Patents

Literature

322results about How to "Reduce hydrogen bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

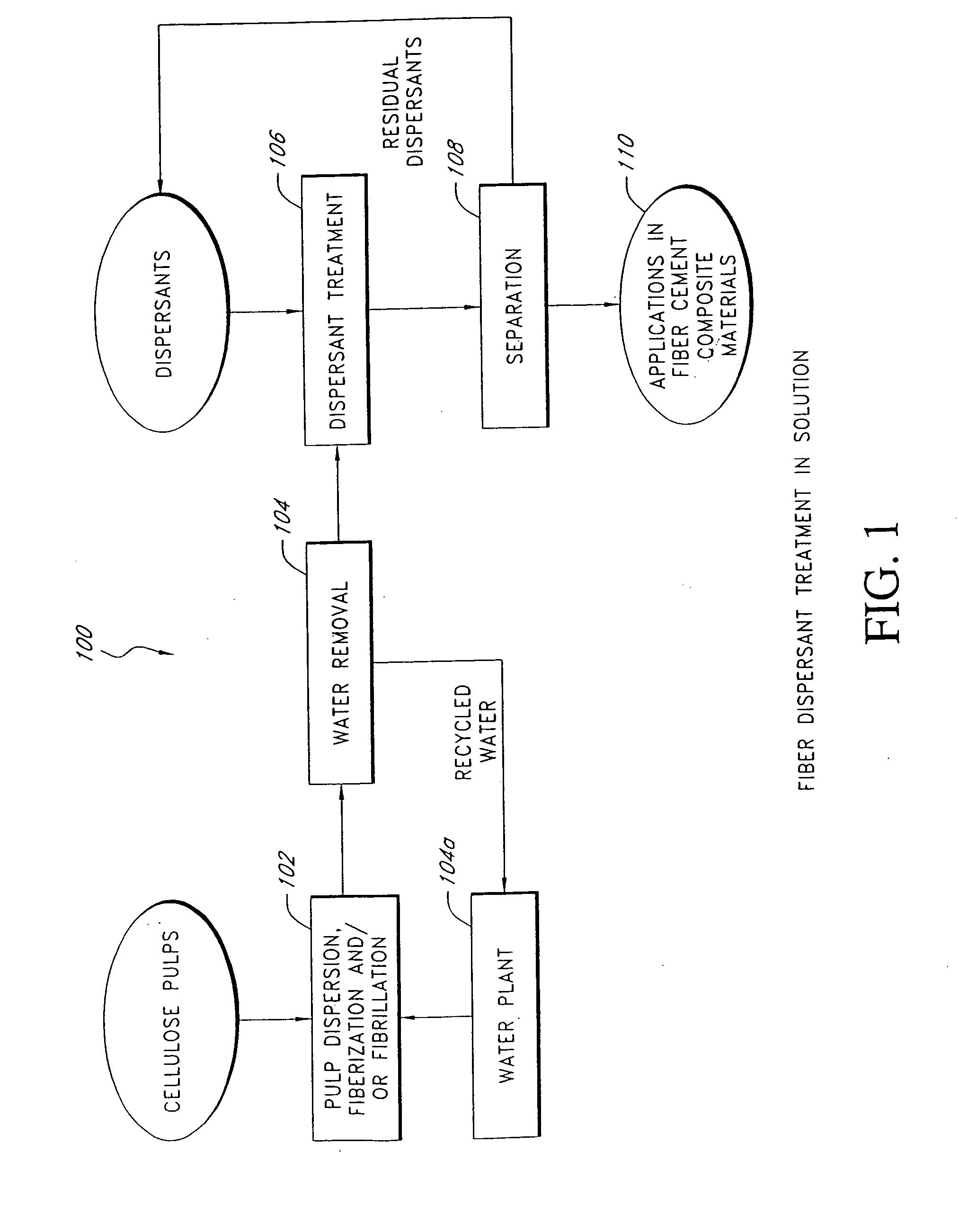

Fiber reinforced cement composite materials using chemically treated fibers with improved dispersibility

InactiveUS7344593B2Improve material propertyIncrease modulusPulp properties modificationSolid waste managementBuilding materialFibre reinforcement

