Patents

Literature

199 results about "Nickel Carbonyl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A colorless, volatile and highly flammable, liquid inorganic compound with a characteristic, musty odor that emits toxic carbon monoxide fumes upon heating. Nickel carbonyl is primarily used for nickel coatings and to manufacture high-purity nickel powder. Exposure to this substance can cause severe dermatitis, skin and asthma-like allergies and affects the lungs, kidneys, gastrointestinal tract and neurological system. Nickel carbonyl is a known carcinogen and is associated with an increased risk of developing lung and nasal cancers. (NCI05)

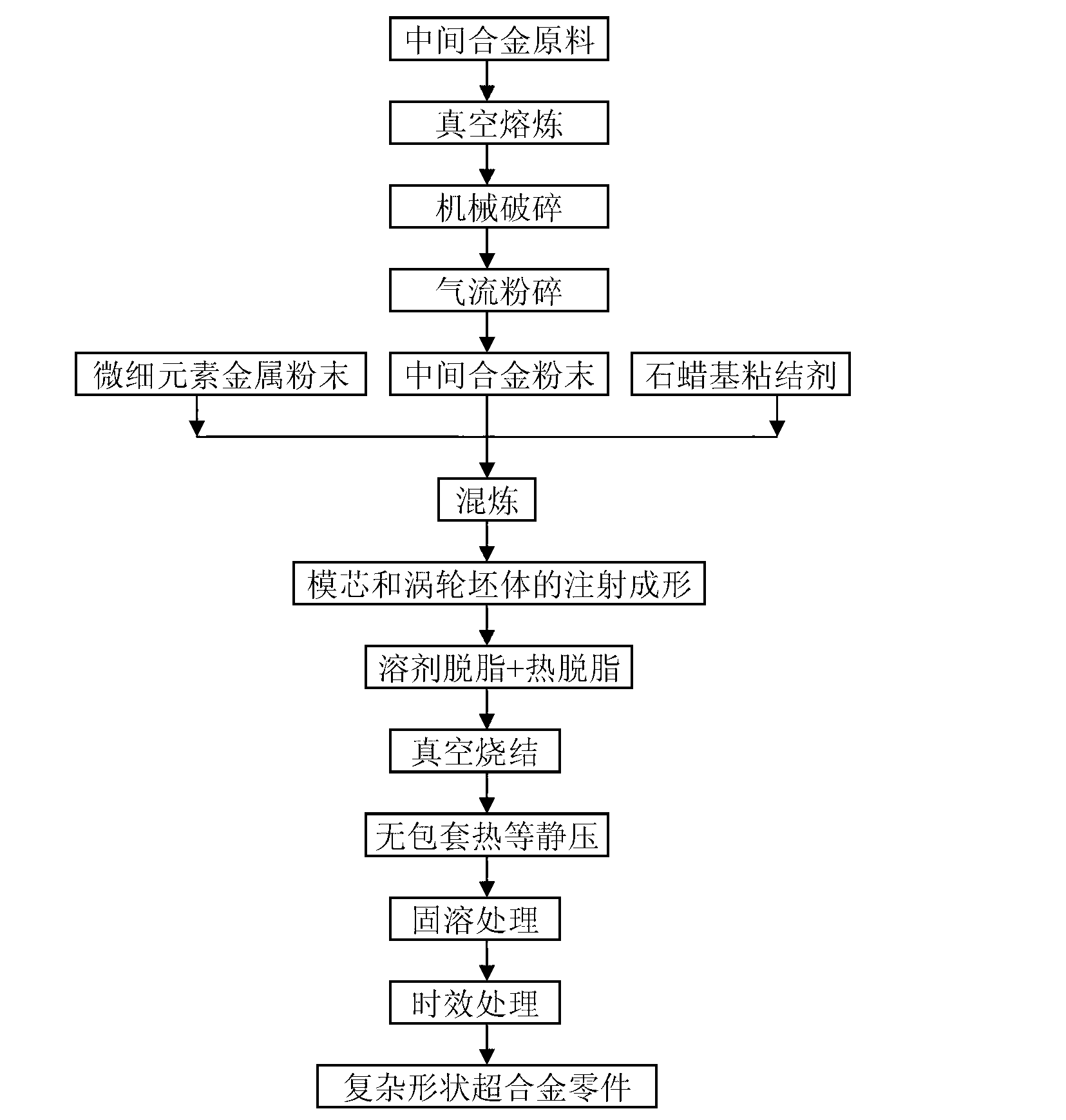

Method for preparing powder super-alloy by near net shape

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

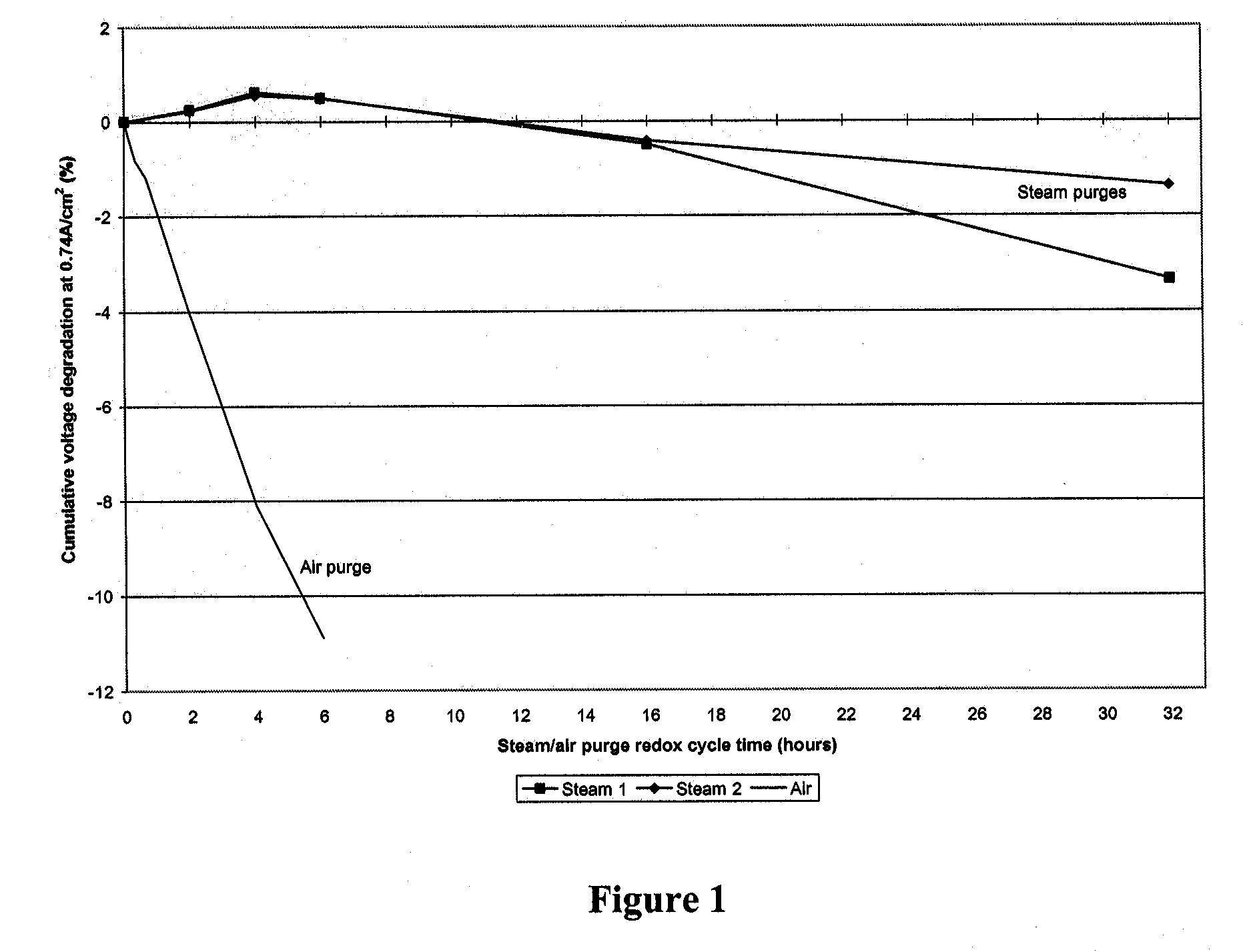

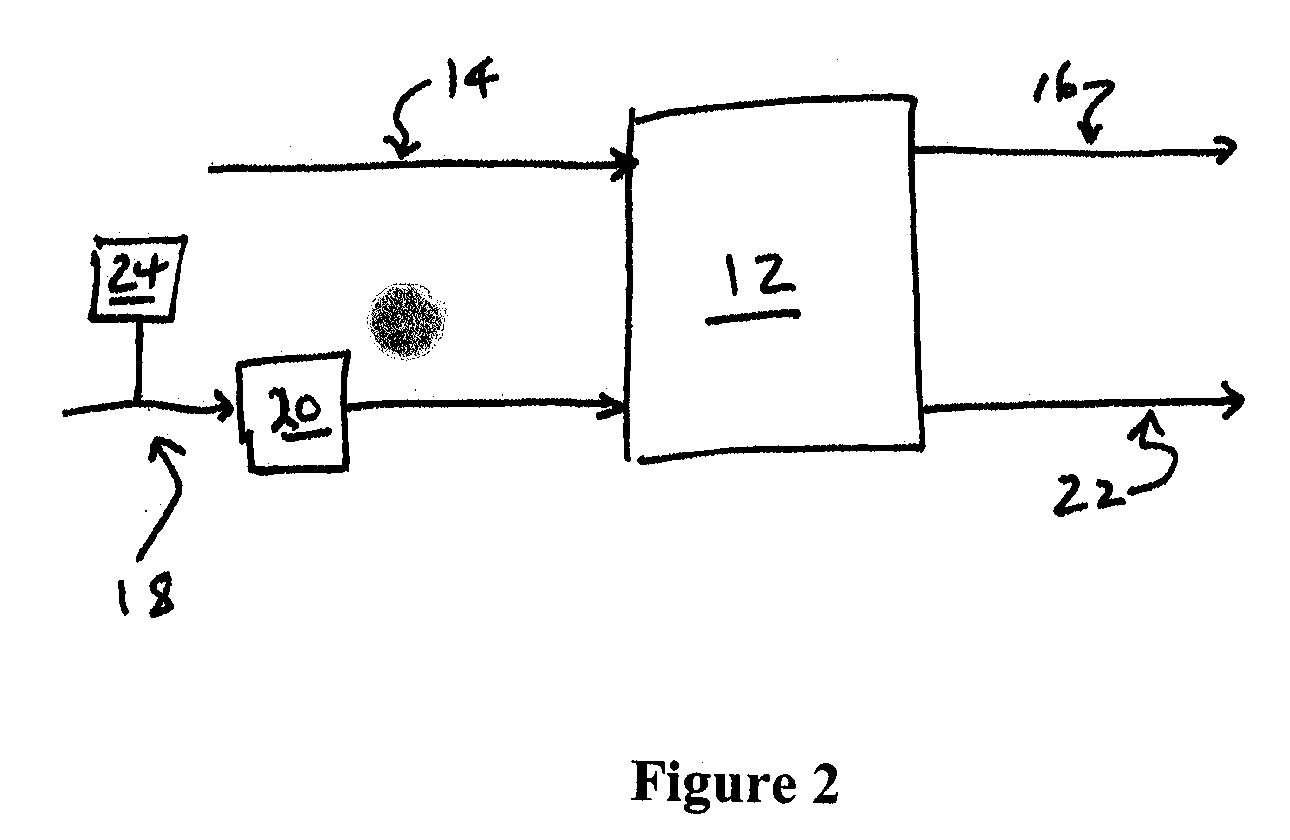

Fuel cell shutdown with steam purging

ActiveUS20050233187A1Lower potentialFuel cell heat exchangeSolid electrolyte fuel cellsFuel cellsEngineering

The present invention relates to a method and apparatus for steam purging a solid oxide fuel cell stack. Purging the SOFC stack with steam has a physical flushing effect, removing carbon monoxide containing reformate and free oxygen gas from the anode area thereby reducing the potential for nickel oxide or nickel carbonyl formation.

Owner:VERSA POWER SYST

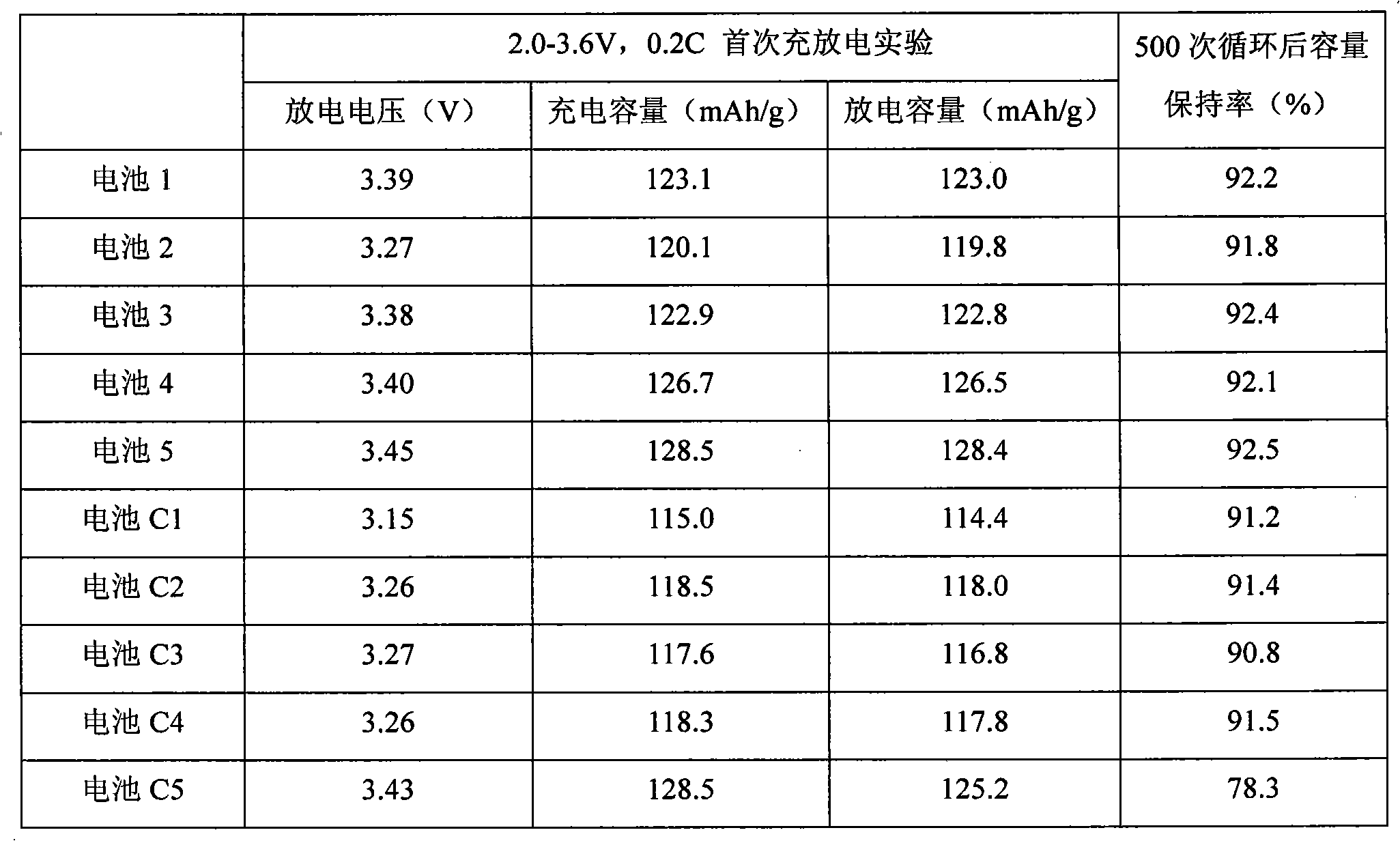

Cathode material of lithium ion battery and battery

ActiveCN102487141ALower internal resistanceHigh specific capacityCell electrodesSecondary cellsFiberConductive polymer

The invention provides a cathode material of a lithium ion battery. The cathode material contains active substance and conductive agent, wherein the conductive agent comprises a first conductive agent and a second conductive agent; the first conductive agent is a conductive polymer containing polar groups, and the second conductive agent is one or more selected from carbon black, graphite, carbon fiber, carbon nanotube, nickel carbonyl powder, copper powder, iron powder, zinc powder and aluminium powder. The invention also provides a lithium ion battery. During a slurry preparation process, polar groups facilitate hydrogen bond formation on the second conductive agent and the anode active substance surface and enhance disperse degree of the second conductive agent and the anode active substance in a solvent, so that the slurry is more easily coated, and the coating thickness is uniform; and the prepared polar sheet has good consistency.

