Patents

Literature

413results about How to "Improve grafting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

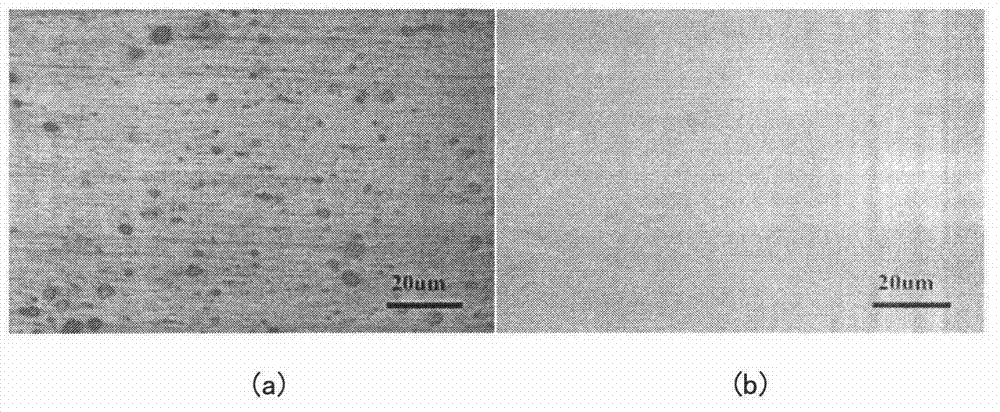

Lubricity coatings preparation method on the medical catheter polymers surface

InactiveCN101455861AImprove surface physicochemical propertiesChange adsorption stateCatheterCoatingsPolymer scienceGraft reaction

The invention discloses a method for preparing a lubricant coating on the surface of polymer materials of a medical catheter, which comprises the following steps: (A), pretreating the surface of the polymer materials of the medical catheter, so as to obtain hydrophilic adsorption active sites; (B), soaking the pretreated polymer materials of the medical catheter in step (A) into a prepared precursor solution of the lubricant coating for adsorption; and (C), performing grafting reaction on the soaked polymer materials of the medical catheter in step (B), and washing and drying the polymer materials of the medical catheter. The method can be widely used for preparing medical polymer materials and coating materials on the surface of a medical apparatus.

Owner:SOUTHEAST UNIV

Pre-irradiation polypropylene graft copolymer and preparation method thereof

The application relates to a pre-irradiation polypropylene graft copolymer and a preparation method thereof. At present, the exploration of methods for improving surface property remains a research hotspot in the field of modification of polypropylene always. The method comprises the following steps: performing pre-irradiation on polypropylene resin after having constant weight at the temperature of 60 DEG C by using a 60 Co radiation source or a DD-1.2 / 1.0-800 type high-frequency high-pressure electron accelerator in air, keeping the dosage rate at 300Gy / min, keeping the dose at 3-50kGy, adding the pre-radiated polypropylene resin into solution containing N, N'-methylenebis acrylamide, auxiliary monomers and additives, keeping the using amount of the N, N'-methylenebis acrylamide to be 0.5-5% by weight of the weight of polypropylene, performing nitrogen filling and oxygen removal on mixed solution for 30 minutes, then heating to 50-75 DEG C for performing reaction for 6 hours under magnetic stirring, nitrogen production and reflux conditions, washing the polypropylene resin which is filtered out with ethanol-water twice, further extracting with ethanol-water solution for 24 hours, drying at the temperature of 60 DEG C and enabling the weight to be constant. The method is used for preparing the polypropylene graft copolymer.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

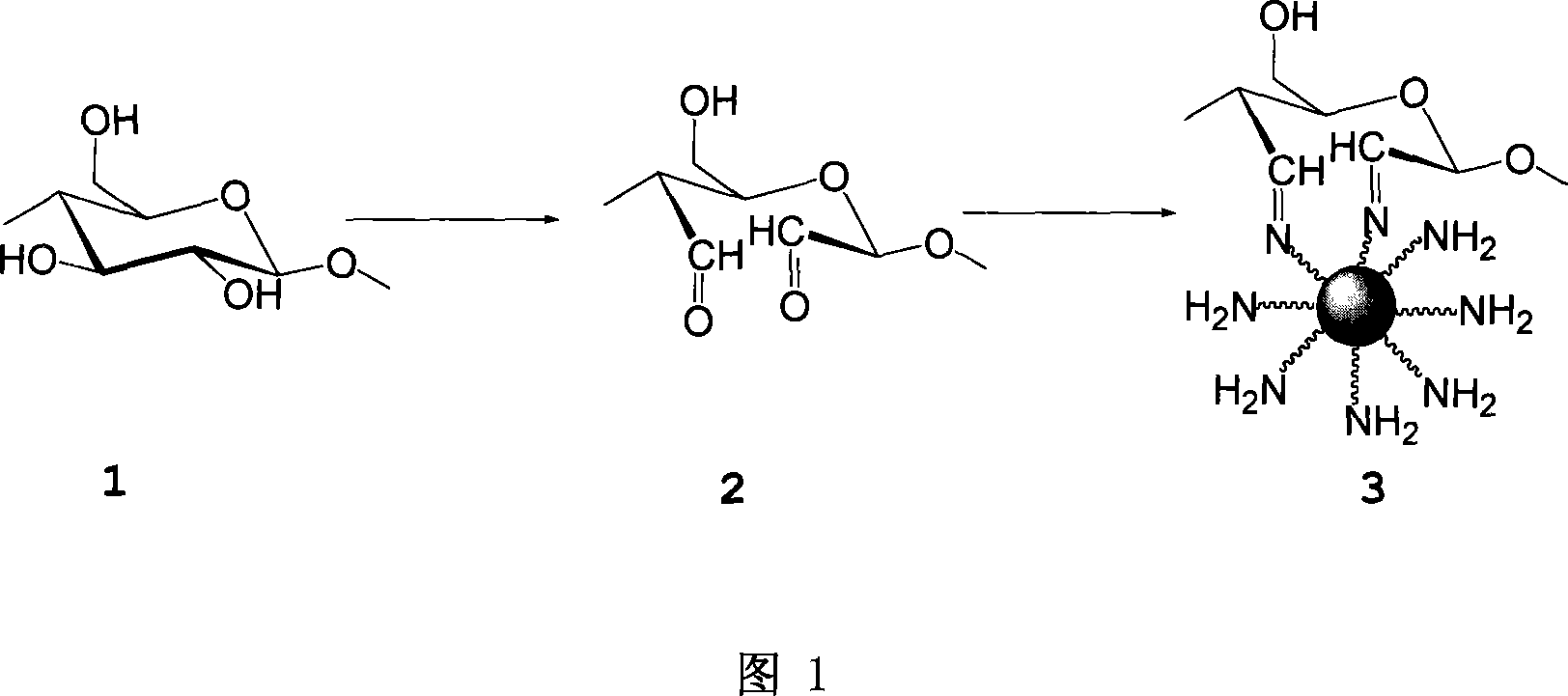

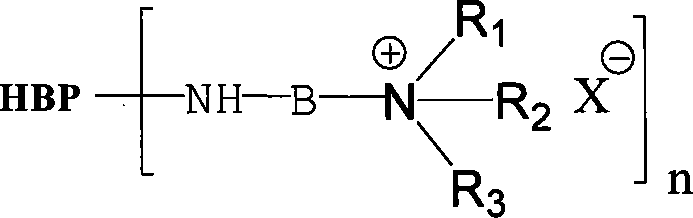

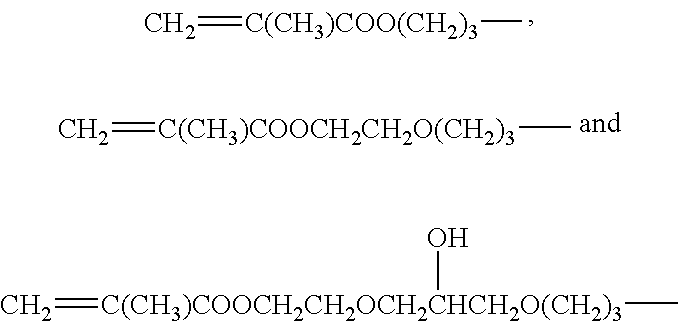

Fibrilia grafting amination modifying process

InactiveCN101225602AQuick responseImprove grafting efficiencyDyeing processVegetal fibresFiberReaction rate

The invention discloses a linen fiber modification method, in particular to a linen fiber graft aminization modification craft, belonging to the technical field of printing and dyeing, which is characterized in that the linen fiber is selectively oxidized with oxidant solution such as sodium periodate, and oxidation linen fiber is obtained; the surface aldehyde group of the oxidation linen fiber is reacted with the surface amino of amine-terminated overbranched compound and the quaternary ammonium salt, which are combined by covalent bond, and the graft aminization linen fiber is prepared; the abundant amino, imino group and quaternary ammonium branched chain are introduced on the surface of obtained fiber, which can increase significantly the dyeing performance of linen fiber, and simultaneously increase the pliability softness, hygroscopicity and antibacterial performance of linen fiber. The linen fiber modification method has the advantages of fast reaction rate, high graft efficiency, good fastness, convenient and easy operation, realization of non-salt dyeing for linen fiber after modification treatment, environment protection, simplified normal dyeing craft and wide potential application.

Owner:SUZHOU UNIV

Process for crosslinking thermoplastic polymers with silanes employing peroxide blends and the resulting crosslinked thermoplastic polymers

A composition comprising at least one silane possessing an unsaturated organic function; at least two free radical initiators, and a process for producing silane-crosslinked thermoplastic polymers comprising providing a cross-linkable compound; at least one thermoplastic polymer; and, reacting the crosslinkable compound under reactive mechanical-working conditions and exposing the crosslinkable compound to moisture to provide crosslinked thermoplastic polymers.

Owner:GENERAL ELECTRIC CO

Chemical modification technique for microfiltering separation film of polyvinylidene fluoride

InactiveCN1772359AChemical modification applicableImprove hydrophilicitySemi-permeable membranesPotassium persulfateFiber

The present invention is chemical modification technique for grafting radical with hydrophilic and ion exchange performance onto the surface of hollow fiber microfiltering film and plate microfiltering film of polyvinylidene fluoride. By using acrylic acid, PVA, acrylamide, methylene bis-acrylamide, potassium persulfate and other reagents as material and through chemical cross-linking polymerization reaction, carboxyl radical and hydroxyl radical are grafted onto the surface of the microfiltering film. The technique has the advantages of simple operation and high grafting efficiency, and can improve the hydrophilic performance of the microfiltering film and raise the treating capacity of the microfiltering film. The modified microfiltering film can eliminate the suspended matter, colloid matter and water soluble heavy metal ion in water simultaneously, and has raised drinking water purifying effect and expanded application field of microfiltering film of polyvinylidene fluoride.

Owner:YANSHAN UNIV

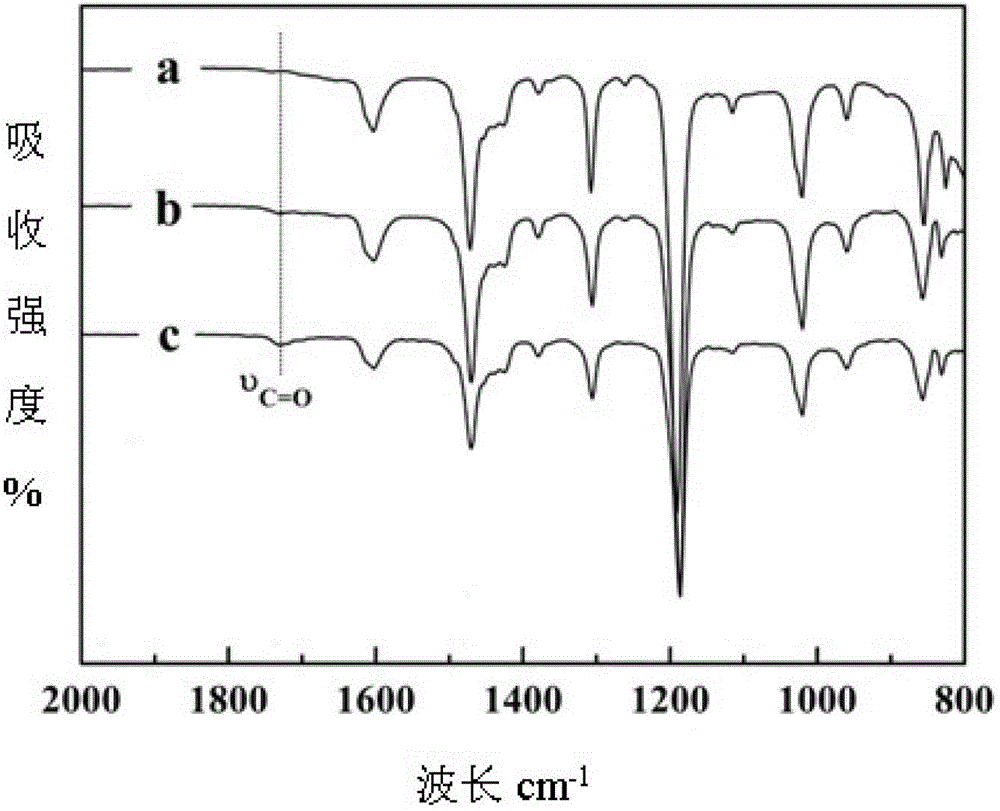

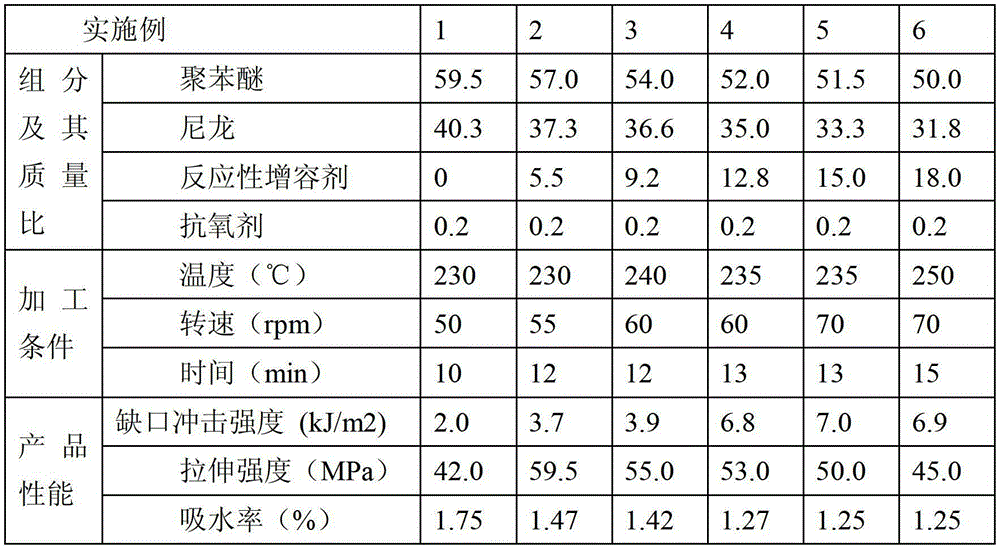

Modification compatibilizer of PPO/PA (Poly-p-phenylene oxide/polyacrylate) alloy and PPO/PA alloy

ActiveCN103146176AImprove grafting efficiencyImprove compatibilityGlycidyl methacrylatePolyphenylene oxide

The invention relates to a modification compatibilizer of PPO / PA (Poly-p-phenylene oxide / polyacrylate) alloy and a PPO / PA alloy. The compatibilizer is characterized by being a grafted copolymer of polyphenyl ether, glycidyl methacrylate and styrene; and the PPO / PA alloy with the compatibilizer is characterized by comprising the following components in percentage by weight: 50-59.5% of polyphenyl ether, 31.5-40.4% of nylon, 0.1-18% of the compatibilizer and 0.1-0.5% of antioxidant. Compared with the prior art, the prescription of the compatibilizer matching with the PPO / PA disclosed by the invention can be used for greatly improving the compatibility of the PPO / PA alloy and improving the mechanical property and water resisting property of the PPO / PA alloy and is in good condition of industrial application.

