Patents

Literature

89results about How to "Improved defect resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

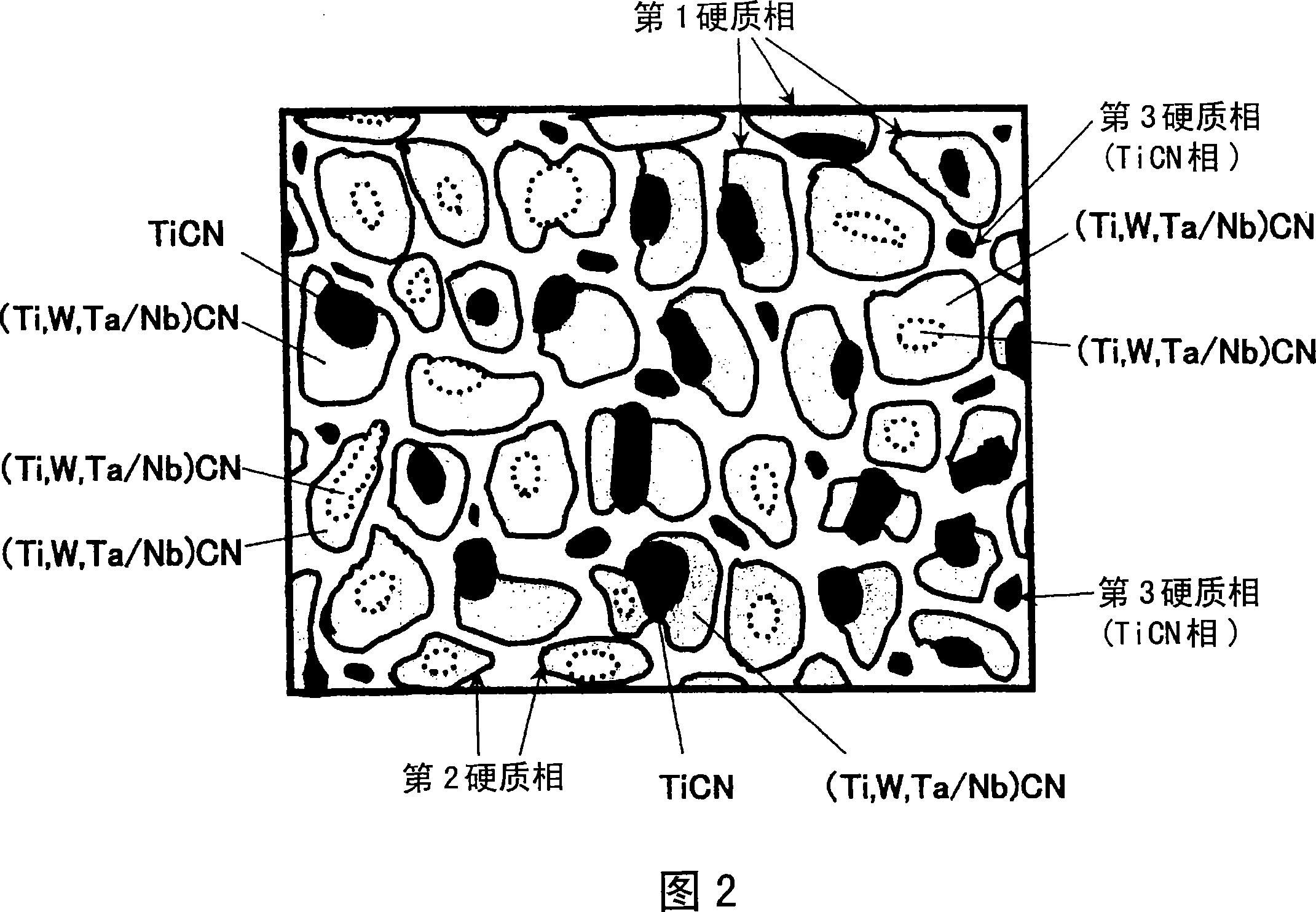

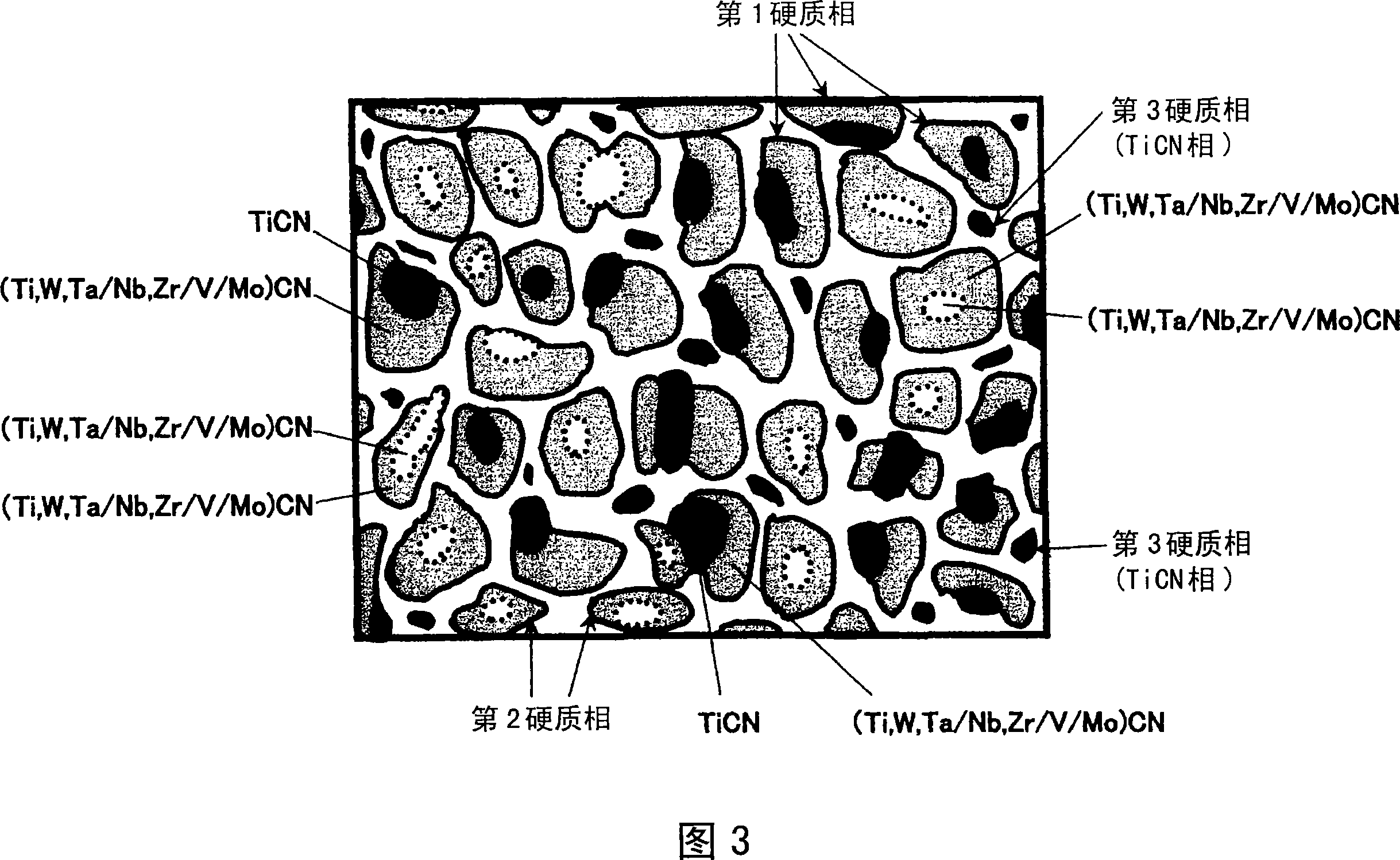

Cermet insert and cutting tool

InactiveCN101189090AExcellent abrasion resistanceImprove wear resistanceTurning toolsCarbideTitanium carbonitride

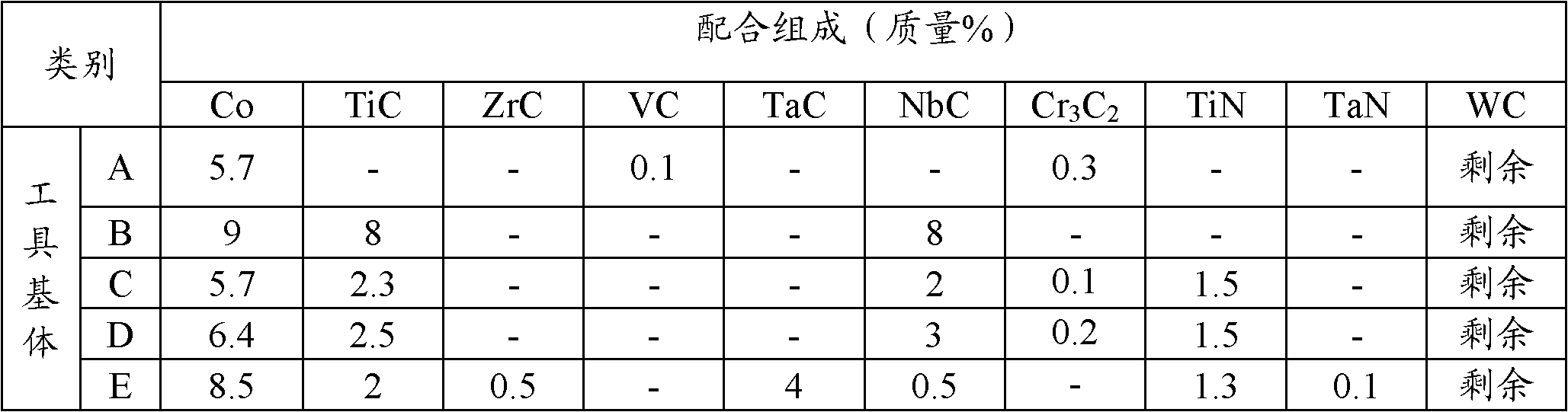

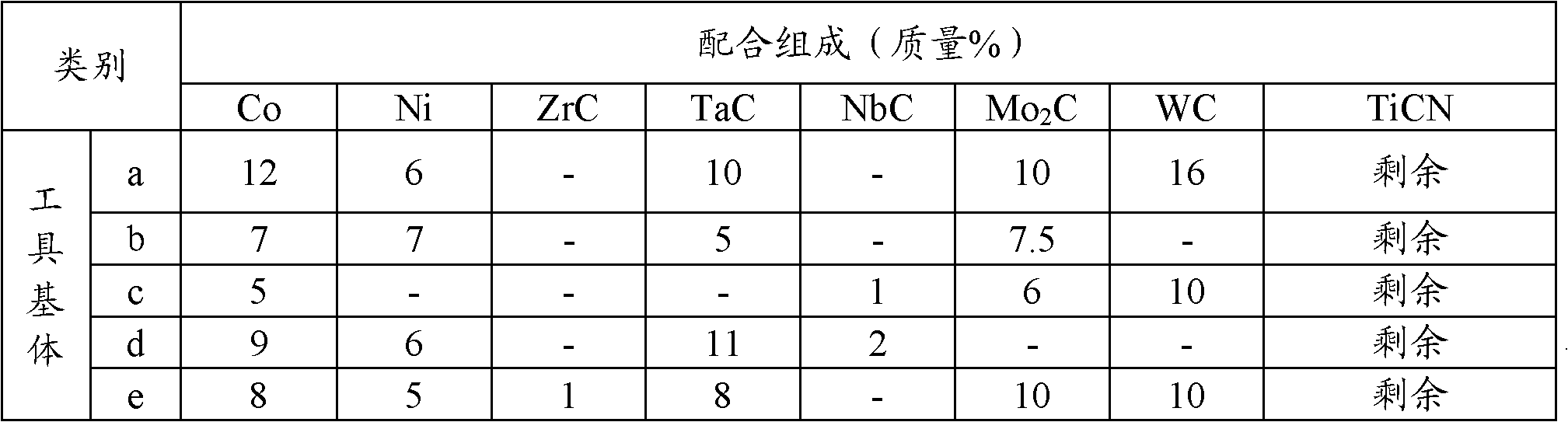

One mode of the blade made of titanium carbonitride-based cermet is that it has a structure composed of 75-90 area % of hard phase and the balance is a binding phase. The hard phase has: the core is made of titanium carbonitride Phase composition, the peripheral part is composed of a first hard phase with a core structure composed of Ta and / or Nb, Ti, and W complex carbonitride (hereinafter expressed as (Ti, W, Ta / Nb)CN) phase; Both the core and the peripheral part are the second hard phase with a core structure composed of (Ti, W, Ta / Nb) CN phase; the third hard phase with a single-phase structure composed of TiCN phase, and the binding phase has: Co: 18-33%; Ni: 20-35%; Ta and / or Nb, and Ti, the total amount: 5% or less; W: 40-60%. Another form of the titanium carbonitride-based cermet blade is the sum of the value of Ti converted into carbonitride, the value of Ta and / or Nb converted into carbide, and the value of W converted into carbide It is 70-95% by mass, the value of W converted into carbide is 20-35% by mass, Co and Ni are 5-30% by mass, and have a structure composed of hard phase and binder phase. The hard phase has (Ti , W, Ta / Nb) CN, the binding phase is mainly composed of Co and / or Ni, and W, and 40-65% by mass of W is contained in the hard phase. This cutting tool has a holder and the cermet blade fixed by the holder.

Owner:MITSUBISHI MATERIALS CORP +1

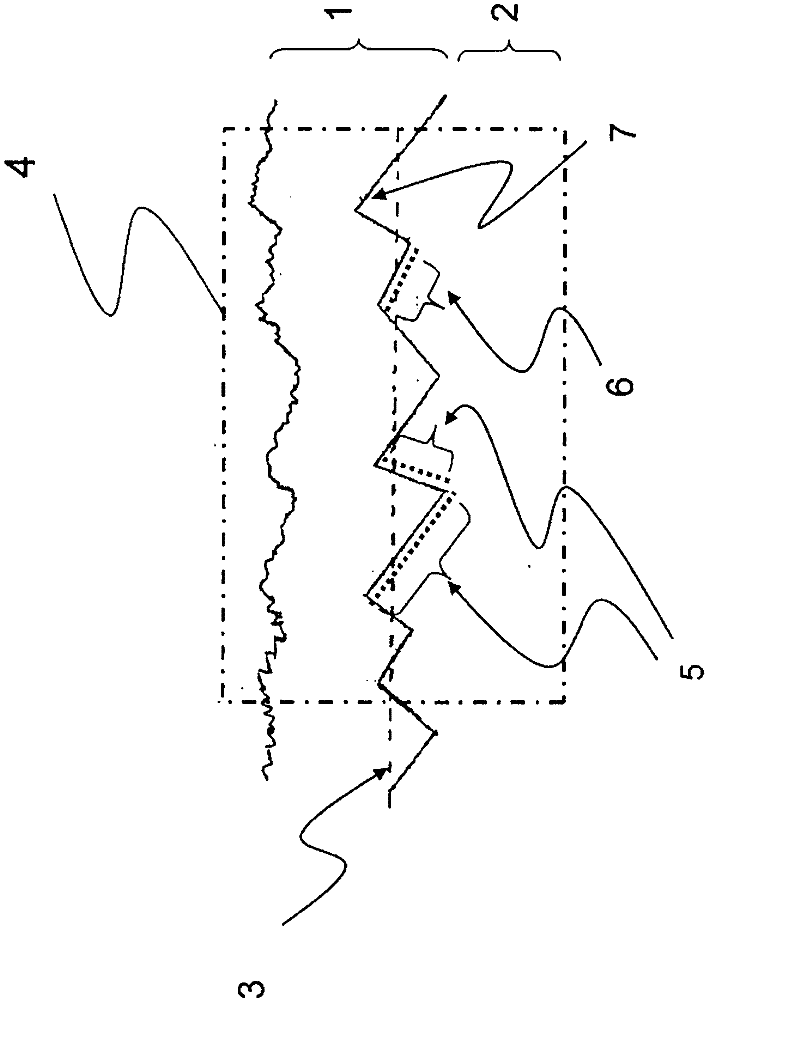

Cutting tool

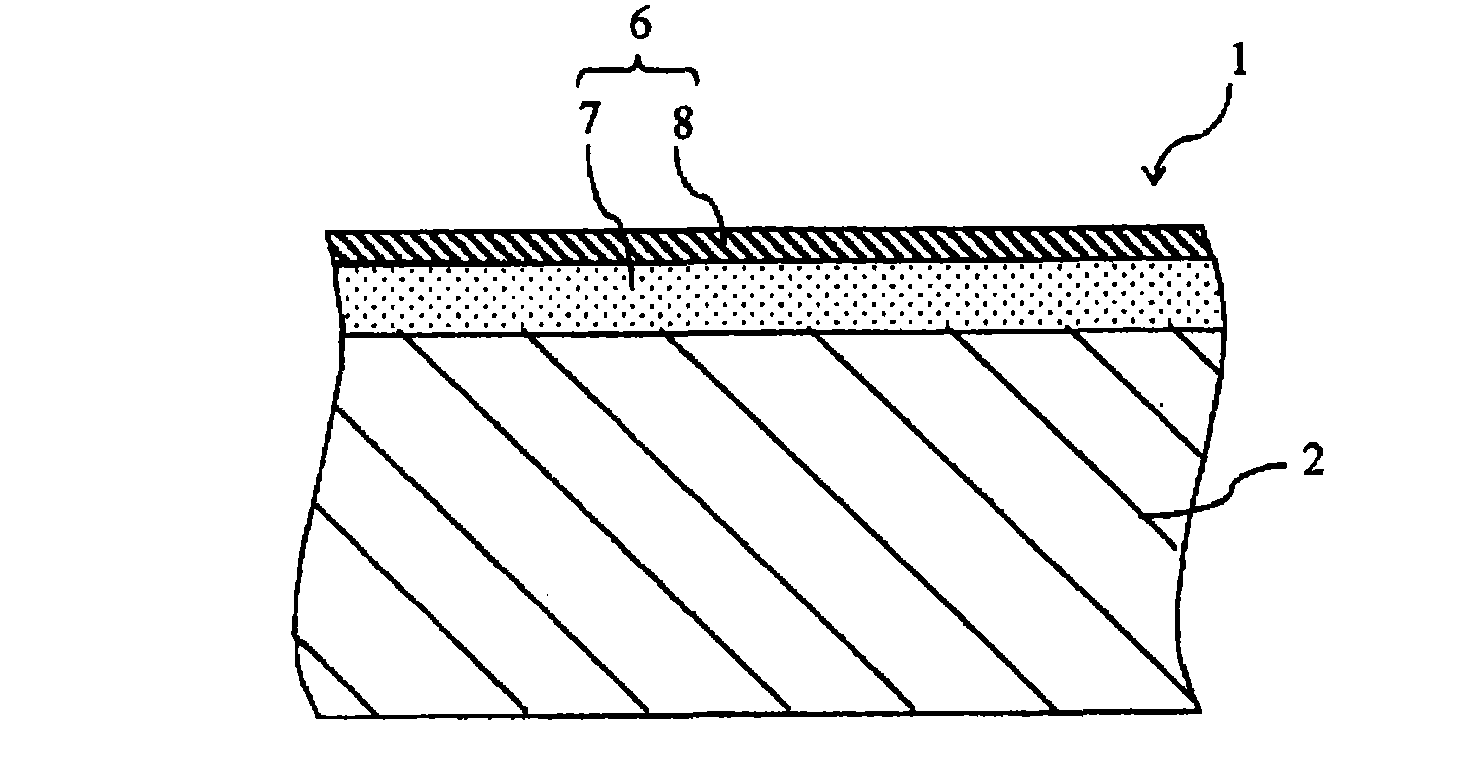

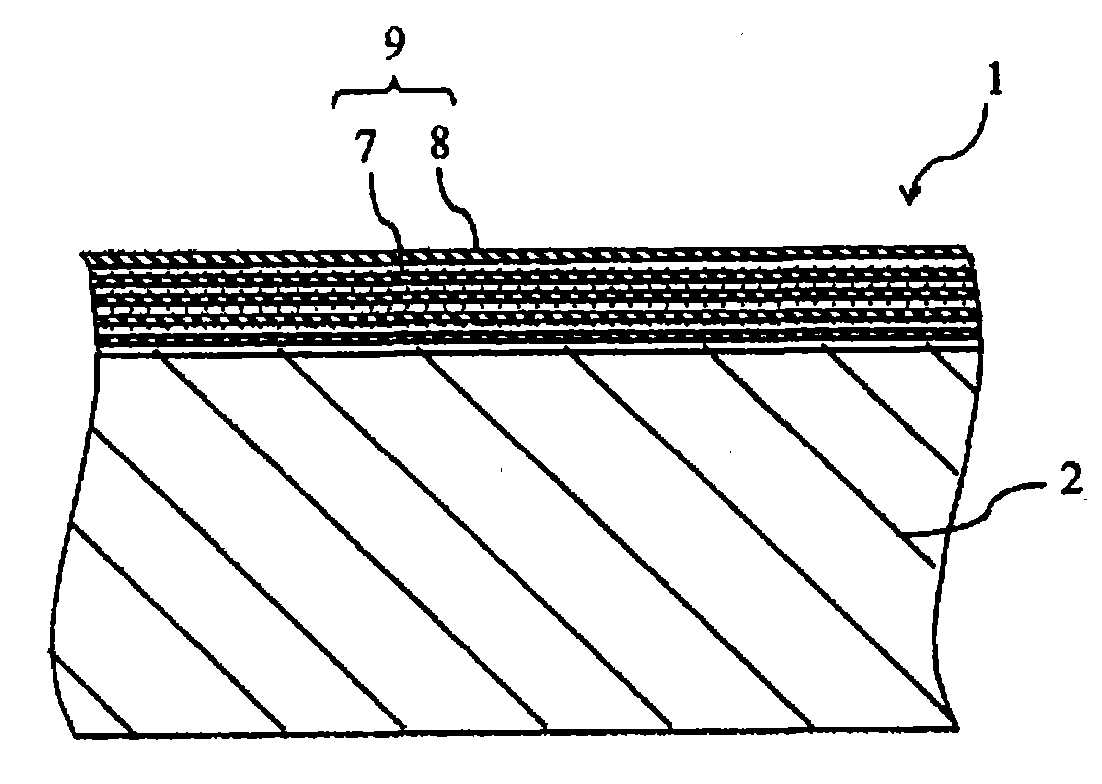

ActiveCN101848782AImprove wear resistanceImprove welding resistanceVacuum evaporation coatingSputtering coatingMetallurgyHigh wear resistance

Disclosed is a cutting tool having high wear resistance, high lubricating properties and excellent defect resistance. Specifically disclosed is a cutting tool (1) comprising a base (2) and a coating layer (6) or (9) that covers the surface of the base (2), wherein the coating layer (6) or (9) comprises a first layer (7) comprising Ti1-a-b-c-dAlaWbSicMd(C1-xNx) [wherein M represents at least one member selected from Nb, Mo, Ta, Hf and Y; 0.45<=a<=0.55; 0.01<=b<=0.1; 0<=c<=0.05; 0.01=<d=<0.1; and 0=<x<=1] and a second layer (8) comprising Ti1-e-f-gAleSifM'g(C1-yNy) [wherein M' represents at least one member selected from Nb, Mo, Ta, Hf and Y; 0.50<=e<=0.60; 0<=f<=0.1; 0.05<=g<=0.15; and 0<=y<=1].

Owner:KYOCERA CORP

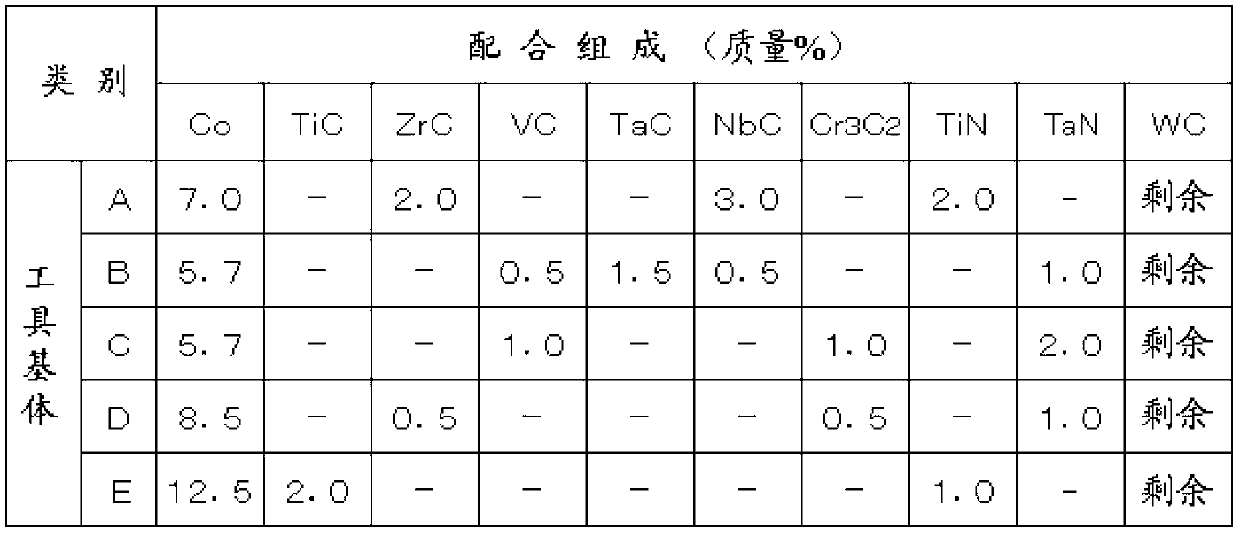

Blade-breakage-resisting surface coating cutting tool with excellent performance of hard coating layer

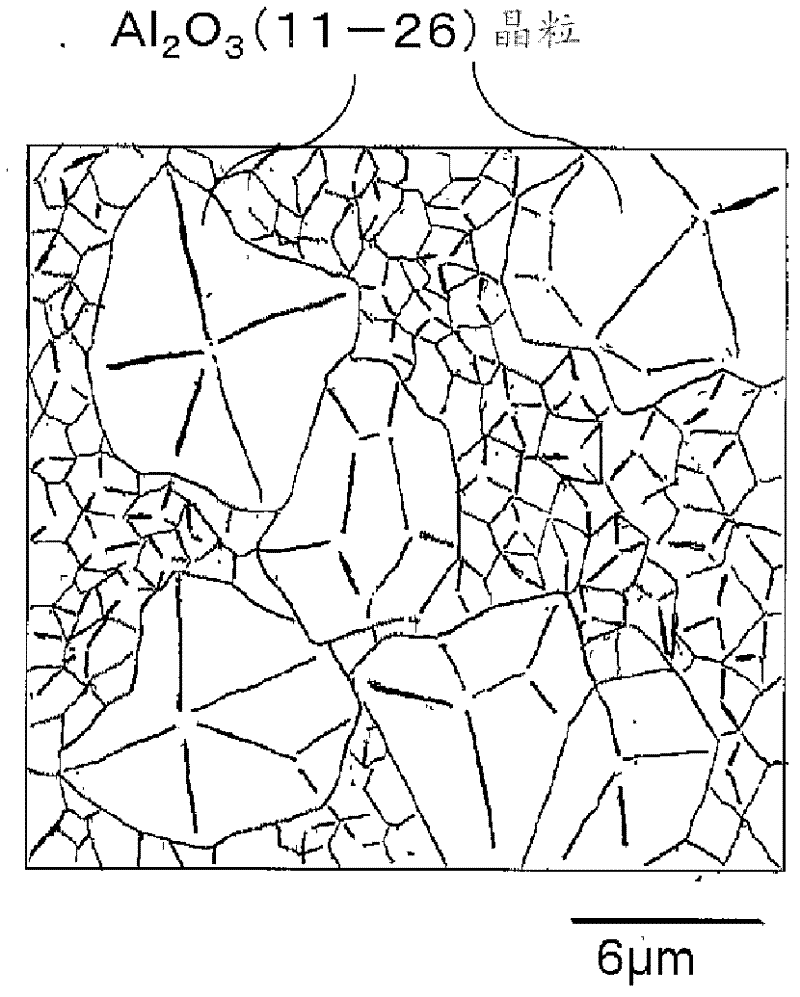

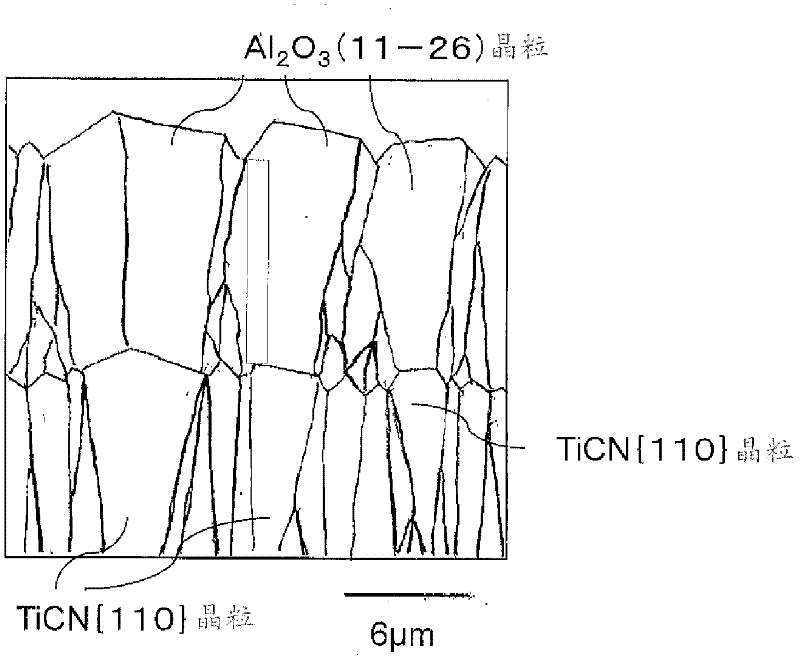

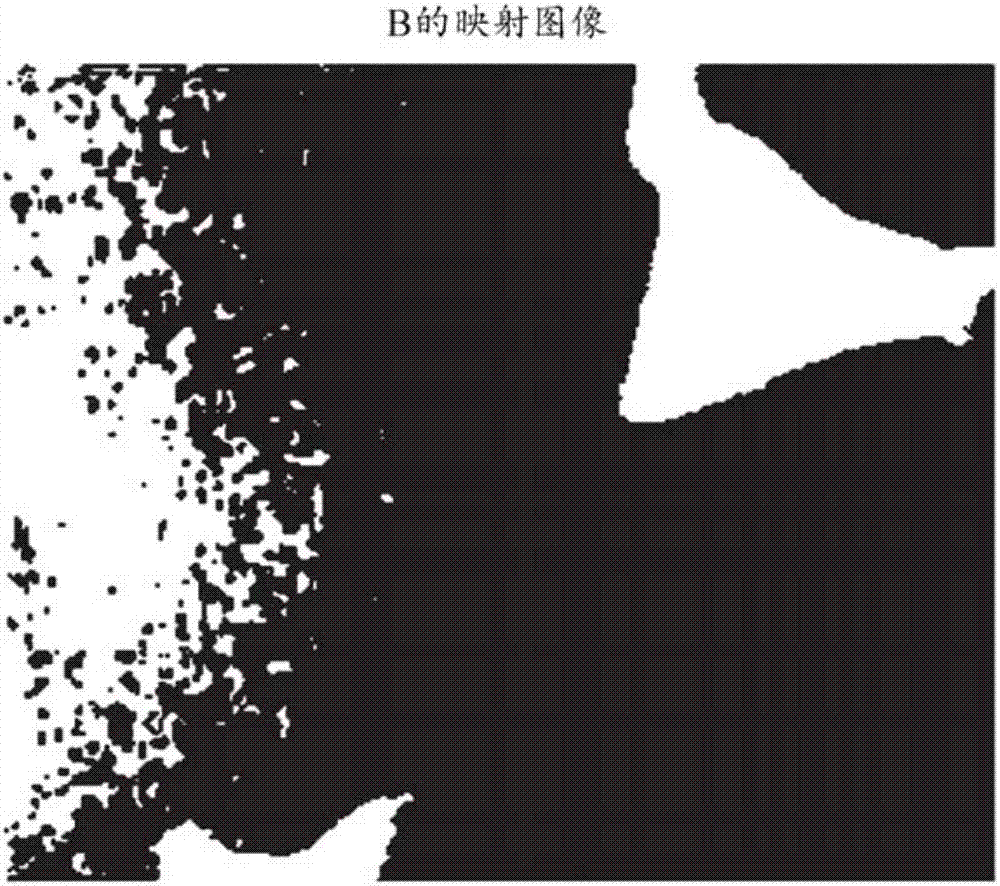

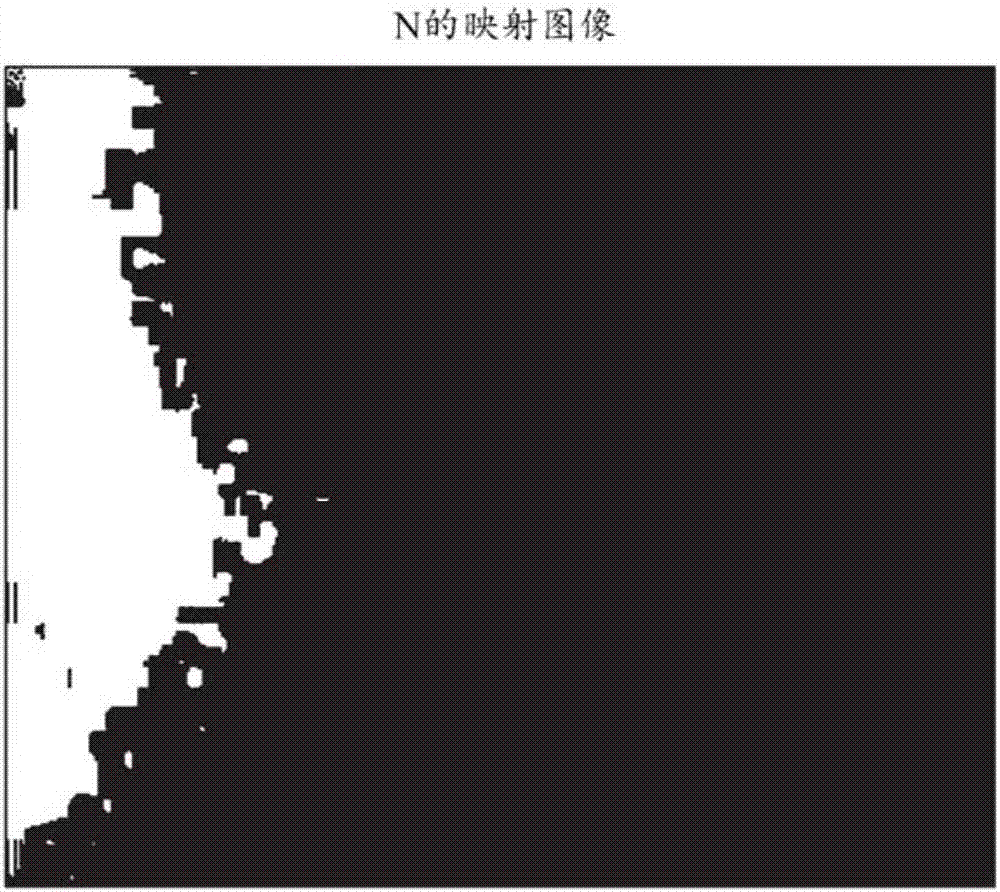

ActiveCN102441686AImprove impact resistanceImprove high temperature strengthMilling cuttersTurning toolsScanning electron microscopeElectron microscope

