Patents

Literature

262results about How to "Strong responsiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber-material modifying method and dyeing process

InactiveCN101070676AGood adsorption effectStrong responsivenessFibre typesDyeing processPrepolymerUrea

The invention provides a brand-new method to change the nature with the fibrous material and the environmental protection staining method to textile printing profession. Its characteristic lies in: join the prepolymer comprising the reactive hydrogen and the response functional group to the fibrous material. Chemical reaction between prepolymer's links the macro-molecule chain polymer, and solidifies on the fibrous material. The prepolymer nitrogen's percentage is: 5-45%. In this prepolymer at least one kind in hydrogen groups and bases, hydroxyl, amidogen and imides-group is included, and one kind of response functional group comprising chloromethyl group, epoxy group and 3-hydroxyl nitrogen heterocyclic ring butyl and the like, or combinations with any proportion of the three response functional groups are also included. After changing the nature, the fibrous material carries on the conventional craft dyeing with the anion dye or the coating in the environment without salt, the alkali, the urea. This invention has the craft to be simple, the dye use factor high, and the assistant amount few, which reduces the production cost, has saved the massive energy, and reduces the environment pollution.

Owner:DYMATIC CHEM

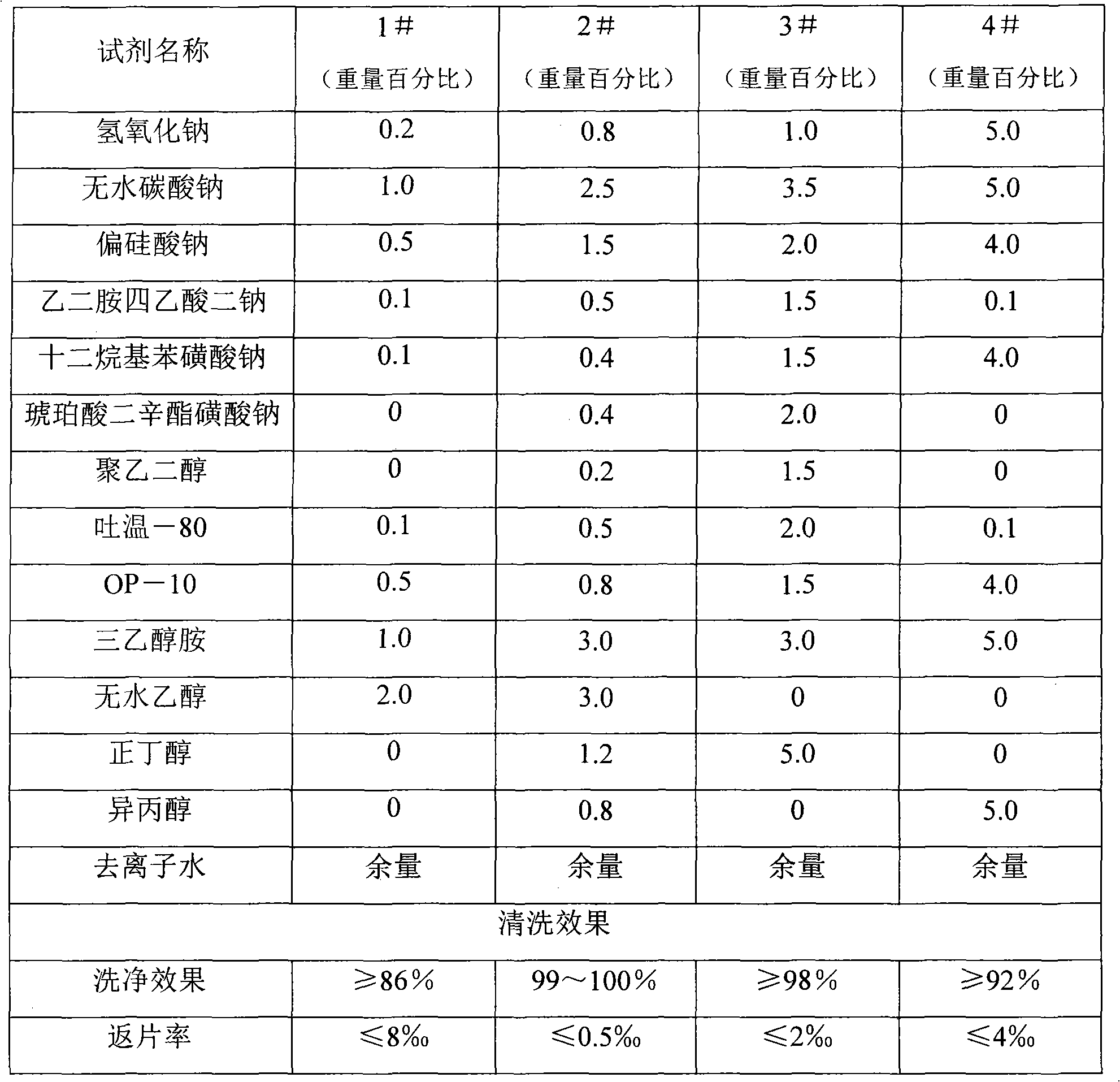

Solar silicon slice cleaning agent and method for preparing same

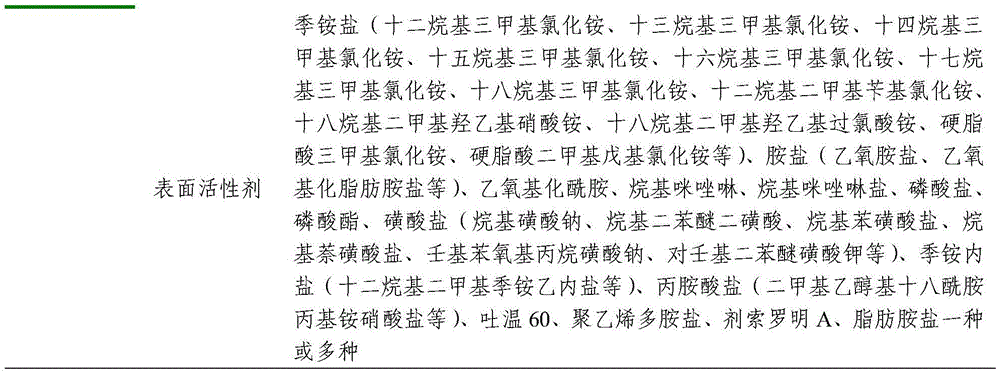

ActiveCN101892132AStrong responsivenessGood dispersionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryTriethanolamine

The invention provides a solar silicon slice cleaning agent, and belongs to the field of cleaning agents for electronic industry. The cleaning agent of the invention mainly comprises sodium hydroxide, sodium carbonate, sodium silicate, disodium edentate, sodium dodecyl benzene sulfonate, sodium dioctyl sulfosuccinate, polyethylene glycol, Tween-80, OP-10, triethanolamine, anhydrous alcohol or normal butyl alcohol or isopropyl alcohol or a composition of anhydrous alcohol, normal butyl alcohol or isopropyl alcohol, and deionized water. The cleaning agent is alkaline, does not contain sulfur and phosphorus additives, and when used as alone, has the advantages of good decontamination and cleaning property, low slice-returning rate, long service cycle, no corrosion to silicon slice, low operational requirements in use, easy treatment of treated waste oil and sewage, and the suitability for manual, semi-automatic and full automatic ultrasonic cleaning production lines of various process; in addition, the cleaning rate is over 99 percent, the slice-returning rate is close to zero, and the cost of the process of the invention is one tenth to one twentieth of that of the conventional cleaning process.

Owner:BEIJING UNIV OF TECH

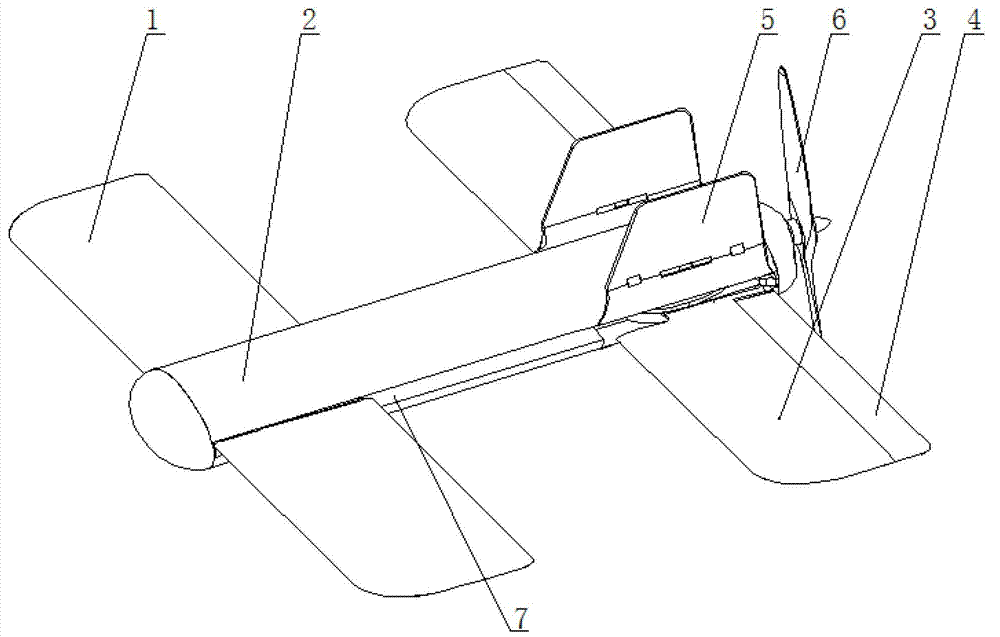

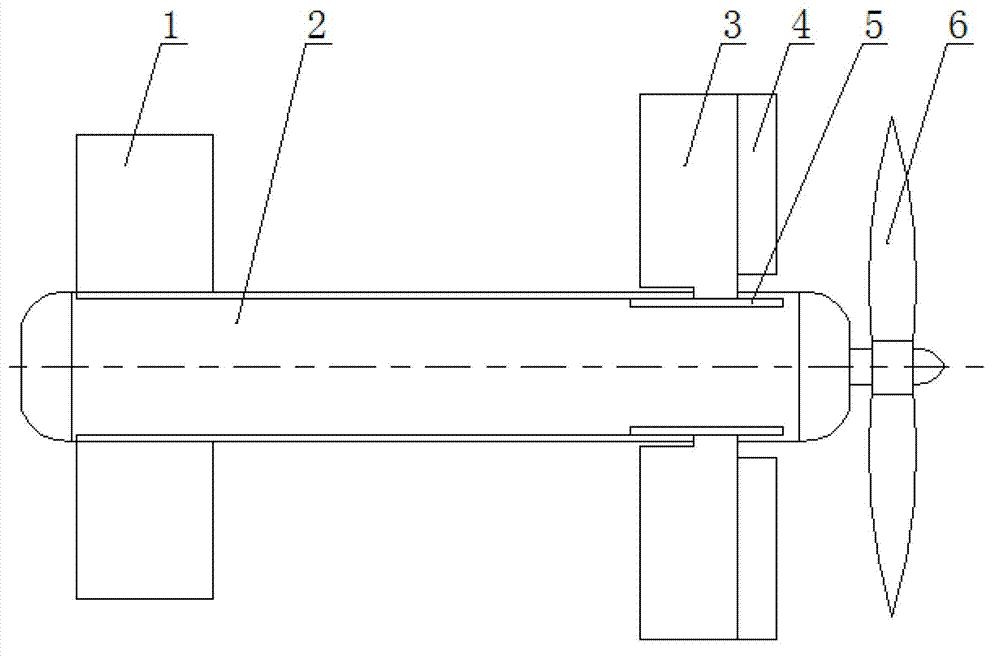

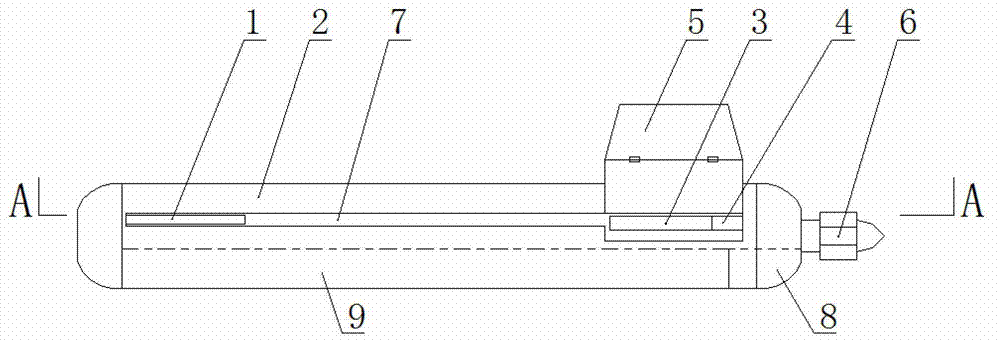

Folding type unmanned plane

The invention relates to a folding type unmanned plane. The unmanned plane comprises a fuselage and wings, wherein the wings are installed symmetrically on two sides of the fuselage; one end of each wing is hinged on a wing main shaft installed coaxially at the middle part inside the fuselage; wing access through-grooves are formed horizontally in two sides of the fuselage in the installation positions of the wings; and the wings are driven and controlled by an motor-driven or pneumatic device installed at the lower part inside the fuselage and rotate around the wing main shaft. The folding type unmanned plane can be used flexibly and rapidly; is mutifunctional, low in flight speed and altitude, high in response speed and wide in application range; can facilitate operation of a staff; has 'zero' preparation time; and can be applied to tasks such as exploration, search, rescue and measurement.

Owner:天津全华时代航天科技发展有限公司

Method and device of obtaining active lime by vacuum calcining limestone

A process for preparing high-activity lime by vacuum calcining of lime stone includes such steps as crushing lime stone, loading in tank, heating in electric vacuum furnace at 750-900 deg.C under 100-1000 Pa, and quick cooling. Its activity is 380-450 ml.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

