Patents

Literature

53results about How to "Increase the amount of grafting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing lubricating coating with strong stability on surface of medical polyurethane material

InactiveCN101612421AImprove the lubrication effectImprove stabilitySurgeryCatheterGas phaseGraft reaction

The invention discloses a method for preparing a lubricating coating with strong stability on the surface of a medical polyurethane material, comprising the following steps of: step 1, pretreating the medical polyurethane material so as to obtain positions with proper surface roughness and reaction activity; step 2, putting the polyurethane polymer material pretreated in the step 1 into a gas phase system of reaction solution or solute for grafting reaction; and step 3, cleaning and drying the reaction products from the step 2. The method can be widely used for preparing medical polymer materials and high-lubricity coating materials on the surface of medical instruments.

Owner:SOUTHEAST UNIV

Method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of laccase-TEMPO process

InactiveCN105734981AImprove grafting efficiencyIncrease the amount of graftingBiochemical fibre treatmentAnimal fibresQuinoneNitrogen oxides

The invention discloses a method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of a laccase-TEMPO process. Quinones active groups are generated through catalyzing tyrosine residual groups in real silks by laccase so that chitosan molecules are grafted on the real silks; then 2,2,6,6-tetramethylpiperidine-nitrogen oxide (TEMPO) is added and is used for catalyzing chitosan and tyrosine in the real silks to generate formyl groups, so that the grafting amount and bonding firmness of the chitosan on the real silks are increased, and the real silk fabric anti-crease and antibacterial finishing is realized. The method comprises the following specific steps of: (1) catalytically oxidizing the tyrosine residual groups in the real silks by the laccase; (2) taking the chitosan and the quinones active groups in the real silks to react; (3) catalyzing the real silks by laccase-TEMPO to graft the chitosan; and (4) washing the real silks with water and then treating. Compared with traditional chemical cross-linking-process vacuum fabric anti-crease and antibacterial finishing, the method has the advantages that the grafting efficiency of the chitosan is high, enzyme treatment conditions are moderate, the real silk fabric anti-crease and antibacterial effect is relatively good and the strength of the fabric is improved.

Owner:JIANGNAN UNIV

Preparation method of nano-silica surface grafted hydroxyl terminated polybutadiene rubber

ActiveCN104962111AGood dispersionHigh temperature resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSilicon dioxideUltrasonic dispersion

The invention discloses a preparation method of a nano-silica surface grafted hydroxyl terminated polybutadiene rubber. The method includes: 1) synthesis of isocyanate terminated nano-silica: dispersing cleaned and activated nano-silica into an acetone solution, conducting ultrasonic dispersion for dozens of minutes, slowly adding a catalyst containing isophorone diisocyanate solution dropwise according to the mass ratio of nano-silica to isophorone diisocyanate of 1:1-3, carrying out reaction at 50-80DEG C for 3-6h, performing centrifugal collection, then using acetone to conduct ultrasonic dispersing, washing and centrifugation three to five times, thus obtaining nano-silica with surface containing an isocyanic acid group; and 2) synthesis of hydroxyl terminated polybutadiene rubber surface grafted modified nano-silica. The modified nano-silica has good dispersibility in butyl acetate solution, and the surface polymer grafting content is high.

Owner:NANJING UNIV

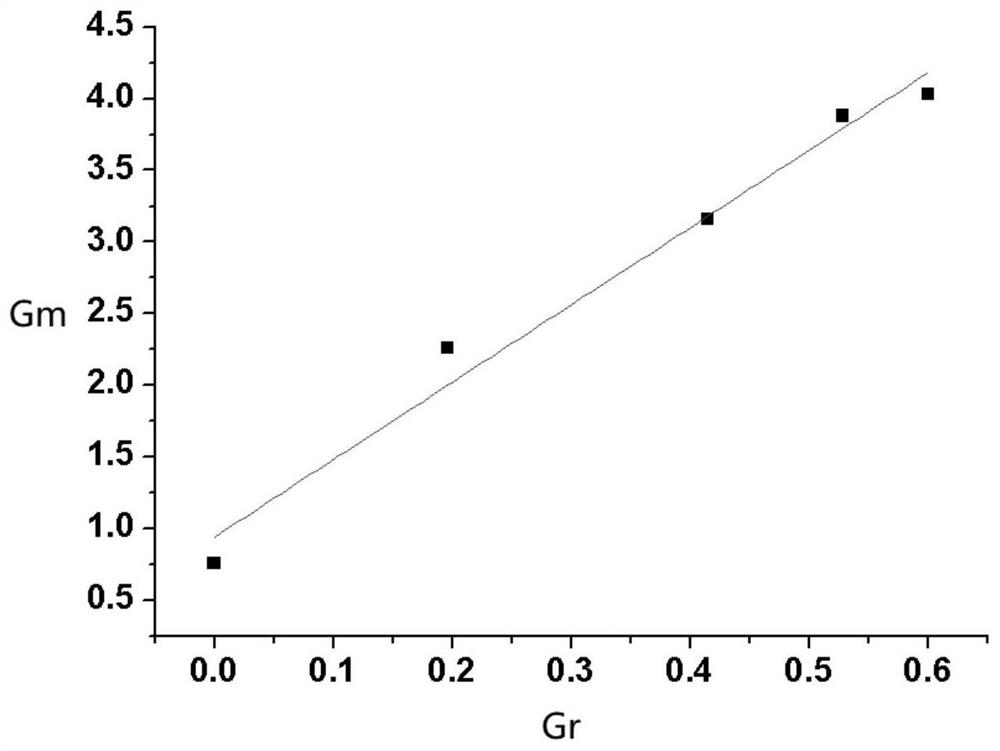

Small-caliber artificial blood vessel with surface grafted with heparin coating and preparation method thereof