Owner:BYD CO LTD

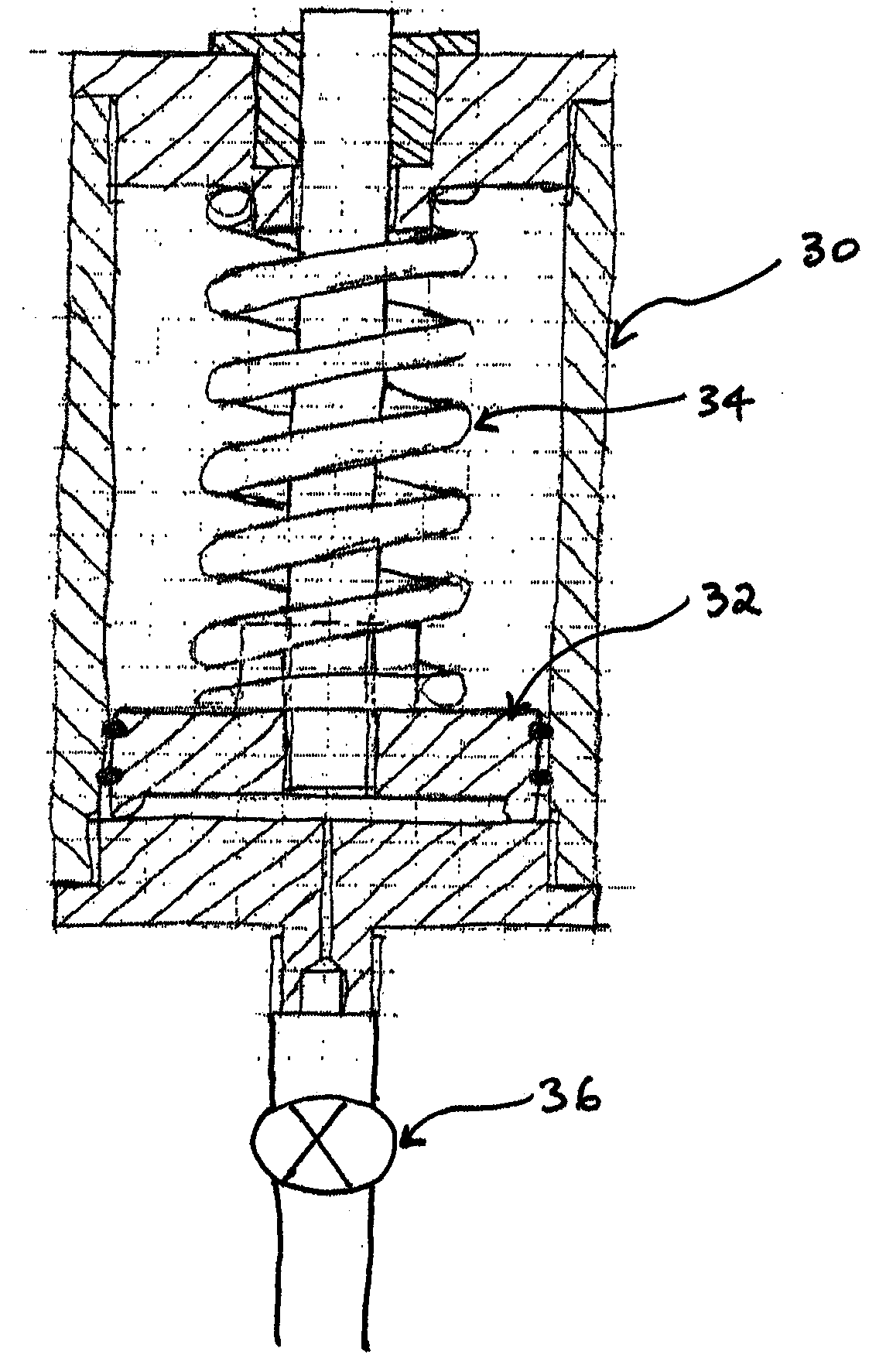

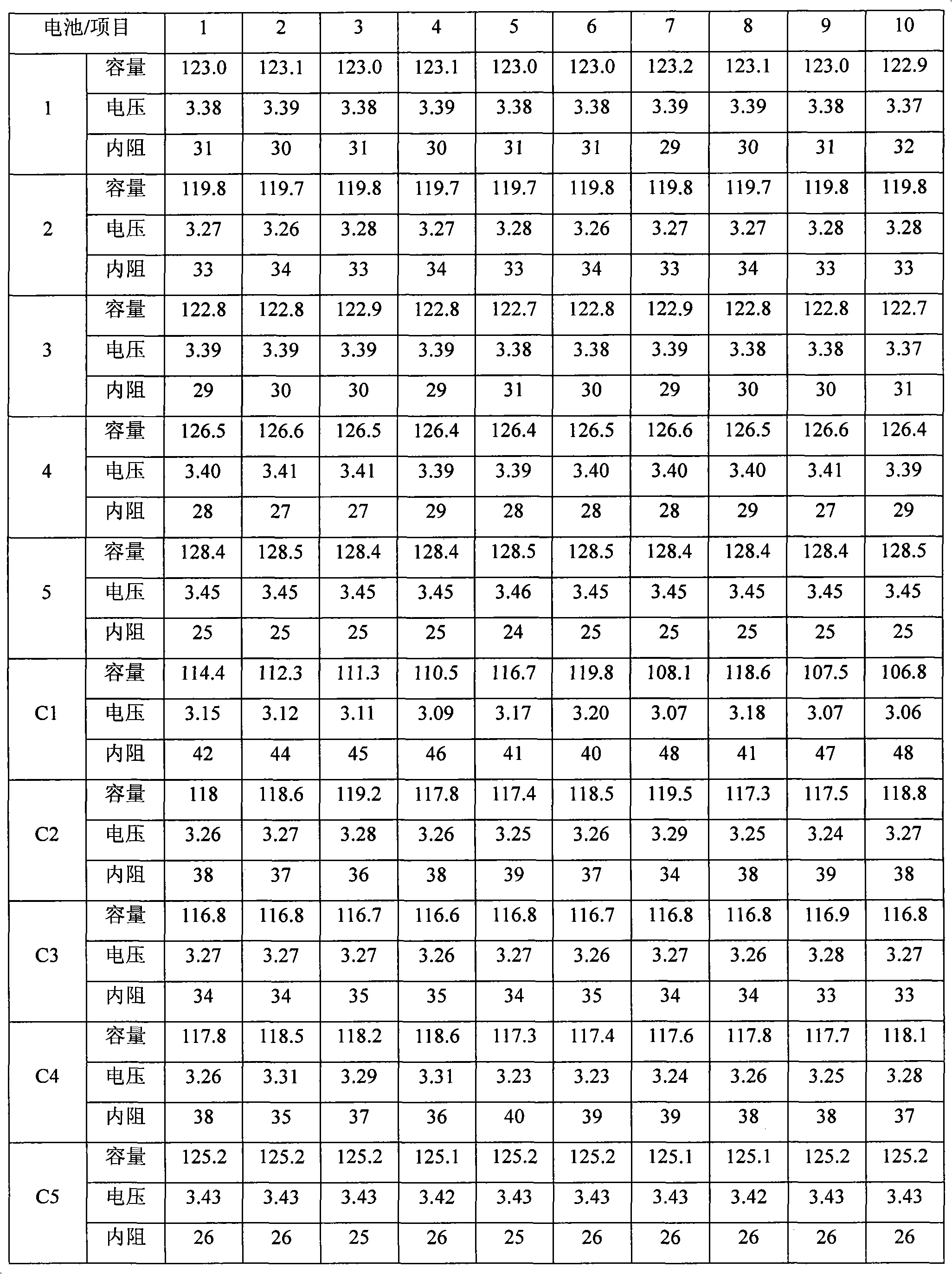

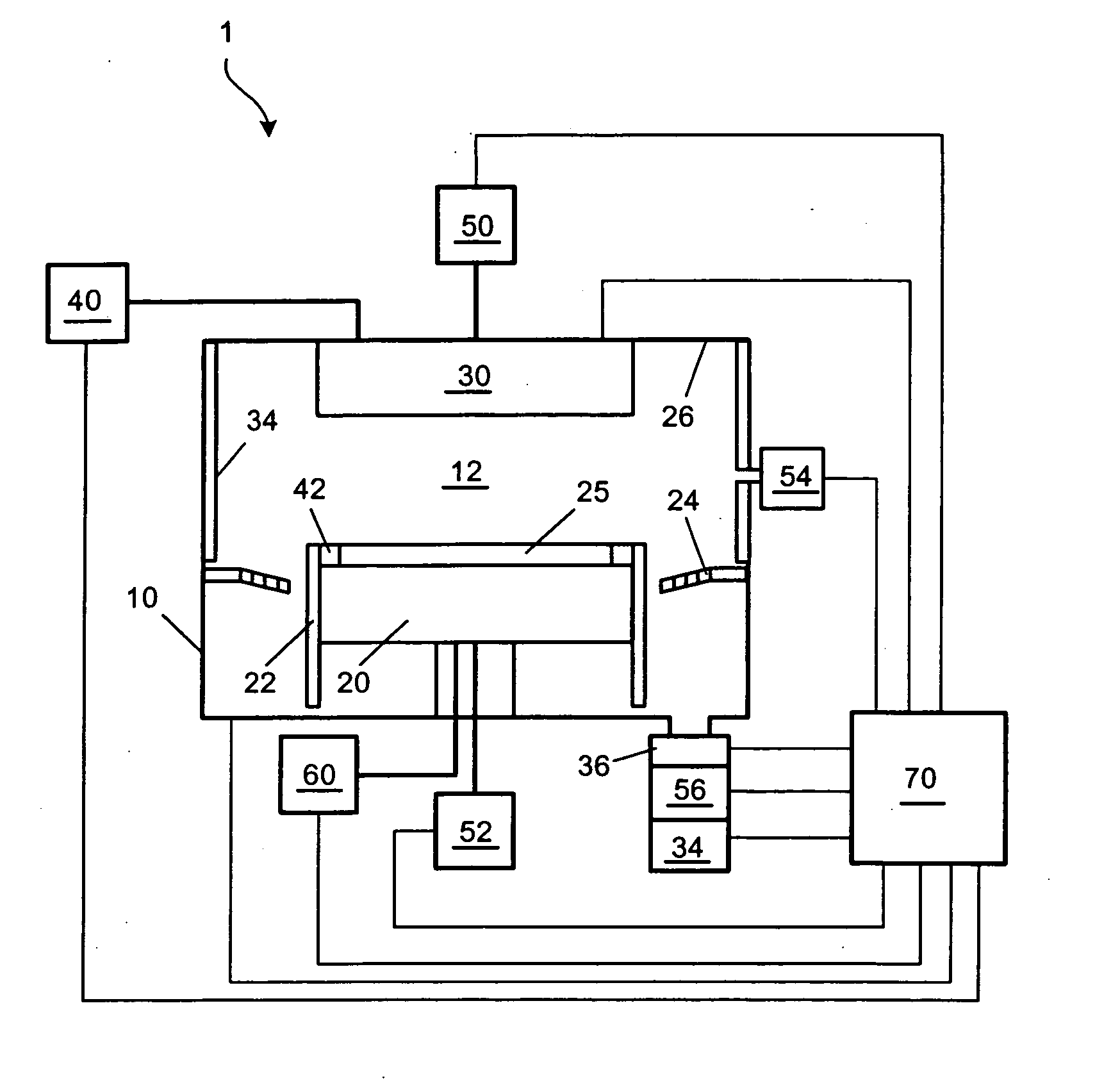

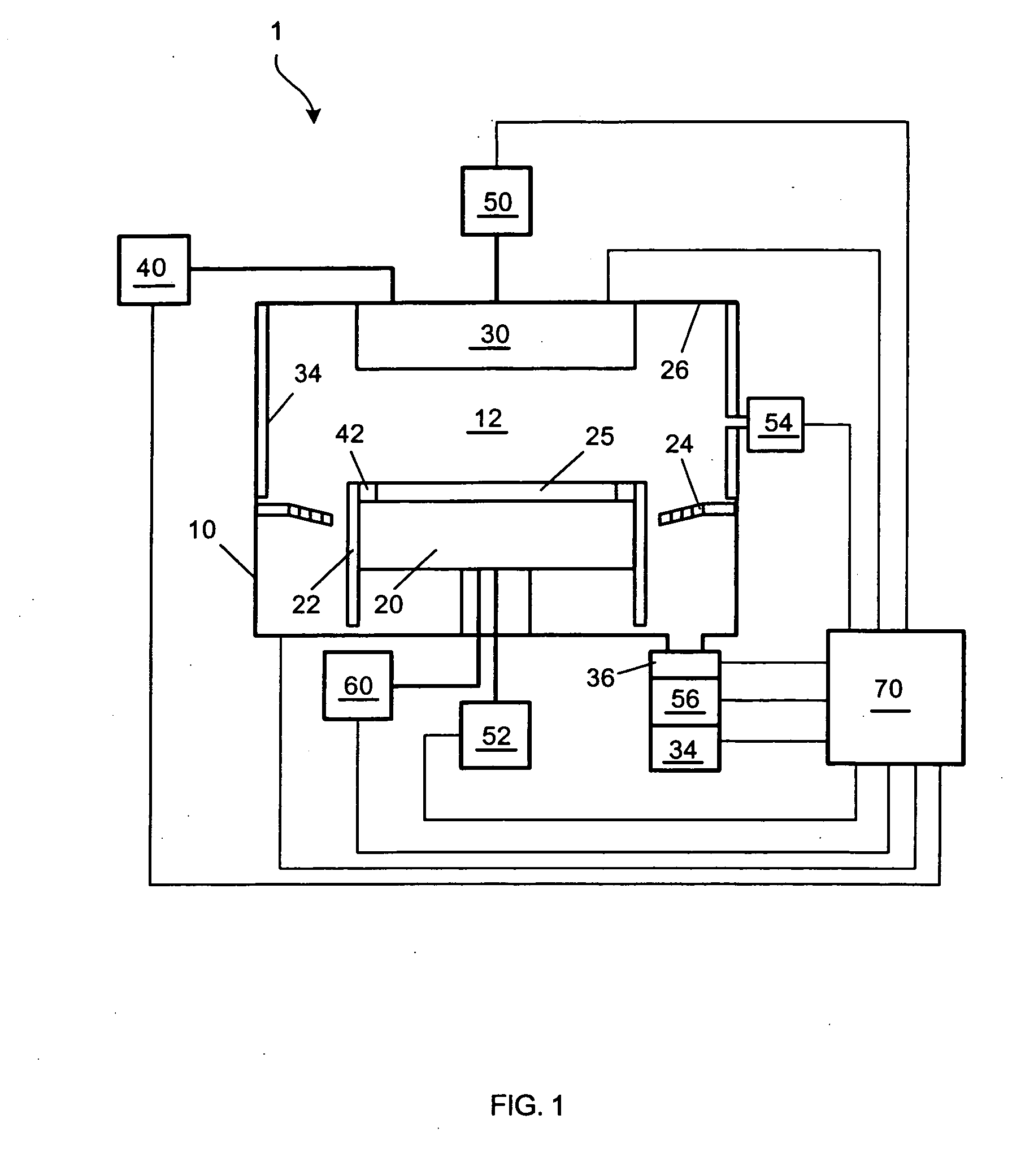

Nickel carbonyl vapour deposition apparatus and method

A closed loop, carbon monoxide self-contained preferably continuous process and apparatus for the production of nickel or nickel coated objects by nickel vapor deposition (NVD), comprising placing an object to be treated with nickel carbonyl in a deposition chamber; feeding a gaseous mixture of nickel carbonyl and carbon monoxide to the chamber; producing the nickel or nickel coated object and a nickel carbonyl-depleted gaseous mixture; removing nickel carbonyl from the nickel carbonyl-depleted gaseous mixture in a primary and subsequent secondary condensation unit and, preferably, a tertiary condensation unit to produce an essentially nickel carbonyl-free gas. The secondary and tertiary condensation units operably freeze out and subsequently thaw nickel carbonyl and most preferably each comprises a pair of units linked in parallel arrangement operative in alternating, alternate freeze-thaw modes. Carbon monoxide-containing gas is recycled to a nickel carbonyl reactor. The process and apparatus provides a more economic to operate, safe and more operably reliable than prior art NVD processes.

