Patents

Literature

269results about How to "Flow field stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

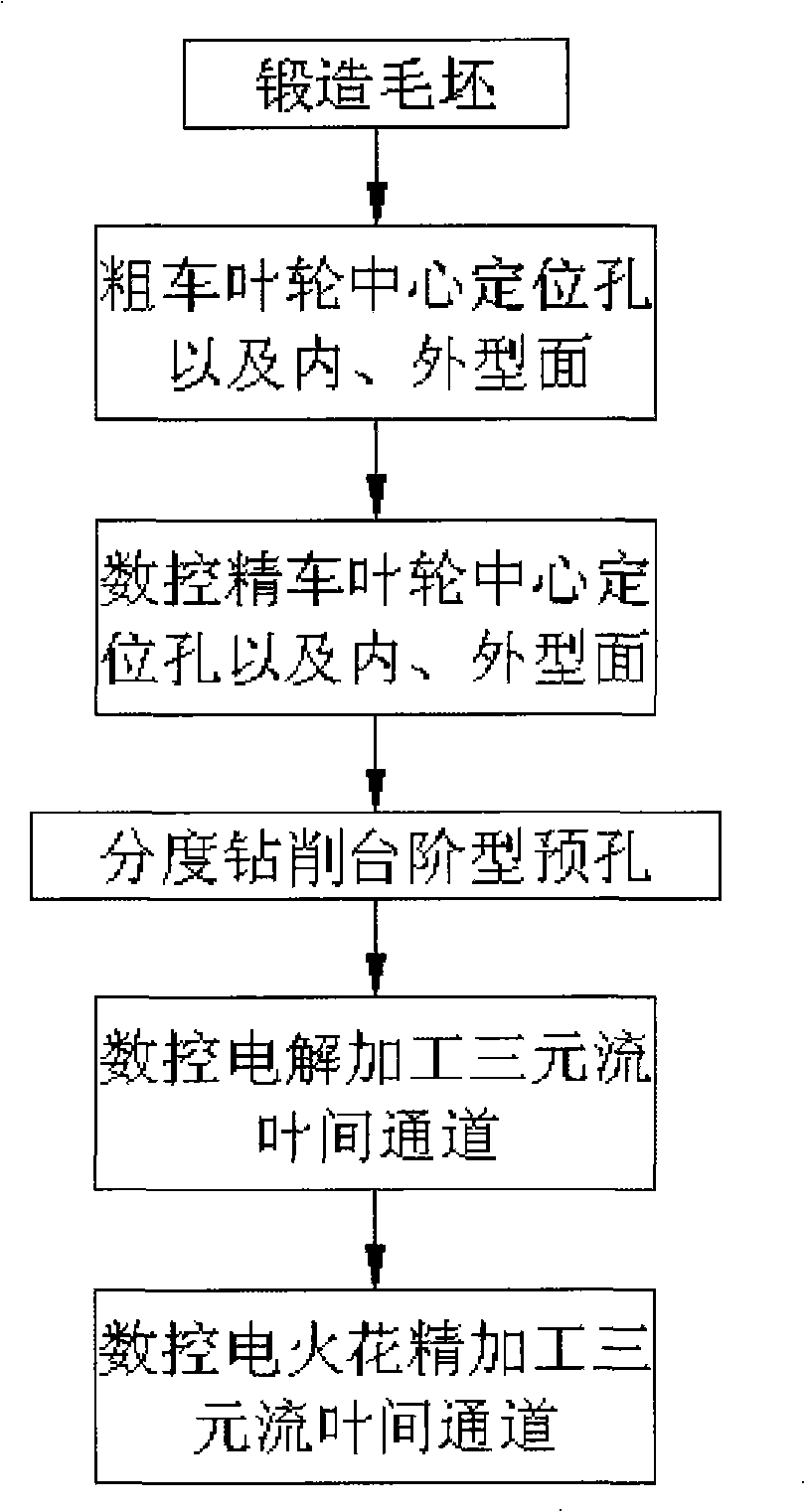

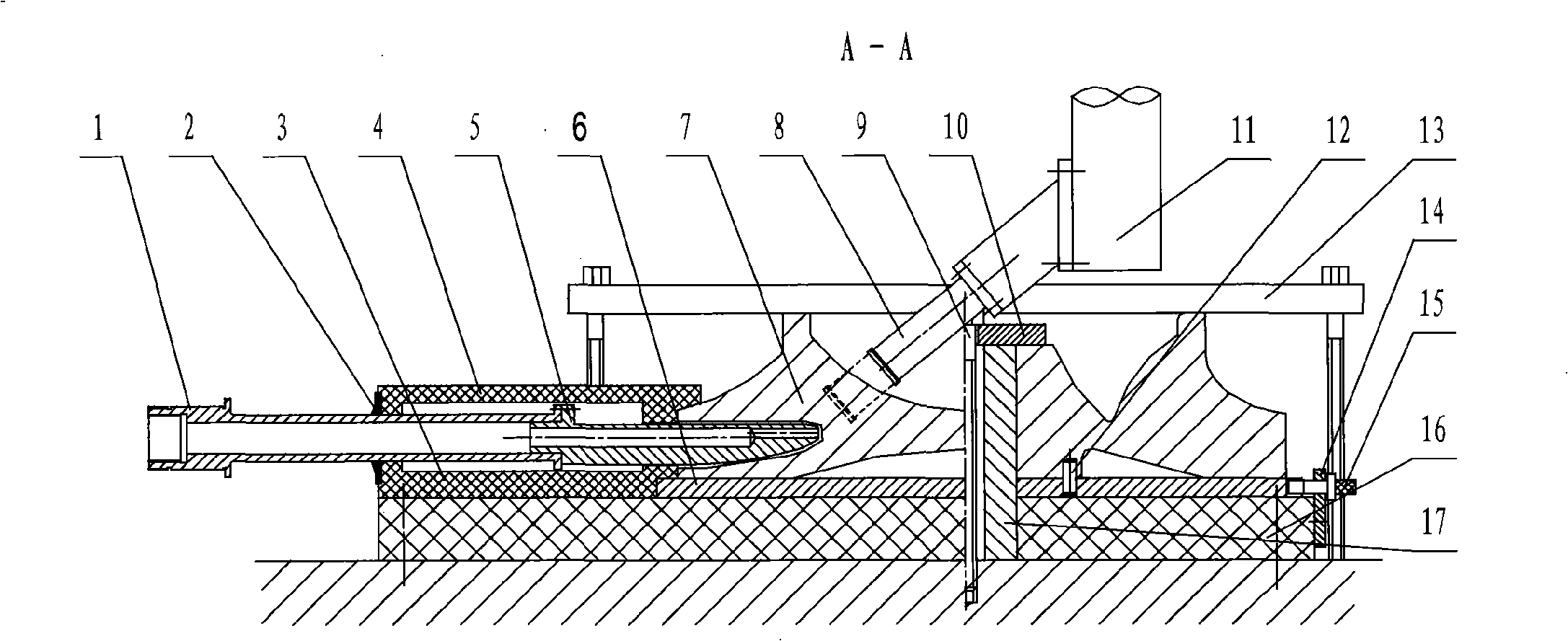

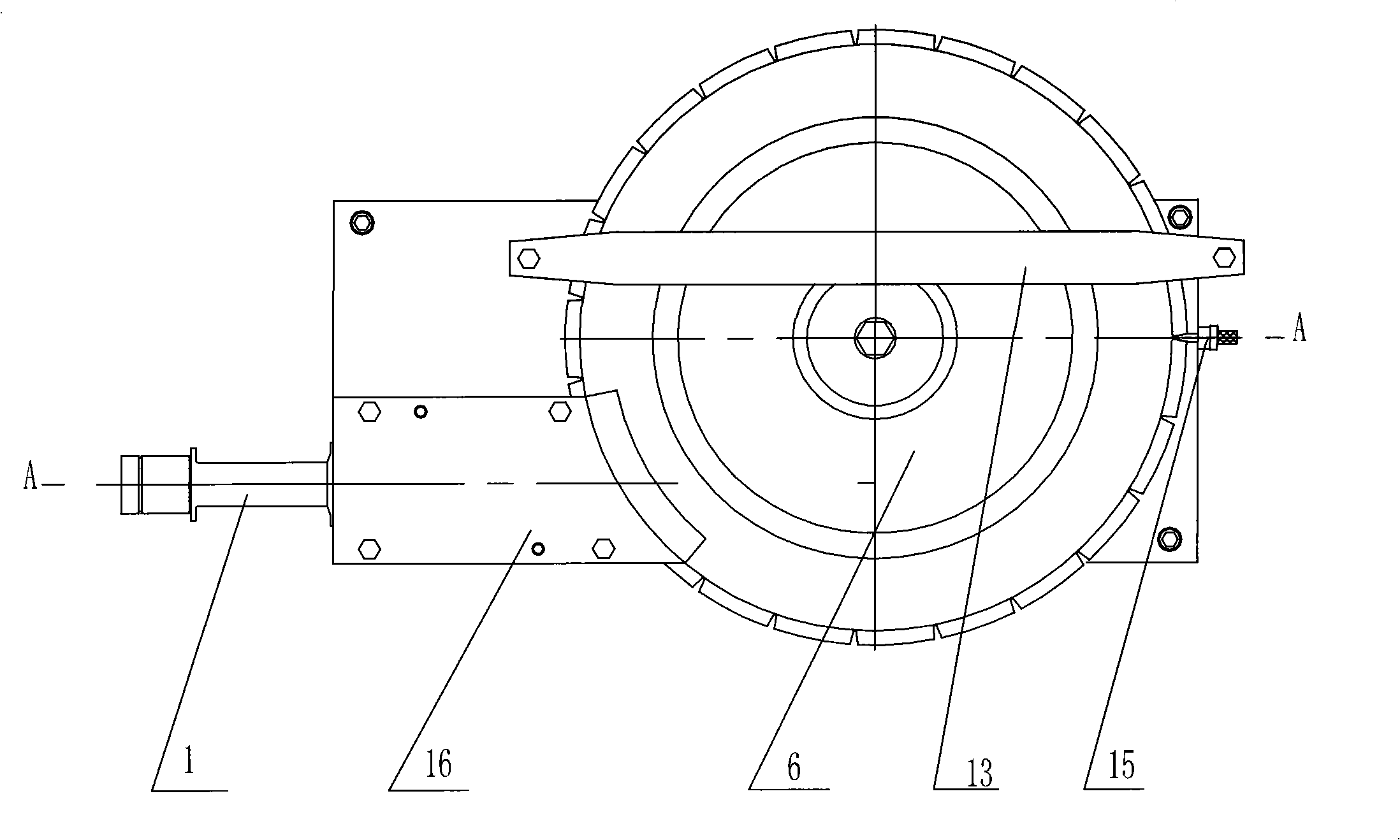

Method for manufacturing three-dimensional flow enclosed-type impeller inter-impeller passage and special clamp thereof

InactiveCN101524805AImprove efficiencyAvoid the phenomenon that is prone to blind spots in processingImpellerEngineering

The invention relates to a method for manufacturing a three-dimensional flow enclosed-type impeller inter-impeller passage and a special clamp thereof. A specially designed and manufactured molding or quasi-molding tool cathode is used for numerical control electrolytic processing to remove most remainder, then a specially designed and manufactured molding or quasi-molding tool electrode is used for numerical control electric spark precision processing to achieve the design requirement, thereby the three-dimensional flow enclosed-type impeller inter-impeller passage that can not be processed resulting from interference of numerical control milling cutter and undercutting can be manufactured, besides, the method has the technical and economical characteristics of high precision and efficiency, and low cost compared with the prior three manufacturing methods of integral casting, divided processing rewelding and numerical control milling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

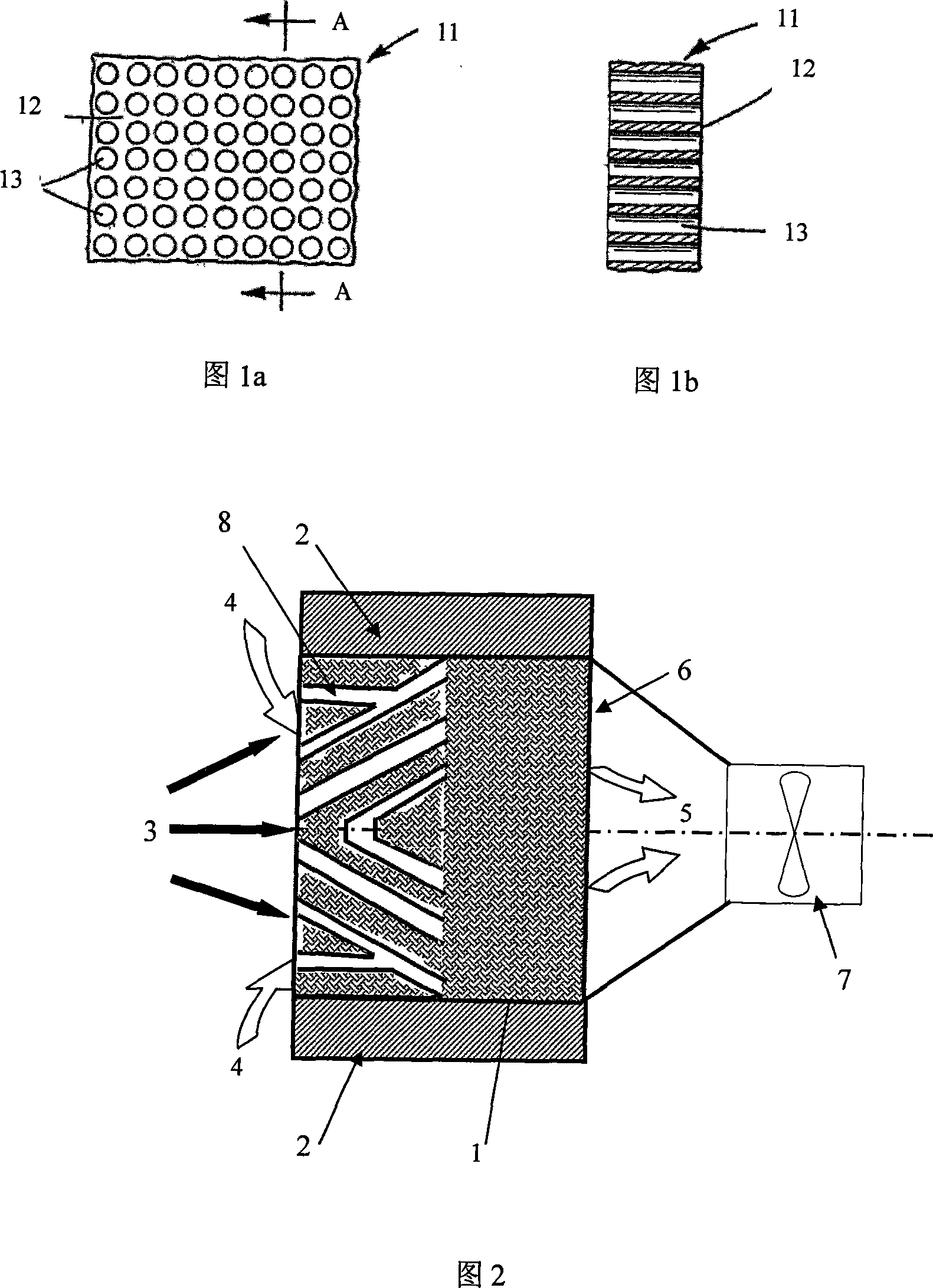

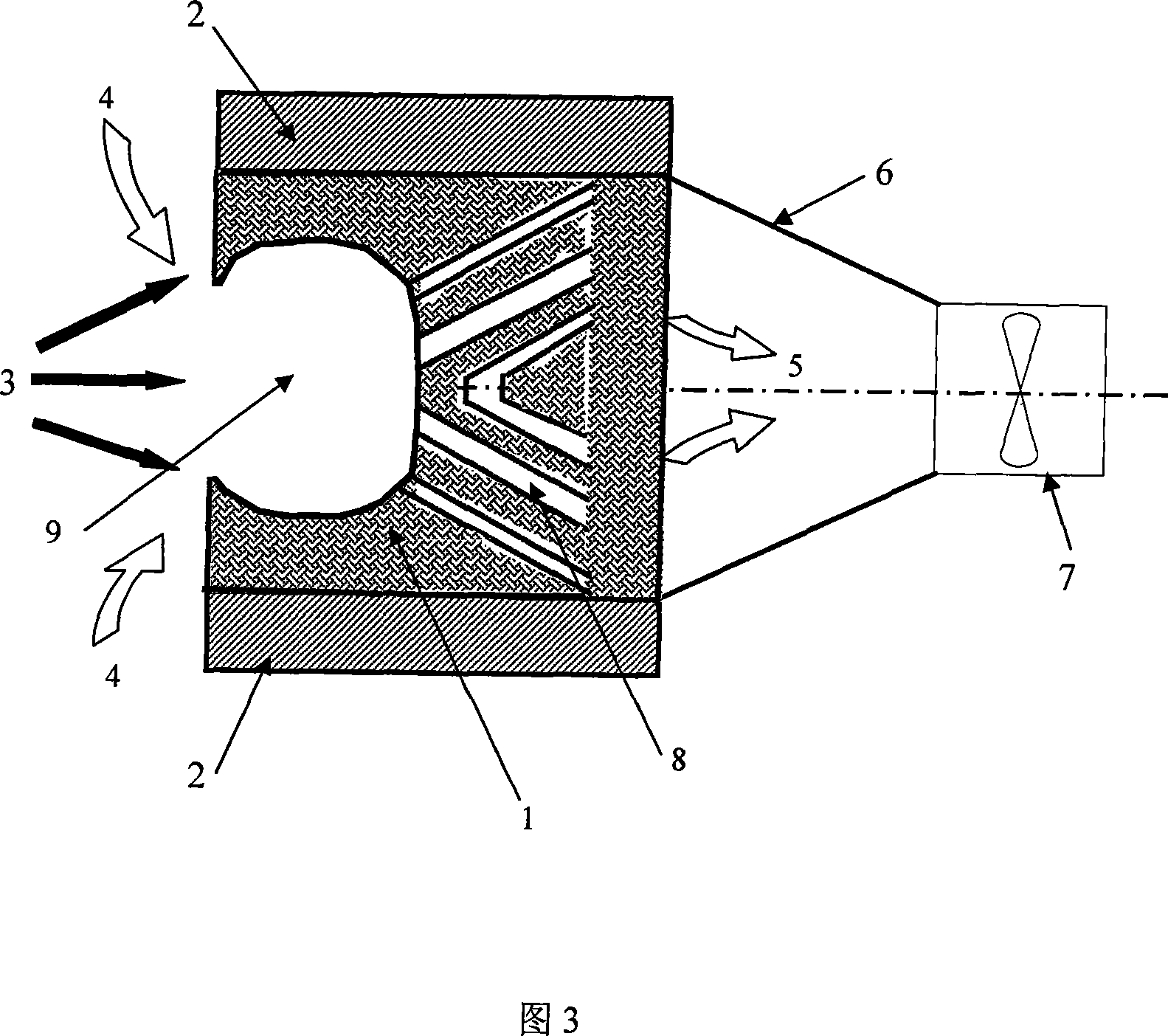

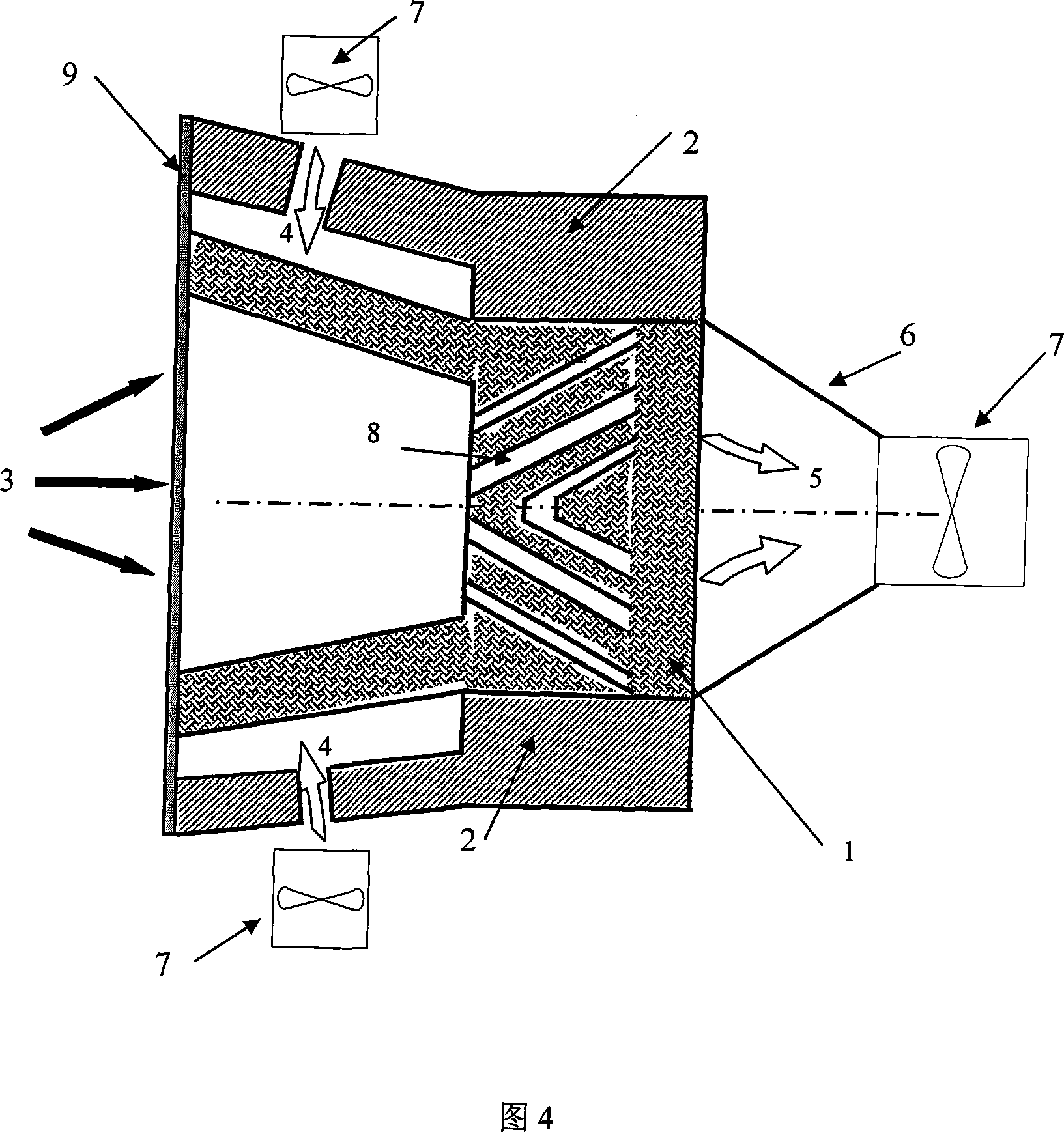

Silicon carbide foam ceramic solar energy air heat-absorbing device

InactiveCN101122425AImprove thermal conductivityFacilitate conductionSolar heating energySolar heat devicesCold airBlackbody cavity

A silicon carbide ceramic foam solar energy air heat absorber uses silicon carbide ceramic foam materials as solar energy absorber. The silicon carbide ceramic foam absorber is wrapped with an insulating layer (2). A radiant heat flux (3) projects onto the surface of the silicon carbide ceramic foam absorber (1) or into an artificial blackbody cavity (9) and is received by the silicon carbide ceramic foam absorber (1). Cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3). Hot air (5) is obtained through heat exchange of thecold air and the radiant heat flux. Or the cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3) or back to the radiant heat flux (3). The hot air (5) of 700 to 1300 DEG C is obtained through the heat exchange of the cold air and the radiant heat flux through a quartz window (10). The silicon carbide ceramic foam absorber (1) buries an air diversion channel (8) beforehand. The invention can effectively receive radiant heat and emit heat to the air and take advantage of self-sensible heat to store heat at the same time.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

