Patents

Literature

295results about How to "Improve chip resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

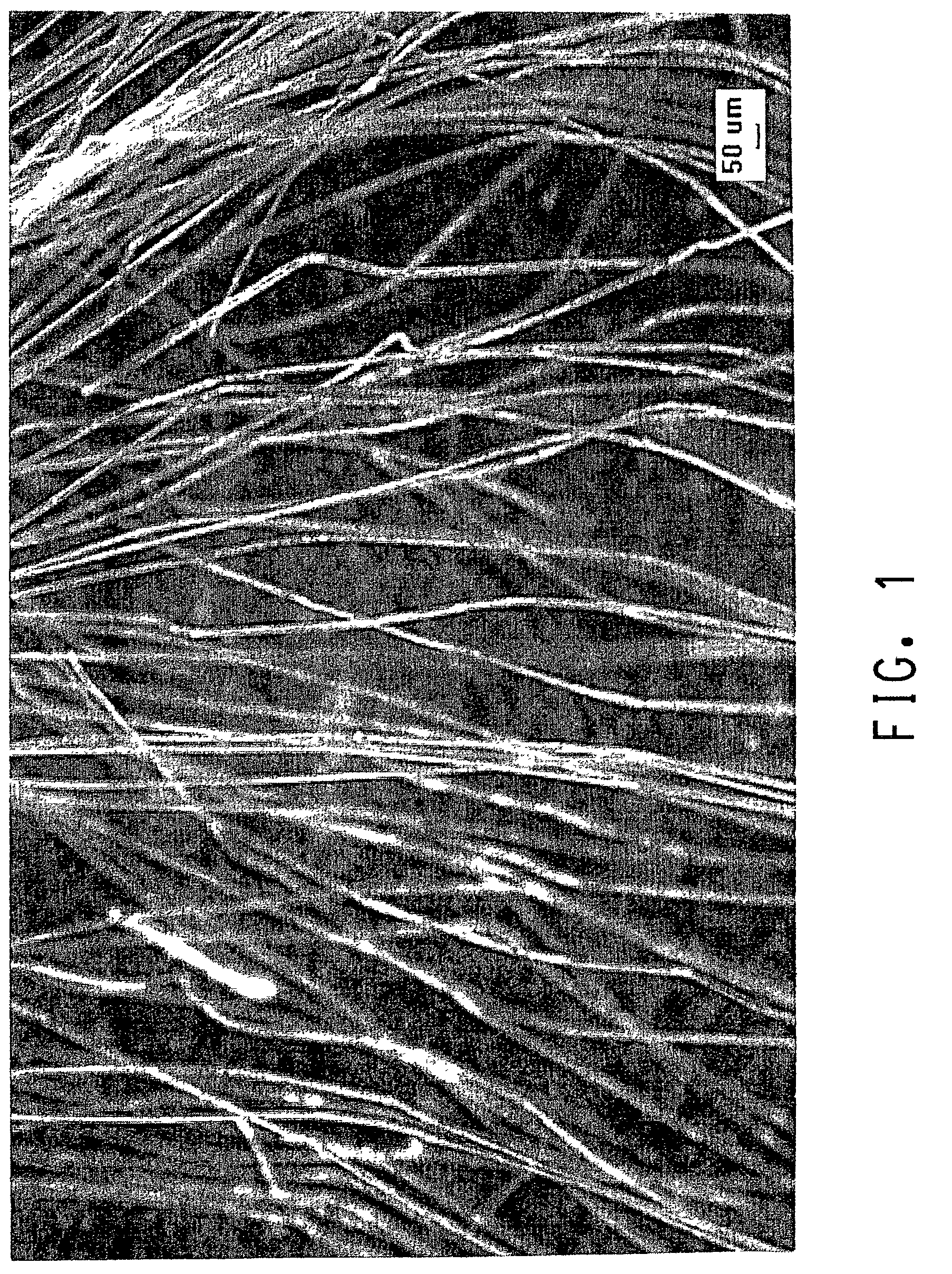

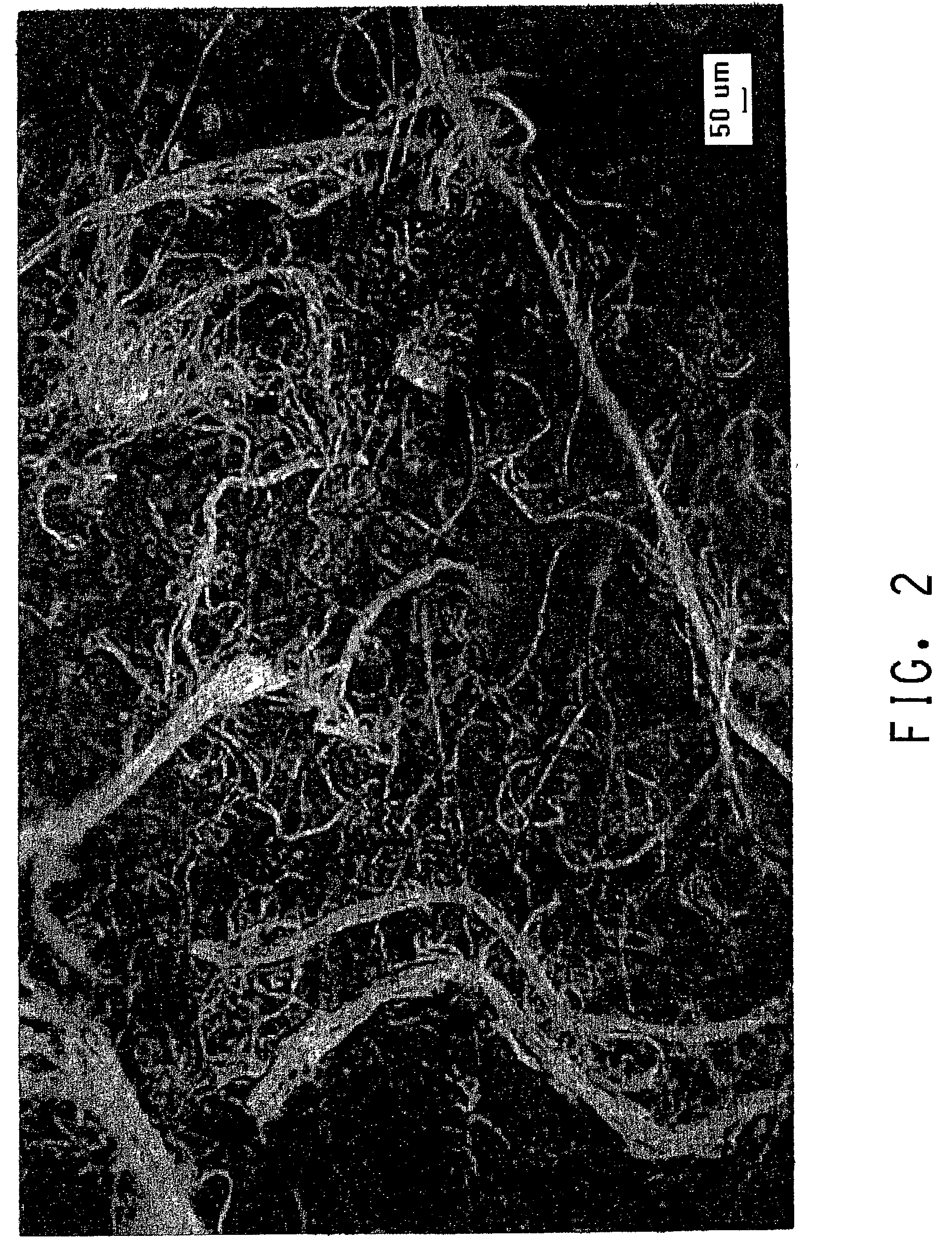

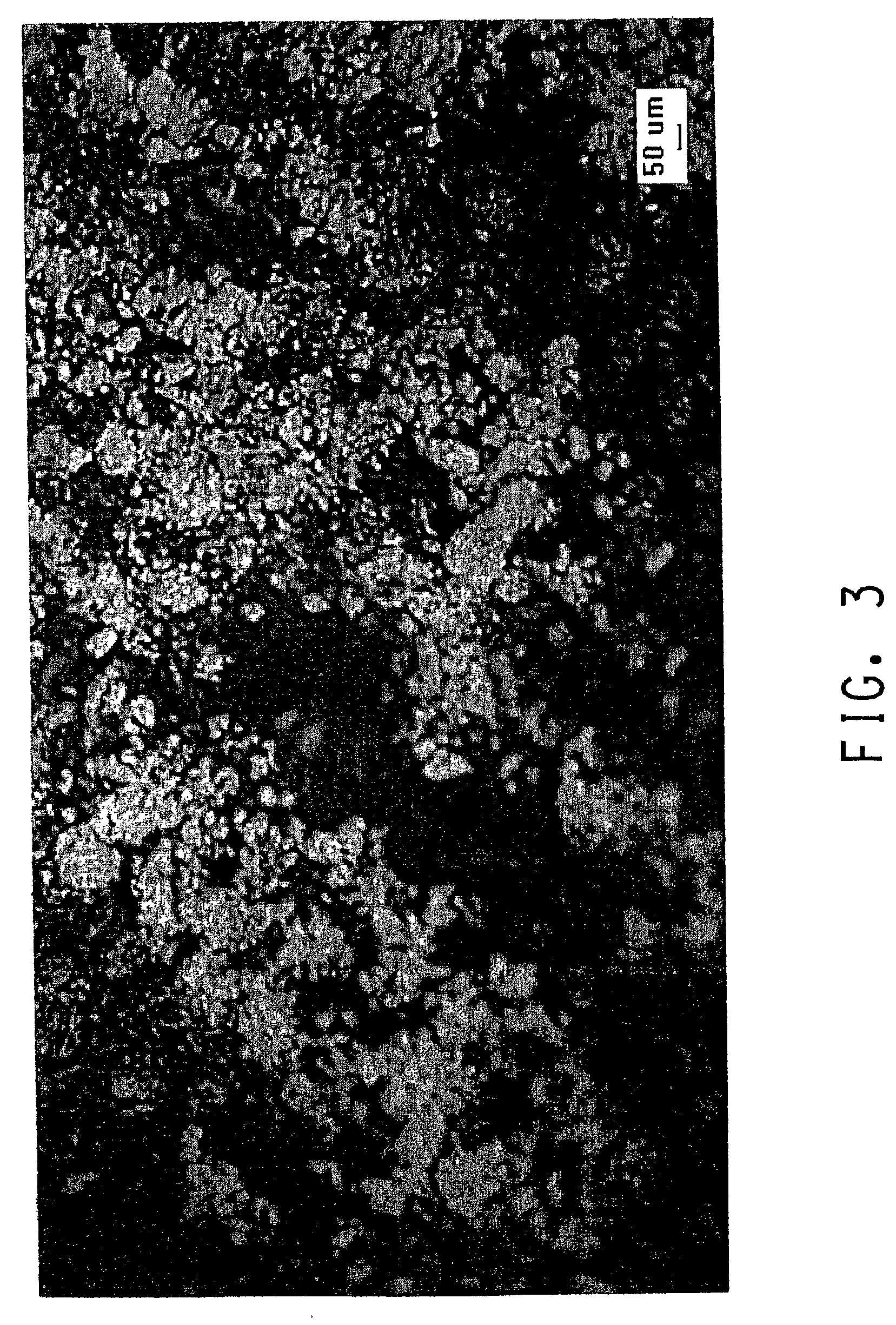

Method of producing micropulp and micropulp made therefrom

InactiveUS20030114641A1More cost-effectivelySmall sizeCellulose coatingsPaper/cardboardFiberSolid component

The present invention is directed to a process for producing micropulp. The process includes contacting organic fibers with a medium comprising a liquid component and a solid component, agitating the medium and the organic fibers to transform the organic fibers into the micropulp dispersed in the medium. If desired, the slurry of the micropulp in the liquid component can be used or the micropulp can be separated from the medium. The micropulp can be readily incorporated into coating compositions such as those used in automotive OEM or refinish applications. The micropulp can also be incorporated into powder coating applications or as a thixotrope or reinforcement in polymer formulations.

Owner:EI DU PONT DE NEMOURS & CO

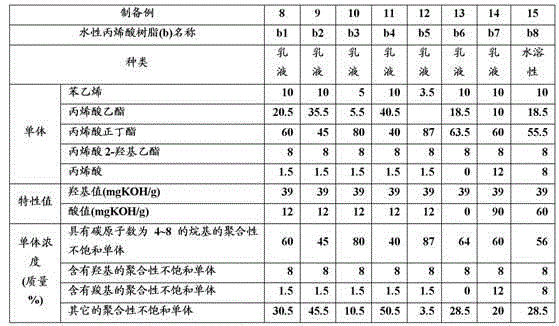

Aqueous paint composition and method for forming coating

ActiveCN104321395AImprove washabilityImprove smoothnessSynthetic resin layered productsPolyurea/polyurethane coatingsCross-linkCLARITY

The objective of the present invention is to provide an aqueous paint composition that can form a coating with excellent smoothness, image clarity, water resistance, and chipping resistance; and that has excellent cleaning properties, as well as a method for forming a coating. As means for achieving this purpose, the present invention provides an aqueous paint composition used as an aqueous first colored paint for a multilayer coating forming method, wherein the paint composition is characterized in including (A) an aqueous film-forming resin, (B) a cross-linking agent, and (C) acrylic urethane resin composite particles. The acrylic resin of the acrylic urethane resin composite particles (C) is obtained by using, as a monomer component, 30 to 80 percent by mass of a polymeric unsaturated monomer (c-1-1) having one polymeric unsaturated group in a single molecule and having a C4-22 alkyl group, 1 to 20 percent by mass of a polymeric unsaturated monomer (c-2) having two or more polymeric unsaturated groups in a single molecule, and 0 to 69 percent by mass of a polymeric unsaturated monomer (c-1-2) having one polymeric unsaturated group other than (c-1-1) in a single molecule.

Owner:KANSAI PAINT CO LTD

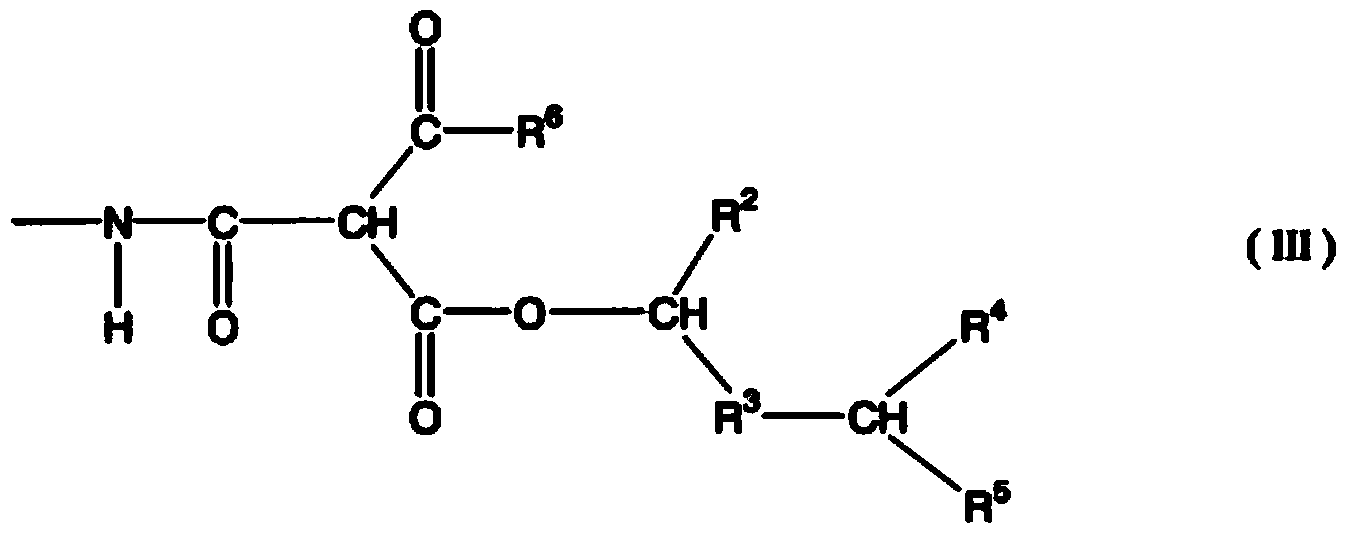

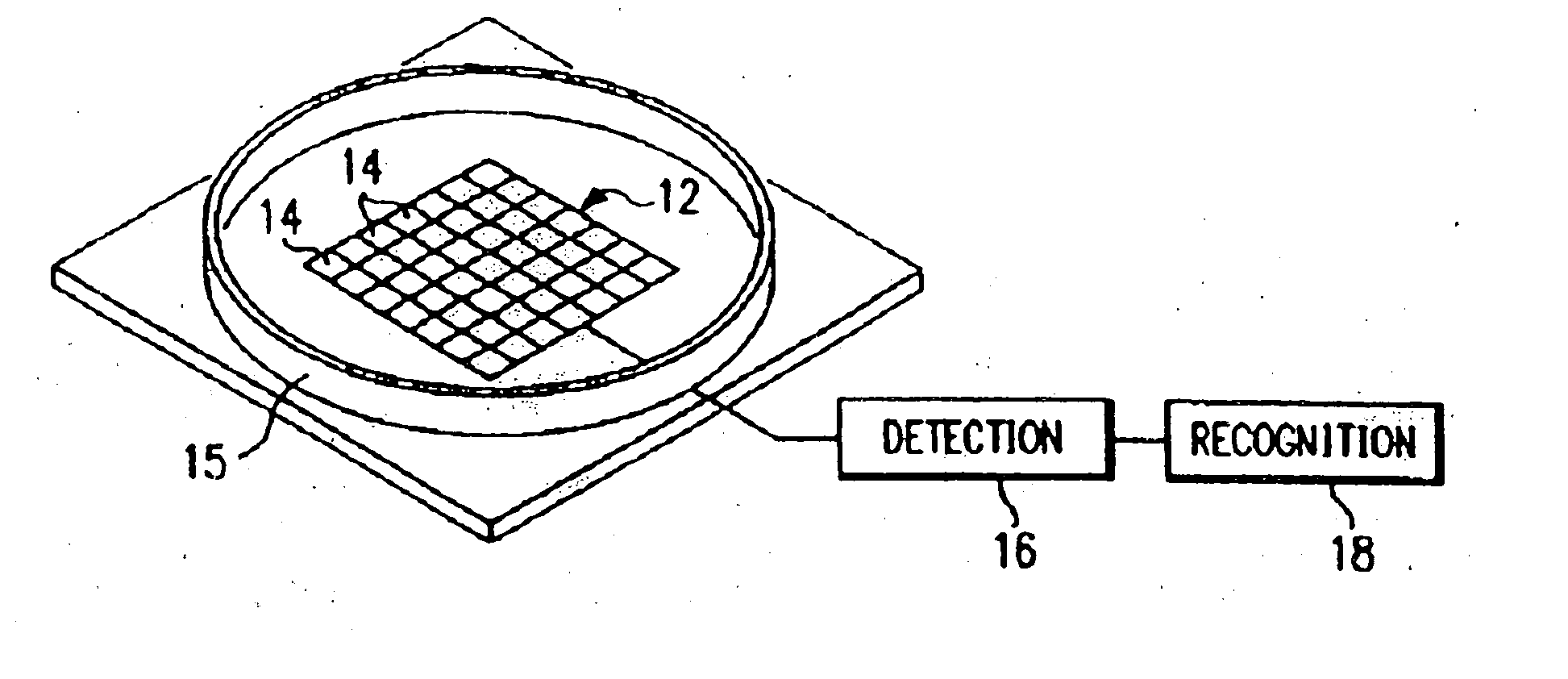

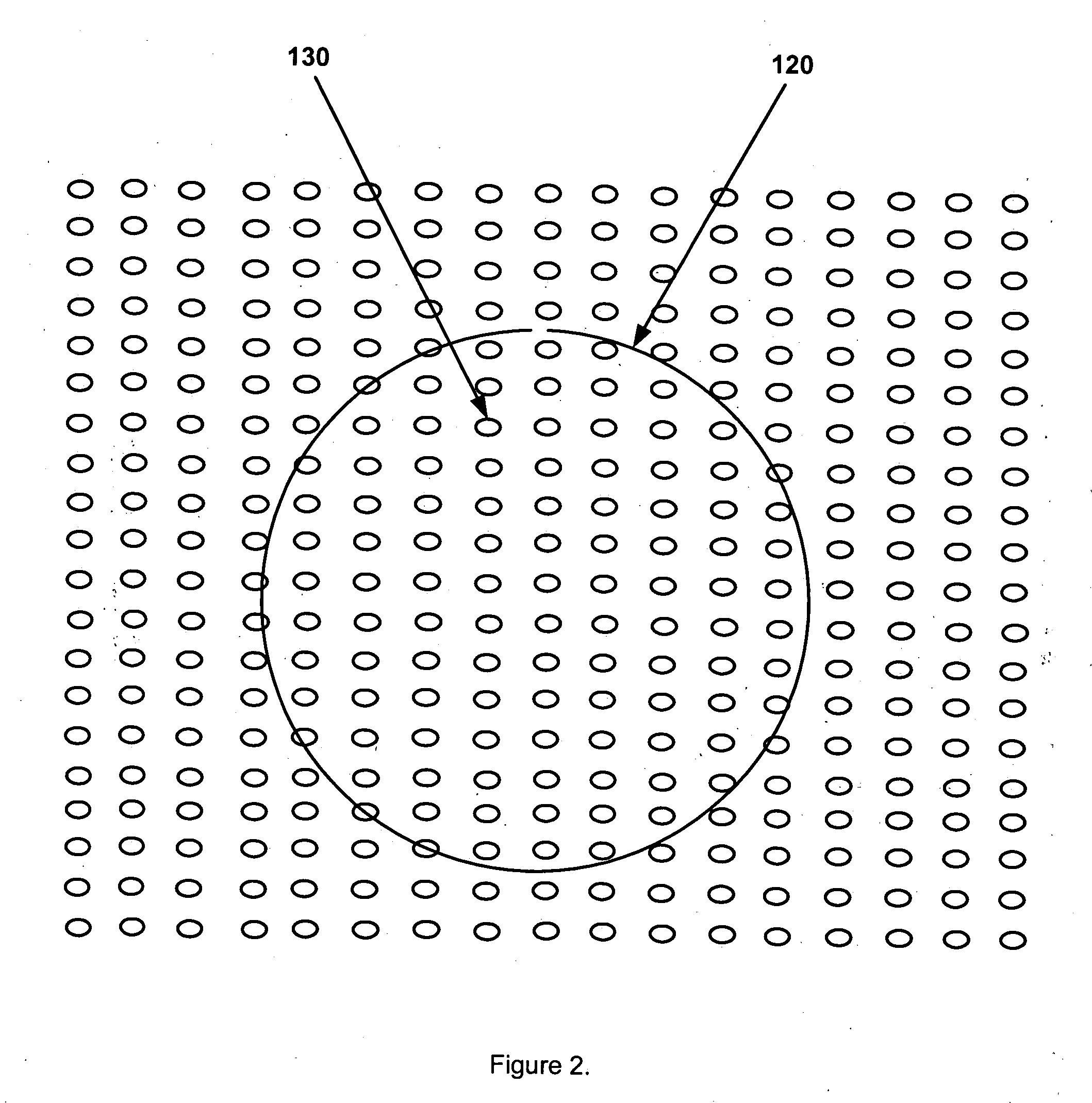

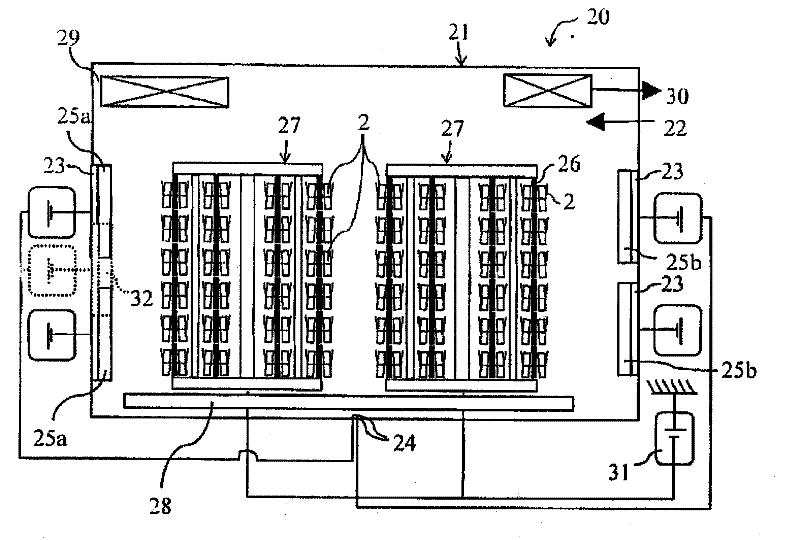

Apparatus and method for identification of biomolecules, in particular nucleic acid sequences, proteins, and antigens and antibodies

InactiveUS20050079598A1Improve chip resistanceThe result is accurateBioreactor/fermenter combinationsBiological substance pretreatmentsAntigenNucleic acid sequencing

An electrical detection system and method using an array of conductive sense sites within a sensing substrate for electrically detecting the successful hybridization or binding reaction between two chemical substances, particularly between biogenic substances such as nucleotides, proteins and ligands, and antigens and antibodies. The method and apparatus provide a an inexpensive, robust, small, repeatable, and intuitively easy to use apparatus for detection of low levels of hybridization with large numbers of closely spaced conductive sense sites within a single substrate.