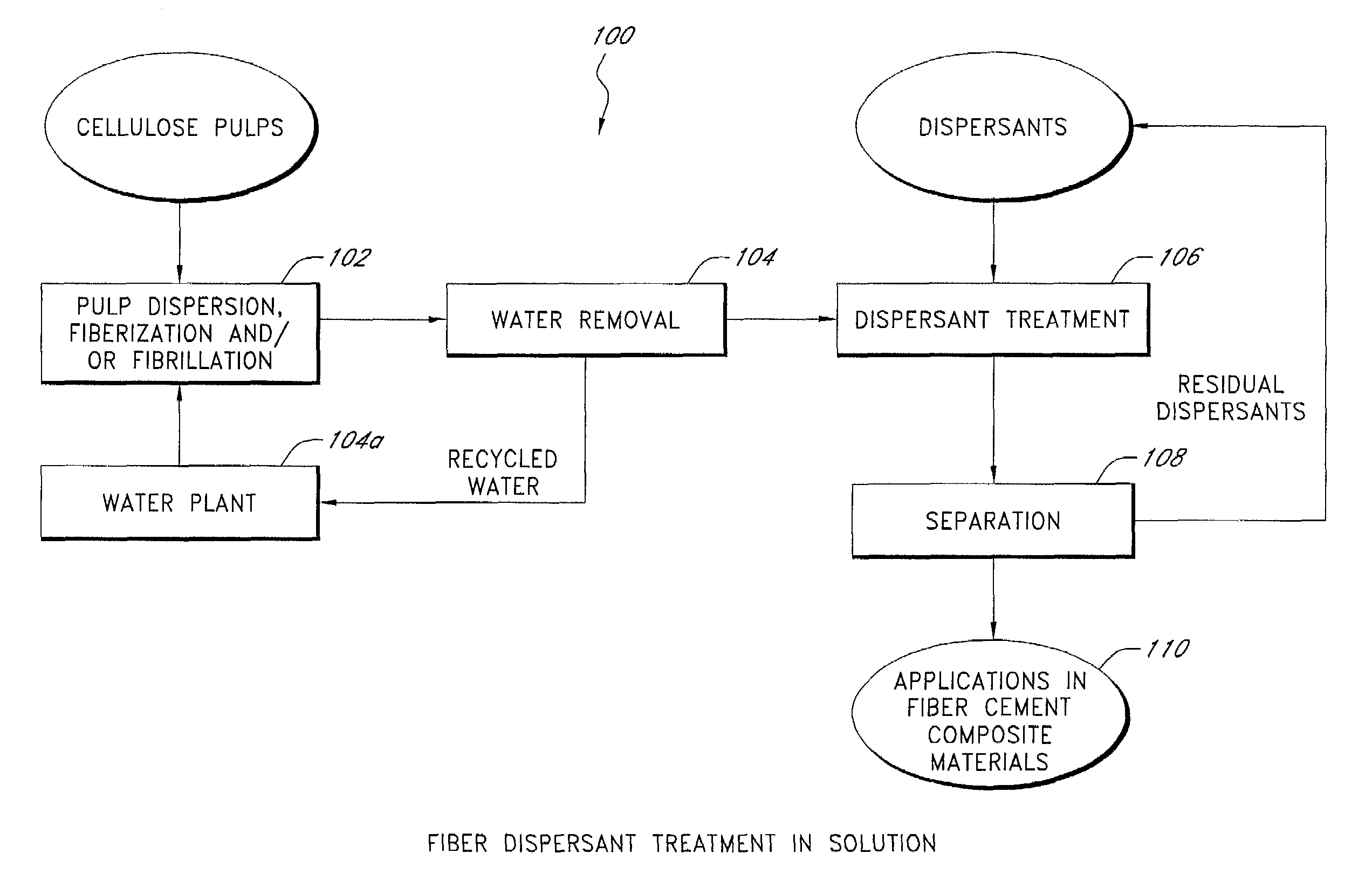

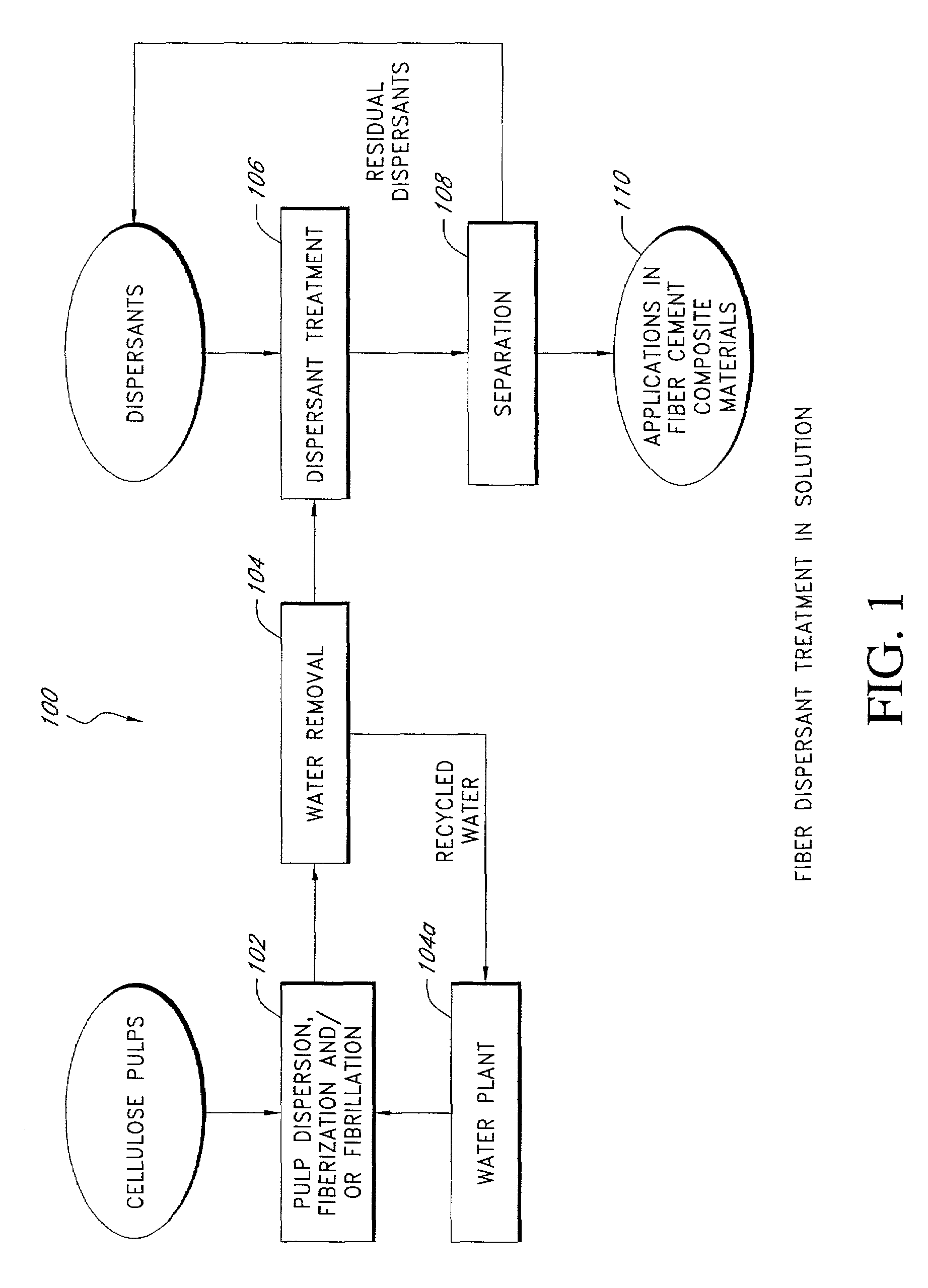

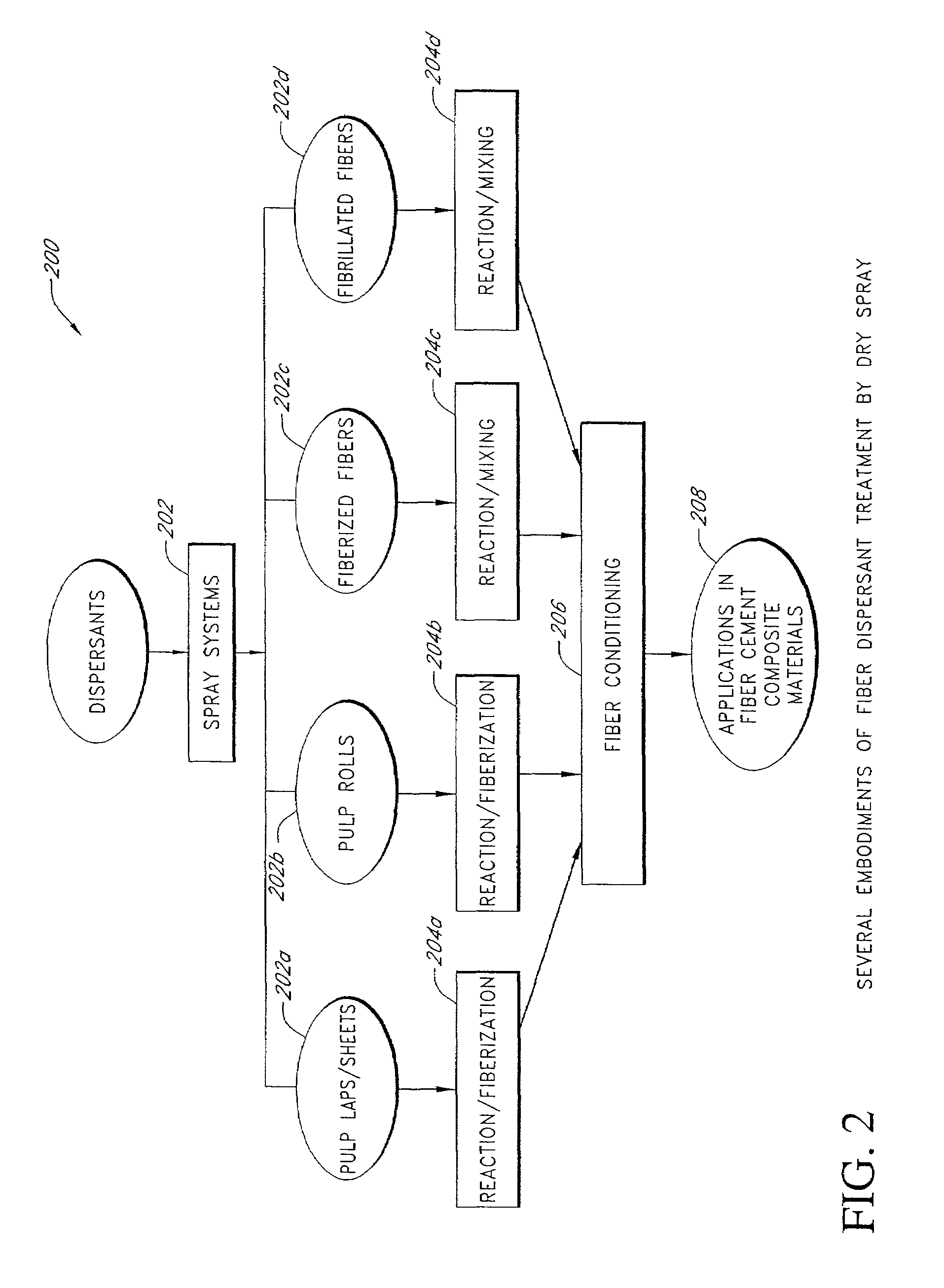

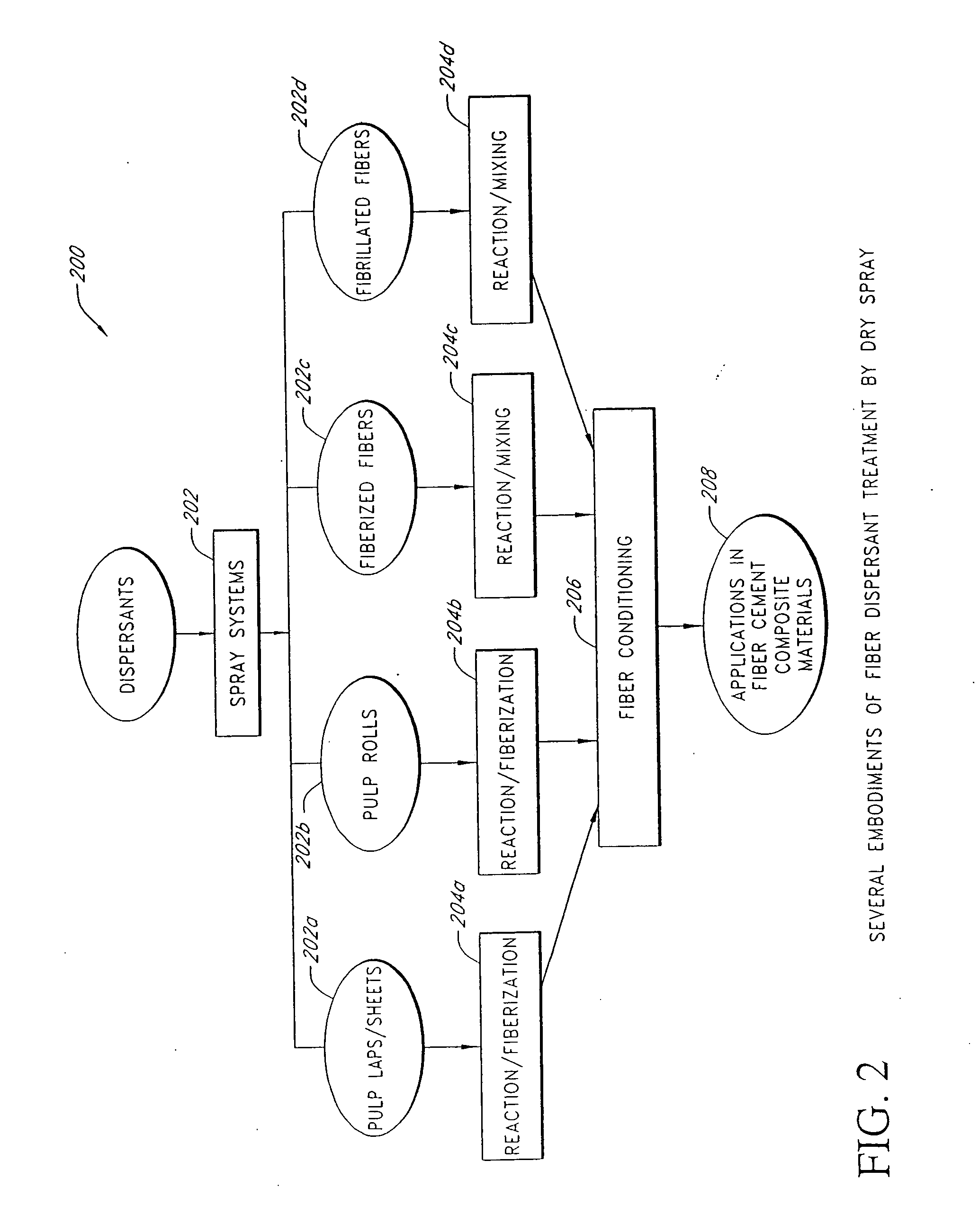

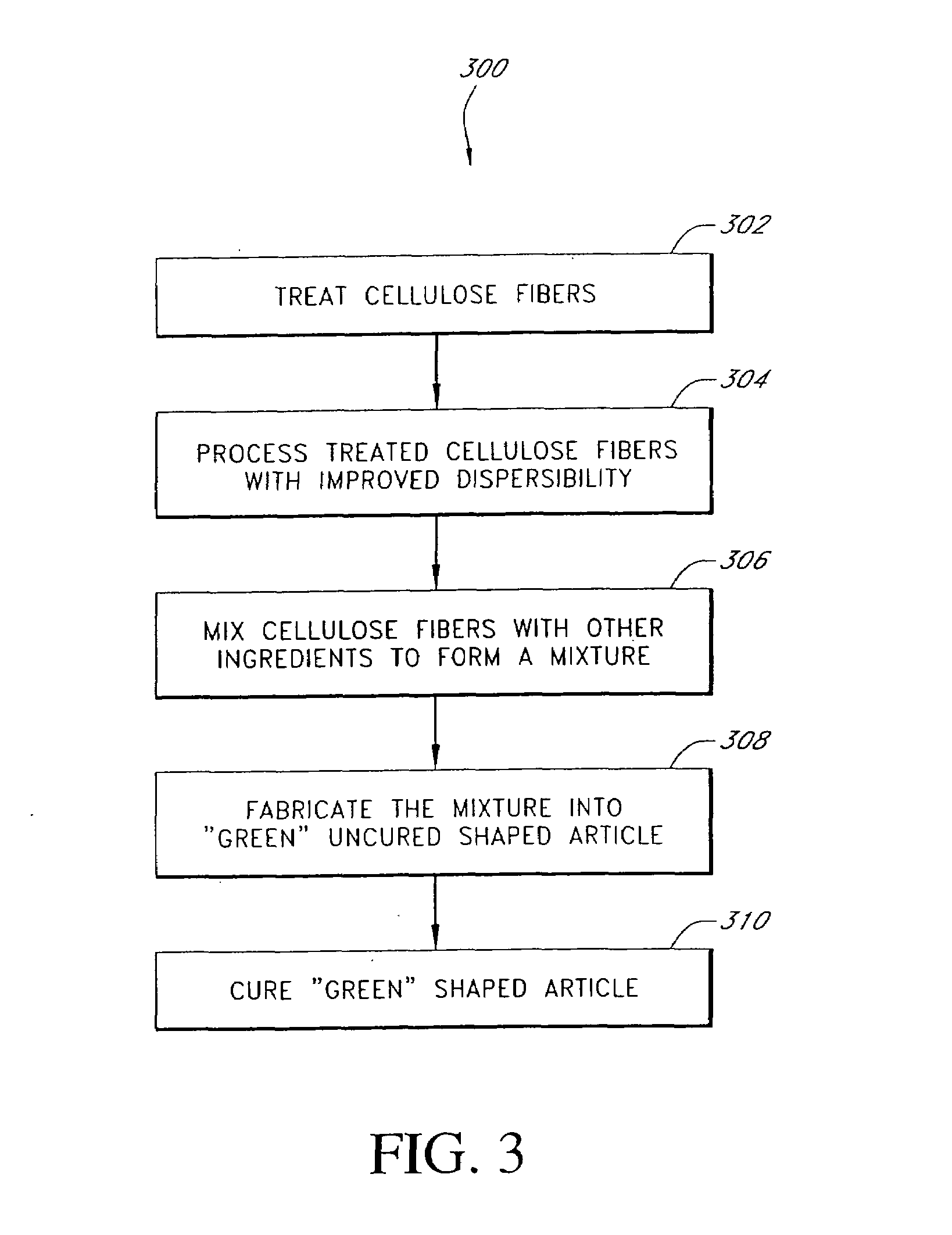

A fiber-reinforced building material in one embodiment incorporates cellulose fibers that are chemically treated with a dispersant to impart improved dispersibility to the fibers. The fibers are treated with a dispersant which deactivates the hydroxyl sites of the fiber surfaces and in some cases, making the fiber surface more hydrophobic. The dispersant inhibits the hydroxyl groups on the cellulose fiber surface from bonding with hydroxyl groups of other fibers and from bonding with hydroxyl groups of the same fiber, thereby significantly reducing inter-fiber and intra-fiber hydrogen bonding. The treated fibers can be readily dispersed and uniformly distributed throughout a mixture without re-clustering or reclumping once the mechanical mixing action stops. The chemically treated fibers with improved dispersibility improve the fiber distribution and reinforcing efficiency, which in turn improves key physical and mechanical properties of the material such as the modulus of rupture, z-direction tensile strength, and toughness, and surface finishes. With improved fiber reinforcing efficiency, less dosage of fiber is needed to achieve the required physical and mechanical properties.

Owner:JAMES HARDIE TECH

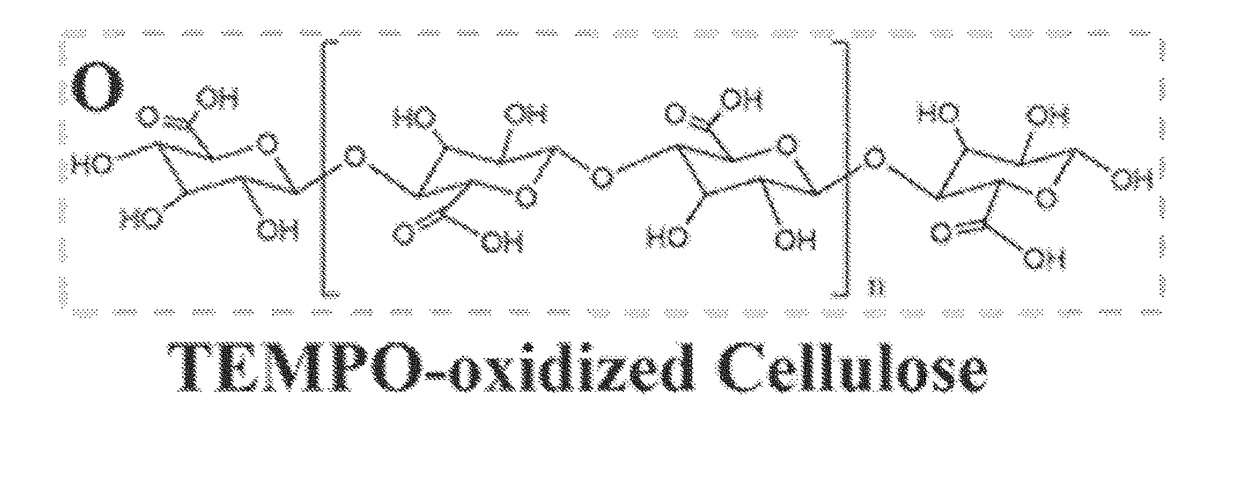

Preparation method of cellulose nano-fiber/polylactic acid composite membrane

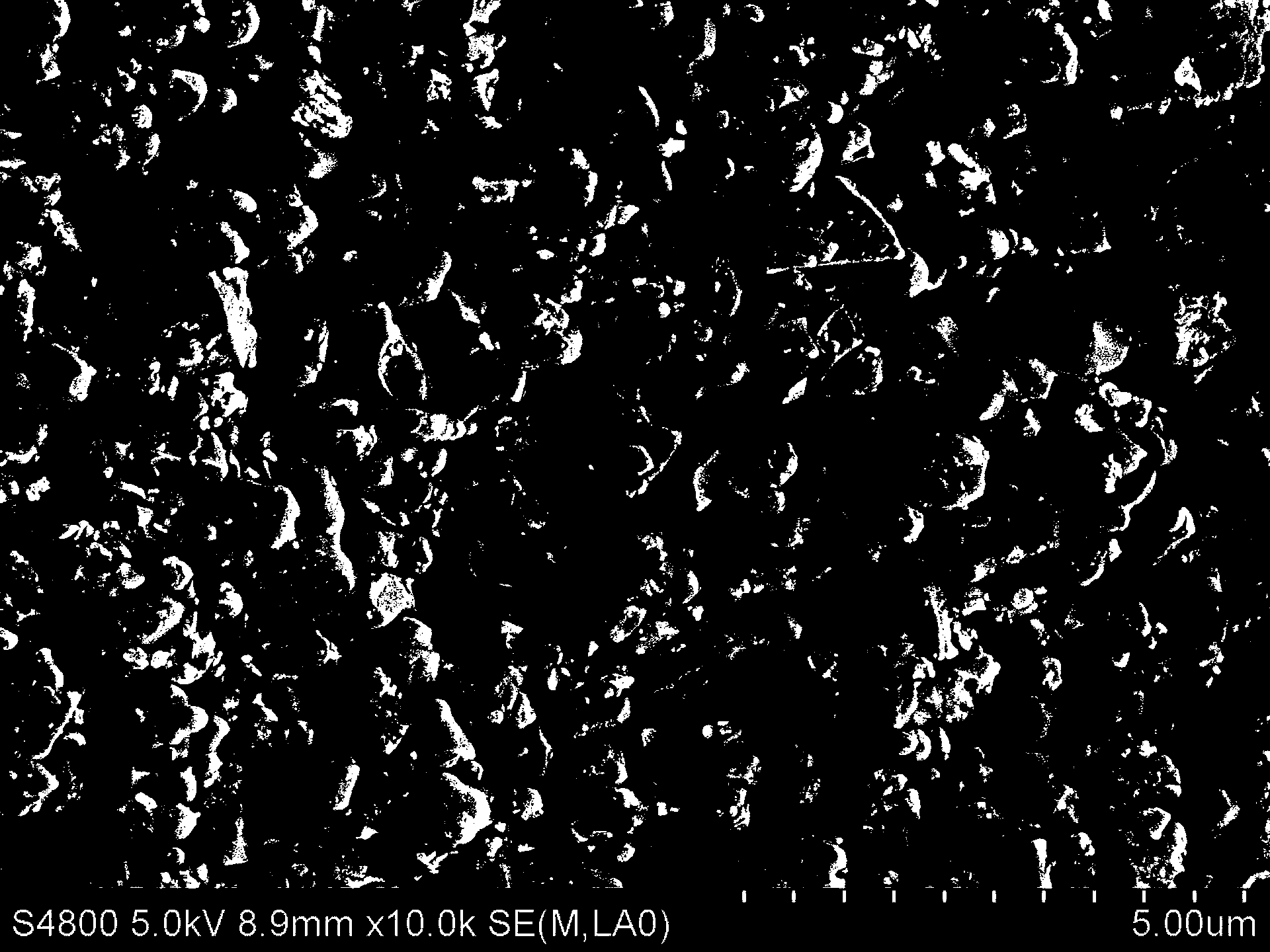

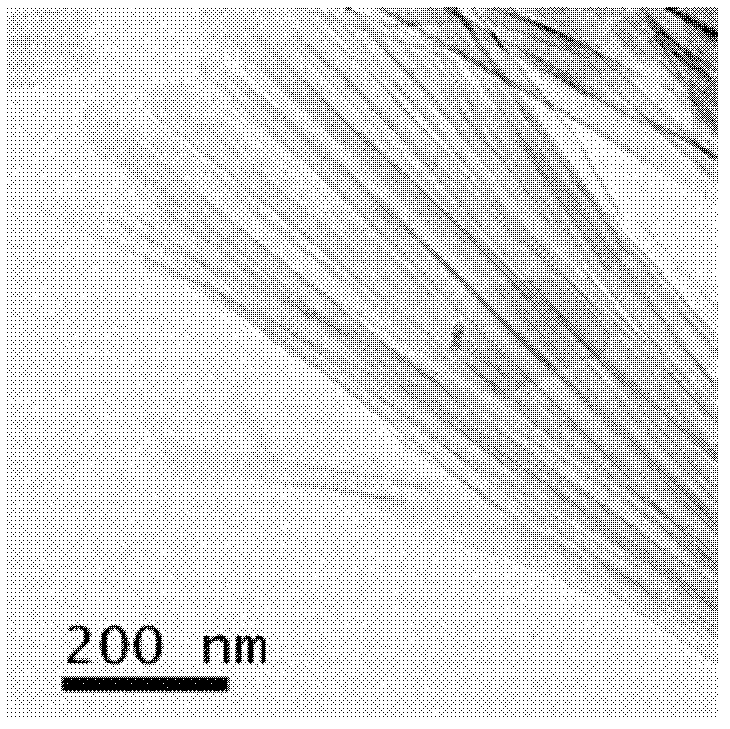

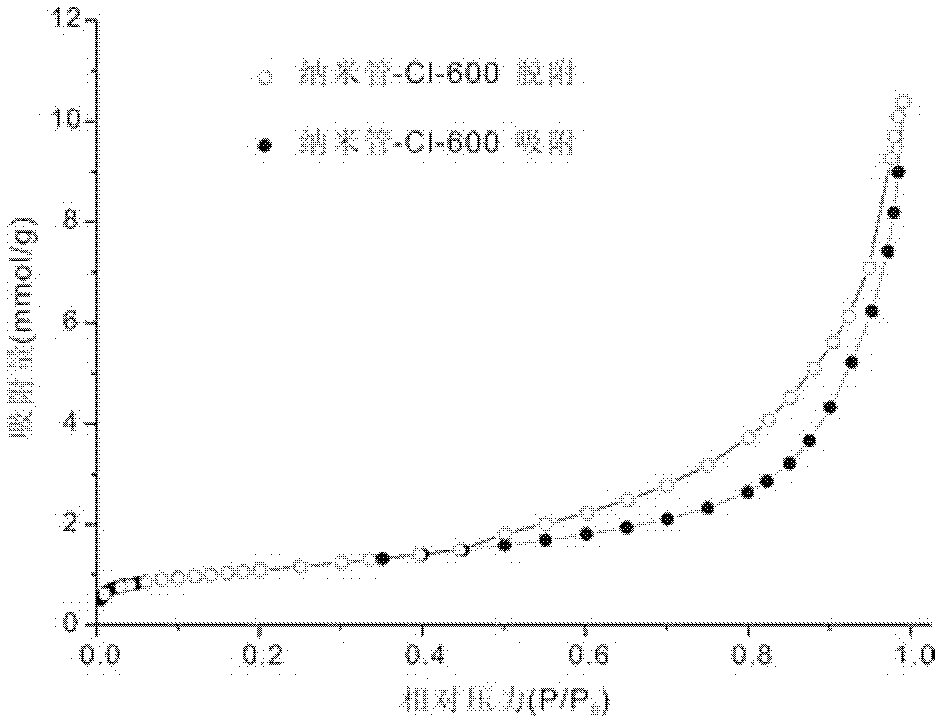

InactiveCN103387688AUniform diameter distributionReduce hydrogen bondingPaper material treatmentFiberChemical treatment