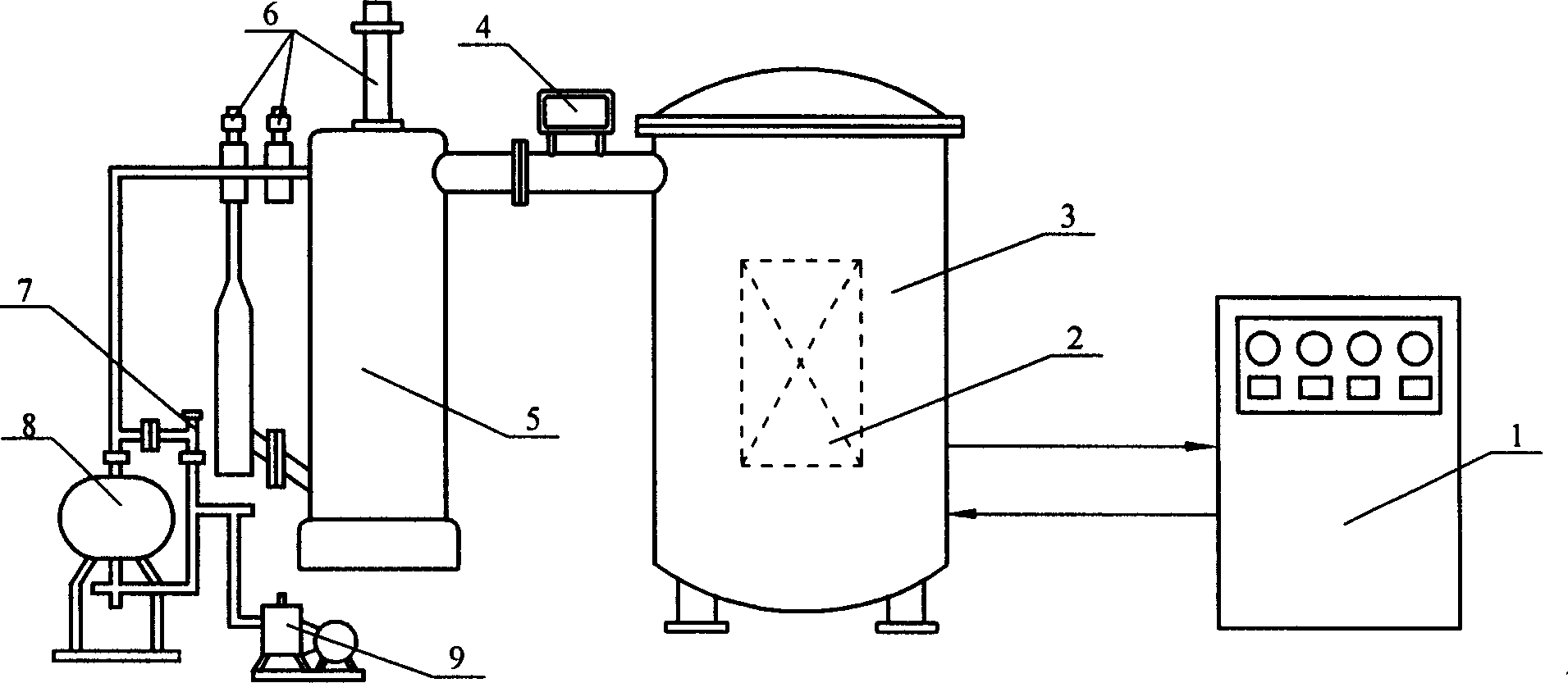

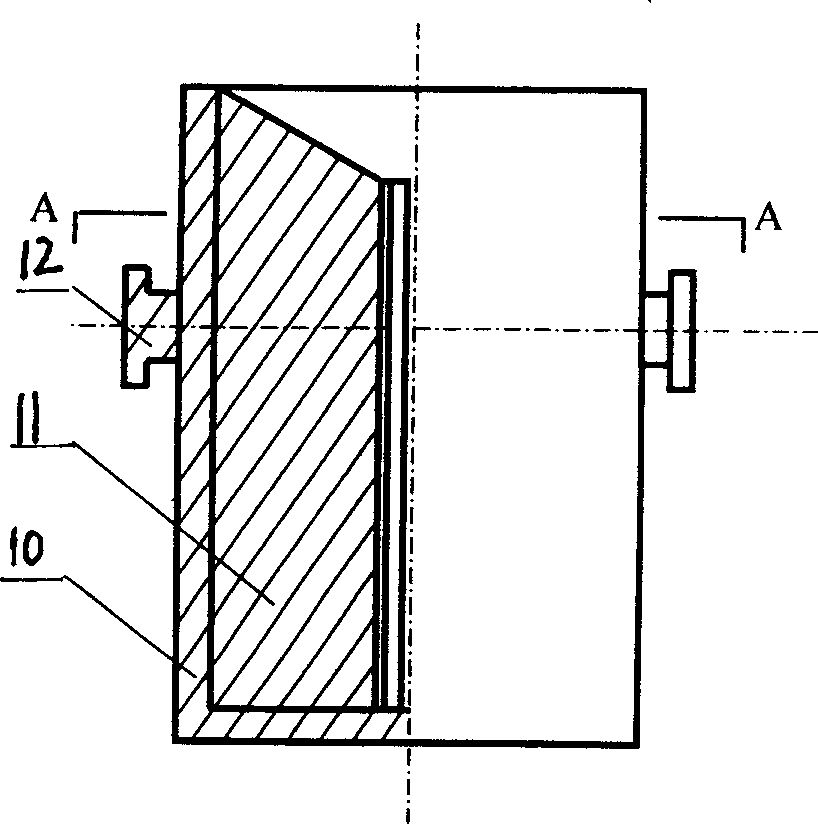

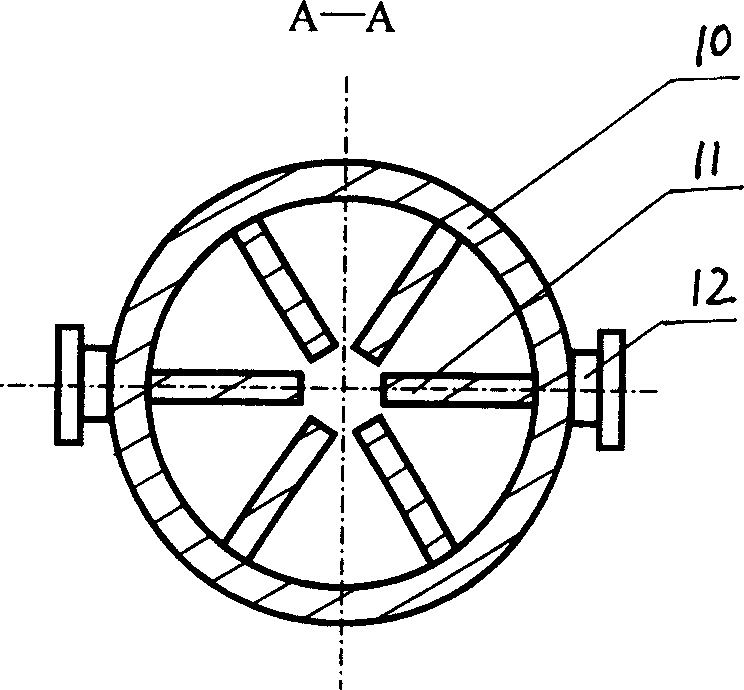

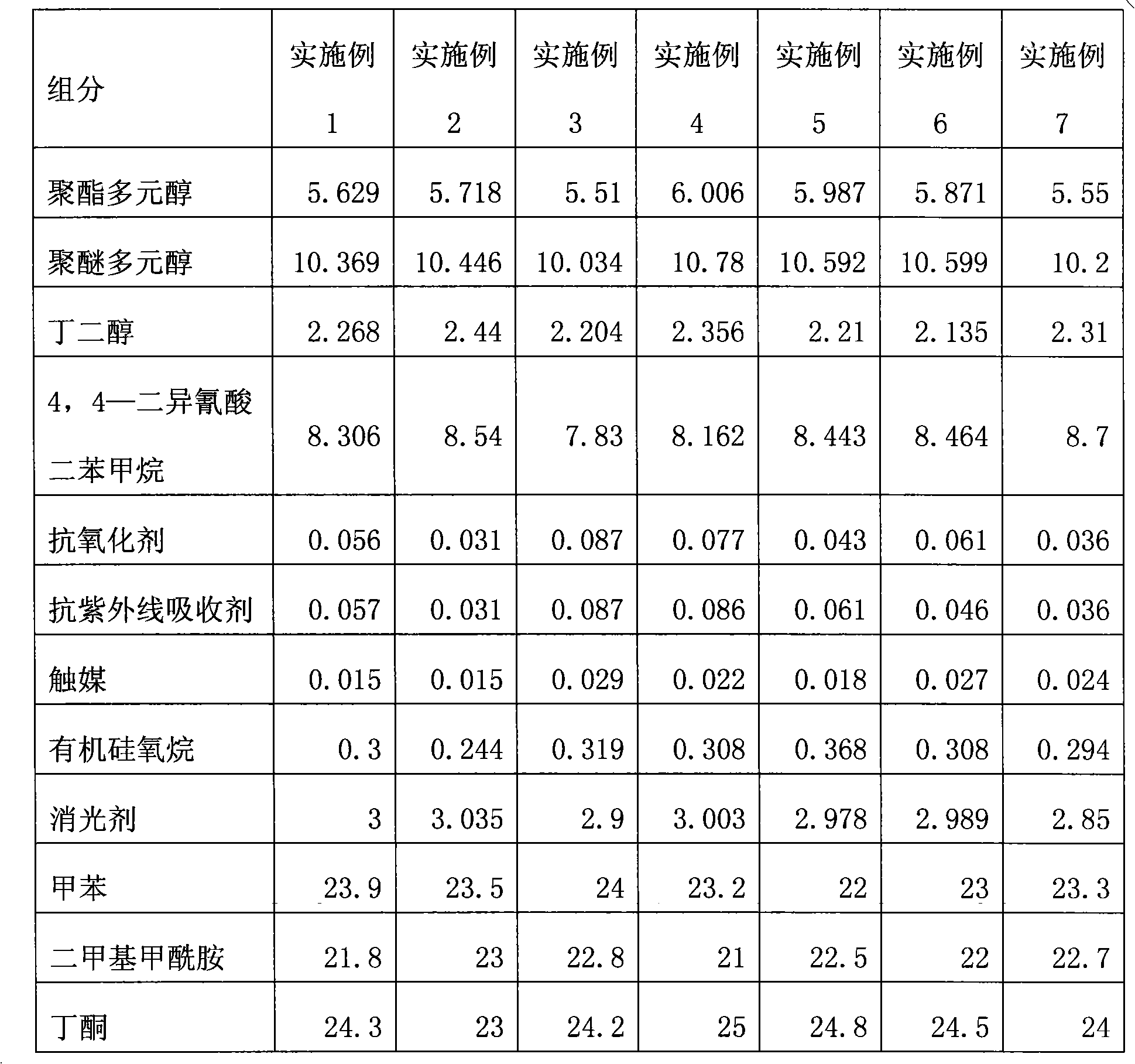

Temperature sensitive type waterproof moisture-penetrating urethane resin and preparation method thereof

InactiveCN101914854AImprove comfortAdd temperature sensing functionFibre treatmentPerspirationHeat rejection

The invention discloses a temperature sensitive type waterproof moisture-penetrating urethane resin and a preparation method thereof. Compared with a general waterproof moisture-penetrating urethane resin used in the market, the temperature sensitive type waterproof moisture-penetrating urethane resin increases a temperature sensitive function; the molecular arrangement mode of the urethane resin is controlled through special formula and process so that the urethane resin has higher response capacity on environmental temperature; when the environmental temperature is higher, the moisture-penetrating amount of the urethane resin is increased, heat rejection and perspiration elimination are accelerated so that people feel cool; when the environmental temperature is lower, moisture-penetrating property is lowered so as to play roles of wind stop, heat preservation and warm keeping, and moisture-penetrability and temperature regulation play a coordination role simultaneously, therefore a wearer can feel comfortable under the conditions of changeable environmental temperature or calorification and perspiration elimination of human bodies, and the like.

Owner:高鼎精细化工(昆山)有限公司

Method for producing high carbon steel by high-catching carbon method

ActiveCN101333578AReduce oxidationReduce erosionManufacturing convertersProcess efficiency improvementHigh carbonSmelting process

The invention provides a method for producing high-carbon steel by a high-carbon-withdrawal method, in particular to a smelting process of high-carbon-withdrawal tapping when a converter adopts a single slag process to produce high-carbon steel. The process comprises the following steps of: (1) putting molten iron and scrap steel into the converter according to the requirements on tapping temperature and a certain hot metal ratio; (2) air refining with the oxygen supply strength of 3.1 to 3.4Nm<3> / min / t in the converter; (3) adding active lime and an ore slagging element into the converter; (4) adopting an oxygen supply system of different lance positions under constant flow, adopting rather high lance positions in the whole course of air refining of the converter, and adopting a lance position system in which lance positions get lower piecewise from the beginning to the end of air refining; (5) adding ore and fluorite in small amount by a plurality of batches when the total air refining oxygen consumption is within 70 percent to 85 percent; (6) finishing the air refining of the converter, deslagging by turning down the converter, temperature measurement and sampling; and (7) converter tapping. The smelting process has advantages of short time of air refining of the converter and active slag, and can meet the dephosphorization effect under the high-carbon-withdrawal condition of molten steel, and realize the high-carbon-withdrawal tapping.

Owner:SHOUGANG CORPORATION

Method of preparing carbon-based high valence silver molecule crystal battery

ActiveCN101058449AEnhance the performance of adsorbing organic toxic and harmful substancesRaise the ratioWater/sewage treatment using germicide/oligodynamic-processChemical reactionPotassium peroxodisulfate

The invention discloses a making method of carbon-based high-valent silver molecular crystal battery, which comprises the following steps: dissolving silver nitrate into pure water; stirring; placing the active carbon in the silver nitrate solution; adsorbing; filtering; drying the active carbon; placing the potassium peroxodisulfate or sodium peroxodisulfate as oxidizer into distilled water; adding sodium hydroxide; diluting; heating; stirring to react with dried active carbon; insulating; filtering; washing four times through pure water; obtaining the product with Ag4O4 distributed evenly on the surface of active carbon; displaying stronger chemical adsorbing ability and chemical reactivity; reinforcing the purifying capacity of organic toxic and harmful material absorbed by active charcoal.

Owner:TAIYUAN YINXIYUAN TECH CO LTD

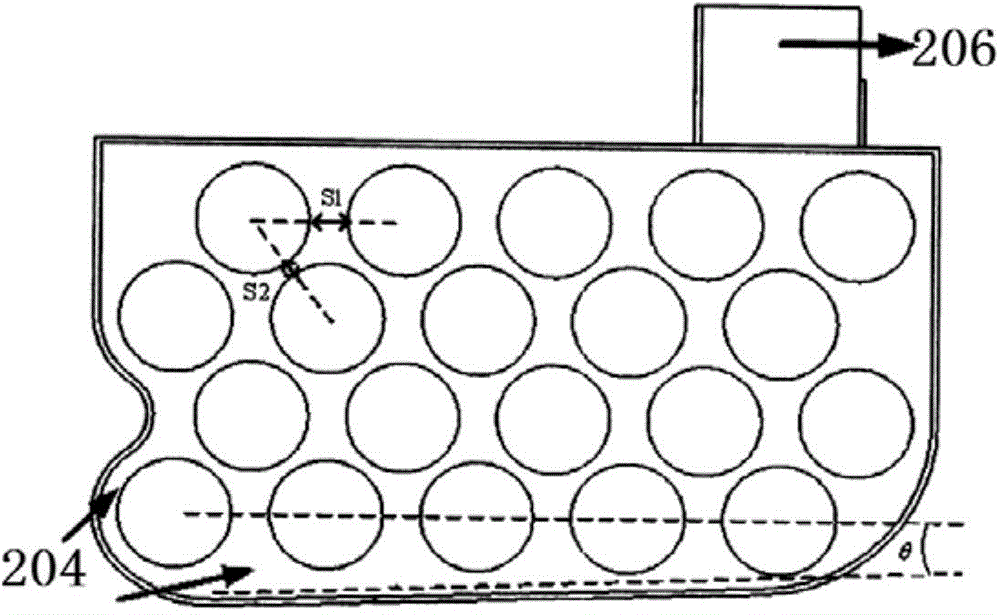

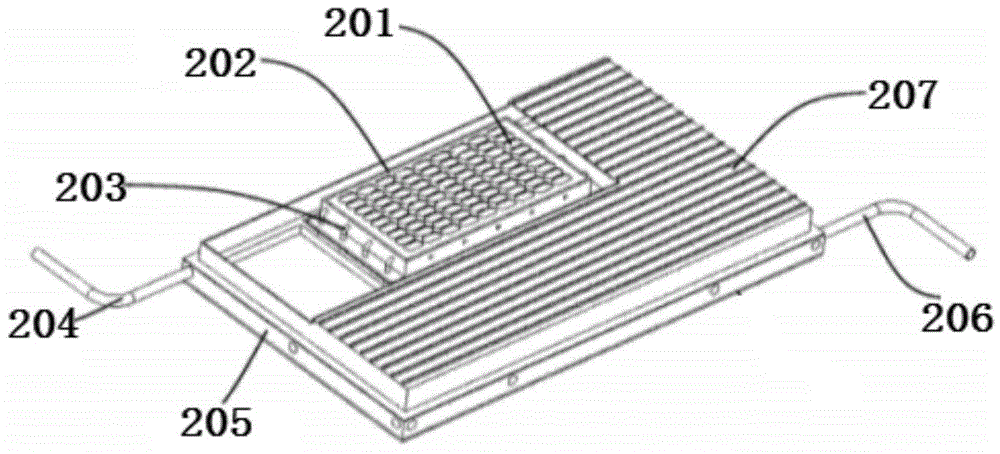

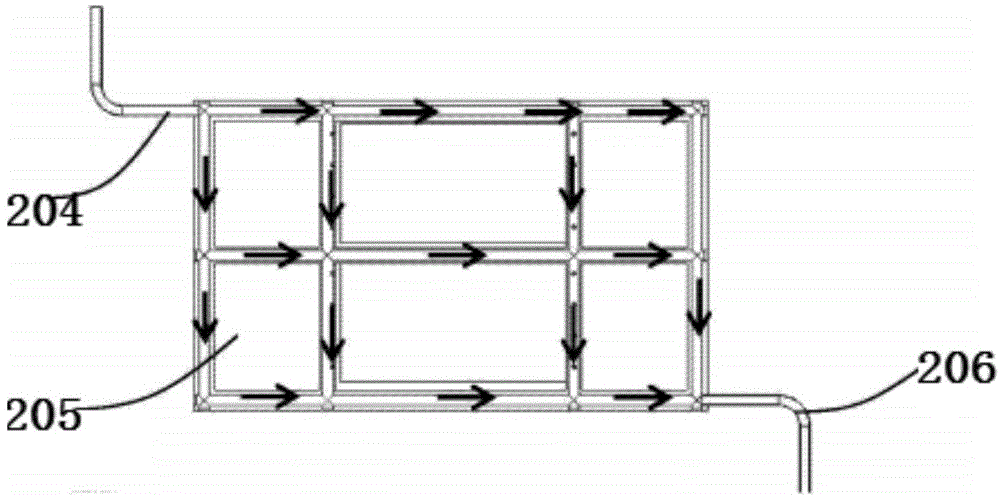

Immersion-liquid-type battery compartment temperature control system

ActiveCN105762437ATemperature controlUniform temperatureSecondary cellsTemperature controlControl system

The present invention relates to an immersion-liquid-type battery compartment temperature control system comprising an immersion-liquid-type battery compartment; a first cooling pipe; a second cooling pipe; a third cooling pipe; a temperature sensor which is disposed on the battery pack side of the immersion-liquid-type battery compartment and is used for detecting battery pack temperature; and a temperature control unit which receives battery pack temperature signals sent by the temperature sensor to control startup and shutdown of a first cooling loop, a second cooling loop, a third cooling loop or a heating device. The immersion-liquid-type battery compartment temperature control system has excellent temperature control and temperature balancing capability.

Owner:CH AUTO TECH CORP CO LTD

Medicated thread for acupoint catgut embedding therapy and preparing method thereof

InactiveCN1631454AStrong responsivenessLong stimulation timeSuture equipmentsUnknown materialsMedicinal herbsAlcohol

Medicated thread for acupoint catgut embedding therapy, wherein the catgut is undergone soup immersion treatment. The invention also provides the method for preparing the medicated thread for acupoint catgut embedding therapy, the medicinal thread is immersed by medical alcohol containing four Chinese medicinal herbs of coptis root, baikal skullcap root, Siberian solomonseal rhizome, and rhubarb horsetails with the same dosages. The medical alcohol has a concentration of 75, the weight ratio of the medical alcohol and the Chinese medicinal herbs is 3:1-3:2.

Owner:杨良机

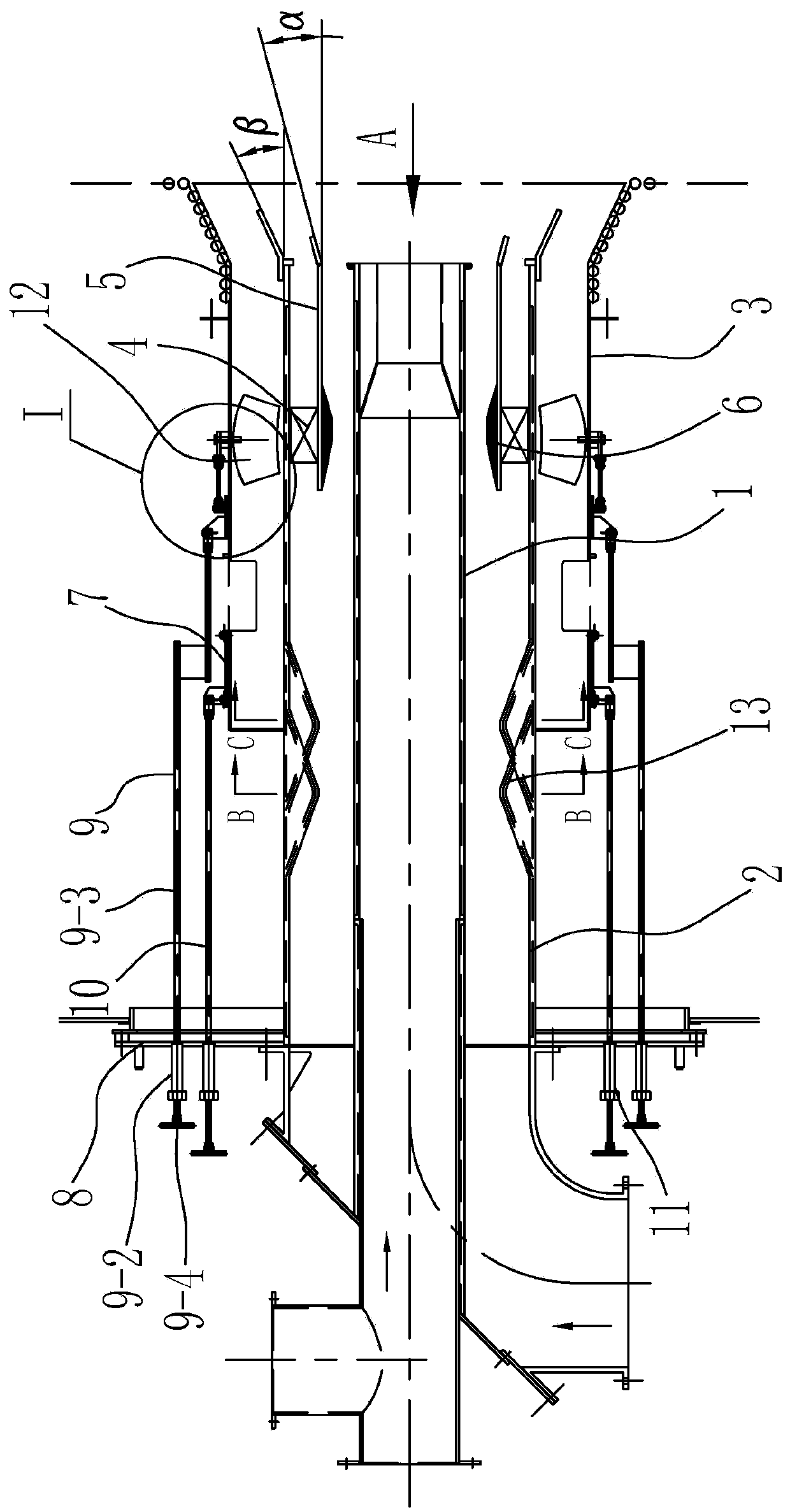

Swirling burner for pulverized coal dense and thin separation of lignite

PendingCN111442263AHigh secondary wind speedIncrease momentumPulverulent fuel combustion burnersNon-combustible gases/liquids supplyBrown coalThermodynamics

The invention relates to a swirling burner for pulverized coal dense and thin separation of lignite, belongs to the technical field of a boiler burner, and aims to solve the problem that the coal-airratio of primary air and the primary air ratio of the existing swirling burner for burning lignite are larger, and the secondary air ratio is smaller, so that the momentum ratio of primary air and secondary air is much different from that of burning bituminous coal, and the flow field and the burning process control of the burner are affected; and thus, the burning process of the burner is not easy to control, the stability of a flame backflow zone is poor, and higher NOx pollutants are produced. The swirling burner for pulverized coal dense and thin separation of lignite comprises a central air pipe, a primary air pipe, a secondary air pipe, a secondary air swirl vane, a venturi pulverized coal concentration pipe, thin-phase swirl vanes, a dense and thin separation isolating barrel and apulverized coal dense and thin separation device, wherein the central air pipe, the dense and thin separation isolating barrel, the primary air pipe and the secondary air pipe are arranged together from inside to outside in a sleeved mode, and every two adjacent components are arranged at intervals; and a plurality of thin-phase swirl vanes which are uniformly distributed on the peripheral direction of the primary air pipe are arranged between the dense and thin separation isolating barrel and the primary air pipe.

