Patents

Literature

70results about How to "Fast catalytic reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of treating refractory pollutants through catalyzing H2O2 oxidation by pyrite cinder

ActiveCN101745197AApplicable to a wide range of pHImprove responseSolid waste disposalWater contaminantsCinderPollutant

A method of treating refractory pollutants utilizes the pyrite cinder as catalyst which forms a heterogeneous Fenton system with H2O2 to catalyze H2O2 to generate hydroxyl radical (.OH) with strong oxidability and degrade the organic pollutants efficiently and quickly. The method comprises the following steps: (1) after the waste water is added in a reactor, a given amount of pyrite cinder original sample or activated and pretreated cinder is added in the waste water; (2) H2O2 solution is added in a mixed liquid of the waste water and the pyrite cinder so as to form an analogous Fenton reagent with the pyrite cinder; (3) stirring is carried out so as to lead the pyrite cinder, the H2O2 solution and the waste water to be mixed for reaction, and the stirring is stopped at the set reaction time; and (4) standing is carried out, the pyrite cinder is quickly precipitated and the supernate is discharged, so that the pyrite cinder can be reused. The invention discovers a novel analogous Fenton oxidation catalyst, extends the resource utilization ways of the pyrite cinder, achieves the purpose of controlling waste by waste and realizes the comprehensive utilization of the waste.

Owner:TONGJI UNIV

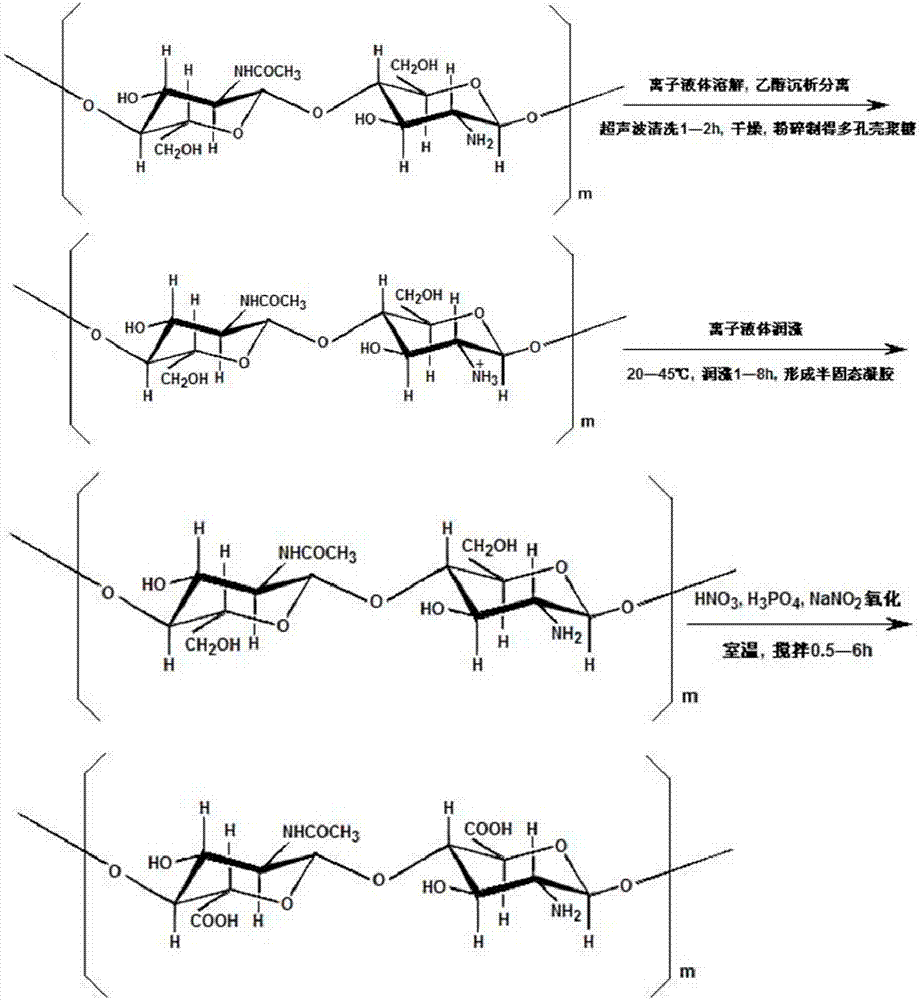

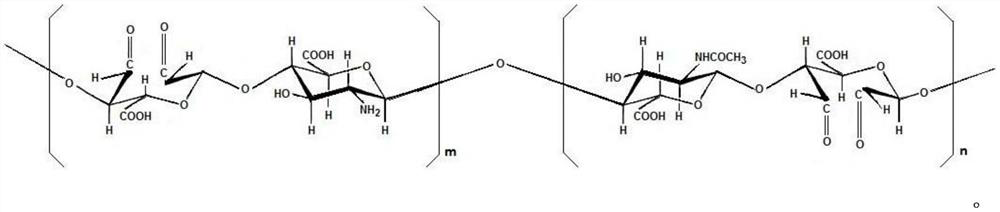

Selective-oxidized chitosan and heterogeneous preparation method thereof

The invention discloses a selective-oxidized chitosan and a heterogeneous preparation method thereof. The method is characterized in that according to preparation of the oxidized chitosan, macromolecular chitosan is dissolved in an ionic liquid, the chitosan is precipitated from the ionic liquid by adding absolute ethyl alcohol, and porous chitosan is obtained after the ionic liquid in a precipitation is fully replaced through absolute ethyl alcohol dipping and ultrasonic oscillation; the porous chitosan is moistened and expanded in the ionic liquid to form a semisolid gel with certain viscosity, and then partial or all hydroxyls at C6 position in pyranose rings of the chitosan are selectively oxidized into carboxyls in an ionic liquid medium to obtain the selective-oxidized chitosan with adoption of a concentrated nitric acid-concentrated phosphoric acid-sodium nitrite system. According to the method, operation is simple and convenient, the oxidation reaction rate is high, the oxidation degree of the chitosan is easily controlled, oxidation products are easy to separate, the yield of the products is high, the prepared carboxyl chitosan has good antibacterial activity and water solubility, and the ionic liquid can be recycled for cyclic utilization, which is environmentally friendly.

Owner:TAIHE KERUNGE GARMENT CO LTD

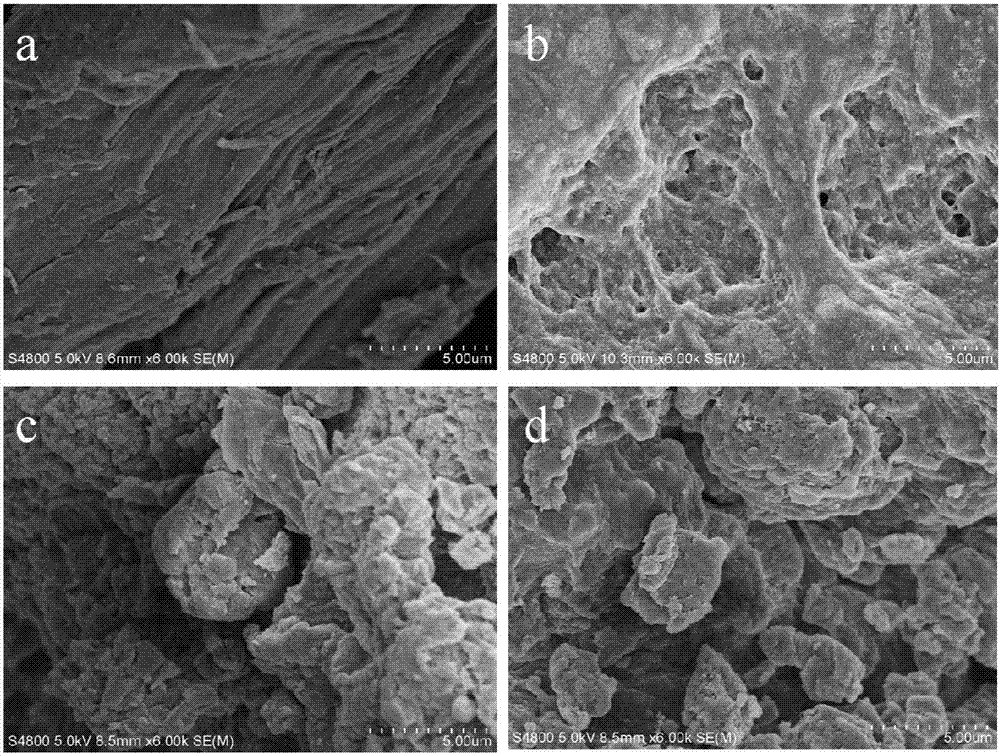

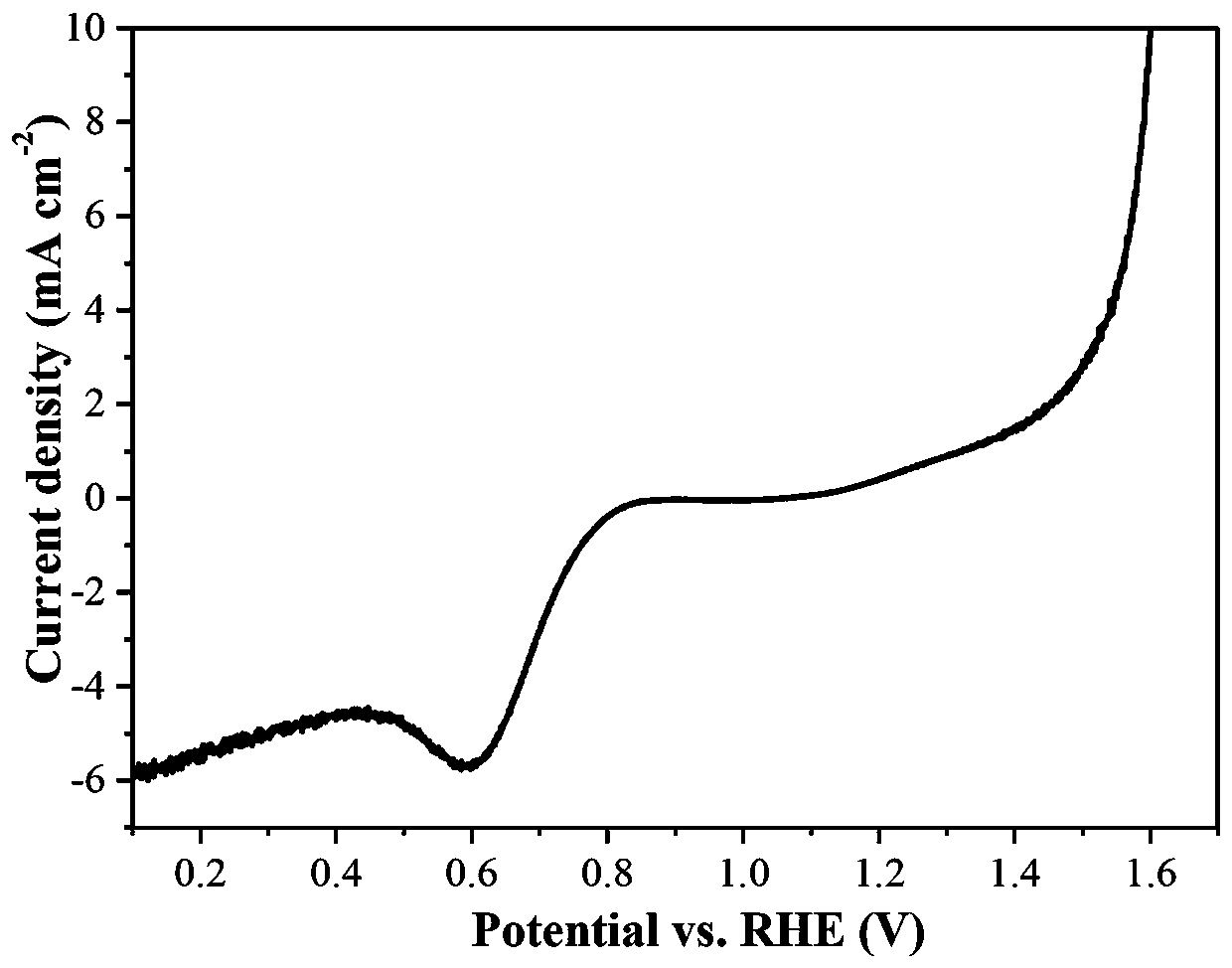

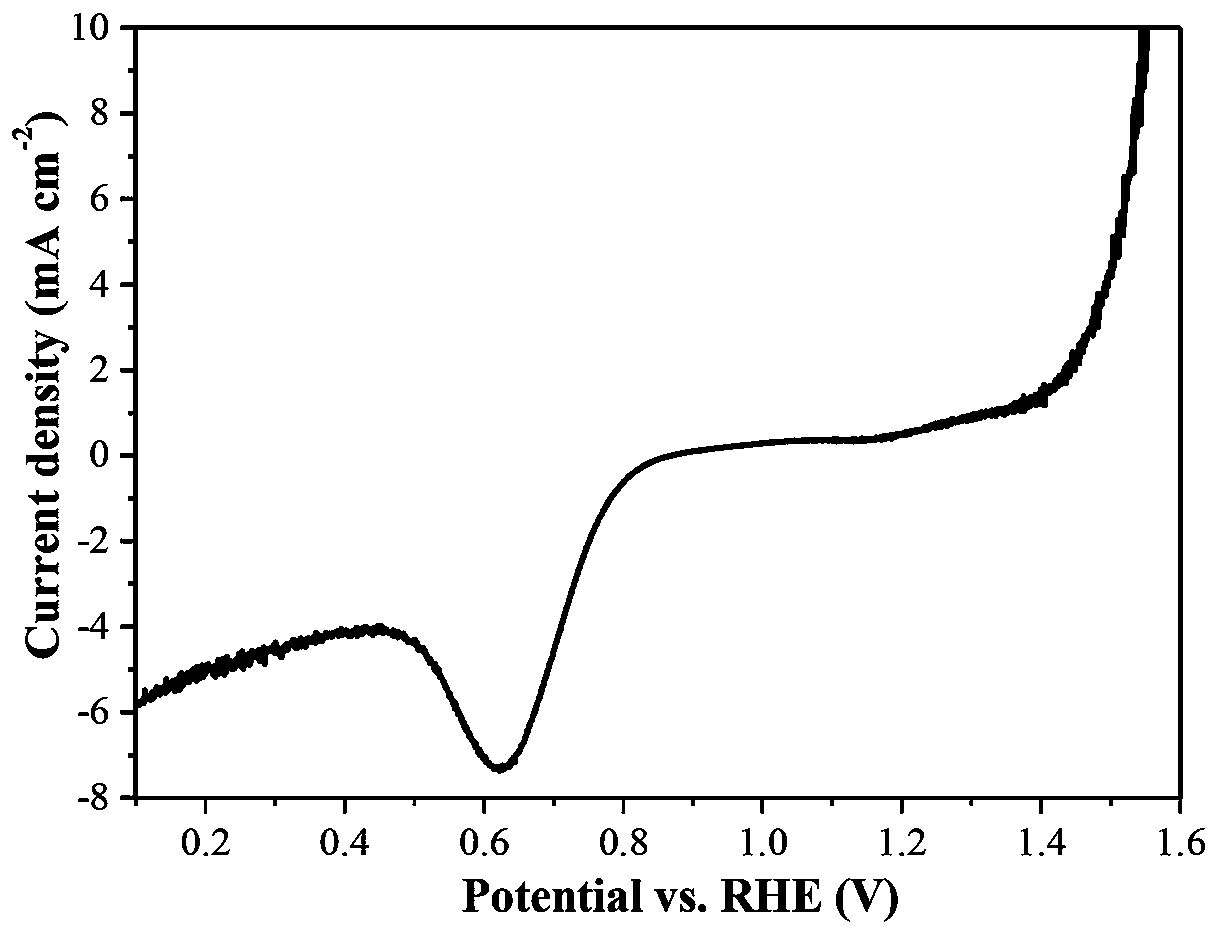

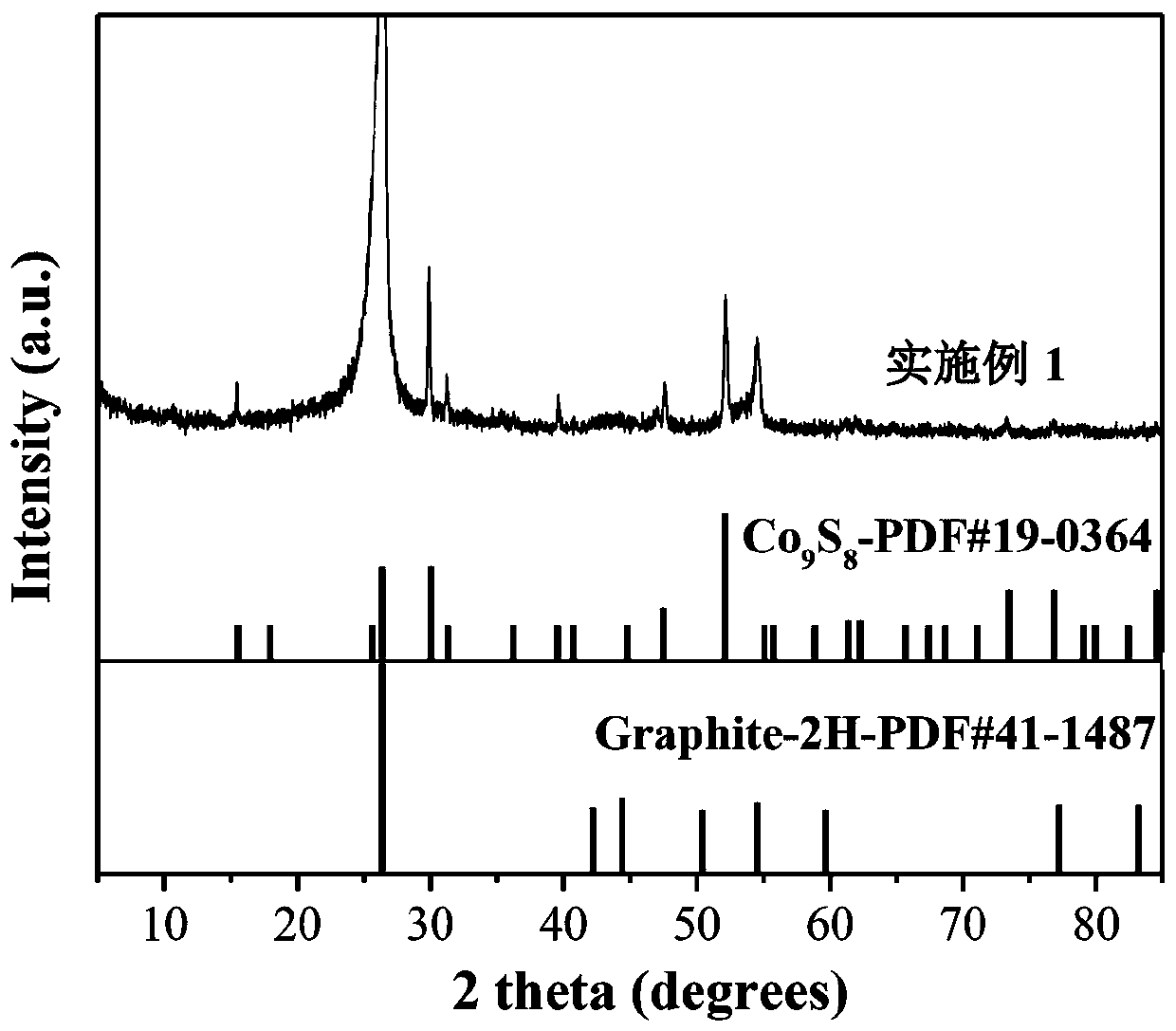

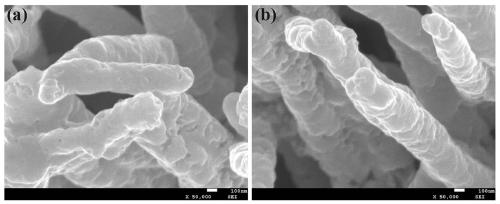

Preparation method of cobalt sulfide and nitrogen-doped carbon composite array electrode

