Patents

Literature

332 results about "Thermal decomposition method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

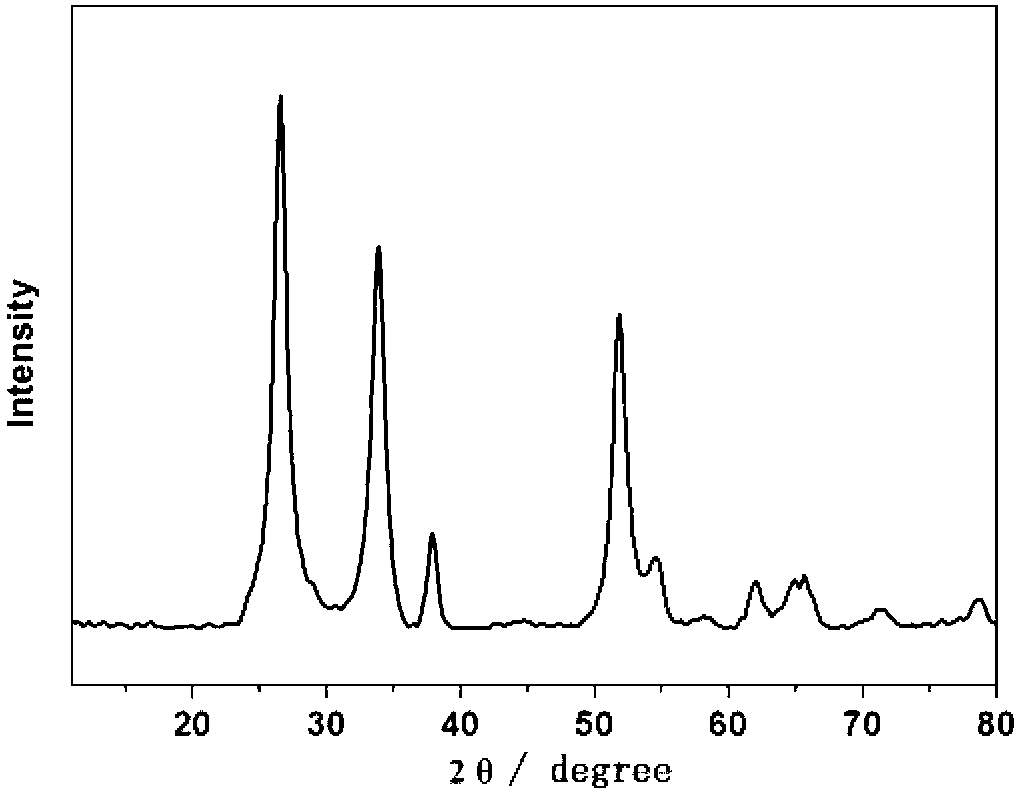

Preparation method of nano porous metal oxide/carbon lithium ion battery cathode material

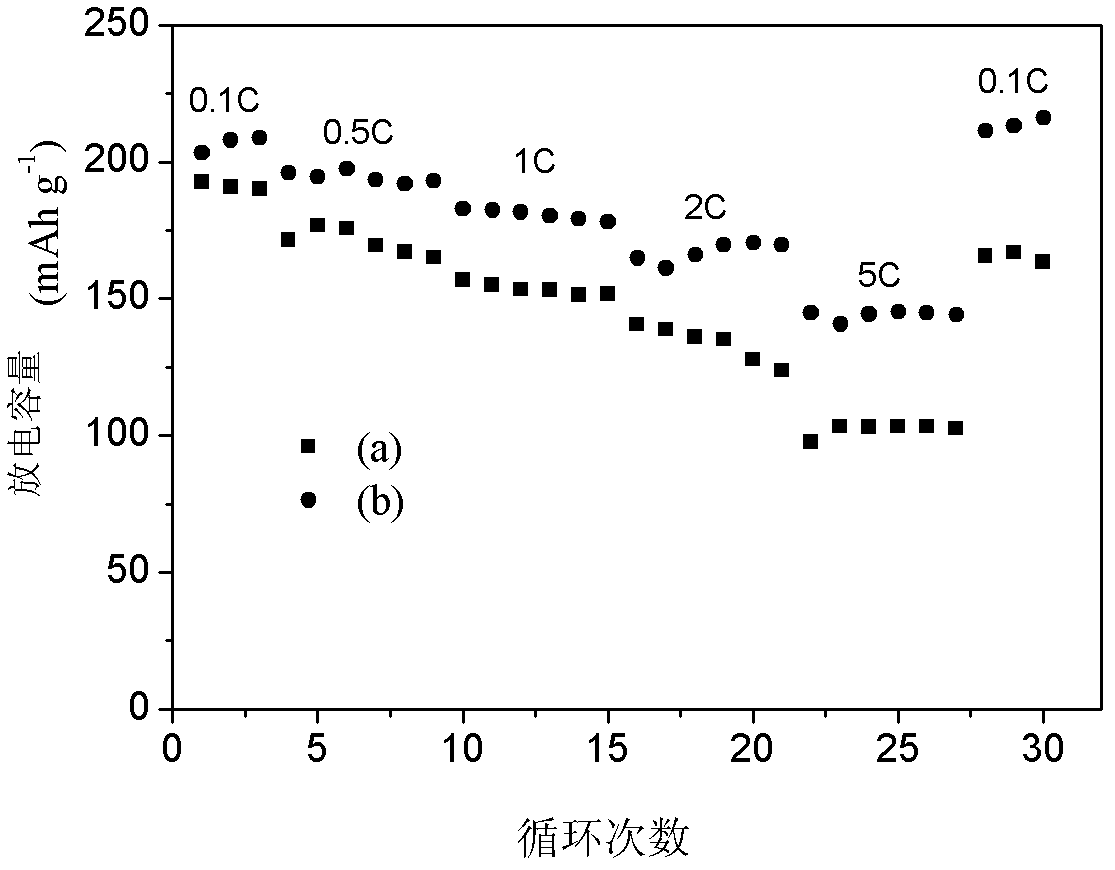

ActiveCN104045116AImprove cycle performanceImprove conductivityMaterial nanotechnologyCell electrodesHigh energyManganese oxide

The invention provides a preparation method of a nano porous metal oxide / carbon lithium ion battery cathode material. The preparation method comprises the following steps: firstly, weighting ferric salt or manganese salt and carboxylate organic ligands, and putting into a high-pressure reaction kettle; and after a polar solvent is added and dissolved, carrying out a hydrothermal reaction for 10-72h at 100-180 DEG C to generate a transition metal coordination polymer precursor; and after the transition metal coordination polymer precursor is washed and dried, decomposing the precursor for 0.5-6h at a temperature of 300-600 DEG C in an inert atmosphere in a tube furnace, thus obtaining a nano porous metal oxide / carbon lithium ion battery cathode material containing iron oxides or manganese oxides. According to the preparation method, since the transition metal coordination polymer precursor which is structurally designable and controllable is used as a template-type precursor, a nano porous metal oxide / carbon lithium ion battery cathode material is obtained by using an in-situ thermal decomposition method. The method is simple in process, and the obtained products have the advantages of high electrical conductivity, high specific capacity, good cycle stability, excellent high-ratio discharge performance and high energy density.

Owner:JIANGSU UNIV

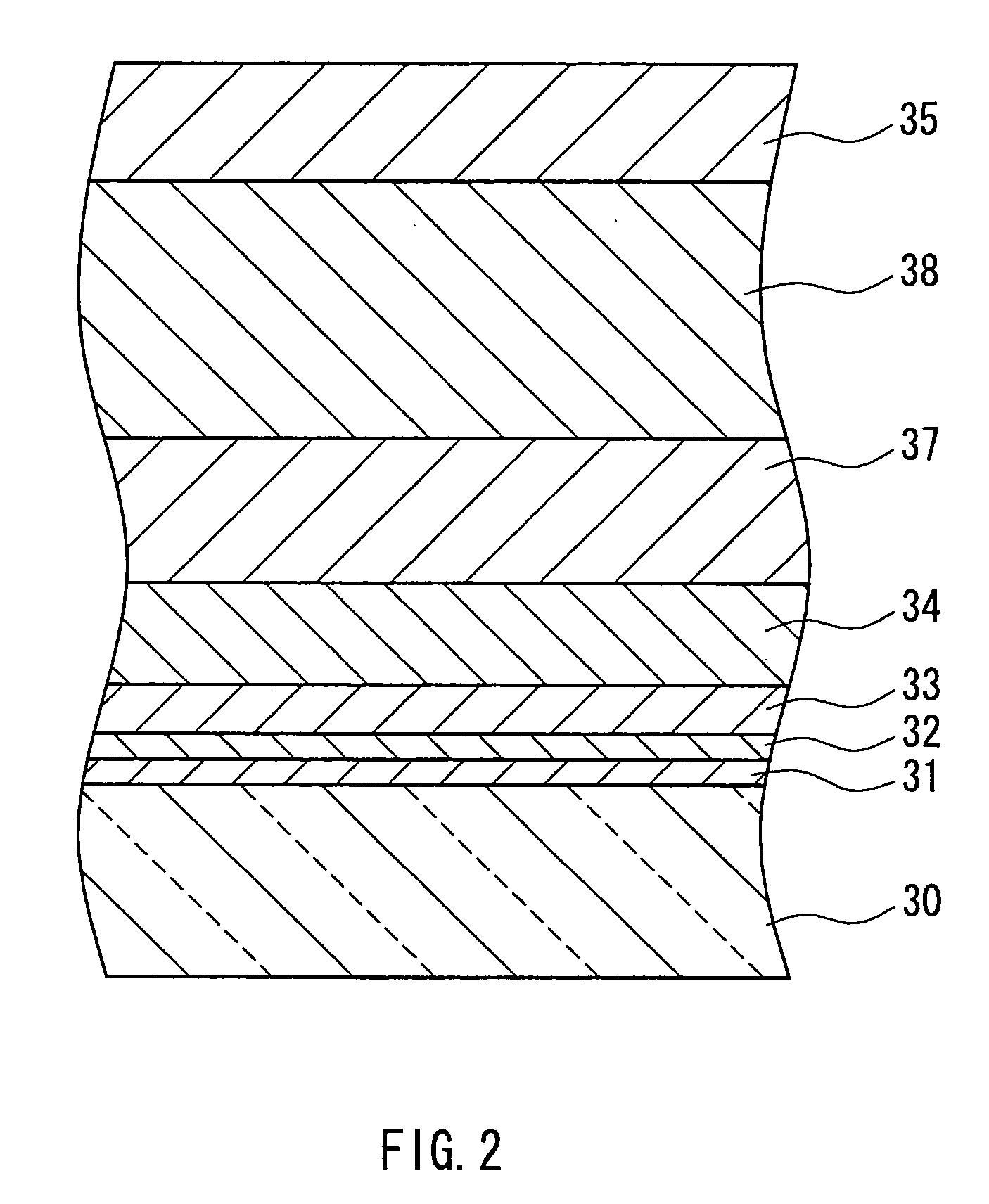

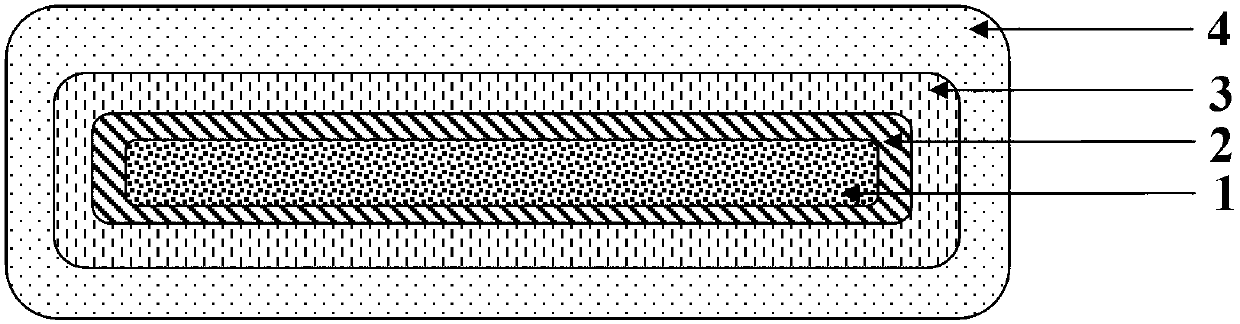

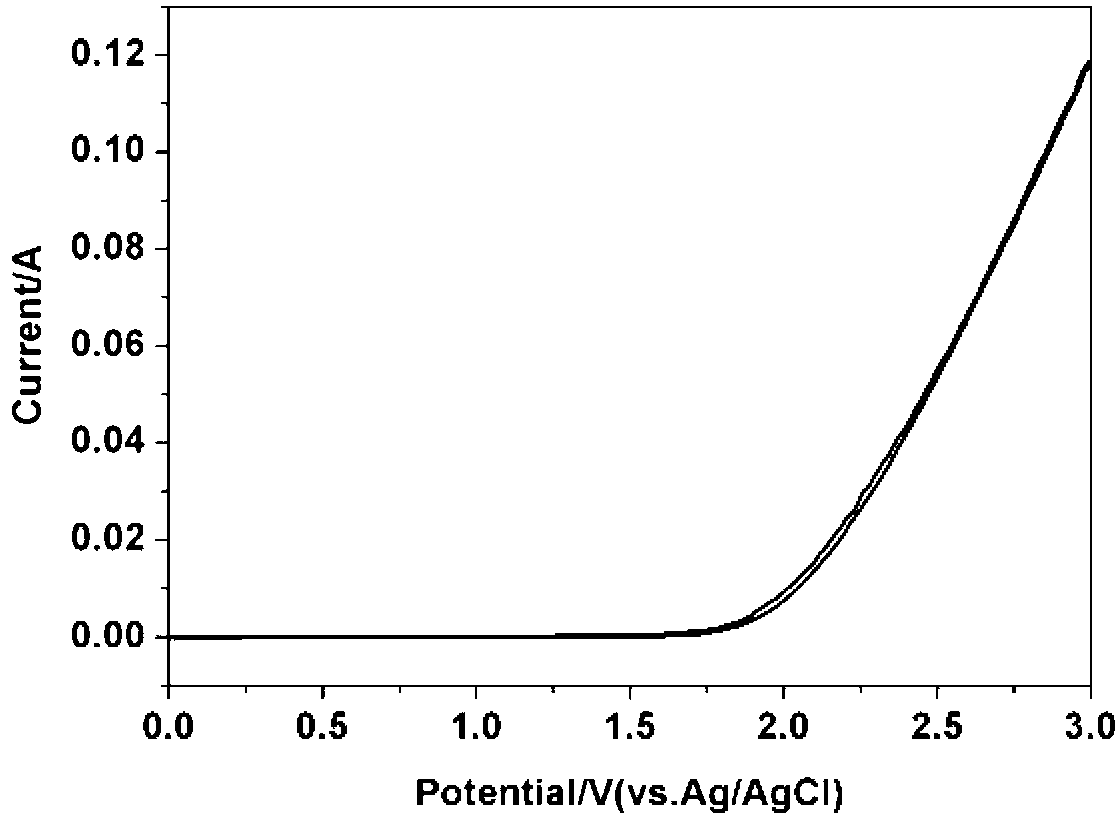

Method of preparing fluorine-containing lead dioxide electrode on titanium basal body

The present invention relates to a process for preparing fluorine containing lead dioxide electrode at titanium substrate. The plating structural of said fluorine containing lead dioxide electrode is as follows: from the titanium substrate surface and from inner to outer, in sequences, there are plated the tin-stibium oxidate bottom layer, alpha-PbO2 layer and fluorine contain containing beta- PbO2 layer. Said method comprises the steps of surface roughening treatment of titanium substrate, then plating the tin-stibium oxidate bottom layer through a thermal decomposition method, and then obtaining titanium substrate fluorine containing beta- PbO2 electrode through alkaline electric plating alpha-PbO2 and acidic composite electric plating beta- PbO2.The fluorine containing lead dioxide electrode prepared through the process and method in accordance with the present invention possesses strong bonding force between the plating layer and the substrate, small limiting surface electric resistance and inner stress, low price amd long service lifetime of electrode, can be applied widely in electrolytic industry fields of acidic system.

Owner:ZHEJIANG UNIV OF TECH

Preparation method for tantalum-contained interlayer metallic oxide electrode

InactiveCN102174704AImprove stabilityImprove protectionLiquid/solution decomposition chemical coatingElectrodesElectrolysisElectrochemistry

The invention belongs to the electrochemical technical field, and relates to a preparation method for a tantalum-contained interlayer metallic oxide electrode. The electrode is suitable for occasions including steel plate high-speed electroplating, seawater electrolysis marine life pollution and damage prevention devices, sodium hypochlorite electrolysis production devices, sewage treatment, cathode protection and the like in the electrochemistry industrial field. The main process comprises three steps, namely substrate pretreatment, tantalum-contained interlayer preparation and oxide coatingpreparation: firstly, a tantalum-contained interlayer is prepared on a titanium substrate by adopting a thermal decomposition method, and then a mixed metallic oxide electro-catalysis coating is prepared on the tantalum-contained interlayer; the mass percent purity of the metallic titanium substrate is larger than 99%; and the process is simple and convenient to carry out, the metallic oxide electrode with larger size or more complicated structure can be prepared, and the tantalum-contained interlayer can better protect the titanium substrate, delay the titanium substrate inactivation, improve the stability of the oxide electrode and prolong the service life.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

