Patents

Literature

76results about How to "High temperature hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

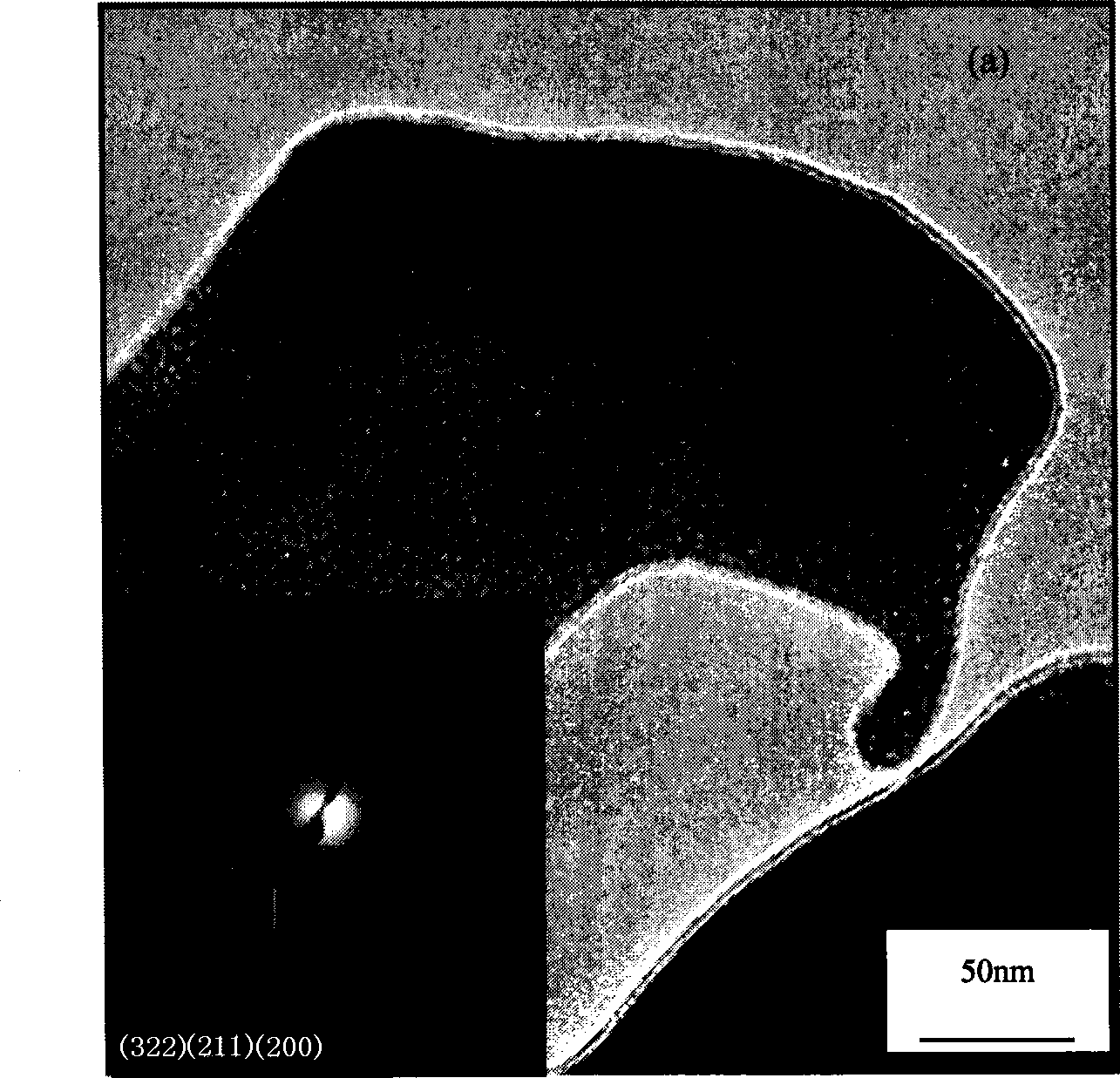

Cermet insert and cutting tool

InactiveCN101189090AExcellent abrasion resistanceImprove wear resistanceTurning toolsCarbideTitanium carbonitride

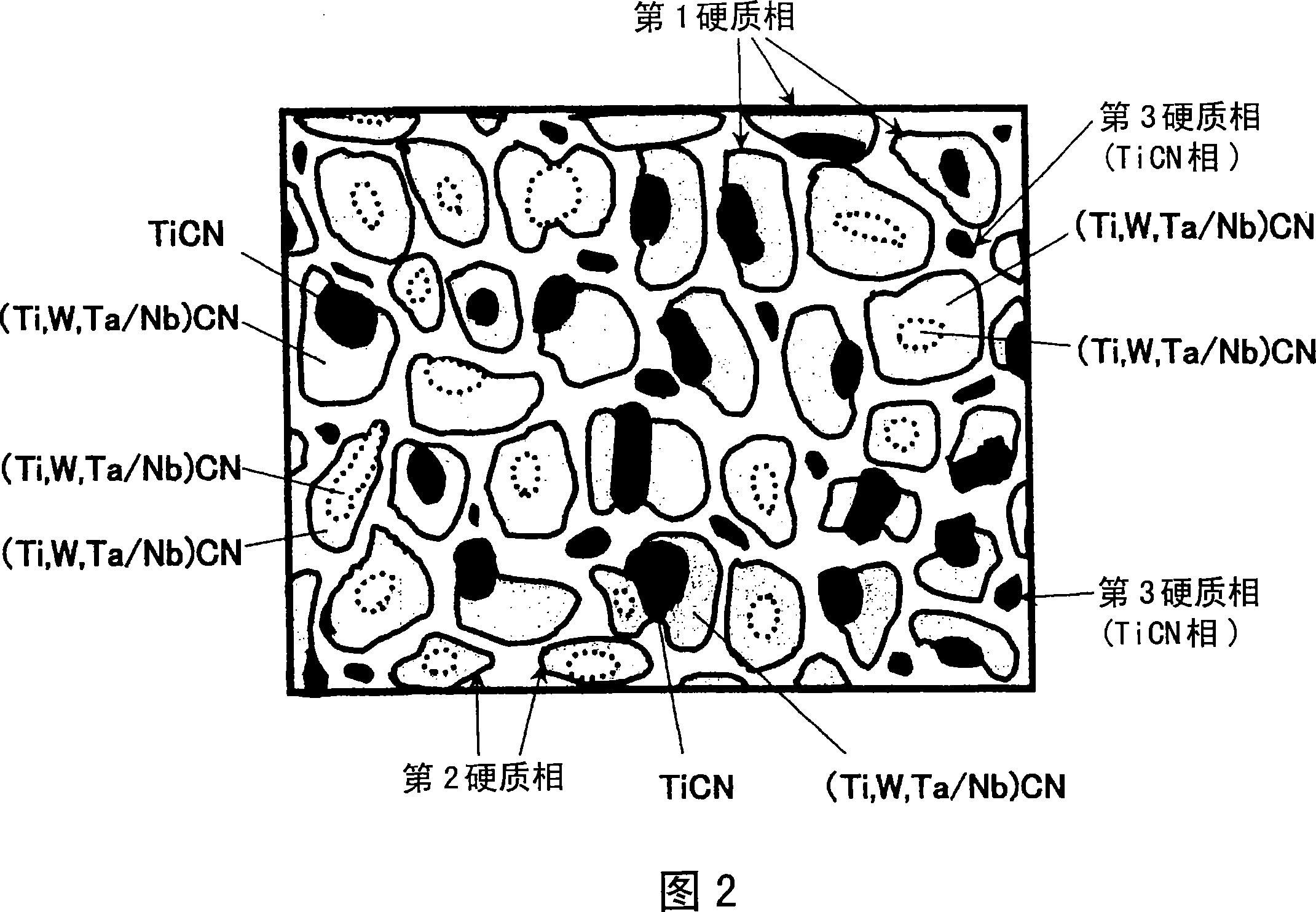

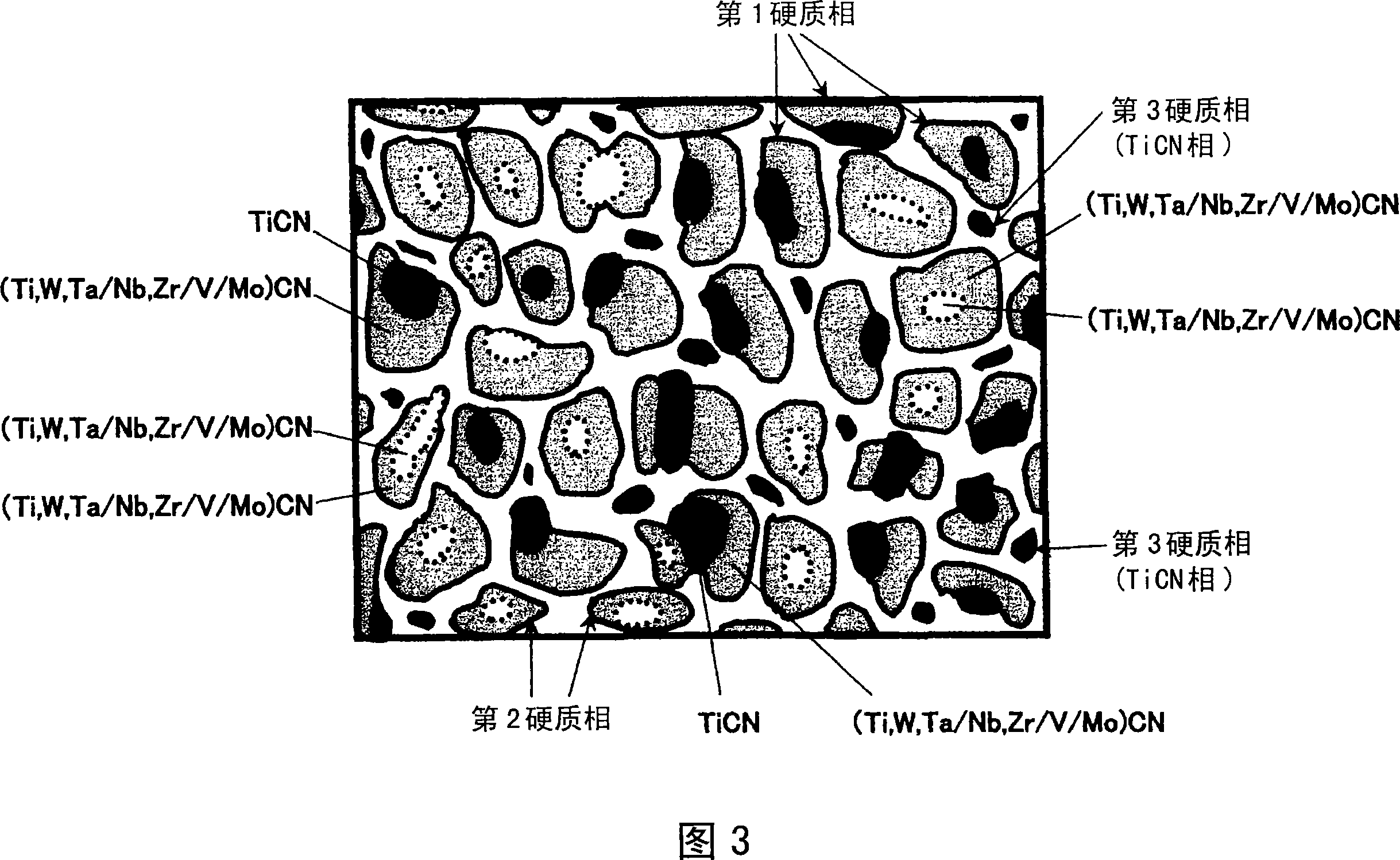

One mode of the blade made of titanium carbonitride-based cermet is that it has a structure composed of 75-90 area % of hard phase and the balance is a binding phase. The hard phase has: the core is made of titanium carbonitride Phase composition, the peripheral part is composed of a first hard phase with a core structure composed of Ta and / or Nb, Ti, and W complex carbonitride (hereinafter expressed as (Ti, W, Ta / Nb)CN) phase; Both the core and the peripheral part are the second hard phase with a core structure composed of (Ti, W, Ta / Nb) CN phase; the third hard phase with a single-phase structure composed of TiCN phase, and the binding phase has: Co: 18-33%; Ni: 20-35%; Ta and / or Nb, and Ti, the total amount: 5% or less; W: 40-60%. Another form of the titanium carbonitride-based cermet blade is the sum of the value of Ti converted into carbonitride, the value of Ta and / or Nb converted into carbide, and the value of W converted into carbide It is 70-95% by mass, the value of W converted into carbide is 20-35% by mass, Co and Ni are 5-30% by mass, and have a structure composed of hard phase and binder phase. The hard phase has (Ti , W, Ta / Nb) CN, the binding phase is mainly composed of Co and / or Ni, and W, and 40-65% by mass of W is contained in the hard phase. This cutting tool has a holder and the cermet blade fixed by the holder.