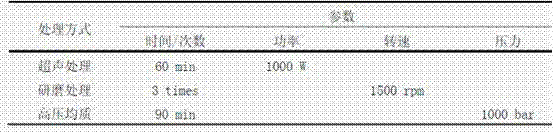

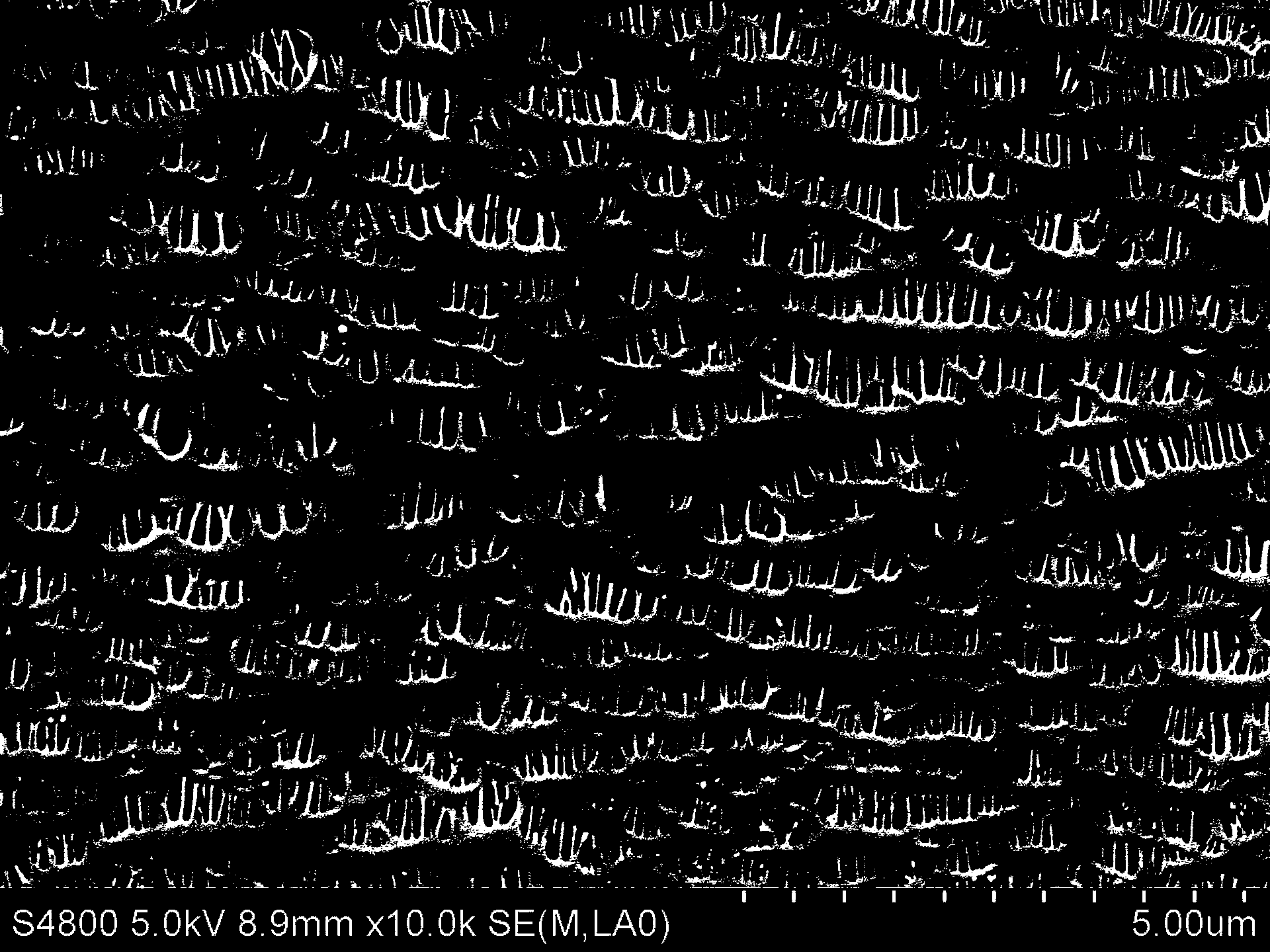

The invention provides a preparation method of a cellulose nano-fiber / polylactic acid composite membrane. The preparation method comprises the following steps of: (1) treating raw materials; (2) performing chemical treatment; (3) performing mechanical treatment; (4) preparing a nano cellulose membrane; (5) preparing a nano cellulose / polylactic acid composite membrane material by using a mixing and dissolving method or an immersion method. The preparation method has the advantages that lignin and most of hemicellulose are removed by using a chemical method, and under a water wet swelling condition, water fills the positions in which most of the hemicellulose and the lignin are removed, so that the hydrogen bond acting force among fibrillae is reduced; then lignocellulose nano fibrillae with uniform morphological sizes and mesh gangles are prepared by adopting mechanical treatment. The nano celluloses prepared by grinding for 30 minutes and homogenizing are small in diameter size and are uniformly distributed, the diameters of the nano fibrillae is 15-50nm, and the length-diameter ratio is high and reaches 1200. The cellulose nano-fiber / polylactic acid composite membrane can be used as a substitute and the like for a flexible display, electronic paper, a solar battery, a flexible circuit and a glass substrate.

Owner:NANJING FORESTRY UNIV

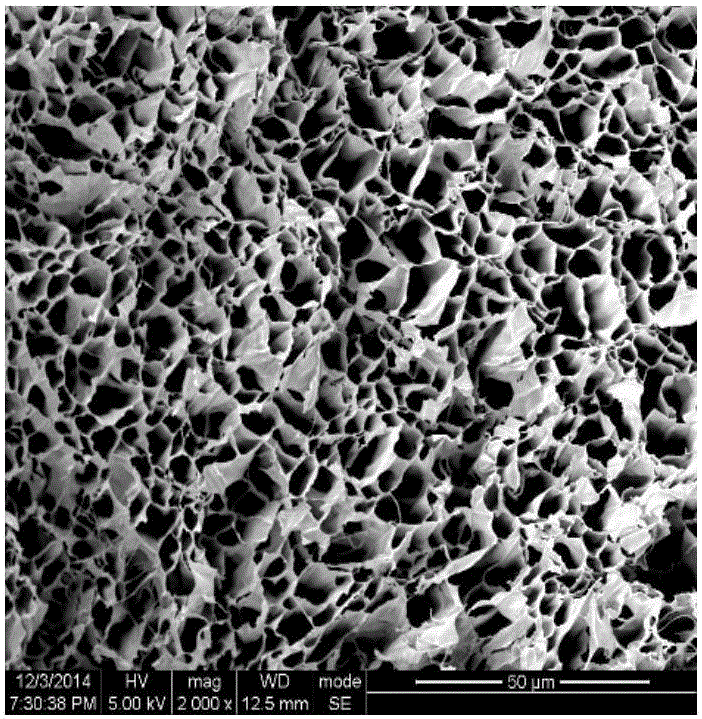

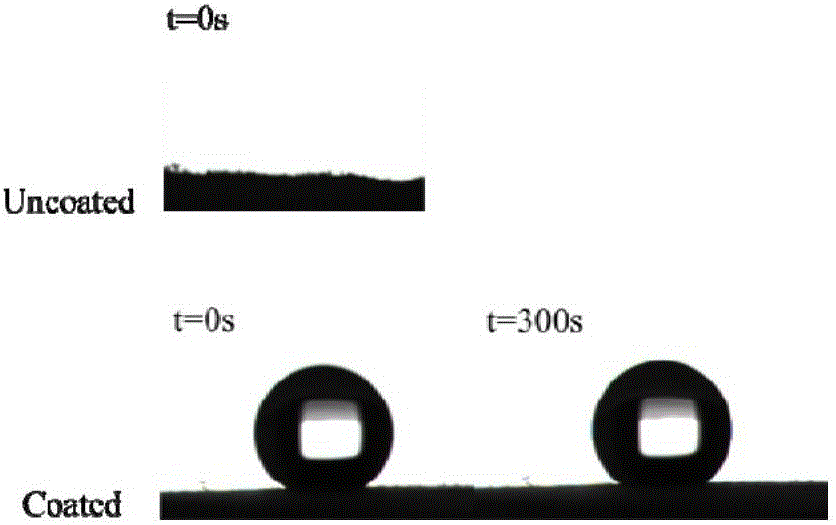

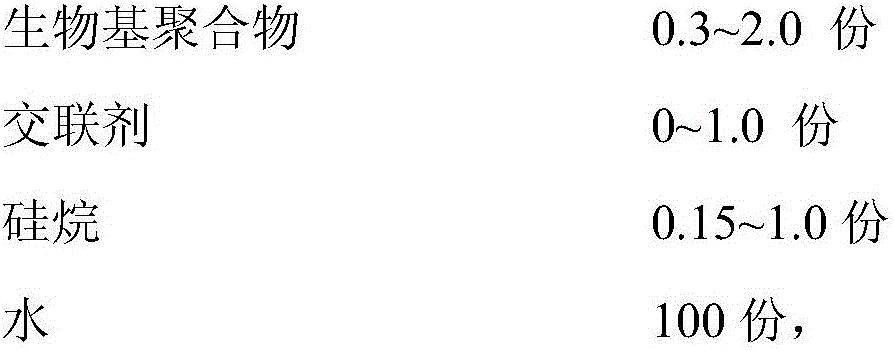

Biology base polymer aerogel oil absorption material and preparation method thereof

The invention discloses a biology base polymer aerogel oil absorption material. The oil absorption material is prepared by the following steps: at first, crosslinking biology base polymers by a crosslinking agent, to obtain a precursor liquid, then freeze-drying the precursor liquid to obtain aerogel, and finally grafting silane onto the aerogel surface to obtain the hydrophobic biology base polymer aerogel oil absorption material. The density of the oil absorption material is 3.8 to 23.1 kg / m3. The water contact angle is at least 117.8 degrees. The adsorption capacities on gasoline, paraffin oil, chloroform, and crude oil are 30.5-109.0 g / g, 33.2-131.2 g / g, 58.2-163.0 g / g, and 24.7-95.8 g / g. After 50 times of gasoline adsorption-extrusion circulation, the retention rate of adsorption capacity is 43 to 99%. The disclosed aerogel oil absorption material has the advantages of large oil absorption capacity and high oil absorption efficiency. Moreover, the oil absorption material can be repeatedly used by simply extruding the oil absorption material, while a high retention rate of adsorption capacity can be maintained. At the same time, the raw material sources are wide, the raw materials are cheap and easily available, the preparation is simple, the technology is matured, the method is environment-friendly, and the requirements of sustainable development can be met.