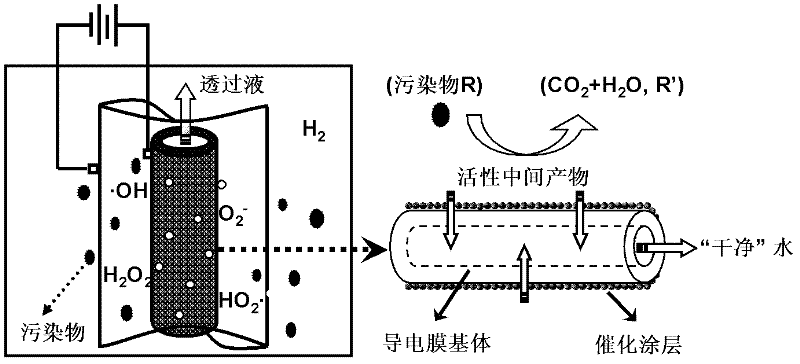

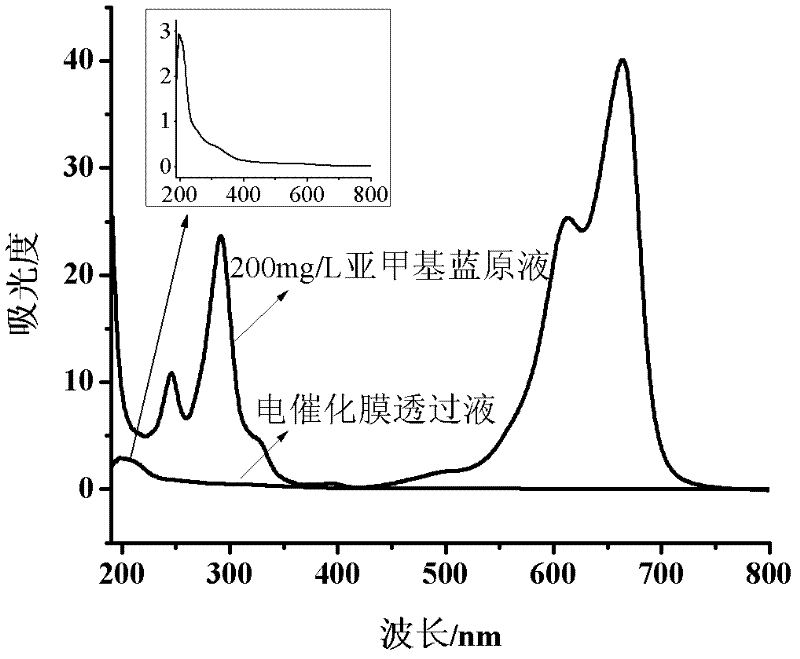

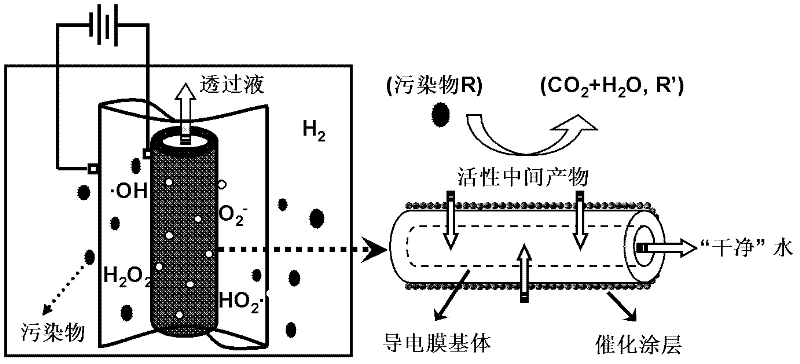

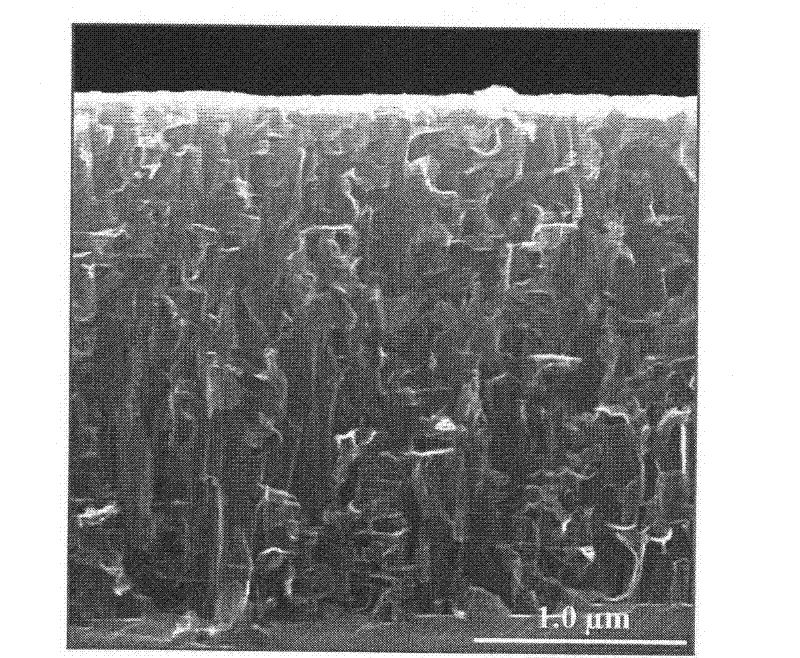

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

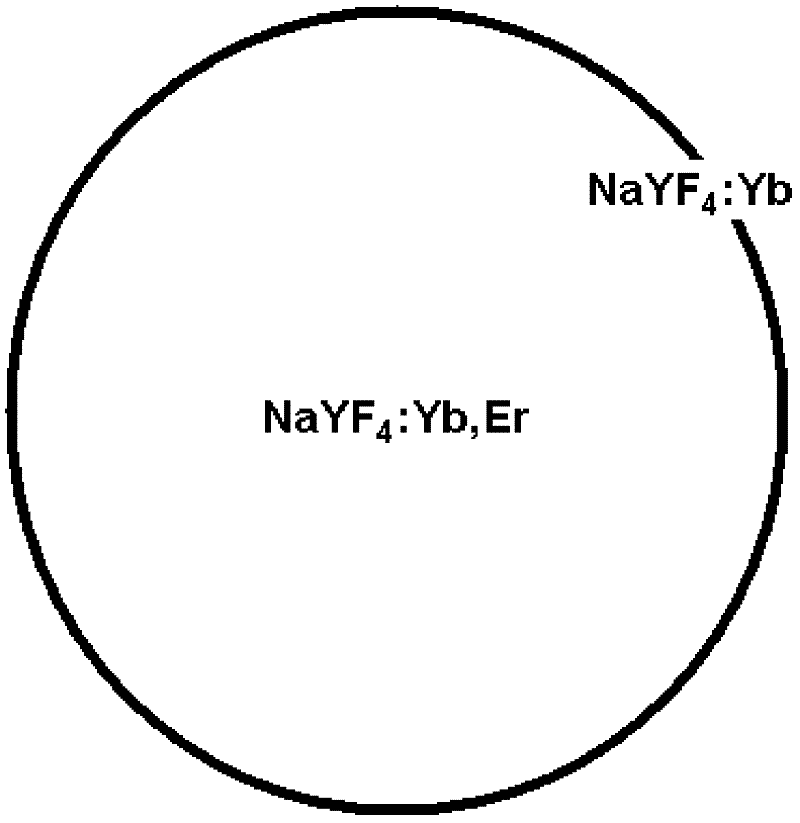

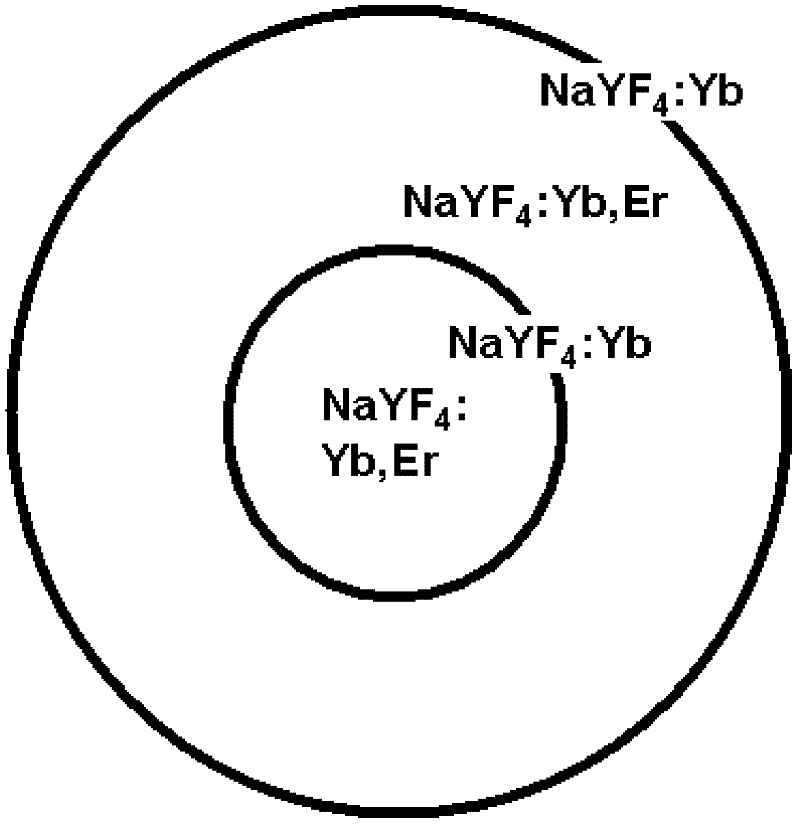

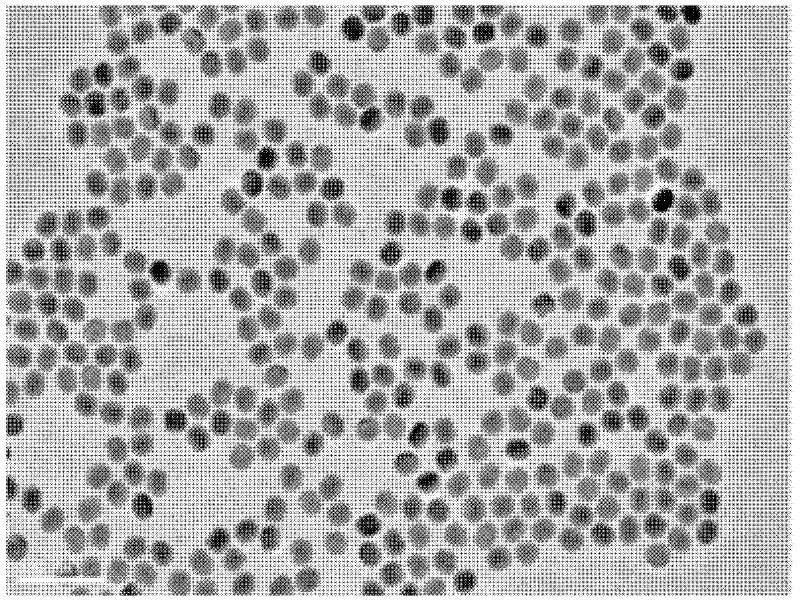

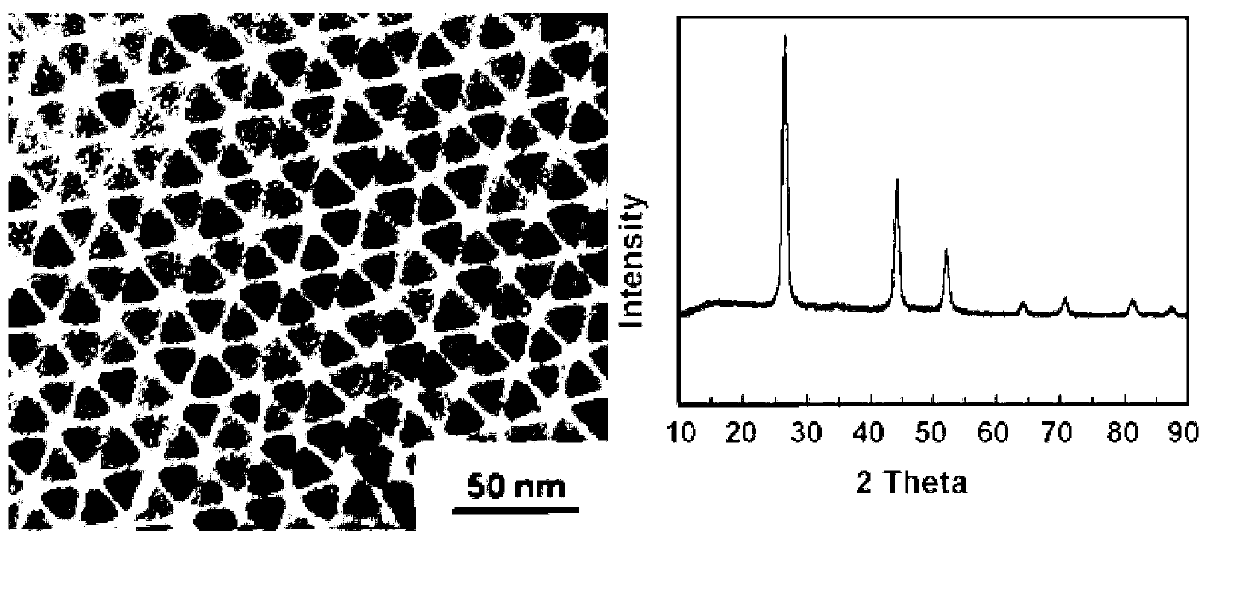

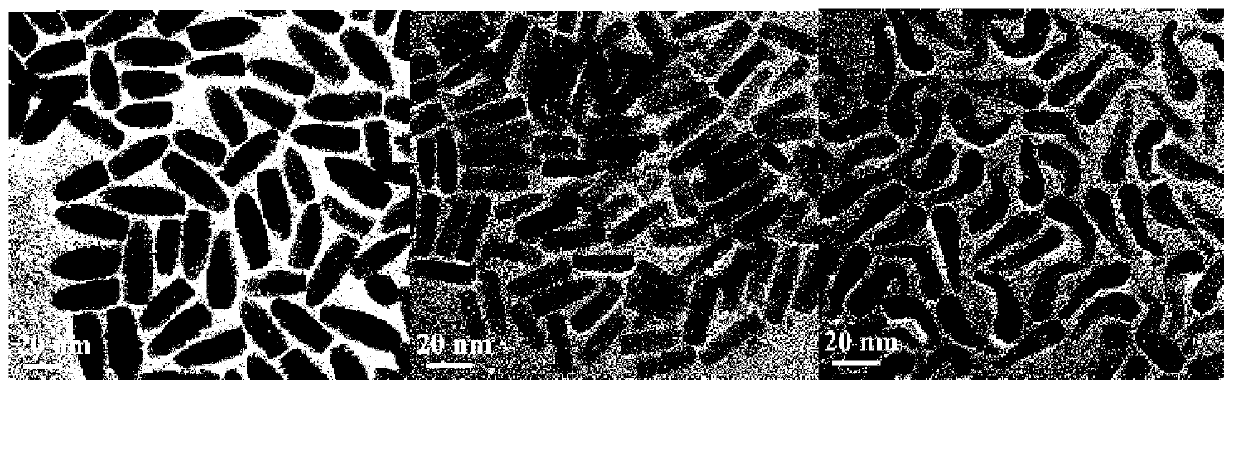

Rare earth up-conversion fluorescent material doped with luminescent center in different regions and preparation method thereof

The invention discloses a luminescent centre regionally doped rare earth upconversion luminescent material and a preparation method thereof, which relates to the technical field of structural design and preparation of luminescent materials. For solving the problems of small doping amount in the luminescent center and low luminescent efficiency of the rare earth upconversion luminescent material, the conventional materials of the same kind take NaYF4 as a matrix, are doped with rare earth sensitized ions and rare earth luminescent ions and has a core / shell structure and nanocrystalline micro structure, wherein a luminescent shell layer is coated outside the core / shell structure, and a sensitized layer is the outmost layer. The preparation method of the rare earth upconversion luminescent material comprises: after a trifluoroacetate thermal decomposition method is implemented, adding a luminescent shell layer precursor into solution of nanoparticle colloid with the luminescent core / shell structure, heating, and reacting to form the luminescent shell layer; cooling the product obtained by the previous step, adding a sensitized shell precursor layer, heating, reacting and obtaining a sensitized shell layer on the outside of the luminescent shell layer; and thus, obtaining the luminescent centre regionally doped rare earth upconversion luminescent material.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Fluorescent salix mongolica regenerated cellulose fibers and preparation method thereof

ActiveCN104357931AGood water solubilityHigh luminous intensityMonocomponent cellulose artificial filamentLuminescent compositionsCellulose fiberUp conversion

The invention discloses fluorescent salix mongolica regenerated cellulose fibers and a preparation method thereof. The preparation method comprises the following steps: peeling off salix mongolica, crushing, sieving, drying and cooling to prepare salix mongolica wood powder; extracting salix mongolica cellulose by adopting an ethanol-acid mixed solution; treating the salix mongolica cellulose by processes of steaming, bleaching and the like to prepare salix mongolica pulp; filtering, decompressing and de-foaming water-soluble up-conversion nano particles and the salix mongolica cellulose to obtain a spinning solution which is uniformly mixed; and spinning the spinning solution by a condensation bath, drafting and molding, refining and drying to obtain the fluorescent salix mongolica regenerated cellulose fibers. A preparation process of the water-soluble up-conversion nano particles comprises the following steps: firstly, synthesizing hexagonal-phase up-conversion luminous nano particles UCNPs by adopting a high-temperature thermal decomposition method; treating the UCNPs with nitrosonium tetrafluoroborate NOBF4, and replacing oleic acid molecules on the surface; finally, reacting with a hydrophilic hyperbranched polymer to obtain the water-soluble up-conversion nano particles. According to the fluorescent salix mongolica regenerated cellulose fibers, the water-soluble up-conversion nano particles and the salix mongolica regenerated cellulose are used as raw materials and are subjected to efficient blending and wet-process spinning to prepare the regenerated cellulose fibers with the excellent fluorescent performance.

Owner:WUJIANG JINGMEIFENG IND

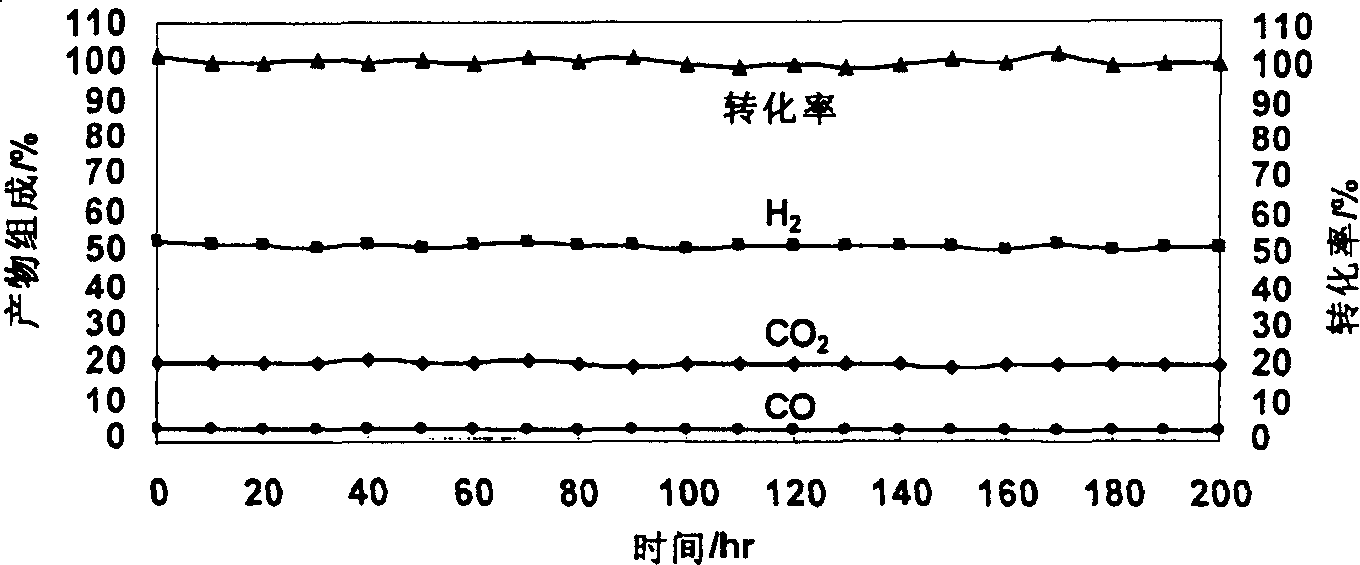

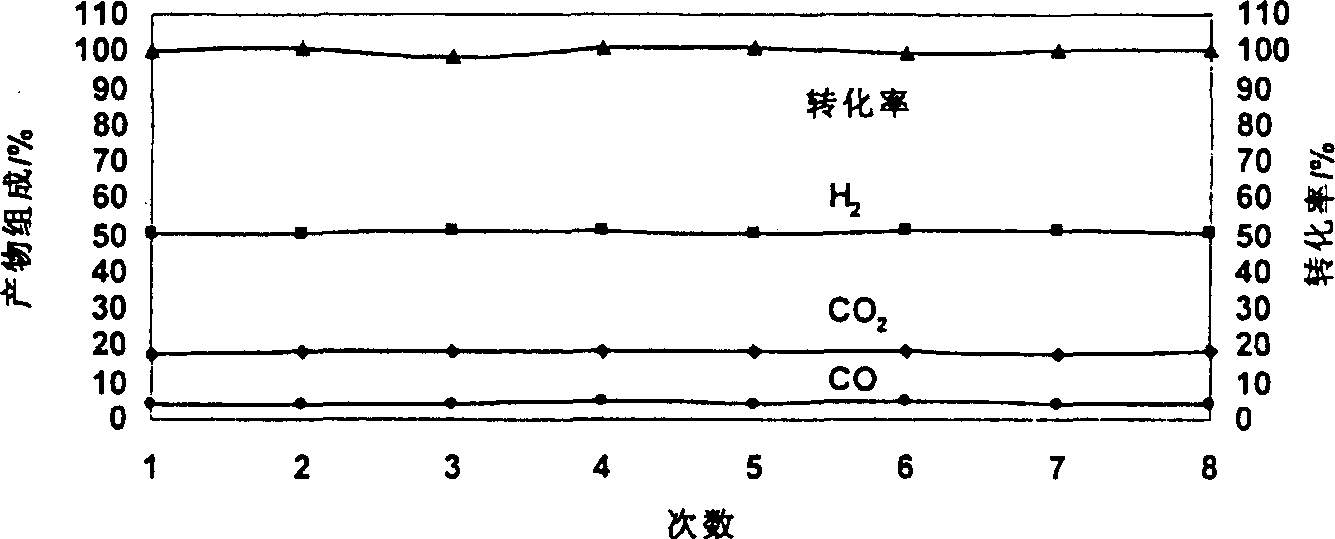

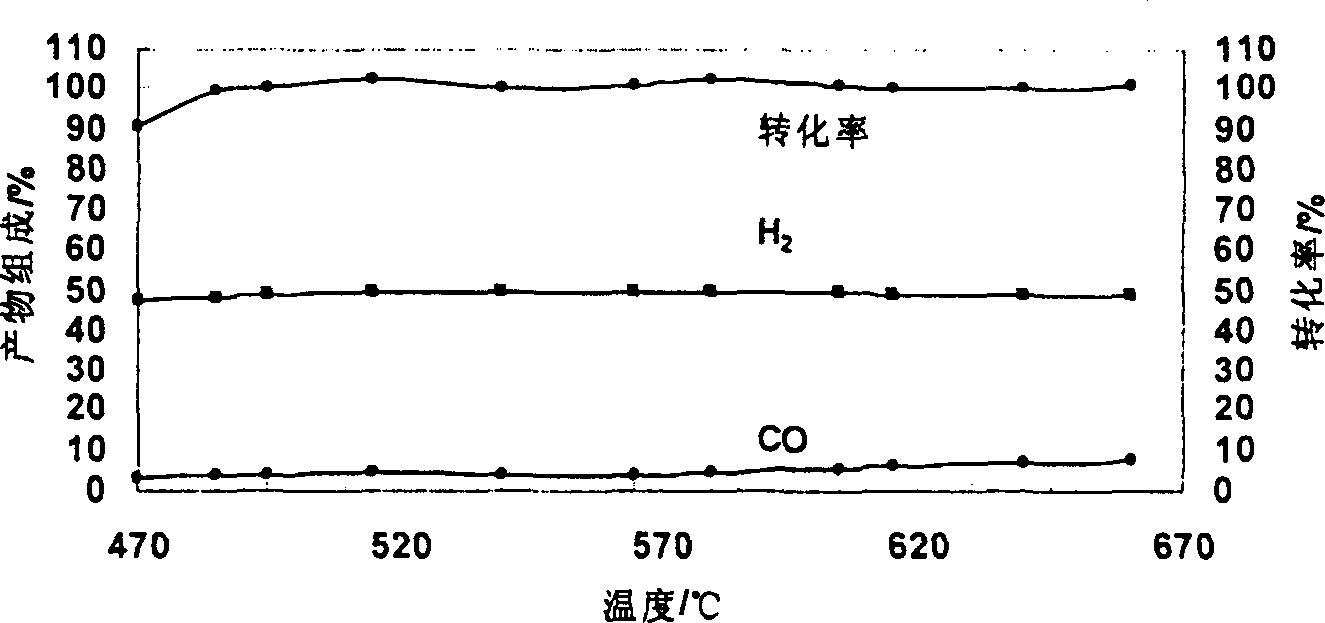

Catalyst for autothermal reformation of methanol to prepared hydrogen and its prepn process and application

InactiveCN1672789AHigh activityImprove heat stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsDecompositionAdhesive

The catalyst has metal oxide without copper and noble metal as main active component and the composite oxide of RE and transition metal as the catalytic assistant, heat stabilizing assistant, structure stabilizing assistant and active catalyst component support. The addition of the composite oxide of RE and transition metal raises the reaction activity of the catalyst as well as its strength and stability greatly. The preparation process may be co-precipitation one, isometric soaking one or hot decomposition one. In the co-precipitation process or soaking process, adhesive and pore creating agent are added, and the adhesive and pore creating agent is mixture water solution of organic acids, inorganic acids, pseudo-thin diasphore and polymer. The catalyst may be used in hydrogen source system of fuel cell with unstable operation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

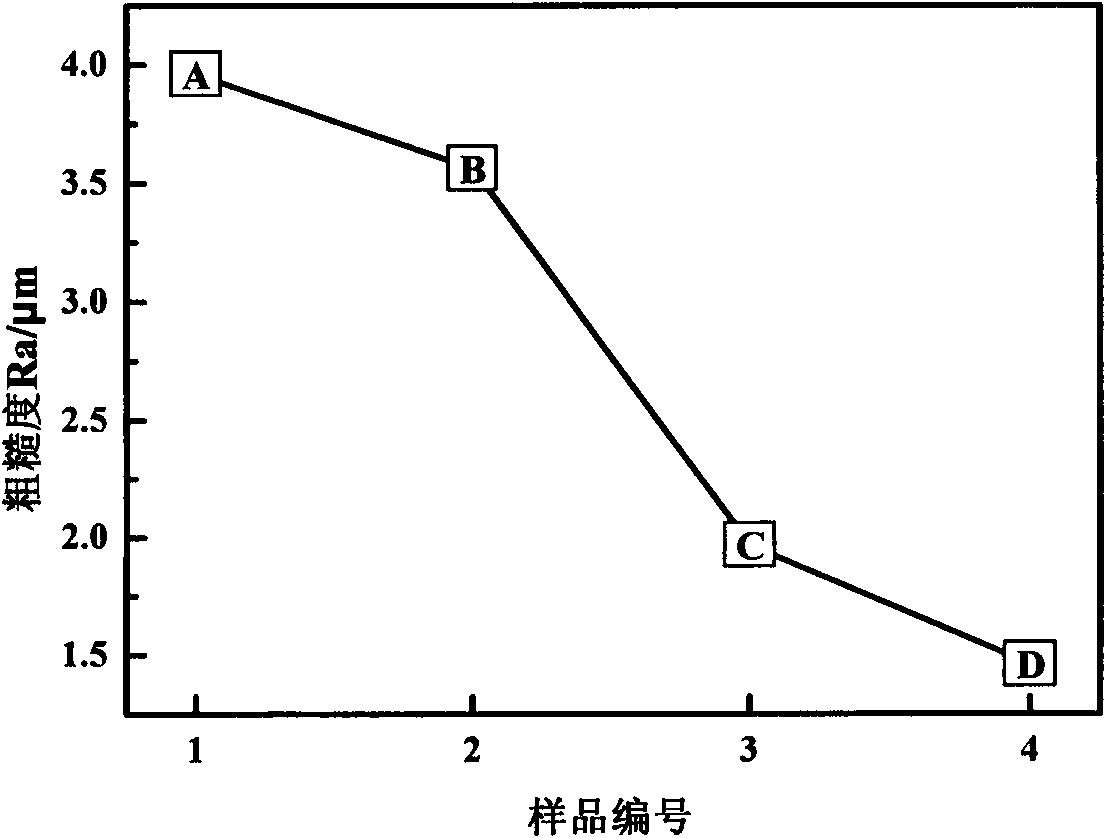

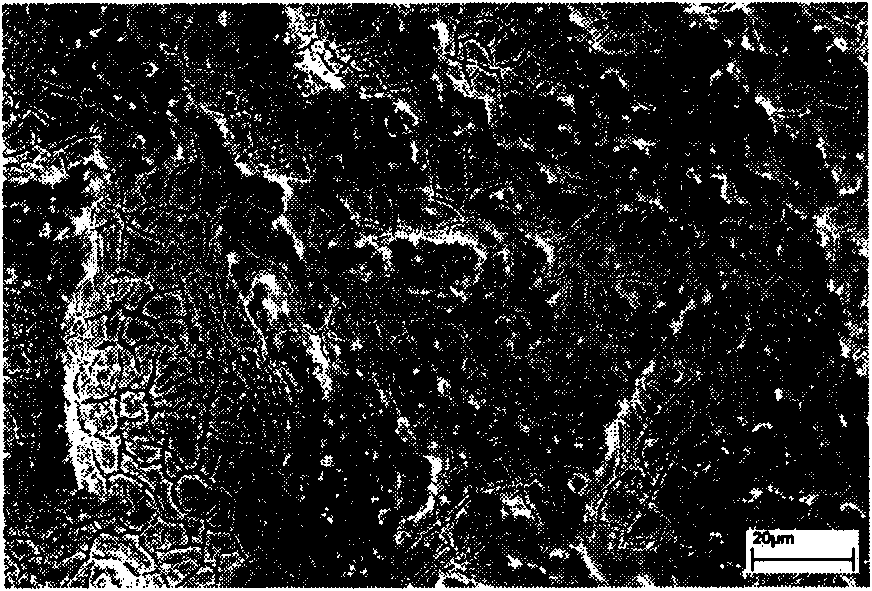

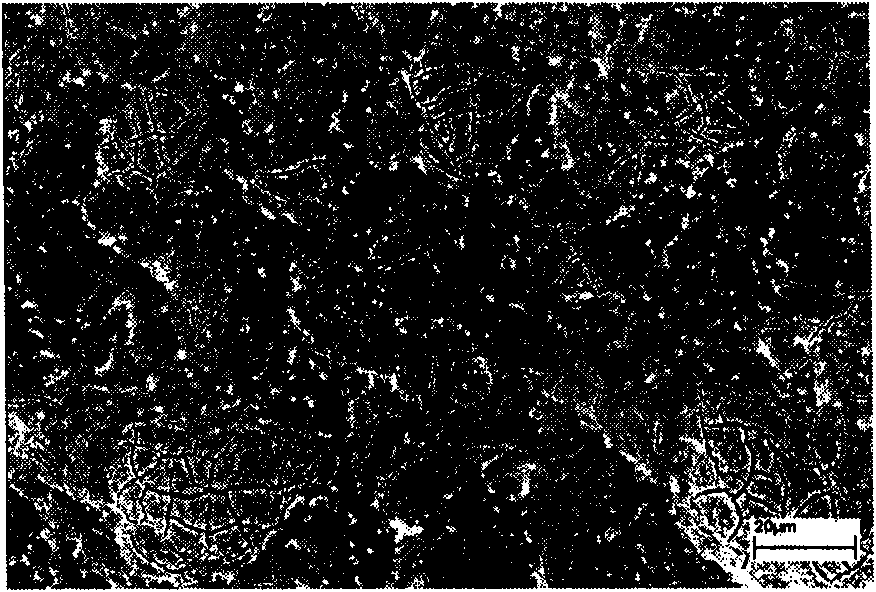

Method for surface pre-treatment of titanium electrode substrate

InactiveCN101565834AOptimal Preprocessing ParametersEnhanced electrocatalytic activity for oxygen evolutionElectrodesTitanium electrodeMetallic materials

The invention belongs to the field of metal material and relates to a method for surface treatment of a titanium electrode substrate. The service life and the electrocatalysis performance of the titanium electrode are greatly increased by the abrasive blasting pretreatment to the substrate. The abrasive blasting treatment is carried out on the titanium substrate; the nozzle pressure of an abrasive blasting machine is 0.3-0.5MPa; the Al2O3 grinding medium of 70-90 meshes is adopted; the blasting angle is 45-90 degrees; the distance from the nozzle to a workpiece is 1-2cm; the coarsening time is 15-30s; the titanium substrate is then pickled for pickling treatment in a 10wt.% of oxalic acid solution for 1.5-2.5 hours at the temperature of 90-95 DEG C; a Ti / IrO2.Ta2O5 oxide coating electrode is prepared on the obtained substrate by a thermal decomposition method, wherein the Ir is chloro-iridic acid, Ta is tantalum pentachloride and the molar ratio of Ir to Ta is 7:3; a coating solution is uniformly coated on the pre-treated titanium substrate by a soft hair brush; the titanium substrate is dried for 10min at the temperature of 120 DEG C, is subsequently arranged in a box-type resistance furnace and sintered for 10min at the temperature of 450 DEG C; the above operations of coating, drying and sintering are repeatedly carried out by 5-20 times; and the final sintering is carried out for 1h at the temperature of 450 DEG C. The method provides optimum pretreatment parameters, greatly prolongs the service life of the titanium electrode, effectively improves the electrocatalytic activity and greatly reduces the running and repairing cost for the electrode.

