Cermet insert and cutting tool

A technology made of cermets and ceramics, which is applied in the manufacture of tools, metal processing equipment, and cutting tools for lathes, etc., can solve the problems of insufficient research on wear resistance and defect resistance, and achieve excellent wear resistance and Effects of chipping resistance and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0135] The titanium carbonitride-based cermet insert (hereinafter also referred to as cutting insert) of the present embodiment is formed of titanium carbonitride-based cermet. As the cutting insert, for example, an insert 11 having a tip shape of ISO standard CNMG120412 shown in FIG. 1 is exemplified.

[0136] The titanium carbonitride-based cermet is a sintered body of compacted powder with the following composition, which contains at least tungsten carbide in mass %: 20-30%, tantalum carbide and / or niobium carbide (hereinafter also referred to as TaC / NbC): 5-10%, Co: 5-10%, Ni: 5-10%, and titanium carbonitride: 50-60%.

[0137] When the structure is observed with a scanning electron microscope, it can be seen that the structure is as follows: a hard phase: 75 to 90 area %, and a binder phase: the balance.

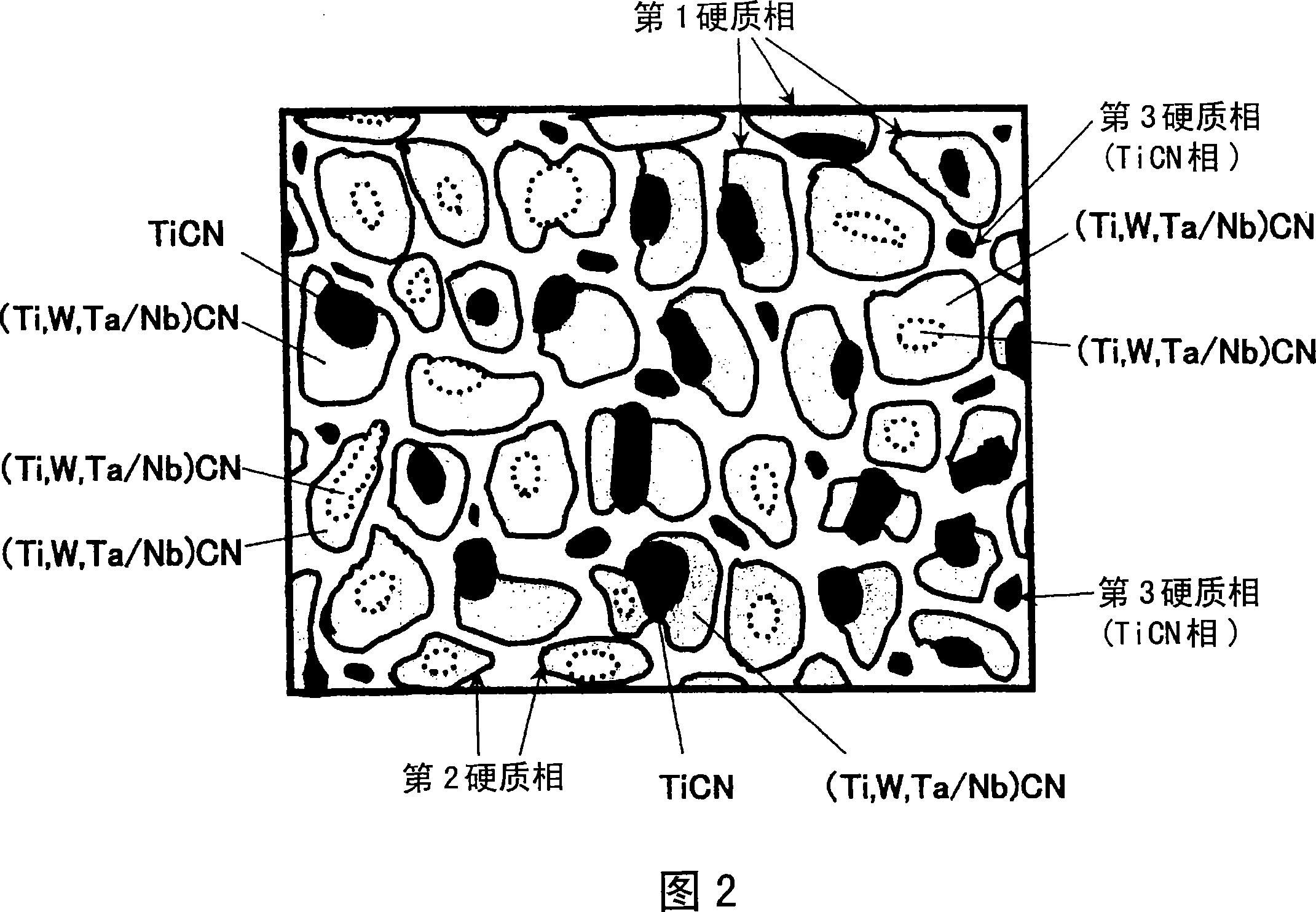

[0138] As shown in the schematic diagram of FIG. 2 , the hard phase includes the following (1) to (3).

[0139] (1) The first hard phase with a core structure, the cor...

no. 2 approach

[0160] The insert made of titanium carbonitride-based cermets (hereinafter also referred to as cutting insert) according to the present embodiment is a sintered body of a green compact having a composition comprising at least tungsten carbide: 20 to 30%, tantalum carbide and / or niobium carbide (hereinafter also referred to as TaC / NbC): 5-10%, one or two of zirconium carbide, vanadium carbide and molybdenum carbide (hereinafter also referred to as ZrC / VC / Mo 2 C): 1-5%, Co: 5-10%, Ni: 5-10%, and titanium carbonitride: 50-60%. For example, the insert 21 etc. which have the tip shape of ISO standard|CNMG120412 shown in FIG. 1 are mentioned, for example.