ActiveCN109797405AHigh degree of polymerizationImprove conductivityPhysical/chemical process catalystsElectrodesCarbon compositesLattice defects

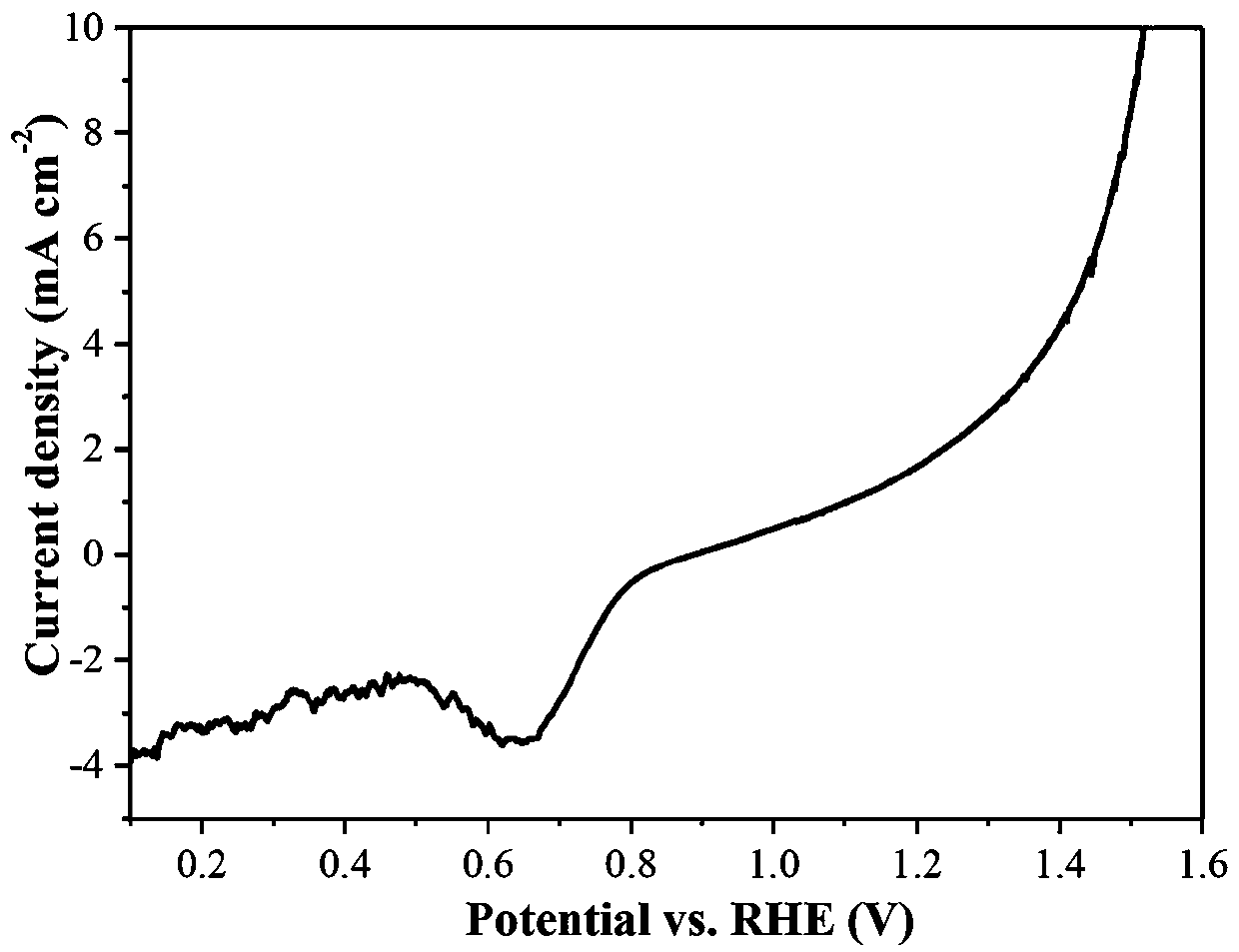

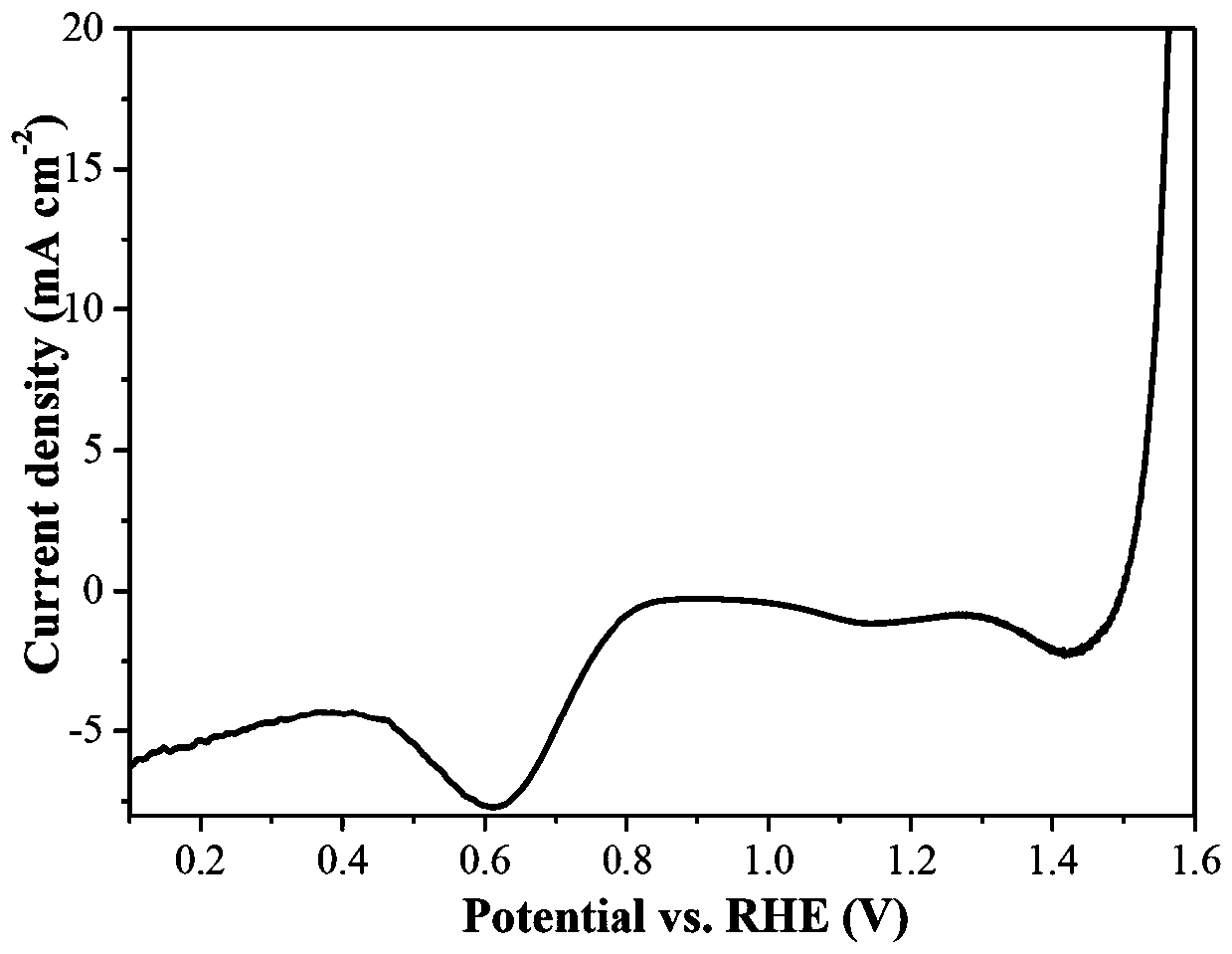

The invention provides a preparation method of a dual-function cobalt sulfide and nitrogen-doped carbon composite array electrode. A chemical bath deposition method is adopted for preparing an alkalitype cobalt needle-shaped array in-situ electrode, after annealing is performed in air, a Co3O4 array is formed, and Co3O4 is annealed under the atmosphere of sulfur gas to form a CoS2 array. Then, dopamine is used for growing poly-dopamine on the surface of the Co3O4 or CoS2 array, then, an annealing reaction is performed under the protective atmosphere, poly-dopamine is converted into a nitrogen-doped carbon material in the reaction process, Co3O4 or CoS2 is converted into Co9S8-Co4S3 under the atmosphere of sulfur or inert gas. According to the product obtained through the technical scheme,due to the fact that the product has various high-electro-catalysis active loci including nitrogen-doped active loci in the carbon material and other lattice defects caused by the loci, and the excellent electro-catalysis oxygen reduction reaction (ORR) performance is achieved; the Co9S8-Co4S3 has the good electro-catalysis oxygen evolution reaction (OER) performance; in addition, the interface formed by Co9S8-Co4S3, the carbon material and the strong interface coupling effect has the excellent electro-catalysis OER and OER performance.

Owner:CHINA THREE GORGES UNIV

Method for preparing Co9S8 and nitrogen doped carbon composite array electrode

ActiveCN109852994AImprove inner motivationLower potentialPhysical/chemical process catalystsElectrodesCarbon compositesHeterojunction

The invention provides a method for preparing a bifunctional Co9S8 and nitrogen doped carbon composite array electrode. The method comprises the steps of preparing an alkali type cobalt salt needle-shaped array in-situ electrode by a chemical bath deposition method, then, growing polydopamine on the surface of an alkali type cobalt salt array by using dopamine, then, adding thiourea in a protective atmosphere, and carrying out a vulcanization reaction by a CVD method, wherein during the reaction, the polydopamine is converted into a nitrogen doped carbon material, and an alkali type cobalt salt is converted into Co9S8 in a thiourea atmosphere. The product obtained by the method provided by the invention has a variety of high-electrocatalytic-activity loci, including nitrogen doped active sites in the carbon material and other crystal lattice defects resulting from the nitrogen doped active sites, thereby having excellent electrocatalytic oxygen reduction reaction (ORR) performance; theCo9S8 has a relatively good electrocatalytic oxygen evolution reaction (OER) performance; and furthermore, a heterojunction formed by the Co9S8 and the carbon material also has excellent electrocatalytic OER and OER performance.

Owner:CHINA THREE GORGES UNIV

Fenton-like oxidation catalyst and application thereof

InactiveCN108654678AReduced Diffusion ResistanceHigh removal rateMolecular sieve catalystsWater treatment compoundsChemical oxygen demandReaction rate

The invention provides a Fenton-like oxidation catalyst and application thereof. A preparation process of the Fenton-like oxidation catalyst comprises the following steps of modifying a microporous ZSM-5 molecular sieve by alkaline so as to prepare a porous ZSM-5 molecular sieve; loading Fe (iron) onto the porous ZSM-5 molecular sieve, so as to obtain the Fenton-like oxidation catalyst. The Fenton-like oxidation catalyst is used for treating the organic amine wastewater, the maximum removal rate of COD (chemical oxygen demand) in water can reach 97%, and the removal rate of ammonia nitrogen can reach 90%. Compared with the conventional organic amine wastewater treatment technique, the Fenton-like oxidation catalyst has the advantages that (1) by performing alkaline modifying, a mesoporousstructure is introduced into the microporous structure of the ZSM-5 molecular sieve, so as to solve the problems of difficulty in molecule diffusion, low catalytic degrading rate of macromolecules andthe like, and accelerate the catalytic reaction rate; (2) the cost is low, the catalyzing activity is high, and the stability is good; (3) the better COD and ammonia-nitrogen removal effect can be realized at the normal pressure and the temperature lower than 100 DEG C, the reaction system is mild, and the treatment effect is good.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Honeycomb ceramic pulse protective agent

InactiveCN102500423AHigh compressive strengthGood acid and alkali resistanceCatalyst protectionPtru catalystKaolinite

The invention discloses a honeycomb ceramic pulse protective agent, which comprises the following components in percentage: 50-60 % of alumina trioxide powder, 30-40 % of silicon oxide powder, 3-6 % of magnesium oxide and 3-5% of kaolinite. The honeycomb ceramic pulse protective agent is internally provided with special net shaped honeycomb holes (2), and is provided with a bent or curved throughhole (1), because a reactant can generate a pulse phenomenon on the interface between a protective agent and a catalyst, and the pulse action can quicken the continuous flowing of oil in the catalyst, the catalytic reaction speed is improved, the catalyst can be ensure not to produce carbon sedimentation and coking too early, further, the service life of the catalyst is prolonged, the pressure drop of a reactor is reduced, the production operating cycle of a fixed bed reactor is improved, the production work efficiency is improved, the oil refining processing cost is reduced, and the economicbenefits of enterprises are increased.