Owner:宁波福天新材料科技有限公司

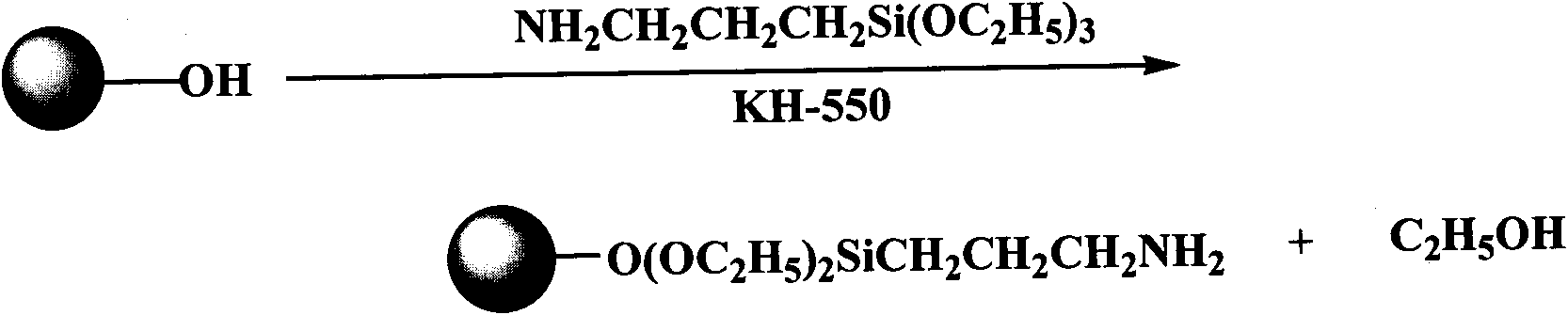

Method for modifying nano metal oxide by coupling graft

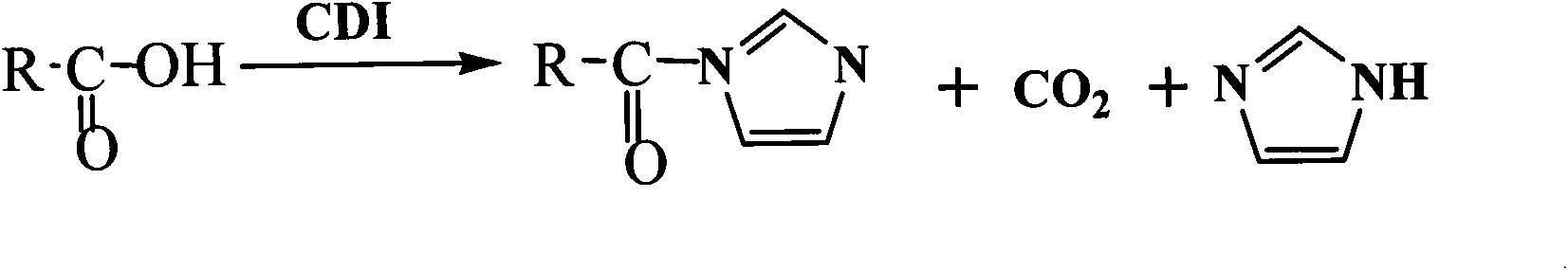

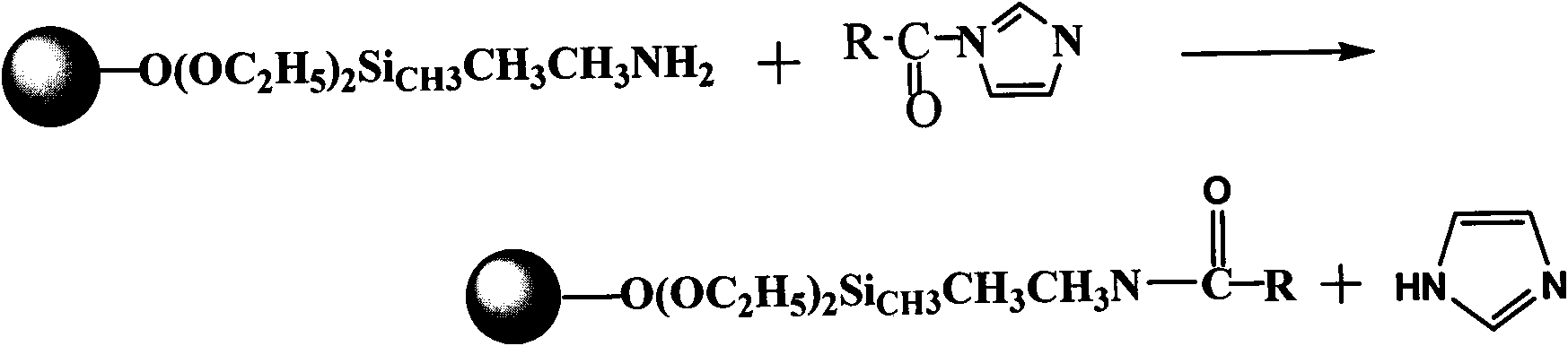

InactiveCN101880482AHigh grafting rateImprove grafting efficiencyPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCarbonyldiimidazoleEnergy conservation

The invention discloses a method for modifying a nano metal oxide by coupling graft, and belongs to the technical field of nano granule surface modification. The nano metal oxide is used as a raw material, N,N'-carbonyl diimidazole (CDI) is used as an activating agent, and a finished product is obtained by simple processes of drying treatment, coupling reaction, separation and purification, coupling graft, re-separation and re-purification. The method has the advantages of simplicity, mild reaction conditions, high grafting efficiency which reaches 87 percent, energy conservation, emission reduction, low cost and suitability for large-scale industrial production. The nano metal oxide prepared by using the method can be widely applied in the fields of rubber, coating, ink, dye, glass, piezoelectric ceramics, photoelectrons, medicament and the like.

Owner:CHONGQING UNIV

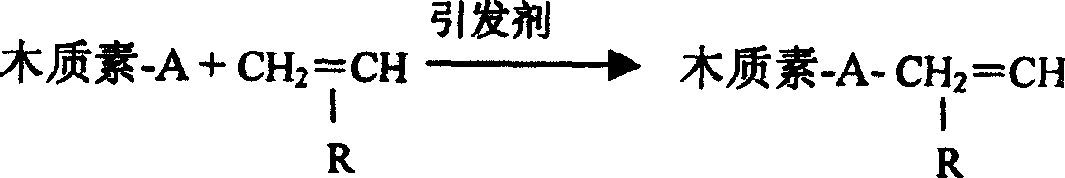

Process for preparing modified lignocellulose sulfonate graft copolymer

A modified lignin sulfonate graft copolymer is prepared through esterifying lignin by propenoyl chloride or acrylic acid or maleic anhdyride to obtain modifier lignin, an graft copolymerizing reaction between said modified lignin and perspex, acrylic acid, butyl acrylate, or substituted olefin in water by emulsion polymerizing method.

Owner:溧阳常大技术转移中心有限公司

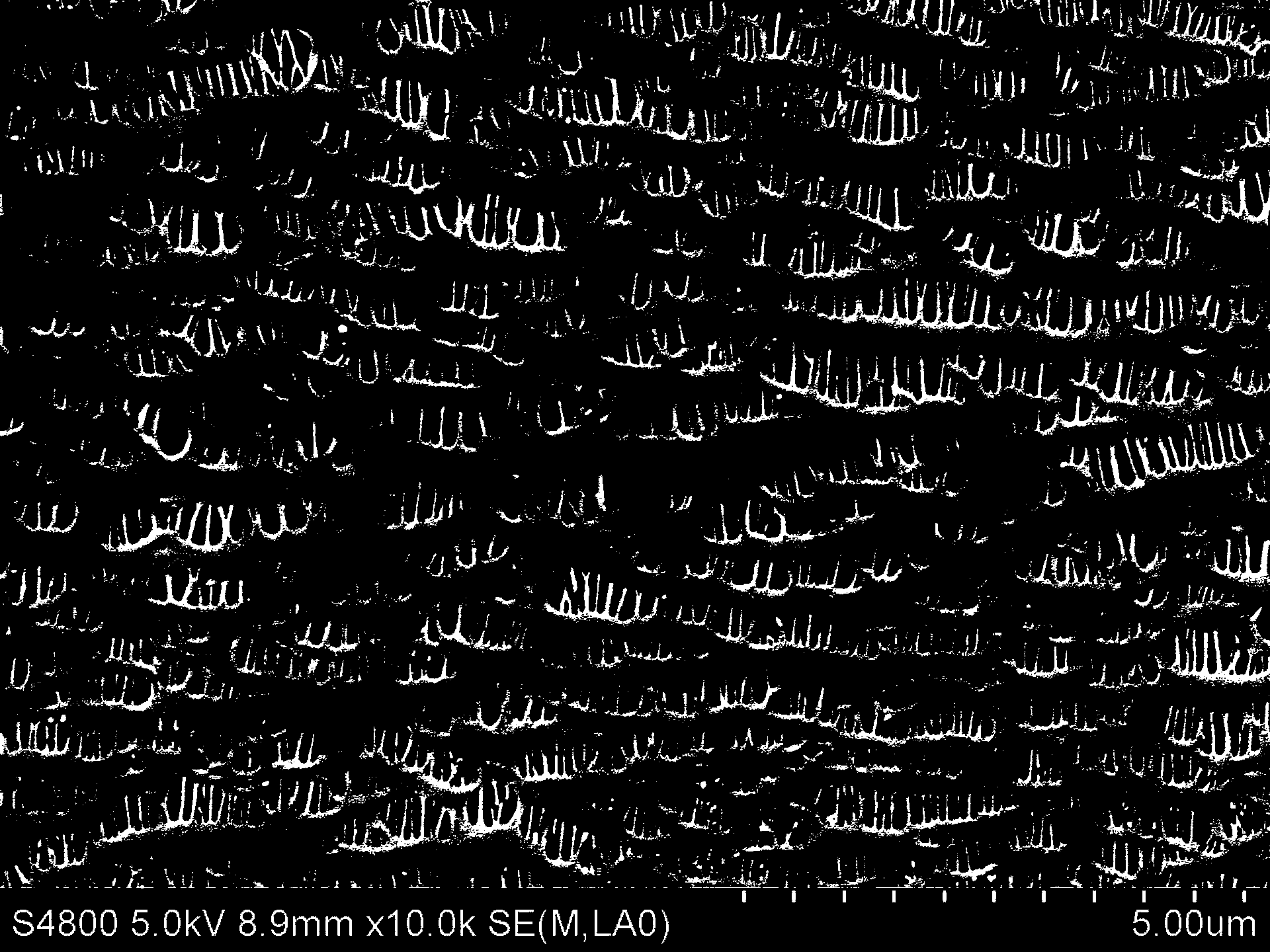

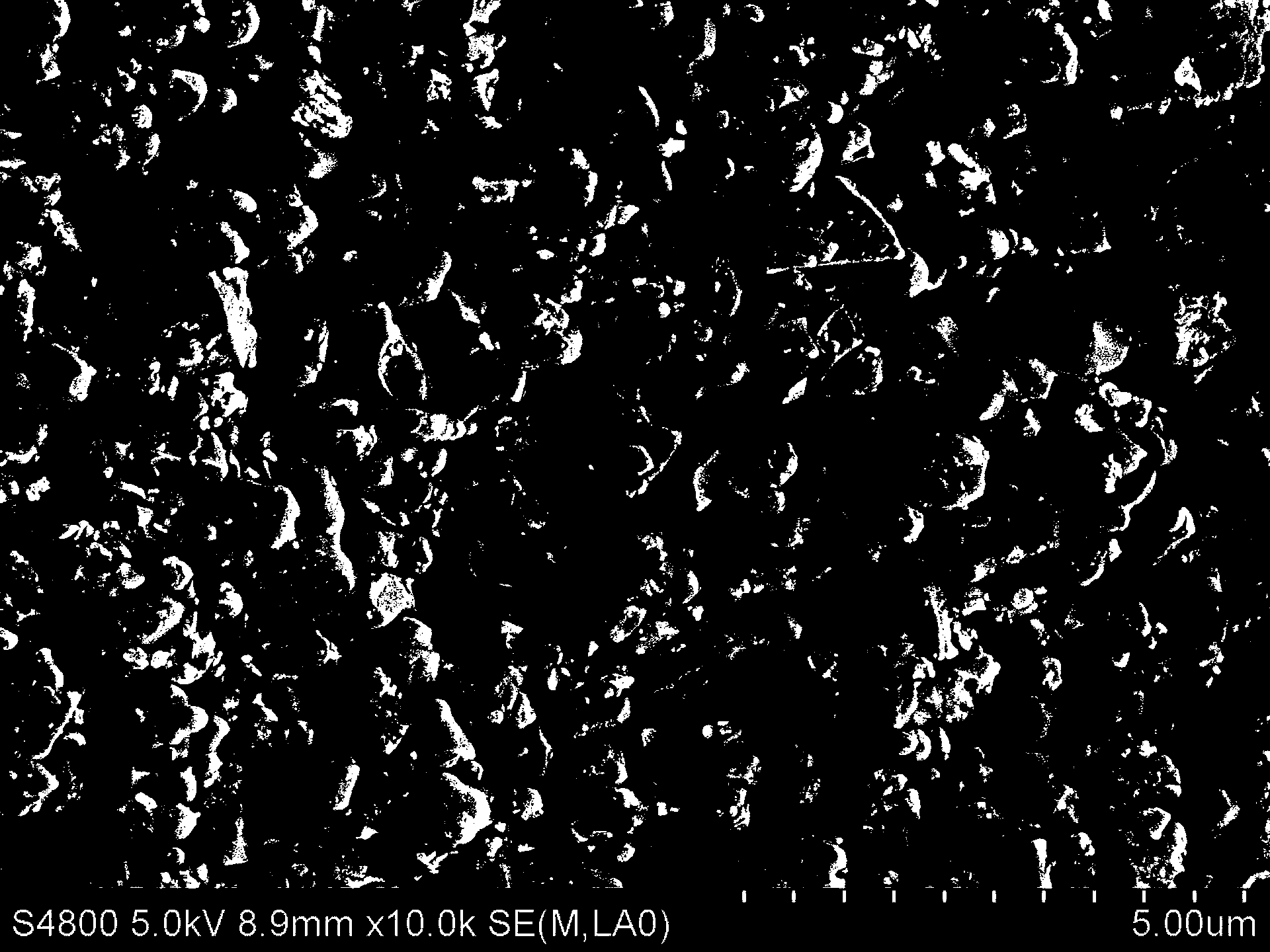

Composite ceramic membrane for lithium ion batteries and preparation method thereof

ActiveCN103956451AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite ceramic membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-on process under the action of a coupling agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:中国东方电气集团有限公司

Graft composition for improved tie layers

ActiveUS20120077048A1Improve grafting efficiencyImprove adhesionAdhesive processesFilm/foil adhesivesElastomerPolymer science

Graft compositions, useful for tie-layer adhesives, are disclosed. The graft compositions comprise the reaction product of a live, grafted polyolefin and an olefin elastomer. The grafted polyolefin is first made by heating a polyolefin and an unsaturated monomer. Further reaction of the live, grafted polyolefin with an olefin elastomer provides the graft composition. Grafting efficiency is boosted dramatically by the presence of the olefin elastomer and use of the additional reaction step. The graft composition, when formulated into a tie-layer adhesive at low concentration, affords multilayer structures with good adhesion and high clarity.

Owner:EQUSR CHEM LP

Method for extruding and preparing maleation polypropylene by supercritical reaction

The invention discloses a method for preparing maleic polypropylene by supercritical reaction extrusion, wherein polypropylene, maleic series, additives and initiators are added into a screw extruder, and supercritical CO2 is injected into the system by a supercritical generation device, which makes up 0.1-20 percent of the total mass of reactant; the rotating speed of main screwed pole of the extruder is 50-600 rpm, and the extruder is divided into a plurality of heating areas, the temperature of the firs area is 180-220 DEG C, and the temperature of the other areas is 140-200 DEG C and the reaction time is 1-20 min. The grafting rate of maleic polypropylene prepared by the invention, with high grafting rate and grafting efficiency, can reach up to 1.2 percent, the grafting efficiency can reach up to 90 percent and the melt flow rate is adjustable within 5-50g / 10min. The method of the invention is suitable for continuous production and has low energy consumption, and is environment-friendly. The product shows superiority in color, uniformity, processing property and mechanical property and so on, which is suitable for the fields of polymer compatilizer, adhesive and surface coating etc.