Owner:HARBIN BOILER

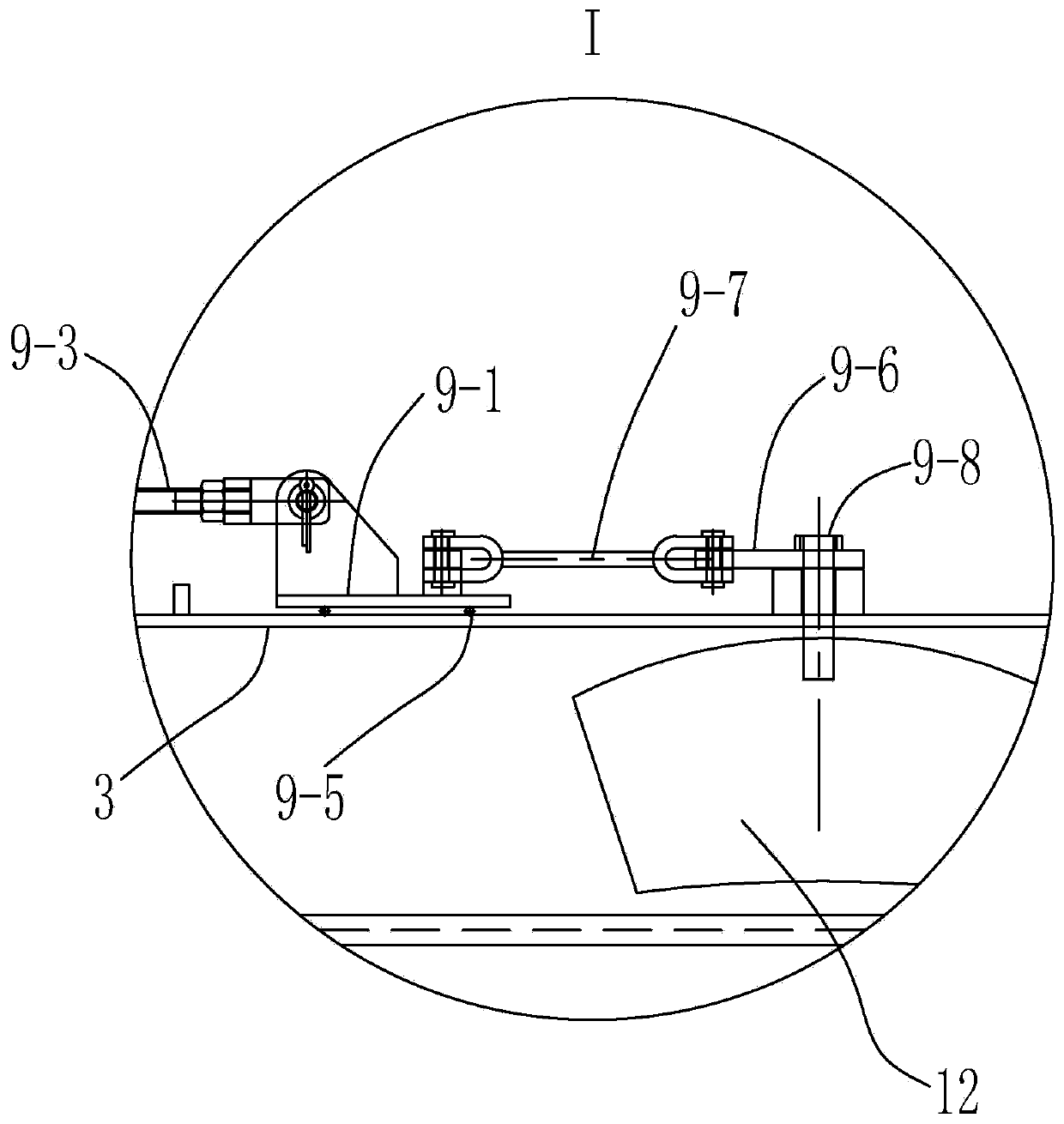

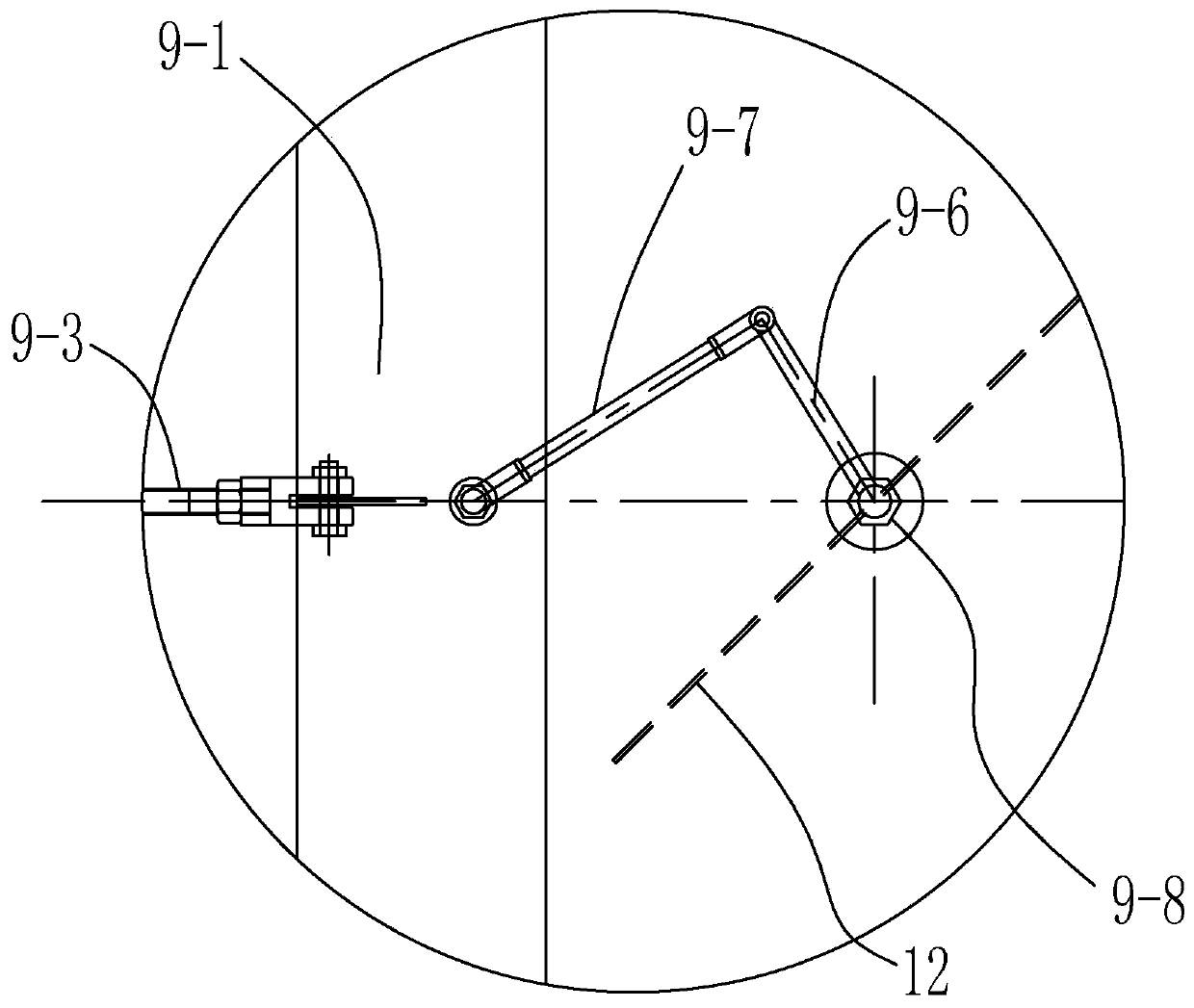

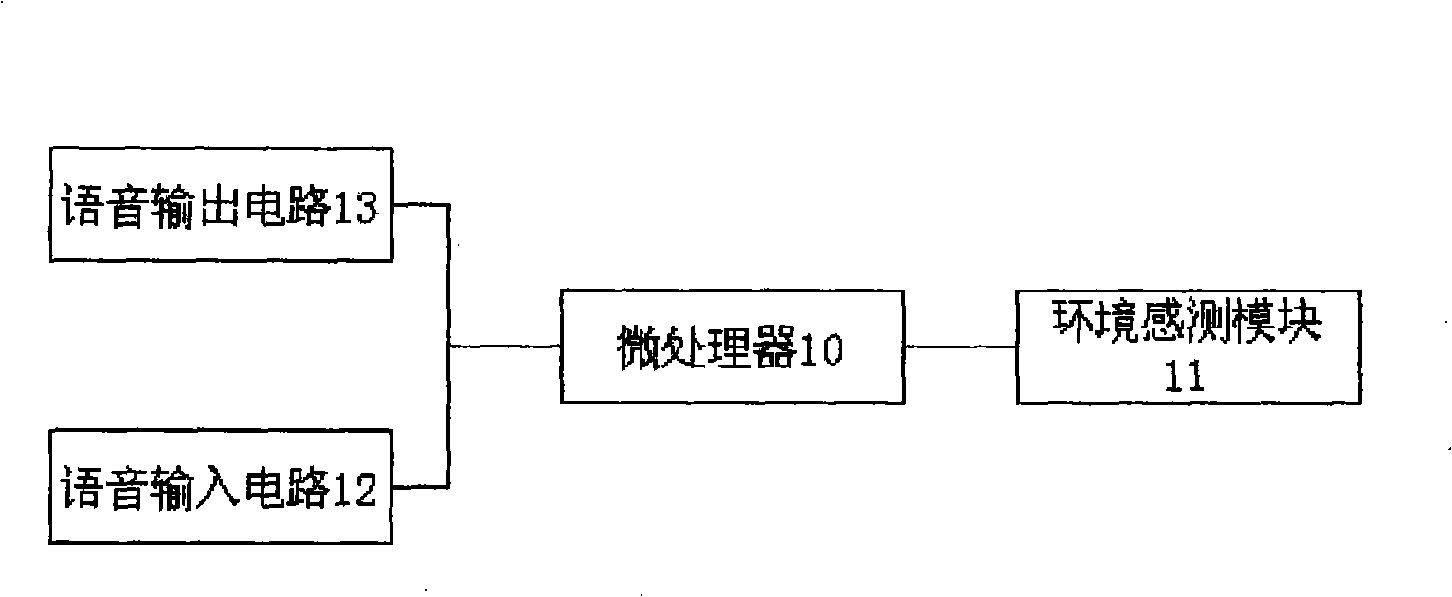

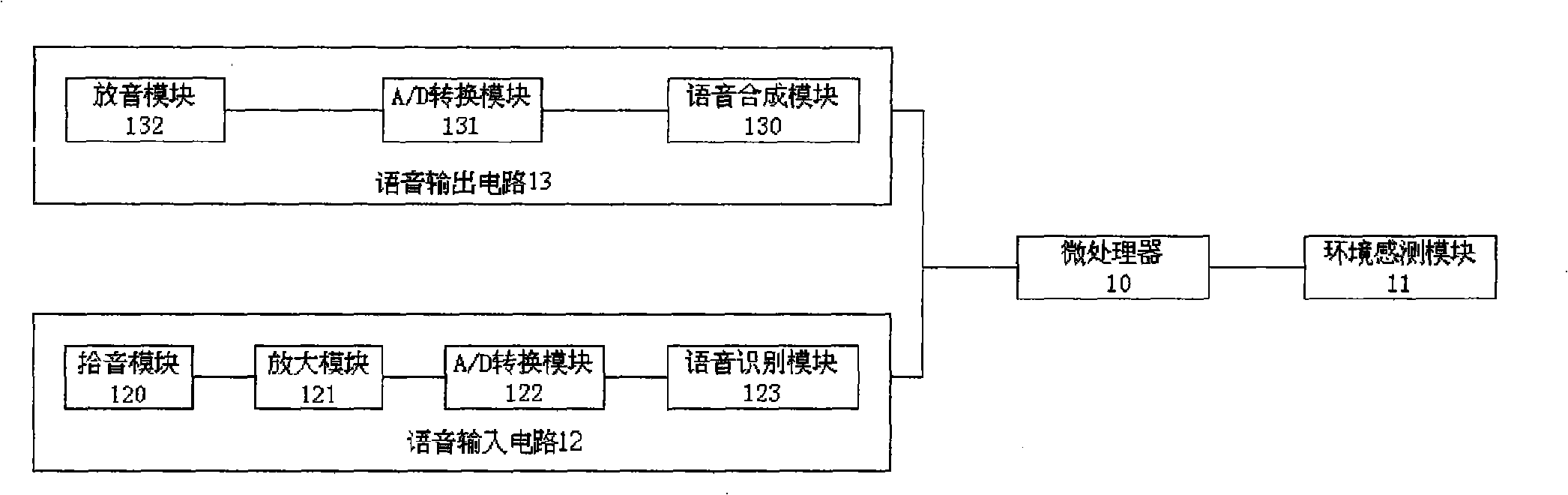

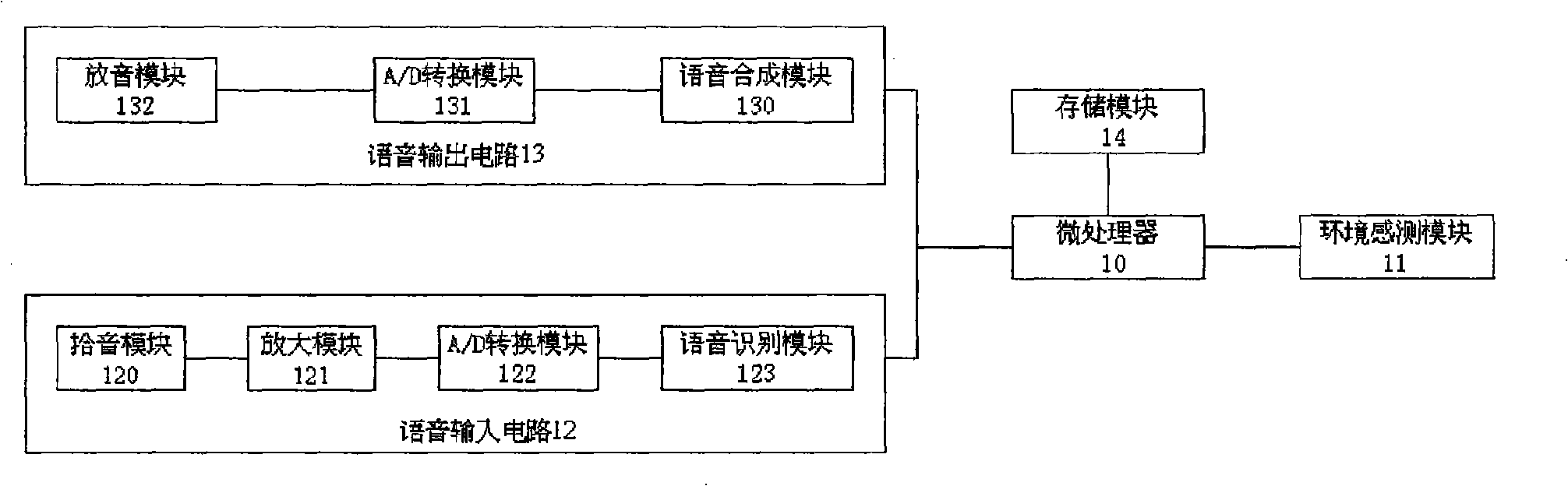

Intelligent toy and use method thereof

The invention provides an intelligent toy which comprises a microprocessor, an environment sensing module that is electrically coupled with the microprocessor and used for sensing variation values of the environment around the toy and outputting environment sensing signals, a speech input circuit which is used for inputting a first pronunciation field and converting the first pronunciation field into a speech input signal, a speech output circuit which is used for outputting a second pronunciation field. The microprocessor sends a pronunciation control order to the speech output circuit according to the received environment sensing signal or speech input signal to trigger the speech out circuit to output the second pronunciation field. The intelligent toy is characterized by high sensitivity, strong responsivity, great interest, interactive communication, rich and renewable contents, and the like, which is a playing partner and a study medium. A use method for playing the intelligent toy is provided either.