Owner:PINGXIANG ANFA COKING ENVIRONMENT PROTECTION FILLING

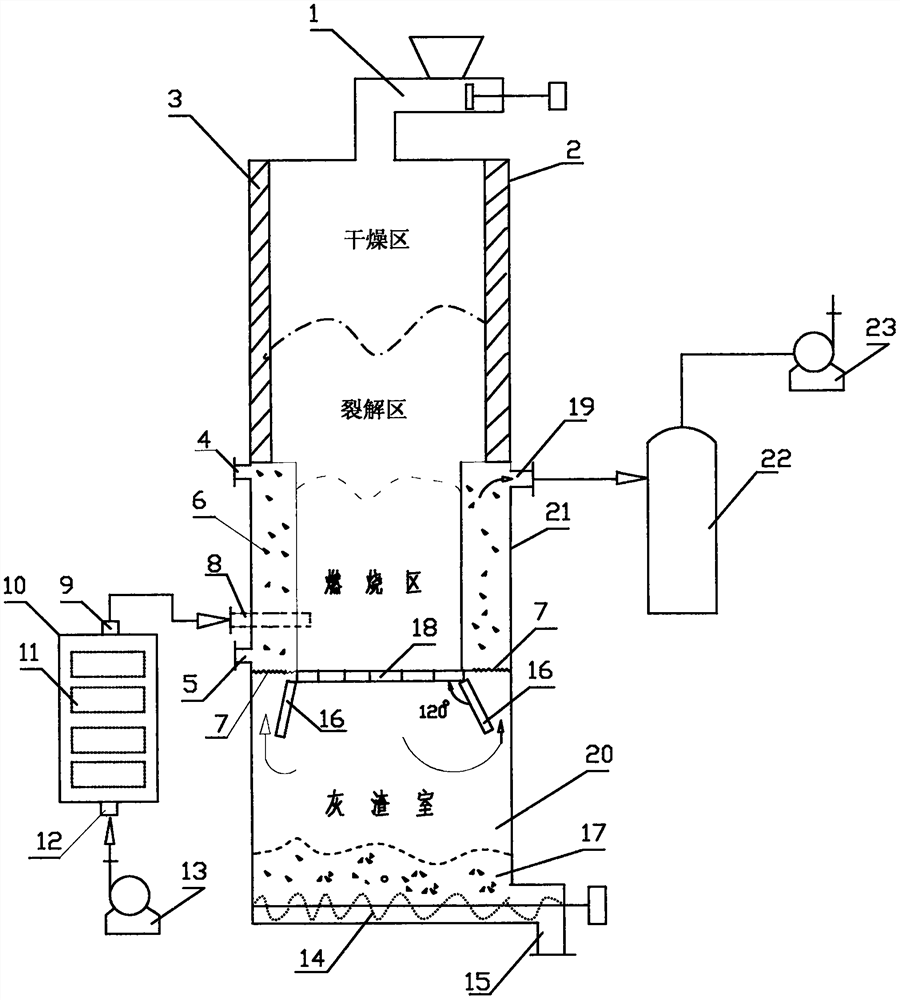

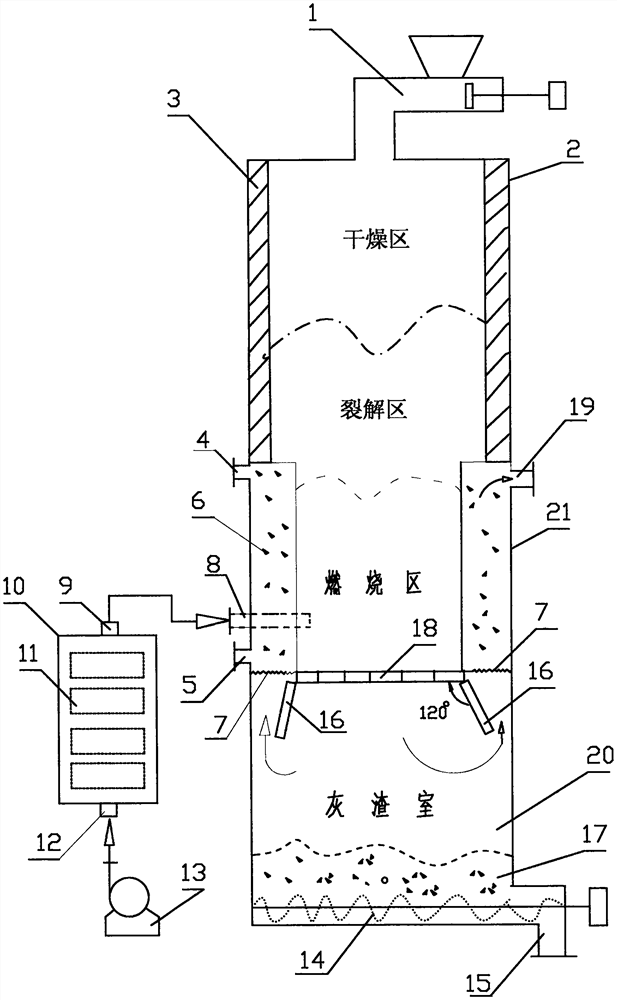

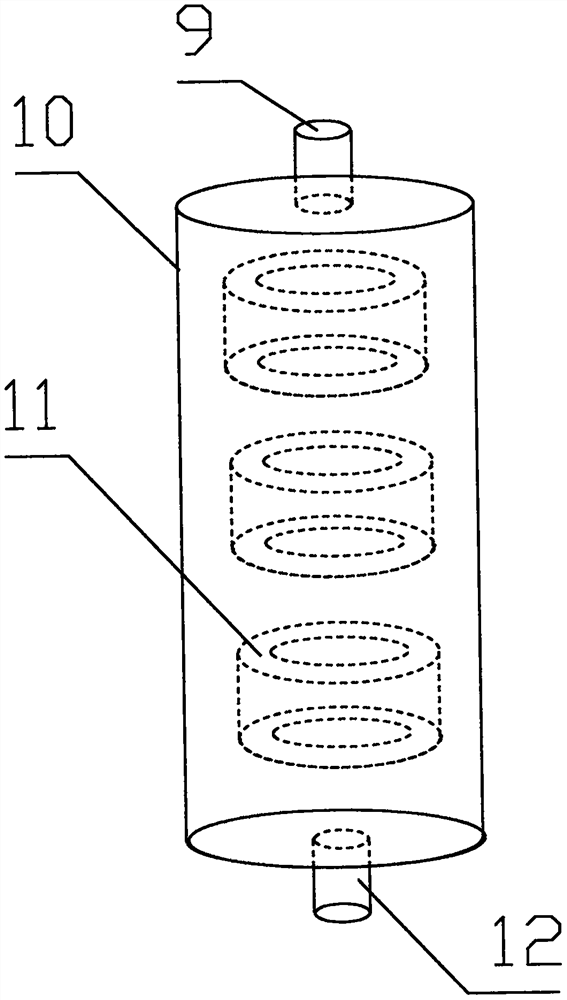

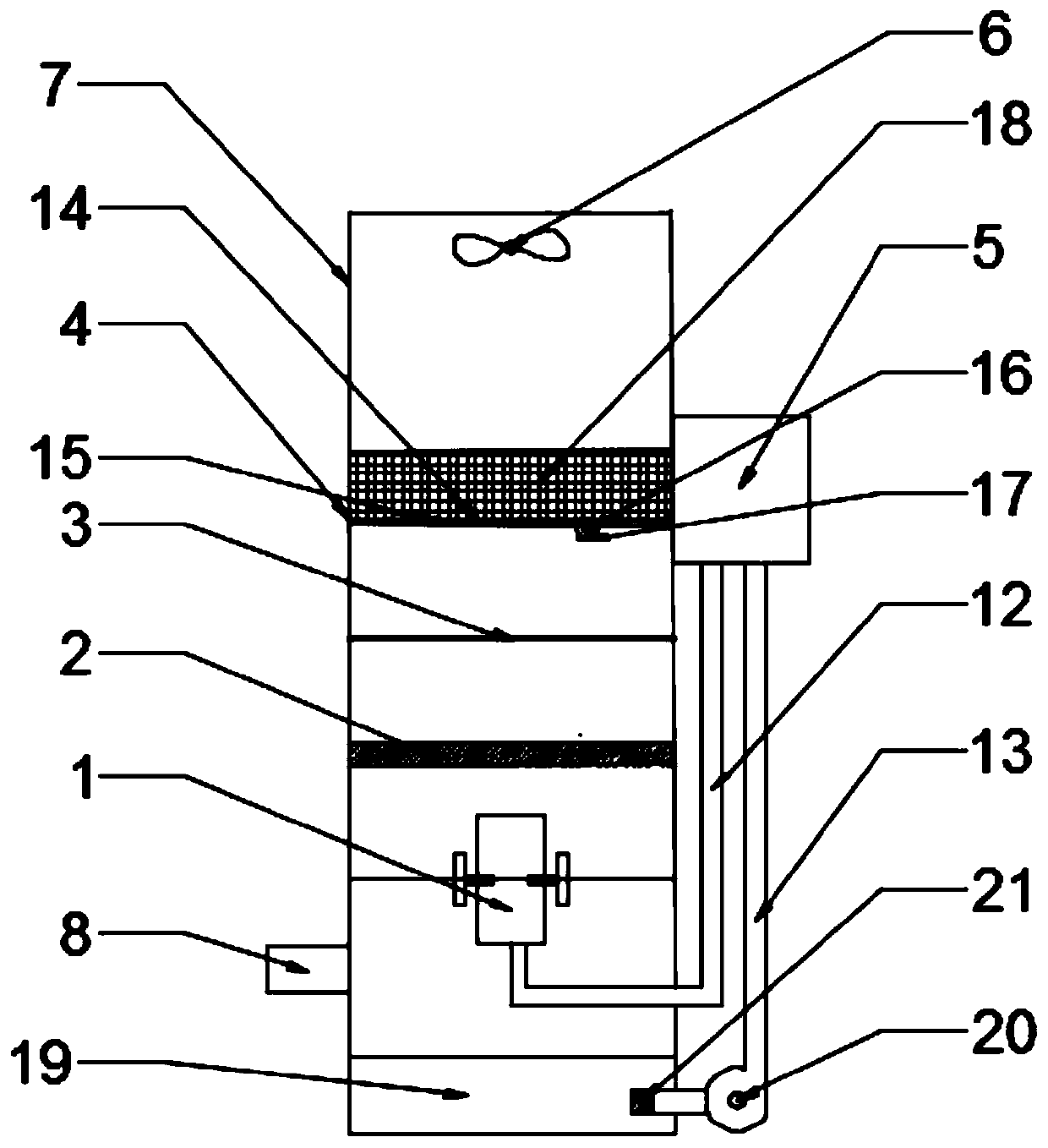

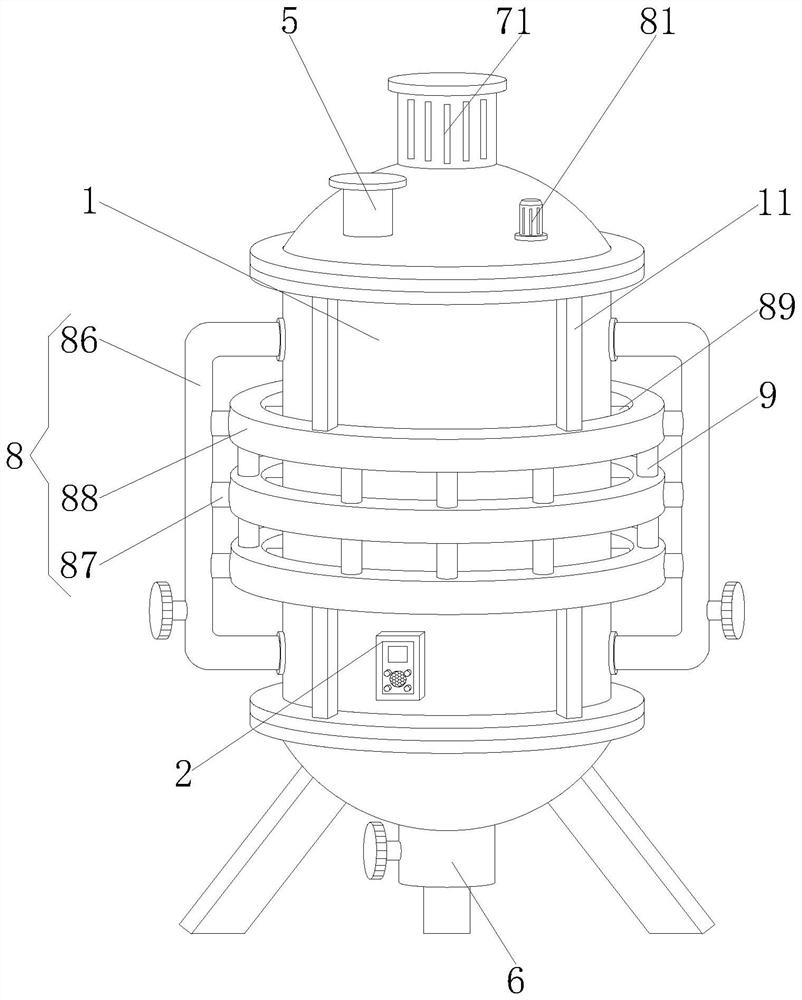

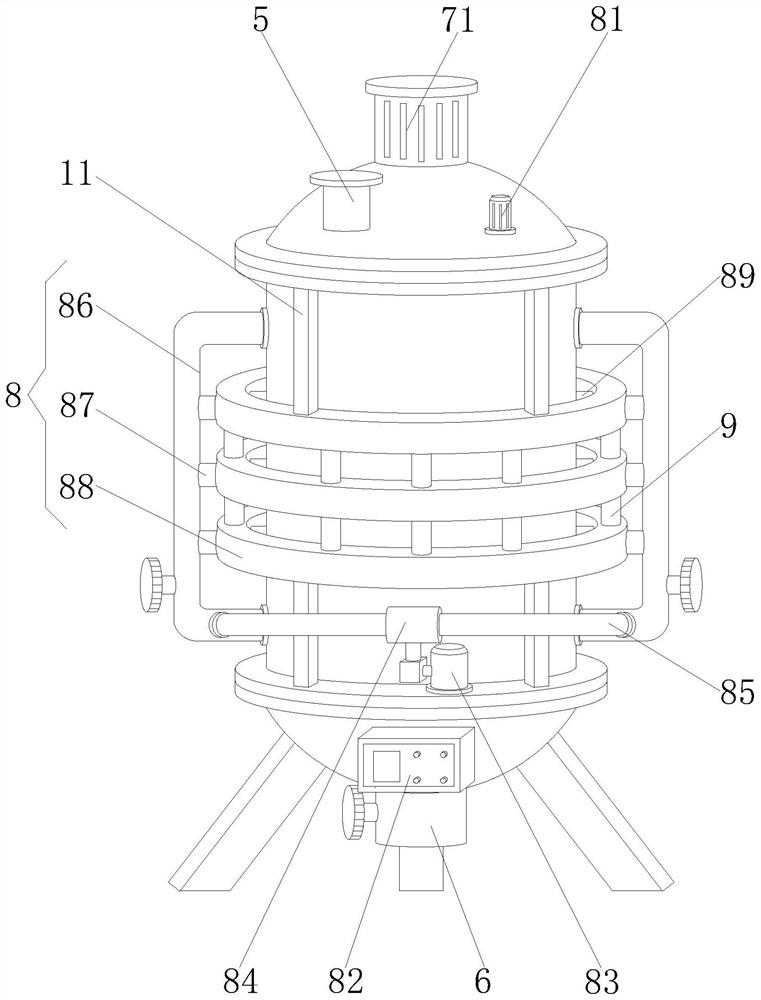

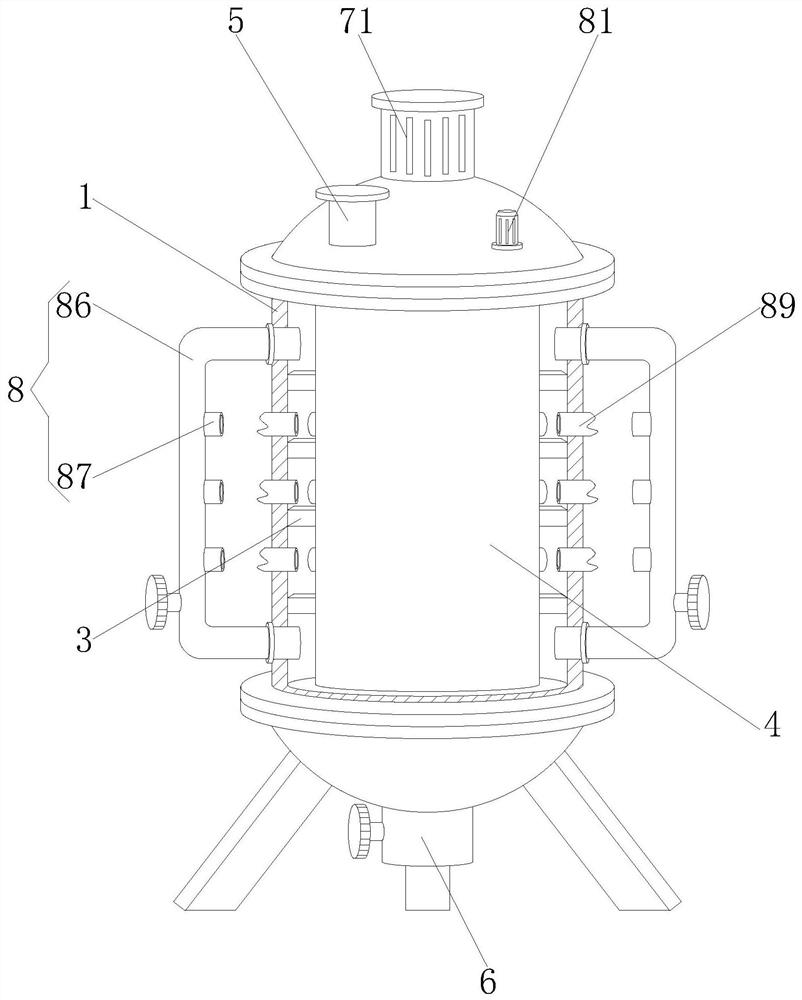

Method and equipment for low-temperature magnetization treatment of garbage

InactiveCN112500872AEliminate overpressure safety incidentsPurification qualityCatalytic crackingDispersed particle separationThermal decomposition methodFixed bed

The invention relates to a thermal decomposition method and equipment for organic garbage, in particular to a method and equipment for low-temperature magnetization treatment of garbage. Firstly, low-temperature magnetized pyrolysis treatment is conducted on garbage raw materials, ash generated by pyrolysis is discharged out of a pyrolyzing furnace by using a discharging machine, and gas generatedby pyrolysis is introduced into a fixed bed for catalytic reaction, hydrocarbons, nitric oxides and carbon monoxide carried in a gas product are converted into harmless water, carbon dioxide and nitrogen, the purified gas is conveyed into gas collection and treatment equipment to be condensed, collected and subjected to tail gas purification treatment to become standard gas, and the standard gasis exhausted into the atmosphere through an induced draft fan. The invention discloses equipment for implementing the method.

Owner:周鼎力

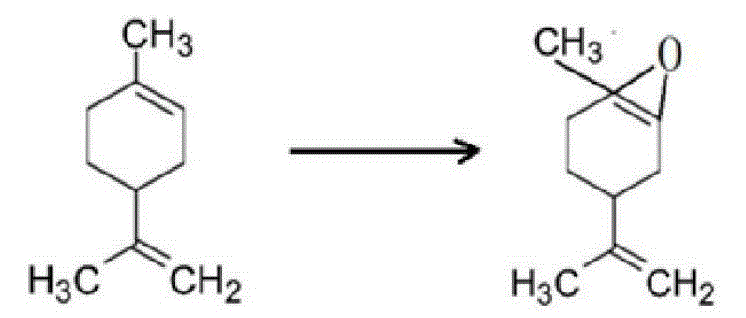

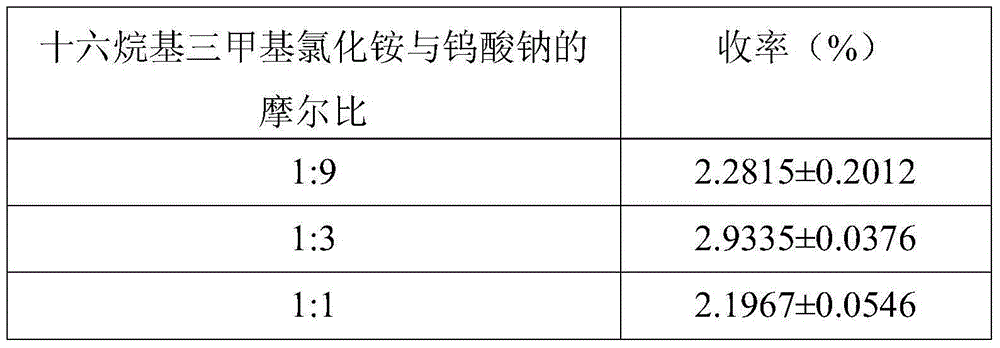

Catalytic synthesis method for limonene-1,2-epoxide

InactiveCN105017179AOvercome the problems of poor selectivity and difficulty in catalytic reactionHigh yieldOrganic chemistryHeteropoly acidSynthesis methods

The present invention discloses a catalytic synthesis method for limonene-1,2-epoxide. The catalytic synthesis method takes boron tungsten heteropoly acid salt as a catalyst, and takes inorganic salt as an additive. With no solvent being present, the limonene reacts with aqueous hydrogen peroxide with the mass concentration of 30% at 40 DEG C for 6-30 h, then the organic layer is centrifugal separated, and separation and purification are performed by using high speed countercurrent chromatography, so as to generate limonene-1,2-epoxide. According to the catalytic synthesis method for limonene-1,2-epoxide, the preparation process of catalyst-boron tungsten heteropoly acid salt and the catalytic process of limonene are optimized, so that the problems such as poor selectivity of limonene catalytic reaction and great difficulty in reaction are overcome, and the yield and purity of synthesis of limonene-1,2-epoxide are effectively improved. The yield can reach greater than 7%, and the purity can reach greater than 91%.

Owner:HUAZHONG AGRI UNIV

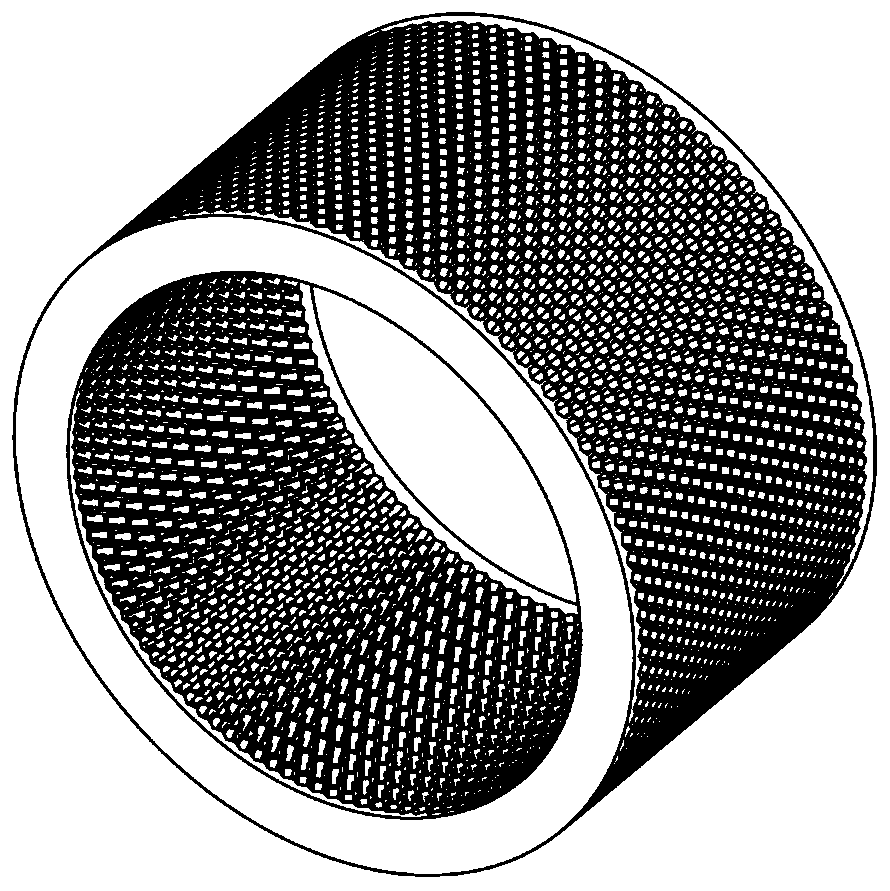

Ceramic silk-screen hydrogenation protective agent

InactiveCN104841491ALow densityHigh compressive strengthCatalyst protectionPorosityHydrodesulfurization

The invention discloses a ceramic silk-screen hydrogenation protective agent which is obtained by the following steps: forming powder materials formed by raw materials of 20-30 wt% of pseudo-boehmite, 40-55 wt% of alumina powders, 10-20 wt% of silicon carbide powders, 2-5 wt% of rare earth magnesium alloy powders, 2-5 wt% of zirconia powders and 3-5 wt% of kaolin; adding an auxiliary agent and appropriate amount of water in the powder materials, carrying out ball-milling and mixing and carrying out blending until viscosity is 22-30s according to a T-4 viscosity cup, and then, carrying out filtering to obtain slurry; dipping a sponge base into the slurry above, standing still, and then taking the sponge base out and removing the surplus slurry to obtain a green body; and after carrying out drying and shaping on the green body, putting the green body into a calcinator, carrying out heating until the temperature reaches 1100-1280 DEG C, and then, carrying out heat preservation baking to obtain the product. The ceramic silk-screen hydrogenation protective agent is light in specific gravity, high in porosity and small in stacking density; impurity tolerance capability of the ceramic silk-screen hydrogenation protective agent is improved by 30% and the above compared with that of a honeycomb pore ceramic protective agent, and is improved by 50% and the above compared with that of a conventional porcelain ball (porcelain ring); and since the protective agent has multiple holes, circulation velocity of liquid is accelerated, activity is enhanced, catalytic reaction speed is improved, and the hydrodesulfurization processing effect is improved.

