Aqueous paint composition and method for forming coating

一种水性涂料、组合物的技术,应用在化学仪器和方法、聚酯涂料、聚脲/聚氨酯涂料等方向,能够解决多层涂膜耐崩裂性不充分、多层涂膜平滑性和鲜映度降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

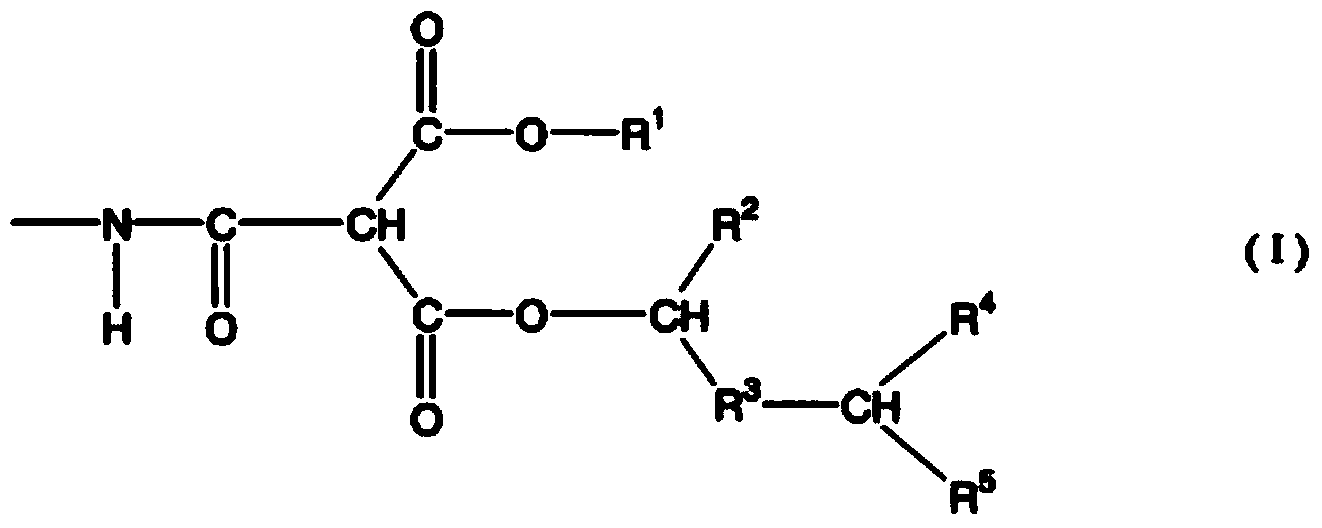

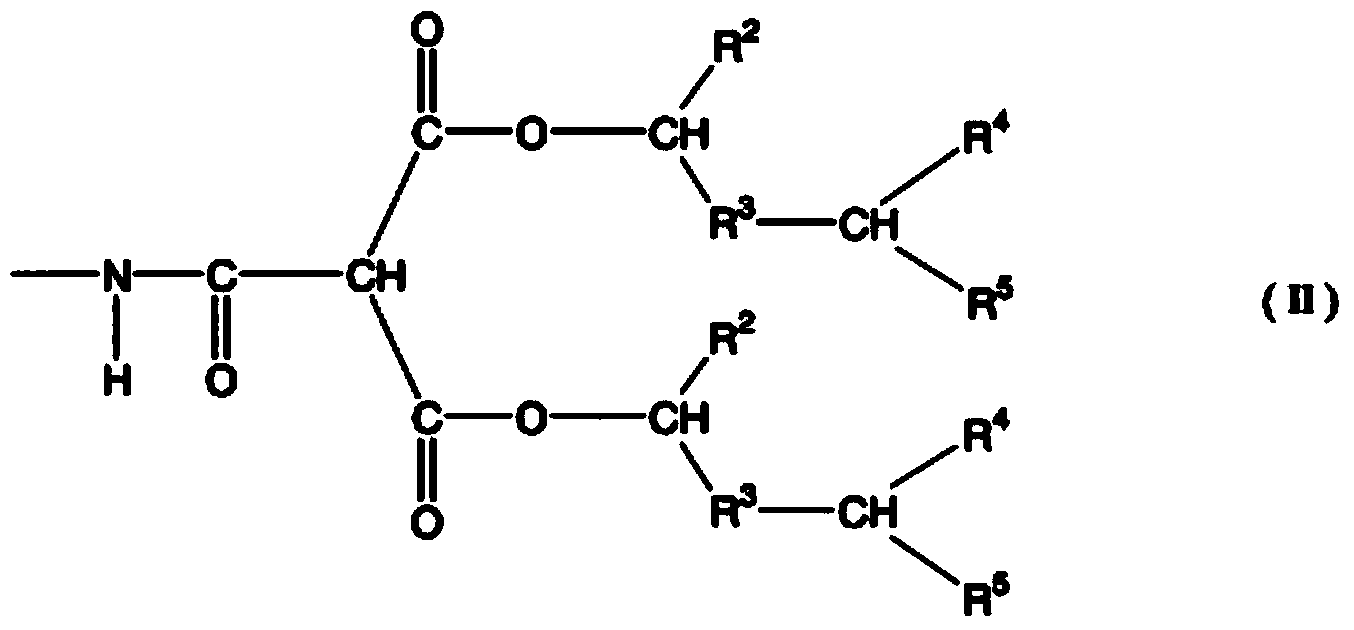

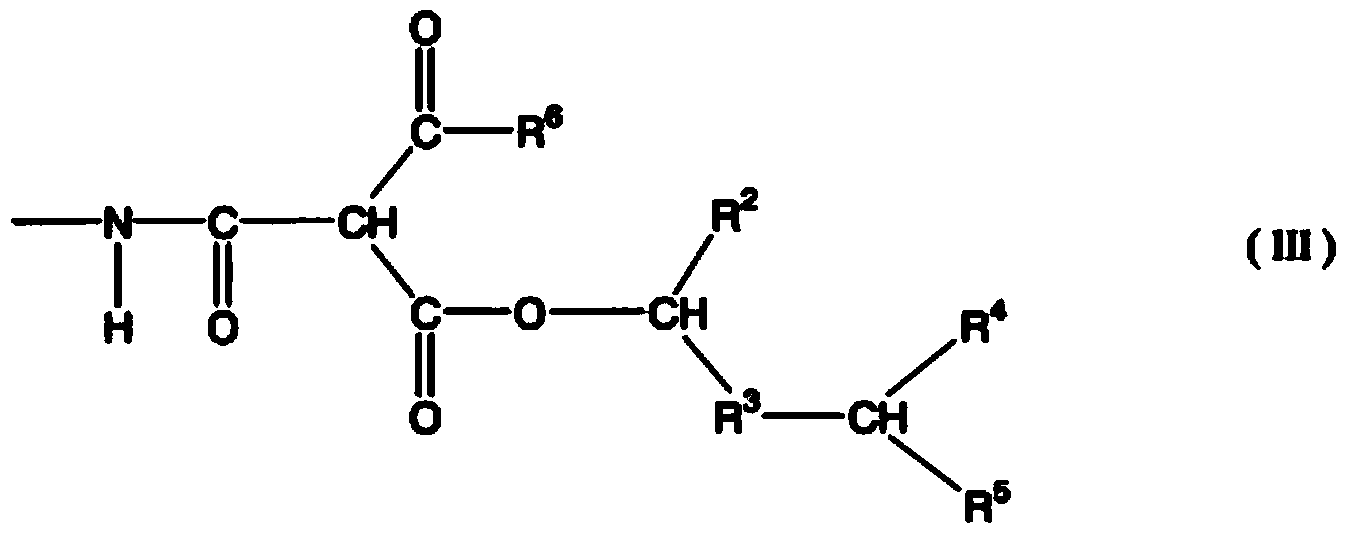

Method used

Image

Examples

preparation example Construction

[0148] The preparation method of the hydroxyl-containing polyester resin (A1) is not particularly limited, and can be carried out according to a conventional method. For example, a hydroxyl-containing polyester resin can be prepared by heating the above-mentioned acid component and alcohol component at about 150° C. to 250° C. for about 5-10 hours in a nitrogen stream to carry out the above-mentioned acid component and alcohol component. Esterification or transesterification of ingredients.

[0149] When subjecting the said acid component and alcohol component to esterification reaction or transesterification, these may be added together to a reaction container, and one or both components may be divided and added several times. Furthermore, after synthesizing the hydroxyl-containing polyester resin first, the obtained hydroxyl-containing polyester resin can be reacted with an acid anhydride to half-esterify it to obtain a carboxyl- and hydroxyl-containing polyester resin. Alt...

Embodiment

[0530] Hereinafter, the present invention will be described more concretely with reference to Examples and Comparative Examples. However, the present invention is not limited to these Examples. It should be noted that "parts" and "%" are all based on mass.

[0531] Preparation of hydroxyl-containing polyester resin (A1)

preparation example 1

[0533] Add 174 parts of trimethylolpropane, 327 parts of neopentyl glycol, 352 parts of adipic acid, 109 parts of isophthalic acid into a reaction vessel equipped with a thermometer, thermostat, stirring device, reflux condenser and water separator and 101 parts of 1,2-cyclohexanedicarboxylic anhydride, heated from 160°C to 230°C over 3 hours, and kept at 230°C while distilling off the generated condensation water with a water separator, and allowed to react until The acid value is 3 mgKOH / g or less. By adding 59 parts of anhydrous trimellitic acid to the reaction product, and performing an addition reaction at 170°C for 30 minutes, cooling to below 50°C, and adding 2-(dimethylamino)ethanol equivalent to the acid group After neutralization, deionized water was gradually added to obtain a hydroxyl group-containing polyester resin solution (A1-1) having a solid content concentration of 45% and a pH of 7.2. Based on the total amount of the acid components of the obtained hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com