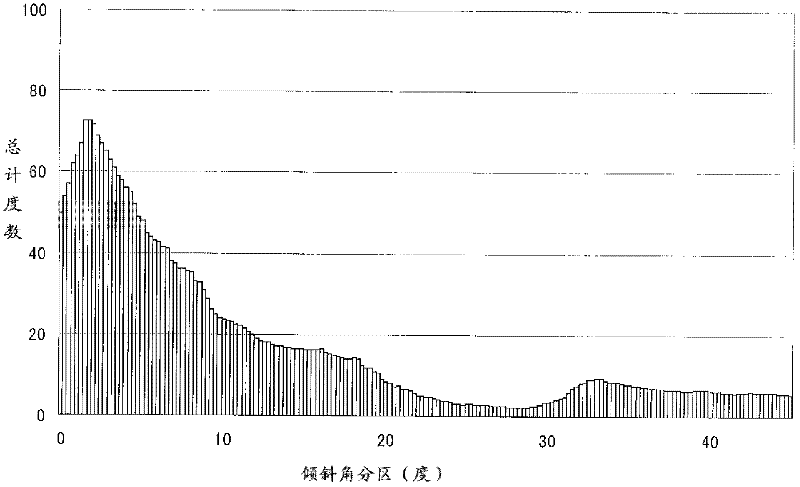

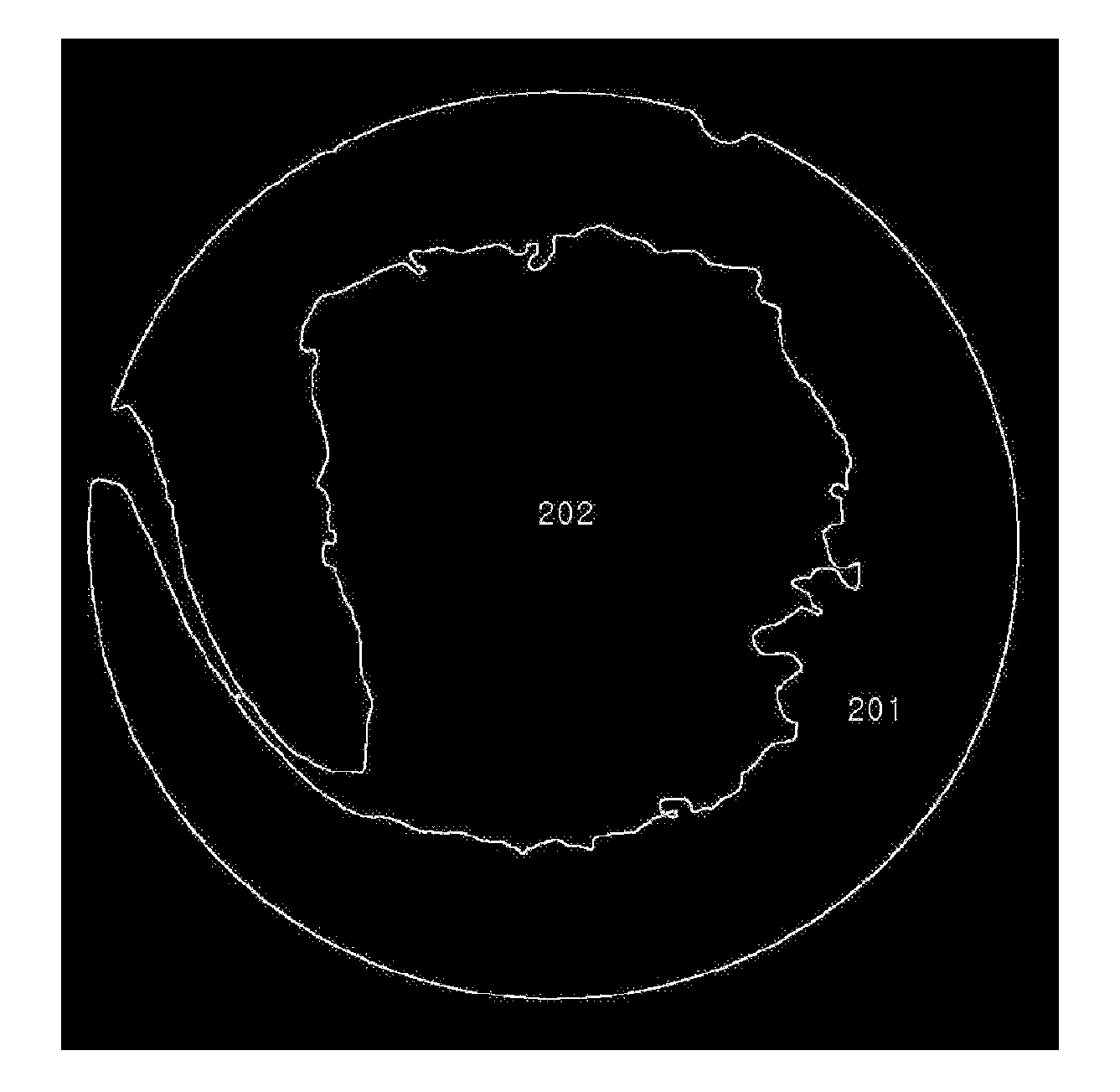

The present invention provides a blade-breakage-resisting surface coating cutting tool with excellent performance of a hard coating layer. A Ti compound layer which at least comprises a TiCN layer is coated on the surface of a tool substrate as a lower layer (a). In the surface coating cutting tool in which an alpha Al2O3 layer is used as an upper layer (b), for the TiCN layer of the lower layer, when an included angle of a normal line of a surface [110] is formed by a field emission scanning electron microscope and is prepared to an inclination angle number distribution graph, the TiCN particles [110] of the inclination angle in the range of 0-10 DEG accounts for more than 50% of the whole particles. Additionally, for the alpha type Al2O3 layer of the upper layer, when the inclination angle which is formed by the normal line of a surface (0001) is measured and prepared to an inclination angle number distribution graph, the Al2O3 crystal particles with the inclination angle in 35-45 DEG accounts for more than 60% of the whole particles. Furthermore when observed in a surface which is vertical to the layer thickness direction, crystal particles of the Al2O3 (11-26) are coarse and large, and average crystal particle diameter of the crystal particles of the Al2O3 (11-26) is 2-5 times of the crystal particles except for the Al2O3 (11-26).

Owner:MITSUBISHI MATERIALS CORP

Methods for manufacturing flux cored wire for welding stainless steel and products thereof

InactiveUS20070039937A1Secure manufacturing efficiencyReduce manufacturing costWelding/cutting media/materialsWelding/soldering/cutting articlesWire rodMaterials science

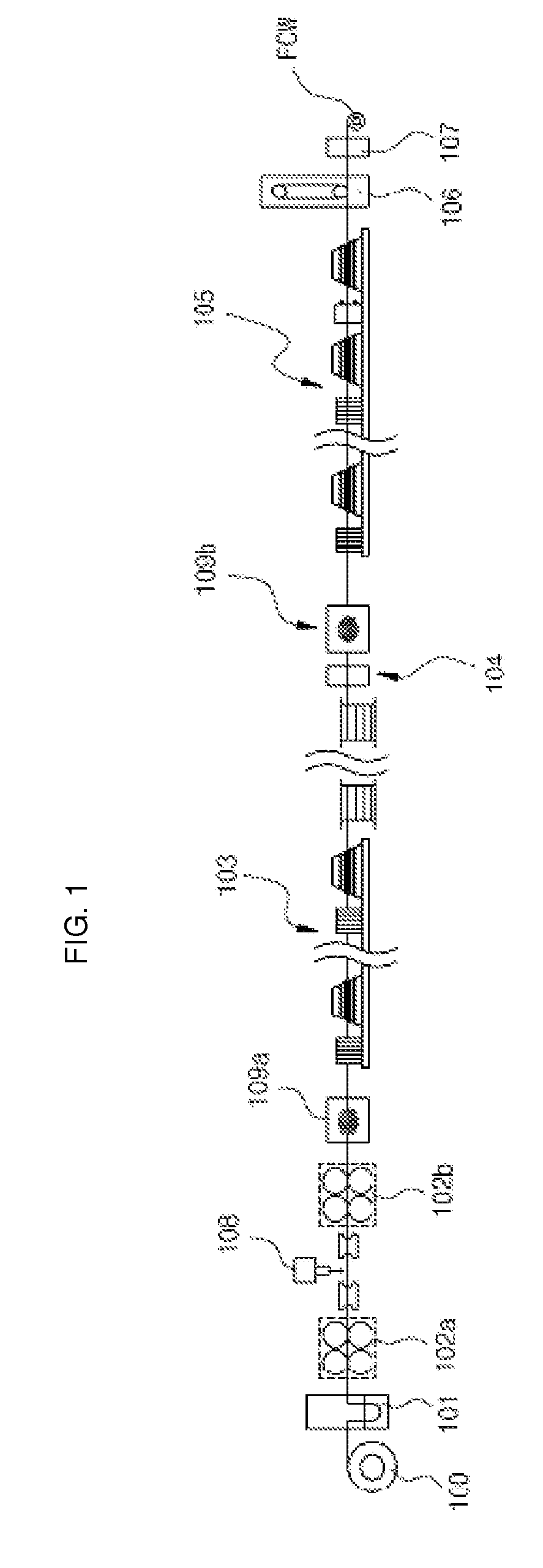

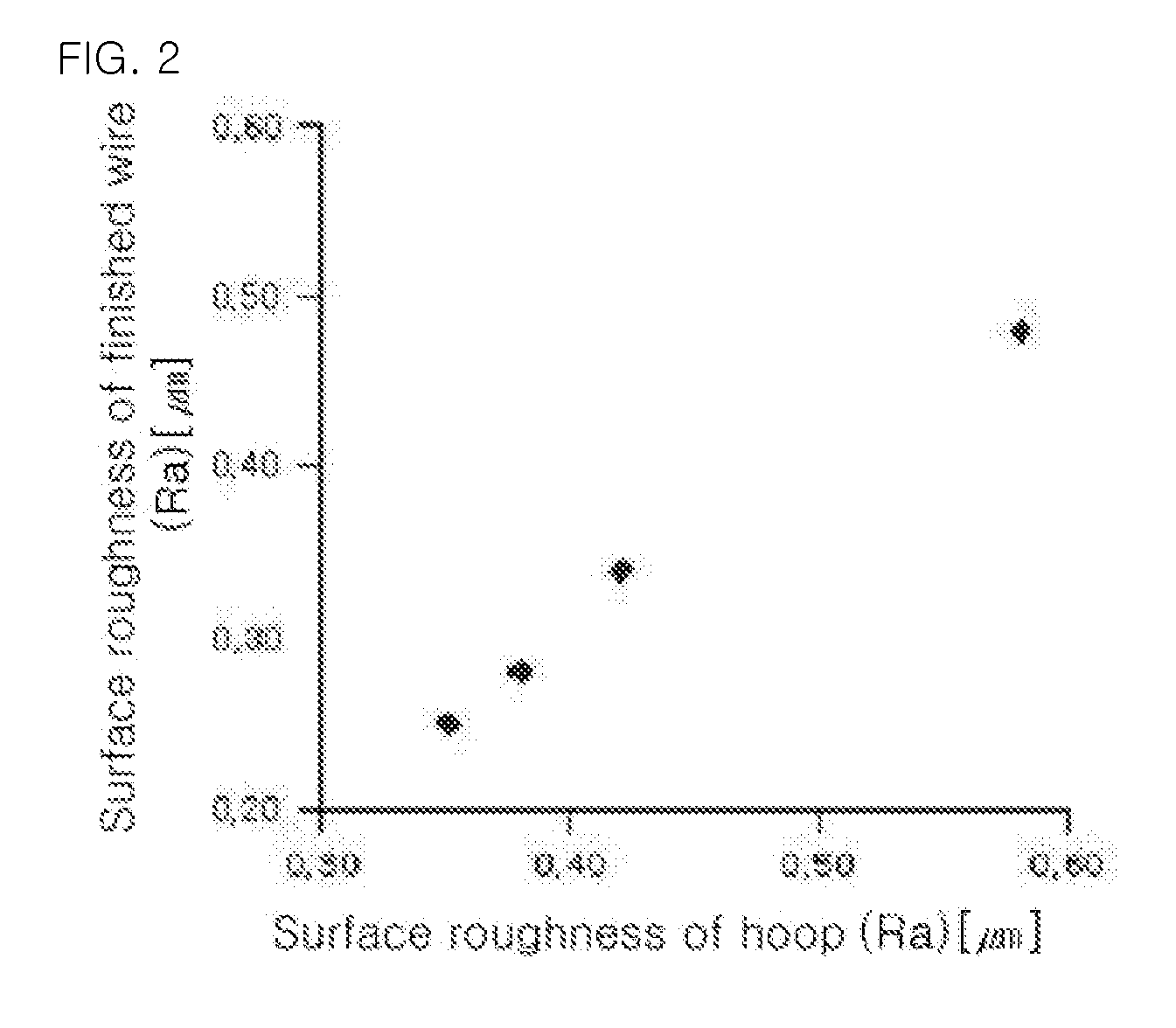

Disclosed is a method for manufacturing a flux cored wire for welding stainless steel of 0.9-1.6 mm in diameter having a seamed portion, which the method includes the steps of: forming a hoop (stainless steel 304L or 316L) into a U-shape and filling the hoop with a flux mixture, thereby forming a tube having a seamed portion; performing a primary drawing process on the tube shaped wire using a lubricant; performing a bright annealing process to relieve work hardening of the primarily drawn wire; performing a secondary drawing process on the wire until an accumulated reduction ratio after the bright annealing process falls within the range of 38-60%; physically removing a lubricant residue on the surface of the secondarily drawn wire; and coating the wire with a surface treatment agent.

Owner:KISWEL LTD

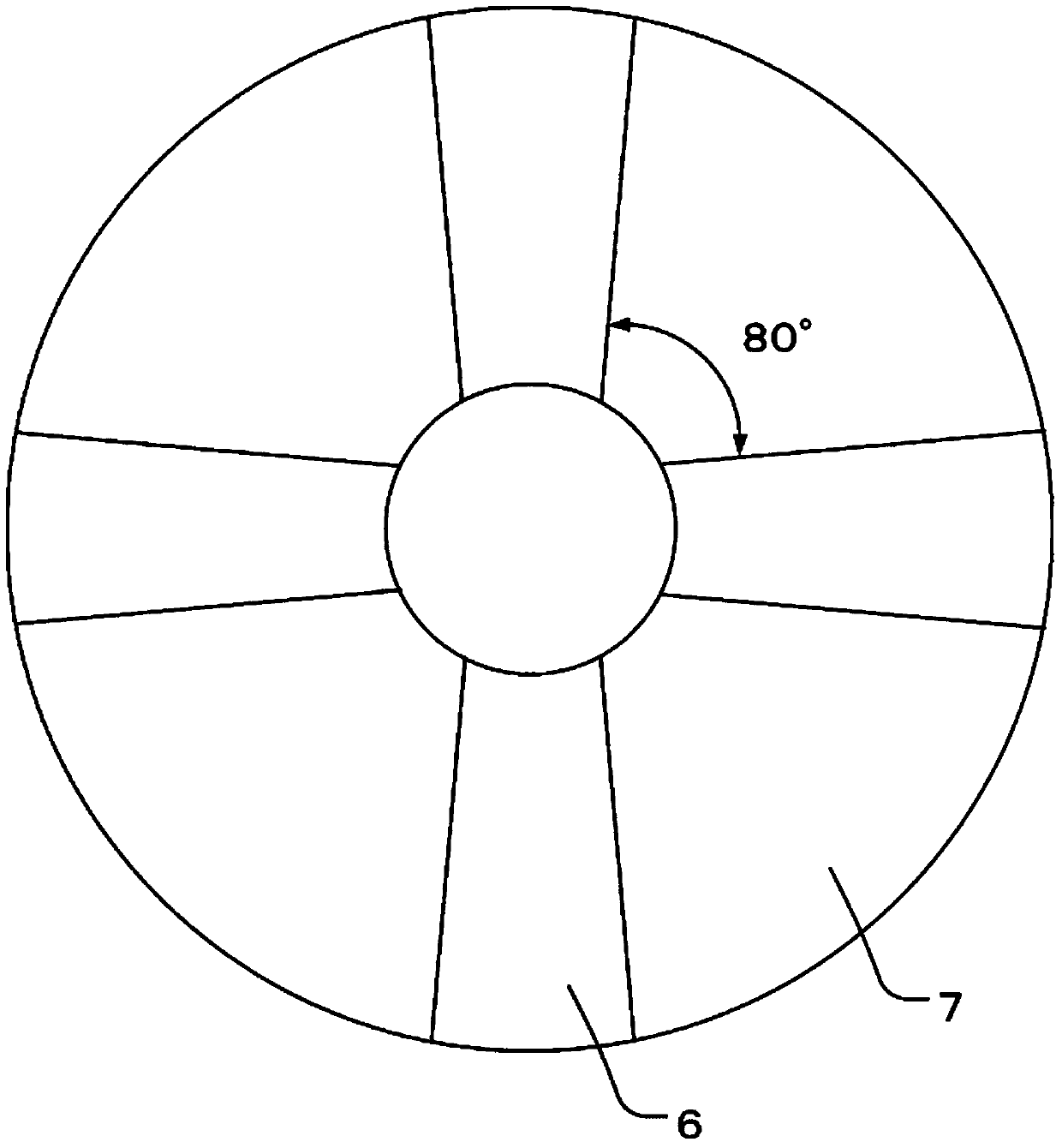

Coated member

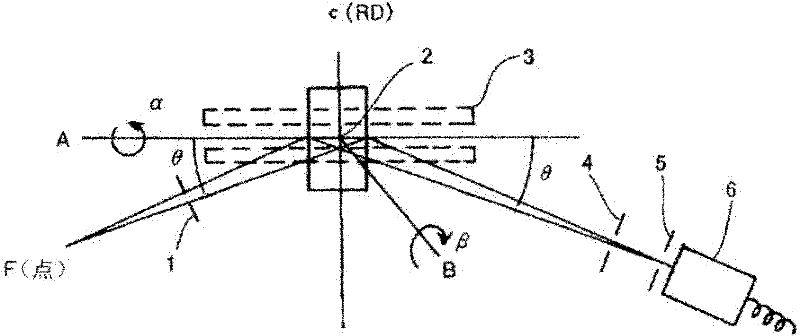

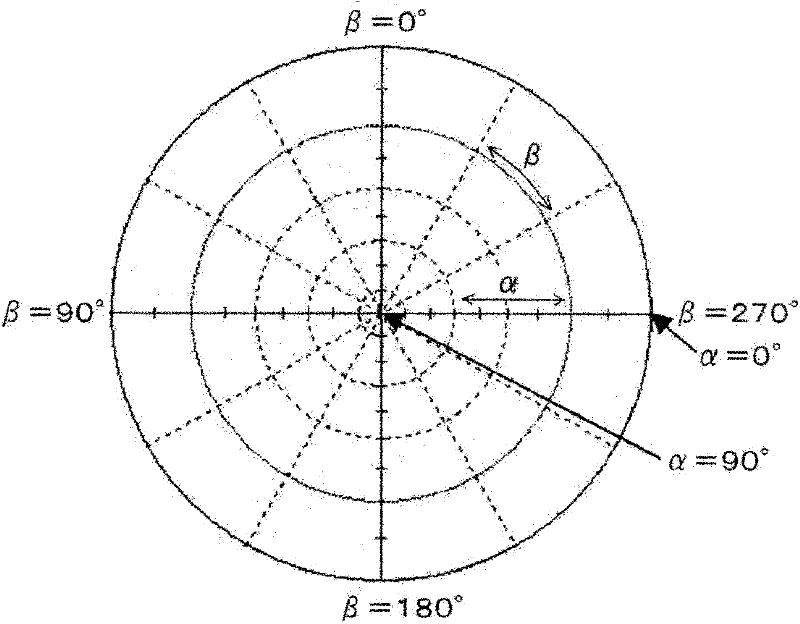

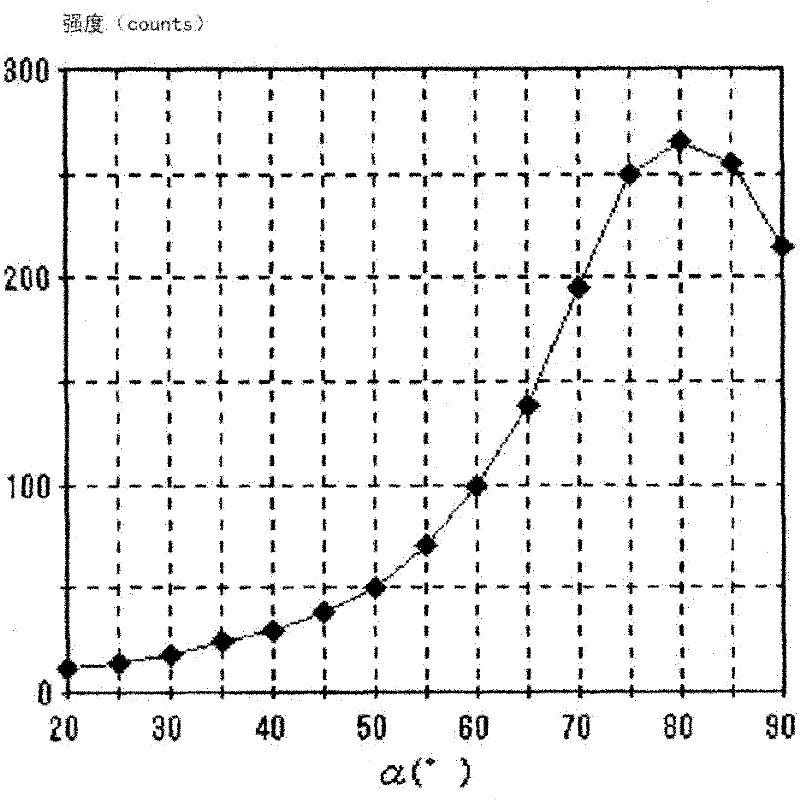

ActiveCN102099138AStrong adhesionImprove abrasion resistanceMilling cuttersVacuum evaporation coatingX-rayHardness

The invention provides a coated member for cutting tools which renders a long life possible under severe cutting conditions as in high-speed processing, high-feed-rate processing, cutting of works having enhanced hardness, and cutting of works difficult to cut. The coated member comprises a base having a surface coated with one or more coating films. At least one of the coating films is a hard film of a cubic metallic compound comprising at least one metallic element (M) selected from Al, Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W and at least one element (X) selected from C, N, and O. In the pole figure for the (111) plane of the hard film, the X-ray intensity distribution in the alpha axis has a maximum intensity in the alpha-angle range of 75-90 DEG. In the pole figure for the (220) plane of the hard film, the X-ray intensity distribution in the alpha axis has a maximum intensity in the alpha-angle range of 75-90 DEG .

Owner:TUNGALOY CORP

High-toughness crystalline cubic boron nitride-based ultrahigh pressure sintering material and cutting tool

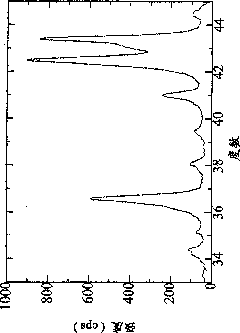

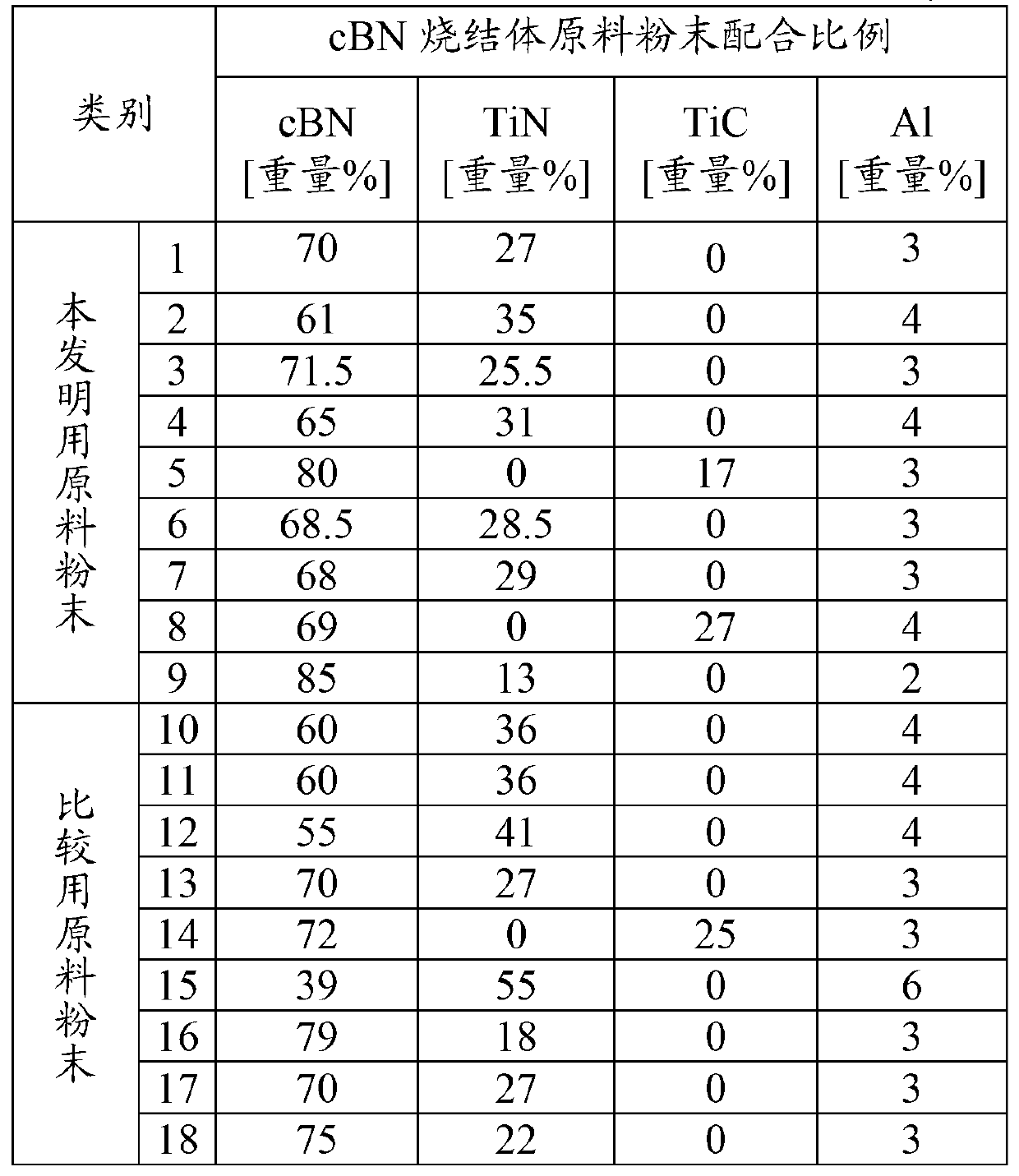

ActiveCN102190497AImprove toughnessGood toughnessTransportation and packagingMilling cuttersOxideBoron nitride

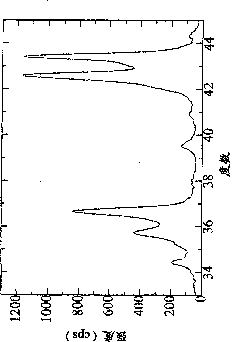

The invention discloses a high-toughness cBN (cubic boron nitride)-based ultrahigh pressure sintering material and a cutting tool manufactured by the same and having excellent crack resistance. The high-toughness cBN cubic boron nitride-based ultrahigh pressure sintering material and the cutting tool made of the same material comprise at least one powder particle such as Ti nitride powder particles and Al, alloy of Al and Ti, oxide of Al and nitride of Ti and Al as a combined phase forming ingredient in a cBN-based ultrahigh pressure sintering material including the organization of a hard dispersed phase and a combined phase, besides, as the hard dispersed phase forming ingredient, the high-toughness cBN cubic boron nitride-based ultrahigh pressure sintering material and the cutting tool made of the same material comprise cBN, wherein 50% of the accumulation grain size of the powder particles which form the combined phase is 0.6-0.9 microns, furthermore, when the cBN-based ultrahigh pressure sintering material is diffracted by X ray, a diffraction peak of a composite compound of Ti, Al and N appears within a diffraction angle range that 2theta is not smaller than 40.5 degrees and not larger than 41.4 degrees, and I / I0 is not smaller than 0.15 and not larger than 0.3 when the intensity of the diffraction peak of the composite compound of Ti, Al and N is set to be I and the intensity of the diffraction peak of cBN is set to be I0.