Owner:UNIV OF SCI & TECH BEIJING

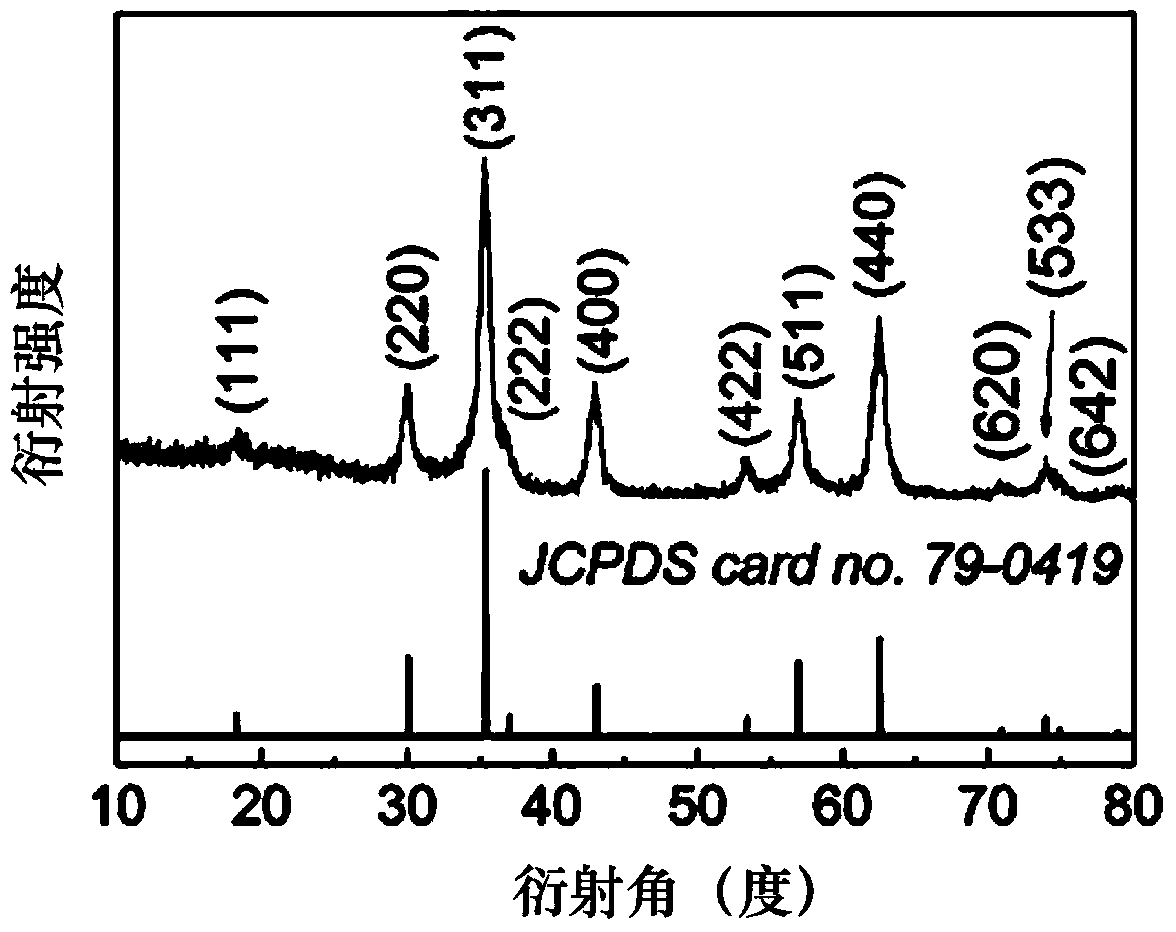

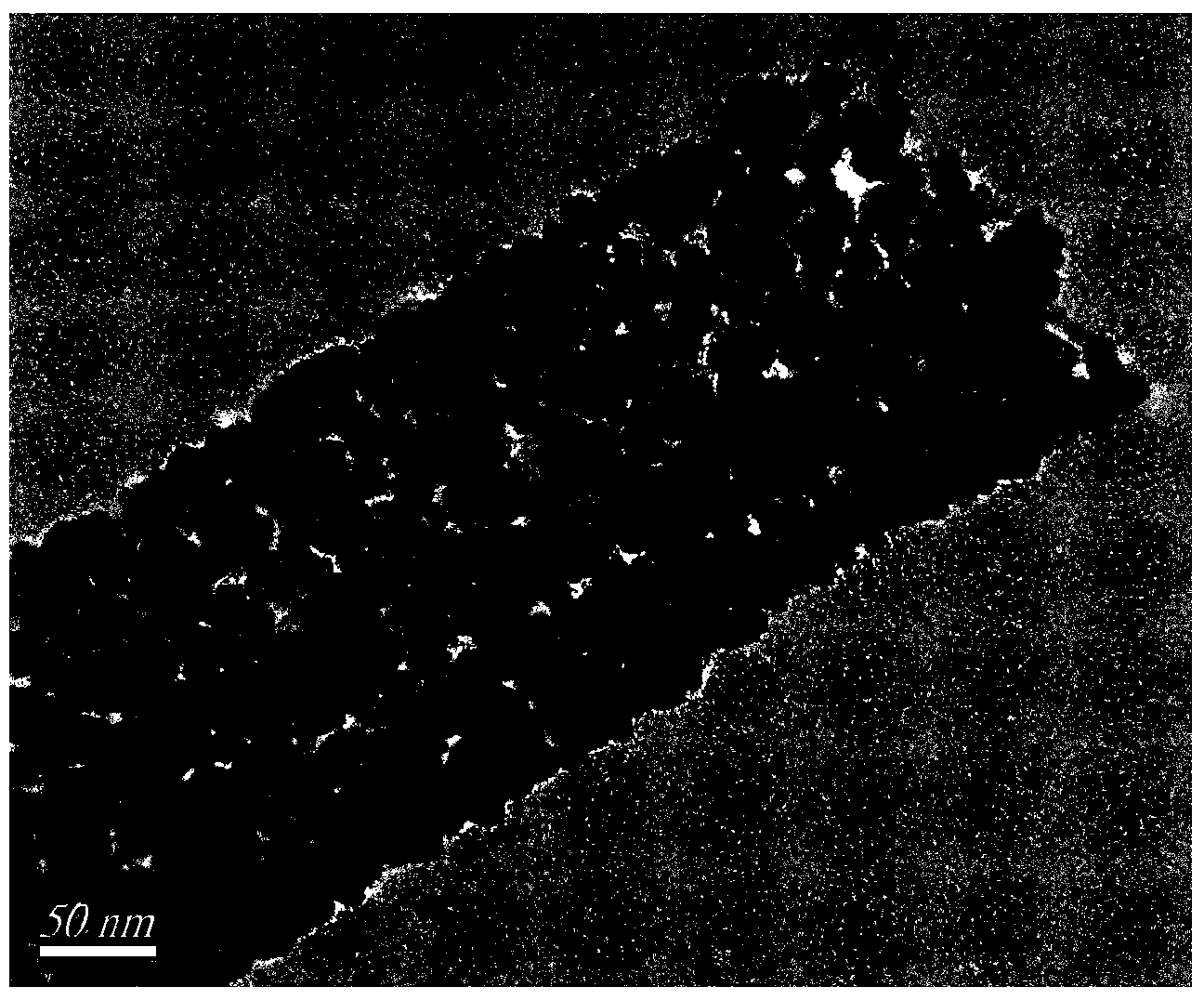

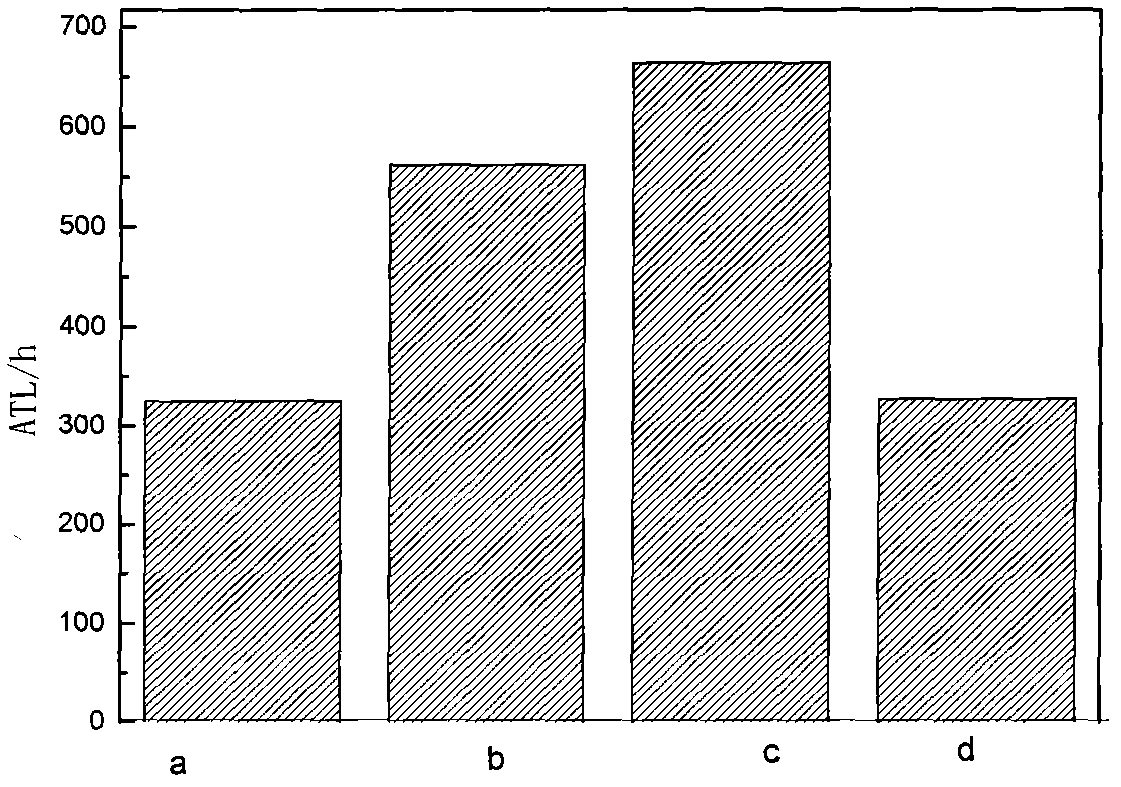

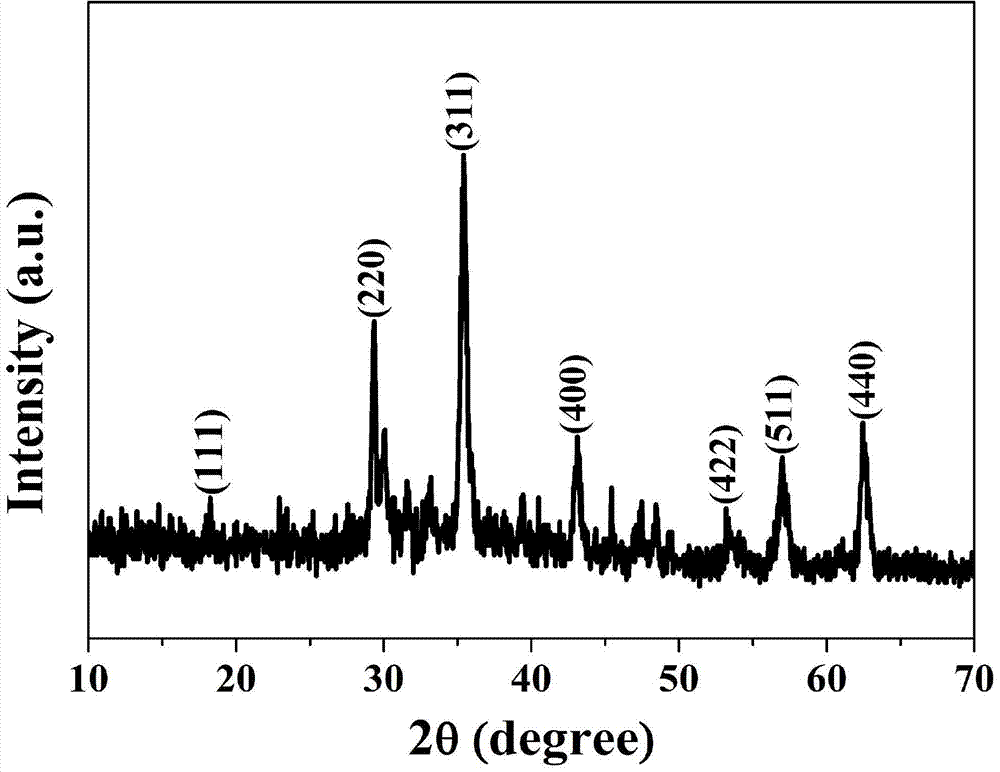

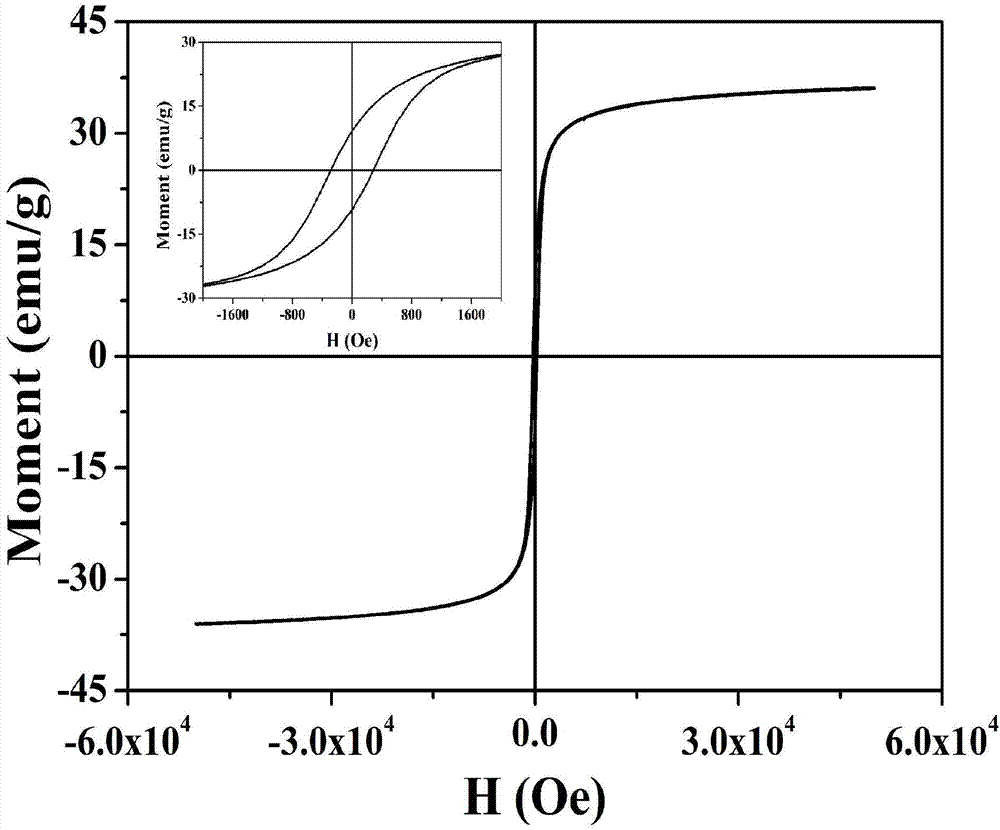

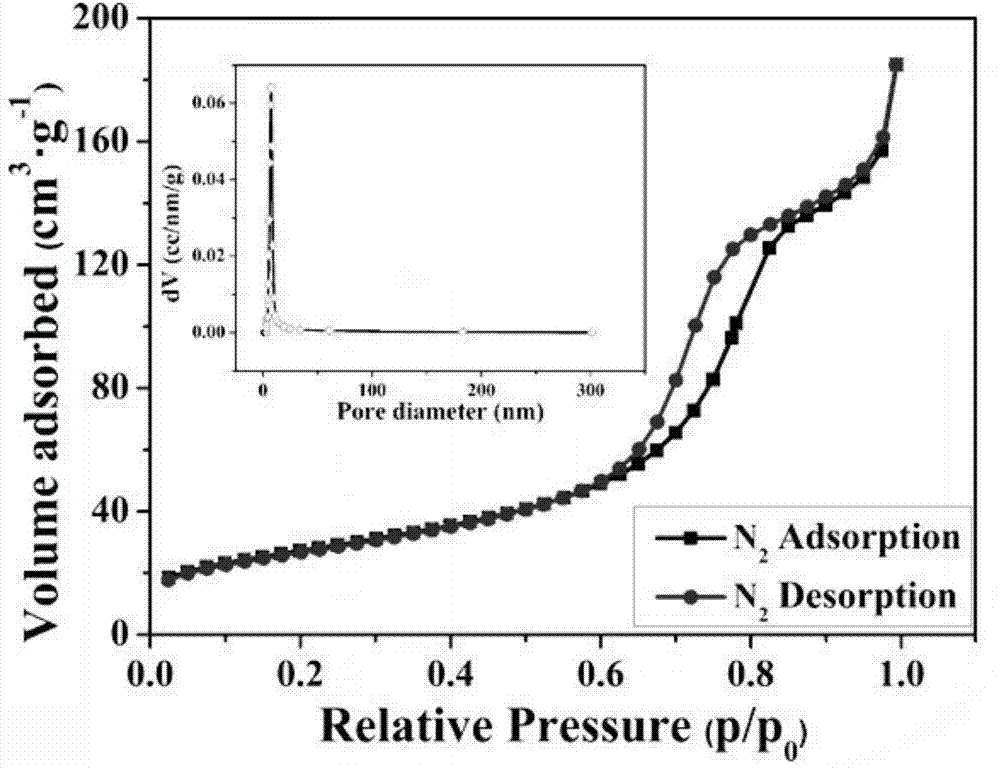

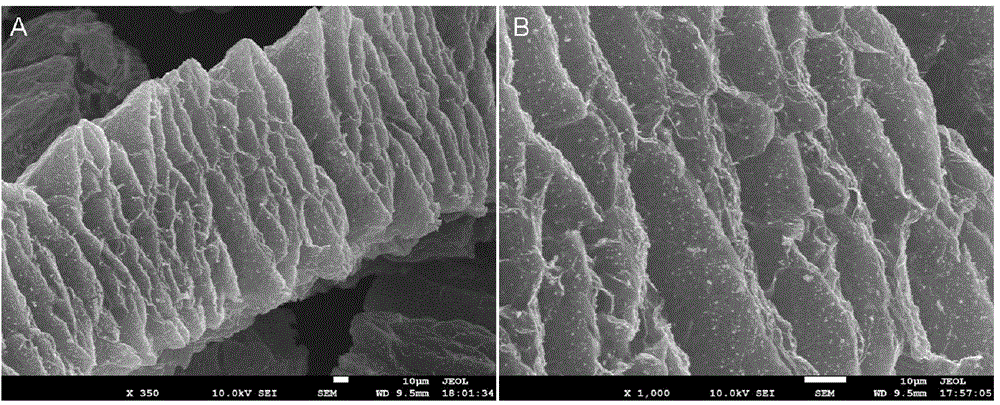

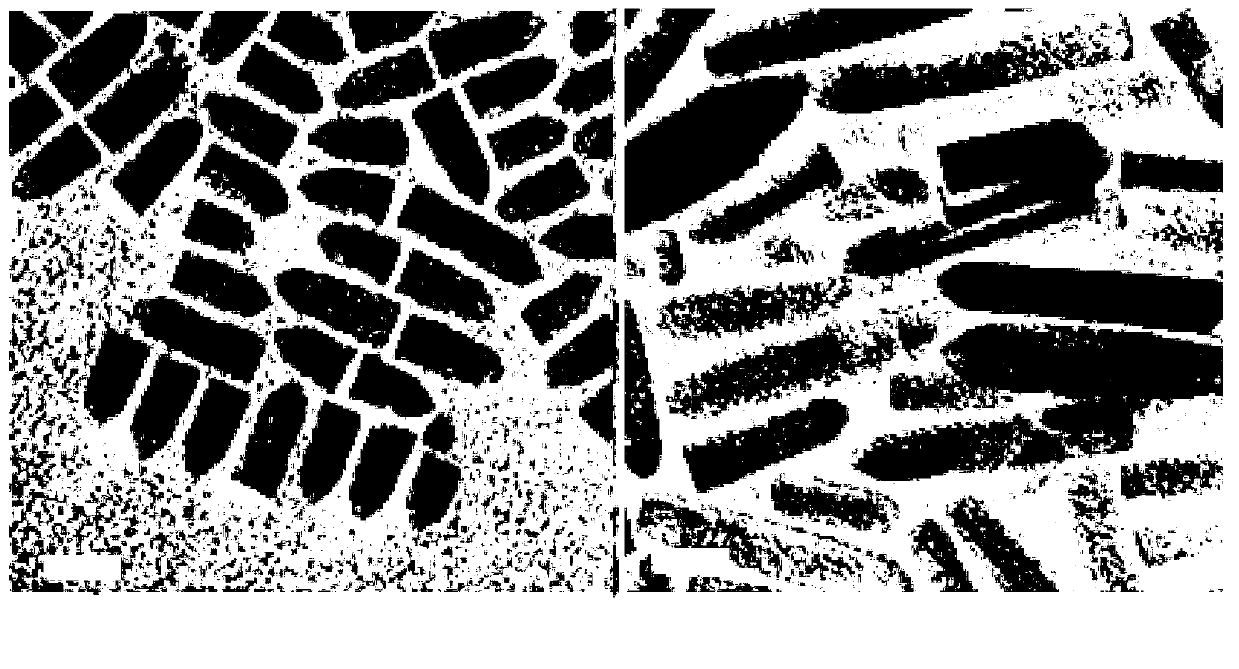

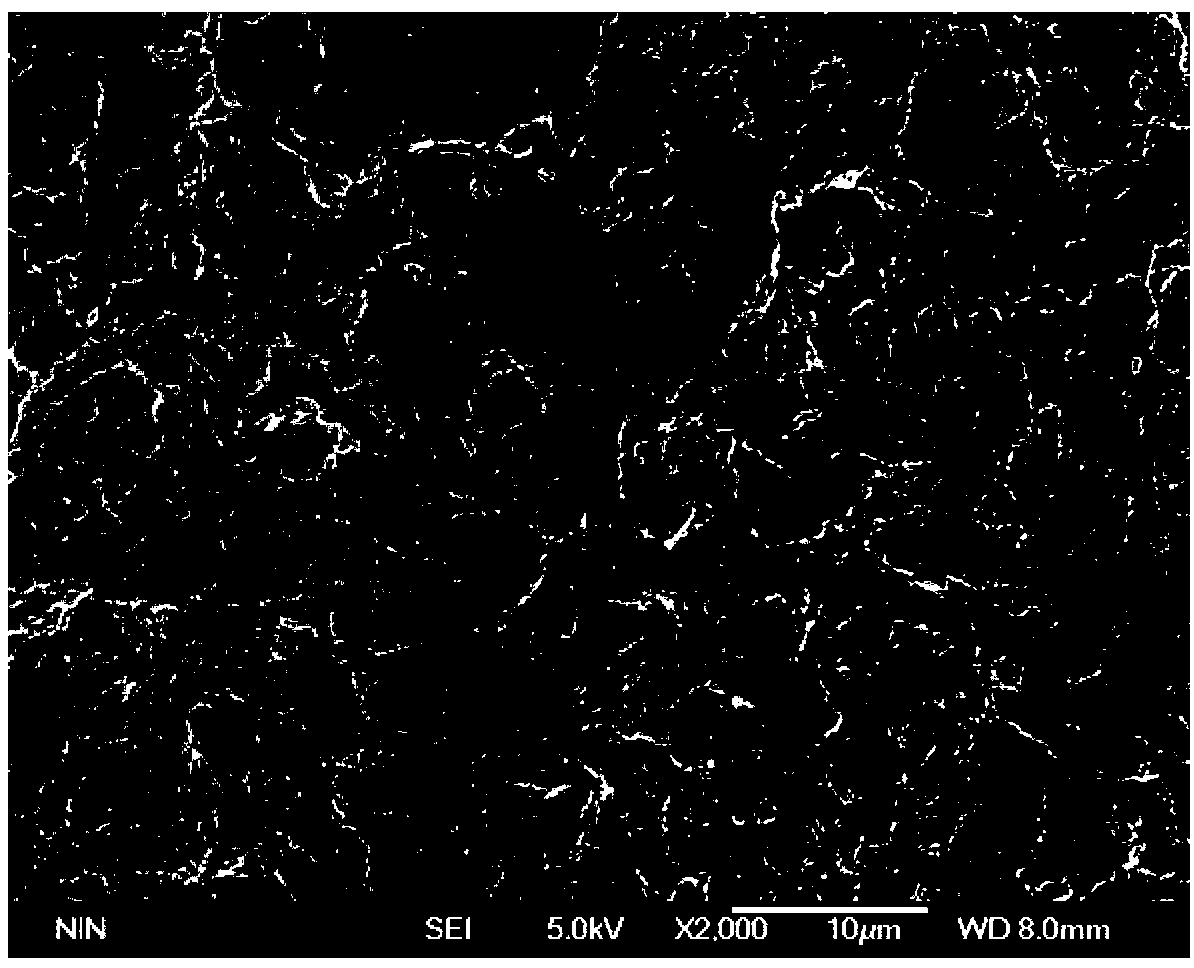

Preparation method of carbon encapsulated magnetic C/Fe3O4 nano composite material and application thereof

InactiveCN104495950ASimple processLow costMaterial nanotechnologyInorganic material magnetismSide effectThermal decomposition method

The invention discloses a preparation method of a carbon encapsulated magnetic C / Fe3O4 nano composite material and an application thereof. The invention belongs to the technical field of a magnetic nano-material, and the carbon encapsulated magnetic C / Fe3O4 nano composite material can be prepared by using a hydrothermal method and a thermal decomposition method through synthesis. The carbon encapsulated magnetic C / Fe3O4 nano composite material is used for processing a dye methylene blue in waste water. The preparation method has the beneficial effect of simple process, high material purity, wide application scope, no residues, no toxic and side effect, and easy separation, and can be expected for wide application in environment engineering field.