Owner:李丽丽

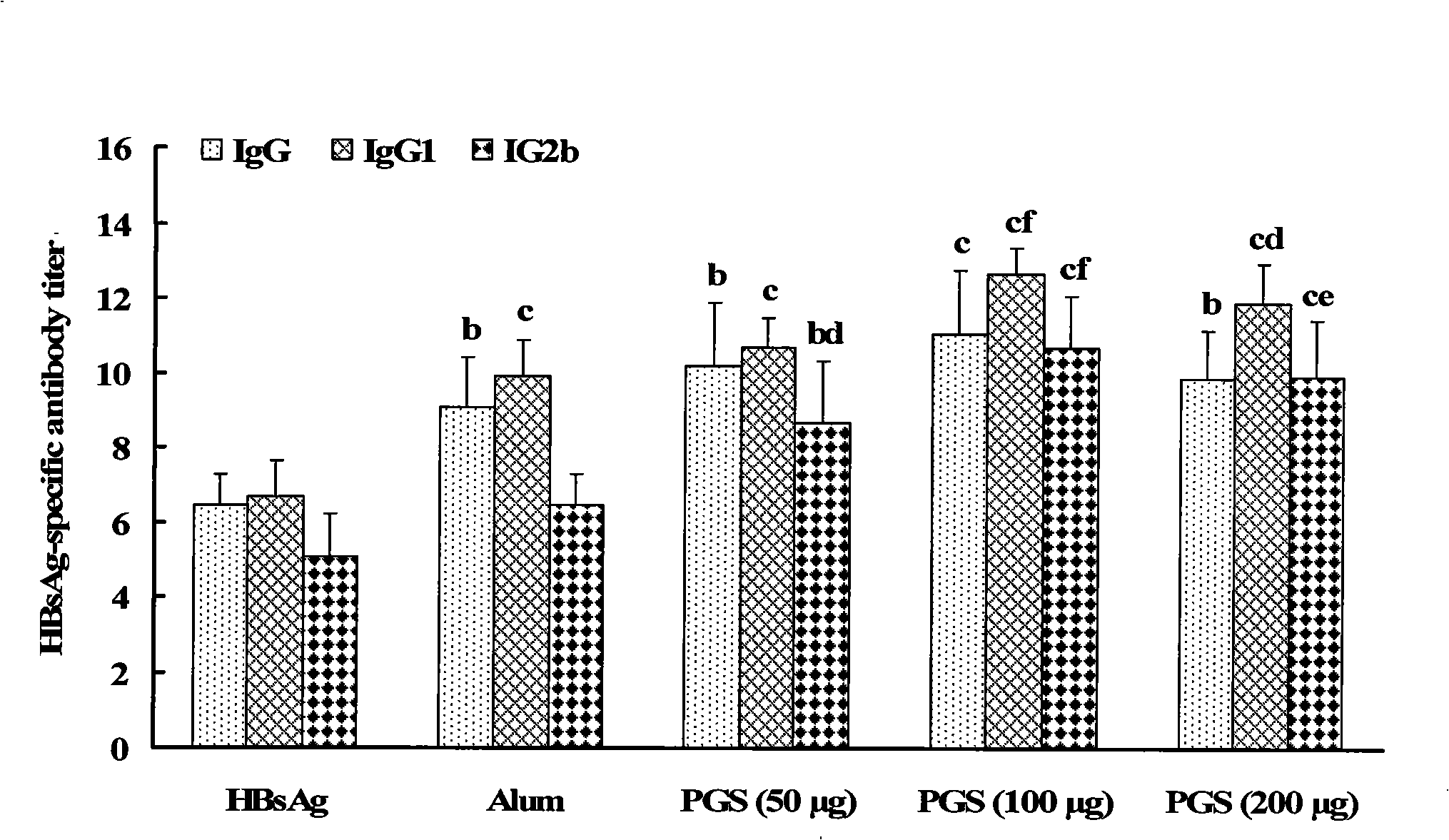

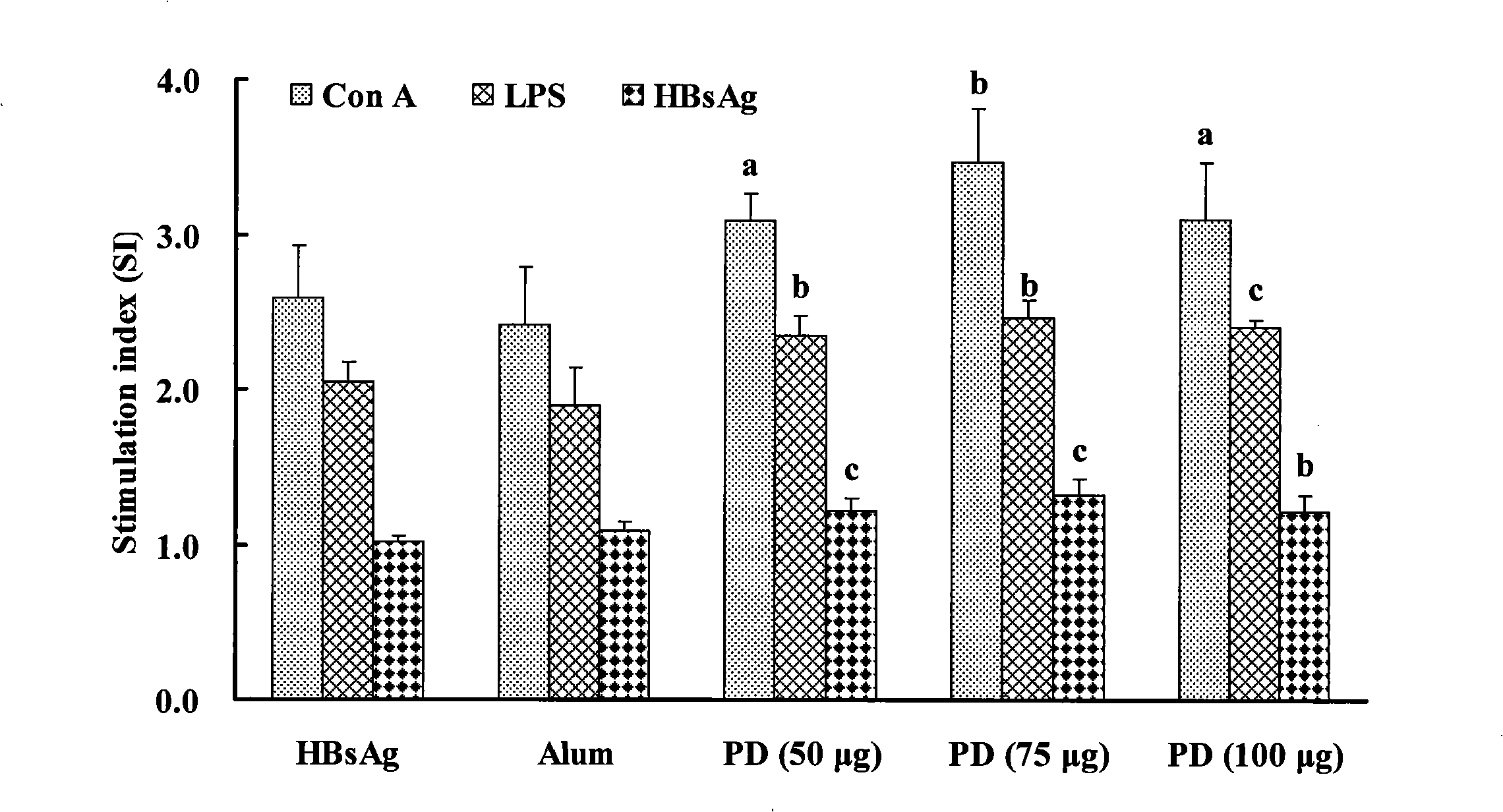

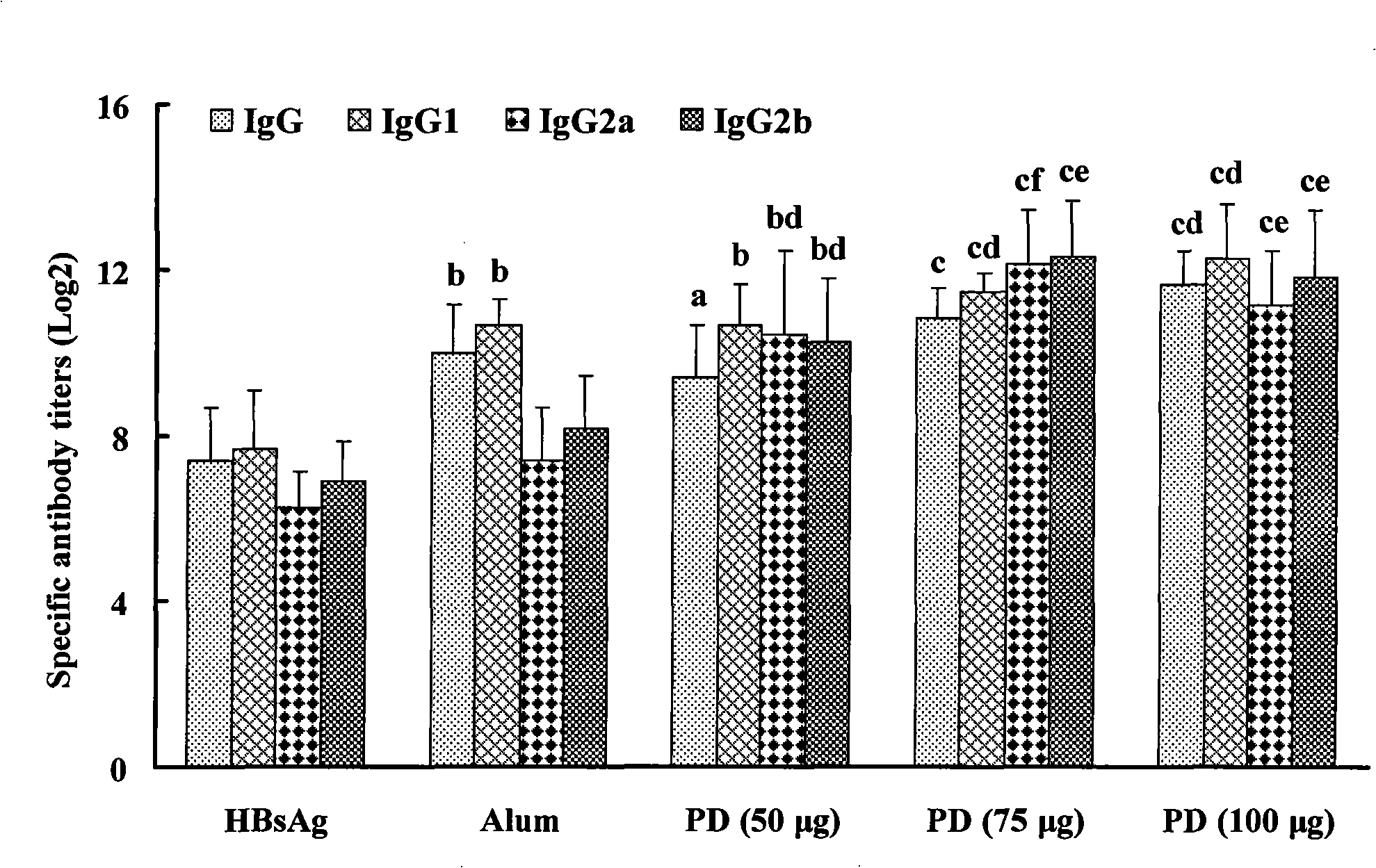

Saponin with immunoadjuvant function, preparation method, vaccine preparation containing the saponin as adjuvant and uses thereof

InactiveCN101402666ASimple preparation processSimple methodAntiinfectivesSteroidsDiseaseCell immune response

The invention relates to a saponin with immune adjuvant function and a preparation method thereof, a vaccine preparation containing the saponin as an adjuvant, and applications of the saponin and the vaccine preparation in the prevention and treatment of infectious diseases and cancers of human and animals. The saponin is platycodin D, platycodin D2, or a total-saponin containing the two saponin compounds. The platycodin D and platycodin D2 are both extracted and separated from balloonflower, a Chinese medicine. The saponin can induce an organism to generate Th1-type and Th2-type immune responses, show the capability of inducing the organism to generate stronger cell immune response and humoral immune response to a vaccine than the alhydrogel adjuvant known in the prior art, and can be taken as the immune adjuvant for a plurality of vaccines and achieve an ideal immunity effect. The vaccine which takes the saponin as the adjuvant has simple preparation technology and simple and convenient method, and the quality is easy to control and the saponin can be reserved by freezing.

Owner:ZHEJIANG UNIV

Landslide displacement dynamic prediction method based on multiple influence factors

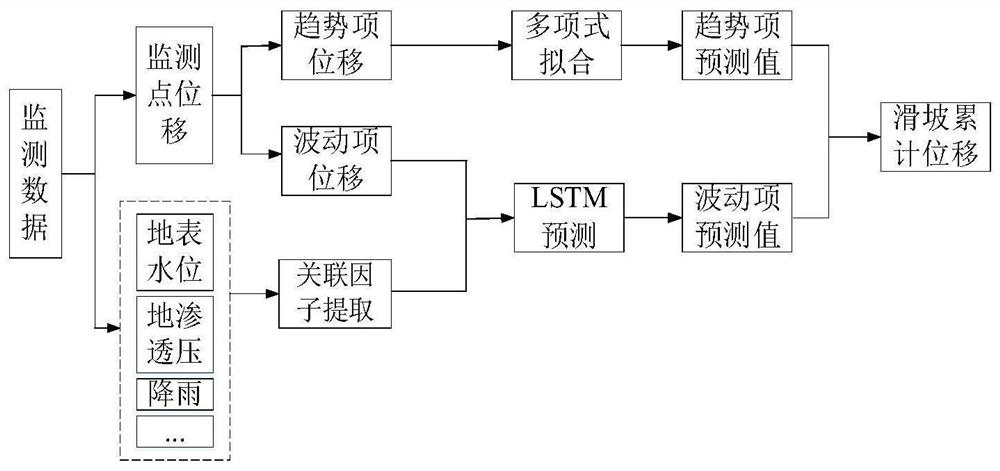

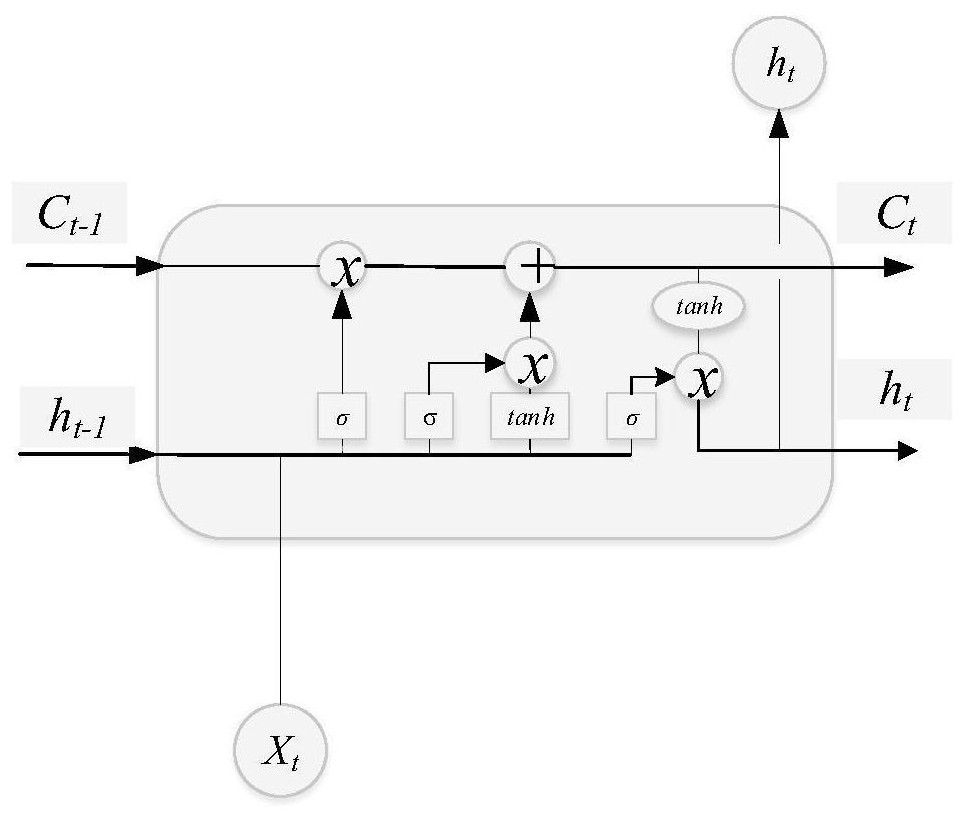

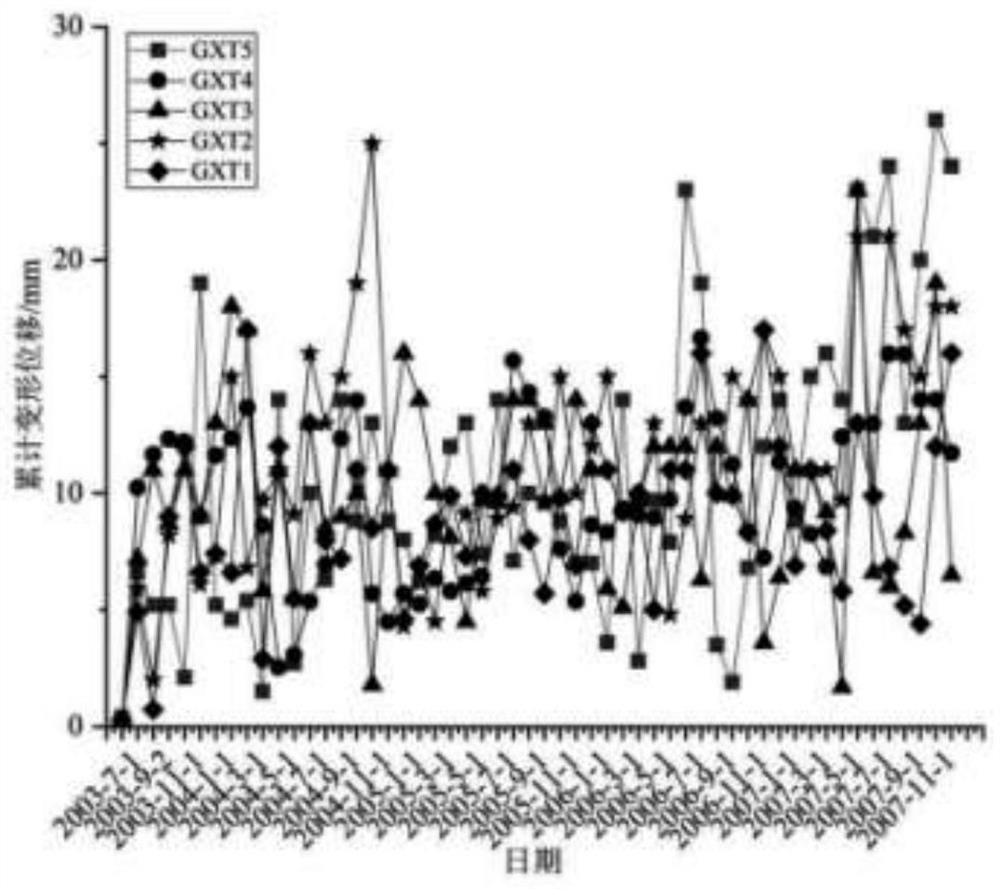

PendingCN112270400ASolution can't be keptSolve the difficulty of integrating multi-source heterogeneous impact factors for collaborationCharacter and pattern recognitionDesign optimisation/simulationMoving averageLandslide

The invention discloses a landslide displacement dynamic prediction method based on multiple influence factors. The landslide displacement dynamic prediction method is specifically implemented according to the following steps of 1, decomposing a landslide cumulative deformation displacement time curve according to a time sequence addition model; 2, extracting trend term displacement from landslidecumulative deformation displacement time curve decomposition by adopting a moving average method; 3, predicting trend term displacement by adopting a cubic polynomial; 4, selecting a main influence factor from the predicted trend term displacement by adopting a grey correlation degree sieve and taking the main influence factor as an initial input vector of a deep learning LSTM neural network model to predict the landslide periodic term displacement; and 5, according to a time sequence decomposition principle, superposing the predicted values of the displacement sub-sequences to obtain a finalpredicted value of the displacement, thereby finishing the dynamic prediction of the landslide displacement, and solving the problem that information at a long ago moment cannot be reserved in the prior art.