Owner:MITSUBISHI MATERIALS CORP

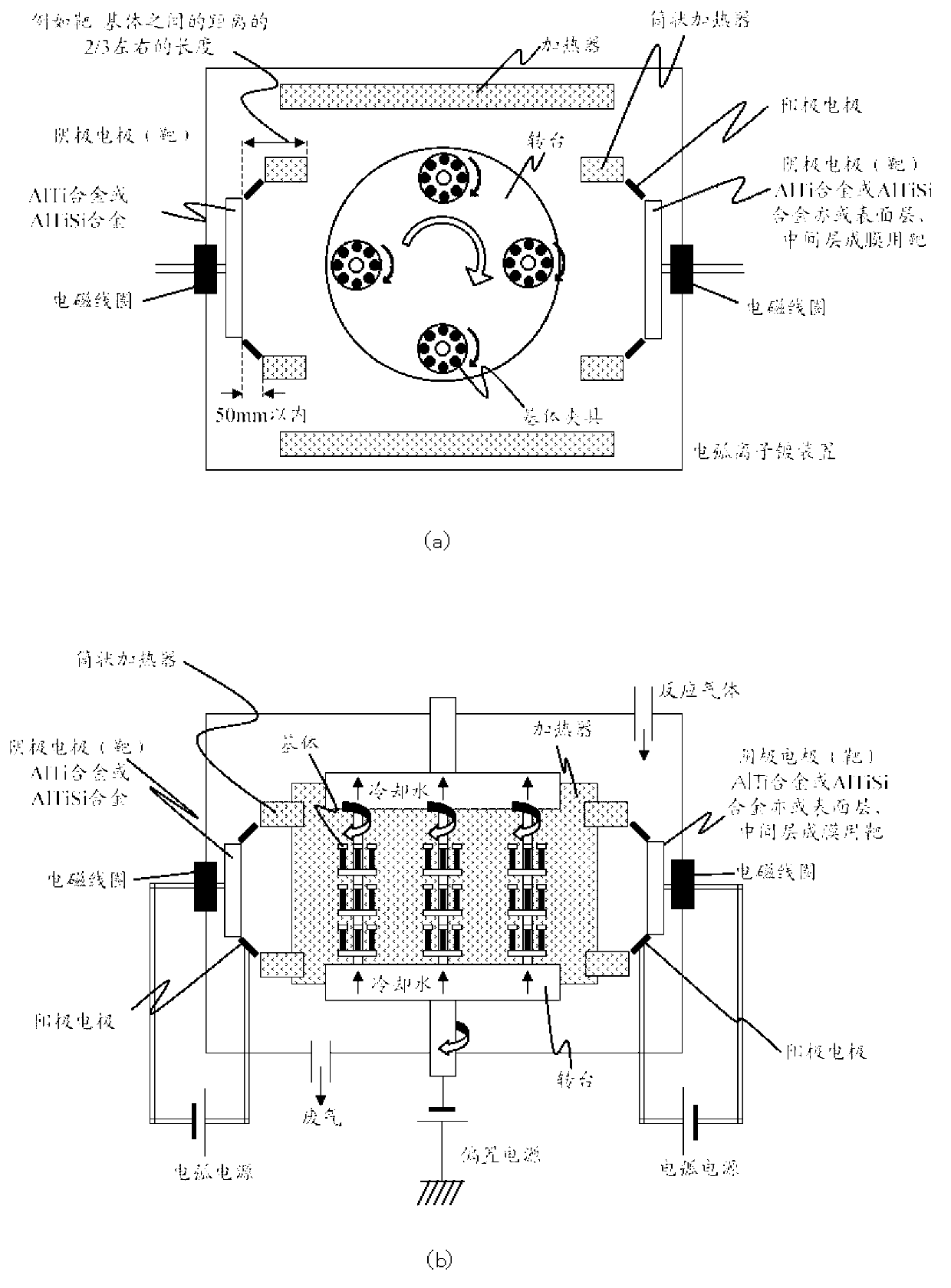

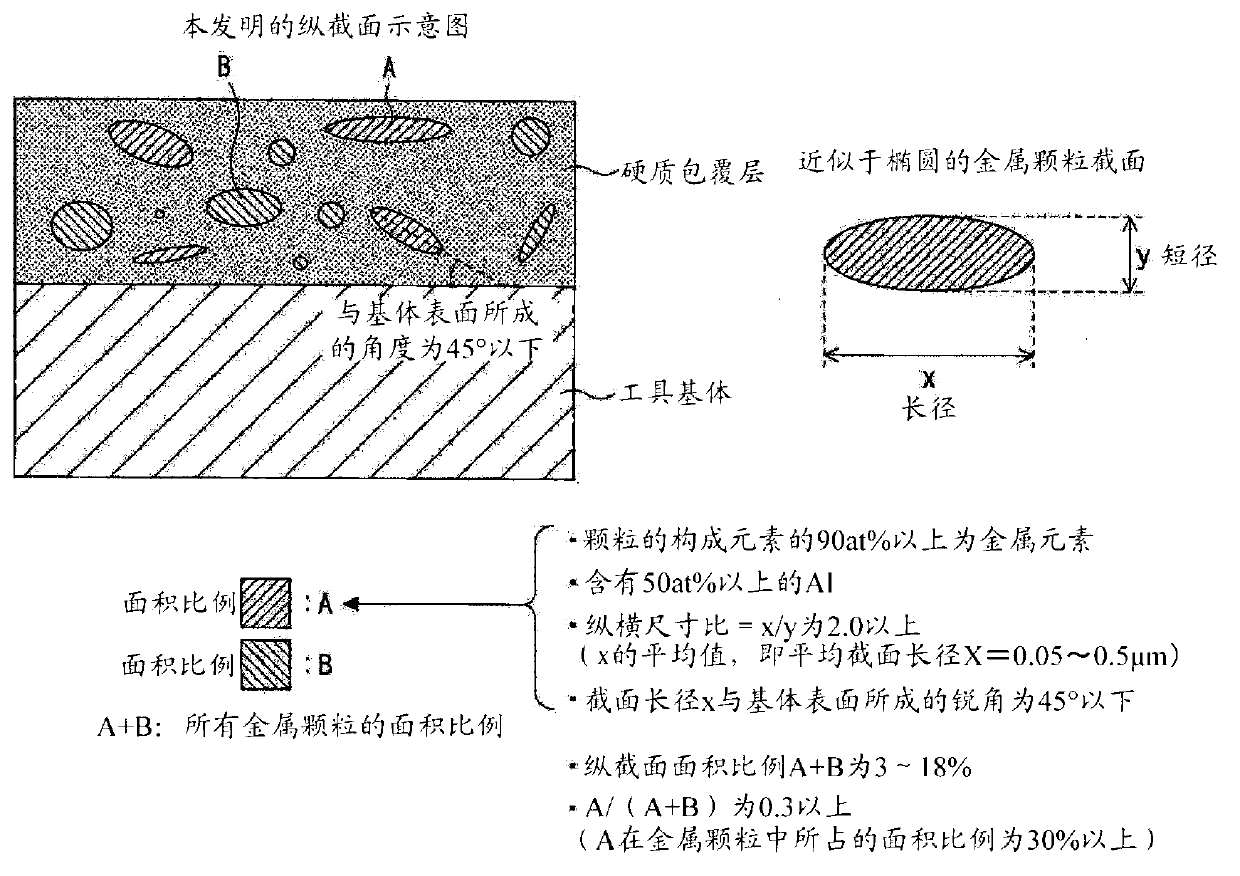

Defect and abrasion resistant surface coating and cutting tool

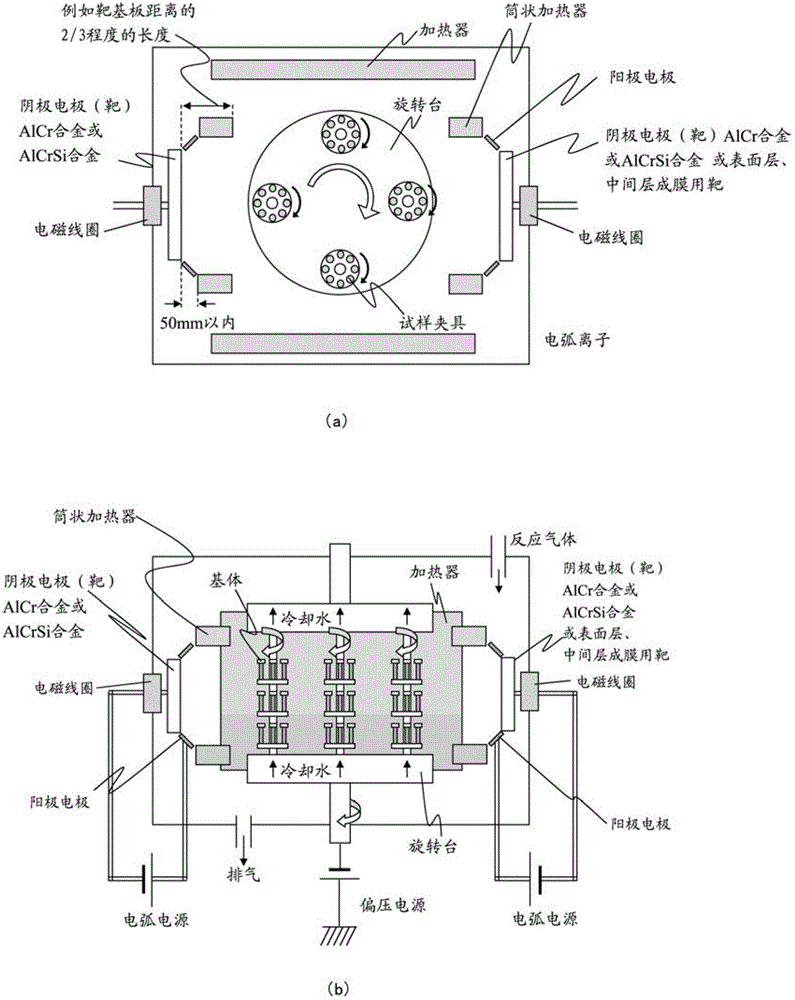

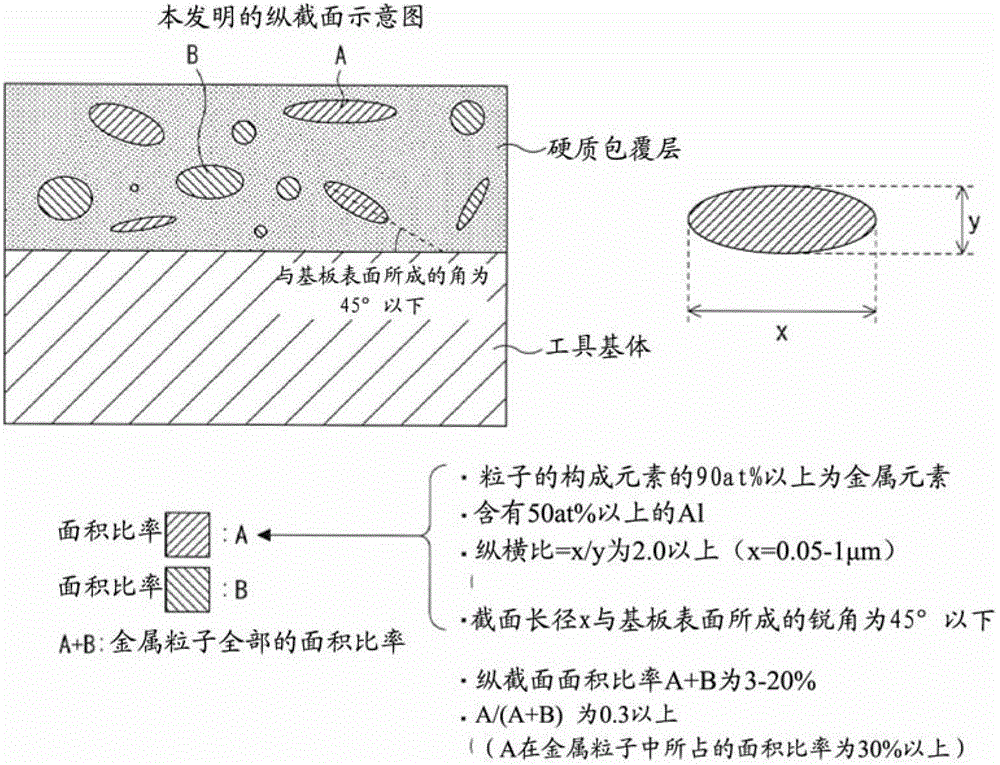

InactiveCN102794492AImprove wear resistanceImproved defect resistanceMilling cuttersLongest DiameterEvaporation

The invention provides a defect and abrasion resistant surface coating and cutting tool. The surface of a body of the tool is coated with a hard coating layer via the physical evaporation. The hard coating layer is composed of a composite arbonitride layer or a nitride layer which is represented by the formula (Al1-x-y CrxSiy)(N1-zCz) and has the average thickness of 0.5 to 8.0[mu]m. The hard coating layer includes metal particles, and above 90 atom % of the elements of the metal particle are metal elements, and the cross section long diameter is from 0.05 to 1.0[mu]m. The metal particles are arranged in the hard coating layer at 3 to 20% of the longitudinal section area rate. In the metal particles, when the elements includes Al of above 50 atom%, and the aspect ratio of the longitudinal section is above 2.0, the cross long diameter form an 45 degree included angle with the surface of the substrate, the longitudinal section ratio is A%, and when the longitudinal section ratio is B%, 0.3<=A / (A+B).

Owner:MITSUBISHI MATERIALS CORP

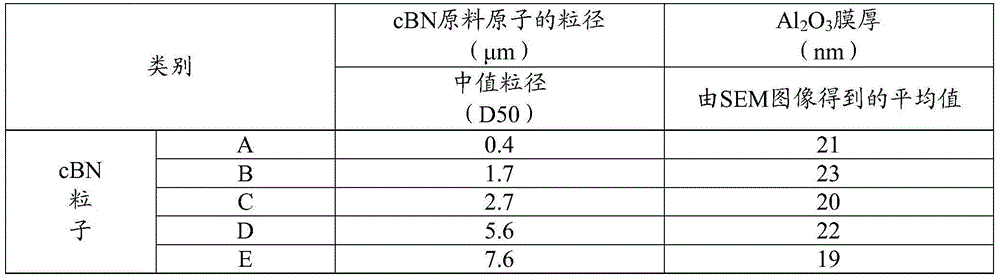

Cutting tool made from cubic boron nitride-based sintered material

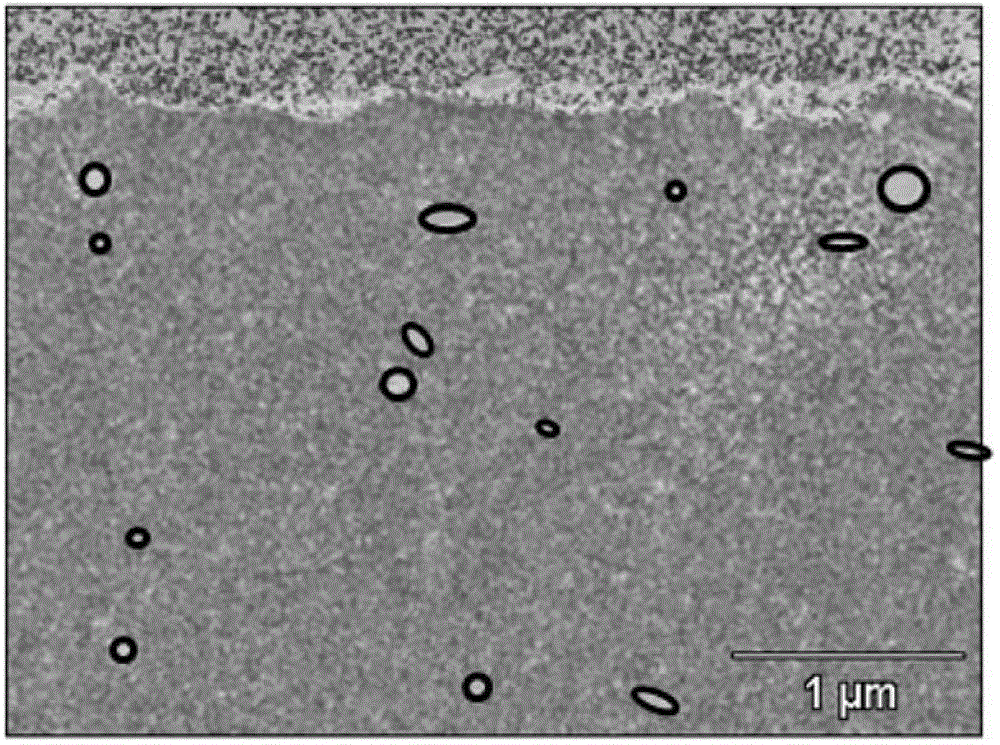

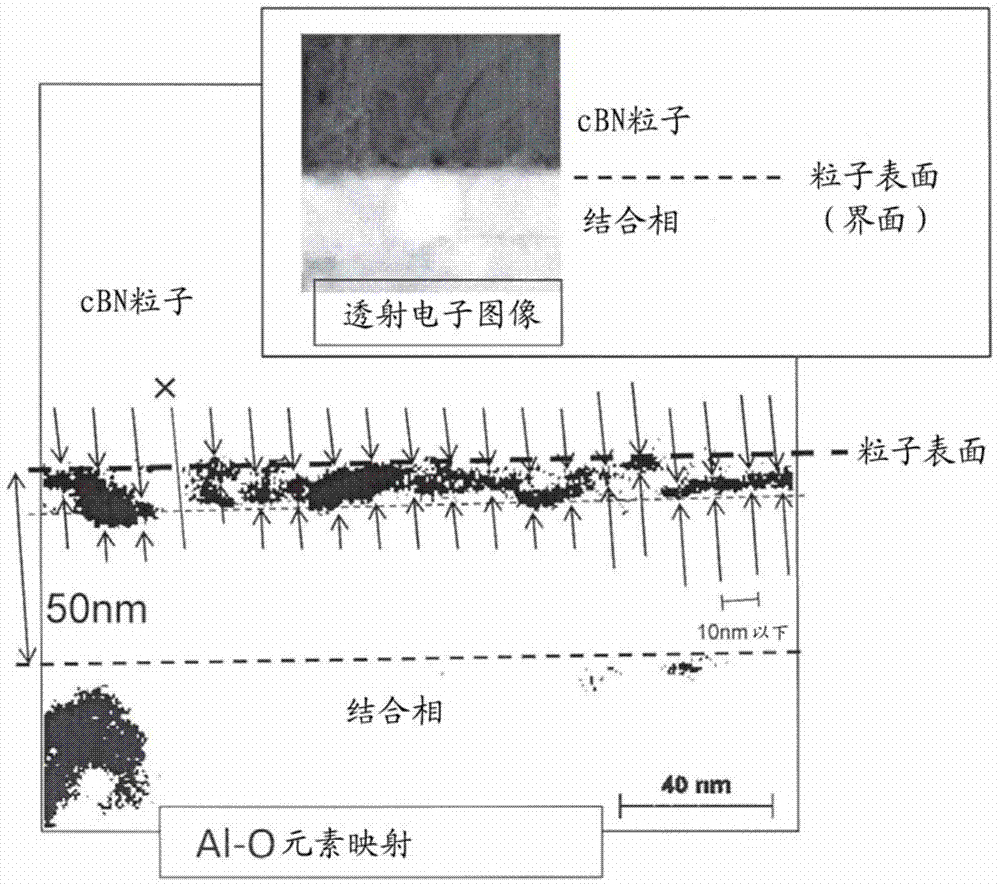

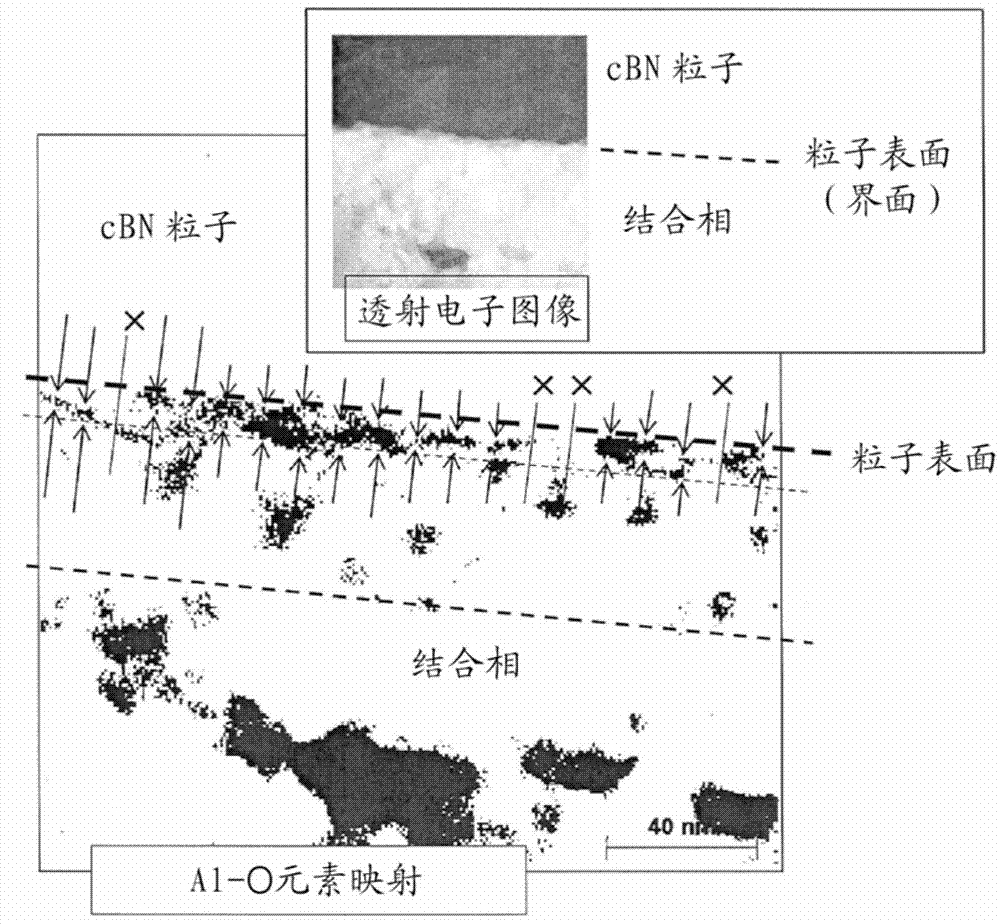

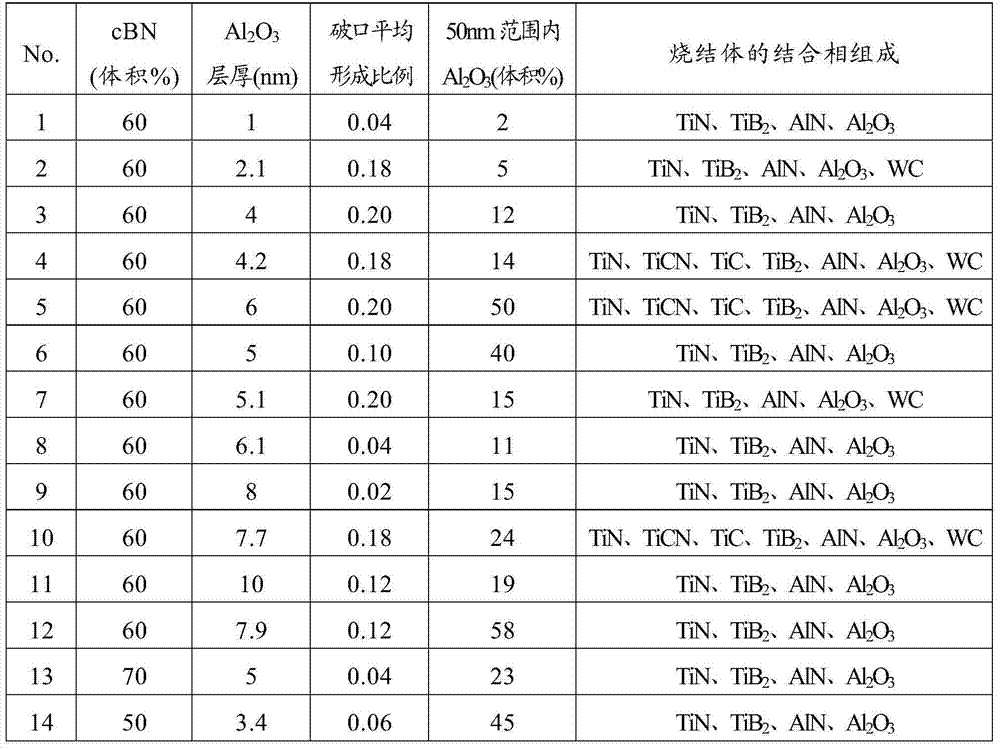

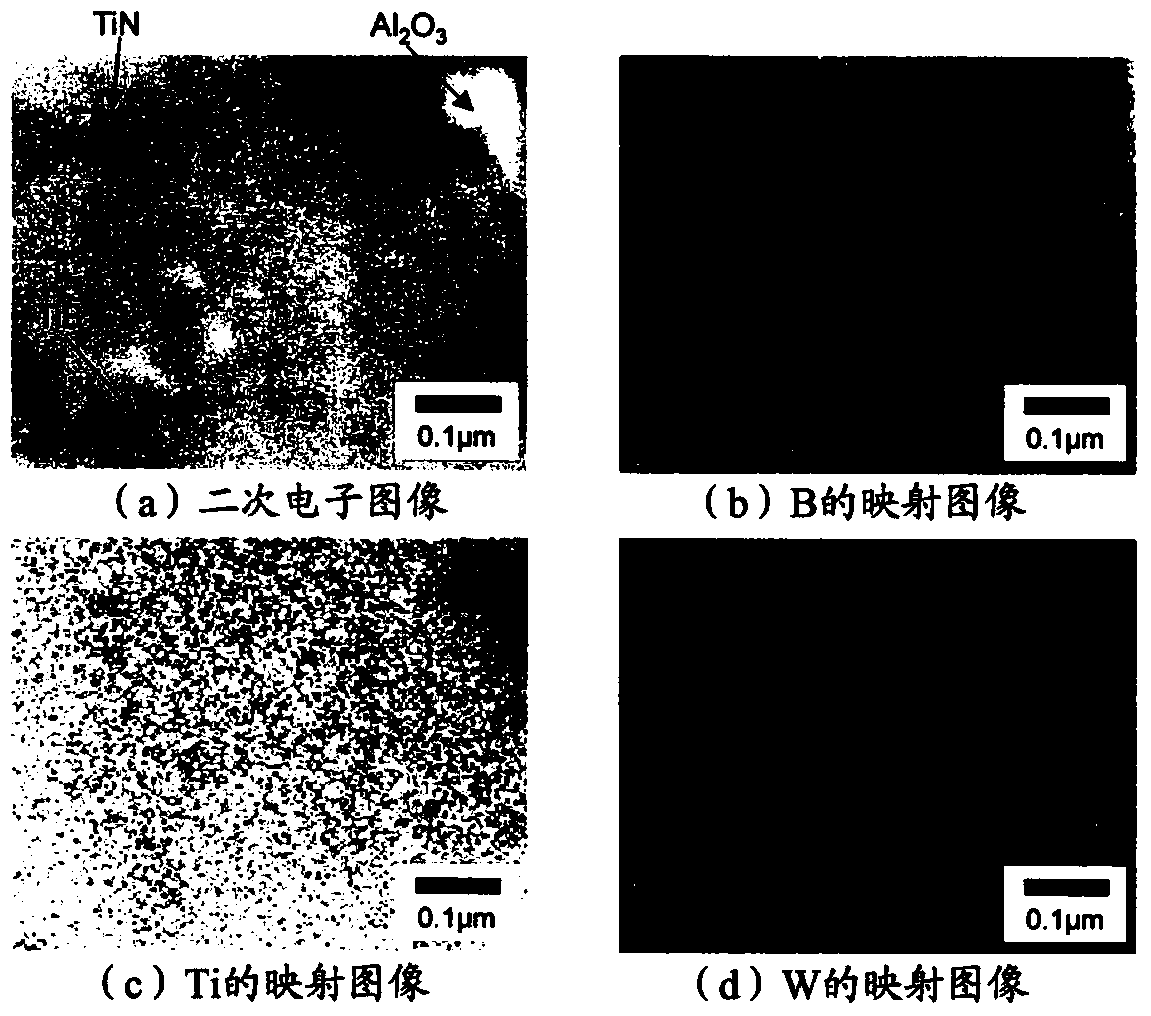

ActiveCN104284747AEfficient manufacturingImprove chip resistanceWorkpiecesTurning toolsBoron nitrideHardness

The purpose of the present invention is to provide a cBN tool which can exhibit excellent chipping resistance and excellent wear resistance even when used for the intermittent cutting of a high-hardness steel and can also exhibit excellent cutting performance throughout long-term use. The purpose can be achieved by providing a cutting tool made from a cBN sintered material, in which a cBN sintered material that contains at least cBN particles as a hard phase component is employed as a tool base, wherein each of the cBN particles has an Al2O3 layer that has, on the surface thereof, slits formed at an average formation ratio of 0.02 to 0.20 inclusive and has an average layer thickness of 1.0 to 10 nm, the cBN sintered material has, around the periphery of each of the cBN particles, a binder phase comprising TiN alone or a combination of TiN and TiC, TiB2, TiCN, AlN, Al2O3, WC or the like, and the sum total of the content of Al2O3 formed on the surface of each of the cBN particles and the content of Al2O3 present in the binder phase is 2 to 40 vol% on average wherein the volume of a region of each of the cBN particles which lies between the surface of each of the cBN particles and a zone located at the depth of 50 nm from the above-mentioned surface is defined as 100 vol%.

