Cellulose aerogel modified by polyionic liquid, preparation method and application thereof

A technology of cellulose airgel and polyionic liquid, which is applied in the field of cellulose airgel modified by polyionic liquid and its preparation, and can solve the problems of poor adsorption effect of cellulose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A kind of preparation method of the cellulose airgel of PIL modification, its synthetic route is as follows:

[0050]

[0051] Wherein, X is selected from any one of the structures shown in formulas (2)-(10):

[0052]

[0053] Specifically, the following method is used to prepare:

[0054] (1) Synthesis of ionic liquid functional monomer IL

[0055]

[0056] Vinylimidazole (VIM) and VBC or BCMBP or BCMB are reacted in a polar solvent at a molar ratio of 1.1:1 at 50°C under an inert gas atmosphere. After the reaction is finished, the product is precipitated by diethyl ether, then the product is purified by dissolution / precipitation (methanol / diethyl ether), and dried to obtain 1-[(4-vinylphenyl)methyl]-3-vinylimidazolium Chloride (EVIM).

[0057] The above polar solvent is selected from any one or more than two of methanol, DMSO, DMF, acetonitrile and acetone.

[0058] Table 1 The dosage table of each reactant

[0059]

[0060] (2) Preparation of pure ce...

Embodiment 1

[0084] A preparation method of a PIL-modified cellulose airgel, the method comprising:

[0085] (1) Synthesis of ionic liquid functional monomers

[0086]

[0087] Vinylimidazole (4.14 g, 0.044 mol) and 4-chloromethylstyrene (6.105 g, 0.040 mol) were added into 10 mL of methanol, and stirred at 50° C. for 24 h under nitrogen.

[0088] After the reaction was finished, the product was precipitated by using 200 mL of diethyl ether, then the product was purified twice by dissolution / precipitation (methanol / diethyl ether), and then the residual solvent was removed by vacuum drying until constant weight, finally obtaining 1-[(4- Vinylphenyl)methyl]-3-vinylimidazolium chloride (EVIM).

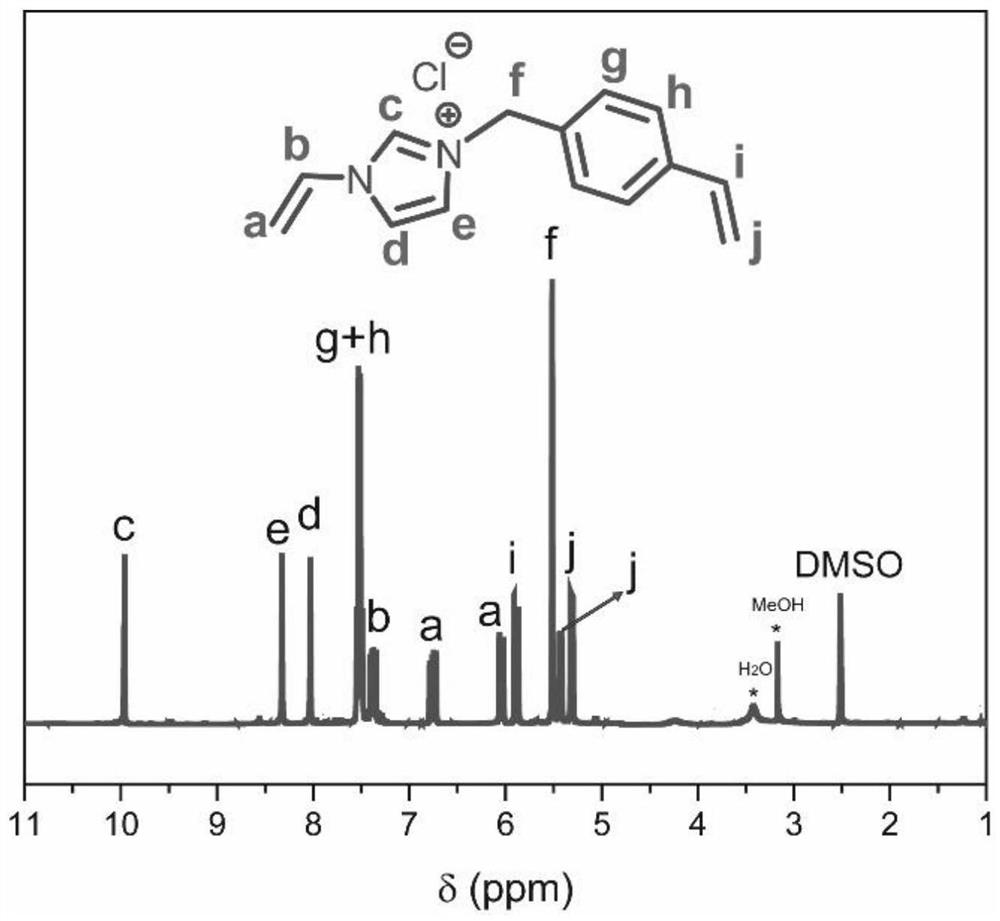

[0089] The NMR characterization spectrum of EVIM can be found in figure 1 , whose characterization data are:

[0090] 1 HNMR(DMSO,400MHz,δppm):9.96(a,1H),8.32(b,1H),8.03(c,1H),7.58-7.546(g+h,4H),7.42-7.32(d,1H), 6.79-6.72(e,1H),6.06-6.01(e,1H),5.91-5.86(i,1H),5.51(f,2H),5.43-5.41(j,1H),5.32-5....

Embodiment 2

[0111] A preparation method of a PIL-modified cellulose airgel is basically the same as that of Example 1, the difference being that the structure of the CTA adopted in step (3) is:

[0112]

[0113] The structure of the obtained CA-g-PIL is:

[0114]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com