Owner:XI'AN POLYTECHNIC UNIVERSITY

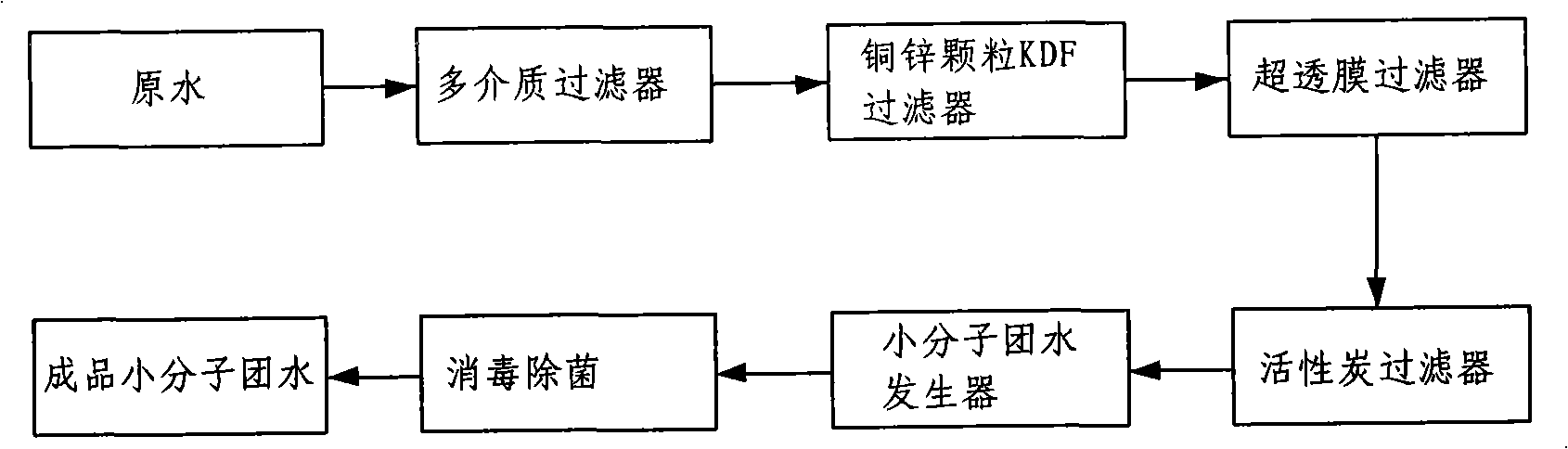

Production process of small micellae water

InactiveCN101353212AEasy dischargeSmall diameterWater/sewage treatment with mechanical oscillationsWater/sewage treatment by electrochemical methodsHazardous substanceFiltration

The invention discloses a process for producing small micelle water, which comprises the steps that: a. filtration is carried out by filters of multi levels, and large particle impurity is filtered out; b. the treated water passes through copper-zinc particle KDF; c. then the water passes through an ultrafiltration membrane filter in which the diameter of filtration pore is less than 0.01mum; d. then filtration is carried out by active carbon; e. and the water is sent to a small micelle water generator for treatment; f. the treatment of antisepsis and sterilization is carried out on the small micelle water which is treated by the small micelle water generator. By the production process of the invention, municipal tap water, or natural water, or pure water can be filtered for removing various harmful substances and impurity contained in water, and small micelle water can be generated by the small micelle water generator, meanwhile microelements in raw water which are beneficial to human body are preserved. The process of the invention is simple and effective, safe and reliable, which can be applicable to popularization and use extensively.

Owner:魏云海

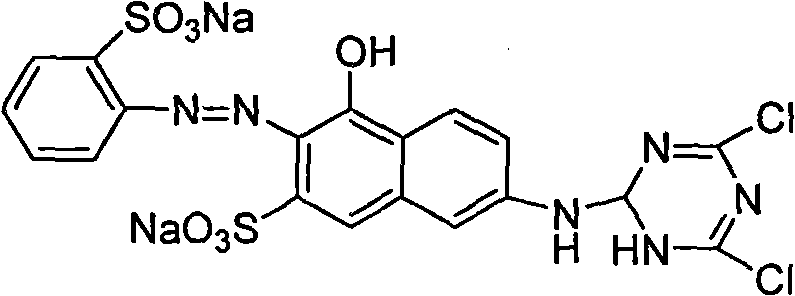

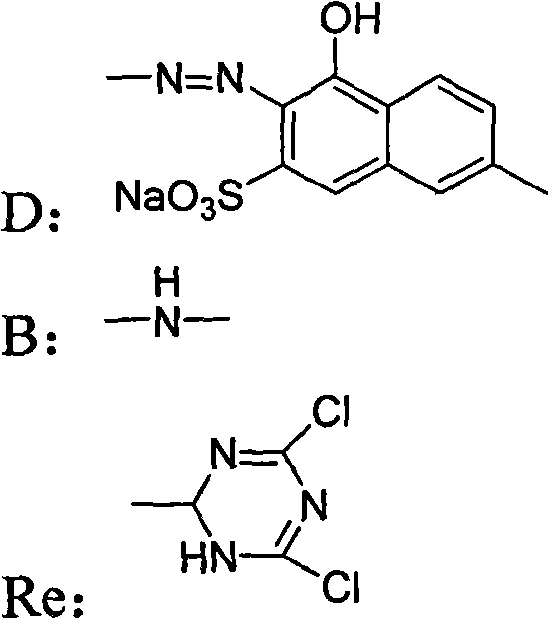

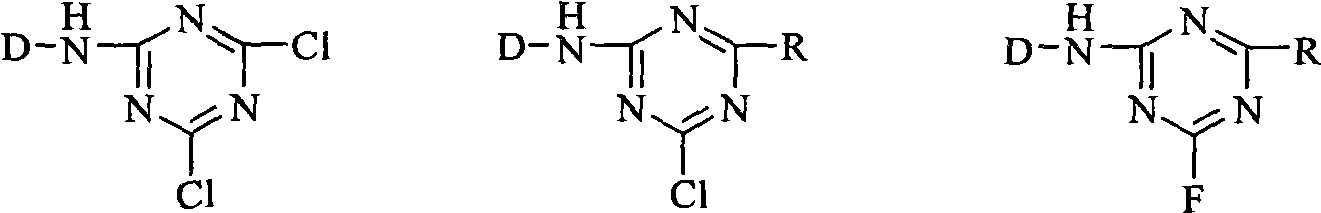

Method for producing coagulant for active dye wastewater

InactiveCN102092830AImprove performanceIncreased sensitivityWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationProcess equipmentVinyl sulfone

The invention relates to a printing and dyeing industrial wastewater treatment technology, and discloses a novel formula of a coagulation decolorant for active dye wastewater. The coagulation decolorant is a compound coagulation decolorant which is prepared by blending sodium polyacrylate serving as an additive, alkaline aqueous solution of polyvinyl alcohol, and dicyandiamine-formaldehyde polycondensate. The process equipment is general equipment, and raw materials are readily available. The formula of the coagulation decolorant is suitable for treating active dye wastewater and wastewater generated after printing and dyeing process production of cotton knitted fabrics, linen knitted fabrics and the like; and the wastewater mainly contains s-triazines, halogenated pyridines, vinyl sulfones and double active radical type compounds. The decolorization rate of the coagulation decolorant is more than 90 percent.

Owner:上海康鸣高科技有限公司

Preprocessing method of raw materials for ferrosilicon smelting

InactiveCN101280356AReduce the degree of deteriorationGood volatileSocial benefitsPretreatment method

The invention relates to the smelting technology, in particular to silicon iron smelting raw material and a preprocessing method. The preprocessing method comprises the following steps: firstly, silicon contained raw material is mixed with the carbonaceous reducing agent according to a certain ratio; secondly, a 40 to 80 mm oval or oblate pellet is pressed into form through a mechanical way; thirdly, after drying, the percentage of moisture is controlled for less than two percent, and then the raw material can be used as silicon iron smelting raw material. The silicon iron smelting raw material and the preprocessing method have the advantages that the raw material resource is rich, the price is inexpensive, and the energy saving effect is obvious, simultaneously, because a great amount of , the silicon fine powder and siliceous colliery waste are adopted by the technology, the social benefit and the environmental benefit are quite good.

Owner:樊玉山

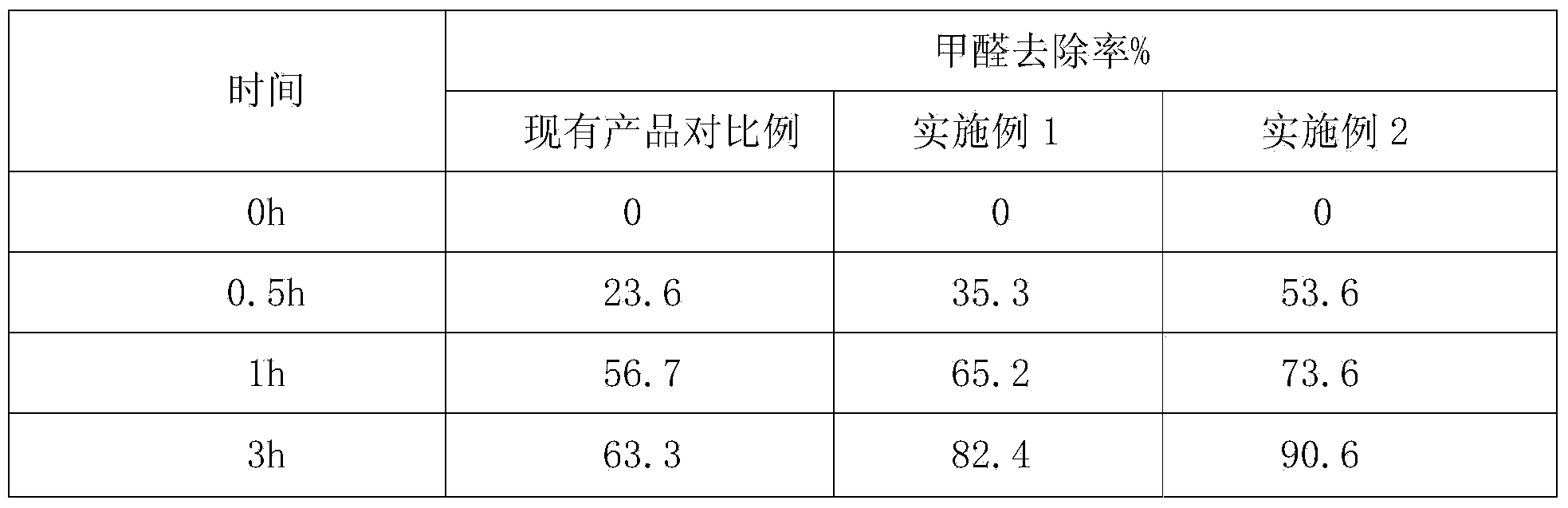

Production method of high-adsorptivity melt-blow non-woven fabrics

ActiveCN103590196AGuaranteed purification efficiencyGuaranteed adsorption effectNon-woven fabricsMANGANESE ACETATEActivated carbon

The invention discloses a production method of high-adsorptivity melt-blow non-woven fabrics. The production method comprises the production steps that (1), formaldehyde removal particles and activated carbon particles are stirred and mixed evenly according to the mass percent of (25-75%):(75%-25%) to obtain annexing agent materials; (2), macromolecule granules and an assisting agent of non-woven fabrics with the weight percent being 25:(0.4-1.6) are mixed and stirred evenly, melt spinning is carried out through a melt-blow method, the mixture is evenly mixed with the annexing agent materials in the step (1) before net formation, and the high-adsorptivity melt-blow non-woven fabrics are obtained by the utilization of air currents or mechanical net formation. The formaldehyde removal particles comprise potassium permanganate, platinum powder, manganese acetate, sodium hydroxide, activated aluminum oxide and titanium dioxide all of which the mass percent is 1:(0.01-0.05):(0.5-1.0):(1-2):(0.3-0.8):(1-3). The formaldehyde removal particles in the non-woven fabrics can capture target molecules and make contact with active constituent in the non-woven fabrics to generate the chemical adsorption reaction, and the formaldehyde removal rate is extremely high.

Owner:广东美沃布朗科技有限公司

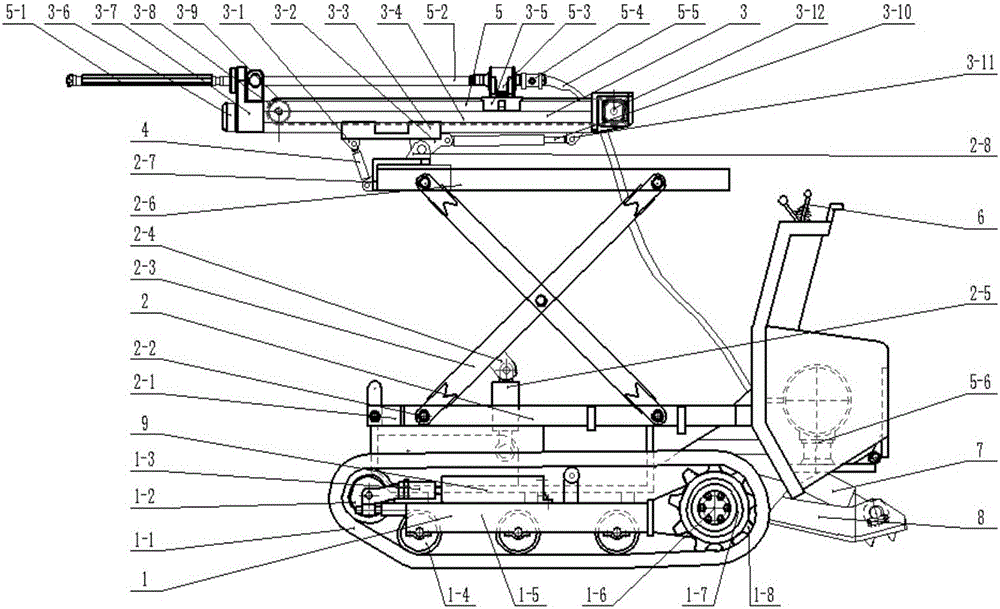

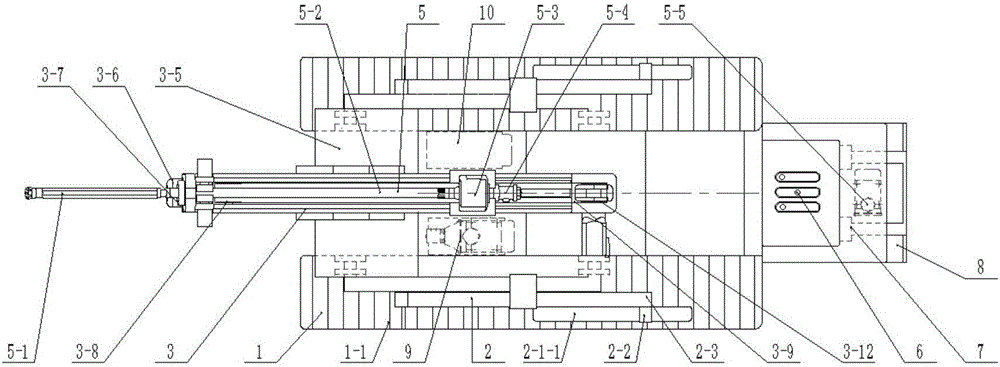

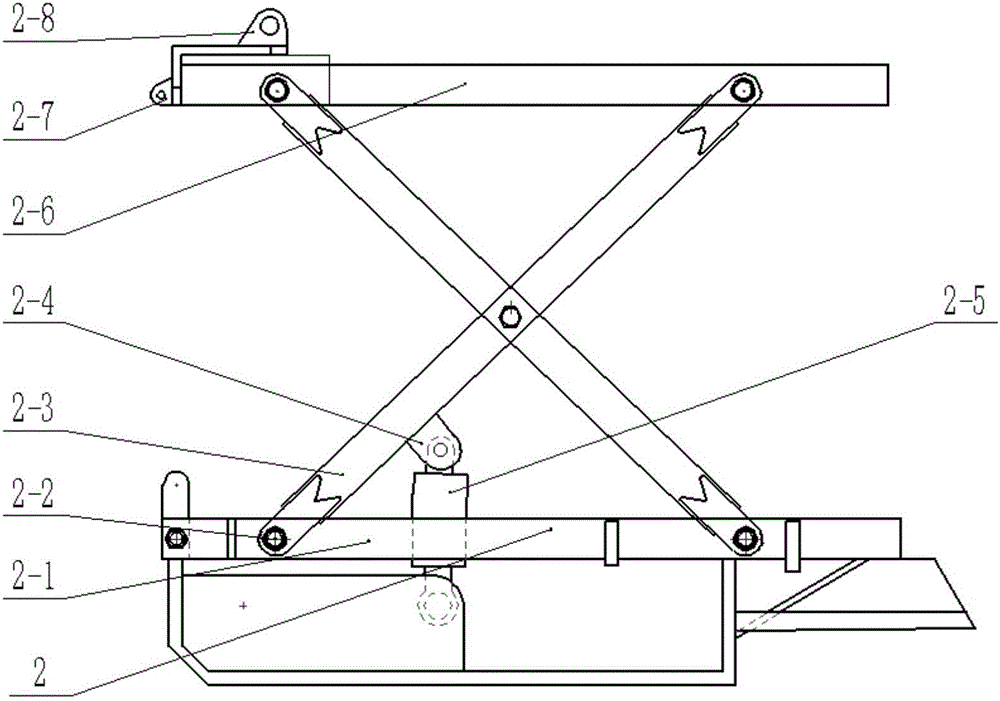

Self-moving type water jet drilling machine

The invention belongs to drilling machine equipment and particularly relates to a self-moving type water jet drilling machine. The self-moving type water jet drilling machine is composed of a walking device, a lifting device, a feeding device, an inclination adjusting oil cylinder, a stabilizing oil cylinder, a water jet drilling device, a control rod, a rear supporting oil cylinder and a rear supporting seat. The drilling machine is capable of achieving crawler belt self-walking, stable in walking, high in climbing ability, capable of turning in situ and flexible; the water jet drilling technology is adopted, and a drill bit is small in size, small in recoil and vibration and convenient to operate; dust and heat emitting are avoided, and the fireproof, anti-explosion and chemical reaction resisting capability is high; meanwhile, the dust fall effect of water can be used for remarkably reducing dust on a working surface, and the field construction condition is improved; the service life of related matching machines can be prolonged with the cooling effect of water; the drilling depth, height and perpendicularity are all adjustable, and the drilling machine is especially suitable for drilling coal mine underground gas extracting and exhausting holes, advanced detection holes, fluid injection fire-fighting holes, coal bed water injection holes, outburst prevention pressure releasing holes and geological exploring holes and other engineering hole construction.