Owner:MITSUBISHI MATERIALS CORP +1

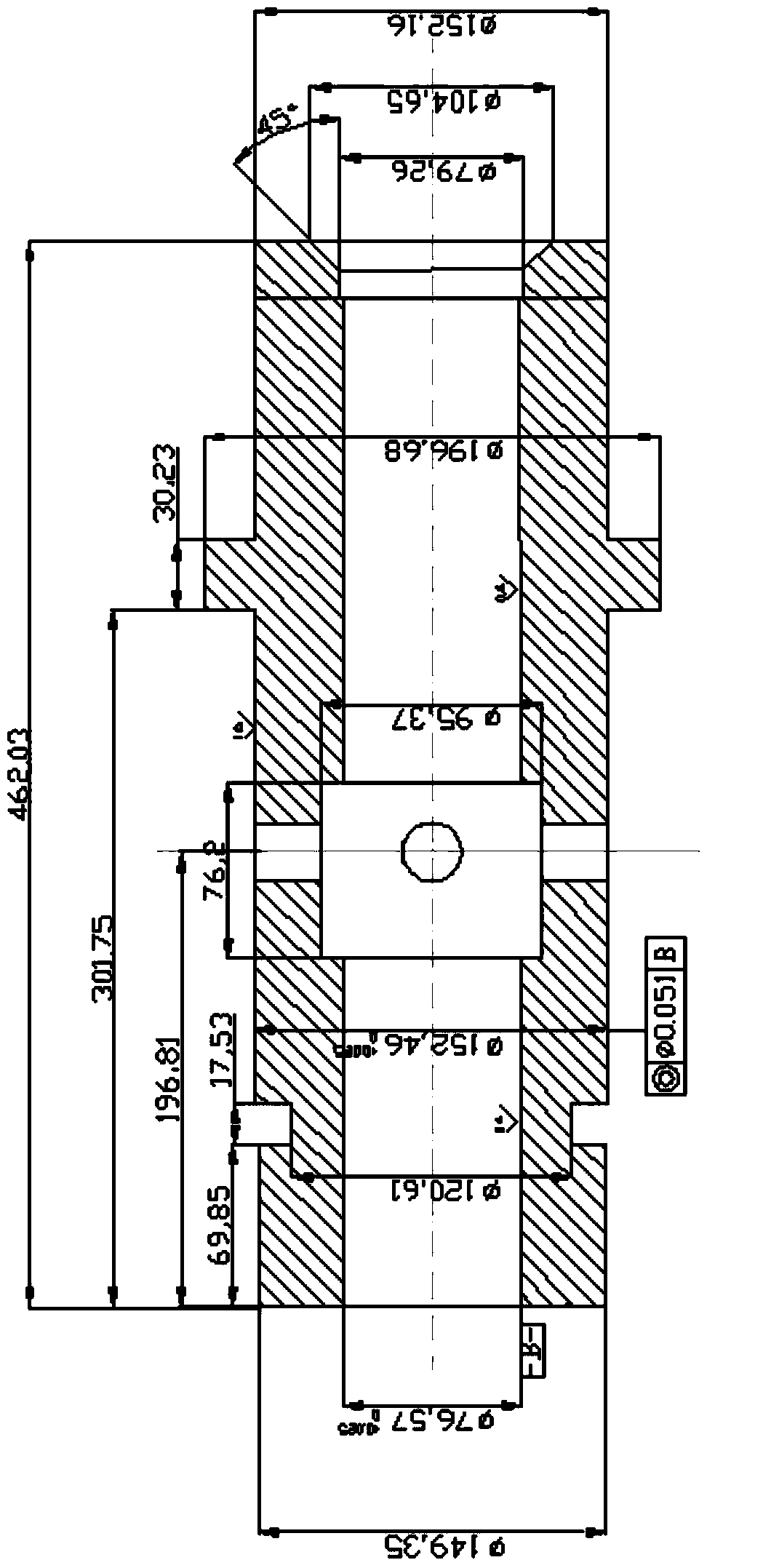

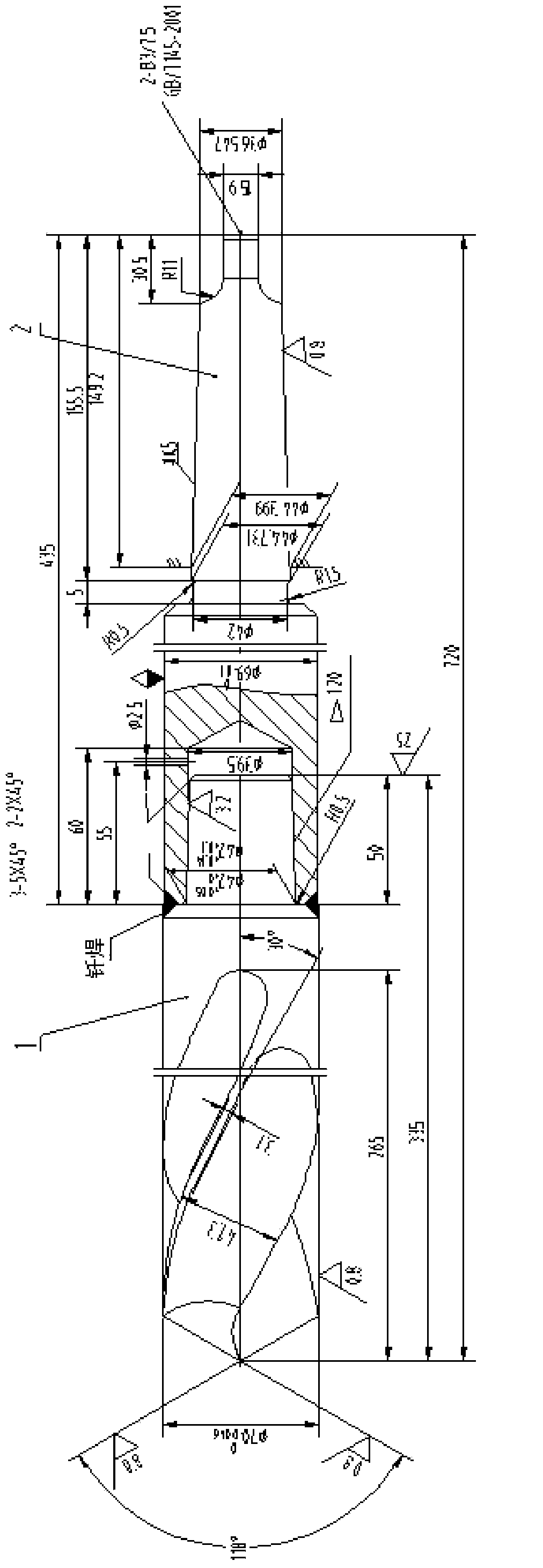

Pipe jacking construction technology through water-mud balance

The invention discloses a pipe jacking construction technology through water-mud balance. The pipe jacking construction technology comprises the steps of construction preparation, equipment mounting and debugging, pipe jacking machine out of a hole, pipe section jacking construction, intermediate jacking station jacking construction, main top jacking and the like, and circulation is conducted till jacking is finished. Through the construction technology, construction is conducted especially aiming at the specific soil texture of the pipe jacking construction technology, the operation difficulty is greatly reduced, the maximum amount of excavation is increased, the construction technology is easy, the construction progress is quick, the construction difficult problems such as ground subsidence are controlled within the range stipulated by standards, and the construction technology is suitable for being applied and popularized.

Owner:ZHEJIANG BAOTIAN ENVIRONMENT CONSTR CO LTD

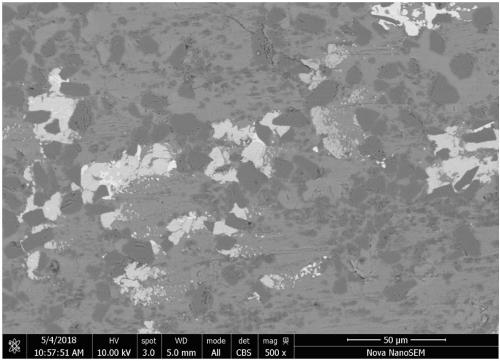

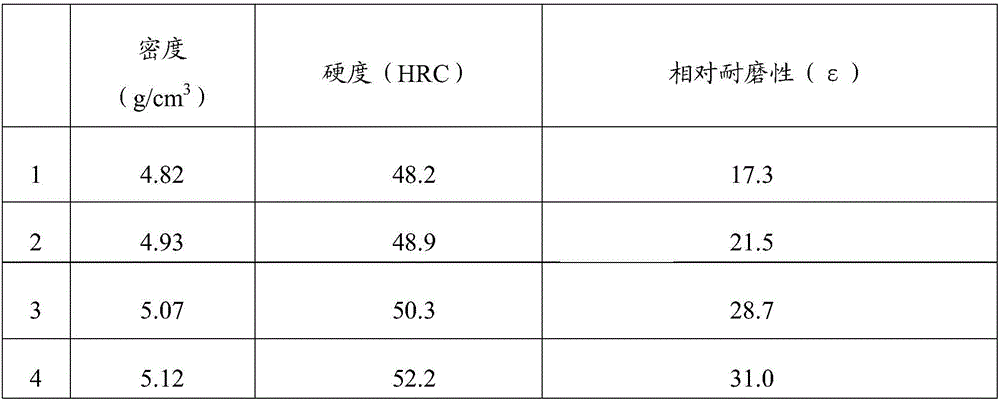

SiC particle-enhanced aluminum based composite with high-temperature wear resistance and preparation method of SiC particle-enhanced aluminum based composite

The invention provides a SiC particle-enhanced aluminum based composite with high-temperature wear resistance and a preparation method of the SiC particle-enhanced aluminum based composite and belongsto the field of aluminum alloy materials. The preparation method comprises the following steps of smelting industrial pure aluminum, aluminum-silicon alloy, aluminum-copper alloy, pure magnesium, thealuminum-copper alloy, aluminum-nickel alloy, aluminum-zinc alloy, aluminum-titanium alloy and aluminum-magnesium alloy at 700-800 DEG C according to a mass ratio; performing degassing refining; performing casting at 700-750 DEG C; using vacuum smelting, stirring and casting equipment to smelt a substrate at 700-800 DEG C; adding micron-size SiC particles; performing semi-solid state stirring at550-570 DEG C; performing casting at 700-750 DEG C; and performing T6 heat treatment. For the SiC particle-enhanced aluminum based composite with the high-temperature wear resistance and the preparation method, the substrate alloy components are designed self according to an alloy phase diagram, and a proper element content is selected, so that a high temperature resistant hard phase occurs aftersubstrate alloy heat treatment, and the substrate hardness at high temperature is ensured; and meanwhile, by adding an SiC-enhanced phase, the high temperature resistance of the composite is further improved.

Owner:TONGJI UNIV

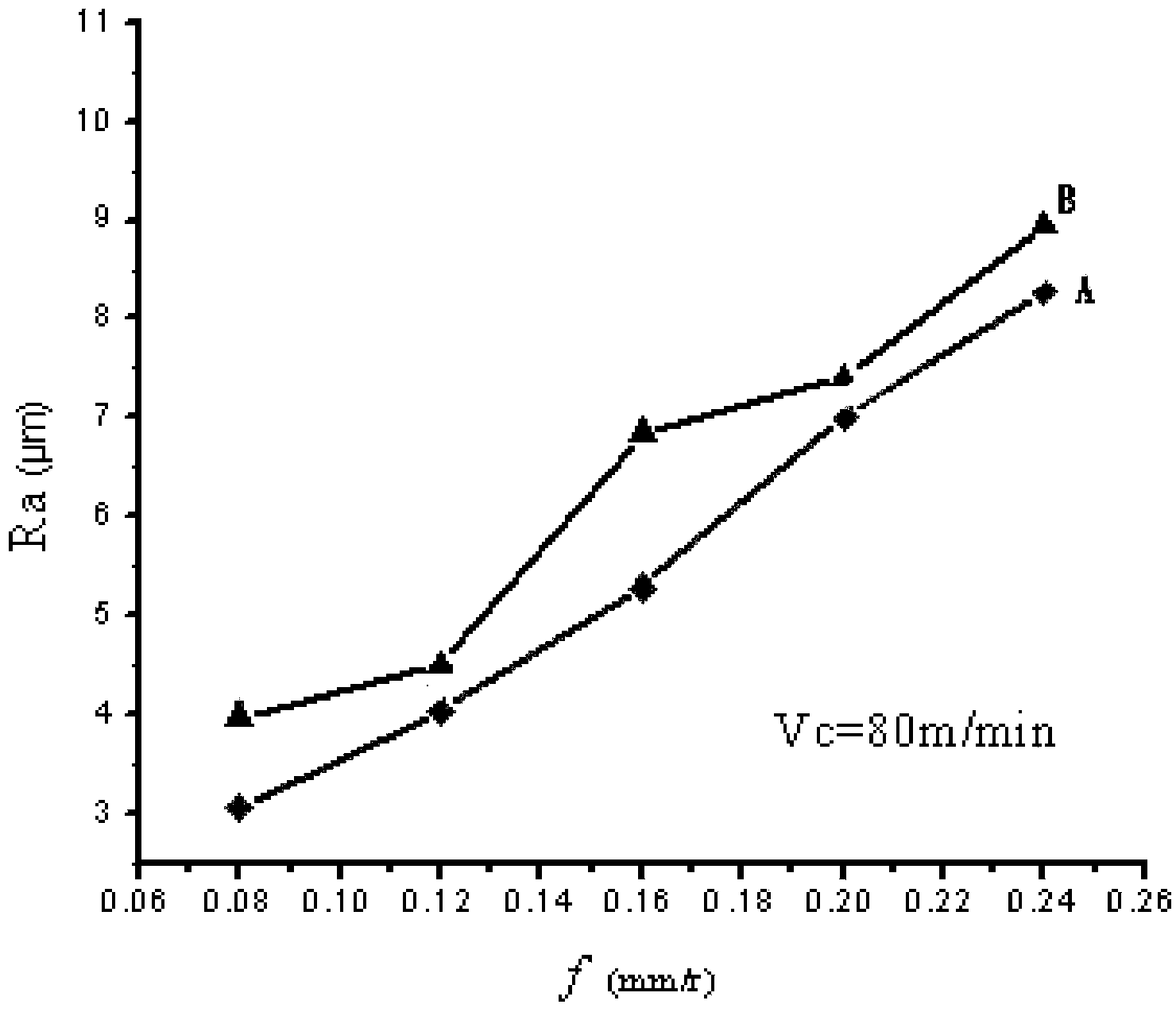

Totally-synthesized water-based stainless steel cutting liquid, and preparation method and using method thereof

ActiveCN103865622AGood instant solubilityEasy to cleanLubricant compositionWater basedPolyethylene glycol

The invention discloses a totally-synthesized water-based stainless steel cutting liquid. The cutting liquid contains the following components: a stainless steel water-based extreme-pressure agent, caprylic-capric acid, boric acid triethanolamine ester, polyethylene glycol, a cation quaternary ammonium salt metal filings settling agent, a dicarboxylic compound antirusting agent, a monobutyl ether coupling agent, a hard-water-resisting agent, a defoamer and distilled water. By virtue of an environmental-friendly total-synthesis formula, the cleaning and settling properties of the cutting liquid are enhanced; an environmental-friendly special water-based extreme-pressure lubricant is used to substitute for the traditional synthetic ester, thereby ensuring the long-time stability of the cleaning and settling properties of the cutting liquid. The cutting liquid plays a very good role in protecting non-ferrous metal and ferrous metal; by virtue of the cation quaternary ammonium salt settling agent, the problem of iron filings settling during the processing of stainless steel is eliminated, and the transparency and stability of the cutting liquid in long-time use are guaranteed.

