High-flux antibacterial anti-pollution polymer separation membrane and preparation method thereof

A technology for separating membranes and polymers, applied in the field of membrane separation, can solve the problems of poor antibacterial stability of antibacterial membranes, unable to maintain the antibacterial effect for a long time, and the antibacterial effect needs to be improved, so as to achieve good antibacterial and antifouling effect and continuous and stable antibacterial and antifouling effect. , the effect of improving hydrophilicity and water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

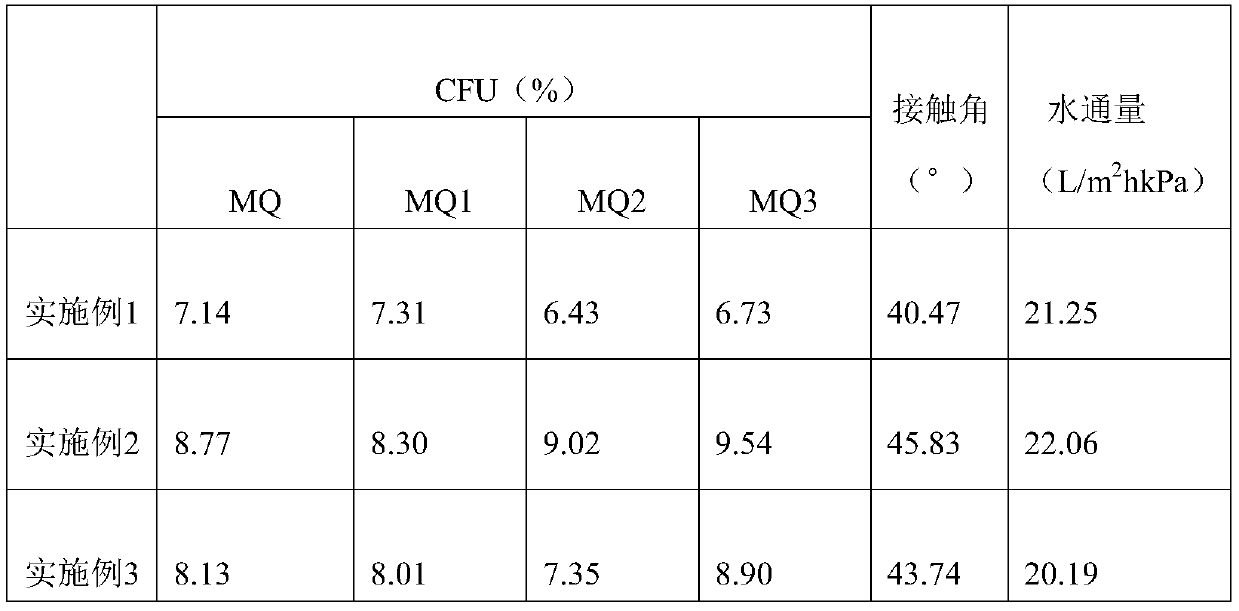

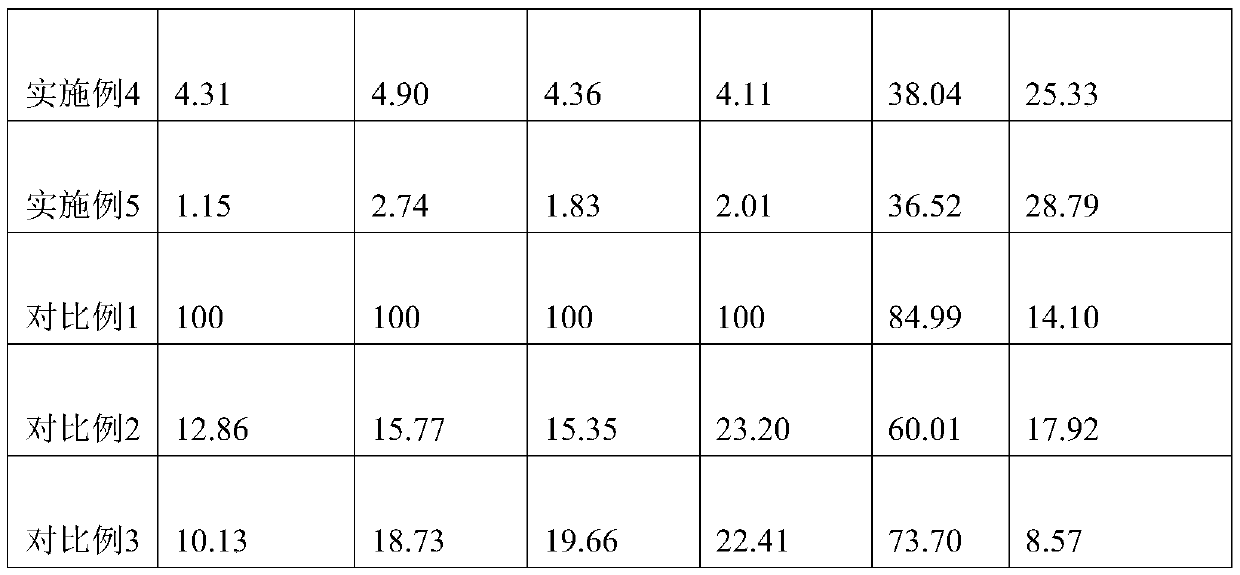

Examples

Embodiment 1

[0032] A method for preparing a high-throughput antibacterial and antifouling polymer separation membrane, comprising the steps of:

[0033] (1) Dissolve 400 mg of dopamine and 400 mg of polyethyleneimine in 200 mL of Tris-HCl buffer solution with a pH of about 8, and pour it into a mold equipped with a polyvinylidene fluoride separation membrane to react to obtain surface-activated polyvinylidene fluoride Separation membrane;

[0034] (2) Add 1.5mL orthosilicate methyl ester to 100mL 1mmol / L HCl solution, mix with 100mL phosphate buffer solution with a pH value of about 5.5 after stirring for 15min, and then mix with the separation membrane obtained in step (1) at room temperature React for 6 hours to obtain a polyvinylidene fluoride membrane separation membrane with nano silicon dioxide deposited on the surface;

[0035] (3) Soak the separation membrane obtained in step (2) in 100 mL of dichloromethane, add 2 mL of triethylamine and 2 mL of 2-bromoisobutyryl bromide, perfor...

Embodiment 2

[0044] A method for preparing a high-throughput antibacterial and antifouling polymer separation membrane, comprising the steps of:

