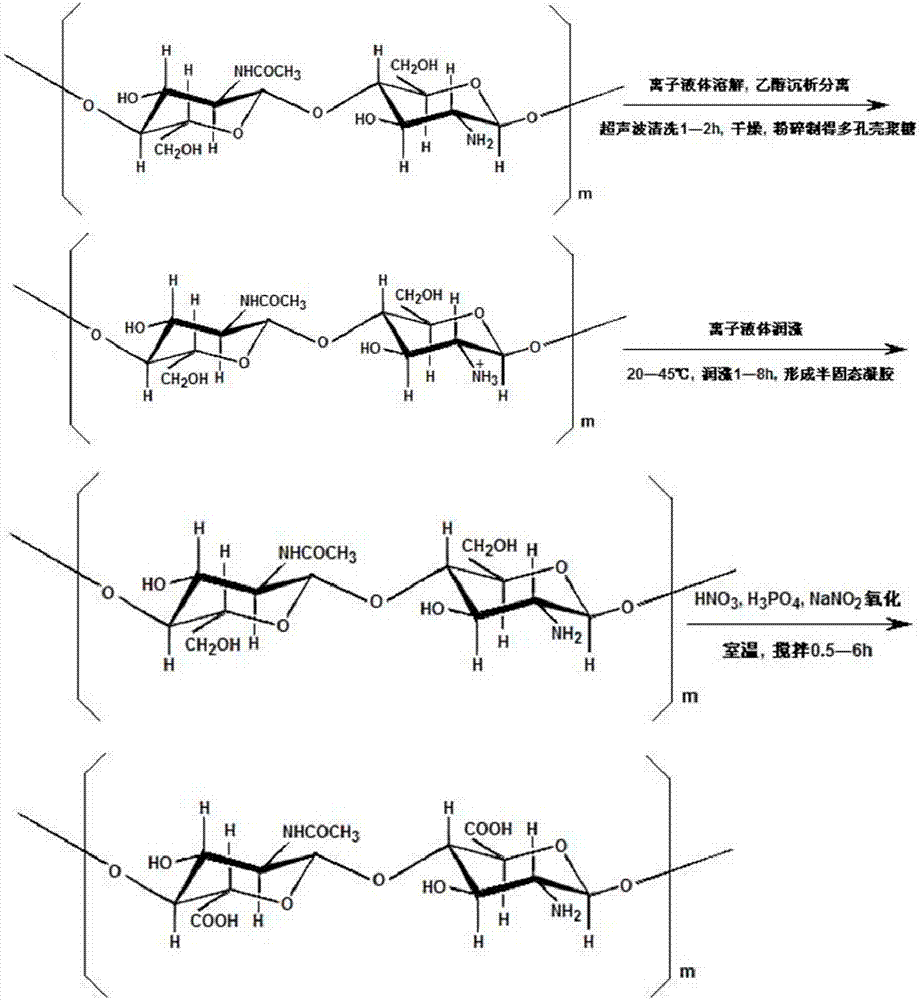

Selective-oxidized chitosan and heterogeneous preparation method thereof

A technology of oxidizing chitosan and selectivity, which is applied in the modification of functional chitosan and the field of high-yield carboxy chitosan prepared by mixed selective oxidation system, to increase accessibility, reduce side reactions of oxidative degradation, water-soluble sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