Owner:CVMR CORP

Method for preparing superfine nickel carbonyl powder by nickel carbonyl thermal decomposition

The invention discloses a method that is used to prepare superfine carbonyl nickel powder by the carbonyl nickel thermal decomposition. The method is that the carbonyl nickel and the carbon monoxide gas are mixed admission the decomposer to mix with the carbon monoxide main heat source gas whose preheating temperature is from two hundred and forty centigrade degree to three hundred twenty centigrade degree to make the carbonyl nickel decompose to from superfine carbonyl nickel powder whose granularity is from twenty nanometer to ten millimeter. The pressure of the decomposer is from 0.02MPa to 0.2MPa in the whole decomposition process. The invention avoids the complicated operation of separating the mixed gas after the decomposition, simplifies the preparation technology, reduces the cost of the production, and greatly reduces the produce of the wall built up.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ceramic with three-dimensional decoration effect and preparation method thereof

ActiveCN105175027ASmall chromophoric salt osmotic gradientEmbody special texture effectDicobalt octacarbonylIron pentacarbonyl

The invention relates to ceramic with a three-dimensional decoration effect and a preparation method thereof. A distributor is firstly utilized to distribute powder into a pattern corresponding to an ink-jetted pattern on the surface; a body is then formed by pressing; the surface of the body is then covered by a layer of overglaze paste with coloring auxiliary after drying, and permeating ink is then jetted after the body is dried again; the body is then fired, and thereby the ceramic is produced; in a ceramic tile, the permeation depth of the permeating ink in the overglaze layer is 0.2mm to 0.5mm; the permeating ink is oil-based ink containing a transitional metal complex, wherein the transitional metal complex comprises nickel carbonyl, iron pentacarbonyl, chromium hexacarbonyl, titanium hexacarbonyl, dicobalt octacarbonyl, titanium(IV)-oxy acetylacetonate, vanadium(IV)-oxy acetylacetonate, chromium acetylacetonate, cobalt acetylacetonate, praseodymium acetylacetonate and iron acetylacetonate. An oil-based system is adopted as the ink, a high-permeability organic solvent with small molecular volume and low surface tension is adopted as a permeation promoter to replace water, and the osmotic gradient of coloring salt is small.

Owner:MONALISA GRP CO LTD

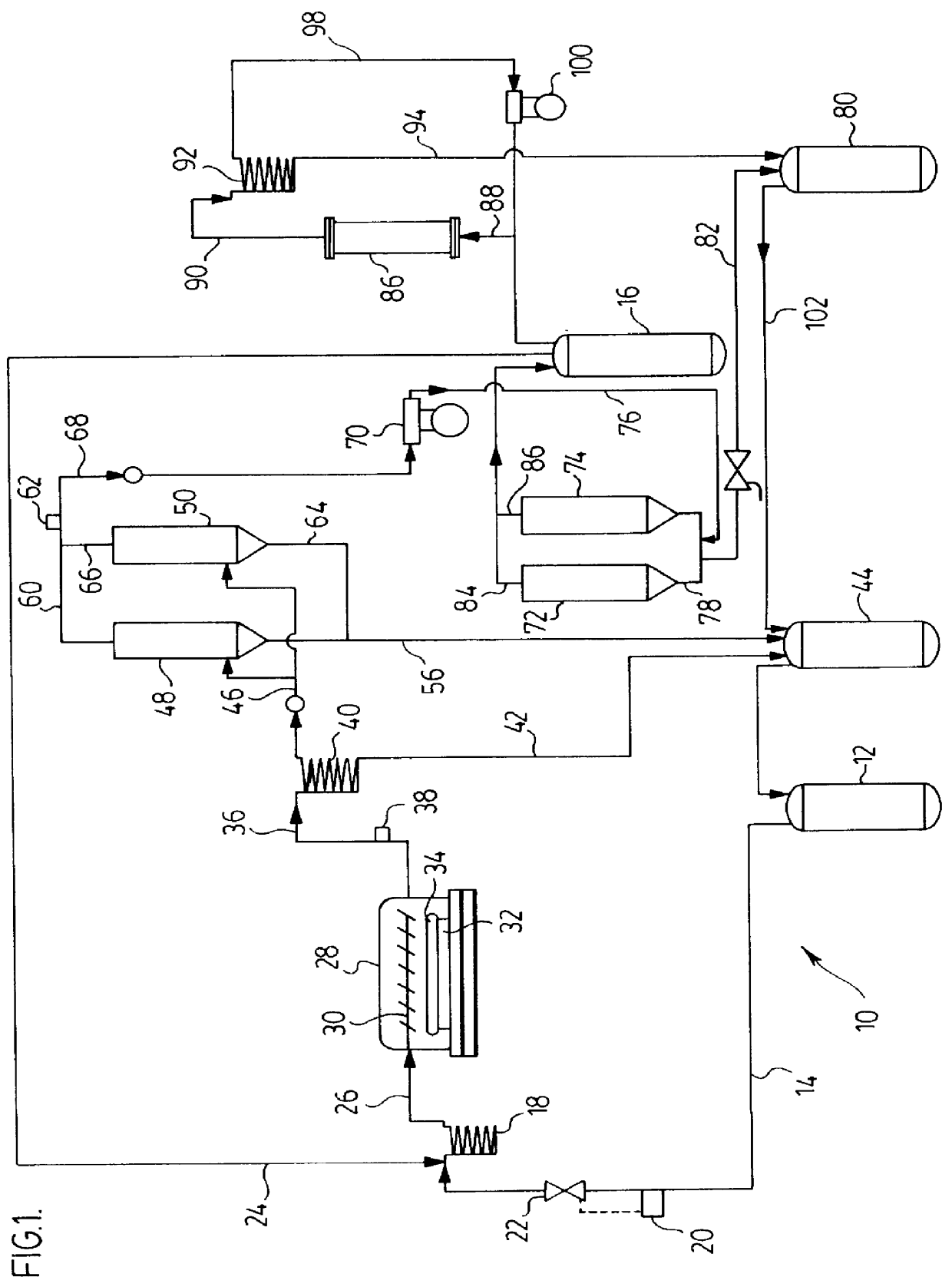

Closed loop carbon monoxide self-contained nickel carbonyl deposition process

InactiveUS6048578ANeed can be usedDispersed particle separationPretreated surfacesFreeze thawingClosed loop

A closed loop, carbon monoxide self-contained preferably continuous process and apparatus for the production of nickel or nickel coated objects by nickel vapor deposition (NVD), comprising placing an object to be treated with nickel carbonyl in a deposition chamber; feeding a gaseous mixture of nickel carbonyl and carbon monoxide to the chamber; producing the nickel or nickel coated object and a nickel carbonyl-depleted gaseous mixture; removing nickel carbonyl from the nickel carbonyl-depleted gaseous mixture in a primary and subsequent secondary condensation unit and, preferably, a tertiary condensation unit to produce an essentially nickel carbonyl-free gas. The secondary and tertiary condensation units operably freeze out and subsequently thaw nickel carbonyl and most preferably each comprises a pair of units linked in parallel arrangement operative in alternating, alternate freeze-thaw modes. Carbon monoxide-containing gas is recycled to a nickel carbonyl reactor. The process and apparatus provides a more economic to operate, safe and more operably reliable than prior art NVD processes.

Owner:CVMR CORP

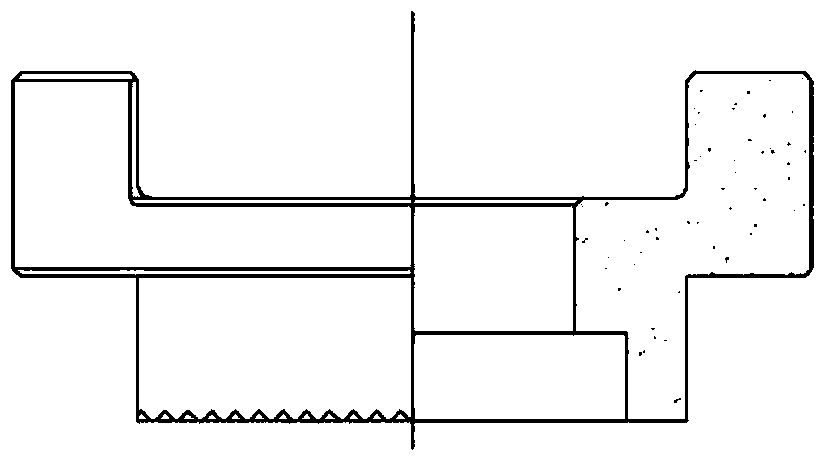

Powder metallurgy method and forming die for producing upper combining part

The invention discloses a powder metallurgy method and forming die for producing an upper combining part. The powder material comprises, by weight, 2.5% of electrolytic copper powder, 1.0% of nickel carbonyl powder, 0.9% of graphite powder or carbon powder, 0.8% of zinc stearate and the balance water atomization iron powder, wherein the zinc stearate is lubricant. The main production procedures comprise powder mixing, forming, sintering, cemented quenching, cleaning drying and tempering. The principles of a powder feeding method and a powder discharging method are adopted, a powder feeding groove and a powder discharging groove are formed in a female die in the aspect of die designing, under the condition that not more operating systems of a molding press need to be added, the filling quantity of all positions of a pressed blank is changed to meet the compression ratio through the powder feeding method and the powder discharging method to guarantee that the formed pressed blank can have even density, the die is simplified, and the number of the operating systems of the press is reduced. Meanwhile, due to cleaning and drying after cemented quenching, a product can be bright and clean in appearance after being tempered and the surface of the product is golden yellow due to oxidation. In addition, the tissue inside the product is changed after tempering, and internal stress is removed.