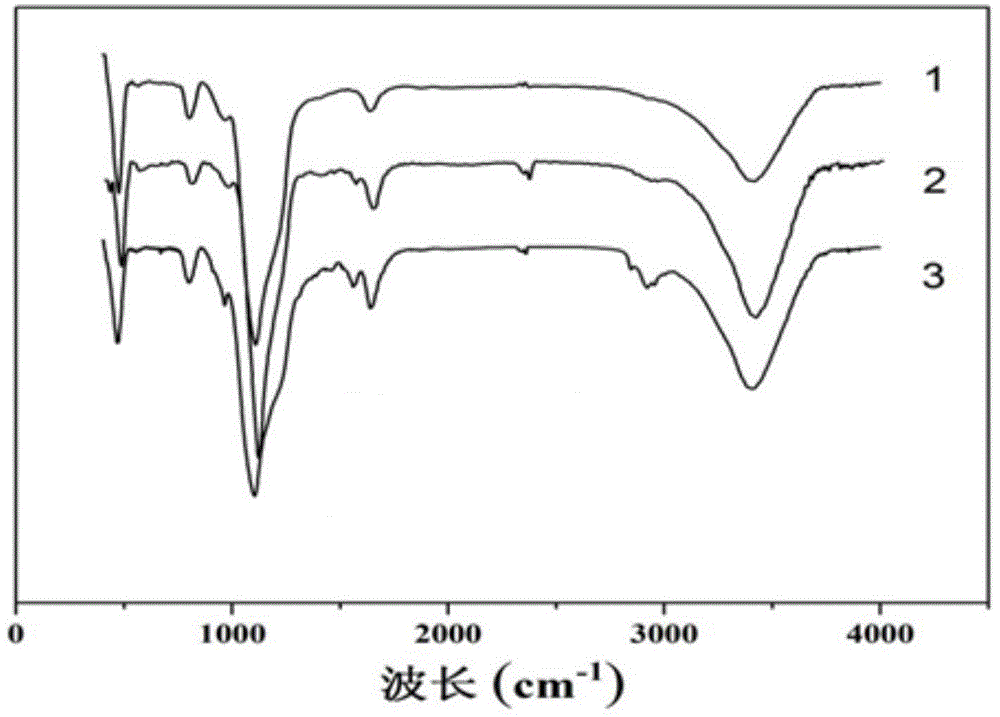

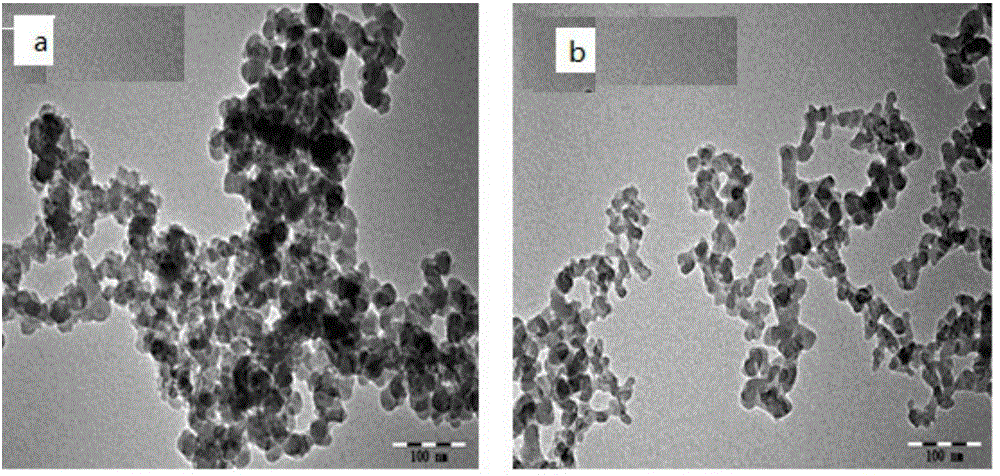

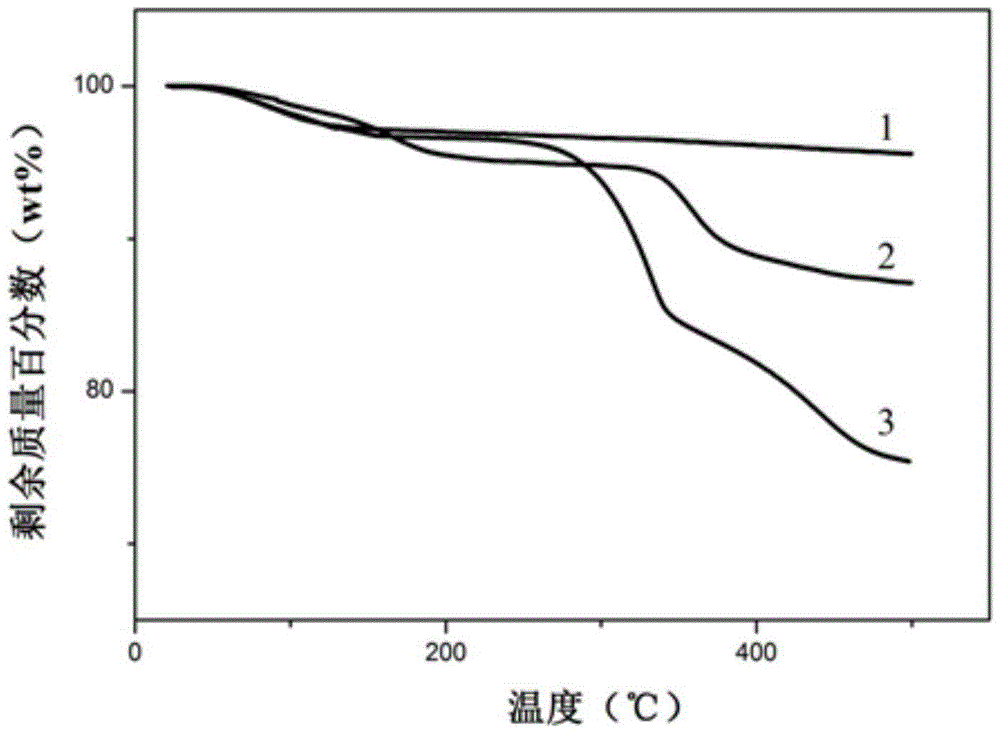

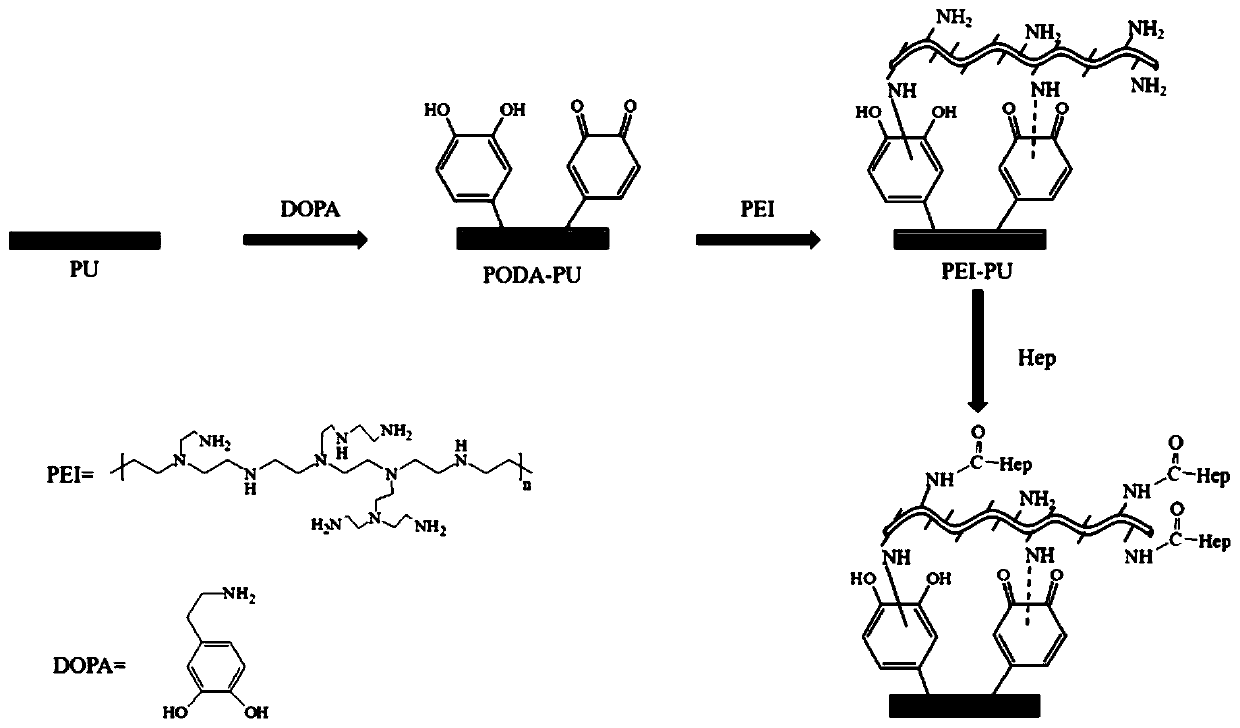

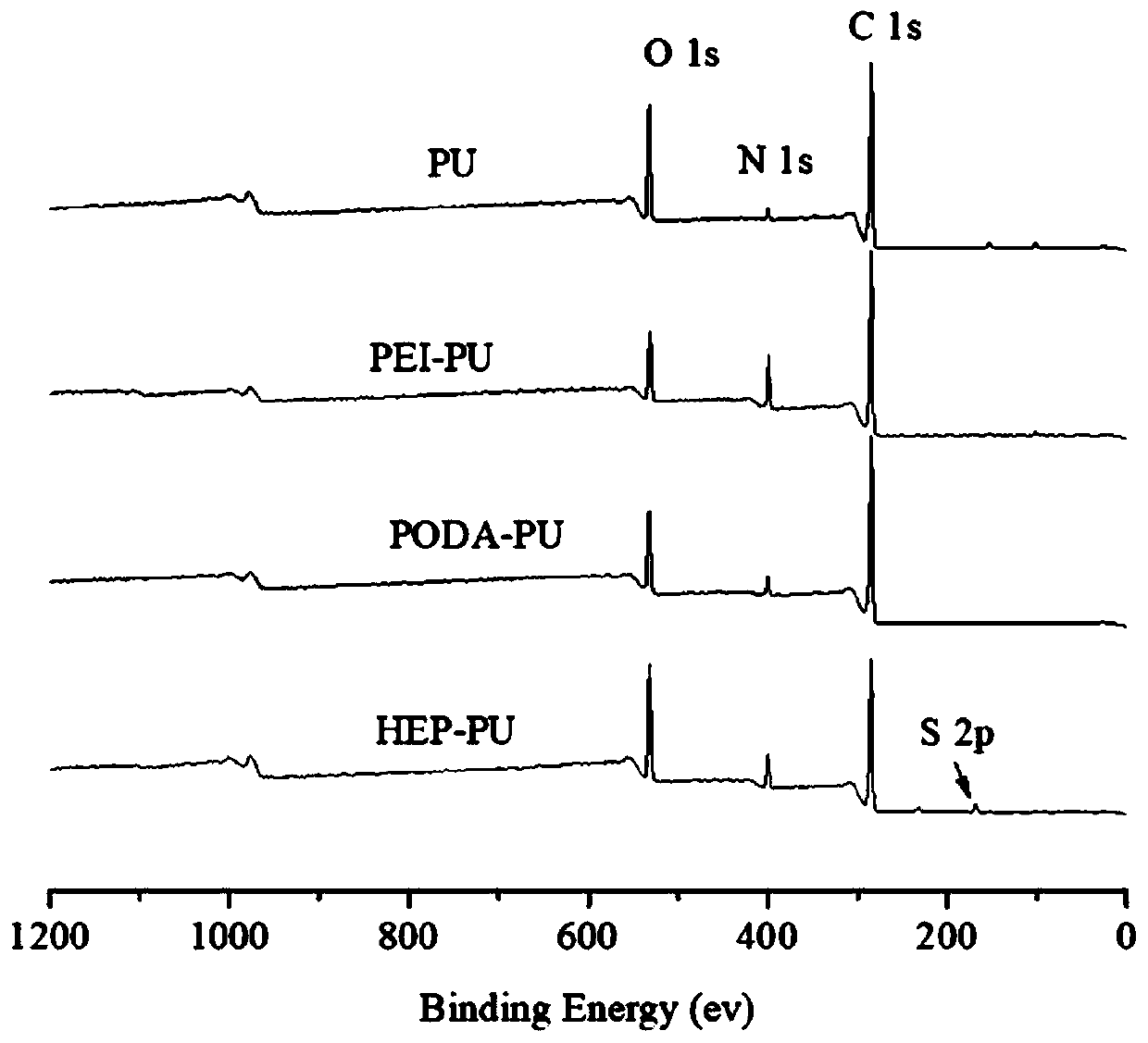

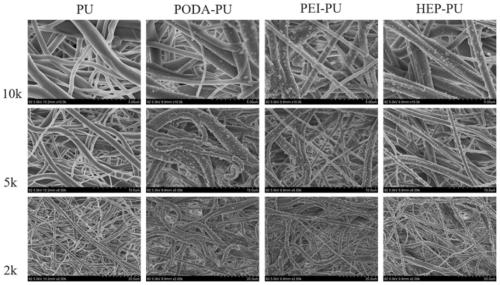

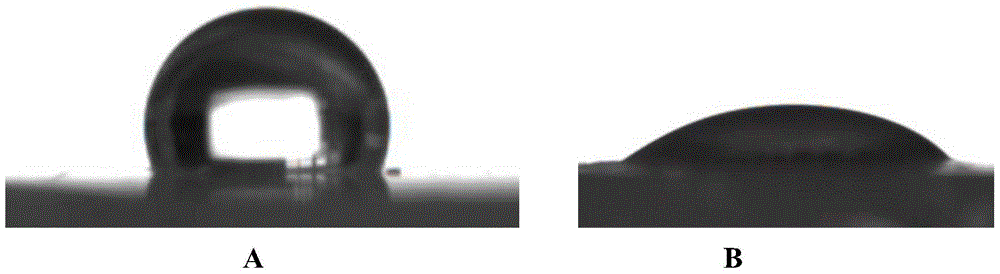

InactiveCN111544646AImprove hydrophilicityIncrease the amount of graftingPharmaceutical containersPharmaceutical delivery mechanismHeparin coatingEthyl group

The invention relates to a small-caliber artificial blood vessel with the surface grafted with a heparin coating and a preparation method of the small-caliber artificial blood vessel. A small-caliberblood vessel is adopted as a substrate. The preparation method comprises the following steps: soaking the surface of the substrate in a dopamine solution for reaction, coating the surface of the substrate with multiple layers of polydopamine coatings, performing chemical bond combination grafting with polyethyleneimine, and finally activating heparin by utilizing 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) and N-hydroxysuccinimide (NHS) to obtain the heparinized surface through amido bond combination. The invention has the characteristics of small caliber, favorable mechanical properties, hydrophilicity and long-acting anticoagulation; the preparation method is environmentally friendly and efficient in compounding, the prepared heparin coating is uniform, the grafting amount of heparin is higher and can reach 4.9 mu g / cm < 2 >, and good market application prospects are achieved.

Owner:DONGHUA UNIV

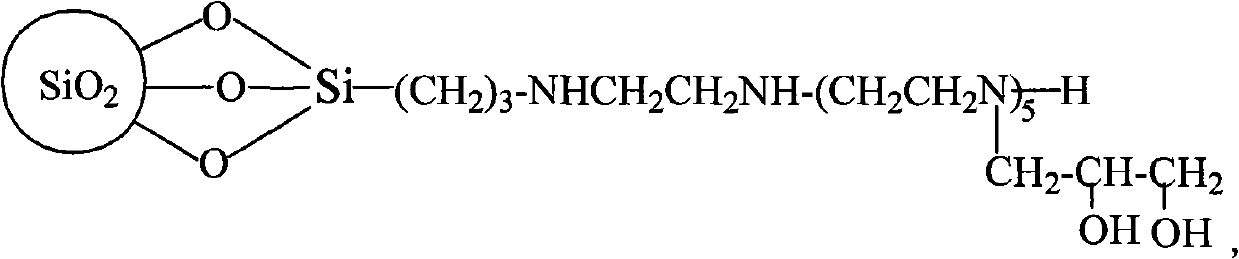

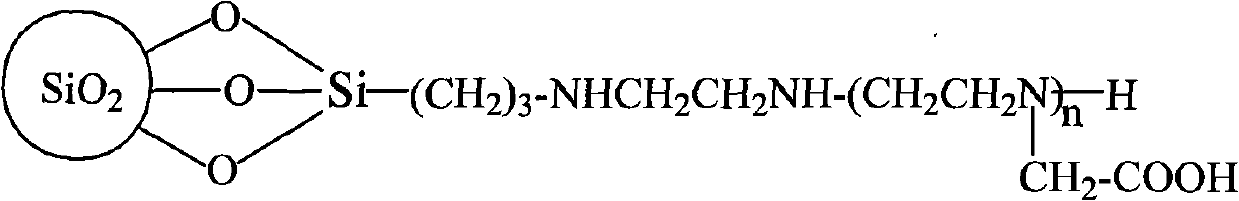

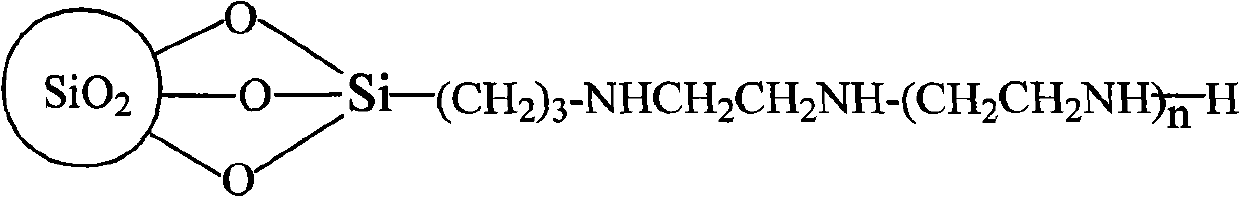

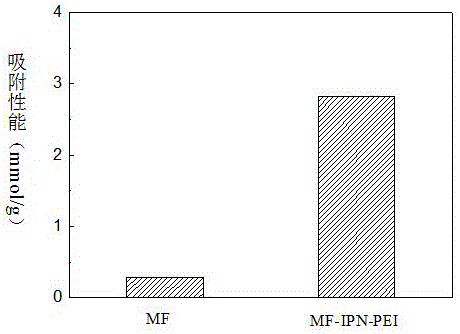

Silica gel-polyethylene polyamine, preparation method and application thereof to absorbing heavy metal ions

InactiveCN101905146AIncrease the amount of graftingHigh adsorption selectivityOther chemical processesSilica gelPyridine

The invention belongs to the technical field of absorbing materials of heavy metal and relates to silica gel-polyethylene polyamine and a polyhydroxy chelate absorbing material, an amine carboxyl chelate absorbing material and a pyridine chelate absorbing material prepared from the silica gel-polyethylene polyamine. In the structural formula of the silica gel-polyethylene polyamine, n value is 1 to 10. An amine group, a polyhydroxy group, an amine carboxyl group and a pyridine group in the absorbing material generate a chemical complexation action with heavy metal ions in a water solution, thereby takes a specificity absorbing function on the heavy metal ions. The invention has the characteristics of high absorbing selectivity, high absorbing capacity, easy regeneration, recycling and low transformation expansion rate in the absorbing-desorbing process.