Owner:苏州安美润滑科技有限公司

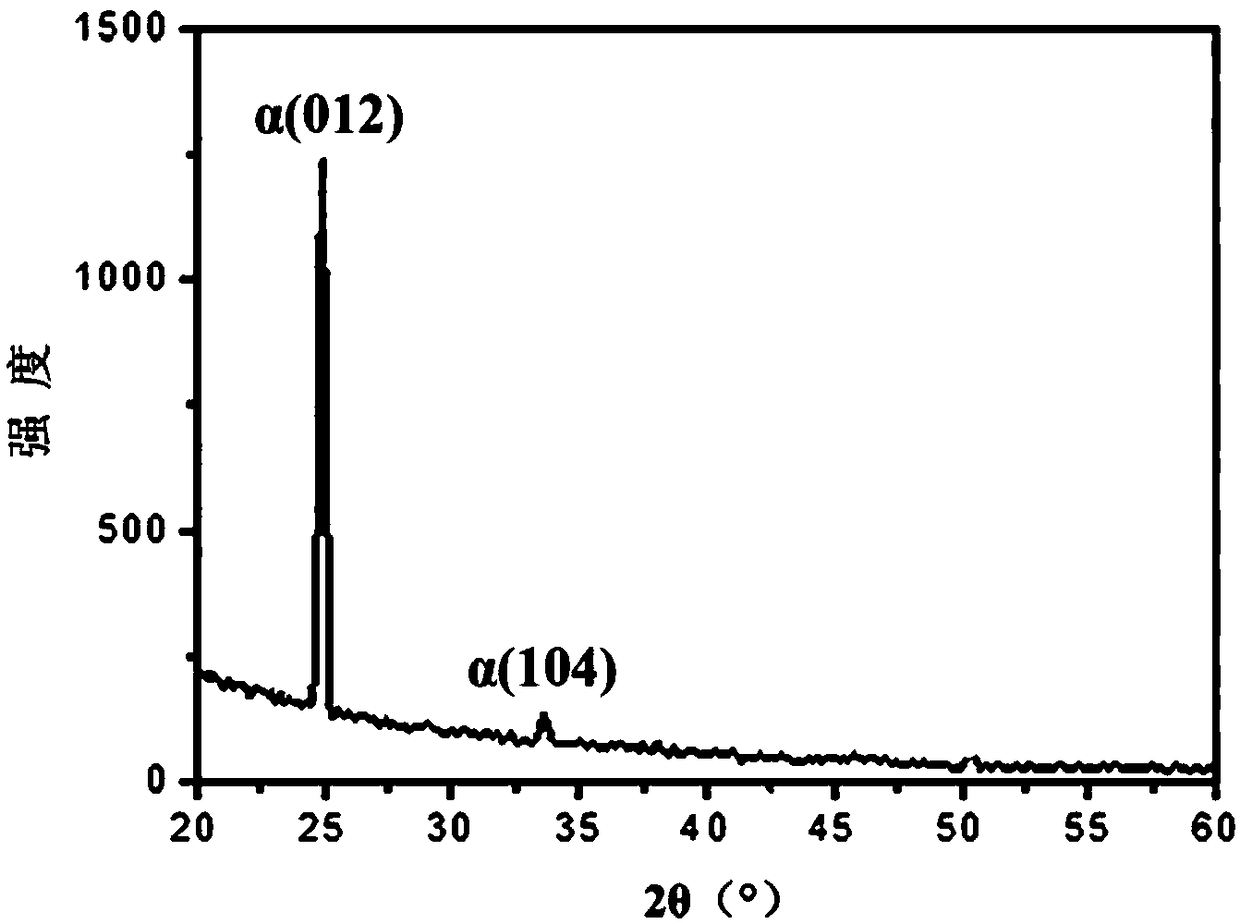

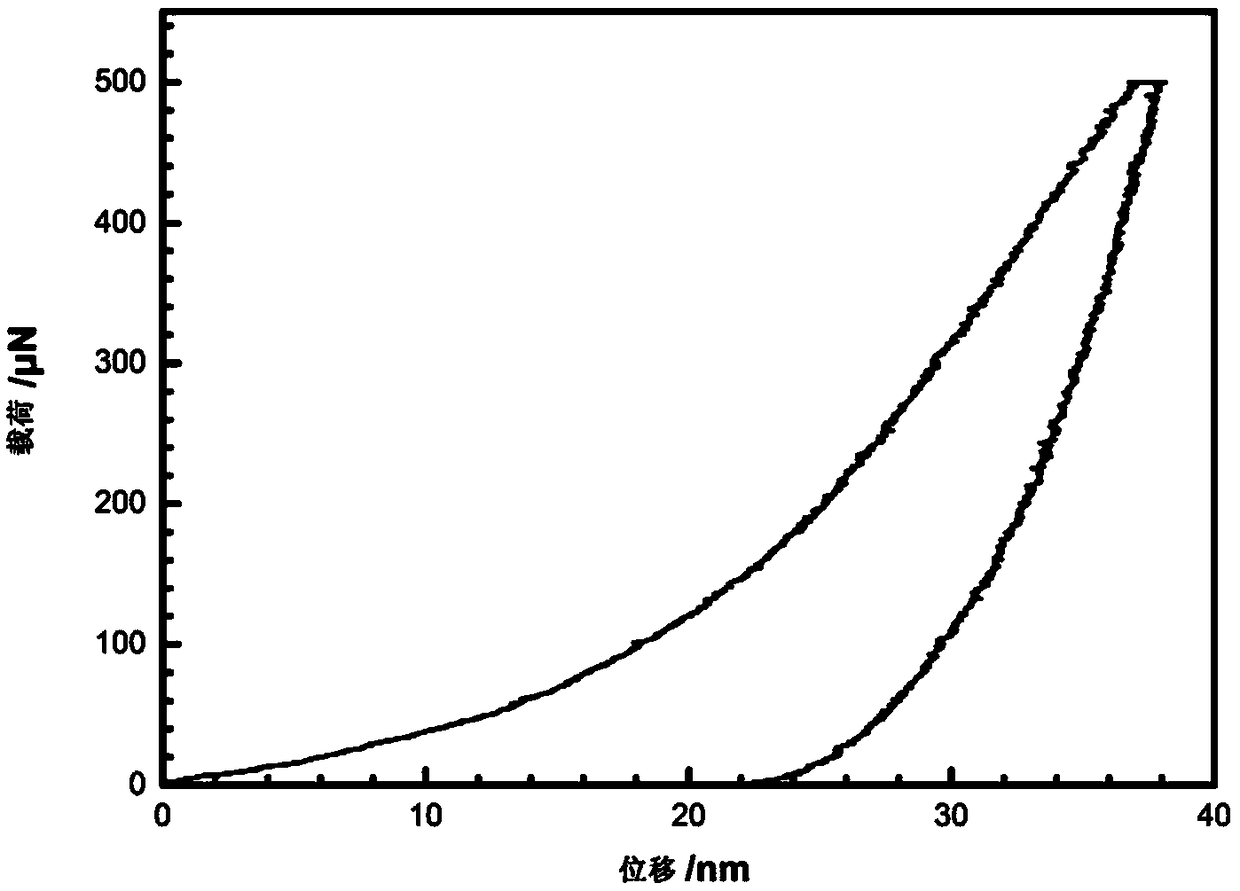

Three-layer film structure coating layer and fabrication method thereof

ActiveCN109082641AReduce stressPrevents Diffusion Adhesive WearVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringSuperalloy

The invention belongs to the technical field of fabrication of a metal coating layer, and discloses a three-layer film structure coating layer and a fabrication method thereof. The three-layer film structure coating layer comprises a dual-phase Cr+Alpha-(Al, Cr)2O3 matrix pasting layer, a single phase Alpha-(Al, Cr)2O3 support layer and a single-phase nanometer Alpha-Al2O3 surface layer. The fabrication method comprises the steps of sequentially depositing the Cr+Alpha-(Al, Cr)2O3 matrix pasting layer and the Alpha-(Al, Cr)2O3 support layer by DC magnetron sputtering and by a CrAl alloy target; and obtaining the single-phase nanometer Alpha-Al2O3 surface layer by radio-frequency magnetron sputtering by an Al+Alpha-Al2O3 compost target. The surface working layer of the obtained coating layer is of a single-phase nanometer Alpha-Al2O3 structure, the coating layer is high in hardness, good in toughness, high in high-temperature thermal stability, low in friction coefficient during friction with a metal matrix and is firmly combined with a matrix such as high-speed steel, a hot work die steel and high-temperature alloy.

Owner:SOUTH CHINA UNIV OF TECH

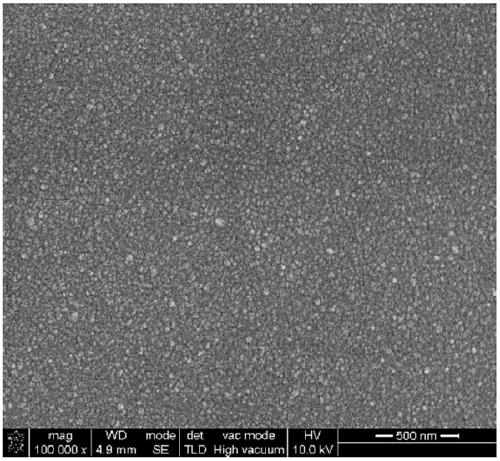

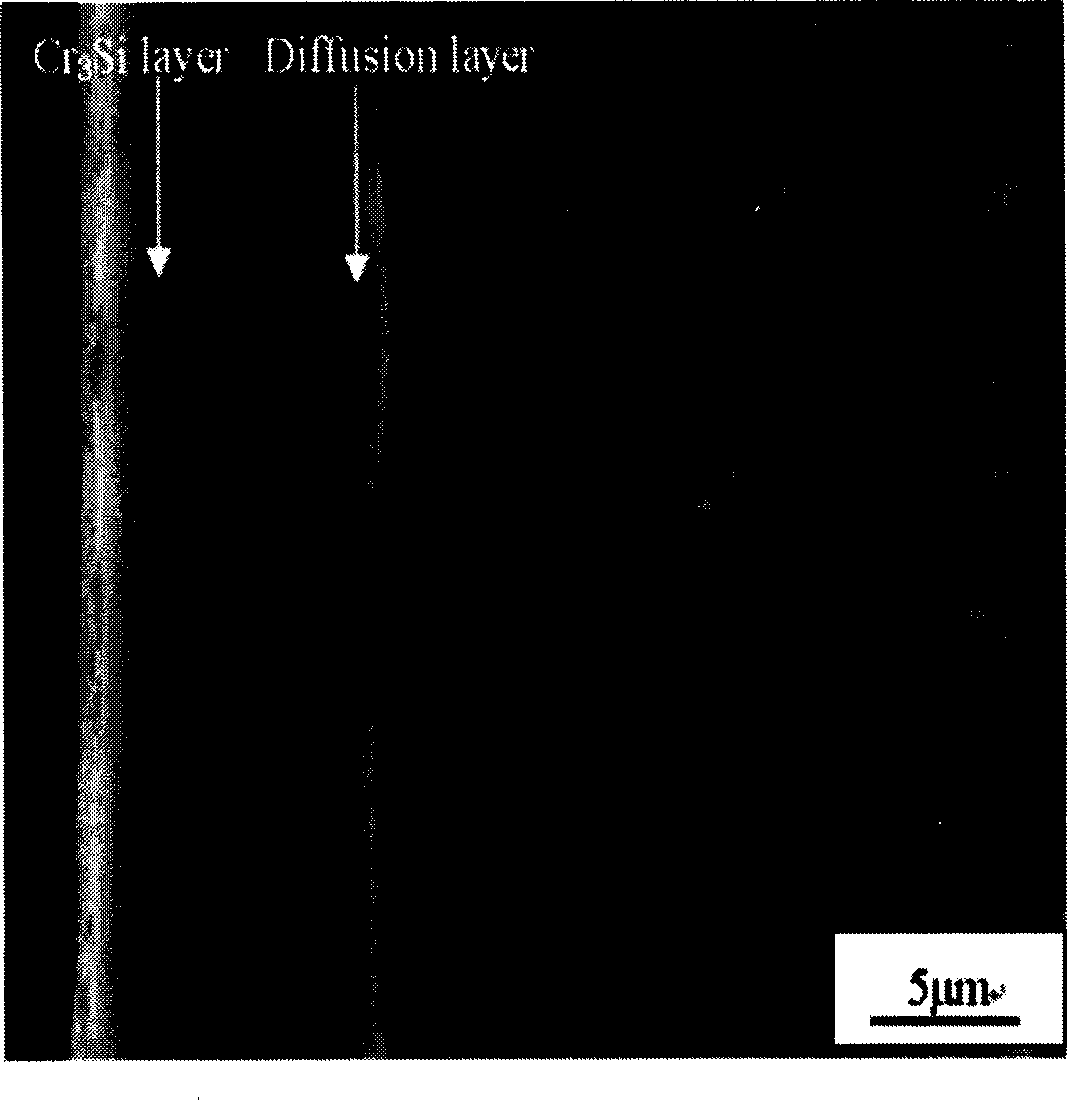

Preparation of high tenacity nanocrystalline silicide coating

InactiveCN101481791AReduce intensityReduce hardnessVacuum evaporation coatingSputtering coatingVoltageTitanium alloy

The invention discloses a preparation method of high-tenacity nanocrystalline silicide coating, which uses the technology of twin cathode plasma sputtering sedimentation to control the sputtering amount of a target material and the temperature of a work surface by adjusting the target material and workpiece voltage as well as argon pressure led into a vacuum chamber; the dense nanocrystalline silicide coating is formed at the surface of titanium alloy; the technological parameters of twin cathode sputtering are as follows: the voltage of the target material is 500 to 1000 V; the workpiece voltage is 300 to 450 V; the distance between the target material and the workpiece is 10 to 30 mm; the argon pressure is 20 to 45 Pa; the type of the sputtered target material is Cr-Si alloy, and the like; and the type of the workpiece material is titanium alloy. Compared with an ordinary macrocrystal silicide material, the nanocrystalline silicide coating prepared by the invention has higher tenacity, oxidation resistance, high temperature resistance and high wearing resistance. The preparation method is applied to the field of propulsion of aviation and aerospace, and the coating is an indispensable special coating material with high temperature resistance and high wearing resistance.

