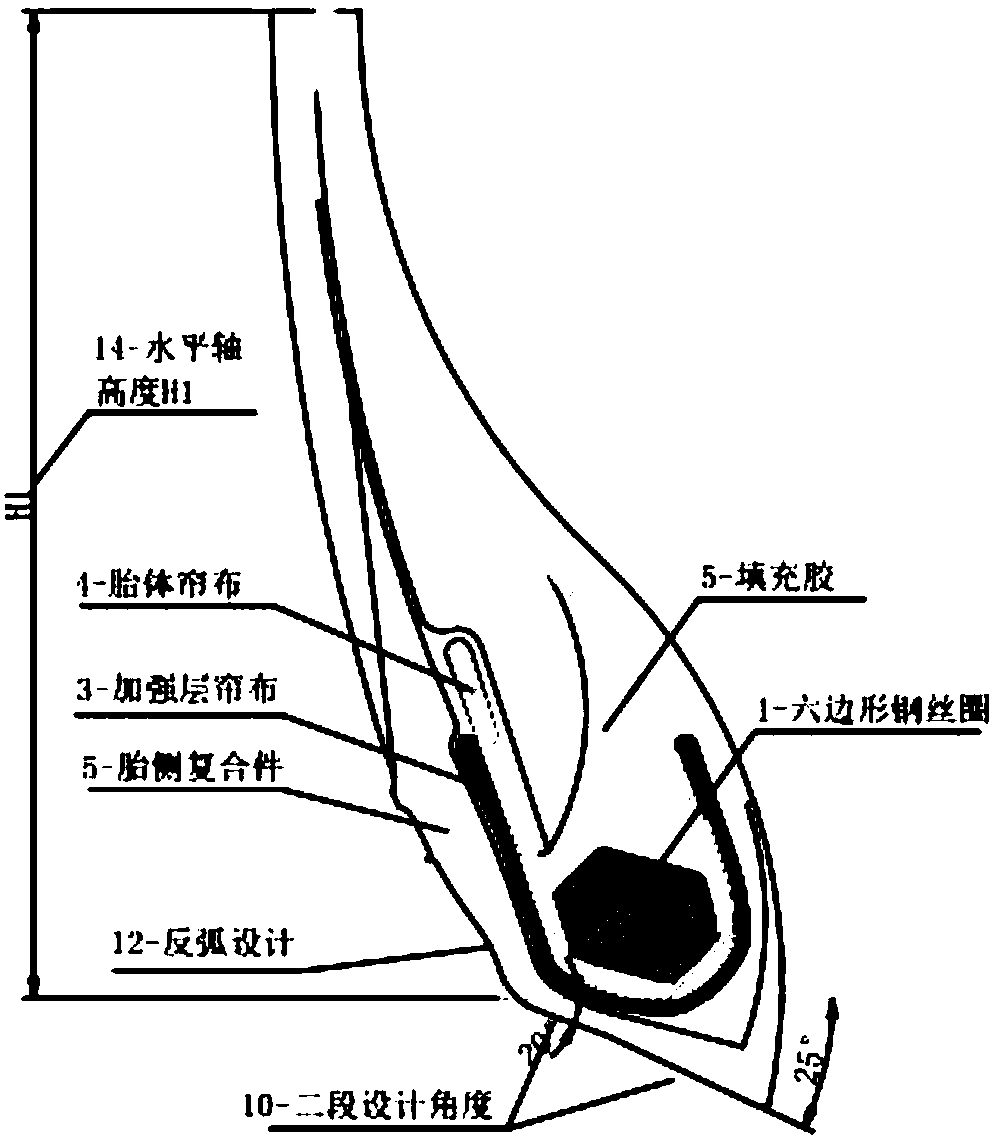

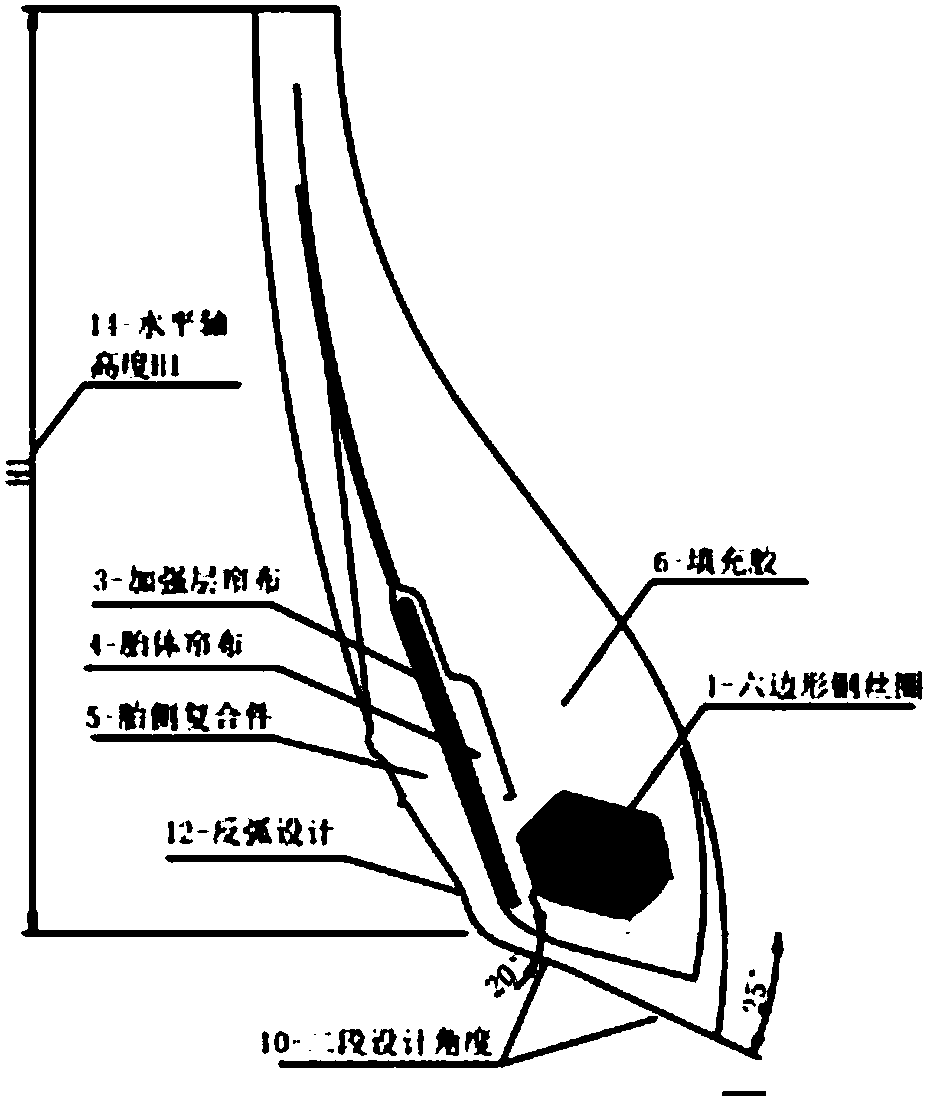

Embodiment 1

[0065] like Figure 7 As shown, a high-load performance all-steel tubeless radial tire includes a composite bead ring, a tire bead bottom profile curve, a tire heel profile curve, a carcass cord, and a reinforcing layer cord. The composite bead ring is internally provided with Rectangular steel traveler, the rectangular steel traveler is made of rectangular steel wire with four vertex angles as inverted circular arcs in cross section. The rubber material at the contact position with the rim is 0.7-1.0mm thicker than the existing design. Both ends of the carcass cord are provided with wrapping films. Between the turn-up section and the carcass, an upper filler and a lower filler are arranged sequentially from top to bottom, and a layer of U-shaped reinforced layer cord is applied on the outer layer of the carcass cord, and both ends of the reinforced layer cord are provided with hemming The film and the inner and outer sides of the reinforcing layer cord are respectively provi...