Owner:LIAOCHENG UNIV

Electrode material with intermediate Ti4O7 coating

InactiveCN105058916AImprove product qualityImprove bonded stateMetal layered productsElectrode potentialAlloy

Owner:KUNMING UNIV OF SCI & TECH

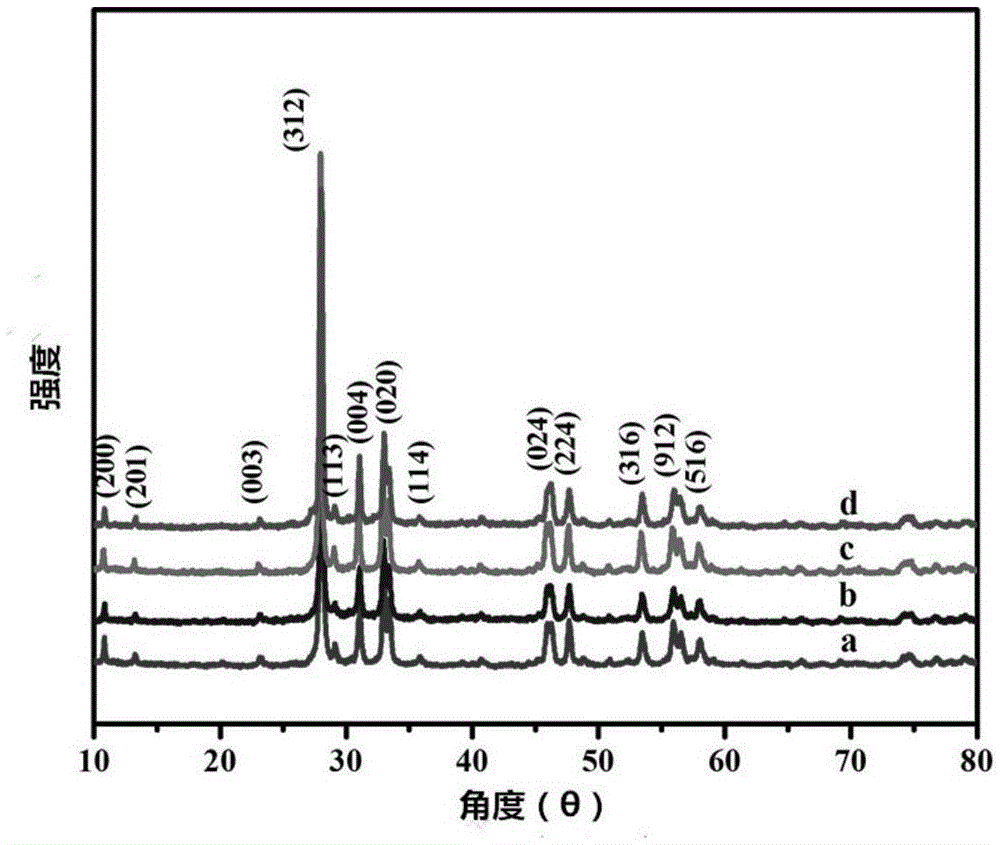

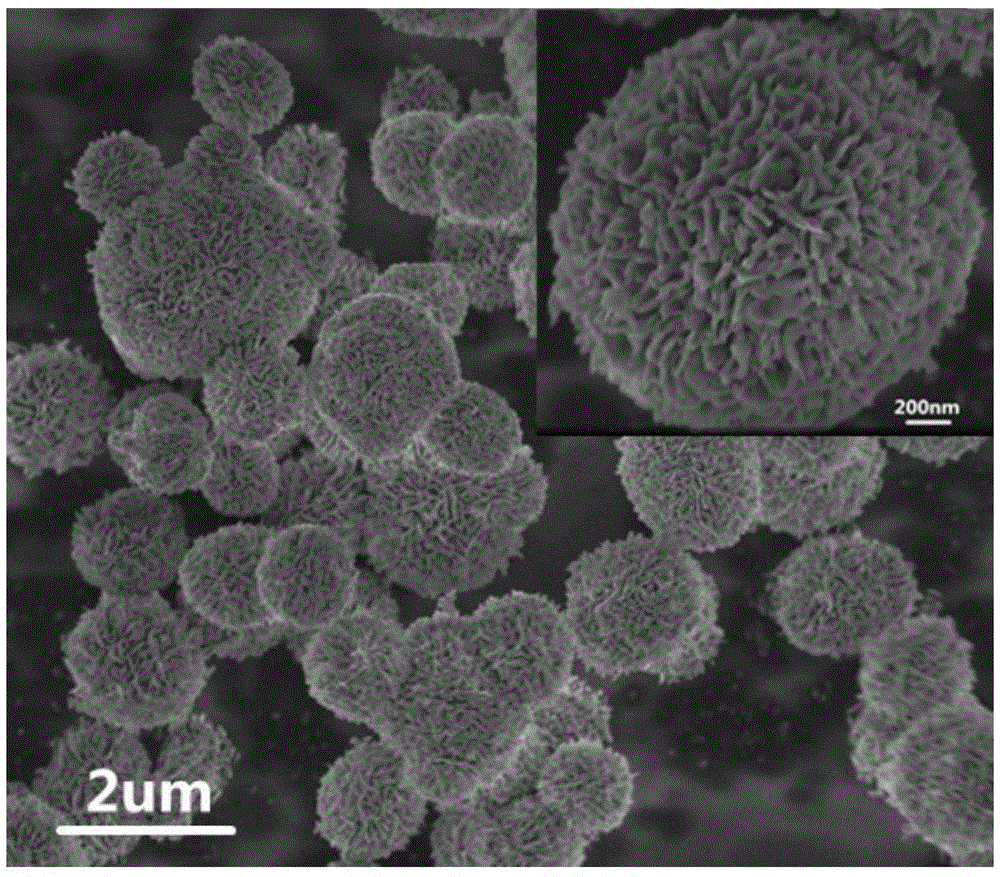

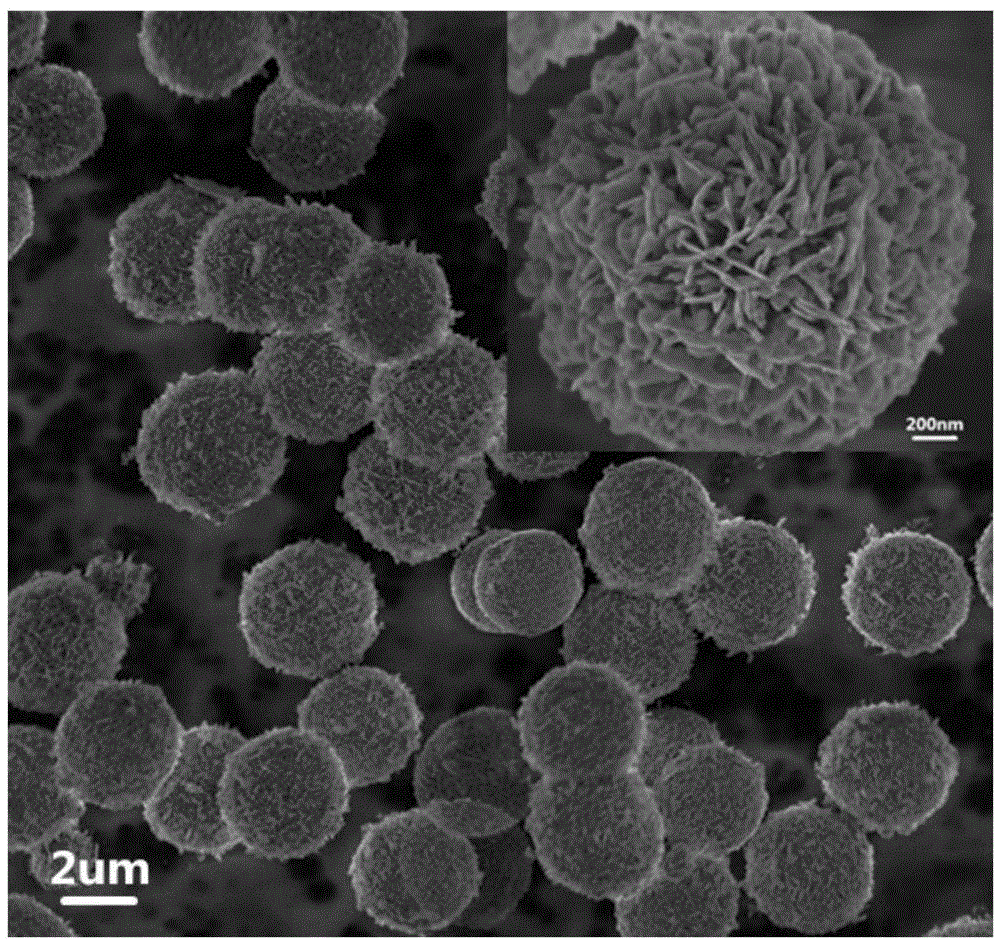

Nano-mesoporous micro-spherical Ln-Bi5O7I photocatalyst and preparation method thereof

InactiveCN105664979AUniform shapeLarge specific surface areaPhysical/chemical process catalystsMethyl orangePhenol

The invention provides a nano-mesoporous micro-spherical Ln-Bi5O7I photocatalyst and a preparation method thereof. The nano-mesoporous micro-spherical photocatalyst is 15-30 nm in surface mesopore diameter, is 1-5 [mu]m in average particle size and has an orthorhombic crystal form, wherein nBi + Ln : nI = 0.85-1:1, and nLn : nBi = 0.01-0.055:1. The preparation method includes the steps of: dissolving a bismuth salt, an iodine salt and nitrate containing rare earth ions respectively in certain-quantity ethylene glycol, performing ultrasonic oscillation, adding the rare earth ion solution to the bismuth-containing solution, adding the iodine-containing solution, and performing magnetic stirring to form a precursor Ln-BiOI; performing a hydrothermal reaction to the precursor to prepare Ln-BiOI powder; and maintaining the temperature of the Ln-BiOI at 425-525 DEG C to prepare the Ln-Bi5O7I powder. The Ln-Bi5O7I photocatalyst has homogeneous appearance, has large specific surface area, is strong in stability and has excellent photocatalytic performance in degradation of rhodamine B, methyl orange, phenol, bisphenol A and the like. The method combines advantages of both hydrothermal and thermal-decomposition methods.

Owner:SHAANXI NORMAL UNIV

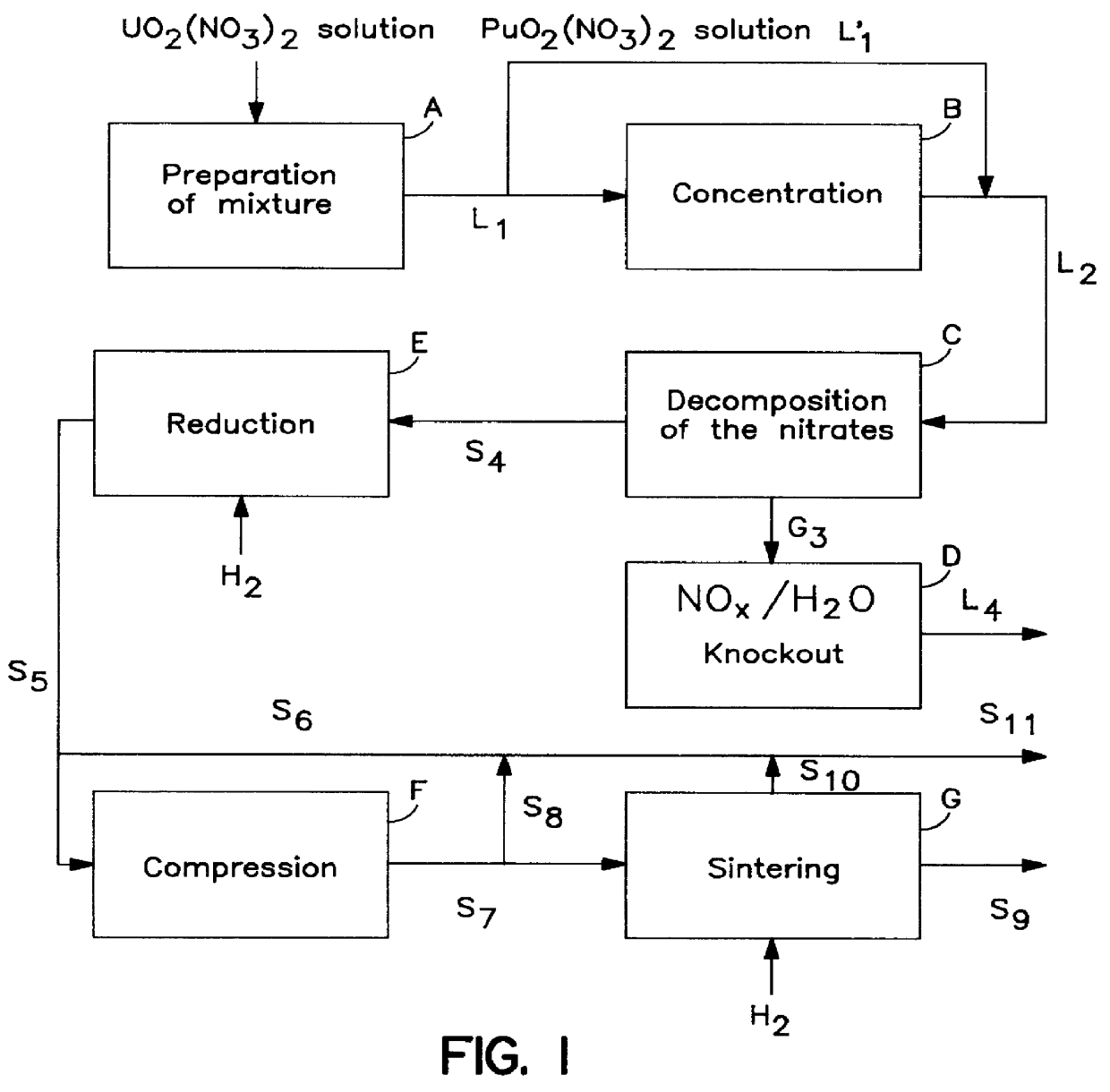

Method for preparing a mixture of powdered metal oxides from nitrates thereof in the nuclear industry

InactiveUS6110437AEasy to recycleImprove responseOxygen/ozone/oxide/hydroxideTransuranic element compoundsPowder mixtureNitrate

PCT No. PCT / FR96 / 01993 Sec. 371 Date Mar. 2, 1999 Sec. 102(e) Date Mar. 2, 1999 PCT Filed Dec. 12, 1996 PCT Pub. No. WO97 / 21629 PCT Pub. Date Jun. 19, 1997A thermal decomposition method useful in the nuclear industry for preparing a powdered mixture of metal oxides having suitable reactivity from nitrates thereof in the form of an aqueous solution or a mixture of solids. According to the method, the solution or the mixture of solids is thermomechanically contacted with a gaseous fluid in the contact area of a reaction chamber, said gaseous fluid being fed into the reaction chamber at the same time as the solution or mixture at a temperature no lower than the decomposition temperature of the nitrates, and having a mechanical energy high enough to generate a fine spray of the solution or a fine dispersion of the solid mixture, and instantly decompose the nitrates. The resulting oxide mixtures may be used to prepare nuclear fuels.

Owner:COMURHEX

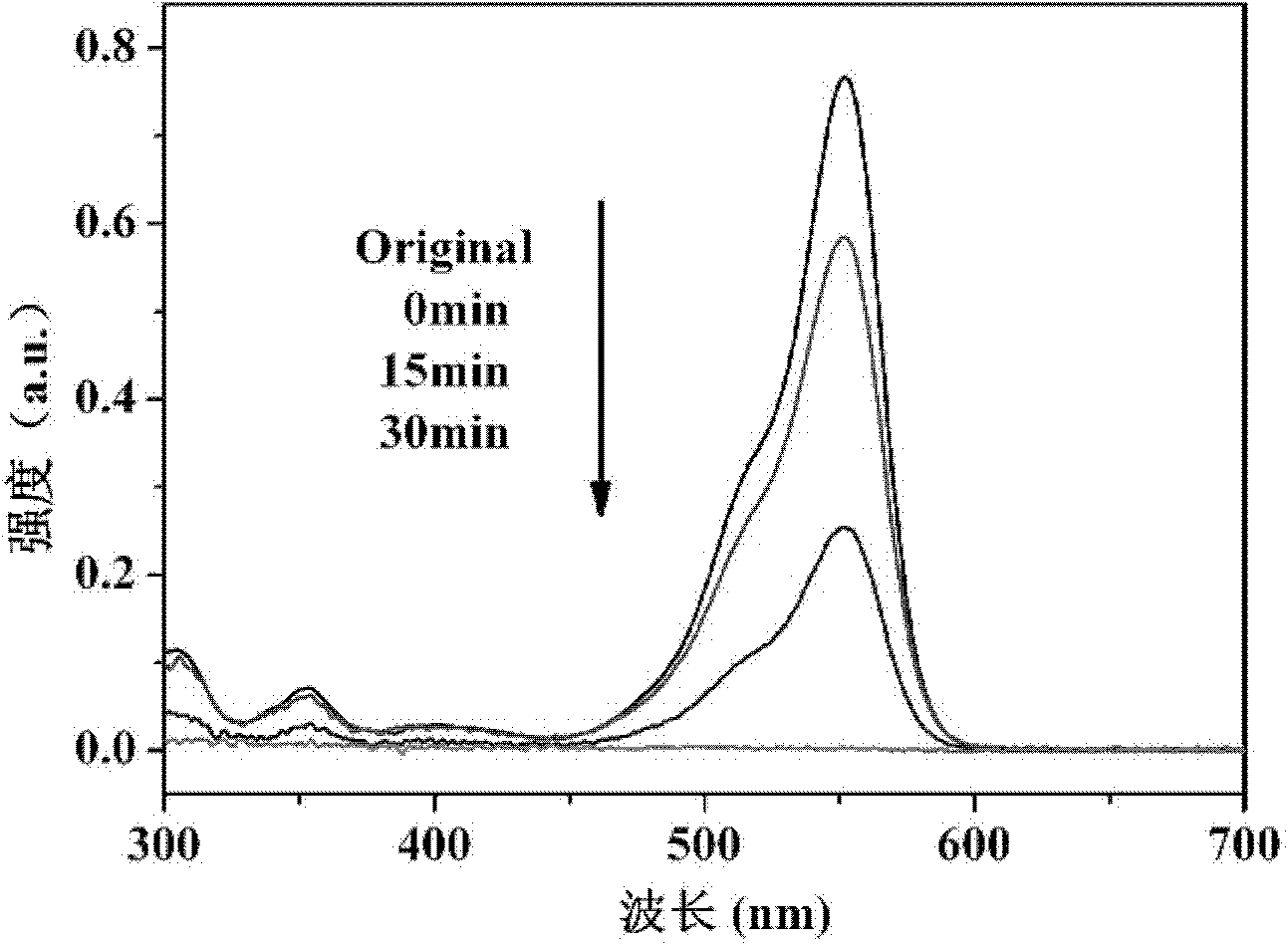

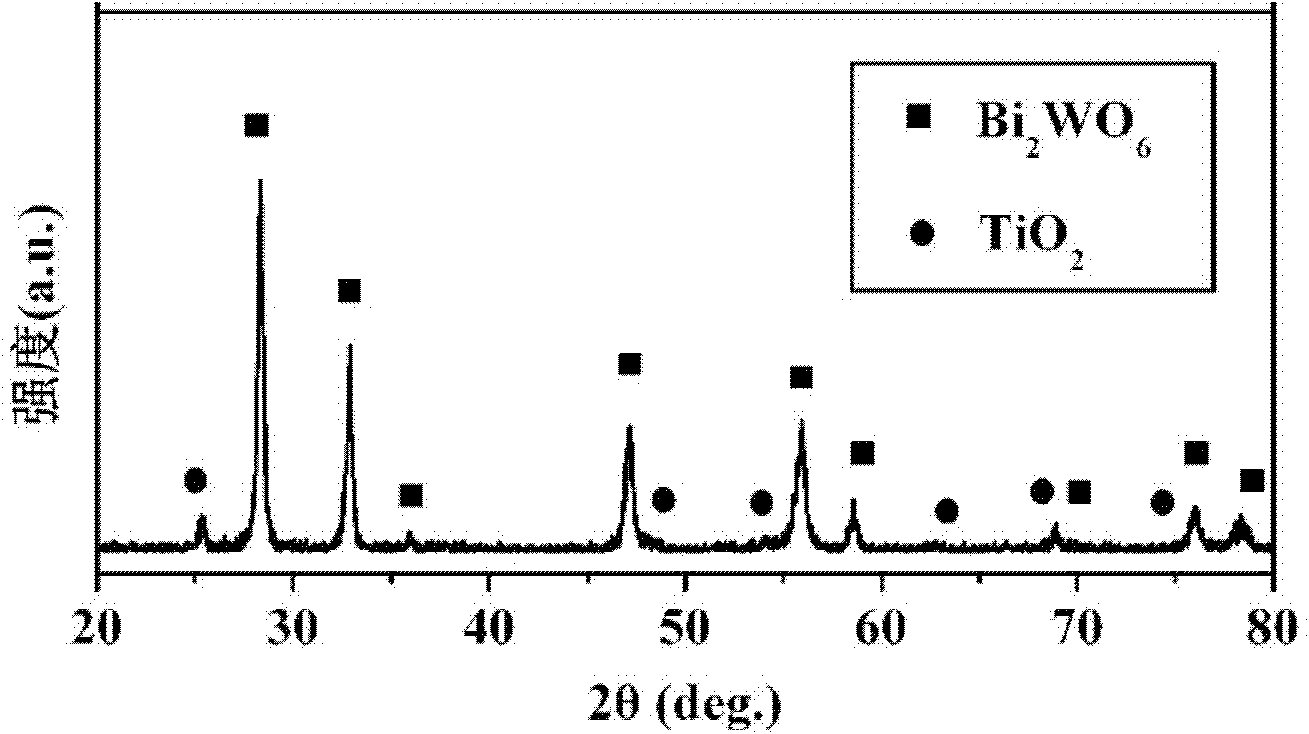

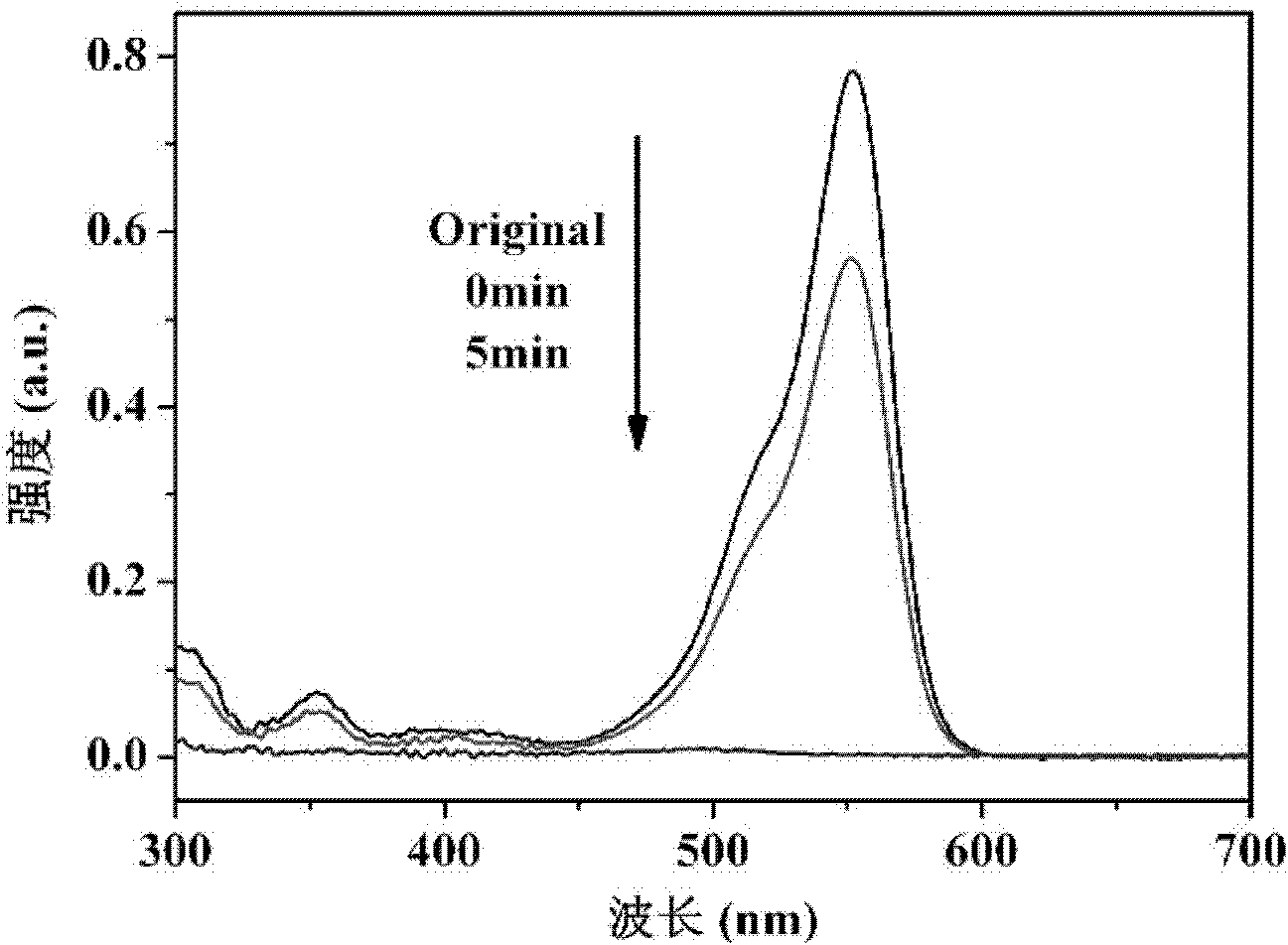

Bismuth tungstate composite photocatalyst, preparation method thereof, and application thereof

InactiveCN102335602AImprove photocatalytic efficiencyMaintain strong oxidative capacityWater/sewage treatment by irradiationDispersed particle separationTungstateThermal decomposition method

The invention belongs to the field of photocatalyst, and specifically relates to a Bi2WO6 (bismuth tungstate) composite photocatalyst, a preparation method thereof, and an application thereof. The Bi2WO6 composite photocatalyst comprises components of, by weight: 1-99% of Bi2WO6 and 1-99% of TiO2. The Bi2WO6 composite photocatalyst can be prepared through a coprecipitation method, a thermal decomposition method, a hydro thermal method, a solvent thermal method, or a sol-gel method. The Bi2WO6 composite photocatalyst provided by the invention has advantages of high catalytic activity, good cyclical stability, and wide photoresponse range. The Bi2WO6 composite photocatalyst can be widely applied in respects of sewage processing, air conditioning, and sterilizing. The Bi2WO6 composite photocatalyst has a wide application prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