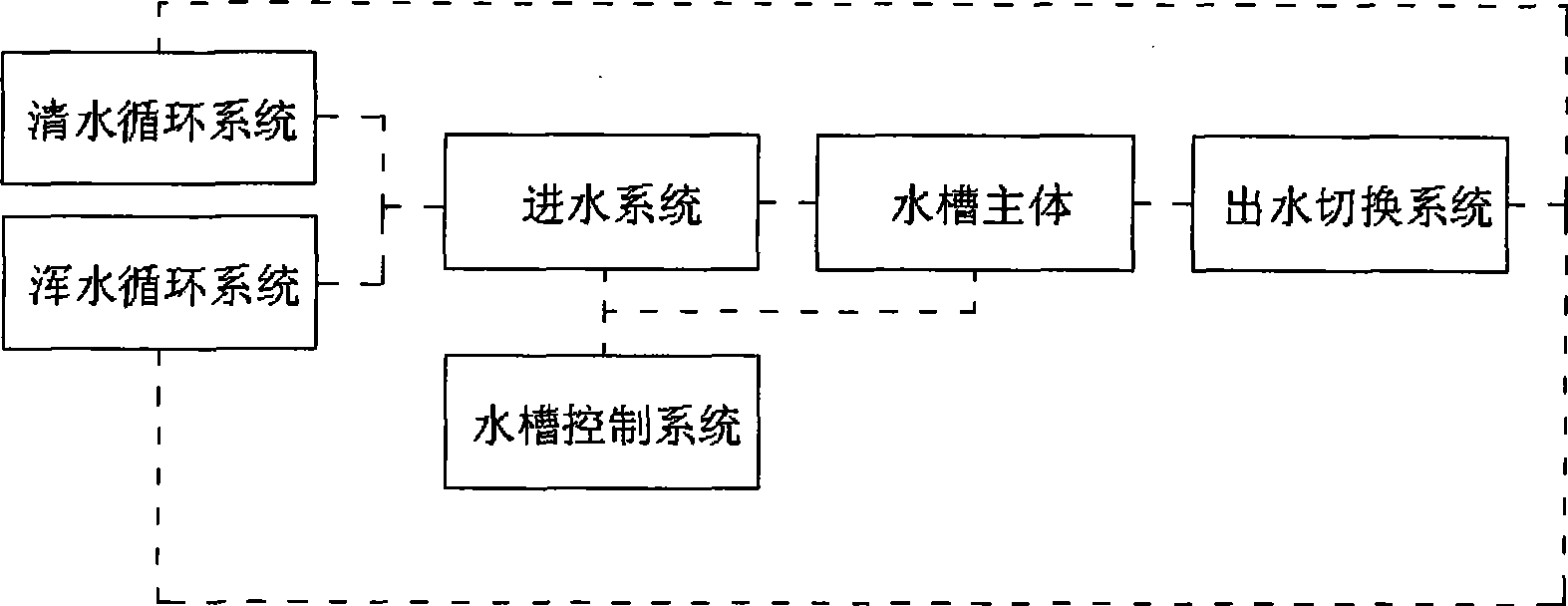

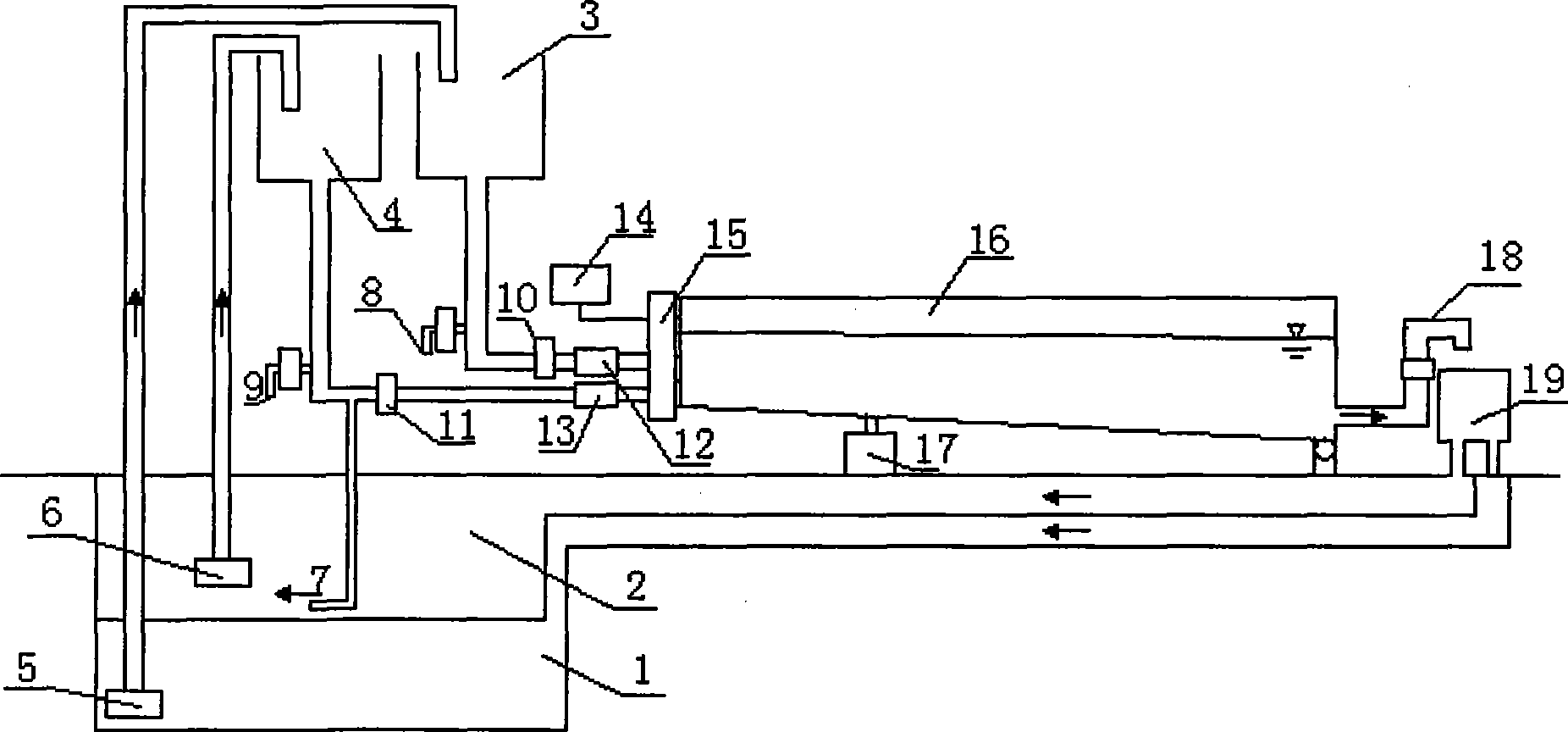

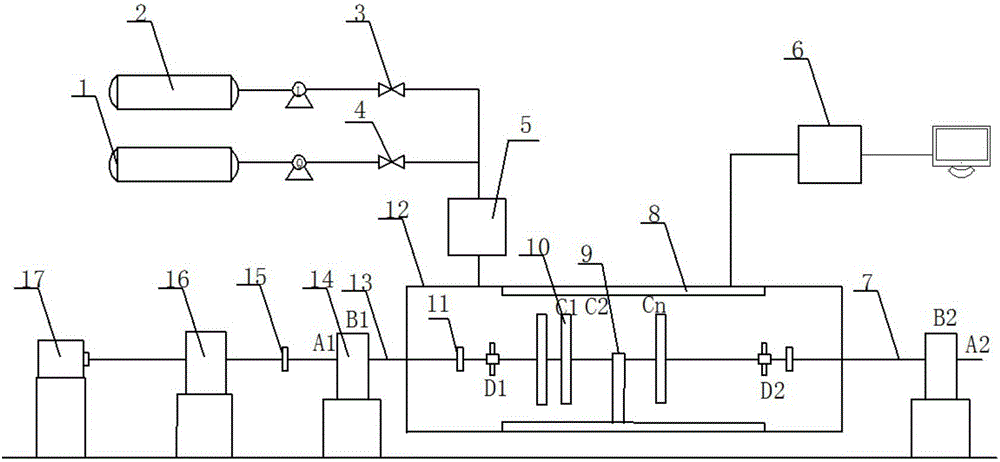

Polyphase fluid experimental tank system

InactiveCN101424587AFlow field stabilityEasy to observeHydrodynamic testingControl systemEngineering

The invention relates to a multiphase flow test flume system which comprises a main body, a clear water circulating system, a muddy water circulating system, a water inlet system, a control system and a water outlet switching system, wherein a support and a jack are arranged at the bottom of the main body and are fixed on the ground by supporting hinges for adjusting the width and the gradient of a flume, and the water inlet system comprises a sampling discharge outlet, a manual valve, a flowmeter and an electromagnetic valve and is connected with the top end of the main body; the control system is arranged at one side of the top end of the main body for controlling all switches, and the water outlet switching system is arranged at one outer side end of a water outlet of the main body and is connected with a clear underground water pool in the clear water circulating system and a muddy underground water pool in the muddy water circulating system. Due to the clear water circulating system and the muddy water circulating system which are independent, the invention reduces test water consumption and test cost and conveniently recycles and treats polluted water samples, and a clear water / muddy water switching device of a water outlet system is easily designed and conveniently operated so as to effectively solve the switching problem among different circulating systems.

Owner:SICHUAN UNIV

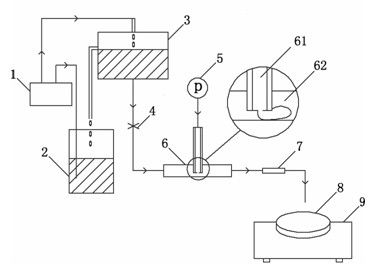

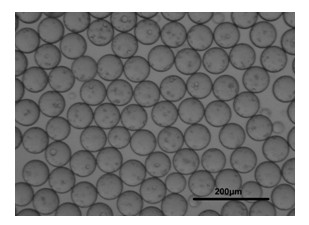

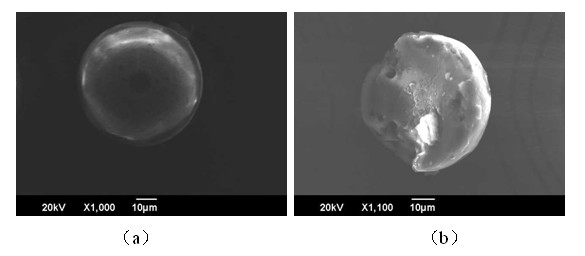

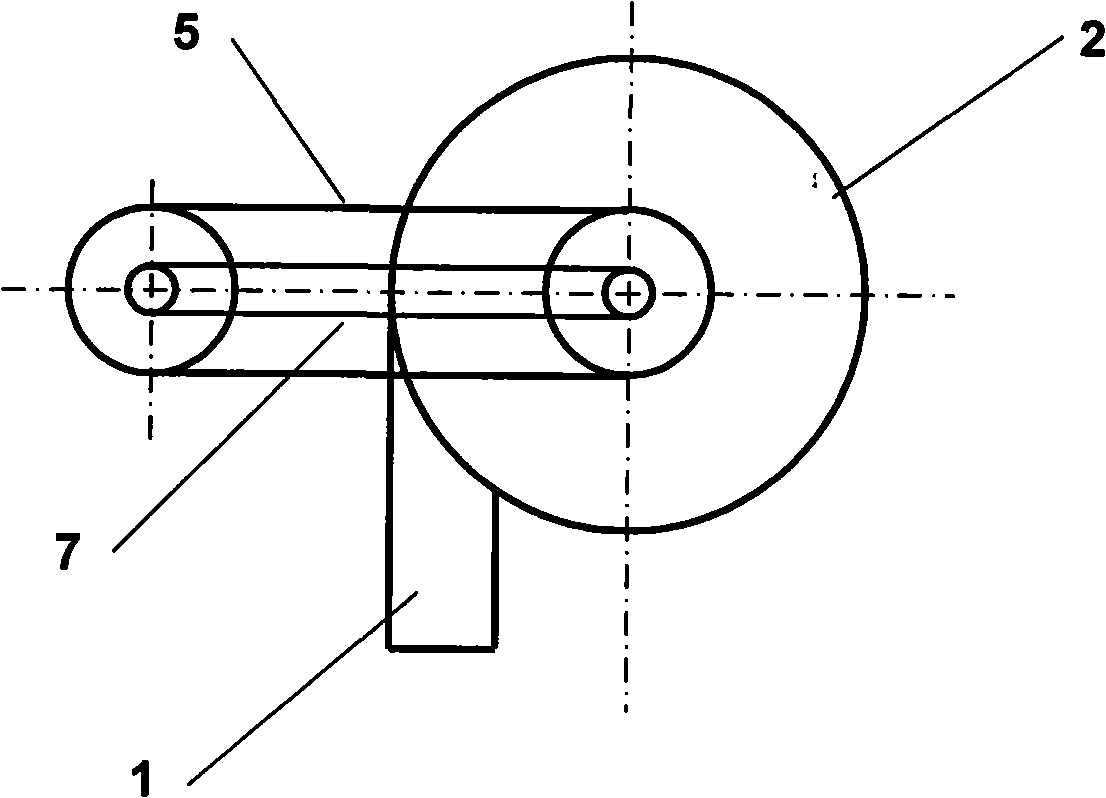

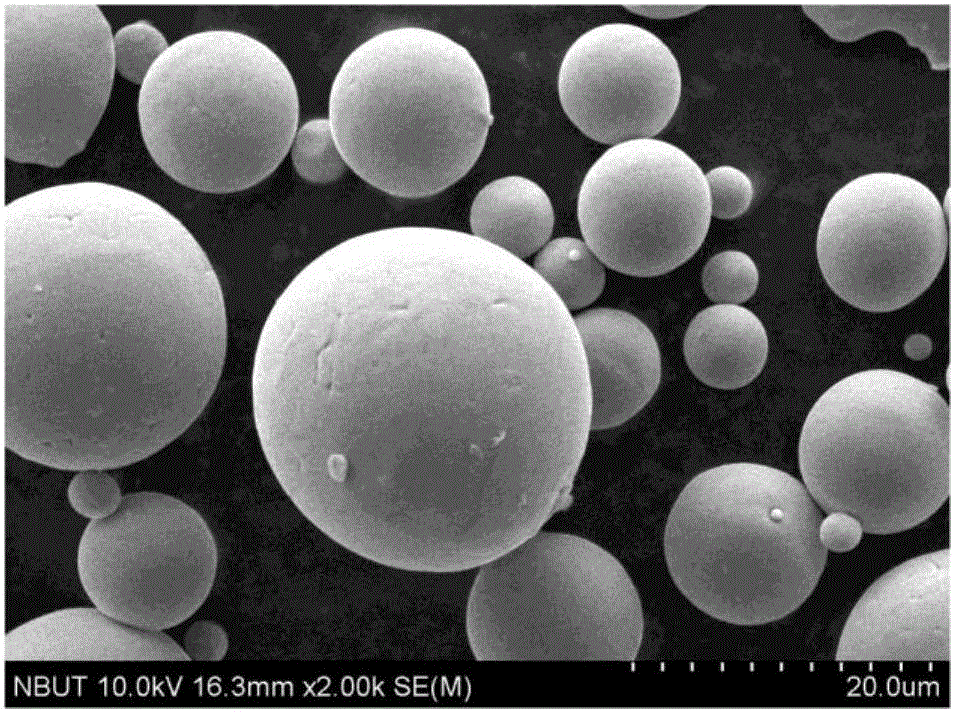

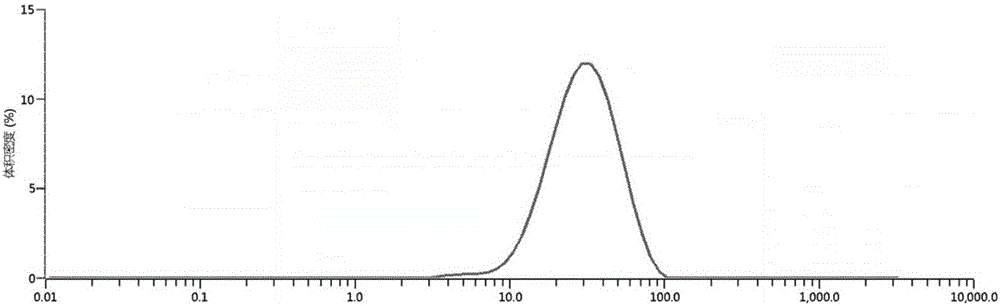

Detachable T-shaped microchannel device and method for preparing monodisperse polymer microspheres by same

InactiveCN102211008AEasy to unblockNarrow particle size distributionPharmaceutical non-active ingredientsChemical/physical/physico-chemical processesOrganic solventMicrosphere

The invention discloses a detachable T-shaped microchannel device and a method for preparing monodisperse polymer microspheres by the same. The method comprises the following steps of: performing heat treatment on a needle tube serving as a disperse phase flowing channel, and processing a duct with the same outer diameter as the needle tube on a pipeline serving as a continuous phase flowing channel to make the disperse phase needle tube and the continuous phase tube form a T-shaped channel; under the stable operating condition, making dispersed fluid form uniform micro liquid drops at a T-shaped tube orifice through the shearing force of continuous phase fluid to the disperse phase fluid; and under the action of a shaker, diffusing an organic solvent out of the liquid drops, and curing the liquid drops to form the polymer microspheres with uniform particle size. The T-shaped microchannel device is simple in equipment and can be detached, and pipelines are easy to dredge after being blocked; and the prepared polymer microspheres have uniform particle size, the particle size distribution coefficient of less than 15 percent, the minimum particle size distribution coefficient of 3 percent, and smooth surfaces without adhesion.