Owner:DAVIS RANDALL W

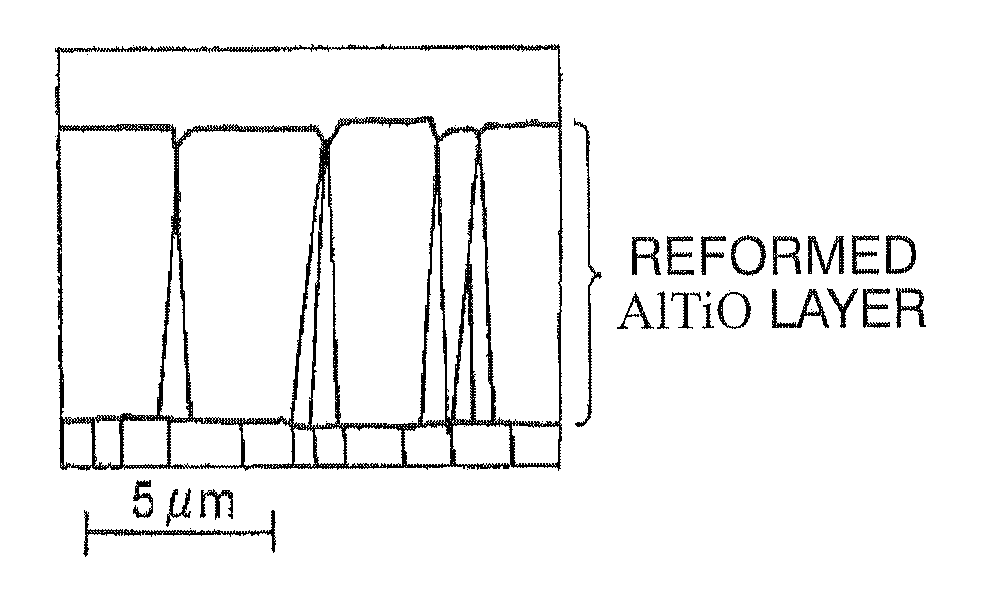

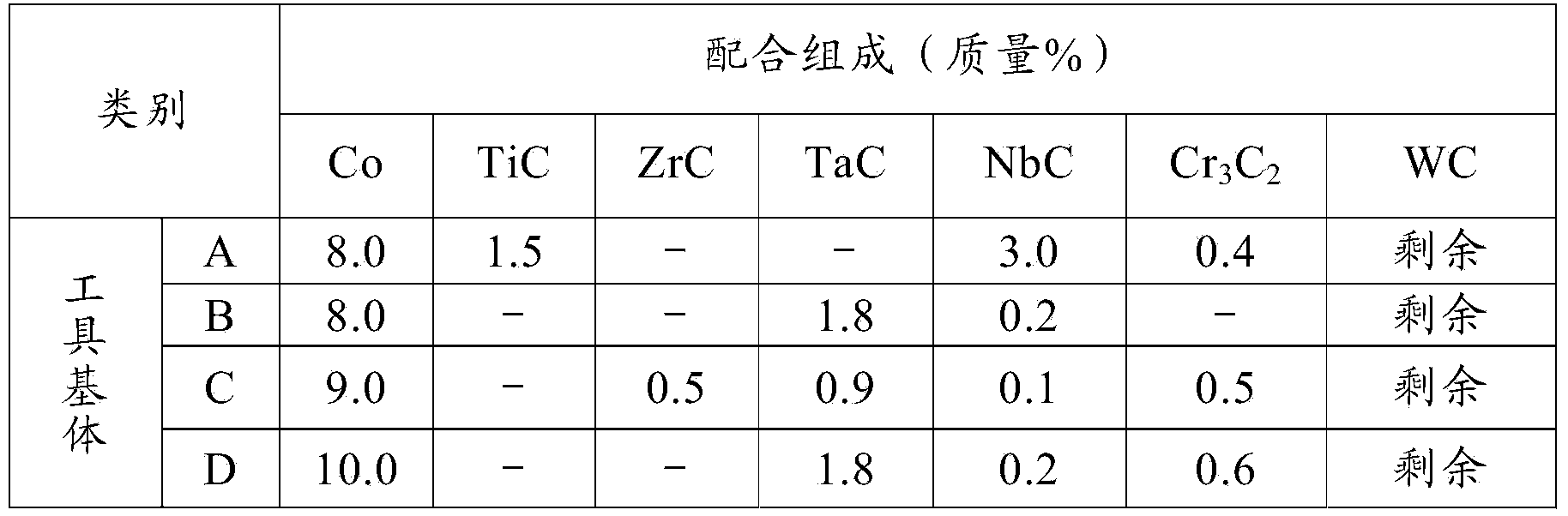

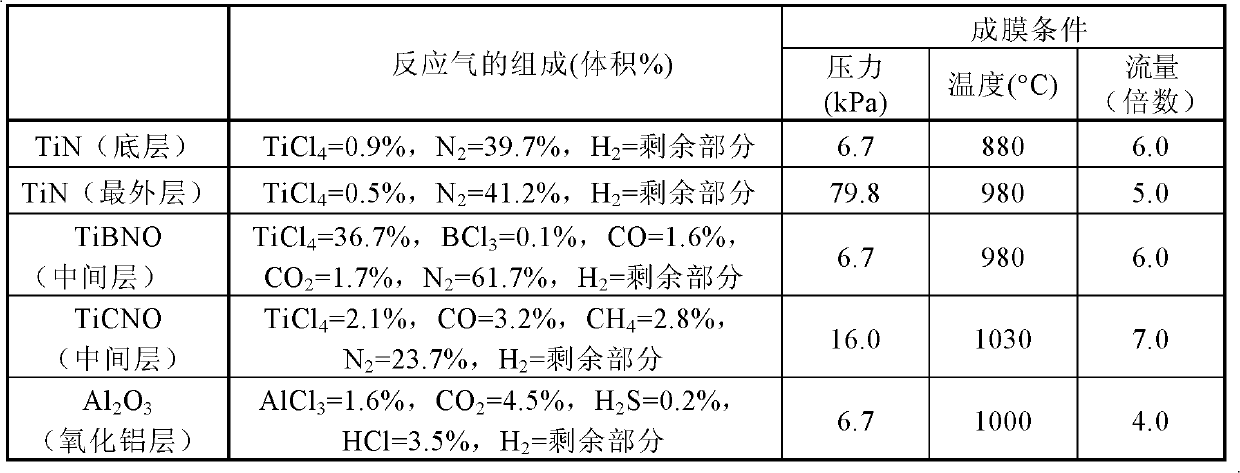

Surface-coated cermet cutting tool with a hard coating layer exhibiting excellent chipping resistance

ActiveUS7276301B2Improve chip resistancePigmenting treatmentOther chemical processesCrystal structureTitanium nitride

A surface-coated cermet cutting tool with a hard-coating layer having excellent chipping resistance. The hard coating layer is formed on a surface of a tool substrate that constitutes the surface-coated cermet cutting tool. The hard coating layer includes(a) as the lower layer, a titanium compound layer having at least one or two of a titanium carbide layer, a titanium nitride layer, a titanium carbonitride layer, a titanium carboxide layer and a titanium oxycarbonitride layer, and (b) as the upper layer, a heat-transformed α-type Al—Zr oxide layer formed by carrying out a heat-transforming treatment in a state that a titanium oxide layer satisfying the composition formula: TiOY, ¥ The heat-transformed α-type Al—Zr oxide layer is chemically deposited on a surface of an Al—Zr oxide layer having a κ-type or θ-type crystal structure and satisfying the composition formula: (Al1−XZrX)2O3 to transform the crystal structure of the Al—Zr oxide layer having the κ-type or θ-type crystal structure into an α-type crystal structure.

Owner:MITSUBISHI MATERIALS CORP

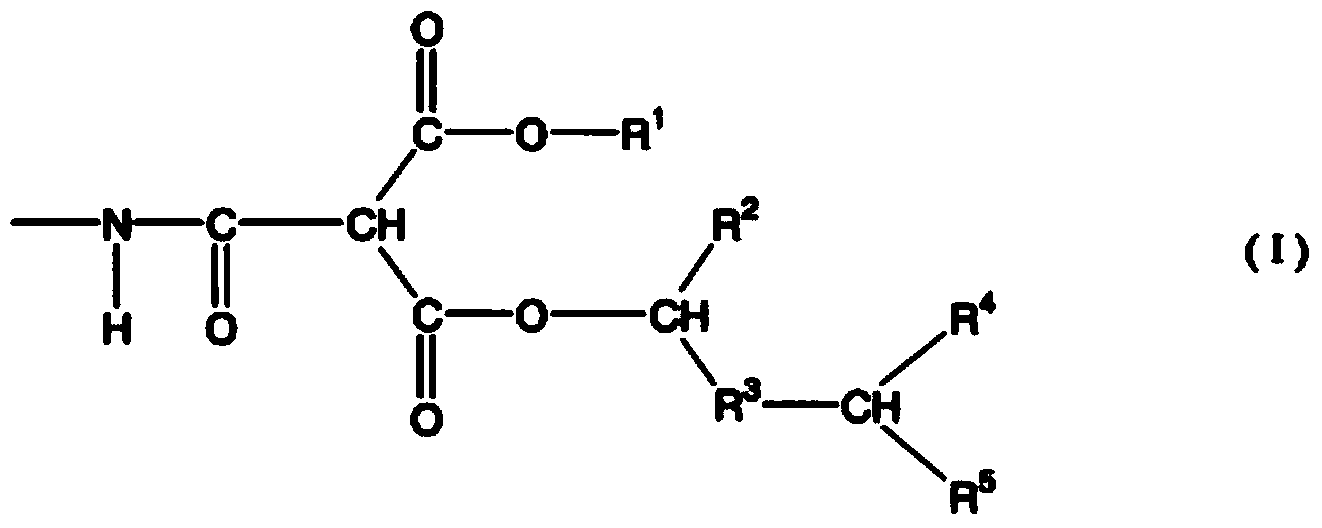

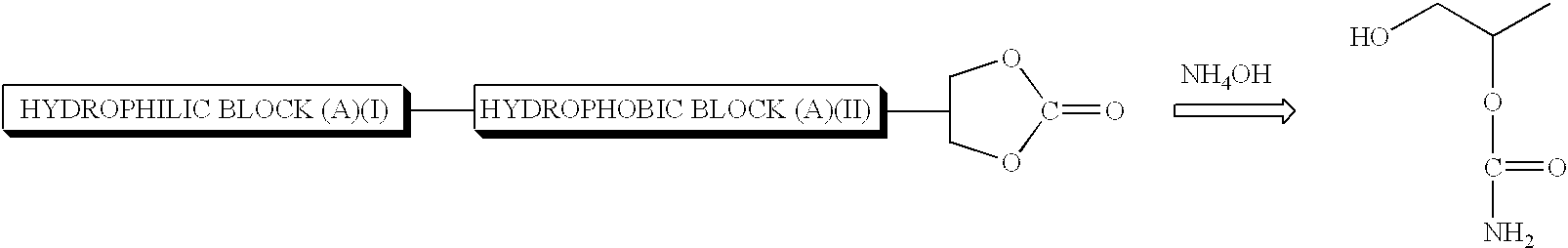

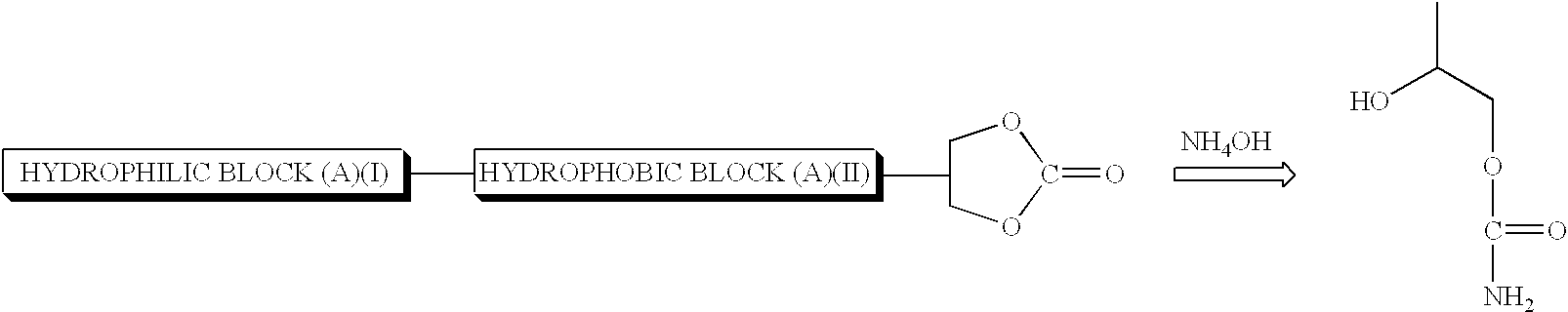

Coating composition including a water-based copolymer cross-linking with a water-dispersible cross-linking agent, method of preparing the same, and a cured film thereof

The present invention is directed to a curable, water-based coating composition utilized in waterborne coating systems such as a waterborne primer system. The coating composition is the reaction product of a water-dispersible cross-linking agent and a water-based copolymer prepared by free-radical polymerization. The copolymer is the reaction product of a first block and a second block. The first block is the reaction product of a plurality of ethylenically unsaturated monomers. One of the ethylenically unsaturated monomers includes a functional group suitable for reaction with the cross-linking agent. The functional group in the first block is preferably a carbonate, carbamate, or hydroxyl functional group. Other monomers in the plurality include acrylic acid and methyl methacrylate. The first block is also the reaction product of a vinylaromatic hydrocarbon monomer such as diphenylethylene. The second block is the reaction product of a non-functional, ethylenically unsaturated monomer. Methods for preparing the coating composition and a cured film are also disclosed.

