Pulse turbulence flow field fluidized mineral separator

A technology of mineral separation and turbulent flow field, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of difficult coal separation, high content of fine coal, low ash content of coarse coal slime, etc., and achieve flexible Adjustable and controllable sorting density to ensure full dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

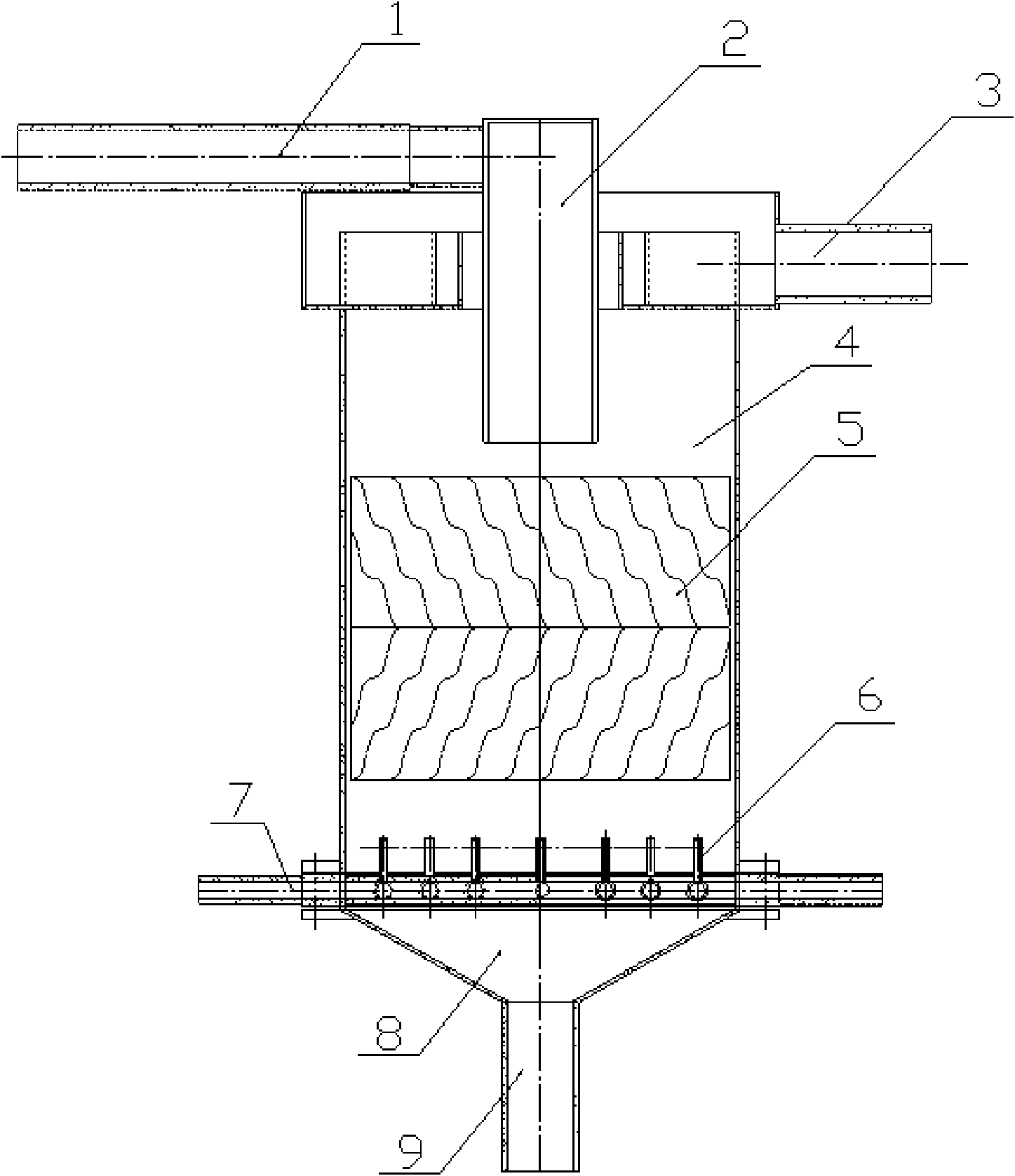

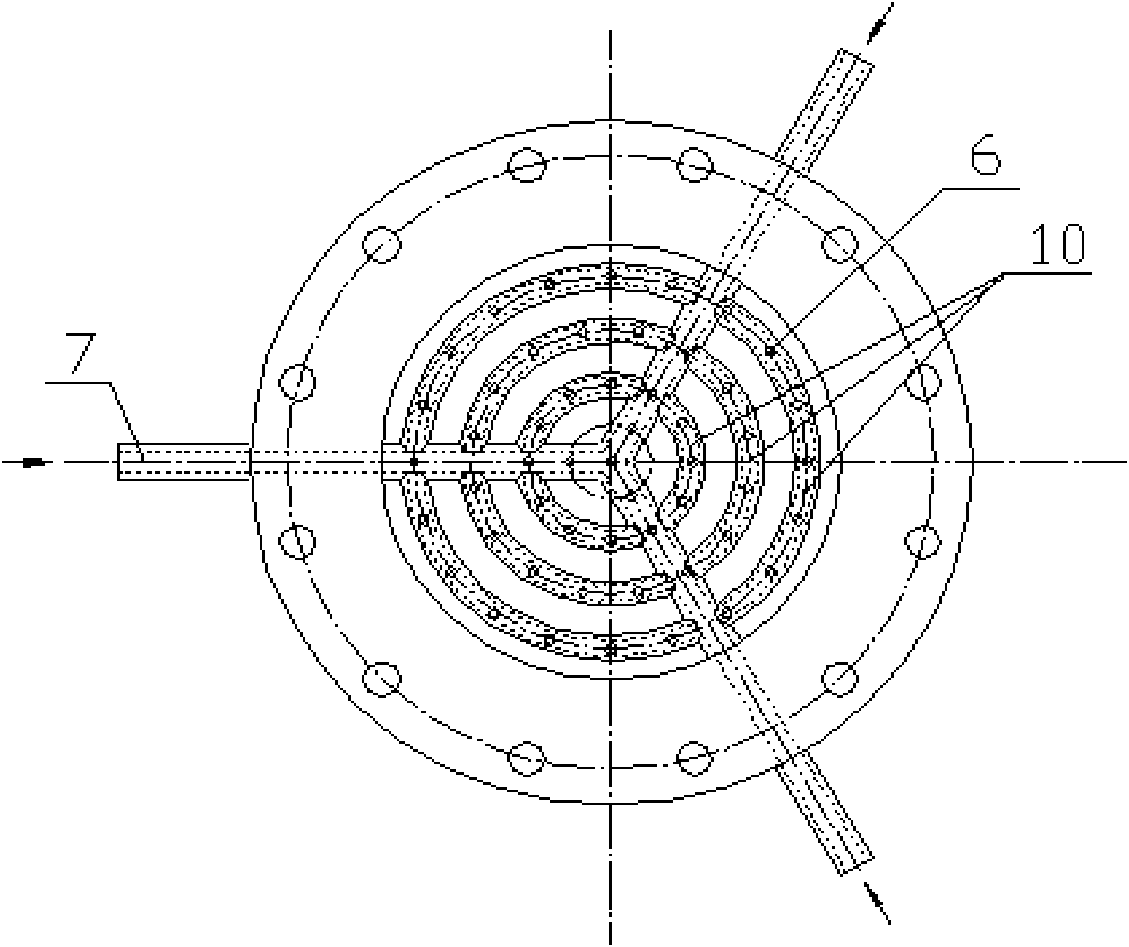

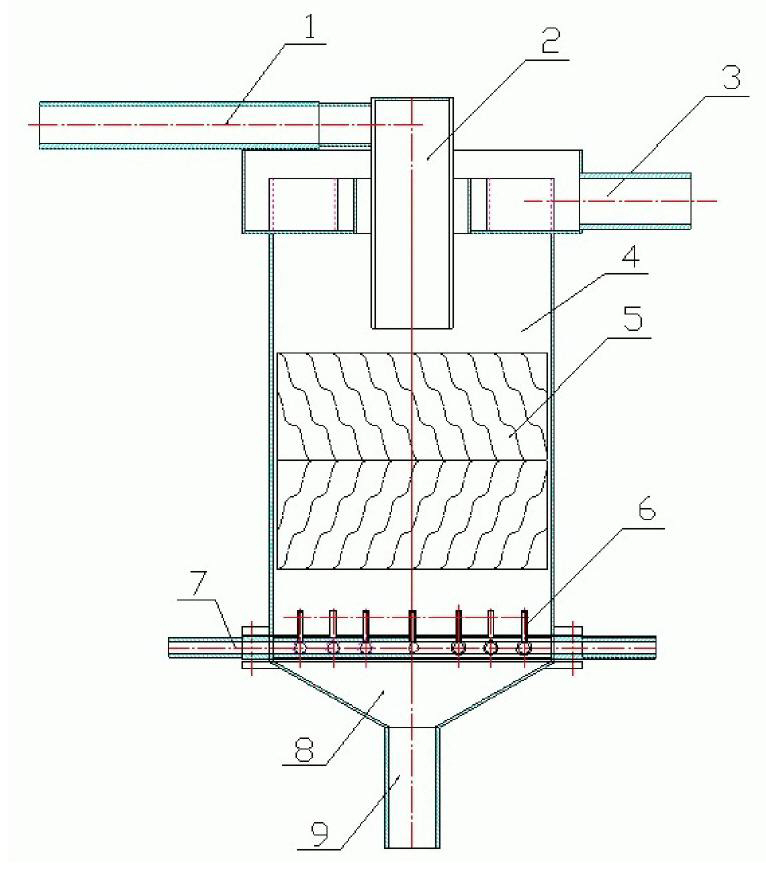

[0013] As shown in the accompanying drawings, a pulse turbulent field fluidized mineral separator is provided with a cylindrical body 4. The cross section of the body 4 is circular, square or other shapes, and its diameter can be from It varies from 1800mm to 3600mm. The height of the body 4 is generally 1.0-1.5 times the diameter. The upper end of the body 4 is provided with a feed well 2 and an overflow pipe 3. The feed well 2 is provided with a feed pipe 1. The pipe 1 is connected with the upper part of the feed well 2 in the form of involute or spiral, and the outlet of the feed well 2 is located at 3 / 4 of the height of the machine body 4, so that the incoming ore slurry is uniform across the entire feed cross-section The ground distribution is conducive to the stability of the flow field at the feeding place. On the other hand, it can also realize the preliminary separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com