Owner:SICHUAN UNIV

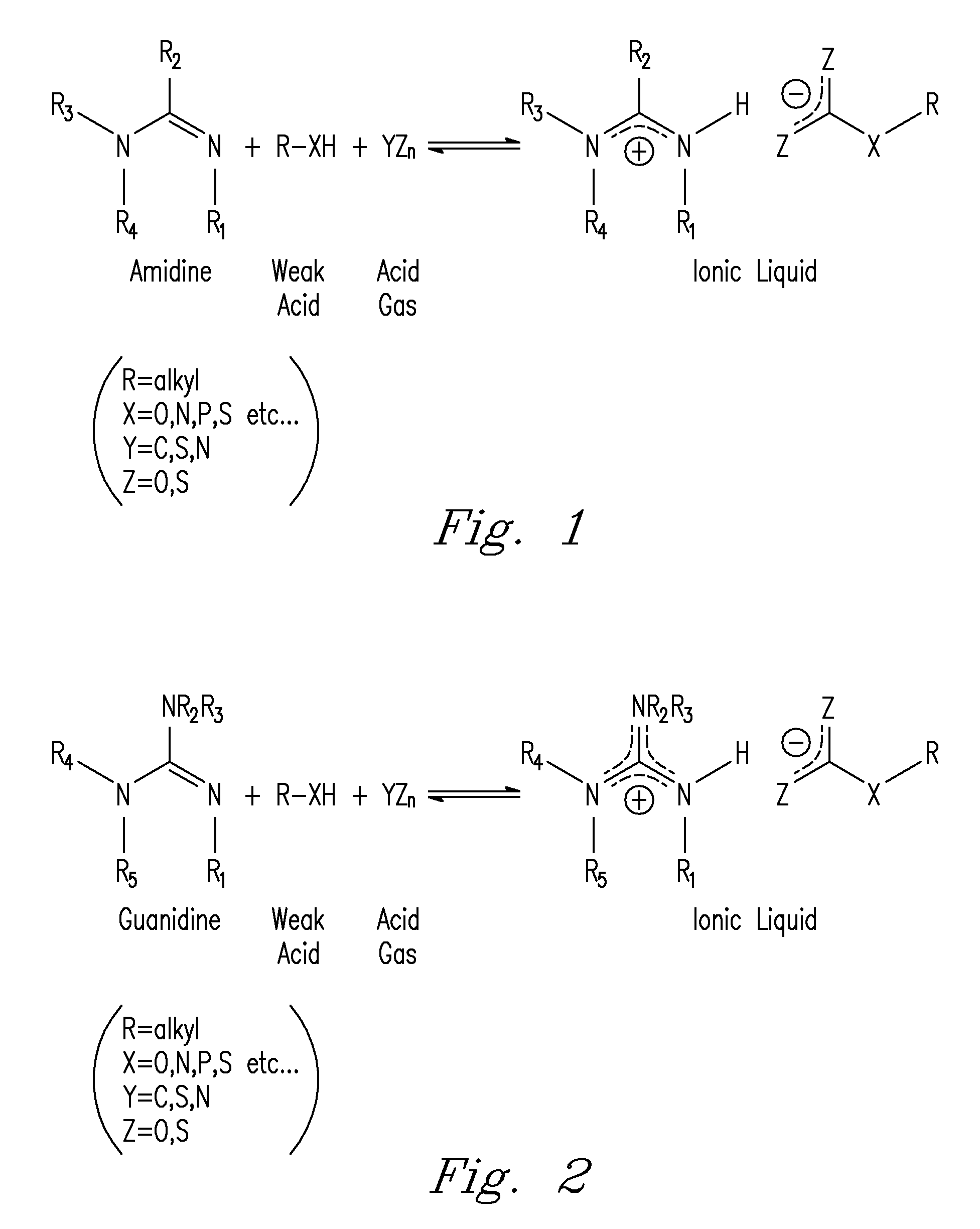

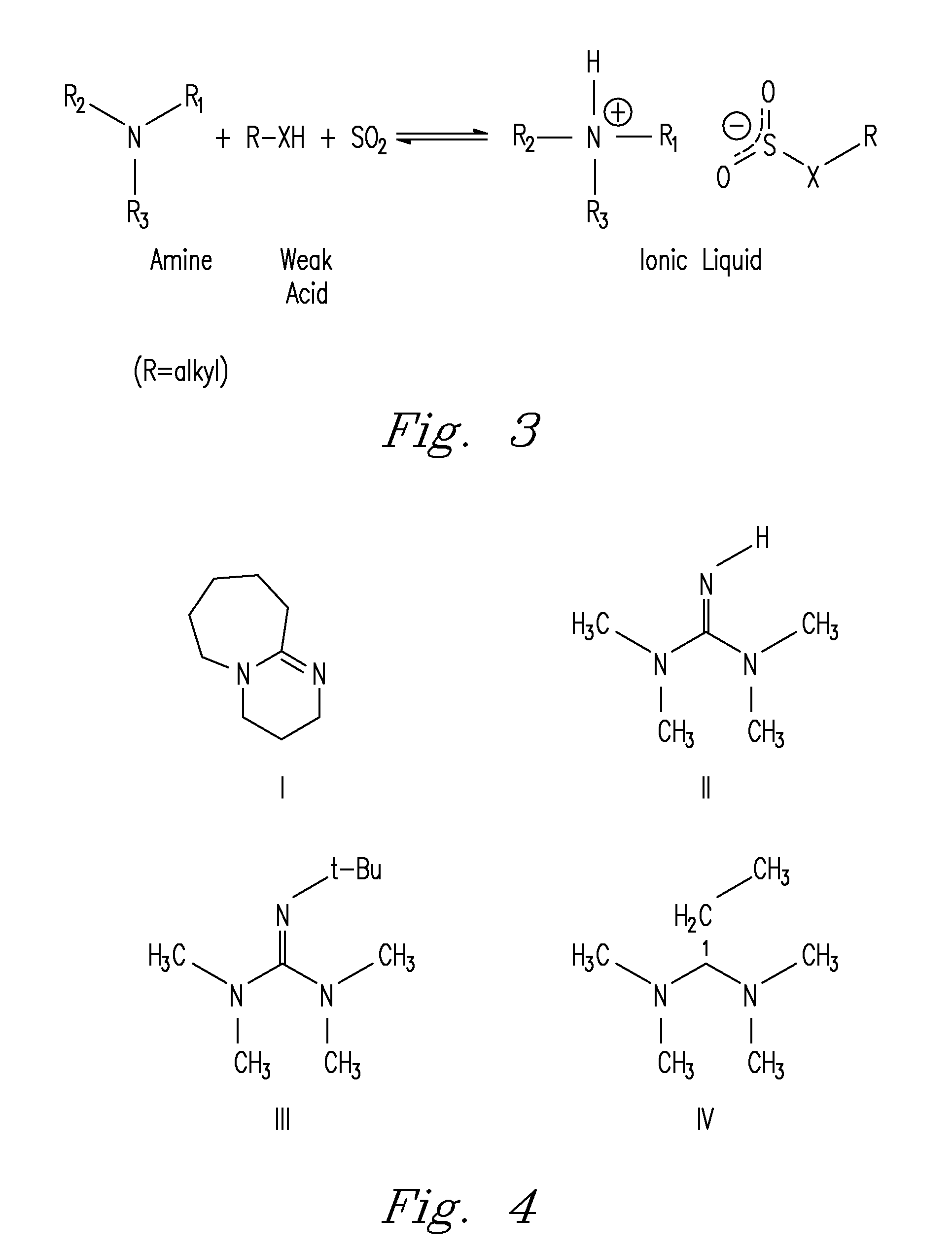

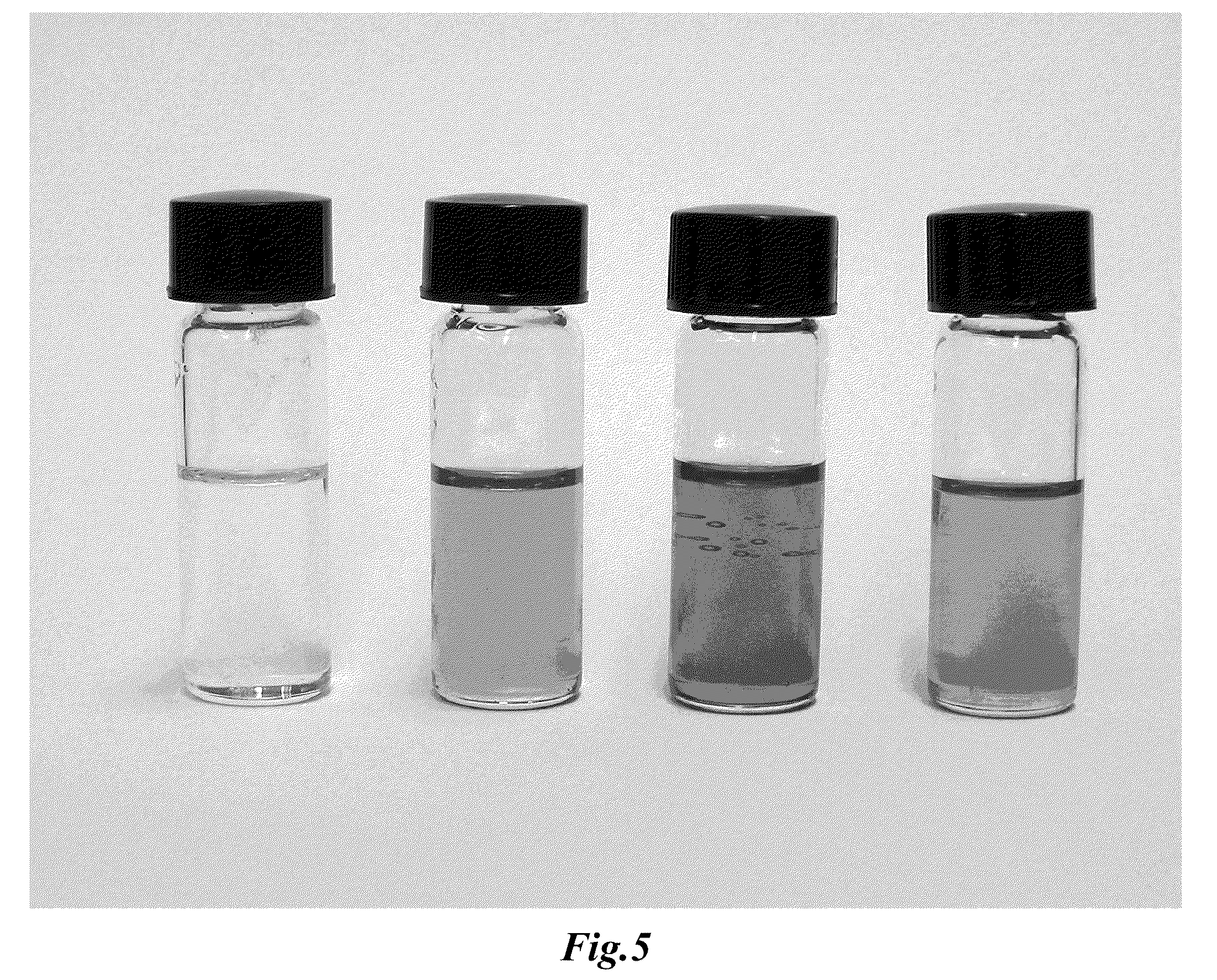

Capture and release of mixed acid gasses with binding organic liquids

ActiveUS7799299B2Reduced thermodynamic stabilityPrevent excessive inputGas treatmentDispersed particle separationChemical reactionOrganic fluid

Reversible acid-gas binding organic liquid systems that permit separation and capture of one or more of several acid gases from a mixed gas stream, transport of the liquid, release of the acid gases from the ionic liquid and reuse of the liquid to bind more acid gas with significant energy savings compared to current aqueous systems. These systems utilize acid gas capture compounds made up of strong bases and weak acids that form salts when reacted with a selected acid gas, and which release these gases when a preselected triggering event occurs. The various new materials that make up this system can also be included in various other applications such as chemical sensors, chemical reactants, scrubbers, and separators that allow for the specific and separate removal of desired materials from a gas stream such as flue gas.

Owner:BATTELLE MEMORIAL INST

Fiber reinforced cement composite materials using chemically treated fibers with improved dispersibility

InactiveUS20080148999A1Good dispersionAvoid bondingPulp properties modificationSolid waste managementChemical treatmentSurface finish

A fiber-reinforced building material in one embodiment incorporates cellulose fibers that are chemically treated with a dispersant to impart improved dispersibility to the fibers. The fibers are treated with a dispersant which deactivates the hydroxyl sites of the fiber surfaces and in some cases, making the fiber surface more hydrophobic. The dispersant inhibits the hydroxyl groups on the cellulose fiber surface from bonding with hydroxyl groups of other fibers and from bonding with hydroxyl groups of the same fiber, thereby significantly reducing inter-fiber and intra-fiber hydrogen bonding. The treated fibers can be readily dispersed and uniformly distributed throughout a mixture without re-clustering or reclumping once the mechanical mixing action stops. The chemically treated fibers with improved dispersibility improve the fiber distribution and reinforcing efficiency, which in turn improves key physical and mechanical properties of the material such as the modulus of rupture, z-direction tensile strength, and toughness, and surface finishes. With improved fiber reinforcing efficiency, less dosage of fiber is needed to achieve the required physical and mechanical properties.

Owner:JAMES HARDIE TECH LTD

Method for preparing cellulose nano-fibril film by utilizing wood powder

InactiveCN102899949AReduce hydrogen bondingHelp removeFibrous raw materialsFibrilPotassium hydroxide

The invention relates to a method for preparing a cellulose nano-fibril film by utilizing wood powder, which comprises the following steps: 1) chemically pre-processing; 2) mechanically separating; and 3) preparing a film. The method has the advantages: the acid-base pre-processing is combined with wood powder grinding and is adopted for preparing; the lignin in the wood powder is removed by mainly utilizing sodium chlorite under an acidic condition; the half-fibril is removed by using the diluted potassium hydroxide and the remained substrate is cellulose; and the diluted hydrochloric acid is used for splitting the cellulose. The acting force of hydrogen bonds in the fibril is reduced by adopting the splitting treatment, so that the biomass cellulose nano-fibril at high length-diameter ratio is obtained; the mineral substance in the fiber is removed by utilizing HCl treatment, the alkali insoluble half-cellulose in the purified cellulose is influenced and the effect of purifying the cellulose fiber is achieved; the chemical constituents are detected through Fourier transform infrared; the grinding treatment is simple and easy to operate and the mass production is performed; the modulus of elasticity is 3105.27MPa; and the tensile strength is 64.24MPa.

Owner:襄垣县鑫瑞达连氏塑木制造有限公司 +1

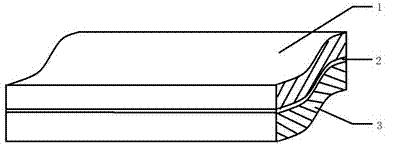

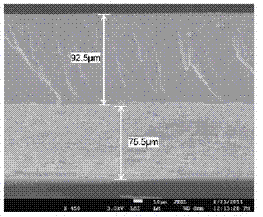

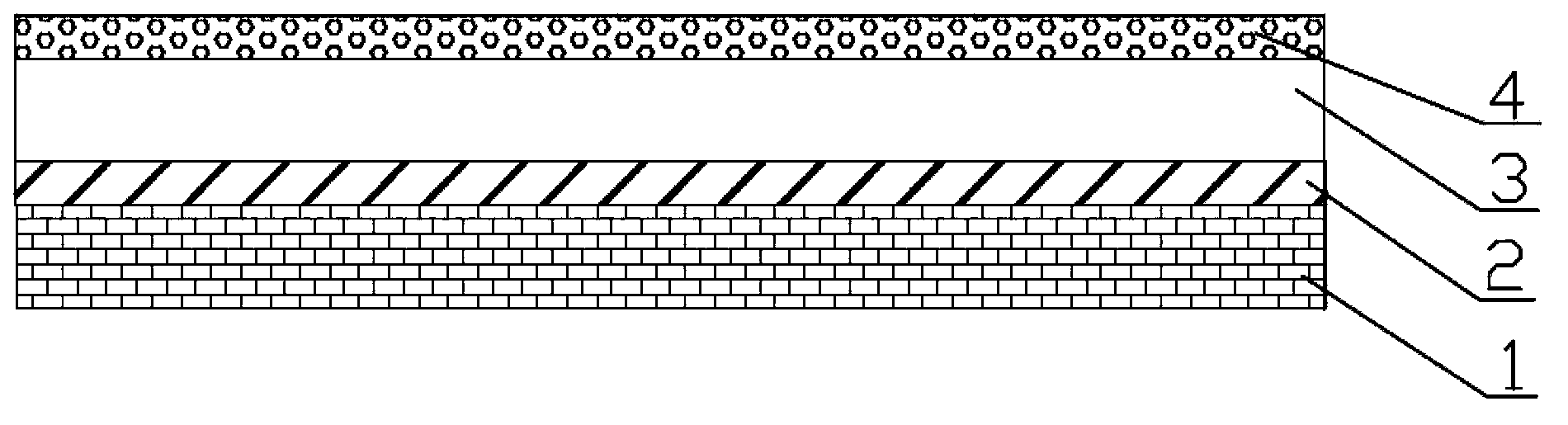

Composite ceramic membrane for lithium ion batteries and preparation method thereof

ActiveCN103956451AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite ceramic membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-on process under the action of a coupling agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:中国东方电气集团有限公司

Modified polylactic acid fiber and preparation method thereof

ActiveCN105220264AImprove performanceLow priceMonocomponent polyesters artificial filamentArtifical filament manufactureDiphenyl phosphateHydroxybutyric acid

The invention discloses a modified polylactic acid fiber and a preparation method thereof. The fiber comprises the following components by mass percentage: 70-98% of polylactic acid, 1-15% of resin, and 1-15% of a modifier. The weight-average molecular weight of polylactic acid is 7-200 ten thousands. The resin is polytrimethylene terephthalate or / and polyhydroxyalkanoate. Polyhydroxyalkanoate is one or two of polyhydroxybutyrate, polyhydroxybutyrate-hydroxyvalerate, 3-hydroxybutyrate and 3-hydroxyhexanoate copolyester, polyhydroxyhexanoate and polyhydroxyoctoate, the weight average molecular weight of polyhydroxyalkanoate is 1-50 ten thousands, and the melt index is 20-50. The modifier is one or two of polydiethylene adipate glycol ester ether, diisononyl phthalate, (2-ethylhexyl)-difenylfosfat, cresyl diphenyl phosphate, tri(2-chloroethyl)phosphate and dioctyl adipate. The fiber has strength of greater than or equal to 1.5cN / dtex and elongation at break of greater than or equal to 40%.

Owner:TIANJIN POLYTECHNIC UNIV

Method for fabricating obstruction coating film of modified polyvinyl alcohol and coating film produced thereby

InactiveCN1687264AReduce hydrogen bondingImprove water resistanceCoatingsPVA - Polyvinyl alcoholPolymer chemistry

The present invention provides a modified polyvinyl alcohol high-barrier coating film and its preparation method. Said method uses PVOH as raw material, and adopts the following steps: after the raw material is catalyzed, making modification, then adding adjuvant to make them into coating material, applying said coating material on the base film so as to form high-barrier coating film. After the PVOH molecular chain is partially catalyzed and condensed, the hydrogen bond action force in the molecular can be reduced, so that its water-proof property can be greatly raised.

Owner:HAINAN SHINER IND

Method for preparing micro-nano cellulose with ultra-low crystallinity

The invention discloses a method for preparing a micro-nano cellulose with ultra-low crystallinity, which comprises the following steps of: allowing a micro-nano cellulose crystal with higher crystallinity to be fully dissolved in a dissolution system of the cellulose and reproducing; changing the cellulose into a loose cellulose II structure; and through mechanical treatment, further destructing a crystalline structure of the cellulose to obtain the micro-nano cellulose with ultra-low crystallinity. Amorphous cellulose intermolecular and intramolecular hydrogen bonding interaction is weakened, the majority of hydroxyl groups on a molecular chain are exposed to enhance the degree of availability and reaction activity of the cellulose, and the water retention value is also increased. Accordingly, the cellulose prepared by the method provided by the invention has ultra-low crystallinity, and extremely high degree of availability and reaction activity, overcomes the defects that the cellulose prepared by the traditional method has high crystallinity and low degree of availability and reaction activity, and can be widely used in application fields of various celluloses.