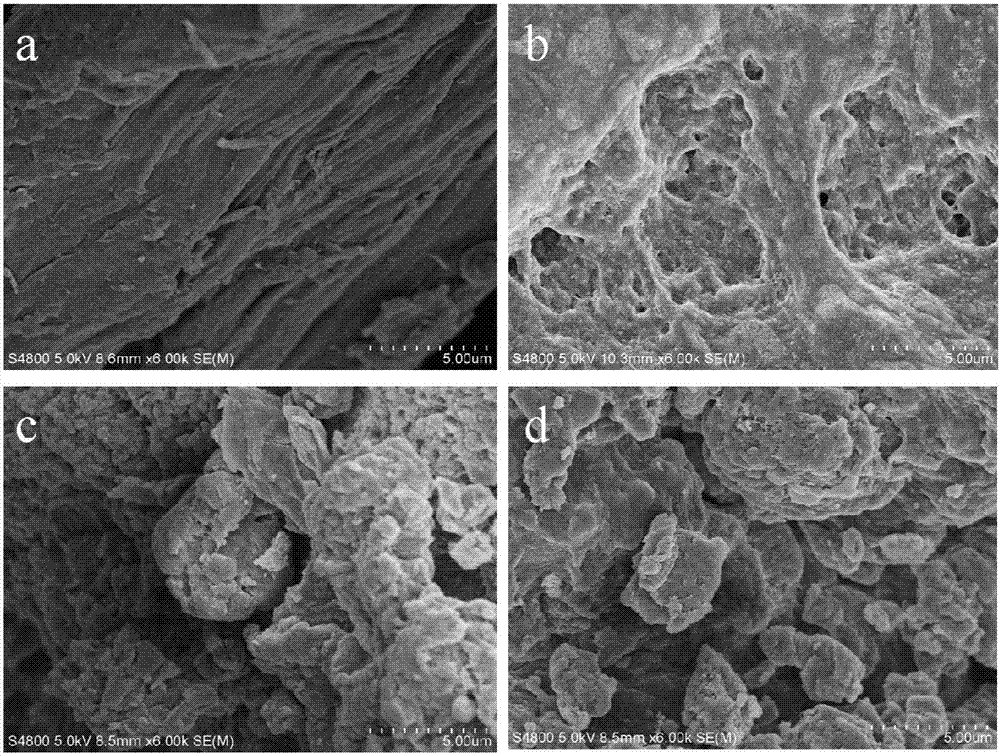

[0032] Weigh 4.0g of chitosan with a viscosity-average molecular weight of 1 million and a deacetylation degree of 92% at a bath ratio of 1:15 (w / v) and stir at 90°C for 2 hours, dissolve in ionic liquid 1-ethyl-3-formazan In imidazole acetate, after cooling to room temperature, add 120mL of absolute ethanol to precipitate chitosan precipitate, the filtered chitosan precipitate is immersed in absolute ethanol for ultrasonic vibration cleaning for 1h, then filtered, dried, pulverized, and passed through 150 mesh Make porous chitosan powder behind the sieve;

[0033] Dried porous chitosan was soaked in 40mL ionic liquid 1-allyl-3-methylimidazolium chloride salt at 40°C for 3h to form a semi-solid gel with a certain viscosity; then add 15mL of concentrated nitric acid and concentrated Mixed acid composed of phosphoric acid (V 浓硝酸 :V 浓磷酸 = 1:1) and sodium nitrite with a mass volume ratio of 0.007 g / mL to the mixed acid, in a light-proof airtight container, continuously stirred a...

Embodiment 2

[0035] Weigh 4.0g of chitosan with a viscosity-average molecular weight of 1 million and a deacetylation degree of 92% at a bath ratio of 1:15 (w / v) and stir at 90°C for 2 hours, dissolve in ionic liquid 1-ethyl-3-formazan In imidazole acetate, after cooling to room temperature, add 120mL of absolute ethanol to precipitate chitosan precipitate, the filtered chitosan precipitate is immersed in absolute ethanol for ultrasonic vibration cleaning for 1h, then filtered, dried, pulverized, and passed through 150 mesh Make porous chitosan powder behind the sieve;

[0036] Dried porous chitosan was swelled in 40mL ionic liquid 1-butyl-3-methylimidazolium chloride salt at 40°C for 5h to form a semi-solid gel with a certain viscosity; then add 15mL of concentrated nitric acid and concentrated phosphoric acid The mixed acid formed (V 浓硝酸 :V 浓磷酸 =2:1) and sodium nitrite with a mass volume ratio of 0.014 g / mL to the mixed acid, in a light-proof airtight container, continuously stirred ...

Embodiment 3

[0038] Weigh 4.0g of chitosan with a viscosity average molecular weight of 1 million and a degree of deacetylation of 92% at a bath ratio of 1:15 (w / v) and stir at 90°C for 4h to dissolve in ionic liquid 1-butyl-3-methyl In imidazole acetate, after cooling to room temperature, add 120mL of absolute ethanol to precipitate chitosan precipitate, the filtered chitosan precipitate is immersed in absolute ethanol for ultrasonic vibration cleaning for 1h, then filtered, dried, pulverized, and passed through a 150-mesh sieve Prepare porous chitosan powder after netting; moisten the dried porous chitosan in 40mL ionic liquid 1-allyl-3-methylimidazolium chloride salt at 40°C for 3 hours to form a semi-solid gel with a certain viscosity , and then add 15mL of mixed acid (V 浓硝酸 :V 浓磷酸 =2:1) and the sodium nitrite that is 0.014g / mL with the mass volume ratio of the mixed acid in a light-proof airtight container, continuously stirred and reacted at room temperature for 6h, and immediatel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com