Owner:ZHEJIANG QUZHOU YONGFENG METAL PROD

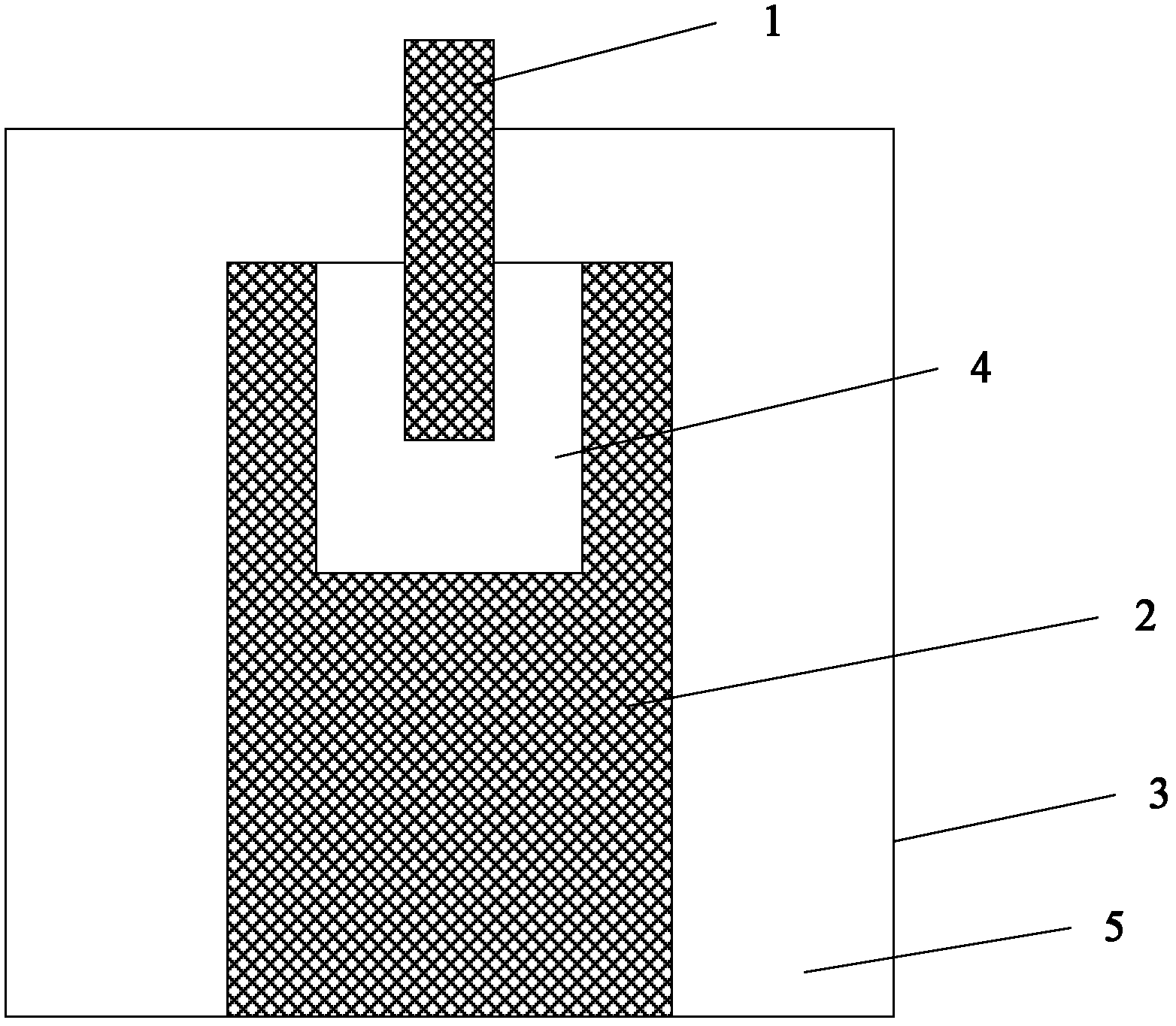

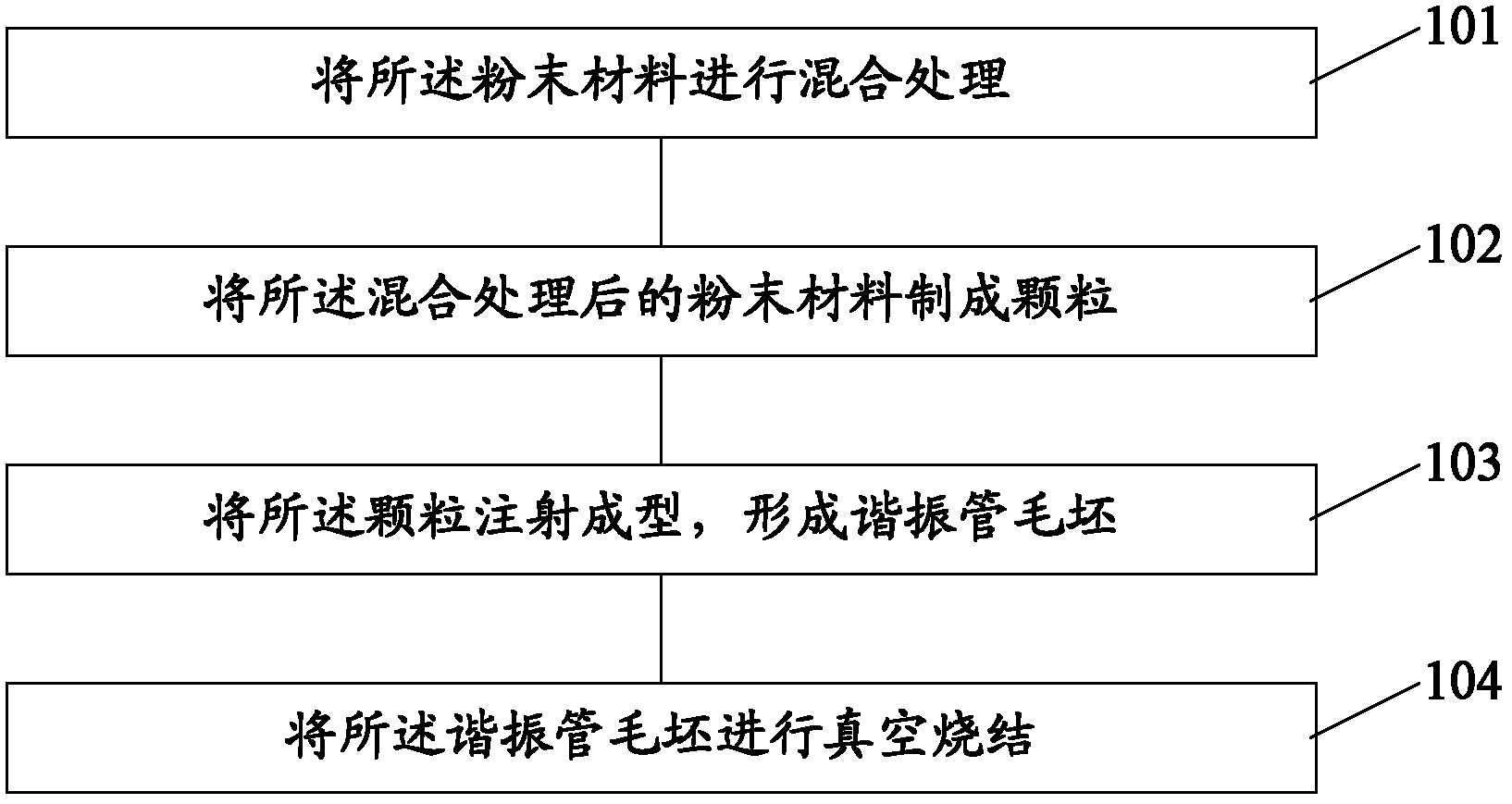

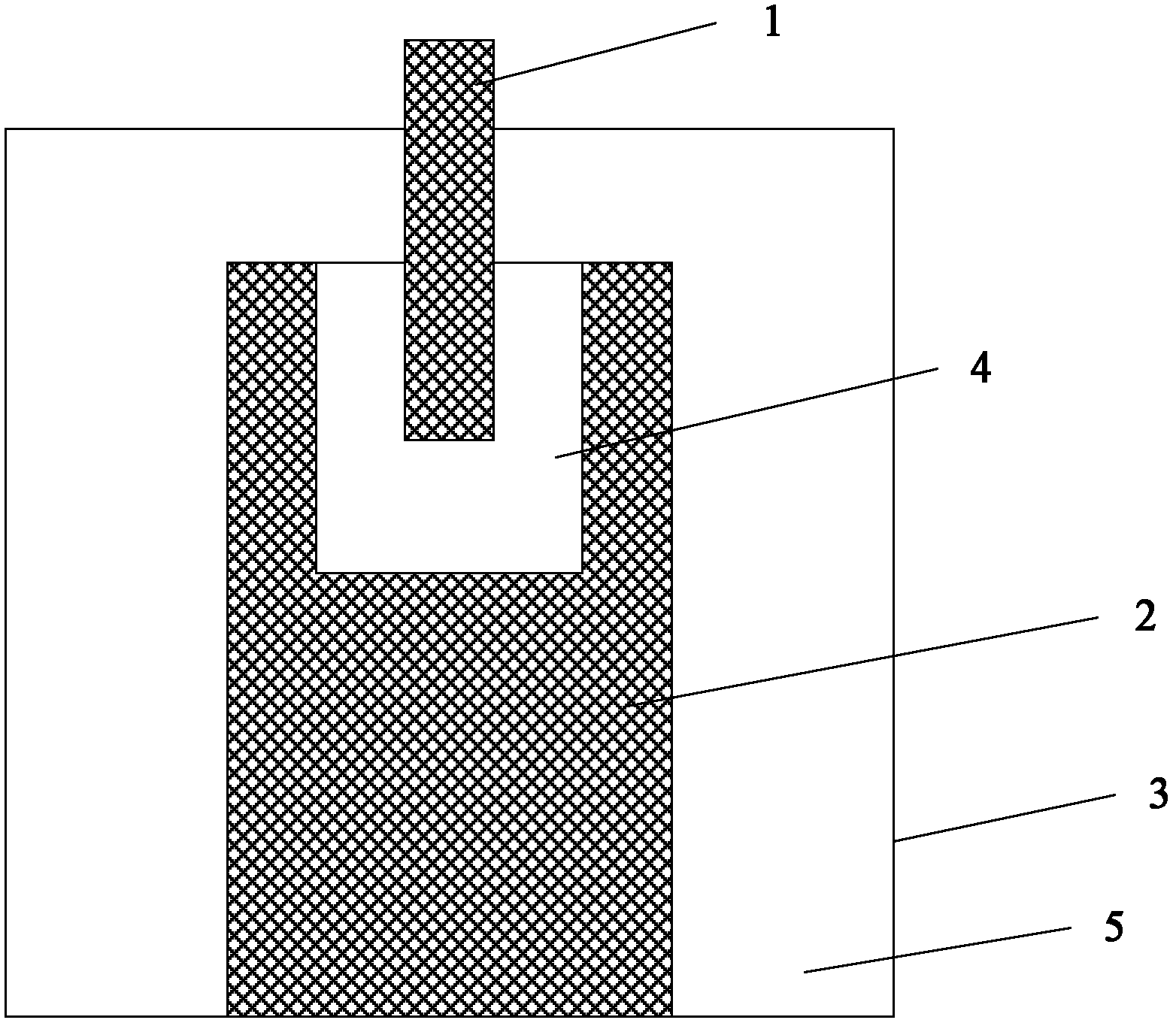

Resonance tube and manufacture method of resonance tube, cavity filter

ActiveCN102569976AImprove applicabilityReduce manufacturing costTransportation and packagingMetal-working apparatusIron powderResonance

The invention provides a resonance tube, a manufacture method of the resonance tube and a cavity filter, belonging to the technical field of the communication equipment. Different degrees of temperature compensation are provided, the production cost is reduced and the production efficiency is increased. The resonance tube is made of a powder material and the powder material comprises at least one of carbonyl iron powder and iron powder and at least one of nickel carbonyl powder and nickel powder, the mass percentage of at least one of carbonyl iron powder and iron powder in the powder material is 58-70% and the mass percentage of at least one of nickel carbonyl powder and nickel powder in the powder material is 30-42%. The resonance tube, the manufacture method of the resonance tube and the cavity filter are used in the communication devices such as a base station.

Owner:HUAWEI TECH CO LTD

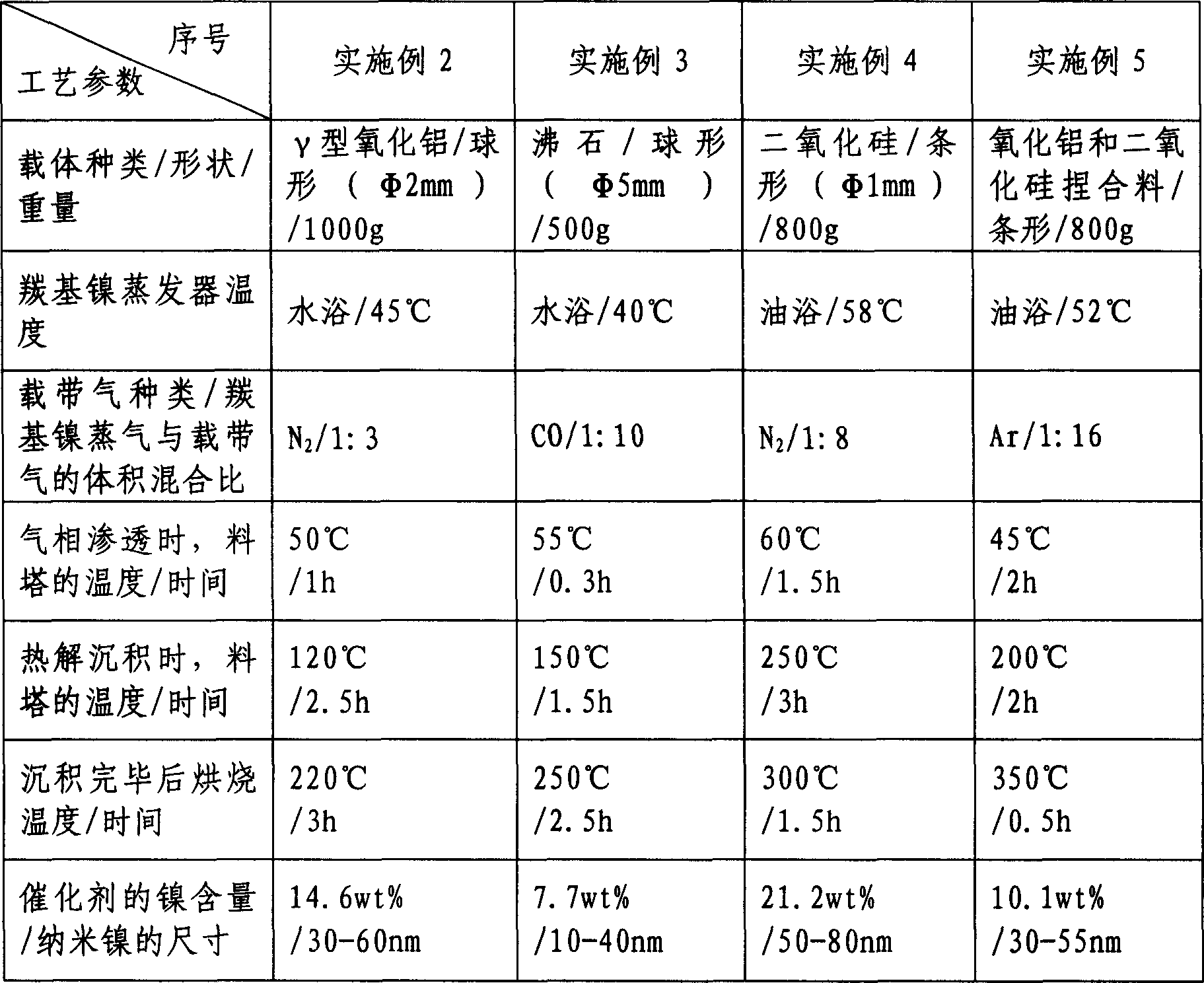

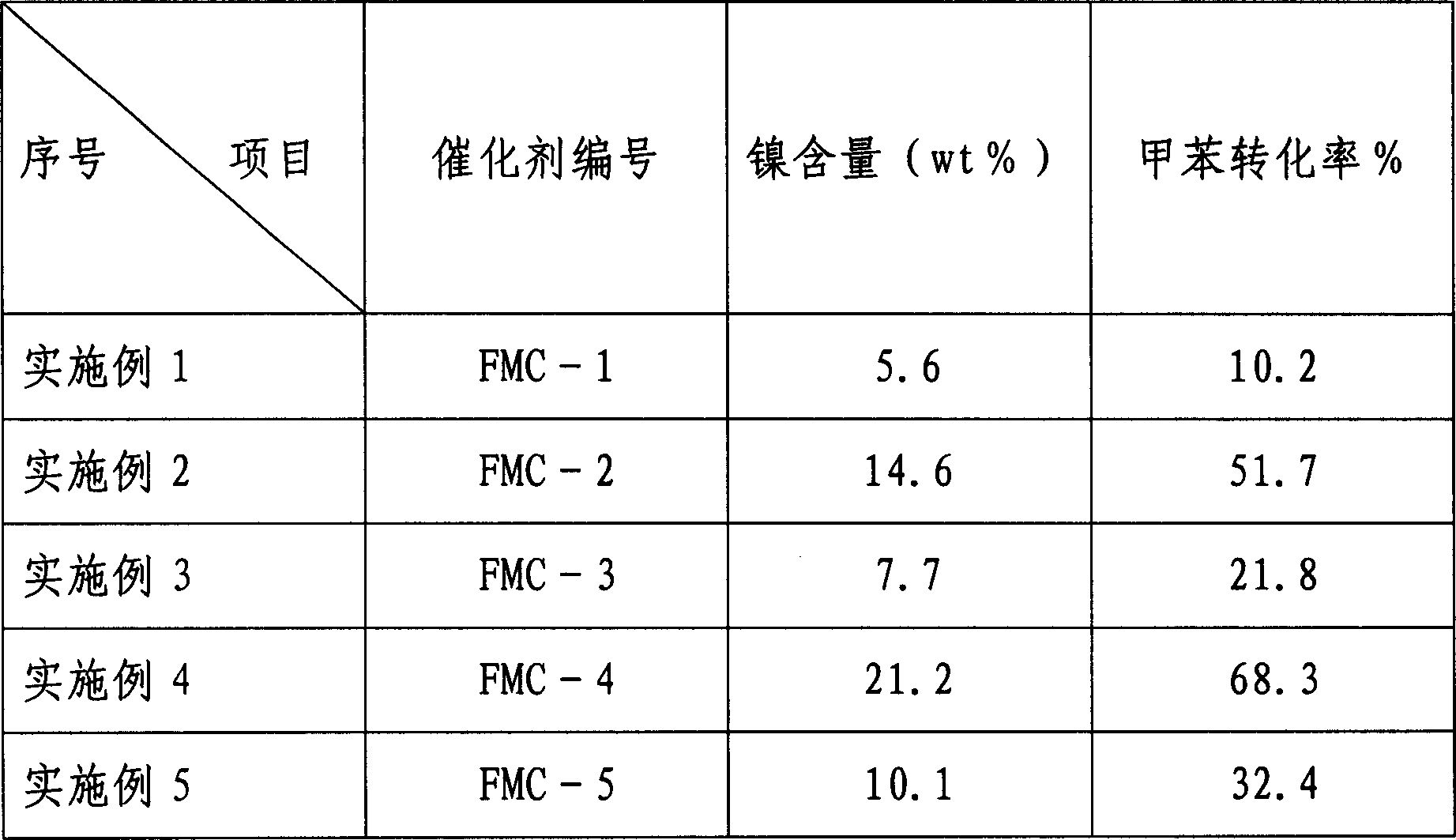

Gas phase permeation precipitation method for preparation of supported nanometer nickel hydrogenation catalyst

InactiveCN1806920ASimple processProcess conditions are easy to controlCatalyst carriersCatalyst activation/preparationNickel catalystGas phase

The invention, belonging to hydrogenation catalyst, relates the method for preparation of loaded nanometer nickel catalyst. The method comprises the following steps: loading the nickel carbonoxide compound into feed tower with carrier gas, nickel carbonoxide penetrating and adsorbing on the carrier, then heating, nickel carbonoxide pyrolyzing and depositing on the carrier, finally calcining the carrier and getting the loaded nanometer nickel catalyst. The method has the advantages of simple technique, easy control, high productivity, low cost, non-pollution and wide applications.

Owner:BEIJING CISRI GAONA TECH

Zirconium oxide-based ceramic tool material and preparation method thereof

The invention provides a zirconium oxide-based ceramic tool material, which is prepared from the following raw materials in parts by weight: 50-60 parts of zirconium oxide, 30-35 parts of aluminium oxide, 1-2 parts of borax, 4-5 parts of barium carbonate, 1-2 parts of sodium humate, 2-4 parts of carboxymethylcellulose, 2-3 parts of carbonyl nickel powder, 3-5 parts of LiSbO3, 4-6 parts of potassium-sodium niobate, 2-3 parts of cerium oxide, 1-1.5 parts of lanthanum nitrate, a proper amount of deionized water, 1-1.4 parts of polyacrylic acid, 0.7-1.2 parts of polyethylene glycol, a proper amount of ethanediol and 3-4 parts of an anti-abrasion aid. Due to addition of carbonyl nickel powder to the ceramic, the thermal conductivity of the ceramic is increased, a tool is prevented from overheating, the ceramic has very high hardness and abrasive resistance, the ceramic tool is suitable for cutting and chipping a high-hardness material and is hardly aged or broken off; due to use of the anti-abrasion aid, the surface smoothness, abrasive resistance and heat resistance of the ceramic are improved.

Owner:安徽上阡科技信息咨询有限公司

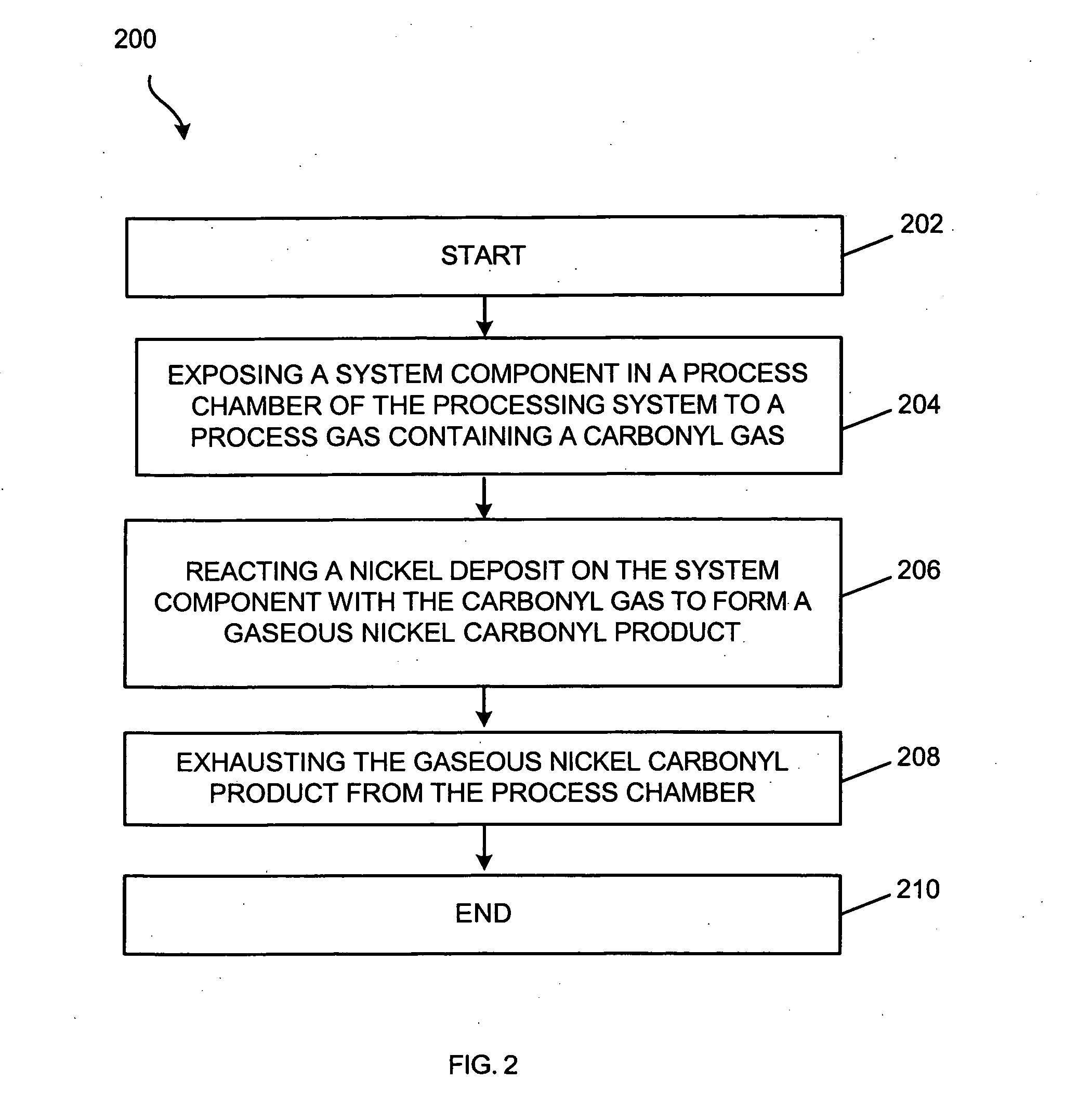

Method for dry cleaning nickel deposits from a processing system

InactiveUS20070074741A1Lighting and heating apparatusHollow article cleaningNickel CarbonylHandling system

A method for dry cleaning a process chamber including a nickel deposit. The method includes exposing a system component in the process chamber to a process gas with a carbonyl gas, reacting the nickel deposit on the system component with the carbonyl gas in a dry cleaning process to form a gaseous nickel carbonyl product, and exhausting the gaseous nickel carbonyl product from the process chamber. A mass signal of the nickel carbonyl product can be used to monitor and control the dry cleaning process.