Owner:SOUTH CHINA UNIV OF TECH

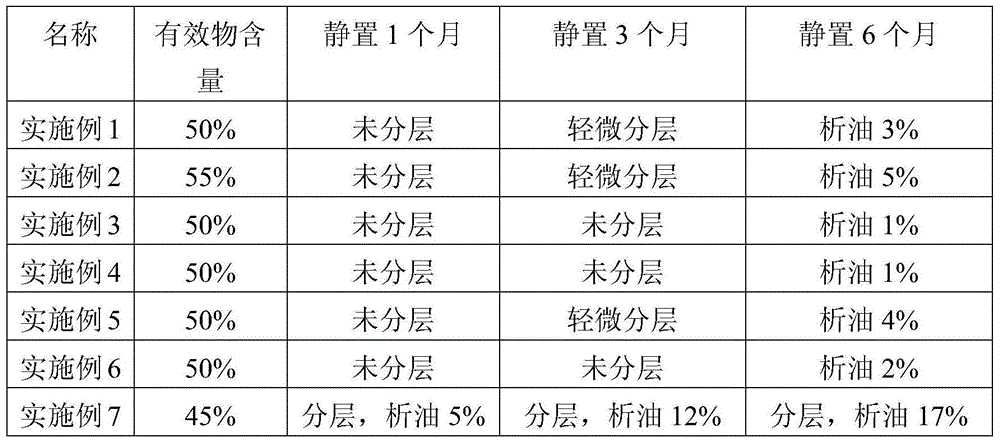

Liquid thickening agent system and application thereof

ActiveCN104861951APromote swellingImprove salt resistanceFluid removalDrilling compositionSalt resistanceOrganic solvent

The invention discloses a liquid thickening agent system including an organic solvent, a plant gum thickener, an organic thickener, an emulsifier and water. According to the thickening agent system disclosed by the invention, the thickening agent system is easy to prepare and has a certain salt resistance; the thickening agent system is fast to swell when used for being mixed with water to prepare a fracturing fluid, the requirement on preparing water is low, and even if sea water (containing salt) is used, the swelling effect of the thickening agent is also not affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly high-strength water-resisting and mildew-resisting adhesive for plywood and preparation method of environment-friendly high-strength water-resisting and mildew-resisting adhesive

InactiveCN105542683AReduced effectReduce hydrogen bondingNon-macromolecular adhesive additivesStarch adhesivesBond ForceP-hydroxybenzoic acid

The invention discloses an environment-friendly high-strength water-resisting and mildew-resisting adhesive for a plywood and a preparation method of the environment-friendly high-strength water-resisting and mildew-resisting adhesive. The environment-friendly high-strength water-resisting and mildew-resisting adhesive is prepared from the following raw materials including polyvinyl alcohol, cassava starch, dibutyl phthalate, sodium pyrosulfite, tannic acid, jade powder, calcium silicate hydrate, asbestos powder, p-hydroxybenzoic acid hydrazide, diammonium hydrogen phosphate, hydroquinone, sodium diethylhexyl sulfosuccinate, triethyltin chloride, phenyl mercury oleate, borax and the like. The polyvinyl alcohol and the cassava starch are subjected to a cross-linking reaction so that crystallization degrees of the polyvinyl alcohol and the cassava starch are reduced and a new cross-linking structure is formed, and furthermore, the thermal stability of the adhesive is improved; the borax is added and the polyvinyl alcohol and the starch can be subjected to further cross linking, so that the cross-linking degree and the initial viscosity of the adhesive are improved, and furthermore, the water resistance and the bonding force of the adhesive can be improved; the triethyltin chloride, the phenyl mercury oleate, the p-hydroxybenzoic acid hydrazide and the like are added so that the mildew-resisting capability of the plywood can be improved.

Owner:倪协照

Method for preparing cellulose nano-grade filament film by using recovered waste paper

InactiveCN102817276AReduce hydrogen bondingHelp removeFibre treatmentPaper recyclingPotassium hydroxideCellulose fiber

The invention relates to a method for preparing a cellulose nano-grade filament film by using recovered waste paper. The method comprises the steps of chemical pretreatment, mechanical separation, and film preparation. The method has the advantages that: the film is prepared through a combination of acid-alkali pretreatment and wood powder grinding; lignin in the wood powder is removed mainly by using sodium chlorite in an acidic condition; hemicellulose in the wood powder is removed by using dilute potassium hydroxide, and the rest is substantially cellulose; and the cellulose is subjected to a fiber-opening process by using dilute hydrochloric acid. With the fiber-opening process, hydrogen bonding interactions in the filaments are reduced, such that biomass cellulose nano-grade filaments with high length-diameter ratios are obtained. Minerals in the fibers are removed through hydrochloric acid treatment, and alkali-insoluble hemicellulose in purified cellulose is affected, such that an effect of cellulose fiber purification is achieved. The chemical components are detected through Fourier transform infrared. The grinding treatment is simple and easy to operate, such that large-scale production can be carried out. An elastic modulus is 2901.14MPa, and a tensile strength is 63.26MPa.

Owner:襄垣县鑫瑞达连氏塑木制造有限公司 +1

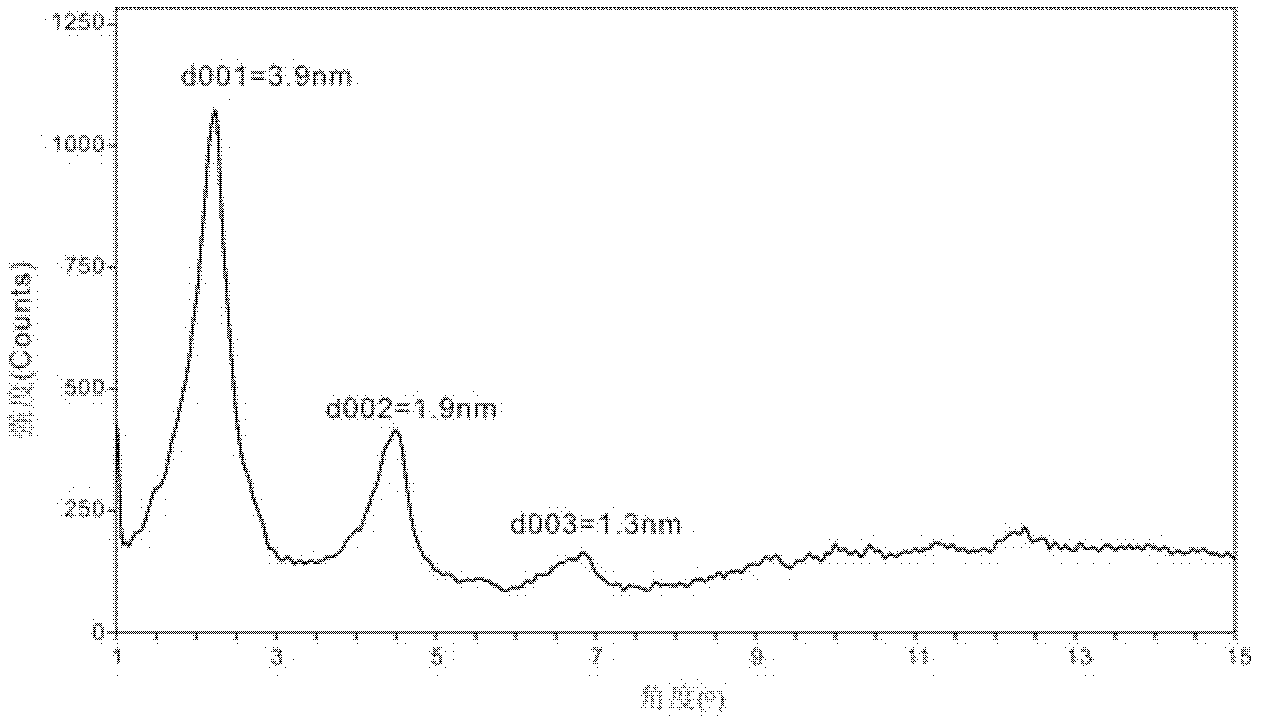

Method for preparing aluminosilicate nanotube by using kaolinite raw material

ActiveCN102583413ASimple stepsSimple processAluminium silicatesNanotechnologyKaoliniteSURFACTANT BLEND

The invention discloses a method for preparing an aluminosilicate nanotube by using a kaolinite raw material. The method comprises the following steps of: preparing a kaolinite-dimethyl sulfoxide compound; preparing a kaolinite-methanol compound; dissolving a cationic surfactant into methanol; adding into the kaolinite-methanol compound obtained in the step 2 for preparing the aluminosilicate nanotube, and the like. The method has the advantages and positive effects that: an aluminosilicate nanotube material with high purity and a uniform structure and shape is prepared, the material has low cost, simple flow, low pollution and low energy consumption, and is easy for popularizing and applying.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method of reed-based biochar adsorption material

InactiveCN108970583AStrong pollutant adsorption capacityRealize the utilization of waste resourcesOther chemical processesAlkali metal oxides/hydroxidesChemistryNitrogen gas

The invention relates to a preparation method of a reed-based biochar adsorption material. The preparation method is technically characterized by comprising the following steps of cleaning the reed stalk, drying and crushing; soaking the crushed reed stalk into a KOH (potassium hydroxide) solution to activate, and drying; putting the dried crushed reed stalk into an atmosphere furnace, and performing oxygen-free high-temperature cracking under the nitrogen or inert gas protection atmosphere; after high-temperature cracking treatment, cooling to room temperature, and cleaning the cracked material to be neutral by an acid solution, so as to prepare the reed-based biochar adsorption material. The preparation method has the advantages that the problems of pollution to environment and waste ofresources due to irresponsible disposal of the wetland plant wastes are solved; compared with the prior art, the specific surface area is large, the pollutant adsorption ability is strong, the environment-friendly value is greatly increased, and the resource utilization of the wastes is realized.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

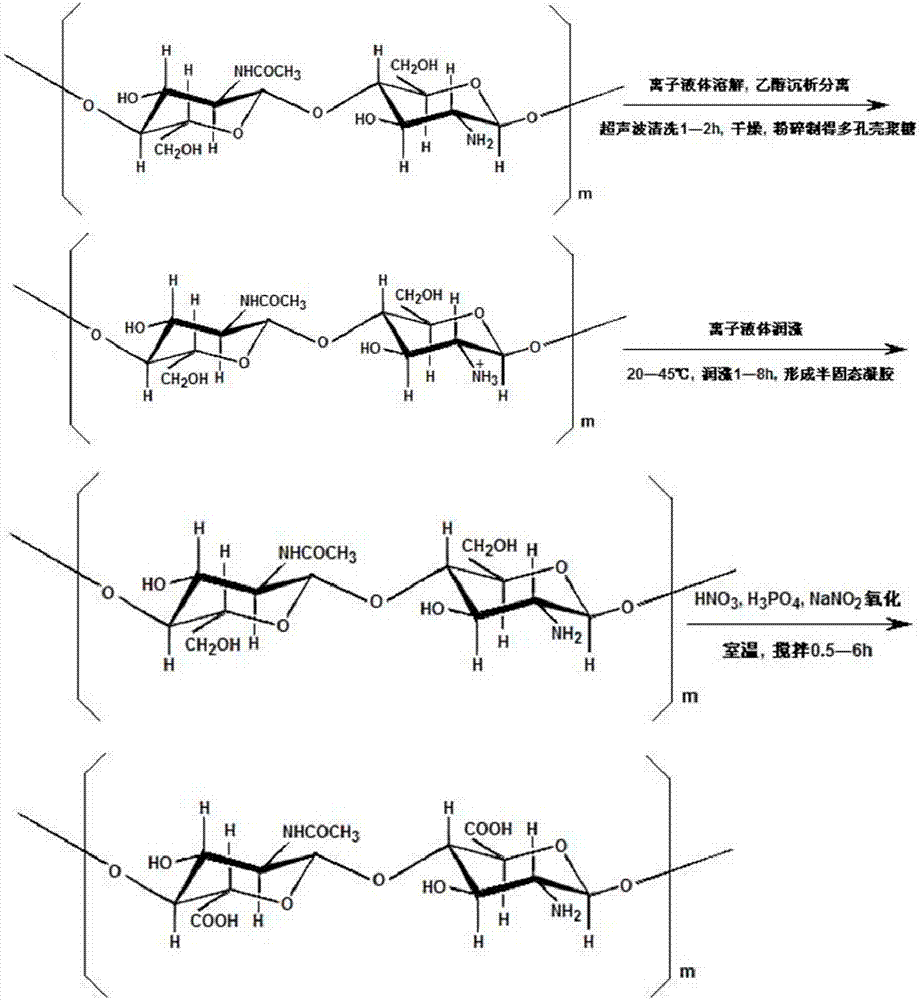

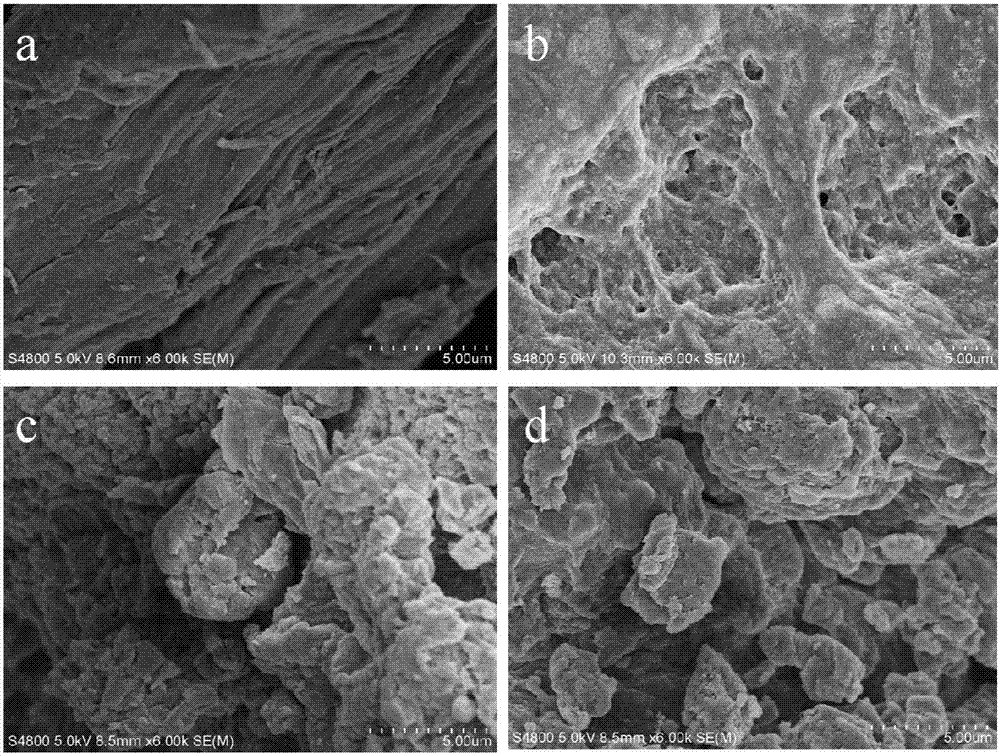

Selective-oxidized chitosan and heterogeneous preparation method thereof

The invention discloses a selective-oxidized chitosan and a heterogeneous preparation method thereof. The method is characterized in that according to preparation of the oxidized chitosan, macromolecular chitosan is dissolved in an ionic liquid, the chitosan is precipitated from the ionic liquid by adding absolute ethyl alcohol, and porous chitosan is obtained after the ionic liquid in a precipitation is fully replaced through absolute ethyl alcohol dipping and ultrasonic oscillation; the porous chitosan is moistened and expanded in the ionic liquid to form a semisolid gel with certain viscosity, and then partial or all hydroxyls at C6 position in pyranose rings of the chitosan are selectively oxidized into carboxyls in an ionic liquid medium to obtain the selective-oxidized chitosan with adoption of a concentrated nitric acid-concentrated phosphoric acid-sodium nitrite system. According to the method, operation is simple and convenient, the oxidation reaction rate is high, the oxidation degree of the chitosan is easily controlled, oxidation products are easy to separate, the yield of the products is high, the prepared carboxyl chitosan has good antibacterial activity and water solubility, and the ionic liquid can be recycled for cyclic utilization, which is environmentally friendly.