Owner:ZHEJIANG UNIV

Xanthan gum graft copolymer oil displacement agent as well as preparation method and application thereof

ActiveCN102051165AImprove heat stabilityImprove biostabilityFluid removalDrilling compositionSide chainHeat resistance

The invention provides a xanthan gum graft copolymer oil displacement agent as well as a preparation method and application thereof. Based on molecular design, at least two of acrylamide (AM), 2-acrylamido-2-methylpropane sulfonic acid (AMPS), N-vinylpyrrolidone (NVP) and N,N-dimethylacrylamide (DMAM) are graft-copolymerized to xanthan gum macromolecules. Since the copolymerized side chain is introduced, the viscoelasticity, heat resistance and biological stability of the xanthan gum macromolecules can be greatly enhanced; the xanthan gum graft copolymer can be used as an oil displacement agent for tertiary oil recovery simultaneously; and the solution rate of the xanthan gum graft copolymer is obviously increased, and the xanthan gum graft copolymer can not easily generate gel in brine. When the xanthan gum graft copolymer oil displacement agent is used in a high-temperature high-salinity oil reservoir, the oil displacement effect is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

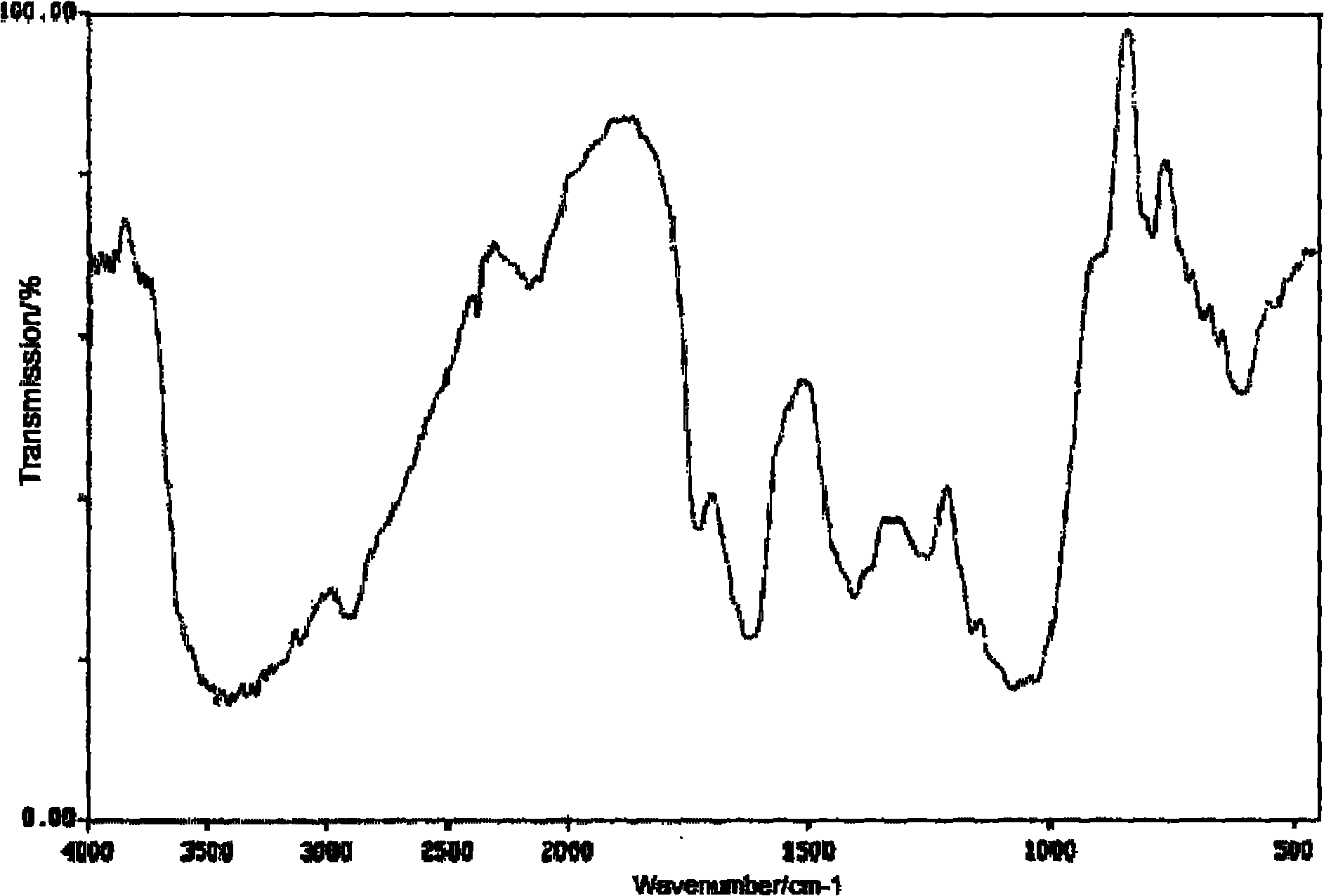

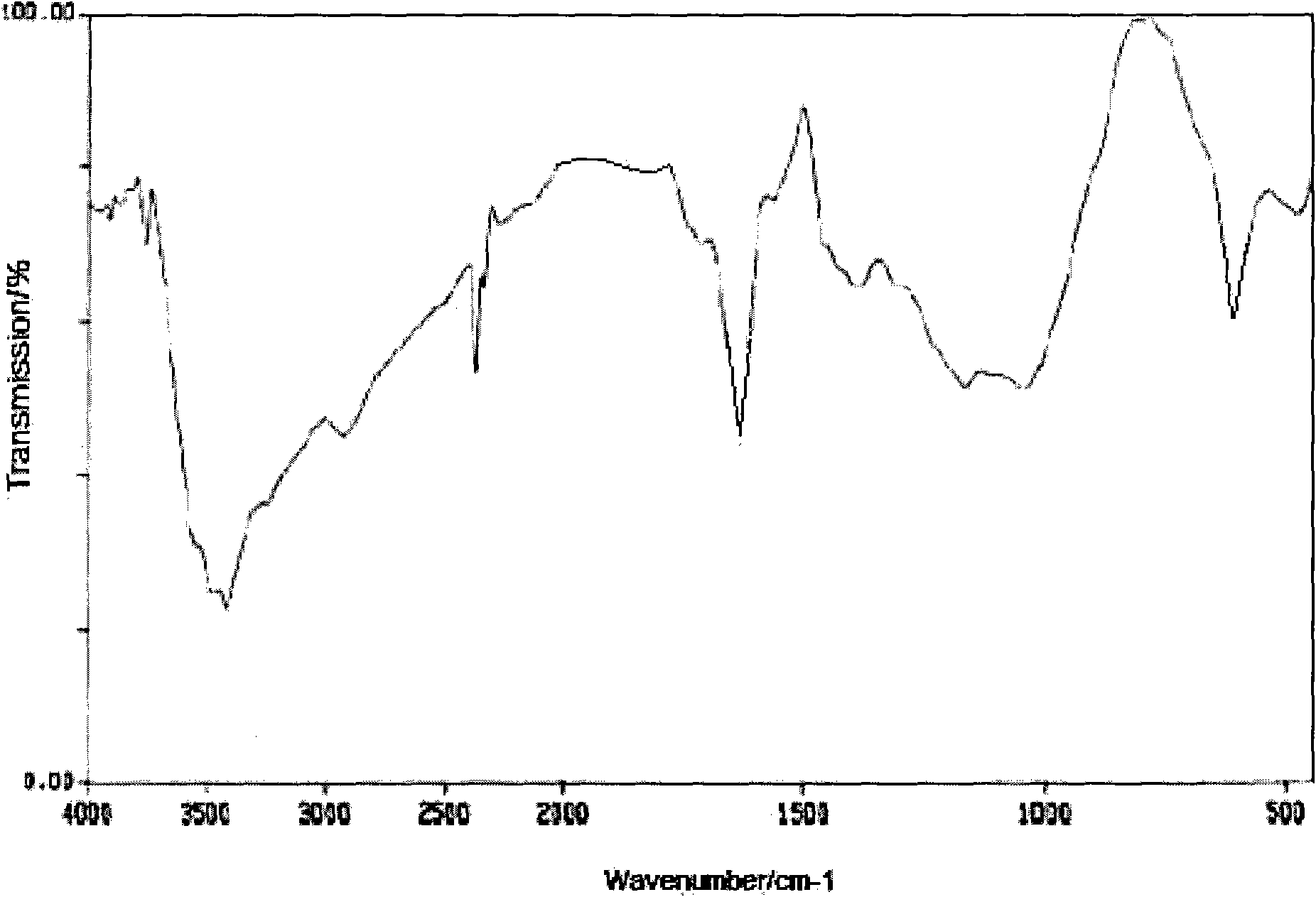

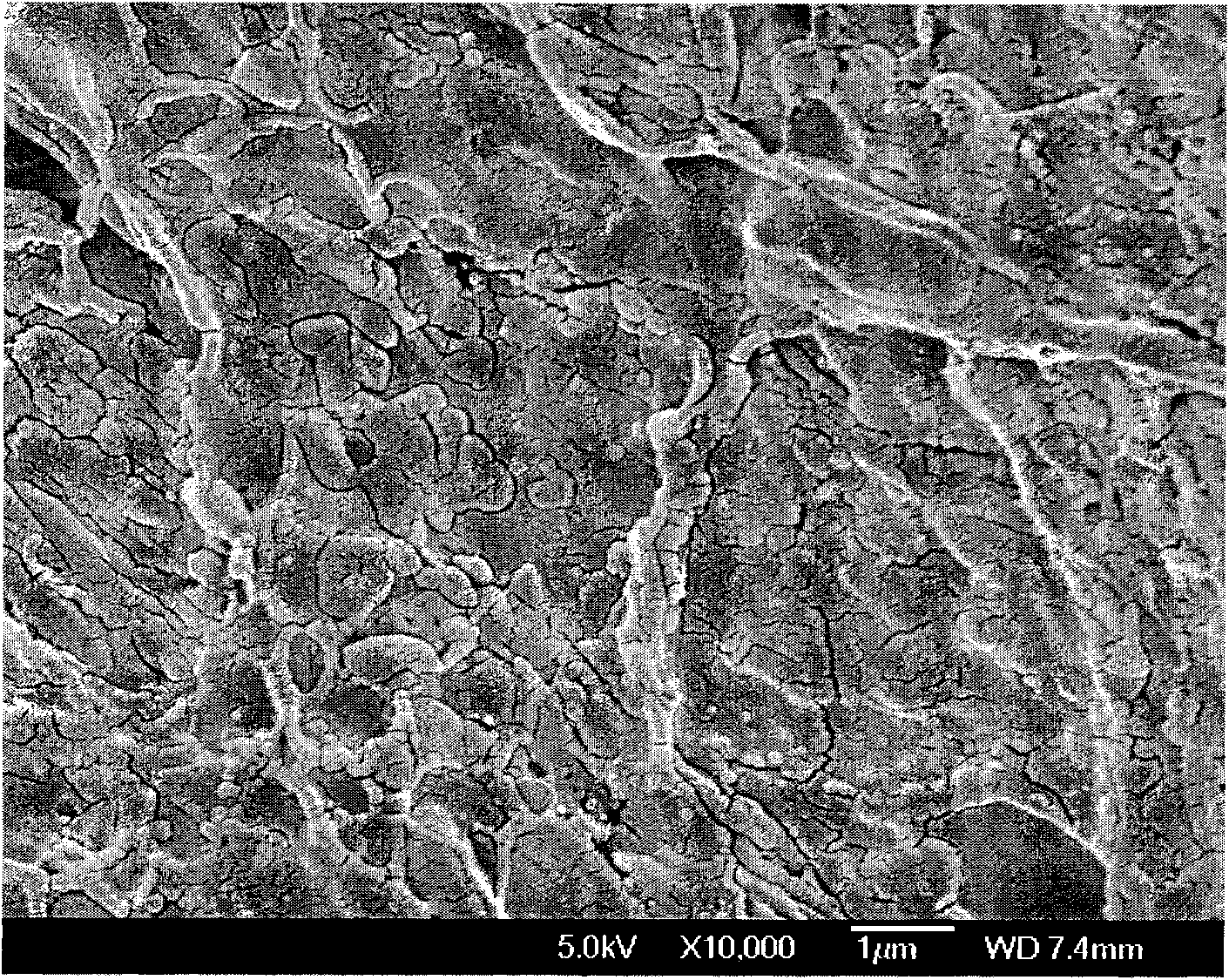

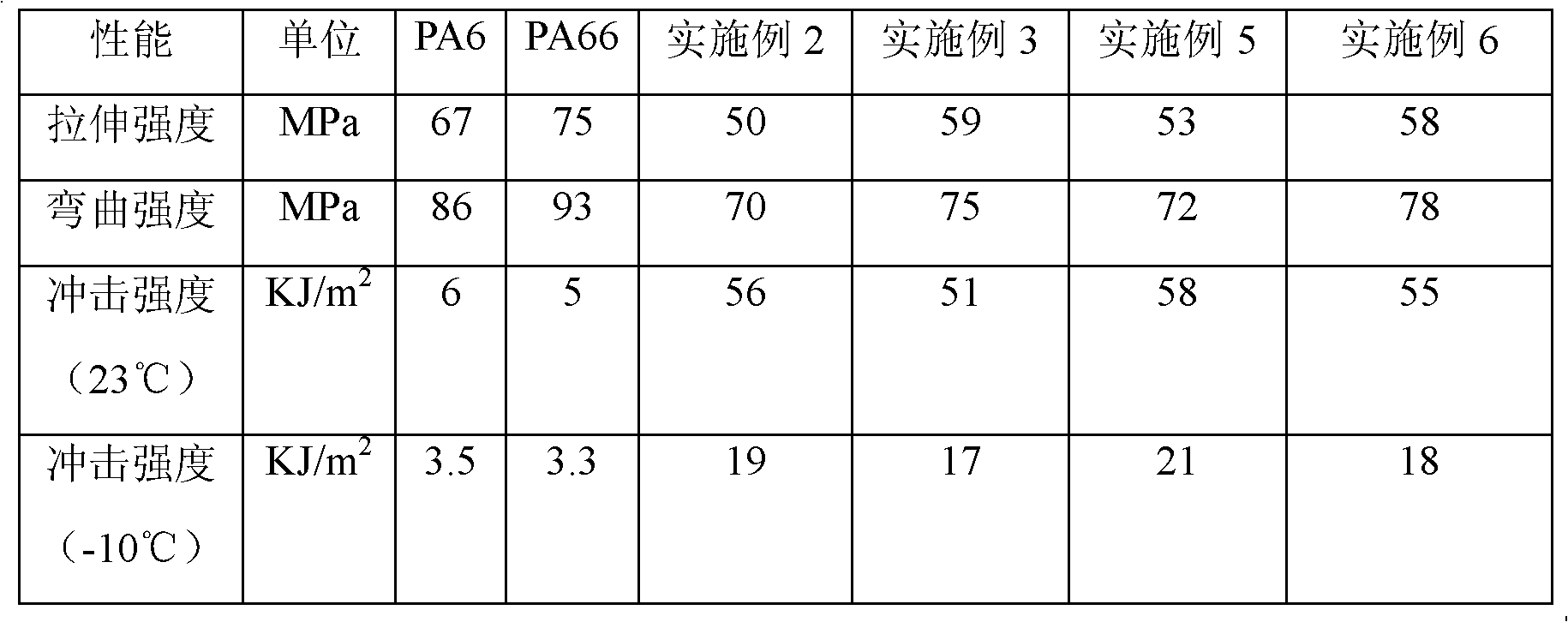

Toughened nylon blend and preparation method thereof

The invention discloses a toughened nylon blend material, which belongs to the technical field of blending, modification and processing of polymers. The blend material comprises the following raw material components in percentage by weight: 75-95 percent of nylon, 5-24 percent of toughening agent and 0.1-1 percent of antioxidant. A preparation method of the blend material comprises the following steps of: adding the nylon, the toughening agent and the antioxidant into a high speed stirrer according to a certain proportion; uniformly stirring the materials at a high speed and adding the mixture into the extruder; and extruding, pelletizing and drying to obtain the toughened nylon blend material, wherein the toughening agent is prepared by performing polar monomer grafting and modification on the blend of an ethylene-1-octylene copolymer (POE), polypropylene (PP) and an ethylene-acrylic acid (EAA) copolymer. The toughened nylon blend obtained by blending the toughening agent and the nylon has high toughness, well keeps the intensity of nylon per se and greatly expands the application range of nylon.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