Owner:BASF CORP

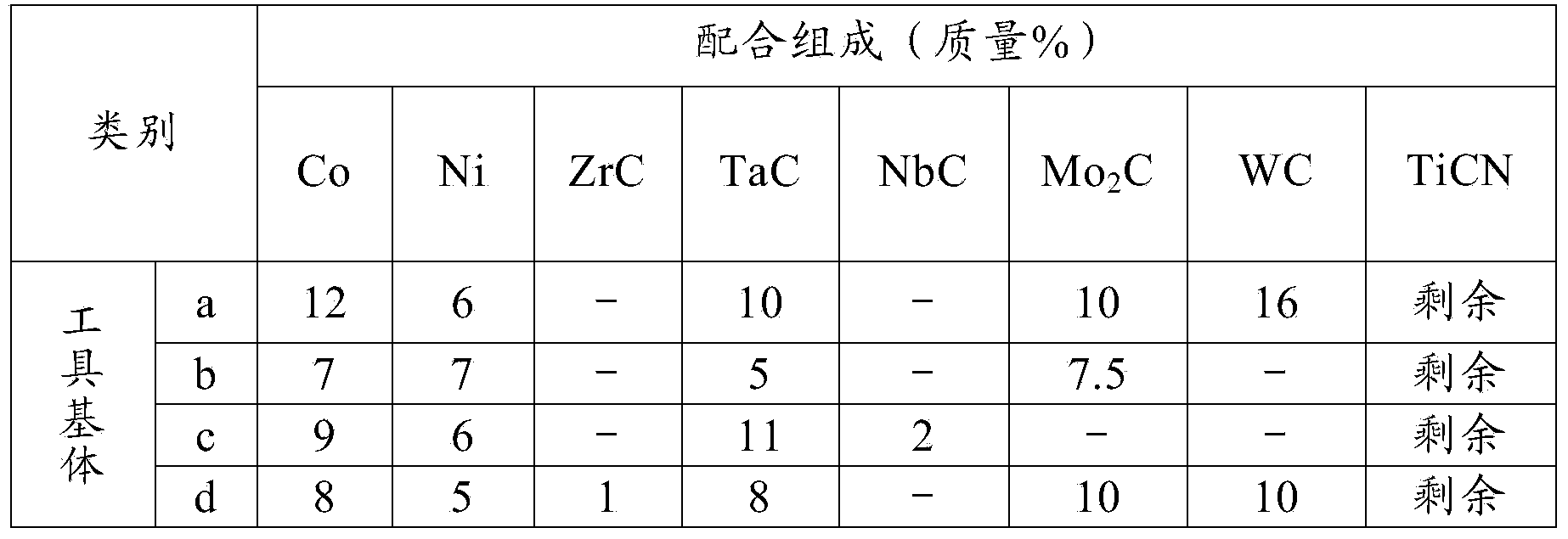

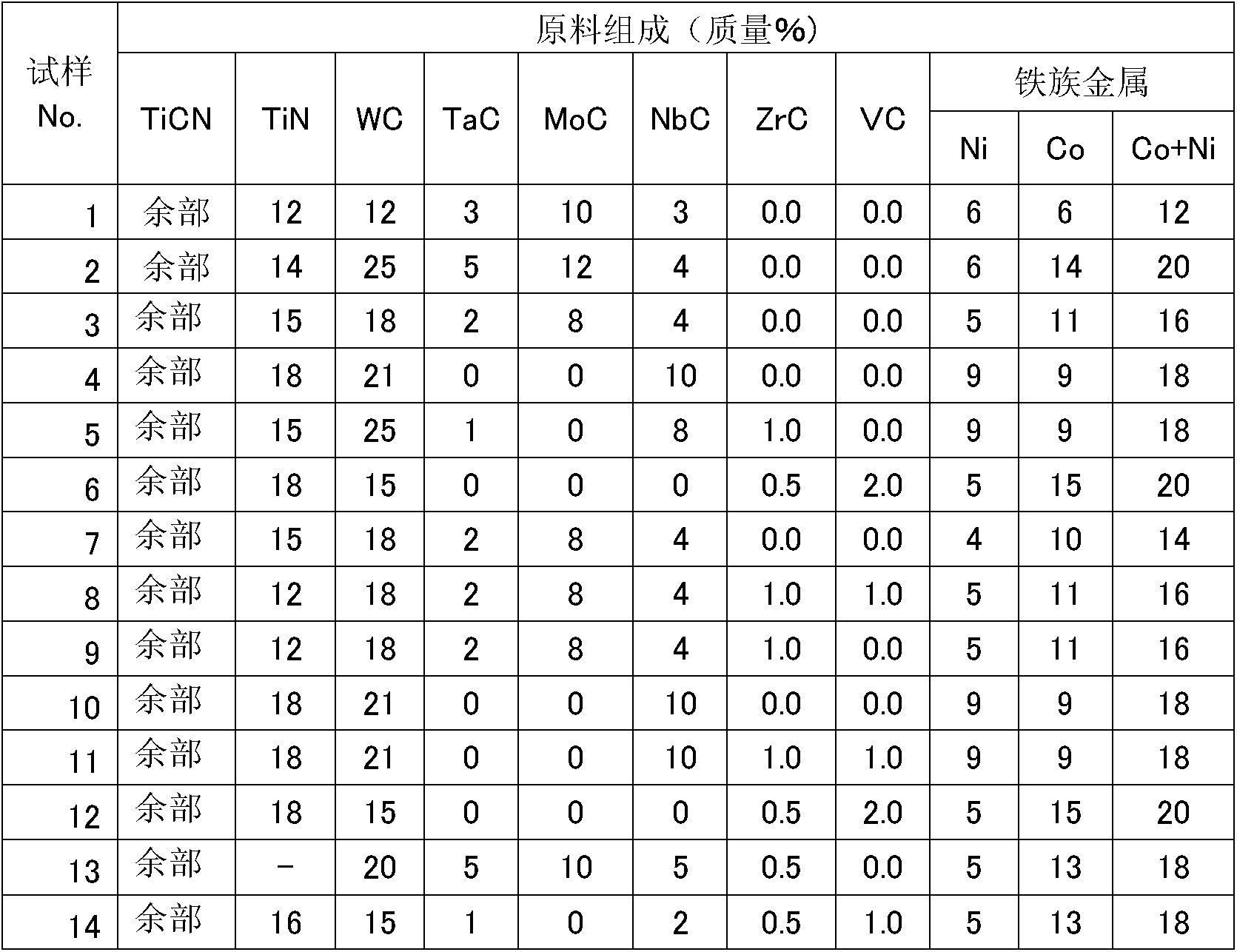

Cermet insert and cutting tool

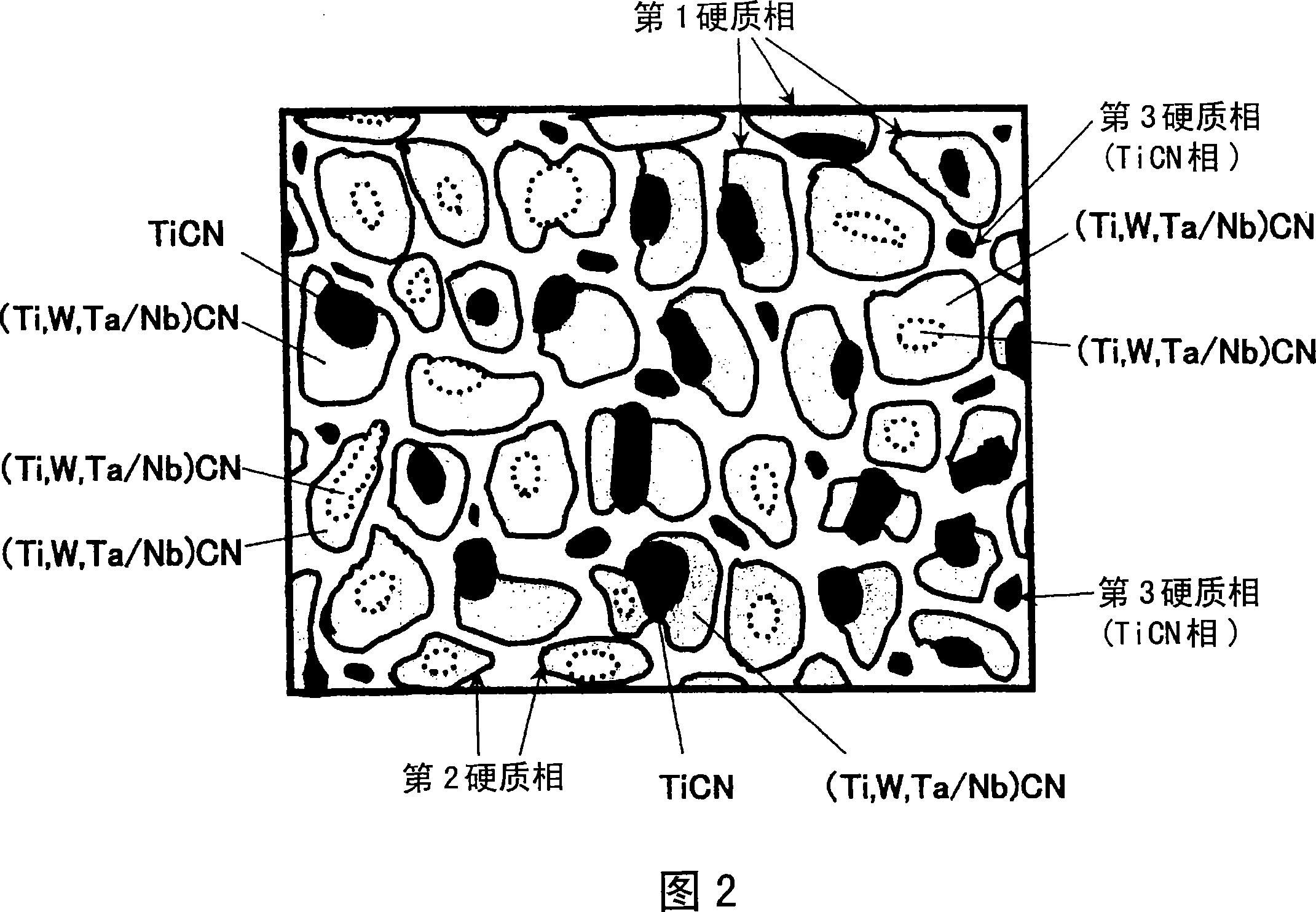

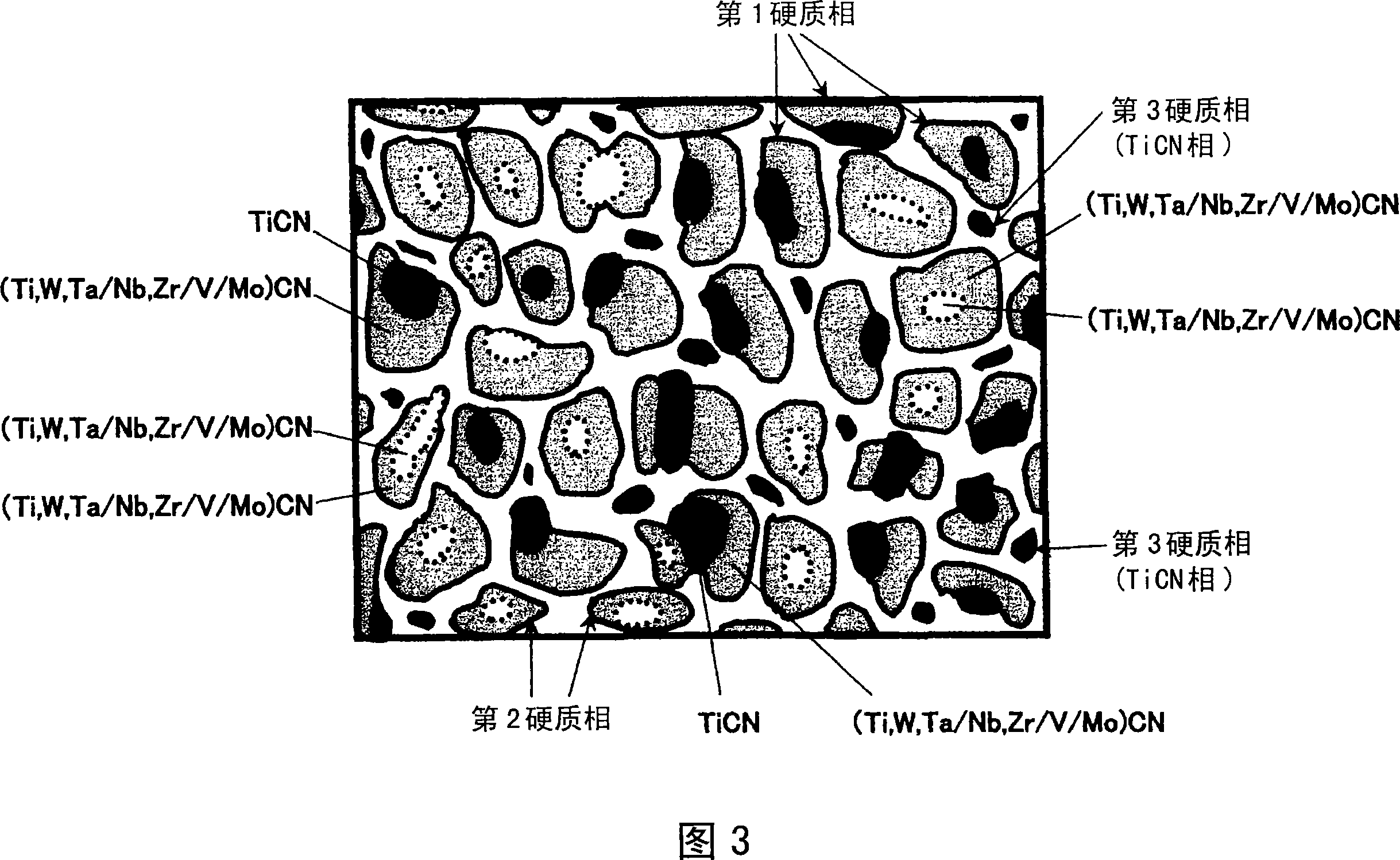

InactiveCN101189090AExcellent abrasion resistanceImprove wear resistanceTurning toolsCarbideTitanium carbonitride

One mode of the blade made of titanium carbonitride-based cermet is that it has a structure composed of 75-90 area % of hard phase and the balance is a binding phase. The hard phase has: the core is made of titanium carbonitride Phase composition, the peripheral part is composed of a first hard phase with a core structure composed of Ta and / or Nb, Ti, and W complex carbonitride (hereinafter expressed as (Ti, W, Ta / Nb)CN) phase; Both the core and the peripheral part are the second hard phase with a core structure composed of (Ti, W, Ta / Nb) CN phase; the third hard phase with a single-phase structure composed of TiCN phase, and the binding phase has: Co: 18-33%; Ni: 20-35%; Ta and / or Nb, and Ti, the total amount: 5% or less; W: 40-60%. Another form of the titanium carbonitride-based cermet blade is the sum of the value of Ti converted into carbonitride, the value of Ta and / or Nb converted into carbide, and the value of W converted into carbide It is 70-95% by mass, the value of W converted into carbide is 20-35% by mass, Co and Ni are 5-30% by mass, and have a structure composed of hard phase and binder phase. The hard phase has (Ti , W, Ta / Nb) CN, the binding phase is mainly composed of Co and / or Ni, and W, and 40-65% by mass of W is contained in the hard phase. This cutting tool has a holder and the cermet blade fixed by the holder.

Owner:MITSUBISHI MATERIALS CORP +1

Biaxially oriented laminated film

ActiveUS20100190037A1Good dimensional stabilityFew voidMagnetic materials for record carriersBase layers for recording layersBoPETSurface roughness

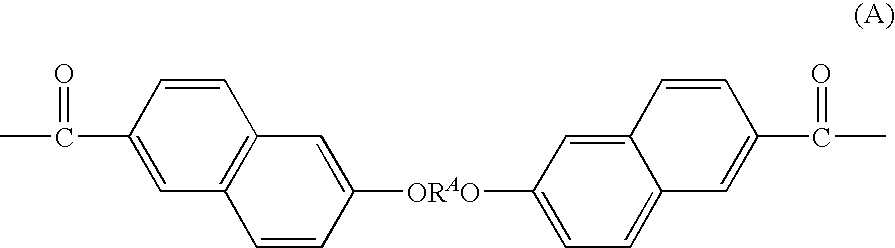

It is an object of the present invention to provide a biaxially oriented laminated polyester film which has excellent dimensional stability to environmental changes such as temperature and humidity variations and excellent flatness and windability.The present invention is a biaxially oriented laminated polyester film comprising a film layer B on one side of a film layer A and having a surface roughness (RaB) on the film layer B side which is 1.0 nm or more larger than the surface roughness (RaA) on the film layer A side, whereinat least one of the film layers comprises an aromatic polyester (I) composed of a glycol component and a dicarboxylic acid component containing 5 mol % or more and less than 80 mol % of a recurring unit represented by the following formula (A):wherein RA is an alkylene group having 1 to 10 carbon atoms.

Owner:TEIJIN LTD

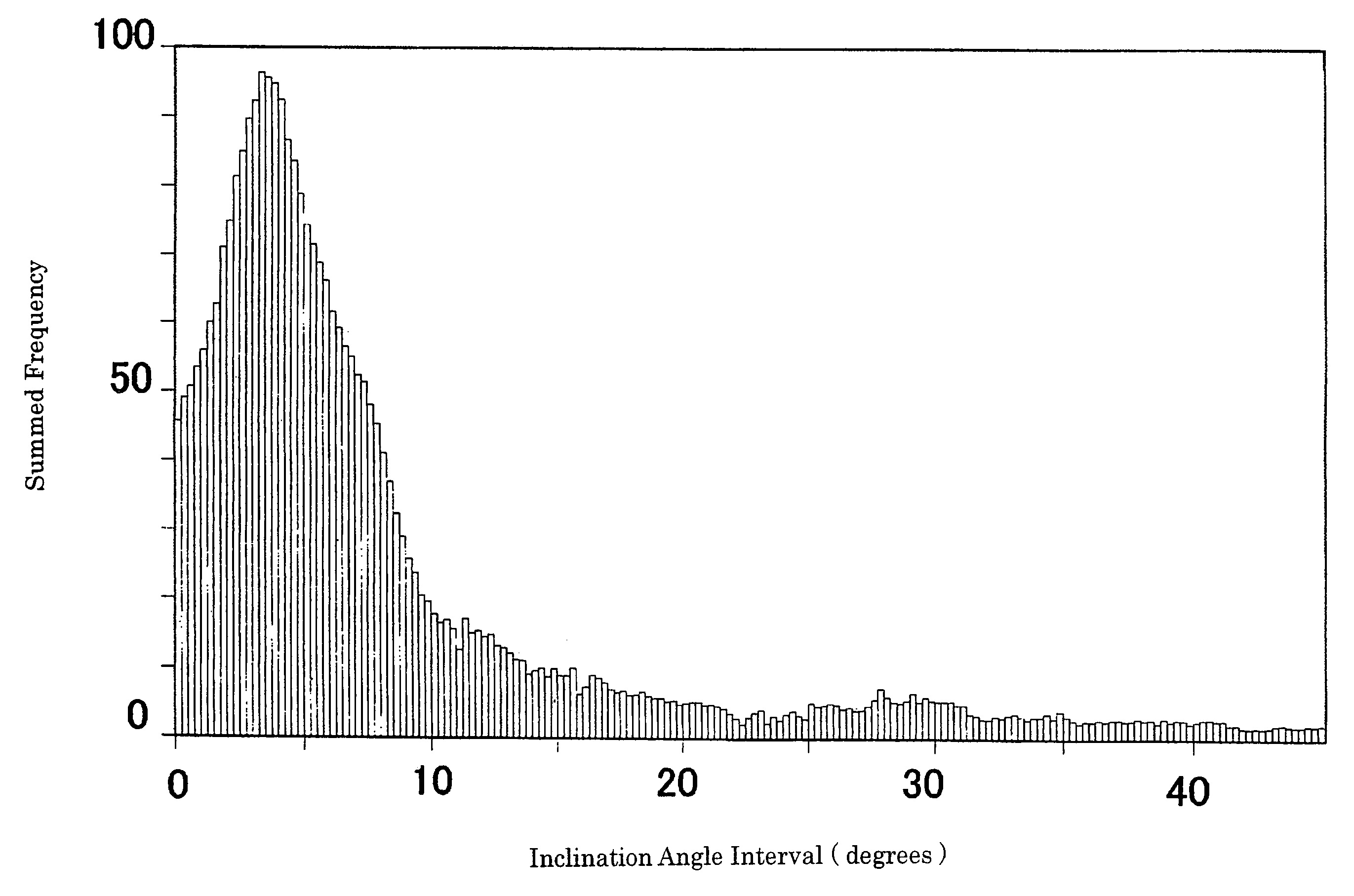

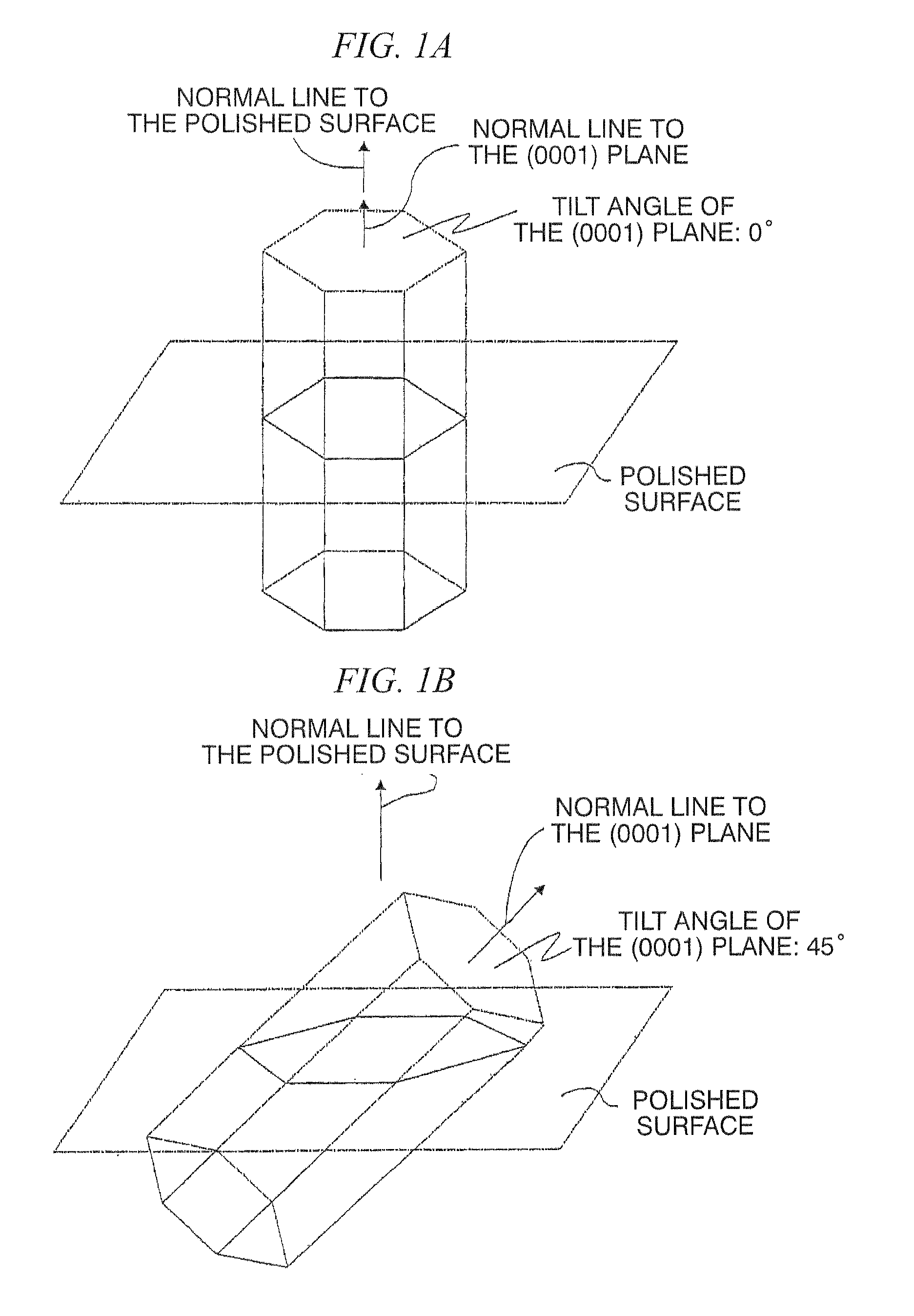

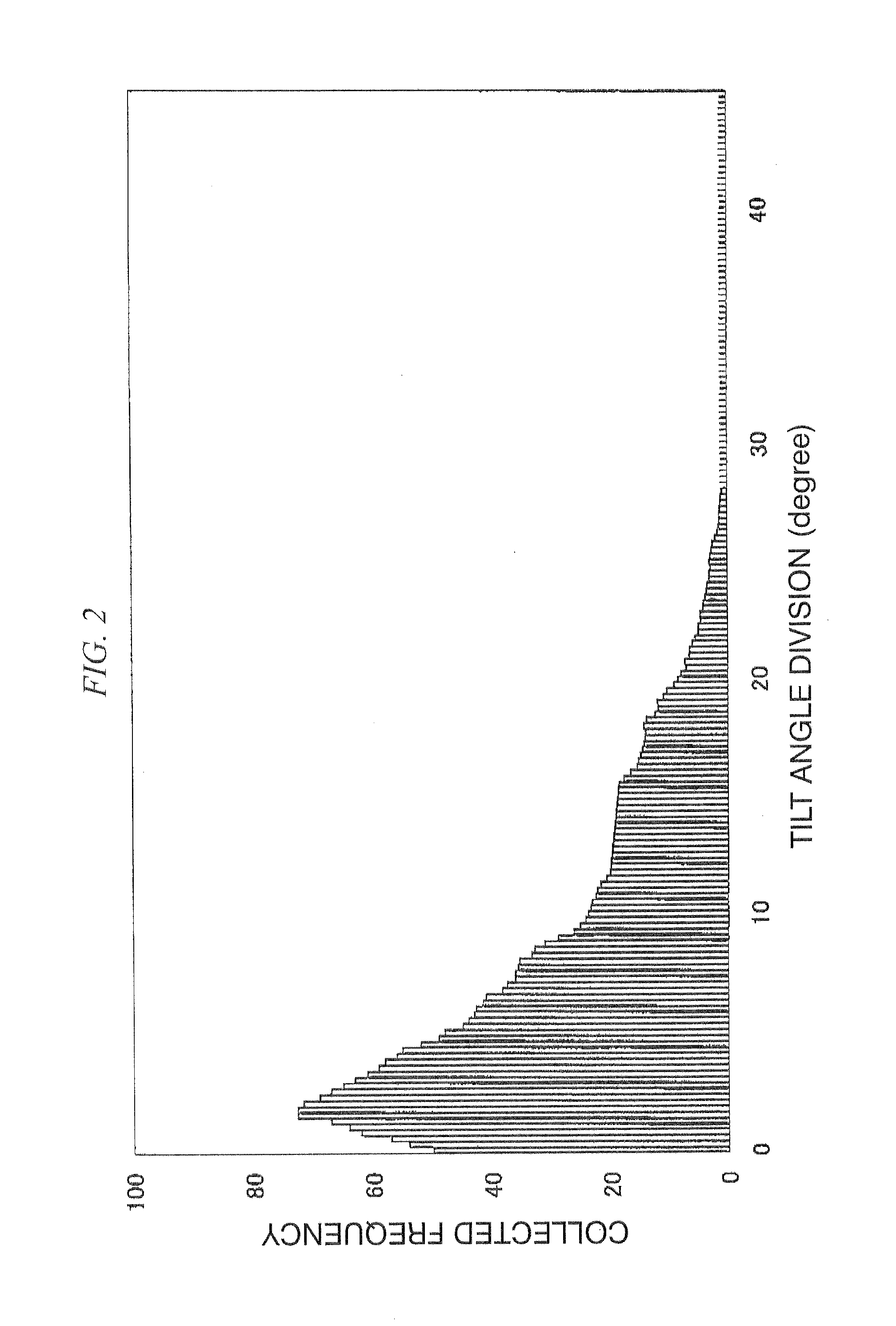

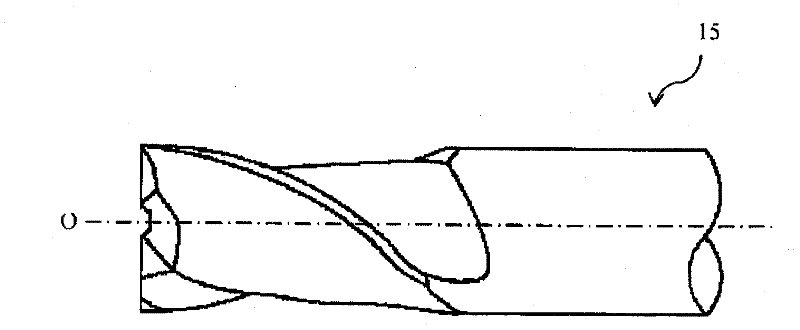

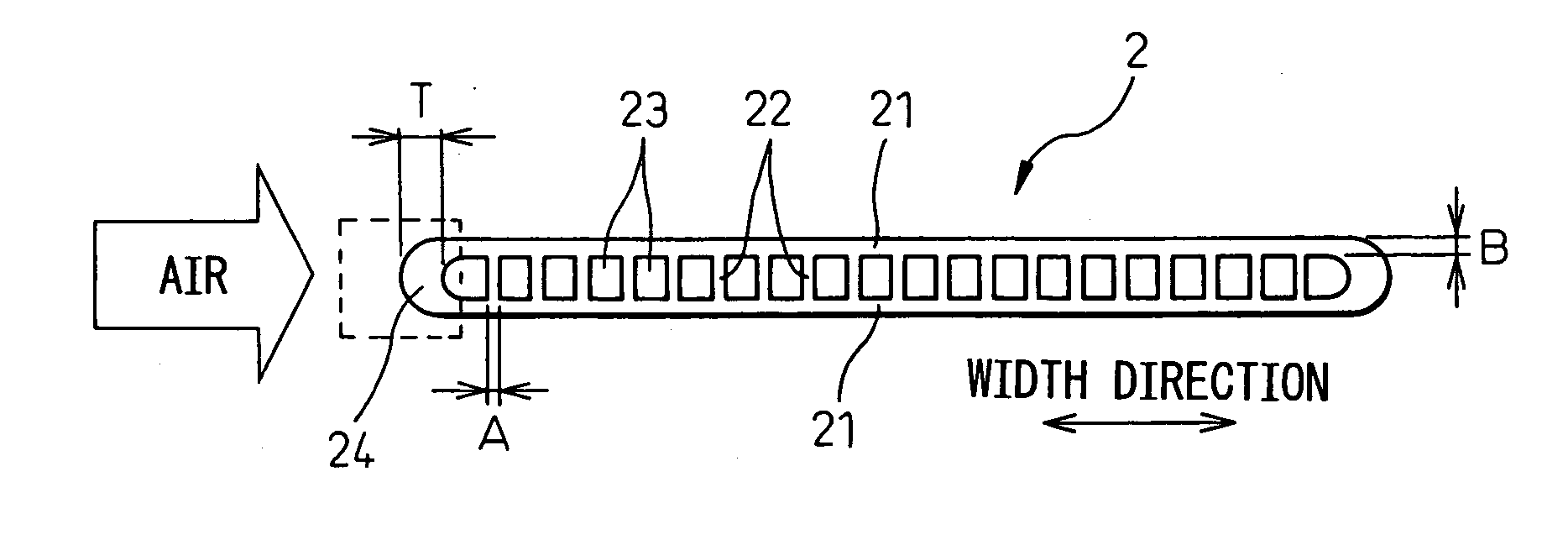

Cutting tool

ActiveUS7201956B2Improve chip resistanceImprove cutting performancePigmenting treatmentMilling cuttersCrystal structureTitanium carbonitride