Owner:TAIHE KERUNGE GARMENT CO LTD

Method for preparing cotton cellulose nano fibril film

ActiveCN102787518AReduce hydrogen bondingEffectFibre treatmentPaper material treatmentFibrilPotassium hydroxide

The invention relates to a method for preparing a cotton cellulose nano fibril film, which comprises the technical steps of 1, chemical pretreatment; 2, mechanical separation; and 3, film preparation. The method has the advantages that the film is prepared by combining acid-base pretreating and grinding wood meal, the method is mainly used for removing lignin in the wood meal under the acidic condition of sodium chlorite, the diluted potassium hydroxide is then used for removing the hemicellulose in the wood meal, the residue is basically cellulose, and finally, the diluted hydrochloric acid is used for splitting the cellulose. The internal hydrogen-bonding acting force of the fibril is reduced through the splitting treatment, so the biomass cellulose nano fibril with high length-diameter ratio is obtained. The hydrochloric acid treatment is utilized to remove the mineral substance in the fiber, the alkaline insoluble hemicellulose of the purified cellulose is influenced, and the effect of purifying the cellulosic fiber is realized. Chemical constituents are detected through Fourier transform infrared. The grinding is simple and easy to operate, and the film can be produced in mass. The elastic modulus is 3463.23 MPa, and the tensile strength is 87.38 MPa.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

Softening technology of facial tissue and ultra-soft facial tissue prepared by softening technology

ActiveCN104452445ASimple processEasy to operate and controlSurfactants additionNon-macromolecular organic additionSodium polyacrylateSurface-active agents

Owner:ANHUI BILUN DOMESTIC PAPER CO LTD

Preparation of cellulose carbamate and low-temperature dissolution spinning method of cellulose carbamate

InactiveCN104072622ALess structural defectsImprove mechanical propertiesArtificial filaments from cellulose solutionsCelluloseFiber

The invention discloses preparation of cellulose carbamate and a low-temperature dissolution spinning method of the cellulose carbamate. The method comprises the following steps: adding cellulose into a sodium hydroxide solution, stirring uniformly, immersing, taking out the cellulose, washing with water to a neutral state to obtain alkalified cellulose, adding urea, stirring uniformly, putting in a drying oven, heating, reacting and drying to obtain the cellulose carbamate; pulverizing the cellulose carbamate into powder, adding the powder into a mixing kettle, adding double solvents of sodium hydroxide, thiocarbamide and deionized water, and stirring uniformly; and carrying out extrusion, deaeration and filtration on the raw material in the mixing kettle, spraying by spinneret orifices of a spinneret, sequentially sending into a first coagulation bath and a second coagulation bath to obtain a solid, washing with water in a water tank, and carrying out stretching and winding by a spinning component to obtain the cellulose carbamate fiber. The method is suitable for preparing the cellulose carbamate by an industrialized large-scale production process route, and has important meanings for implementing low-temperature dissolution spinning engineering and industrialized production of cellulose.

Owner:DONGHUA UNIV

Method for preparing carbon nano tube modified bipolar membrane with anion groups

InactiveCN102580549AGood compatibilityHigh water dissociation efficiencySemi-permeable membranesCell component detailsCelluloseAcetic acid

The invention relates to a method for preparing a carbon nano tube modified bipolar membrane with anion groups. The method comprises the following steps of: preparing a sodium carboxymethylcellulose (CMC) aqueous solution or a sodium alginate (SA) aqueous solution by using sodium carboxymethylcellulose or sodium alginate, adding a carbon nano tube with the anion groups, stirring and defoaming under reduced pressure to obtain viscous membrane liquid; casting the viscous membrane liquid in a smooth culture dish to prepare a cation exchange membrane; stirring and dissolving chitosan in 1 to 10 mass percent of acetic acid aqueous solution to prepare 1 to 10 mass percent of chitosan acetic acid aqueous solution, dripping 2.5 volume percent of glutaraldehyde solution slowly with stirring, and defoaming under the reduced pressure to obtain a chitosan (CS) anion membrane liquid; and forming a membrane of the CS anion membrane liquid, fixing the membrane to a prepared cation membrane layer, and airing at room temperature to obtain the bipolar membrane. Due to the adoption of the carbon nano tube modified cation membrane layer with the anion groups, the bipolar membrane has the characteristics of high water dissociation efficiency, small membrane impedance, low tank voltage, high compatibility of two membrane layers and the like.

Owner:FUJIAN NORMAL UNIV

Method for preparing heavy oil viscosity reduction agent through hydrophobic modification carbon nanometer pipe

InactiveCN107022348AMeet flowable viscosity requirementsGood viscosity reduction effectPipeline systemsDrilling compositionCarbon nanotubeOil viscosity

The invention discloses a method for preparing a heavy oil viscosity reduction agent through a hydrophobic modification carbon nanometer pipe. The method belongs to the technical field of heavy oil viscosity reduction agent preparation and comprises the steps of using a coupling agent for carrying out surface treatment on the carbon nanometer pipe; then adopting methyl methacrylate, octadecyl acrylate and styrene as raw materials for preparing to obtain an encapsulated liquid; coating the surface of the carbon nanometer pipe with the encapsulated liquid, and drying to obtain the hydrophobic modification carbon nanometer pipe; finally mixing the hydrophobic modification carbon nanometer pipe, a surface active agent and solvent oil to obtain the heavy oil viscosity reduction agent. When the heavy oil viscosity reduction agent prepared through the hydrophobic modification carbon nanometer pipe is added into the heavy oil, a polar basal body can be introduced, so that hydrogen-bond interaction between colloid and asphaltene in the heavy oil can be reduced, the aims of reducing the heavy oil viscosity and improving the crude oil mobility can be achieved, the usable range is wide, a better viscosity reduction effect can be realized on different oil products, and a viscosity reduction effect is durable and effective.

Owner:CHANGZHOU UNIV

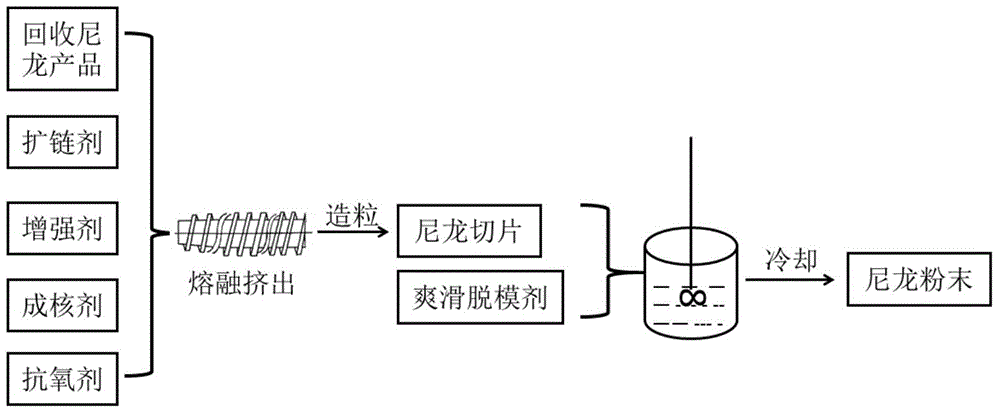

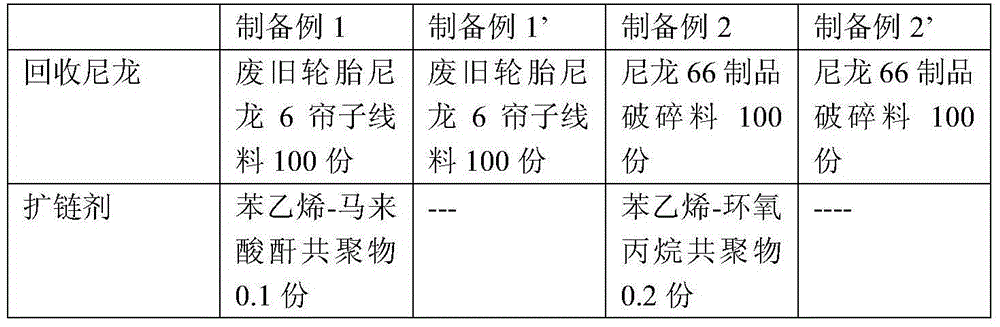

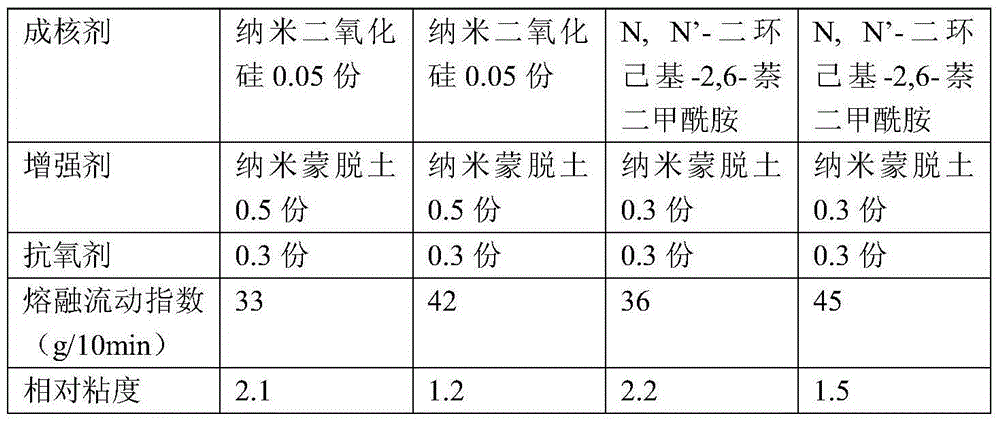

Method for using recycled nylon for preparation of polyamide powder

ActiveCN105566894AReduce hydrogen bondingAvoid secondary pollutionSelective laser sinteringPolymer science

The present invention provides a method for using recycled nylon for preparation of polyamide powder, the method is as follows: recycled nylon 6 or nylon 66, a chain extender, a reinforcing agent, a nucleating agent and an antioxidant are mixed, and melt-extruded at 200-240 DEG C to obtain nylon chips; and the nylon chips and a smooth release agent are dissolved in a solvent, then stirred for 1-3 hours at 180-240 DEG C, cooled to precipitate a solid, dried and then pulverized to obtain the polyamide powder. Compared with a product with no added chain extender, melt flow index is increased, and mechanical properties are better. The present invention further provides application of the polyamide powder in a selective laser sintering process, and a prepared laser sintered sample strip has better impact strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

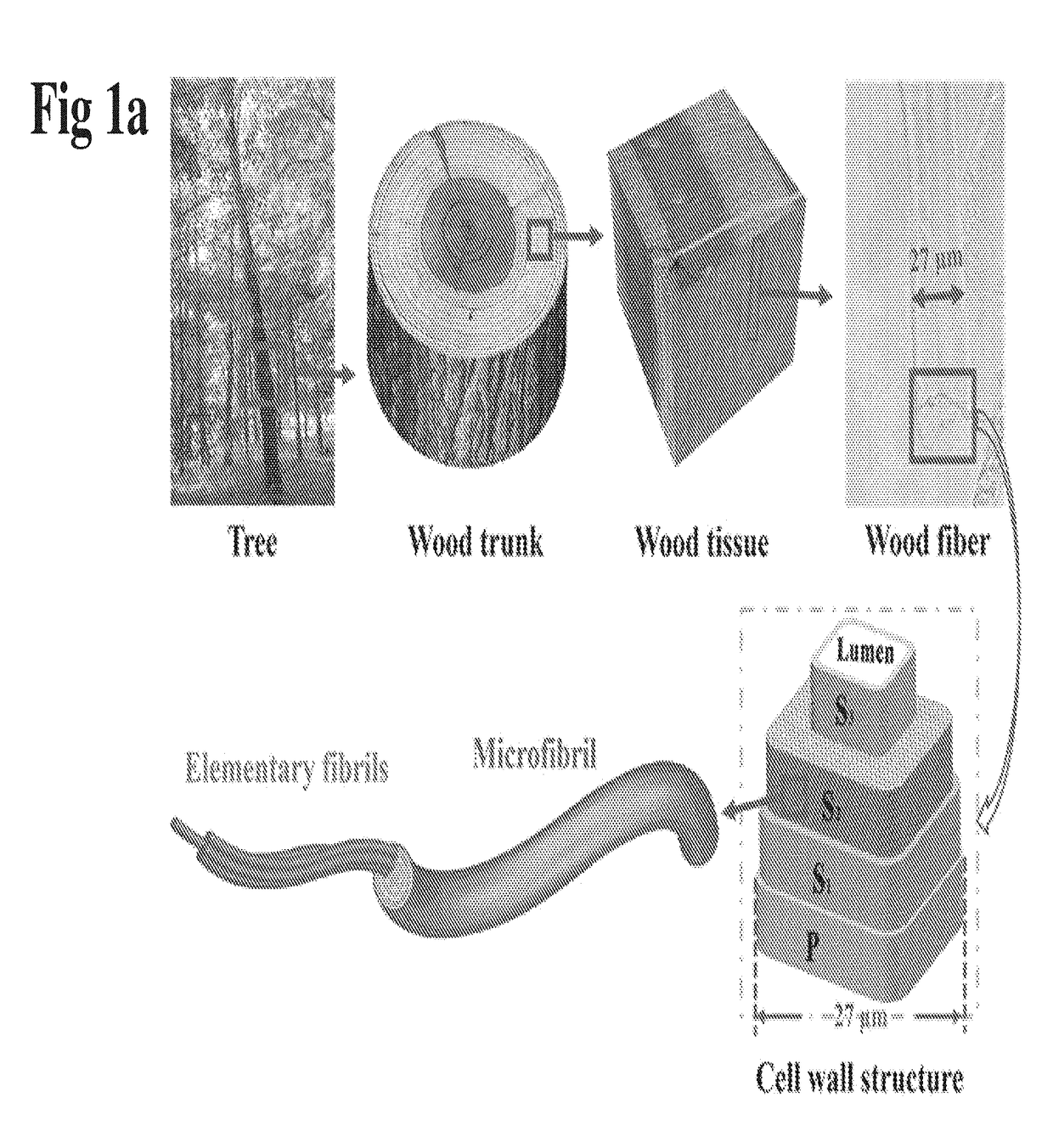

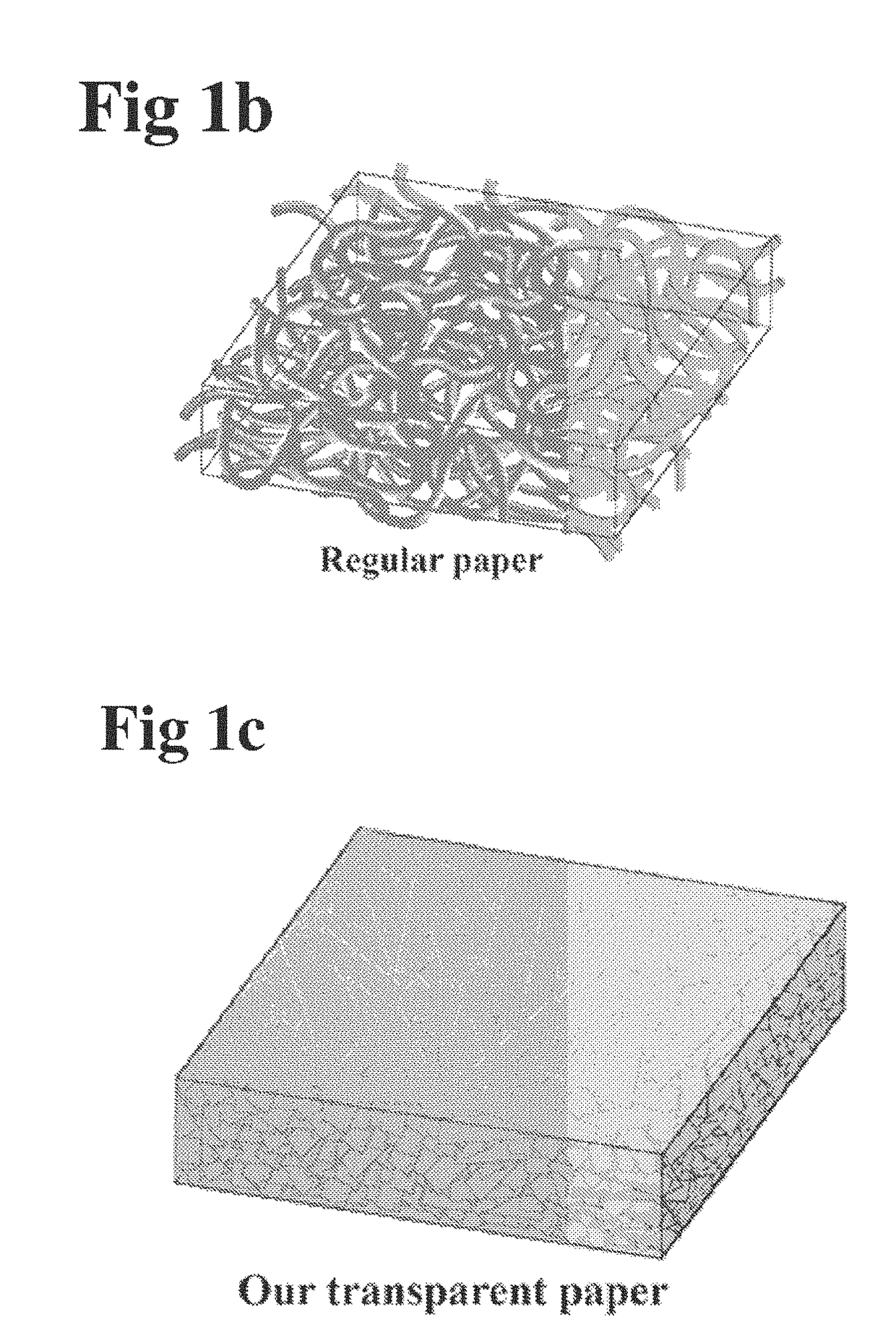

Super clear cellulose paper

ActiveUS20180010299A1Ultra-high optical transparencyLow costNon-macromolecular organic additionPhotovoltaicsFiberCellulose