Owner:MITSUBISHI MATERIALS CORP

Surface-coated cutting tool with hard coating layer having excellent abrasion resistance

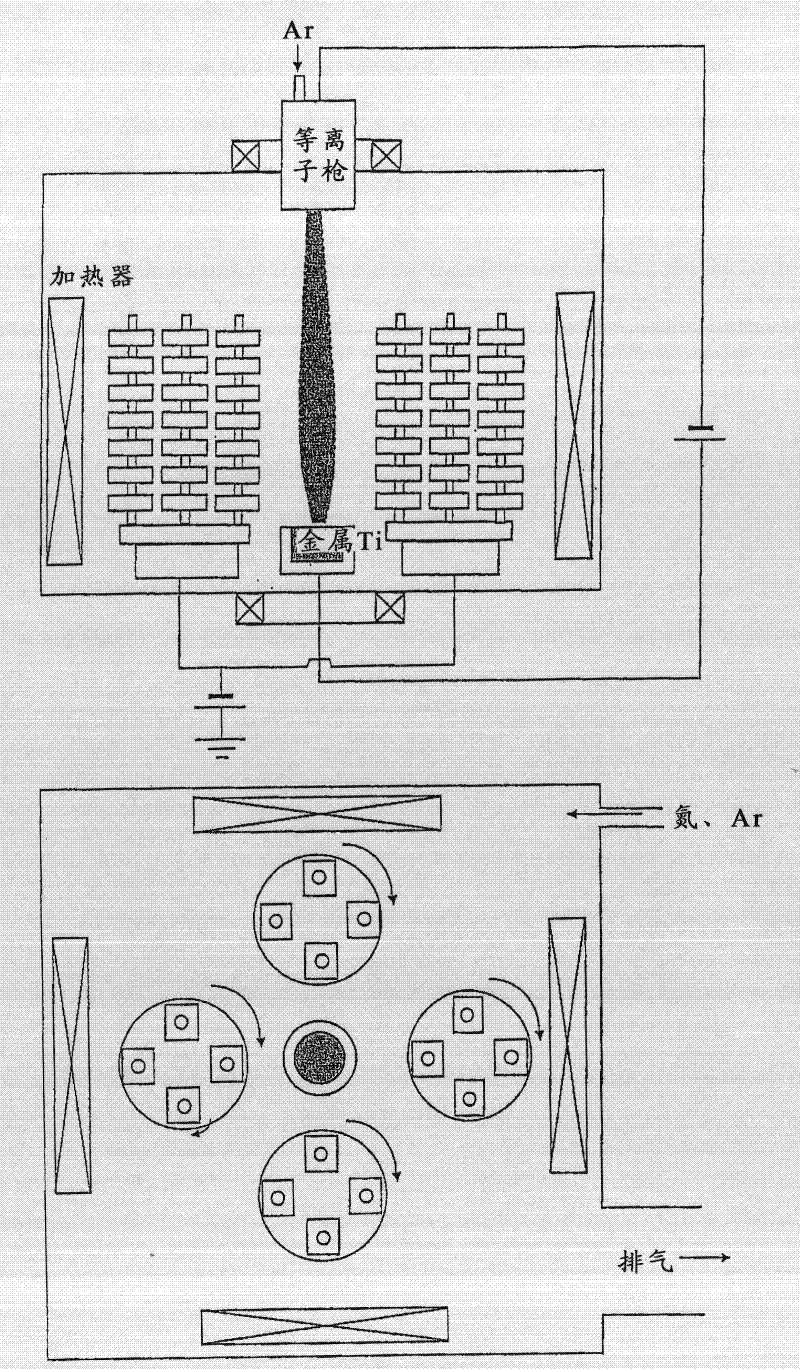

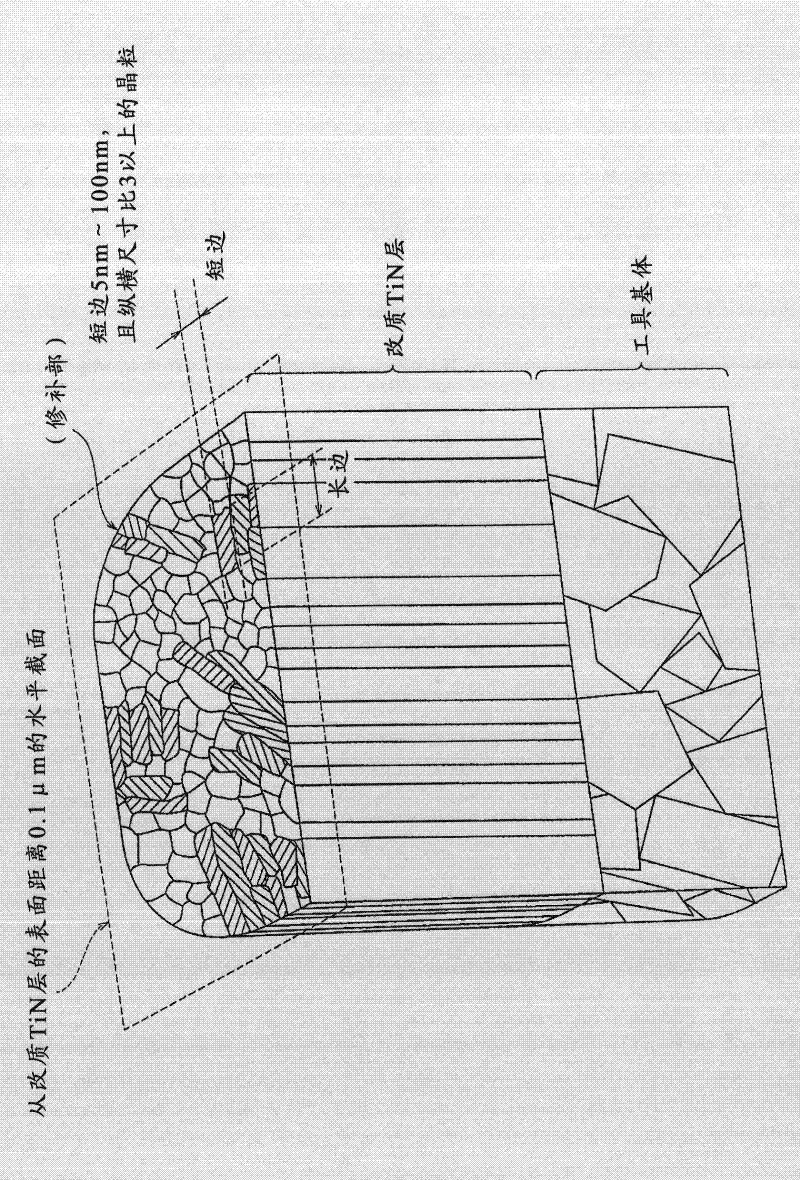

InactiveCN102051577ASolution to short lifeImprove flexural strengthVacuum evaporation coatingSputtering coatingCemented carbideGrain structure

The invention provides a surface-coated cutting tool with a hard coating layer having excellent abrasion resistance, wherein the hard coating layer has excellent abrasion resistance in intermittent re-cutting process. According to the invention, the base surface of a WC base cemented carbide tool is subject to physical vapor deposition to form a hard coating layer of a surface-coated cutting tool made of TiN layer. The height of the TiN layer is equal to that of an average layer. The TiN layer is made of elongated plate-shaped TiN crystalline grains, which grows along the vertical direction relative to the base surface of the tool. In addition, when the TiN crystalline grain structure of the horizontal section of the TiN layer with a height of 0.1 mu m is observed, the occupied area ratio of the elongated plate-shaped TiN crystalline grains with the short side thereof 5 -100 nm and the aspect ratio of 3 or more to the entire horizontal cross-sectional area is more than 30 %.

Owner:MITSUBISHI MATERIALS CORP

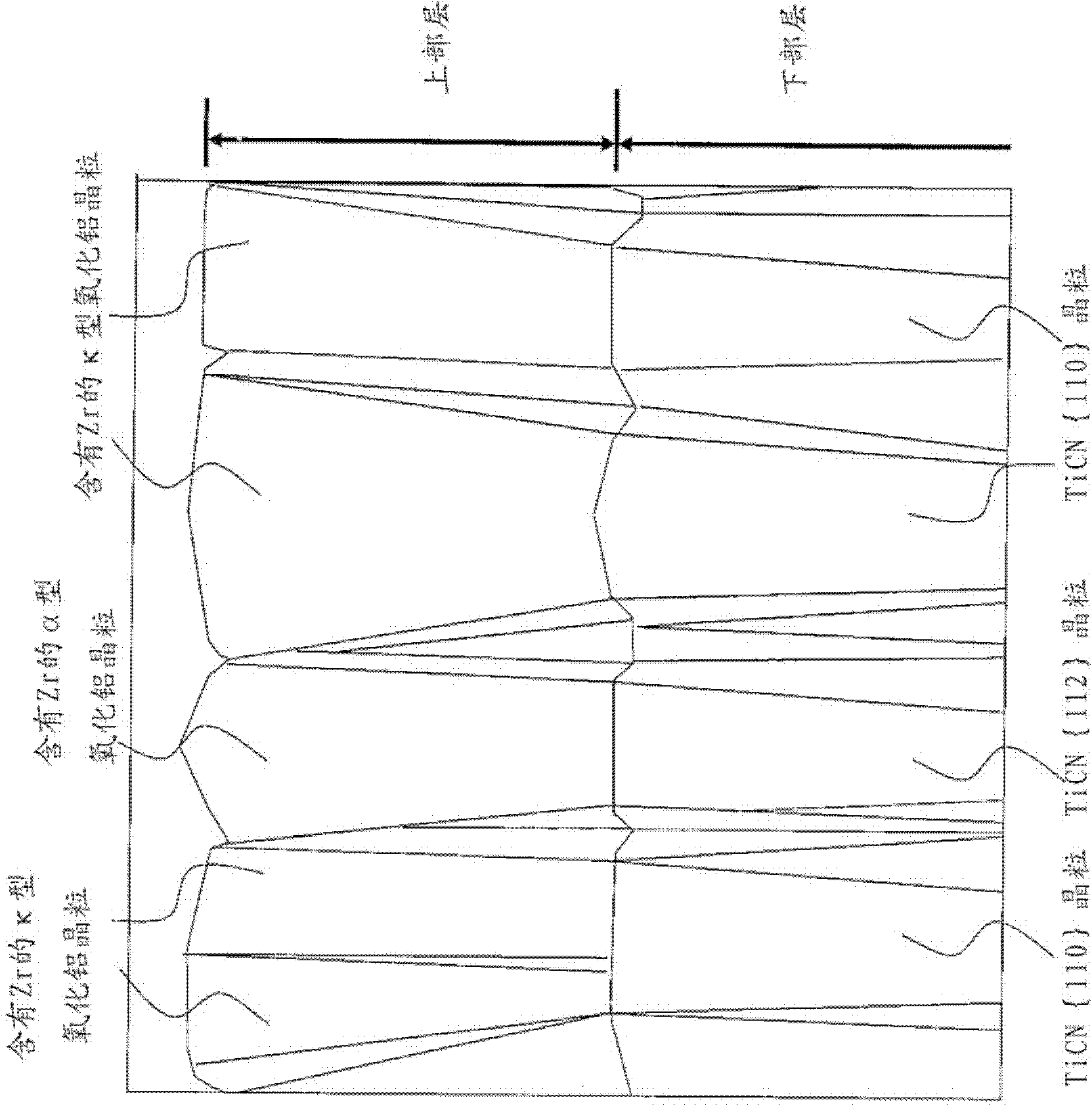

Surface-coated cutting tool with knife broken resistance and excellent performance of hard-coated layer

ActiveCN102581324AHigh hardnessImprove heat resistanceTurning toolsChemical vapor deposition coatingCrystallite

The invention provides a surface-coated cutting tool with knife broken resistance and excellent performance of hard-coated layer in high-speed cutting processing. In the surface-coated cutting tool, a Ti compound layer at least including a TiCN layer is formed as a lower layer on the surface of the tool body, an Al2O3 layer including Zr as the upper layer, wherein kappa-Al2O3 crystallites containing Zr and alpha-Al2O3 crystallites containing Zr are included, In addition, kappa-Al2O3 crystallites containing Zr as an upper layer is fomed over the TiCN[110] crystallites, and alpha-Al2O3 crystallites containing Zr as an upper layer is formed over TiCN[112]. More than 30% of the alpha-Al2O3 crystallites comprises Al2O3[0001] crystallites, and the crack density of alpha-Al2O3 crystallites containing Zr is high than that of kappa-Al2O3 crystallites containing Zr.

Owner:MITSUBISHI MATERIALS CORP

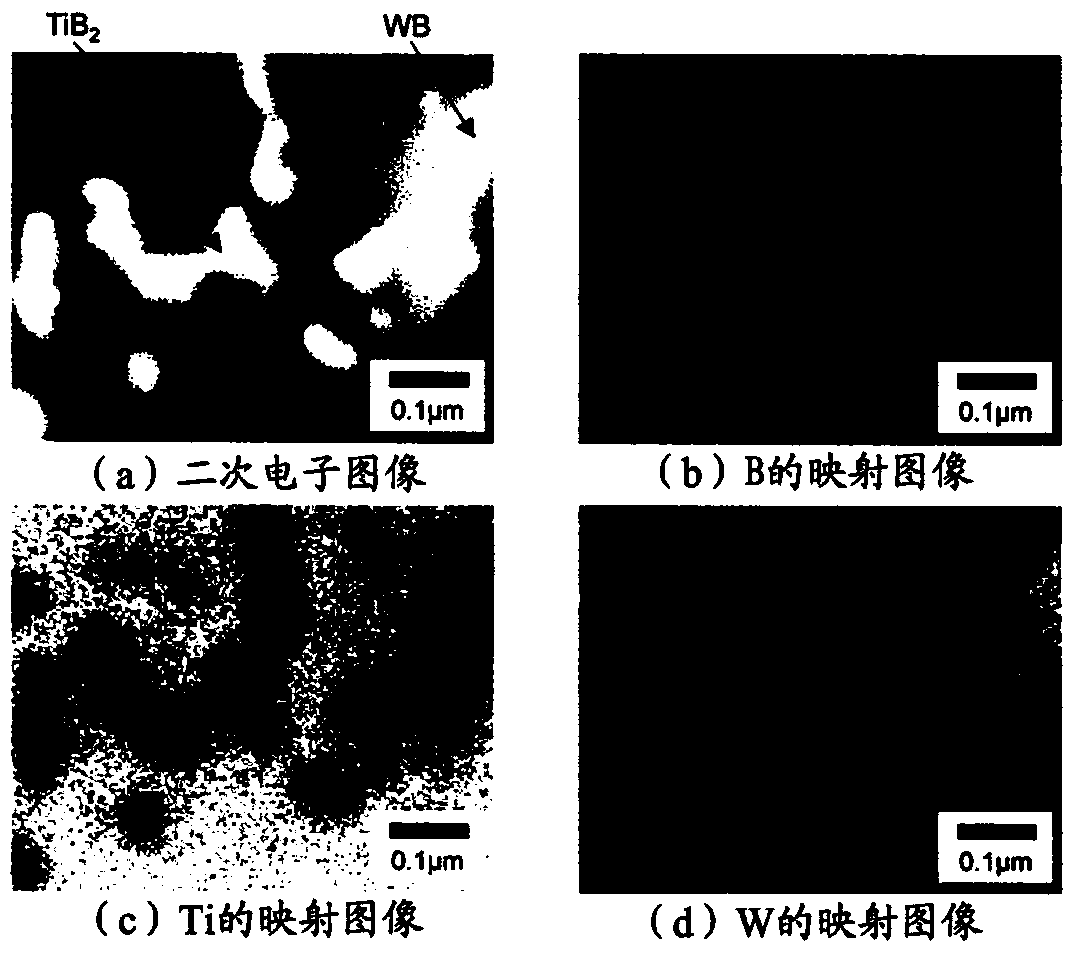

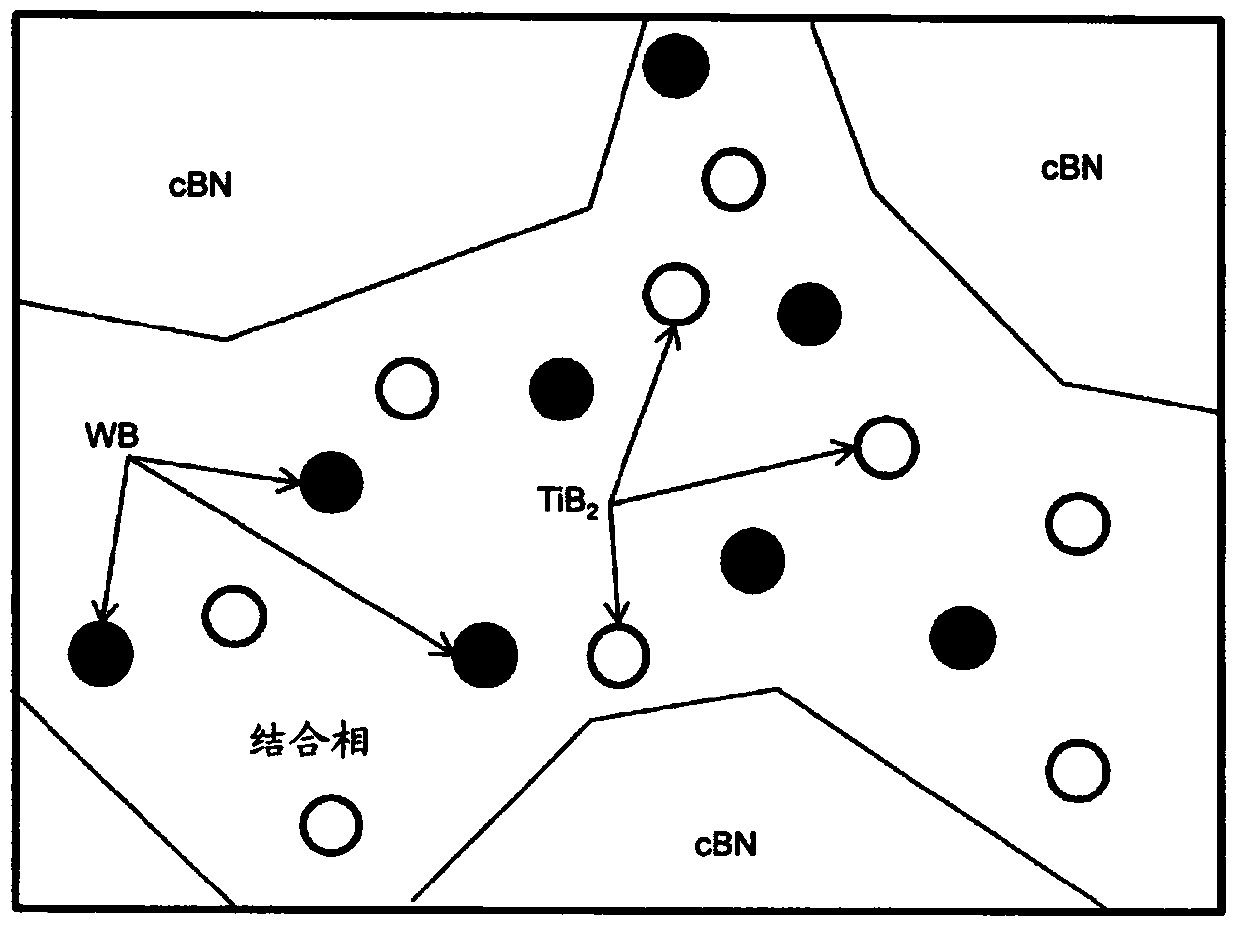

Cubic boron nitride ultrahigh pressure sintered body cutting tool and surface coated cutting tool

The invention provides a cutting tool and a surface coated cutting tool. The cutting tool is excellent in defect resistance, and a cBN ultrahigh pressure sintered body with excellent toughness is adopted to be a tool base body. The cBN ultrahigh pressure sintered body containing cBN particles, a combination phase, TiB2 phases and WB phases are employed to be tool base bodies of the cutting tool and the surface coated cutting tool. In terms of the cubic boron nitride ultrahigh pressure sintered body, the average particle size of the cBN particles is 0.5 to 3.5 micrometers, and the content is 40 to 75%; the slightly thin TiB2 phases and the WB phases, 50 to 500 nanometers in average particle size, are dispersedly distributed in the combination phase; 15% to 35% contents of the combination phase are at least more than one of nitrides and oxides of Al, the remaining being at least more than one of nitrides, carbides, borides or carbontrides of Ti and being inevitable impurities; and a relationship, 0.5<=(the production of the WB phases) / (the production of the TiB2 phases)<=1.0, is satisfied.

Owner:MITSUBISHI MATERIALS CORP

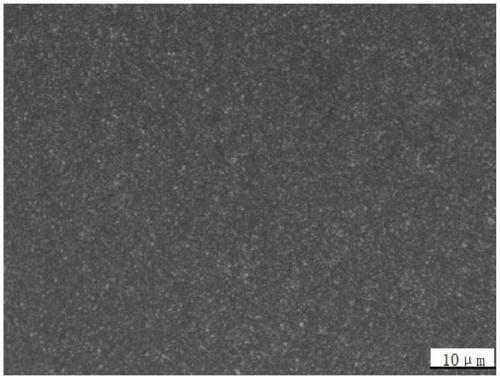

High-hardness and high-strength WC-Co-based hard alloy and preparation method thereof and cutting tool

ActiveCN111118376AHigh strengthHigh hardnessTurbinesOther manufacturing equipments/toolsAlloyHardness

The invention discloses a high-hardness and high-strength WC-Co-based hard alloy. The high-hardness and high-strength WC-Co-based hard alloy comprises the following raw materials in parts by weight: 80-90 parts of WC powder, 5-15 parts of Co powder and 0.5-3 parts of an additive, wherein the additive consists of metal carbide and metal nitride; and the bending strength of the hard alloy is as highas 4810N / mm < 2 >, and the hardness of the hard alloy is as high as 94.5HRa. The invention further discloses a preparation method of the hard alloy. The hard alloy is prepared by performing multi-stage sintering on the raw materials of 0.8 microns m or below, and the adopted additive effectively inhibits the formation of polycrystalline in the sintering growth of the alloy, so that the high-hardness and high-strength performance of the hard alloy is realized. The invention further discloses a cutting tool prepared from the hard alloy. Due to the increase of the strength and the hardness of the cutting tool, the defect resistance is improved, and the service life is obviously prolonged.

Owner:江西江钨硬质合金有限公司

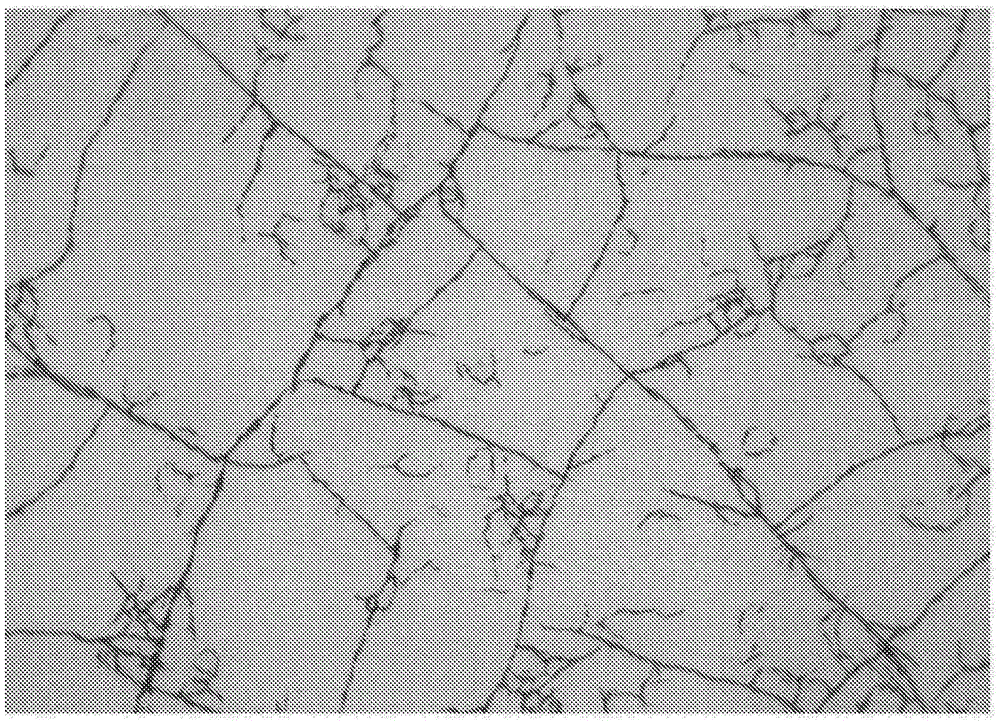

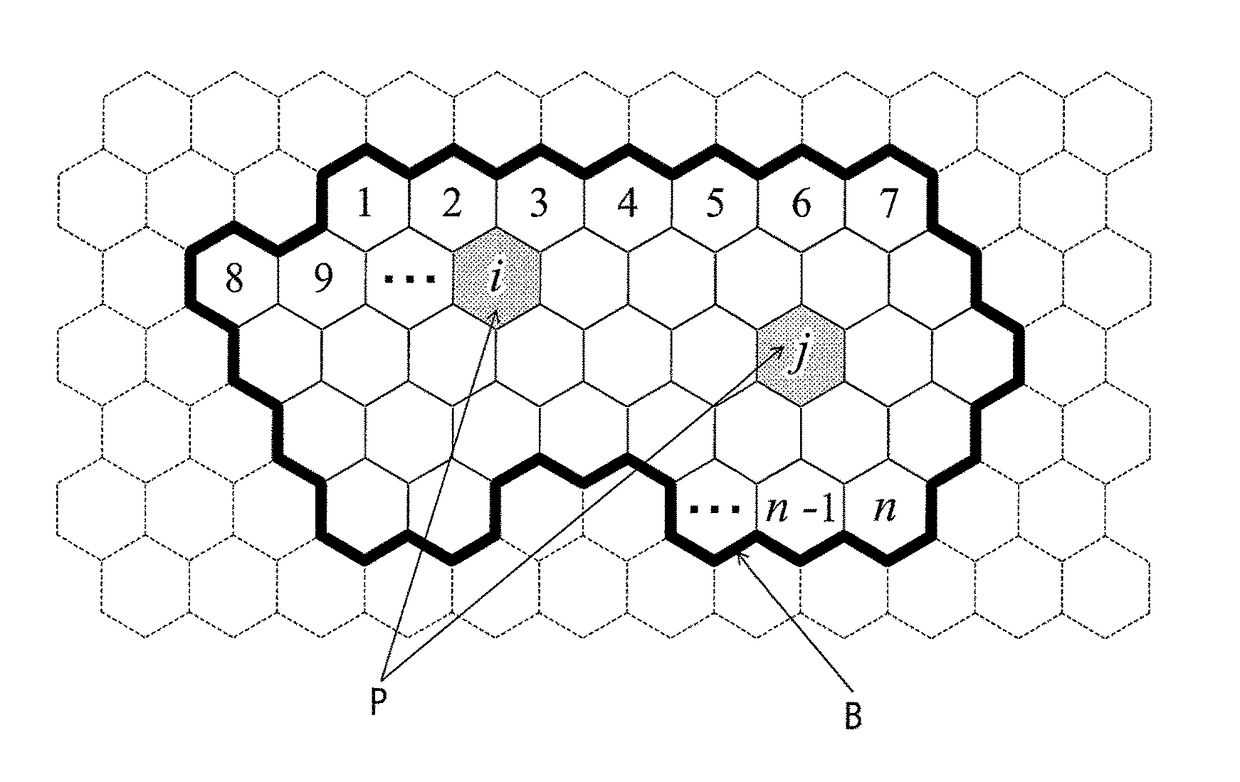

Coated cutting tool

ActiveCN105579171AExtend your lifeMaintain wear resistanceTransportation and packagingMilling cuttersNumber densityVolumetric Mass Density

Provided is a coated cutting tool provided with a substrate and a coating layer formed on the outer surface of the substrate in order to obtain a coated cutting tool having superior resistance to chipping, wear and damage while having a long service life, wherein: the coating layer includes at least one Ti compound layer; the Ti compound layer comprising a compound containing elemental titanium and at least one element selected from the group consisting of C, N, O and B; a region surrounded by cracks is provided in the Ti compound layer when a grinding surface substantially parallel to the surface of the substrate is seen from above; the region is internally provided with intermittent cracks in which one end or both ends of the cracks do not abut the cracks that constitute the region; and the average number density (A) of the region and the average number density (B) of the cracks satisfies the relationship of 0.7<B / A<2.