Owner:TOKYO ELECTRON LTD

Method for preparing superfine carbonyl iron powder in use for high performance magnetic powder core

The invention discloses a manufacture method for high capacity magnetic powder core using superfine carbonyl iron dust that includes the following steps: compounding pure CO and iron raw material in compounding kettle under 3-15MPa pressure and 100-200 degree centigrade to gain iron pentacarbonyl, after taking condensation, gas liquid separation, the liquid iron pentacarbonyl would be sent into tank; pouring iron pentacarbonyl, nickel carbonyl, nitrogen gas, and alkaline air into decomposition furnace, controlling the temperature between 180 and 350 degree centigrade to gain superfine carbonyl iron dust with special electromagnetic property. The invention has the feature of short flow, low energy consumption. The product has wide application field, and high product additional value.

Owner:JIANGXI YUEAN SUPERFINE METAL

Diamond drill bit composition used for sapphire bar drawing-out and preparing method of diamond drill bit composition

ActiveCN106756648AGood edgeExtended bit lifeTurbinesOther manufacturing equipments/toolsMaterials processingCobalt

The invention belongs to the field of hard and brittle material machining and provides a diamond drill bit composition used for sapphire bar drawing-out. The composition includes diamond and carcass powder. The carcass powder includes, by weight, 20-30 parts of superfine cobalt powder, 5-15 parts of nickel carbonyl powder, 0-20 parts of copper-tin pre-alloyed powder, 10-20 parts of superfine iron powder, 1-10 parts of phosphorus-copper powder, 5-15 parts of tungsten-copper pre-alloyed powder and 1-5 parts of beta-silicon carbide whiskers. The invention further provides a preparing method of the diamond drill bit composition used for sapphire bar drawing-out. A diamond drill bit used for sapphire bar drawing-out and prepared through the diamond drill bit composition used for sapphire bar drawing-out has the beneficial effects that both toughness and embrittlement are good, the diamond exposure is good, the drawing-out efficiency is high, the service life of the drill bit is long, and the drawing-out yield is high.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Oxo-process of preparing nickel carbonyl from coarse ore nickel

InactiveCN1398792AShort reaction timeImprove work efficiencyNickel carbonylsReaction temperatureNickel Carbonyl

The present invention is an oxo synthesis process of preparing cabonyl nickel from coarse nickel ore. The synthesis process has coarse nickel mineral as direct reactant, CO as reactant gas and H2S gas as catalyst, and in the operation conditions of 160-200 deg.C reaction temperature, 3.0-8.5 MPa reaction pressure and 8-12 hr reaction time, cabonyl nickel is produced with nickel extracting rate as high as 98%. The present invention has short reaction period, no need of treating reaction material and simple reaction process.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing nickel foil

InactiveCN102719801ANot easy to oxidize and spontaneously combustSimple processChemical vapor deposition coatingAlloyNickel Carbonyl

The invention provides a method for preparing a nickel foil, and relates to a method for preparing a nickel foil by adopting a carbonyl process. The method is characterized by comprising the steps: carrying out oxonation between nickel-containing water-quenched alloy as a raw material and carbon monoxide gas in a synthesizing kettle in the preparation process to prepare nickel carbonyl gas; and decomposing prepared nickel carbonyl gas in a decomposer, depositing decomposed nickel on a substrate suspended in the middle of the decomposer, cooling, discharging and stripping to obtain the nickel foil. By adopting a thermal decomposition manner to prepare the nickel foil, the components can be controlled, the cost is lowered, the environment is not polluted, and the prepared nickel foil is uniform in thickness.

Owner:JINCHUAN GROUP LIMITED

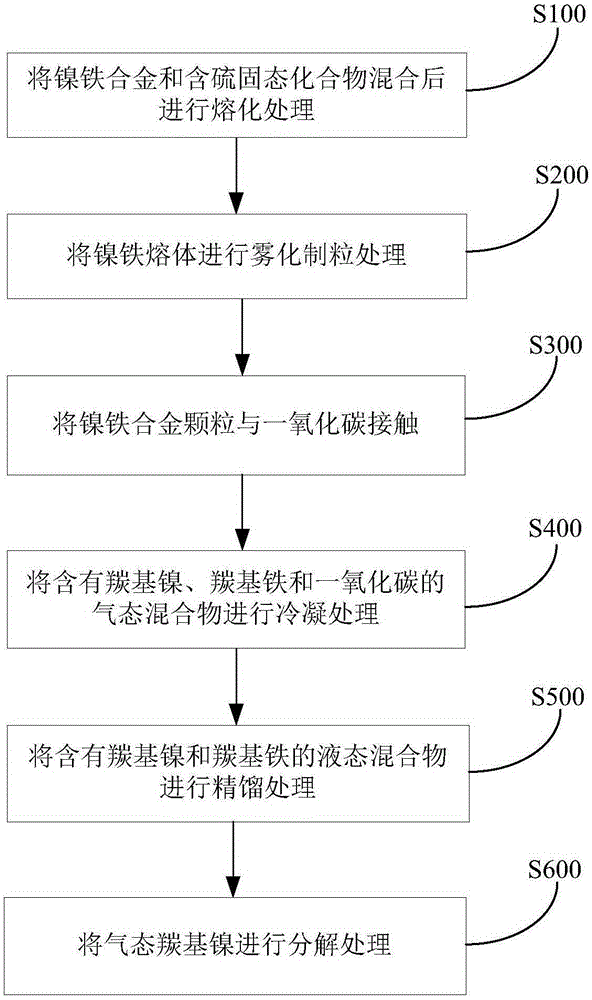

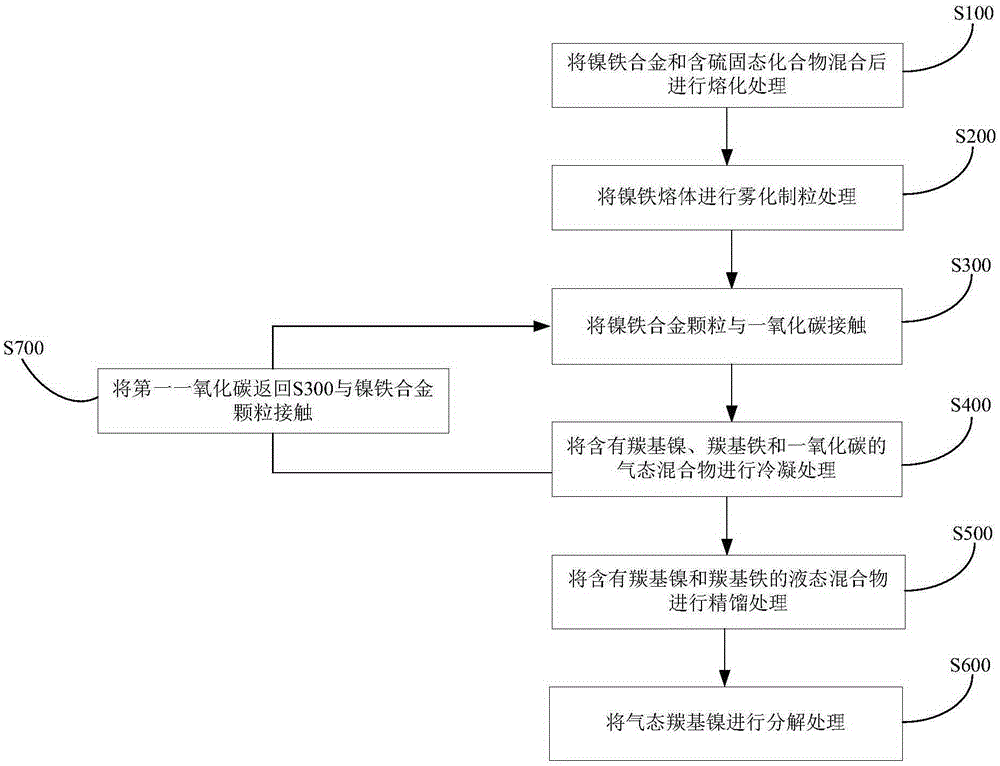

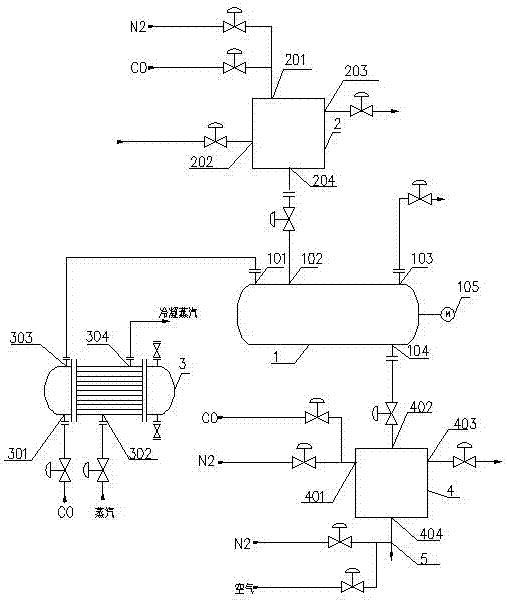

Method and system for preparing nickel carbonyl powder through nickel-iron alloy

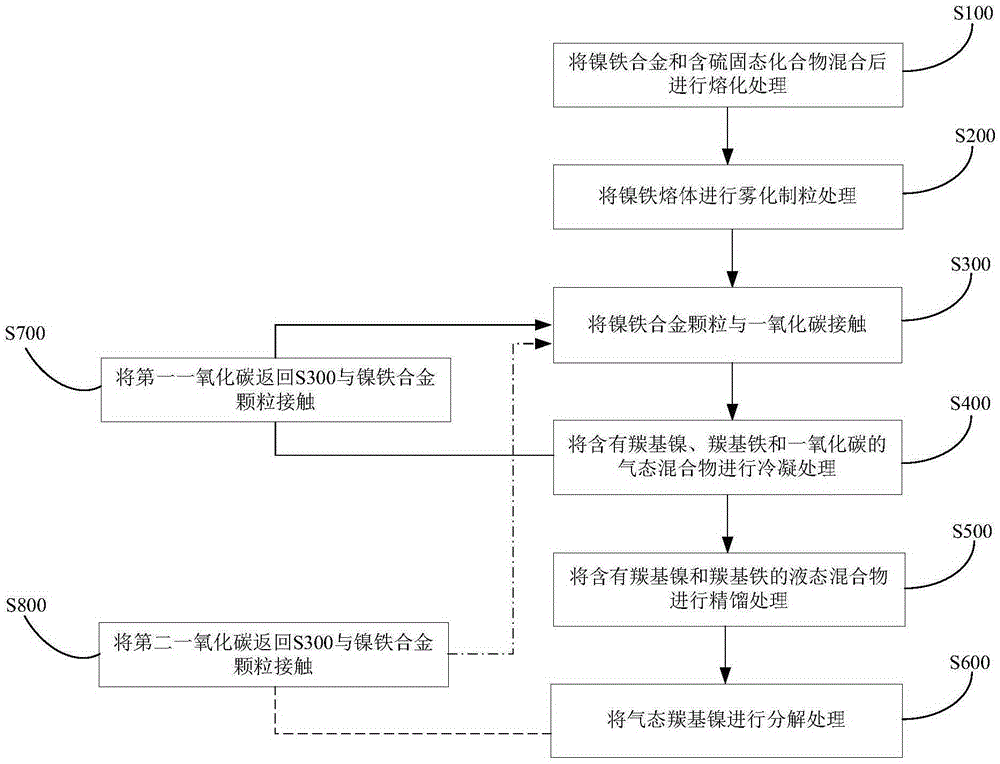

The invention discloses a method and system for preparing nickel carbonyl powder through nickel-iron alloy. The method includes the steps that (1) the nickel-iron alloy and a sulfur-containing solid compound are melted to obtain nickel-iron melt after being mixed; (2) the nickel-iron melt is atomized and granulated to obtain nickel-iron alloy particles; (3) the nickel-iron alloy particles make contact with carbon monoxide to obtain a gaseous mixture and iron powder, and the gaseous mixture contains nickel carbonyl, carbonyl iron and carbon monoxide; (4) the gaseous mixture containing nickel carbonyl, carbonyl iron and carbon monoxide is condensed to obtain a liquid mixture and first carbon monoxide, and the liquid mixture contains nickel carbonyl and carbonyl iron; (5) the liquid mixture containing nickel carbonyl and carbonyl iron is subjected to rectifying treatment to obtain gaseous nickel carbonyl; and (6) the gaseous nickel carbonyl is decomposed to obtain the nickel carbonyl powder and second carbon monoxide. The method can improve the utilization value of the nickel-iron alloy and meanwhile reduce production cost of the nickel carbonyl powder.

Owner:SHENWU TECH GRP CO LTD

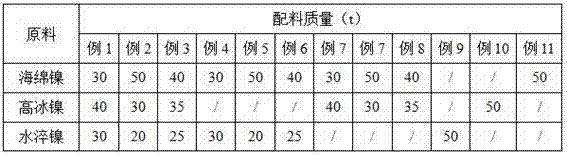

Nickel carbonyl synthesizing method

The invention belongs to the field of powder metallurgy, especially relating to a method for synthesizing nickel carbonyl, including the following steps of: (1) preparing active carbonyl synthesizing raw material: firstly heating the alloy to melt at 1600 deg.C-1650 deg.C, then rapidly condensing the melt by 0.3-0.5 MPa high pressure water spray, where the water temperature is controlled at 10 deg.C-15 deg.C and the spraying speed is 4-5 kg / min, and the size of the obtained alloy particles is 0.5 mm-5 mm, and the proportion of the particles of 0.5 mm-2 mm is not less than 85% and that of the particles of 2mm-5mm is not greater than 15%; (2) synthesizing nickel carbonyl: placing the prepared alloy particles in a high pressure kettle of 10 liter, and the carbonyl synthesizing conditions: the CO content fed in the high pressure kettle >=92%; CO circulating speed in the carbonyl synthesizing system is 8-12 times / h, and the pressure is 5-12 MPa, the temperature is 100 deg.C-150 deg.C, and the synthesizing time is 24-32 hours. The invention has the advantages of simple technique, low equipment manufacturing cost, high carbonyl synthesis ratio as compared with the existing technique.