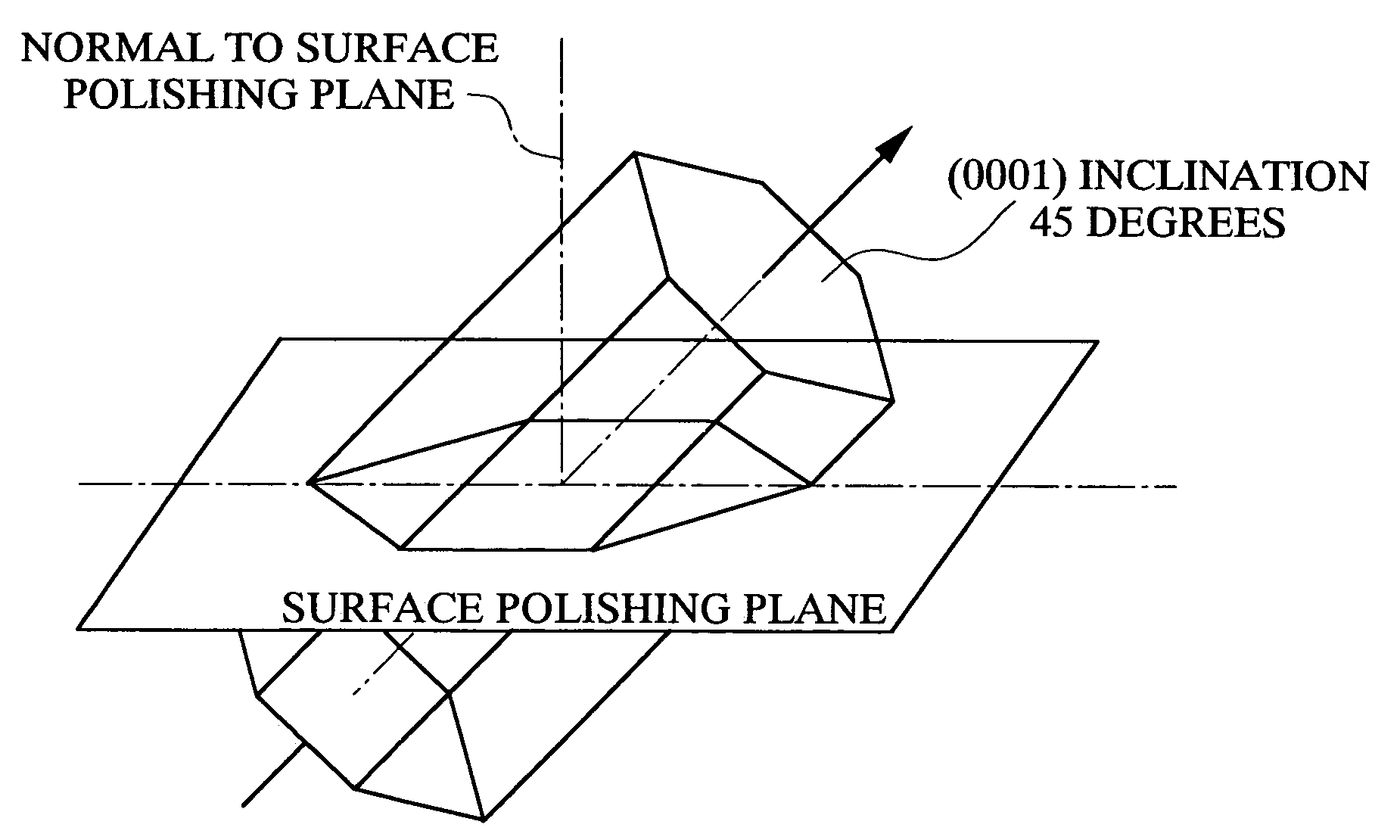

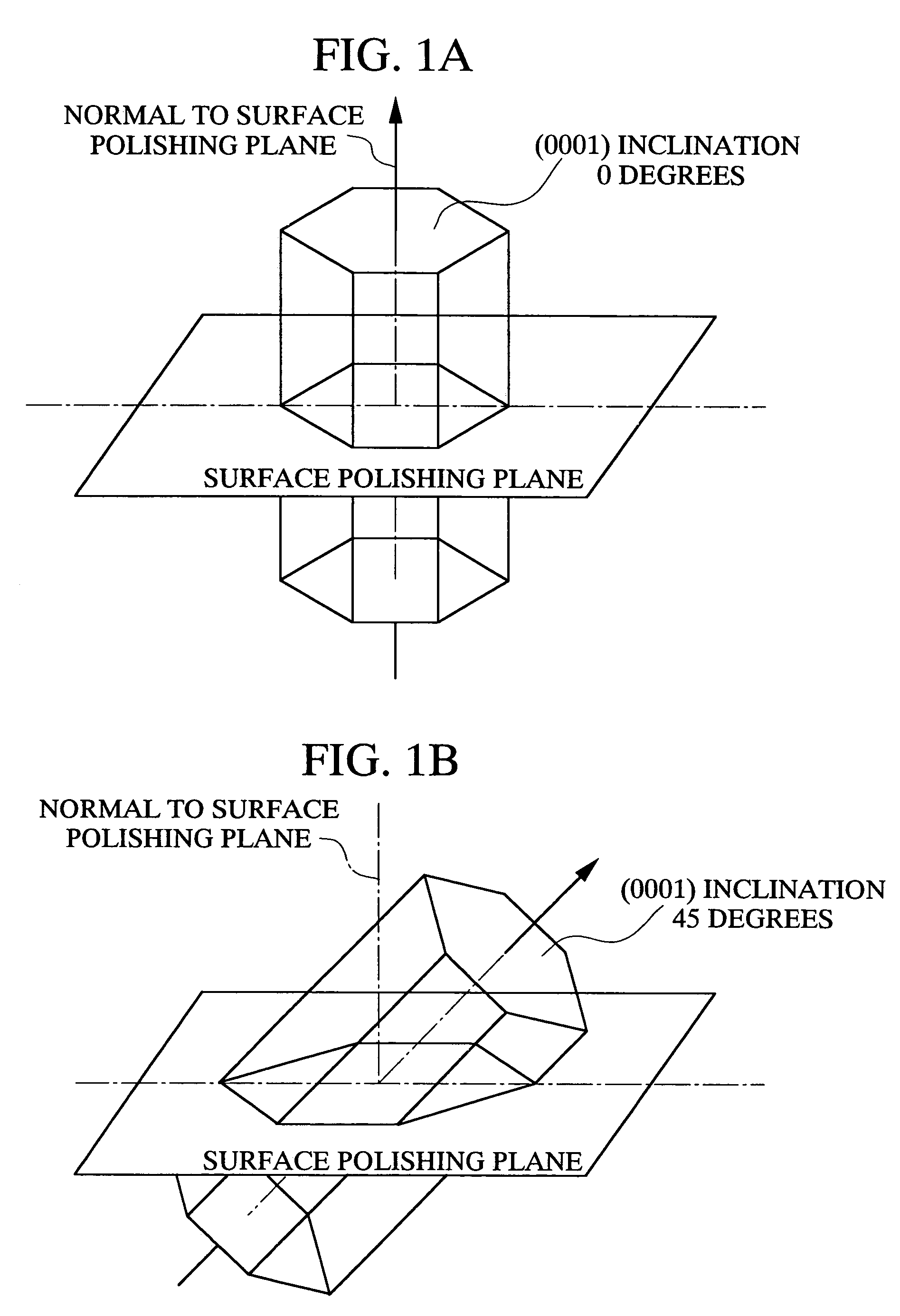

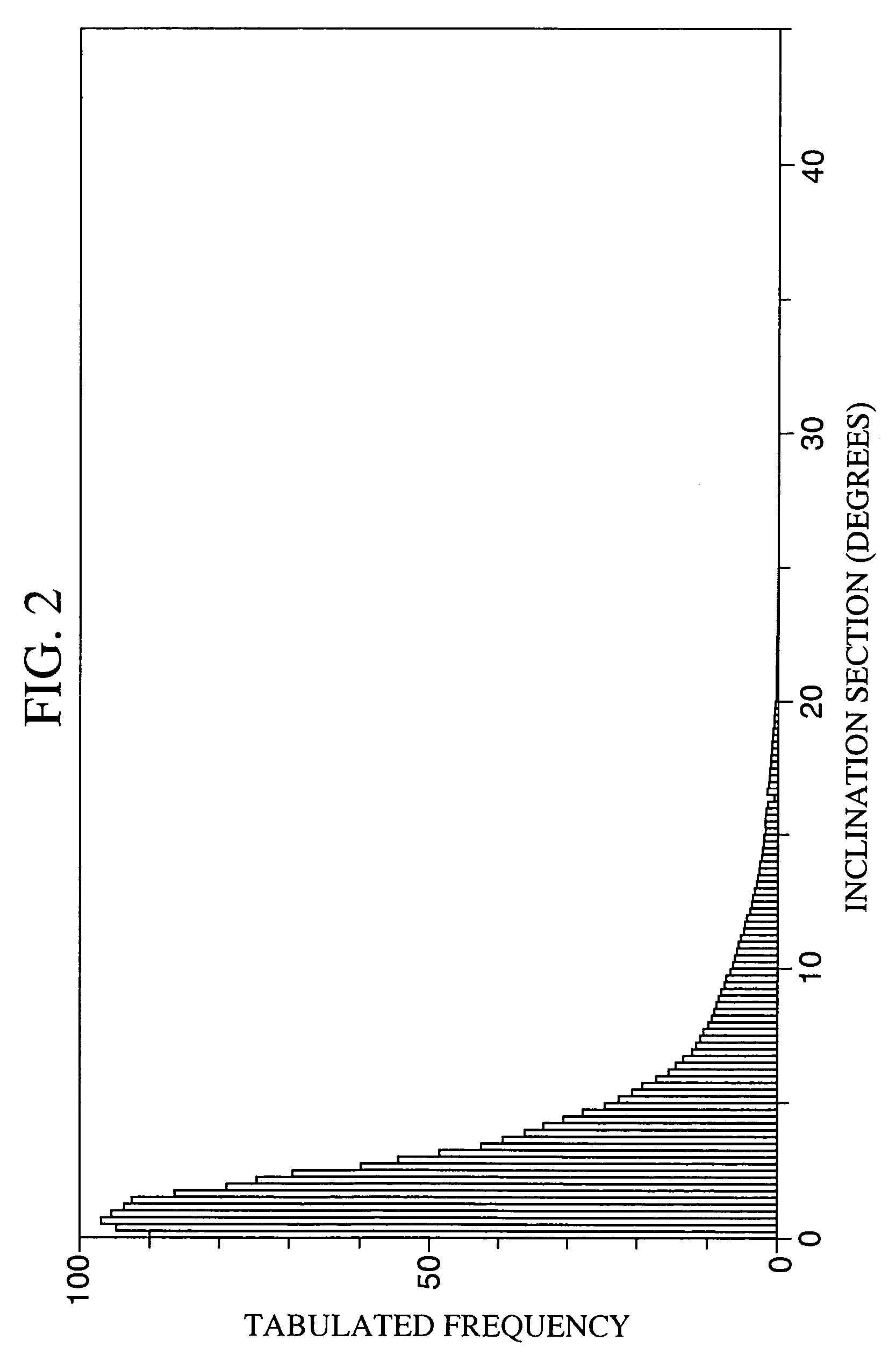

The present invention provides a cutting tool in which the hard coating layer demonstrates superior chipping resistance. The cutting tool has a tool base composed with tungsten carbide-based cemented carbide or titanium carbonitride-based Cermet, and a hard coating layer provided on the surface thereof; wherein the hard coating layer includes: (a) a Ti compound and / or Zr compound layer, which is a lower layer, comprising one or more layers of a TiC layer, TiN layer, TiCN layer, TiCO layer, TiCNO layer, ZrC layer, ZrN layer, ZrCN layer, ZrCO layer, ZrCNO layer and (b) an aluminum oxide layer having an α crystal structure which is an upper layer, including the highest peak in the inclination section within a range of 0–10.

Owner:MITSUBISHI MATERIALS CORP

Surface-coated cutting tool

ActiveUS20120003452A1Improve high temperature strengthImprove surface propertiesLayered productsTurning toolsTitanium nitrideTitanium carbonitride

A surface-coated cutting tool includes a tool substrate made of tungsten carbide-based cemented carbide or titanium carbonitride-based cermet; and a hard coating layer formed by vapor-depositing in order, a lower layer (a), an intermediate layer (b), and an upper layer (c) on the tool substrate. The lower layer (a) is a Ti layer composed of one or more of a titanium carbide layer, a titanium nitride layer, a titanium carbonitride layer, a titanium carboxide layer, and a titanium oxycarbonitride layer, and having a thickness of 3 to 20 μm. The intermediate layer (b) is an aluminum oxide layer having a thickness of 1 to 5 μm, and having an α-type crystal structure in a chemically vapor-deposited state. The upper layer (c) is an aluminum oxide layer having a thickness of 2 to 15 μm, and containing one or more elements of Ti, Y, Zr, Cr, and B.

Owner:MITSUBISHI MATERIALS CORP

Tyre

InactiveCN101450594AMaintain ice resistanceMaintain wet skid resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention discloses a tyre, which comprises (A) tread rubber, (B) tread basal rubber, (C) sidewall rubber, (D) rebate protective rubber, (E) carcass layer rubber, (F) lining layer rubber, (G) triangle rubber, (H) belted layer rubber, (I) air-tight layer rubber and (J) tyre bead steel wire rubber. The tyre components consist of rubber compositions, wherein the rubber compositions of the (A) tread rubber, the (B) tread basal rubber, the(C) sidewall rubber and the (D) rebate protective rubber adopt white carbon black and carbon black with high specific surface area as reinforcing fillers; and the rubber compositions of the (E) carcass layer rubber, the (F) lining layer rubber, the (G) triangle rubber, the (H) belted layer rubber, the (I) air-tight layer rubber and the (J) tyre bead steel wire rubber adopt white carbon black and carbon black with low specific surface area as reinforcing fillers. The tyre has the advantages of good puncture resistance and chunking resistance, low rolling resistance and heat generating performance, and greatly-reduced production cost. The full-steel giant engineering tyre is particularly suitable for an adverse road environment such as a large-scale mine yard.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

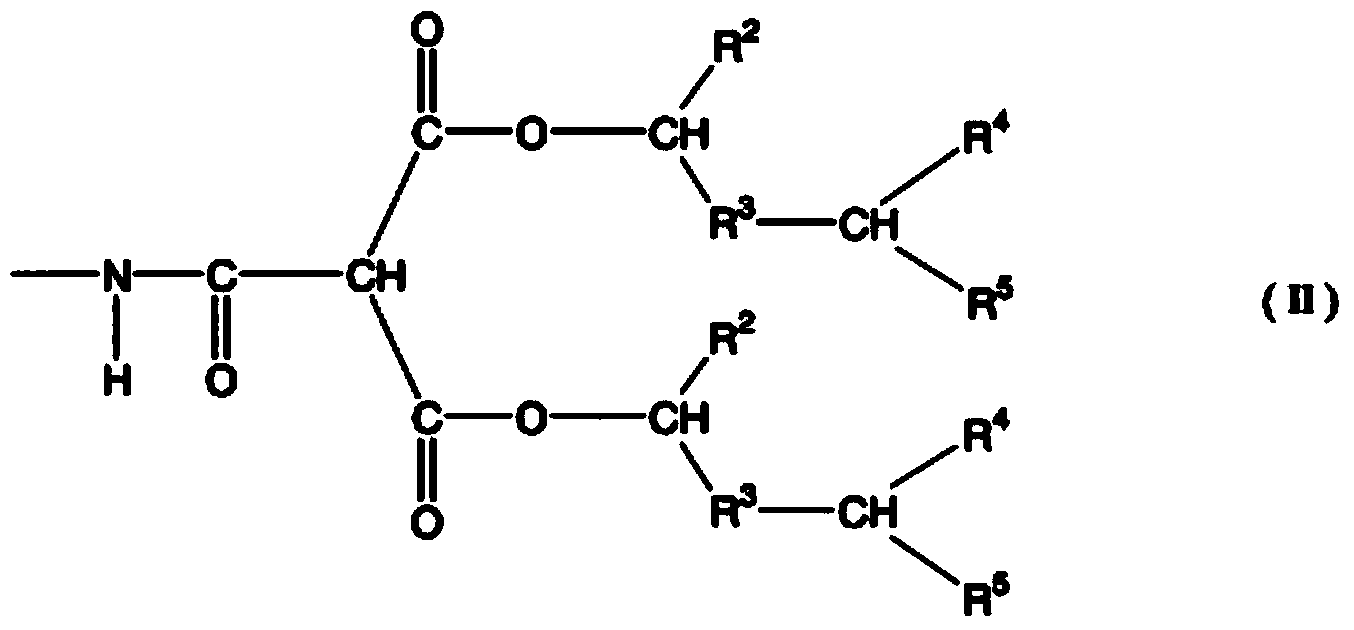

Heat-curable powder coating composition

InactiveUS20090270533A1Excellent long-term heat resistanceOutstanding flexibilityAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolymer chemistry

Disclosed is a heat-curable powder coating composition that allows the formation of a coating film having outstanding long-term corrosion resistance, as well as outstanding chipping resistance, flexibility, and adhesion.The disclosed heat-curable powder coating composition is characterized by a resin having crosslinkable functional groups that are solid at room temperature (A), a curing agent capable of reacting with said crosslinkable functional groups (B), a fibrous filler (C), and heat-expandable resin particles (D).

Owner:BASF COATINGS JAPAN

CBN sintered compact and cutting tool using the same

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

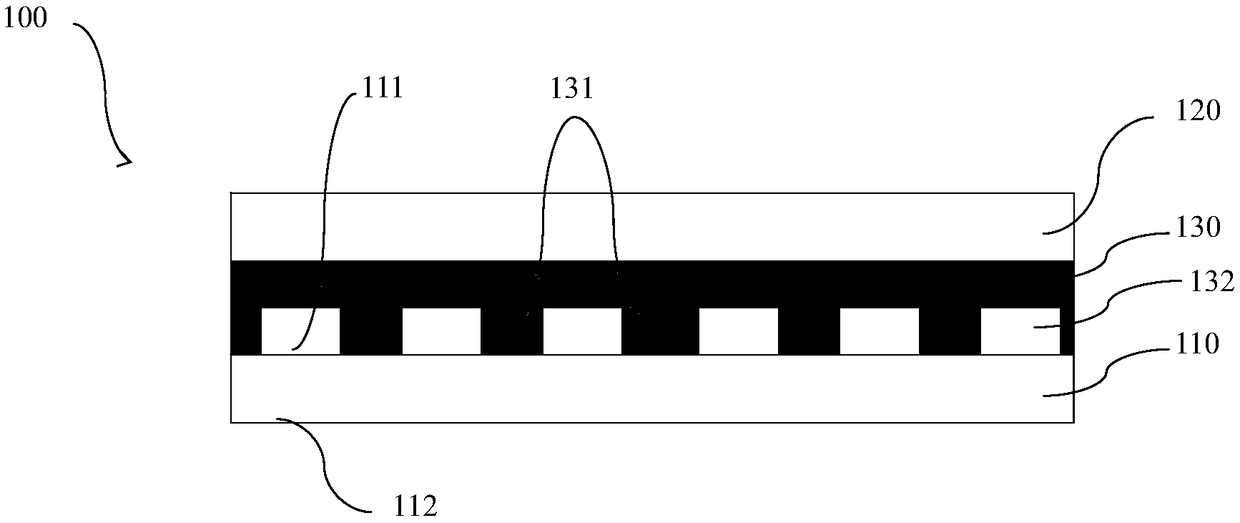

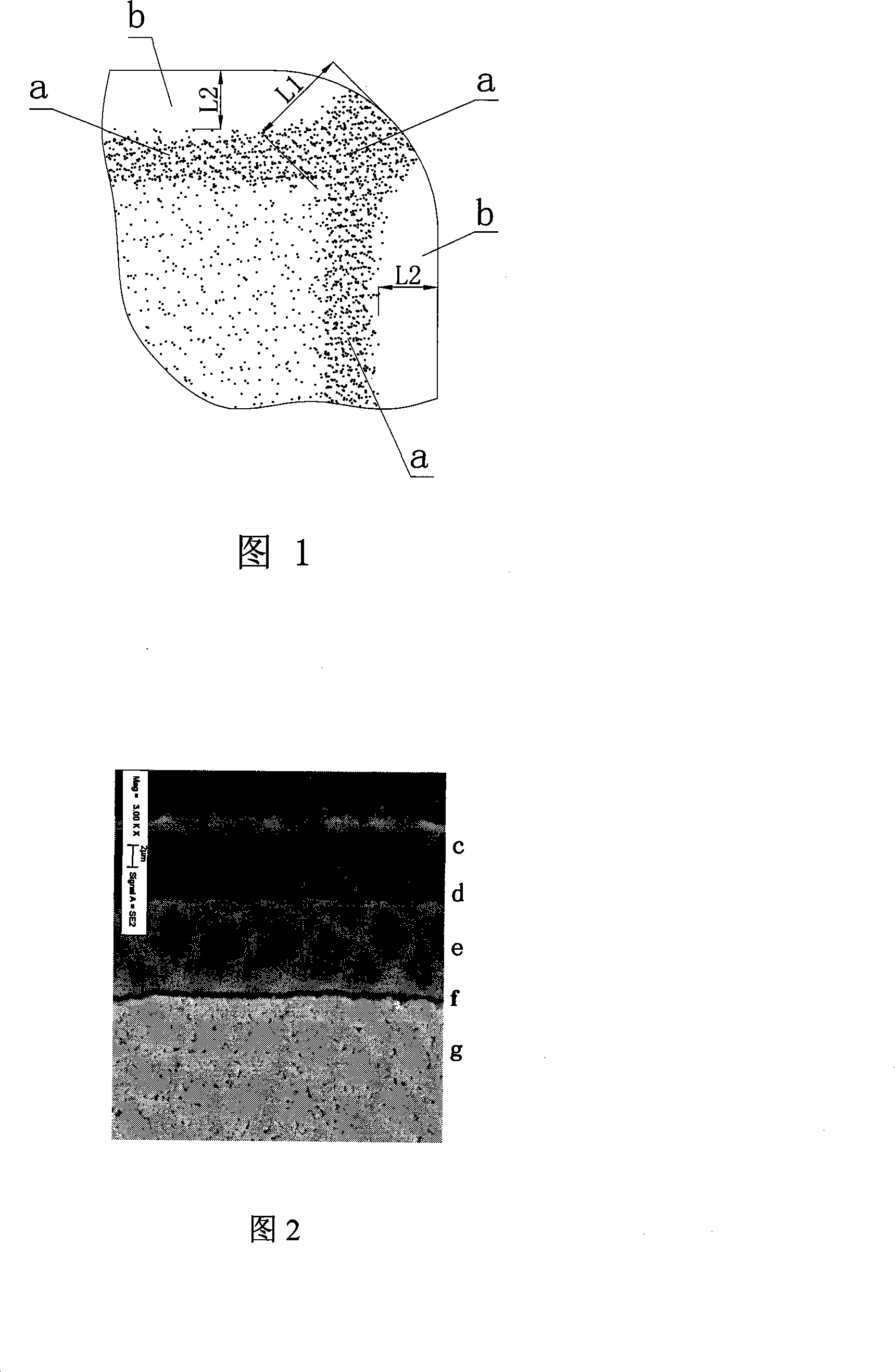

Cover plate and manufacturing method thereof, flexible display module and electronic equipment

ActiveCN109326220AImprove shear resistanceImprove chip resistanceInput/output processes for data processingIdentification meansEngineeringFlexible display

The invention provides a cover plate for a flexible screen and a manufacturing method thereof, a flexible display module and electronic equipment, wherein, the cover plate comprises: a base plate; a first cladding layer covering the first surface of the base plate; a first adhesive layer which adheres the first cladding layer with the base plate and forms a hollow structure between the base plateand the first cladding layer through at least one first bulge arranged on the first surface of the first adhesive layer. The invented cover plate effectively improves the anti-cracking intensity through the buffering action and the stress dispersing action of the bulges.