Owner:TUNGALOY CORP

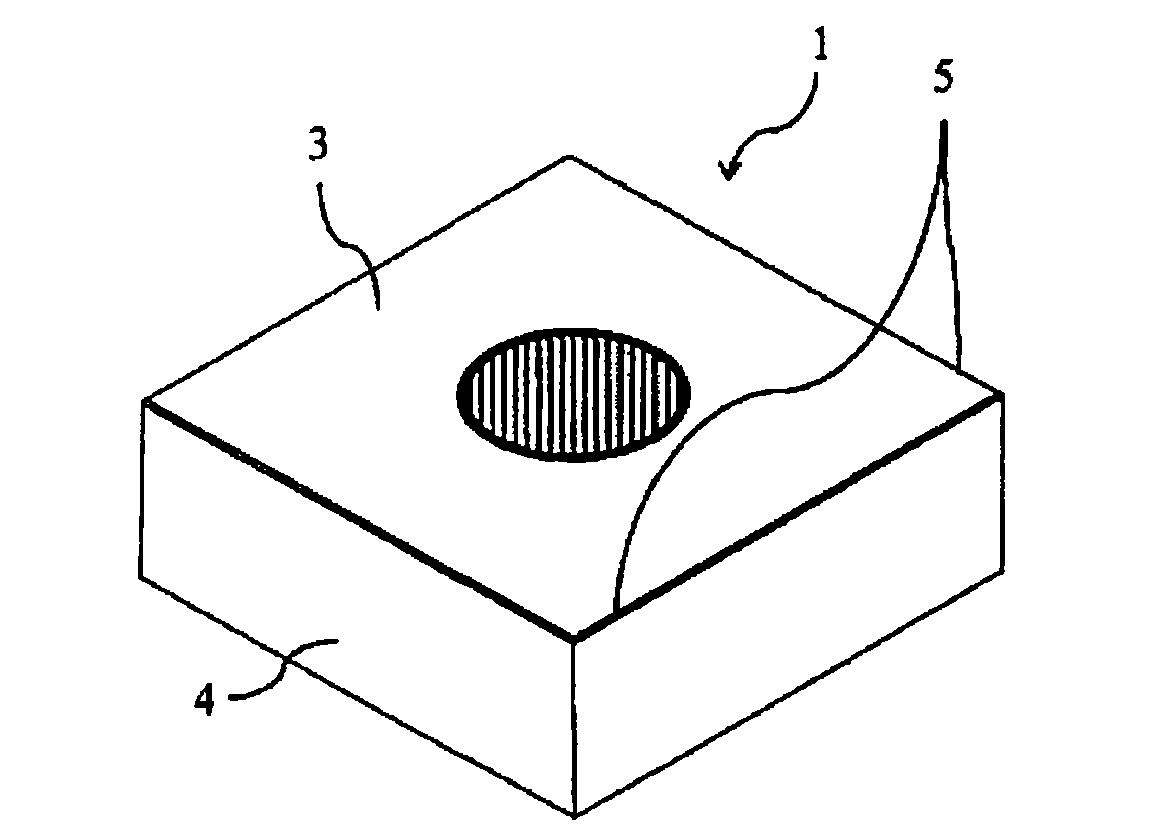

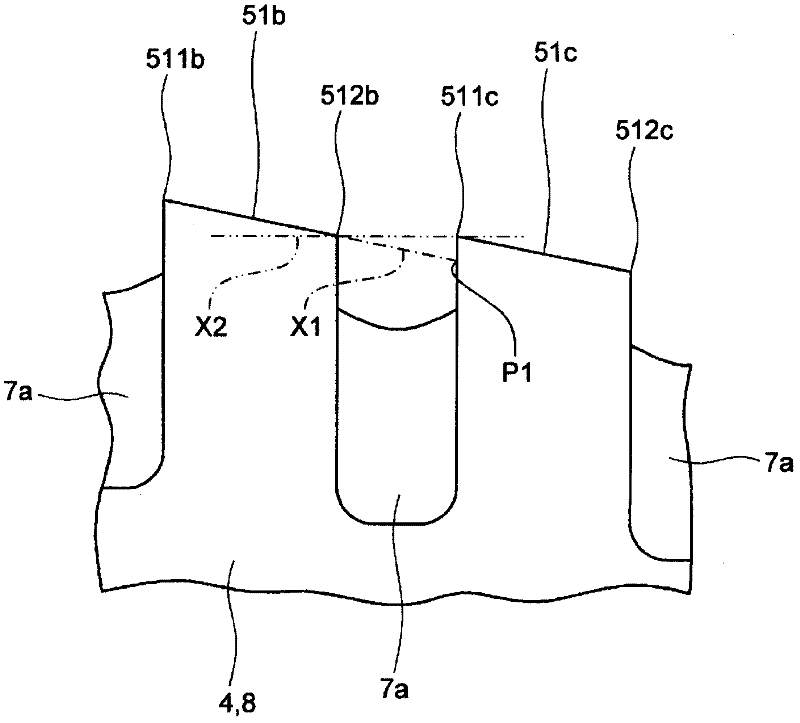

Cutting insert, cutting tool, and cutting method of workpiece using the cutting tool

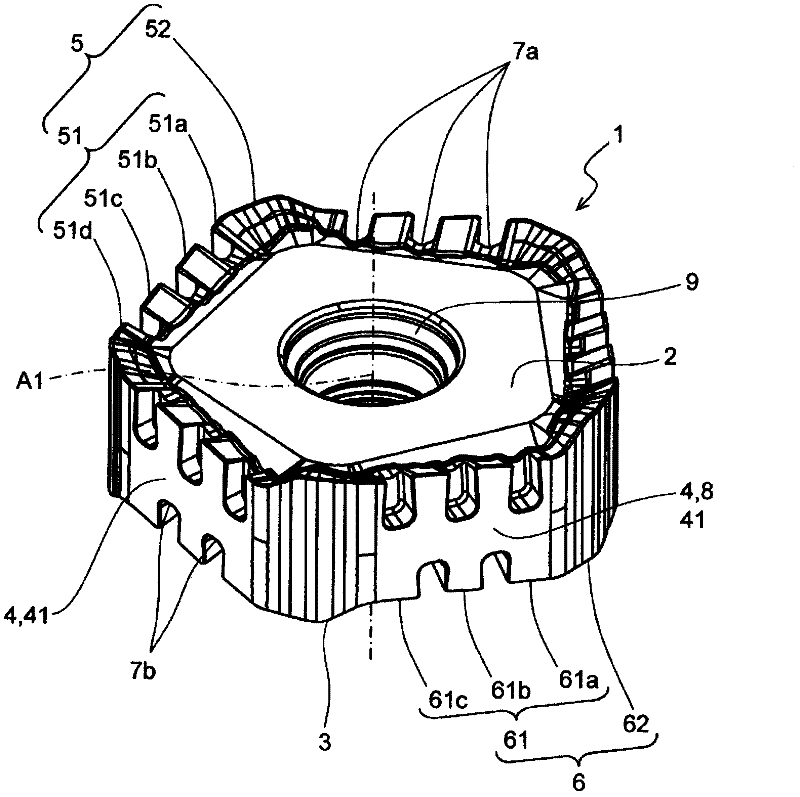

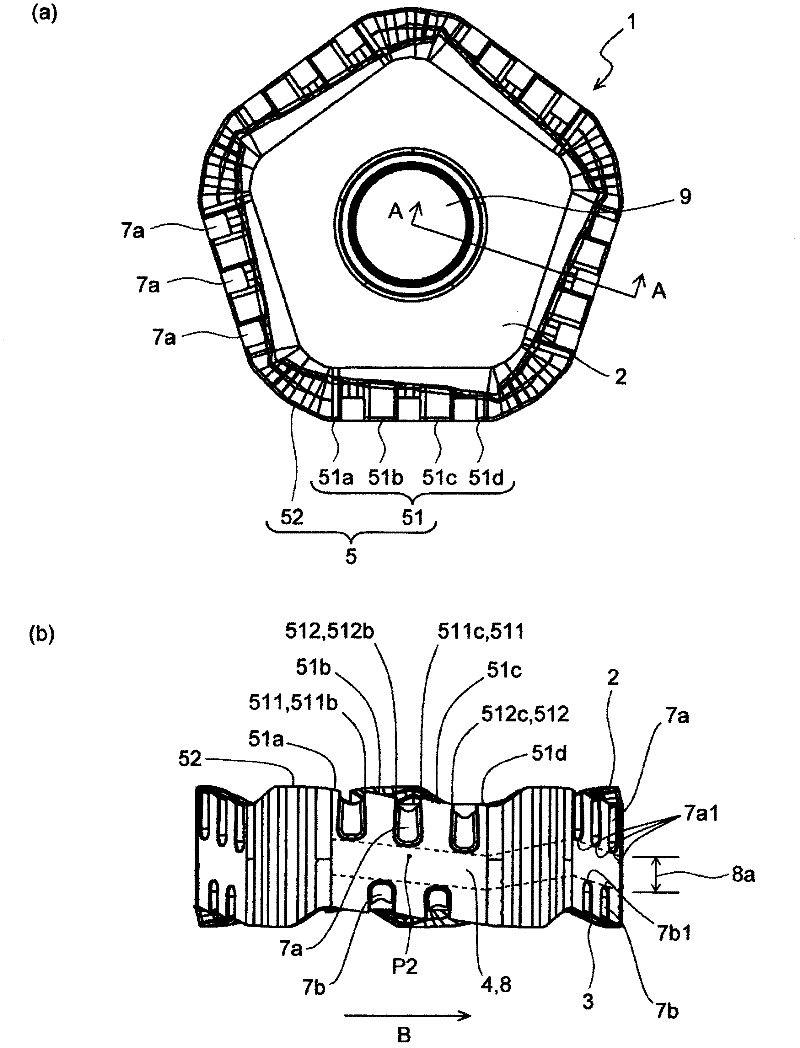

InactiveCN102300657AReduce cutting resistanceImproved defect resistanceTransportation and packagingMilling cuttersEngineering

Provided is a cutting insert comprising side surfaces located between the upper surface and the lower surface thereof and having upper recesses extending to the upper surface, and also comprising separated upper cutting edges located along the line of intersection between the upper surface and each side surface and separated from each other by upper recesses. Each of the separated upper cutting edges has a first end and a second end and is tilted so as to approach the lower surface from the first end toward the second end. The separated upper cutting edges comprise first separated upper cutting edges and second separated upper cutting edges, and each first separated upper cutting edge and each second separated upper cutting edge are adjacent to each other. In a side view, the first end of the second separated upper cutting edge is located at a position above the intersection between a line extended from the first separated upper cutting edge and a line passing through the first end of the second separated upper cutting edge and parallel to the center axis of the cutting insert, and the position is the same as or below the position of the second end of the first separated upper cutting edge. Also provided are a cutting tool provided with the cutting insert and a method of cutting a material to be cut using the cutting tool.

Owner:KYOCERA CORP

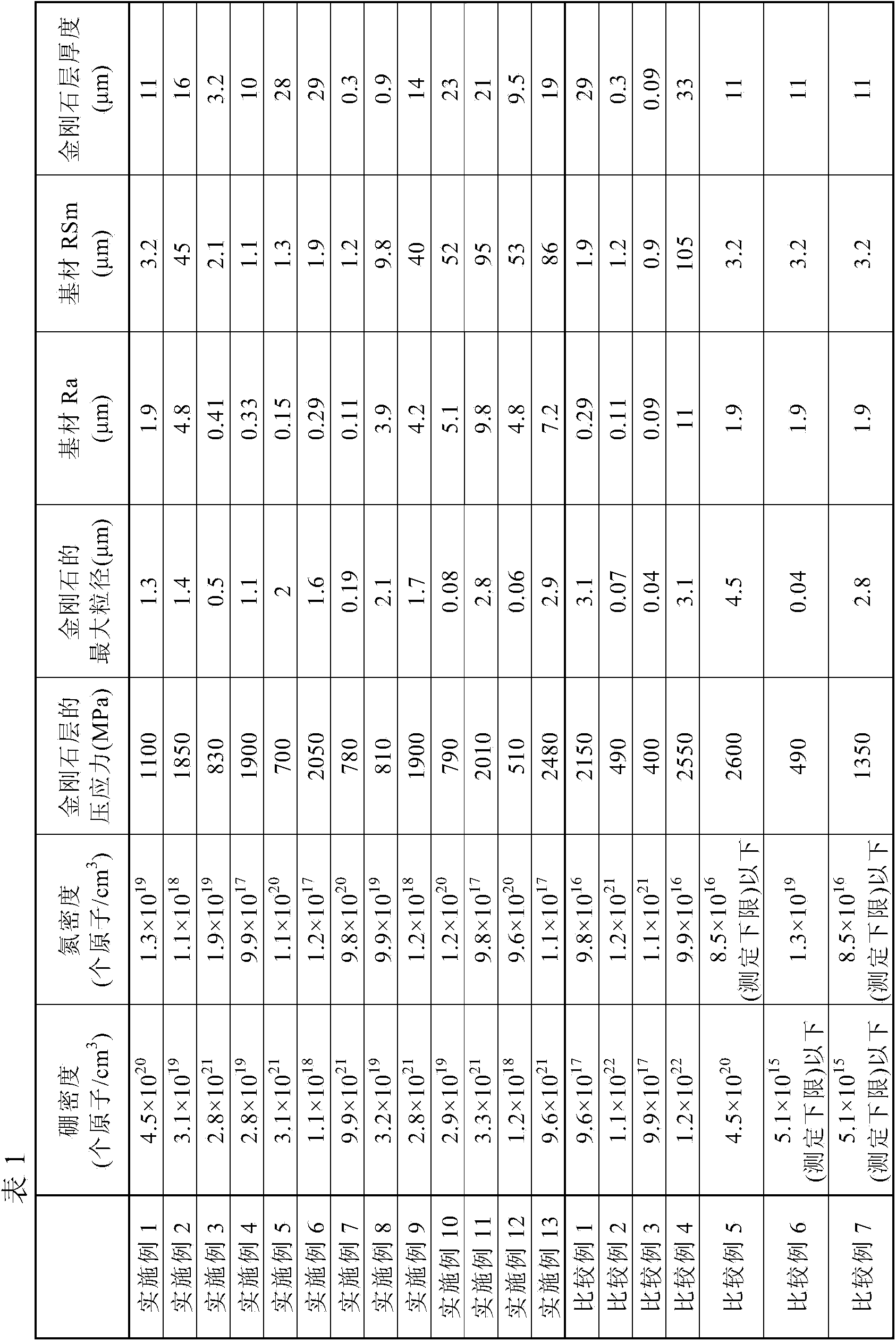

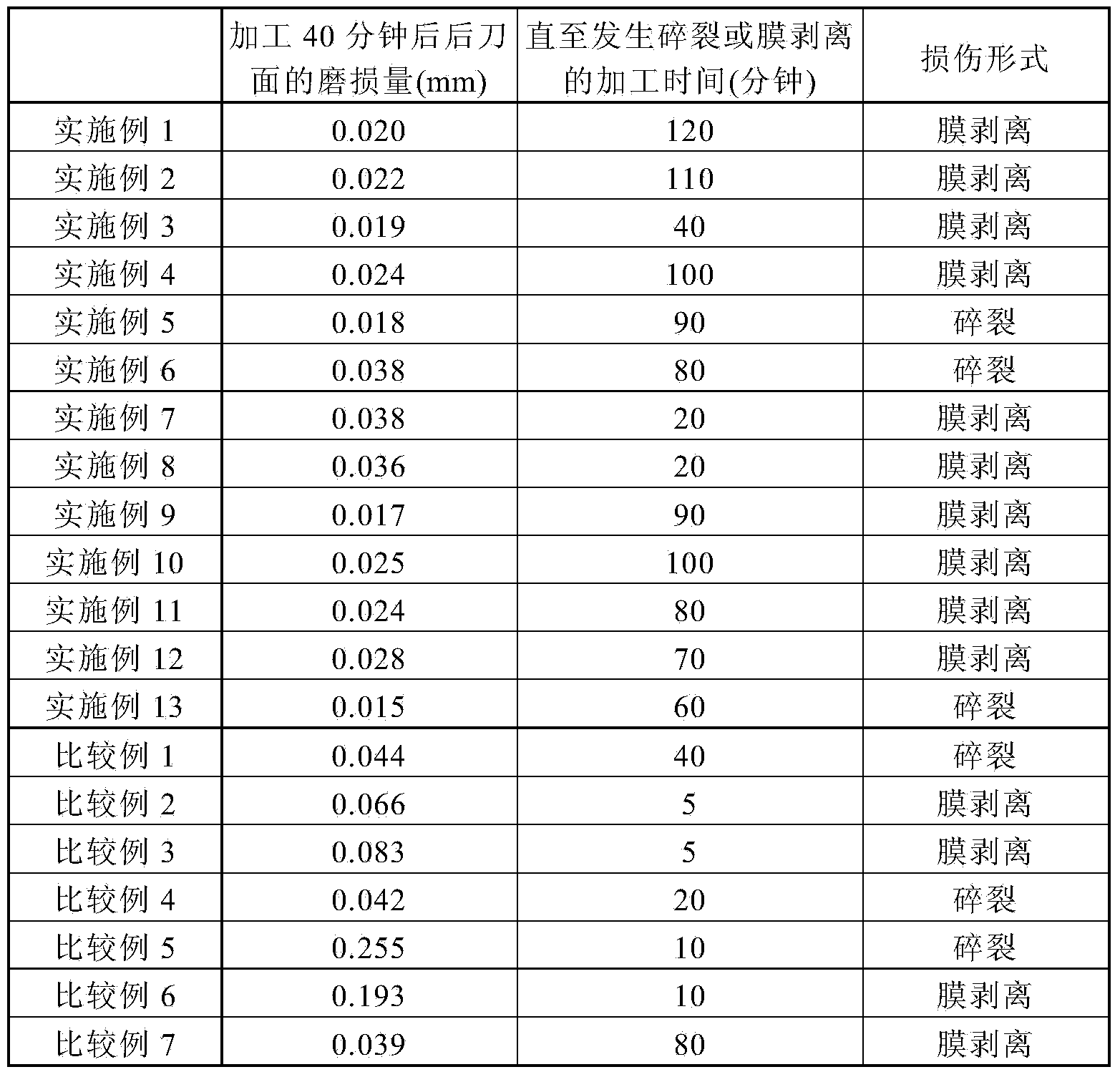

Diamond-coated tool

InactiveCN104053517AImprove overall lifespanImprove oxidation resistanceTransportation and packagingMilling cuttersNitrogenBoron

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

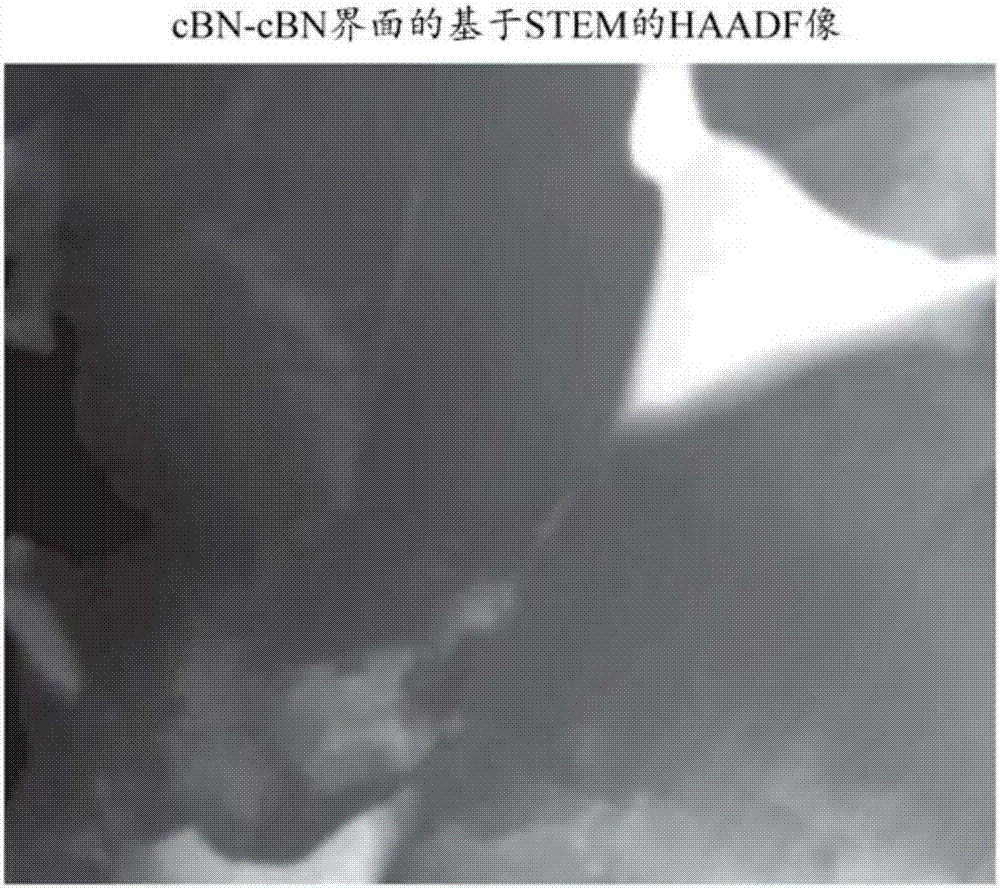

Sintered object based on cubic boron nitride, and cutting tool constituted of sintered object based on cubic boron nitride

A sintered object based on cubic boron nitride, the sintered object including 70-95 vol% cubic boron nitride grains. When the structure of a cross-section of the sintered object is examined, a binder phase having a width of 1-30 nm is observed between adjacent cubic boron nitride grains, the binder phase being constituted of a compound containing at least Al, B, and N, the ratio of the oxygen content to the Al content in the binder phase being 0.1 or less (in terms of atomic ratio).

Owner:MITSUBISHI MATERIALS CORP

Diamond coated tool

InactiveUS20140341664A1Improvement of lifetime characteristicImproves defect resistanceTransportation and packagingMilling cuttersBoronA diamond

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

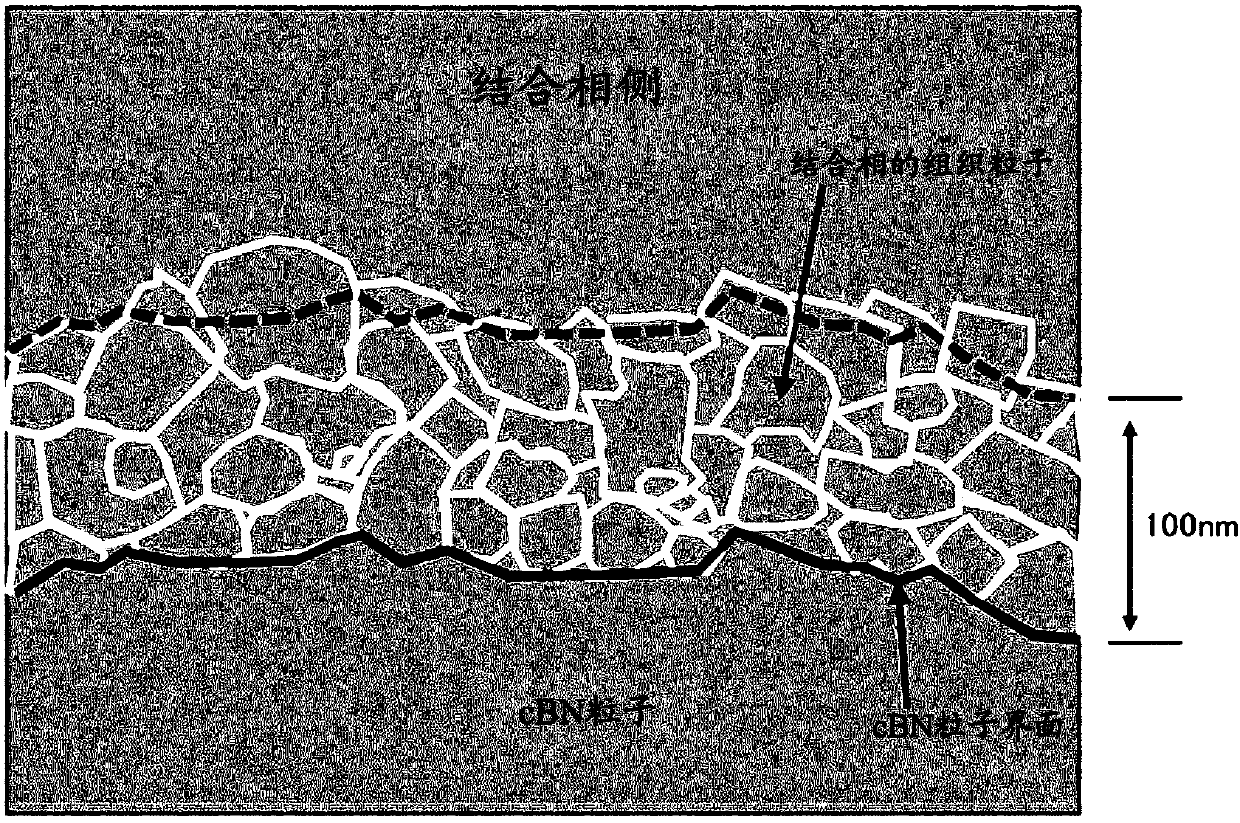

CBN sintered body cutting tool with excellent toughness

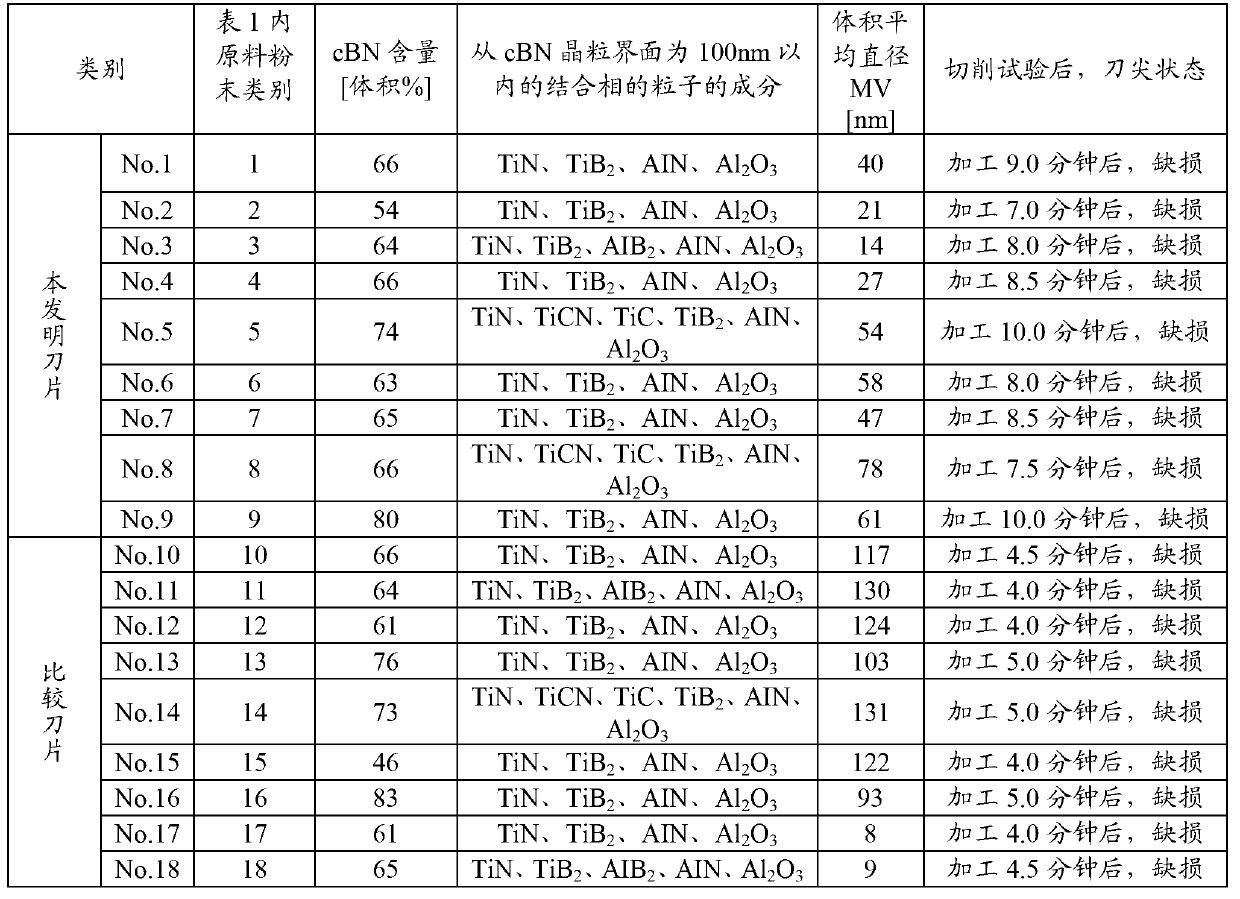

An object of the present invention is to provide a cBN sintered body cutting tool with excellent toughness. While being used for interrupted cutting of high-hardness steel even if in the situation requiring high-load cutting conditions, the cutting tool provided by the invention is prevented from proneness to the cracks and defects of the blade and has excellent cutting performance which can be maintained for a long term. The cBN sintered body cutting tool comprises a sintered body including cubic boron nitride and a binder phase as a tool substrate, wherein a binder phase structure is existed in the area within 100nm from the grain boundary of the cubic boron nitride towards the binder phase, and is composed of one or more than two selected from the group of nitrides, carbides, carbon nitrides and borides of Ti, nitrides, borides and oxides of Al, and solid solution of more than two of them, and inevitable impurities, and has fine structures with an average volume diameter MV of 10-80 nm. Thus, the object of the present invention is achieved.

Owner:MITSUBISHI MATERIALS CORP

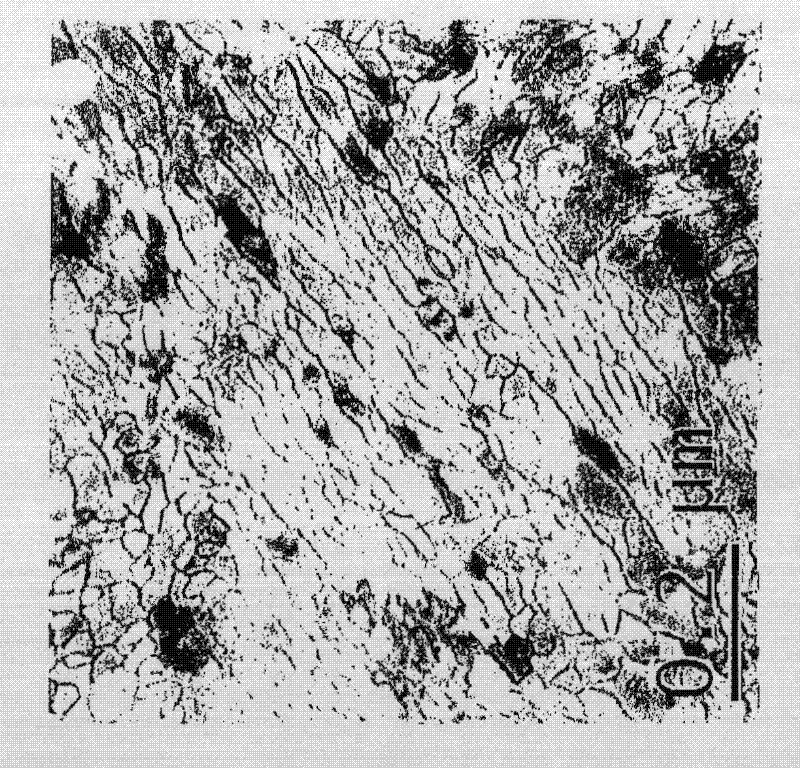

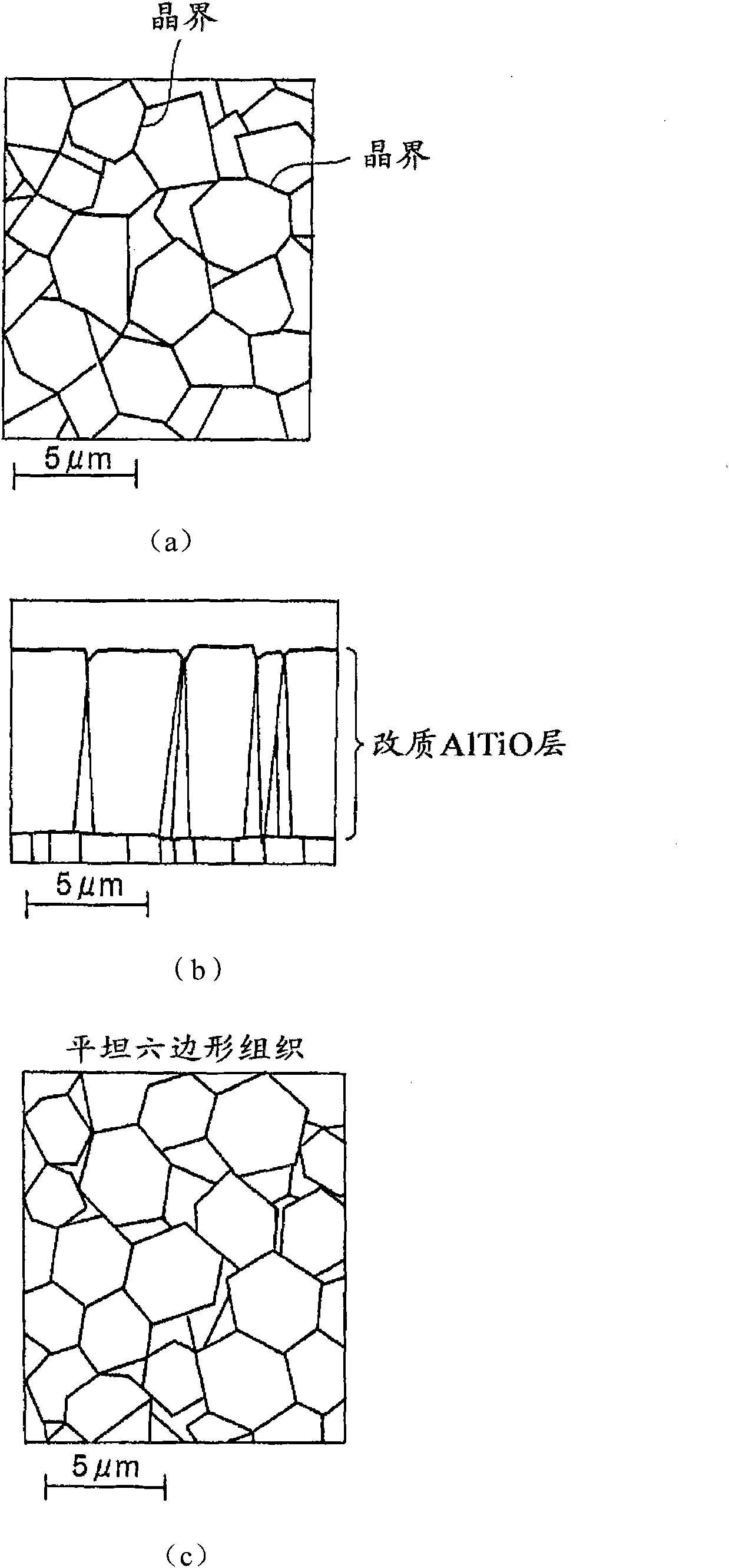

Blade-breaking-resistant surface-coated cutting tool with excellent rigid coating layer performance

InactiveCN102465257ANo chippingNo defectsVacuum evaporation coatingSputtering coatingGrain structureMachining

The invention provides a blade-breaking-resistant surface-coated cutting tool with an excellent rigid coating layer performance during high-speed heavy-cutting machining. On the surface of a tool matrix, for a lower part layer (a), a Ti compound layer is formed through vapor deposition, and for an upper part layer, an alpha-type Al2O3 surface which has a panel polygon (consisting of a flat hexagon) and vertical long grain structure and contains Ti is formed through vapor deposition to be coated on the cutting tool, and among the grains of the upper part layer, the interiors of the grains with the area ratio being more than 60% are segmented by at least two lattice interfaces which are expressed by sigma 3 and constituted in the form of constituent atom common lattice points.