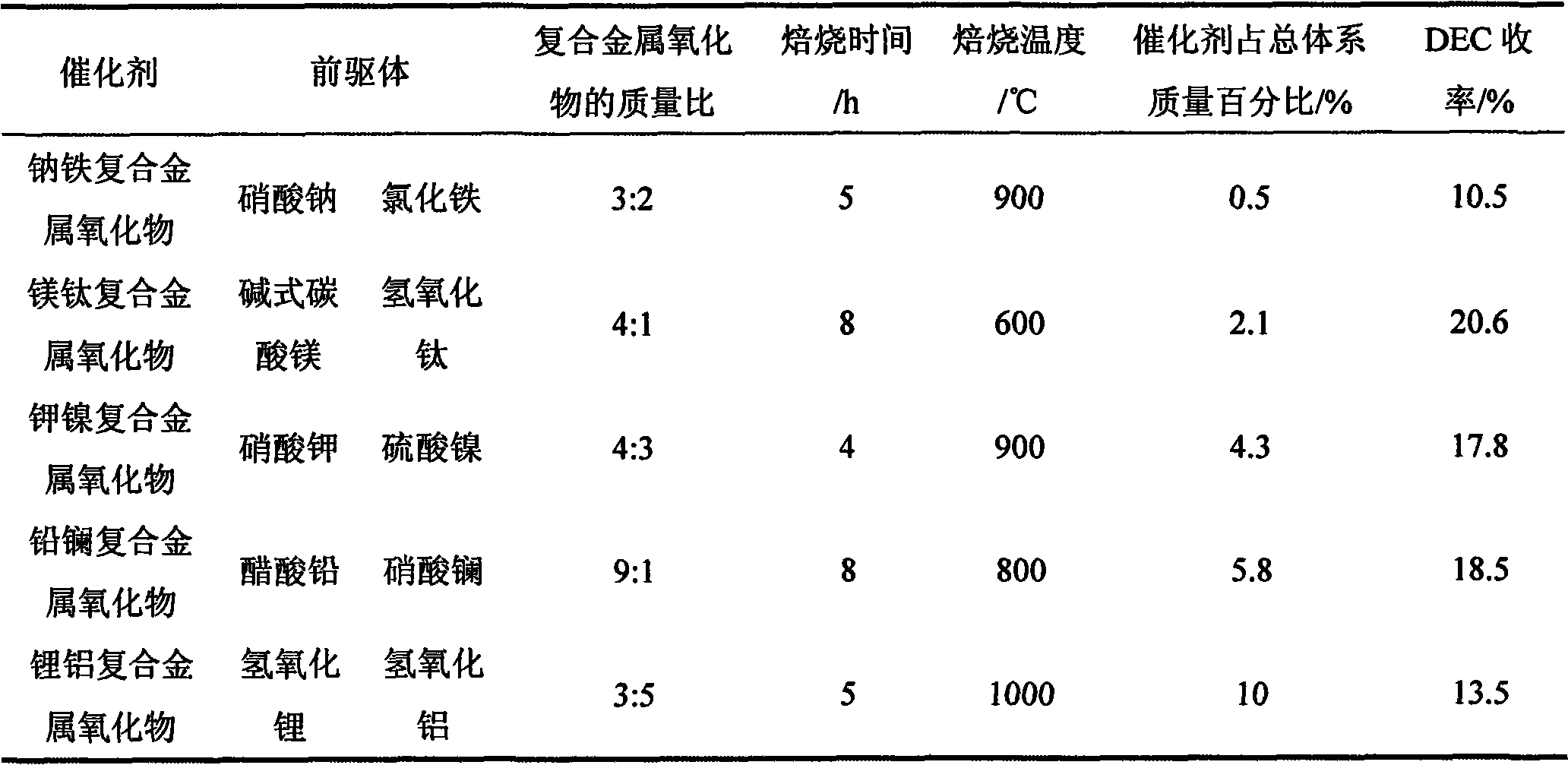

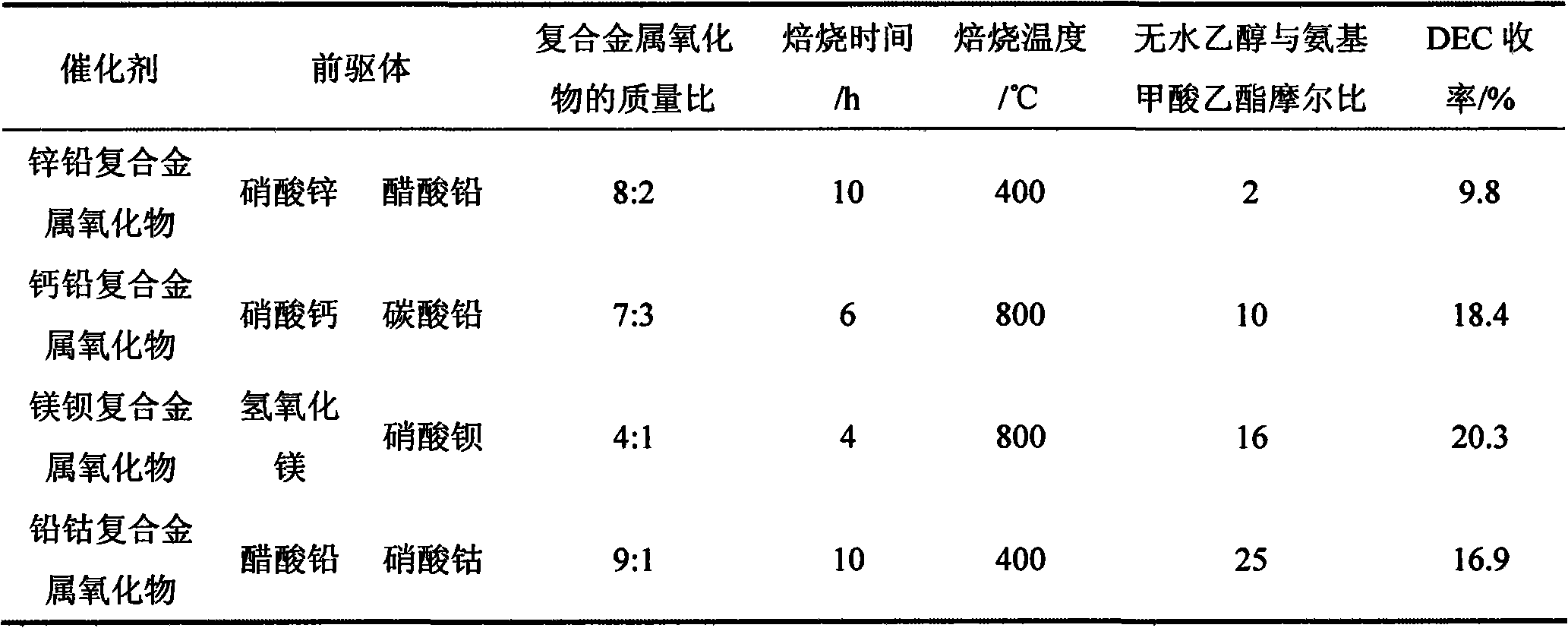

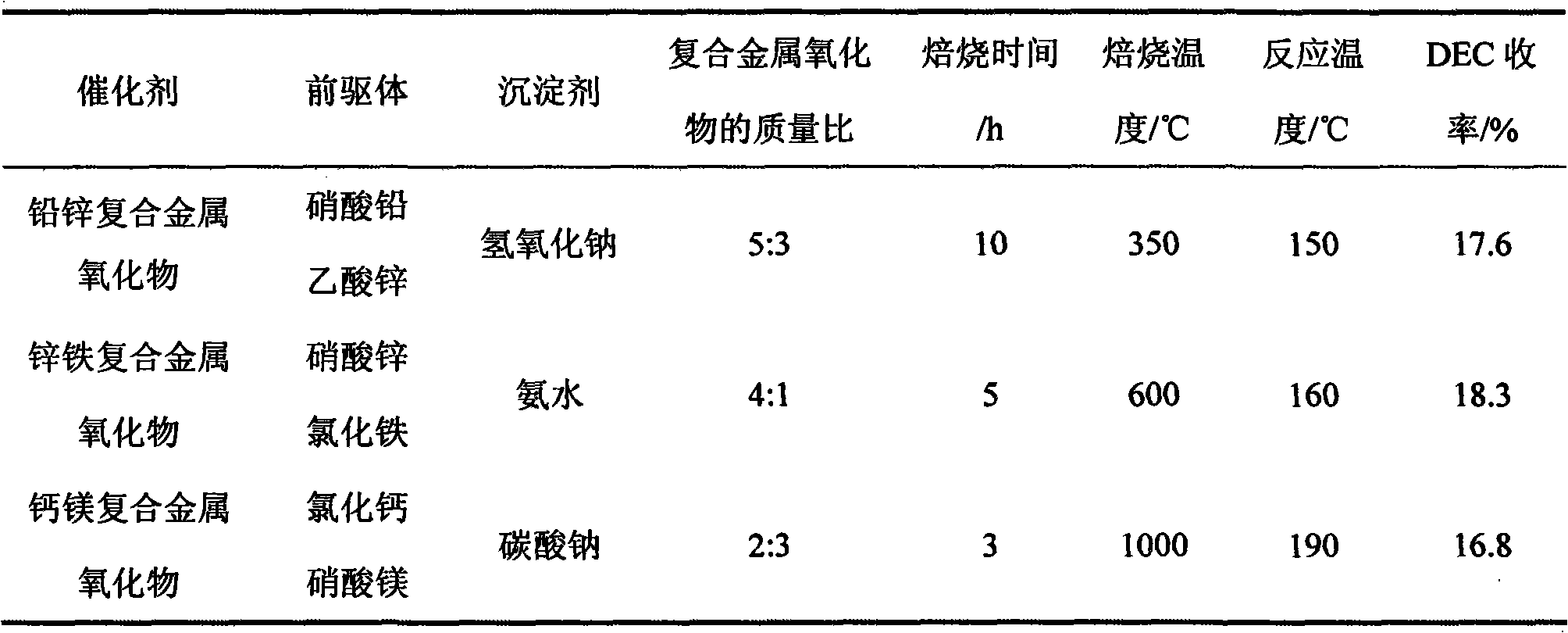

Technology of preparing diethyl carbonate by urea alcoholysis method

ActiveCN101659616AThe preparation process has no special requirementsEasy to prepareOrganic compound preparationCatalyst activation/preparationFiltrationHigh pressure

The invention belongs to the synthesis of organic carbonates and relates to a technology of synthesizing diethyl carbonate by a urea alcoholysis method. The technology comprises the steps of: adding anhydrous ethyl alcohol, ethyl carbamate and a catalyst into a high pressure reaction kettle, wherein the mole ratio of the anhydrous ethyl alcohol to the ethyl carbamate is 2 to 25, and the catalyst is combined metal oxide, and accounts for 0.5 to 10 percent of the whole system by mass percent; raising the temperature to 150 to 200 DEG C by stirring so as to carry out reaction for 1 to 15 hours; and taking out the reaction liquid after the reaction, and realizing the separation of the catalyst and the reaction liquid by simple filtration. The combined metal oxide is prepared by 2 to 3 metal oxide precursors among Li, Na, K, Ca, Mg, Ba, Sr, Al, Sn, Pb, La, Ti, W, Zr, Fe, Co, Ni, Cu and Zn through thermal decomposition method or coprecipitation method. The preparation method of the technology is simple, the catalyst activity is high, the stability is good, and the separation and recycling are easy.

Owner:HEBEI UNIV OF TECH

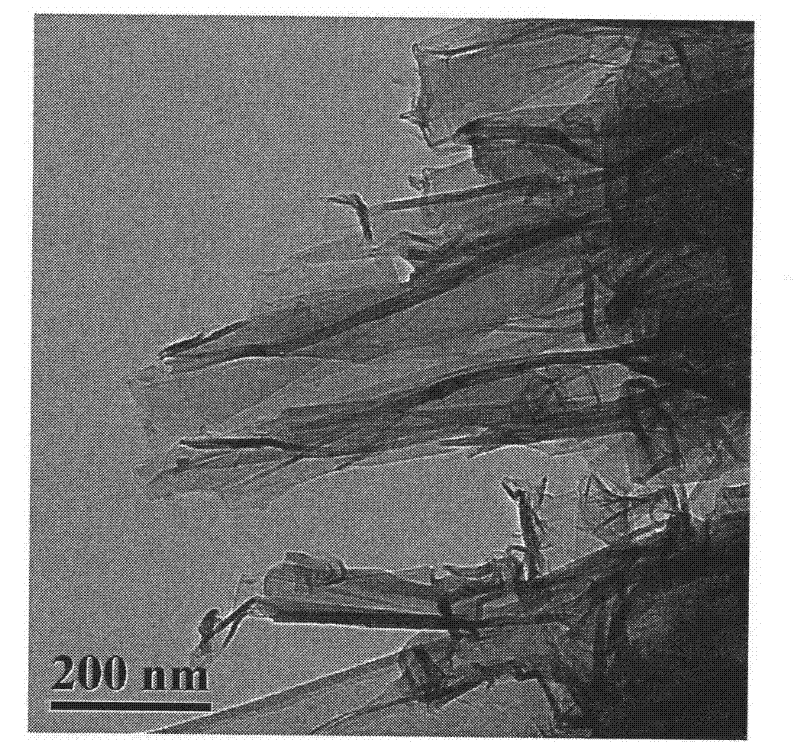

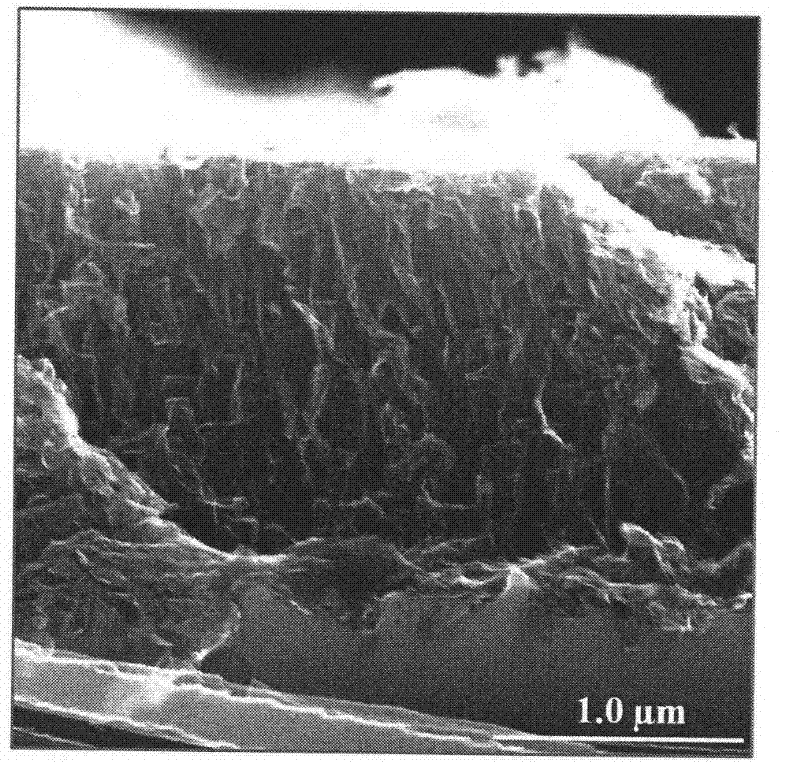

Preparation method for carbon nanotube or graphene nano-carbon material

InactiveCN102190294AAchieving controllable equipmentGood repeatabilityGraphene nanoribbonsThermal decomposition method

The invention discloses a novel preparation method for nano-carbon material without metal catalyst. The method is a silicon carbide high temperature thermal decomposition method, wherein the high-efficiency and controllable preparation of carbon nanotube and graphene nano-carbon material is realized through modulating the atmosphere in the preparation process. According to the method, high purity nano-carbon material without metal catalyst is produced, thus the influence of metal on the physicochemical property of nano-carbon material is overcome fundamentally. The method is a simple high-efficiency novel method with good repeatability for producing nano-carbon material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