Owner:PINGXIANG ANFA COKING ENVIRONMENT PROTECTION FILLING

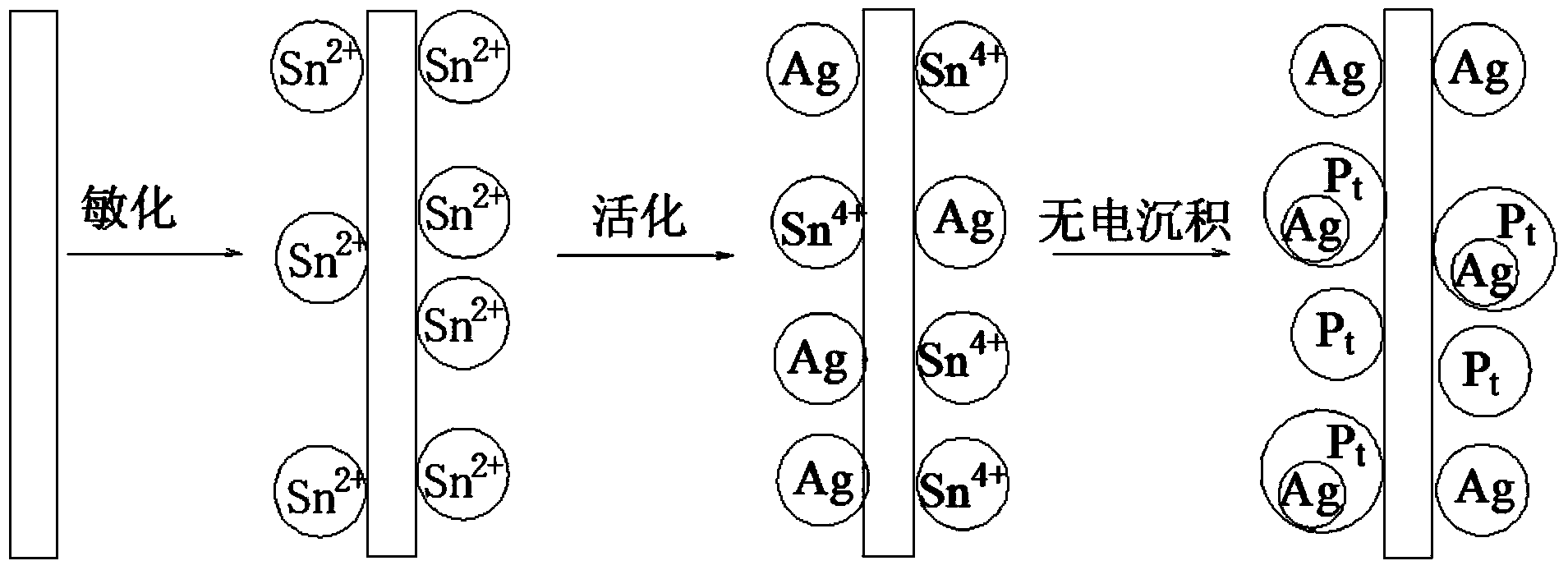

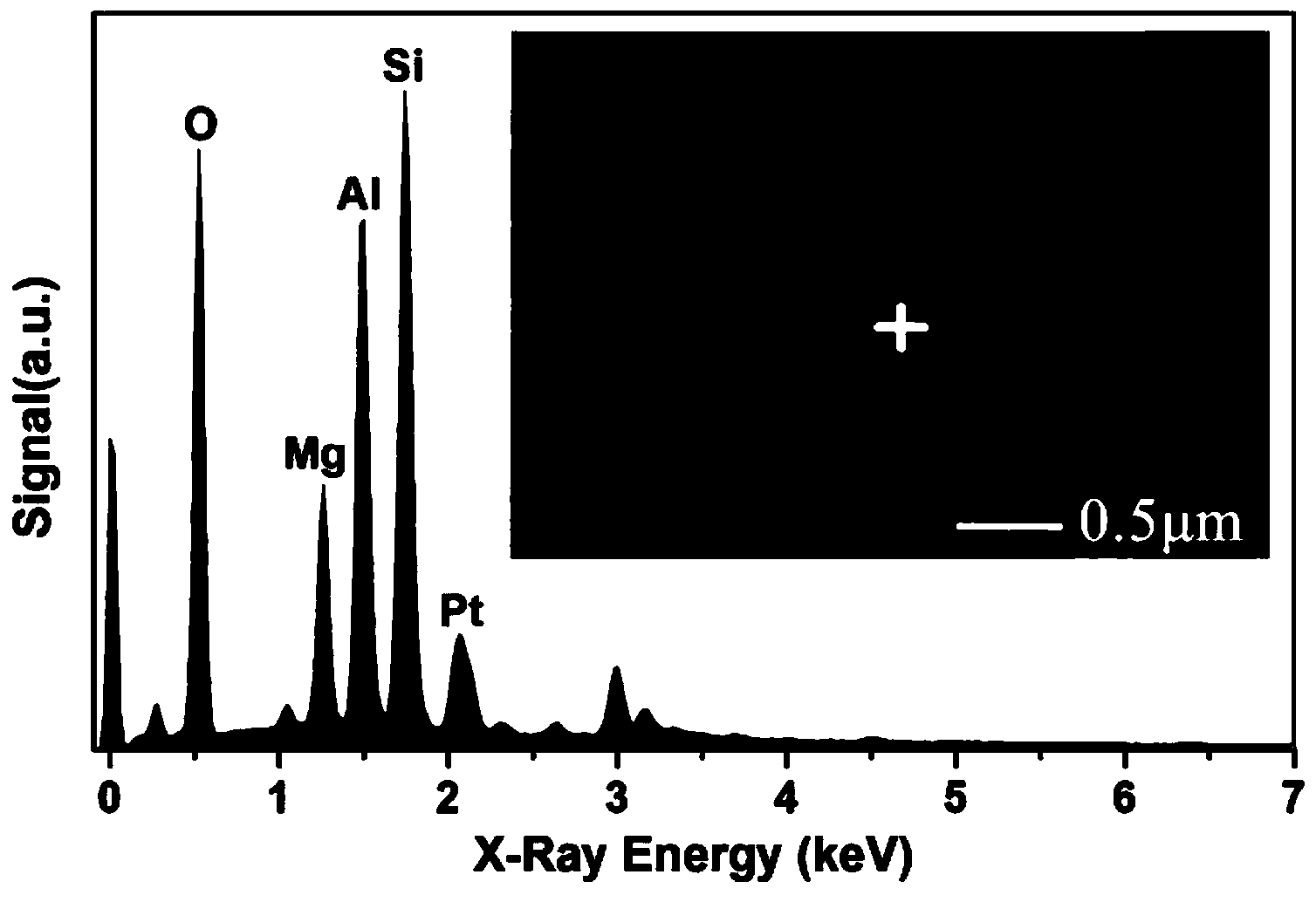

Method for coating motor vehicle exhaust cleaning catalyst

ActiveCN103977842AReduce dosageAvoid uneven loadCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsEngineeringElectroless deposition

The invention provides a method for coating a motor vehicle exhaust cleaning catalyst. The method comprises the following steps: (1) pretreating a carrier; (2) sensitizing the carrier; (3) activating the carrier; and (4) carrying out electroless-deposition. The method for coating the motor vehicle exhaust cleaning catalyst overcomes technical bottlenecks of a traditional impregnation method, a precipitation method, a vacuum coating method and the like, enables the uniform load of precious metal catalysts in wall-flow-type honeycomb ceramic carrier micropores as well as on straight-through-type honeycomb ceramic carrier coatings to be realized successfully; moreover, the precious metal catalysts prepared by the invention have the particle size of 50-100nm, have performances of nano particles, have large specific surface areas, improve the catalytic reaction speed and reaction activities greatly compared with those of great-size catalysts under the same condition; additionally, precious metal salt is used for the method, and is low in price, so that the using quantity of precious metal can be reduced greatly; techniques of high-temperature forging and the like are not required; the method is simple to operate, can be realized, and is wide in carrier application range.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

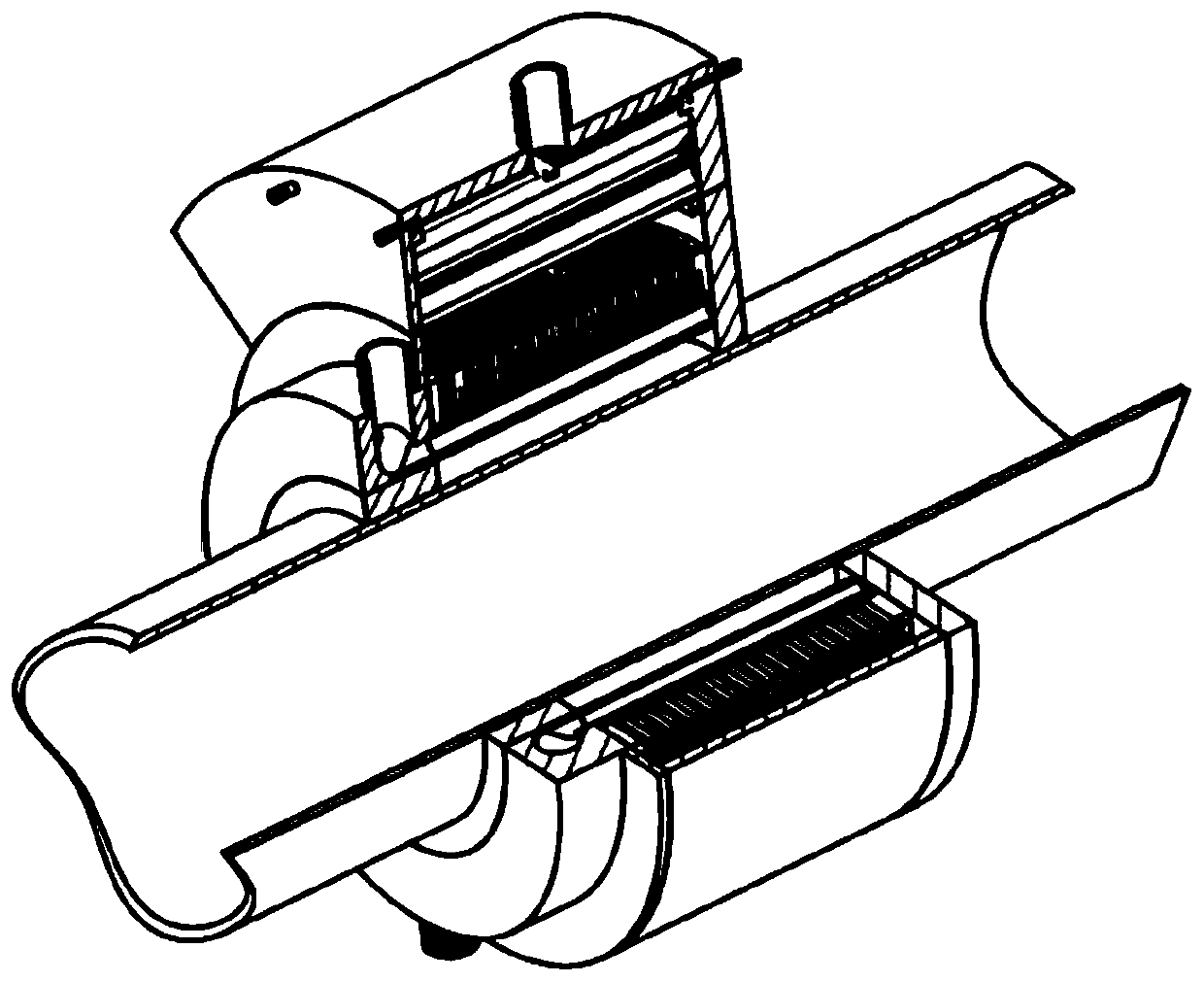

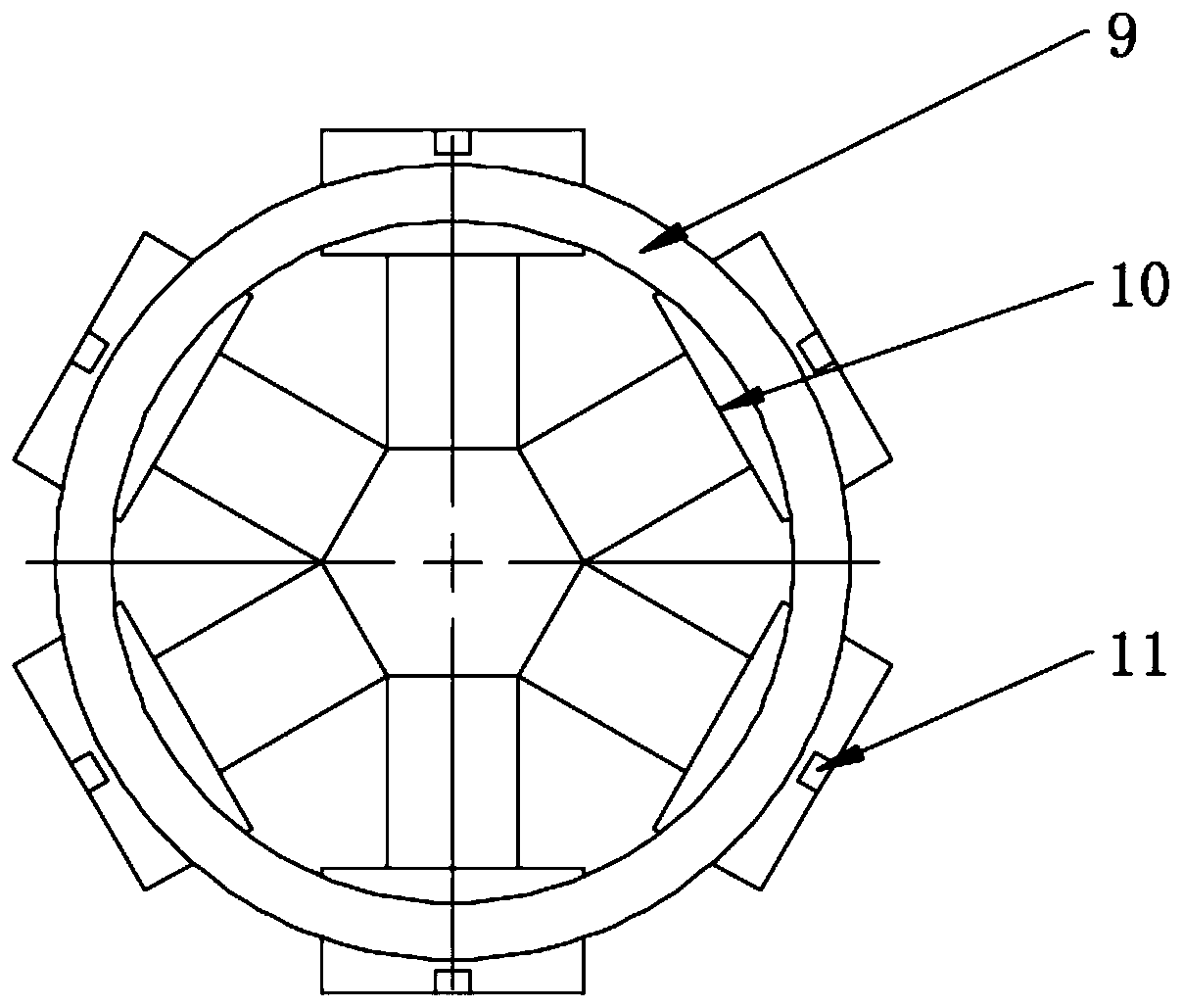

Efficient self-adaptation catalytic cracking device suitable for regenerative cooling detonation combustion chamber

InactiveCN110319457AImprove cooling efficiencyHigh stability detonationExplosive combustion chamberDetonationCombustion chamber

The invention provides an efficient self-adaptation catalytic cracking device suitable for a regenerative cooling detonation combustion chamber. On the basis of the regeneration cooling scheme, the device comprises a bottom-layer heat exchange layer, a middle-layer catalytic cracking layer, a top-layer gas-liquid separation layer and a device fixing structure. By utilization of a radial fuel jetting port and an expansion outlet channel evenly distributed in the circumferential direction of the heat exchange layer in an interphase manner are utilized for achieving uniform heating and flowing speed reduction of fuel, and accordingly, a large amount of micromolecule gas-state fuel is generated in a middle-layer honeycomb-shaped catalytic cracking layer coated with an efficient catalyst, wherein the micromolecule gas-state fuel is excellent in detonation performance and narrow in component kind range. Through an adaptively-adjusted N-shaped baffle plate structure in the gas-liquid separation layer, fuel oil liquid drops unfavorable to detonation and combustion in products can be effectively separated and split. The device can achieve efficient fuel splitting, mixed gas-state fuel withhigh explosion performance is continuously obtained; and in addition, the device can sufficiently utilize physical and chemical heat sink of the fuel, and the cooling efficiency of the detonation combustion chamber is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method for catalyst based on waste steel slag

ActiveCN106111138AFast catalytic reactionHigh degradation rate of CODMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationSlagReaction speed

The invention discloses a preparation method for a catalyst based on waste steel slag, wherein the preparation method comprises the following steps: 1) raw material grinding and crushing; 2) raw material mixing; 3) blank molding; 4) blank drying: drying the blank prepared in the step 3) at the temperature of 200-220 DEG C to make the water weight percentage content be less than 0.8%; and 5) blank sintering: sintering the blank dried in the step 4) at the temperature of 900-1150 DEG C, to obtain the catalyst based on the waste steel slag. The catalyst has the advantages of fast catalytic reaction speed on ozone, high COD degradation rate, less ozone consumption rate, no secondary pollution when in use, and high specific surface area.

Owner:格丰环保科技有限公司

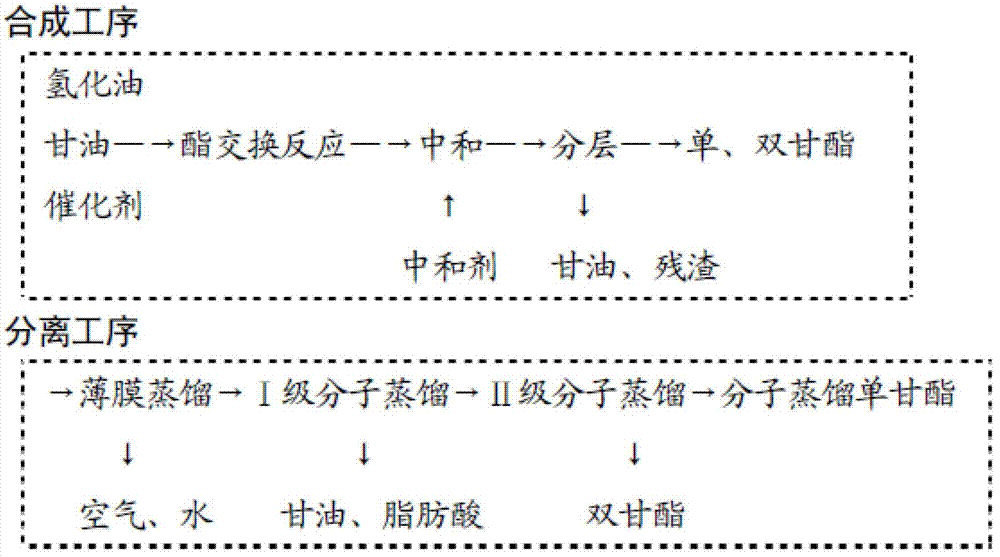

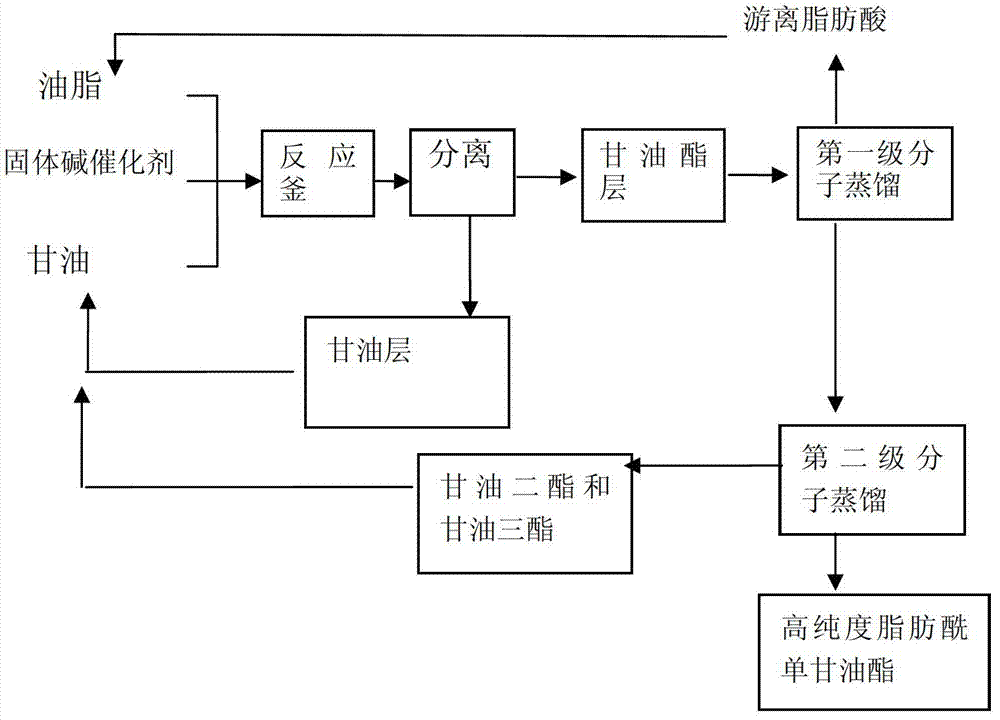

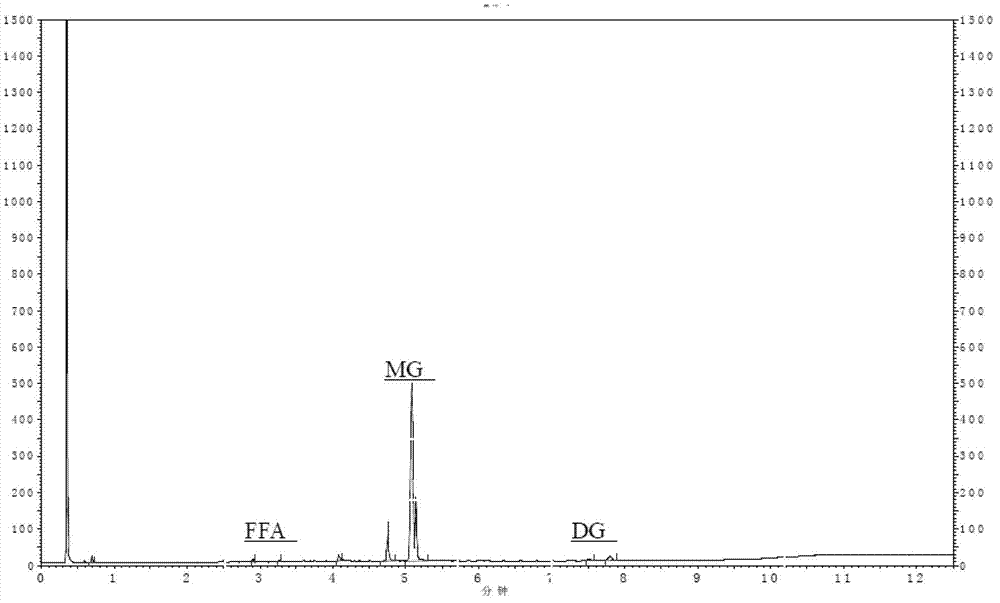

Method for synthesizing and purifying high-purity fatty acyl monoglyceride

ActiveCN102864023AEliminates the need for wipe-off film degassingReduce processFatty acid esterificationMonoglycerideDistillation