Wood fibers possess natural unique hierarchical and mesoporous structures that enable a variety of new applications beyond their traditional use. For the first time we dramatically modulate the propagation of light through random network of wood fibers. A highly transparent and clear paper with transmittance >90% and haze <1.0% applicable for high-definition displays is achieved. By altering the morphology of the same wood fibers that form the paper, highly transparent and hazy paper targeted for other applications such as solar cell and anti-glare coating with transmittance >90% and haze >90% is also achieved. A thorough investigation of the relation between the mesoporous structure and the optical properties in transparent paper was conducted, including full-spectrum optical simulations. We demonstrate commercially competitive multi-touch touchscreen with clear paper as a replacement for plastic substrates, which shows excellent process compatibility and comparable device performance for commercial applications. Transparent cellulose paper with tunable optical properties is an emerging photonic material that will realize a range of much improved flexible electronics, photonics and optoelectronics.

Owner:UNIV OF MARYLAND

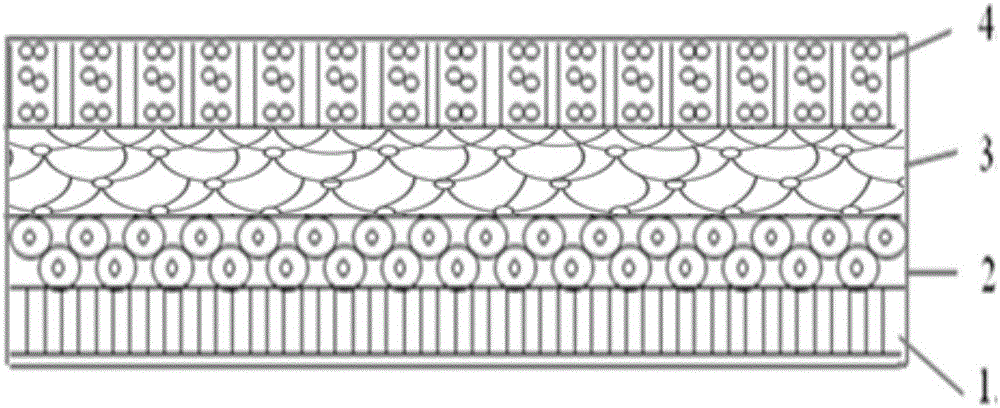

Composite membrane quick-drying type dye-sublimation transfer printing digital paper

ActiveCN103381721AGood transfer effectStrong water permeabilitySynthetic resin layered productsCellulosic plastic layered productsIonInterpenetrating polymer network

The invention belongs to the field of transfer printed paper and particularly relates to composite membrane quick-drying type dye-sublimation transfer printing digital paper which comprises base material paper, a hydrophobic layer coated on the surface of the base material paper and an ink absorption layer coated on the surface of the hydrophobic layer, wherein a surface layer is coated on the upper surface of the ink absorption layer. The ink absorption layer is made of positive ion polyacrylamide cellulose interpenetrating polymer network resin. The surface layer is one or a combination of two of polyvinyl alcohol-vinyl acetate copolymer or polyvinyl butyral or polyvinyl alcohol. The hydrophobic layer is made of organosilicone modified acrylic resin. The composite membrane quick-drying type dye-sublimation transfer printing digital paper is provided with the surface layer which is one or a combination of two of polyvinyl alcohol-vinyl acetate copolymer or polyvinyl butyral or polyvinyl alcohol and can transfer a strong water permeation capability to the ink absorption layer on the condition of normal temperature. The number of intermolecular hydrogen bonds is reduced on the condition of high temperature, the surface layer can provide a large gap, dye molecules quickly and sufficiently sublimate in transfer printing digital paper coating materials, the transfer printing effect is ideal, and the composite membrane quick-drying dye-sublimation transfer printing digital paper has a wide application prospect.

Owner:杭州华大海天科技股份有限公司

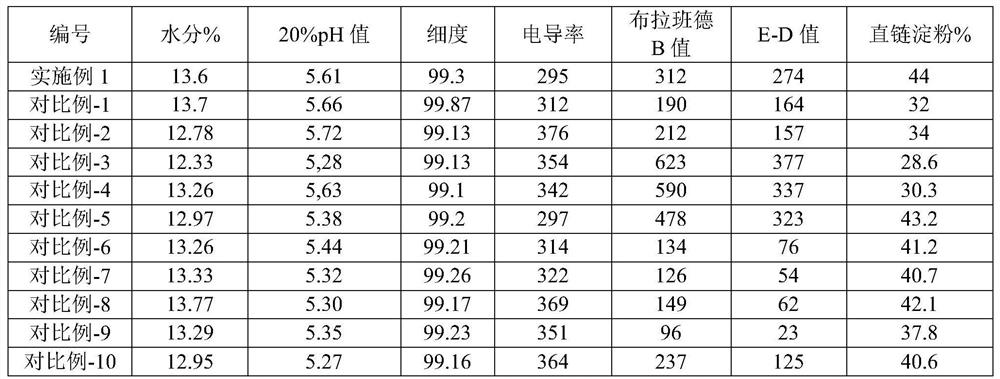

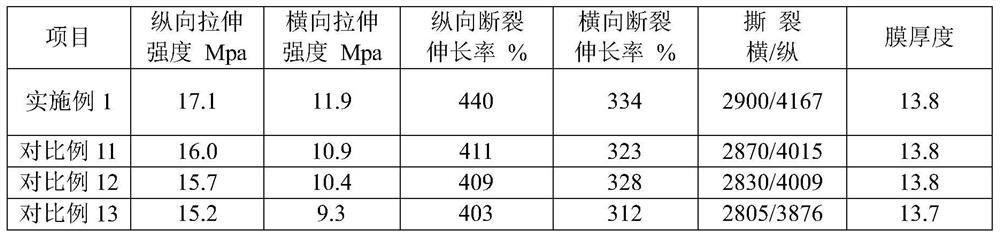

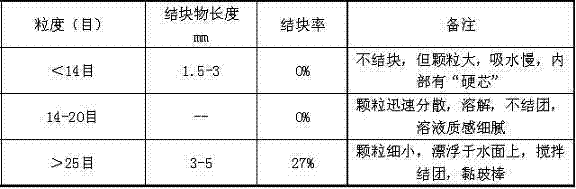

Preparation method of high-strength TPS starch for degradable materials

ActiveCN113024897AReaction conditions are easy to controlMild responseBio-packagingFermentationThermoplasticPolymer science

The invention relates to the field of high polymer materials, and discloses a preparation method of high-strength TPS starch for degradable materials. The preparation method comprises the following steps: firstly, by utilizing a wet modified starch production process, adding a bio-enzyme preparation under the conditions of controlling the temperature and pH value, then controlling the temperature of obtained slurry, adding an inhibitor, carrying out cross-linking agent and esterification treatment to obtain modified starch, mixing and adding a starch matrix reinforcement material into powder in a dry method for treatment, adding a proper amount of glycerol and a modifier, extruding by a twin-screw extruder, air-cooling, slitting and granulating to obtain a thermoplastic TPS starch granular material with good strength. Compared with common starch, the thermoplastic TPS starch particle material has the advantage that the mechanical property can be improved by adding the thermoplastic TPS starch particle material into a degradable material.

Owner:HANGZHOU PAPERMATE SCI & TECH

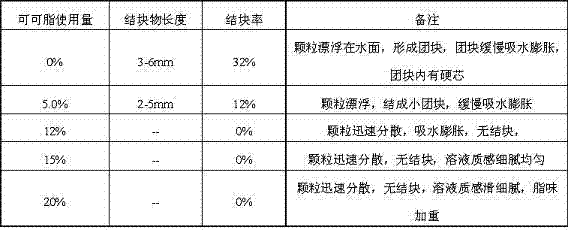

Mixed product comprising beta-glucan and preparation method of mixed product

ActiveCN102919964AUnited will notImprove function and effectFood preparationBiotechnologyButter cocoa

The invention relates to a mixed product comprising beta-glucan, which is prepared by the following raw materials in ratio by weight: 7.5-80% of beta-glucan, 6-20% of cocoa butter, 0-30% of supermicro carrot powder, 0-30% of supermicro highland barley, and 0-40% of erythritol. Meanwhile, the invention further discloses a preparation method of the product. In the mixed product, beta-glucan can be quickly dissolved in daily drinking water. The mixed product has a certain healthcare effect, is convenient to have and good in taste, and can meet the recommended dose of beta-glucan to reach the health keeping effect.

Owner:TIBET TIANMAILI HEALTH PROD CO LTD

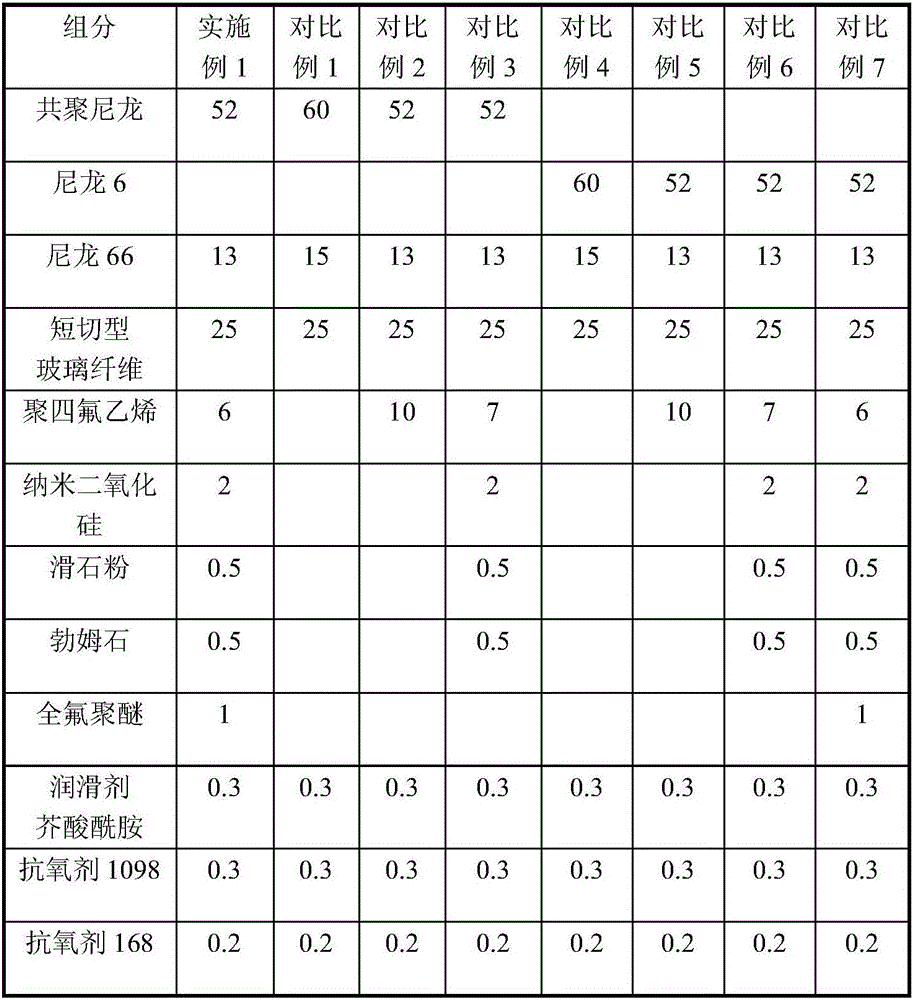

Wear-resistant high-impact-resistance nylon composite material, and preparation method and application thereof

The invention relates to a wear-resistant high-impact-resistance nylon composite material which comprises the following components in parts by weight: 20-80 parts of nylon resin, 10-50 parts of fiber material, 10-40 parts of anti-wear agents, 0.1-2 parts of surface treating agent perfluoropolyether, 0.1-1.0 part of lubricant and 0.1-0.6 part of antioxidant. The preparation method comprises the following steps: uniformly mixing different types of anti-wear agents at medium speed; heating to 90-100 DEG C, adding the perfluoropolyether, and uniformly mixing at high speed; adding the nylon resin, lubricant and antioxidant, and continuing mixing uniformly; and carrying out melt blending extrusion, drawing, cooling, and granulation on the obtained mixture and fiber material through a double screw extruder, thereby obtaining the wear-resistant high-impact-resistance nylon composite material. The wear-resistant high-impact-resistance nylon composite material has the advantages of low friction factor, favorable wear resistance, high mechanical strength, favorable heat resistance, excellent toughness, excellent impact resistance, low mold shrinkage rate, favorable dimensional stability, favorable flowability and high processability.