Owner:ZHEJIANG UNIV

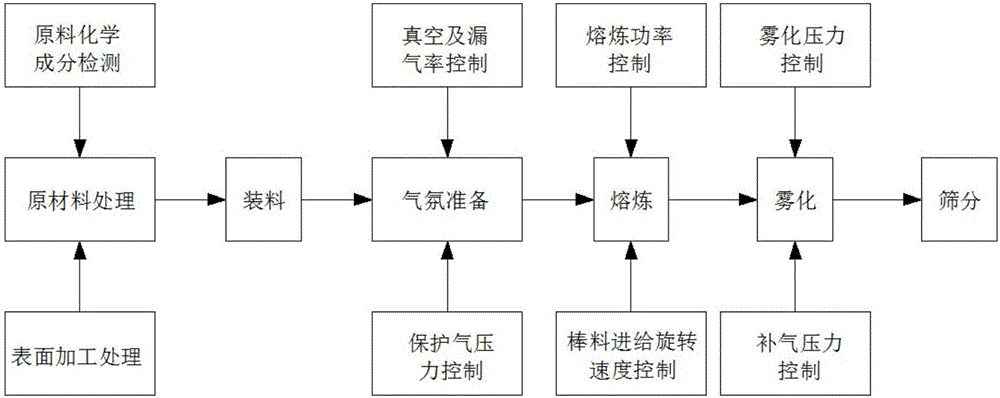

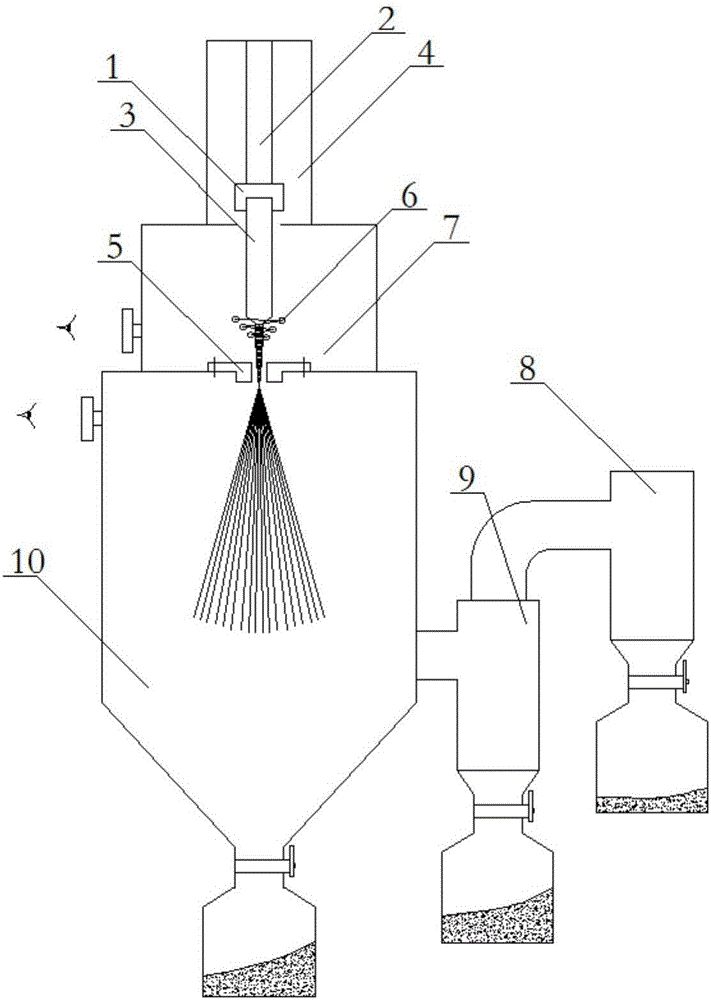

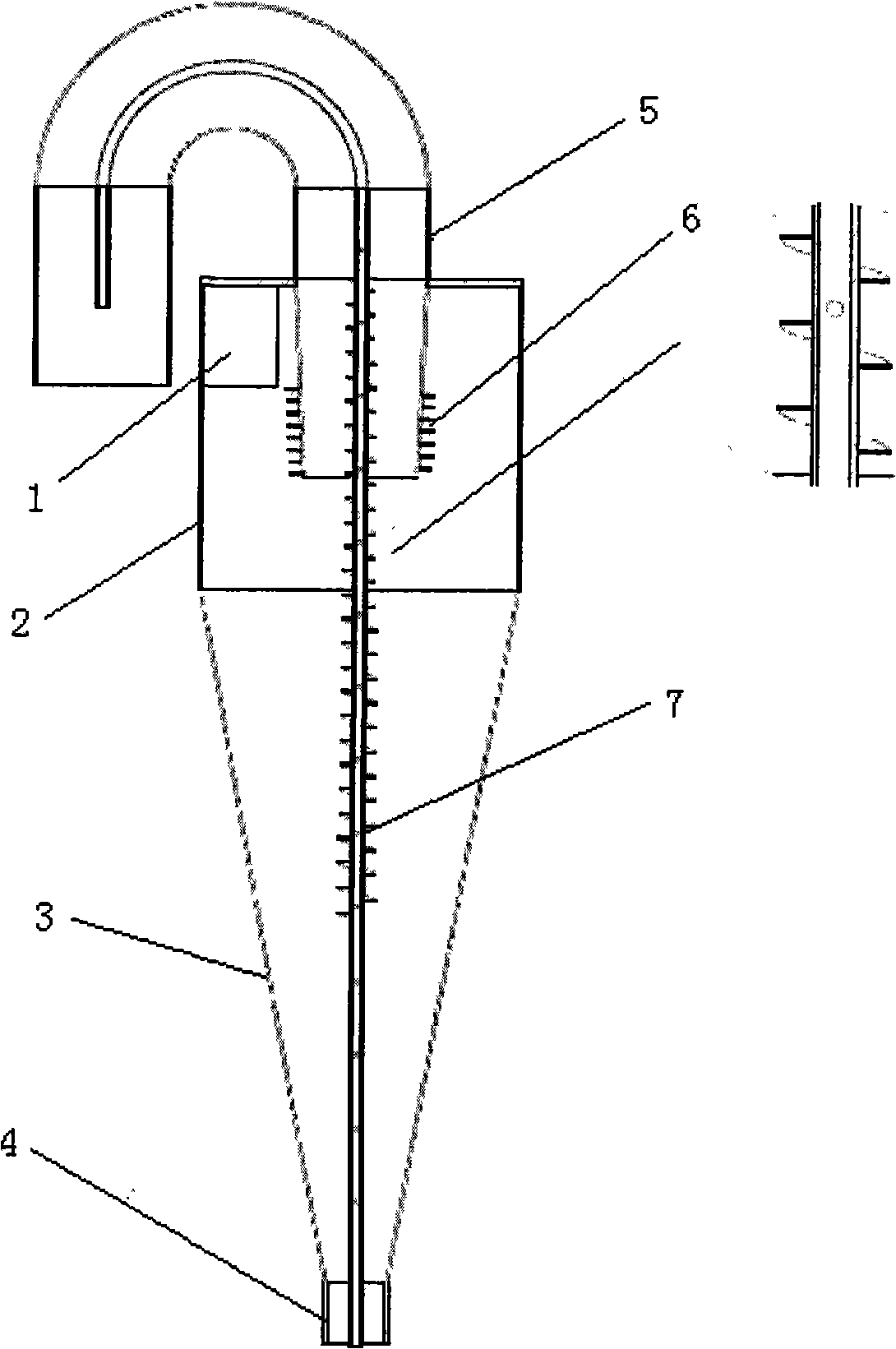

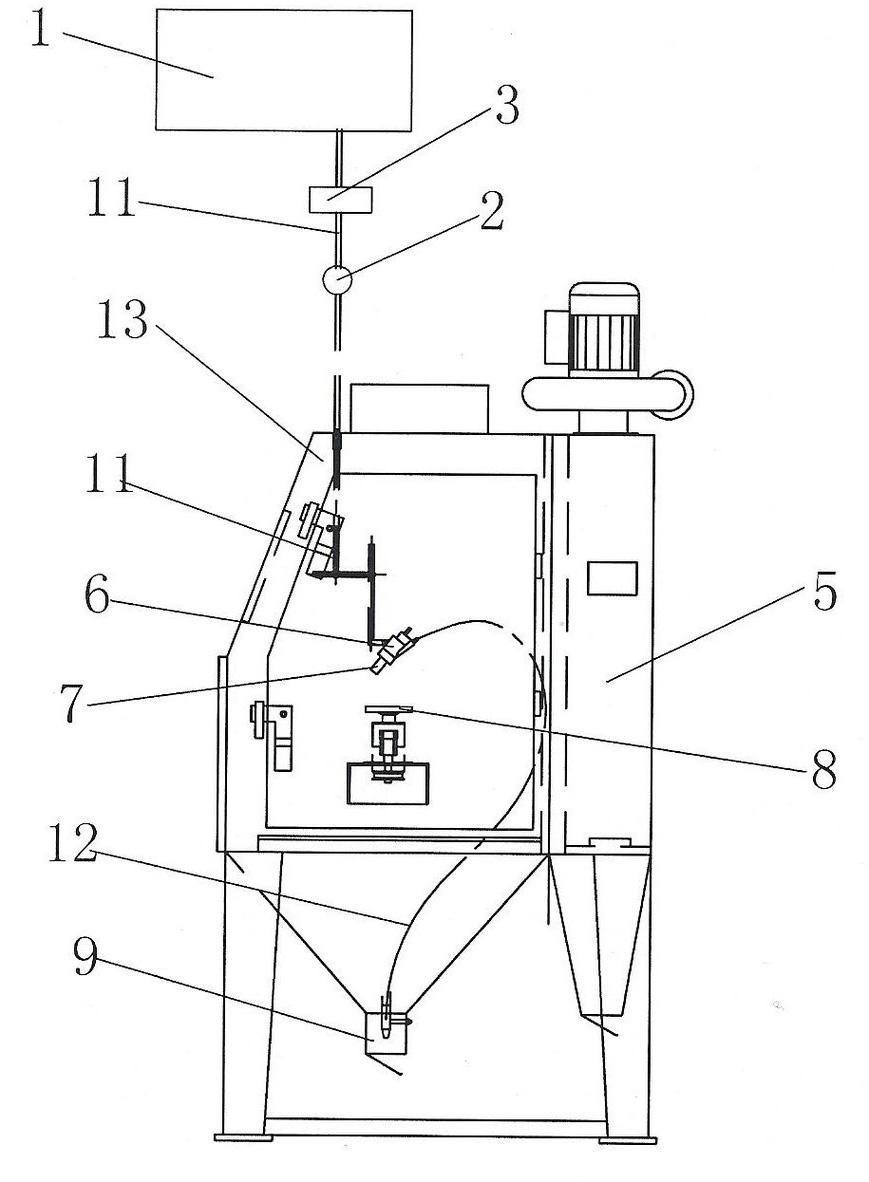

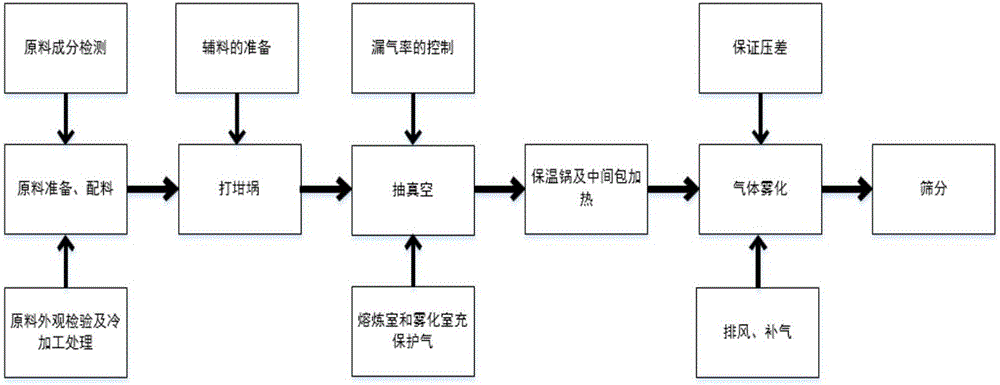

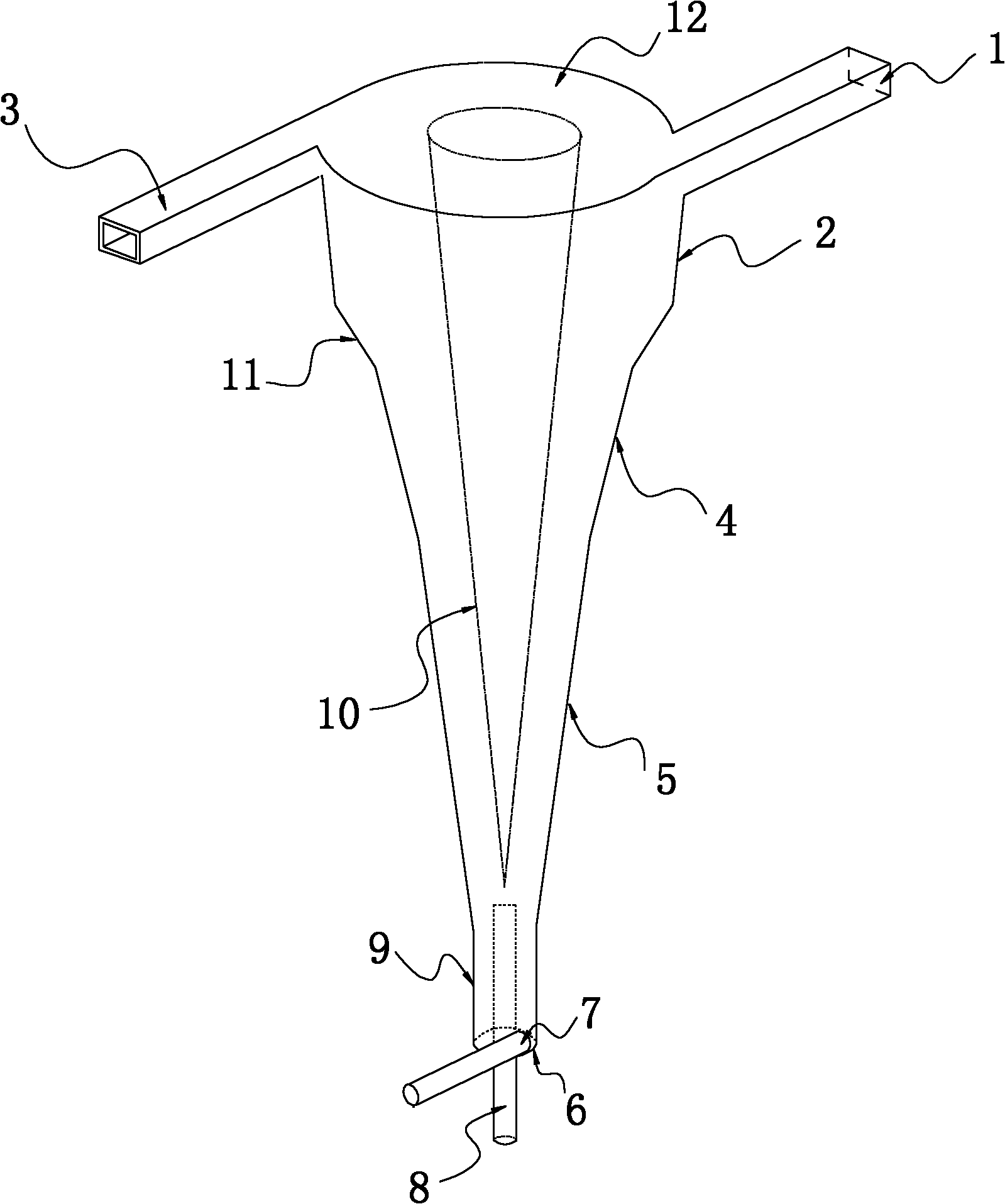

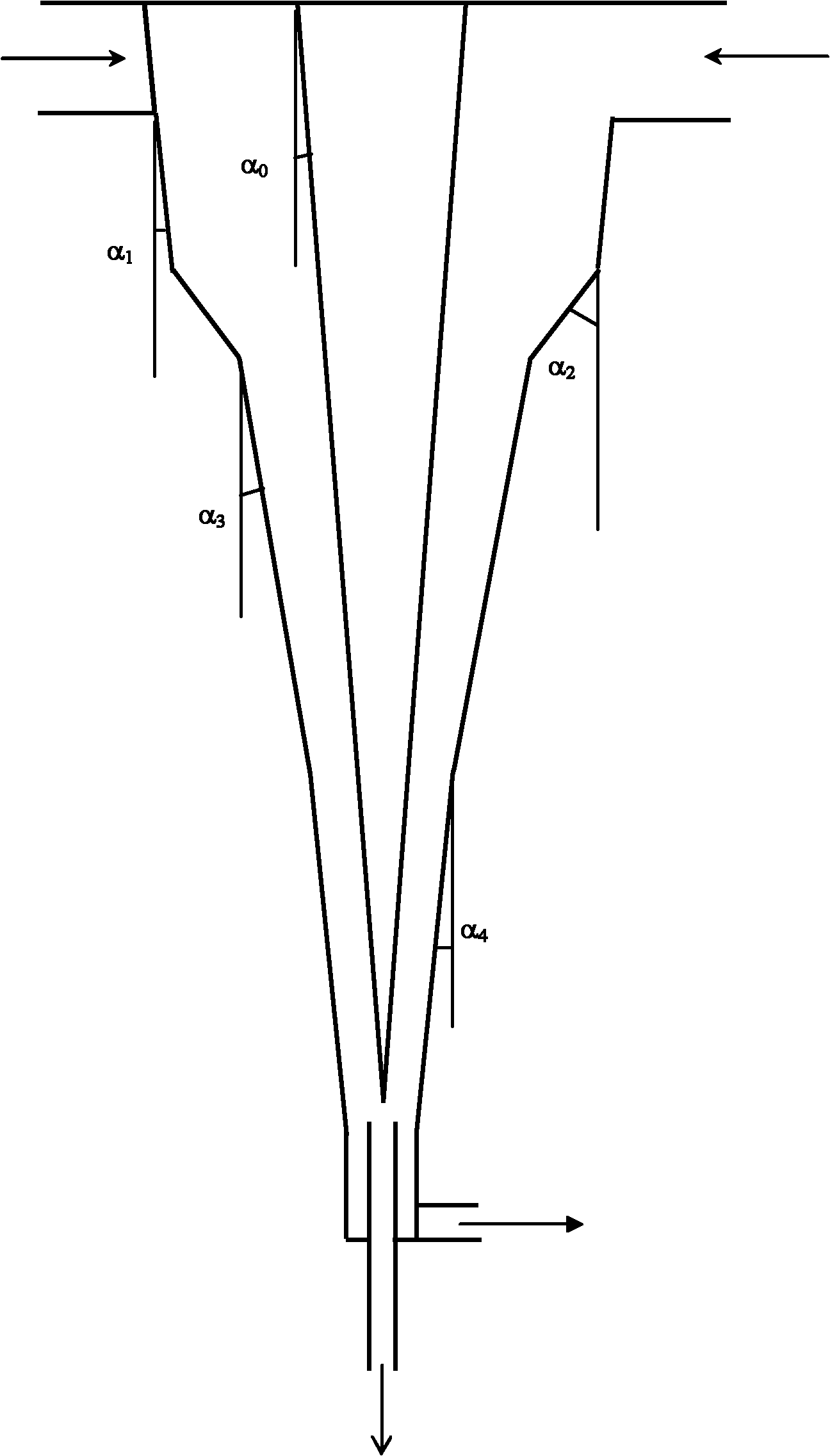

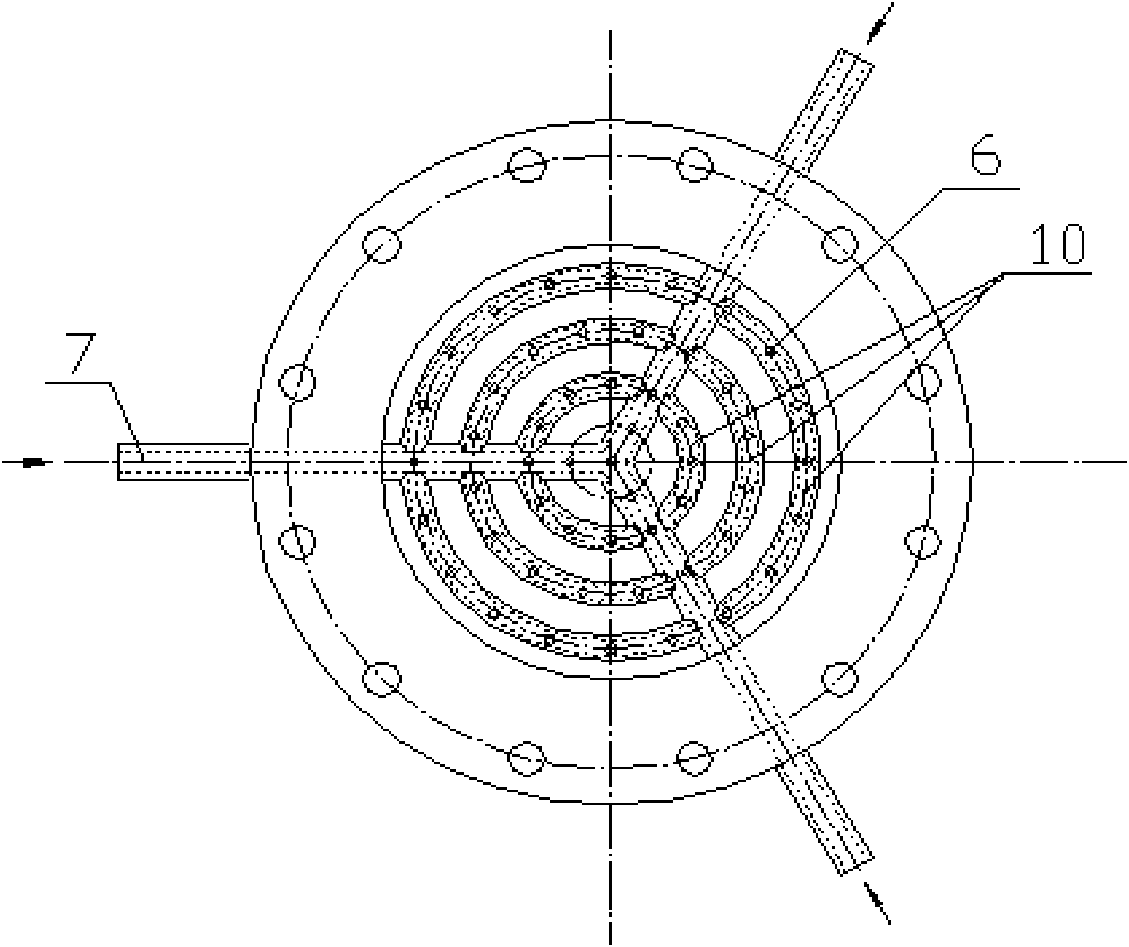

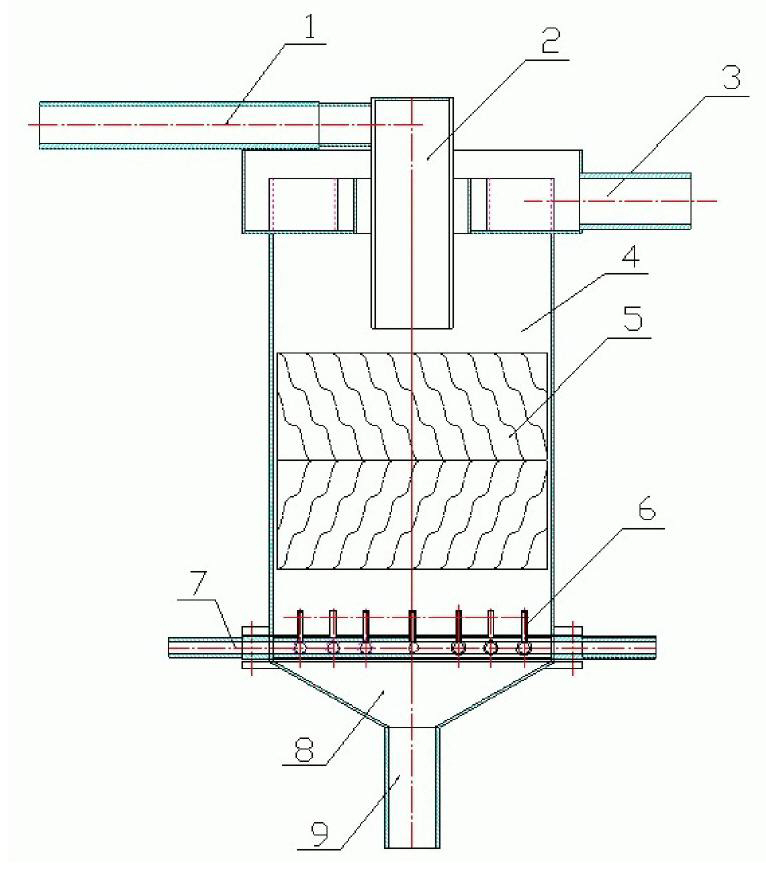

Preparation method of titanium alloy powder for 3D printing

ActiveCN106166617AEffective introductionIncrease productivityAdditive manufacturing apparatusTitanium alloyImpurity

The invention discloses a preparation method of titanium alloy powder for 3D printing, and belongs to the technical field of 3D printing / material additive manufacturing. The method comprises the specific steps that raw materials are loaded and clamped after being treated; pre-vacuum-pumping treatment is carried out on a smelting chamber and an atomization furnace, and high-purity argon is introduced into the smelting chamber and the atomization furnace when the vacuum degree reaches 10<-5>-10<-3> Pa; a gate valve is opened, a feeding mechanism is turned on, and bar materials are heated at the temperature of 1550-1700 DEG C; metal molten drop or liquid flow is atomized through a supersonic speed tight coupling gas atomization nozzle, and finally screening is carried out. The preparation method has the advantages that impurities introduced in the smelting and atomization process can be effectively reduced, and it is ensured that power oxygen content is controlled to be below 200 ppm; continuous production can be carried out after bar materials are replaced, and the powder is uniform in granularity, good in degree of sphericity and good in flowability.

Owner:中航迈特增材科技(北京)有限公司 +1

Water cyclone with improved base pipe and overflows structure

InactiveCN101254489ASimple structureReduce energy consumptionReversed direction vortexCycloneEngineering

The invention belongs to a device for solid-liquid separation / classification and non-homogeneous separation, specifically a hydraulic cyclone with improved structure of central post and overflow pipe. The device comprises a feed pipe, a cylindrical section, a coniform section, an overflow pipe and a hollow tubular central post with partial-spiral fins and spiral flow deflectors and provided outside the overflow pipe. The central post is a hollow tube provided thereon with a plurality of holes. The spiral flow deflectors are provided on the outer surface of the central post. The spiral fins are provided on the overflow pipe from the bottom of the overflow pipe to a height below the bottom of an inlet pipe. Compared with the prior art, the separation efficiency of the hydraulic cyclone is increased by 5-10% and the energy consumption is reduced by 20%. The hydraulic cyclone has high stability and reliability in separation efficiency and is suitable for solid-liquid separation in ore dressing, dredging, chemical and petroleum industries.

Owner:EAST CHINA UNIV OF SCI & TECH

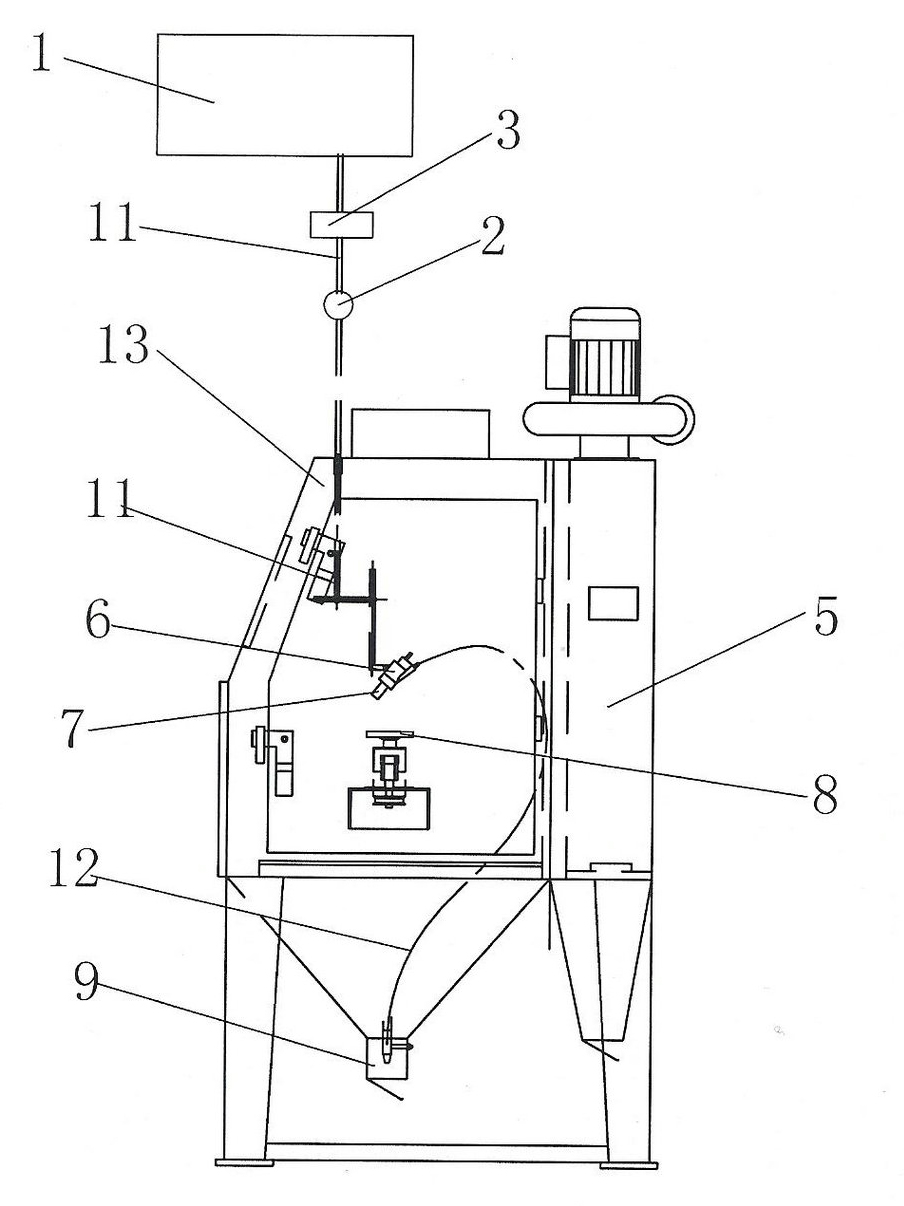

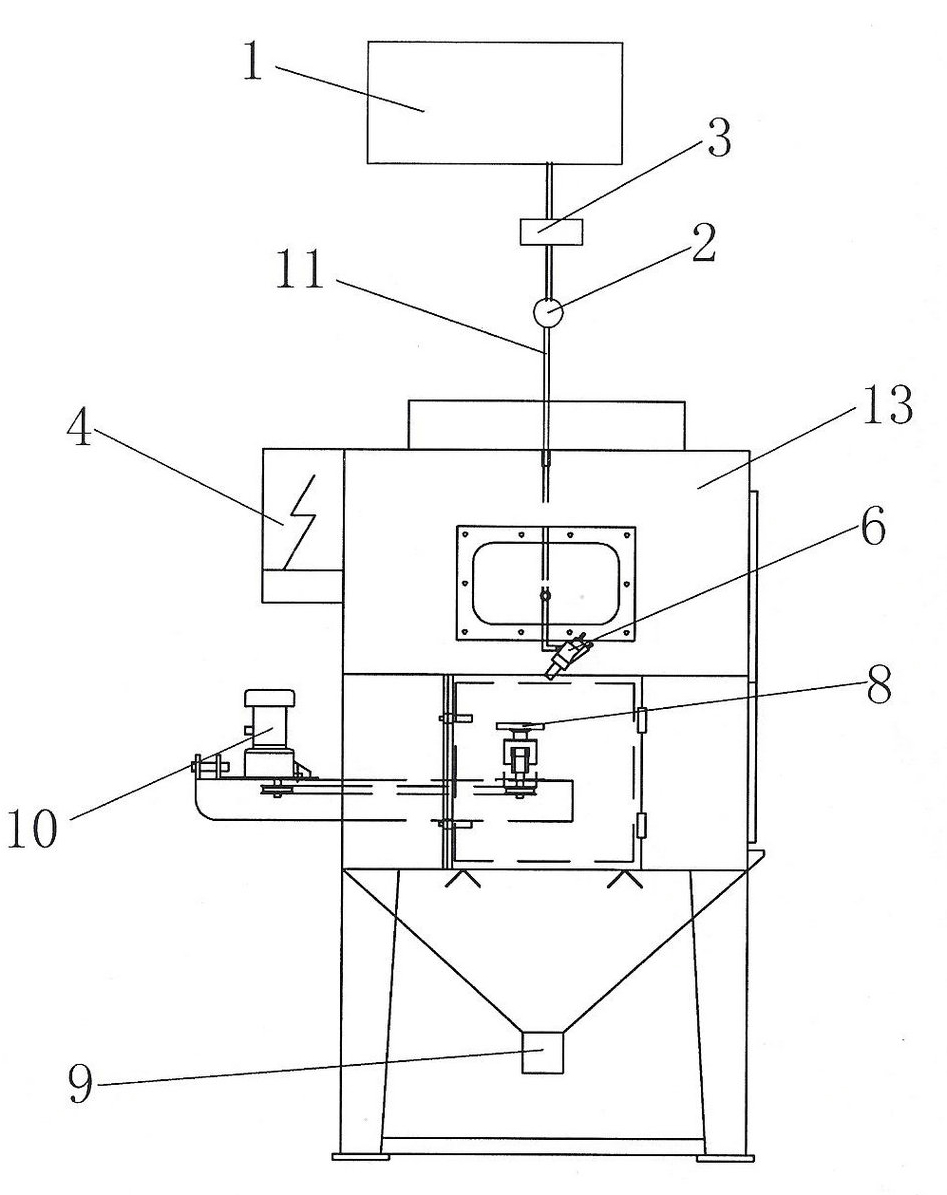

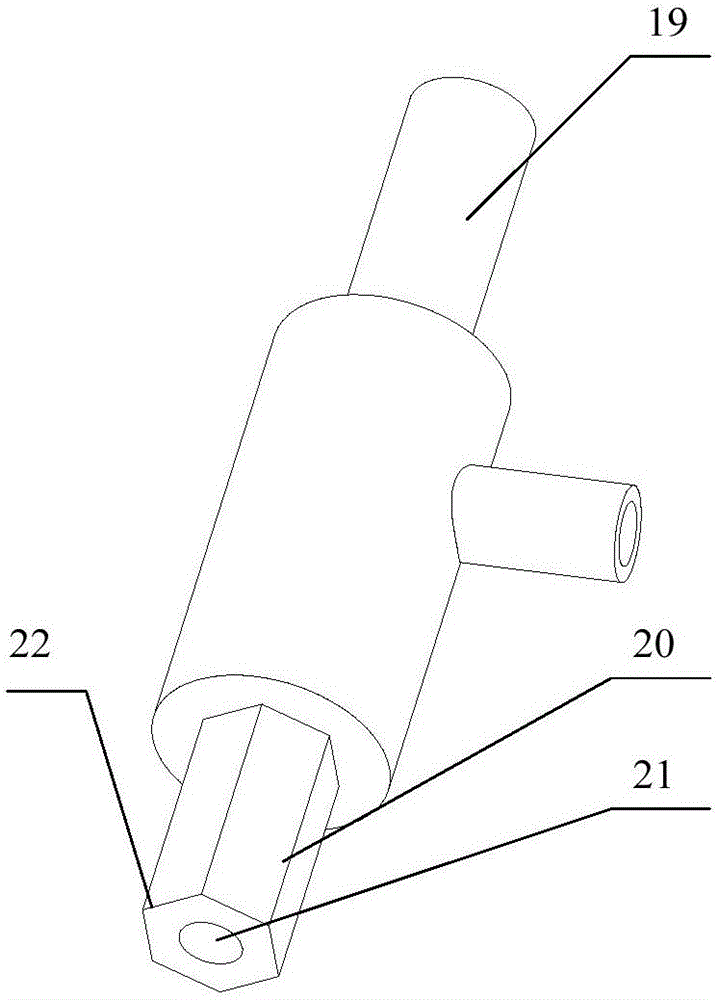

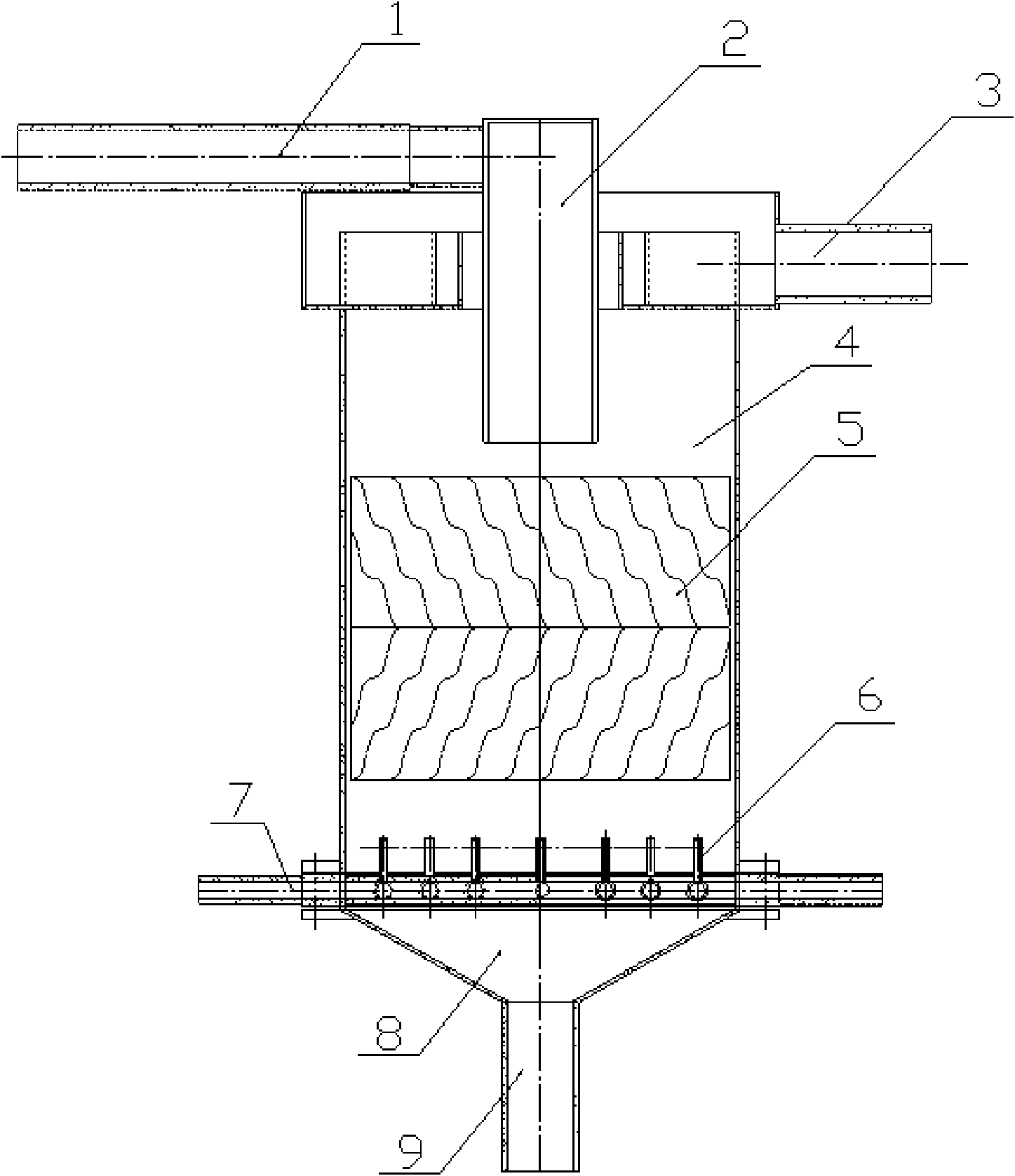

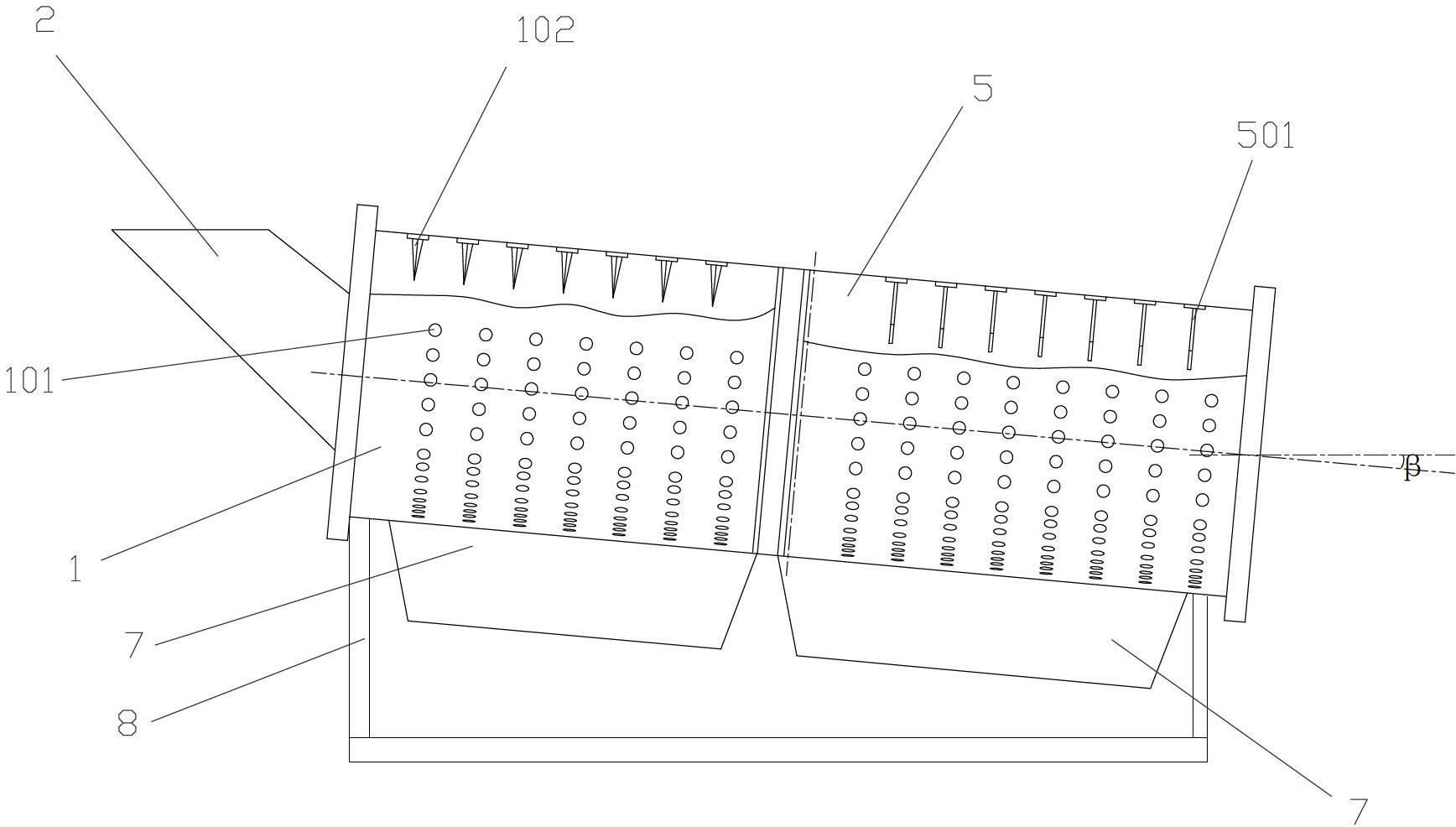

Jet type gas/solid erosion test device

InactiveCN102288538AFlow field stabilityPrecise control of impact angleWeather/light/corrosion resistanceSpray nozzleEngineering

The invention discloses a jet type gas / solid erosion test device, which is composed of an air compressor, a pressure gauge, a pressure control valve, a control box, a dust collector, a spray gun, a nozzle, a sample turntable, a sand storage room, a frequency conversion motor, The air compressor is connected with the spray gun through the gas delivery pipe, the sand delivery pipe and the body. The air compressor is connected with the spray gun. The gas delivery pipe is equipped with a pressure gauge and a pressure control valve. There is a nozzle at the lower end of the spray gun. The sample turntable is located under the nozzle. Driven by a frequency conversion motor, the sand storage chamber is connected to the spray gun through the sand delivery pipe. The spray gun and the sample turntable are located in the closed body, and the sand storage chamber is located at the bottom of the body. Air compressor, pressure gauge, pressure control valve, control box , The dust collector and the frequency conversion motor are located outside the body, and the dust collector is used for dust removal inside the body; the spraying angle of the spray gun is 10° to 90°; the invention makes the sample be eroded by the gas / solid two-phase flow at the same time; the invention is in the working process The medium flow field is stable, and the impact angle can be precisely controlled.