The invention discloses a method for synthesizing and purifying high-purity fatty acyl monoglyceride. The method comprises the following steps: mixing fat, glycerol and solid base catalyst, vacuumizing, stirring and heating to obtain a fat mixture; under vacuum conditions, connecting a condensation return pipe to carry out ester exchange reaction; filtering the reaction product, and standing or carrying out centrifugal stratification, wherein the supernatant is a glyceride layer, and the understratum is a glycerol layer; carrying out primary molecular distillation on the glyceride layer to remove free fatty acid and glycerol; and carrying out secondary molecular distillation on the glyceride layer without the free fatty acid and glycerol to obtain a distillate and distillation residues, wherein the distillate is the high-purity fatty acyl monoglyceride, and the distillation residues are diglyceride and triglyceride. The invention shortens the procedure, and saves the equipment investment; compared with the solid acid catalysis technology, the invention uses fat as the raw material, and does not need fatty acid; and the invention does not need to dropwisely add glycerol, control the temperature of cooling water or the like, and thus, has the advantages of simpler reaction operation, higher solid base catalysis reaction speed and higher production efficiency.

Owner:暨科优脂(佛山)科技研发有限公司

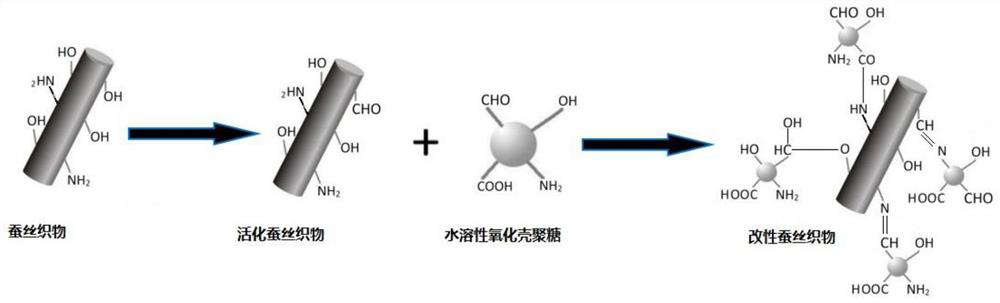

Water-soluble oxidized chitosan and method for finishing fabric by using water-soluble oxidized chitosan

ActiveCN114000350AShort and uniform reaction timeIncrease oxidation rateWrinkle resistant fibresBiochemical treatment with enzymes/microorganismsHydrogen SulfateO-Phosphoric Acid

The invention discloses water-soluble oxidized chitosan and a finishing method of the water-soluble oxidized chitosan on a fabric. The water-soluble oxidized chitosan is prepared by the following steps: dissolving chitosan in a 1-carboxymethyl-3-methylimidazolium hydrogen sulfate aqueous solution, oxidizing C2 and C3 sites of the chitosan by sodium periodate under microwave radiation to generate aldehyde groups, and then oxidizing primary hydroxyl at C6 site of the dialdehyde chitosan in an ionic liquid by concentrated nitric acid-concentrated phosphoric acid to generate carboxyl. The water-soluble oxidized chitosan can be used for modifying fabrics. Compared with a traditional chemical cross-linking agent modified fabric, the method has the advantages that the grafting efficiency of the oxidized chitosan is high, the enzyme treatment condition is mild, the reaction process is simple, the fabric is crease-resistant, antibacterial, efficient and lasting, the fabric is comfortable to wear, and the requirements of people on lasting functional ecological textiles are met.

Owner:ANHUI AGRICULTURAL UNIVERSITY

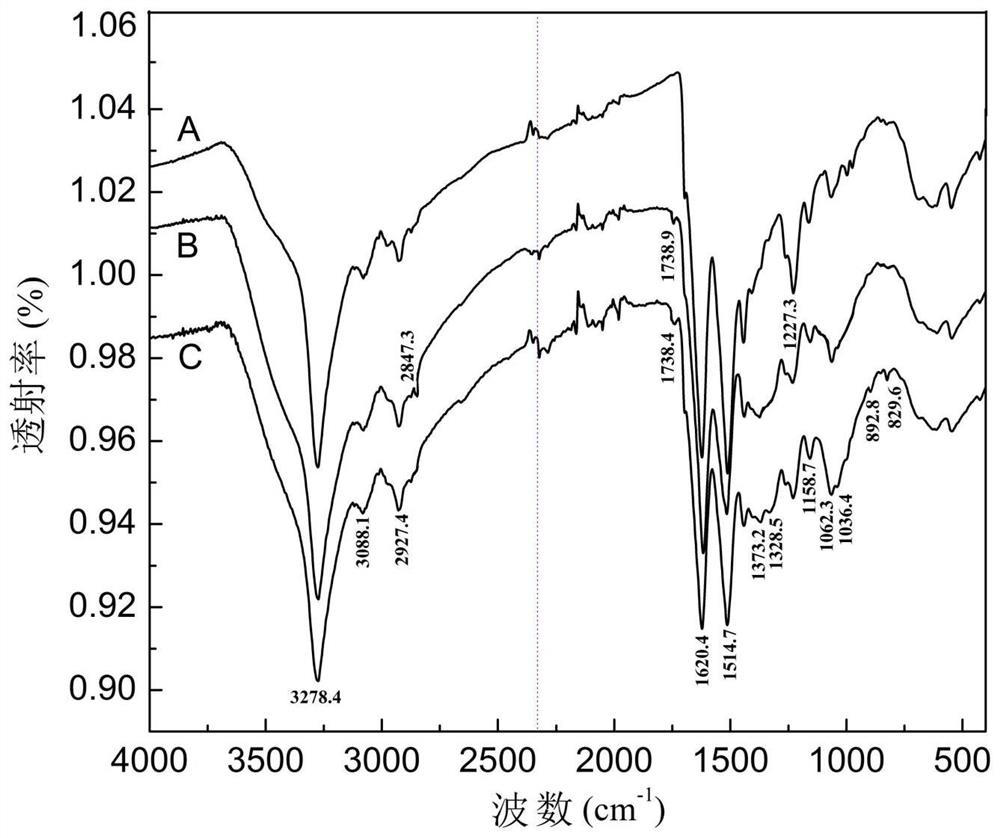

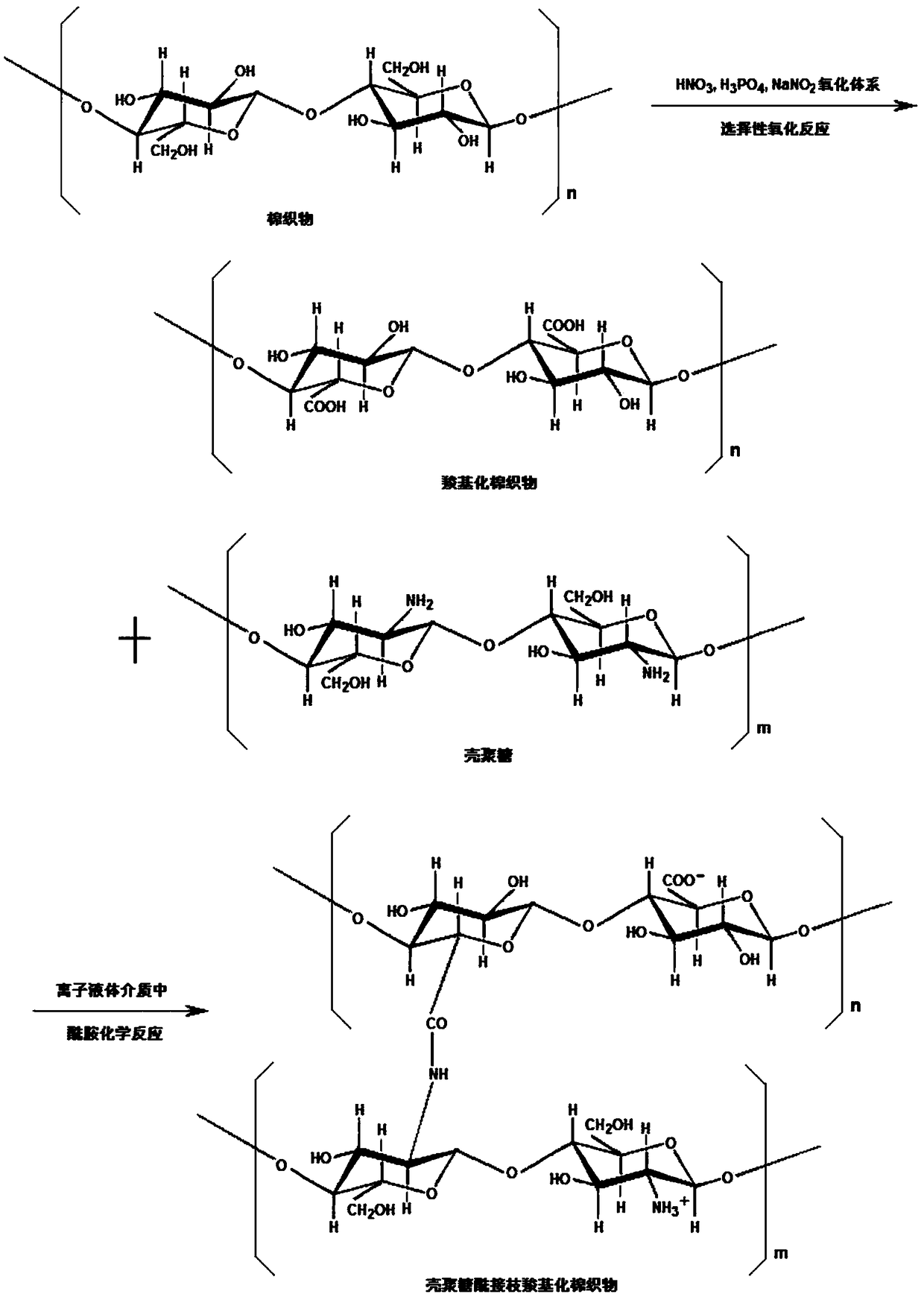

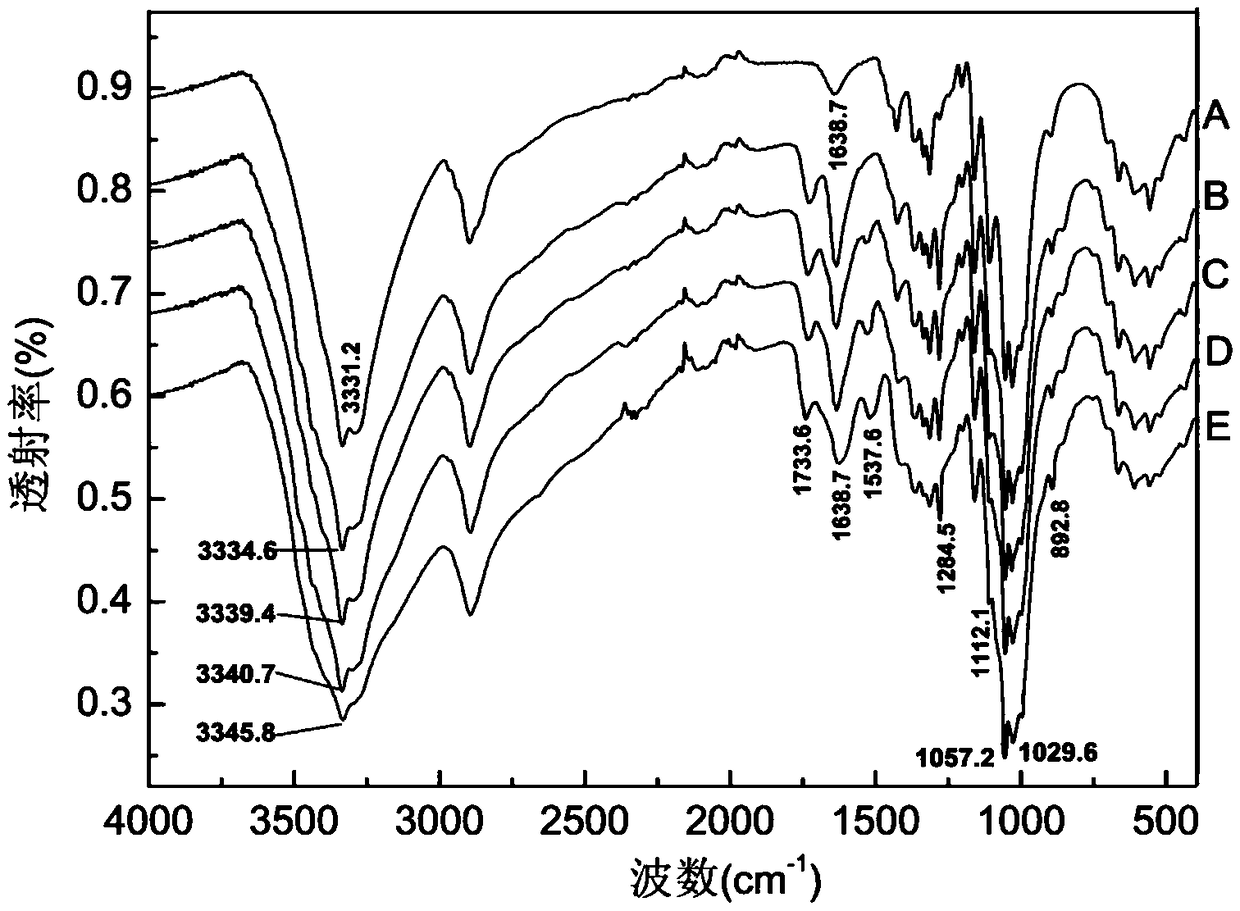

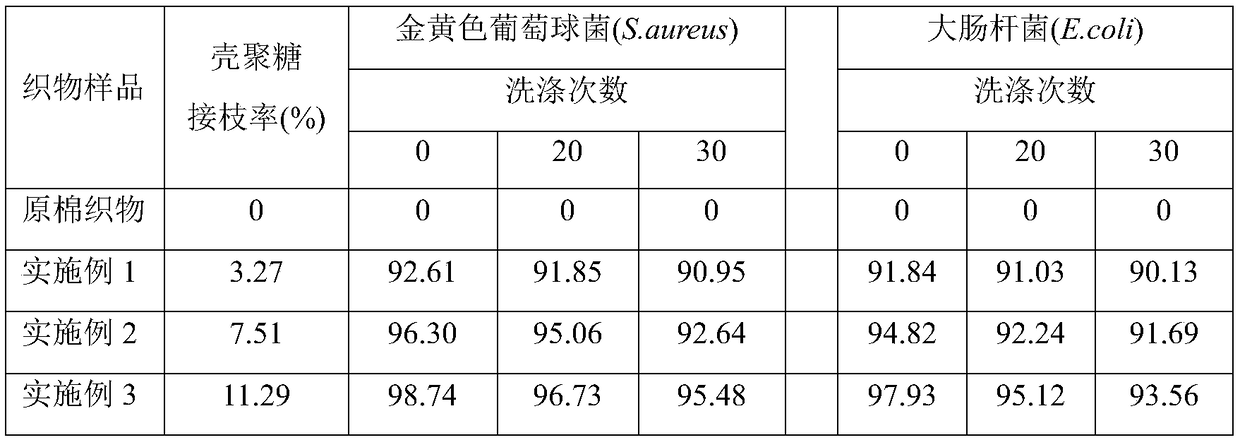

Method for preparing chitosan modified carboxylation cotton fabric in ionic liquid medium

ActiveCN109338724ALittle mechanical damageReduce hydrogen bondingBiochemical fibre treatmentWrinkle resistant fibresCross-linkChemical reaction

The invention discloses a method for preparing a chitosan modified carboxylation cotton fabric in an ionic liquid medium. The method is characterized by comprising the following steps: firstly, dissolving low-crystallization chitosan into an ionic liquid, carrying out selective oxidation on a cotton fabric after desizing and boiling in isopropanol in a concentrated nitric acid / strong phosphoric acid-sodium nitrite system, further stirring a carboxylation cotton fabric and chitosan in the ionic liquid medium at 30-40 DEG C to implement an amide chemical reaction, removing the ionic liquid, carrying out vacuum drying and water washing, thereby obtaining the chitosan modified carboxylation cotton fabric. The method disclosed by the invention is simple and feasible, rapid in amide reaction, high in grafting rate, possible in ionic liquid recycling and green and environmentally friendly, the prepared chitosan amide modified cotton fabric has a long-lasting and efficient antibacterial capability, is affiliative to human bodies, is safe and sanitary and good in wearing comfort, overcomes adverse influence caused by chemical cross-linking agents and acid solutions upon excellent propertiesof cotton fabrics and human health in conventional chitosan modification, and has wide practical application prospects.

