High-hardness and high-strength WC-Co-based hard alloy and preparation method thereof and cutting tool

A cemented carbide, high-strength technology, used in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problem of difficulty in improving the strength of alloys, achieve increased strength and hardness, achieve high hardness and high strength performance, and inhibit aggregation. The effect of crystal formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

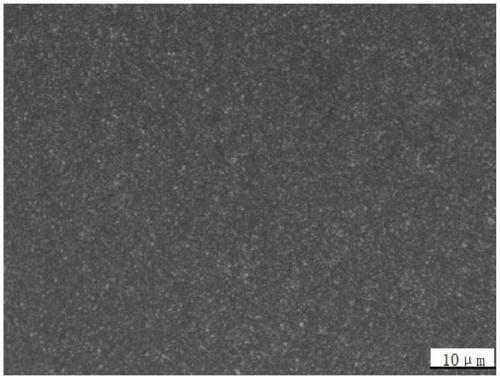

Image

Examples

Embodiment 1

[0028] A high-hardness and high-strength WC-Co-based cemented carbide, comprising the following raw materials in parts by weight: 80 parts of WC powder, 5 parts of Co powder, and 0.5 parts of additives;

[0029] The additive is composed of metal carbide Cr 3 C 2 and metal nitride Cr 3 N 2 composition.

[0030] The metal carbide accounts for 0.1% of the total mass of the raw material.

[0031] The metal nitride accounts for 0.1% of the total mass of raw materials.

[0032] The average particle size of the WC powder and Co powder is 0.3 μm.

[0033] A preparation method of high-hardness and high-strength WC-Co-based cemented carbide, comprising the following steps:

[0034] S1: Take WC powder, Co powder, and additives in proportion, use ethanol as the grinding medium, PEG (polyethylene glycol) as the binder, and mix them into initial materials. Under the same conditions, the ball mill was fully ground for 10 hours to form a mixture, which was dried, sieved, and molded int...

Embodiment 2

[0042] A high-hardness and high-strength WC-Co-based cemented carbide, comprising the following raw materials in parts by weight: 85 parts of WC powder, 10 parts of Co powder, and 1 part of additive;

[0043] The additives consist of metal carbides VC and metal nitrides VN.

[0044] The metal carbide accounts for 0.3% of the total mass of the raw material.

[0045] The metal nitride accounts for 0.3% of the total mass of raw materials.

[0046] The particle size of the WC powder and Co powder is 0.6 μm.

[0047] A preparation method of high-hardness and high-strength WC-Co-based cemented carbide, comprising the following steps:

[0048] S1: Take WC powder, Co powder, and additives in proportion, use ethanol as the grinding medium, PEG (polyethylene glycol) as the binder, and mix them into initial materials. Under the condition of ball milling for 15 hours, the mixture was fully ground. The mixture is dried, sieved, and molded into a sample strip under a one-way load of 5-1...

Embodiment 3

[0056] A high-hardness and high-strength WC-Co-based cemented carbide, comprising the following raw materials in parts by weight: 90 parts of WC powder, 15 parts of Co powder, and 3 parts of additives;

[0057] The additive consists of metal carbide TiC and metal nitride TaN.

[0058] The metal carbide accounts for 0.5% of the total mass of the raw material.

[0059] The metal nitride accounts for 0.5% of the total mass of raw materials.

[0060] The particle size of the WC powder and Co powder is 0.8 μm.

[0061] A preparation method of high-hardness and high-strength WC-Co-based cemented carbide, comprising the following steps:

[0062] S1: Take WC powder, Co powder, and additives in proportion, use ethanol as the grinding medium, PEG (polyethylene glycol) as the binder, and mix them into initial materials. Under these conditions, the ball mill was fully ground for 20 hours to form a mixture. The mixture is dried, sieved, and molded into a sample strip under a one-way load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com