Owner:陈东升 +2

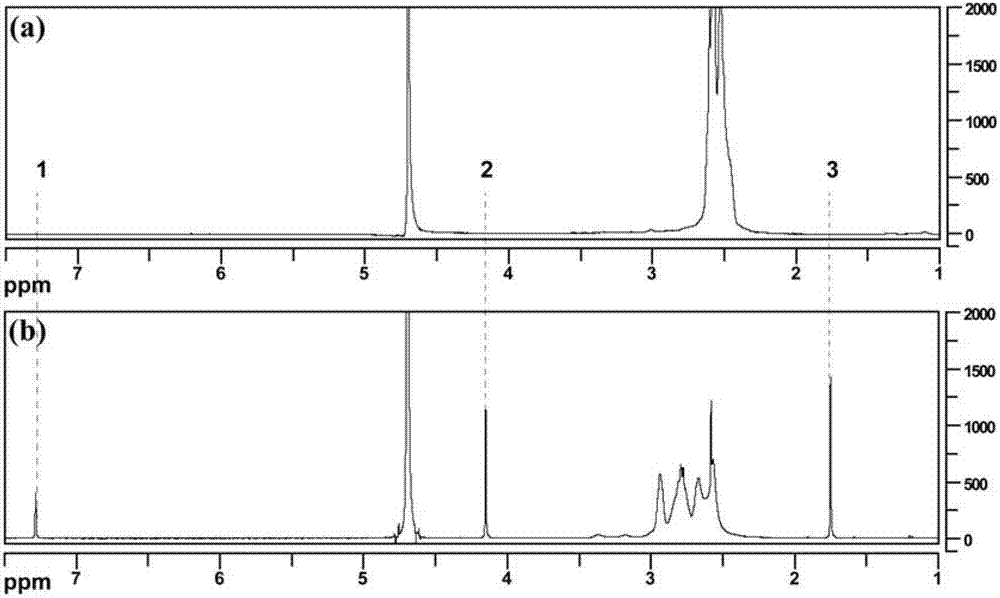

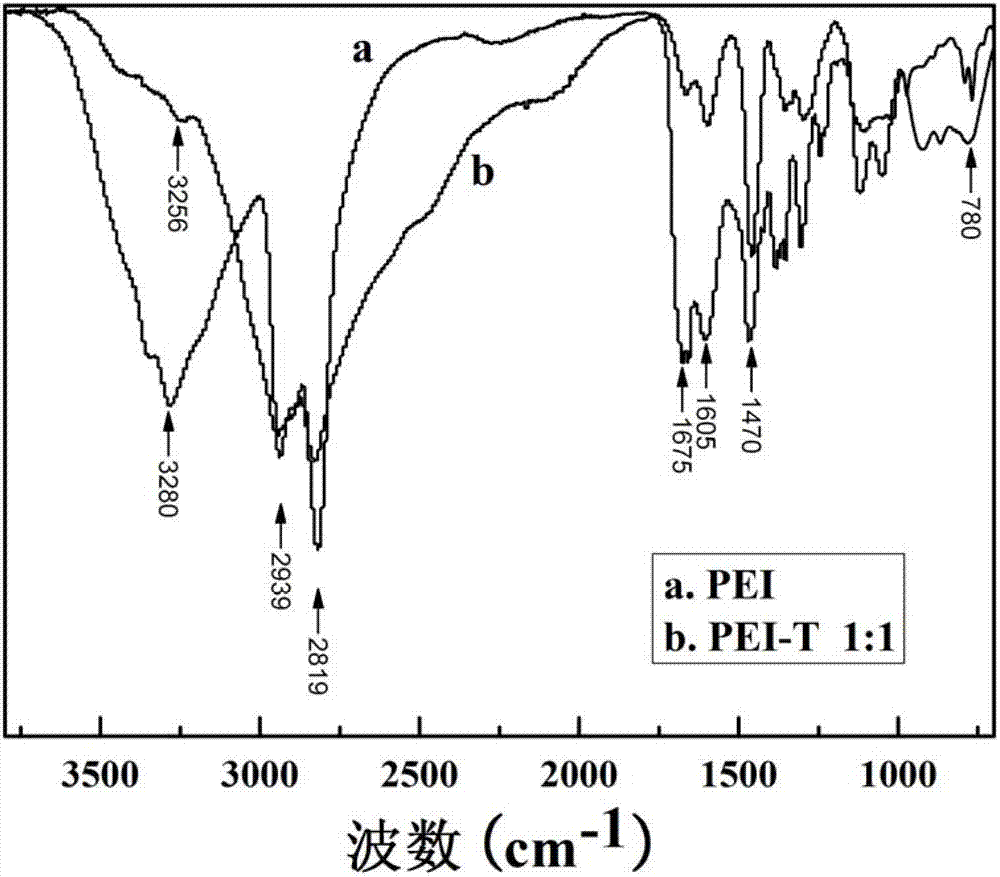

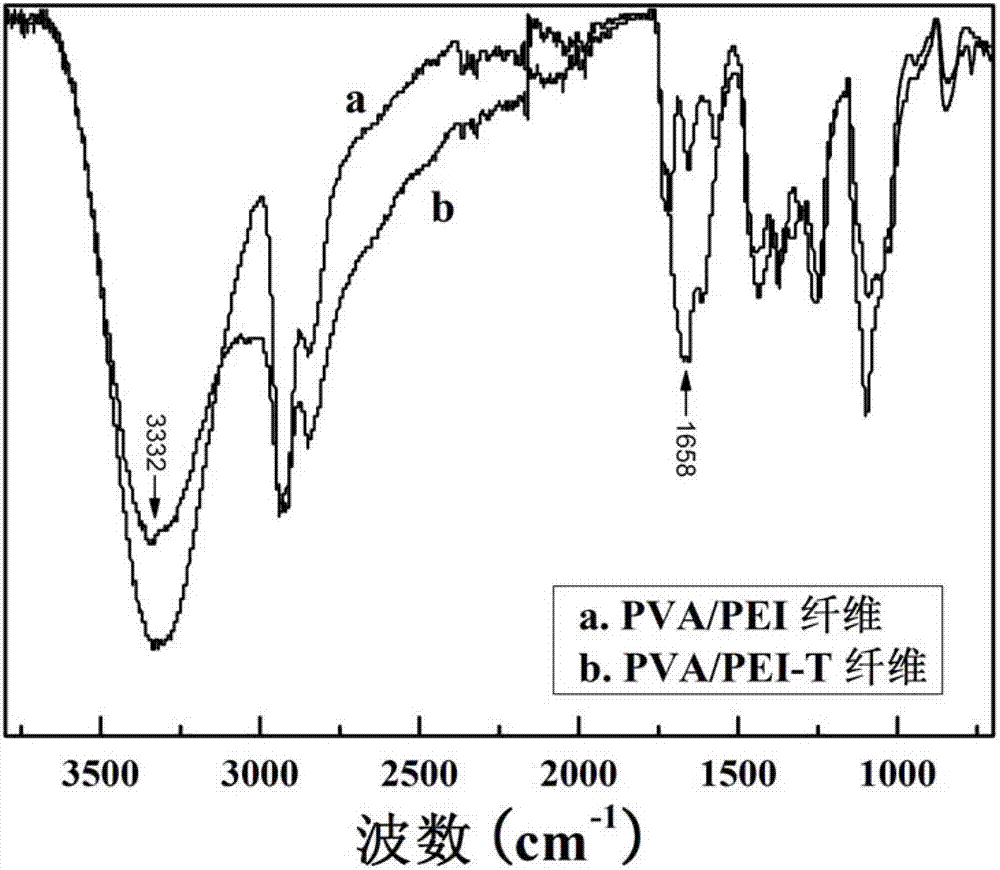

Preparation method of PVA (Polyvinyl Acetate)/PEI (Polyethylenimine)-T nanofiber membrane capable of specifically adsorbing mercury ions

The invention relates to a preparation method of a PVA (Polyvinyl Acetate) / PEI (Polyethylenimine)-T nanofiber membrane capable of specifically adsorbing mercury ions. The preparation method comprises the following steps of: (1) dissolving thymine-1-acetic acid into water, adding EDC (Ethylene Dichloride), stirring for 2-5hours to obtain a solution, then adding a PEI solution, reacting through stirring, and carrying out dialyzing and freeze drying to obtain PEI-T; and (2) mixing a PVA aqueous solution and the PEI-T to obtain a polyvinyl alcohol PVA / PEI-T solution, and carrying out electrostatic spinning, glutaraldehyde steam crosslinking, rinsing and vacuum drying to obtain the PVA / PEI-T nanofiber membrane. A using method of the PVA / PEI-T nanofiber membrane comprises the following steps of: adding a pH buffer solution of mercuric salts into the PVA / PEI-T nanofiber membrane, carrying out adsorption under the condition of room temperature, sampling, and testing the variation of the concentration of the mercury ions. According to the preparation method disclosed by the invention, the preparation process is simple and is easy to operate, the stability of fiber materials water is good, the fiber materials water is convenient to recover and is high in repeated utilization ratio, and the mercury ions have high specific adsorption.

Owner:DONGHUA UNIV

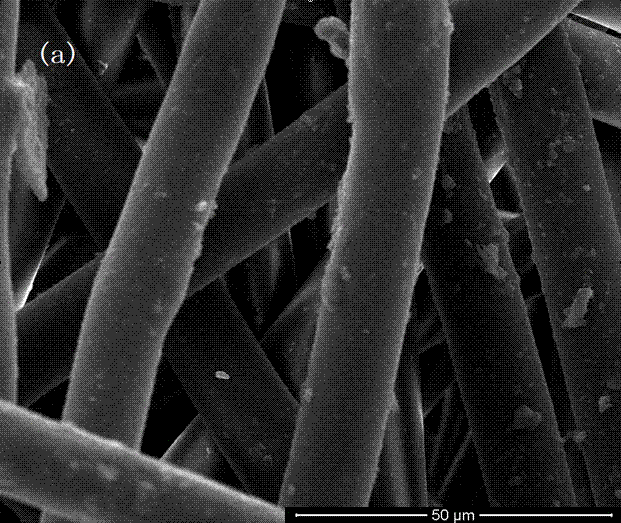

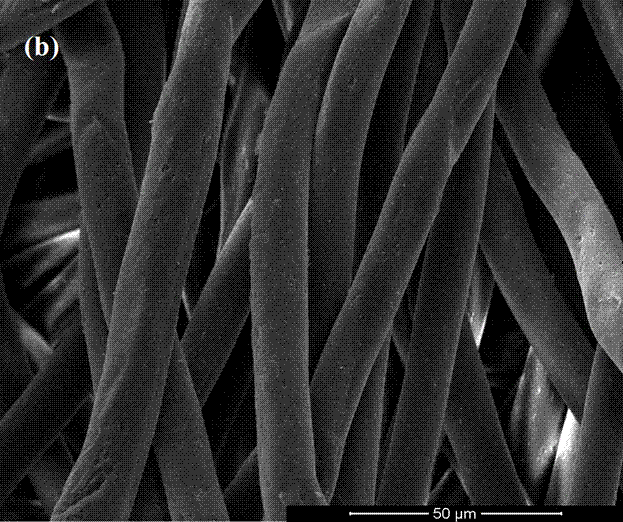

Preparation method of PET non-woven fabric with photocatalytic degradation function

InactiveCN106978722AImprove hydrophilicityIncrease the amount of graftingOrganic-compounds/hydrides/coordination-complexes catalystsFibre typesPhotocatalytic degradationChemistry

The invention discloses a preparation method of a PET non-woven fabric with a photocatalytic degradation function. The preparation method sequentially comprises a first step, a second step, a third step and a fourth step, wherein the first step is a sample preparation step and comprises non-sequential first substep and a second substep, the first substep is preparation of cationic nano-wood cellulose, and the second substep is pretreatment of the PET non-woven fabric; the second step is an alkali etching step; the third step is a nano-wood cellulose grafting step; and the fourth step is a titanium dioxide grafting step. By comprehensively utilizing technical measures of alkali etching, acrylic acid bonding, cationic nano-wood cellulose modification and the like, the PET non-woven fabric which is originally difficult to be grafted can be effectively grafted with titanium dioxide, so that the PET non-woven fabric with the photocatalytic degradation function can be prepared from a large number of waste PET non-woven fabrics of factories such as an aluminum factory and can be applied to sewage treatment so as to realize reutilization.

Owner:HENAN INST OF ENG

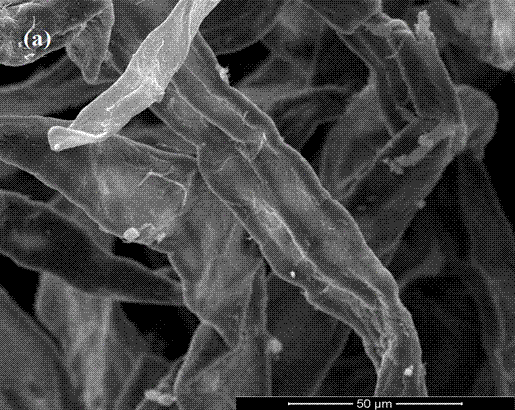

Method for preparing modified carbon nanotube-chitosan composite material

InactiveCN106750577AIncrease the amount of graftingEasy to operateBiocideDisinfectantsEscherichia coliVibrio anguillarum

The invention discloses a method for preparing a modified carbon nanotube-chitosan composite material. The method comprises the following steps: (1) modifying multi-walled carbon nanotubes with dopamine, so as to obtain dopamine modified carbon nanotubes; (2) subjecting a chitosan solution and a glutaraldehyde solution to a stirred and mixed reaction, and carrying out dialysis in distilled water, so as to obtain a chitosan-glutaraldehyde solution; preparing a 2mmol / L modified carbon nanotube solution from the modified carbon nanotube material obtained in the step (1), adding the modified carbon nanotube solution into the chitosan-glutaraldehyde solution, carrying out a reaction, then, adding a sodium borohydride solution, carrying out dialysis in distilled water, and then, carrying out standing, suction filtration, washing and drying. According to the method, the operation is simple, and the prepared modified carbon nanotube-chitosan composite material is high in chitosan graft amount, which is 71.78%, and presents excellent bacteriostatic performance to Escherichia coli, Staphylococcus aureus and Vibrio anguillarum, thereby having broad-spectrum bacteriostatic performance.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

Preparation method of surface-heparinized anticoagulation medical device based on ionic bond-covalent bond synergistic action

The invention relates to the field of medical devices, in particular to a preparation method of a surface-heparinized anticoagulation medical device based on ionic bond-covalent bond synergistic action. The method comprises the following steps: firstly, fixing heparin on the surface of a medical device by utilizing a hydrophilic polymer modified by low-molecular-weight hyperbranched polyethyleneimine as a side chain in an ionic bond combination manner; and furthermore, grafting a stable heparin coating through covalent bonds, so as to obtain the anticoagulant biomedical device with high anticoagulant activity and high anticoagulant stability. The device has a wide application value in the field of biomedical treatment. The method is simple in preparation process, high in controllability and low in material price, does not involve toxic reagents in the experiment process, has universality for various medical device structures, and is suitable for industrial production.