Owner:SHAOXING MAIBAO TECH CO LTD

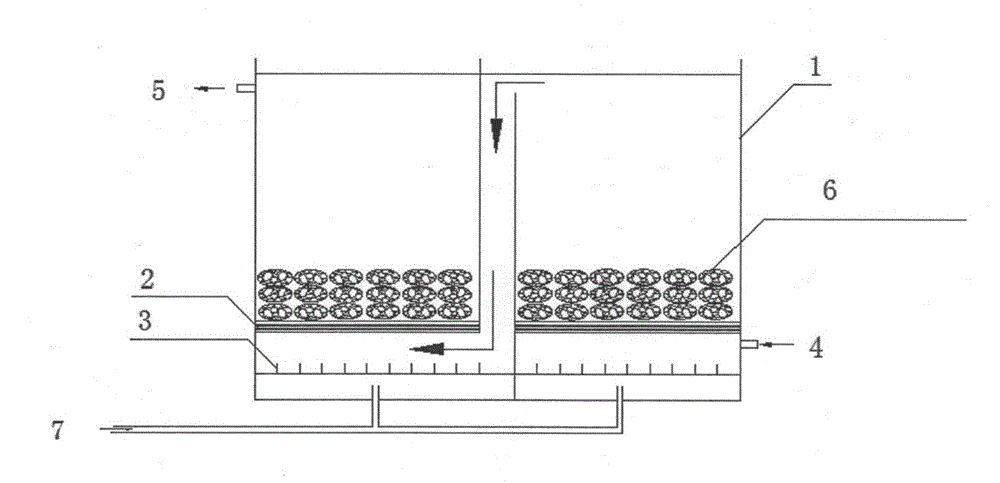

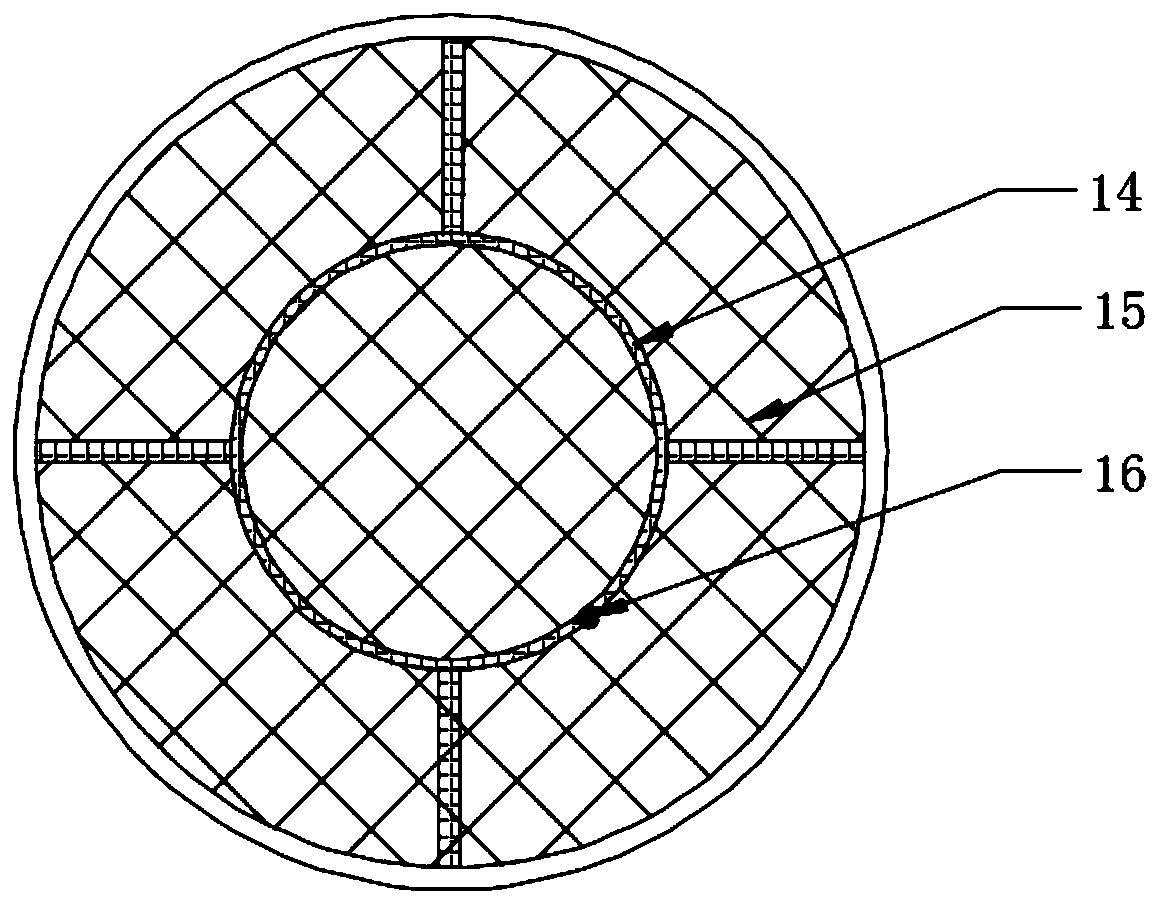

Rare-earth catalytic oxidation device and method for printing and dyeing wastewater

ActiveCN104386800AQuick responseFast catalytic reactionHeterogenous catalyst chemical elementsMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention provides a rare-earth catalytic oxidation device and a rare-earth catalytic oxidation method for printing and dyeing wastewater. The rare-earth catalytic oxidation device for printing and dyeing wastewater is characterized by comprising a reaction tank, wherein a gridded clapboard and an aeration device which is arranged below the gridded clapboard are arranged in the reaction tank; a catalytic oxidation reaction ball or a catalytic oxidation reaction bag is arranged on the gridded clapboard; a water inlet and a water outlet are formed in the side wall of the reaction tank; the water inlet is positioned between the aeration device and the gridded clapboard; and the water outlet is positioned above the catalytic oxidation reaction ball or the catalytic oxidation reaction bag. The device disclosed by the invention has high COD (Chemical Oxygen Demand) removal rate on high-concentration refractory organic wastewater.

Owner:上海浦希环境科技发展有限公司

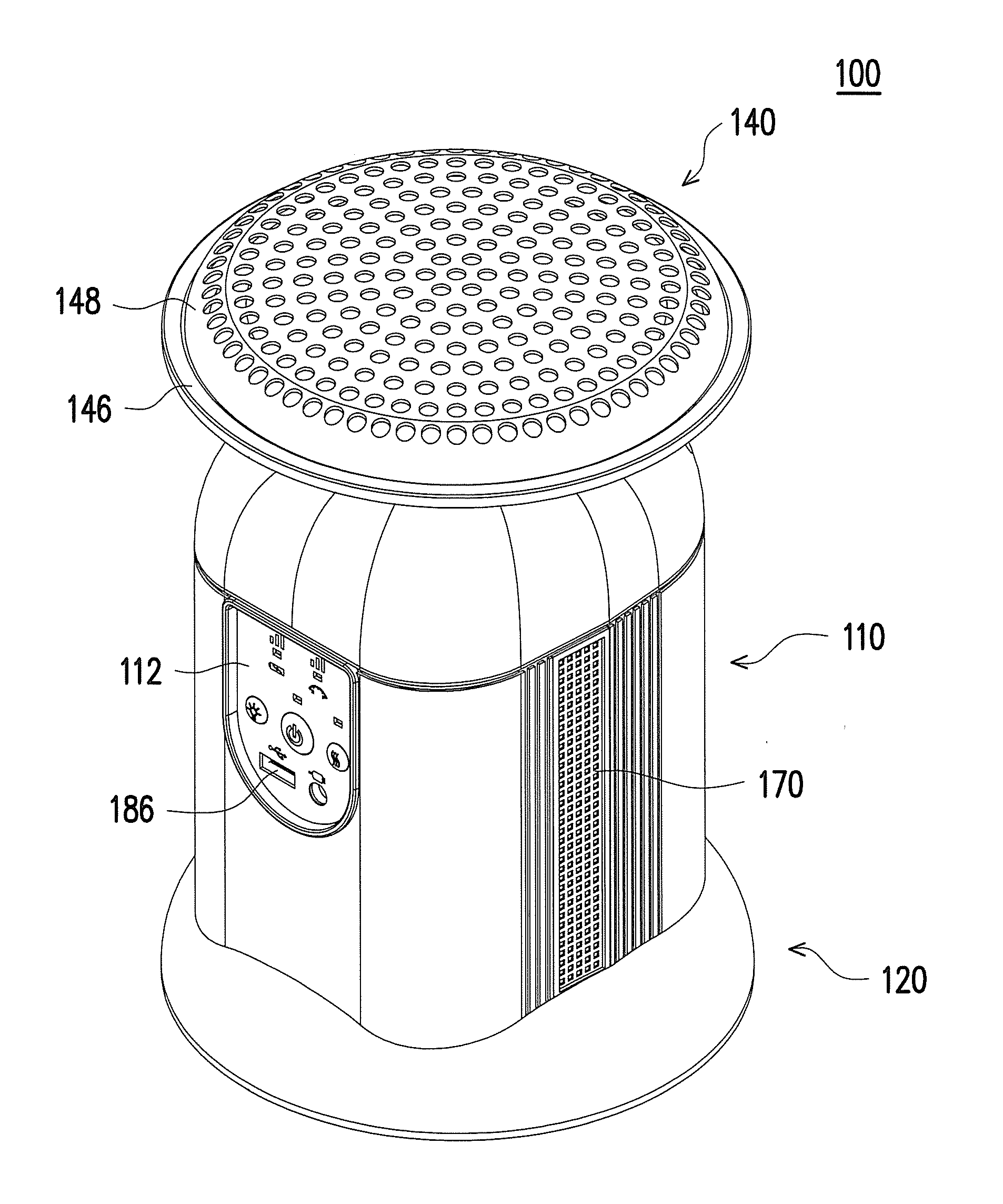

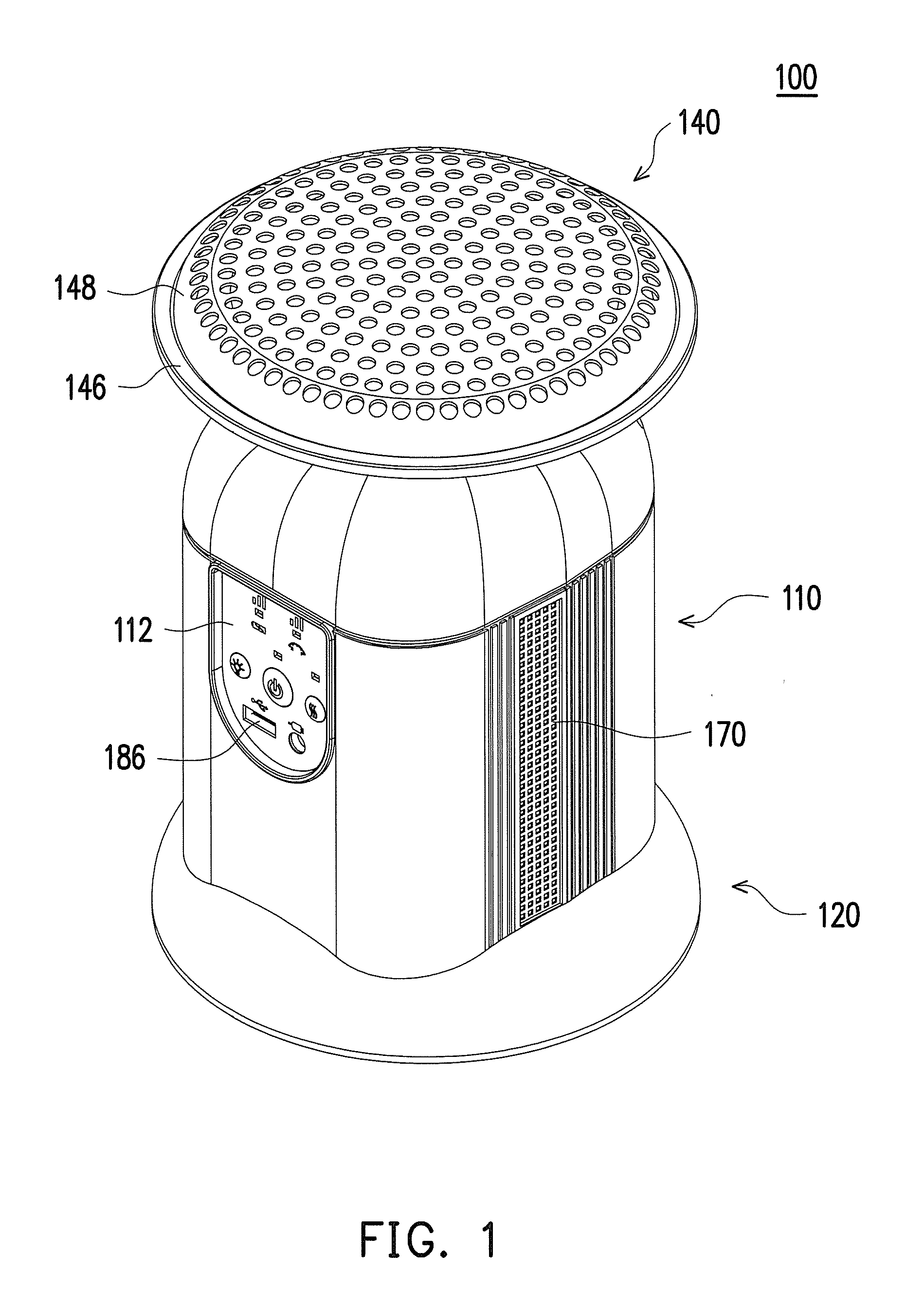

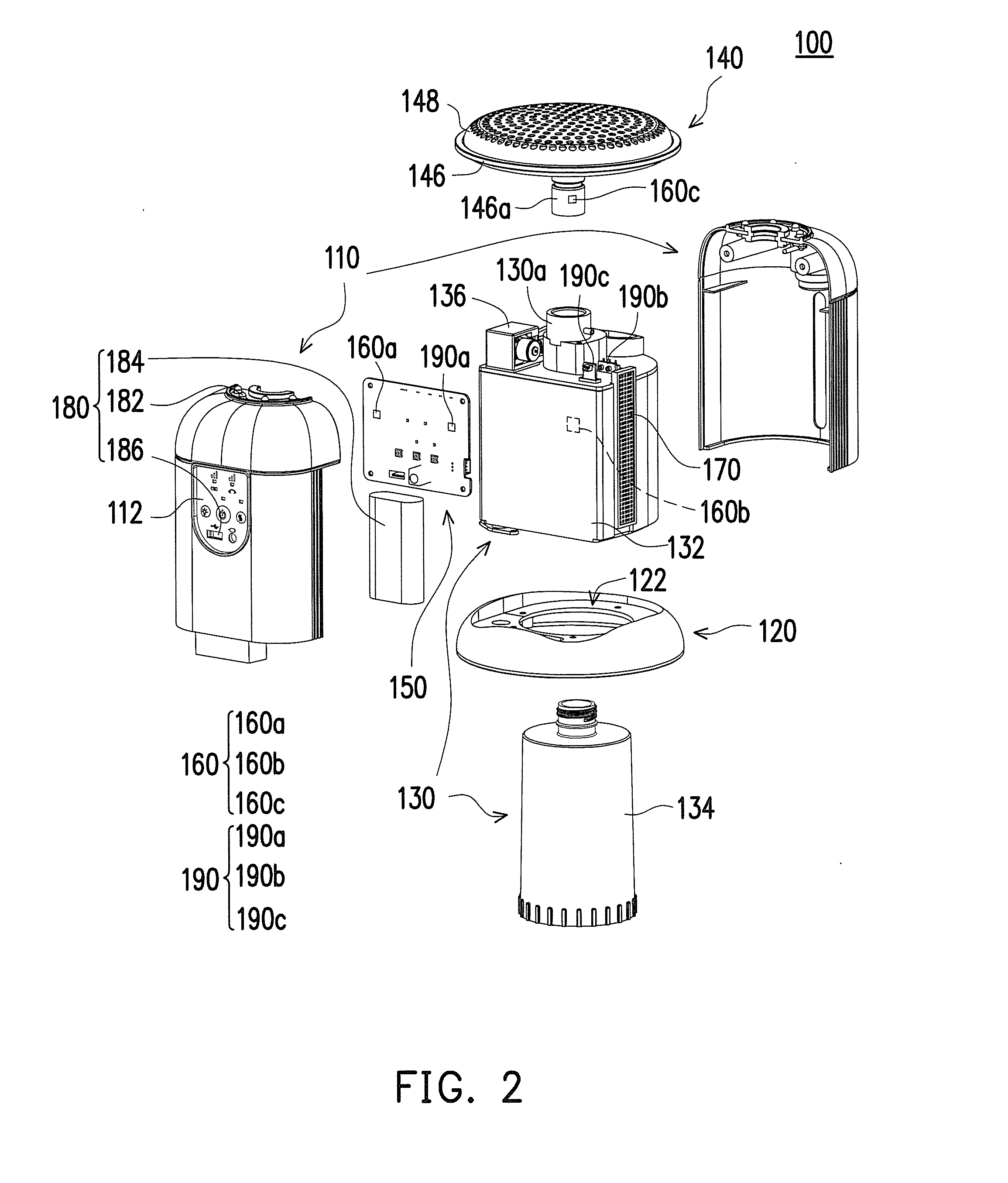

Air purification device based on ultrasonic technology

PendingCN110193262AIncrease the amount of air purificationExtend your lifeCombination devicesParticulatesWater circulation

Relating to the field of air purification, the invention discloses an air purification device based on ultrasonic technology. The device includes an ultrasonic atomization dust removal module, a ceramic heating module, a filtering module, an ultrasonic vibration gas purification module, a water tank, a water circulation module, a fan, an external shell and a drive circuit module. During work, airenters from a side of the bottom and moves upward to firstly pass through the atomization dust removal module with water fed by the water tank; then the air passes through the ceramic heating area forheating drying; then the treated air passes through the filtering module and the ultrasonic vibration purification module in order; and finally the treated air is discharged by the top fan. Specifically, the settled and condensed water containing particulate matters in the ultrasonic atomization dust removal module flows into a sink below, passes through a filter layer, and then flows back into the water tank through a water pump from an upstream water pipe. The air purification device based on ultrasonic technology provided by the invention can be used for indoor and outdoor air purification, has comprehensive functions, also can purify gas pollutants according to needs, has compact unit modular structure, can be combined with street lamps, isolation guardrails and the like, and fills inthe blank of purification system in the field of municipal facilities.

Owner:XI AN JIAOTONG UNIV

Method of treating refractory pollutants through catalyzing H2O2 oxidation by pyrite cinder

ActiveCN101745197BApplicable to a wide range of pHImprove responseSolid waste disposalWater contaminantsResource utilizationPyrite

A method of treating refractory pollutants utilizes the pyrite cinder as catalyst which forms a heterogeneous Fenton system with H2O2 to catalyze H2O2 to generate hydroxyl radical (.OH) with strong oxidability and degrade the organic pollutants efficiently and quickly. The method comprises the following steps: (1) after the waste water is added in a reactor, a given amount of pyrite cinder original sample or activated and pretreated cinder is added in the waste water; (2) H2O2 solution is added in a mixed liquid of the waste water and the pyrite cinder so as to form an analogous Fenton reagent with the pyrite cinder; (3) stirring is carried out so as to lead the pyrite cinder, the H2O2 solution and the waste water to be mixed for reaction, and the stirring is stopped at the set reaction time; and (4) standing is carried out, the pyrite cinder is quickly precipitated and the supernate is discharged, so that the pyrite cinder can be reused. The invention discovers a novel analogous Fenton oxidation catalyst, extends the resource utilization ways of the pyrite cinder, achieves the purpose of controlling waste by waste and realizes the comprehensive utilization of the waste.