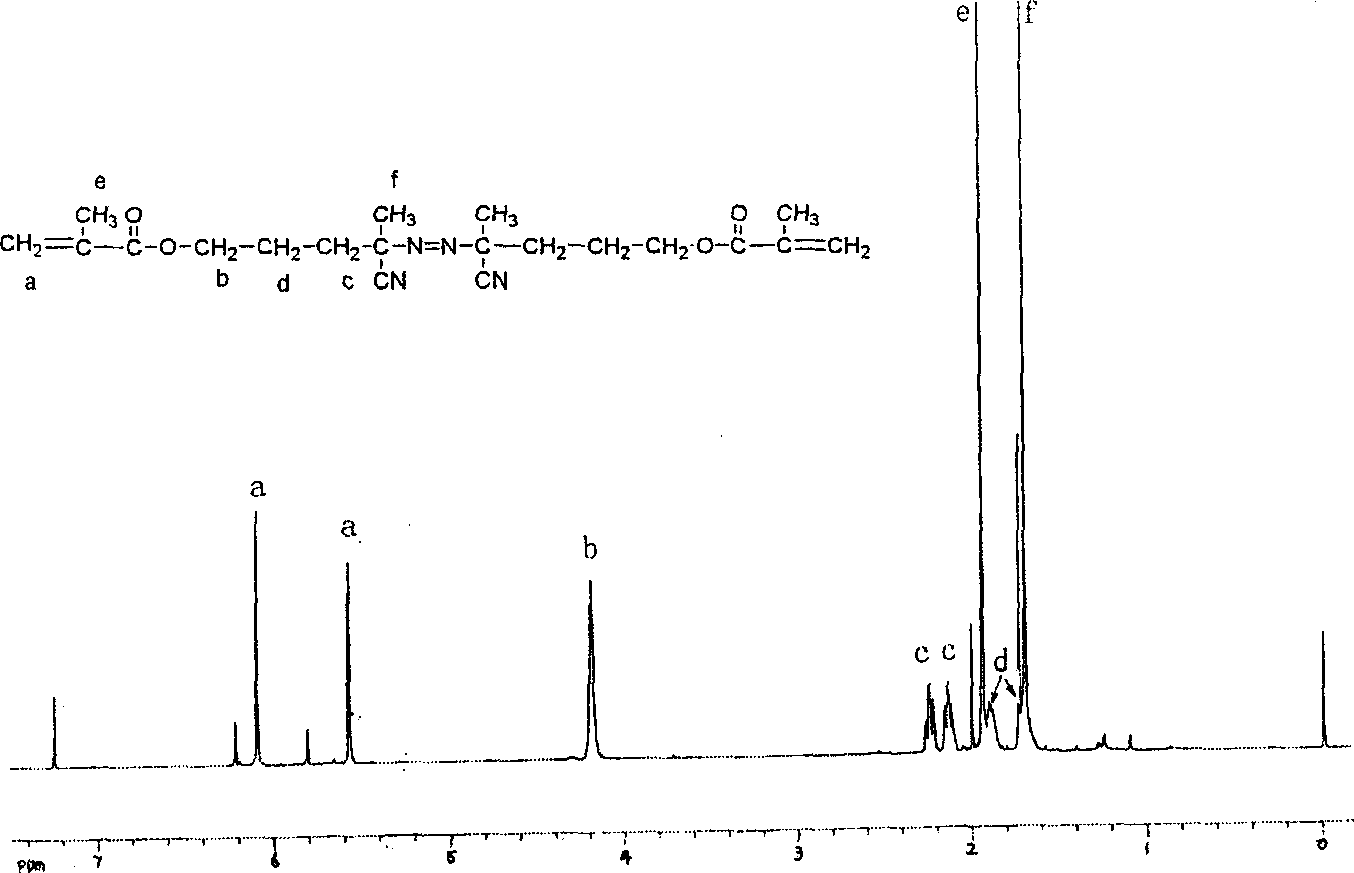

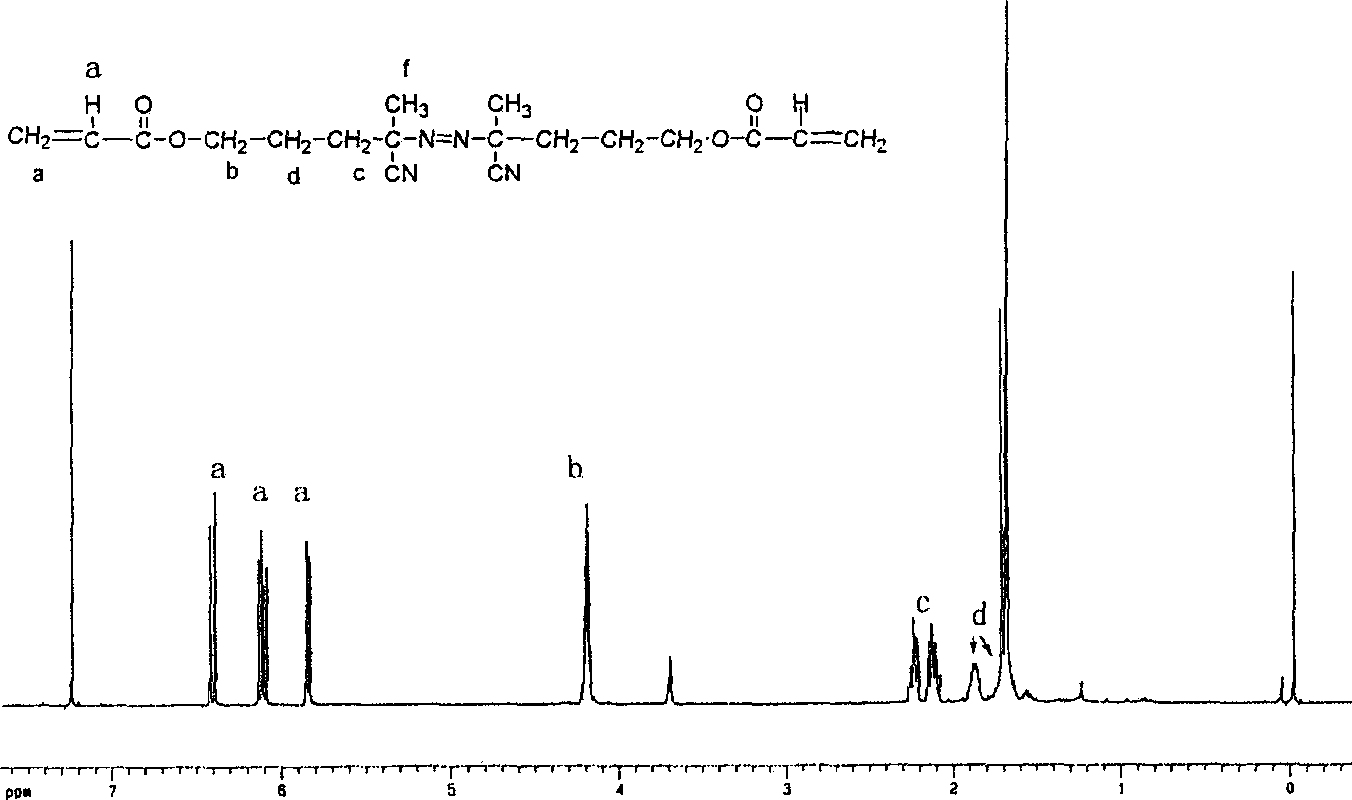

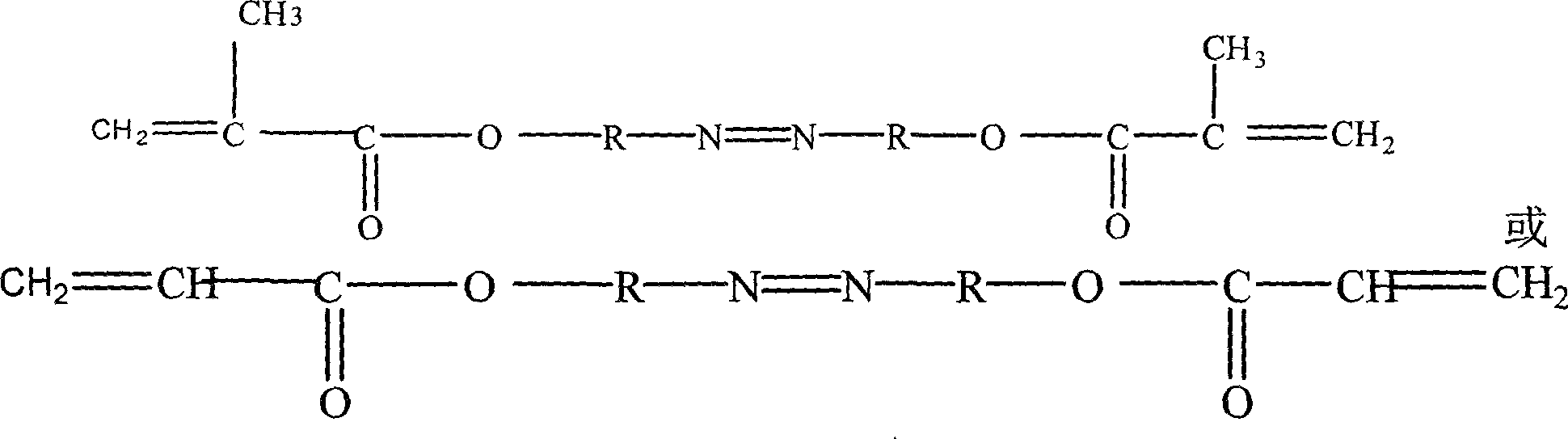

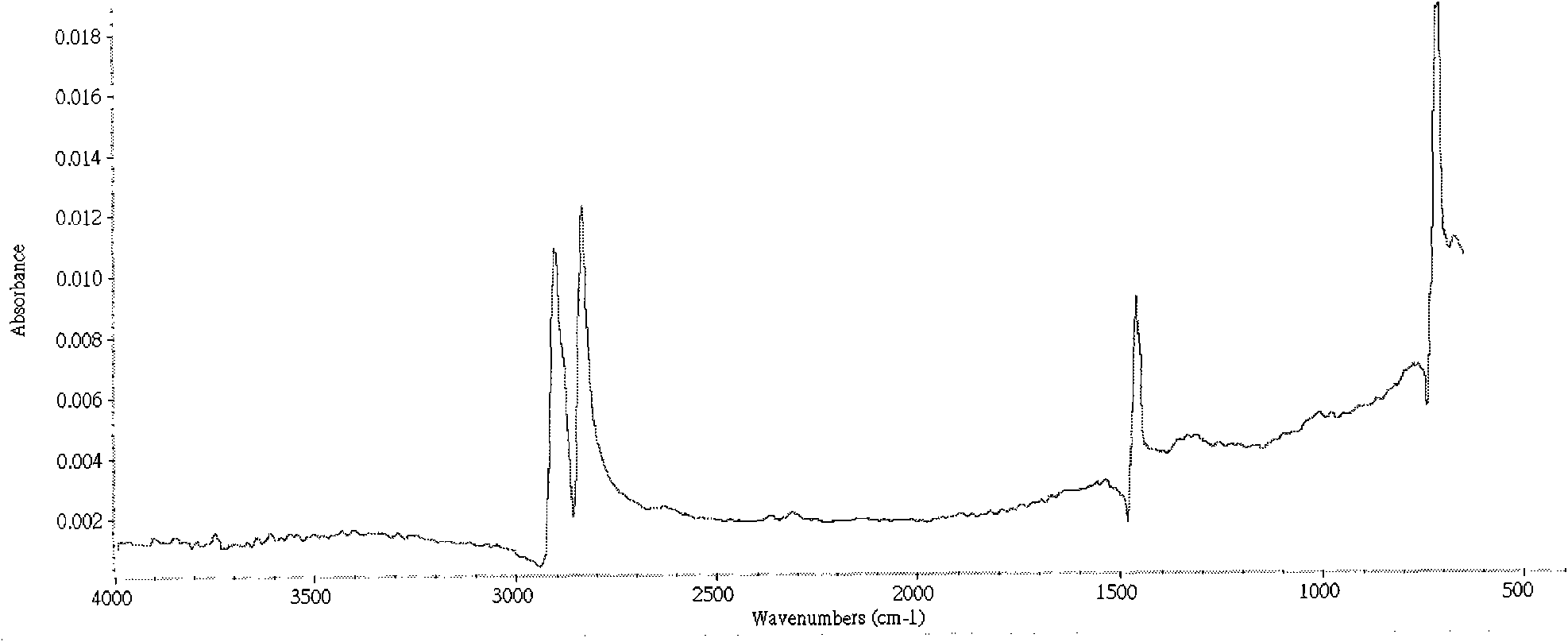

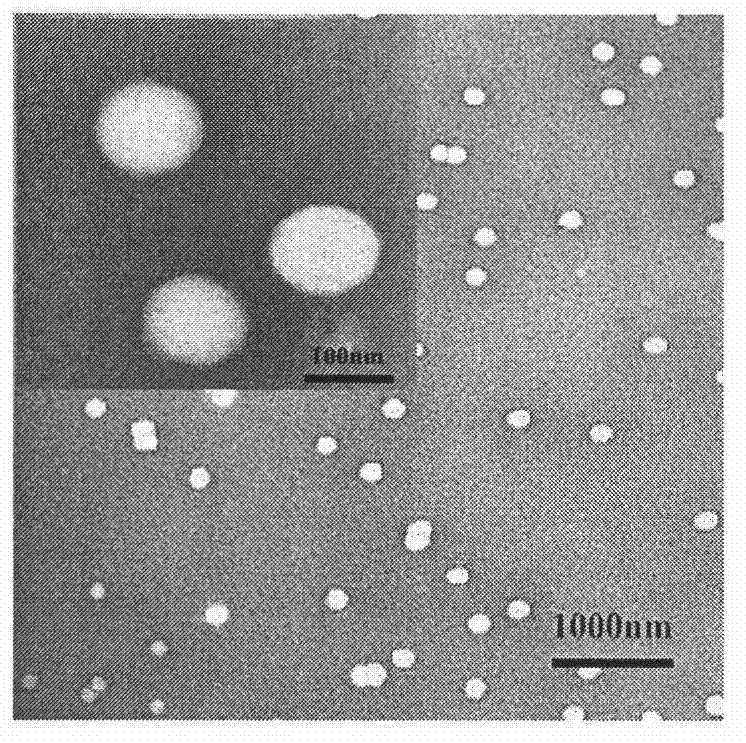

Method for promoting grafting efficiency of acrylate core/shell structure latex particle

The invention relates to a method for increasing grafting efficiency for emulsion particle with acrylate being core-shell, belonging to high molecular chemical field, and especially relating to composite of high molecular compound. The polymer of acrylate core-shell employs cross-linked acrylate rubber polymer as core, the grafting rate of which is low, between 20-30%. The invention comprises following steps: preparing initiator monomer containing azo group for initiating function and polymerisable ethenyl double bond; then, preparing acroleic acid butyl seed latex at low temperature with redox initiating system, employing methacrylic acid gylcol ester or methylol propane triacrylate as crosslinking agent; finally, adding shell monomer, heating, and the azo group breaking into free radical and initiating shell monomer polymerization. The free radical is connected on main chain of polyacrylacid ester with chemical bond, which increases initiating rate; and the two ends of azo monomer is provided with polymerization double bond, which increases grafting efficiency to above 70%.

Owner:BEIJING UNIV OF CHEM TECH

Grafting method of ornamental elm

The invention provides a grafting method of an ornamental elm. Scion used in the operation process is treated by 2% cross-linked chitosan solution before storage, so that the fresh-keeping effect of the scion is improved and the stored scion has higher activity; when a rootstock is cut, the section of the rootstock is formed a 15-degree angle with limb, so that the separation of cortex and xylem is more favorable, and the grating efficiency is increased; when the scion is cut, two faces are long cutting faces, so that the contact area between the rootstock and a scion forming layer is increased, and the combination of the rootstock and the scion is more firm; moreover, since the grating method provided by the invention is fast in speed and high in efficiency, the water loss of the rootstock and the scion is less, and the oxidation and browning degree of the incision is low, so the survival rate of the graft can be greatly improved, and the survival rate of the graft is above 95%. The grating method of the ornamental elm provided by the invention is simple and easy to carry out; the ornamental elm grafted by the method can grow fast and shape rapidly, the crown size in the current year can reach above 1.2 m; the ornamental elm can be transplanted in the same year for grafting, thus, the grafting method is a garden and horticultural technique with stronger practicability.