Owner:株洲时代工程塑料实业有限公司

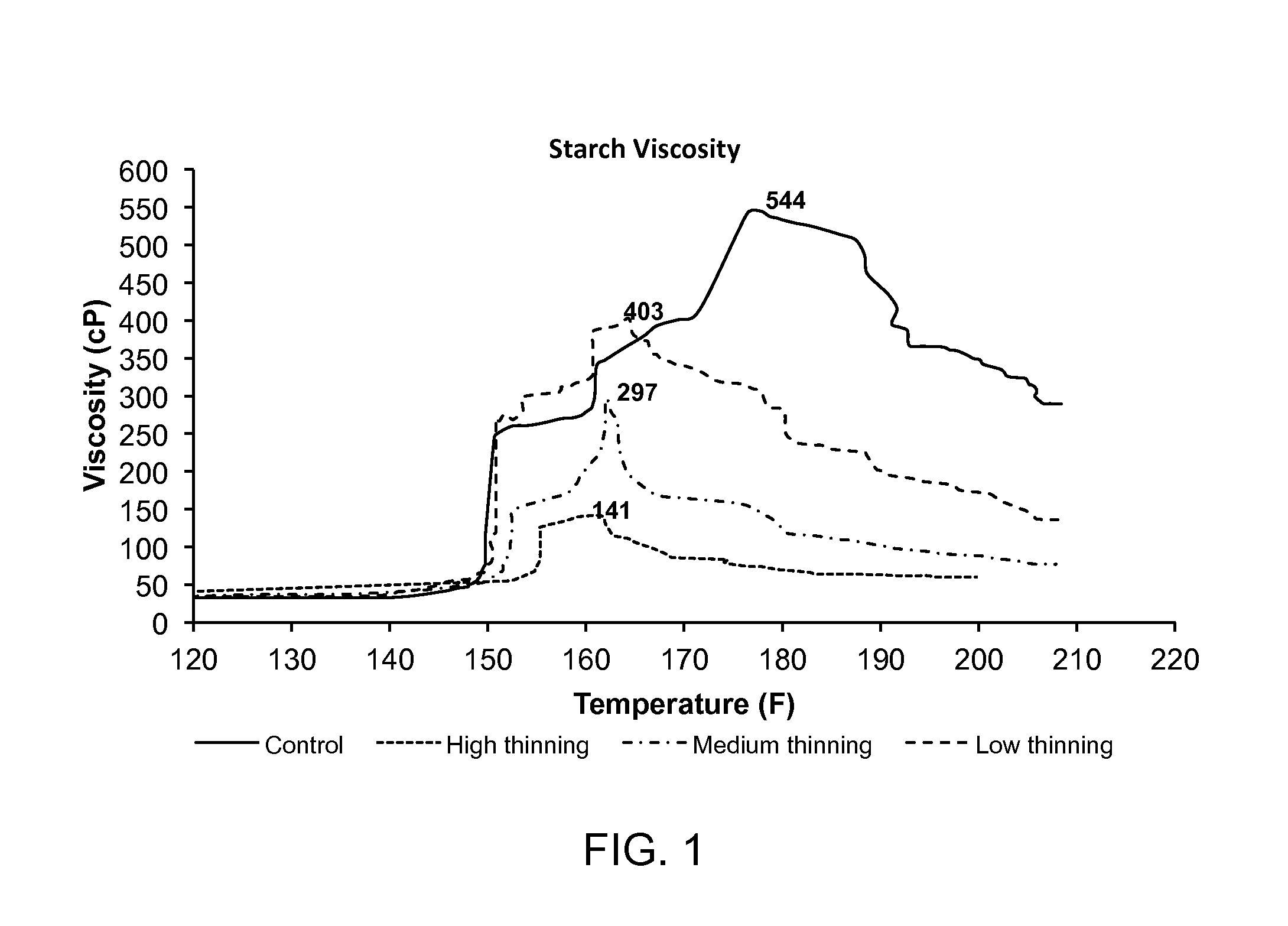

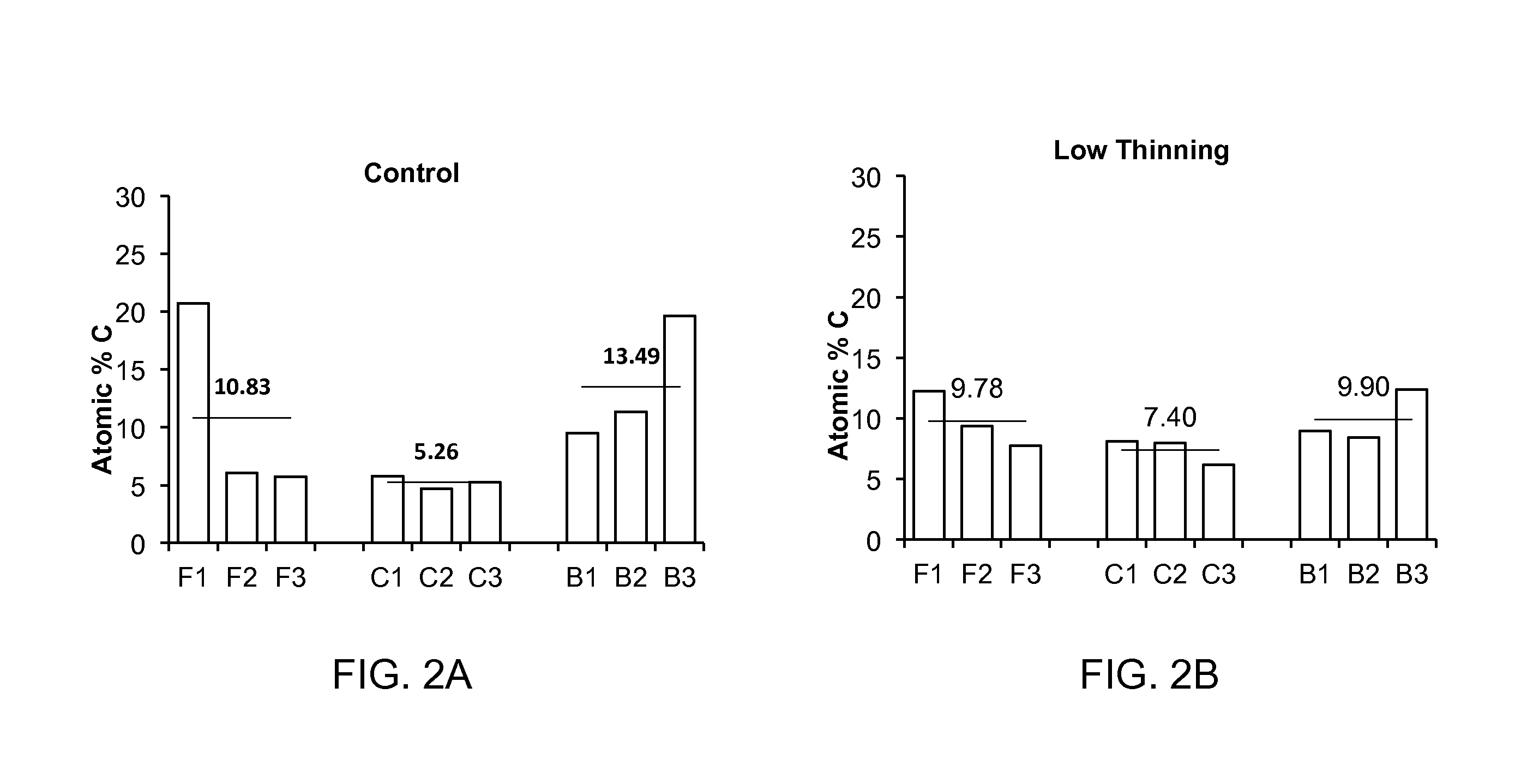

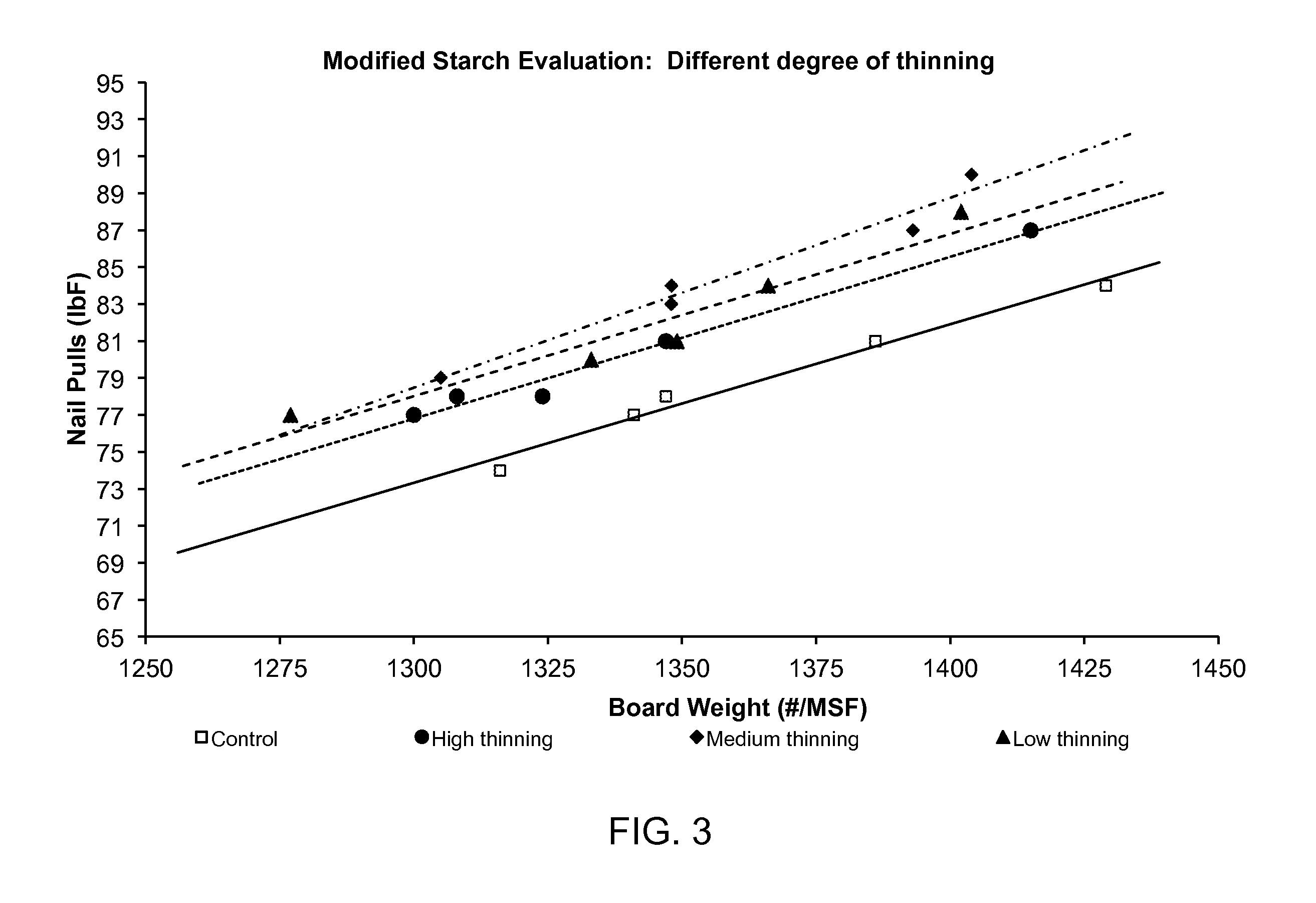

Gypsum board with improved starch binder

ActiveUS20150175482A1Reduce peak gelling temperatureReduce hydrogen bondingSolid waste managementCellulosic plastic layered productsChemical modificationMaterials science

Gypsum board having improved performance is obtained by controlling the distribution of starch in the gypsum core of the board and the gelling temperature of the starch. Starch migration in the board is controlled by the degree of acid-modification, to adjust the starch viscosity profile. The starch gelling temperature is controlled by chemical modification of the starch —OH groups.

Owner:GOLD BOND BUILDING PROD LLC

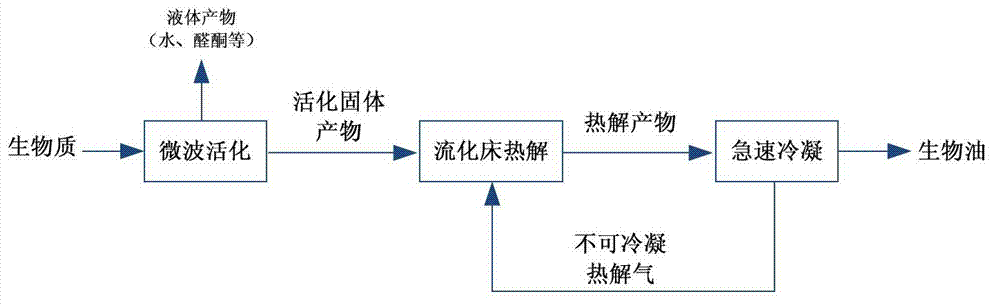

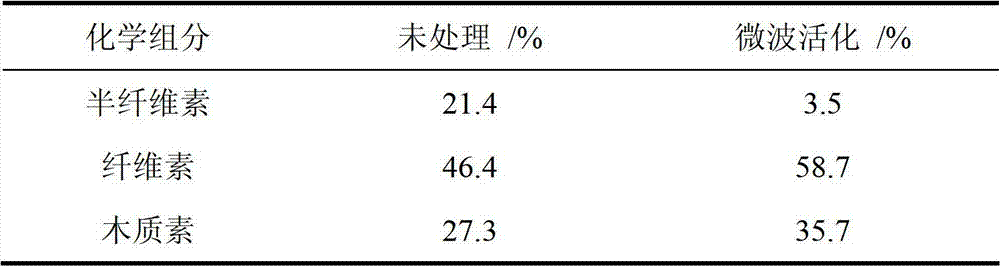

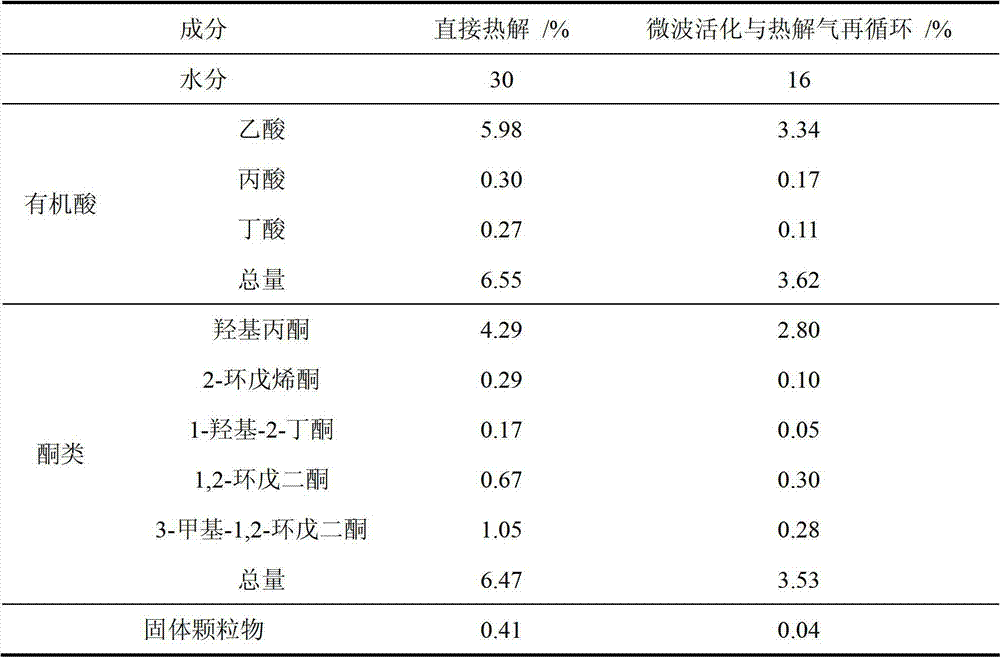

Method for preparing high-quality bio-oil based on microwave activation and pyrolysis gas recycling

ActiveCN102807885AReduce generationLow content of unstable componentsLiquid hydrocarbon mixture productionParticulatesCellulose

The invention discloses a method for preparing high-quality bio-oil based on microwave activation and pyrolysis gas recycling. The method includes: based on obvious differences of main chemical component structure of biomass and unique functions of the microwave activation, firstly subjecting biomass raw materials to microwave activation pretreatment on a microwave pyrolysis reactor, selectively decomposing hemicellulose components in the biomass raw materials to reduce formation of moisture and carbonyl compound during a quick pyrolysis stage, activate cellulose components and improve conversion efficiency of the cellulose at the quick pyrolysis stage, subjecting the pretreated products to quick pyrolysis reaction in a fluidized bed, changing composition of pyrolysis products by recycling pyrolysis gas to provide reactive atmosphere, further reducing formation of the carbonyl compound during the quick pyrolysis process, and simultaneously subjecting pyrolysis steam to in situ filtering for removal of solid particles in the pyrolysis steam. The finally obtained bio-oil is lower in content of water, the carbonyl compound and the solid particles, good in storage stability and high in heat value.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Instant-drying type high-ink-absorption heat sublimation transfer printing digital paper

ActiveCN106245461AIncrease drying speedShorten drying timeSurface covering paperPaper coatingCross-linkCellulose

The present invention relates to the technical field of heat sublimation transfer printing, and discloses instant-drying type high-ink-absorption heat sublimation transfer printing digital paper, which sequentially comprises base paper, a water absorption and water permeation layer, a porous mesh bag layer and a surface channel layer from bottom to top, wherein the porous mesh bag layer is a three-dimensional mesh-bag-like interpenetrating network resin formed by cross-linking cellulose or carboxymethyl cellulose sodium or starch and cation modified polyacrylamide, or a three-dimensional mesh-bag-like interpenetrating network resin formed by cross-linking polyacrylamide or cellulose or carboxymethyl cellulose sodium and cation modified starch so as to significantly increase the ink absorption. According to the present invention, the water permeability is increased by regulating the composition of the resin and controlling the network density, such that the water molecules rapidly enter the water absorption and water permeation layer; and the instant-drying type high-ink-absorption heat sublimation transfer printing digital paper has characteristics of high ink absorption capacity, rapid ink absorption, instant drying after printing, good transfer printing effect and the like, and meets the fast printing and efficient production requirements of various dark fabrics.

Owner:杭州华大海天科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com