Owner:TONGJI UNIV

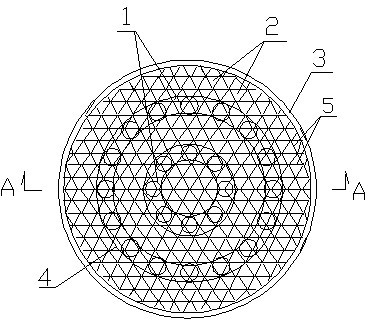

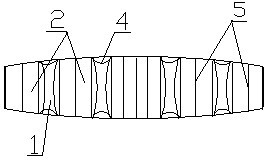

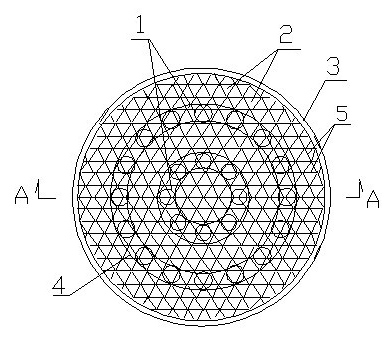

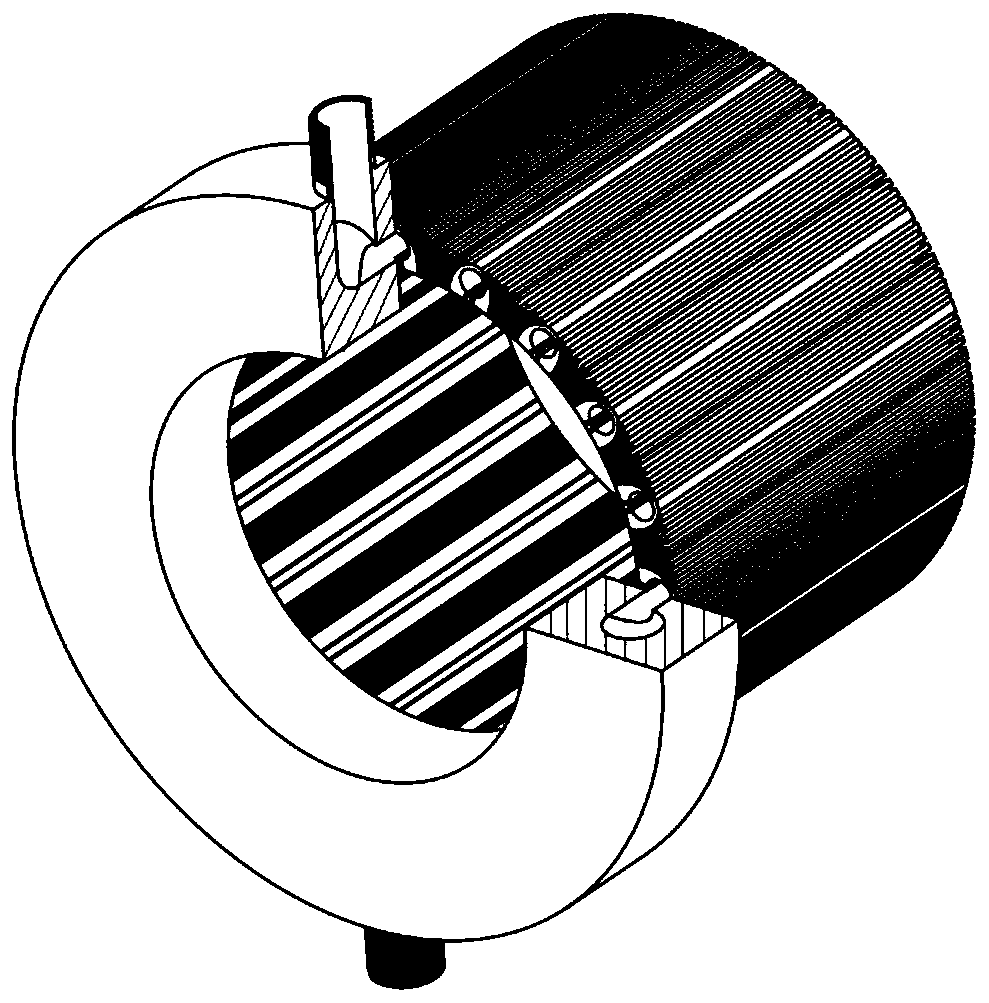

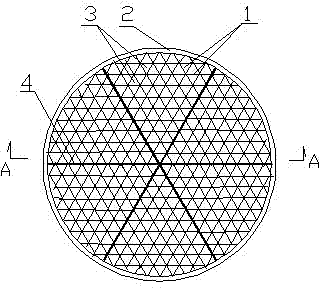

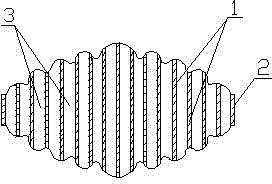

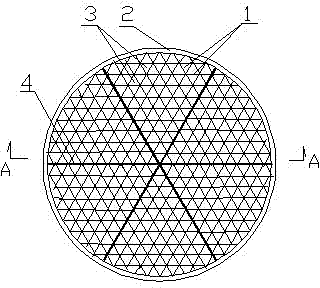

Effective, environment-friendly and high-strength nest type support protecting agent and preparation method thereof

The invention discloses an effective, environment-friendly and high-strength nest type support protecting agent. The agent comprises a main body (2), wherein the two ends of the main body are of a shape of a flat circular body with an externally convex curved surface; honeycomb holes (3) distributed in a mesh structure are formed in the main body; reinforced ribs (4) are arranged among the honeycomb holes at intervals; and the main body consists of the following components in percentage by weight: a composition prepared from 70 to 90 percent of environment-friendly fine silicon carbide powder and 10 to 30 percent of organic clay, 5 to 10 percent of hydroxymethyl cellulose, 5 to 10 percent of Chinese wood oil, 5 to 10 percent of silica sol and 4 to 8 percent of magnesium stearate. Mine resources can be saved; environmental protection is beneficial; the agent has high hardness, compressive resistance, acid and alkali resistance, corrosion resistance, thermal erosion resistance, heat conductivity and heat stability; support protecting ability can be greatly improved; the utilization period of a catalyst is prolonged; the activity of the catalyst can be ensured; the reaction speed is increased; the production cost is reduced; and the working efficiency of a reactor is improved.

Owner:PINGXIANG ANFA COKING ENVIRONMENT PROTECTION FILLING

Method for synthesizing acrylic acid low-carbon alcohol ester through carbonylation of acetylene

InactiveCN106831425ALow costFast catalytic reactionOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionAlcoholNickel compounds

The invention relates to a method for synthesizing acrylic acid low-carbon alcohol ester through carbonylation of acetylene. A nickel-containing compound and a bidentate ligand containing nitrogen and a VIA-th group element serve as catalysts, and acetylene, carbon monoxide and low-carbon alcohol are subjected to carbonylation reaction in a solvent to synthesize the acrylic ester at one step. The method has the characteristics of low catalyst cost, high reaction speed, no carbon deposition in the reaction process and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

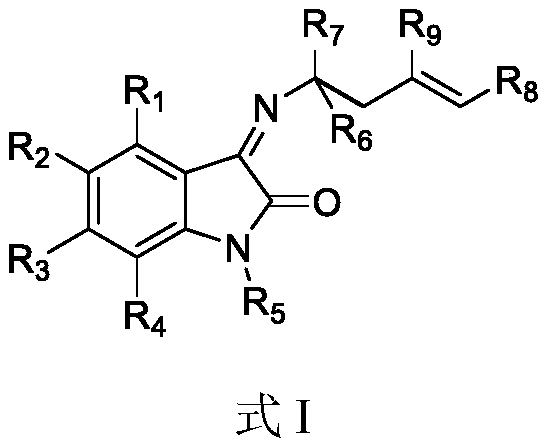

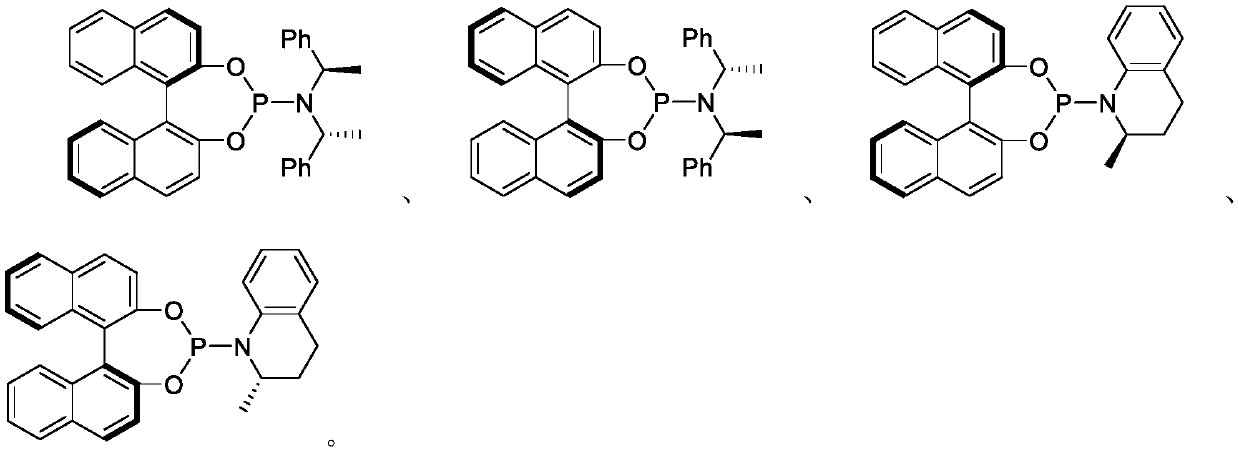

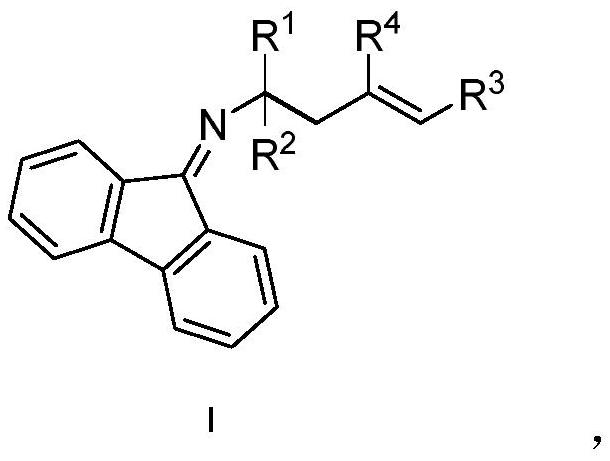

Chiral alpha-fluoroallamine derivative as well as preparation method and application thereof

ActiveCN110294702ACorrespondence is goodEasy to synthesizeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIridiumOrganic solvent

The invention discloses a method of synthesizing a chiral alpha-fluoroallamine derivative through a novel Ir-catalyzed fluoroindirubin-participated dipole reversal allylation / 2-aza-Cope rearrangementreaction. The synthesis method comprises the following steps of in an organic solvent, under the inert gas protection, allyl carbonic ester and fluoroindirubin are used as raw materials; Ir catalystsare used as catalysts; reaction is performed for 12 to 36 hours at the temperature of 25 DEG C; a target compound is obtained through column chromatography.

Owner:WUHAN UNIV

Heating device

InactiveUS20160010893A1Easy to useHigh activityFuel cell combinationsExothermal chemical reaction heat productionTemperature controlElectricity

A heating device including a heating unit, a temperature sensing module, a control unit, and a hydrogen generating unit having a first tank, a second tank, and a driving element is provided. The first tank contains a liquid reactant. The second tank contains a solid reactant. The driving element is connected between the first tank and the second tank, drives the liquid reactant to move from the first tank to the second tank, such that the liquid reactant reacts with the solid reactant to generate hydrogen. The heating unit is connected to the hydrogen generating unit and includes a catalyst layer. At least a part of hydrogen moves from the second tank to the heating unit and contacts the catalyst layer to react to generate heat energy. The control unit is electrically connected to the driving element, and controls the driving element according to a temperature of the heating device.

Owner:CORETRONIC

Western medicine dissolver with high dissolving efficiency

InactiveCN112354420AIncrease contact areaEnhanced Dissolving Mixing EffectTransportation and packagingRotary stirring mixersPhysicsElectric machinery

A western medicine dissolver with high dissolution efficiency comprises a box body, a controller is bolted to the bottom of the front surface of the box body, supporting legs are welded to the periphery of the bottom of the box body, mounting seats are bolted to the periphery of an inner cavity of the box body, cylinders are bolted to the inner sides of the mounting seats, and the left sides of the opposite tops of the box body and the cylinders communicate with a feeding pipe. Through cooperation of a high-speed motor, a stirring shaft, a stirring frame, stirring holes and an auxiliary stirring rod, medicine components in the cylinders can be fully scattered and dissolved, the contact area between the medicine components is enlarged, and therefore the overall dissolving and mixing effectbetween the medicine components is directly enhanced; through cooperation of a temperature sensor, the temperature between the box body and the cylinders can be sensed in real time, then a signal instruction is sent to the controller, and the periphery of the cylinders can be uniformly heated through cooperation of an electric heater, a pressurizing air pump, a three-way connector, an air pipe, amain pipe, branch pipes, an annular frame and air spraying heads.

Owner:杨爱琴

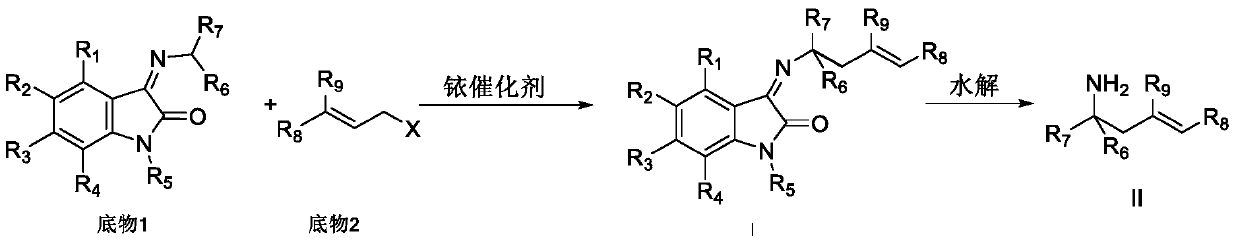

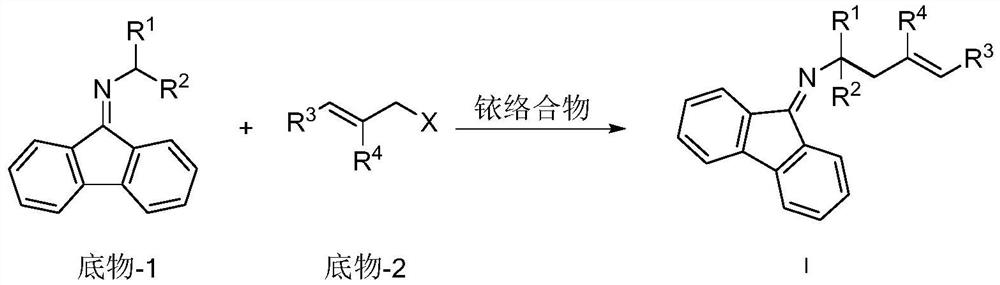

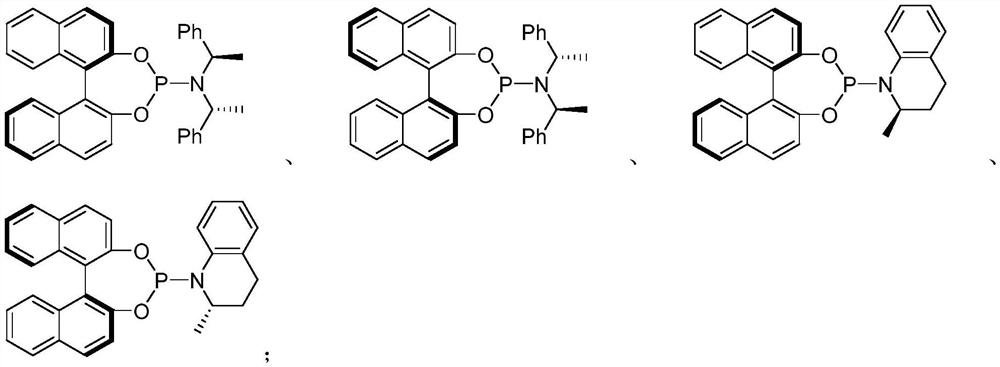

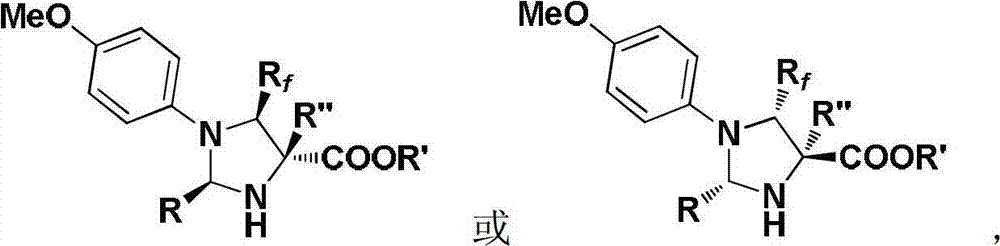

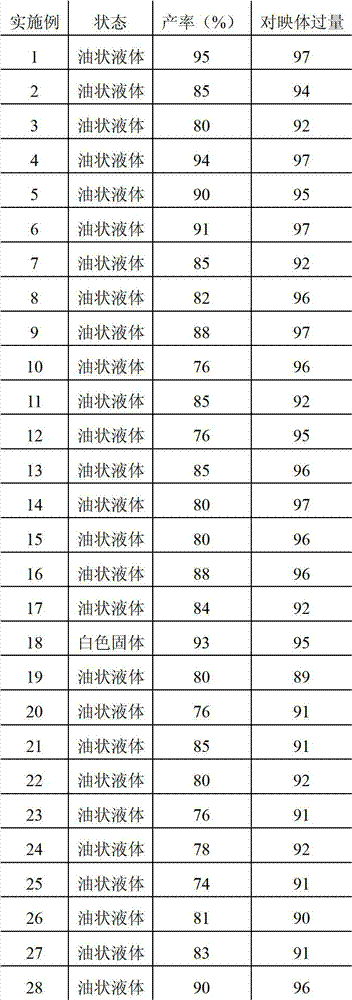

Chiral alpha-polysubstituted-alpha-fluorine-containing homoallylamine compound, preparation method and application thereof

InactiveCN112279770ACorrespondence is goodEasy to synthesizeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsStructural unitPerylene derivatives

The invention discloses a chiral alpha-polysubstituted-alpha-fluorine-containing homoallylamine compound, a preparation method and application thereof. The preparation method of the chiral alpha-polysubstituted-alpha-fluorine-containing homoallylamine compound comprises the following step of: taking an iridium complex as a catalyst, carrying out catalytic reaction on a substrate 1 and a substrate2 to obtain the chiral alpha-polysubstituted-alpha-fluorine-containing homoallylamine compound shown in the formula. The chiral alpha-polysubstituted-alpha-fluorine-containing homoallylamine compoundcan be applied to preparation of a chiral alpha-polysubstituted-alpha-fluorine-containing homoallylamine compound II and preparation of a derivative with a chiral tetrahydropyrrole structure. The method disclosed by the invention is simple, low in cost and high in yield, the obtained reaction target compound is good in corresponding selectivity, the yield is 50-95%, the corresponding selectivity excess is greater than 90%, and the method has extremely high reference value for synthesizing a drug containing a chiral alpha-polysubstituted-alpha-fluorine-containing homoallylamine structural unit.

