Optical lens, molecular thin film coated on such optical lens, and manufacturing method of such molecular thin film

A technology of optical lenses and manufacturing methods, applied in optics, optical components, instruments, etc., can solve problems such as fungal growth, poor antibacterial properties, wear and tear and light transmission effects, and avoid dust and dirt. Attached, the effect of increasing the service life and improving the light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

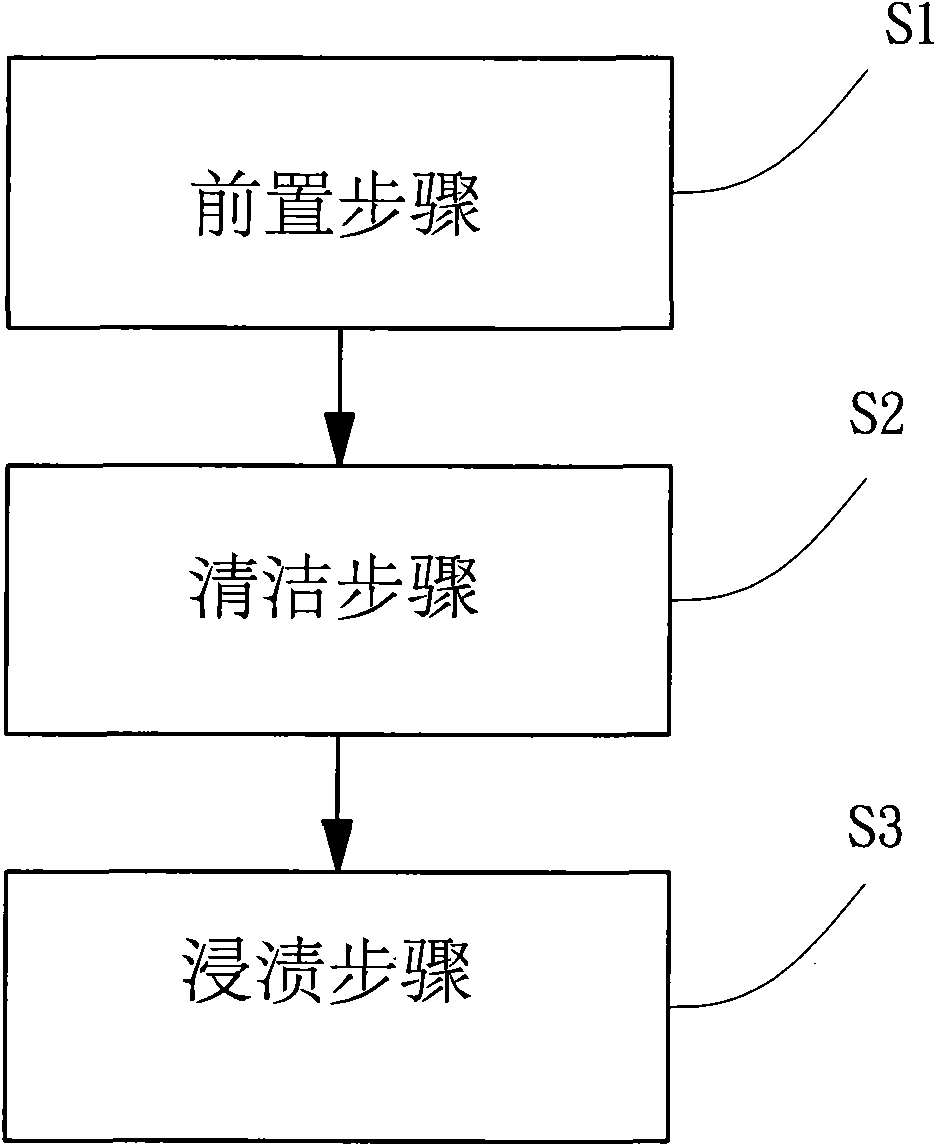

[0040] Please refer to figure 1 As shown, a method for manufacturing a molecular thin film coated on an optical lens in the present invention includes a pre-step S1, a cleaning step S2, and a dipping step S3.

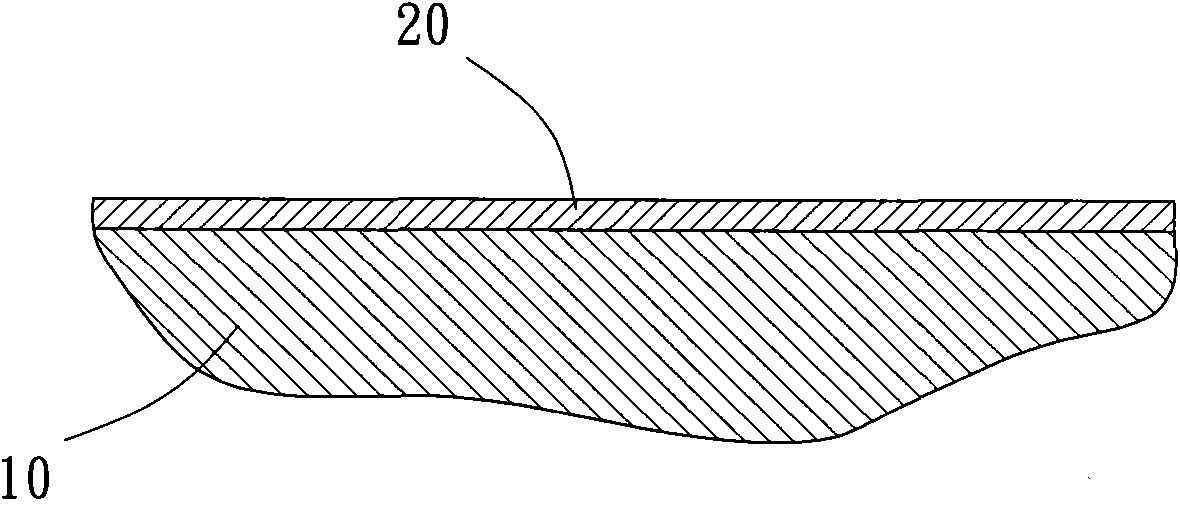

[0041] The pre-step S1 is to pre-preset a matrix, n-octadecyltrichlorosilane solution (OTS solution) and an antibacterial agent, wherein the matrix can be SiO 2 Glass, MgF 2 Glass or other materials that can be used as optical lenses; and the antibacterial agent is a bioflavonoid-related agent. More specifically, the antibacterial agent of this embodiment is a commercial bioflavonoid antibacterial agent (Citrox Ltd.; Geelong), and the bioflavonoid antibacterial agent is prepared with deionized water at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com