Owner:JILIN UNIV

Preparation method of aluminum alloy powder for additive manufacturing

InactiveCN106392089ASmall granularityHigh sphericityAdditive manufacturing apparatusTundishHigh pressure cell

The invention discloses a preparation method of aluminum alloy powder for additive manufacturing, and belongs to the technical field of 3D printing additive manufacturing. The preparation method comprises the steps that impurities in raw materials are removed; a graphite rod is added in a crucible to be roasted at the temperature of 300-500 DEG C; a smelting chamber and an atomization chamber are subjected to vacuum pumping treatment, wherein the vacuum degree reaches 1*10<-4>-1*10<-2> Pa; a heat preservation pot and a tundish are heated; metal liquid flow which perpendicularly drops is broken into small liquid drops through a nozzle with a negative pressure drainage effect under the high pressure of 0.5-6 MPa and high-purity argon, powder is formed through cooling and spheroidizing solidification, and a 5-30 kw high-pressure fan is adopted; and after the temperature is lower than 50 DEG C, screening is carried out under the atmosphere of high-purity argon. The preparation method has the advantages that industrial production can be achieved, the domestic urgent demand for high-performance aeronautical aluminum alloy powder materials is met, and the manufacturing cost is effectively saved.

Owner:中航迈特粉冶科技(北京)有限公司

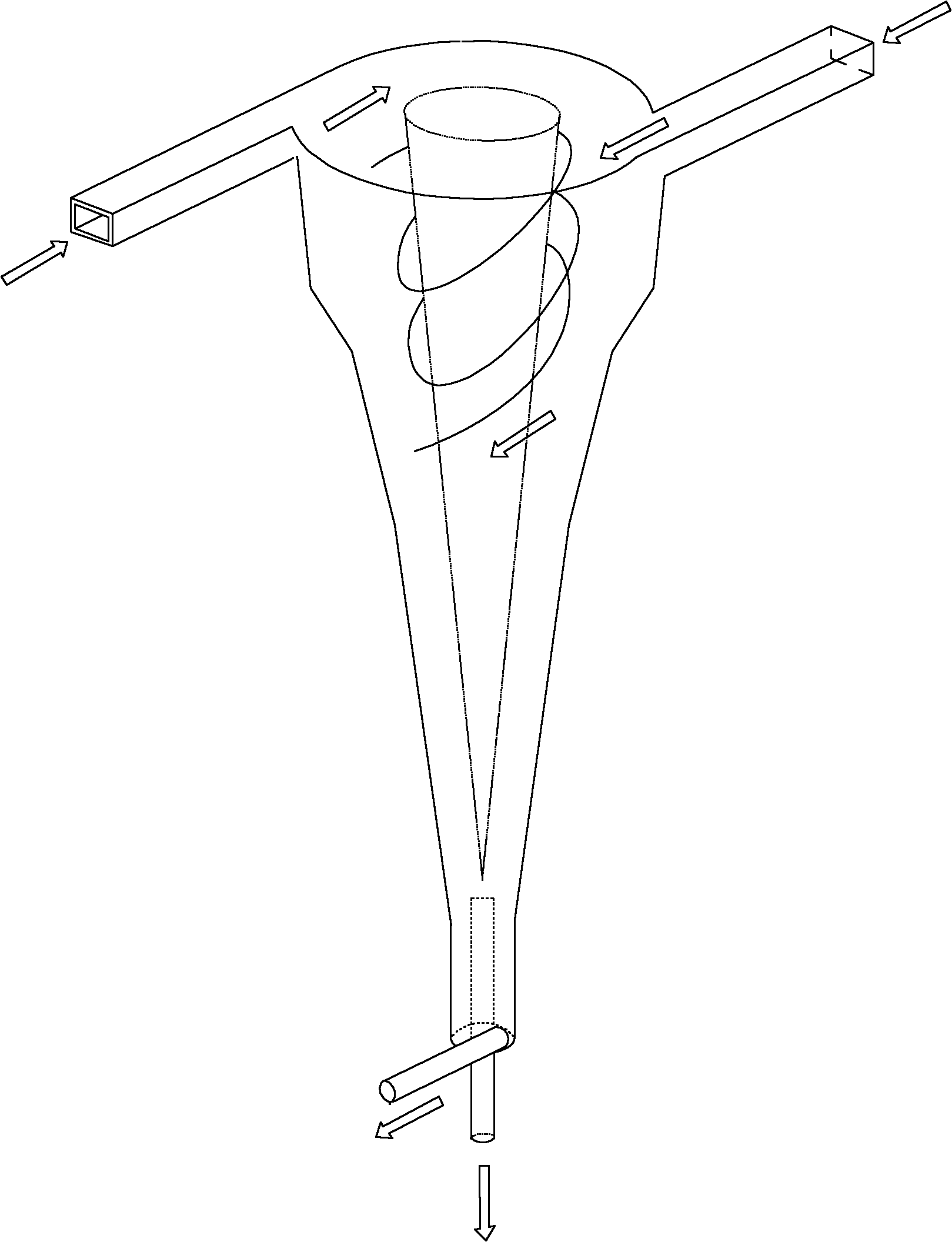

Equidirectional drainage reverse taper type high-efficiency rotational flow separator

InactiveCN101983779AReduce volumeSmall footprintReversed direction vortexPetroleum engineeringHydrocyclone

The invention relates to an equidirectional drainage reverse taper type high-efficiency rotational flow separator, which mainly solves the problems of poor separation effect of tiny oil drops, large volume and inconvenient installation of the traditional hydraulic cyclone separator. The invention is mainly characterized in that a rotational flow cavity section, a large taper section, a small taper section, a tail pipe section and an outlet section are successively distributed between upper and lower sealing faces; the components form a rotational flow cavity body gradually converged towards the central axis after being successively connected; a tapered thimble in the rotational flow cavity body is fixed on inner side surface of the upper sealing face; the taper top of the tapered thimble points to one side of the lower sealing face; an oil outlet pipe is vertically and fixedly connected to the lower sealing face through the center of the lower sealing face; the pipe orifice of the oil outlet pipe is positioned on the lower part of the taper top of the tapered thimble; and a water outlet pipe is horizontally connected to the bottom end of the outlet section along the tangential direction of a cycle. The rotational flow separator has the characteristics of good elimination effect on the tiny oil drops. Compared with the traditional hydraulic rotational flow separator, the rotational flow separator has the advantages of stable flow field and high separation efficiency, and is convenient for technological installation.

Owner:NORTHEAST GASOLINEEUM UNIV

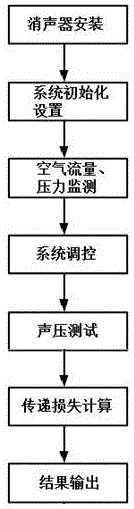

Muffler transmission loss testing system and muffler transmission loss testing method for aiming at aerodynamic noise

PendingCN106383035AFlow field stabilitySimple structureVehicle testingTransmission lossSound pressure

The invention provides a muffler transmission loss testing system and a muffler transmission loss testing method for aiming at aerodynamic noise, and particularly relates to a system and a method for testing aerodynamic noise muffling capability of an automotive intake / exhaust muffler. The muffler transmission loss testing system comprises a variable-frequency centrifugal fan, a fan noise muffler, an air flow sensor, an air pressure sensor, a standing wave tube, a microphone set, an electronic air pressure relief valve, a pressure relief valve muffler, an analog / digital conversion board, a gain amplifier and a computer. The muffler transmission loss testing method comprises the steps of fixing a to-be-tested muffler on a table; starting the testing system and performing initialization setting on the testing system; monitoring an air flow and pressure in the standing wave tube; controlling the fan and the pressure relief valve for sustaining the flow and the pressure in the system; testing a sound pressure value at a corresponding position in the standing wave tube; calculating the transmission loss; and outputting a result. The muffler transmission loss testing system and the muffler transmission loss testing method have advantages of simple structure, convenient operation and high accuracy. The muffler transmission loss testing system and the muffler transmission loss testing method fill in gaps in testing the aerodynamic noise transmission loss of the automotive intake / exhaust system.

Owner:BRILLIANCE AUTO

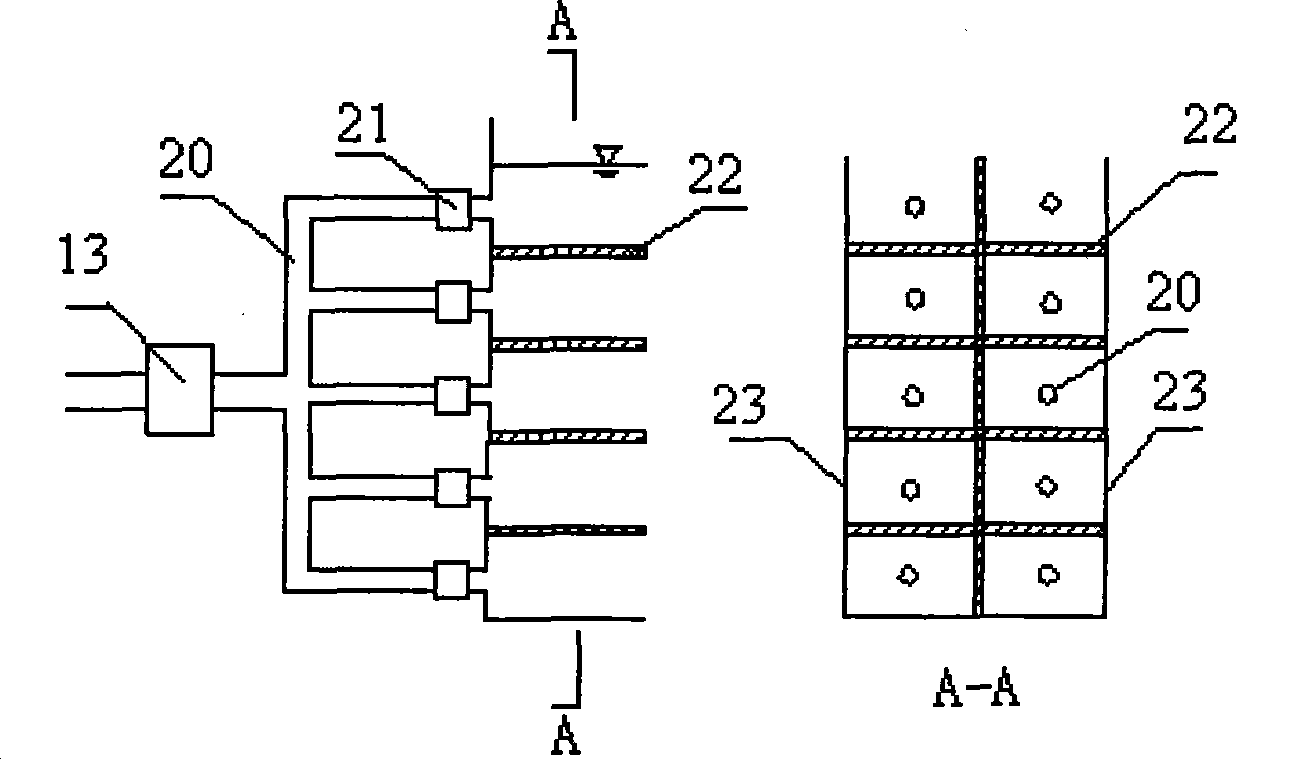

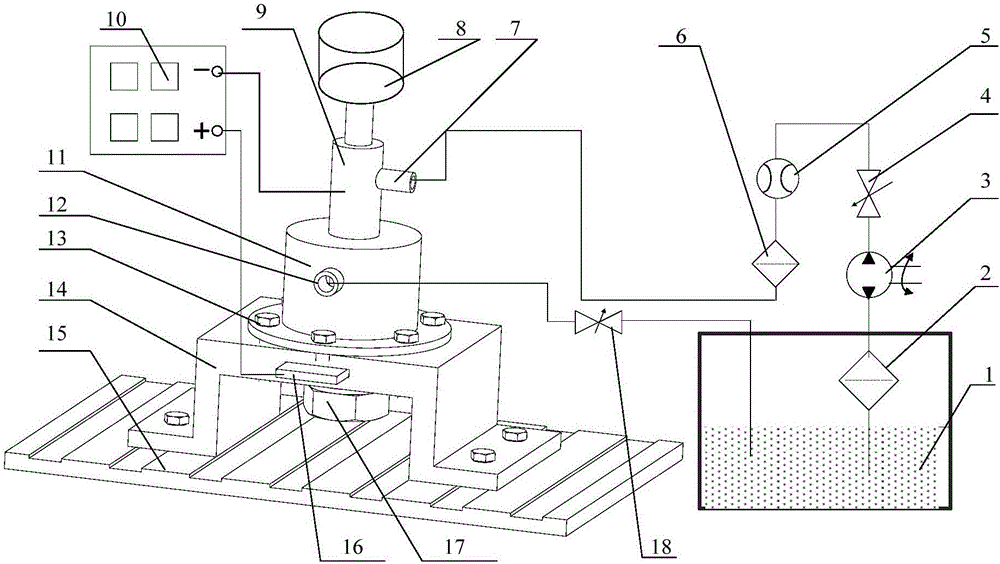

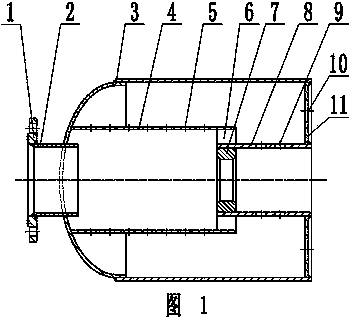

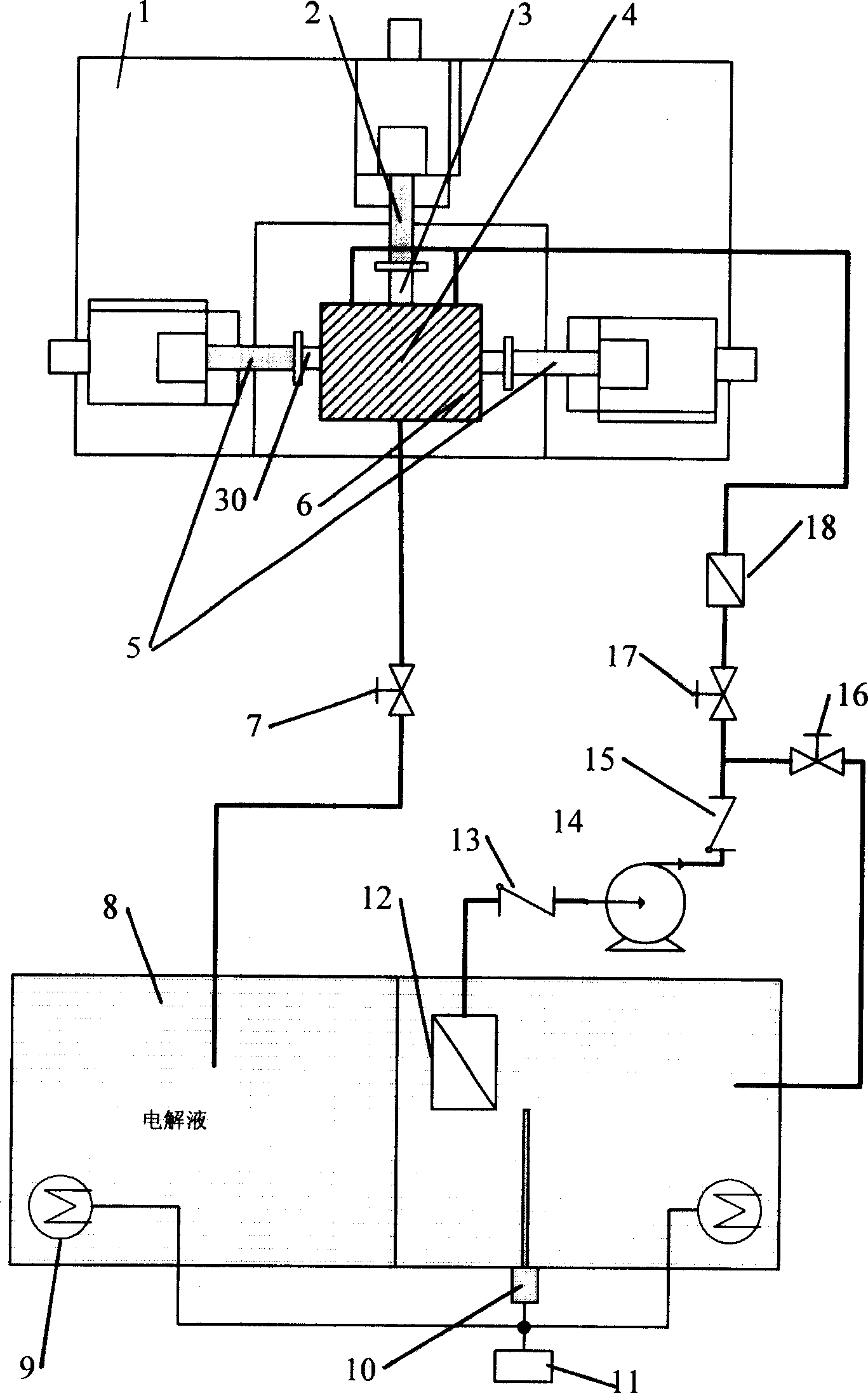

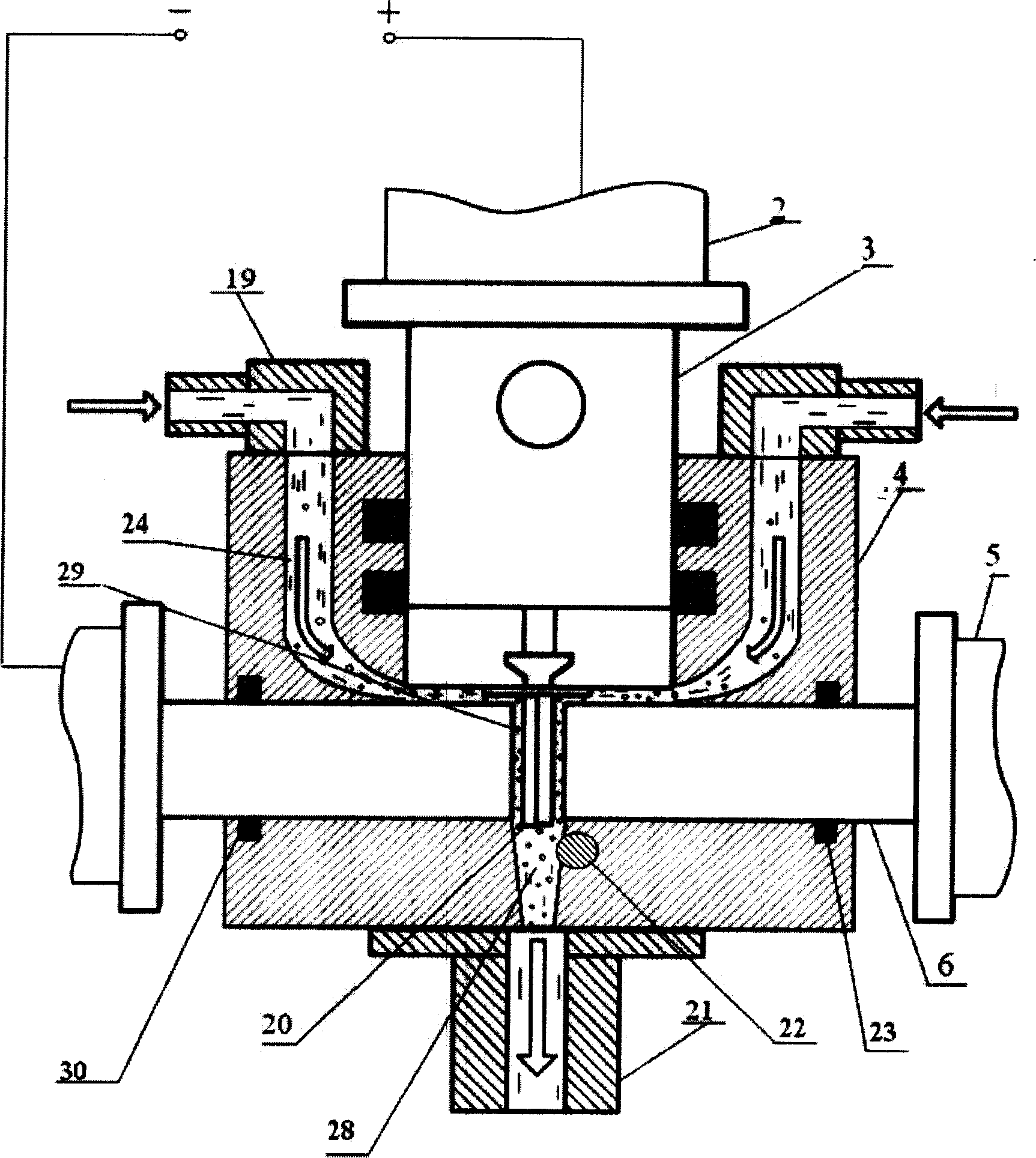

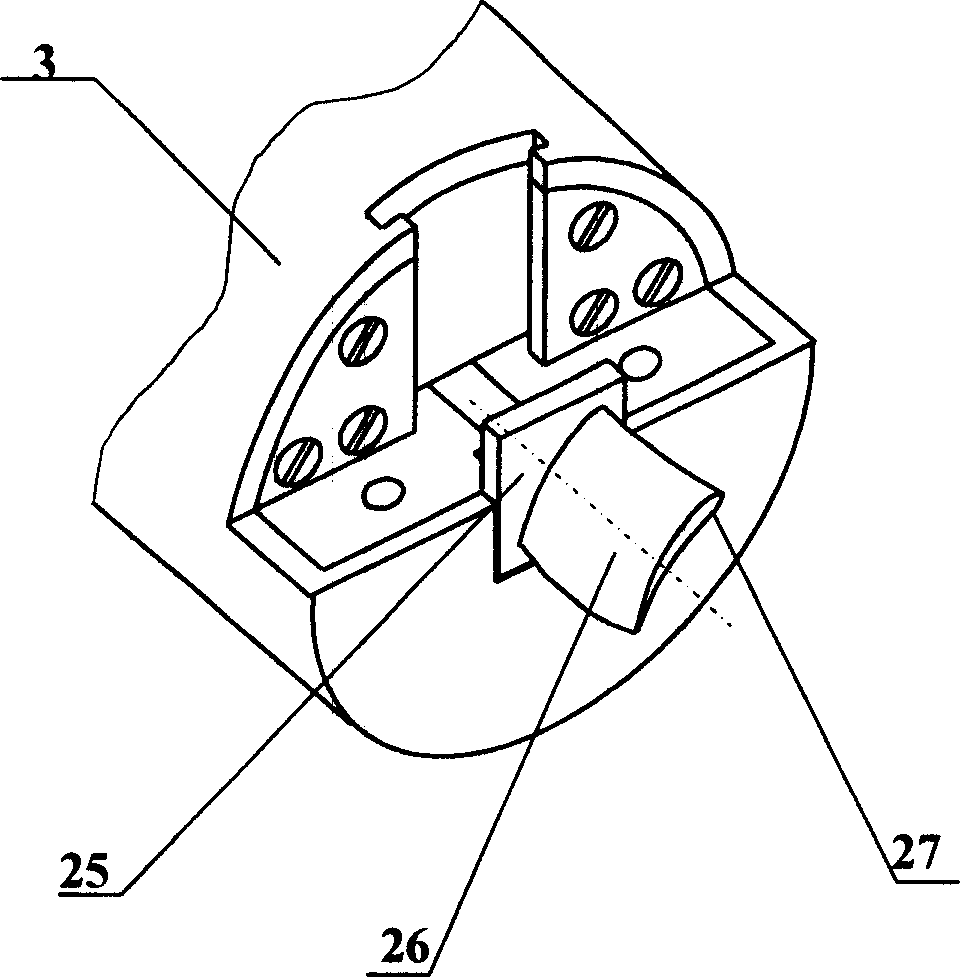

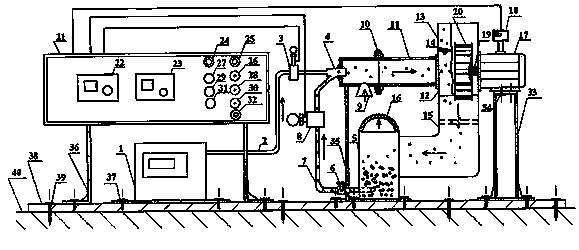

Hexagon-hole electrolytic machining device

InactiveCN106541192ASimple structureReduce economic costsMachining working media supply/regenerationElectrolysisEngineering

The invention discloses a hexagon-hole electrolytic machining device, and belongs to the field of electrolytic machining. The device provided by the invention comprises a tool cathode device, an electrolysis tooling fixture device, a workpiece, a machine tool system and an electrolyte circulation system. The tool cathode device is connected with a main shaft of the machine tool system; the workpiece is connected and fixed by the tooling fixture device; one end of the electrolyte circulation system is connected to the tool cathode device, and the other end of the electrolyte circulation system is connected to the tooling fixture device. An electrolyte flows through a gap formed by a tool cathode and the workpiece at high speed under the action of a pulsed power supply, thus completing the hexagon electrolytic machining; the flow field stability is guaranteed by a sealed electrolyte cavity and the regulation of an electrolyte outlet valve, and a series of hexagon-hole electrolytic machining is realized through the movement of the workpiece in a tooling slot. The hexagon-hole electrolytic machining device has the characteristics that the flow field stability is realized, the flow field uniformity of the electrolyte is guaranteed, the electrolytic machining efficiency and electrolytic machining quality are improved, short circuit is not easy to generate during the electrolytic machining, and the practical value is extensive.