Owner:MITSUBISHI MATERIALS CORP

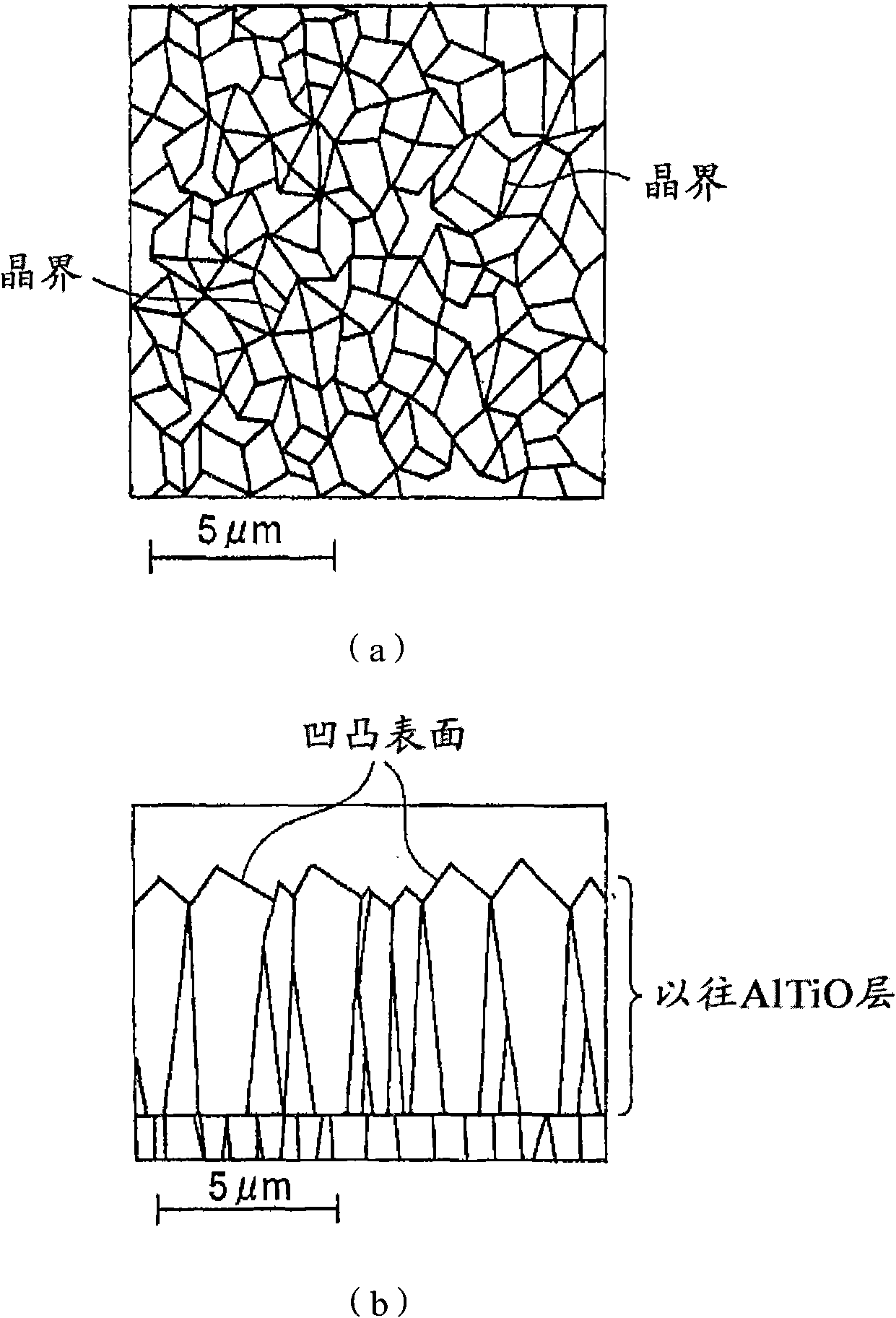

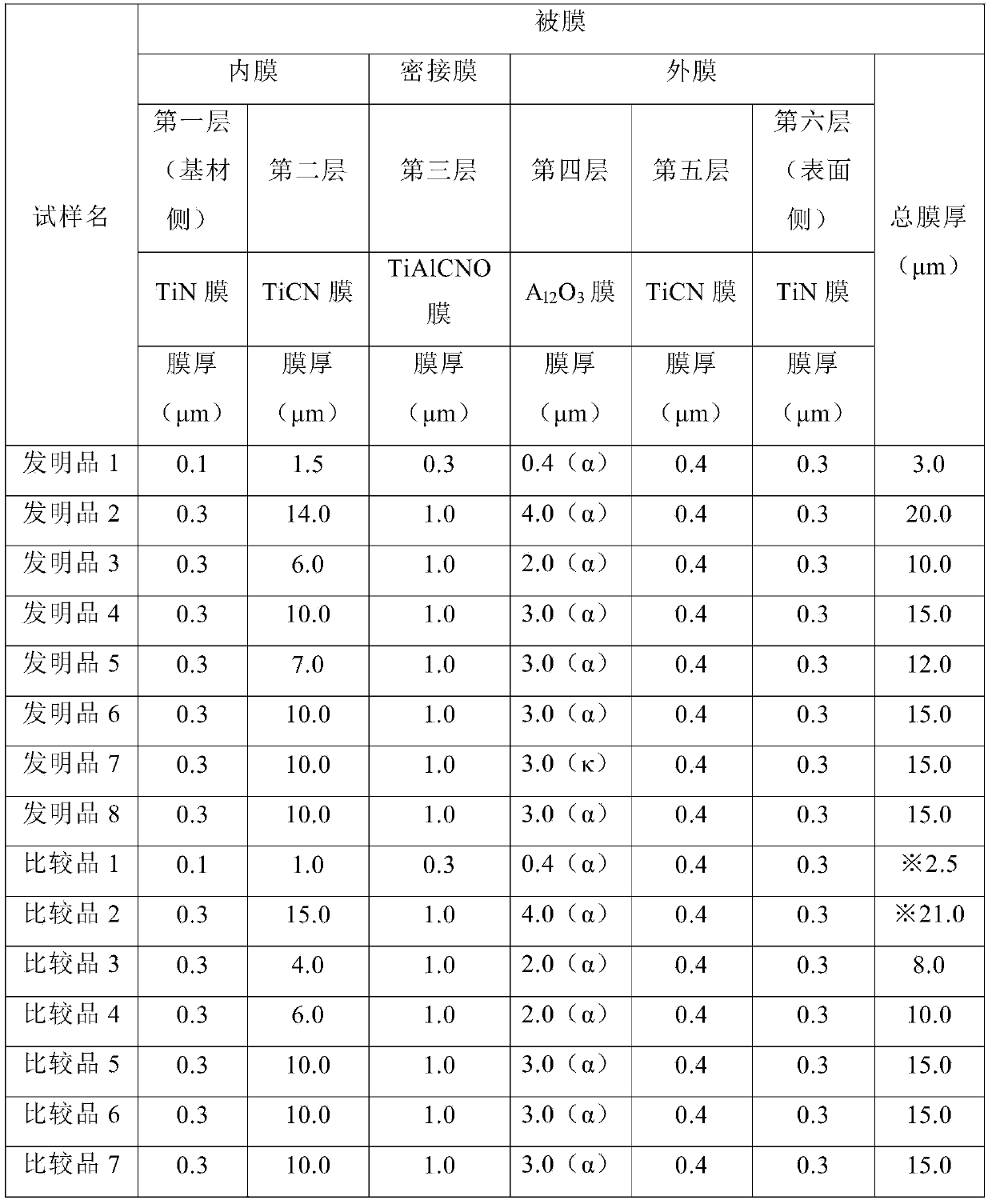

Surface-coated cutting tool with excellent cutter breakage resistance by hard coating layer

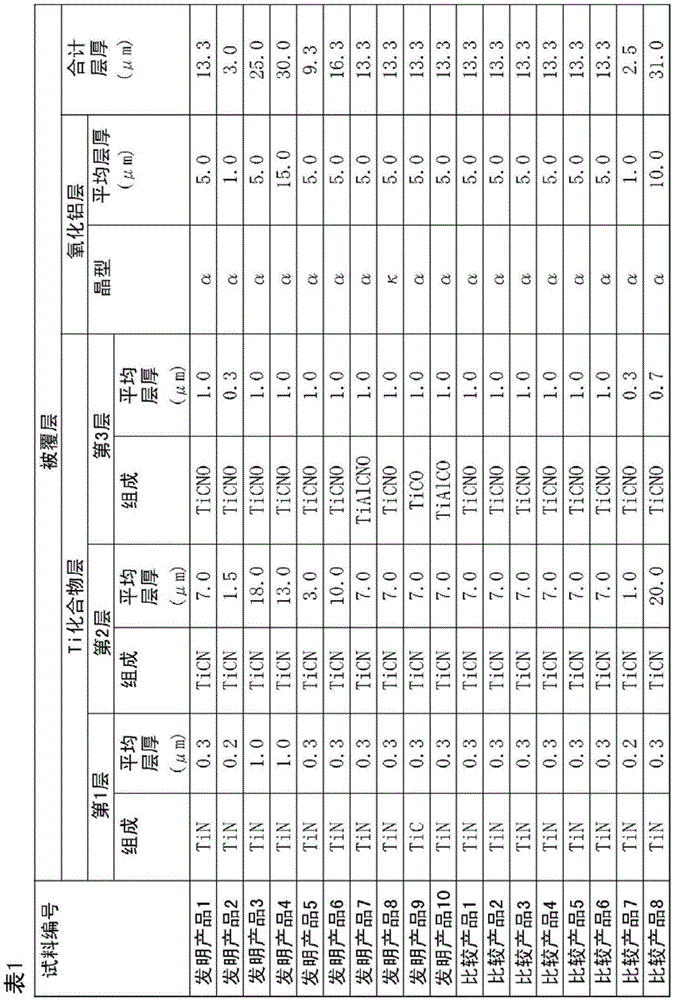

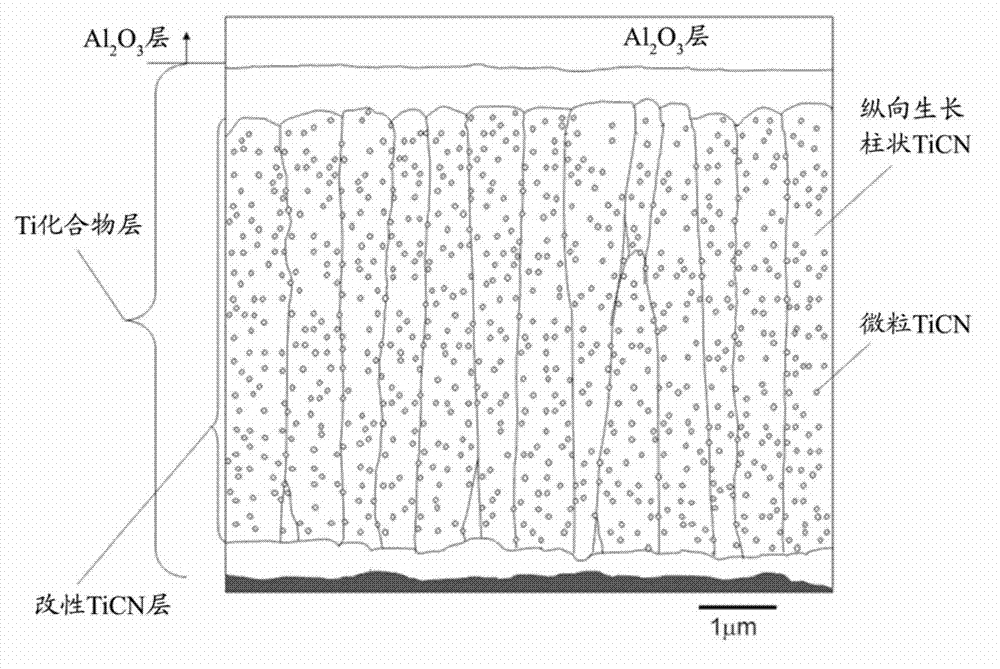

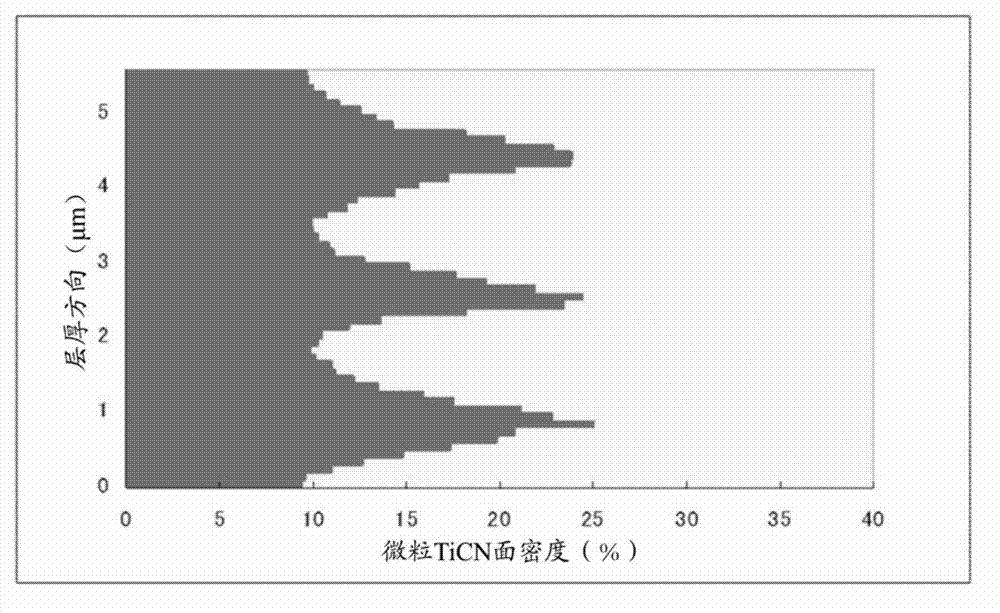

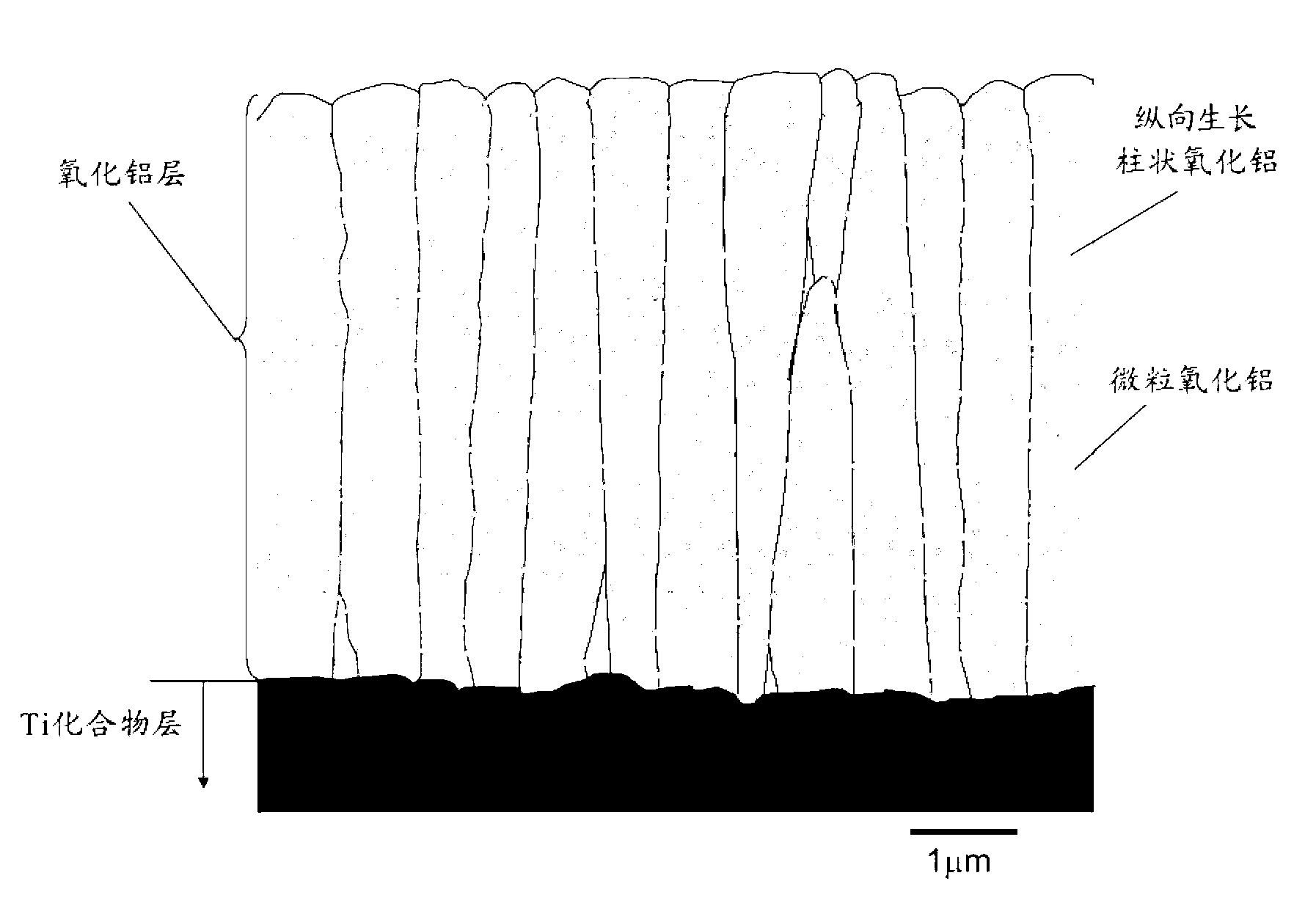

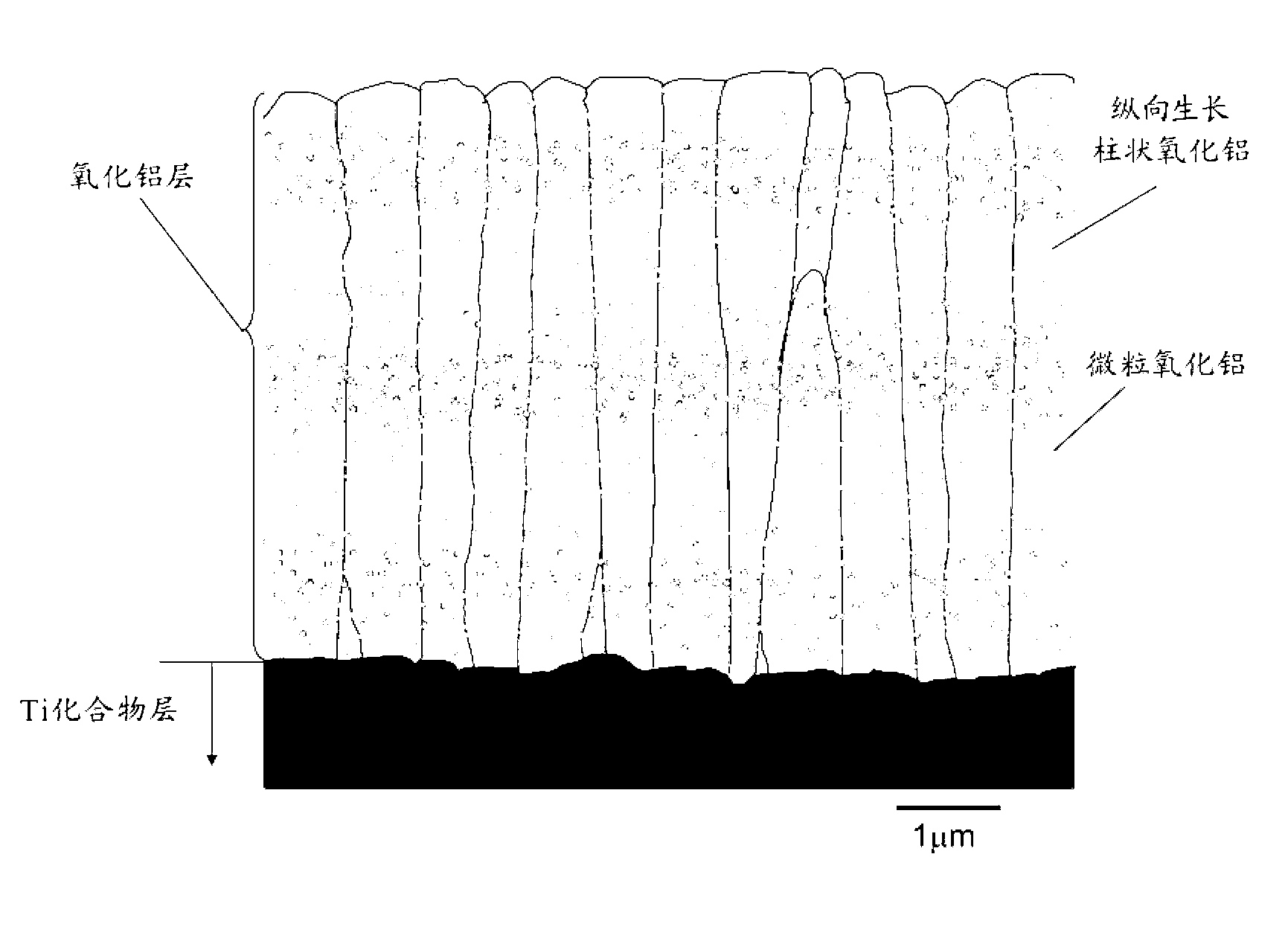

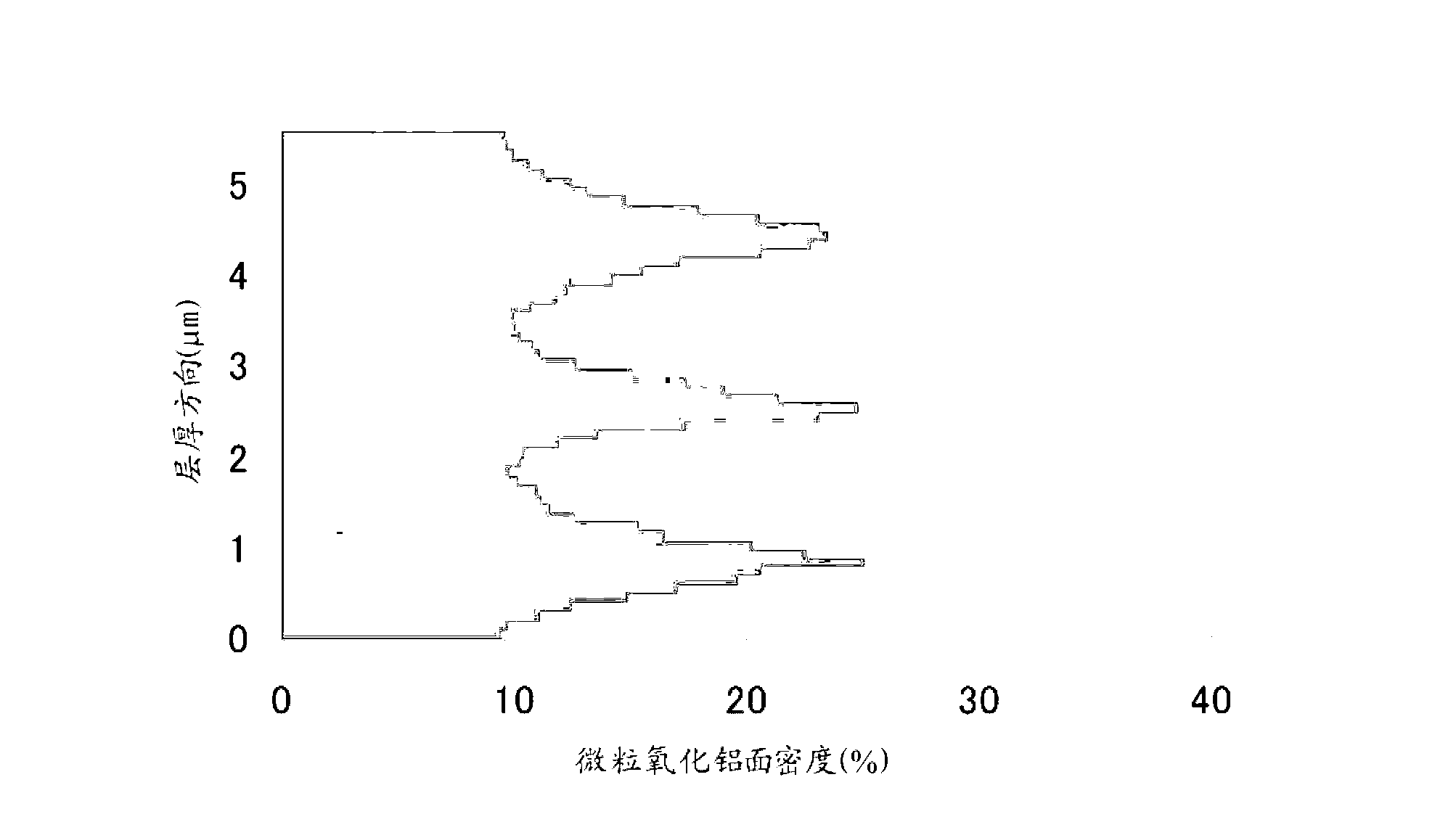

ActiveCN103008696AAchieve long lifeImprove impact performanceTurning toolsChemical vapor deposition coatingLayer thicknessChemical vapor deposition

The present invention provides a surface-coated cutting tool with excellent cutter breakage resistance and fracture resistance by a hard coating layer in high-speed intermittent cutting machining. The surface-coated cutting tool provided by the invention settles the task according to a technical solution which is characterized in that: the hard coating layer is composed of a lower layer and an upper layer which are treated by chemical vapor deposition; (a) the lower layer is Ti compound layer, the Ti compound layer at least comprises one Ti carbonitride layer and one layer or more than two layers of layers with a sum average layer thickness of 3-20 mu m; (b) the upper layer is an aluminum oxide layer with an average layer thickness of 1-25 mu m; at least one Ti carbonitride layer which constitutes the lower layer is provided with a cylindrical longitudinal-growing TiCN crystal tissue, and furthermore particle TiCn are dispersedly arranged in the tissue of the Ti carbonitride layer.

Owner:MITSUBISHI MATERIALS CORP

Cutting tool prepared from cubic crystalline boron nitride ultrahigh pressure sintering material

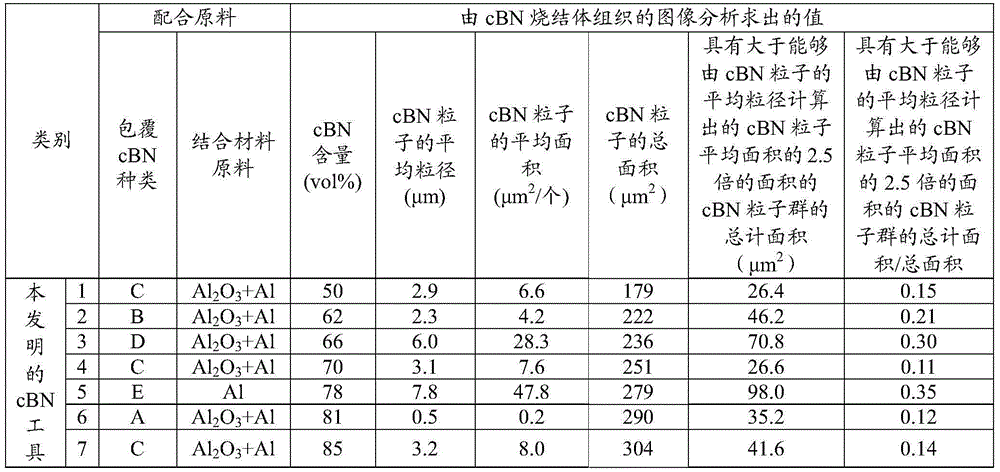

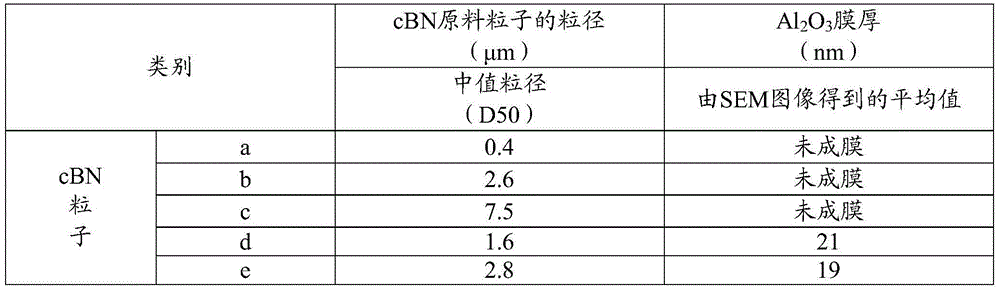

ActiveCN104942555AExtend your lifeImproved defect resistanceTurning toolsBoron nitrideMaterials science

The invention provides a cutting tool prepared from a cubic crystalline boron nitride ultrahigh pressure sintering material, and the cutting tool exhibits excellent defect resistance in steel and cast-iron cutting. The cutting tool prepared from the cubic crystalline boron nitride ultrahigh pressure sintering material comprises, by volume, 50-85%, preferably 70-85%, of cubic crystalline boron nitride particles, with the balance mainly being aluminum oxide. When the detection is carried out on the cross section of the cubic crystalline boron nitride ultrahigh pressure sintering material, the total area of cubic crystalline boron nitride particles swarms accounts for higher than 10% and lower than 35% of the total area of the cubic crystalline boron nitride particles, the area of the cubic crystalline boron nitride particles swarms is larger more than 2.5 times of the average area of the cubic crystalline boron nitride particles, and the average area can be obtained through the calculation on the average particle size of the cubic crystalline boron nitride particles, so that the defect resistance is improved.