Owner:宿州学院

Method for producing coal gasification formed coke

InactiveCN101440295AHigh mechanical strengthUniform particle sizeSpecial form destructive distillationPolyvinyl alcoholCarbonization

The invention relates to a method for manufacturing coal gasification type coke. Blind coal is used as a main material, is added with a caking agent and is pressurized to form type coal; the type coal is subjected to middle-temperature carbonization and high-temperature oxygen-isolated carbonization to manufacture type coke, wherein raw material coal comprises 75 to 90 percent of blind coal, 3 to 10 percent of one-third coking coal, 5 to 12 percent of fat coal and 2 to 10 percent of graphite; the composite caking agent is made from a mixture of hydrochloric acid and sodium hydroxide accounting for 0.1 to 0.5 percent of the weight pulverized coal, a polyvinyl alcohol modified solution accounting for 7 to 10 percent of the weight the pulverized coal, weathered coal accounting for 5 to 10 percent of the weight the pulverized coal and high aluminium powder accounting for 0.5 to 3 percent of the weight the pulverized coal according to proportion. The manufactured product has high fixed carbon and high heating power, can substitute for the blind coal or the coke to produce water gas, does not need to make any reconstruction on the prior gas generating furnace, can reduce the production cost of the water gas, improve the economic value of the pulverized coal of the blind coal, can be widely applied to fertilizer, metallurgy, building materials and other industries, and has good market application prospect.

Owner:福建龙耀煤业科技有限公司

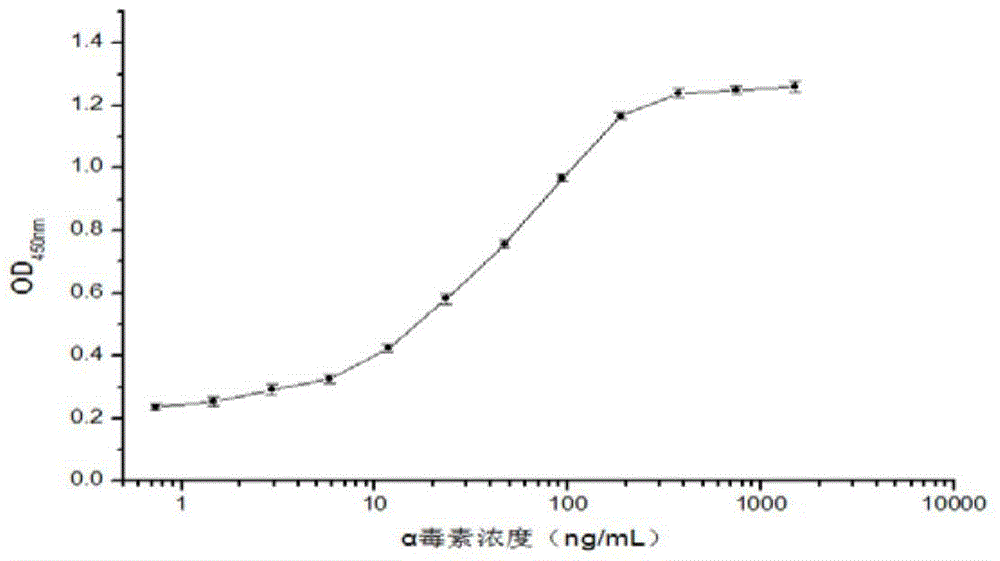

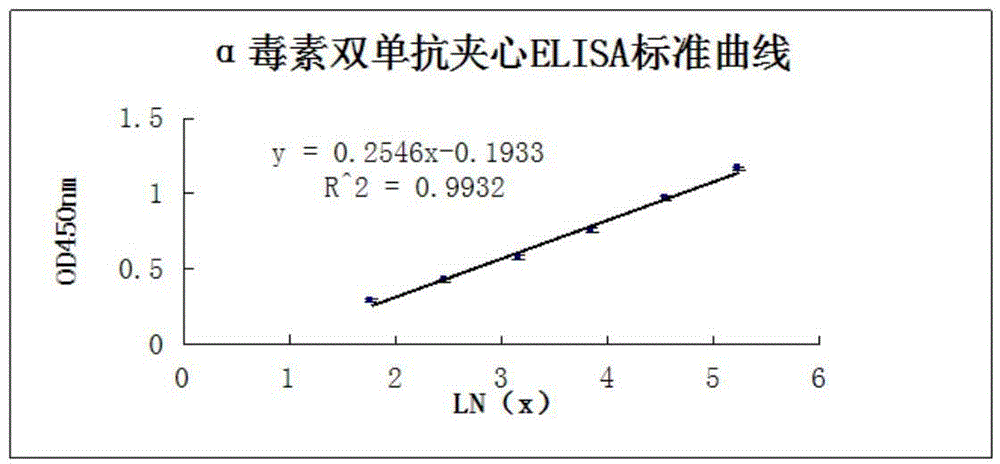

Clostridium perfringens alpha toxin double-antibody sandwich ELIS quantitative determination method

ActiveCN103941004AStrong specificityStrong responsivenessMaterial analysisAlpha-toxinClostridium perfringens toxoid

The invention relates to a clostridium perfringens alpha toxin double-antibody sandwich ELIS quantitative determination method. According to the clostridium perfringens alpha toxin double-antibody sandwich ELIS quantitative determination method, alpha toxin protein obtained via prokaryotic expression is taken as an immunogen; monoclonal antibodies obtained via hybridoma technique are taken as detection antibodies and capture antibodies; reaction conditions are optimized via experiments; alpha toxin protein samples with a series of concentration are used for construction of a standard curve; the double-antibody sandwich ELIS method is established; and indexes of the double-antibody sandwich ELIS are verified. The clostridium perfringens alpha toxin double-antibody sandwich ELIS quantitative determination method specifically comprises following steps: (1) prokaryotic expression of alpha toxin; (2) preparation of anti-alpha toxin monoclonal antibodies; (3) establishment of the double-antibody sandwich ELIS method; (4) establishment of the standard curve; and (5) performance evaluation on the double-antibody sandwich ELIS method. The clostridium perfringens alpha toxin double-antibody sandwich ELIS quantitative determination method is excellent in specificity, and high in sensitivity and stability, is fast and convenient, and can be used for effective quantitative determination of alpha toxin in A-E type clostridium perfringens cultural supernatants; and the high-efficient detection method is provided for alpha toxin determination.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

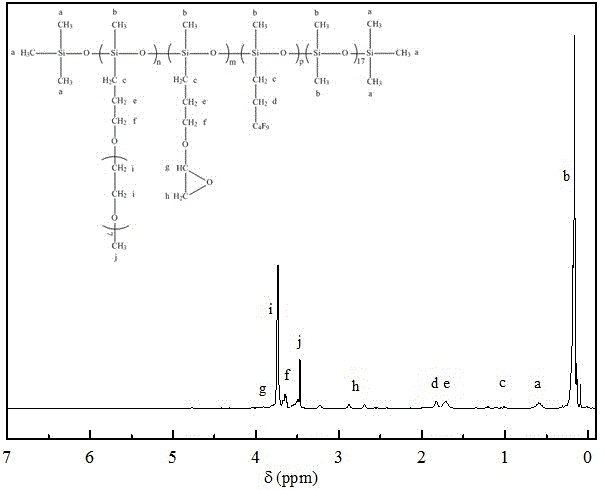

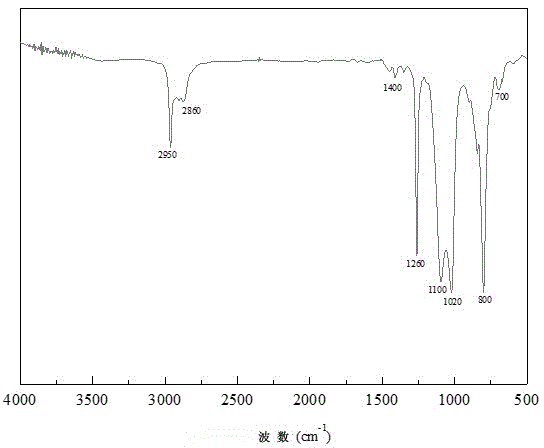

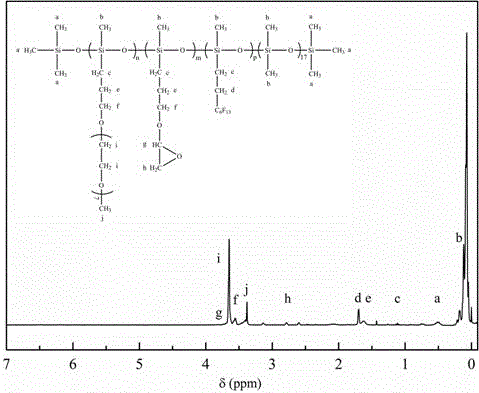

Fabric finishing agent and preparation method thereof

InactiveCN105484046AImprove water and oil repellencyImprove washabilityFibre treatmentEngineeringFluorine containing

The invention relates to a fabric finishing agent and a preparation method thereof, and belongs to the technical field of printing and dyeing auxiliary agents. The fabric finishing agent contains a polyether chain segment, an epoxy group and a fluorine-containing chain segment at the same time, and the one end of the fluorine-containing chain segment contains an alkene. the characteristics of being safe in raw materials, simple in technology and the like are provided when the fabric finishing agent is applied to printing and dyeing and the preparation method is applied to prepare the fabric finishing agent, the fabric finishing agent is capable of keeping original clothes performances and hand feeling of fabrics, and also is capable of effectively improving the water-repellent oil-repellent properties of fabrics.

Owner:浙江七色彩虹纺织整理有限公司

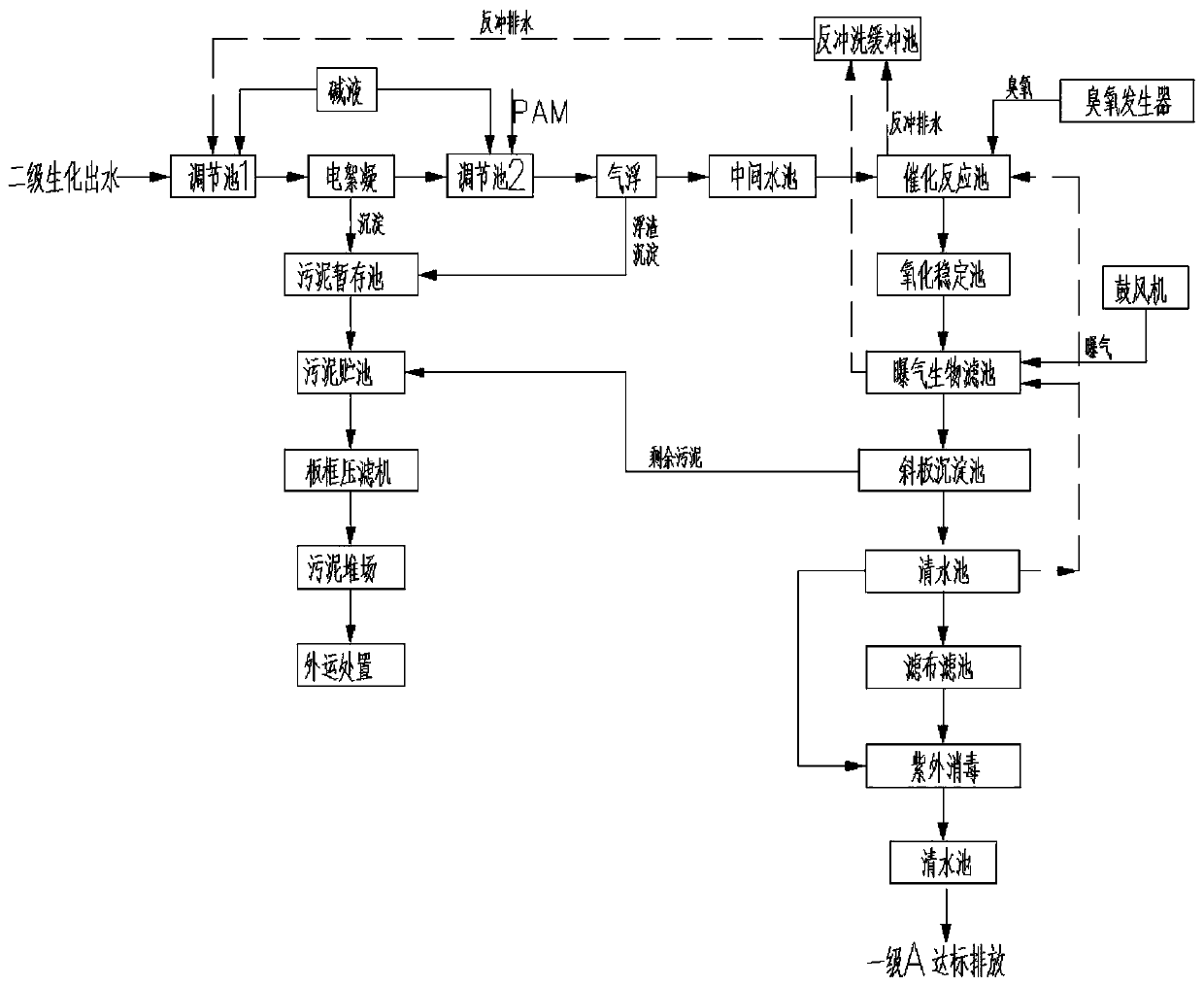

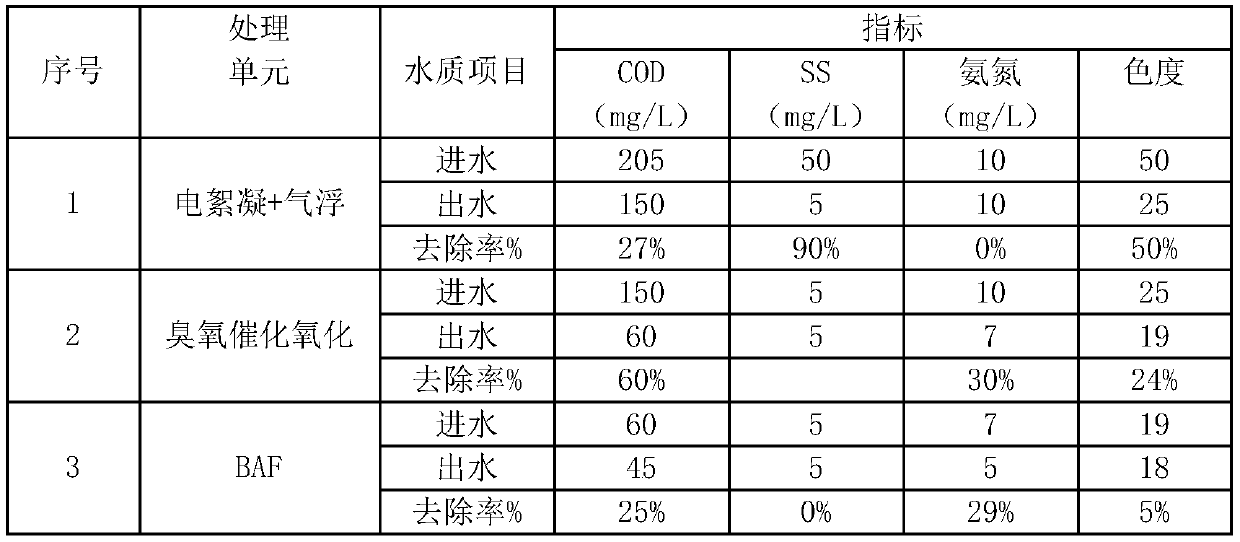

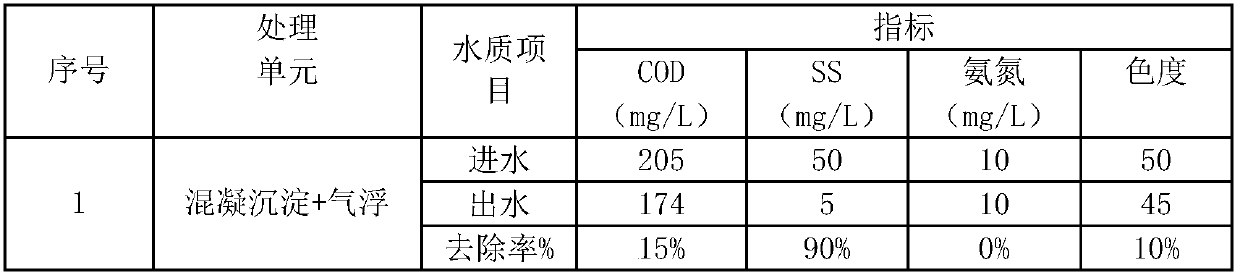

Advanced treatment process for chemical industry park wastewater

PendingCN110422964AGood removal effectImprove removal efficiencySludge treatment by de-watering/drying/thickeningTreatment using aerobic processesChemical industryDecomposition

The invention relates to the field of environmental engineering sewage treatment, in particular to an advanced treatment process for chemical industry park wastewater. Directed at the secondary biochemical effluent from chemical industry park sewage plants, the process utilizes electric flocculation and air flotation for pretreatment to separate suspended matters, the separated wastewater is subjected to ozone catalyzed oxidation decomposition and destruction of heterocyclic hardly degradable organic matters in wastewater, and the wastewater chroma is lowered, then the wastewater enters a biological aerated filter system for biological enhanced treatment, and the treated effluent enters a clean water tank, thus finally realizing discharging meeting the first level standard A. The advancedtreatment process is economical and feasible, and provides a reliable, efficient and stable combination technology for advanced treatment of chemical industry park wastewater.

