A new method for grading pre-selection and fine separation of magnetic-red-diamond mixed iron ore

A fine separation technology for iron ore, which is applied in the separation of magnetic-red-diamond mixed iron ore and the field of magnetic-red-diamond mixed iron ore dressing, which can solve the problems of large water consumption, complicated process, coarse and fine Problems such as large amount of ore regrinding, etc., to achieve the effect of less production and high comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

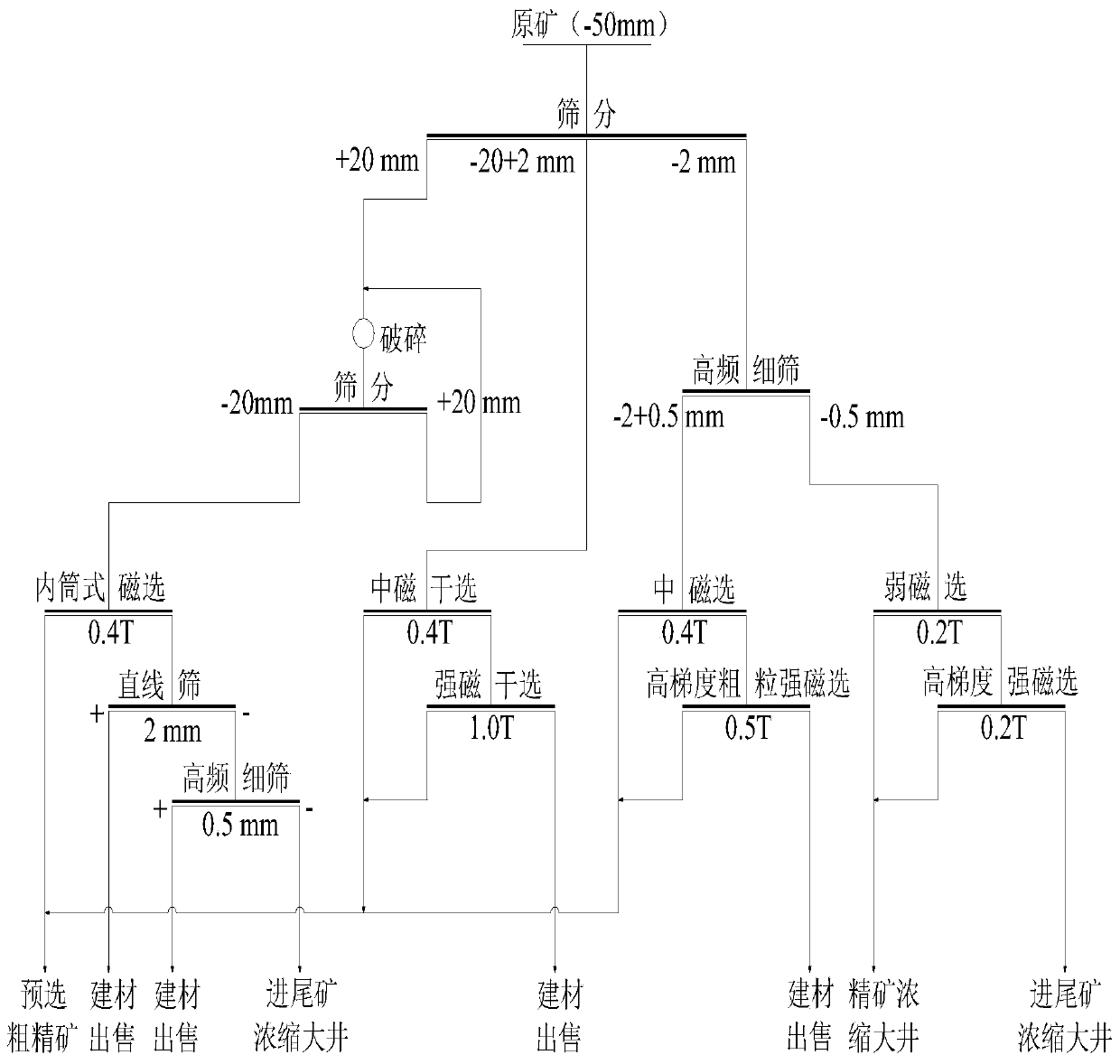

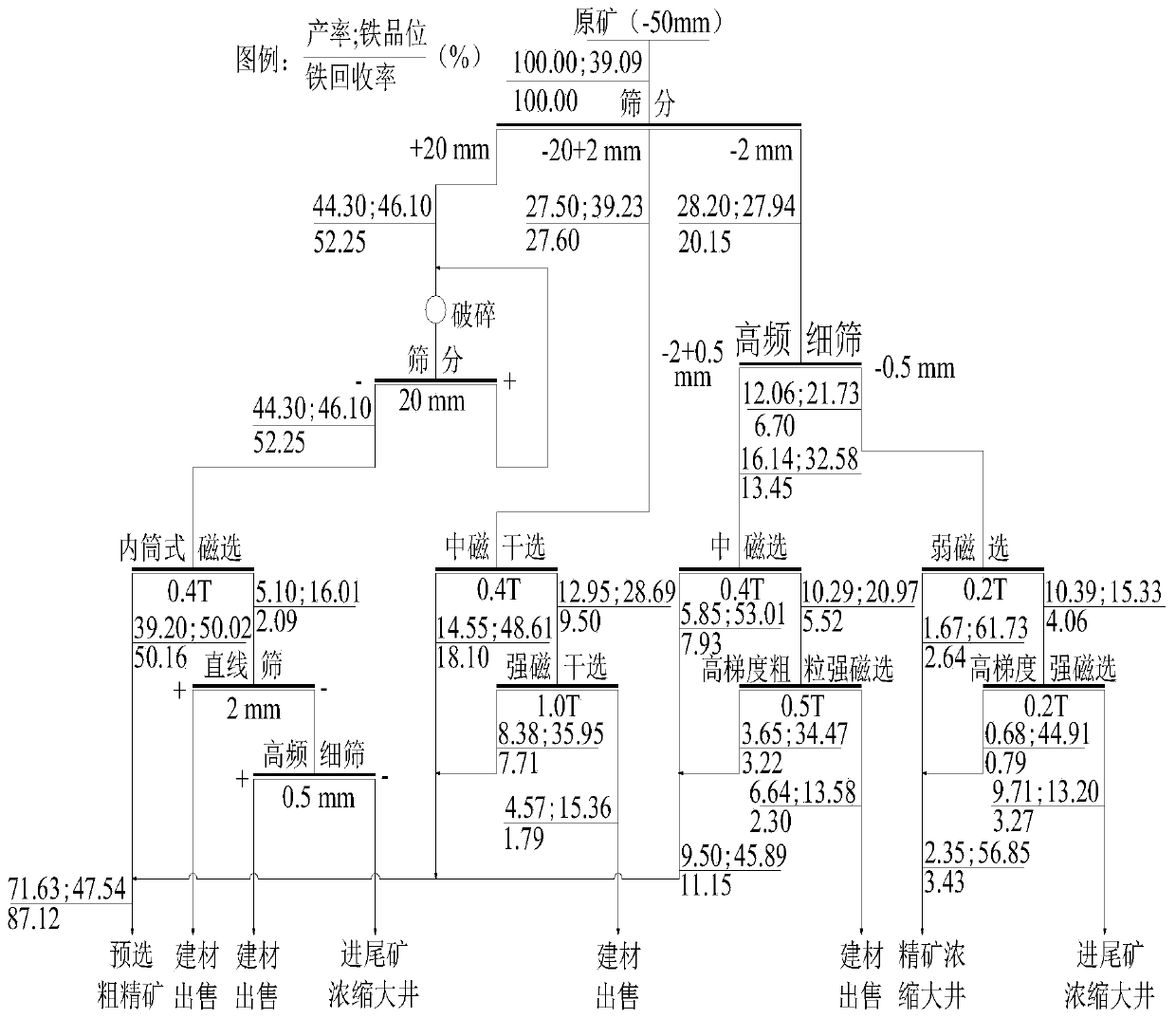

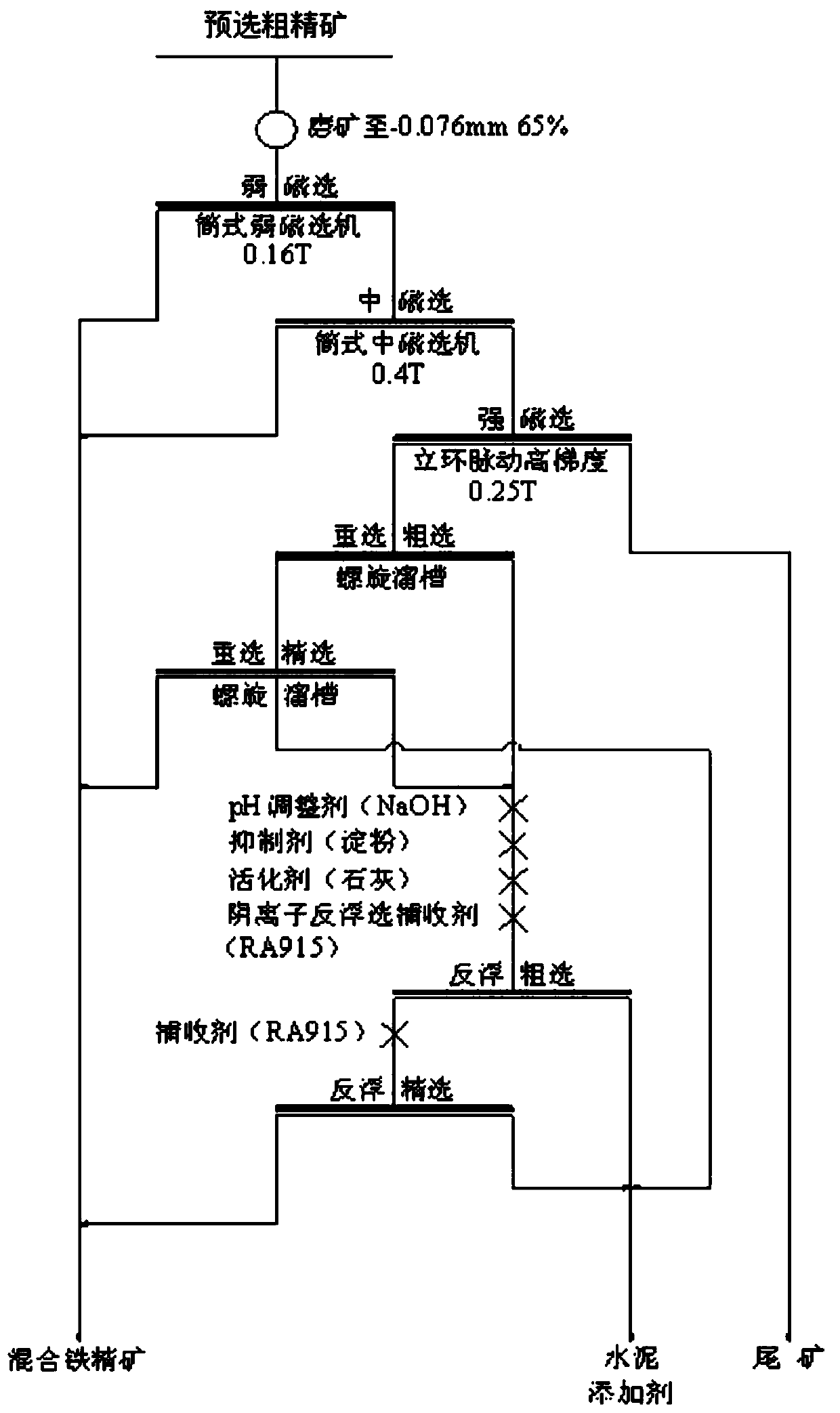

Method used

Image

Examples

Embodiment Construction

[0054] In order to further describe the present invention, a new method for grading pre-selection and fine separation of magnetic-red-diamond mixed iron ore of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0055] The magnetic-red-side mixed iron ore is taken from an iron mine in Jiangsu. The results of chemical multi-element analysis of the raw ore are shown in Table 1, and the results of iron phase analysis are shown in Table 2.

[0056] Table 1 The chemical multi-element analysis results of magnetic-red-diamond mixed iron ore

[0057] element TF S P CaO MgO Al 2 o 3

SiO 2

content% 39.38 1.26 0.325 6.41 1.74 3.09 17.10

[0058] Table 2 Analysis results of iron phase of magnetic-red-diamond mixed iron ore

[0059] mineral name Iron phase iron content (%) Occupancy (%) magnetite 20.13 51.12 Red (brown) iron ore 9.41 23.90 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com