Owner:CHANGZHOU INST OF TECH

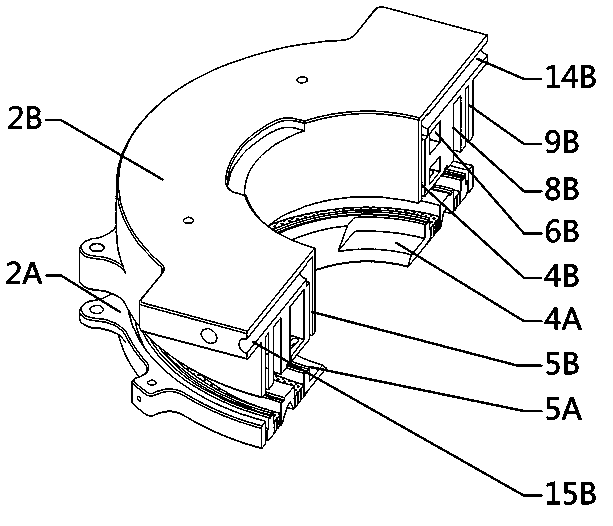

Co-rotating outflow internal-hole type high performance swirling separator

InactiveCN102225381AReduce turbulenceFlow field stabilitySingle direction vortexEngineeringFunnel shape

The invention discloses a co-rotating outflow internal-hole type high performance swirling separator. In the prior art, an effect of removal of fine oil drop of hydroclone is poor. According to the swirling separator, a problem of the prior art is solved. The swirling separator is characterized in that: a circular table-shaped multi-stage internal swirling body is fixed between an upper sealing surface and a lower sealing surface, wherein a inner cylinder in the swirling chamber portion, a inner cylinder in the large conoid portion, a inner cylinder in the small conoid portion, and a inner cylinder in the tail tube portion are sequentially connected from the top to the bottom to form the circular table-shaped multi-stage internal swirling body; the inner cylinder in the small conoid portion has a hollow structure, and is provided with oil collecting holes; a funnel-shaped oil collecting cone is arranged in the inner cylinder in the tail tube portion, an upper open of the oil collecting cone is communicated with the inner chamber of the inner cylinder in the small conoid portion, and a lower open of the collecting cone passes through the center of the lower sealing surface, and forms a fixed connection with a oil output tube, wherein the oil output tube is introduced vertically; a water output tube is connected to the bottom of a outer swirling body, wherein the water output tube is introduced along tangent line direction to the circle of the outer swirling body and is communicated with a swirling inner chamber, swirling water output direction of the water output tube is the same as the swirling direction in the swirling inner chamber. The swirling separator has characteristics of removal of the tiny oil drop in the water, high separation efficiency and simple structure.

Owner:NORTHEAST GASOLINEEUM UNIV

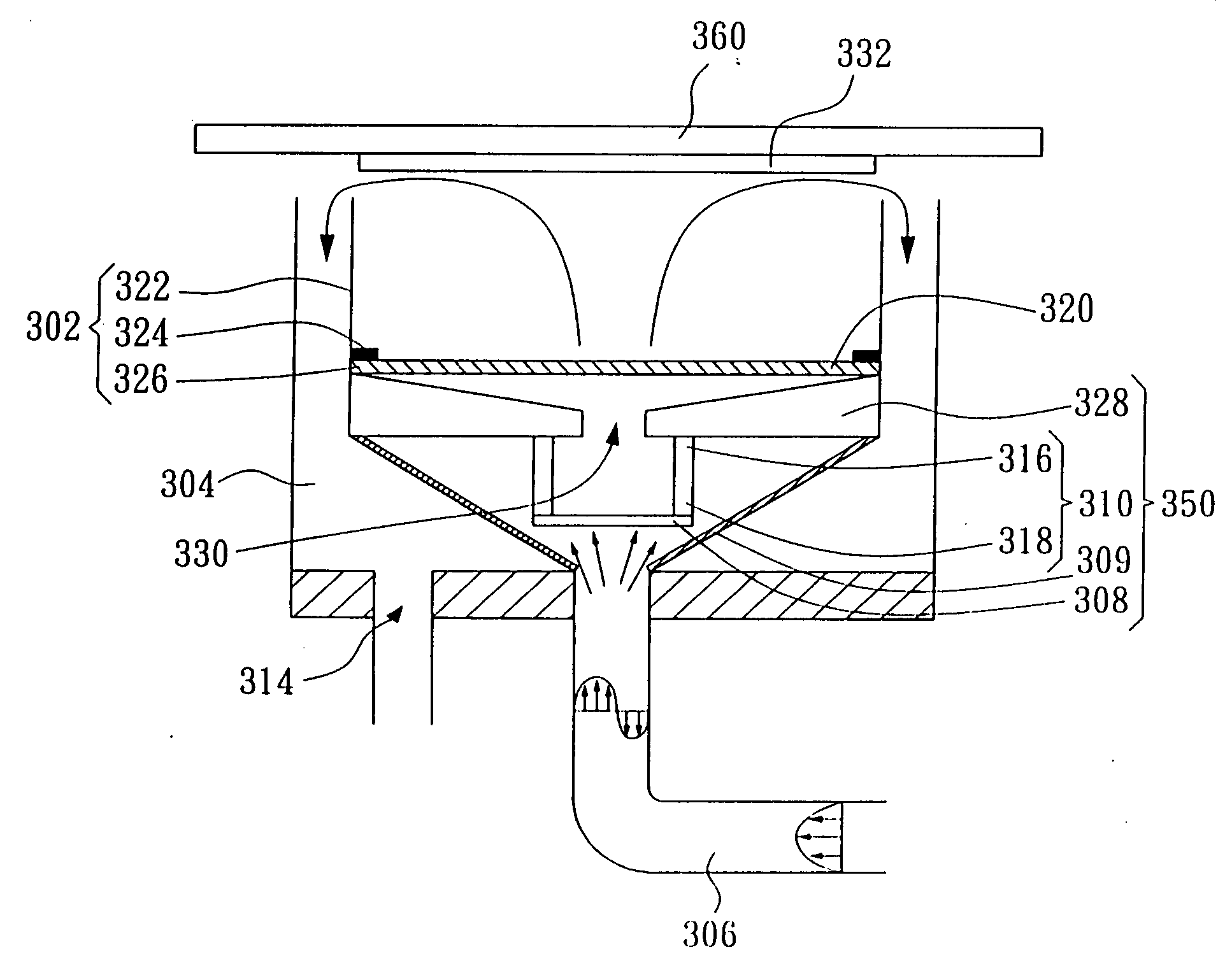

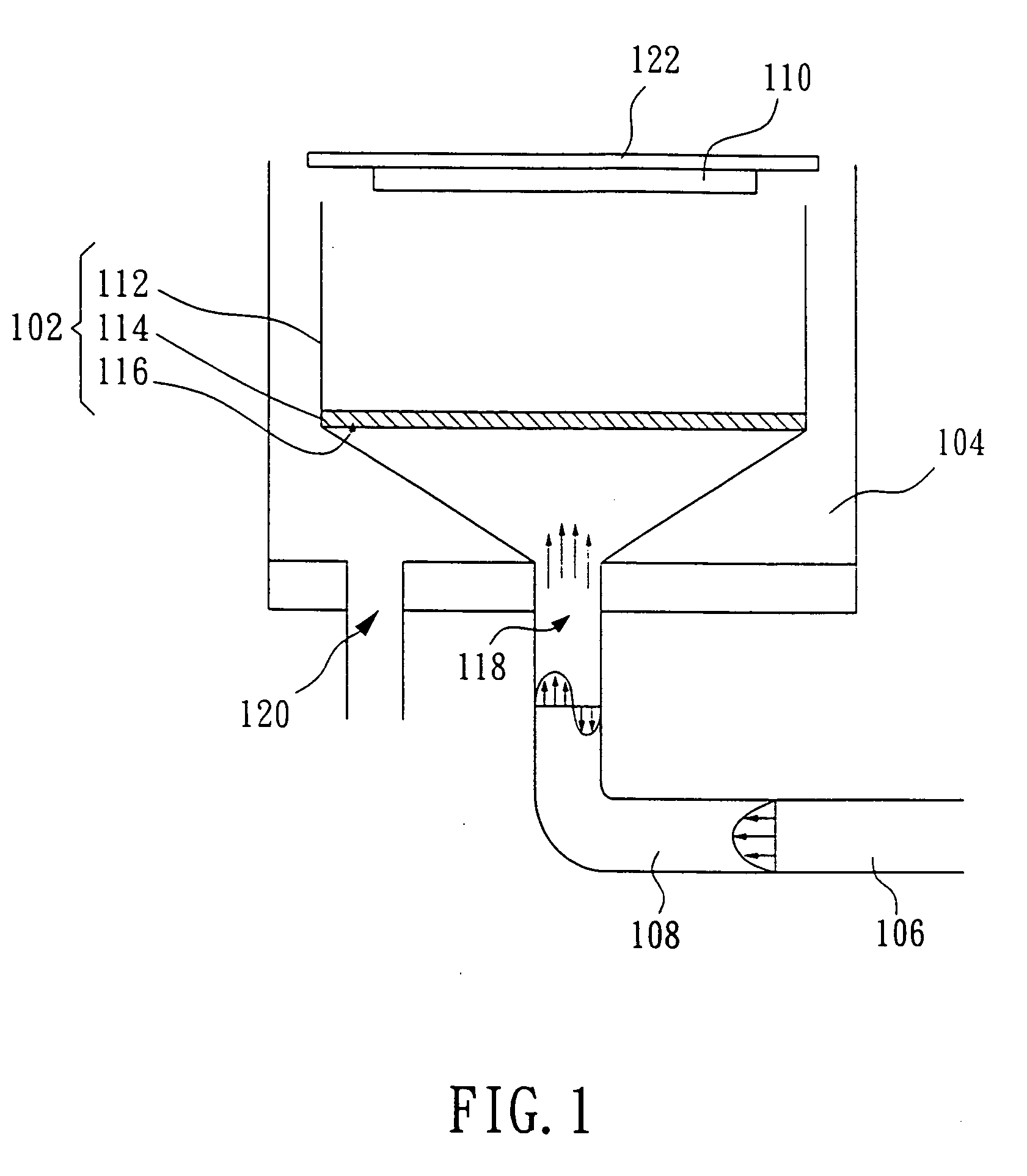

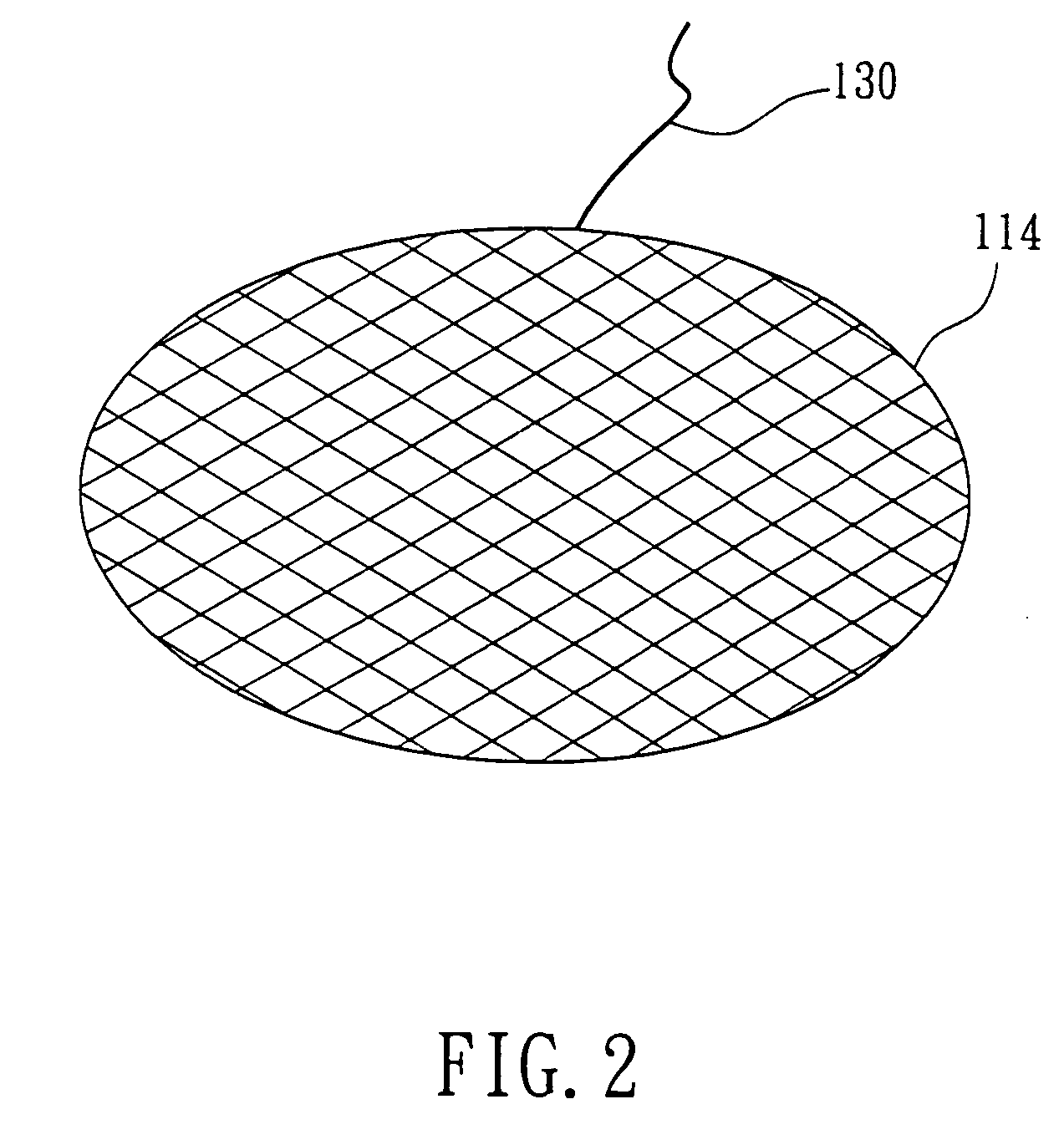

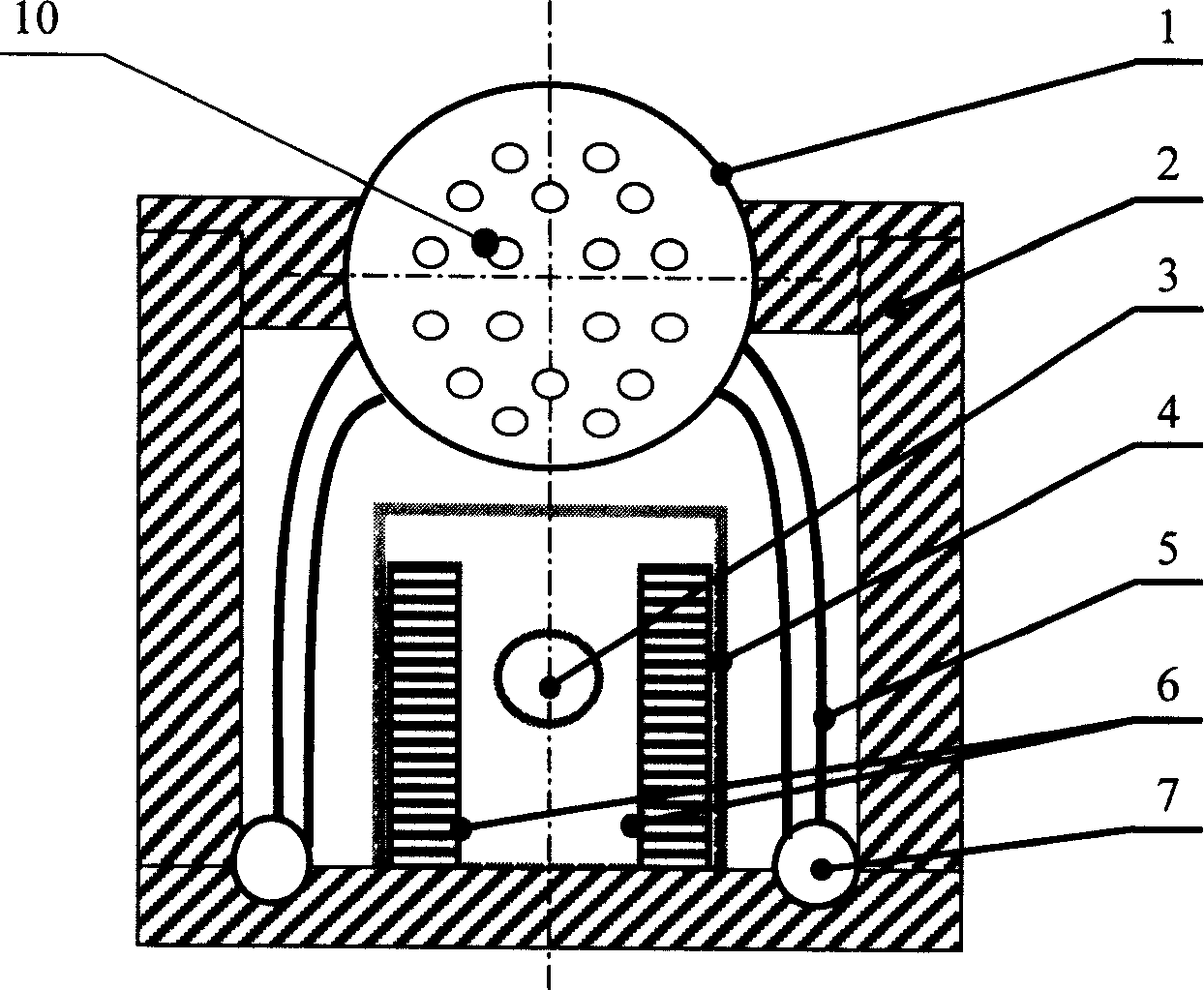

Electroplating apparatus with functions of voltage detection and flow rectification

InactiveUS20050051425A1Flow field stabilityImprove homogeneityCellsCurrent/voltage measurementEngineeringElectroplating

The present invention provides a fountain-type electroplating apparatus with functions of voltage detection and flow rectification, comprising: an electroplating tank, a rectification device, and an overflow tank, wherein the electroplating tank is positioned inside the overflow tank, and the rectification device is arranged under the electroplating tank, in addition, the electroplating tank is composed of a shell, a cathode electrode, and an mesh shaped anode. The apparatus of the present invention further comprises: a power supplier, a switcher, a plurality of detection circuits, and a plurality of connecting line, which is used for monitoring the same.

Owner:IND TECH RES INST

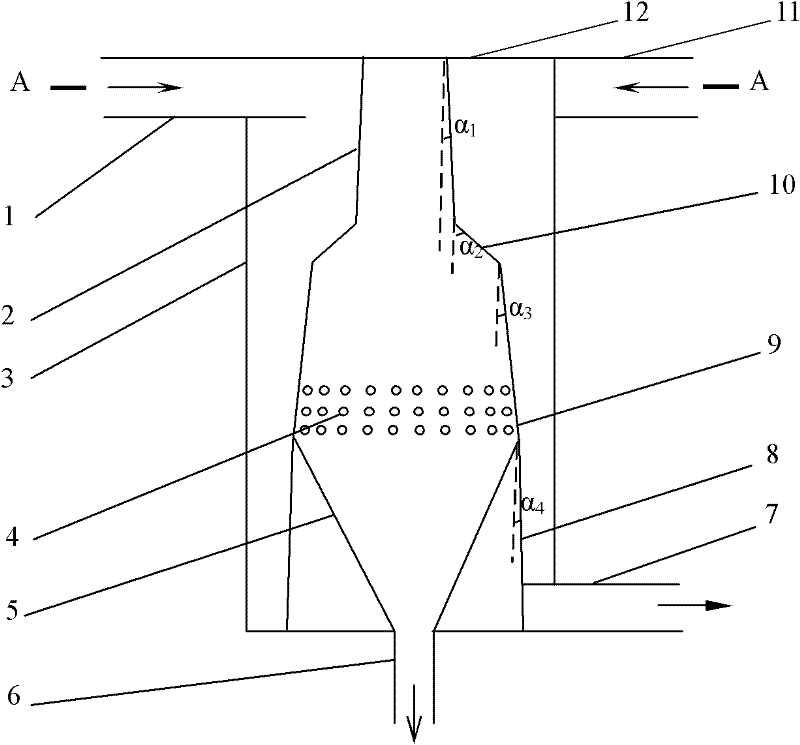

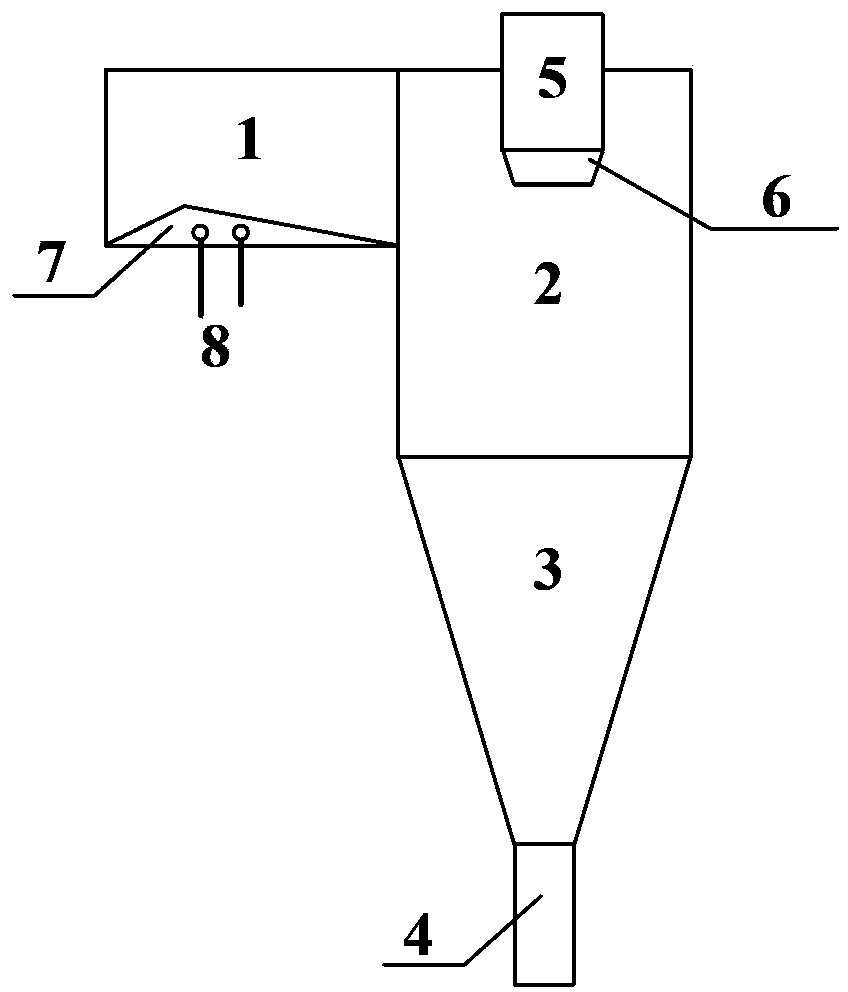

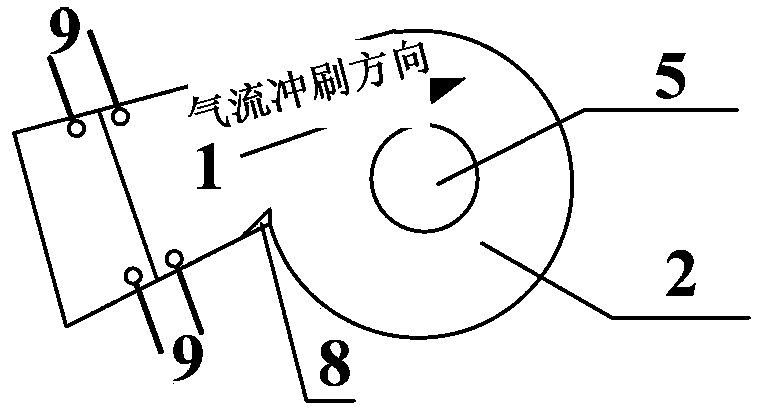

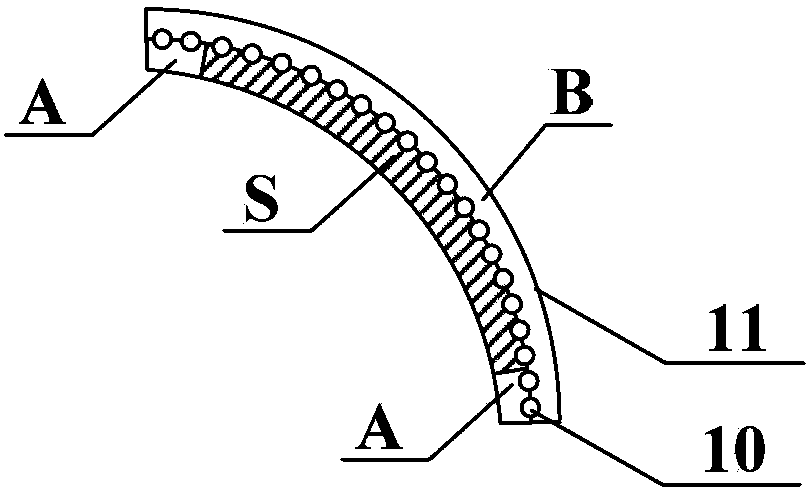

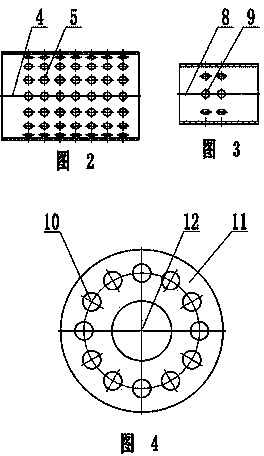

Cyclone separator with wear-resistant target section and guiding device for circulating fluidized bed boiler

ActiveCN103398375AIncreased flow velocityIncrease flow rateFluidized bed combustionApparatus for fluidised bed combustionRefractory wearCyclone

A cyclone separator with a wear-resisting target section and a guiding device for a circulating fluidized bed boiler. The cyclone separator comprises a separator inlet flue, a separator barrel body connected with an outlet of the separator inlet flue, a separator cone and a separator standpipe, which are successively connected below the separator cylinder body, and a separator central cylinder inserted into the upper part of the separator barrel body. The lower part of the separator central cylinder is provided with a central cylinder necking; the separator inlet flue is a tapered inlet flue, which is provided inside with a smoke guiding boss, and a smoke diversion part at the outlet; the smoke guiding boss and the smoke diversion part are covered with a high-strength refractory wear-resistant material layer; and one or a plurality of soot blowing mouths are arranged surrounding the smoke guiding boss. Optimization on the flow field in the cyclone separator reduces the direct impact of airflow and wear on the refractory wear-resistant material in the target section, and can improve the continuous operation cycle of the circulating fluidized bed boiler.