Owner:DESIGN ENG OF SYRICI

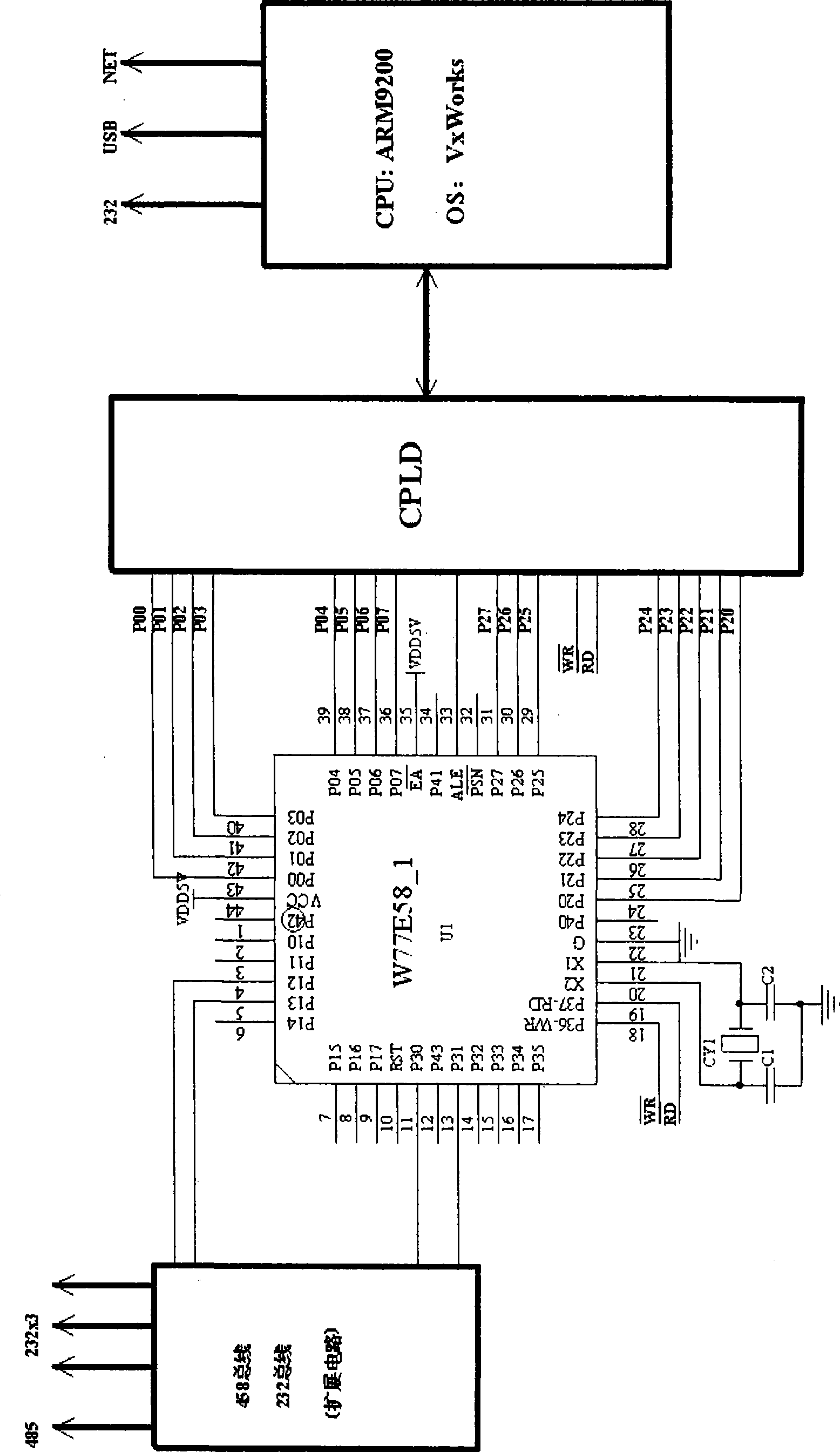

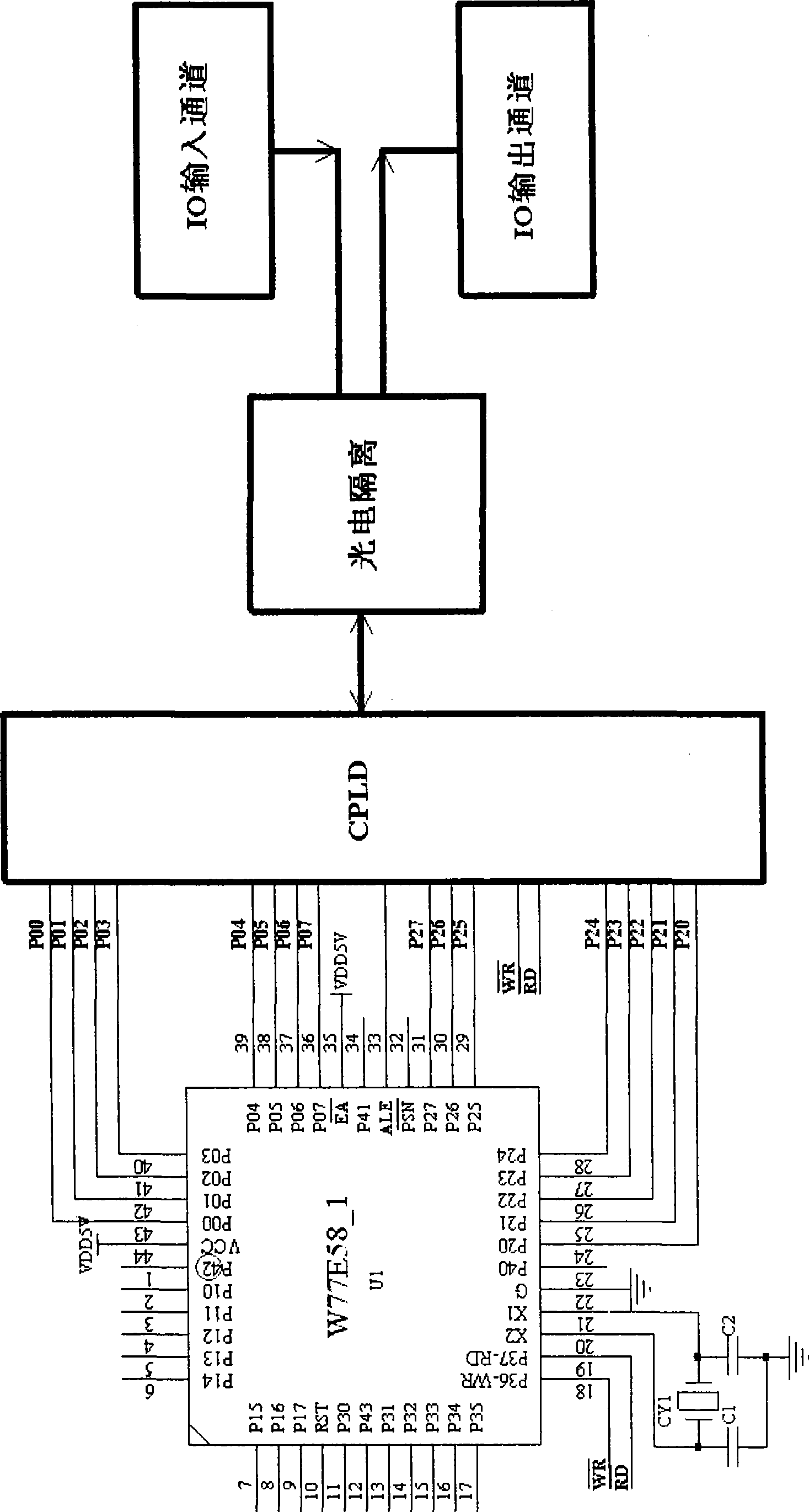

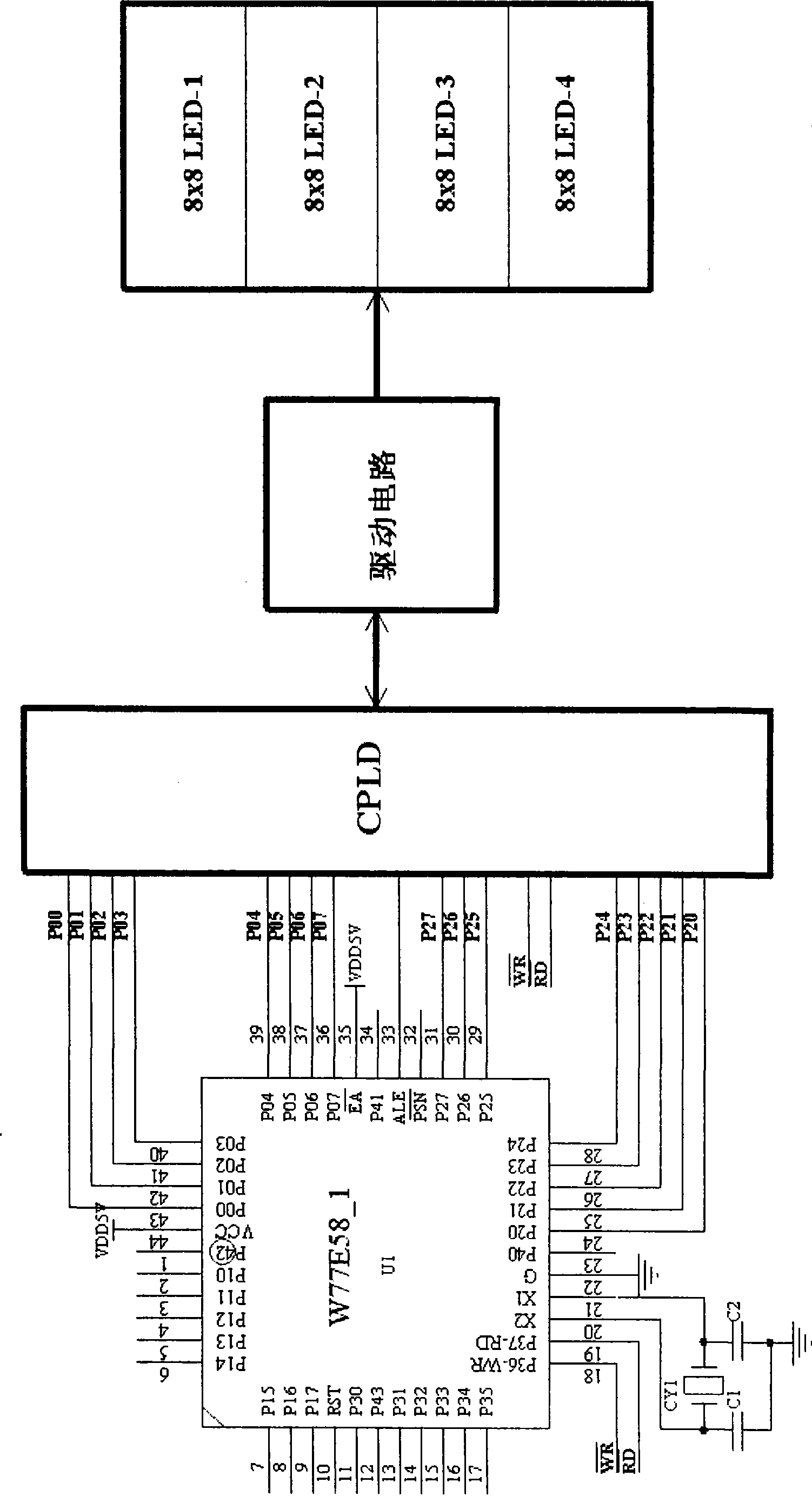

Built-in control system of special gate for rail traffic

InactiveCN101482980APowerfulStrong responsivenessProgramme controlTicket-issuing apparatusOperating modelJob demotion

An embedded control system for special turnstile for track traffic has a control center of the system constructed by closely combining an embedded ARM9200 CPU used as core control chip with a DCU-1 hardware module and DCU-2 hardware module; extremely strong real-time responsibility; a hardware system with modularized design and high integration; a hardware module with bus structural connection; parallel high-activity processing of system with separated service process and equipment control which operated independently and simultaneously; a multifunctional TFT passenger display; multiple demotion operating modes; function of sleep for saving energy and electricity; functions of remote monitoring, remote diagnosis, and repairing; and a designed powerful integrated simulation test platform matched with the control system of the gate machine.

Owner:天津市先志越洋科技有限公司

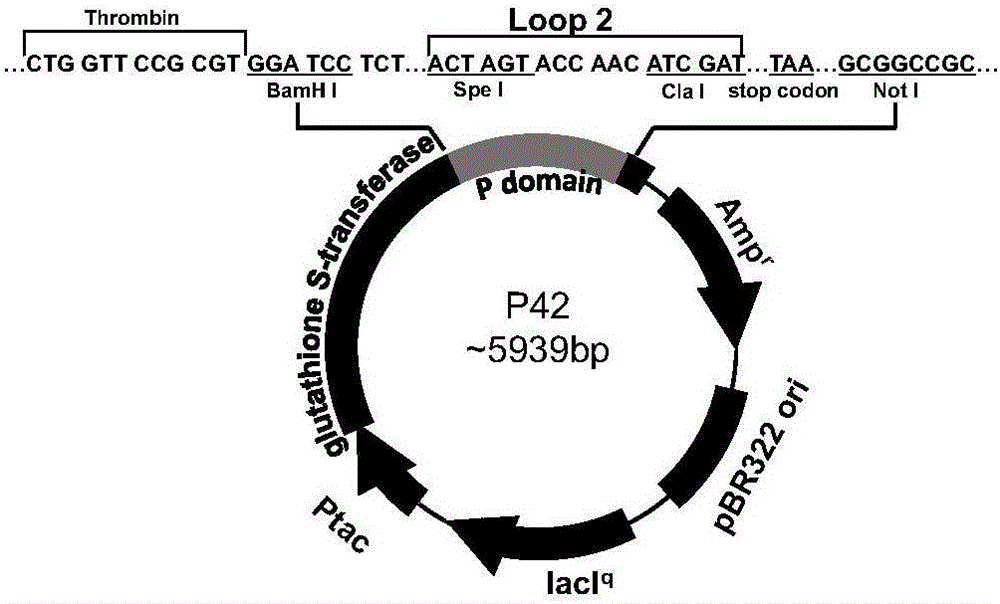

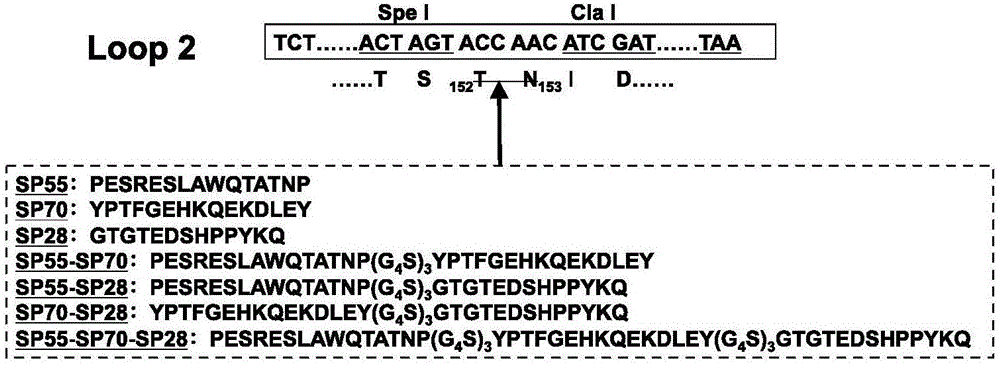

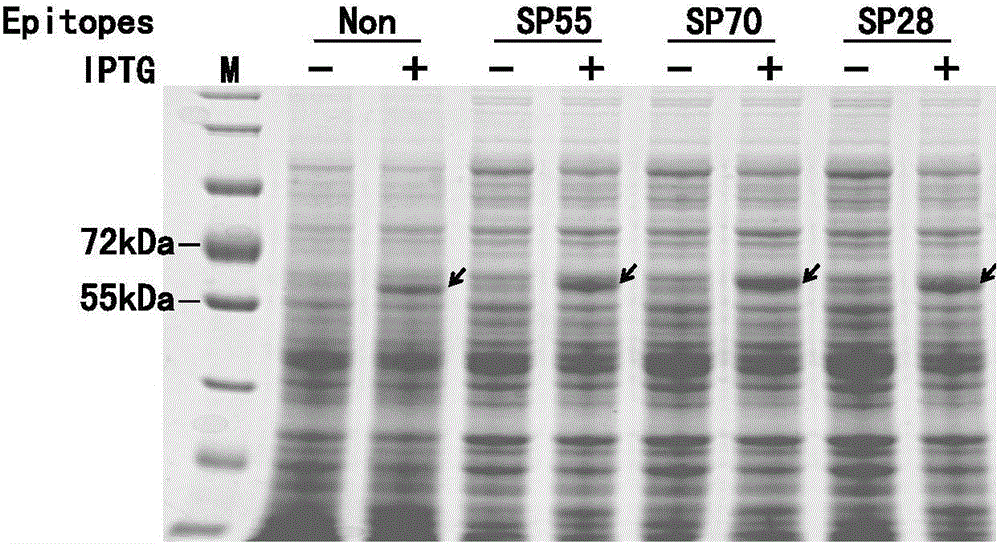

Establishing and expressing method for chimeric vector of EV71 neutralization epitope and norovirus P structure domain

PendingCN106220738AHigh purityEasy to makePeptide preparation methodsHybrid peptidesEnterovirusAntigen

The invention aims at providing chimeric protein of enterovirus EV71 neutralization epitope and a human norovirus P structure domain and an establishing method of a chimeric vector. By means of immunoblotting, it is verified that the chimeric protein of the enterovirus EV71 neutralization epitope and the norovirus P structure domain can be used for research and development of detection kits of EV71 and norovirus and novel bivalent subunit vaccines.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

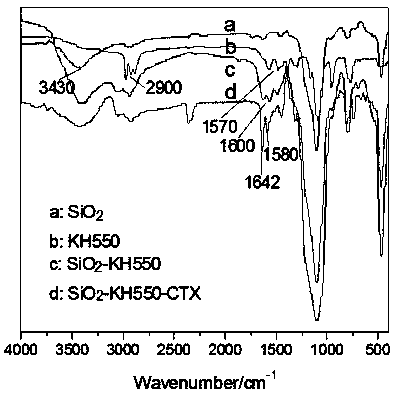

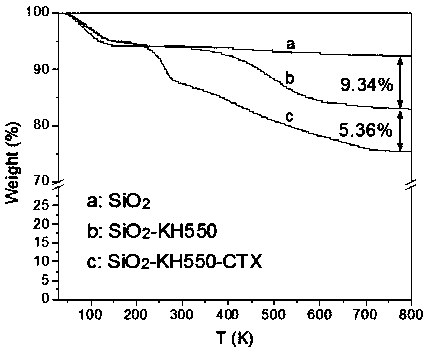

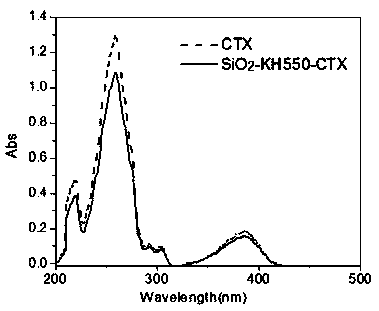

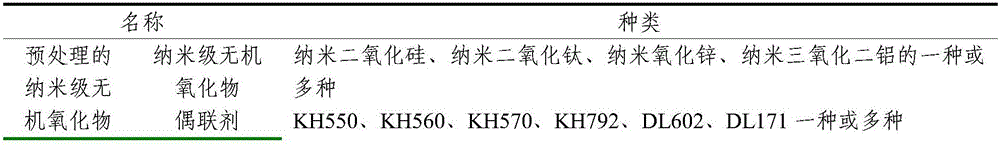

Inorganic nano-particle surface grafted photoinitiator and application thereof

The invention discloses an inorganic nano-particle surface grafted photoinitiator and application thereof. The photoinitiator is prepared by the following steps: (S1) dispersing inorganic nano-particles into an ethanol water solution, adding a silane coupling agent to react, so as to obtain surface silane coupling agent modified inorganic nano-particles; and (S2) dispersing the surface silane coupling agent modified inorganic nano-particles in the step (S1) into a good solvent of the photoinitiator, and adding the photoinitiator to react, so as to obtain the inorganic nano-particle surface grafted photoinitiator. The photoinitiator has the beneficial effects that an intermediate of the photoinitiator is non-toxic and environment-friendly, the reaction conditions are mild, the operation issimple and convenient, the silane coupling agent can be taken as a bridge of a thioxanthone photoinitiator and the nano-particles, the universality is strong, and the photoinitiator has excellent ultraviolet absorbing capacity when serving as the photoinitiator and is capable of effectively improving the mechanical properties, particularly the bending strength of photocuring materials when servingas filler.