Owner:JIANGSU STMED TECH CO LTD

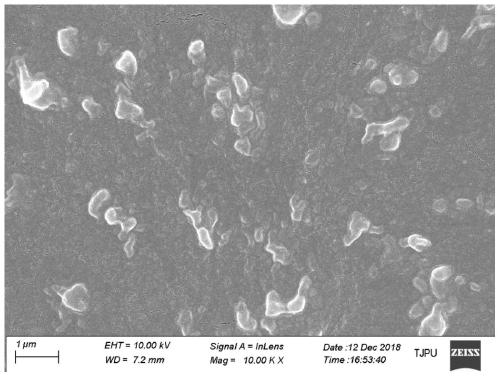

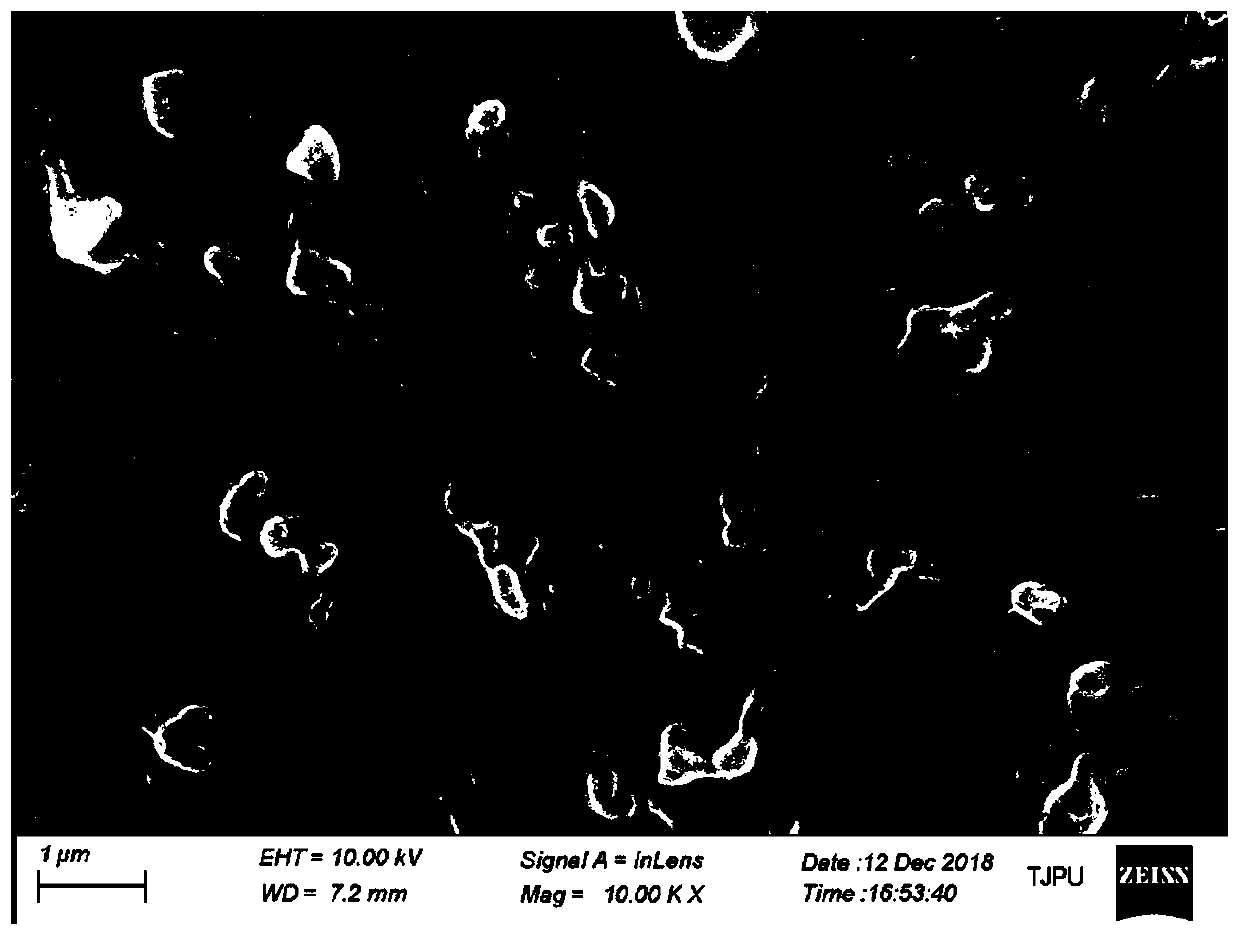

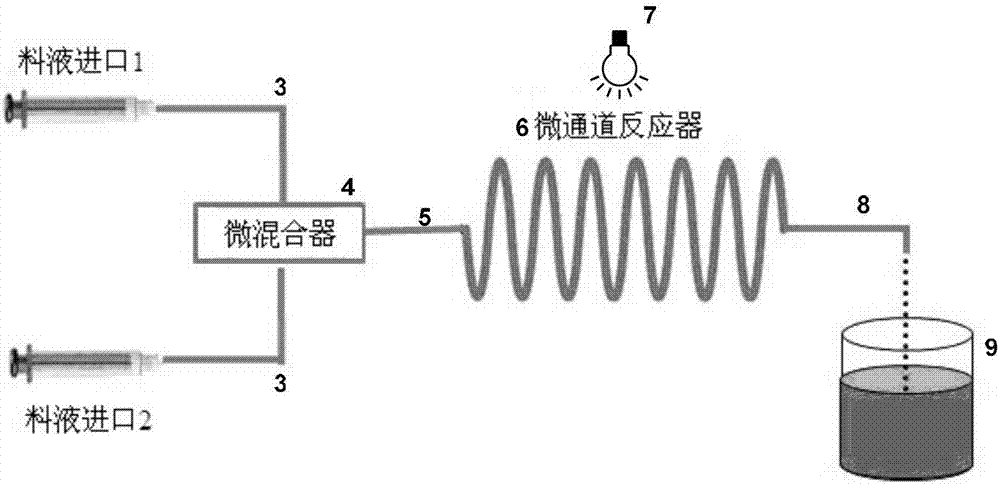

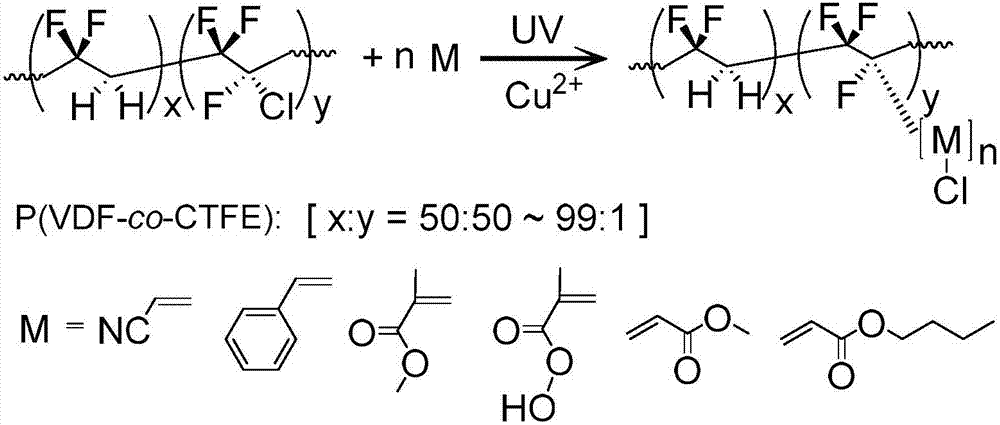

Microfluidic photoinduction polymer modification method

The invention discloses a microfluidic photoinduction polymer modification method. According to the microfluidic photoinduction polymer modification method, in a microreactor, photoinduction is adopted for grafting modifying of poly(vinylidene fluoride-co-chlorotrifluor ethylene) via free radical polymerization. Compared with the prior art, the microfluidic photoinduction polymer modification method possesses following advantages: microfluidic technology is capable of realizing accurate control and adjusting of reaction conditions, reducing catalyst using amount, and adjusting grafting amount; and the obtained modified polymer is high in application value in the field of microelectronics.

Owner:NANJING UNIV OF TECH

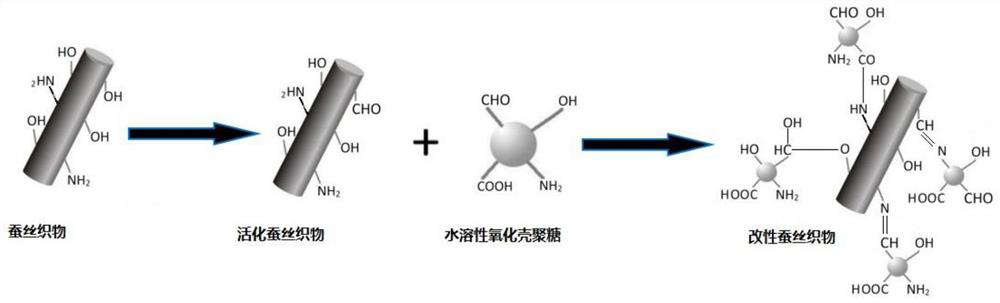

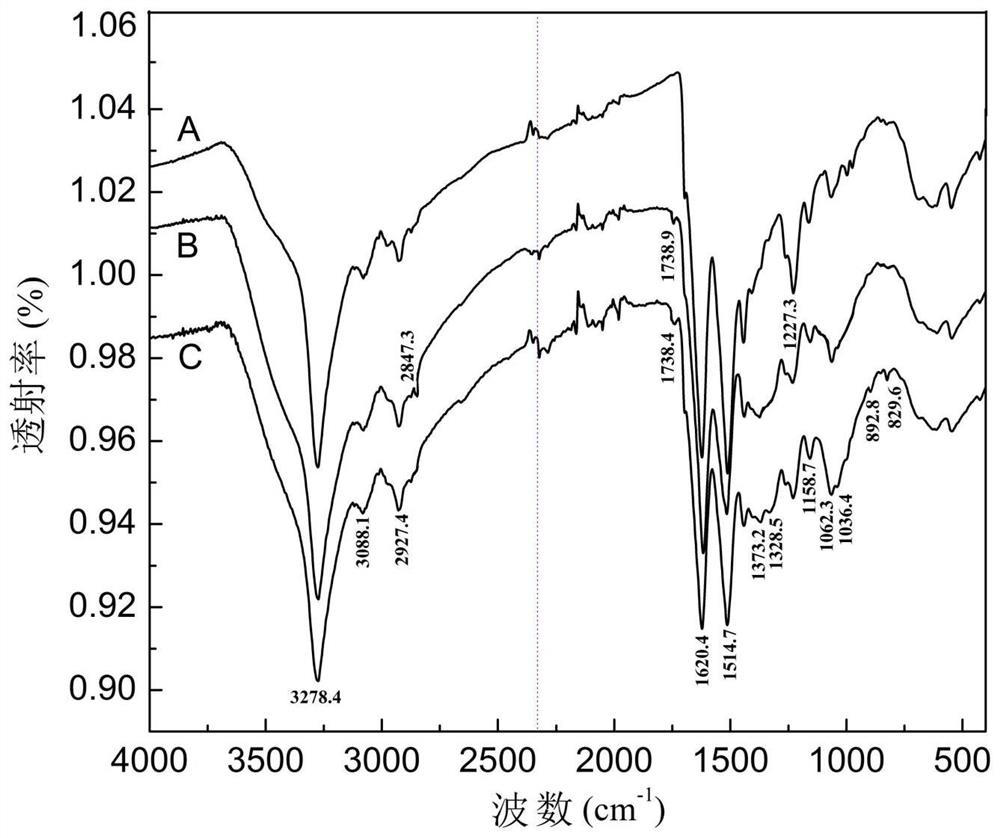

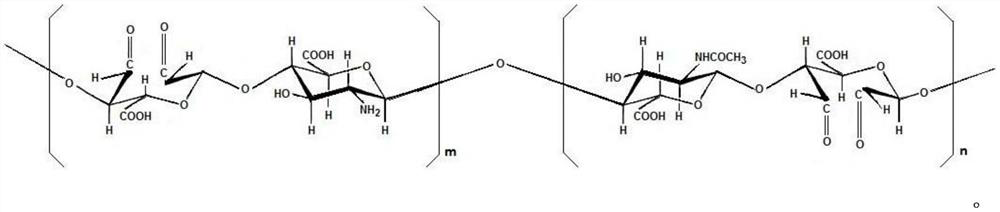

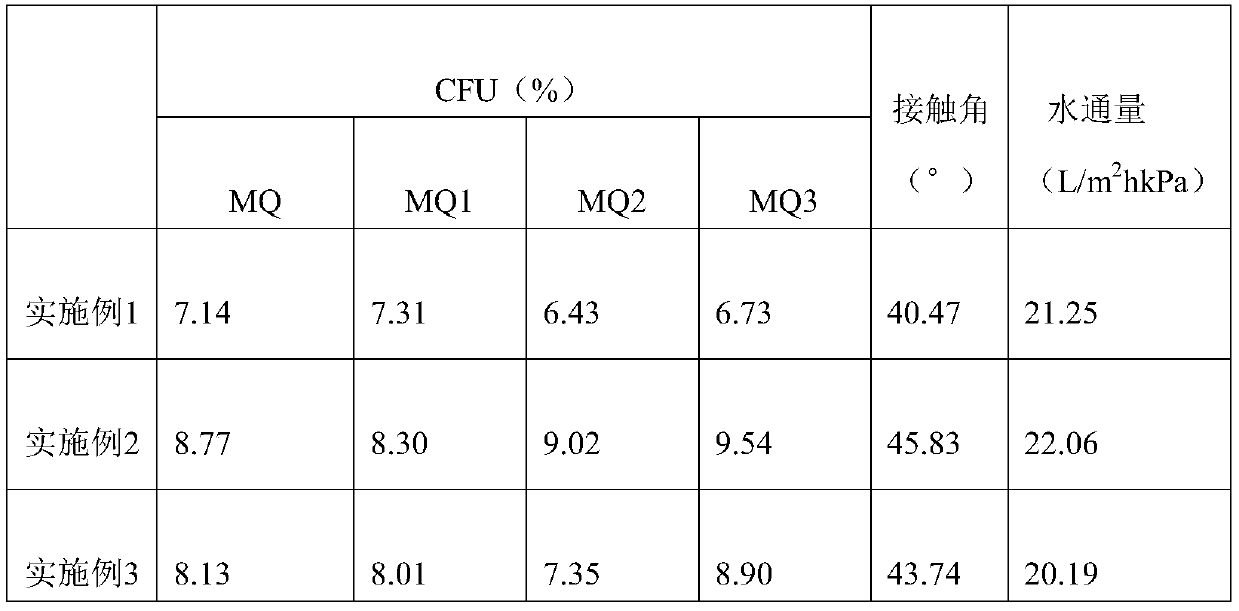

Water-soluble oxidized chitosan and method for finishing fabric by using water-soluble oxidized chitosan

ActiveCN114000350AShort and uniform reaction timeIncrease oxidation rateWrinkle resistant fibresBiochemical treatment with enzymes/microorganismsHydrogen SulfateO-Phosphoric Acid

The invention discloses water-soluble oxidized chitosan and a finishing method of the water-soluble oxidized chitosan on a fabric. The water-soluble oxidized chitosan is prepared by the following steps: dissolving chitosan in a 1-carboxymethyl-3-methylimidazolium hydrogen sulfate aqueous solution, oxidizing C2 and C3 sites of the chitosan by sodium periodate under microwave radiation to generate aldehyde groups, and then oxidizing primary hydroxyl at C6 site of the dialdehyde chitosan in an ionic liquid by concentrated nitric acid-concentrated phosphoric acid to generate carboxyl. The water-soluble oxidized chitosan can be used for modifying fabrics. Compared with a traditional chemical cross-linking agent modified fabric, the method has the advantages that the grafting efficiency of the oxidized chitosan is high, the enzyme treatment condition is mild, the reaction process is simple, the fabric is crease-resistant, antibacterial, efficient and lasting, the fabric is comfortable to wear, and the requirements of people on lasting functional ecological textiles are met.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Preparation method of high-quality breathable hot melt adhesive film

ActiveCN105670524AImprove heat resistanceImprove water resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceBenzoyl peroxide

The invention discloses a preparation method of a high-quality breathable hot melt adhesive film. The preparation method comprises steps as follows: BPO (benzoyl peroxide) and DCP (dicumyl peroxide) in a mass ratio being 3:(1-1.5) are dissolved by ethyl acetate with the concentration of 30%, and an initiator solution is prepared; an EAA (ethylene acrylic acid copolymer) and MAH (maleic anhydride) in a mass ratio being 100:(1.5-2) are uniformly stirred in a blender mixer, the initiator solution is added to the blender mixer and is uniformly stirred, and then a modified hot melt adhesive raw material is prepared through melt grafting granulation by means of a double-screw granulator with seven temperature regions; an antioxidant, a hyperdispersant and an anti-blocking agent are added to the modified hot melt adhesive raw material, and a mixture is placed in a kneading machine for mixing; the mixture is subjected to extrusion by a single-screw extruder and is processed by an embossing and piercing roller, a casting machine and an expander, and a product is prepared. The modified hot melt adhesive adopts the EAA with low AA content, the EAA-graft-MAH grafting ratio is enabled to be higher and the MAH residue quantity is enabled to be lower through initiator compounding, preparation of the fisheye-free hot melt adhesive film with high polarity and excellent heat resistance is facilitated; the heat resistance and the adhesion performance are balanced, and the preparation method has wider application prospect.