Owner:HENAN UNIV OF SCI & TECH

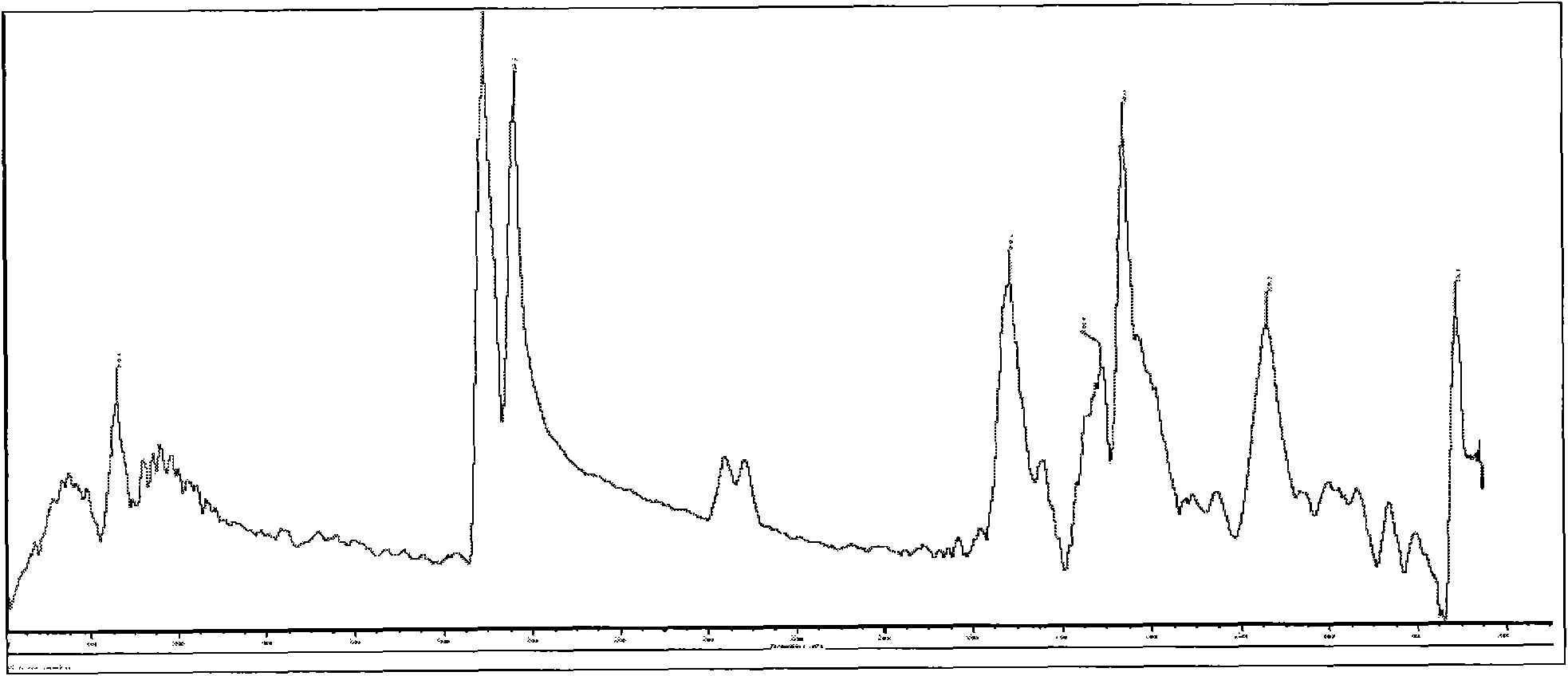

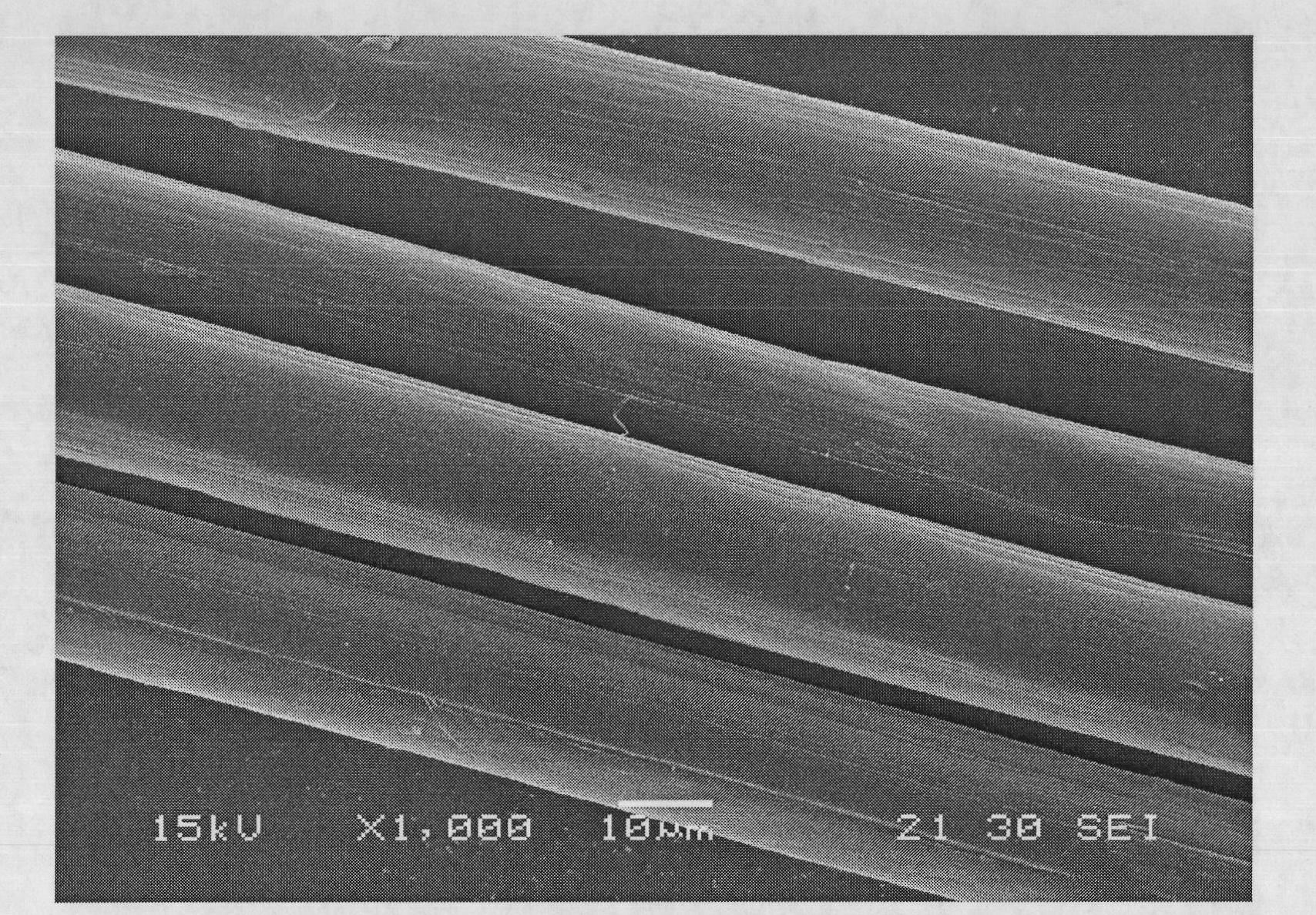

Ultraviolet radiation two-step grafting method on surface of polyethylene fiber with ultrahigh molecular weight

The invention relates to an ultraviolet radiation two-step grafting method on the surface of polyethylene fiber with ultrahigh molecular weight. The method comprises the following steps of: coating a photosencitizer on the surface of preprocessed polyethylene fiber with ultrahigh molecular weight; soaking the polyethylene fiber in a first grafting monomer solution; forming a surface dormant group by adopting ultraviolet radiation or direct illumination; then, soaking in a second grafting monomer solution; initiating a secondary monomer surface free radical grafting reaction by ultraviolet radiation or heating; and finally, post-processing. Compared with the prior art, the invention has the advantages that the polar group is introduced to the surface of the polyethylene fiber with ultrahigh molecular weight, the reaction is controllable, the grafting efficiency and the grafting rate are higher, the second monomer with higher reaction activity is grafted on a primary grafting basis, and the adhesive performance of a matrix and the polyethylene fiber with ultrahigh molecular weight is greatly improved.

Owner:SHANGHAI RES INST OF CHEM IND

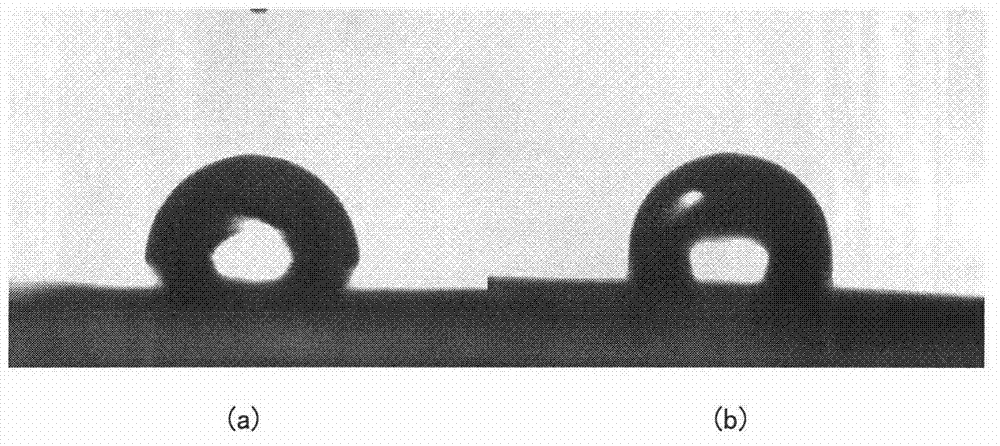

Preparation method for core-shell fluorinated polyurethane-acrylate latex

InactiveCN102924664AImprove grafting efficiencyFast polymerization rateCoatingsPolymer scienceFunctional monomer

The invention relates to a preparation method for core-shell fluorinated polyurethane-acrylate latex. The method comprises the following steps: placing polyether glycol and toluene diisocynate into a stirrer to prepare polyurethane; and emulsifying an emulsifier, butyl acrylate, methyl methacrylate, a functional monomer and a proper amount of water at high speed to prepare the core-shell fluorinated polyurethane-acrylate latex. By the method, the defects that the fluorinated acrylate in the prior art is independent of oil and water phases due to hydrophobicity and lipophobicity, effective micelle is difficult to form by the general surfactant and the grafting ratio is low are overcome. The core-shell fluorinated polyurethane-acrylate latex has a core-shell structure and the fluorinated acrylate is enriched in the shell, so a latex film has a large water contact angle. The using amount of the fluorinated acrylate monomer (G04) is 1 to 2 percent of the weight of the monomer and the using amount of polyurethane (PU) is 10 percent of the weight of a composite latex solid, so the preparation cost is low. The emulsifier does not need a fluorine-containing surfactant, so the polymerization rate is high, the grafting efficiency of the fluorinated acrylate monomer is high and the latex is stored stably.