Owner:HUANENG CLEAN ENERGY RES INST

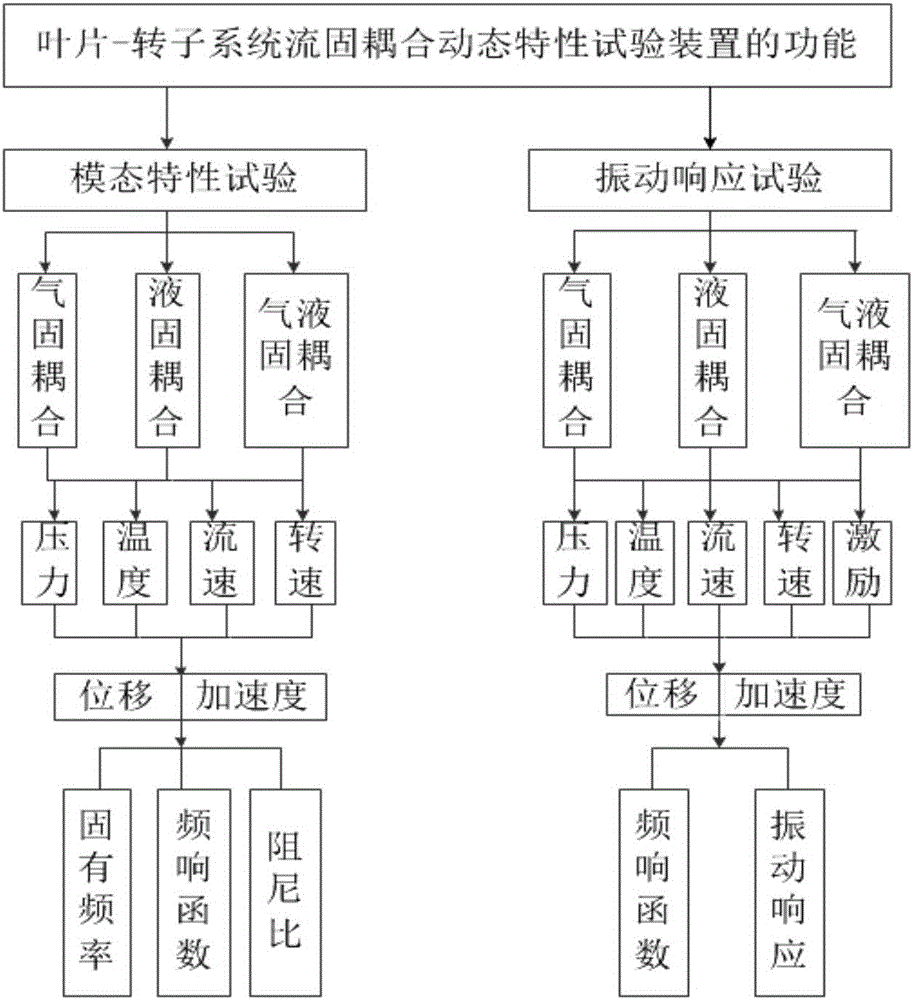

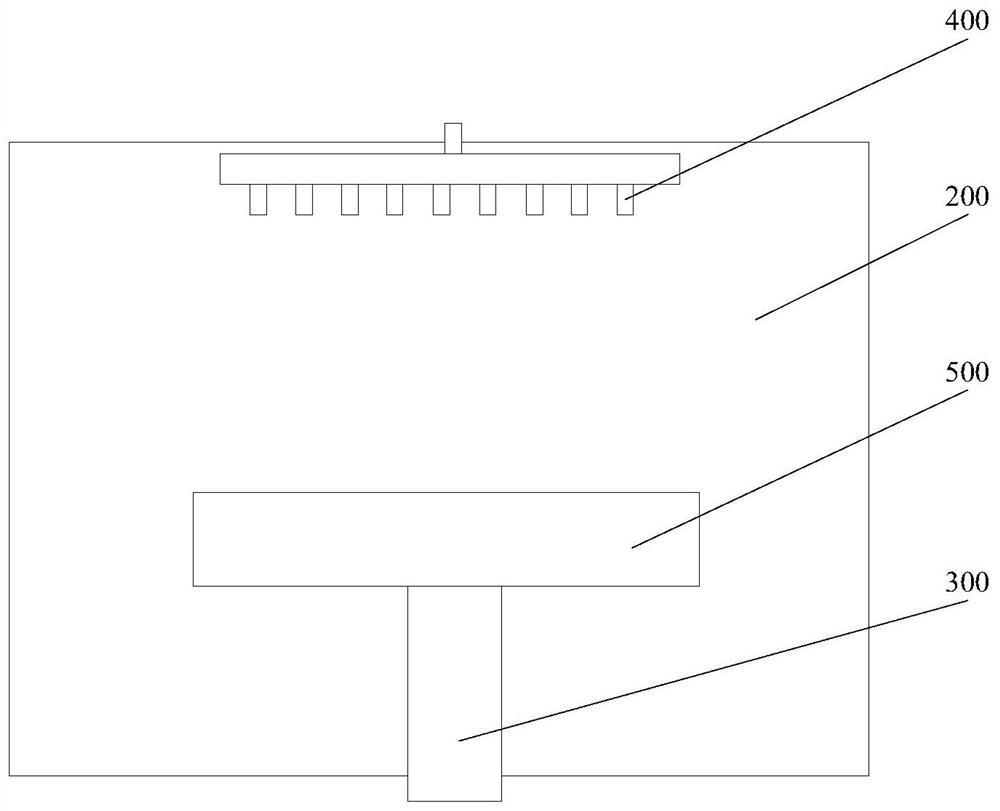

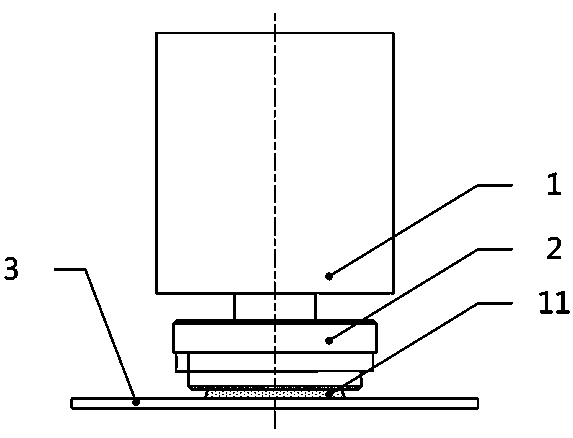

Fluid-structure interaction dynamic property testing device for blade-rotor system

ActiveCN105699074AFlow field stabilityReduce vibrationMachine gearing/transmission testingHydrodynamic testingData processing systemVibration acceleration

The invention discloses a fluid-structure interaction dynamic property testing device for a blade-rotor system. The device includes a testing cylinder, a fluid storage and conveying system used for conveying fluid medium to the inner part is arranged on the outer part of the testing cylinder. A rotor structure is arranged in the testing cylinder. A drive device drives the rotor structure to rotate through a transmission device. A displacement sensor I measuring blade vibration displacement is mounted on the inner wall of the testing cylinder. An acceleration sensor I used for measuring the vibration acceleration of the transmission shaft and a displacement sensor II used for measuring vibration displacement of the transmission shaft are mounted on the transmission device. An acceleration sensor II used for measuring the vibration acceleration of the rotary shaft of the rotor is mounted in the testing cylinder. The displacement sensor I, the acceleration sensor I, the displacement sensor II and the acceleration sensor II are all connected with a data processing system. The data processing system analyzes the vibration properties of the blade-rotor system in a fluid-structure interaction state under different working conditions according to data of the different sensors.