Owner:JIANGSU HUAYANG PIPE & FITTINGS +1

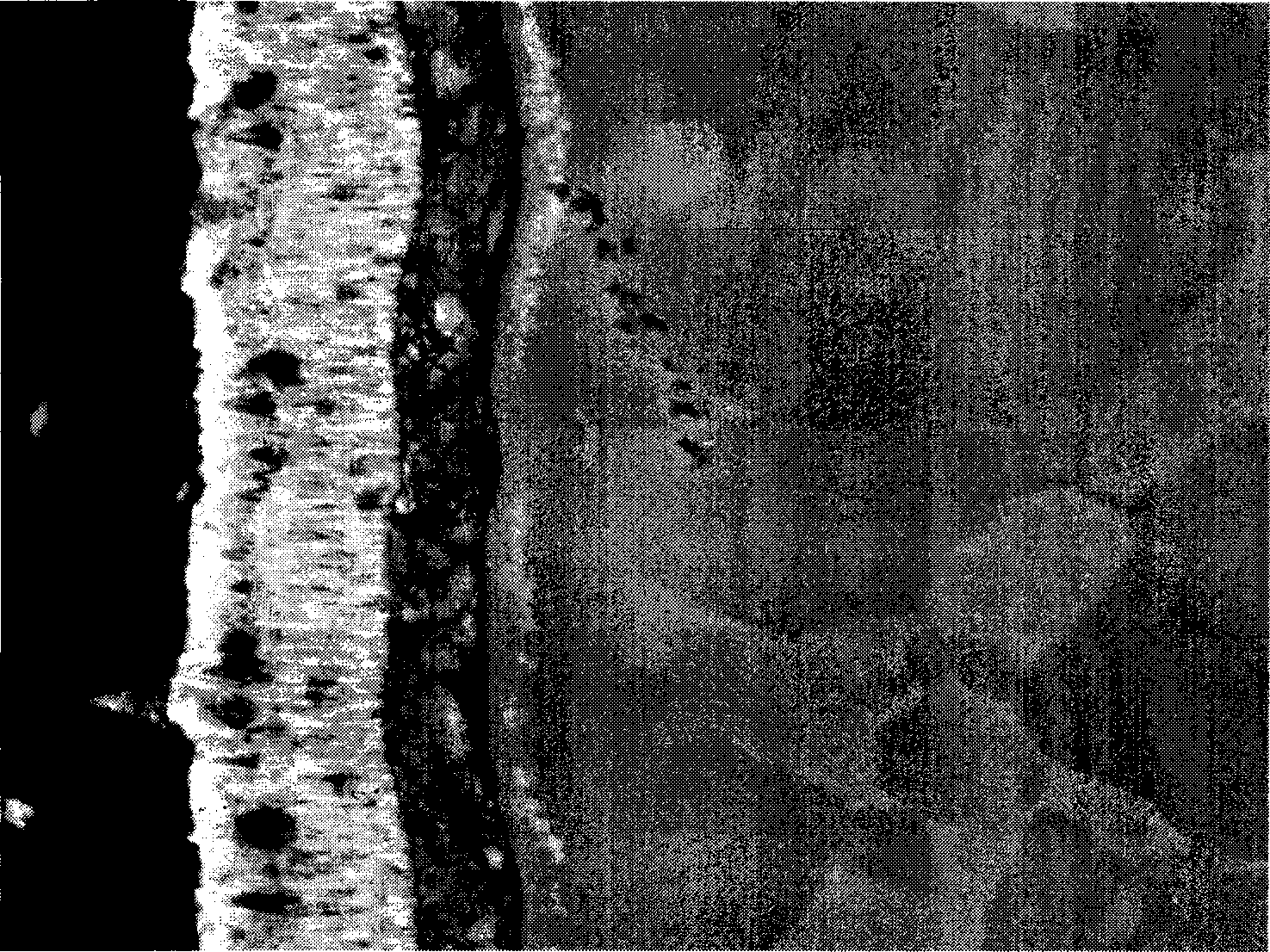

Metal composite ceramic cylinder sleeve and ceramic infiltration method thereof

InactiveCN103883418AStable structureWon't fall offCylinder headsCylindersComposite filmCeramic composite

The invention discloses a metal composite ceramic cylinder sleeve. Composite film ceramic is attached to the inner surface of the cylinder sleeve, and new material is formed on the metal surface through interdiffusion between the film ceramic and a cylinder sleeve base body material. A ceramic film is BN-SiN, the molecular structure of the ceramic film is of a hexagonal crystal structure and has self-lubrication performance, after ceramic infiltration, the friction coefficient of the inner surface of the cylinder sleeve is reduced to one sixth, and the hardness is improved by 41%. The thickness of the ceramic film layer is 3 micrometers -6 micrometers, and the infiltration depth is 35 micrometers-55 micrometers; and the ceramic composite film grows in the environment at the low temperature of 255 DEG C-265 DEG C. The composite film structure of the metal composite ceramic cylinder sleeve is firm and can not fall off, the inner surface of the cylinder sleeve is resistant to abrasion and high temperature and small in friction coefficient, so that engine power is improved, oil consumption is reduced, and emission pollution is reduced.

Owner:江苏爱吉斯海珠机械有限公司

Low-cobalt hard alloy resistant to high temperature, abrasion and corrosion and preparation method thereof

The invention belongs to the technical field of powder metallurgy, and relates to a low-cobalt hard alloy resistant to high temperature, abrasion and corrosion and a preparation method thereof. The low-cobalt hard alloy resistant to high temperature, abrasion and corrosion comprises the following ingredients in parts by mass: 0.1-1.0 part of Co, 0.4-0.6 part of Cr3C2, 6.0-8.0 parts of TaC, 0.6-1.0 part of NbC, 2.0-4.0 parts of TiC and 75-90 parts of WC. The low-cobalt hard alloy provided by the invention is relatively small in WC grain size and is uniform in distribution, and has an average grain size being 0.30-0.35 [mu]m; meanwhile, the low-cobalt alloy has hardness of HRA94.6-96.5, bending strength of 2300-2700N / mm<2>, has good high temperature resistance, good abrasion resistance and good corrosion resistance, can effectively prolong the service life of a tool, and can improve cutting efficiency of the tool.

Owner:HEYUAN ZHENGXIN HARDMETAL CARBIDE

Preparation method of high-temperature anti-wear Fe-Cr-B-Al alloy

InactiveCN104164668AHigh hardnessHigh strengthMetallic material coating processesAl powderIron powder

The invention discloses a preparation method of a high-temperature anti-wear Fe-Cr-B-Al alloy and belongs to the technical field of wear-resistant materials. The alloy is prepared by adopting a laser cladding process. The preparation method comprises the following steps: firstly, uniformly mixing 12.0wt%-15.0wt% of low-carbon Cr-Fe powder, 12.0wt%-15.0wt% of high-carbon Cr-Fe powder, 6.0wt%-8.0wt% of B-Fe powder, 5.0wt%-6.0wt% of metal Al powder, 1.5wt%-2.0wt% of re-Si-Fe powder, 4.0wt%-5.0wt% of Fe2O3 powder and 52wt%-57wt% of pure Fe powder, wherein the particle size of the powder is within a range of 100-160 meshes; and secondly, inputting heat by adopting an optical fiber laser device, and feeding the powder materials by adopting a laser cladding synchronous powder feeder to obtain the Fe-Cr-B-Al alloy which is high in hardness and good in high-temperature wear resistance, wherein in the cladding process, the powder feeding rate is 15-20g / min, the laser power is 1500-2500W, and the scanning speed is 3-8mm / s.

Owner:BEIJING UNIV OF TECH

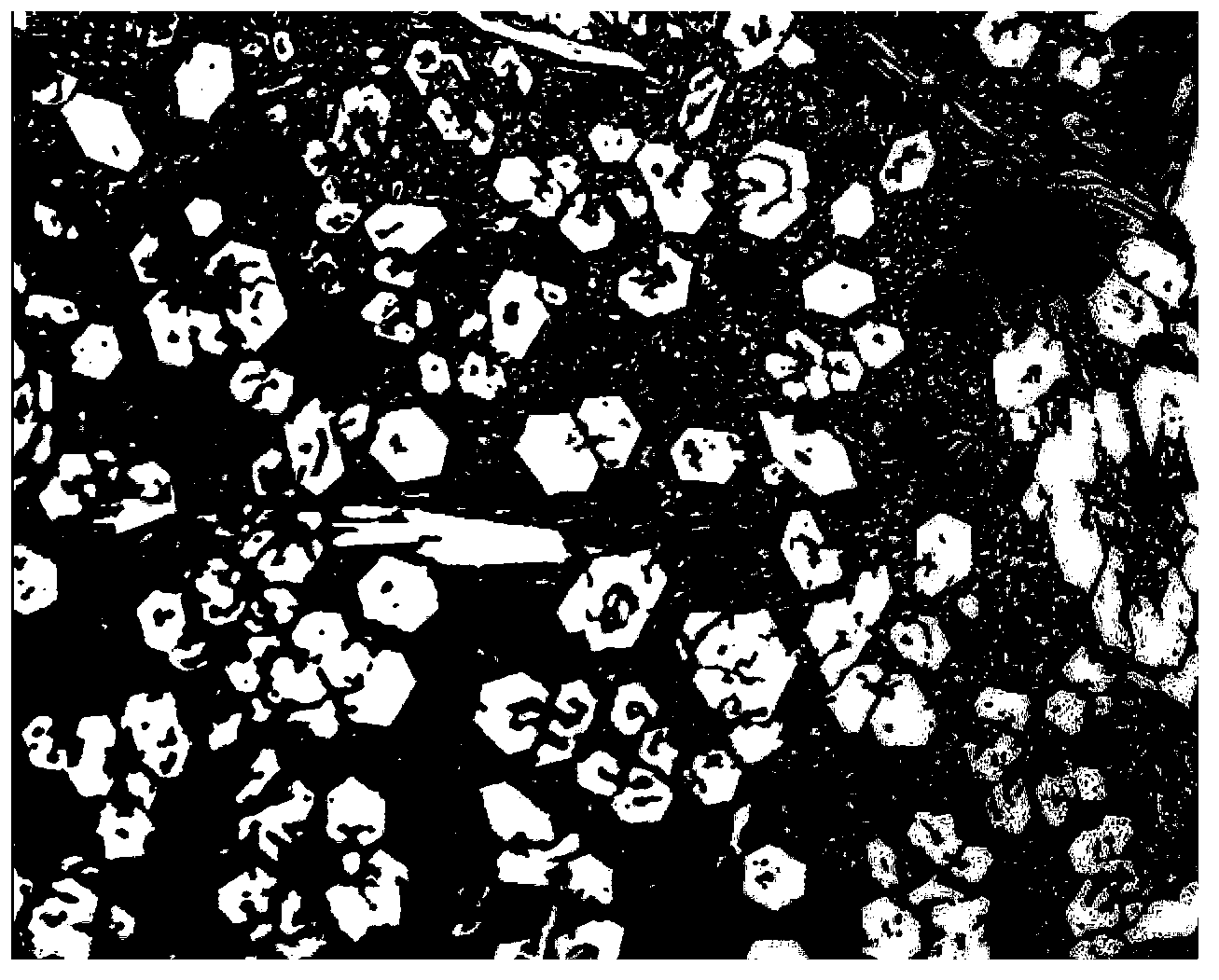

Wear resistant surfacing alloy containing ceramic phase with molybdenum and chromium elements and production technology thereof

InactiveCN103769765AIncrease production costLow costPlasma welding apparatusWelding/cutting media/materialsWear resistantAlloy

The invention discloses a wear resistant surfacing alloy containing ceramic phase with molybdenum and chromium elements and a production technology thereof. The wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements is characterized in that alloy composition comprises 15 to 30 % of chromium, 3 to 12 % of molybdenum, 0.5 to 1 % of nickel, 6 to 10 % of carbon and the remaining is ferrum and unavoidable impurities. The production technology of the wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements comprises mechanically mixing ferrochrome powder, molybdenum powder, nickel powder, graphite and reduced iron powder; uniformly mixing through a dry type ball mill of a ball grinder; coating the powder on a carbon steel plate after the powder is cooled; uniformly mixing into a coating layer with the thickness of 4 mm through water glass; standing under room temperature; drying in a drying oven; enabling the temperature to be cooled to the room temperature in the drying oven; performing ion surfacing. The production technology of the wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements has the advantages of being simple in technological process, less in added alloy variety and low in cost and enabling hard phase of obtained alloy surfacing layer to be good in bonding performance with base materials, not easy to fall off, high in rigidity and wear resistance, obvious in adhesive wear resistant effect compared with other iron-based surfacing wear resistant alloy.

Owner:SHENYANG POLYTECHNIC UNIV

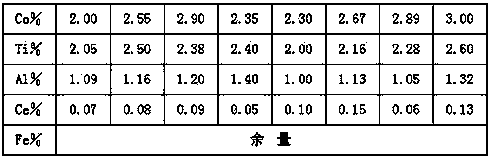

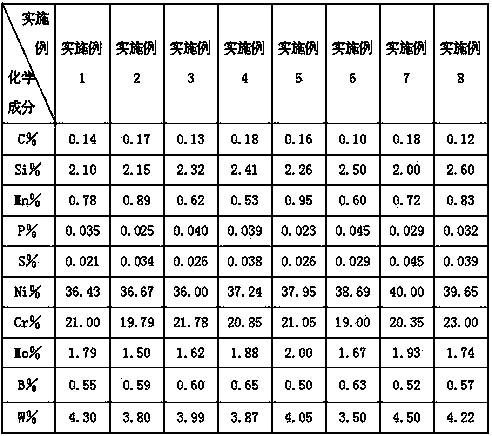

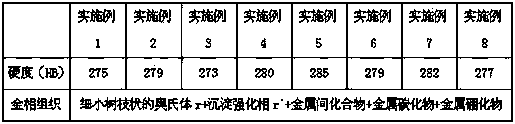

High-temperature-resistant alloy casting and preparation method thereof

ActiveCN104195474AHigh strengthImprove high temperature creep resistanceFoundry mouldsFoundry coresChemical compositionCarbide

The invention relates to a high-temperature-resistant alloy casting and a preparation method thereof. The alloy casting comprises the following chemical components by mass percent: 0.10% to 0.18% of C, 2.0% to 2.6% of Si, less than or equal to 1% of Mn, less than or equal to 0.045% of P, less than or equal to 0.045% of S, 19% to 23% of Cr, 36% to 40% of Ni, 1.5% to 2.0% of Mo, 0.50% to 0.65% of B, 3.5% to 4.5% of W, 1.0% to 1.4% of Al, 2.0% to 2.6% of Ti, 2% to 3% of Co, 0.05% to 0.15% of Ce and the balance of Fe. The preparation method comprises the following steps of the preparation of a wax mould; the preparation of a mould shell; smelting; and pouring. The as-cast hardness of the alloy casting is HB273-285; and an as-cast metallographic structure of the alloy casting is composed of a fine and small dendritic austenite r, a precipitation strengthening phase r', an intermetallic compound, a metal carbide and a metal boride. The obtained inner core cup casting is strong in high-temperature creep resistance, high-temperature resistance and oxidation resistance and is high in strength and stability under a high-temperature condition, so that the long service life of the casting is realized.

Owner:BAODING FENGFAN PRECISION CASTING

Laser cladding alloy powder for repairing and remanufacturing hot-working die

ActiveCN105132913AHigh temperature hardnessGood toughness, crack resistanceMetallic material coating processesRare-earth elementYttrium

The invention provides laser cladding alloy powder for repairing and remanufacturing a hot-working die. In order to solve the problem that nickel-based or cobalt-based thermal spraying powder is expensive, iron-based alloy powder is adopted in the invention. While the iron-based alloy is formed through replacing pure iron with waste steel, the reutilization of the waste is realized. However, as the impurity content in the waste steel is high, the removal of phosphorous, carbon and sulphur is required in the refining process so as to obtain molten steel of which the components and temperature are qualified. The traditional method usually removes the impurities through slagging in the form of furnace slag, but has the problems of high heat energy requirement, large metal losses and serious splashing. In order to solve the problems, a traditional slag former is replaced by yttrium oxide, and waste steel impurities and glomeration inclusions are removed through the purifying functions of rare-earth elements. Meanwhile, deposited metal is endowed with excellent anti-fatigue performance.