Owner:PINGHU ZHANPENG HOT MELT ADHESIVE WEB & FILM

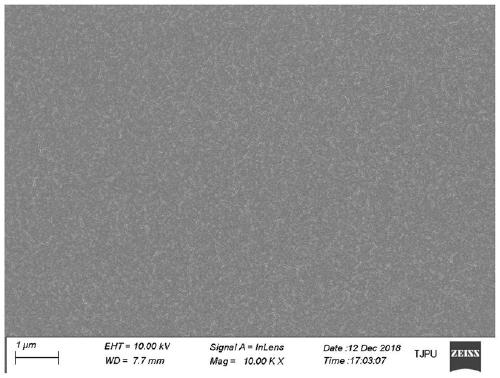

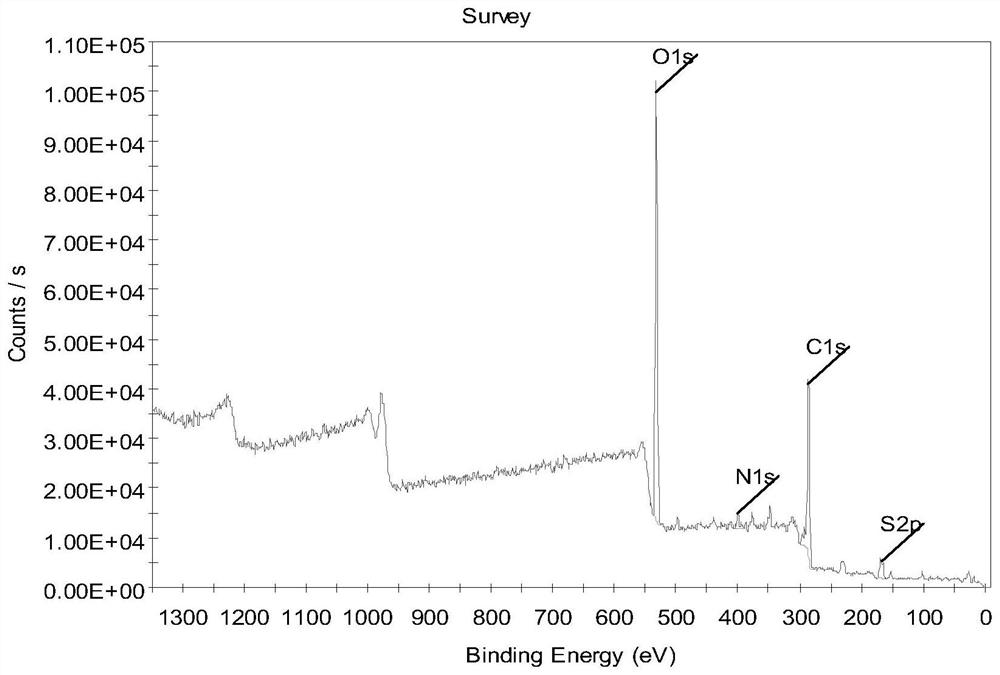

High-flux antibacterial anti-pollution polymer separation membrane and preparation method thereof

InactiveCN109966927AImprove hydrophilicitySustained and stable antibacterial and anti-pollution effectSemi-permeable membranesMembranesSilica particleQuaternary ammonium cation

The invention discloses a high-flux antibacterial anti-pollution polymer separation membrane and a preparation method thereof, and belongs to the technical field of membrane separation. The method comprises the following steps: firstly the surface of a polymer separation membrane is activated, nano silicon dioxide particles are deposited in situ on the surface of the surface-activated polymer separation membrane to enhance water permeability of the membrane, then a quaternary ammonium salt is used as a bactericide, and the quaternary ammonium salt is grafted onto the polymer separation membrane on which the nano silicon dioxide particles are deposited by adopting an electron transfer regeneration catalyst atom transfer free radical polymerization method. The method provided by the invention is simple to operate, the surface of the modified polymer separation membrane prepared by adopting the method can effectively inhibit growth and adhesion of bacteria and microorganisms, and the membrane has high water permeability and sustained and stable antibacterial and anti-pollution effects.

Owner:TONGJI UNIV

Anticoagulant antimicroorganism coating and preparation method and use thereof

PendingCN113209394AImprove hydrophilicityIncrease the number ofSurgeryPharmaceutical containersEthyl groupPharmacology

The invention provides an anticoagulant antimicroorganism coating and a preparation method and use thereof. The anticoagulant antimicroorganism coating based on dopamine-assisted codeposition has a structure as follows: a side close to a base material is taken as an inner side, a dopamine coating and an anticoagulant antimicroorganism composite layer are sequentially arranged from inside to outside and the dopamine coating and the anticoagulant antimicroorganism composite layer are coated on a surface of the base material; wherein the dopamine coating takes dopamine or levodopa and polyethyleneimine as raw materials, and the anticoagulation antimicroorganism composite layer takes an anticoagulation material, an antimicroorganism material, EDC(1-(3-dimethylaminopropyl)-3-ethylcarbodiimide) and NHS(N-hydroxysuccinimide) as raw materials; and hydroxyls and quinonyls of the dopamine coating are covalently bound with aminos and carboxyls of the anticoagulant antimicroorganism composite layer to realize chemical compounding of the two layers.

Owner:济南金泉生物科技有限公司

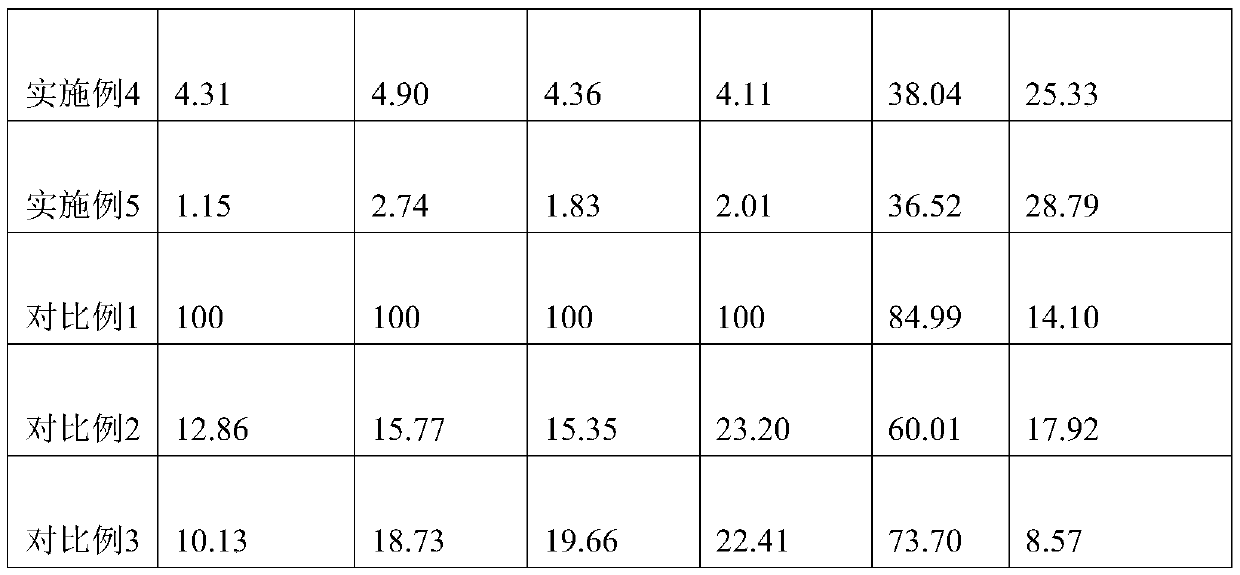

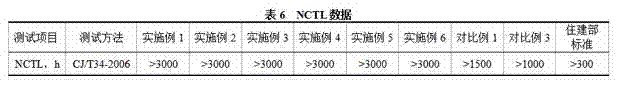

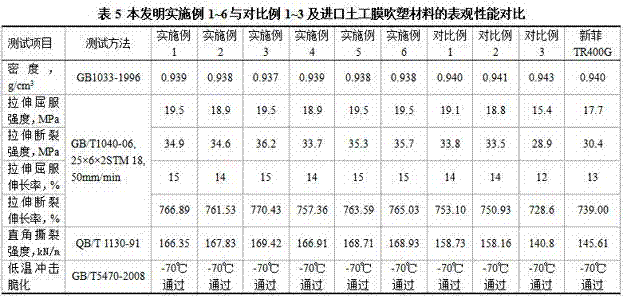

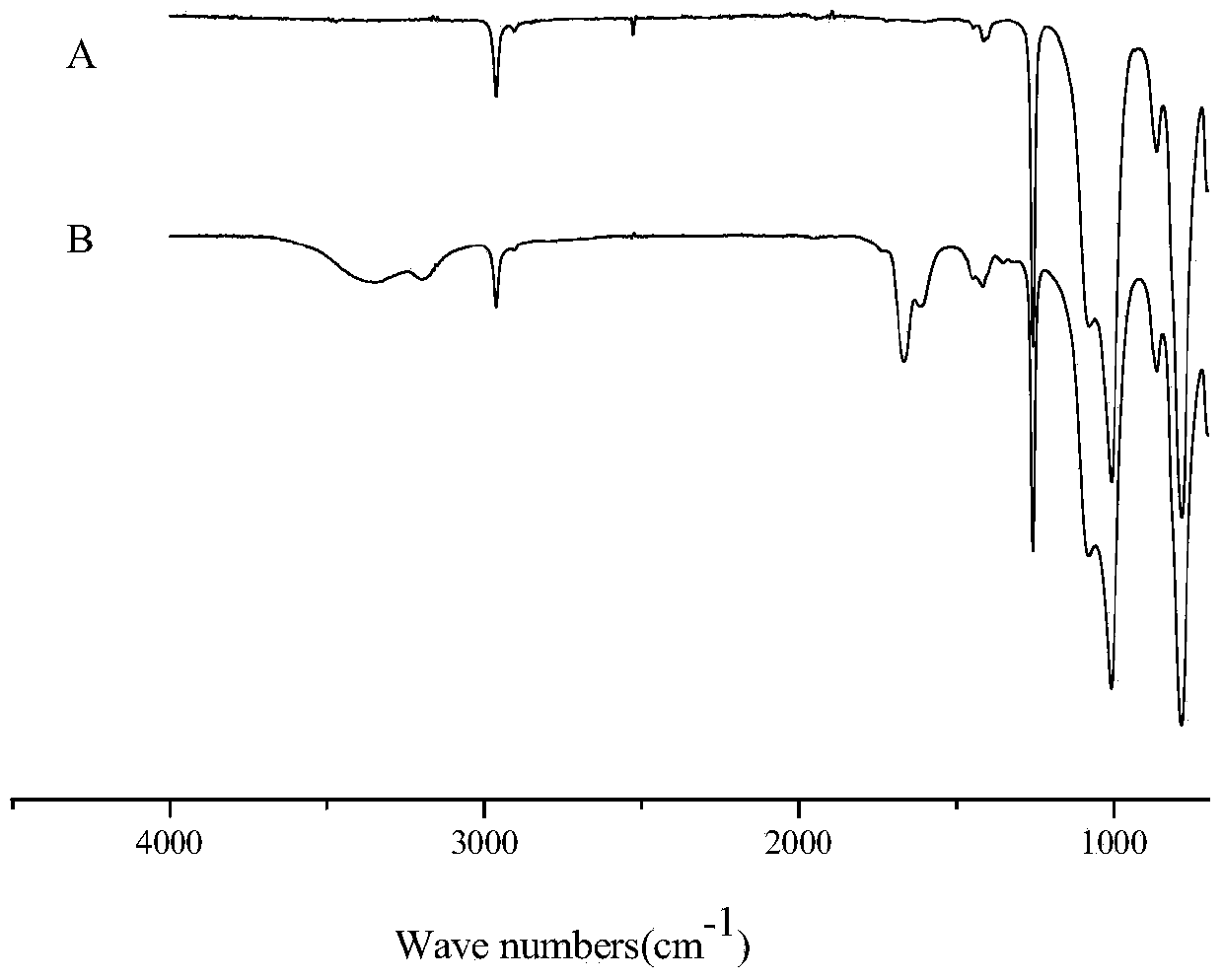

Preparation method of high-hexene grafted high-density polyethylene geomembrane blow molding material

ActiveCN104744795AImprove conversion efficiencyIncrease the amount of graftingBulk chemical productionBlow moldingPtru catalyst

The invention discloses a preparation method of a high-hexene grafted high-density polyethylene geomembrane blow molding material. The method comprises the following steps: (1) when a diluting agent is always under a circulation state, placing monomer ethylene and 1-hexene in a reaction vessel; adding an antistatic agent and an catalyst subjected to an activation treatment; adjusting the reaction temperature in the reaction vessel to 92-98 DEG C until the melt flow rate of a reaction product is 10.0-13.0g / 10min and the density of the reaction product is 0.937-0.939kg / m<3>, thereby obtaining ethylene-hexene polyethylene copolymer base resin with weight average molecular weight of 200,000 to 300,000, 1-hexene content of not less than 1.20% and crystallinity of 46.5-49.5%; (2) uniformly mixing 99.5-99.8 parts of the ethylene-hexene polyethylene copolymer base resin and 0.20-0.50 part of an antioxidant; and adding the mixture to a mixer for extrusion granulation, so as to obtain the geomembrane blow molding material. According to the method, a high-activity novel chromium catalyst is adopted, the equipment limitation of a loop slurry process is overcome, and high-hexene grafted high-density polyethylene is produced. With the method, reaction scale is effectively ameliorated, a reactor wall attachment phenomenon is reduced, production is smooth, and the productivity of the special material is high.