[0045] (1) 800 mg of tannic acid was dissolved in 200 mL of Tris-HCl buffer solution with a pH of about 8, and poured into a mold equipped with a polyvinylidene fluoride separation membrane to react to obtain a surface-activated polyvinylidene fluoride separation membrane;

[0046] (2) Add 1.5mL tetraethyl orthosilicate to 100mL 1mmol / L HCl solution, mix with 100mL phosphate buffer with a pH value of about 5.5 after stirring for 15min, and then mix with the separation membrane obtained in step (1) at room temperature React for 6 hours to obtain a polyvinylidene fluoride separation membrane with nano silicon dioxide deposited on the surface;

[0047] (3) Soak the separation membrane obtained in step (2) in 100 mL of toluene, add 2 mL of 2-methoxypyridine and 2 mL of methyl 2-bromopropionate, perform a deoxygenation operation on the reaction syste...

Embodiment 3

[0051] A method for preparing a high-throughput antibacterial and antifouling polymer separation membrane, comprising the steps of:

[0052] (1) Dissolve 400 mg of dopamine and 400 mg of tannic acid in 200 mL of Tris-HCl buffer solution with a pH of about 8, and pour it into a mold equipped with a polyvinylidene fluoride separation membrane to react to obtain a surface-activated polyvinylidene fluoride separation membrane. membrane;

[0053] (2) Add 1.5mL orthosilicate methyl ester to 100mL 2.5mmol / L HCl solution, mix with 100mL phosphate buffer solution with a pH value of about 5.5 after stirring for 15min, and then mix with the separation membrane obtained in step (1) at room temperature React for 6 hours to obtain a polyvinylidene fluoride membrane separation membrane with nano silicon dioxide deposited on the surface;

[0054] (3) Soak the separation membrane obtained in step (2) in 100 mL of dichloromethane, add 1 mL of 3-picoline and 1 mL of 2-bromoisobutyryl bromide, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com