Owner:江苏日出化工有限公司 +1

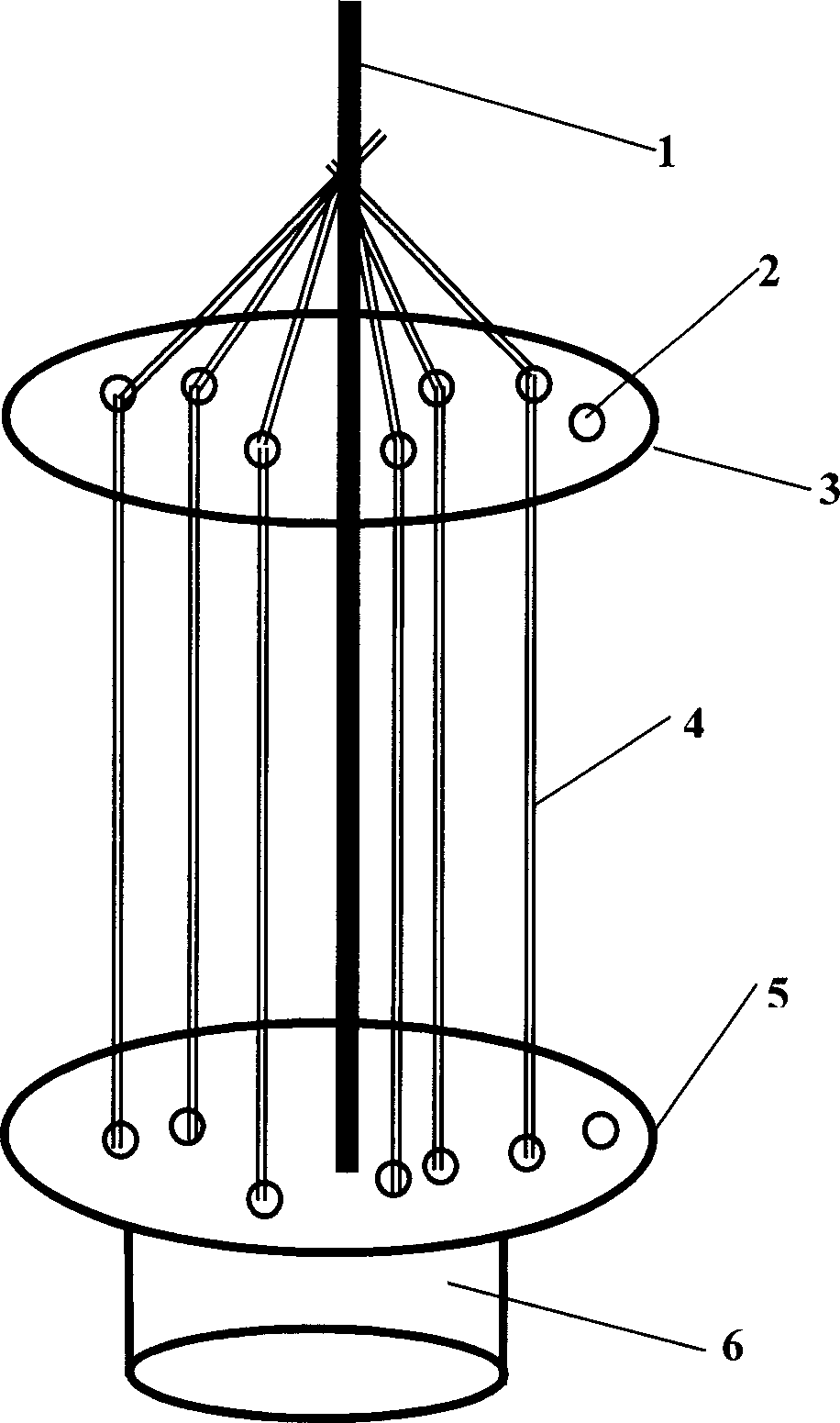

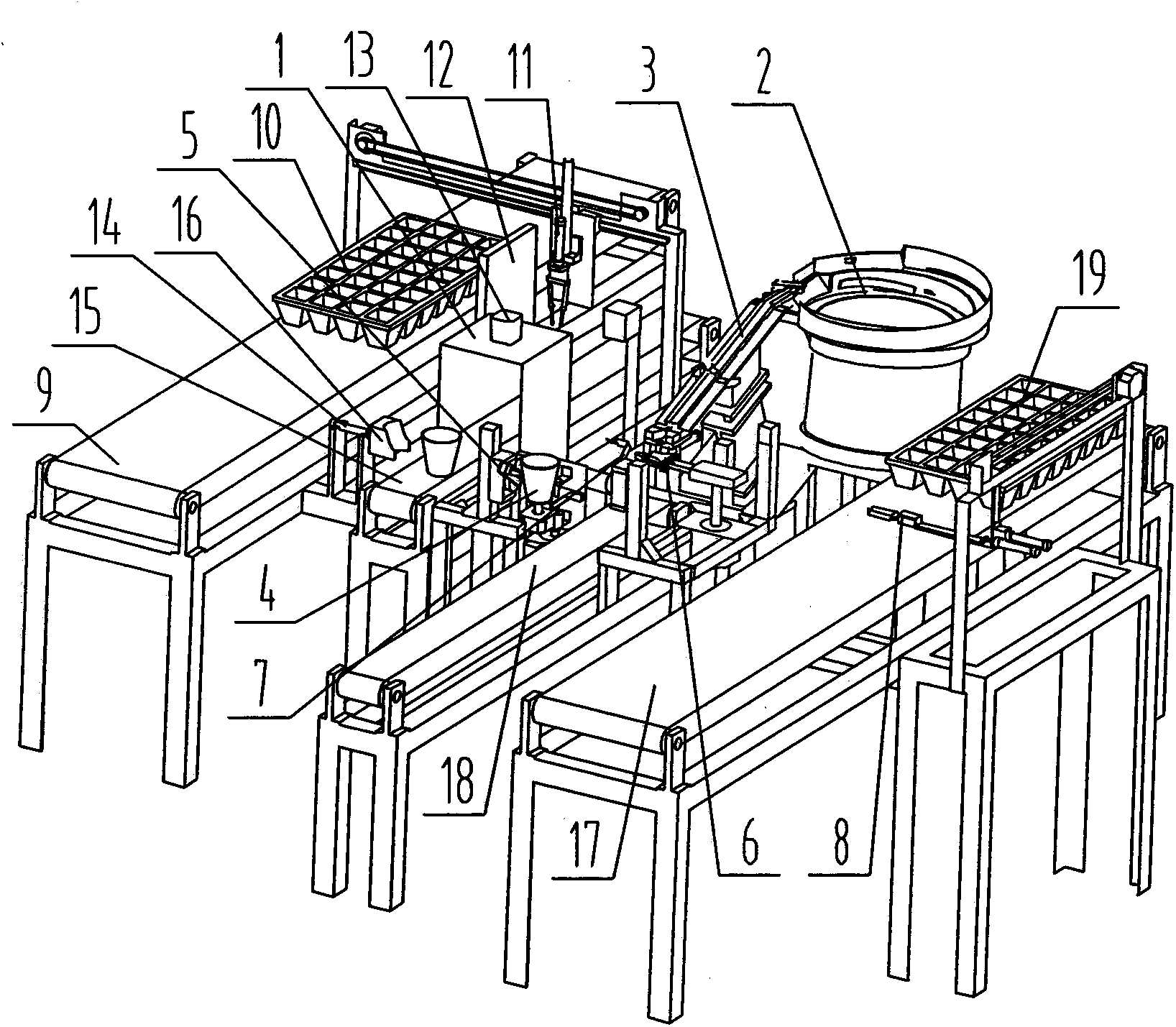

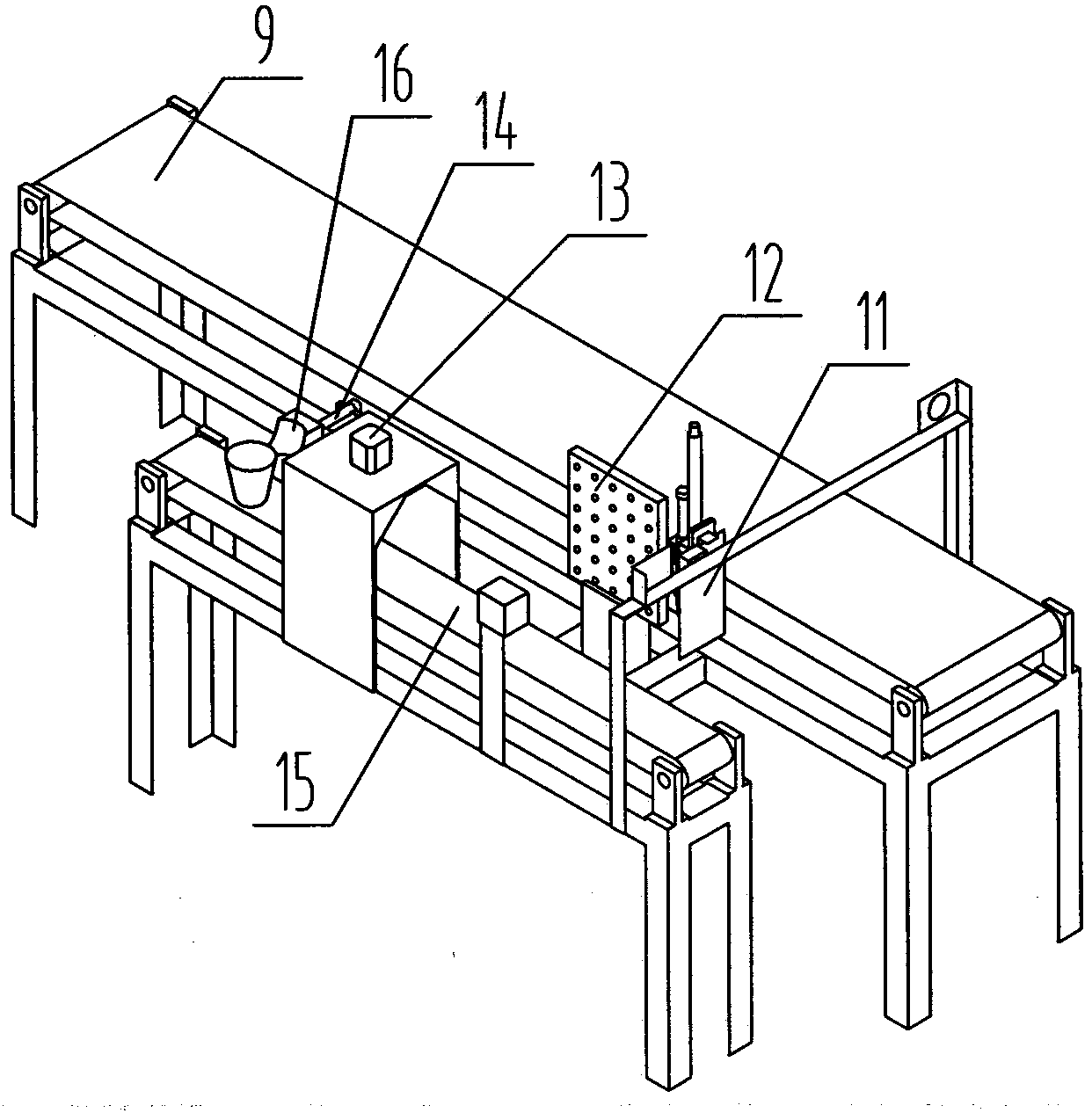

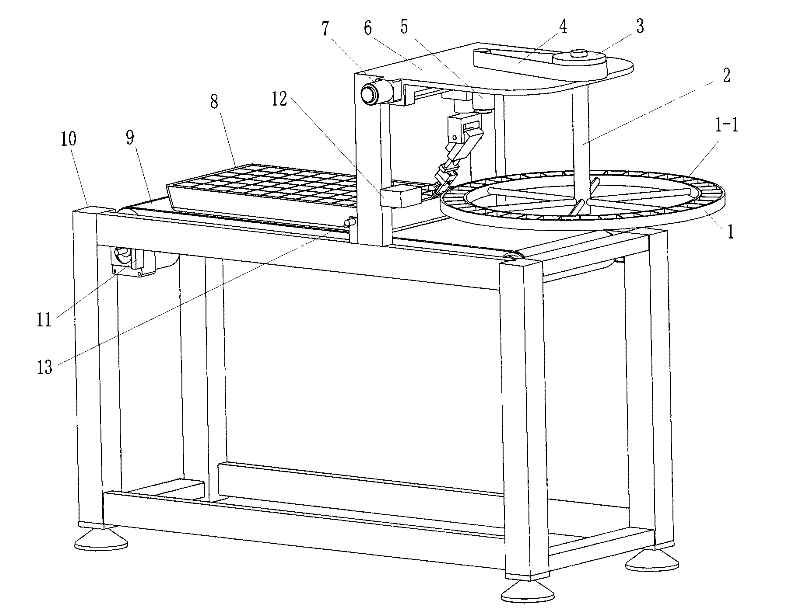

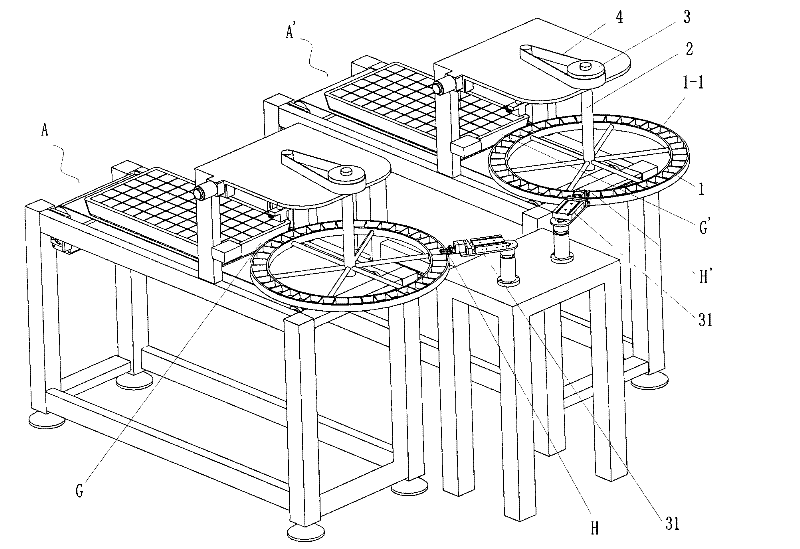

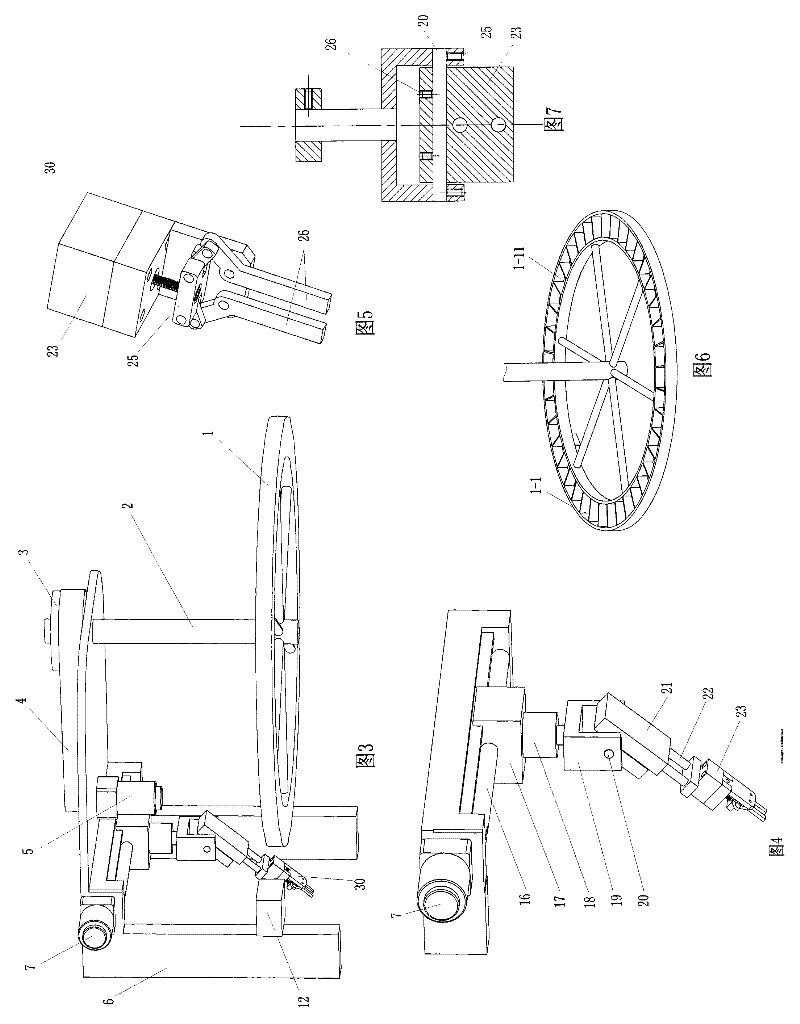

Full-automatic melon stock and scion grafting machine

InactiveCN103843594AGood success rate of graftingImprove accuracyHorticultureControl systemRootstock

The invention discloses a full-automatic melon stock and scion grafting machine, and aims to provide a full-automatic melon stock and scion grafting machine which is high in grafting efficiency, high in grafting quality, reliable in performance and convenient to use. The full-automatic melon stock and scion grafting machine comprises a main stander, and a stock seedling visual grading and transplanting device, an electromagnetic vibration sequencing clamp conveying device, a vibration type clamp feeding device, a stock seedling positioning and carrying device, a stock cutting device, a scion positioning and carrying device, a scion cutting device, a scion seedling taking device and a control system which are arranged on the main stander, wherein a stock seedling transplanting manipulator of the stock seedling visual grading and transplanting device is transversely arranged above a stock seedling disk conveying belt and a seedling basin conveying belt through a portal frame; a seedling basin simulation module is arranged at the piston rod end of a seedling basin pushing conveying cylinder and is opposite to a tray of the stock seedling positioning and carrying device. The full-automatic melon stock and scion grafting machine is suitable for full-automatic stock and scion grafting work of melons.

Owner:SHENYANG AGRI UNIV

Preparation method of starch grafted acrylamide flocculating agent

InactiveCN101704928AHigh solid contentHigh molecular weightWater/sewage treatment by flocculation/precipitationParaffin waxEmulsion

The invention provides a preparation method of a starch grafted acrylamide flocculating agent, which comprises the following concrete step of polymerizing starch and acrylamide in a reversed emulsion formed by liquid paraffin, water and a compounded emulsifying agent to form a graft copolymer of the starch and the acrylamide, wherein potassium permanganate is used as an initiator, and the compounded emulsifying agent comprises span 80, Tween 80 and alkylphenol polyoxyethylene (4) in a mass ratio of 7-9:0.1-0.5:0.9-2.5. The method adopts the compounded emulsifying agent comprising the span 80, the Tween 80 and the alkylphenol polyoxyethylene (4) for preparing the reversed emulsion, thereby stabilizing the system of the reversed emulsion, providing a stable reaction environment for polyreaction, and being helpful for improving the stability of products. In addition, in the method, the potassium permanganate is also selected as the initiator, thereby effectively improving the efficiency of initiating the polyreaction.

Owner:GUANGZHOU UNIVERSITY

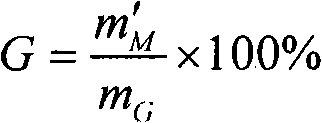

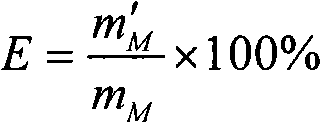

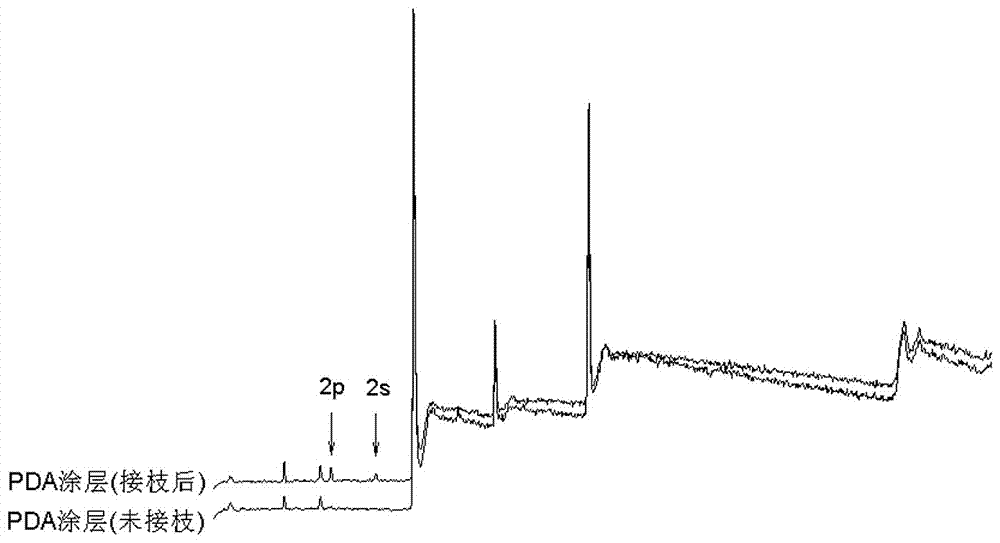

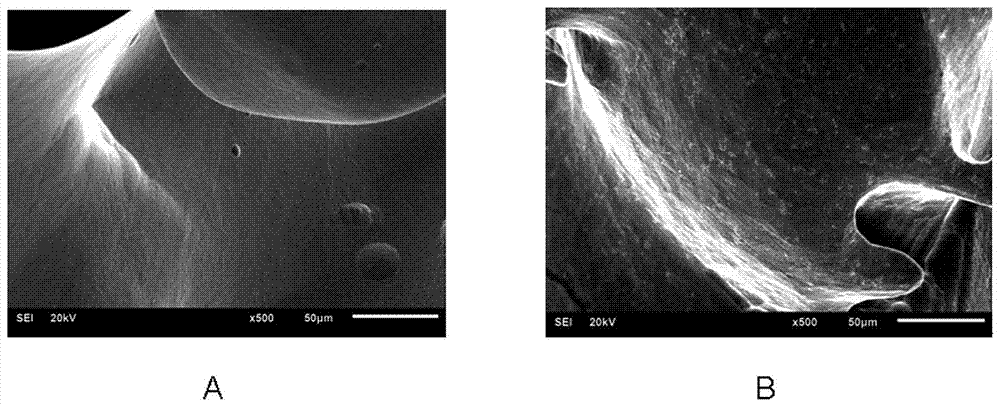

Porous scaffold provided with surface oriented functionally modified coating and preparation method of porous scaffold

The invention provides a porous scaffold provided with a surface oriented functionally modified coating and a preparation method of the porous scaffold. The surface of the porous scaffold material structure is coated with a polydopamine coating structure, and a functional component structure layer capable of releasing drug molecules or biomolecules with bioactive function / action in a biological fluid environment is grafted in a modular way to a hydroxyl and / or amino part on the surface of the polydopamine coating structure. During preparation, firstly, the polydopamine coating is deposited on the surface of the porous scaffold; then, hydroxyl groups and / or amino groups in the surface of the scaffold material and corresponding functional components are subjected to azidation or alkynylation respectively; finally, a graft structure layer of the functional components is formed on the surface of the polydopamine coating of the porous scaffold material structure after specific azide-alkynyl modular grafting. The grafting efficiency of the functional components on the surface of the porous scaffold material is high, the grafting structure layer is firmer, the application field of the scaffold material is broadened, more function selections are provided for the scaffold material, and novel means are particularly provided for bone repair, blood vessel therapy, cancer therapy and the like.