Owner:WUHAN UNIV

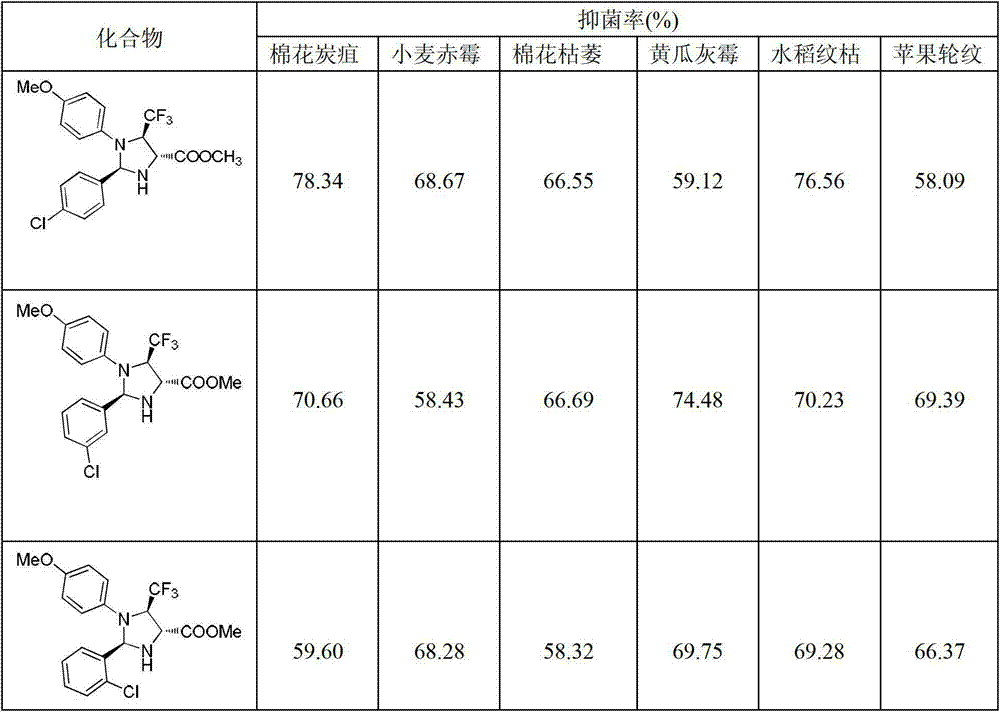

Chiral tetrahydroimidazolidine compound with CnFmH2n+1-m structure unit and synthesis method thereof

InactiveCN102964305AGood antibacterial effectHas antibacterial activityBiocideOrganic chemistryOrganic baseSynthesis methods

The invention discloses a chiral tetrahydroimidazolidine compound with a CnFmH2n+1-m structure unit and a synthesis method thereof. The synthesis method comprises the following steps of: in an organic solvent and under the protection of inert gas, by taking fluorine-containing alkylmethyleneanisidine and methylamino acid-derived imine as raw materials and taking a complex of metal lewis acid / chiral ligand as a catalyst, adding carbonate or organic base, sufficiently reacting at (-40)-30 DEG C, steaming to remove solvent, and performing column chromatography to obtain the target compound. The compound can be used as an active ingredient of an antibacterial agent.

Owner:WUHAN UNIV

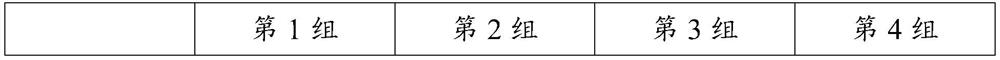

Method for improving phospholipase D transesterification activity and method for producing phosphatidylserine by using phospholipase D transesterification activity

PendingCN112352051AImprove lipotransfer activityFast catalytic reactionHydrolasesEnzyme stabilisationPhospholipinPhospholipase

Provided is a method for improving phospholipase D transesterification activity, comprising: adding an alcohol substance, which is a short-chain primary alcohol and / or secondary alcohol, to an enzymereaction system for producing phosphatidylserine by enzyme catalysis, the method being capable of accelerating the speed of an enzyme catalytic reaction and reducing the amount of enzyme used, while shortening at least half of the reaction time, universal applicability. The invention also provides a method for producing phosphatidylserine by enzyme catalysis, which comprises the following steps: mixing phosphatidylcholine-containing natural phospholipid with water, Lserine, calcium chloride, alcohol substances and phospholipase D, and stirring to react at 39-43 DEG C for 4-6 hours; wherein thealcohol substance is short-chain primary alcohol and / or secondary alcohol; the method has the advantages of short enzyme reaction time, high conversion rate and low production cost.

Owner:BONTAC BIO ENG SHENZHEN +1

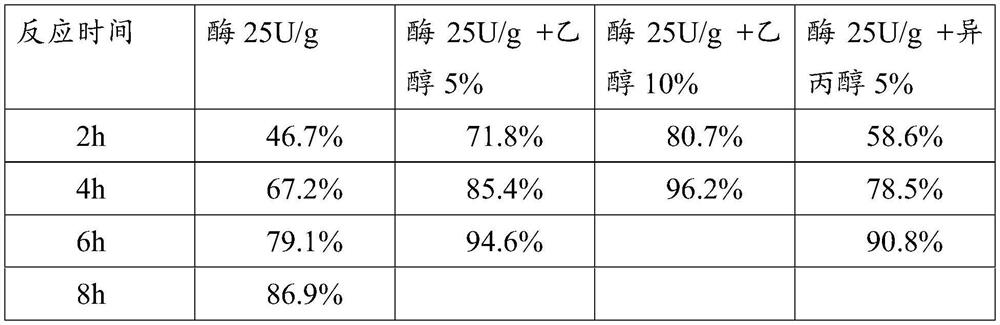

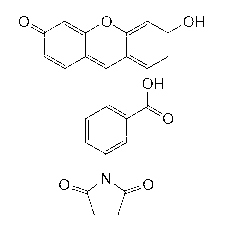

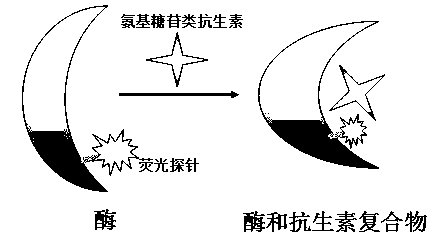

Fluorescently-labeled aminoglycoside adenosine modification enzyme and method for detecting antibiotics with same

InactiveCN103074313AEasy to prepareLow costMicrobiological testing/measurementTransferasesGlycosideAdenosine

The invention discloses a fluorescently-labeled aminoglycoside adenosine modification enzyme and a method for detecting antibiotics with the same. A fluorophore containing or modifying a sulfydryl is labeled on the free sulfydryl Cys198 of the fluorescently-labeled aminoglycoside adenosine modification enzyme, and is fluorescein-5-maleimide. The invention further discloses the method for detecting antibiotics with the fluorescently-labeled aminoglycoside adenosine modification enzyme. As the fluorescently-labeled aminoglycoside adenosine modification enzyme prepared according to the invention is simple to reagent preparation, low in cost, and fast and sensitive in enzyme catalytic reaction, residual antibiotic medicines in foods and environments can be detected conveniently, fast and efficiently without the limitation of laboratory operation.

Owner:NANJING UNIV OF POSTS & TELECOMM

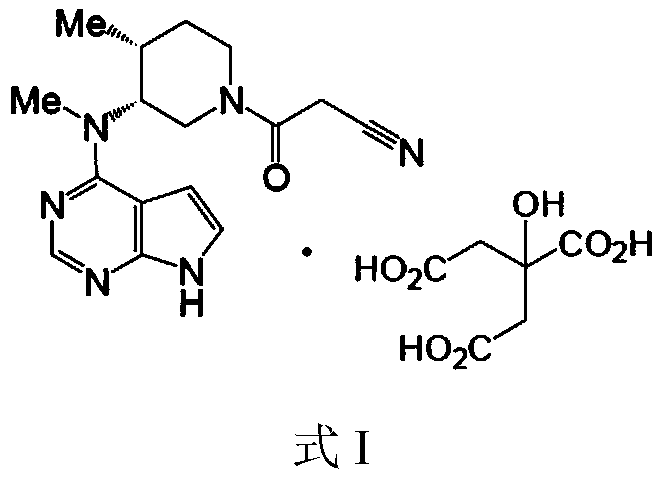

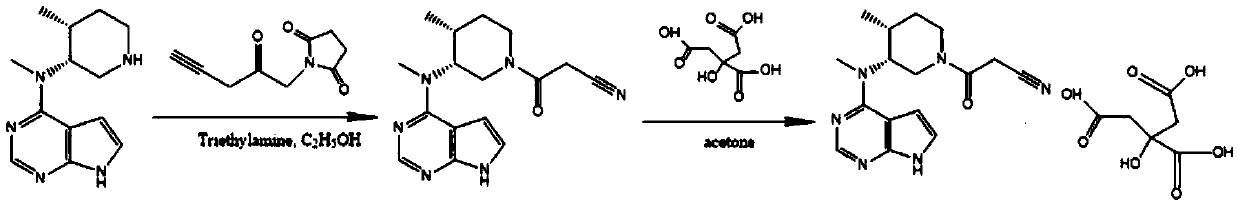

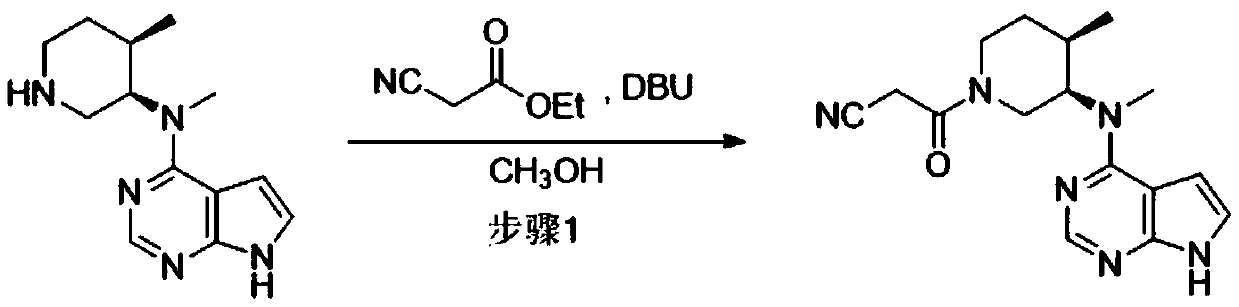

Method for preparingtofacitinib citrate

ActiveCN110343111ALow priceEasy to getOrganic compound preparationCarboxylic acid salt preparation4-methylpiperidineFiltration

The invention provides a method for preparing tofacitinib citrate. The method for preparing tofacitinib citratecomprises the following steps that1, N-methyl-N-((3R,4R)-4-methylpiperidine-3-yl)-7H-pyrrolo[2,3-d]pyrimidin-4-amine and ethyl cyanoacetate are added into methyl alcohol for condensation reaction to prepare and obtain 3-((3R,4R)-4-methyl-3-(methyl(7H-pyrrolo[2,3-d]pyrimidin-4-yl)amino)piperidin-1-yl)-3-oxopropanenitrile;and 2,3-((3R,4R)-4-methyl-3-(methyl(7H-pyrrolo[2,3-d]pyrimidin-4-yl)amino)piperidin-1-yl)-3-oxopropanenitrileis added to a mixed solvent and subjected to 80+ / -5 DEG reflux, additionally, citric acid is dissolved in the mixed solvent and then added slowly to a reflux system forsalt forming reaction, cooling, filtration, washing, and drying to obtain 3-((3R,4R)-4-methyl-3-(methyl(7H-pyrrolo[2,3-d]pyrimidin-4-yl)amino)piperidin-1-yl)-3-oxopropanenitrile citrate. According to the method for preparing tofacitinib citrate, operation isconvenient, time consumption isless, the yield rate is high, product impurity is low,and purity is good.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

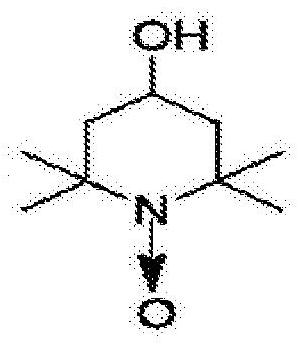

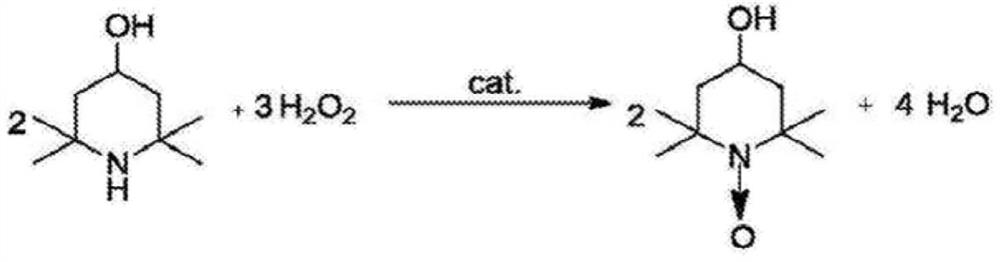

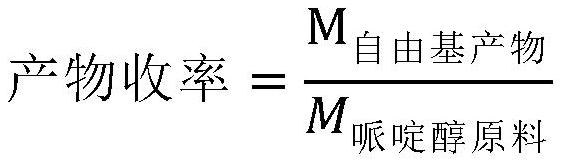

Catalyst, preparation method thereof and use thereof in production of nitroxide radical piperidinols

ActiveCN112604677AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic chemistryPtru catalystAlcohol

The invention discloses a catalyst, a preparation method thereof and use thereof in production of nitroxide radical piperidinols The catalyst for synthesizing nitroxide free radical piperidinol comprises, by total weight of the catalyst, 0.1-5.0% of a titanium element, 30-48% of a silicon element and the balance of an oxygen element. The catalyst is prepared by the following method: providing a mixed solution of tetraethyl silicate and water, wherein the mass ratio of tetraethyl silicate to water being 0.05-0.5; adjusting the pH value of the solution to 10.0-12.0, and stirring the solution; providing a mixed solution of tetraethyl titanate and absolute ethyl alcohol, wherein the mass ratio of tetraethyl titanate to absolute ethyl alcohol is 0.02-0.5; and mixing the two mixed solutions, and carrying out stirring and roasting to obtain a catalyst product.

Owner:SHANGHAI HUAYI NEW MATERIAL

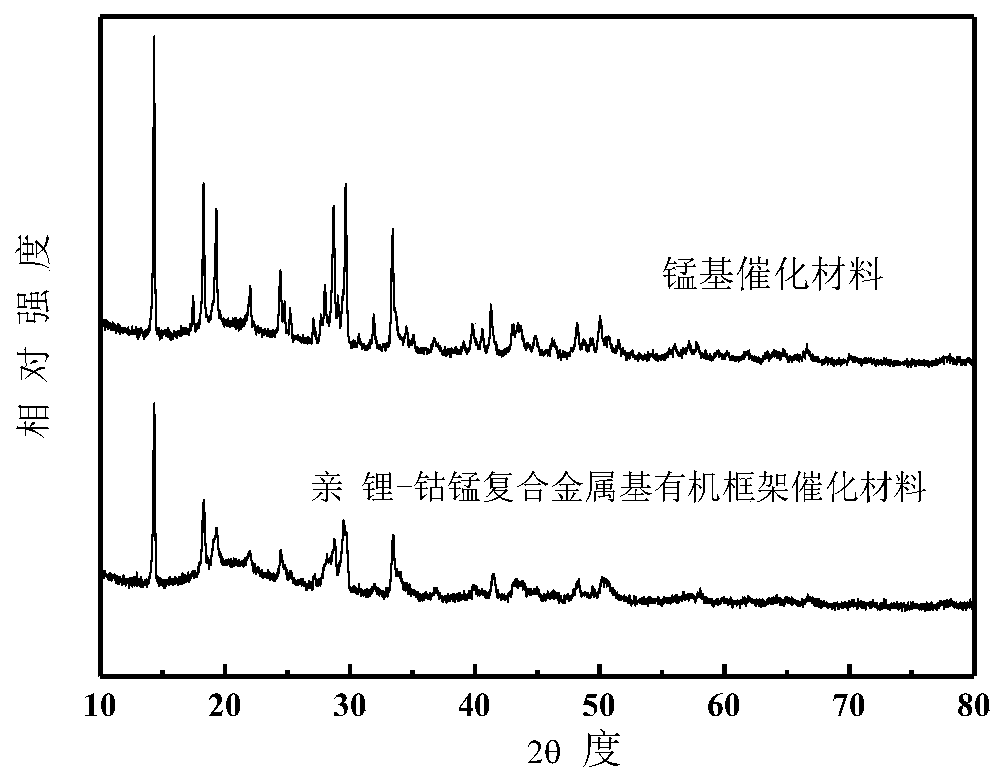

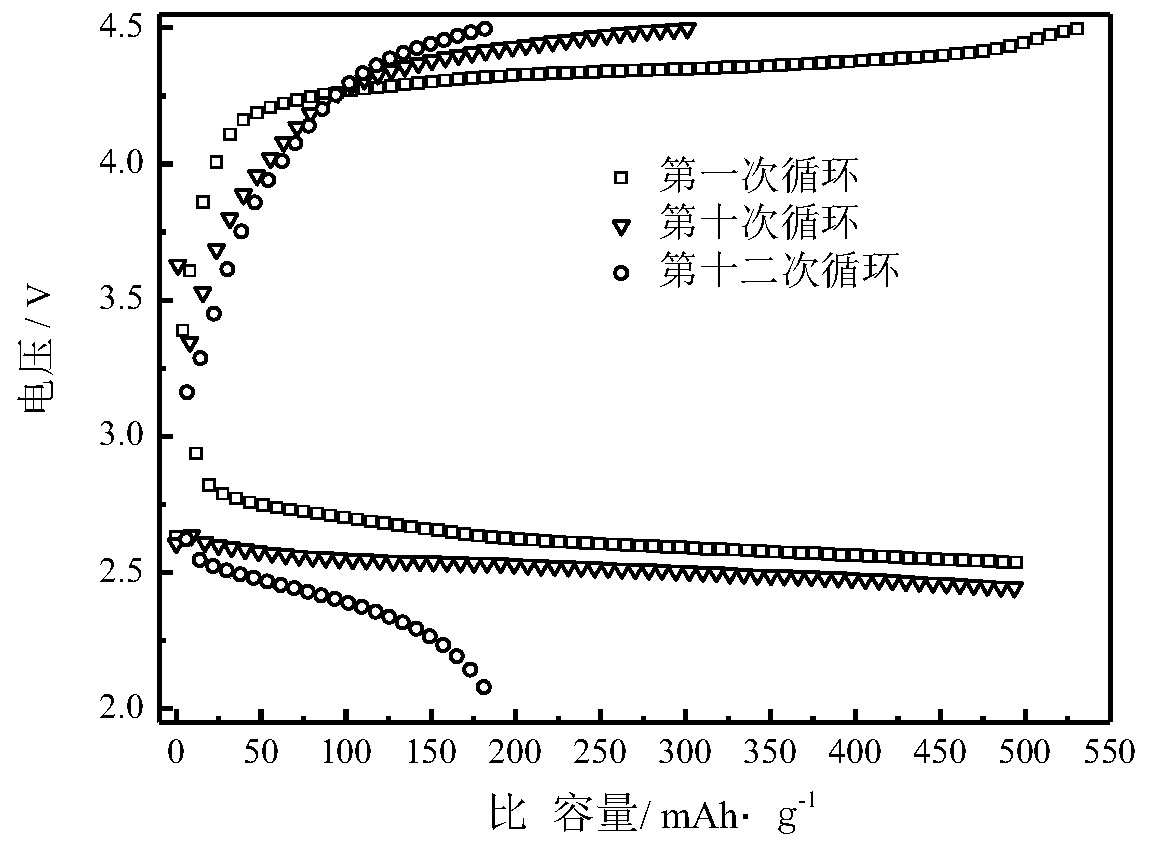

Preparation method and application of lithium affinity-cobalt and manganese composite metal based organic frame catalyst of lithium-oxide battery cathode

PendingCN109830701AImprove cycle lifeEasy to prepareFuel and secondary cellsCell electrodesMANGANESE ACETATECobalt acetate

The invention relates to a preparation method and application of a lithium affinity-cobalt and manganese composite metal based organic frame catalyst of a lithium-oxide battery cathode. Cobalt acetate, manganese acetate and terephthalic acid are added to N,N-dimethyl formamide, and then transferred to a hydrothermal reactor for hydrothermal reaction; the mixture is washed by enthanol and then undergoes centrifugation, a supernatant solution is removed, and a centrifugation product is reserved; and the centrifugation product is dried, ground and sieved to obtain the cobalt and manganese composite metal based organic frame catalysis material. The preparation method is simple and easy to operate, the specific surface area is larger, more active sites are included, and the electron conductivity is high; and the material applied to a lithium affinity ZnO / CNT as a leveling layer of the cathode can attract lithium ions, catalytic reaction can be carried out in a better and rapider way, and the circulation life of the lithium-oxide battery is prolonged.

Owner:BOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com