Owner:BEIJING VISIONOX TECH

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

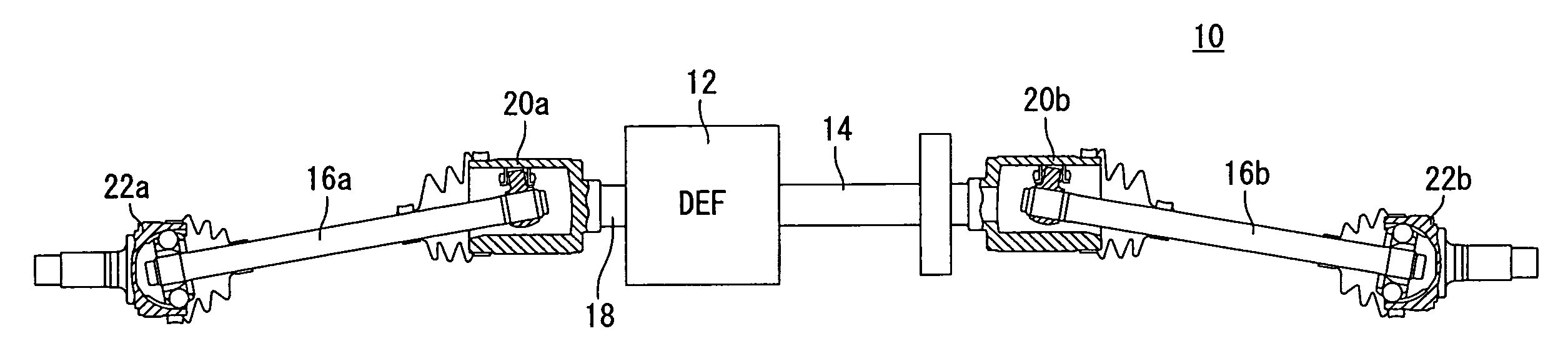

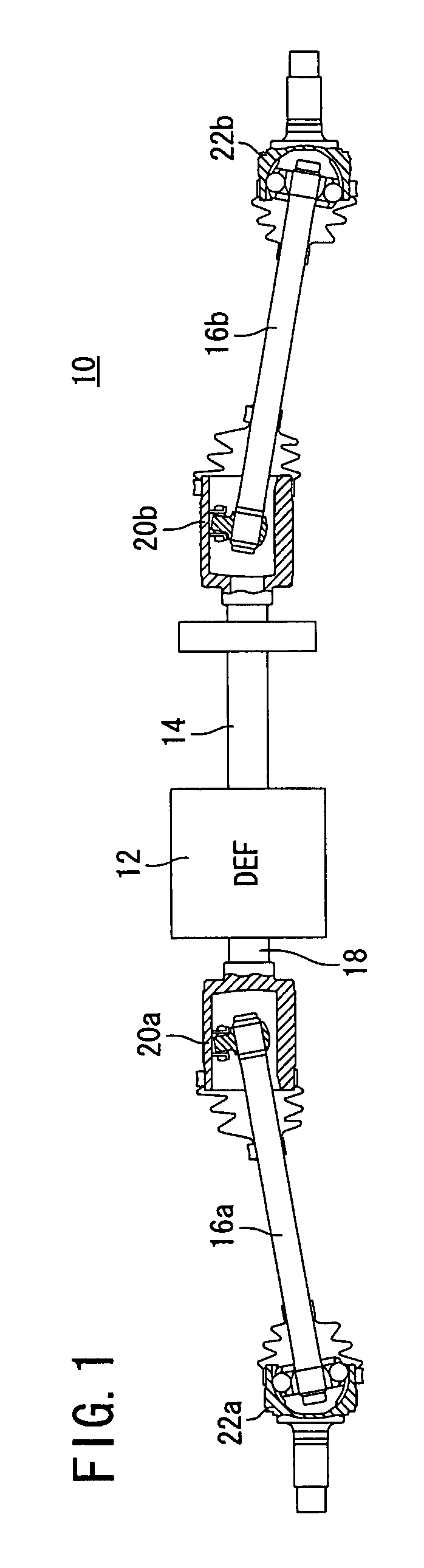

Coating Composition and Structural Member of Automotive Body

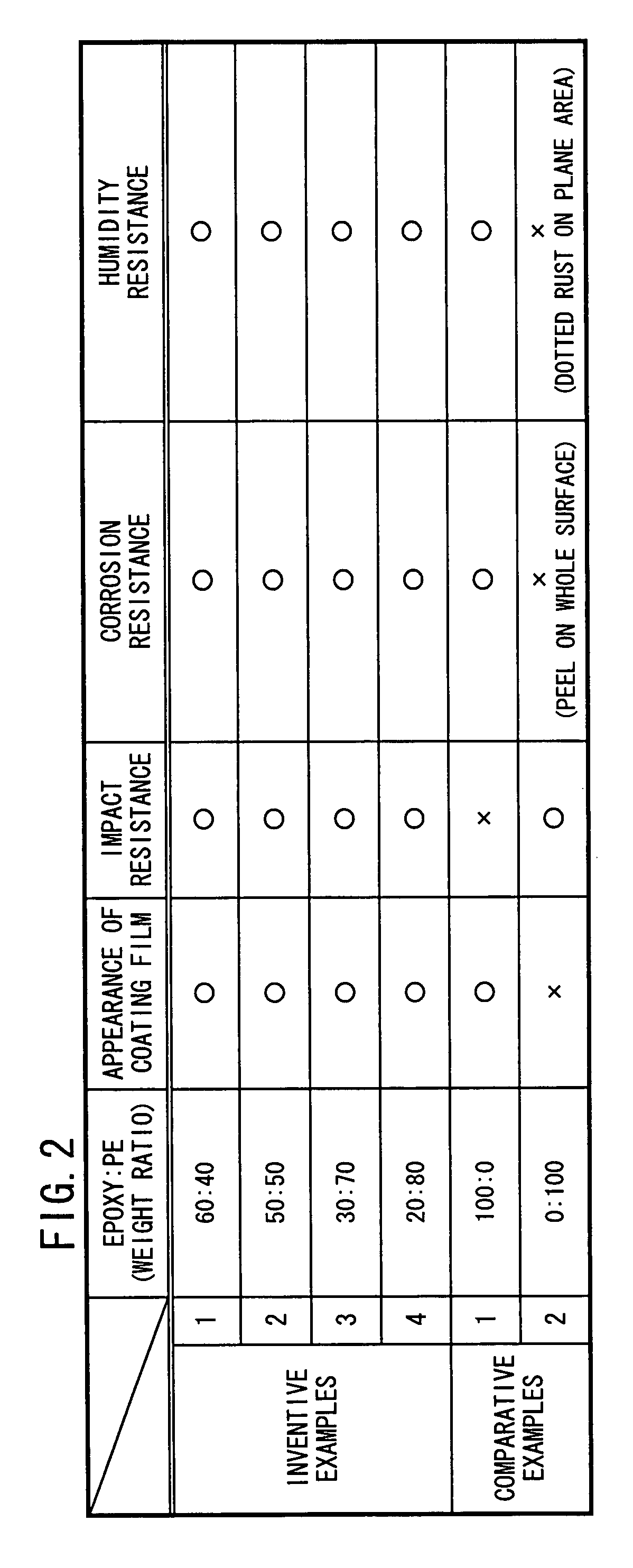

InactiveUS20080102283A1Improve propertiesImprove the immunitySynthetic resin layered productsVehicle componentsEpoxyPolyolefin

There is provided a coating film applied onto structural members of automotive body, such as drive shaft, which coating film is formed by hardening of a coating composition comprising an epoxy resin powder coating material and at least either a polyolefin resin or a modified olefin resin containing a polar group. As the polyolefin resin or modified olefin resin containing a polar group, there can be selected those of 0.1 to 80 g / 10 min melt index at 190° C. and −100° to −20° C. brittle temperature. In the coating composition, the ratio between epoxy resin powder coating material and polyolefin resin or modified olefin resin containing a polar group on a weight ratio basis is set for 1 to 70 : 99 to 30.

Owner:HONDA MOTOR CO LTD +1

Coating compositions that include a polyester polyol, related coated substrates, multi-layer coating and methods

Coating compositions are disclosed comprising a polyester comprising at least two reactive hydroxyl groups, a material comprising at least two functional groups reactive with the hydroxyl groups of the polyester, and a free acid. Methods of using the coatings, methods for refinishing an article with the coatings, and the substrates coated therewith, are also disclosed.

Owner:PPG IND OHIO INC

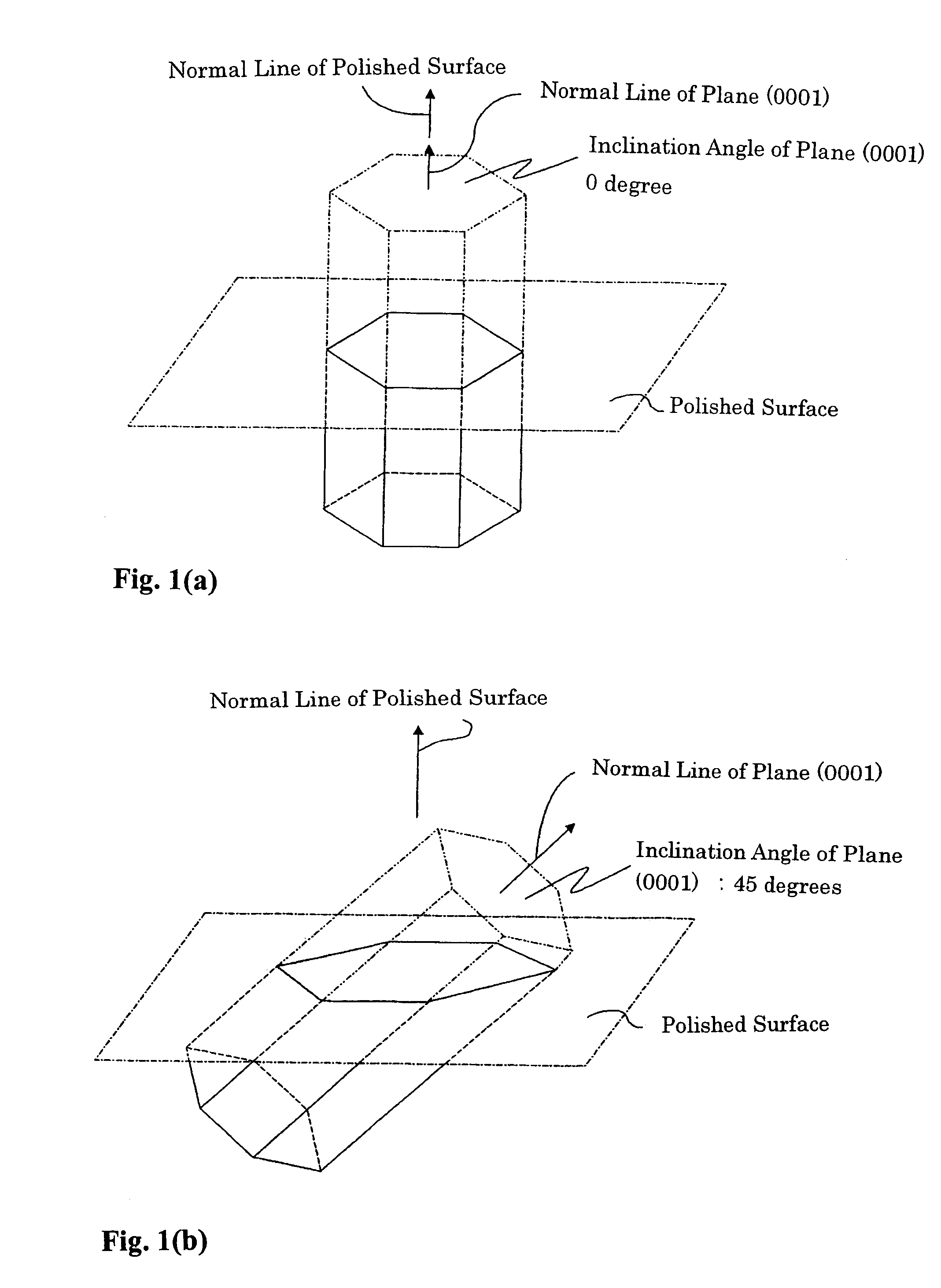

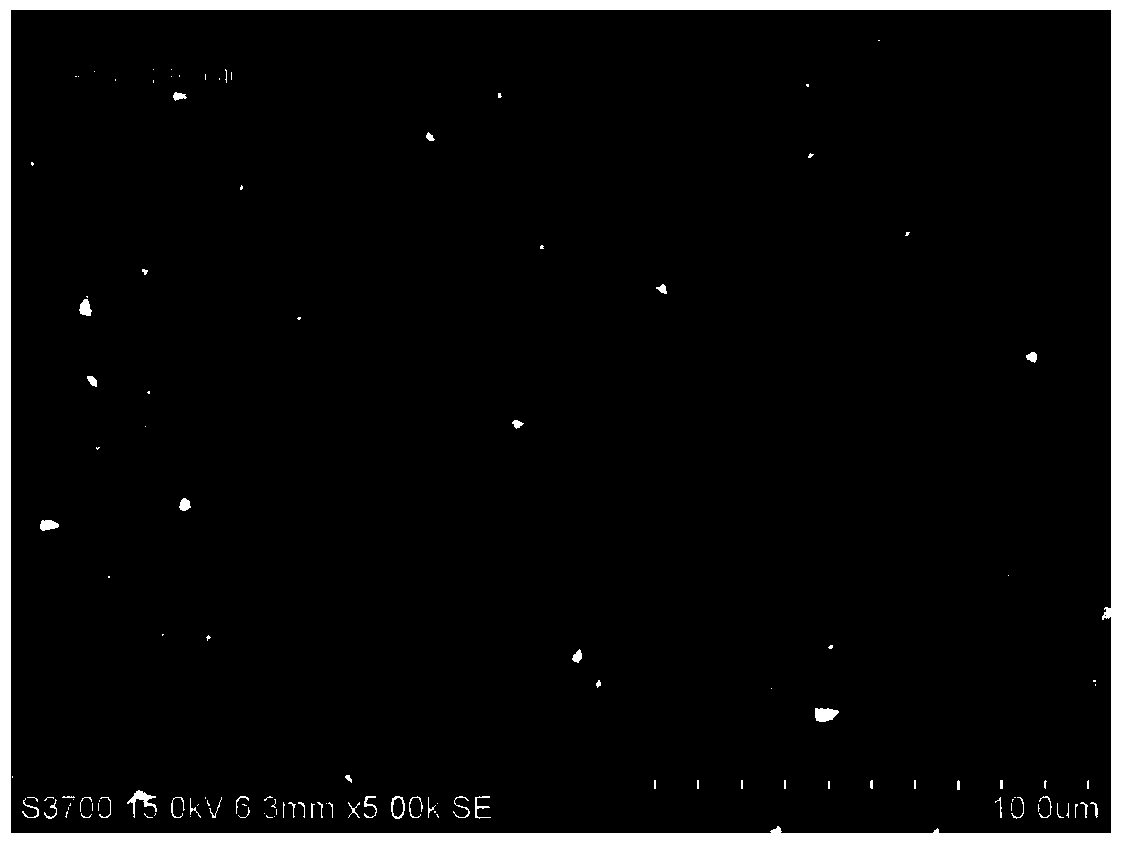

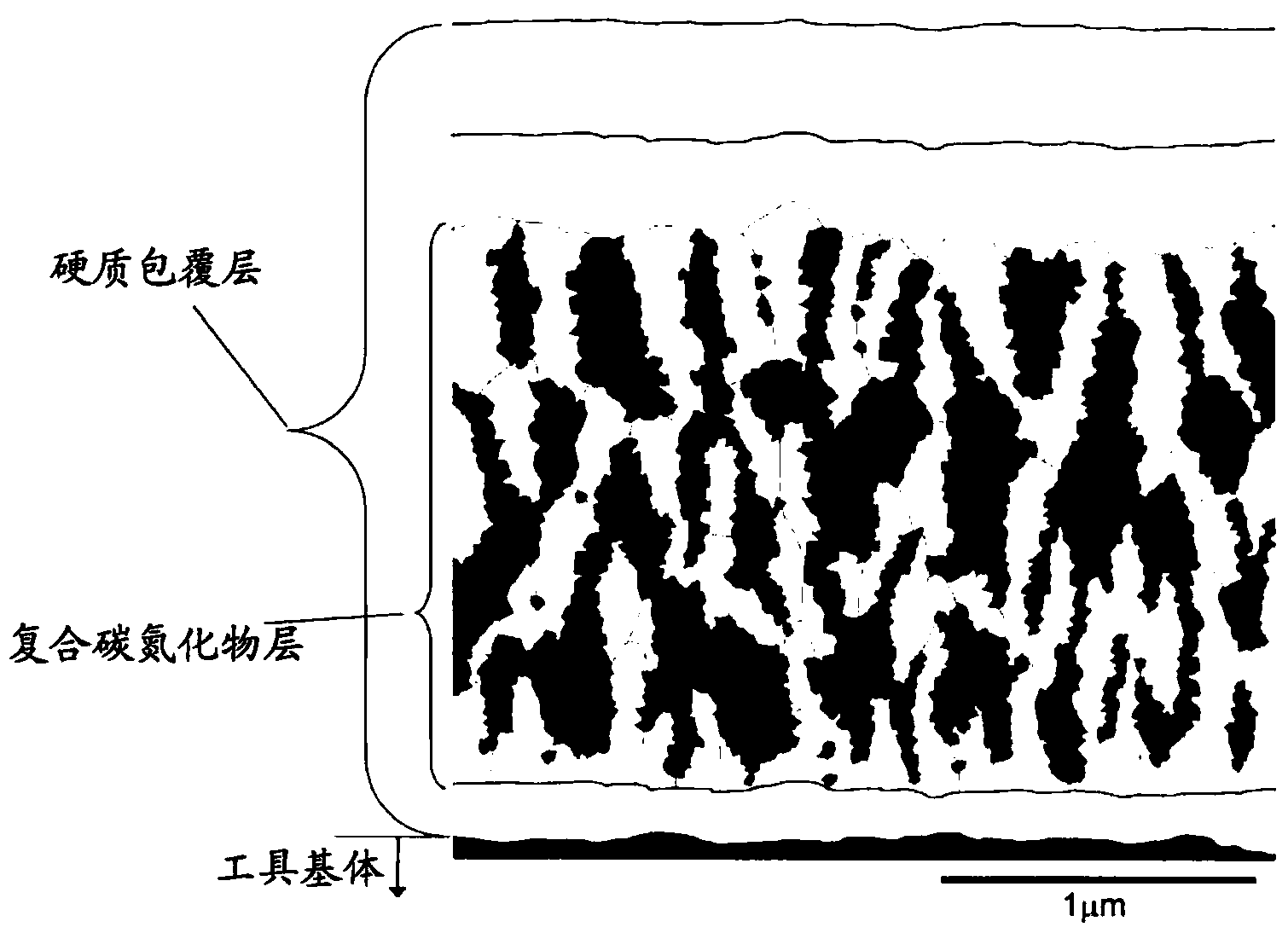

Blade-breakage-resisting surface coating cutting tool with excellent performance of hard coating layer

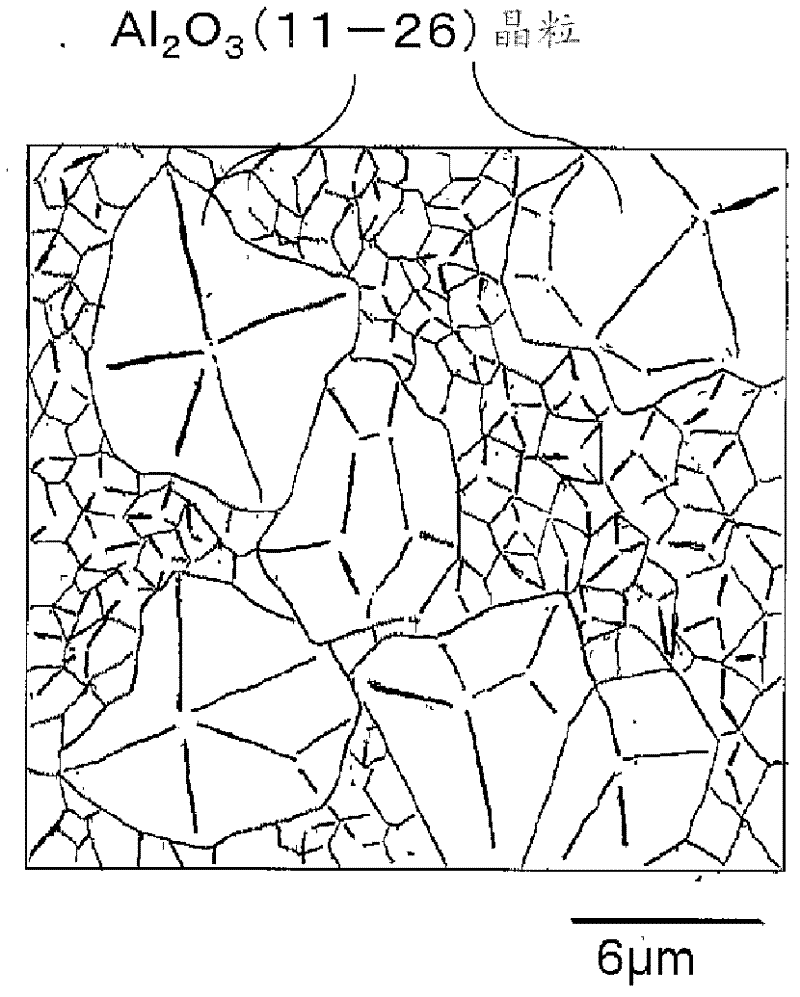

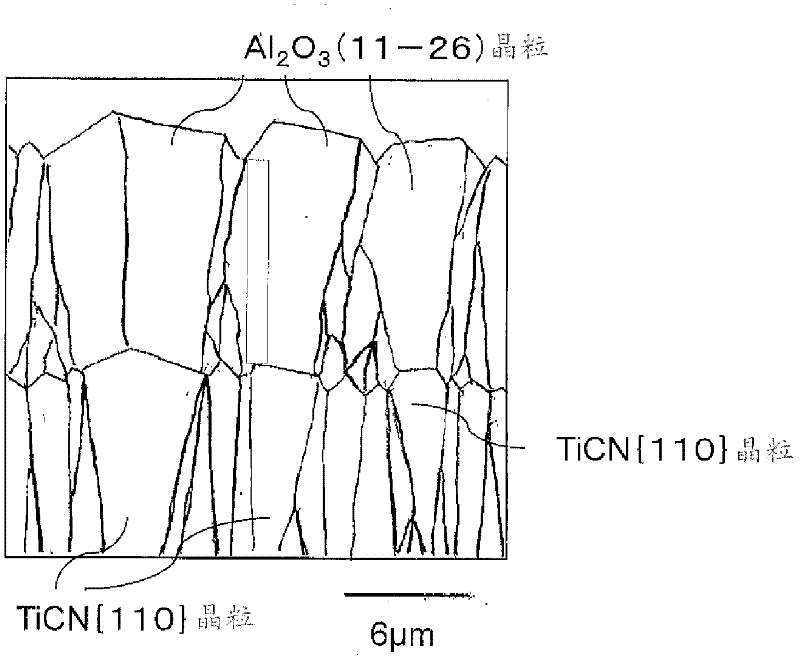

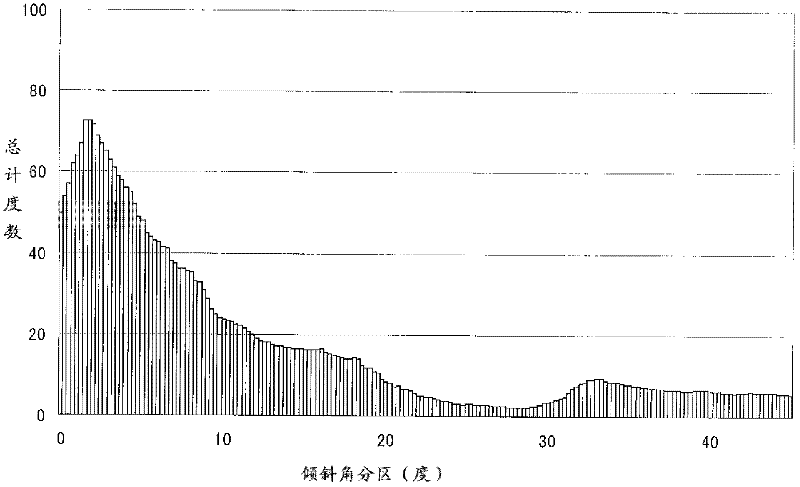

ActiveCN102441686AImprove impact resistanceImprove high temperature strengthMilling cuttersTurning toolsScanning electron microscopeElectron microscope

The present invention provides a blade-breakage-resisting surface coating cutting tool with excellent performance of a hard coating layer. A Ti compound layer which at least comprises a TiCN layer is coated on the surface of a tool substrate as a lower layer (a). In the surface coating cutting tool in which an alpha Al2O3 layer is used as an upper layer (b), for the TiCN layer of the lower layer, when an included angle of a normal line of a surface [110] is formed by a field emission scanning electron microscope and is prepared to an inclination angle number distribution graph, the TiCN particles [110] of the inclination angle in the range of 0-10 DEG accounts for more than 50% of the whole particles. Additionally, for the alpha type Al2O3 layer of the upper layer, when the inclination angle which is formed by the normal line of a surface (0001) is measured and prepared to an inclination angle number distribution graph, the Al2O3 crystal particles with the inclination angle in 35-45 DEG accounts for more than 60% of the whole particles. Furthermore when observed in a surface which is vertical to the layer thickness direction, crystal particles of the Al2O3 (11-26) are coarse and large, and average crystal particle diameter of the crystal particles of the Al2O3 (11-26) is 2-5 times of the crystal particles except for the Al2O3 (11-26).