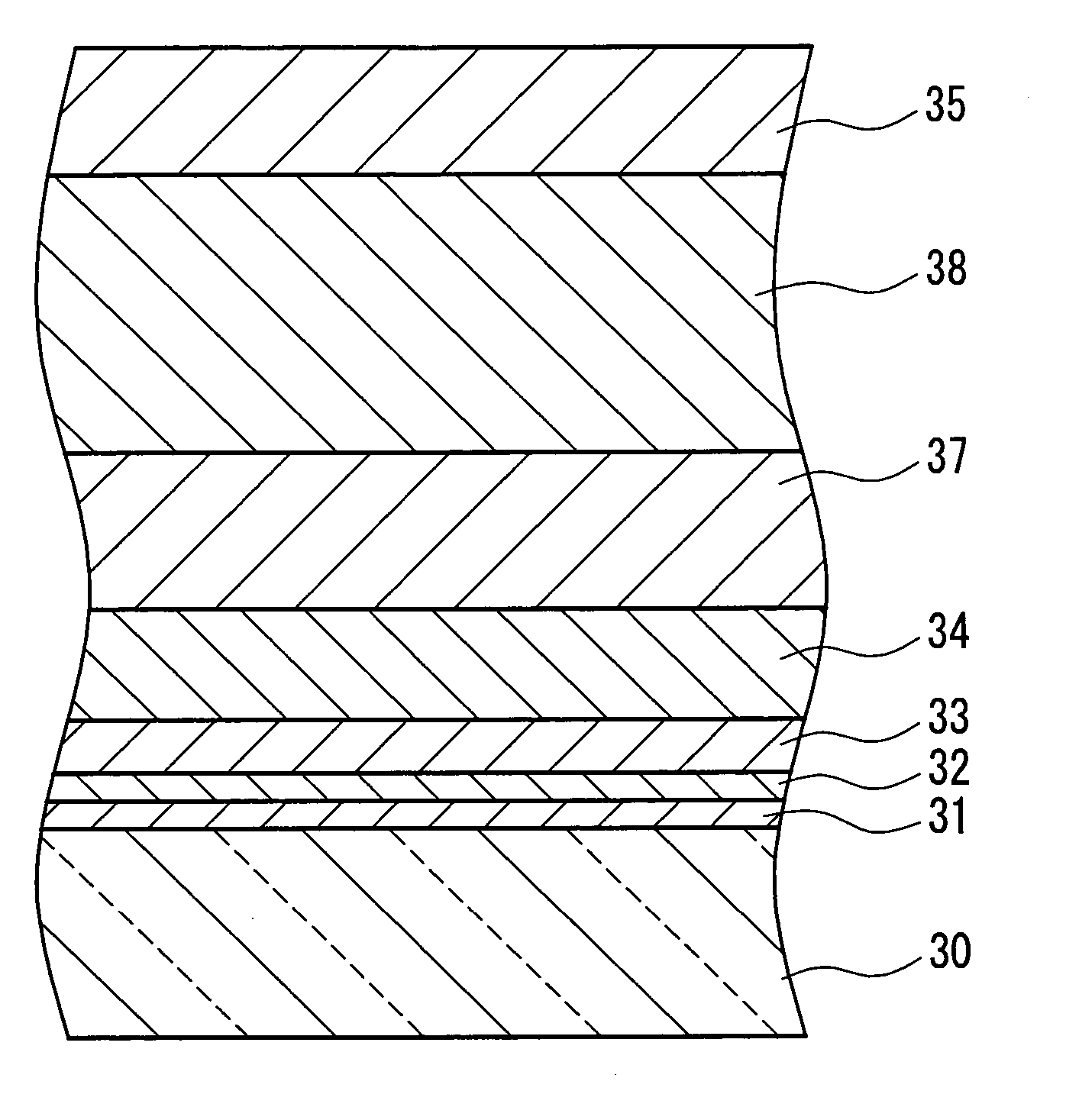

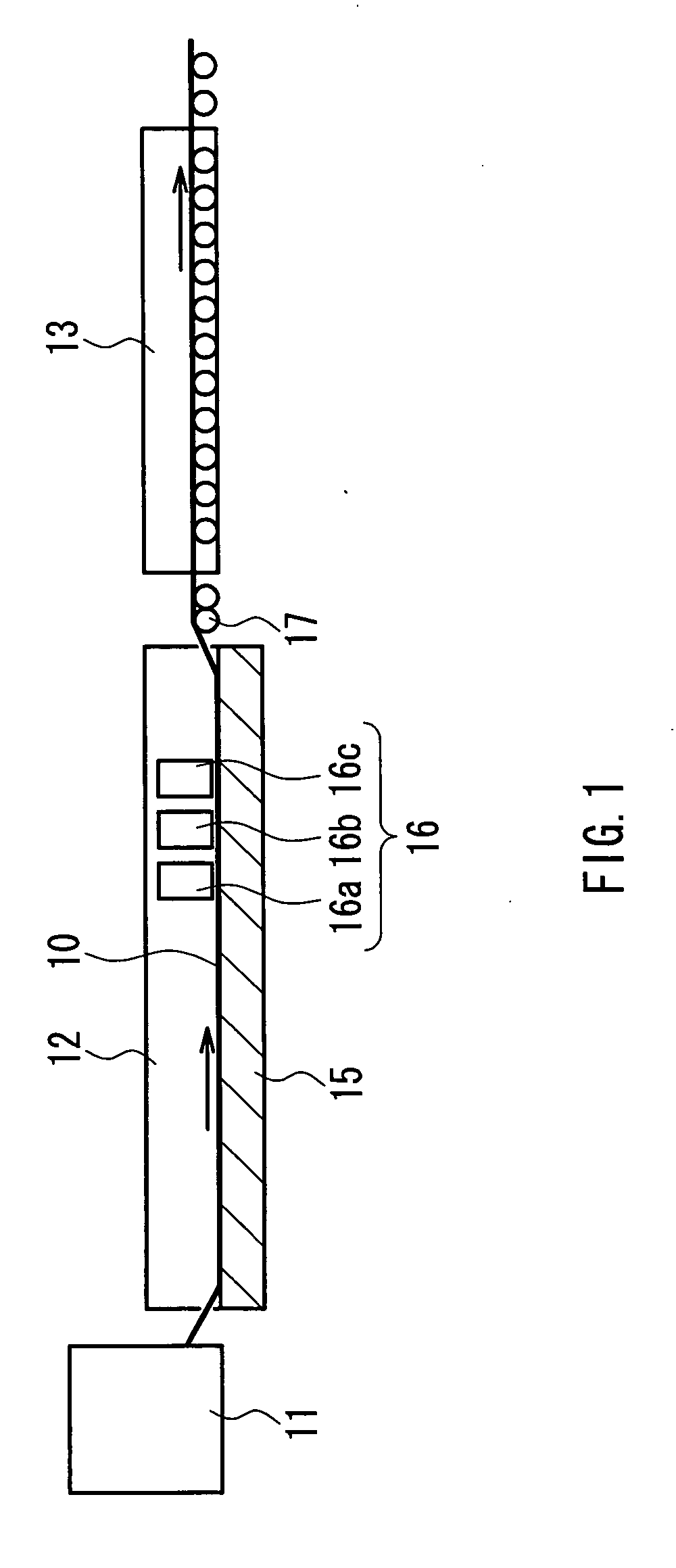

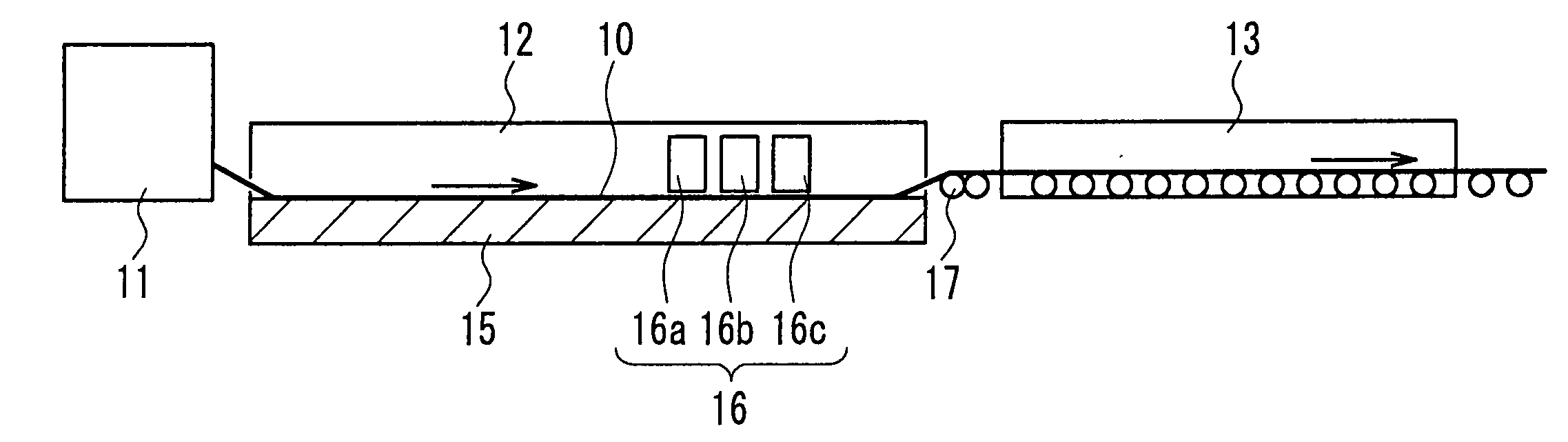

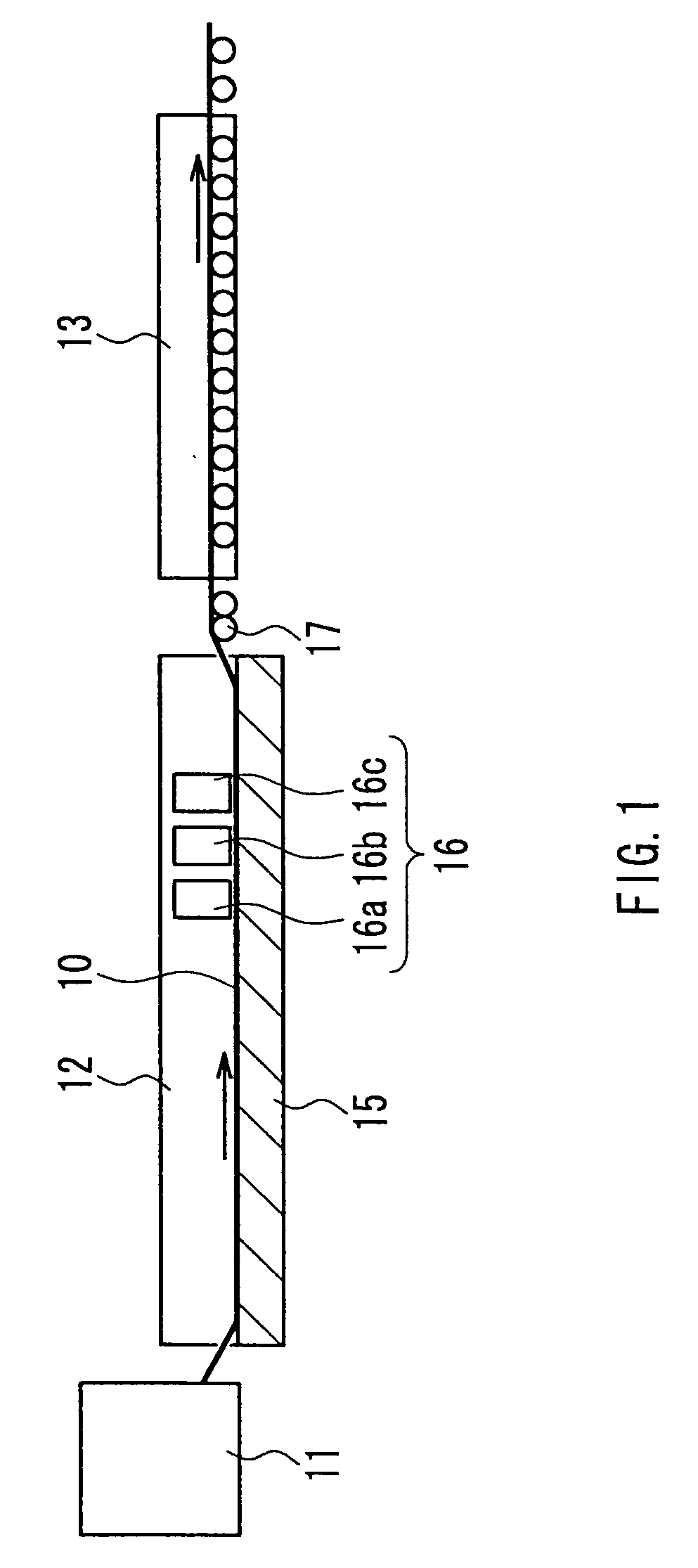

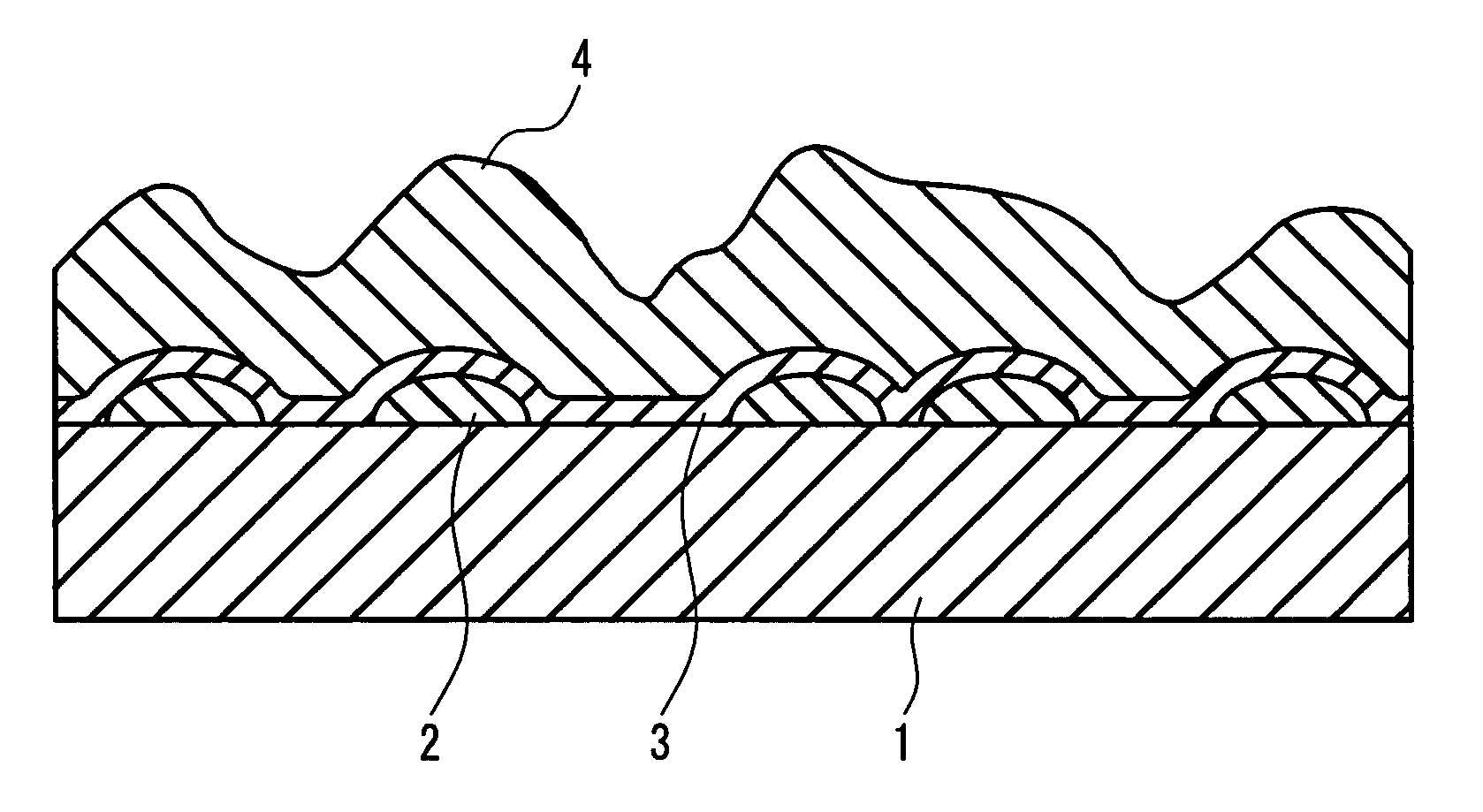

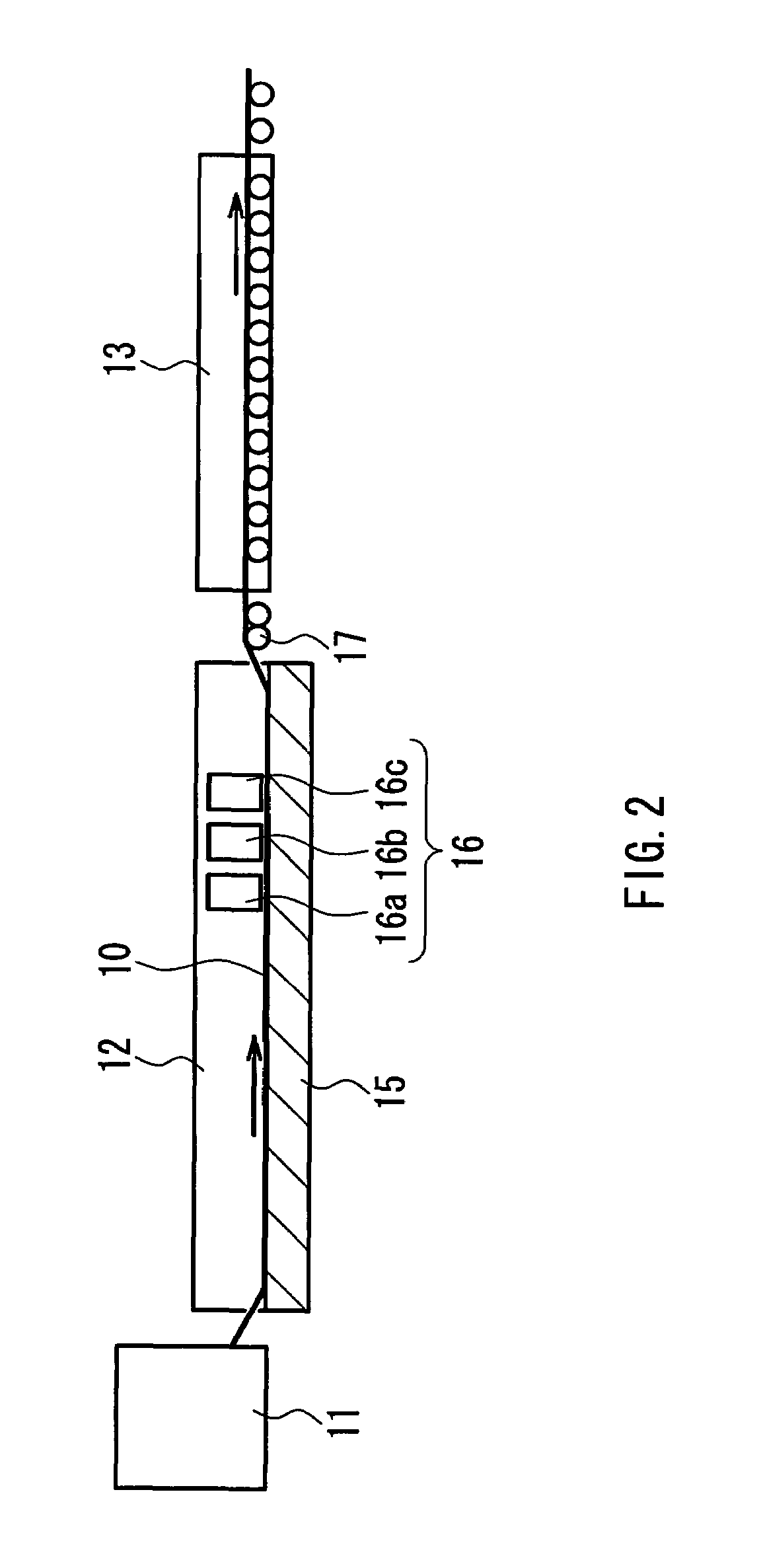

Method for forming thin film, substrate having transparent electroconductive film and photoelectric conversion device using the substrate

ActiveUS20050121070A1Film deposition rateReduced responseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingWide areaMetal chloride

The present invention provides a thin film-forming method by which, even when a thin film containing a crystalline metal oxide as the main component is formed over a wide area within a short time utilizing a thermal decomposition method, the thickness of the thin film becomes relatively uniform. A thin film-forming method of the present invention includes forming a thin film using a raw material containing a chloride of a metal, and prior to the forming of the thin film, 1) disposing metal-containing particles on the substrate, or 2) forming, at a film deposition rate slower than a film deposition rate for the thin film, a metal-containing thin film on the substrate, and wherein, in the case of the step 2), the thin film containing the metal oxide as the main component is directly formed on the metal-containing thin film.

Owner:NIPPON SHEET GLASS CO LTD

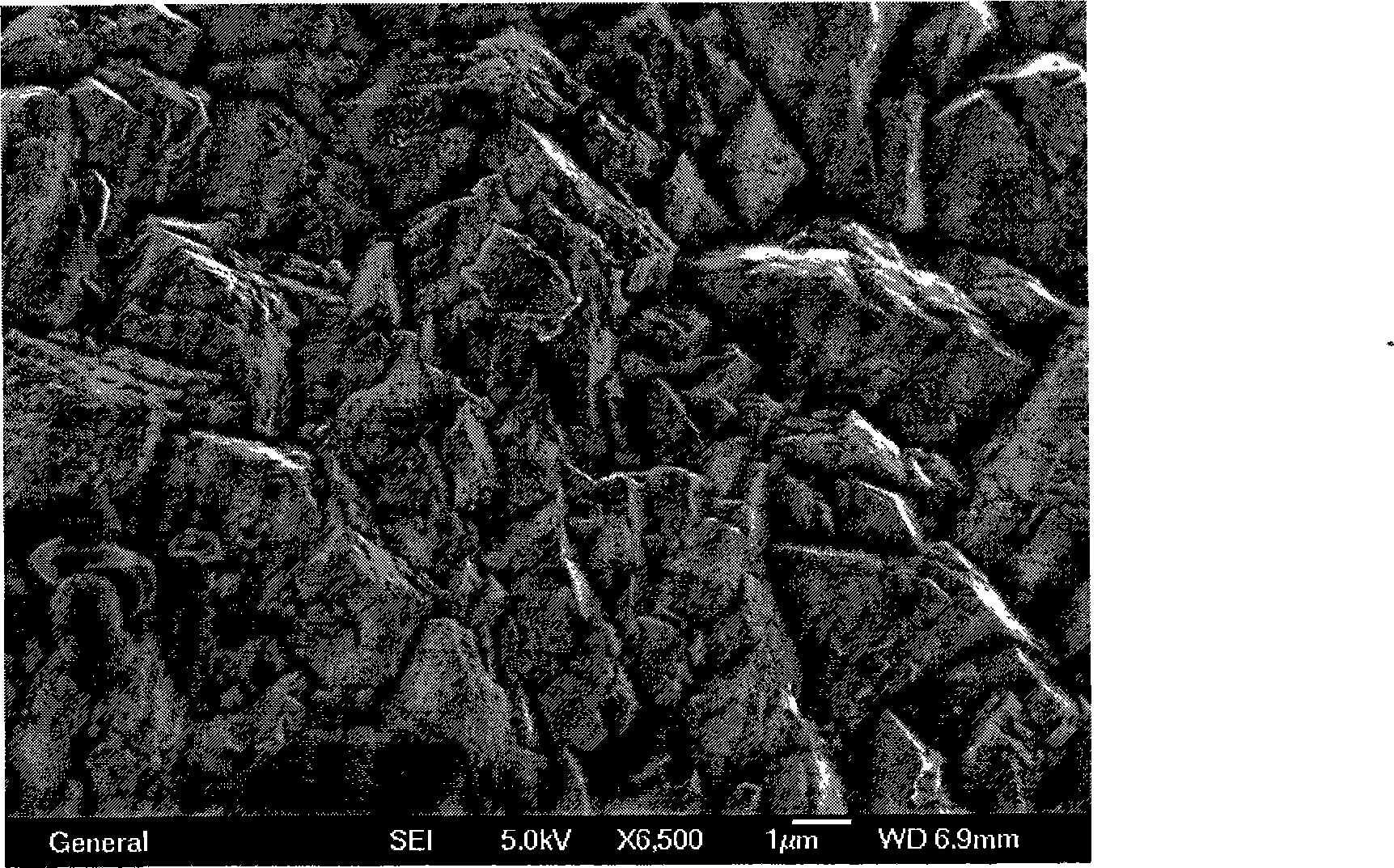

Method for forming thin film, substrate having thin film formed by the method, and photoelectric conversion device using the substrate

InactiveUS20050130416A1Improve thermal characteristicsShort timeSemiconductor/solid-state device manufacturingFlat/ribbon cablesMetal chlorideWide area

The present invention provides a method of forming a thin film containing a metal oxide as the main component, the film thickness of which is relatively uniform, at a high film deposition rate over a wide area and over a long time. The present invention is a method for forming a thin film containing a metal oxide as the main component on a substrate using a mixed gas stream containing a metal chloride, an oxidizing material, and hydrogen chloride, by a thermal decomposition method at a film deposition rate of 4500 nm / min. or greater, performing at least one selected from: 1) prior to mixing the metal chloride and the oxidizing material in the mixed gas stream, contacting hydrogen chloride with at least one selected from the metal chloride and the oxidizing material, and 2) forming a buffer layer in advance on a surface of the substrate on which the thin film containing a metal oxide as the main component is to be formed.

Owner:NIPPON SHEET GLASS CO LTD

Method for manufacturing titanium base lead dioxide electrode capable of controlling coating granularity

InactiveCN101245469AImprove stabilityChange in electrochemical activityElectrodesInter layerLead dioxide

The invention relates to a preparation method of titanium base lead dioxide electrode with controllable coated particle size. The method comprises the steps: pretreatment of titanium, preparation a middle layer of tin-antimony oxide by adopting a thermal decomposition method and preparation of lead dioxide coating containing fluorine by adopting an electrodeposition method. The titanium base lead dioxide electrode of the invention is easy to carry out industrial operation, has strong bonding performance with a base body, has low price with size scale being 10-500nm and has potential application value.

Owner:JILIN UNIV

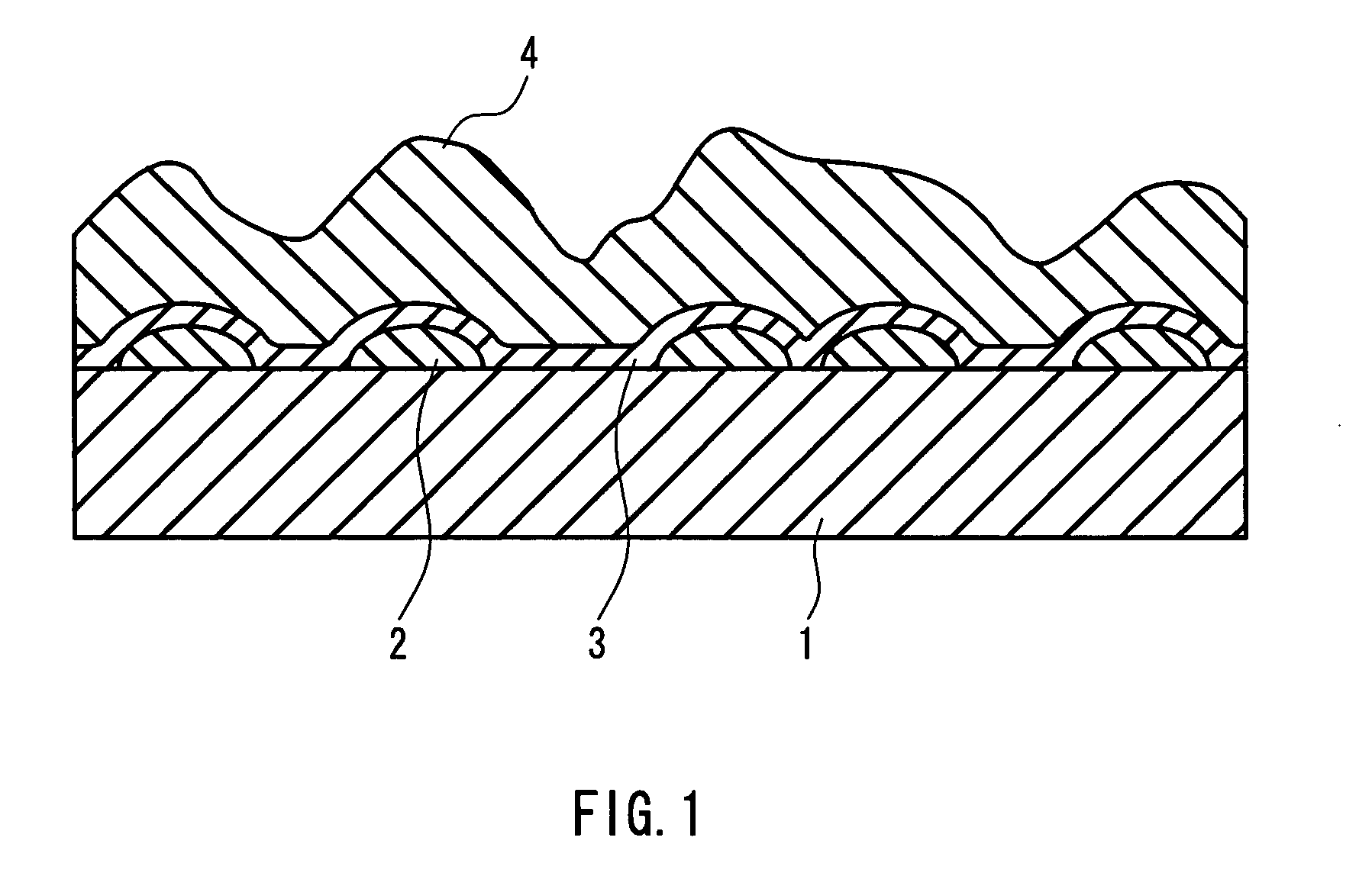

Glass substrate and method of manufacturing the same

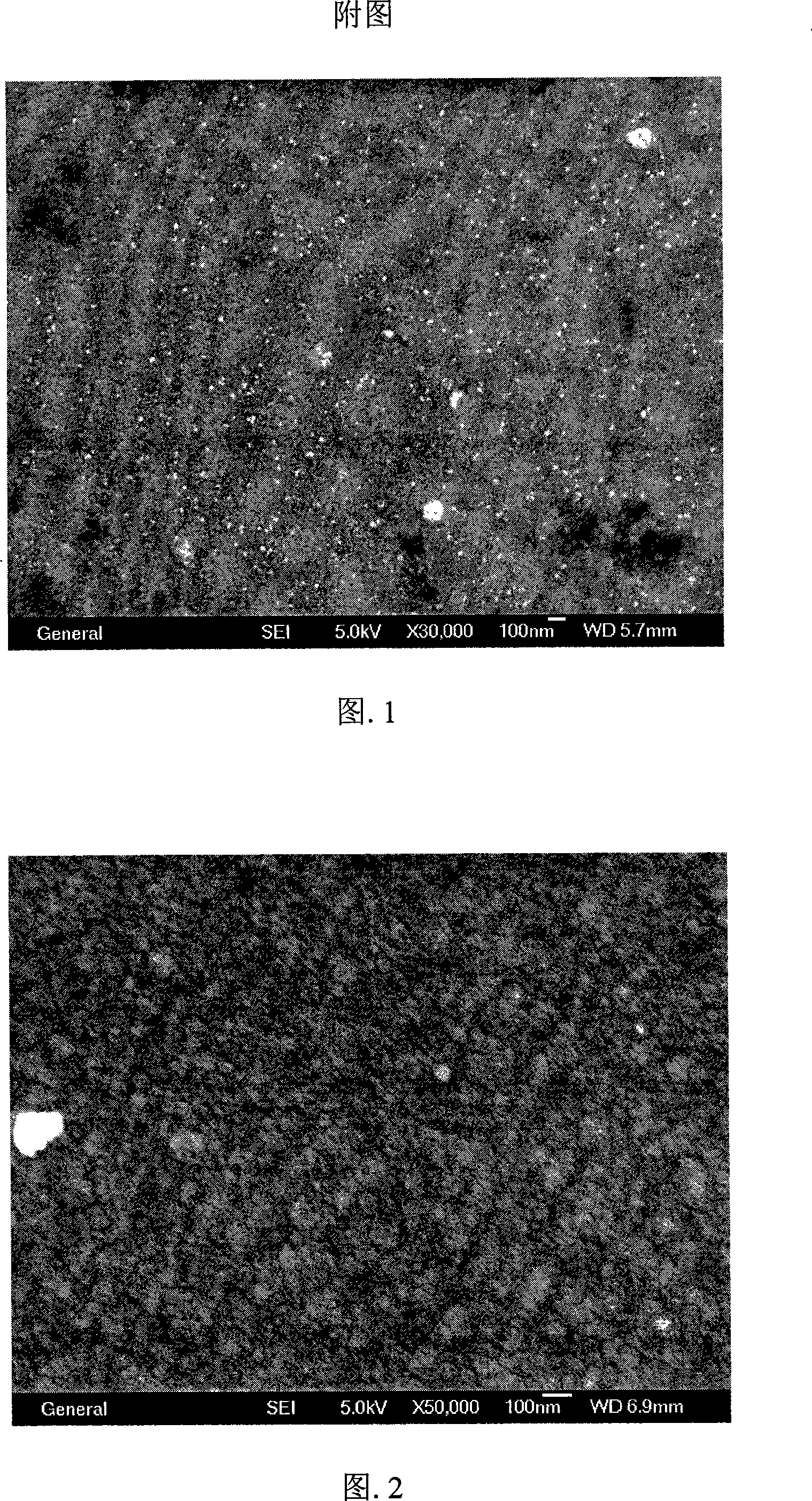

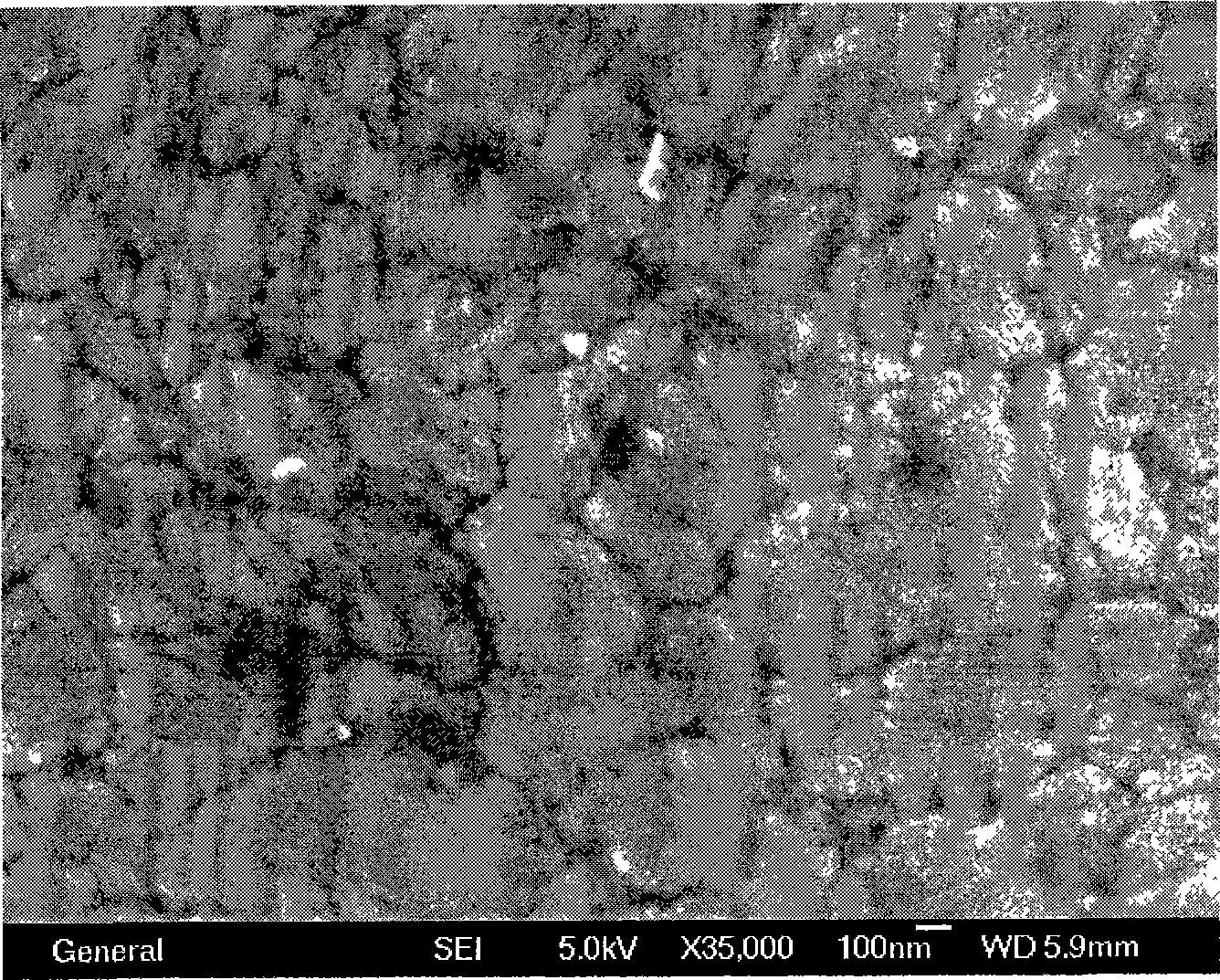

ActiveUS7320827B2Large surface roughnessLight trappingGlass rolling apparatusGlass/slag layered productsMetal chlorideThermal decomposition method

The present invention provides a glass substrate including a glass sheet, a thin film containing silica as its main component, and a group of metal oxide particles separated from one another, the metal oxide particles and the thin film being stacked on the glass sheet in that order from the glass sheet side, wherein the average height of the metal oxide particles is 10 to 100 nm. The present invention also provides a method of manufacturing the glass substrate, the method including forming a group of metal oxide particles by a thermal decomposition method including an inorganic metal chloride as a raw material.

