Method for preparing fibred cobalt nickel powder and composite oxides powder of cobalt nicker

A technology of composite oxides and nickel-cobalt alloys, which is applied in the direction of nickel oxide/nickel hydroxide, cobalt oxide/cobalt hydroxide, etc., can solve the problems of difficult control of operating conditions, low oxidation activity, and high powder density, and achieve operational Ease of control, high purity, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

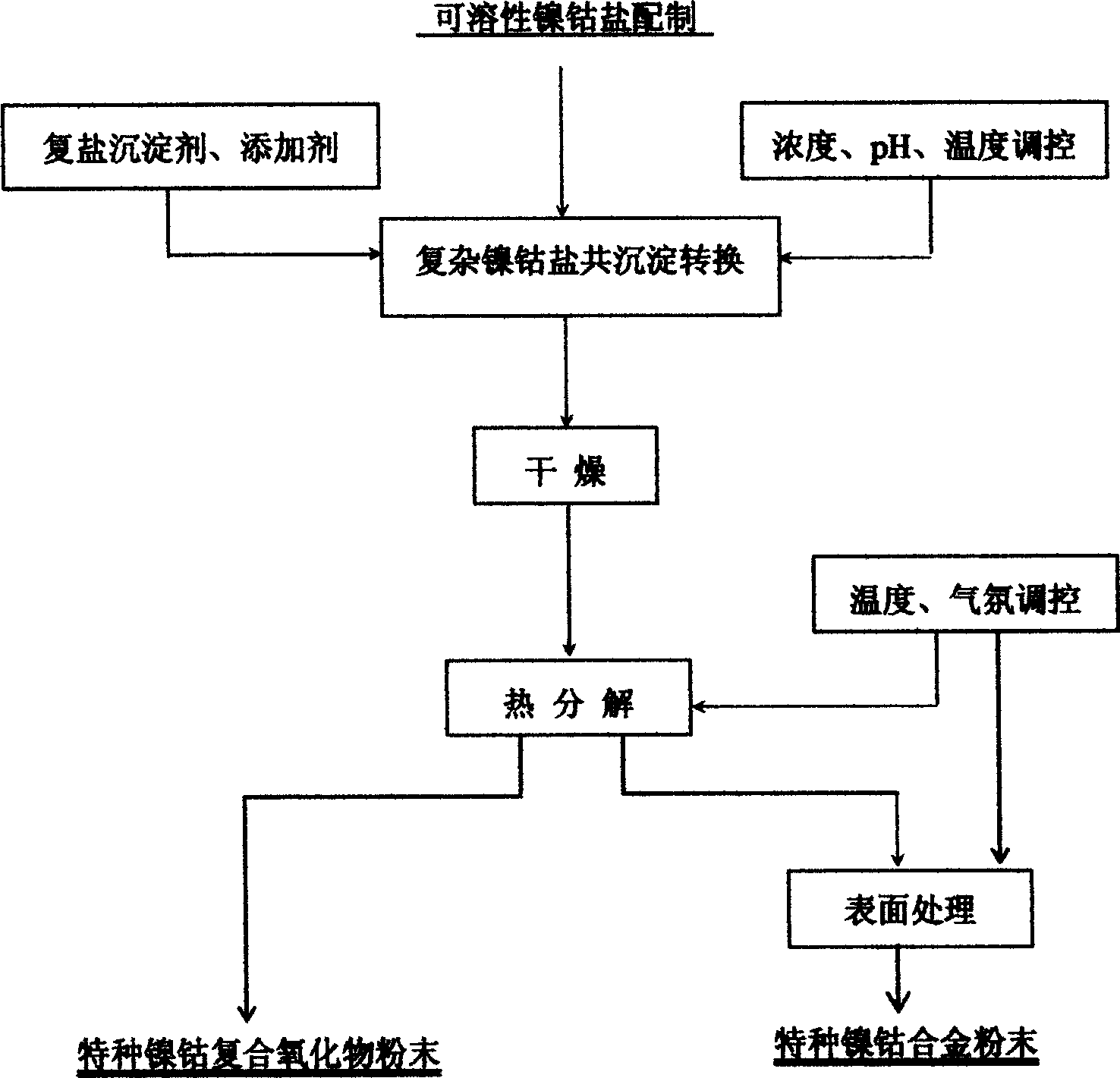

Method used

Image

Examples

Embodiment 1

[0045] The nickel chloride solution and the cobalt chloride solution with a ratio of nickel to cobalt of 4:1 are uniformly mixed, and then the mixed solution and the composite precipitant solution composed of ammonia, ammonium oxalate and dispersant PVP are added to the reactor through the feeding device. Ni 2+ -Co 2+ -NH 3 -NH 4 + -Cl - -C 2 O 4 2- -H 2 The composite precipitation transformation is carried out in the O system, the temperature is controlled at about 60℃, the pH is adjusted to about 8.0 with ammonia water, and the initial Ni in the material liquid 2+ And Co 2+ The total concentration is 0.6mol / L, C 2 O 4 2- The concentration is 0.66mol / L.