Owner:BEIJING CISRI GAONA TECH

Hard alloy resistant to high pressure and high temperature and preparation method thereof

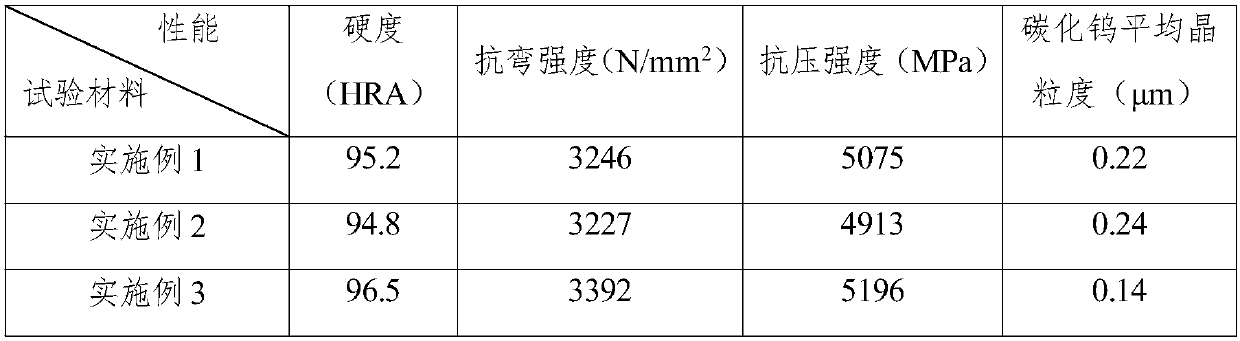

The invention belongs to the technical field of powder metallurgy, and particularly relates to a hard alloy resistant to high pressure and high temperature and a preparation method thereof. The hard alloy resistant to high pressure and high temperature comprises the following raw materials, by mass, 0.1-1.0 part of cobalt, 0.1-0.3 part of rhodium, 0.5-1 part of nickel carbonyl powder, 0.1-1.0 partof vanadium carbide, 10-20 parts of tantalum carbide, 0.6-1.0 part of niobium carbide, 2.0-4.0 parts of titanium carbide, 0.3-0.5 part of hafnium carbide, 0.1-0.5 part of aluminum nitride and 75-90 parts of tungsten carbide. In the hard alloy resistant to high pressure and high temperature, tungsten carbide is small in particle size and uniform in distribution, and the average grain size reaches0.10-0.25 micron; and meanwhile, the hard alloy resistant to high pressure and high temperature can reach HRA96.5, the bending strength can reach 3400 N / mm<2>, the compressive strength can reach 5200MPa, and good high pressure and high temperature resistant performance is achieved.

Owner:HEYUAN ZHENGXIN HARDMETAL CARBIDE

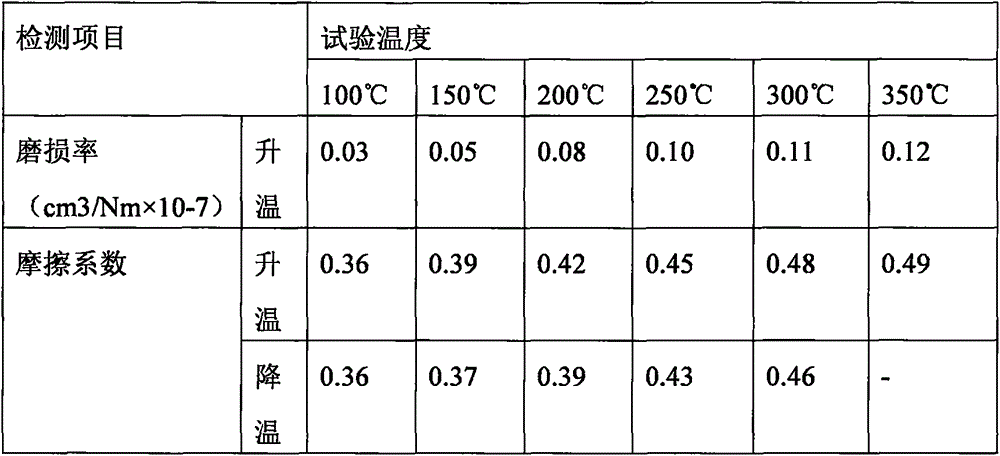

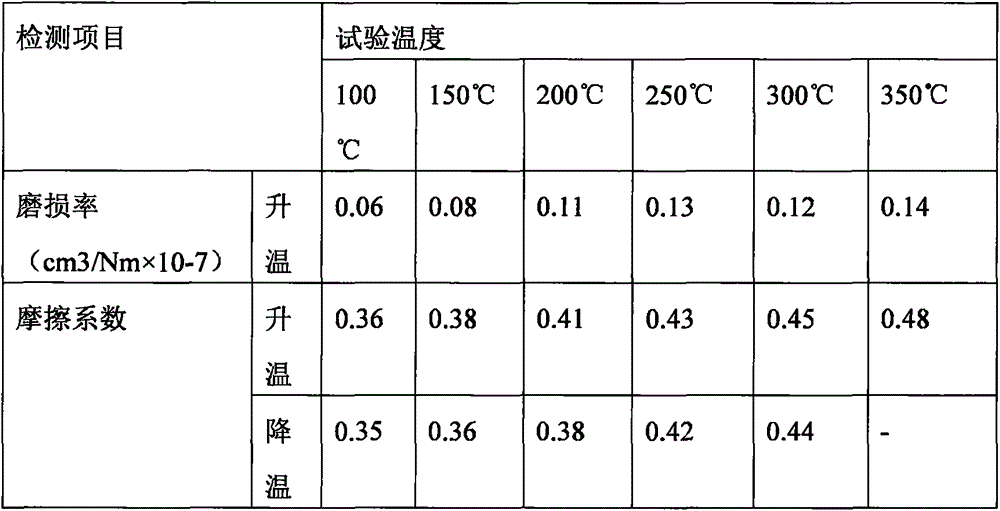

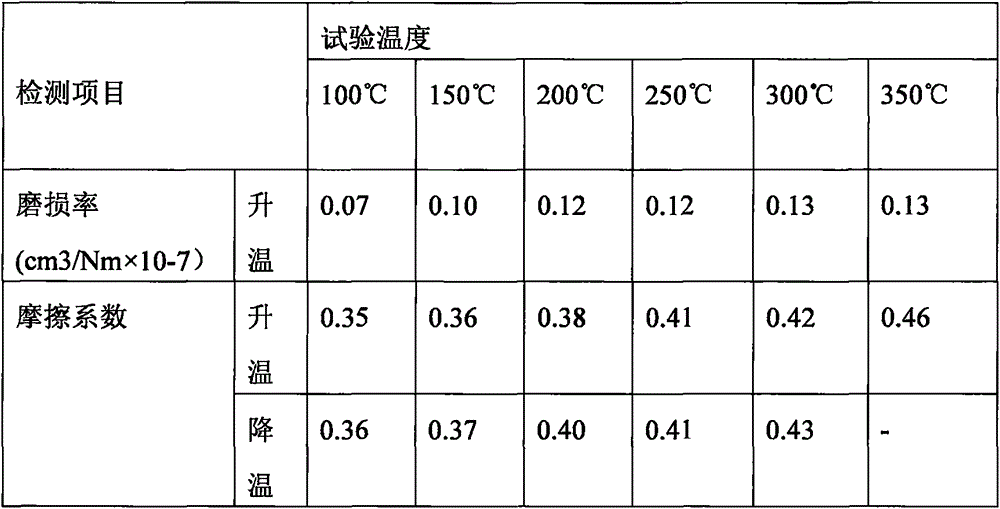

Friction material and preparation method thereof

The invention provides a friction material and a preparation method thereof. The friction material is prepared from iron-zinc alloy powder, polyether-ether-ketone, tungsten sulfide, molybdenum sulfide, spherical graphite, nickel carbonyl powder, zirconium carbide, tantalum carbide, phenolic resin and the balance halloysite nanotube. The halloysite nanotube has excellent heat radiation performance. The iron-zinc alloy powder has high high-temperature hardness, compressive strength, impact toughness and friction performance. The polyether-ether-ketone has excellent mechanical performance, chemical performance and tribology performance. The hardness and compressive strength of a matrix are remarkably improved through the nickel carbonyl powder. The strength and friction forming capacity of the material can be remarkably improved through the spherical graphite. The zirconium carbide and the tantalum carbide have the beneficial effects of being low in density, good in wear resistance, high in coefficient of friction and the like. The above components are compounded, and interaction and mutual effects of ingredients are achieved; and the prepared friction material has the beneficial effects of being low in price, excellent in friction performance, stable in performance and the like.

Owner:宁波联华汽车部件有限公司

Method for preparation electrode of molten carbonate fuel cell thorugh dry process

InactiveCN1761092AImprove development environmentHigh strengthCell electrodesFuel cellsMolten carbonate fuel cell

The method includes following steps: (1) dry process is carried out for powder of nickel carbonyl as raw material and binding material; and the two kinds of powder are mixed; (2) the mixed powder is put into two hoppers of roller press; nickel baseplate with holes punched is inserted between two rollers; and distance between two rollers is adjusted; while rolling, rollers roll down powder to the nickel baseplate so as to obtain raw baseplates; (3) under reducing atmosphere, discharging sticky objects and reduced reduce sntering are carried out for raw baseplates in tape transport type temperature programming stove so as to obtain cathodes or anodes. Features are: compact structure of fuel cell, simple technical process, and suitable to industrialized volume production.

Owner:SHANGHAI JIAO TONG UNIV

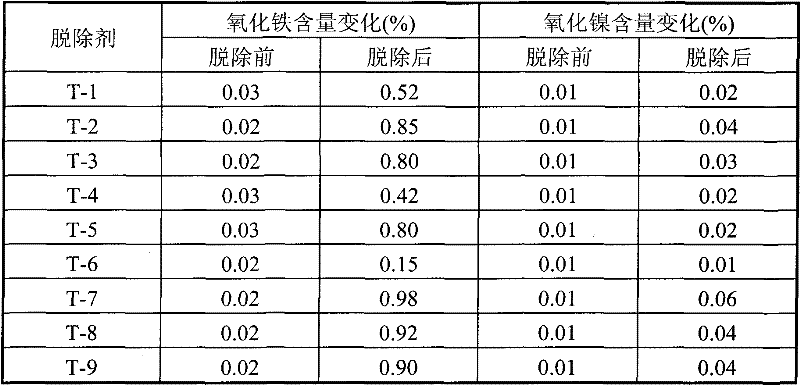

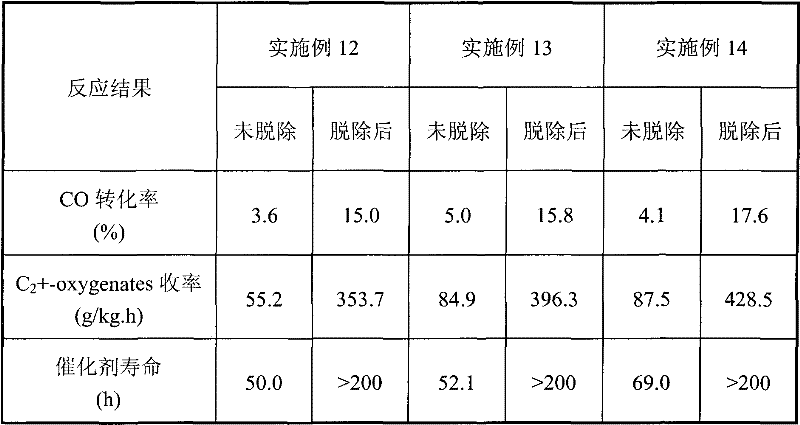

Removing agent for removing carbonyl iron and carbonyl nickel in syngas and preparation method thereof

InactiveCN102218295AAddressing slow performanceSolve the problem of longevityOther chemical processesDispersed particle separationPotassiumAlkali metal

The invention relates to a removing agent for removing carbonyl iron and carbonyl nickel in syngas and a preparation method thereof, and mainly solves the problem in the prior art that carbonyl iron and carbonyl nickel in raw material syngas can cause catalyst poisoning and thereby influence the product yield and the catalyst life. Through the technical scheme that carbonyl iron and carbonyl nickel in syngas are removed by using a removing agent with copper or its oxides as main metal components and alkali metal magnesium, potassium, calcium, or their oxides and mixtures as auxiliary metal components, the invention solves the problem well, and is applicable to the industrial production of preparing C2+-oxygenates by syngas.

Owner:CHINA PETROLEUM & CHEM CORP +1

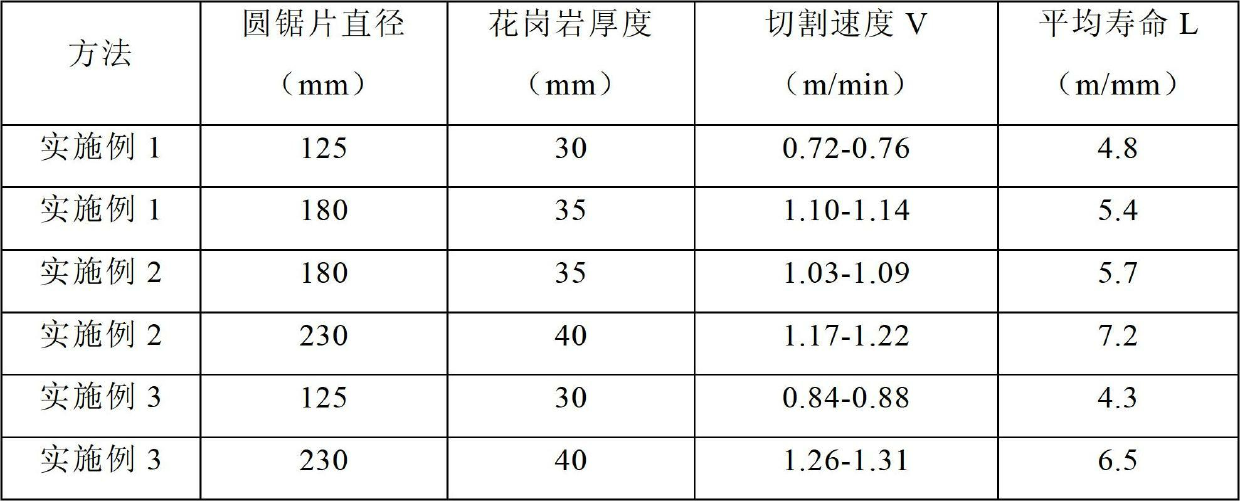

Tungsten-copper based diamond cutter bit and diamond round saw blade and manufacture method thereof

ActiveCN102672824ASolve the problem that the continuous dry cutting speed gradually slows downFast and continuous dry cuttingStone-like material working toolsParaffin waxIron powder

The invention provides a tungsten-copper based diamond cutter bit and belongs to the field of diamond round saw blades. The tungsten-copper based diamond cutter bit is prepared by the following raw materials by weight percentage: 25-40% of superfine tungsten-copper alloy powder, 20-30% of copper-tin alloy powder, 15-25% of nickel carbonyl powder, 3-8% of silver powder, 10-25% of iron powder, 0.5-1.0% of liquid paraffin and 1-1.5% of diamond. The invention further provides a diamond round saw blade and a manufacture method thereof. The diamond round saw blade solves the problem that blade edge is not apt to form on the diamond in the prior art, synchronous abrasion of a blank and the diamond is achieved, fast continuous dry-cutting processing of the saw blade is achieved, and the diamond round saw blade can cut stone materials large in hardness in dry mode and is particularly suitable for fast and continuously processing hard granite with the thickness larger than 30mm in dry mode.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

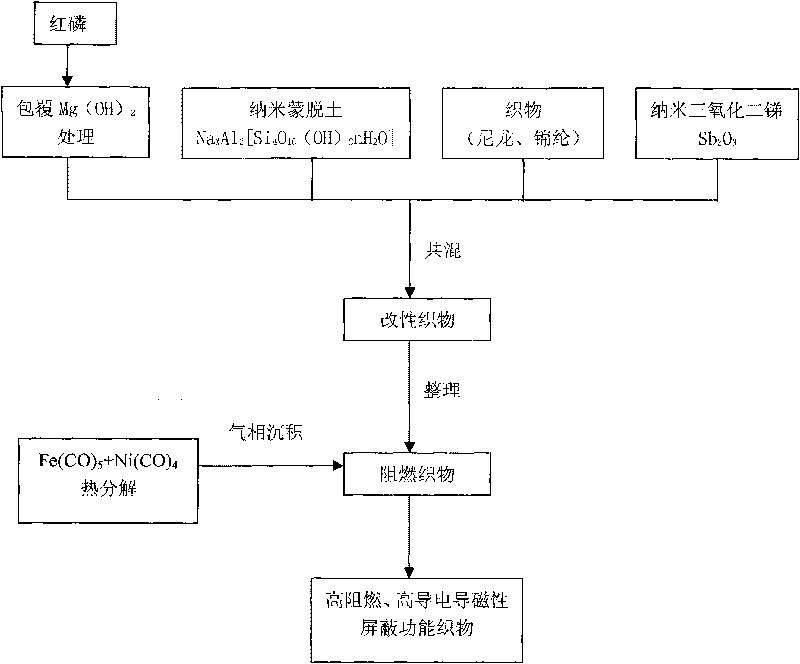

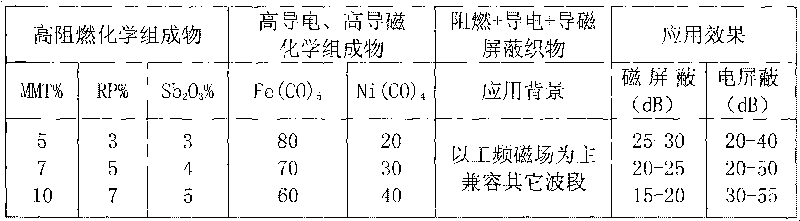

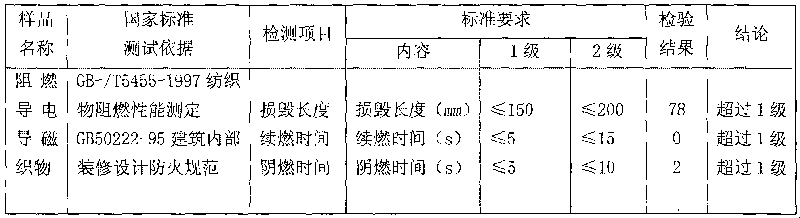

Shielding functional textile integrating high fire resistance, high electric conduction and high magnetic permeability

InactiveCN101709510AImprove flame retardant performanceImprove conductivityFlame-proof filament manufactureMagnetic/electric field screeningTextile fiberEngineering

The invention relates to a shielding textile integrating high fire resistance, high electric conduction and high magnetic permeability. A preparation method of the shielding textile integrating high fire resistance, high electric conduction and high magnetic permeability comprises the following steps of: injecting fire resistant factors into textile fibers comprising nylon, terylene and chinlon textile fibers to form fire resistant textile fibers, wherein the fire resistant factors comprise the following materials and chemical components in percentage by weight: 5-10 percent of nano imvite NaXAl2[Si4O10(OH)2nH2O], 3-8 percent of red phosphorus master batch (RP) and 3-6 percent of nano antimonous oxide (Sb2O3); mixing carbonyl iron Fe(CO)5 and nickel carbonyl Ni(CO)4 according to a certain proportion by adopting a carbonyl chemical vapor deposition method; and carrying out vapor deposition at 400 DEG C under the protection of inert gas N2 to form a high electric conduction and high magnetic permeability magnetic film on fiber cloth so as to obtain the high fire resistance, high electric conduction and high magnetic permeability shielding textile. The invention is suitable for the field of electromagnetic shielding and is particularly suitable for microwave shielding occasions and power frequency magnetic field shielding occasions.

