Swirling burner for pulverized coal dense and thin separation of lignite

A swirl burner and concentration separation technology, applied in the burners, burners, combustion methods and other directions of burning powder fuel, can solve the problems affecting the flow field and combustion process of the burner, the poor stability of the flame recirculation zone, the secondary air rate Small and other problems, to achieve the effect of stable flow field, small unburned heat loss, and reduction of air volume and momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

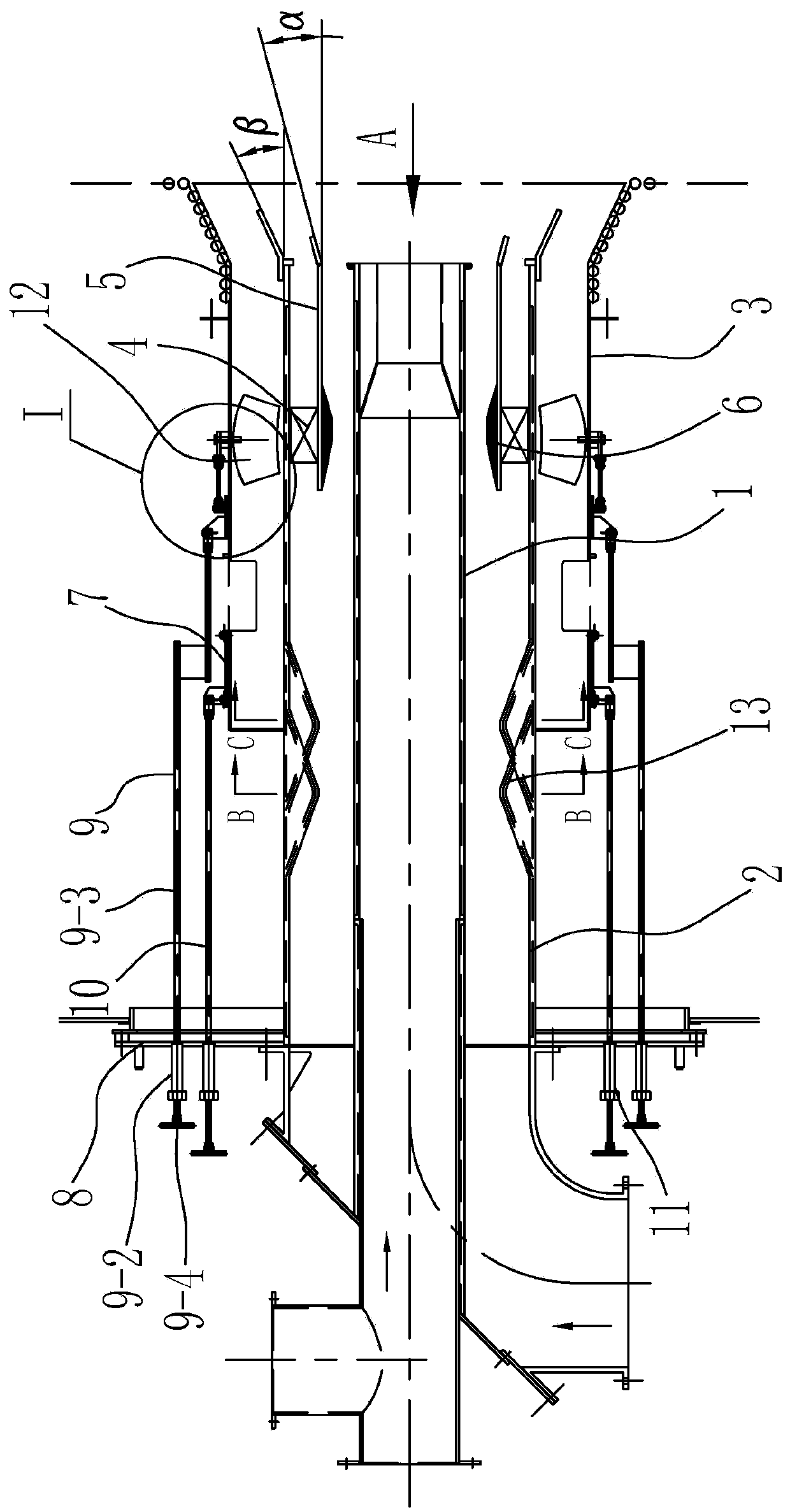

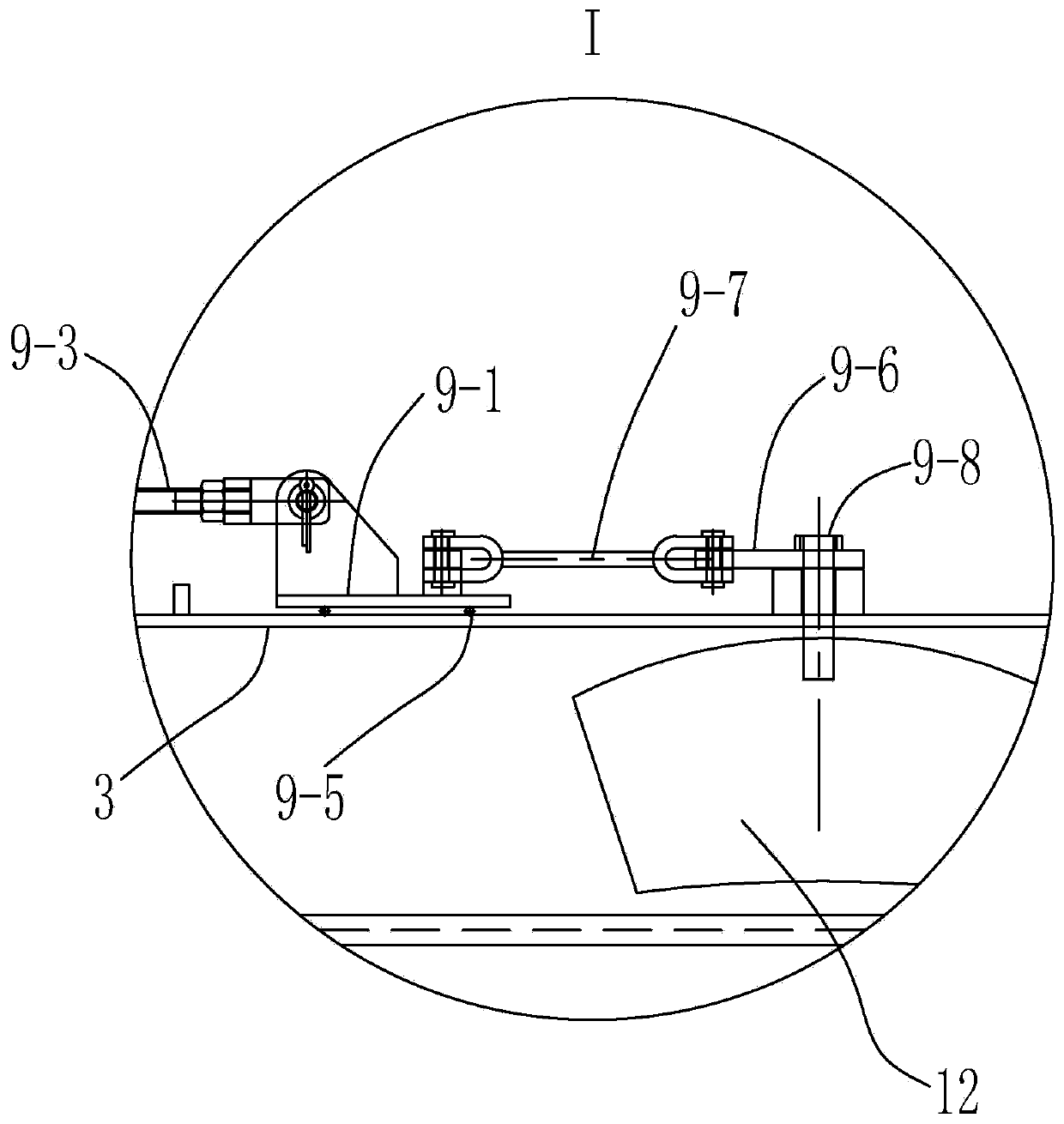

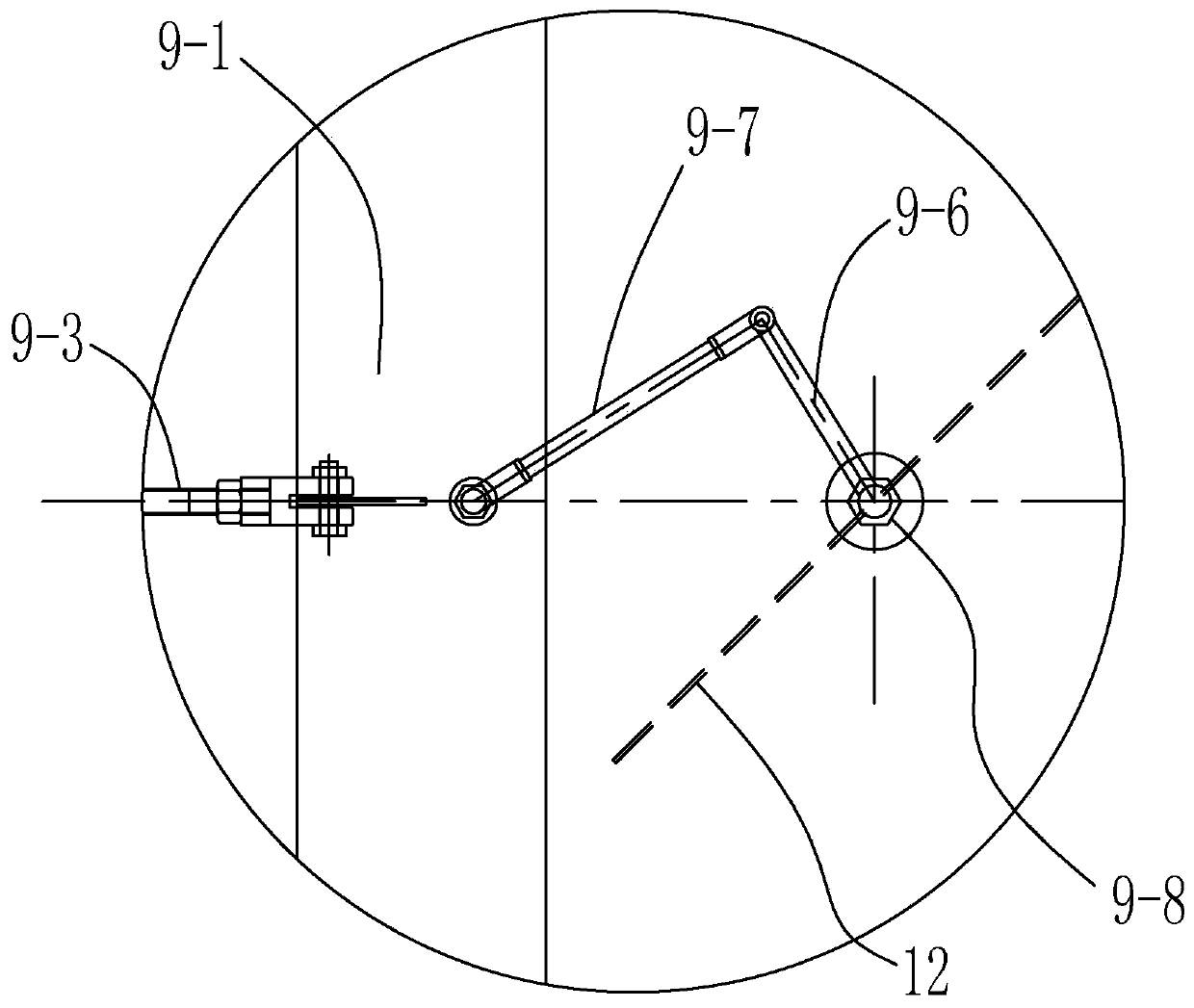

[0021] Embodiment 1: as figure 1 As shown, the present embodiment relates to a swirl burner suitable for separation of pulverized coal concentration and thinness of lignite, central air duct 1, primary air duct 2, secondary air duct 3, secondary air swirl blades 12 and Venturi coal Powder concentrating pipe 6 is characterized in that it also includes dilute phase swirl blade 4, thick-lean separation cylinder 5, pulverized coal concentration separation device 13, central air duct 1, thick-lean separation cylinder 5, primary air duct 2 and secondary The air ducts 3 are set together from the inside to the outside, and the adjacent two are arranged at intervals. There are a plurality of light-phase swirls evenly distributed along the circumferential direction of the primary air duct 2 between the thick-thin separation compartment 5 and the primary air duct 2. Blades 4, between the primary air duct 2 and the secondary air duct 3 are provided with a plurality of secondary air swirl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com