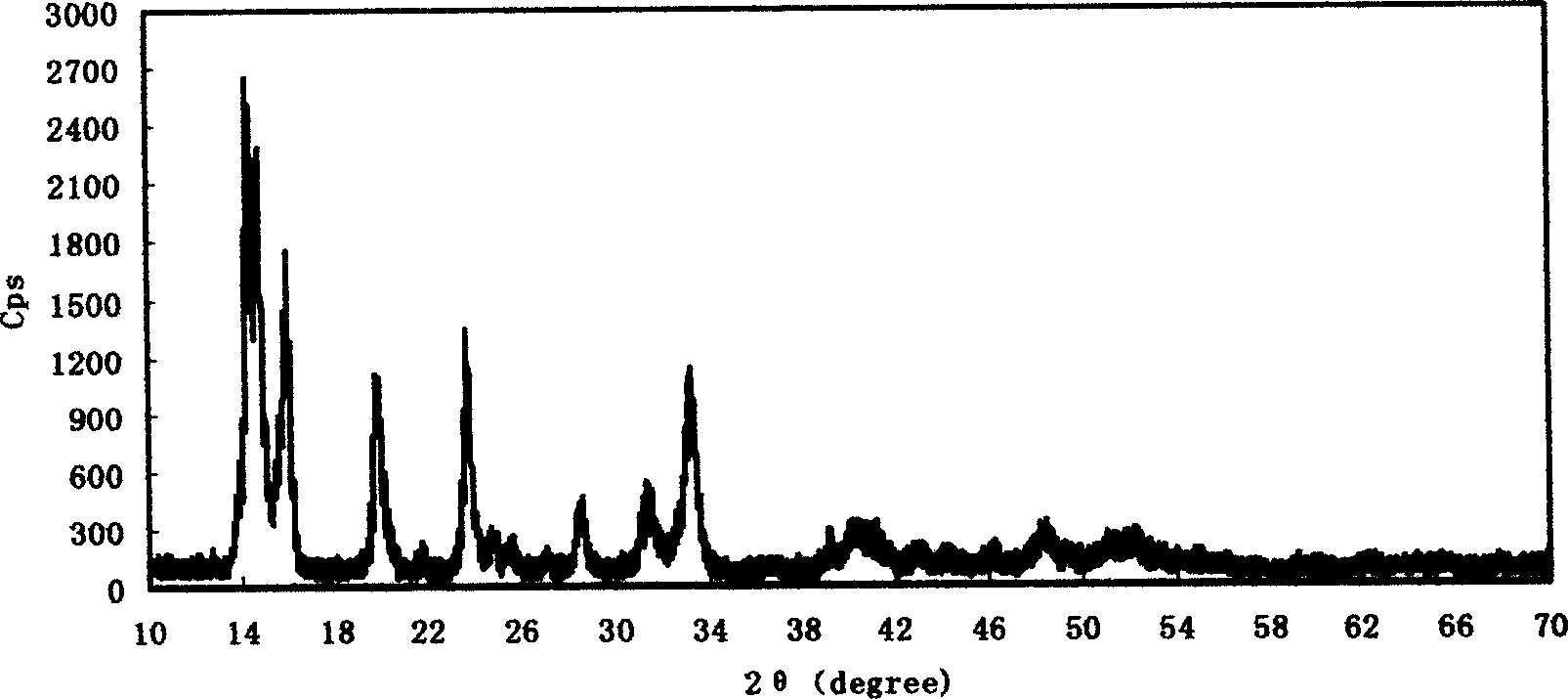

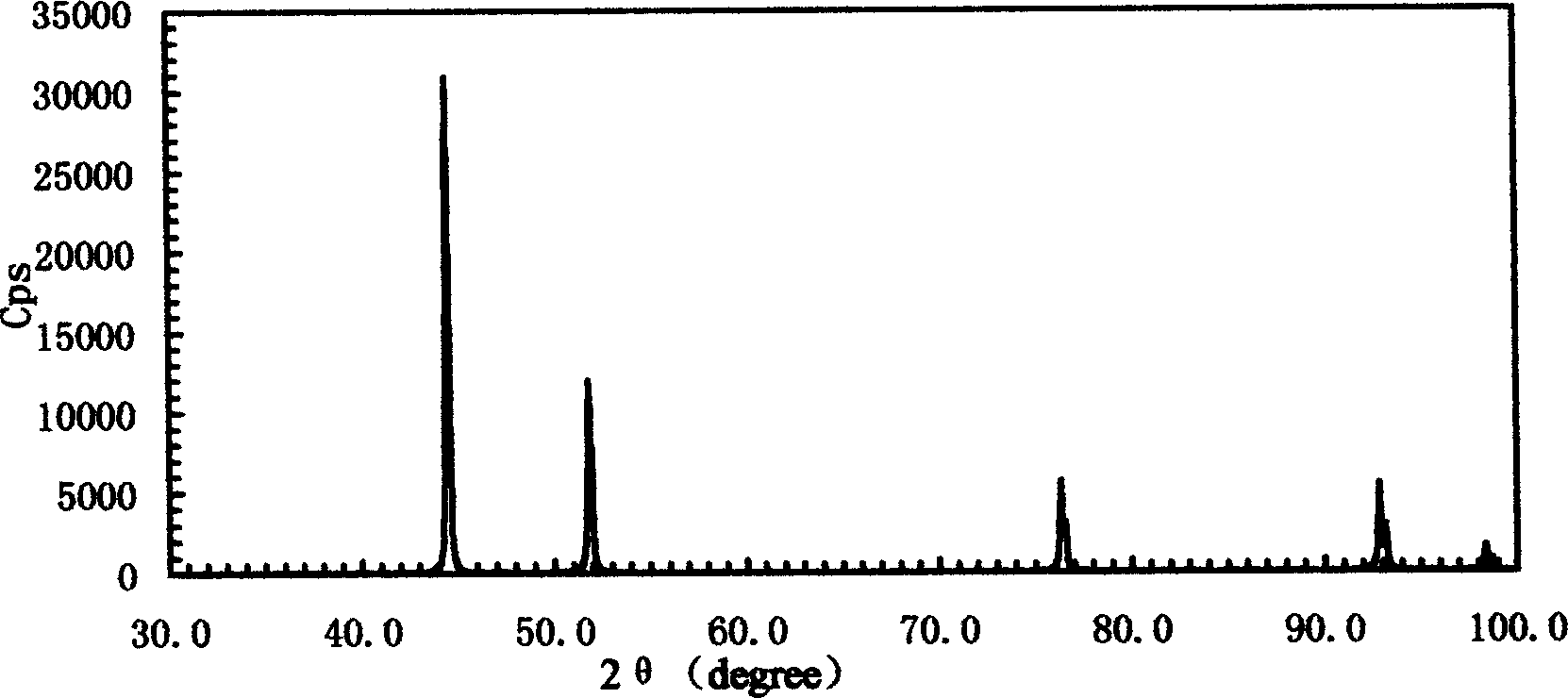

[0046] After the reaction is completed, the obtained composite precipitate is washed, filtered and dried to become the nickel-cobalt alloy powder precursor. After that, the precursor is put into a burning boat and placed in a PID-adjusted electric furnace, and the temperature is controlled to be about 400°C. And in (H 2 +N 2 ...

Embodiment 2

[0048] The nickel nitrate solution and the cobalt nitrate solution with a ratio of nickel to cobalt of 7:3 are uniformly mixed, and then the composite precipitation agent solution composed of the mixed solution and the dispersant PVP is added to the reactor through the feeding device, and the Ni 2+ -Co 2+ -NH 3 -NH 4 + -NO 3 - C 2 O 4 2- -H 2 The composite precipitation transformation is carried out in the O system, the temperature is controlled to be about 65℃, the pH is about 8.2, and the initial Ni in the feed liquid 2+ And Co 2+ The total concentration is 0.7mol / L, C 2 O 4 2- The concentration is 0.72mol / L.

[0049] After the reaction is completed, the obtained composite precipitate is washed, filtered and dried to become the precursor of nickel-cobalt alloy powder. After that, the precursor is put into a burning boat and placed in a PID-adjusted electric furnace, and the temperature is controlled to be about 450°C. And in N 2 Thermal decomposition is carried out under atm...

Embodiment 3

[0051] The nickel sulfate solution and the cobalt sulfate solution with a ratio of nickel to cobalt of 4:1 are uniformly mixed, and then the mixed solution and the composite precipitation agent solution composed of ammonia, ammonium oxalate and dispersant PVP are added to the reactor through the feeding device, and the Ni 2+ -Co 2+ -NH 3 -NH 4 + -SO 4 2- -C 2 O 4 2- -H 2 The composite precipitation transformation is carried out in the O system, the temperature is controlled at about 70℃, the pH is about 8.4, and the initial Ni in the feed liquid 2+ And Co 2+ The total concentration is 0.8mol / L, C 2 O 4 2- The concentration is 0.88mol / L.

[0052] After the reaction is completed, the obtained composite precipitate is washed, filtered and dried to become the precursor of nickel-cobalt alloy powder. After that, the precursor is put into a burning boat and placed in a PID-adjusted electric furnace, and the temperature is controlled to be about 360°C. And in (H 2 +N 2 ) Thermal deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com