Blade-breakage-resisting surface coating cutting tool with excellent performance of hard coating layer

A cutting tool, surface coating technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

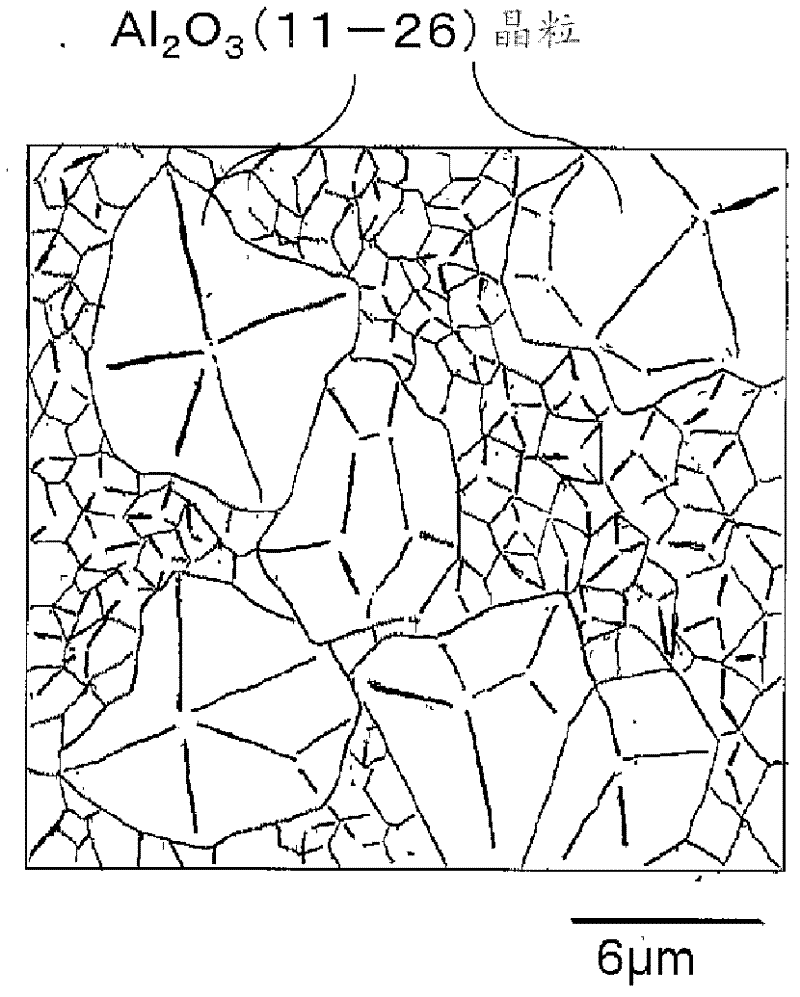

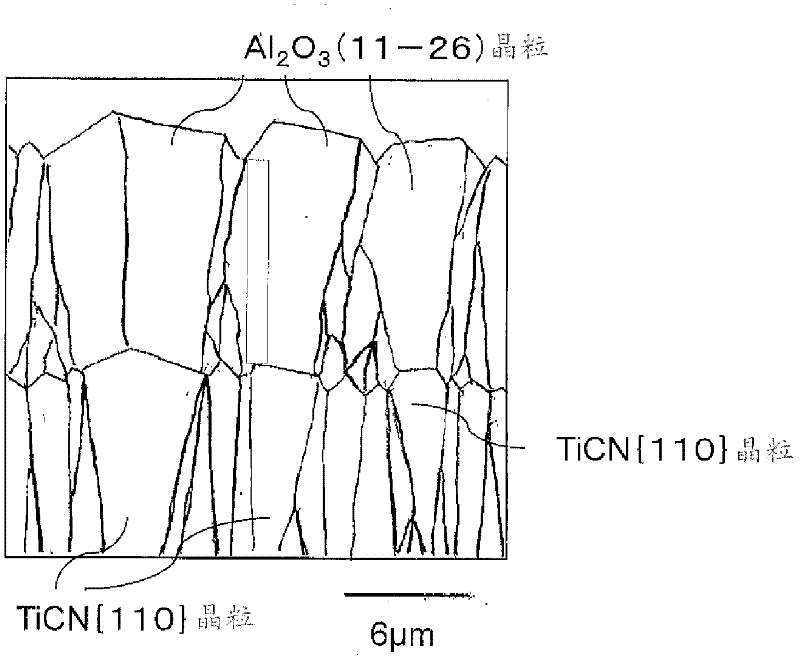

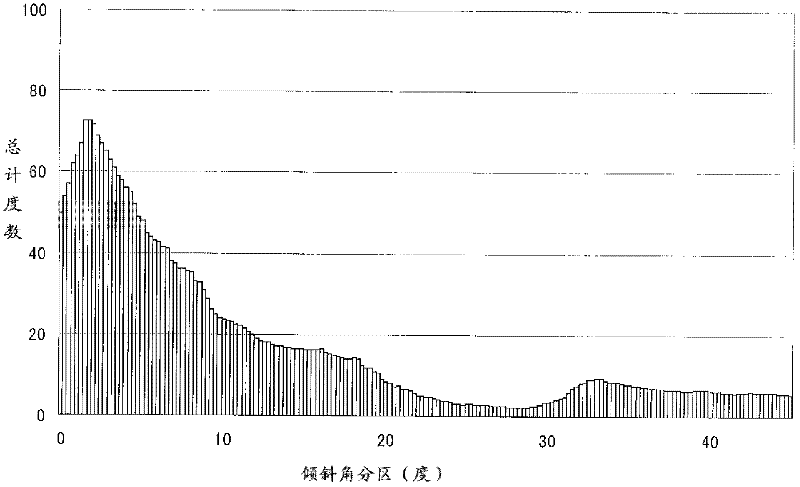

[0107] Next, the covering tool of the present invention will be specifically described by way of examples.

[0108] As raw material powders, prepare the powders shown in Table 1 each having an average particle diameter of 1 to 3 μm, mix these raw material powders into the compounding composition shown in Table 1, add paraffin, ball mill and mix in acetone for 24 hours, and dry under reduced pressure. Afterwards, the green compact is extruded into a predetermined shape with a pressure of 98 MPa, and vacuum sintered under the condition of maintaining a predetermined temperature in the range of 1370-1470 ° C for 1 hour in a vacuum of 5 Pa. After sintering, the green compact is passed A honing process of R: 0.07 mm was applied to the blade portion to produce WC-based cemented carbide tool bases 1 to 10 each having a multi-blade shape specified in ISO·CNMG160412.

[0109] In addition, as raw material powders, powders shown in Table 2 each having an average particle diameter of 0.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com