Owner:SHANDONG UNIV

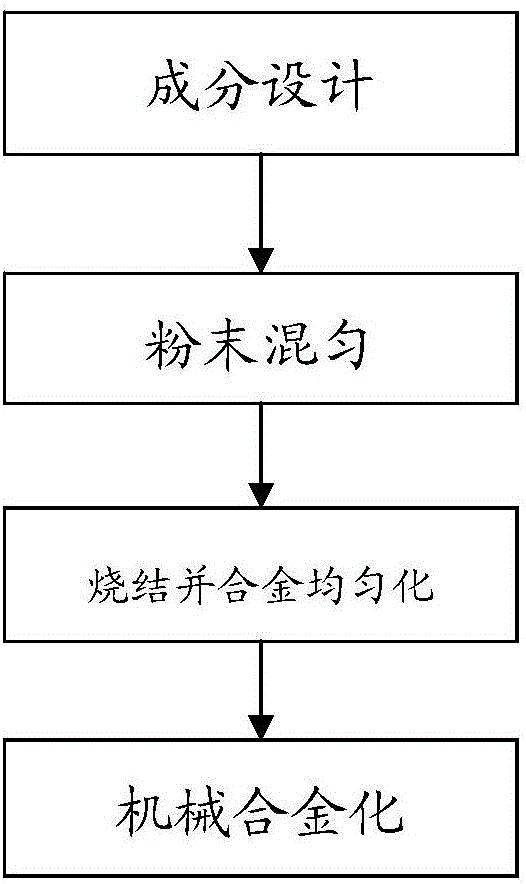

Titanium-based tungstenic alloy material used for 3D printing and preparation method thereof

ActiveCN106756240AHigh temperature hardnessExcellent high temperature wear resistanceAdditive manufacturing apparatusCorrosionHardness

The invention discloses a titanium-based tungstenic alloy material used for 3D printing. The material contains tungsten carbide, nickel, niobium, vanadium, copper, molybdenum and titanium. A preparation method comprises the steps that metal powder is fully mixed after component design is completed; the mixed powder is subjected to sintering and alloy homogenizing; and then alloy powder is obtained through mechanical alloying. A 3D printing finished product of the obtained material has the advantages of being low in weight, high in high-temperature hardness, excellent in high-temperature abrasion resistance, and resistant to corrosion.

Owner:康硕电气集团有限公司

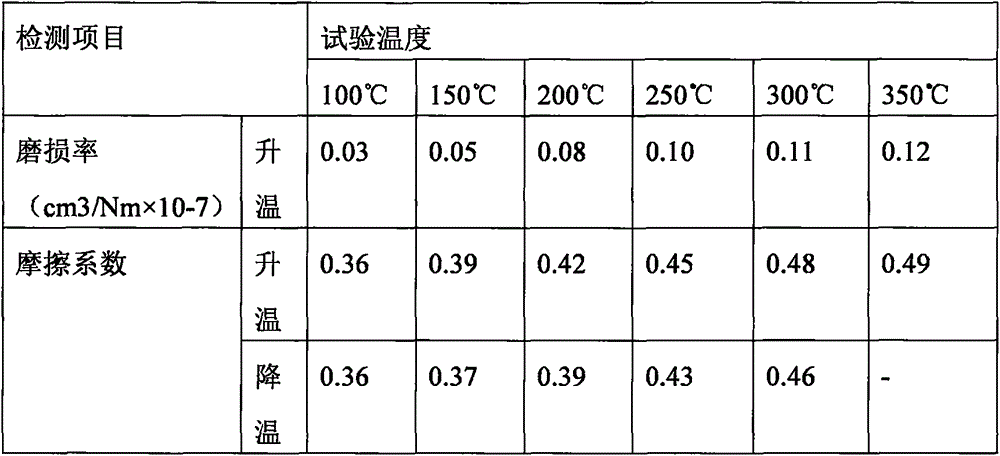

Friction material and preparation method thereof

The invention provides a friction material and a preparation method thereof. The friction material is prepared from iron-zinc alloy powder, polyether-ether-ketone, tungsten sulfide, molybdenum sulfide, spherical graphite, nickel carbonyl powder, zirconium carbide, tantalum carbide, phenolic resin and the balance halloysite nanotube. The halloysite nanotube has excellent heat radiation performance. The iron-zinc alloy powder has high high-temperature hardness, compressive strength, impact toughness and friction performance. The polyether-ether-ketone has excellent mechanical performance, chemical performance and tribology performance. The hardness and compressive strength of a matrix are remarkably improved through the nickel carbonyl powder. The strength and friction forming capacity of the material can be remarkably improved through the spherical graphite. The zirconium carbide and the tantalum carbide have the beneficial effects of being low in density, good in wear resistance, high in coefficient of friction and the like. The above components are compounded, and interaction and mutual effects of ingredients are achieved; and the prepared friction material has the beneficial effects of being low in price, excellent in friction performance, stable in performance and the like.

Owner:宁波联华汽车部件有限公司

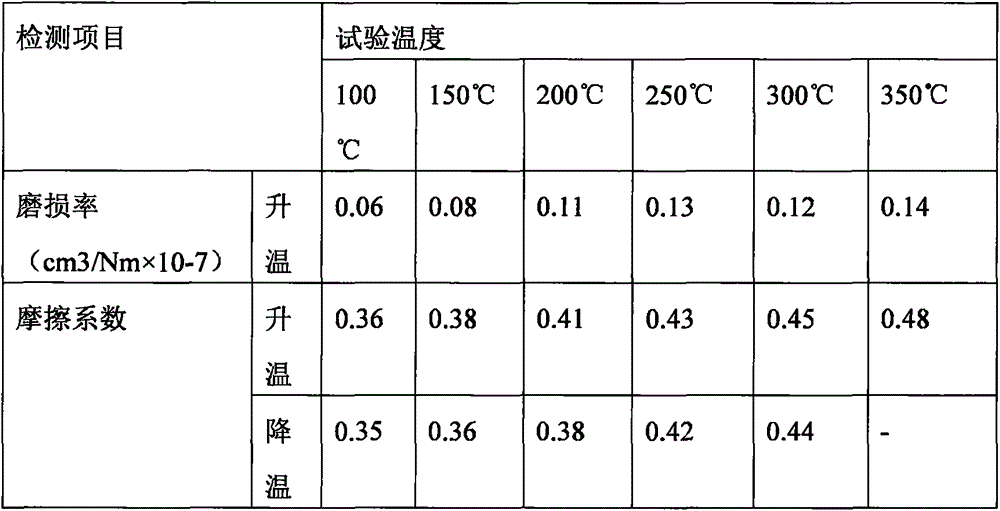

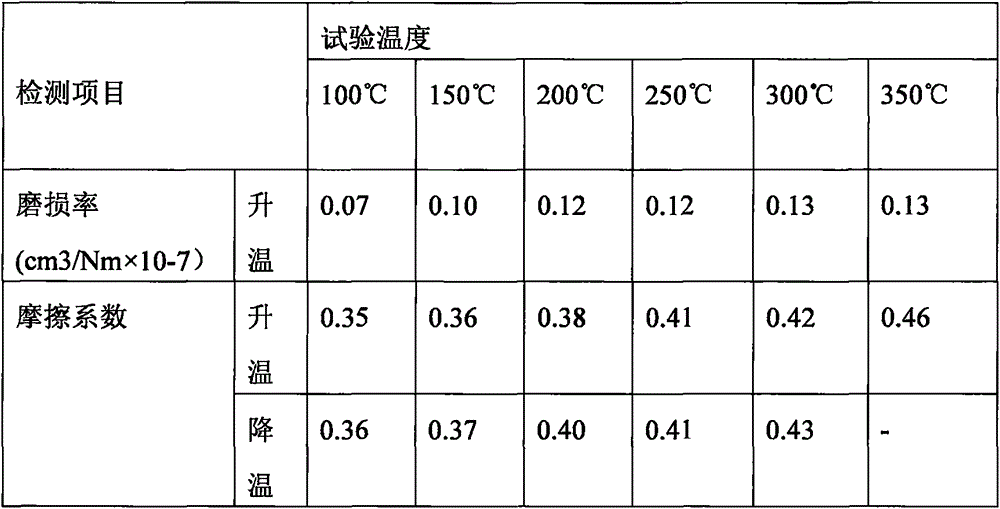

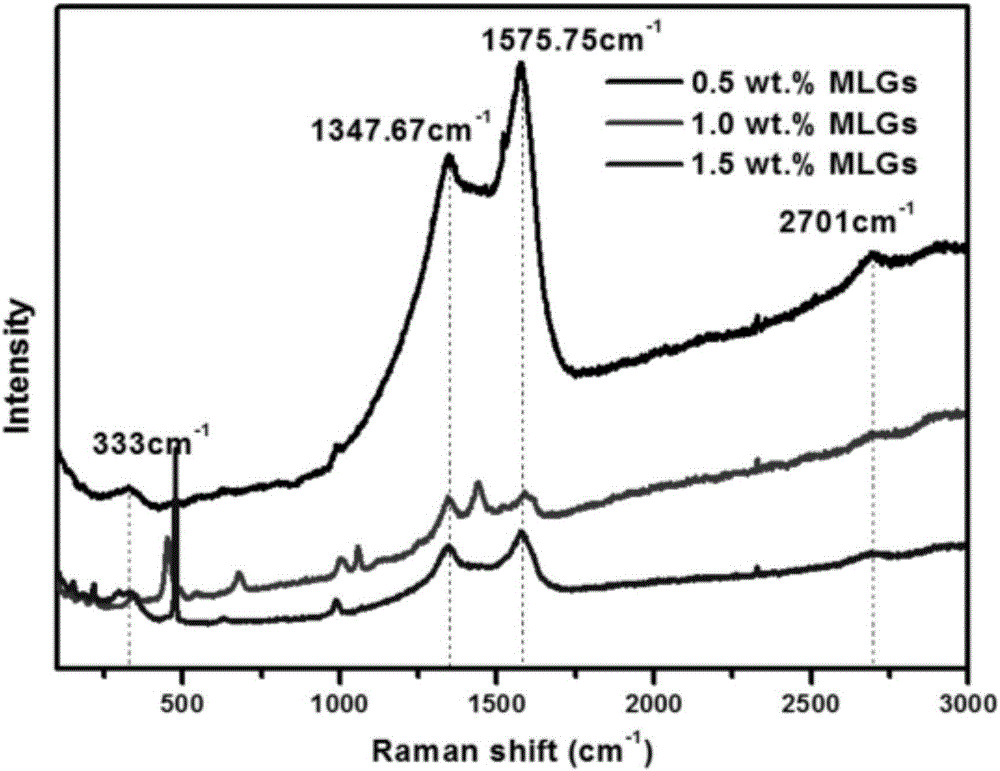

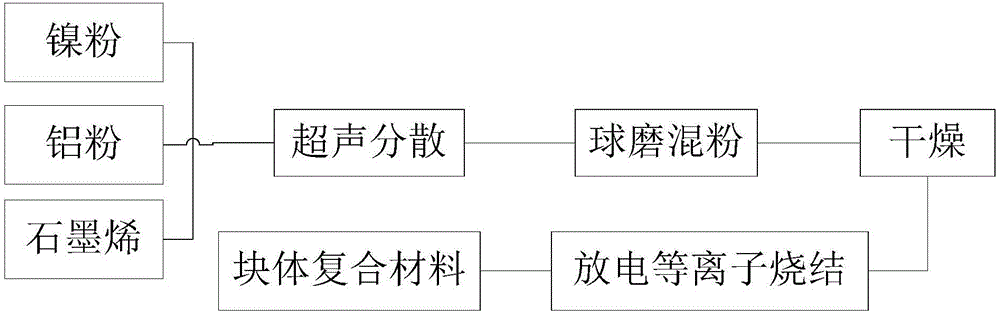

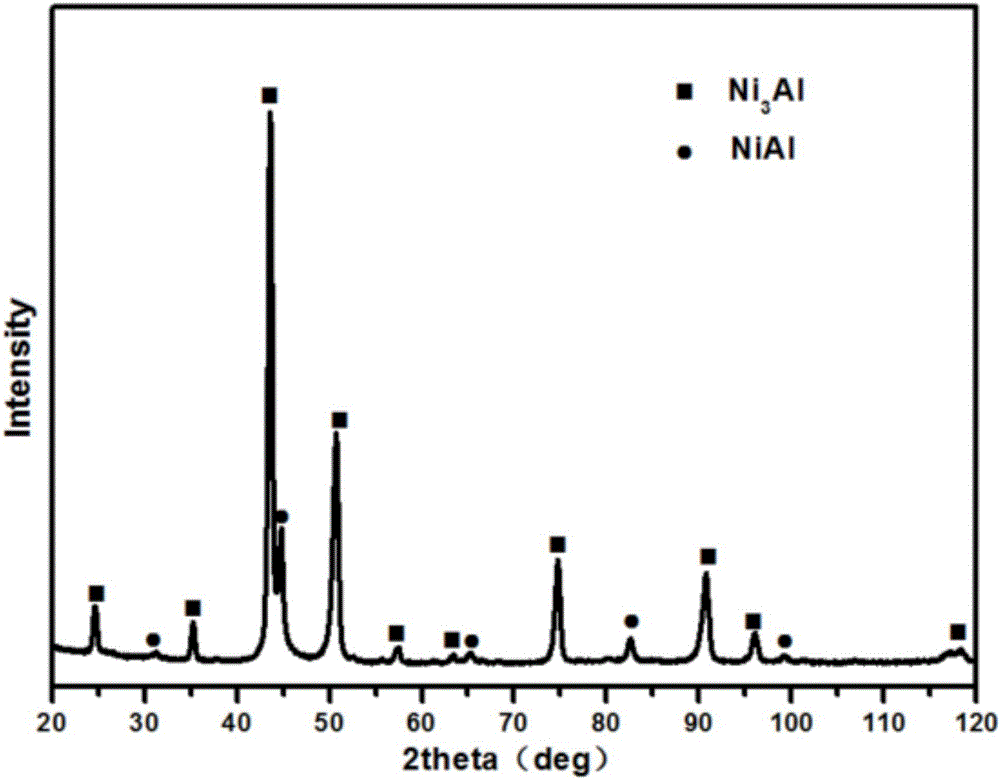

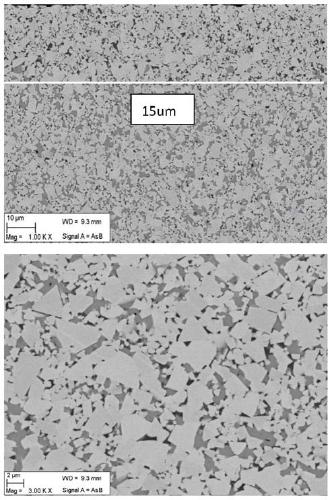

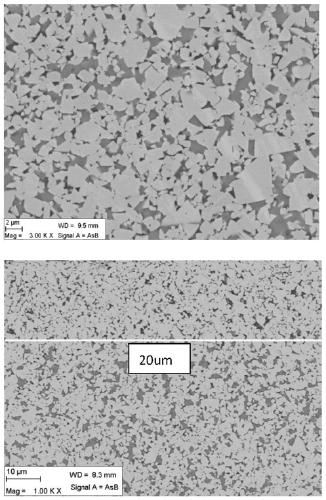

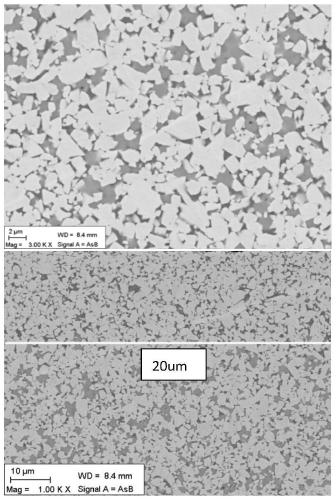

Graphene-reinforced biphase metal aluminide composite material and preparation method thereof

The invention provides a graphene-reinforced biphase metal aluminide composite material. The graphene-reinforced biphase metal aluminide composite material comprises a main crystal phase and a reinforcement phase, wherein the main crystal phase is a biphase mixture of NiAl and Ni3Al, and the reinforcement phase is graphene. A metal aluminide composite material system is designed, wherein the graphene is adopted as reinforcement, and particularly, a (NiAl-Ni3Al) biphase mixture is used as a high temperature composite material of a matrix. The metal aluminide has the distinctive physical and chemical properties such as the strong bond combination property allowing metallic bonds and covalent bonds to coexist, the high high-temperature hardness and special chemical components, the graphene has the properties such as excellent mechanical property, excellent matching property of high temperature strength and toughness and good high temperature oxidation resistance, and therefore the nickel-aluminum metal aluminide composite material can have high specific strength.

