Method for preparing superfine carbonyl iron powder in use for high performance magnetic powder core

A technology of carbonyl iron powder and magnetic powder core, which is applied in the field of preparation of ultra-fine carbonyl iron powder for high-performance magnetic powder cores, achieving the effects of improved cost performance, short process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

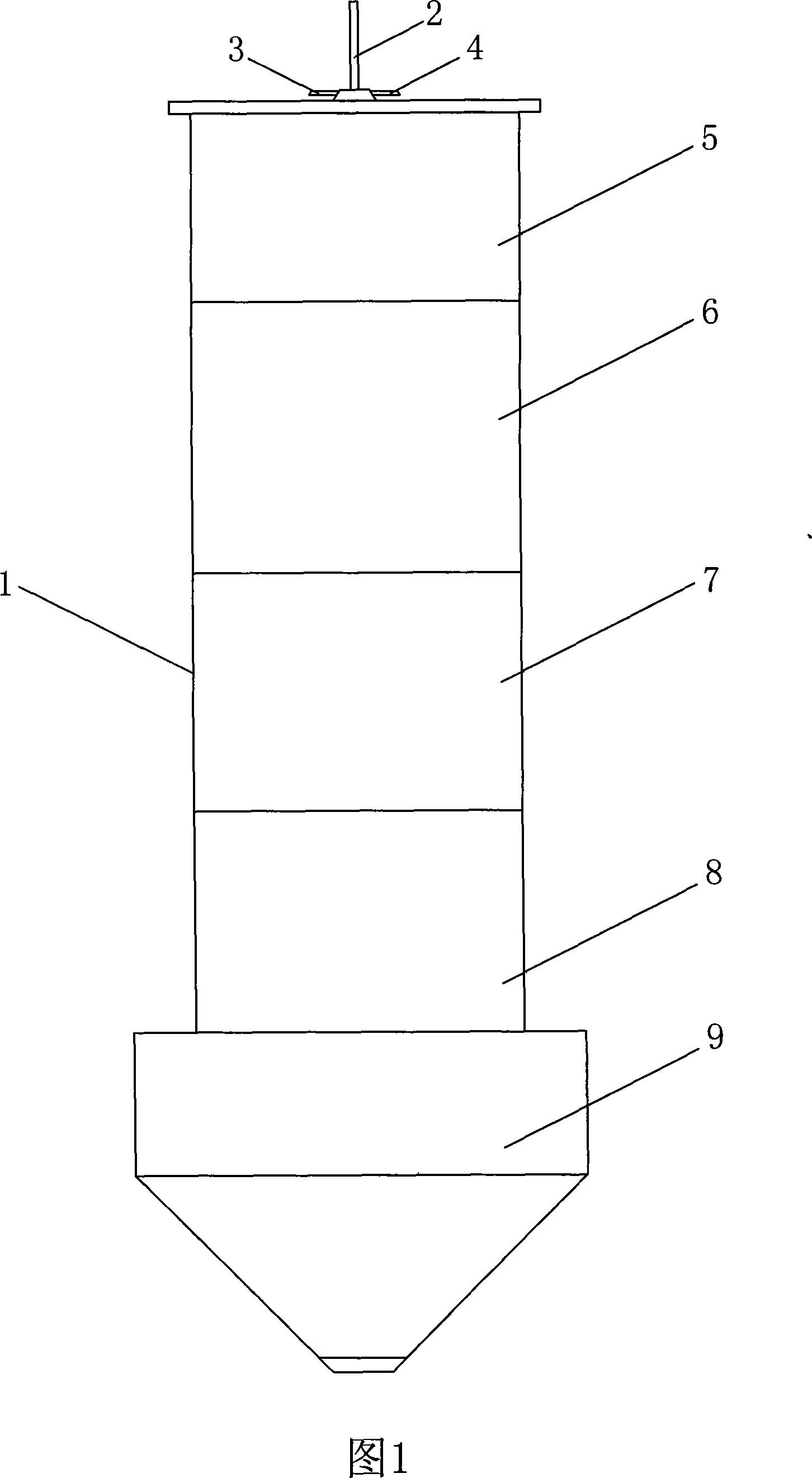

[0014] Put pure carbon monoxide and iron raw materials in a synthesis kettle, synthesize iron pentacarbonyl under the pressure of 3-9.5 MPa and temperature of 100-200 ° C, and send the liquid iron pentacarbonyl into the storage tank after condensation and gas-liquid separation; Carbonyl iron powder is heated to 100-135°C to make it vaporized, and simultaneously feed pentacarbonyl iron vapor, carbonyl nickel vapor, nitrogen, and ammonia into the decomposition furnace, and the flow rate of raw materials is controlled as pentacarbonyl iron 14-16L / H, carbonyl nickel 0.5-0.6L / H, nitrogen 30-40L / min, ammonia 1-3L / min.

[0015] The temperature in the decomposition furnace is controlled in sections, the temperature in the heating zone I is 180-240°C, the heating zone II is 220-260°C, the heating zone III is 240-280°C, the cooling zone is 100-120°C and the powder collecting bin is 50-70°C, so that the raw materials In the decomposition furnace, the superfine carbonyl iron powder with u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com