Owner:SICHUAN UNIV

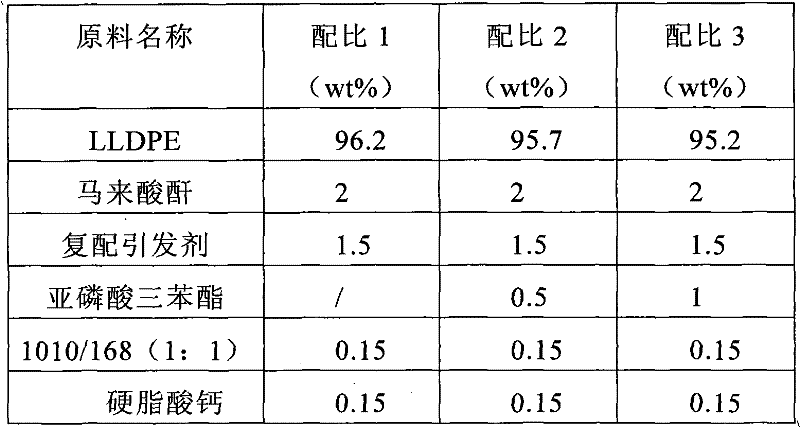

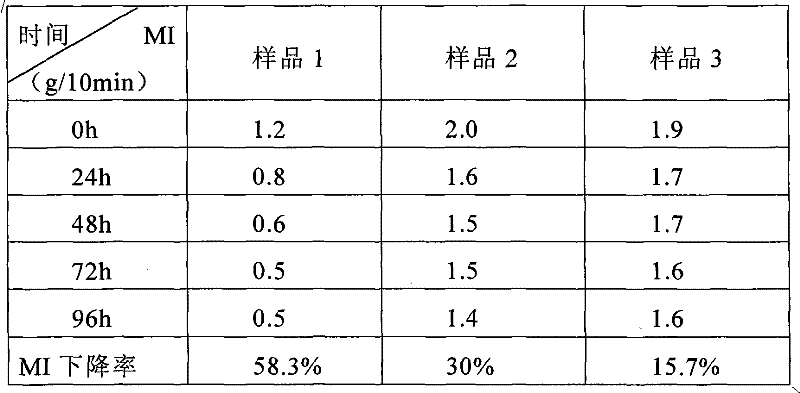

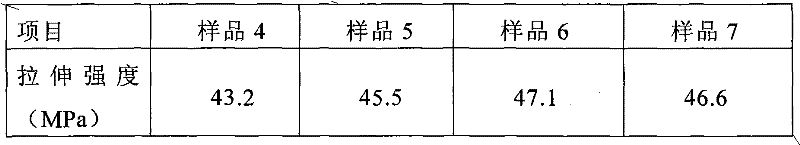

Environment-friendly polyethylene compatilizer and preparation method thereof

The invention relates to an environment-friendly polyethylene compatilizer and a preparation method thereof. The environment-friendly polyethylene compatilizer comprises the following components in percentage by weight: 75 to 98 percent of polyethylene, 1 to 10 percent of functional monomer, 0.1 to 10 percent of initiator, 0.1 to 9 percent of anti-crosslinking agent, 0.1 to 3 percent of antioxidant and 0.1 to 3 percent of lubricating agent. The preparation method comprises the following steps of: placing the components in a highly mixing machine in a ratio; mixing; feeding the mixture into a double-screw extruder in a side feeding manner; extruding by using the double-screw extruder; and performing ultrasonic treatment to obtain the product. Compared with the prior art, the environment-friendly polyethylene compatilizer and the preparation method thereof have the advantages that: the polyethylene compatilizer with high grafting ratio is obtained by a compound initiating system and an ultrasonic technology; the problems of high monomer residual amount and serious gelling phenomenon are solved; emission of toxic substances is reduced; and the environment and healthiness of users are protected.

Owner:SHANGHAI SUNNY

Preparation method of graphene oxide modified waterborne polyurethane anti-corrosive emulsion

ActiveCN107880237AImprove dispersion stabilityReduce van der Waals forcesAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyN dimethylformamide

The invention relates to a preparation method of a graphene oxide modified waterborne polyurethane anti-corrosive emulsion, relating to the technical field of preparation of aqueous coatings. The preparation method comprises the following steps: firstly, mixing N,N-dimethylformamide, graphene oxide, a catalyst and glycidyl neocyanate to react to obtain modified graphene oxide; then mixing the graphene oxide, isophorone diisocyanate and polyadipic acid-1,4-butanediol ester, raising the temperature to 85 DEG Ca and then reducing the temperature to 60 DEG C; then adding dibutyltin dilaurate, 5-N-methyl pyrrolidone, epoxy resin, 2,2-dimethylolpropionic acid and trimethylolpropane to react; adding triethylamine to react at the temperature of a reaction material of 60 DEG C; then adding deionized water at 60 DEG C to react; reducing the temperature to 40 DEG C; carrying out filtration; and taking the filtered object to obtain the graphene oxide modified waterborne polyurethane anti-corrosiveemulsion. The shielding capacity of a graphene oxide sheet layer can be further improved by means of hydrophobic effect formed by a long alkyl chain grafted to the surface of graphene oxide.

Owner:海安常州大学高新技术研发中心

Method for grafting pitaya with pitaya flowers as stocks

The invention relates to a method for grafting pitaya with pitaya flowers as stocks. The method particularly includes the steps of selecting the pitaya flowers as stock seedlings, using pitaya branches as scions, and grafting the pitaya scions to the pitaya flowers at the right moment, wherein dipping and disinfection processing are carried out on the base portions of the scions and the cut portions of the stocks with an ABT1 solution and a carbendazim solution before grafting is carried out; after the pitaya scions are grafted to the pitaya flower stocks, smearing all exposed wounds after the butt joint with a layer of Vaseline, and finally binding the butt joint portions of the scions and the stocks through plastic wrap to fix the scions and the stocks in a coincident mode. By means of the method, due to the fact that the wild pitaya flowers have the advantages of being abundant in resource and excellent gene and the like, after the pitaya is grafted on the pitaya flowers, the pitaya fruited on the pitaya flowers is high in yield, good in taste and good in quality after grafting is carried out; meanwhile, pitaya grafting is of great significance on the effects of sustainable utilization, the low-yield improvement and waste recycling of the pitaya flower resources, the effect of rapidly enlarging the planting area of the pitaya and the like.

Owner:平果县农业局

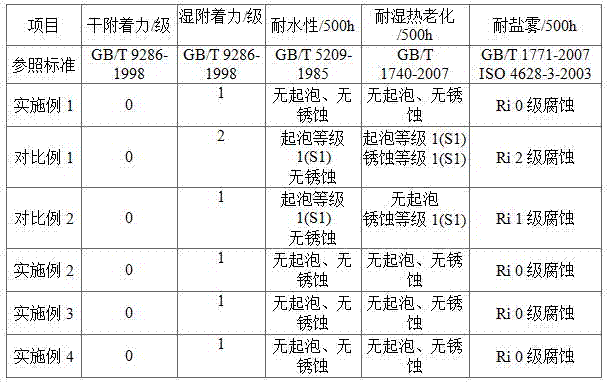

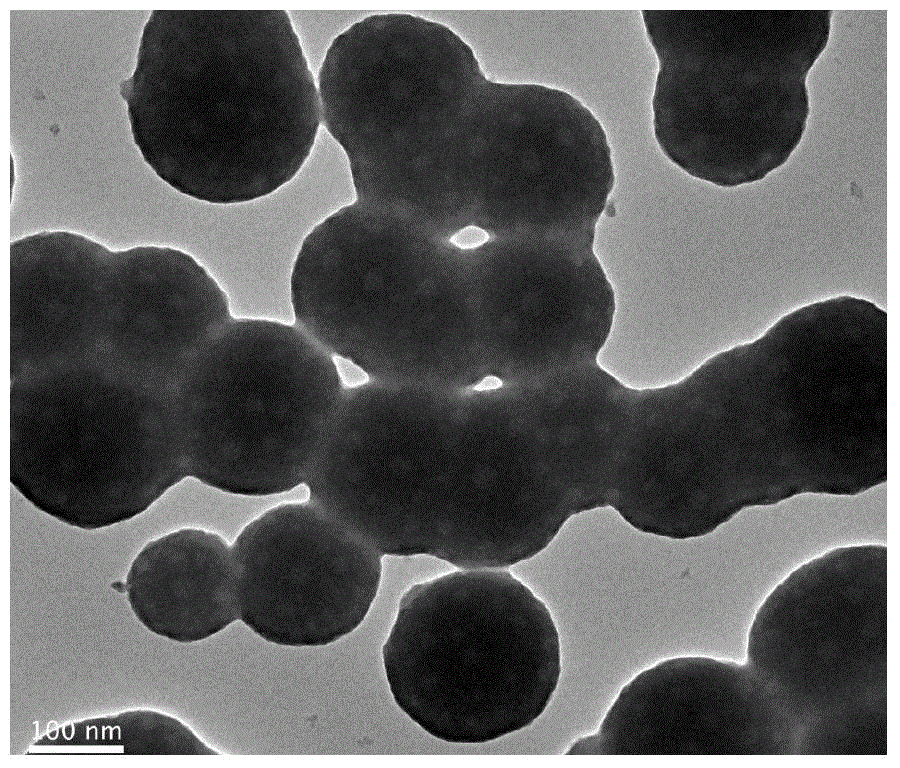

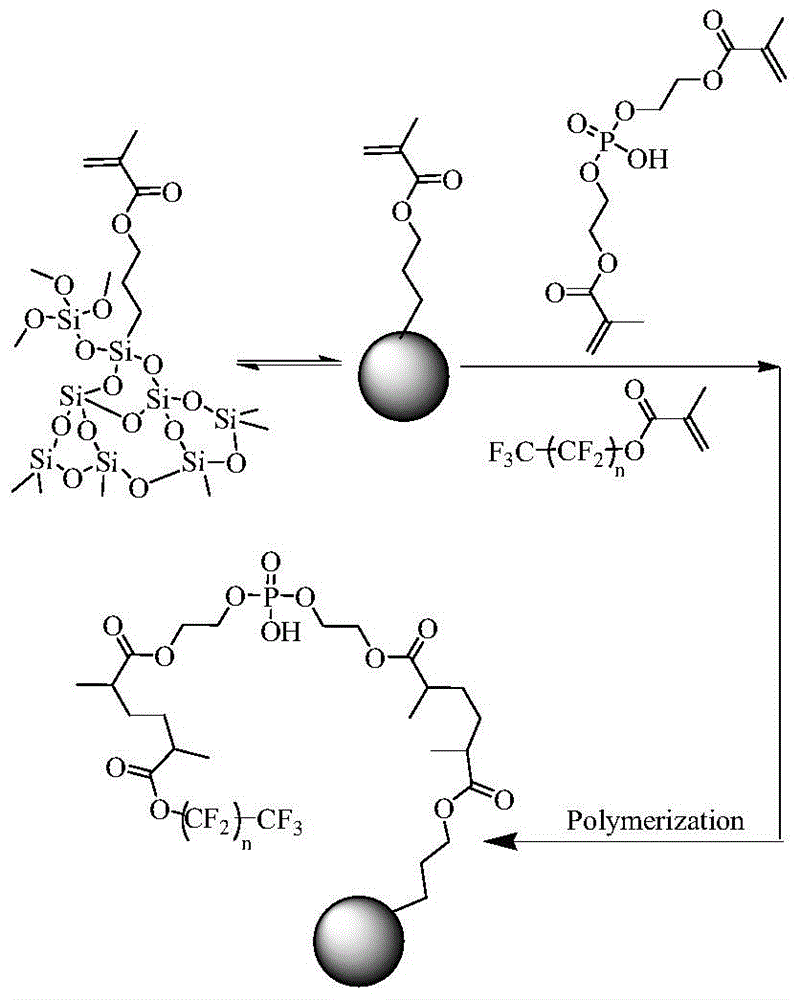

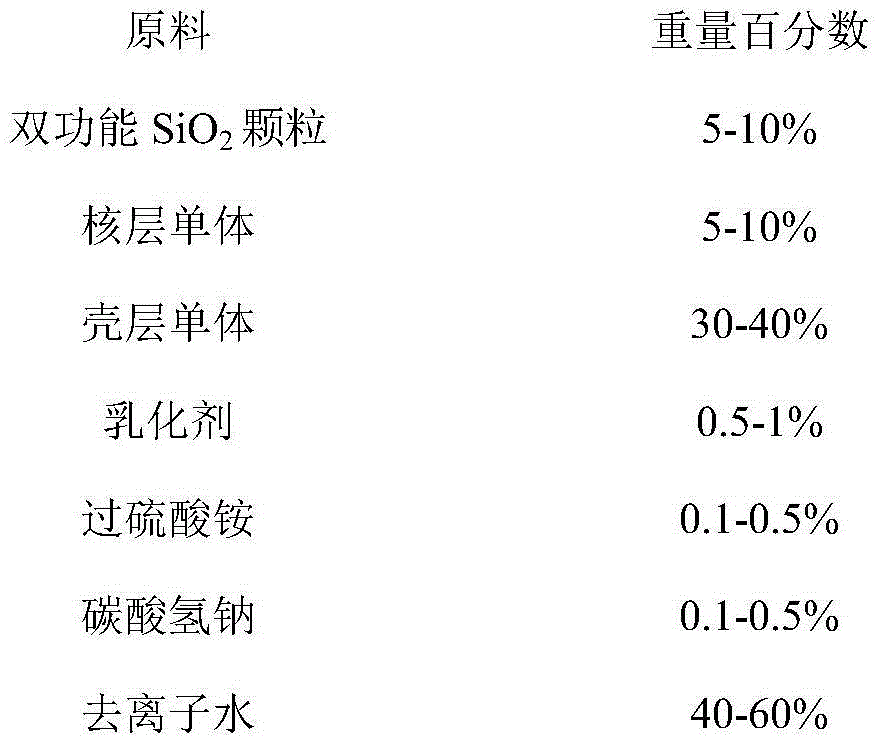

Waterborne single-component transparent anti-corrosion coating based on dual-functionalized nano-SiO2 and preparation method of coating

InactiveCN104530845AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsDouble bondOrganophosphate

The invention discloses a waterborne single-component transparent anti-corrosion coating based on dual-functionalized nano-SiO2 particles and a preparation method of the coating. The dual-functionalized nano-SiO2 particles are prepared by introducing double bonds on the surfaces of nano-SiO2 particles, further grafting with di(methacryloyloxyethyl) hydrogen phosphate and a fluorine-containing monomer and simultaneously introducing phosphate groups and fluorocarbon chains on the surfaces of the nanoparticles to prepare the dual-functionalized nano-SiO2 particles; and further polymerizing the dual-functionalized nano-SiO2 particles and an emulsion to obtain dual-functionalized nano-SiO2 hybrid styrene-acrylic emulsion, so that the corrosion resistance of the styrene-acrylic emulsion system is greatly increased. Under the condition that an anti-rust pigment is not added, the emulsion can reach ISO4628-3-2003 Ri 0-level anti-corrosion standard after the emulsion is subjected to salt spray for 500 hours.

Owner:CHANGZHOU UNIV

Method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of laccase-TEMPO process

InactiveCN105734981AImprove grafting efficiencyIncrease the amount of graftingBiochemical fibre treatmentAnimal fibresQuinoneNitrogen oxides

The invention discloses a method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of a laccase-TEMPO process. Quinones active groups are generated through catalyzing tyrosine residual groups in real silks by laccase so that chitosan molecules are grafted on the real silks; then 2,2,6,6-tetramethylpiperidine-nitrogen oxide (TEMPO) is added and is used for catalyzing chitosan and tyrosine in the real silks to generate formyl groups, so that the grafting amount and bonding firmness of the chitosan on the real silks are increased, and the real silk fabric anti-crease and antibacterial finishing is realized. The method comprises the following specific steps of: (1) catalytically oxidizing the tyrosine residual groups in the real silks by the laccase; (2) taking the chitosan and the quinones active groups in the real silks to react; (3) catalyzing the real silks by laccase-TEMPO to graft the chitosan; and (4) washing the real silks with water and then treating. Compared with traditional chemical cross-linking-process vacuum fabric anti-crease and antibacterial finishing, the method has the advantages that the grafting efficiency of the chitosan is high, enzyme treatment conditions are moderate, the real silk fabric anti-crease and antibacterial effect is relatively good and the strength of the fabric is improved.