Owner:SHANDONG UNIV

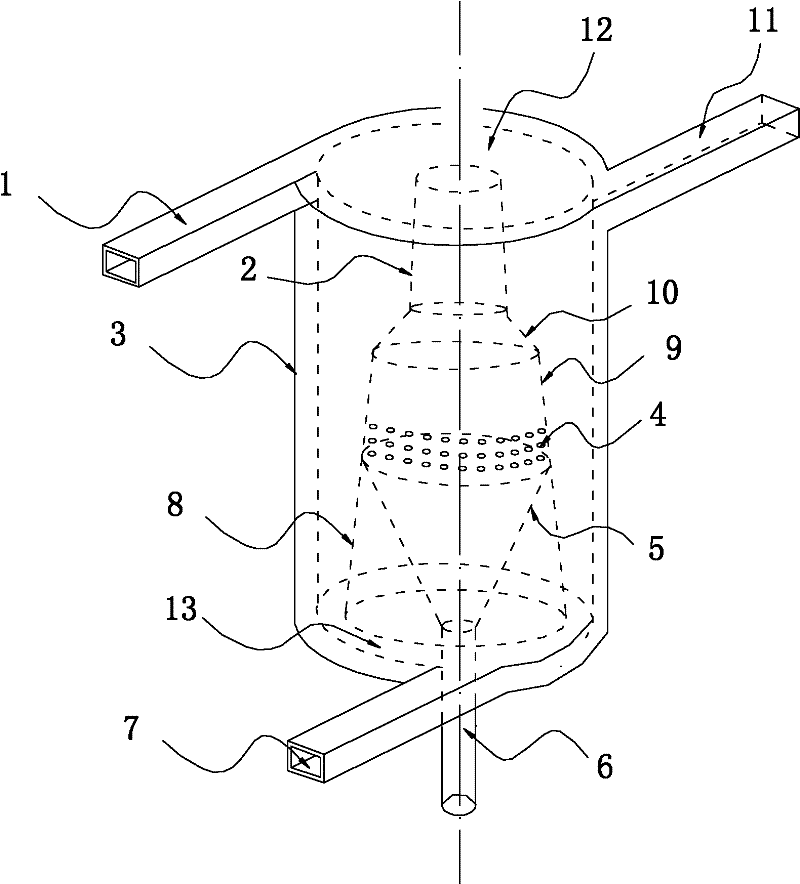

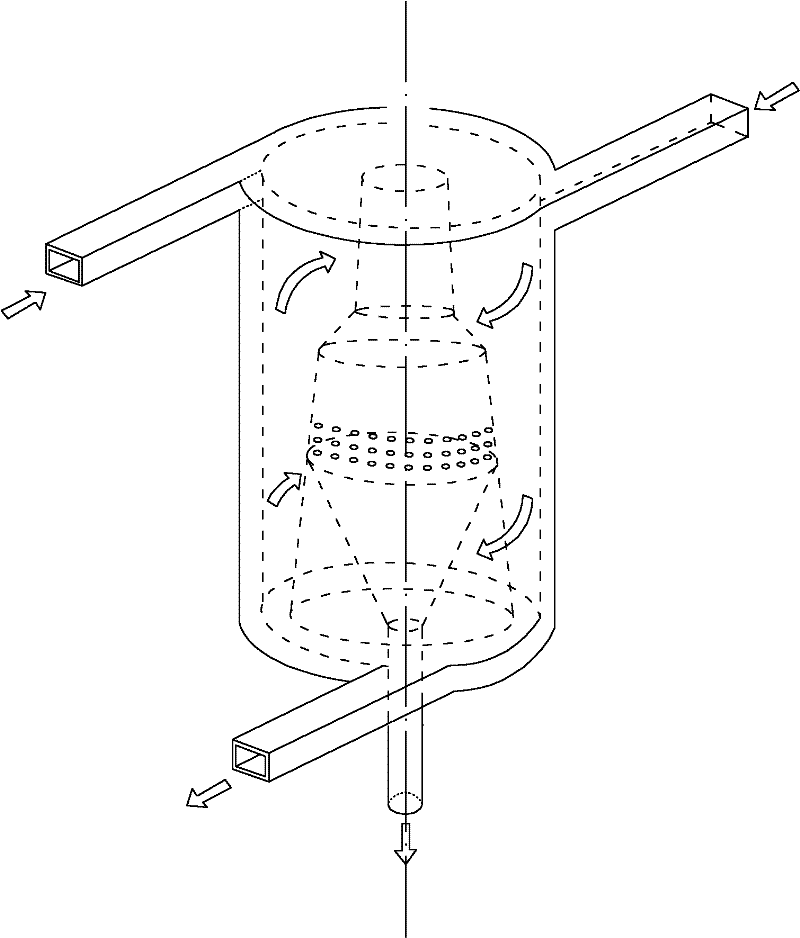

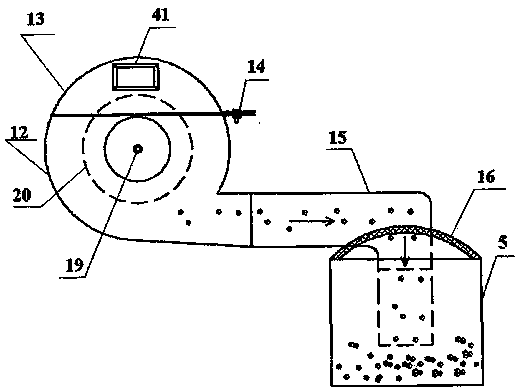

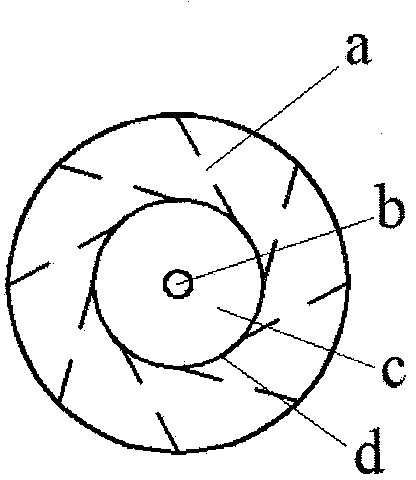

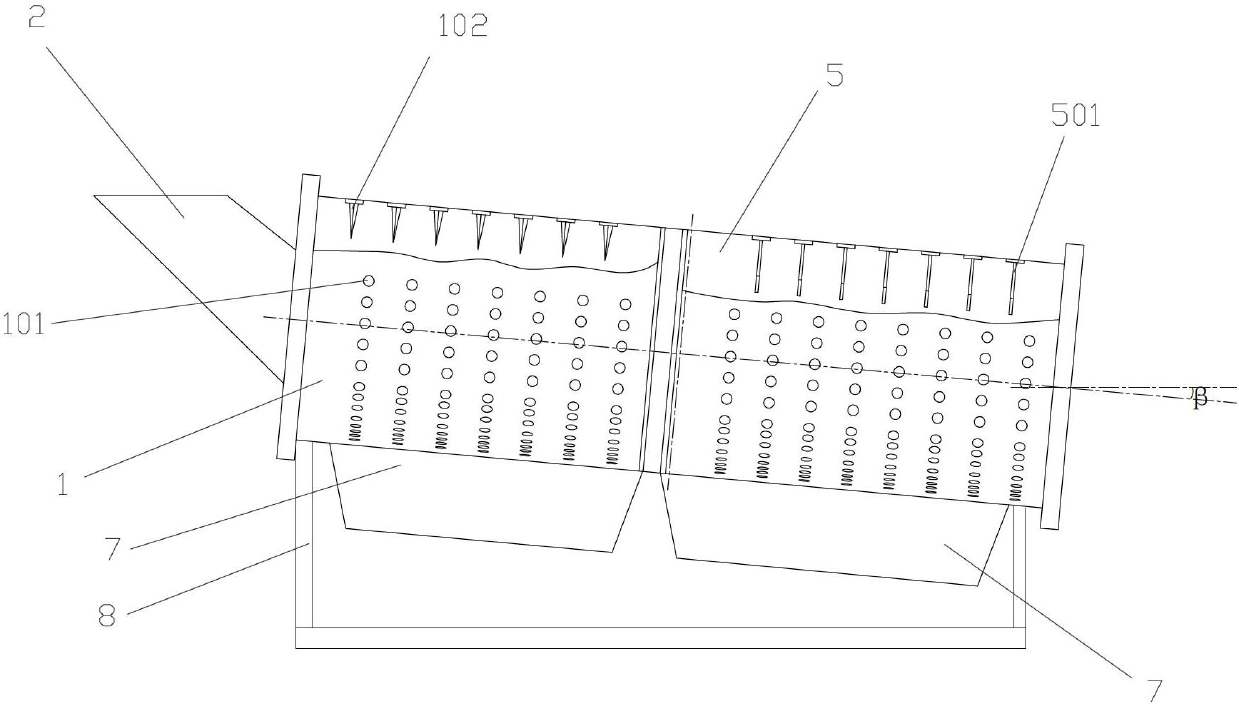

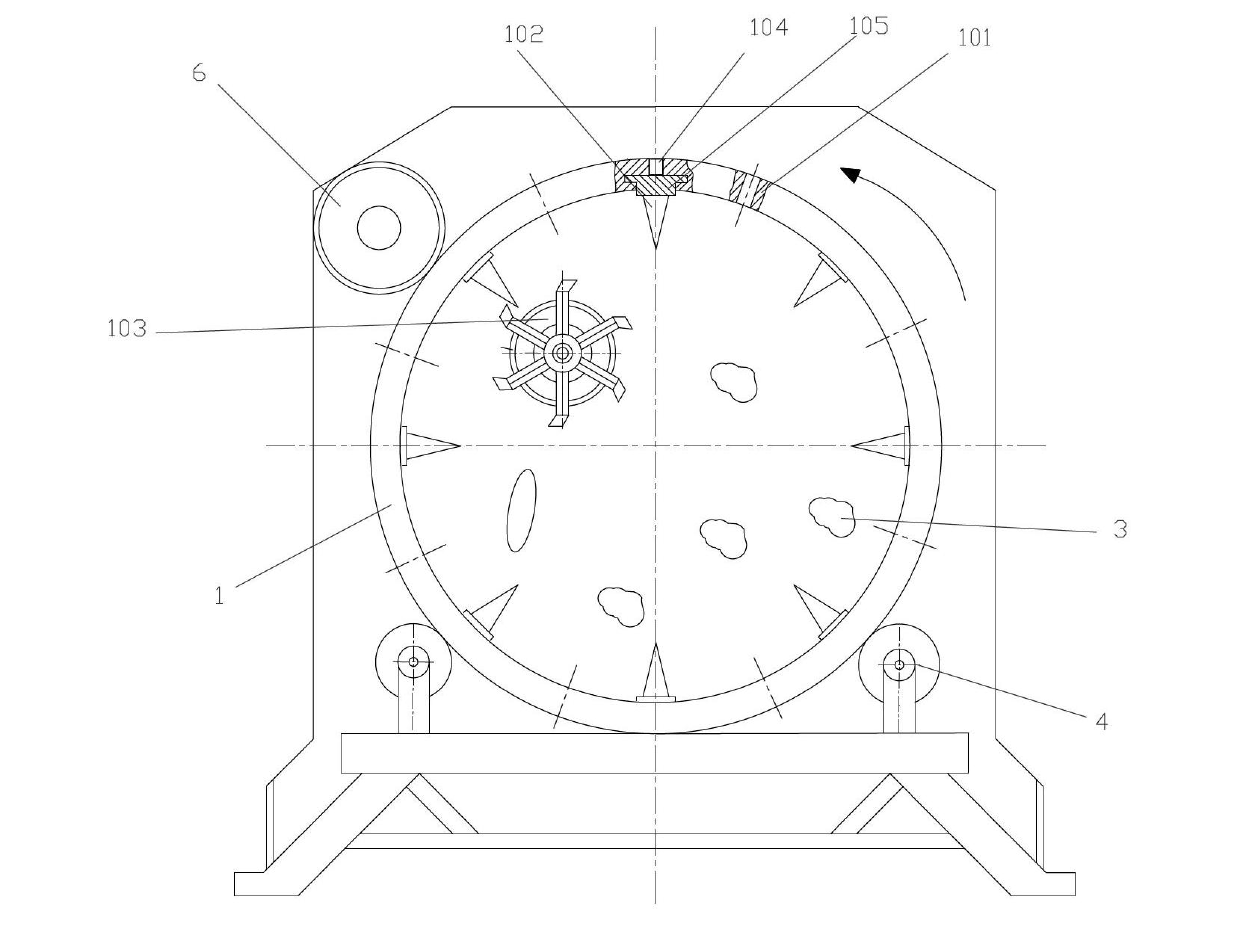

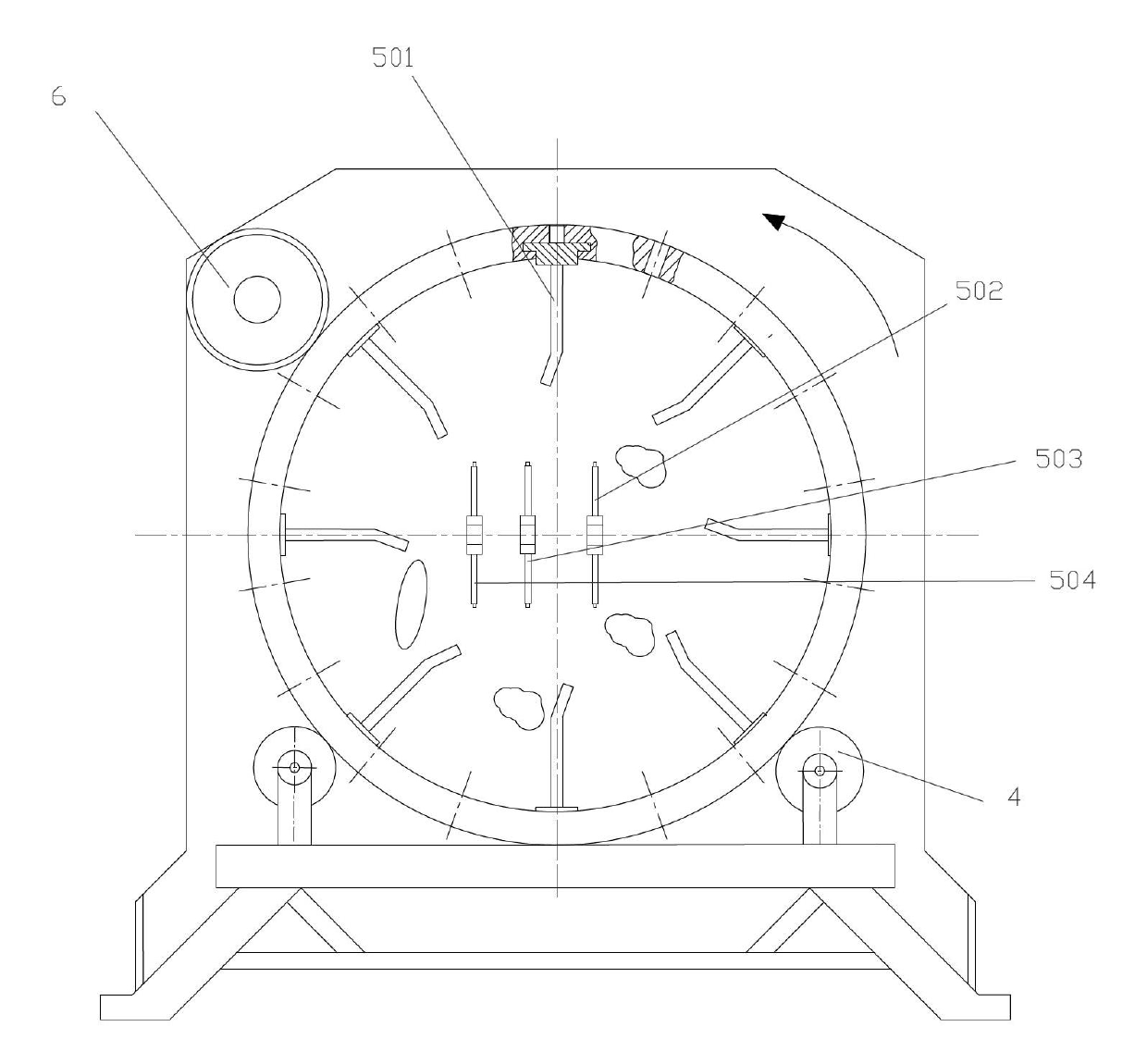

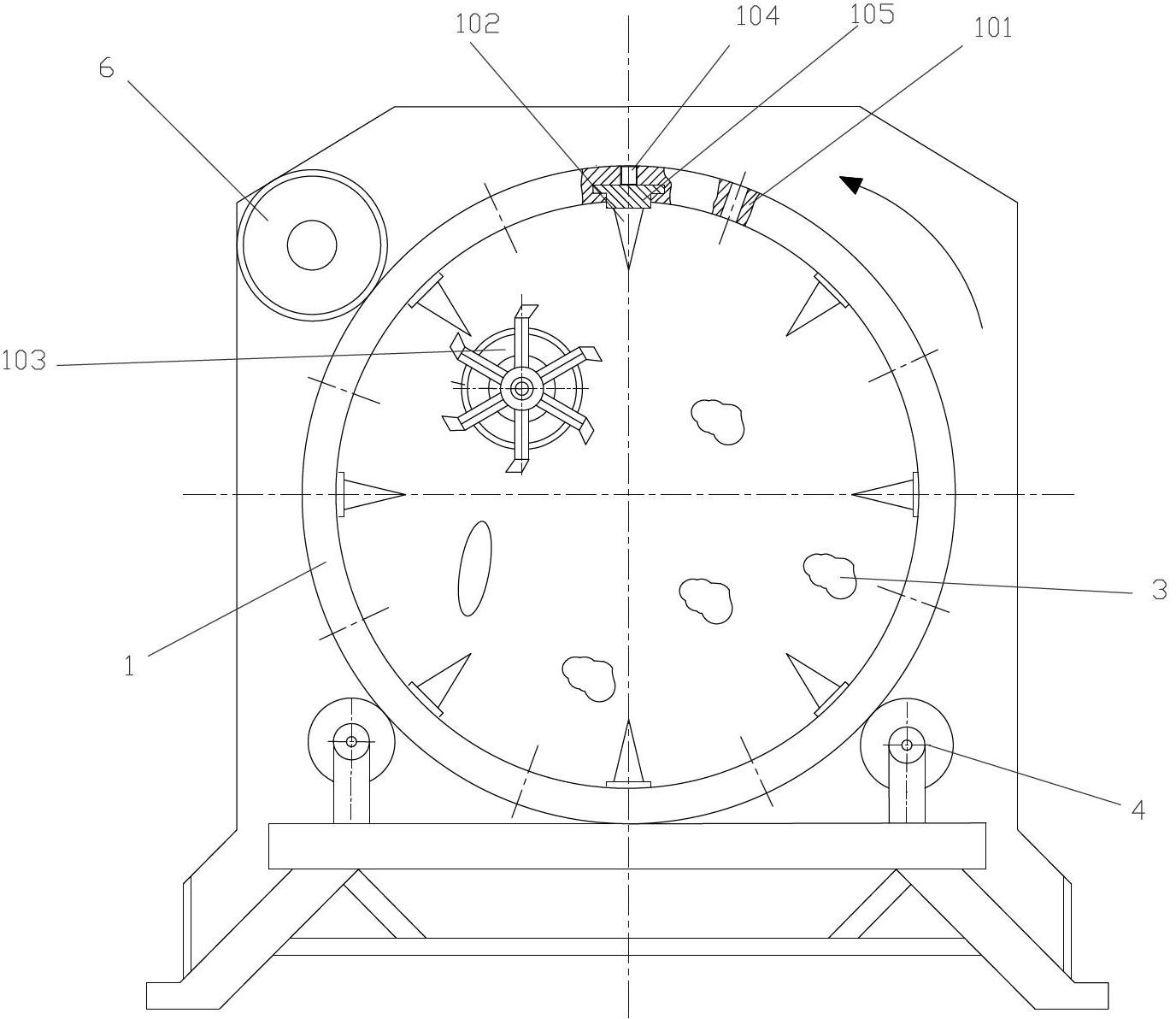

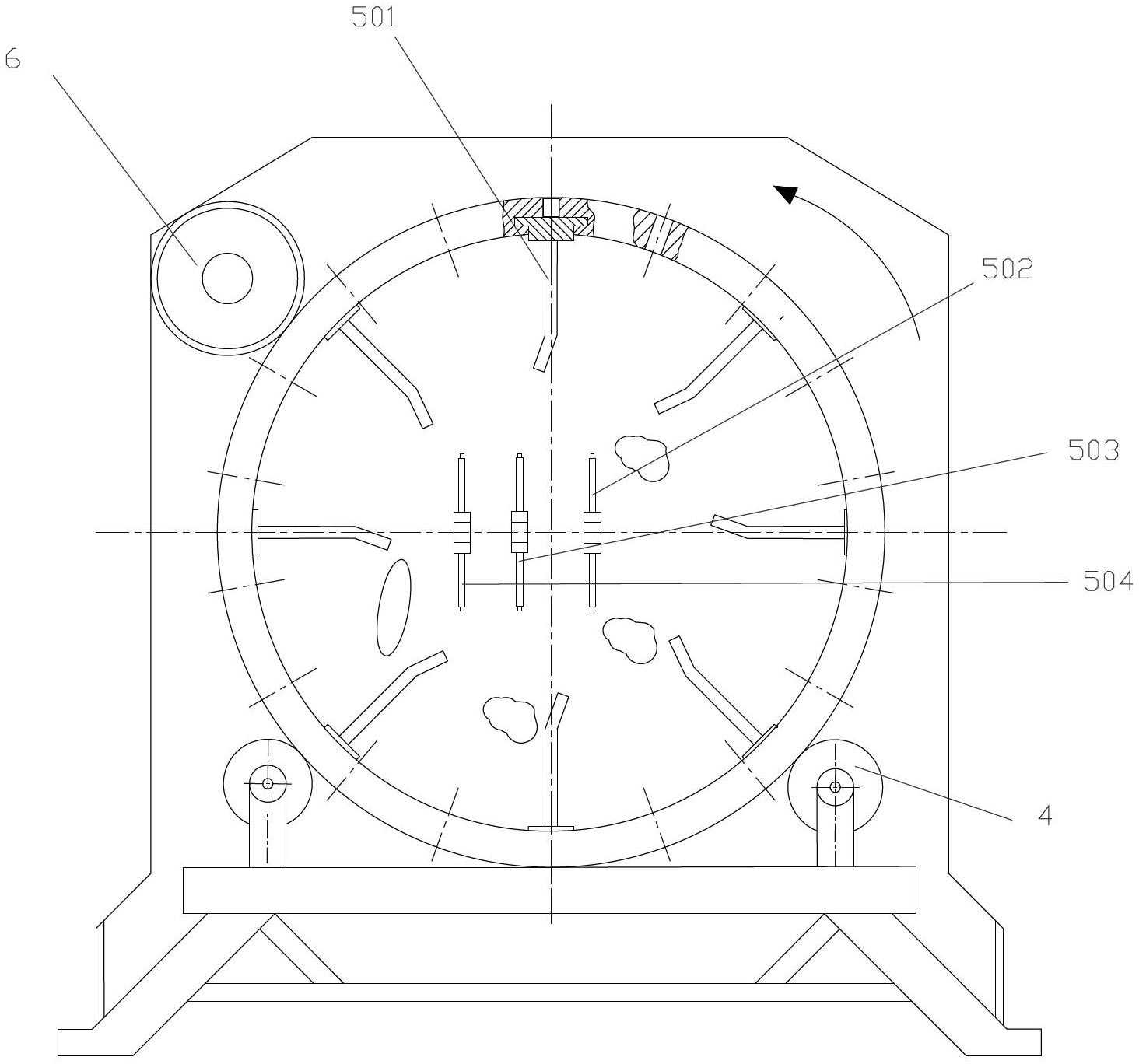

Pulse turbulence flow field fluidized mineral separator

InactiveCN101927210ARealize preliminary sortingFlow field stabilityWet separationSeparation technologyPulverized fuel ash

The invention relates to mineral separation machinery, in particular to a high-separation precision pulse turbulence flow field fluidized mineral separator. The mineral separator is characterized in that: the separator is provided with a cylindrical machine body; a feed well and an overflow pipe are arranged at the upper end of the machine body; a feed pipe is arranged on the feed well; a discharge cone is arranged at the lower end of the machine body; a discharge port is formed on the discharge cone; and a fluid distributor and a separator which consists of separating plates are arranged inside the machine body. The invention is novel separation technology with the advantages of high efficiency and high treatment capacity of self-production medium and low operating cost, combines the fluidization technology, the pulse turbulence flow field hindered falling technology and the irregular inclined corrugated plate separation technology, uses coarse particle high-density materials in the feed materials as a self-medium solid, makes the separating bed fluidized by using hydraulic jump upward flow, improves the separating medium density, makes materials with density higher than that of the separating medium pass through the bed to be settled at the bottom, makes materials with density lower than that of the separating medium float upward to enter overflow, and has the advantages of unique structural design, high adaptability to feed concentration and material properties, and capacities of controlling the cleaned coal ash no more than 15 percent through separation at one time and controlling 42 to 80 percent tailings coal ash to follow material property.

Owner:WEIHAI HAIWANG HYDROCYCLONE

Water pipe flow stabilizing broadband muffler

The invention discloses a water pipe flow stabilizing broadband muffler which comprises a water delivery pipe and a muffler casing. An expanded perforated pipe is fixedly installed on the inner side of one end of a muffler casing body fixedly connected with the water delivery pipe. An end plate is fixedly arranged at the other end of the muffler casing. A shunting perforated pipe is further fixedly connected onto the end plate, and a throttle ring is fixedly arranged at the port position of the inner end of the shunting perforated pipe. The inner diameter of the expanded perforated pipe is larger than the outer diameter of the shunting perforated pipe, the inner end of the expanded perforated pipe and the inner end of the shunting perforated pipe are in fixedly sleeved connection in a gapped mode, and the flowing cross area of the water delivery pipe is smaller than the sum of the hole flowing cross area of the end plate and the flowing cross area of the shunting perforated pipe. The water pipe flow stabilizing broadband muffler can achieve broadband muffling of the water pipe, effectively stabilize a flow field at the outlet end of the water pipe, reduce the water spraying-flowing speed and pressure, accordingly reduce water pipe port noise effectively and achieve the effects of flow stabilizing and broadband muffling.

Owner:JIANGSU YEAN IND ENVIRONMENTAL PROTECTION EQUIP TECH

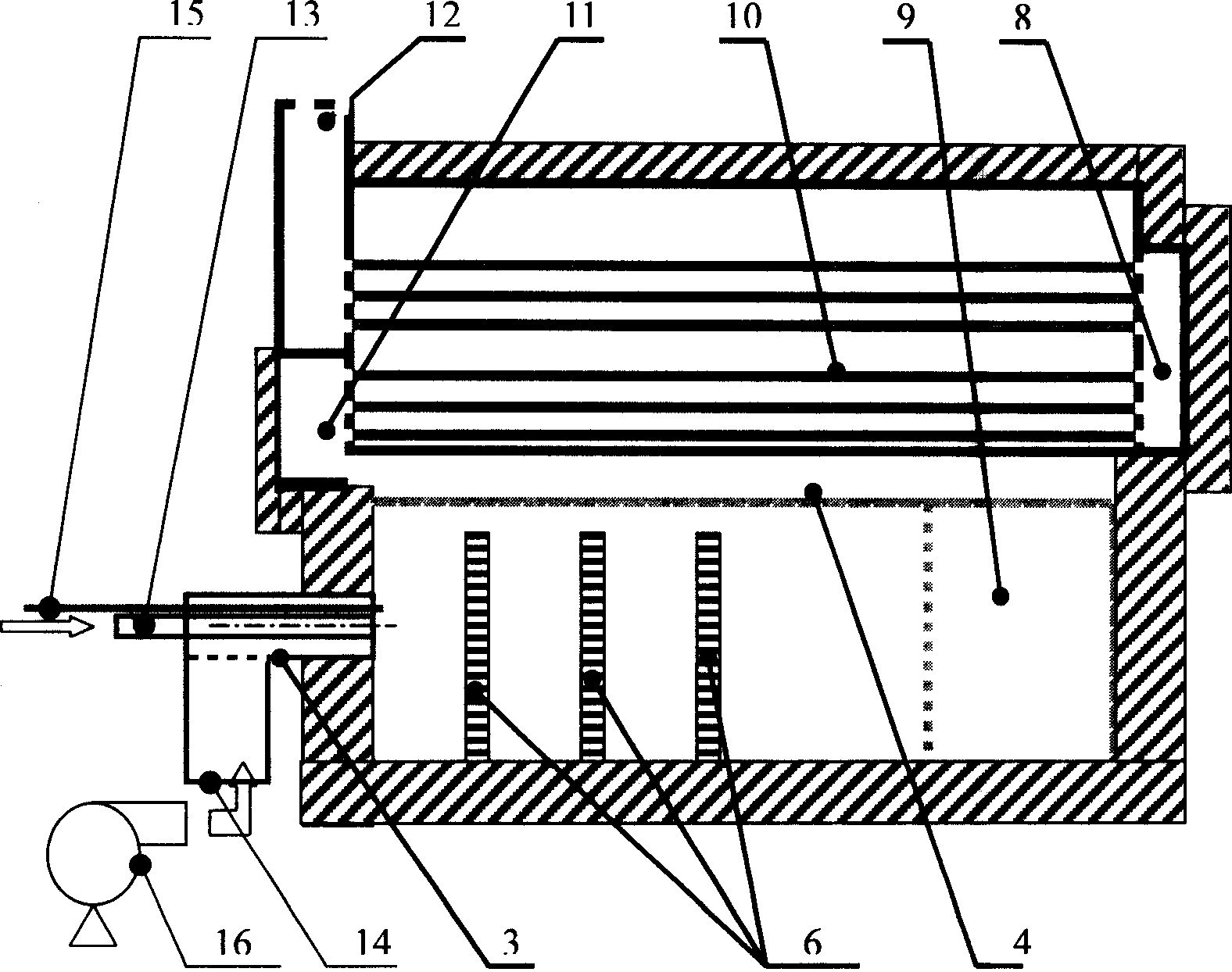

Efficient powder selecting machine with power material scattering device

InactiveCN104624499AFully dispersedFlow field stabilityGas current separationMaterial scatteringMechanical engineering

The invention provides an efficient powder selecting machine with a power material scattering device. A lower part power material scattering device (10) is arranged at the lower part of the powder selecting machine; the lower part power material scattering device (10) is composed of a material scattering disc (16), a supporting device (17) connected with the material scattering disc (16), and a second transmission device (18) connected with the supporting device (17). The efficient powder selecting machine has the following technical effects that the power material scattering device is arranged at the lower part so that powder materials to be selected are sufficiently dispersed, and a stable and uniform flow field is provided for rotor grading the next step; the powder selecting efficiency is improved by 10%-15%; feeding is carried out at a lower part: the power selecting concentration of a rotor of the powder selecting machine is greatly reduced and the power consumption of the rotor is reduced by 15%-20%; discharging is carried out at the lower part: large-particle materials and iron blocks are directly discharged from the lower part of a discharging opening, the upper part sealing is not blocked, and the abrasion of an upper guide blade is small.

Owner:JIANGSU XINYE HEAVY IND

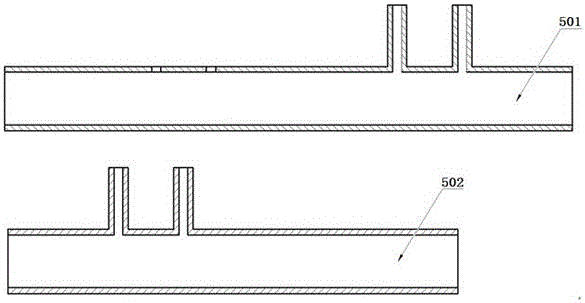

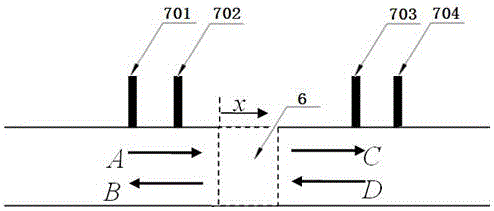

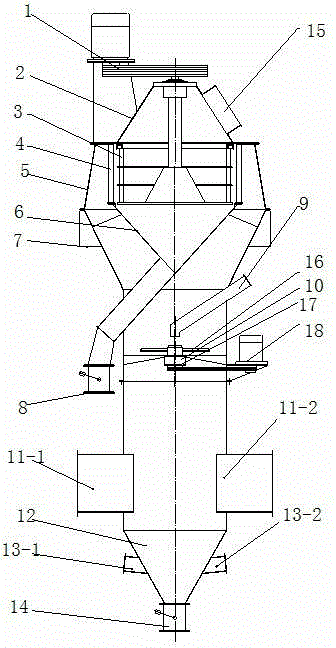

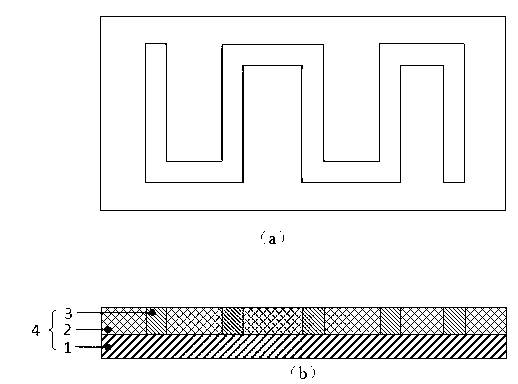

Method for processing micro-channels on surface of metal bipolar plate by adopting plate electrode in electrolytic transfer, as well as plate electrode thereof

InactiveCN103182573AImprove localizationEasy to processMachining electrodesElectrical-based machining electrodesElectrolysisPhotoresist

The invention discloses a method for processing micro-channels on the surface of a metal bipolar plate by adopting a plate electrode in electrolytic transfer, and belongs to the field of electrochemical machining. The method is characterized by comprising the following steps: (a), filling a hollowed-out photoresist channel with metal, and producing a plate tool negative electrode (4); (b) fixing the plate tool negative electrode (4) with a workpiece positive electrode (6) and reserving a small gap; (c), connecting the plate tool negative electrode (4) and the workpiece positive electrode (6) with the anode and the cathode of a power supply (7) respectively; (d) introducing an electrolyte (5) between the plate tool negative electrode (4) and the workpiece positive electrode (6); and (e), connecting the power supply (7) for electrochemical machining. With the adoption of the method and the plate electrode thereof, the binding force between an insulating layer and a base is enhanced, tight combination between the insulating layer and the base is guaranteed, and the utilization rate of tool electrodes is improved; besides, the adoption of the plate electrode can guarantee the timely update of the electrolyte in a processing area, and the locality of the electrolytic processing is improved effectively.

Owner:NANTONG UNIVERSITY

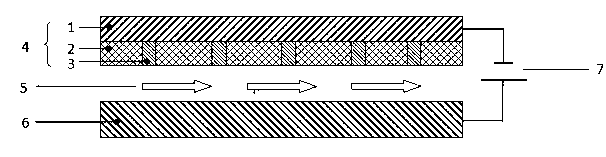

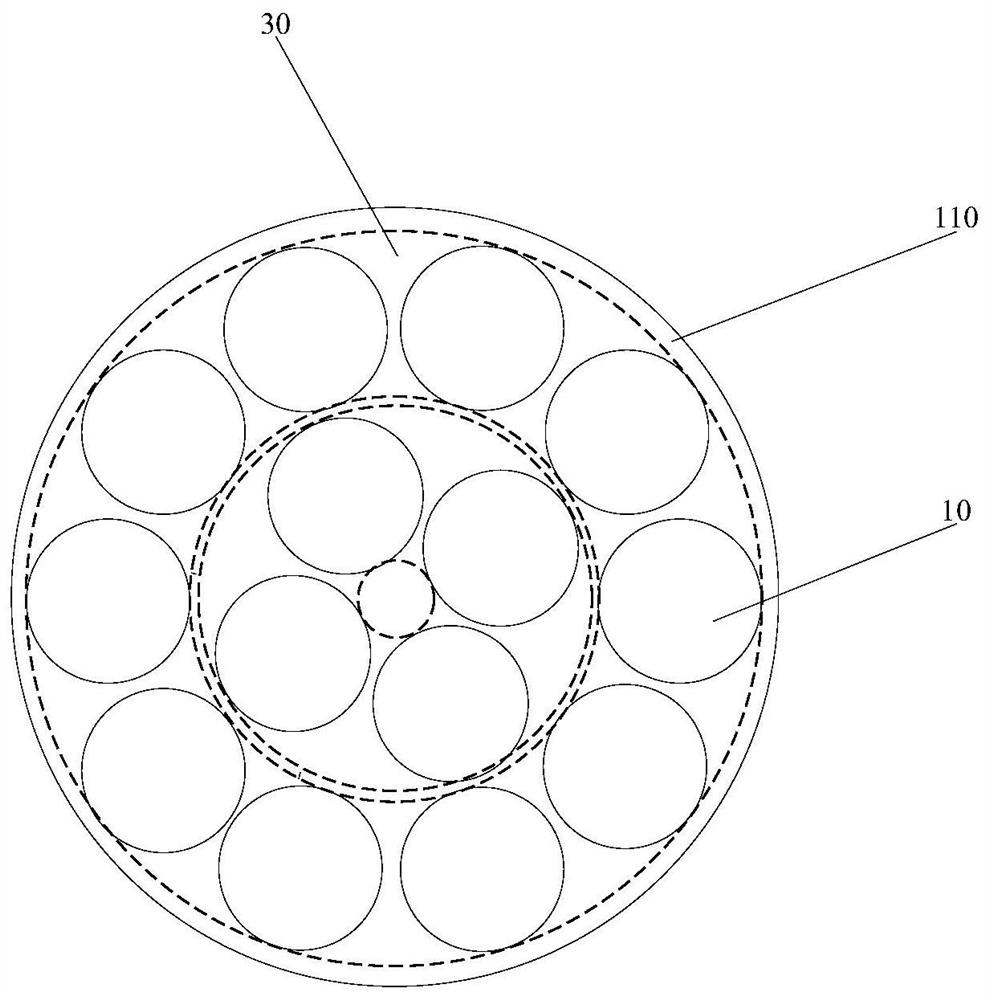

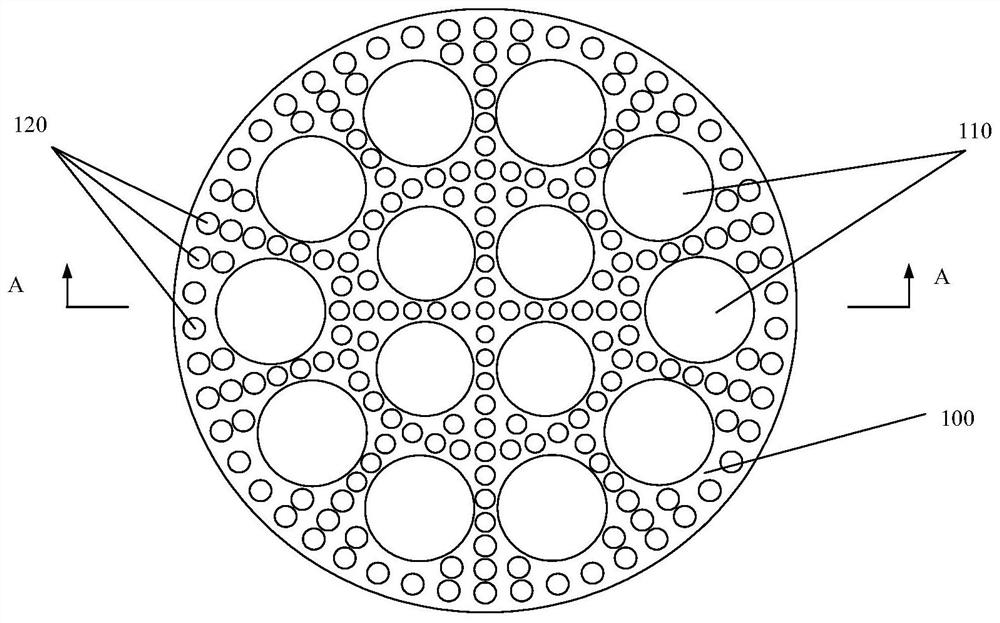

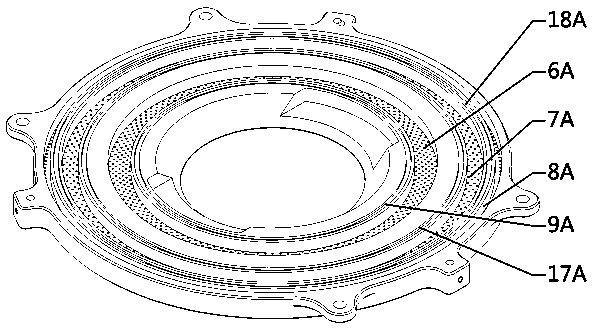

Graphite base and MOCVD equipment

InactiveCN112359414AImprove consistencyReduce viscous resistanceFrom chemically reactive gasesChemical vapor deposition coatingCircular discGraphite

The invention provides a graphite base and MOCVD equipment, and belongs to the technical field of semiconductors. The graphite base is of a disc-shaped structure, the first circular end face of the graphite base comprises a plurality of epitaxial wafer containing grooves and a plurality of cambered surface grooves, the epitaxial wafer containing grooves are arranged in a multi-layer circular ringmode in the radial direction of the first circular end face, and the circle center of the circular ring coincides with the circle center of the first circular end face. The cambered surface grooves are uniformly formed in the first circular end surface among the plurality of epitaxial wafer containing grooves at intervals, and the inner surfaces of the cambered surface grooves are spherical crown-shaped. The first circular end face of the graphite base comprises the plurality of epitaxial wafer containing grooves and the plurality of cambered surface grooves, and the cambered surface grooves are uniformly formed in the first circular end face between the epitaxial wafer containing grooves at intervals, so that the uniformity of the epitaxial layer at the edge position of the graphite baseis improved, and the consistency of epitaxial wafers is improved.

Owner:HC SEMITEK SUZHOU

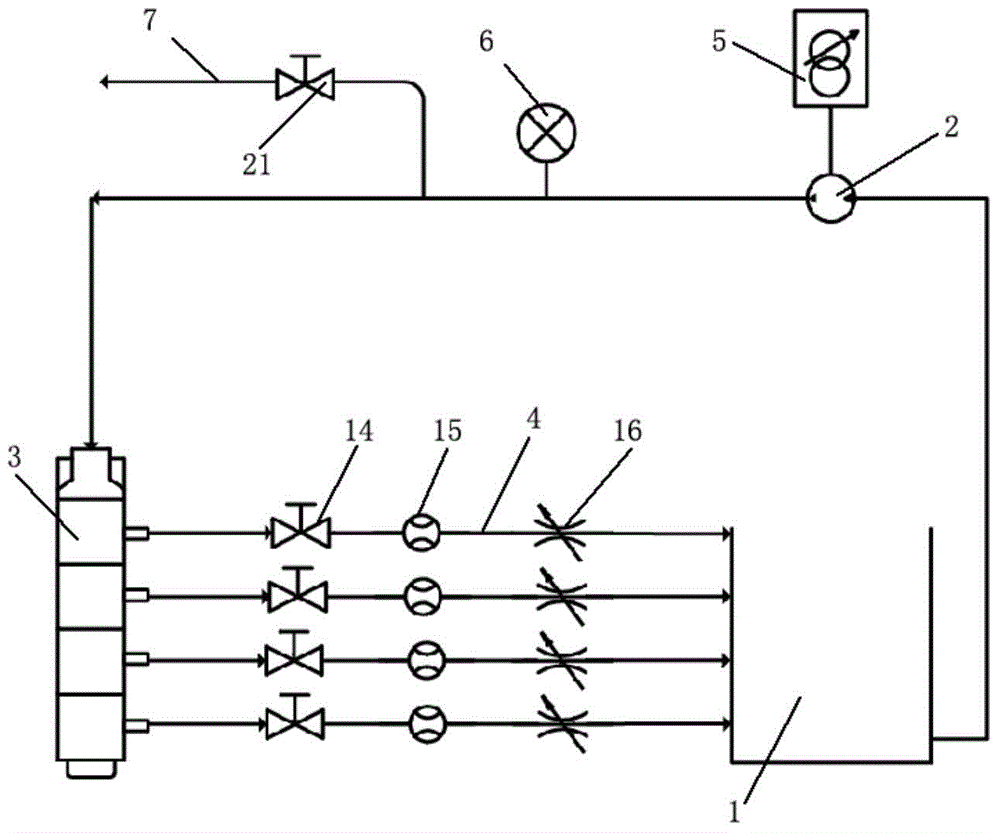

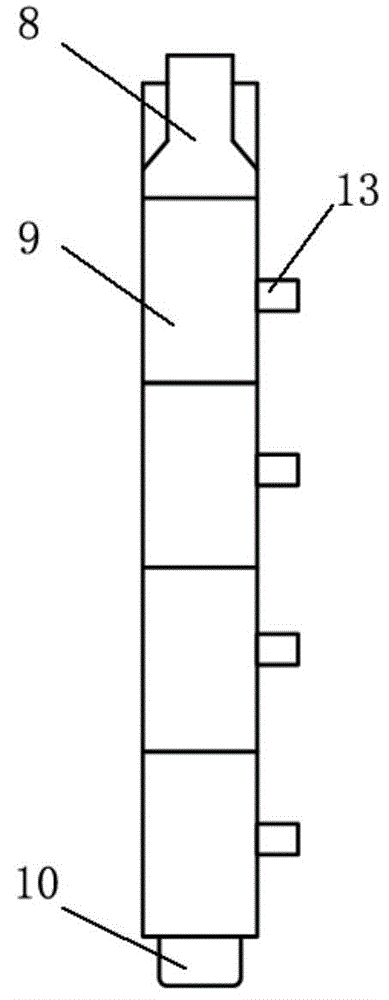

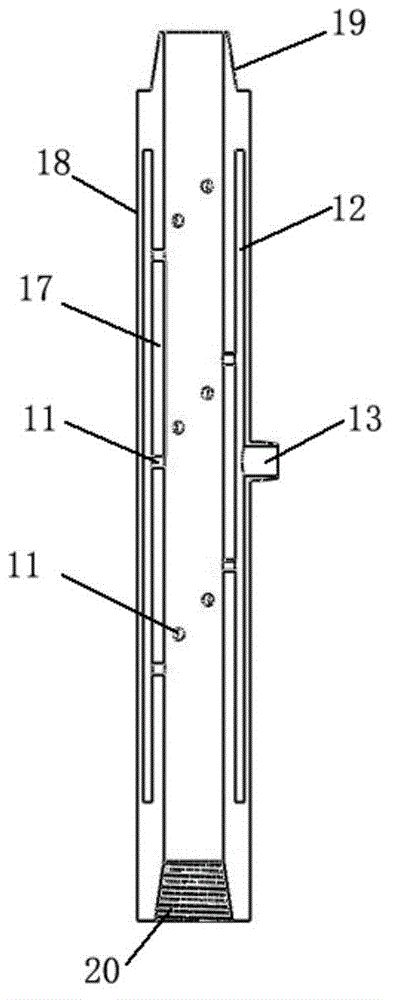

Experimental device and method for mechanical sealing through ball sealers

ActiveCN104695938ALow critical displacementFlow field stabilitySurveyFluid removalFracturing fluidEngineering

The invention provides an experimental device and method for mechanical sealing through ball sealers, and belongs to the technical field of sleeve sealing through the ball sealers in an oil reservoir ball put layering improvement technology. A water tank is used for holding fracturing fluid, a plunger pump is connected with the water tank through a pipeline, and an experimental tubing string is connected with the plunger pump through a pipeline. The experimental tubing string comprises a connector, a sleeve tubing string and a sleeve plug, wherein the connector, the sleeve tubing string and the sleeve plug are connected in sequence. The connector is communicated with the plunger pump through the pipeline. The sleeve tubing string is composed of a plurality of perforated sleeves in a sequential connection mode, the upper end of the sleeve tubing string is connected with the connector, and the lower end of the sleeve tubing string is sealed through the sleeve plug. According to the invention, the purpose of testing the minimum critical displacement for sealing of test holes through the ball sealers is achieved, the purpose of testing the influence of the number of the holes on the minimum fluid displacement for achieving sealing of the holes through the ball sealers is achieved, the purpose of testing the influence of the difference between the water absorption amount of stratums on sealing of the stratums through the ball sealers is achieved, and the guidance is provided for determination of the construction displacement of the fluid for conveying the ball sealers.