Owner:NIPPON SHEET GLASS CO LTD

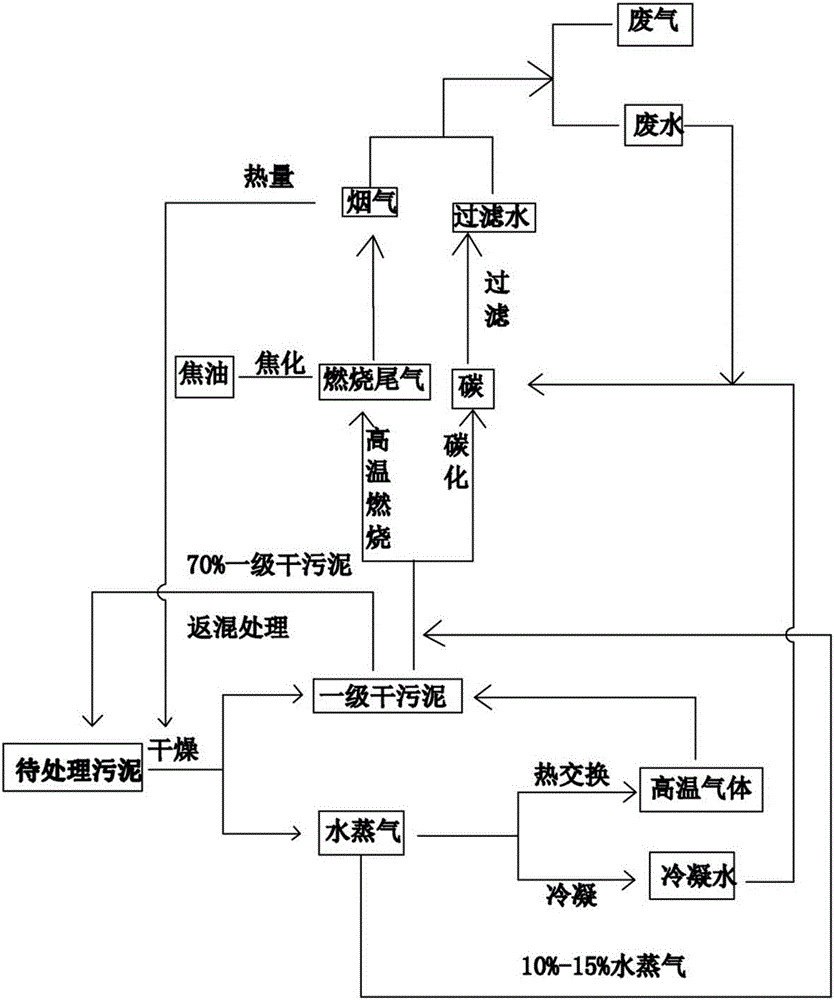

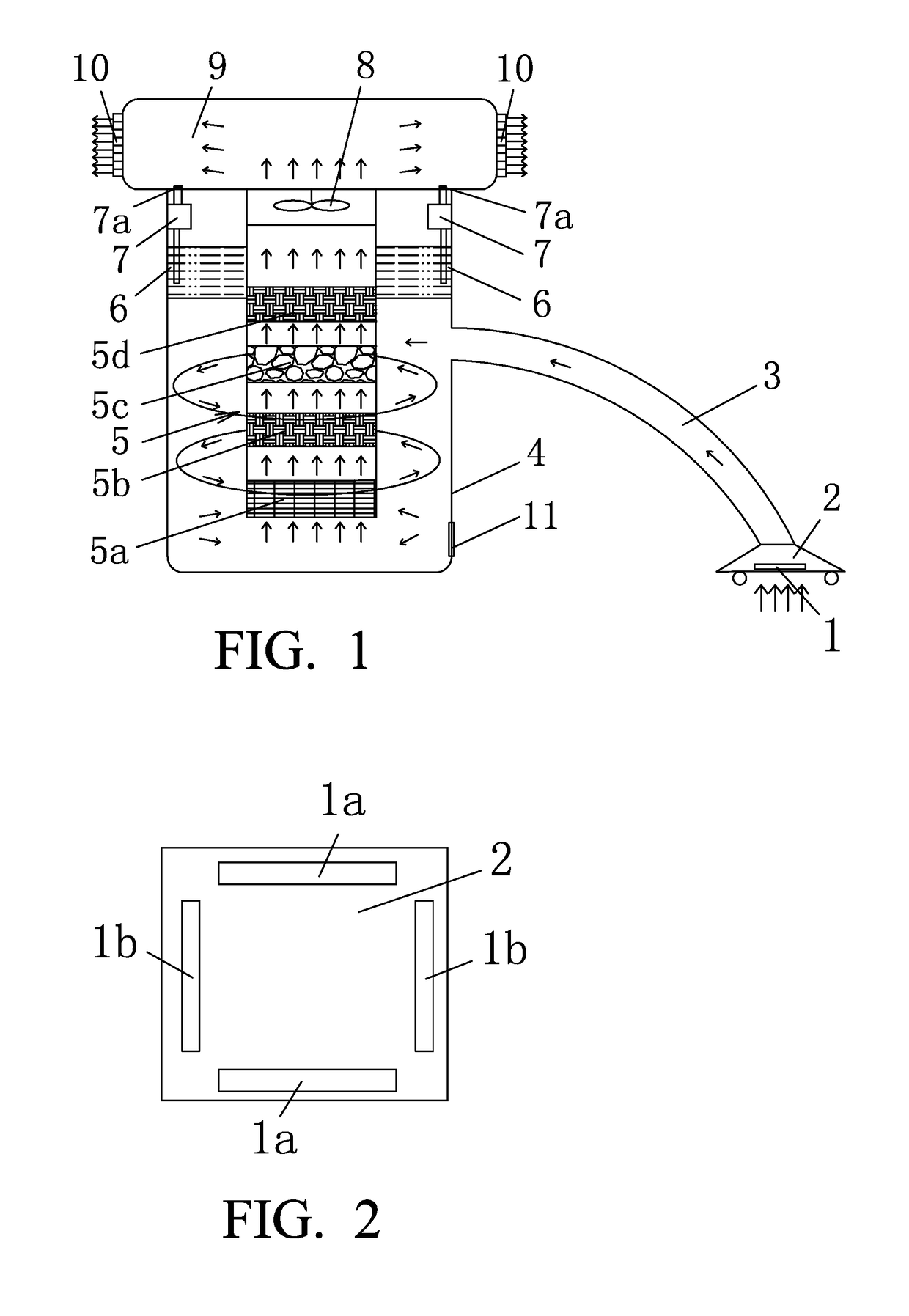

Continuous thermal decomposition method and apparatus for sludge

InactiveCN104986934AReduce the temperatureReduce lossSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeWater vapor

The invention relates to a continuous thermal decomposition method and apparatus for sludge. The method comprises the following steps: drying and carbonization: a step of drying and carbonizing to-be-treated sludge at negative pressure; heat exchange and recovery: a step of subjecting high-temperature water vapor produced in the drying process of the sludge to heat exchange and condensation, recovering heat, applying the recovered heat to drying, adsorbing and filtering condensed water with carbon produced by carbonization and then recovering the treated condensed water for cyclic utilization; and treatment of combustion tail gas: a step of cooling flue gas produced by carbonization with the outer wall of a drying system, washing the flue gas with the condensed water, discharging the washed flue gas and subjecting waste water produced in washing to adsorption and impurity removal by carbon produced by carbonization of the sludge so as to form filtered water for cyclic utilization. The continuous thermal decomposition method for the sludge makes full use of heat and products produced in drying and carbonization of the sludge, recovers the heat and cyclically applies the recovered heat to drying and carbonization of the sludge, so a self-sufficient heat energy supply system is established, and no extra energy is consumed; thus, the method is energy-saving and environment-friendly.

Owner:李学文

Production of coating anode for electrolysis

InactiveCN1680625AImprove conductivityCan control the thicknessSuperimposed coating processElectrodesPlatinumElectrolysis

A process of preparing coating positive pole for electrolyzation. The coating positive pole bases Ti. Middle layer is oxide Ti. Outside layer is Pt or Pt-Ru oxidate. The coat can be obtained by way of electrochemical oxidation or heat decomposition.

Owner:SHANGHAI UNIV +1

Nano mesoporous microspherical Bi5O7I photocatalyst and hydrothermal-thermal decomposition preparation method thereof

InactiveCN105536824AUniform shapeImprove stabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereDecomposition

The invention relates to a nano mesoporous microspherical Bi5O7I photocatalyst and a hydrothermal-thermal decomposition preparation method thereof. The Bi5O7I photocatalyst is of a nano mesoporous microspherical shape; the average particle size of microspheres is 1 to 5 microns, and the average aperture of mesoporous on the surface of the microspheres is 7 to 9 nm. The method comprises the following steps: respectively dissolving bismuth salt and iodine salt into quantitative ethylene glycol, performing ultrasonic oscillation treatment, slowly adding iodine salt solution into bismuth salt solution after complete dissolving, performing magnetic stirring to obtain a precursor BiOI, performing hydrothermal reaction on the precursor to prepare BiOI powder, heating the powder body in a tubular furnace under high temperature for decomposition, and preserving the temperature for 2 h to prepare Bi5O7I powder. The Bi5O7I powder prepared by the hydrothermal-thermal decomposition method has the characteristics of uniform shape, high stability and good photocatalysis performance, integrates the advantages of the hydrothermal method and the thermal decomposition method, and is short in reaction time, simple in technological process, lower in raw material cost and suitable for industrial popularization and application.

Owner:SHAANXI NORMAL UNIV

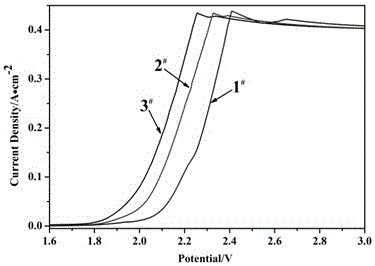

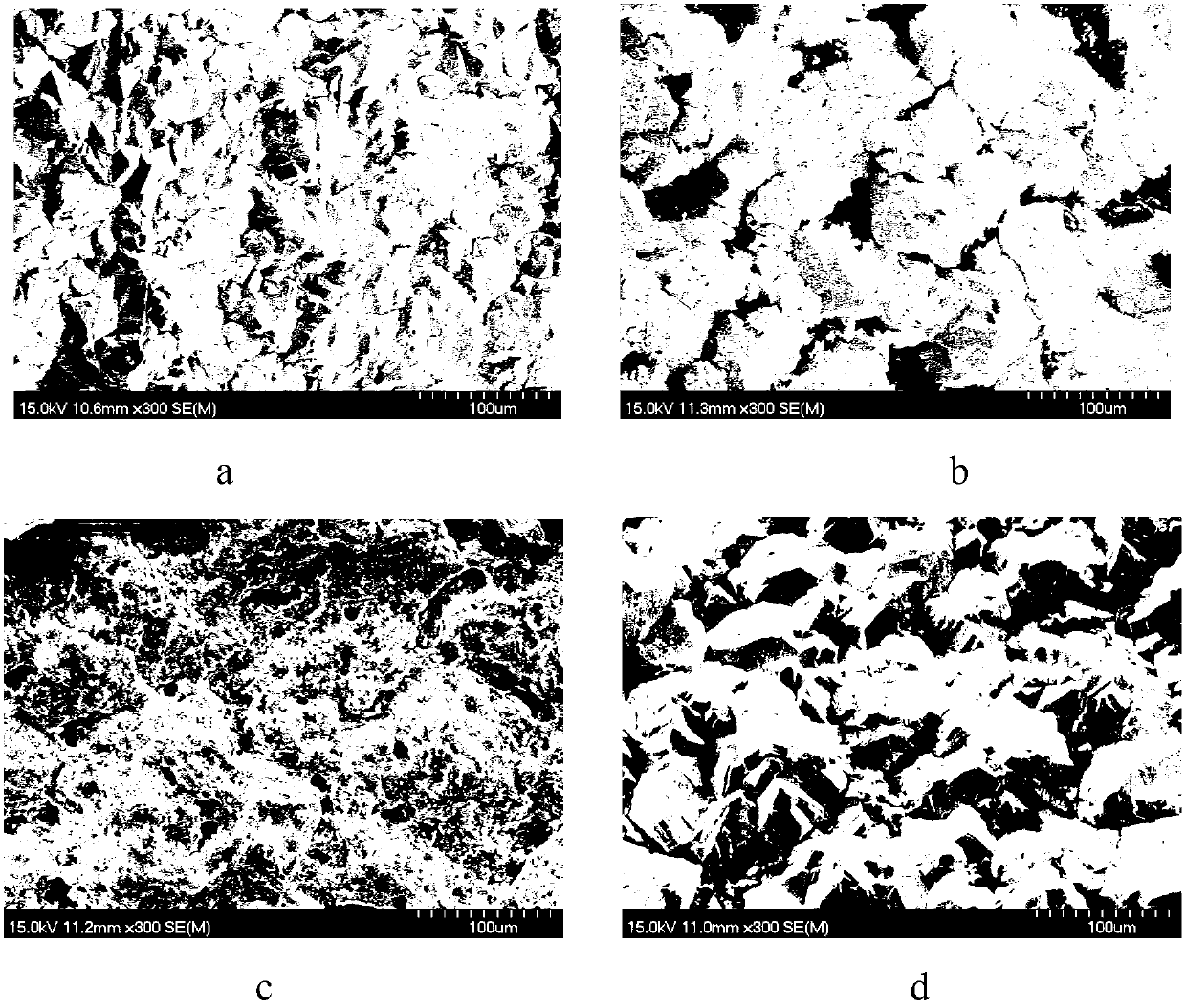

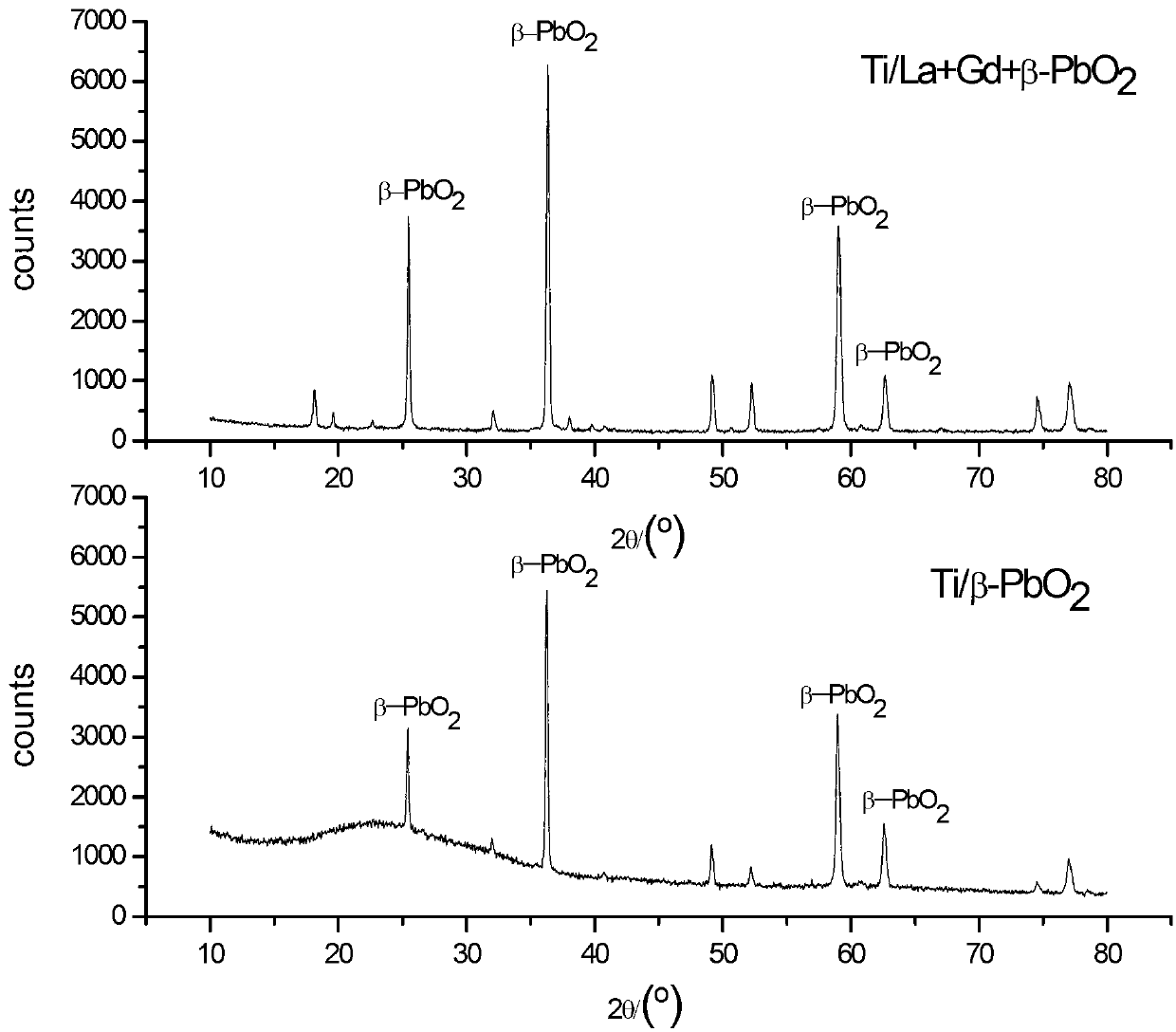

Lanthanum-gadolinium co-doping titanium-based lead dioxide electrode and preparation method and application thereof

ActiveCN103132076AUniform structureComplete structureElectrolytic inorganic material coatingWater/sewage treatmentLead dioxideRare earth

The invention provides a preparation method of a lanthanum-gadolinium co-doping titanium-based lead dioxide electrode. Rough processing is carried out on the surface of a titanium-based body, a tin antimony oxide bottom layer is prepared in a plating mode through a thermal decomposition method, then an alpha-PbO2 layer is electroplated in an alkalinity mode, finally a beta-PbO2 layer containing rare-earth metal oxide is electroplated in an acidity mode, and the lanthanum-gadolinium co-doping titanium-based lead dioxide electrode is prepared. Through the co-doping of the lanthanum and the gadolinium, a certain synergistic effect is achieved, the provided electrode can process and degrade organic matters under the normal temperature and the normal pressure, processing effect is good, cost is low, and good application value is achieved.

Owner:ZHEJIANG UNIV OF TECH

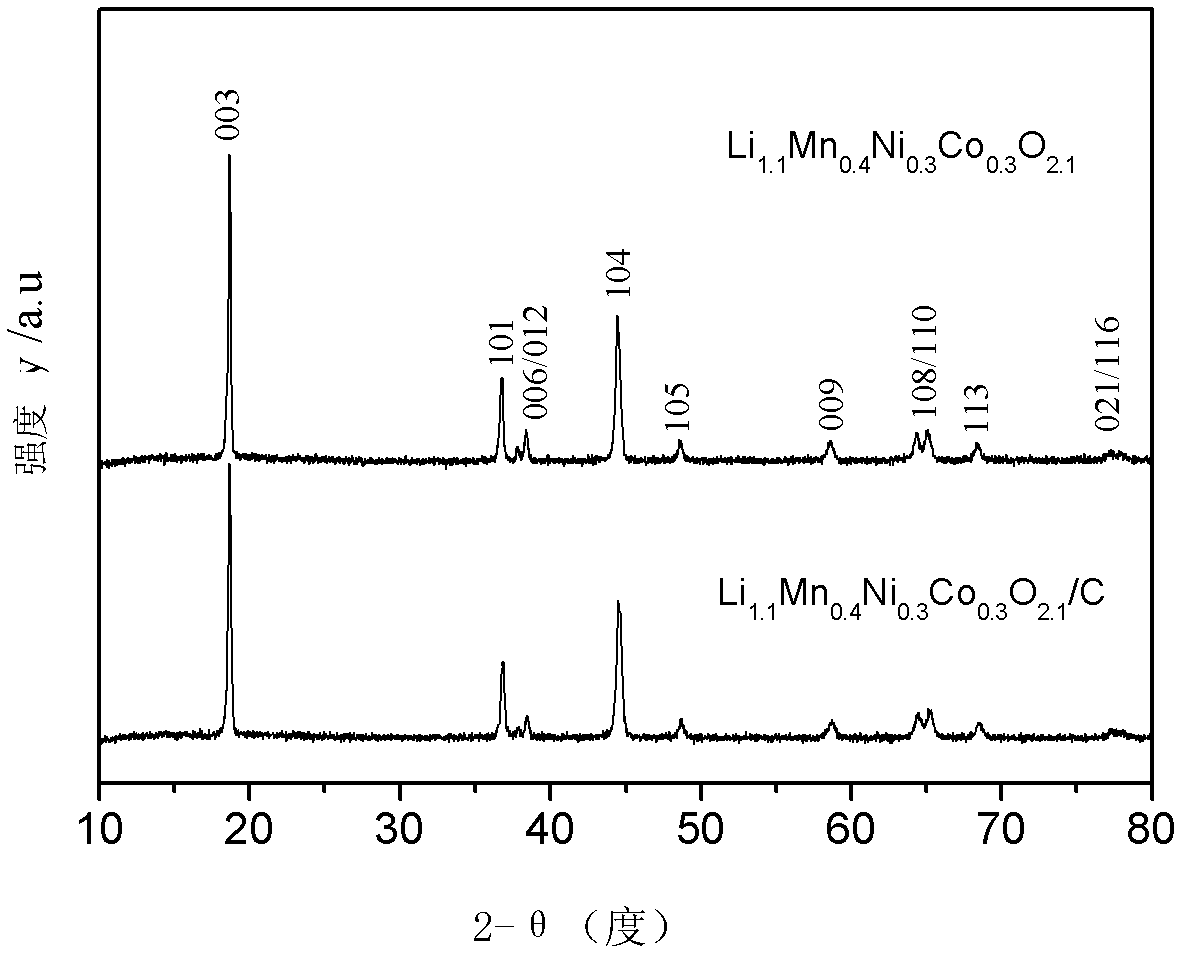

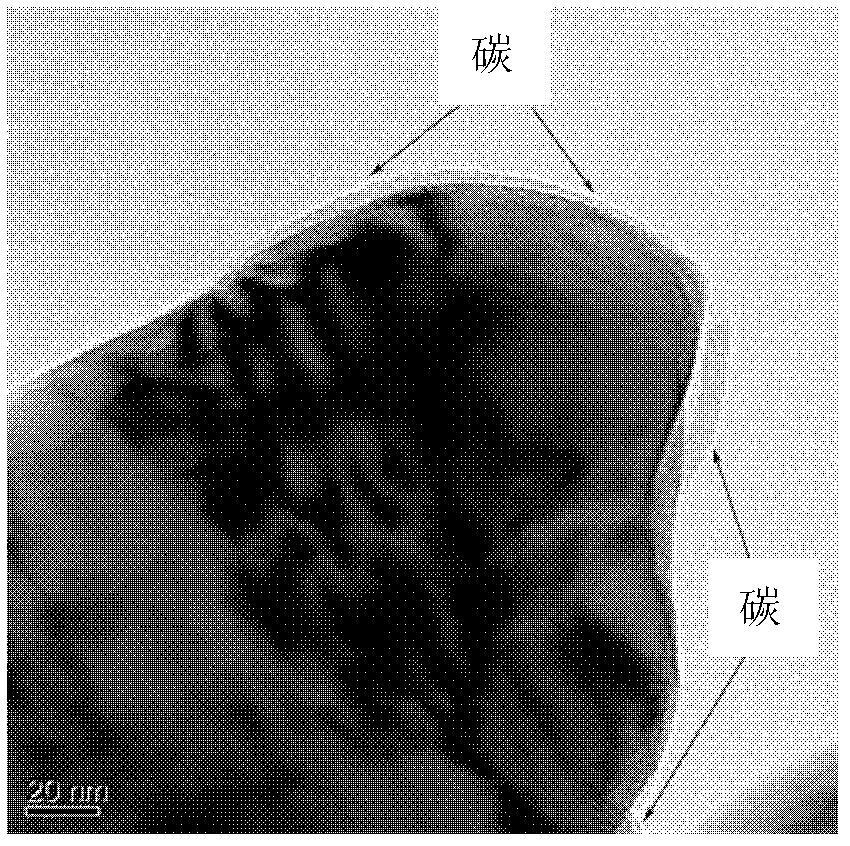

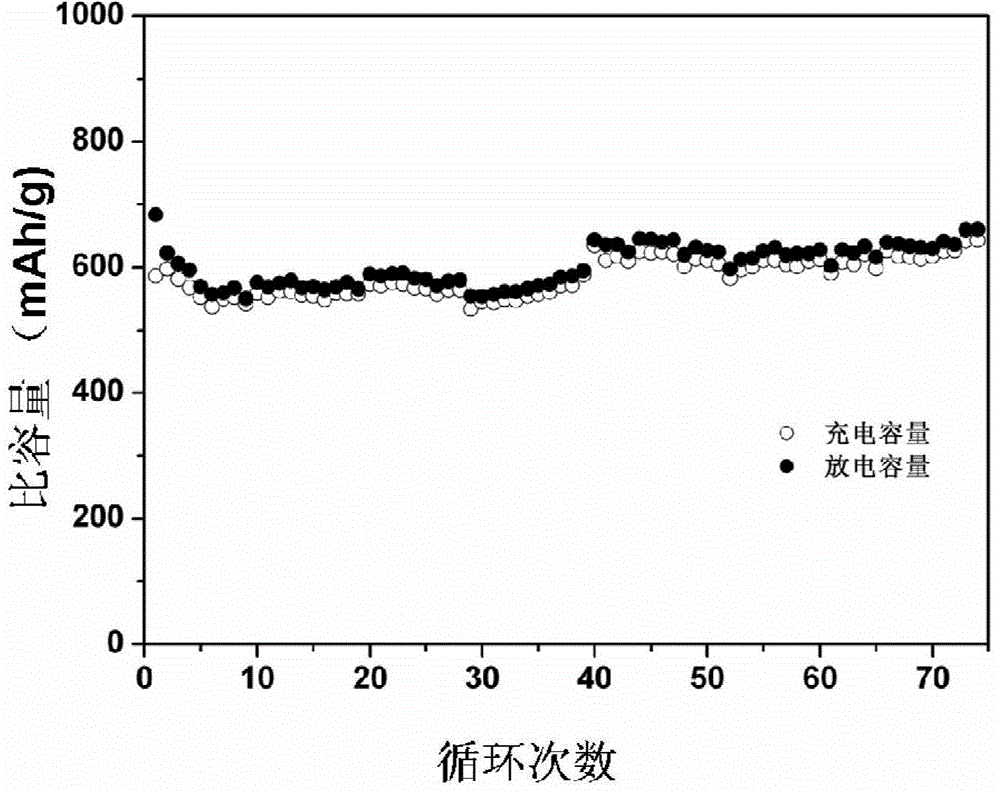

A layered oxide lithium ion battery positive electrode and preparation method thereof

InactiveCN102299316AImprove cycle stabilityImproved magnification performanceCell electrodesLithium oxideCarbon layer

The invention relates to a positive electrode of a layered oxide lithium ion battery and a preparation method thereof. The positive electrode includes a pole piece and a carbon layer on the pole piece. The carbon layer is formed by magnetron sputtering under an inert atmosphere using a graphite target The carbon source is formed by sputtering on the surface of the pole piece. The present invention uses the magnetron sputtering method to coat the positive electrode with carbon, which breaks through the limitation of the traditional thermal decomposition method to coat the positive electrode material, and prepares the positive electrode of the carbon-coated lithium-rich layered structure oxide lithium ion battery. By using the carbon layer The effect of effectively preventing the side reaction between the active material and the electrolyte during the charging and discharging process improves the cycle stability and rate performance of the positive electrode of the layered lithium-rich lithium-ion battery. Experiments have found that it can meet the requirements of power lithium-ion batteries.

Owner:浙江吉能电池科技有限公司

Method for preparing Fe2O3 and expanded graphite composite material of lithium ion battery

InactiveCN104953103AAvoid destructionBreak down evenlyCell electrodesSecondary cellsMicrowaveThermal decomposition method

The invention provides a method for preparing a Fe2O3 and expanded graphite composite material of a lithium ion battery. The method particularly comprises the steps that expanded graphite is used as a carrier material, the ferrocene is used as the precursor of Fe2O3, the expanded graphite and the Fe2O3 are mixed based on the mass ratio being 1:2-12, and the Fe2O3 and expanded graphite composite material is prepared by adopting the high pressure decomposition method or the microwave reaction method or the high temperature thermal decomposition method. The method is wide in raw material source, low in cost, simple in preparation technology, low in investment, high in operability and suitable for large-scale production. The Fe2O3 and expanded graphite composite material can be used as a negative electrode material of a common or flexible lithium ion battery, and has the advantages of being high in capacity, good in circulation and rate capability and the like.

