Method and equipment for low-temperature magnetization treatment of garbage

A magnetization treatment and garbage technology, applied in lighting and heating equipment, chemical instruments and methods, combustion methods, etc., can solve problems such as overpressure safety hazards, blocked gas pipelines and valves, shutdown and maintenance, etc., to eliminate overpressure safety accidents , The effect of purifying gas quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not limited thereto.

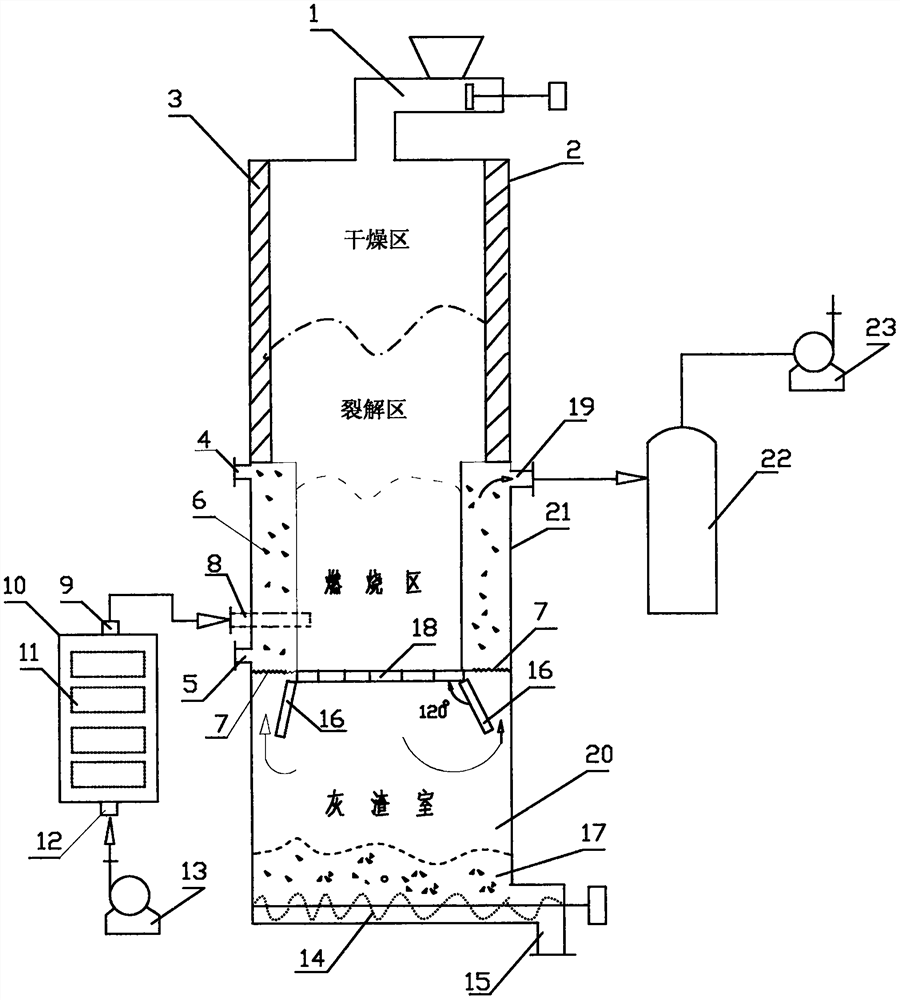

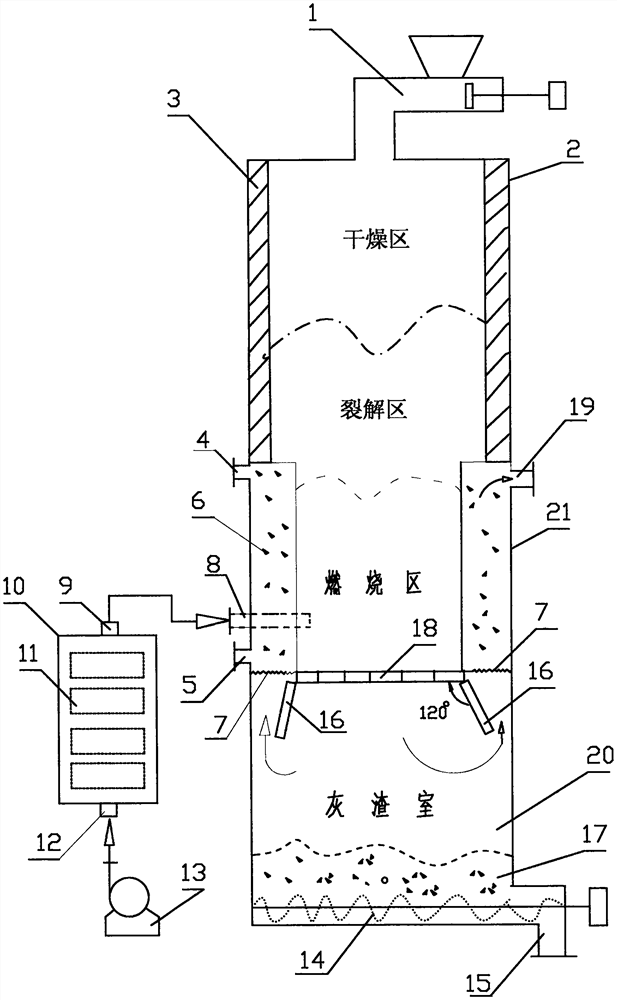

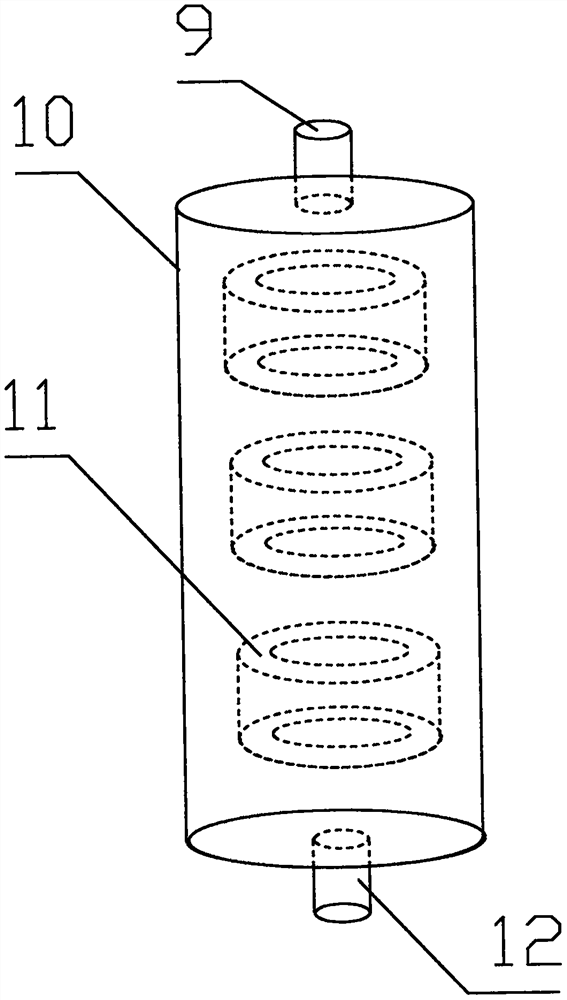

[0044] Such as figure 1 , figure 2 with image 3 As shown, a low-temperature magnetization treatment of garbage equipment, comprising: the furnace body (1) of the pyrolysis furnace, the top of the furnace body (1) is equipped with a feeding port and a feeder (1), and the furnace body (1) has a drying zone, cracking zone and combustion zone, the combustion zone is in communication with the magnetized air delivery pipe (8) discharged from the air magnetizer (10), and the bottom of the combustion zone is equipped with a grate (18) for discharging ash, and a grate (18) The ash plate (16) is configured below, and a jacketed catalytic fixed bed (21) is arranged on the periphery of the combustion zone of the body of furnace (1), and a granular catalyst (6) is housed in the jacketed catalytic fixed bed (21). The upper part of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com