Friction material and preparation method thereof

A friction material and raw material technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of semi-metallic brake pads, such as easy corrosion, high copper fiber density, and easy corrosion and oxidation, and achieve excellent mechanical properties, high friction coefficient, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

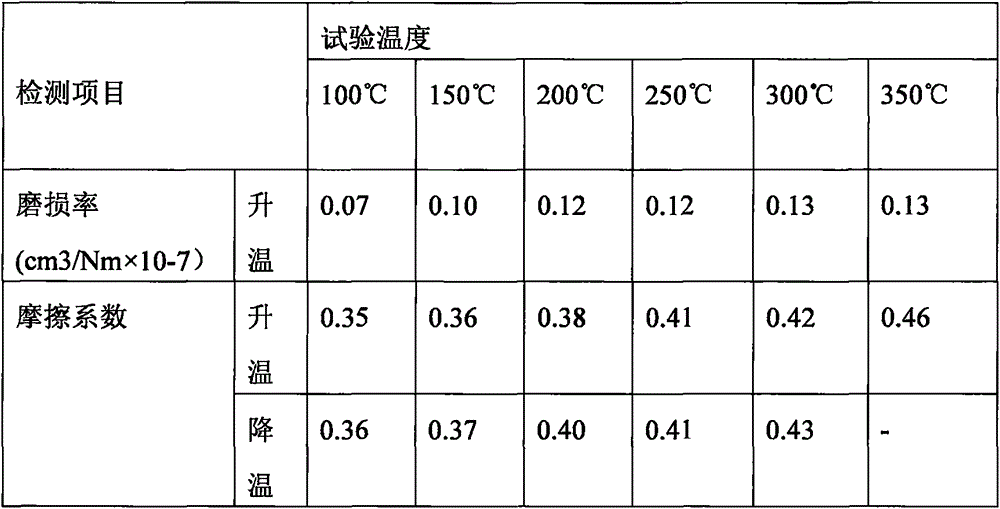

Examples

preparation example Construction

[0061] Correspondingly, the present invention also provides a preparation method of the above friction material, comprising the following steps: step a) dispersing halloysite nanotubes in 0.01-0.15 mol / L nitric acid solution to obtain 0.1-0.5 g / mL The mixed solution is ultrasonically treated, then transferred to a hydrothermal reaction kettle for 5-10 hours at 120-180°C, cooled, filtered, washed, and dried; step b) the halloysite nanotubes and iron-zinc alloys obtained in step a Powder, polyetheretherketone, tungsten sulfide, molybdenum sulfide, spherical graphite, carbonyl nickel powder, zirconium carbide, tantalum carbide and phenolic resin are mixed, stirred, placed in a hot pressing mold at 160-180°C under the condition of 15-20MPa Keep for 30-50s, exhaust 2-5 times in the middle, then treat for the first time at 160-180°C for 2-5 hours, raise the temperature to 250-300°C for the second time for 0.5-3 hours, cool down to room temperature, and get friction material.

[0062]...