Owner:CHINA PETROLEUM & CHEM CORP

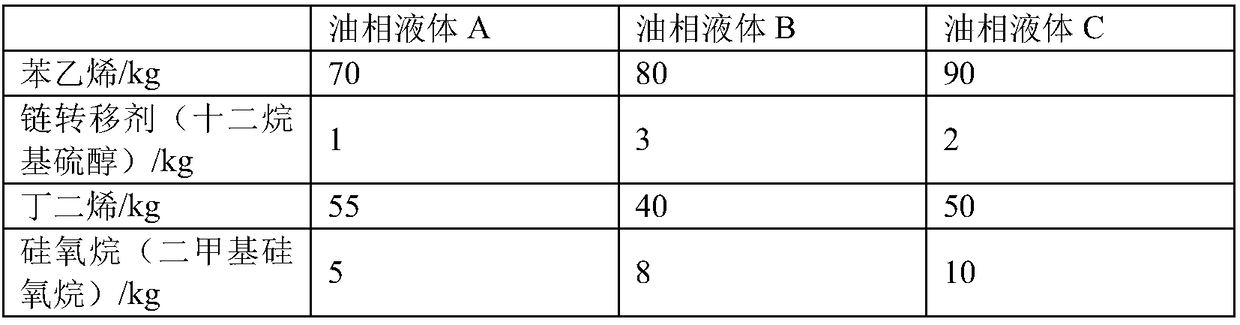

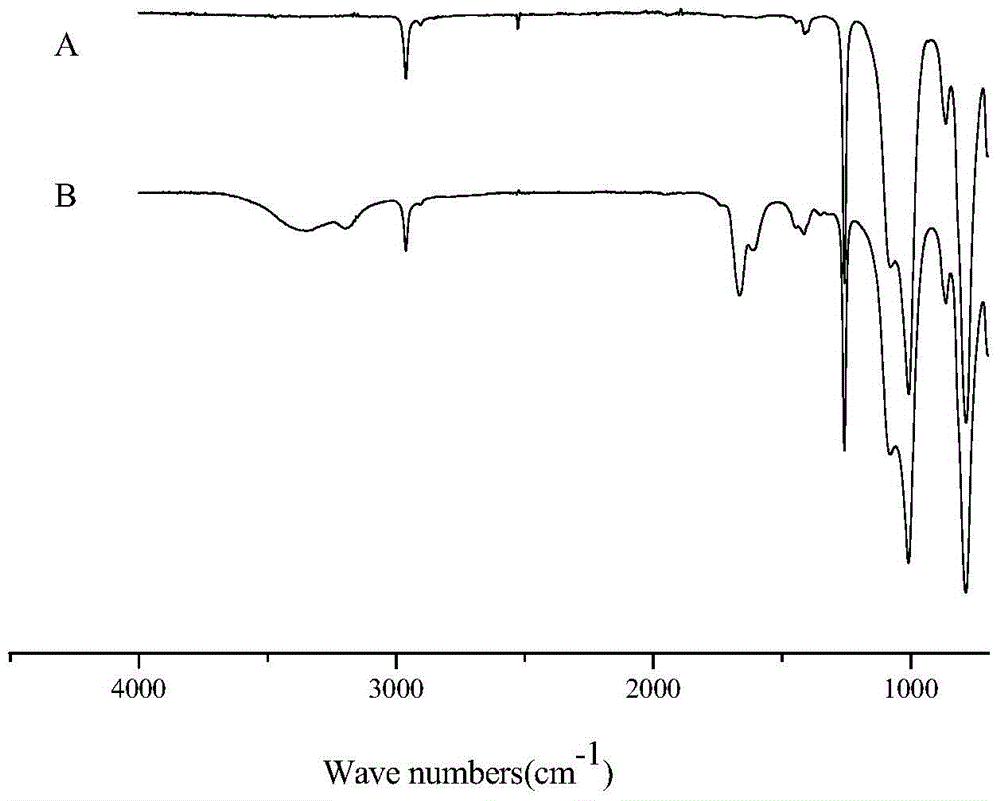

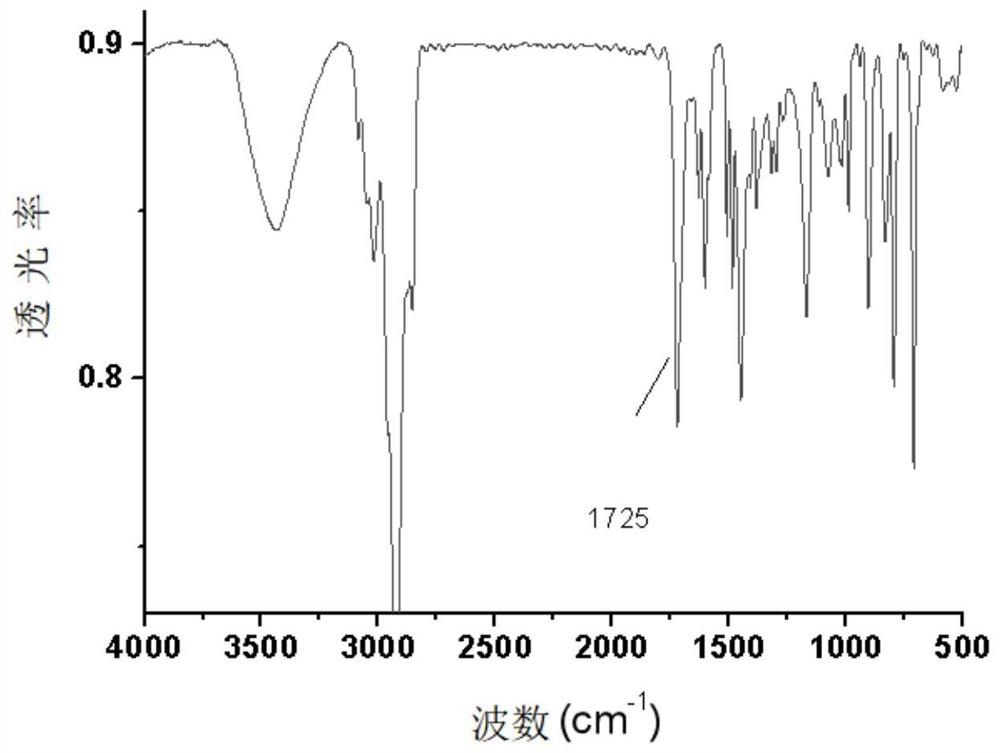

Preparation method of biocompatible silicone rubber

The invention provides a preparation method of biocompatible silicone rubber. The method comprises the following steps: (1) fully stirring polydimethylsiloxane, adding a mixed crosslinking agent of a deoximation type crosslinking agent and a dealcoholization type crosslinking agent, continuously vacuumizing and stirring, adding a catalyst and vulcanizing at room temperature; (2) treating room temperature vulcanized silicone rubber by virtue of plasmas and generating hydroxyl active sites on the surface of the silicone rubber; adding silicone rubber and organic amine treated by plasma into a nonpolar solvent, stirring under an icy salt bath, dropwise adding a mixed liquid containing a brominating agent and a nonpolar solvent, removing the icy salt bath, raising to room temperature, and continuously stirring in a dark place to obtain silicone rubber with a bromine group on the surface; and (3) putting the silicone rubber with the bromine group on the surface, an acrylamide monomer and a CuCl / bpy catalyst in a reaction container, injecting a degassed solvent into the reaction container by virtue of an injector, and putting the reaction container in a constant temperature oil bath to react; and washing and drying to obtain hydrophilic silicone rubber grafted with polyacrylamide on the surface.

Owner:CHANGZHOU UNIV

Chitosan grafted polylactic acid copolymer, and preparation method and application thereof

The invention discloses a chitosan grafted polylactic acid copolymer, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) adding chitosan into an ionic liquid EMIMAc, and heating and stirring to obtain a uniform chitosan solution; and (2) adding a D,L-lactide monomer and a catalyst DMAP into the uniform chitosan solution prepared in step (1), and carrying out a reaction at a reaction temperature of 100 + / -5 DEG C for 5 + / -0.1 h to obtain the chitosan grafted polylactic acid copolymer. When the grafting amount of the polylactic acid islow, the grafted copolymer can be dissolved in water and an organic solvent; and when the grafting amount of polylactic acid is high, the grafted copolymer cannot be dissolved in water and can only bedissolved in the organic solvent. The grafted copolymer prepared in the invention has good film-forming property; and copolymers with different polylactic acid grafting amounts have different degradation rates, so that controllable degradation of the chitosan grafted polylactic acid copolymer can be realized.

Owner:SOUTH CHINA UNIV OF TECH

Solid amine interpenetrating network porous amino resin and its preparation method and use

ActiveCN106064082AImprove adsorption capacityNothing producedGas treatmentOther chemical processesToxic gasSolvent based

The invention discloses solid amine interpenetrating network porous amino resin and its preparation method and use. The preparation method comprises uniquely introducing polyacrylic acid into porous amino resin so that interpenetrating network porous amino resin is obtained and carrying out further amination treatment to obtain the solid amine interpenetrating network porous amino resin for physical and chemical combined adsorption of CO2 so that an adsorption amount is substantially improved. In preparation of the interpenetrating network porous amino resin, the preparation method is free of a pore forming agent, a catalyst and an initiator and realizes interpenetrating network porous amino resin preparation through direct solvent-based thermopolymerization at a low temperature. The product has strong stability, can be simply and easily prepared, can be massively produced, does not produce odor and toxic gas, can be post-treated simply and can satisfy green production requirements. Through use of acrylic acid, the product greatly improves swelling properties than those of the porous amino resin, can be fast swelled directly through water, can improve an amination reagent grafting amount and can realize physical and chemical combined high efficiency adsorption of CO2.

Owner:SUN YAT SEN UNIV

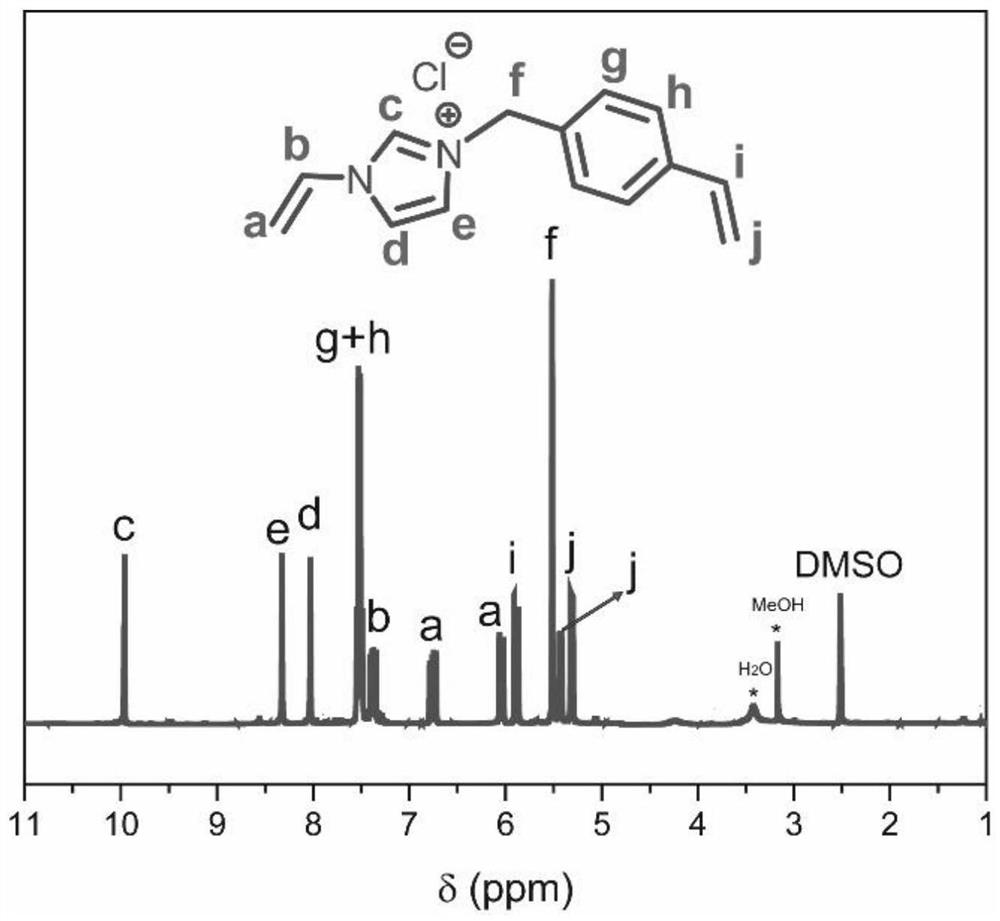

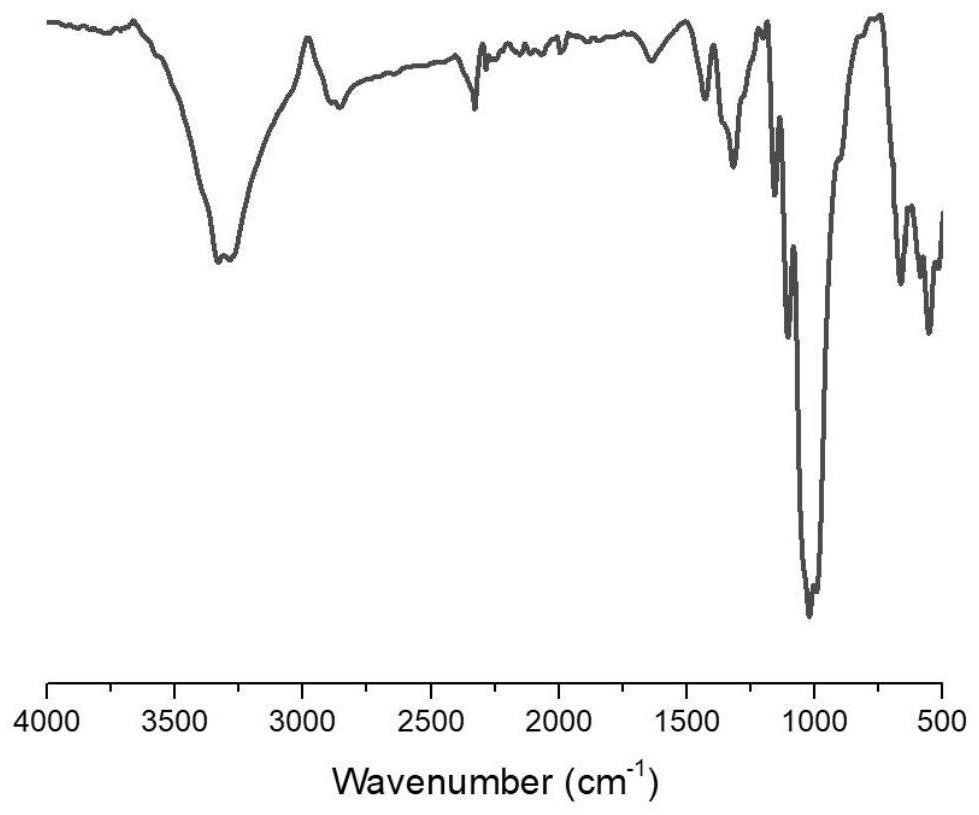

Cellulose aerogel modified by polyionic liquid, preparation method and application thereof

ActiveCN111944195AImprove adsorption capacityAdsorption is easyOther chemical processesWater contaminantsCellulosePolymer science

The invention discloses a cellulose aerogel modified by a polyionic liquid, a preparation method and application thereof. The cellulose aerogel is obtained by reacting cellulose aerogel CA-CTA modified by a chain transfer agent with an ionic liquid monomer and an initiator in DMSO at 50-80 DEG C in an inert gas atmosphere. According to the cellulose aerogel CA, hydroxyl on the surface of a cellulose aerogel is activated through carbonyl diimidazole CDI, hydrogenation esterification reaction is carried out on the CA to obtain chain transfer agent CTA modified CA, and then in-situ reversible addition fragmentation RAFT polymerization is carried out on the CTA modified CA surface to obtain the PIL functionalized CA material with high PIL grafting amount. The method has the advantages that thereaction conditions are mild, the grafting rate is high, and the obtained cellulose aerogel has an adsorption effect on anionic dyes, aromatic ring functional groups or anionic antibiotics.