Owner:SHANXI UNIV

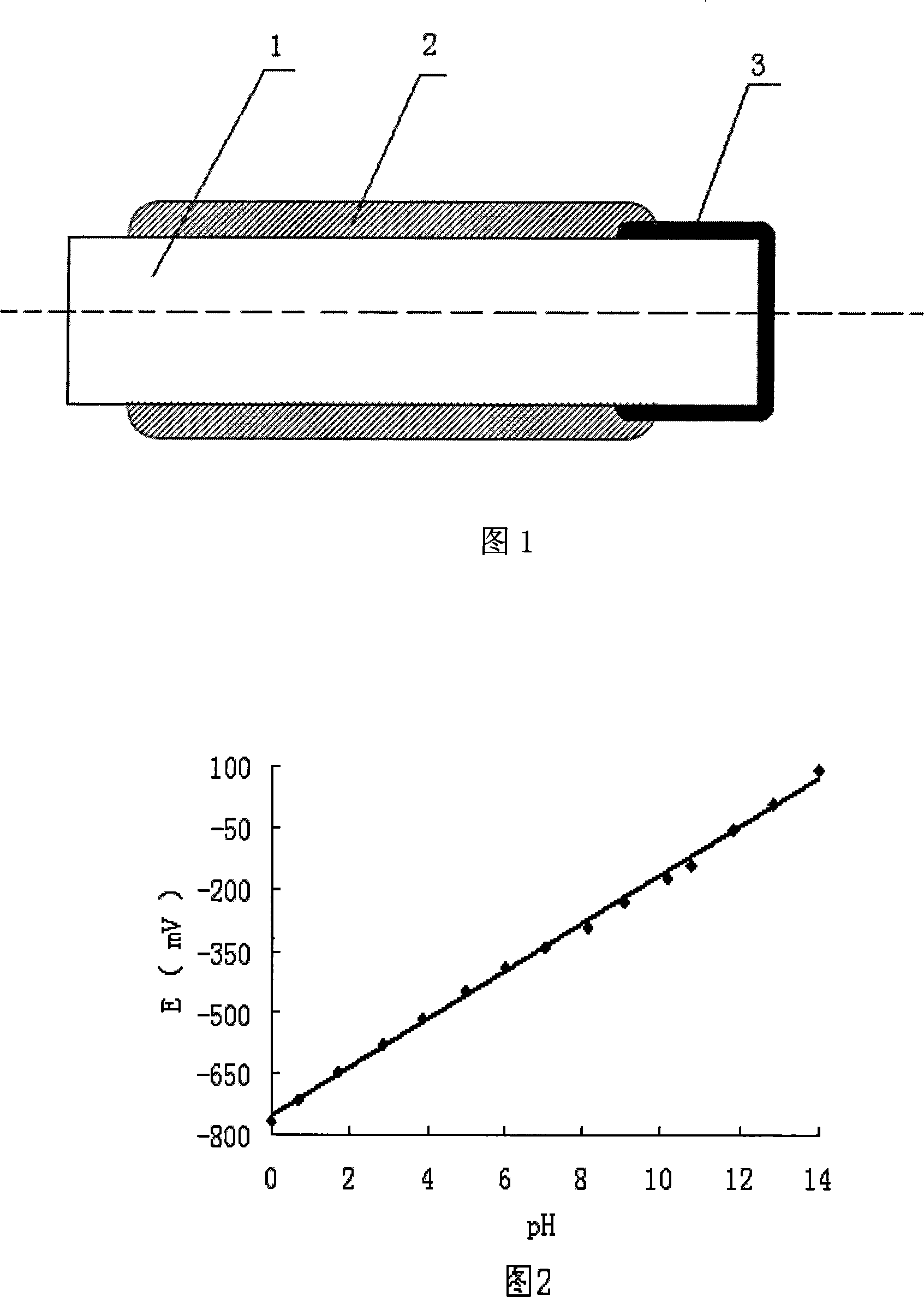

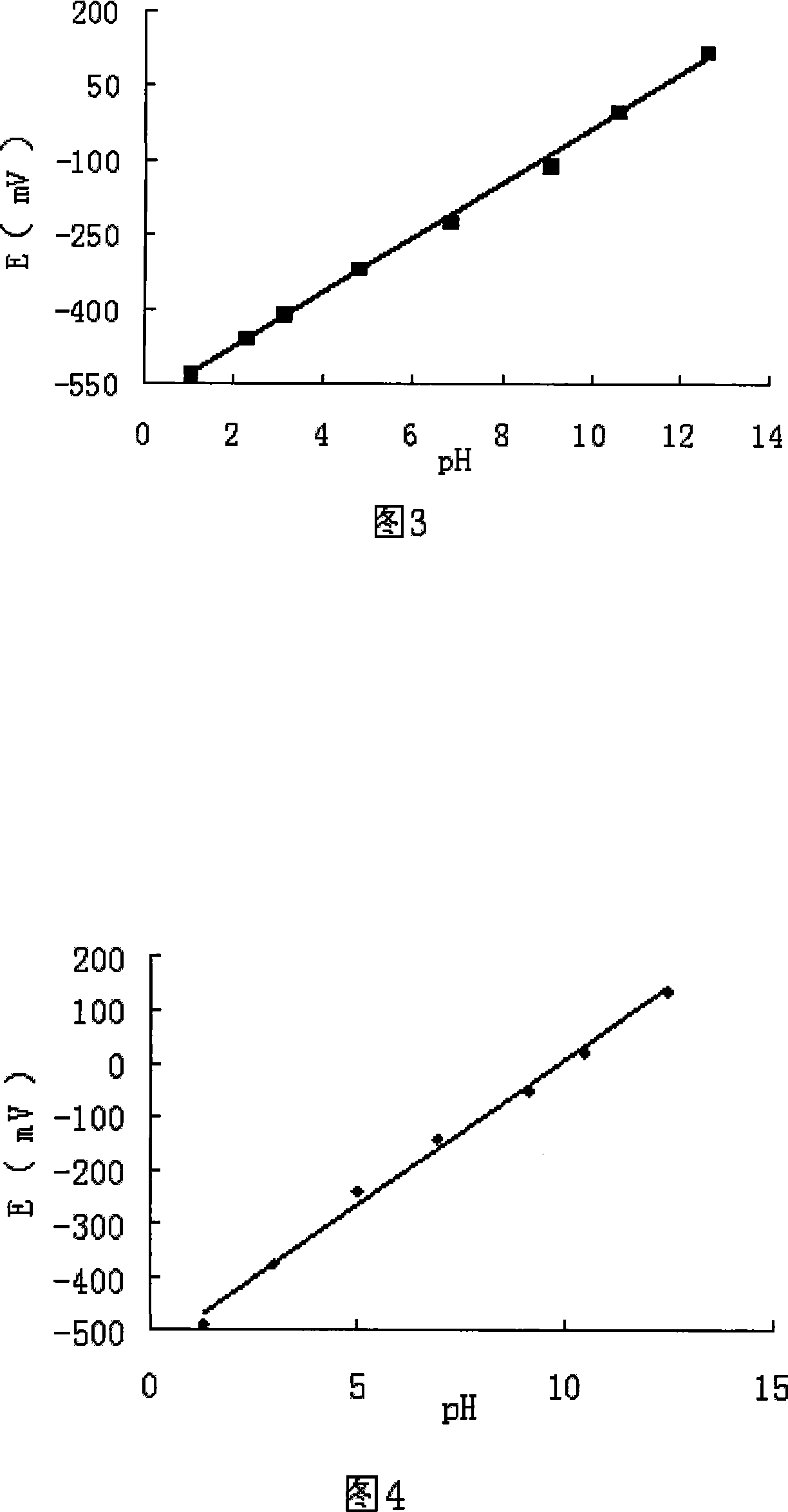

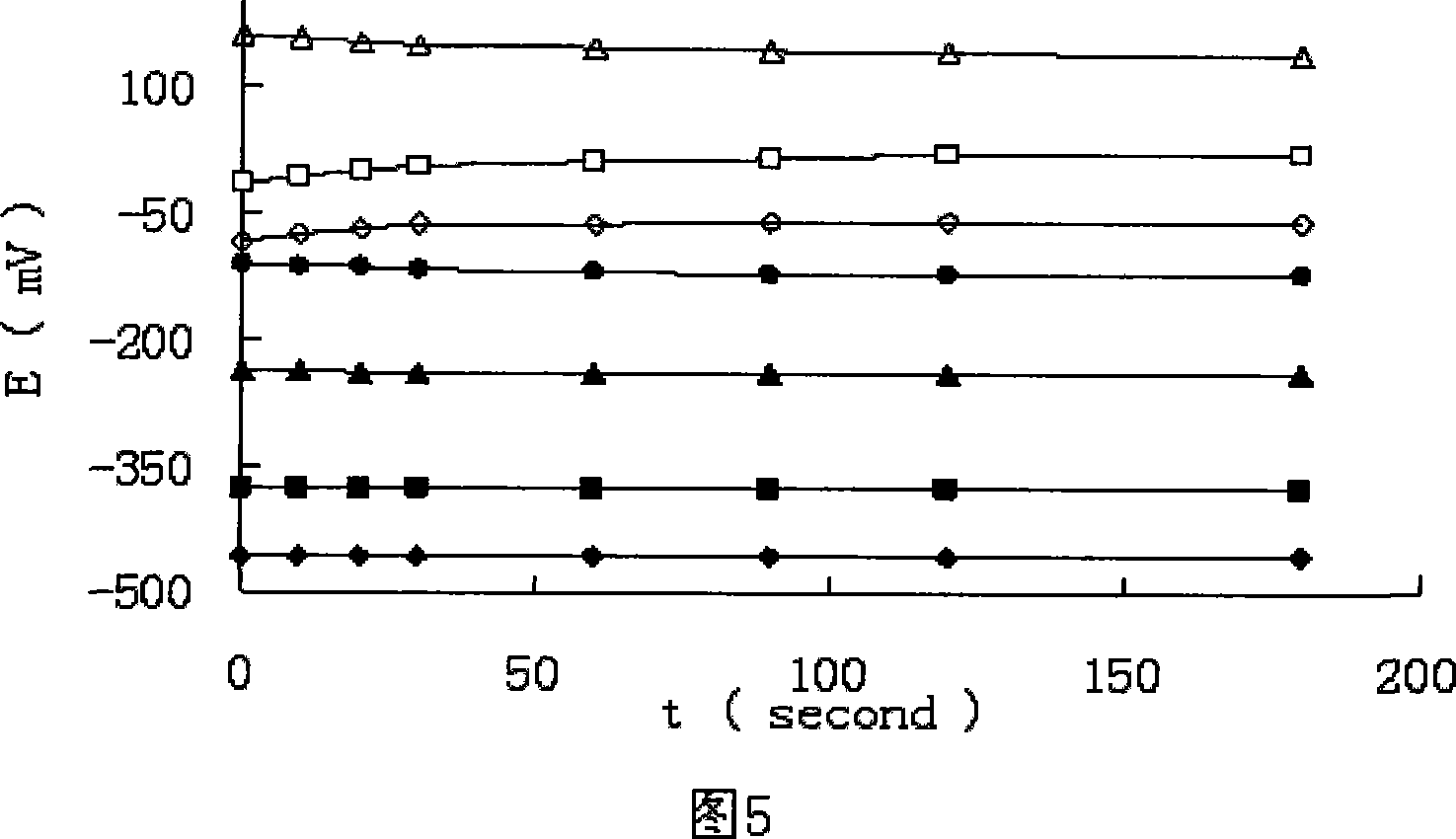

Metal-metallic oxide pH electrode and method for making same

InactiveCN101210902ASimple preparation processLow priceMaterial electrochemical variablesChemical cleaningHydrogen ion

The invention provides a metal-metal oxide pH electrode and a preparation method thereof. The method comprises the following steps of: using a chemically stable metal filament is used as a basal body, removing the original oxide film on the surface of the metal filament by mechanical polishing and chemical cleaning, and forming a IrOx (x=1 to 3) active oxide film sensitive to hydrogen ion on the treated metal filament surface with the thermal decomposition method. Comparing with glass pH electrode and conventional metal-metal oxide pH electrode, the inventive metal-metal oxide pH electrode has the advantages of simples preparation method, low cost, easiness for batch production, high mechanical strength, low fracture liability, small volume, high sensitivity of pH measurement, and rapid response speed, wide response range; and is suitable for pH measurement of low-temperature solution with wide pH range, particularly solution below zero degree (such as anti-freezing fluid and refrigerating fluid).

Owner:FUZHOU UNIV

Preparation method of copper-based nano solar battery material

InactiveCN103112885ASimple preparation processEasy to operateMaterial nanotechnologyGallium/indium/thallium compoundsCrystallinityPhosphine oxide

The invention relates to a preparation method of a copper-based nano solar battery material, which belongs to the preparation technique of semiconductor nano solar battery materials. A metallic compound is taken as a precursor, mercaptan, elemental sulfur, elemental selenium and the like as sulfur raw materials, and oleylamine, oleic acid, 1-octadecene and TOPO (Tri-Octyl-Phosphine Oxide) as a main high-boiling-point solvent. By adopting a thermal decomposition method, the copper-based nano solar battery material which is different in morphology, good in crystallinity degree, good in monodispersity, controllable in phase structure and adjustable in optical property is prepared under unharsh reaction condition, thus basis is established for application and industrial production of the high-quality nano copper-based solar material in the aspects of solar battery preparation and photocatalyst design. The copper-based nano solar battery material has the characteristics of controllable product property, high quality, simple production process, environmental-friendliness and the like, and is easy to industry.

Owner:NANJING UNIV OF TECH

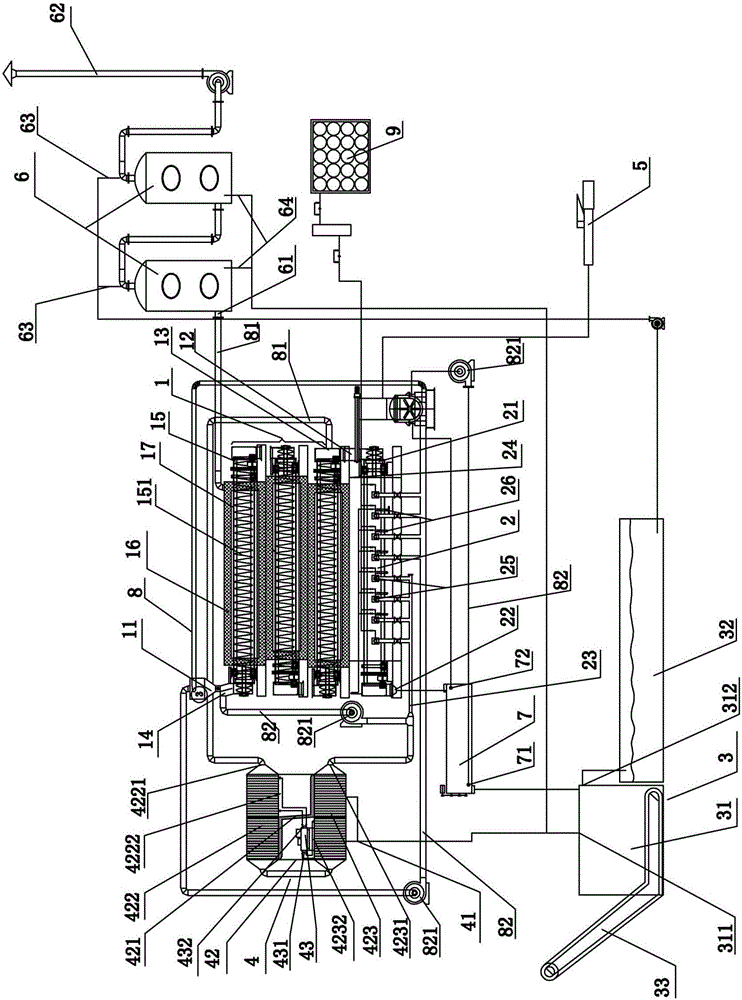

Multifunctional air purifying device for removing indoor pollution by thermal decomposition

ActiveUS20190015780A1DecontaminationPromotes volatilization speedCombination devicesMechanical apparatusThermal decomposition methodInfrared lamp

A multifunctional air purifying device for removing indoor pollution by a thermal decomposition method comprises an air treatment unit and an air collection heater. The air collection heater is provided with an infrared lamp tube and an ultraviolet lamp tube. An annular water tank is arranged on an inner side of the upper part of the air treatment unit. A filter screen runs through the annular water tank and is connected with an air cap, and a fan is provided at a joint between the filter screen and the air cap. The filter screen includes an early effect filter screen, a HEPA filter screen, an activated carbon filter screen and a cold catalyst filter arranged in that order from a bottom to a top. A humidifier connects the annular sink and a nozzle located at an exhaust port.

Owner:DALIAN UNIV OF TECH

Fabrication method of long-life titanium base electrode

The invention discloses a fabrication method of a long-life titanium base electrode, which comprises the steps of fabricating a titanium oxide layer on a titanium substrate by a dipping-thermal decomposition method, reducing the titanium oxide layer in a reducing atmosphere, synchronously depositing a tin metal simple substance and an antimony metal simple substance in proportion on the surface of the titanium oxide layer by an electrodeposition method, and conducting thermal oxidation to allow an antimony doped tin oxide layer to be tightly combined with the titanium oxide layer connected with the titanium substrate to form a solid solution structure. The prepared titanium base tin dioxide electrode has the advantages of long service life, high oxygen evolution potential, high electrocatalytic activity, high generation efficiency of ozone from electrolyzed water, and the like. In addition, the cost of the fabrication process is low, the requirement of equipment is low, the operation is easy to control, and industrial mass production is facilitated.

Owner:XI AN JIAOTONG UNIV

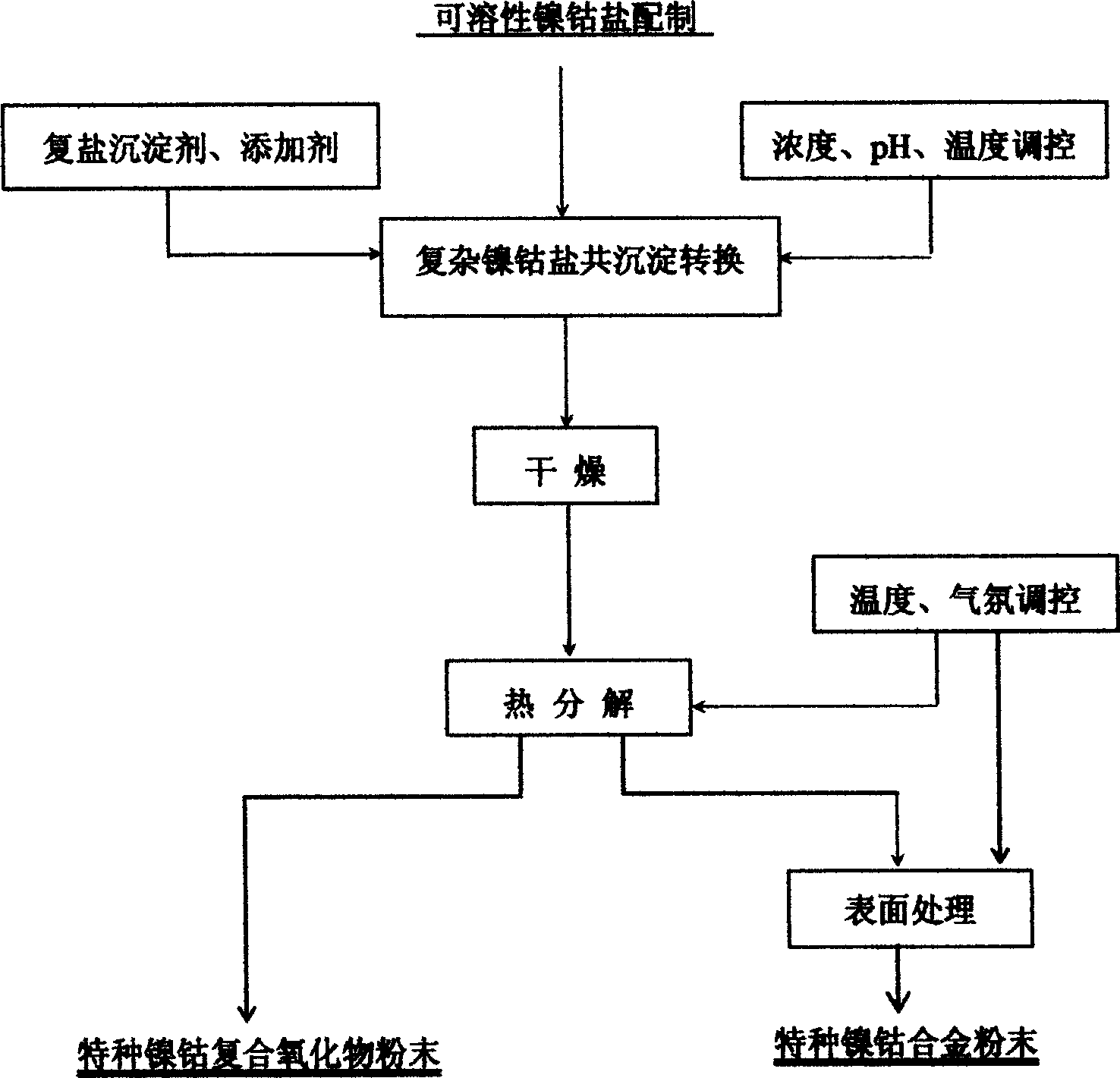

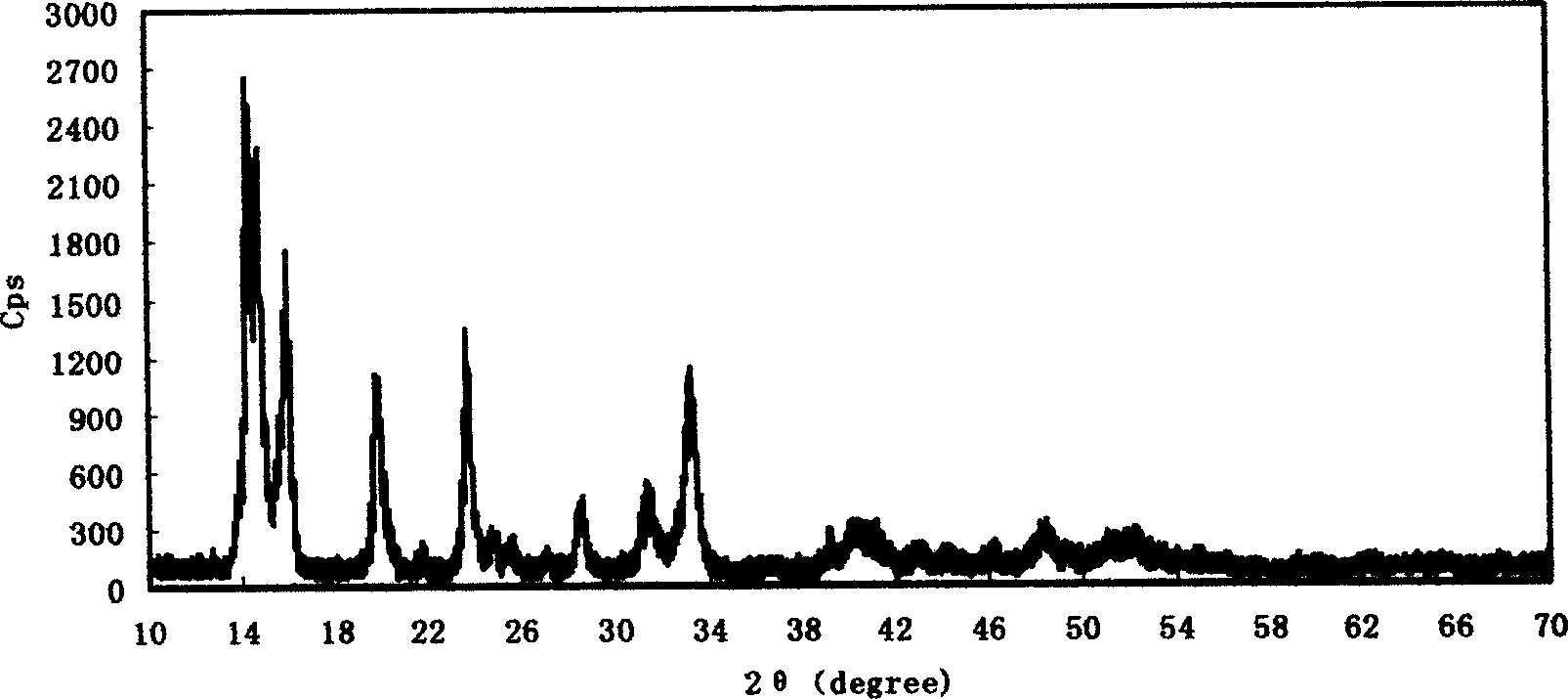

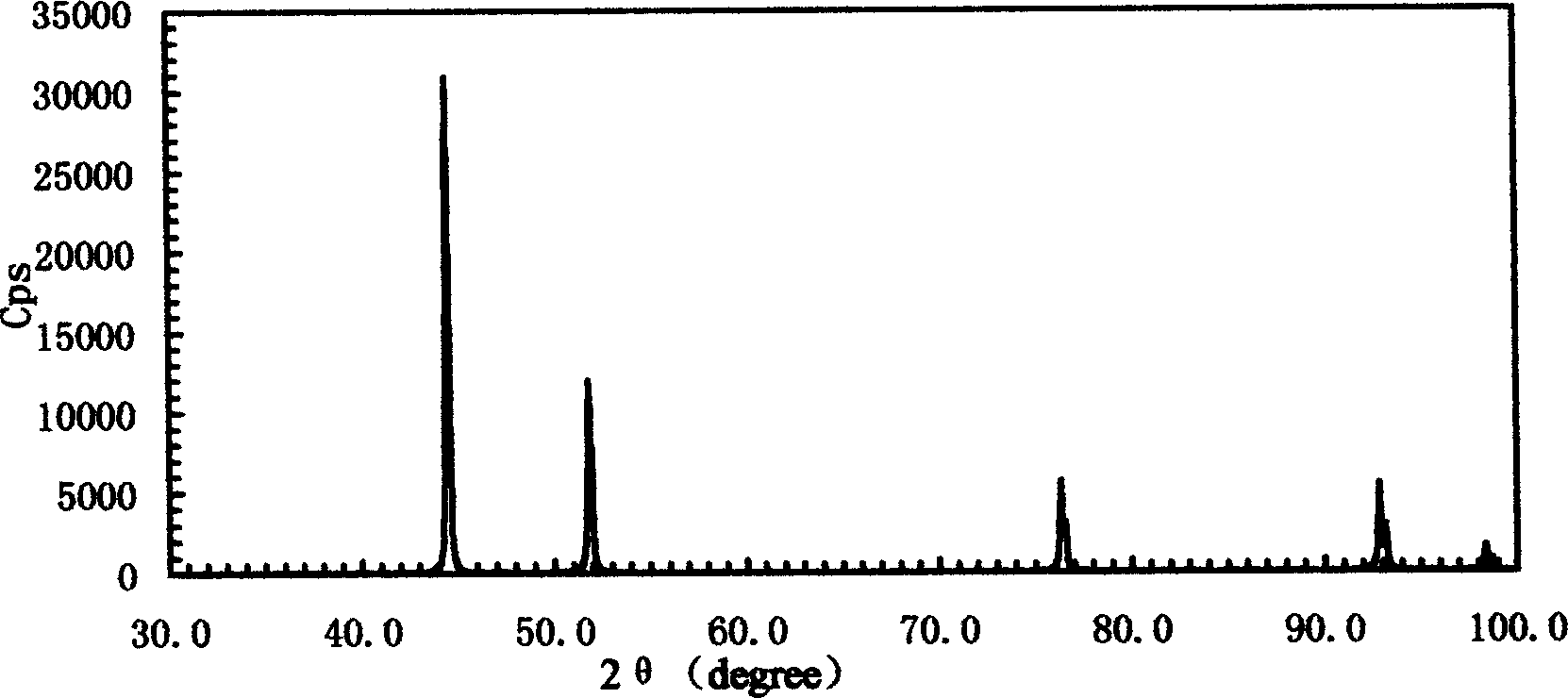

Method for preparing fibred cobalt nickel powder and composite oxides powder of cobalt nicker

InactiveCN1600479AThe thermal decomposition process is safe and reliableNo pollution in the processNickel oxides/hydroxidesCobalt oxides/hydroxidesThermal decomposition methodRoom temperature

A process for preparing the fibrous NiCo alloy powder and the fibrous nickel cobalt oxide powder features that a depost-transforming thermal decomposition method is used, which includes synthesizing the deposit of their precursor in Ni-Co-NH3-NH4-SG-C2O4-H2O system and the precursor is thermally decomposd ni oxidizing atmosphere to obtain fibrous nickel cobalt oxide powder, or the precursor is thermally decomposed in non-oxidizing atmopshere to obtain fibrous NiCo alloy powder.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com