Iron tailing dry separation system

A technology of dry separation of iron tailings, applied in the directions of magnetic separation, solid separation, filtration, etc., which can solve the problems of environmental pollution, low grade, land occupation, etc., and achieve the effect of reducing environmental hazards and realizing the comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

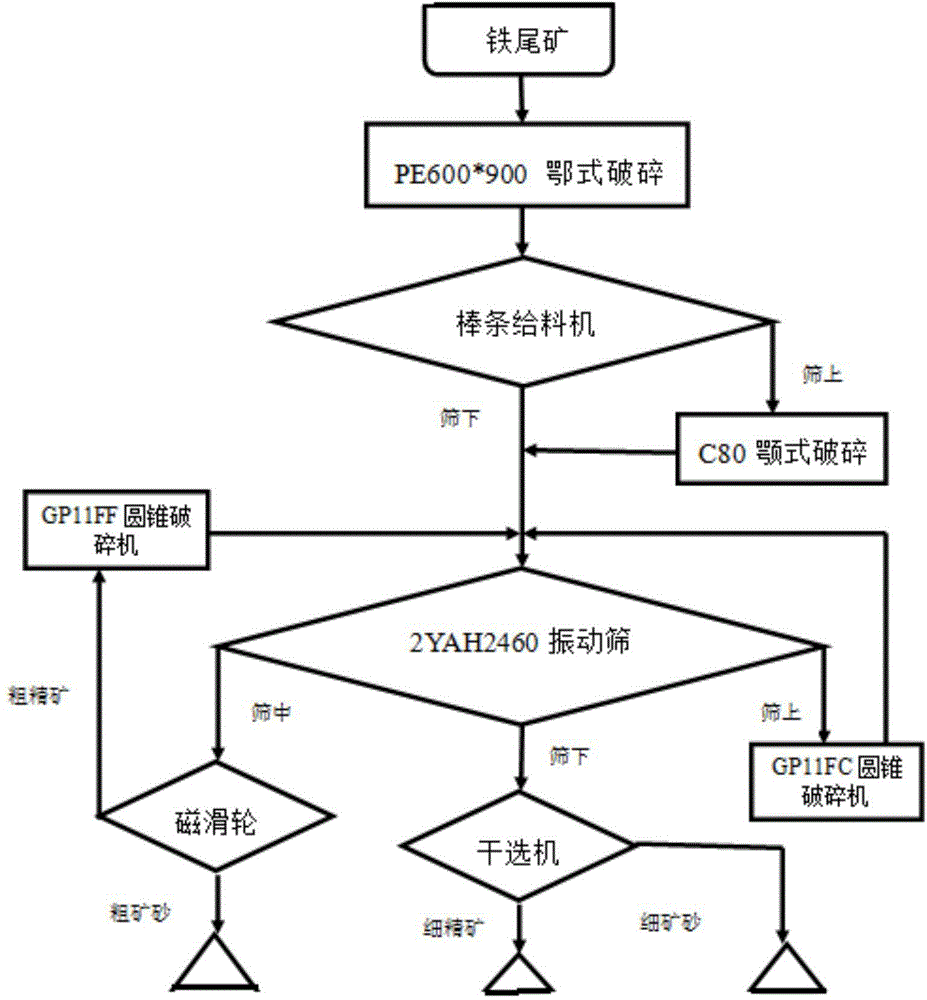

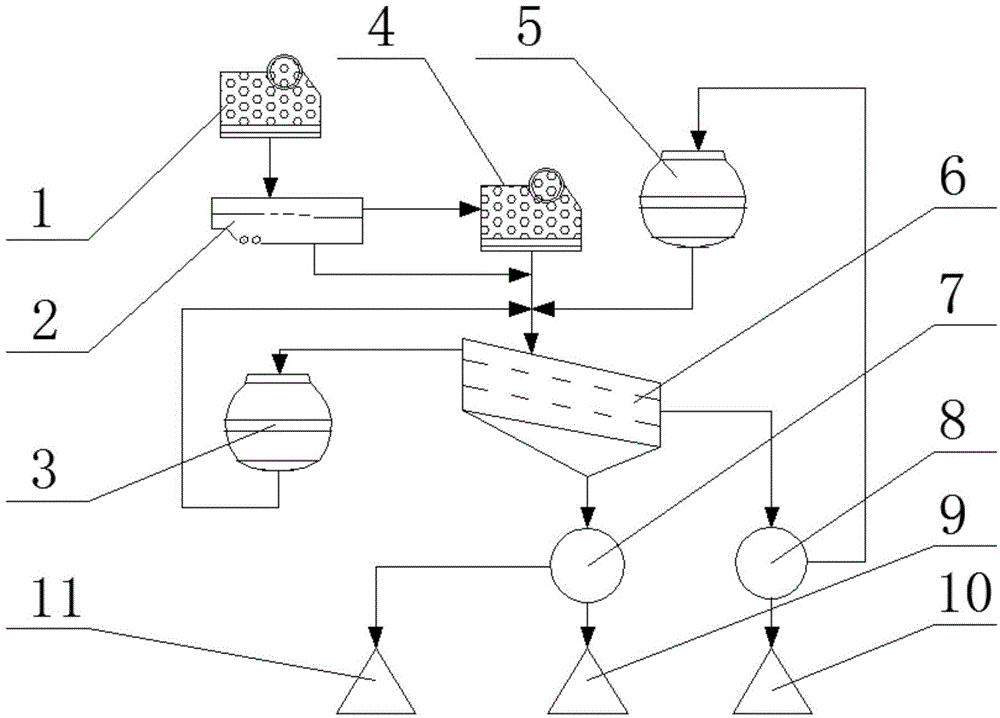

[0011] Such as figure 1 , 2 As shown, a dry separation system for iron tailings includes jaw crusher one 1, bar feeder 2, cone crusher one 3, jaw crusher two 4, cone crusher two 5, and three layers of vibration Sieve 6, plate dry separator 7 and magnetic pulley 8. During production, large pieces of iron tailings enter PE600×900 jaw crusher-1 for coarse crushing, and the coarsely crushed products are fed into the rod feeder 2 Carry out pre-screening, screen out qualified products, the sieved product of rod feeder 2 is fed into jaw crusher 2 4, the crushed product of jaw crusher 2 4 and the product under the screen of rod feeder 2 are fed together Enter the three-layer vibrating screen 6 (wherein the upper layer of the polyurethane screen is 30×30mm, and the lower layer is 12×25mm), and the product on the upper screen of the three-layer vibrating screen 6 is fed into the above-mentioned cone crusher-3 for intermediate crushing, and the intermediate crushing product Then feed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com