Owner:PETROCHINA CO LTD

Electrochemical processing method for tri-end flexible feeding blade

InactiveCN1883860AImprove machining accuracyReduce side clearanceElectrochemical machining apparatusElectrolysisCoaxial line

The present invention relates to an electrolytic machining method of a three-start flexible feed lamina, belonging to electrolytic machining field. It adopts a blade basin cathode and a blade back cathode of automatic feed set in the same axes oppositely and an automatic feed anion vertical to the cathode. The blade roughcast connects with the anion via a clamp. In processing, the blade basin cathode, the blade back cathode and the anion feed simultaneously with adjustable feed speed in order to guarantee optimal feed angles or optimal feed curves for processing to the blade basin and the blade back. To the blade with relatively big torsion degree to the molding surface, sectional feed method can be used. The method can realize once molding of the blade body, marginal plate and inlet(outlet) edges and omnibearing electrolytic machining in order to improve blade machining precision and surface quality. Meanwhile, the present invention also provides a novel electrolyte feed method, which means to make the electrolyte flow along the blade marginal plate, blade body and tip and finally return to electrolyte flume. In this way, it can stabilize the flow field and further improve machining quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Controllable sand flow infinitely variable speed fan blade abrasion testing device

InactiveCN103645103AReduce pollutionKeep healthyInvestigating abrasion/wear resistanceParticle flowWear testing

The invention discloses a controllable sand flow infinitely variable speed fan blade abrasion testing device which consists of an air compressor, a gas delivery pipe, a pressure sensor, a spray gun, a sand storage chamber, a sand flow control valve, a sand pipe, a particle flow sensor, an air inlet pipeline, an erosive wear test chamber, an erosive wear test chamber upper cover, an air outlet pipeline, a deduster, a motor, a frequency converter, a fan propeller, a control cabinet, a motor bracket, an air inlet pipeline bracket, a control cabinet bracket and an angle iron bracket. A series of technical problems that the erosive wear working conditions of a rotary fan blade cannot be really simulated by a conventional erosive wear testing device are overcome.

Owner:JILIN UNIV

Boiler using gas or fuel oil

InactiveCN1862090AHigh thermal efficiencyOvercome uniformity issuesCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberFuel oil

There is disclosed a gas-firing or oil-burning boiler, in which, a combustion stirring reactor and a combustion chamber connected with a liquid or gaseous fuel feeding device are mounted in the hearth. The hearth bed is used as the boiler bed and the side wall of the hearth is connected with the boiler bed. The surface of the hearth side wall is made of materials capable of resisting the temperature not below 1500 deg. c. The fuel feeding device is connected with the combustion chamber through the front boiler wall and at the exhaust nozzle is disposed an igniter. When the temp. on the wall surface of the combustion chamber is not below 850 deg. c. the boiler can realize non-flame burning in the boiler.

Owner:UNIV OF SCI & TECH OF CHINA

Plastic wood prepared from mixed plastic in domestic garbage and wood powder, and preparation method of plastic wood

Owner:四川川润环保能源科技有限公司 +1

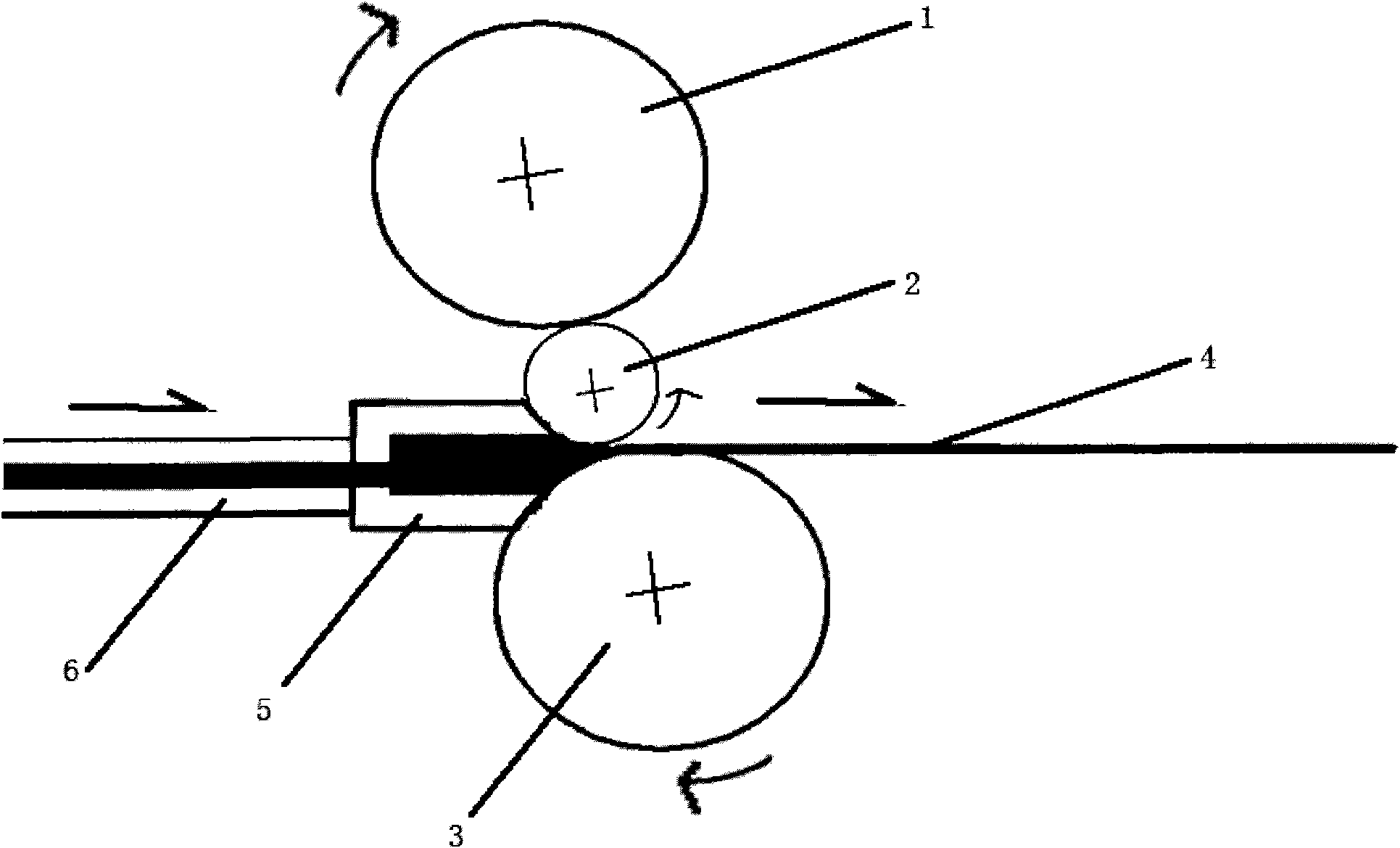

Magnesium alloy wide plate casting-rolling equipment

InactiveCN101811136ASimple structural designFlow field stabilityMetal rolling stand detailsMetal rolling arrangementsWater coolingMagnesium alloy

The invention relates to a magnesium alloy wide plate casting-rolling machine, which is used for directly casting and rolling liquid magnesium alloy into a wide cast-rolled plate blank with the width of 800 to 1,800 millimeters. The casting-rolling machine is characterized in that the casting-rolling machine is a three-roll casting-rolling machine, has a pair of equal diameter double-drive rolls with the diameter of 800 to 1,200 millimeters and the same turning directions, namely an upper driving roll 1 and a lower driving roll 3, and has a driven roll 2 with the diameter of 200 to 600 millimeters, wherein the lower driving roll 3 and the driven roll 2 form a casting-rolling roll pair which has an internal water-cooled structure, the upper driving roll 1 is a supporting roll for the driven roll 2, and the plane of the axes of the three rolls is inclined towards one side of a casting nozzle; and the inclination angle is 0 to 15 degrees. The unequal diameter casting-rolling working rolls of the inclined three-roll casting-rolling machine have the advantages of a two-roll casting-rolling machine and a four-roll casting-rolling machine, can overcome the defects of the two-roll casting-rolling machine and the four-roll casting-rolling machine, and have the characteristics of high solidifying and cooling speed, high rolling pressure and good plate shape control. The three-roll casting-rolling machine casts and rolls the liquid magnesium alloy into a cast-rolled plate belt with the width of 800 to 1,800 millimeters and with large width, small deformation amount and good plate shape.

Owner:山西银光华盛镁业股份有限公司

Airtight and two-level porous gas-liquid recycling device for immersion-type photoetching machine

ActiveCN104035290AReduce vibrationReduce disturbancePhotomechanical exposure apparatusMicrolithography exposure apparatusInjection portWaste management

The invention discloses an airtight and two-level porous gas-liquid recycling device for an immersion-type photoetching machine. The airtight and two-level porous gas-liquid recycling device comprises an airtight and gas-liquid isolation device which is installed between a projection objective group and a silicon wafer and comprises an immersion unit lower end cover and a substrate; the immersion unit lower end cover is provided with a central taper hole, a lens injection port, a lens recycling port, a gas-liquid separation cavity, a second-level recycling cavity, a gas injection cavity, a flow-field multilevel buffer structure, a gas buffer groove, an inner sealing groove, an intermediate sealing groove and an outer sealing groove; the immersion unit substrate is provided with a central through hole, a lens injection cavity, a lens recycling cavity, a gas recycling cavity, a substrate second-level recycling cavity, a substrate gas injection cavity and a liquid recycling cavity. A great amount of waste liquid produced in the photoetching process can be recycled through the lens recycling structure, and the rapidness for updating a flow field can be realized; the liquid can be recycled through a two-level porous structure, the stability of the boundary of the flow field can be maintained, the gas-liquid separation is realized, and the primary sealing of the flow field is realized; the leakage of the liquid can be prevented by adopting the airtight structure.

Owner:ZHEJIANG CHEER TECH CO LTD

Wood polymer composite prepared by using mixed plastic and cotton stalks in domestic garbage, and method for preparing wood polymer composite

InactiveCN102660067AReduce white pollutionRealize resource recyclingGas current separationPolypropyleneAntistatic agent

The invention discloses a wood polymer composite prepared by using mixed plastic and cotton stalks in domestic garbage, and a method for preparing the wood polymer composite. The method is suitable for recycling urban domestic garbage. The wood polymer composite consists of the following components in percentage by mass: 35 to 45 percent of polyethylene, 4 to 7 percent of polypropylene, 7 to 12 percent of polrvinyl chloride, 33 to 40 percent of cotton stalk fiber, 5 to 8 percent of compatilizer, 0.2 to 2.4 percent of coupling agent, 0.2 to 0.5 percent of light stabilizer, 0.2 to 0.5 percent of antioxidant, 2.1 to 4.2 percent of lubricant, 1.2 to 2.8 percent of colorant, 0.1 to 0.5 percent of antistatic agent and 0.2 to 0.4 percent of deodorization sterilization preservative, wherein polyethylene, polypropylene and polrvinyl chloride are directly from the urban domestic garbage; and the effect of performing recycling and innocent treatment on the urban domestic garbage can be achieved, white pollution caused by plastic can be reduced, and the construction of environment-friendly society can be facilitated.

Owner:四川川润环保能源科技有限公司 +1

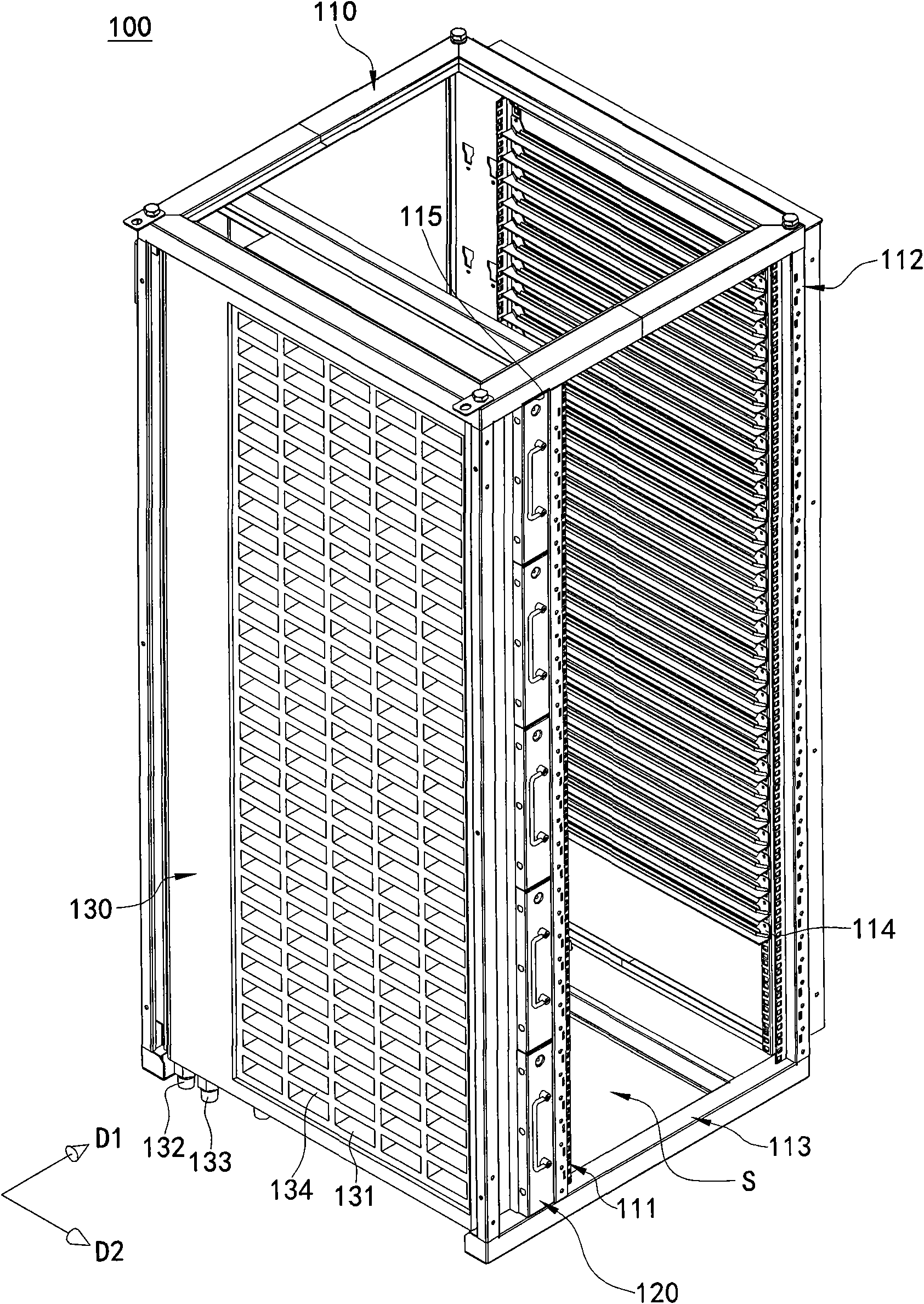

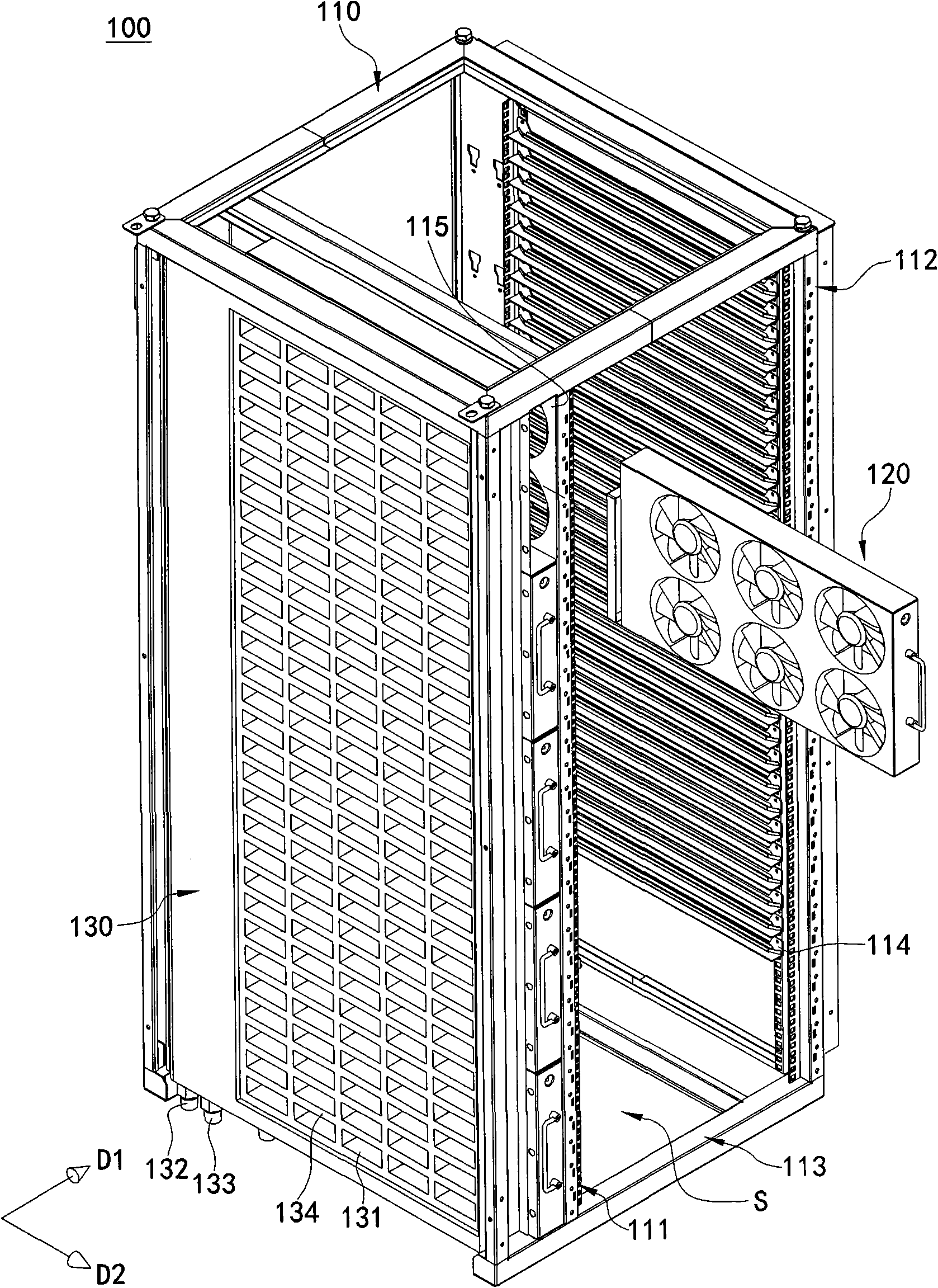

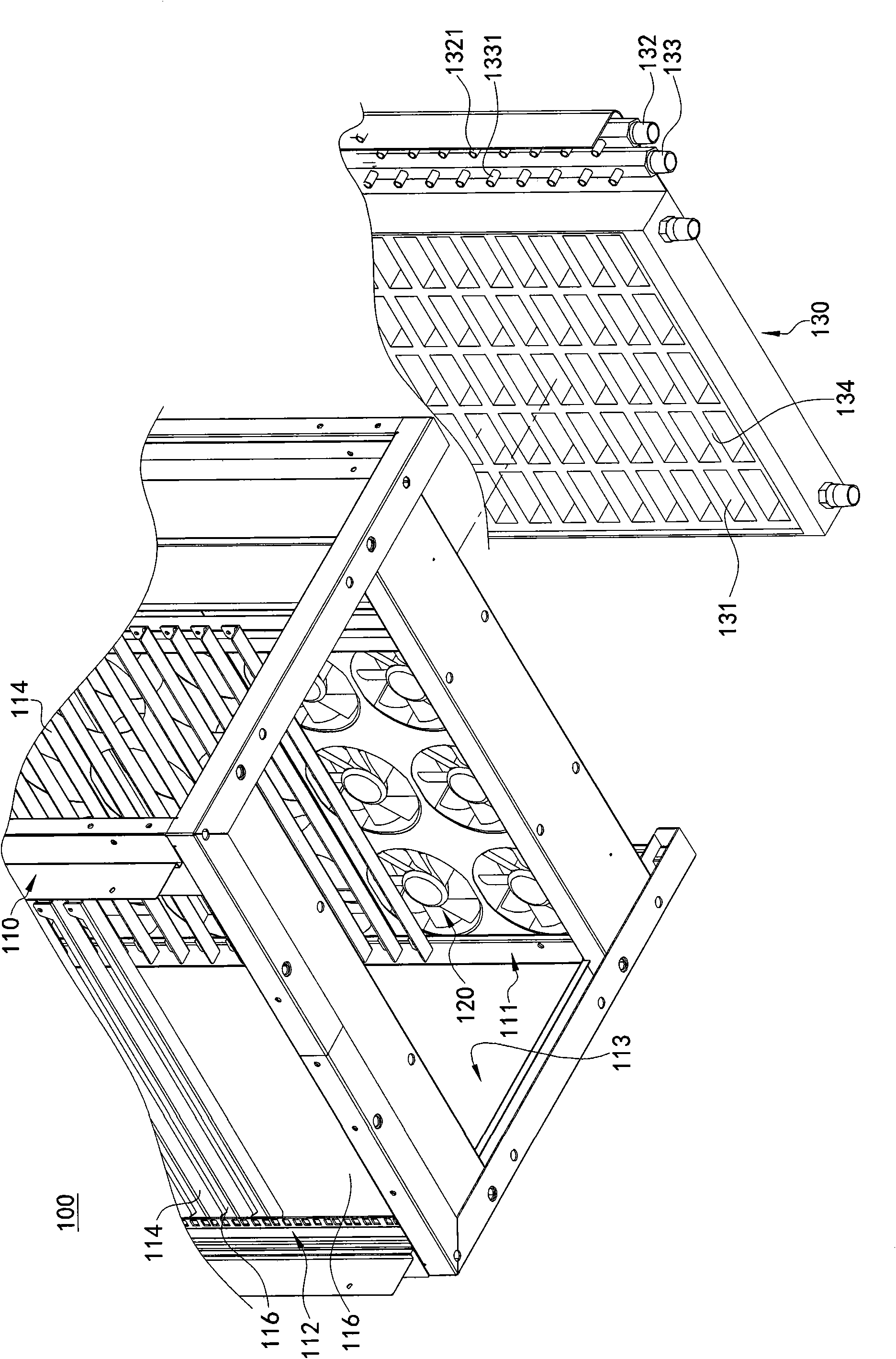

Server cabinet

InactiveCN102467203AFlow field stabilityConditions that affect cooling performanceDigital data processing detailsCooling/ventilation/heating modificationsEngineeringHeat sink

The invention relates to a server cabinet comprising a machine body, at least one assembling frame, a radiator and at least one fan module, wherein the machine body is provided with a first framework and a second framework which are opposite; the assembling frame and the radiator are sequentially arranged on the first framework; a cooling liquid is conveyed by the radiator and circularly flows in a plurality of radiating fins of the radiator; the fan module is arranged in the assembling frame and used for guiding an airflow to enter into the first framework from the radiator; and the airflow is wafted from the machine body to the second framework so that the temperature in the machine body is lowered.

Owner:INVENTEC CORP

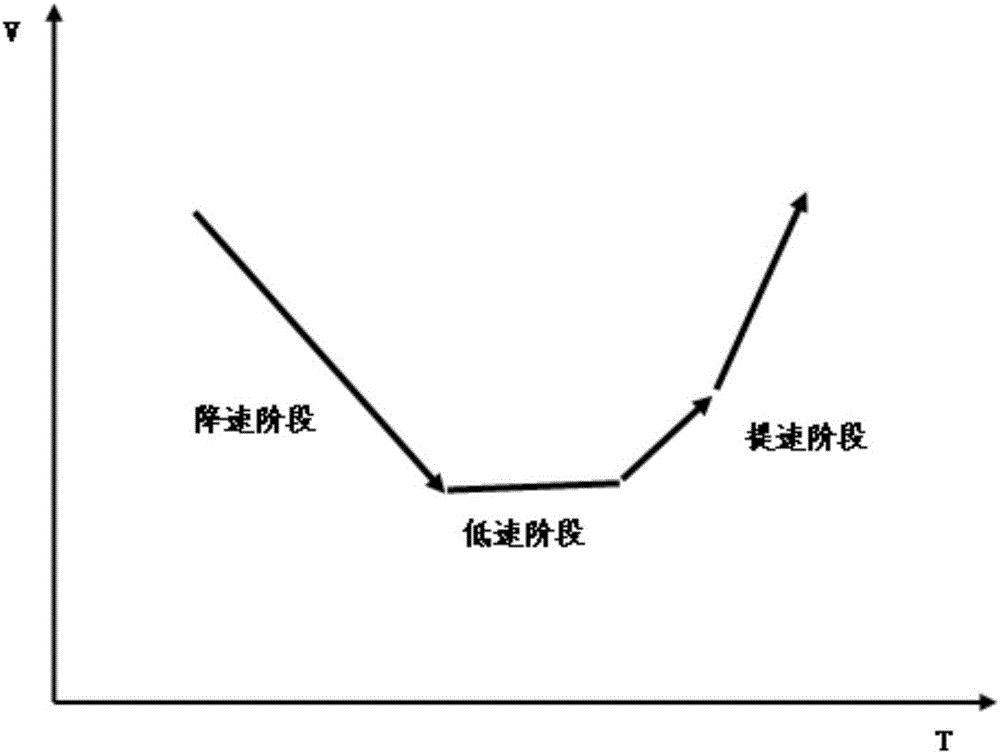

Wide and thick plate continuous casting machine dry capping method

The invention relates to a wide and thick plate continuous casting machine dry capping method, and belongs to the technical field of continuous casting technologies. The wide and thick plate continuous casting machine dry capping method particularly comprises the following steps and parameters that in the speed reduction stage, according to the actual measurement tundish tons, in cooperation the tundish measurement actual liquid level, the pull speed is reduced to 0.25 m / min; in the low-speed and constant-speed running stage, according to the tundish tons and the actual measurement liquid level, when the depth of the liquid face of molten steel in a tundish ranges from 100 mm to 300 mm, a plug bar is closed, meanwhile, the pull speed is reduced to 0.15 m / min to 0.2 m / min, and low-speed running is kept; and in the speed increasing process, the blank tail is pulled out of a crystallizer, and the pull speed is increased to a target pull speed. The wide and thick plate continuous casting machine dry capping method has the beneficial effects that slag is not wasted, slag fishing is avoided, low-speed weak-cold control is achieved, and therefore the effective improvement of the tail blank quality is achieved, the tail blank flaw detection yield is improved, the tail blank waste cutting amount is reduced, and the metal yield is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com