[0161] When the structure is observed with a scanning electron microscope, it can be seen that it has the following structure: a hard phase: 75 to 90 area %, and a binder phase: the balance.

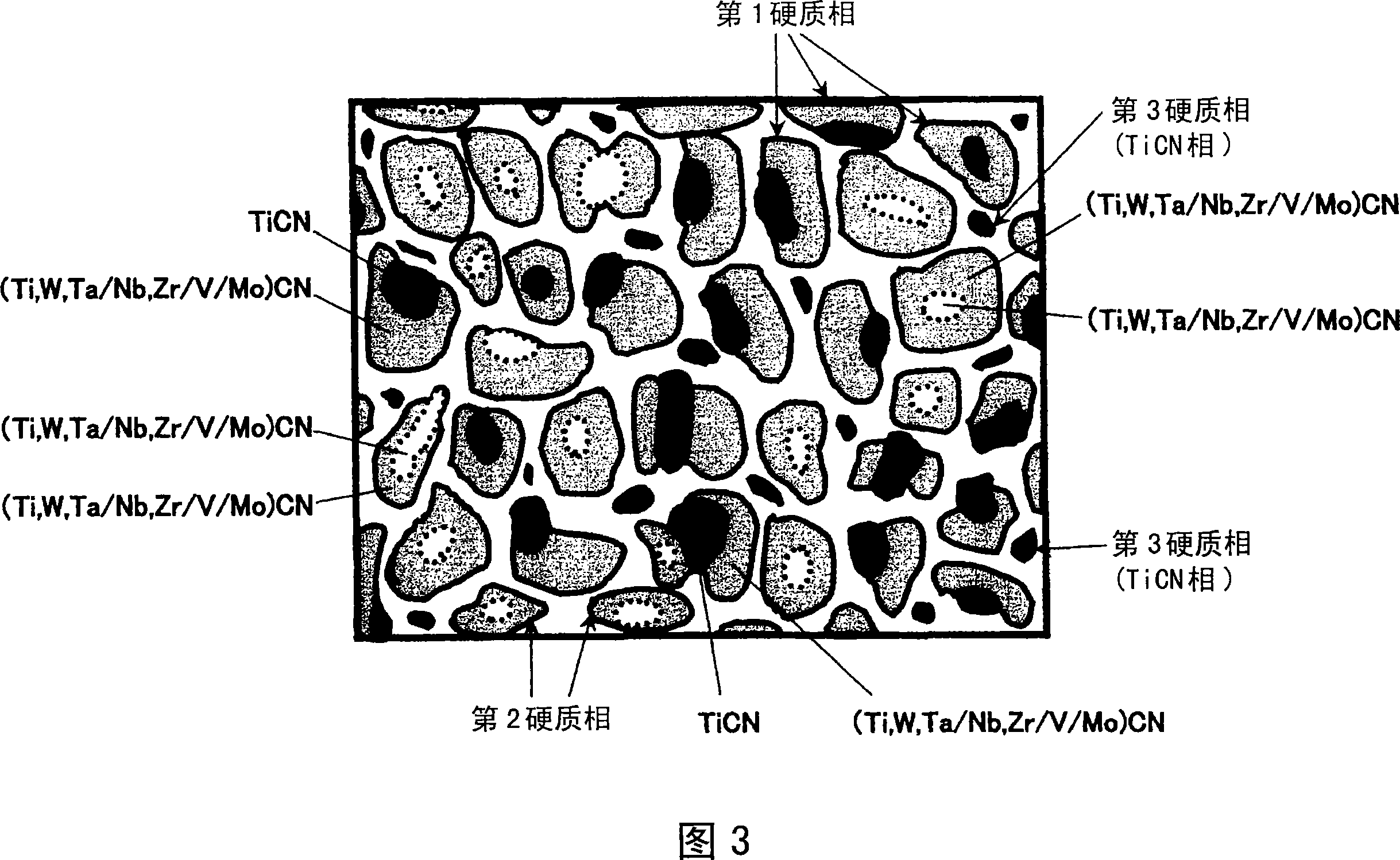

[0162] As shown in the schematic diagram of FIG. 3 , the hard phase includes the following (1) to (3).

[0163] (1) The first hard pha...

no. 3 approach

[0184] The titanium carbonitride-based cermet insert 1 of the present embodiment is a cutting insert composed of a sintered body having a shape of ISO standard: SNGN120408, as shown in FIG. 5 .

[0185] The insert 1 is formed of a titanium carbonitride-based cermet composed of a sintered body containing Ti, Ti and / or Nb (hereinafter also referred to as Ta / Nb), and W.

[0186] The composition of the sintered body of the insert 1 is shown below.

[0187] The total of the value converted from Ti to carbonitride, the value converted from Ta and / Nb to carbide, and the value converted from W to carbide is 70% as a ratio to the entire structure constituting the sintered body. ~95% by mass.

[0188] In addition, the value of W converted into carbides is 20 to 35% by mass relative to the entire structure, and the ratio of Co and Ni to the entire structure is 5 to 30% by mass.

[0189] Ti is contained in an amount of 45 to 60% by mass in terms of carbonitrides, and Ta and / or Nb is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com