Preparation method of high-hexene grafted high-density polyethylene geomembrane blow molding material

A high-density polyethylene and geomembrane technology, applied in the production of bulk chemicals, etc., can solve the problems of difficult to control production, inability to dissipate heat of reaction, fluctuation of reaction, etc., achieve good resistance to environmental stress cracking, overcome device limitations, The effect of improving production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

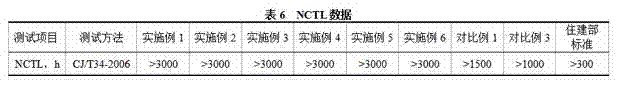

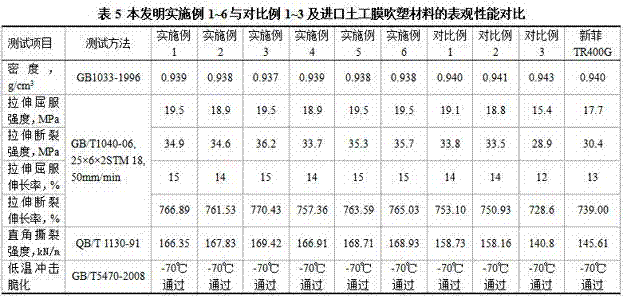

Examples

Embodiment 1

[0031] Preparation of ethylene-hexene copolymerized polyethylene resin:

[0032] The diluent isobutane is always in a circulating state. The monomers ethylene and 1-hexene are injected into the loop reactor respectively, and the antistatic agent ASA and the activated NTR-975 chromium catalyst are added for reaction. The reaction temperature is 92.8 ℃, ethylene feed rate 38t / h, 1-hexene feed rate 1440 kg / h, catalyst feed rate 149 kg / h, isobutane feed rate 38.0 kg / h, antistatic agent 0.39 kg / h, reacted to the reaction product The melt flow rate is 11.9g / 10min and the density is 0.937~0.939kg / m 3 , stop the reaction to obtain ethylene hexene copolymerized polyethylene resin.

[0033] Raw material (parts by weight) of geomembrane blow molding material:

[0034] Ethylene hexene copolymerized polyethylene resin 99.55 parts

[0035] Antioxidant 0.45 parts

[0036] Wherein the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0037...

Embodiment 2

[0040] Preparation of ethylene-hexene copolymerized polyethylene resin:

[0041] The diluent isobutane is always in a circulating state. The monomers ethylene and 1-hexene are injected into the loop reactor respectively, and the antistatic agent ASA and the activated NTR-975 chromium catalyst are added for reaction. The reaction temperature is 93.7 ℃, ethylene feed rate 38t / h, 1-hexene feed rate 1897 kg / h, catalyst feed rate 169 kg / h, isobutane feed rate 38.6 kg / h, antistatic agent 0.56 kg / h, reacted to the reaction product The melt flow rate is 12.3g / 10min and the density is 0.938kg / m 3 , stop the reaction to obtain ethylene hexene copolymerized polyethylene resin.

[0042] Raw material (parts by weight) of geomembrane blow molding material:

[0043] Ethylene hexene copolymerized polyethylene resin 99.70 parts

[0044] Antioxidant 0.30 parts

[0045] Wherein the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0046] Prep...

Embodiment 3

[0049] Preparation of ethylene-hexene copolymerized polyethylene resin:

[0050] The diluent isobutane is always in a circulating state. The monomers ethylene and 1-hexene are injected into the loop reactor respectively, and the antistatic agent ASA and the activated NTR-975 chromium catalyst are added for reaction. The reaction temperature is 95.2 ℃, ethylene feed rate 36t / h, 1-hexene feed rate 2059 kg / h, catalyst feed rate 198 kg / h, isobutane feed rate 36 kg / h, antistatic agent 0.36 kg / h, react until the reaction product The melt flow rate is 12.6g / 10min and the density is 0.937kg / m 3 , stop the reaction to obtain ethylene hexene copolymerized polyethylene resin.

[0051] Raw material (parts by weight) of geomembrane blow molding material:

[0052] Ethylene hexene copolymerized polyethylene resin 99.80 parts

[0053] Antioxidant 0.20 parts

[0054] Wherein the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0055] Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com