Process for preparing fibrous nickel powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

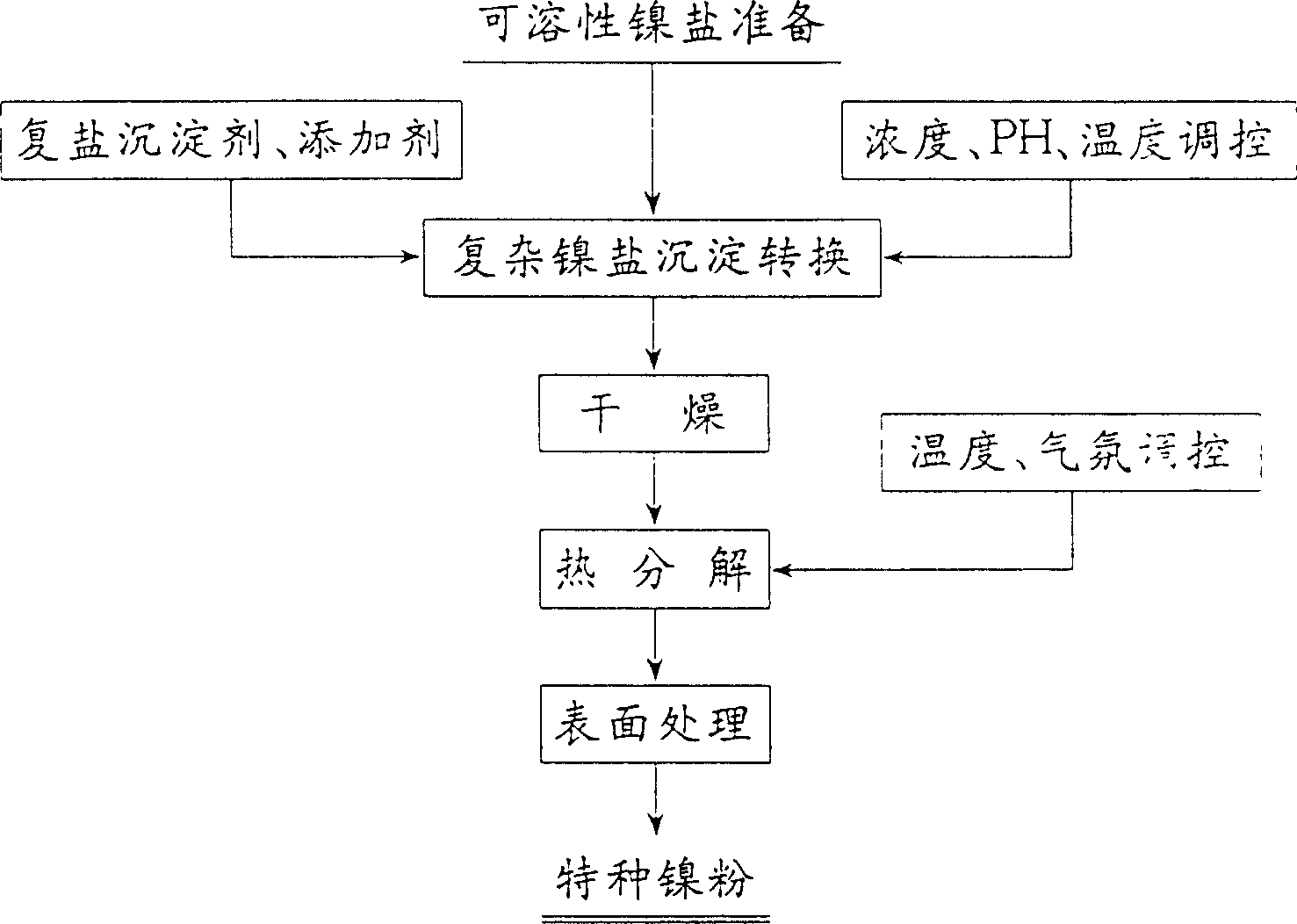

[0020] figure 1 The preparation process of fibrous nickel powder is described:

[0021] ① The soluble nickel salt solution and the composite precipitant solution are fed into the reactor from different containers in parallel through the spray feeding device. 2+ -NH 3 -NH 4 + -Cl - -C 2 o 4 2 -H 2 The O system undergoes complex precipitation conversion, the temperature is controlled at 55-85°C, the pH is 7.0-9.0, and the initial Ni in the feed solution 2+ The concentration is 0.4~1.2mol / l;

[0022] ② The composite precipitate obtained after the reaction is completed is washed, filtered and dried to become the nickel powder precursor;

[0023] ③Put the nickel powder precursor into a PID-regulated electric furnace, control the temperature at 350-600°C, and 2 +N 2 ) under the atmosphere control to carry out thermal decomposition;

[0024] ④ After the thermal decomposition is completed, the nickel powder is cooled and the surface is anti-oxidized to room temperature, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com