Owner:XIJING UNIV

Preparation method for acrylate-modified epoxy resin cathode electrophoresis emulsion

ActiveCN108912931AReduce the chance of aggregationImprove anti-corrosion performancePaints for electrolytic applicationsOrganic acidEmulsion

The invention discloses a preparation method for an acrylate-modified epoxy resin cathode electrophoresis emulsion. The method adopts a monoprotic organic acid containing a double bond and a biproticorganic acid containing a double bond or / and an acid anhydride to react with epoxy resin, double bonds are introduced into a main chain of the epoxy resin, acrylic resin is grafted into the epoxy resin by utilizing copolymerization of the double bonds and an acrylate monomer, more acrylic resin can be introduced onto the main chain of the epoxy resin, adjustment and control of an introduction amount of the acrylate monomer are achieved through control of the content of the double bonds, and a molecular weight of the main epoxy resin is adjusted through a ratio of carboxyl to epoxy groups; themain body of the prepared product is epoxy resin, so that good anticorrosive performance of a paint film is guaranteed; and when the epoxy resin is aminated, two different organic amines are added step by step for a reaction, so that the reaction process is milder. According to the method disclosed by the invention, the acrylate-modified epoxy resin emulsion prepared by the method has good performance of a paint film and good ultraviolet and salt spray resistance, and can be used for workpieces under conditions of exposure under the sun.

Owner:吴让君

Silk floss finishing method

InactiveCN111705512AHigh catalytic efficiencyIncrease the amount of graftingBiochemical treatment with enzymes/microorganismsVegetal fibresFiberPolymer science

The invention discloses a silk floss finishing method. The silk floss finishing method comprises the following steps of: A, preparing an amino-containing antibacterial agent finishing liquid, whereinthe amino-containing antibacterial agent comprises polylysine, chitosan with deacetylation exceeding 85% and chitosan quaternary ammonium salt with deacetylation exceeding 85% and substitution degreeof 60-90%, and dipping silk floss into the finishing liquid; B, adding laccase into the finishing liquid in the step A, and continuously dipping the silk floss subjected to dipping treatment in the step A; C, cleaning the silk floss treated in the step B in water; and D, drying the silk floss treated in the step C. The silk floss finishing method disclosed by the invention has the advantages thatby virtue of the laccase, the amino-containing antibacterial agent is grafted on the surface of silk floss fiber by catalysis, so that the silk floss product is endowed with antibacterial effect; andthe silk floss finishing method has the characteristics of safe treatment process and lower production energy consumption, and ecological functional processing of the silk floss product is realized.

Owner:徐州光彩丝绵制品有限公司

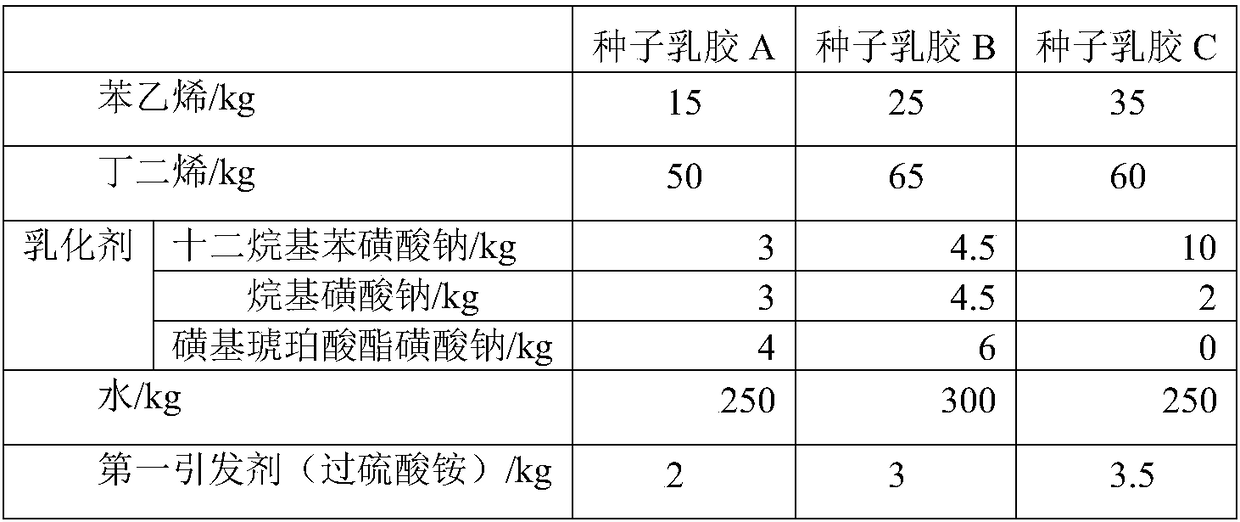

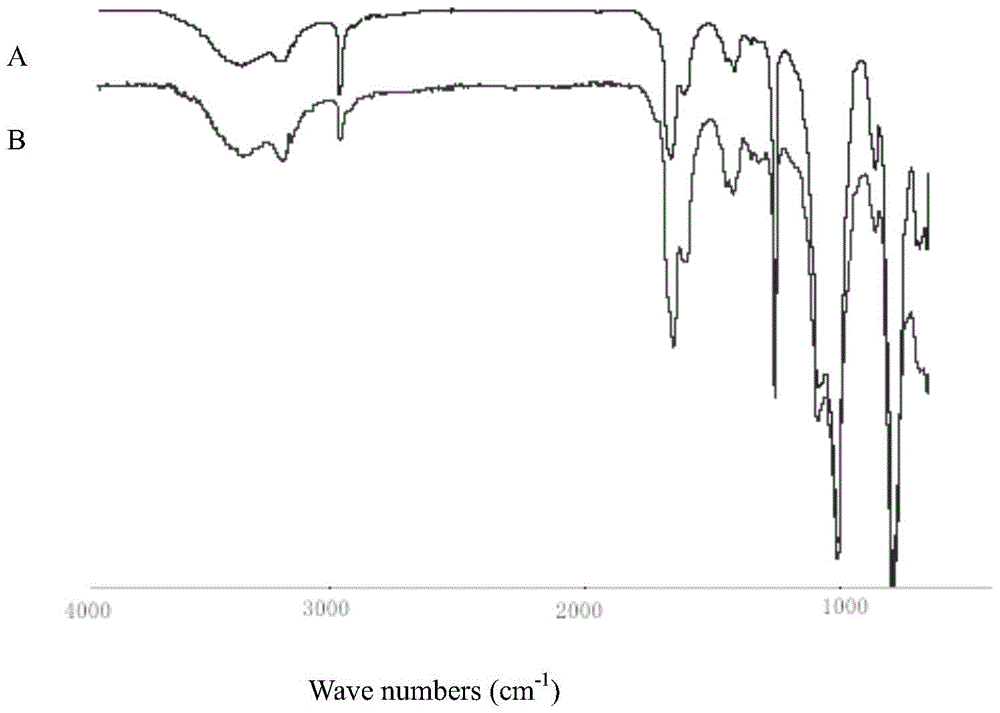

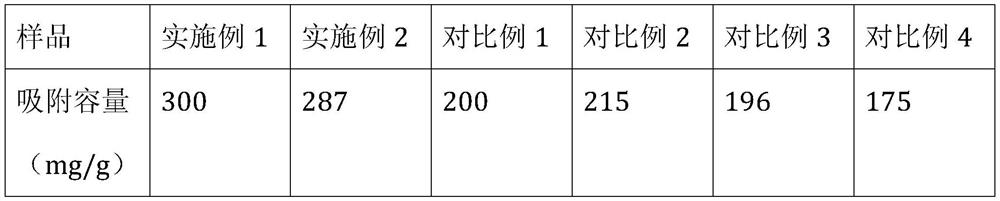

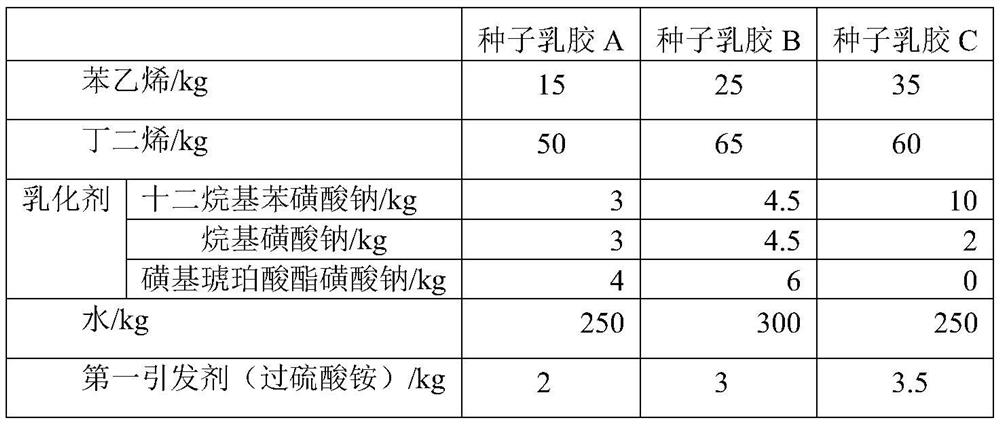

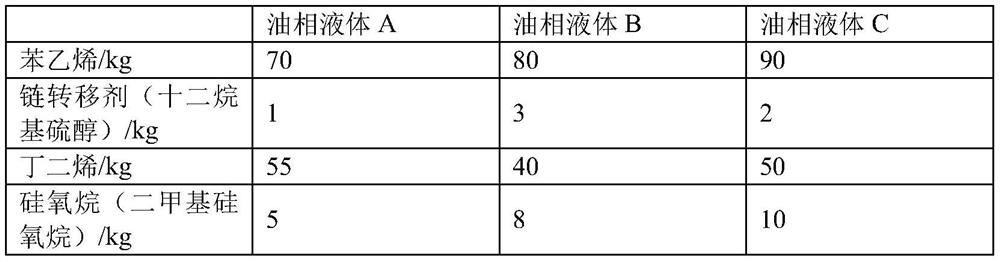

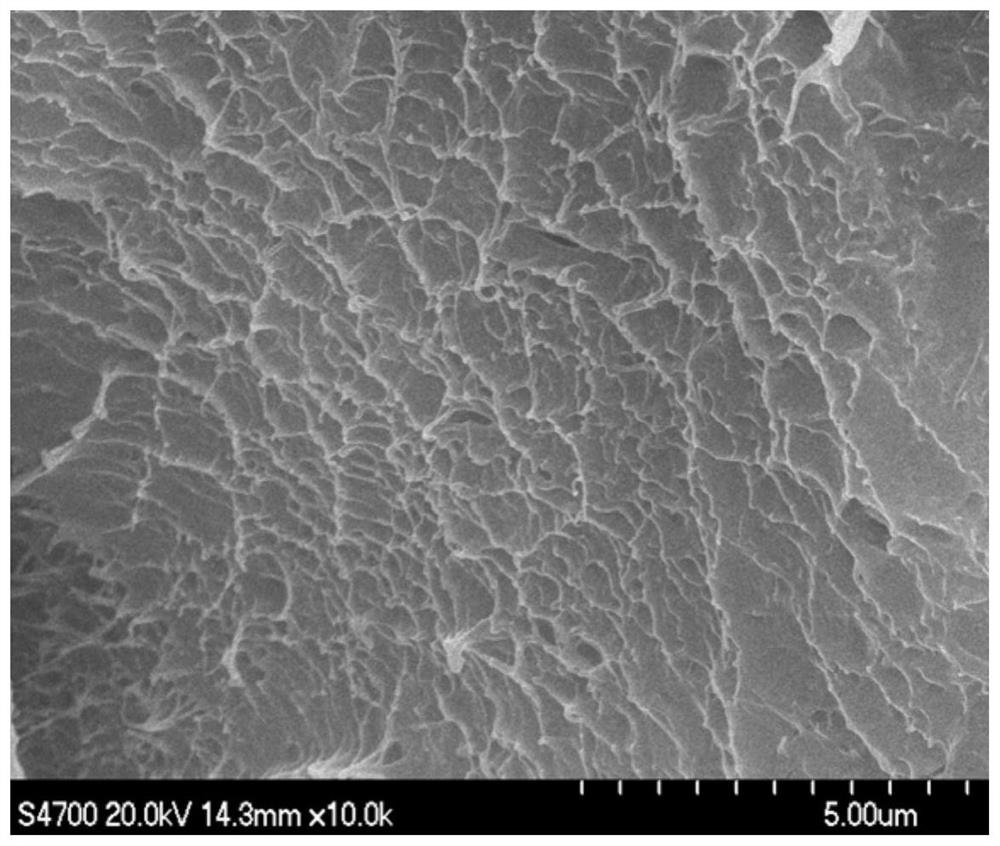

Glass fiber mesh cloth latex and preparation method thereof

ActiveCN109503764AReduce adhesionReduce flakingConjugated diene hydrocarbon adhesivesHigh concentrationGlass fiber

The invention relates to the field of adhesives, discloses glass fiber mesh cloth latex and a preparation method thereof, and solves the problems that bonding strength between an existing latex coating and glass fiber is reduced and peeling is easy. According to the key points of the technical scheme, the glass fiber mesh cloth latex is prepared from raw materials such as seed latex, oil phase liquid, aqueous phase liquid, an initiator solution and soft water through seed emulsion polymerization, wherein the raw material oil phase liquid, which is used for forming a shell structure, contains siloxane, and the oil phase liquid is completely added once during the seed emulsion polymerization, so that high-concentration siloxane is mixed in the obtained shell structure, silicon-oxygen bonds in the siloxane can react with free hydroxyl groups on the surface of glass fiber, the adhesive force and bonding strength between the coating and the surface of the glass fiber and the adhesion resistance of the coating are improved, and the possibility that the coating is peeled off from the glass fiber is further reduced.

