Preparation method of water-resistant plant adhesive

An adhesive and water resistance technology, applied in the direction of monocarboxylic acid ester copolymer adhesive, unsaturated alcohol copolymer adhesive, adhesive type, etc., can solve the problems of unsatisfactory water resistance and difficult popularization and application, etc. Achieve the effects of improving storage stability, improving grafting efficiency and enhancing cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 3Kg of polyvinyl alcohol, add 65Kg of water, dissolve it completely at 95°C, cool down to 50°C, add 12Kg of pregelatinized tapioca starch and 0.5Kg of urea, adjust the viscosity of the mixture to 2000mPa.s with borax, and heat up to 60°C, keep warm and stir for 30min, cool down to 45°C, keep warm for 120min, then cool down to 35°C, add vinyl acetate-ethylene copolymer emulsion (ethylene content is 14-18%, w / w, 35Kg, stir for 10min, then Add Tween-800.2Kg, stir and react for 30 minutes, add 0.1Kg of isothiazolinone, and stir evenly to obtain a water-resistant plant adhesive.

Embodiment 2

[0020] Take 5Kg of polyvinyl alcohol, add 70Kg of water, dissolve it completely at 95°C, cool down to 35°C, add 15Kg of pregelatinized tapioca starch and 0.3Kg of urea, adjust the viscosity of the mixture to 3000mPa.s, and heat up to 75 ℃, heat preservation and stirring reaction for 10min, cool down to 55℃, hold for 60min, then cool down to 40℃, add 30Kg of vinyl acetate-ethylene copolymer emulsion (ethylene content is 14-18%, w / w), stir for 30min, then add Tween-800.3Kg, stirring and reacting for 20min, adding 0.3Kg of isothiazolinone, and stirring evenly to obtain a water-resistant plant adhesive.

Embodiment 3

[0022] Take 6Kg of polyvinyl alcohol, add it to 75Kg of water, dissolve it completely at 95°C, cool down to 40°C, add 14Kg of pregelatinized tapioca starch and 0.8Kg of urea, adjust the viscosity of the mixture to 2500mPa.s, and heat up to 70°C, heat preservation and stirring reaction for 20min, cool down to 65°C, heat preservation and stirring reaction for 30min, then cool down to 55°C, add vinyl acetate-ethylene copolymer emulsion (ethylene content 14-18%, w / w) 25Kg, stir reaction for 20min, Then add Tween-80 0.4Kg, stir and react for 10min, finally add 0.15Kg of isothiazolinone, stir evenly, and obtain the water-resistant plant adhesive.

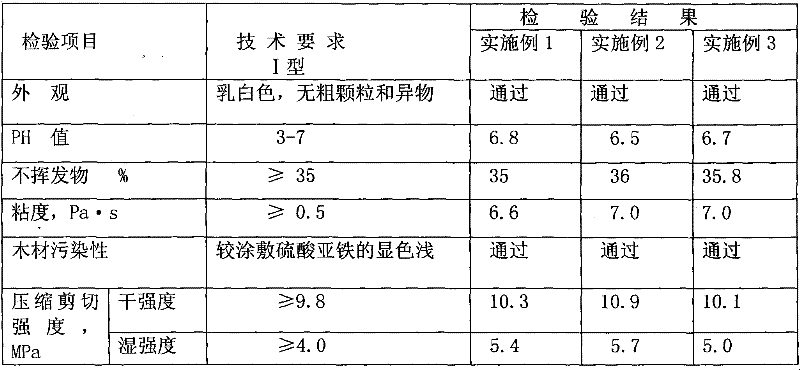

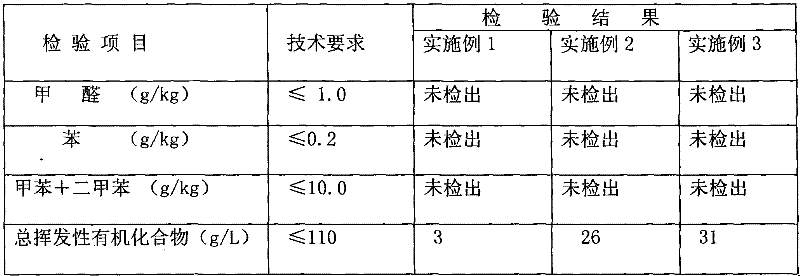

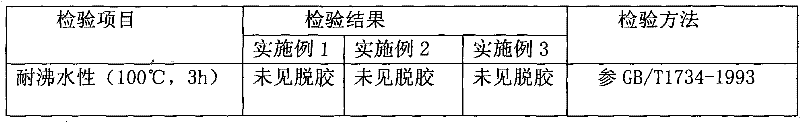

[0023] The product that above-mentioned embodiment is made sends quality inspection department to carry out performance inspection according to HG / T2727-1995 " polyvinyl acetate emulsion wood adhesive " requirement, and the result is as shown in following table 1; According to GB18583-2008 " interior decoration material adhesive The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com