Owner:MITSUBISHI MATERIALS CORP

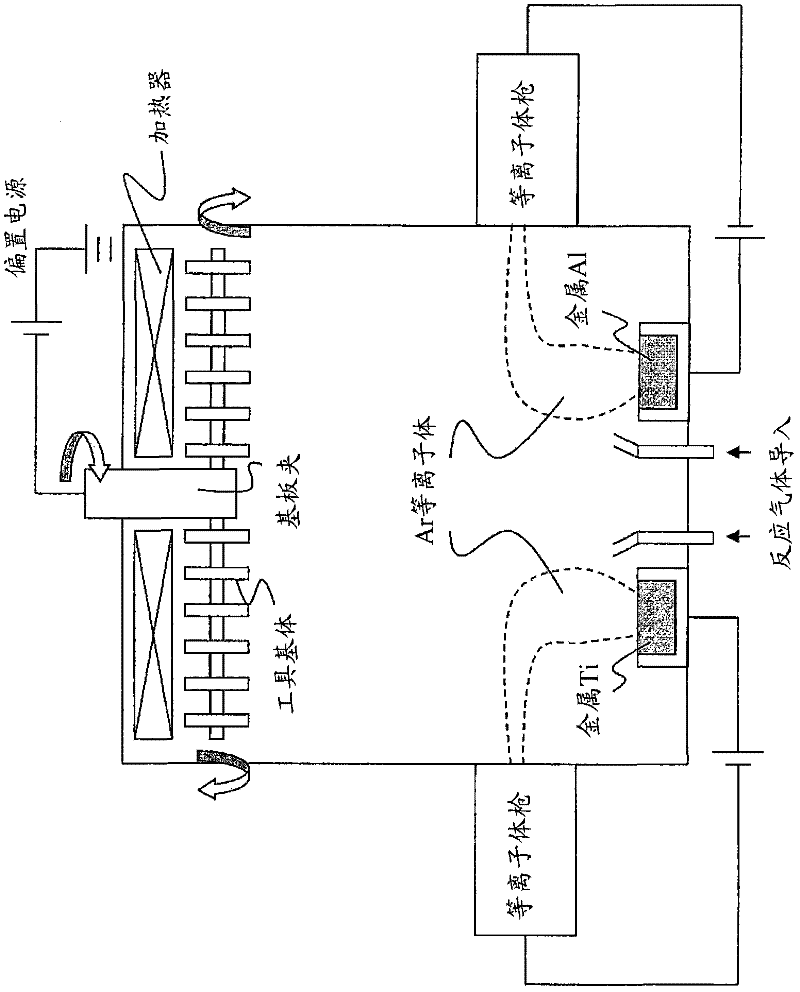

Surface wrapping cutting tool having excellent defect resistance and stripping resistance of hard wrapping layer

ActiveCN102371378AImproved defect resistanceEnhanced resistance to peelingLayered productsTransportation and packagingEngineeringSmall caliber

The invention provides a surface wrapping cutting tool giving plays to excellent defect resistance, stripping resistance and adhesive strength during a small-caliber low speed cutting or high speed heavy cutting process and having a heterogeneous extension interface of a hard wrapping layer. The surface wrapping cutting tool is characterized by wrapping to form a columnar crystal organization TiA1N layer on a WC hard substrate surface via a physical vapor deposition, and when the crystal particle interface length in which [0001]WC is parallel with [110] TiA1N and [10-10]WC is parallel with [001] TiA1N is XA, and the crystal particle interface length in which [0001]WC is parallel with [111] TiA1N and [11-20]WC is parallel with [110] TiA1N is XC, possessing the heterogeneous extension interface satisfying the relationship of 1>(XA+XC) / X>=0.3(wherein, the X represents the interface total length) on the WC hard substrate surface and the surface of the TiA1N layer.

Owner:MITSUBISHI MATERIALS CORP

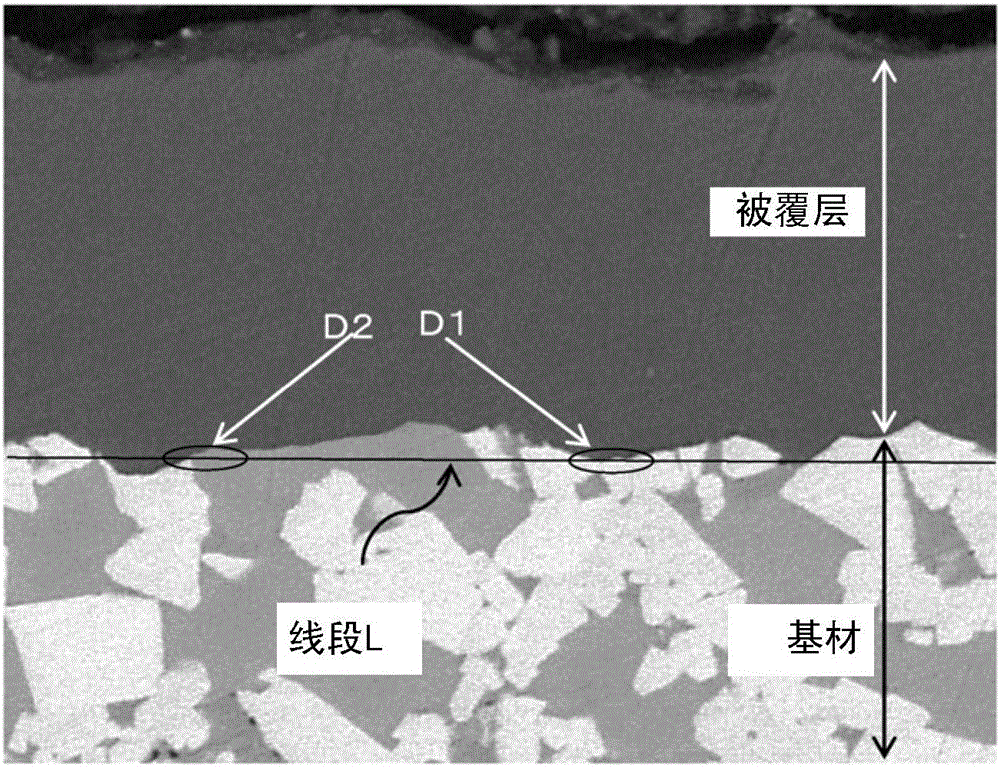

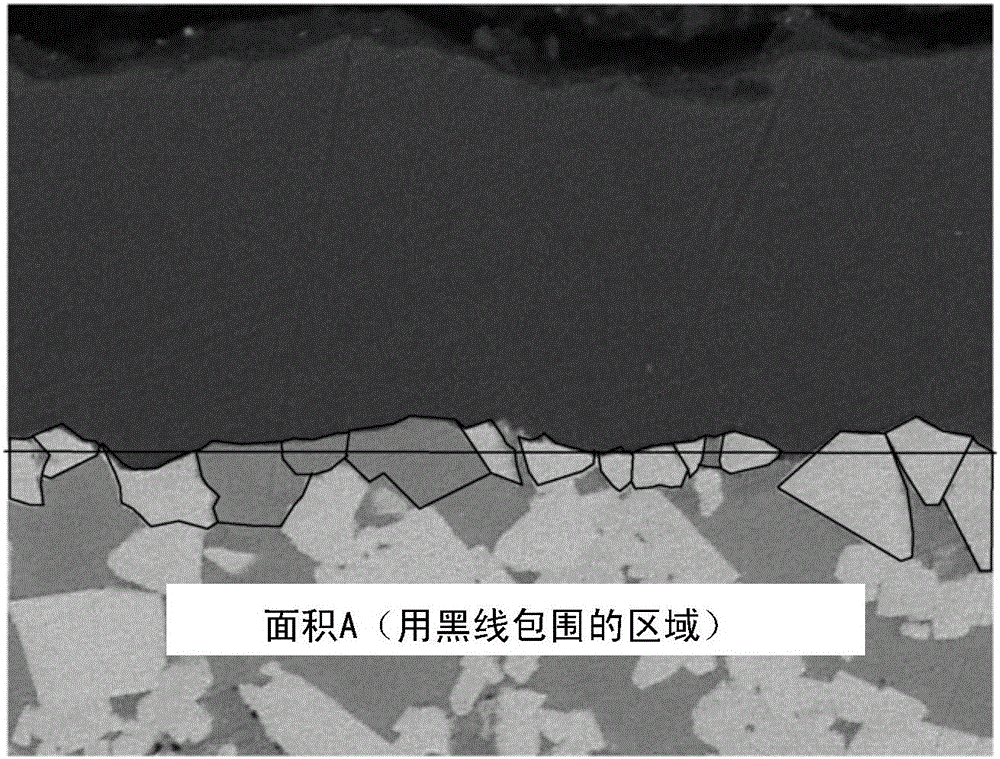

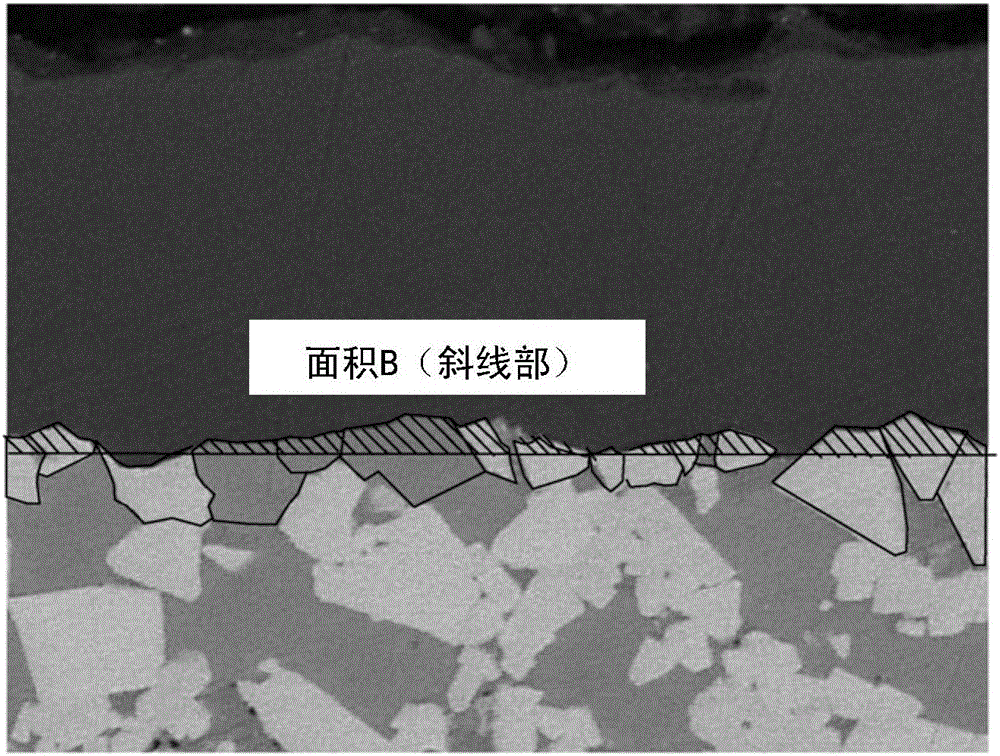

Coated tool

ActiveCN105764638AExcellent abrasion resistanceEnhanced resistance to peelingTransportation and packagingMilling cuttersWear resistantLine segment

Provided is a coated tool which is wear-resistant and damage resistant, and which has a long service life. This coated tool comprises a base material and a coating layer. The base material comprises a plurality of hard particles and a bonding phase that bonds the plurality of hard particles. The coating layer contains a compound layer. The ratio B / A determined by procedures (1) to (6) is at least 0.2 but less than 0.5. (1) A cross section perpendicular to the surface of the base material is extracted along a reference length (S) in a direction parallel to the surface of the base material. (2) In the cross section thus extracted, the total area (A) of the cross section of hard particles that touch the coating layer is determined. (3) At the interface between the coating layer and the base material, of the plurality of interface parts that are formed between adjoining hard particles, the first interface part (D1) which is at the deepest position, and the second interface part (D2) which is at the second deepest position, are determined. (4) A line (L) is drawn to pass through D1 and D2. (5) In the cross section of the hard particles which touch the coating layer, the total area (B) of the cross section that is on the coating layer side of the line (L) is determined. (6) The value for B / A is calculated.

Owner:TUNGALOY CORP

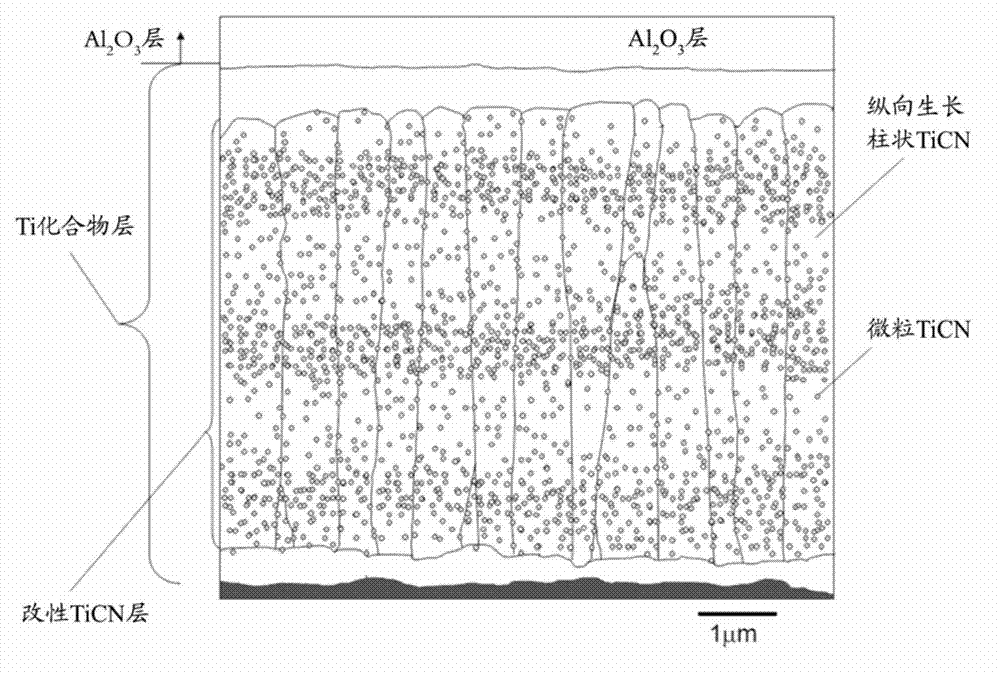

Surface coating cutting tool with hard coating layer playing excellent fracture resistance

InactiveCN103084598AAchieve long lifeImprove toughnessTurning toolsChemical vapor deposition coatingOxideAluminium oxide

The present invention provides a surface coating cutting tool with a hard coating layer playing excellent fracture resistance and excellent defect resistance in high-speed heavy cutting. The hard coating layer comprises a lower layer and an upper layer formed through chemical vapor deposition, wherein (a) the lower layer is a Ti compound layer which comprises at least one layer or more than two layers from the groups of a Ti carbonitride layer, a nitride layer, a carbonitride layer, a oxycarbide layer and a oxycarbonitride layer, and has a total average layer thickness of 3-20 [mu]m; and (b) the upper layer is an alumimum oxide layer having an average layer thickness of 2-25 [mu]m, the alumimum oxide layer forming the upper layer has a columnar longitudinal growth alumimum oxide crystal structure in which particles alumimum oxide are dispersed and distributed.

Owner:MITSUBISHI MATERIALS CORP

Surface-coated cutting tool having hard coating layer that exhibits excellent chipping resistance

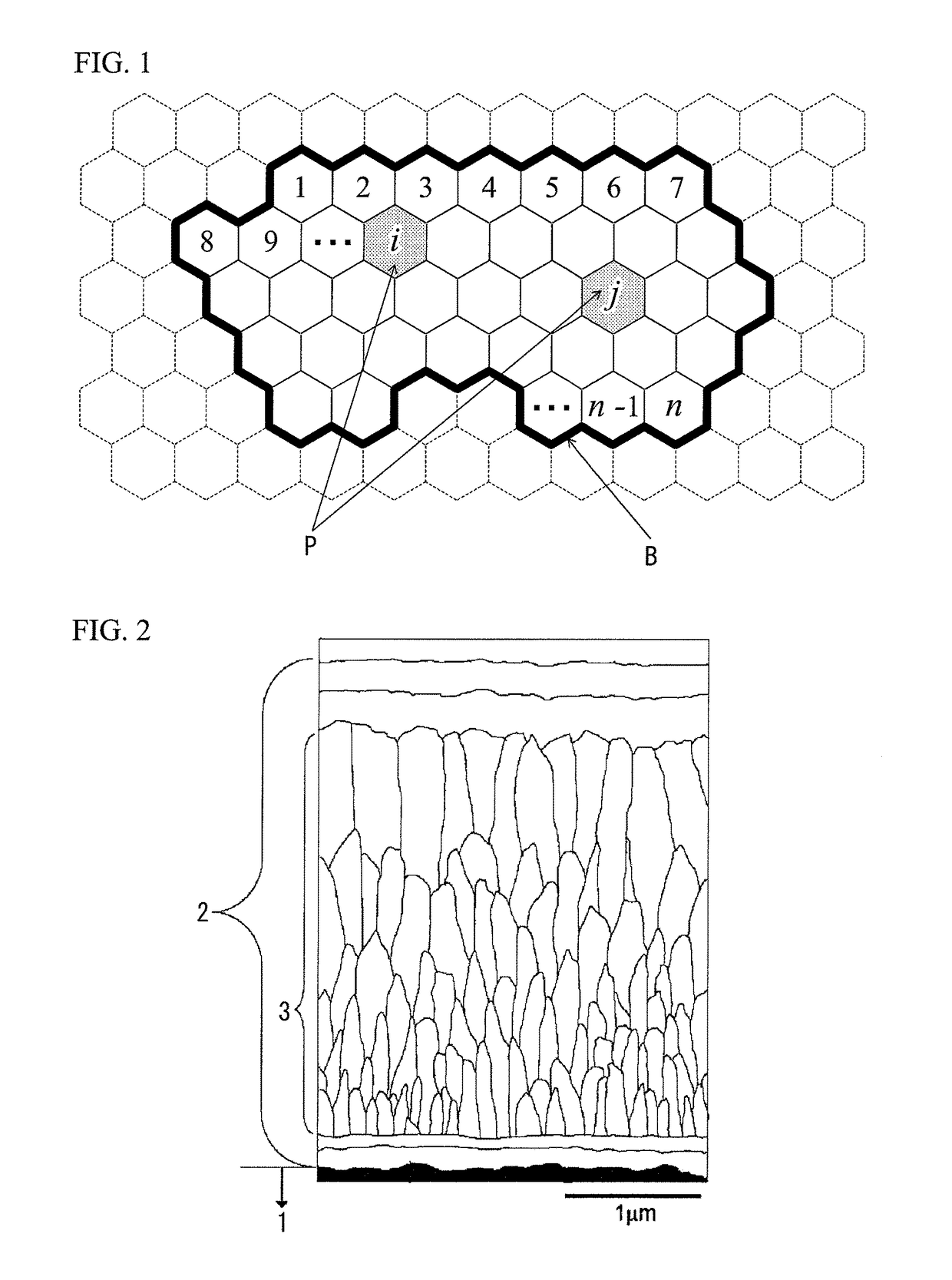

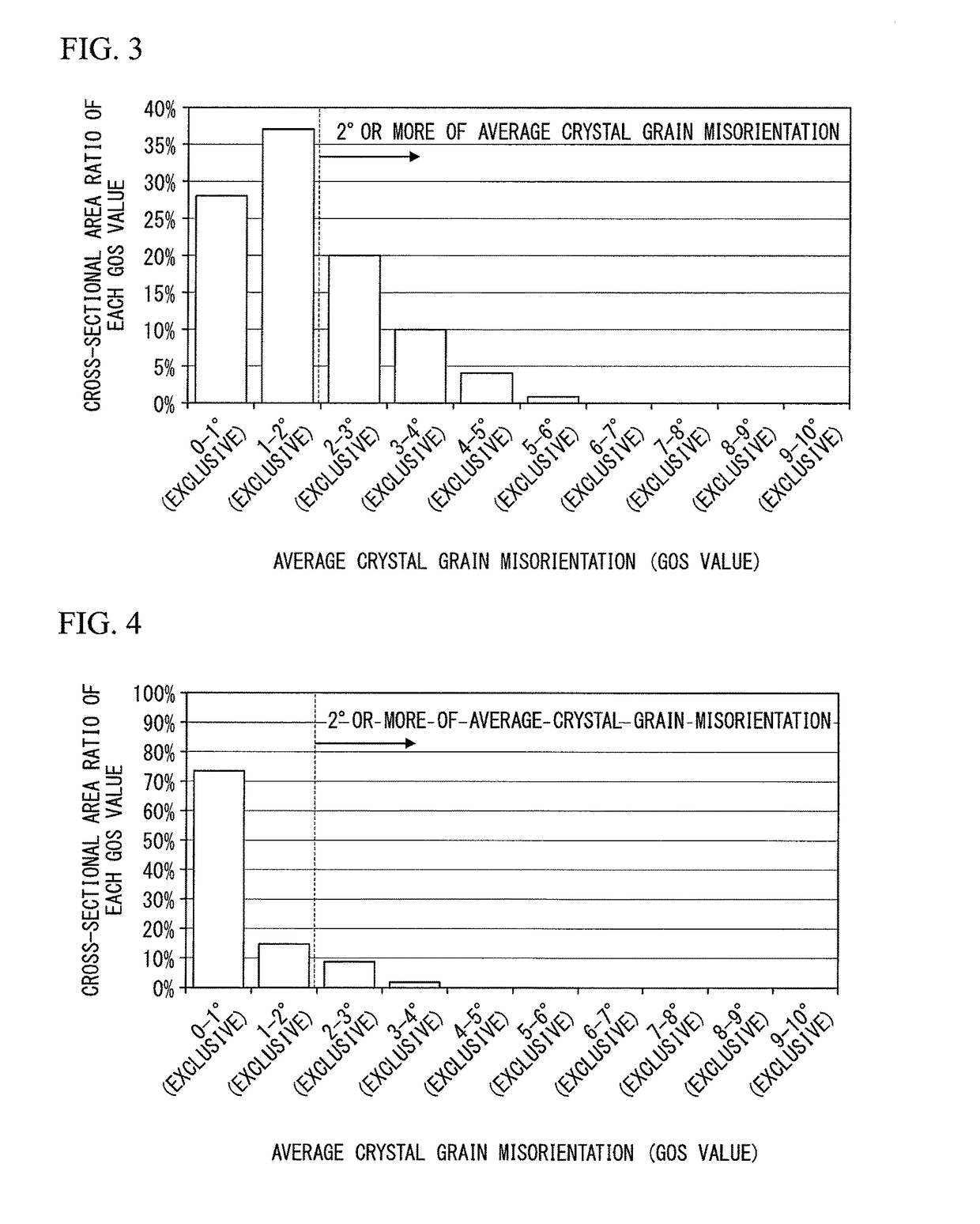

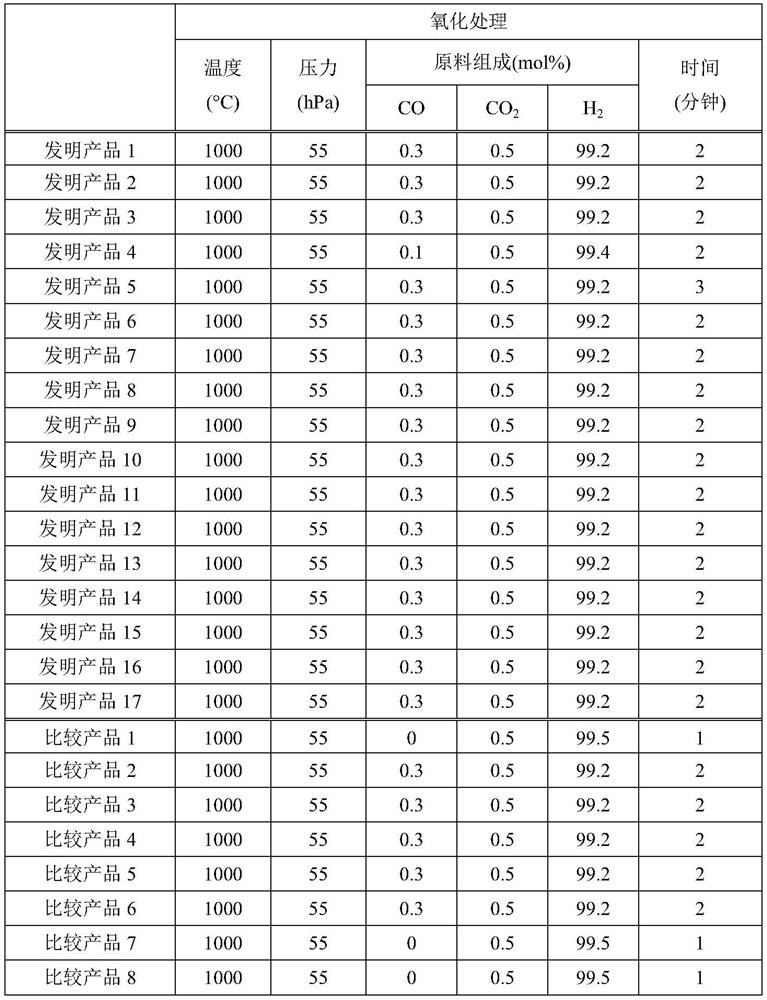

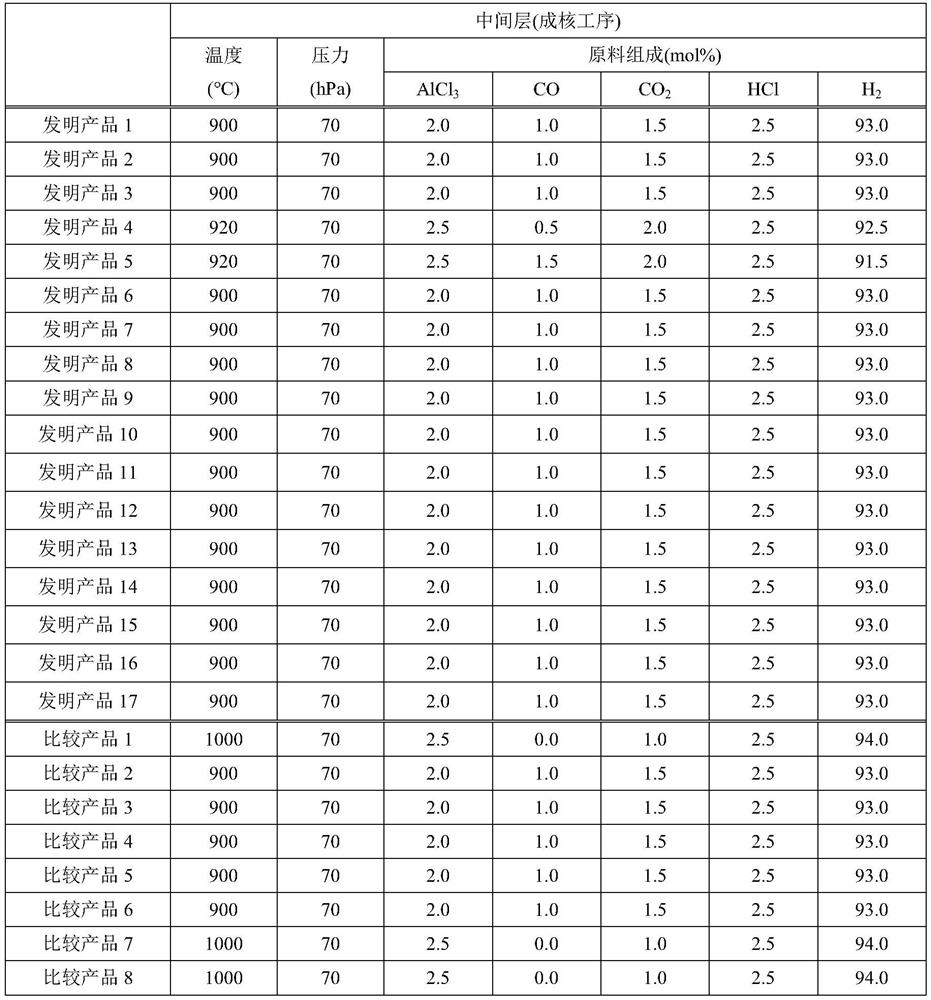

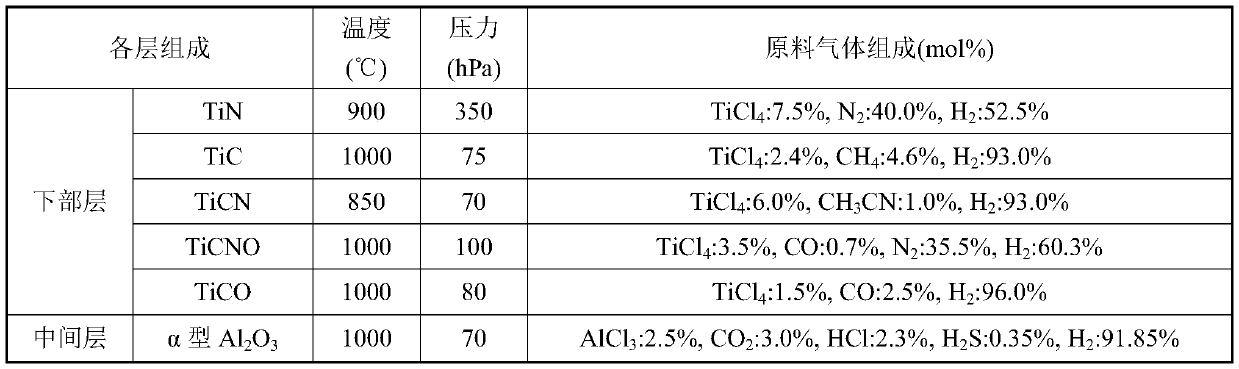

ActiveUS20170198400A1Reduce resistanceImprove cutting performanceTurning toolsChemical vapor deposition coatingNitrideMaterials science

The hard coating layer includes at least a complex nitride or complex carbonitride layer expressed by the composition formula (Ti1-xAlx)(CyN1-y). The average Al content ratio xavg the average C content ratio yavg satisfy 0.60≦xavg≦0.95 and 0≦yavg≦0.005, respectively, each of the xavg and yavg is in atomic ratio. The crystal grains constituting the complex nitride or complex carbonitride layer include a crystal grain having the cubic structure. Predetermined average crystal grain misorientation and inclined angle distribution exist in the crystal grains having the cubic structure.