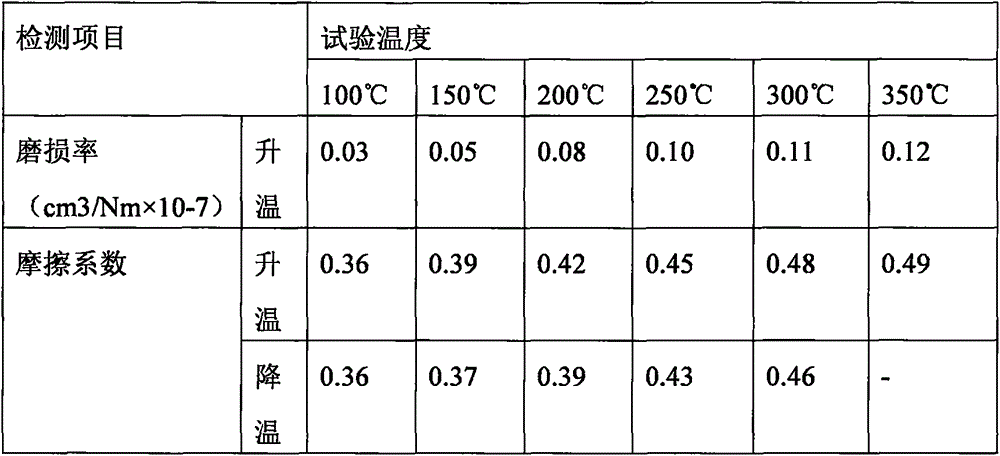

Embodiment 1

[0068] 1) First prepare a 0.05mol / L nitric acid solution, then weigh a certain amount of halloysite and disperse it into the nitric acid solution to form a mixture with a concentration of 0.3g / mL, and transfer it to a hydrothermal reaction kettle after ultrasonic treatment for 5 hours treated at 150°C for 6h, cooled to room temperature, filtered and washed with deionized water, and dried at 110°C for 15h;

[0069] 2) Weigh and mix the materials according to the following proportions

[0070] Iron-zinc alloy powder 5wt%, polyetheretherketone 5wt%, tungsten sulfide 0.9wt%, molybdenum sulfide accounted for 0.5wt% of the total mass, spherical graphite accounted for 8wt% of the total mass, carbonyl nickel powder accounted for 4wt% of the total mass, carbonized Zirconium accounts for 5wt% of the total mass, tantalum carbide accounts for 3wt% of the total mass, phenolic resin accounts for 3.5wt% of the total mass, and the rest is halloysite nanotubes prepared in step 1). Put the abo...

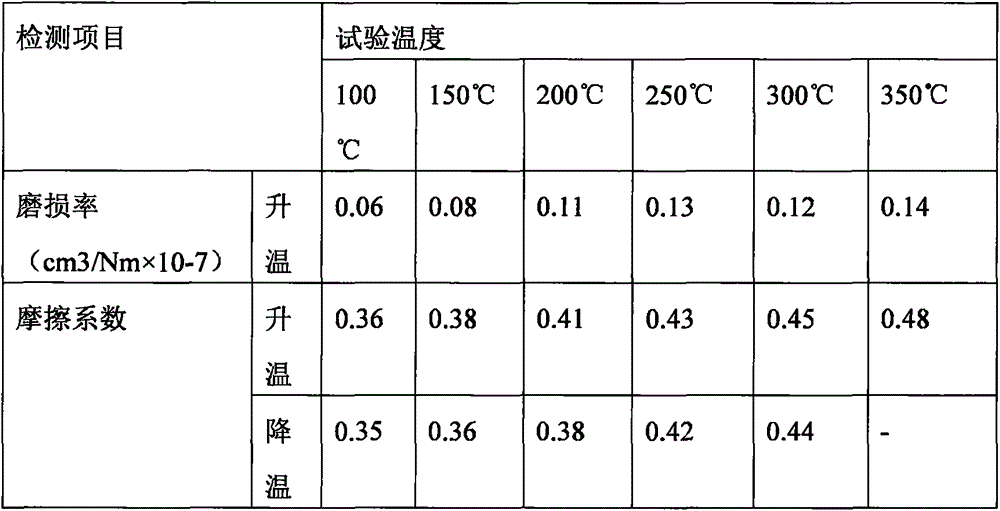

Embodiment 2

[0078] 1) First prepare a 0.15mol / L nitric acid solution, then weigh a certain amount of halloysite and disperse it into the nitric acid solution to form a mixture with a concentration of 0.5g / mL, and transfer it to the hydrothermal reaction kettle after ultrasonic treatment for 1h treated at 180°C for 5h, cooled to room temperature, filtered and washed with deionized water, and dried at 150°C for 8h;

[0079] 2) Weigh and mix the materials according to the following proportions

[0080] Iron-zinc alloy powder 10wt%, polyether ether ketone 2wt%, tungsten sulfide 0.5wt%, molybdenum sulfide accounted for 0.8wt% of the total mass, spherical graphite accounted for 15wt% of the total mass, carbonyl nickel powder accounted for 2wt% of the total mass, carbonized Zirconium accounts for 6wt% of the total mass, tantalum carbide accounts for 6wt% of the total mass, phenolic resin accounts for 5wt% of the total mass, and the rest is halloysite nanotubes prepared in step 1). Put the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com