Owner:SUZHOU UNIV

Carbide blade and preparation method thereof

The invention provides a carbide blade and a preparation method thereof, and belongs to the field of mechanical technology. The carbide blade solves the problem that existing cutting blades are not high in universality and have certain limitations. The carbide blade uses Co as a bonding phase, and tungsten carbide and titanium-containing cubic phase compound as hard phases; mass fraction of the bonding phase is 4.5-9.5 wt.%, and mass fraction of the hard phases is 90.5-95.5 wt.%; mass fraction of the titanium-containing cubic phase compound in the carbide blade ranges from 2 wt.% to 8 wt.%; grain distribution of the tungsten carbide is of a double-peak structure; the tungsten carbide comprises coarse grain tungsten carbide and fine grain tungsten carbide; the average grain size of the coarse grain tungsten carbide is 1.5-3.0 microns; and the average grain size of the fine grain tungsten carbide ranges from 0.4 micron to 1.0 micron. The carbide blade is high in hardness, toughness and strength, and is excellent and stable in cutting performance.

Owner:台州市锐安硬质合金工具有限公司

Manufacturing method of welding rod special for corrosion-resisting steel welding

ActiveCN105665969AImprove stabilityGrain refinementWelding/cutting media/materialsSoldering mediaRare-earth elementAdhesive

The invention belongs to the technical field of welding materials, and in particular discloses a manufacturing method of a welding rod special for corrosion-resisting steel welding. The manufacturing method comprises the following steps: (1) preparation of an adhesive; (2) pretreatment of a coating; (3) preparation of the welding rod. The manufacturing method has the following technical advantages that due to reasonable formula design, the chromium content of a core wire of the welding rod is optimized; a small number of rare earth elements are added, and impurity elements are controlled; on the basis of ensuring that welding metal has certain intensity and low-temperature impact toughness, the welding rod is high in hydrogen sulfide corrosion and seawater corrosion resistance. The adopted adhesive is better in low and high-temperature resistance; core powder is difficult to slide off in a welding process; meanwhile, the melting speed of the core powder can be increased, and normal welding construction can be effectively guaranteed.

Owner:浙江申嘉焊材科技有限公司

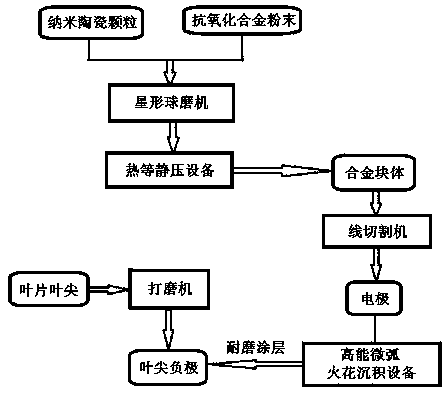

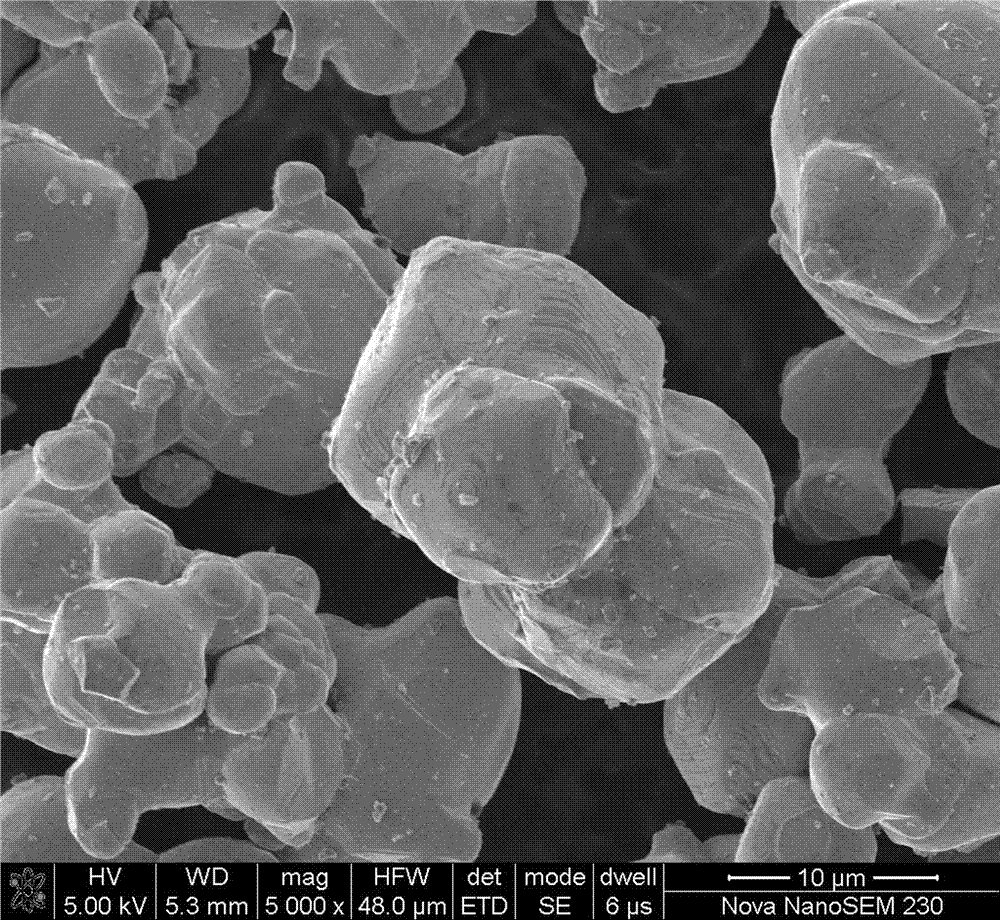

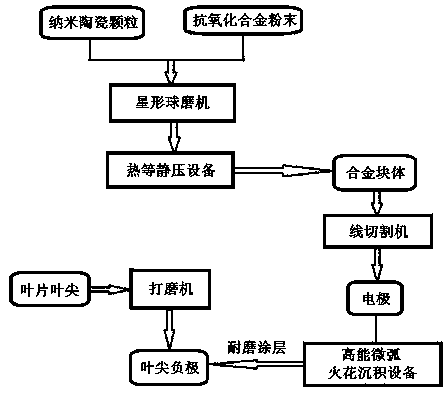

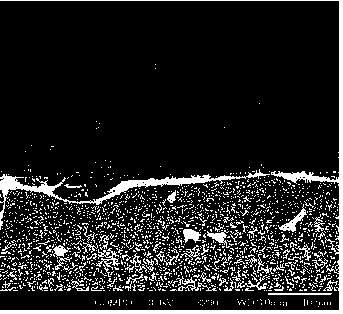

Preparation method of nanoparticle reinforced wear-resistant coating layer on blade top of single-crystal turbine blade

ActiveCN108486567AImprove performanceThere will be no "segregation" phenomenonMetallic material coating processesCeramic particleTurbine blade

The invention discloses a preparation method of a nanparticle reinforced wear-resistant coating layer on a blade top of a single-crystal turbine blade. The preparation method is characterized by taking a single-crystal high-temperature alloy turbine blade as a base material and a nano ceramic particle-doped reinforced anti-oxidation alloy composite material as a coating material, and by adopting ahigh-energy micro-arc spark deposition technology, thus preparing a nano ceramic particle reinforced wear-resistant coating layer in oriented epitaxial growth with a structure of the base material. According to the preparation method disclosed by the invention, by virtue of a high-temperature gradient formed during a high-energy micro-arc spark deposition process, a high cooling speed and a condition close to one-dimensional rapid solidification, nano ceramic particles are uniformly distributed in a coating layer, and the oriented epitaxial growth of the microstructure of the coating layer iskept, so that good high-temperature wear resistance is obtained; meanwhile, due to extremely high energy density, the width of a heat affected zone in an interface between the coating layer and the single-crystal turbine blade is extremely wide, and change of the microstructure of a single-crystal matrix and generation of heat cracks are avoided.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

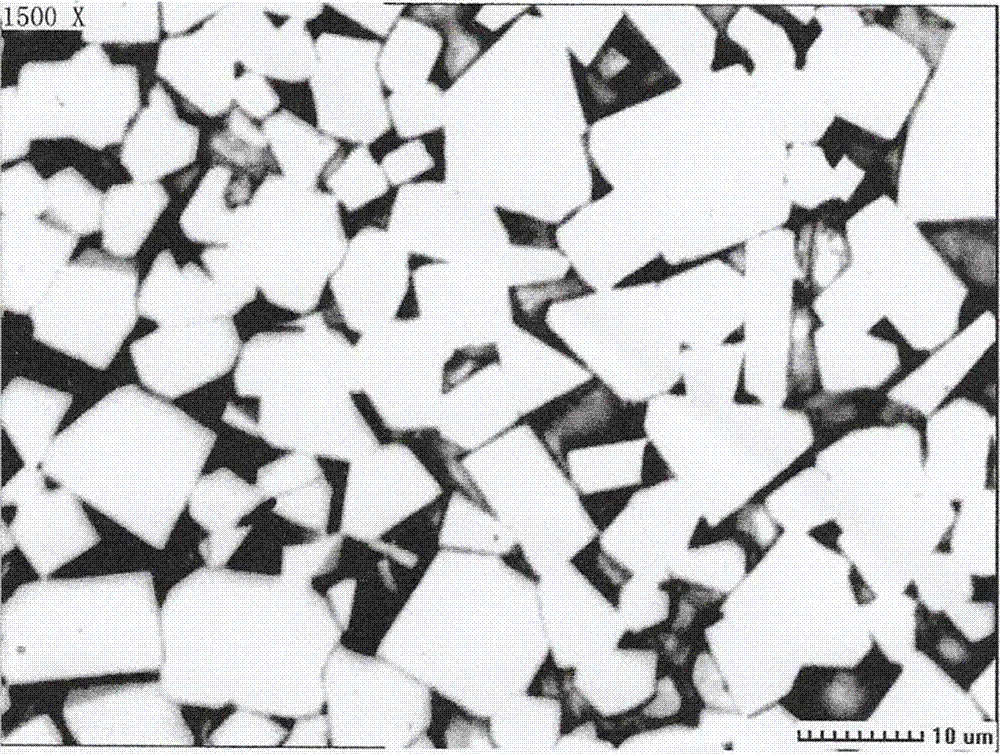

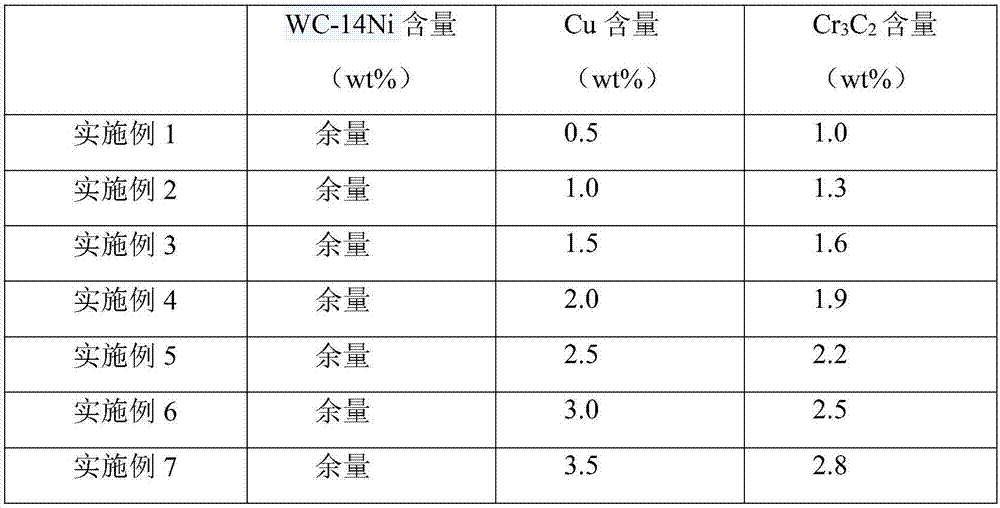

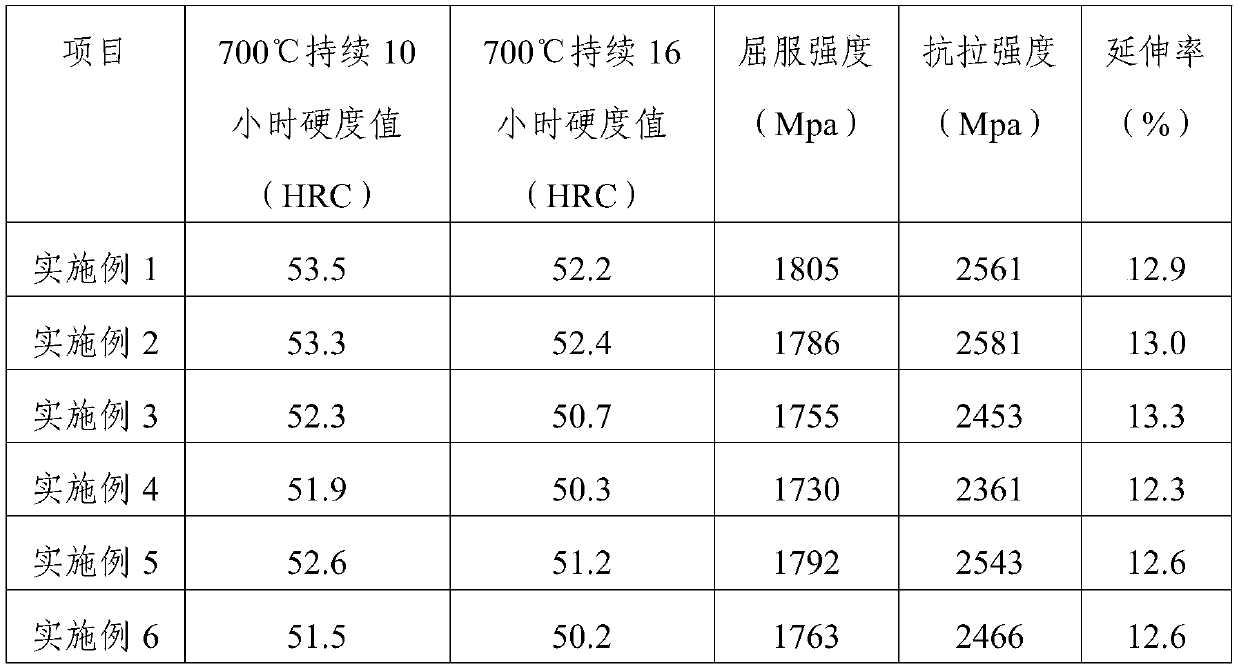

Hard alloy for soaking plate and soaking plate made of hard alloy

ActiveCN108004451AImprove thermal conductivityGood high temperature oxidation resistanceGlass reforming apparatusEconomic benefitsHardness