Owner:杭州龙驹合成材料有限公司

A kind of preparation method of bioaffinity silicone rubber

Owner:CHANGZHOU UNIV

How to Graft Black Bella

ActiveCN104969780BImprove the survival rate of graftingCrowning time shortenedGraftingCamellia oleiferaBud

Owner:GUANGXI NANNING BIWAN GARDAN ENG

A kind of method of anti-crease and antibacterial finishing of real silk fabrics by laccase-tempo method

InactiveCN105734981BImprove grafting efficiencyIncrease the amount of graftingBiochemical fibre treatmentAnimal fibresQuinoneWrinkle skin

The invention discloses a method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of a laccase-TEMPO process. Quinones active groups are generated through catalyzing tyrosine residual groups in real silks by laccase so that chitosan molecules are grafted on the real silks; then 2,2,6,6-tetramethylpiperidine-nitrogen oxide (TEMPO) is added and is used for catalyzing chitosan and tyrosine in the real silks to generate formyl groups, so that the grafting amount and bonding firmness of the chitosan on the real silks are increased, and the real silk fabric anti-crease and antibacterial finishing is realized. The method comprises the following specific steps of: (1) catalytically oxidizing the tyrosine residual groups in the real silks by the laccase; (2) taking the chitosan and the quinones active groups in the real silks to react; (3) catalyzing the real silks by laccase-TEMPO to graft the chitosan; and (4) washing the real silks with water and then treating. Compared with traditional chemical cross-linking-process vacuum fabric anti-crease and antibacterial finishing, the method has the advantages that the grafting efficiency of the chitosan is high, enzyme treatment conditions are moderate, the real silk fabric anti-crease and antibacterial effect is relatively good and the strength of the fabric is improved.

Owner:JIANGNAN UNIV

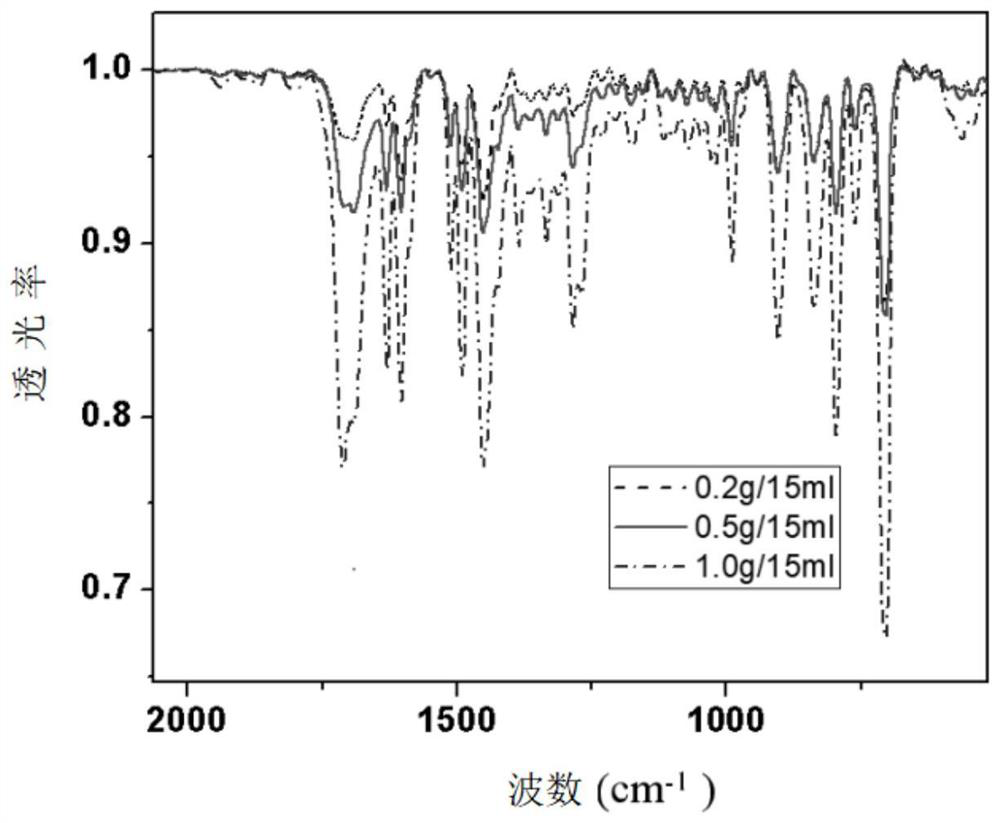

Surface modification method of macroporous polystyrene resin for blood purification and blood purifier

ActiveCN112831087ADoes not affect adsorptionImprove hydrophilicityOther chemical processesDialysis systemsGraft reactionPolystyrene

The invention relates to a surface modification method of macroporous polystyrene resin for blood purification and a blood purifier. The surface modification method comprises the following steps: irradiating the macroporous polystyrene resin, and placing the irradiated macroporous polystyrene resin in a solution containing a modifying monomer for grafting reaction, with the modifying monomer containing a hydrophilic group. The large-aperture polystyrene adsorption resin for blood purification has better anticoagulant property and blood compatibility, and the modification method is simple and environment-friendly.

Owner:珠海健科医用材料有限公司 +1

Macroporous ion exchange resin with function of highly selectively adsorbing rhenium metal ions and preparation method of macroporous ion exchange resin

InactiveCN112029143AReduce resistanceIncrease exchange rateCation exchanger materialsOther chemical processesIon exchangePhysical chemistry

The invention relates to a preparation method of a macroporous ion exchange resin capable of highly selectively adsorbing rhenium metal ions. According to the invention, gradient pore-forming is carried out by adopting a multi-element pore-forming agent, so that the pore channel structure is improved, the ion exchange resistance is reduced, and the ion exchange rate is increased. Glutaraldehyde isused as an amino modified cross-linking agent, so that the amino grafting amount is increased, the active center is increased, rapid diffusion and ion exchange of rhenium are facilitated, and the exchange capacity is further improved. Fe and Ce are adopted to carry out inorganic modification on the ion exchange resin together, so that the rhenium adsorption capacity is enhanced, and the selectivity is improved. When other ions are contained, the macroporous ion exchange resin prepared by the method has high rhenium selectivity, and the result shows that the macroporous ion exchange resin hashigh rhenium selectivity.

Owner:ANHUI WANDONG CHEM

Preparation method of high-quality hot melt adhesive breathable film

ActiveCN105670524BImprove heat resistanceImprove water resistanceNon-macromolecular adhesive additivesFilm/foil adhesives without carriersBenzoyl peroxidePolymer science

Owner:PINGHU ZHANPENG HOT MELT ADHESIVE WEB & FILM

A kind of glass fiber mesh cloth latex and preparation method thereof

ActiveCN109503764BReduce adhesionReduce flakingConjugated diene hydrocarbon adhesivesGlass fiberPolymer science

The invention relates to the field of adhesives, discloses a glass fiber mesh cloth latex and a preparation method thereof, which solves the problem that the bonding strength between the existing latex coating and glass fiber is reduced and is easy to peel off, and the main point of the technical solution is a glass fiber Mesh cloth latex is polymerized by seed emulsion, including seed latex, oil phase liquid, water phase liquid, initiator solution, soft water, etc., wherein the raw material oil phase liquid used to form the shell structure contains siloxane, and the oil phase The liquid is added completely in the seed emulsion polymerization at one time, so that the obtained shell structure is mixed with a high concentration of siloxane, and the silicon-oxygen bond in the siloxane can react with the free hydroxyl groups on the surface of the glass fiber to improve the adhesion between the coating and the surface of the glass fiber. Adhesion, bond strength and improved coating blocking resistance, further reducing the possibility of coating peeling from the glass fiber.

Owner:杭州龙驹合成材料有限公司

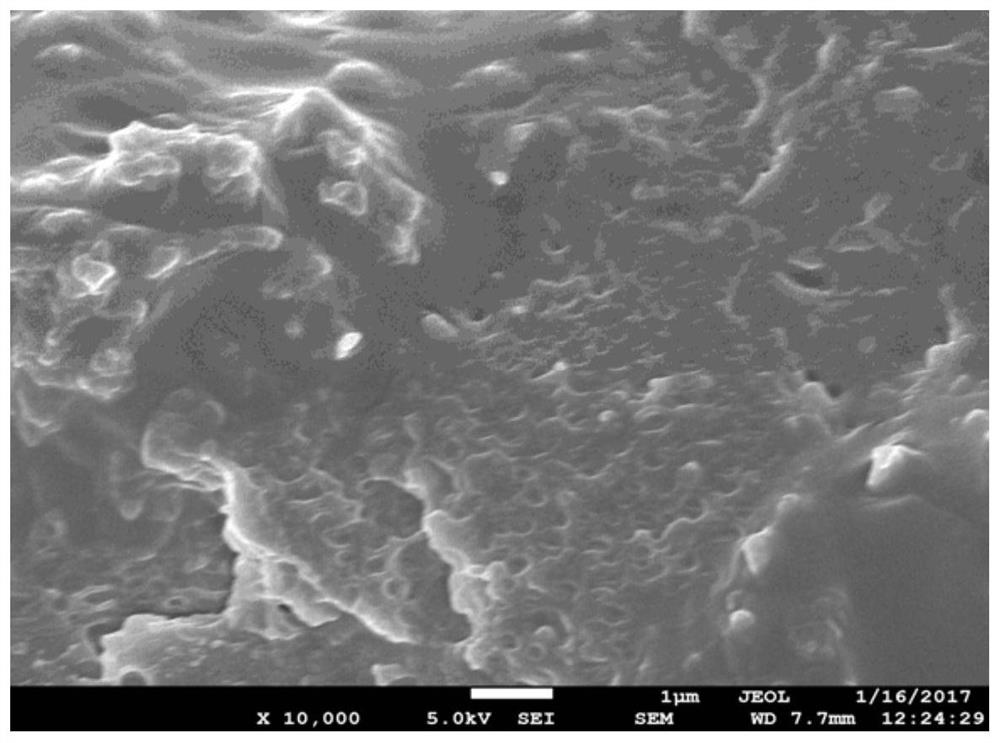

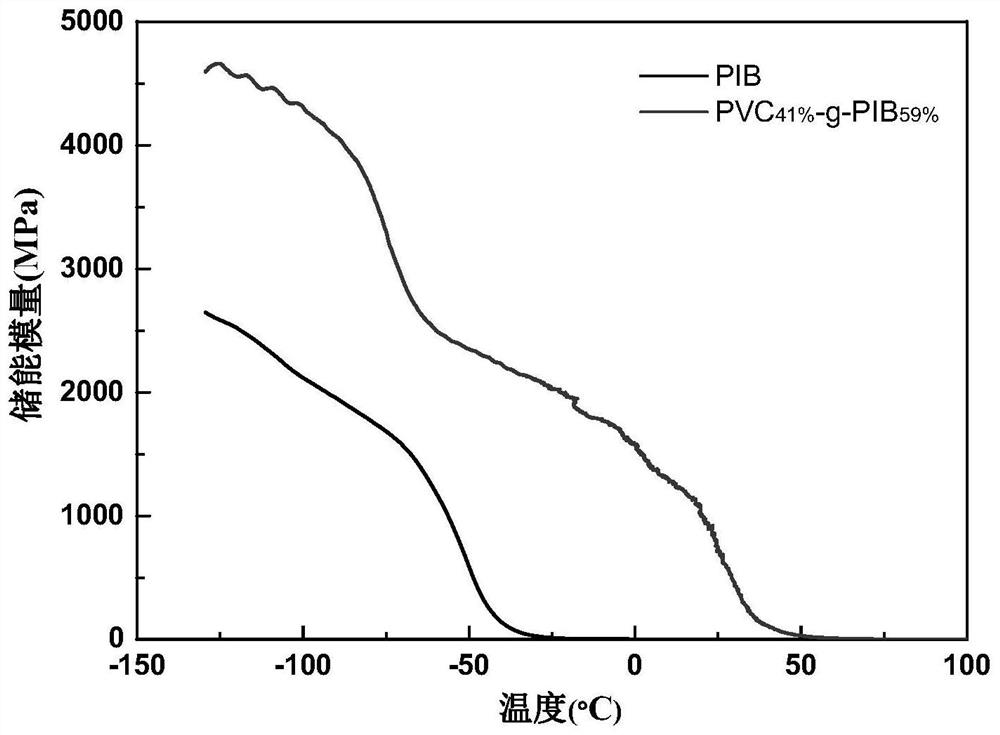

Polarized isobutylene-based polymer and its preparation method

The invention belongs to the field of polyolefins, and relates to a polarized isobutylene-based polymer and a preparation method thereof. The polarized isobutene-based polymer is an isobutene-based polymer connected with multiple polyvinyl chloride segments, the content of the isobutene-based polymer is 26-80 wt%, and the weight-average weight of the polarized isobutene-based polymer is The molecular weight is 105-800kg / mol, and the molecular weight distribution index is 1.2-5.0. The present invention realizes the graft copolymerization of isobutylene on polyvinyl chloride in a relatively large grafting amount range, and obtains a copolymerization product with a high grafting amount, which not only improves the polarity of the isobutylene-based polymer material, but also improves the polyvinyl chloride. The processability of vinyl chloride, more importantly, can be used to increase the blending compatibility of the two polymers, greatly improving the mechanical properties of the blend and other properties.

Owner:北京引发科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com