Synthetic rubber processing waste water treatment device and method

A technology for processing waste water and synthetic rubber, which is applied in natural water treatment, multi-stage water treatment, aerobic process treatment, etc. It can solve the problems of difficult discharge of waste water, difficult discharge of effluent, unsatisfactory effect, etc., to achieve treatment Thorough, comprehensive utilization of resources, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

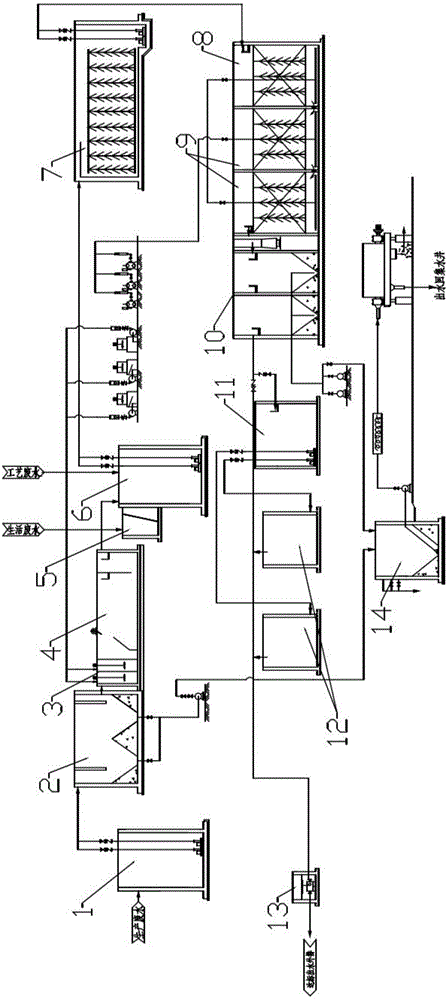

[0051] see figure 1 , a synthetic rubber processing wastewater treatment device, comprising a water collection well 1, a grit chamber 2, a reaction tank 3, an air flotation tank 4, a grid well 5, a regulating tank 6, a hydrolysis tank 7, an A tank 8, an O tank 9, two Settling tank 10, clean water tank 11, carbon filter tank 12, discharge well 13 and sludge thickening tank 14, the water collection well 1, grit chamber 2, reaction tank 3, air flotation tank 4 form a production wastewater pretreatment system, and the grid Well 5 and adjustment pool 6 form a process wastewater and domestic sewage pretreatment system; hydrolysis pool 7, A pool 8, O pool 9, and secondary sedimentation pool 10 form a biochemical treatment system; clean water pool 11, carbon filter tank 12, and drainage well 13 Physicochemical checkpoint treatment system; the water collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com