Owner:JIANGNAN UNIV

Carbon nano tube/chitosan mesoporous spherical composite material as well as preparation method thereof

ActiveCN103933949AWon't fall offEasy separationOther chemical processesAlkali metal oxides/hydroxidesCarbon nanotubeSpherical form

The invention relates to a carbon nano tube / chitosan mesoporous spherical composite material as well as a preparation method thereof. The preparation method of the spherical composite material comprises the following steps: (1) carrying out acid treatment and dispersion treatment on carbon nano tube raw materials; (2) preparing a chitosan solution with the degree of deacetylation of 80-100%; (3) adding the carbon nano tube which is treated by the step (1) into the chitosan solution obtained by the step (2), and mixing uniformly so as to a spherical liquid; (4) dissolving alkaline solute into water so as to obtain a solidified liquid; (5) dropwise adding the spherical liquid into the solidified liquid so as to prepare a composite sphere; (6) placing the composite sphere generated by the step (5) into a crosslinking agent solution to crosslink, and stirring so as to obtain a crosslinking composite sphere; (7) refrigerating and drying the crosslinking composite sphere obtain by the step (6) so as to obtain the carbon nano tube / chitosan mesoporous spherical composite material. The carbon nano tube / chitosan mesoporous spherical composite material disclosed by the invention is nontoxic, and has favorable adsorption performance.

Owner:梁吉 +1

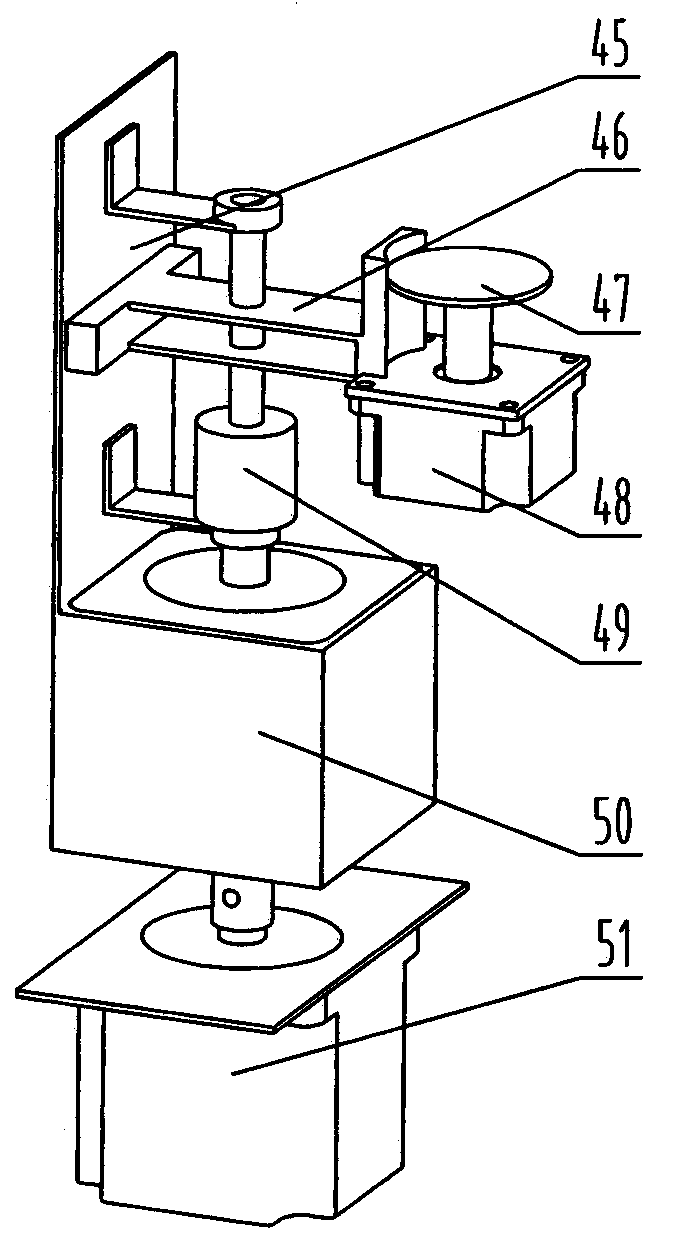

Vision based matching mechanism of fruit and vegetable grafting machine for seedling to be grafted

InactiveCN102124905AReliable cooperationImprove grafting efficiencyHorticultureRootstockVision based

The invention relates to a matching mechanism for stock seedlings and cion seedlings, aiming to provide a mechanism having the characteristics of higher automation degree, reliable property, simple structure, convenience for operation and lower cost. The invention adopts the technical scheme that the vision based matching mechanism of a fruit and vegetable grafting machine for seedling to be grafted comprises a conveying platform and a mounting frame arranged on the conveying platform, wherein the top surface of the conveying platform is provided with a conveying mechanism for conveying stock seedling hole trays or cion seedling hole trays to an operation position; the mounting frame is provided with a turntable for placing the stock seedlings or the cion seedlings, a turntable mechanism for driving the turntable to rotate, a mechanical claw for handling the stock seedlings and the cion seedlings to the turntable from the hole trays, a moving mechanism for driving the mechanical claw to move, a photoelectric sensor for detecting the positions of the stock seedling hole trays or the cion seedling hole trays and a CCD (Charge Coupled Device) camera for collecting stock seedling or cion seedling images and transmitting the images to a computer for processing; and the conveying mechanism comprises a belt wheel driven by a motor and a conveying belt which is driven by the belt wheel and horizontally arranged.

Owner:ZHEJIANG SCI-TECH UNIV

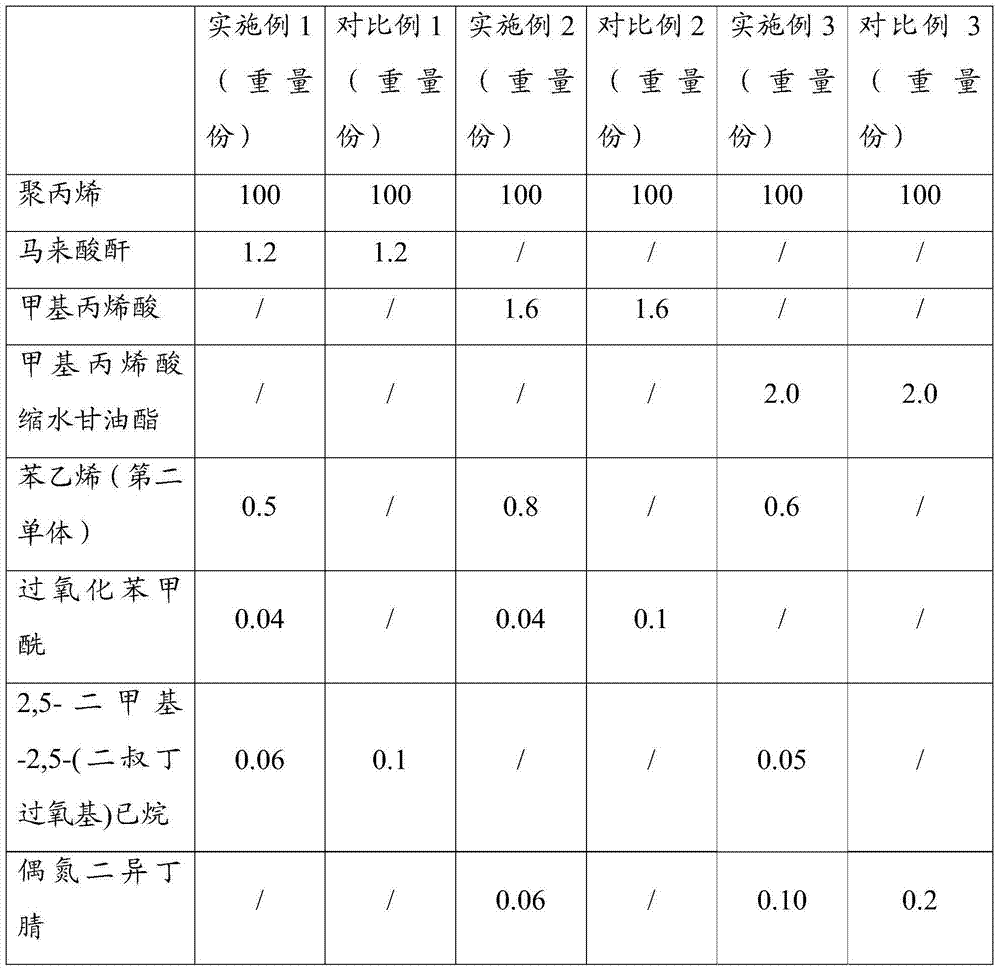

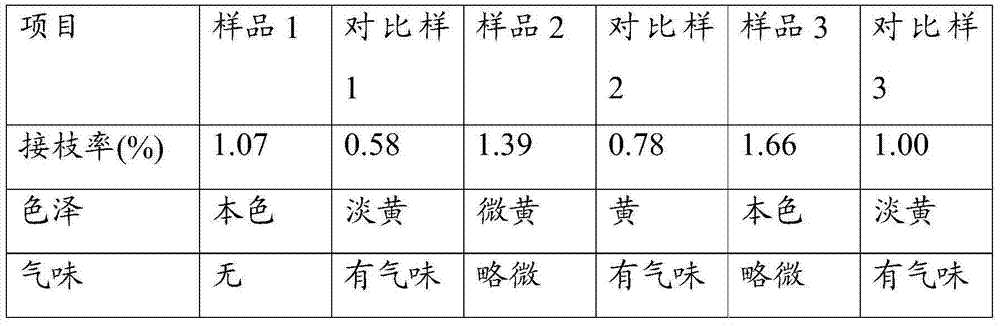

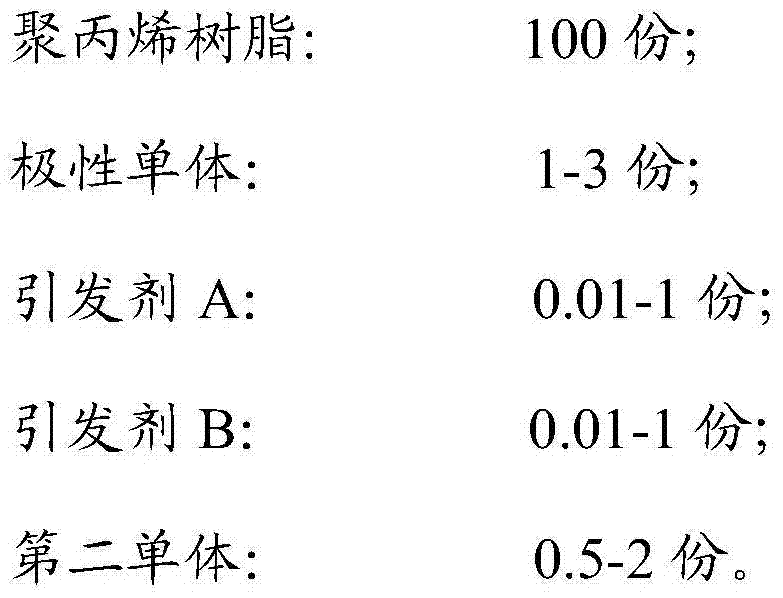

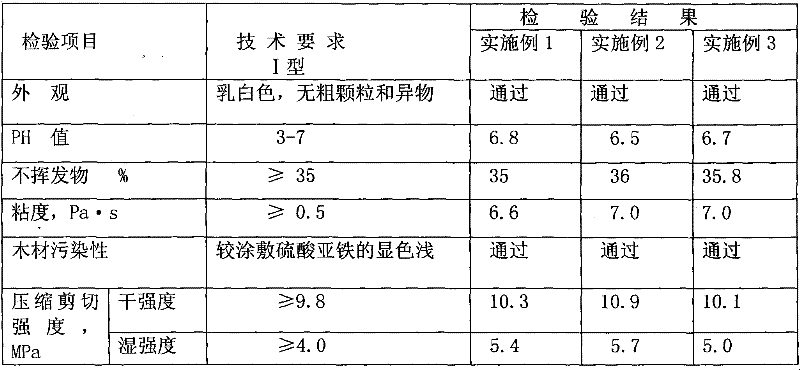

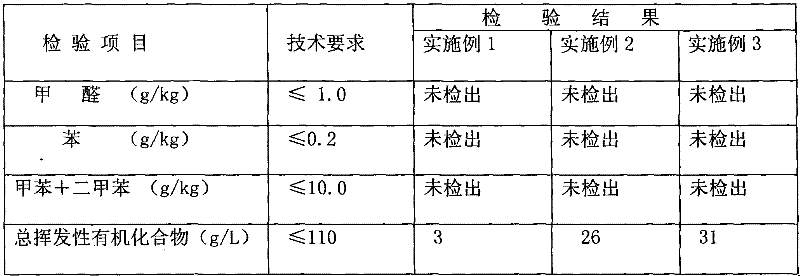

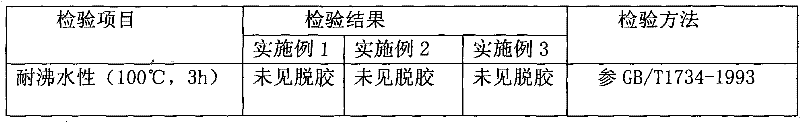

High-grating-rate and low-odor polypropylene resin composition and preparation method thereof

The invention provides a high-grating-rate and low-odor polypropylene resin composition and a preparation method thereof. The polypropylene resin composition consists of the following components in parts by weight: 100 parts of polypropylene resin, 1-3 parts of a polar monomer, 0.01-1 part of an initiator A, 0.01-1 part of an initiator B and 0.5-2 parts of a second monomer. The preparation method comprises the steps of weighing raw materials according to the weight part, mixing the raw materials in a high-speed mixer for 2-5min and discharging materials; and implementing reactive extrusion grafting on the mixed raw materials through a dual-screw extruder. The polypropylene resin composition disclosed by the invention, through selecting initiator and comonomer, reduces pungent odor of materials and improves grafting efficiency. The prepared polypropylene disclosed by the invention has the advantages of light product odor, high grating rate and low gel rate, and is applicable to a flexibilizer and a compatilizer of polar monomer and non-polar polymer alloy; the polypropylene resin composition is used for filling or strengthening polypropylene, and is capable of improving the mechanical performance and the heat resistance of the material.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Preparation method of water-resistant plant adhesive

InactiveCN102234494AImprove grafting efficiencyReduce moisture contentMonocarboxylic acid ester polymer adhesivesStarch adhesivesAdhesivePolyvinyl alcohol

The invention discloses a preparation method of a water-resistant plant adhesive. The preparation method comprises the following steps: adding 3-6 parts by weight of polyvinyl alcohol into 60-75 parts by weight of water; cooling to 35-50 DEG C after dissolving; adding 10-15 parts by weight of pre-gelatinized cassava starch and 0.3-0.8 part by weight of urea, adjusting the viscosity of the mixed liquid to 2000-3000 mPa.s by use of a crosslinking agent, raising the temperature to 60-75 DEG C, carrying out reaction under heat insulating condition for 10-30 minutes, cooling to 45-65 DEG C, carrying out heat preservation for 30-120 minutes, cooling to 35-55 DEG C, adding 25-35 parts by weight of vinyl acetate-ethylene copolymer emulsion, stirring for 10-30 minutes, then adding 0.2-0.5 part by weight of emulsifier and 0.1-0.3 part by weight of anticorrosion agent, and stirring for 10-20 minutes to obtain the water-resistant plant adhesive. Compared with the existing starch adhesive, the adhesive provided by the invention has water resistance increased by more than 2 times, and is still adherent to boil in water for 3 hours or more.

Owner:王钱生

Temperature-sensitive type cell culture surface and preparation method thereof

ActiveCN105219644AWith temperature sensitive response functionImprove grafting efficiencyTissue/virus culture apparatusBiological material testing proceduresMass ratioSolvent

The invention relates to a temperature-sensitive type cell culture surface and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a temperature-sensitive primary liquid: adding temperature-sensitive compounds and radical initiators to solvents and stirring to dissolve the materials to obtain the temperature-sensitive primary liquid, wherein the mass ratio of the temperature-sensitive compounds to the solvents is (2-50) to 100; the mole ratio of the radical initiators to the temperature-sensitive compounds is (0.5-50) to 100; (2) reacting a cell culture surface for 5-120 minutes under the condition of 50-150 DEG C after distributing the temperature-sensitive primary liquid on the cell culture surface, thus obtaining the temperature-sensitive type cell culture surface. The preparation method has the beneficial effects that the cell culture surface with the temperature-sensitive response function can be obtained by directly initiating graft polymerization of the temperature-sensitive compounds on the cell culture surface by utilizing the common chemical radical initiators; compared with the prior art, the preparation method has the advantages that the production cost of the temperature-sensitive type cell culture surface is greatly reduced; the grafting ratio is high; the preparation method is environmentally friendly.

Owner:GUANGZHOU JET BIOFILTRATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com