Owner:MITSUBISHI MATERIALS CORP

Surface coating cutting tool with excellent defect resistance and abrasion resistance

ActiveCN103124608AImprove wear resistanceImproved defect resistanceMilling cuttersVacuum evaporation coatingTO-18Acute angle

Provided is a surface coating cutting tool with superior defect resistance and abrasion resistance. A surface coating cutting tool having a hard coating layer coated and formed on the surface of a tool substrate by means of a physical vapor deposition method, wherein the hard coating layer is formed of a compound carbonitride layer or a compound nitride layer with an average layer thickness of 0.5 to 8.0 [mu]m expressed by the compositional formula (Al1-x-yTixSiy)(N1-zCz), the hard coating layer contains metallic particles with an average sectional major axis of 0.05 to 0.5 [mu]m in which 90 at% or more of the constituent elements are metallic elements, the metallic particles are dispersed and distributed in the hard coating layer at a longitudinal section area ratio of 3 to 18 %, the constituent elements contain Al of 50 at% or more among the metallic particles, and when the longitudinal sectional area ratio of a particle satisfying conditions such as the aspect ratio of the longitudinal sectional shape being 2.0 or more and the acute angle formed between the sectional major axis and the substrate surface being 45 DEG or less is taken as A%, and when the longitudinal sectional area ratio of another particle is taken as B%, 0.3<=A / (A+B).

Owner:MITSUBISHI MATERIALS CORP

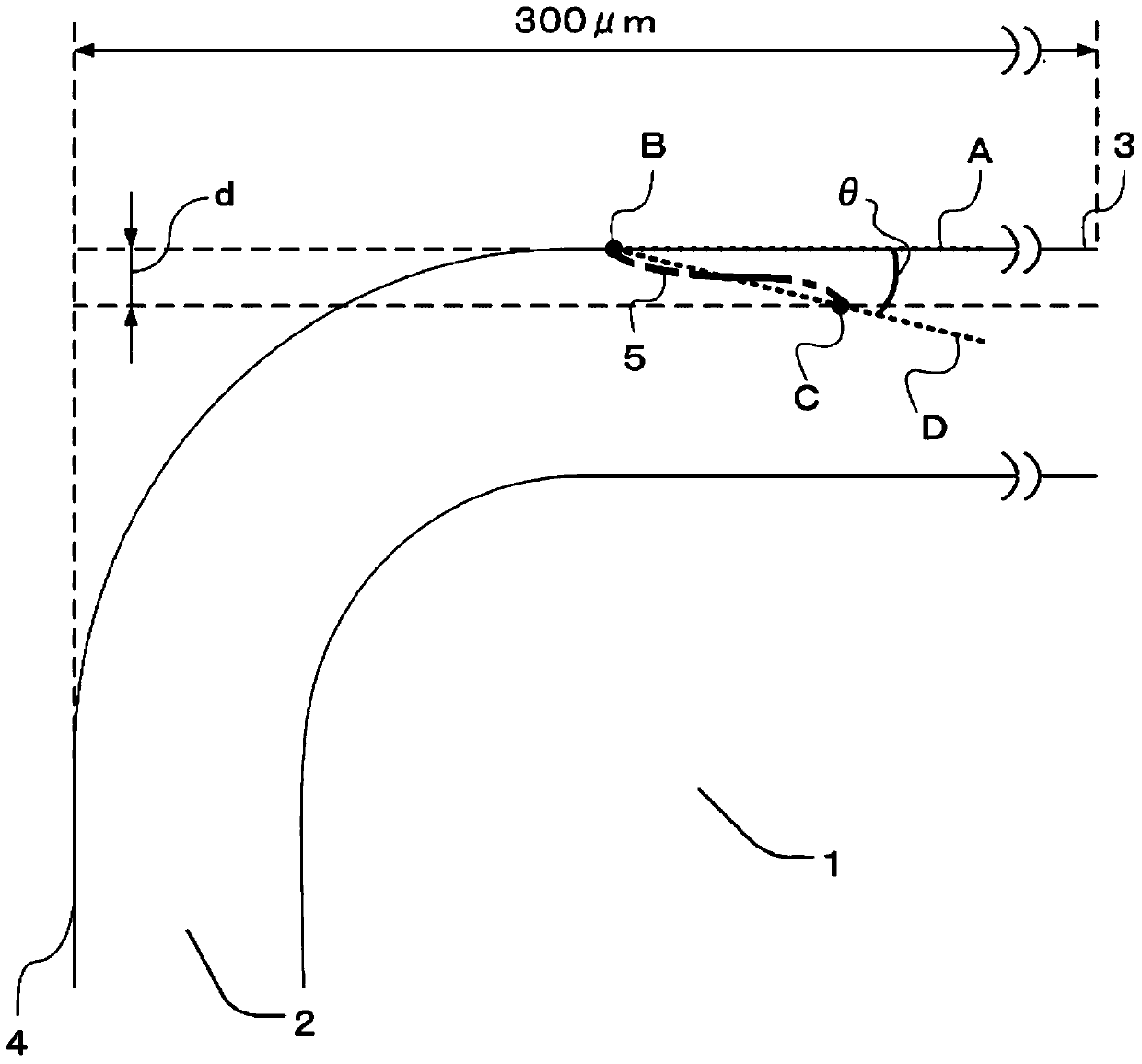

Surface-coated cutting tool

ActiveCN103826781AImprove peeling resistanceImproved defect resistanceMilling cuttersWorkpiecesDiagonal crackCemented carbide

The present invention provides a surface-coated cutting tool having excellent defect resistance, and relates to a surface-coated cutting tool characterized in comprising: a base material of WC-based cemented carbide and a coating formed by chemical vapor deposition on the surface of the base material; a cutting face, a flank face, and a cutting-blade ridgeline part disposed between the cutting face and the flank face being provided; the total film thickness of the entire coating having an average value of 3-20 [mu]m; and at least one diagonal crack having an advance angle of 45 DEG or less in relation to the surface of the coating being present on the cutting surface within 300 [mu]m of the cutting blade ridgeline part.

Owner:TUNGALOY CORP

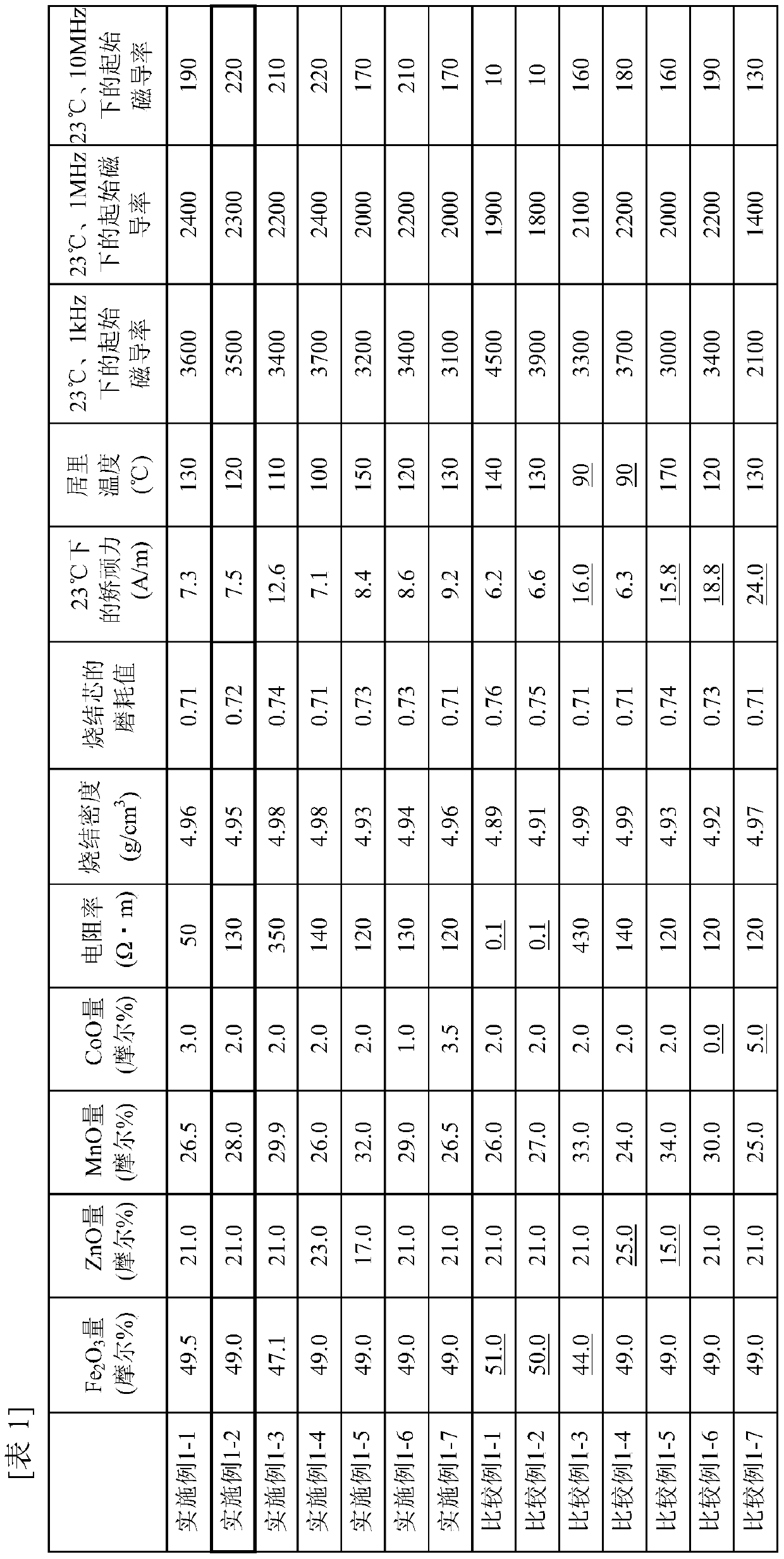

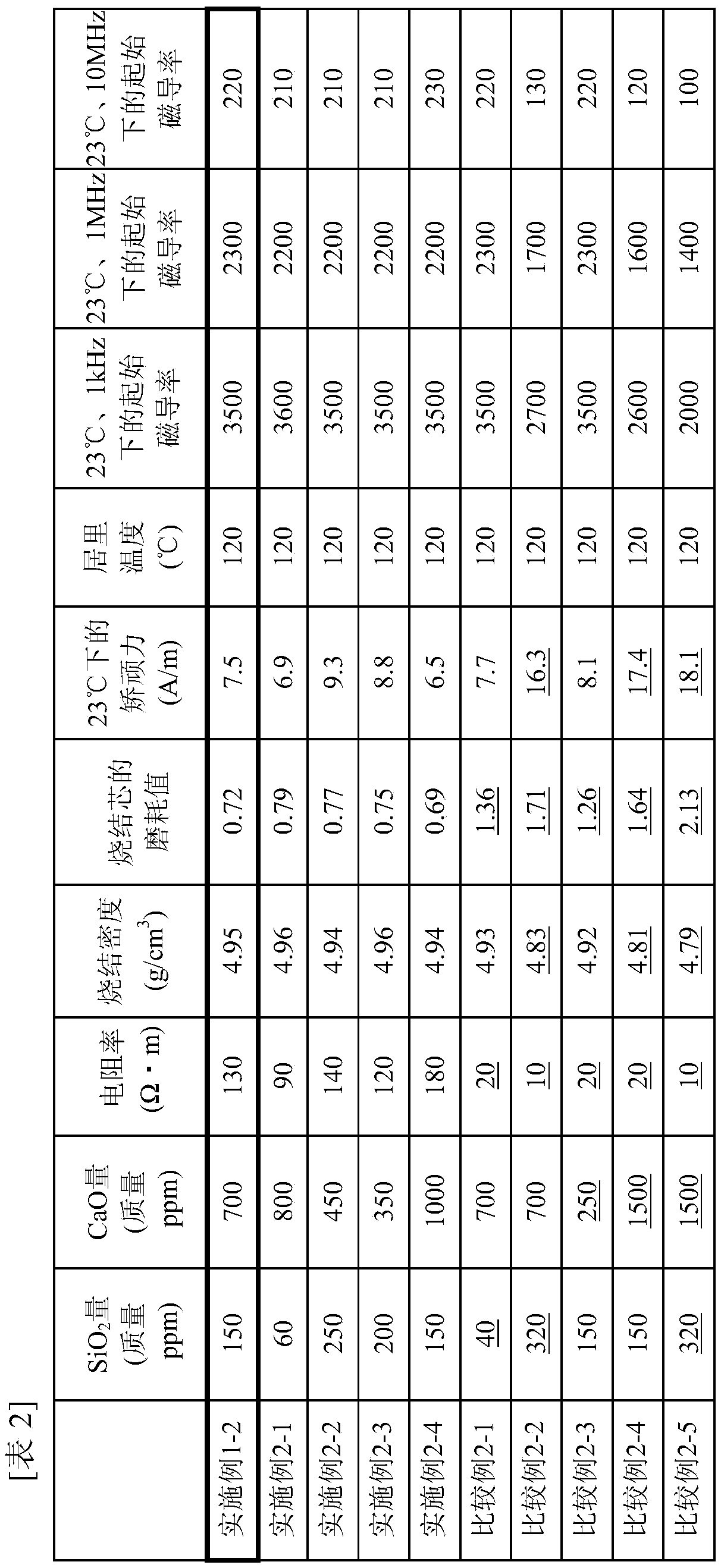

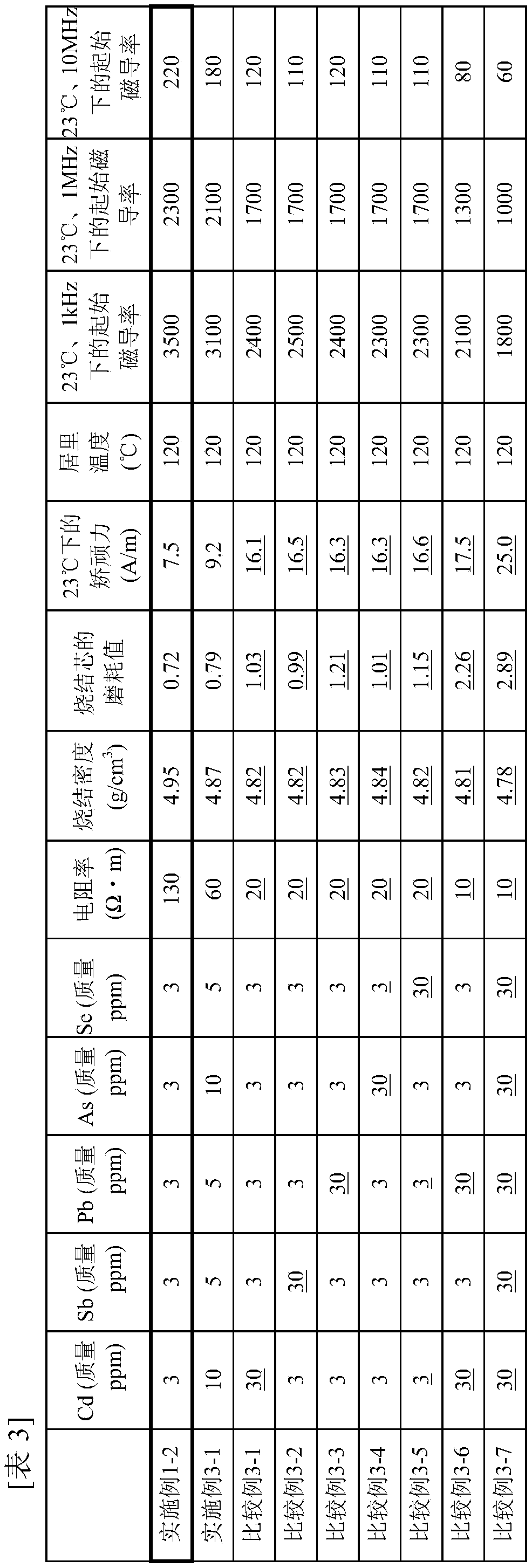

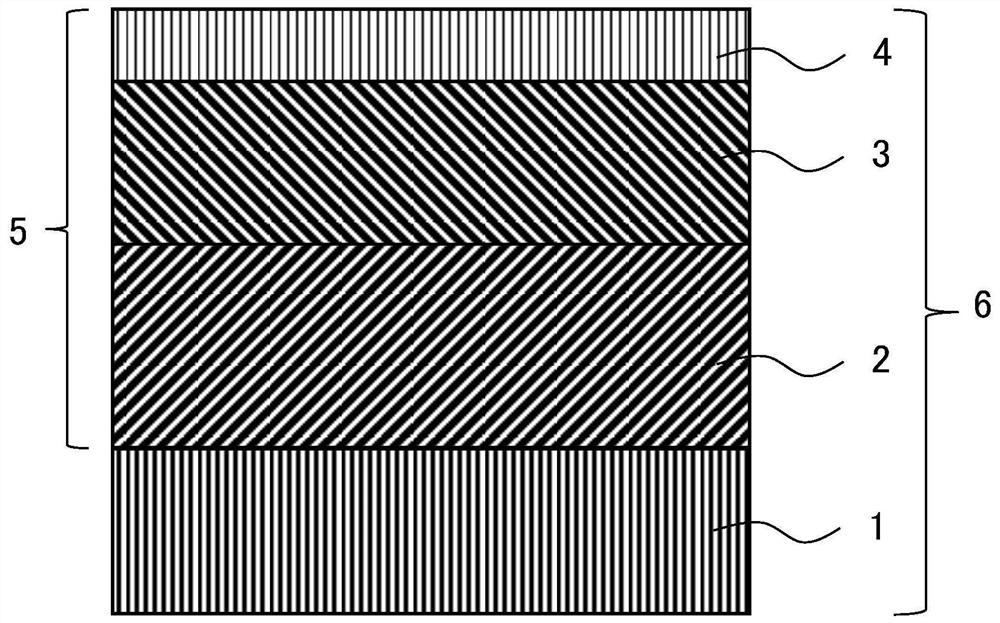

Mncozn ferrite and production method therefor

ActiveCN110178191AImproved defect resistanceGrowth inhibitionInorganic material magnetismIron compoundsHigh resistanceCurie temperature

This invention provides an MnCoZn ferrite containing, as basic constituents, 45.0% by mole or more but less than 50.0% by mole of iron calculated as Fe2O3, 15.5 to 24.0% by mole of zinc calculated asZnO, and 0.5 to 4.0% by mole of cobalt calculated as CoO with the balance being manganese, and containing, as sub-constituents to the basic constituents, 50 to 300 ppm by mass of SiO2 and 300 to 1300ppm by mass of CaO, with the balance being unavoidable impurities, wherein the amounts of Cd, Pb, Sb, As and Se in the unavoidable impurities are suppressed to less than 20 ppm by mass each, and furthermore, the Rattler value is brought to less than 0.85%, the coercive force at 23 DEG C to 15 A / m or lower, the specific resistance to 30 ohm*m or higher, and the Curie temperature to 100 DEG C or higher. In this manner, the MnCoZn ferrite not only has excellent magnetic properties of high resistance and low coercive force, but also has excellent mechanical strength.

Owner:JFE CHEMICAL CORP

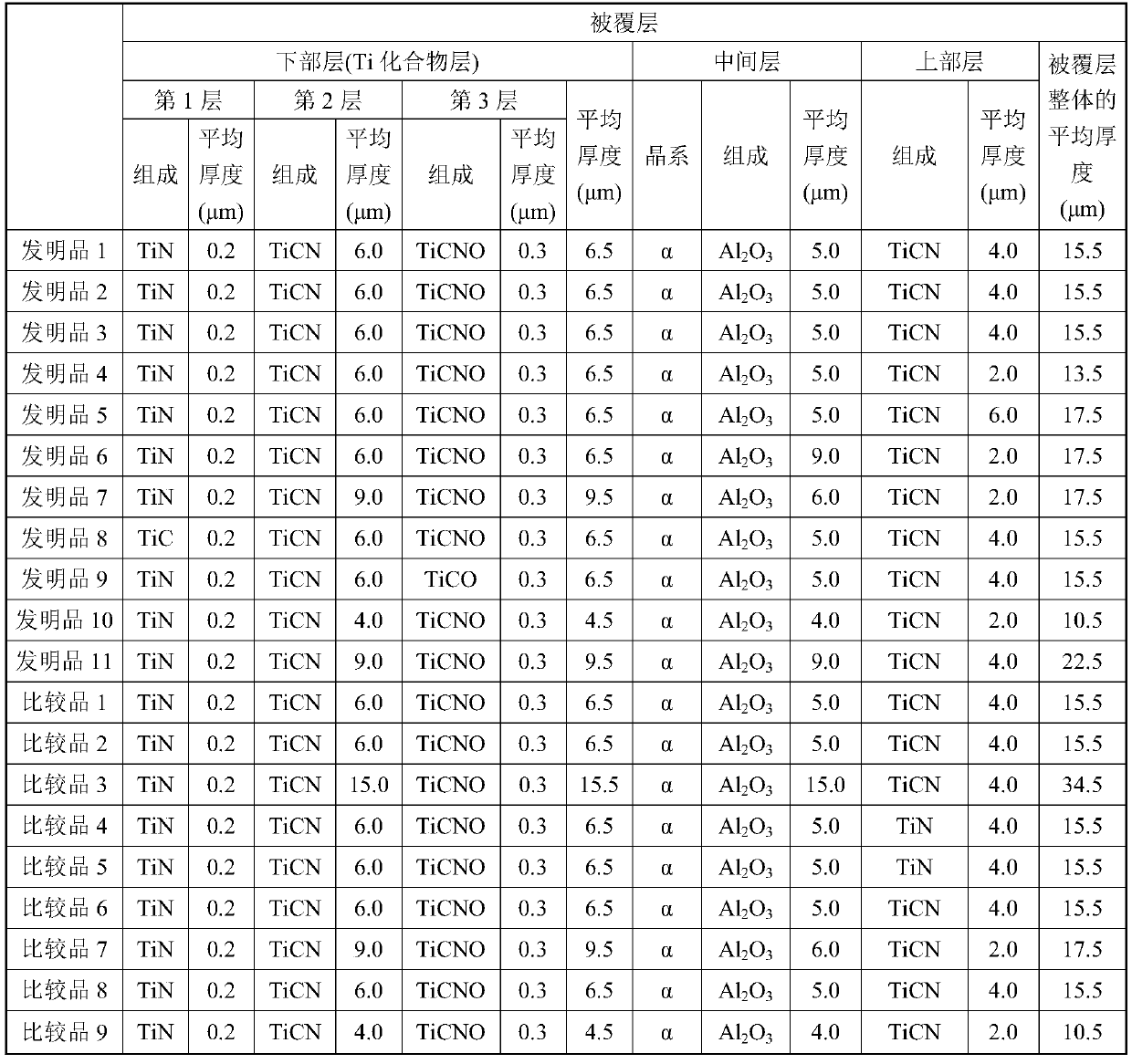

Coated cutting tool

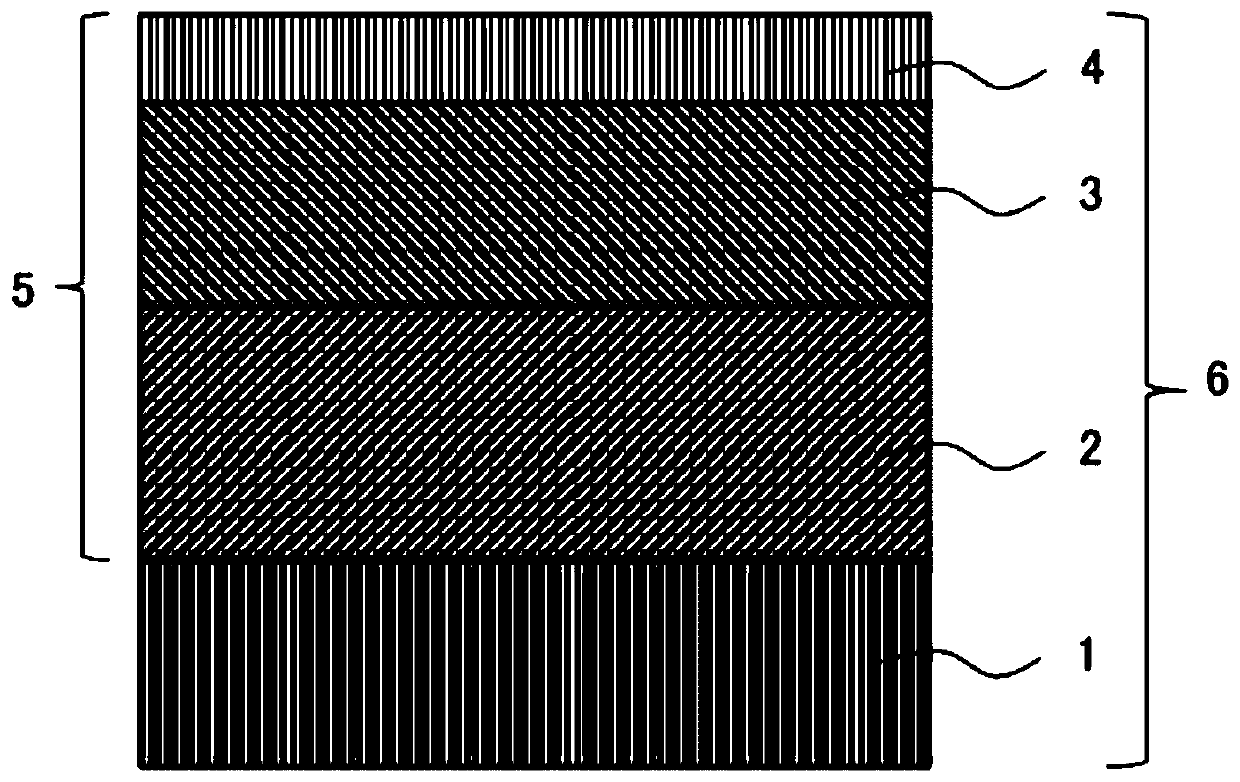

ActiveCN111940769AImprove wear resistanceImproved defect resistanceTransportation and packagingMilling cuttersInter layerEngineering

The invention provides a coated cutting tool which has excellent wear resistance and defect resistance, so that the service life of the tool can be prolonged. The coated cutting tool comprises a substrate and a coating layer formed on a surface of the substrate, wherein the coating layer includes a predetermined lower layer, an intermediate layer comprising alpha-Al2O3, and an upper layer comprising TiCN; the lower layer, intermediate layer, and upper layer have predetermined average thicknesses; a condition represented by formula (1) [RSA>=40 (1)] is satisfied; the interface of the intermediate layer on the upper layer side has a kurtosis roughness (Sku) of more than 3.0; the interface of the intermediate layer on the upper layer side has a skewness roughness (Ssk) of less than 0; and a condition represented by formula (2) [RSB>=40 (2)] is satisfied.

Owner:TUNGALOY CORP

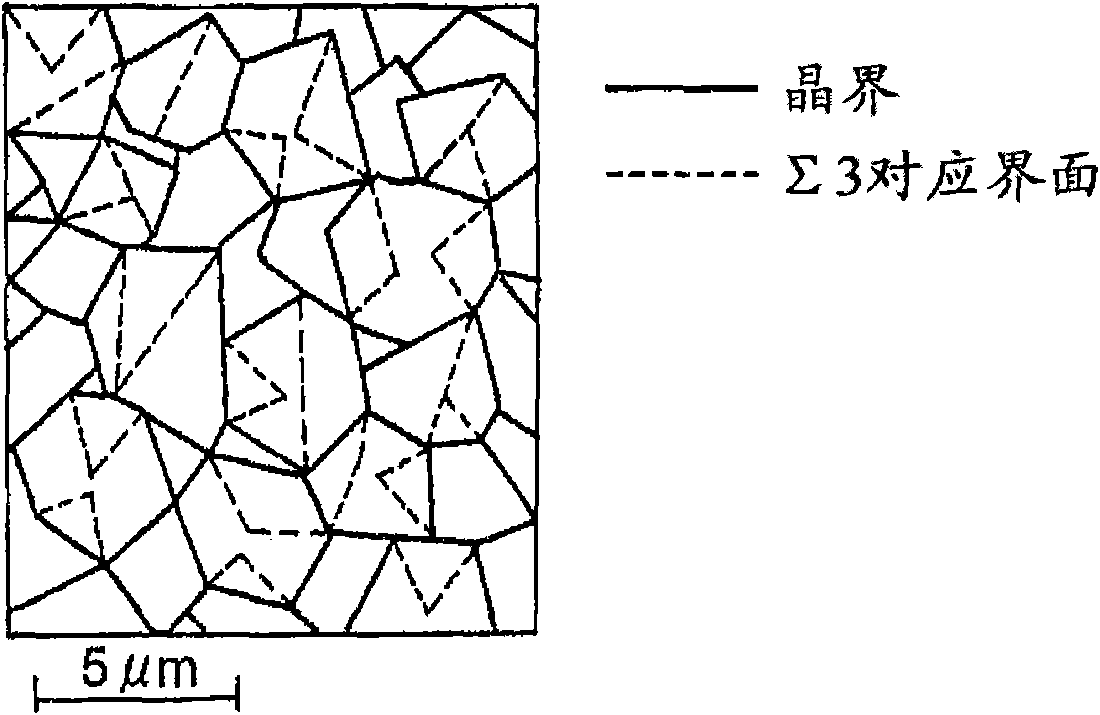

Coated cutting tool

ActiveCN110871279AImprove wear resistanceImproved defect resistanceWorkpiecesTurning toolsWear resistanceGrain boundary

An object of the present invention is to provide a coated cutting tool which has excellent wear resistance and fracture resistance and which accordingly allows for an extended tool life. The inventionrelates to a coated cutting tool comprising a substrate and a coating layer formed on a surface of the substrate, wherein: the coating layer comprises a lower layer, an intermediate layer and an upper layer, the lower layer, the intermediate layer and the upper layer being laminated in order from the substrate side toward a surface side of the coating layer; the lower layer comprises one Ti compound layer or two or more Ti compound layers; the intermediate layer contains alpha-Al2O3; the upper layer contains TiCN; an average thickness of the lower layer is from 4.0 [mu]m or more to 10.0 [mu]mor less; an average thickness of the intermediate layer is from 3.0 [mu]m or more to 10.0 [mu]m or less; an average thickness of the upper layer is from 1.5 [mu]m or more to 6.5 [mu]m or less; a ratio of a length of sigma3 grain boundaries to a total 100% length of all grain boundaries in a specific region of the upper layer is from 20% or more to 60% or less; and a ratio of (111)-oriented grainsin the upper layer is 30 area% or more.

Owner:TUNGALOY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com