The invention discloses a hard alloy for a soaking plate. The hard alloy is characterized in that the hard alloy is prepared by means of the method that Cr3C2 and Cu are added into a super coarse grain WC-14Ni alloy, wherein all raw materials are weighed according to the mode that the raw materials comprise, by weight, 1.0-2.8% of Cr3C2, 0.5-3.5% of Cu and the balance super coarse grain WC-14Ni alloy. By adopting super coarse grain WC and adjusting the component ratio of Cr3C2 and Cu, a compact oxidation film protection layer is formed on the alloy surface of the soaking plate under the high-temperature work condition, thus the soaking plate has extremely good high-temperature-oxidation-resisting performance, and the heat conductivity and high-temperature hardness of the soaking plate canbe improved; and according to the hard alloy, preparation is easy, the performance of the soaking plate can be effectively improved, the gap of the field in China is filled up, and the current situation that the soaking plate of China relies on a foreign product is overcome, and huge economic benefits are achieved.

Owner:ZHUZHOU SANXIN HARD ALLOY PRODN CO LTD

Production method of ceramic-infiltrated aluminum alloy cylinder liner

InactiveCN106282617AImprove thermal conductivityReduce weightSolid state diffusion coatingMolten stateIntermediate frequency

The invention discloses a production method of a ceramic-infiltrated aluminum alloy cylinder liner. The method comprises steps as follows: step 1, preparation: Ti and Si are added when Al is in a liquid state; step 2, smelting: prepared raw materials are placed in an intermediate frequency furnace for smelting at the smelting temperature of 1530 plus / minus 10 DEG C, so that the raw materials are melted into molten iron; step 3, inoculation of the molten iron: after the raw materials in the molten state are discharged out of the furnace, an inoculant with the mass being 0.5%-0.7% of that of the raw materials is added for treatment; step 4, molten iron casting: the raw materials in the molten state are injected into centrifugal casting equipment for production of a cylinder liner casting, a centrifugal forming step is performed under a magnetic field, and the casting rotating speed is 130 G plus / minus 3 G. The magnetic field is added in the centrifugal casting process, rotating speed difference can be produced between melt at the solidification front and solidified parts, the melt continuously scours the solidification front, so that agglomeration and adhesion of reinforcing particles are avoided, the bonding strength of the particles with a substrate is improved, and comprehensive mechanical and thermal properties of the cylinder liner are further improved.

Owner:ZYNP GRP ANHUI CO LTD

Production method of wear-resistant cylinder sleeve

InactiveCN106041012AImprove wear resistanceReduce coefficient of frictionCylinder headsCylindersWear resistantAlloy

The invention discloses a production method of a wear-resistant cylinder sleeve. The production method comprises the following steps that 1, high-quality steel scrap, molten iron and intermediate alloy are used as raw materials to be smelted in a medium frequency furnace; 2, the smelted product is inoculated at twice; 3, the rotational speed of a centrifugal casting machine is set to 480-520 rad / min, and the inoculated product is poured; 4, the drainage interval time is 30-35 s after the pouring is completed, and then the poured product is water-cooled to be lower than 200 DEG C; 5, a cylinder sleeve is tempered in a heat treatment furnace; 6, a cylinder sleeve casting is placed in a ceramic-penetrated furnace to be electrified and preheated for 2.5 h; 7, the ceramic-penetrated furnace is vacuumized; 8, nitrogen, silane and borane are introduced in the ceramic-penetrated furnace; 9, the ceramic-penetrated furnace is insulated, and ceramic penetrates through the cylinder sleeve; and 10, the cylinder sleeve is cooled and discharged. Compared with the prior art, the production method has the beneficial effects that the wear resistance of the material is improved, the friction coefficient of the material is reduced, and oil consumption of an engine is reduced.

Owner:ZYNP GRP ANHUI CO LTD

Manufacturing process of hot work die steel for high performance die-casting die

InactiveCN111057933ATissue uniform refinementHigh strengthSolid state diffusion coatingFurnace typesTemperingManufacturing technology

The invention provides a manufacturing process of hot work die steel for a high performance die-casting die and relates to the technical field of die steel. The manufacturing process of the hot work die steel comprises the following steps of (1) smelting; (2) high-temperature homogenization treatment; (3) forging; (4) annealing treatment; (5) quenching and tempering treatment; (6) nitriding treatment; and (7) tempering treatment. The hot work die steel is prepared from the following components in percent by weight: 0.33-0.46% of C, 1.5-2.3% of Si, 0.32-0.45% of Mn, 1.6-2.3% of Mo, 2.6-3.6% ofW, 0.16-0.27% of Nb, 2.8-3.7% of Cr, 0.21-0.53% of Sr, 0.16-0.31% of Ti, 0.05-0.09% of Ce, less than or equal to 0.003% of S, less than or equal to 0.03% of P and the balance Fe. The hot work die steel prepared by the manufacturing process has relatively high surface hardness and wear resistance, relatively good impact toughness and excellent fatigue resistance and strength, so that the service life of the hot work die steel for the die-casting die is prolonged effectively.

Owner:宁波海琰伟业金属制品有限公司

Method for manufacturing copper-iron-based diamond cutter teeth

The invention discloses a method for manufacturing copper-iron-based diamond cutter teeth. The method is characterized by including the following steps of preparing green body material through framework material and adhesive metal, mixing the material after preparation, packaging the material after mix so as to be subjected to thermal pressing formation, cooling the material after thermal pressing formation, and machining the material after cooling, wherein the material prepared in the green body material preparation process include, by weight, 35% of iron powder, 50% of copper powder, 5% of cobalt powder, 5% of nickel powder and 5% of manganese powder, diamond accounting for 5.04% of the total weight of the green body material is added in the mixing process, the material is mixed in a stainless steel ball mill, the material to ball ratio is 1:2, the rotation speed of the ball mill is 46 r / min, the material mixing time ranges from 12 hours to 35 hours, the sintering temperature in thermal pressing formation is 1020 DEG C, the sintering time ranges from 5 minutes to 10 minutes, the pressure ranges from 12 Mpa to 13 Mpa, and the tapping temperature is 550 DEG C.

Owner:铜陵长江金刚石工具股份有限公司

Metal ceramic material

The invention discloses a metal ceramic material, and belongs to the technical field of metal ceramic materials. The metal ceramic material comprises, by weight, 60-80 parts of a principal phase, 16-20 parts of a binding phase, 5-10 parts of carbide, 3-10 parts of an additive, 5-10 parts of whiskers and 5-10 parts of auxiliaries. SiC and / or TiC serve / serves as the whiskers, and carbon nano tubes serve as the auxiliaries. Through adding of the whiskers Sic and / or TiC and the auxiliary carbon nano tubes, the strength of the metal ceramic material is high, toughness is enhanced, and the application range of a metal ceramic cutter manufactured through a powder metallurgy manner is wide.

Owner:自贡市希力数控工具有限公司

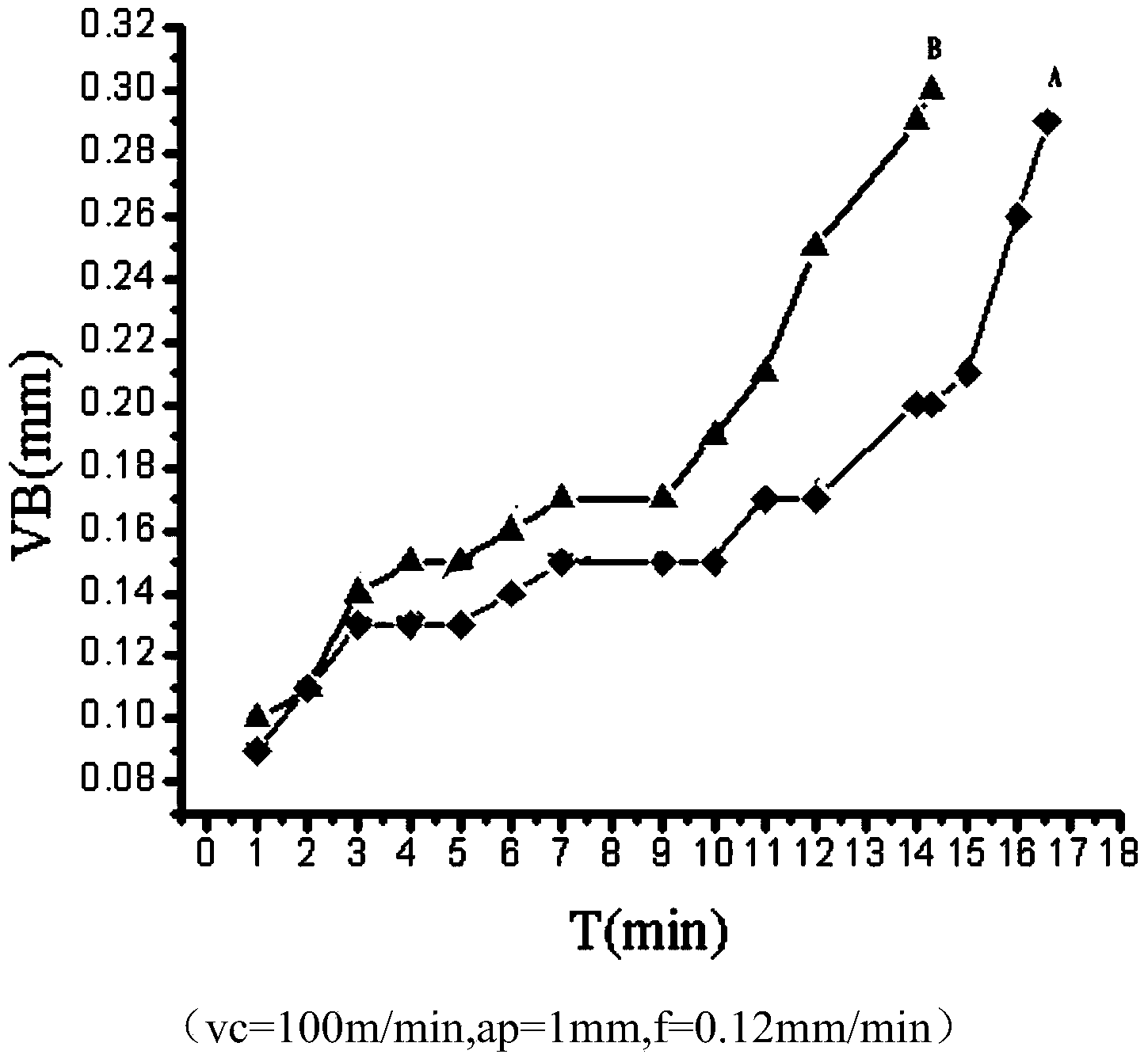

Method for rough turning turbine seal sleeve made of high-temperature alloy GH901

InactiveCN103659160ANo bending deformationMeet technical requirementsTwist drillsAlloyThermal treatment

The invention provides a method for rough turning a turbine seal sleeve made of high-temperature alloy GH901 to solve the problems that when the seal sleeve is made of the high-temperature alloy GH901 and the high-temperature alloy GH901 is machined through an existing tool and according to conventional cutting parameters, machining is difficult to conduct and scrapped products easily occur due to the fact that the high-temperature alloy GH901 is a typical material difficult to machine, and relates to the method for rough turning the turbine seal sleeve. The method includes the first step of rough turning an outer circle, the second step of drilling an inner hole, and the third step of turning an inner hole. According to the turbine seal sleeve which is made of the high-temperature alloy GH901 and is machined through the rough turning method and an inner hole drill bit tool, and a drill bit can be unceasingly used for more than 30min. In addition, when the turbine seal sleeve is machined according to the cutting parameters, no bending deformation occurs after thermal treatment is conducted on the part, the effect is quite good, the technical requirement for a seal sleeve pattern is completely met, the quality is stable and reliable, and the mature process standard is reached. The method can be used for rough turning the turbine seal sleeve made of the high-temperature alloy GH901.