Owner:MITSUBISHI MATERIALS CORP

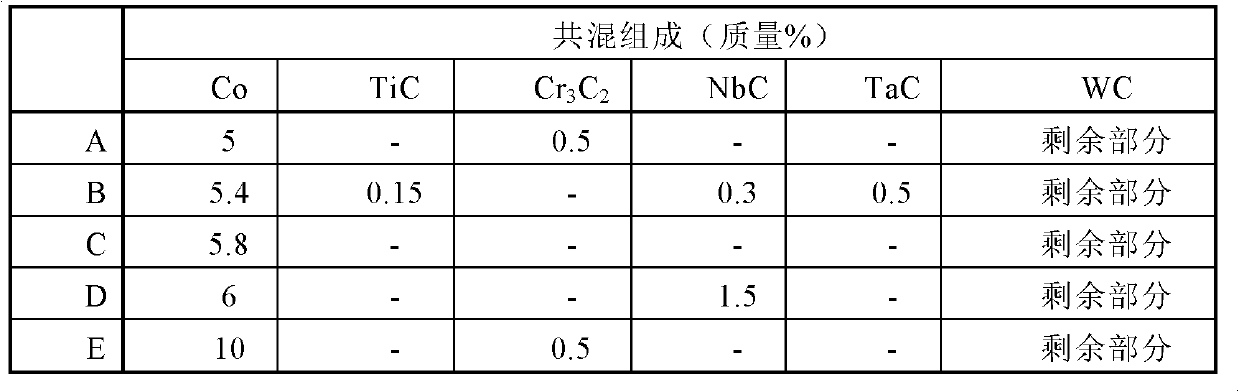

Cemented Carbides

InactiveUS20080276544A1Avoid grain growthHigh hardnessPigmenting treatmentOther chemical processesIron groupAlloy

The present invention provides a cemented carbide with superior strength and toughness by refining the WC in the alloy uniformly and by restricting the growth of coarse WC efficiently. In this cemented carbide, WC with a mean particle diameter of no more than 0.3 microns serves as a hard phase and at least one type of iron group metal element at 5.5-15 percent by mass serves as a binder phase. In addition to this hard phase and binder phase, this cemented carbide contains 0.005-0.06 percent by mass of Ti, Cr at a weight ratio relative to the binder phase of at least 0.04 and no more than 0.2, with the remaining portion being formed from inevitable impurities. In particular, this cemented carbide does not contain Ta.

Owner:SUMITOMO ELECTRIC IND LTD +1

Coating blade for processing cast iron

ActiveCN101214743ADecreased strength and toughnessStrong enoughLayered productsAlloyCemented carbide

The invention discloses a coated tip used to processing cast iron, which comprises a hard alloy basal body and a coating. The invention is characterized in that the hard alloy basal body comprises 2 percent to 12 percent of cobalt by weight and 0.2 percent to 3.5 percent of cubic-structure compound of metallic elements from the families of IVb, Vb and / or VIb in the periodic table by weight. A binding phase surface enrichment area is formed on both sides of the cutting edge of the basal body. The middle pie-slice section of the binding phase surface enrichment area is a cubic structure enrichment area. The coating comprises an innermost layer of equiaxed grain TiCxNyOz, a middle layer of columnar crystal TiCxNy 2 microns to 13 microns thick, a transition layer of TiCxNyOz and an outer layer of fine crystal Alpha-Al2O3 4 microns to 12 microns thick. The tip disclosed by the invention not only has the characteristics of high wearing feature, high strength and high versatility, but also integrates the toughness and the plastic deformation resistance well. Accordingly, the invention is in particular applicable for processing cast iron.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Coating layer on blade base body

ActiveCN104085142AReduce crackingReduce internal stressLayered productsChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention discloses a coating layer on a blade base body. The total thickness of the coating layer is 5-40 mu m. The coating layer at least comprises an aluminium oxide layer deposited by employing a chemical vapor deposition manner. The aluminium layer has the thickness of 1 mu m to 15 mu m, has extremely obvious fine-columnar crystal structure. Each crystal grain in the aluminium layer is arranged at a same direction and grows directionally uniformly. The columns of the columnar crystal have same width of 0.2 mu m to 4 mu m. On the one hand, the coating layer is capable of effectively reducing the internal stress of the coating, improving the toughness of the coating, preventing expansion of cracks and reducing tipping of a blade; and on the other hand, the coating layer is capable of improving the wear resistance of the blade. The coating layer of the cutting tool has excellent toughness and good wear resistance, and has excellent cutting performance in fields of cutting of materials such as steel, cast iron, stainless steel and the like.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

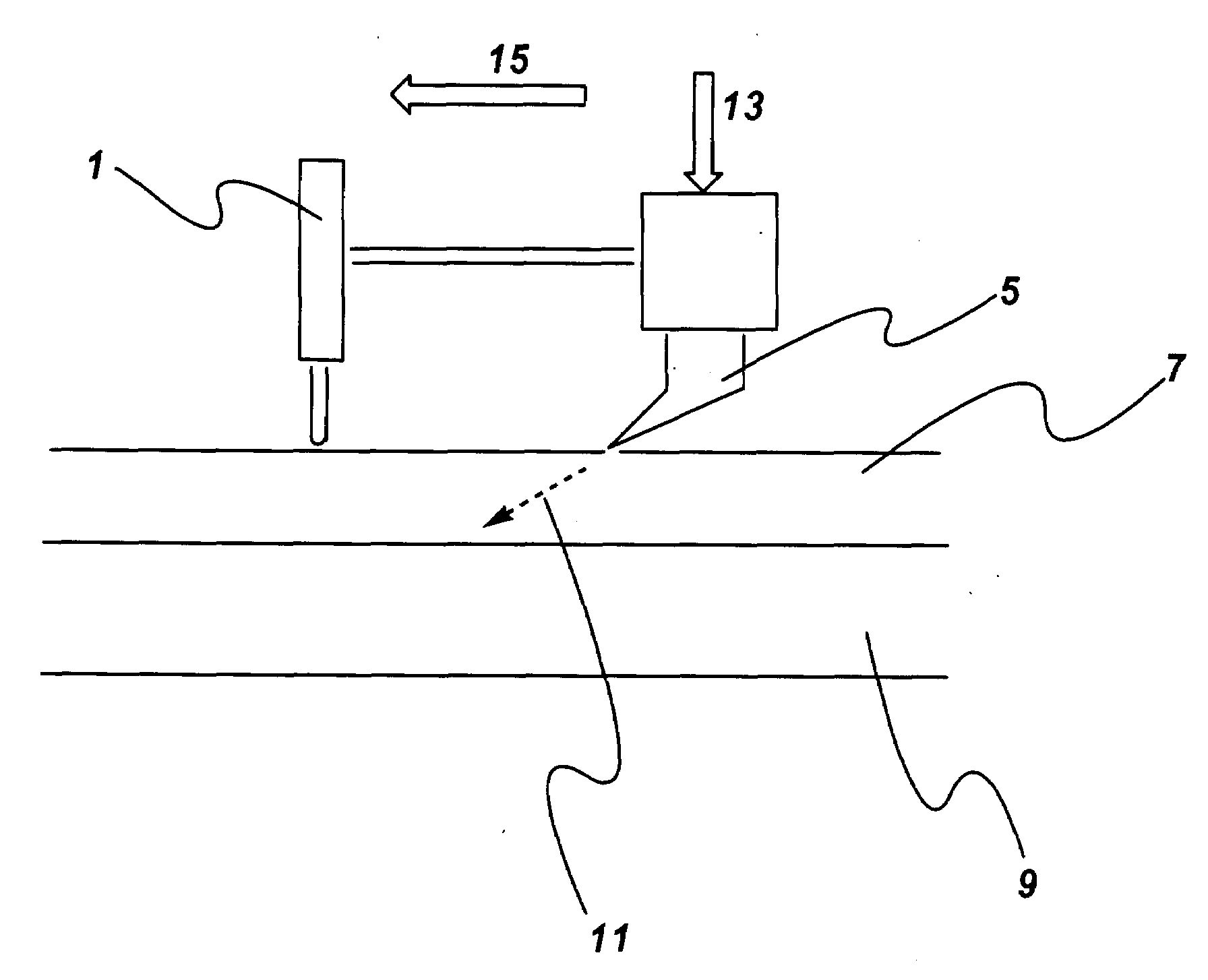

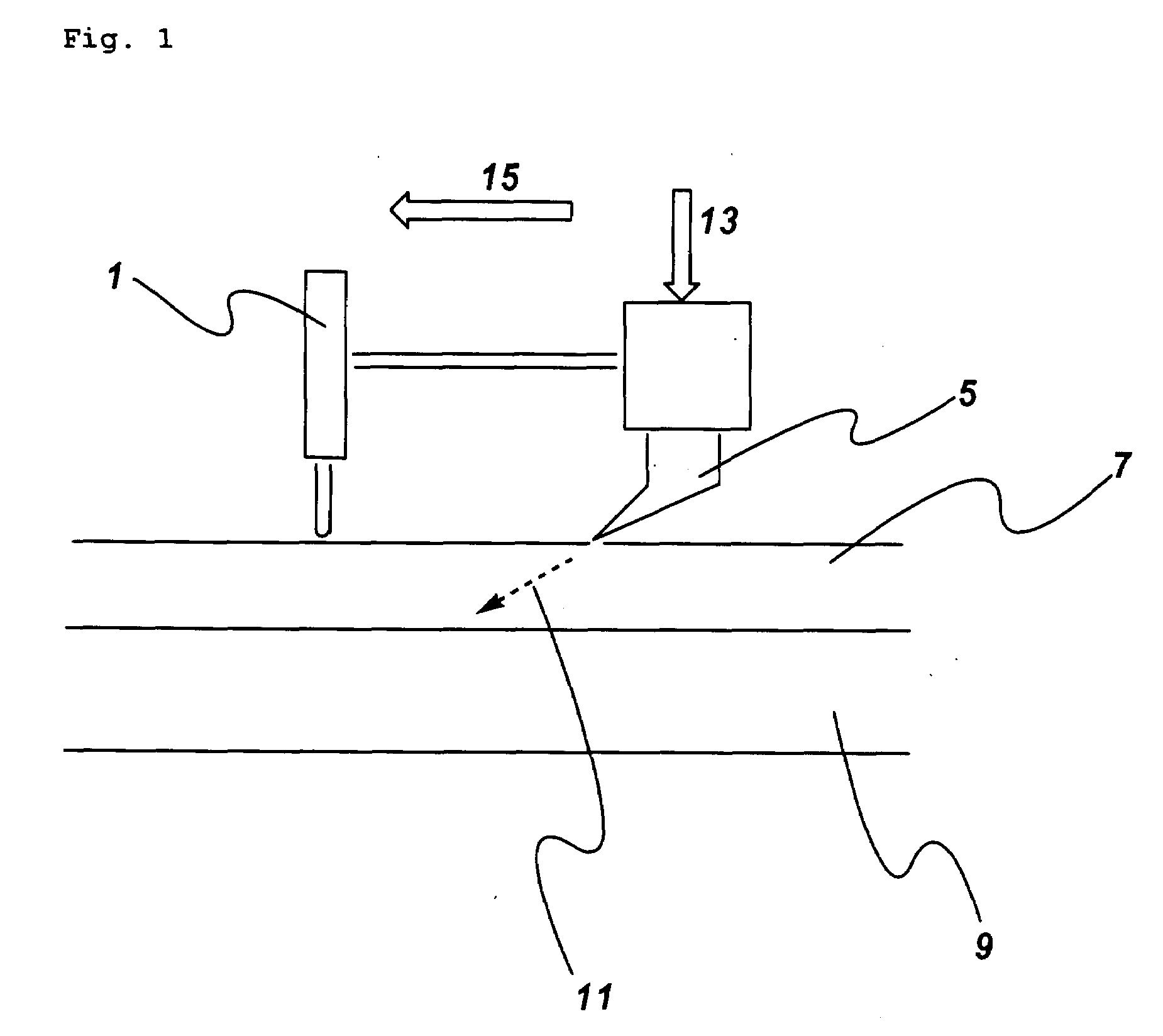

Method for producing multi layered coating film

InactiveUS20080138527A1Improve the immunityImprove abilitiesPretreated surfacesPolyester coatingsPolymer sciencePolyester resin

The present invention relates to an intermediate coating composition, which comprises(a) a polyester resin comprising a polyester resin (i) and a polyester resin (ii),(b) a bisphenol type epoxy resin, and(c) an imino group-containing melamine resin, each of which contents of the components (a), (b) and (c) is relative to weight of the resin solid contents in the composition,whereina weight ratio of the polyester resin (a) / the imino group-containing melamine resin (c) [(a) / (c)] is within a range of 50 / 50 to 70 / 30.Therefore, the present invention can provide an intermediate coating composition which can form a multi layered coating film having an excellent chipping resistance, as well as, a method for producing a multi layered coating film by using the intermediate coating composition.

Owner:NIPPON PAINT CO LTD

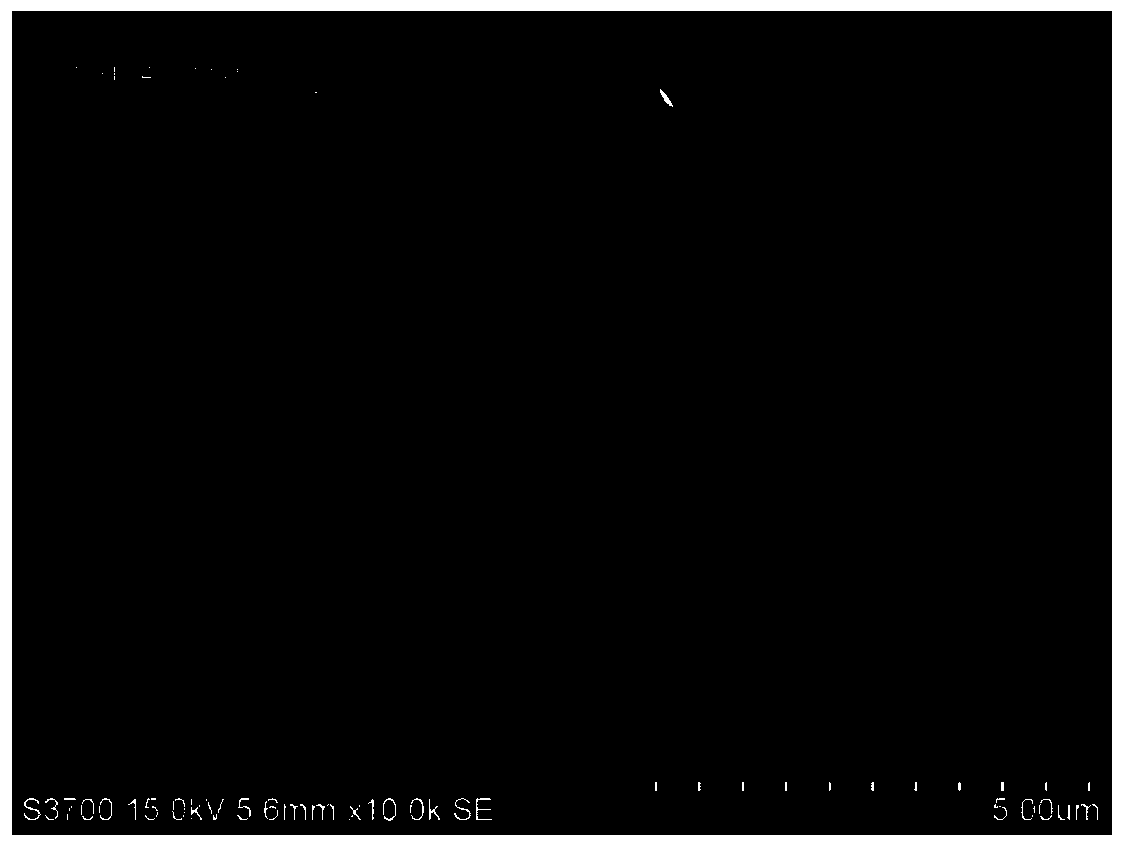

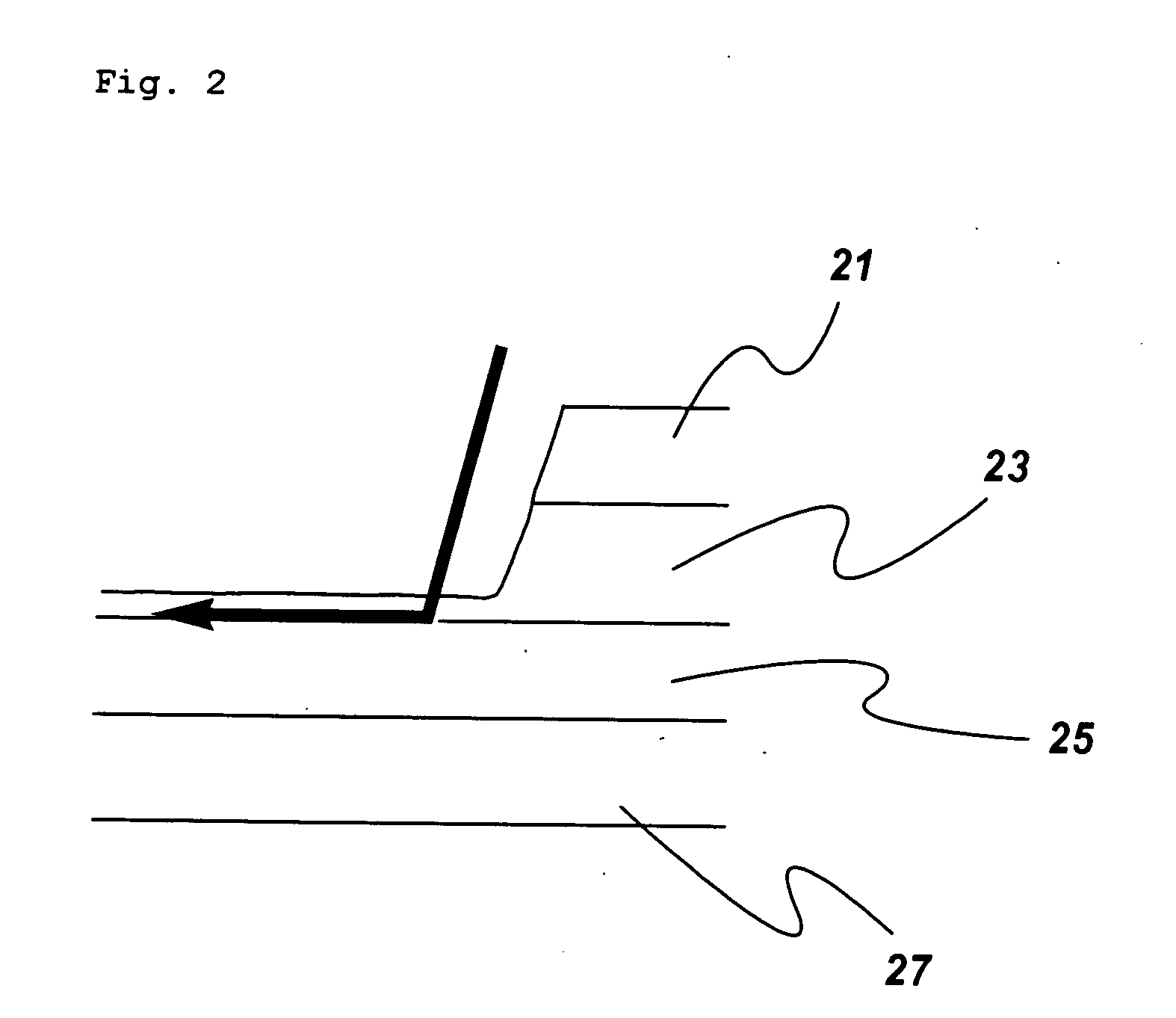

Surface covered tool

ActiveCN102196874AThe average crystal width is smallReduce distribution densityMilling cuttersVacuum evaporation coatingVolumetric Mass DensityUpper floor

Disclosed is a surface covered tool, such as a cutting tool (1), wherein the surface of a base body (2) is covered with a cover layer (6), the cover layer (6) is composed of a lower layer (8) and an upper layer (9), and the lower layer (8) and the upper layer (9) are both composed of columnar particles (10) extending perpendicularly to the surface of the base body (2). The average crystal width of the columnar particles (10b) constituting the upper layer (9) is smaller than the average crystal width of the columnar particles constituting the lower layer, dispersed particles containing tungsten exist in both the lower layer and the upper layer, and the distribution density of the dispersed particles existing in the upper layer is smaller than the distribution density of the dispersed particles existing in the lower layer. The surface covered tool is provided with the cover layer which improves abrasion resistance and defect resistance.