Owner:NANCHANG UNIV

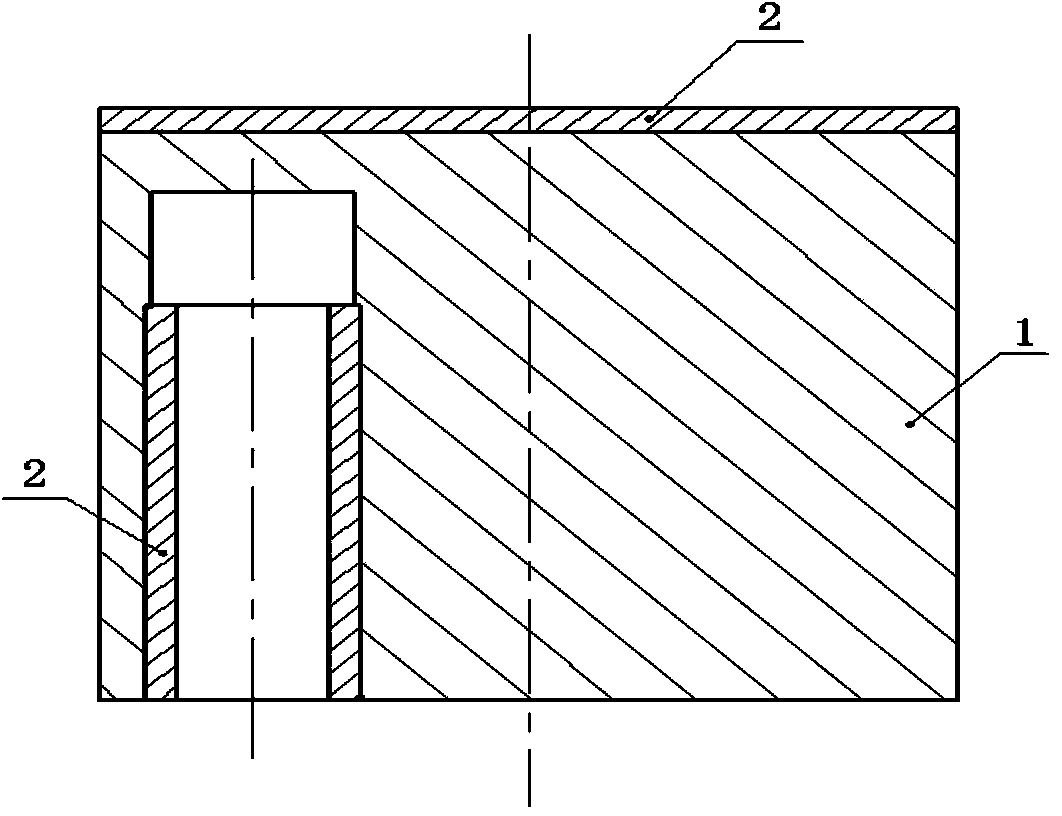

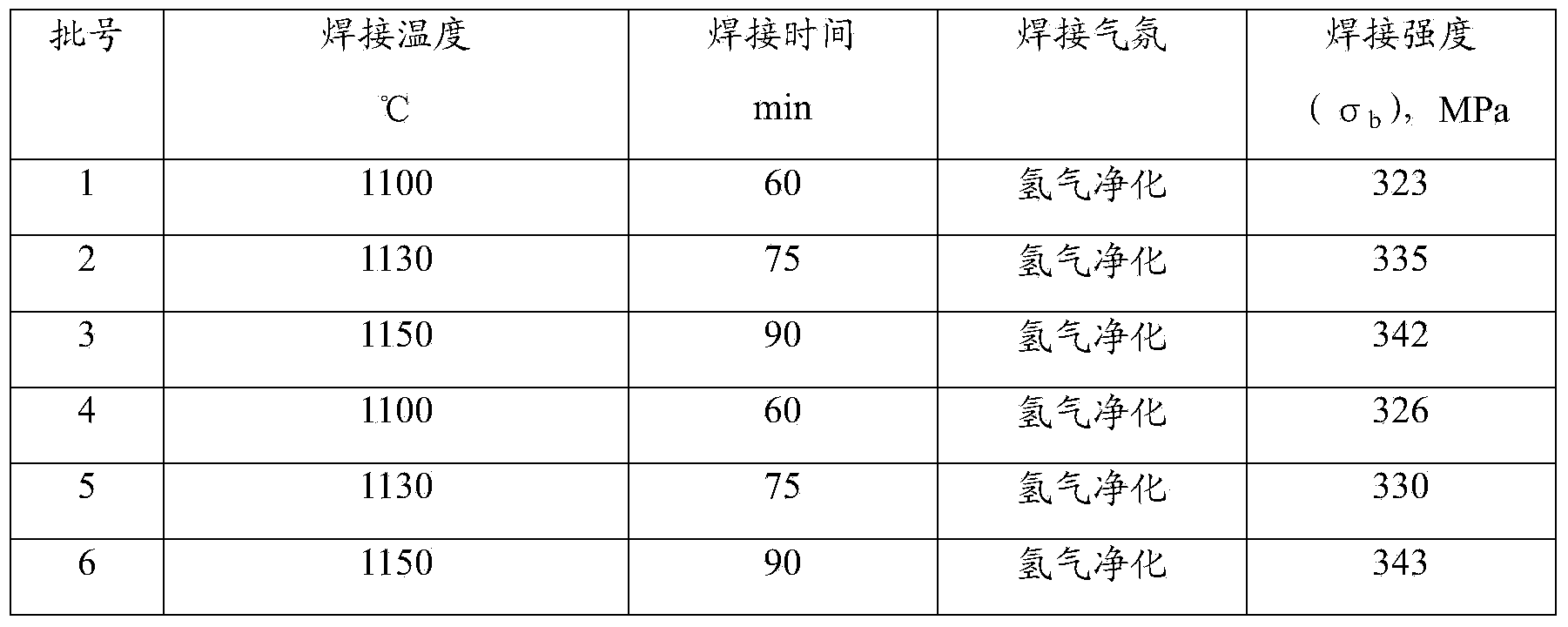

Steel-steel double-metal rotor and manufacturing method thereof

InactiveCN103758746AHigh densityHigh strengthPositive displacement pump componentsLiquid fuel engine componentsNickel CarbonylCopper leaching

The invention belongs to the field of metallurgical materials, and particularly relates to a steel-steel double-metal rotor and a manufacturing method thereof. A rotor substrate is made by adopting steel or nodular cast iron, a friction reducing layer is made by adopting a self-lubricating wear-resistant steel material, and a final product of the self-lubricating wear-resistant steel material is chemically composed of, by mass, 0.5-1% of C, 11-13% of Cr, 8-10% of Ni, 1.5-2.5% of Mo, 25-30% of Cu, 3-9% of MoS2, 0.5-1.5% of nano alpha-Al2O3 and the balance Fe. The rotor is manufactured by the following method including preparing the self-lubricating wear-resistant steel friction reducing layer material, namely mixing graphite powder, ferrochrome powder, ferromolybdenum powder, nickel carbonyl powder, nano alpha-Al2O3 powder and a binder with iron powder for pressing and sintering; performing copper leaching to obtain the self-lubricating wear-resistant steel friction reducing layer material; spreading the self-lubricating wear-resistant steel friction reducing layer material on a flow distributing face and a plunger hole surface of the rotor respectively, and preparing a friction reducing layer through a diffusion welding process, wherein welding temperature is 1100-1150 DEG C, and welding time is 1-2 hours.