Owner:HARBIN TURBINE

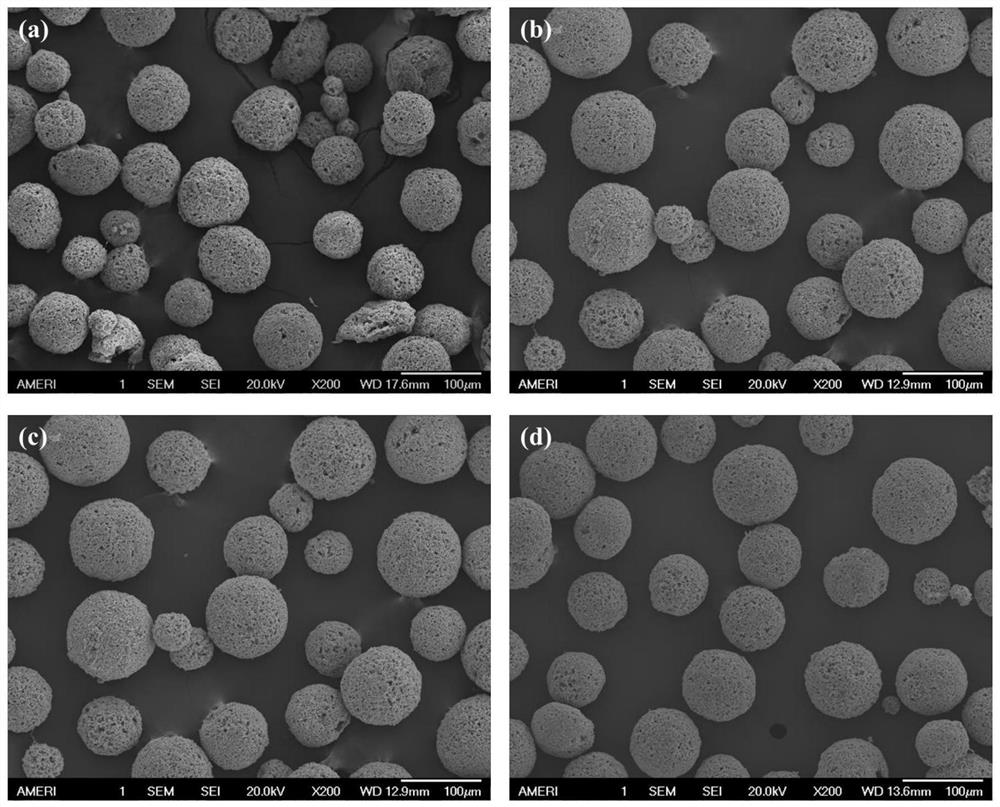

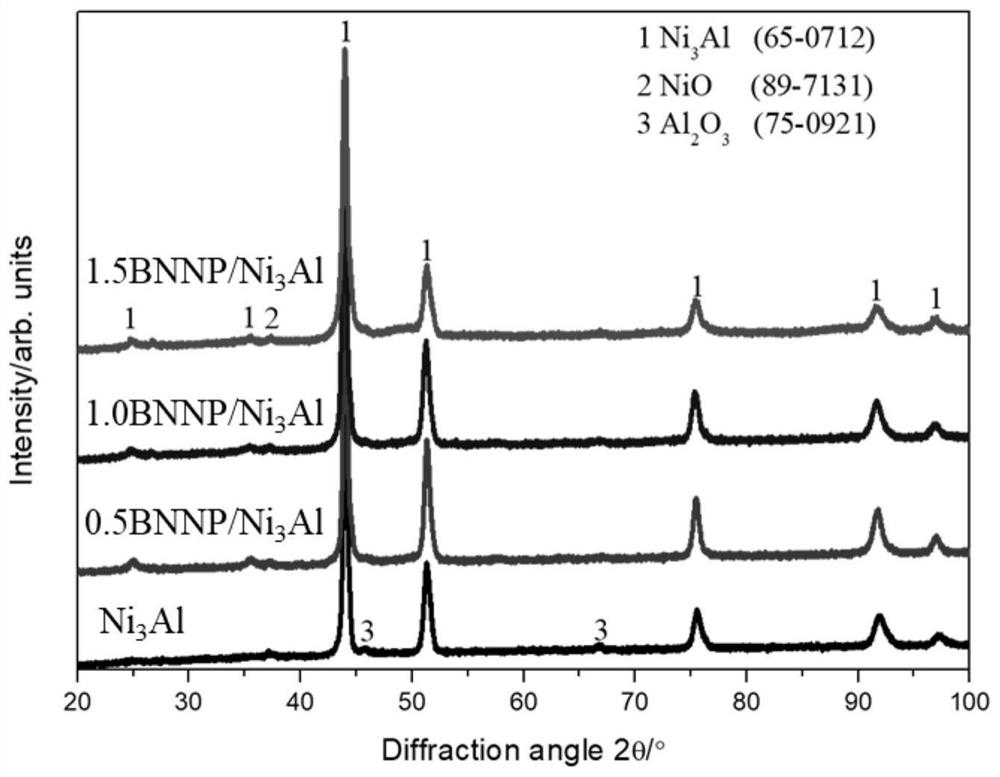

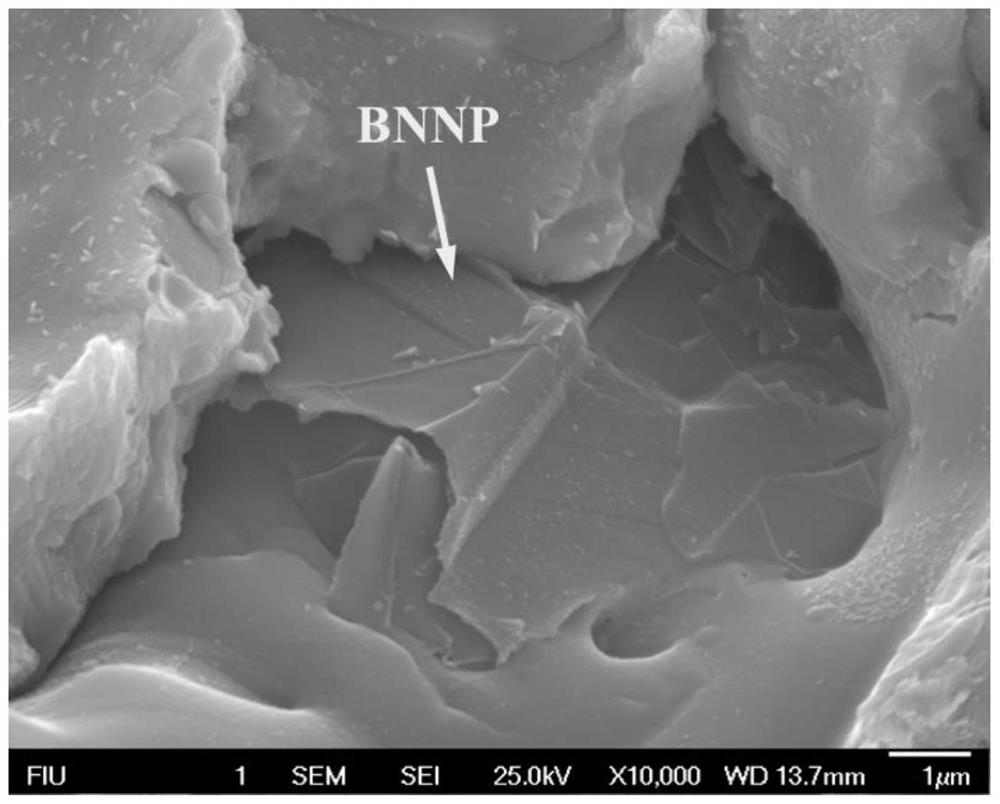

Boron nitride nanosheet reinforced nickel-aluminum intermetallic compound composite coating and preparation method thereof

InactiveCN112553566ASpecial chemical compositionImprove mechanical propertiesMolten spray coatingSpray GranulationAluminium powder

The invention provides a preparation method of a boron nitride nanosheet reinforced Ni3Al intermetallic compound composite coating. The method comprises the following steps: mixing nickel powder and aluminum powder to obtain mixed powder; mixing and drying the mixed powder and boron nitride nanosheet dispersion liquid so as to obtain powder; carrying out spray granulation on the powder to obtain aspray feed; and carrying out plasma spraying on the spray feed so as to obtain the boron nitride nanosheet reinforced Ni3Al intermetallic compound composite coating. The invention provides the preparation method of the intermetallic compound composite coating with light weight, high strength and toughness and lubricating property, and the novel boron nitride nanosheet reinforced Ni3Al intermetallic compound composite coating with various excellent properties such as high temperature resistance, wear resistance, corrosion resistance, low friction coefficient and the like is obtained. The invention further provides the boron nitride nanosheet reinforced Ni3Al intermetallic compound composite coating.

Owner:SUZHOU UNIV

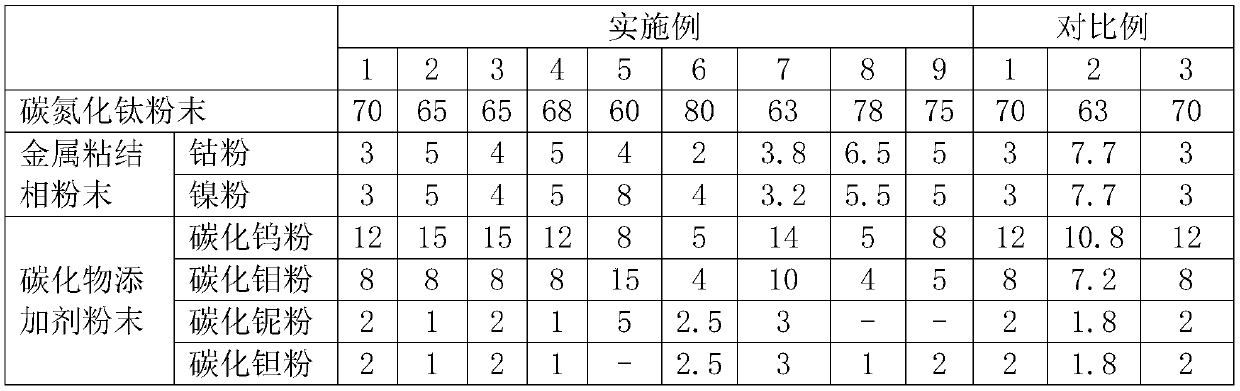

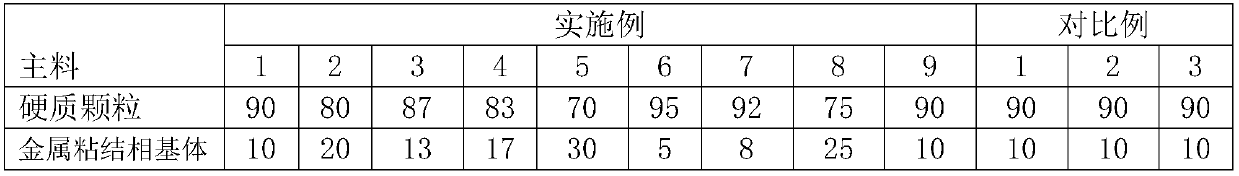

Titanium carbonitride metal ceramic material for extrusion die and preparation method thereof

ActiveCN111500913AImprove high temperature performanceImprove thermal shock performanceExtrusion diesTitanium nitrideTitanium carbonitride

The invention provides a titanium carbonitride metal ceramic material for an extrusion die and a preparation method thereof, and solves the technical problems of high consumption cost of the extrusiondie and lack of extrusion die materials with good wear resistance, high-temperature hardness and long service life in the prior art. The titanium carbonitride metal ceramic material is prepared fromthe following main materials in percentage by weight: 70-95% of hard particles and 5-30% of metal binding phase matrix, wherein the sum of the weight percentages of the hard particles and the metal binding phase matrix is 100%; and the metal binding phase matrix comprises VIII B platinum group transition metal element powder. The titanium carbonitride metal ceramic material for the extrusion die has the advantages of good wear resistance, high-temperature hardness and low friction coefficient, and can effectively prolong the service life of the extrusion die, improve the processing efficiencyand reduce the processing cost.

Owner:CHENGDU MET CERAMIC ADVANCED MATERIALS

Novel high-toughness high-speed steel

A novel high-toughness high-speed steel comprises 0.78-0.938% of C, 0.15-1.55% of Si, 0.20-0.55% of Mn, 3.5-5.0% of Cr, 0.50-2.50% of W, 2.50-6.0% of Mo, 0.50-2.20% of V, 0-2% of Co, 0-0.03% of P, 0-0.03% of S, and the balance Fe. With the adoption of the novel high-toughness high-speed steel, the novel high-speed steel adopting Mo as a base element remains certain red hardness and abrasion resistance on the premise that the red hardness elements W and Co are decreased, and meanwhile, the problems of low toughness and fatigue resistance can be solved; in addition, the contents of W and CO elements which are high in price are decreased, so that the production cost of the high-speed rail is further decreased.

Owner:蒂思特(苏州)模具材料技术应用有限公司

Manufacturing process of metal ceramic material for numerical control cutter

InactiveCN110064760AGood dispersionGrind evenlyTransportation and packagingMetal-working apparatusPorosityNumerical control

The invention discloses a manufacturing process of a metal ceramic material for a numerical control cutter, and belongs to the technical field of numerical control cutter materials. The manufacturingprocess comprises the steps of (1), mixing raw materials, and filtering after wet grinding to obtain mixed slurry; (2), carrying out spray drying granulation on the mixed slurry through a closed-circuit solvent recovery spray drying tower; (3), pressing the mixed granules obtained in the step (2) into a green body by adopting an extrusion method; and (4), placing the prepared green body into a degreasing and pressurizing integrated sintering furnace, vacuumizing and filling argon into the sintering furnace before heating, filling hydrogen to completely replace the argon after heating, fillingthe argon again to completely replace the hydrogen when the temperature is continuously heated to 500-600 DEG C after glue discharging is completed, vacuumizing with a pump, continuously heating to 1,350-1,550 DEG C, keeping the temperature for 8-12 minutes before refilling with the argon, keeping the temperature for more 40-60 minutes, and naturally cooling to room temperature after reducing thetemperature to 900 DEG C by de-energizing. The manufactured material has zero porosity, high toughness, uniform structure, excellent mechanical property and durability.

Owner:自贡市希力数控工具有限公司

A kind of preparation method of single crystal turbine blade tip nano particle reinforced wear-resistant coating

ActiveCN108486567BThere will be no "segregation" phenomenonEvenly distributedMetallic material coating processesHeat-affected zoneSingle crystal superalloy

The invention discloses a preparation method of a nanparticle reinforced wear-resistant coating layer on a blade top of a single-crystal turbine blade. The preparation method is characterized by taking a single-crystal high-temperature alloy turbine blade as a base material and a nano ceramic particle-doped reinforced anti-oxidation alloy composite material as a coating material, and by adopting ahigh-energy micro-arc spark deposition technology, thus preparing a nano ceramic particle reinforced wear-resistant coating layer in oriented epitaxial growth with a structure of the base material. According to the preparation method disclosed by the invention, by virtue of a high-temperature gradient formed during a high-energy micro-arc spark deposition process, a high cooling speed and a condition close to one-dimensional rapid solidification, nano ceramic particles are uniformly distributed in a coating layer, and the oriented epitaxial growth of the microstructure of the coating layer iskept, so that good high-temperature wear resistance is obtained; meanwhile, due to extremely high energy density, the width of a heat affected zone in an interface between the coating layer and the single-crystal turbine blade is extremely wide, and change of the microstructure of a single-crystal matrix and generation of heat cracks are avoided.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com