Owner:KYOCERA CORP

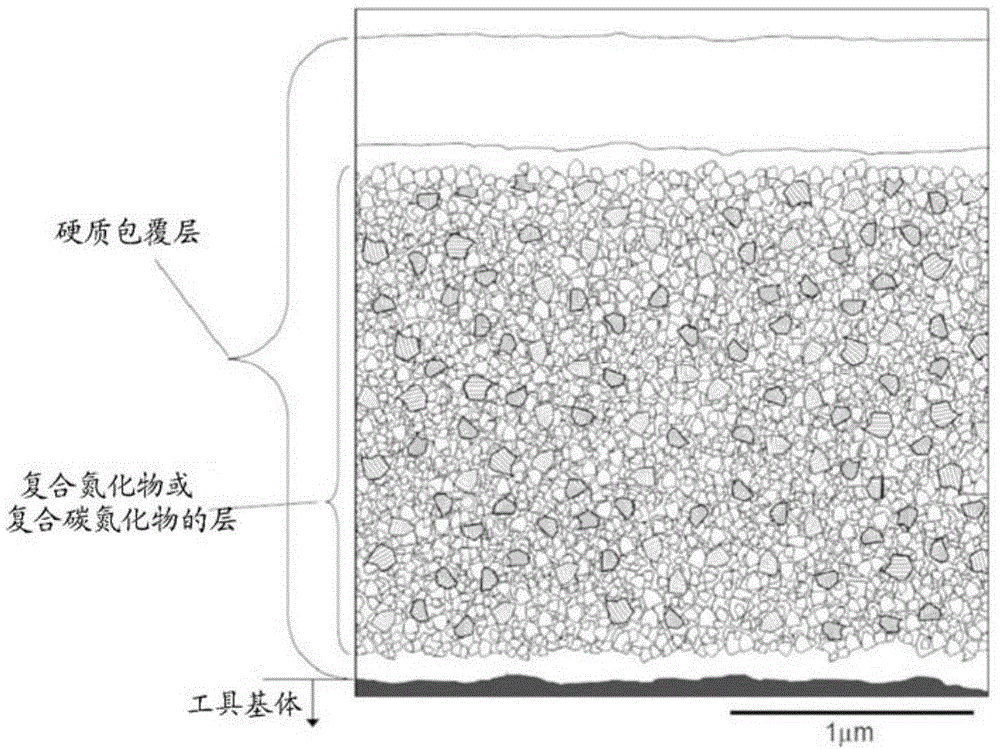

Surface coating cutting tool hard coating layer of which gives play to excellent anti-tipping performance

InactiveCN104789938AHigh hardnessImprove wear resistanceTurning toolsChemical vapor deposition coatingHardnessNitride

The subject of the invention is to provide a surface coating cutting tool a hard coating layer of which has excellent hardness and toughness and gives play to anti-tipping performance and defect-resistant performance. The hard coating layer contains a composite nitride represented by a compositional formula of (Ti<1-x-y>Al<x>Me<y>)(C<z>N<1-z>) or a layer of the composite nitride, wherein Me is an element selected from Si, Zr, B, V and Cr, the average contained proportion Xav of Al, the average contained proportion Yav of Me, the average contained proportion Zav of C meet 0.60<=Xav<=0.95, 0.005<=Yav<=0.10, 0<=Zav<=0.005 and Xav+Yav<=0955, the Xav, the Yav and the Zav are atomic ratios; and the layer at least contains cubic grains and has a granular structure the average particle width W of the cubic grains of which is 005-1.0[mu]m and the average aspect ratio A of which is lower than 5, and specified-period concentration changes of Ti, Al and Me exist in the cubic particles, so the subject is solved.

Owner:MITSUBISHI MATERIALS CORP

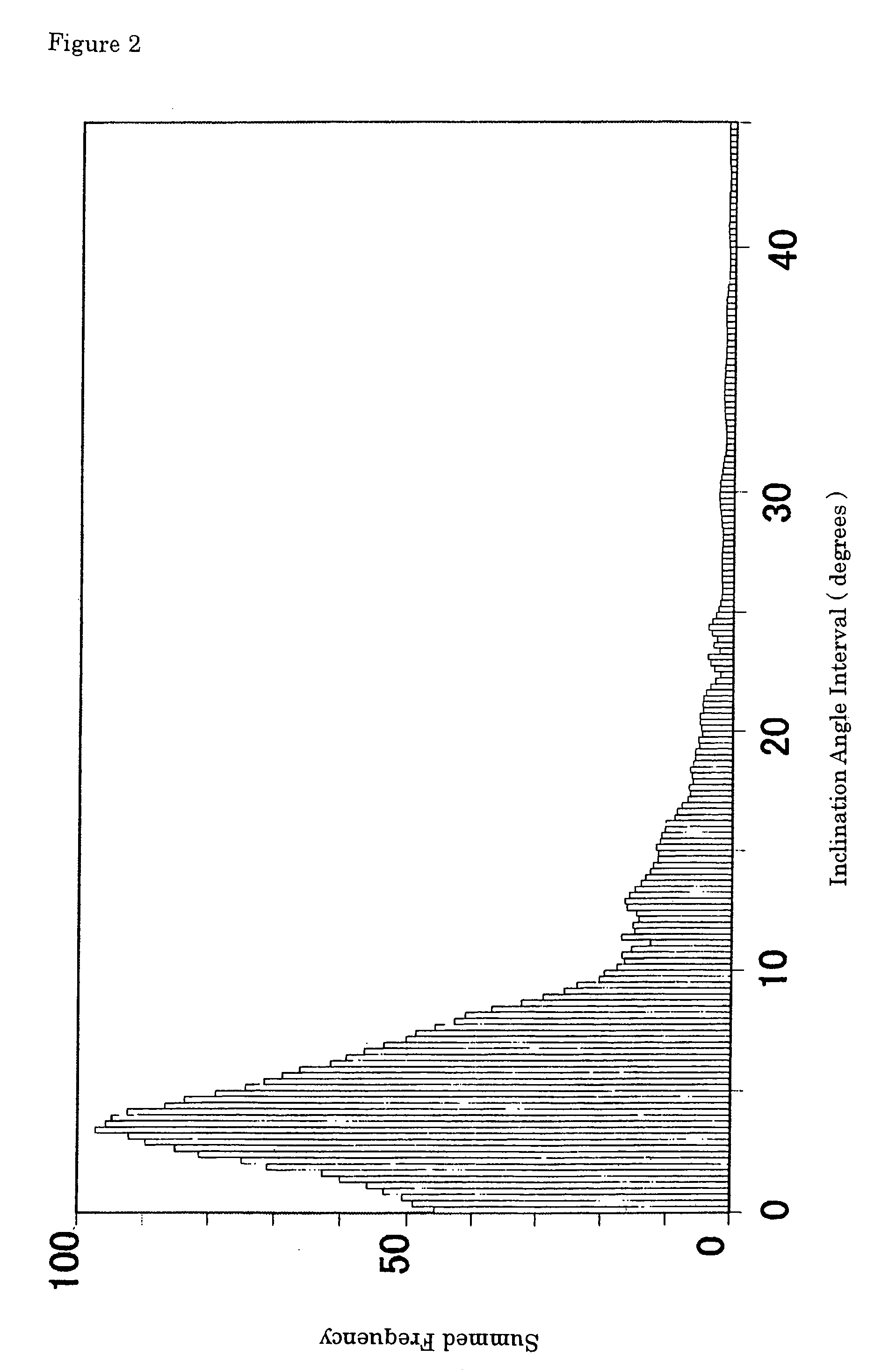

Surface coating cutting tool

ActiveCN103801718ASuppresses chippingSuppression defectMilling cuttersTurning toolsPeak valueCemented carbide

The invention provides a surface coating cutting tool which coats a (Til-XA1X)(CYN1-Y) layer formed by hexagonal phase and cubic phase mixed organization forming a film by means of chemical vapor deposition by taking A1 (CH3) as reaction gases on a matrix surface formed by WC-base cemented carbide, TiCN-base metal ceramics, cBN-base ultrahigh pressure sintered body, wherein X and Y are 0.60<=X<=0.95 and 0.0005<=Y<=0.005 by means of atomic ratio. When an inclined angle formed by the normal line of the surface (0001) of a particle of the hexagonal phase relative to the normal line direction of the surface of the matrix is detected, the zoning of the inclined angle in the range of 2-12 degrees has peak value and the degree proportion occupied in the zoning of the inclined angle is more than 40%, preferably, the average aspect ratio Alpha c of the cubic phase is less than 2, the average particle width Omega c is less than 0.3 [mu]m, and moreover, the average aspect ratio Alpha h of the hexagonal phase is more than 2, and the average particle width Omega h is in the range of 0.1-2 [mu]m.

Owner:MITSUBISHI MATERIALS CORP

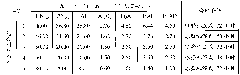

High-toughness crystalline cubic boron nitride-based ultrahigh pressure sintering material and cutting tool

ActiveCN102190497AImprove toughnessGood toughnessTransportation and packagingMilling cuttersOxideBoron nitride

The invention discloses a high-toughness cBN (cubic boron nitride)-based ultrahigh pressure sintering material and a cutting tool manufactured by the same and having excellent crack resistance. The high-toughness cBN cubic boron nitride-based ultrahigh pressure sintering material and the cutting tool made of the same material comprise at least one powder particle such as Ti nitride powder particles and Al, alloy of Al and Ti, oxide of Al and nitride of Ti and Al as a combined phase forming ingredient in a cBN-based ultrahigh pressure sintering material including the organization of a hard dispersed phase and a combined phase, besides, as the hard dispersed phase forming ingredient, the high-toughness cBN cubic boron nitride-based ultrahigh pressure sintering material and the cutting tool made of the same material comprise cBN, wherein 50% of the accumulation grain size of the powder particles which form the combined phase is 0.6-0.9 microns, furthermore, when the cBN-based ultrahigh pressure sintering material is diffracted by X ray, a diffraction peak of a composite compound of Ti, Al and N appears within a diffraction angle range that 2theta is not smaller than 40.5 degrees and not larger than 41.4 degrees, and I / I0 is not smaller than 0.15 and not larger than 0.3 when the intensity of the diffraction peak of the composite compound of Ti, Al and N is set to be I and the intensity of the diffraction peak of cBN is set to be I0.

Owner:MITSUBISHI MATERIALS CORP

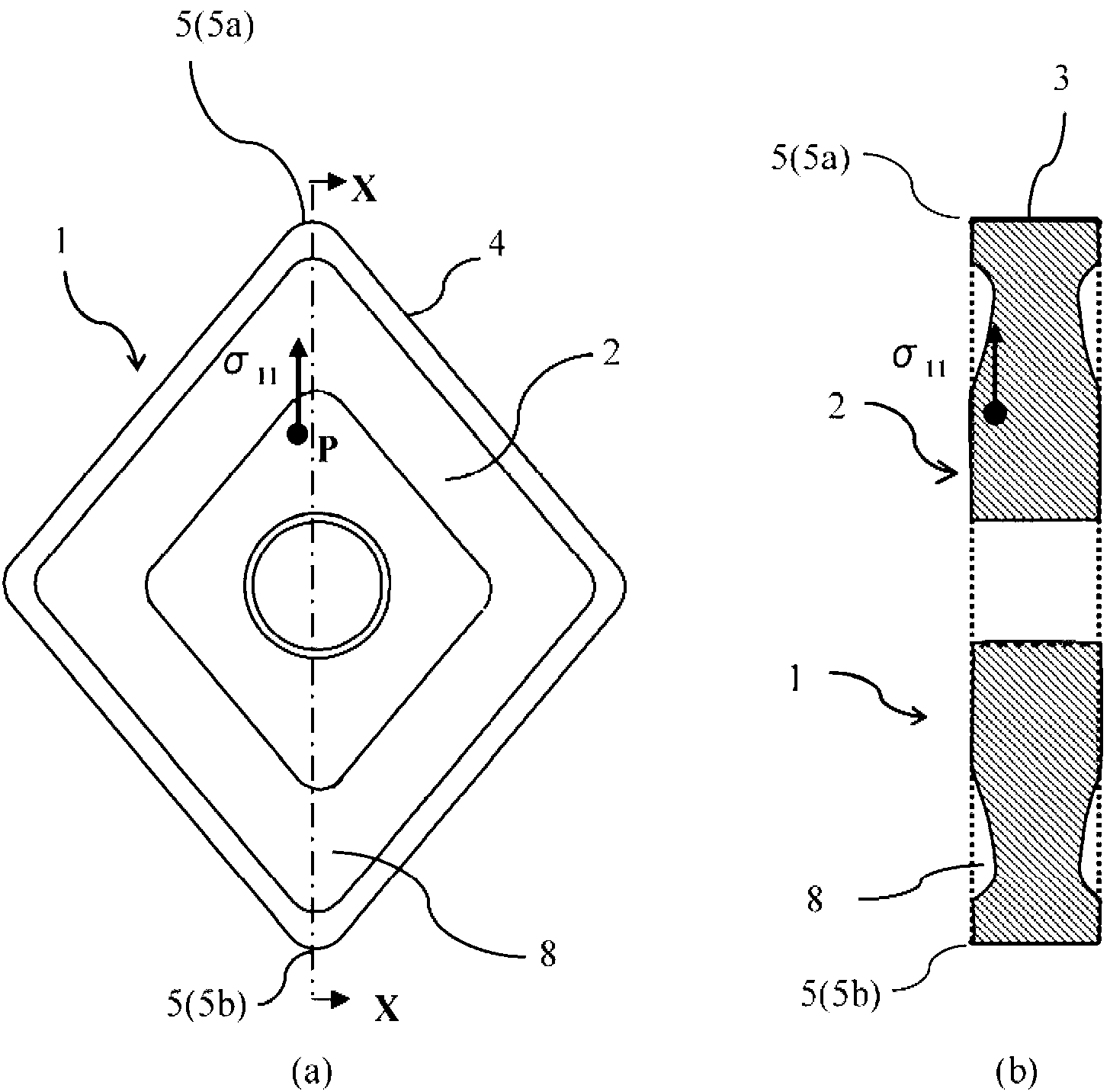

Cutting tool

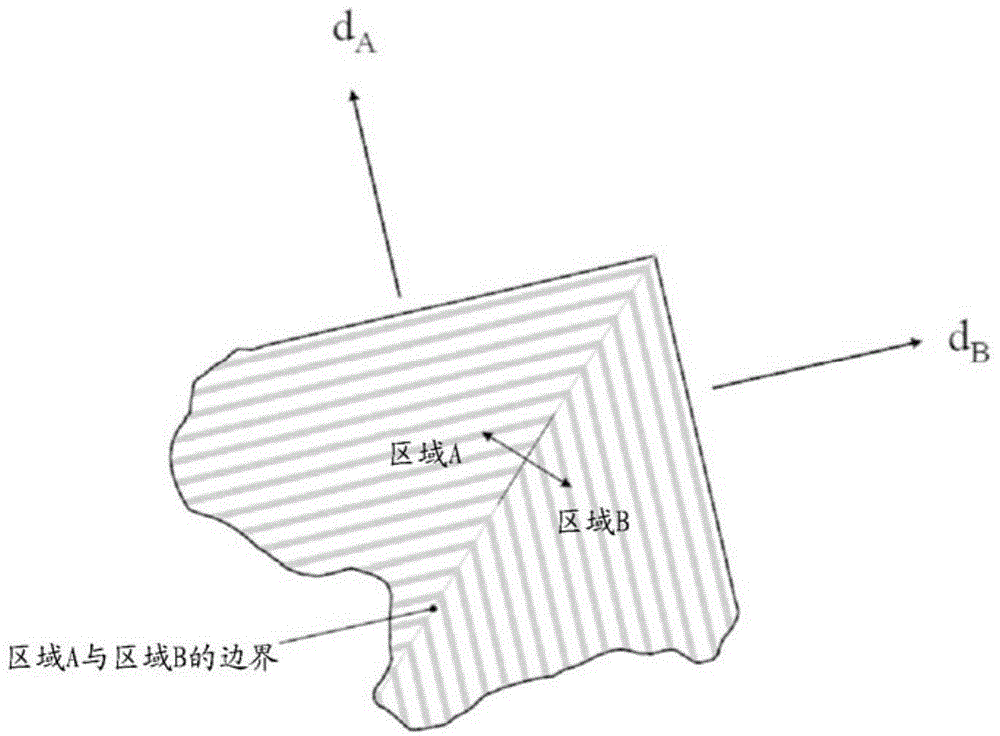

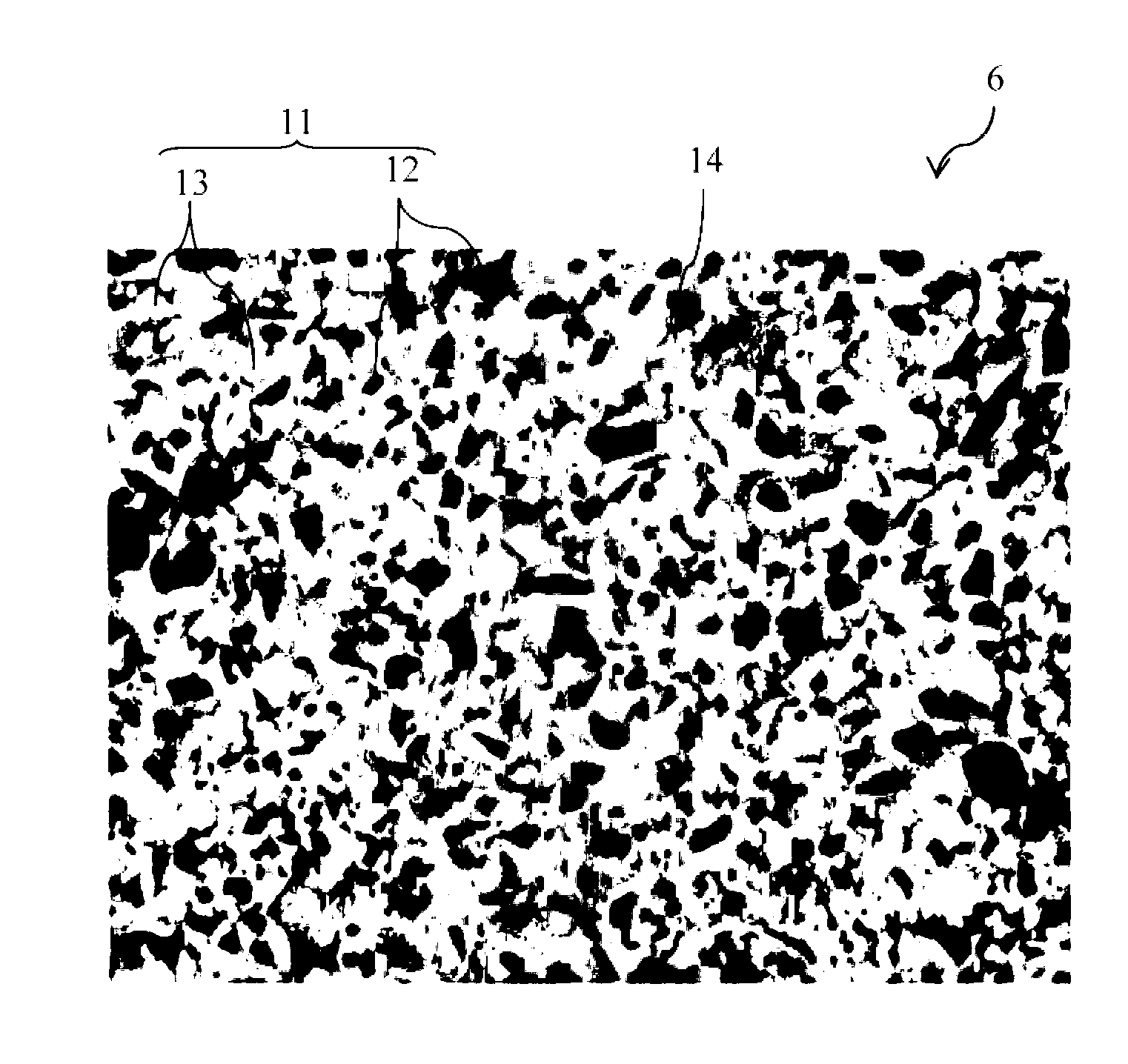

ActiveCN103282147AImprove chip resistanceImprove toughnessWorkpiecesTurning toolsCompressive strengthUltimate tensile strength

[Problem] To provide a cutting tool which is formed from a cermet sintered body that is reduced in deformation due to firing and has high strength. A cutting tool (1) which is composed of a cermet sintered body (6) that is configured of a hard phase (11) which is composed of two kinds of hard phases, namely a first hard phase (12) and a second hard phase (13), and a binder phase (14) that is composed of Co and / or Ni. At a depth of 400 [mu]m or more from the rake face (2)-side surface of the cermet sintered body (6), the residual stress sigma11[1i] in the s11 direction of the first hard phase (12) is a compressive stress of 80 MPa or more (sigma11[1i] = -80 MPa), the residual stress s11[2i] in the s11 direction of the second hard phase (13) is a compressive or tensile stress of from -50 MPa to 50 MPa (sigma11[2i] = -50 MPa to 50 MPa), and the residual stress sigma11[bi] in the s11 direction of the binder phase (14) is a compressive or tensile stress of from -50 MPa to 50 MPa (sigma11[bi] = -50 MPa to 50 MPa) as determined by a 2D method.

Owner:KYOCERA CORP

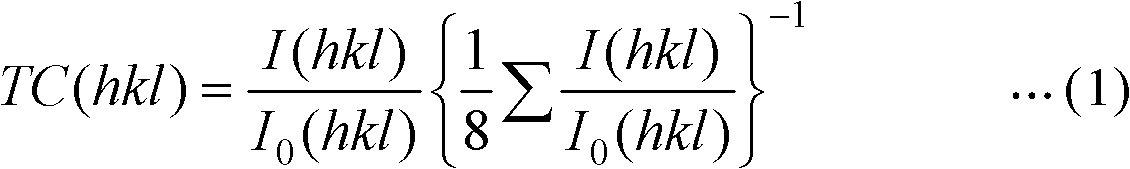

Surface-coated cutting tool and method for manufacturing same

ActiveCN102858483AImprove wear resistanceImprove chip resistanceTransportation and packagingMilling cuttersMaterials scienceCrystallization

This surface-coated cutting tool is characterized in that the tool includes a base material, and a film formed on the base material, the film includes at least one TiCN layer, the TiCN layer has a column crystal region, the column crystal region has a composition represented by the formula TiCxNy (0.65=x / (x+y)=0.90), a lattice spacing of (422) planes is 0.8765-0.8790 AA, and that an index (TC(220)) is highest in orientation index (TC (hkl)).