Owner:CENT IRON & STEEL RES INST

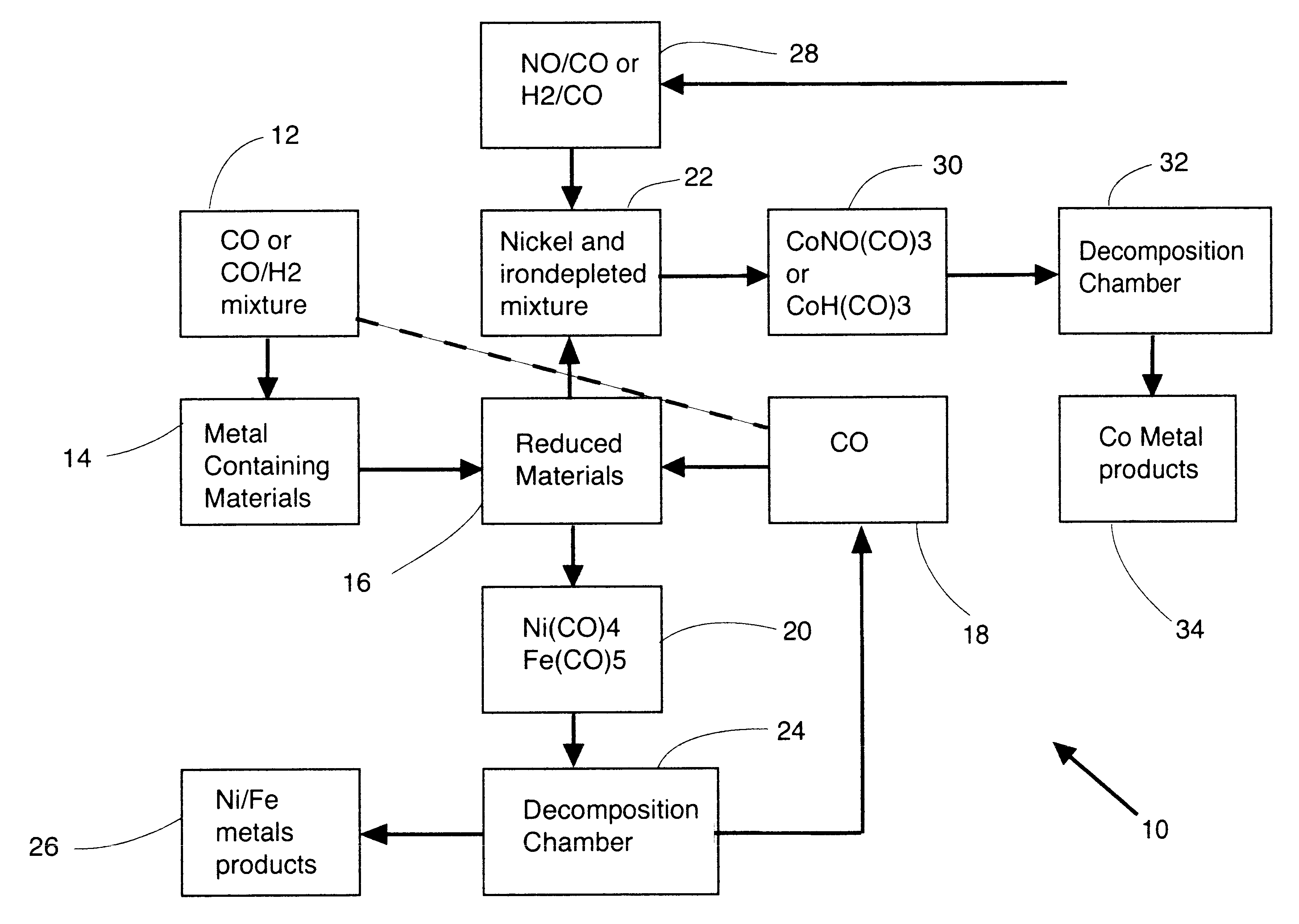

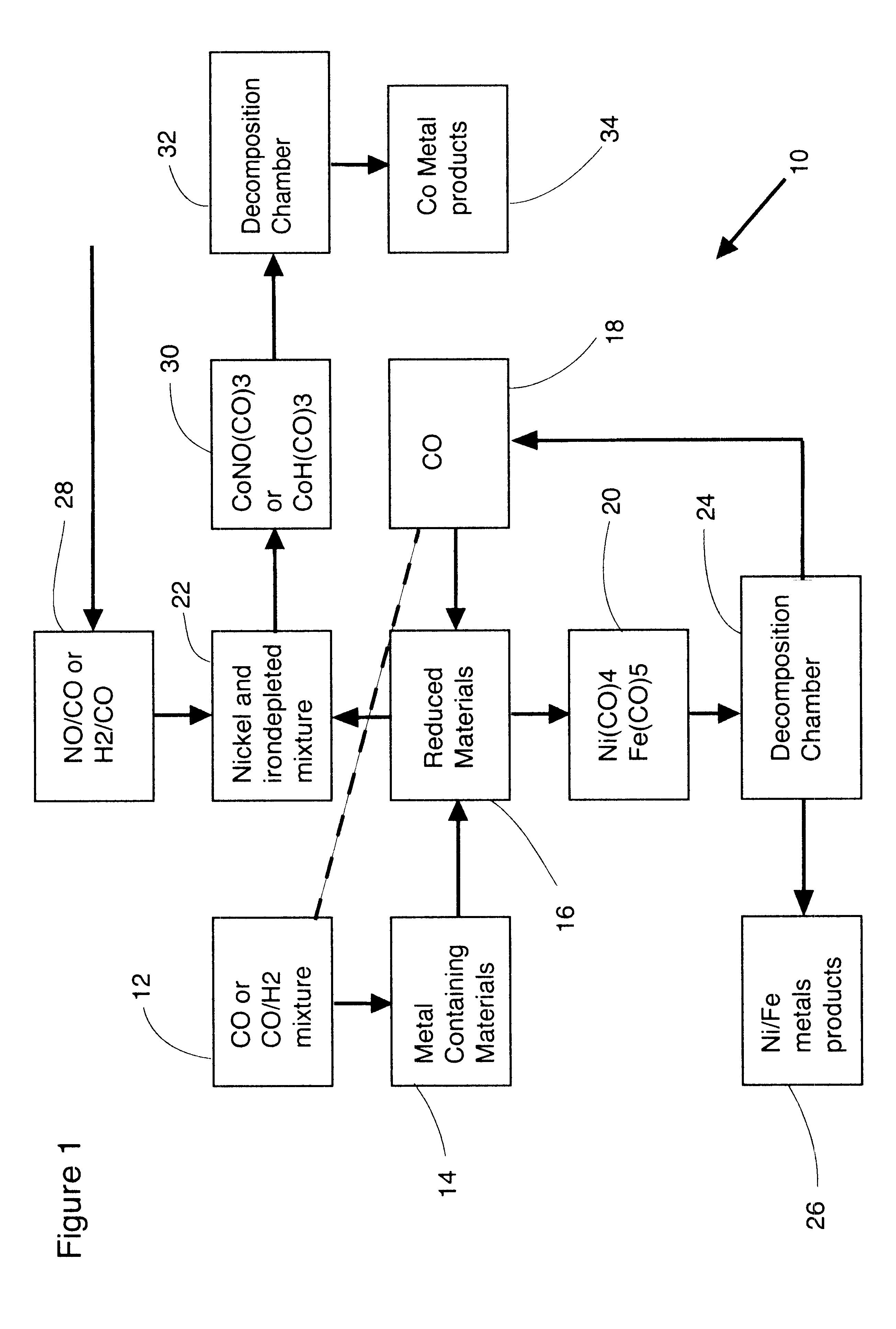

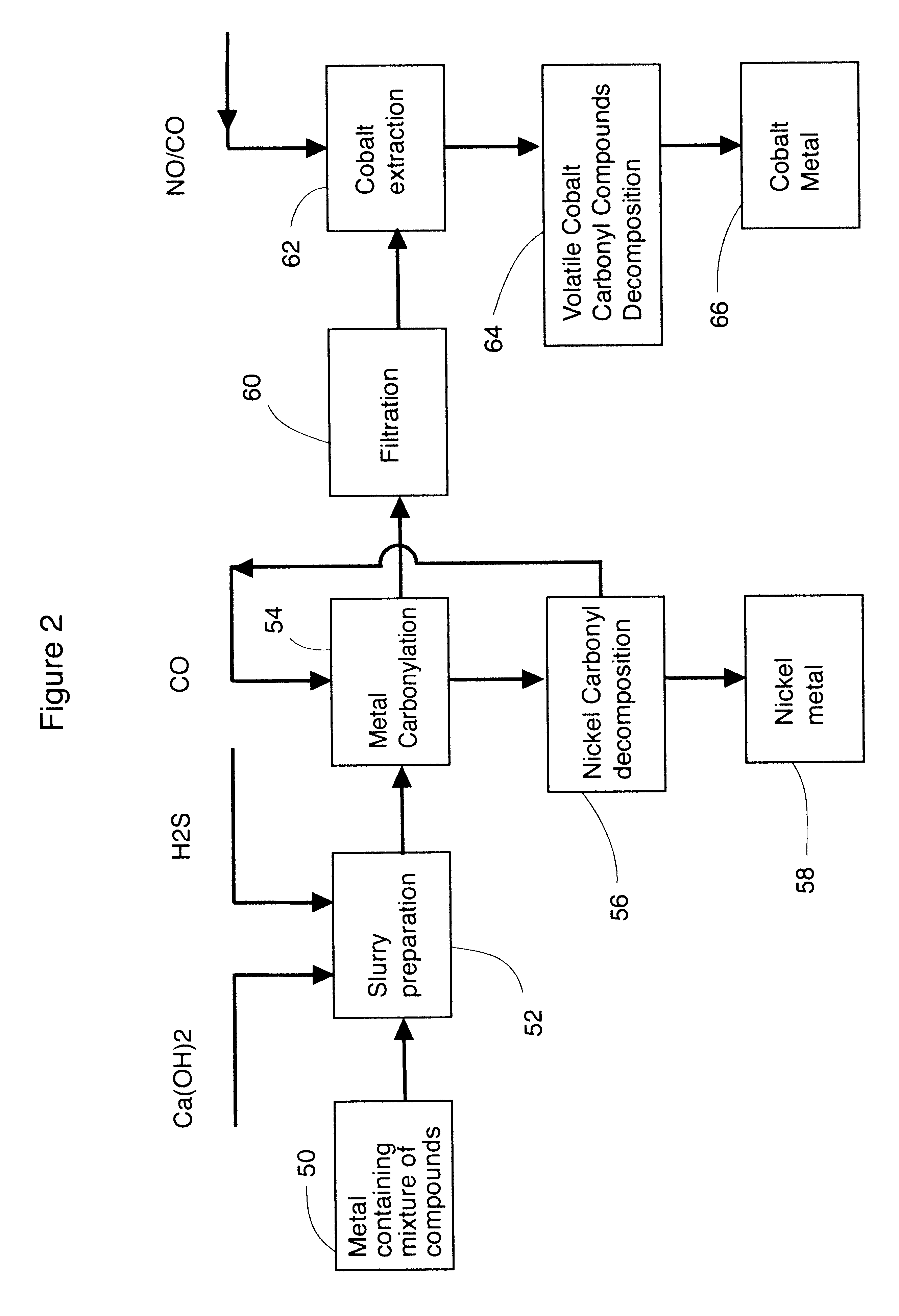

Cobalt recovery process

A process for producing purified cobalt from a mixture comprising metallic species of cobalt and metallic species of at least one of the group consisting of nickel and iron, comprising producing a metal carbonyl mixture of cobalt carbonyl and at least one of nickel carbonyl and iron carbonyl from the metallic species mixture; separating the nickel carbonyl and / or iron carbonyl from the cobalt carbonyl; treating the cobalt carbonyl with an effective amount of a complexing gaseous mixture of nitric oxide / carbon monoxide to produce cobalt nitrosyl tricarbonyl; and decomposing the purified cobalt nitrosyl carbonyl to provide purified cobalt and regenerated complexing gaseous mixture for recycle. The process provides cobalt of improved quality in an optionally, Continuous and closed-loop manner. Preferred processes include either aqueous and / or gaseous process steps.

Owner:CVMR CORP

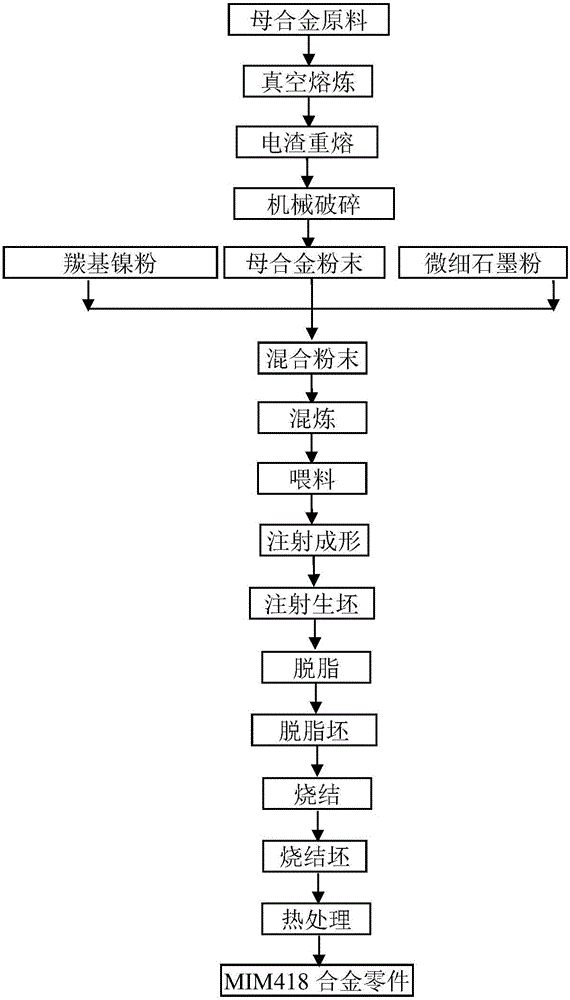

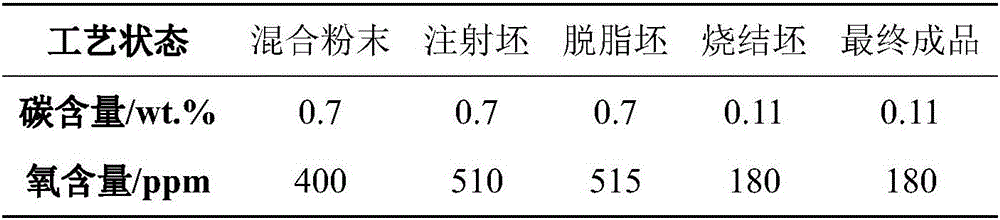

Method of preparing MIM418 alloy through low-oxygen content mother alloy method

ActiveCN106756148AReduce segregationReduce oxygen contentIncreasing energy efficiencyPolyethylene glycolSuperalloy

The invention discloses a method of preparing MIM418 alloy through a low-oxygen content mother alloy method. The method comprises the following steps: first, designing to obtain a mother alloy component, wherein the liquidus temperature of the mother alloy component is far lower than that of prealloy MIM418; preparing mother alloy powder through vacuum induction melting, electroslag remelting and mechanical disruption, mixing the mother alloy powder with nickel carbonyl powder and superfine graphite powder to obtain a mixture, uniformly mixing the mixture with a polyethylene glycol based water-soluble binder, and obtaining a part blank with a complicated shape through injection forming; and then, obtaining the high-performance MIM418 alloy through degreasing, vacuum sintering and thermal treatment. According to the invention, oxide segregation is reduced, oxygen content in a finished product and the oxygen content increased in the degreasing technology are reduced. During the vacuum sintering process, sintering deforming is reduced to control size precision through adjusting the heating rates of different temperature intervals. The cost and technological energy consumption of the raw material powder are remarkably reduced, the oxygen content and inclusion content of a superalloy part are effectively reduced, the oxygen content of a finished product is lower than 200 ppm, and the prepared superalloy is close to full-compact, uniform in organization structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

Cleaning agent for removing iron carbonyl and nickel carbonyl in synthesis gas and preparation method and application of cleaning agent

InactiveCN102814160AHigh removal accuracyCarbonyl iron + carbonyl nickel content is lowOther chemical processesDispersed particle separationReaction temperatureEngineering

The invention discloses a cleaning agent for removing iron carbonyl and nickel carbonyl in synthesis gas and a preparation method and application of the cleaning agent. The invention belongs to the field of gas purification. The general formula of the cleaning agent is CuZnAl(O)-carrier; the molar ratio of Cu to Zn to Al is (58-62):(26-21):(16-17), and the mass ratio of the carrier to CuO is (1.7-2):1. The preparation method for the cleaning agent comprises the following steps of in sequence: preparing soluble salt with active ingredients into a solution A; soaking to obtain a cleaning agent precursor A; drying to obtain a cleaning agent precursor B; preparing the soluble salt with the active ingredients into a solution B; soaking to obtain a cleaning agent precursor C; drying; adding bentonite and water; extruding; and roasting to obtain the cleaning agent, wherein the reaction temperature is 170-300 DEG C, the reaction pressure is 0-2.0MPa, and the reaction airspeed is 500-8000h-1. The cleaning agent with higher removal precision more meets the requirements of the methanol large-scale synthesis gas purification aspect at present.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Zirconium oxide-based nanometer ceramic tool and die material and preparation method thereof

The invention provides a zirconium oxide-based nanometer ceramic tool and die material and a preparation method thereof. The preparation method is characterized in that yttrium-stabilized nanometer zirconium oxide is used as a substrate; micrometer alumina is added as a reinforcing phase; micrometer molybdenum, micrometer nickel carbonyl and graphene oxide are used as sintering additives; the hot-pressing sintering is performed. The preparation method comprises the following steps of firstly, respectively dispersing the nanometer zirconium oxide powder and the micrometer-micrometer alumina powder, performing ball milling, and drying, so as to obtain powder; sintering by a hot pressing method. The zirconium oxide-based nanometer ceramic tool and die material has the advantages that the comprehensive mechanic property is better, the hardness, abrasion-resistant property and heat conduction property are high, and the zirconium oxide-based nanometer ceramic tool and die material can be used for manufacturing ceramic tools and dies of extrusion dies, drawing dies, cutting tools and the like, and other abrasion and corrosion-resistant parts and components.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

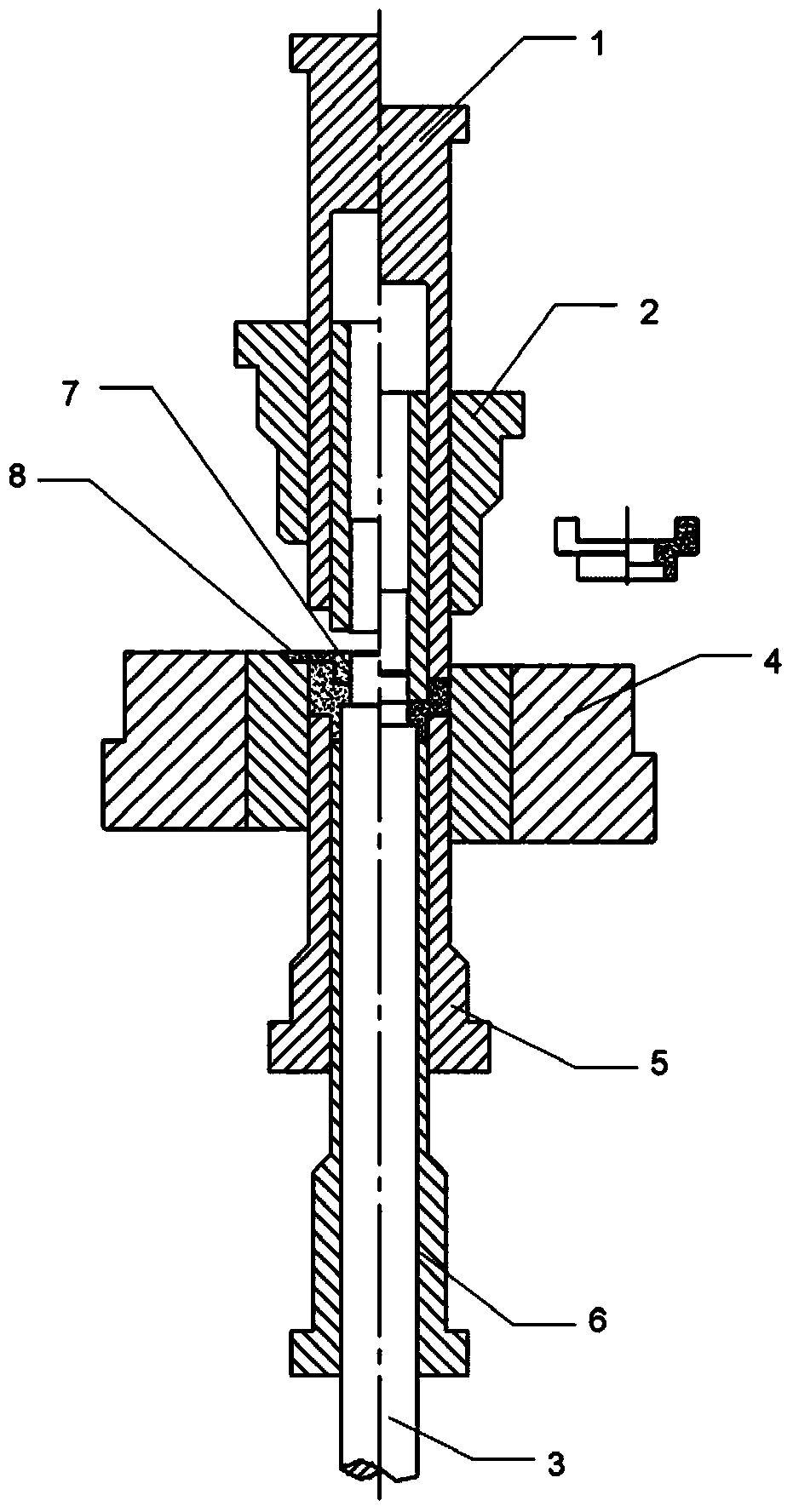

Nickel carbonyl synthesizer and synthesizing method of nickel carbonyl

InactiveCN107115835APrevent oxidationSufficient supplyChemical/physical/physico-chemical stationary reactorsFeed devicesSlagReaction speed

The invention discloses a nickel carbonyl synthesizer and a synthesizing method of nickel carbonyl, belongs to the technical field of nickel refining and solves the problems of low efficiency and single raw material in a nickel carbonyl synthesizing process. The device comprises a horizontal type synthesizing kettle, a raw material cabin, a CO heater and a slag cabin, wherein a first air inlet, a first feeding opening, a first air exhausting opening and a first discharging opening are formed in the horizontal type synthesizing kettle; a second air inlet, a second feeding opening, a second air exhausting opening and a second discharging opening are formed in the raw material cabin; a third air inlet, a steam inlet, a third air exhausting opening and a steam outlet are formed in the CO heater; a fourth air inlet, a slag inlet, a fourth air exhausting opening and a slag outlet are formed in the slag cabin; the first air inlet is connected with the third air exhausting opening, the first feeding opening is connected with the second discharging opening, and the first discharging opening is connected with the slag inlet. The nickel carbonyl synthesizing method comprises the five steps of preparing material, pretreating, reacting, discharging slag and unloading slag. The nickel carbonyl synthesizing method disclosed by the invention has high reaction speed, simple technology, sufficient raw material and guaranteed production.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com