Owner:GUANGDONG UNIV OF TECH

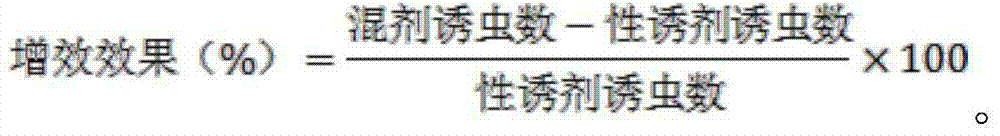

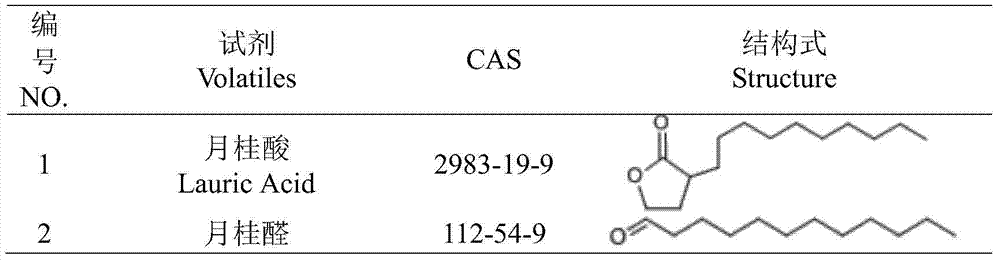

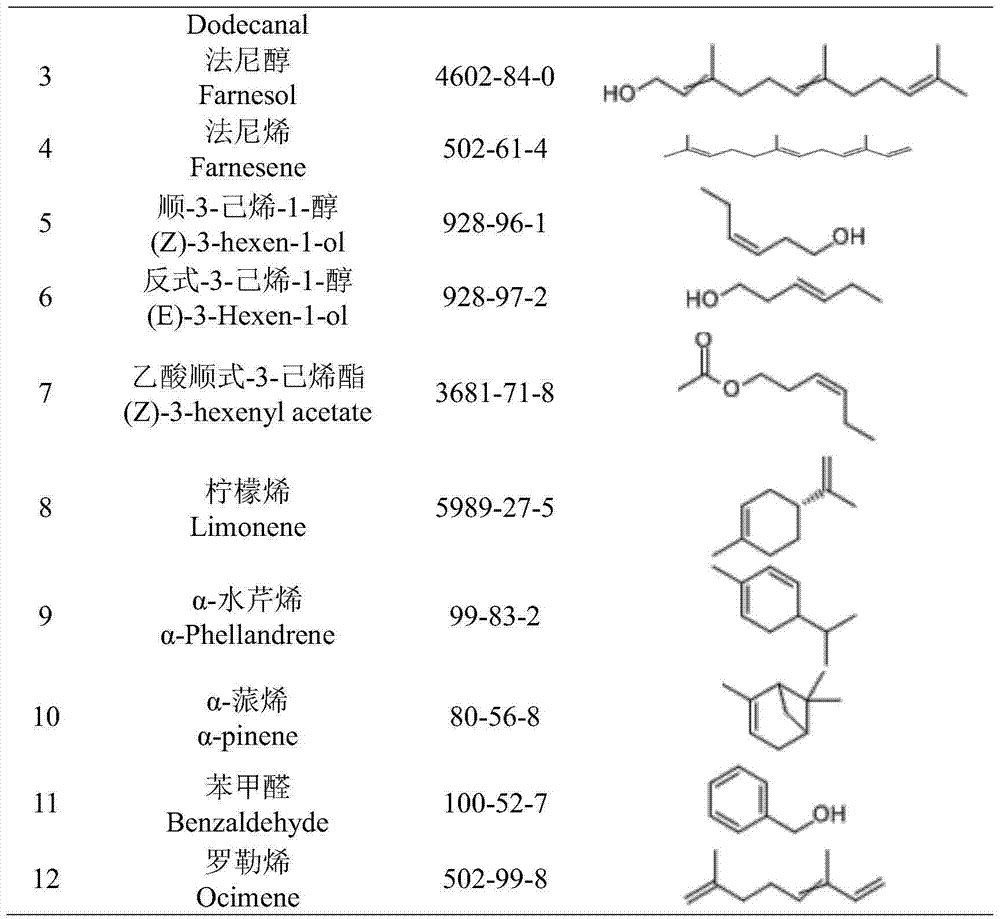

Acetic acid cis-3-hexenyl ester synergistic holotrichia parallela sex attractant

The invention discloses an acetic acid cis-3-hexenyl ester synergistic holotrichia parallela sex attractant, wherein the weight ratio of the sex attractant and acetic acid cis-3-hexenyl ester is (3-7):1. The sex attractant comprises a holotrichia parallela sex pheromone component and an organic solvent, wherein the holotrichia parallela sex pheromone component comprises methyl L-isoleucinate, (R)-(-)-linalool and 1-aminocyclohexanecarboxylic acid in a weight ratio of 6: 1: 0.1 and the weight ratio of the holotrichia parallela sex pheromone component and the organic solvent is 1: 3. The organic solvent is one or more of dichloromethane, methanol or acetone. Behavior experiments show that EAG and selective reaction rate of male and female worms on a mixture of the sex attractant and acetic acid cis-3-hexenyl ester are relatively good. The field trapping experiments on holotrichia parallela show that acetic acid cis-3-hexenyl ester has a synergistic effect on the trapping effect of the sex attractant, thereby providing a ground for monitoring and preventing and treating holotrichia parallela by using plant volatile matters and insect sex pheromone in a synergistic manner.

Owner:青岛罗素生物技术有限公司

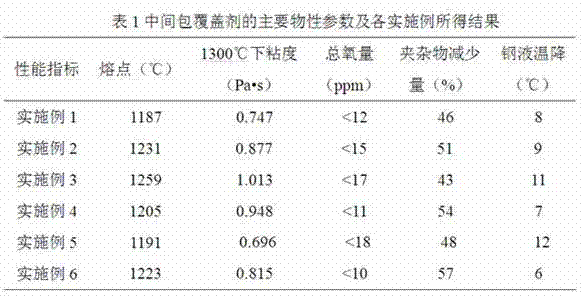

Tundish covering agent for continuous casting of low-carbon steel containing Al and Ti and application thereof

InactiveCN105436447AContinuous casting production went smoothlyEffective absorptionAlkalinityThermal insulation

The invention provides a tundish covering agent for continuous casting of low-carbon steel containing Al and Ti and an application thereof. The tundish covering agent is prepared from, by mass, 32%-43% of CaO, 7%-14% of SiO2, 25%-32% of Al2O3, 6%-14% of MgO, 6%-13% of (Na2O+Li2O), 3%-7% of B2O3, 0.5%-1.5% of C and 1.1%-2% of TiO2. The tundish covering agent is low in melting temperature and viscosity and high in alkalinity. The tundish covering agent has the advantages that the tundish covering agent is suitable for continuous casting of the low-carbon steel containing Al and Ti, the mass percentage of C is smaller than or equal to 0.1%, the content of Al is smaller than or equal to 0.5%, and the content of Ti is smaller than or equal to 0.5%, inclusions in the low-carbon steel containing Al and Ti can be efficiently absorbed, the cleanliness of molten steel in a tundish is increased, secondary oxidation of the molten steel is well avoided, recarburization is avoided, the quality of a casting blank is improved, and meanwhile good thermal insulation performance is achieved.

Owner:CENT SOUTH UNIV

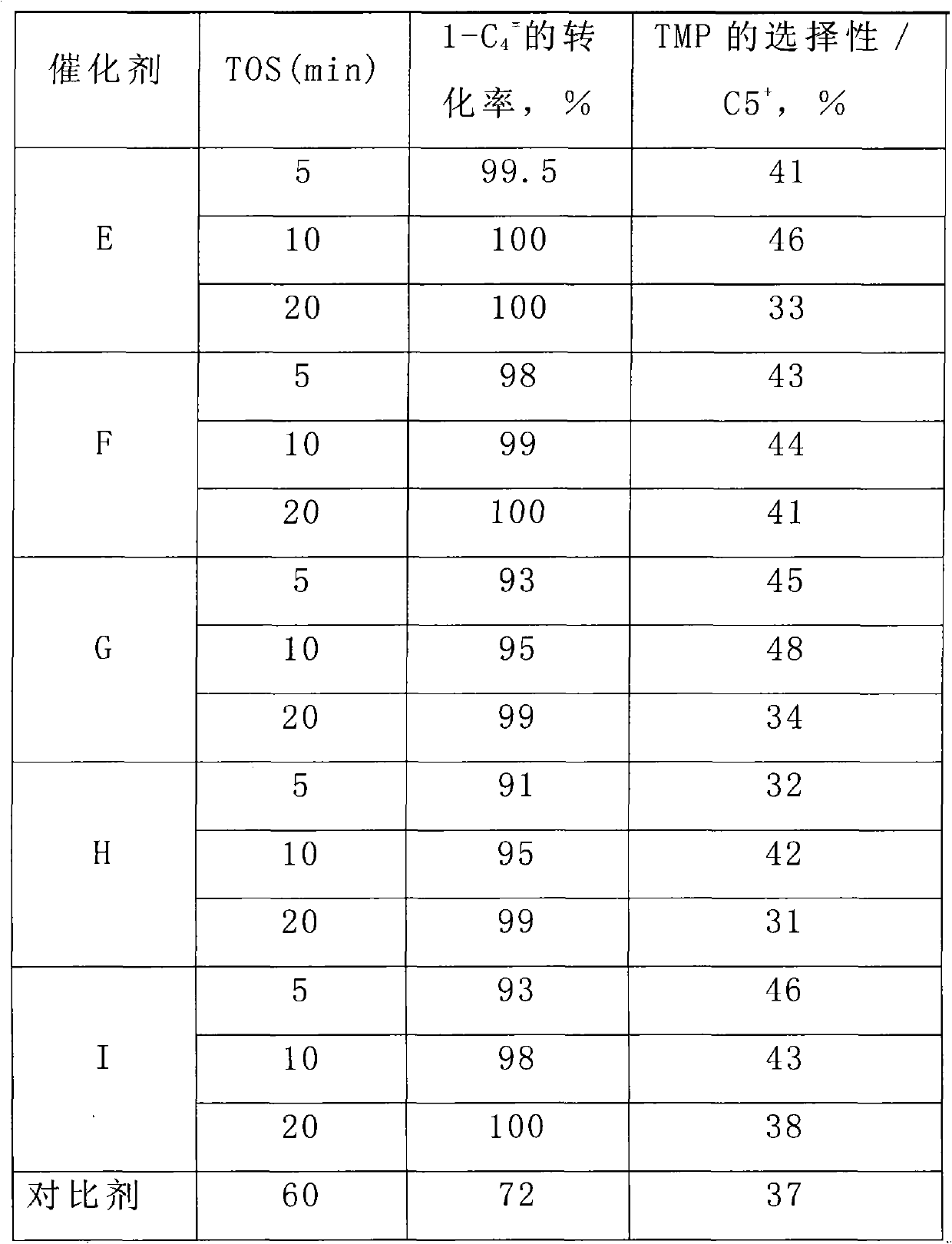

Alkylation catalyst

ActiveCN102553636AImprove conversion rateSolution to short lifeMolecular sieve catalystsHydrocarbon from saturated and unsaturated hydrocarbon additionAlkyl transferALUMINUM PHOSPHATE

The invention discloses a catalyst, in particular an alkylation catalyst. Aiming at the problems of high activity lowering speed and short service life in the use process of the alkylation catalyst in the prior art, the invention provides a novel alkylation catalyst comprising 2-98wt% of modified zeolite and 98-2wt% matrix material weighted on the basis of the total weight of the catalyst; the modified zeolite is one or more of H-Y zeolite, hydrogen USY-zeolite and hydrogen beta-zeolite; the matrix material consists of a component A, a component B and a component C, wherein the component A is aluminum oxide, the component B is aluminum phosphate and the component C is any one of silicon dioxide, titanium dioxide, zirconium oxide and clay. Compared with the prior art, the alkylation catalyst has stronger alkylation reaction performance and stability and has the advantages of capability of increasing the conversion rate of alkylation isoparaffin , no hydrogen consumption, no noble metals and long service life; and a device is easy to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

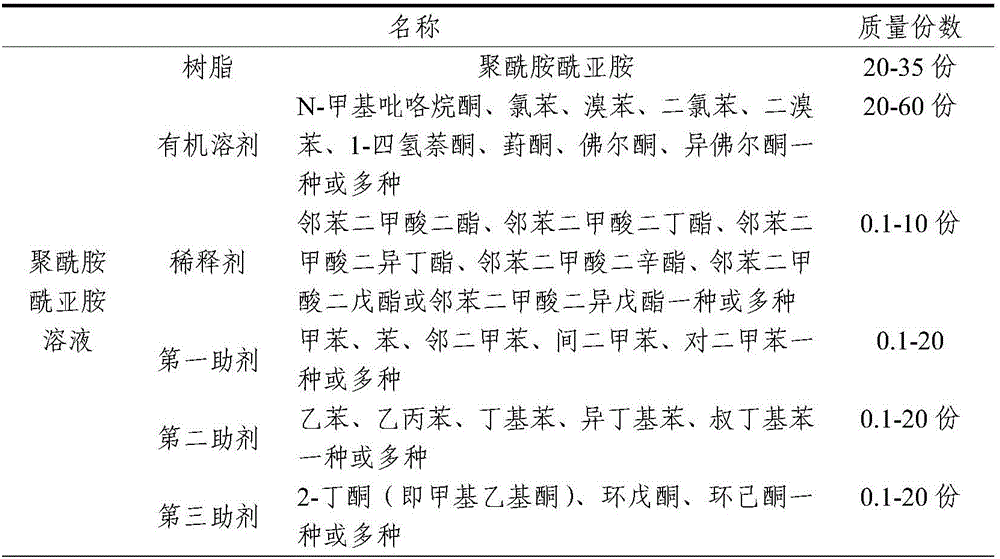

Nanometer polyamide imide film containing inorganic oxide and preparation method of nanometer polyamide imide film

The invention discloses a nanometer polyamide imide film containing inorganic oxide. The nanometer polyamide imide film containing the inorganic oxide is prepared from the following components in parts by weight: 100 to 120 parts of polyamide imide solution and 0.5 to 10 parts of pretreated nanometer inorganic oxide material. The thickness of the nanometer polyamide imide film containing the inorganic oxide is 10 to 100nm; the polyamide imide solution is prepared from the following components in parts by weight: 20 to 35 parts of polyamide imide resin and 20 to 60 parts of organic solvent. The pretreated nanometer inorganic oxide material is obtained by pretreating nano inorganic oxide, a coupling agent and a surfactant according to the weight ratio of 10:(2 to 6):(0.2 to 0.5). The nanometer polyamide imide film disclosed by the invention has the advantages of excellent mechanical property, stable chemical properties, high temperature resistance, high self-lubricating property and long service life, and can be widely applied in the enamelled wire industry.

Owner:GUANGDONG JINGDA REA SPECIAL ENAMELED WIRE CO LTD +1

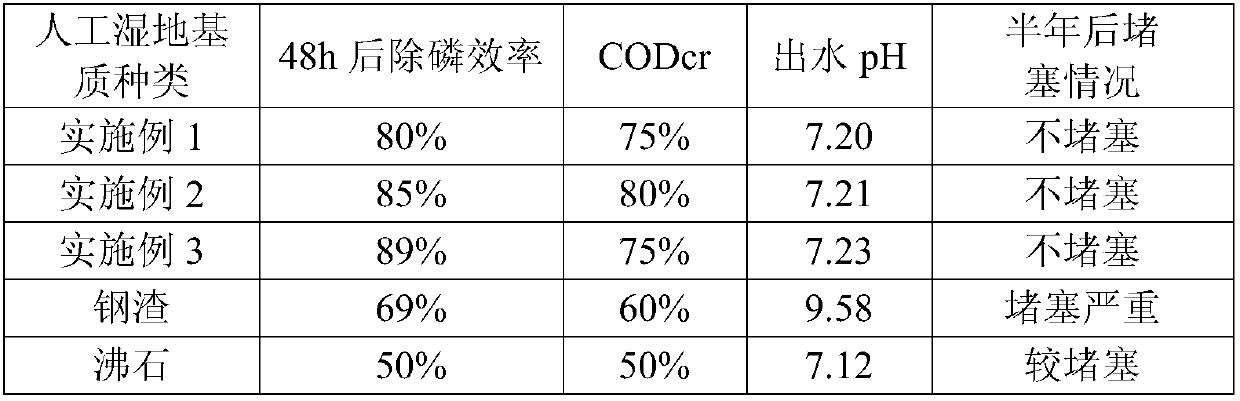

Artificial wetland phosphorous removal porous composite substrate filler and preparation method thereof

InactiveCN107804915ALow costCause harmWater treatment compoundsWater contaminantsConstructed wetlandAlkalinity

The invention discloses an artificial wetland phosphorous removal porous composite substrate filler which is prepared from, in weight percent, 40-50% of steel slag, 15-25% of calcium carbonate powder,10-25% of crop straws and tree leaves and 10-20% of binding agents. According to the filler, total phosphorus treating efficiency of an artificial wetland composite substrate is improved, waste resources are cycled, production cost is reduced, phosphorous is removed by the aid of calcium carbonate and the steel slag, substrate holes are enlarged by the aid of straw and tree leaf powder, substrateblocking is reduced, alkalinity caused by the steel slag is neutralized, pH (potential of hydrogen) of outlet water is buffered, organic nutrition is provided for microorganisms by the straws and tree leaves, wetland purification efficiency is improved, and phosphorous removal is finally optimized.

Owner:河南永泽环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com