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

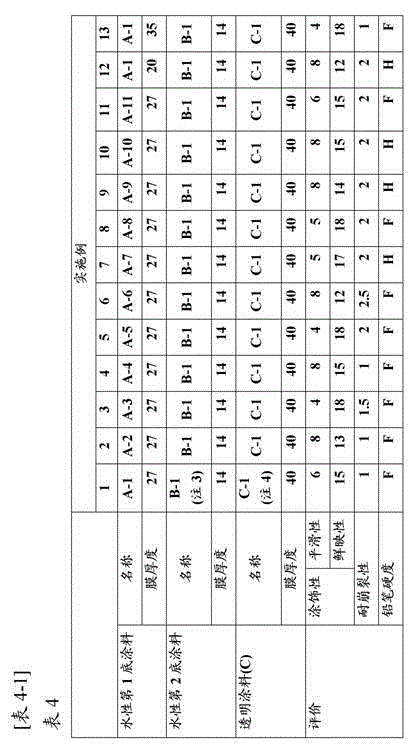

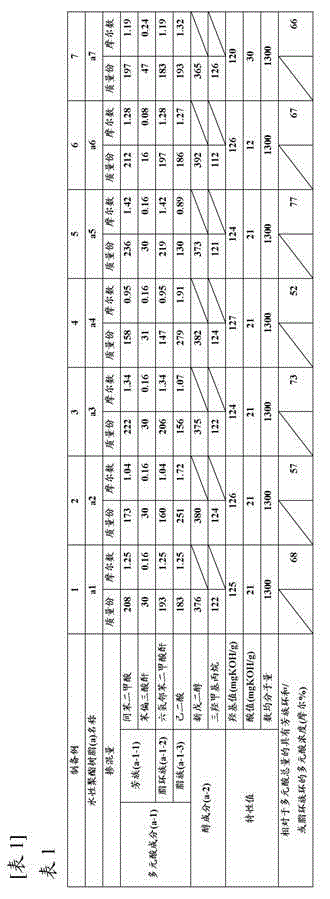

Method for forming multilayered coating film

InactiveCN104136135AImprove smoothnessImprove sharpnessLiquid surface applicatorsPolyurea/polyurethane coatingsWater basedWater dispersible

The present invention provides a method for forming a multilayered coating film which comprises applying a first water-based base coating composition, thereafter applying a second water-based base coating composition without preheating the first water-based base coating composition, preheating the applied compositions, further applying a clear coating composition, and then curing the three layers, i.e., the films of the first water-based base coating composition, second water-based base coating composition, and clear coating composition, at the same time, wherein the first water-based base coating composition is a coating composition that contains a specific water-dispersible polyester resin, a specific water-dispersible acrylic resin, a water-dispersible urethane resin, and a melamine resin. With this method, it is possible to form a multilayered coating film that is excellent in terms of smoothness, reflected-image clarity, chipping resistance, and hardness.

Owner:HONDA MOTOR CO LTD +1

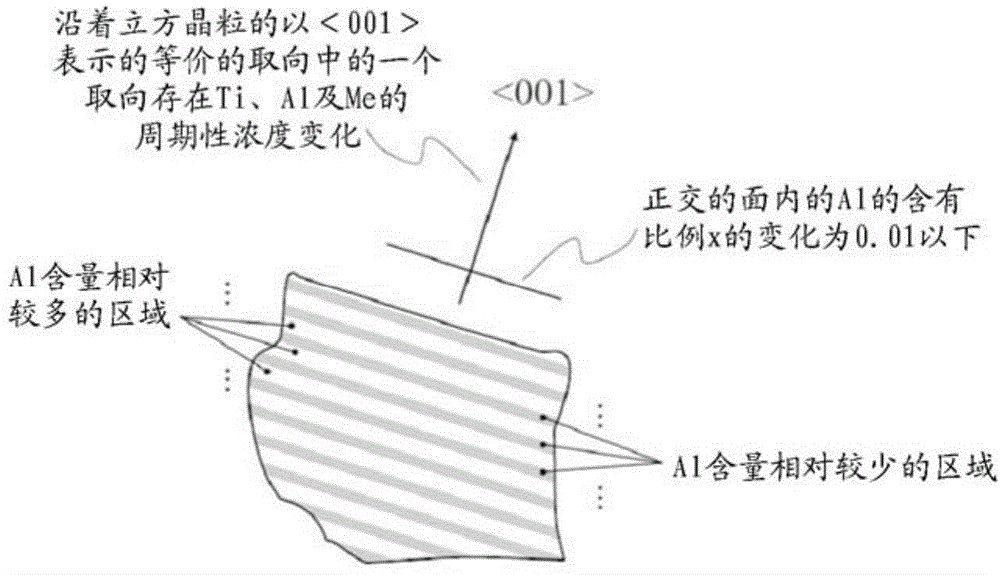

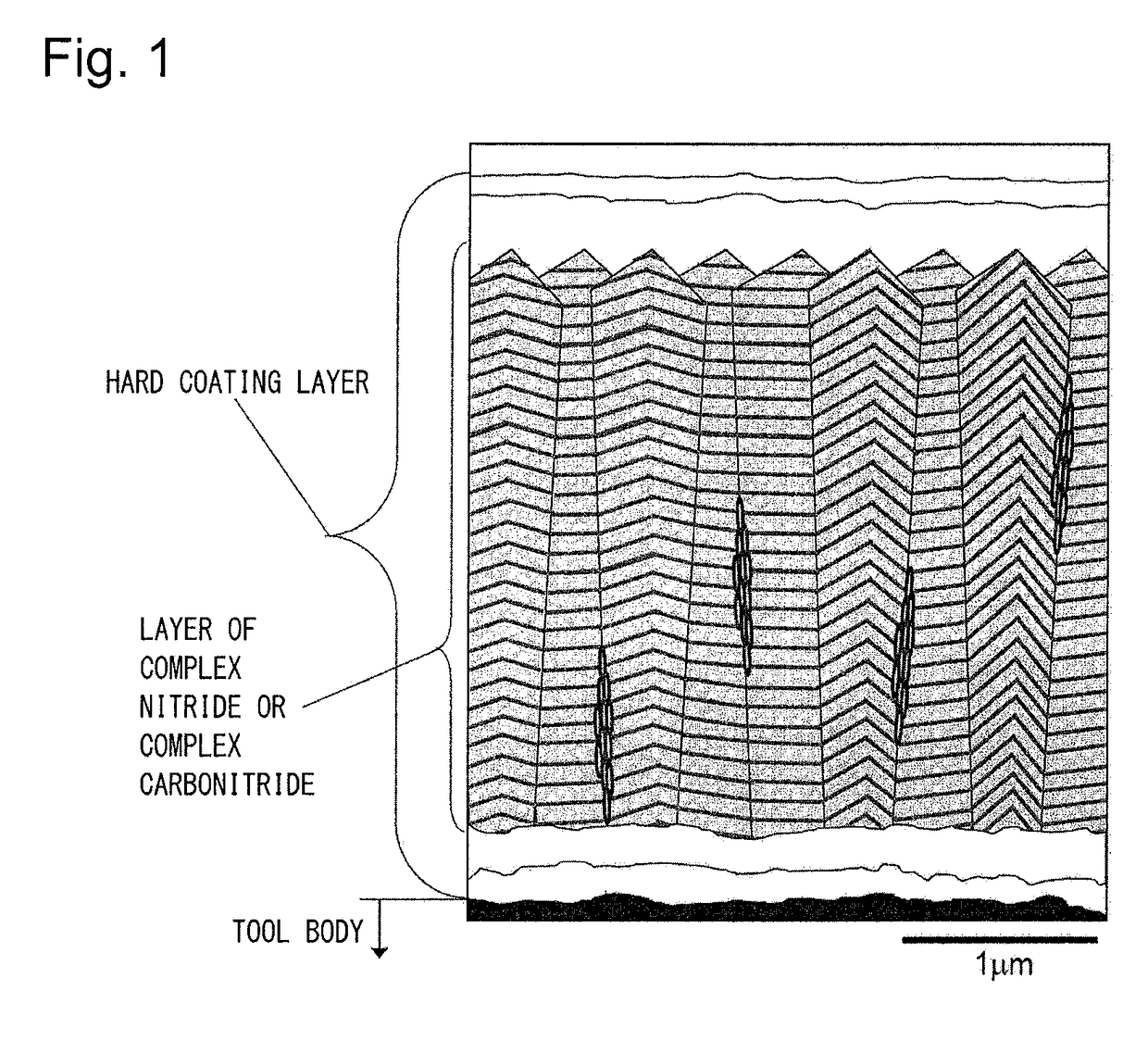

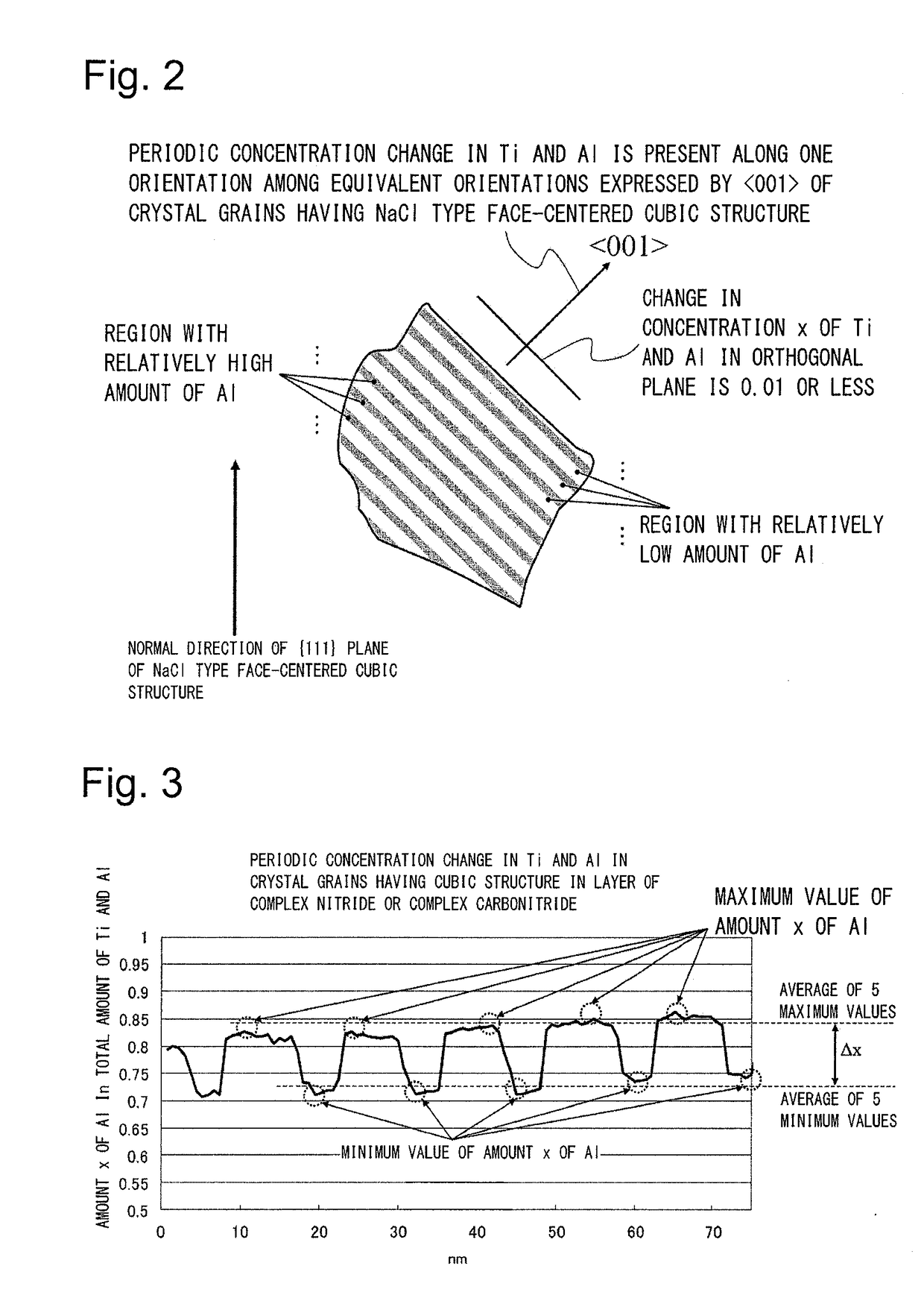

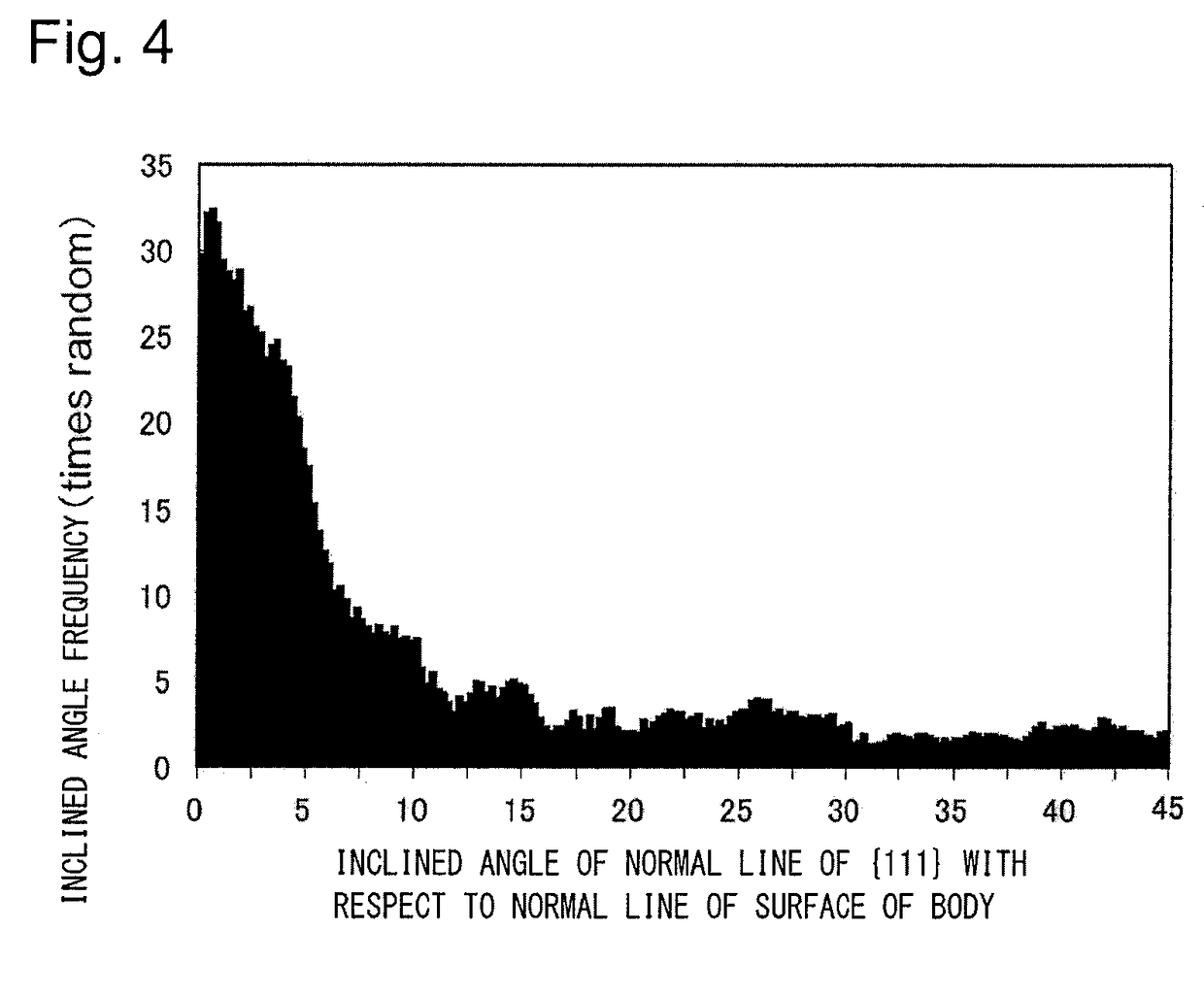

Surface-coated cutting tool in which hard coating layer exhibits excellent chipping resistance

ActiveUS20170297117A1Improve chip resistanceImprove cutting performanceWorkpiecesTurning toolsCompositional variationCrystallite

A surface-coated cutting tool has a hard coating layer on a tool body. The hard coating layer includes a (Ti1−xAlx)(CyN1−y) layer (the average amount Xavg of Al and the average amount Yavg of C satisfy 0.60≦Xavg≦0.95 and 0≦Yavg≦0.005). Crystal grains having an NaCl type face-centered cubic structure in the layer have {111} orientation, a columnar structure in which the average grain width of the individual crystal grains having an NaCl type face-centered cubic structure is 0.1 μm to 2.0 μm and the average aspect ratio is 2 to 10 is included, and in the individual crystal grains having an NaCl type face-centered cubic structure, a periodic compositional variation in Ti and Al in the composition formula: (Ti1−xAlx)(CyN1−y) is present and the difference between the average of maximum values of x and the average of minimum values thereof is 0.03 to 0.25.

Owner:MITSUBISHI MATERIALS CORP

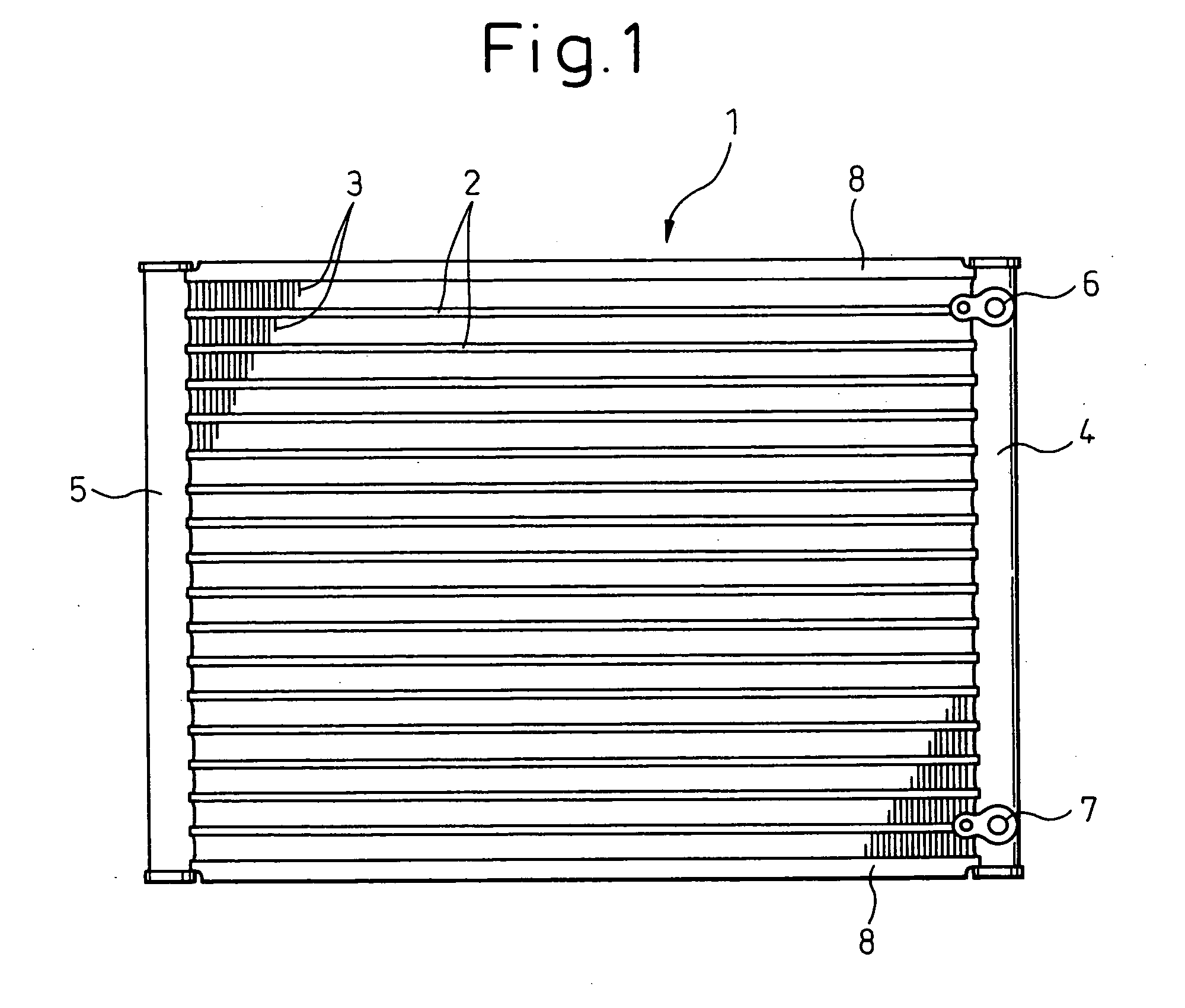

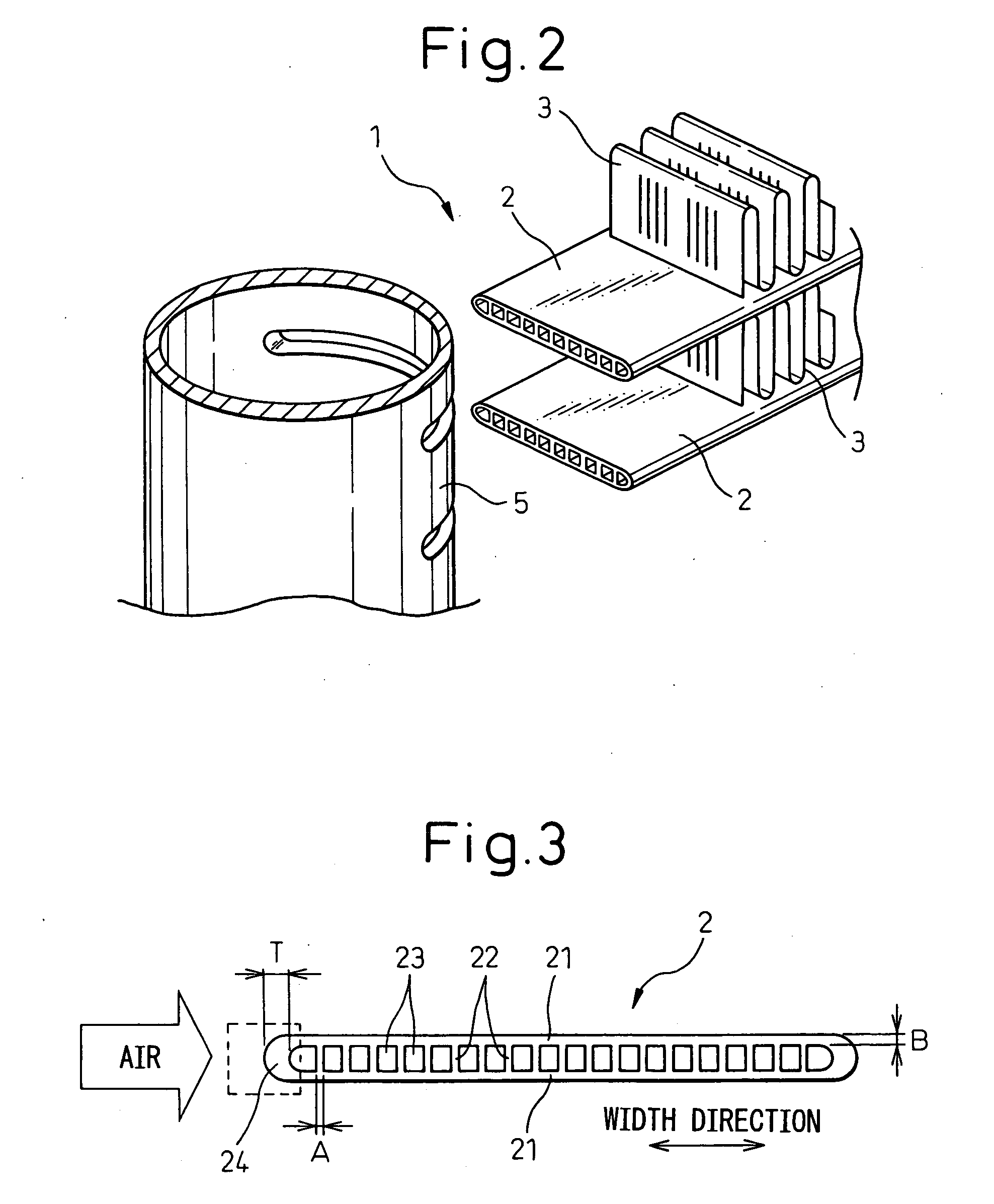

Heat exchanger tube and heat exchanger

InactiveUS20070071920A1Improve staminaPerformance requirementLayered productsStationary conduit assembliesEngineeringMechanical engineering

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com