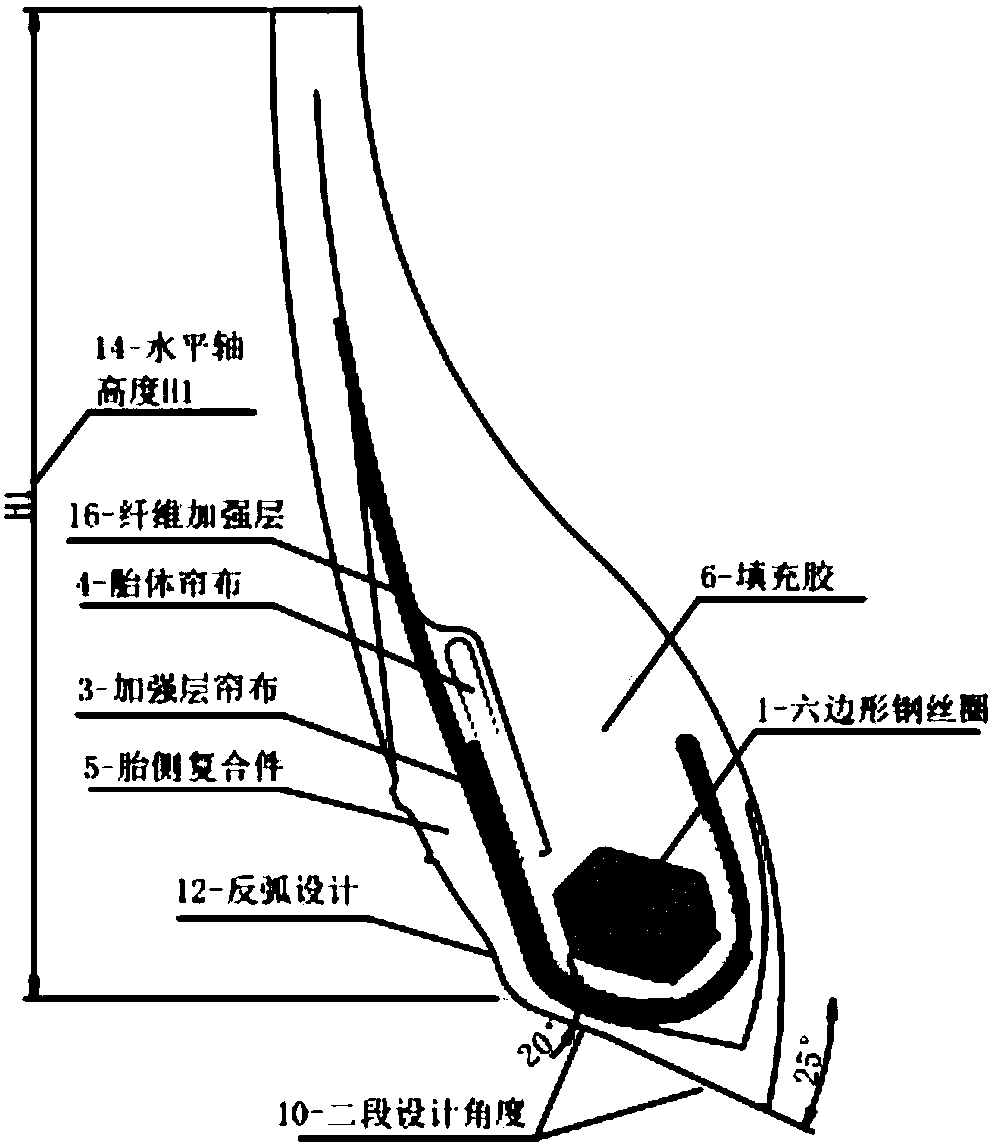

Embodiment 2

[0073] On the basis of embodiment 1, different from embodiment 1, Figure 8 , Figure 9 , Figure 11 and Figure 12 Shown, a kind of manufacture method of the all-steel tubeless radial tire of high load performance specifically comprises the steps:

[0074] a. Production of rectangular traveler:

[0075] Arrange 8 to 9 rectangular steel wires with rounded corners in parallel to form a row, wind several layers around the winding disc according to the required load capacity, and wrap a layer of viscosifying film outside the wound steel traveler. A piece of semicircular glue is glued on the top and bottom of the ring, and then a layer of fiber cord is wound on the outer surface to fix the traveler. The semi-finished traveler is sent to the vulcanization tank and pre-vulcanized under the set temperature, pressure and time to form a composite traveler. ;

[0076] b. Production of bead composite parts:

[0077] Composite the composite parts of the lower filler and the upper fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com